Patents

Literature

82results about How to "Uniform luminous effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

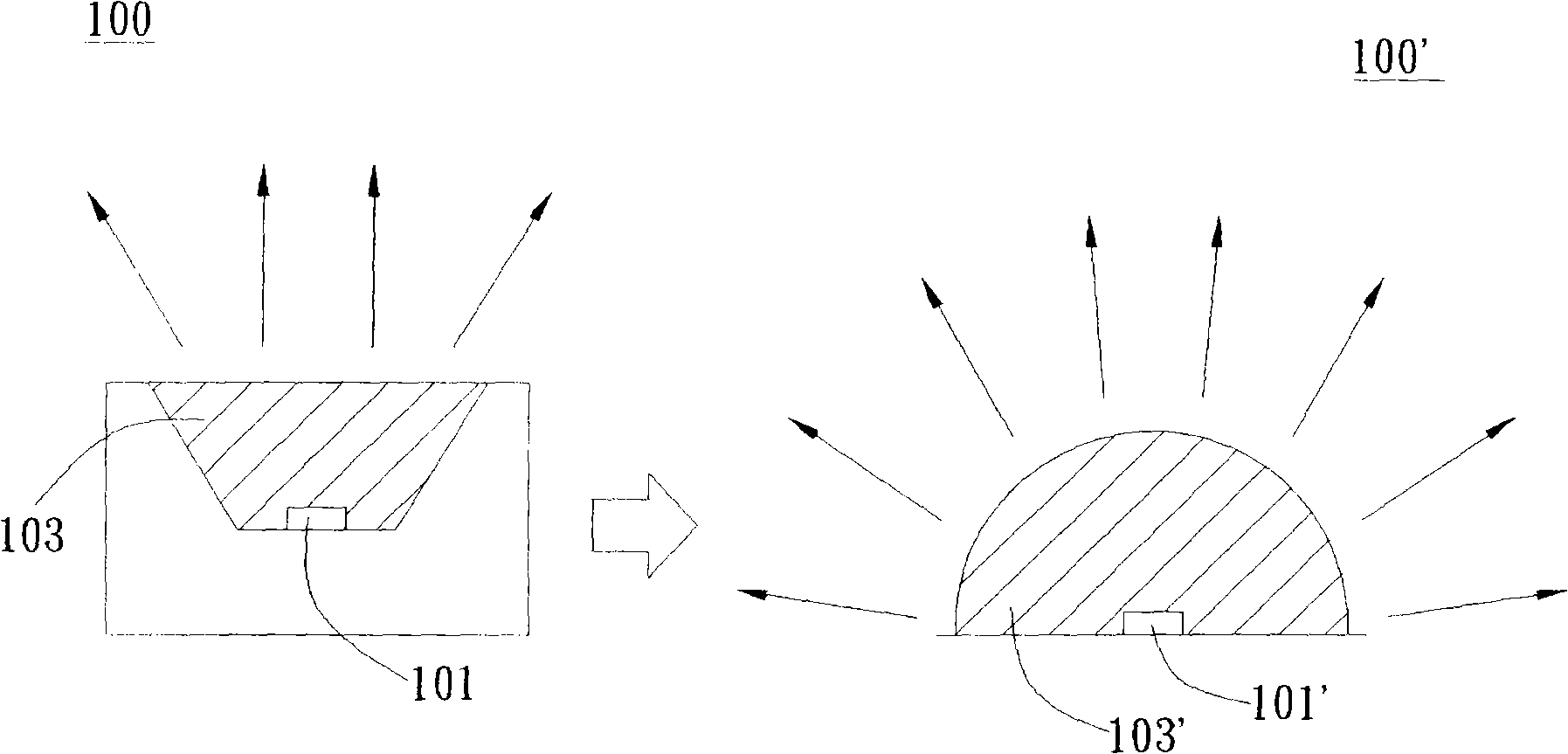

Light source device

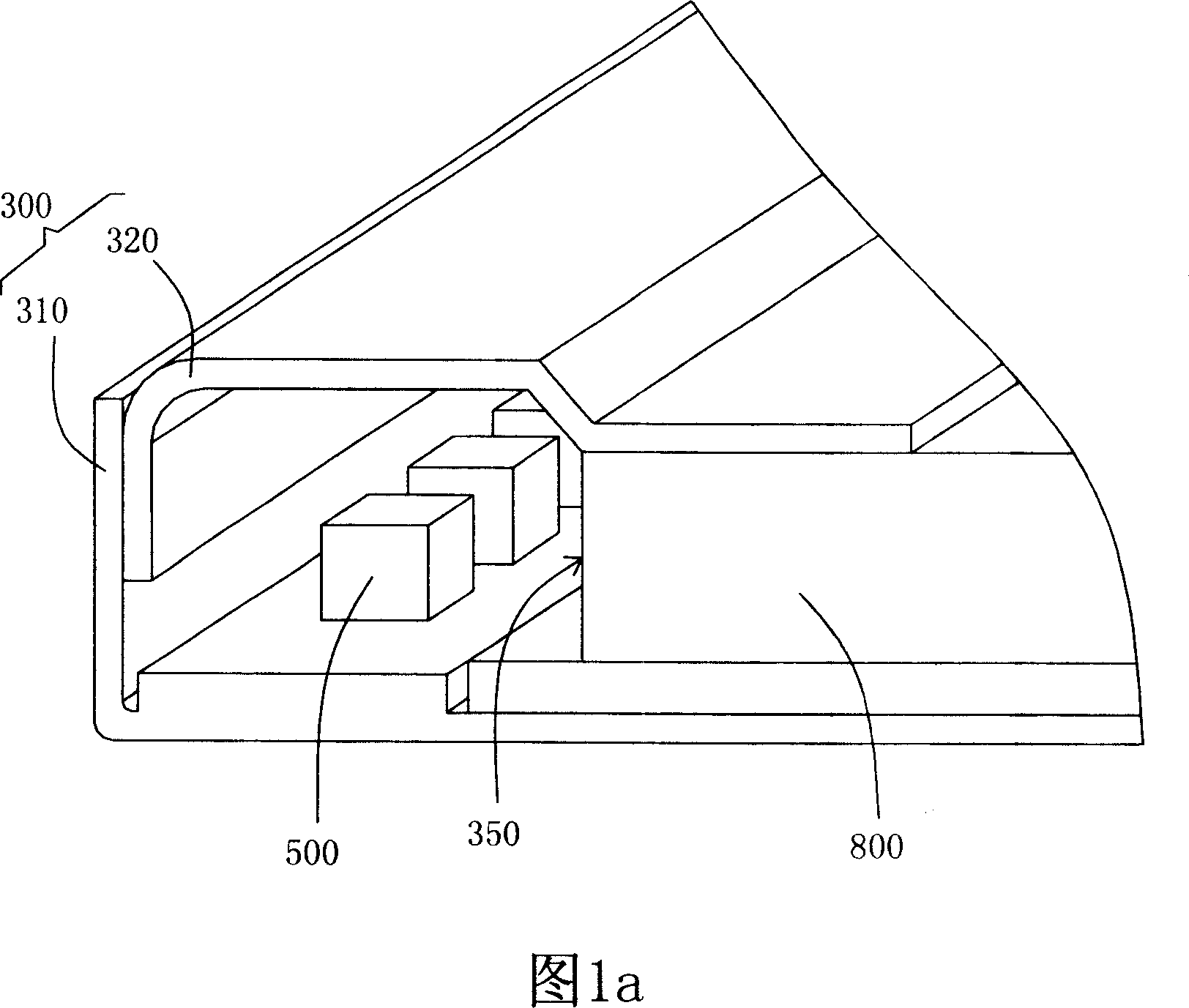

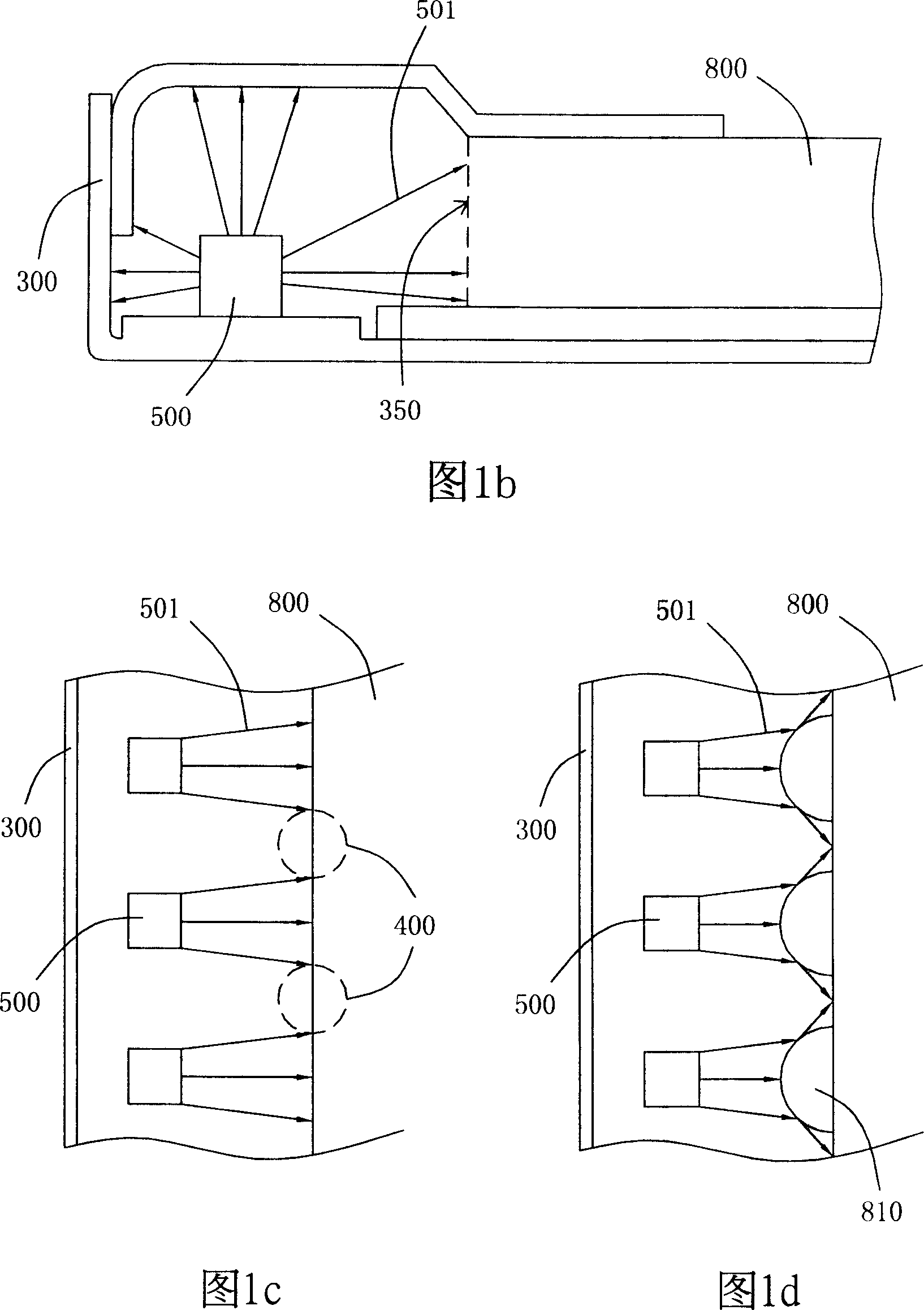

InactiveCN101017284AUniform luminous effectIncrease brightnessPoint-like light sourceElectric lightingLight guideLight reflection

This light source device for use of one aphototropism module use, wherein, the light source device is set by one side of the light conductive board; the light source device comprises mask film and light source; the mask film has one open end, first side wall and second side wall; the first and second side walls are in relative two sides of open end with reflection part inside; the light source is for light diode inside mask film relative to light reflection part; the mask film comprises light reflection slice down light source; in best example, the first side wall is set relative to open end section with light reflection slice; the light source device also comprises circuit board down light reflection.

Owner:AU OPTRONICS CORP

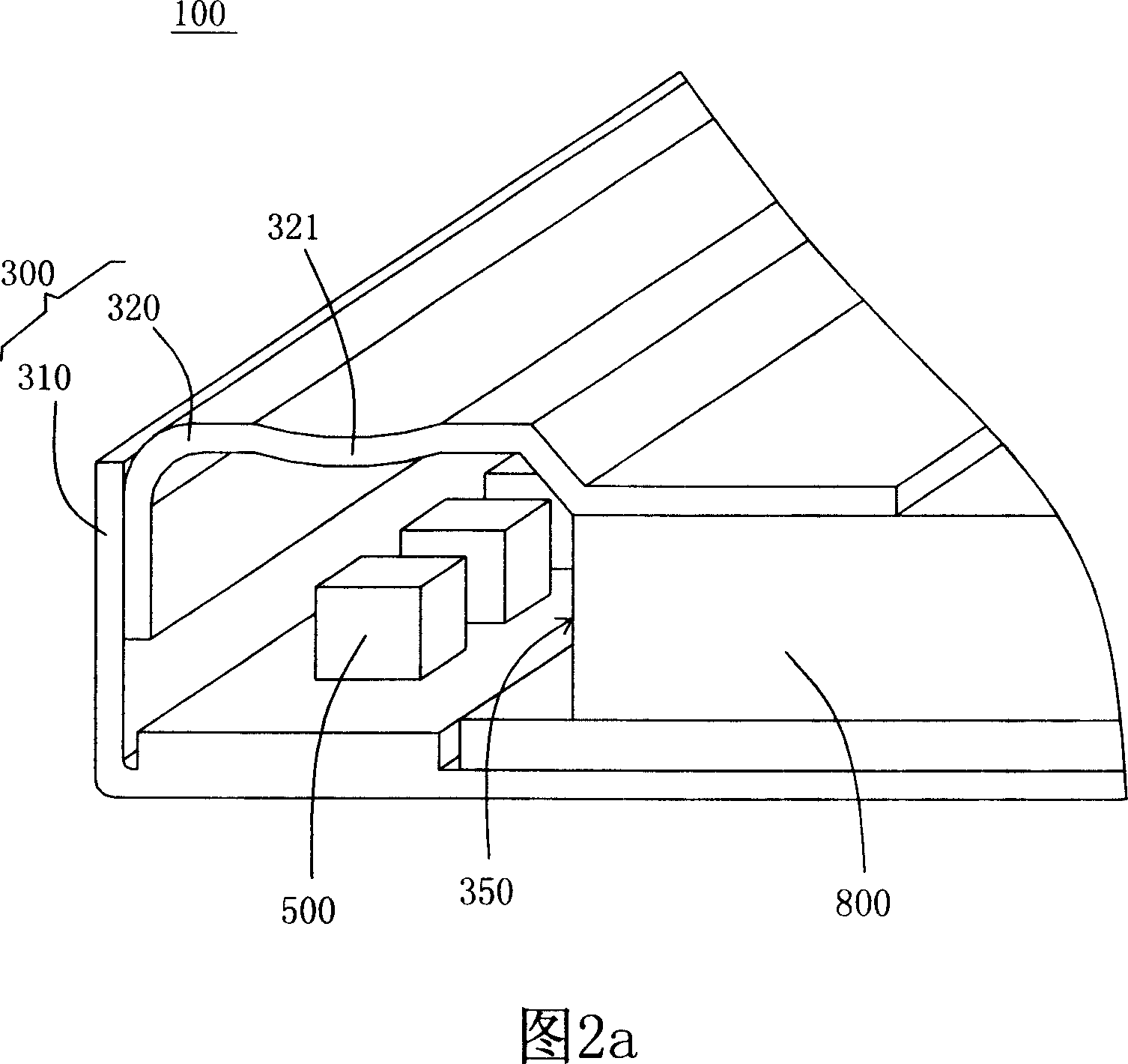

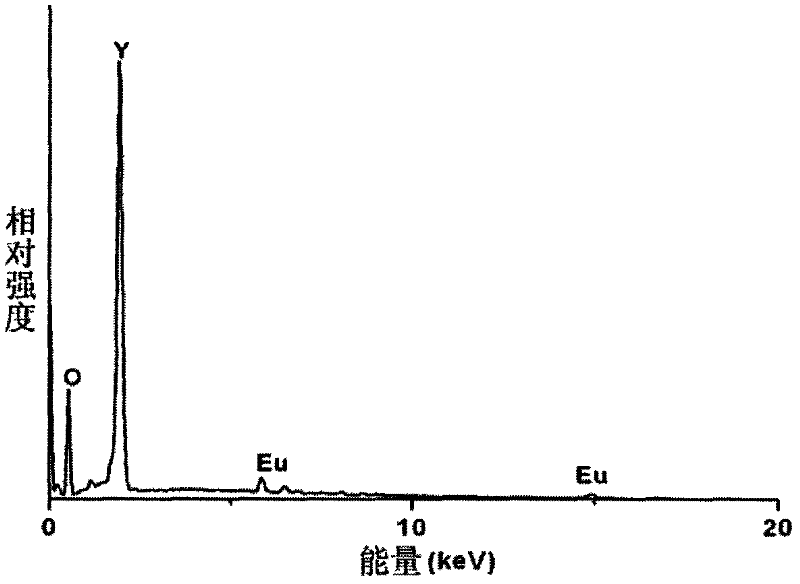

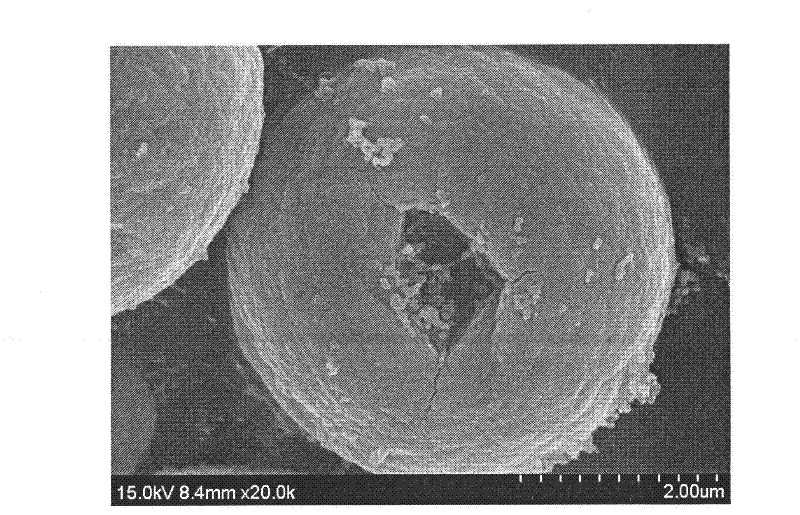

Hydro-thermal preparation method for spherical boric acid yttrium doped europium fluorescent powder in hollow structure

The invention discloses a hydro-thermal preparation method for spherical boric acid yttrium doped europium fluorescent powder in a hollow structure. 0.01 to 1.0 mole / liter yttrium ions, europium ions and boric acid are mixed, the mole ratio of the yttrium ions to the europium ions to the boric acid in the mixed solution is 19 / 1 / 20, organic topography induction reagents are added into the mixed solution, the ratio of the mol number of the added organic topography induction reagents to the sum of the mol number of the yttrium ions and the europium ions is 3 / 2, 1 to 8 milliliters of nucleating reagents are added into the mixed solution, and suspending liquid is obtained; the alkali liquor is used for regulating the pH to be 8 to 10; the suspending liquid is moved into a 100mL reaction kettlefor carrying out hydrothermal reaction; and the heat treatment is carried out on powder products after the hydrothermal reaction, and the spherical fluorescent powder in the hollow structure is obtained. The spherical boric acid yttrium doped europium fluorescent powder has the smaller specific gravity because of the adoption of the hollow structure, and requirements of luminescent devices on light weight of fluorescent luminescent materials can be met.

Owner:ZHEJIANG SCI-TECH UNIV

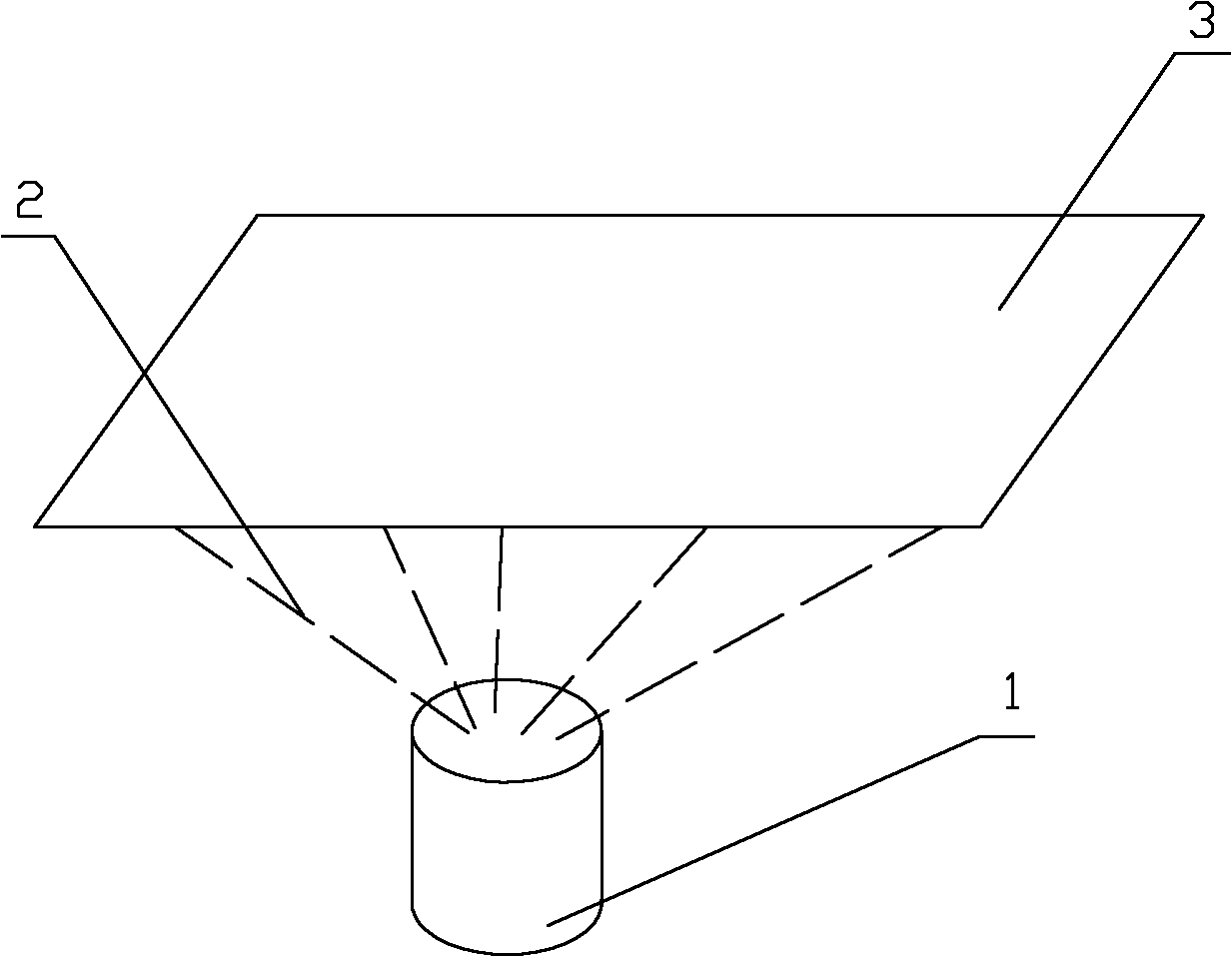

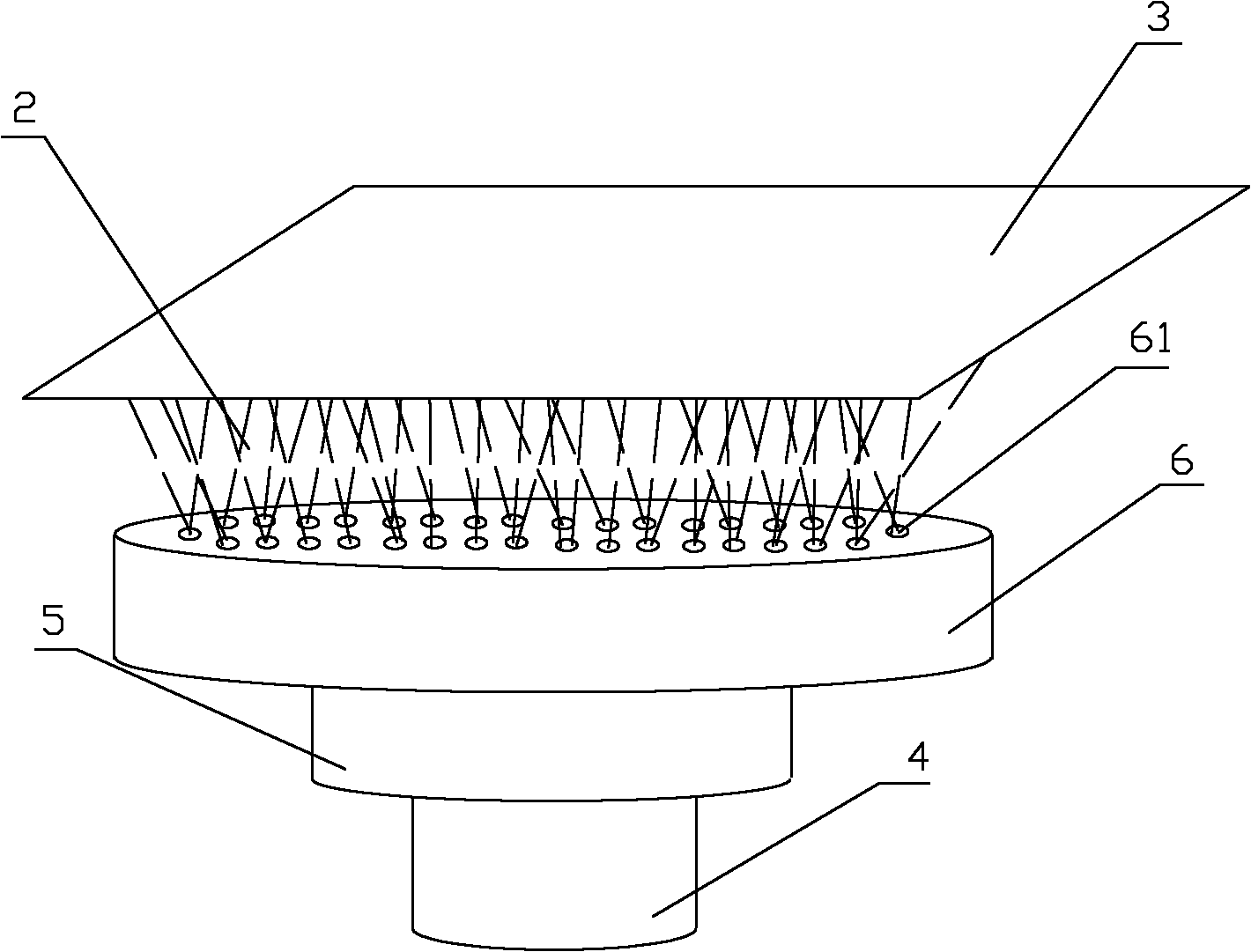

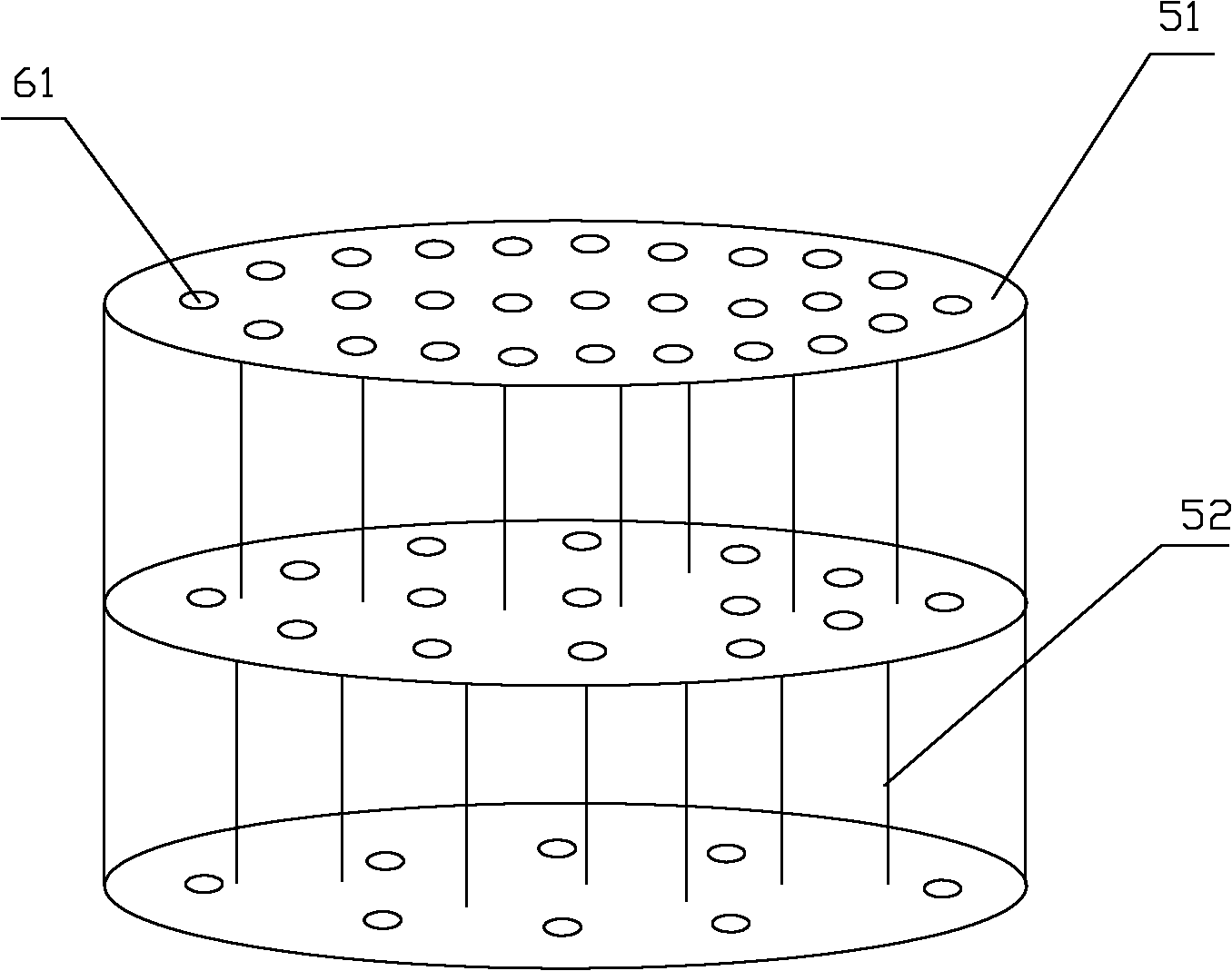

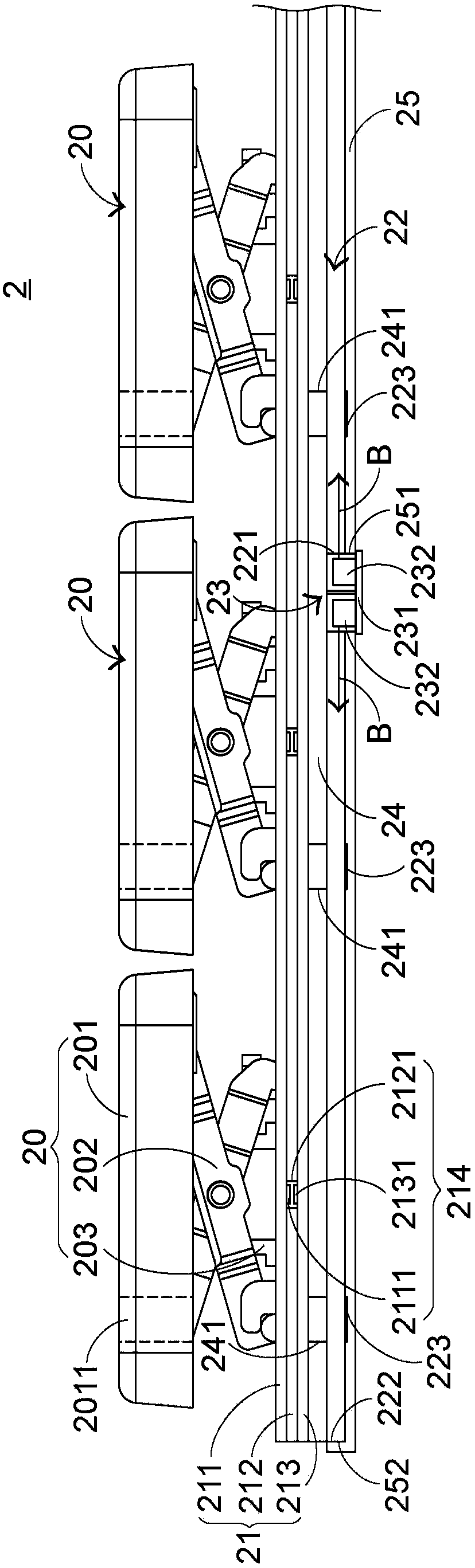

Film coating source, vacuum film coating device and film coating process thereof

InactiveCN101988185AExpand the evaporation areaReduce distanceVacuum evaporation coatingSputtering coatingLayered structureAirflow

The invention provides a film coating source and a vacuum film coating device thereof which can carry out even evaporation on a base plate with a large area. The film coating source is provided with a container part, a heating device, an evaporation airflow adjusting part and an evaporation coating top plate, wherein the evaporation airflow adjusting part is in a porous layered structure and is used for controlling the direction and distribution of the evaporation airflow; and evenly distributed jet orifices are arranged on the evaporation coating top plate and used for jetting the evaporation airflow. By the airflow adjusting part of the porous layered structure, the invention furthest enlarges the evaporation coating area of the evaporation coating top plate, and enables the material to be deposited on the surface of the base plate as evenly as possible, thereby achieving the effect of evaporation with high evenness in a large area. When the invention is used for carrying out vacuum film coating of organic materials on an organic light-emitting diode (OLED), especially for carrying out film coating on the base plate with a larger area, a film coating layer with good pattern accuracy and even film thickness can be obtained, thereby ensuring even luminescent properties and color balance of the OLED.

