Patents

Literature

456results about How to "Meet lightweight requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

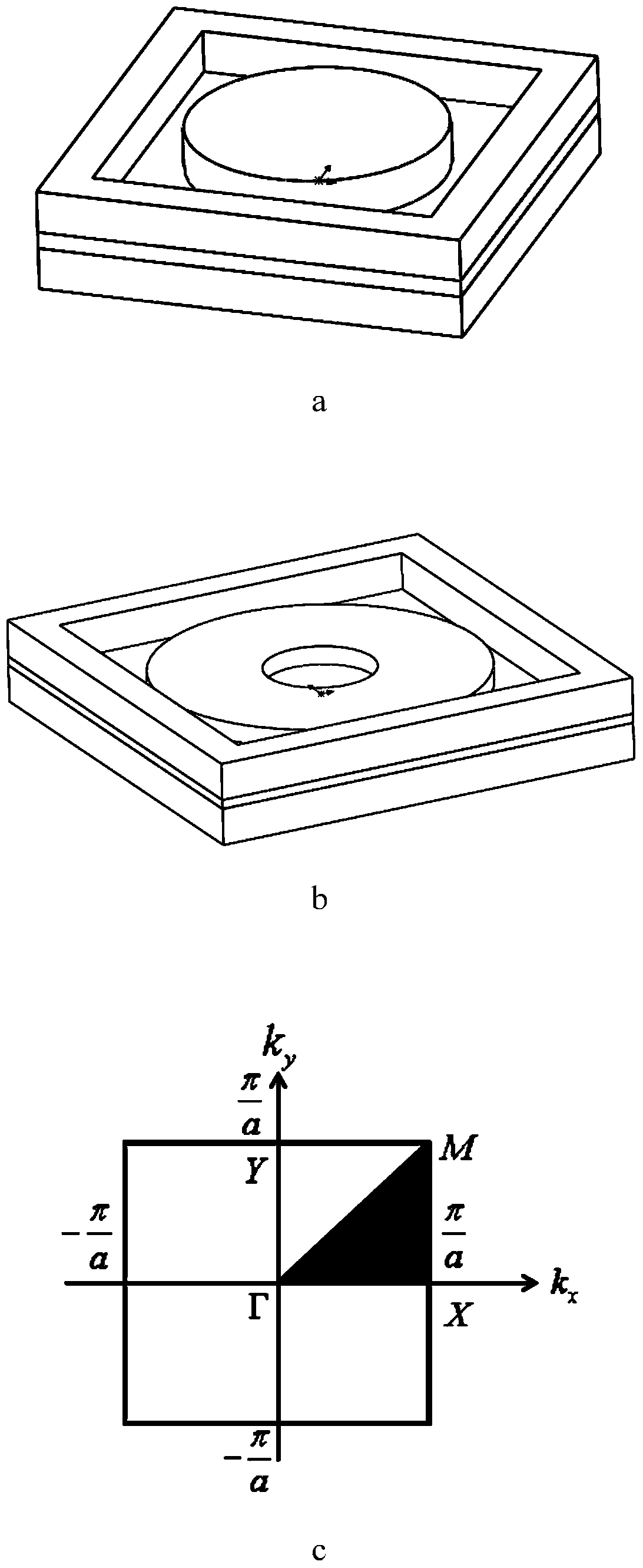

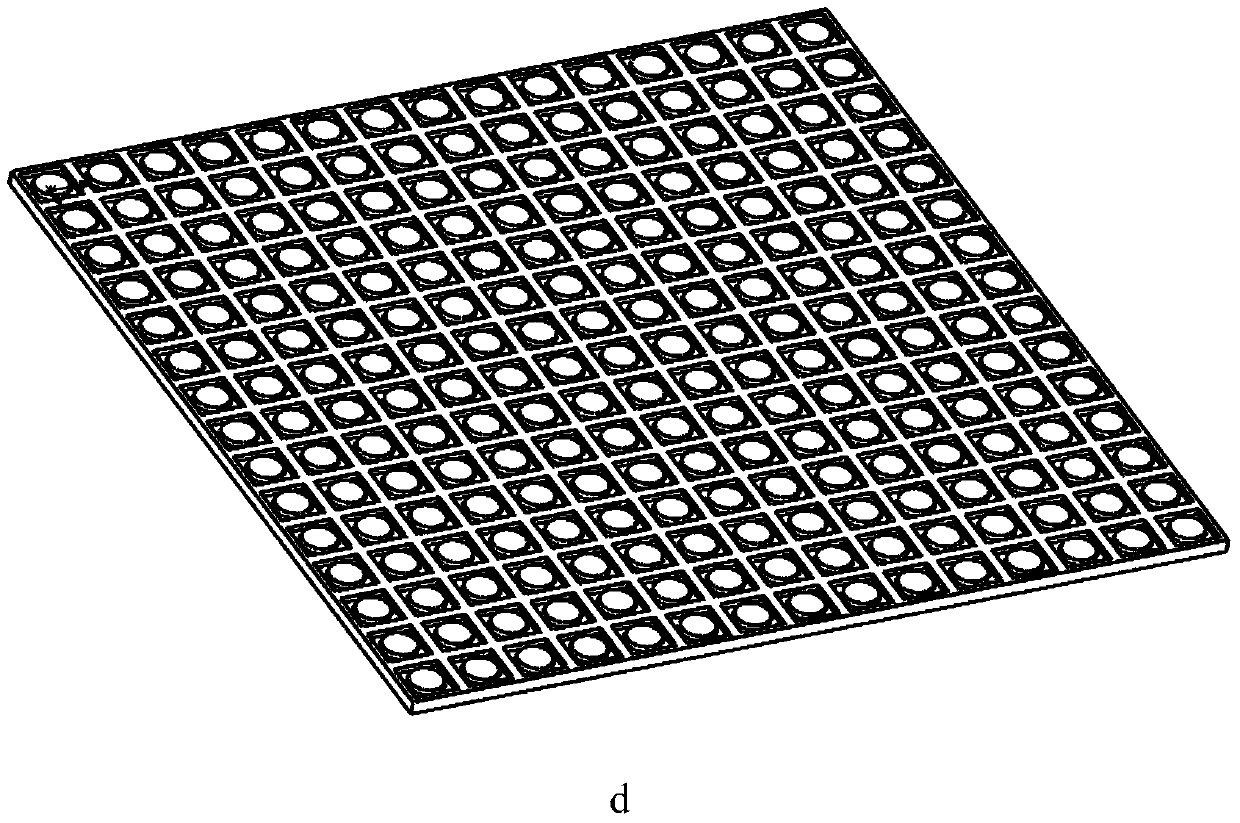

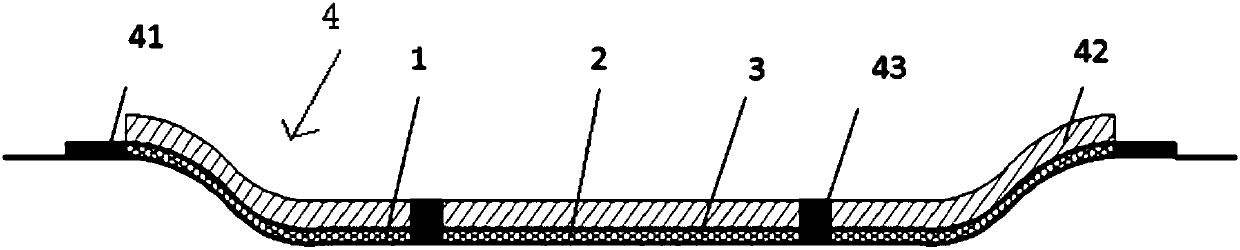

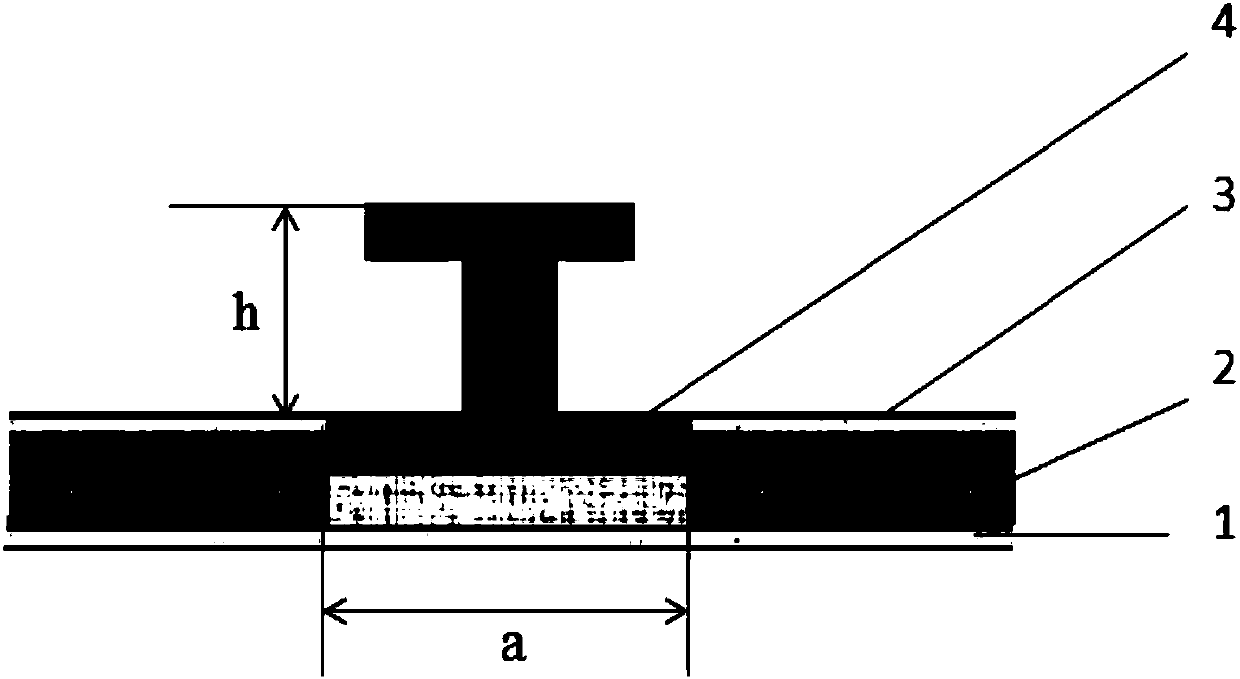

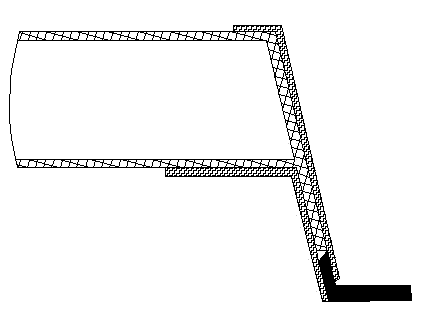

Elastic membrane-type low-frequency sound insulation metamaterial structure

InactiveCN103996395AMeet the requirements of low frequency sound insulationImprove sound insulationSound producing devicesLow noiseBroadband

The invention discloses an elastic membrane-type low-frequency sound insulation metamaterial structure which comprises two frames and a silicone rubber elastic membrane arranged between the two frames. A plurality of mass blocks are pasted on one side of the silicone rubber elastic membrane, and the mass blocks are separated with one another through the frames. The elastic membrane-type low-frequency sound insulation metamaterial structure solves the problems that a traditional sound insulation material is poor in low-frequency sound insulation performance, large in thickness, heavy in mass and the like and meets the five requirements of low-frequency sound insulation, wherein the five requirements include the low-frequency sound insulation requirement for noise below 500 Hz, the broadband requirement, the requirement for low structural thickness and low weight, and the requirement of easy design processing and low processing difficulty. The elastic membrane-type low-frequency sound insulation metamaterial structure has excellent low-frequency sound insulation performance, can effectively isolate low-frequency noise ranging from 200 Hz to 500 Hz, and can be applied to various carrying tools such as planes, automobiles, trains and ships and various types of building decoration. A brand new sound insulation solution is provided for creating low-noise working and living environments.

Owner:XI AN JIAOTONG UNIV

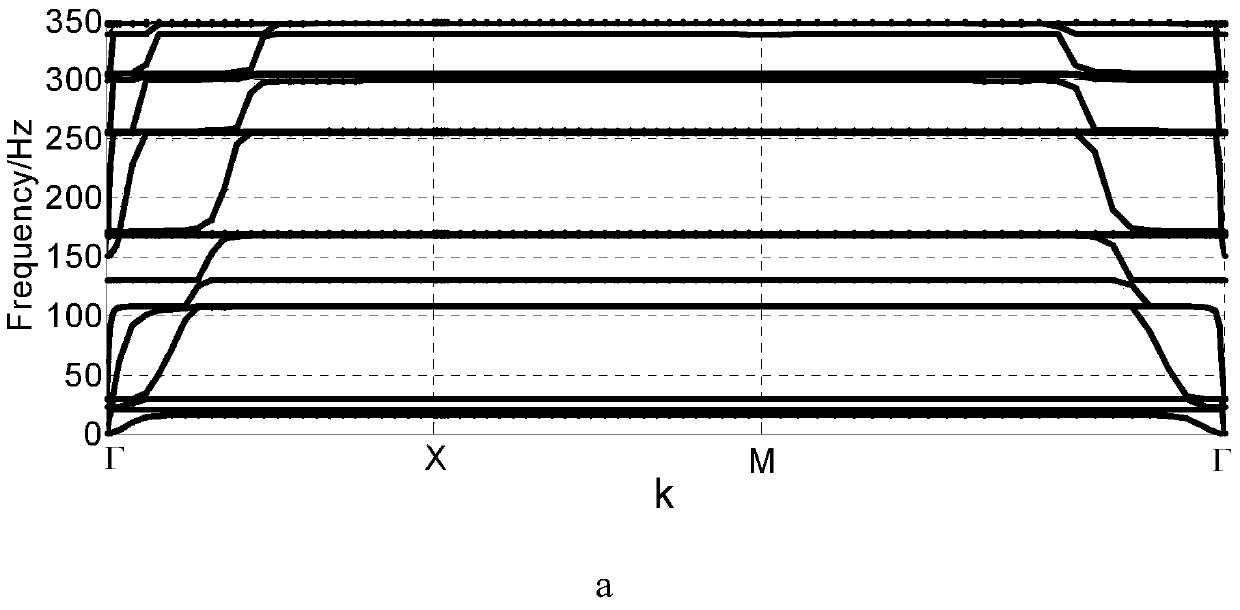

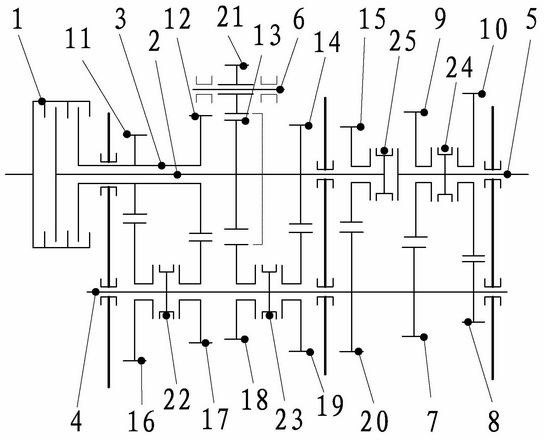

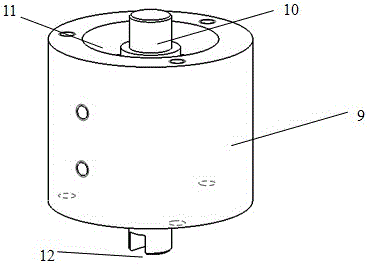

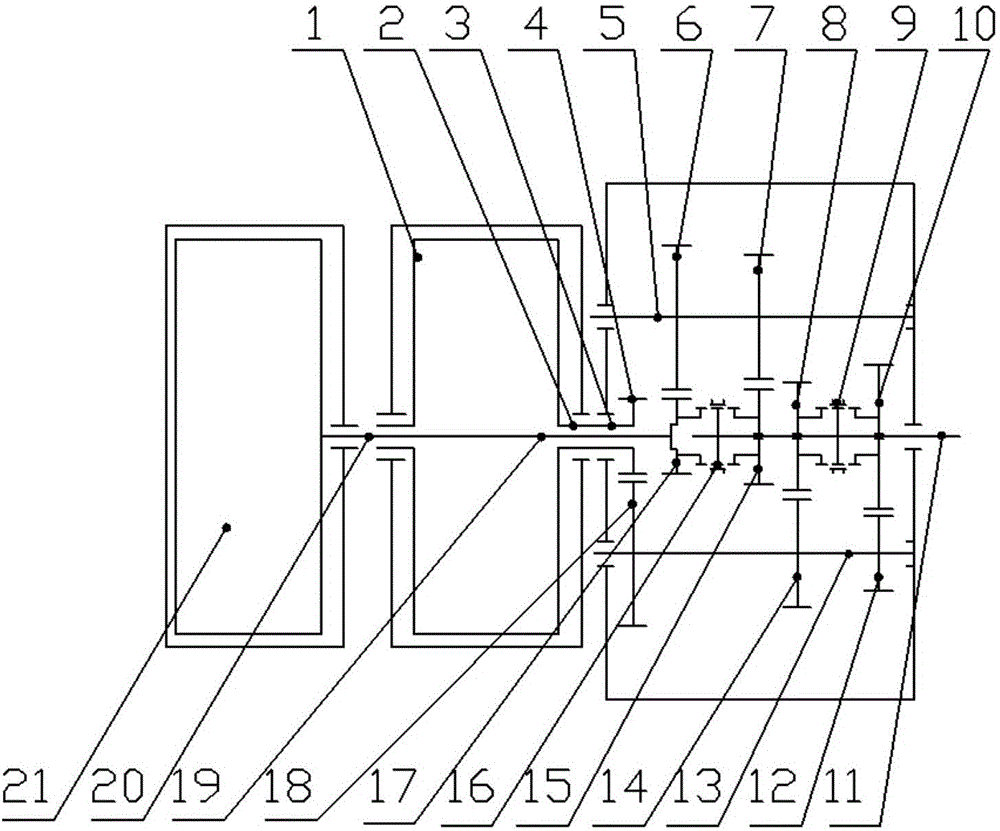

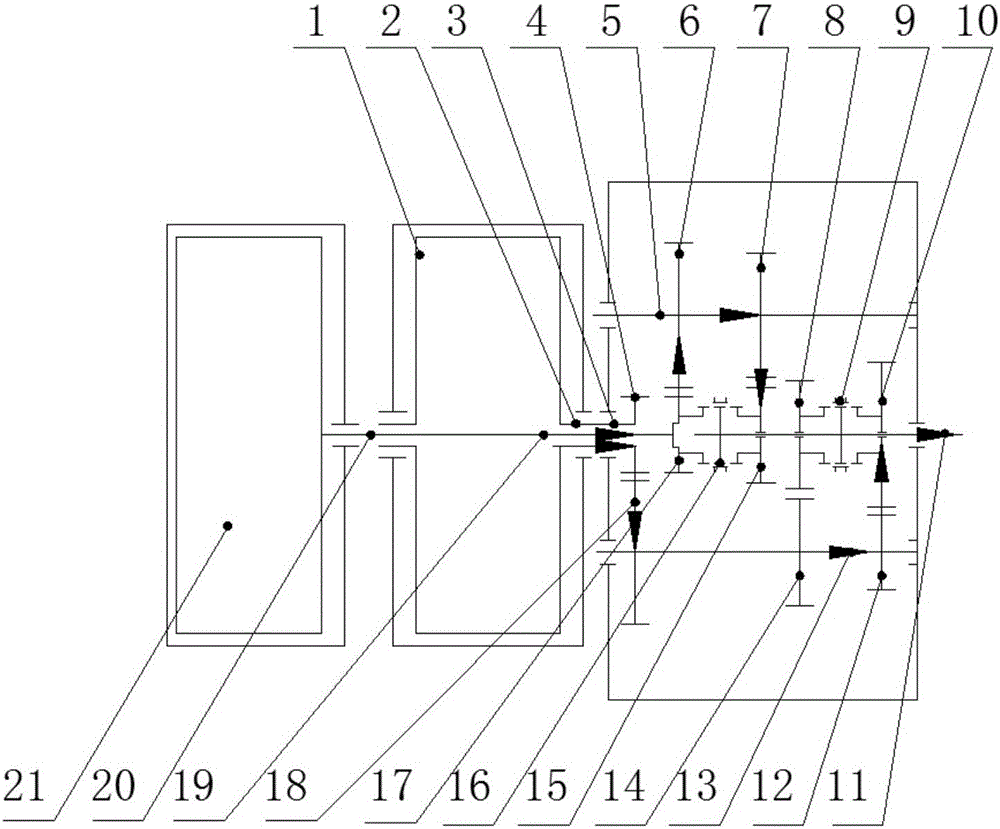

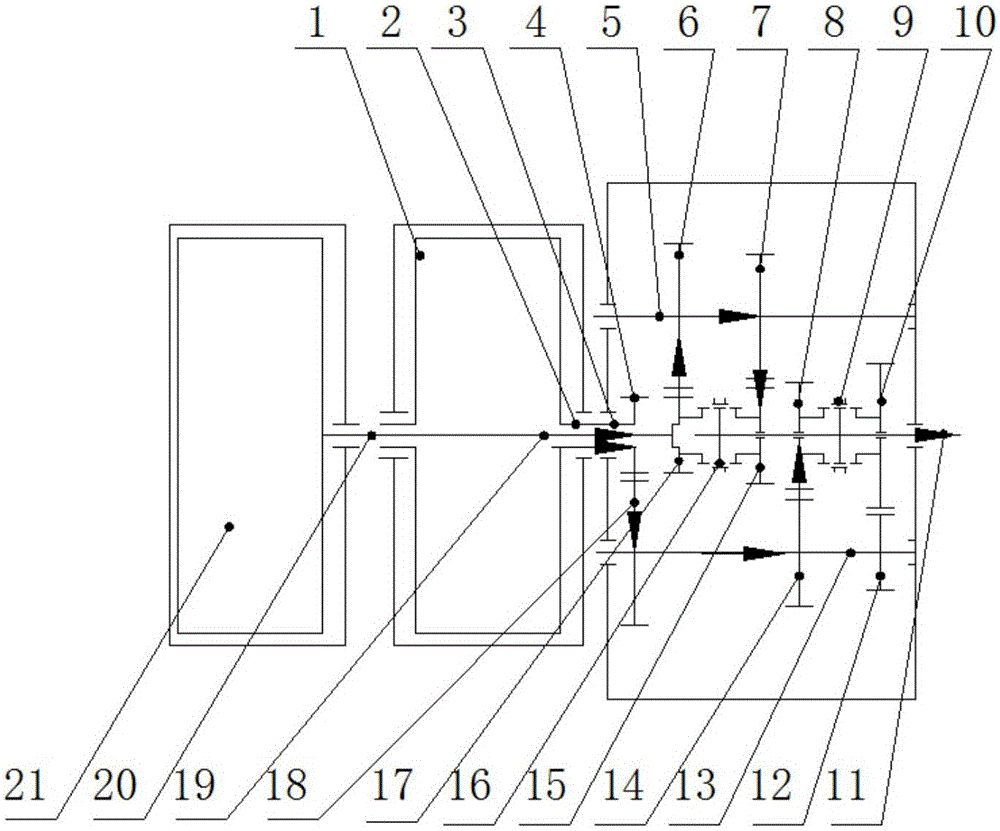

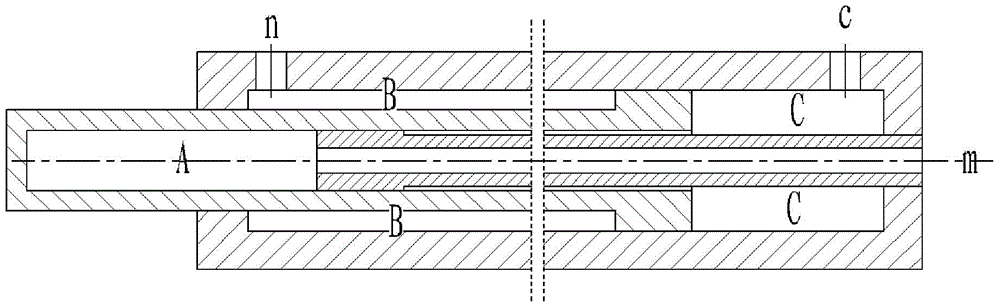

Multi-gear vertical dual clutch transmission

The invention discloses a multi-gear vertical dual clutch transmission, which comprises a nesting shaft, an intermediate shaft, an output shaft and a reverse gear shaft, wherein the intermediate shaft, the output shaft and the reverse gear shaft are parallel with each other; the nesting shaft and the output shaft are collinear; the solid input shaft of the nesting shaft is provided with a dual clutch; all gears of gear pairs are respectively arranged on a hollow input shaft and the intermediate shaft, or the solid input shaft and the intermediate shaft; the intermediate shaft and the output shaft are provided with a high-speed gear pair, a low-speed gear pair, a first synchronizer and a second synchronizer; the output shaft is provided with a fourth synchronizer; and a third synchronizer is arranged on the intermediate shaft and is located between a high-speed driving gear and a low-speed driving gear, or is arranged on the output shaft and is located between a high-speed driven gear and a low-speed driven gear. In the multi-gear vertical dual clutch transmission, the implementation of all gears needs to be completed by the joint participation of 1-2 synchronizers; on the premise of not increasing the number of meshing gear pairs, through the joint utilization of all the gears of the gears and the alternating action of the four synchronizers, multi-gear drive and a wider drive ratio range are realized, and the number of the gears and the synchronizers is reduced, so that the layout of the vertical transmission is more compact, the manufacturing cost is saved, and the lightweight requirement of a whole vehicle is met. The multi-gear vertical dual clutch transmission of the vehicle can realize eight forward gears and two reverse gears at most.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

