Patents

Literature

39results about How to "High rate of live bacteria" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

ActiveCN103333840AHigh activityLow freezing pointBacteriaFood preparationBacterial strainRefrigeration

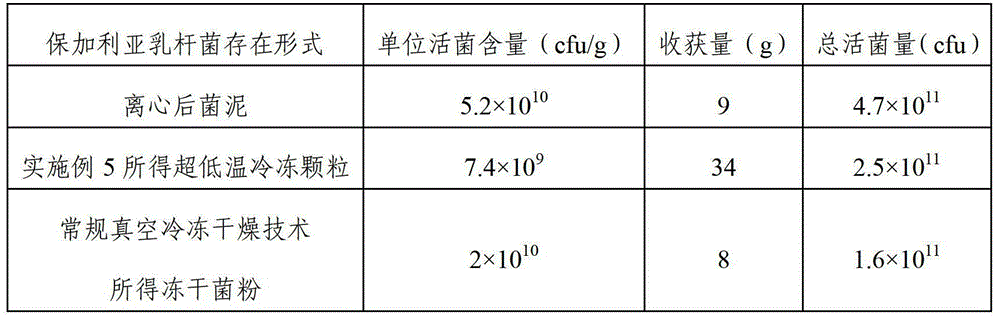

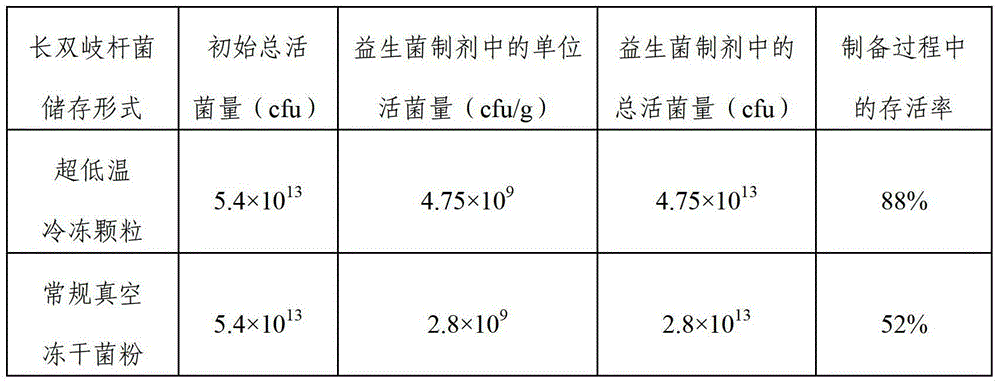

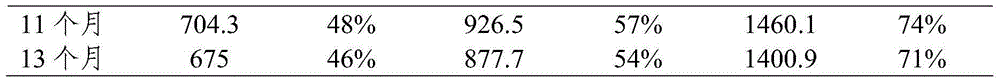

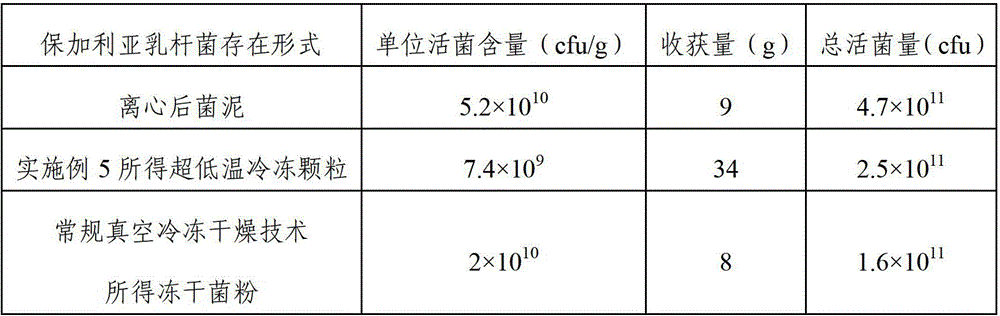

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

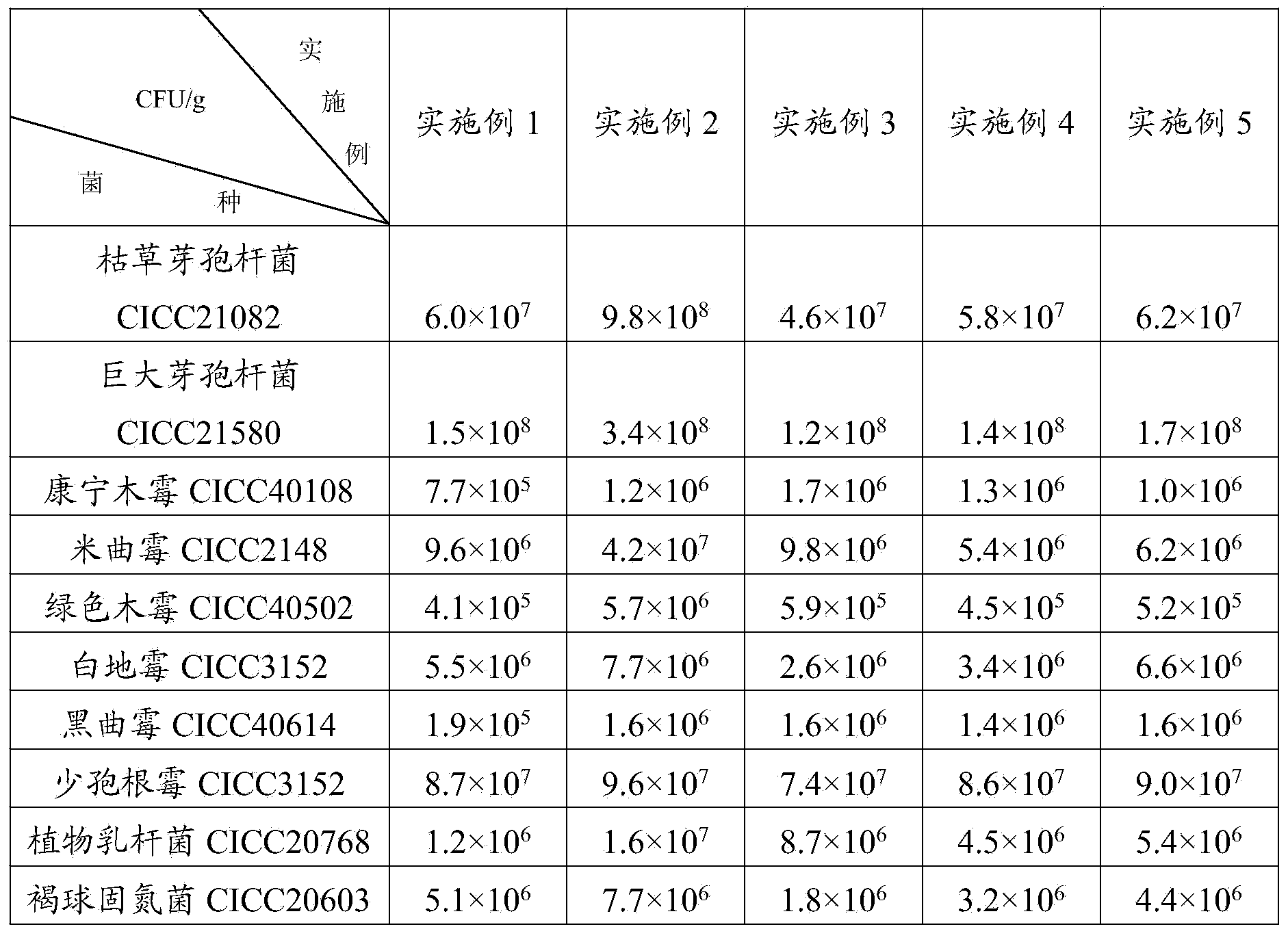

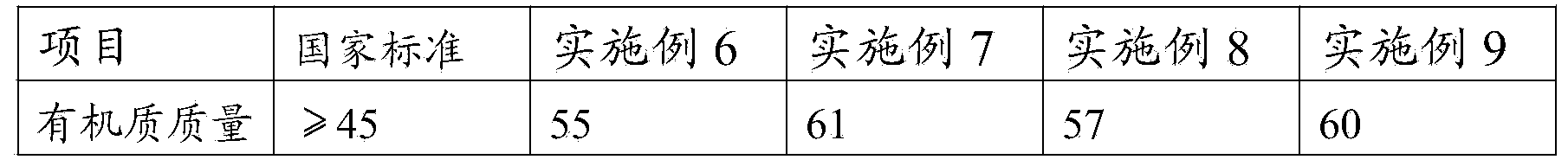

Complex microbial inoculant and method for preparing organic fertilizer by using same

InactiveCN103898032AImprove qualityEffective cooperationBio-organic fraction processingFungiFiberAzotobacter chroococcum

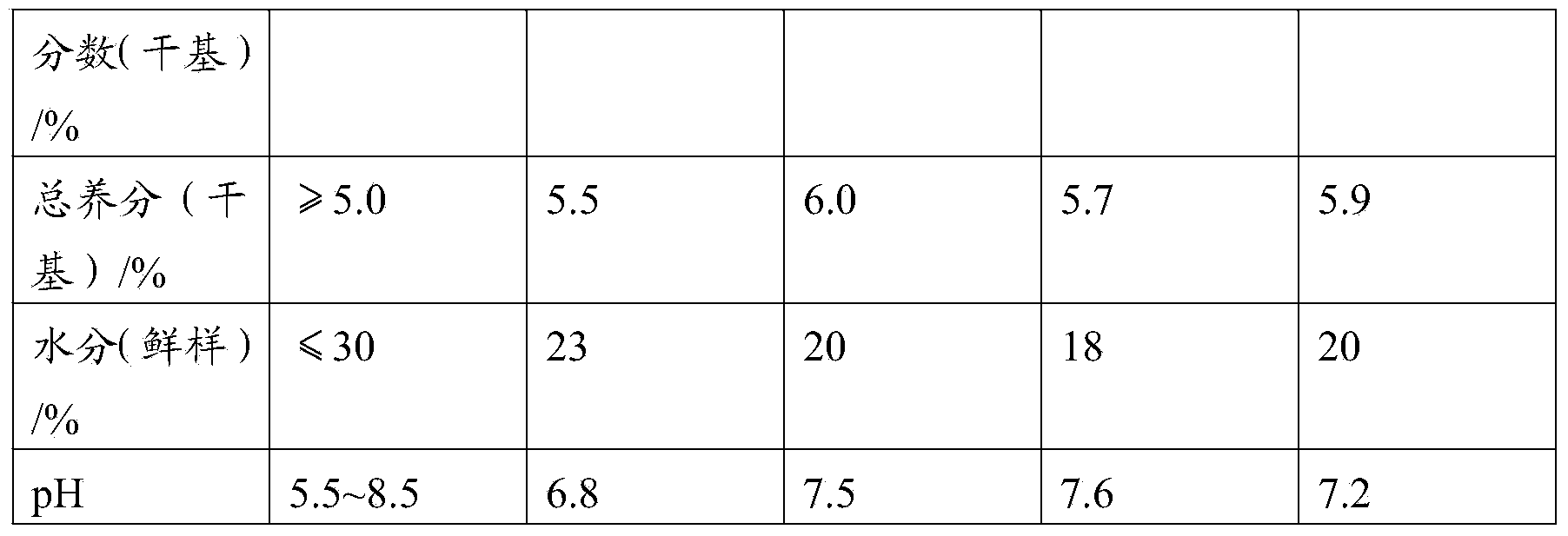

The invention discloses complex microbial inoculant which comprises the following active ingredients: bacillus subtilis, bacillus megatherium, trichoderma koningii, aspergillus oryzae, trichoderma viride, geotrichum candidum, aspergillus niger, rhizopus oligosporus, lactobacillus plantarum CICC20768 and azotobacter chroococcum. Correspondingly, the invention further discloses a method for preparing an organic fertilizer from the complex microbial inoculant. The method comprises the following steps: a. uniformly mixing the complex microbial inoculant with a plant fiber raw material to obtain a fermented raw material; b, composting and fermenting the fermentation raw material; c, drying the composted fermentation raw material to obtain the organic fertilizer. microbes of the complex microbial inoculant have no antagonism, and can effectively cooperate in the production process of the organic fertilizer, and the chemical components of the production raw materials can be sufficiently utilized to finally produce the high-quality organic fertilizer. The produced organic fertilizer reaches the parameter indexes of the standard (NY884-2012) of China, can improve the planting property of soil, is beneficial to optimization of soil microbial flora, and can provide comprehensive nutrients to a plant root system.

