Patents

Literature

164results about How to "Significant weight loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensitive adhesive composition, articles made therewith and method of use

ActiveUS6893718B2Significant weight lossWithout significant weight lossFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveChemistry

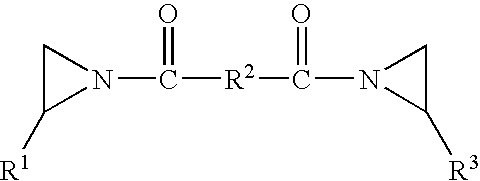

A pressure sensitive adhesive composition is described, comprising the reaction product of a copolymer and a bisamide crosslinking agent, (A) the copolymer comprising the reaction product of (i) a (meth)acrylate ester of a non-tertiary alcohol in which the alkyl group contains between 1 and 4 carbon atoms, inclusive, and (ii) a carboxylic acid-functional, ethylenically unsaturated co-monomer, and (B) a bisamide crosslinking agent having the formula: where,R1 and R3 independently, are selected from the group consisting of H and CnH2n+1,n is an integer ranging from 1 to 5,R2 is a divalent radical selected from the group consisting of benzeno (—C6H4—), substituted benzeno, triazine, CmH2m, and combinations thereof,m is an integer ranging from 1 to 10, andthe relative amounts of the carboxylic acid-functional, ethylenically unsaturated co-monomer and the bisamide crosslinking agent providing a ratio of the number of equivalents of amide groups to the number of equivalents of carboxylic acid groups of less than about 0.1. Articles made with the pressure sensitive adhesive composition and methods for its use are also described.