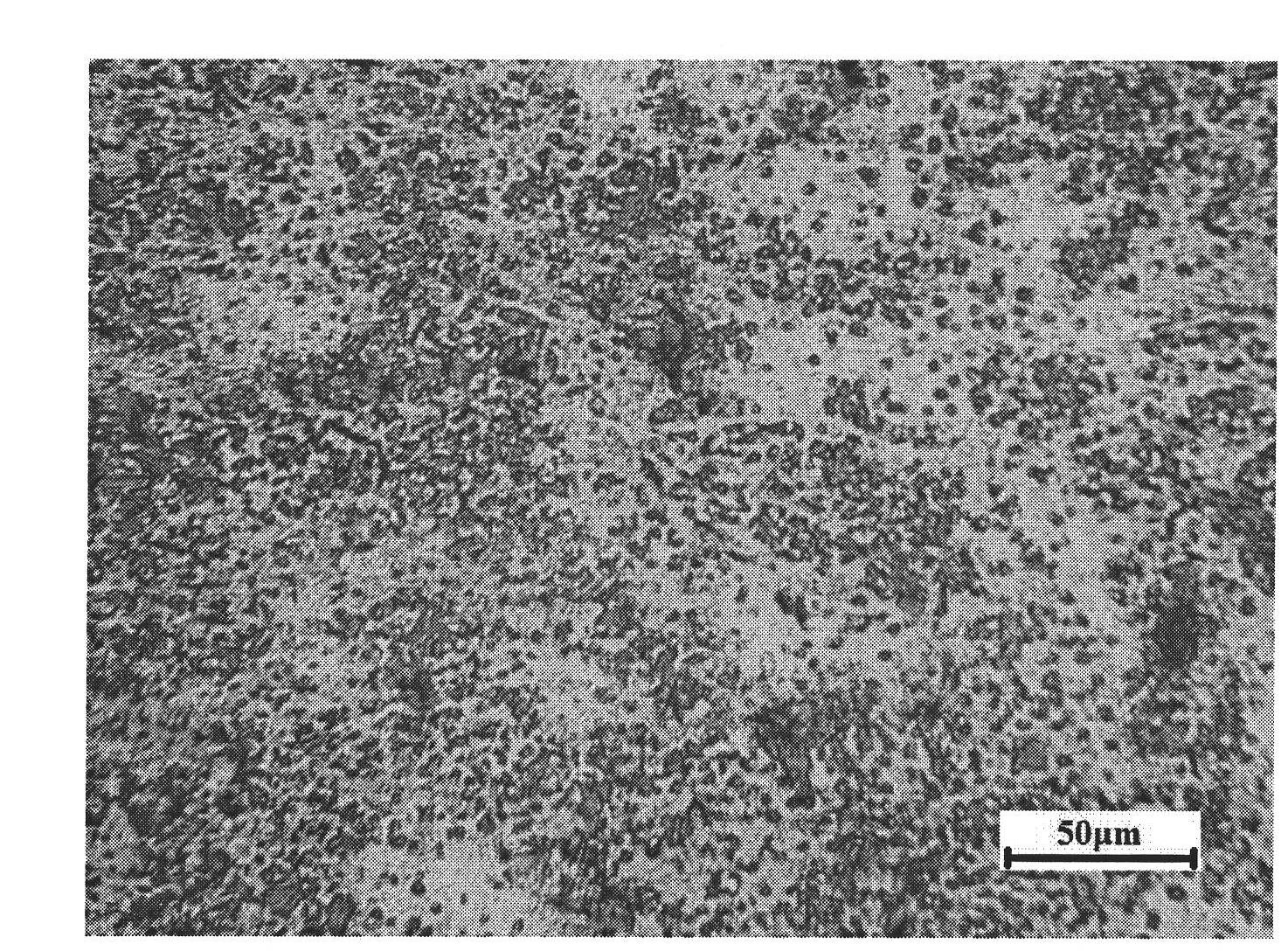

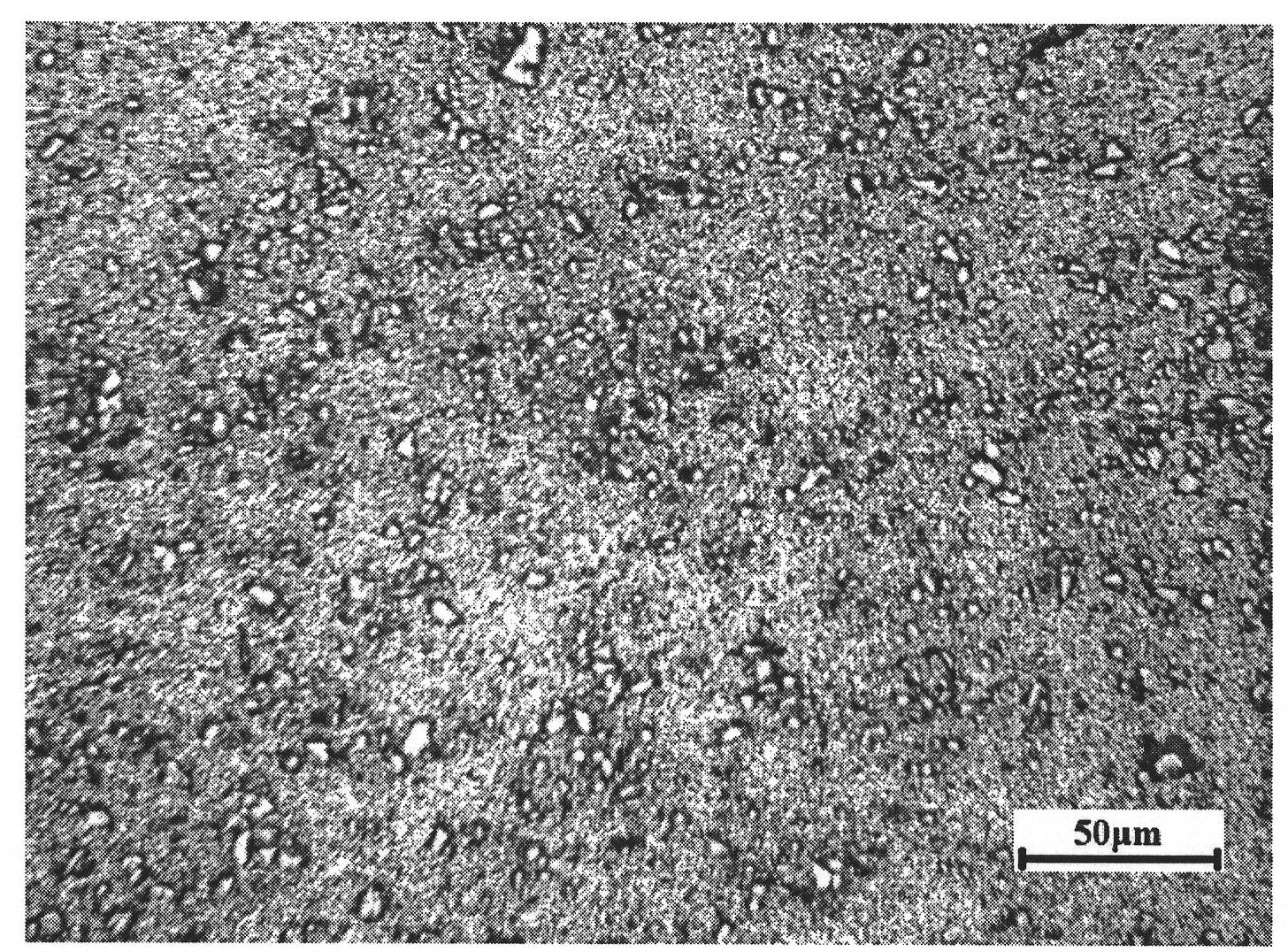

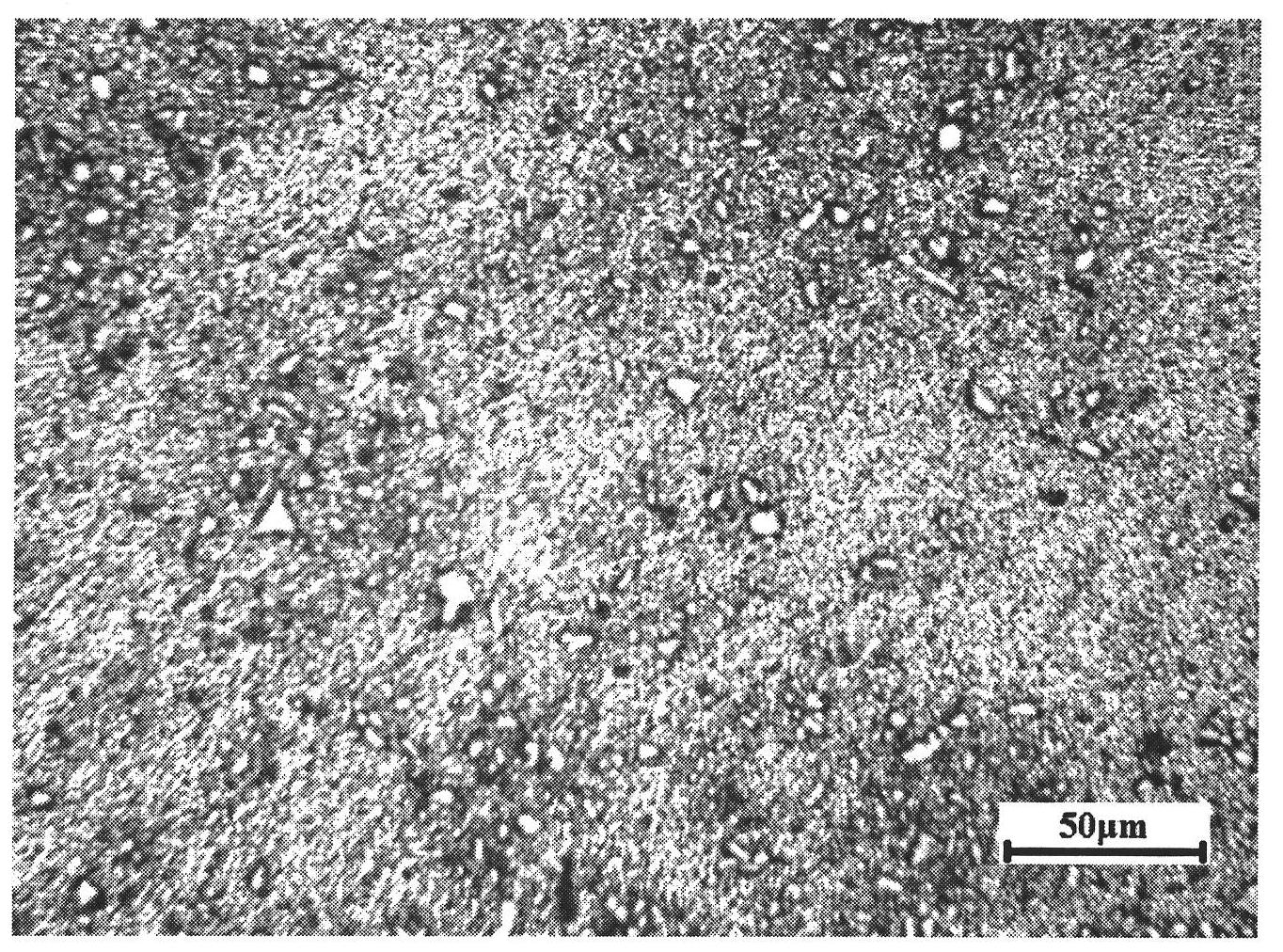

Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

The invention belongs to the field of aluminum-based composite material and preparation technology thereof and in particular discloses a ceramic particle reinforced aluminum-based gradient composite material, a preparation method thereof and a device used by the method. The composite material uses aluminum alloy as a matrix; the volume fractions of ceramic particles serving as a reinforcement material in the surface layer and the bottom layer are between 30 and 40 percent and between 0 and 5 percent respectively; the ceramic particles perform continuous gradient variation from the surface layer to the bottom layer; and the preparation method comprises the following steps: introducing the ceramic reinforced particles to a high-pressure airflow channel by a discharge amount regulation device to form a solid phase flow and a gas phase flow; atomizing molten aluminum alloy liquid, mixing the molten aluminum alloy liquid and the ceramic particles of the solid phase flow and the gas phase flow, and precipitating the mixture on a deposition matrix to prepare a deposition billet; and controlling the discharge amount regulation device and output air pressure through a programmable logic controller according to the height information of the deposition billet to obtain the ceramic particle reinforced aluminum-based gradient composite material. The preparation method of the invention has convenient operation and high automation degree; and the prepared composite material has the advantages of light weight, high wear resistance and anticorrosion of the surface and the like.

Owner:HUNAN UNIV

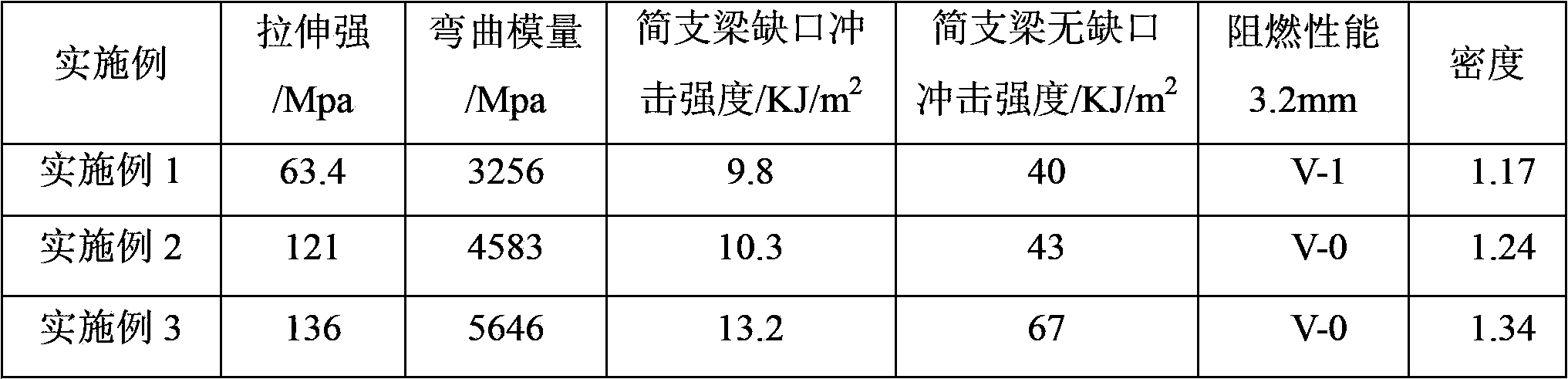

Lightweight flame retardant modified polyamide material and its preparation method

The invention belongs to the technical field of polymer materials, and relates to a lightweight flame retardant modified polyamide material and its preparation method. The material comprises the following components by weight: 100 parts of nylon 66, 0-60 parts of glass fiber, 16-28 parts of a flame retardant, 5-15 parts of hollow glass bead, 5-18 parts of a compatibilizer, 0.3-1 part of an antioxidant and 0.3-1 part of a lubricant. The prepared lightweight flame retardant modified polyamide material is low in density, meets the lightweight requirements of modern society on materials, is conducive to energy saving and emission reduction, and has the characteristics of good processing fluidity, excellent surface quality, outstanding physical mechanical properties.

Owner:HEFEI GENIUS NEW MATERIALS

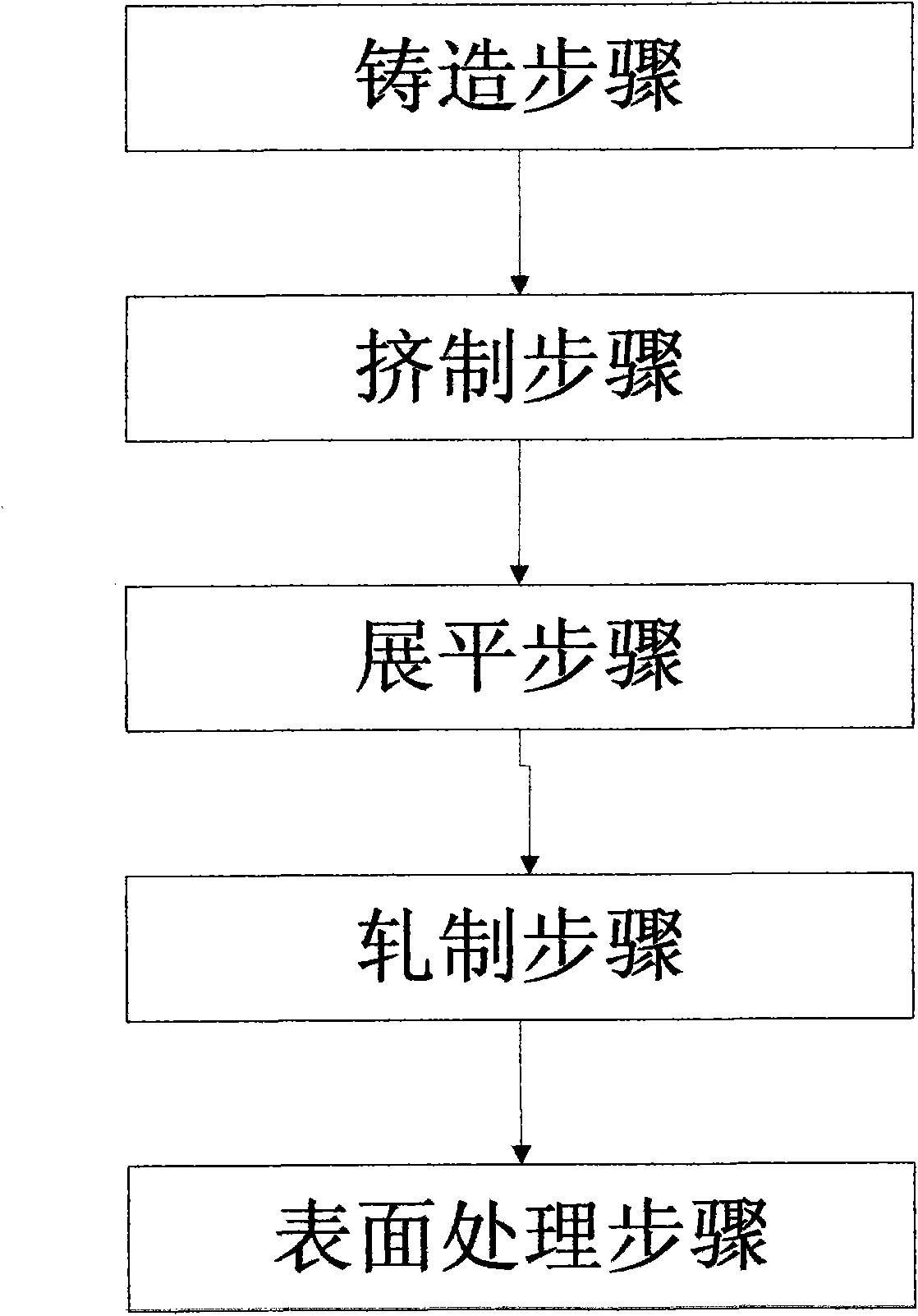

Method for producing magnesium alloy sheet

ActiveCN101579817ALow costImprove market competitivenessOther manufacturing equipments/toolsSolid phasesWave shape

The invention relates to a method for producing a magnesium alloy sheet, comprising the following steps: casting step: fused magnesium alloy which is added with grain refiner and has the solid phase with weight proportion between 10% and 15% is supplied between at least one pair of rollers, and a board with the thickness of 4.0-6.0mm is formed by continuous casting at the temperature that is 40-50 DEG C higher than the fusion temperature of the alloy; extruding step: the magnesium alloy board which is formed by continuous casting is further extruded into a wave-shaped magnesium board, and the extruded magnesium board has the thickness within the range of 2.0-3.5mm; flattening step: the wave-shaped magnesium board is rolled and unfolded to be a tabulate magnesium board; rolling step: the tabulate magnesium board is rolled to be the thinner magnesium alloy sheet with the width of 450-500mm and the thickness of 0.5-1.5mm; surface treatment step: surface coating is carried out on the magnesium alloy sheet to prevent oxidation corrosion. The thinner magnesium alloy sheet produced by the method can be applied to 3C products.