Owner:江苏联海生物科技有限公司

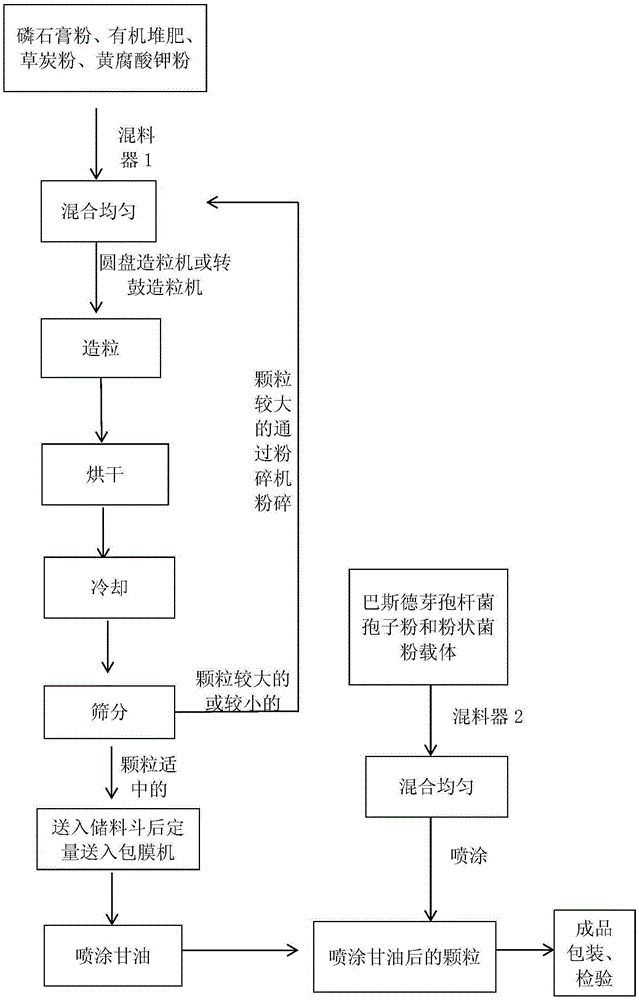

Compound soil remediation agent containing microorganism bacteria and preparation method thereof

ActiveCN103951532AIncrease the granular structureIncrease organic matterFertilizer mixturesArbuscular mycorrhizal fungiPotassium

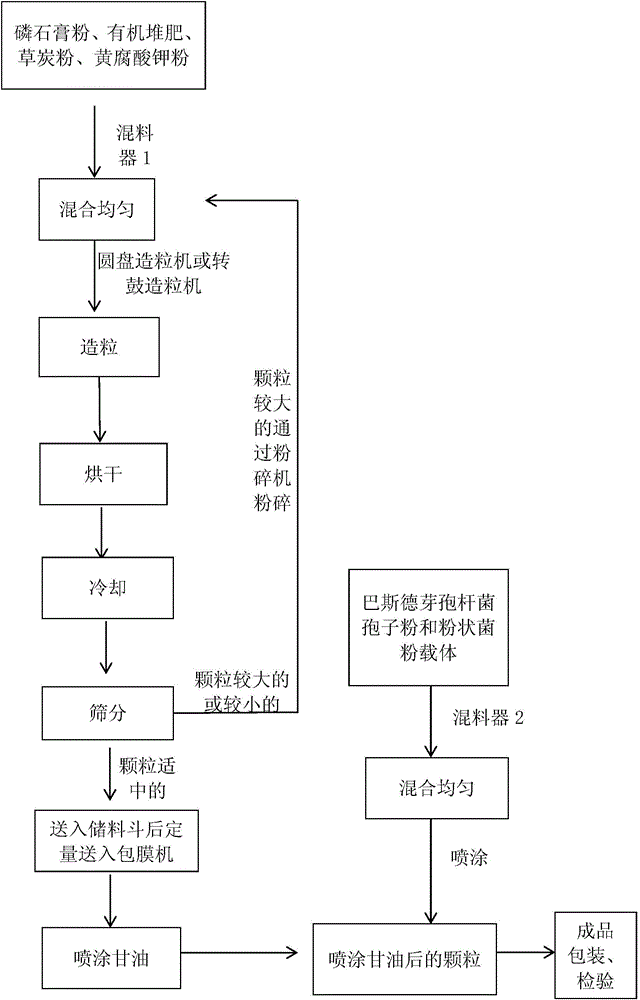

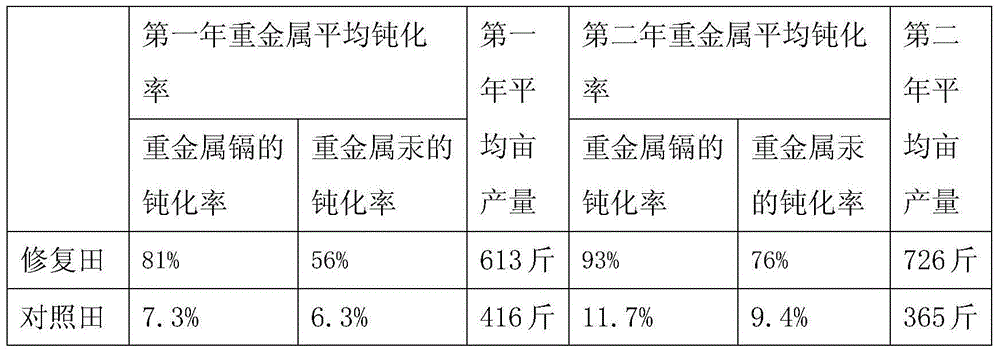

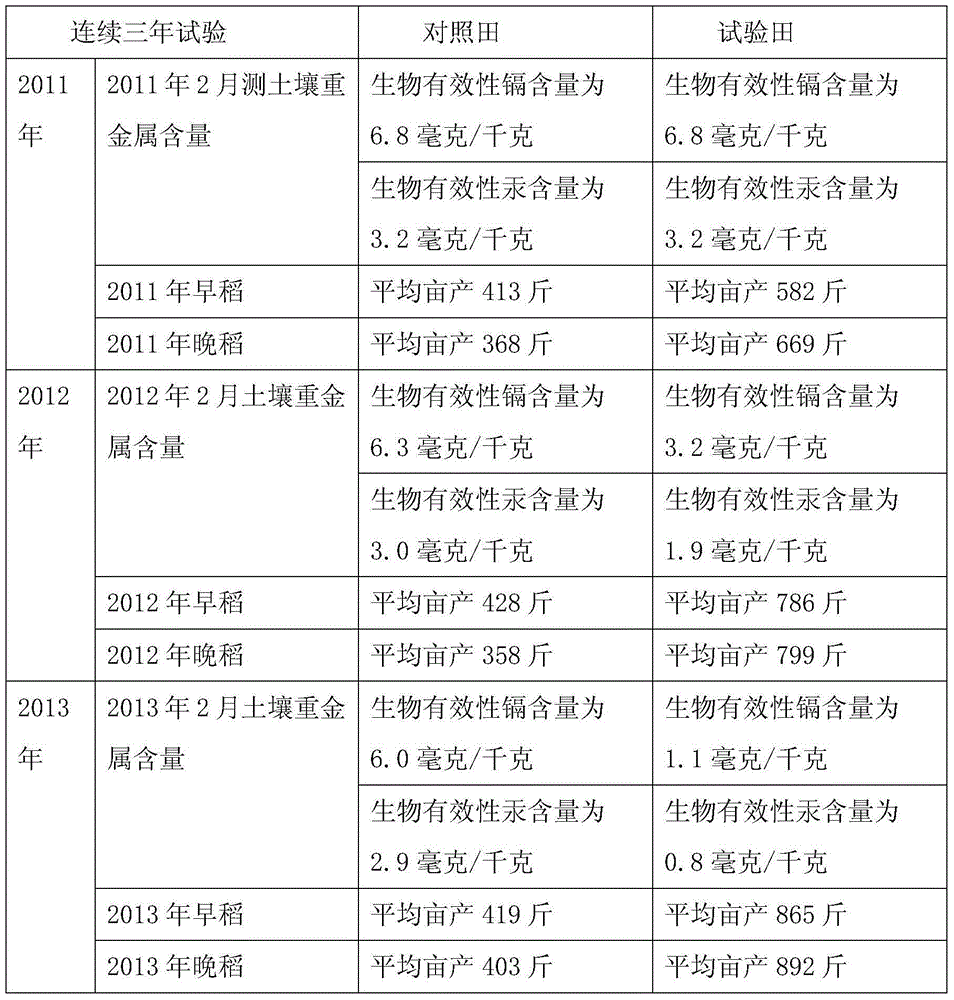

The invention relates to a compound soil remediation agent containing microorganism bacteria and a preparation method thereof. The remediation agent comprises the following components in parts by weight: 0.01-3 parts of bacillus pasteurii spore powder, 5-50 parts of phosphogypsum powder, 10-60 parts of organic compost, 5-50 parts of turf powder, 1.5-5 parts of potassium fulvate powder, 0.2-0.5 part of powdery bacteria powder carriers and 0.15-1 part of glycerin. The remediation agent has round and smooth grains and high grain hardness, is harmless to seeds, can serve as a base fertilizer together with other fertilizers, can be sown together with seeds, integrates multiple remediation functions including organic complexation and passivation remediation, inorganic passivation remediation, microorganism passivation remediation and the like, has a comprehensive and strong soil remediation function, and can stimulate growth and reproduction of arbuscular mycorrhizal fungi at the roots of crops, accelerate heavy metal passivation, stimulate crop growth and enhance the immunities of crops.

Owner:安徽莱姆佳生物肥业有限公司

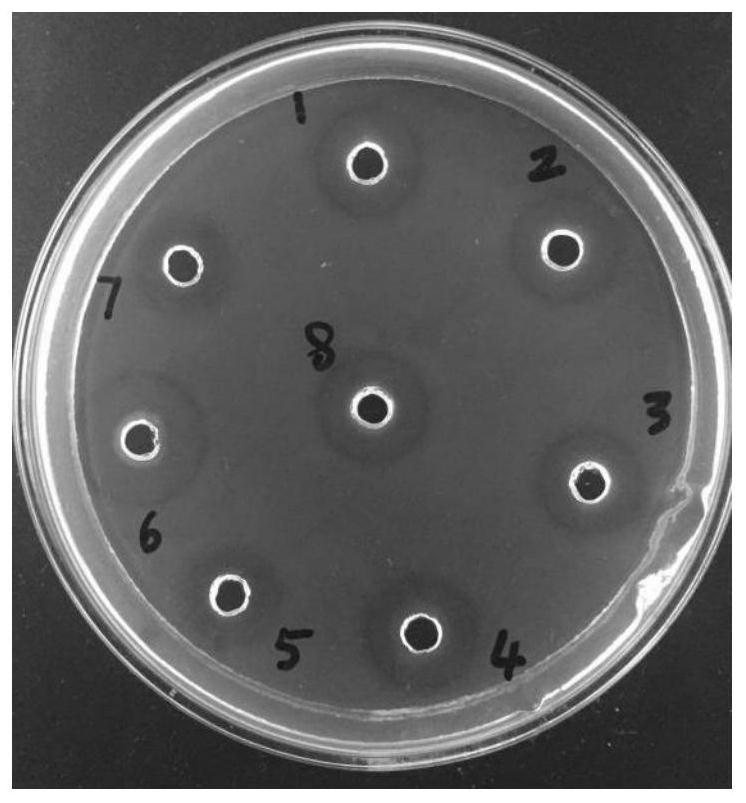

Cryptococcus bacteria capsule and preparation thereof

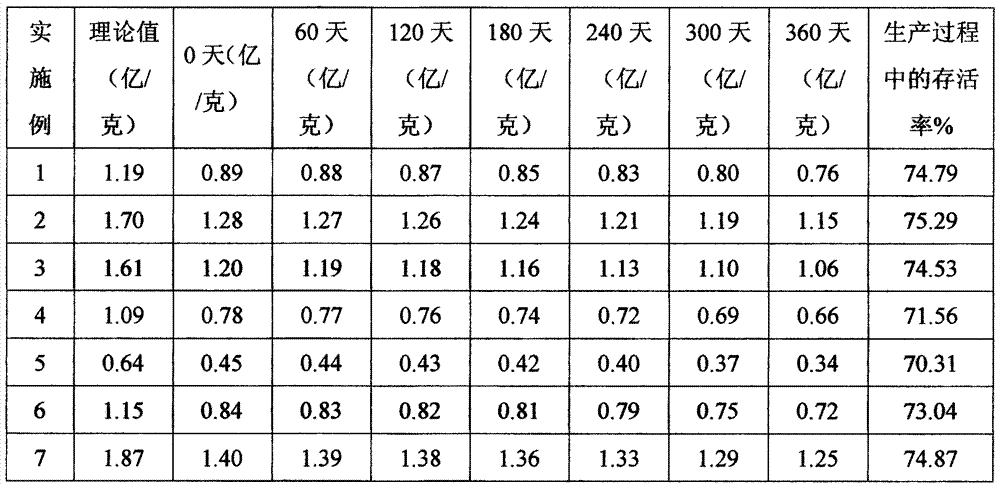

InactiveCN101503661AHigh rate of live bacteriaLow costFungiMicroorganism based processesOrganismDrug biological activity

The invention discloses Cryptococcus capsules and a method for preparing the same. The method for preparing the Cryptococcus capsules comprises the step of mixing a solution of alginate, Cryptococcus, multivalence metal cations to obtain the Cryptococcus capsules. Experiments show that the viable bacterium rates of the Cryptococcus capsules prepared by the method are all above 70 percent; the highest viable bacterium rate is up to 90 percent; and the activity of bacteria is not reduced. The Cryptococcus capsules of the invention can be stored at both low and normal temperature, the effect of storage for one month at normal temperature is substantially the same as that of the storage at low temperature and the biological activity of the bacteria are not influenced. Therefore, the method has wide application prospect in the preparation of biological agents and the preservation of other organisms.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

Solid ocean red yeast preparation as well as preparation method and application thereof

The invention discloses a solid ocean red yeast preparation which is mainly prepared from a composite protective agent and ocean red yeast bacterial sludge according to a mass ratio of (1.5-2.2):1, wherein the cell density of ocean red yeast in the solid ocean red yeast preparation is 200-400 billion / gram, the cell activity is 70-80%, and the protective agent comprises skim milk powder and cane sugar. The invention further discloses a preparation method of the solid ocean red yeast preparation, The preparation method comprises the following steps: firstly, performing high-density cultivation on the ocean red yeast in a cultivation mode of continuous liquid flow layer ventilation, and further drying by using a vacuum freezing drying method. According to the solid ocean red yeast preparation, the survival rate of the ocean red yeast can be increased to be 70-80%, the cell density in the preparation can be 200-400 billion / gram, and the preparation can be also used in aquatic product feeds as an additive as a product of the preparation is in a solid manner, long in expiration date and convenient to transport.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

High-nutrient microbial bacterium composite fertilizer and production method thereof

InactiveCN104557312AMeet growth needsSufficient contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDouble wall

The invention discloses a high-nutrient microbial bacterium composite fertilizer and a production method thereof. The high-nutrient microbial bacterium composite fertilizer comprises the following components in parts by weight: 16-190 parts of double-wall layer composite microbial bacterium microcapsules (containing 3-5 parts of composite microbial bacteria), 150-450 parts of monoammonium phosphate, 0-400 parts of urea powder, 100-200 parts of potassium chloride, 200-350 parts of ammonium chloride, 20-100 parts of ammonium bicarbonate, 0-150 parts of ammonium sulfate and 0-50 parts of attapulgite. The production method comprises the following steps: adsorbing the microbial bacteria by adopting germ powder thereof, performing first wall layer embedding by adopting a chemical cross-linking method, performing second wall layer embedding by adopting a spray drying process, and finally coating on the surface of chemical fertilizer granules, and split charging. The composite fertilizer is sufficient in nutrient and high in viable count, so that the microbial bacteria can be slowly released, yield increase of crops is guaranteed, the incidence rate of insect pests is reduced, and soil hardening caused by application of chemical fertilizers is improved.

