Patents

Literature

105 results about "Crashworthiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crashworthiness is the ability of a structure to protect its occupants during an impact. This is commonly tested when investigating the safety of aircraft and vehicles. Depending on the nature of the impact and the vehicle involved, different criteria are used to determine the crashworthiness of the structure. Crashworthiness may be assessed either prospectively, using computer models (e.g., LS-DYNA, PAM-CRASH, MSC Dytran, MADYMO) or experiments, or retrospectively by analyzing crash outcomes. Several criteria are used to assess crashworthiness prospectively, including the deformation patterns of the vehicle structure, the acceleration experienced by the vehicle during an impact, and the probability of injury predicted by human body models. Injury probability is defined using criteria, which are mechanical parameters (e.g., force, acceleration, or deformation) that correlate with injury risk. A common injury criterion is the Head impact criterion (HIC). Crashworthiness is assessed retrospectively by analyzing injury risk in real-world crashes, often using regression or other statistical techniques to control for the myriad of confounders that are present in crashes.

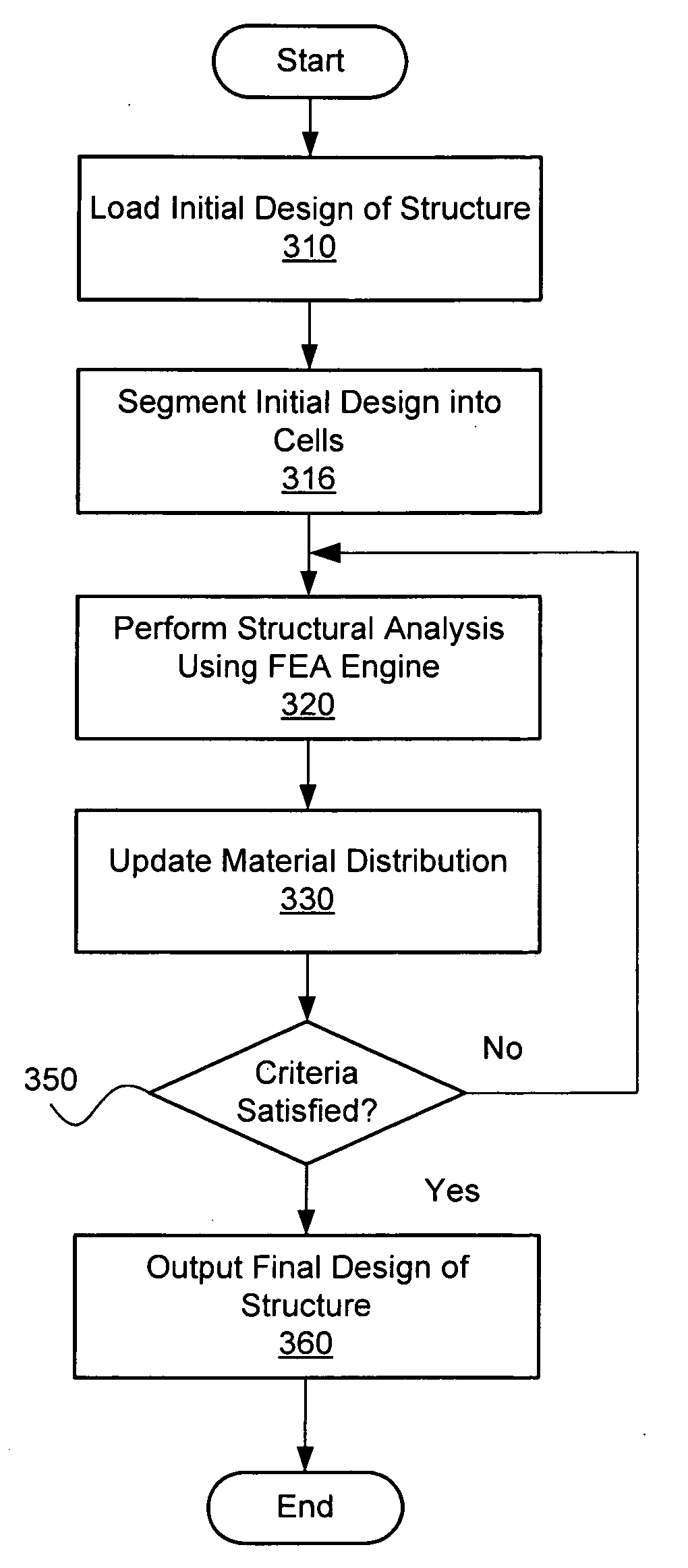

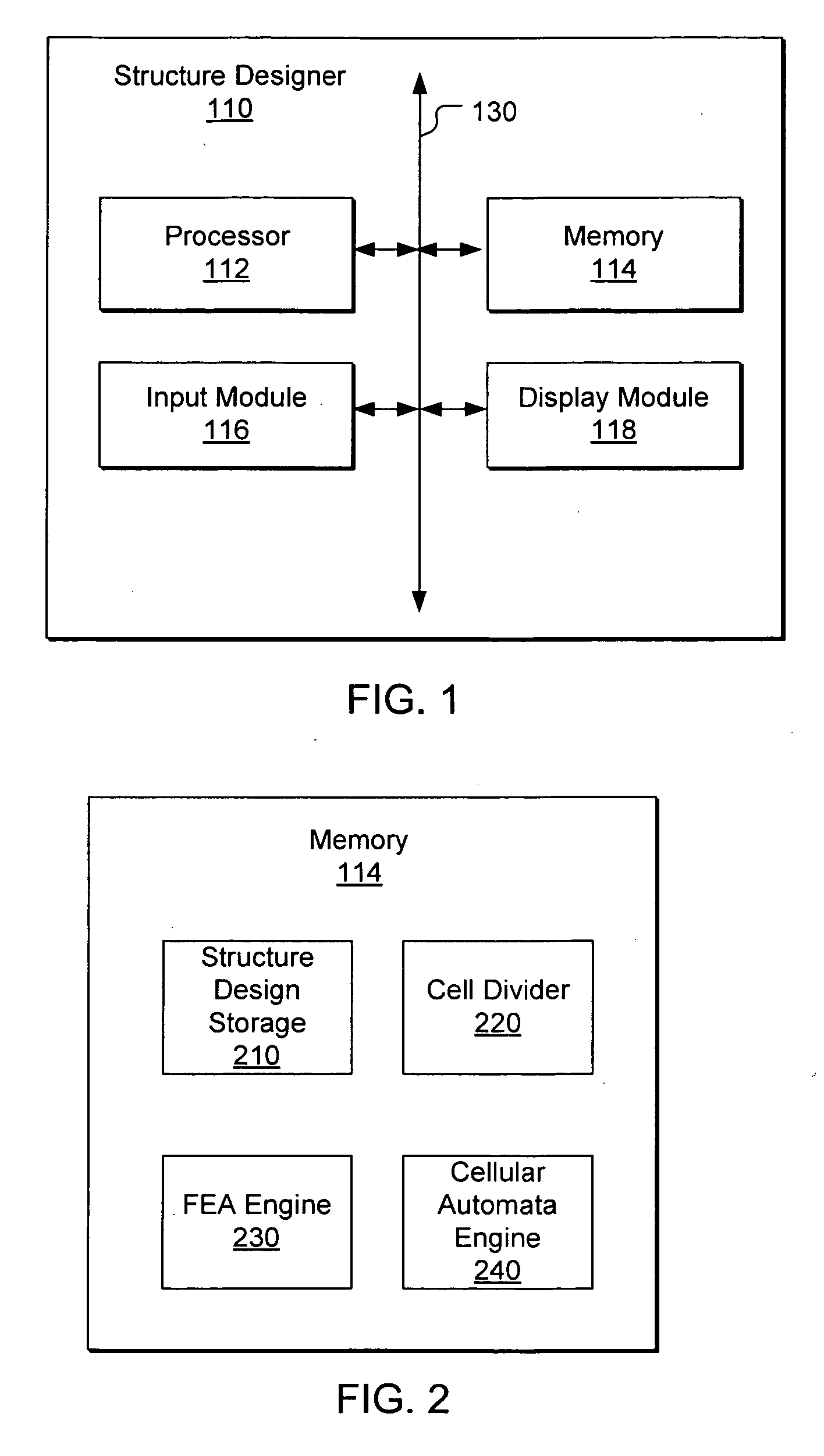

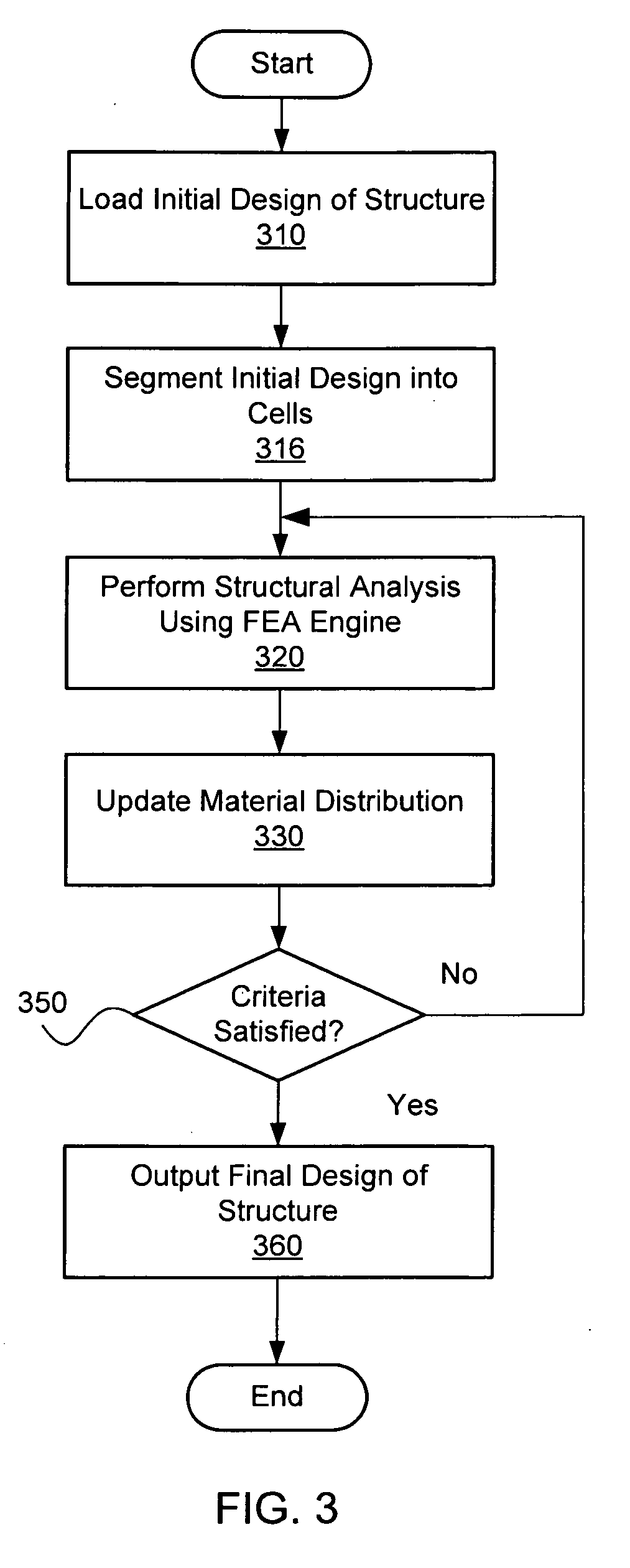

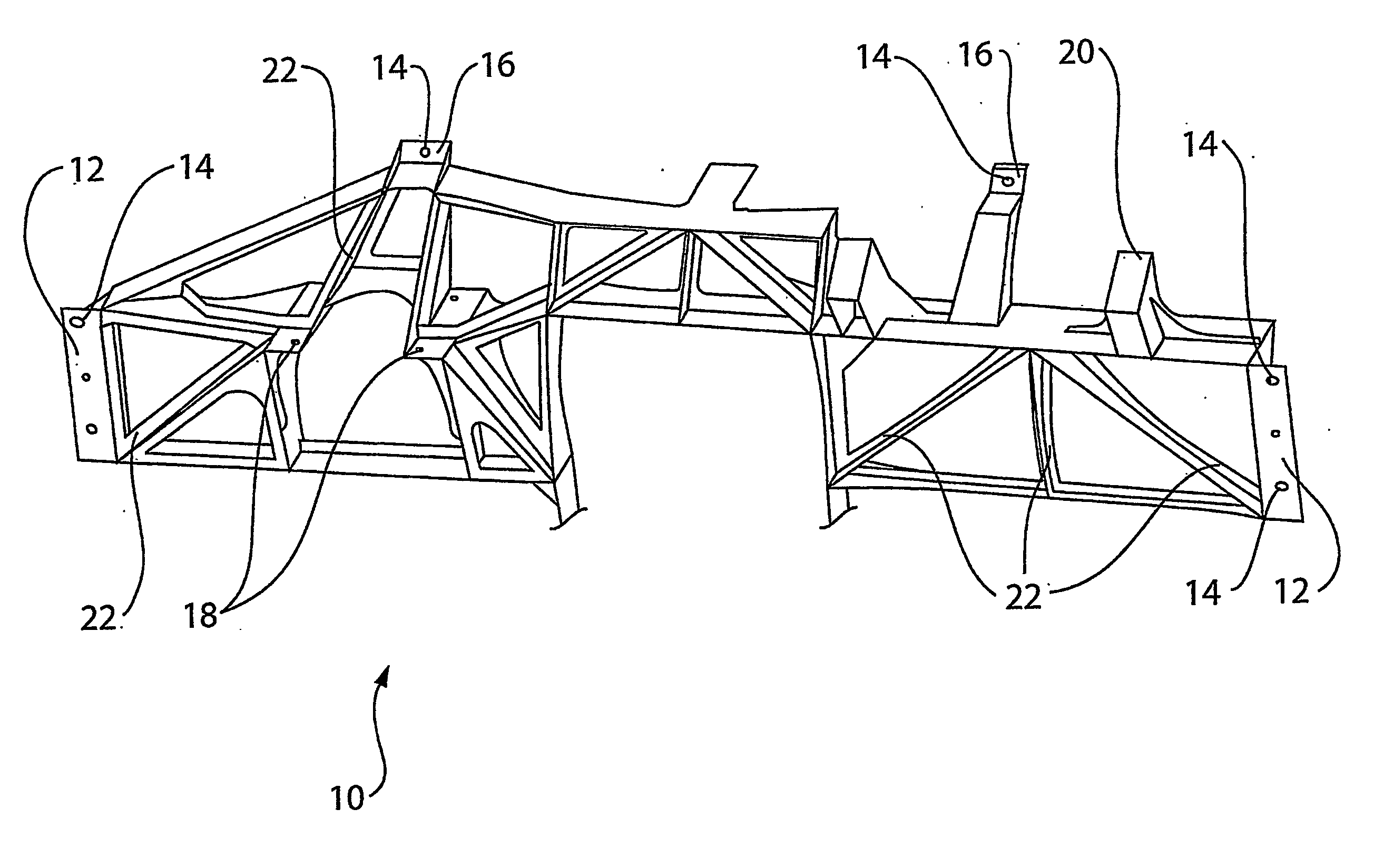

Crashworthiness design methodology using a hybrid cellular automata algorithm for the synthesis of topologies for structures subject to nonlinear transient loading

InactiveUS20090164178A1Design moreEqually distributedGeometric CADDesign optimisation/simulationElement analysisEngineering

Crashworthiness designing of a structure using a Hybrid Cellular Automata (HCA) algorithm where field states are computed using finite element analysis (FEA) and the material distribution of the structure is updated at each iteration using cellular automata method. The HCA algorithm optimizes the topology of the structures to achieve certain performance within the limits of various constraints applied to ensure crashworthiness of the structures. The HCA algorithm may also be applied to designing of structures to be fabricated by an extrusion method having the same cross section along the direction of extrusion or stamped structures having thickness varying across the structure.

Owner:UNIV OF NOTRE DAME DU LAC +1

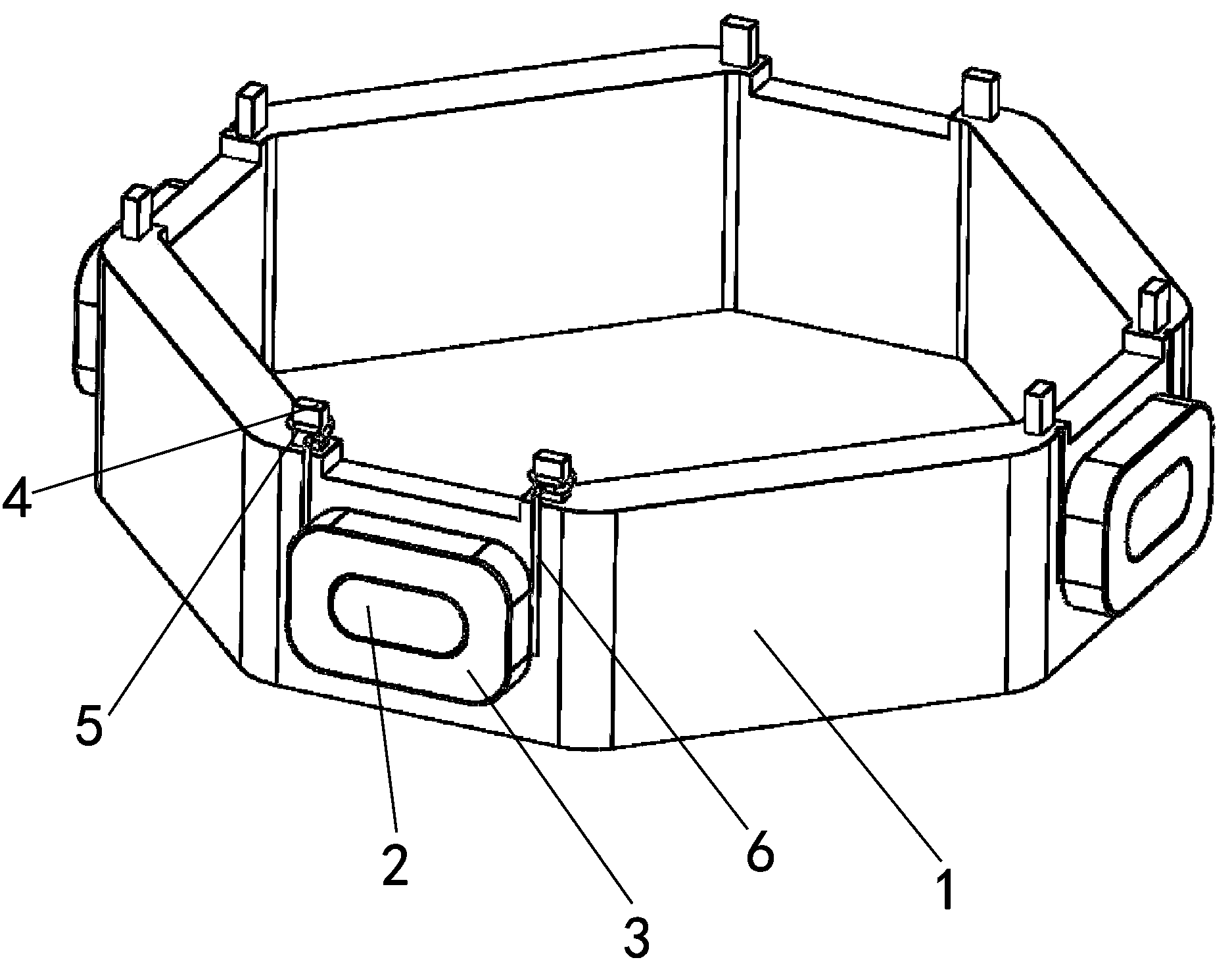

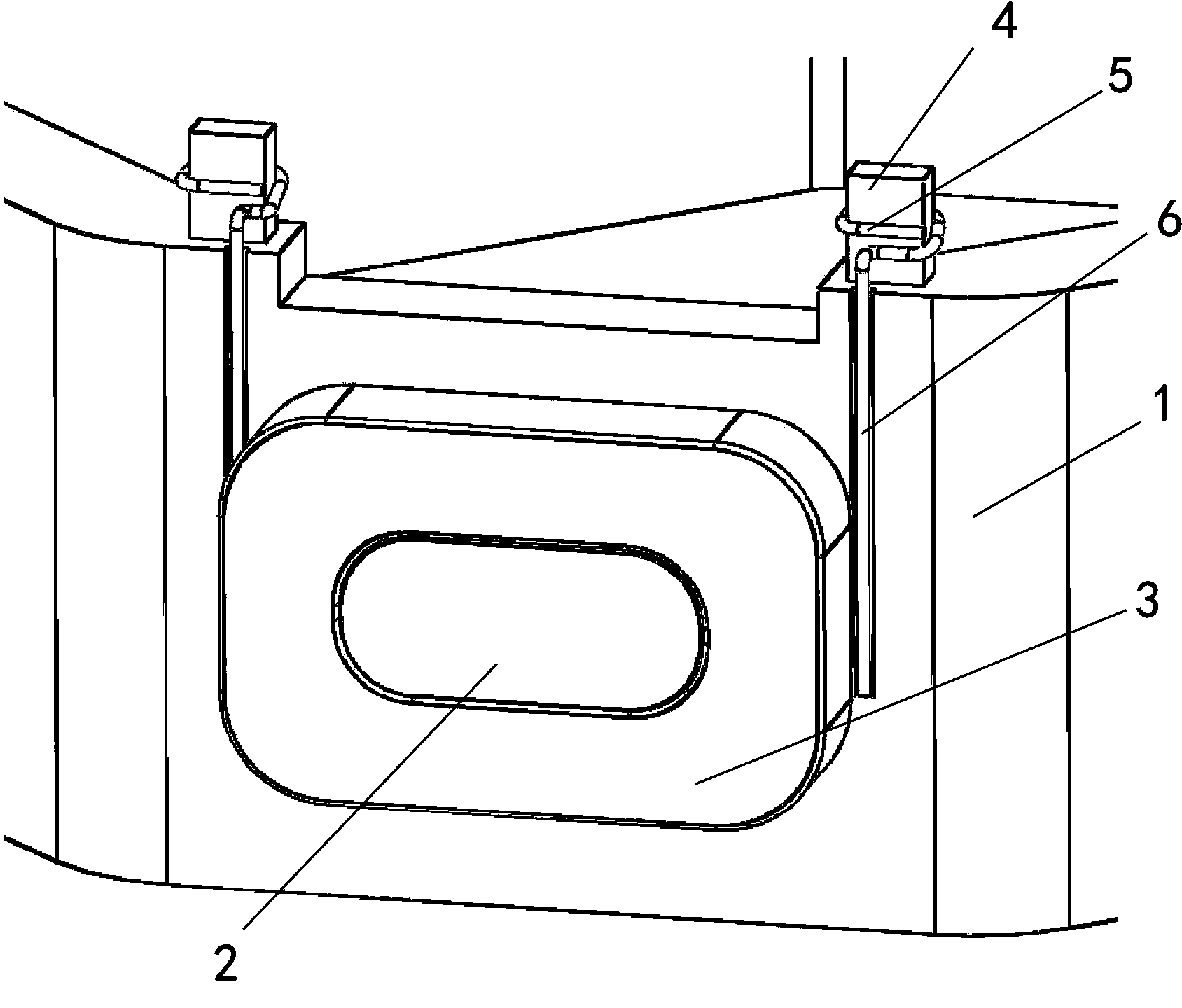

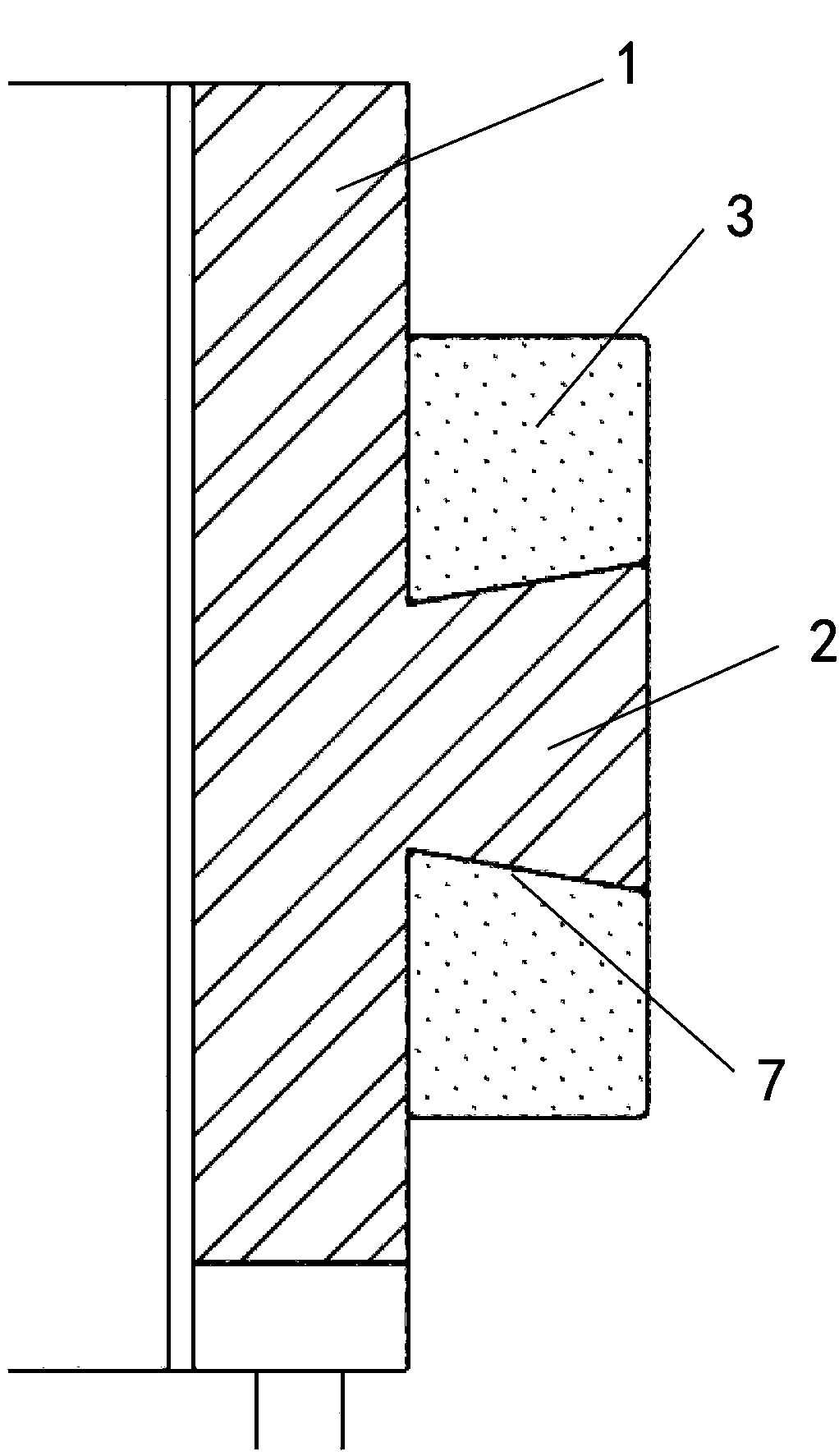

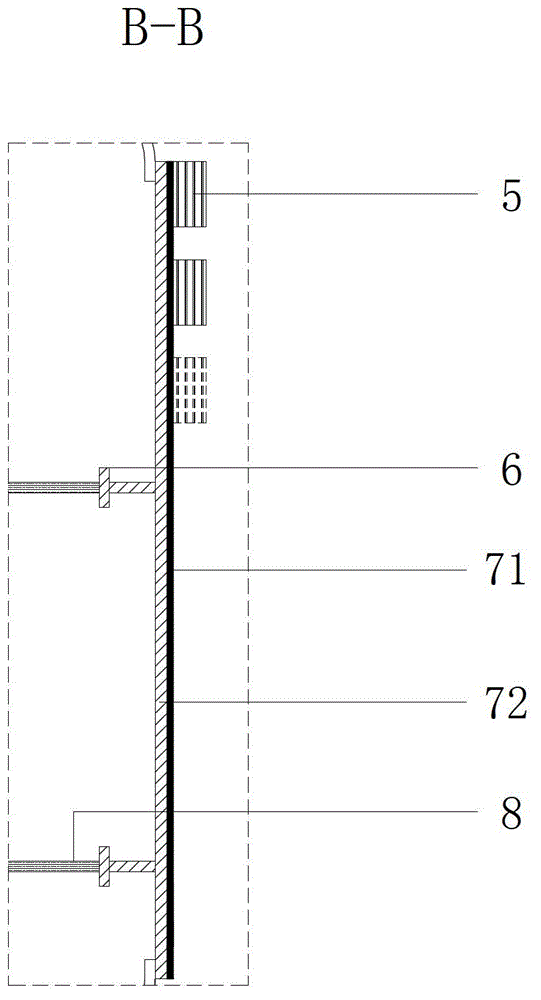

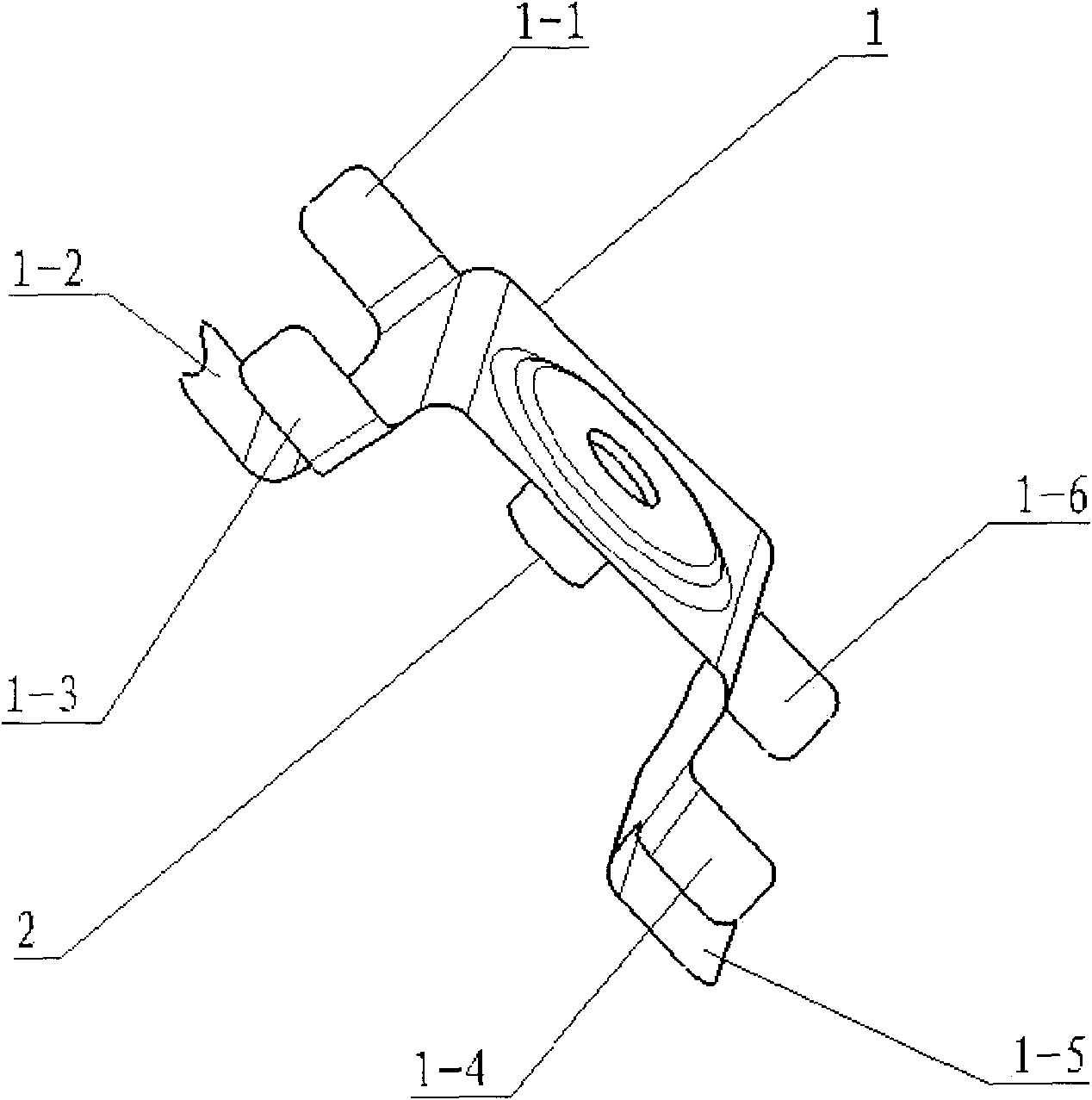

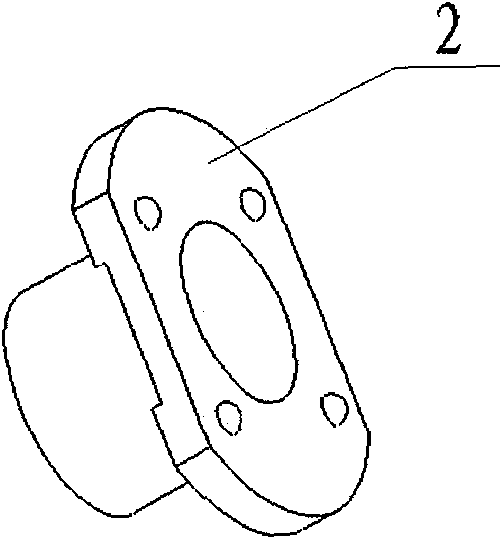

Miniature tilt-shift type optical anti-vibration voice coil motor structure facilitating production and assembling method

A miniature tilt-shift type optical anti-vibration voice coil motor structure facilitating production comprises a base, a shell, a lens carrier, three or more magnets, an elastic material, a coil carrier, coils and bosses, wherein the number of the coils and the number of the bosses are each equal to that of the magnets. The base and the shell are fixedly installed together, the lens carrier is installed on the coil carrier through the elastic material, the bosses are installed on the outer side of the coil carrier, each coil is wound around the corresponding boss, the magnets are fixedly installed on the lens carrier, and the magnets are arranged corresponding to the coils. Compared with previous technologies, the motor structure can be simplified effectively; meanwhile, the number of mechanical and electronic connection processes needed during production assembling can be reduced, the motor structure supports the process that the coils are directly wound around the coil carrier, mass production is facilitated, and even full automatic mass production can be achieved. Thus, compared with existing technologies, the motor structure can improve production efficiency and increase the percent of pass, reduce the number of assembling staff, reduce material cost and meanwhile enhance mechanical crashworthiness.

