Patents

Literature

60results about How to "Eliminates the drying step" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

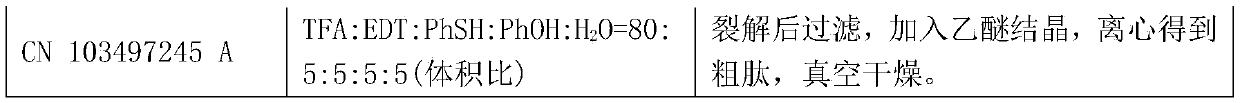

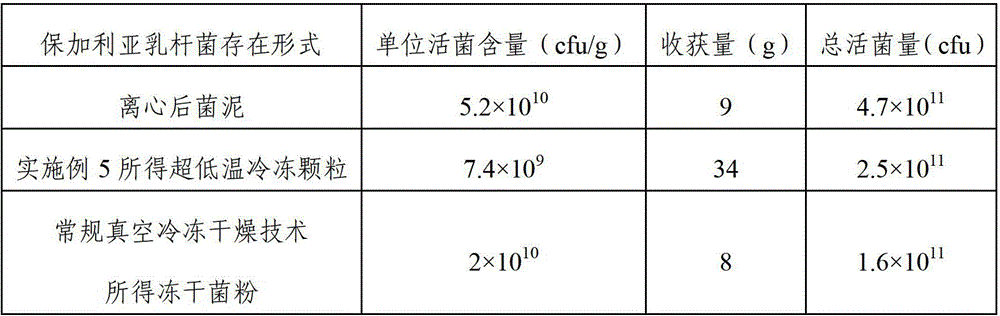

Probiotic ultralow temperature refrigeration technology and applications thereof in probiotic preparation

ActiveCN103333840AHigh activityLow freezing pointBacteriaFood preparationBacterial strainRefrigeration

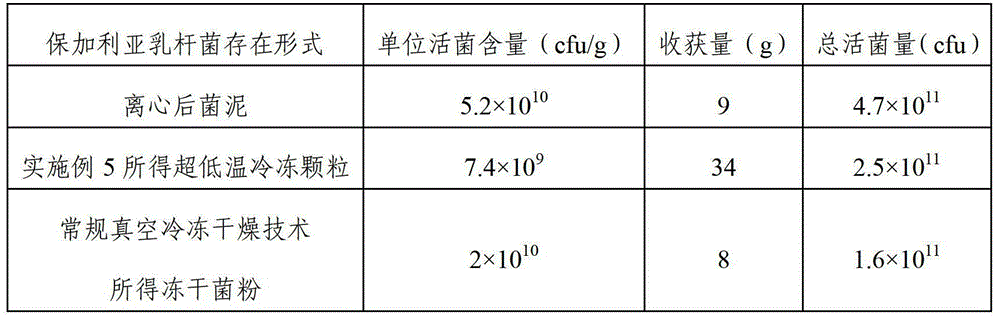

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

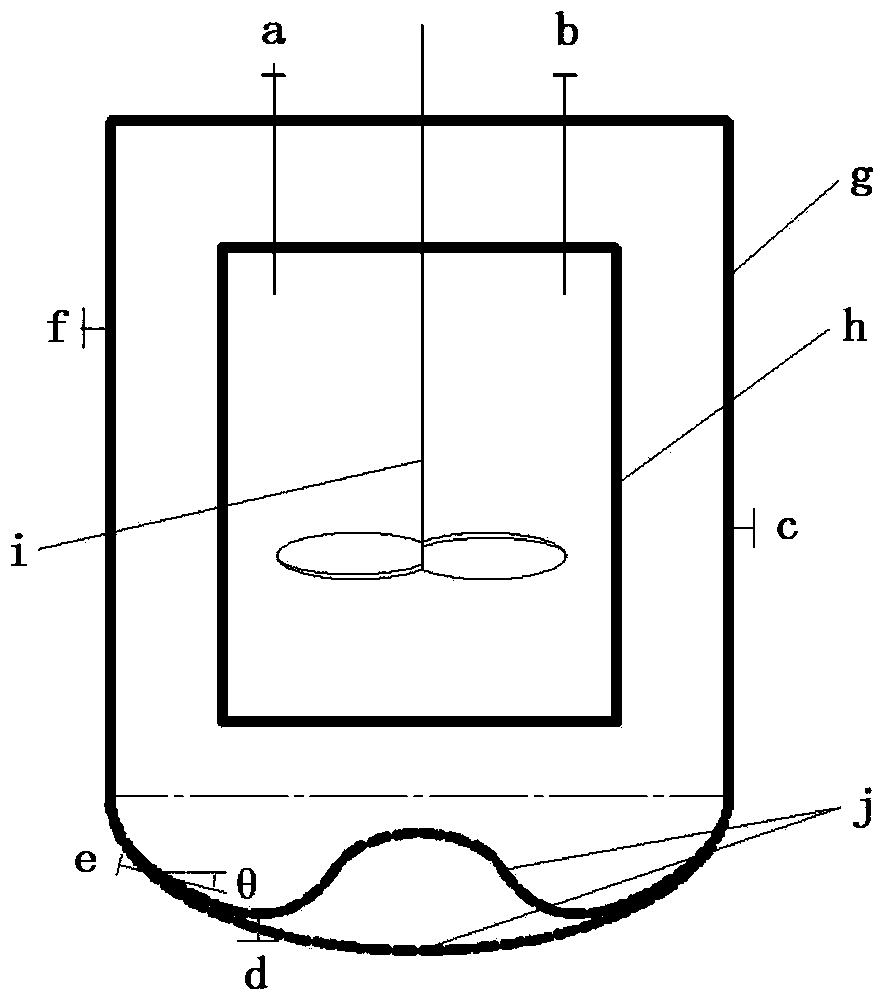

Method for preparing black fungus puffed ultramicro powder

InactiveCN102763817AGood effectThe solution is hard and not suitable for chewingFood preparationFlavorAdditive ingredient

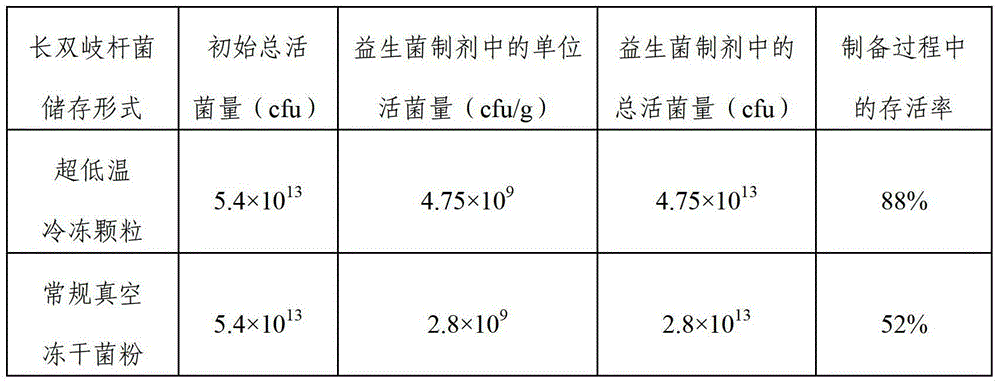

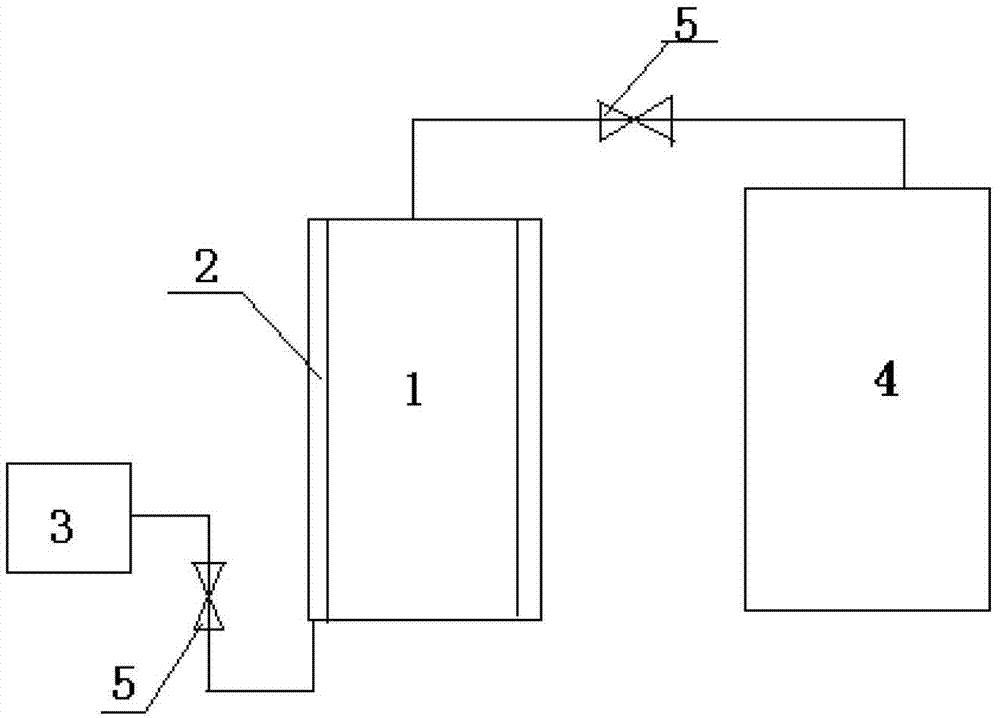

The invention discloses a method for preparing a black fungus puffed ultramicro powder. The method includes selecting black fungus sporophores to serve as a raw material, puffing black funguses by an instantaneous alternating temperature and pressure difference of a puffing tank of a puffing device, maintaining a valve between the puffing tank of the puffing device and a vacuum tank to be in an opening state all the time, subjecting the black funguses in the puffing tank to a vacuum drying, and subjecting the puffed black funguses to a coarse grinding and a superfine grinding to obtain the black fungus puffed ultramicro powder. According to the method, a high pressure gas serves as a carrier, by means of a puffing wall breaking process, a black fungus organization structure is subjected to a cytoclasis to release whole nutritional ingredients and medicinal effect ingredients which are easy to digest and use by human bodies, and problems that the black funguses are hard and not suitable for being chewed, digested and used are solved. Besides, when the black fungus puffed ultramicro powder can be mixed with foods of flours, cakes and the like, the black fungus puffed ultramicro powder has flavor and nutrition of the black funguses, and smoothing taste is increased. The method is low in production cost and suitable for industrialization production, and products are used for foods, health care foods, medicines and raw material extraction.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

Processing method for humic acidic ammonium complex blending fertilizer

InactiveCN1990432AEliminates the drying stepAvoid lossFertilizer mixturesAmmonium compoundsHumic acid

The invention relates to a humic acid fertilizer, which in detail relates to a process for preparing humic acid ammonium compound fertilizer. The process comprises following steps: (1) grinding weathered coal in which the weight proportion of humic acid dry material is 50-75% and weight proportion of water is 20-30%, with roller mill into weathered coal powder, and 90% of the weathered coal powder can come across the screen of 80 fineness; (2) mixing the weathered coal powder with ammonium bicarbonate for agricultural use according to ratio of 30-70: 6-18, and said ammonium bicarbonate is disintegrated with mill so that it can cross screen of 40 fineness; (3) adding nitrogen, phosphorus, potassium and / or medium-micro element that can cross the screen of 40 fineness into material in step (2); (4) packing mixed humic acid ammonium compound fertilizer, and storing for 3-7 days, then leaving factory. The invention is characterized by short process and saved energy.

Owner:郭宗恒

Spicy and hot flavoring material, preparation method and applications thereof

The invention provides a spicy and hot flavoring material. The spicy and hot flavoring material comprises the following raw materials in parts by weight: 3-15 parts of amino acid, 3-15 parts of reducing sugar, 10-30 parts of protein substances, 10-30 parts of spices, 15-40 parts of carriers, 3-10 parts of oil and 0-10 part of water. The preparation method comprises the following steps of raw material mixing, extrusion reaction, cooling and crushing. The spicy and hot flavoring material provided by the invention has the characteristics of being harmonious, being mixed with meat flavor, blending spicy and hot aroma and meat aroma, being sufficient and real, fresh and fragrant, complete in spicy and hot flavor, freshness and fragrance, and mellow in mouthfeel, wherein the aftertaste can last for a long time; and the spicy and hot flavoring material kills most microorganisms through a high-temperature high-pressure extrusion technology, can meet the microorganism index requirement without irradiation, can directly act as external dusting powder for puffing snack food and biscuits, also can be used as the seasoning in instant noodle soup base, the seasonings in meat preparation of sausages and the like, and also can act as the family seasoning for various applications.