Owner:HEBEI CHUNCHAO BIOLOGICAL TECH

Preparation method and application of high-stress-resistant probiotics

InactiveCN106434438AImprove stress resistanceIncreased growth and reproduction rateFungiBacteriaBiotechnologySynthetic Polymeric Macromolecules

The invention discloses a preparation method and application of high-stress-resistant probiotics. The preparation method comprises the steps that a porous material is placed in a culture medium, the culture medium is inoculated with probiotics, and the probiotics are cultured, wherein the culture medium contains growth promotion factors capable of promoting growth and propagation of the probiotics, and a natural polysaccharide or natural protein or synthetic macromolecule homopolymer or copolymer is adopted as the porous material; the probiotics gather on the surface of the porous material or in the porous material or on the surface of the porous material and in the porous material, and then the gather-state probiotics are obtained. According to the preparation method, the stress-resistant properties including the heat resistance, the acid and alkali resistance and the drug resistance of the probiotics can be significantly improved, the survival rate of the probiotics in application scenes such as a digestive system is increased, wide application of the probiotics in products such as food, health care products, medicines, feed, environmental treatment products, hygienic products and daily chemical products is promoted, and the activity of the probiotics in the product processing period and the shelf period can be effectively guaranteed.

Owner:杭州益儒信息科技有限公司

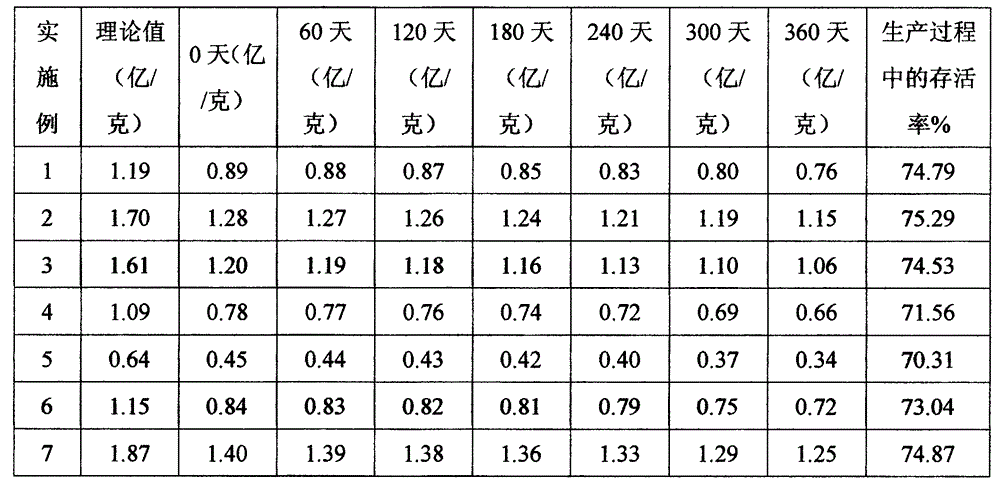

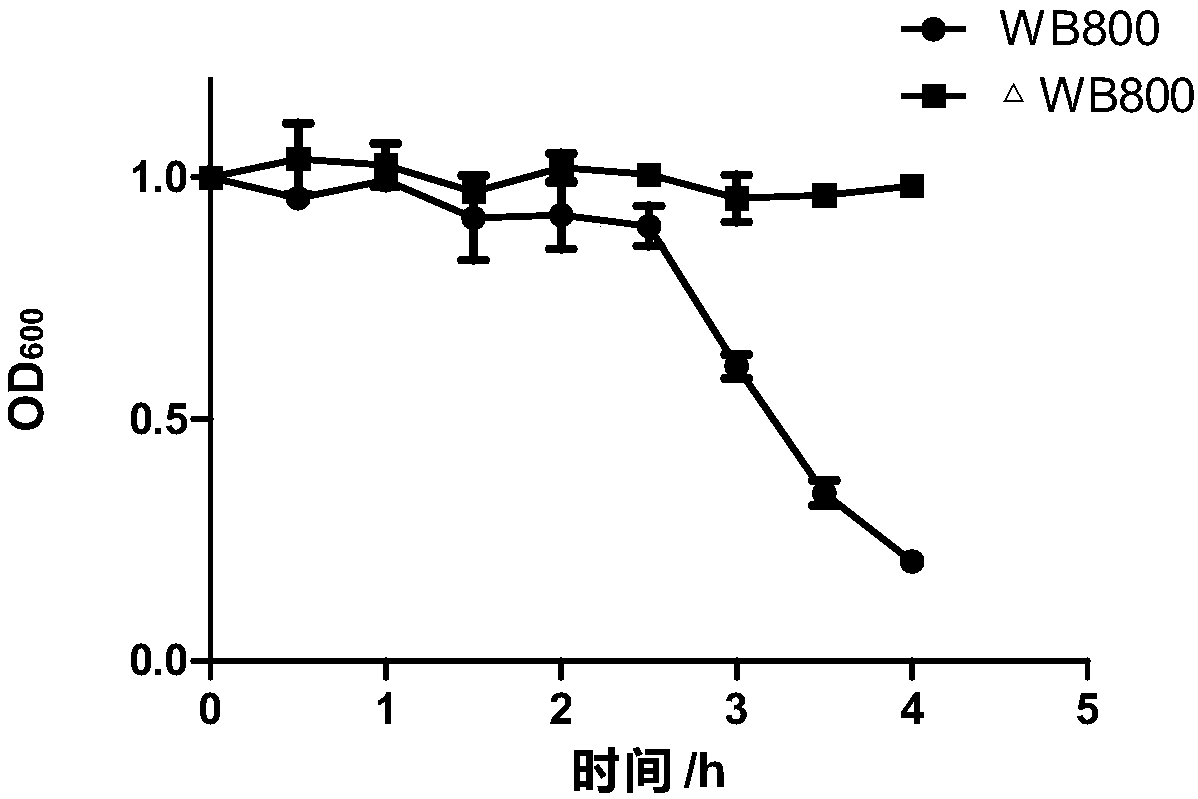

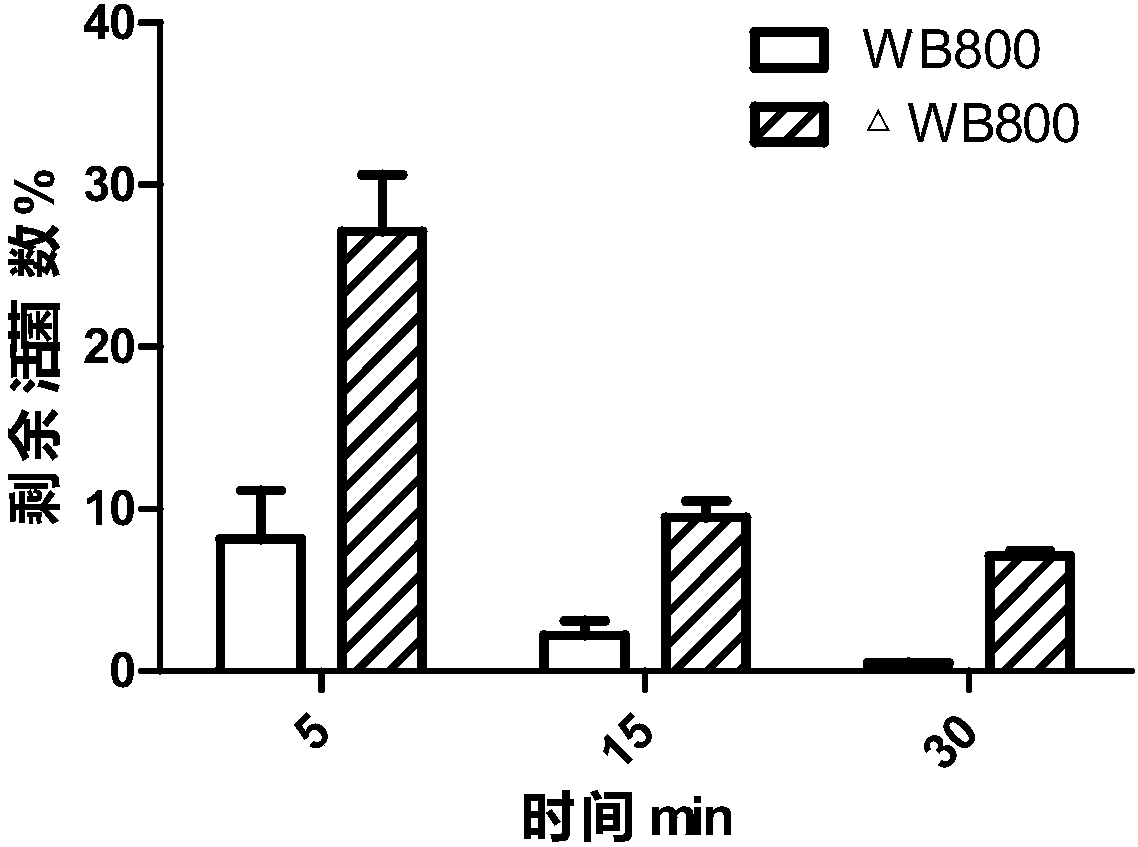

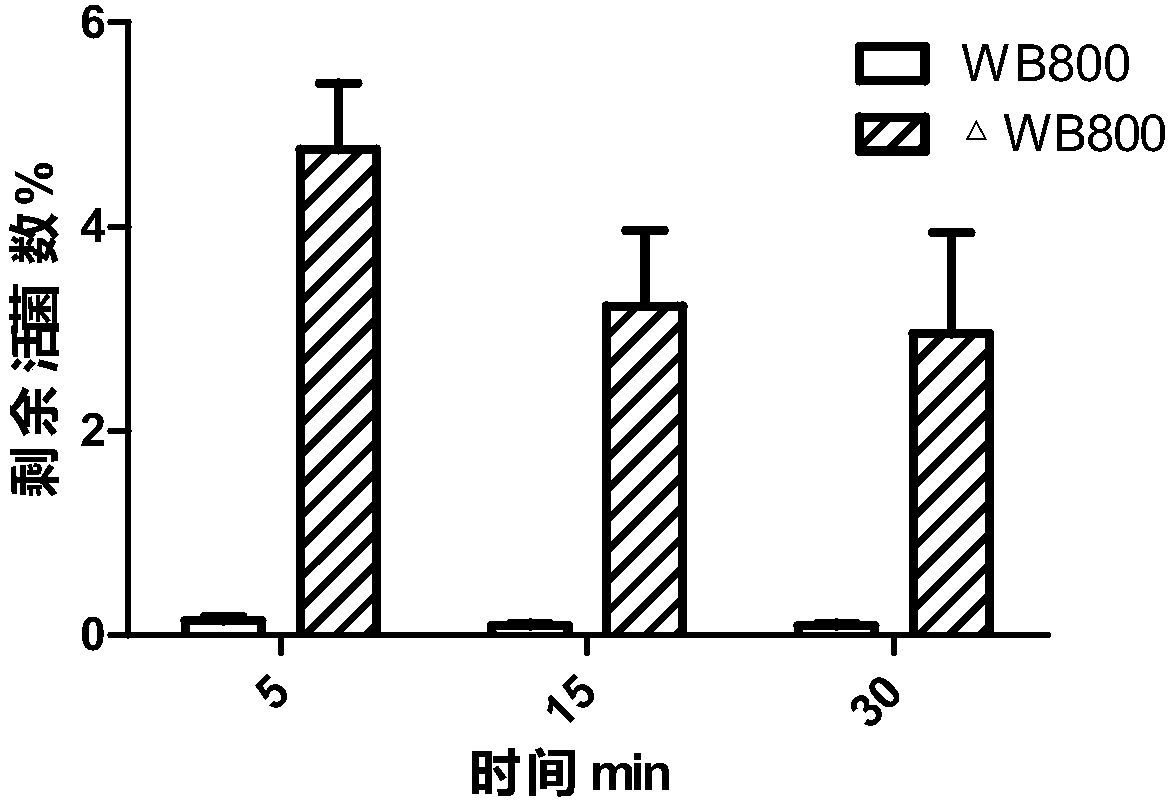

Bacillus subtilis and preparation method thereof

ActiveCN108441462AAutolysis inhibitionKnockout strains have enhanced resistance to autolysisBacteriaMicroorganism based processesHeat resistanceMicrobiology

The invention relates to Bacillus subtilis delta WB800 and a preparation method thereof, and belongs to the technical field of bioengineering. By means of knockout of autolysis related genes skfA, sdpC, lytC and xpf of the Bacillus subtilis WB800, an autolysis inhibiting strain delta800 is obtained, and the strain has excellent heat resistance, acid resistance and cholate resistance and shows better industrial application prospect.

Owner:CANVEST WUHAN BIOTECH

Probiotics microcapsule bacterial powder and preparation method and application thereof

InactiveCN110604307AHigh rate of live bacteriaHigh activityFood shapingBiotechnologyPhysiological function

The invention relates to probiotics microcapsule bacterial powder and a preparation method and application thereof. The probiotics microcapsule bacterial powder is prepared from core materials and wall materials, the core materials comprise probiotics, and the wall materials comprise polysialic acid. The polysialic acid creatively serves as the wall materials of microcapsules, the probiotics serves as the core materials of the microcapsules, thus the polysialic acid and the probiotics can exert respective physiological functions and can also synergistically act, a probiotics preparation can exert better properties, and the bacterial survival rate of the probiotics is remarkably increased; the activity of the probiotics can also be improved; and meanwhile the probiotics can be smoothly colonized in the intestinal tract, and the physiological effect is exerted better.

