Patents

Literature

1439 results about "Glass wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass wool is an insulating material made from fibres of glass arranged using a binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets result in high thermal insulation properties. Glass wool is produced in rolls or in slabs, with different thermal and mechanical properties. It may also be produced as a material that can be sprayed or applied in place, on the surface to be insulated. The modern method for producing glass wool was invented by Games Slayter while he was working at the Owens-Illinois Glass Co. (Toledo, Ohio). He first applied for a patent for a new process to make glass wool in 1933.

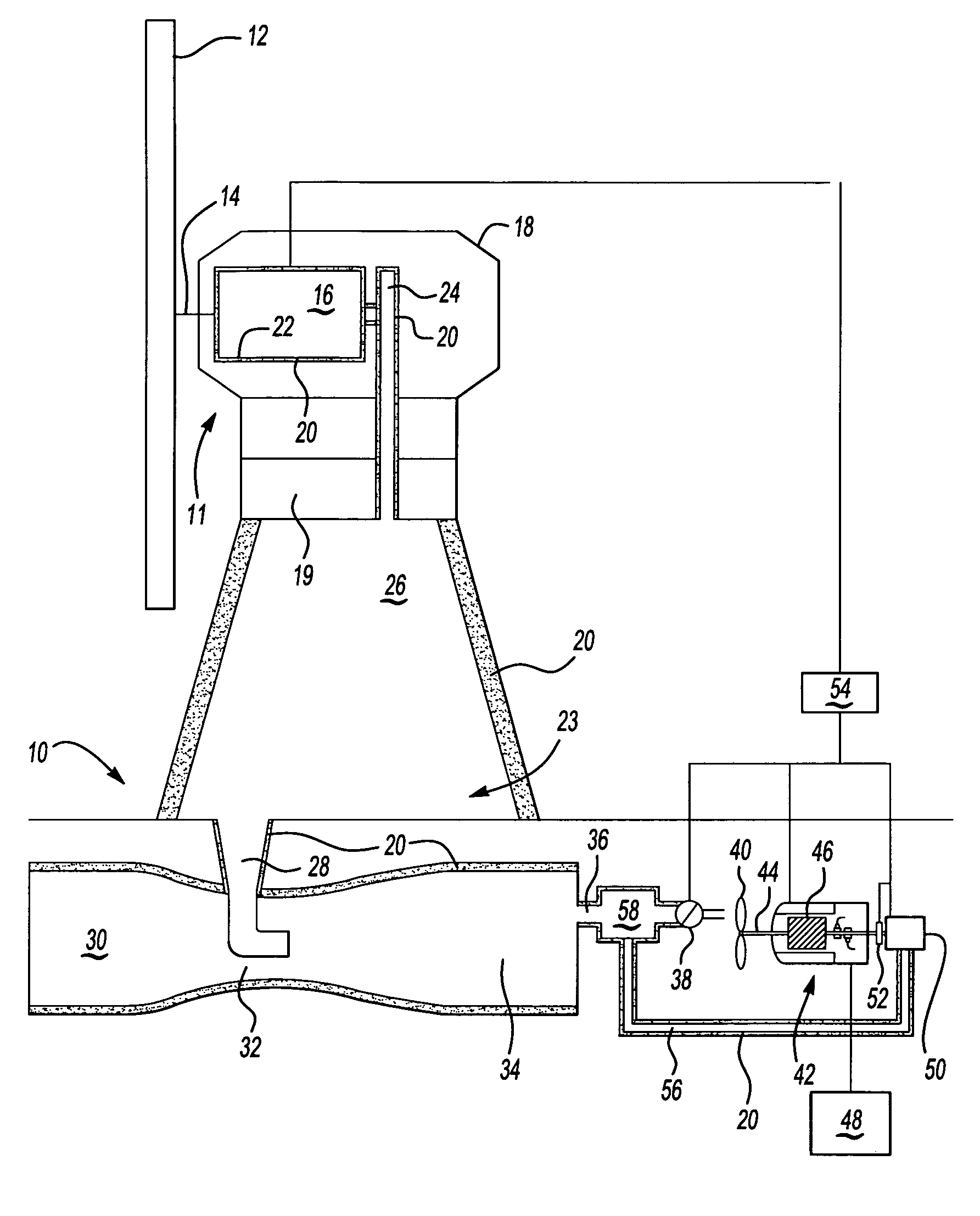

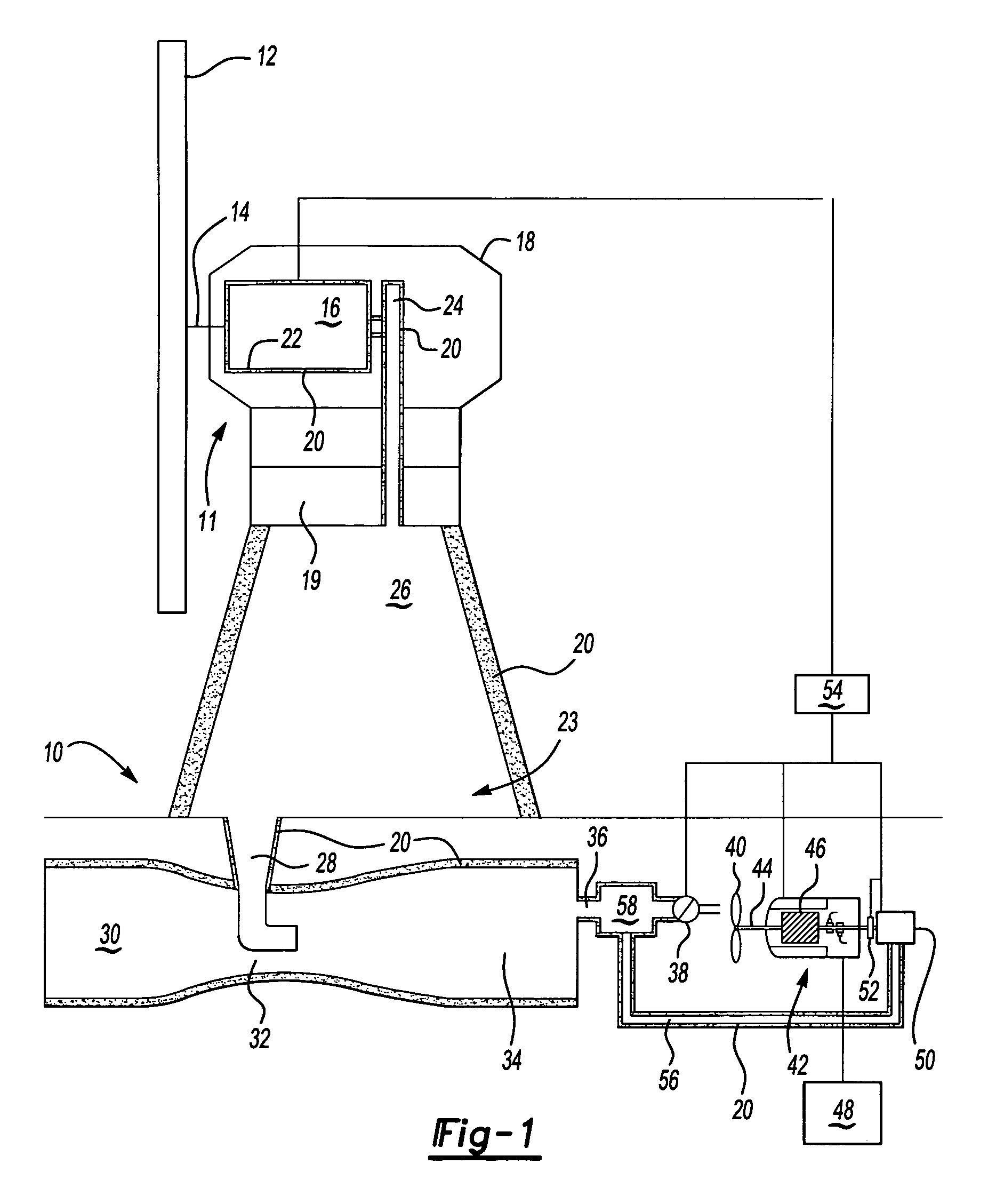

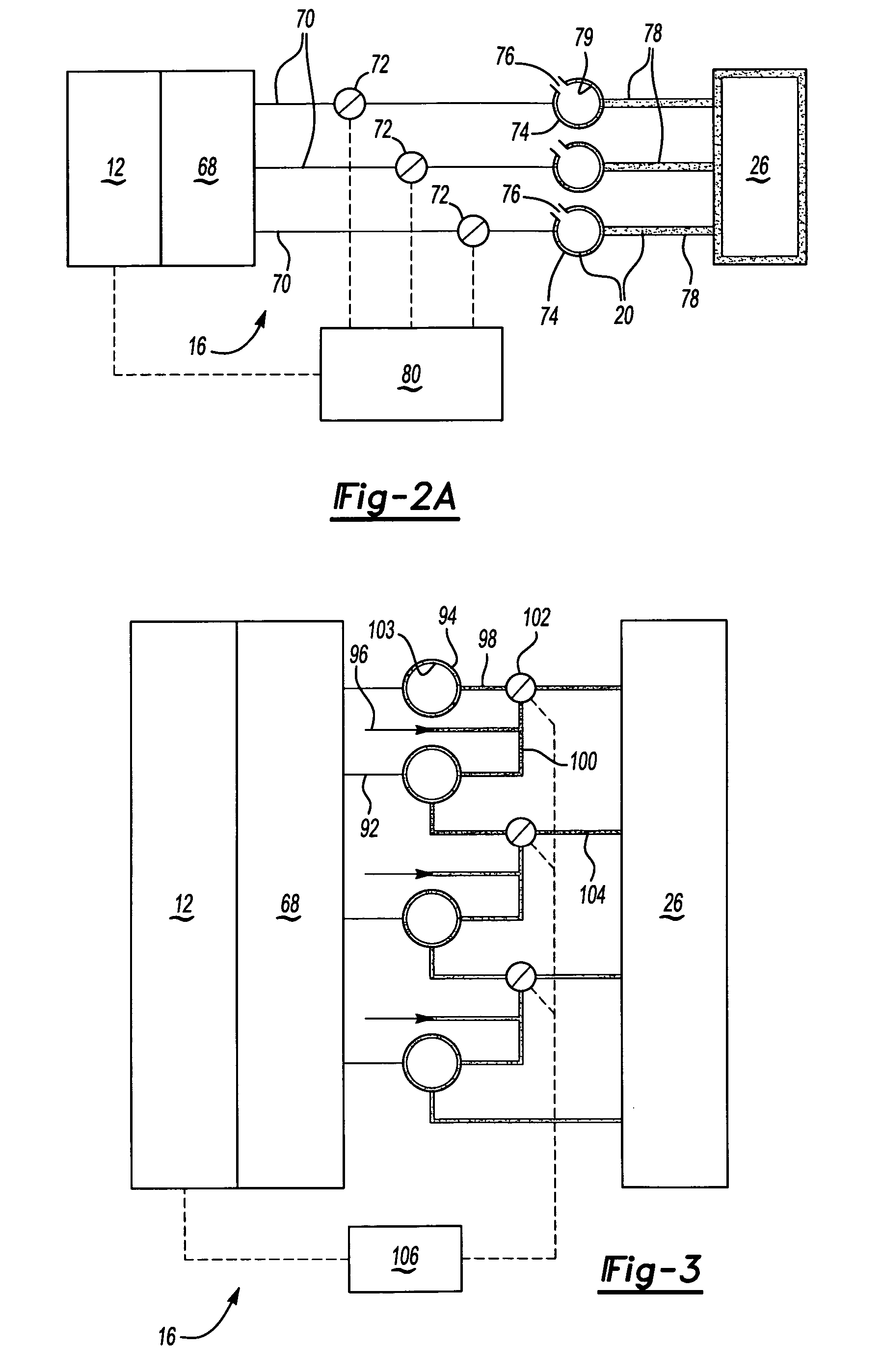

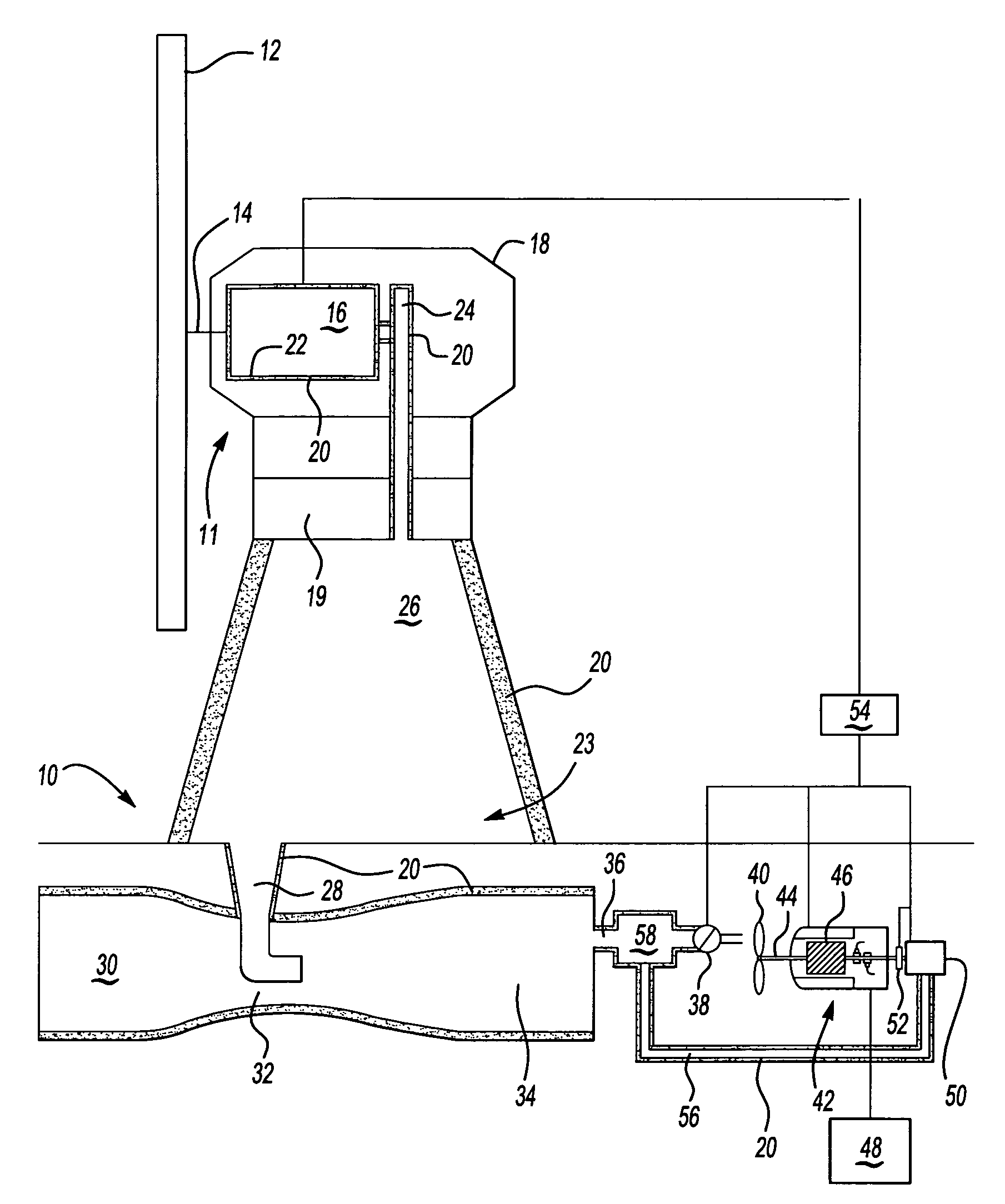

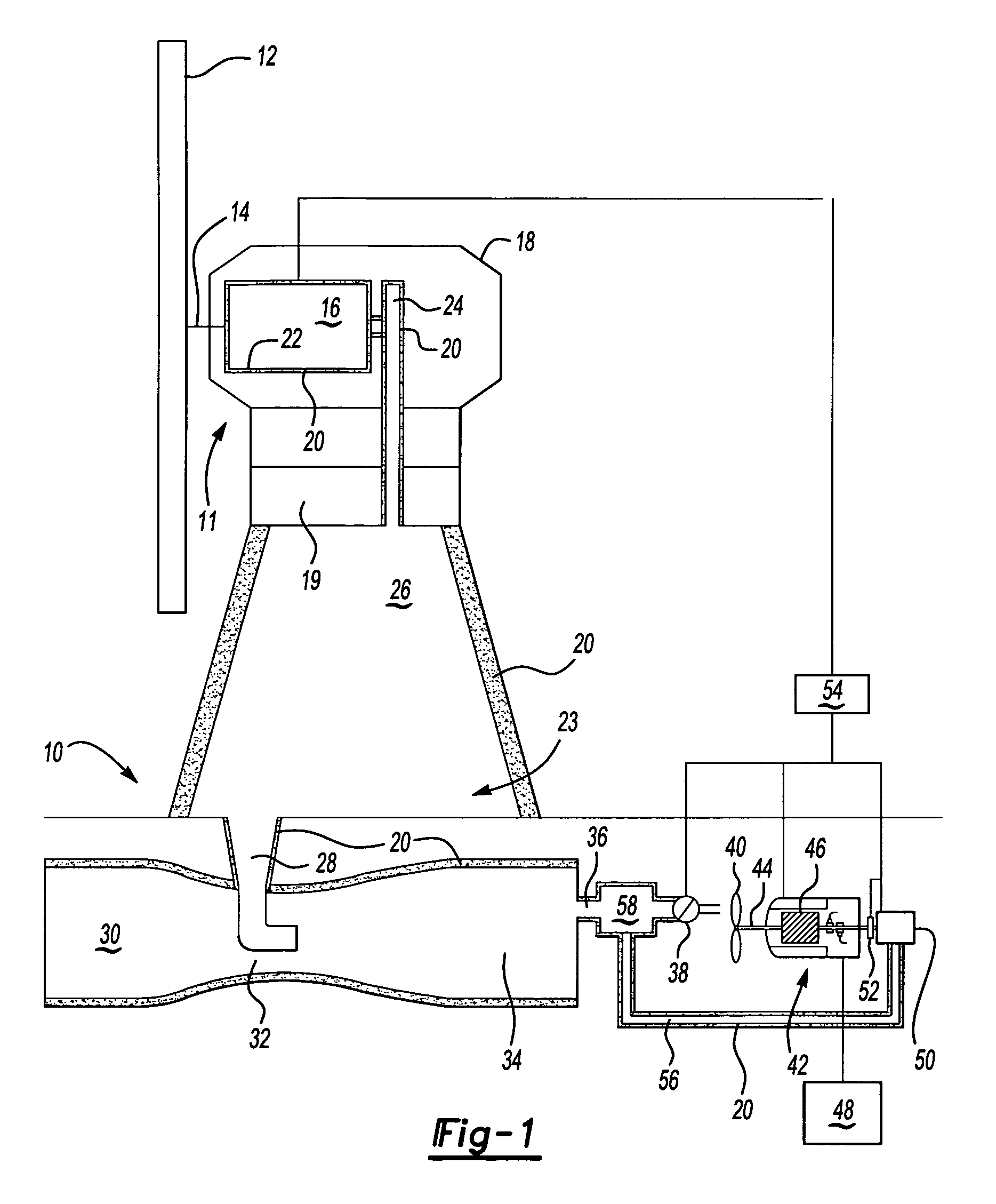

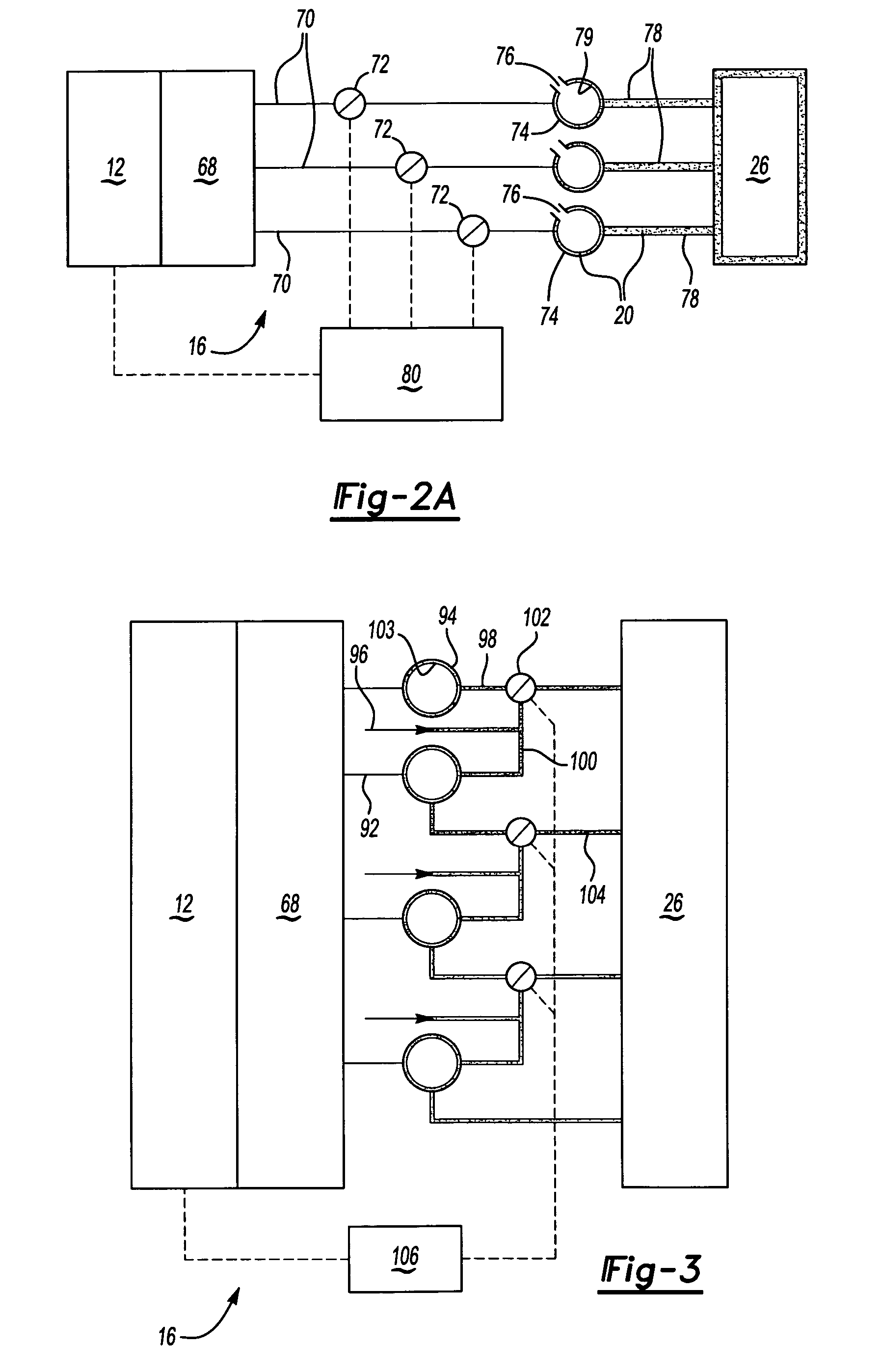

Wind power system for energy production

InactiveUS20050275225A1Slow changeOperation efficiency is highEngine fuctionsWind energy with garvitational potential energyElectricityCombustion

A wind power energy system includes a compression system that produces pressurized air with a first temperature that is received by a storage system at a second temperature that is approximately equal to the first temperature. The wind power energy system is insulated with about ten centimeters of glass-wool insulation to create an essentially adiabatic system. The pressurized air is utilized by a generator and generate electricity for a power grid. The generator also includes a combustion engine input. A control system detects fluctuation in wind power and commands the combustion engine to provide an appropriate amount of input energy to the generator such that the sum of the wind energy and combustion engine inputs produces a predetermined amount of electrical output by the generator.