Owner:AP PHOTONICS SHEN ZHEN

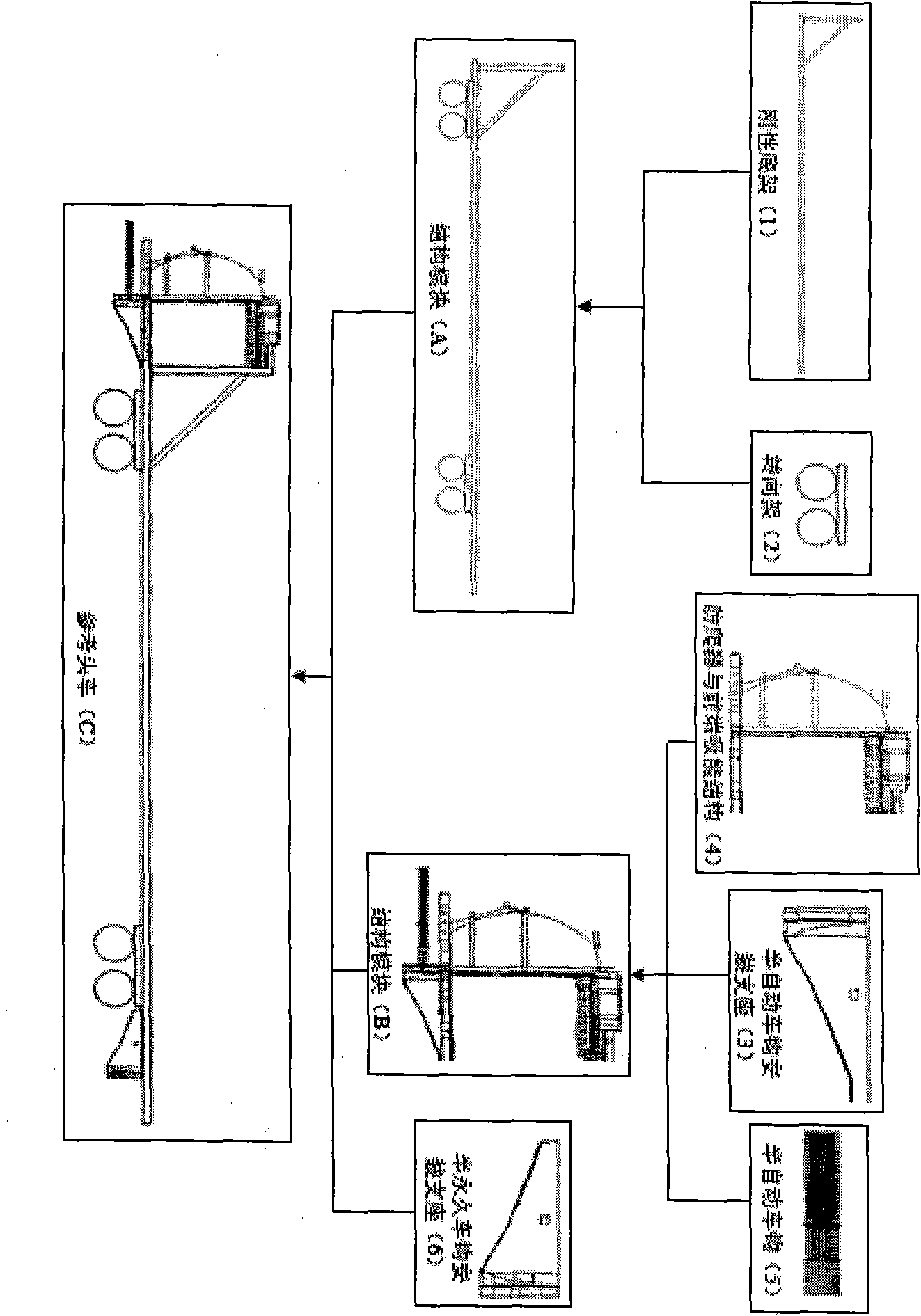

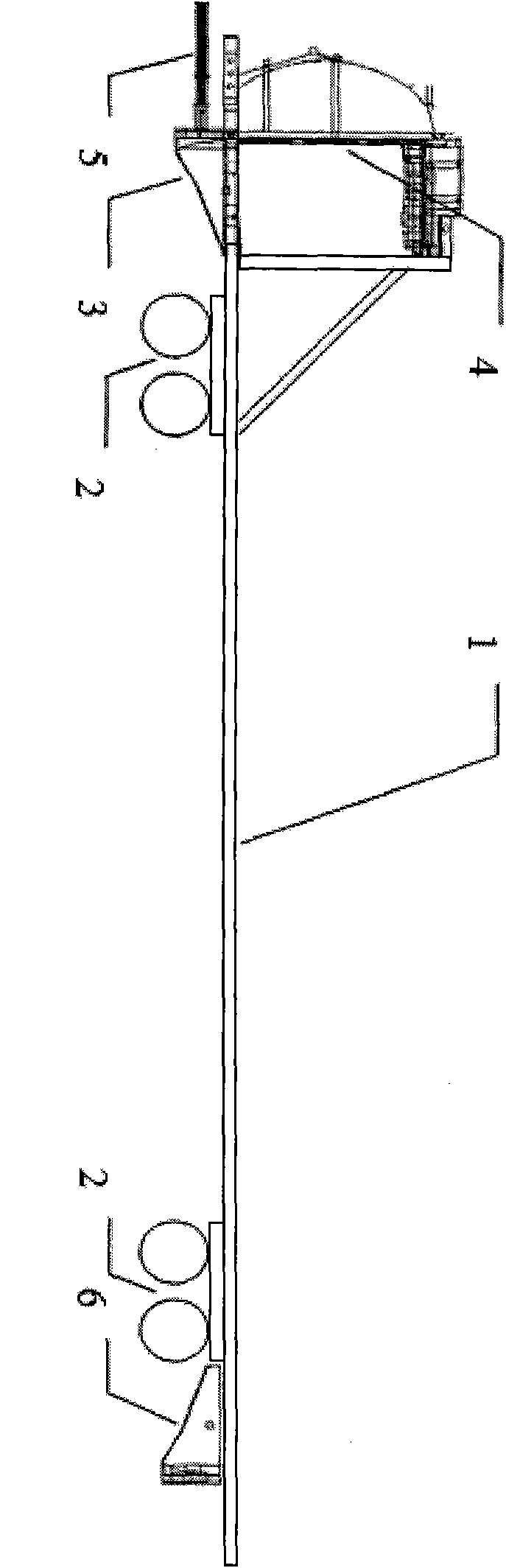

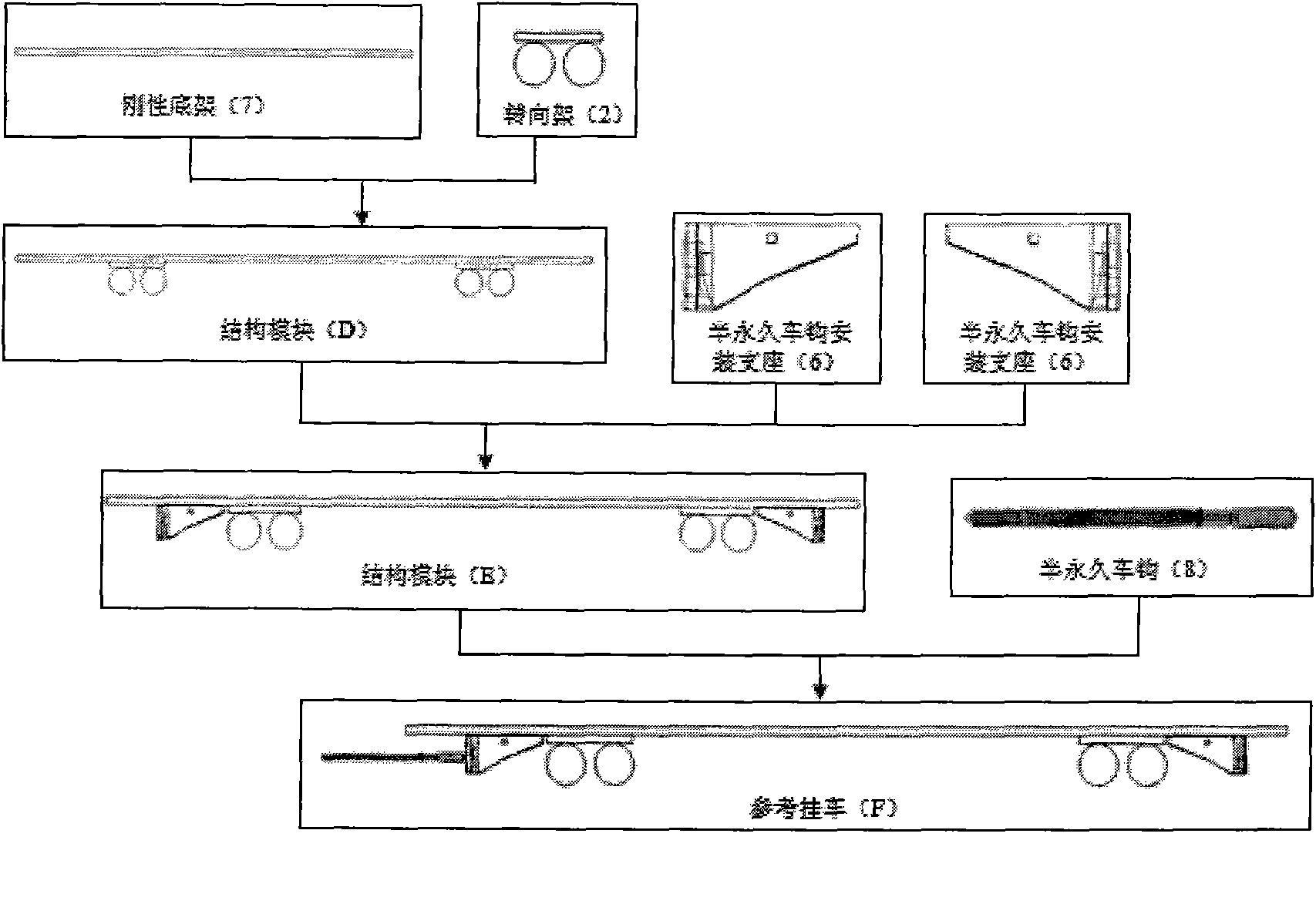

Method for assembling reference train unit collision model

InactiveCN102175414AComprehensive assessment of crashworthinessRailway vehicle testingShock testingCollision resistanceCollision test

The invention discloses a method for assembling a reference train unit collision model. The method comprises the following steps: assembling a reference train head, assembling a reference trailer, assembling a reference trailer unit, assembling a train unit and assembling a trail unit counterweight. According to the method provided by the invention, a 'reference train unit collision test model' and a 'reference train unit collision simulation model' can be acquired, thereby supplying test and analysis means to different stages of train unit collision resistance design and greatly increasing the reliability of train unit collision resistance design. In the early stage of train body collision resistance design, the reference train unit collision test and simulation are introduced, thereby greatly shortening the researching and developing period. The reference train unit collision test model has repeatability, thereby obviously lowering the cost of collision test and achieving the effect as same as the effect of a real train unit collision test. The method provided by the invention has important engineering practice significance for increasing the level of train unit collision resistance design.

Owner:肖锋

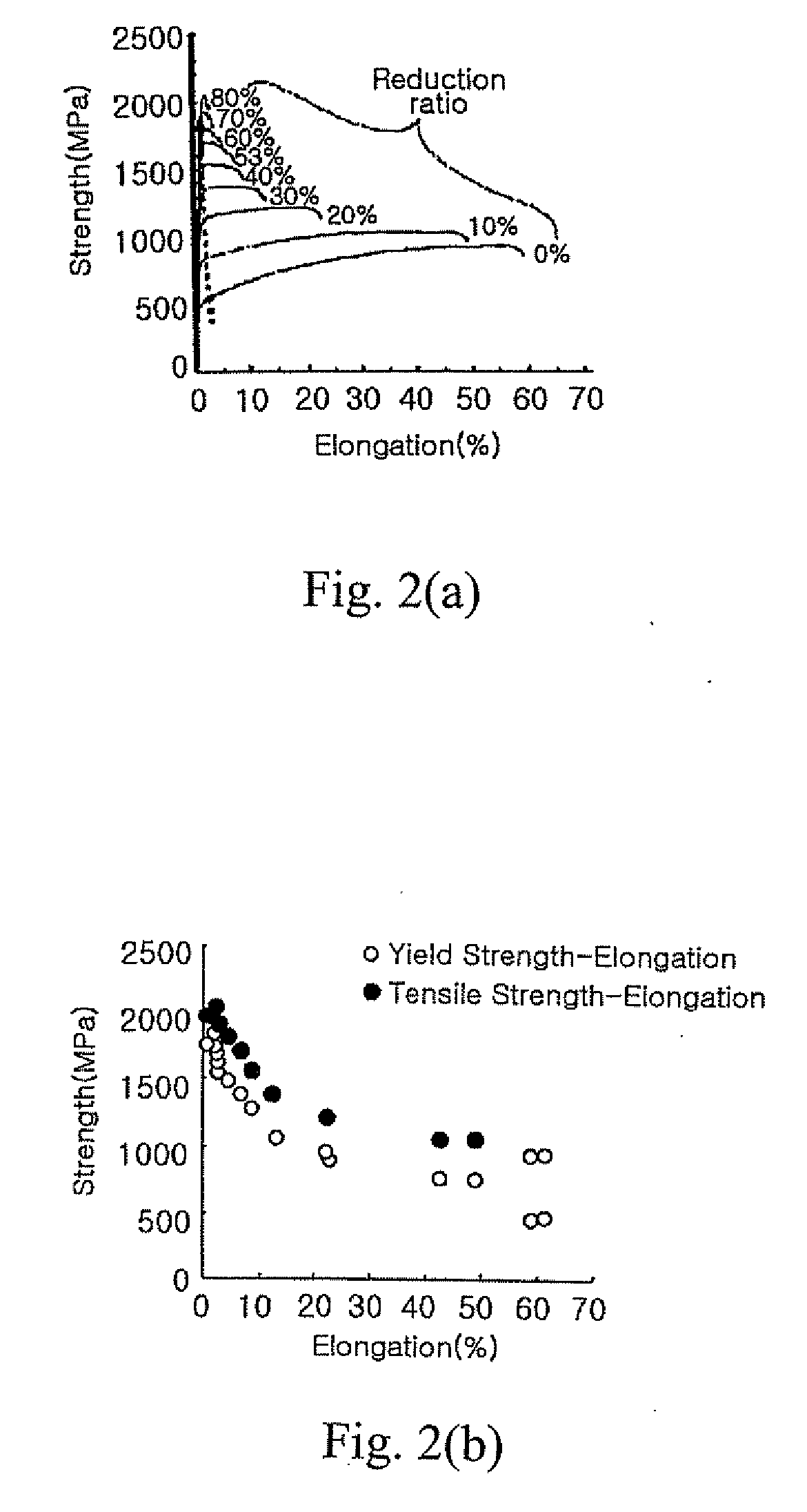

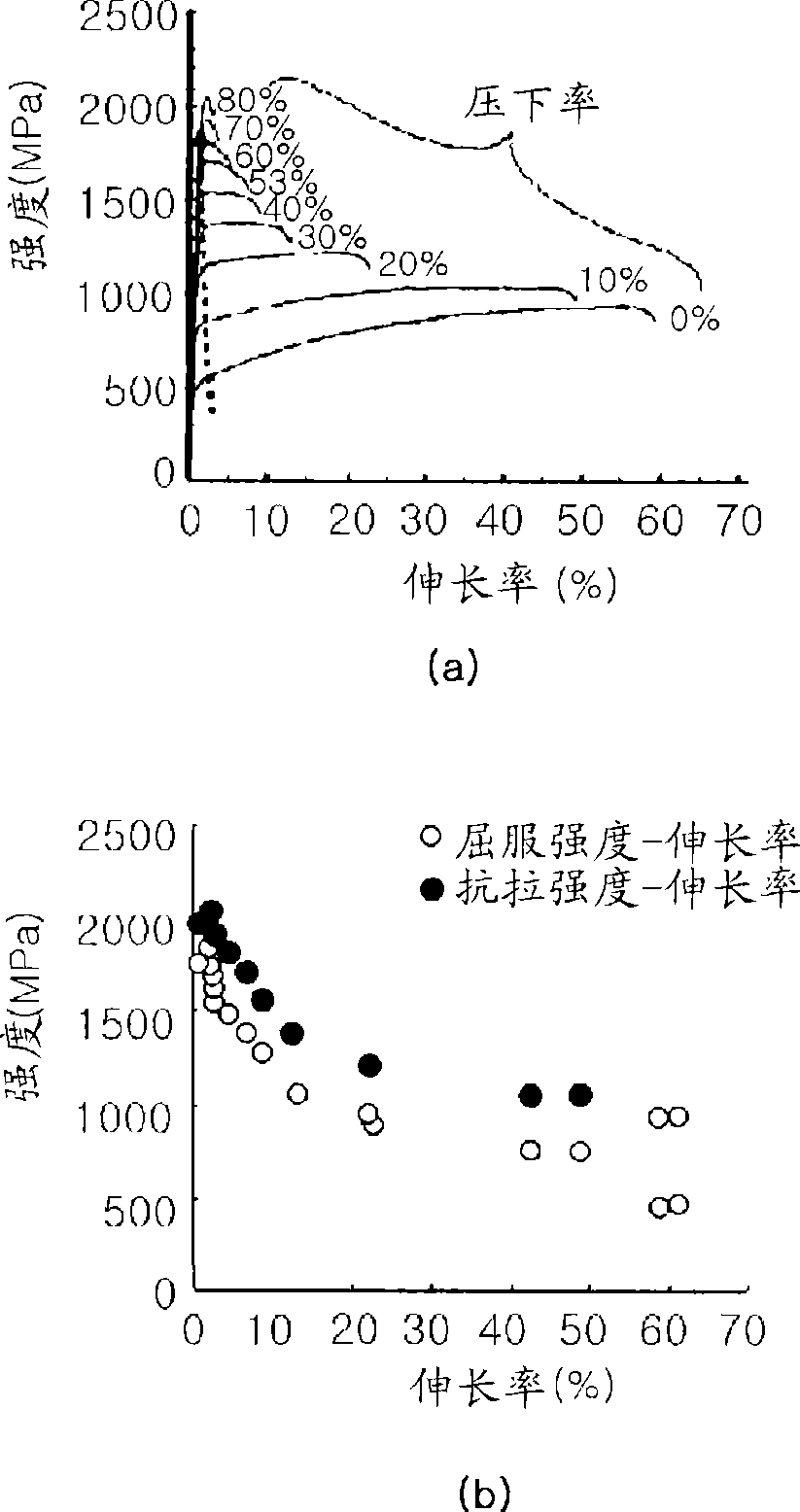

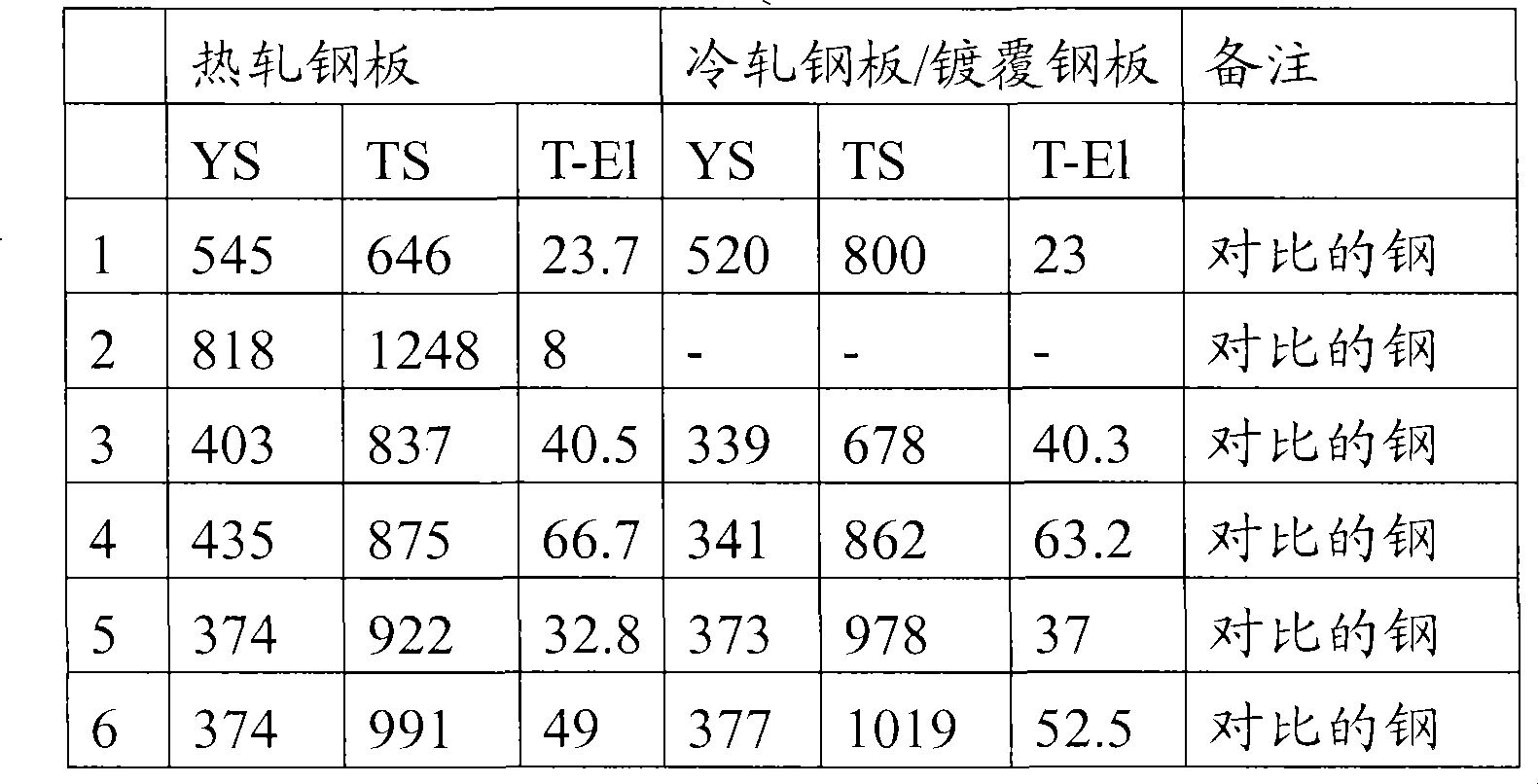

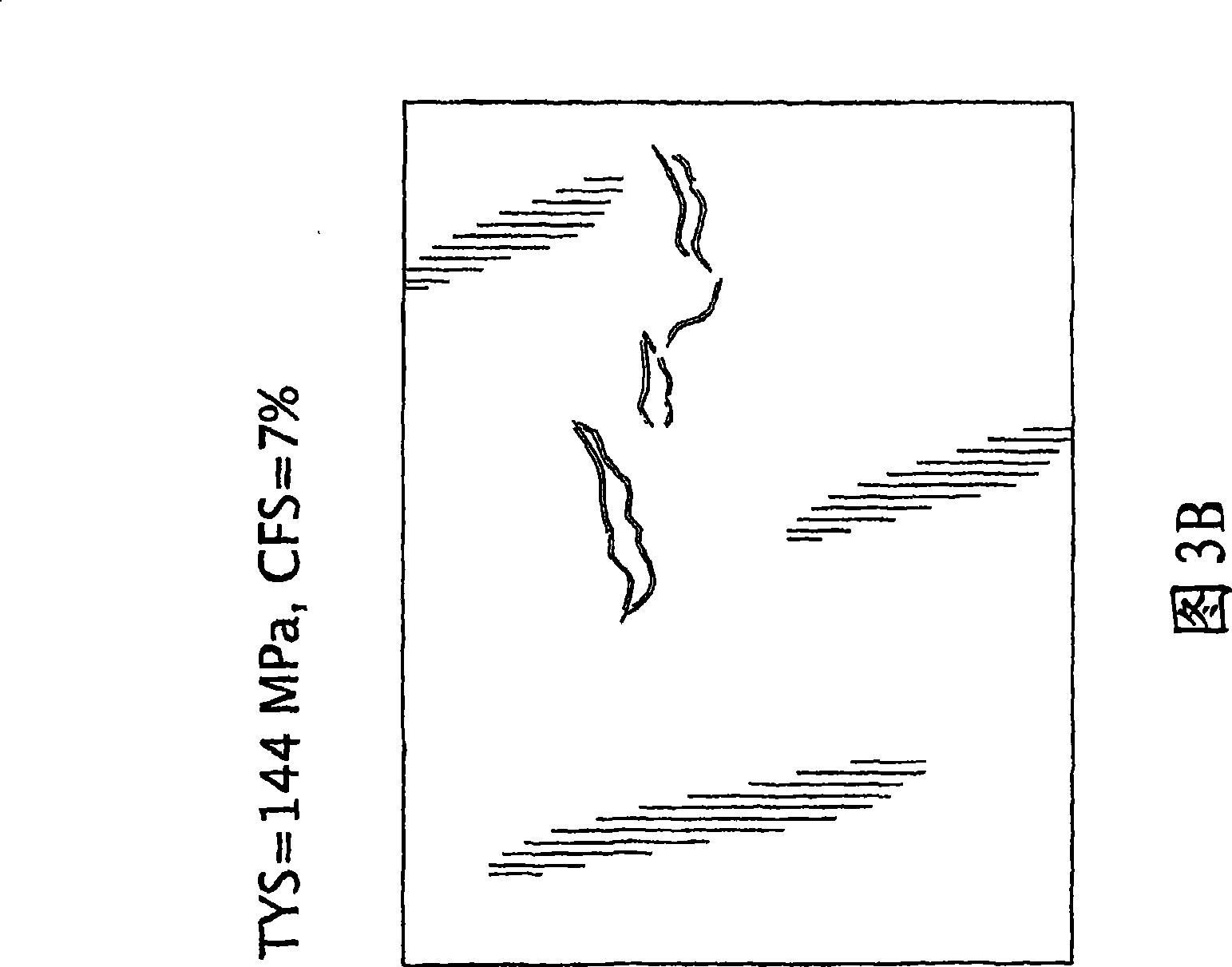

High manganese high strength steel sheets with excellent crashworthiness and method for manufacturing of it

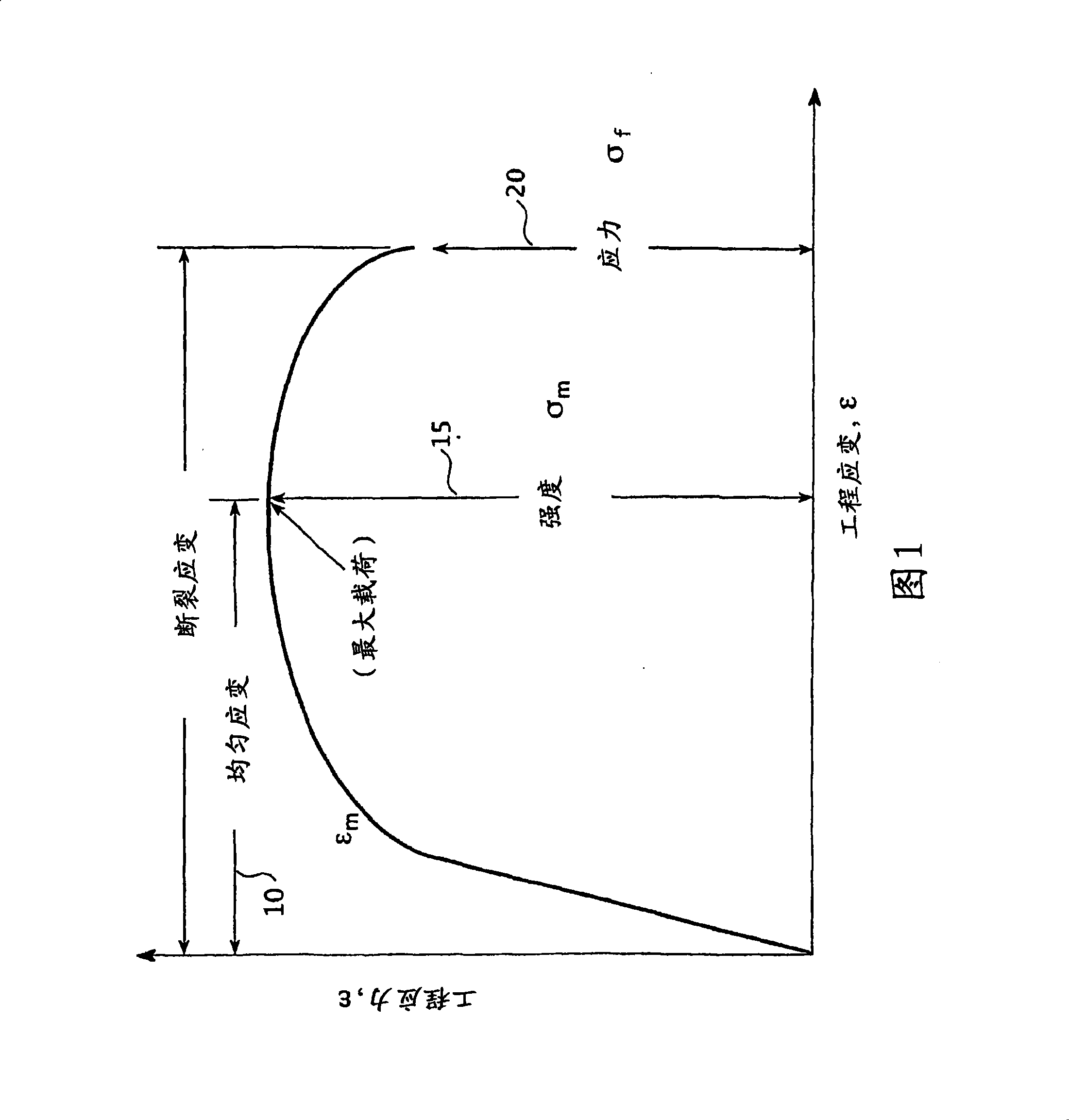

InactiveUS20090074605A1High elongationImprove impact absorption performanceMetal rolling arrangementsNiobiumManganese

There are provided a high-workability high strength steel sheet with excellent workability due to the high elongation and excellent crashworthiness due to the high yield strength, and a method for manufacturing of it. The high manganese steel sheet includes, by weight: carbon (C): 0.2 to 1.5%, manganese (Mn): 10 to 25%, aluminum (Al): 0.01 to 3.0%, phosphorus (P) 0.03% or less, sulfur (S): 0.03% or less, nitrogen (N): 0.040% or less, at least one selected from the group consisting of silicon (Si): 0.02 to 2.5%, titanium (Ti): 0.01 to 0.10% and niobium (Nb): 0.01 to 0.10%, and the balance of Fe and other inevitable impurities. The high manganese steel sheet may be a hot-rolled steel sheet, a cold-rolled steel sheet, or a plated steel sheet, and is suitable for elaborate internal sheets as well as structural members of a car body since it has press workability due to the high elongation and high strain hardening index. Also, the high manganese steel sheet may be used for parts such as a front side member of an automobile since, among its characteristics, the steel sheet has an excellent impact absorbing ability.