Owner:无锡虹彩科技发展有限公司 +1

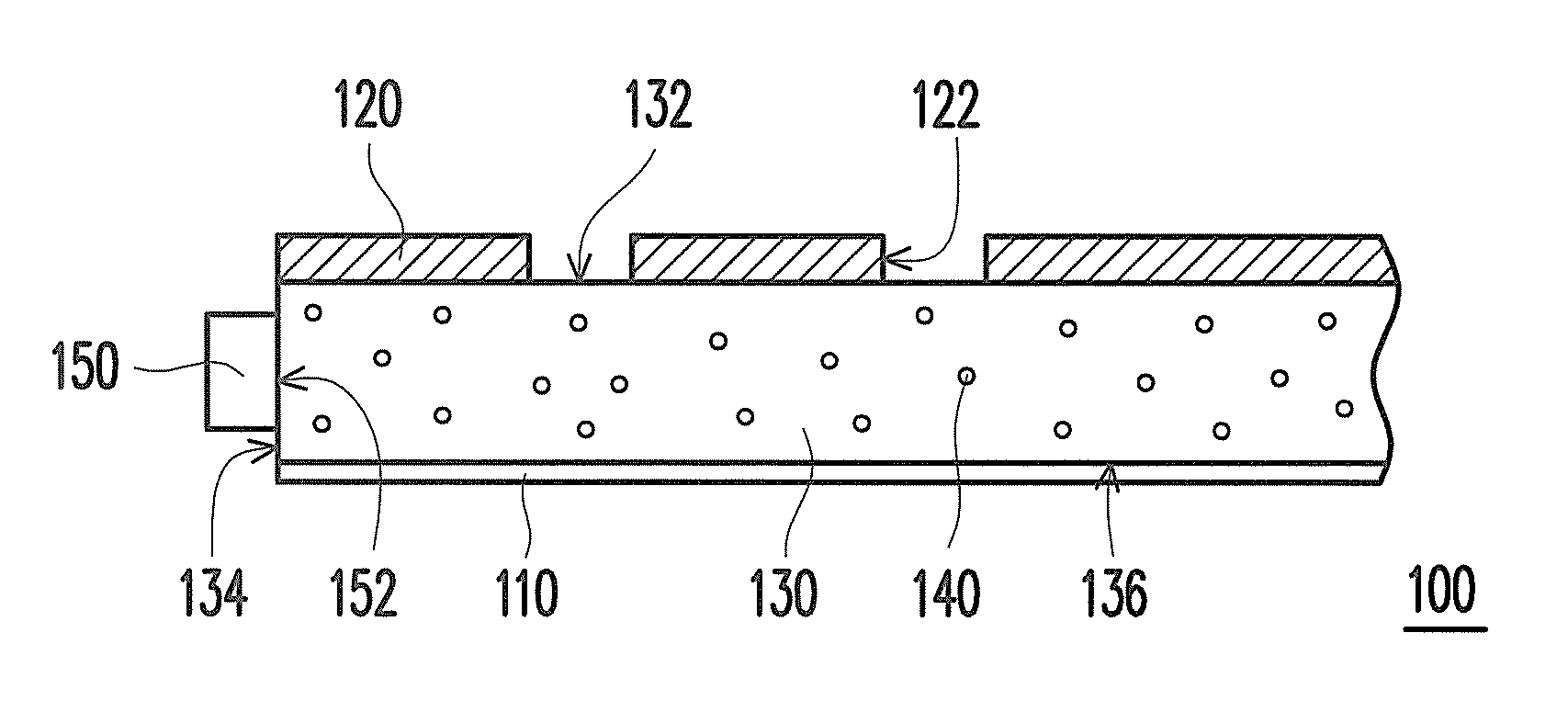

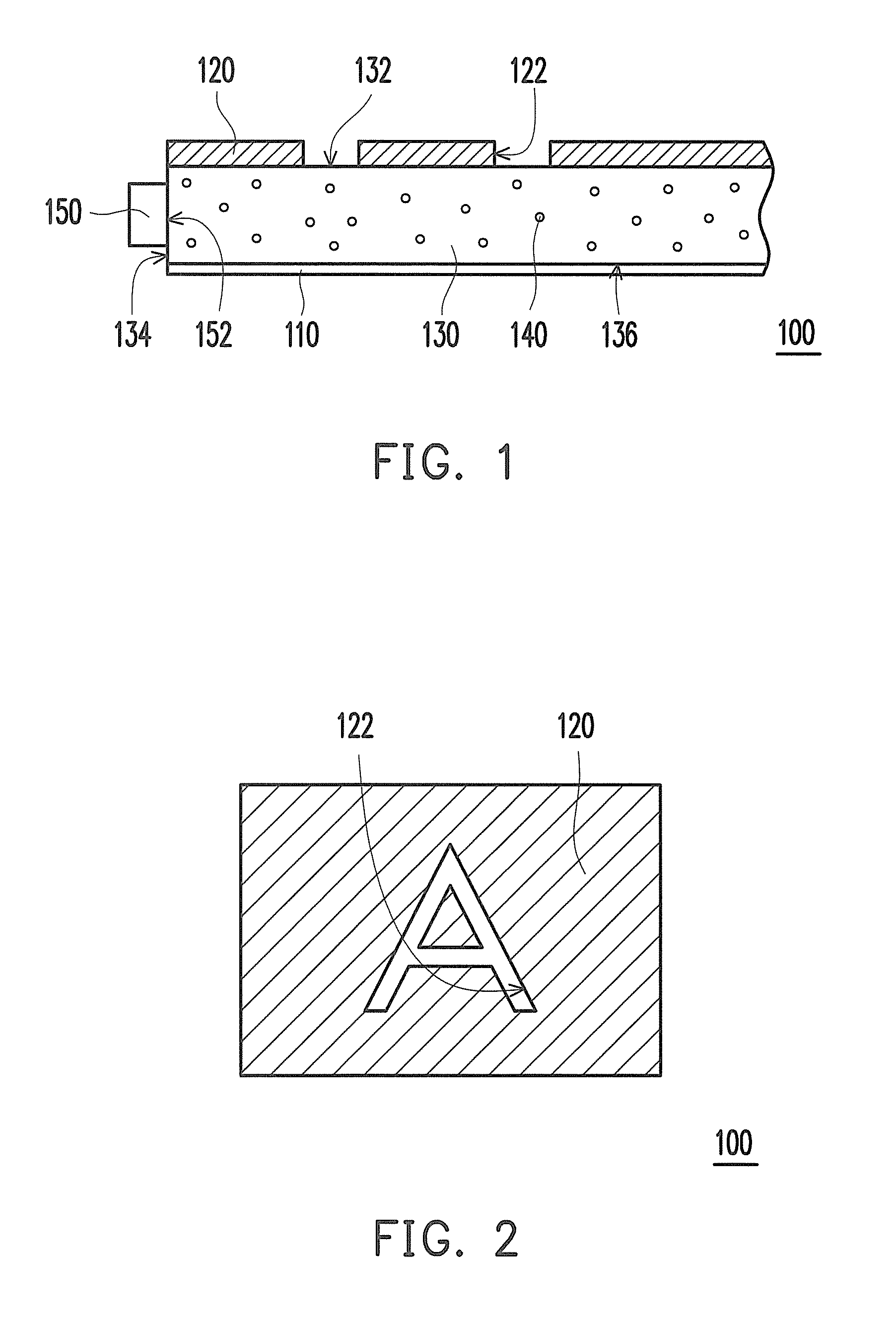

Decoration panel

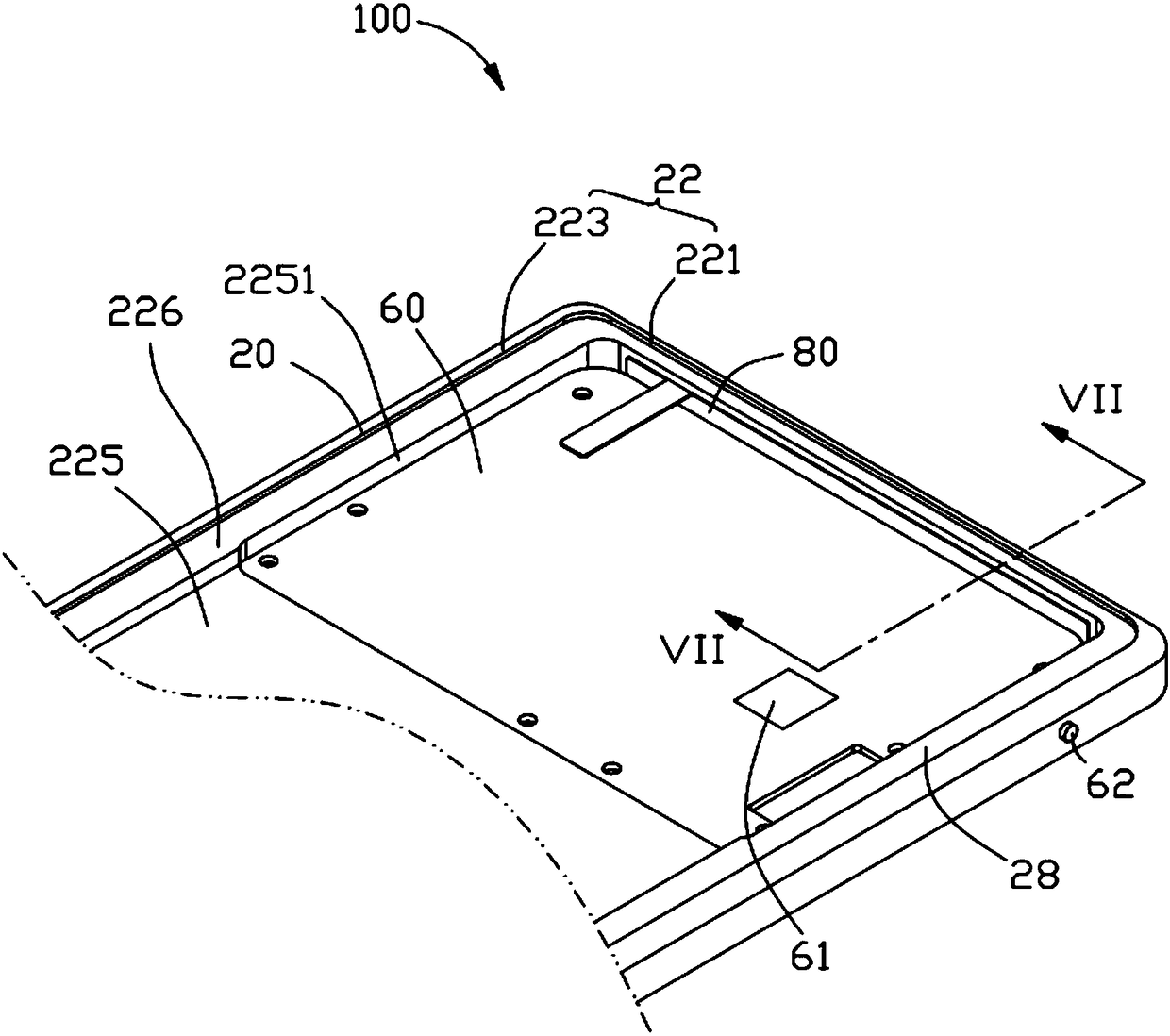

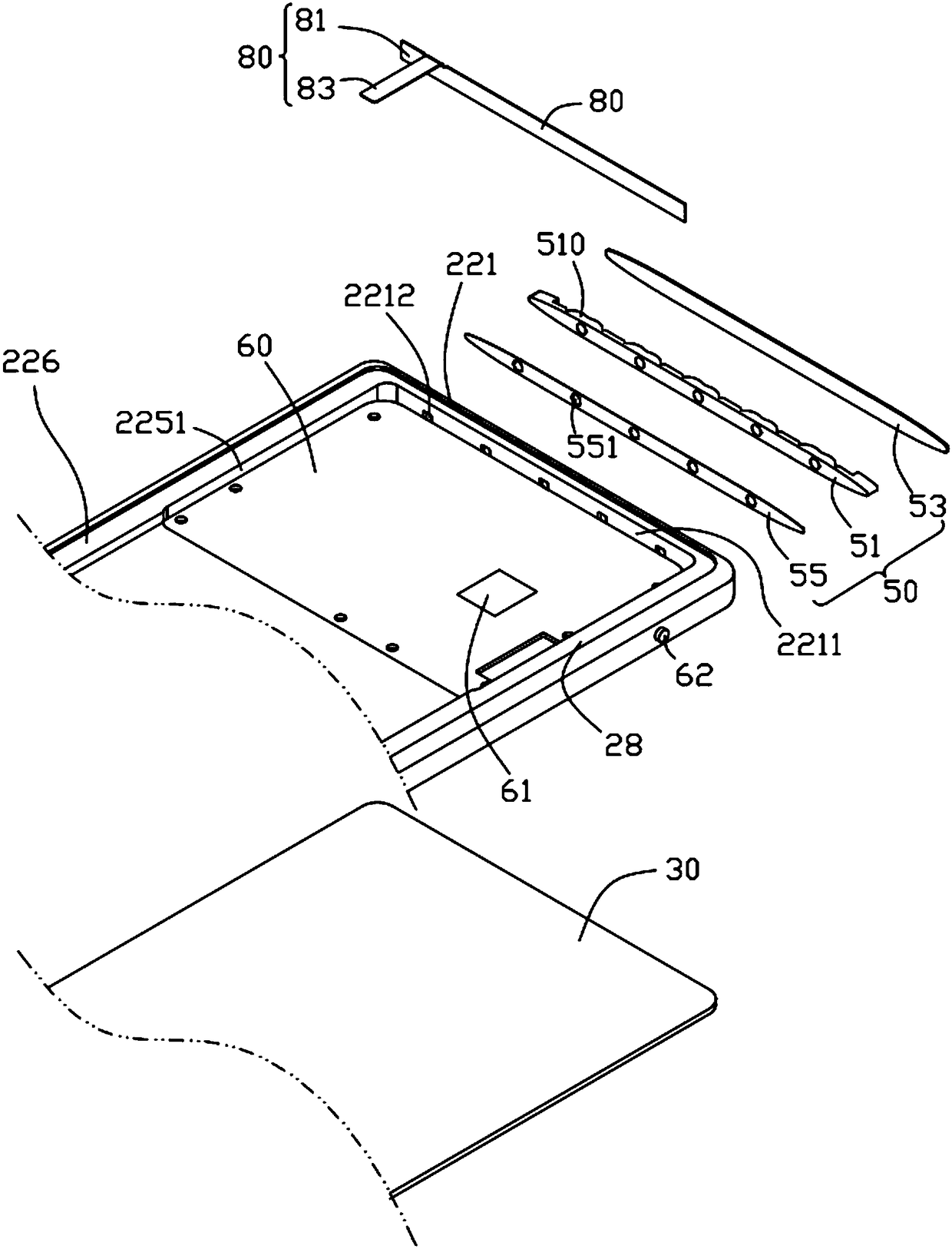

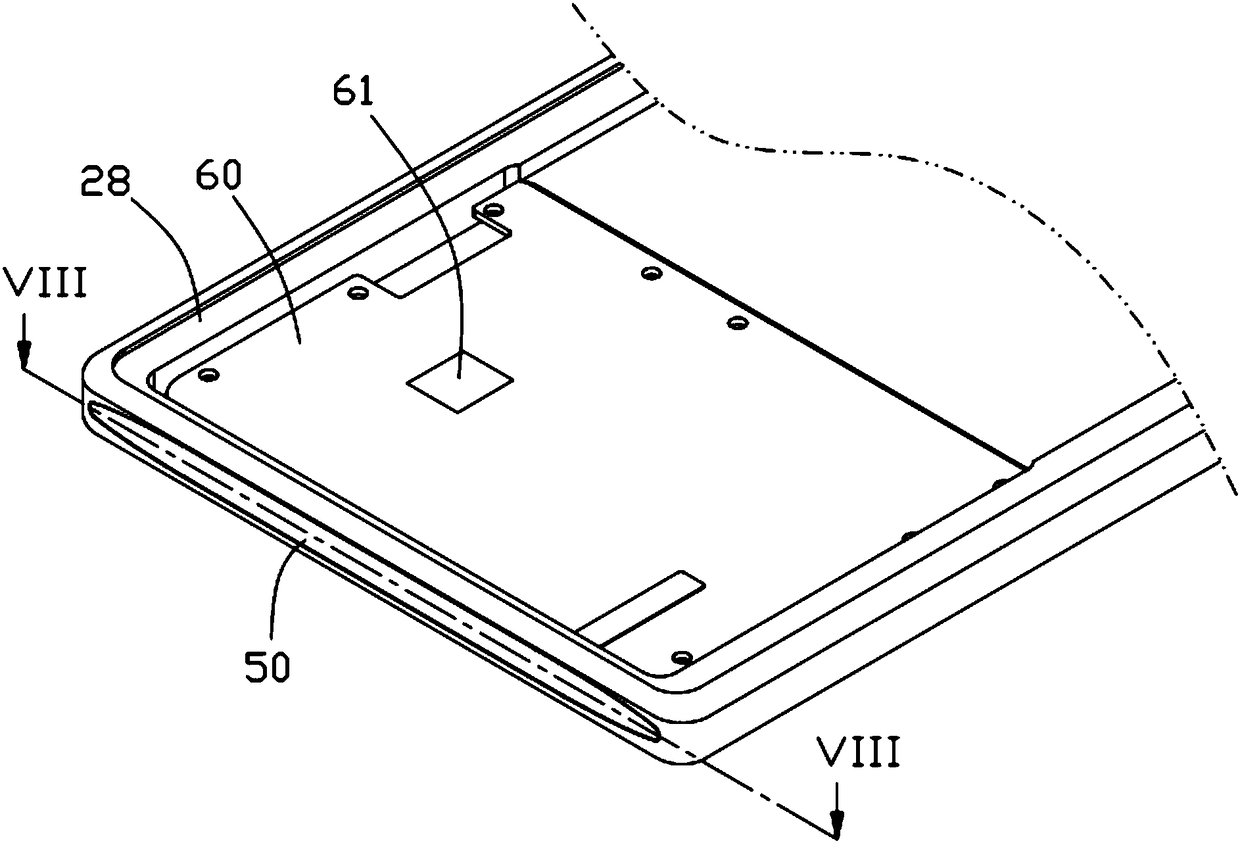

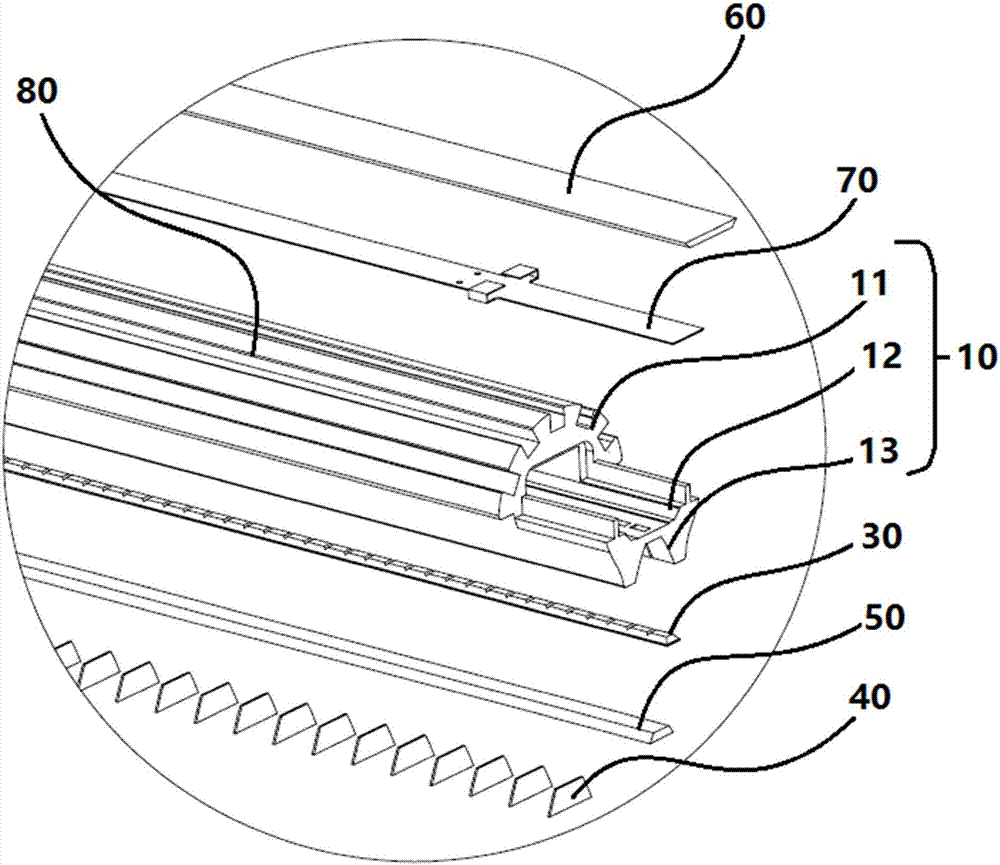

ActiveUS20110194305A1Simple elementsOverall small sizePlanar/plate-like light guidesIlluminated signsLight guideReflective layer

A light guide module capable of illuminating and being applied in a device for decoration is provided. The light guide module includes a reflective layer, a light guide with a plurality of diffusing particles, and a light source. The light guide has a side surface, a reflective surface and a light-exiting surface, thereby allowing a light from the light source to enter and reflect and exit the light guide respectively. The reflective layer is disposed on the reflective surface of the light guide for reflecting the light to the light-exiting surface. The light guide forms a portion of an outer surface of the device.

Owner:COMPAL ELECTRONICS INC

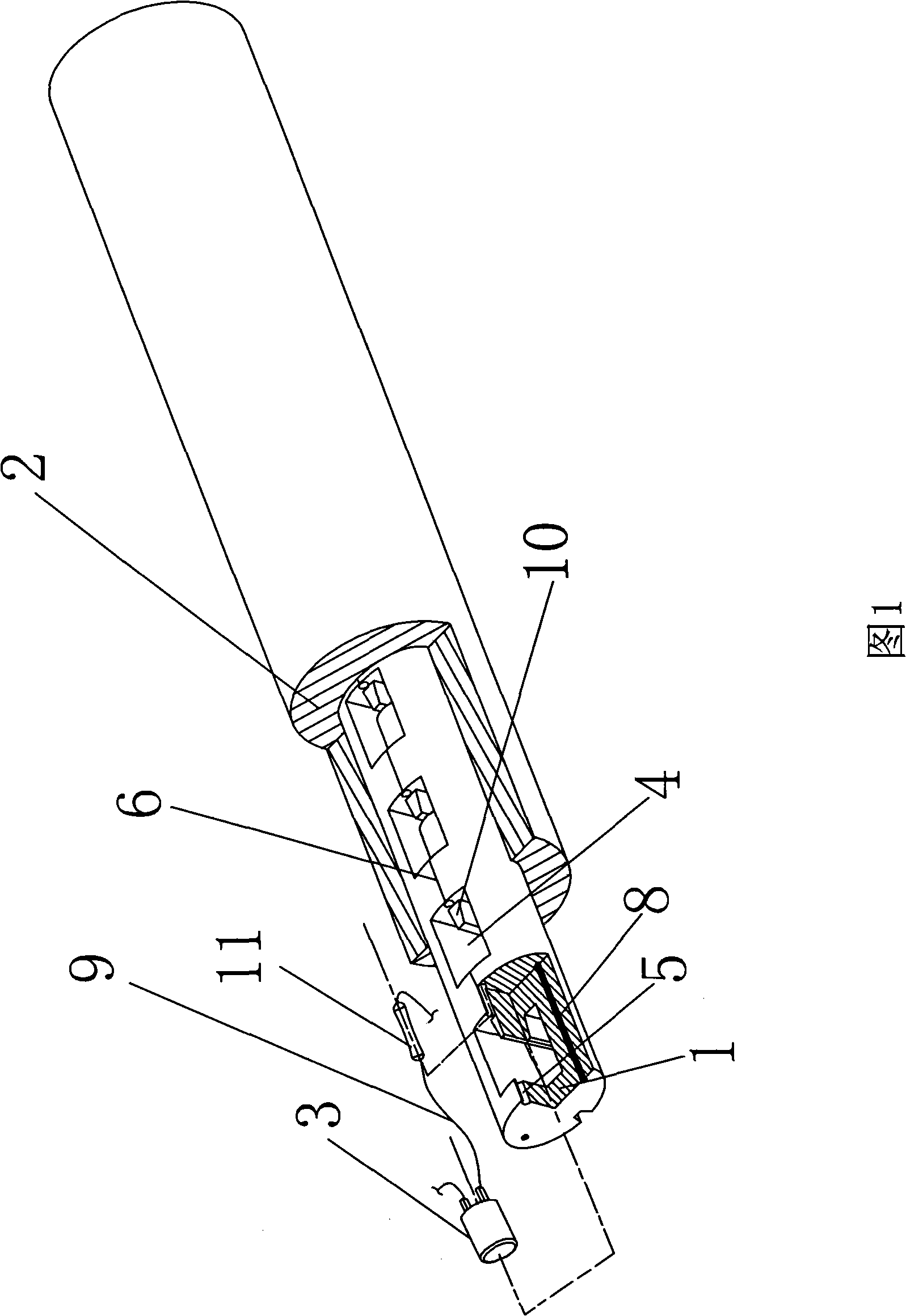

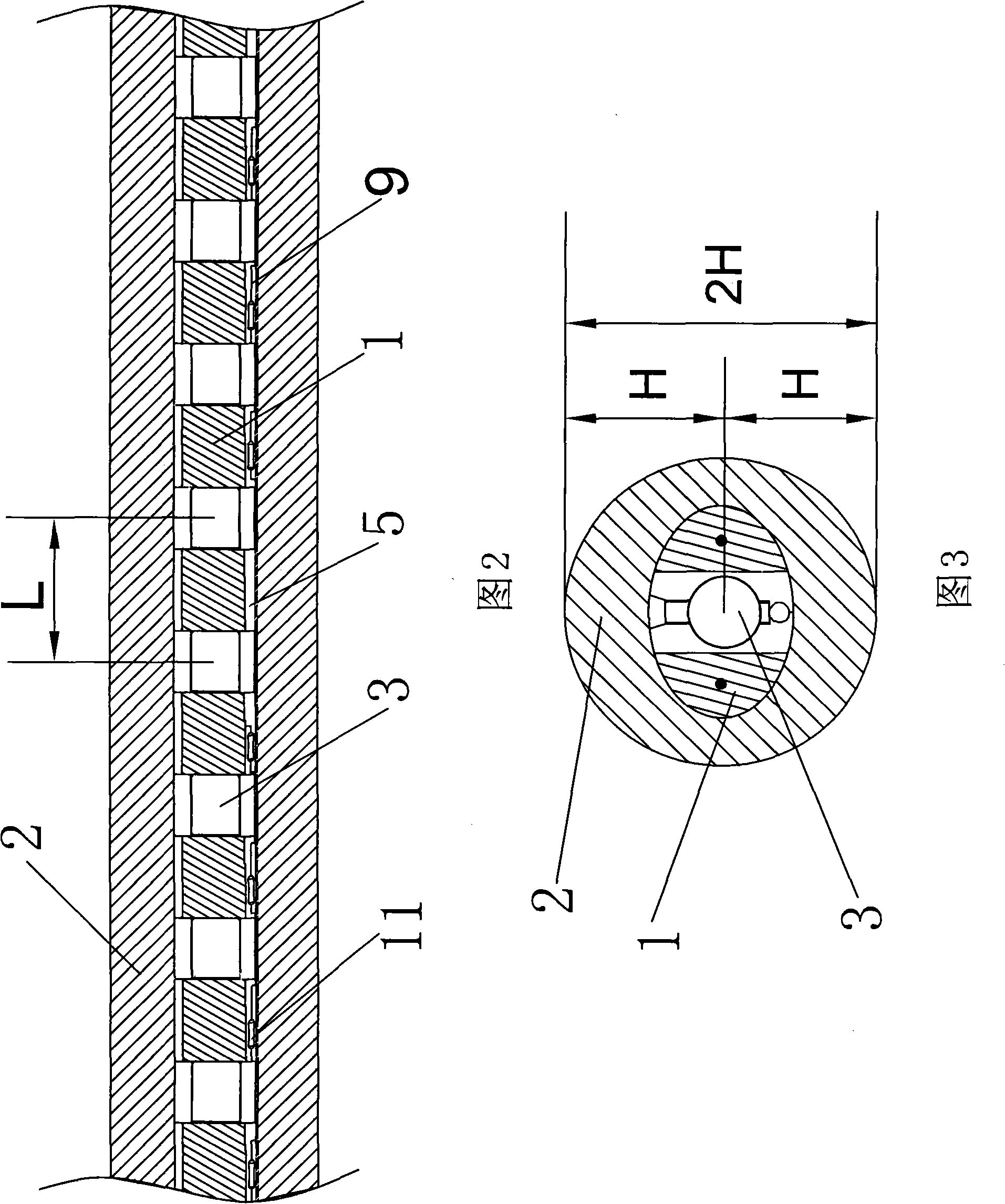

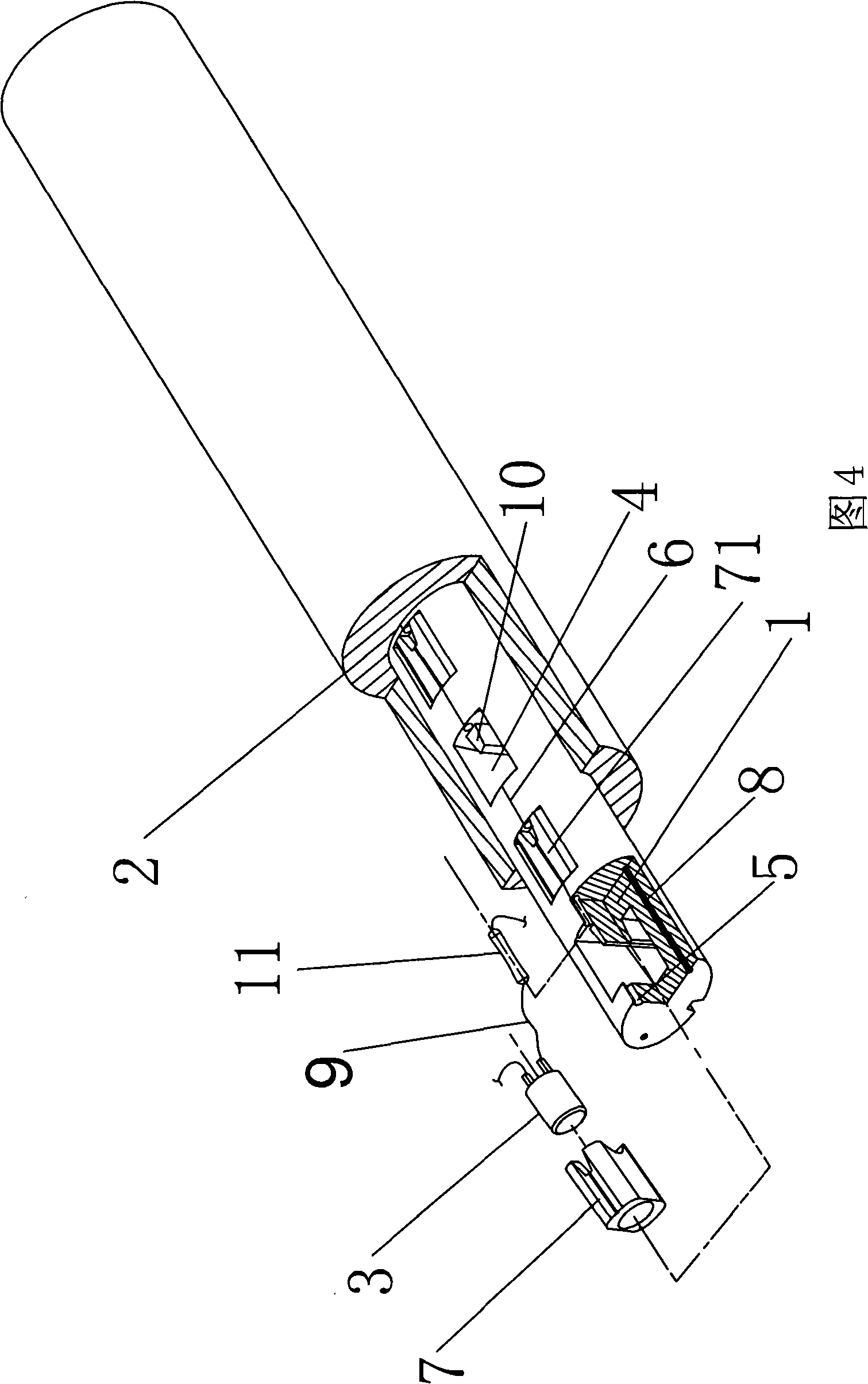

Flexible neon bar with whole body illuminating

InactiveCN101358697AEasy to placeImprove light extraction efficiencyPoint-like light sourceElectric circuit arrangementsElectrical resistance and conductanceWhole body

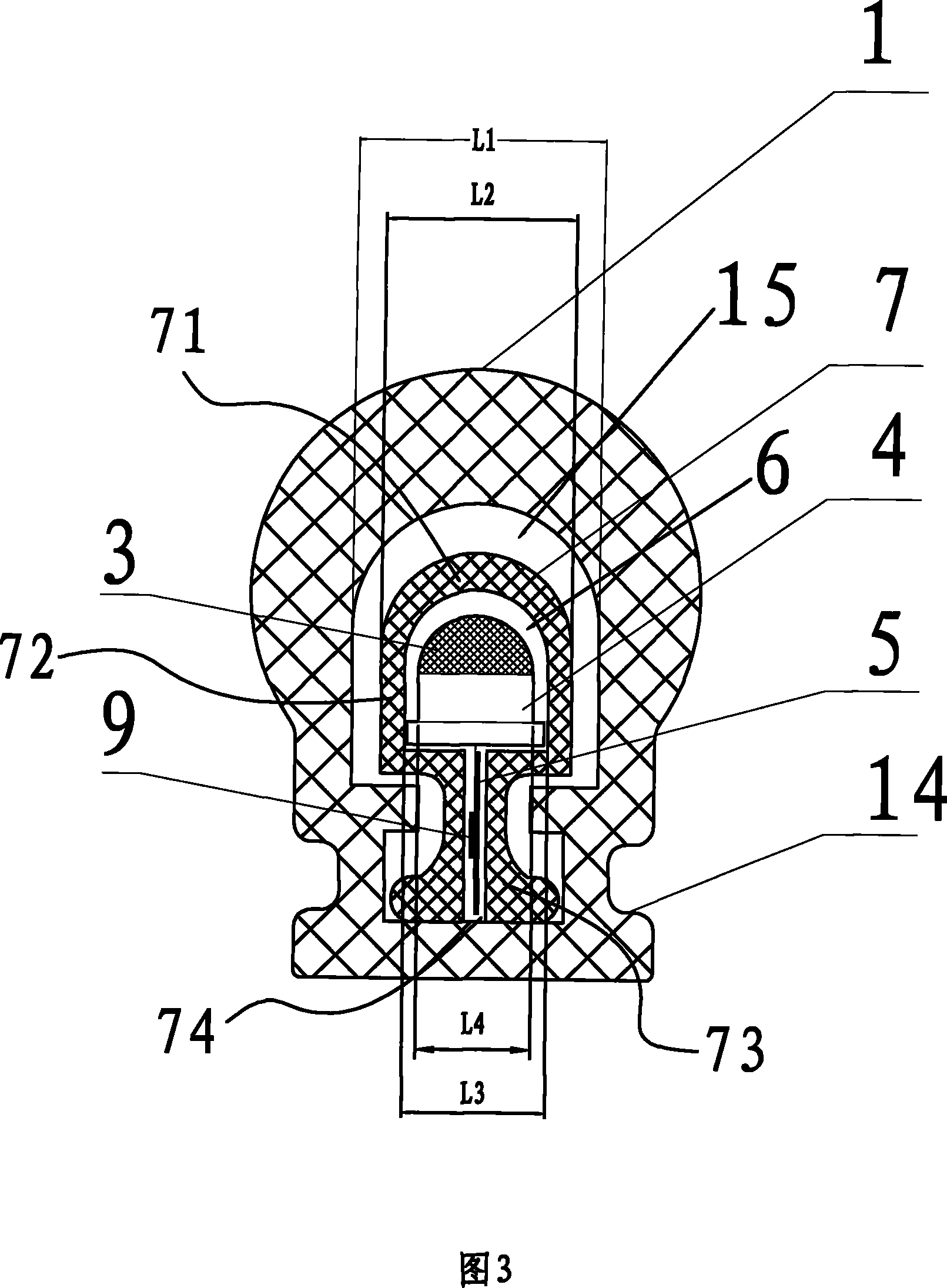

An entire lighting flexible neon light strip includes a flexible core line, a plurality of LED illuminants arranged in the core line as well as a flexible light dispersing layer uniformly coated outside the core line; transverse holes are uniformly arranged on the core line in a spacing way; the LED illuminants are arranged in the transverse holes; a longitudinal hole penetrating all the transverse holes is arranged in the core line; a longitudinal cut is arranged on the longitudinal hole; a protection resistance and a lamp base connection line are arranged in the longitudinal hole by the longitudinal cut; in the invention, the protection resistance is arranged in the longitudinal hole deviating from the axis of the core line and is misplaced with the LED illuminants. Compared with the prior art, the defects of low light extraction efficiency and having shadows of the illuminants are avoided; the beams given out by the LED illuminants are dispersed to a solid space after being dispersed by the light dispersing layer and entirely lights by 360 degrees, thereby improving the light extraction efficiency of the illuminants and leading the light extraction efficiency of the illuminants to be more uniform and continuous.