Owner:CABIO BIOTECH WUHAN CO LTD

Freeze-drying protective agent for listeria monocytogenes standard substance, freeze-drying preserving method and application

InactiveCN110106114AHigh rate of live bacteriaFreeze-dried storage method is simple and feasibleBacteriaMicroorganism based processesFreeze-dryingTyrosine

The invention relates to a freeze-drying protective agent for a listeria monocytogenes standard substance, a freeze-drying preserving method and application. The freeze-drying protective agent is a special freeze-drying protective agent for the listeria monocytogenes standard substance. Through the cooperation of the four specific components (skim milk, polyvinylpyrrolidone, cane sugar and tyrosine) according to the specific mass percentage contents, the synergistic interaction can be realized, the freeze-dried listeria monocytogenes standard substance reaches the high living bacterium rate, and the living bacterium rate of the standard substance can still be kept at a high level after the standard substance is stored for a long time.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Probiotics sea buckthorn fruit puree jelly and preparation method thereof

PendingCN109329699AHigh rate of live bacteriaViable count reductionFood preservationFood ingredient functionsBifidobacteriumFood industry

The present invention discloses a probiotics sea buckthorn fruit puree jelly and a preparation method thereof, and belongs to the field of probiotics. A sea buckthorn fruit puree jelly is used as a carrier of probiotics; proteins, polysaccharides and other ingredients in sea buckthorn fruit puree are utilized; and at the same time, a gel substance is combined with thalli of bifidobacteria, lactobacillus, etc. to form the probiotics sea buckthorn fruit puree jelly. The probiotics sea buckthorn fruit puree jelly effectively reduces heat, oxidation and drying damages to the probiotics during a conventional drying process, achieves a purpose of long-term preservation of the probiotics, at the same time plays a role of resisting oxidation damages, effectively prevents vigor loss of bacterial strains during a storage process, also improves the additional nutritional value of the probiotics, and is widely used in food industry.

Owner:ZHONGBEI UNIV

Protein type health-care food composition and preparation method thereof

InactiveCN107811227AGood point attachmentGood biological barrierLipidic food ingredientsFood shapingSucroseLicorice roots

The invention relates to the technical field of health-care foods, in particular to a protein type health-care food composition and a preparation method thereof. Effective components of the composition consist of the following raw materials: poultry egg liquid, soybeans, collagen, cane sugar, linseed oil, honey, traditional Chinese medicine powder, sucrose fatty acid ester, xanthan gum, and microcapsule composite probiotics, wherein the traditional Chinese medicine powder is prepared from the following raw materials of radix codonopsis, haws, dried orange peel, sea-buckthorns and licorice roots. The protein is extracted from natural food materials, animal collagen is added, and the probiotics and traditional Chinese medicine components are effectively combined and jointly achieve the effect, so that the absorption and utilization rate of the protein is increased. A glue milling homogenizing technology is adopted, so that protein granules are changed into granules which are suitable forabsorption by human bodies, and digestion and absorption by the human bodies are facilitated. A secondary embedding technique is used, so that the activity of probiotics is reserved to the maximum extent, a secondary embedding wall material is modified starch resistant to high temperature, and the viable bacteria rate of the probiotics after UHT sterilization is greatly increased.

Owner:河南汇元特殊医学用途配方食品有限公司

Orange velvet oat set yogurt and preparation method thereof

PendingCN111480696AGreat tasteImprove sensory propertiesMilk preparationBiotechnologyCow's milk protein

The invention provides orange velvet oat set yoghurt and a preparation method thereof. The orange velvet oat set yogurt is prepared from the following raw materials: raw milk, white granulated sugar,milk protein powder, low-fat milk powder, a compound stabilizer, jam and a direct vat set starter. According to the orange velvet oat set yoghurt, orange velvet oat pulp is added into the yoghourt forthe first time, a specific direct vat set starter is adopted, low-fat milk powder and protein powder are additionally utilized to increase the solid content and reduce the additive amount of a stabilizer to achieve the suspension characteristic, and the solidified yoghourt with uniformly distributed orange velvet oat jam with excellent sensory characteristics and texture characteristics is prepared.

Owner:YANGZHOU YANGDA KANGYUAN DAIRY

A fermented bacterium agent for promoting ripening and increasing flavor of bean chili sauce and its preparation method

The invention discloses a broad-bean chili sauce maturity-promotion and aroma-enhancement fermentation bacterium agent and a preparation method thereof. The preparation method comprises the following steps: performing propagation culture on bacillus pumilus, lactobacillus fermentum, lactobacillus bifermentans, saccharomyces rouxii and aspergillus oryzae; mixing, inoculating to a sterilization matrix carrier culture medium by 4%-8%, and culturing at 32 DEG C for 48 hours, wherein the colony count is 108-1,010cfu / mL; after the fermentation is finished, adding 6%-10% of sucrose, 1%-5% of gelatin and 2%-5% of glycerin as heat-resistant protectants, flatly laying on a thin layer, performing far-infrared drying at 50-60 DEG C for 2-3 hours, and packaging in vacuum. According to the fermentation bacterium agent, the maturity promotion, aroma enhancement and fermentation of broad-bean chili sauce are enhanced and the quality of the broad-bean chili sauce is stabilized and improved.

Owner:GUIZHOU UNIV

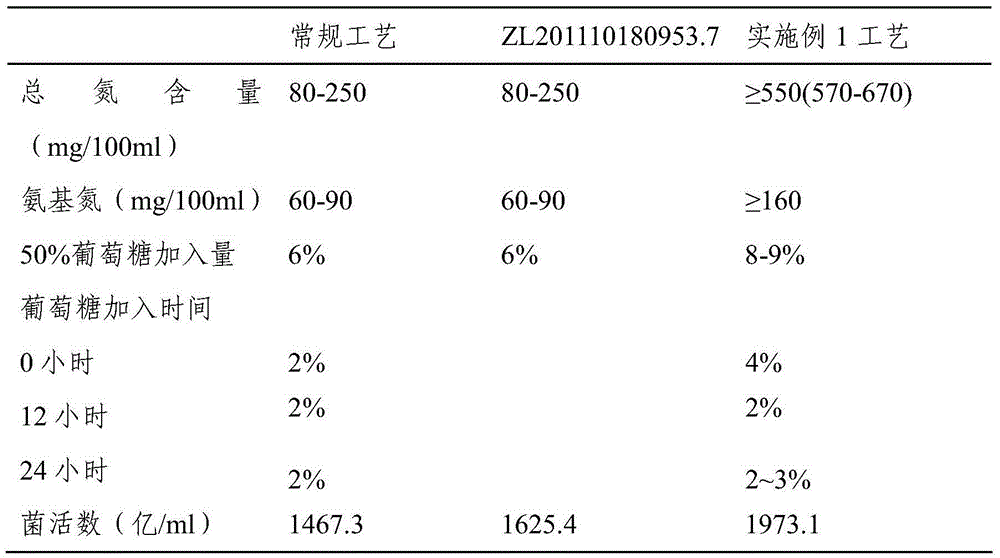

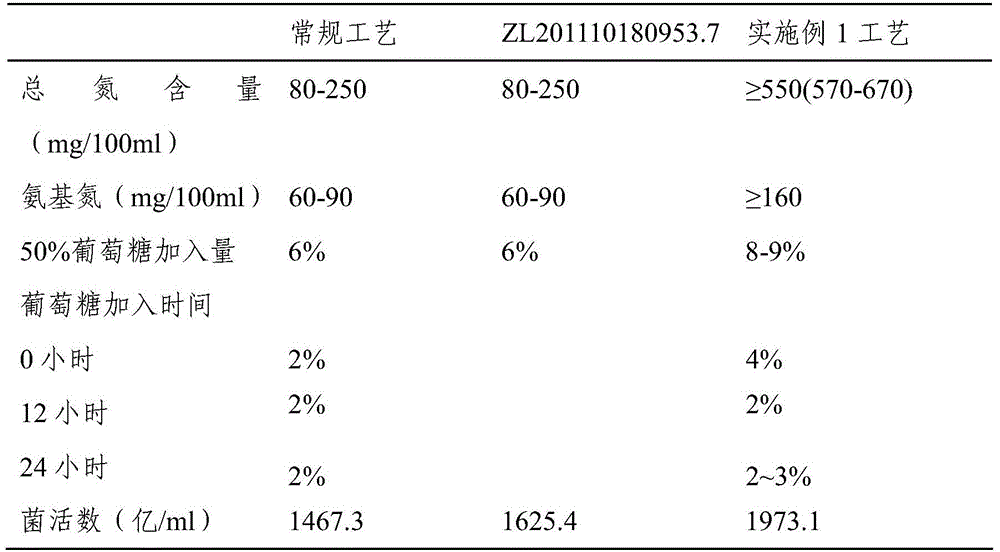

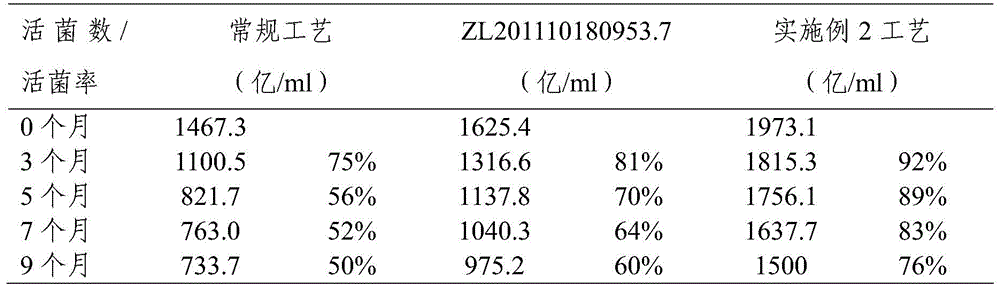

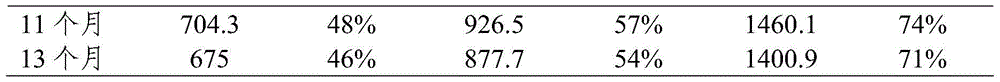

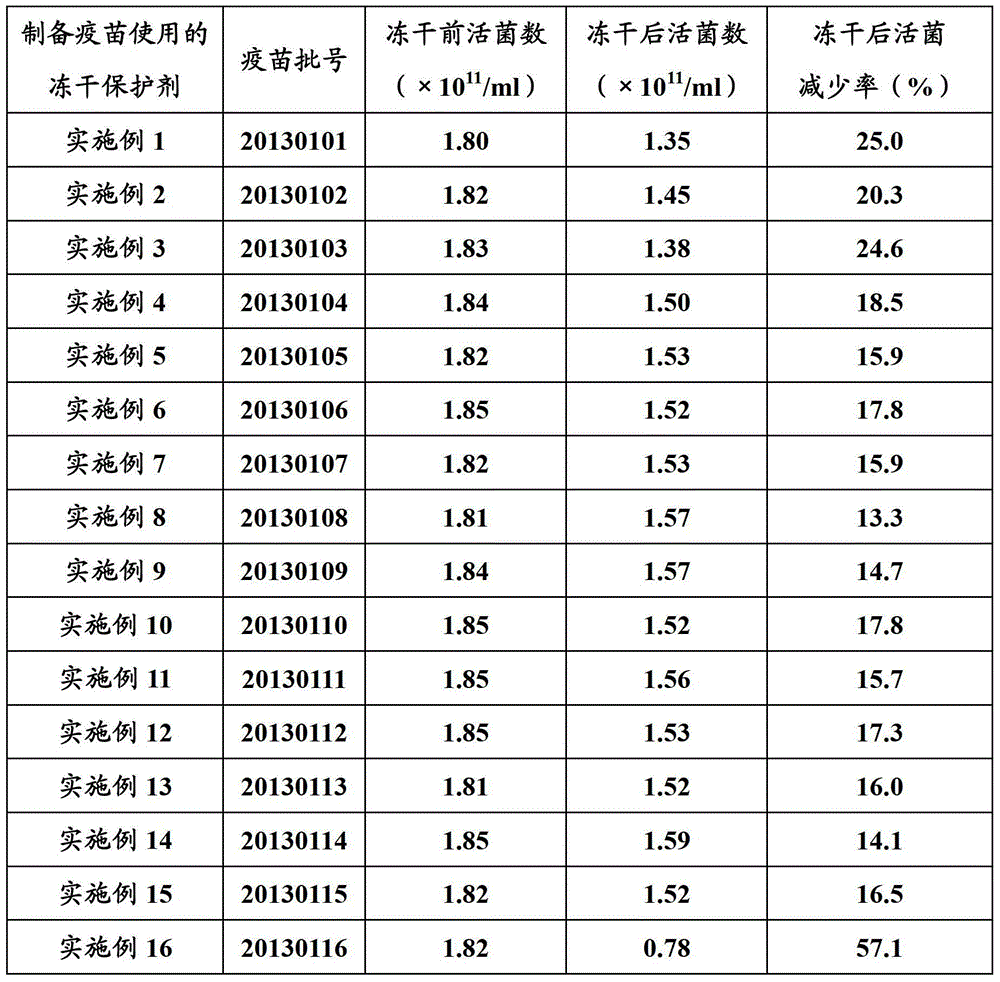

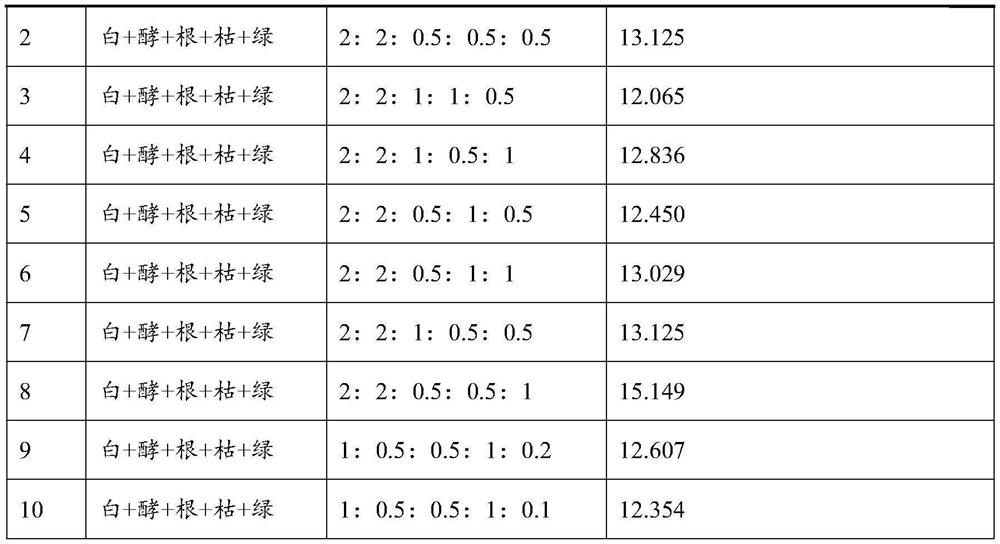

Method for improving living bacterium rate of brucellosis live vaccine product

ActiveCN104560781AHigh rate of live bacteriaImprove survival rateBacteriaMicroorganism based processesFreeze-dryingMicrobiology

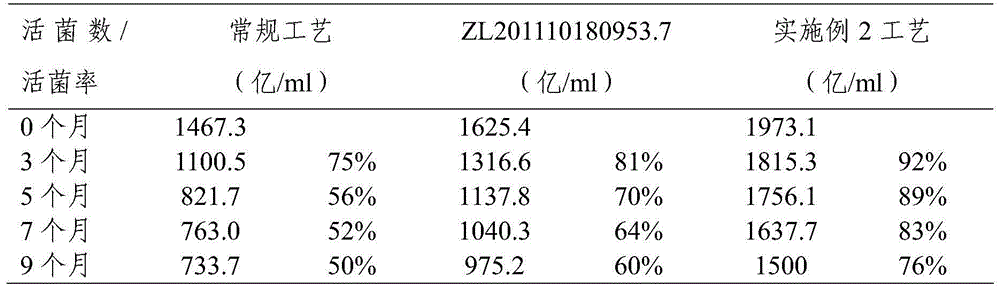

The invention provides a method for improving living bacterium rate of a brucellosis live vaccine product. The method comprises primary strain preparation, secondary strain preparation and bacterium solution cultivation. By increasing the addition of 50% of glucose liquid, the content of ammonia nitrogen and total nitrogen in a culture medium is improved, living bacterium count is improved by controlling air filling amount, so that the method can be used for effectively improving the living bacterium rate of the brucellosis live vaccine product, keeping a relatively high bacterium activity and increasing the survival rate of bacteria during a preservation period after freeze-drying. Through the method disclosed by the invention, the living bacterium count of a cultivated bacterium liquid can achieve 180-220 billion / ml, the living bacterium count can achieve 140-170 billion / ml in 13 months of the preservation period, and the living bacterium rate is 63-77%; and the method has the advantages of being high in yield, long in preservation period, low in production cost and the like.