Owner:POHANG IRON & STEEL CO LTD

High manganese high strength steel sheets with excellent crashworthiness, and method for manufacturing of it

Owner:POHANG IRON & STEEL CO LTD

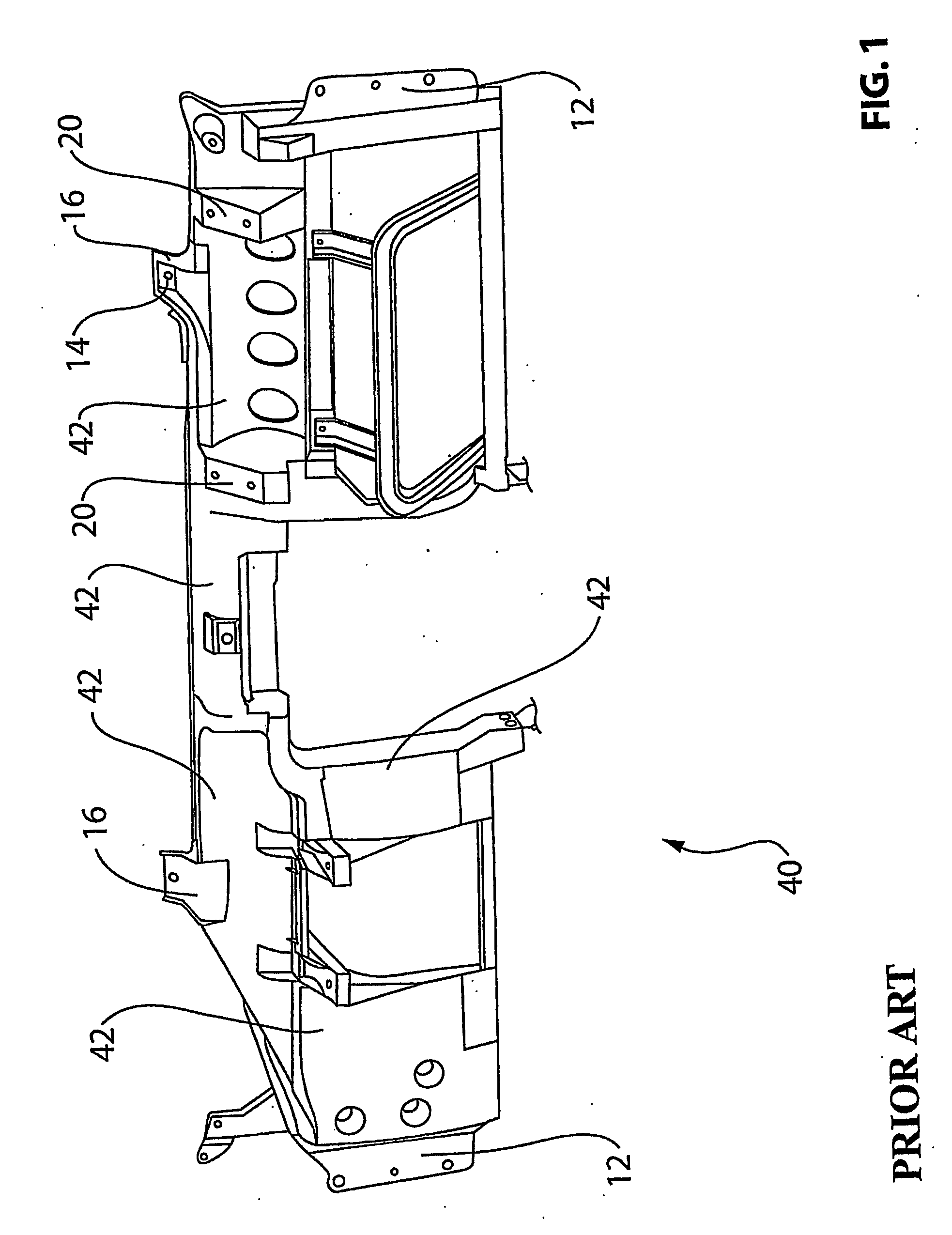

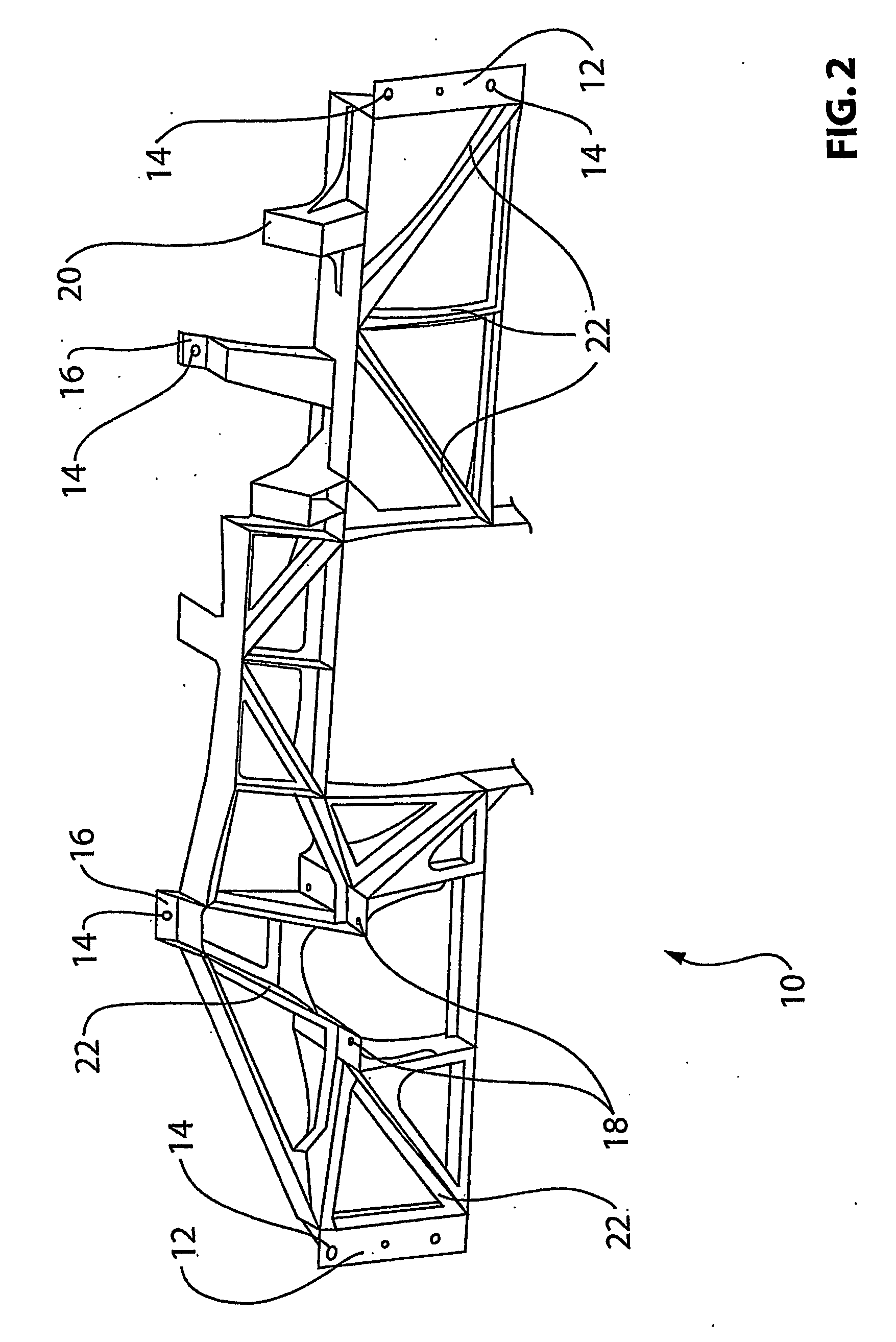

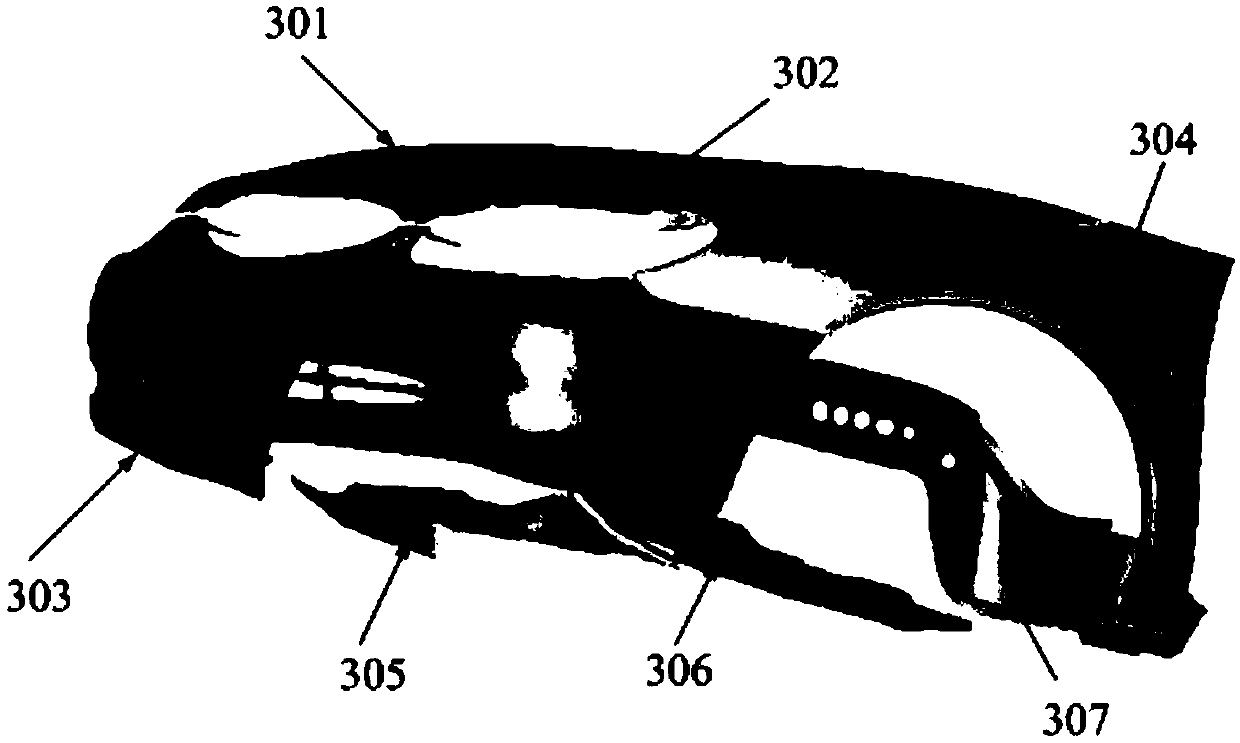

Instrument panel rib structure

A vehicle instrument panel support structure is provided having fixing and mounting surfaces linked together by ribs in an open space frame structure. The ribs are sized, shaped and positioned to create critical load paths and eliminate the outer skin of the instrument panel support structure. Magnesium alloy material is only placed where it is needed for structure and function. The functionality of the vehicle instrument panel support structure is maintained as are the stiffness and crashworthiness when compared to the traditional design, but the weight of the instrument panel structure and the projected area are reduced. A method of designing an instrument panel support structure using a computer aided engineering platform is also provided.

Owner:SIMONDS GLEN +1

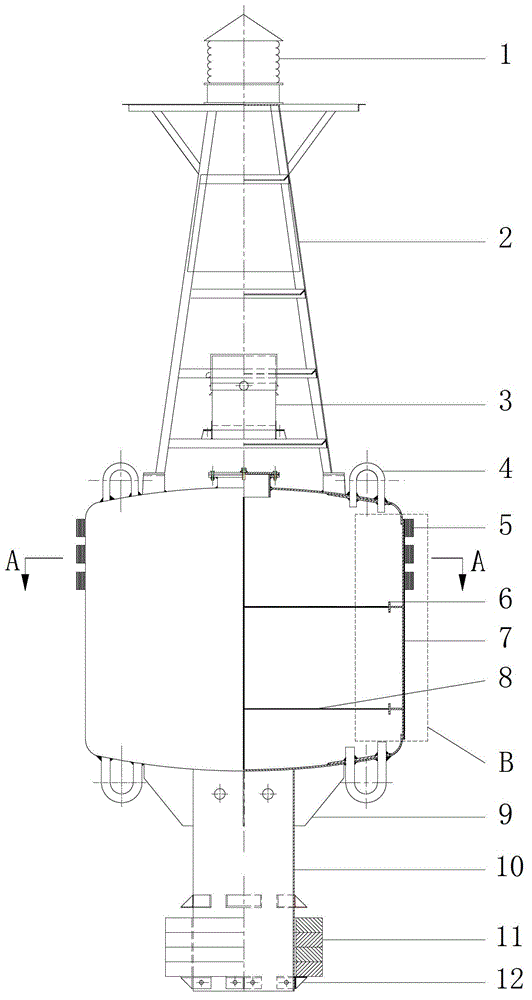

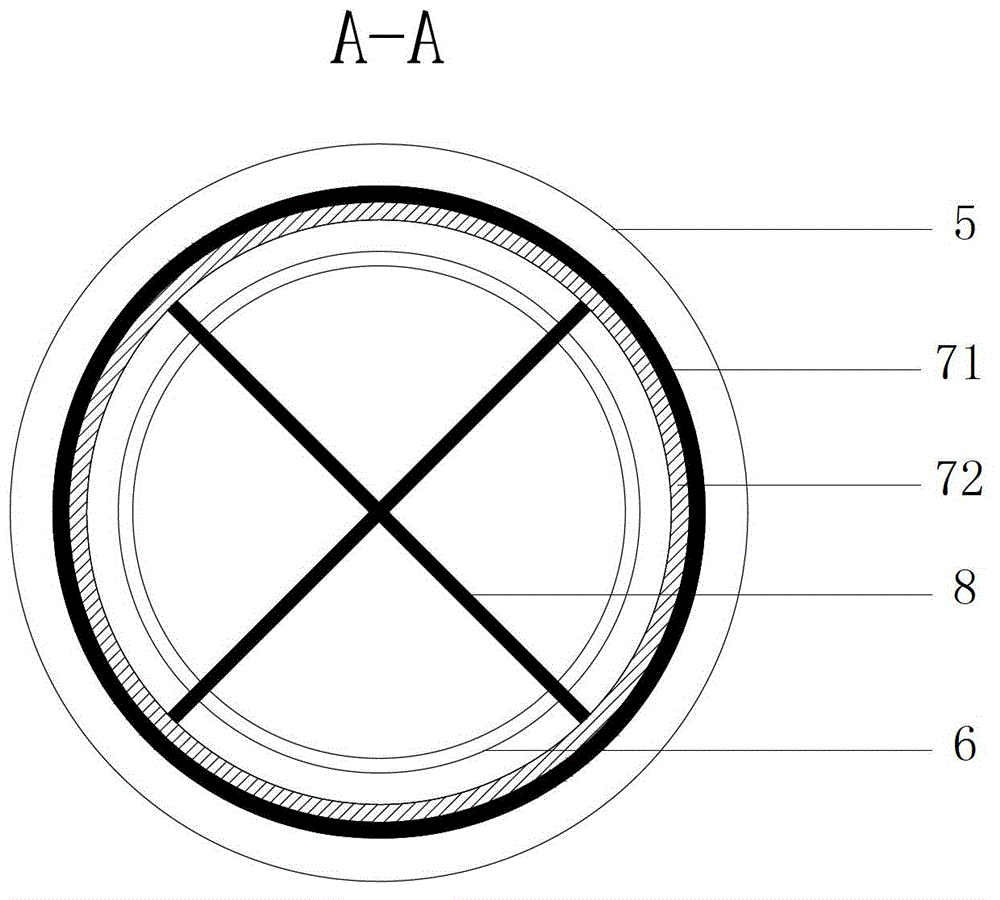

Crashworthy anti-sinking multi-cabin buoy

InactiveCN103332268AImprove anti-collision and anti-sinking performanceWork lessWaterborne vesselsBuoysGlass fiberBuoy

The invention discloses a crashworthy anti-sinking multi-cabin buoy which comprises a buoy body. A lamp bracket is fixedly arranged on the upper portion of the buoy body and connected with a lamp, a tail pipe is fixedly arranged on the lower portion and connected with a balance weight iron ring, the buoy body is of a hollow structure, a clapboard is arranged in the buoy body and divides an inner cavity of the buoy body into at least two sealed cabins, a rubber retainer is fixedly installed above the water line of the buoy body in a sleeved mode, and a shell of the buoy body comprises a steel plate layer and a glass fiber reinforced plastic layer from inside to outside. The glass fiber reinforced plastic layer is adopted for being combined with the steel plate layer, material is saved, self weight is reduced, maintenance is convenient, and operating cost is reduced. The rubber retainer improves crashworthiness of the buoy and prolongs service life of the buoy. Due to the subdivision design inside the buoy body, buoy sinking is prevented, other auxiliary electronic devices of the buoy can be also effectively protected, ship collision losses are reduced, and working reliability of the buoy is effectively enhanced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heat-hardened steel with excellent crashworthiness and method for manufacturing heat-hardenable parts using same

InactiveUS20140083574A1High strengthImprove crashworthinessHot-dipping/immersion processesFurnace typesManganeseHardened steel

Disclosed are heat-hardened steel with excellent crashworthiness and a method for manufacturing heat-hardenable parts using the same. The heat-hardened steel according to the invention comprises, based on wt %; C: 0.12-0.8%; Cr: 0.01-2%; Mo: 0.2% or less; B: 0.0005-0.08%; Ca: 0.01 or less; Sb: 1.0% or less; and Ti and / or Nb: 0.2%; and the reminder being Fe and inevitable impurities. In addition, the heat-treatment hardening steel satisfies anyone of following conditions i)-iv), wherein condition i) comprises Si: 0.5-3%; Mn: 1-10% and Al: 0.05-2%; condition ii) comprises Si: 1% or less; Mn: 0.5-5%; Al: 0.1-2.5%; and Ni: 0.01-8%; condition iii) comprises Si: 0.5-3%; Mn: 1-10%; Al: 0.1% or less; and Ni: 0.01-8%; and condition iv) comprises Si: 0.5-3%; Mn: 1-10%; Al: 0.1-2.5%; and Ni: 0.01-8%.

Owner:HYUNDAE STEEL CO LTD

A high crashworthiness al-si-mg alloy and methods for producing automotive casting

The present invention provides a casting having increased crashworthiness including an an aluminum alloy of about 6.0 wt % to about 8.0 wt % Si; about 0.12 wt % to about 0.25 wt % Mg; less than or equal to about 0.35 wt % Cu; less than or equal to about 4.0 wt % Zn; less than or equal to about 0.6 wt % Mn; and less than or equal to about 0.15 wt % Fe, wherein the cast body is treated to a T5 or T6 temper and has a tensile strength ranging from 100 MPa to 180 MPa and has a critical fracture strain greater than 10%. The present invention further provides a method of forming a casting having increased crashworthiness.