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

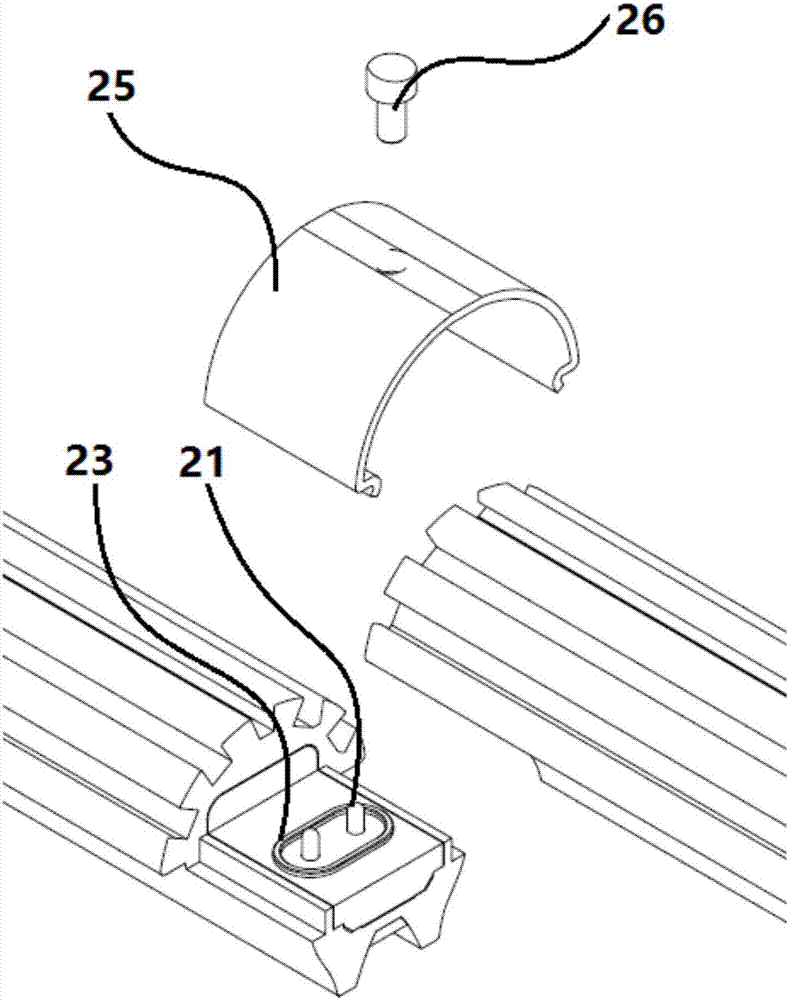

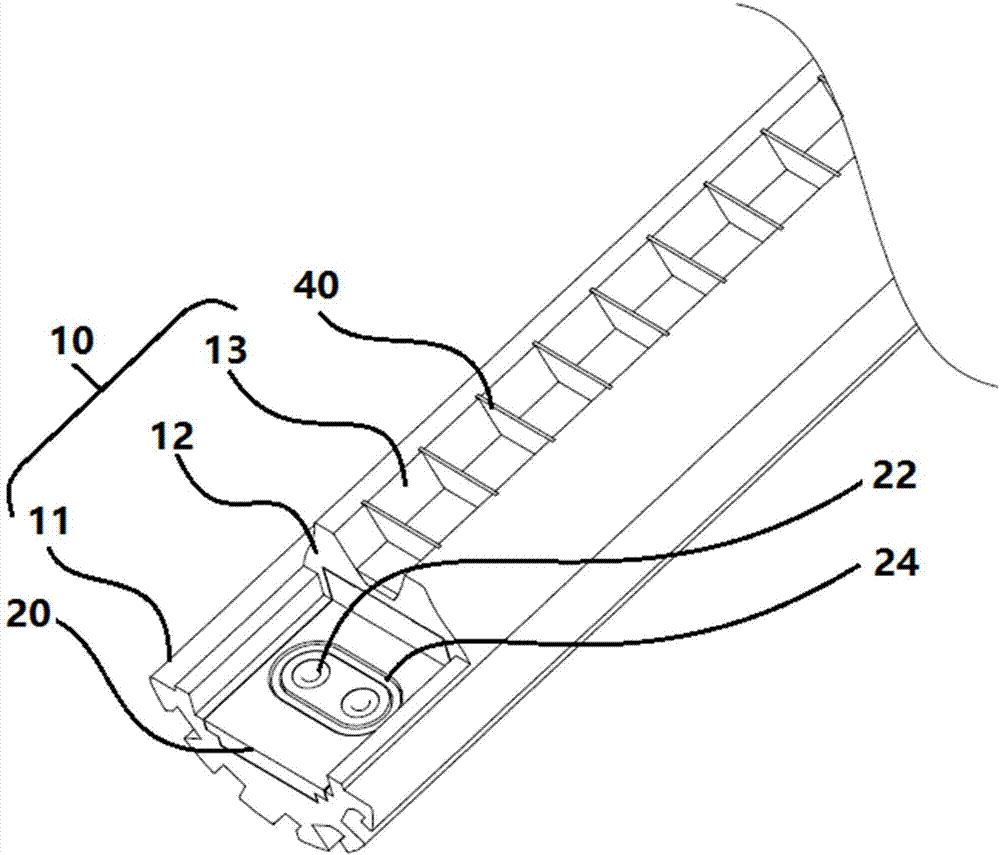

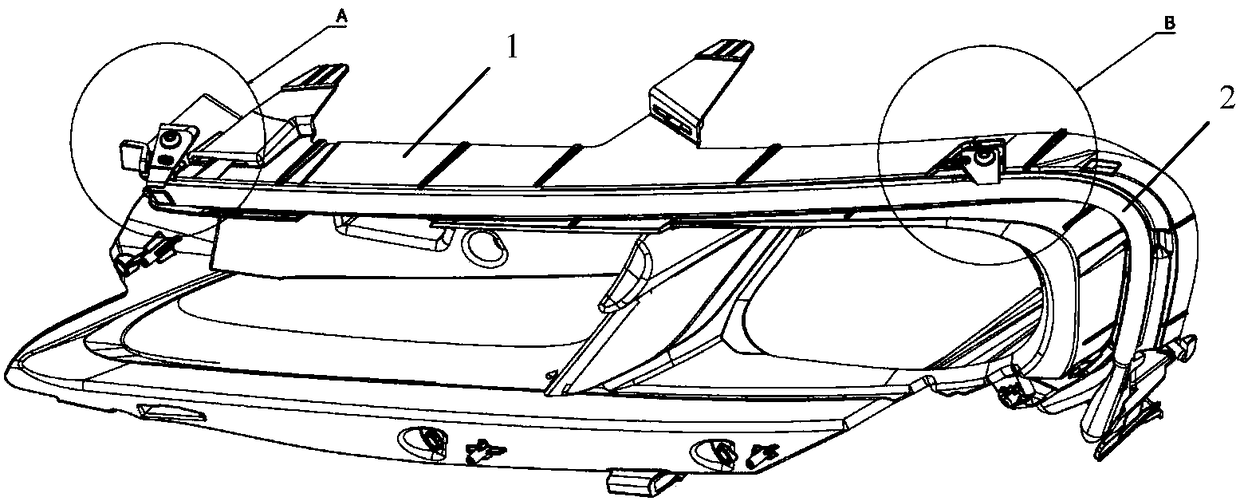

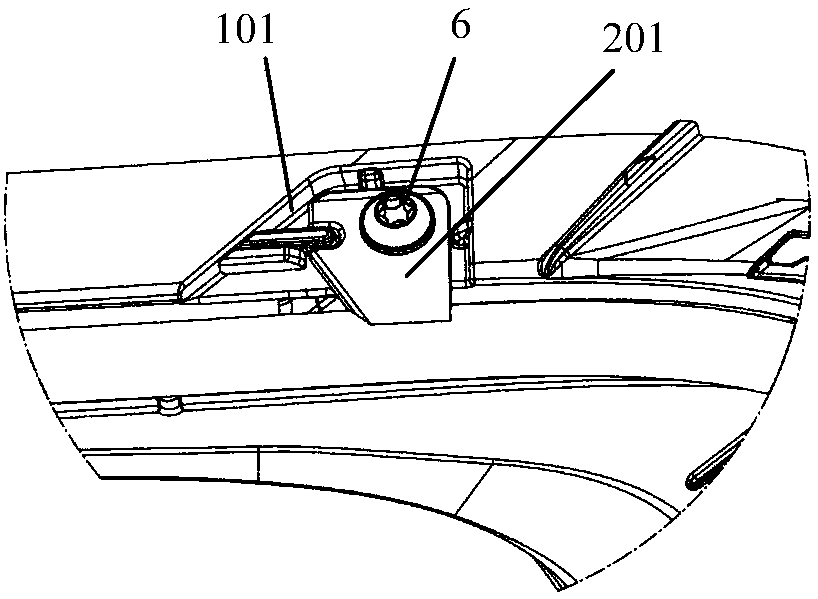

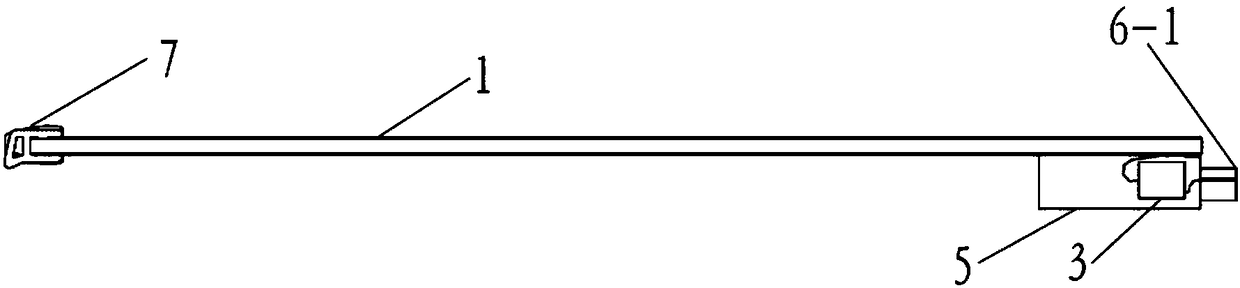

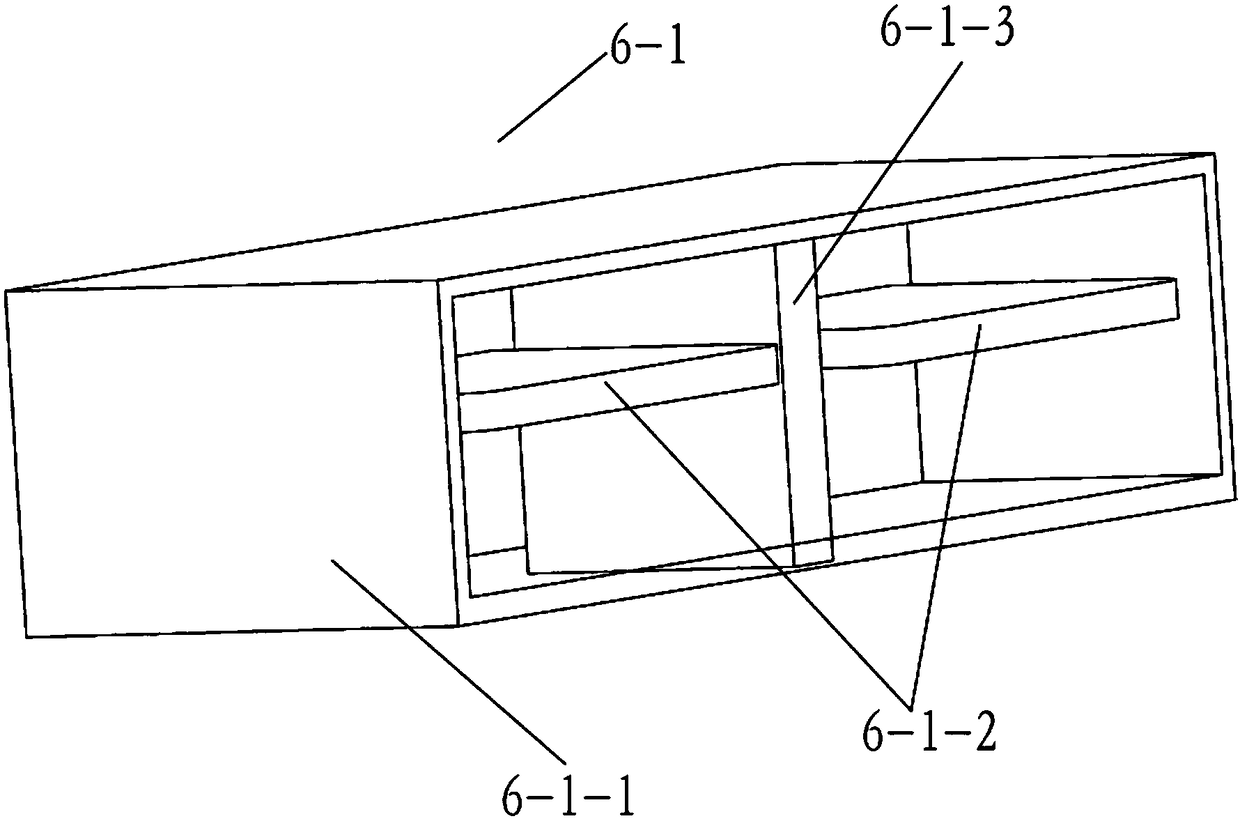

Decoration strip structure and air conditioner

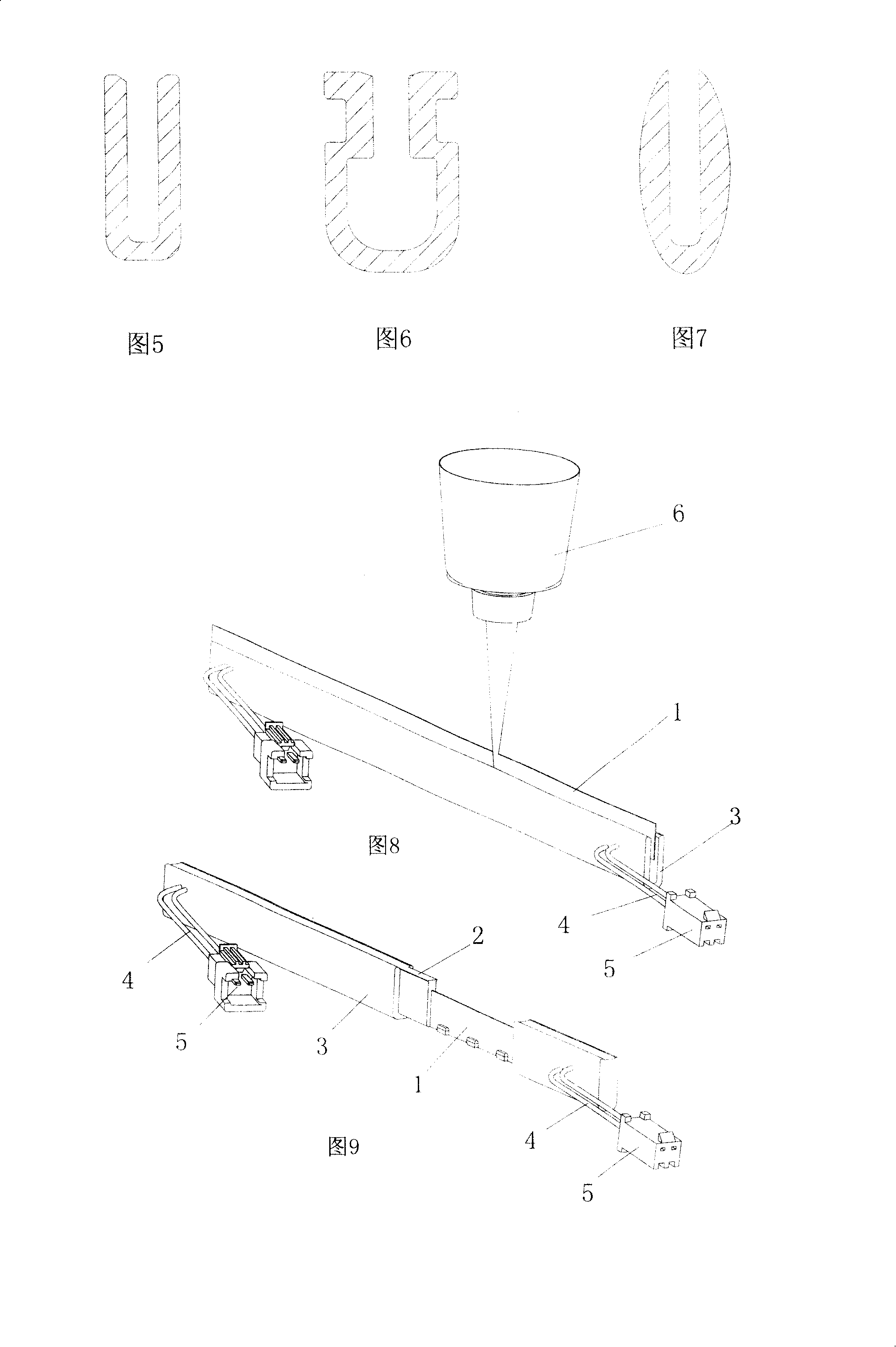

ActiveCN103363646AImprove aestheticsUniform luminous effectMechanical apparatusHeating and ventilation casings/coversLight guideTop cap

The invention is applicable to the technical field of air conditioner structures, and provides a decoration strip structure. The decoration strip structure comprises a decoration strip body, a light source and a light guide piece arranged on the decoration strip body, wherein the light guide piece is provided with a first incident plane facing towards the light source and a scattering surface facing towards the outer side of the decoration strip body; and the light source injects light into the first incident plane of the light guide piece and emits the light outwards from the scattering surface. With the adoption of the light source and the light guide piece, the light can be emitted outwards from the side part of the decoration strip body, so that a light emitting function of the decoration strip structure is realized, and a visual effect of the decoration strip structure is improved. The invention further provides an air conditioner which comprises a top cap, an air outlet housing and an air inlet housing, wherein the bottom end of the air outlet housing is mounted and fixed at the top of the air inlet housing; the top cap is mounted and fixed at the top end of the air outlet housing; and the decoration strip structures are arranged at the top of the top cap, a matching position between the top cap and the air outlet housing and a matching position between the air outlet housing and the air inlet housing.

Owner:MIDEA GRP CO LTD

Heat radiation fan with evenly luminous effect

InactiveCN1884843AUniform luminous effectUniform illumination effectPump componentsPump installationsEngineeringLight particle

The invention relates to a radiation fan with uniform lighting effect, which comprises a frame, a circuit board, a fan wheel, and a lighting unit, wherein said frame comprises one annular frame, one base plate at the center of annular frame and several ribs connecting the annular frame and base plate; the circuit board is arranged on the base plate; the fan wheel is rotationally mounted the circuit board while it comprises one fan hub and several transparent leaves on the circumference of fan hub; each leaf has several light particles, to form frog station in concave-convex shape; when the light of lighting unit is emitted to all leaves, it will generate uniform reflection.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

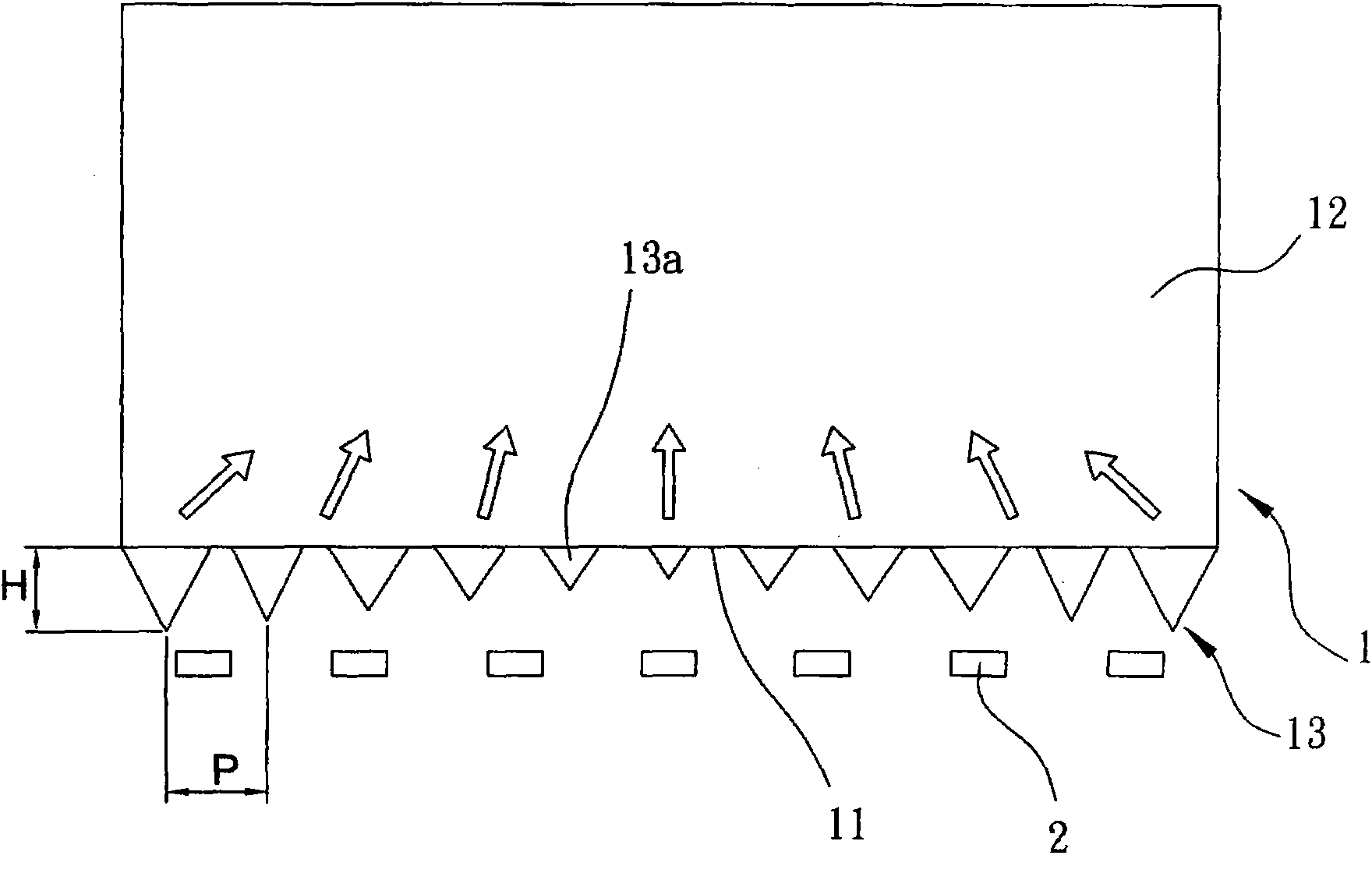

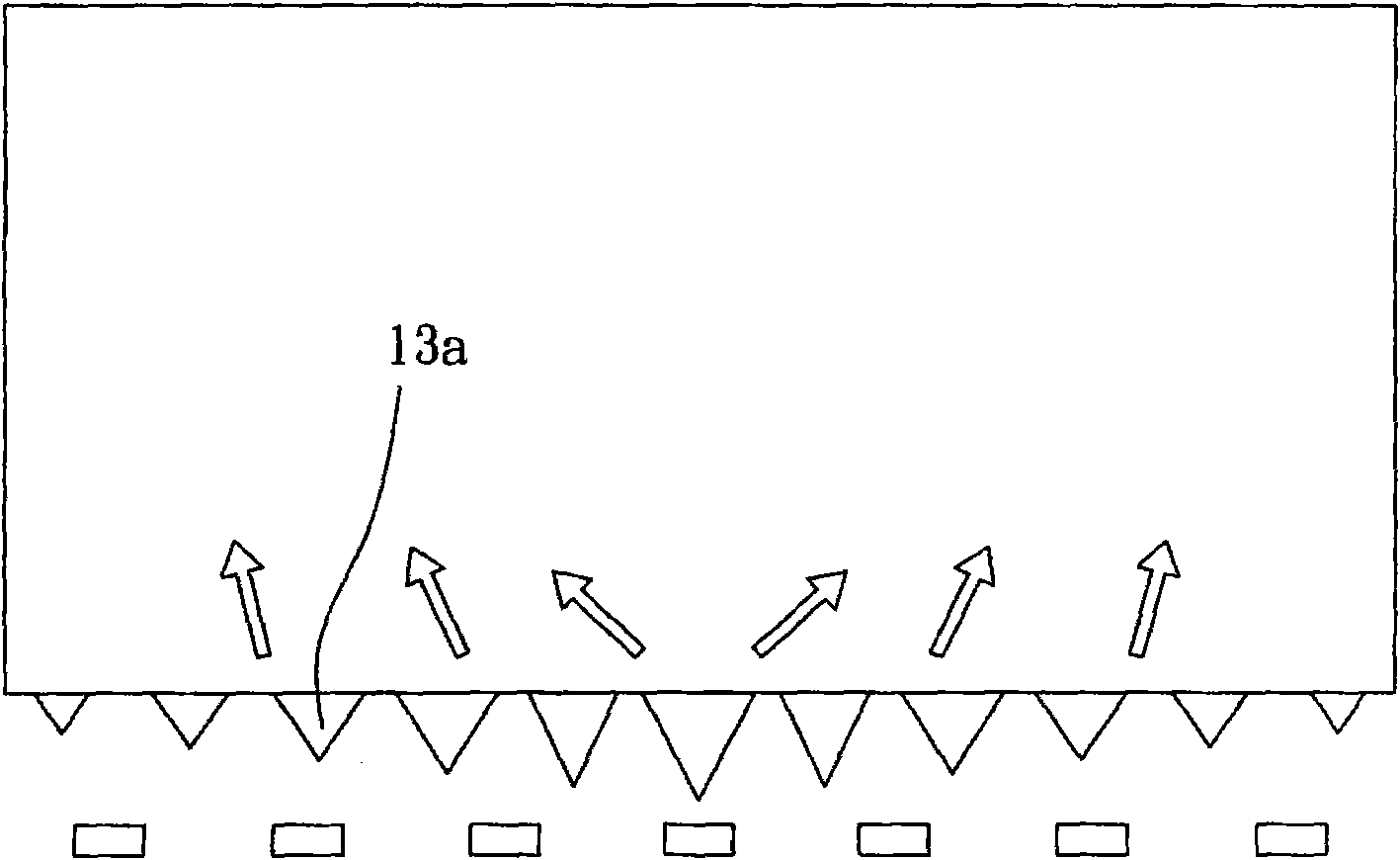

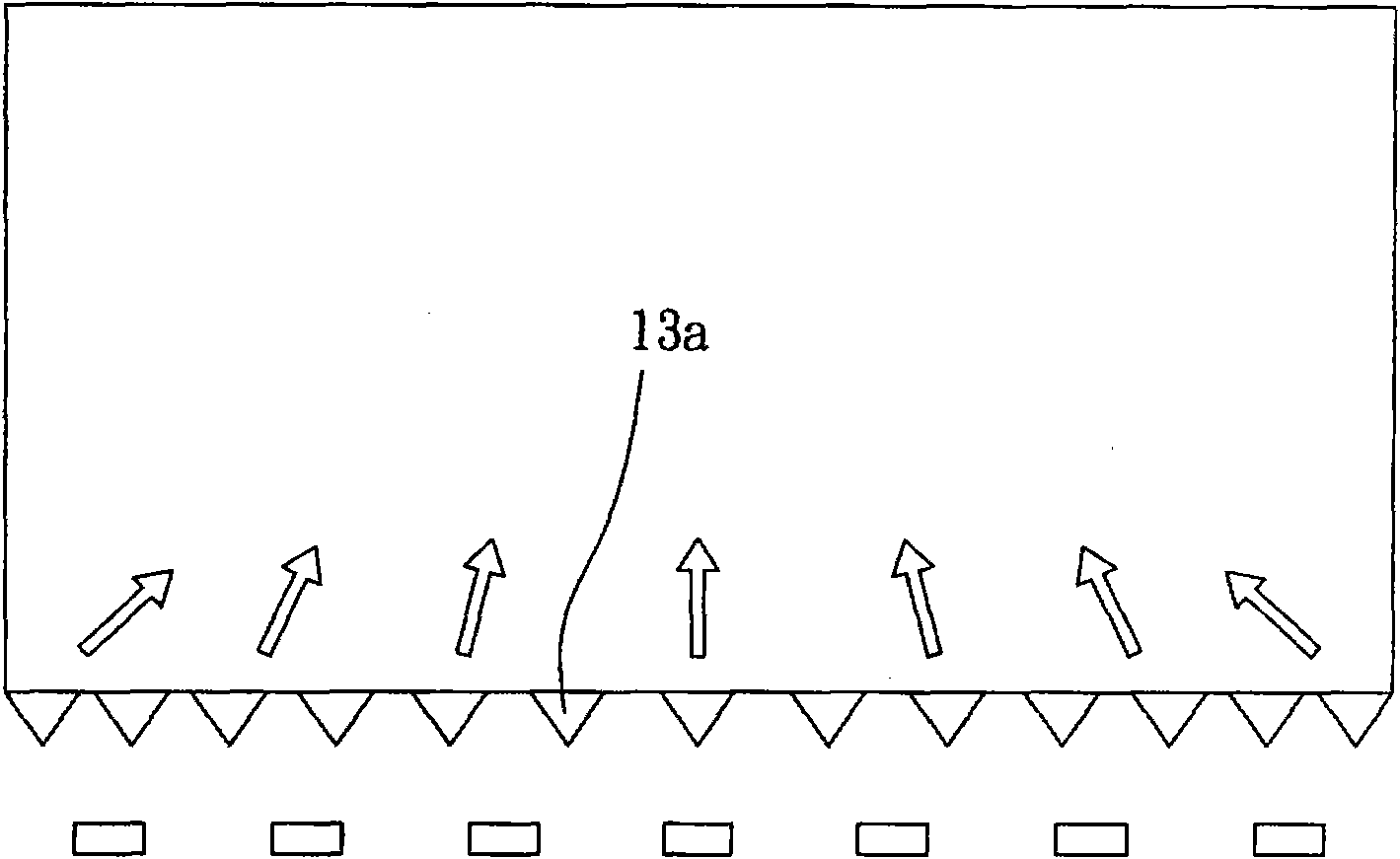

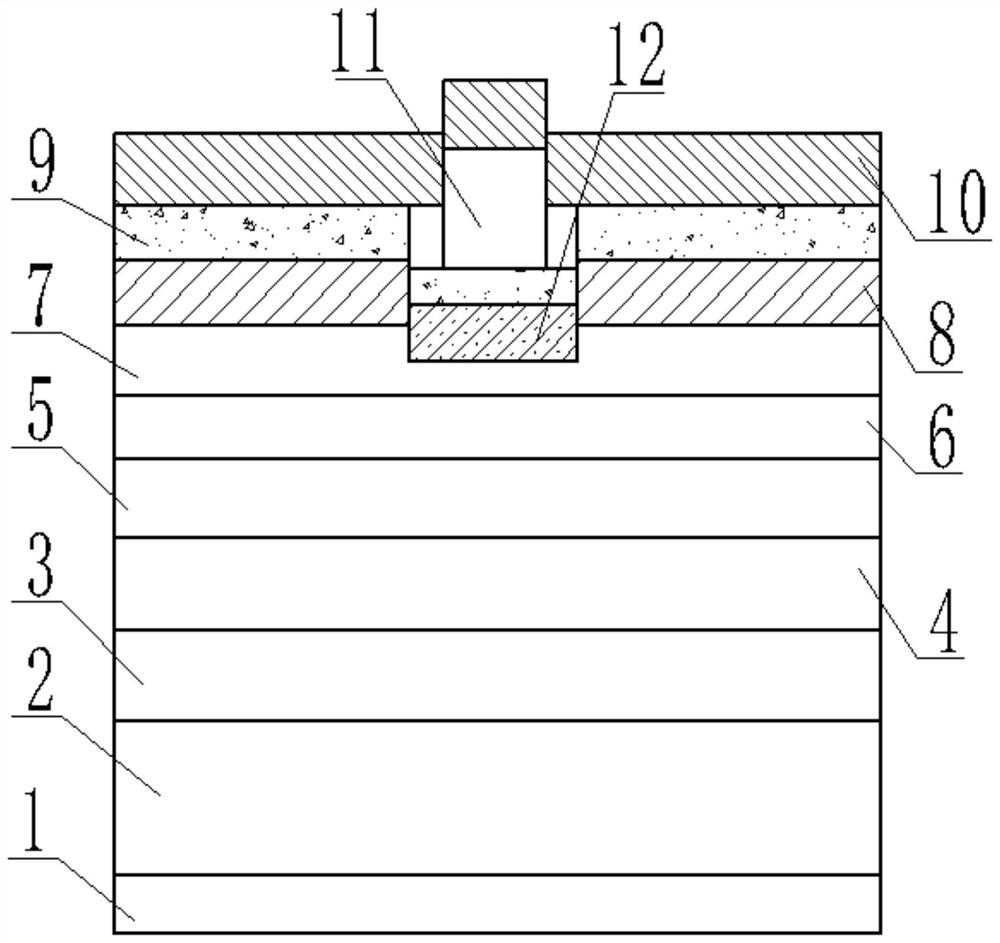

Structure for predominating light-emitting brightness or uniformization of light guide plate

InactiveCN102052634ADifferent brightness effectsUniform luminous effectMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

The invention relates to a structure for predominating the light-emitting brightness or the uniformization of a light guide plate. A plurality of microstructures are arranged on a light incident surface of the light guide plate, so that light penetrates through the microstructures to enter the light guide plate; with the reflection or refraction of the light, the brightness in a specific area of the light guide plate can be improved or the light emitting of the light guide plate is uniformized; the microstructures can be objects protruded from the light incident surface of the light guide plate or concave parts lower than the light incident surface; a pitch is formed between two protruded objects and two concave parts; each protruded object or concave part is provided with a height or a concave part; and the pitch is matched with the height or the concave part to change according to the brightness degree to be acquired by the light guide plate so as to generate different amount of light entering the light guide plate.