Owner:3M INNOVATIVE PROPERTIES CO

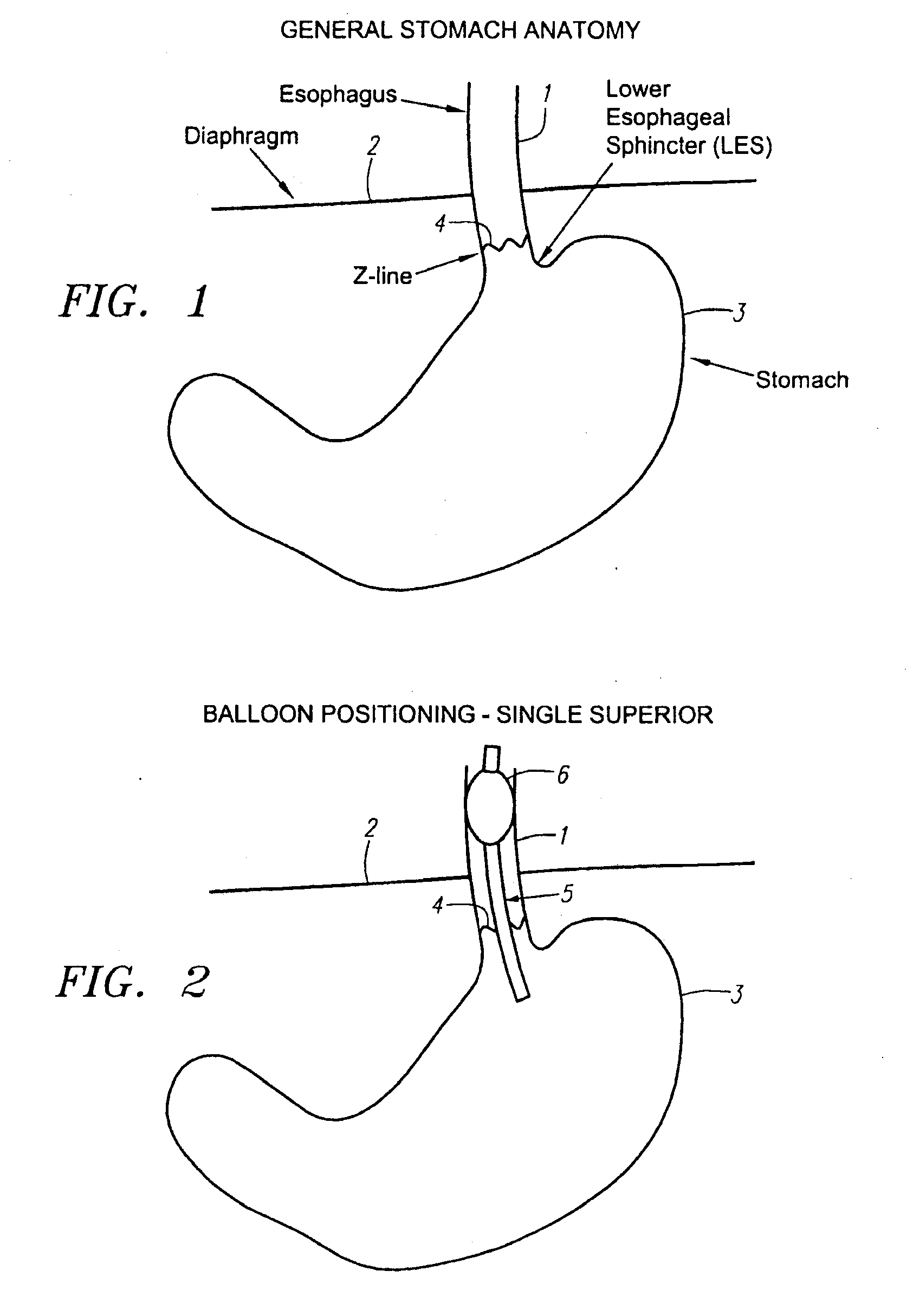

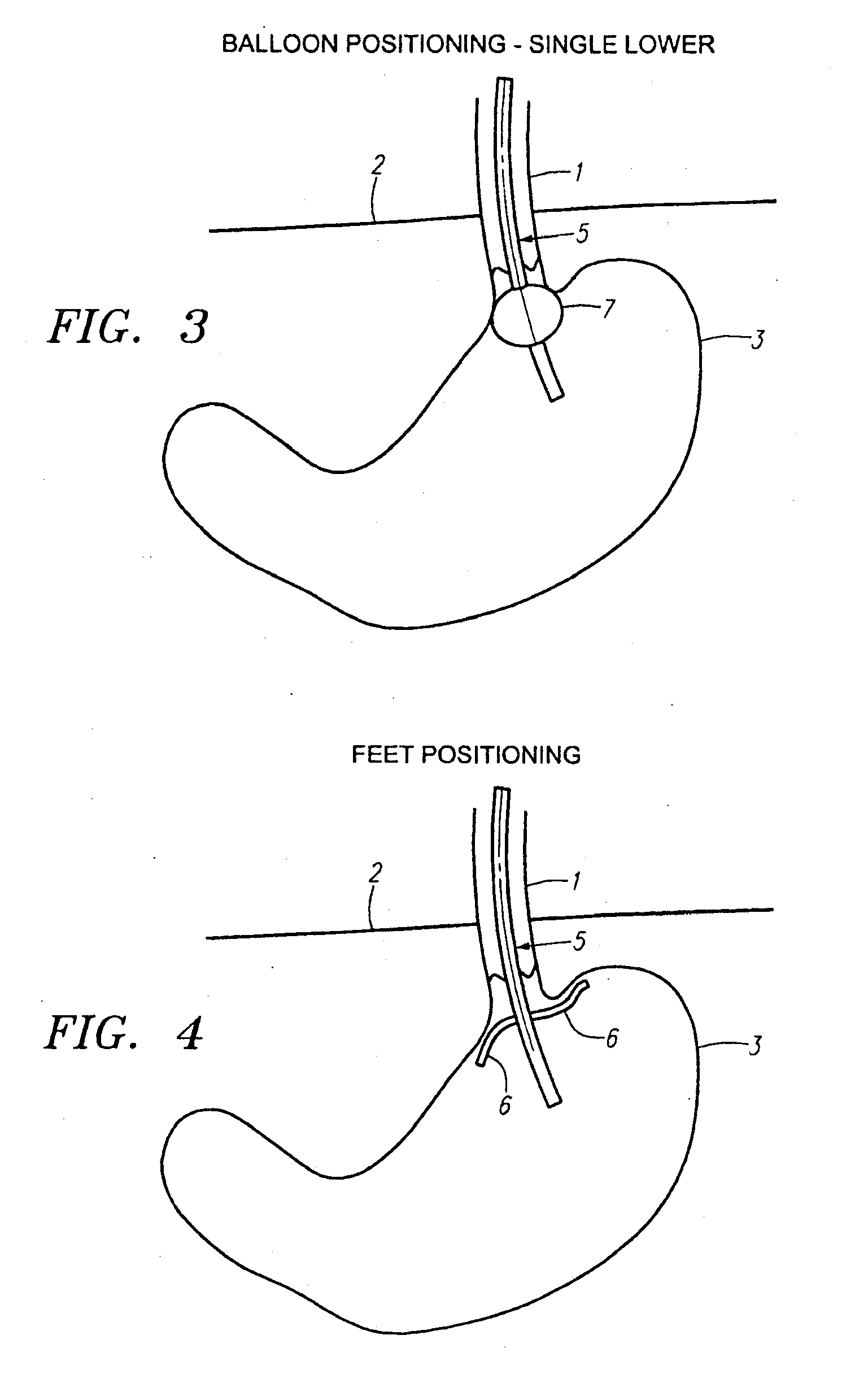

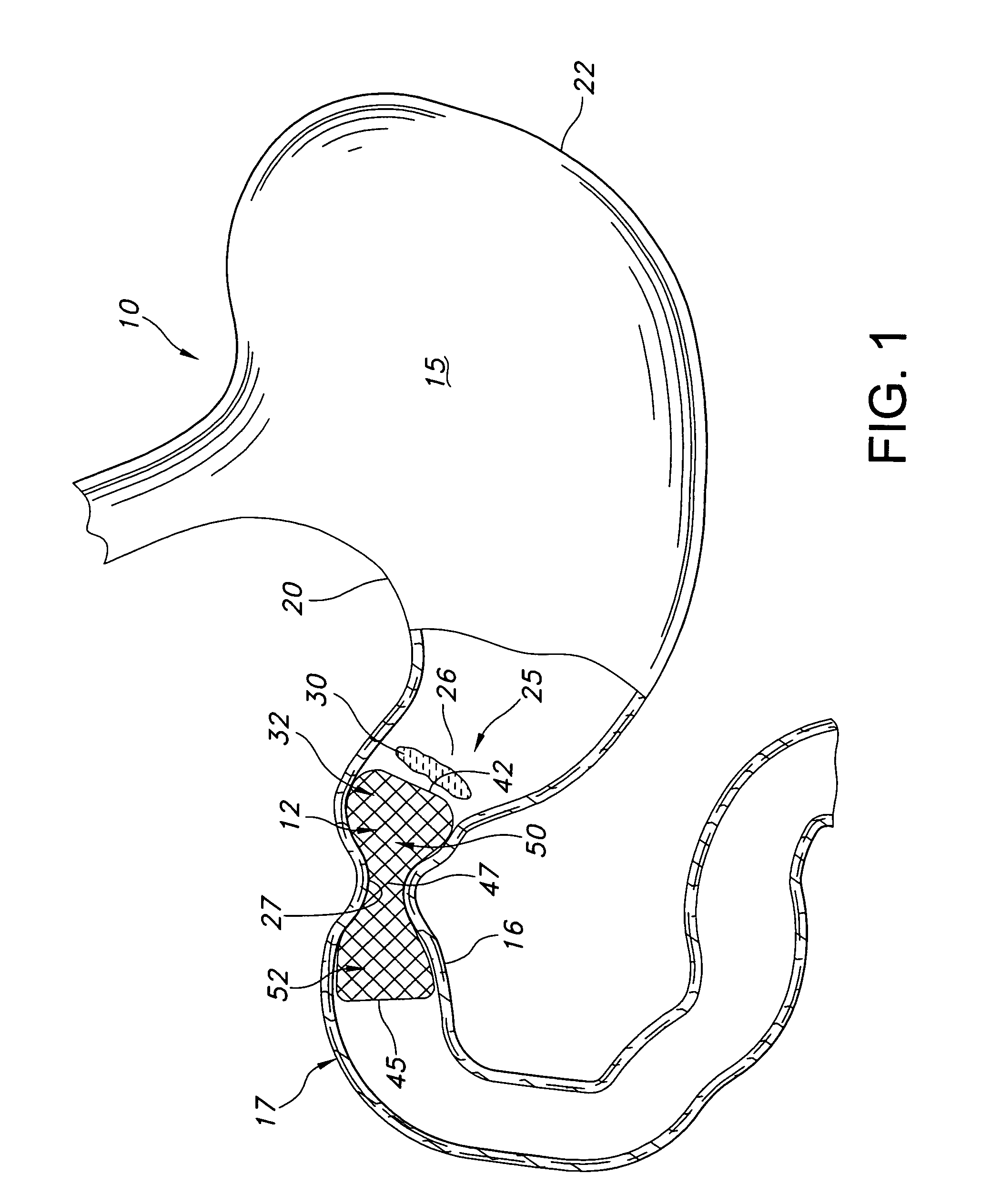

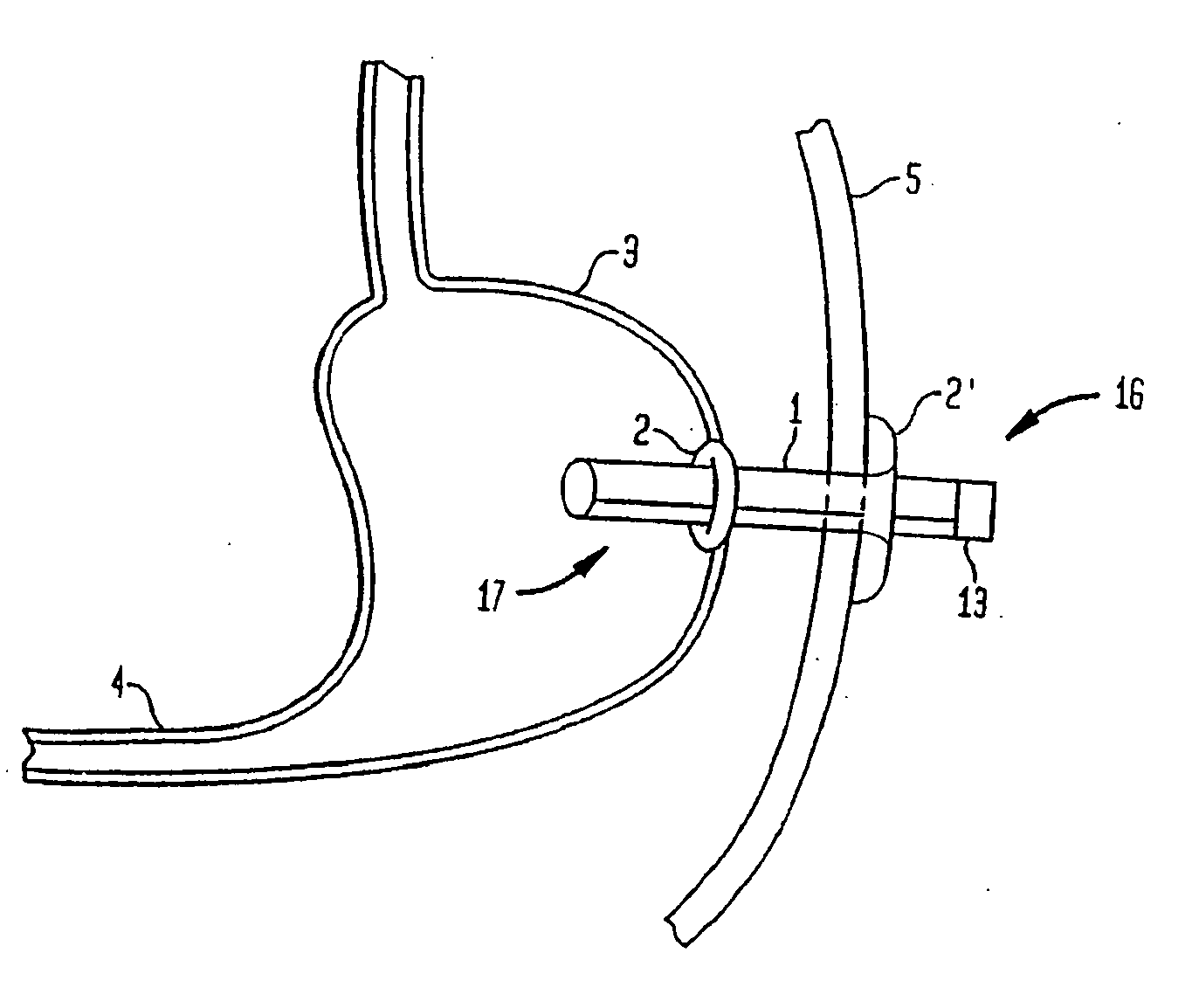

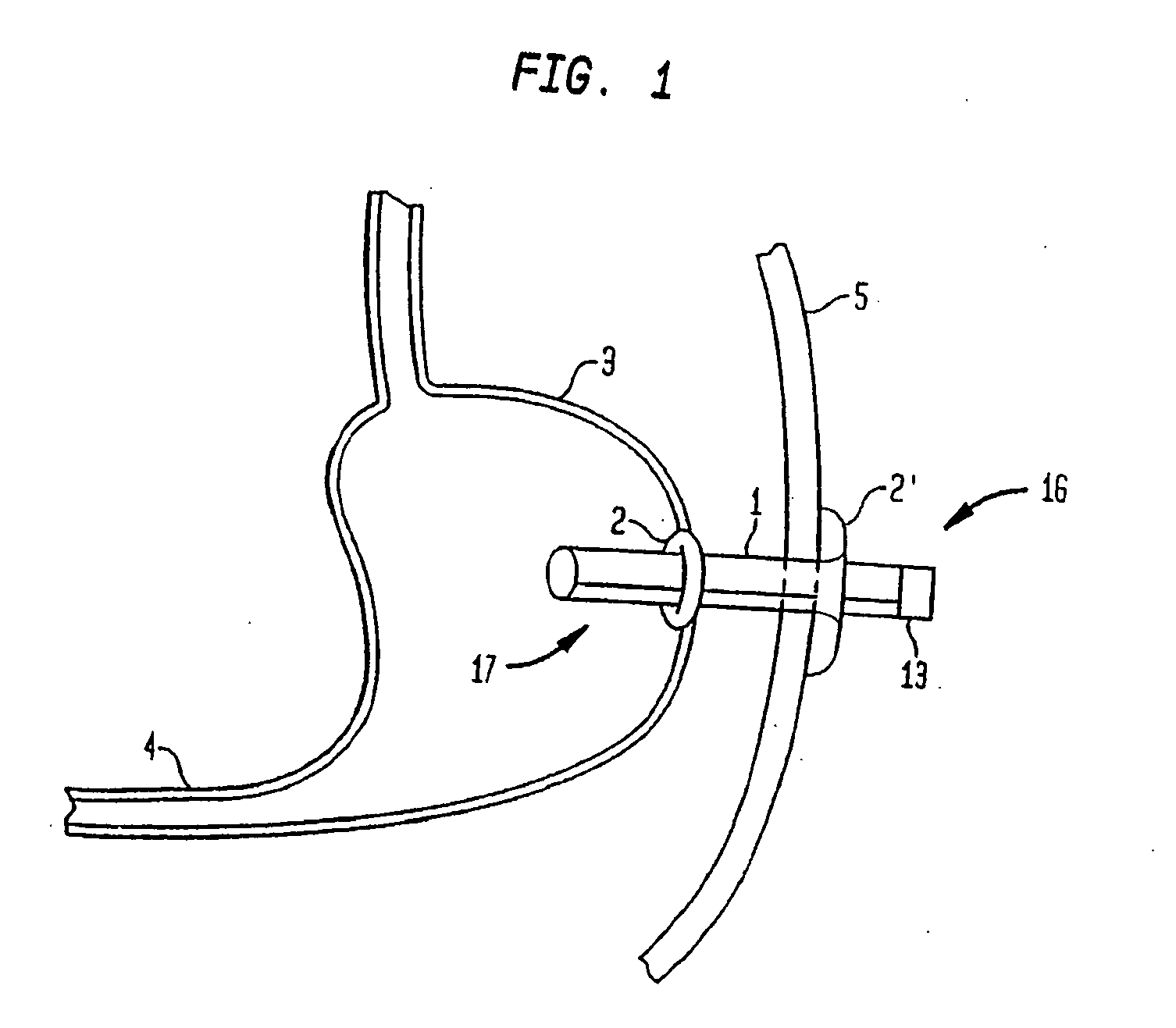

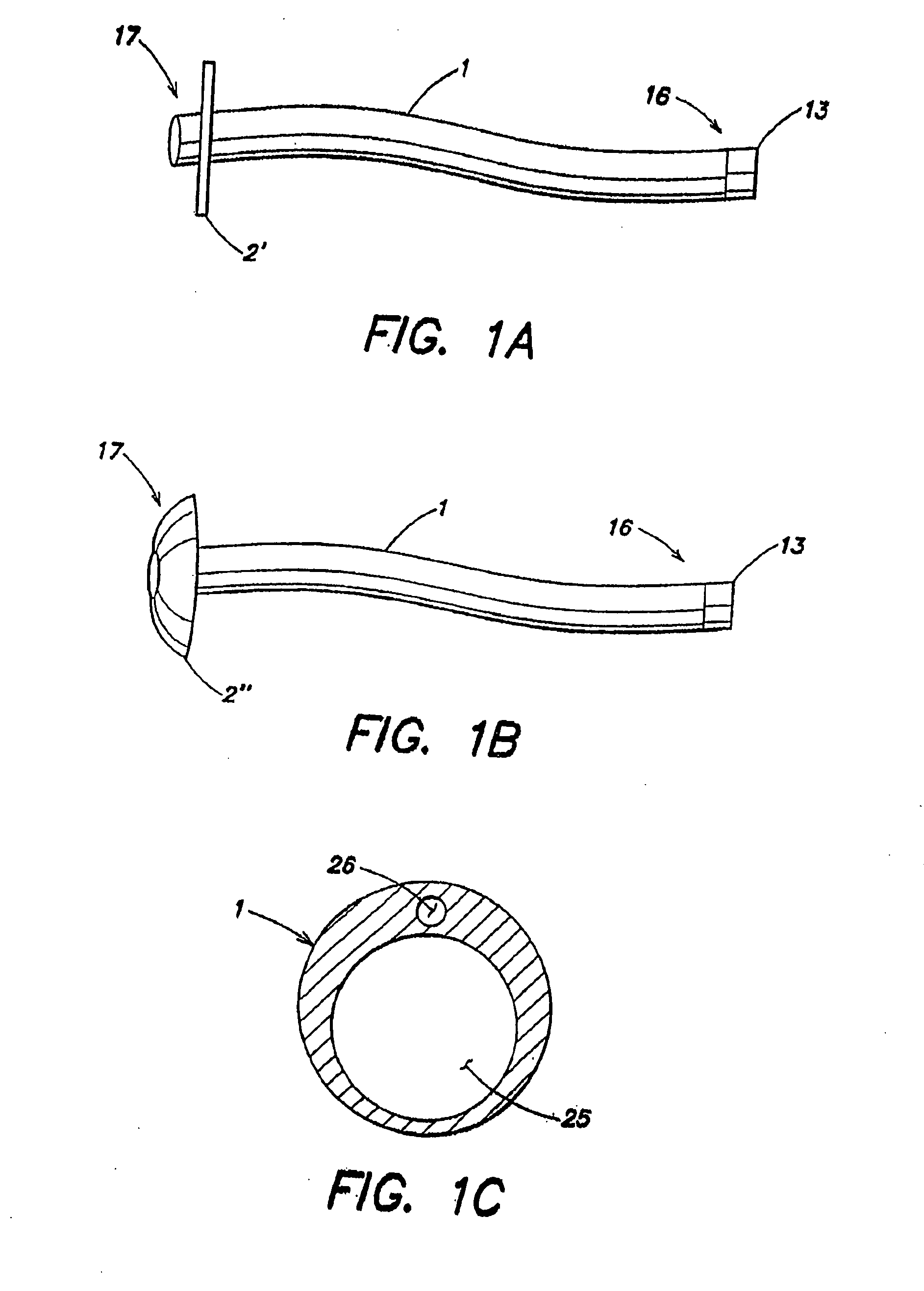

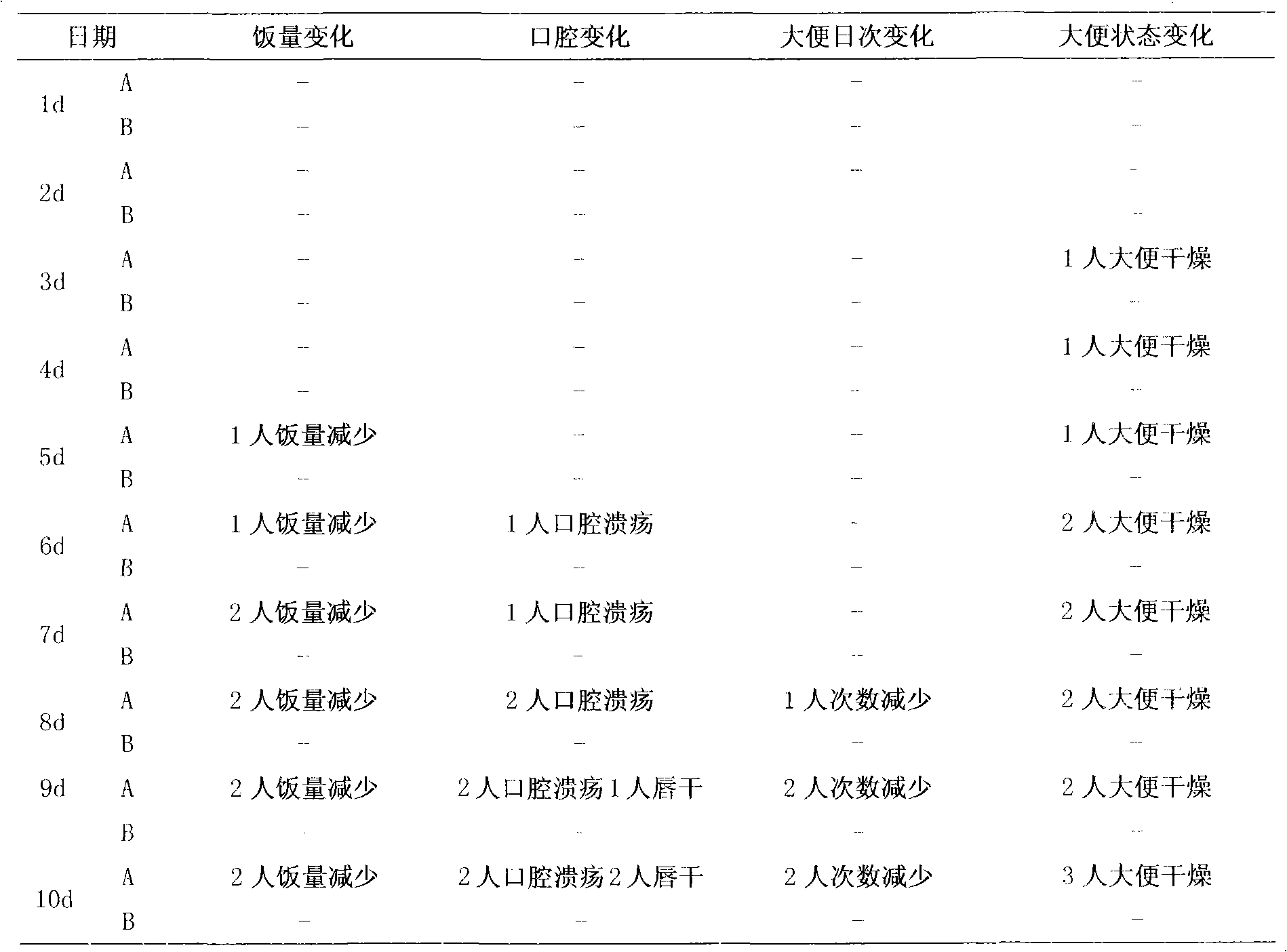

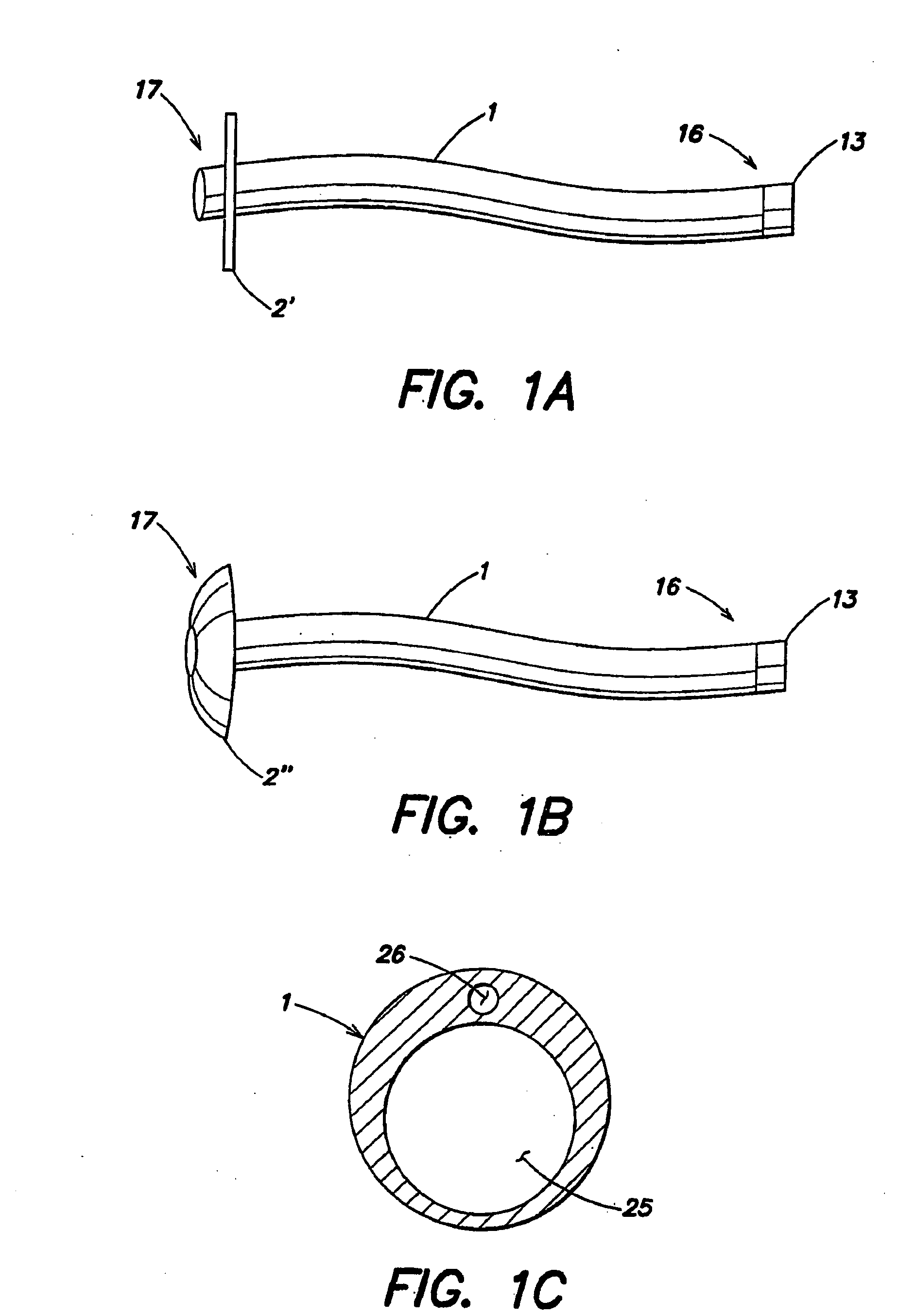

Apparatus for treating obesity by extracting food

ActiveUS20050277900A1Good for weight lossEasy to implementMedical devicesCatheterSide effectAbdominal wall