Owner:ZENGCHENG HANDYWARE SEASONING

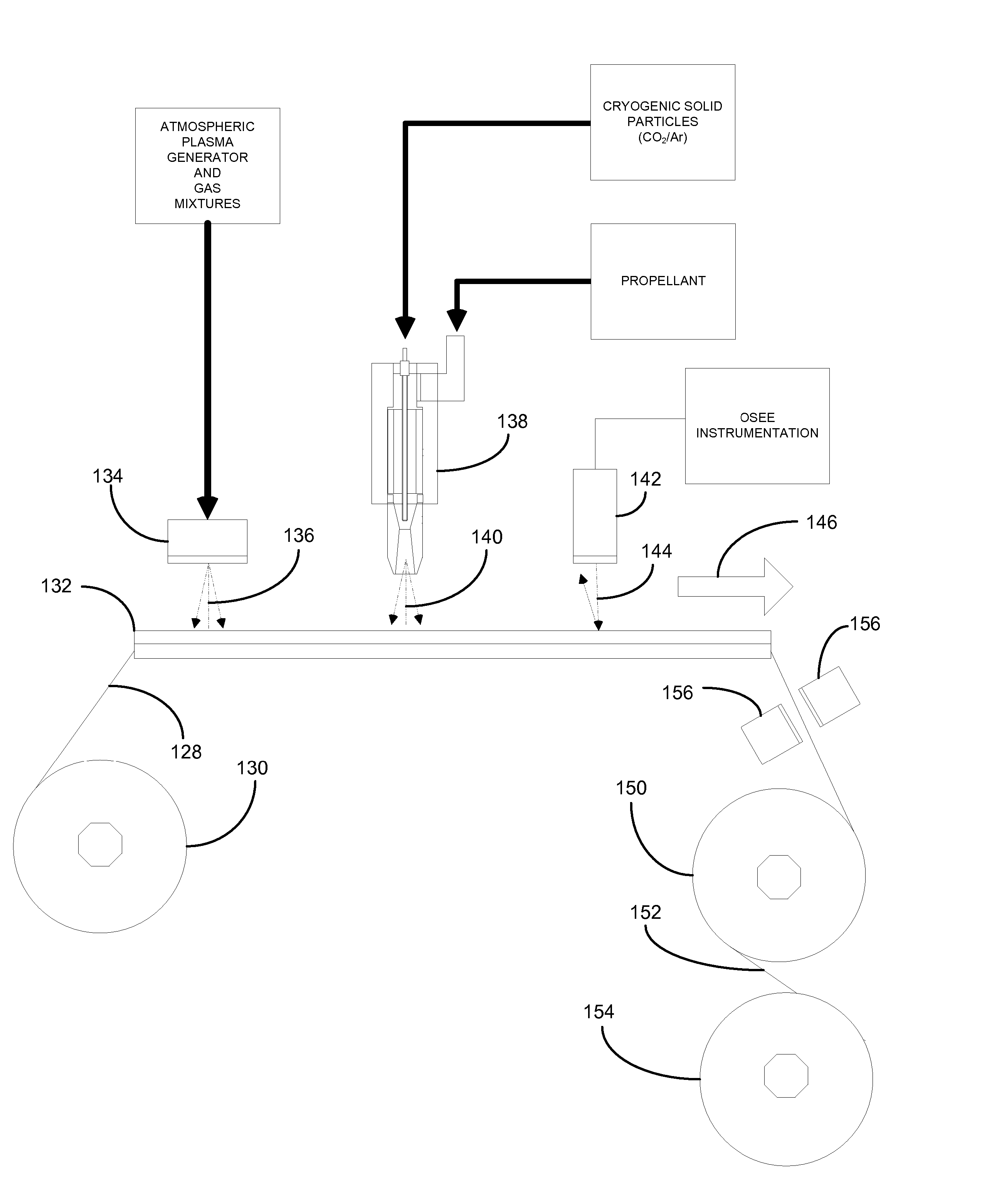

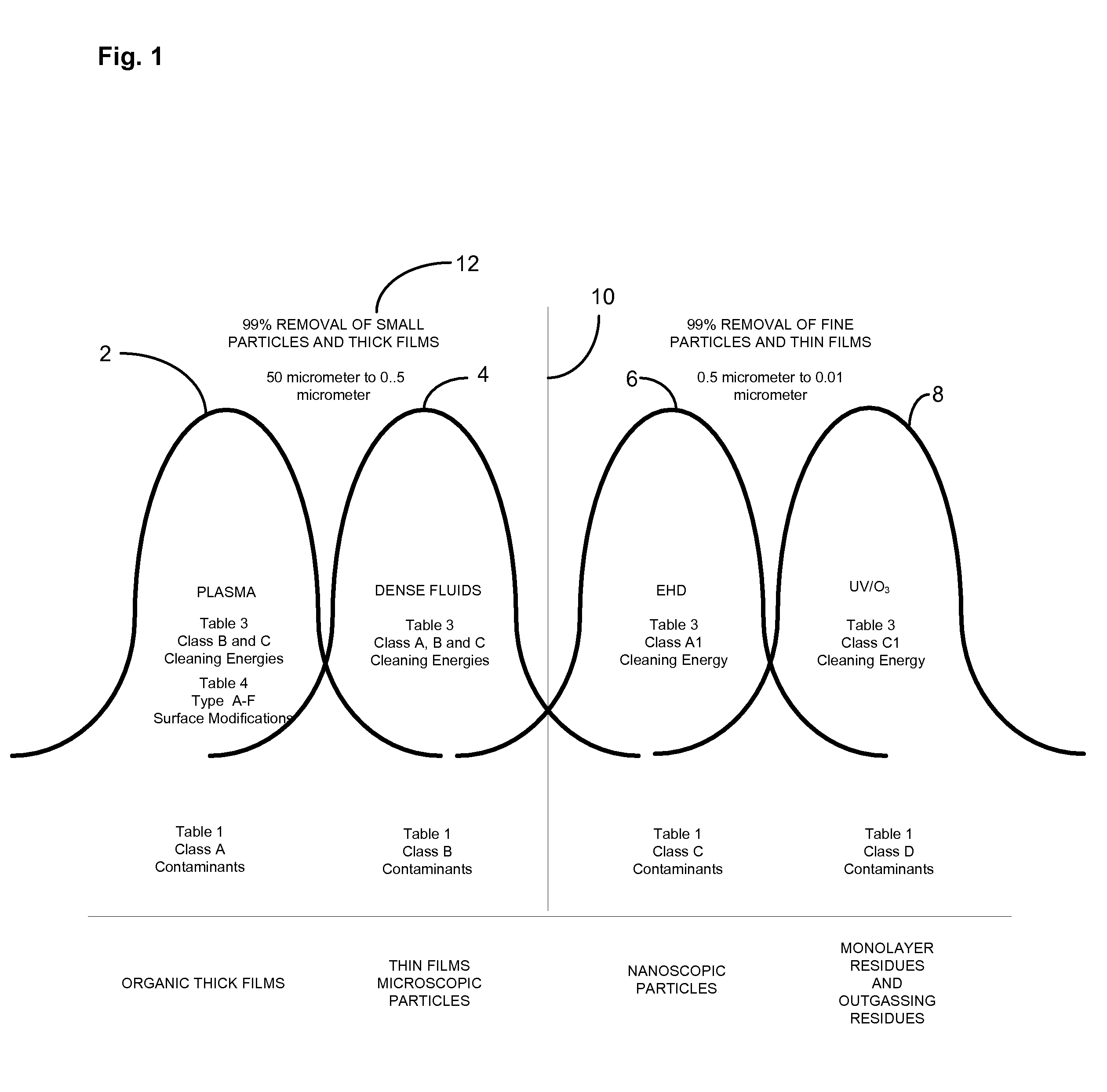

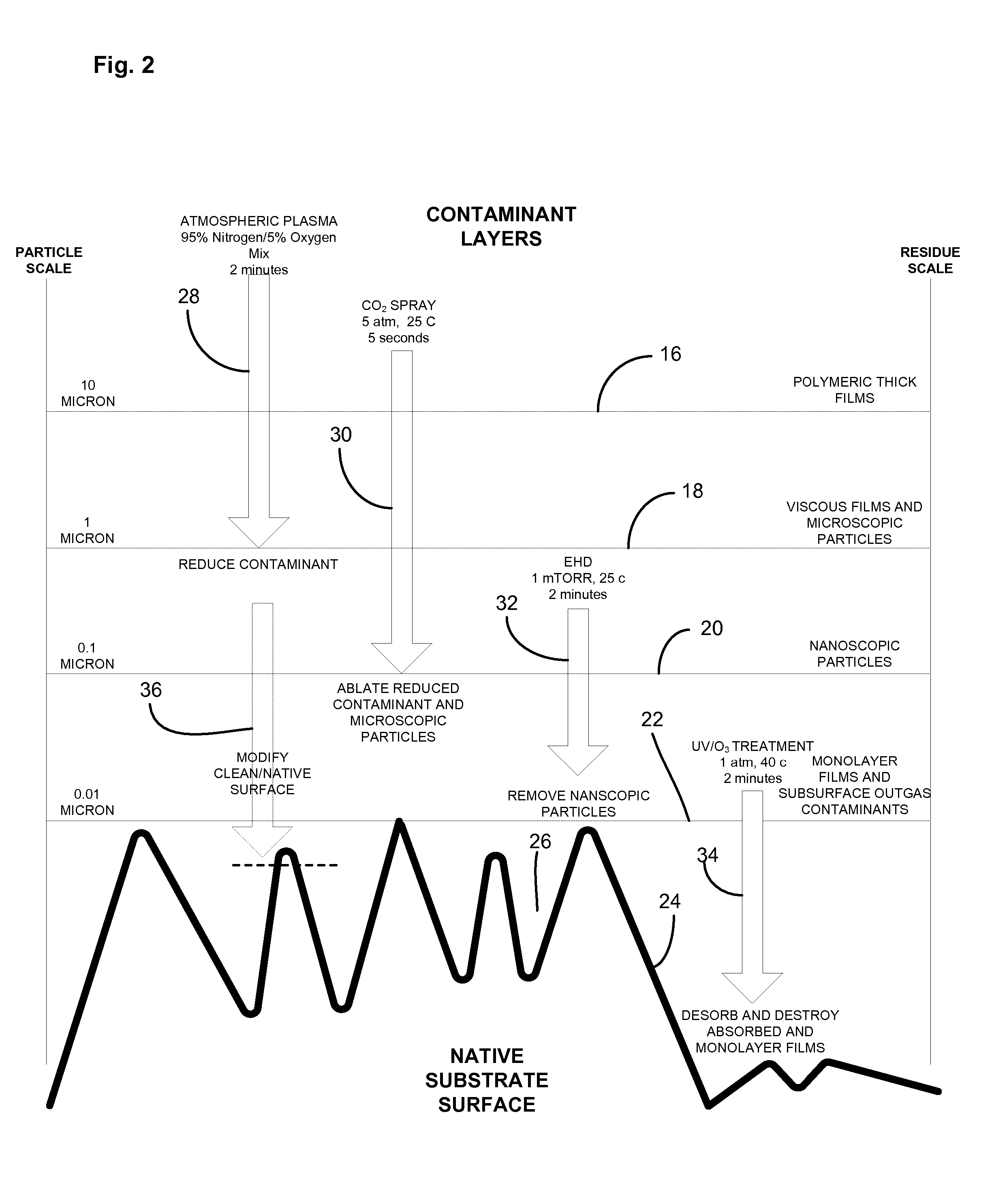

Method of treating a substrate

InactiveUS20070246064A1Reduce repollutionEliminates wet processingElectrostatic cleaningSemiconductor/solid-state device manufacturingTime segmentEngineering

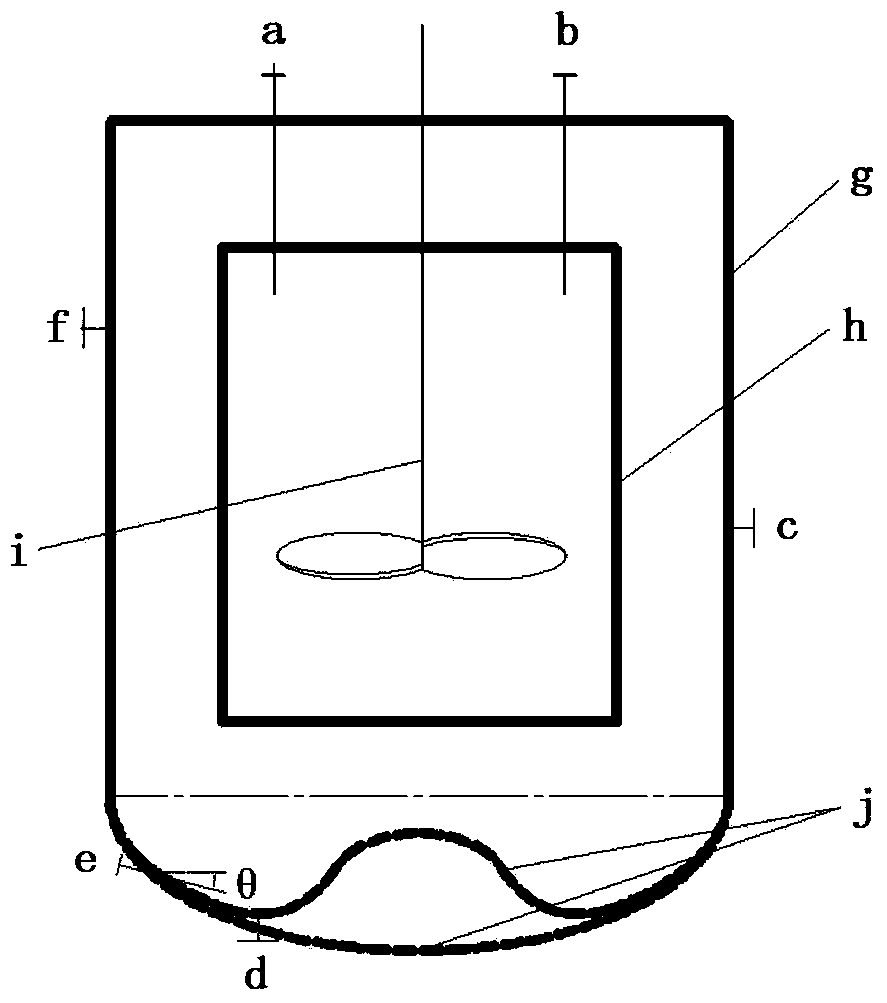

A method of cleaning a substrate within a controlled environment includes placing the substrate into a high pressure vessel. The high pressure vessel is then supplied with a dense fluid under pressure. The dense fluid is contacted with the substrate for a selected period of time to at least partially remove a contaminant contained on the substrate. After the selected period of time, the vessel is depressurized to at least partially convert the dense fluid into a vapor. The vapor is then subjected to an energy field to form a plasma within the vessel which is used to treat the substrate for a second selected period of time. The thus cleaned substrate is then removed from the vessel.