Owner:SHANGHAI XIANGLONG ELECTRONICS TECH

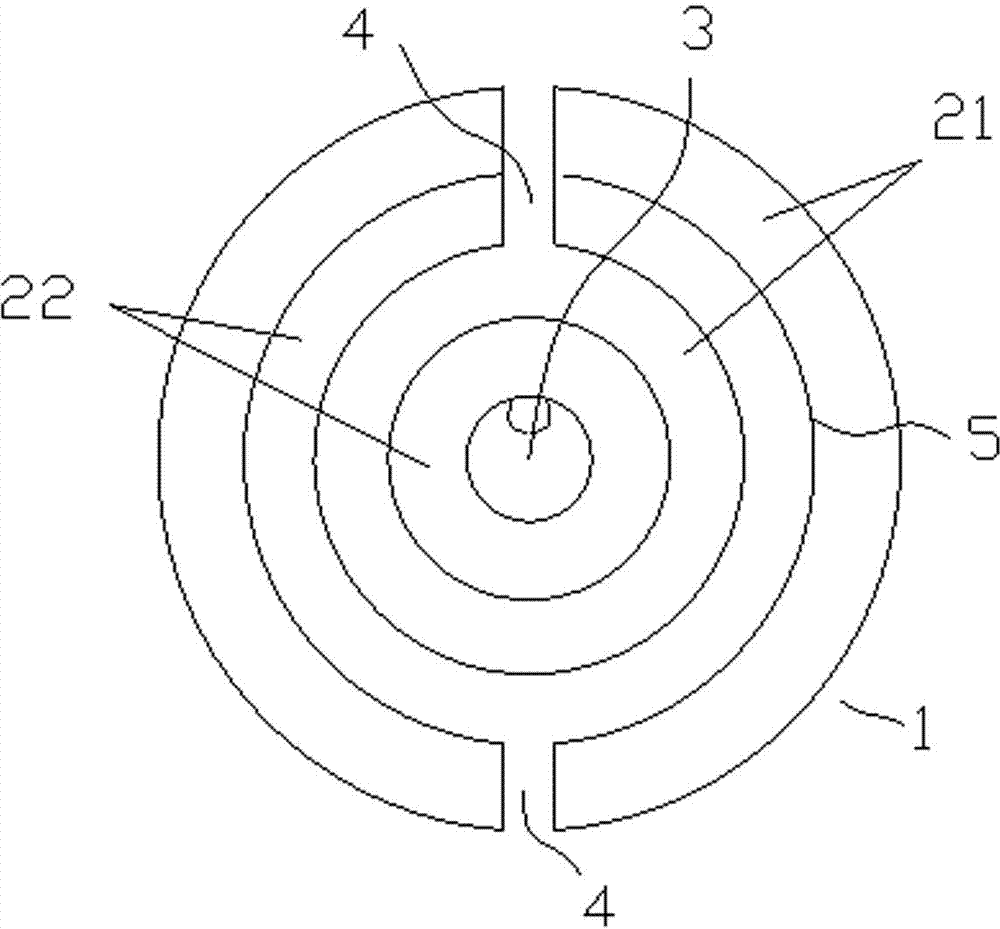

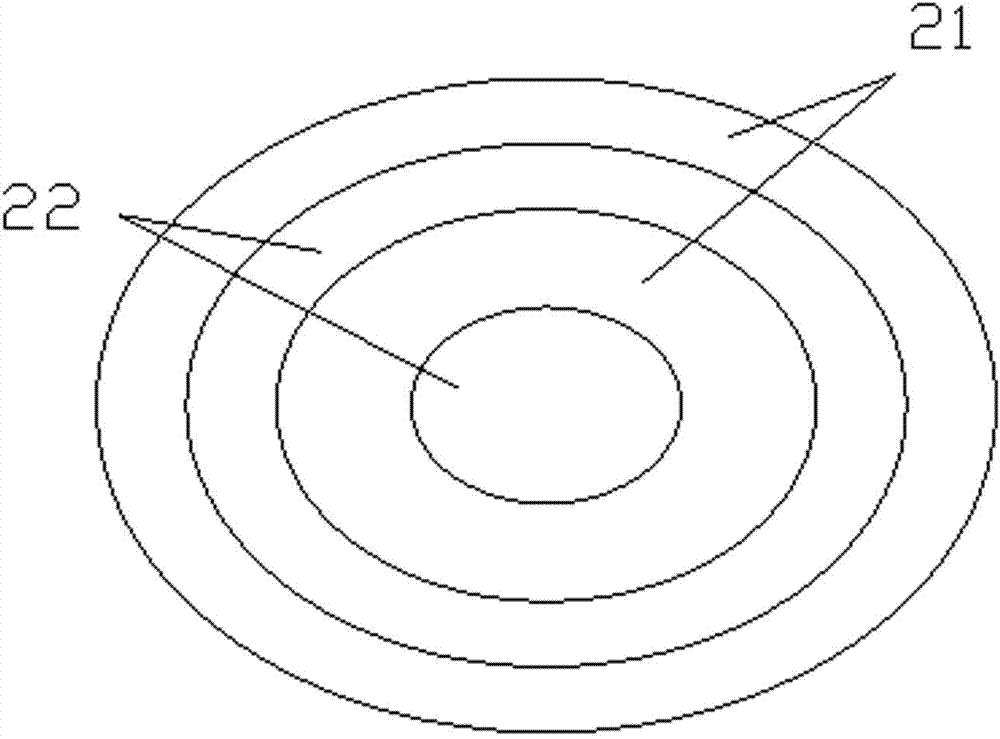

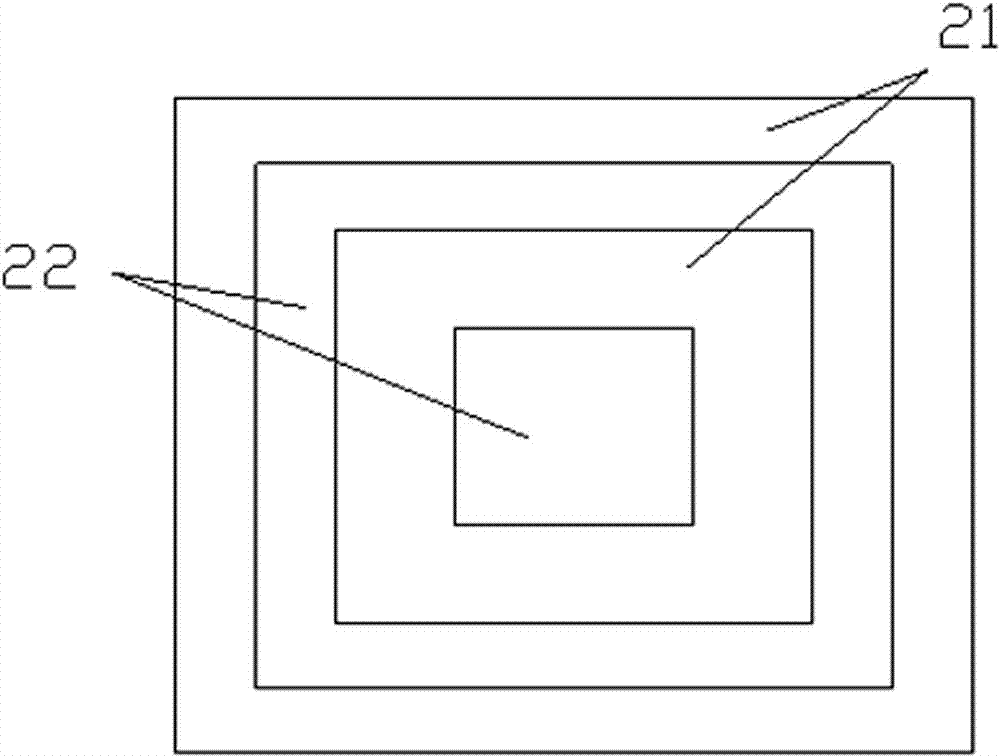

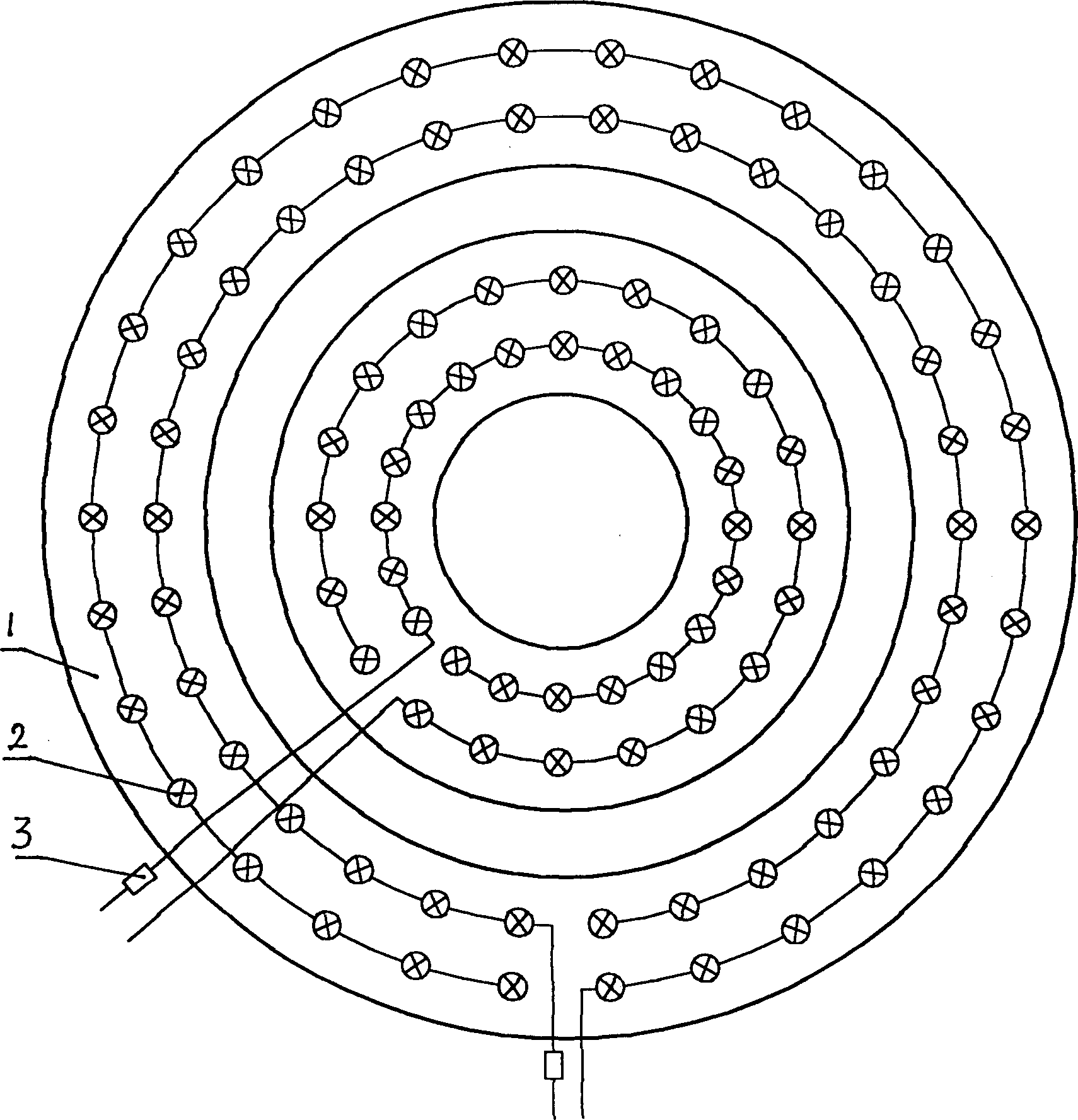

Dimmable light emitting diode (LED) integrated optical source based on annular distribution

ActiveCN103175010AColor temperature adjustableClosely arrangedPlanar light sourcesPoint-like light sourceElectrical connectionSource area

The invention discloses a dimmable light emitting diode (LED) integrated optical source based on annular distribution. The dimmable LED integrated optical source based on the annular distribution comprises a substrate, wherein regular geometric figure areas are arranged on the substrate and are divided into different annular areas with the same center, annular areas included in a cool white optical source area and annular areas included in a warm white optical source area are arranged alternately from inside to outside, LED chips in the cool white optical source area are in electrical connection with a first controllable power supply unit arranged outside, and LED chips in the warm white optical source area are in electrical connection with a second controllable power supply unit arranged outside. According to the dimmable LED integrated optical source based on the annular distribution, a single-body LED optical source is constructed in a mode of combination by different areas, the areas are distributed evenly and alternately, the light emitting effect is even, and color temperature of the whole optical source can be controlled and enabled to be continuously adjustable; the areas are closely arranged with no spacing basically, and therefore a lens can be arranged on the light-emitting surface of the optical source for light condensation, and requirements of a film and television shoot optical source are met; the area division method is suitable for wiring; and light emitting power can reach to dozens of watts or even hundreds of watts.

Owner:ZHUHAI JILI DEV +1

Water-proof LED flexible light stripe and its manufacturing method

InactiveCN101220947AHigh quality and reliabilitySafe to usePoint-like light sourceElectric circuit arrangementsColloidEngineering

The invention provides a waterproof LED flexible optical strip, including an LED flexible optical strip which is coated with a colloid layer which is spliced with a tegmen; meanwhile, the invention also provides a preparation method of the waterproof LED flexible optical strip. The invention has the advantages that the products of the waterproof LED flexible optical strip have high quality reliability and good application safety, the method has low manufacturing cost, and mass yield can be realized; furthermore, the invention can produce arbitrary length according to requirement, which has extremely high product yield and superiority which is incomparable with other waterproof LED flexible optical strips.

Owner:上海宜美电子科技有限公司

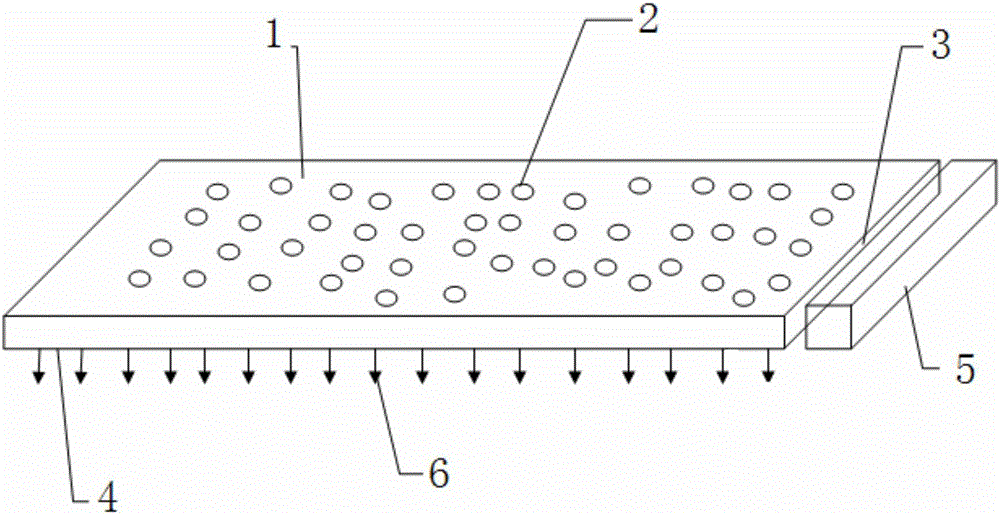

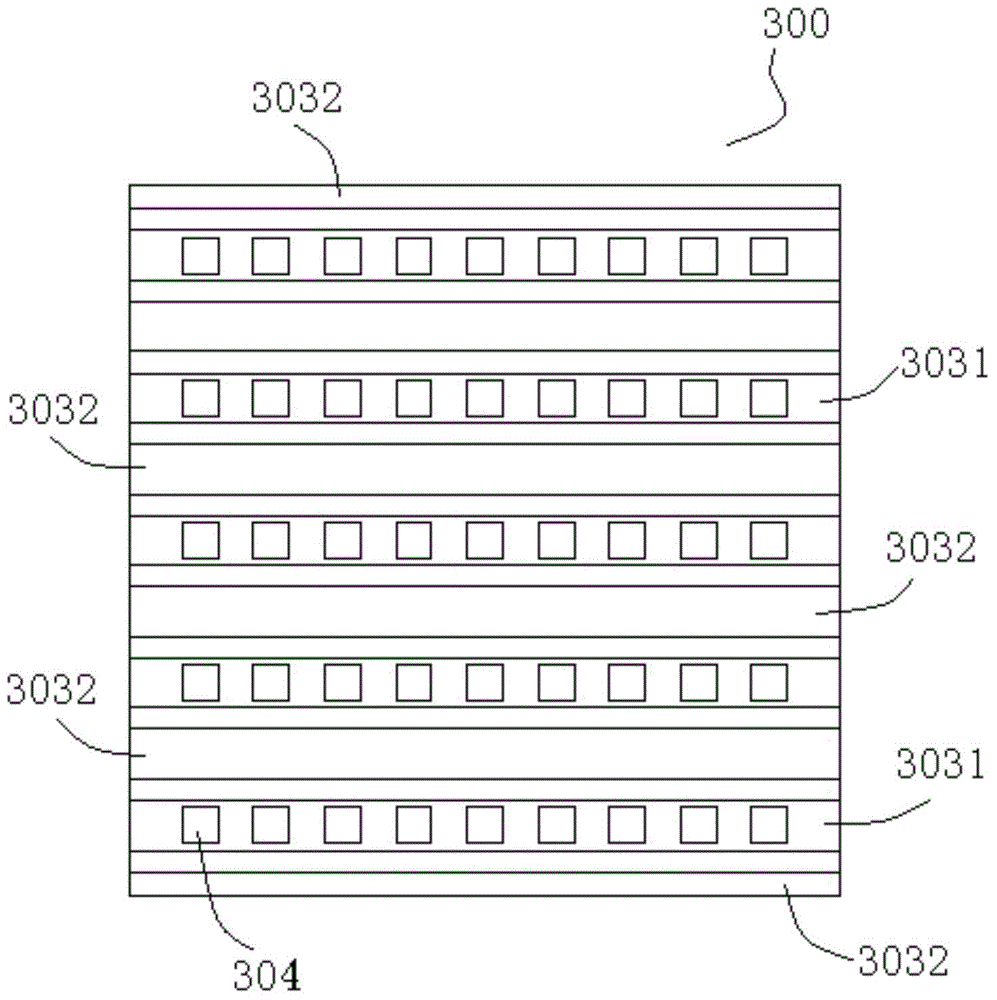

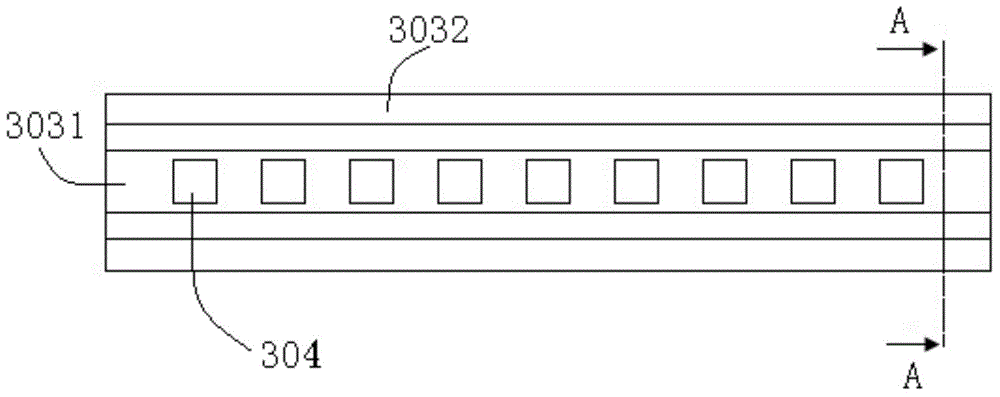

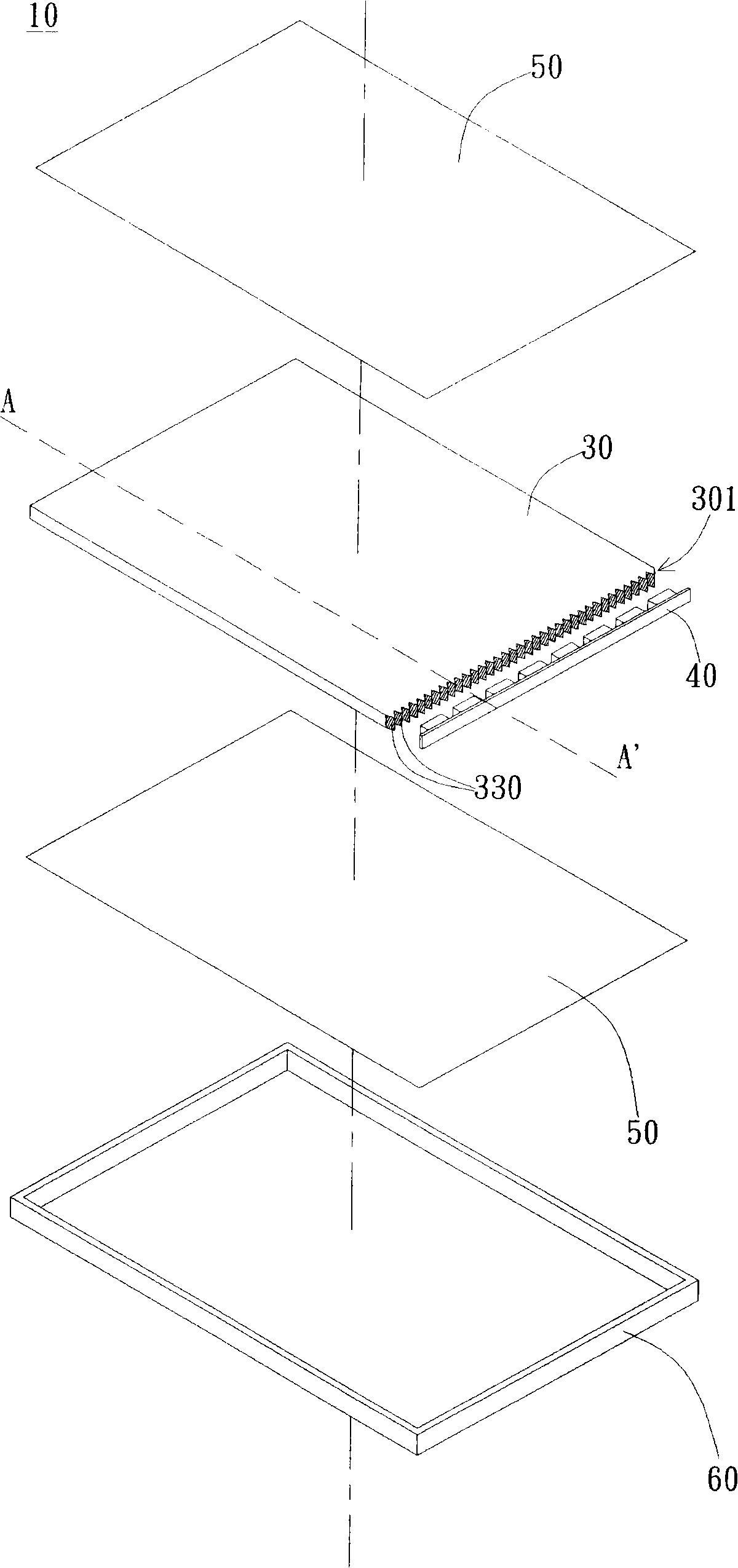

Light guide plate, printing ink, and manufacturing method for ink-jet printing light guide plate

ActiveCN104991304AUniform luminous effectImprove luminous performanceOptical light guidesLight guidePrinting ink

The invention discloses a light guide plate and a manufacturing method for an ink-jet printing light guide plate. The light guide plate is provided with a light incoming surface, a light outgoing surface, and a lattice point surface. The light incoming surface is located on a side surface of the light guide plate, and the light outgoing surface is opposite to the lattice point surface. The lattice point surface is provided with an array composed of a plurality of ink printing lattice points, and the intervals among the lattice points decrease along with the increases of the distances from the lattice points to the light incoming surface of the light guide plate. The sizes of all lattice points remain unchanged, or the sizes of all lattice points increase along with the increase of the distances from the lattice points to the light incoming surface of the light guide plate and the intervals among the lattice points remain unchanged. The invention also discloses printing ink for the lattice ink-jet printing of the light guide plate, and particles of the printing ink comprise PMMA or an organosilicone microballoon wrapping layer, and titanium oxide or calcium carbonate nano solid sphere particles wrapped by the PMMA or an organosilicone microballoon wrapping layer. According to the invention, the optical effect and machining efficiency of the light guide plate can be optimized.

Owner:创联胜光电(广东)有限公司

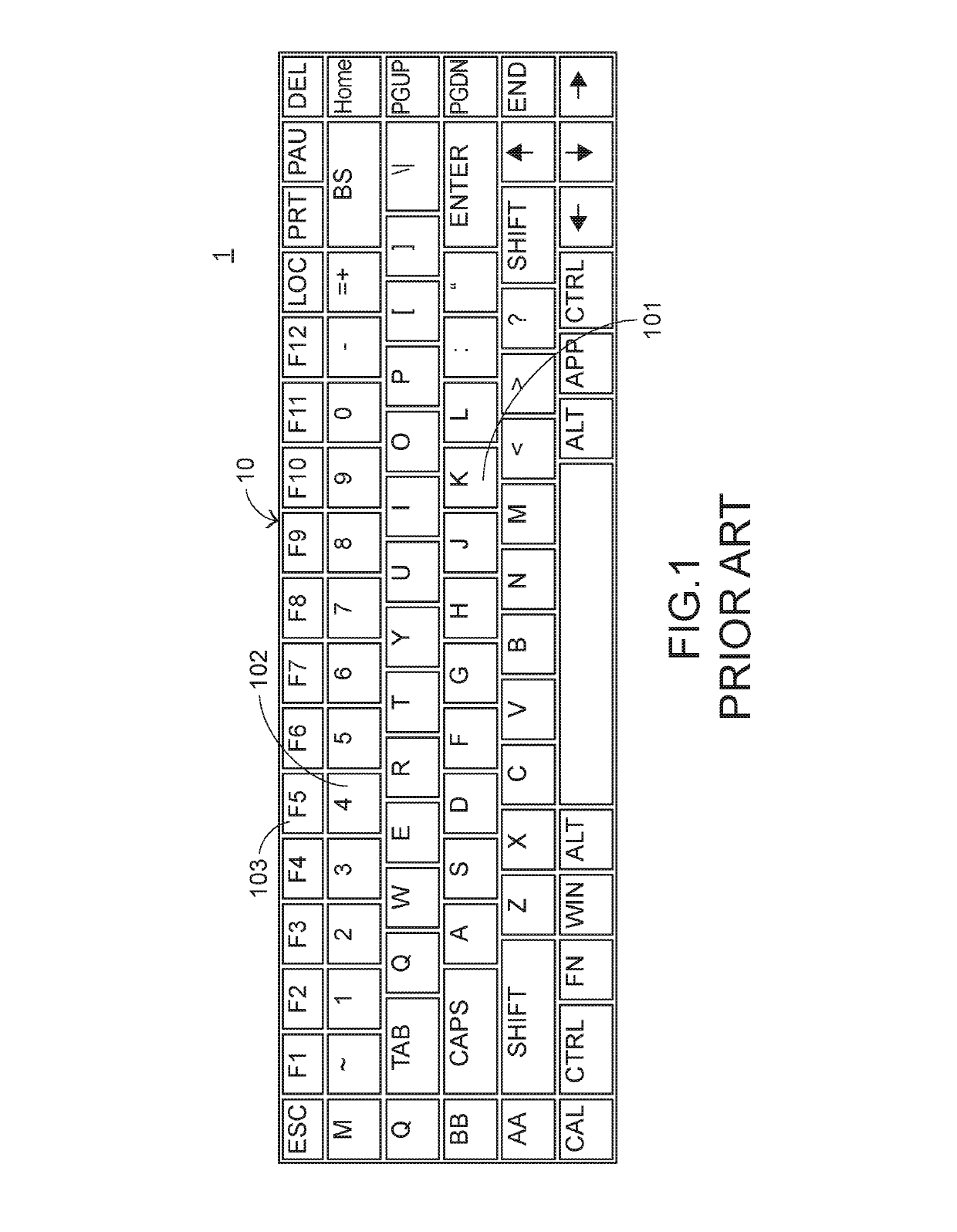

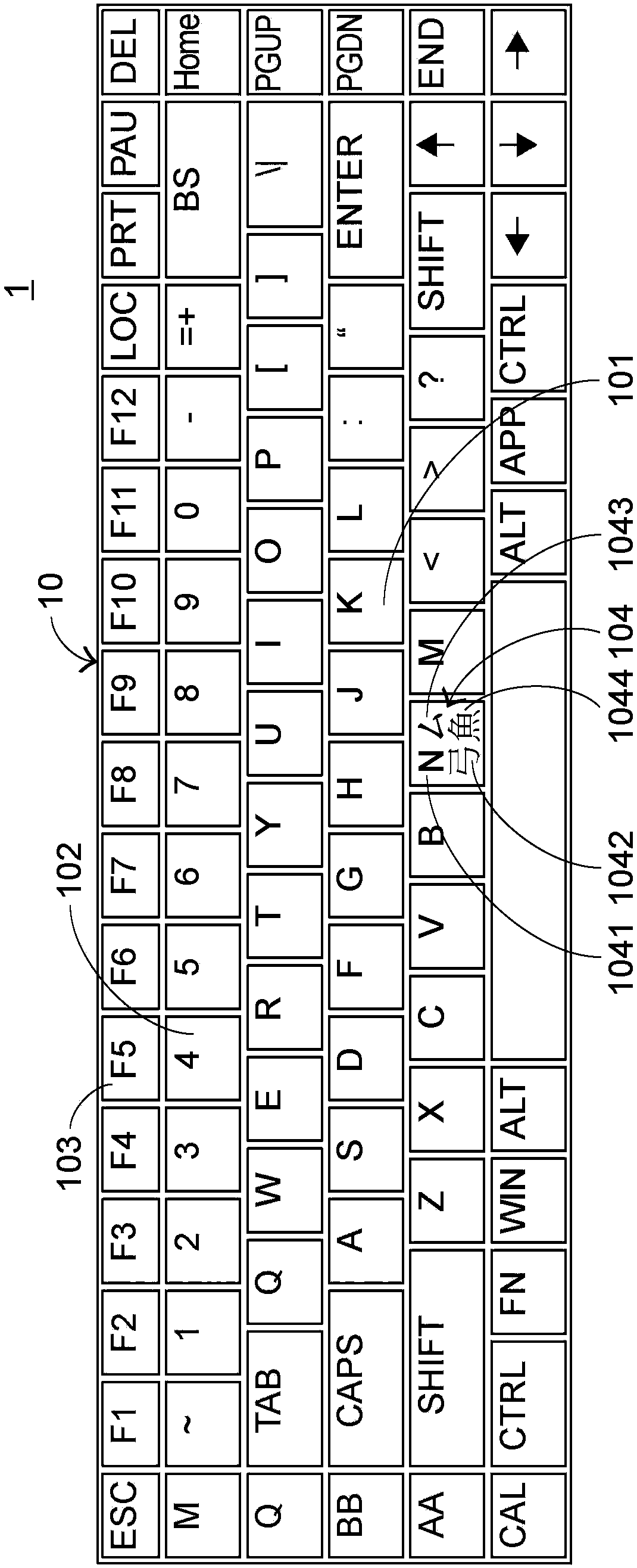

Luminous keyboard

ActiveUS20190171297A1Uniform illuminating efficacyUniform luminous effectInput/output for user-computer interactionLegendsLight beamComputer module

A luminous keyboard includes plural key structures, a switch circuit board, a supporting plate, a backlight module and plural ring-shaped structures. The switch circuit board is located under the keycaps of the key structures. The supporting plate is located under the switch circuit board and connected with the key structures. The backlight module is located under the supporting plate. The backlight module generates a light beam. The plural ring-shaped structure are disposed on the switch circuit board and arranged around the corresponding key structures. When the light beam is reflected by the key structures, the light beam is received by the plural ring-shaped structure. Due to the material properties of the ring-shaped structures, the periphery regions of the keycaps generate a uniform luminous effect.

Owner:PRIMAX ELECTRONICS LTD

Energy-saving lamp fluorescent powder

InactiveCN104560043AUniform luminous effectGood luminous stabilityLuminescent compositionsMetallurgyLuminous flux

The invention relates to energy-saving lamp fluorescent powder which consists of a component A, a component B and a component C, wherein the component A consists of Y2O3, BaCO3, MgO and MoO3 by weight; the component B consists of Sb2O3, CaF2, BaO.Al2O3 and SrCO3; and the component C consists of CaHPO4, Na2B4O7 and Y2O3. The energy-saving lamp fluorescent powder provided by the invention is uniform in luminous effect, high in luminous stability and high in luminous strength during use, and the luminous flux of the manufactured energy-saving lamp can be 75lm / w. Moreover, the processing method of the fluorescent powder is simple, dry gas protection is used in the processing process and during subsequent treatment, the drying step is eliminated, and the processing time consumption is low.