Owner:汽车铸造技术公司

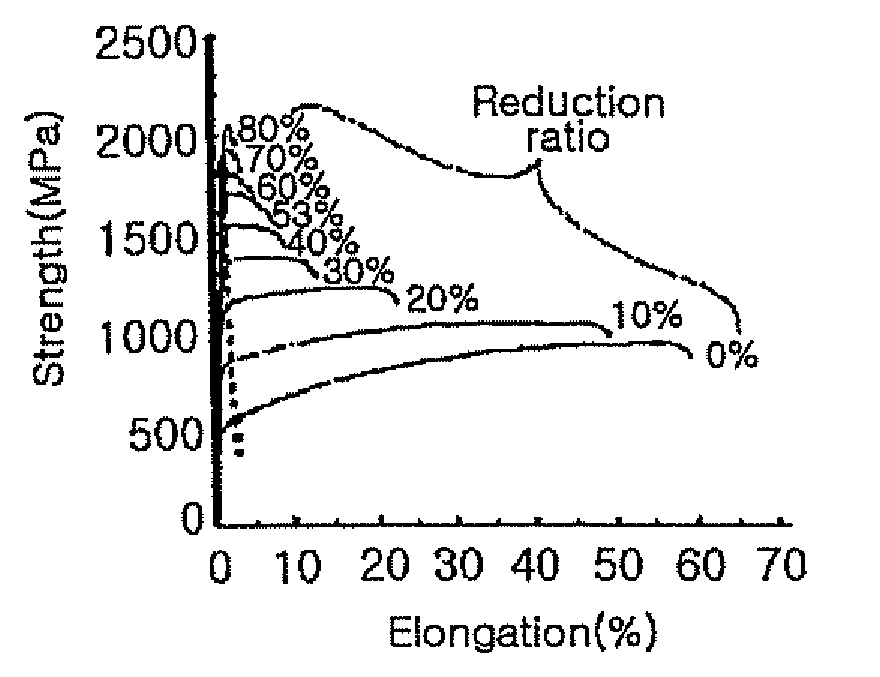

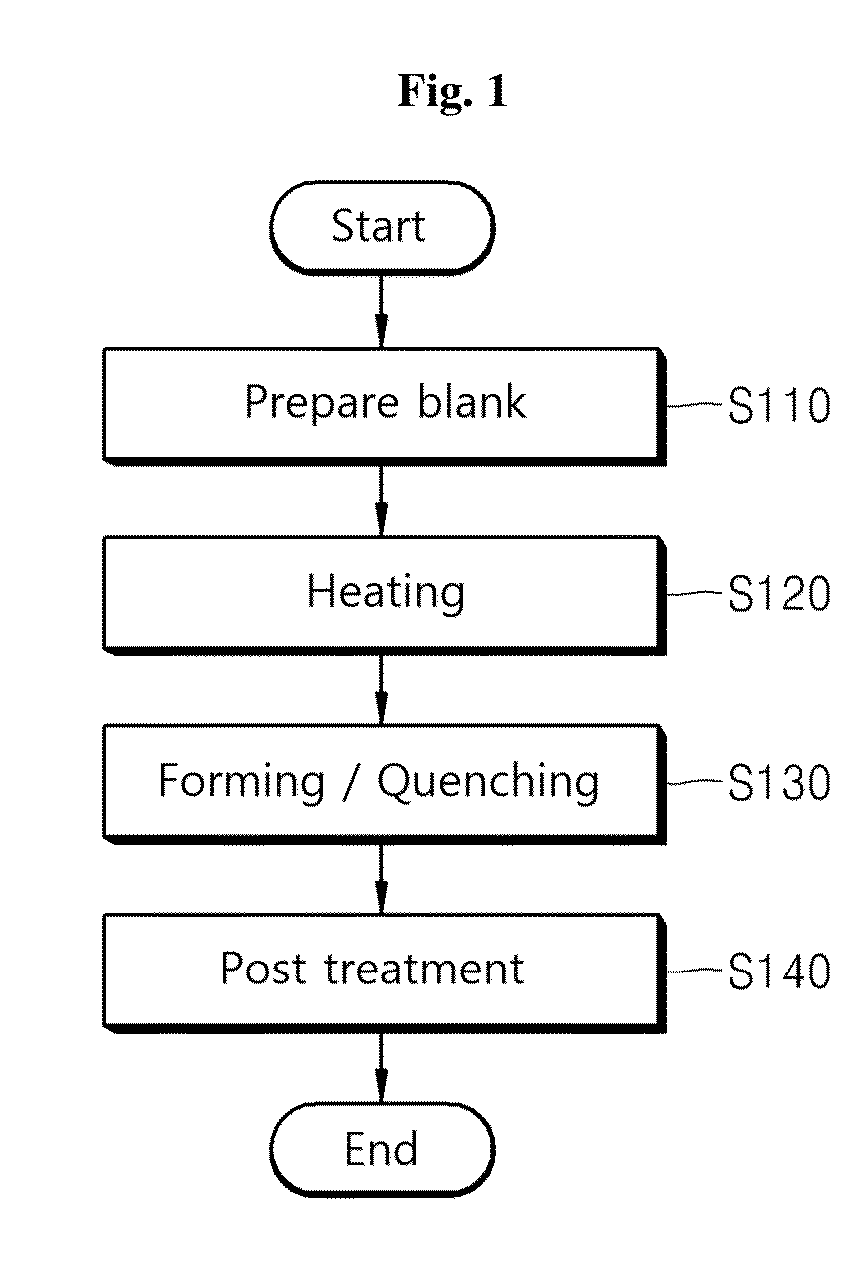

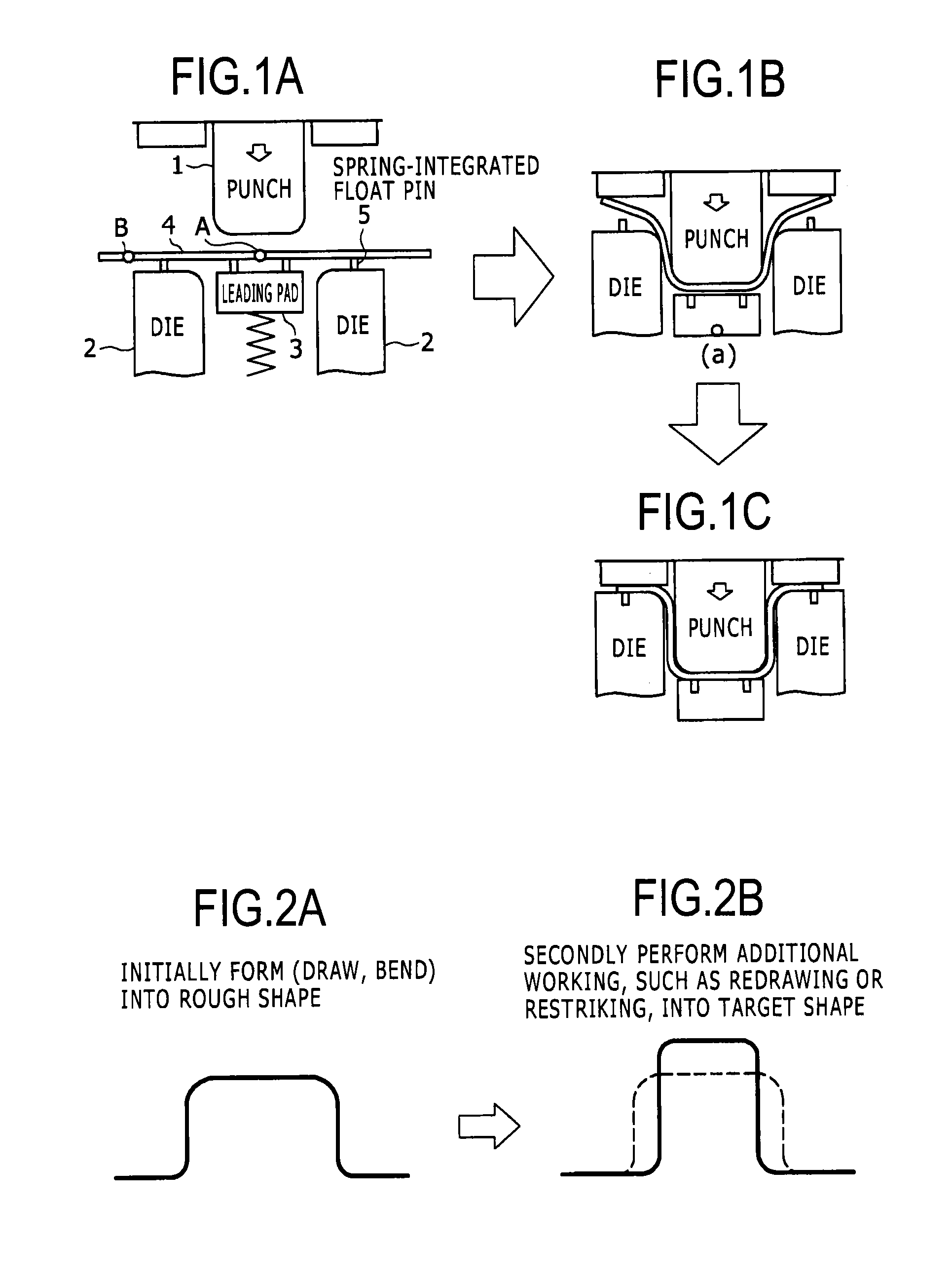

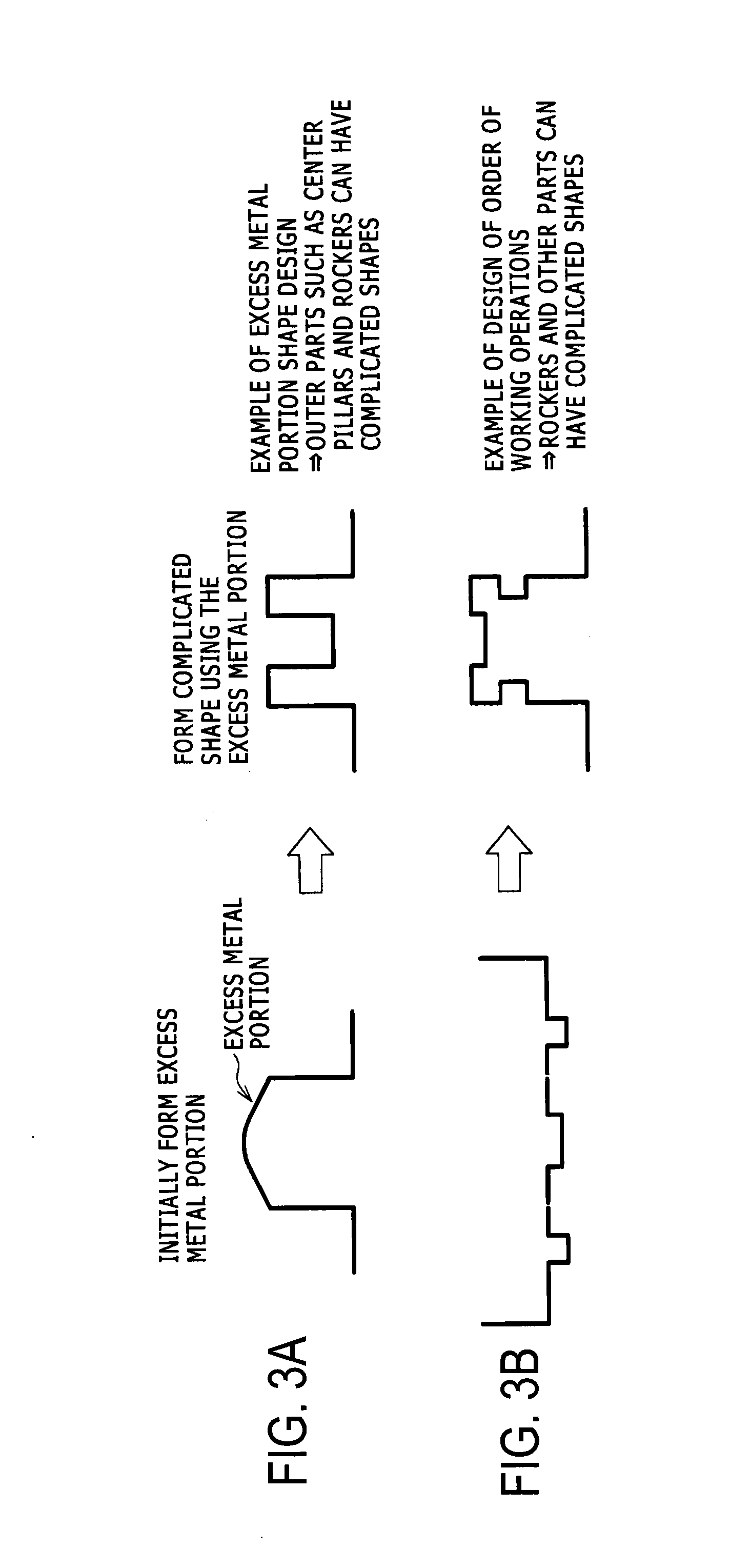

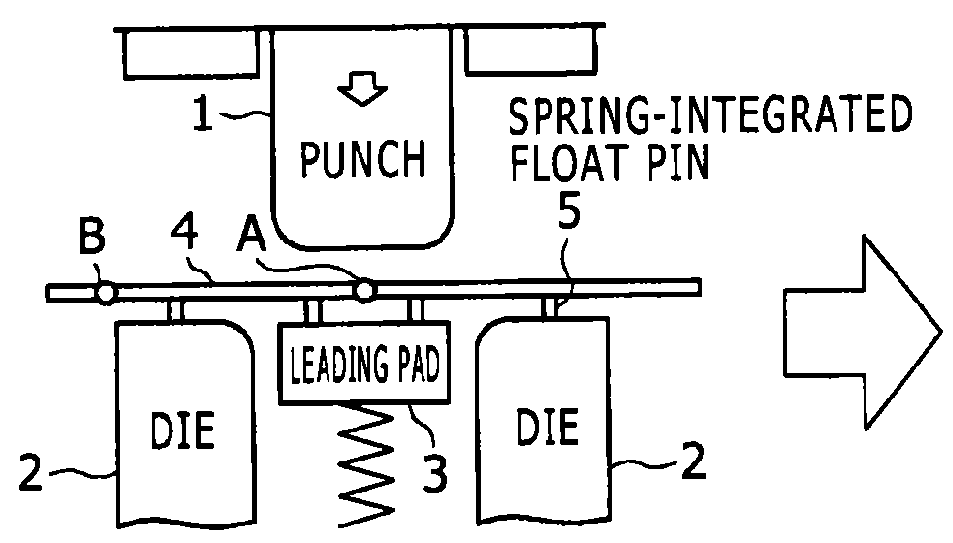

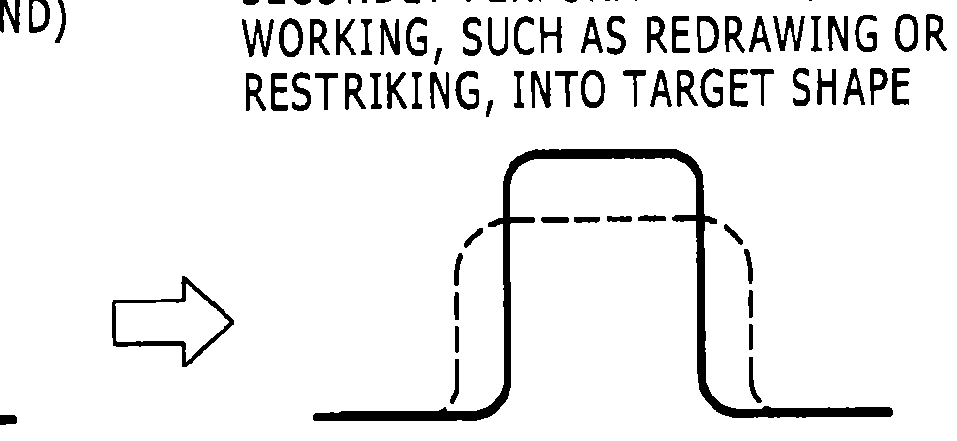

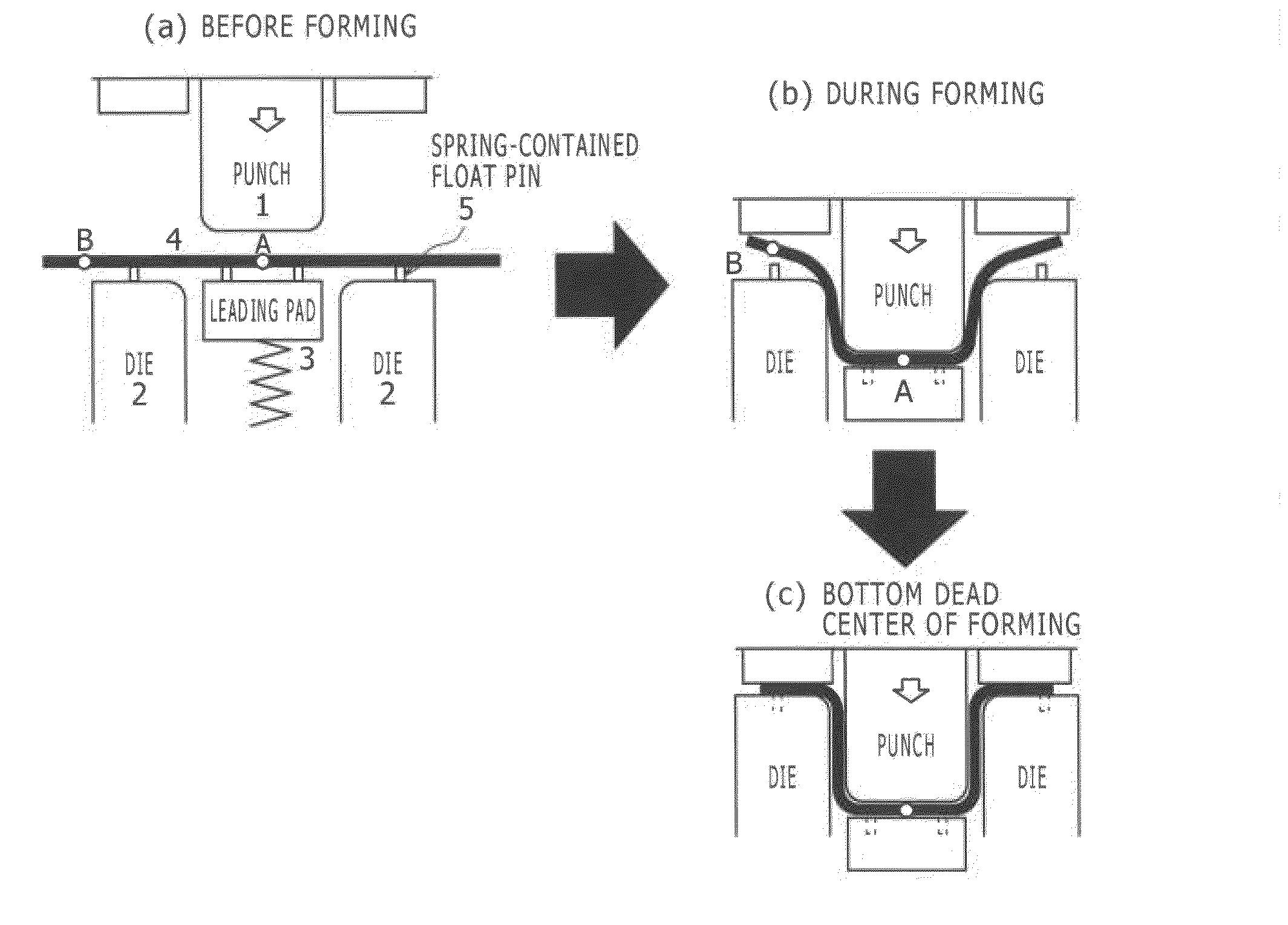

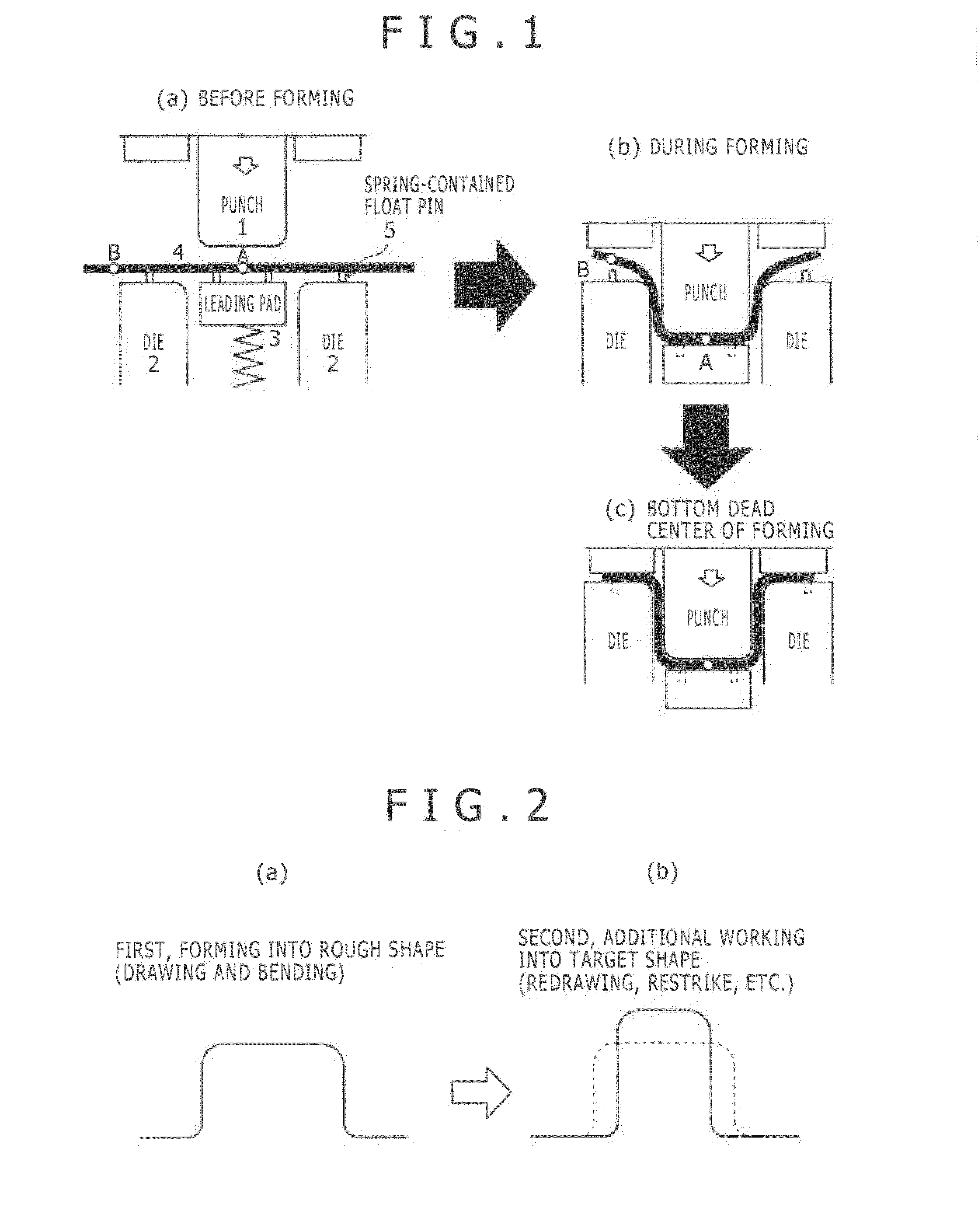

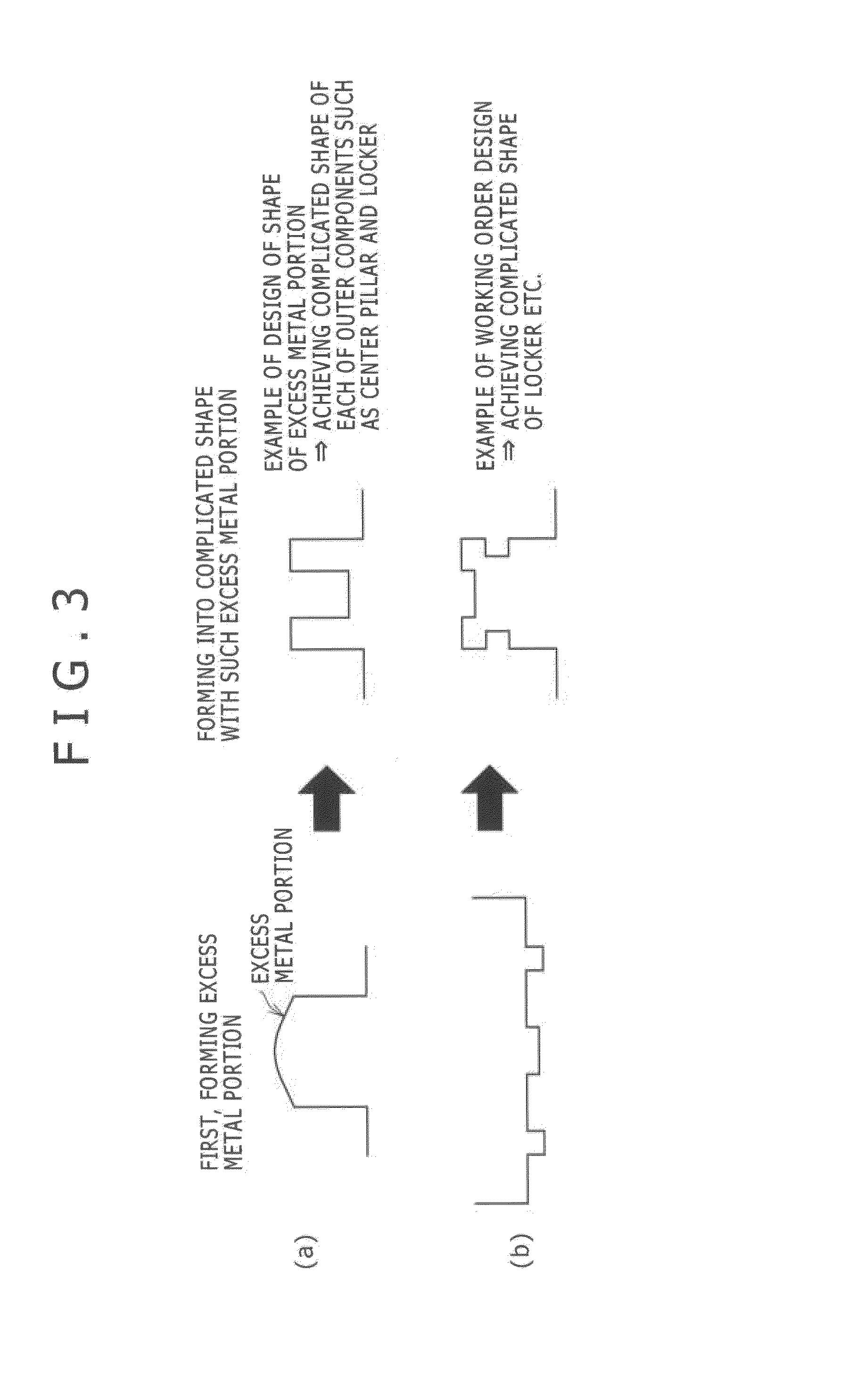

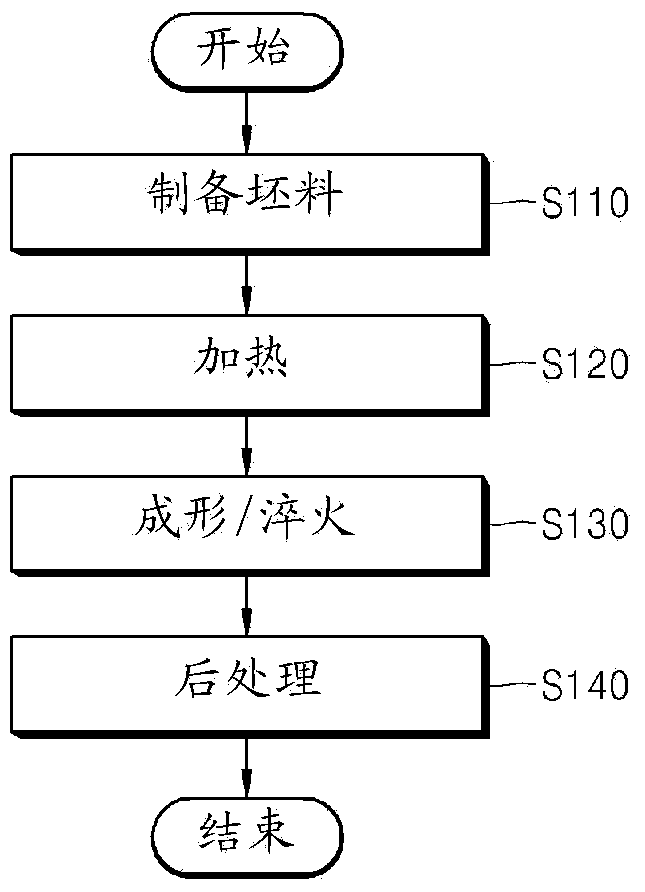

Manufacturing method for hot press formed steel member

ActiveUS20150354035A1High strengthExcellent strength-ductility balanceHeat treatment process controlVehicle componentsChemical compositionHigh intensity

Provided is a method for manufacturing a hot press formed steel member that has high strengths, an excellent balance between strength and ductility, and good deformation properties upon crush on collision (crashworthiness). The manufacturing method is highly efficient and allows a high degree of freedom with respect to the shape to be formed. The method manufactures a steel member by heating a steel sheet having a specific chemical composition and subjecting the steel sheet to at least one time of hot press forming. In the method, the heating temperature is equal to or higher than the Ac3 transformation temperature, and a starting temperature of the hot press forming is in the range from the heating temperature to martensite start (Ms) temperature. Cooling from [(Ms temperature)−150° C.] down to 80° C. is performed so that a tempering parameter (λ) specified by Expression (1) is in the range from 7100 to 8030.

Owner:KOBE STEEL LTD

Manufacturing method for hot press formed steel member

ActiveUS9359663B2High strengthExcellent strength-ductility balanceVehicle componentsMetal layered productsChemical compositionSheet steel

Owner:KOBE STEEL LTD

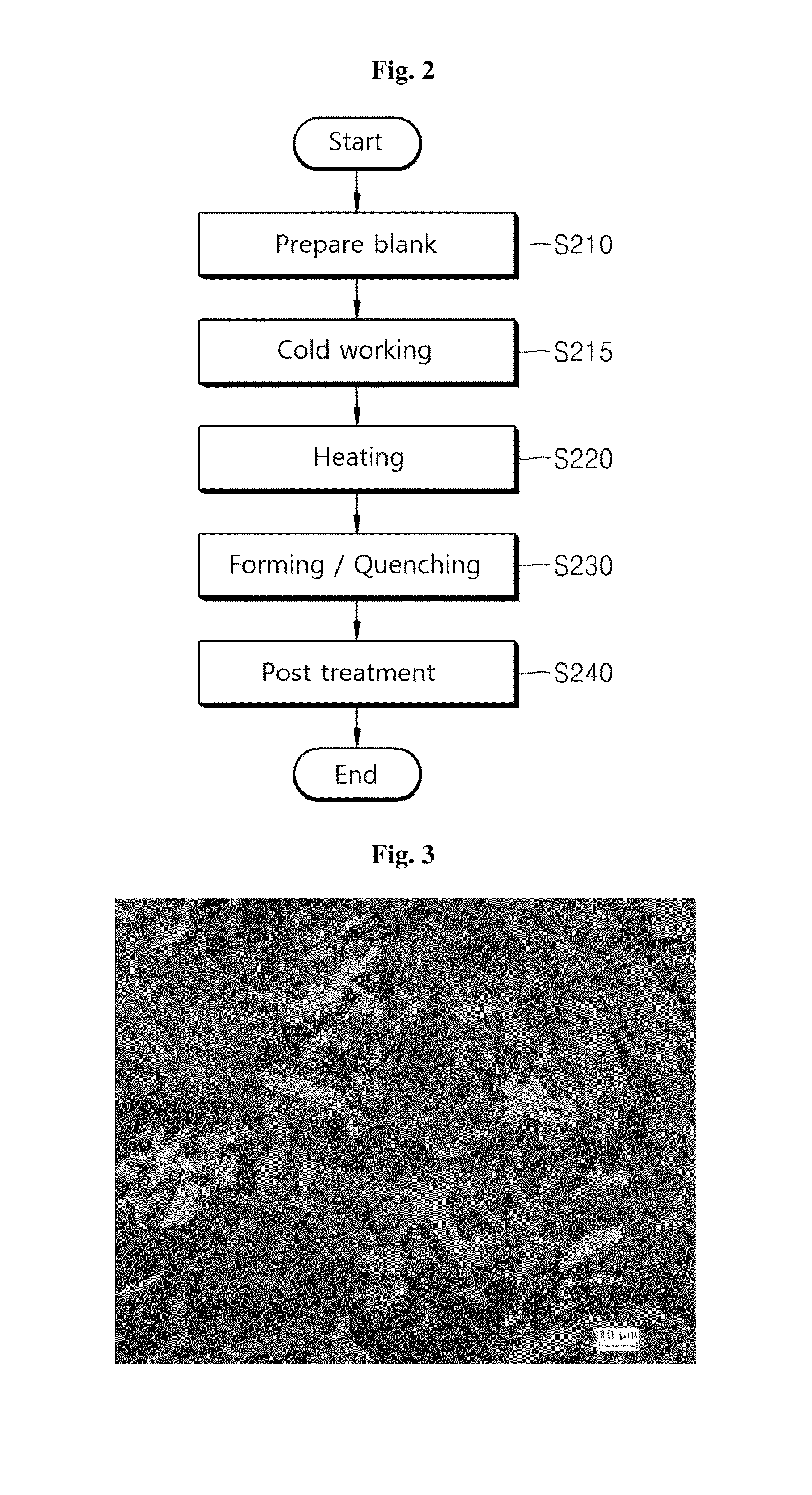

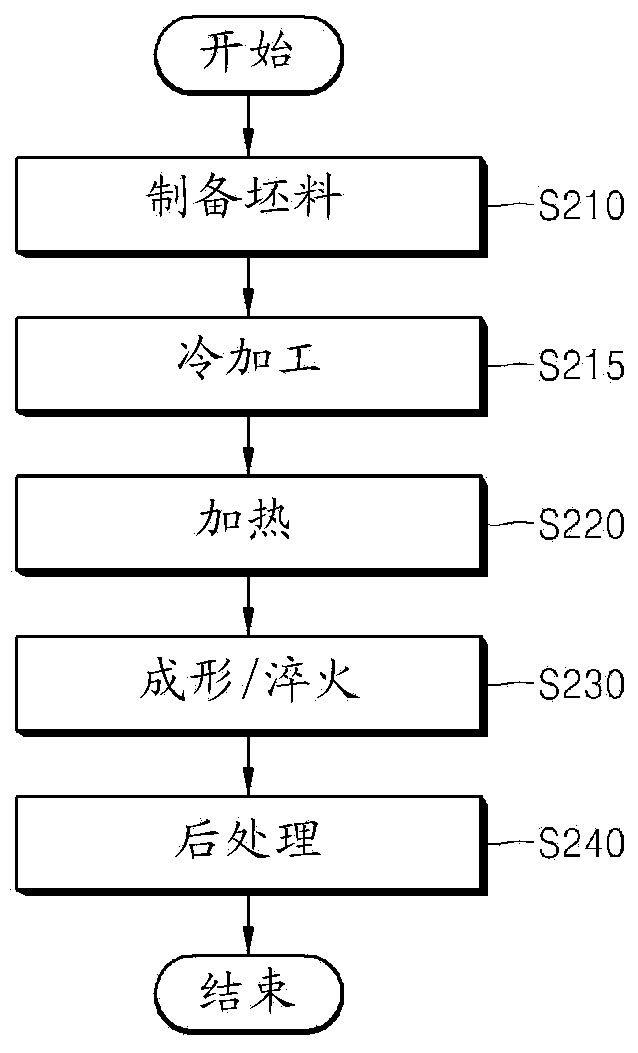

Method of manufacturing hot-press-formed steel member

ActiveUS20140144560A1High strengthImprove ductilityFurnace typesHeat treatment furnacesChemical compositionHigh intensity

To establish a method for obtaining a hot-press-formed steel member, which exhibits high strength, high tensile elongation (ductility) and high bendability, thereby having excellent deformation characteristics at the time of collision crush (crashworthiness), and which is capable of ensuring excellent delayed fracture resistance. A method for producing a hot-press-formed steel member by heating a steel sheet, which has a chemical component composition containing 0.10% (% by mass, and hereinafter the same shall apply) to 0.30% (inclusive) of C, 1.0% to 2.5% (inclusive) of Si, 1.0% to 3.0% (inclusive) of Si and Al in total and 1.5% to 3.0% (inclusive) of Mn, with the balance consisting of iron and unavoidable impurities, and hot press forming the steel sheet one or more times. The method for producing a hot-press-formed steel member is characterized in that: the heating temperature is set to not less than the Ac3 transformation point; the starting temperature of the hot pressing is set to not more than the heating temperature but not less than the Ms point; and the average cooling rate from (the Ms point−150° C. to 40° C. is set to 5° C. / s or less.