Owner:JACKSON DAVID P

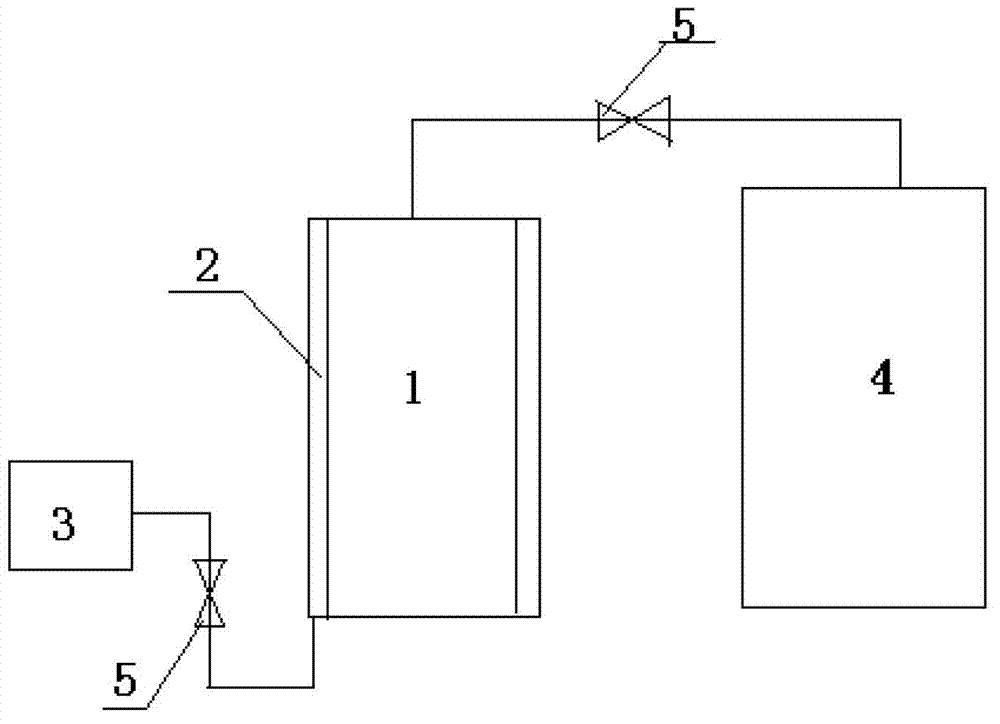

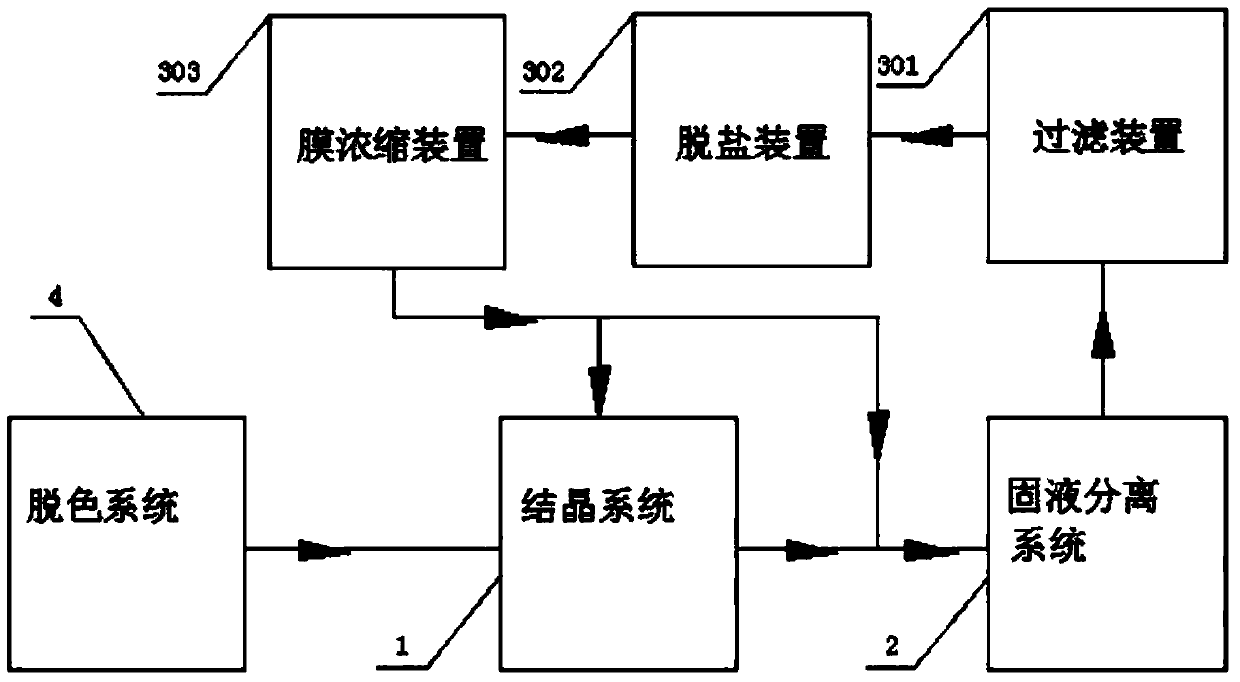

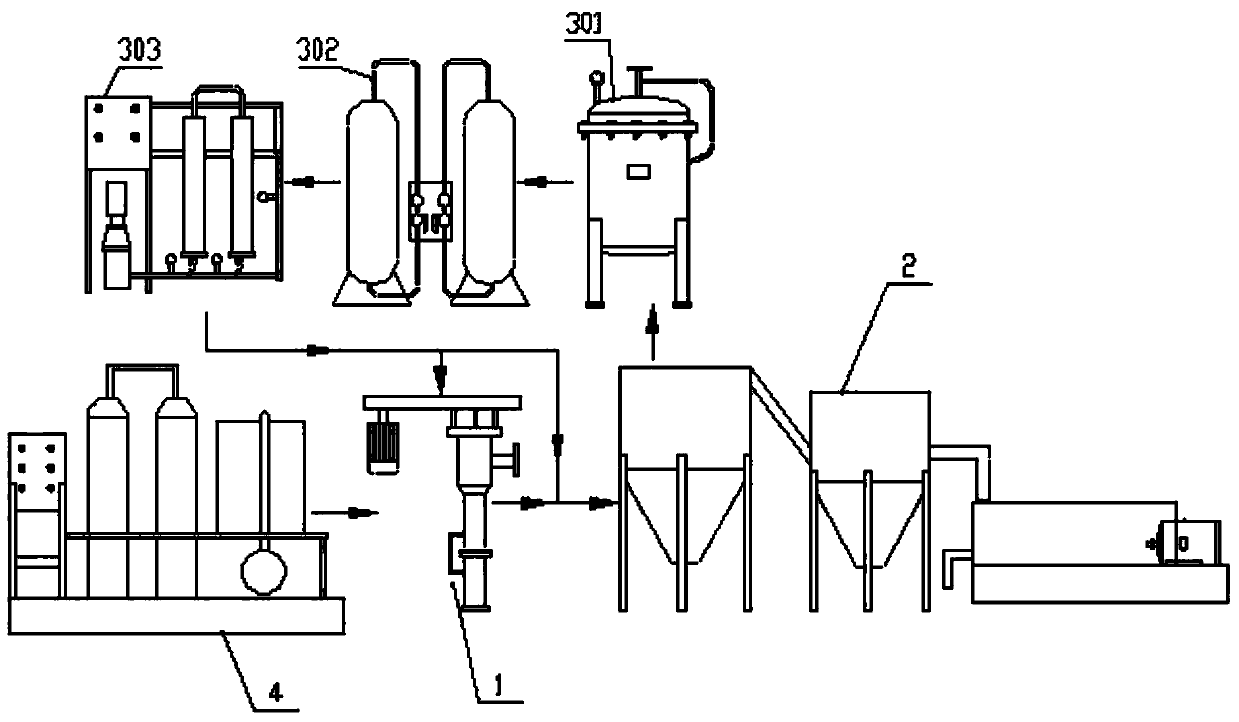

Separation and purification system of organic synthesis feed liquid and separation and purification method thereof

InactiveCN104174181AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentChemical industryPurification methods

The invention aims at the field of chemical industry and relates to a separation and purification system of organic synthesis feed liquid and a separation and purification method of the organic synthesis feed liquid. The separation and purification system comprises a crystallization system and a solid-liquid separation system which are sequentially arranged from front to back, wherein the crystallization system comprises a mixed suspension-mixed product-removal (MSMPR) crystallizer and a draft-tube-baffled (DTB) crystallizer which are connected with each other in series; the separation and purification system also comprises a liquid processing system used for processing waste liquid produced by the solid-liquid separation system; the liquid processing system comprises a desalting device and a membrane concentration device which are sequentially arranged from front to back. By virtue of the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof, the organic synthesis feed liquid is separated and purified by using a continuous crystallization technology, an electrodialysis technology and a membrane separation and concentration technology; the produced waste liquid is fully recycled and used, so that the separation and purification efficiency is improved, the purity and the yield of products are improved and the discharge of the waste liquid is reduced; the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof are strong in production industrialization and low in costs, and are especially suitable for producing iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

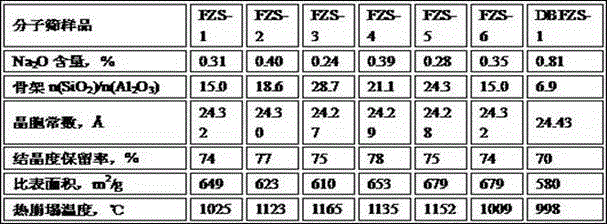

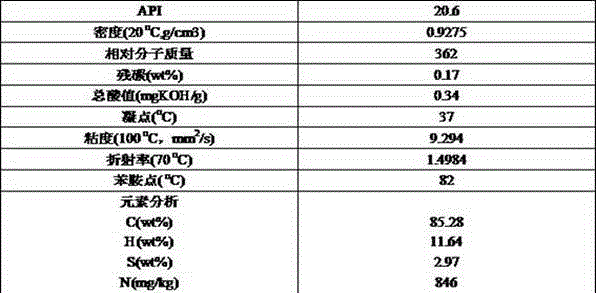

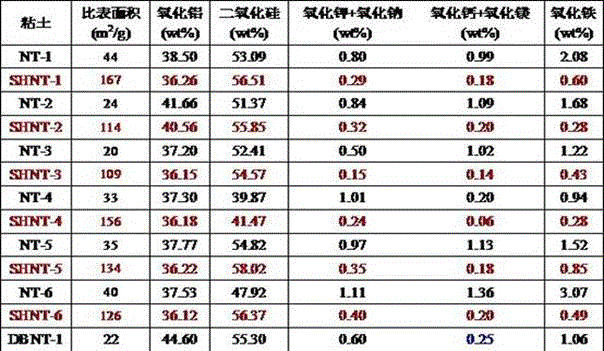

Preparation method of catalytic cracking catalyst

ActiveCN106732745AHigh crystallinity retentionImprove thermal stabilityCatalytic crackingMolecular sieve catalystsHigh concentrationGas phase

The invention relates to a preparation method of a catalytic cracking catalyst. According to the method, the NaY molecular sieve raw powder and halogen-containing gas are contact to perform gas phase ion exchange reaction; the sodium reduction and the ultra-stabilization of the NaY molecular sieve raw powder are completed in one step; the low-sodium high-silica-alumina-ratio molecular sieve is prepared. According to the method, different kinds of clay raw ores are compounded and are treated by high-concentration acid to obtain acid active composite clay; then, the low-sodium high-silica-alumina-ratio molecular sieve, the acid active composite clay, bonding agents, rare earth and decationized water are mixed and pulped; then, spraying granulation is performed; roasting and curing are performed; washing and drying are not needed; a finished product of the catalytic cracking catalyst is obtained. The catalytic cracking catalyst has the advantages that the olefin content in the gasoline can be obviously reduced; the light oil yield is improved; the preparation flow process of the catalyst is short; no ammonia and no nitrogen are discharged.

Owner:REZEL CATALYSTS CORP

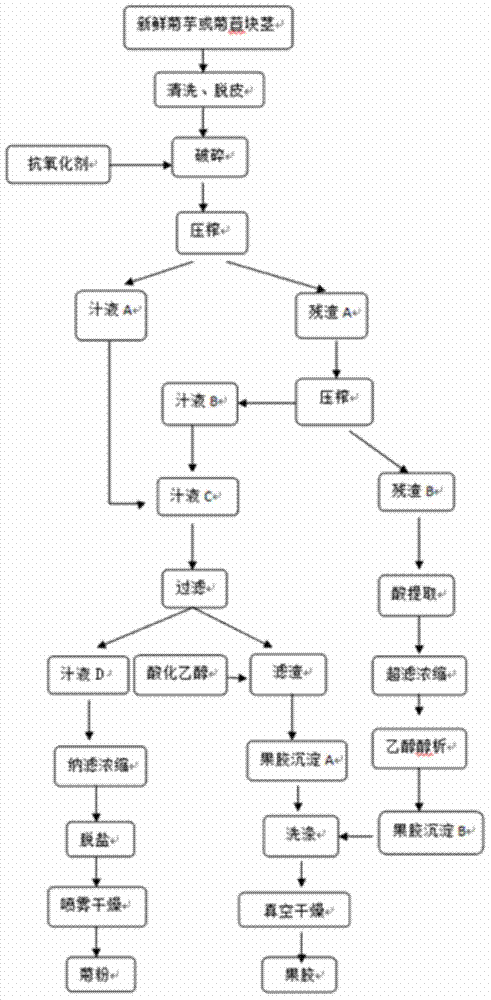

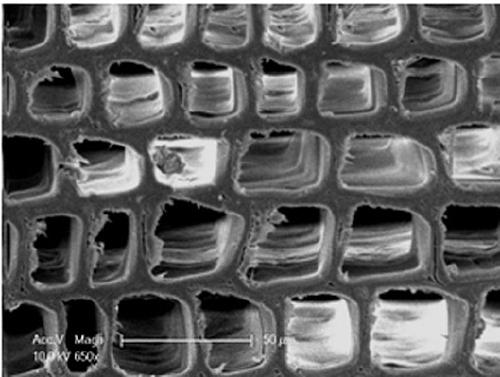

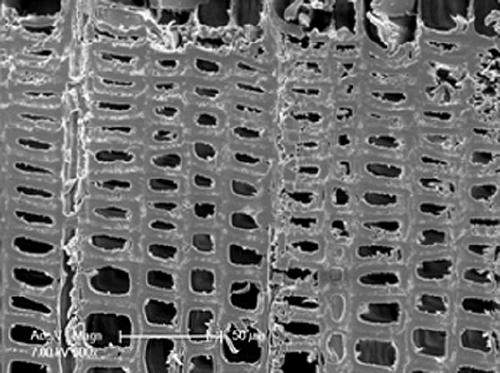

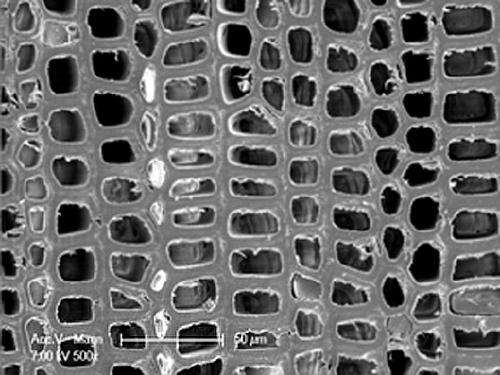

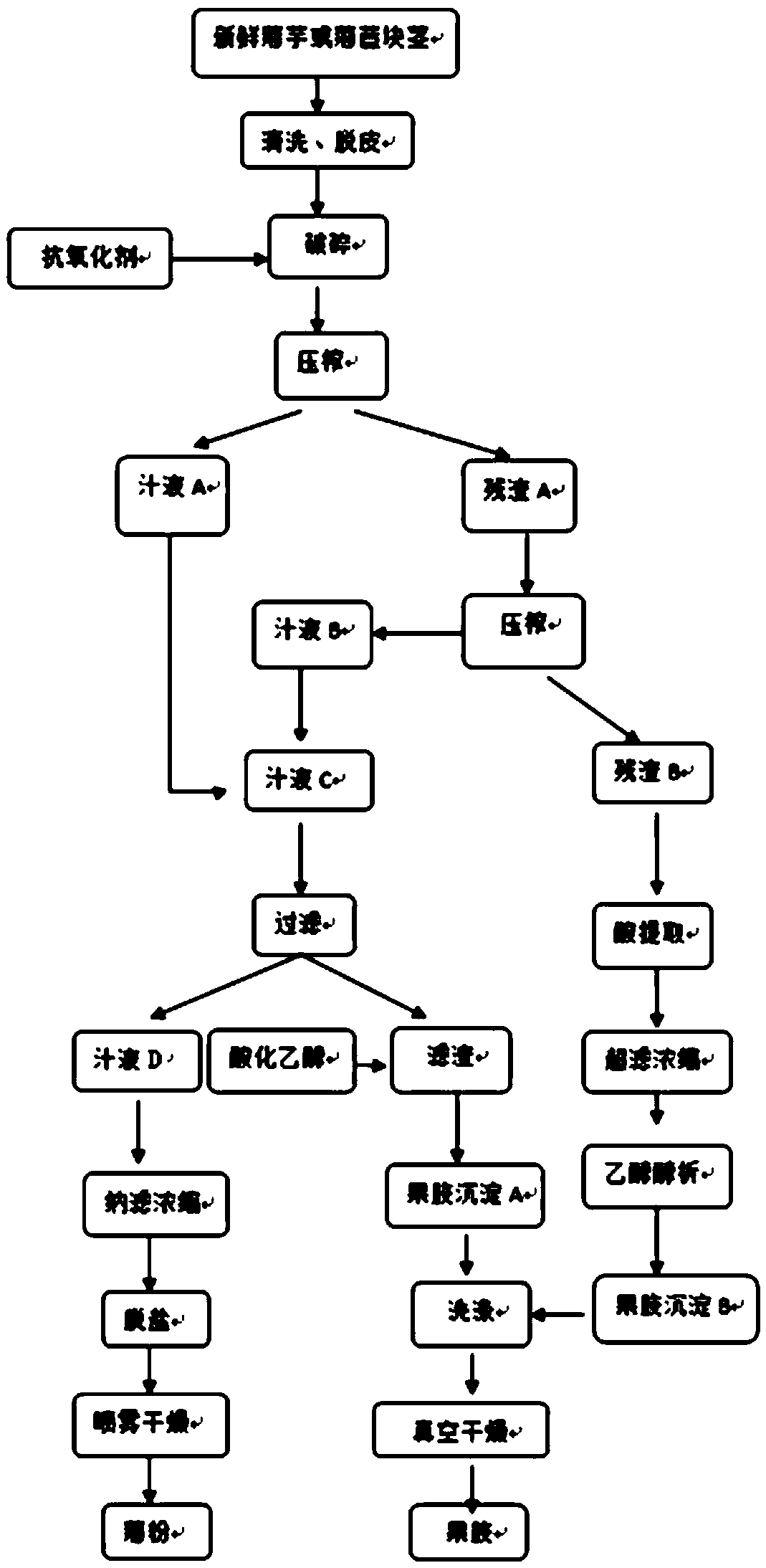

Method for continuously preparing inulin and pectin by using jerusalem artichoke and/or endives