Owner:CHINA ANIMAL HUSBANDRY IND

A kind of ultra-low temperature freezing process of probiotics and its application in probiotic preparations

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

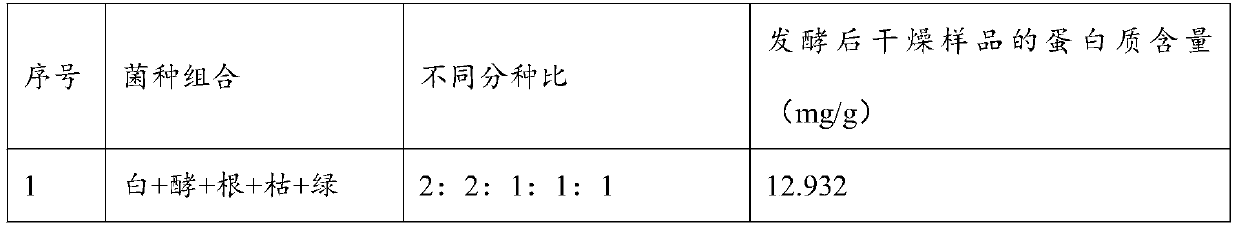

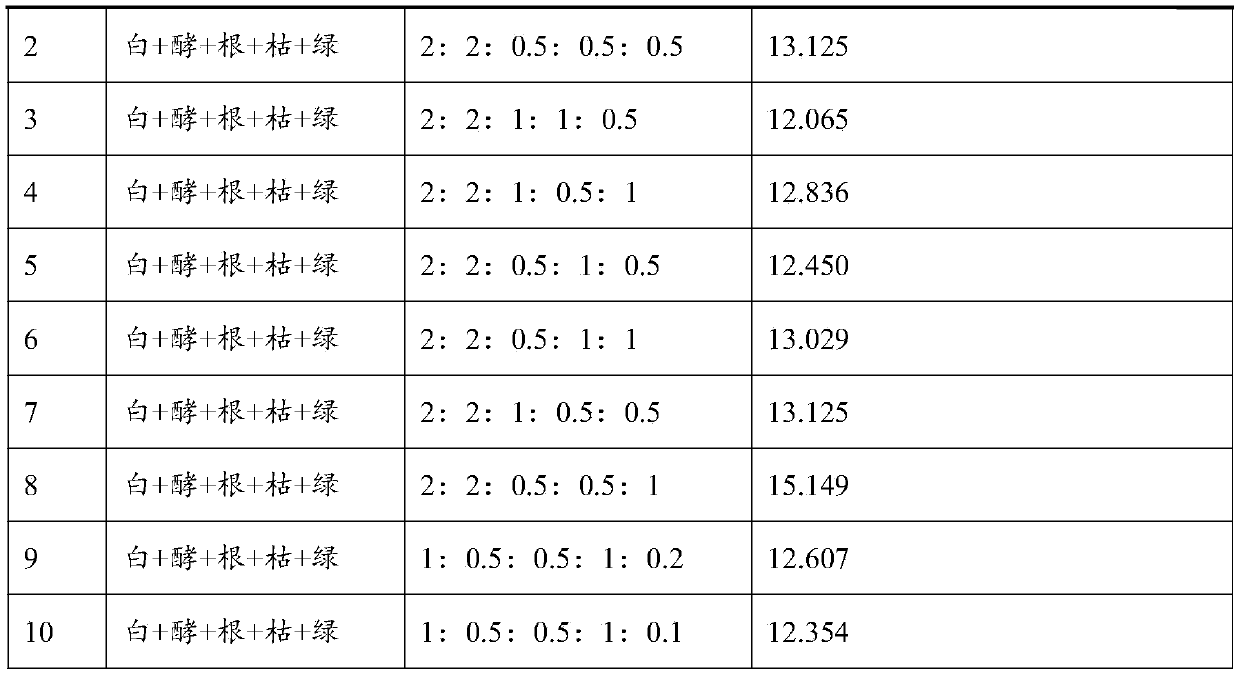

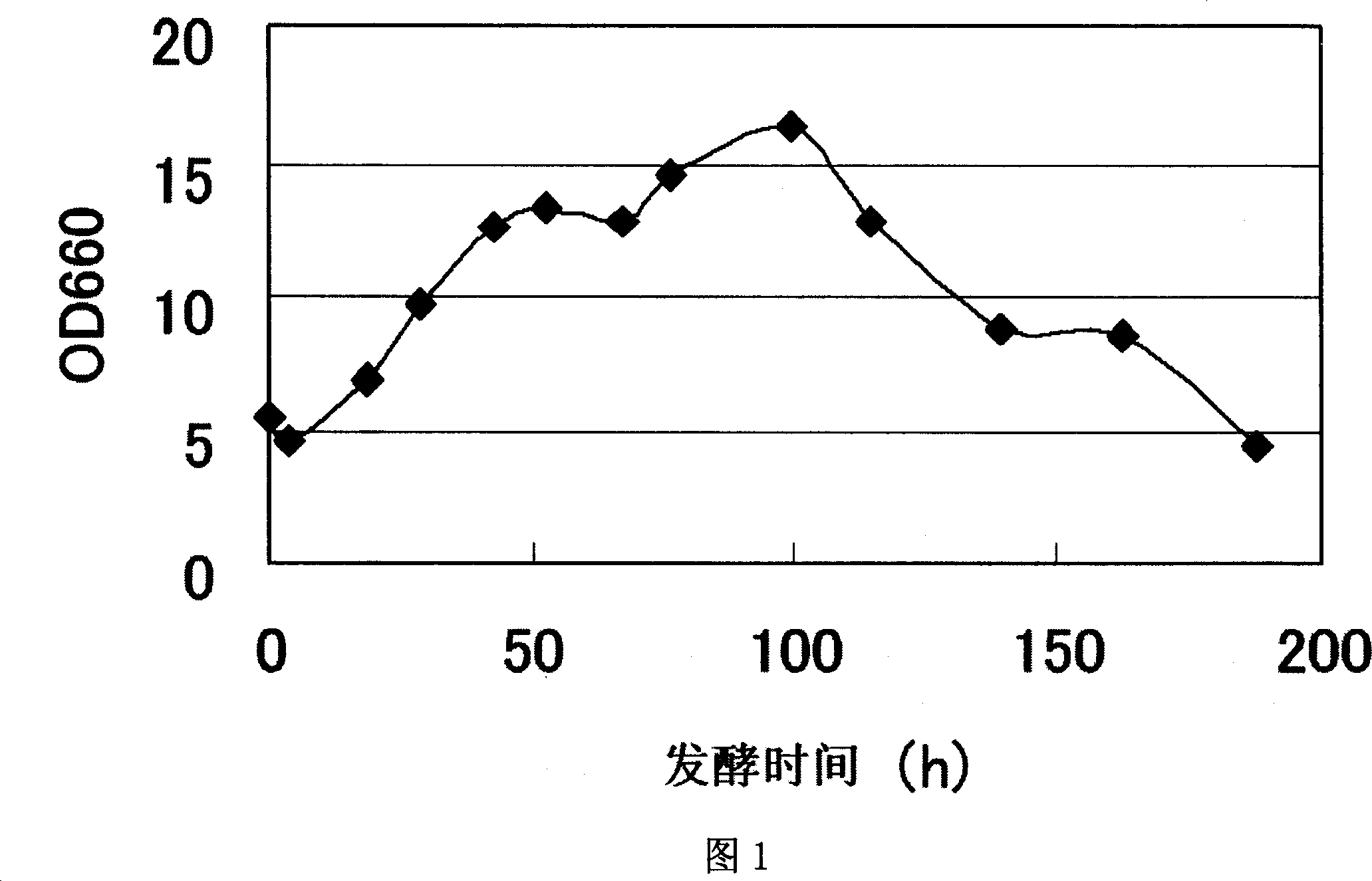

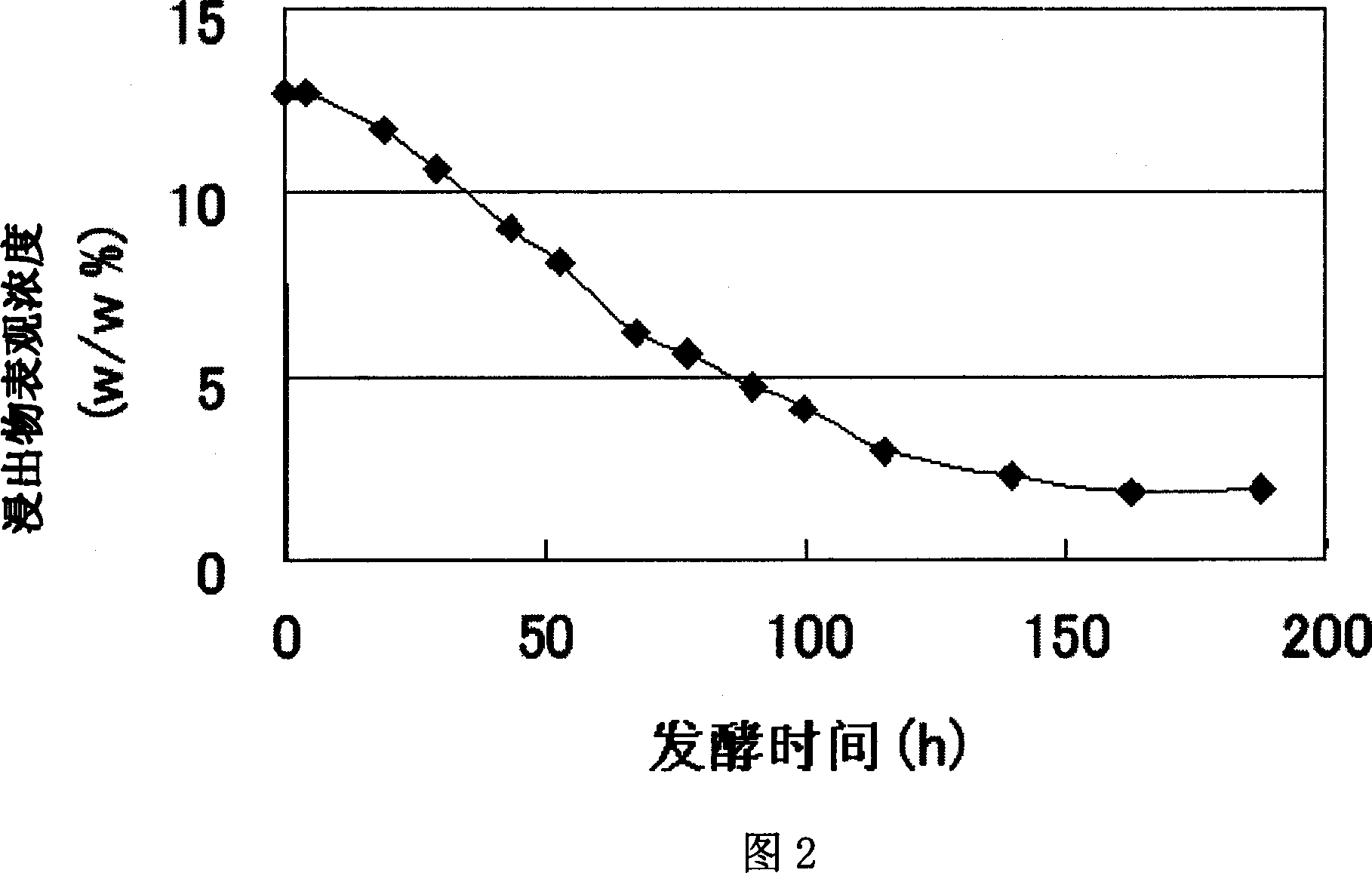

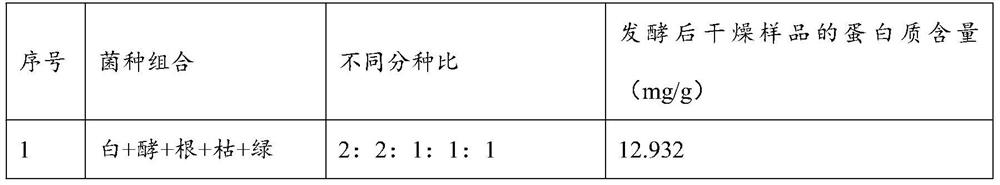

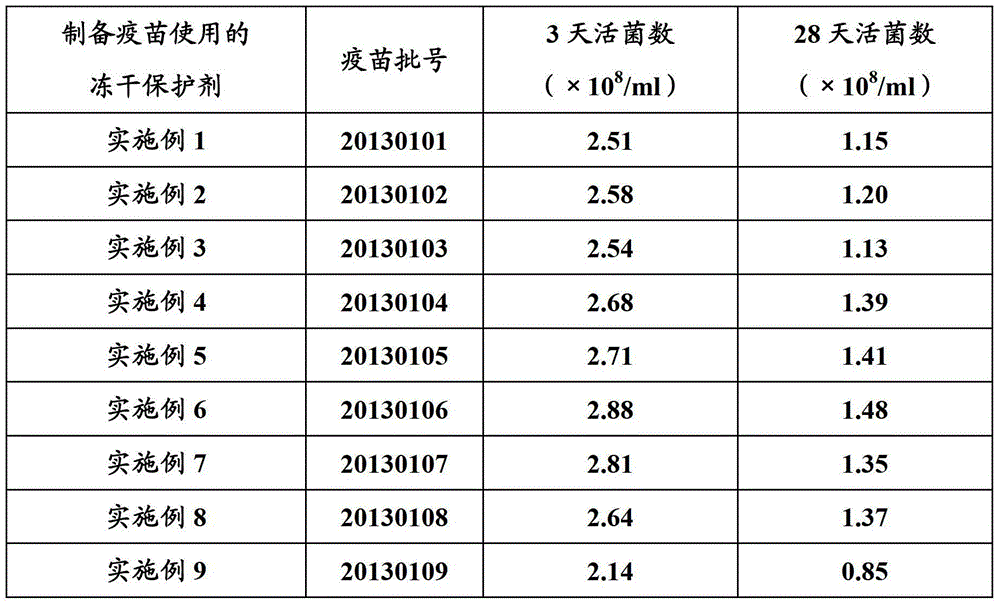

Composite micro-organism agent and freeze-dried micro-organism agent for fermenting apple pomace, and apple pomace protein feed