Owner:BEIJING NORTH LIGHT ALLOY

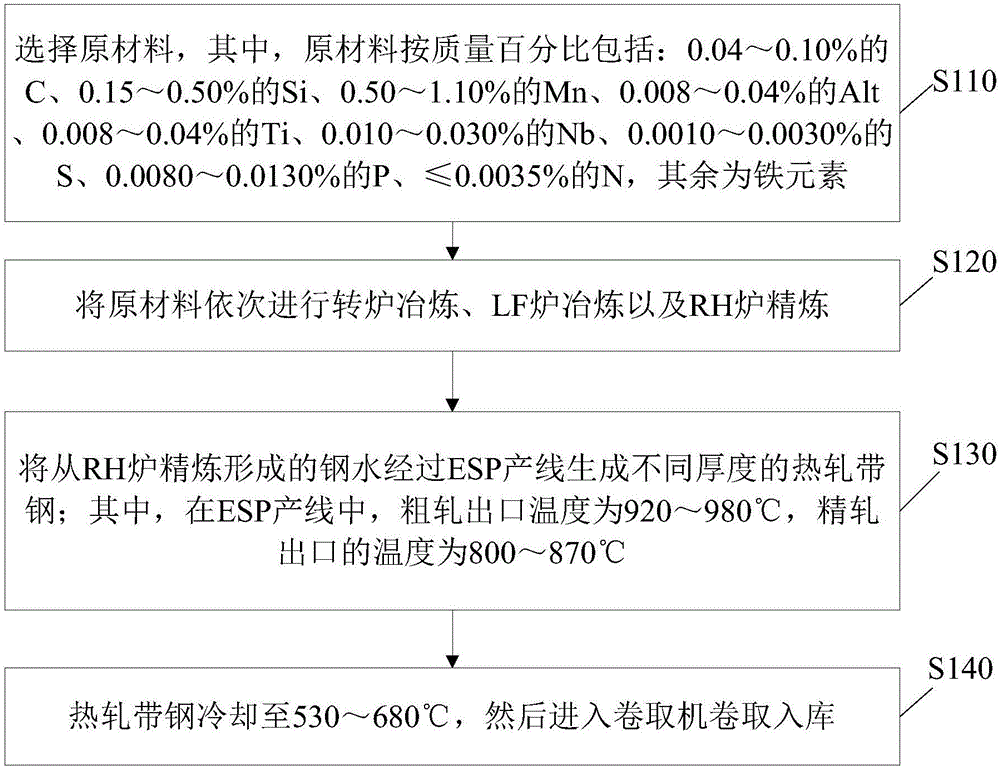

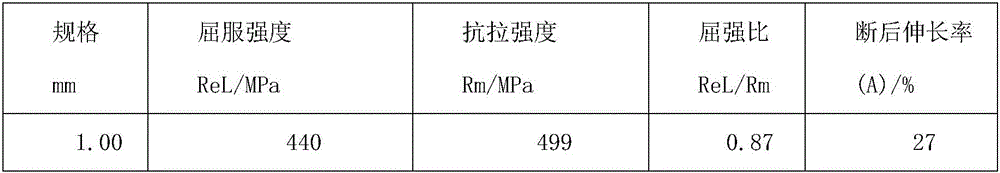

Method for producing thin REH380LA steel based on ESP thin slab continuous casting and rolling process

The invention provides a method for producing thin REH380LA steel based on an ESP thin slab continuous casting and rolling process. The method includes the steps that raw materials are selected, and the raw materials comprise, by mass, 0.04-0.10% of C, 0.15-0.50% of Si, 0.50-0.10% of Mn, 0.008-0.04% of Alt, 0.008-0.04% of Ti, 0.010-0.030% of Nb, 0.0010-0.0030% of S, 0.0080-0.0130% of P, no more than 0.0035% of N, and the balance Fe; the raw materials are sequentially smelted in a converter, an LF furnace and an RH furnace; molten steel obtained after refining in the RH furnace is manufactured into hot-rolled strip steel of different thicknesses through an ESP production line, wherein, in the ESP production line, the temperature of a rough rolling outlet is 920-980 DEG C, and the temperature of a fine rolling outlet is 800-870 DEG C; and the hot-rolled strip steel is cooled to 530-680 DEG C, and then the strip steel enters a winder to be wound and stored in a warehouse. By means of the method, the problems that subsequent cold rolling and annealing are required in the traditional production technology are solved.

Owner:RIZHAO STEEL HLDG GROUP

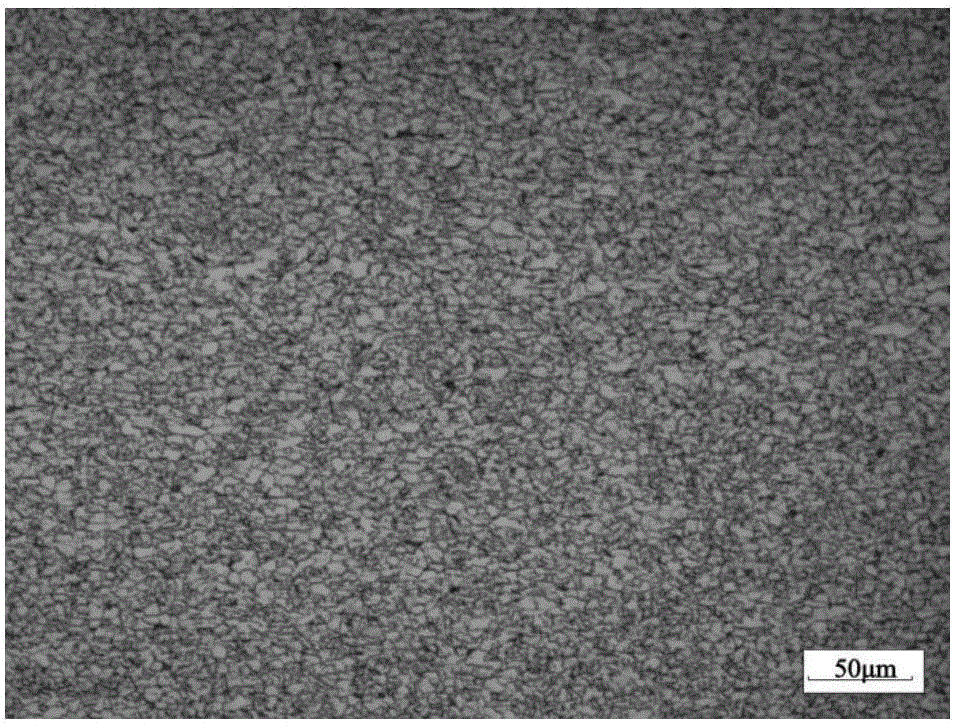

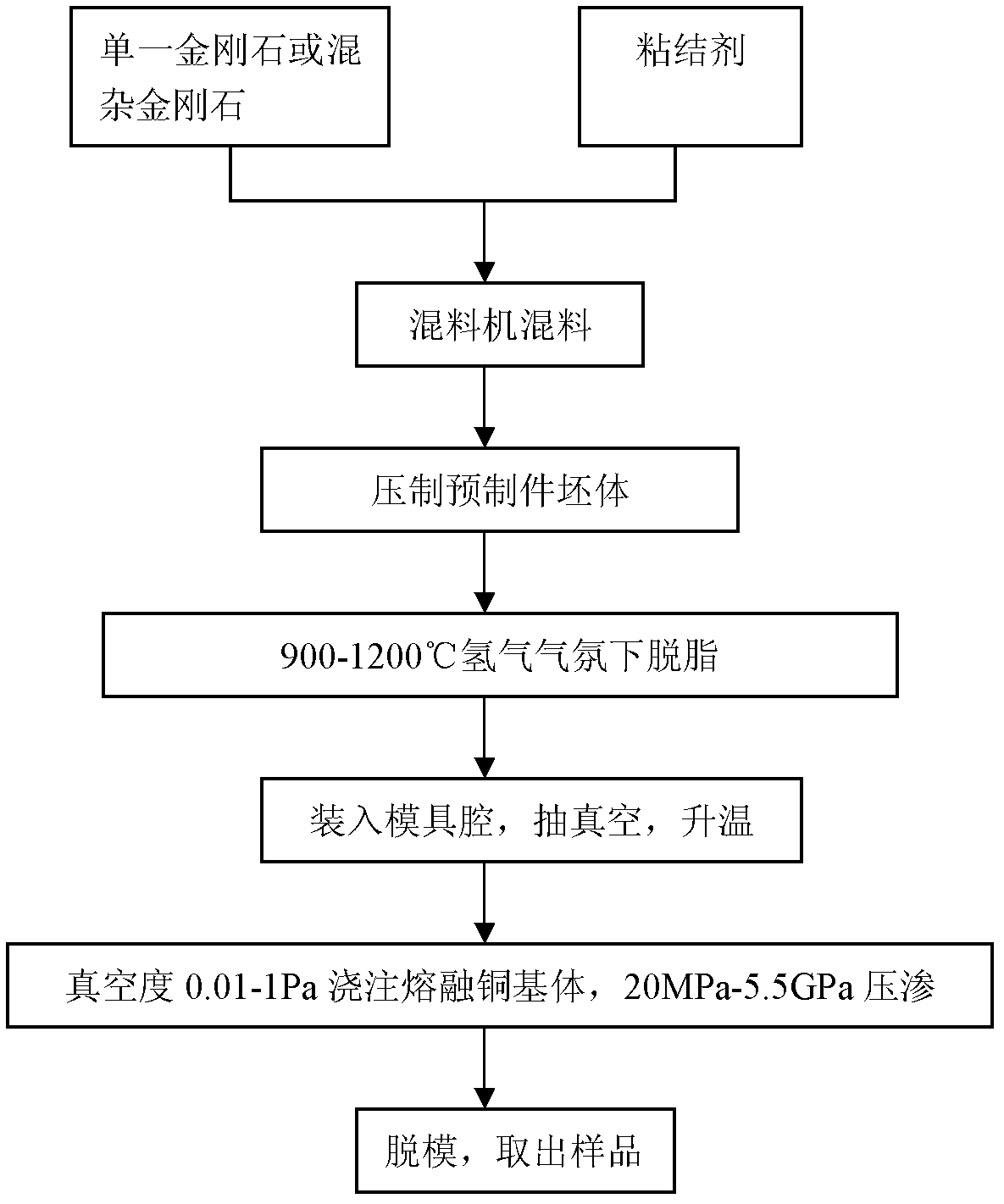

High-thermal conductivity diamond/copper composite material applicable to wide temperature range and method

InactiveCN103184363AImprove thermal conductivityLow densityGearingCylindersThermal expansionInjection molding process

The invention relates to a high-thermal conductivity diamond / copper composite material applicable to a wide temperature range and a method, belonging to the technical field of preparation of thermal management materials. The copper-based composite material is prepared through the following steps: preparing a prefabricated reinforcement component from a reinforcement and a binder by using an injection molding process for a prefabricated component, wherein the reinforcement is prepared by mixing one or two different diamond particles; and casting fused copper liquid on the prefabricated reinforcement component and carrying out pressure infiltration, wherein a copper substrate is pure copper or copper alloy, and a volume ratio of a diamond to the copper substrate is 50-75%: 50-25%. The diamond / copper composite material prepared by using pressure infiltration is applicable to a wide temperature range of 40 to 350 K, has higher thermal conductivity compared with molybdenum-copper and tungsten-copper in the temperature range of 40 to 350 K, a low thermal expansion coefficient and small density and is a good option for a heat dissipation material used in a spatial refrigeration environment.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

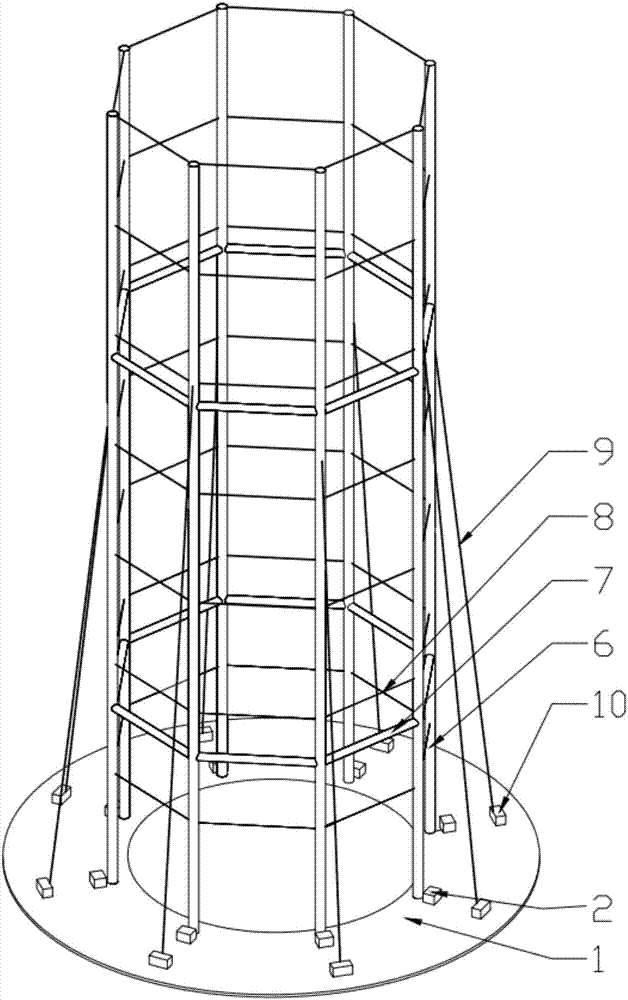

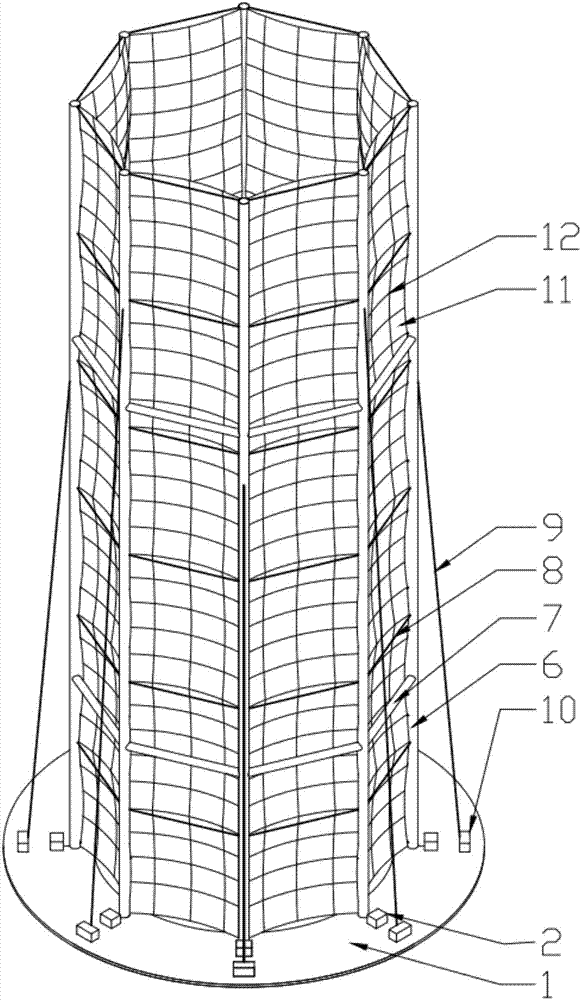

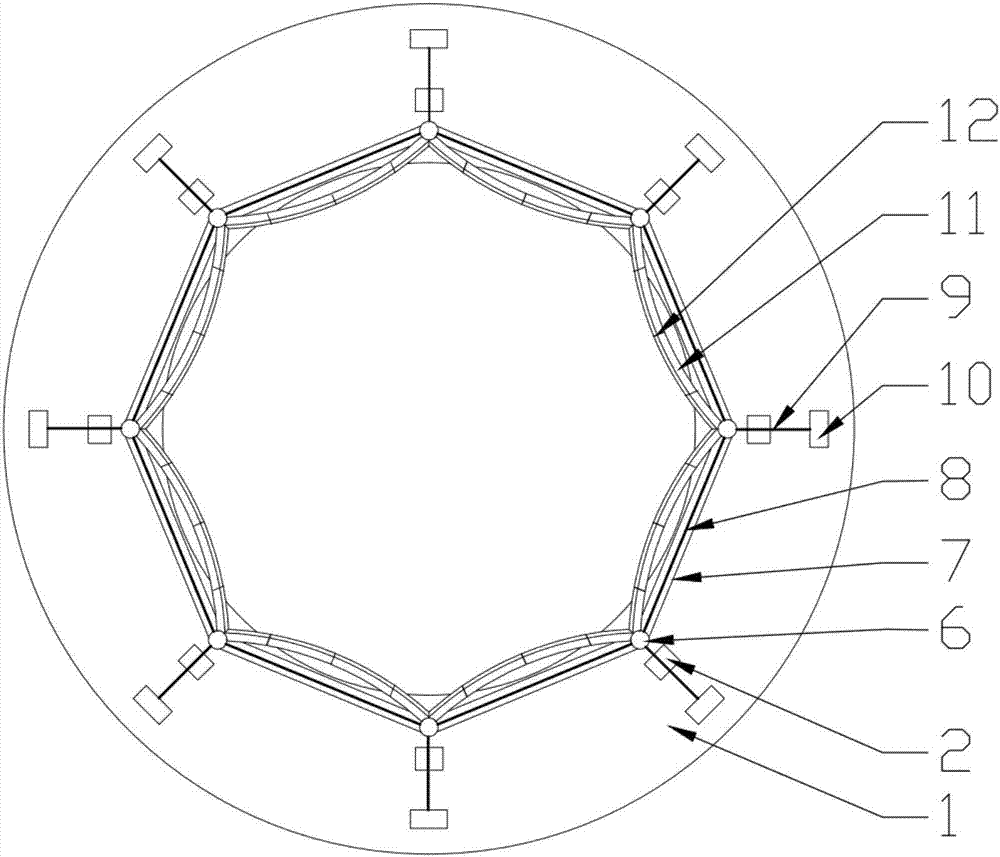

Large-sized air-inflating thin film light-shielding cover structure with expanded space

The invention discloses a large-sized air-inflating thin film light-shielding cover structure with expanded space. The large-sized air-inflating thin film light-shielding cover structure comprises a light-shielding cover base fixedly connected with a space camera base, and folding cylinders distributed along the light-shielding cover base; the folding cylinders are sleeved with an air-inflating pipe framework; the large-sized air-inflating thin film light-shielding cover structure also comprises adjusting rope-rods which are expanded and pulled on the surface of the air-inflating pipe framework and used for performing unfolding control of the air-inflating pipe framework, and a light-shielding thin film which is glued on the outer side of the air-inflating pipe framework to form rope net reinforcement of the light-shielding cover; and air-inflating tanks which are corresponding to and connected with the air-inflating pipe framework are arranged on the light-shielding cover base, wherein the air-inflating tanks and the folding cylinders on the light-shielding cover base are fixedly connected with the light-shielding cover base in a manner of inward arrangement in sequence based on the peak position of a regular n polygon in the radial direction. By adoption of the large-sized air-inflating thin film light-shielding cover structure, feedback control can be performed by only adjusting the rope length / rope force in the unfolding process, without needing other driving and sensing apparatuses; and in addition, the large-sized air-inflating thin film light-shielding cover structure has the advantages of simple structure, light weight, small size, low storage space requirement, low manufacturing cost and the like, and can satisfy the light weight requirement of a spacecraft.

Owner:XIDIAN UNIV

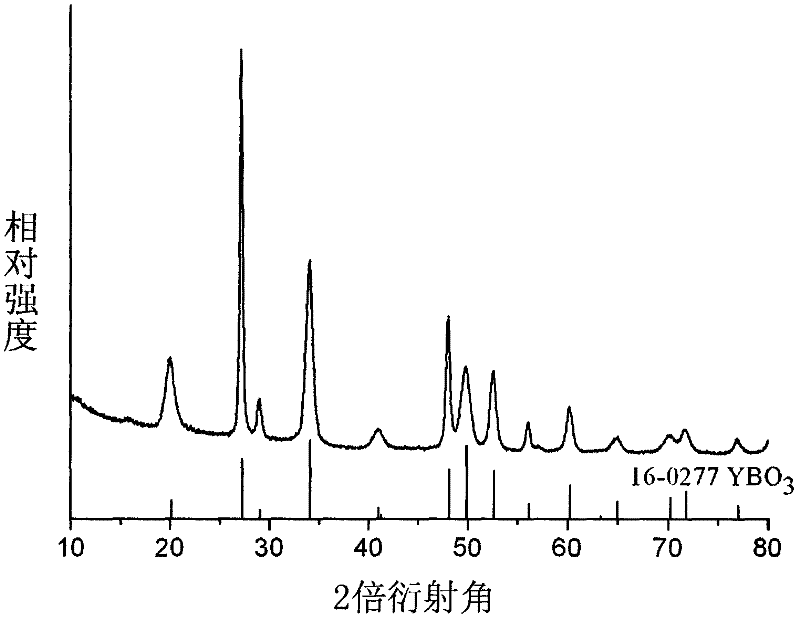

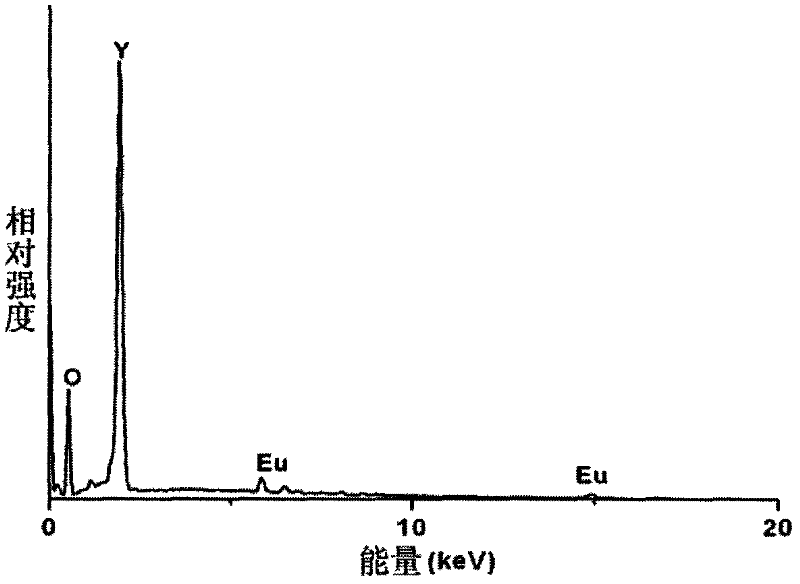

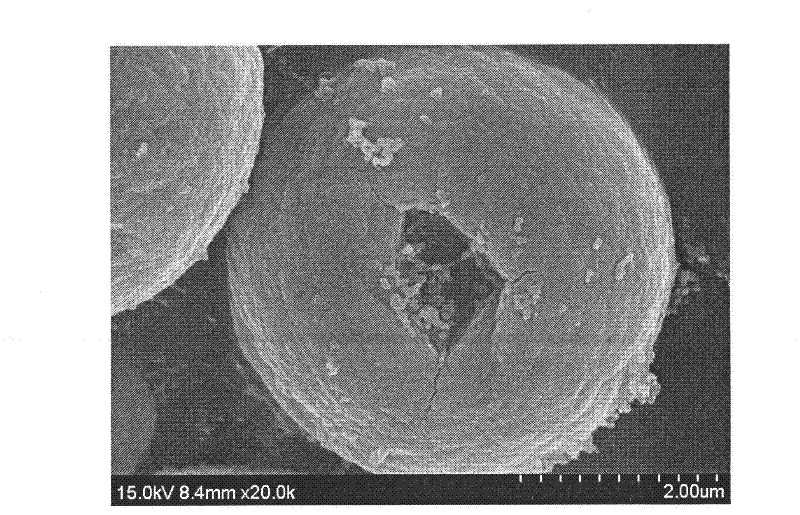

Hydro-thermal preparation method for spherical boric acid yttrium doped europium fluorescent powder in hollow structure

The invention discloses a hydro-thermal preparation method for spherical boric acid yttrium doped europium fluorescent powder in a hollow structure. 0.01 to 1.0 mole / liter yttrium ions, europium ions and boric acid are mixed, the mole ratio of the yttrium ions to the europium ions to the boric acid in the mixed solution is 19 / 1 / 20, organic topography induction reagents are added into the mixed solution, the ratio of the mol number of the added organic topography induction reagents to the sum of the mol number of the yttrium ions and the europium ions is 3 / 2, 1 to 8 milliliters of nucleating reagents are added into the mixed solution, and suspending liquid is obtained; the alkali liquor is used for regulating the pH to be 8 to 10; the suspending liquid is moved into a 100mL reaction kettlefor carrying out hydrothermal reaction; and the heat treatment is carried out on powder products after the hydrothermal reaction, and the spherical fluorescent powder in the hollow structure is obtained. The spherical boric acid yttrium doped europium fluorescent powder has the smaller specific gravity because of the adoption of the hollow structure, and requirements of luminescent devices on light weight of fluorescent luminescent materials can be met.