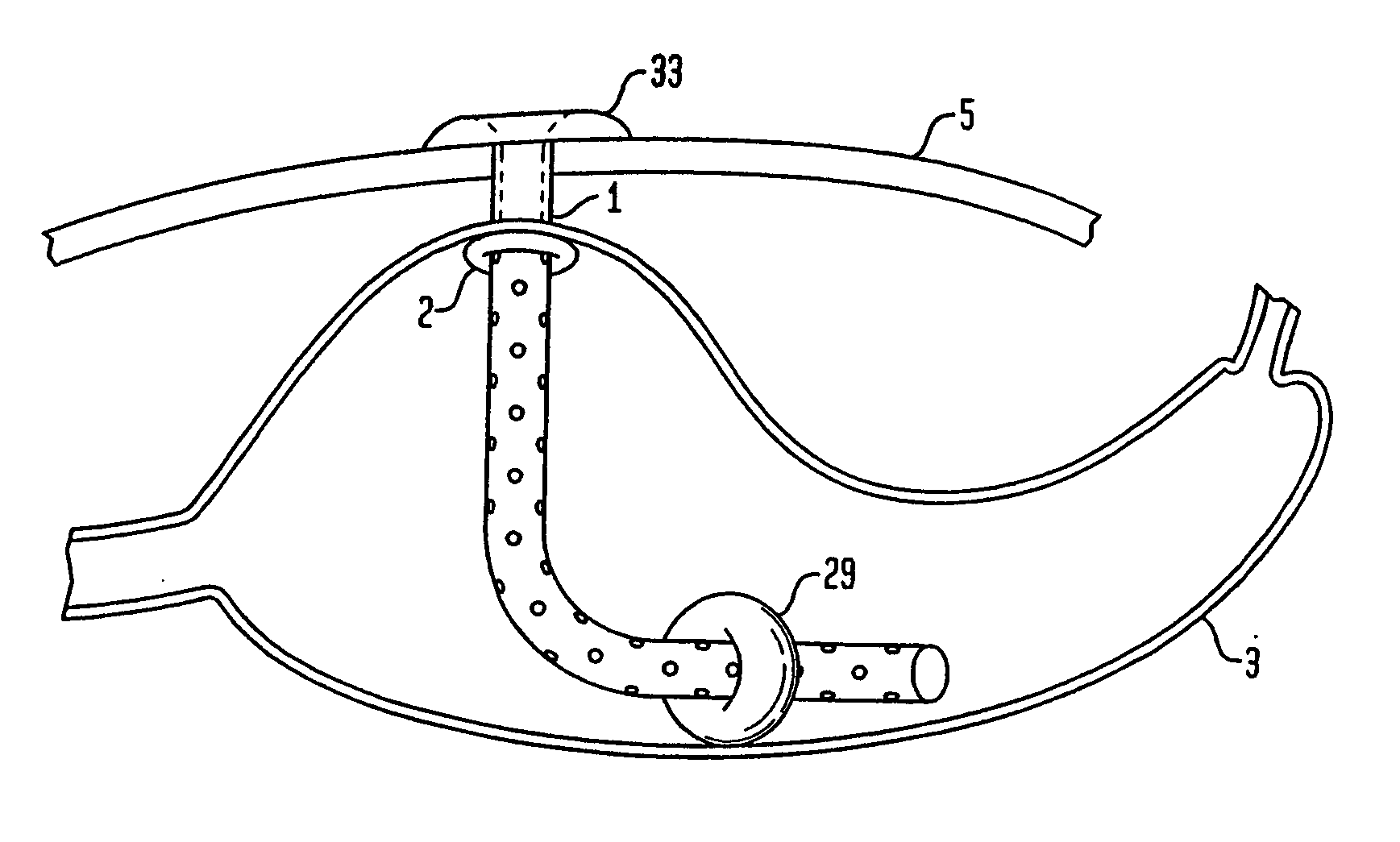

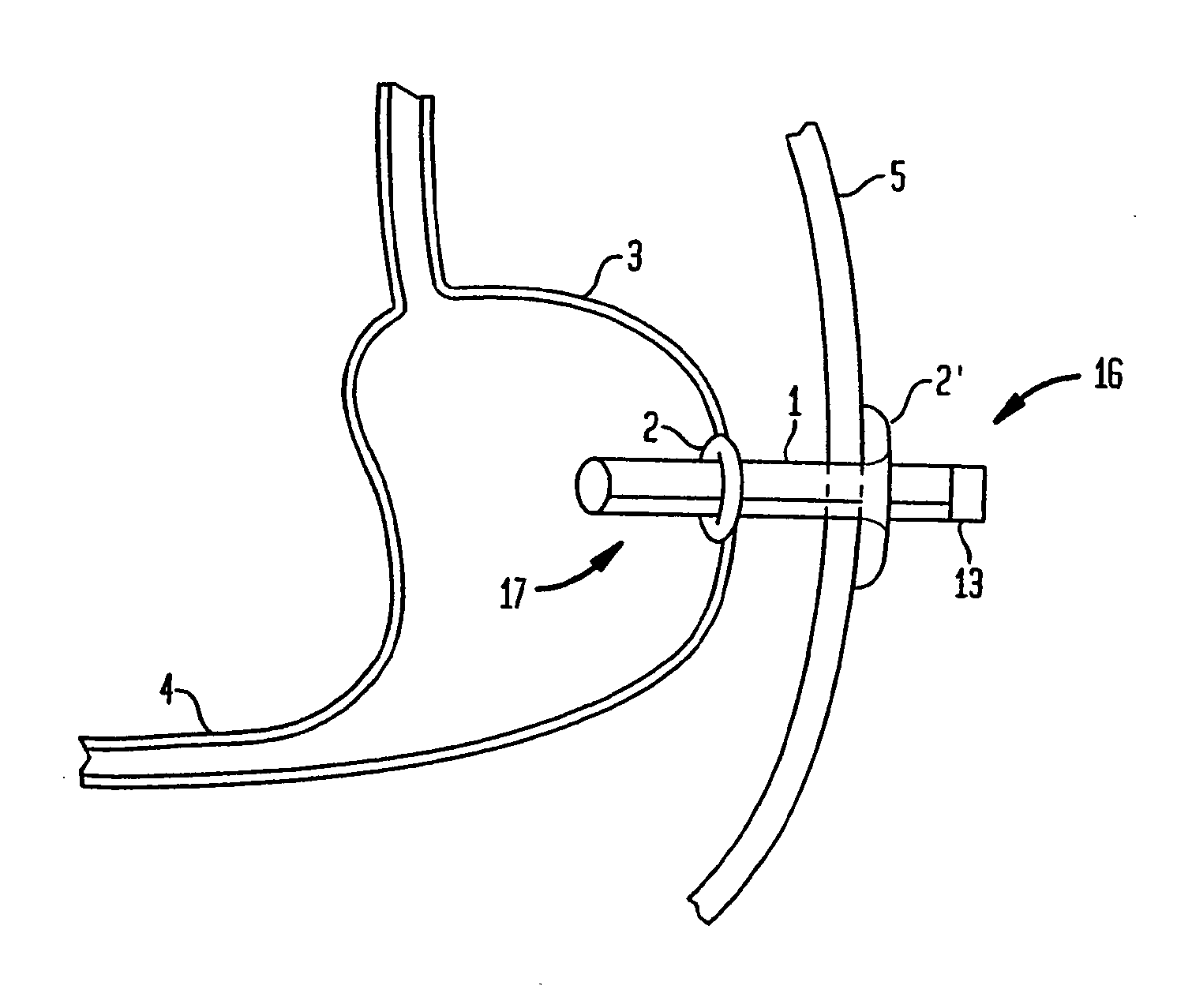

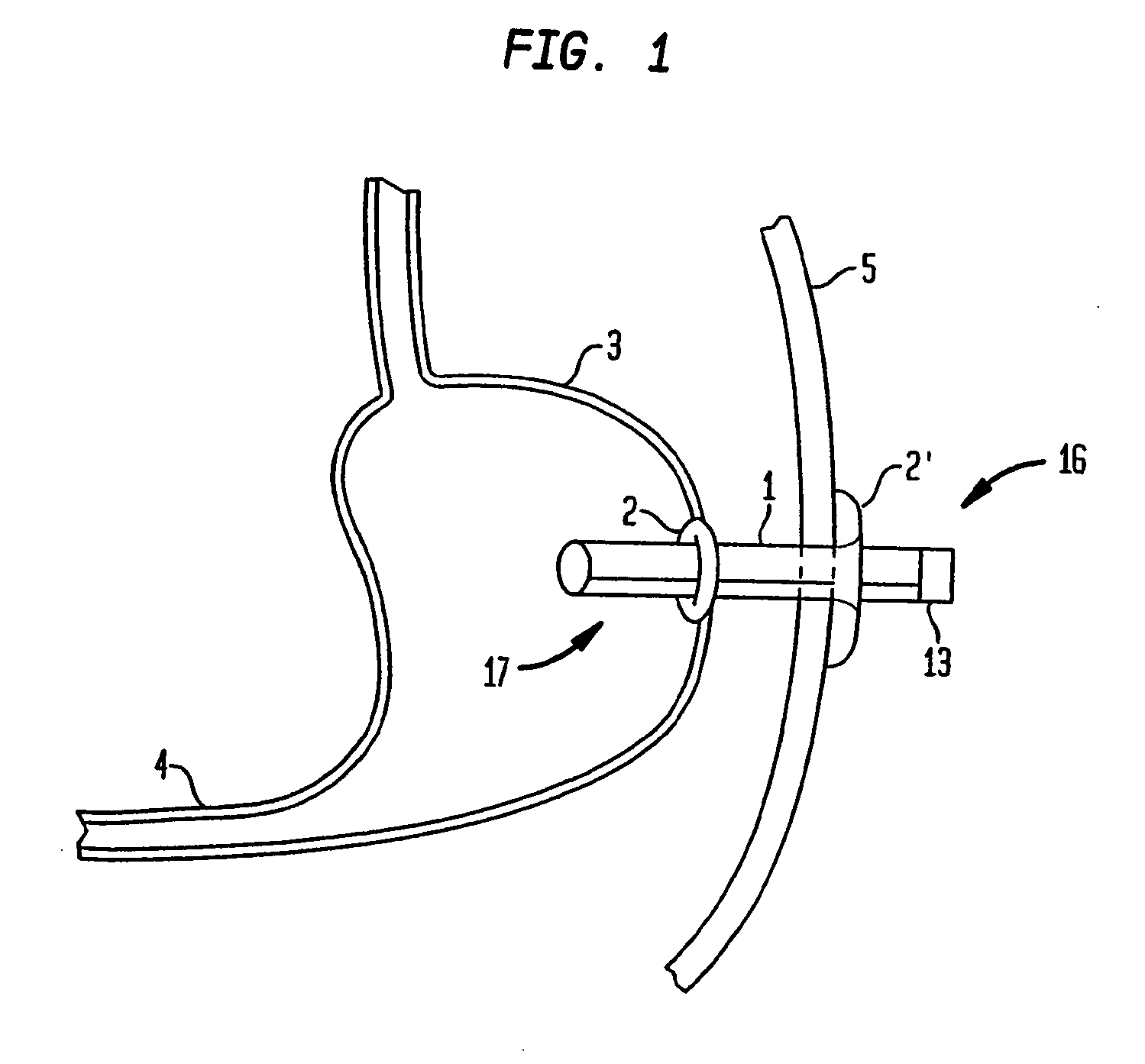

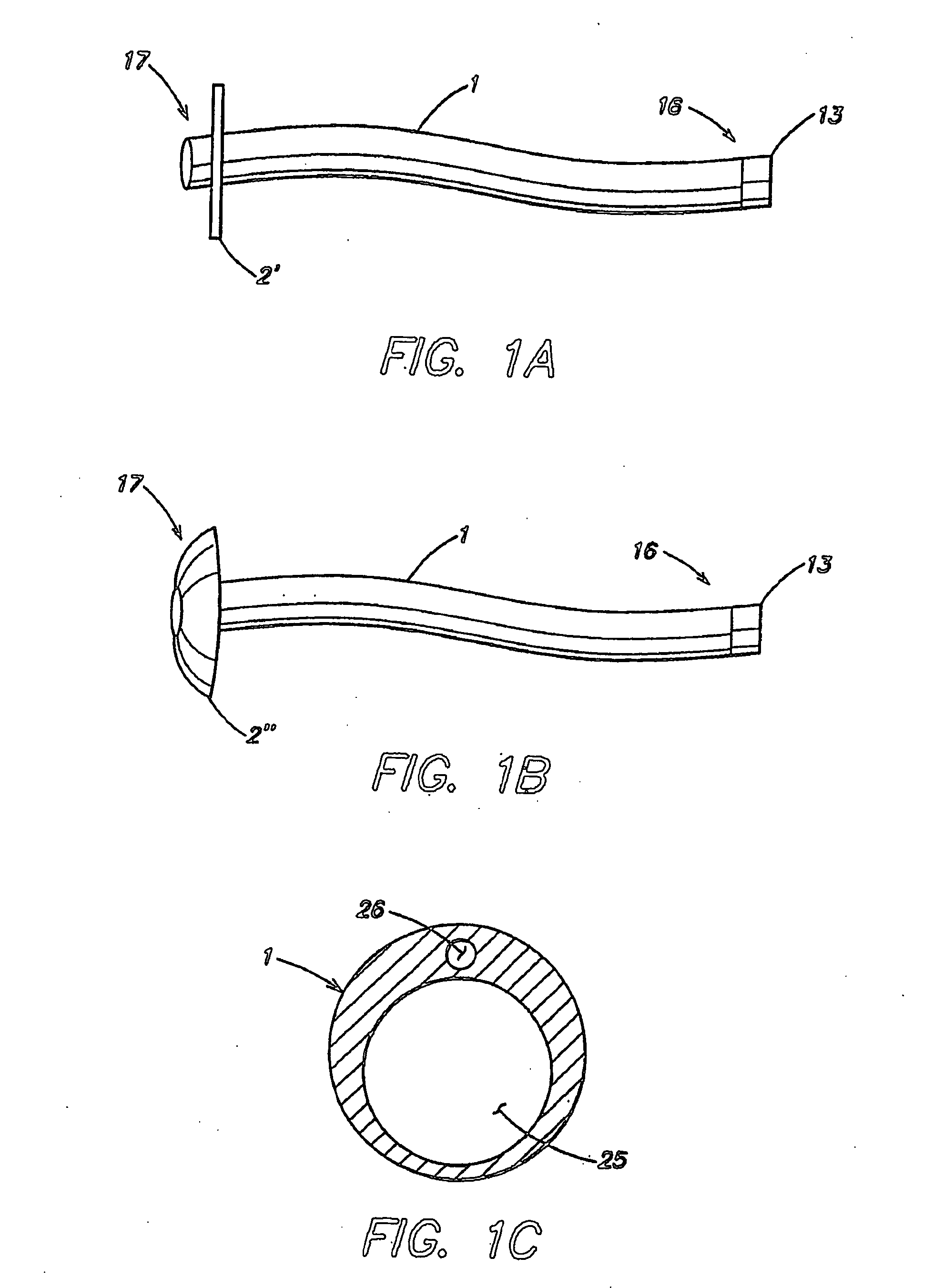

The present invention is directed to an apparatus and method for treating obesity. A tube is positioned that passes through a patient's abdominal wall into the upper digestive system of the patient. The patient is allowed to carry out his / her everyday affairs including ingesting food. After the patient has ingested food, the food is extracted by pumping it out of the upper digestive system through the tube. The present invention is less invasive than current surgical procedures for reducing weight and allows patients to live a normal and active lifestyle without experiencing adverse side effects.