The present invention provides a composite micro-organism agent and a freeze-dried micro-organism agent for fermenting apple pomace, and an apple pomace protein feed, and relates to the technical field of animal fermented feeds. The composite micro-organism agent for fermenting the apple pomace comprises the following components in parts by volume: 29-36 parts of geotrichum candidum, 16-36 parts of yeasts, 8-31 parts of bacillus subtilis, 8-17 parts of rhizopus and 8-17 parts of trichoderma viride; and effective viable micro-organism number of the geotrichum candidum, yeasts, bacillus subtilis, rhizopus and trichoderma viride are respectively independently larger than or equal to 1x10<9> cfu / ml. The composite micro-organism agent can compensate defects for each other during fermentation and is subjected to synergistic mutual fermentation. The apple pomace protein feed produced by the provided composite micro-organism agent has a crude protein content of 20% or more, the total of 16 amino acids is more than 7.54 g / 100 g, and the composite micro-organism agent is low in fiber, comprehensive in nutrition, green, safe, low in cost and high in benefits.

Owner:GANSU ANIMAL HUSBANDRY & VETERINARY MEDICINE INST

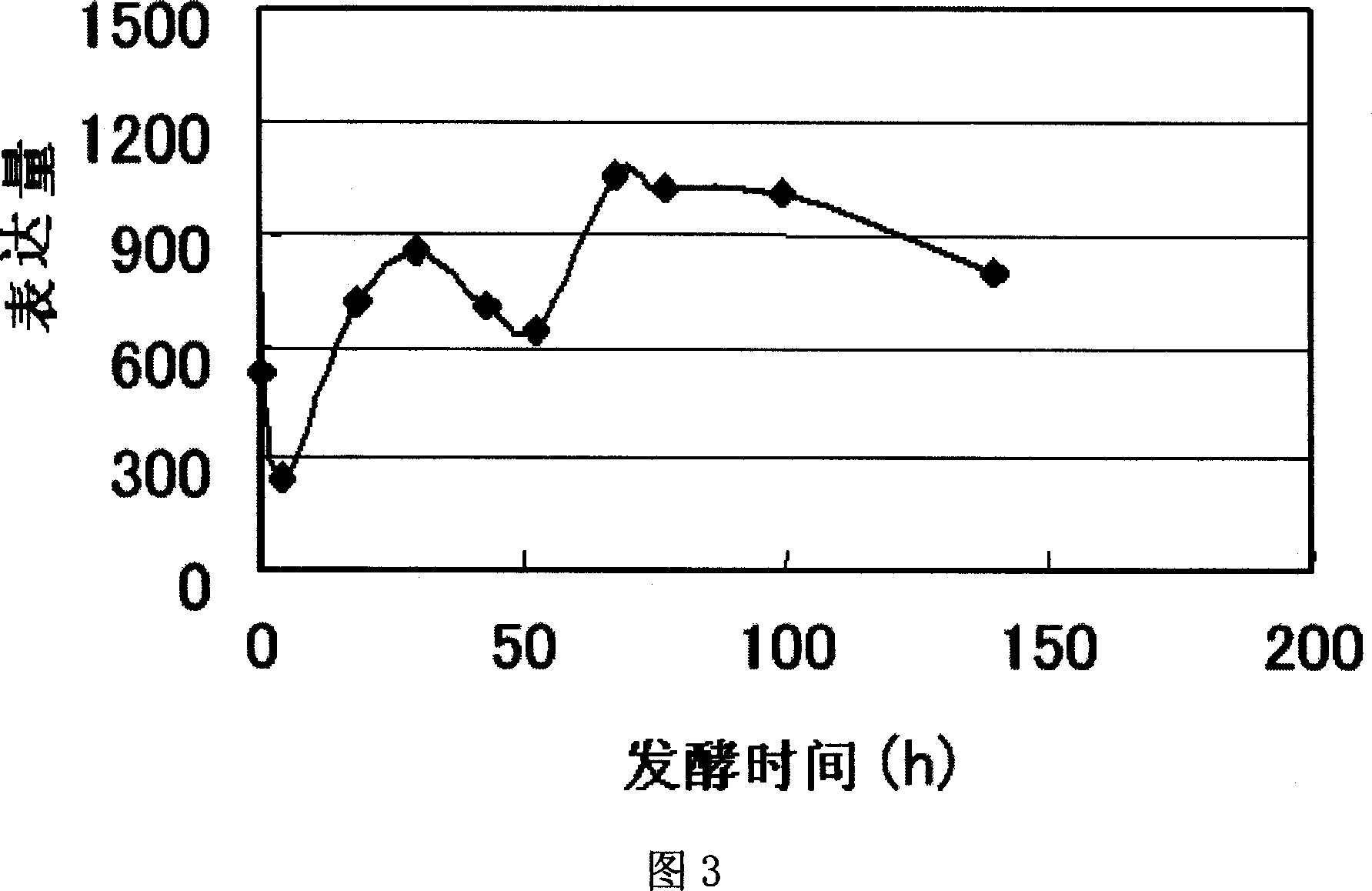

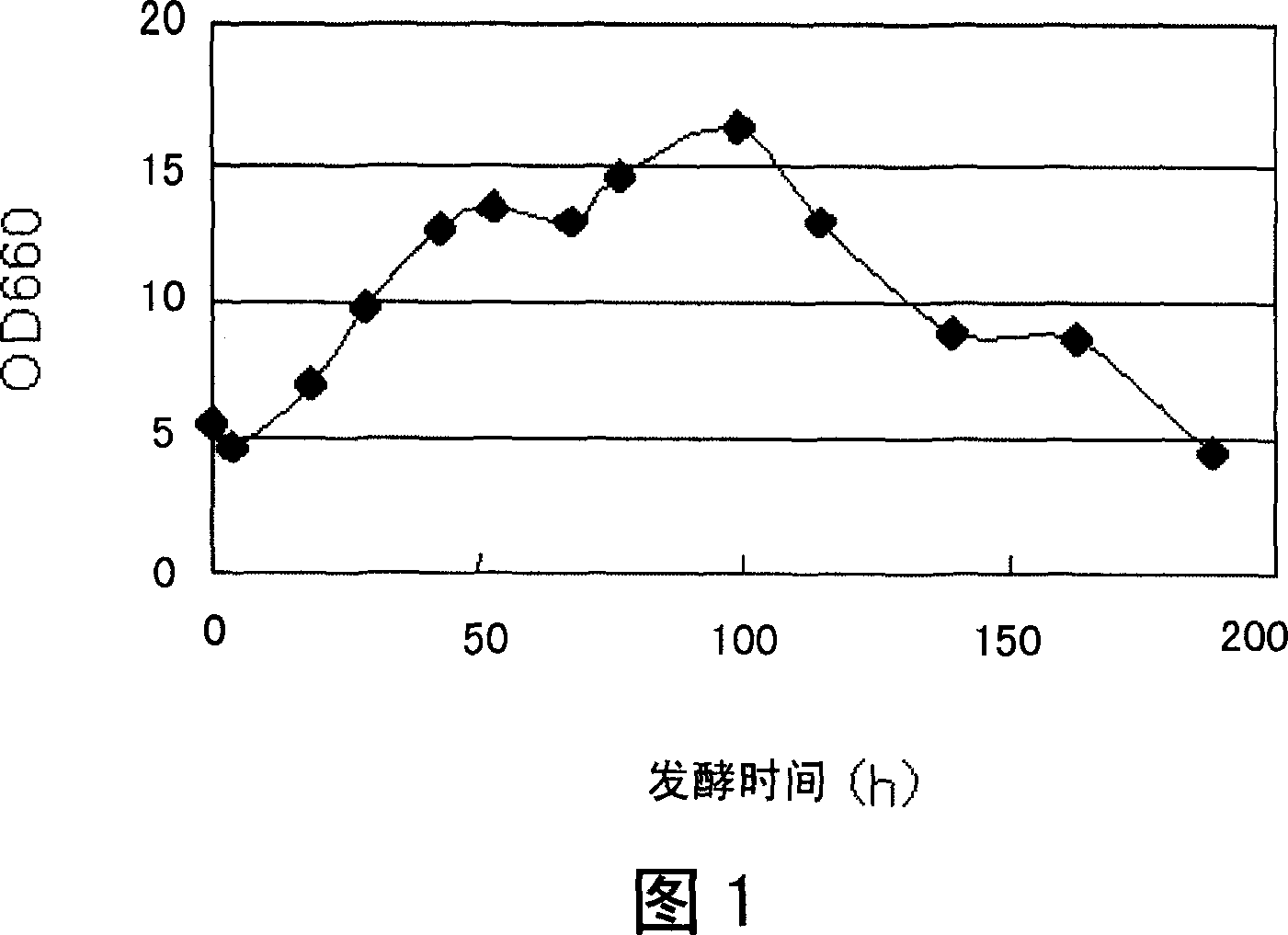

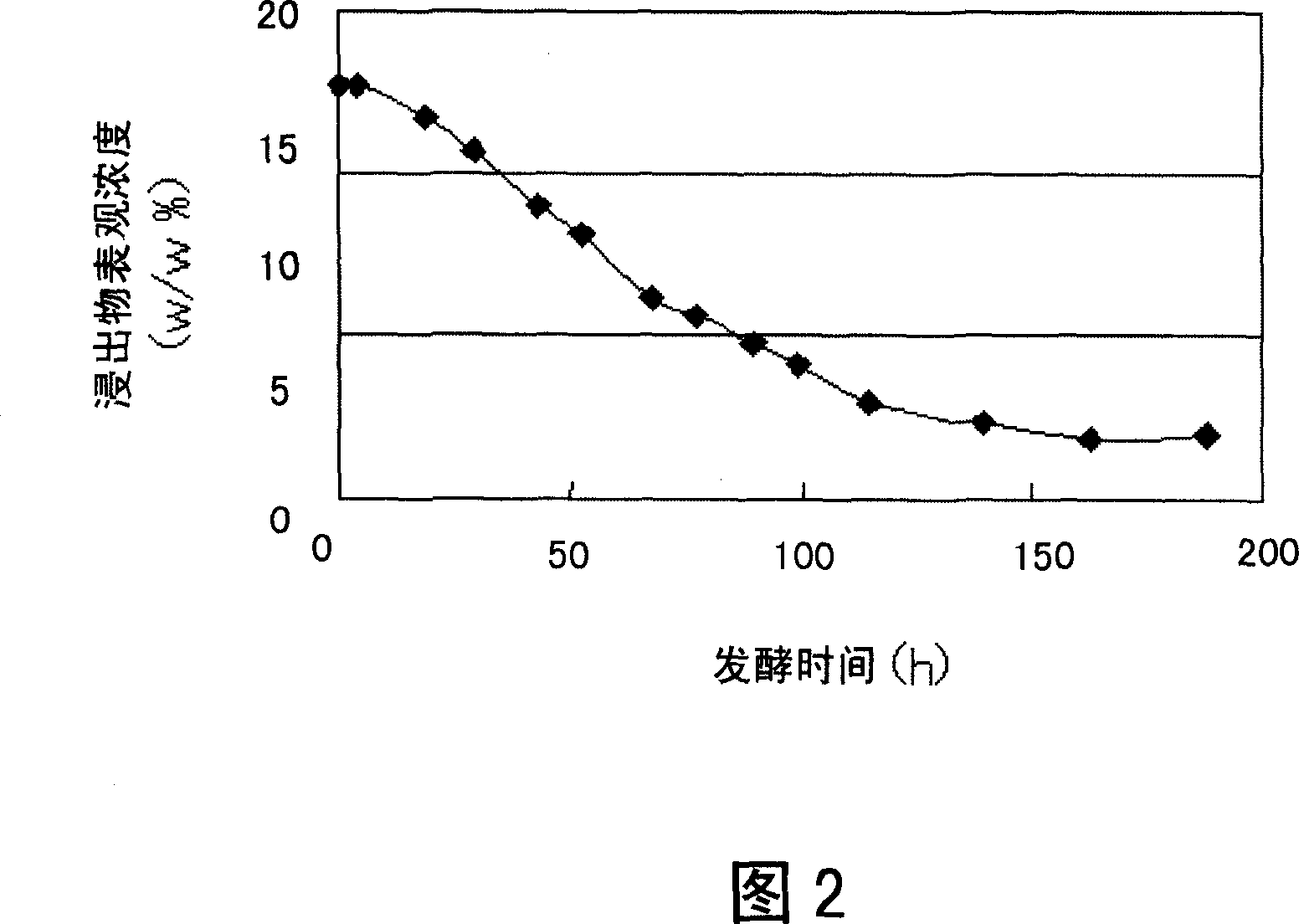

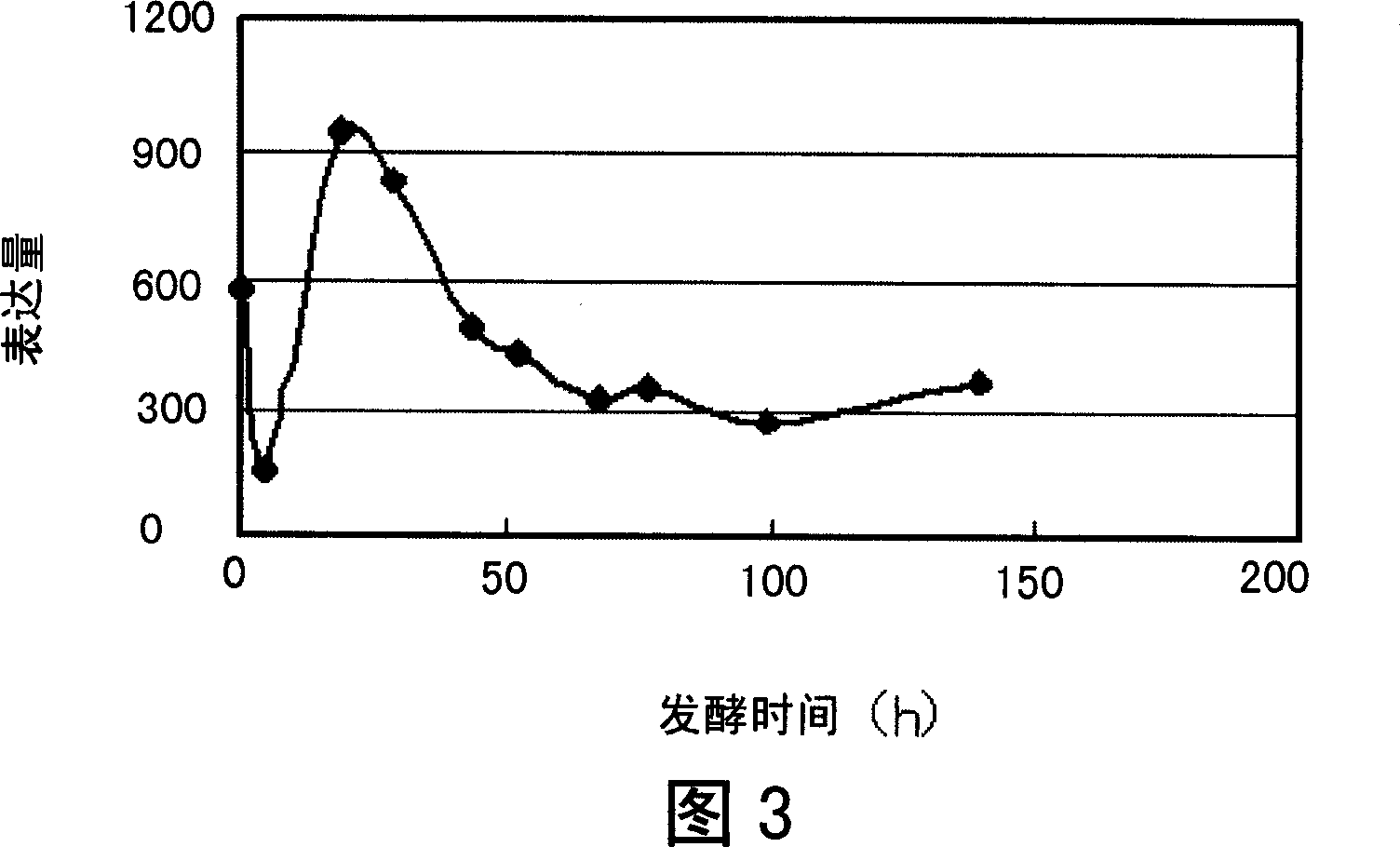

Gene encoding trehalose-6-phosphate phosphatase and use thereof

InactiveCN101041827AHigh rate of live bacteriaEliminate tough problemsFungiHydrolasesBiotechnologyYeast

The present invention relates to a gene encoding trehalose-6-phosphate phosphatase and use thereof, in particular, a yeast for practical use with superior resistance property to dryness and / or low-temperature storage, alcoholic beverages produced with said yeast, and a method for producing said beverages. More particularly, the present invention relates to a yeast, whose resistance property to dryness and / or resistance property to low-temperature storage is enhanced by amplifying expression level of TPS2 gene encoding a trehalose-6-phosphate phosphatase Tps2p in brewer's yeast, especially non-ScTPS2 gene specific to a lager brewing yeast and to a method for producing alcoholic beverages with said yeast, etc.

Owner:SUNTORY HLDG LTD

A method for embedding lactic acid bacteria using Maillard products as wall material

ActiveCN104531664BImprove survival rateImprove stabilityMicroorganism based processesOn/in organic carrierBiotechnologyEgg White Proteins

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

Lactic acid bacterium or yeast porous starch embedding and protecting method

