Patents

Literature

657results about How to "Suitable for productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-temperature-resistant aerogel and aerogel-type porous ceramics

PendingCN107098352AImprove high temperature resistanceAvoiding Densification ProblemsSilicaZirconium compoundsThermal insulationWhiskers

The invention discloses a preparation method of high-temperature-resistant aerogel. The method comprises: adding high-temperature-resistant powder or crystal whiskers to sol, performing in-situ compounding of sol and high-temperature-resistant powder or crystal whiskers, and performing aging, modification and drying to obtain high-temperature-resistant aerogel. The invention further discloses a preparation method of aerogel-type porous ceramics. Porous ceramics having an aerogel hole structure kept is obtained by sintering the high-temperature-resistant aerogel. The prepared high-temperature-resistant aerogel and aerogel-type porous ceramics can resist high temperature of 1000-1800 DEC C or more, keep the nanometer hole structure from collapse, have high porosity and strength and have hole diameters which can be adjusted from micropores to large holes. The aerogel and aerogel-type porous ceramics can be used as a super thermal insulation material and can be widely applied to fields of purification separation, adsorption, chemical industrial catalytic carriers, sound absorption and damping, sensing elements and electrochemistry. The method is simple and easy to carry out and suitable for massive production, and allows high temperature resistance of aerogel to be improved and application fields of aerogel to be broadened.

Owner:浙江圣润纳米科技有限公司

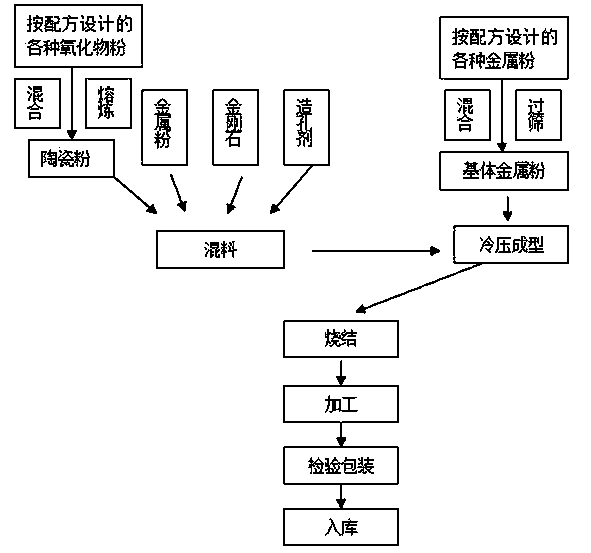

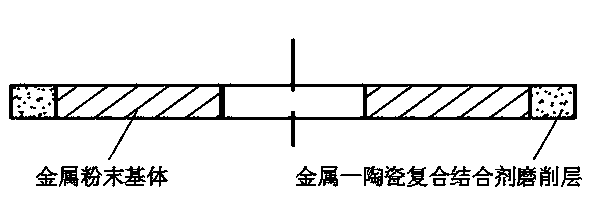

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

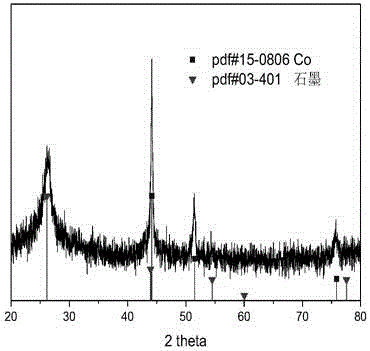

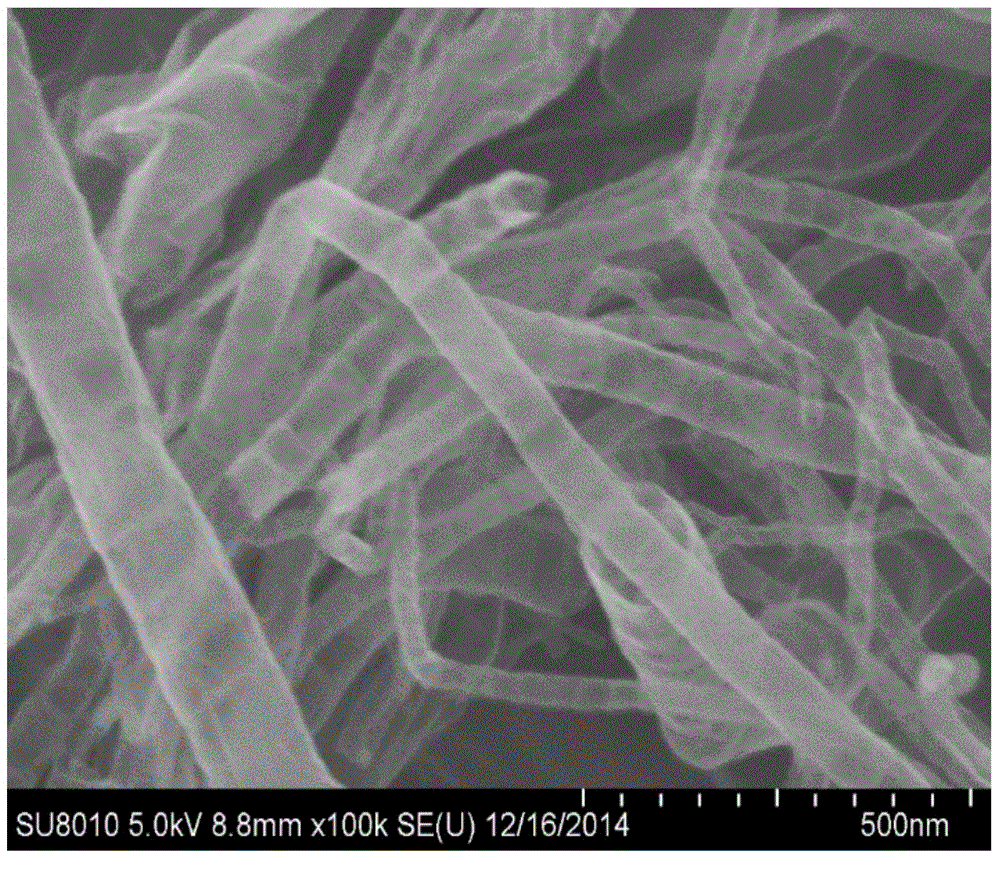

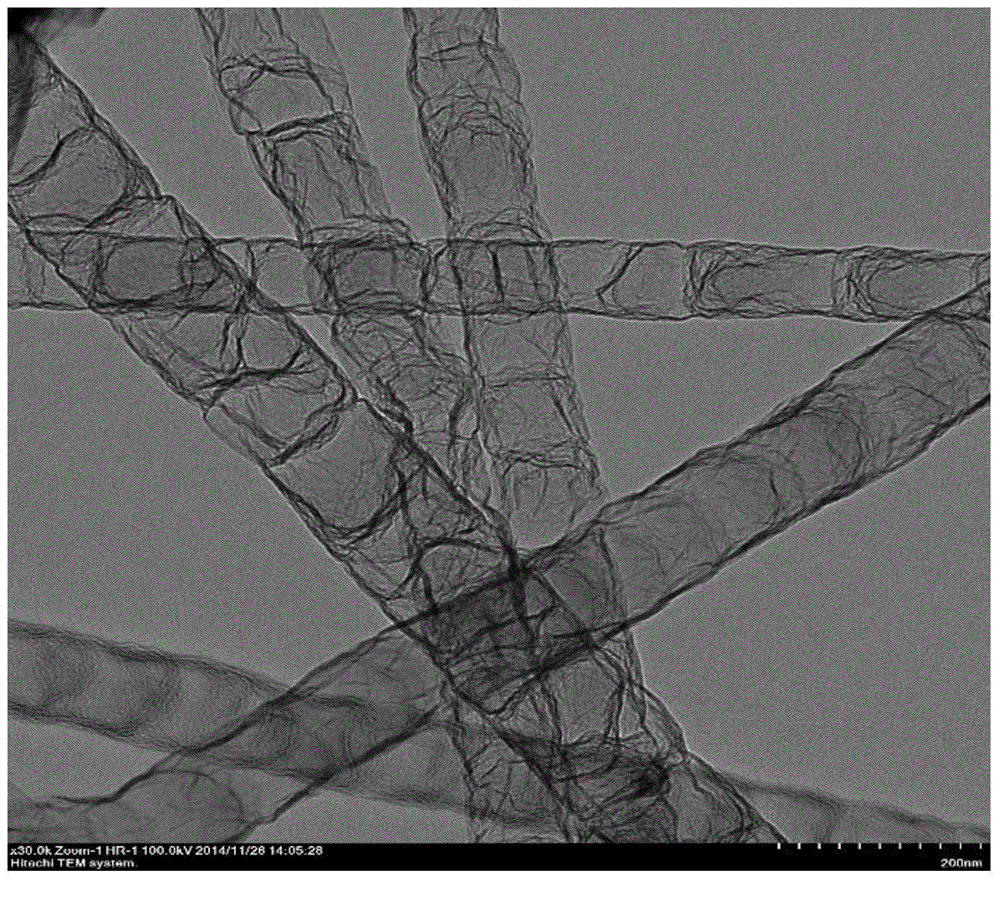

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

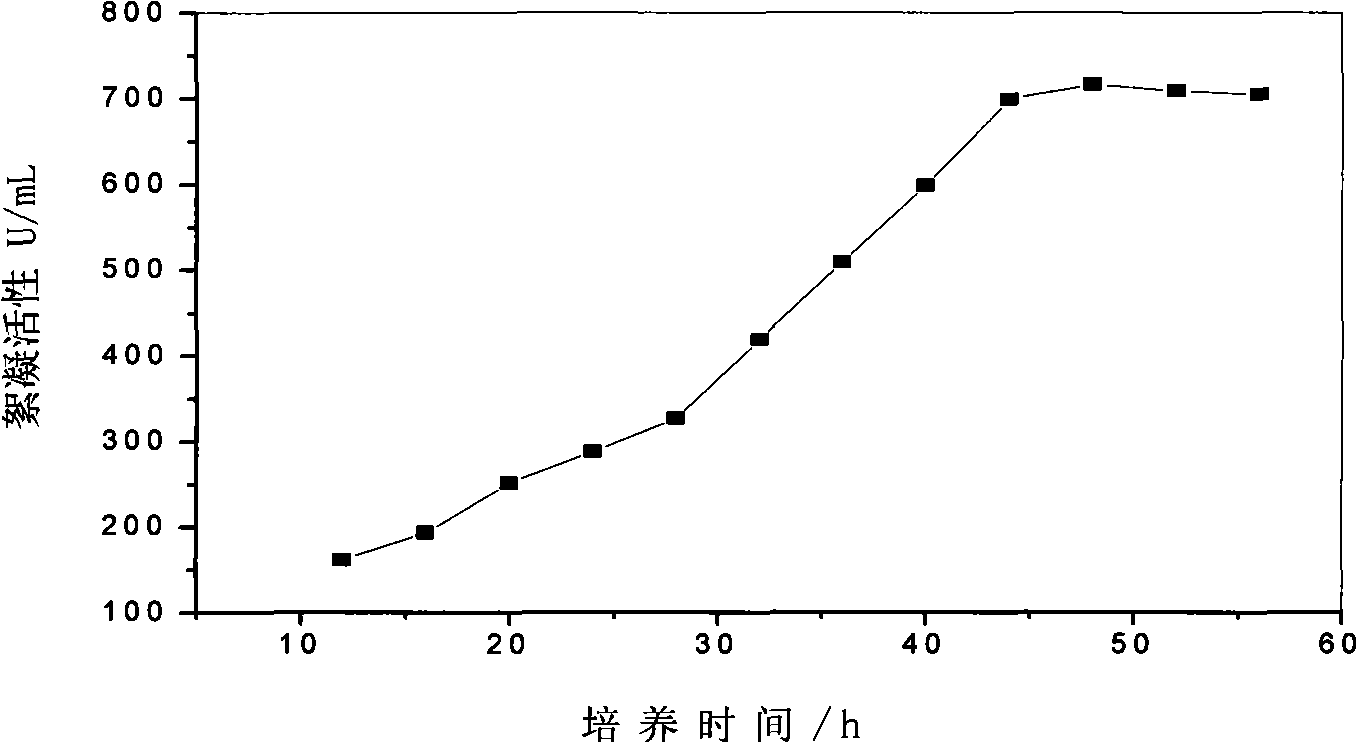

Method for preparing bioflocculation by Bacillus licheniformis

InactiveCN101503709ANo secondary pollutionLow costMicroorganism based processesFermentationBacillus licheniformisFlocculation

The invention provides a method for preparing biological flocculant by utilizing Bacillus licheniformis, which relates to a biological flocculant. The invention provides a method for preparing biological flocculant by utilizing Bacillus licheniformis, which has high flocculation activity, low cost for raw materials and great industrial application potential. A microorganism is Bacillus licheniformis. The method comprises the following steps that: lawn on a fresh inclined plane is transferred to a seed culture medium for culture and then transferred to a fermentation culture medium for culture so as to obtain biological-flocculant fermentation broth; the biological-flocculant fermentation broth is centrifuged to remove precipitate and collect supernatant; the supernatant is added with ethanol, kept to stand, centrifuged and then removed; the precipitate is added with absolute ethanol, stirred and centrifuged to remove the supernatant; ethanol precipitate is added with hexadecyl trimethyl ammonium bromide and centrifuged to remove the supernatant so as to obtain the precipitate; the precipitate is dissolved in a NaCl solution, added with the absolute ethanol, stirred, stood and centrifuged to remove the supernatant so as to obtain the precipitate; and the precipitate is frozen and dried in vacuum so as to obtain pure biological flocculant.