Owner:HAMILTON SUNDSTRAND CORP

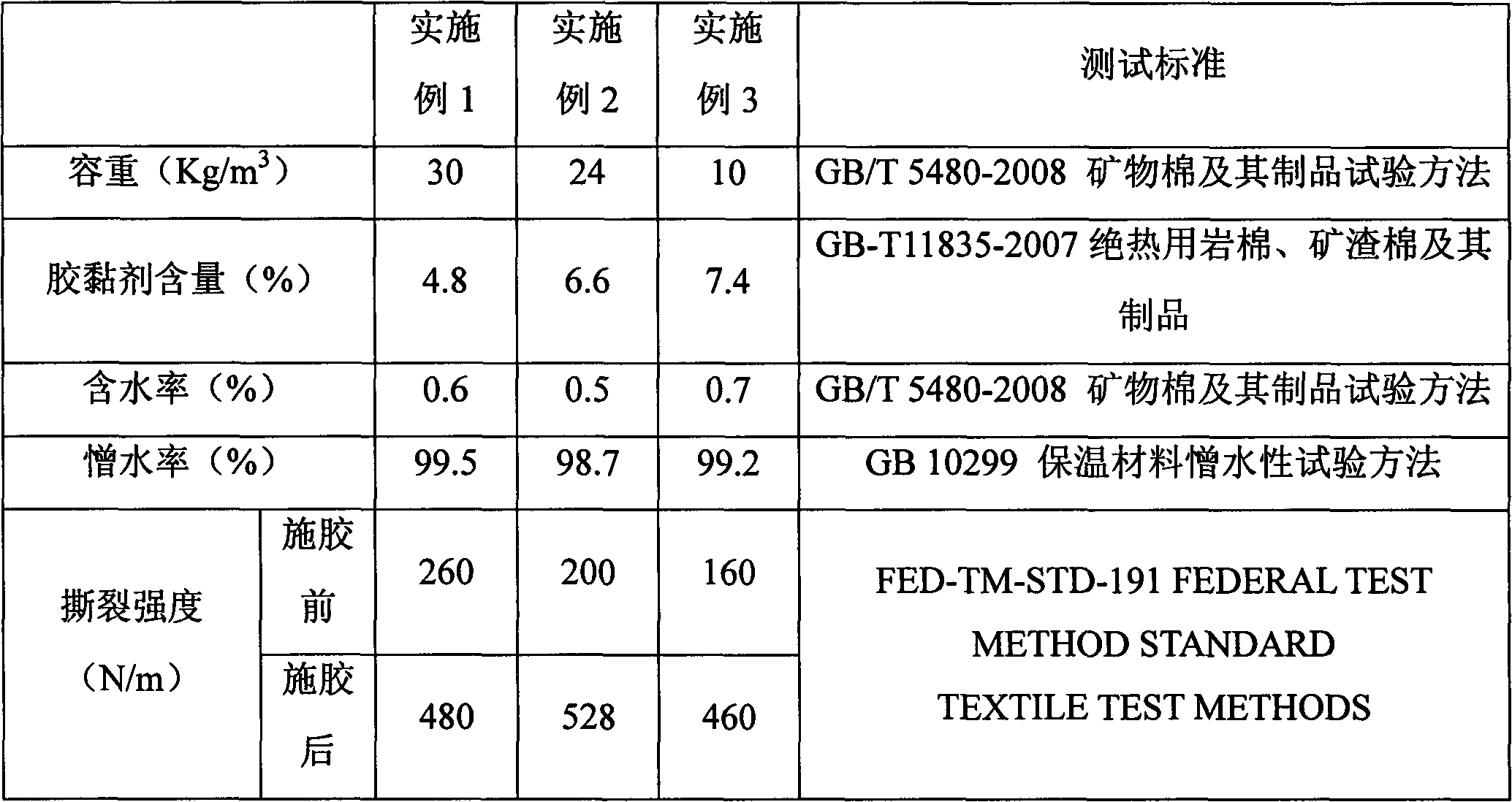

SiO2 aerogel/inorganic cotton compound thermal insulation felt and preparation method thereof

The invention relates to a SiO2 aerogel / inorganic cotton compound thermal insulation felt and a preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The method comprises the following steps of: compounding silica sol and inorganic cotton; ageing the silica sol and the inorganic cotton; carrying out modification and solvent replacement processing; and drying at normal pressure to obtain the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt, which is disclosed by the invention, is characterized in that cheap and easily-obtained industrial raw materials, such as industrial sodium silicate, industrial silica sol, glass wool, rock wool and mineral wool are adopted, the production cost can be lowered, and the ordinary pressure drying technology is convenient and easy to realize, is simple to operate and is suitable for large-scale industrial production. Meanwhile, the product is nontoxic and harmless and does not pollute the environment.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Composite material thermal insulation plate

InactiveCN1511808ANo pollution in the processStrong self-breathing functionThermal insulationSolid waste managementAdhesiveHeat conducting

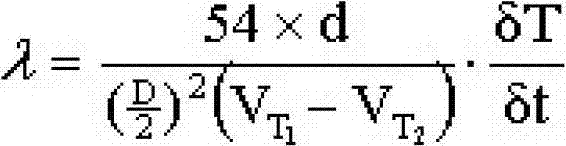

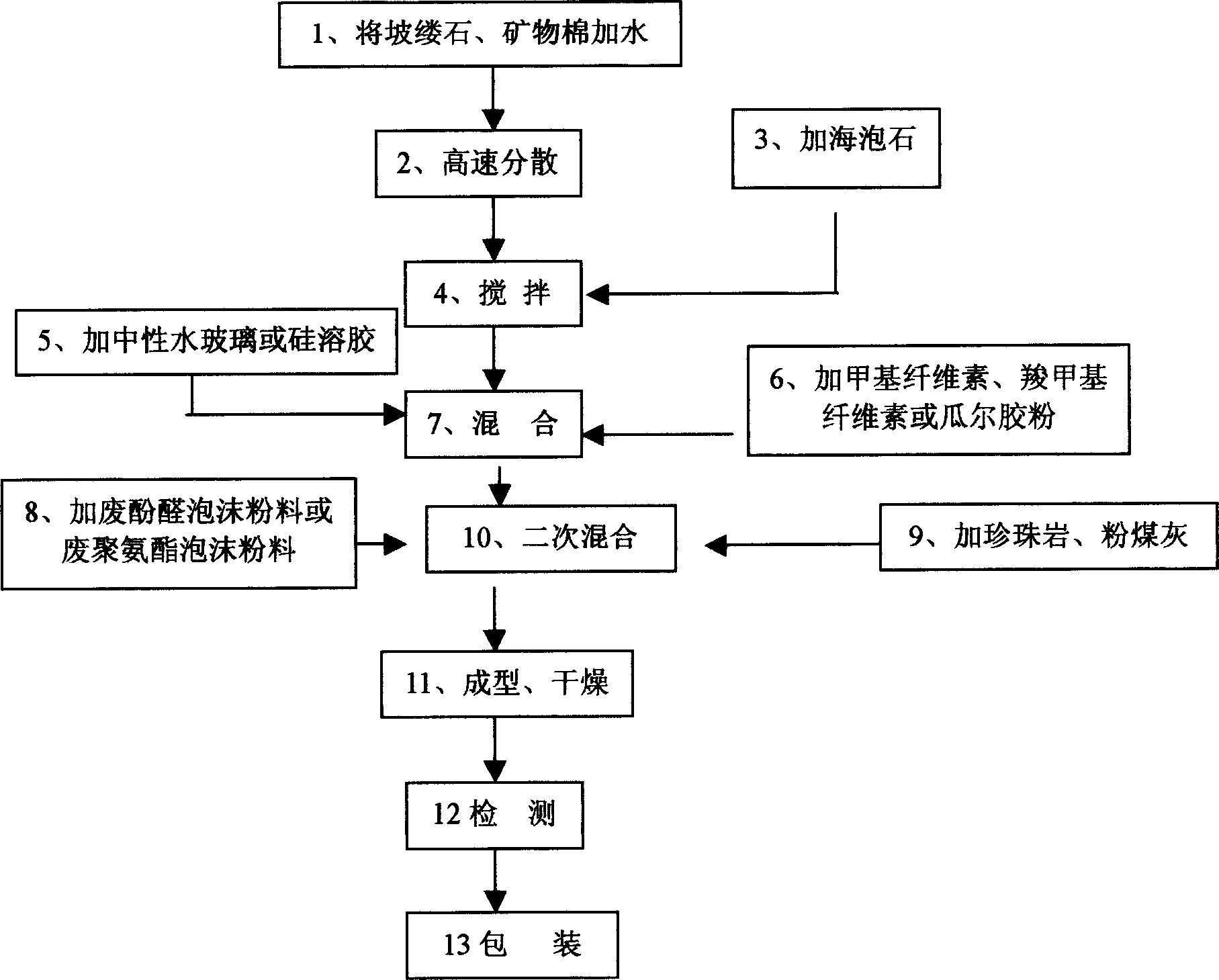

The thermal insulating plate of composite material is produced with waste foamed phenolic plastic powder as basic heat insulating material, flyash as stuffing, expanded perlite as aggregate, mineral wool, glass wool, sepiolite and palygorskite as reinforcing material, neutral water glass or silica sol as inorganic adhesive and guar gum, methylcellulose or CMC as organic adhesive, and through high speed dispersion, stirring, mixing, molding, forming and drying. The thermal insulating plate has low heat conducting coefficient, is non-inflammable, smell-less, non-toxic, long in service life and wide in application range. The production process adopts industrial waste as main components and produces no waste, and used plate may be reused, so that the present invention is significant in environment protection.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

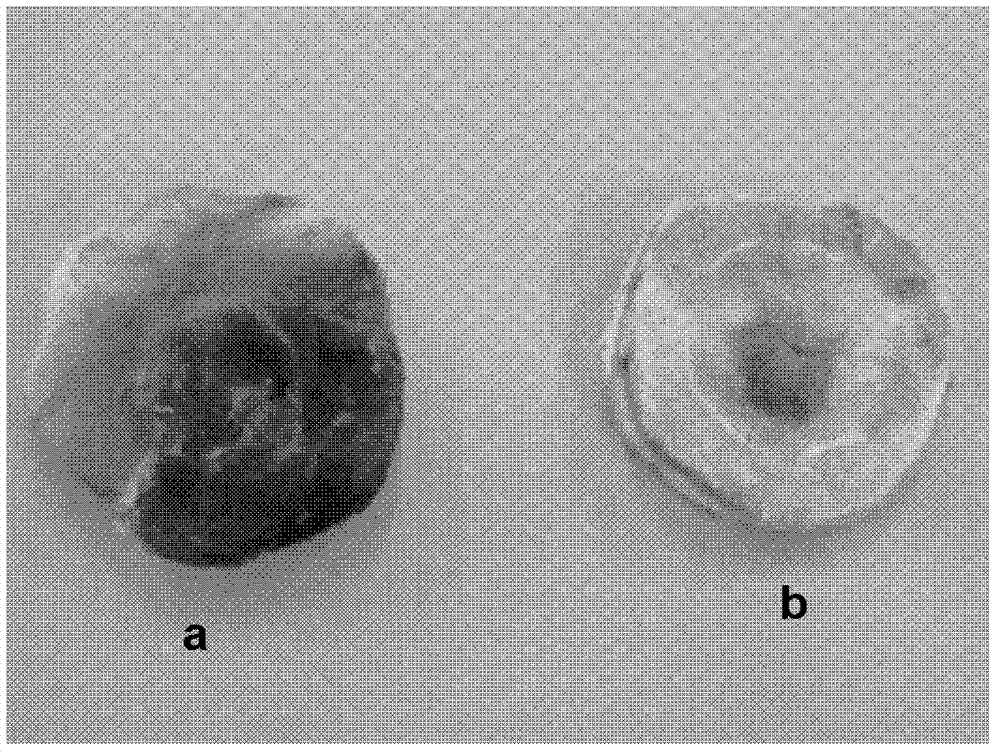

Membraneless and mediatorless microbial fuel cell

InactiveUS20050208343A1Raise the pHActivity of microorganisms distributed in the anode compartment is kept constantFuel cell auxillariesActive material electrodesMicrobial fuel cellFuel cells