Owner:KOBE STEEL LTD

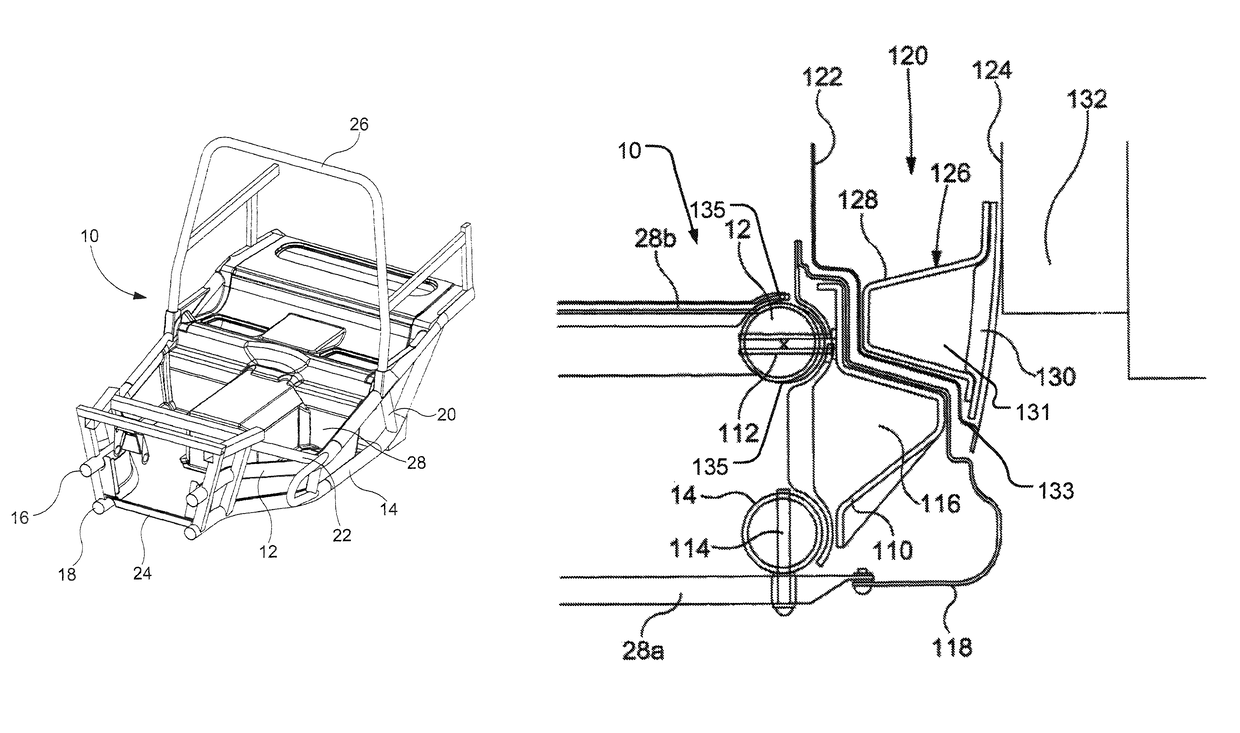

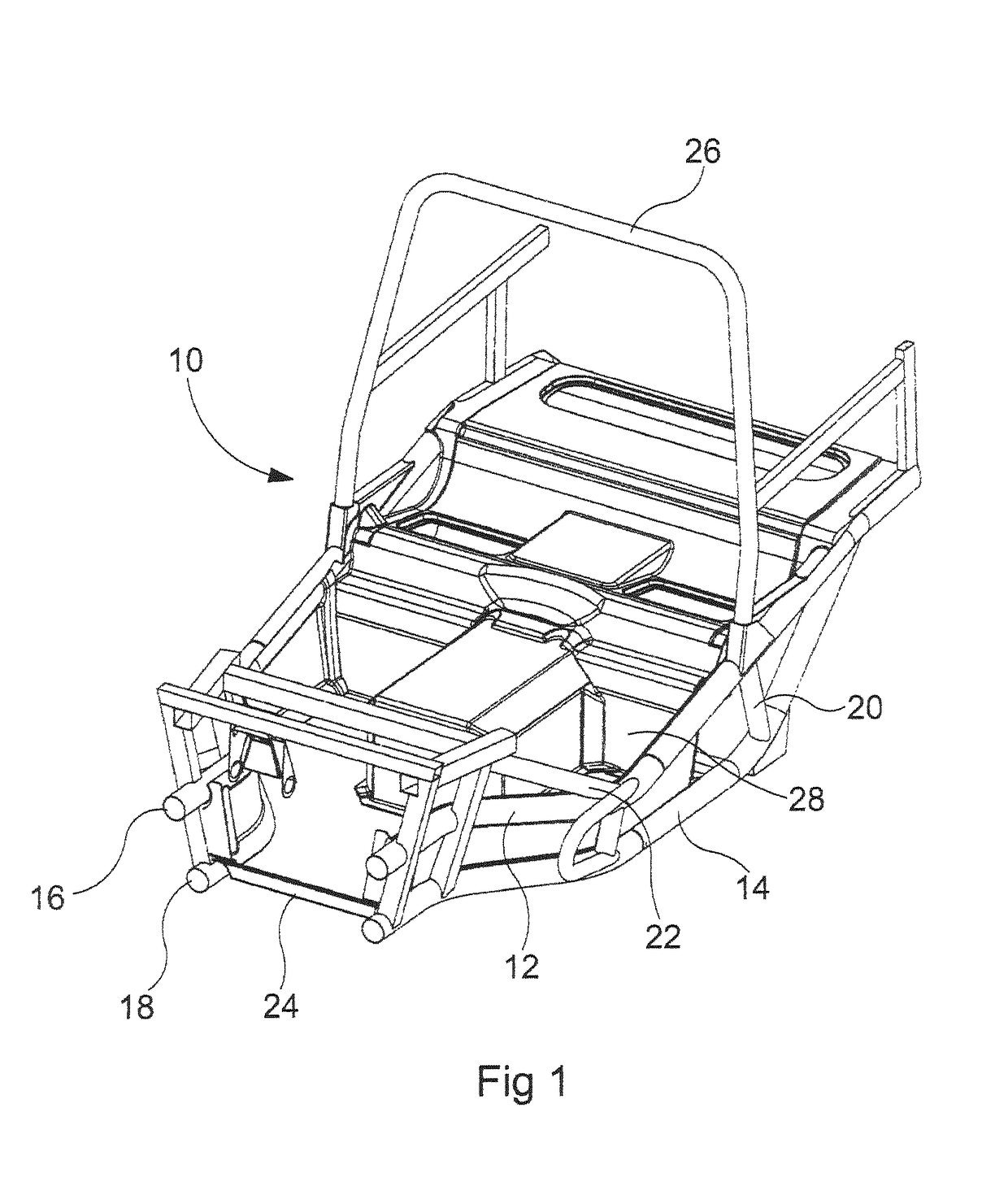

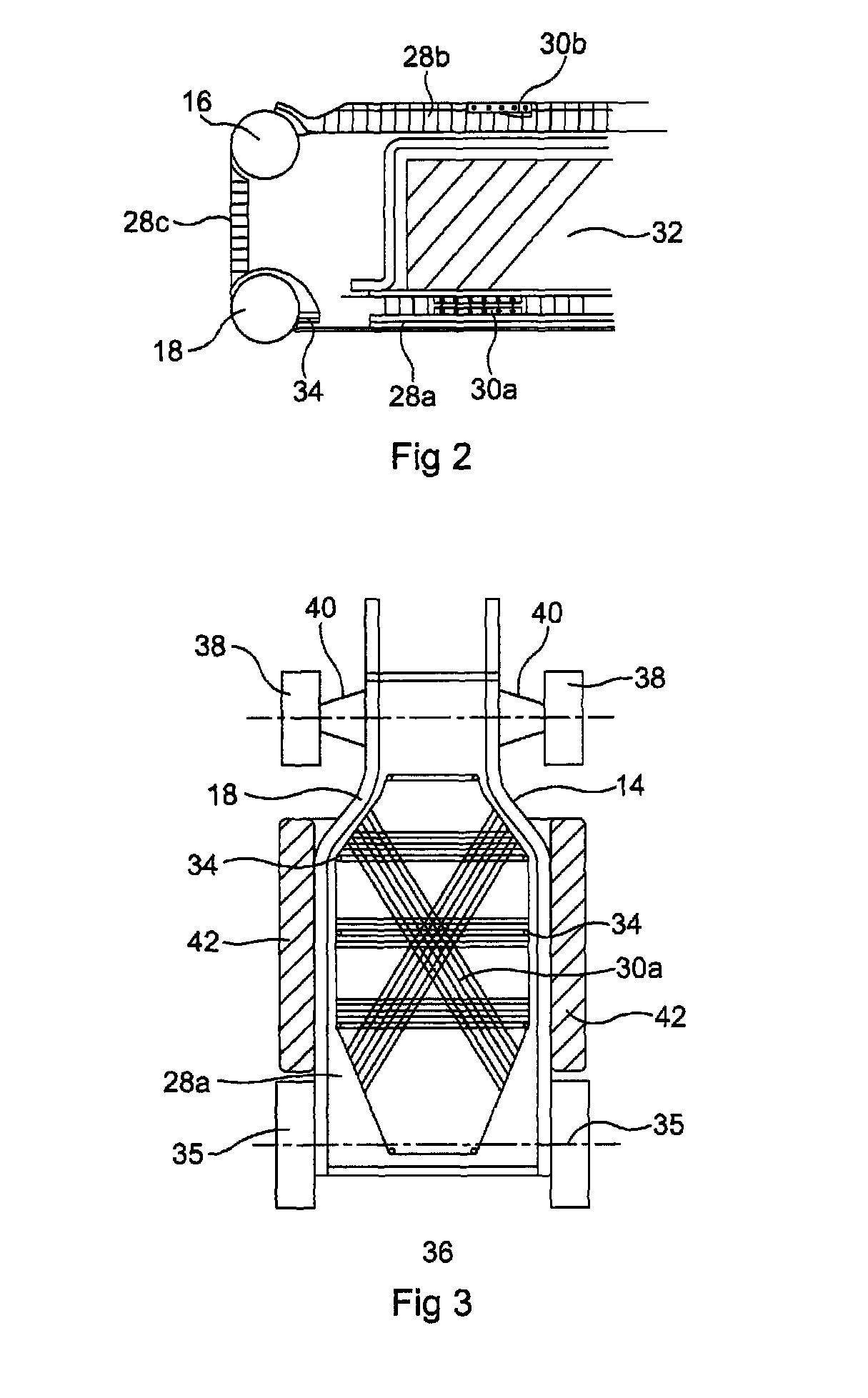

Vehicle Crashworthiness

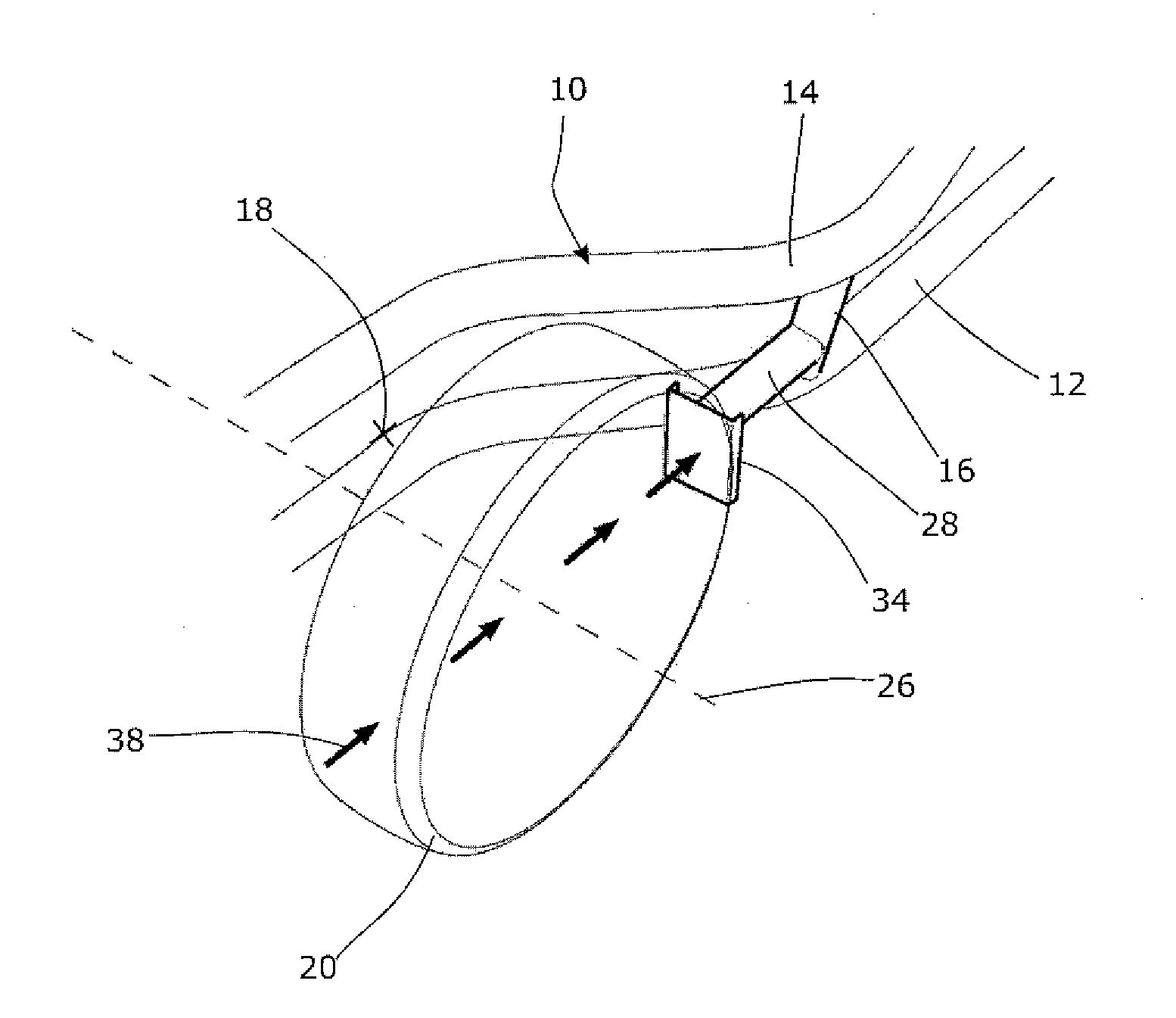

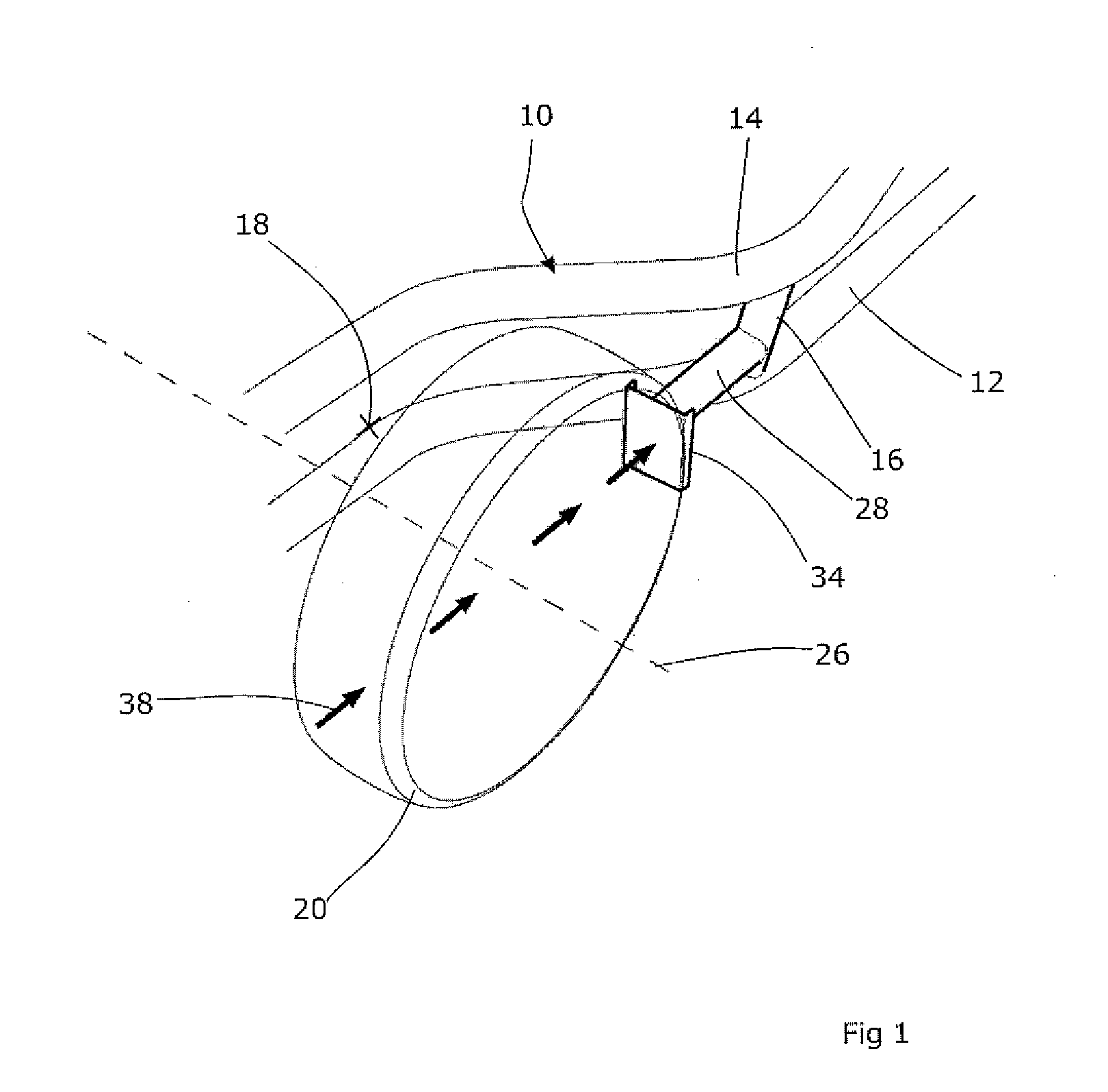

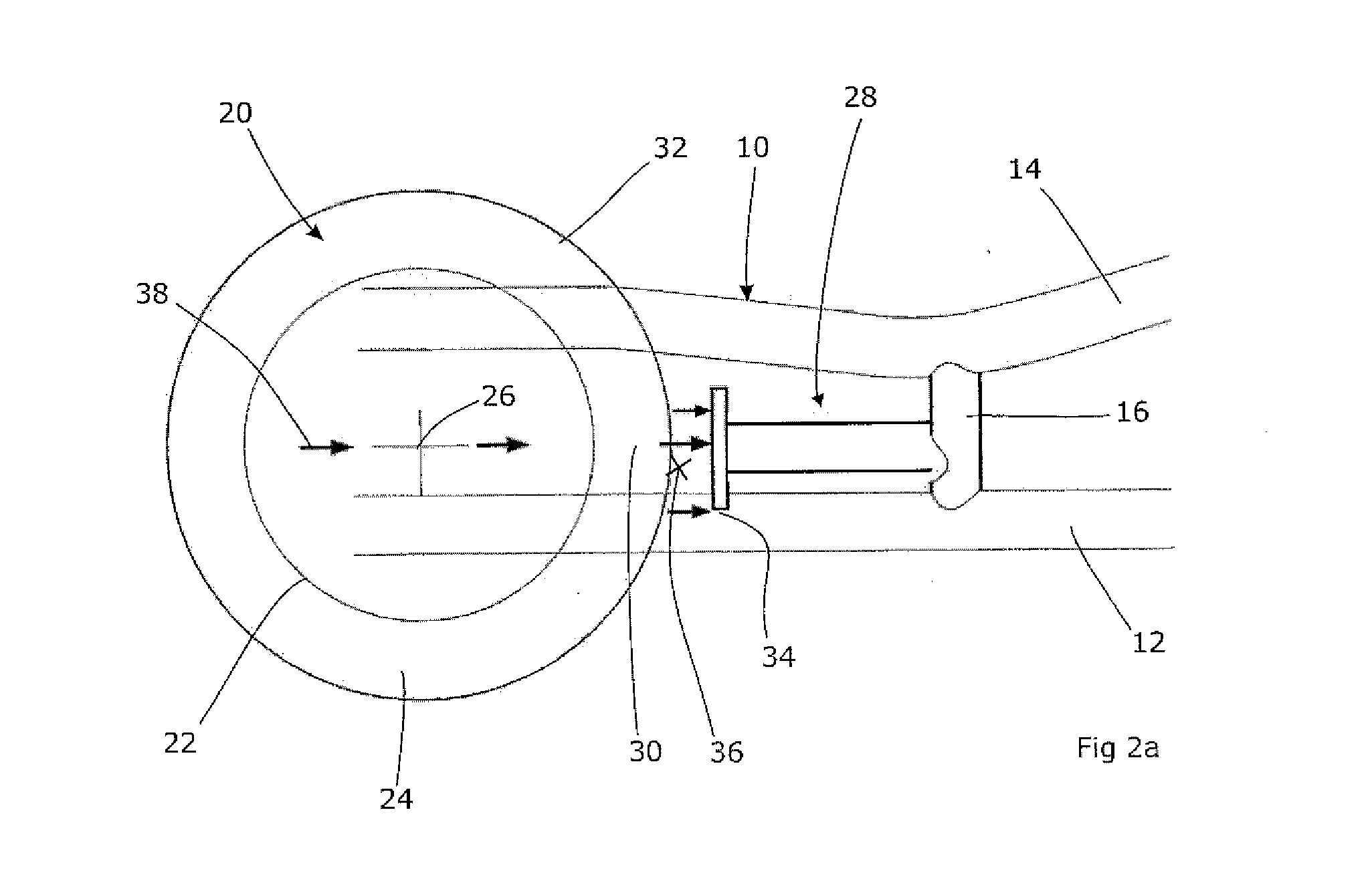

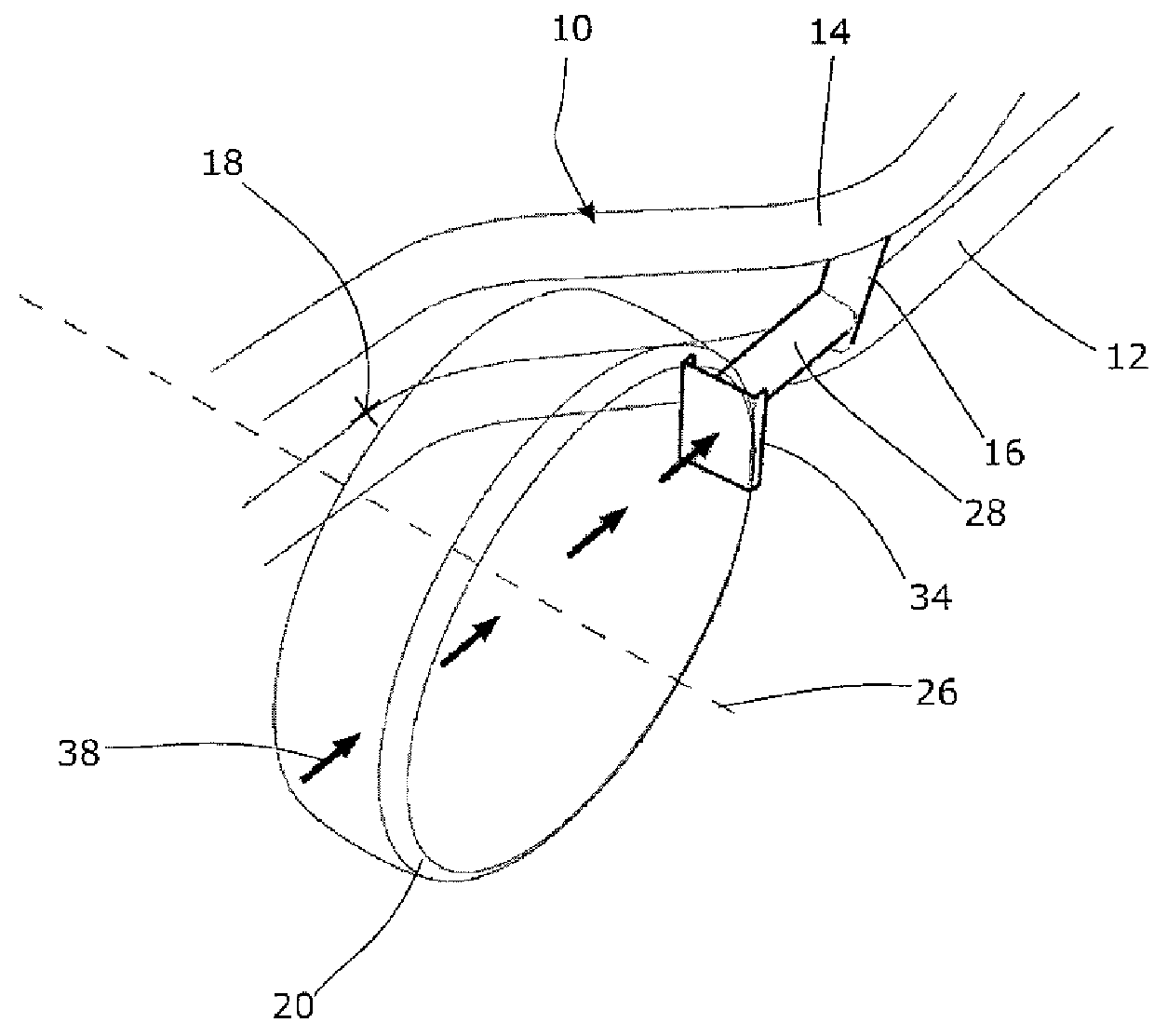

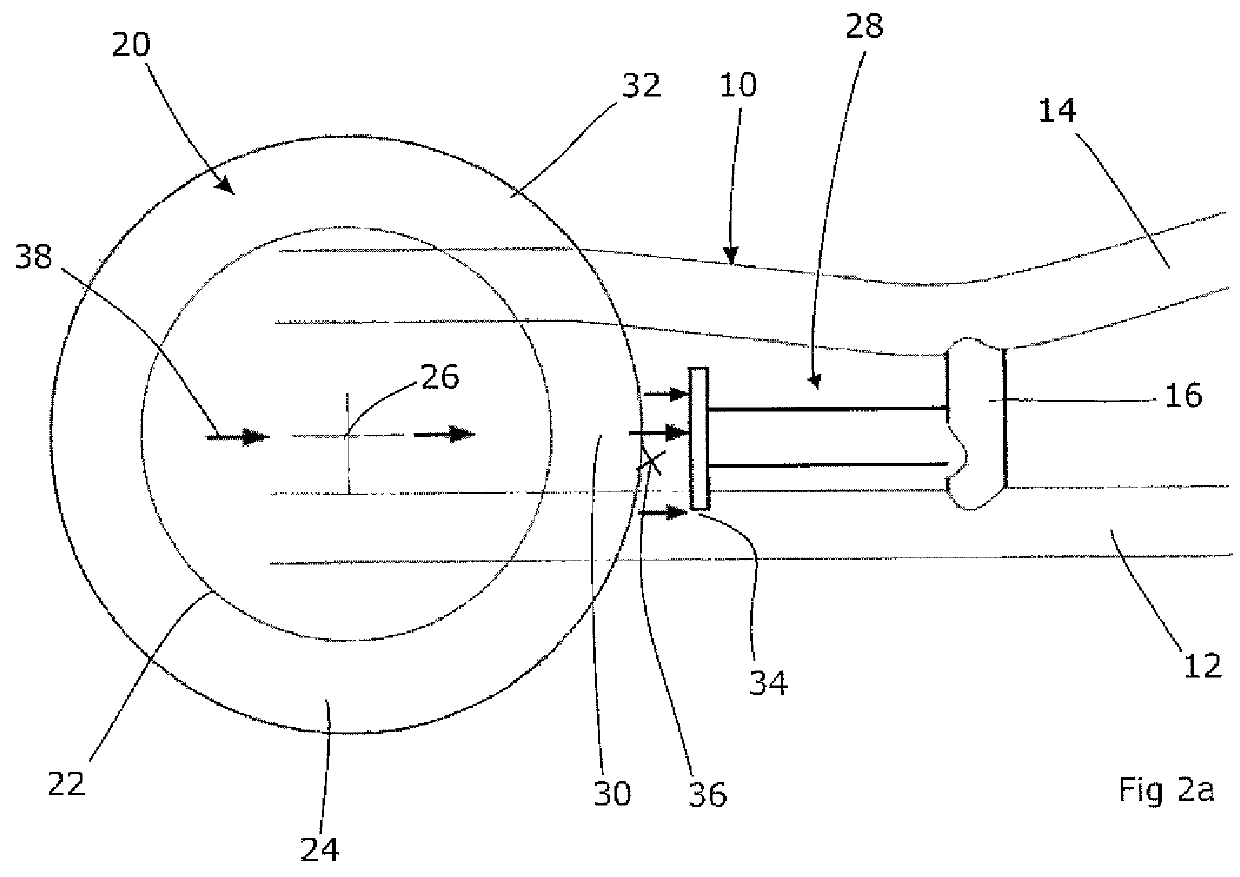

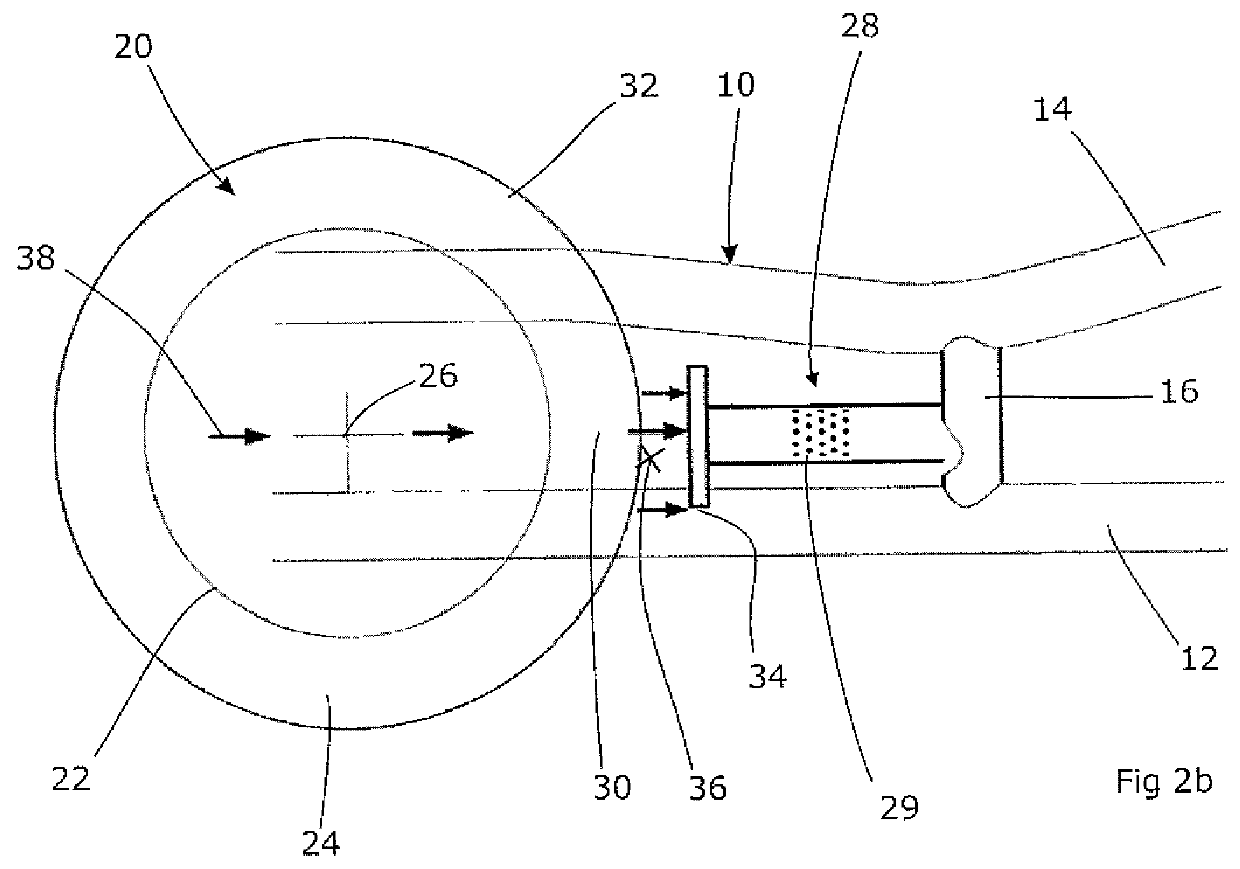

ActiveUS20130161932A1Improve rigidityLimit frontal damageSuspensionsSteering linkagesEngineeringCrashworthiness

A chassis for a vehicle has a locally narrower portion within which is mounted a wheel, and a rigid member extending from the chassis toward the quiescent position of the wheel and ending at a point which is spaced radially from the outer profile and located axially within the thickness of the wheel. Under an impact, the wheel itself will be crushed against the rigid member, absorbing some of the impact energy. The impact energy can also be transmitted via the rigid member to the remainder of the chassis, providing a load path to major mass concentrations elsewhere in the vehicle and allowing energy to be dissipated by the deformation of other structures elsewhere. This can then limit frontal damage to the vehicle and hence reduce the risk of intrusions into the passenger cell. The rigid member can be a column extending towards the wheel, and can end with a flat plate that is positioned tangentially to a local portion of the outer profile. It preferably extends from a point on the chassis outside the locally narrower portion. Oriented in this direction, the rigid member is more able to transfer the impact forces from the crushing wheel to the remainder of the chassis.

Owner:GORDON MURRAY DESIGN

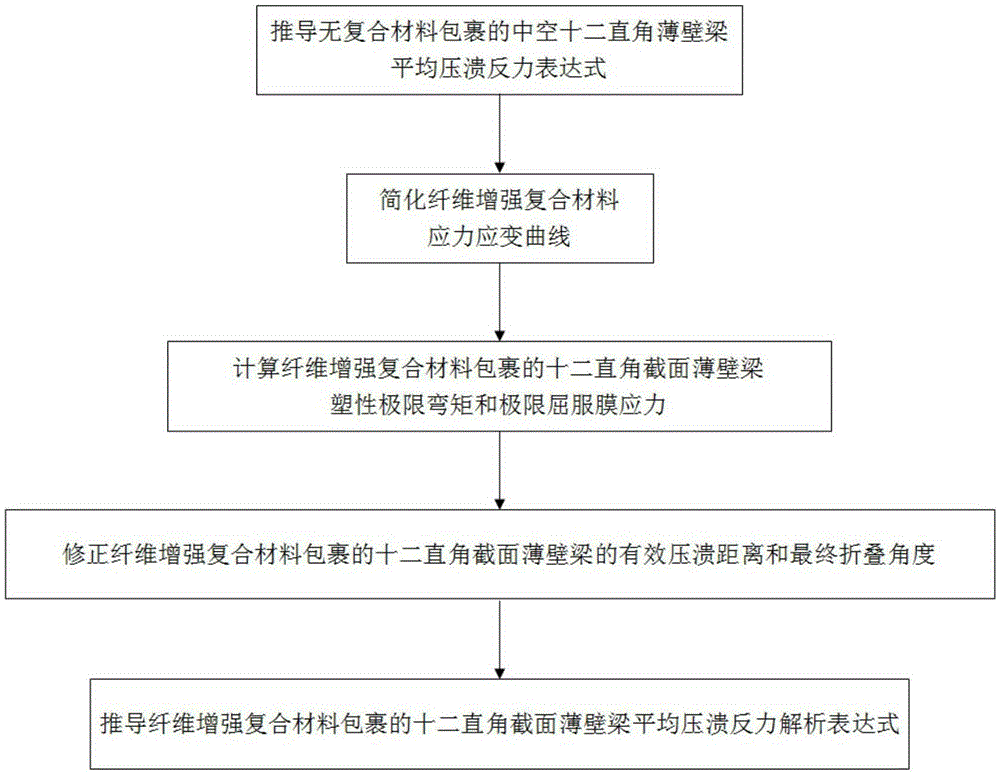

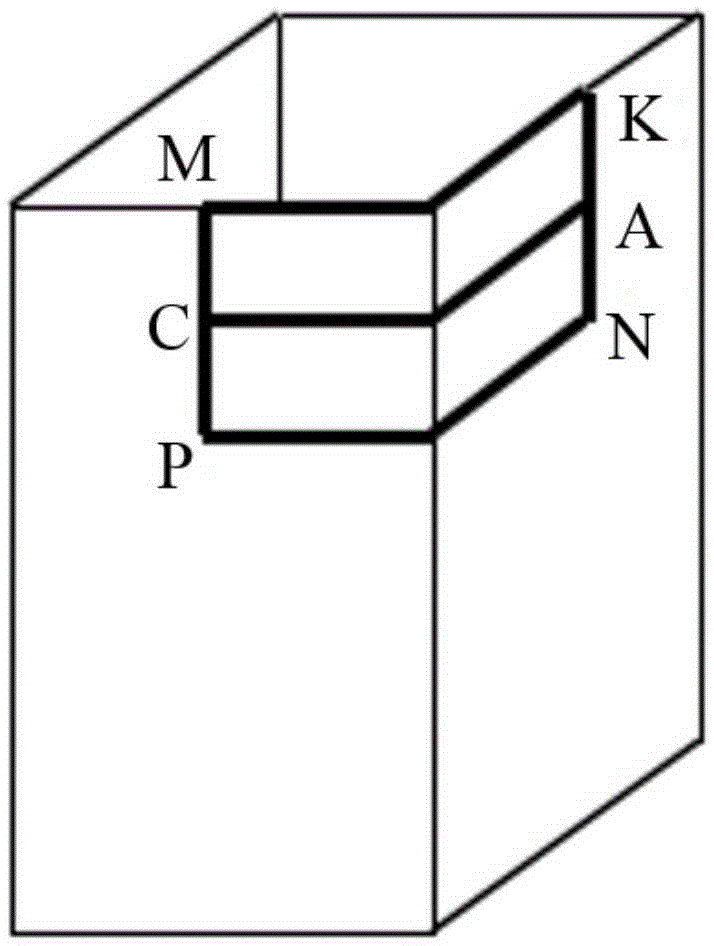

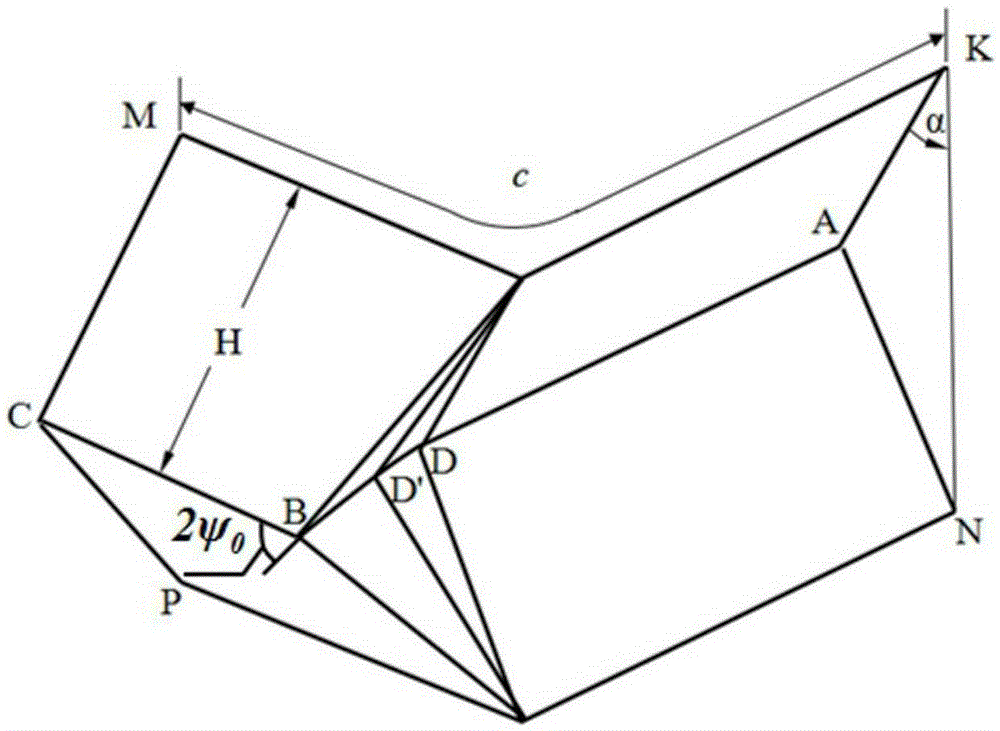

Method for analyzing crushing property of composite material coated twelve-rectangular-cross-section thin-walled beam

InactiveCN105389433AAccurate prediction of crush characteristicsQuick calculation of crush performanceGeometric CADDesign optimisation/simulationMembrane stressStress–strain curve

The present invention discloses a method for analyzing a crushing property of a composite material coated twelve-rectangular-cross-section thin-walled beam and aims to solve the problem that crushing property analysis of the thin-walled beam cannot be performed by using a finite element method or an experimental method due to a shortage of a geometrical model with a detailed structure in a conceptual design stage of crashworthiness of a car body. The method comprises the steps: 1, deducing an average crushing counter force analytic expression of a non composite material coated hollow twelve-rectangular thin-walled beam; 2, simplifying a stress-strain curve of a fiber reinforced composite material, i.e. in the stretching process, a stress-strain relationship is shown as linearity until the fiber reinforced composite material is broken, and in the compressing process, the stress is kept at a certain level without a change after yielding; 3, calculating a plastic limit bending moment and a limit yielding membrane stress of the fiber reinforced composite material coated twelve-rectangular-cross-section thin-walled beam; 4, correcting an effective crushing distance and a final folding angle of the fiber reinforced composite material coated twelve-rectangular-cross-section thin-walled beam; and 5, deducing the average crushing counter force analytic expression of the fiber reinforced composite material coated twelve-rectangular-cross-section thin-walled beam.

