Complex microbial inoculant and method for preparing organic fertilizer by using same

A technology of composite bacterial agents and strains, which is applied in the field of rapid resource processing of cassava distiller's grains, can solve problems such as difficulty in ensuring product quality stability and large-scale production of high-quality organic fertilizers, and achieves easy realization and preparation The method is simple and the effect of high live bacteria rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

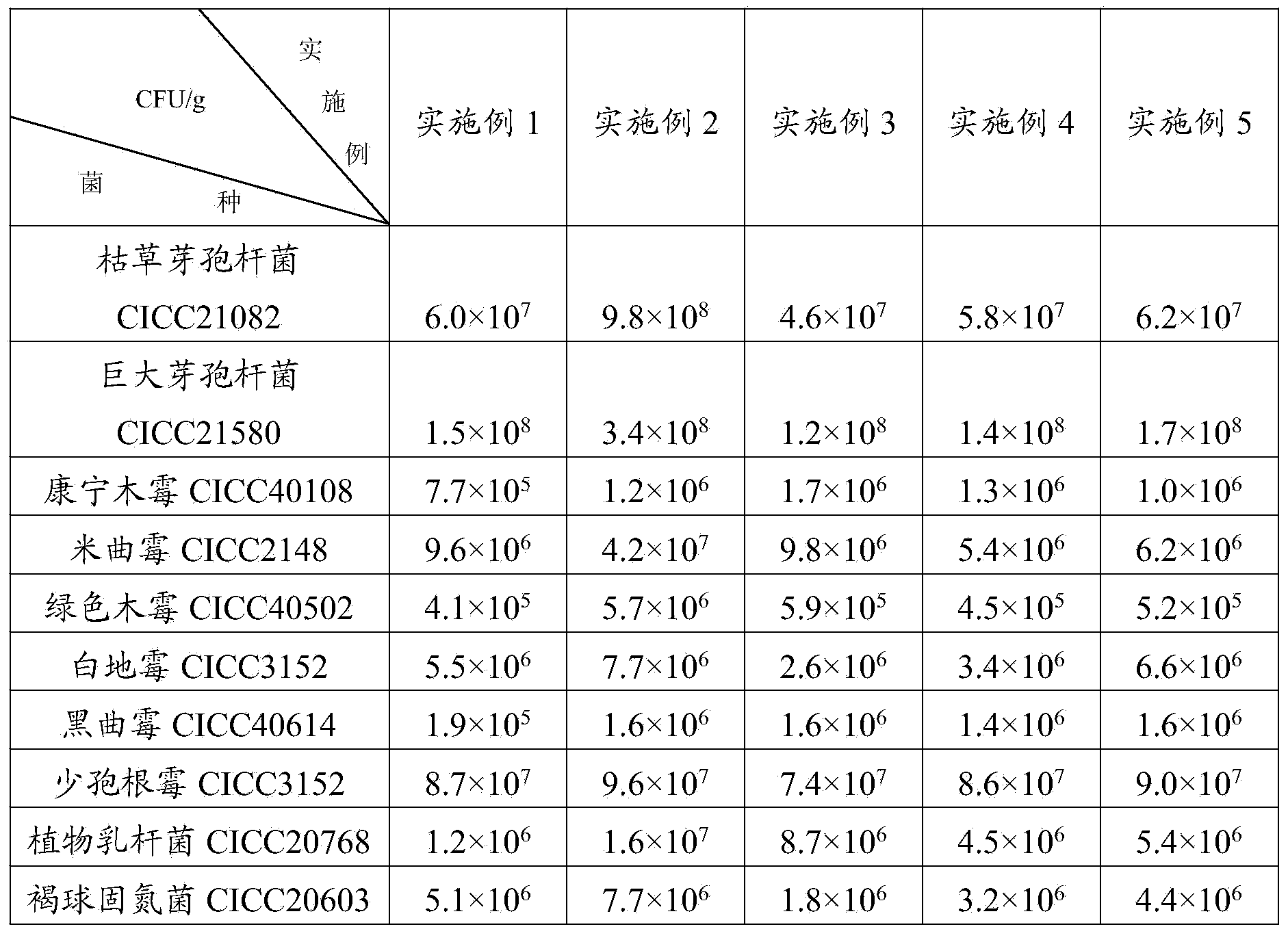

[0041] Composite microbial agent, its active ingredients include Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, Rhizopus oligosporum CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter phenococcus CICC20603.

[0042] Preparation of compound bacterial agent:

[0043] ⅰ Activation culture: the slant strains stored in the refrigerator at 4°C: Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, sporeless roots Mold CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter sphaeroides CICC20603 were respectively inoculated with 1 loop of strains into the corresponding 500ml activation medium for activation culture to obtain the activated strain liquid of ea...

Embodiment 2

[0059] Composite microbial agent, its active ingredients include Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, Rhizopus oligosporum CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter phenococcus CICC20603.

[0060] Preparation of compound bacterial agent:

[0061]ⅰ Activation culture: the slant strains stored in the refrigerator at 4°C: Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, sporeless roots Mold CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter sphaeroides CICC20603 were respectively inoculated with 2 rings of strains into the corresponding 50ml activation medium for activation culture to obtain the activated strain liquid of eac...

Embodiment 3

[0077] Composite microbial agent, its active ingredients include Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, Rhizopus oligosporum CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter phenococcus CICC20603.

[0078] Preparation of compound bacterial agent:

[0079] ⅰ Activation culture: the slant strains stored in the refrigerator at 4°C: Bacillus subtilis CICC21082, Bacillus megaterium CICC21580, Trichoderma koningen CICC40108, Aspergillus oryzae CICC2148, Trichoderma viride CICC40502, Geotrichum candidum CICC3152, Aspergillus niger CICC40614, sporeless roots Mold CICC3152, Lactobacillus plantarum CICC20768 and Azotobacter sphaeroides CICC20603 were respectively inoculated with 1 loop of strains into the corresponding 500ml activation medium for activation culture to obtain the activated strain liquid of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com