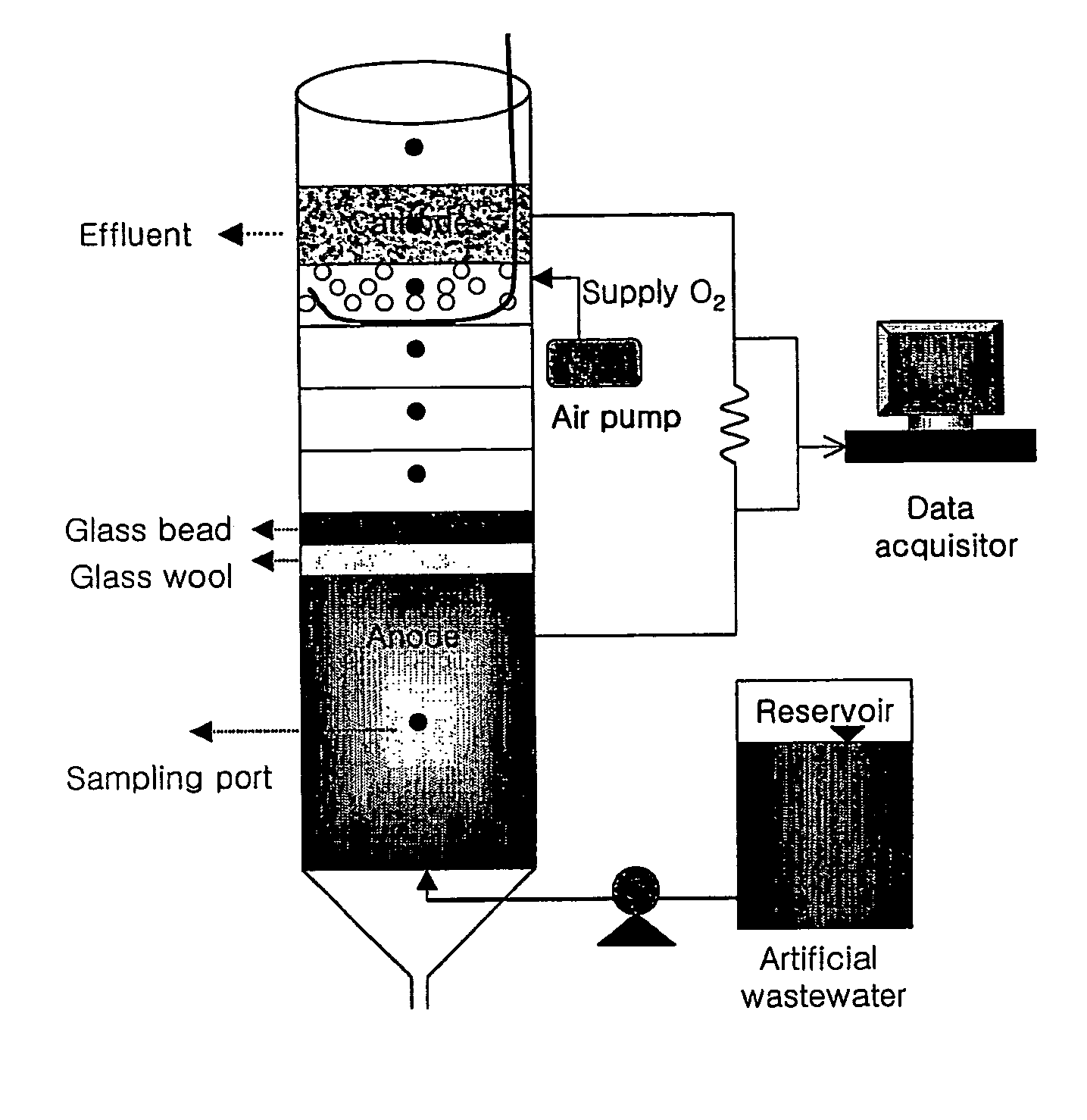

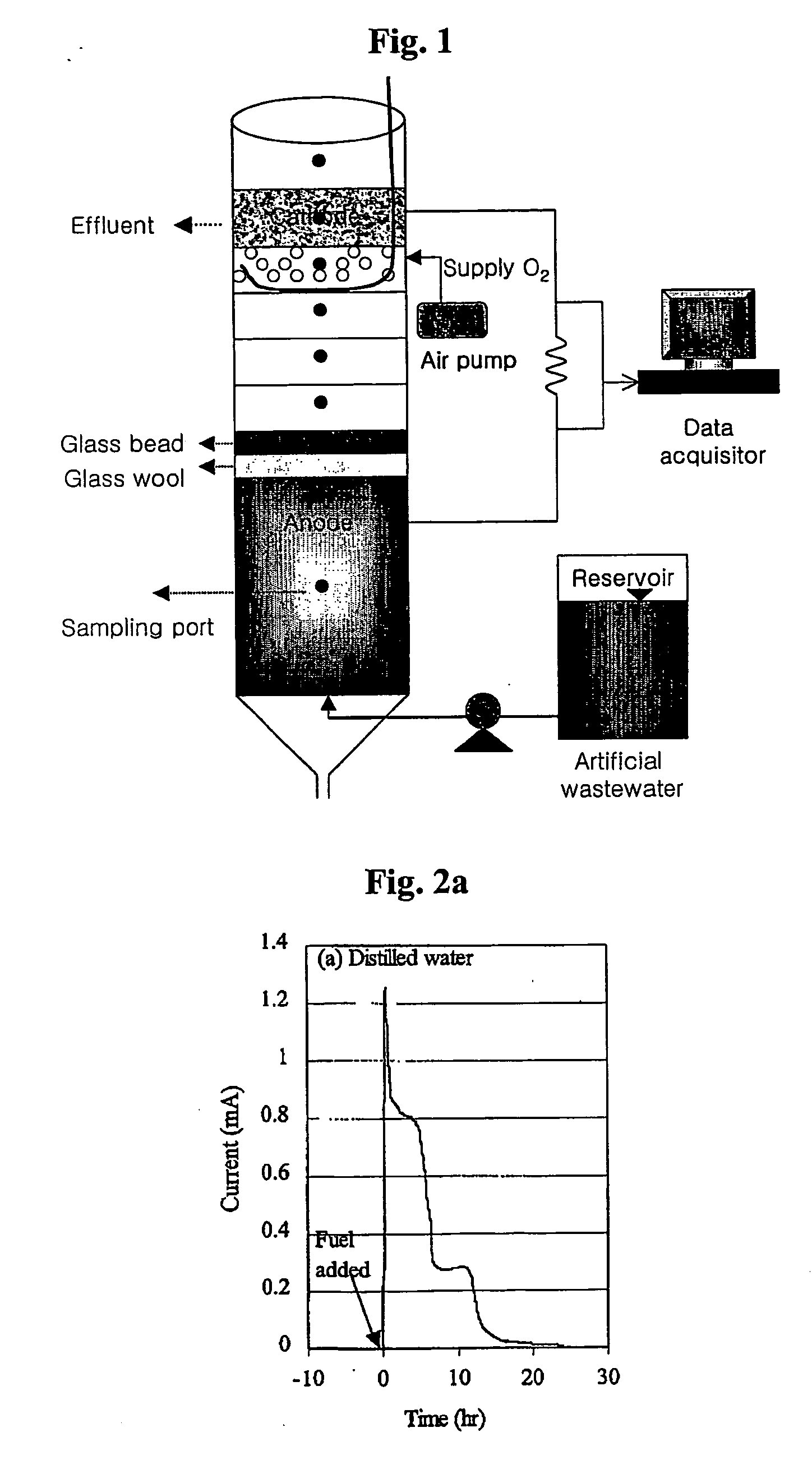

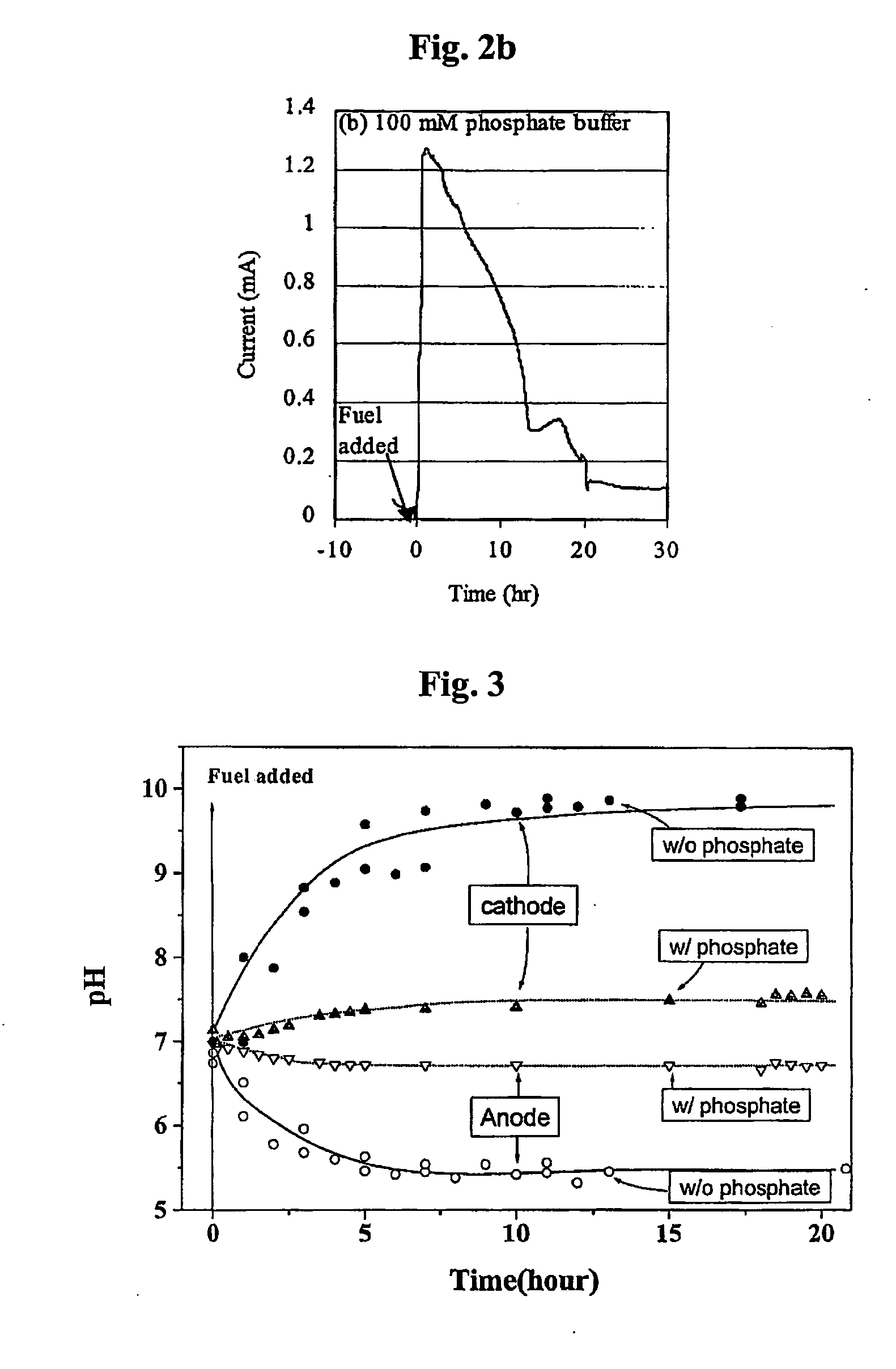

Disclosed is a mediator-less microbial fuel cell comprising a cathode compartment, an anode compartment, with or without glass wool and glass bead for separating the two compartments, an element for feeding air to the cathode compartment, and an element for feeding wastewater to the anode compartment. The cell further comprises an element for controlling the distance between the cathode compartment and the anode compartment. Graphite felt or graphite felt coated with a metal such as platinum is used as an electrode of the cathode compartment, and a buffer solution is used in the anode compartment. A mediator-less microbial fuel cell according to the present invention can be operated without using an expensive cation-exchange membrane, of which efficiency is by no means inferior to prior wastewater treatment methods.

Owner:REMPUS INC

Vapor deposition and in-situ purification of organic molecules

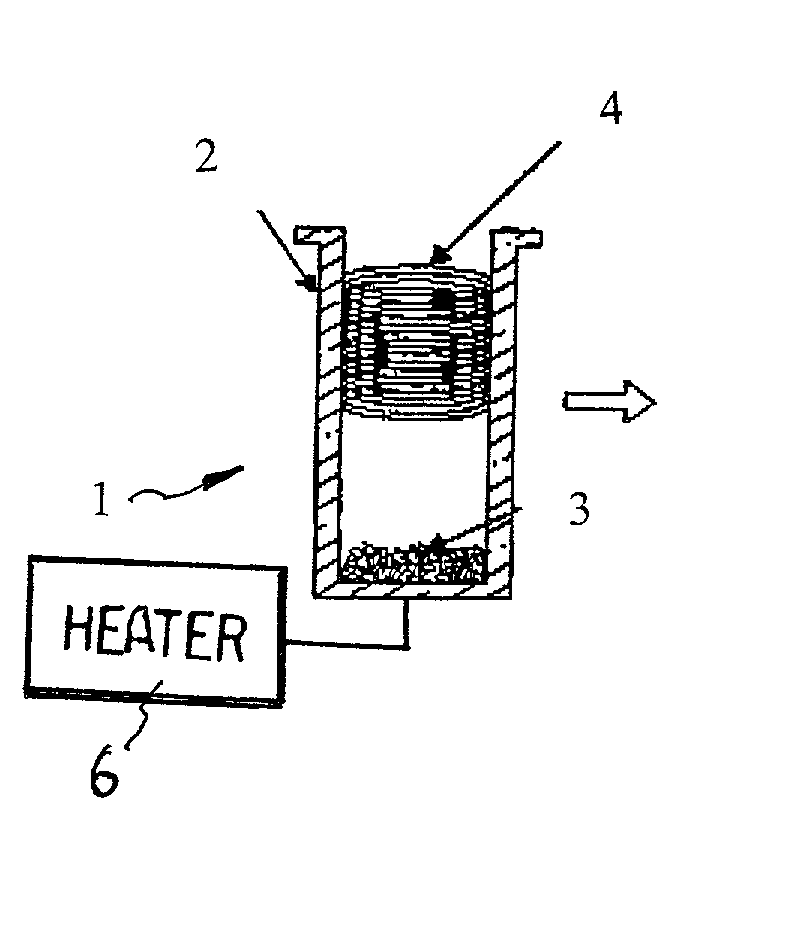

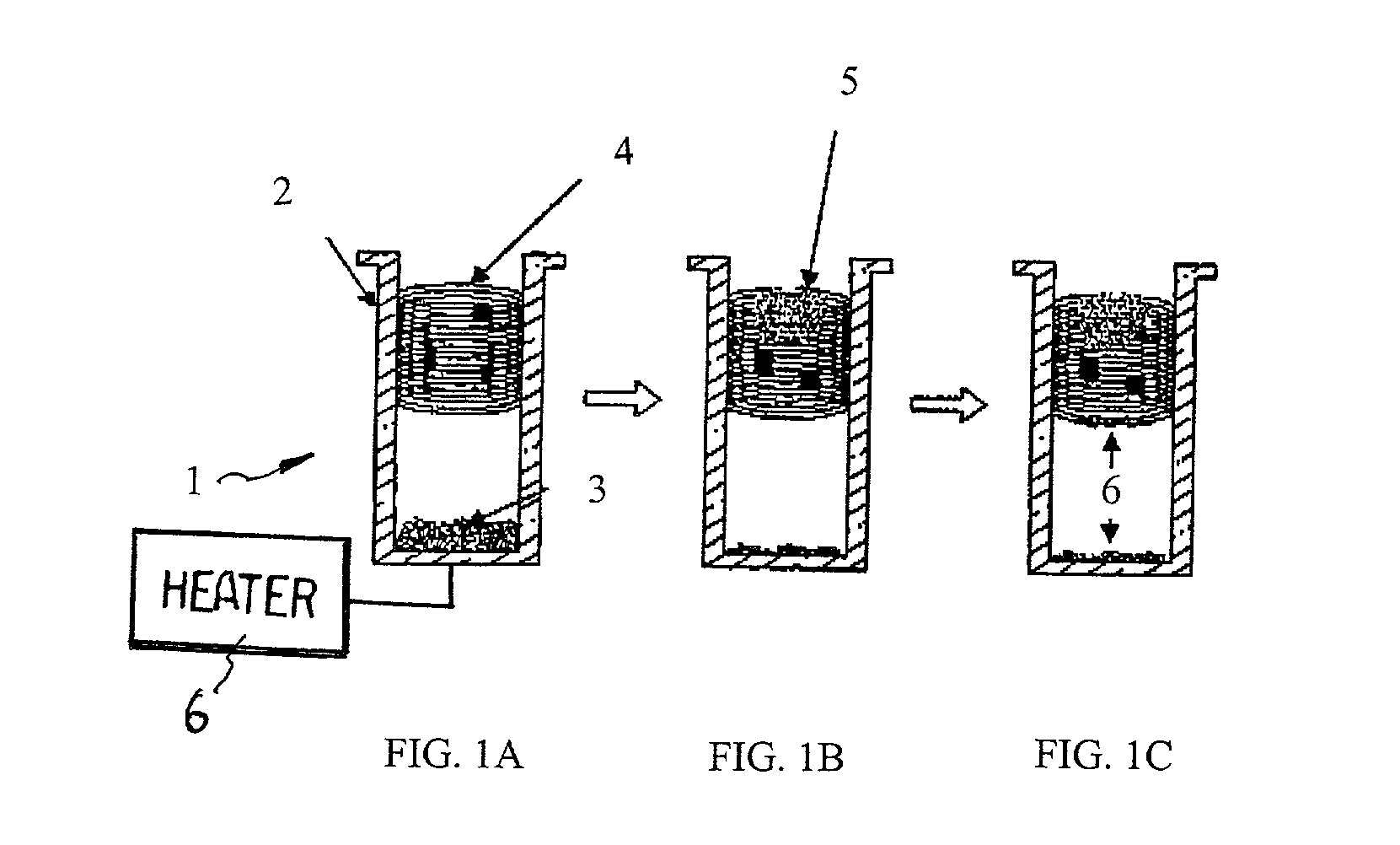

A process for in-situ purification of organic molecules and vapor deposition of the purified molecules involves vaporizing the organic molecules from a crude material, condensing the organic molecules on a glass wool baffle, re-vaporizing the condensed organic molecules, and depositing the re-vaporized organic molecules on a substrate. An apparatus adapted for practicing the process includes a crucible, a glass wool baffle in the crucible above the bottom of the crucible, and a heater configured to heat the crucible and glass wool baffle.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

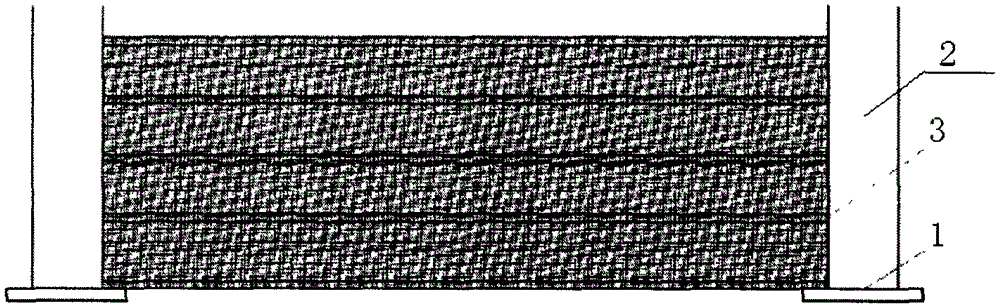

Glass fiber blanket and producing method thereof

ActiveCN103103695AImprove adhesionGood peeling effectGlass making apparatusNon-woven fabricsGlass fiberFlat glass

The invention discloses a glass fiber blanket and a producing method thereof. The method comprises the steps of mixing the following components , by mass, 35-40 parts of silica flour, 5-12 parts of feldspar, 9-14 parts of borax, 1-3.5 parts of calcite, 6-8 parts of dolomite, 11-14 parts of soda ash, and 15-25 parts of sheet glass to form a mixture; melting the mixture to obtain glass metal; placing the glass metal in a centrifugal machine for spinning treatment to obtain glass fiber and spraying water and binders onto the surface of the glass fiber in a vaporific mode at the same time; placing the glass fiber coated with the binders in a cotton collecting machine to enable the glass fiber to evenly fall onto the cotton collecting machine under the action of a negative-pressure fan to form a glass cotton layer; and conveying the glass cotton layer well laid to a curing oven through a conveyer to be cured to obtain the glass fiber blanket.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

Production method of superfine glass wool product

The invention discloses a production method of a superfine glass wool product. The production method comprises the following steps of: recovering shattered glass, cleaning and crushing; preparing raw materials including feldspar, dolomite, sodium carbonate and borax, and testing and analyzing the components of the raw materials; calculating the use levels of the raw materials according to the required proportion of the compound in a batch mixture, and weighting and mixing the raw materials and the shattered glass to prepare the batch mixture; founding the batch mixture to obtain uniform, purified and transparent molten glass; preparing a binder; fiberizing the molten glass to obtain glass wool, and spraying the binder into the glass wool; solidifying and sizing and the glass wool; and carrying out aftertreatment on the glass wool product. In the invention, the water soluble resin binder is used so that the produced glass wool product has good elasticity and is uniform. Since the recovered waste glass is adopted as the main raw material, the recycle of resource is realized, the environment is protected, and the cost is saved. In addition, the production method of the superfine glass wool product has simple operation.

Owner:许立江

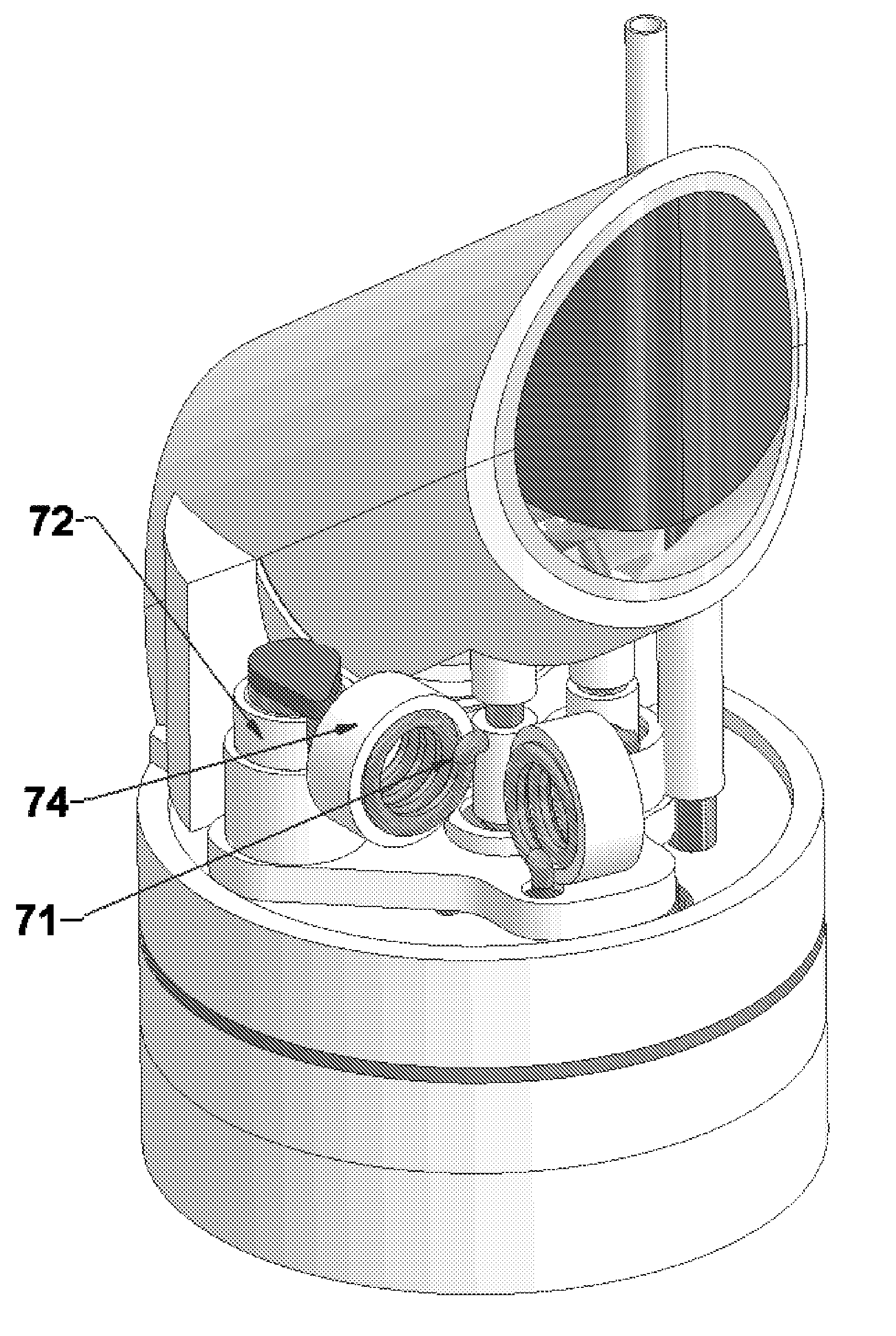

NMR CryoMAS Probe for High-field Wide-bore Magnets

InactiveUS20060176056A1Reduce riskImprovement factorElectric/magnetic detectionMeasurements using magnetic resonancePartial solutionNitrogen gas

An MAS probe is disclosed for obtaining a substantial improvement in signal to noise (S / N) in triple-resonance high-resolution (HR) magic-angle-spinning (MAS) NMR of samples near room temperature (RT) in high-field magnets where the magnet's RT shim bore is greater than 60 mm. All critical circuit components, including the sample coils, are located along with the spinner assembly in a thermally insulated cold zone pressurized with helium gas. The spinner assembly attaches to a sealed, curved, rotor-loading tube to permit automatic sample change, and it is surrounded by a partially insulated jacket cooled with a cryogenic fluid, generally nitrogen gas. The MAS probe is also compatible with magic angle gradients, variable temperature operation, field locking, and commonly available closed-cycle cold fingers. One major challenge in implementing CryoMAS is solving the problem of gas leakage from the spinner bearing, drive, and exhaust nitrogen into the cold zone, as some components will necessarily be ceramic, some plastic, and some metal. It is not desirable to use helium for the spinner bearing and drive gases for cost reasons and to prevent risk of degradation of o-ring-sealed magnet cryostats. A pressurized helium atmosphere in the cold zone may be utilized to prevent nitrogen flow from the spinner exhaust streams or atmosphere into the cold zone. The drawback to a pressurized cold zone is that the heat transfer coefficient in dense helium at low temperatures is very high, making it challenging to cool the sample coils and all the large, critical, circuit components in a practical manner. Part of the solution here is to use a first-stage cooling-jacket around the major heat leaks near the spinner exhaust flows. The critical components may be insulated with fine glass wool or teflon foam and conduction cooled without cooling much of the cold zone below the temperature of the first-stage cooling. The use of coaxial sapphire capacitors allows the noise contributions from the most critical capacitors to be reduced to a minor fraction of the total.