Owner:ANHUI HUSN COUNTY WANXIN ELECTRONICS TECHCO

Liquid-crystal display television, backlight module and manufacturing method thereof

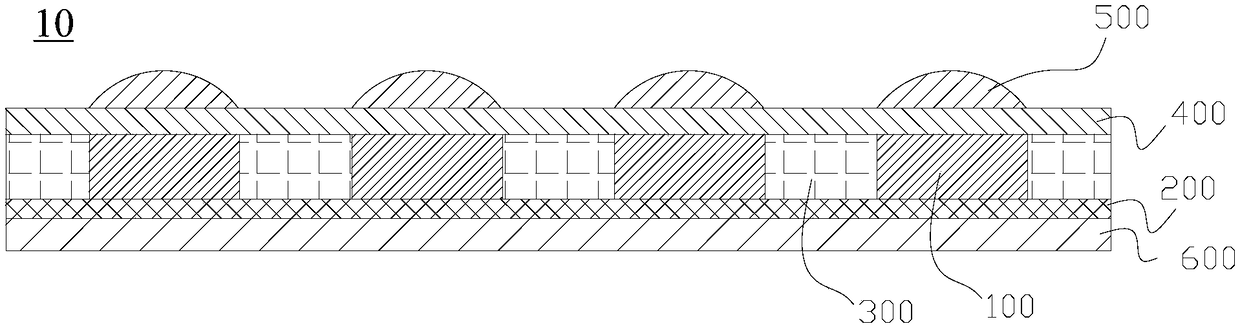

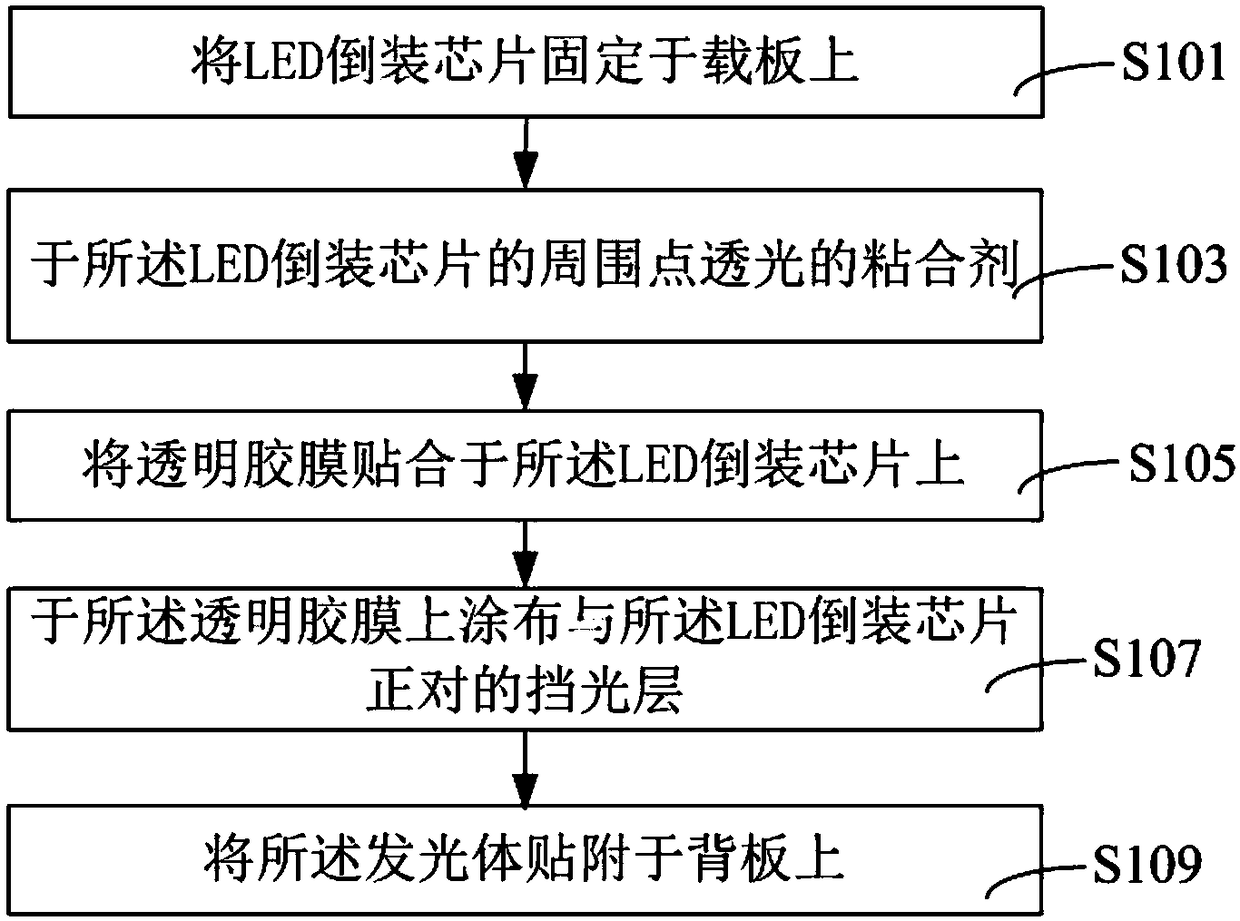

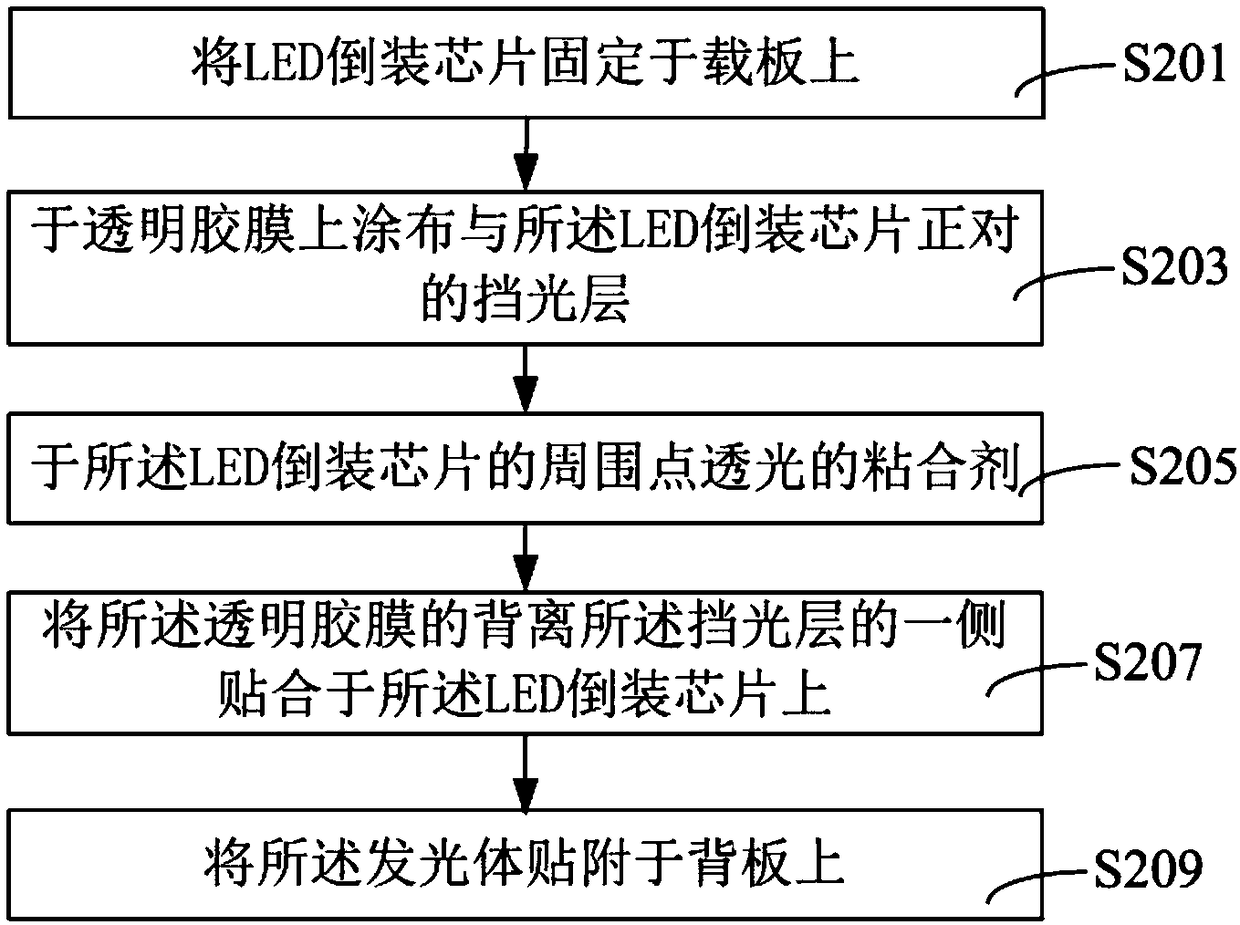

PendingCN108761905AThe overall thickness is thinReduce axial light intensityNon-linear opticsBlock layerBlocking layer

The invention relates to a liquid-crystal display television, a backlight module and a manufacturing method thereof. The manufacturing method of the backlight module comprises the steps that an LED flip chip is fixed to a carrier plate; a photic adhesive is applied around the LED flip chip, and an adhesive layer is formed around the LED flip chip; transparent film fits the LED flip chip, and the transparent film is arranged to be opposite to the carrier plate; a light blocking layer directly facing the LED flip chip is spread on the transparent film so as to form a luminous body; the luminousbody is attached to a backing plate. According to the manufacturing method, light emitted by the LED flip chip is mostly spread to the side face, and the effect that on the condition that no lens exists, and the light comes to a diffusion plate to achieve uniform glowing is achieved; finally, the luminous body is attached to the backing plate. Due to the fact that the lens does not need to be installed on the backing module obtained through the backing module manufacturing method, the overall thickness of the backing module is thinner.

Owner:TCL VERY LIGHTING TECH HUIZHOU CO LTD +1

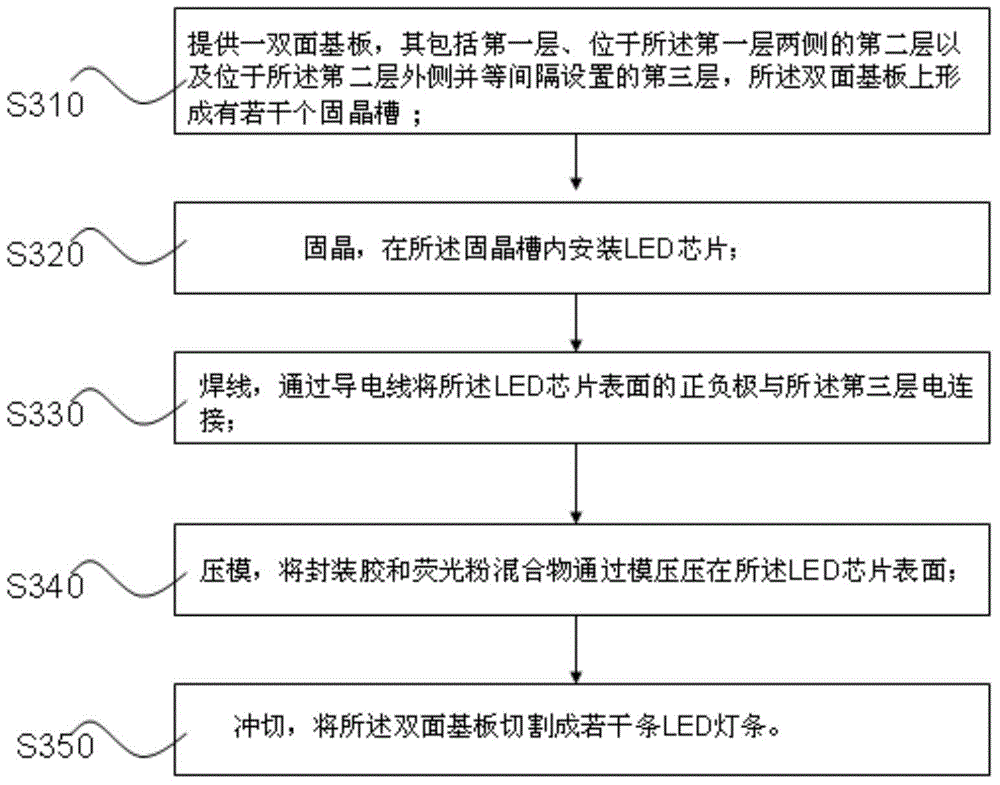

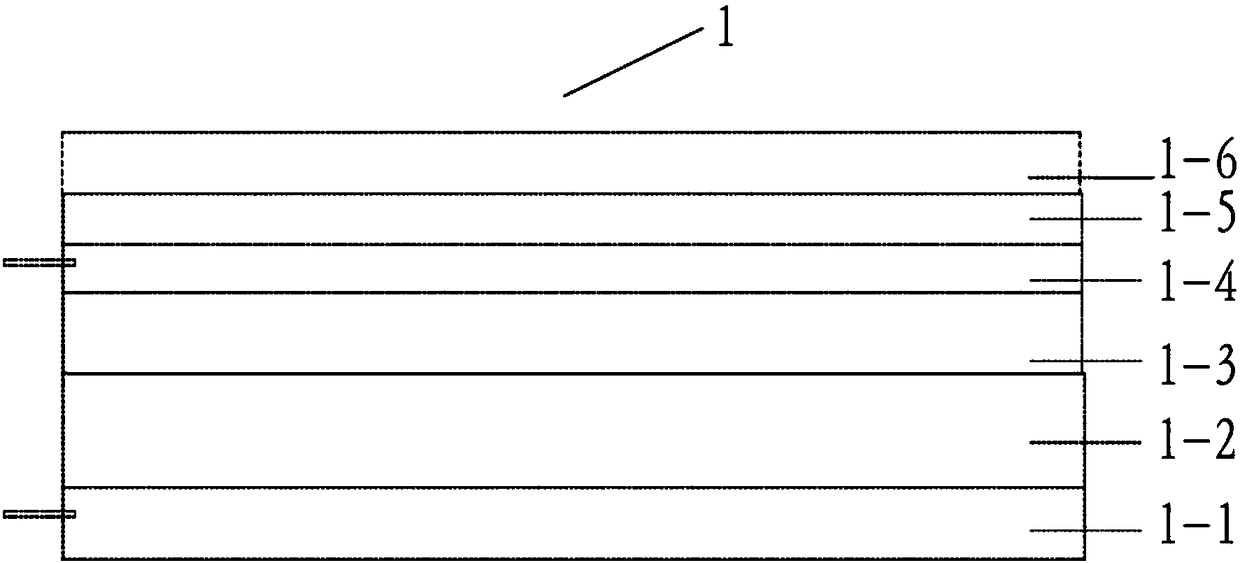

Manufacturing technology of LED lamp strip capable of emitting light from two sides

InactiveCN104051603ASimple processIncrease productivitySolid-state devicesSemiconductor devicesEngineeringLED lamp

The invention provides a manufacturing technology of a LED lamp strip capable of emitting light from the two sides. The manufacturing technology comprises the following steps that a two-sided substrate is provided, wherein the two-sided substrate comprises a first layer, second layers located on the two sides of the first layer and third layers located on the outer sides of the second layers and arranged at an equal interval; a plurality of crystal fixing grooves are formed in the two-sided substrate. Compared with the prior art, the LED lamp strip capable of emitting light from the two sides is simple in technology and better and evener in light emitting effect.

Owner:YANCHENG DONGSHAN PRECISION MANUFACTURING CO LTD

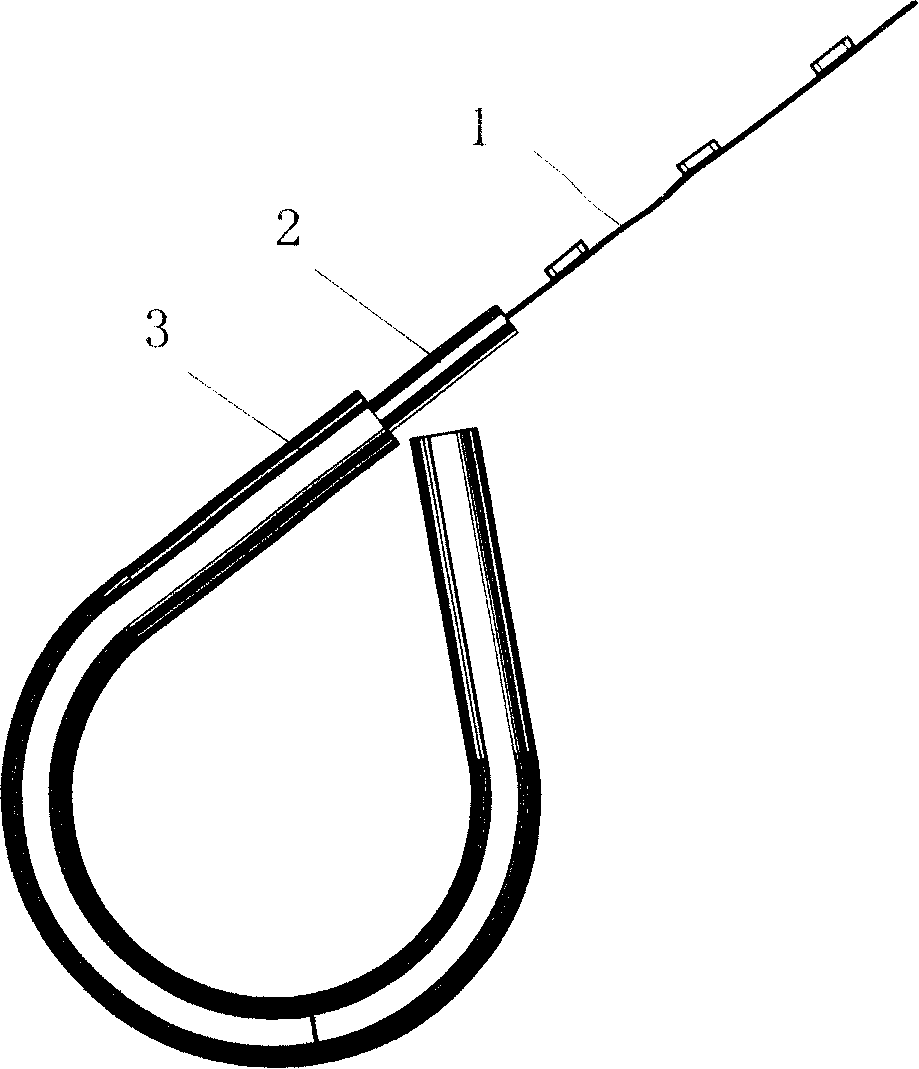

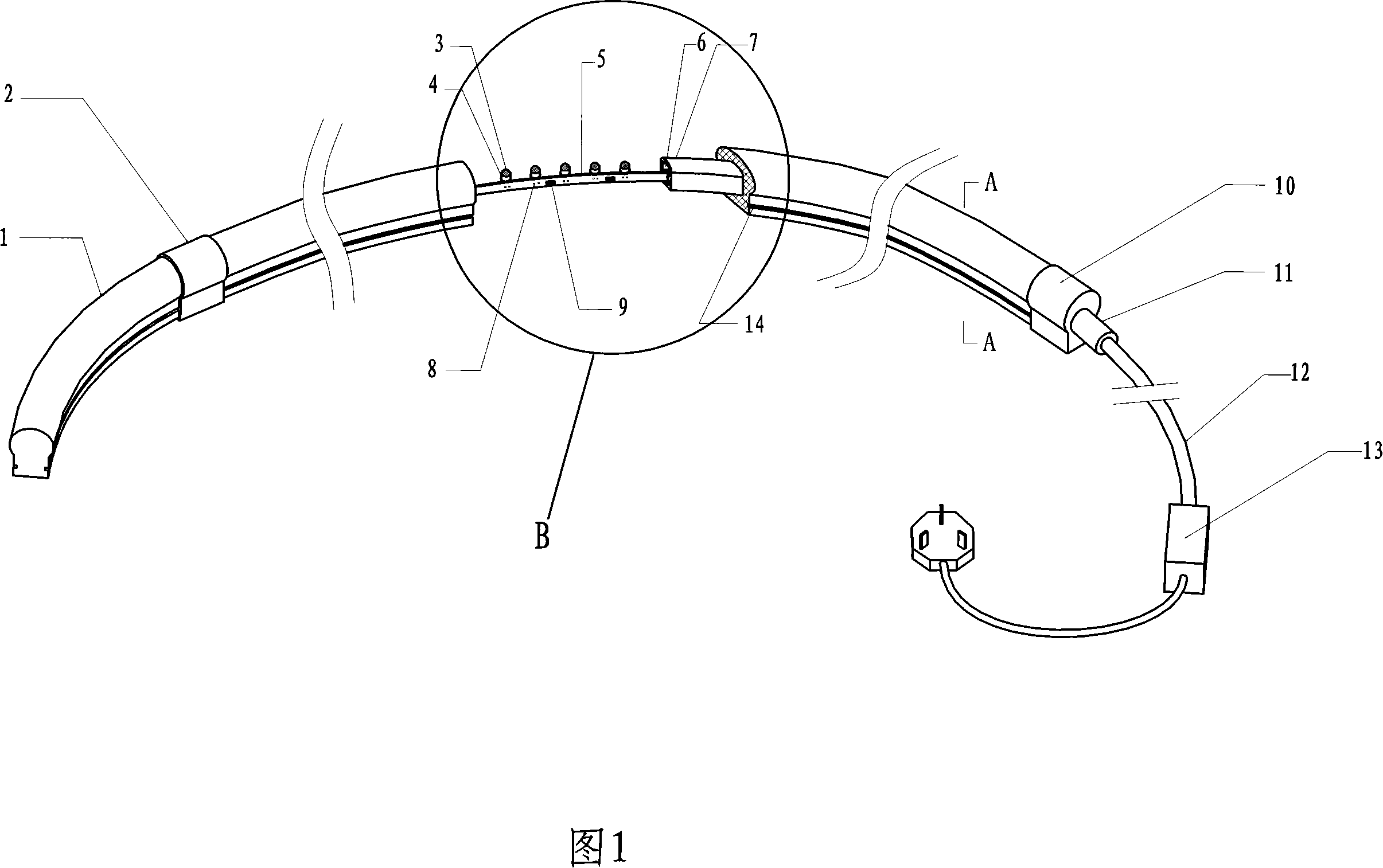

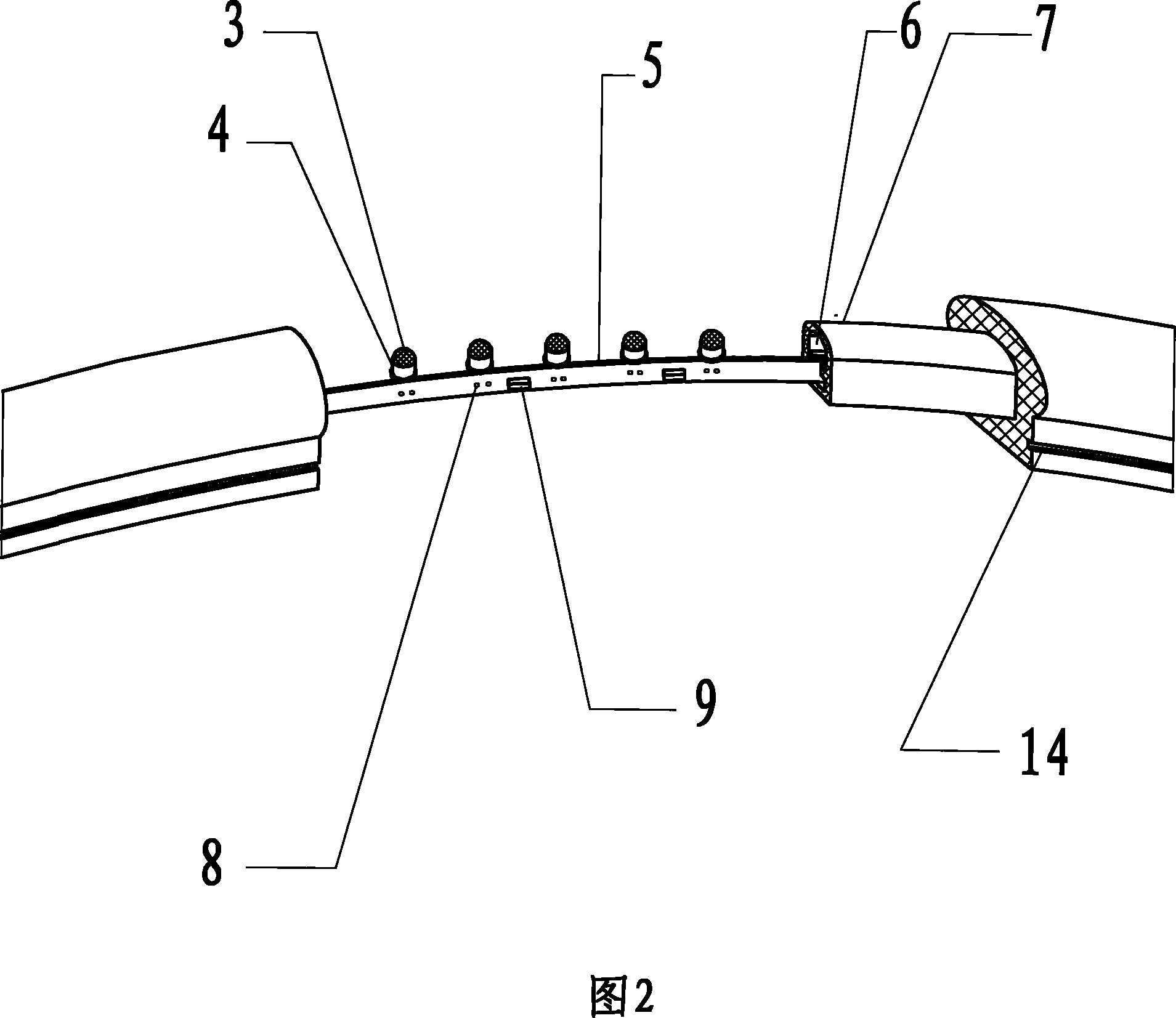

LED flexible neon lamp strip

InactiveCN101482237BSimple structureSimple processing technologyMechanical apparatusPoint-like light sourceElectrical resistance and conductanceCurrent limiting

The invention discloses an LED flexible neon light strip, comprising an FPC flexible circuit board, a semi-transparent light conductor chip strip and a semi-light-conducting colloid jacket from inside to outside. A plurality of LED lamps and a current limiting resistance are arranged on the circuit board, the two ends of the light strip are respectively provided with a light strip end cover, and an LED driving power supply is arranged between each end cover and the commercial power. The light strip can be bent to any angle and can be cut for use within a certain length range, therefore, for decoration engineering, the construction is flexible and convenient, and the requirements for artistic models of point, line, face, sphere and abnormal three-dimensional shapes can be realized.