Owner:XIAMEN UNIV

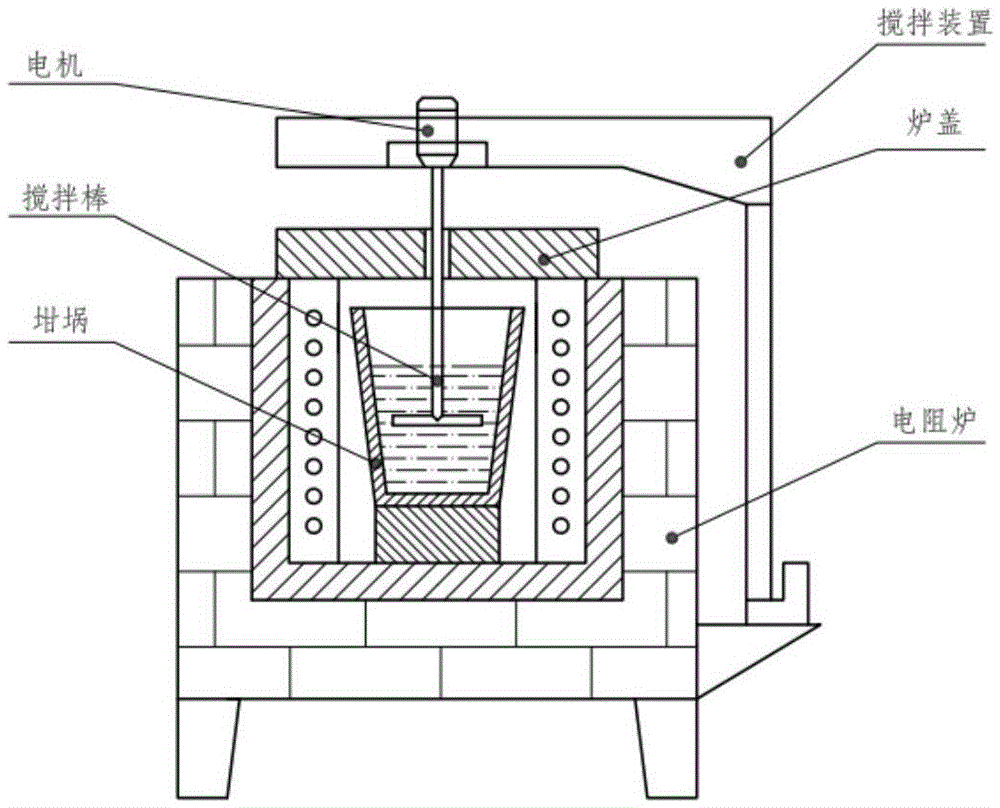

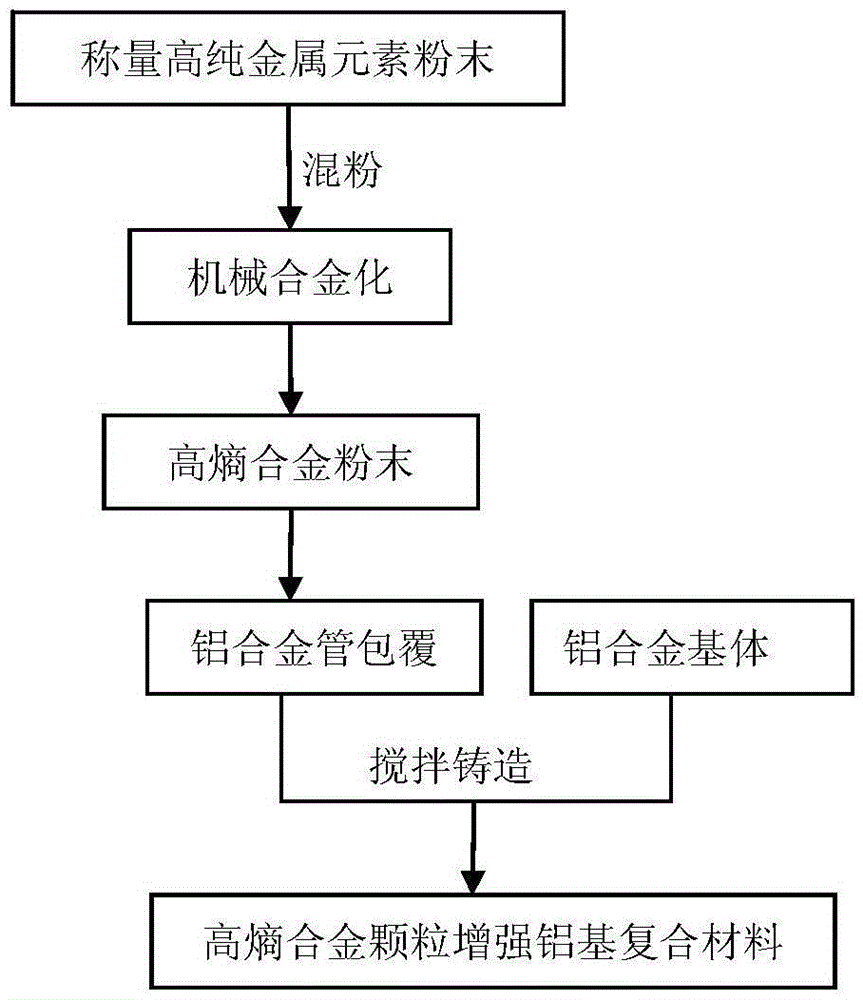

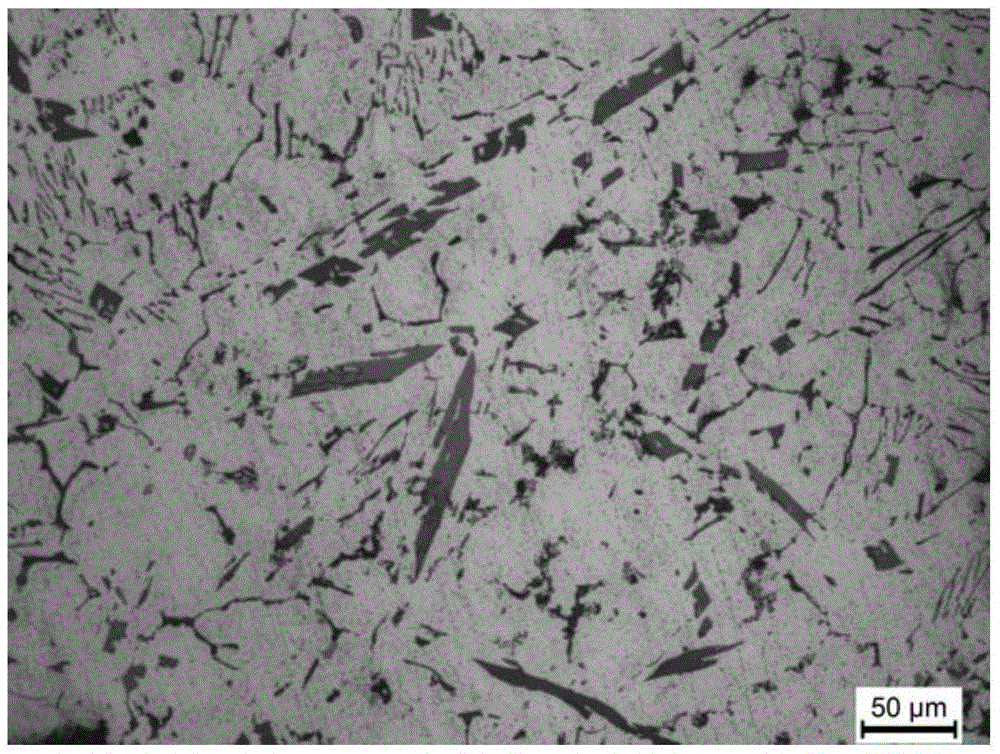

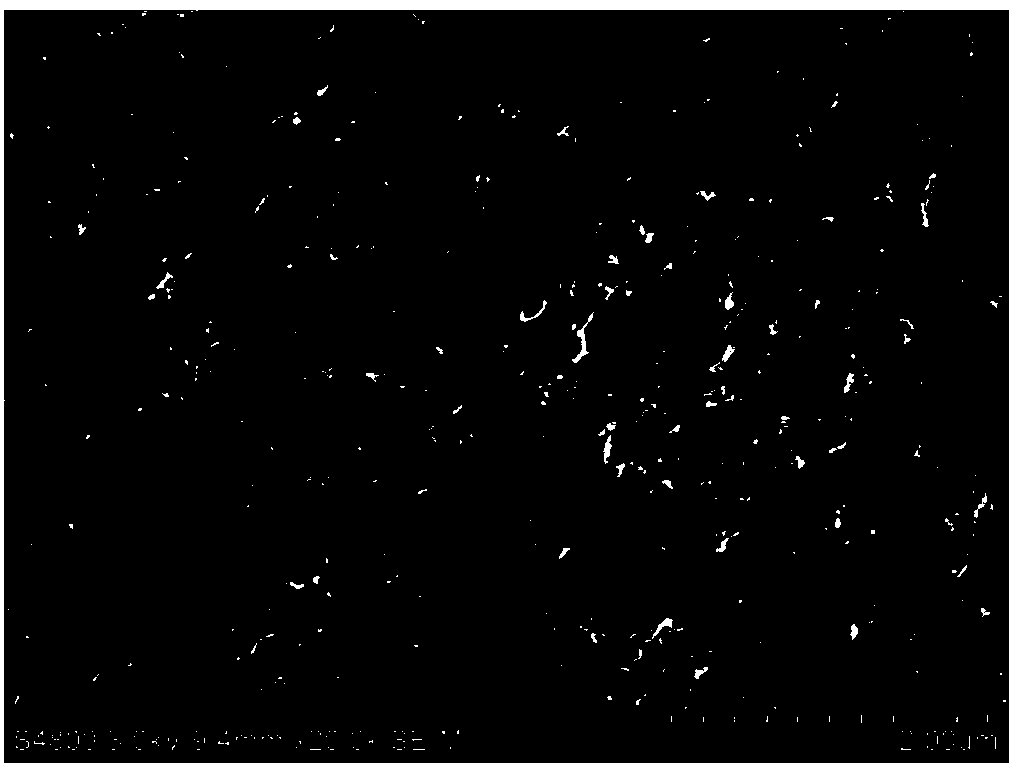

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

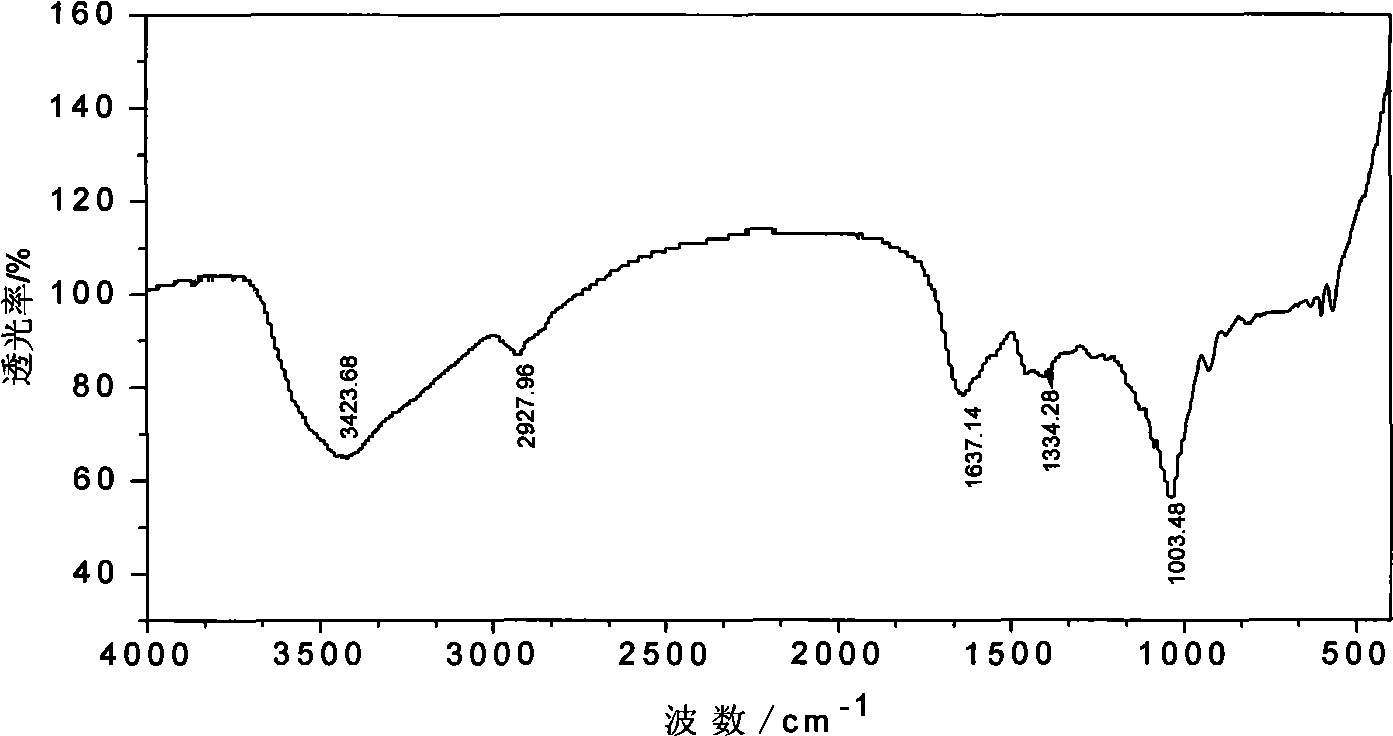

Carbon nano tube composite film and preparation method thereof

ActiveCN103435027AEvenly dispersedAvoid reunionMaterial nanotechnologyCarbon compoundsComposite filmCatecholamine

The invention discloses a preparation method for a carbon nano tube composite film. The method comprises the following steps: first, allowing a phenolic hydroxyl group, a quinonyl group and other functional groups to be introduced on the surface of a carbon nano tube through oxidation autopolymerization reaction of catecholamine under an alkalescence condition, so as to realize the modification for the surface of the carbon nano tube; then, using water-soluble polymers with amino groups or mercapto groups as raw materials to realize layer-by-layer self-assembly under the action of chemical bonds formed by Schiff base or Michael Addition reaction, thereby obtaining the carbon nano tube composite film. The method has the advantages of mild reaction condition, environmental protection, simplicity and feasibility, and is suitable for industrialized production. The carbon nano tube composite film prepared by the method has the advantages of excellent thermal and chemical stability, ductility, mechanical strength and transparency.

Owner:ZHEJIANG UNIV

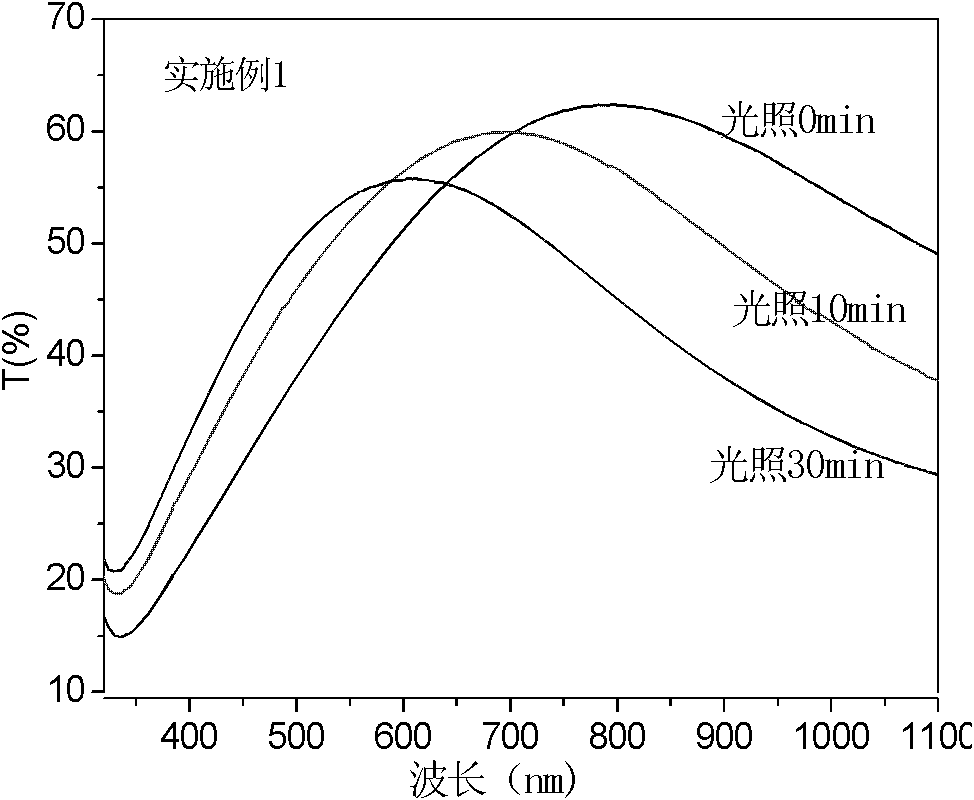

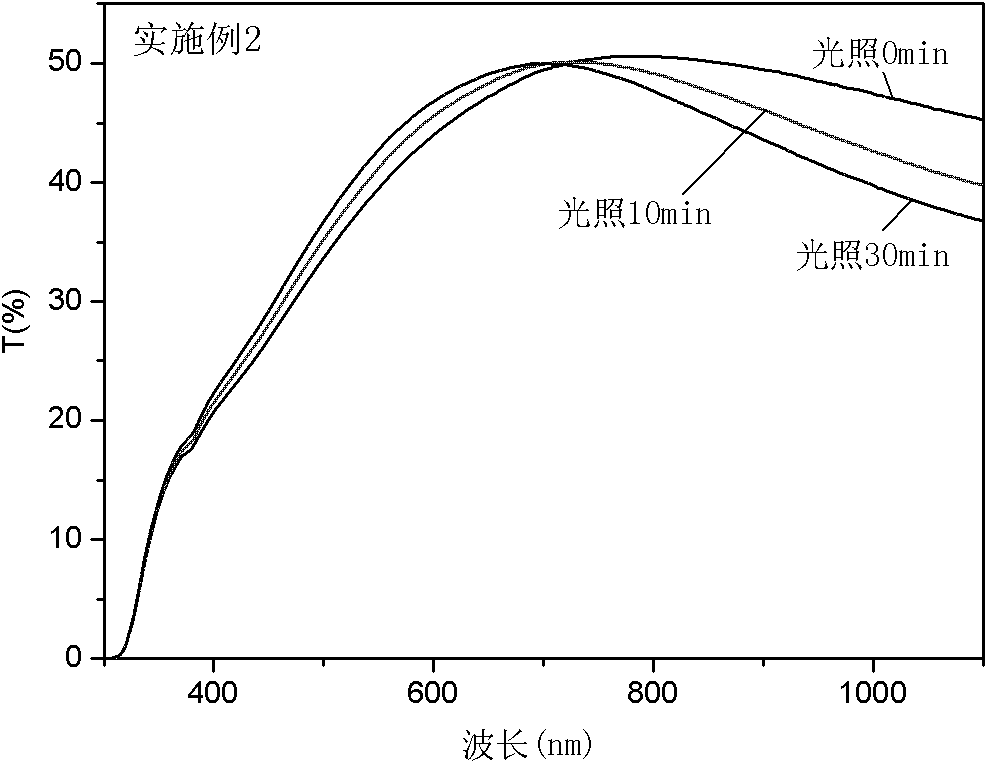

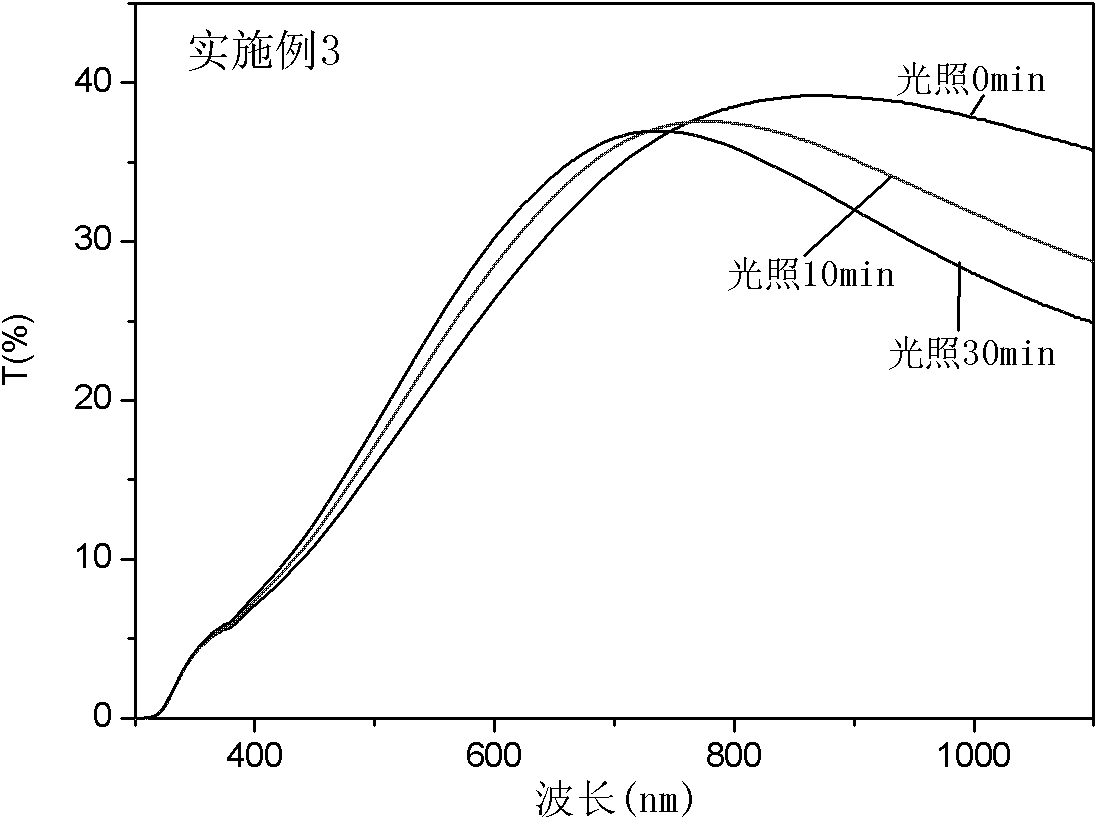

A kind of glass transparent thermal insulation coating and preparation method thereof

A glass transparent heat-insulating coating and its preparation method, the coating contains cesium tungsten bronze powder with a general formula of Cs0.1-3.5WO3, the crystal phase composition of the powder is Cs0.2WO3 or Cs0.32WO3, the powder The particle size is 100-1300nm, and the specific surface area is 7-50m2 / g. The glass transparent heat-insulating coating of the present invention has the functions of visible light transmission and near-infrared shielding, and has the function of light self-regulation, that is, with the extension of light intensity and light time, the effects of visible light transmission and near-infrared shielding will be further enhanced , so it is especially suitable for preparing transparent thermal insulation film on the surface of glass. It is an intelligent transparent thermal insulation coating for glass and has broad application prospects in the fields of thermal insulation of architectural window glass and automotive glass. The coating has simple components and is suitable for large-scale industrial production and practical application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Process for preparing silicon dioxide aerogel using rice husk ash as raw material

InactiveCN1449997ALarge specific surface areaReduce manufacturing costSilicaSolid waste disposalHYDROSOLSilicon dioxide

The method for preparing silicon dioxide aerogel utilizing waste material rice husk ash obtained by combusting rice husk includes the following steps: soaking the rice husk ash in organic alkaline aqueous solution, using inorganic acid to neutralize alkaline solution to produce silicon dioxide hydrosol, ageing said hydrosol, substituting water content in the hydrosol with organic solvent, then substituting organic solvent with liquid CO2, then supercritical CO2 drying so as to obtain white silicon dioxide aerogel whose specific surface area is 297.3 sq.m / g, apparent density is 0.532 g / cu.cm and internal microporous average pore size is 22.3 nano.