The invention provides a method for continuously preparing inulin and pectin by using jerusalem artichoke and / or endives. According to the technical scheme, the method comprises the following steps: cleaning, peeling and crushing the jerusalem artichoke and / or the endives, and pressing so as to obtain juice A and residues A; adding water to the residues A, and pressing again so as to obtain juice B and residues B; combining the juice A and the juice B so as to obtain juice C, filtering the juice C subjected to impurity removal so as to obtain juice D and residues, washing residues by using acidized ethyl alcohol, and carrying out centrifugal separation so as to obtain pectin precipitates A; concentrating the juice D so as to obtain the inulin; carrying out acid extraction on the residues B so as to obtain pectin clear liquor; obtaining pectin precipitates B by using the pectin clear liquor; and carrying out vacuum drying on the pectin precipitates A and the pectin precipitates B so as to obtain pectin. The method provided by the invention has the advantages that the production of the inulin and the pectin is combined through optimization of a preparation technology, the raw materials are fully utilized, the production cost is saved, and the production benefits are increased.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

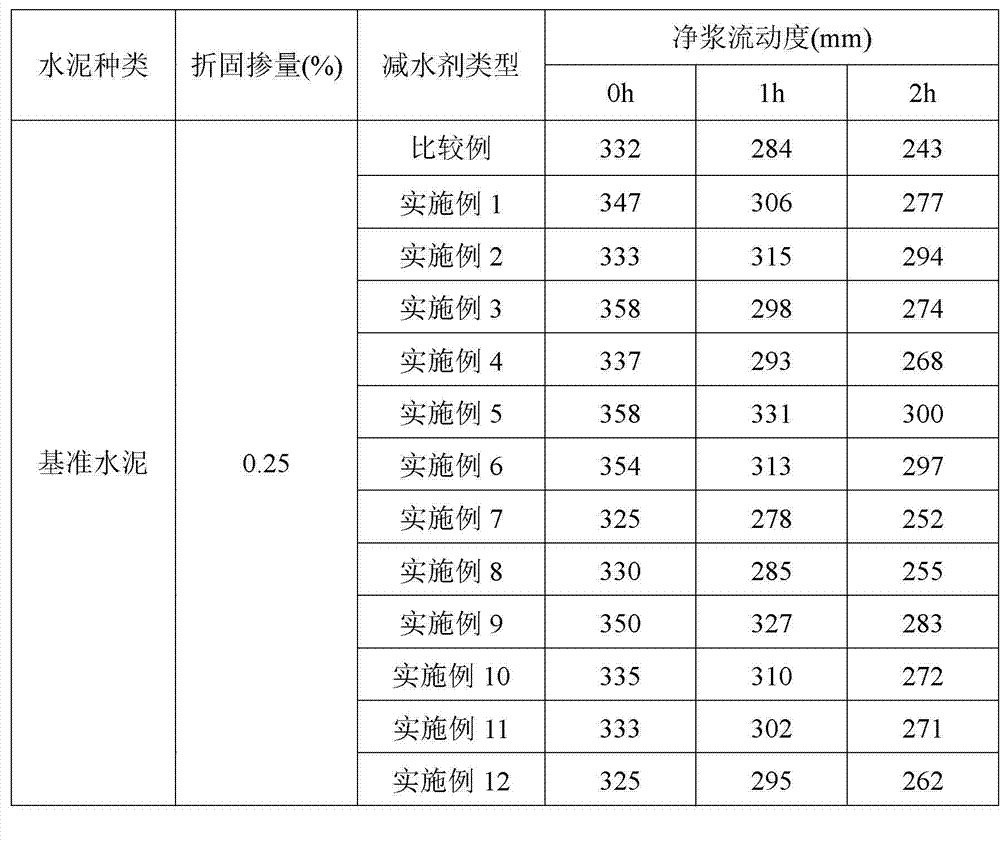

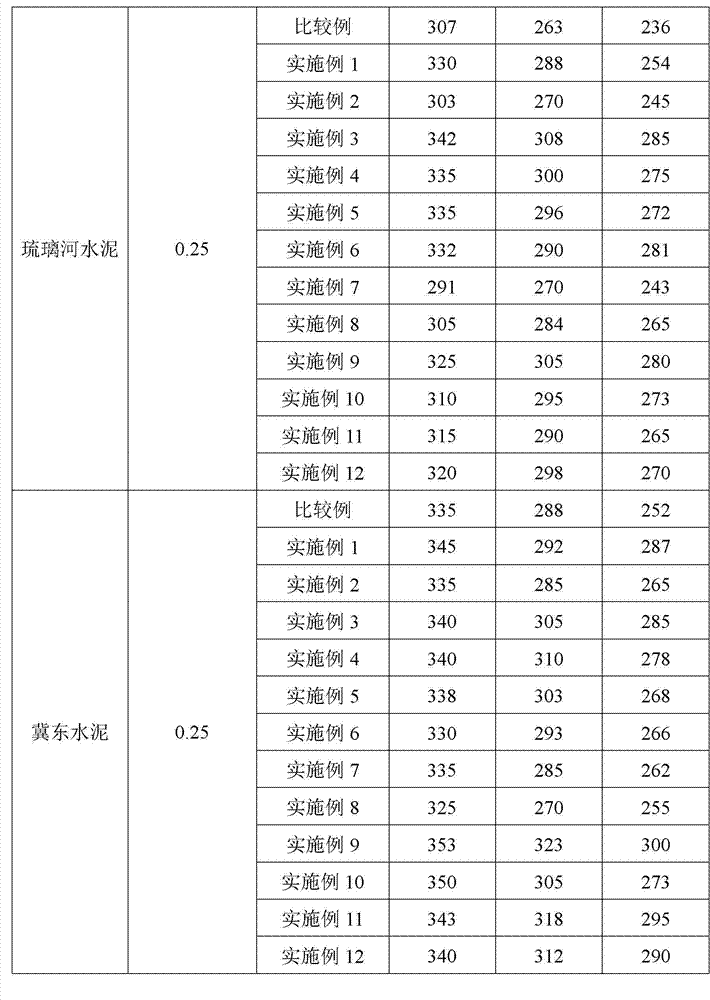

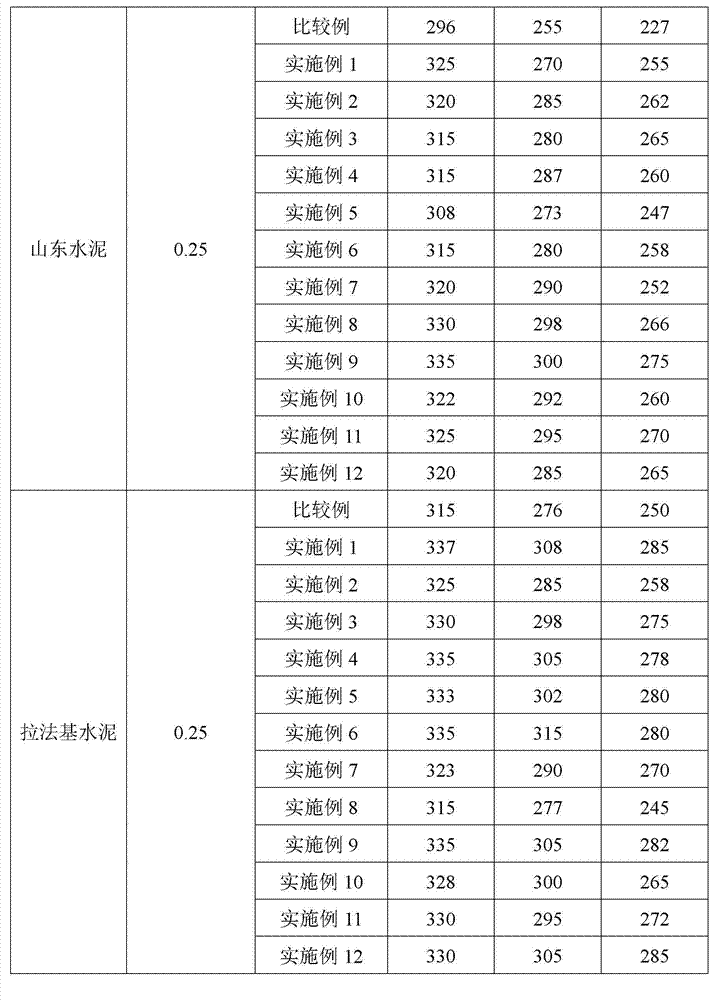

A method for directly synthesizing pure solid polycarboxylate high-performance water reducer in one step

The invention relates to a method for directly synthesizing a pure solid high-performance polycarboxylate water-reducer in one step, belonging to the field of water-reducers. According to the method, the pure solid high-performance polycarboxylate water-reducer is prepared by taking an acrylic compound and unsaturated polyoxyethylene ether as polymerization reaction monomers, adding a molecular weight regulator and carrying out free-radical polymerization reaction under the action of an initiator and under a solvent-free environment. The method disclosed by the invention is strong in controllability, high in polymerization degree, low in cost, environment-friendly and pollution-free, achieves the purpose of preparing the absolutely anhydrous pure solid polycarboxylate water-reducer by bulk polymerization, not only has the fluidity and holding property of cement paste, cement adaptability and concrete application performance which are similar to those of a polycarboxylate water-reducer prepared from a common solution by polymerization and can be prepared into any concentration of solution according to actual demands as the pure solid high-performance polycarboxylate water-reducer prepared by direct polymerization is an anhydrous pure solid, but also is free of postprocessing working procedures, such as heat drying or solvent separation and is more convenient to transport, saved in transport cost and favorable in market competitiveness and application prospect.

Owner:HUIZHOU JIANKE IND

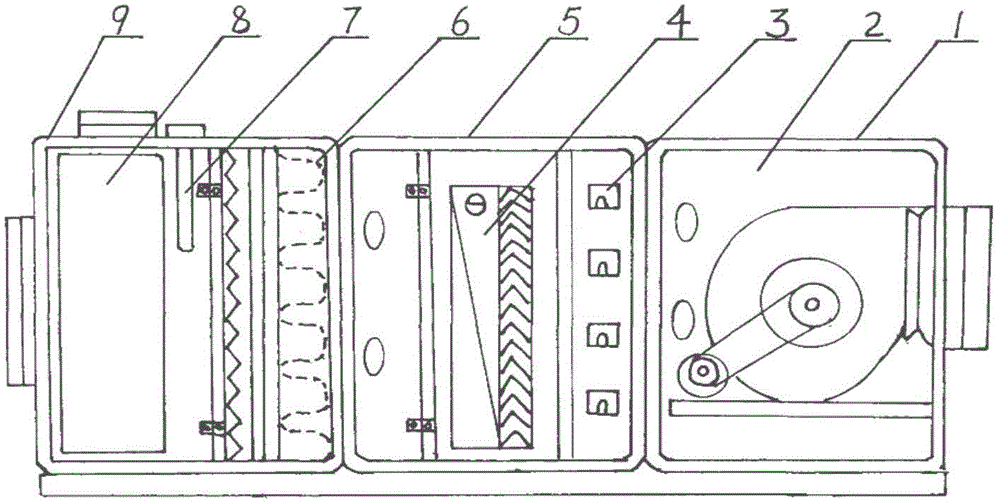

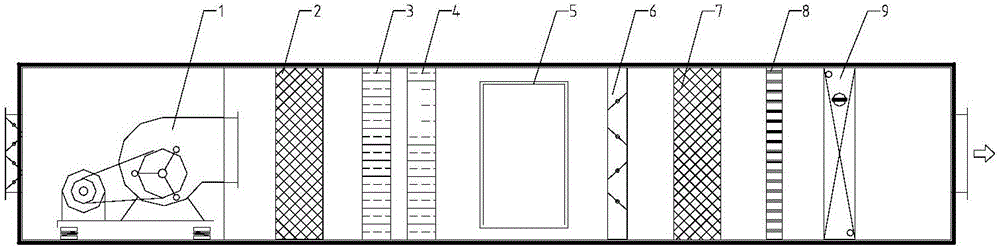

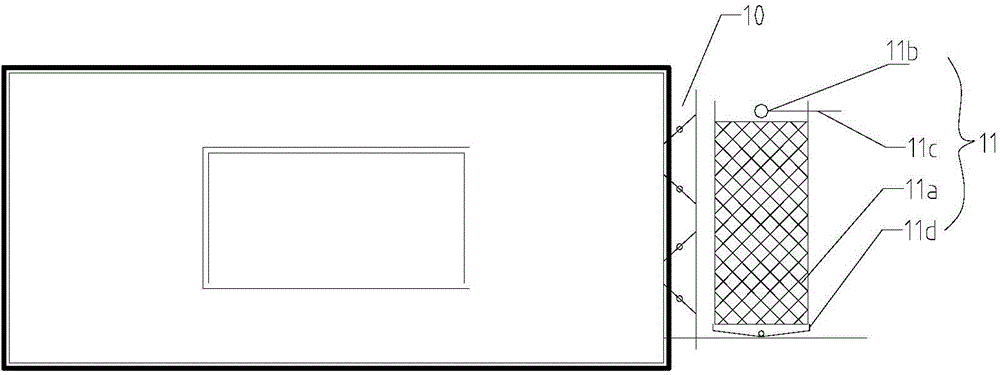

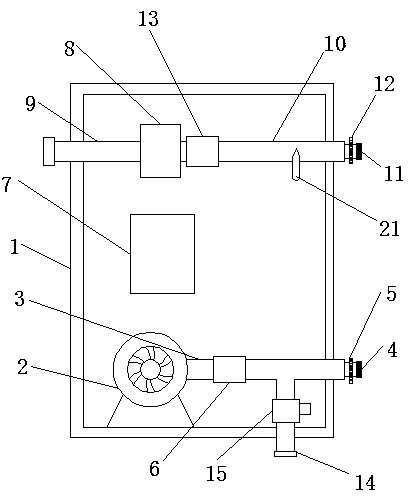

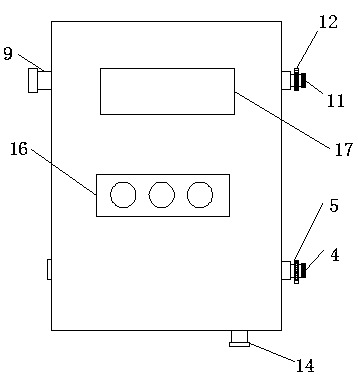

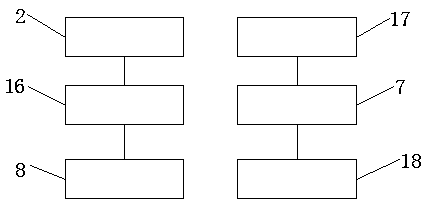

Air conditioning unit and control device used for cleaning air conditioning unit

InactiveCN105299850ARealize automatic switchingEliminates the drying stepSpace heating and ventilation safety systemsLighting and heating apparatusAir conditioningDust collector