Owner:JILIN UNIV

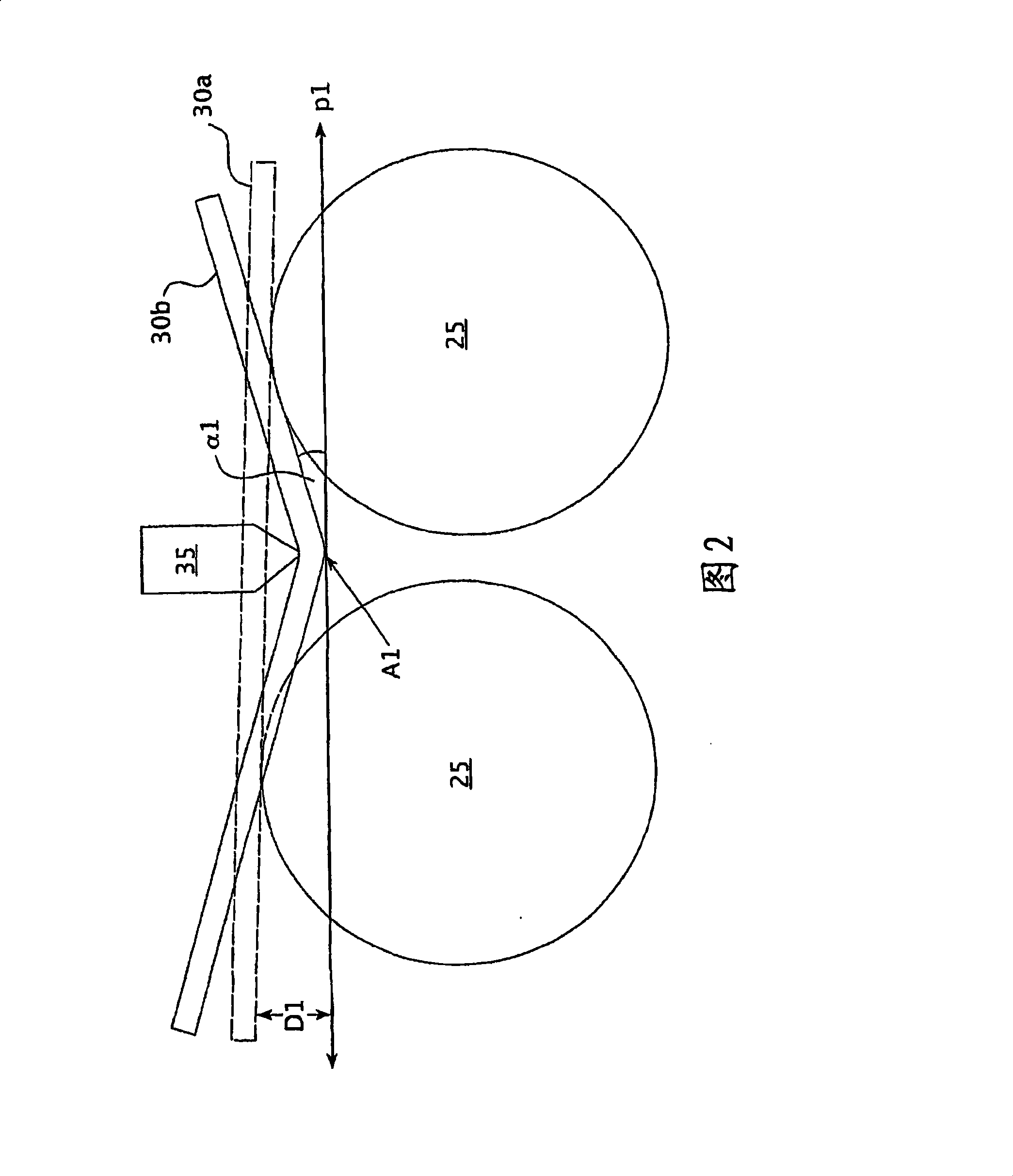

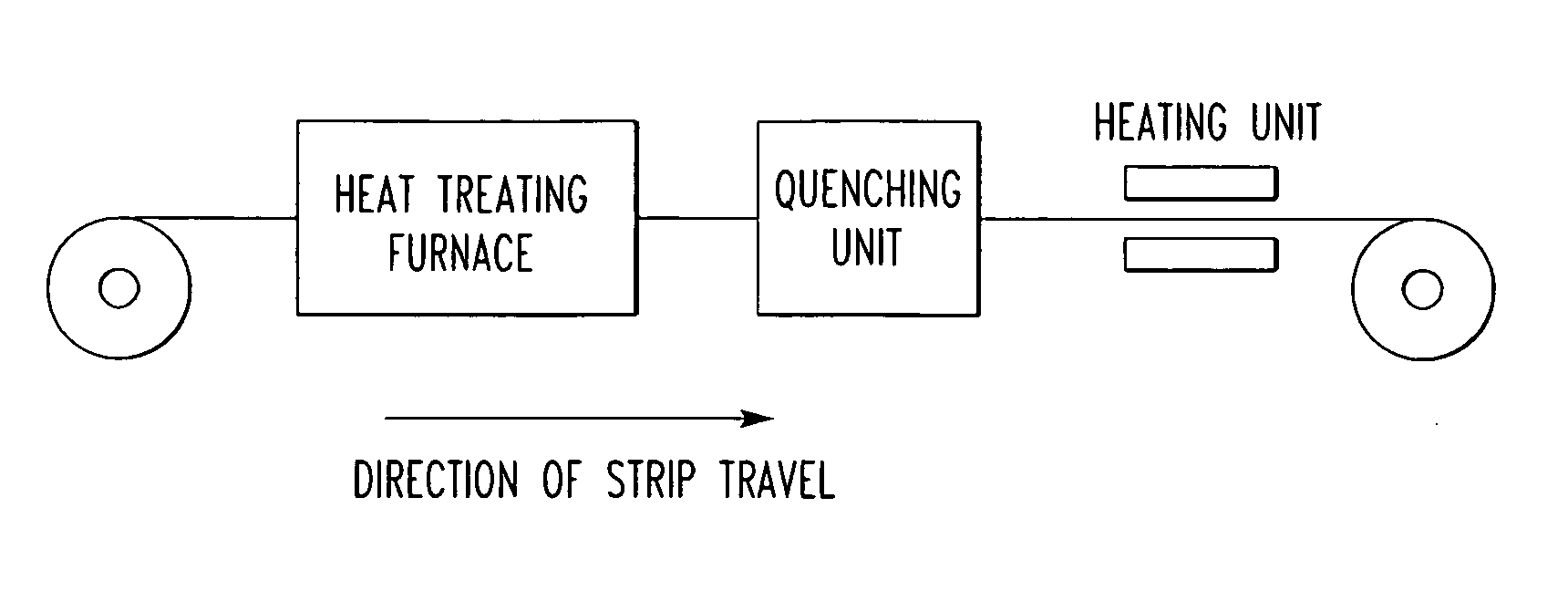

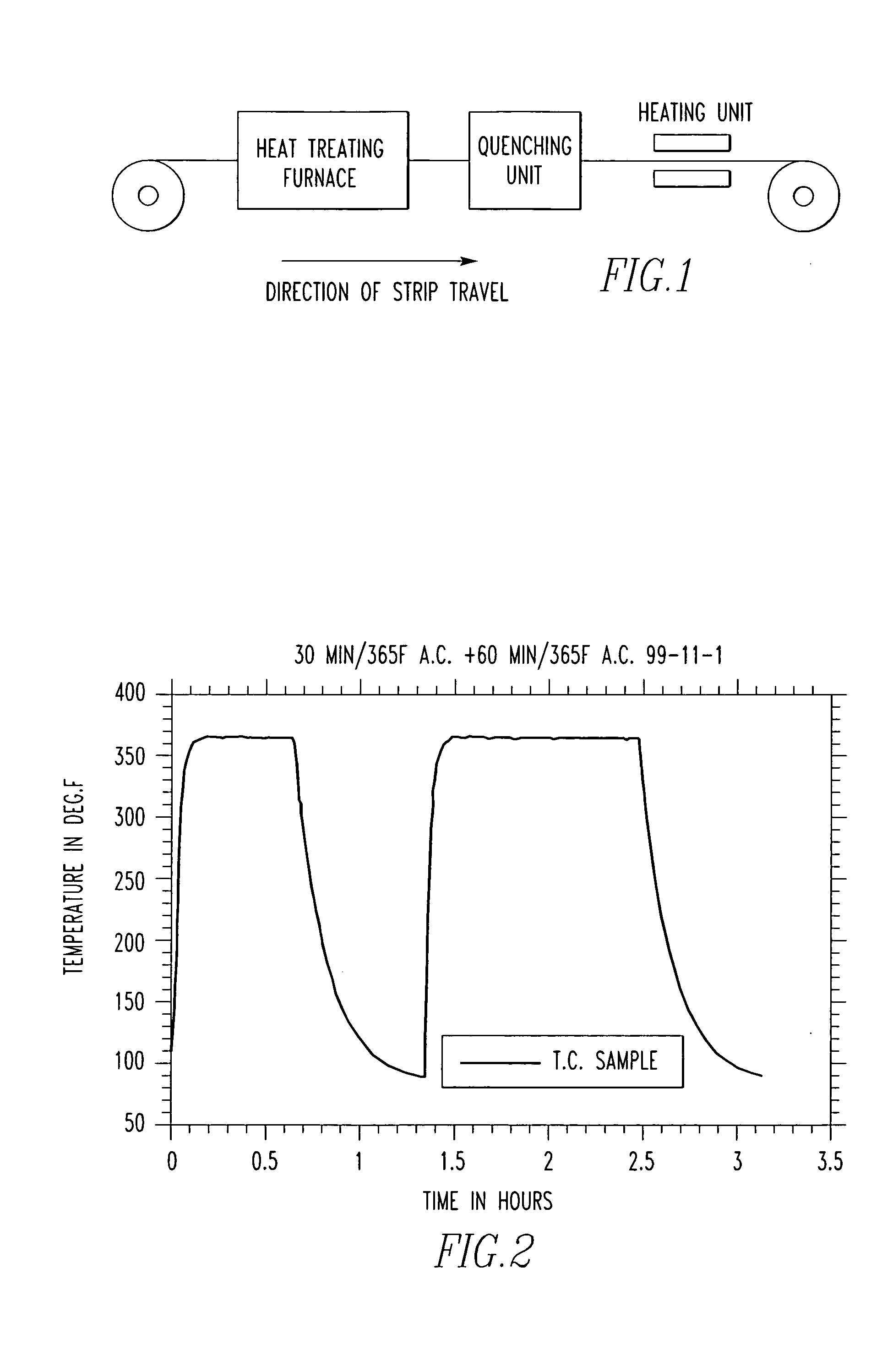

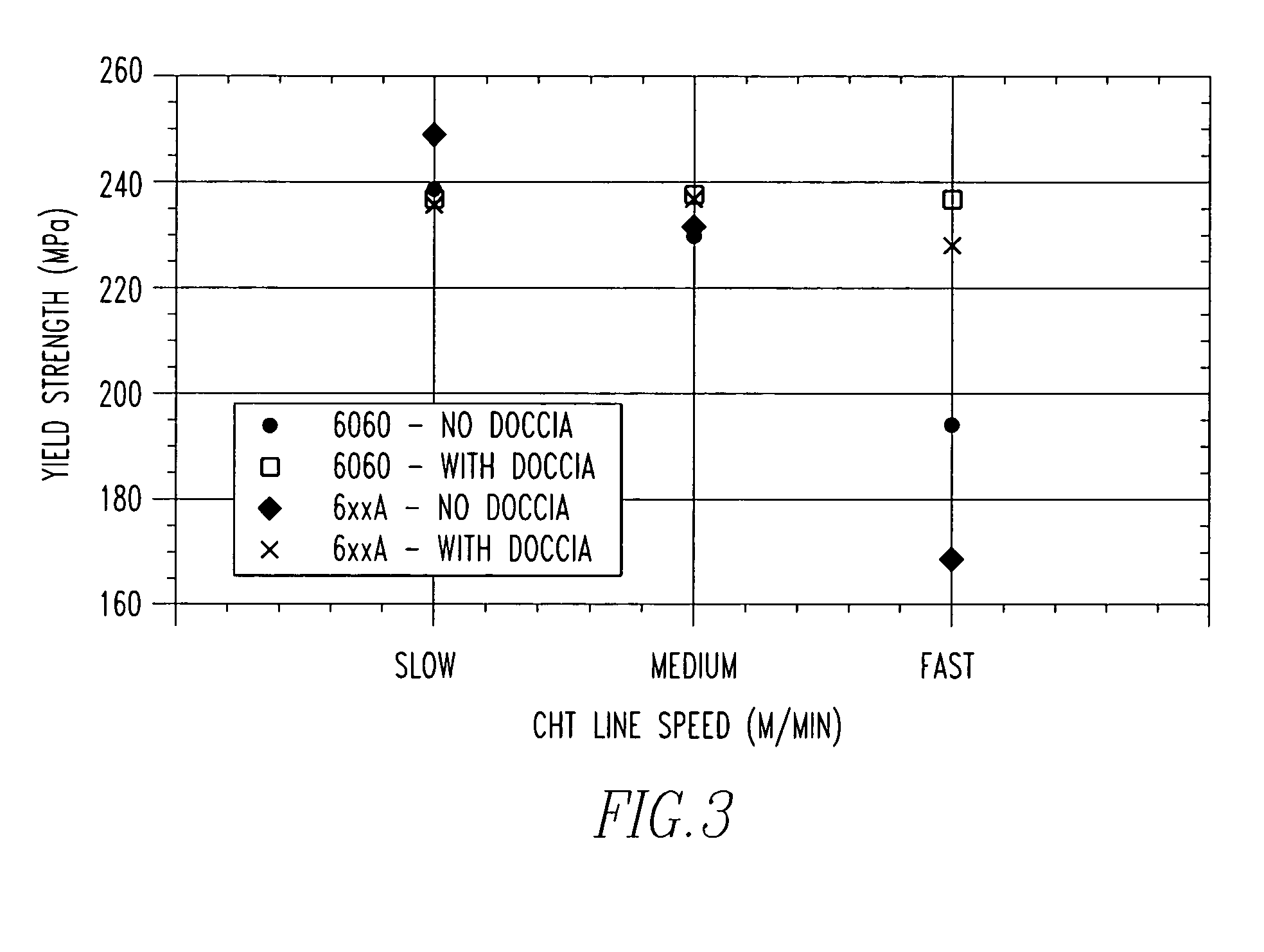

Crash resistant aluminum alloy sheet products and method of making same

Aluminum sheet products having high strengths and favorable crashworthiness are disclosed. The aluminum alloys include Si, Mg and Mn in controlled amounts which provide high yield strengths while retaining formability and crash resistant properties. The sheet products undergo heat treatment and slow quenching. The sheet products are particularly suitable for use as auto body sheet products.

Owner:ARCONIC INC

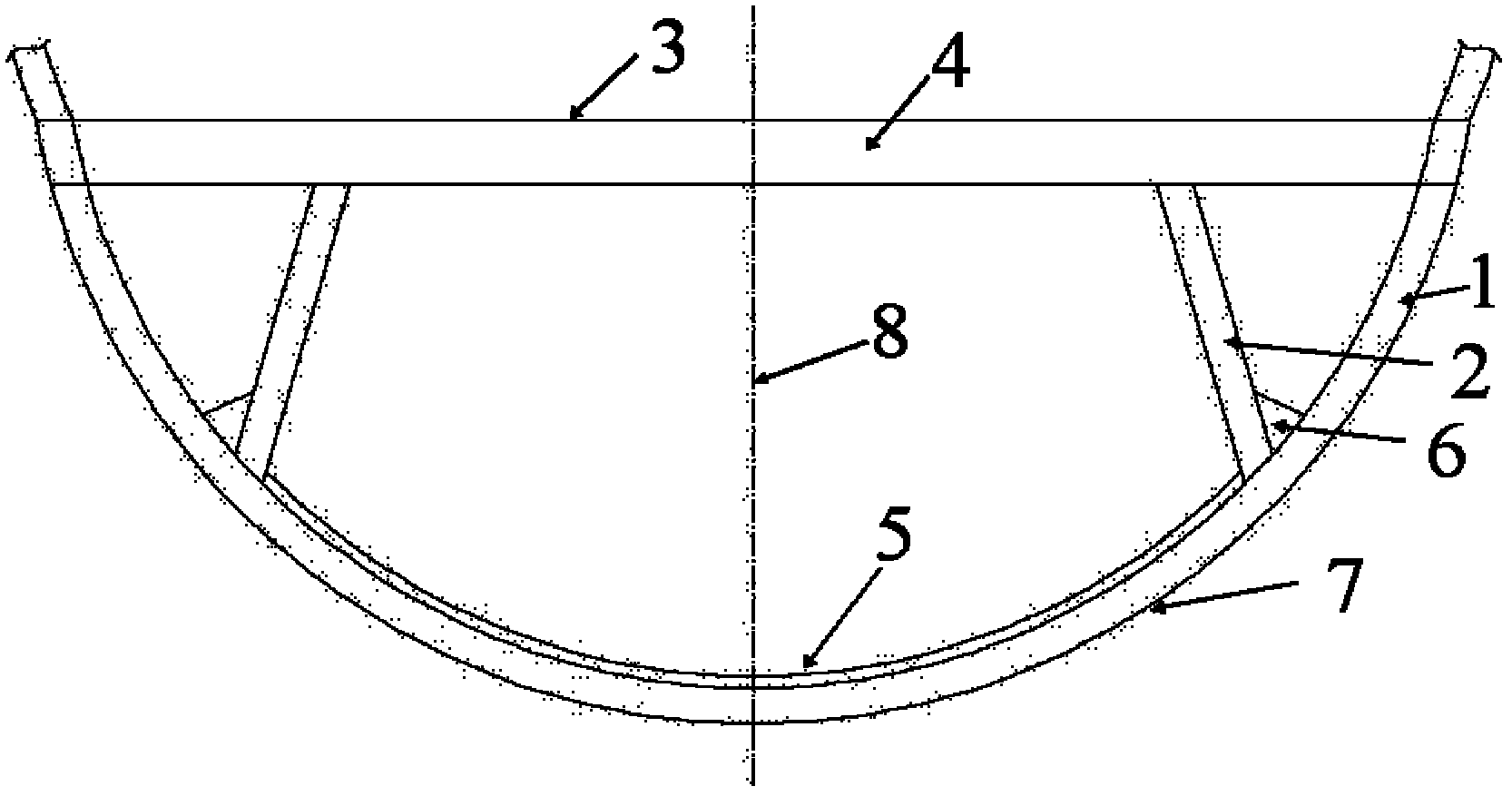

Energy absorption scheme and layout mode of lower square tube supporting rod structure of passenger cabin floor of civil aircraft

InactiveCN102582821AImprove energy absorptionImprove crashworthinessAircraft floorsEnergy absorptionHigh energy

The invention discloses an energy absorption scheme and a layout mode of a lower square tube supporting rod structure of a passenger cabin floor of a civil aircraft. A square tube is used as a structure with high energy absorption efficiency and is applied to design of an energy absorption structure for the body of the civil aircraft. The supporting rod structure is positioned on the lower part of the passenger cabin floor and has the main effect of supporting the passenger cabin floor; the upper part and the lower part of the supporting rod structure are riveted with the lower parts of a passenger cabin floor beam and a body bulkhead respectively; and the lower part of the supporting rod is connected with the body bulkhead by using a reinforcing ribbed plate. The layout mode of the supporting rod structure is that the supporting rod is vertically arranged, and the junction of the lower part of the supporting rod structure and the body bulkhead is positioned at a position of quarter circular arc of the lower bulkhead of the passenger cabin floor of the body. The invention provides the scheme in which the square tube structure is used as the lower supporting rod of the passenger cabin floor, so that the crashworthiness of the body structure can be greatly improved, and the structural design of the original body is not required to be changed.

Owner:BEIHANG UNIV

Vehicle crashworthiness

ActiveUS9340230B2Limit frontal damageReduce riskSuspensionsSteering linkagesEngineeringCrashworthiness

A chassis for a vehicle has a locally narrower portion within which is mounted a wheel, and a rigid member extending from the chassis toward the quiescent position of the wheel and ending at a point which is spaced radially from the outer profile and located axially within the thickness of the wheel. Under an impact, the wheel itself will be crushed against the rigid member, absorbing some of the impact energy. The impact energy can also be transmitted via the rigid member to the remainder of the chassis, providing a load path to major mass concentrations elsewhere in the vehicle and allowing energy to be dissipated by the deformation of other structures elsewhere. This can then limit frontal damage to the vehicle and hence reduce the risk of intrusions into the passenger cell. The rigid member can be a column extending towards the wheel, and can end with a flat plate that is positioned tangentially to a local portion of the outer profile. It preferably extends from a point on the chassis outside the locally narrower portion. Oriented in this direction, the rigid member is more able to transfer the impact forces from the crushing wheel to the remainder of the chassis.

Owner:GORDON MURRAY DESIGN LTD

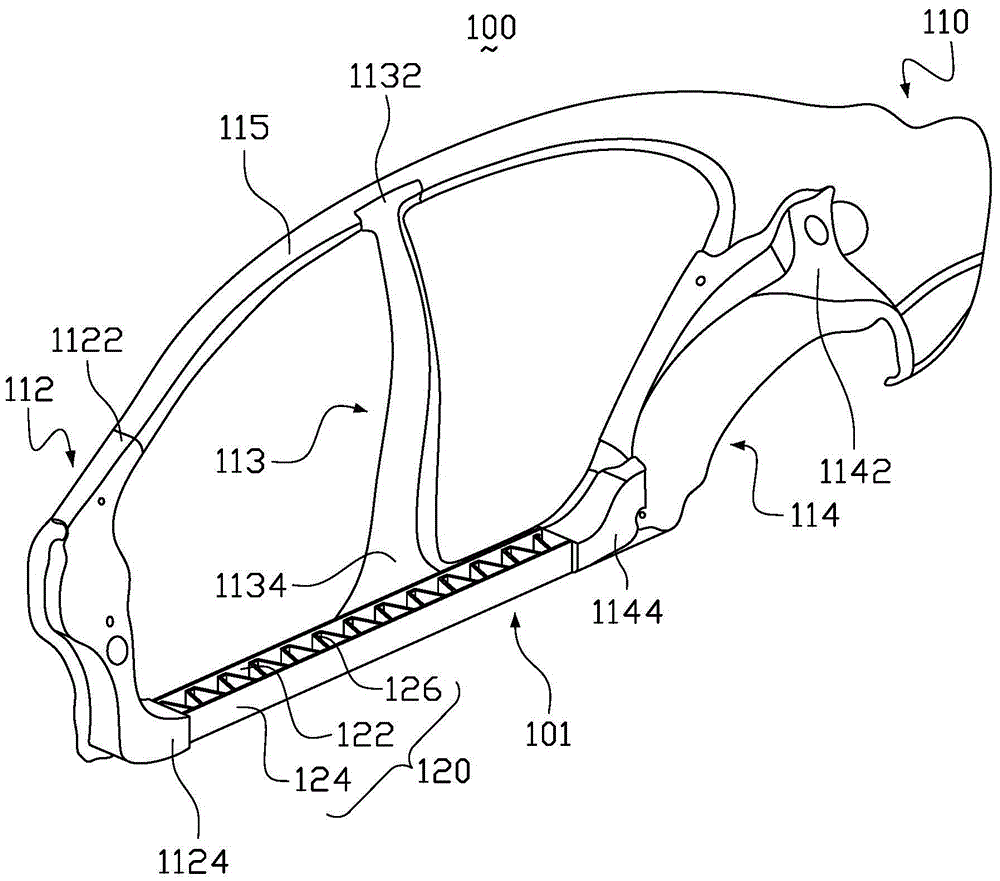

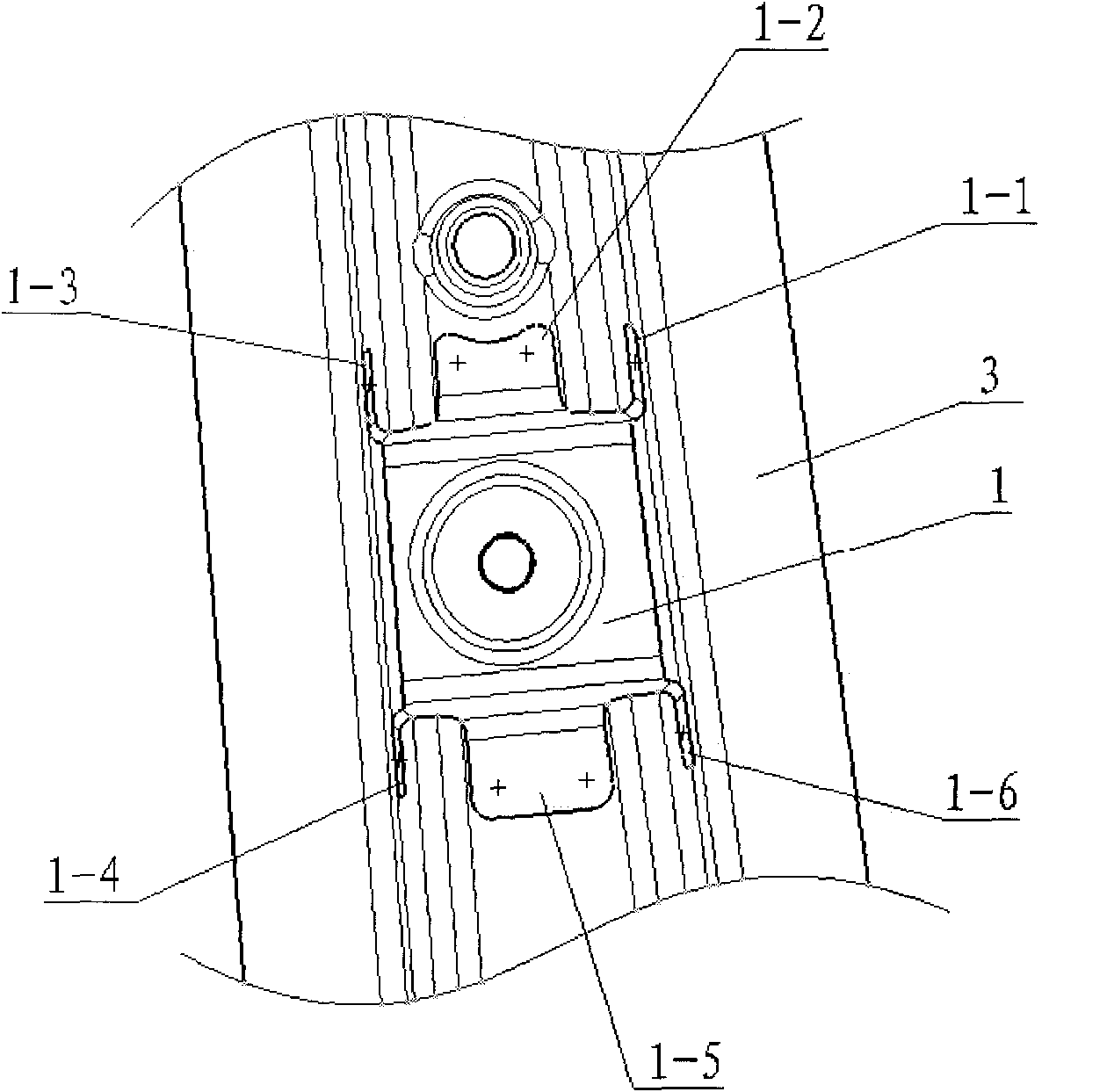

Automobile threshold reinforcement structure and automobile

ActiveCN104443061AImprove structural strengthImprove crashworthinessSuperstructure subunitsEngineeringLarge deformation

An automobile threshold reinforcement structure comprises a first side plate, a second side plate and a reinforcement rib plate structure, wherein the first side plate and the second side plate are arranged opposite to each other, and the reinforcement rib plate structure is connected between the first side plate and the second side plate. The automobile threshold reinforcement structure can reinforce the structural strength of an automobile threshold, improve crashworthiness of the side faces of an automobile, and reduce the personnel injury rate caused by large deformation of a passenger chamber of the automobile during collision. The invention further relates to the automobile provided with the automobile threshold reinforcement structure.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Heat-hardened steel with excellent crashworthiness and method for manufacturing heat-hardenable parts using same

ActiveCN103534372AHigh strengthImprove toughnessHot-dipping/immersion processesFurnace typesHardened steelCrashworthiness

Disclosed are heat-hardened steel with excellent crashworthiness and a method for manufacturing heat-hardenable parts using the same. The heat-hardened steel according to the invention comprises, based on wt%, C: 0.12-0.8 %, Cr : 0.01-2 %, Mo: 0.2 % or less, B: 0.0005-0.08 %, Ca: 0.01 or less, Sb: 1.0 % or less, and Ti and / or Nb: 0.2 %, and the reminder being Fe and inevitable impurities. In addition, the heat-hardened steel satisfies any one of following conditions i)-iv), wherein condition i) comprises Si: 0.5-3 %, Mn: 1-10 % and Al: 0.05-2 %, condition ii) comprises Si: 1 % or less, Mn: 0.5-5 %, Al: 0.1-2.5 %, and Ni: 0.01-8 %, condition iii) comprises Si: 0.5-3 %, Mn: 1-10 %, Al: 0.1 % or less, and Ni: 0.01-8 %, and condition iv) comprises Si: 0.5-3 %, Mn: 1-10 %, Al: 0.1-2.5 %, and Ni: 0.01-8 %.