Owner:ASPIRE BARIATRICS

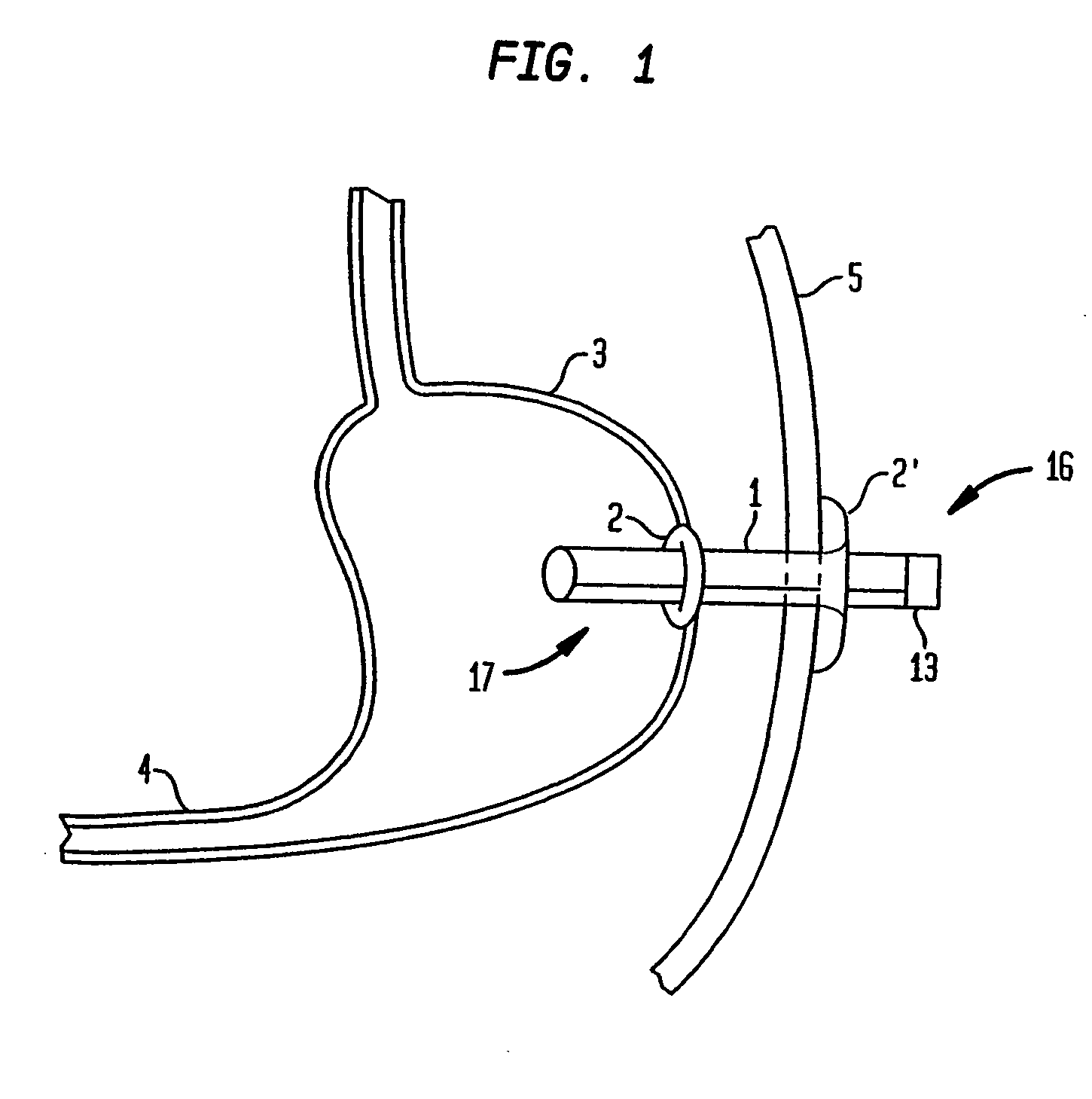

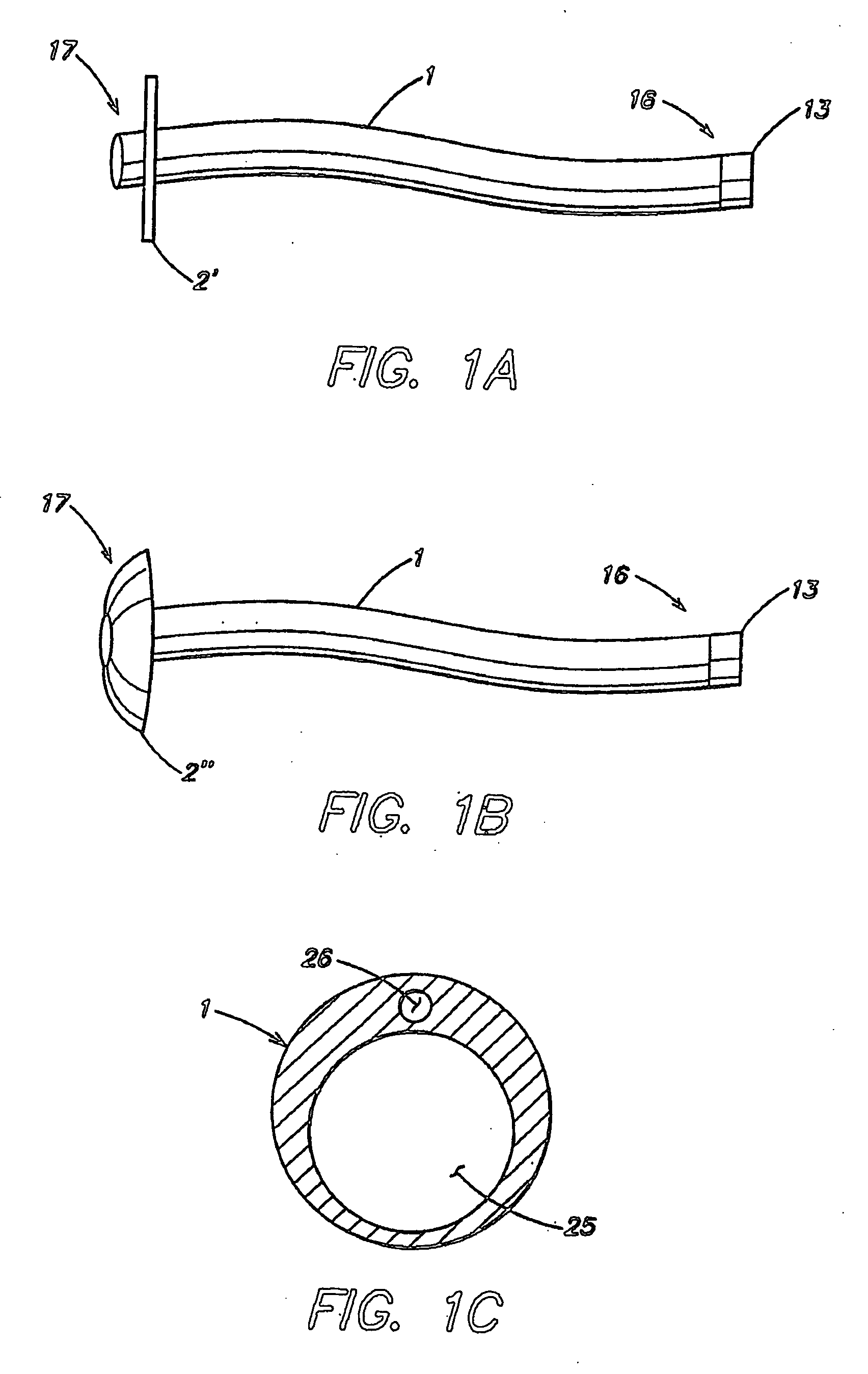

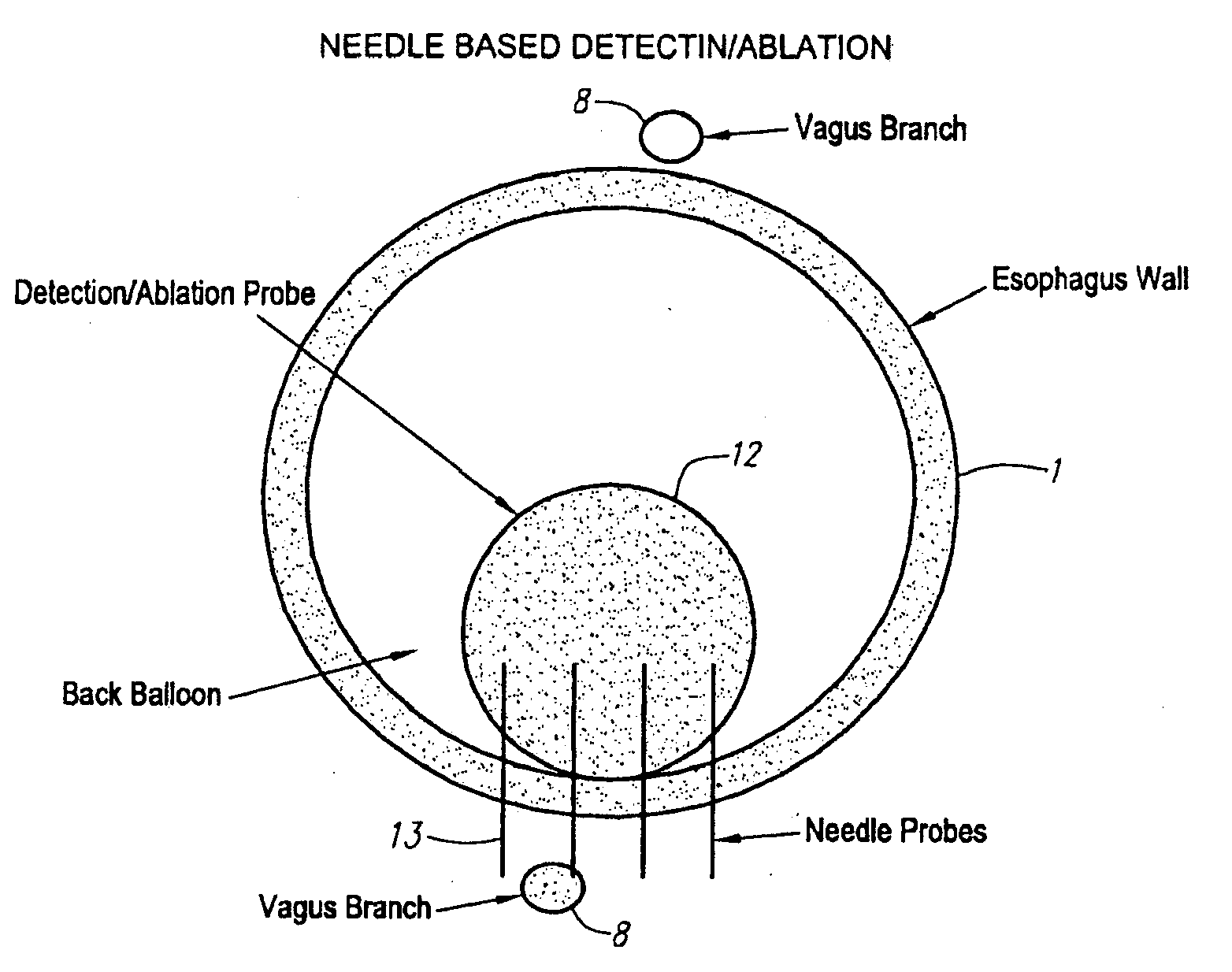

Methods and apparatus for treatment of obesity

InactiveUS20110015548A1Significant weight lossUltrasound therapySurgical needlesObesityVagus nerve function

Owner:ENDOVX

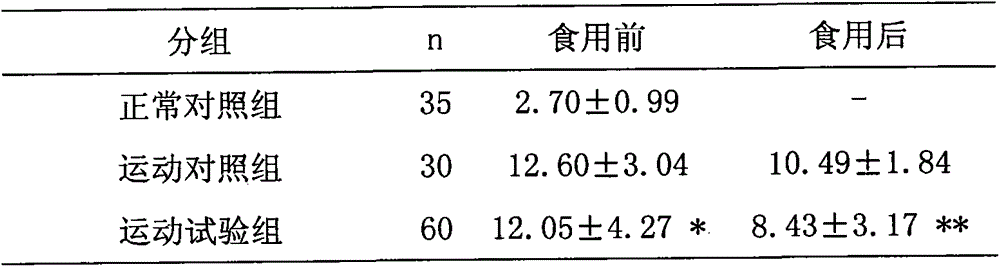

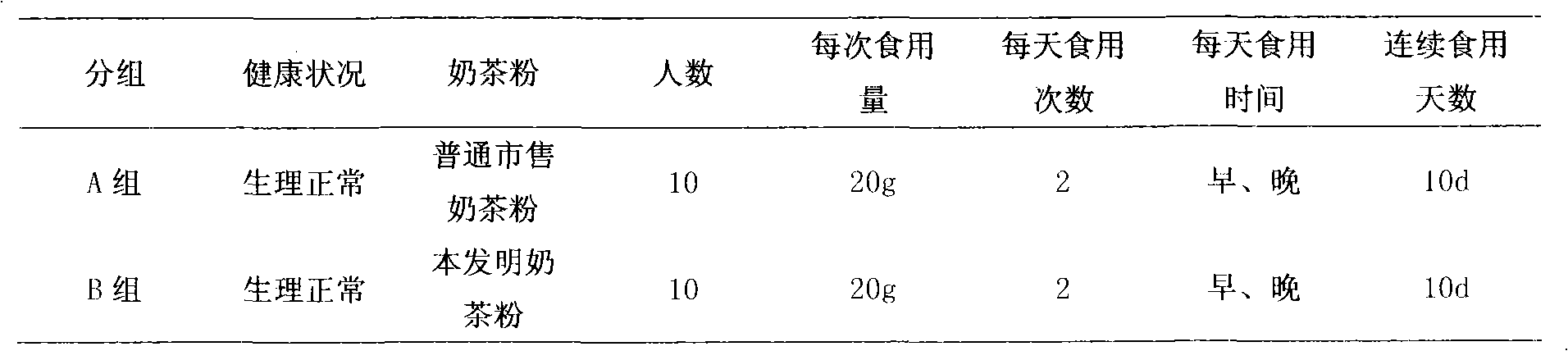

Ugine sport nutrition milk tea powder and preparation method thereof

The invention discloses ugine sport nutrition milk tea powder and a preparation method thereof and belongs to the technical fields of solid drinks, modified milk powder and nutritious foods. The milk tea powder is characterized by comprising whole milk powder, skim milk powder, whey protein powder, collagen powder, soy peptides powder, maize oligopeptide, inulin, maltodextrin, soluble soybean polysaccharide, instant tea powder, phospholipid, L-carnitine, a vitamin premix and a mineral premix. The milk tea powder disclosed by the invention has the advantages of giving a full play to the effects of nutrition complementation and cooperative gain, filling a market vacancy and integrating the functions of supplementing calcium, strengthening bones, losing the weight, relieving fatigues, keeping fit and the like; the milk tea powder is good in taste, convenient to eat, good in safety, strong in acceptability, free of toxic or side effects, simple in production process and easy to product and has a great market development potential.

Owner:BEIJING SANLIYUAN FOOD TRADING

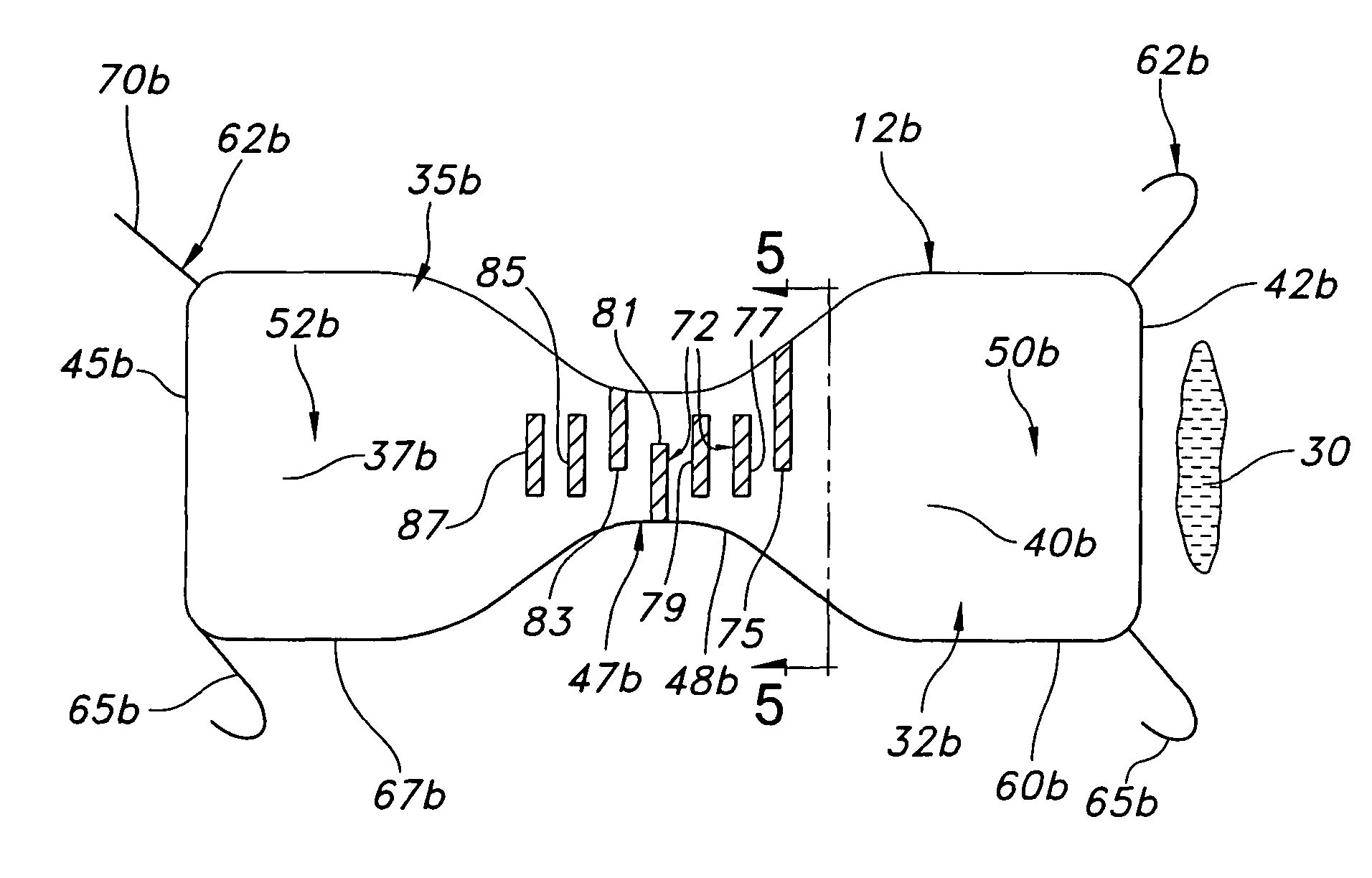

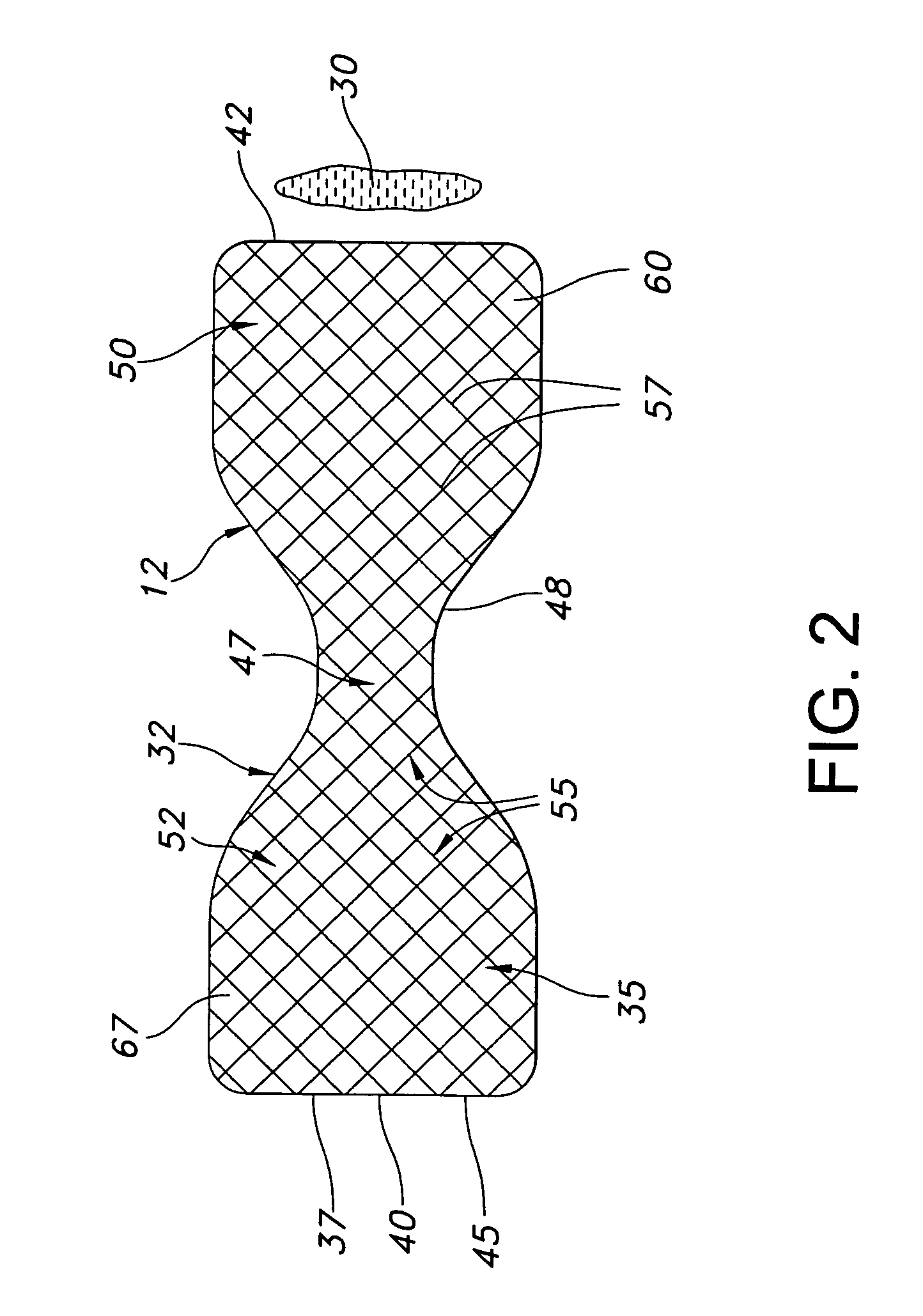

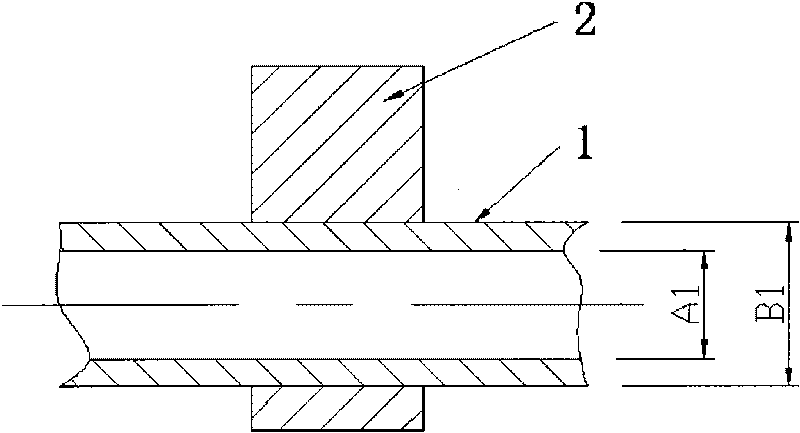

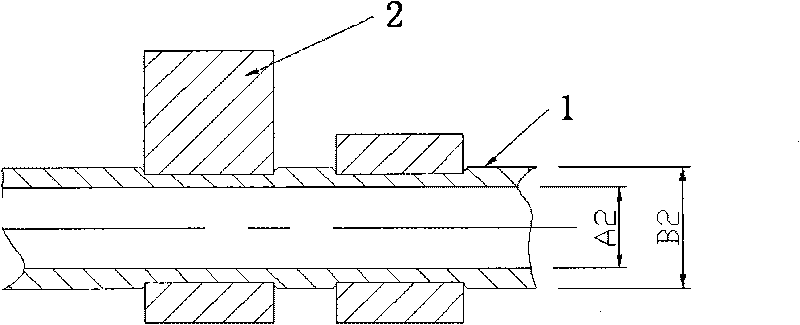

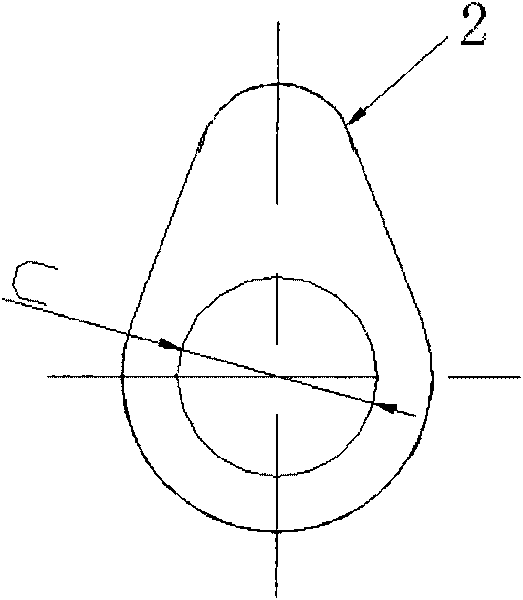

Pyloric obesity valve

The pyloric obesity valve includes a tubular valve body having proximal and distal ends. The valve body has an intermediate section which is between the proximal and distal ends. The proximal end is enlarged transversely relative to the intermediate section. The valve body has an inner surface and a lumen. The inner surface which is within the intermediate section has a cross-sectional area which is smaller than a cross-sectional area of the inner surface which coincides with the proximal end to resist a flow through the lumen of the valve body from the proximal end to the intermediate section.