Owner:TSINGHUA UNIV

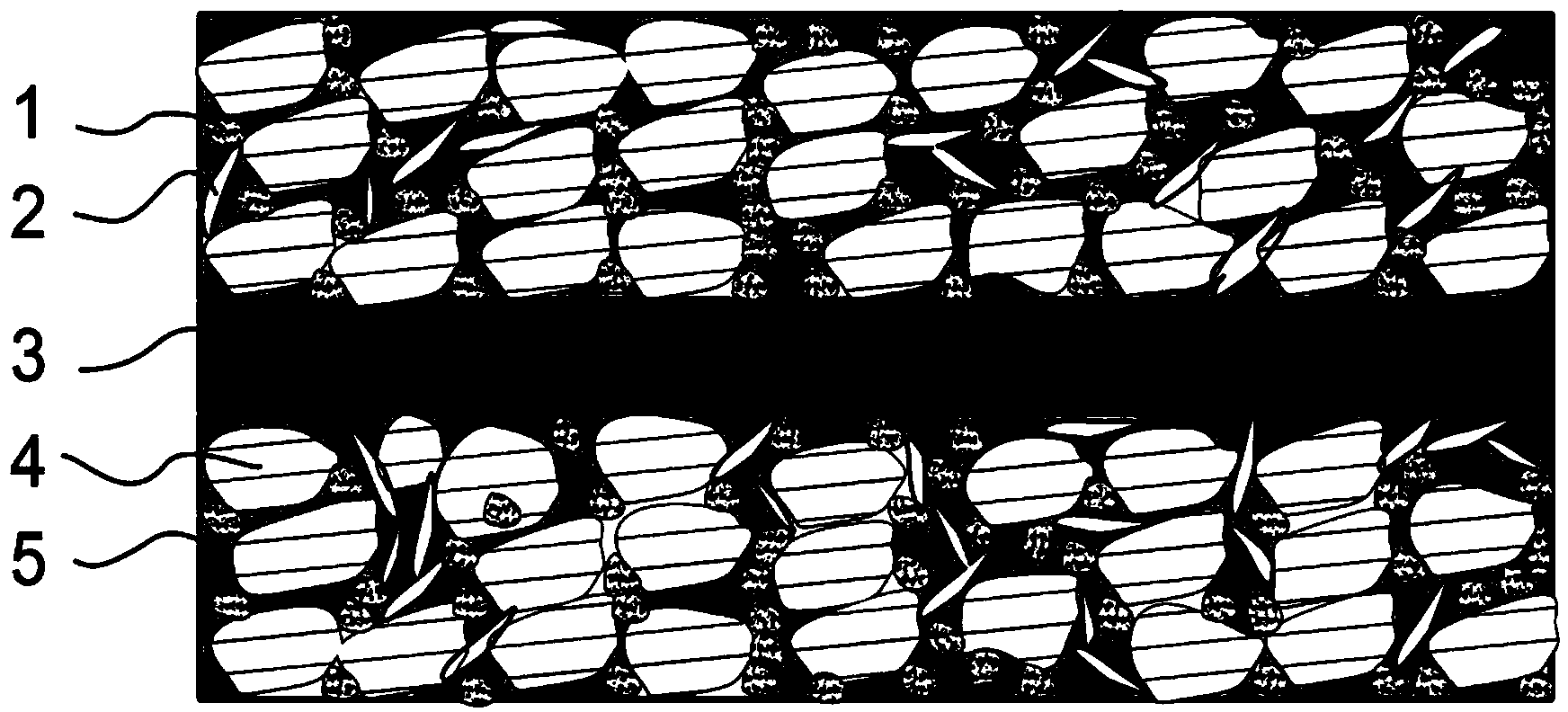

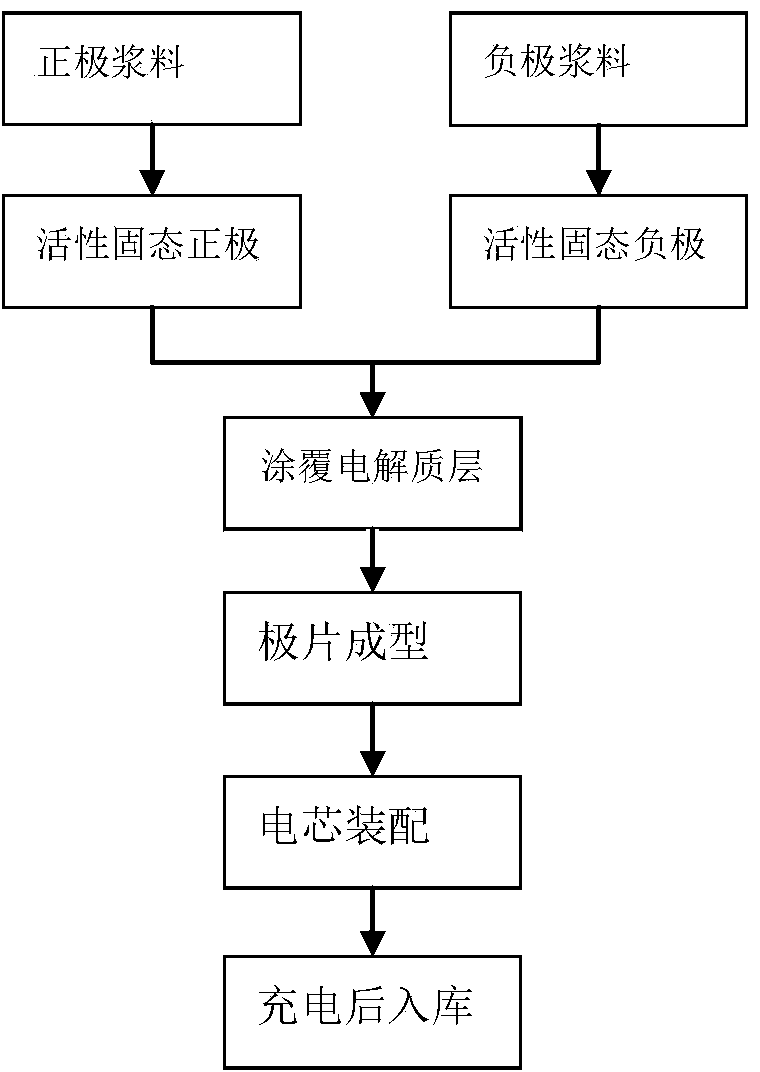

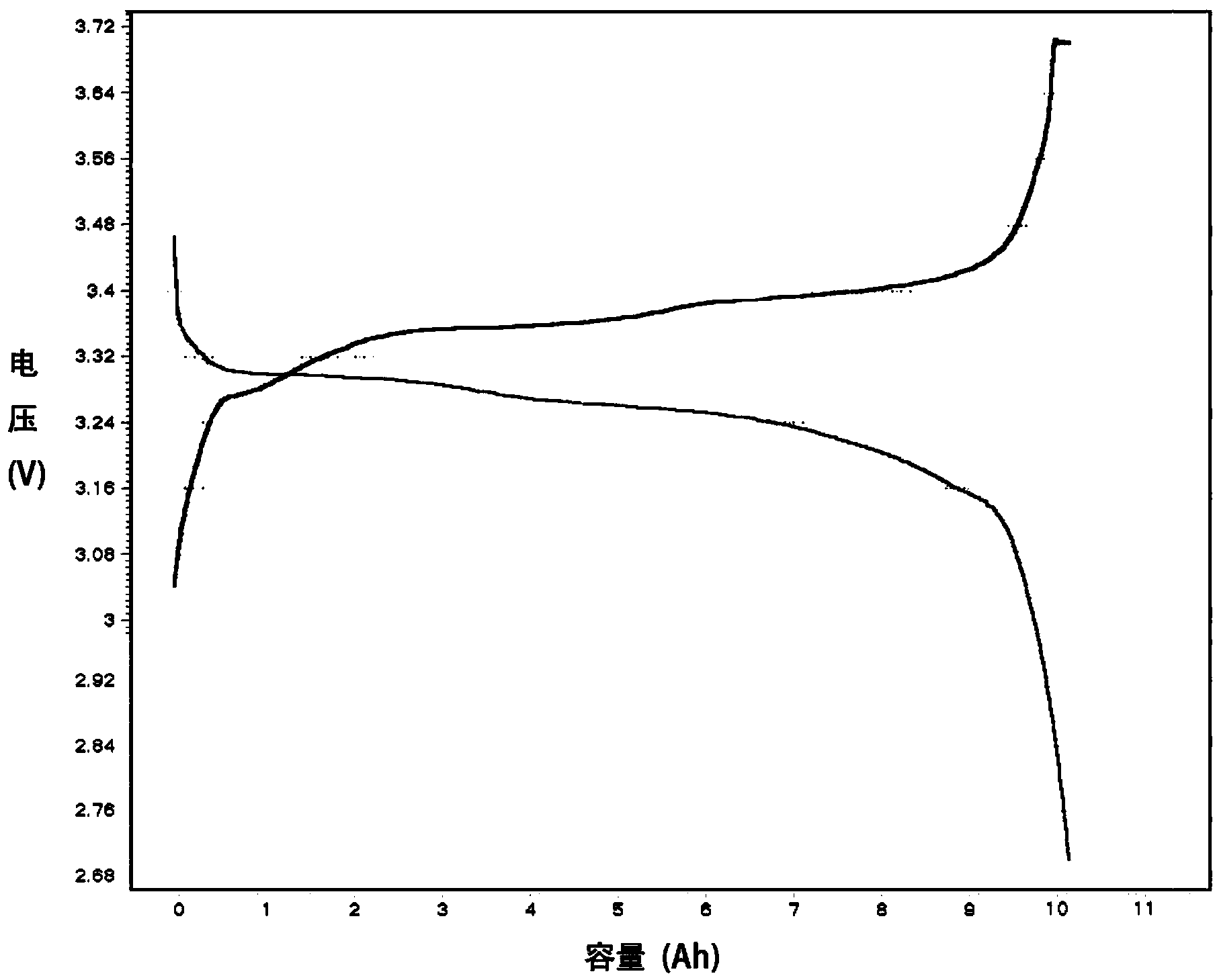

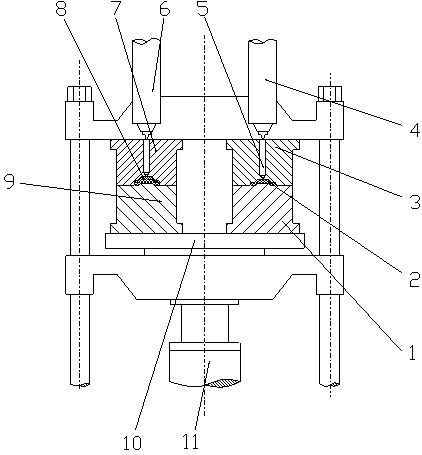

Solid-state lithium ion electrode, solid-state lithium ion battery and preparation method of solid-state lithium ion electrode

InactiveCN103474620ASuitable for continuitySuitable for productivityFinal product manufactureNon-aqueous electrolyte accumulator electrodesSolid state electrolytePowder method

The invention provides a solid-state lithium ion electrode, a solid-state lithium ion battery and a preparation method of the solid-state lithium ion electrode. The solid-state lithium ion battery electrode is composed of a metal current collector, and an active material, a conductive agent, solid electrolyte and a binder, which are attached on the current collector. During the electrode manufacture, the slurry containing the active material and the like is coated on the current collector, the method is suitable for continuous and batch production compared with a deposition method and a compression powder method.

Owner:向勇

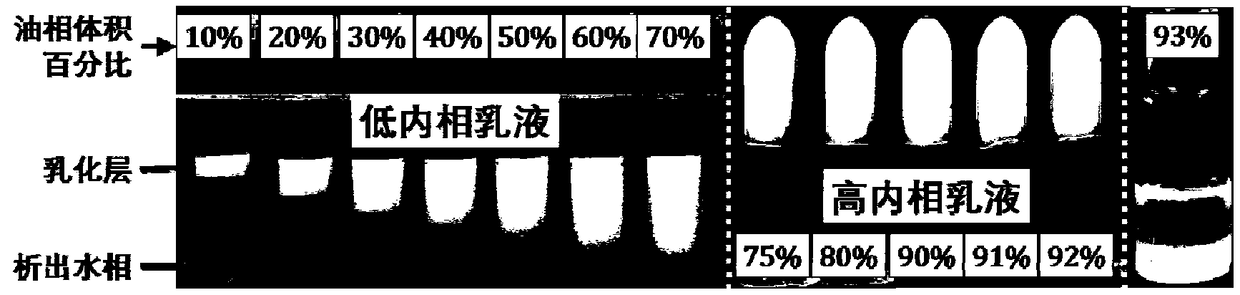

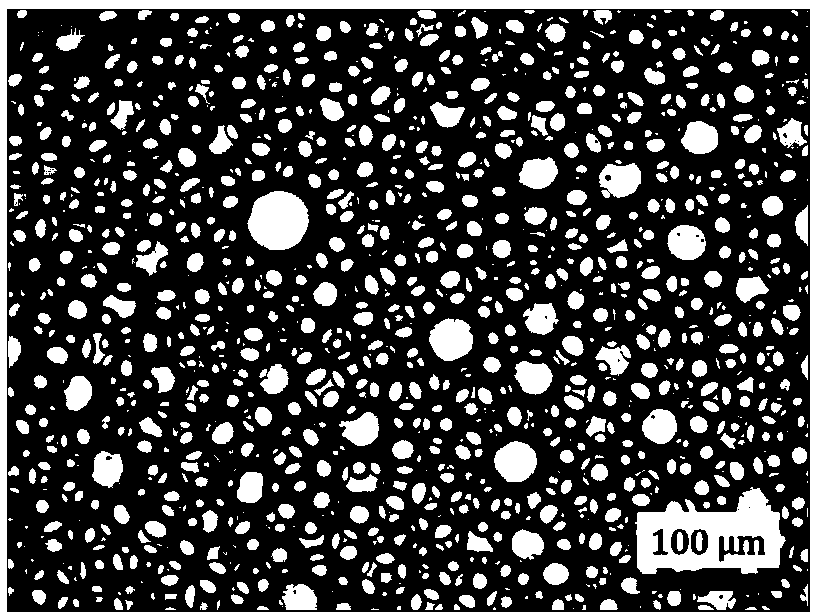

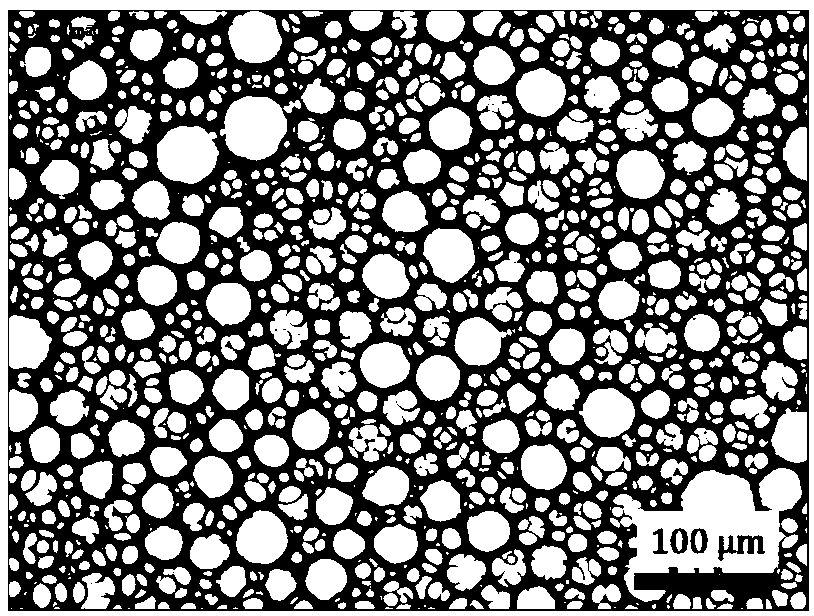

Stable-protein high-internal-phase oil-in-water emulsion and preparation method thereof

The invention belongs to the technical field of emulsion preparation, and discloses a stable-protein high-internal-phase oil-in-water emulsion and a preparation method thereof. The method comprises the following steps: a protein is dispersed into water, after the protein is fully hydrated, an aqueous phase protein solution is obtained, an oil phase is added, emulsification is performed, and therefore the stable-protein high-internal-phase oil-in-water emulsion is obtained. The method disclosed by the invention does not need any coagulants or surfactants, and the obtained high-internal-phase oil-in-water emulsion has good viscoelasticity, high heat stability and storage stability, and an excellent protection or controlled release effect on the oil phase; and the emulsion has good gelling performance, strong plasticity and remoldability, facilitates further processing, and has good application prospects in the fields of chemical products, daily chemicals, pharmaceuticals, food and healthcare products.

Owner:SOUTH CHINA UNIV OF TECH

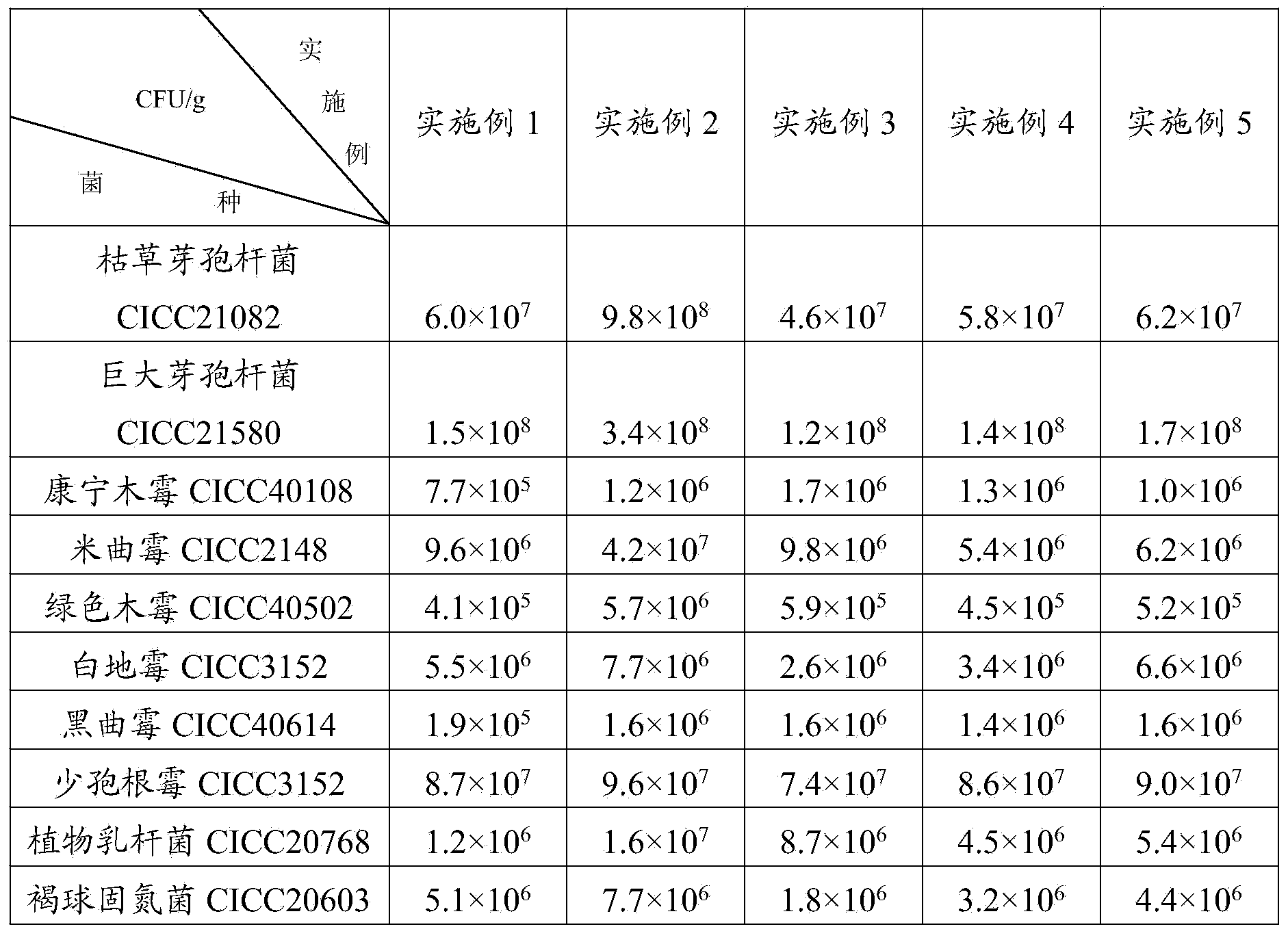

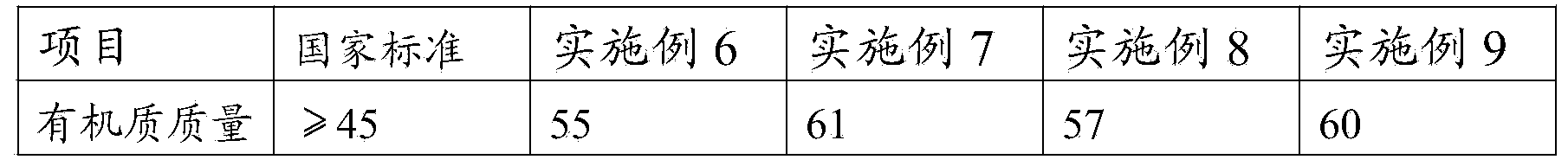

Complex microbial inoculant and method for preparing organic fertilizer by using same

InactiveCN103898032AImprove qualityEffective cooperationBio-organic fraction processingFungiFiberAzotobacter chroococcum

The invention discloses complex microbial inoculant which comprises the following active ingredients: bacillus subtilis, bacillus megatherium, trichoderma koningii, aspergillus oryzae, trichoderma viride, geotrichum candidum, aspergillus niger, rhizopus oligosporus, lactobacillus plantarum CICC20768 and azotobacter chroococcum. Correspondingly, the invention further discloses a method for preparing an organic fertilizer from the complex microbial inoculant. The method comprises the following steps: a. uniformly mixing the complex microbial inoculant with a plant fiber raw material to obtain a fermented raw material; b, composting and fermenting the fermentation raw material; c, drying the composted fermentation raw material to obtain the organic fertilizer. microbes of the complex microbial inoculant have no antagonism, and can effectively cooperate in the production process of the organic fertilizer, and the chemical components of the production raw materials can be sufficiently utilized to finally produce the high-quality organic fertilizer. The produced organic fertilizer reaches the parameter indexes of the standard (NY884-2012) of China, can improve the planting property of soil, is beneficial to optimization of soil microbial flora, and can provide comprehensive nutrients to a plant root system.

Owner:江苏联海生物科技有限公司

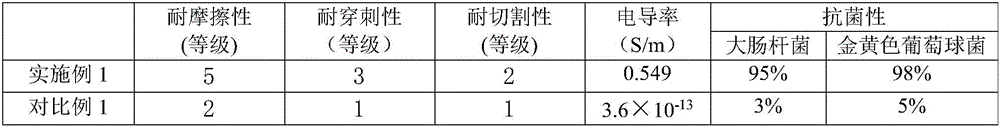

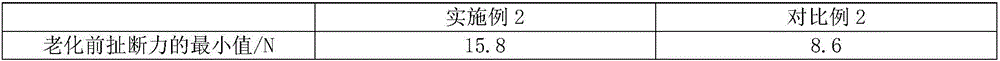

Graphene-latex functional high-strength protection glove and production method thereof

InactiveCN106065095AComfortable to wearImprove friction resistanceGlovesBulk chemical productionElectricityAviation

The invention discloses a graphene-latex functional high-strength protection glove and a production method thereof. The method comprises the following steps: (1) immersing a glove blank in a coagulating agent, immersing the glove blank in a graphene-latex composite liquid, and drying the immersed glove blank to obtain the glove; or (2) immersing the glove blank in the coagulating agent, drying the immersed glove blank, immersing the dried glove blank in the graphene-latex composite liquid, leaching the immersed glove blank, crimping the leached glove blank, drying the crimped glove blank, vulcanizing the dried glove blank, leaching the vulcanized glove blank, and drying the leached glove blank to obtain the glove. Compared with gloves in the prior art, the graphene-latex functional high-strength protection glove produced in the invention fully performs the advantages of high electricity conductivity, high strength, friction resistance and strong bacteriostasis of graphene, and has wide uses in the fields of the manufacturing industry, the medical industry, the chemical engineering industry and the space flight and aviation industry.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

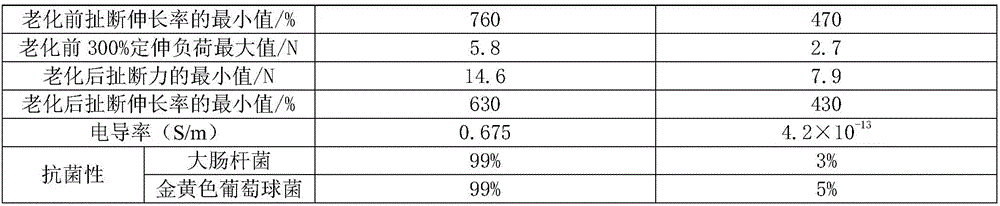

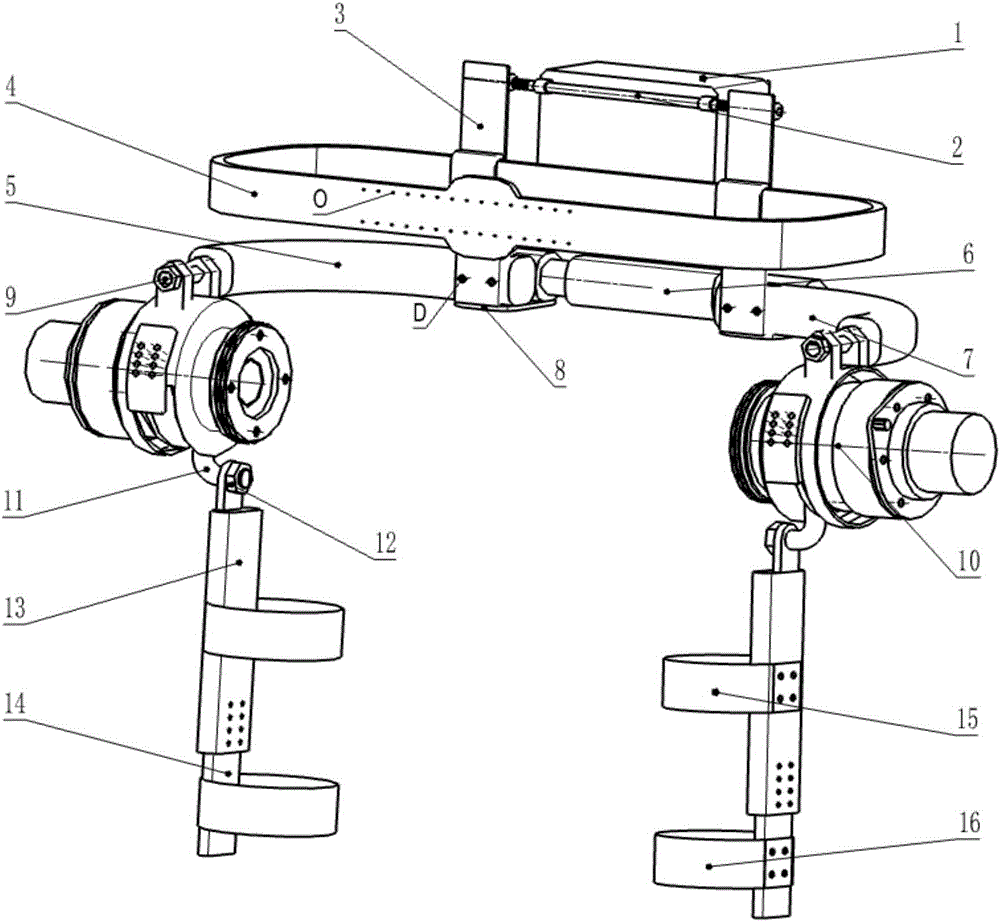

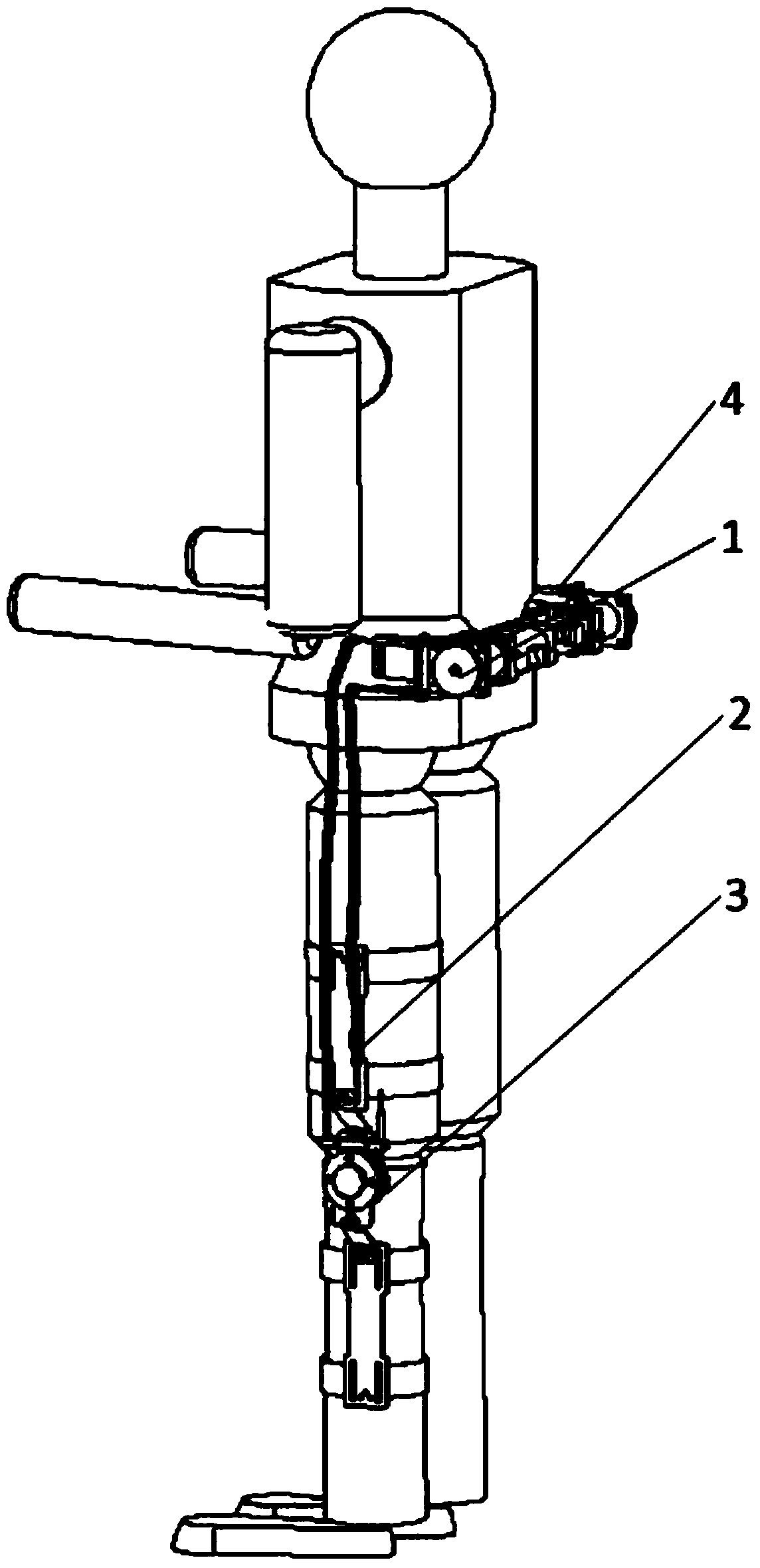

Portable hip joint assisting mechanism

InactiveCN106142056ASuitable for everyday wearAccurate control precisionProgramme-controlled manipulatorThighMotor drive

The invention provides a portable hip joint assisting mechanism. A left waist support and a right waist support are the same in structure, i.e., both of an L-shaped structure. One ends of the left waist support and the right waist support are fixedly connected to two sides of a waist adjusting mechanism by means of connecting flanges. Two back support plates are fastened and connected to side surfaces of the left waist support and the right waist support by means of screws, and both perpendicular to the waist supports. Two support connecting rods arranged in parallel up and down are in threaded connection with the back support plates. A control box is suspended to the support connecting rods. A waist belt passes through sleeve holes in the middle portions of the back support plates. Hip driving mechanisms are located at lower sides of the waist supports and in threaded connection with the other ends of the left waist support and the right waist support by means of connecting shafts. A joint execution mechanism is formed by a first thigh connecting rod, a second thigh connecting rod, a first thigh binding band and a second thigh binding band. The portable hip joint assisting mechanism provides a motor-driven hip joint assisting mechanism for providing extra torque with the requirements of simple structure, low weight, safety and controllability and high practical and economical values on the mechanism.