ActiveCN101904420BImprove adsorption capacityFully adsorbedAnimal feeding stuffAccessory food factorsLactic acid bacteriumYeast

The invention discloses a lactic acid bacterium or yeast porous starch embedding and protecting method. Lactic acid bacteria or yeasts are cultured in a fermentation tank with high density to make the total amount of the lactic acid bacteria in a fermentation liquor reach 3.4 to 4.5 * 10<9>CFU / mL and the total amount of the yeasts reach 2 to 3 * 10<10>CFU / mL; the fermentation liquor is concentrated by 15 to 20 times in vacuum to obtain a concentrated bacterial liquid; porous starch, dried whey and trehalose are added into the concentrated bacterial liquid; and after being uniformly stirred until the mixture is pasty, the mixture is dried to obtain a product with relatively high viable bacteria content. The amount of the viable bacteria in the lactic acid bacterium or yeast embedding preparation produced by the technique is over 10<10>CFU / g; the product is resistant in storage; the production process is simple; and the cost is low.

Owner:HUNAN AGRICULTURAL UNIV

Gene encoding glycogen synthase and use thereof

InactiveCN101041826AHigh rate of live bacteriaEliminate tough problemsFungiBeer fermentationAlcohol drinkGlycogen synthase I

Owner:SUNTORY HLDG LTD

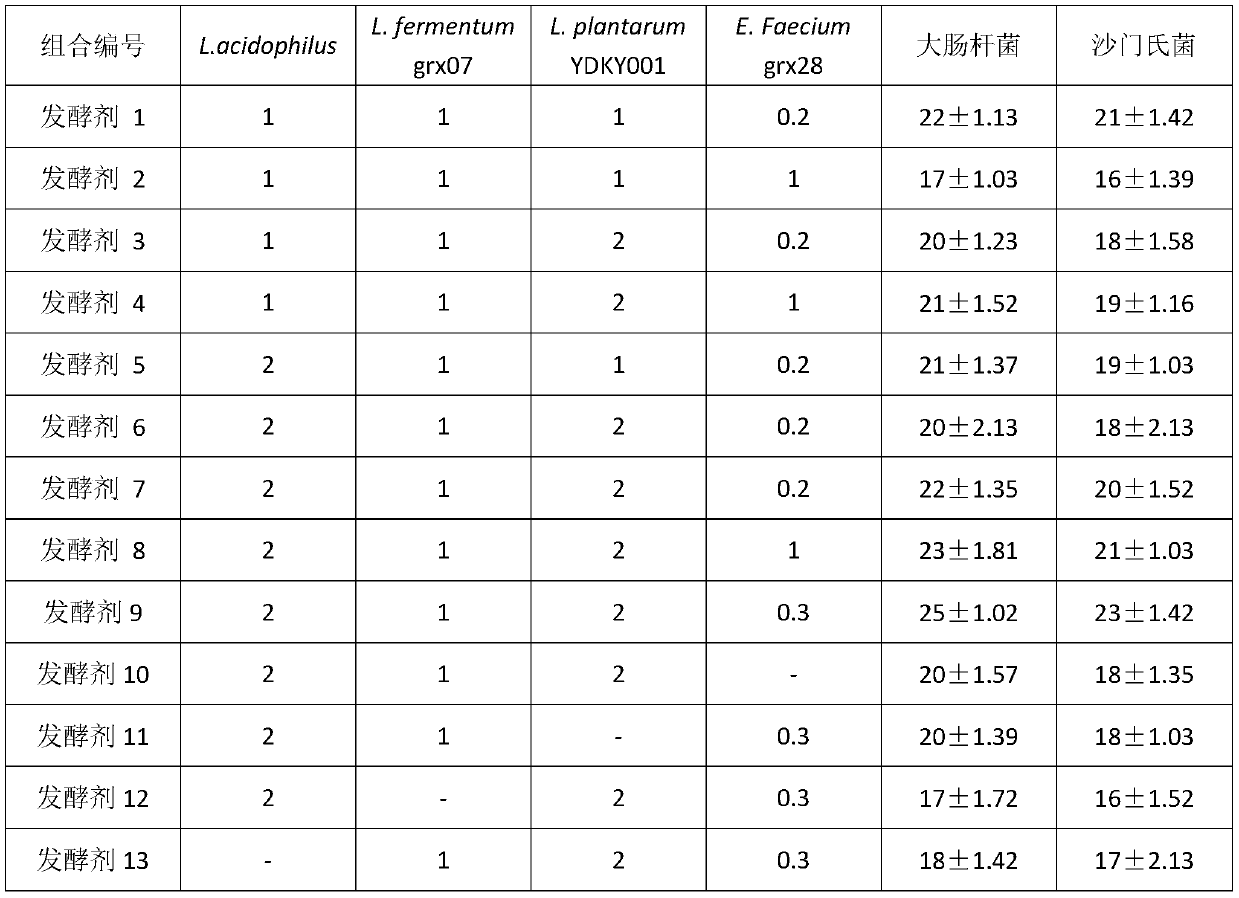

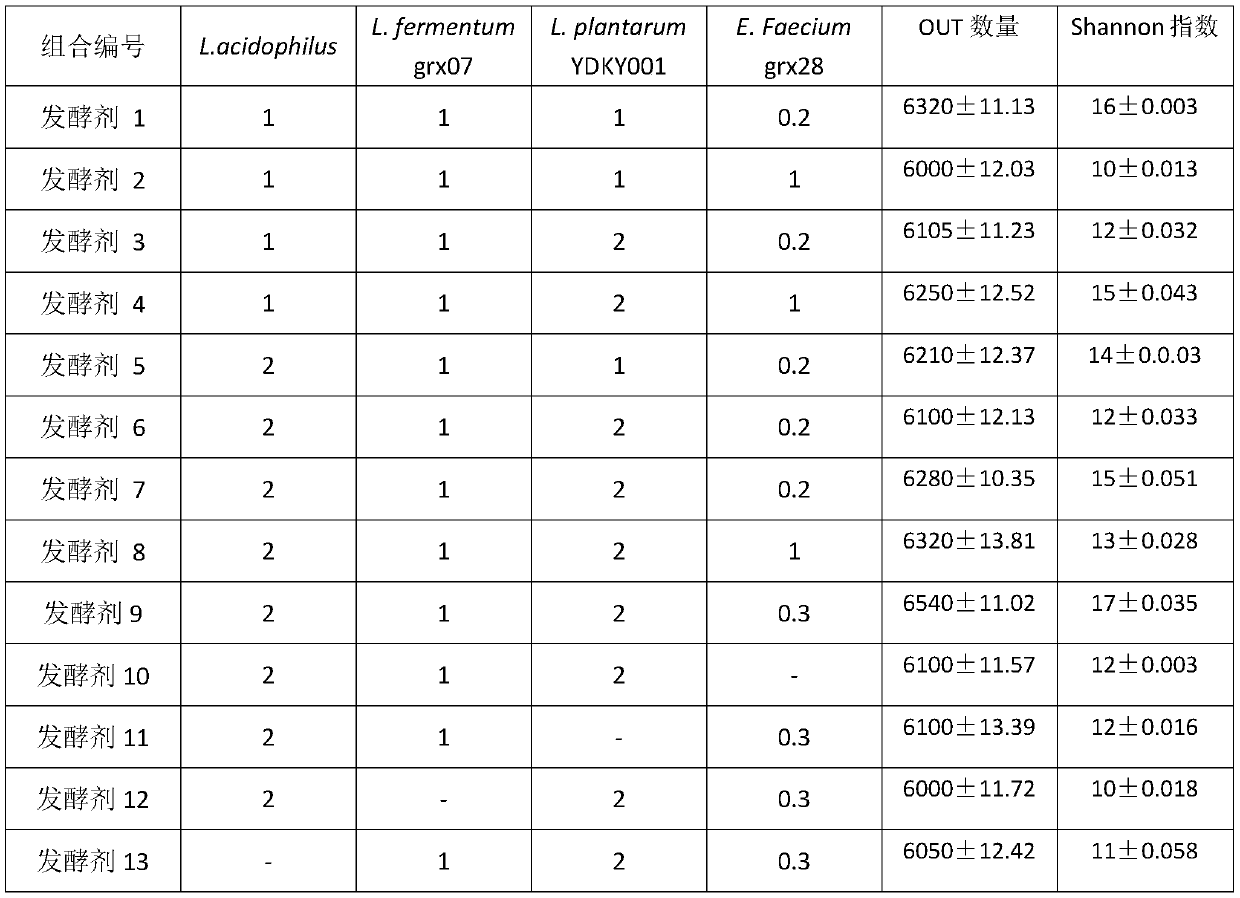

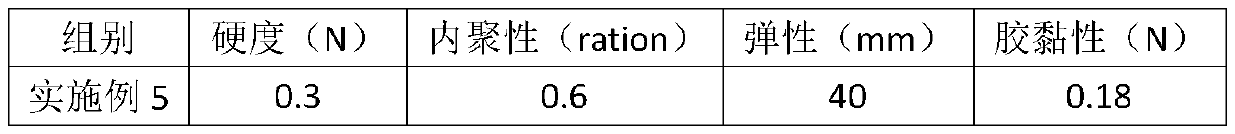

Method for Improving Live Bacteria Rate of Brucellosis Live Vaccine Products

ActiveCN104560781BHigh rate of live bacteriaImprove survival rateBacteriaMicroorganism based processesDiseaseTotal nitrogen

The invention provides a method for increasing the live bacteria rate of live brucellosis vaccine products, the method comprising the preparation of primary strains, preparation of secondary strains and culture of bacterial liquid. By increasing the amount of 50% glucose solution added, increasing the content of ammonia nitrogen and total nitrogen in the medium, and controlling the amount of air intake to increase the number of viable bacteria, it can effectively increase the rate of viable bacteria in live vaccines against brucellosis and maintain a high level of bacteria Vitality, improve the survival rate of bacteria in the storage period after freeze-drying. The number of viable bacteria in the bacterial solution cultivated by the method of the present invention can reach 180-220 billion / ml, and the number of viable bacteria can reach 140-170 billion / ml with a storage period of 13 months, and the viable bacteria rate accounts for 63%-77%. It has the advantages of high yield, long storage period and low production cost.