The invention relates to an air conditioning unit. The air conditioning unit sequentially comprises a draught fan, a primary filter, electrostatic dust collectors and a surface air cooler from an air inlet to an air feeding port. The air conditioning unit is characterized in that a first air valve is arranged between the electrostatic dust collectors and the surface air cooler, and a window and a second air valve are arranged at the portions, between the electrostatic dust collectors and the first air valve, of the wall of a unit box body. By the adoption of the air conditioning unit, dust in the air conditioning unit can be treated without water, the drying step in water method dust removal is omitted, and a work mode and a dust removal mode of the air conditioning unit can be automatically switched. The invention further relates to a control device used for cleaning the air conditioning unit.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

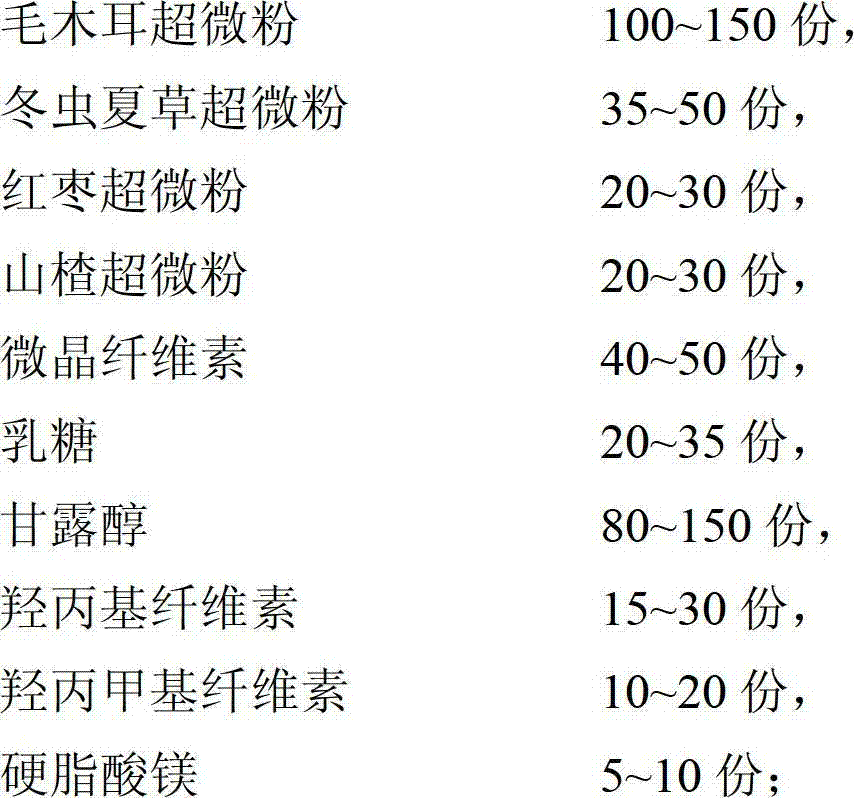

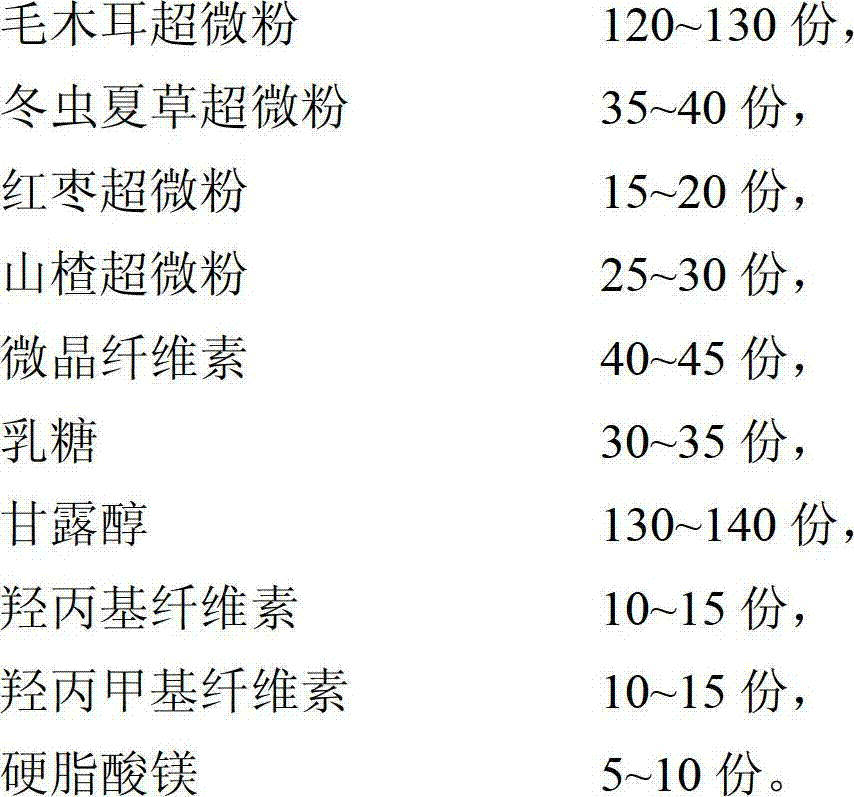

Auricularia polytricha compound nutrition tablet and preparation method thereof

InactiveCN102805337ASignificant functional valueFully playFood preparationMANNITOL/SORBITOLAdditive ingredient

The invention relates to an auricularia polytricha compound nutrition tablet. A preparation method of the auricularia polytricha compound nutrition tablet comprises the following steps: taking auricularia polytricha superfine powder, cordyceps sinensis superfine powder, red jujube superfine powder and hawthorn superfine powder as main raw materials, uniformly mixing with microcrystalline cellulose, lactose, mannitol, hydroxypropyl cellulose, hydroxypropyl methyl cellulose and magnesium stearate accessories and tabletting. The auricularia polytricha composite nutrition tablet has the beneficial effects that by utilizing a variable-temperature differential puffed technology and in combination with superfine grinding, the cell wall of auricularia polytricha is broken to a maximum extent, and functional components are dissolved out to a maximum limit; and the quality is stable, and the efficacy is remarkable, and a good effect of preventing cardiovascular and cerebrovascular diseases is achieved. The auricularia polytricha compound nutrition tablet is suitable for crowds with different physiques.

Owner:山东省农业管理干部学院

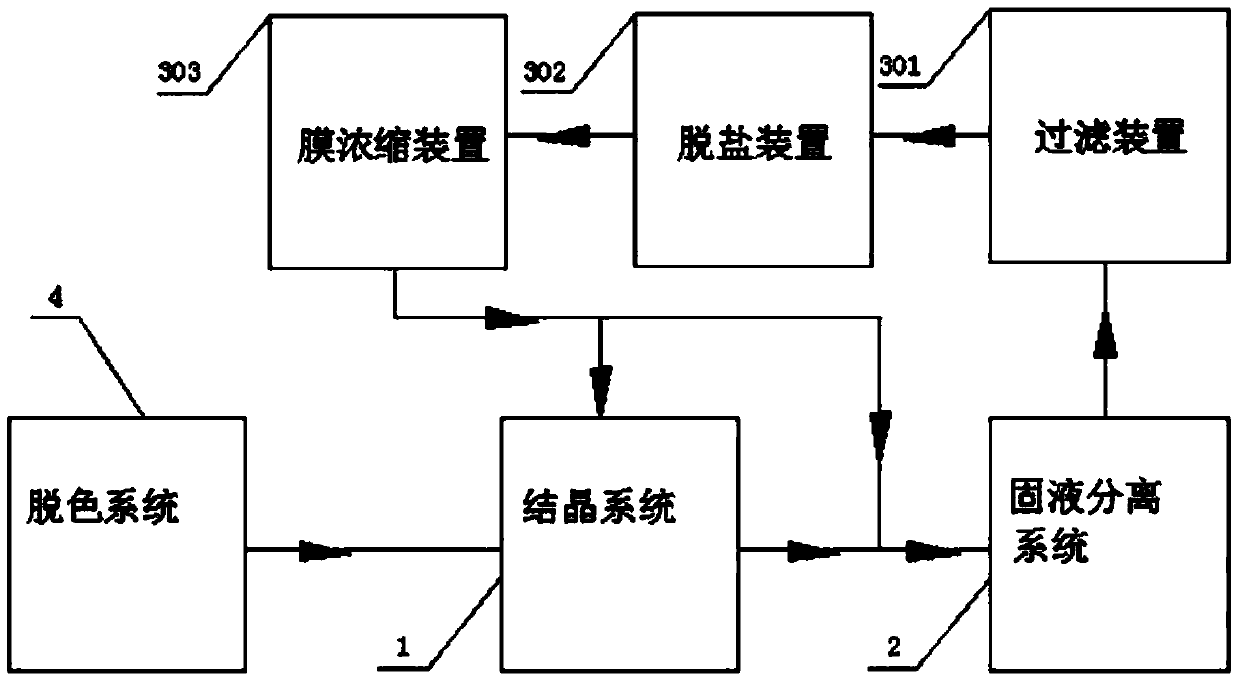

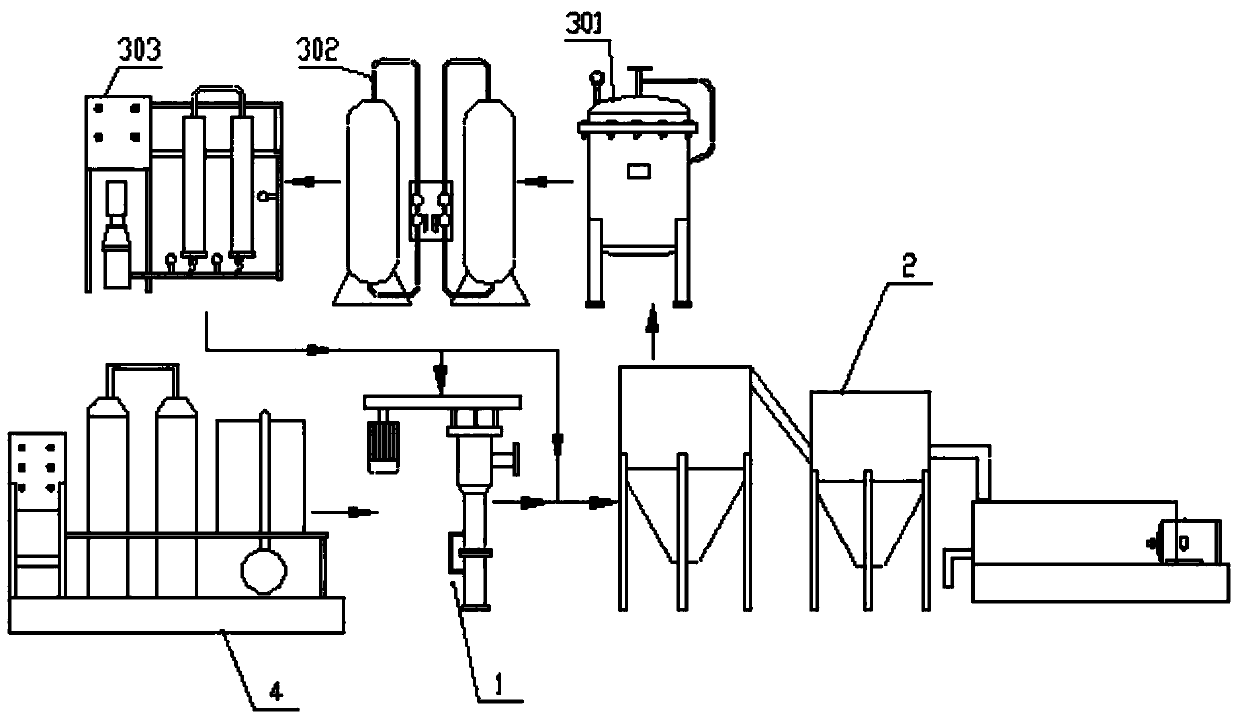

Recycling system and recycling method for waste liquor produced in separation and purification of organically synthesized feed liquid

InactiveCN104176844AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentElectricityOrganic synthesis

The invention relates to a recycling system and a recycling method for waste liquor produced in separation and purification of an organically synthesized feed liquid, and belongs to the field of chemical engineering. The recycling system for the waste liquor comprises a filter device, a desalting device and a membrane concentrating device which are arranged from the front to the rear in sequence, or the filter device is replaced with a filtrate collecting slot, wherein the filter device is used for filtering and collecting the waste liquor; the filtrate collecting slot is used for stewing and collecting the waste liquor; the desalting device is used for desalting the collected waste liquor; the membrane concentrating device is used for concentrating a liquid which is desalted by virtue of the desalting device; and the desalting device is preferably an electrodialysis device. According to the recycling system and the recycling method, a membrane separating and concentrating technology, an electrodialysis technology and the like are comprehensively utilized to separate and purify the organically synthesized feed liquid, and the produced waste liquor is sufficiently recycled, the separating and purifying efficiency and the purity and the yield of products are improved, discharge of the waste liquor is reduced, the production industrialization is strong and the cost is low, and thus, the recycling system and the recycling method are especially suitable for being applied in production of iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

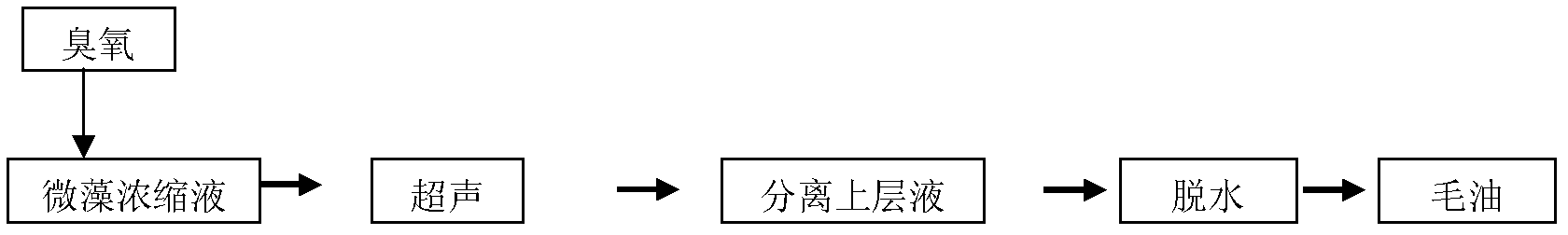

Microalgal wall-breaking method

InactiveCN103160439AImprove wall breaking efficiencyEliminates the drying stepMicroorganism lysisFatty-oils/fats productionEngineeringExtraction ratio

The invention provides a microalgal wall-breaking method, which includes: adding microalgae into a sealed container, then introducing ozone into the sealed container, and simultaneously carrying out an ultrasonic treatment on the microalgae. The method has the advantages of high wall breaking efficiency, oil extraction rate up to more than 80%, or even to over 90%, low energy consumption, simple process, and easy realization of large-scale enlargement, thus being suitable for industrialized application.