Owner:HYUNDAE STEEL CO LTD

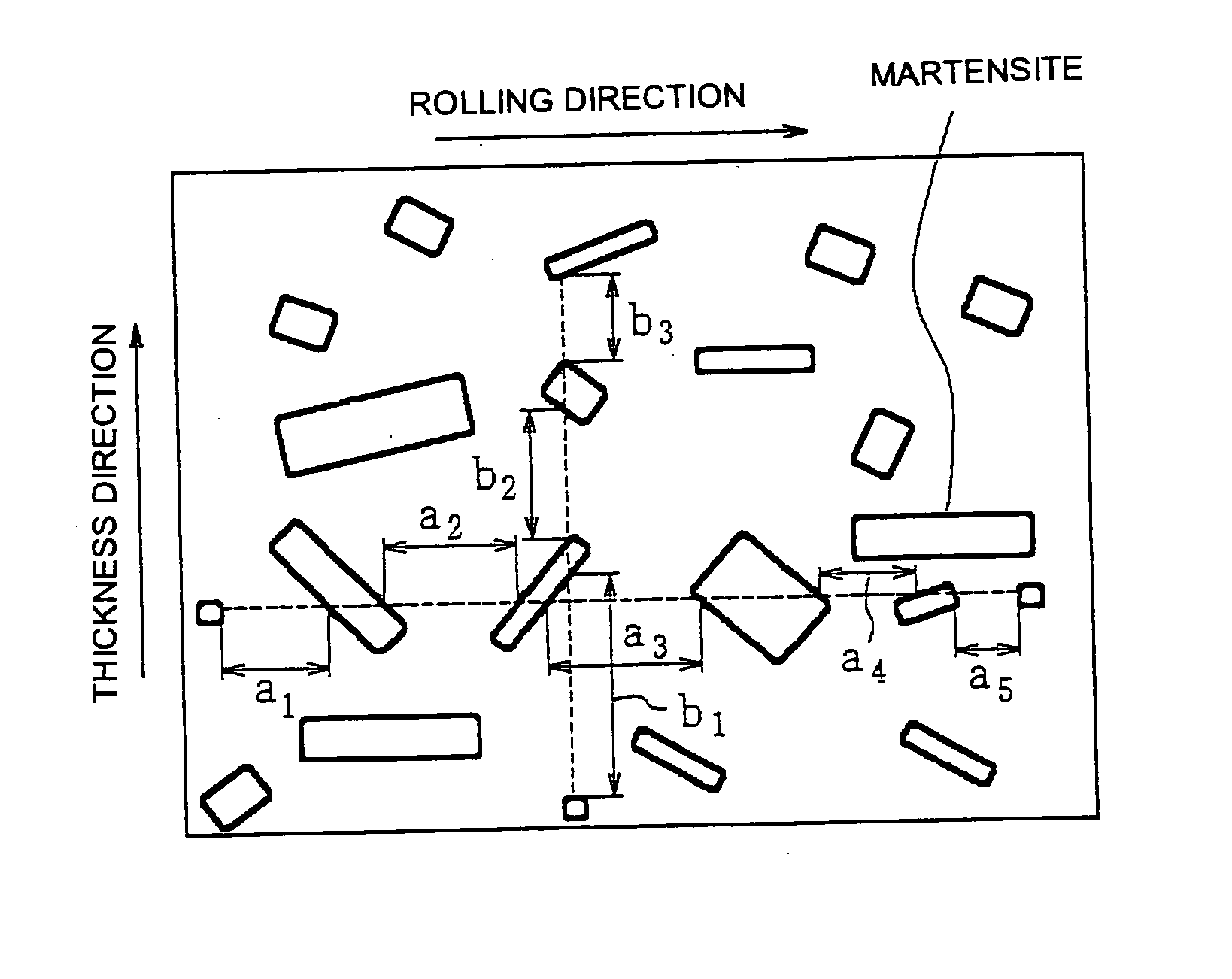

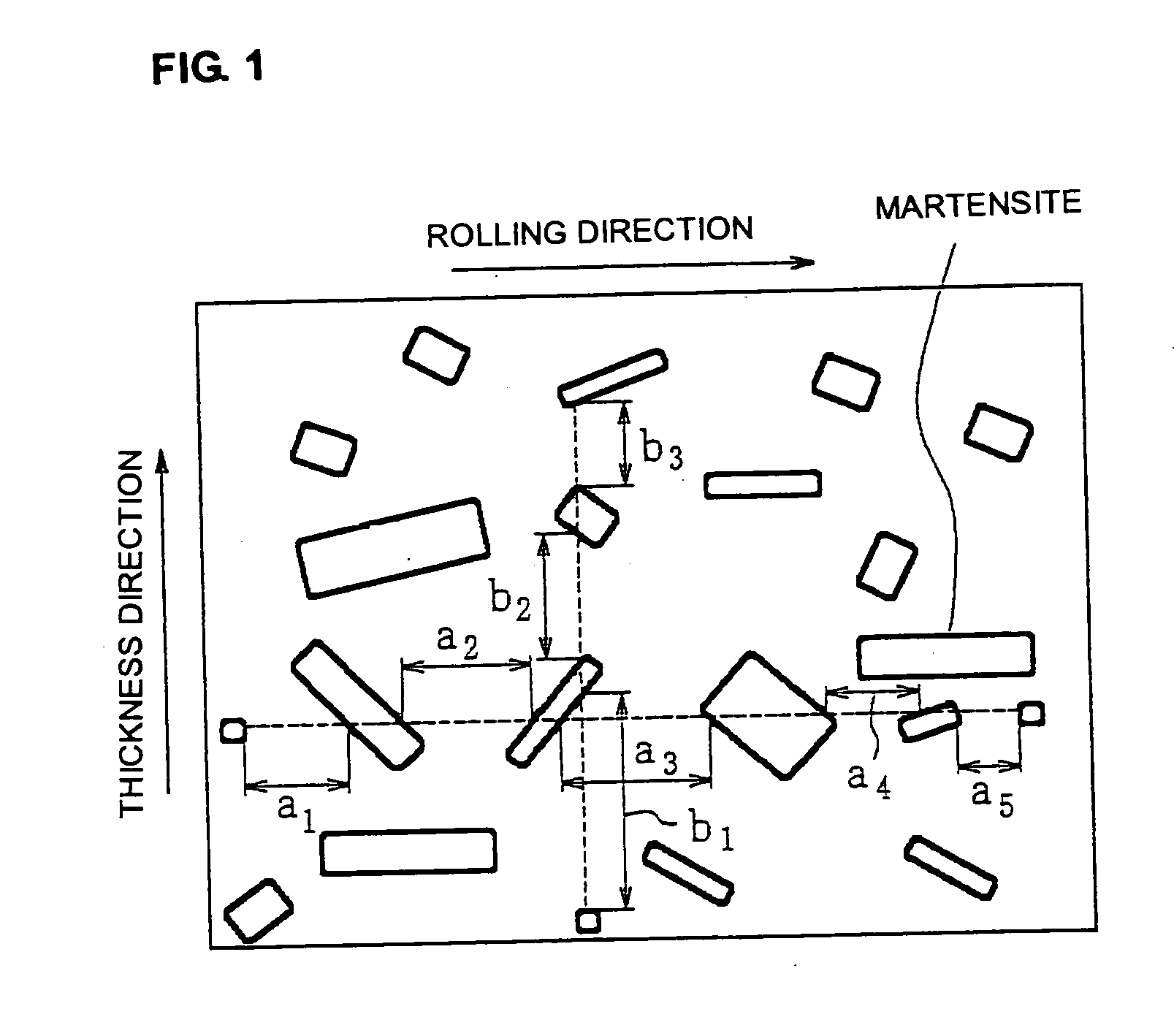

High tensile strength cold-rolled steel sheet and method for production thereof

InactiveUS20060231176A1Improve balanceImprove crashworthinessFurnace typesHeat treatment furnacesMartensiteUltimate tensile strength

The high tensile cold-rolled steel sheet consists essentially of 0.04 to 0.13% C, 0.3 to 1.2% Si, 1.0 to 3.5% Mn, 0.04% or less P, 0.01% or less S, 0.07% or less Al, by mass, and balance of Fe and inevitable impurities, has a microstructure containing 50% or larger area percentage of ferrite and 10% or larger area percentage of martensite, has 0.85 to 1.5 of ratio of intervals of the martensite in the rolling direction to those in the sheet thickness direction, and has 8 GPa or larger nano strength of the martensite. The high tensile cold-rolled steel sheet has a good strength-elongation balance, and shows excellent crashworthiness at about 10 s−1 of strain rate. Therefore, the high tensile cold-rolled steel sheet is suitable for reinforcing members for pillar and dashboard of automobile.

Owner:JFE STEEL CORP

Front safety belt upper pivot mounting bracket

InactiveCN101786443AImprove side impact strengthImprove security levelBelt anchoring devicesChinese charactersEngineering

The invention discloses a front safety belt upper pivot mounting bracket, which comprises a bracket body and a T-shaped nut, and is characterized in that the section of the bracket body is in a shape like a Chinese character 'JI', the two lower ends of the bracket body are respectively provided with a flange, the middle of the upper surface of the bracket body is provided with a through hole, and the lower part of the T-shaped nut passes through the through hole and is welded on the bracket body. The invention has good stiffness and high strength, can reasonably transmit load, has good crashworthiness, not only meets the mounting of the front safety belt upper pivot, but also meets the requirements of automobile structure stiffness and collision regulations, simultaneously improves the welding efficiency, saves the mounting cost and improves the assembly accuracy.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Vehicle and chassis therefor

ActiveUS9944325B2Reducing necessary size (and weight)Easy to disassembleUnderstructuresMonocoque constructionsSteel frameCrashworthiness

Owner:GORDON MURRAY DESIGN LTD

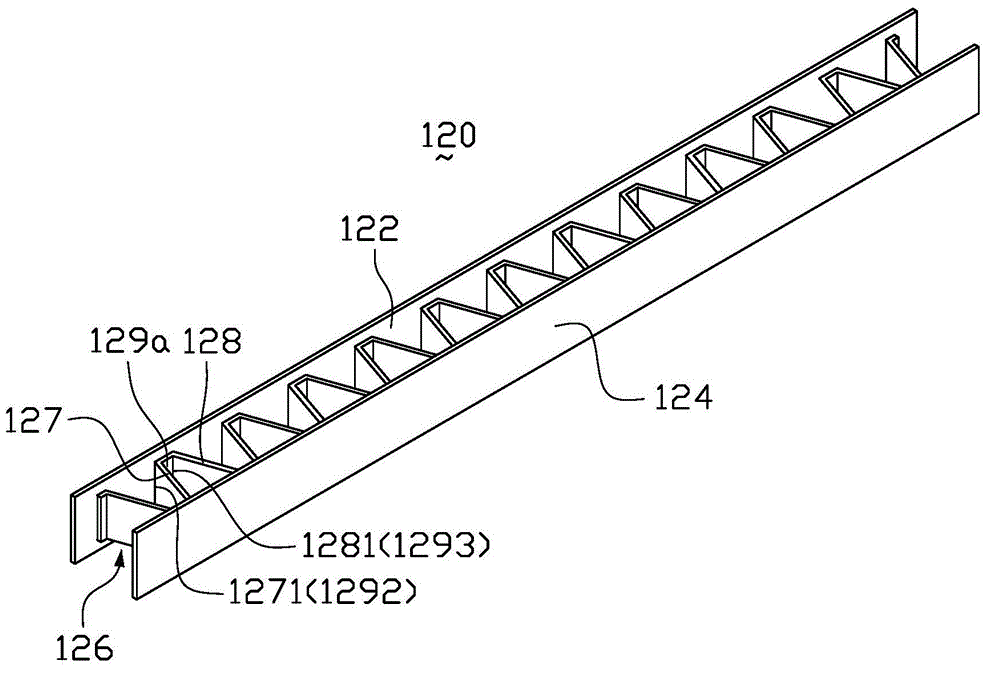

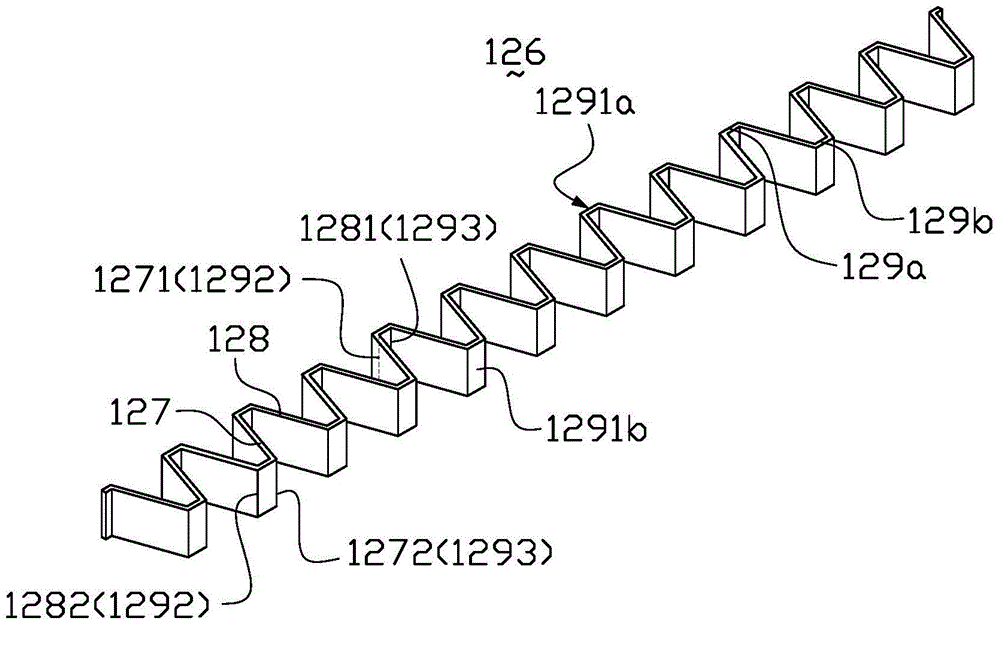

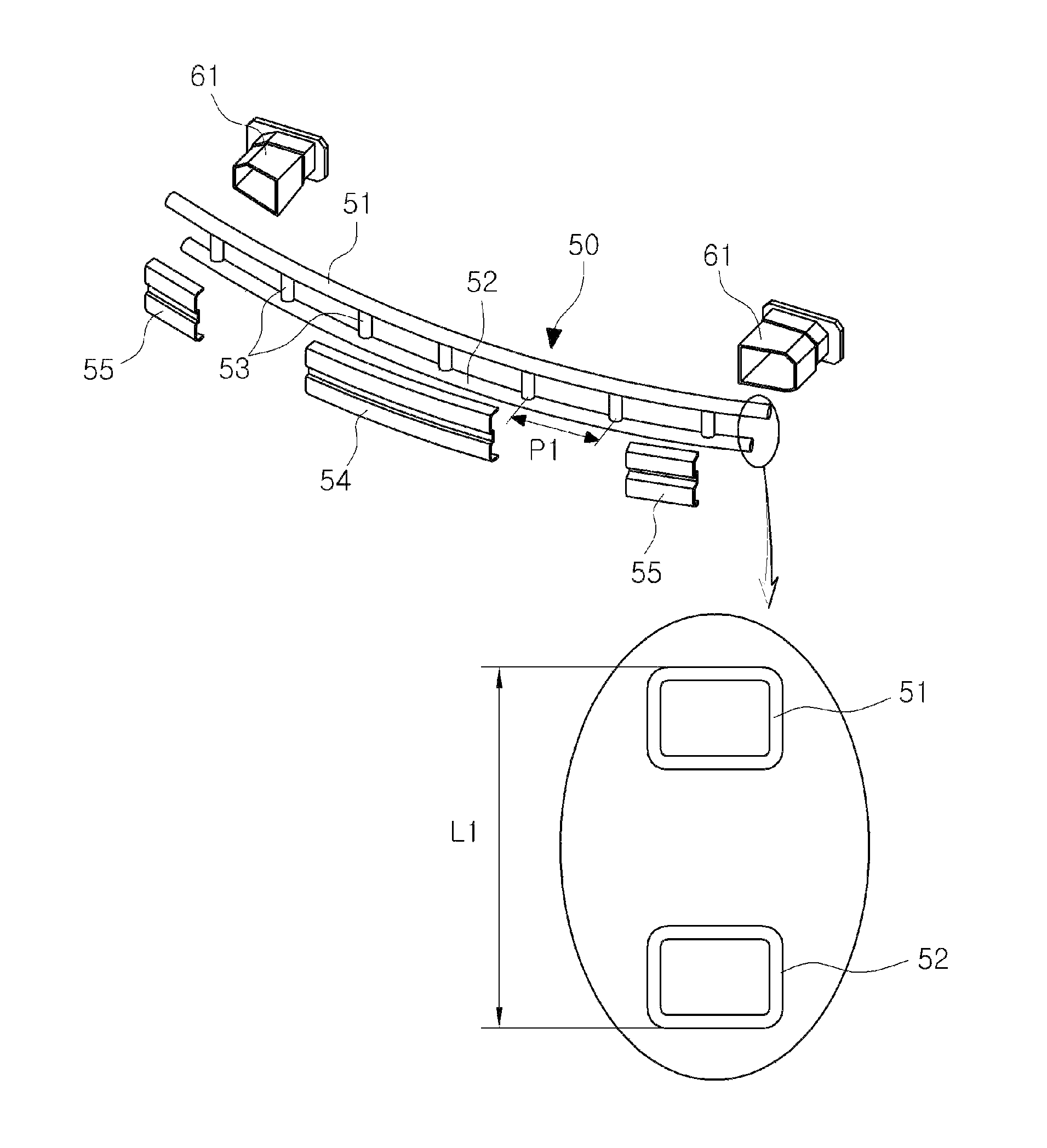

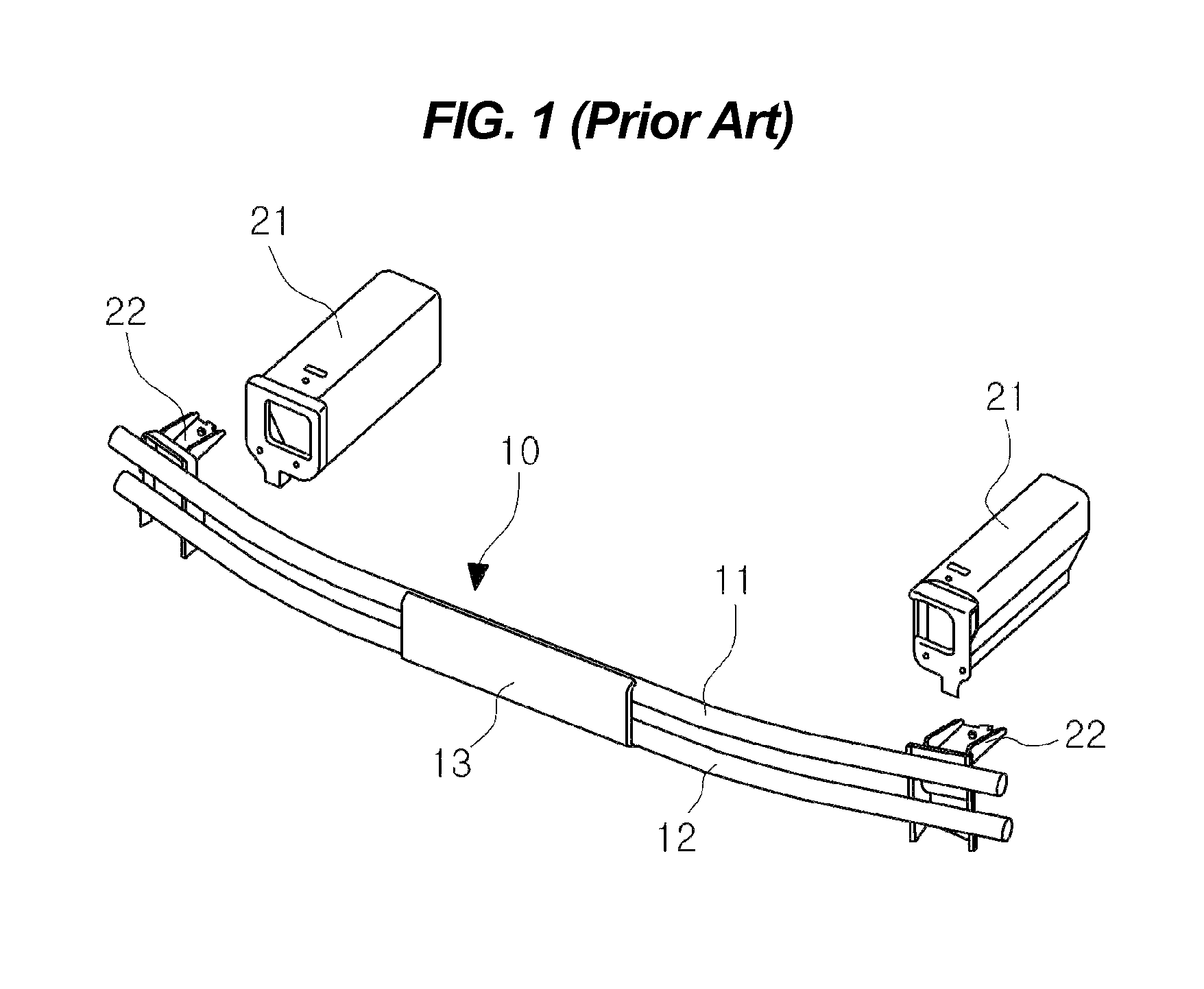

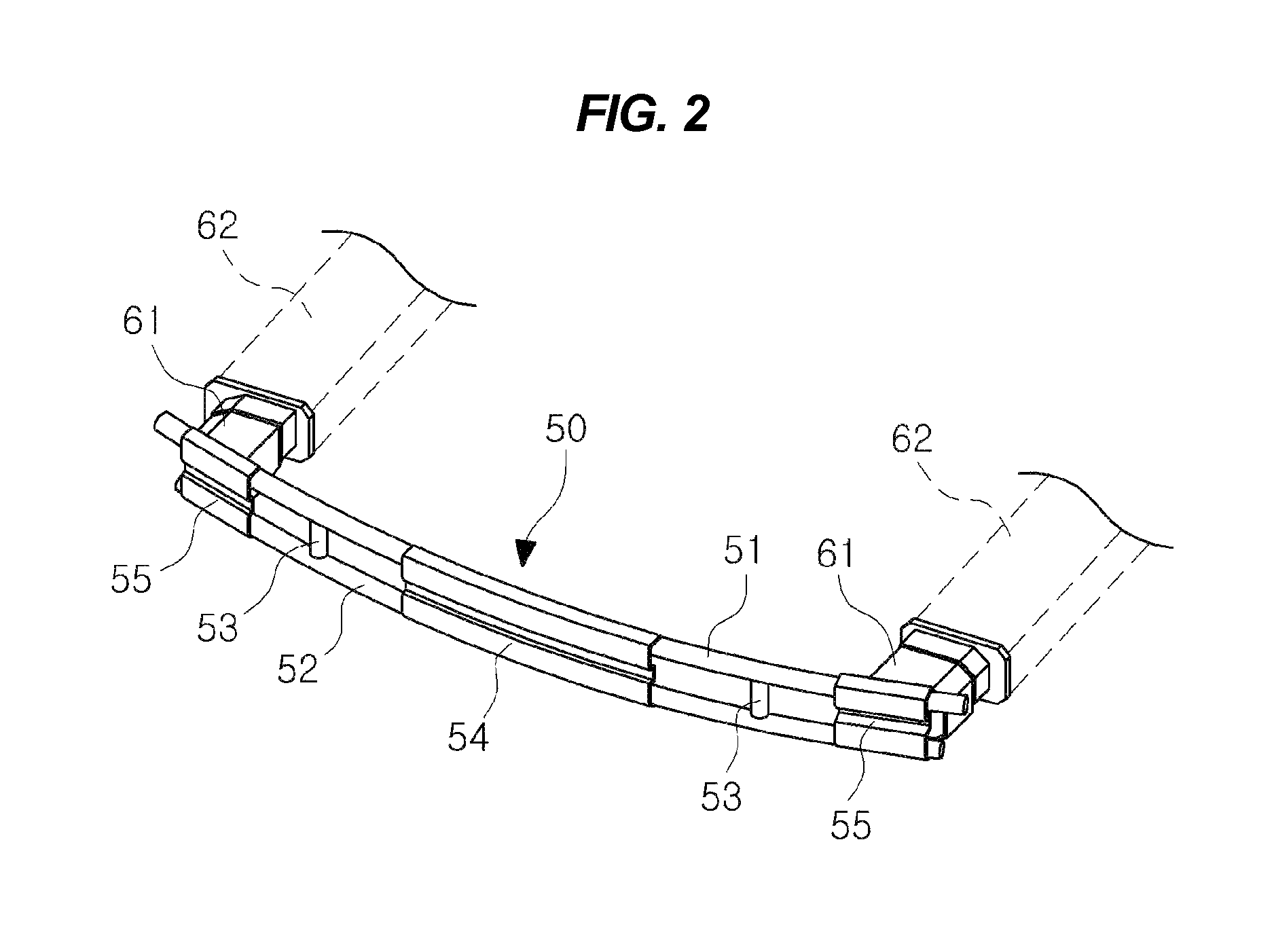

Tubular back beam for vehicle

ActiveUS8864198B2Improve connection rigidityAvoid separationVehicle seatsDashboardsEngineeringCrashworthiness

Owner:HYUNDAI MOTOR CO LTD +1

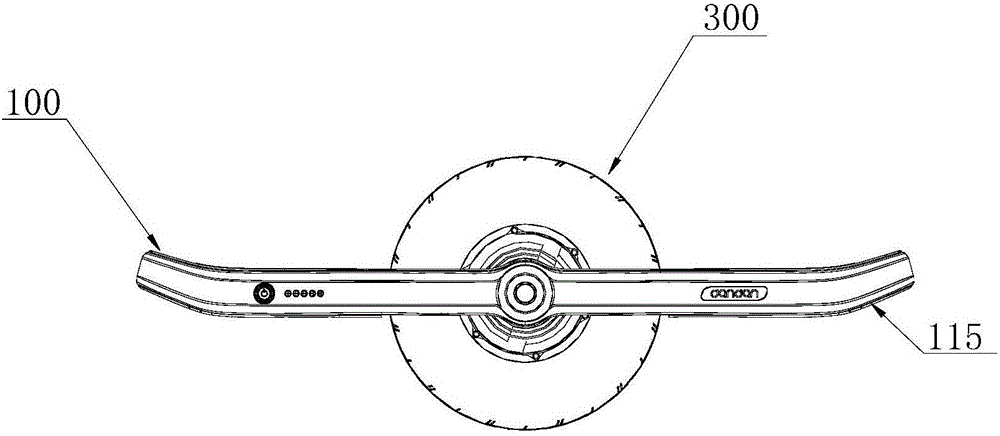

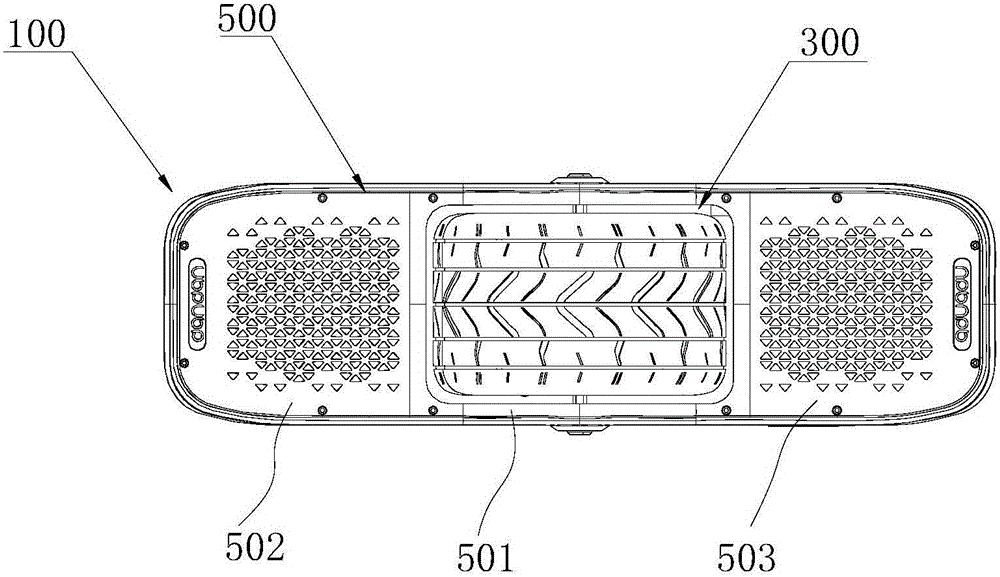

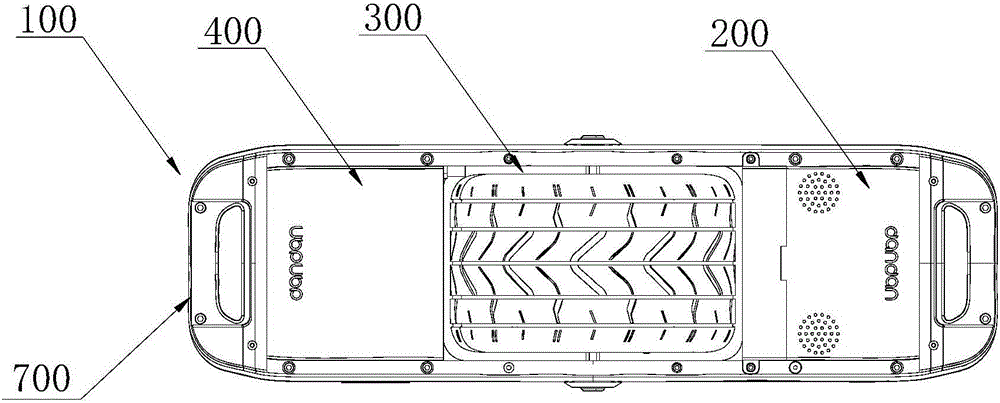

Electric one-wheel pedal balance bike

InactiveCN105905203AEasy to masterSafe and reliable performanceUnicyclesCarrying capacityRemote control

The invention relates to an electric one-wheel pedal balance bike, comprising a frame assembly, a control box provided with a controller, a hub motor wrapped with a tire, a battery case provided with a battery pack, and a pedal. The electric one-wheel pedal balance bike is characterized in that the frame assembly is formed by splicing two frame monoblocks; the length direction of the frame monoblocks is vertical to the axial direction of the hub motor; the frame assembly is formed by splicing the two frame monoblocks; the ends of the frame monoblocks are provided with splicing portions on the same side; the splicing portions of the two frame monoblocks are fixedly connected through connecting blocks, to form a frame-type one-wheel bike frame. The electric one-wheel pedal balance bike is more secure in performance, more convenient to carry, more compact in size, easier to control and capable of realizing the remote control. In addition, the electric one-wheel pedal balance bike also has the advantages of simple structure, high carrying capacity, and good crashworthiness and the like.