Owner:JIANGSU UNIV

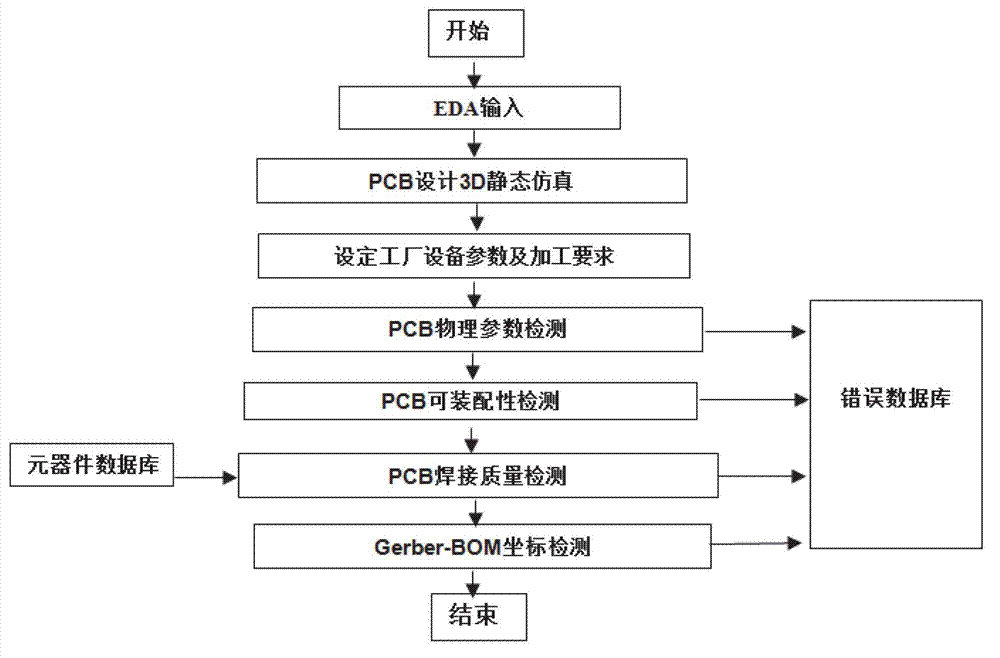

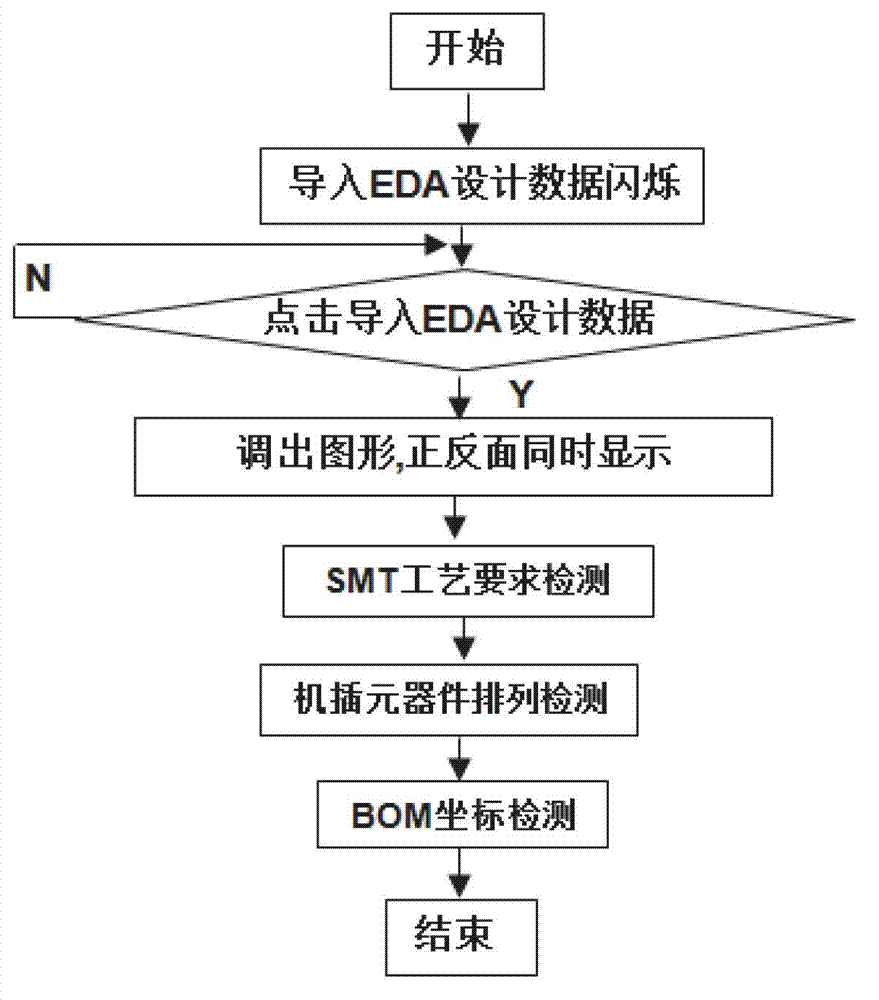

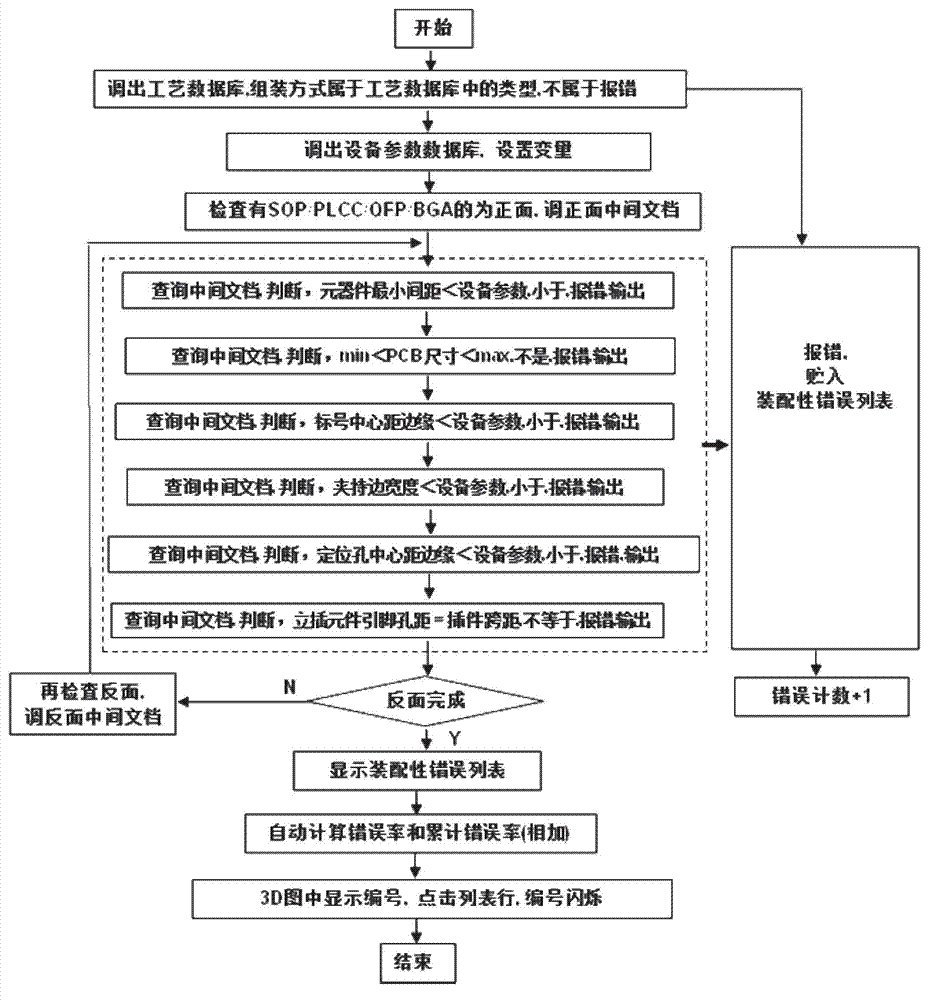

Visualization detection method of electronic product electronic design automation (EAD) design manufacturability

ActiveCN102930114AImprove efficiencyQuality improvementSpecial data processing applicationsInformation processingGraphics

The invention discloses a visualization detection method of electronic product electronic design automation (EDA) design manufacturability. Printed circuit board (PCB) three dimensional (3D) simulation of an EDA design document is conducted, PCBphysical parameter detection, PCB assembling ability, PCB welding quality detection and Gerber bill of material (BOM) coordinate detection are conducted in sequence, and specific error positions and types of former four steps of detection are displayed in visualization mode on a PCB 3D figure. On the basic of complete actual production experiences, the visualization detection method and a system of the EAD design manufacturability are developed according to international standard of information processing center (IPC), the PCB physical parameter detection, the PCB assembling ability, the PCB welding quality detection and the gerber BOM coordinate detection which are all designed by EDA are integrated, the various actual problems which are the contradictions of manufacture and design of PCB and are faced by enterprises are resolved, and efficiency and quality of electronic manufacture in particular to an original equipment manufacturer (OEM) are improved.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

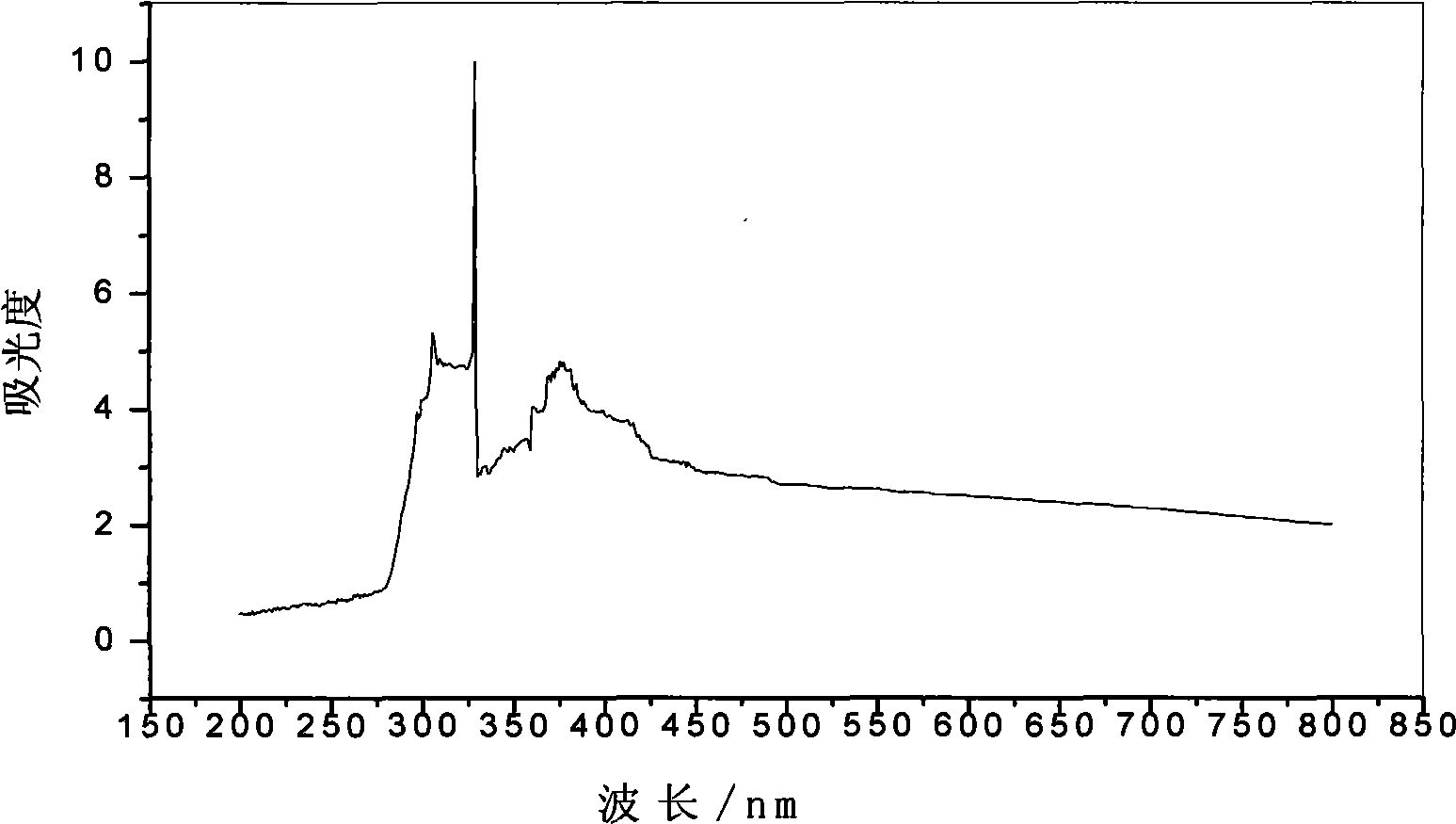

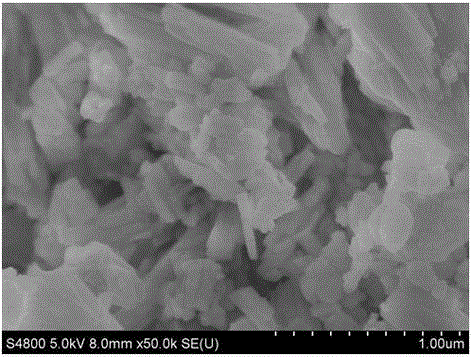

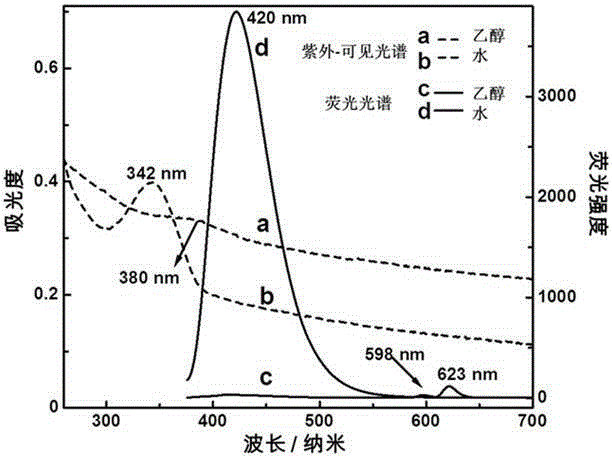

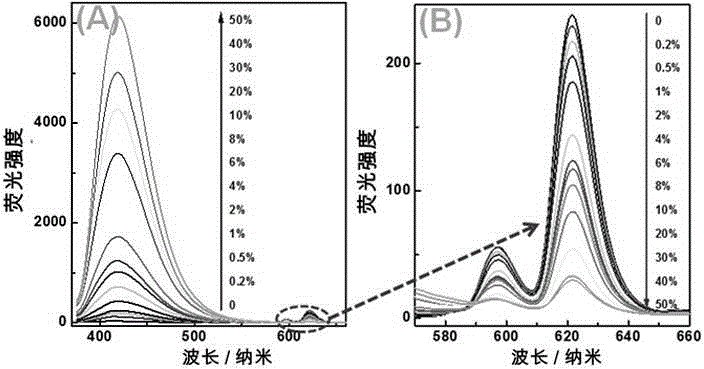

Bicolor Eu-MOFs/CDs fluorescent material as well as preparation and application thereof

InactiveCN105219376AThe synthetic route is simpleReduce cost inputFluorescence/phosphorescenceLuminescent compositionsN dimethylformamideUltraviolet

The invention discloses a bicolor Eu-MOFs / CDs fluorescent material as well as preparation and an application thereof. Europium ions, trimesic acid and carbon quantum dots are used as raw materials, and the bicolor fluorescent material is prepared through heat treatment in a solvent prepared by mixing N,N-dimethylformamide, distilled water and cyclohexanol. Under irradiation of ultraviolet lamps, the material can emit red fluorescence when dispersed in organic solvents and can emit blue fluorescent when dispersed in water, so that fluorescent colorimetric sensors for measuring water content in organic solvents can be prepared from the material, the prepared sensors are high in sensitivity, good in stability and low in cost and have higher population value and brighter application prospect.

Owner:FUZHOU UNIV

Method for manufacturing three-dimensional circuit on surface of injection molded part

ActiveCN104955278AReduce usageReduce volumeIncreasing energy efficiencyLiquid/solution decomposition chemical coatingCopper platingOptoelectronics

The invention discloses a method for manufacturing a three-dimensional circuit on a surface of an injection molded part. The method comprises the steps of A. performing injection molding on a substrate layer through a double-material injection molding machine; B. performing injection molding on the upper surface of the substrate layer through the double-material injection molding machine for forming a metal powder injection-molded layer,, performing pressure-keeping cooling, and opening a mold for taking the injection molded part out; C. performing selective sintering on the metal powder injection molded layer on the surface of the injection molded part through the laser head a CO2 laser in a vacuum environment according to a pre-designed circuit wiring pattern path for forming a primary three-dimensional circuit; and D. performing electroless copper plating on the copper powder which is bared after laser sintering for obtaining an electroless copper-plated layer, thereby forming a copper lead. Relative to a traditional method for manufacturing the three-dimensional circuit, the method of the invention has a simple process and is suitable for high-precision batch production. According to the method of the invention, the three-dimensional circuit can be manufactured on the high-strength injection molded part, and use number of plate type printed circuit boards can be reduced, thereby reducing size and cost of an electronic product and satisfying a requirement for a specific structure.

Owner:马鞍山塑丞精密制造有限公司

Method for preparing silicon dioxide aerogel by normal pressure drying method using rice hull ash as raw material

A method for dry producing the silica dioxide aerogel from rice husk ash as raw material in atmosphere pressure, belongs to the technical field of chemical industry materials producing, which comprises the following steps: leaching the rice husk ash formed by rice husk burning in the inorganic strongly basic aqueous solution and inorganic corrosive acid neutralizing basic solution to get the silica dioxide hydrosol, treating the hydrosol with organo-silicon compound to get the hydrogel, then ageing, water scrubbing, replacing the moisture in hydrogel with a organic solvent, and drying in atmosphere pressure to get the silica dioxide aerogel with the specific surface area about 400-800 m.