Owner:惠州市路森光电科技有限公司

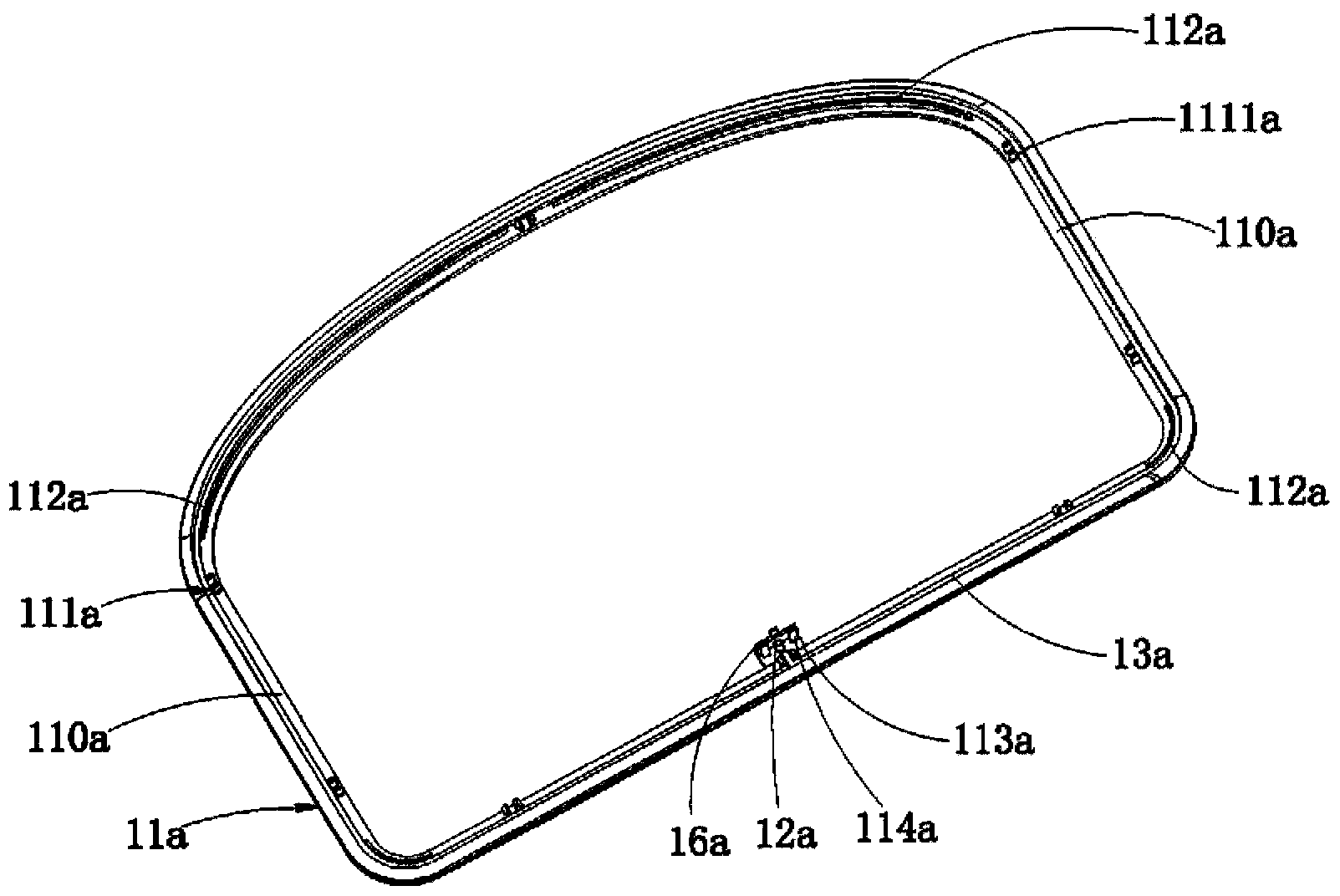

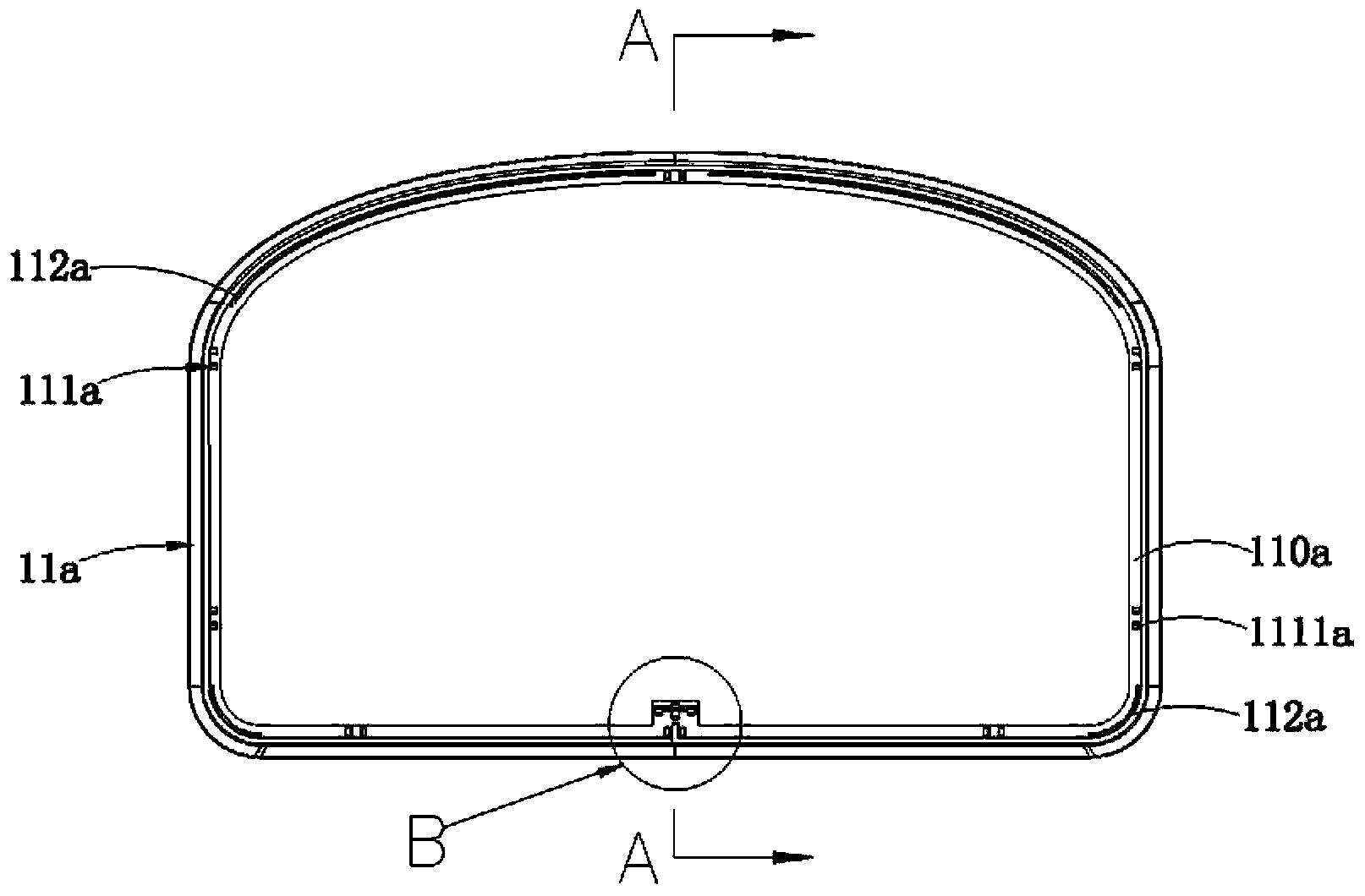

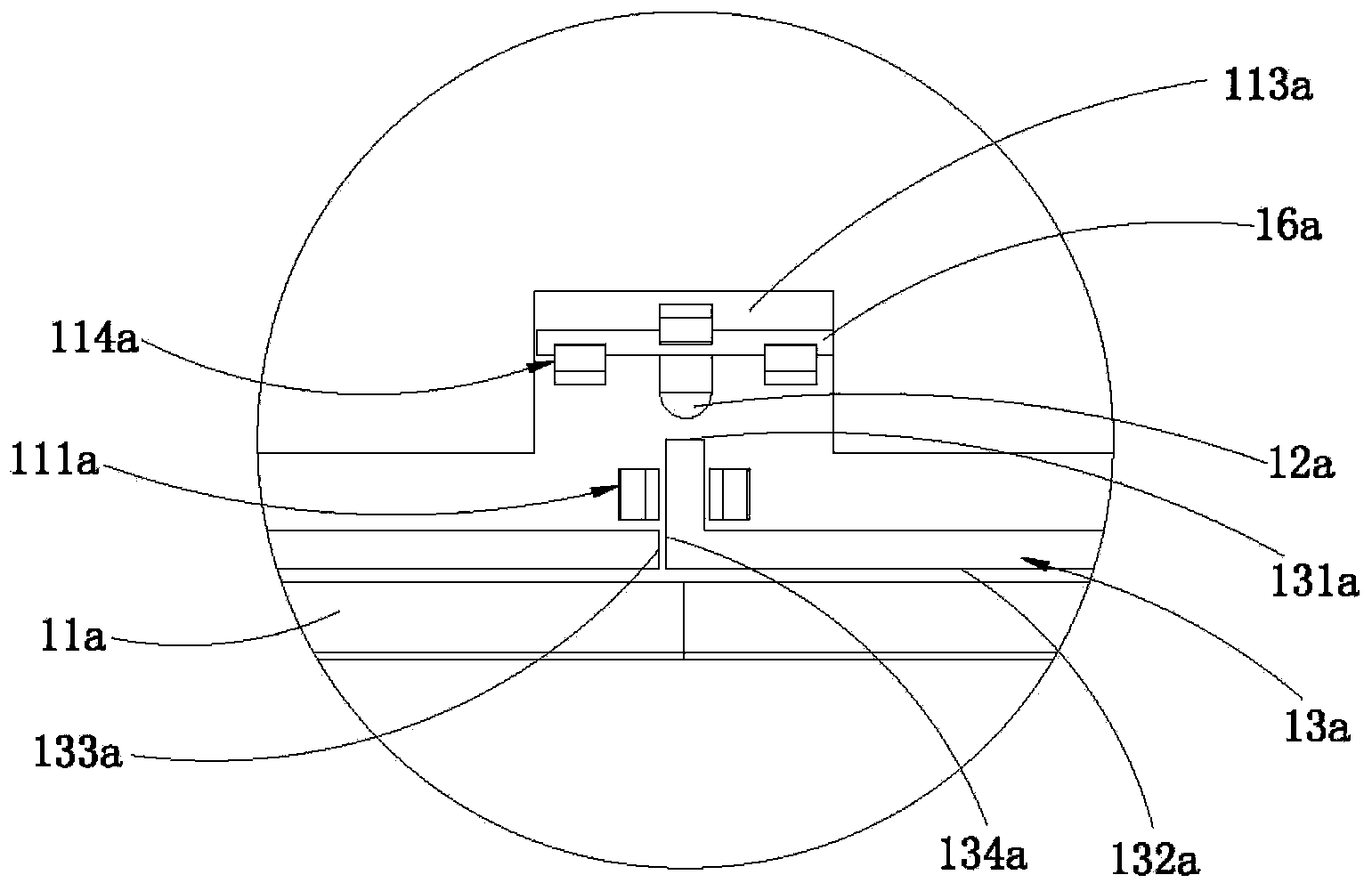

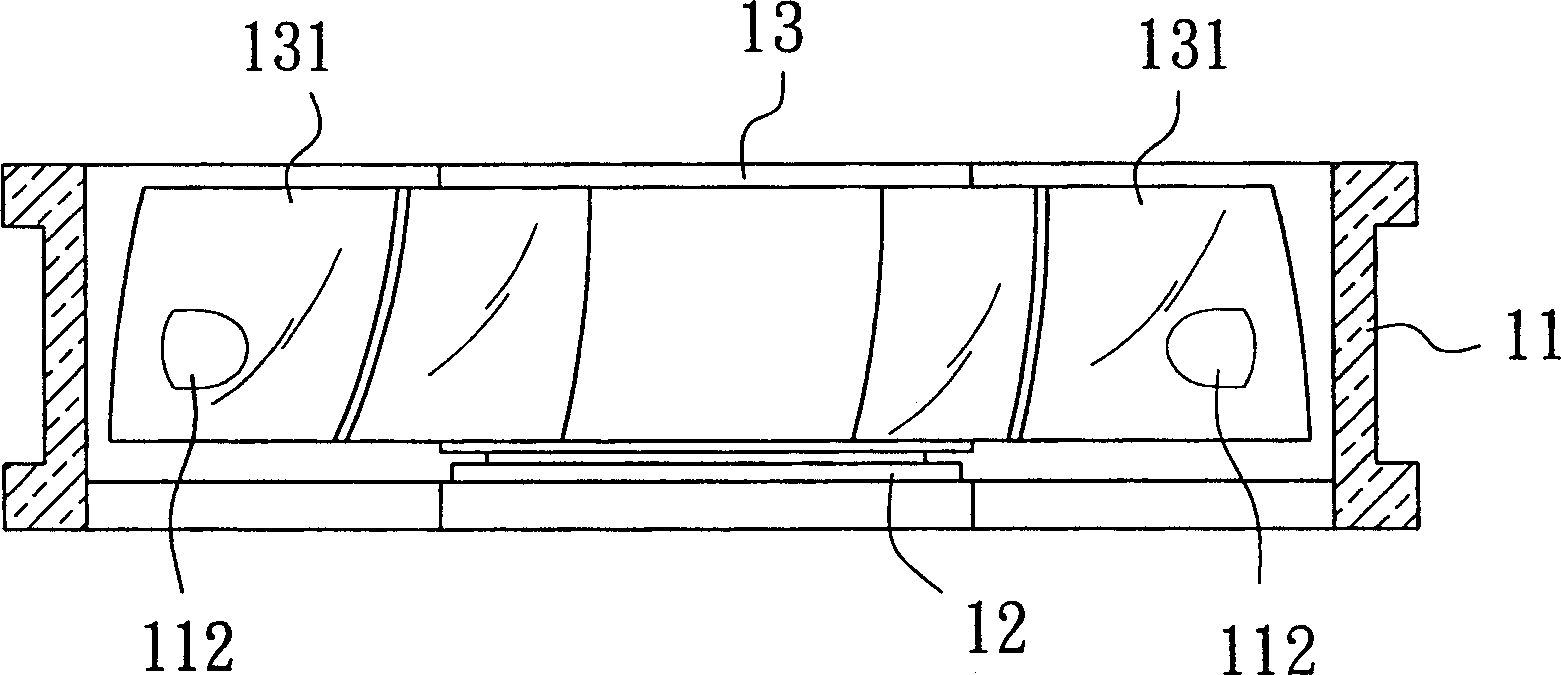

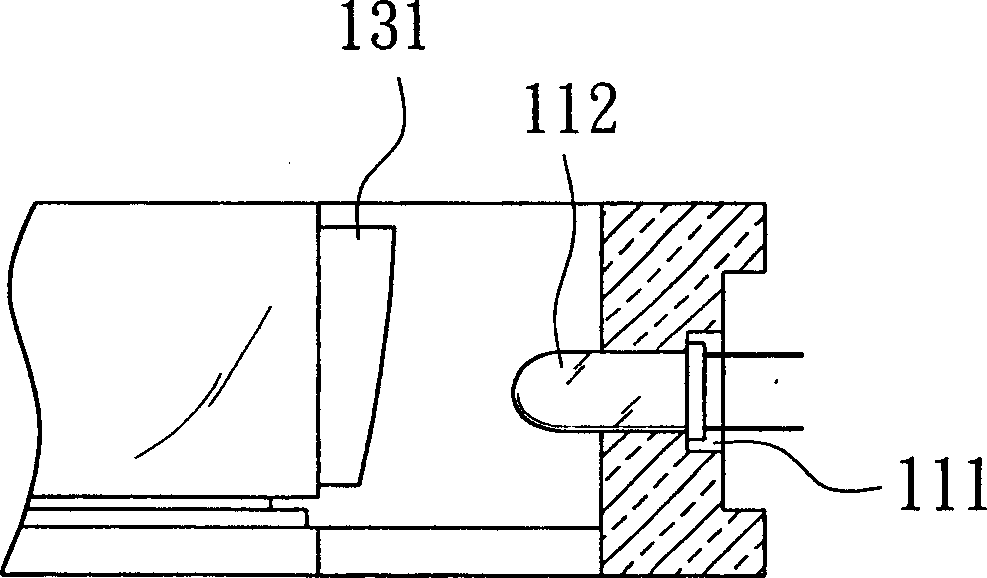

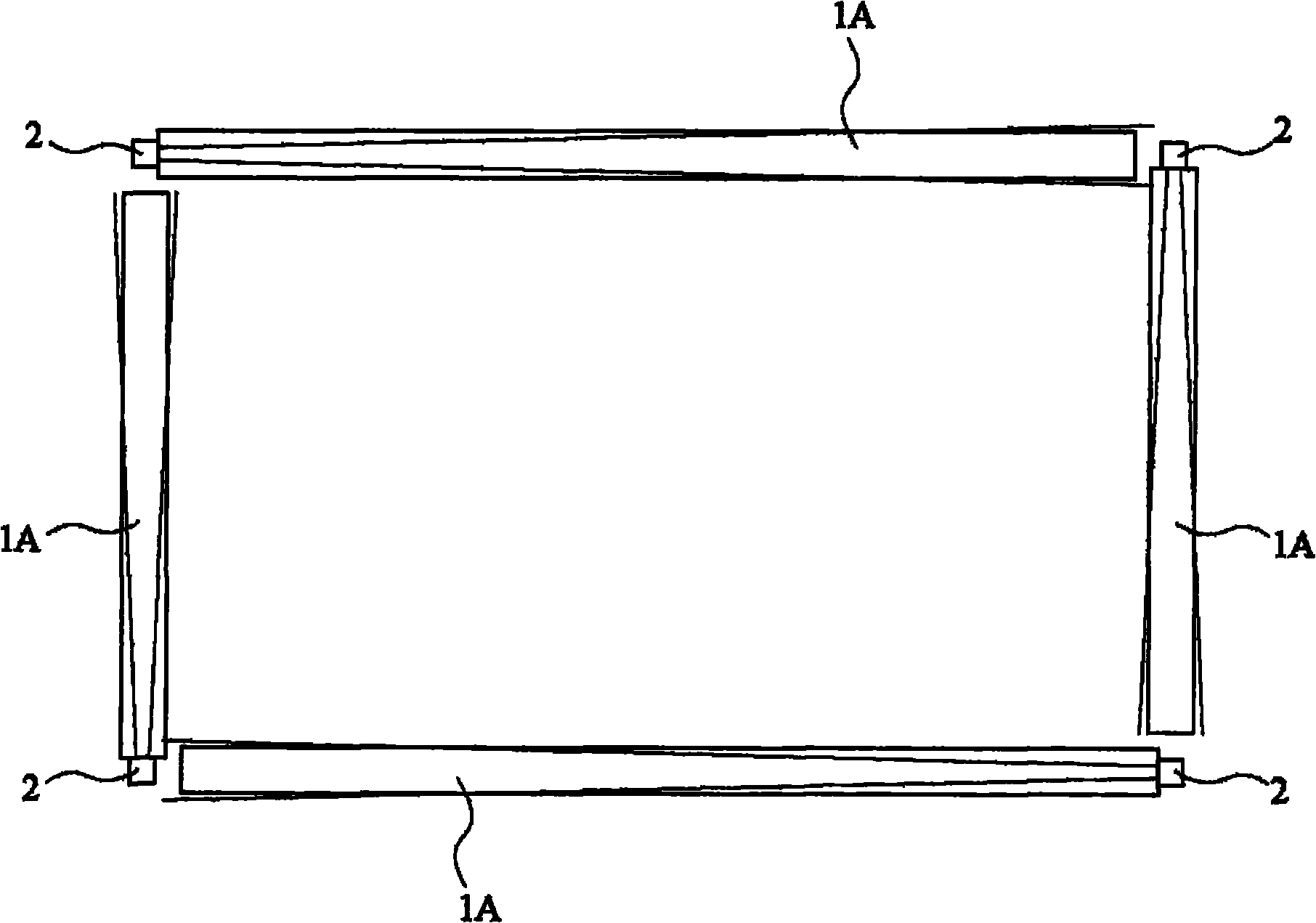

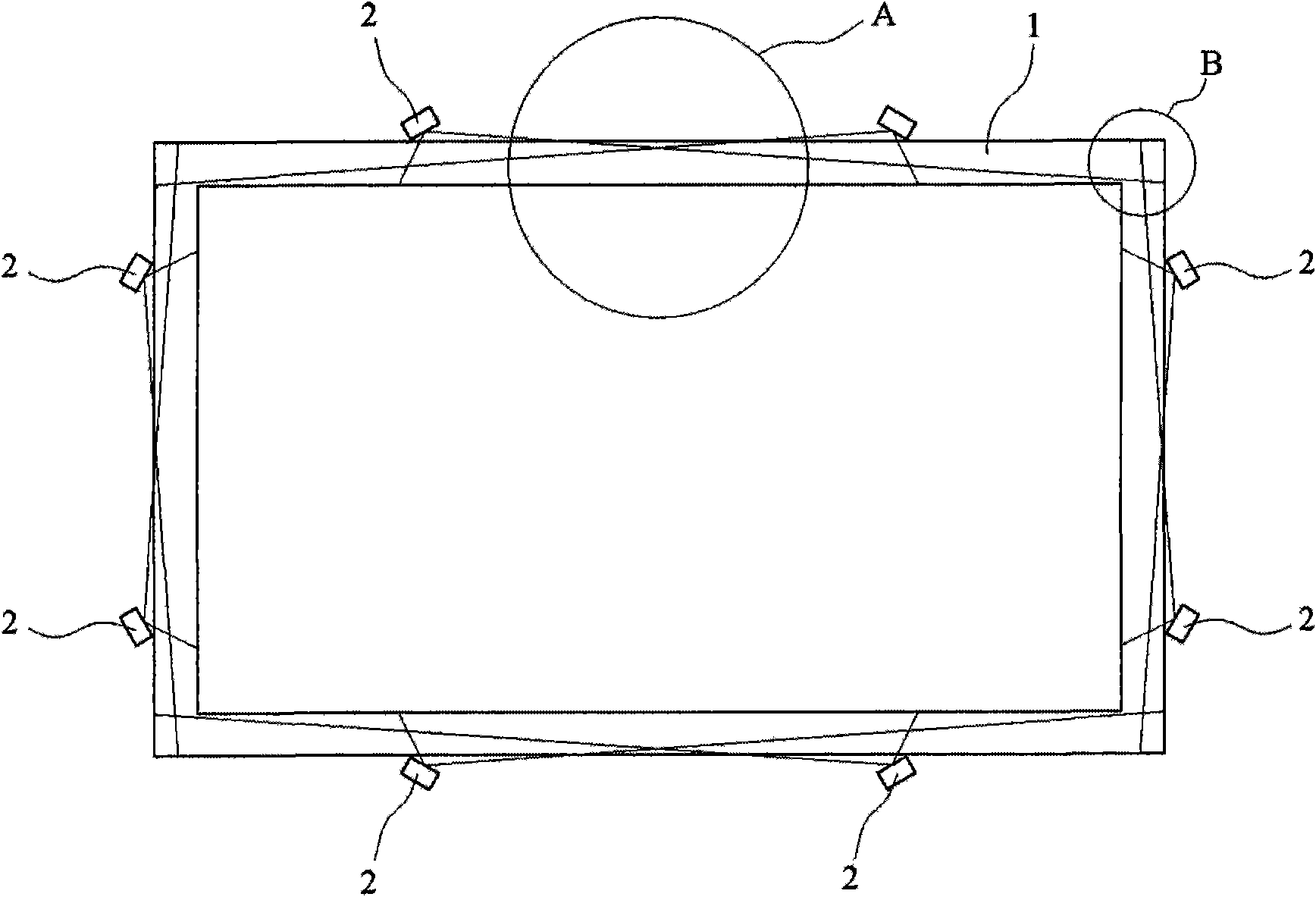

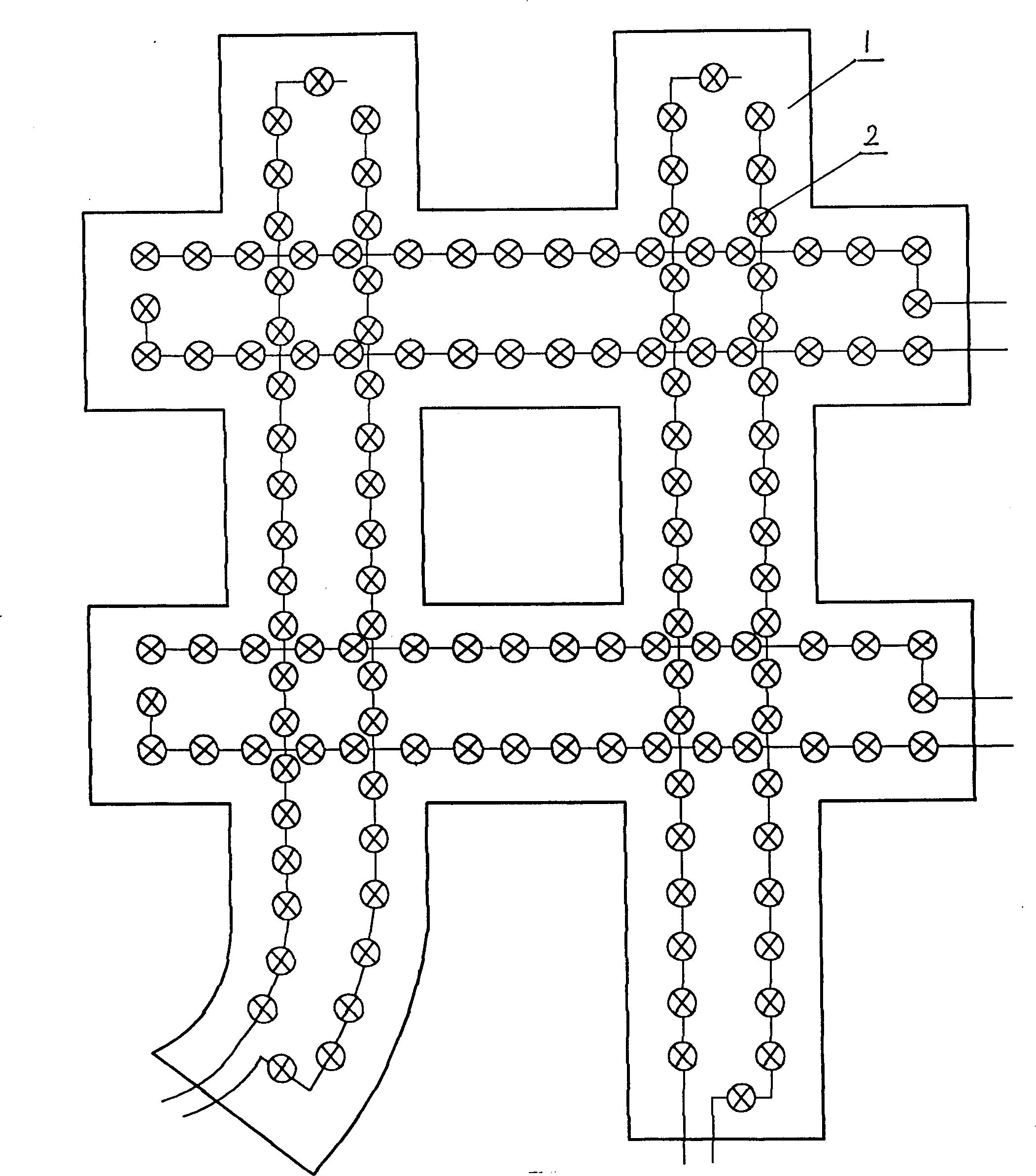

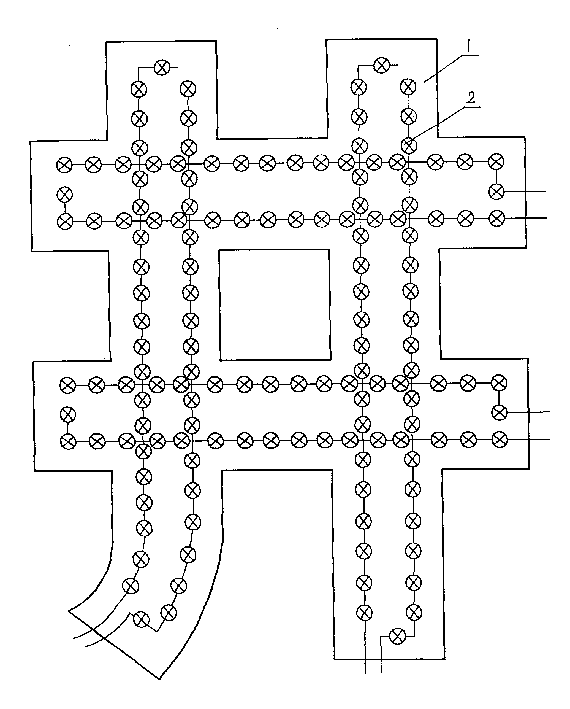

Device and method for generating luminous effect in frame body

ActiveCN101893183ASoft visual effectDecreased visual sensitivityMechanical apparatusPoint-like light sourceLight guideVisual sensitivity

The invention relates to a device and a method for generating luminous effect in a frame body. The device of the invention comprises a multilateral frame body and a plurality of LEDs, wherein the multilateral frame body is a light guide assembly with light guide property; at least two or more groups of LEDs are arranged on each side of the multilateral frame body; an included angle is formed between the projection directions of light rays of every two adjacent groups of LEDs into the side of the multilateral frame body, on which the two adjacent groups of LEDs are positioned. The device and the method have the advantages of making visual effect soft by mixing the light rays of more than two groups of LEDs without painstakingly screening the brightness and chromaticity of the LEDs so as to reduce visual sensitivity of the brightness and chromaticity and make the whole luminous effect more uniform.

Owner:苏州茂立光电科技有限公司

Light-guiding structure, housing and electronic device

PendingCN108508525AUniform luminous effectMeet fashion needsMechanical apparatusLight guides detailsLight guideEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

LED lamp with seamless spliced structure

PendingCN107166185AUniform luminous effectSimplify the installation processLighting support devicesSemiconductor devices for light sourcesEngineeringLED lamp

The invention discloses an LED lamp with a seamless spliced structure. The LED lamp comprises a lamp body, a light-emitting assembly, a light distribution part and side covers. The LED lamp is characterized in that the light-emitting assembly and the light distribution part are installed in the lamp body; the side covers are assembled on the two sides of the lamp body; a splicing station is reserved, and an electricity conduction terminal is arranged on the splicing station; and the side end can be spliced with the side ends of other lamp bars, and the light distribution part keeps in seamless joint. By means of the LED lamp with the seamless spliced structure, due to side plates which are in butt joint, the light distribution part can be directly attached together, seamless joint of a light-emitting face is maintained, direct splicing is conducted through the lamp bars in modular design, each independent lamp module can be directly spliced in a seamless manner, the overall light-emitting effect is uniform and consistent after the spliced positions are lightened, and the seamless effect on optical illumination is achieved. In addition, all the modules are consistent and can be directly spliced, the installation process is simple, splicing is simple and easy to conduct, and the labor cost and the installation difficulty are lowered.