Owner:BOSTON SCI SCIMED INC

Compounds for altering food intake in humans

InactiveUS20060105066A1Limitation to intakeChange eating habitsBiocideAnimal repellantsDietary supplementMedicine

The present invention relates to a process of providing an extract containing at least one simmondsin compound. The extract is provided from jojoba plant, and used as a dietary supplement for use in a weight control regiment in humans. The present invention also provides a method of treating an overweight human in need of such treatment, and comprises administering a therapeutically effective amount of such an extract.

Owner:AVOCA

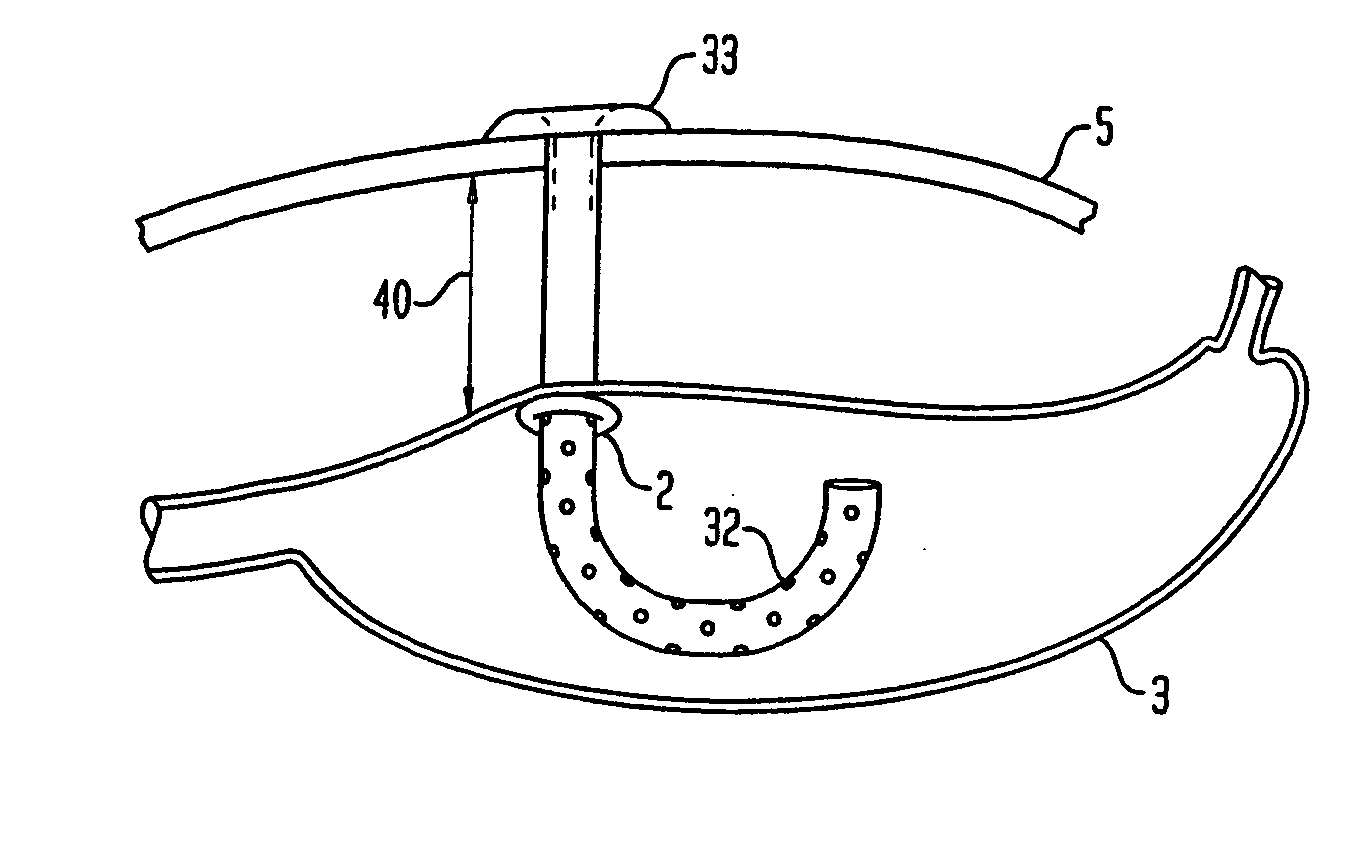

Shunt Apparatus For Treating Obesity By Extracting Food

InactiveUS20110178480A1Significant weight lossGood for weight lossCatheterObesity treatmentAbdominal wallObesity

To treat obesity, a tube is positioned so that it passes through a patient's abdominal wall into the upper digestive system of the patient. The patient is allowed to carry out his / her everyday affairs including ingesting food. After ingestion, food is extracted by pumping it out of the upper digestive system through the tube. The embodiments described herein take advantage of some properties of ePTFE to provide a number of significant advantages.

Owner:ASPIRE BARIATRICS

Areca nut brine

The invention relates to self-service areca nut brine. The brine contains lotus leaf products and / or lotus leaf extracts and / or chitosan and derivatives thereof, wherein nuciferine and / or lotus leaf flavones in the lotus leaf extracts have obvious functions of weight losing, fat reducing, bacteria suppressing, virus resisting, detoxifying and oxidation resisting; and the chitosan and derivatives thereof have the functions of controlling cholesterol, suppressing bacteria, preventing and controlling hypertension and adsorbing and discharging heavy metals. The brine has the beneficial effects that not only is the variety of the areca nut brine expanded, but also the special functions of the areca nut brine are added; as the areca nut brine is independently packaged and is isolated from the areca nut semi-finished products, the areca nut product can not suffer from scumming, thus making up for the defects of the existing areca nut products and the deficiency of the brine preparation technology; and consumers can voluntarily select the variety and intake of the brine.

Owner:刘凌

Bamboo shoot edible fiber composite health-care food and production method thereof

The present invention discloses a method of preparation that the bamboo shoot is combined with the dietary fiber, belonging to the technical field of food. The dietary fiber takes the high grade tender bamboo shoot and the root and the soy as the major raw materials, and also the KGM is added into the dietary fiber so as to provide the alimentation and the health protection ingredients needed by the human health; the obtained product contains rich dietary fiber, plant protein, mineral matter and various nutritional ingredients, which is a functional food which takes the dietary fiber as the essential ingredients and has the health functions such as obvious weight-losing and sugar-lowering, etc. The present invention contains the bamboo shoot dietary fiber, the large tailing powder, the KGM and the routine food additive, the Beta - cyclodextrine and the maltitol.

Owner:HUBEI UNIV

Functional milky tea powder and preparation method thereof

ActiveCN101810223AStrong targetingImprove immunityMilk preparationPre-extraction tea treatmentToxic materialDigestion

The invention discloses functional milky tea powder and a preparation method thereof. The functional milky tea powder is characterized by containing or being strengthened with various nutrients such as taurine, magnesium, zinc, vitamins and the like and integrating various functions of clearing away heat and toxic materials, preventing dental ulcers, invigorating stomachs and promoting digestion, loosening bowels and relieving constipation, lowering blood fat, blood pressure and blood sugar, losing weight, resisting fatigue and the like. The invention has the advantages that the preparation method creatively enables the milky tea powder to be subdivided, has reasonable proportioning, strong pertinence and obvious synergy function and fills the market blank; and the milky tea powder has the characteristics of the mellow and smooth taste of milk, the delicate fragrance of tea and the like and has the advantages of convenient edibility and carrying, simple production process, easy production and very great market development potential.

Owner:呼伦贝尔海乳乳业有限责任公司

Method for treating obesity by extracting food

ActiveUS20100106131A1Significant weight lossGood for weight lossMedical devicesOesophagiSide effectAbdominal wall

Owner:ASPIRE BARIATRICS

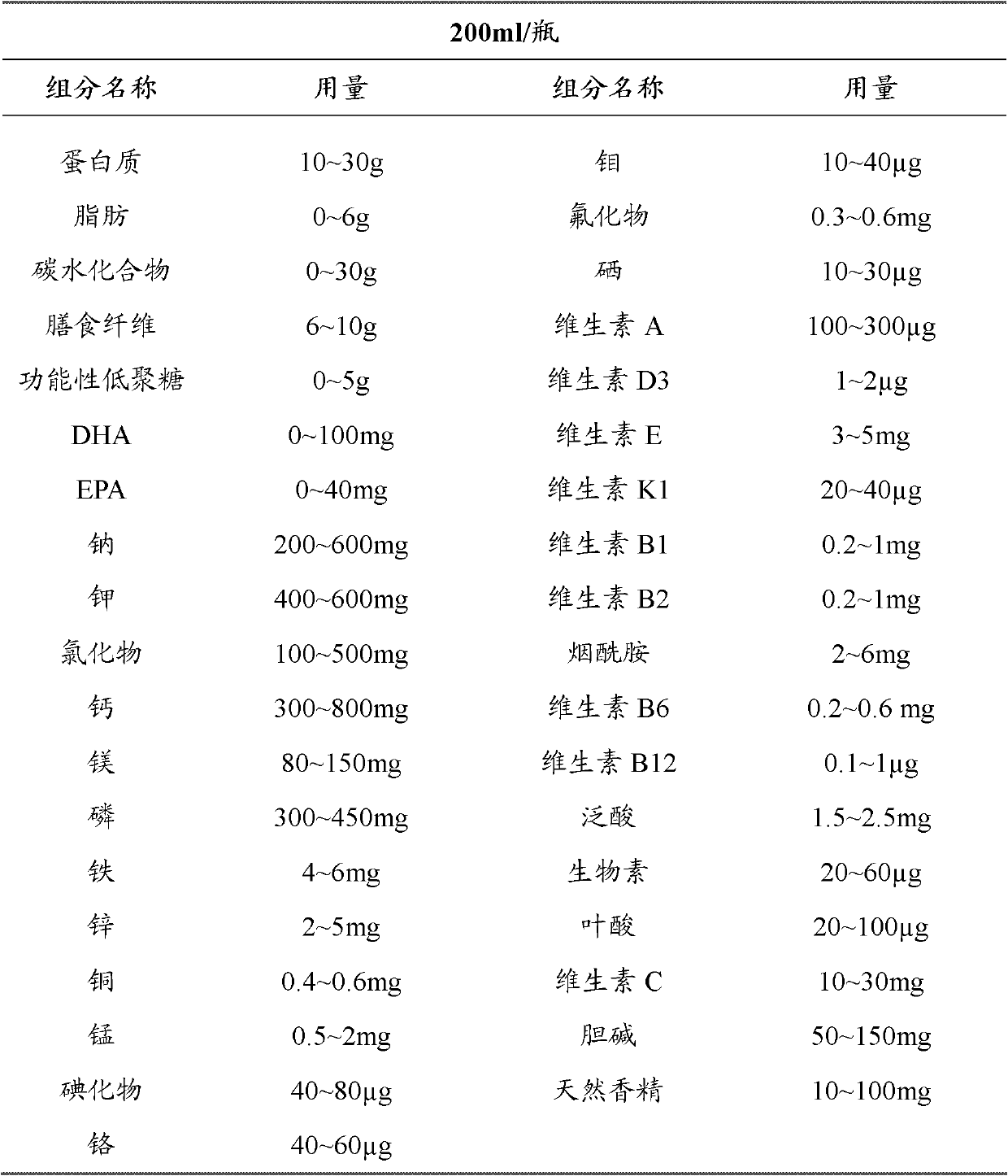

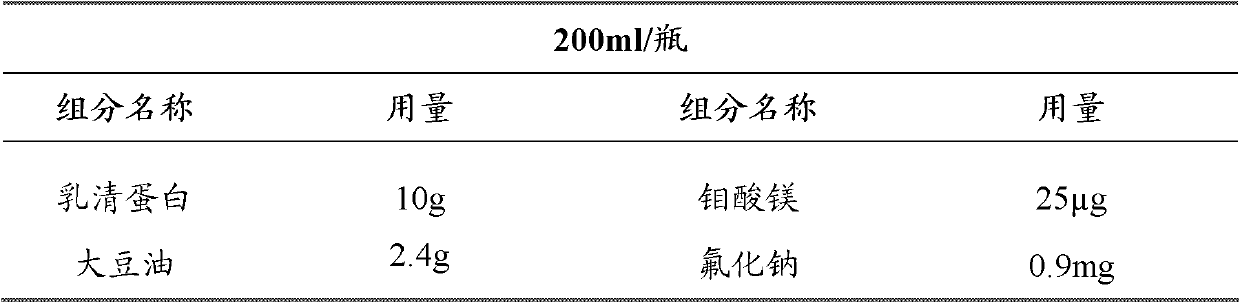

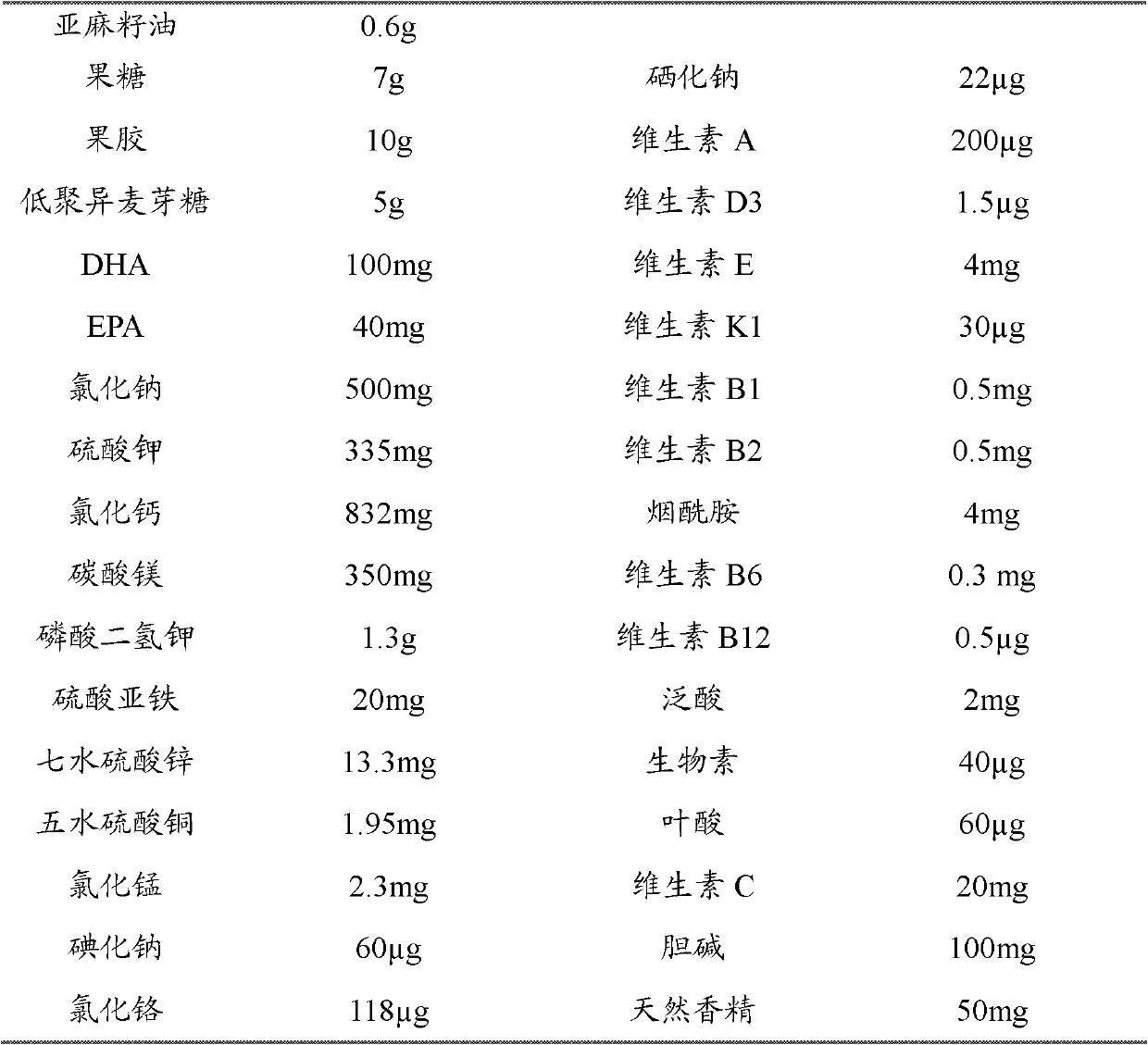

Low-calorie and total-nutrient beverage and preparation method thereof

InactiveCN102429307AImprove vitamin metabolismTo promote metabolismFood preparationLow calorieOligosaccharide

The invention discloses low-calorie and total-nutrient beverage and a preparation method thereof. The nutrient beverage contains abundant complete protein, dietary fiber, calcium, a small quantity of carbohydrates and fat, as well as vitamins, microelements and mineral substances which are essential to a human body; and meanwhile functional oligosaccharide and functional polyunsaturated fatty acid are added. In energy supply aspect of the low-calorie and total-nutrient beverage, intake of carbohydrates and fat is lowered, thus achieving the purposes of diet regulation, weight control and nutritional healthcare on the basis of maintaining balance of nutrient substances in a body.