Owner:ENN SCI & TECH DEV

Tea dedusting device

ActiveCN104365893AEasy to separateImprove dust removal effectPre-extraction tea treatmentDynamic motionEngineering

The invention discloses a tea dedusting device comprises a box and a dedusting screen. The dedusting screen is cylindrical and is vertically located in the box; a spiral air duct is arranged between the box and the dedusting screen, one side of the spiral air duct is an opened one connected to the outer wall of the dedusting screen, the upper end of the box is provided with an air sucking pipe, the side of the upper portion of the box is provided with a dedusting air sucking port communicated with the box, and the dedusting air sucking port is connected to a negative pressure suction recovery pipe; the outer wall of the bottom of the box is provided with a feeding pipe communicated with the inner wall of the dedusting screen, the bottom of the box is provided with a funnel-shaped discharging port, and the lower end of the discharging port is connected to a storage box. By the aid of the device, the disadvantages that an existing tea dedusting device dedusts in vibration and screen manners, and dedusting effect is poor are overcome, dedusting is performed during the dynamic motion of tea, and the dedusting effect is fine.

Owner:缪童宇

Preparation method of ascorbic acid aliphatic ester

InactiveCN1428339AEliminates washing stepsEliminates the drying stepOrganic chemistrySolventFatty acid

The present invention relates to a method for preparing ascorbic acid aliphatic ester, and said method includes the following steps: preparing a mixture containing 95-100 wt% of sulfuric acid, ascorbic acid and aliphatic acid, making the described mixture produce reaction to obtain the reaction produce mixture containing ascorbic acid aliphatic ester, and separating out ascorbic acid aliphatic ester from it, the mole ratio of ascorbic acid and aliphatic acid is 1 to less than 1.25, and the weight ratio of sulfuric acid and ascorbic acid is at least 6. The reaction mixture is mixed with ice whose volume dose is 2-10 times that of sulfuric acid and / or water whose temp. is below 5 deg.C, then mixed with an aromatic hydrocarbon solvent, and said mixture is hented, and cooled to obtain an organic phase, said organic phase is filtered and dried so as to obtain a solid, i.e. the invented product.

Owner:BEIJING CHENAO HIGH SCI & TECH DEV

Energy-saving lamp fluorescent powder

InactiveCN104560043AUniform luminous effectGood luminous stabilityLuminescent compositionsMetallurgyLuminous flux

The invention relates to energy-saving lamp fluorescent powder which consists of a component A, a component B and a component C, wherein the component A consists of Y2O3, BaCO3, MgO and MoO3 by weight; the component B consists of Sb2O3, CaF2, BaO.Al2O3 and SrCO3; and the component C consists of CaHPO4, Na2B4O7 and Y2O3. The energy-saving lamp fluorescent powder provided by the invention is uniform in luminous effect, high in luminous stability and high in luminous strength during use, and the luminous flux of the manufactured energy-saving lamp can be 75lm / w. Moreover, the processing method of the fluorescent powder is simple, dry gas protection is used in the processing process and during subsequent treatment, the drying step is eliminated, and the processing time consumption is low.

Owner:ANHUI HUSN COUNTY WANXIN ELECTRONICS TECHCO

Hose sealability detection device

InactiveCN109269740AIncrease air pressureControl pressure valueMeasurement of fluid loss/gain rateSolenoid valveEngineering

The present invention relates to a hose sealability detection device. The device comprises a box body; an air inflation pump is arranged at the bottom of the inner cavity of the box body; the air outlet of the air inflation pump is connected with a first flow guide tube; one end of the first flow guide tube passes through the other side of the box body; a first sealing ring is disposed at the end opening of the first flow guide tube; a first hose clamp is arranged to one side of the first sealing ring; the first flow guide tube is provided with a first check valve and a pressure relief tubewhich are sequentially arranged from the left side to the right side of the first flow guide tube; one end of the pressure relief tube passes through the lower end of the box body; the pressure relieftube is provided with a solenoid valve; a PLC is disposed above the air inflation pump; a water pump is arranged above the PLC; one side of the water pump is connected with a water incoming tube; thewater incoming tube passes through the top of one side of the box body; and the other side of the water pump is connected with a second flow guide tube. The hose sealability detection device has theadvantages of simple structure and reasonable design. With the hose sealability detection device of the invention adopted, a method that applies direct water injection to realize detection can be avoided, a drying step can be eliminated, work efficiency can be improved, and a leak point can be tracked when a hose leaks.

Owner:扬州尚翔汽车零部件有限公司

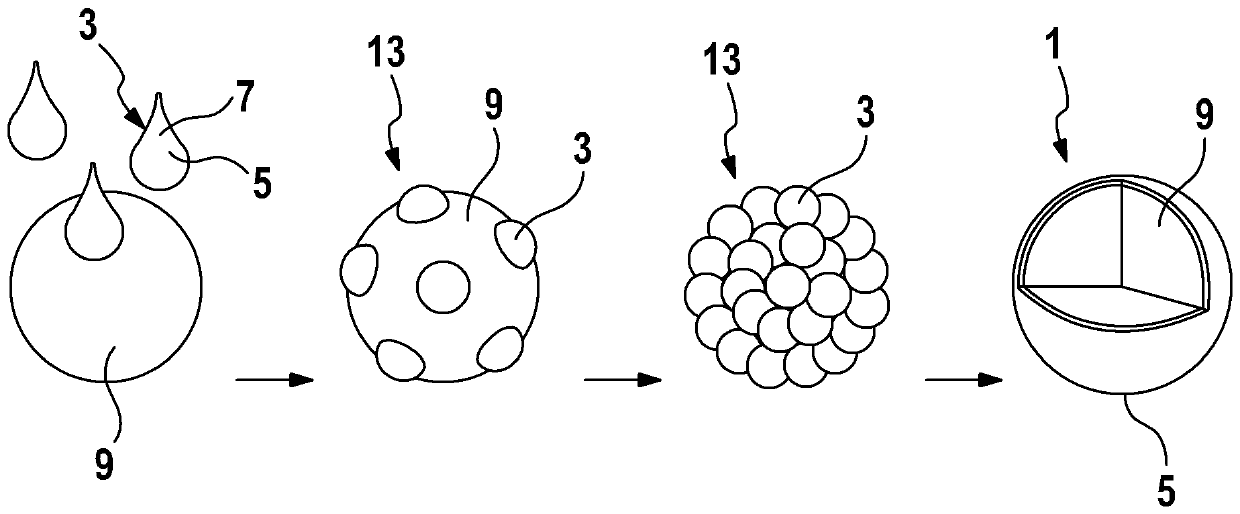

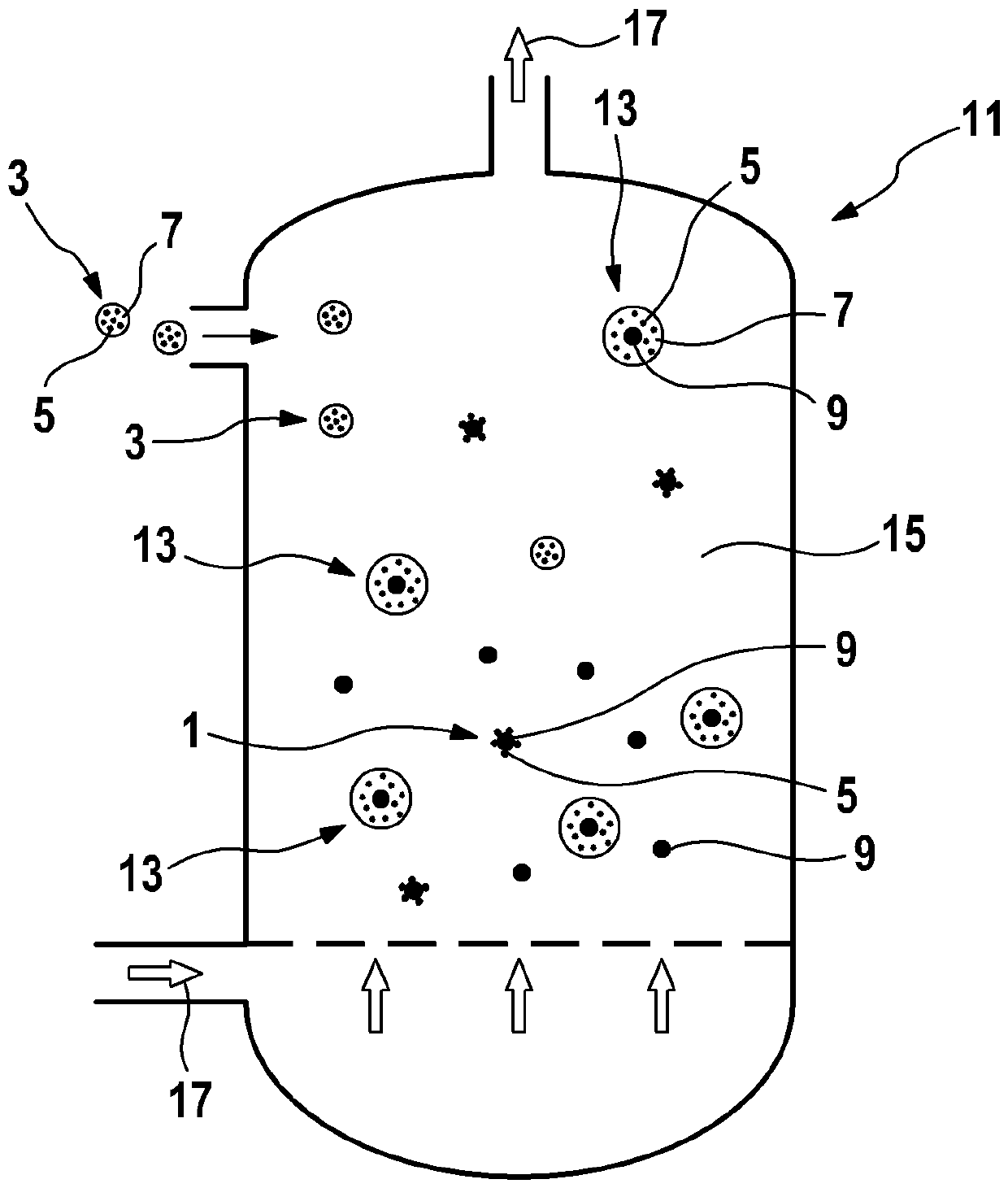

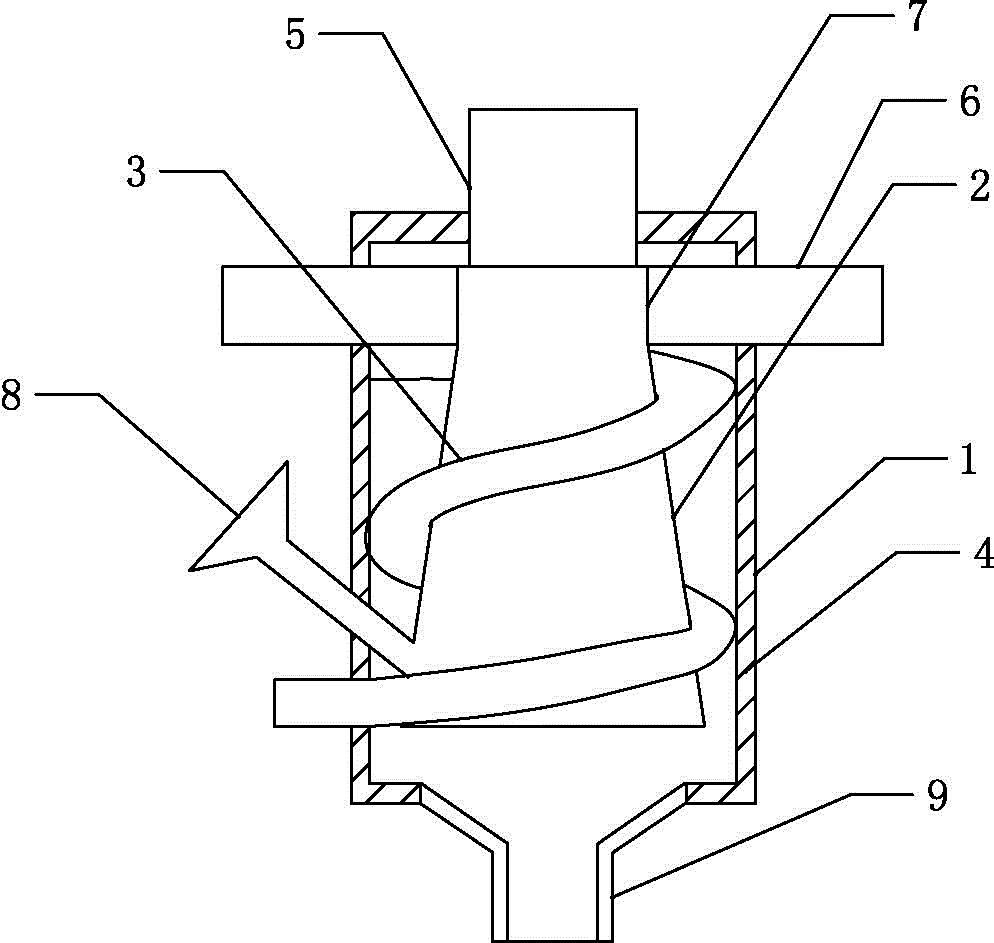

Method for producing an electrode material

The invention relates to a method for producing an electrode material (1) comprising the following steps: a. providing a mixture (3) consisting of a binder (5) and a solvent (7); b. pre-adding and stirring a powdered active material (9) in a mixing device (11), wherein the active material preferably contains lithium; c. adding the mixture (3) into the mixing device (11), wherein the powdered active material (9) is coated with the binder (5) so as to obtain coated particles (13); and d. optimally removing the solvent (7) from the coated particles (13) partially so as to obtain particles of theelectrode material (1). Furthermore, the invention relates to a battery and use of the battery.

Owner:ROBERT BOSCH GMBH

Dust removal device for tea

ActiveCN104365893BEasy to separateImprove dust removal effectPre-extraction tea treatmentDynamic motionEngineering

The invention discloses a tea dedusting device comprises a box and a dedusting screen. The dedusting screen is cylindrical and is vertically located in the box; a spiral air duct is arranged between the box and the dedusting screen, one side of the spiral air duct is an opened one connected to the outer wall of the dedusting screen, the upper end of the box is provided with an air sucking pipe, the side of the upper portion of the box is provided with a dedusting air sucking port communicated with the box, and the dedusting air sucking port is connected to a negative pressure suction recovery pipe; the outer wall of the bottom of the box is provided with a feeding pipe communicated with the inner wall of the dedusting screen, the bottom of the box is provided with a funnel-shaped discharging port, and the lower end of the discharging port is connected to a storage box. By the aid of the device, the disadvantages that an existing tea dedusting device dedusts in vibration and screen manners, and dedusting effect is poor are overcome, dedusting is performed during the dynamic motion of tea, and the dedusting effect is fine.