Owner:安徽大明之光照明科技有限公司

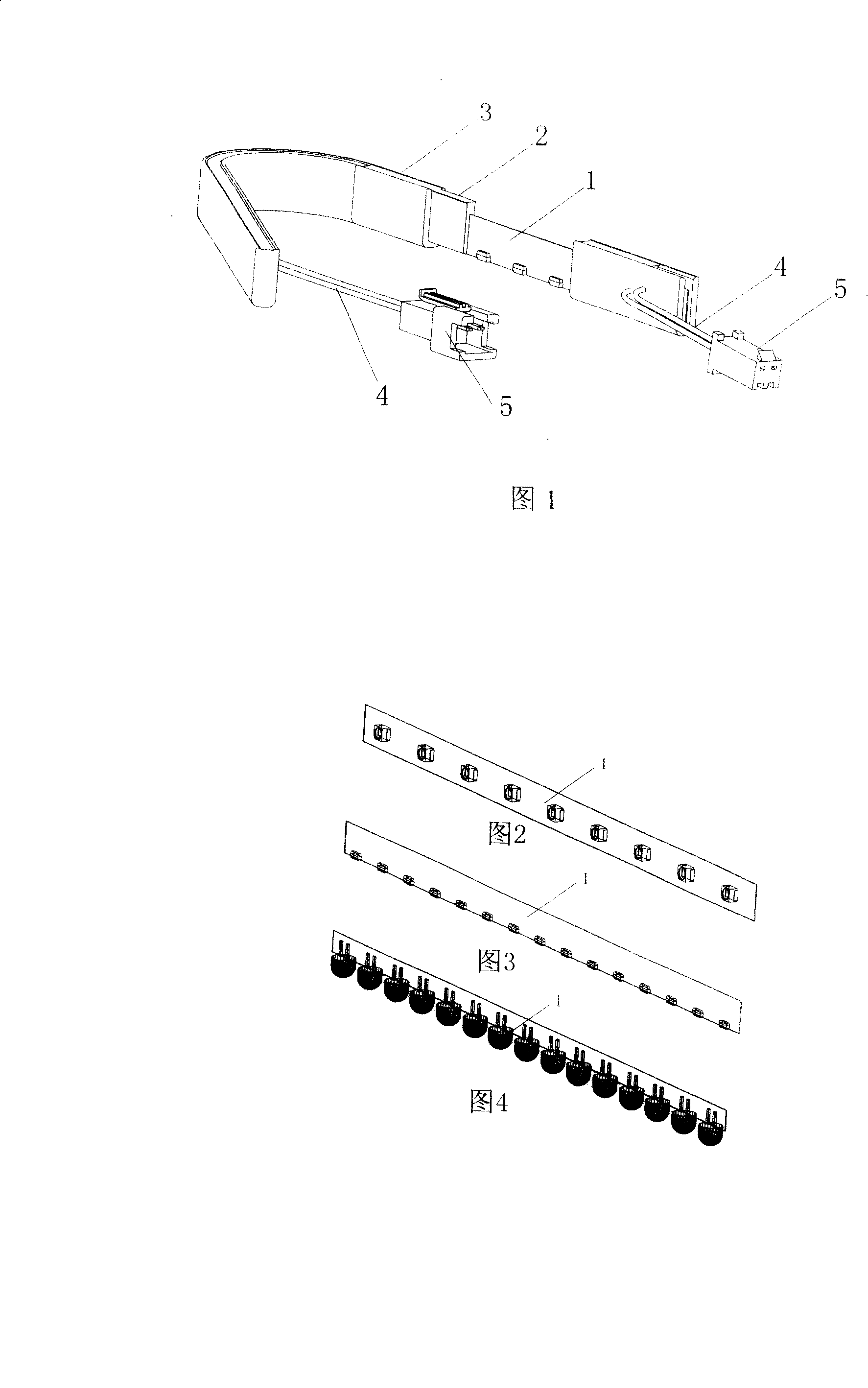

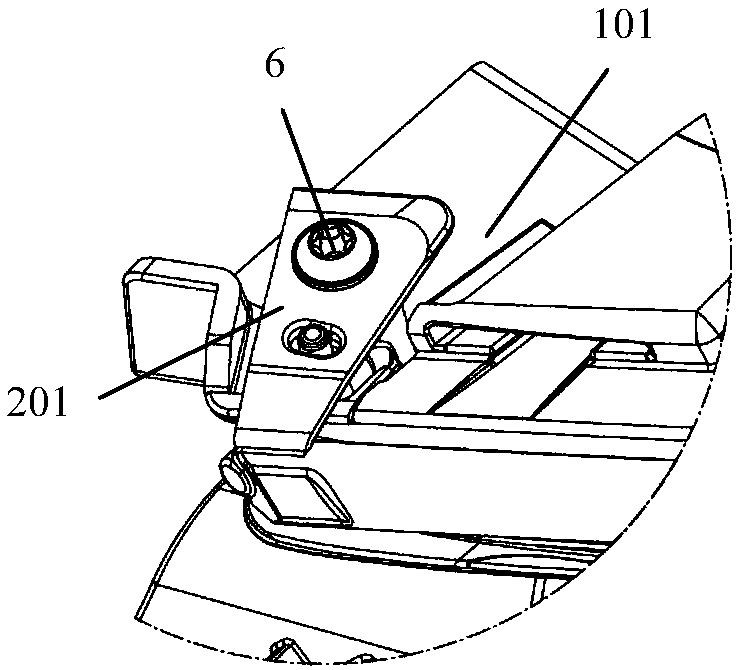

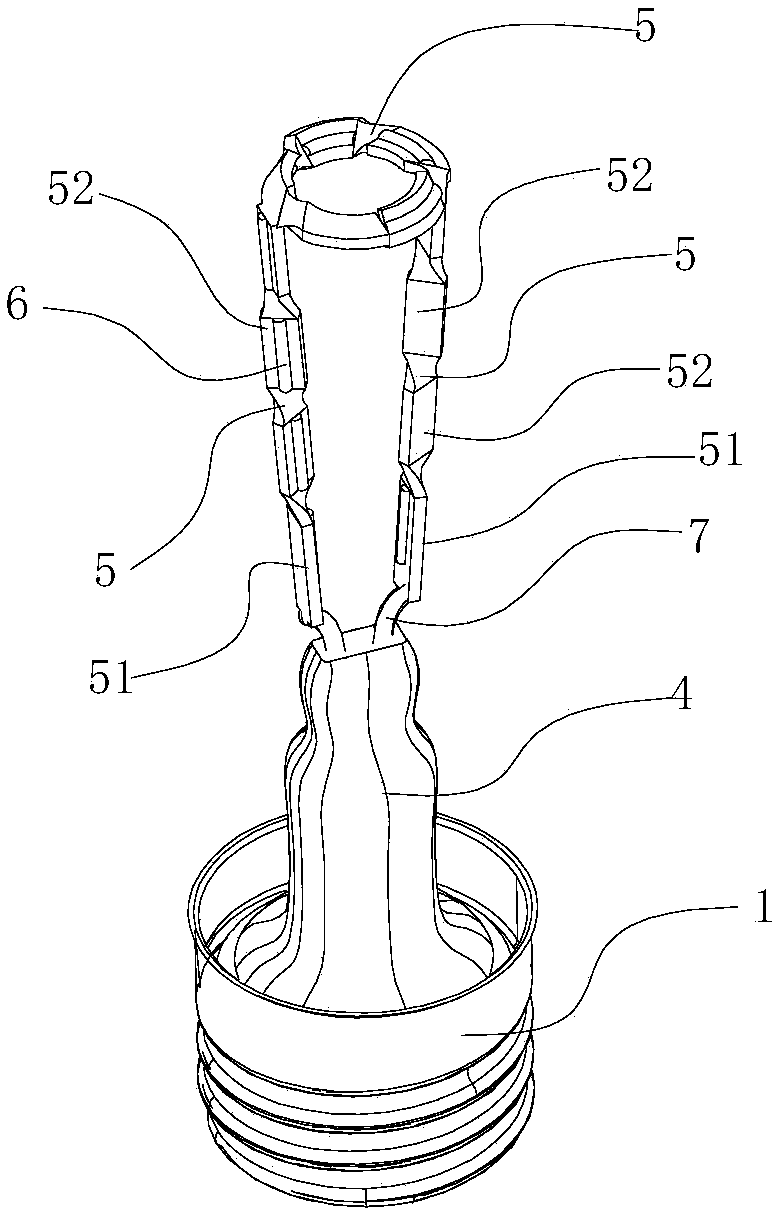

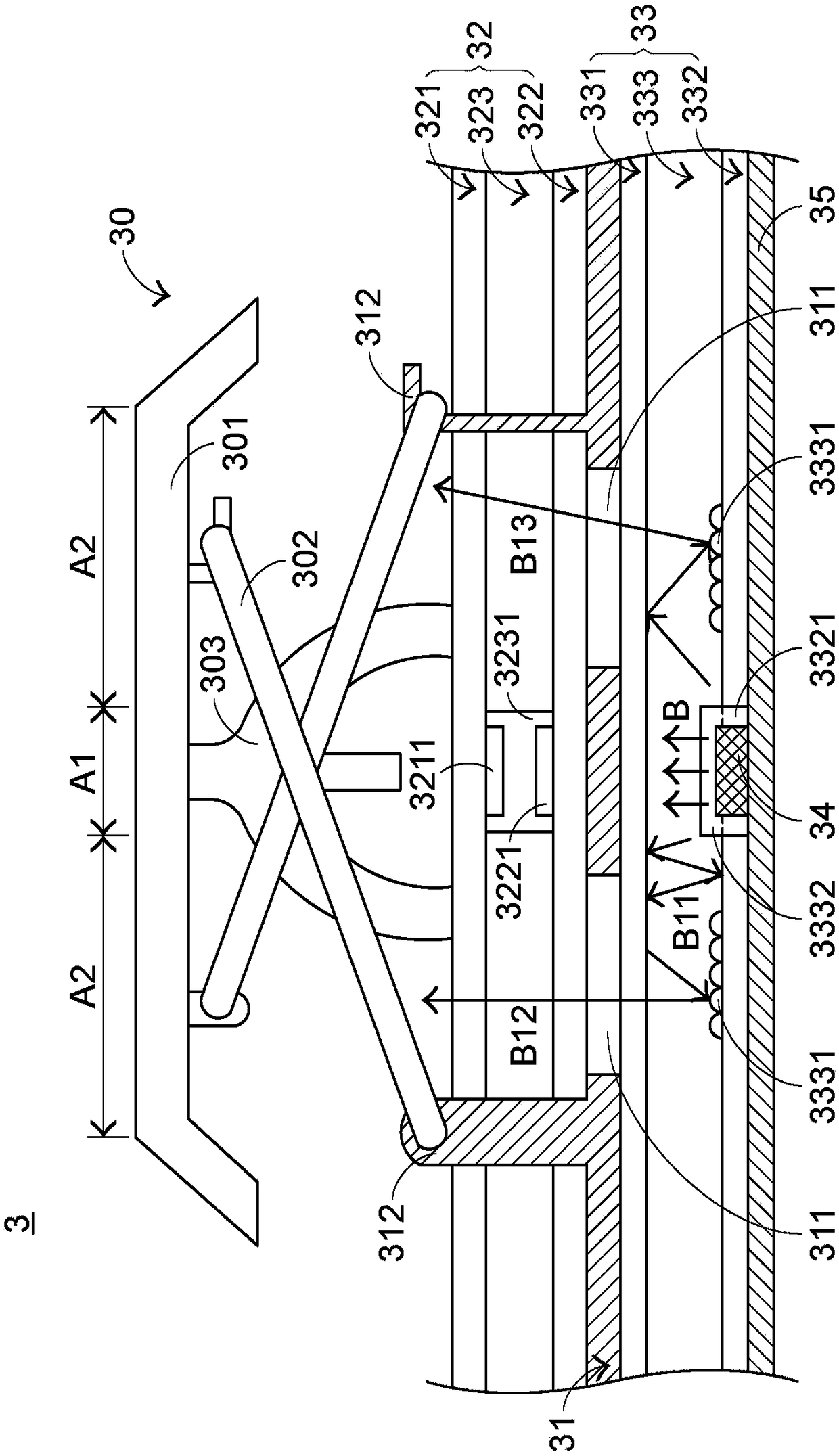

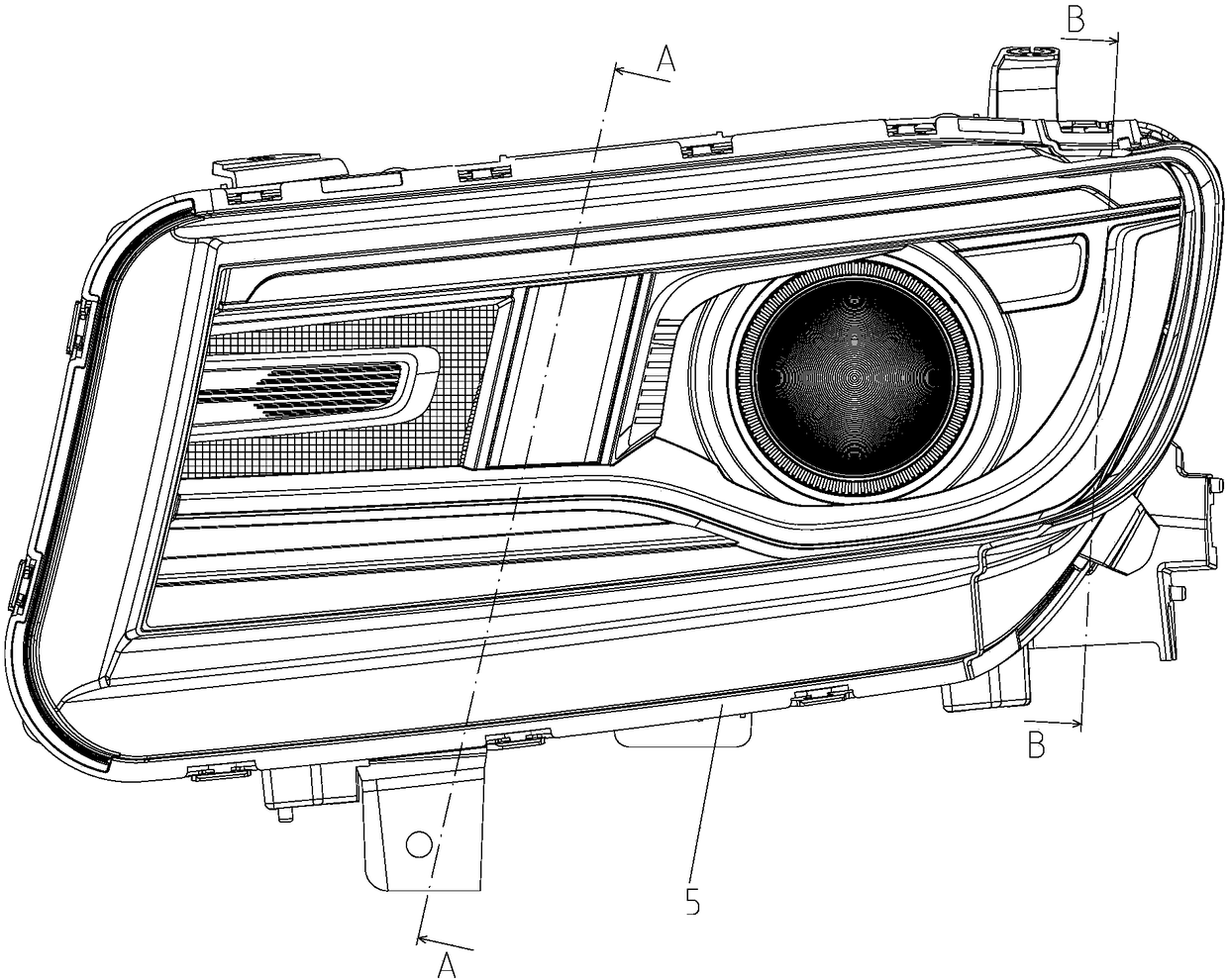

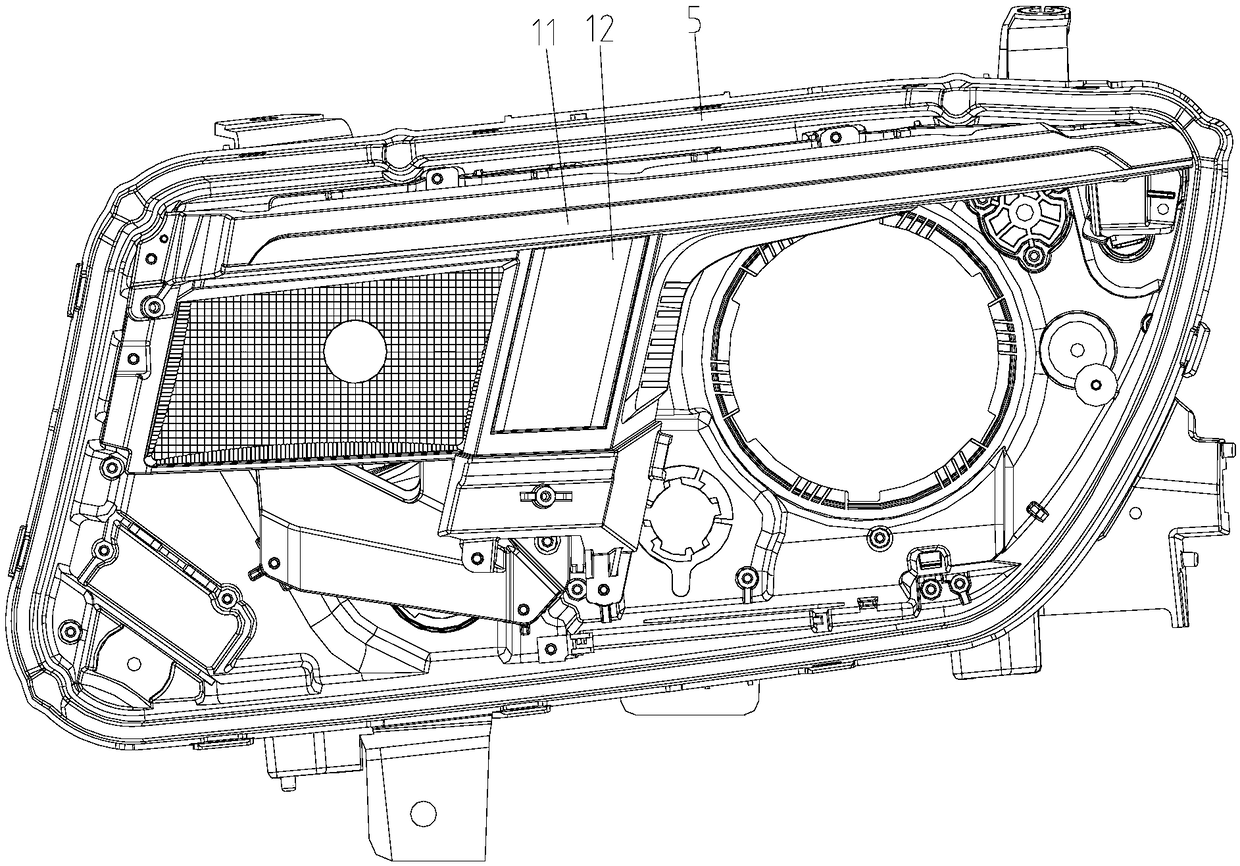

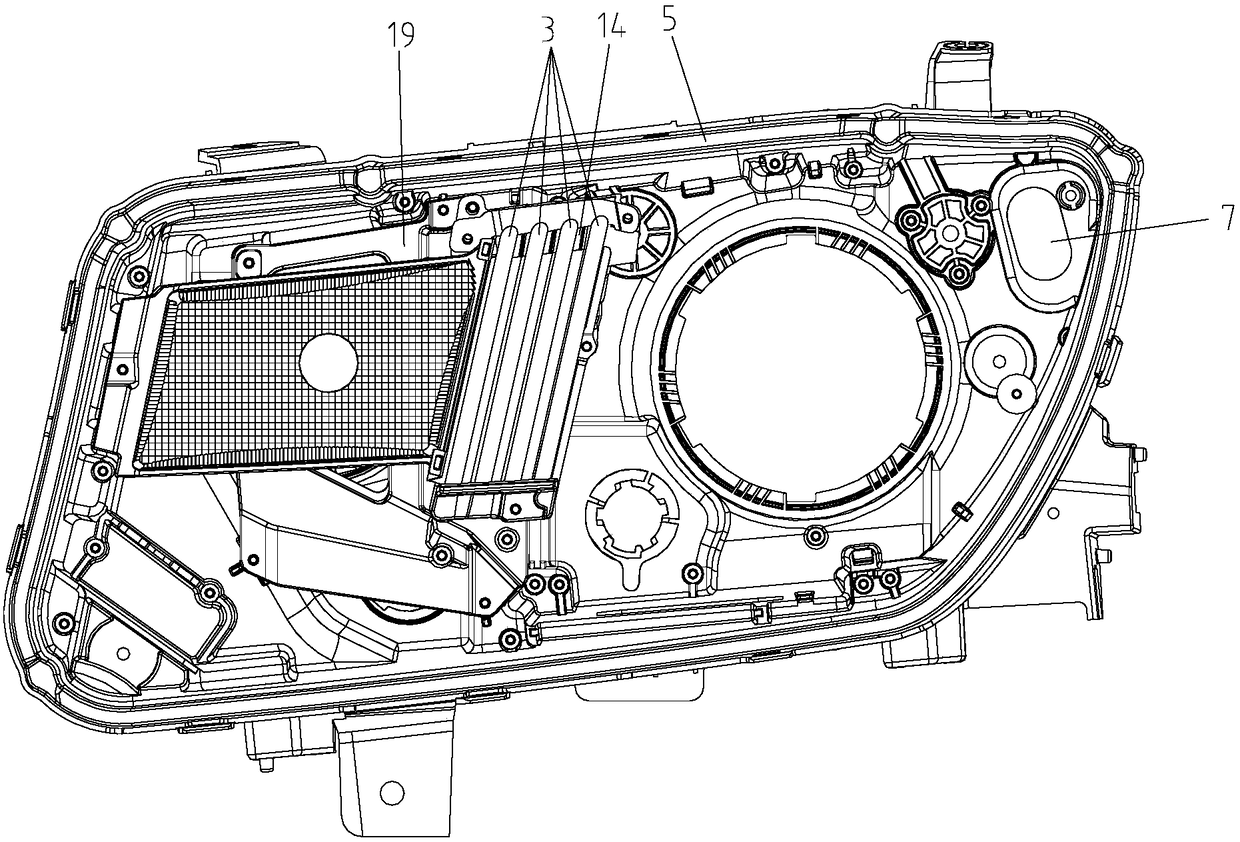

Light guide fixing assembly for vehicle lamp, vehicle lamp and vehicle

InactiveCN108375041AUniform structureUniform luminous effectMechanical apparatusVehicle headlampsLight guideMan-hour

The invention relates to a light guide fixing assembly for a vehicle lamp, the vehicle lamp and a vehicle. The light guide fixing assembly comprises a main lining frame (1), a light guide (2) and a front lining frame (3), a light guide containing groove (7) is formed in the main lining frame (1), and the light guide (2) is mounted on the light guide containing groove (7) and comprises a first ribpart (21) and a second rib part (22) which extend on the whole length of the light guide (2) and radially relatively protrude out. The front lining frame (3) is fixed to the main lining frame (1) andcovers the partial outer surface of the light guide (2), a first gap (4) and a second gap (5) are formed between the main lining frame (1) and the front lining frame (3), and the first rib part (21) and the second rib part (22) of the light guide (2) are clamped into the first gap (4) and the second gap (5) correspondingly. According to the light guide fixing assembly, when the light guide (2) isturned on, light emitting uniformity can be kept on the whole length of the light guide (2), and the part material cost and the man-hour cost in the assembly process are reduced.

Owner:PEZHO SITROEN AUTOMOBILS SA

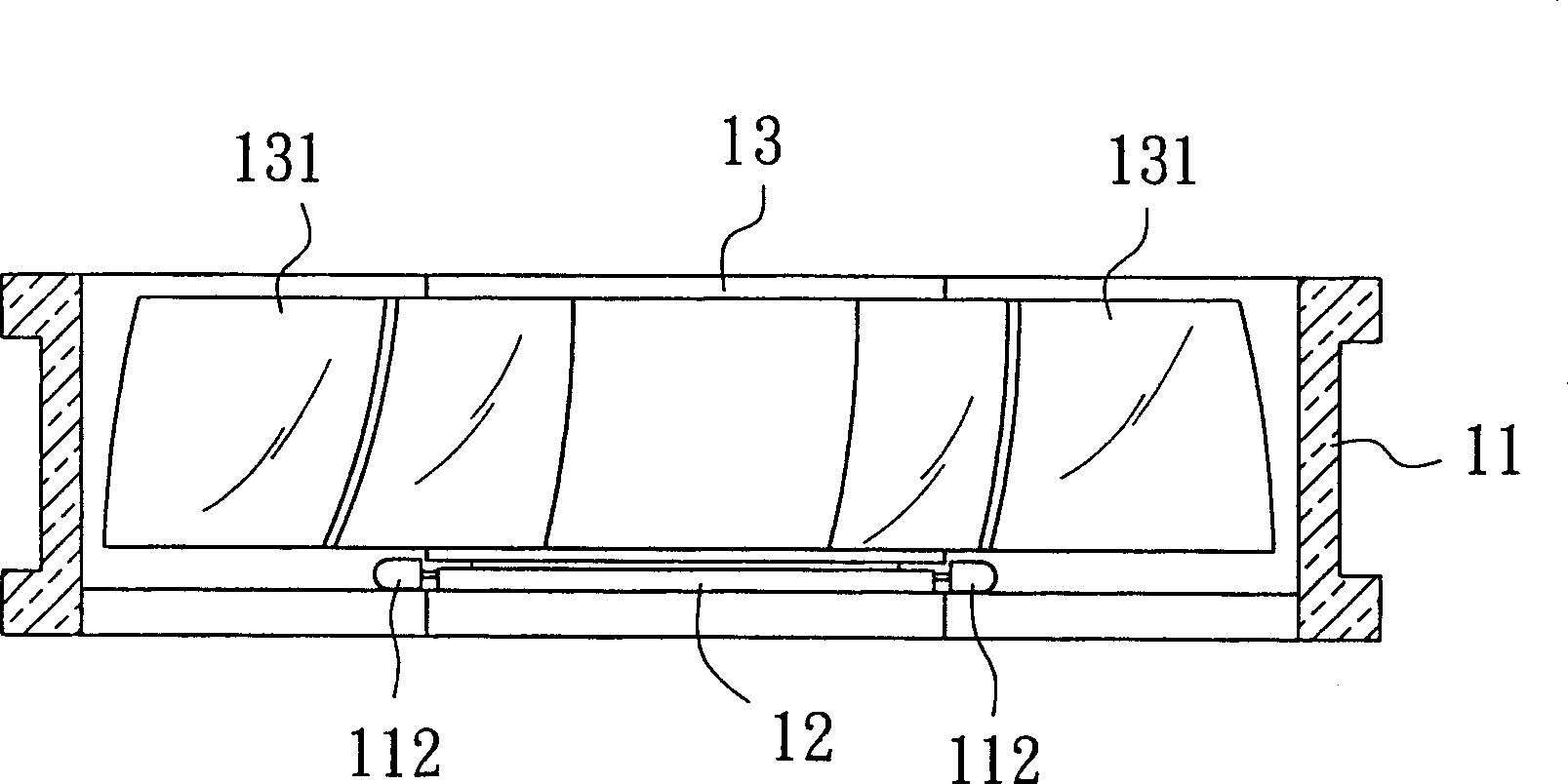

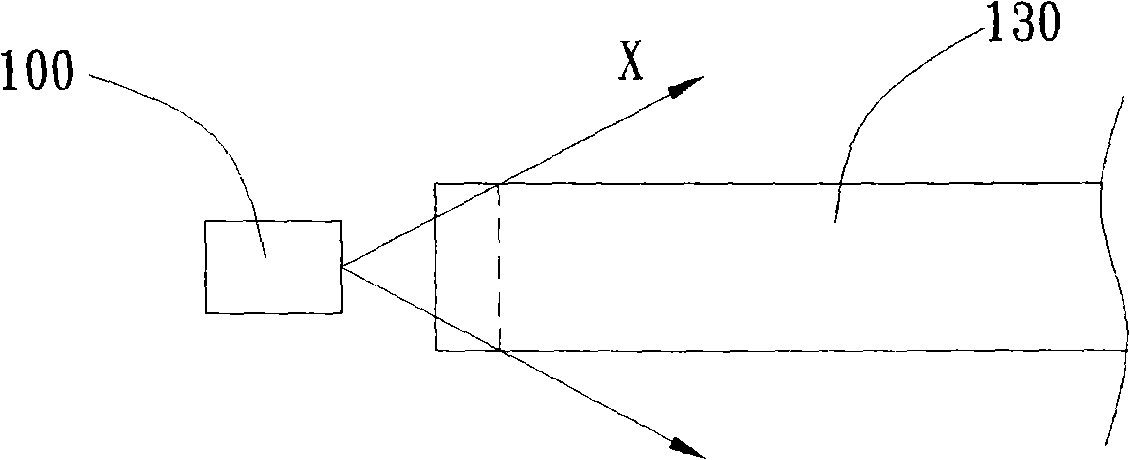

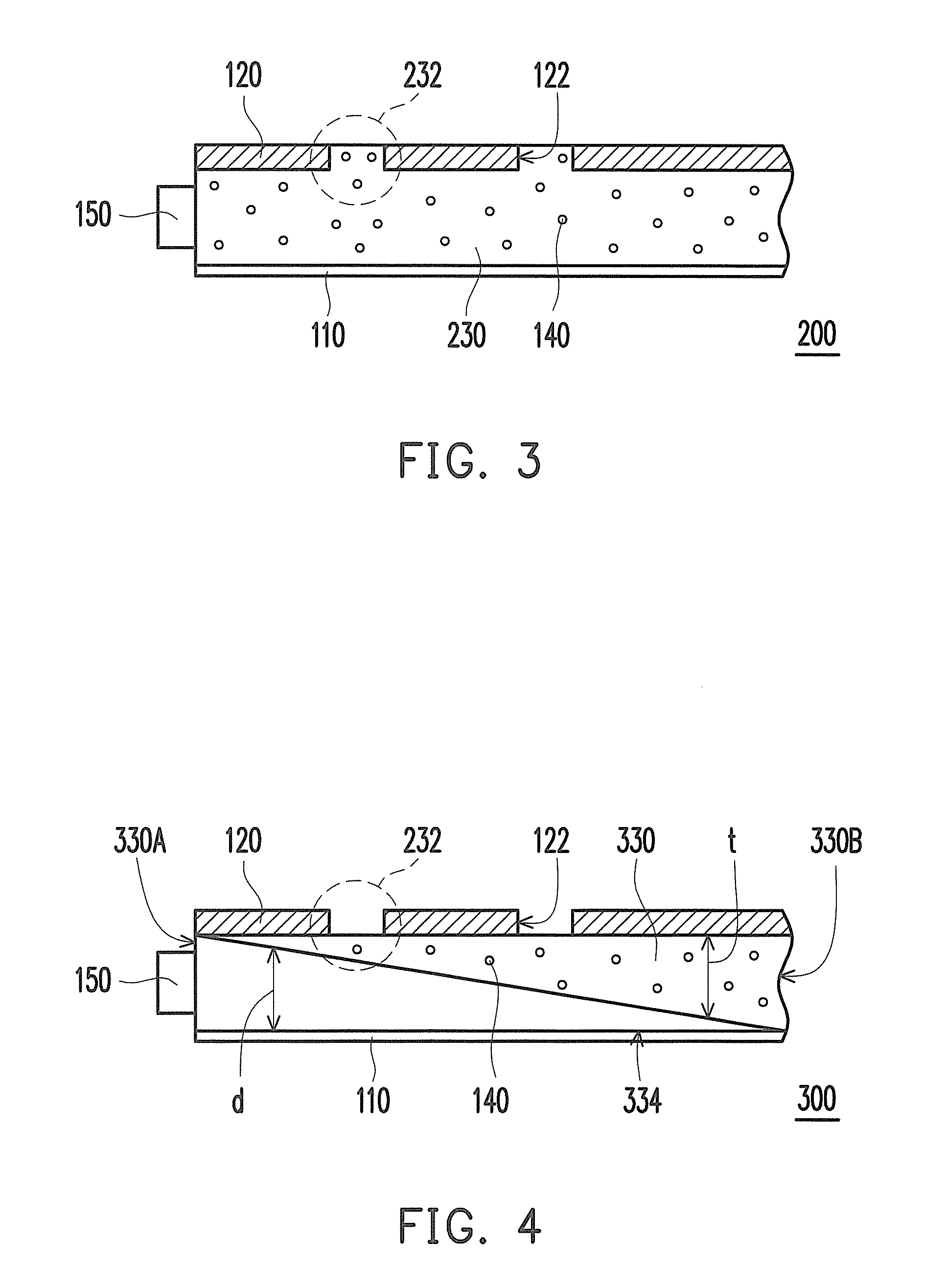

Backlight module

InactiveCN101308289AImprove luminous efficiencyUniform luminous effectOptical light guidesNon-linear opticsPhysicsOptoelectronics

The invention provides a backlight module, which has a light-emitting element and a light guide plate. The light guide plate has a light entry surface; the light-emitting element is arranged at one side corresponding to the light entry surface of the light guide plate to provide light which enters the light guide plate from the light entry surface; the light travels in the light guide plate to provide uniform light-emitting effect. A plurality of micro-structures are arranged on the light entry surface, with each micro-structure having a micro-structure depth; the light guide plate is provided with a thickness of a plate body; the ratio of the depth of the micro-structure to the thickness of the plate body is between 0.003 and 0.0625 in essence.

Owner:AU OPTRONICS CORP

Process for producing integrated energy saving neon lamp

The production process of integrated energy saving neon lamp includes the following steps: making mold, compounding material, setting bulbs, casting, demolding, installing lamp board, combination and test. The mold is made through projecting the writing sample or pattern to a mold plate, carving the mold core, painting mold silicone rubber, cutting, taking out the core to obtain the hollow mold. Inside the mold, serial bulb string is set and connected to a flush controller, mixed material of epoxy resin, agate resin, colour paste, fluorescent powder, curing agent and promoter are molded, and then neon lamp is produced through further polishing and regulation. The lamp bulbs may be also installed in the back to reach homogeneous lighting and other purposes.

Owner:潘二保

Luminous shelf assembly for refrigerator and refrigerator

InactiveCN108072221AGuaranteed insulation effectUniform brightnessLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention relates to the technical field of refrigeration equipment, particularly to a luminous shelf assembly for a refrigerator and the refrigerator. The luminous shelf assembly for the refrigerator provided by the invention is arranged in a refrigeration chamber of the refrigerator, and comprises a luminous shelf and an electric connector electrically connected with the luminous shelf, wherein the luminous shelf is manufactured from an electroluminescent material; the whole surface of the luminous shelf can uniformly give out light after the luminous shelf is energized, edge bright bands are avoided, brightness of all corners in the refrigeration chamber of the refrigerator is uniform, and user experience is improved; besides, the luminous material can give out light through frequency control, heat is not generated, and the heat preservation effect and luminous effect of the refrigerator are guaranteed; the electric connector comprises a male end terminal and a female end terminal which are in fit socket connection; one of the male end terminal and the female end terminal is arranged on the luminous shelf, and the other of the male end terminal and the female end terminal isarranged on the refrigeration chamber of the refrigerator; and the luminous shelf is in socket connection with the female end terminal through the male end terminal, so that detachable connection with the refrigeration chamber is achieved, cleaning is convenient, and sanitary and utilization effects are guaranteed.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

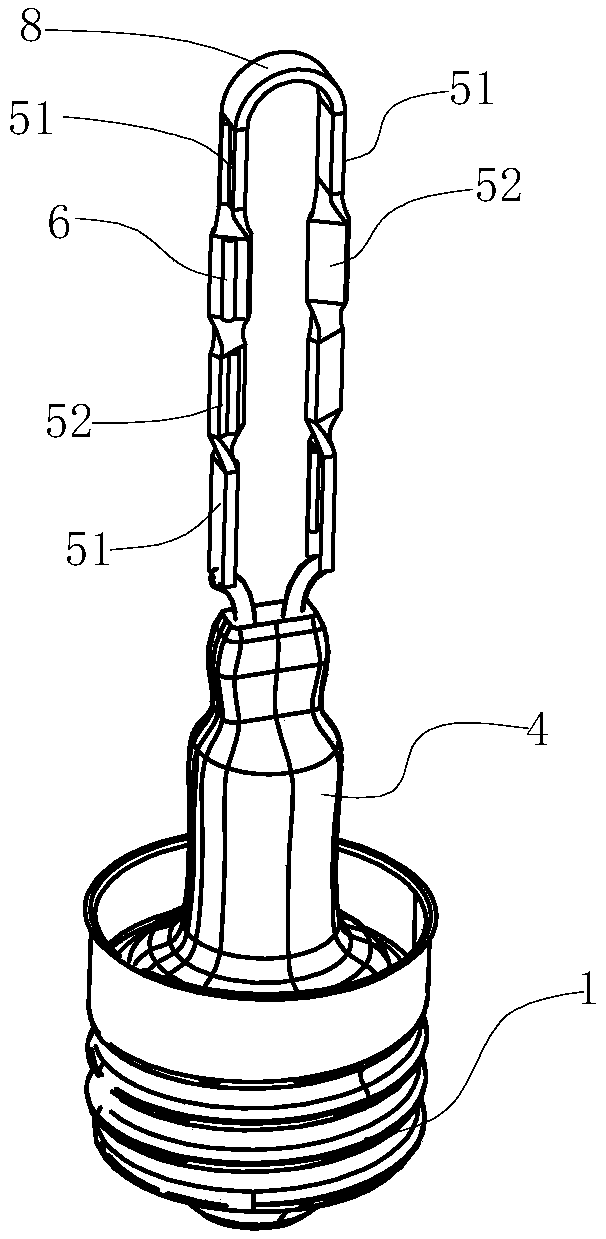

Novel LED filament

PendingCN108826032AEasy to processImprove yieldLight source combinationsLight fasteningsElectricityLED filament

The invention relates to a novel LED filament which comprises one or more filament base plates. The novel LED filament is characterized in that the each filament base plate comprises two or more sections of base plate bodies which are mutually connected sequentially, each base plate body is provided with two opposite luminous surfaces, the luminous surfaces of the adjacent base plate bodies are twisted with the extending direction of the filament base plates as the axis, and LED luminous elements are arranged on the luminous surfaces. According to the LED filament structure, heat dissipating is facilitated, the multiple luminous surfaces in the different directions are formed, thus the LED filament can give out light at multiple angles, and the more even and all-round luminous effect is achieved; and the LED luminous elements on multiple filaments can also be arranged in multiple electrical connection modes, the LED luminous elements of different colors can be arranged, and thus the multiple luminous effects are controlled.

Owner:HANGZHOUSIJUNSITECHCOLTD

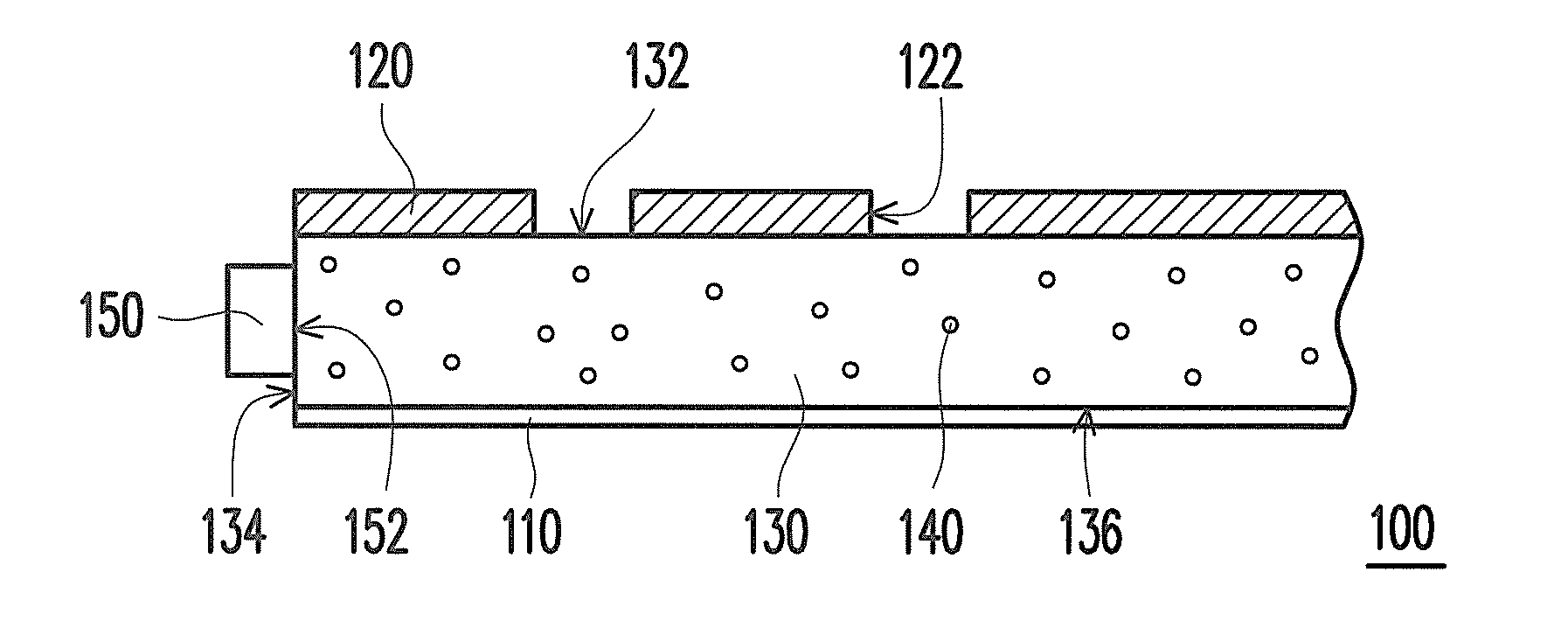

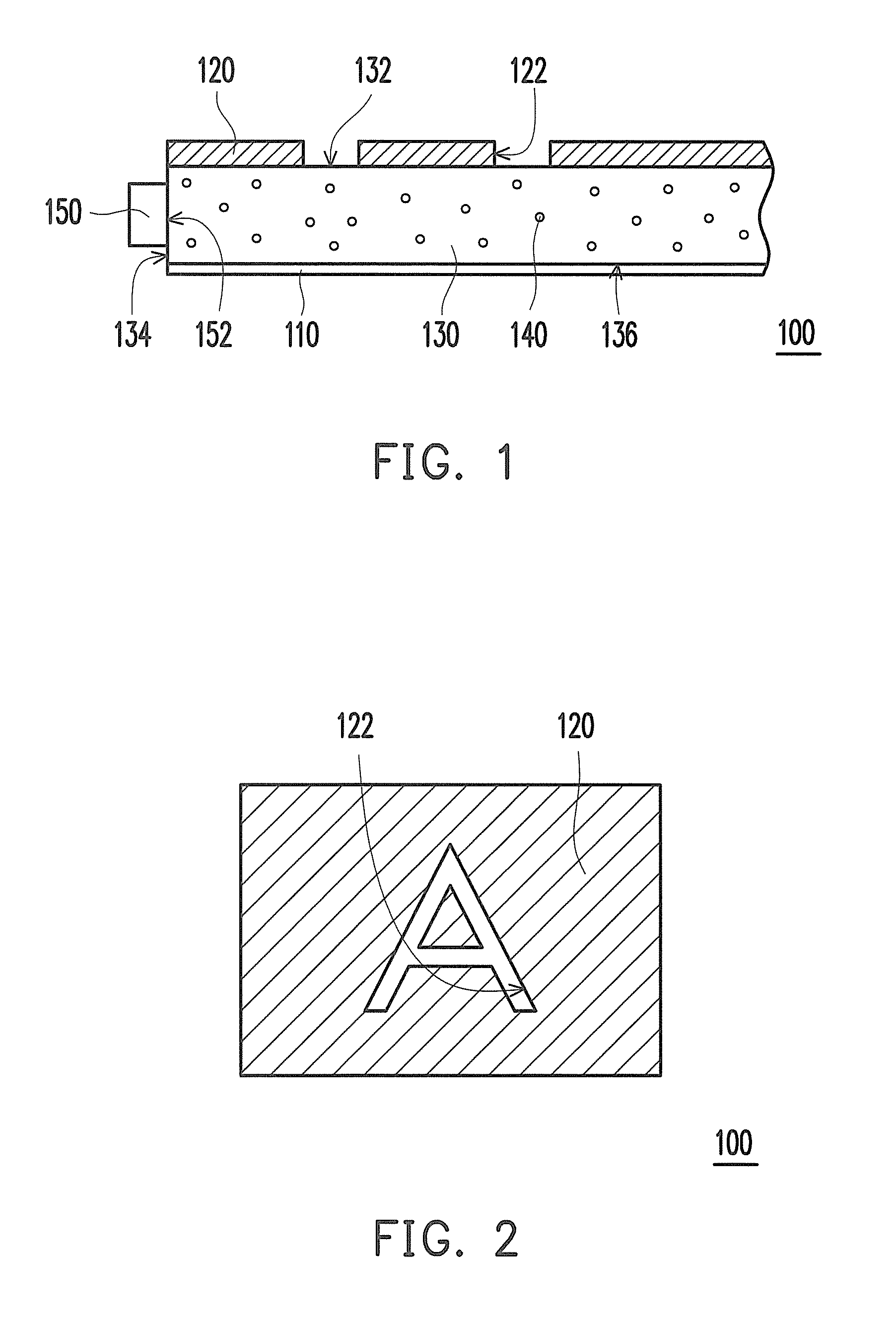

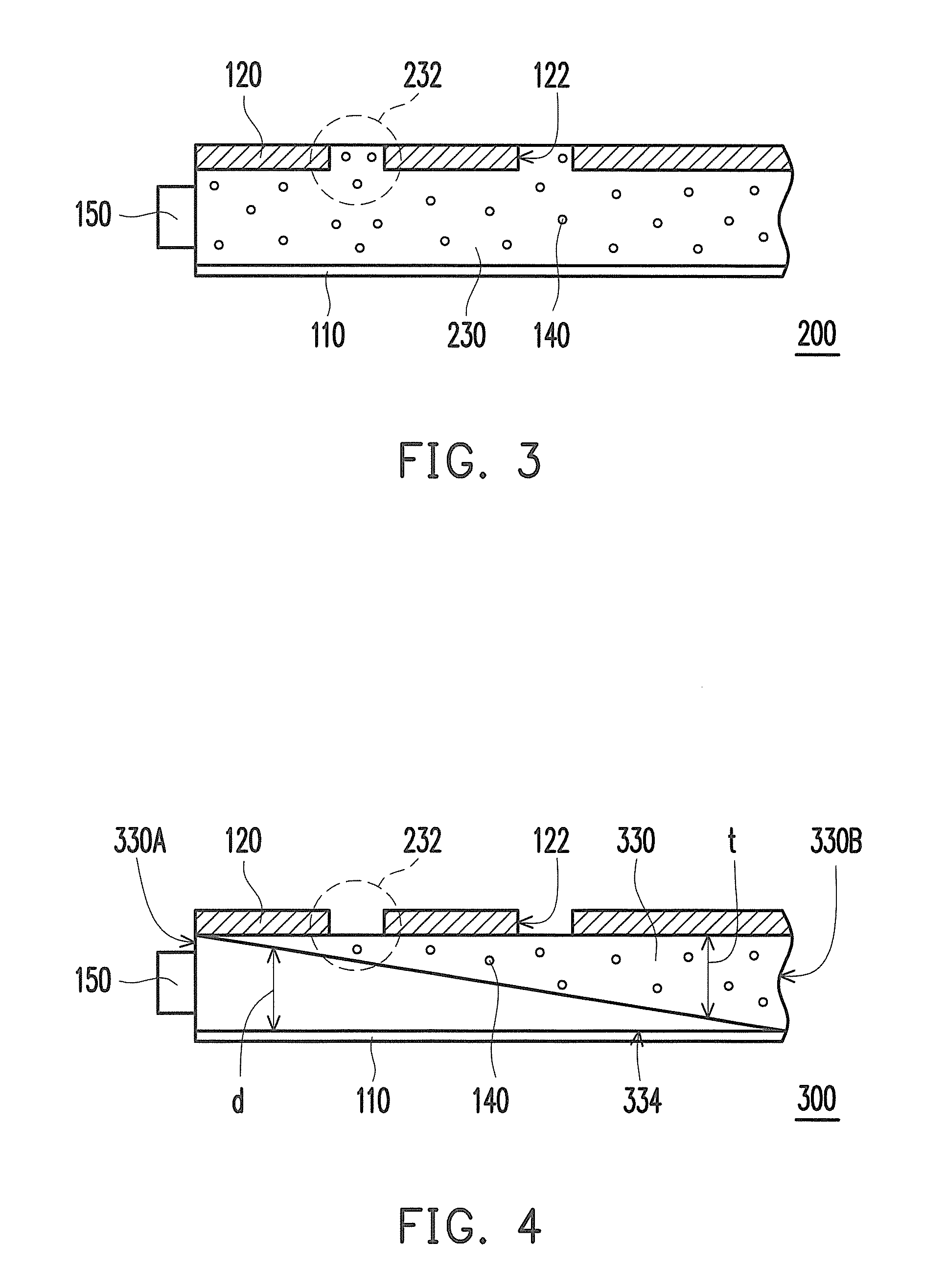

Decoration panel

ActiveUS8459859B2Simple elementsOverall small sizePlanar/plate-like light guidesIlluminated signsLight guideReflective layer

A light guide module capable of illuminating and being applied in a device for decoration is provided. The light guide module includes a reflective layer, a light guide with a plurality of diffusing particles, and a light source. The light guide has a side surface, a reflective surface and a light-exiting surface, thereby allowing a light from the light source to enter and reflect and exit the light guide respectively. The reflective layer is disposed on the reflective surface of the light guide for reflecting the light to the light-exiting surface. The light guide forms a portion of an outer surface of the device.