Owner:XIAN LIBANG PHARMA

Method for manufacturing combined cam shaft

InactiveCN101733632AAvoid displacementAvoid deformationMetal working apparatusLaser beam welding apparatusNumerical controlEngineering

The invention belongs to the technical field of machining, and relates to a method for manufacturing a combined cam shaft, in particular to the method for manufacturing the combined cam shaft with a hollow tube mandrel. The method comprises the following manufacturing processing steps: firstly, straightening the hollow tube mandrel; secondly, performing tight fit and cold assembled positioning on a cam, a shaft neck component and a mandrel by using a numerical controlled assembling machine, and then realizing close connection of the cam, a shaft neck and the mandrel by machining expanding, so that the mandrel which generates plastic deformation is firmly combined with the cam and the shaft neck which generate elastic deformation; and finally, fixing drive components at the two ends of the cam shaft by a laser welding method. The method for manufacturing the combined cam shaft has the advantages of simple overall process, obviously reduced weight compared with a cast iron cam shaft, low integrated cost and high assembly precision, and completely meets the using requirements on the cam shafts of various automobile engines.

Owner:CENT IRON & STEEL RES INST

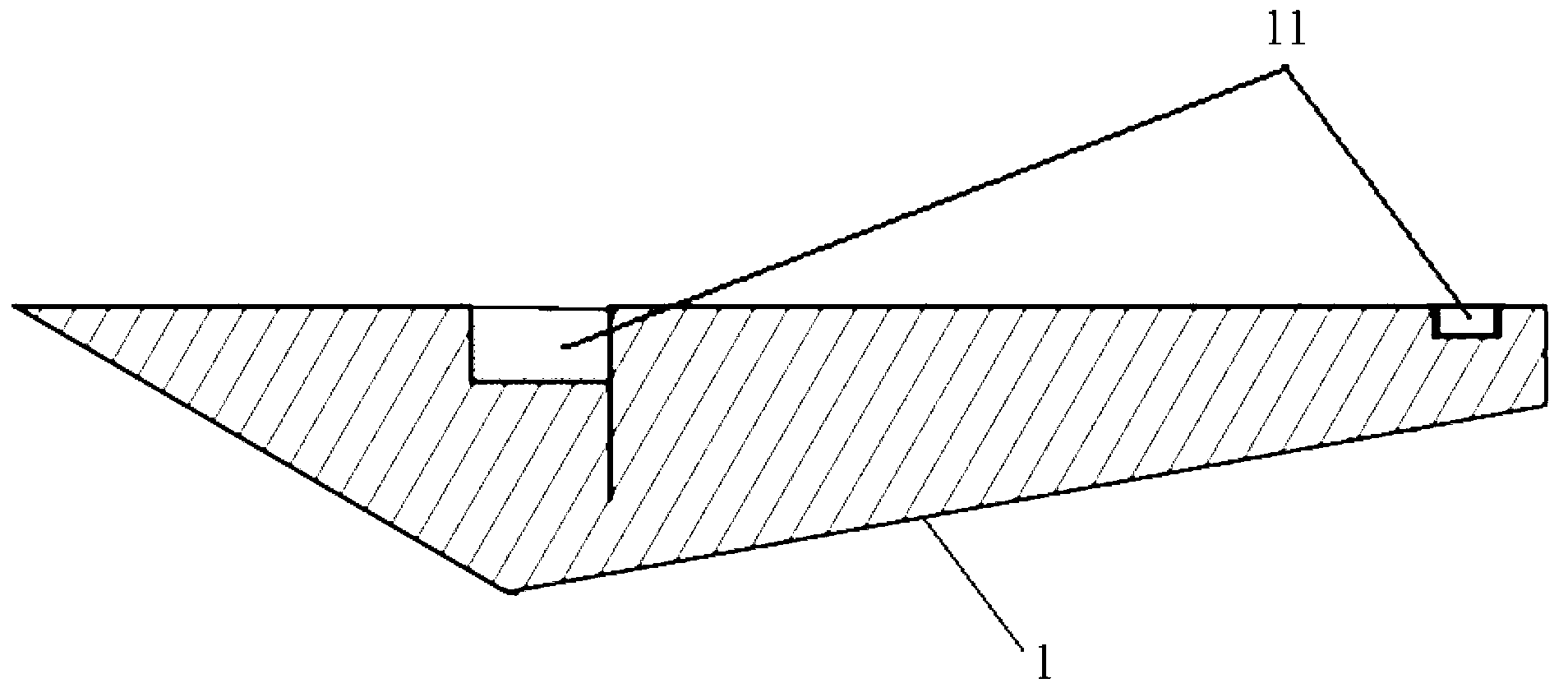

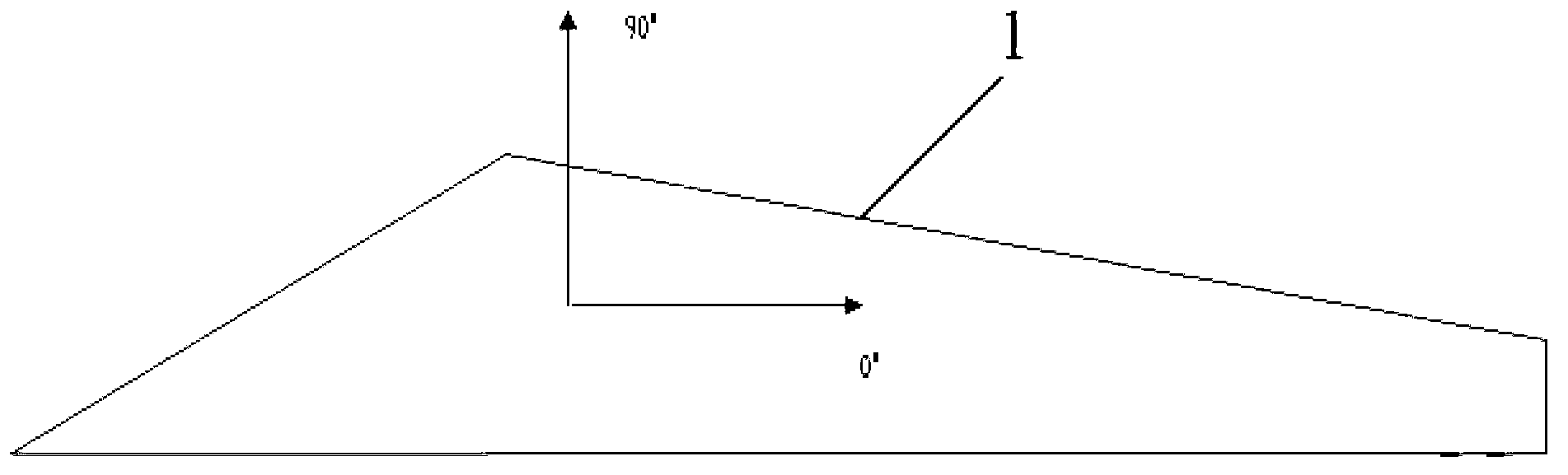

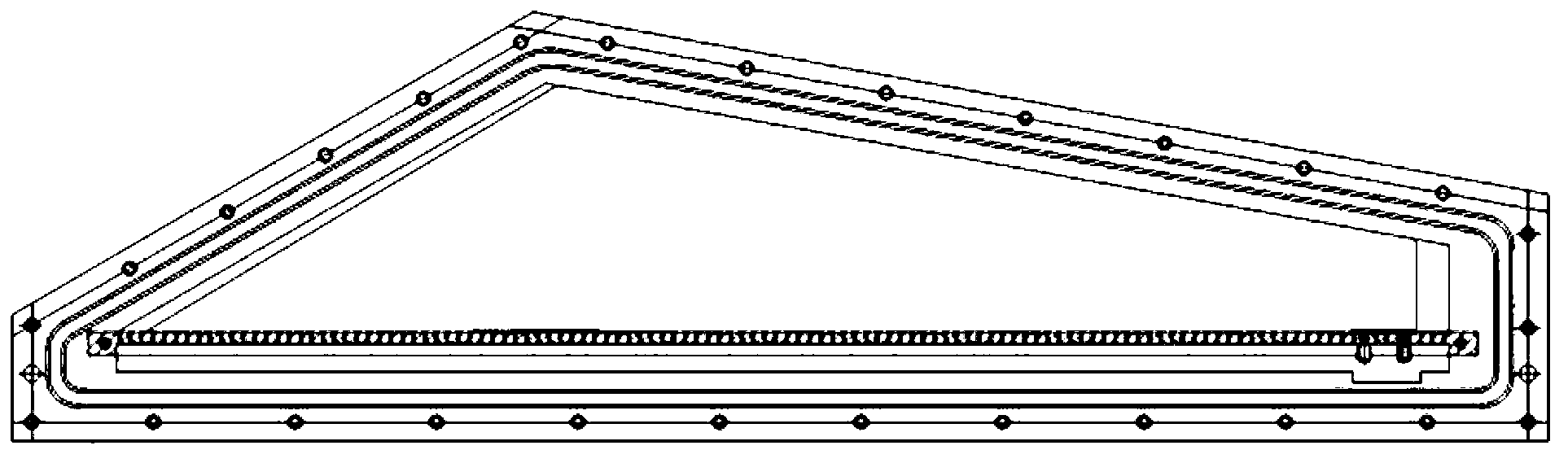

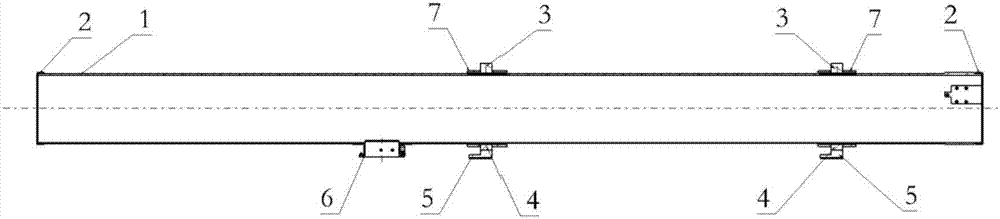

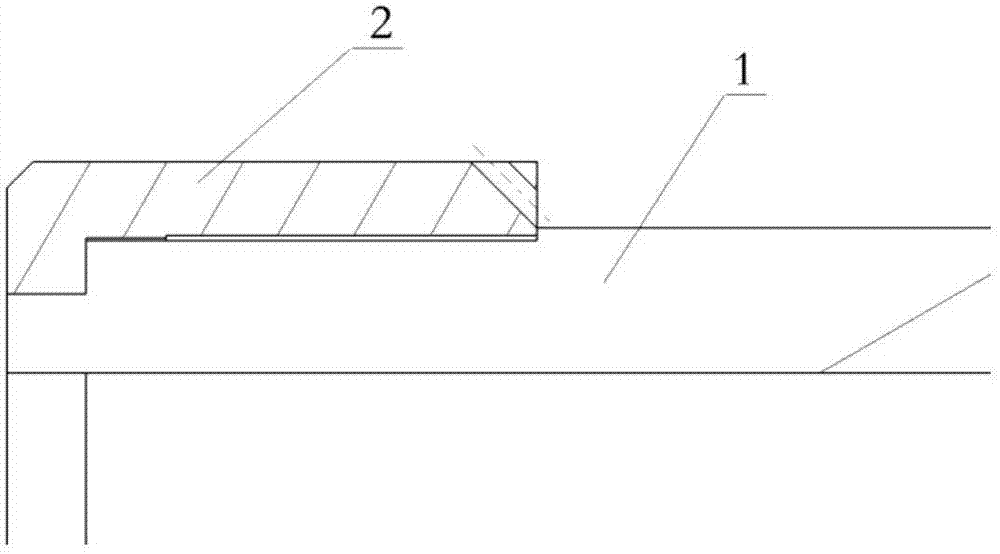

Preparation method of composite material missile wing

The invention discloses a preparation method of a composite material missile wing. The method comprises the following steps: setting the best laying angle and laying thickness, calculating the quantity of fiber cloth at each angle, cutting the fiber cloth according to the set laying angle and the calculated quantity of the fiber cloth, embedding at least two metal pieces into foam material, gradually laying the cut fiber cloth on upper and lower surfaces of the foam material according to the designed laying angle and sequence so as to obtain a premolded body, installing the premolded body in a rigid forming die, and performing solidification forming through a resin transfer molding technology, so as to obtain the composite material missile wing. The missile wing prepared by the method has the characteristics of low weight, high rigidity, uniform apparent color and good uniformity of external dimensions.

Owner:湖北三江航天江北机械工程有限公司

Method for preparing high-temperature baking type water-soluble damping coating for vehicles

InactiveCN105602371AImprove mechanical propertiesImprove damping performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinAssembly line

The invention discloses a method for preparing high-temperature baking type water-soluble damping coating for vehicles. The method comprises the following steps: (1) numbering water-soluble acrylic resin emulsions having a glass-transition temperature of negative 10 DEG C, 0 DEG C, 20 DEG C and 50 DEG C respectively to be emulsion No.1, emulsion No.2, emulsion No.3 and emulsion No.4 in a weight ratio of (0.5-1):(1-1.5):(1.5-2.5):(0.5-1), wherein the emulsions account for 20-45 percent of the weight of the coating; (2) selecting wollastonite powder, mica powder and ground calcium carbonate in a weight ratio of (0.5-1):(2-3):(1.5-2.5) as functional packing, wherein the functional packing accounts for 50-65 percent of the weight of the coating; and (3) adding water into a reaction kettle, adding the following materials in percentage by weight: 0.2-0.5 percent of dispersant, 0.2-0.5 percent of a wetting agent, 0.2-0.5 percent of a defoaming agent, 0.2-0.5 percent of a bactericide, 0.2-0.5 percent of coalescing agent and 0.2-0.5 percent of color paste, stirring for 10-15 minutes, adding the emulsions, and keeping on stirring for 15-20 minutes, adding the functional packing, stirring and dispersing for 20-25 minutes, adding 0.1-0.4 percent of thickener to regulate the viscosity. The coating can be cured when being baked at 140 DEG C for 15-20 minutes, can be applied to the assembly line of a vehicle maker, and has good damping performance, weather resistance, adhesive force and environmental friendliness.

Owner:JIANGSU TONGMENG AUTO PARTS IND CO LTD

Preparation process of sweet potato vermicelli

The invention discloses a preparation process of sweet potato vermicelli. The preparation process comprises the following steps: uniformly mixing sweet potato starch, radix puerariae powder and water, and pouring the mixture into a stirrer to stir; then, adding table salt and edible vegetable oil, uniformly mixing, and thickening with a mixture of cornstarch and water to prepare starch flour; putting the kneaded starch flour into a vacuum machine, and pumping air bubbles in the starch flour; braising the starch flour by using steam; placing the starch flour into a gourd dipper of a vermicelli leaking machine to carry out leakage test, and enabling vermicelli to fall into a vermicelli boiler when the vermicelli is completely uniform; drawing out the vermicelli in the boiler, and immediately refrigerating the vermicelli to a refrigeration house; taking out the vermicelli and unfreezing; drying in a shaping drier; cutting off the vermicelli and packing; and filling small packets of vermicelli into cartons, and sealing to obtain a finished product of the sweet potato vermicelli. The sweet potato vermicelli has the effects of beautifying and preserving the health, tonifying spleen and promoting appetite as well as clearing away the lung heat and calming the nerves; and the sweet potato vermicelli is uniform, rich in tenacity, not easy to be burnt after being boiled for a long term and delicious, thereby having a certain development prospect.

Owner:GUIZHOU HUALI AGRI CHEM ENG

Composite missile launching canister and preparation method thereof

The invention relates to a composite missile launching canister and a preparation method thereof. The launching canister comprises a composite canister body, a guide rail, a locking mechanism installing block, metal joints arranged at the two ends of the canister body, hoisting blocks, supports, support legs, annular reinforcing ribs, plugs, a falling window and the like. The canister body is made of a complete composite, and the purpose of overcoming own weaknesses by acquiring strong points of others is achieved through the characteristics that fiber glass reinforced plastic is high in strength, good in tenacity but insufficient in rigidity and carbon fiber reinforced plastic is high in strength, good in rigidity but insufficient in tenacity; in addition, the weight is decreased obviously, and the even more complex launching environment requirements are effectively met. According to the preparation method of the launching canister, the canister body, the guide rail and the internal installing block are integrally formed, the metal structures at the two ends are adhered through a structural adhesive and sealed through a sealing agent, the sealing effect is good, the technology is simple, and the production efficiency is improved.

Owner:绍兴宝旌复合材料有限公司 +1

Apparatus for treating obesity by extracting food

InactiveUS20100241090A1Significant weight lossGood for weight lossMedical devicesCatheterSide effectAbdominal wall

The present invention is directed to an apparatus and method for treating obesity. A tube is positioned that passes through a patient's abdominal wall into the upper digestive system of the patient. The patient is allowed to carry out his / her everyday affairs including ingesting food. After the patient has ingested food, the food is extracted by pumping it out of the upper digestive system through the tube. The present invention is less invasive than current surgical procedures for reducing weight and allows patients to live a normal and active lifestyle without experiencing adverse side effects.

Owner:ASPIRE BARIATRICS

Anti-senile longevity noodle

InactiveCN1943405AObvious fat reductionSignificant hypoglycemiaFood preparationAdditive ingredientInstant noodle

The anti-aging longevity noodles comprise of more than 10 food, such as animal and plant food, sea food , algae food and vegetables, said ingredients through careful selection, rinsing, drying and powdering, and through noodles machine, instant noodle machine and squeezer machine for a kind of noodle made by buckwheat, sorghum flour etc., then light dark green colored nutrition balanced food to be finished, shaped as vermicelli, instant noodles and said kind of noodles.