Owner:TSINGHUA UNIV

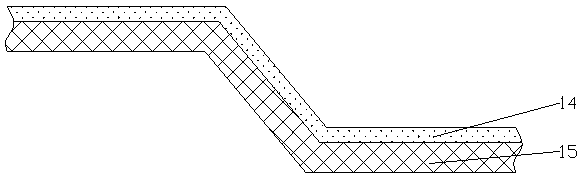

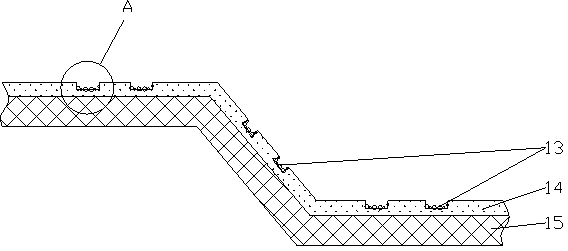

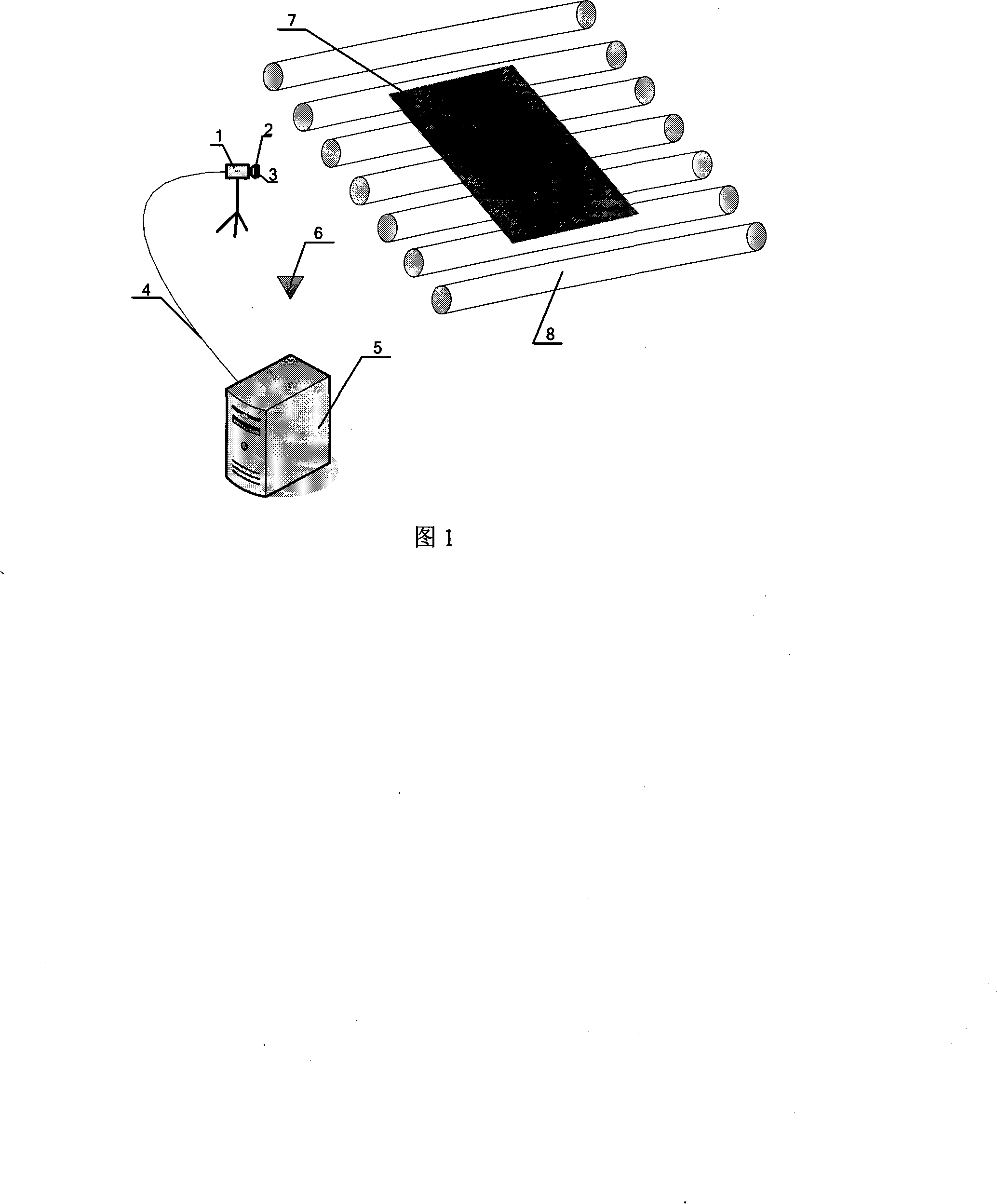

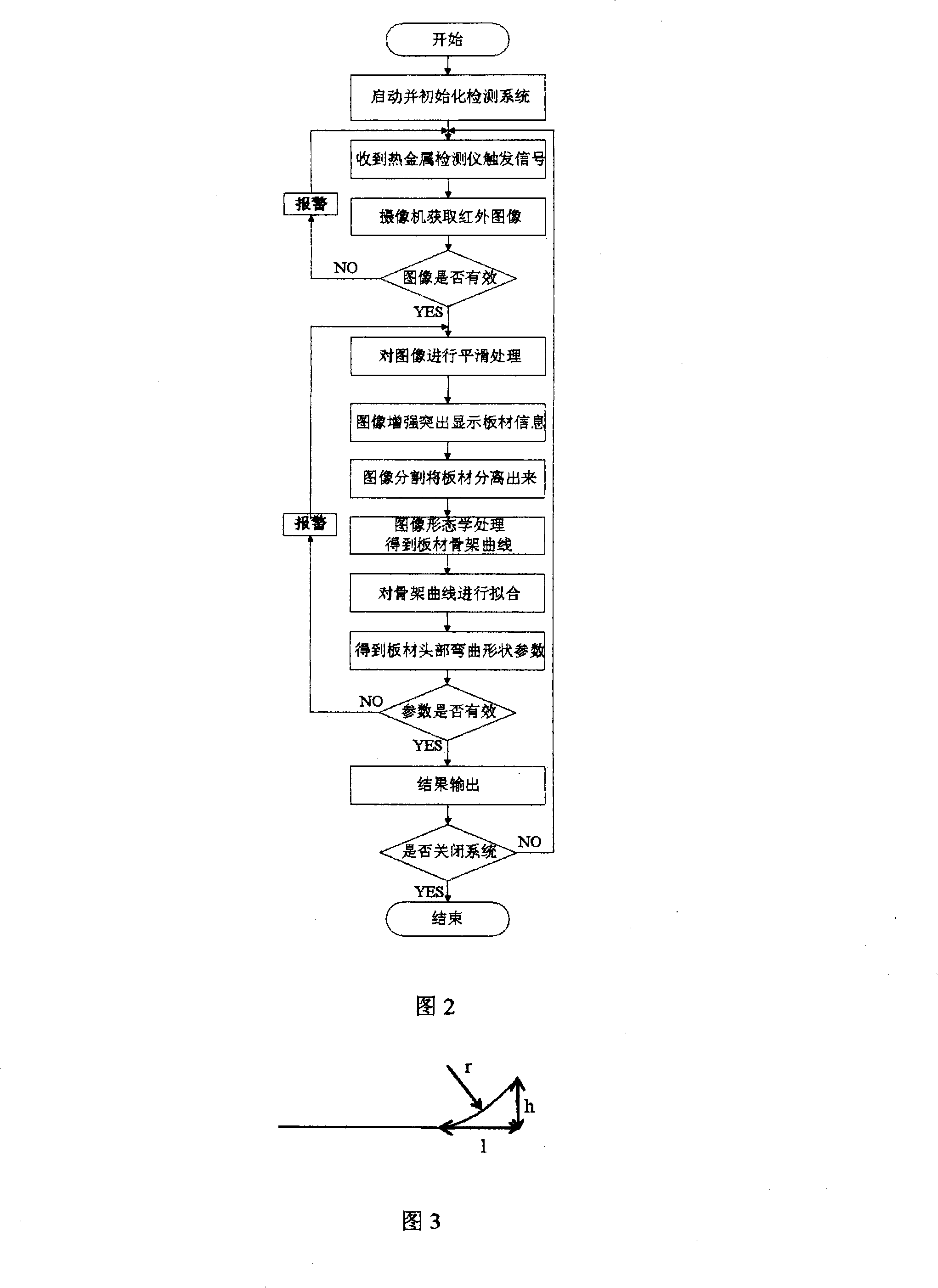

Plate head bending shape detection device based on nearing fared image and method thereof

InactiveCN101224472AEliminate distractionsThe detection process is fastMeasuring devicesUsing optical meansWater vaporImage segmentation

The invention provides a plate head bent shape detection device which is based on a far infrared image. A measurement method gains the images by the heat radiation of the plate, without any external heat sources or light sources. The invention mainly comprises a CCD camera (charge coupling device), an infrared filter system, an image collecting card, and an image disposal system. The detection device is arranged beside a roller bed which is arranged behind (in front of) a rolling mill; when a hot plate is delivered to the detection system through the roller bed, the CCD camera which is provided with a far infrared filter gains the images of the head of the plate; the image disposal system achieves a smoothening disposal, an image reinforcement disposal, an image cutting disposal, an image morphology disposal, etc. of the gained images so as to gain a shape curve of the head, and fits the curve so as to gain the parameters such as the bent height, the bent curvature, the length of the bent section, etc. of the head of the plate. The invention can eliminate the interference of the steam in the production site to the gained images, the detection speed is fast, the installation of the equipment is simple, the original production process is not changed, and the invention is stable and reliable and suitable for the production sites of medium thick plates and hot continuous rolling.

Owner:NORTHEASTERN UNIV

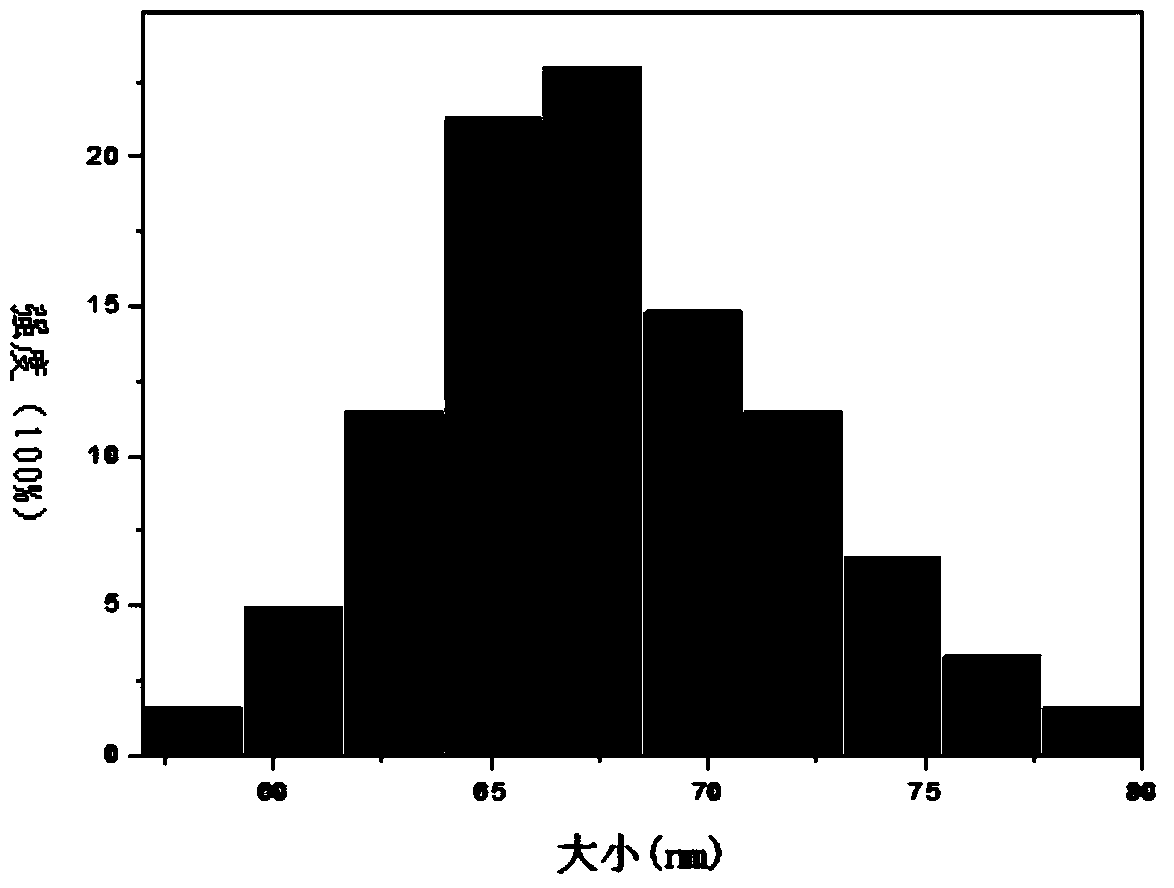

Method for preparing magnetic nano microparticles with biological compatibility

InactiveCN1461020AUniform and controllable particle sizeAdjustable crystallinityNanomagnetismNanostructure manufactureBoiling pointChemical compound

The preparation method of magnetic nano particle with bio-compatibility includes the following steps: heating and decomposing metal organic iron compound in high boiling point polar solvent in the presence of bio-compatibility molecule, precipitating and separating so as to obtain said magnetic nano particles with bio-compatibility. By adopting bio-compatibity molecules containing double-functional group (for example double-functional group polyglycol and its derivative, etc.) to make modification the magnetic nano particles whose surface has different functional groups can be obtained. By adopting different iron materials the nano particles with different types of Fe, gamma-Fe2O3 and Fe3O4 can be obtained.

Owner:苏州欣影生物医药技术有限公司

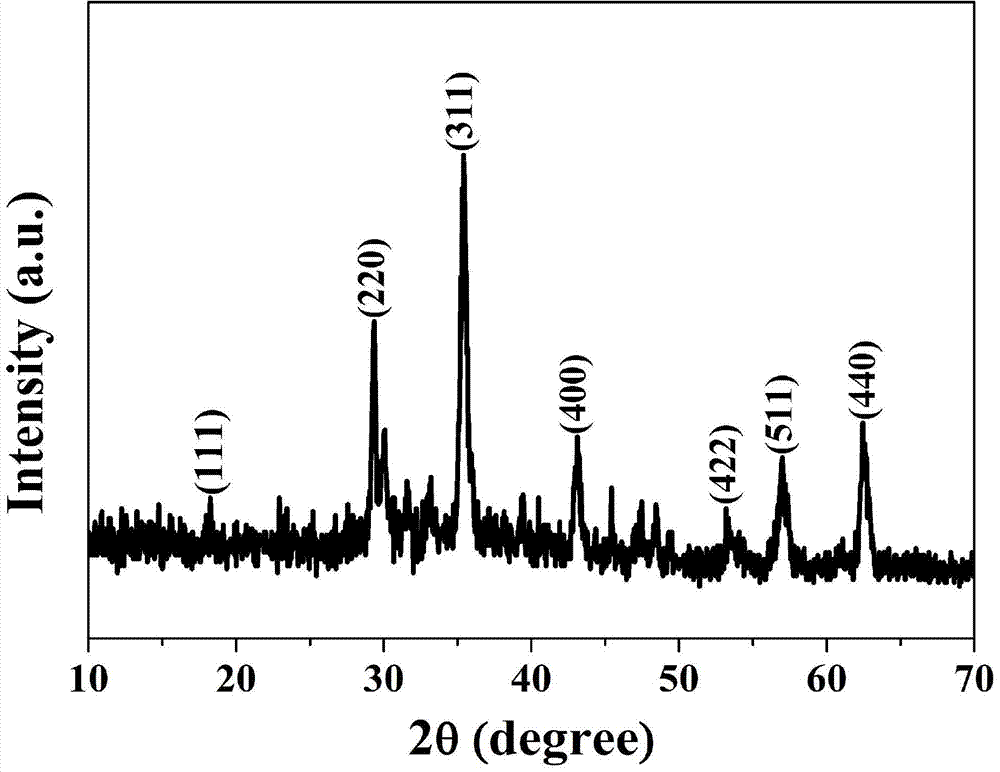

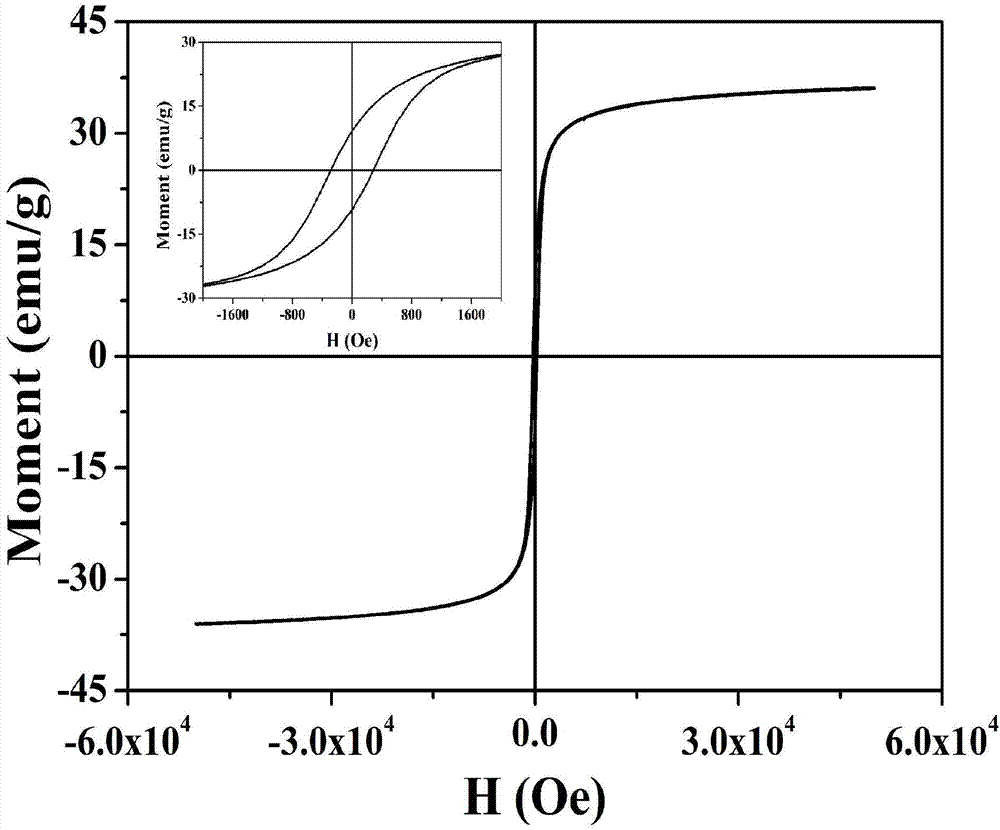

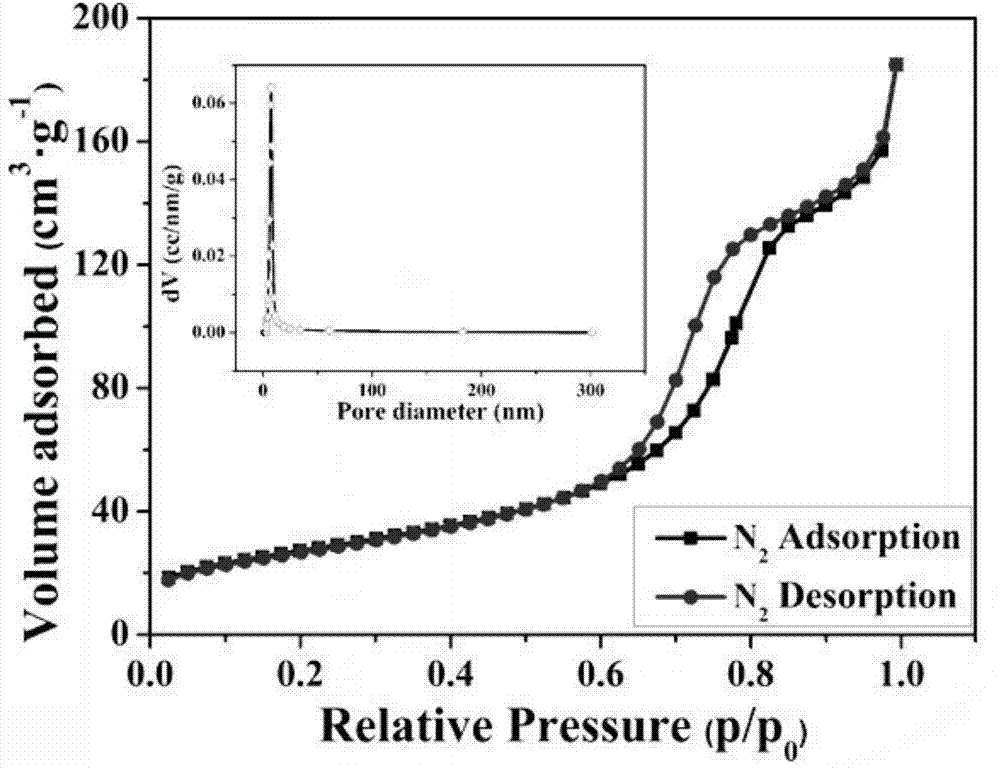

Preparation method of carbon encapsulated magnetic C/Fe3O4 nano composite material and application thereof

InactiveCN104495950ASimple processLow costMaterial nanotechnologyInorganic material magnetismSide effectThermal decomposition method

The invention discloses a preparation method of a carbon encapsulated magnetic C / Fe3O4 nano composite material and an application thereof. The invention belongs to the technical field of a magnetic nano-material, and the carbon encapsulated magnetic C / Fe3O4 nano composite material can be prepared by using a hydrothermal method and a thermal decomposition method through synthesis. The carbon encapsulated magnetic C / Fe3O4 nano composite material is used for processing a dye methylene blue in waste water. The preparation method has the beneficial effect of simple process, high material purity, wide application scope, no residues, no toxic and side effect, and easy separation, and can be expected for wide application in environment engineering field.