Owner:ZHEJIANG SCI-TECH UNIV

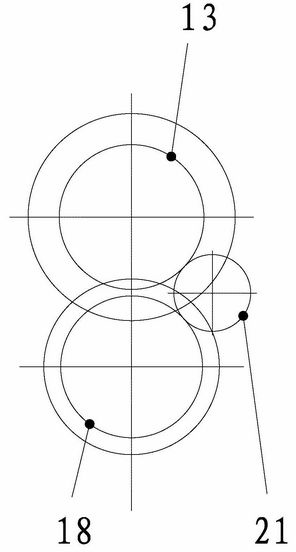

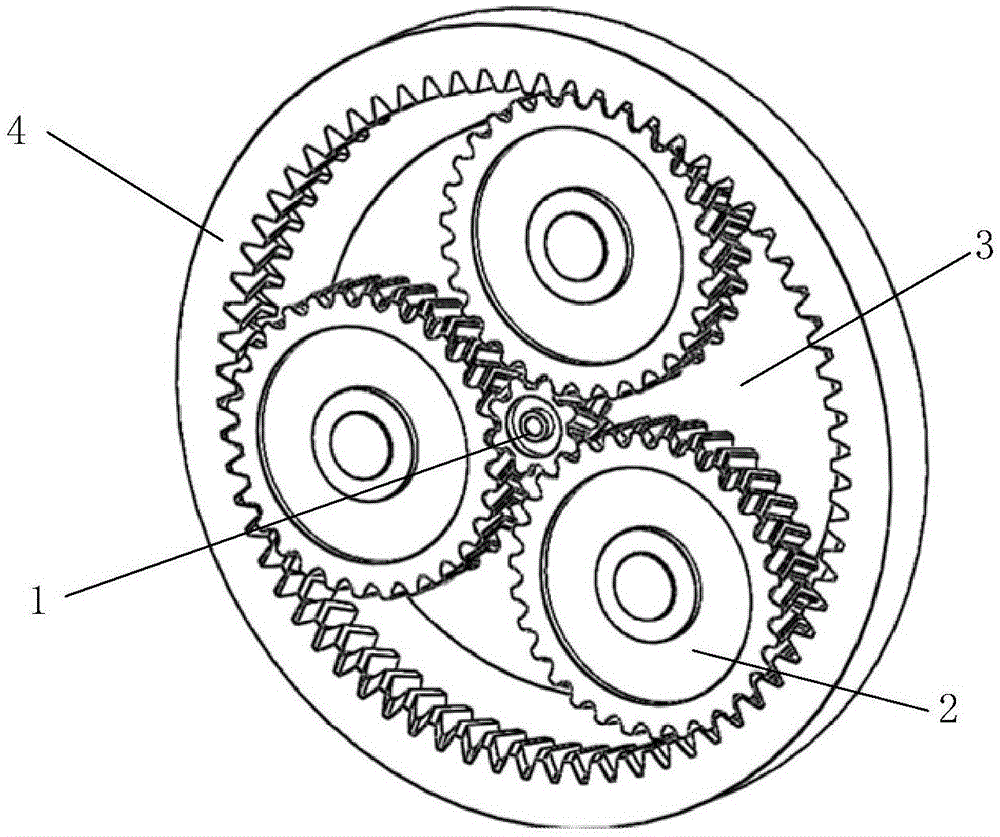

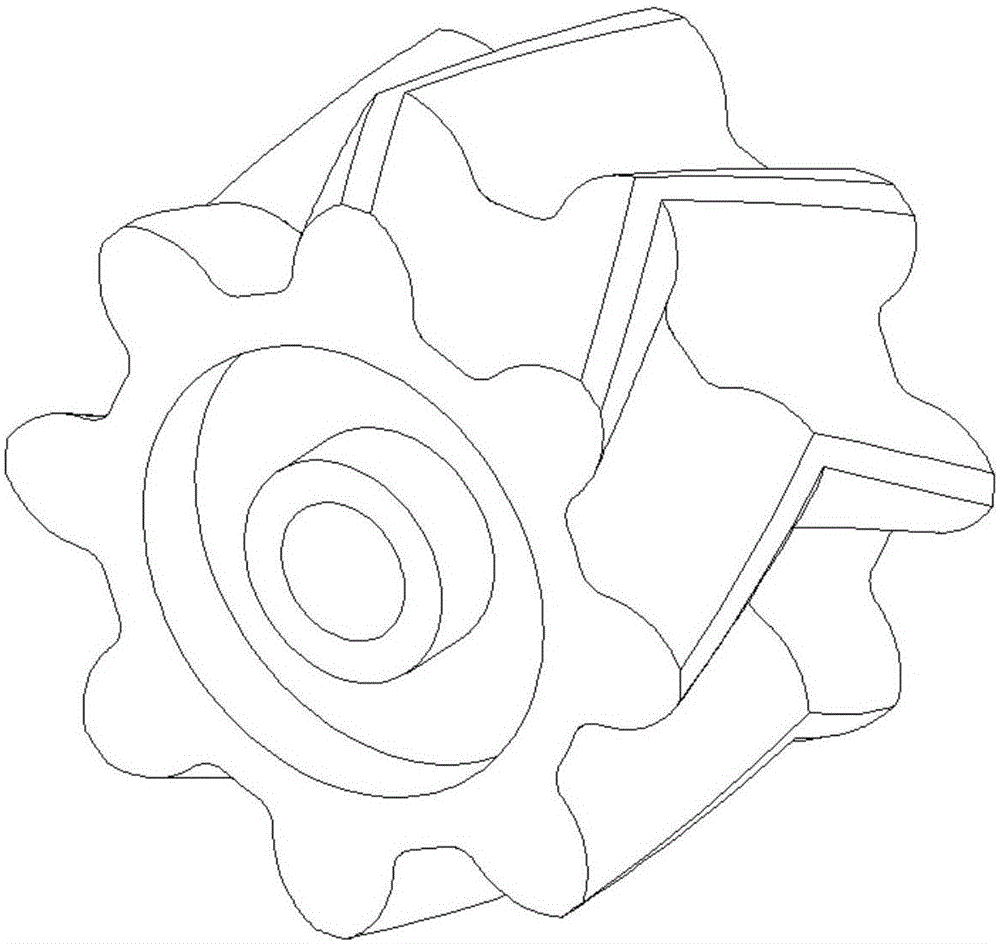

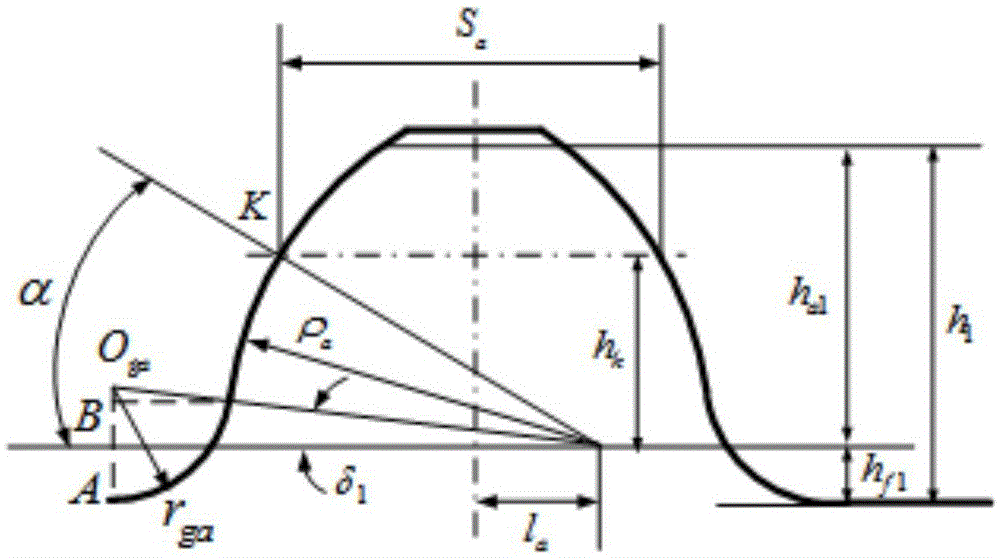

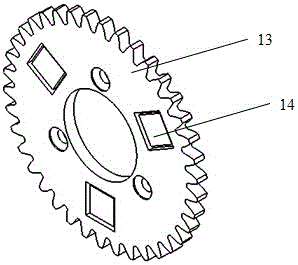

Planetary gear transmission device based on conjugate curve herringbone gear

ActiveCN105114542AReduce weightReduce slidingPortable liftingToothed gearingsGear transmissionEngineering

The invention relates to a planetary gear transmission device based on a conjugate curve herringbone gear, and belongs to the technical field of gear transmission. The planetary gear transmission device comprises a sun gear, a planet gear, a planet carrier and an inner gear ring. The sun gear and the planet gear are driven by the conjugate curve herringbone gear to form a sun gear and planet gear engagement pair, and contact curves formed by tooth surface engagement points are conjugate curves. The planet gear and the inner gear ring are driven by the conjugate curve herringbone gear to form a planet gear and inner gear ring engagement pair, and contact curves formed by tooth surface engagement points are conjugate curves. According to the planetary gear transmission device based on the conjugate curve herringbone gear, few-tooth large-modulus optimization design can be carried out, the whole machine weight is effectively reduced, and the requirement for low weight is met; the bearing capacity is high, no axial force influence exists in the gear surface engagement process, relative gear surface sliding is reduced through point contact engagement, the transmission efficiency is effectively improved, and the whole machine service life is effectively prolonged.

Owner:CHONGQING UNIV

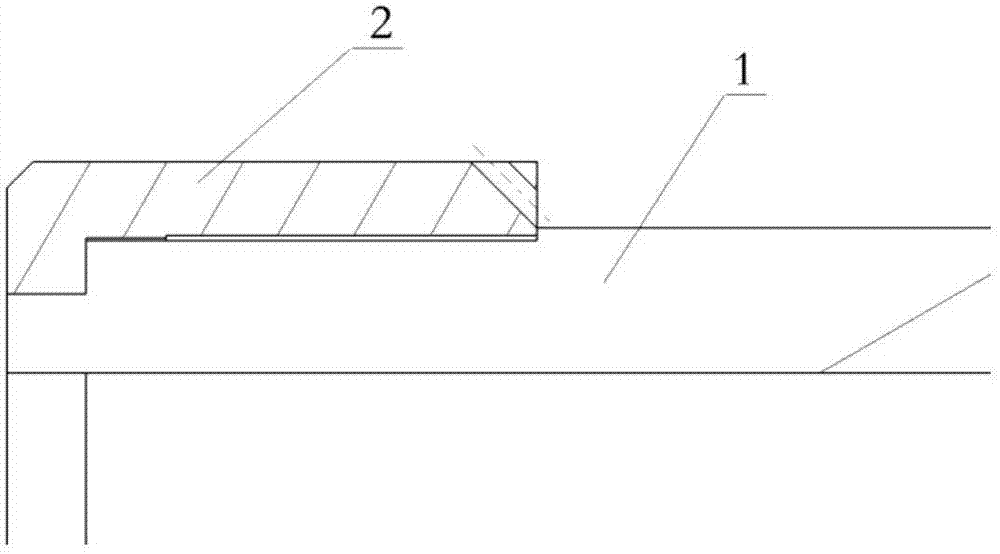

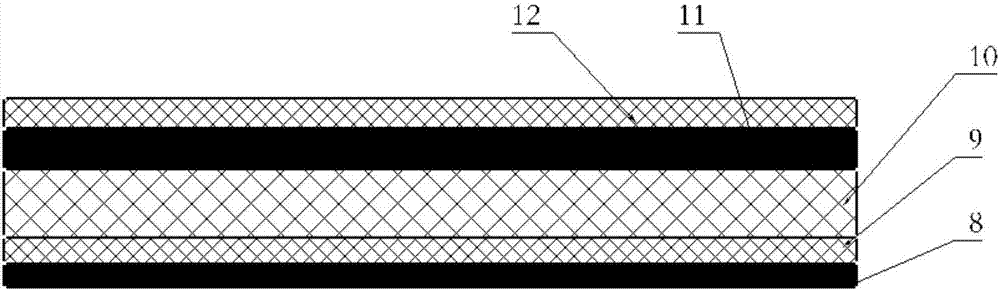

Skirt plate structure of rail traffic vehicle body and forming method of skirt plate structure

ActiveCN107553997AMeet lightweight requirementsGuaranteed Surface AccuracySynthetic resin layered productsAxle-box lubricationMetallic materialsHoneycomb

An embodiment of the invention provides a skirt plate structure of a rail traffic vehicle body and a forming method of the skirt plate structure, and belongs to the technical field of composite structure forming. The skirt plate structure of the rail traffic vehicle body comprises an outer skin layer, a honeycomb core layer, an inner skin layer and a support frame, wherein upper and lower surfacesof the honeycomb core layer are connected with the outer skin layer and the inner skin layer respectively, a mounting groove is formed in the inner skin layer and the honeycomb core layer, the support frame is located in the mounting groove and connected with the outer skin layer, the outer skin layer and the inner skin layer are made of a composite material, and the support frame is made of a metal material or a composite material. The skin layers are made of the composite material, uniform radian of the inner and outer skin layers is realized by the honeycomb core, and surface precision ofthe large curved skirt plate structure is guaranteed; mechanical strength of the large skirt plate structure is guaranteed by the support frame; with adoption of the composite materials and a hollow structure, the weight of the large skirt plate structure is reduced by about 20%, and the requirement for the light vehicle body is met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

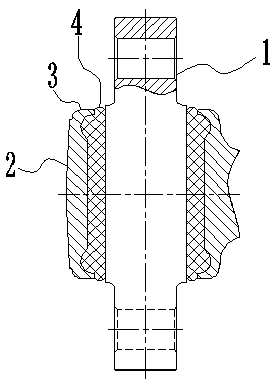

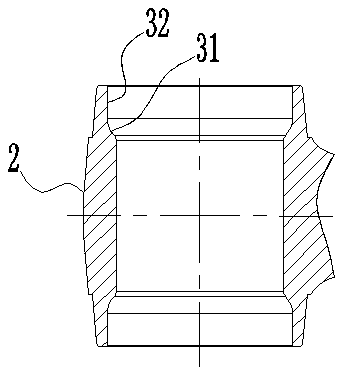

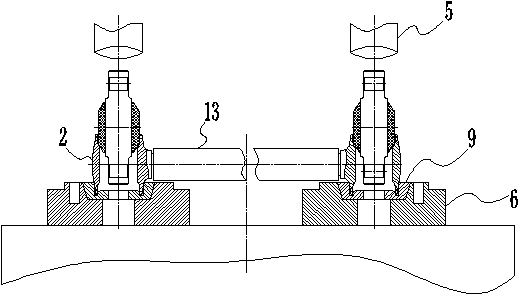

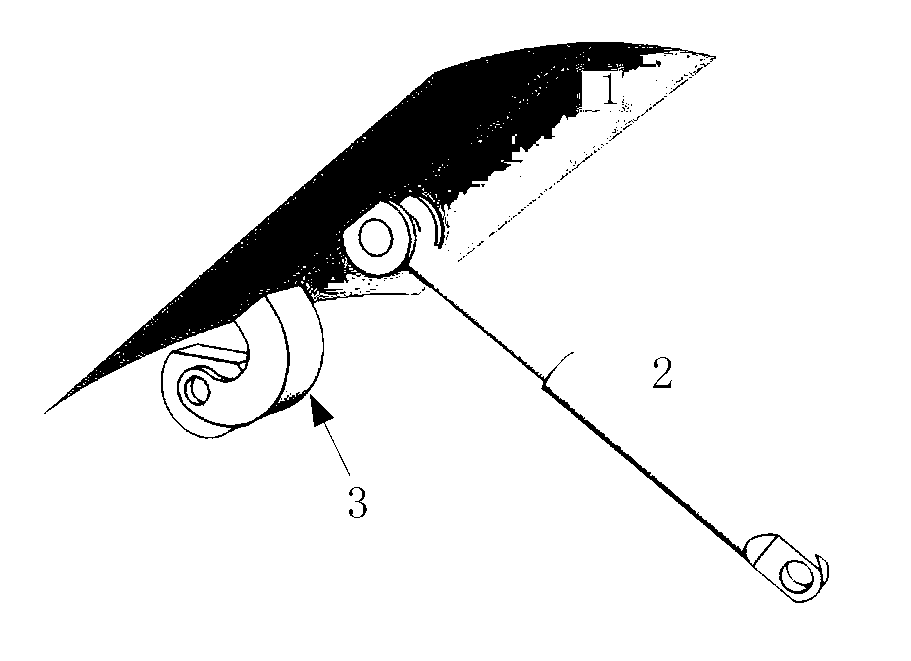

Traction bar ball assembly, and assembling tool and assembling method for traction bar ball assembly

The invention discloses a traction bar ball assembly, an assembling tool and an assembling method for the traction bar ball assembly. The traction bar ball assembly comprises a traction bar ball joint and a traction bar ball, wherein the traction bar ball comprises a traction bar ball body and turnup structures arranged at the two ends of the traction bar ball body, the turnup structures and the traction bar ball body are integrally formed, and the turnup structures at the two ends of the traction bar ball body are matched with the traction bar ball joint to limit the traction bar ball joint in the traction bar ball. The turnup structures arranged at the two ends of the traction bar ball and integrated with the traction bar ball are buckled on the traction bar ball joint, and the traction bar ball joint is limited in the traction bar ball, so that the traction bar ball assembly is simple in structure and free from maintenance, the manufacturing cost of the traction bar ball assembly is lowered, the weight is relatively light, and the requirements of light weight is completely met. When the assembling tool and the assembling method are used to assemble, the operation is simple, the assembling time is shortened, and the assembling efficiency is improved.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

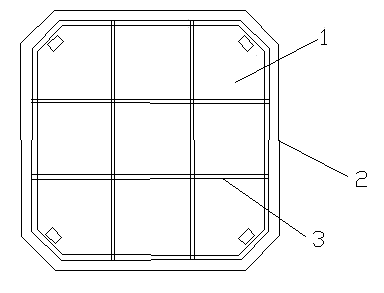

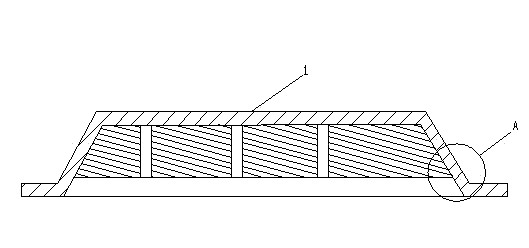

Integral bursting type composite material launching box cover and manufacturing method thereof

ActiveCN102313491AImprove operational responsivenessLaunch does not affectLaunching weaponsSiloMissile

The invention relates to a box cover for a missile launching silo, in particular to an integral bursting type composite material launching box cover and a manufacturing method thereof. The integral bursting type composite material launching box cover comprises frame bodies; the frame bodies are octagonal; the frame bodies are mutually separated into frames and cover plates; the frames are octagonal; and the cover plates are matched with the shapes of the frames and are mounted on the frames. In order to make up the disadvantages on the aspect and improve the combat response capability of an army, the octagonal top bursting type composite material launching box cover is developed. The box cover necessarily meets certain storage pressure without being damaged, and further, in a pressure-bearing state, a cover body cannot deform largely. After a box body is suffered from the synchronous actions of four thrusting barrels, the box body condignly flies off a launching box integrally prior to a missile, and the launching of the missile is not influenced. Through the overall design of the main body, not only can the deformation of the cover body be effectively controlled, but also the light weight of the cover body is achieved. Further, in a bursting process, the higher the integral rigidity of the cover body is, the better the integrity in the separation of the main body and the frames is.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