Owner:CHINA ANIMAL HUSBANDRY IND

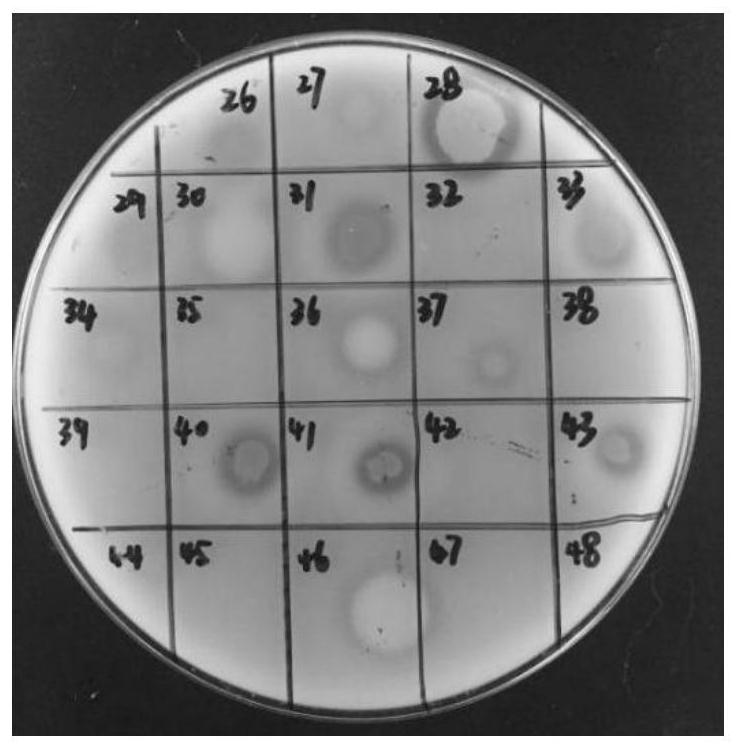

A Bacillus coagulans producing fibrinolytic enzyme and the preparation method of fibrinolytic enzyme and live bacteria tablet

ActiveCN109706092BGood susceptibilityGood antibacterial effectBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention provides bacillus coagulans HQ-1 capable of generating plasmin. The bacillus coagulans HQ-1 is preserved in China general microbiological culture collection center, wherein the preservation number is CGMCC No.16058, and the classification designation is bacillus coagulans (Bacillus coagulans). The invention further provides a method for preparing the plasmin and viable bacteria tablets by using the bacillus coagulans HQ-1. The prepared bacillus coagulans has favorable drug sensitivity, bacterial inhibition and resistance to acid base environment. The obtained bacillus coagulans is high in plasmin activity, and can achieve 383.1U / mL. The obtained viable bacteria tablets are simple in preparation method, and high in viable bacteria rate, and have favorable practical applicationprospects.

Owner:SICHUAN AGRI UNIV

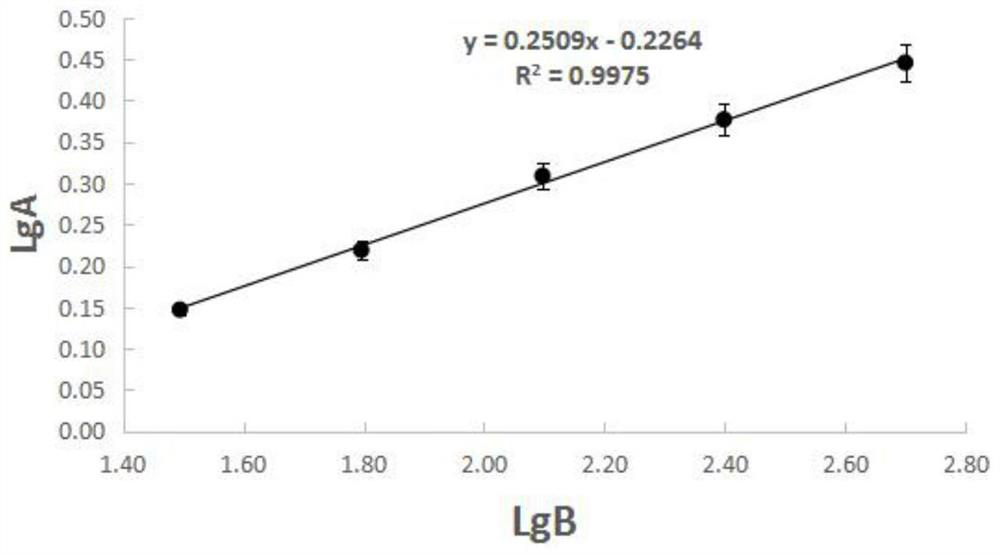

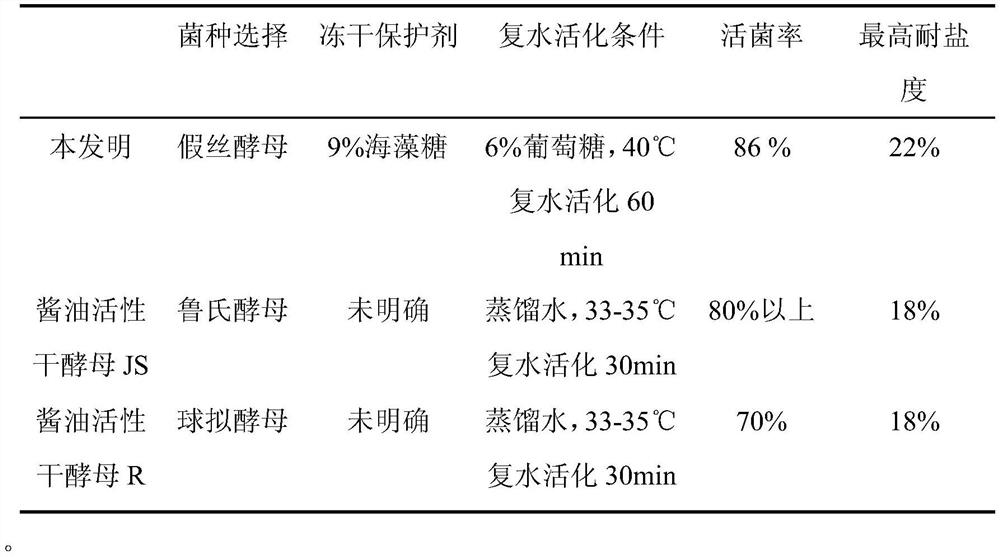

Active soy sauce dry yeast prepared from candida and method for fermenting soy sauce by utilizing active soy sauce dry yeast

InactiveCN111748481AHigh rate of live bacteriaImprove salt toleranceFungiMicroorganism based processesBiotechnologyFreeze-drying

The invention relates to active soy sauce dry yeast prepared from candida. The preparation method comprises the following steps: (1) activating candida by using a YPD liquid culture medium with the salt concentration of 2-2.2%, and carrying out enlarged culture and enrichment on the candida by using a double-concentration YPD culture medium with the salt concentration of 10-12%; (2) stimulating candida at 35 DEG C for 90min, recovering to 30 DEG C, culturing for 2-3h, and centrifugally collecting; and (3) carrying out vacuum freeze drying after centrifugal collection, and carrying out vacuum freeze drying at -80 DEG C for 20-22 hours by taking a trehalose aqueous solution with the mass concentration of 9% as a protective agent so as to obtain the active soy sauce dry yeast. According to the method, the active dry yeast is high in viable organism rate and good in salt tolerance, and when the active dry yeast is applied to fermentation of high-salt liquid-state soy sauce and solid-liquidcombined soy sauce, compared with soy sauce added with fresh yeast, indexes such as amino acid nitrogen and reducing sugar of a soy sauce finished product are improved.

Owner:TIANJIN UNIV OF SCI & TECH

A kind of composite soil remediation agent containing microbial bacteria and preparation method thereof

ActiveCN103951532BIncrease the granular structureIncrease organic matterFertilizer mixturesArbuscular mycorrhizal fungiPotassium

The invention relates to a compound soil remediation agent containing microorganism bacteria and a preparation method thereof. The remediation agent comprises the following components in parts by weight: 0.01-3 parts of bacillus pasteurii spore powder, 5-50 parts of phosphogypsum powder, 10-60 parts of organic compost, 5-50 parts of turf powder, 1.5-5 parts of potassium fulvate powder, 0.2-0.5 part of powdery bacteria powder carriers and 0.15-1 part of glycerin. The remediation agent has round and smooth grains and high grain hardness, is harmless to seeds, can serve as a base fertilizer together with other fertilizers, can be sown together with seeds, integrates multiple remediation functions including organic complexation and passivation remediation, inorganic passivation remediation, microorganism passivation remediation and the like, has a comprehensive and strong soil remediation function, and can stimulate growth and reproduction of arbuscular mycorrhizal fungi at the roots of crops, accelerate heavy metal passivation, stimulate crop growth and enhance the immunities of crops.

Owner:安徽莱姆佳生物肥业有限公司

Freezing and drying protecting agent for amyxis brucella live vaccine

ActiveCN103285399BImprove stabilityImprove efficiencyAntibacterial agentsPowder deliveryMonosodium glutamateSterile water

The invention discloses a freezing and drying protecting agent for an animal derived gelatin-free vaccine. The vaccine freezing and drying protecting agent takes sterile water for injection as a solvent and each litre of the freezing and drying protecting agent comprises 20-100g of saccharose, 5-20g of sodium glutamate and 5-20g of thiourea. The freezing and drying protecting agent is applied to the freezing and drying protection of a brucella live vaccine for amyxis.

Owner:NAT INST FOR FOOD & DRUG CONTROL

Composite bacterial agent, freeze-dried bacterial agent and apple pomace protein feed for fermenting apple pomace

The present invention provides a composite micro-organism agent and a freeze-dried micro-organism agent for fermenting apple pomace, and an apple pomace protein feed, and relates to the technical field of animal fermented feeds. The composite micro-organism agent for fermenting the apple pomace comprises the following components in parts by volume: 29-36 parts of geotrichum candidum, 16-36 parts of yeasts, 8-31 parts of bacillus subtilis, 8-17 parts of rhizopus and 8-17 parts of trichoderma viride; and effective viable micro-organism number of the geotrichum candidum, yeasts, bacillus subtilis, rhizopus and trichoderma viride are respectively independently larger than or equal to 1x10<9> cfu / ml. The composite micro-organism agent can compensate defects for each other during fermentation and is subjected to synergistic mutual fermentation. The apple pomace protein feed produced by the provided composite micro-organism agent has a crude protein content of 20% or more, the total of 16 amino acids is more than 7.54 g / 100 g, and the composite micro-organism agent is low in fiber, comprehensive in nutrition, green, safe, low in cost and high in benefits.

Owner:GANSU ANIMAL HUSBANDRY & VETERINARY MEDICINE INST

Brucellin live vaccine freezing-drying protecting agent for intradermal injection

ActiveCN103301451BReduce allergic reactionsHigh rate of live bacteriaAntibacterial agentsPowder deliveryFreeze-dryingThiourea

The invention discloses a vaccine freezing-drying protecting agent without animal origin gelatin components. The agent takes sterile injection water as a solvent, and each liter of the protecting agent contains 10-100g of lactose, 5-20g of sodium glutamate and 5-20g of thiourea. The vaccine freezing-drying protecting agent is applied to freezing-drying protection on brucellin live vaccines for intradermal injection.

Owner:NAT INST FOR FOOD & DRUG CONTROL

A kind of high-nutrient microbial bacteria compound fertilizer and its production method

InactiveCN104557312BMeet growth needsSufficient contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDouble wall

The invention discloses a high-nutrient microbial bacterium composite fertilizer and a production method thereof. The high-nutrient microbial bacterium composite fertilizer comprises the following components in parts by weight: 16-190 parts of double-wall layer composite microbial bacterium microcapsules (containing 3-5 parts of composite microbial bacteria), 150-450 parts of monoammonium phosphate, 0-400 parts of urea powder, 100-200 parts of potassium chloride, 200-350 parts of ammonium chloride, 20-100 parts of ammonium bicarbonate, 0-150 parts of ammonium sulfate and 0-50 parts of attapulgite. The production method comprises the following steps: adsorbing the microbial bacteria by adopting germ powder thereof, performing first wall layer embedding by adopting a chemical cross-linking method, performing second wall layer embedding by adopting a spray drying process, and finally coating on the surface of chemical fertilizer granules, and split charging. The composite fertilizer is sufficient in nutrient and high in viable count, so that the microbial bacteria can be slowly released, yield increase of crops is guaranteed, the incidence rate of insect pests is reduced, and soil hardening caused by application of chemical fertilizers is improved.

Owner:HEBEI CHUNCHAO BIOLOGICAL TECH

Gene encoding protein having trehalose synthesis-promoting activity and use thereof

InactiveCN101041823AHigh rate of live bacteriaEliminate tough problemsFungiMicrobiological testing/measurementAlcohol drinkOrganic chemistry

The present invention relates to a gene encoding a protein having a trehalose synthesis-promoting activity and use thereof, in particular, a yeast for practical use with superior resistance property to dryness and / or low-temperature storage, alcoholic beverages produced with said yeast, and a method for producing said beverages. More particularly, the present invention relates to a yeast, whose resistance property to dryness and / or resistance property to low-temperature storage is enhanced by amplifying expression level of TSL1 gene encoding a protein Tsl1p having a trehalose synthesis-promoting activity in brewer's yeast, especially non-ScTSL1 gene specific to a lager brewing yeast and to a method for producing alcoholic beverages with said yeast, etc.

Owner:SUNTORY HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com