Owner:LIAOCHENG UNIV

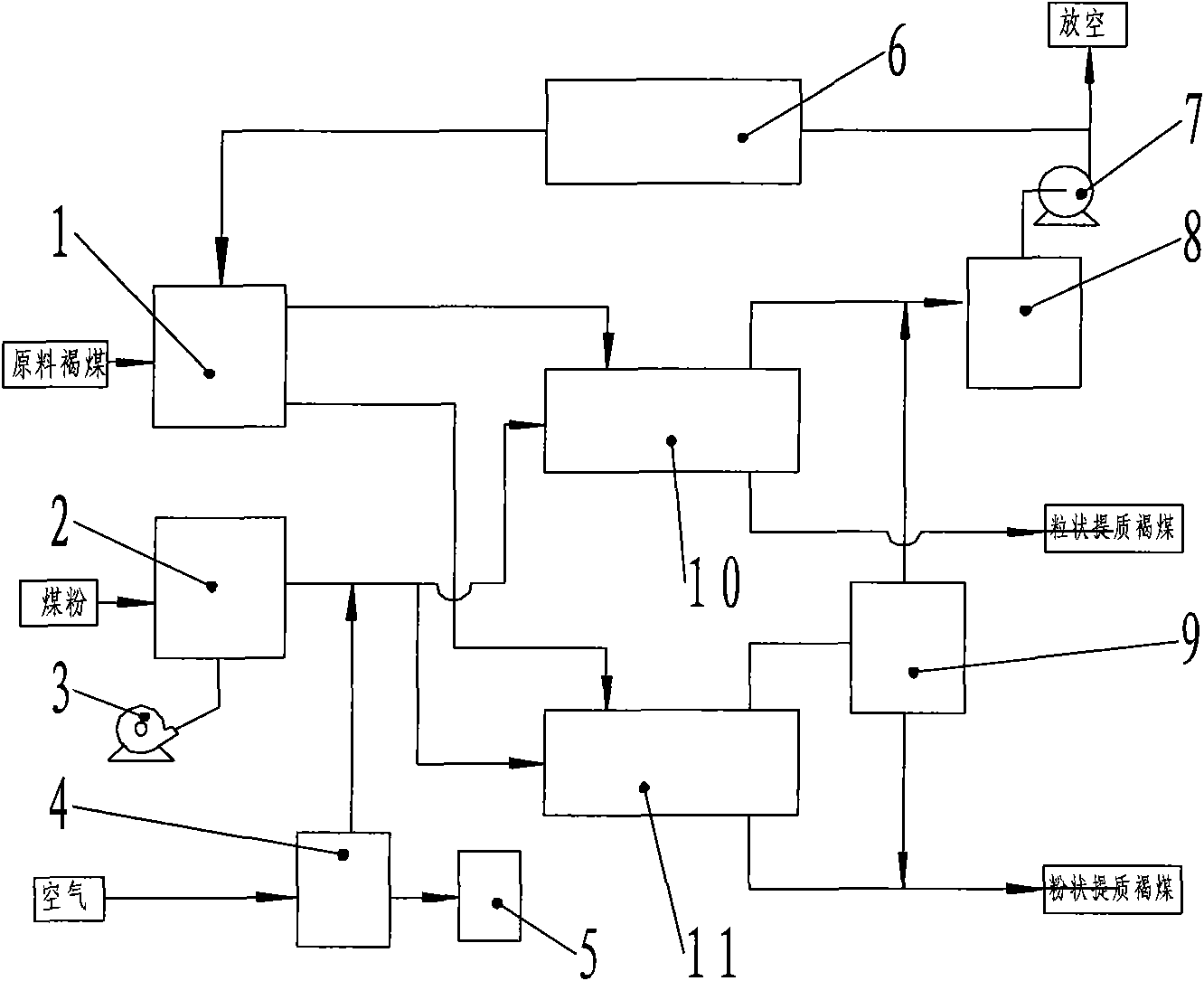

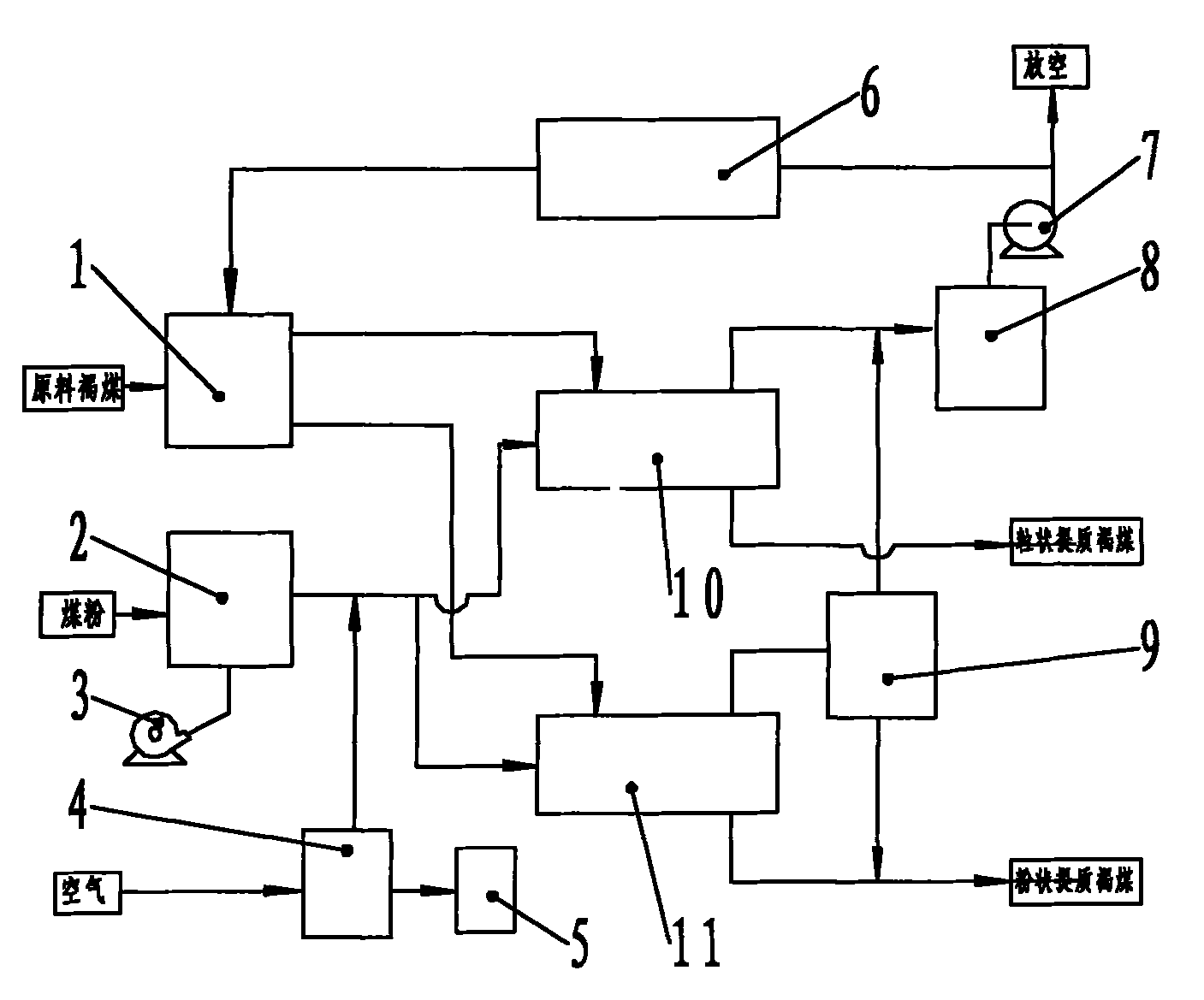

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

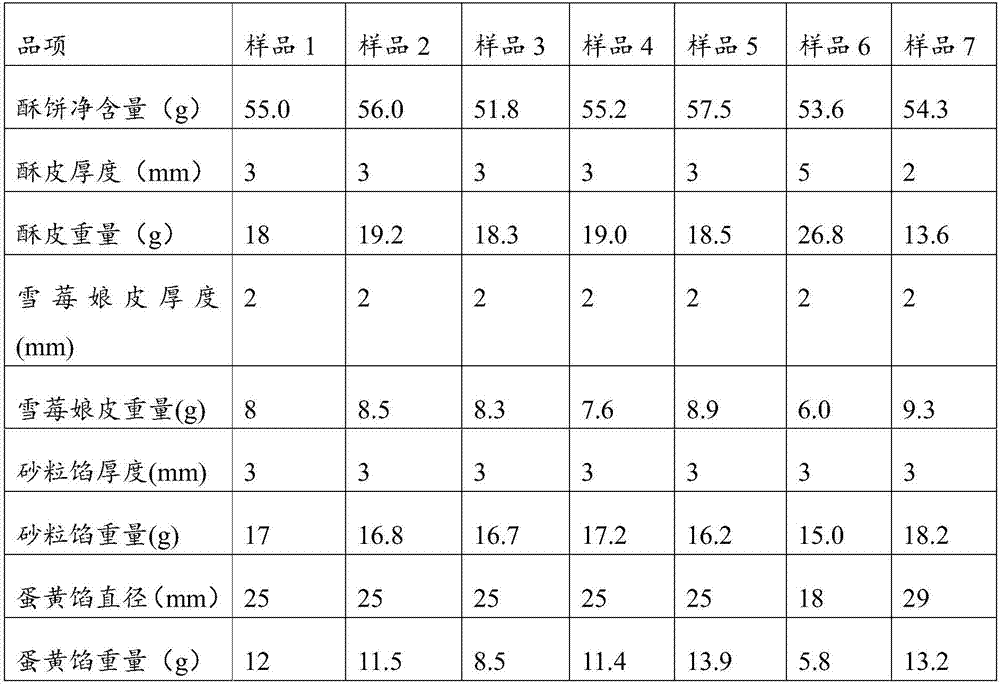

Egg-yolk puff and preparation method for same

The egg-yolk puff is made of the following raw material according to weight by parts: 10 to 40 parts of bread flour, 5 to 25 parts of cake flour, 8 to20 parts of butter, 2 to 10 parts of white sugar; 20 to 50 parts of ghee, 45 to 150 parts of stuffing, 0.01 to 0.04 part of foodstuff additive and 1 to 10 parts of water. The invention further provides an eggy-yolk puff preparation method for the same. The technology process is formed by weighing raw material, preparing doughs, covering ghee, pressing the doughs, opening the ghee, injecting stuffing, forming, brushing egg liquid, baking, cooling and packaging. The raw material can be easily achieved; the egg-yolk puff prepared by the method contains well-bedded multi-layered stuffing; the external layer is compact and crispy; the stuffing is soft and tender but not sweet and greasy; the puff cake has pure taste and fragrance and is not greasy; the egg-yolk puff is produced via a semi-mechanical way, so labor intensity can be reduced and production efficiency can be reduced; and the egg-yolk puff quality can be easily remained the same.