Owner:DOTY SCI

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for producting superfine glass wool

The invention discloses a method for producting a superfine glass wool, which comprises the following steps of: reclaiming, washing and crushing cullet; preparing raw materials such as feldspar, dolomite, sodium carbonate and sodium borate, assaying and analyzing the components of the raw materials; counting the dosage of each raw material according to the required proportion of compound in a mixed material; weighing and mixing the raw materials and the cullet to make into the mixed material; founding the mixed material to obtain even, purified and transparent glass liquid; and guiding the glass liquid into a centrifugal machine, and fibering to obtain the glass wool. The method adopts the reclaimed waste glass as main raw material, realizes the cyclic utilization of resources, protects the environment, saves the cost, is simple in operation and not complex, and can prepare the superfine glass wool with small diameter and high flexibility.

Owner:许立江

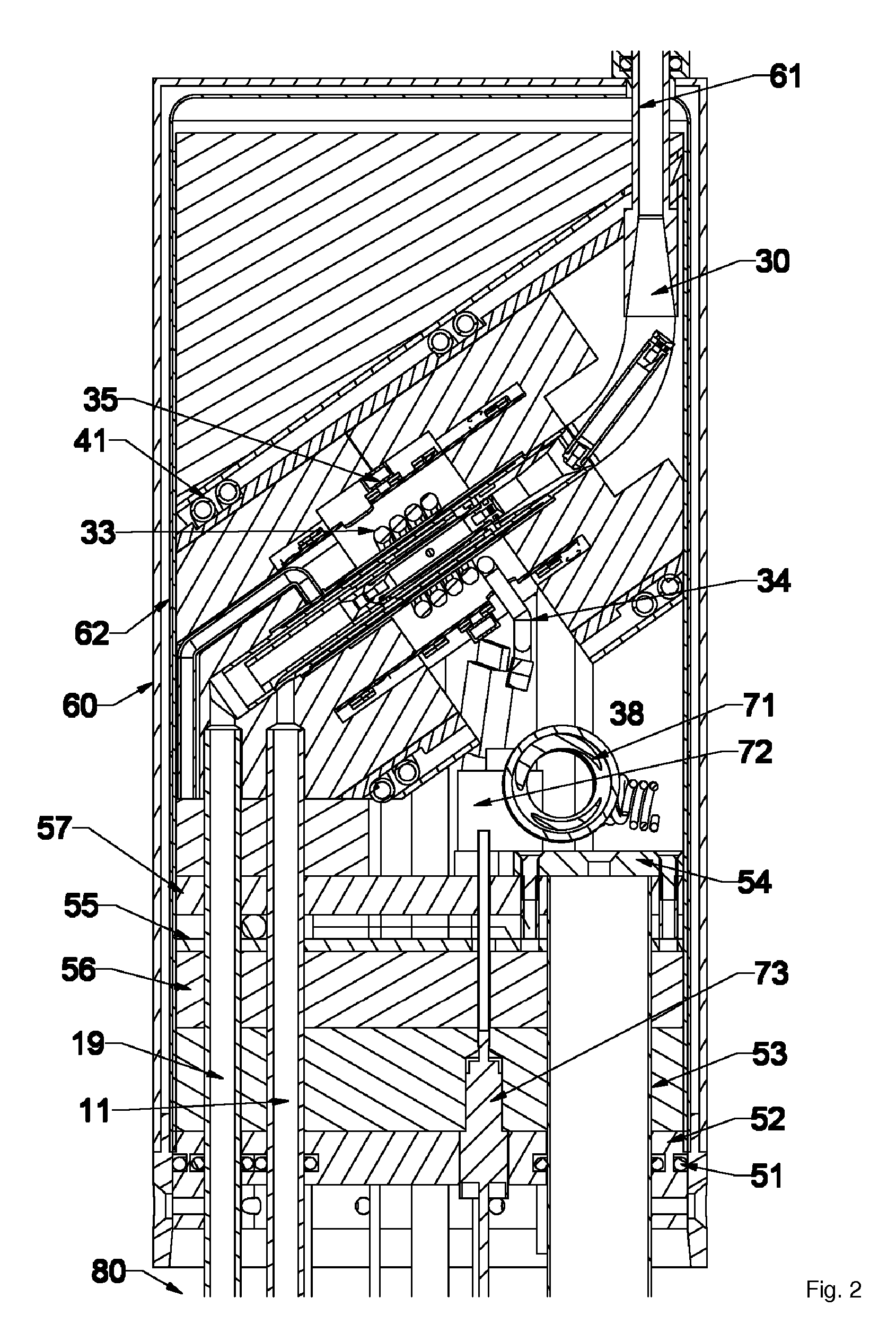

Wind power system for energy production

InactiveUS7719127B2Slow changeHigh operating requirementsEngine fuctionsWind energy with garvitational potential energyElectricityCombustion

A wind power energy system includes a compression system that produces pressurized air with a first temperature that is received by a storage system at a second temperature that is approximately equal to the first temperature. The wind power energy system is insulated with about ten centimeters of glass-wool insulation to create an essentially adiabatic system. The pressurized air is utilized by a generator and generate electricity for a power grid. The generator also includes a combustion engine input. A control system detects fluctuation in wind power and commands the combustion engine to provide an appropriate amount of input energy to the generator such that the sum of the wind energy and combustion engine inputs produces a predetermined amount of electrical output by the generator.

Owner:HAMILTON SUNDSTRAND CORP

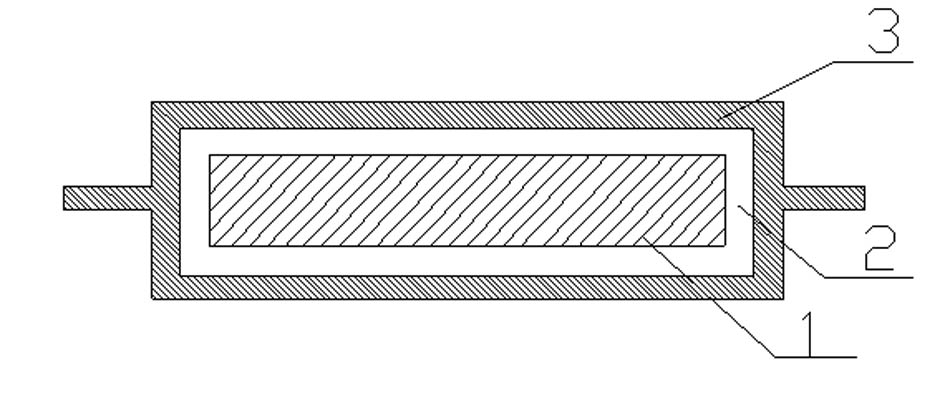

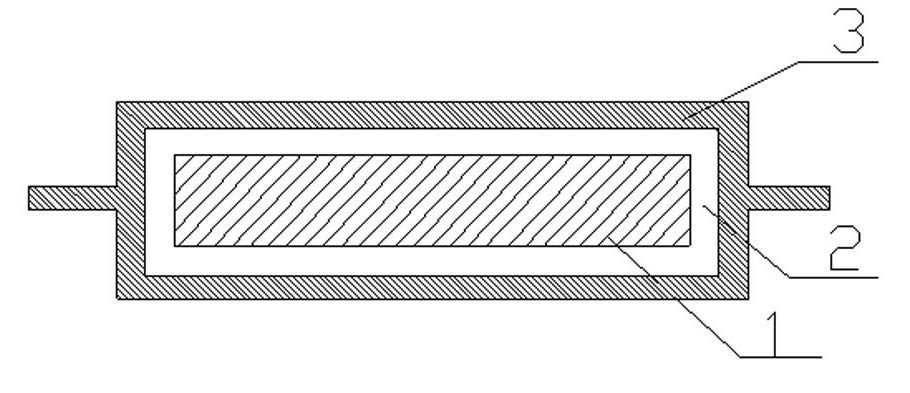

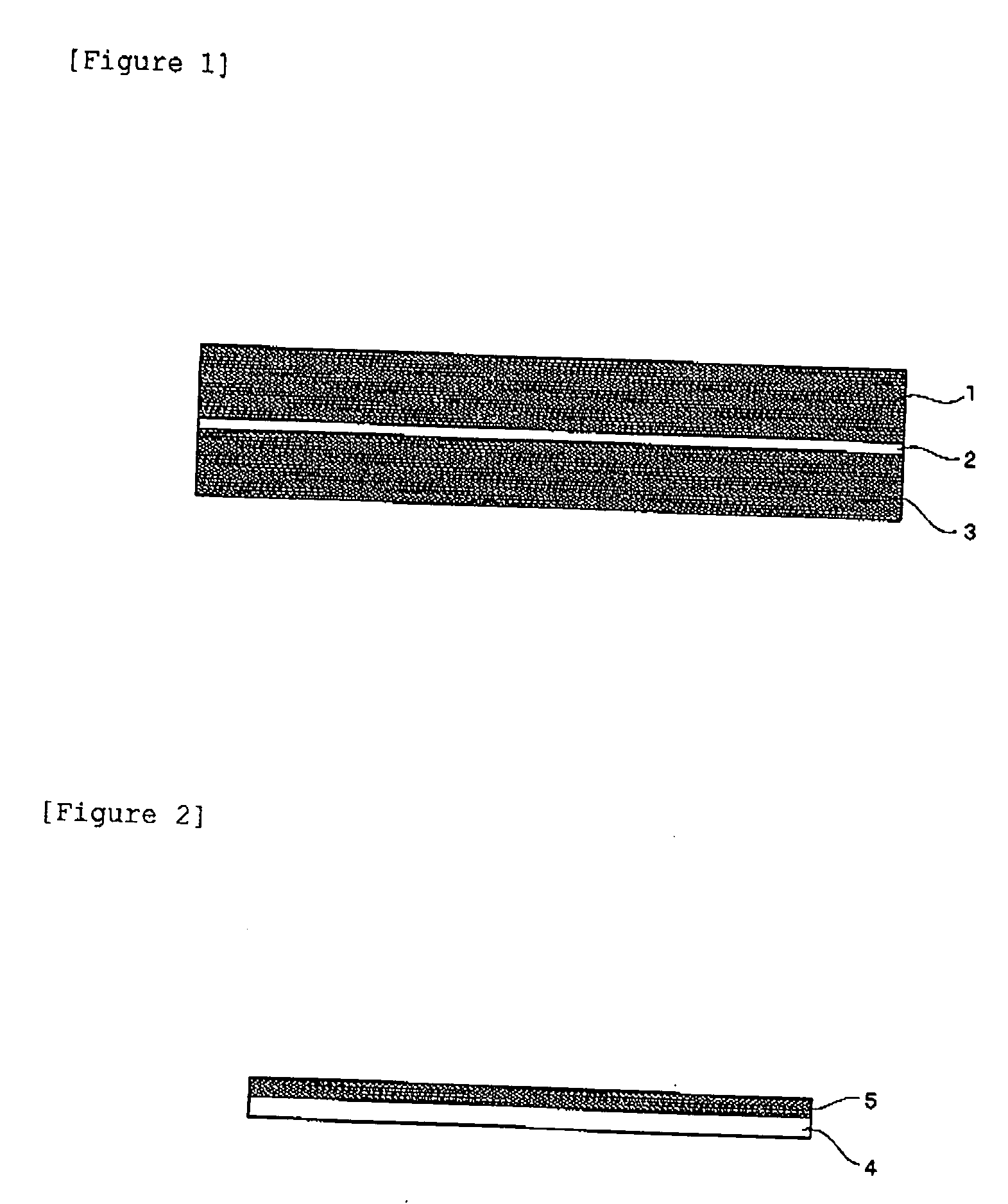

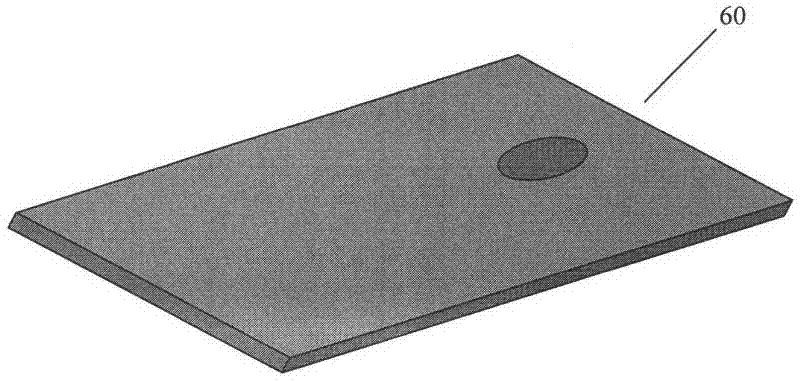

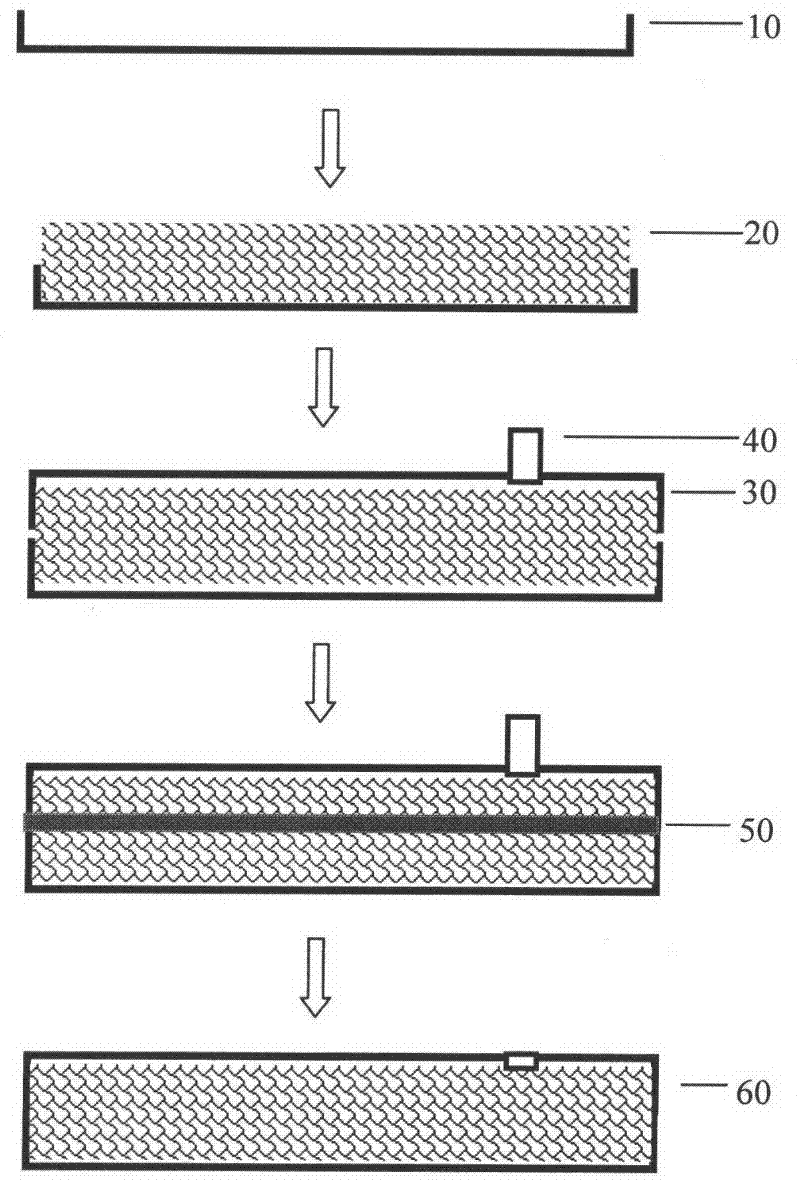

Vacuum insulated panel produced from superfine glass wool with wet process and method for producing same

ActiveCN102062277AReduce weightLow conductivityThermal insulationPipe protection by thermal insulationAging resistanceGlass wool

The invention discloses a vacuum insulated panel produced from superfine glass wool with a wet process. The vacuum insulated panel comprises a core material, a gas adsorption material layer and an isolating film layer, wherein the core material is in the innermost layer and is a core panel produced from superfine glass wool, the gas adsorption material layer wraps the outer surface of the core material, and the isolating film layer wraps the outer part of the gas adsorption material layer. The invention further discloses a method for producing the vacuum insulated panel. The vacuum insulated panel has light weight, low conductivity, good elasticity, corrosion resistance, aging resistance, high stability, good heat insulation effect and ideal sound-absorbing effect and is non-toxic, non-combustible and pollution-free. The vacuum insulated pane has the thickness of 8-30 mum, the service life of over 15 years, the use temperature of -50-70 DEG C and the conductivity of 0.0018-0.0028W / m.K at 20 DEG C.

Owner:许立江

Mineral-modified organic heat-insulating granules fireproof heated board and manufacture technology thereof

InactiveCN101767974AReduce weightImprove insulation effectSolid waste managementManufacturing technologyAdhesive

The invention discloses a mineral-modified organic heat-preserving grandules fireproof heated board, characterized in that the raw materials include water glass adhesive containing 40-5 percent of solid, alumina, zinc oxide, calcium oxide, calcium carbonate, fly ash, magnesia, magnesium chloride, starch, water repellent substance and polyphenyl granules or extruded granules or polyurethane granules. The fireproof performance of the fireproof heated board which is a noncombustible material can reach the national A-level demand for fireproof material. Because of light weight, good heat preservation effect and big coefficient of heat conductivity, the fireproof heated board can substitute rock wool, silicate cotton and glass wool, with energy-conserving and environment-protecting performances. The fireproof heated board realizes low cost and high benefit because a lot of waste polyphenyl granules can be recycled. The manufacture process needs no coal for combustion and discharges no three wastes,namely, waste gas, waste water and industrial residue, belonging to the clean manufacture process and saving water and energy.

Owner:金同芳

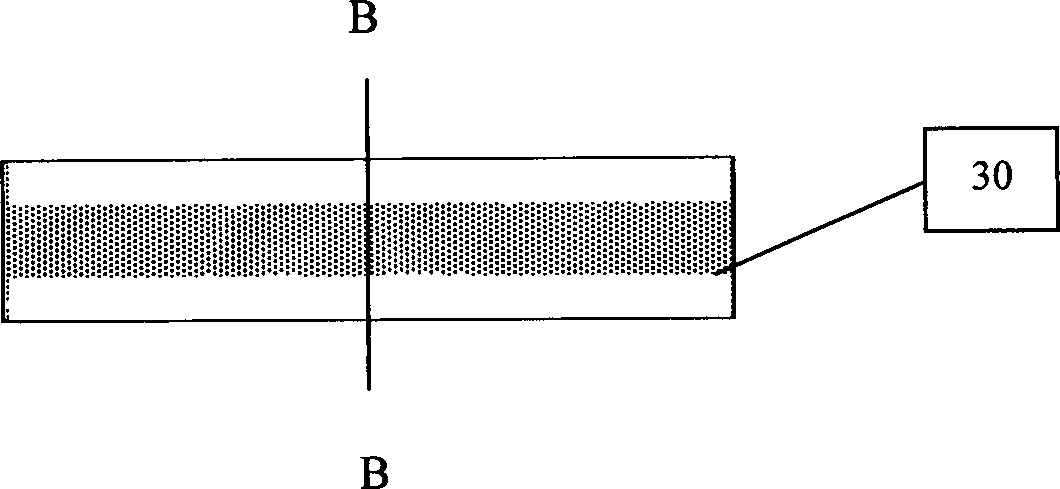

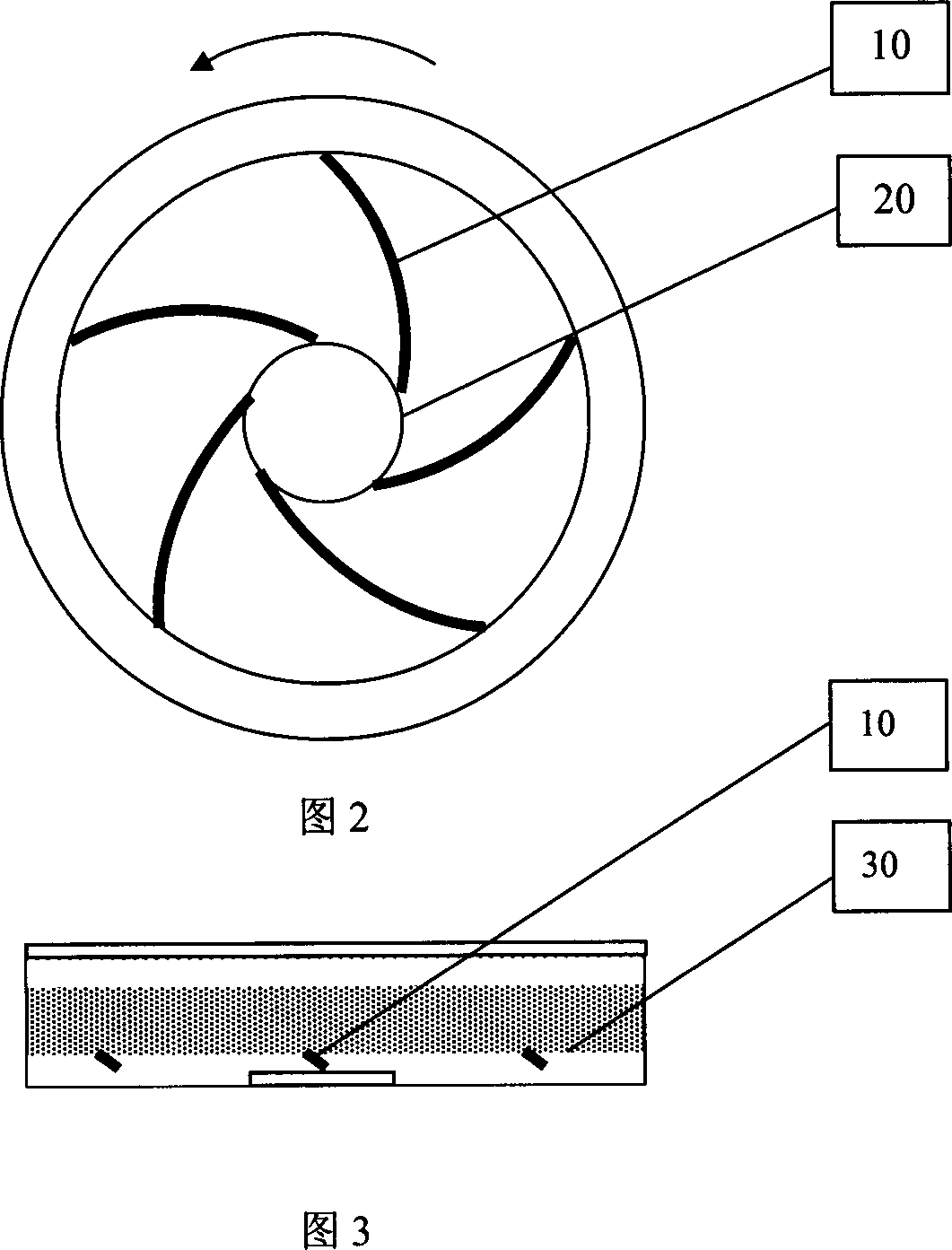

Centrifugal disc for producing glass wool

InactiveCN103723913AGood fibrillationUniform diameter distributionGlass making apparatusFiberEngineering