Owner:COMPAL ELECTRONICS INC

Method for improving manufacturing yield of LED chip

ActiveCN112447890AImprove manufacturing yieldSimple process operationSemiconductor devicesPhysicsThin membrane

The invention discloses a method for improving the manufacturing yield of an LED chip. The method comprises the steps: firstly carrying out the growth of a wafer epitaxial layer, then carrying out thecorrosion of a second highly-doped pGaP window layer to form an exposed region, and then depositing an oxide film; and then evaporating an ITO film on the surface of the epitaxial layer, continuouslymanufacturing a P-surface electrode and an N-surface electrode, finally evaporating a protective film on the surface of the P-surface electrode, then performing cutting, ultrasonically removing the protective film through hot water after cutting, and finally cleaning and expanding the film of the chip to form independent single core particles. According to the method, preparation of the LED chipis effectively achieved, the light-emitting effect of the chip is improved, MgF2 / CaF2 films alternately grow on the surface of the wafer, the light-emitting surface is smooth, the problems that in thecutting process, a diamond knife makes direct contact with an ITO film, and corner breakage, cracks and the like are likely to be generated are solved, the product quality and reliability are greatlyimproved, chippings and water stain and dirt residues in the cutting process are avoided, the product appearance yield is increased, and high practicability is achieved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

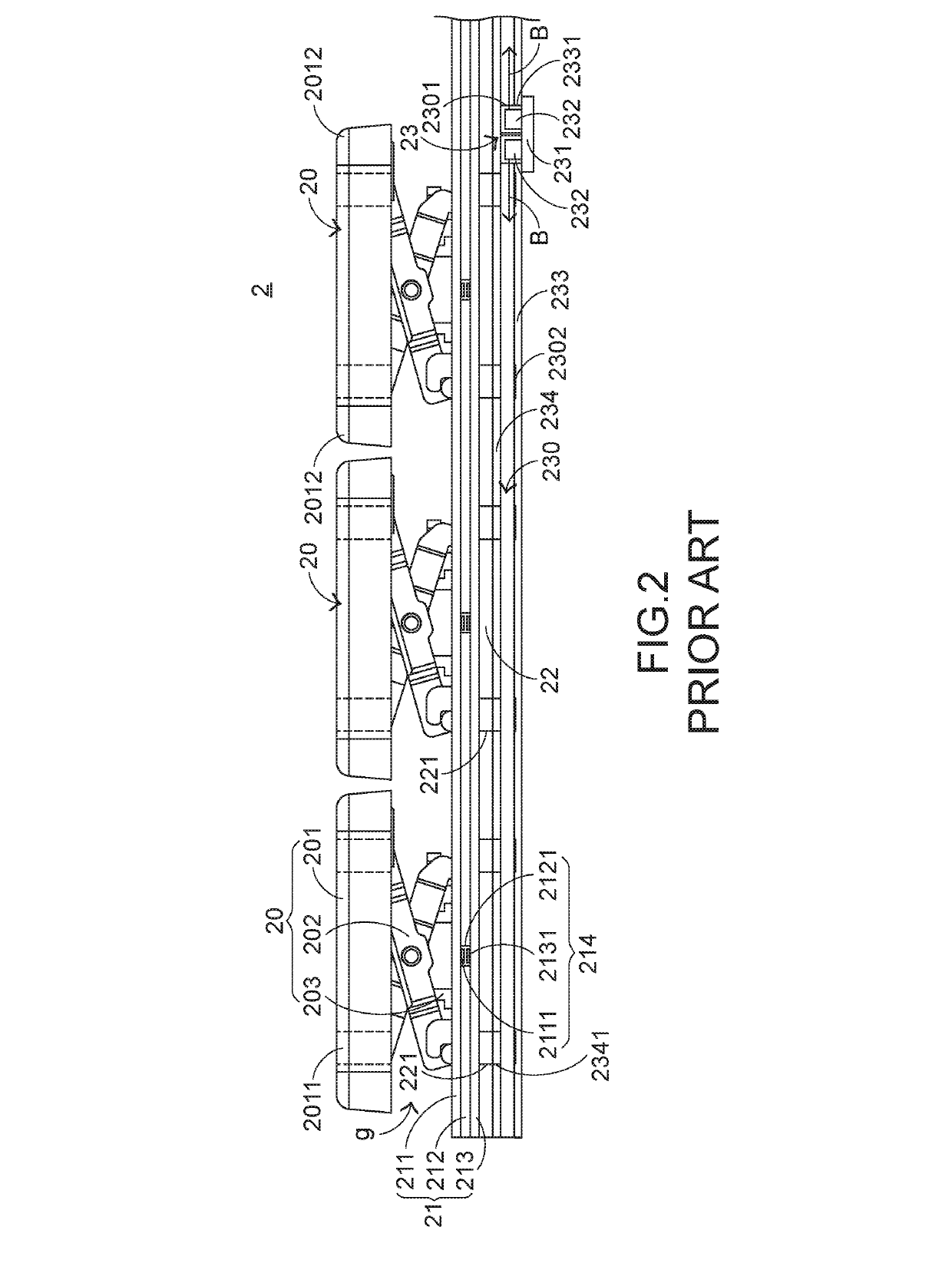

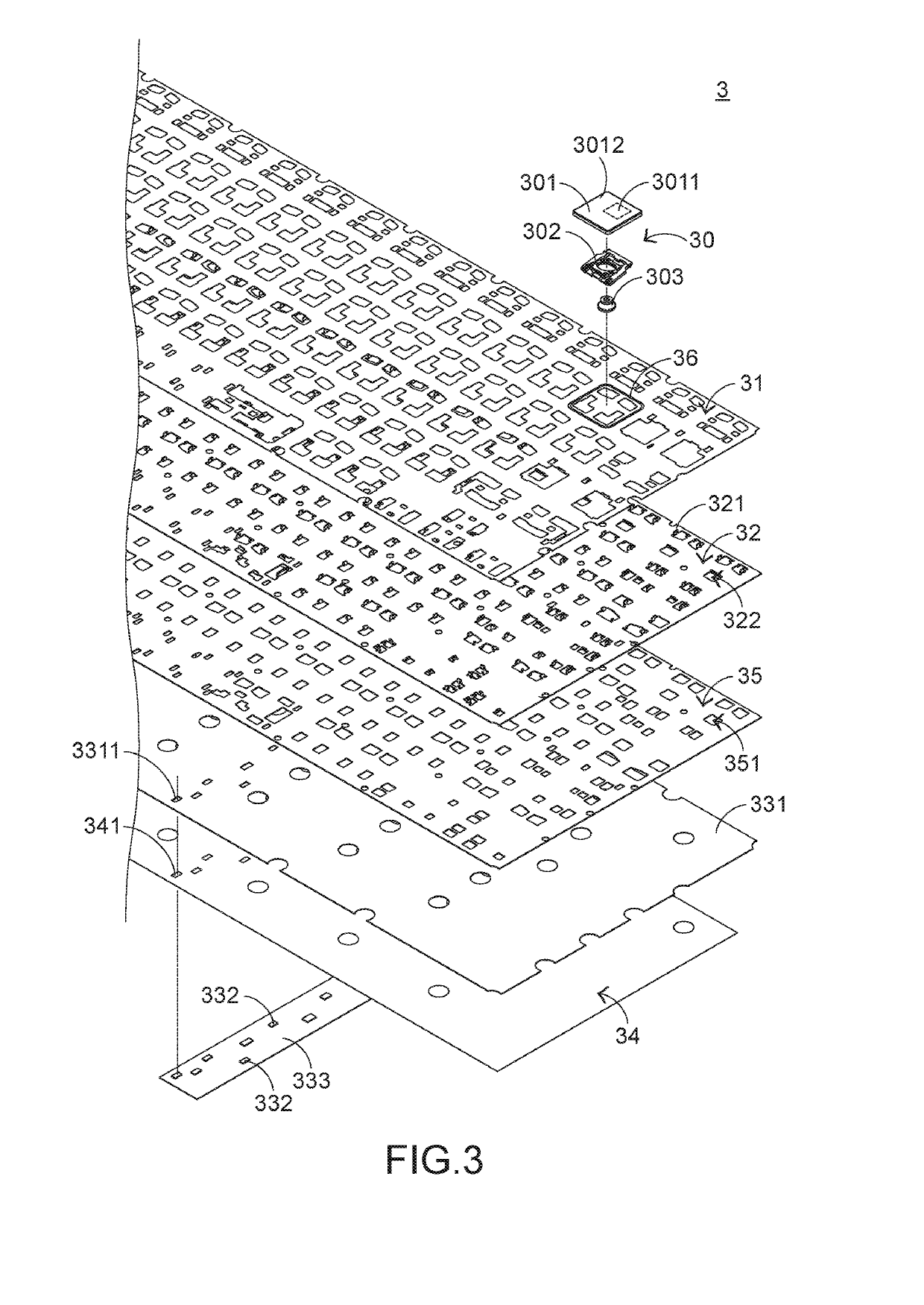

Luminous keyboard

A luminescent keyboard include keys, A support plate have openings in that support plate, A switch circuit board arranged on the support board, The backlight module comprises an upper reflective sheet, a lower reflective sheet and a light guide plate positioned between the upper reflective sheet and the lower reflective sheet, and the straight-down light emitting element extends into the light guide plate opening through the lower reflective sheet opening of the lower reflective sheet. A light beam output from a direct-down light emit element is transmitted to a light guide plate, and that light beam conduct in the light guide plate travels in the direction of the openings in the support plate through a plurality of microstructures in the light guide plate, and is project to keys after passing through the openings in the support plate and the switch circuit board.

Owner:PRIMAX ELECTRONICS LTD

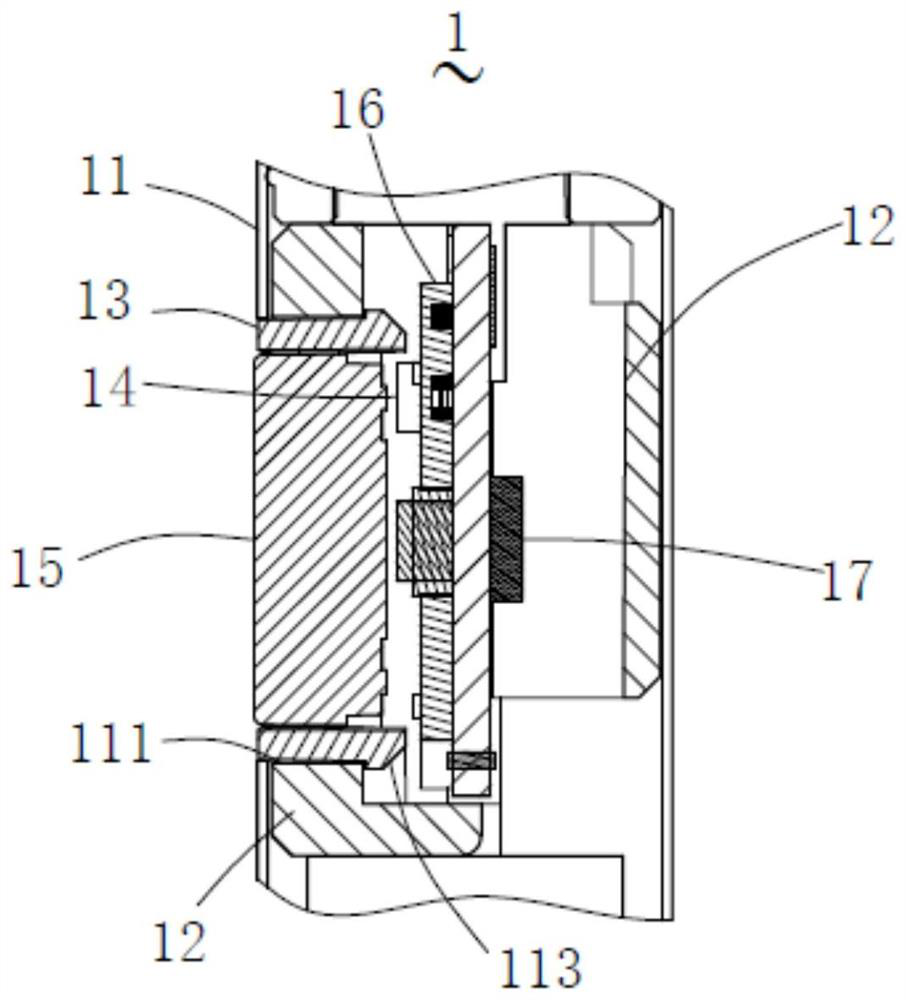

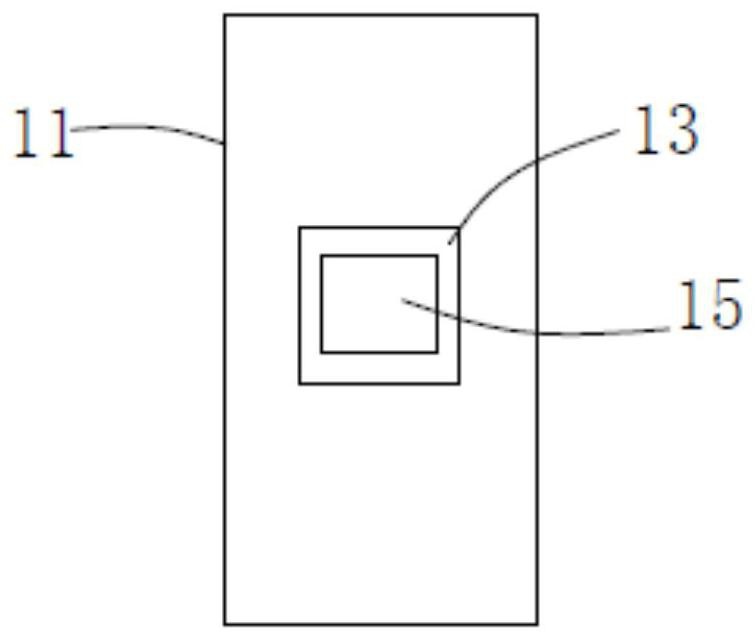

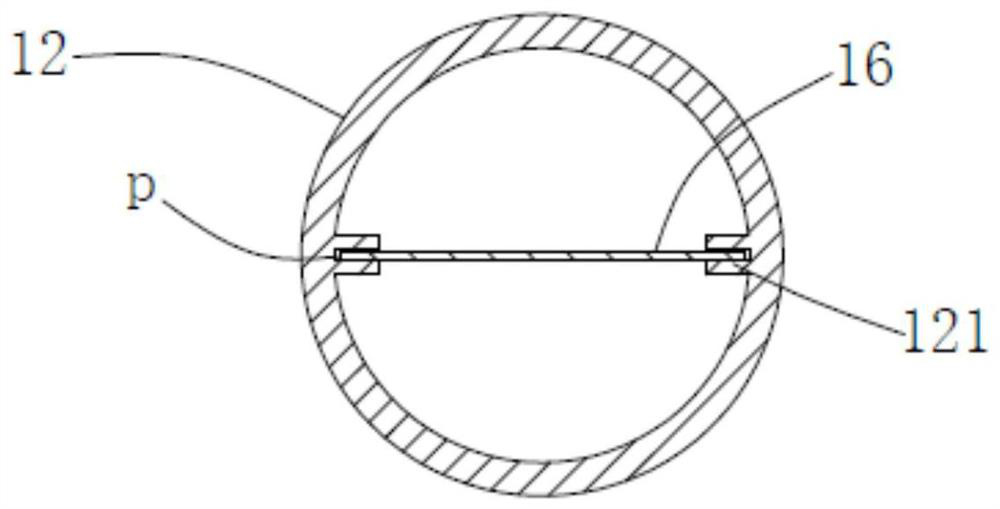

Key light guide device and method and aerosol generating device

PendingCN112490038AImprove user experienceUniform luminous effectElectric switchesLight guideFluorescence

The invention relates to the field of aerosol generating devices, and particularly discloses a key light guide device and method and an aerosol generating device. A transparent support and a first light source are arranged in a shell, and a light guide piece and a key are arranged in a mounting hole in the shell, so that the first light source in the shell emits light and then passes through the support; the support absorbs light based on the fluorescent substance and the transparent material and then refracts and reflects the light, the light guide piece can absorb the corresponding light based on self-illumination of the support, the light guide piece emits light to illuminate an annular area formed by the side face of the key, and a user can rapidly find the key located in the center ofthe light guide piece based on observation of the annular light guide piece. The position of the key is prevented from being mistakenly touched and found in the dark, and the use experience of a useris improved. The light is uniformly diffused based on the fluorescent substance in the support, and the bracket emits uniform light into the light guide piece, so that the light guide piece is more uniform in light emitting effect, the lighting effect is improved, and the light source utilization rate is increased.

Owner:SHENZHEN JIYOU TECH CO LTD

Lamp and headlamp

InactiveCN108302451AImprove aestheticsSmall footprintVehicle headlampsElectric circuit arrangementsElectricityHeadlamp

The invention relates to the field of automobile lamps, and provides a lamp and a headlamp. The lamp comprises a first module, a second module and a control unit. The first module comprises a first light guiding strip and a first light source used for transmitting light rays into the first light guiding strip. The second module comprises second light guiding strips and second light sources used for transmitting light rays into the second light guiding strips. One end of each second light guiding strip is adjacent to the middle portion of the first light guiding strip, the included angle between the first light guiding strip and each second light guiding strip ranges from 42 degrees to 90 degrees, and each of the first light guiding strip and the second light guiding strips comprises a rearsurface with reflection lines and a smooth front surface, and accordingly the rear surfaces can reflect out the light rays from the front surfaces. The control unit is electrically connected with thefirst light source and the second light sources, and accordingly, the lamp is switched between a daytime lamp mode and a position lamp mode by adjusting the grading value of the first light source and the grading value of the second light sources. After the lamp is powered on, the uniform light emitting effect similar to the T shape can be achieved, and the attractiveness of the lamp is improved.

Owner:GREAT WALL MOTOR CO LTD

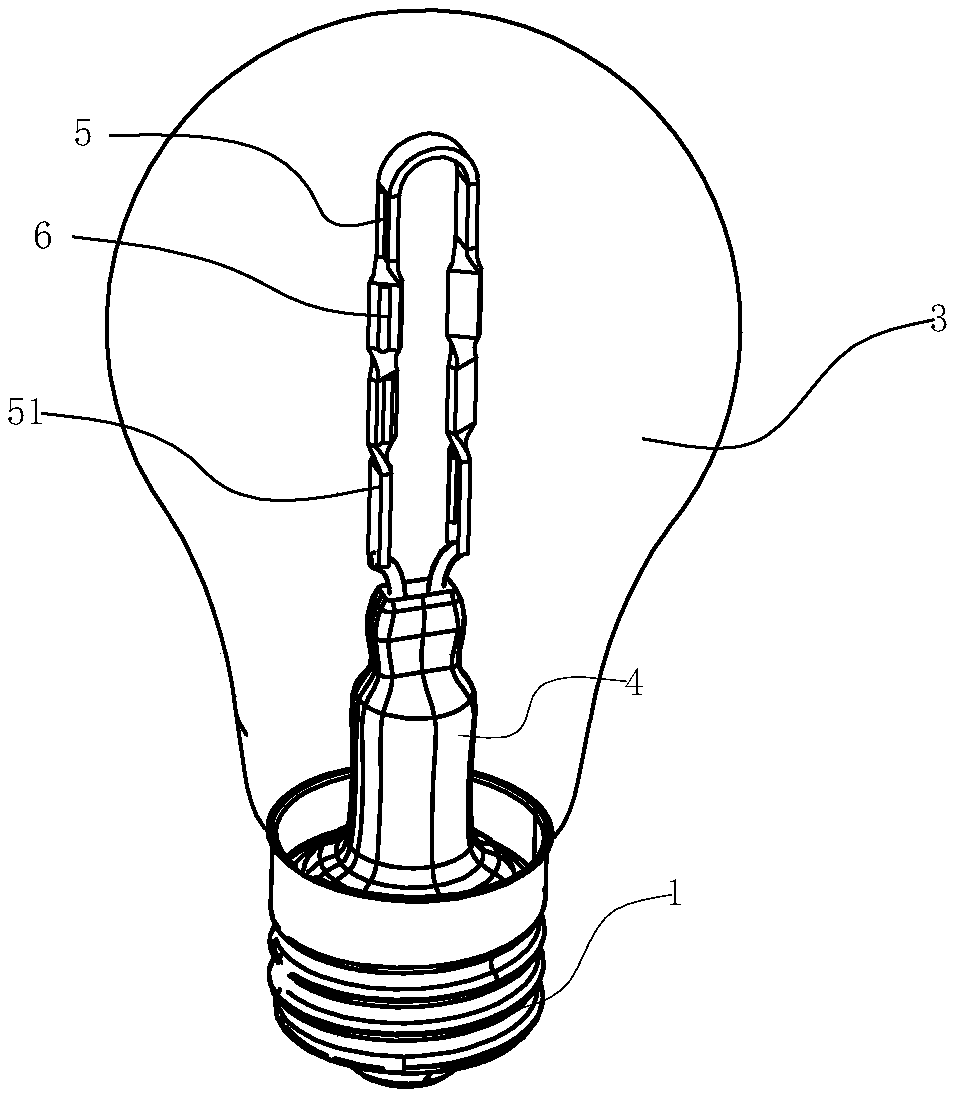

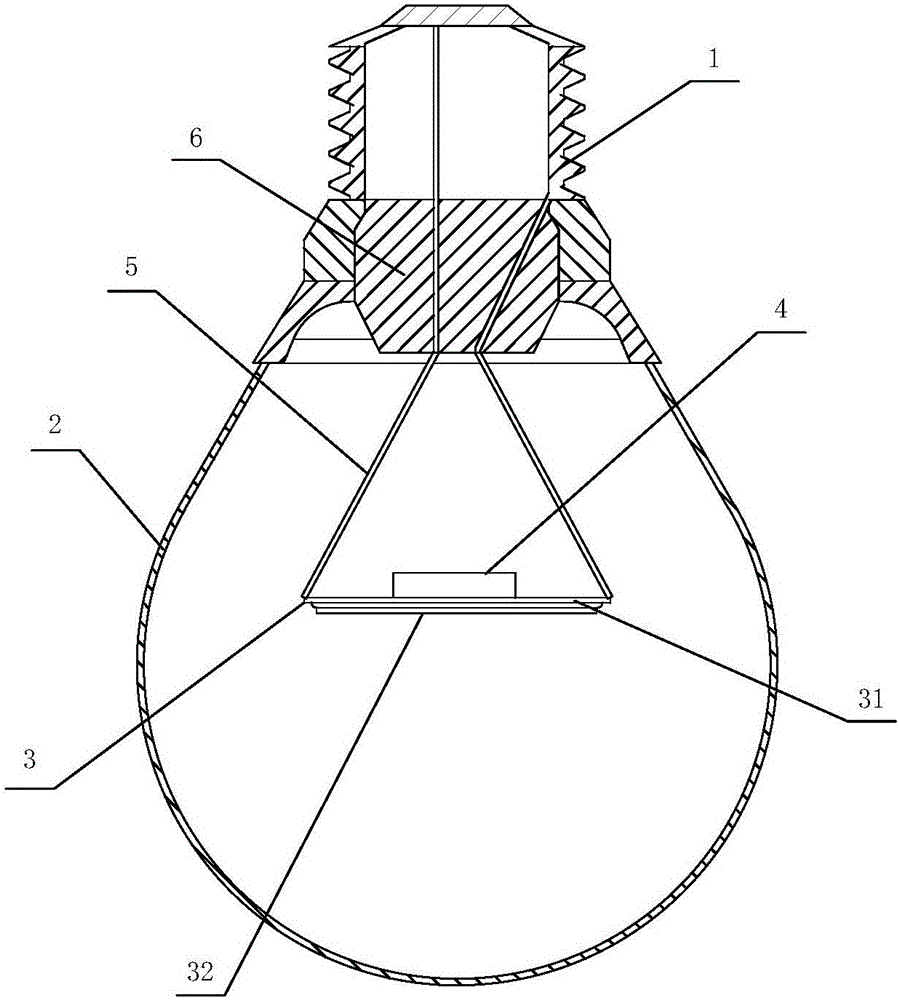

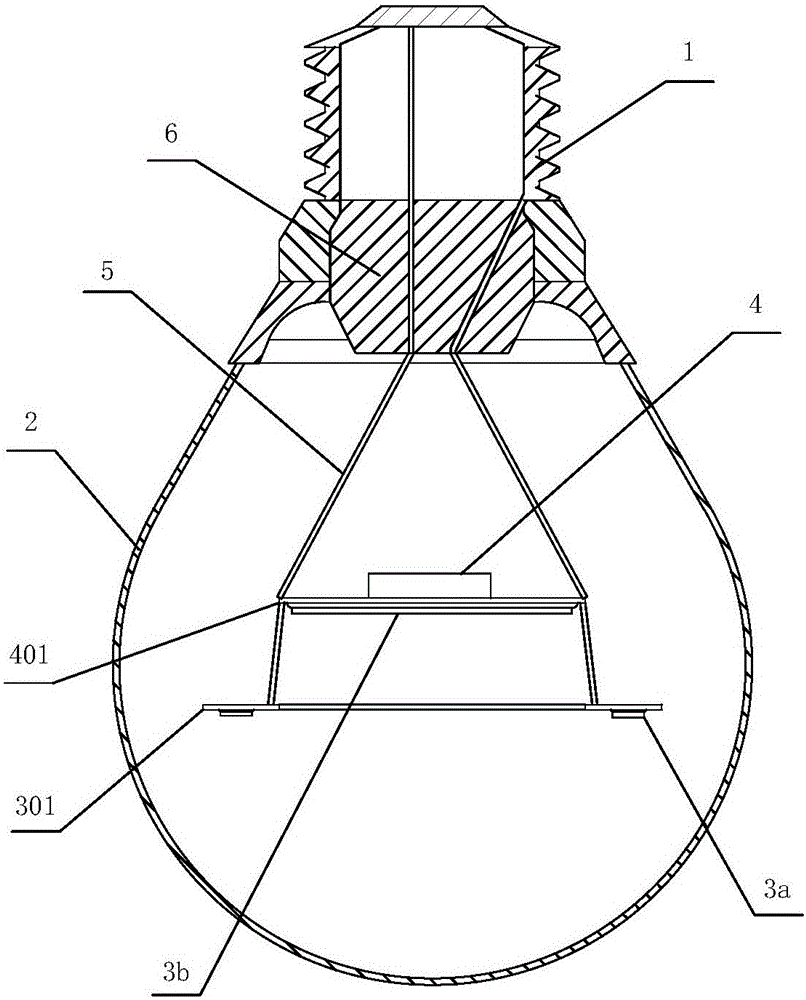

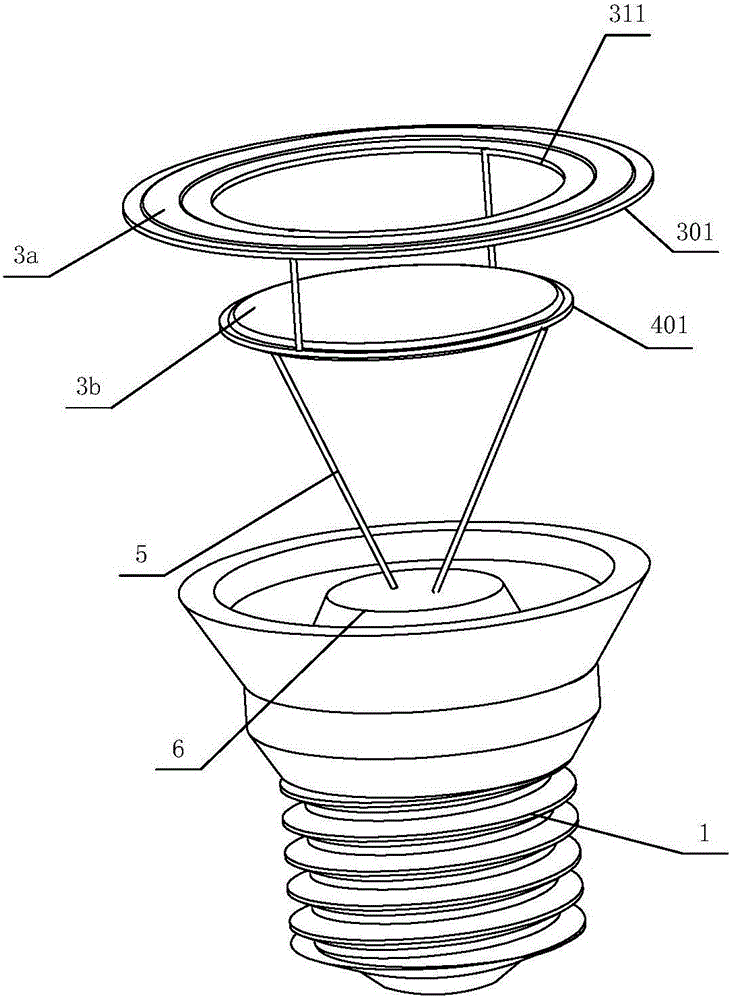

Low-cost LED bulb lamp easy to dissipate heat

PendingCN105953102AUniform luminous effectImprove lighting effectsElectric circuit arrangementsLighting heating/cooling arrangementsHeat conductingEngineering

The invention relates to a low-cost LED bulb lamp easy to dissipate heat. The LED bulb lamp comprises a lamp cap, and a bulb shell connected to the lamp cap and having a sealed accommodating space; and an LED light source forming the space positioning corresponding to the bulb shell is arranged in the bulb shell. The LED bulb lamp is characterized in that the LED light source includes a substrate, an LED light-emitting chip arranged on a single side of the substrate and a driving power supply integrated and packaged on the substrate and arranged on the substrate with the LED light-emitting chip; and inert gas for conducting heat is introduced into the bulb shell. The driving power supply and the LED light-emitting chip use the substrate to dissipate heat; then, the heat of heat conducting gas is transferred to the bulb shell; and the LED bulb lamp needs no additional heat dissipation structure, is simple in structure, greatly simplifies the production assembly process, greatly reduces the production cost, and is relatively good in heat dissipation effect.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com