Owner:缪童宇

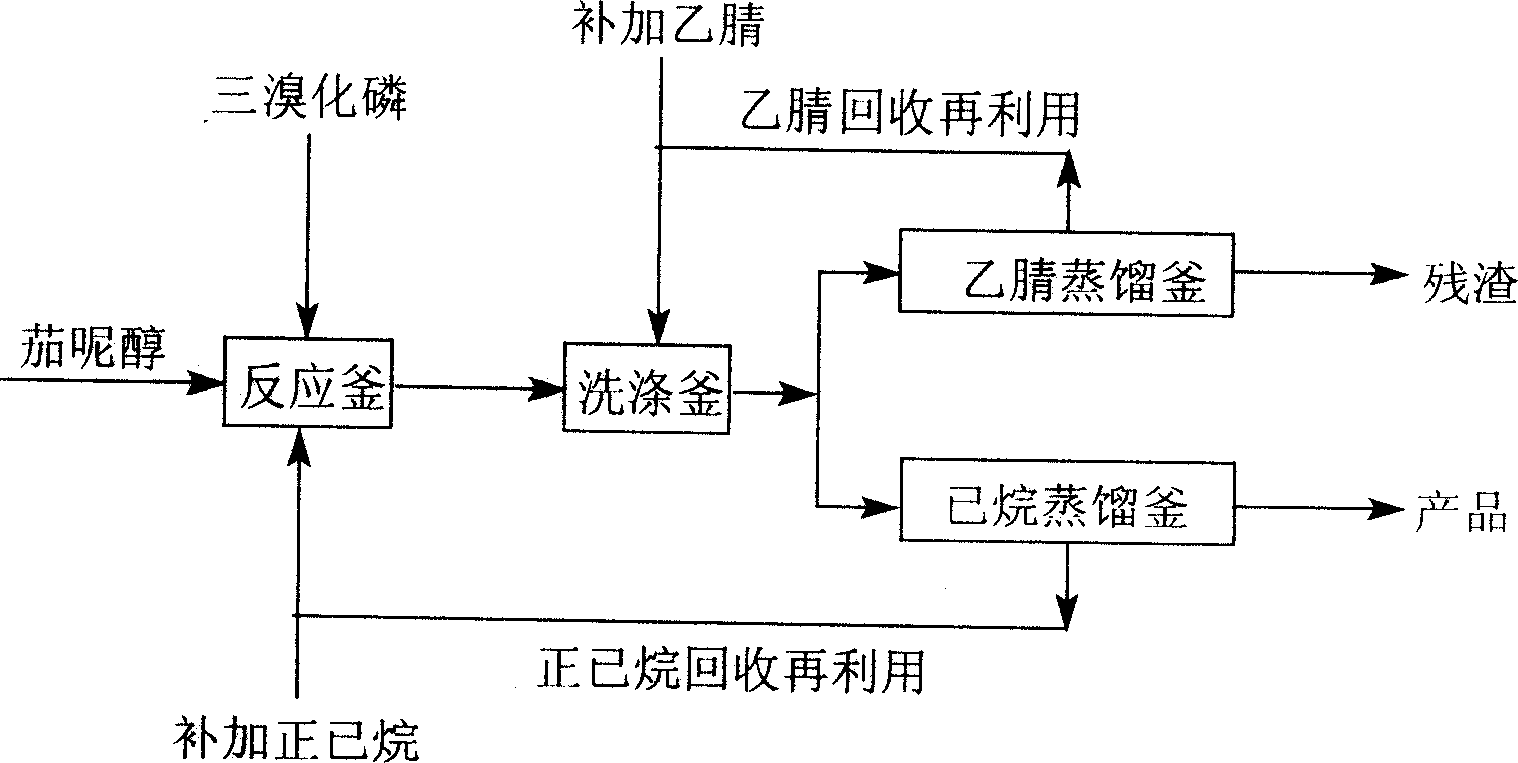

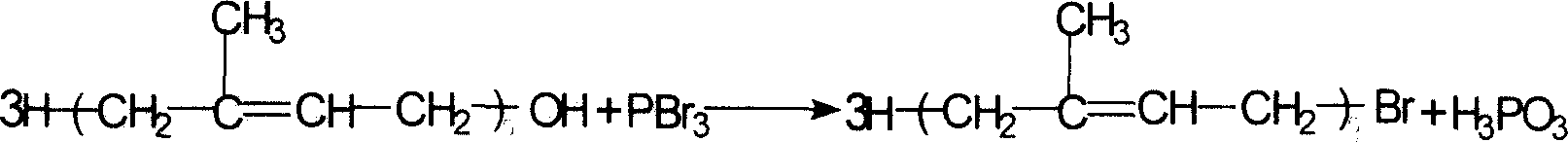

Solanesyl bromine preparation process and its refining method

InactiveCN1762936AReduce operating proceduresIncrease production capacityHalogenated hydrocarbon preparationBromineChromatographic column

The present invention relates to the preparation process and refining method of solano bromide. Solano bromide is prepared with solanesol as initial material and the preparation process includes the main steps of bromination with phosphorus tribromide in non-polar solvent and subsequent direct washing with polar solvent to refine. The said refining method has no extraction, drying, chromatographic column refining and other steps and thus has no emulsification, decomposition, so that the present invention has high product yield and purity and lowered cost.

Owner:YUNNAN KEEN BIOENG

Wax composition for application to wet surfaces

ActiveUS20070251417A1Eliminates the drying stepHigh glossWax coatingsMixing methodsWaxPolymer chemistry

A wax composition for application to a wet surfaces utilizing a polymeric emulsion with a cross-linked copolymer of acrylic acid and C10-30 alkyl acrylate whereby upon application to the surface to be waxed the hydrophilic portion of the polymer instantly collapses releasing the oil phase and providing immediate coverage of the application surface forming a film upon drying, and buffing the waxed surface with an absorbent material leaves a protective coating of wax of the surface which does not easily re-emulsify or wash off when further exposed to water.

Owner:NITEO PROD LLC

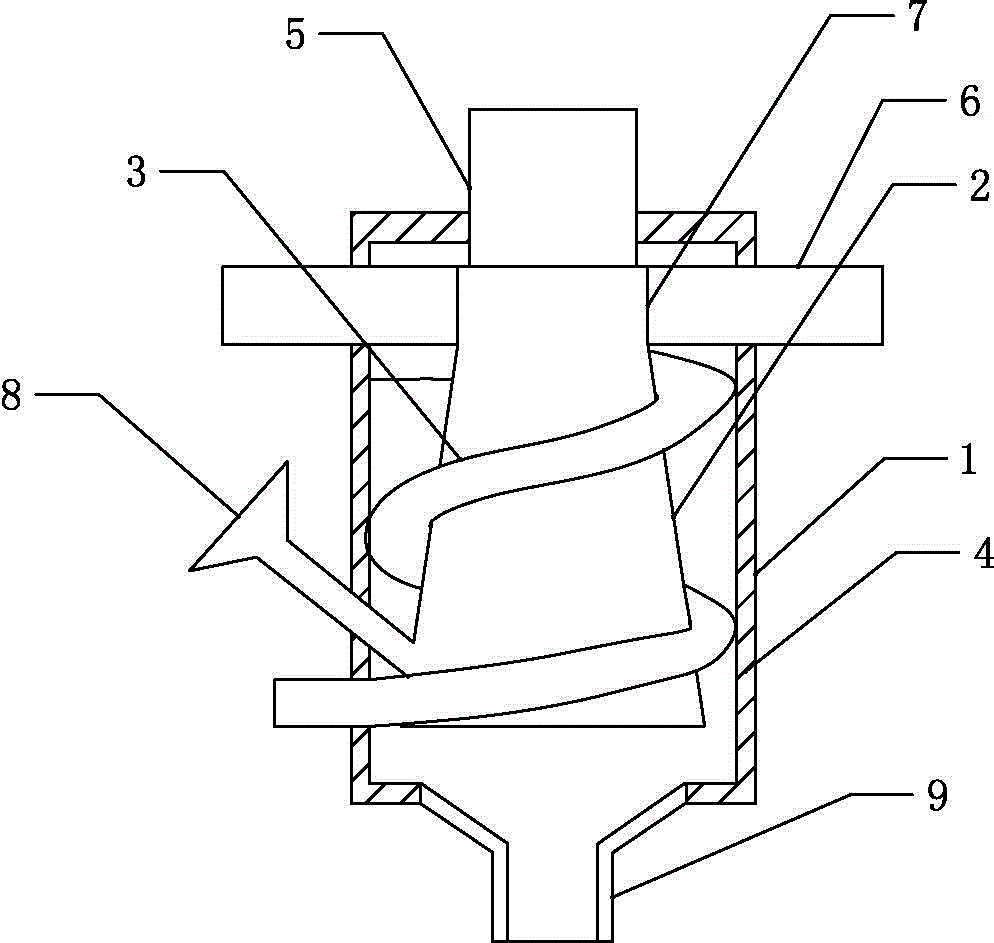

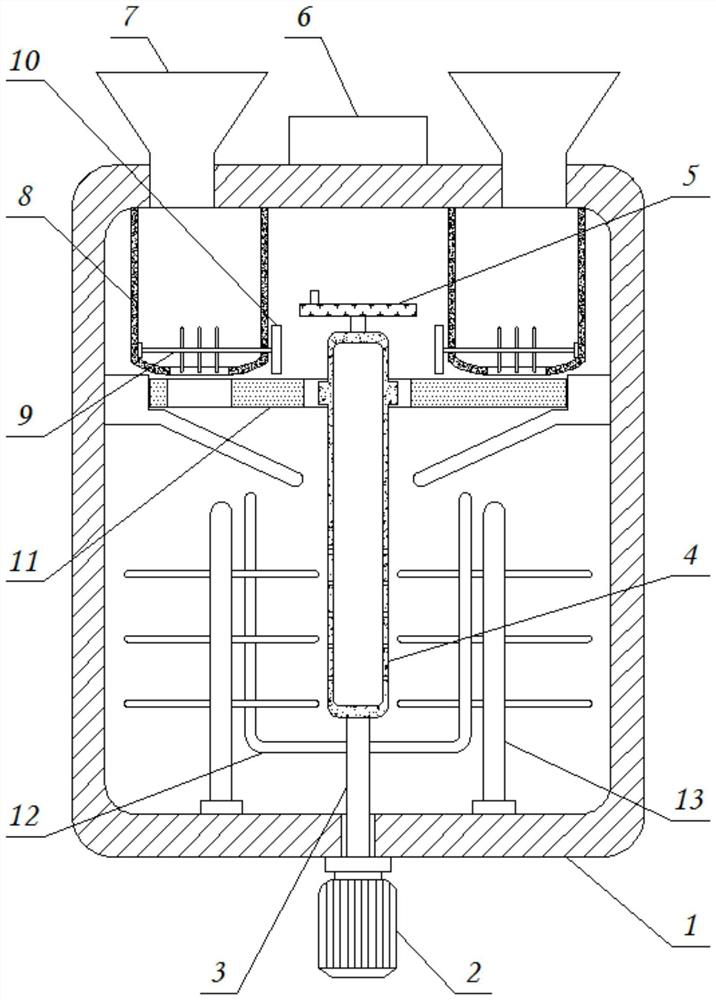

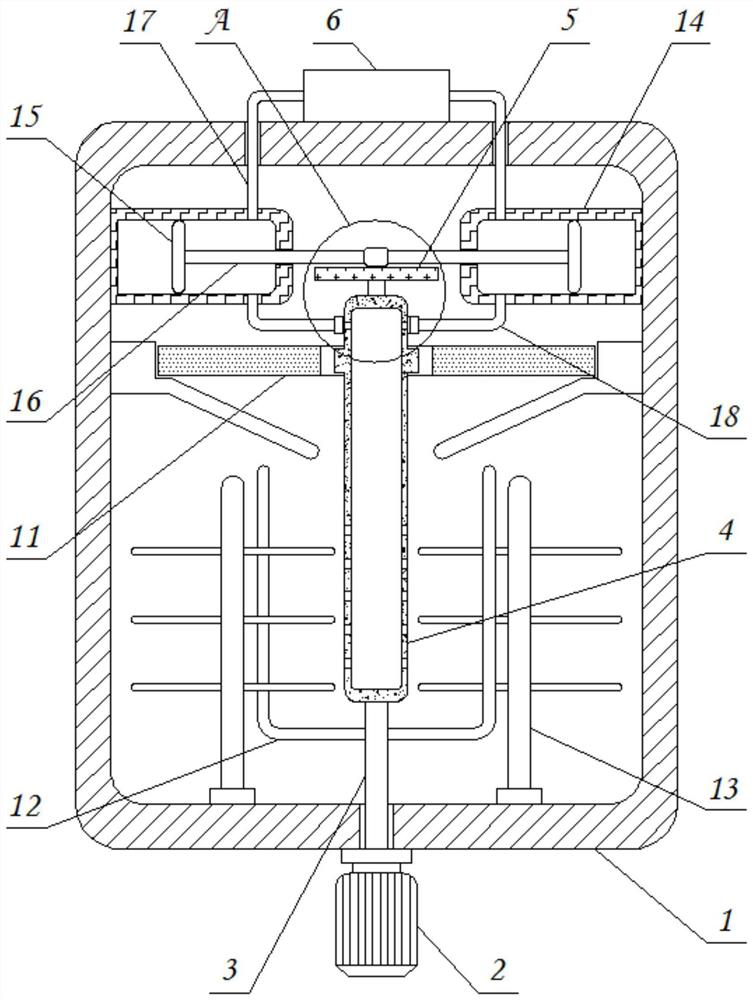

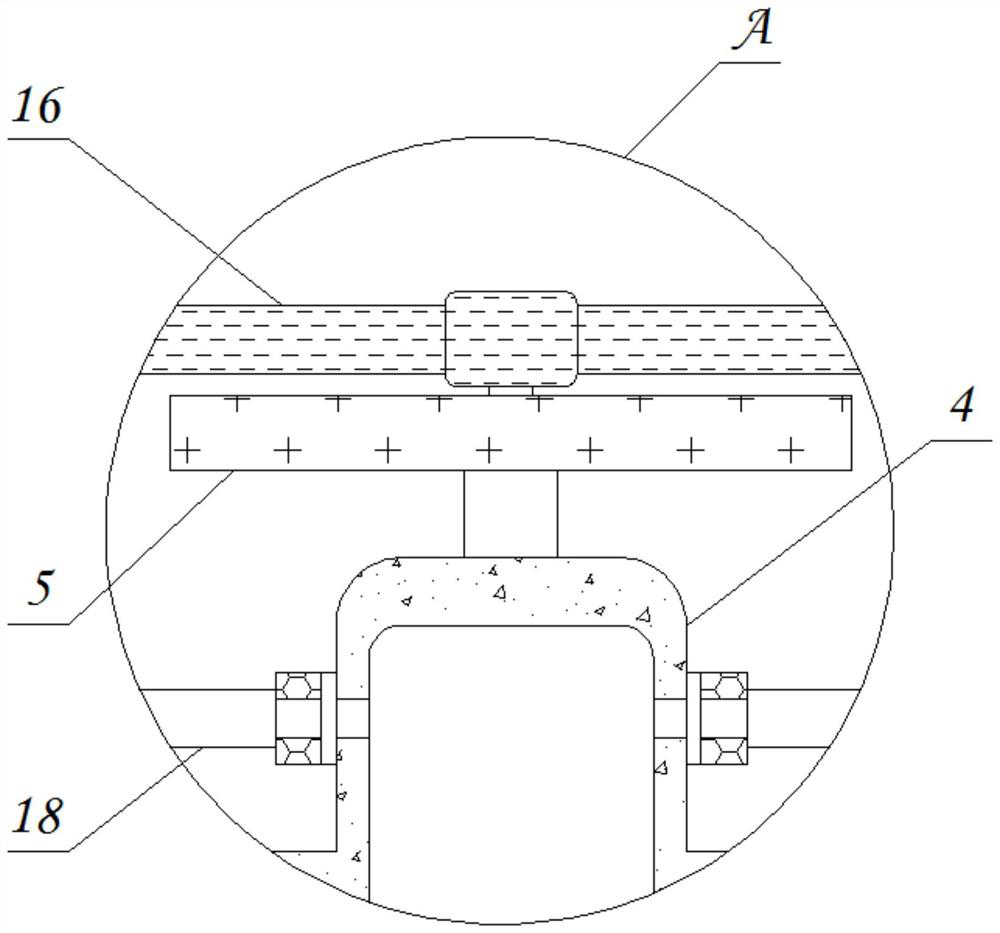

Energy-saving and environment-friendly chemical raw material mixing and stirring device