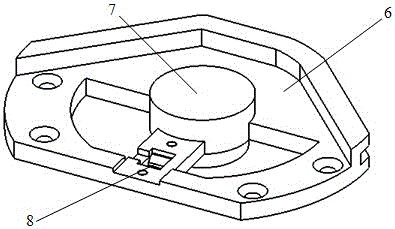

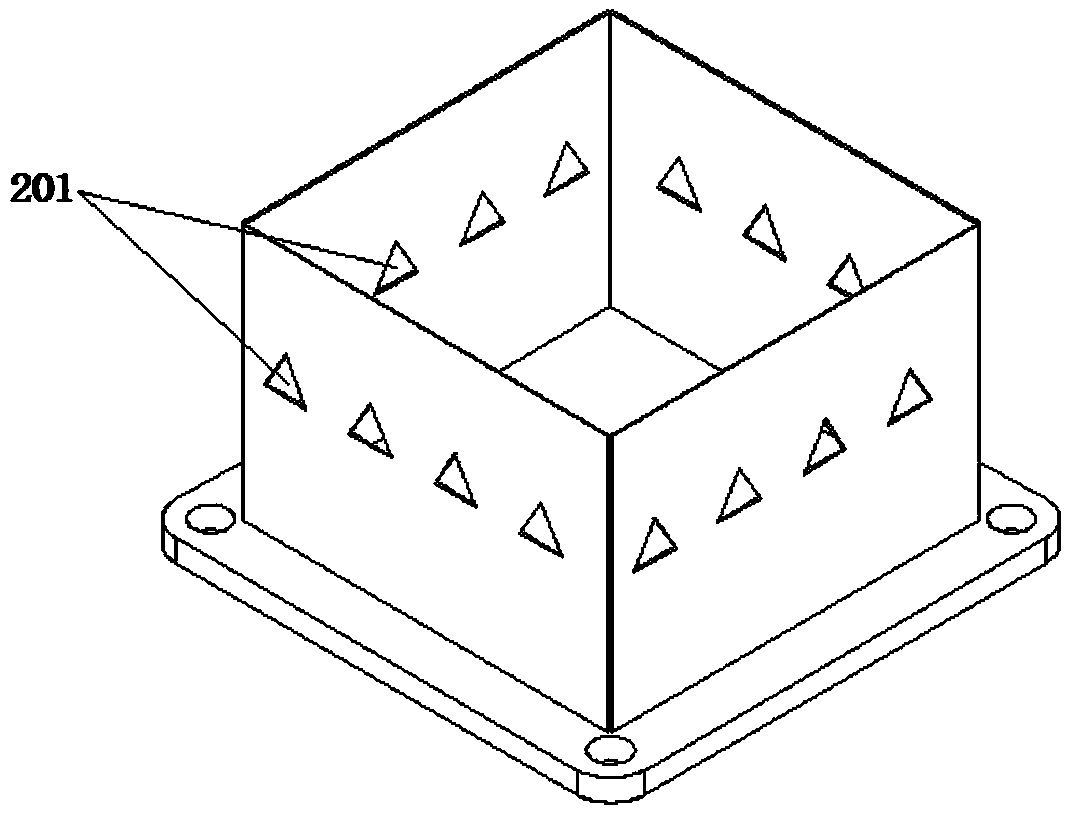

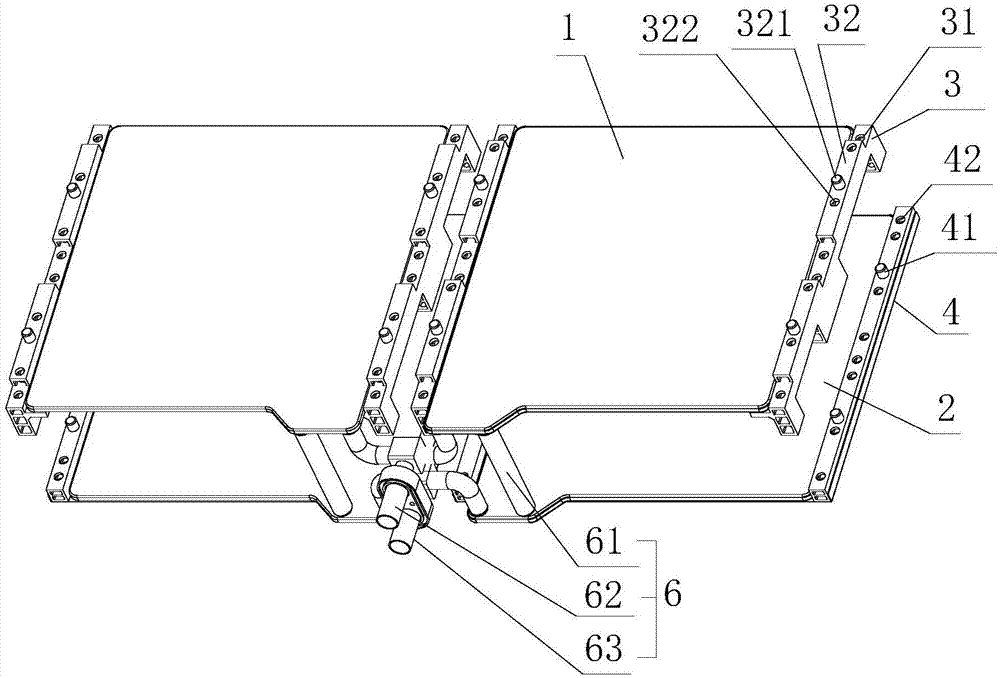

Cubesat brake sail de-orbit device

ActiveCN105799956ACompatible with miniaturization requirementsMeet lightweight requirementsCosmonautic vehiclesSystems for re-entry to earthBand shapeEngineering

The invention discloses a cubesat brake sail de-orbit device. The cubesat brake sail de-orbit device is composed of two completely identical cubesat brake sail de-orbit sub-devices. Each cubesat brake sail de-orbit sub-device comprises a de-orbit device body and a partition board arranged on the top of the de-orbit device body, wherein the de-orbit device body is of a central symmetry structure and comprises a main frame, an upper end cover, a sail storage chamber guide rail, a Hall sensor, a base plate and two expanding mechanisms, the main frame is Z-shaped, the main frame is divided into two identical chambers with the center of the main frame as the symmetry center, and the two expanding mechanisms are arranged in the two chambers respectively. Four film sails are expanded in four directions by means of tape spring masts to increase the normal sectional area of satellite movement, so as to successfully solve the problem that a cubesat stays on the original track for a long time after fulfilling a task and becomes space debris.

Owner:NANJING UNIV OF SCI & TECH

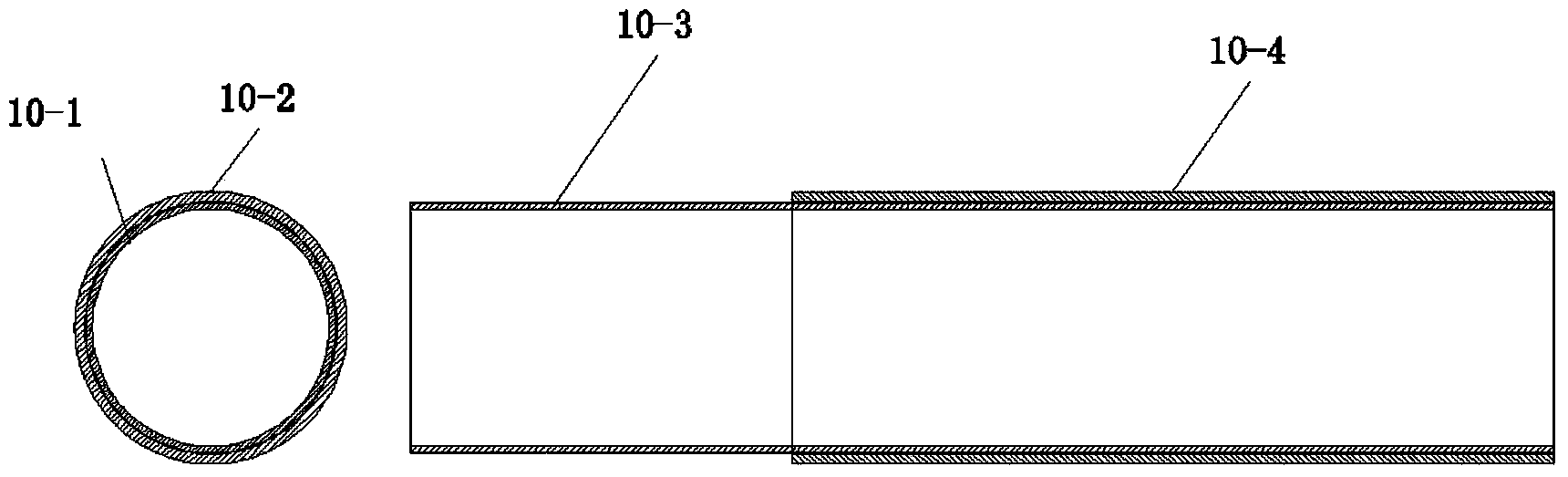

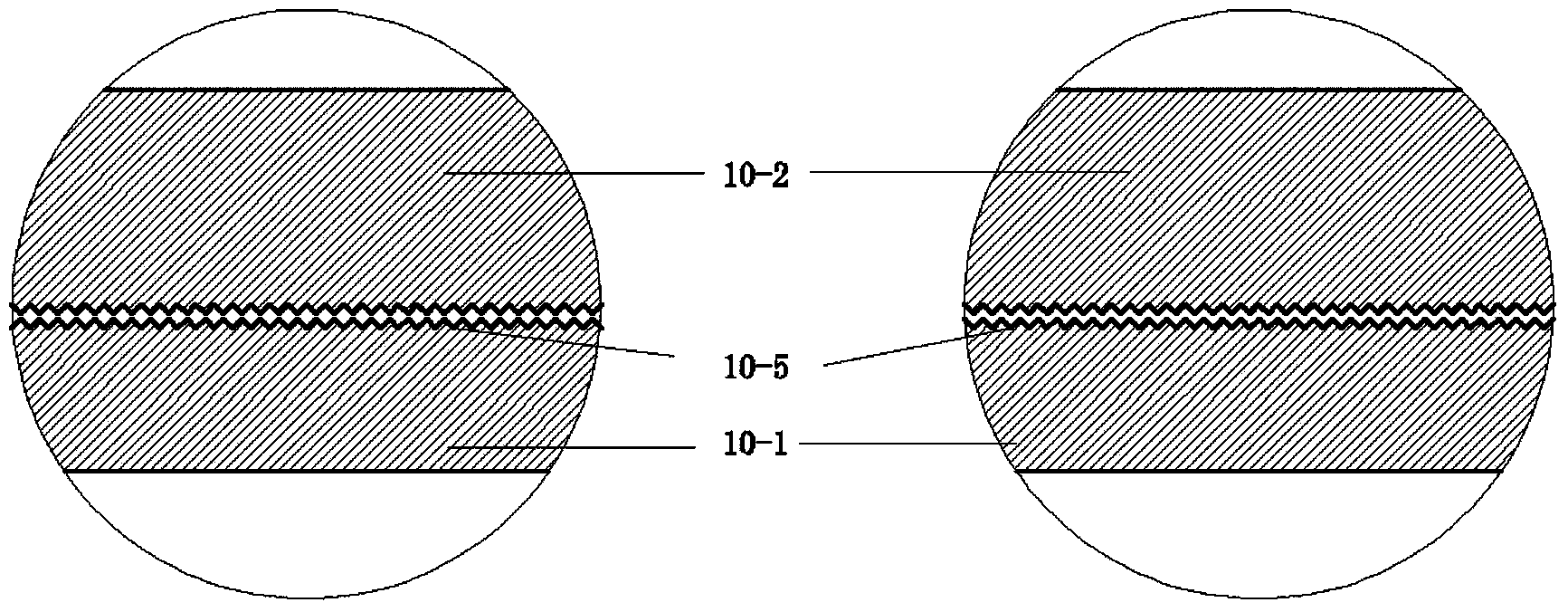

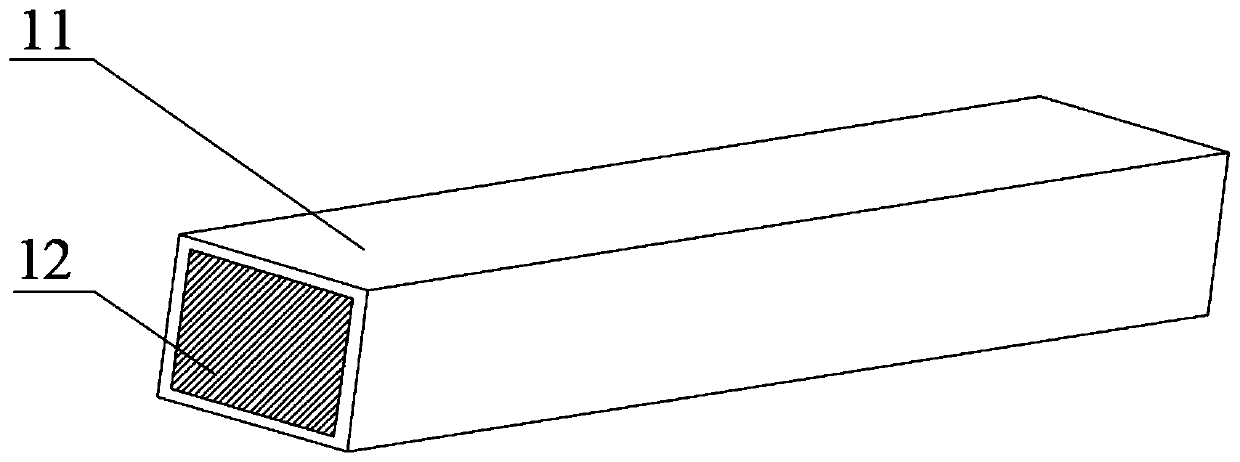

Device and method for machining composite energy absorption tube

The invention discloses a composite energy absorption tube machining device which comprises a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a mould frame (9), a constraint mould (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), an exhaust vent (16), a fixing groove (17) and a wire hole (18). Compared with a hydraulic forming method and a mechanical bulging method, a composite metal energy absorption forming method based on the electromagnetic forming principle and used in the composite energy absorption tube machining device is high in machining efficiency and high in the pipe fitting forming speed and enables composite metal tubes to be formed under the high strain rate; due to the fact that the high strain deformation process can be used for forming metal materials which are deformed difficultly through a conventional method, the plasticity of the metal materials is greatly improved, and the yield strength of the materials is greatly improved. Different wave forms and reinforcing ribs can be formed by changing the shape of the constraint mould in a mould body, and the machining flexibility is high.

Owner:HUNAN UNIV

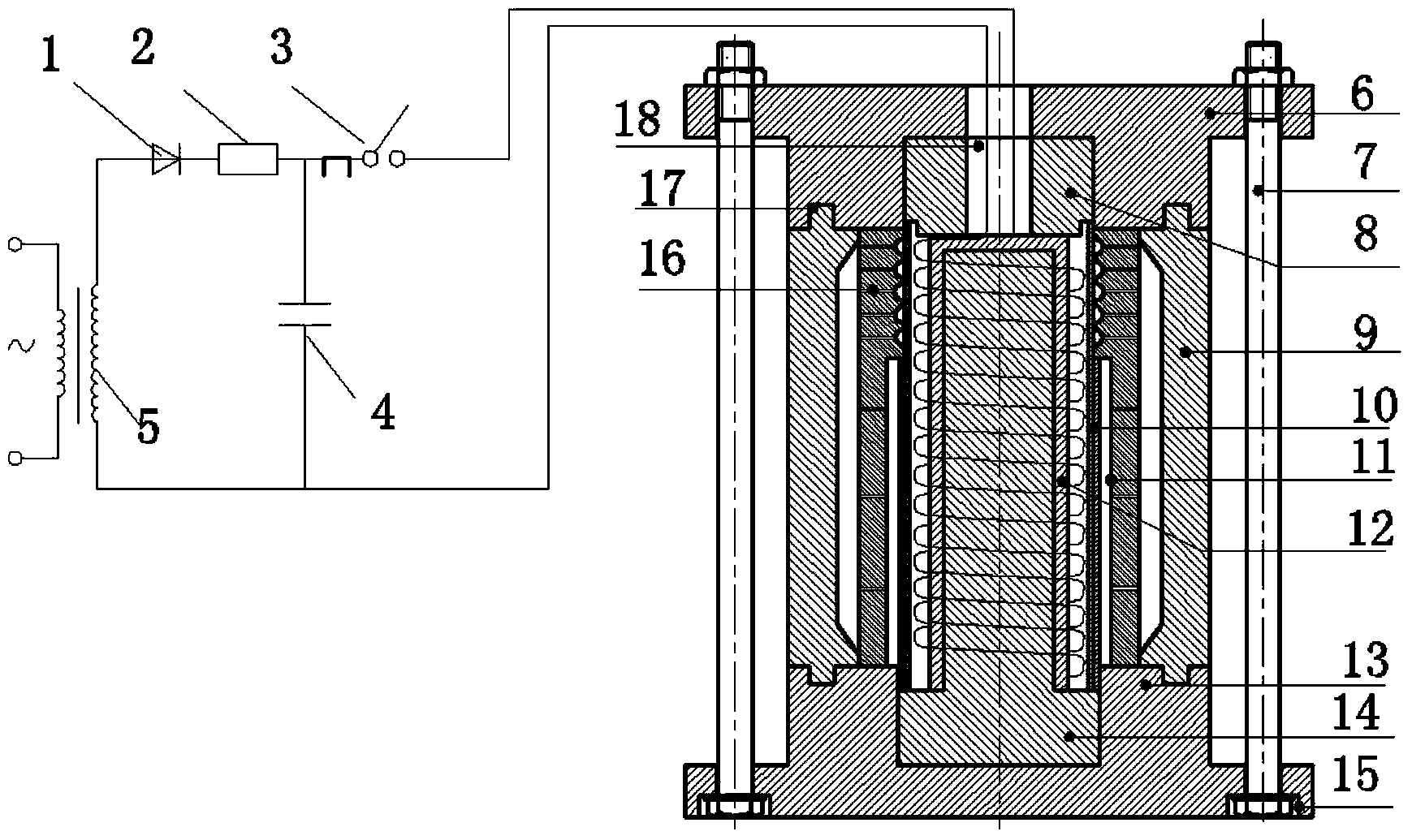

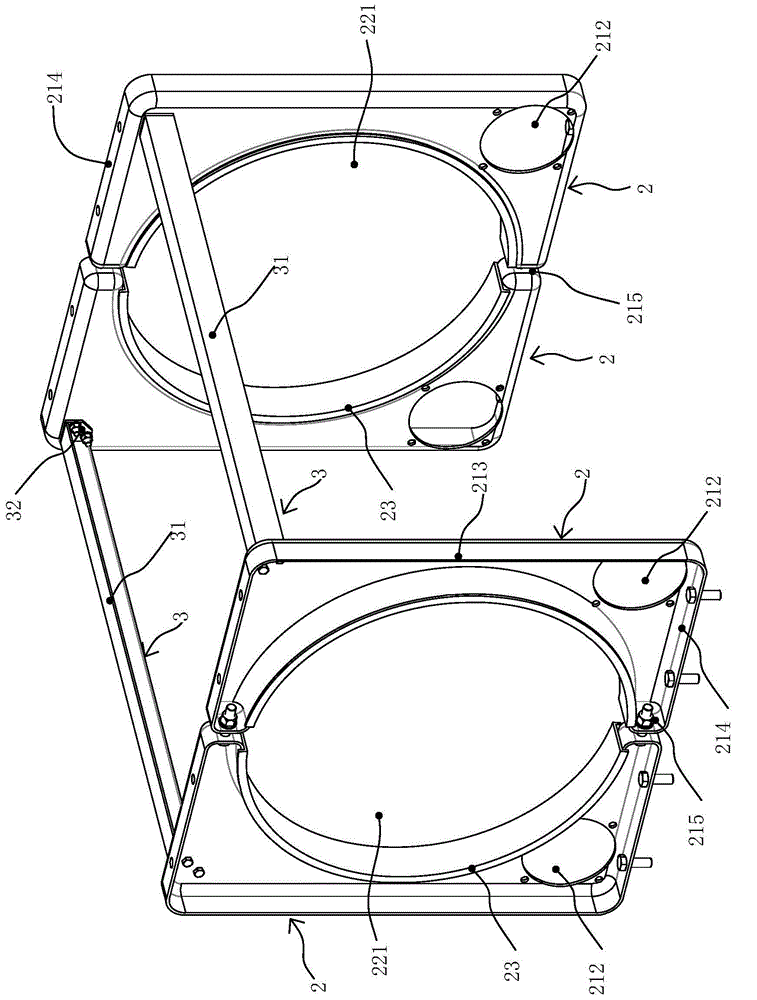

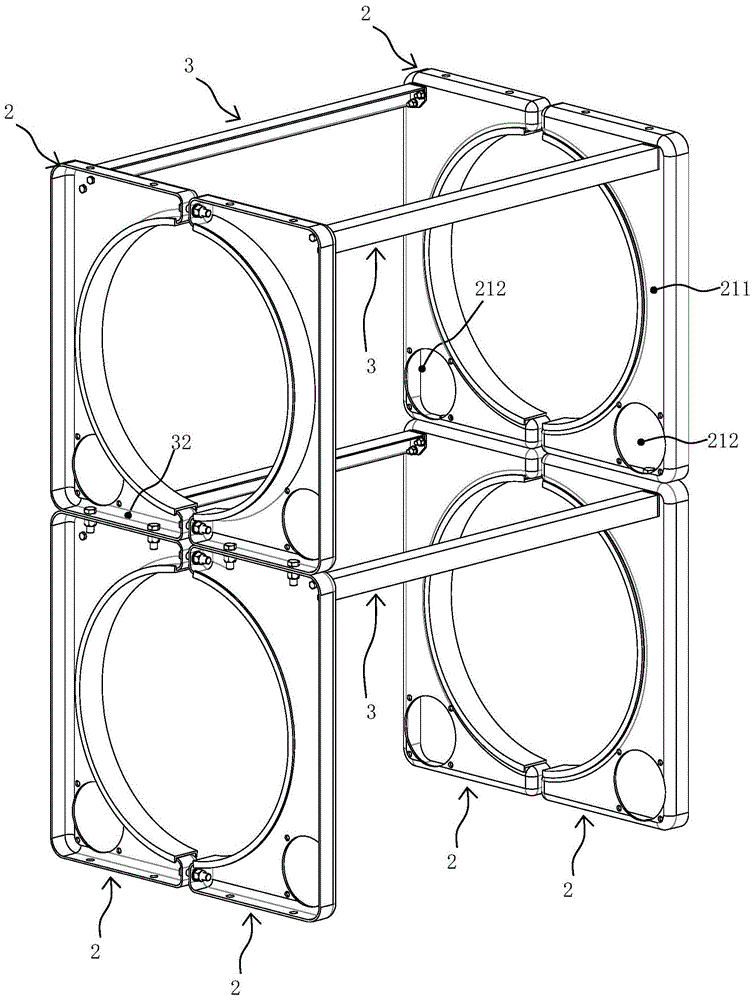

Gas cylinder fixing rack, gas cylinder frame, LNG gas supply system and vehicle

InactiveCN105003824AHigh precisionImprove quality stabilityContainer filling methodsContainer discharging methodsGas cylinderFixed frame

The invention provides a gas cylinder fixing rack, a gas cylinder frame, an LNG gas supply system adopting the frame, and a vehicle. The gas cylinder frame comprises an external fixing connection portion, an internal holding portion and a supporting connection part arranged between the external fixing connection portion and the internal holding portion, the fixing connection portion is fixedly connected with a vehicle body or other parts, the holding portion internally holds and fixes a gas cylinder, the supporting connection part is connected to the fixing connection portion and the holding portion, the fixing frame is evenly divided into at least two modularized mounting racks, and the modularized mounting racks have a same shape. Batch production and rapid connecting use are realized, so the cost is saved, and the precision and the quality stability of the frame are improved.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +2

Strength-strengthening method for use in super-thin complicated part processing

InactiveCN101069949AMeet lightweight requirementsReduce processing deformationPositioning apparatusMetal-working holdersAlloyUltimate tensile strength

The invention belongs to mechanical cool-working technology, which relates to an intensity enhancing method to process ultra-thin complex parts. The invention casts low melting point alloy outside the parts to process ultra-thin (<= 0.5mm) complex cavity parts. It can process ultra-thin products with different shapes to meet the lightweight requirements. It has small processing distortion and the roundness errors of the processed holes are controlled within 0.007mm. It has high processing precision and can realize multi-surface process with one clamping, which can guarantee the correlating size precision. The shapes of the workpieces can be designed as cuboids to facilitate the clamping and positioning.