The invention relates to a centrifugal disc for producing glass wool. The centrifugal disc is characterized in that a curved slot for guiding the flowing direction of glass metal is formed in the bottom surface of the centrifugal disc, and the curve is in the shape of an Archimedean spiral; a main shaft installing hole in the bottom surface of the centrifugal disc is used as the starting end of the curved slot, a lower terminated line of a hole in the inner wall of the centrifugal disc is used as the ending end of the curved slot, and the curved slot is arranged in the same direction as the rotating direction of the centrifugal disc. The curved slot in the shape of the Archimedean spiral is formed in the bottom of the centrifugal disc, and is arranged in the same direction as the rotating direction of the centrifugal disc, therefore, the centrifugal disc has the characteristic of guiding the glass metal to adhere on the lateral wall of the centrifugal disc continuously and evenly so as to prevent the glass metal from generating turbulence in a centrifugal process; the centrifugal fiber-forming effect of the glass wool is significantly improved. The centrifugal disc can be widely applied to the field of preparing the glass wool in different levels, and can provide references for other fields of preparing materials in a centrifugal method.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Hydrophobic type glass wool blanket and adhesive proportion thereof

InactiveCN103572503AImprove hydrophobicityIncrease elasticityMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberThermal insulation

The invention discloses a hydrophobic type glass wool blanket and an adhesive proportion thereof. The hydrophobic type glass wool blanket is composed of centrifugal glass wool fibers and a highly hydrophobic adhesive, wherein the content of the adhesive is 3-25%, and the adhesive contains water soluble resin, a silane coupling agent, a moisture repellent, a curing agent, a pH conditioning agent, dust laying oil and softened water. According to the invention, the water soluble resin with good mobility serves as a raw material, so that the prepared glass wool blanket has excellent hydrophobic performances. At the same time, the invention relates to the adhesive proportion of the hydrophobic glass wool blanket. The adhesive product in the invention is excellent in bonding strength, hydrophobic performances, hydrolytic resistance, rebound resilience and corrosion resistance, and widens the application field of the glass wool blanket, such that the glass wool blanket can be used for thermal insulation and sound insulation in the fields of buildings, aviation, aerospace, navigation and the like.

Owner:陈照峰 +1

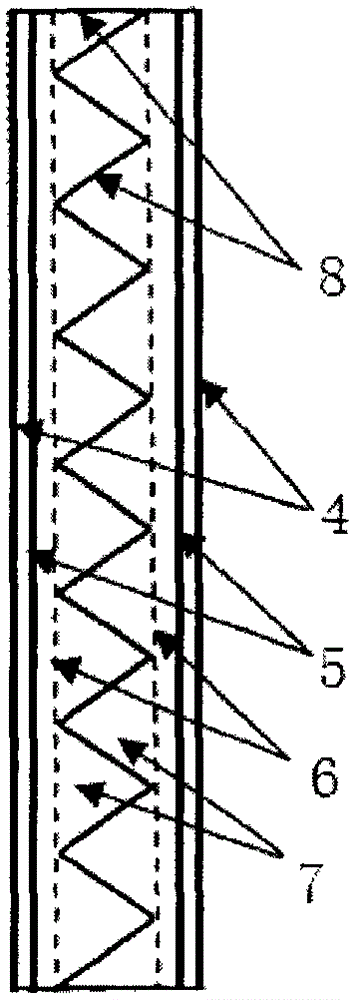

Noise prevention and sound insulation barrier for building structure

InactiveCN105297646AHigh strengthNo deformationNoise reduction constructionCeramicwareFiberSound barrier

The invention relates to a noise prevention and sound insulation barrier for a building structure. The noise prevention and sound insulation barrier comprises a foundation. A plurality of stand columns are fixed to the foundation. A plurality of sound barrier unit boards are fixed between the adjacent stand columns. Each sound barrier unit board comprises two layers of aluminum fiber sheets, two layers of concrete sound absorption boards, two layers of foamed ceramic boards, a cavity, a foldable noise absorption board and a peripheral framework, wherein the aluminum fiber sheets are arranged on the outer surfaces of the two sides of the sound barrier unit board respectively, the two layers of concrete sound absorption boards are arranged in the two layers of aluminum fiber sheets, the two layers of foamed ceramic boards are arranged in the two layers of concrete sound absorption boards, the cavity is formed between the two layers of foamed ceramic boards, the foldable noise absorption board is made of glass wool and arranged in the cavity in a vertically and continuously folded and connected mode, and the two layers of aluminum fiber sheets, the two layers of concrete sound absorption boards and the two layers of foamed ceramic boards are sequentially fixed in the peripheral framework from outside to inside. Serving as a part of the building structure, the noise prevention and sound insulation barrier is simple in structure and low in manufacturing cost and achieves a very good sound absorption and insulation effect.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

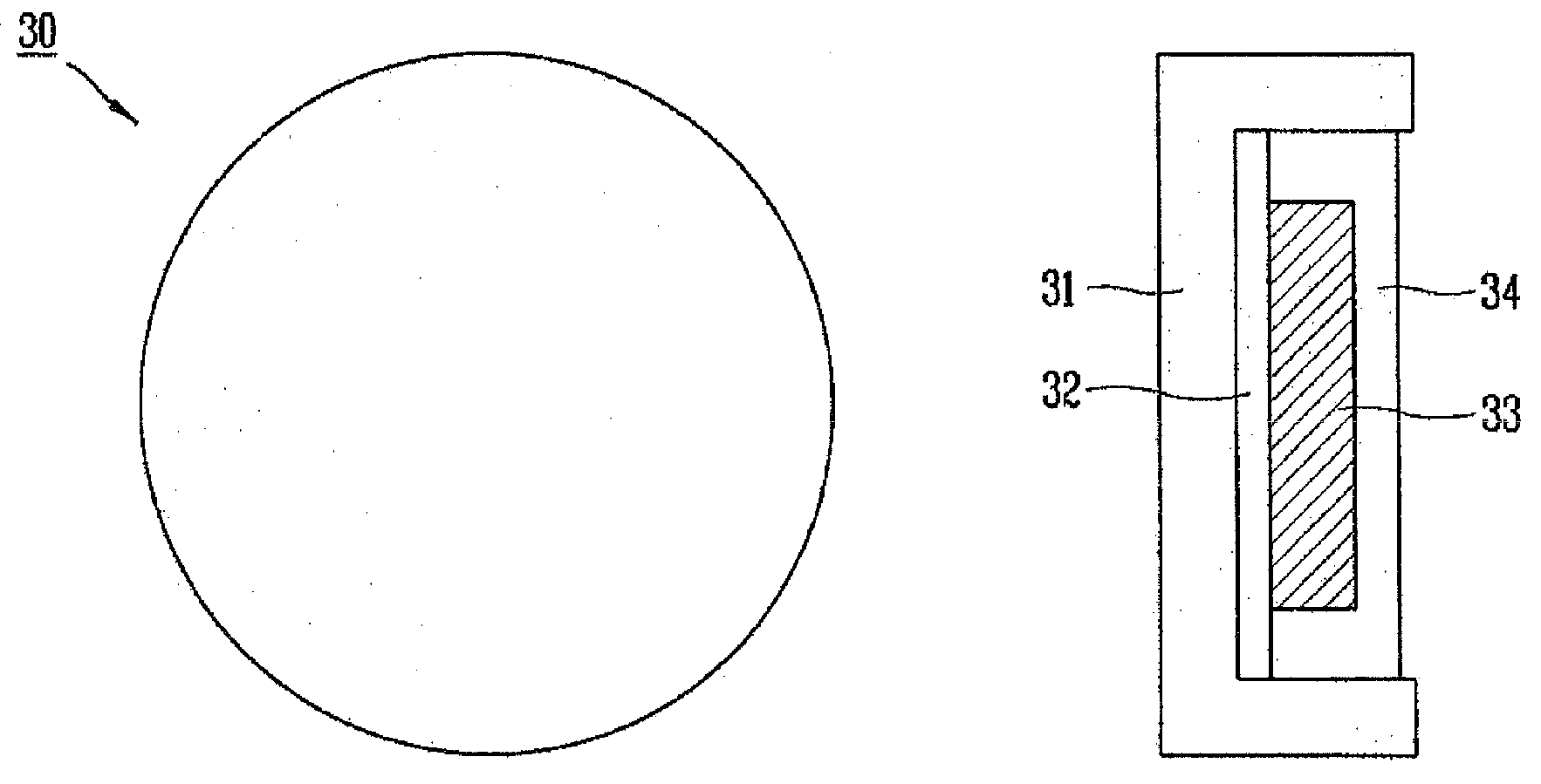

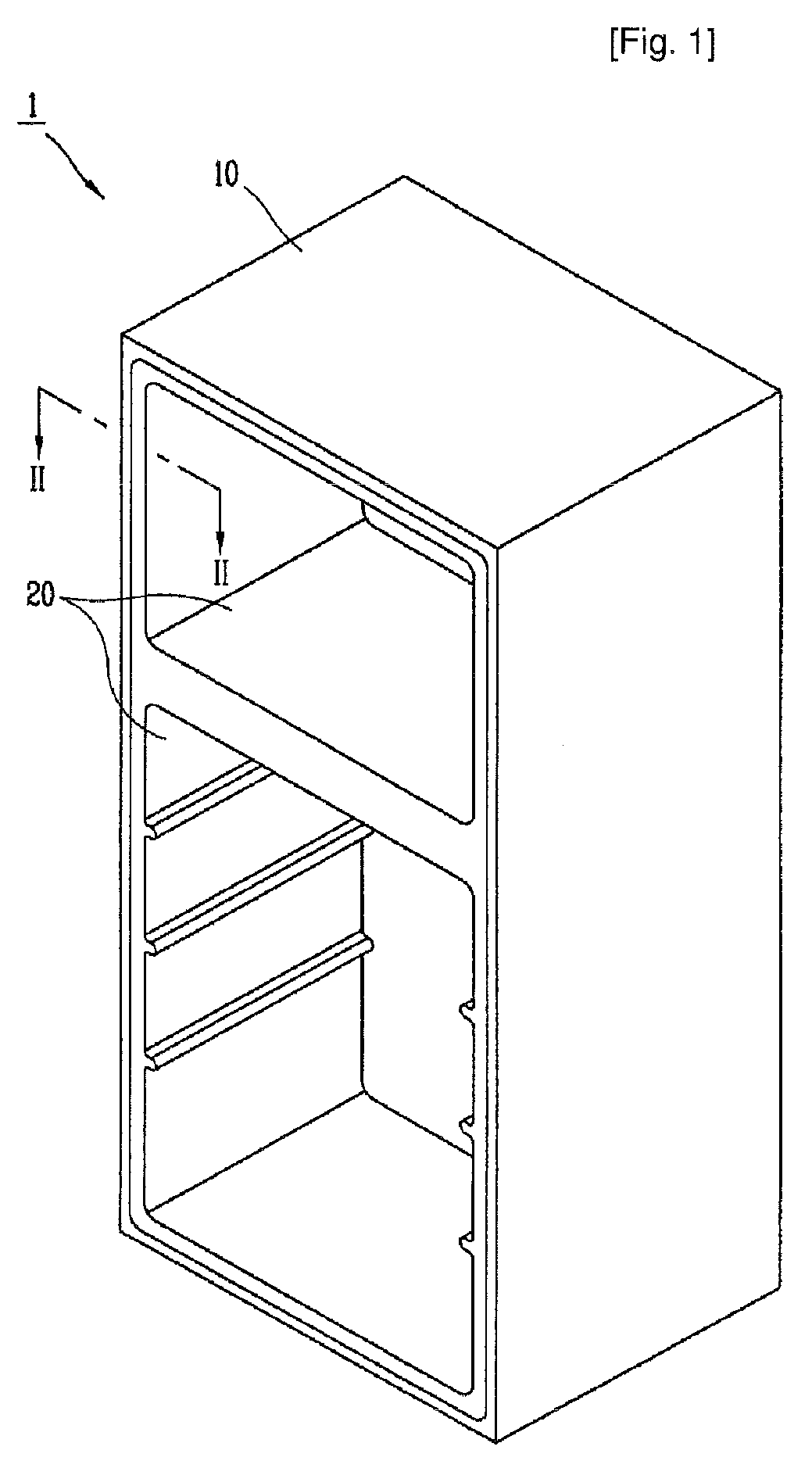

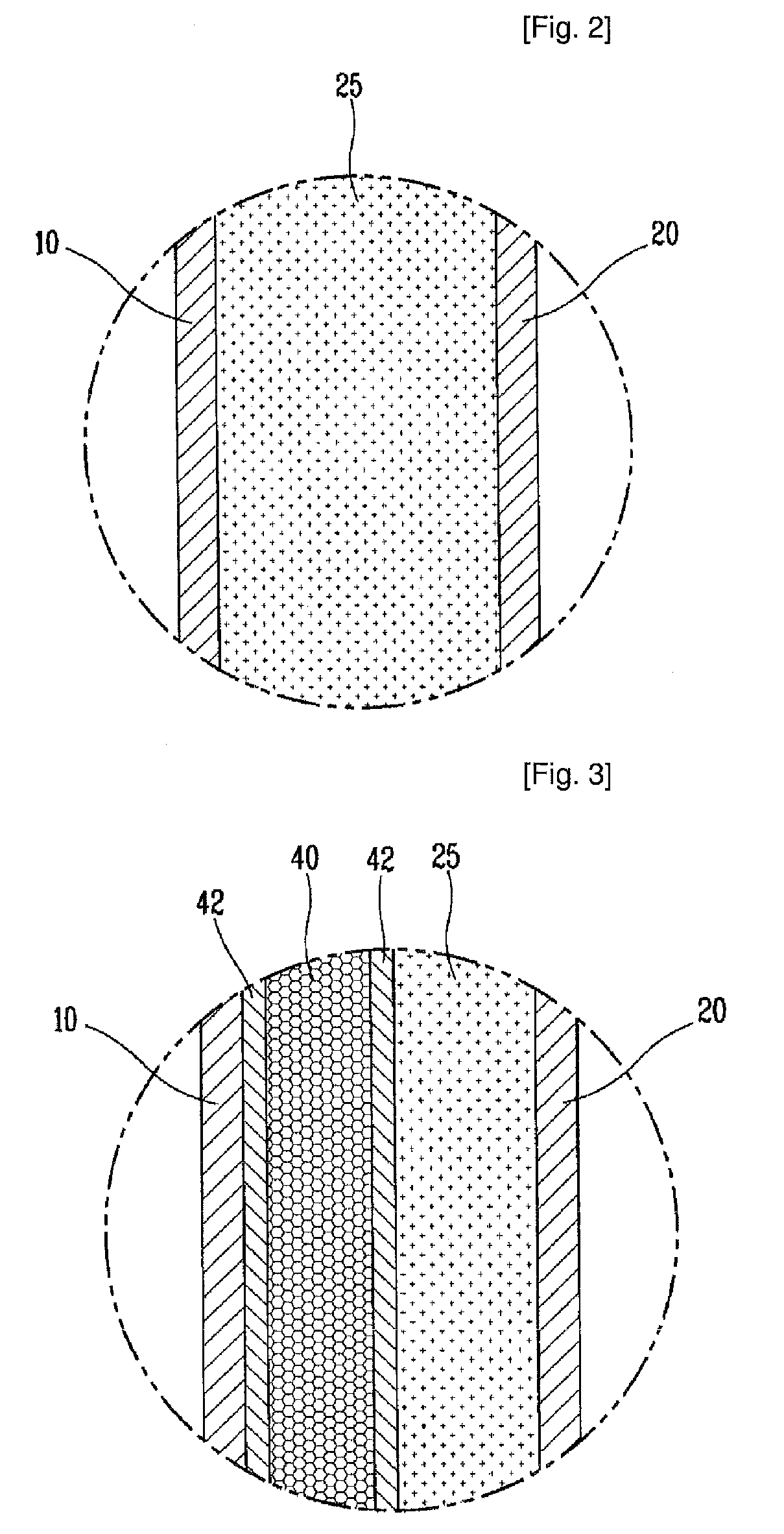

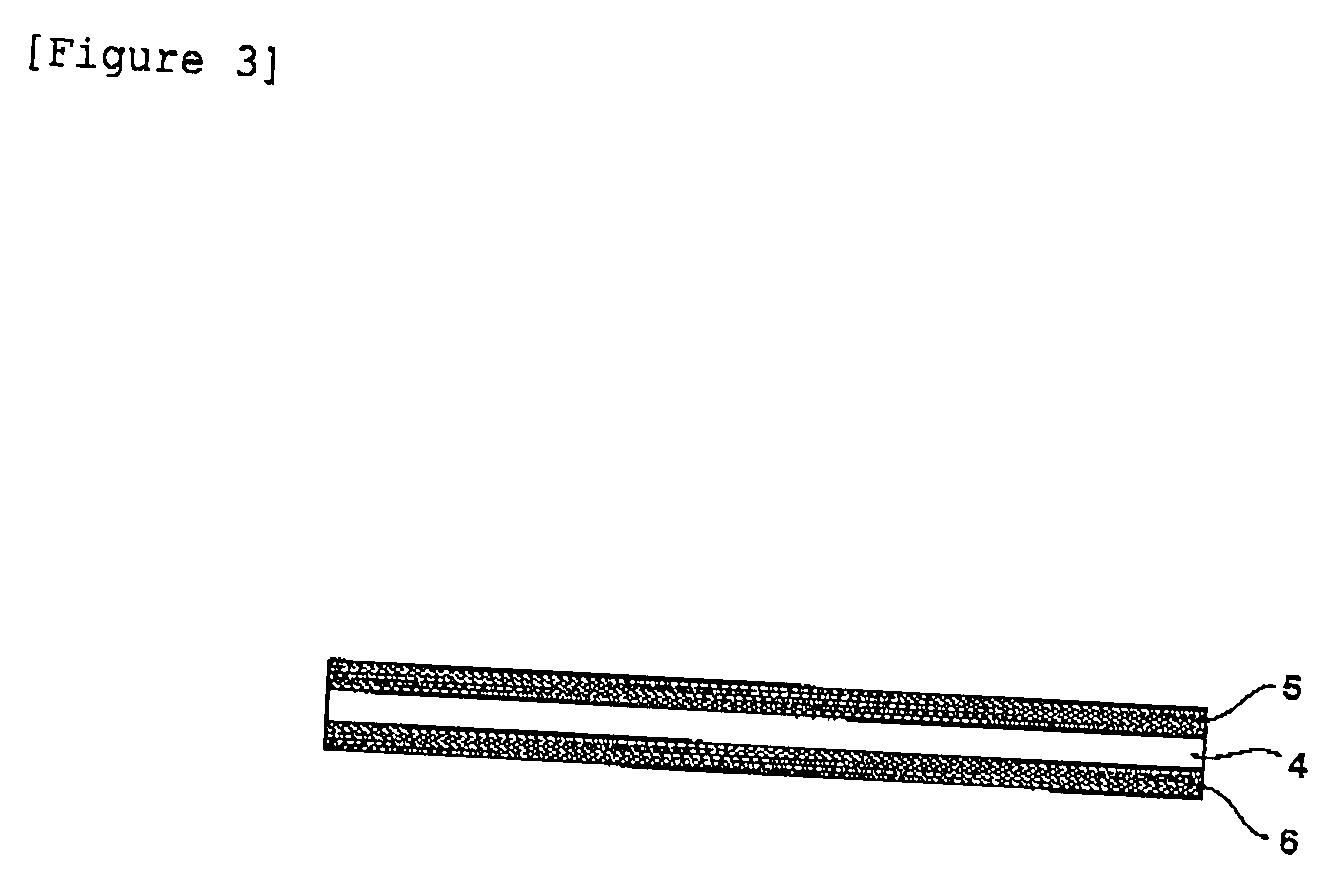

Vaccum Insulation Panal And Insulation Structure Of Refrigerator Using The Same

InactiveUS20080280090A1Low costImprove insulation efficiencyShow cabinetsLighting and heating apparatusGlass fiberEngineering

Disclosed are a vacuum insulation panel and an insulation structure of a refrigerator using the same. The vacuum insulation panel comprises a core material formed by gather glass fiber, a getter having a container to receive an absorbent having quicklime of 90 wt % or greater as a main component, and a sealing cover formed to surround the core material and the getter. The core material can be formed at low cost in such a manner that glass fiber is tangled and gathered by penetrating glass wool having glass fiber using a needle. Since the getter is made of quicklime that can first remove water corresponding to a main component of the absorbent, the getter can be manufactured at low cost and has improved insulation efficiency.