InactiveCN112370999AImprove initial mixingImprove mixing efficiencyRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention relates to the technical field of chemical equipment, and discloses an energy-saving and environment-friendly chemical raw material mixing and stirring device. The device comprises a boxbody, a motor is fixedly connected to the bottom of the box body, a rotating shaft is rotatably connected to the top of the motor, a rotating cylinder is fixedly connected to the top of the rotatingshaft, a hot air box and two feeding hoppers are fixedly connected to the top of the box body, two material receiving boxes are fixedly connected to the inner top wall of the box body, a rotating circular plate is arranged at the bottoms of the material receiving boxes, cylinder bodies are fixedly connected to the front inner wall and the rear inner wall of the box body correspondingly, pistons are movably connected to the interiors of the two cylinder bodies correspondingly, and a movable rod is fixedly connected between the two pistons. The motor drives the rotating shaft to rotate reversely, the rotating shaft drives the rotating circular plate to rotate through a rotating cylinder, a discharging hole alternately penetrates through the bottoms of the two material receiving boxes, then chemical raw materials in the two material receiving boxes alternately fall into the box body from the discharging hole, and therefore the effect of improving the initial mixing degree when the two chemical raw materials enter the box body is achieved.

Owner:景昊文案策划(温州)有限公司

Refining method for microalgae biodiesel

InactiveCN105969512AImprove harvesting efficiencyReduce manufacturing costFatty acid esterificationBiofuelsProcess engineeringAlgae

The invention relates to a refining method for microalgae biodiesel. The method includes the following steps that microalgae smashing is carried out, wherein after microalgae are harvested, algae liquid is introduced into a smashing tank, and the microalgae are smashed with ultrasonic waves; the algae liquid obtained after the microalgae are smashed is made to flow into a settling tank through a water pump, natural settling is performed, upper and lower layers are formed with upper-layer liquid being water and lower-layer liquid being algae slurry, and the lower-layer algae slurry is pumped into a reaction tank; in-situ extraction is carried out, wherein a reactant and an extraction agent are added into the reaction tank with the algae slurry, the mixture is heated to 60-80 DEG C and stirred constantly, and in-situ extraction starts; separation and purification are carried out, wherein after extraction is completed, upper-layer liquid is pumped into a collecting tank, heating and stirring are carried out at the same time, the extraction agent evaporates and enters a condenser, and the material remaining in the reaction tank is biodiesel. The method has the advantages that the material loss is reduced, the steps are simple, operation is easy and convenient, and the yield is close to 100%.

Owner:KUNSHAN QINGXU ENVIRONMENT TECH

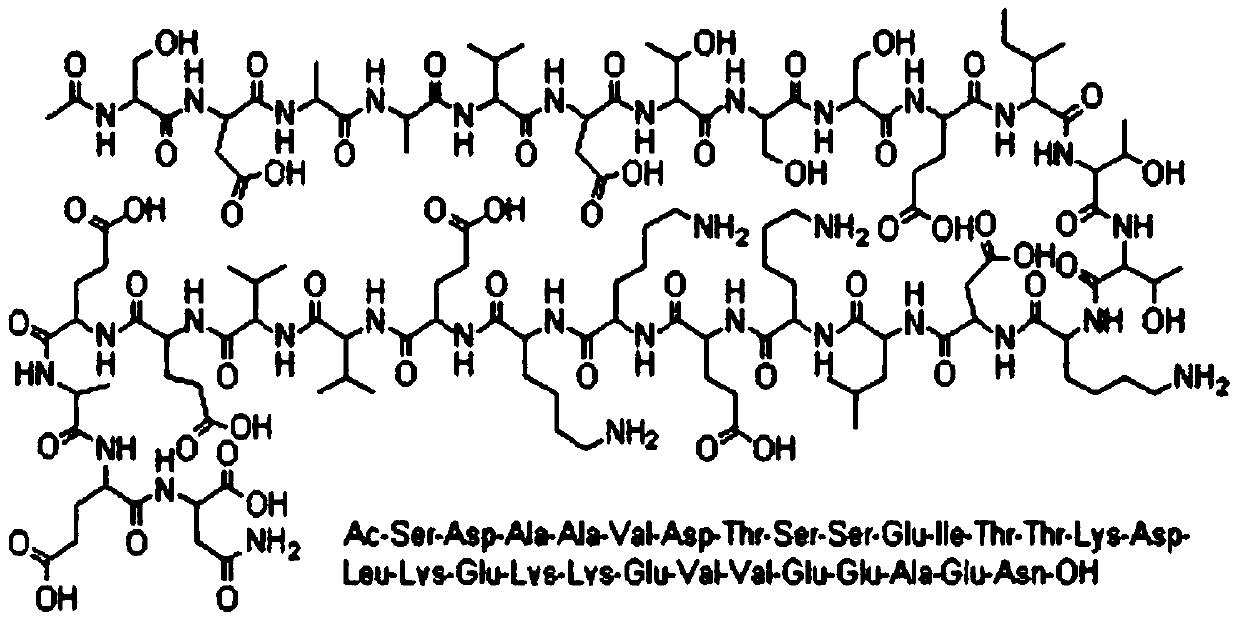

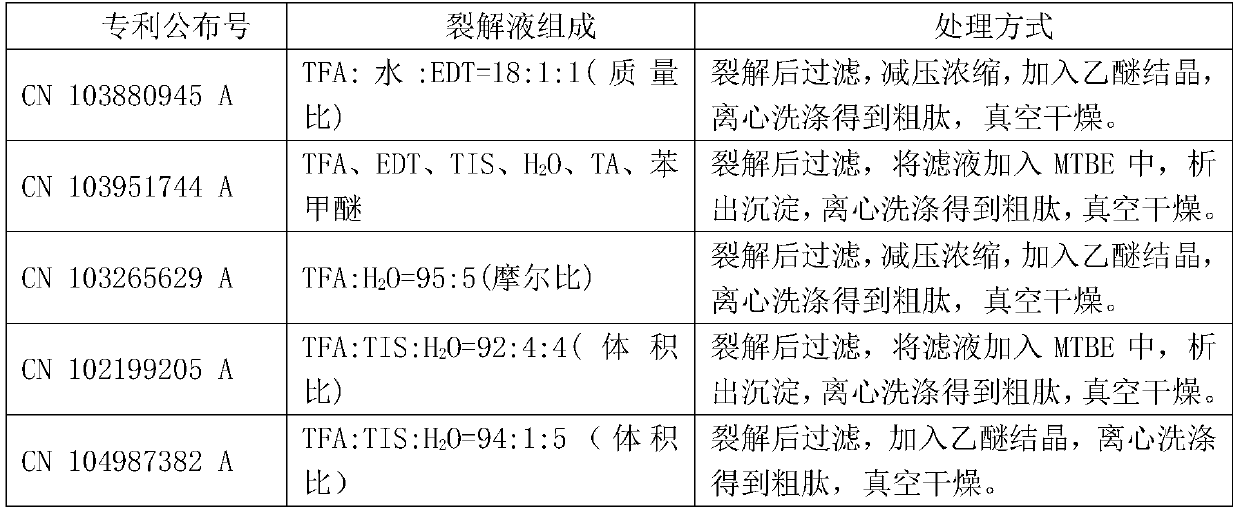

Thymalfasin peptide resin pyrolysis method

InactiveCN109762057AReduce dosageReduce the risk of explosionHormone peptidesPeptide preparation methodsSodium bicarbonateVacuum pressure

The invention discloses a thymalfasin peptide resin pyrolysis method, and belongs to the field of polypeptide solid-phase synthesis. The method comprises the steps of taking thymalfasin peptide resin,adding a lysate which is 6-12 times the volume of the resin, conducting pyrolysis at 10-30 DEG C for 1-3 h, and filtering out resin to obtain a filtrate; adding the filtrate into ether which accountsfor 6 times or more of the volume of the filtrate; adding a 0.5M-1.5M sodium bicaronate or ammonium hydroxide solution which is 0.5-1 time the volume of the solution into the solution; adding an alkaline solution until the solution is clarified; conducting standing and layering, taking an upper-layer organic phase, adding a moderate amount of water for washing, merging the upper-layer organic phase with a lower-layer aqueous phase, and conducting vacuum pressure reduction to remove residual ether; adding acid to adjust the pH value to 2-8, and conducting filtering and purification. By means of the method, there is no need to use ether to wash crude peptide, the use amount of the ether is greatly reduced, the centrifuging operation is omitted at the same time, and the fire blast risk of the ether is lowered; the crude peptide drying step is omitted, the production labor hour is shortened, the risk of thymalfasin degradation is also lowered, and the purity of crude products is improved.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD

A kind of ultra-low temperature freezing process of probiotics and its application in probiotic preparations

The invention discloses a probiotic ultralow temperature refrigeration technology, a formula of a total-salt cryoprotectant which is suitable for the probiotic ultralow temperature refrigeration technology, and probiotic ultralow temperature refrigeration particles prepared by using the probiotic ultralow temperature refrigeration technology. The probiotic ultralow temperature refrigeration technology comprises following steps: (1) preparing a fermentation medium; (2) culturing probiotics; (3) centrifuging; (4) preparing the cryoprotectant; (5) adding the cryoprotectant; and (6) quick-freezing and moulding. The invention also provides a probiotic preparation prepared by using the probiotic ultralow temperature refrigeration particles, and a preparation method of the probiotic preparation. The probiotic ultralow temperature refrigeration particles are probiotic refrigerated bacterial strains which do not need to be dried and possesses advantages of fast refrigeration speed, high living bacterial rate and excellent rehydration performance. The probiotic ultralow temperature refrigeration particles contain water, can be dissolved in solutions more quickly, and are capable of preventing probiotic cells from damage caused by rehydration of normal low temperature refrigeration dried probiotic powder, and increasing the living bacterial rate of the probiotic preparation greatly.

Owner:THANKCOME BIOLOGICAL SCI & TECH CO LTD

Purifying method for acetylacetonatodicarbonyl rhodium

InactiveCN104610369AReduce Chloride ContentNo extra economic costRhodium organic compoundsIonChemistry

The invention relates to a purifying method for acetylacetonatodicarbonyl rhodium. The method comprises the following concrete steps: (1) adding deionized water into a crude acetylacetonatodicarbonyl rhodium product, carrying out full stirring, then carrying out standing, dropwise adding a silver nitrate solution until supernatant is no longer turbid, then replenishing a certain amount of the silver nitrate solution, carrying out stirring and filtering, and washing the obtained filter cake with water; and (2) adding the filter cake into an appropriate organic solvent, adding a moisture scavenger under stirring, carrying out filtering, and treating the obtained filtrate in the manners like concentrating crystallization or cooling crystallization so as to obtain solid acetylacetonatodicarbonyl rhodium, or using the obtained filtrate as a further reaction solution for the preparation of acetylacetonatocarbonyltriphenylp hosphinerhodium. The method provided by the invention omits the step of drying in conventional preparation of acetylacetonatodicarbonyl rhodium; under the condition of no additional operation process, the problem of inactivation of an acetylacetonatodicarbonyl rhodium catalyst in hydroformylation reaction due to susceptibility to affection by chloride ions can be conveniently, quickly and effectively overcome; meanwhile, the method is applicable to industrial production.

Owner:KUNMING INST OF PRECIOUS METALS

Furfuryl alcohol resin gas-phase modification method for wood material

ActiveCN111070357AAvoid churnReduce wasteWood treatment detailsPressure impregnationPolymer scienceOrganic chemistry

The invention discloses a furfuryl alcohol resin gas-phase modification method for a wood material. According to the method, a two-step modification process is adopted, that is, an organic weak acid solution is injected into wood, bamboo and other wood materials in a vacuum pressure impregnation mode, then furfuryl alcohol gas is deposited in the cell walls of the wood materials through a vapor deposition method; then heating and curing are conducted, and therefore the performance of the wood materials is improved. The method can significantly improve the furfuryl alcohol curing effect, reducethe raw material loss and reduce the drying difficulty, and has a good application prospect.

Owner:FUJIAN AGRI & FORESTRY UNIV

Drying-free extrusion technology of PET nano reinforced plate

The invention discloses a drying-free extrusion technology of a PET nano reinforced plate, and the technology can substantially reduce residual quantity of water and low molecular leakage in a finished product. 0.5-1 wt.% of polymer processing auxiliary agent is added into a raw material, and water and low molecular leakage are discharged through an adsorption apparatus during an extrusion process. According to the invention, the raw material is added with the polymer processing auxiliary agent, and a drying of a fused raw material is omitted, so as to simplify the extrusion technology; besides, residual quantity of water and low molecular leakage in the PET nano reinforced plate finished product is reduced, so as to improve quality of the finished product and especially improve transparency substantially.

Owner:江苏民扬塑胶科技有限公司

Method for extracting and purifying microalgae biodiesel

InactiveCN106433946AImprove harvesting efficiencyEliminates the drying stepFatty acid esterificationBiofuelsBiodieselMaterial consumption

The invention relates to a method for extracting and purifying microalgae biodiesel. The method comprises the following steps: crushing microalgae, namely, introducing an algae liquid into a crushing tank, crushing microalgae with ultrasonic waves, feeding into a settling pond, performing natural precipitation to form an upper layer and a lower layer, and sucking algae slurry of the lower layer into a reaction tank, wherein the upper layer is water, and the lower layer is algae slurry; performing in-situ extraction, namely, adding a reaction agent and an extraction agent into the reaction tank with the algae slurry, heating till the temperature is 60-70 DEG C, and stirring all the time; performing separation purification, wherein n-hexane is adopted as an extraction agent; the volume ratio of the reaction agent to the extraction agent is 1:1; the volume ratio of the reaction agent to the algae slurry is (1-2):1; and the extraction agent needs to be replaced once every 4-6 hours; and after extraction is completed, sucking the upper liquid obtained after extraction into a collecting tank, stirring while heating, and evaporating the extraction agent into a condenser, thereby obtaining the biodiesel which is left in the reaction tank. The method has the advantages that material consumption is reduced, the steps are simple, the operation is simple and convenient, and the yield can be approximate to 100%.

Owner:QINGDAO WINCHANCE TECH

A method for continuously preparing inulin and pectin from Jerusalem artichoke and/or chicory

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com