Owner:中国航空工业第一集团公司第六一三研究所

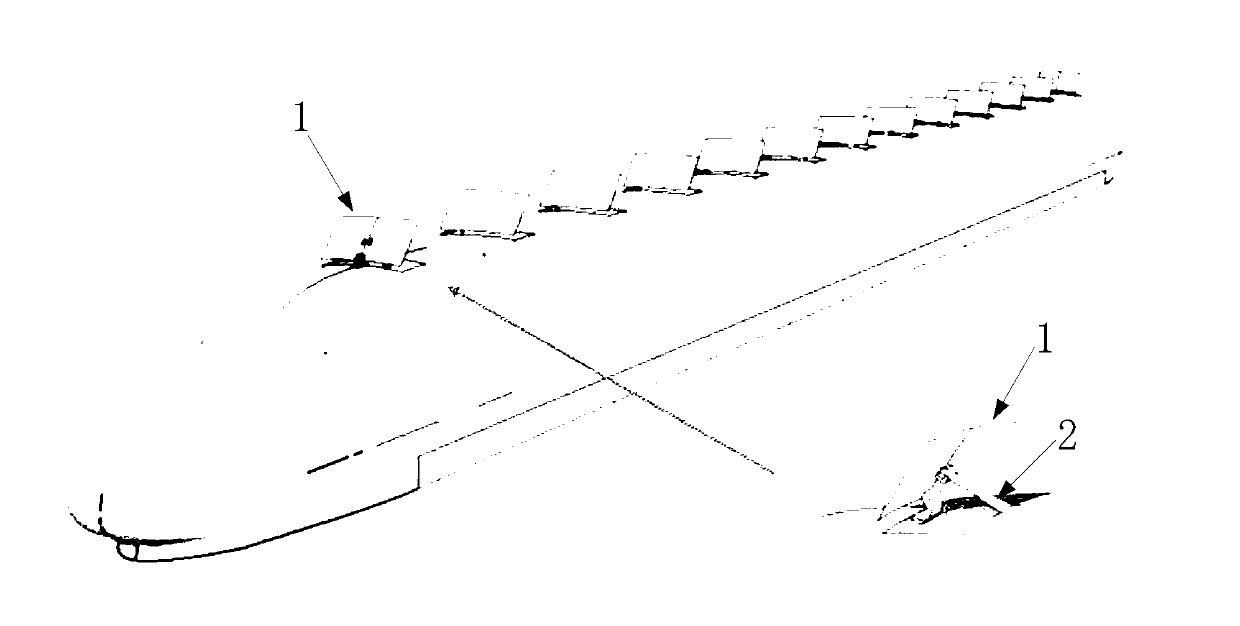

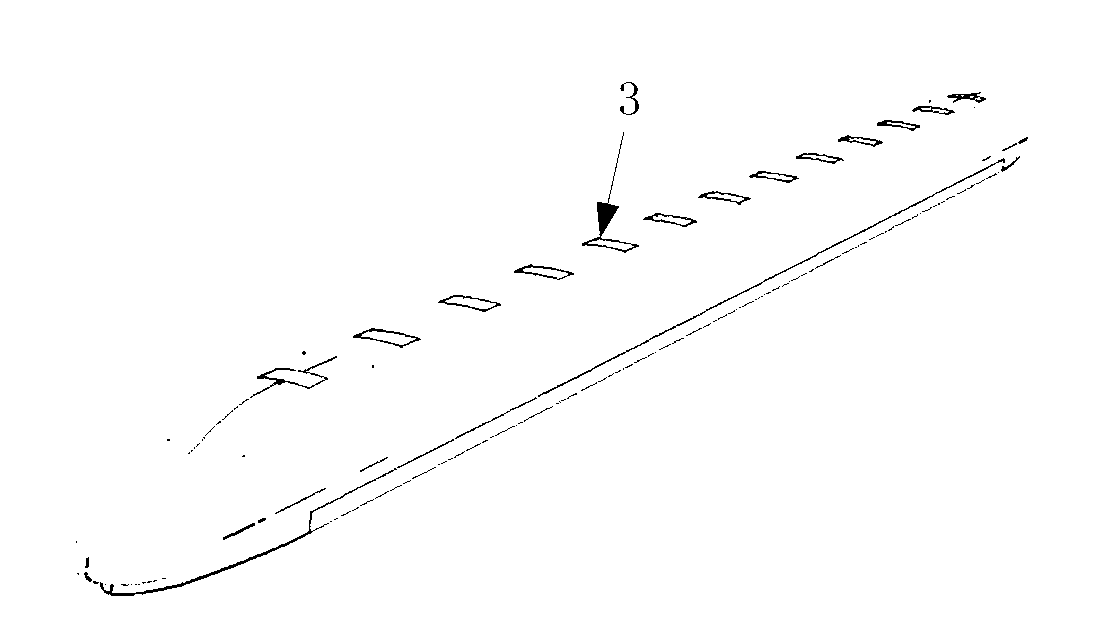

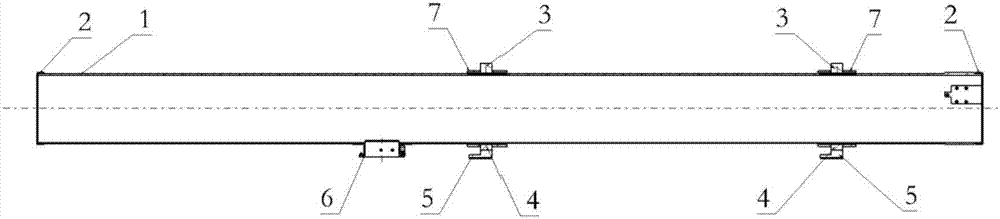

Wind resistance braking device applied to high-speed train

InactiveCN103213599ANo contact friction lossPromote repairAerodynamic brakesAerodynamic dragFriction loss

The invention discloses a wind resistance braking device applied to a high-speed train. Speed brakes for braking and decelerating by using air resistance are arranged on a locomotive of the high-speed train and the top outer surface of each carriage. During conventional braking or emergent braking of a train running at a high speed, the speed brakes are opened, and pressure difference resistance generated by air flow is taken as main braking power for conventional braking and auxiliary braking power for emergent braking, so that the comfort of passengers is improved during conventional braking of the high-speed train, and friction loss caused by braking with a brake disc is avoided; meanwhile, the braking distance of emergent braking is shortened, and the running safety of high-speed train is improved. Moreover, the air resistance is in direct proportion to the square of the speed, so that the effects of the speed brakes are best for the train running at a high speed. Meanwhile, the air resistance is generated by air power without consuming energy additionally, so that pollution is prevented; and moreover, the wind resistance braking device is simple in structure, and is easy to implement.

Owner:BEIHANG UNIV

Drive system of double-motor double-shaft input speed changing box and gear shifting control method of drive system

ActiveCN105927714ASave layout spaceReduce weightElectric propulsion mountingToothed gearingsAutomatic transmissionCoupling

The invention belongs to the technical field of electric vehicle transmission, and specifically relates to a drive system of a double-motor double-shaft input speed changing box and a gear shifting control method of the drive system. The system comprises a drive motor I, a drive motor II and an electronic control mechanical automatic transmission. The electronic control mechanical automatic transmission comprises a first-gear gear set, a second-gear gear set, a third-gear gear set, a fourth-gear gear set, a coupling sleeve I, a coupling sleeve II, a transmission input shaft I, a transmission input shaft II and a transmission output shaft. The electronic control mechanical automatic transmission provides three gears for power output of the drive motor I and the drive motor II. By means of coupling of the drive motor I, the drive motor II and the electronic control mechanical automatic transmission and drive of the drive motor I and the drive motor II, shifting of three gears can be achieved. According to the system, the arrangement space of a finished vehicle is saved, the gears do not affect one another, the requirements for bearing and gear rotating speed are not high, and the life is long.

Owner:NANJING YUEBOO POWER SYST CO LTD

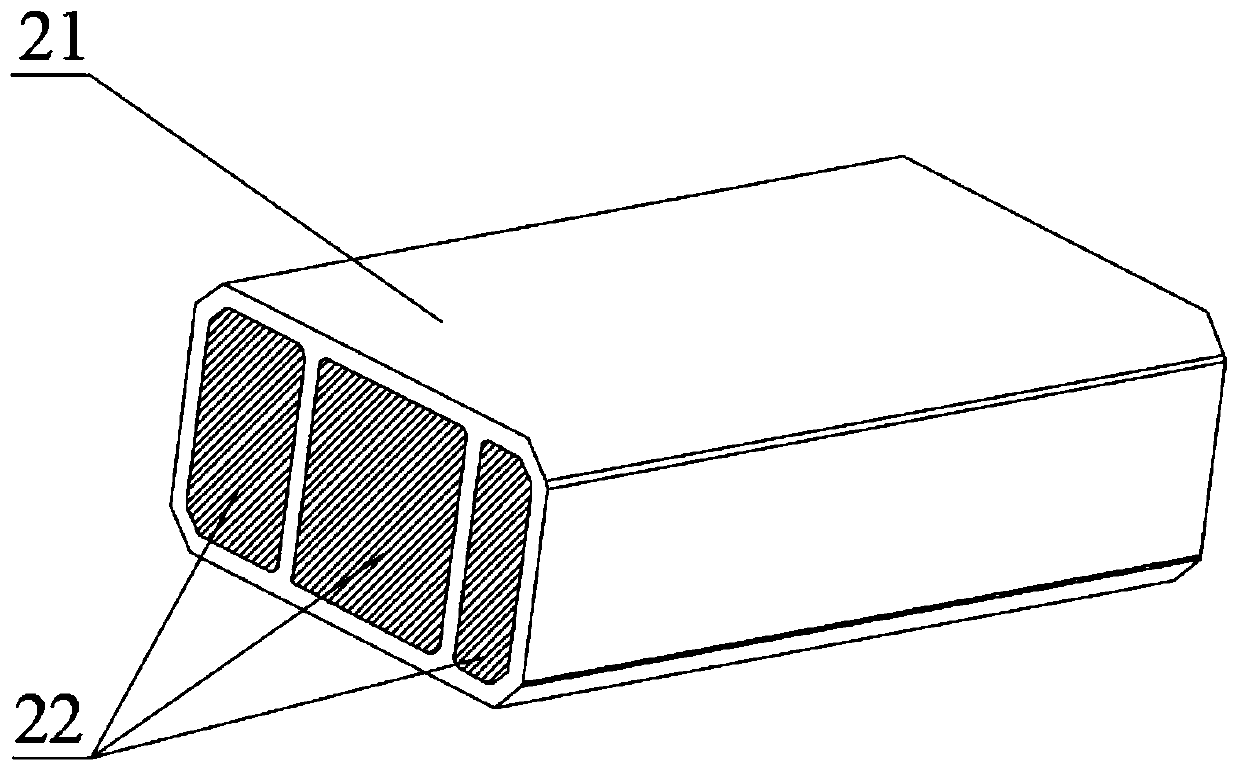

Automobile collision energy absorbing box capable of achieving high-efficiency and stable energy absorption

The invention provides an automobile collision energy absorbing box capable of achieving high-efficiency and stable energy absorption. The automobile collision energy absorbing box comprises flanges,a square thin-walled outer shell, lattice structures and a sandwich plate; the flanges are arranged at the upper and lower ends of the square thin-walled outer shell, the lattice structures are arranged on the upper and lower ends of the sandwich plate, and the lattice structures and the sandwich plate are integrally arranged in the square thin-walled outer shell; each lattice structure is formedby distributing aluminum tubes according to the body square diagonal; the sandwich plate comprises two layers of carbon fiber sheets and a honeycomb structure arranged between the two layers of carbonfiber sheets; the honeycomb structure is formed by staggered distribution of regular octagons and regular squares; the lattice structures and the sandwich plate are connected into a whole through spot welding, and the square thin-walled outer shell and the flanges are connected into a whole through spot welding; and the flanges are connected and fixed to a transverse beam and a longitudinal beamof an automobile through bolts. The automobile collision energy absorbing box solves the problems that a traditional energy absorbing box is unstable in energy absorption, poor in multi-angle impact adaptability, discontinuous, low in efficiency and the like.

Owner:HUAQIAO UNIVERSITY

Composite missile launching canister and preparation method thereof

The invention relates to a composite missile launching canister and a preparation method thereof. The launching canister comprises a composite canister body, a guide rail, a locking mechanism installing block, metal joints arranged at the two ends of the canister body, hoisting blocks, supports, support legs, annular reinforcing ribs, plugs, a falling window and the like. The canister body is made of a complete composite, and the purpose of overcoming own weaknesses by acquiring strong points of others is achieved through the characteristics that fiber glass reinforced plastic is high in strength, good in tenacity but insufficient in rigidity and carbon fiber reinforced plastic is high in strength, good in rigidity but insufficient in tenacity; in addition, the weight is decreased obviously, and the even more complex launching environment requirements are effectively met. According to the preparation method of the launching canister, the canister body, the guide rail and the internal installing block are integrally formed, the metal structures at the two ends are adhered through a structural adhesive and sealed through a sealing agent, the sealing effect is good, the technology is simple, and the production efficiency is improved.

Owner:绍兴宝旌复合材料有限公司 +1

Preparation method of aluminum alloy casting with cavity filled with foamed aluminum

The invention discloses a preparation method of an aluminum alloy casting with cavity filled with foamed aluminum. The preparation method comprises the following steps of providing formed foamed aluminum with soldering flux on the surface; fixing the formed foamed aluminum with the soldering flux on the surface in a mold; and casting through using a molten aluminum alloy. According to the preparation method of the foamed aluminum filled aluminum alloy cavity casting, the foamed aluminum is used for replacing a traditional sand core, so that higher strength is obtained while lightweight requirements are met, procedures of sand vibrating, shakeout, sand blowing, sand recovering and the like are further omitted, and the production efficiency is improved.

Owner:CITIC DICASTAL

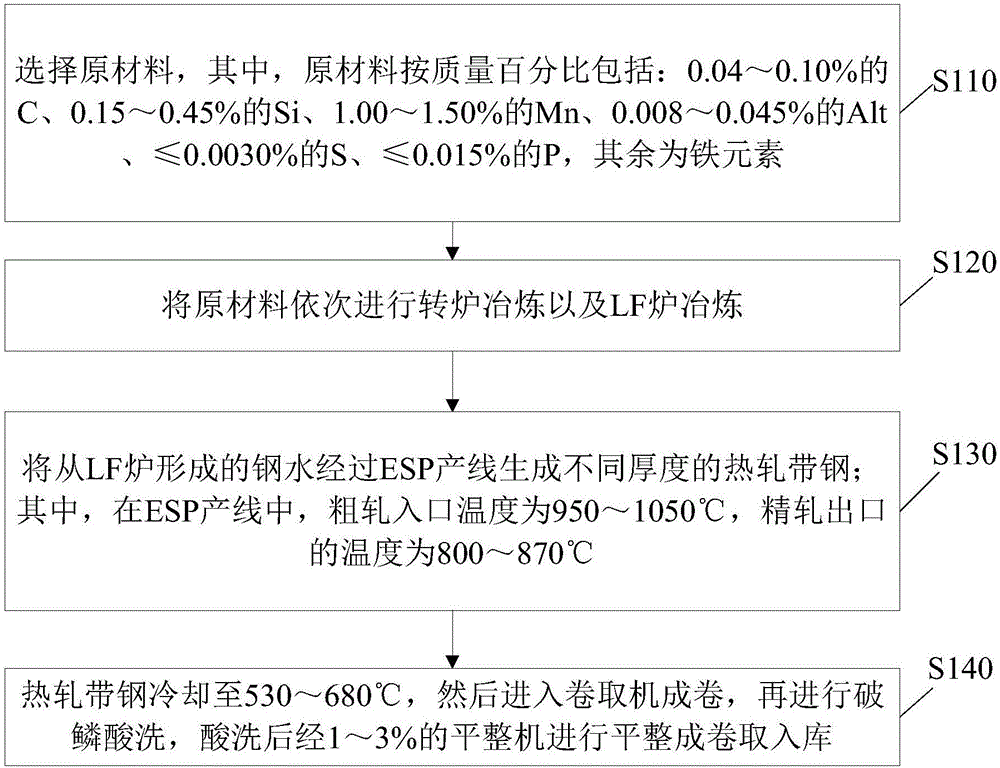

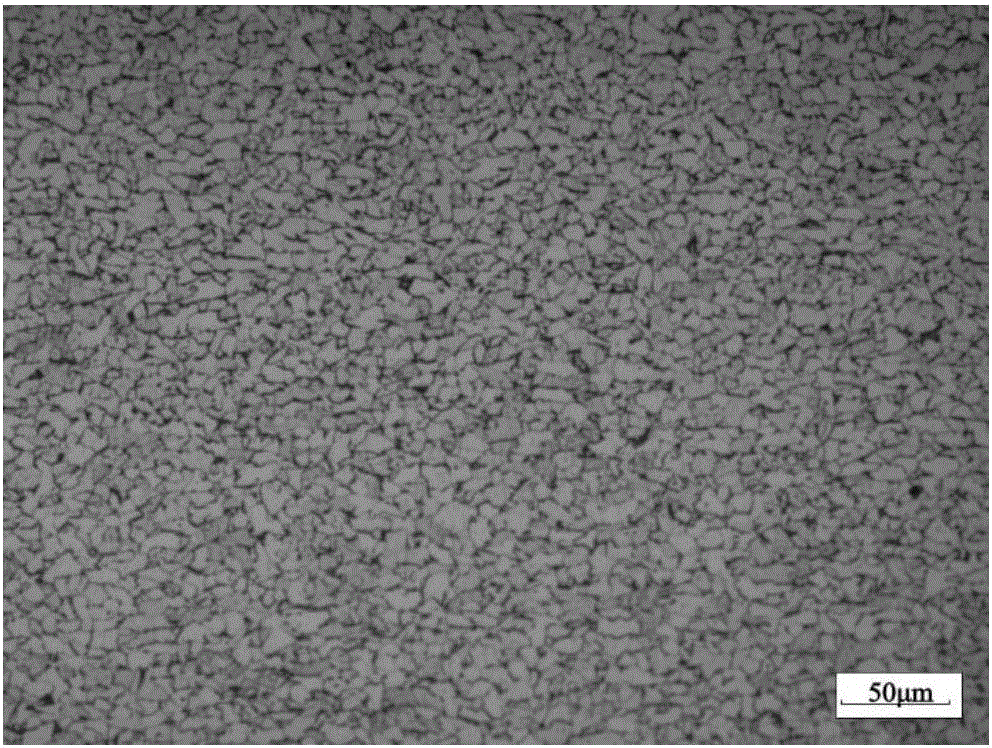

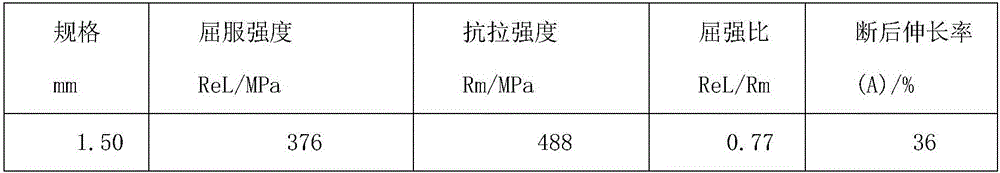

Method for producing thin-specification SAPH440 steel based on ESP thin slab continuous casting and rolling process

ActiveCN106834924AShort production processSave energyTemperature control deviceMetal rolling arrangementsProduction lineThin slab

The invention provides a method for producing thin-specification SAPH440 steel based on an ESP thin slab continuous casting and rolling process. The method includes the steps that raw materials are selected, wherein the raw materials include, by mass percent, 0.04%-0.10% of C, 0.15%-0.45% of Si, 1.00%-1.50% of Mn, 0.008%-0.045% of Alt, smaller than or equal to 0.0030% of S, smaller than or equal to 0.015% of P and the balance iron; the raw materials are subjected to converter smelting and LF furnace smelting; molten steel formed from an LF furnace passes through an ESP production line to generate hot-rolled strip steel different in thickness, wherein in the ESP production line, the temperature of a rough rolling inlet ranges from 950 DEG C to 1050 DEG C, the temperature of a finish rolling outlet ranges from 800 DEG C to 870 DEG C; and the hot-rolled strip steel is cooled to the temperature ranging from 530 DEG C to 680 DEG C and then enters a coiling machine to be coiled, then scale breading acid pickling is conducted, and the hot-rolled strip steel is flattened through a 1%-3% flattening machine and is coiled to be put into a warehouse. By means of the method, the problem that subsequent cold rolling and annealing are needed in the traditional production technology is solved.