Owner:广西朗盛食品科技有限公司

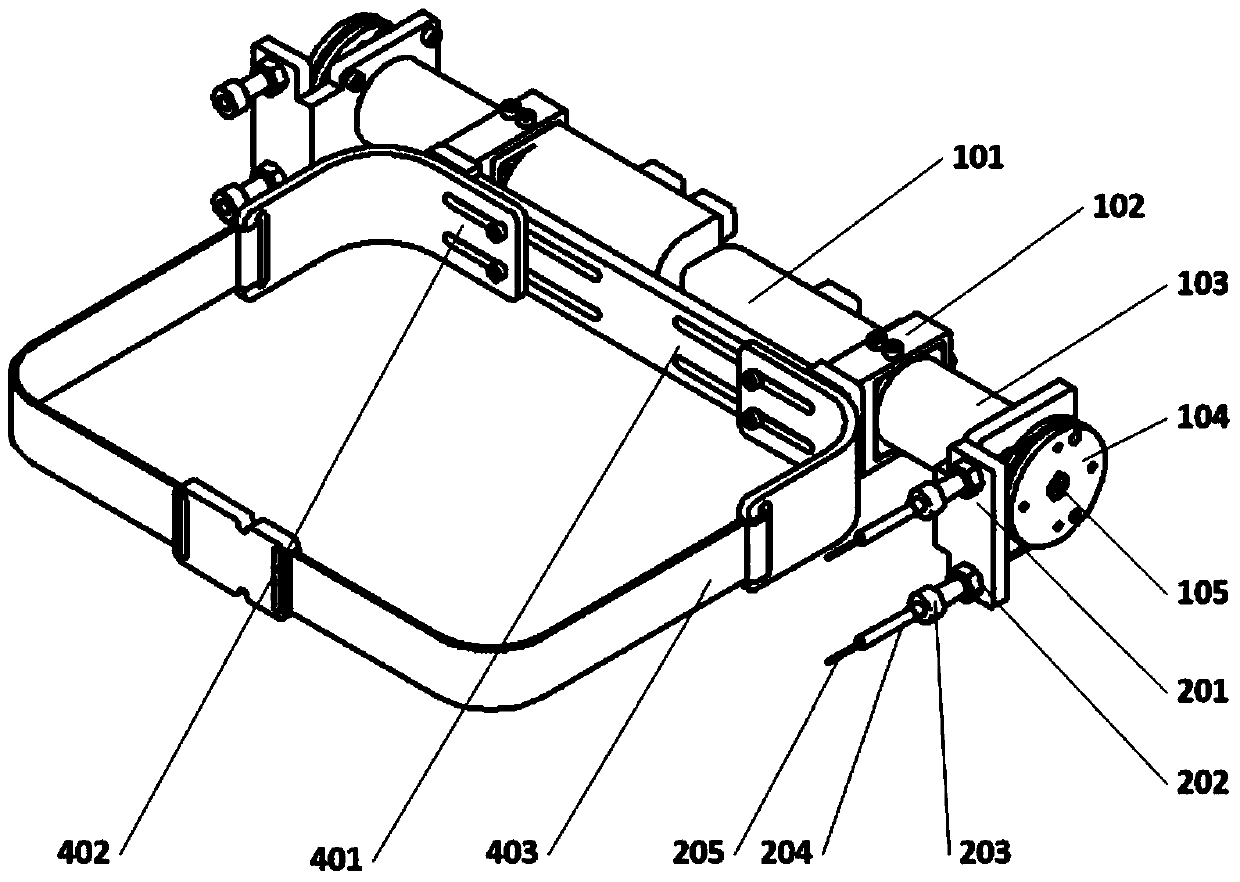

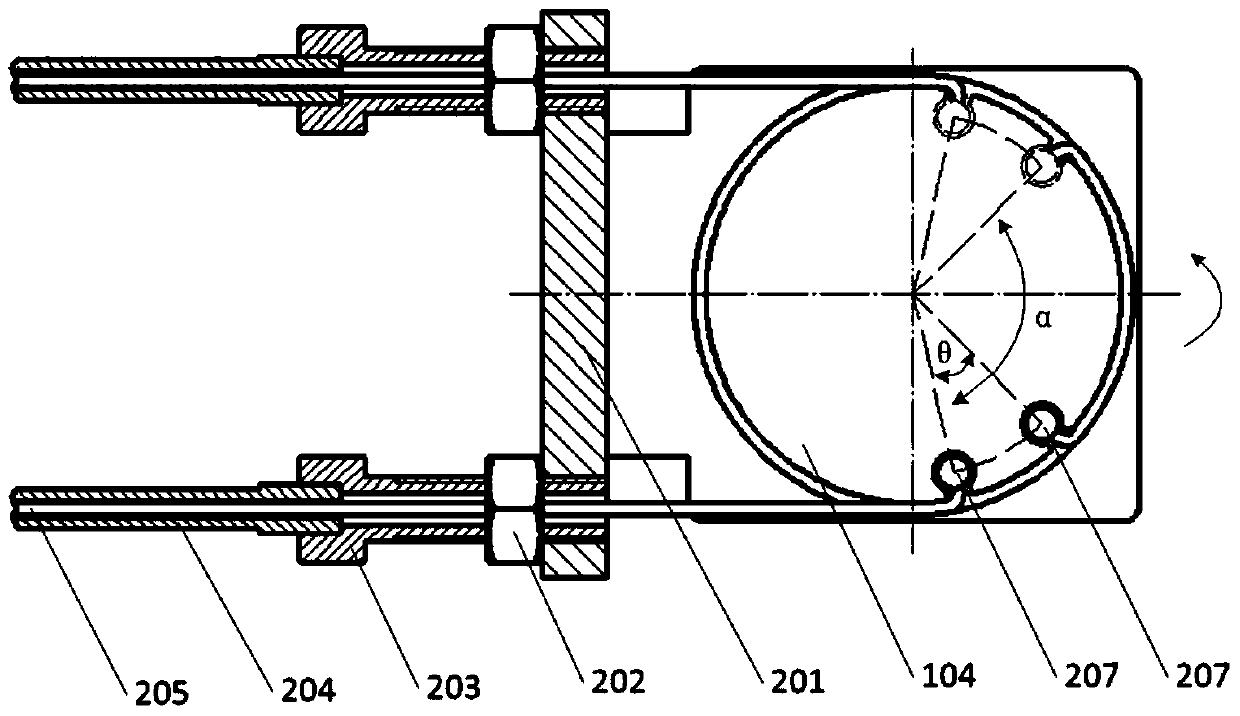

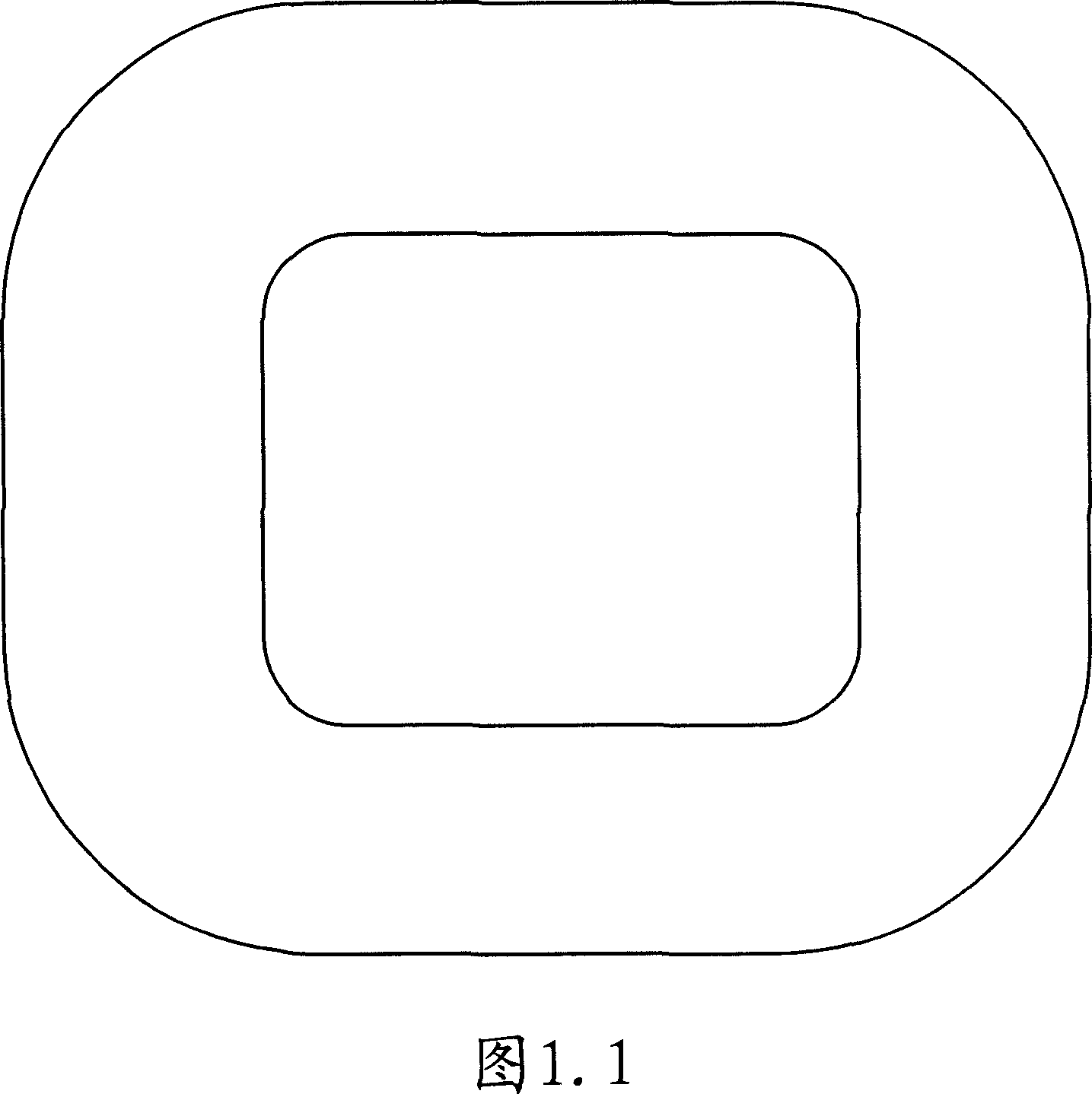

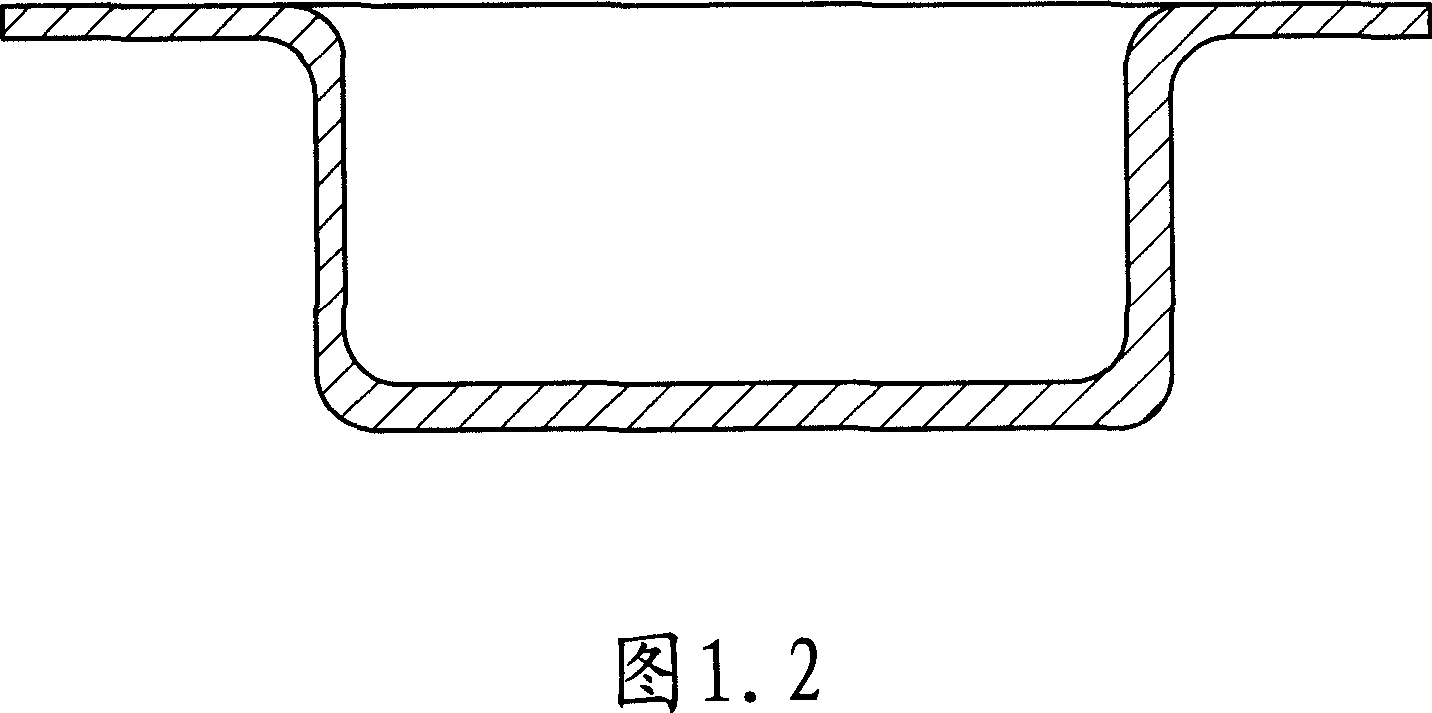

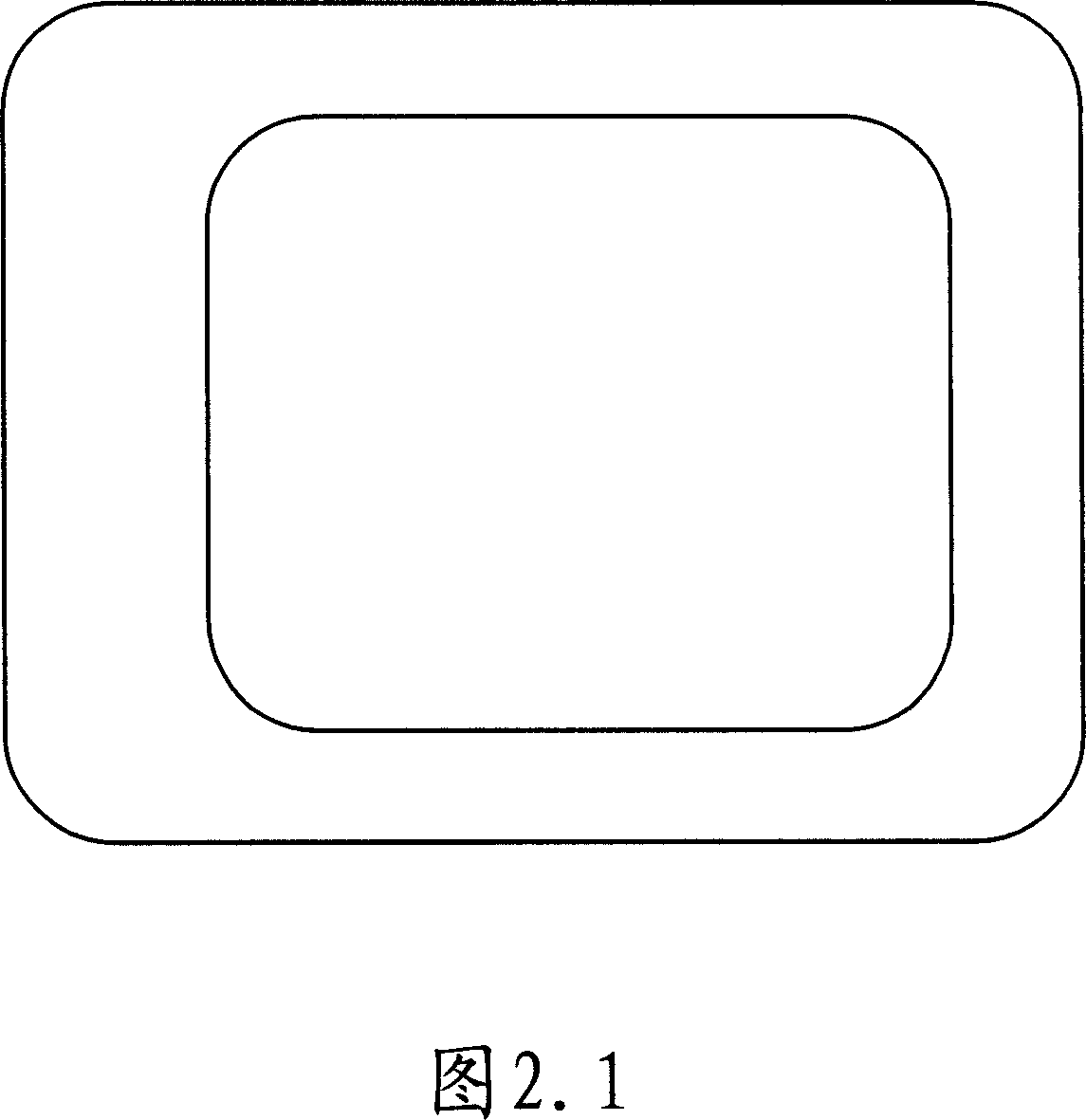

Rope-drive-based assisted knee joint rehabilitation apparatus

ActiveCN104188786ALarge angle of training and rehabilitationLight structureChiropractic devicesWalking aidsPhysical medicine and rehabilitationKnee Joint

The invention discloses a rope-drive-based assisted knee joint rehabilitation apparatus. The rope-drive-based assisted knee joint rehabilitation apparatus is characterized by comprising a supporting positioning unit and two execution units; each execution unit comprises a rope drive sub-unit, a rope transmission sub-unit and a knee joint sub-unit; every rope drive sub-unit is connected to the supporting positioning unit; the rope transmission sub-units are connected with both the rope drive sub-units and the knee joint sub-units. The rope-drive-based assisted knee joint rehabilitation apparatus allows a larger rehabilitation training angle, is simple in structure and light in weight, is safe and simple to control and is convenient to industrially produce and widely apply.

Owner:SOUTHEAST UNIV

Method for producing microecological feed additives for livestocks by using agricultural and sideline products

InactiveCN103070292AIncrease production capacityGood for healthFood processingAnimal feeding stuffBiotechnologyMetabolite

The invention provides a method for producing microecological feed additives for livestocks by using agricultural and sideline products. The method comprises the following steps of: mixing agricultural and sideline products main ingredients, agricultural and sideline products auxiliary materials and starch in parts by weight so as to obtain culture medium; mixing saccharomycetes, lactic acid bacteria and bacillus subtilis according to a viable count proportion of 1-3:0.5-2:0.5-3 so as to prepare mixed culture; mixing the culture medium and distilled water, and then inoculating; evenly stirring and fermenting; and after fermenting, naturally drying so as to obtain the final product. The microecological feed additives for the livestocks prepared by the agricultural and sideline products contain rich beneficial bacteria such as yeast, lactic acid bacteria and bacillus subtilis, metabolites of the beneficial bacteria, rich amino acid, low molecular peptide and growth promotion active ingredients; after the livestocks ingest, the growth and development of the beneficial microorganisms in alimentary canals of the livestocks can be promoted, the digestion function can be improved, certain nutrient substances can be provided for the livestocks, the production performance of the livestocks can be improved, and the health situation of the livestocks can be improved.

Owner:TANGSHAN NORMAL UNIV

Method for making stainless steel ware

InactiveCN1923451AHigh hardnessHigh tensile strengthOther manufacturing equipments/toolsHeat treatment process controlMachiningMaterials science

Owner:玉环海荣金属制品有限公司

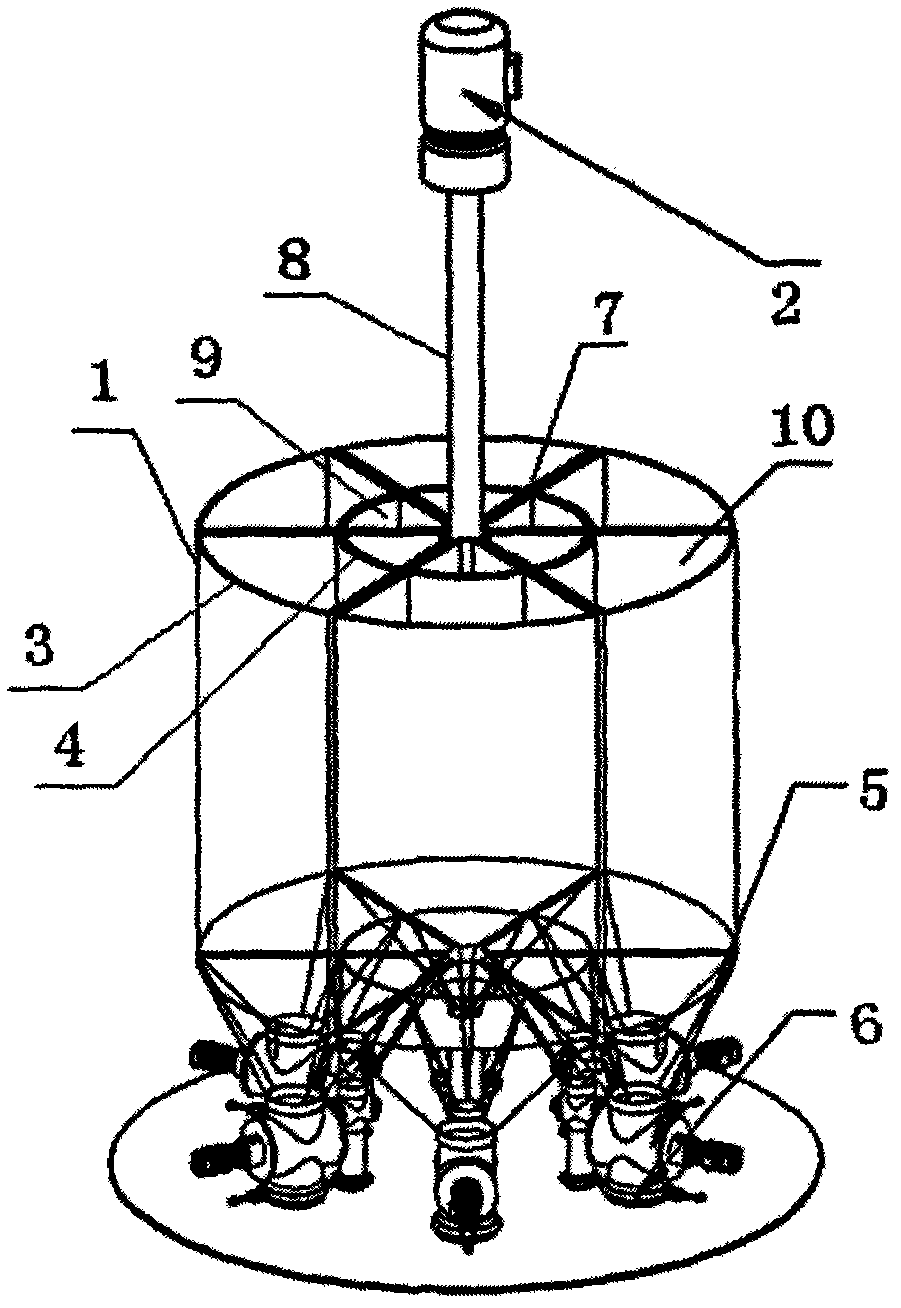

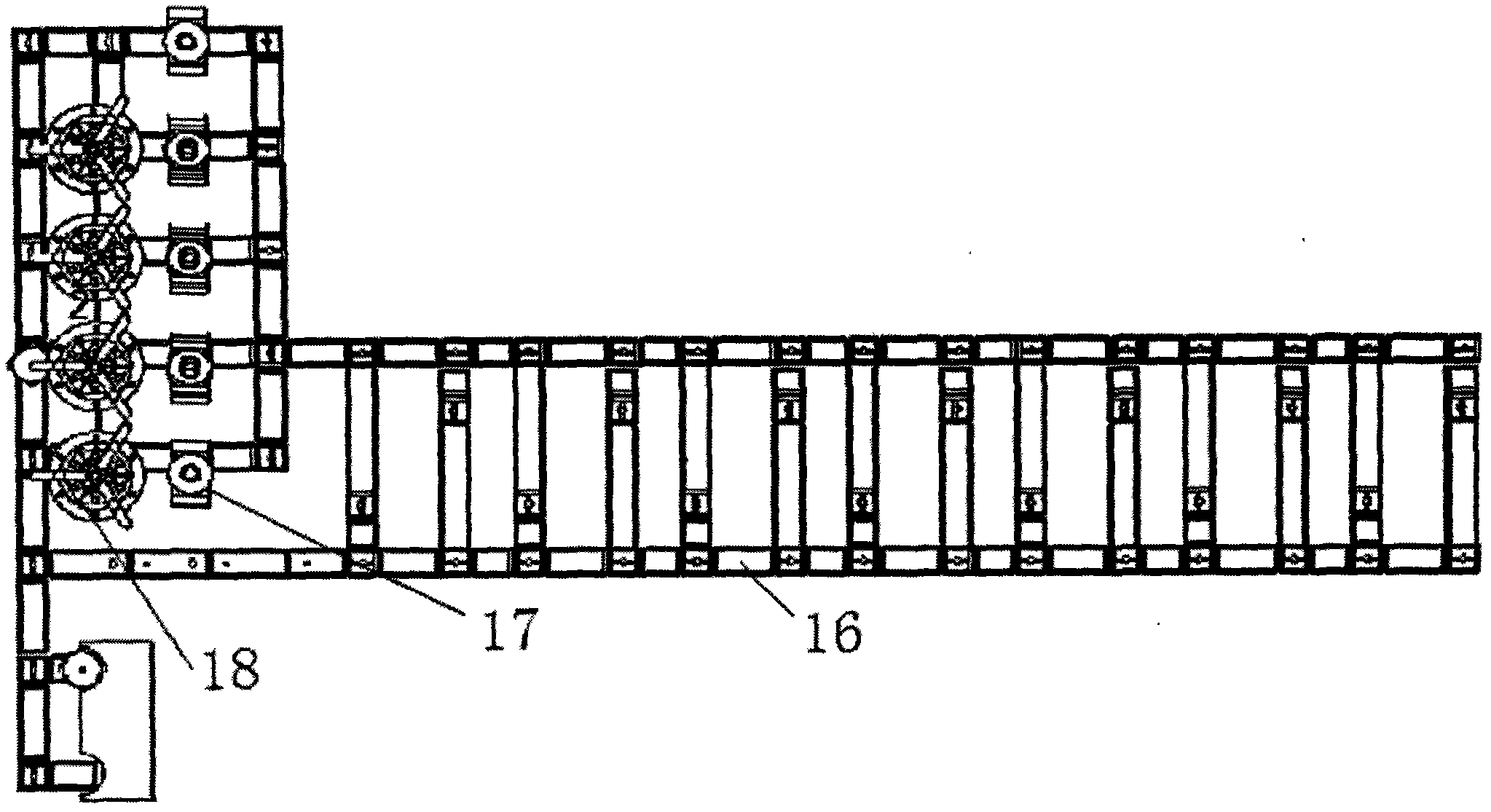

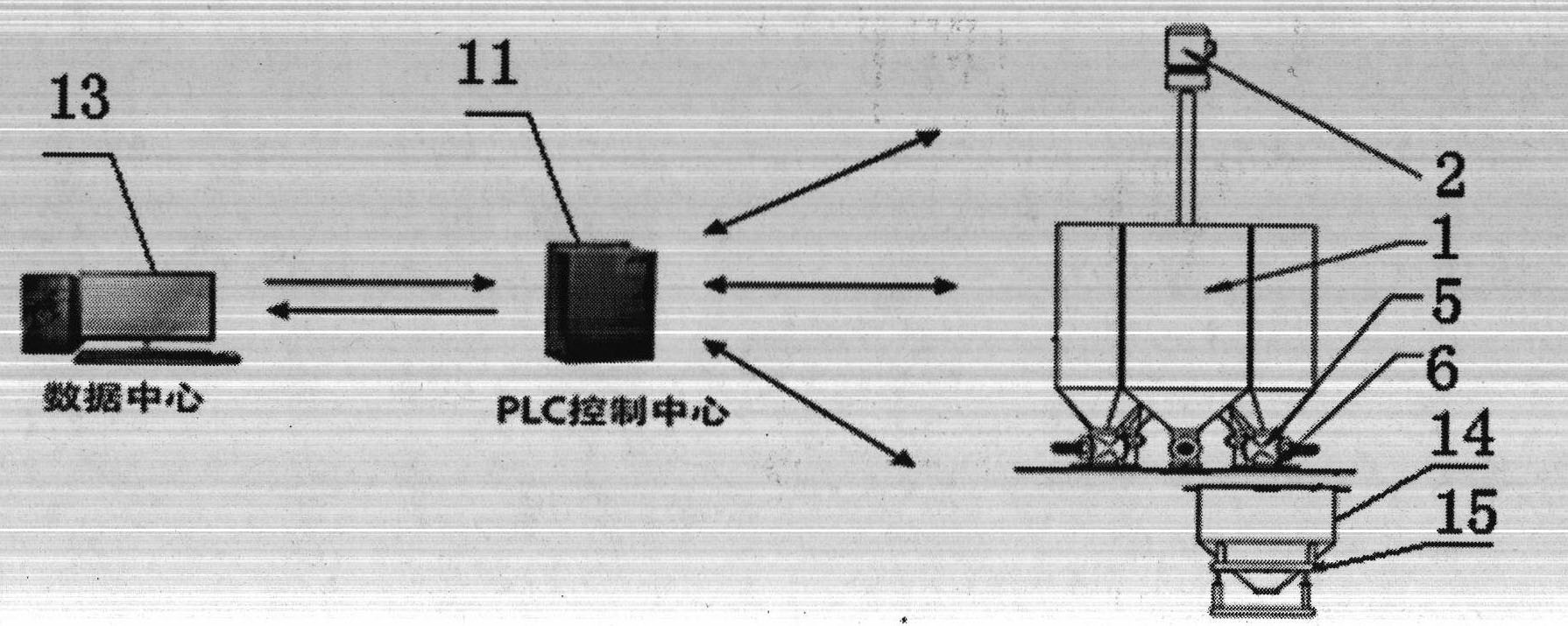

Automatic proportioning machine, automatic proportioning system of powder coating and proportioning method of powder coating

ActiveCN102166493AReasonable structural designRealize integrationMixing methodsMixer accessoriesFilling materialsPneumatic valve

The invention relates to an automatic proportioning machine, an automatic proportioning system of a powder coating and a proportioning method thereof, belonging to the technical field of powder coating proportioning systems. The automatic proportioning machine comprises a material tank and an asynchronous machine arranged on a central shaft of the material tank, and is characterized in that: the material tank consists of an outer tank body and an inner tank body sharing the central shaft with the outer tank body; a required number of clapboards are connected to the shaft wall of the central shaft; the other ends of the clapboards are connected with the outer tank body; the material tank is averagely divided into independent chambers by the clapboards; each chamber comprises an inner chamber for accommodating pigments and accessory ingredients, and an outer chamber for accommodating resin and filling materials; and the bottom of the material tank is provided with a material discharge machine communicated with each chamber, and the material discharge machine is connected with a pneumatic valve. According to the automatic proportioning machine, the automatic proportioning system and the proportioning method disclosed by the invention, the structure and design are reasonable, raw materials can be automatically and rationally selected and proportioned automatically, and toning can be automatically finished.

Owner:SHANDONG SHENGSHIDA MECHANICAL TECHNOLOGY CO LTD

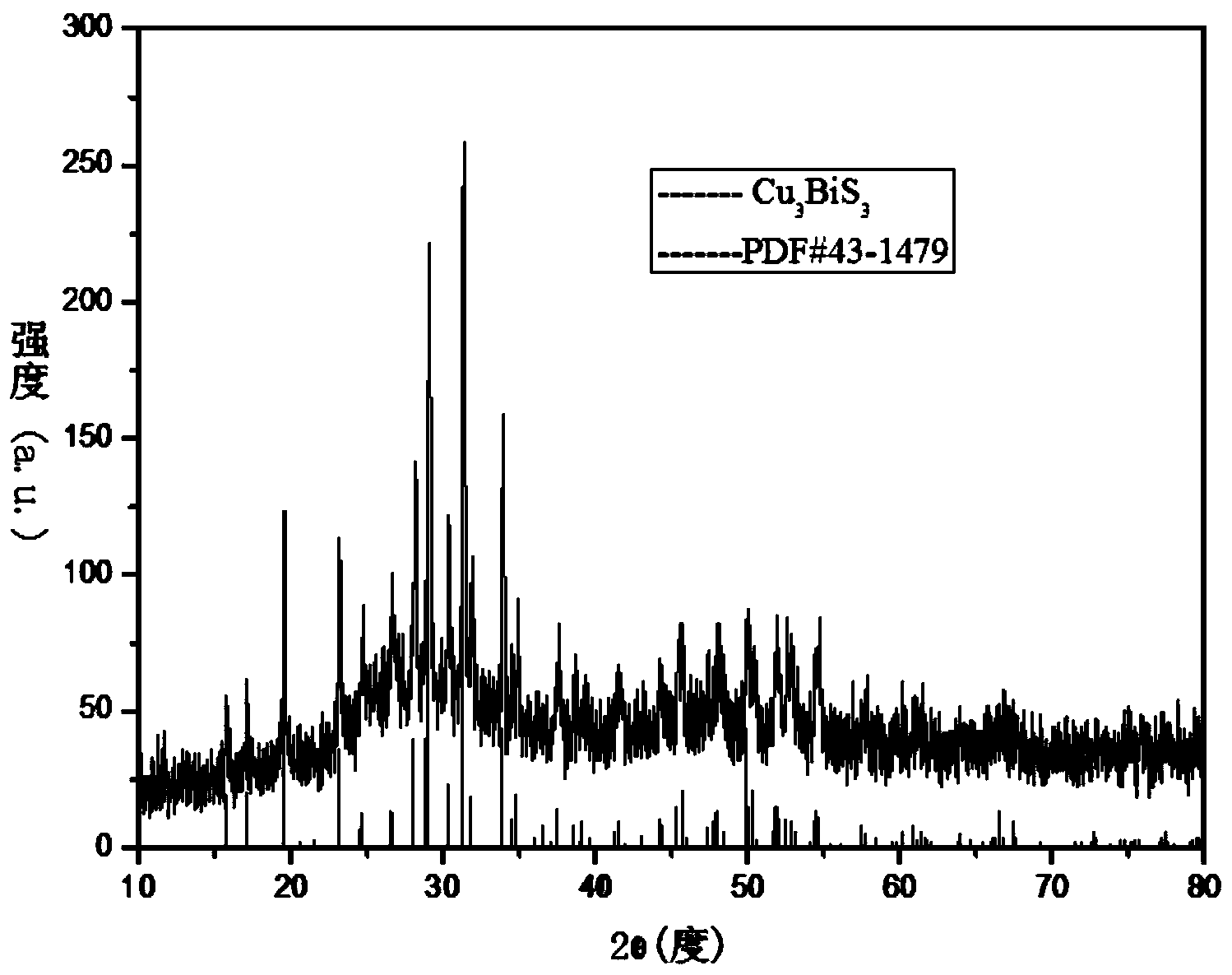

Cu3BiS3 ternary sulfur nano material and preparation method thereof

InactiveCN103553130APromote absorptionLow costMaterial nanotechnologyEnergy modified materialsSolventThermal effect

The invention discloses a Cu3BiS3 ternary sulfur nano material and a preparation method thereof, belonging to the field of inorganic nano materials. The Cu3BiS3 ternary sulfur nano material is nano particles which are prepared by adopting a high-temperature pyrolysis method by taking oleic acid, oleylamine and octadecene as reaction solvents, Cu(NO3)2.3H2O and Bi(NO3)3.5H2O as raw materials and sodium diethyldithiocarbamate as a complexing agent and a sulfur source. The Cu3BiS3 nano particles have better absorbability in an ultraviolet / visible light area, and are proved to have a good photo-thermal effect; besides, the Cu3BiS3 ternary sulfur nano particles can be used for performing CT (computed tomography) imaging, so that the nano particles can be well applied in the field of biomedicine. Moreover, the preparation method of the Cu3BiS3 ternary sulfur nano material has many advantages of simple operation, low raw material cost, availability and the like, and is suitable for industrial production and application.