Owner:LG ELECTRONICS INC

Preparation method of aerosil composite glass cotton fiber needled felt

The invention provides a preparation method of an aerosil composite glass cotton fiber needled felt. The method mainly utilizes compounding of modified aerosil slurry and a glass cotton fiber needled felt; raw materials of the modified aerosil slurry comprise aerosil, a modifier, a surfactant and a solvent. According to the invention, the aerosil and the glass cotton fiber needled felt with fireproof performance are compounded, so that the heat conductivity coefficient of the glass cotton fiber needled felt can be greatly reduced, meanwhile, the high-temperature resistance and the waterproofness are improved, the use thickness of the glass cotton fiber needled felt under the same requirements is reduced and the glass cotton fiber needled felt is convenient to construct, and thus, construction efficiency of workers is improved and the cost of comprehensive construction is reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

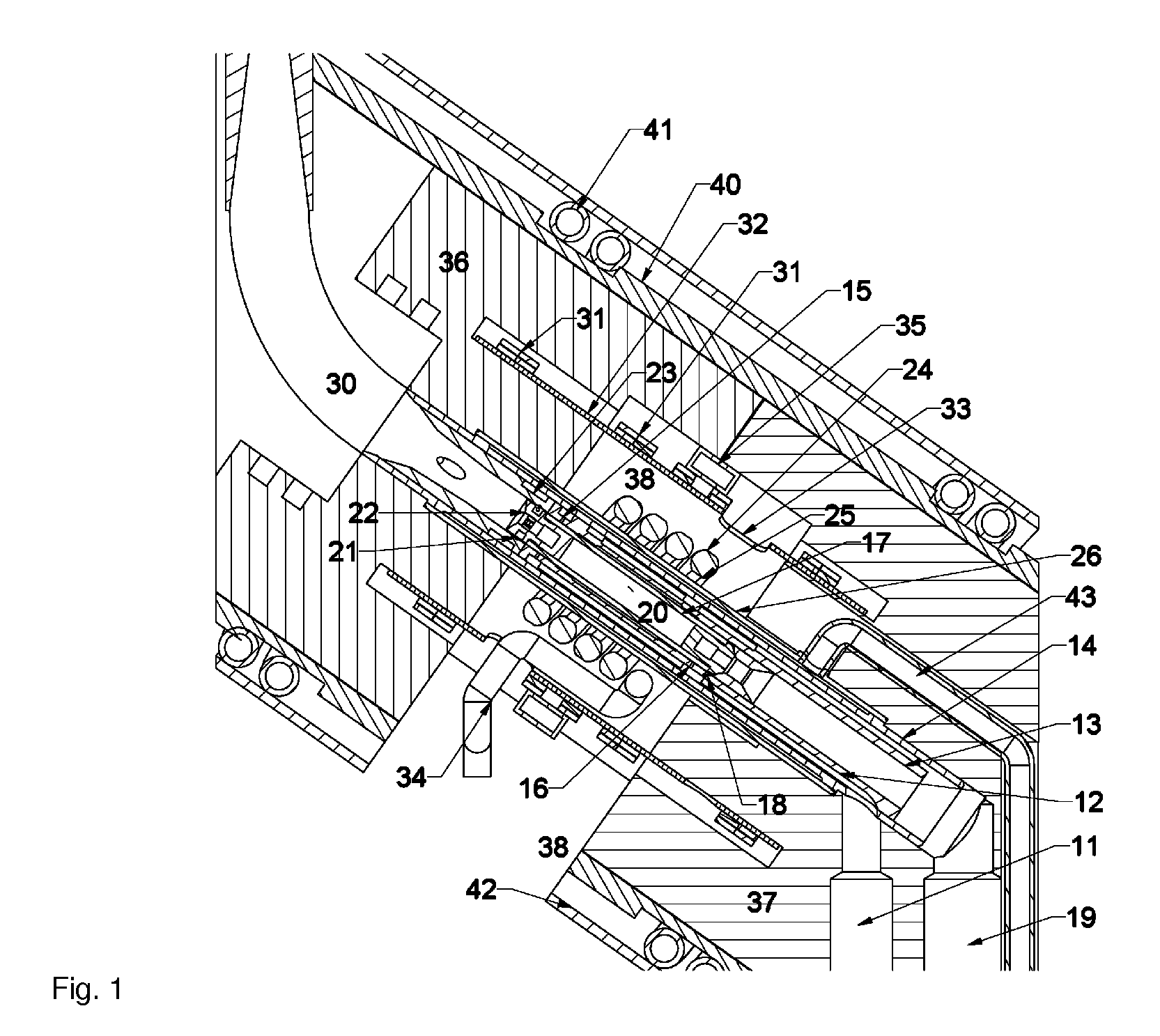

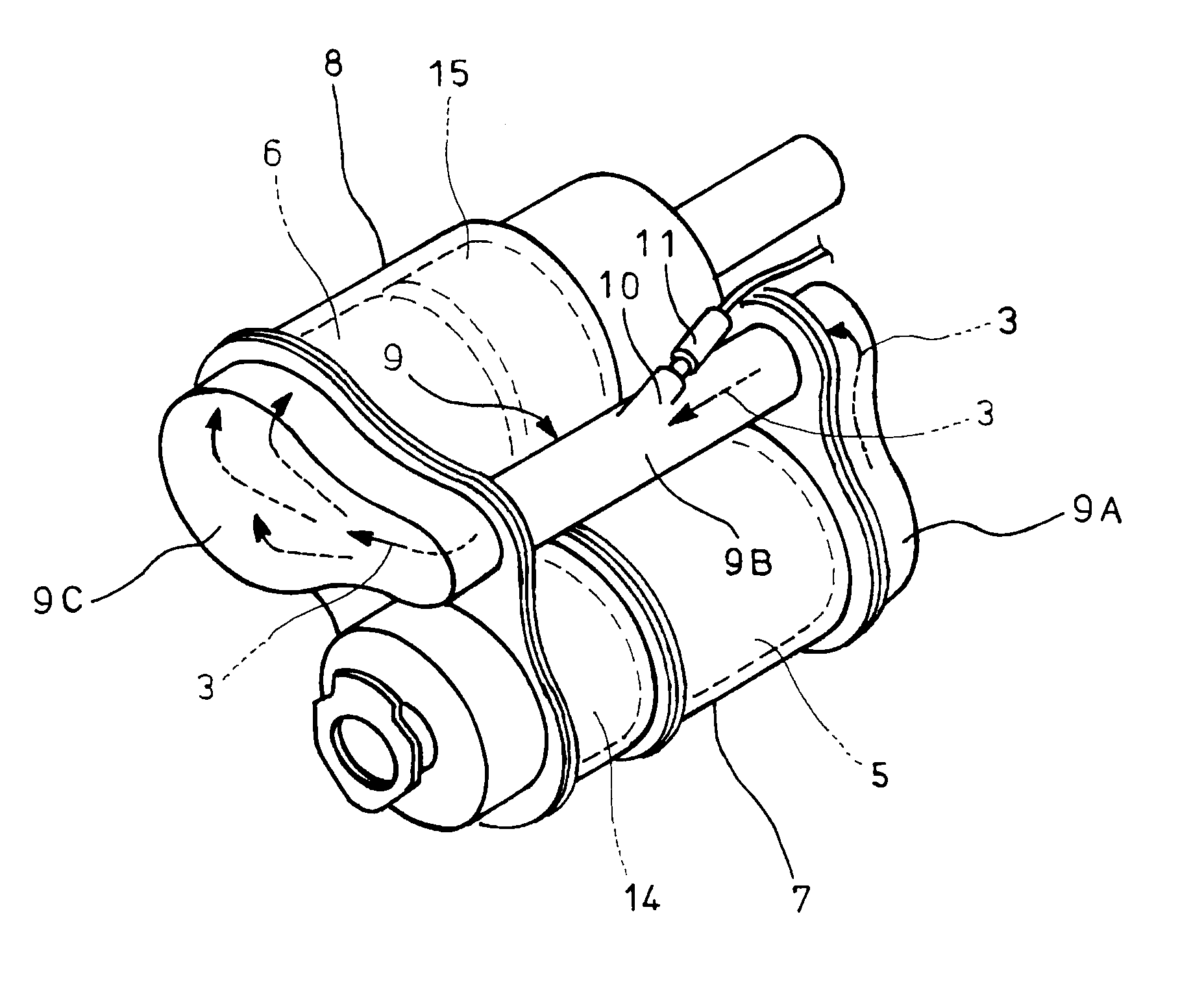

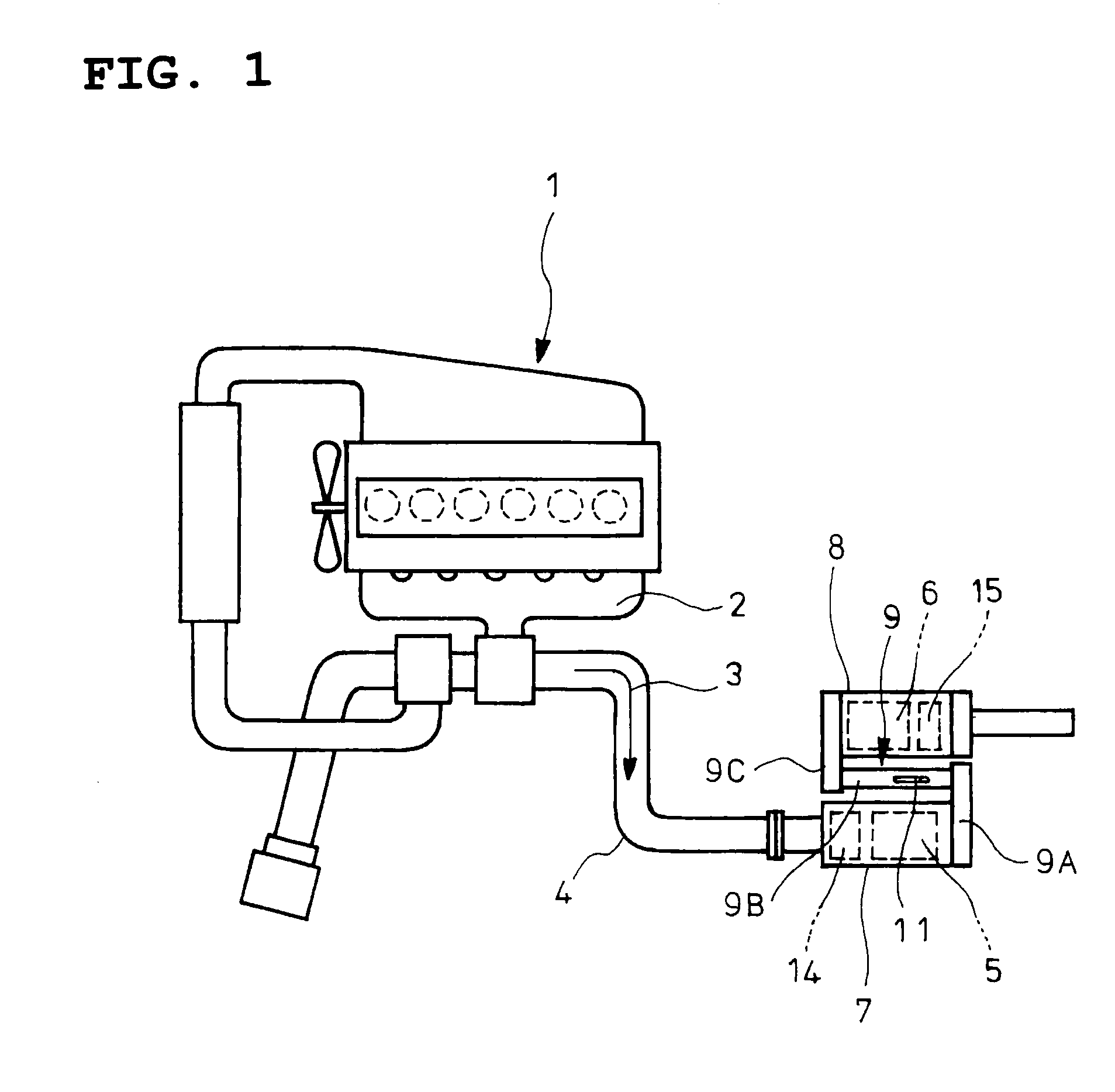

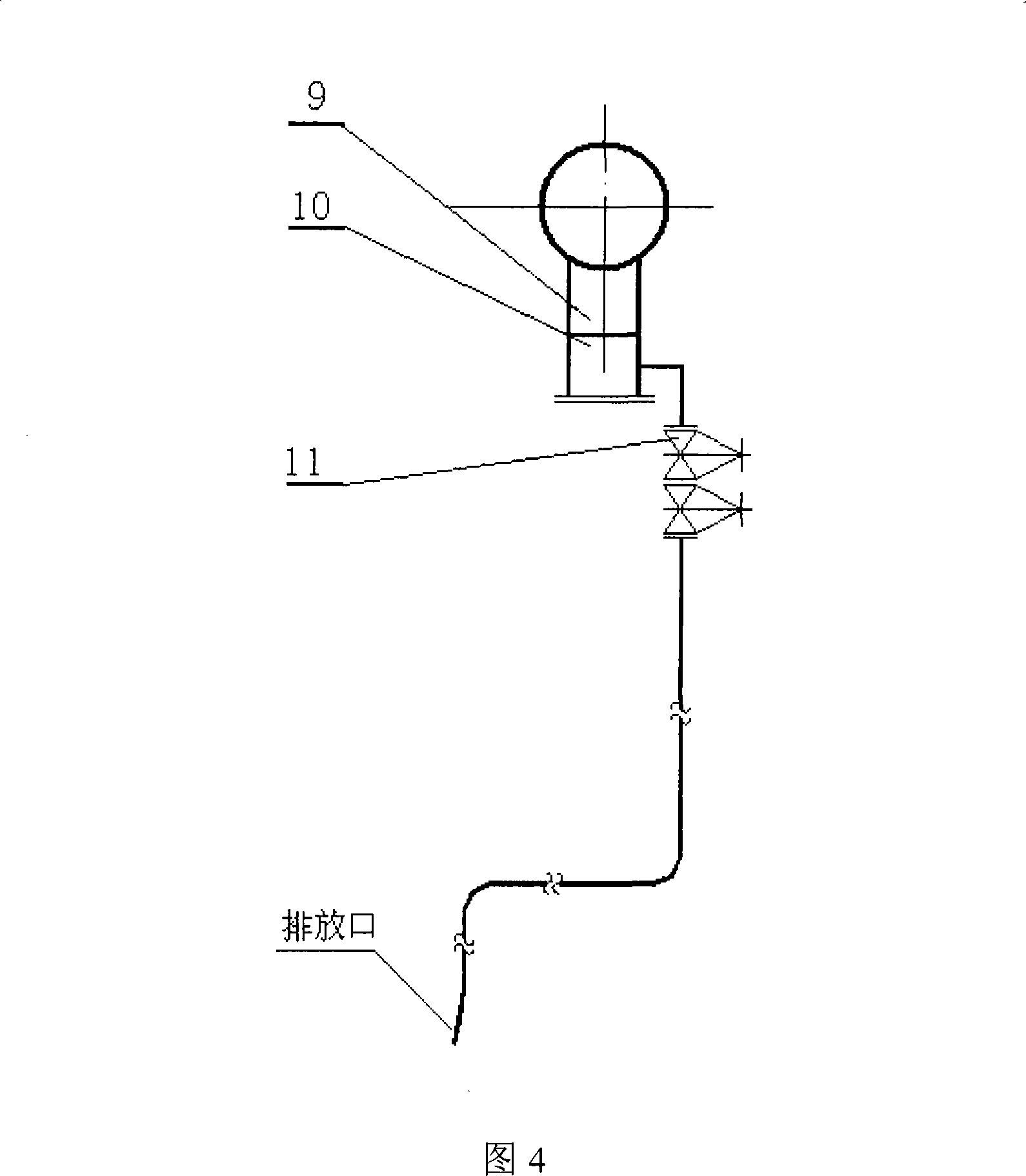

Exhaust emission control device

ActiveUS20100257849A1Easy to disperseAvoid hard collisionInternal combustion piston enginesFlow mixersParticulatesExhaust fumes

An object of the invention is to provide an exhaust emission control device which eliminates the use of a heat-retention structure using heat-insulating material such as glass wool so as to attain substantial lessening in production cost. A discharge end of a gas gathering chamber is connected to an entry end of a mixing pipe so as to encase the entry end of the mixing pipe and close an opened end face in a required spaced-apart relationship. Moreover, a side surface of the entry end of the mixing pipe adjacent to the discharge side of the particulate filter is formed with an opening; and gas guide passages are formed in the gas gathering chamber by guide fins for tangential introduction of all of the exhaust gas from the discharge side of the particulate filter to the opening. An extra space isolated from the gas guide passages is ensured in the gas gathering chamber as a heat-retention chamber surrounding the entry end of the mixing pipe.

Owner:HINO MOTORS LTD

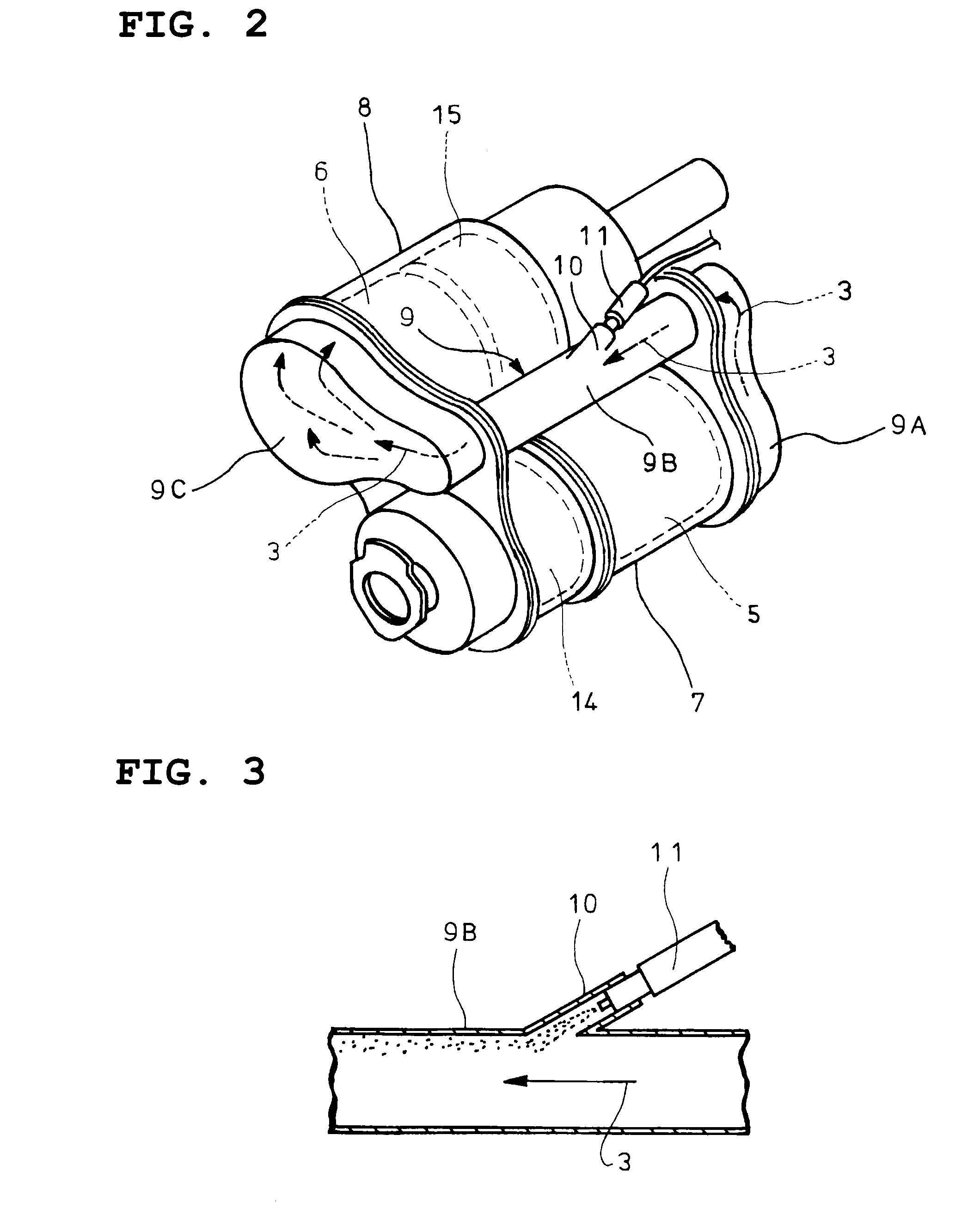

Automotive sound-absorbing material

A thin and light-weight automotive sound-absorbing material with a superior sound-absorbing property, which can be used, for example, for automotive insulator to keep the interior of an automobile quiet. This automotive sound-absorbing material has a laminate structure comprising a sound-absorbing layer, an intermediate layer, and a sound-absorbing layer. The intermediate layer comprises a film made of thermoplastic resin with a thickness of 10 to 100μ, on which small pores are uniformly opened in such a manner that the aperture ratio would be 0.05 to 5%. The sound-absorbing layers comprise an aggregate of fibers such as felt, glass wool, etc. or porous synthetic resin layer, such as urethane foam, etc.