Owner:RIZHAO STEEL HLDG GROUP

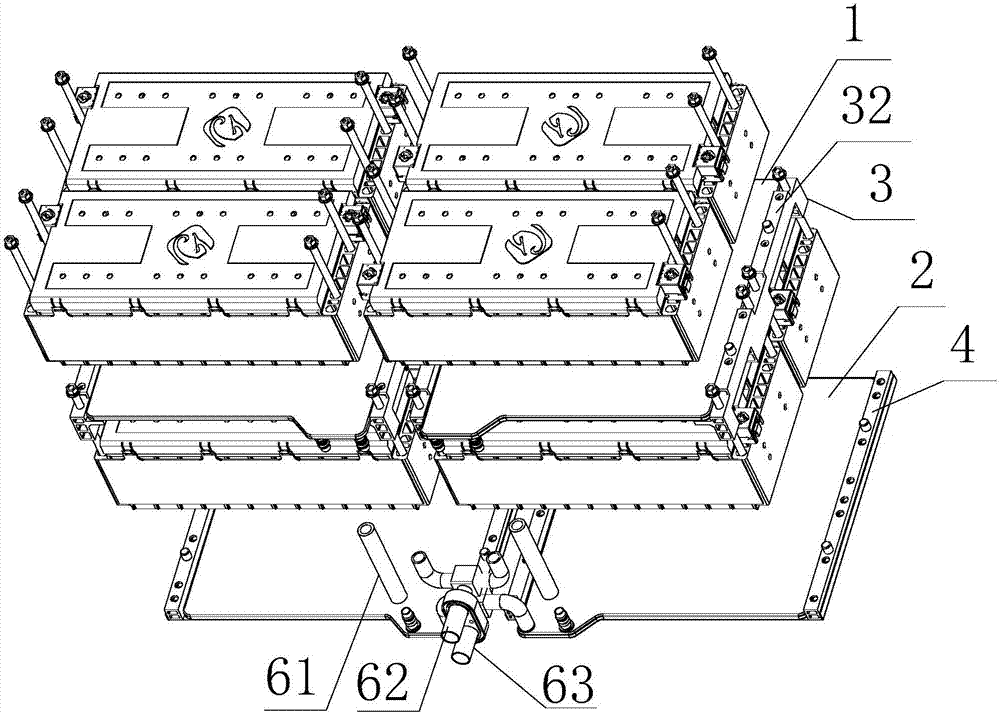

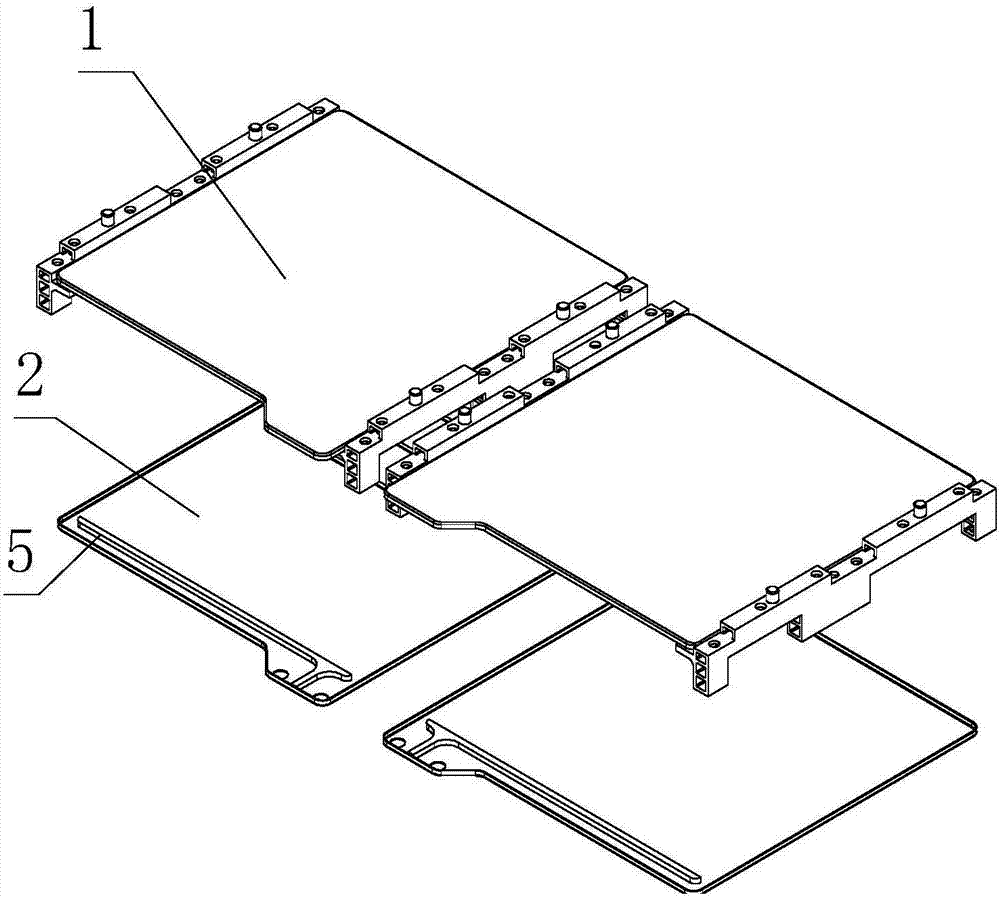

Liquid-cooled fixing structure for battery system

ActiveCN107359292ACost minimizationLow costSecondary cellsCell component detailsEngineeringCooling medium

The invention discloses a liquid-cooled fixing structure for a battery system. The liquid-cooled fixing structure comprises an upper water cooling plate and a lower water cooling plate, wherein the upper water cooling plate and the lower water cooling plate are arranged up and down and are connected with each other, each of the interior of the upper water cooling plate and the interior of the lower water cooling plate is provided with a medium flow passage for a cooling medium to flow, and the medium flow passage inside the upper water cooling plate communicates with the medium flow passage inside the lower water cooling plate to form a circuit; lower installation bases fixed to two sides of the lower water cooling plate are arranged on two sides of the lower water cooling plate, the lower installation bases on the two sides are matched with each other, a lower installation surface for a battery module to install is formed above the lower water cooling plate, and a lower fixing mechanism for fixing the battery module is arranged on the lower installation surface. According to the liquid-cooled fixing structure, a fixing device and a cooling device of the battery module are combined into one, the maximum utilization of system inner space is realized, the lightweight requirement of the system is met, and simultaneously the reliability requirement of the structure is further met.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

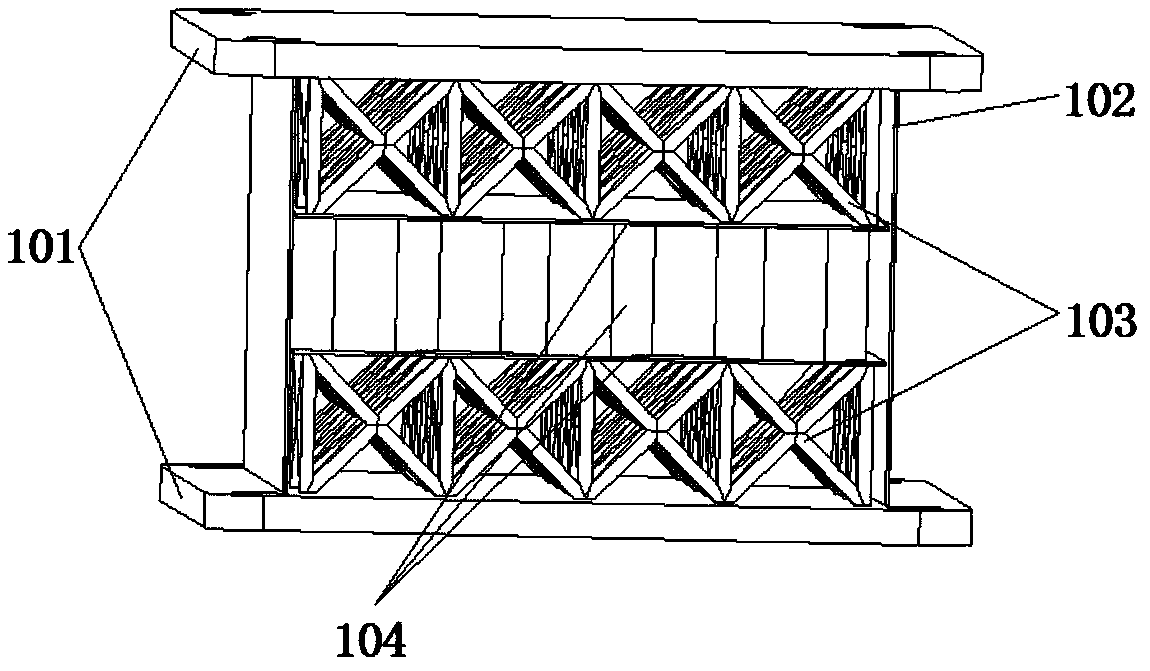

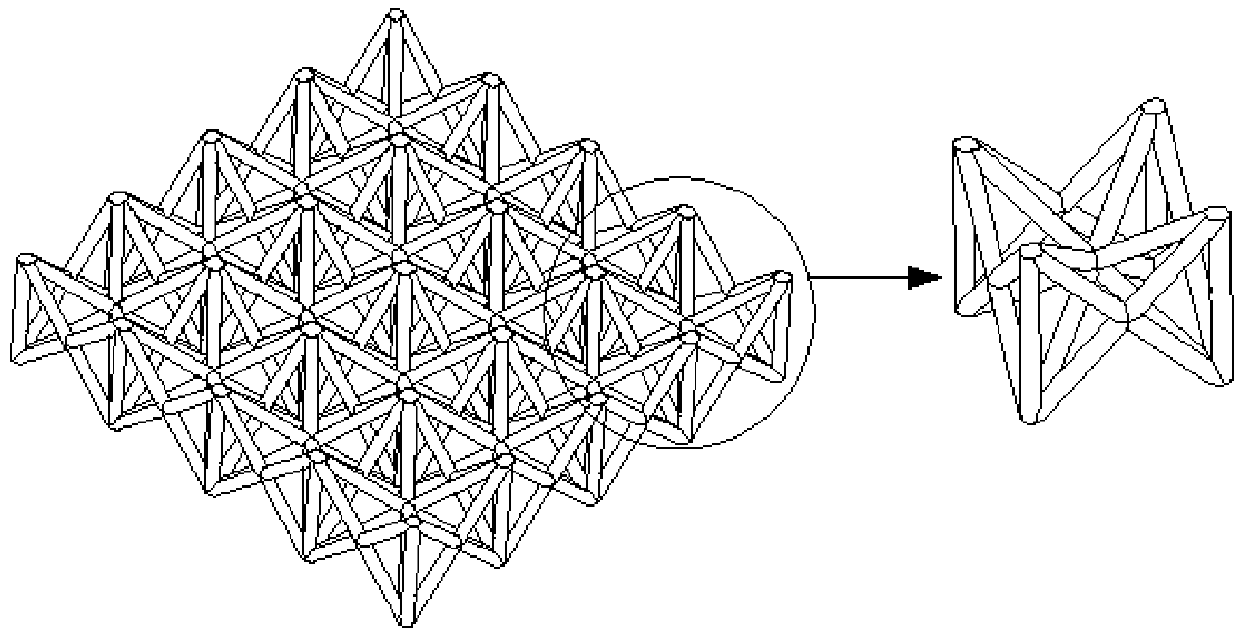

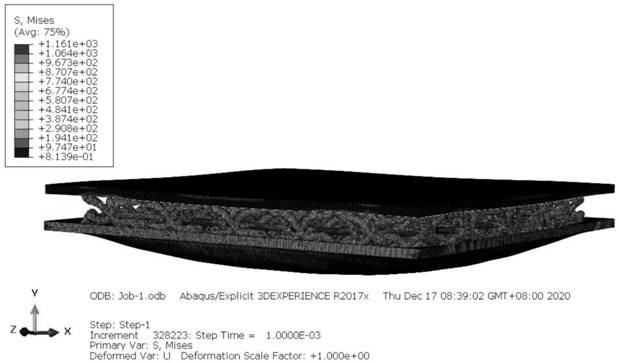

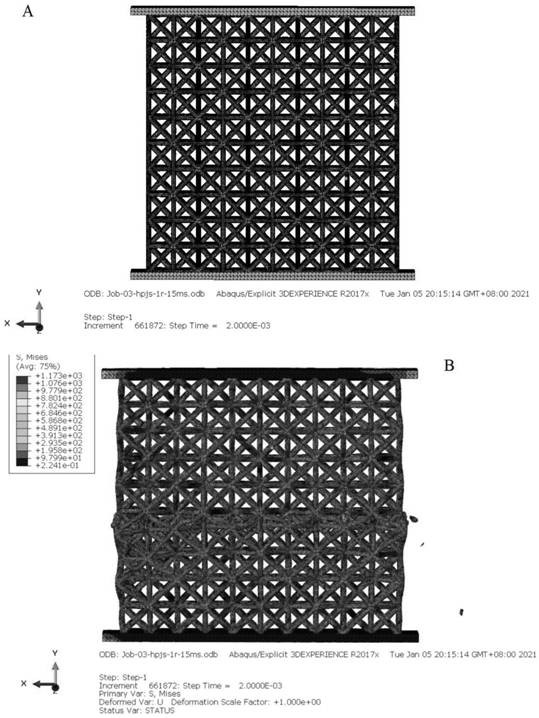

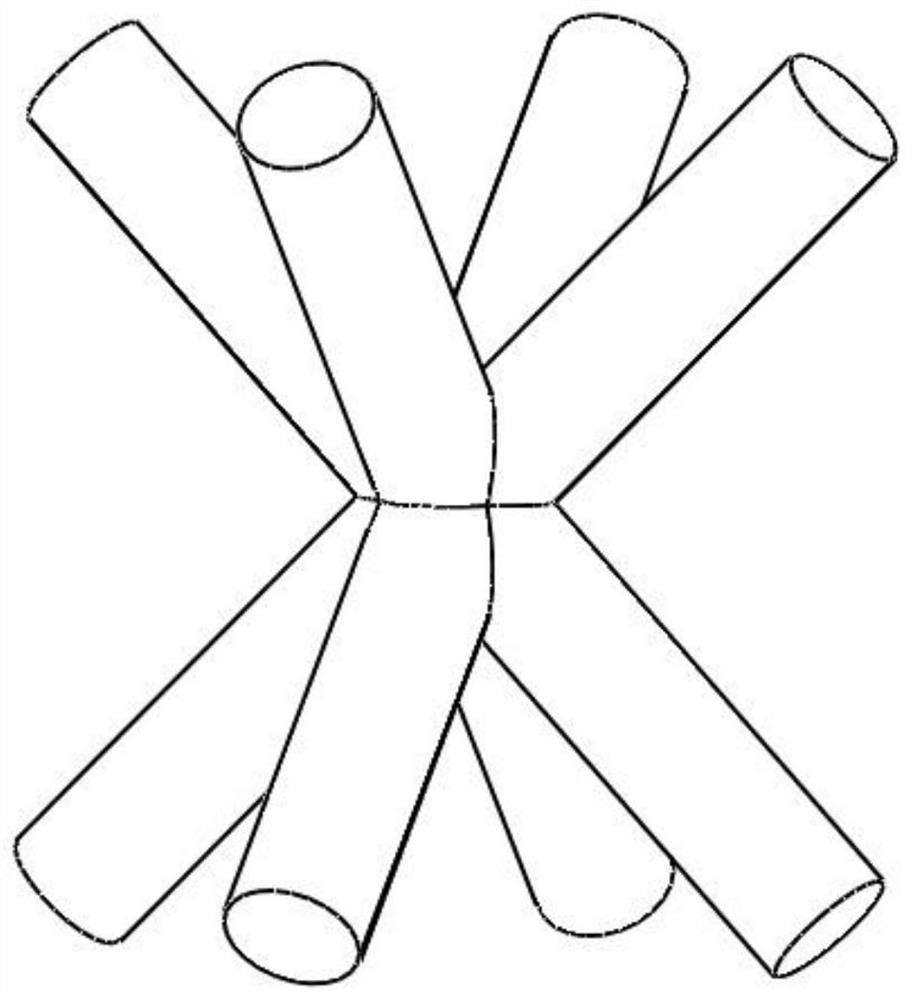

Reinforced unit cell structure, preparation method and application thereof and sandwich panel

ActiveCN112848553AMeet lightweight requirementsExcellent anti-penetration abilityAdditive manufacturing apparatusProtective equipmentForeign matterOctahedron

The invention provides a reinforced unit cell structure, a preparation method and application thereof and a sandwich panel, and belongs to the technical field of additive materials. The reinforced unit cell structure provided by the invention comprises an octagonal lattice structure and a BCC body-centered cubic lattice structure, wherein in a stress mode, the octagonal lattice structure consists of 40 same rod pieces, from the total volume of the space, the octagonal lattice structure is composed of 28 same rod pieces, and the rod pieces of the BCC body-centered cubic lattice structure make contact with the eight rod pieces of the octahedron of the inner layer of the octagonal lattice structure. According to the invention, the parts, prone to buckling, of the octagonal lattice structure in the external force bearing process are reinforced through the BCC body-centered cubic lattice structure, so that the overall rigidity of the octagonal lattice structure is improved; and the sandwich panel prepared by utilizing the reinforced unit cell structure not only can be used as an energy absorption structure in the explosion impact process to absorb energy generated by external explosion impact waves, but also has outstanding penetration resistance when resisting high-speed impact of foreign matters such as elastic sheets and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

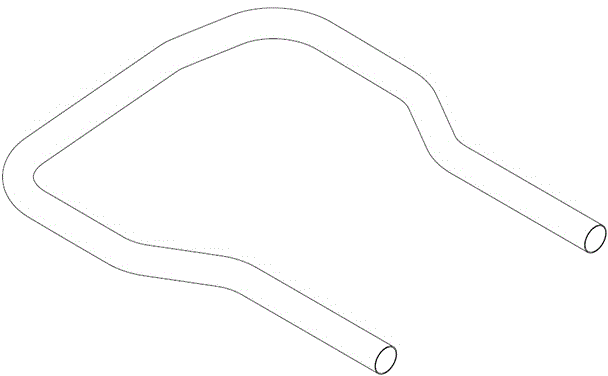

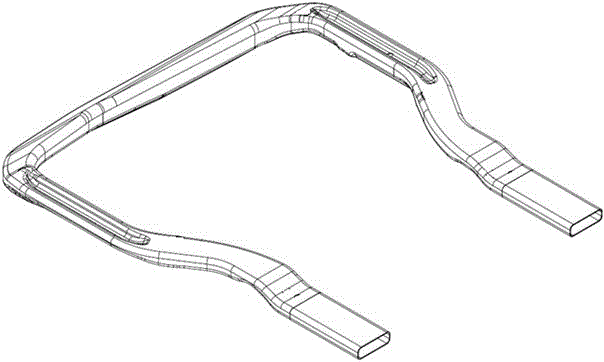

Car auxiliary frame and forming method

The invention relates to the machining field of car components, particularly to an auxiliary frame and a forming method thereof. The car auxiliary frame is formed by directly molding a uniform-wall-thickness cylindrical pipe and is of one piece. The forming method comprises the following steps: firstly selecting the uniform-thickness cylindrical pipe as a raw material, and then bending the round pipe to obtain an elbow pipe; then pre-molding the elbow pipe, hydraulically molding the pre-molded frame pipe, and finally cutting the end part of the formed frame to obtain a needed component. According to the auxiliary frame and the forming method, one round pipe is sequentially bent, pre-molded and hydraulically-molded to finally obtain the needed auxiliary frame. Compared with the auxiliary frame component manufactured in a traditional stamping welding way, the forming method has advantages of high production efficiency, fewer molds, light component weight, high strength and low comprehensive component cost; while the material cost is reduced, the light-weight requirement of vehicles can be realized, and the product competence can be improved.

Owner:SHANGHAI BAOSTEEL NEW TECH PARTS

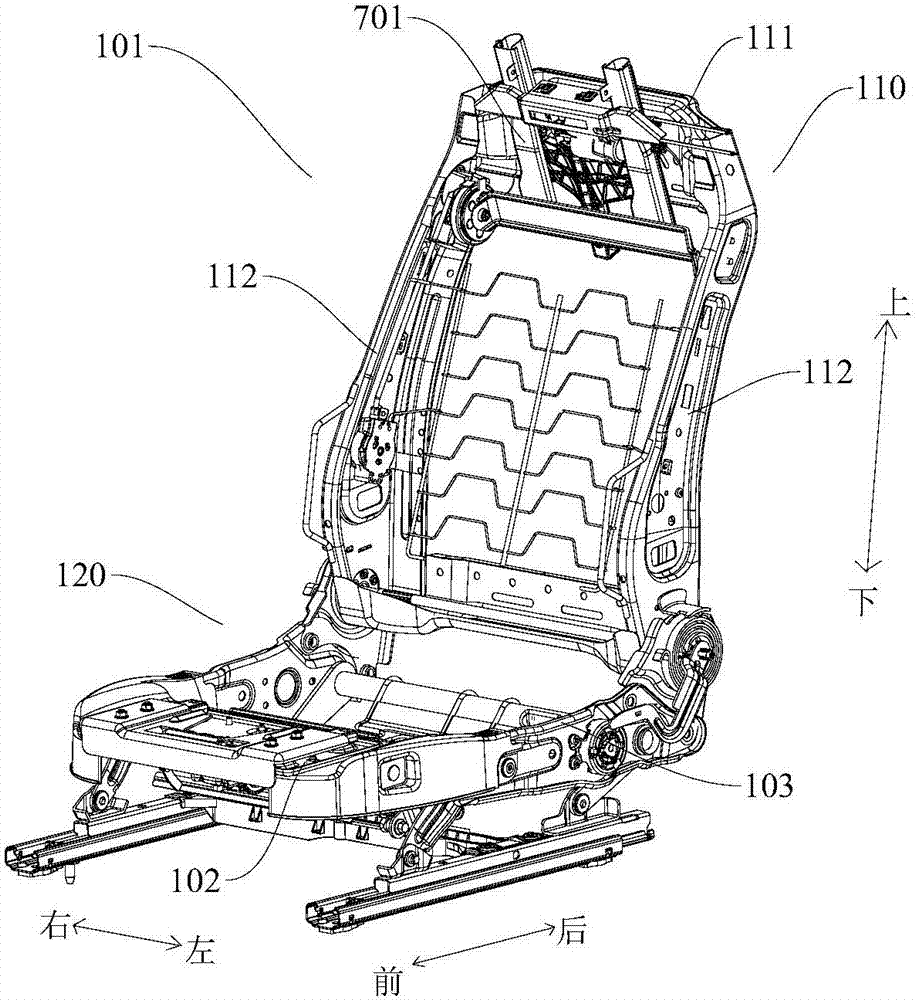

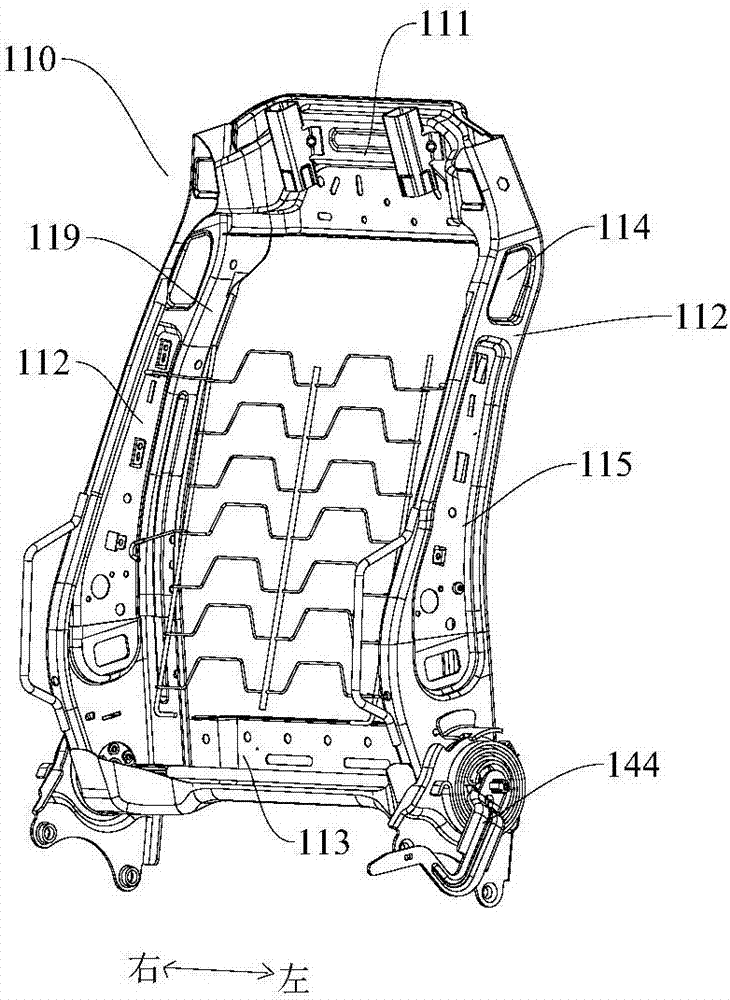

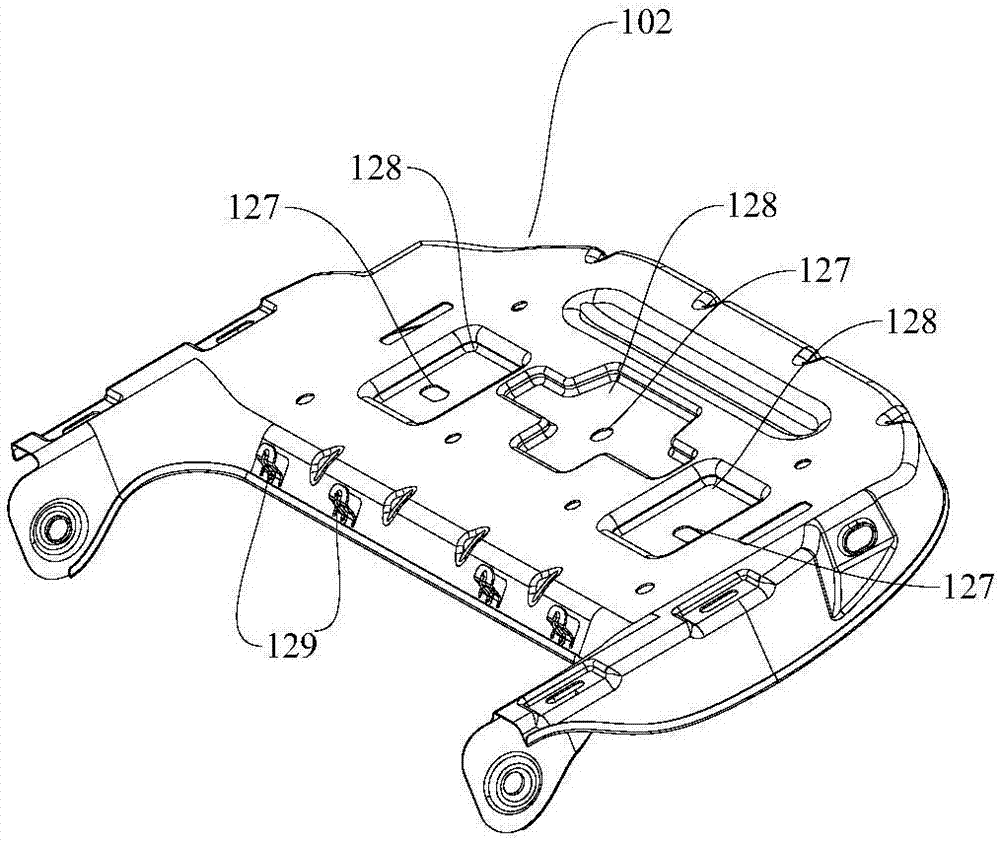

Seat and vehicle

The invention provides a seat and a vehicle. The seat comprises a seat framework and at least one function module. The seat framework comprises a backrest framework and a cushion basin assembly, and the backrest framework comprises an upper cross plate, a lower cross plate and two edge plates; a basin is arranged on the front side of a cushion, and the cushion comprises two cushion side plates, a front linkage rod and a rear linkage rod, wherein the front linkage rod and the rear linkage rod are separated from each other; and the at least one function module is arranged on the seat framework and comprises a cushion basin assembly front-rear adjusting mechanism, a shoulder adjusting mechanism, a backrest framework angle adjusting mechanism and a basin height adjusting pump. In this way, the seat is simple in structure and light, can accord with the lightweight requirement of the vehicle and can have various adjusting functions.