Owner:SHANGHAI NORMAL UNIVERSITY

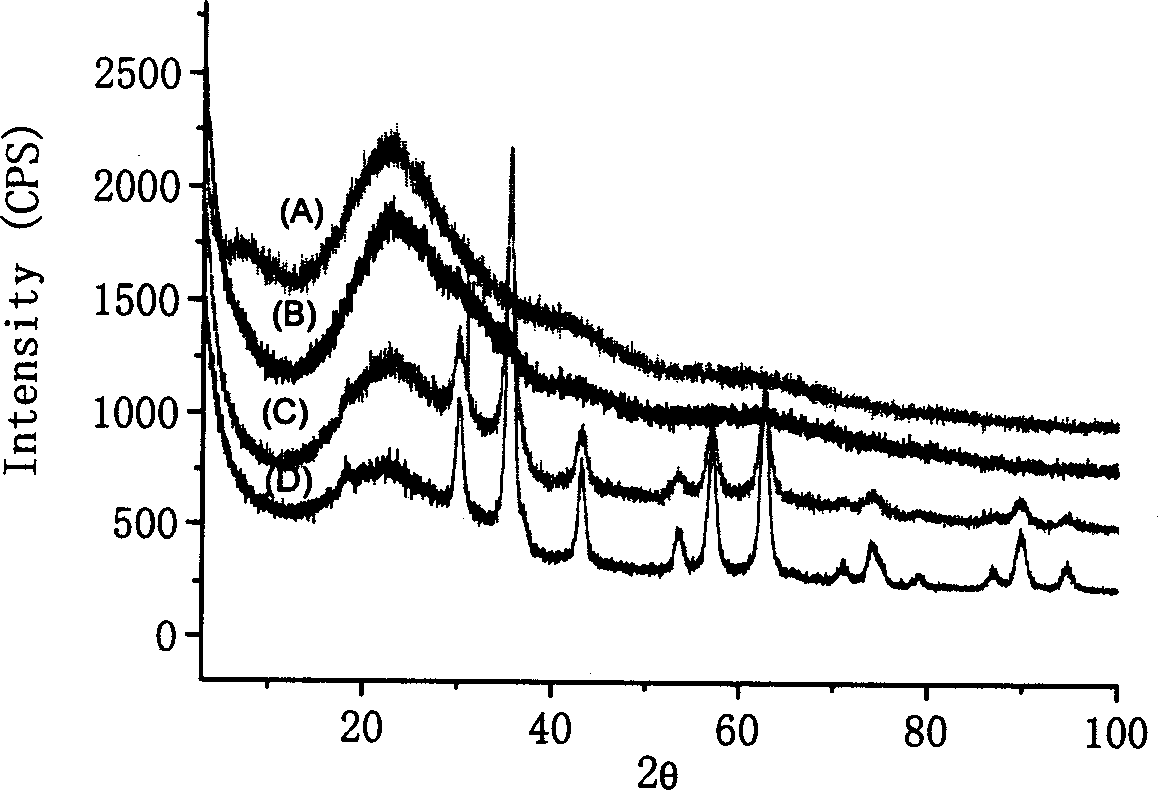

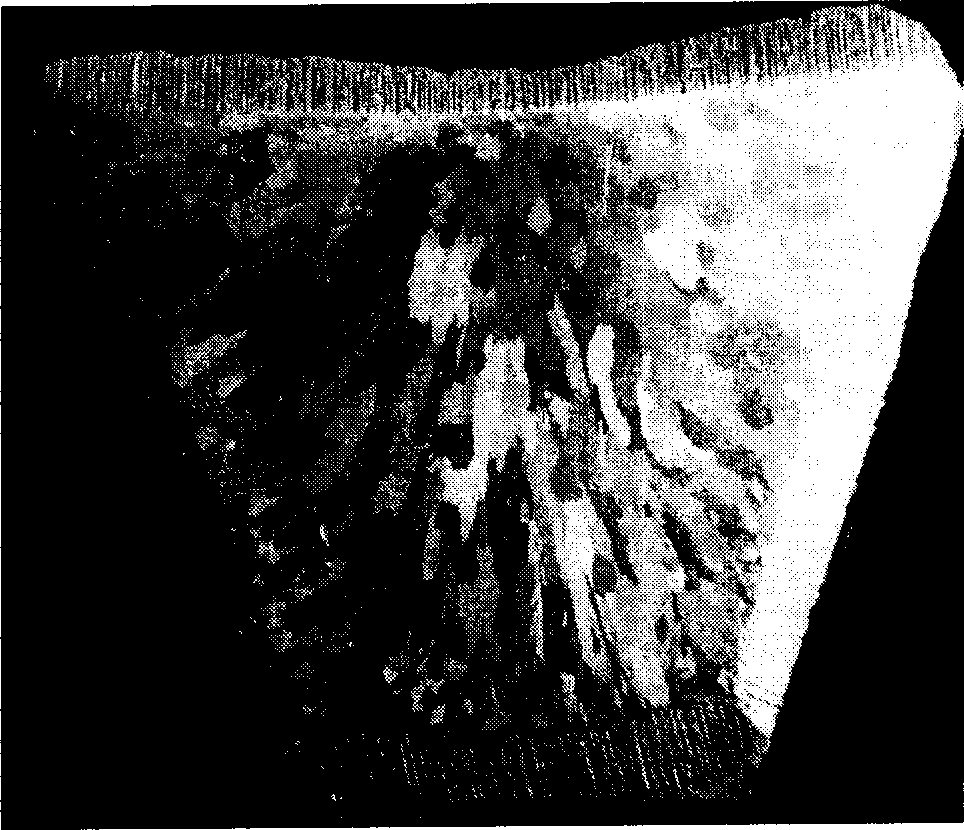

Prepn process of composite Al-Ti-C grain refining agent for aluminium and aluminium alloy

The present invention is preparation process of composite Al-Ti-C grain refining agent for aluminum and aluminum alloy with raised cooling speed, less Ti-C particle interface aggregation and raised Al-Ti-C grain refining performance. The preparation process includes: mixing material in certain weight proportion, pressing the mixture into cylindrical prefabricated block, stoving at 15-200 deg.c for 2 hr, pressing prefabricated block into aluminum melt at 760-820 deg.c to reach Ti content of 3-5%, hot-blast synthesis reaction and maintaining at 760-820 deg.c for 2 min, stirring the aluminum melt mechanically at 60-100 rpm for 5-10 min for the synthesized material to be diluted and dispersed well in the aluminum melt, standing for 5-10 min and casting in metal mold to obtain the product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

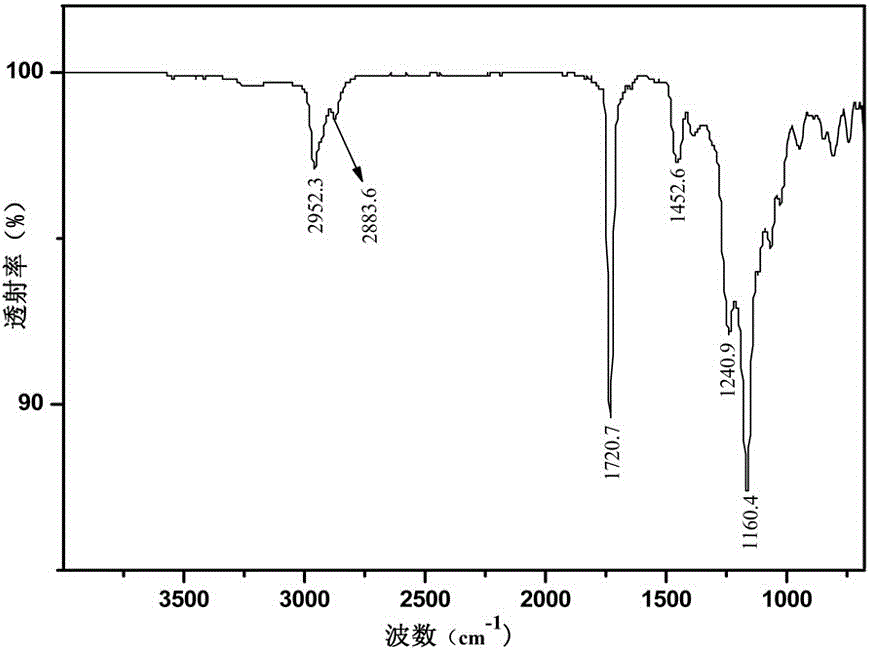

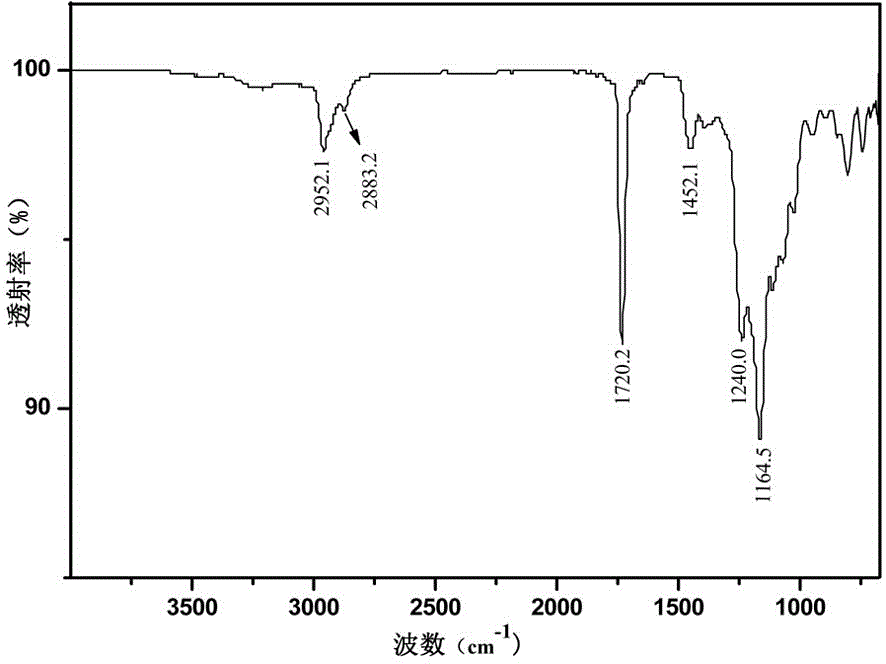

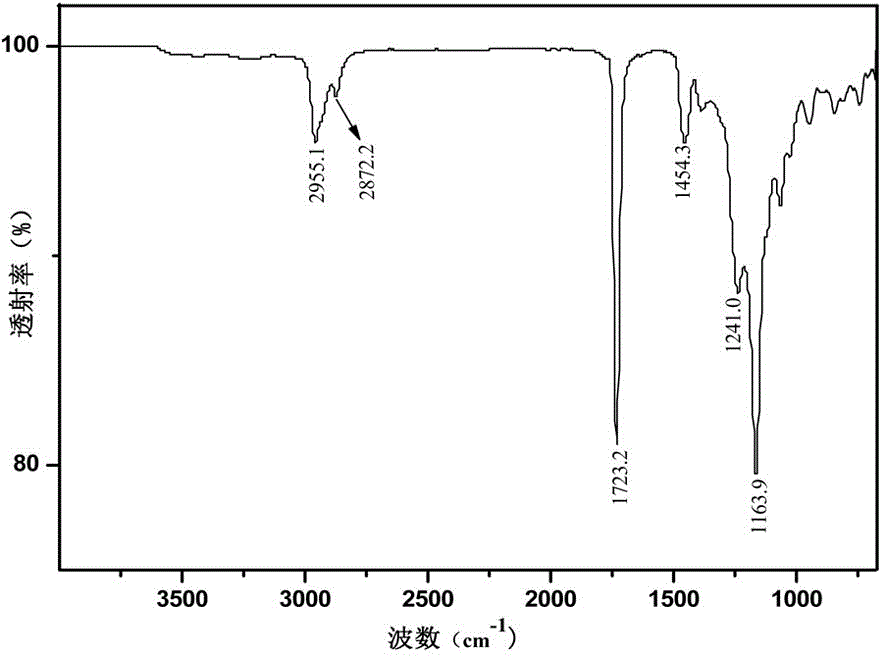

Water and oil repellent finishing agent for fabrics and preparation method of finishing agent

ActiveCN104594045AImprove shielding effectExcellent water and oil repellencyFibre treatment(Hydroxyethyl)methacrylateEmulsion

The invention discloses a water and oil repellent finishing agent for fabrics and a preparation method of the finishing agent. The active ingredient of the finishing agent refers to perfluoroalkyl silicone acrylate copolymer. The preparation method comprises the following steps: mixing perfluoroalkyl silicone acrylate, butyl acrylate, methyl methacrylate and hydroxyethyl methylacrylate, initiating free radical emulsion copolymerization by virtue of a water-soluble initiator under the emulsification actions of a nonionic surfactant and an anionic surfactant, thereby obtaining the emulsion type perfluoroalkyl silicone acrylate water and oil repellent finishing agent with high stability for fabrics. The finishing agent is applied for finishing cotton fabrics, and the water and oil repellent effects are obviously improved. The water and oil repellent finishing agent provided by the invention is mild in preparation conditions, simple and convenient in preparation process and suitable for industrial production.

Owner:苏州章贡纺织科技有限公司

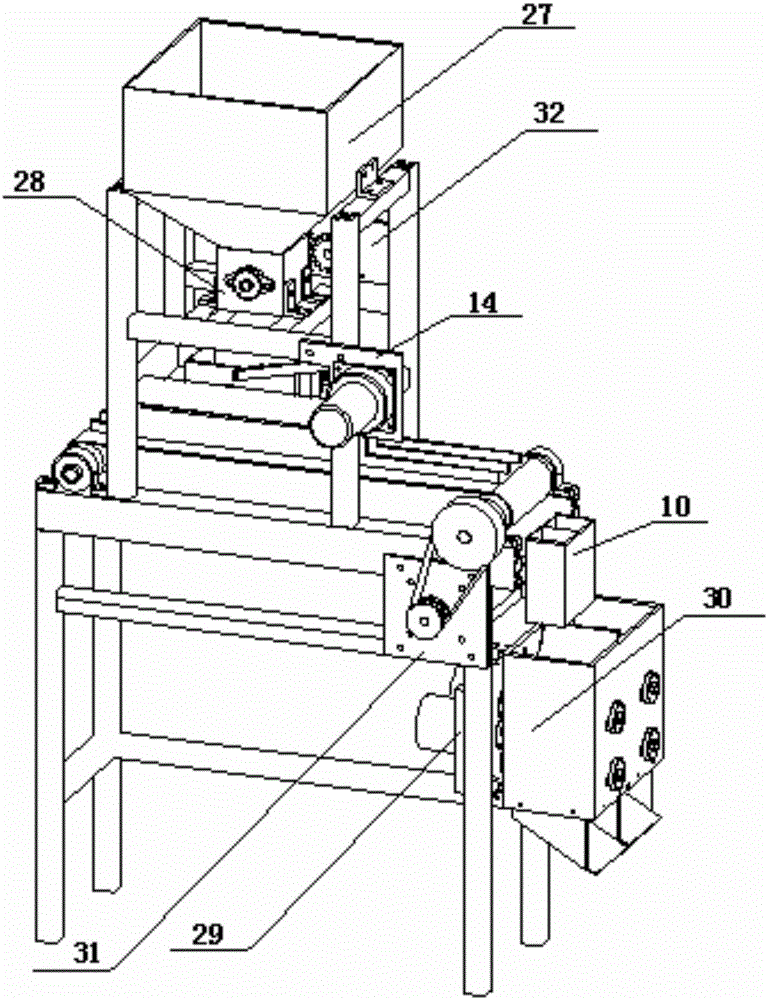

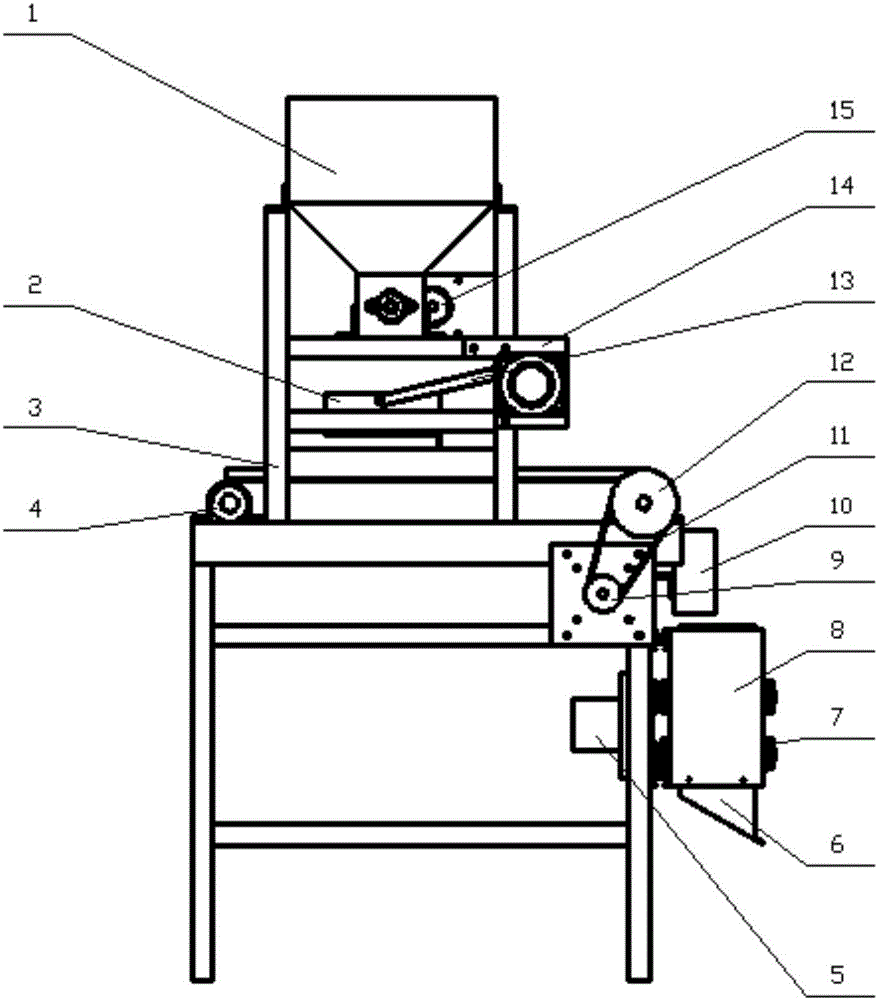

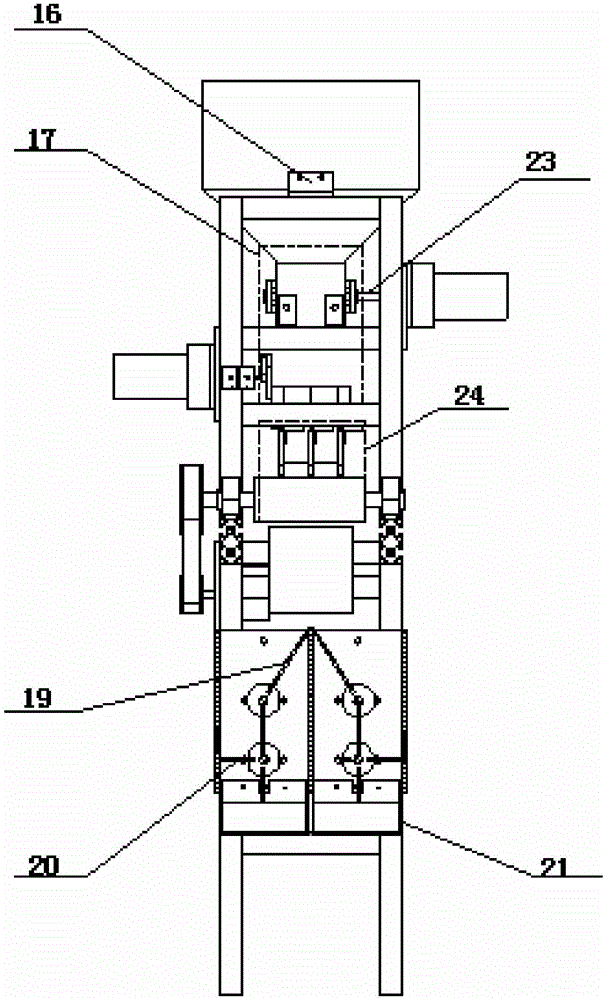

Hair ring split charging machine

InactiveCN106218962ARealize accurate counting and dispensingFill the gap in packingConveyorsPackaging automatic controlEngineeringMechanical engineering

The invention discloses a hair ring split charging machine. At present, ring packaging is manually operated, and the packaging efficiency is low. The hair ring split charging machine comprises a feeding hopper, a rotation mechanism, a transverse moving screening mechanism, a material dividing device, counters and a discharging device; the rotation mechanism is arranged at the bottom of a discharging hopper, the transverse moving screening mechanism is arranged below the rotation mechanism, and raw materials are evenly discharged; three split strips are arranged between a conveying belt mechanism of the material dividing device and a screen of the transverse moving screening mechanism, the position, between every two adjacent split strips, of the output end of the conveying belt mechanism is provided with one counter, and the discharging device is arranged below the counters and comprises a discharging barrel, first rotating shafts, second rotating shafts and a flow combining part; and the discharging barrel is divided into two discharging chambers, first discharging clamping rings are fixed to the first rotating shafts in the discharging chambers, clamping grooves in the tops of the first discharging clamping rings are fixed to first baffles, second discharging clamping rings are fixed to the second rotating shafts, and two second baffles are fixed in two clamping grooves in the bottoms of the second discharging clamping rings. A gap of flexible material split charging in industrial production is filled up by means of the hair ring split charging machinej.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com