Owner:HOWA TEXTILE IND

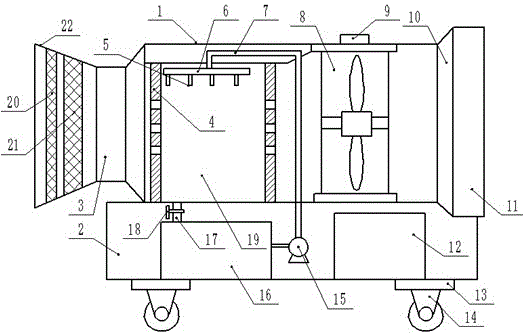

Movable mine ventilation device

The invention discloses a movable mine ventilation device. The movable mine ventilation device comprises a ventilation device body, a base, a spraying room, a low-frequency silencing layer and a high-frequency silencing layer. The ventilation device body is installed on the base. A frequency converter is arranged on the ventilation device body. A draught fan is arranged on the left portion of the interior of the ventilation device body. An air inlet pipe port is formed in the right end of the ventilation device body. A filter screen is arranged on the air inlet pipe port. An air outlet pipe port is formed in the left end of the ventilation device body. A water return pipe is arranged at the bottom of the spraying room. A diffusion plate is arranged at the left end of the air outlet pipe port. The low-frequency silencing layer and the high-frequency silencing layer are arranged in the diffusion plate. The low-frequency silencing layer and the high-frequency silencing layer are made of waterproof centrifugal glass wool. According to the movable mine ventilation device, through the arrangement of the spraying room, the air humidity can be increased, and the content of dust in air can be reduced, so that the air quality in a mine roadway is improved; and through the arrangement of the low-frequency silencing layer and the high-frequency silencing layer, noise can be lowered.

Owner:徐州安普瑞特能源科技有限公司

Glass wool for dry vacuum insulated panel core material and production method thereof

The invention discloses a glass wool for a dry vacuum insulated panel core material and a production method thereof. The production method comprises the following steps of mixing the following components in parts by mass to form a mixture: 10.0-40.0 parts of quartz powder, 10.0-12.5 parts of feldspar, 9.0-11.0 parts of sodium borate, 1.5-3.5 parts of calcspar, 2.5-7.0 parts of dolomite, 7.0-15.0 parts of sodium carbonate and 15.0-60.0 parts of plate glass; adding the mixture into a melting tank of a kiln to melt and prepare vitreous humour; putting the vitreous humour into a bushing well and a centrifugal plate, and conveying to a centrifugal machine to spin and prepare the glass wool. The glass wool disclosed by the invention can be directly prepared into the dry vacuum insulated panel core material. Compared with the insulated panel core material produced by a wet process, the glass wool is short in production flow; and wet pulp is prepared without adding water or baking. Therefore, the production efficiency is improved; the energy source is greatly saved; the price of the insulated panel is reduced, and strong popularization and use of the market are facilitated.

Owner:安徽吉曜玻璃微纤有限公司

Rigid vacuum insulating plate and manufacturing method thereof

InactiveCN102434758AImprove carrying capacityImprove compactnessThermal insulationPipe protection by thermal insulationPorosityGas phase

The invention discloses a rigid vacuum insulating plate, which is characterized in that the rigid vacuum insulating plate is combined by a sealed metal separating plate housing and internal inorganic porous core material; the heat conductive coefficient of the vacuum insulating plate is 3-10mW / m.K; each one square meter of the vacuum insulating plate can bear 1-2 ton of counter without being deformed and can be kept airproof when the insulating board is punctured by needles and grinded by grains of sand; the housing of the separating plate is made from stainless steel or titanium alloy with thickness of 0.2-1.2mm, but is not limited to stainless steel or titanium alloy; the inorganic porous core material is glass wool felt or gas phase silicon dioxide with porosity of 40-80%, but is not limited to glass wool felt or gas phase silicon dioxide. A manufacturing method for the rigid vacuum insulating plate is further disclosed in the invention. The vacuum insulating board provided by the invention can be directly used as insulating materials for buildings as well as insulating floors for refrigeration houses and ships.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

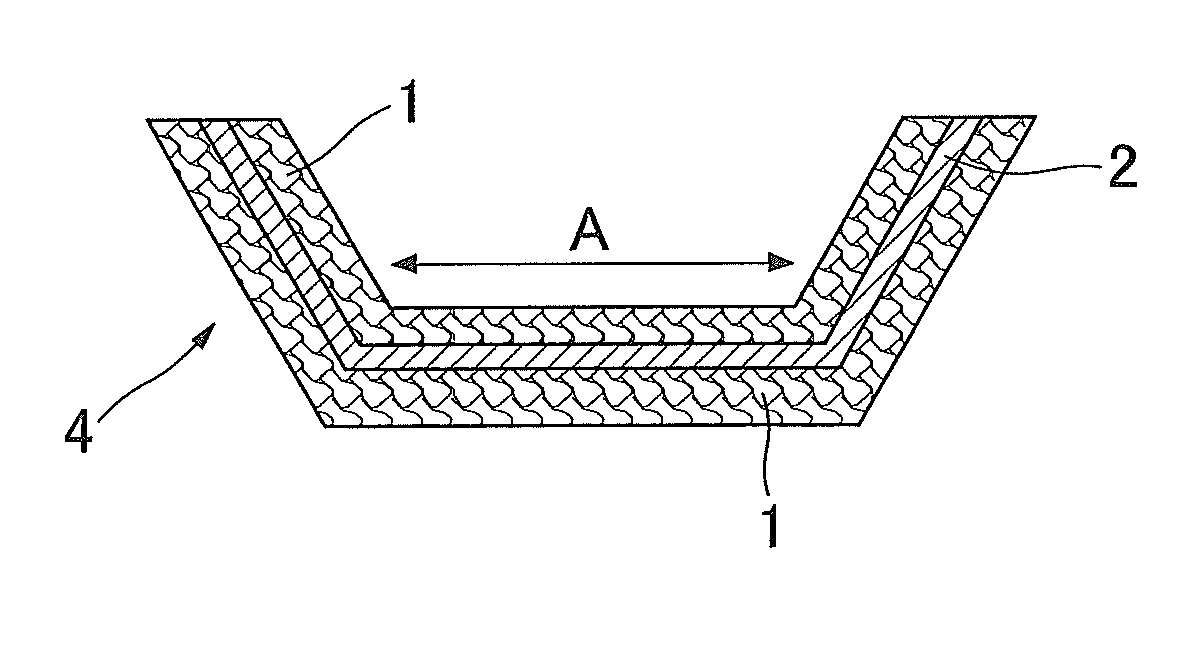

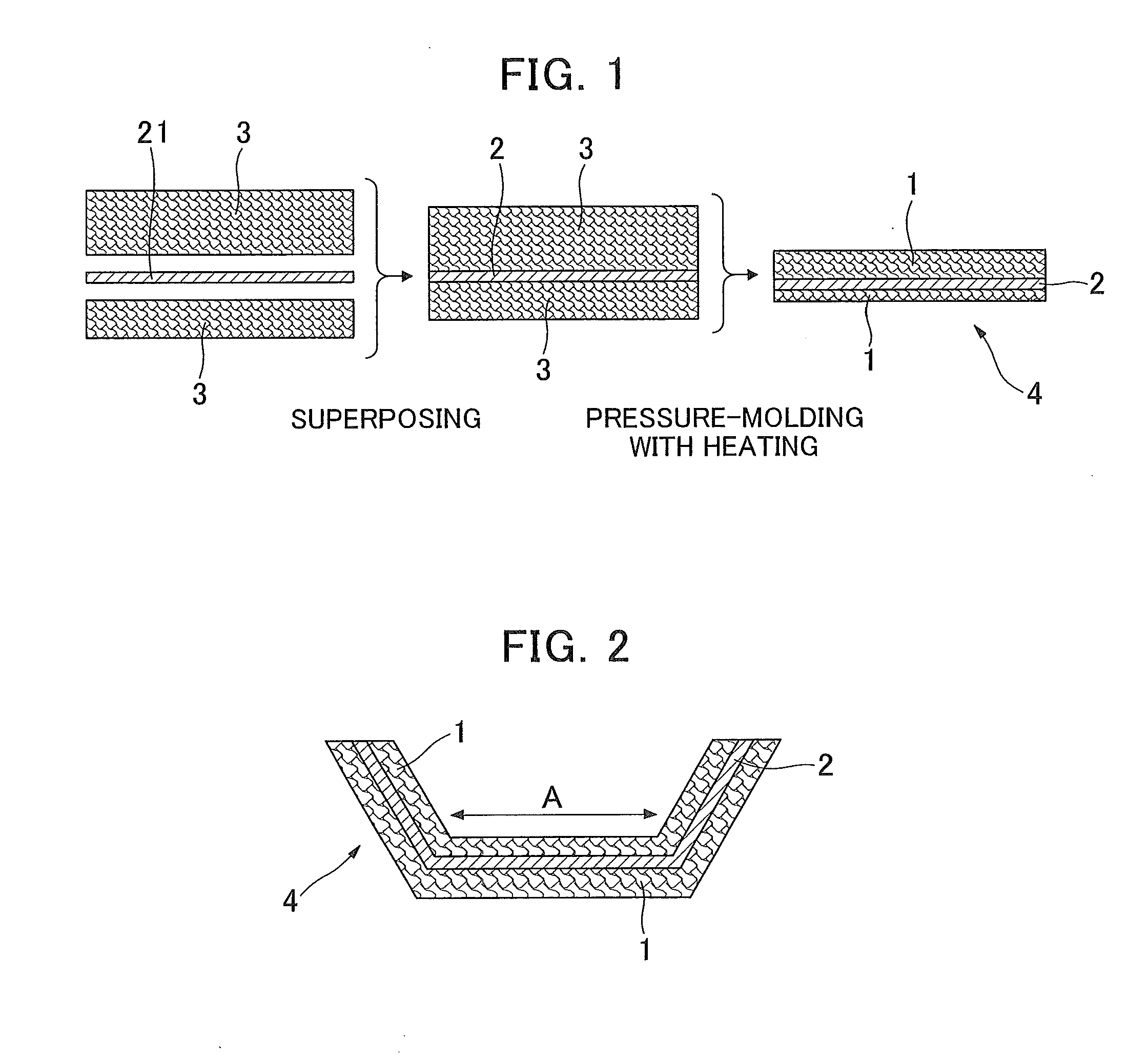

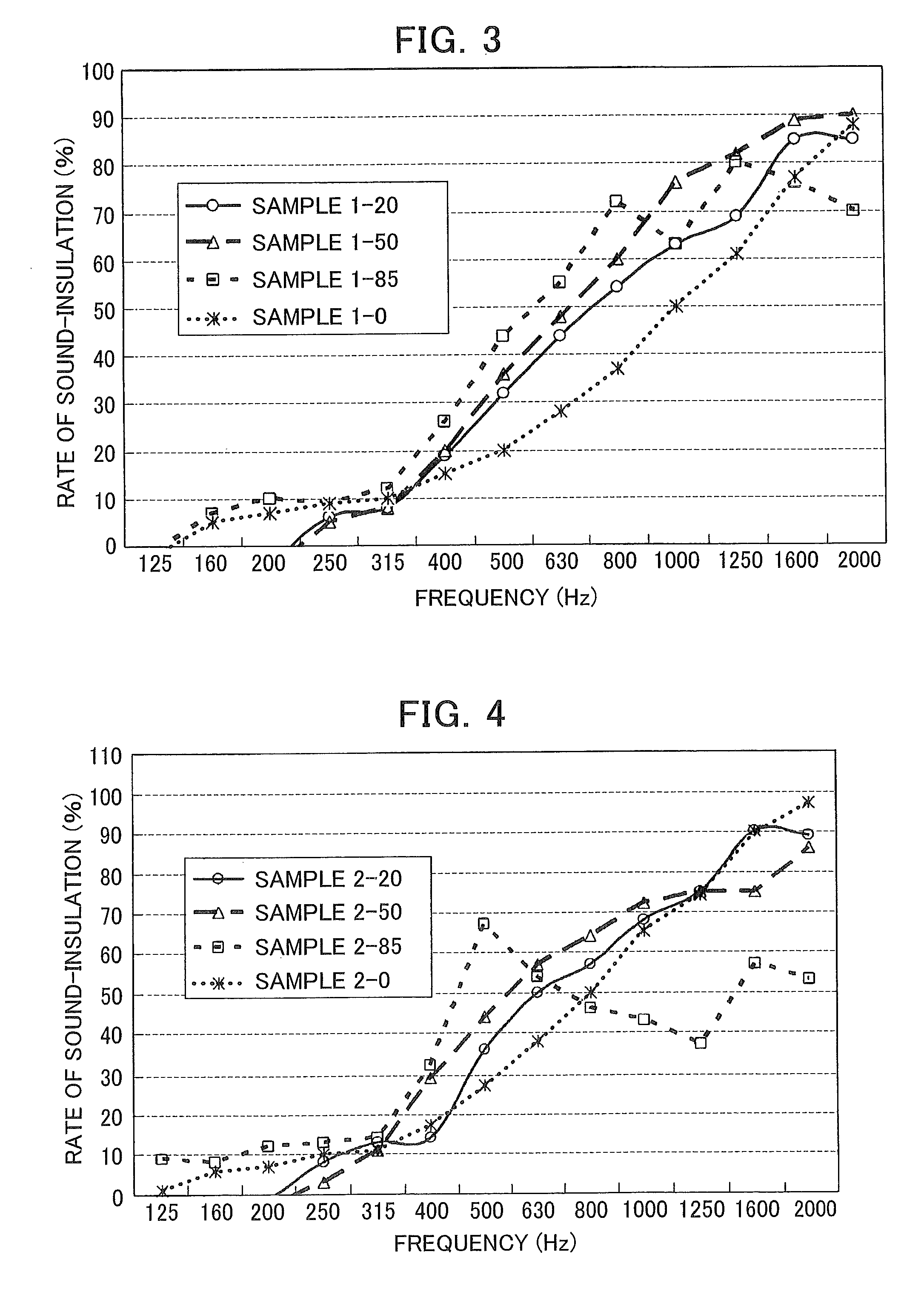

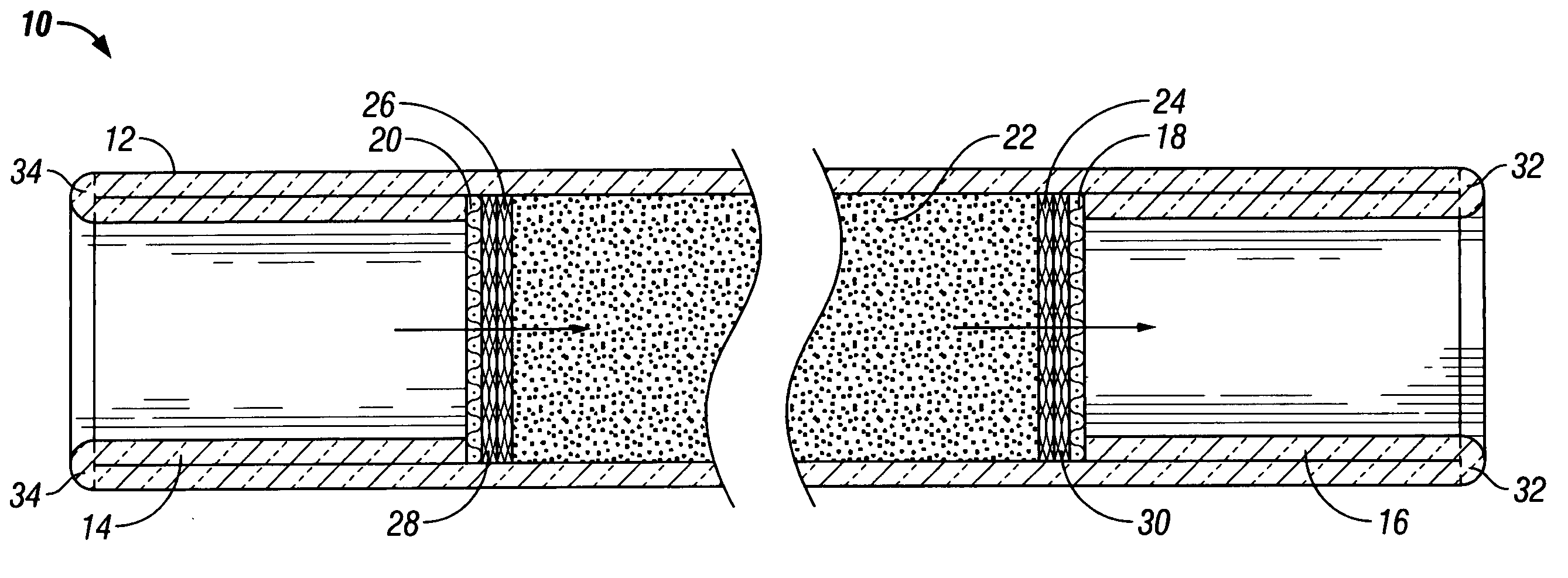

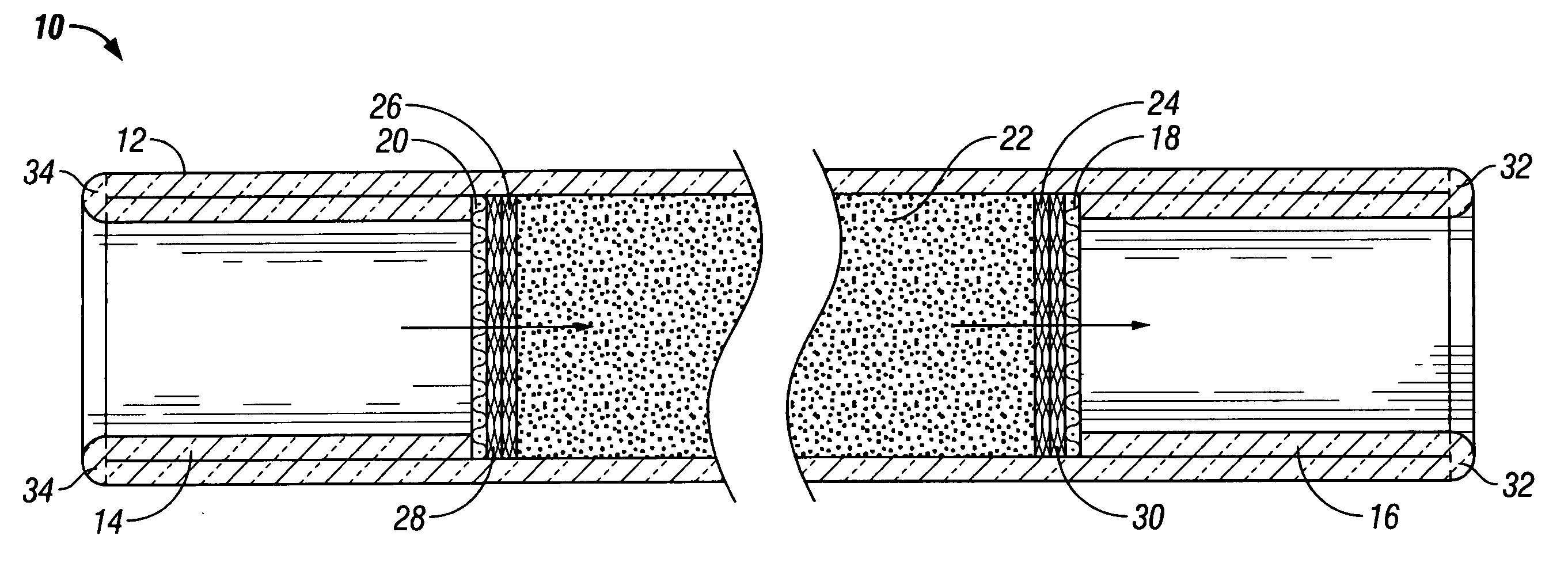

Sound-insulating laminated structure and method for the production thereof

InactiveUS20100101891A1Good low frequencyImprove insulation performanceWallsSound proofingMetal foilGlass wool

Herein provided is a sound-insulating laminated structure which is excellent in the ability of insulating low frequency sounds whose frequency falls within the range of from 200 to 1000 Hz.The sound-insulating laminated structure comprises a first glass wool layer, a metal foil layer free of any opening and a second glass wool layer. The first and second glass wool layers are ones each prepared by collecting and combining short glass fibers through the application of an uncured thermosetting phenol resin to the short glass fibers to thus give a web of glass wool prepreg and then molding, with heating, the web into a sound-insulating laminated structure having a desired shape.