Owner:GREAT WALL MOTOR CO LTD

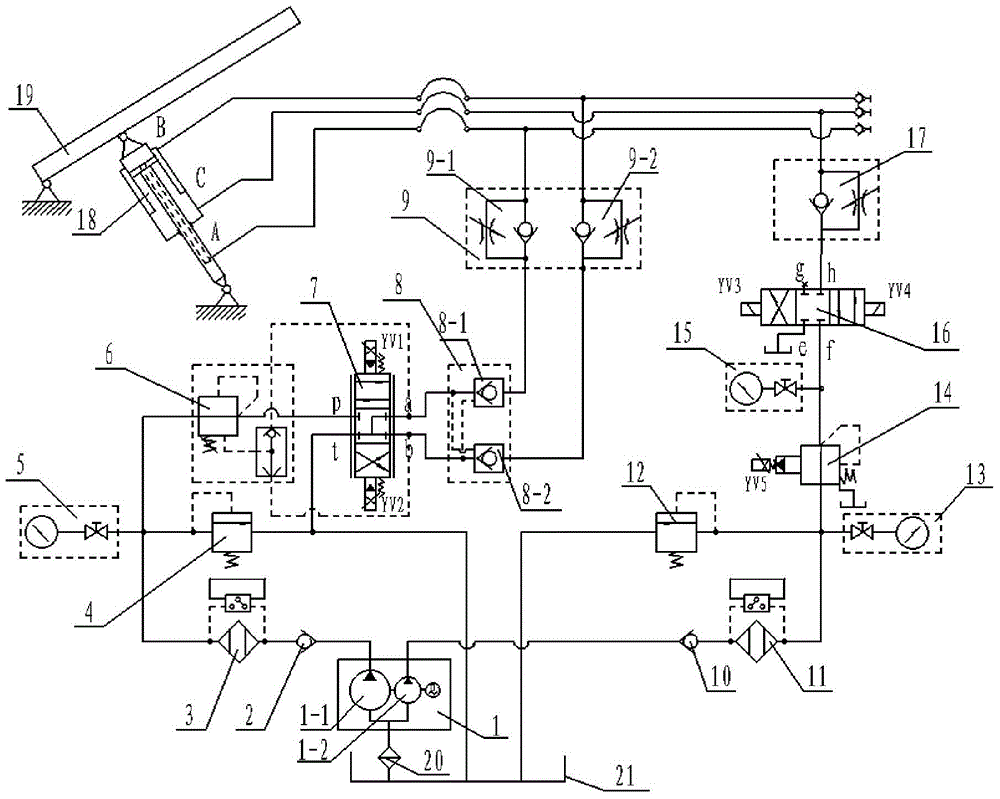

Heavy long rod hoisting mechanism hydraulic system and control method

InactiveCN104863910ARealize precise position controlGuaranteed stabilityServomotorsCranesHydraulic cylinderCheck valve

The invention discloses a heavy long rod hoisting mechanism hydraulic system. The hydraulic system is provided with a double-linkage fixed displacement vane pump set used for supplying oil and comprises a speed control loop and a position control loop. The speed control loop is connected with an upper cavity and a lower cavity of a three-cavity hydraulic cylinder through a large pump of the double-linkage fixed displacement vane pump set, the large pump is connected with a check valve and an oil sucking filter, and the oil sucking filter is connected with a pilot overflow valve and a proportional servo valve. Non-balanced disturbance can be effectively inhibited in the hoisting process of a heavy long rod, stability of a servo system is guaranteed, and accurate balance control and positioning control are achieved.

Owner:NANJING UNIV OF SCI & TECH

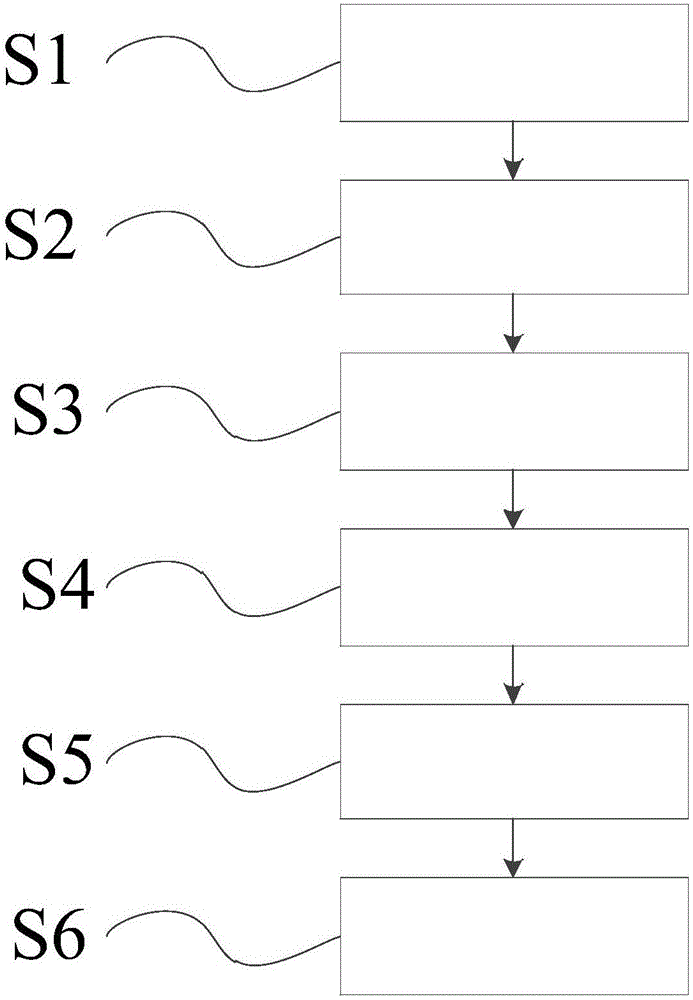

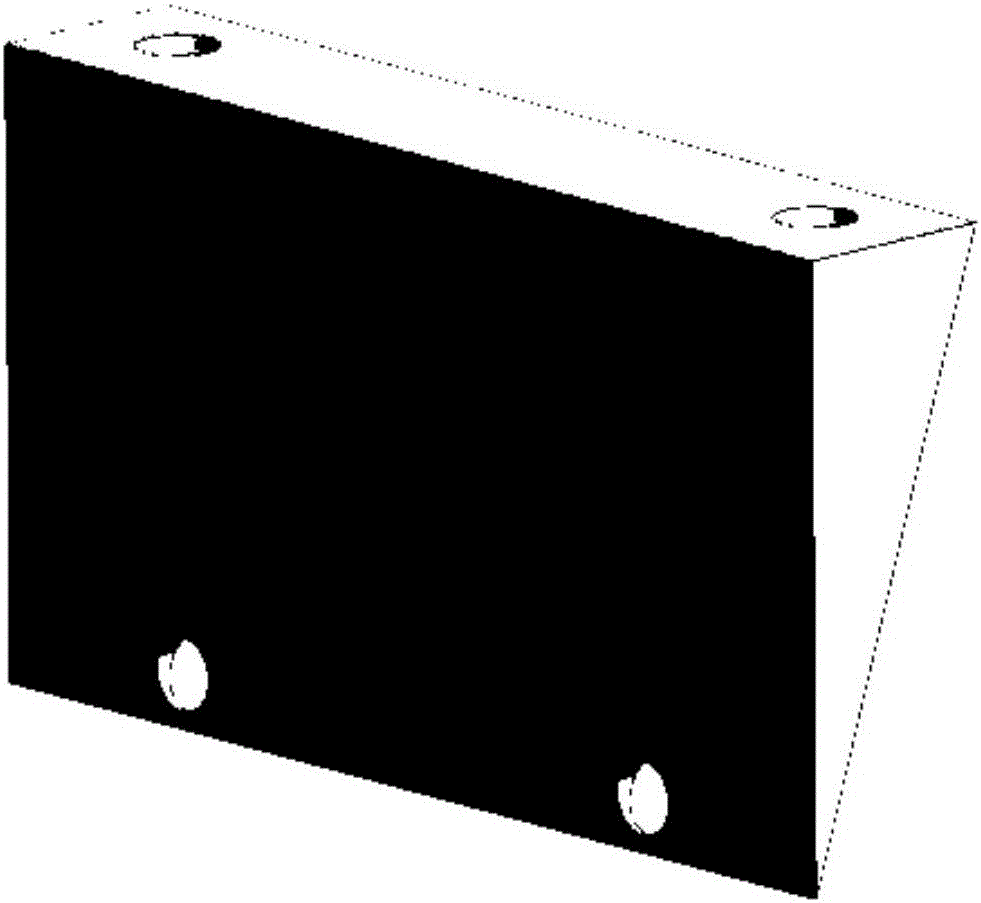

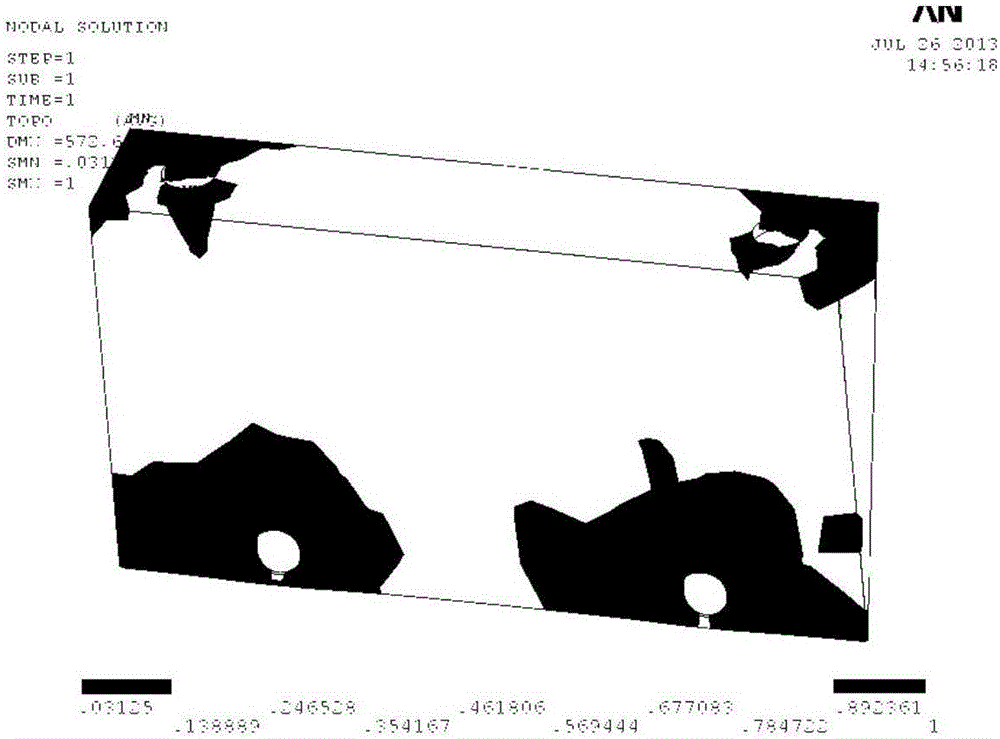

Method for optimized design of external support of engine

InactiveCN105975734AMeet lightweight requirementsShort development cycleGeometric CADDesign optimisation/simulationDesign stageEngine mount

The invention relates to a method for optimized design of an external support of an engine. The method comprises a step S1 of design input, a step S2 of scheme design, a step S3 of technical design, a step S4 of detailed design, a step S5 of intensity check and a step S6 of determination. According to the method for optimized design of the external support of the engine, through optimization, weight reduction and intensity check on the support of the engine at a design stage, the weight of the engine support is reduced as far as possible on the basis of meeting the intensity requirements, the requirements on lightweight of the engine are met, the research and development cycle of the engine is shorter, the performance of the engine is more excellent, the research and development cost is reduced, and the research and development cycle is shortened.

Owner:AECC SHENYANG ENGINE RES INST

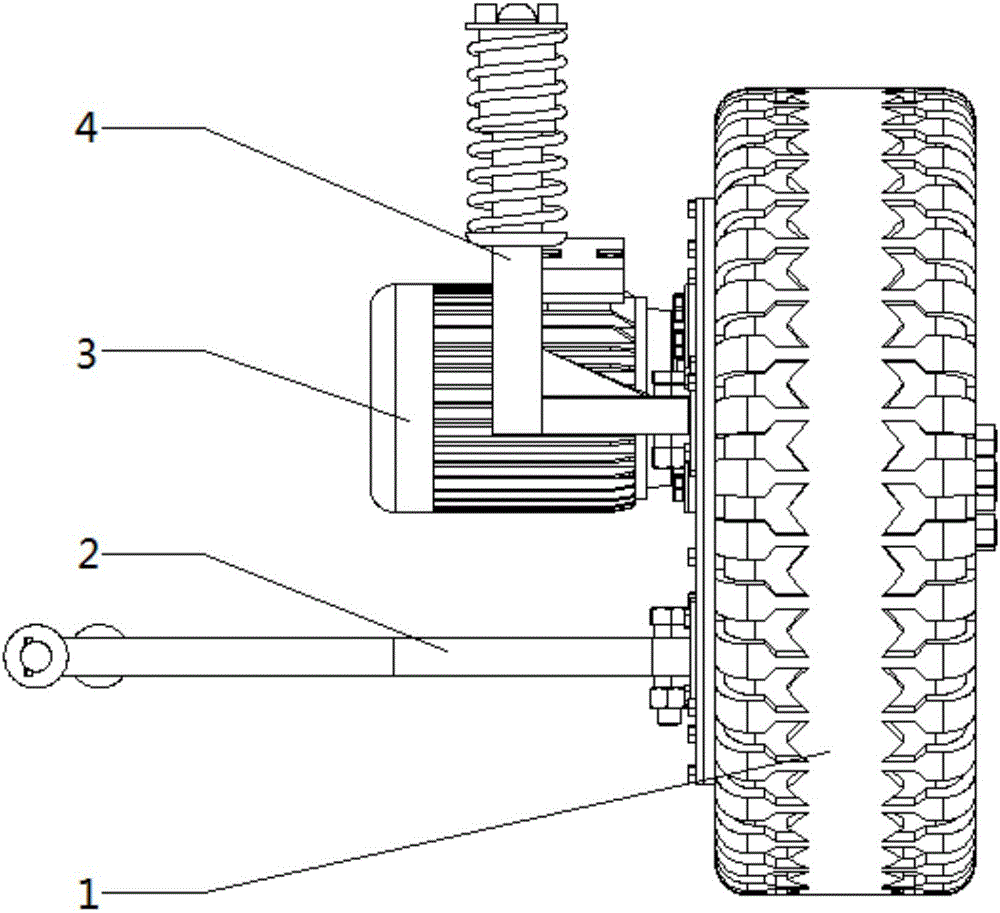

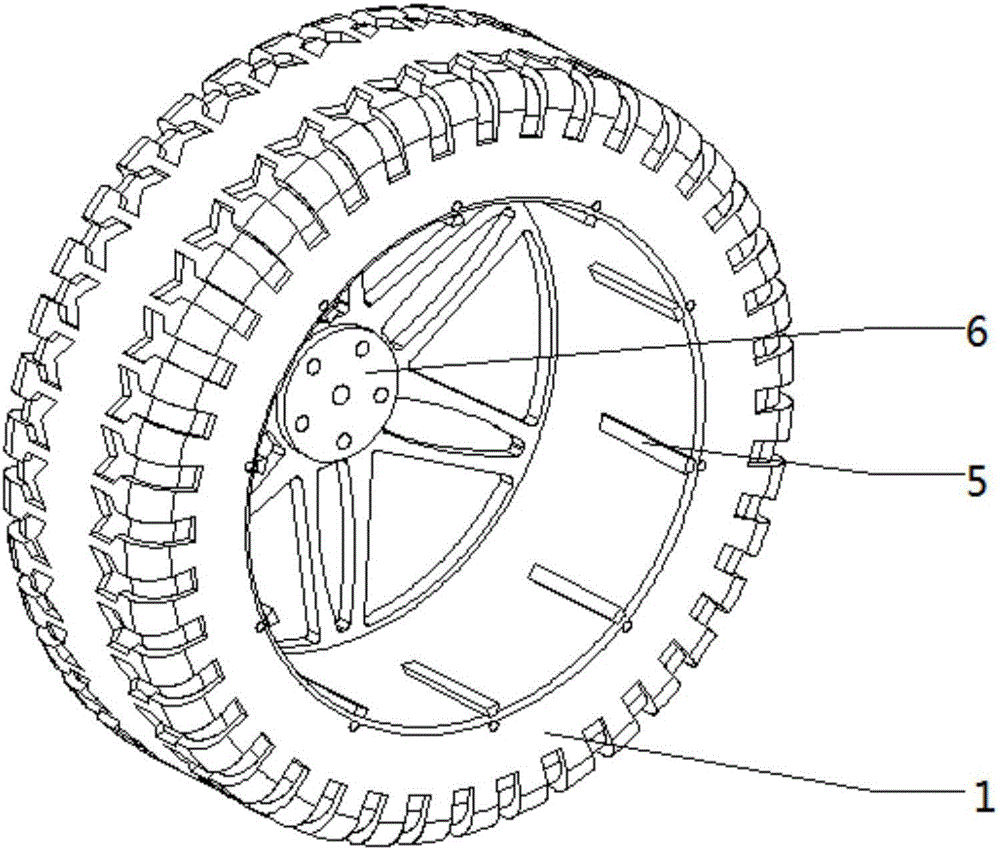

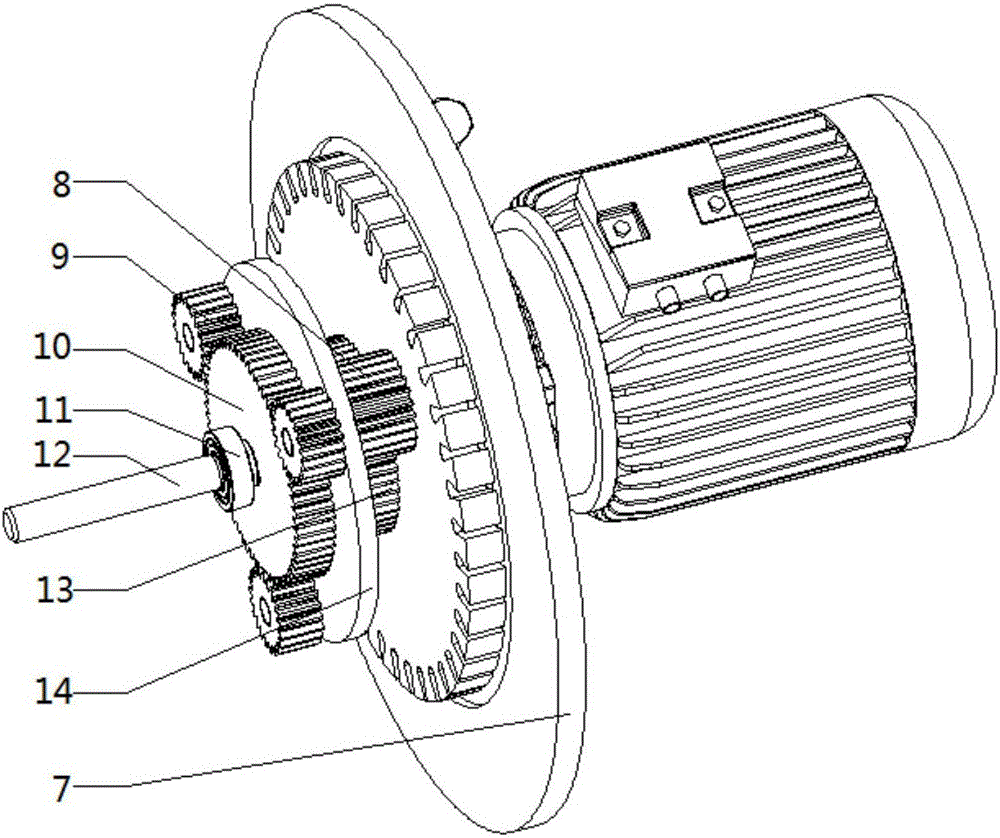

Electric vehicle wheel side driving system and driving method

ActiveCN104986030ALight in massCompact structureMotor depositionAutomotive engineeringElectric vehicle

The invention discloses an electric vehicle wheel side driving system and a driving method. The electric vehicle wheel side driving system comprises a deceleration driving system disposed in a wheel hub and a direct driving system fixedly connected with the wheel hub and directly driving a wheel. The electric vehicle wheel side driving method is realized via the electric vehicle wheel side driving system. By the use of the electric vehicle wheel side driving system and the driving method, motors of various systems can be guaranteed to work within the rated power and motor output efficiency can be ensured; demands for normal power can be met and overall vehicle weight can be reduced; large transmission ratio is achieved and high mechanical transmission efficiency is provided; and the electric vehicle wheel side driving system possesses compact structure, facilitates spatial arrangements and meets requirements for light weight of the electric vehicle.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com