Owner:林树芳

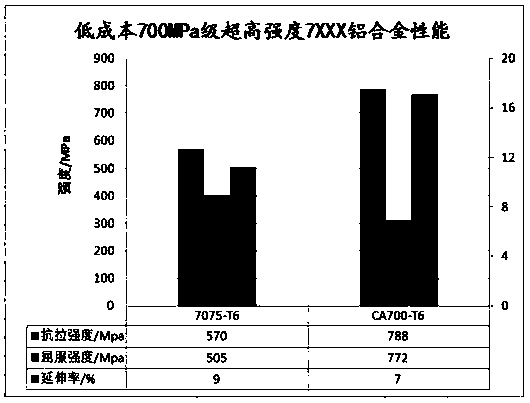

Solid-solution ageing technology for ultrahigh-strength 7-series aluminum alloy material for heavy-haul train traction rod

The invention provides a solid-solution ageing technology for an ultrahigh-strength 7xxx-series aluminum alloy material. The solid-solution ageing technology comprises the following steps: firstly, extruding an aluminum alloy casting ingot to prepare an extruded material; then carrying out solid-solution quenching on the extruded material obtained by the previous step and then placing; after carrying out manual ageing, obtaining the 7xxx-series aluminum alloy material. According to the solid-solution ageing technology provided by the invention, a specific solid-solution system is used for thealuminum alloy extruded material; the solid-solution quenching is firstly carried out; then the step of placing is carried out and the manual ageing is carried out; especially, after the solid-solution quenching is carried out on an aluminum alloy and the placing treatment is carried out so that the mechanical strength and rigidity of the alloy are improved; after the aluminum alloy material is subjected to the solid-solution quenching, a large part of compound phase is dissolved into an alloy matrix; then the specific manual ageing step is combined so that the strength of the aluminum alloy is remarkably improved. A preparation technology is simple and a production speed completely meets a normal production speed; the solid-solution ageing technology is low in cost and suitable for beingpopularized and applied in industrial large-scale production, and has important practical significance.

Owner:SOUTHWEST ALUMINUM GRP

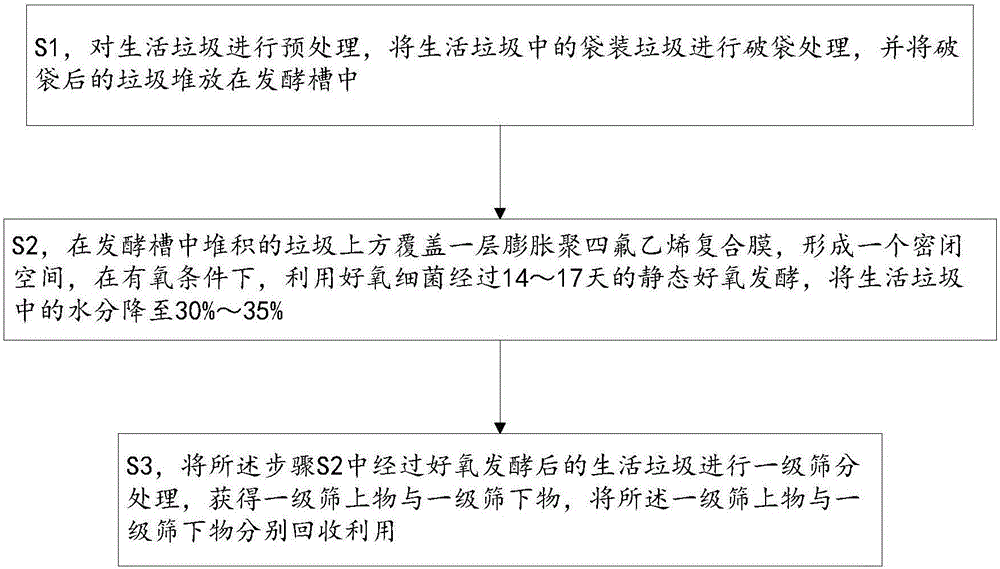

Household waste handling method

The invention discloses a domestic garbage treatment method and relates to the technical field of solid waste disposal. The domestic waste treatment method includes the following steps: S1, pretreating the domestic waste, breaking the bagged waste in the domestic waste, and stacking the broken bag in a fermentation tank; S2, fermenting The garbage accumulated in the tank is covered with a layer of expanded polytetrafluoroethylene composite film to form a closed space. Under aerobic conditions, aerobic bacteria are used for 14 to 17 days of static aerobic fermentation to reduce the moisture in domestic garbage. to 30% to 35%; S3, performing primary sieving treatment on the domestic garbage after aerobic fermentation in the step S2 to obtain the first-level sieve and the first-level sieve, and the first-level sieve The material and the undersize of the primary sieve are recycled separately. The beneficial effect of the invention is that the domestic waste can be decomposed and dried at low cost, the water content in the domestic waste can be reduced, the process is simplified, and the system investment and operation cost are reduced.

Owner:HUNAN VARY TECH

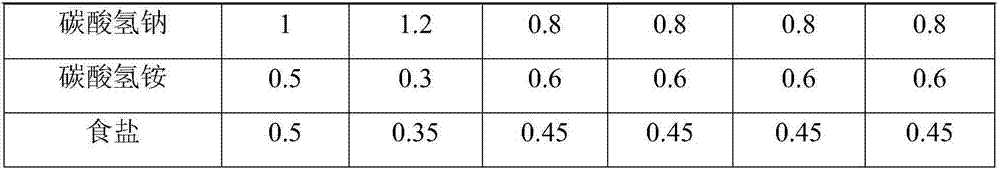

Biscuit with effects of purging gut, detoxifying, maintaining beauty and keeping young and preparing method thereof

ActiveCN107279231AHigh nutritional valueRich in nutrientsDough treatmentPre-baking dough treatmentChemistryWhey protein powder

The invention belongs to the technical field of food, and particularly relates to a biscuit with the effects of purging the gut, detoxifying, maintaining beauty and keeping young and a preparing method thereof. The biscuit is prepared from wheat flour, quinoa flour, oat flour, chia seed powder, potato flour, white kidney bean flour, whey protein powder, trehalose, resistant dextrin, white granulated sugar powder, red-yeast millet flour, Chinese-soapberry-fruit peel powder, jasmine flower extract, coconut oil, sodium bicarbonate, ammonium bicarbonate and salt. The biscuit with the effects of purging the gut, detoxifying, maintaining beauty and keeping young does not contain a preservative and an artificially-synthesized sweetening agent, the compatibility of components of all raw materials is scientific, paste forming is easy, and the made biscuit is high in dietary fiber content, balanced in nutrition, fragrant and sweet, delicious, good in quality and low in fat and sugar; the obvious satiety feeling exists after the biscuit is eaten, and the biscuit has the obvious effects of losing weight, purging the gut, detoxifying, maintaining beauty, keeping young and the like.

Owner:广东四季优美实业有限公司

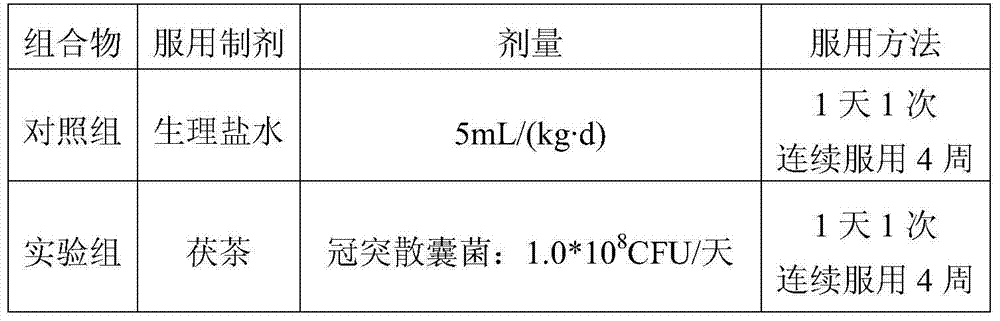

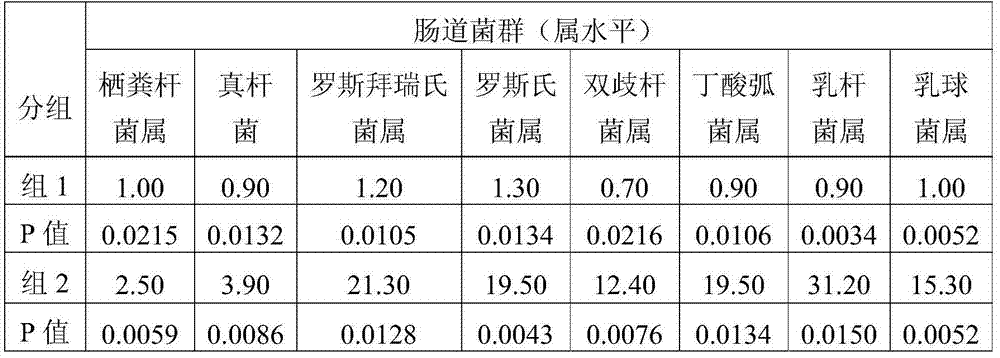

Fu tea and preparation method and use thereof

The invention discloses Fu tea and a preparation method and use thereof. The method comprises the following steps: providing a eurotium cristatum spore suspension; and inoculating the eurotium cristatum spore suspension in raw dark green tea and fermenting to obtain the Fu tea. By virtue of the method, the Fu tea with flourishing golden flowers can be effectively prepared, and the method is simple and is easy to operate and control.

Owner:BGI SHENZHEN CO LTD +1

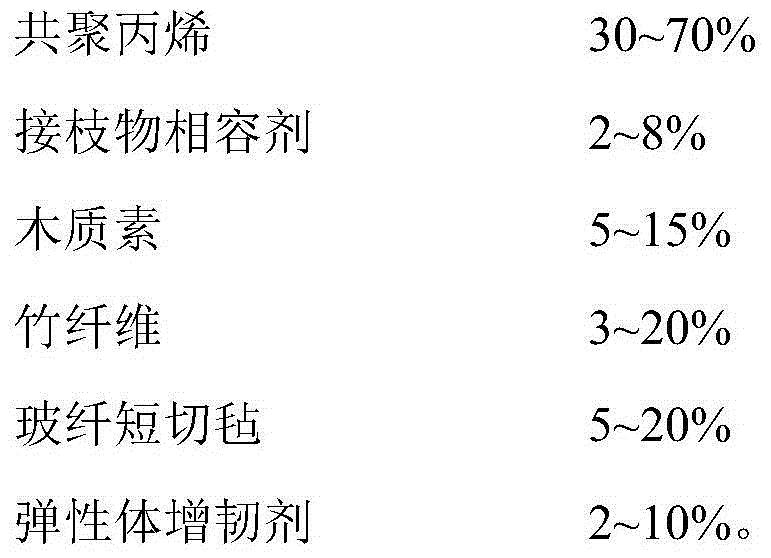

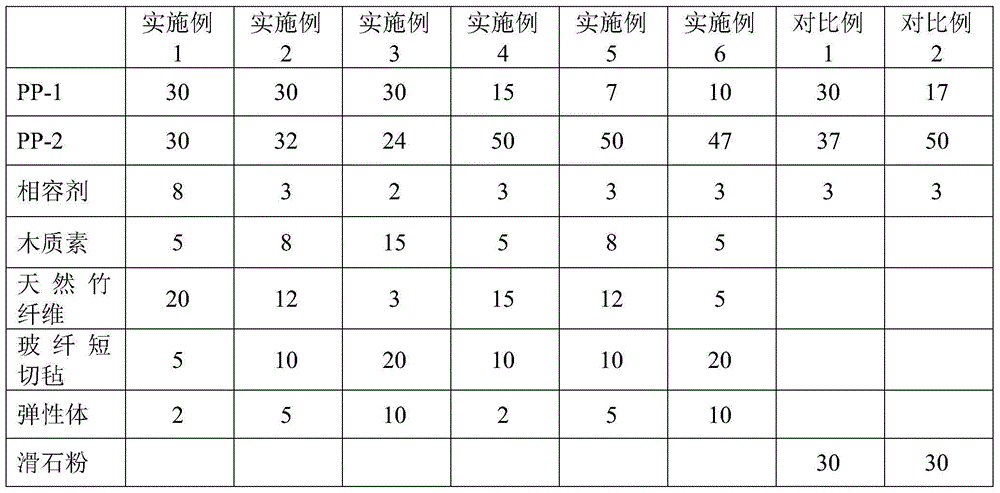

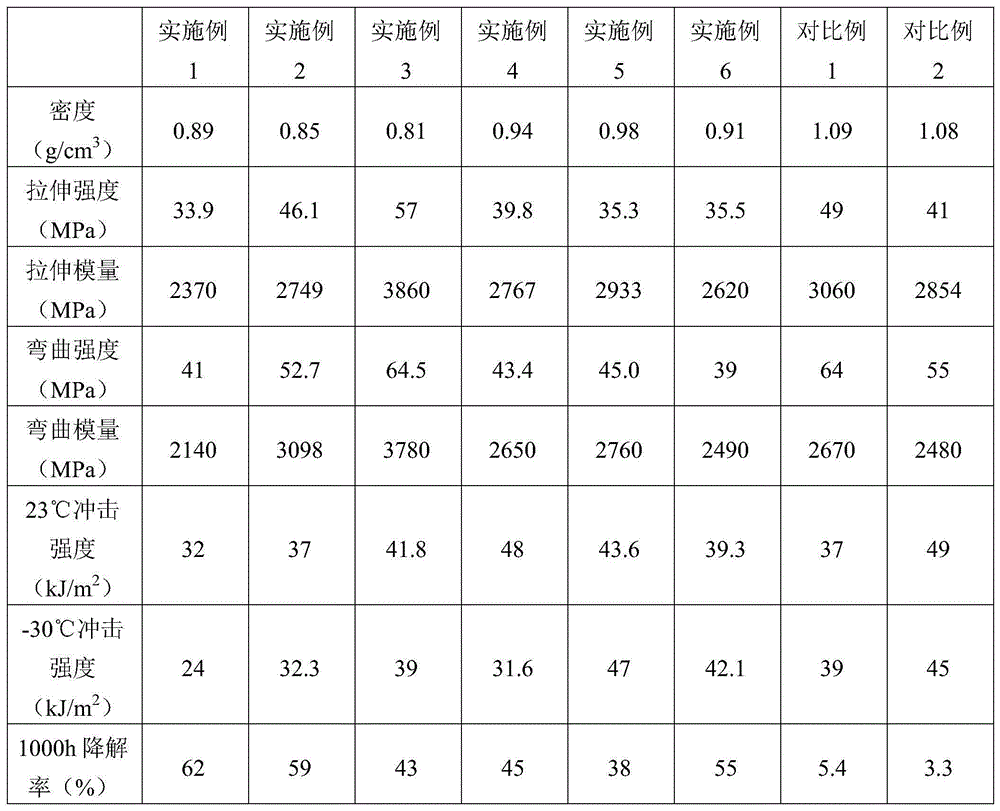

Micro-foamed multiphase fiber-reinforced polypropylene composite material and preparation method thereof

ActiveCN104945823AGood mechanical propertiesHigh foaming rateMechanical properties of carbon nanotubesPolypropylene composites

The invention relates to a high-degradability micro-foamed multiphase fiber-reinforced polypropylene composite material which is composed of the following raw materials in percentage by weight: 30-70% of propylene copolymer, 2-8% of graft compatilizer, 5-15% of lignin, 3-20% of natural bamboo fiber, 5-20% of glass fiber chopped felt and 2-10% of elastomer toughener. The micro-foamed multiphase fiber-reinforced polypropylene composite material obtained according to the technical scheme has the advantages of low density, favorable foaming property, favorable mechanical properties, high degradability and the like. The lignin and natural fibrilia endow the reinforced polypropylene composite material with degradability. After the micro-foaming technique treatment, the composite material has lower density and higher degradability. Compared with the common talcum powder filled polypropylene composite material, on the premise of equivalent mechanical properties, the density of the reinforced polypropylene composite material is lowered by 15-25%, and the degradability can be obviously improved. The degradation rate of higher than 50% can be implemented by a simple landfilling-biodegradation process. The composite material has excellent characteristics of greenness and environment friendliness.

Owner:中广核俊尔(上海)新材料有限公司

Akebiaquinata health-care tea and preparation method thereof

InactiveCN104068154AImprove sub-health statusGood treatment effectPre-extraction tea treatmentAcute hyperglycaemiaDisease

The invention discloses akebiaquinata health-care tea and a preparation method thereof. The akebiaquinata health-care tea contains the following raw materials in parts by weight of dried product: 10 parts of akebia trifoliate peel, 0.5-1 part of orange peel, 0.5-1 part of mango skin, 0.5-1 part of dragon fruit skin, 0.5-1 part of tea leaves, 0.5-1 part of honeysuckle, 0.5-1 part of snow chrysanthemums and 0.5-1 part of rose. The preparation method comprises the following steps: 1, picking fresh akebia trifoliate peel, orange peel, mango skin and dragon fruit skin, slicing the peel and skin into blocks, and picking fresh tea leaves; 2, fermenting the four kinds of peel and tea leaves; 3, drying the fermented materials so as to reduce the moisture content to be 8-10 percent, and thus obtaining initial tea; 4, adding dried honeysuckle, snow chrysanthemums and rose into the initial tea according to a design ratio, and stirring to be uniform to obtain the finished product. After being drunk frequently, the akebiaquinata health-care tea can effectively improve sub-health conditions of the human body and has the effects of nourishing yin and tonifying kidney, invigorating the stomach and beautifying and treating diseases such as hypertension, hyperlipidemia, hyperglycemia, frequent micturition and lactation promotion in an assisted mode.