Owner:CENT GLASS CO LTD

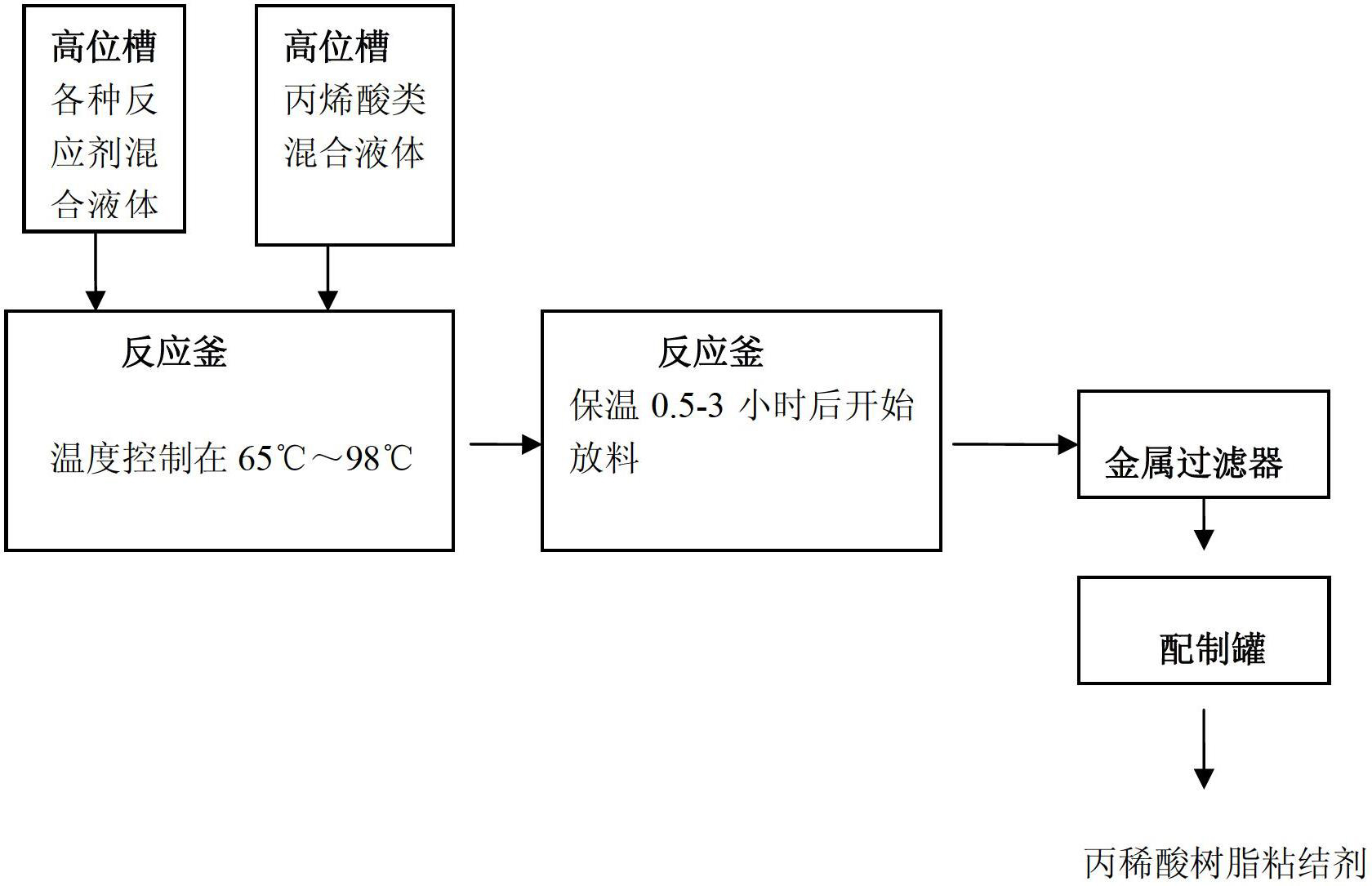

Preparation method of thermosetting acrylic resin binder

ActiveCN102690618AReduce intensityLow moisture absorptionNon-macromolecular adhesive additivesGraft polymer adhesivesPolyesterAcrylic resin

The invention discloses a preparation method of a thermosetting acrylic resin binder which does not contain formaldehyde. The preparation method comprises the following steps: carrying out graft copolymerization reaction on a acrylic acid type compound and an acrylic acid polyester compound under the action of an initiator, a chain transfer agent and a retarder so as to obtain a thermosetting acrylic resin; subsequently adding a softening agent, a curing agent, an emulsifying agent and a mildew preventive; stirring uniformly and filtering so as to prepare the thermosetting acrylic resin binder used for glass wool. The binder prepared by using the method does not contain free formaldehyde and free phenol, so the product does not release free aldehyde during the application process and is an environment-friendly green binder.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL +1

Organic fiber friction material composition for brake pad

ActiveCN103059805AReduce noiseImprove comfortOther chemical processesFriction liningLow noiseCarbon fibers

The invention relates to an organic fiber friction material composition for a brake pad, which is prepared from the following components in parts by weight: 3-7 parts of chromite, 4-8 parts of barite, 5.5-7 parts of calcined petroleum coke, 3-6 parts of flaky graphite, 10-14 parts of boric acid modified phenolic resin, 3-6 parts of meerschaum fiber, 4-7 parts of ceramic fiber, 1.5-3 parts of antimony sulfide, 4-7 parts of bronze powder, 3-5 parts of glass wool, 1-2.5 parts of zirconite, 6-10 parts of flaky potassium titanate, 8-11 parts of vermiculite powder, 1-2.5 parts of carbon fiber, 4-6 parts of aramid fiber pulp, 1-2.5 parts of wood pulp cellulose, 3-6 parts of viscose fiber, 6-9 parts of silicon carbide and 6-10 parts of cellulose fiber. The invention has the advantages of small specific gravity, high wear resistance, favorable toughness, low noise, long service life and the like. The glass wool, bronze powder and other heat dissipation materials added in the formula can effectively perform the functions of heat insulation and heat dissipation.

Owner:摩擦一号制动科技(仙桃)有限公司

Production method of centrifugal glass cotton-like fiber

InactiveCN103130410ALow densityLow thermal conductivityGlass making apparatusChemical reactionCentrifugation

The invention discloses a production method of a centrifugal glass cotton-like fiber. According to the production method of the centrifugal glass cotton-like fiber, materials of quartz sands, orthoclases, limestones, glass cullet, soda ashes, borax and the like are adopted, the materials are mixed in a reasonable proportion, glass liquids can be obtained after physical and chemical reactions through kiln high-temperature melting, and short glass fiber cotton aggregates can be thrown out through high-speed centrifugal injection. Material produced through the production method of the centrifugal glass cotton-like fiber has the advantages of being small in density, low in heat conductivity, high in acoustic absorptivity, flame-resistant, frost-resistant, and not prone to decay. The material is ideal heat preservation and heat insulation material, and is mainly used in the heat insulation process of building rail structures, industrial equipment, and pipe networks, and fireproofing and the like of the buildings. The material can further used as a sound absorber which absorbs and eliminates sounds, sound-absorbing barriers, sound-absorbing wall faces and the like.

Owner:吴振华

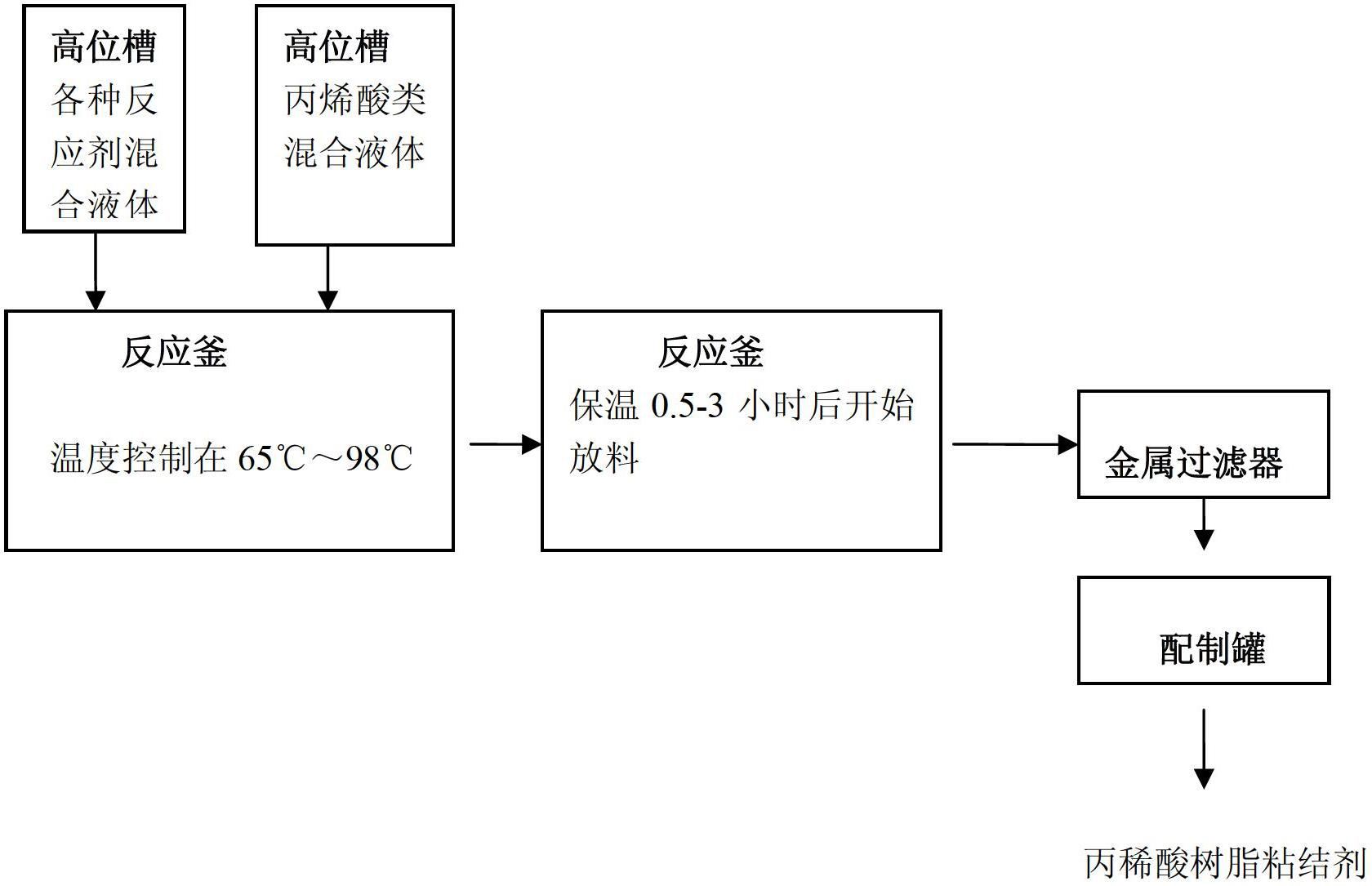

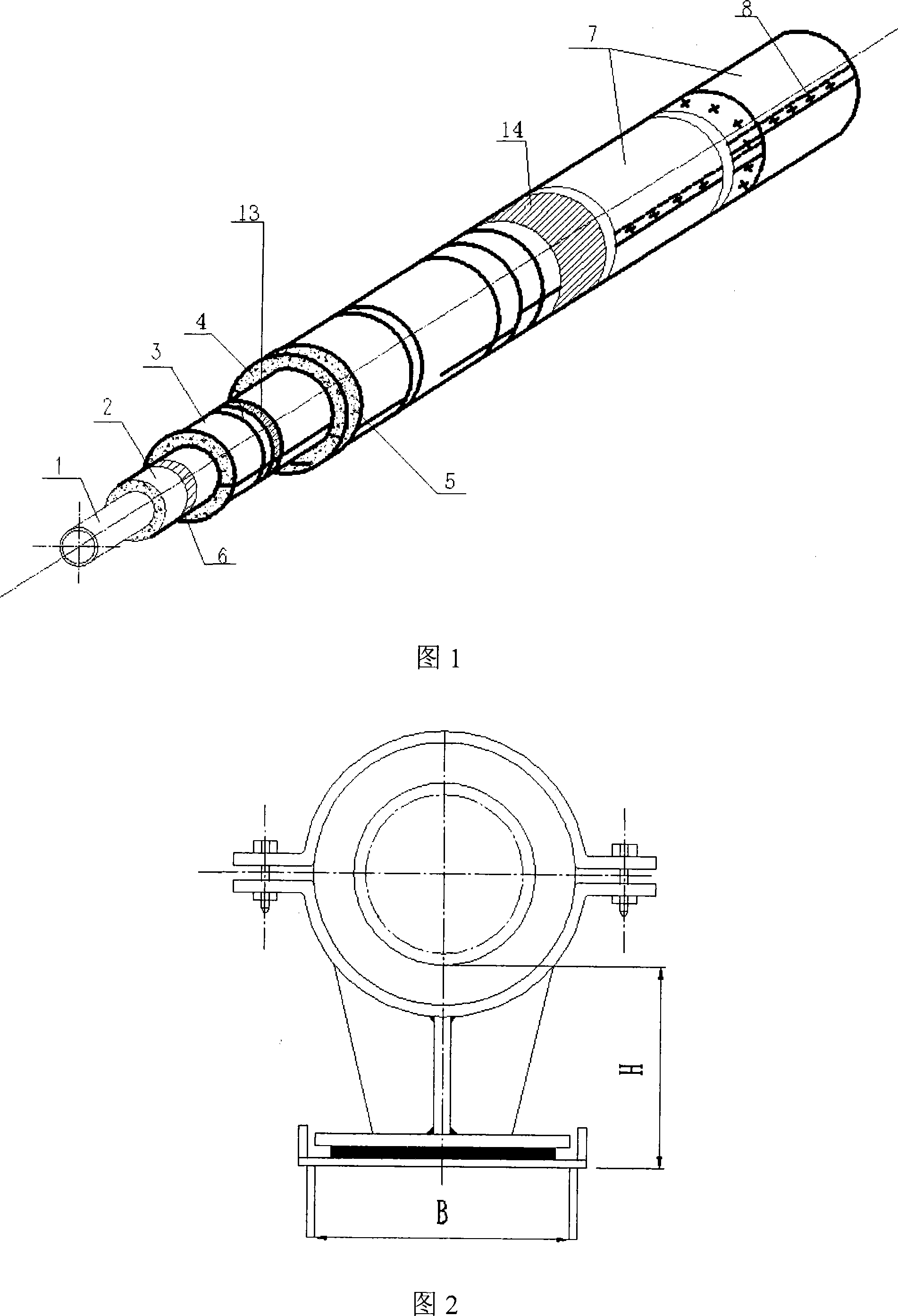

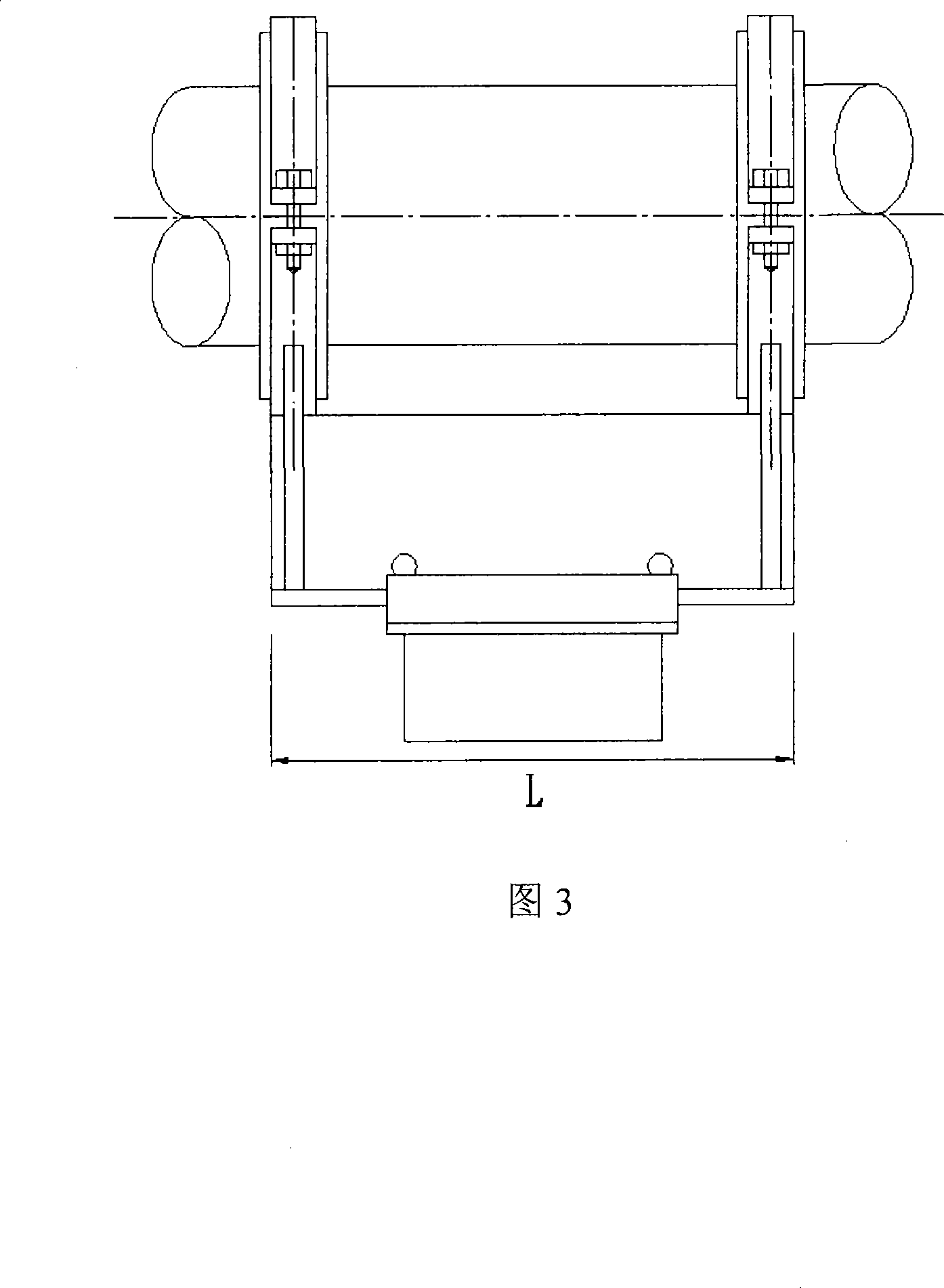

Long heat transport net technology

ActiveCN101135468AEnsure heating parametersReduce heat lossThermal insulationPipe protection by thermal insulationResistFiber

The invention relates a long- distance delivery heat network technique. Its characteristics as following: utilizing high temperature glass wool thermal insulating material and multi-layer heat insulating structure, an external top thermal insulating layer with a layer high temperature glass wool is added at external top part of outermost thermal insulating layer; flame resist aluminum foil glass fiber cloth reflective layer is coated at every layer of thermal insulating material; utilizing effective heat isolating energy sliding pipe carrier, color -wash plate is laded at outermost layer; steam pipeline is set at front and middle part of steam pipe network to start drainage; starting drainage and continuous drainage is set at rear part of the steam pipe network. The invention can lower effectively heat loss during the process of steam transporting.

Owner:南京苏夏设计集团股份有限公司

Centerless ground thermal desorption tube and method without frit

InactiveUS20050180893A1Easy constructionThe material is lowAnalysis using chemical indicatorsWithdrawing sample devicesFritSorbent

A centerless ground thermal desorption tube comprises an outer barrel and one or more inner spacers insertably positioned within the outer barrel. A suitable sorbent material is positioned within the outer barrel which may be held in place by friction and / or with glass wool plugs, and / or screens, and / or the inner spacers. In one preferred embodiment one glass inner spacer is fused to one end of a glass outer barrel prior to the glass outer barrel being centerless ground to a high precision. The sorbent and / or any wool plugs and / or screens are inserted into a second opposite end of the outer barrel after the centerless grinding process. A second glass is fused to the second end of the glass outer barrel whereby the glass fusing may change the precise tolerance of the centerless ground glass outer barrel at the second end only.

Owner:HANDLY ROBERT A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com