Owner:HUNAN UNIV OF ARTS & SCI

Lilium-brownii radix-puerariae vermicelli preparation technology

InactiveCN103652555AOvercome bad tasteUniform strandsFood shapingFood ingredient functionsProcess engineeringMouthfeel

A lilium-brownii radix-puerariae vermicelli preparation technology comprises the following steps: taking lilium brownii starch, sweet potato starch, radix puerariae starch and water, mixing uniformly, pouring into a stirrer for stirring, and thickening to prepare dough; putting kneaded dough in a vacuum machine and pumping out bubbles in the dough; steaming the dough with steam; putting the dough in a perforated ladle of a filament leaking machine for leakage test, when vermicelli is completely uniform, enabling vermicelli to drop into a vermicelli boiling pot; getting vermicelli out of the vermicelli boiling pot, immediately sending to a refrigeration house for refrigeration; taking vermicelli out and unfreezing; sendin to a forming drying machine to dry vermicelli; when the water content of vermicelli is 20-25%, naturally drying vermicelli to have a water content of 10-12%, cutting and packaging; and putting small-bag vermicelli in cartons and sealing to obtain a finished product. The lilium-brownii radix-puerariae vermicelli has the effect of maintaining beauty, preserving health, invigorating spleen, stimulating appetite, clearing lung heat and tranquilizing, overcomes the disadvantages of bad mouthfeel of the raw material radix puerariae, is uniform, good in toughness, not overcooked after long time cooking, and delicious in taste, and has certain development prospect.

Owner:GUIZHOU FANJING TIANXIN BIOLOGICAL TECH

Lotus leaf jelly

InactiveCN101433360ASignificant weight lossDoes not cause excretory burdenFood preservationFood preparationFlavoring essencesNuciferine

The invention discloses lotus leaf fruit jelly containing edible glue, a sweet agent and edible flavoring essence. The lotus leaf fruit jelly also contains lotus leaf extract comprising nuciferine and lotus leaf flavone. The lotus leaf fruit jelly comprises the following components by weight percentage: 0.01 to 0.05 weight percent of nuciferine, 0.05 to 0.5 weight percent of lotus leaf flavone, 0.6 to 1.2 weight percent of edible glue, 0.04 to 16 weight percent of sweet agent, 0.07 to 0.10 weight percent of edible flavoring essence, and the balance being water. The nuciferine and the lotus leaf flavone have remarkable functions of weight losing, blood fat reduction, bacteriostasis, antivirus, detoxication and oxidation resistance. Not less than 10g of the lotus leaf fruit jelly for everyday has obvious effects of reducing blood fat, losing weight, promoting the urination and relaxing the bowels, and removing intestine toxin. For long-time taking, the lotus leaf fruit jelly can resist ageing and can not cause impacts like excretion burden due to excessive taking.

Owner:NINGBO UNIV

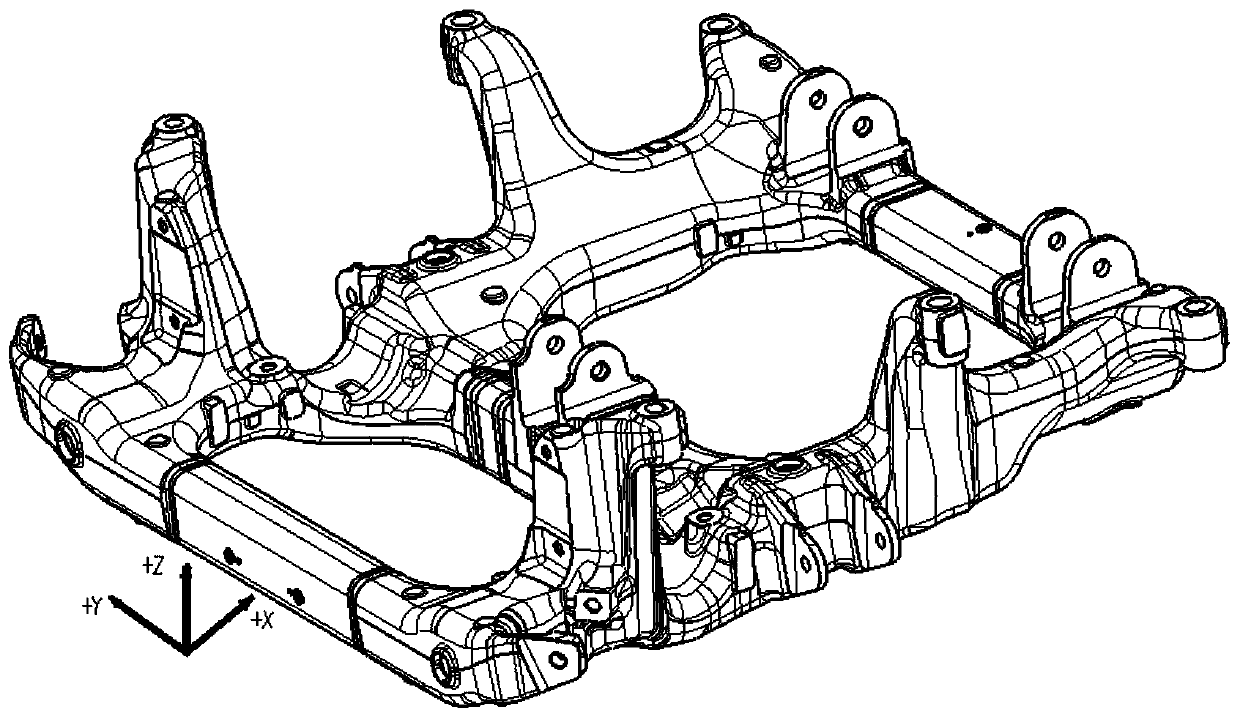

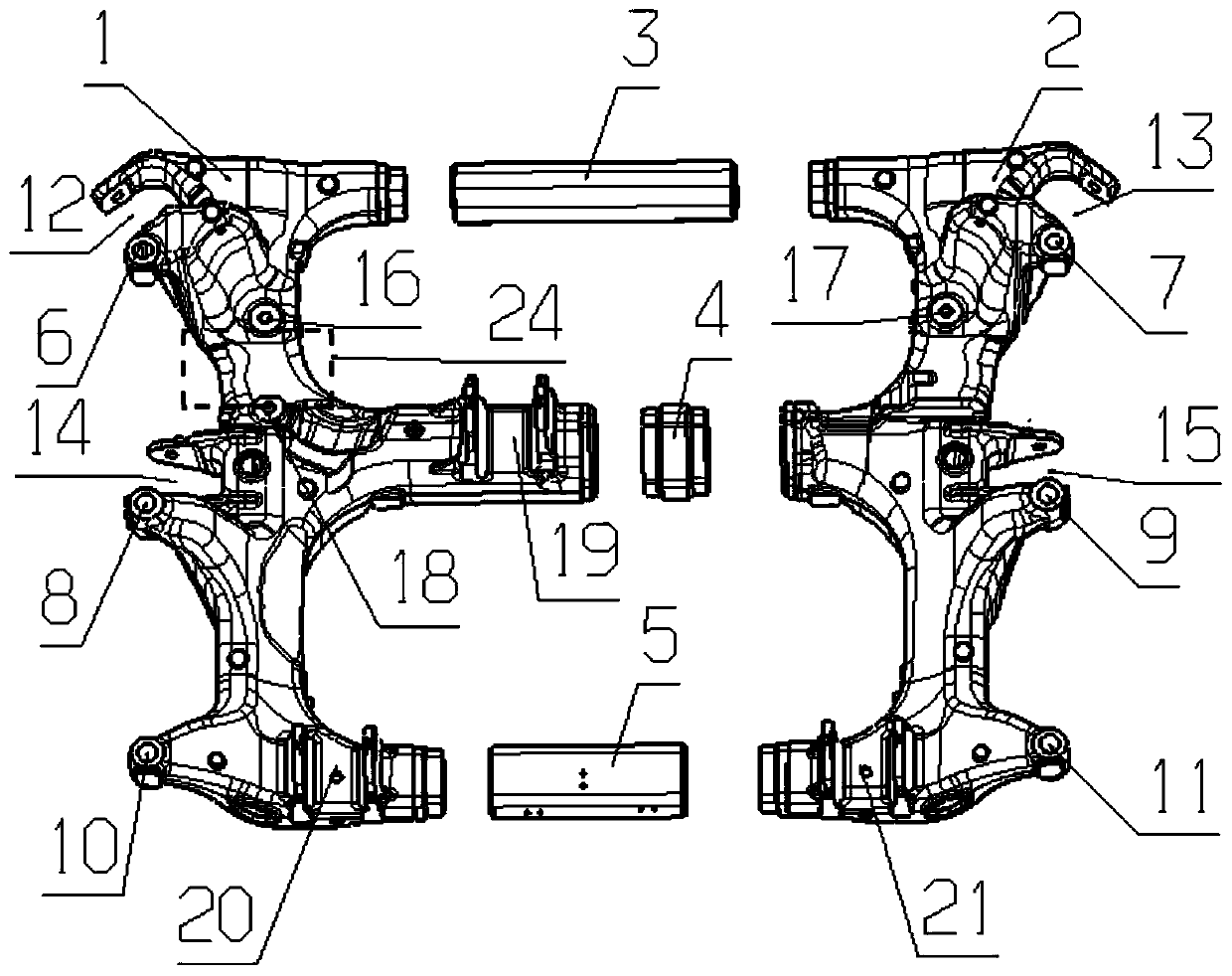

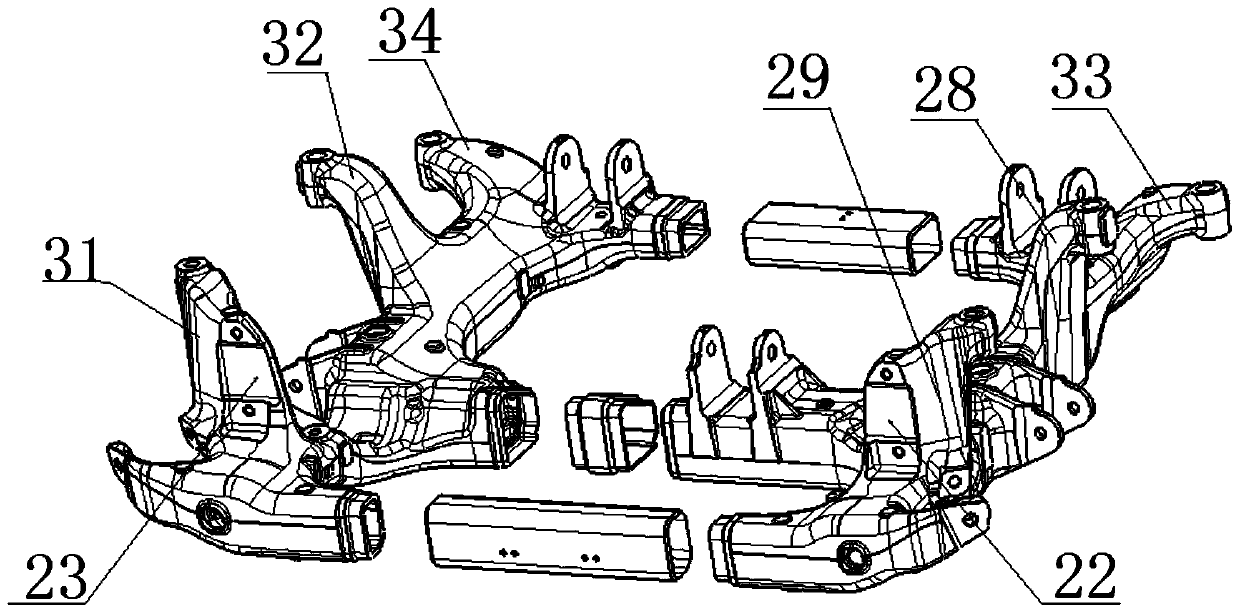

Auxiliary frame obtaining through welding hollow cast aluminum and aluminum profiles

ActiveCN110203284ASolve the unmanufacturableSolve casting difficultiesUnderstructuresDouble wishbone suspensionVehicle frame

The invention belongs to the technical field of passenger car parts, and particularly relates to an auxiliary frame obtained through welding hollow cast aluminum and aluminum profiles. The auxiliary frame comprises a left hollow cast body, a right hollow cast body, a front cross beam, a middle cross beam, a rear cross beam, a left front control arm installation support, a left front car body installation hole supporting column, a left rear control arm installation support, a left middle car body installation hole supporting column, a left rear car body installation hole supporting column, a right front control arm installation support, a right front car body installation hole supporting column, a right rear control arm installation support, a right middle car body installation hole supporting column, a right rear car body installation hole supporting column, a front suspension installation support of a power assembly, a left rear suspension installation support of the power assembly and a right rear suspension installation support of the power assembly. The problem that the inblock cast of the large-scale aluminum auxiliary frame is difficult is solved, the arrangement, function and crashworthiness requirements of Macpherson double wishbone suspension on the auxiliary frame are met, and the advantages of high strength, high rigidity, light weight and the like are achieved.

Owner:CHINA FIRST AUTOMOBILE

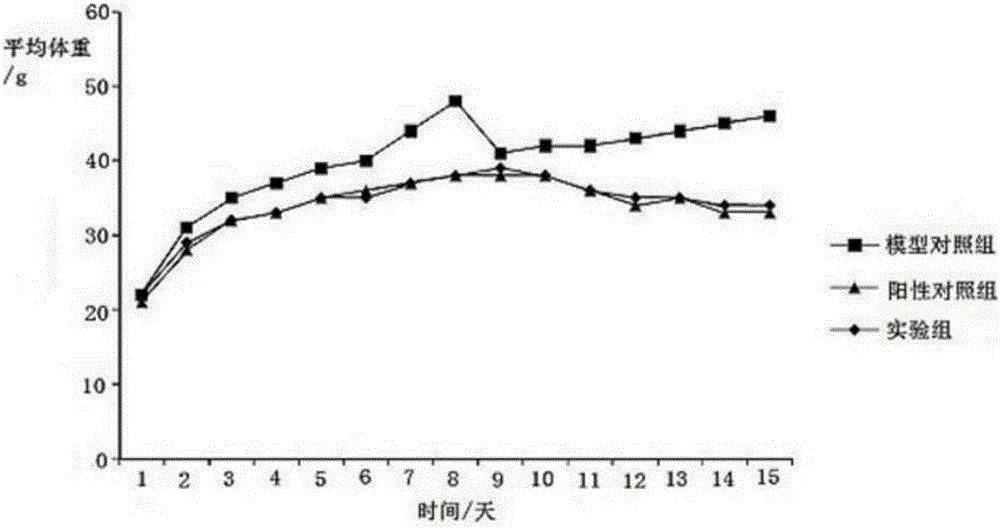

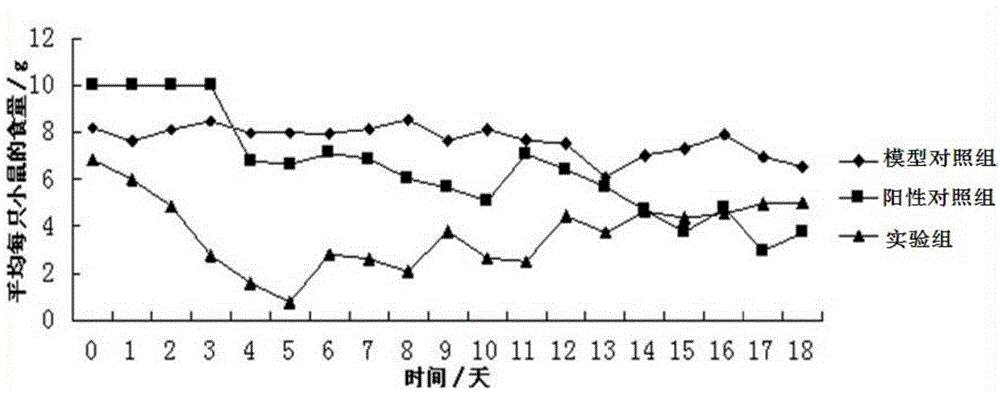

Composition with weight losing and blood fat reducing functions and preparing method and application thereof

ActiveCN105727205AEnhance memoryAnti agingMetabolism disorderKetone active ingredientsDietary fiberSide effect

The invention relates to a composition with weight losing and blood fat reducing functions and a preparing method and application thereof.The composition is prepared from, by weight, 5-17 parts of white kidney bean extract, 2-12 parts of agaricus bisporus extract, 2-12 parts of dietary fibers, 0.5-7 parts of green tea extract and 0.5-7 parts of radix curcumae longae extract.According to the composition, raw material composition and matching between all the raw materials are fully considered, all the raw materials are matched and take effect in cooperation under a specific matching ratio, and the functions of losing weight and reducing blood fat are achieved; the composition has the remarkable weight losing and blood fat reducing functions, and is small in toxic and side effect, high in safety, simple in composition and low in cost as the composition only comprises five raw materials.

Owner:ZHANGZHOU PIEN TZE HUANG PHARM

Compound bitter gourd peptide oral medicine for activating insulin and treating diabetes, and preparation method of compound bitter gourd peptide oral medicine

PendingCN110755598AImprove productivity and puritySignificantly lower blood pressure and blood fatPowder deliveryOrganic active ingredientsOligosaccharideGynura

The invention discloses a compound bitter gourd peptide oral medicine for activating insulin and treating diabetes, and a preparation method of the compound bitter gourd peptide oral medicine. The compound bitter gourd peptide oral medicine is prepared from the components in parts by weight: 20-30 parts of bitter gourd peptide powder, 4-6 parts of American ginseng, 10-12 parts of radix astragali,3-5 parts of ganoderma lucidum powder, 8-10 parts of yam powder, 10-15 parts of wheat bran, 10-12 parts of guava leaf powder, 5-10 parts of an onion extract, 5-10 parts of fructus lycii, 12-15 parts of a gynura procumbens extract, 1-2 parts of coix seeds, 5-8 parts of konjac glucomannan, 8-10 parts of lotus leaves and 5-8 parts of xylo-oligosaccharide. According to the compound bitter gourd peptide oral medicine and the preparation method, the content of active components of bitter gourd peptide is increased through a special bitter gourd peptide extraction technology, and a better hypoglycemic effect is achieved through cooperative use of the active components of the bitter gourd peptide and other natural plant components.

Owner:李玉保 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com