Owner:MILE TECH TIANJIN CO LTD

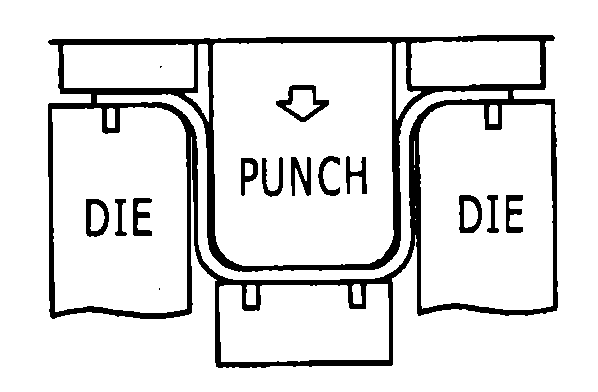

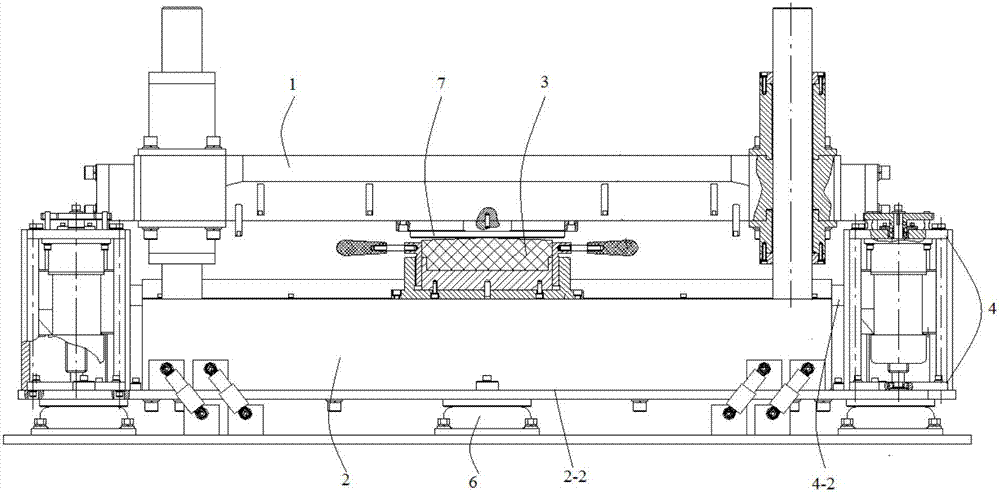

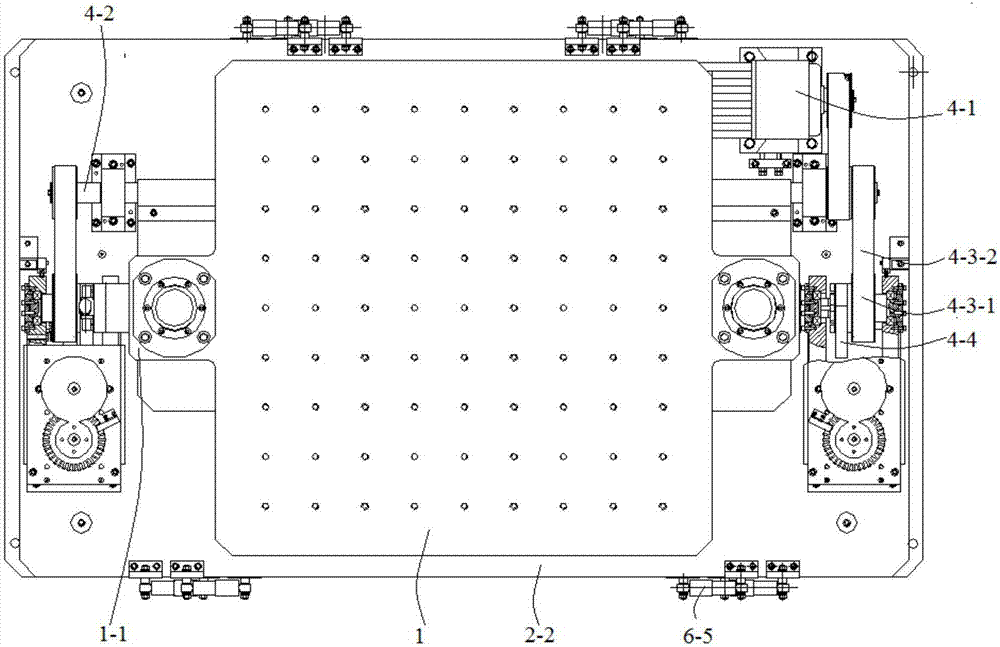

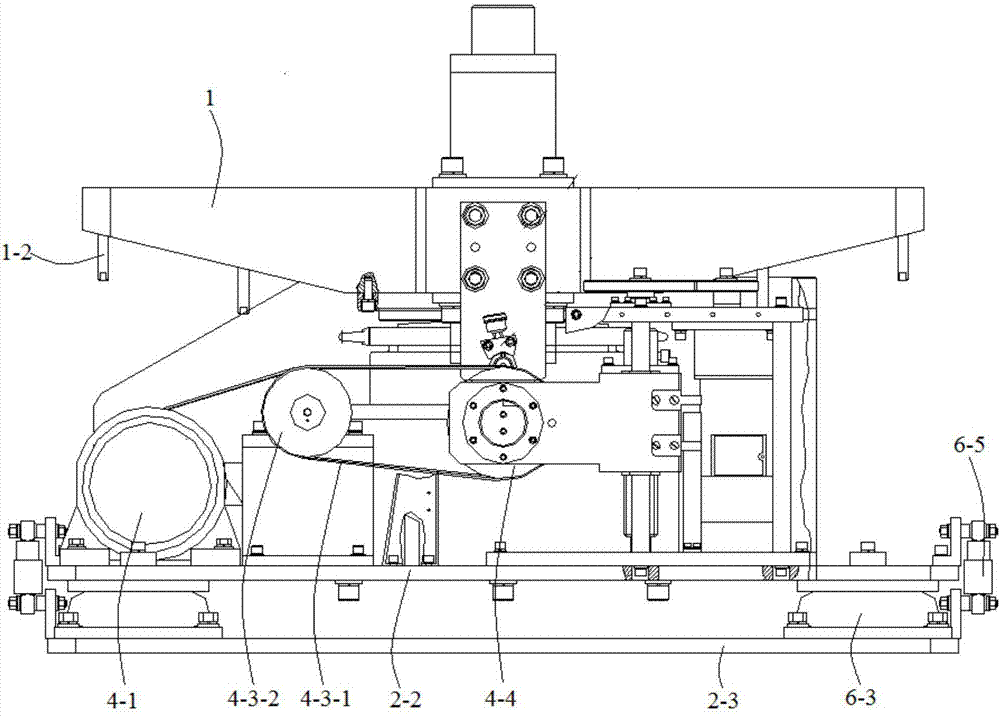

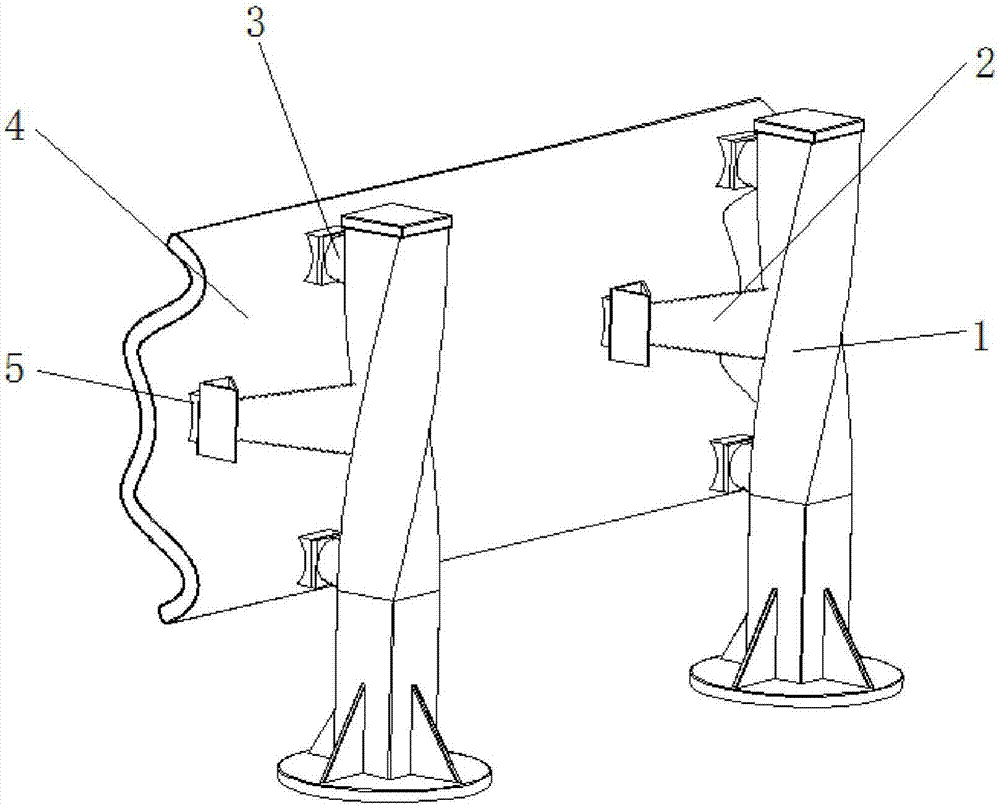

Mechanical structure crashworthiness simulation experiment platform

A mechanical structure crashworthiness simulation experiment platform disclosed by the present invention comprises a table-board, a table body, synchronous drive systems, a waveform generation device and shock isolation devices. A punch is arranged on the table-board, the waveform generation device is arranged between the table-board and a pedestal and is located in the center of the table-board, the synchronous drive systems are arranged at the two sides of the table-board respectively and are connected together via a main shaft, and the plurality of shock isolation devices are distributed between an upper bottom plate and a lower bottom plate evenly. The mechanical structure crashworthiness simulation experiment platform of the present invention adopts the dual-upright column table-board, is large in size and can carry out the whole machine test. The waveform generation device of the present invention does not need to replace an elastic cushion, but just needs to adjust the clamping area of a sleeve to the elastic cushion, and the adjustment process is simple and rapid. The shock isolation devices are arranged between the table body and the ground, thereby not needing the special-purpose foundation, and saving the cost. Meanwhile, the collision waveform is optimized, the generation of the high-frequency harmonic is reduced, and the natural frequency of a collision table is less than 1 HZ.

Owner:西安从吾电子科技有限公司

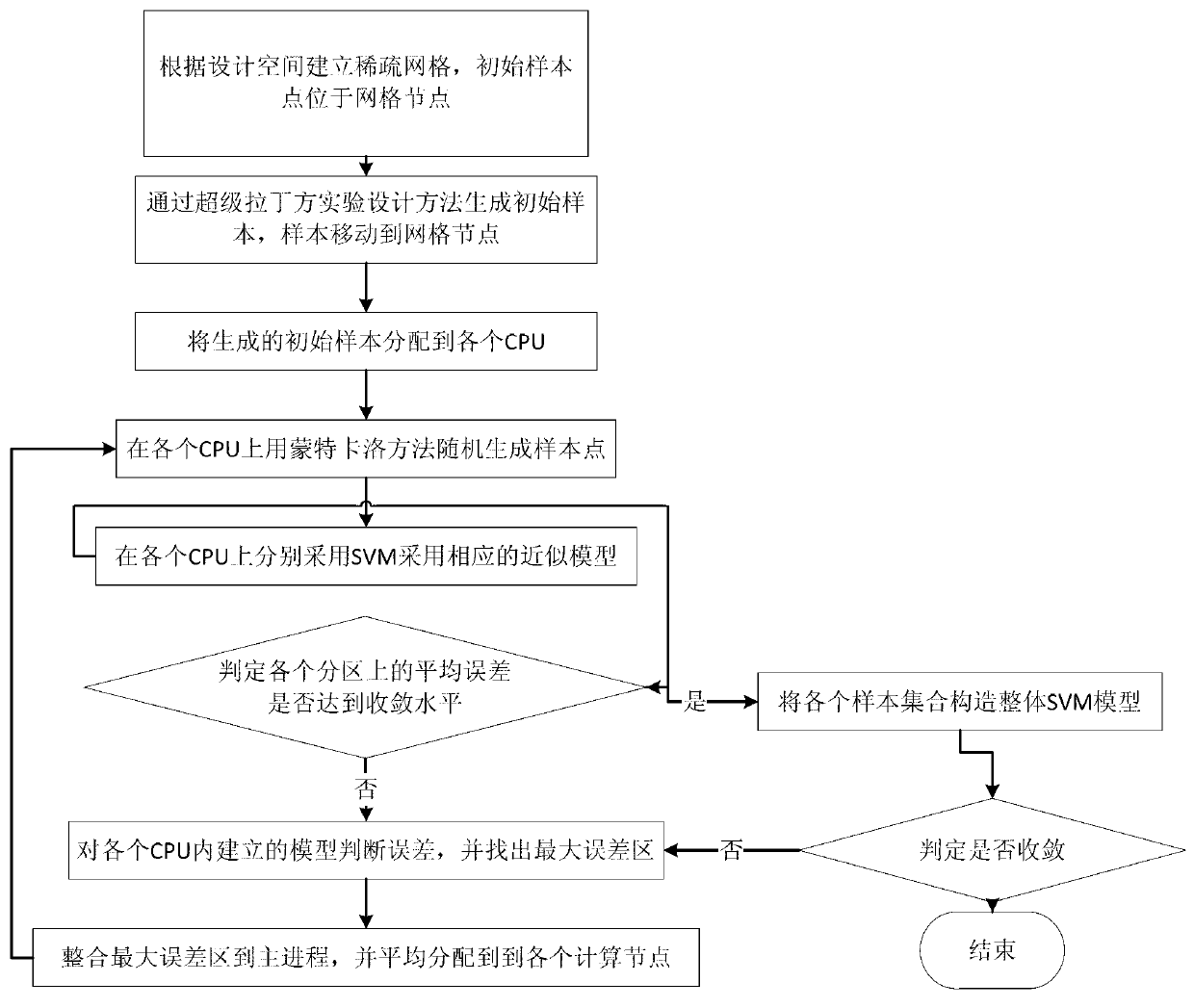

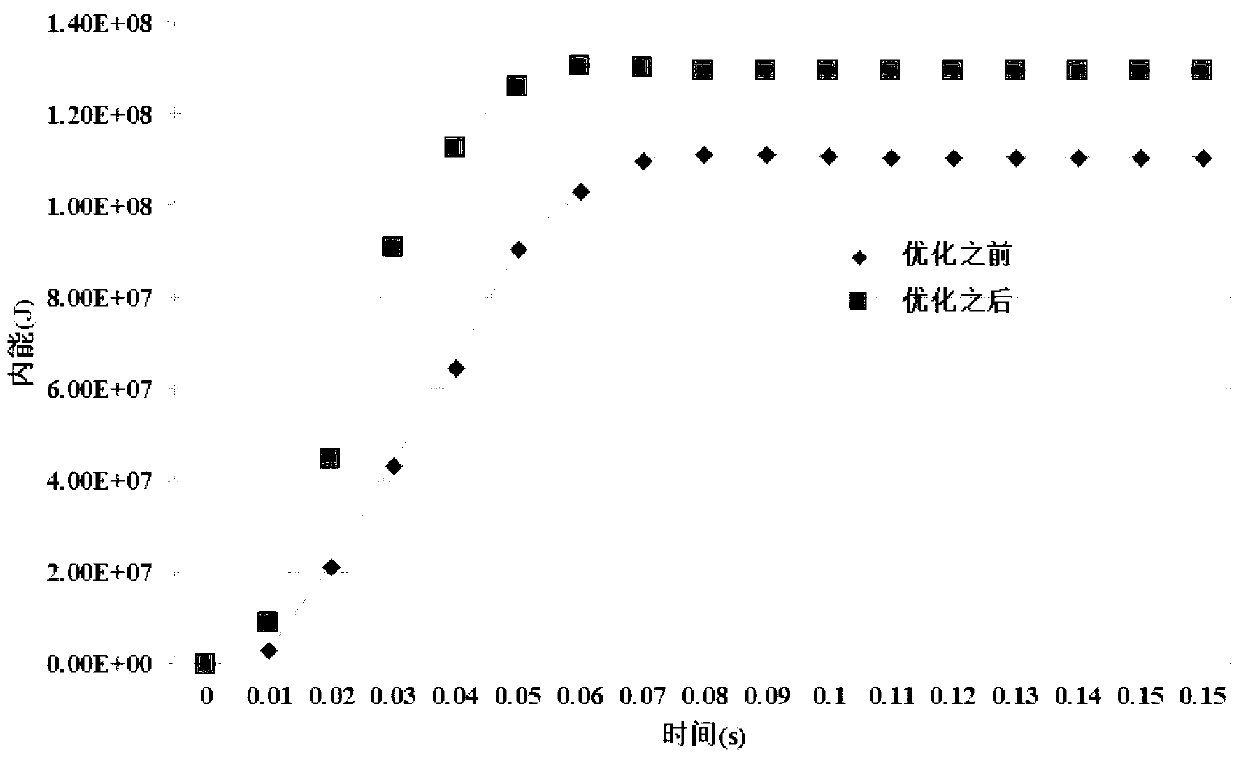

Parallel support vector machine approximate model optimization method based on automobile crashworthiness

ActiveCN102999672AHigh precisionEasy to convergeSpecial data processing applicationsMaximum errorSupport vector machine

The invention relates to a parallel support vector machine approximate model optimization method based on automobile crashworthiness. The parallel support vector machine approximate model optimization method comprises the steps of (1) establishing a network; (2) generating initial samples, and automatically transferring the initial samples to a grid node; (3) distributing the initial samples to calculating nodes; (4) generating sample points at random; (5) establishing an approximate model based on SVM (Support Vector Machine); (6) obtaining an error standard of an SVM approximate model, and judging whether the error standard reaches the convergence level or not; if so, constructing an entire SVM model by adopting all the generated nodes; (7) judging whether the entire SVM model converges or not; if so, finishing the process, otherwise, skipping to the step (8); (8) finding out the maximum error region; and (9) calculating the sum of the information of the error region, generating samples at random in the region after the summation, uniformly distributing the samples to the calculation nodes, and skipping to the step (4) till the process is finished. According to the parallel support vector machine approximate model optimization method, the mode that the SVM (support vector machine) is subjected to parallel processing is adopted, so that the modeling speed is greatly increased and the optimization efficiency and the precision are improved.

Owner:HUNAN UNIV

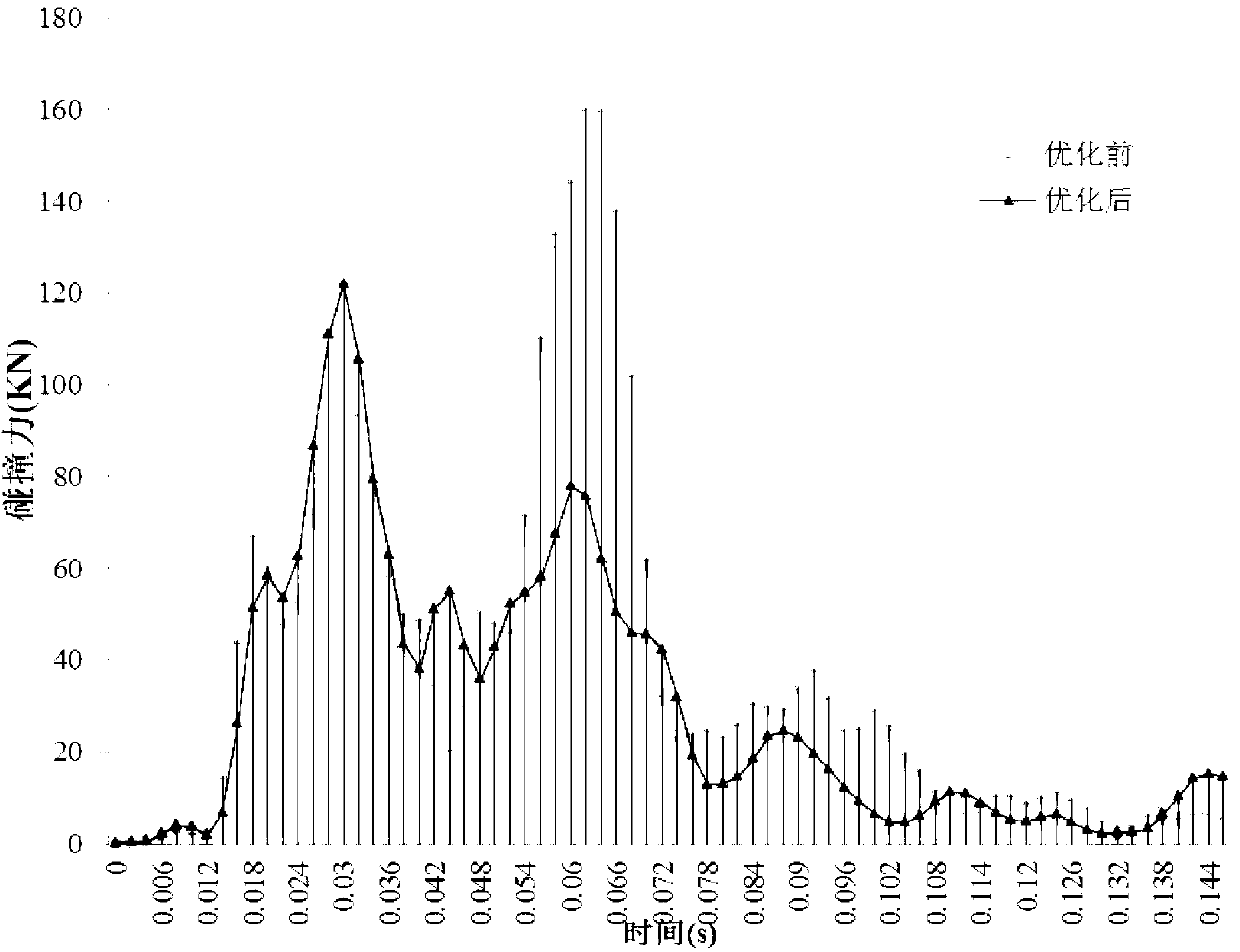

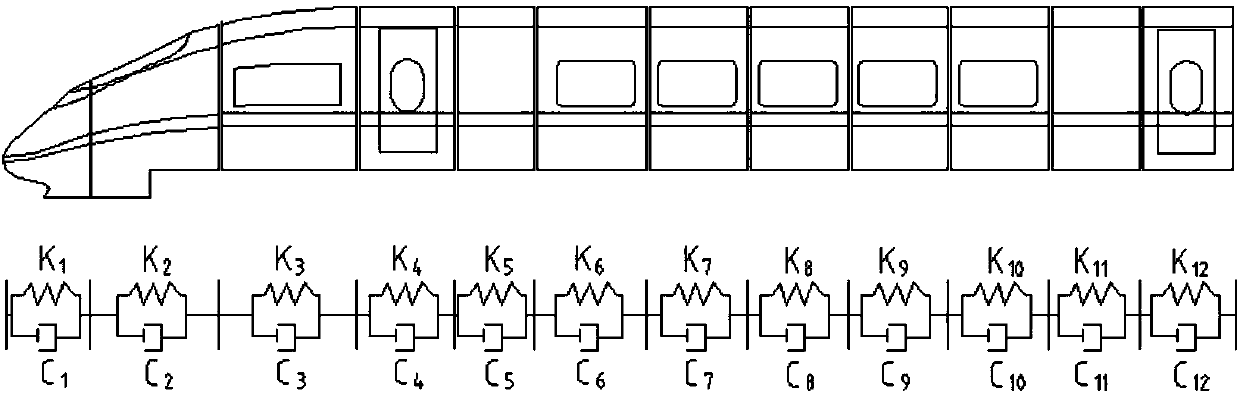

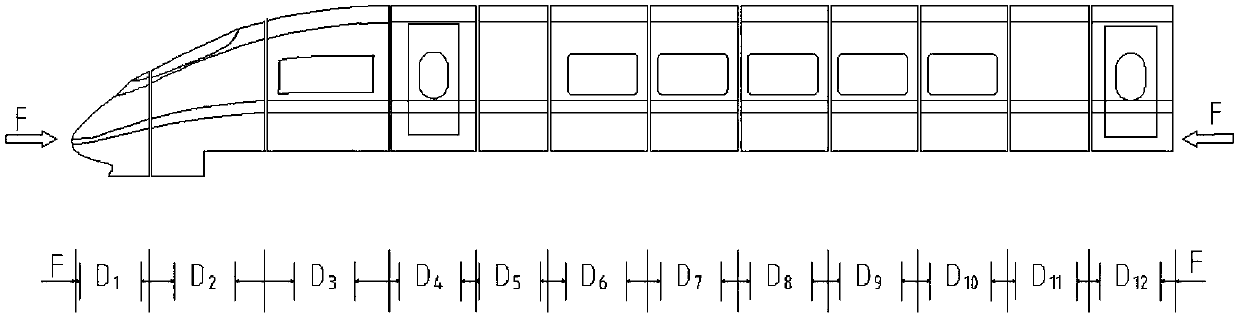

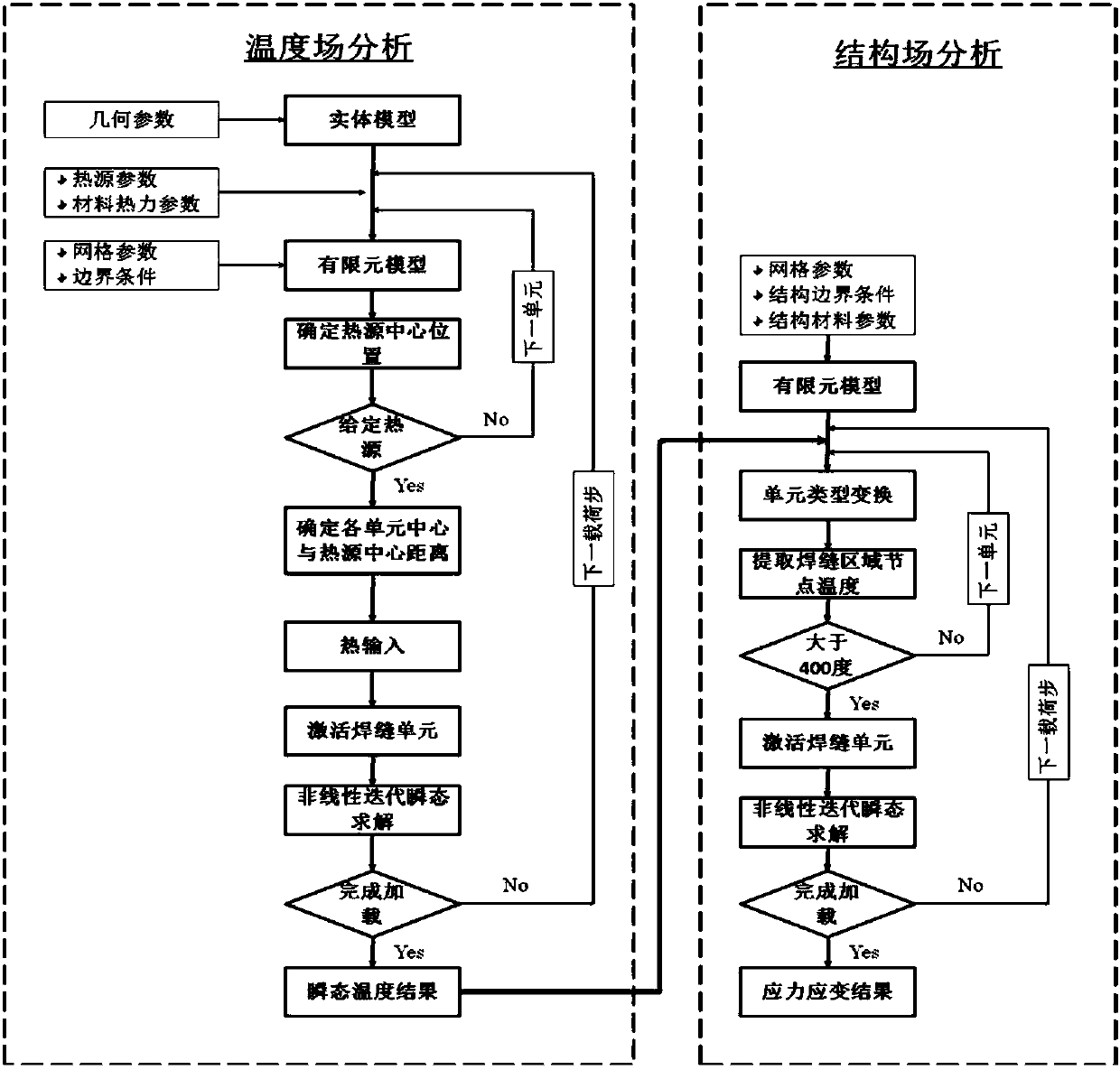

Method for evaluating crashworthiness of welding structure based on explicit-implicit continuous solving

InactiveCN107818231ACalculation speedReduce computing costGeometric CADDesign optimisation/simulationEngineeringStructure based

The invention relates to a method for evaluating the crashworthiness of a welding structure. The method is characterized by comprising the following steps: dividing finite element grids of a train body; longitudinally loading the train body so as to actually measuring or calculating a rigidity value and damping value of each node; carrying out computer simulation on a hot machine coupled welding structure, simulating a residual stress field of each welding line by virtue of an actual welding temperature field, or simulating an actual welding temperature field to actually measuring residual stress field of each welding line as an initial load of each node; loading the train body, carrying out crash test or computer simulation at a certain speed, and continuously solving based on explicit-implicit loads; and evaluating the energy flow of a train head welding structure, actually measuring the plastic deformation of a train head, or carrying out computer simulation, if the plastic deformation exceeds a failure set value, determining that the crashworthiness is insufficient, and otherwise, determining that the crashworthiness is qualified. The method is applied to a typical local welding structure of a high-speed train body, and an evaluation result is relatively true, objective and reliable.

Owner:BEIJING JIAOTONG UNIV

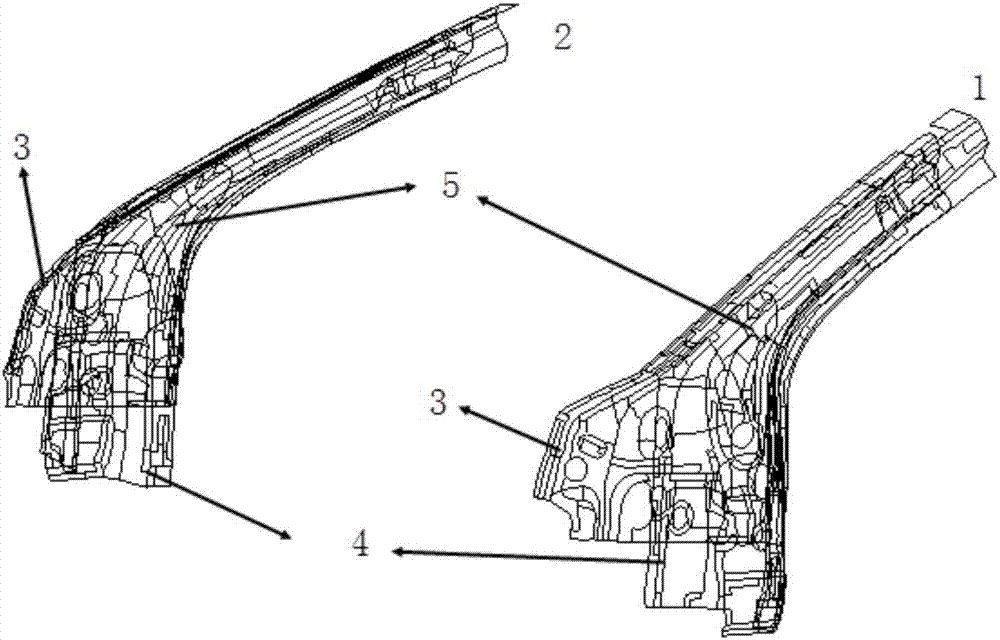

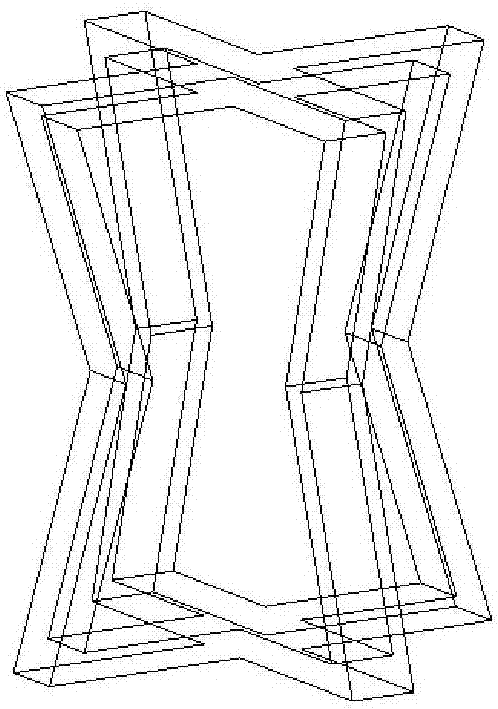

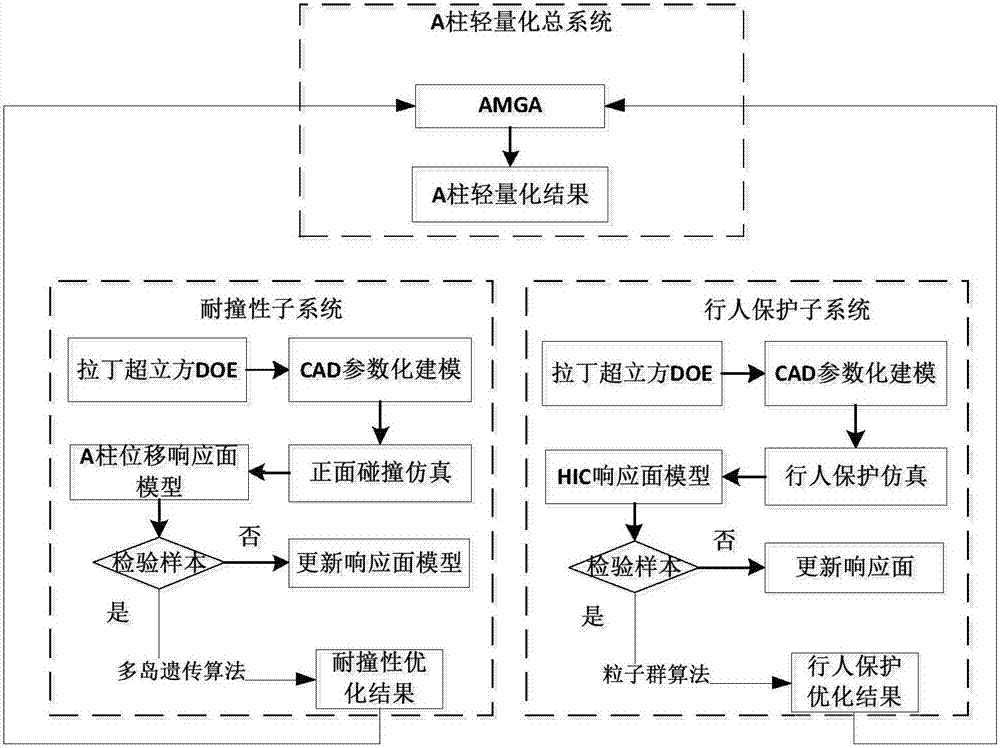

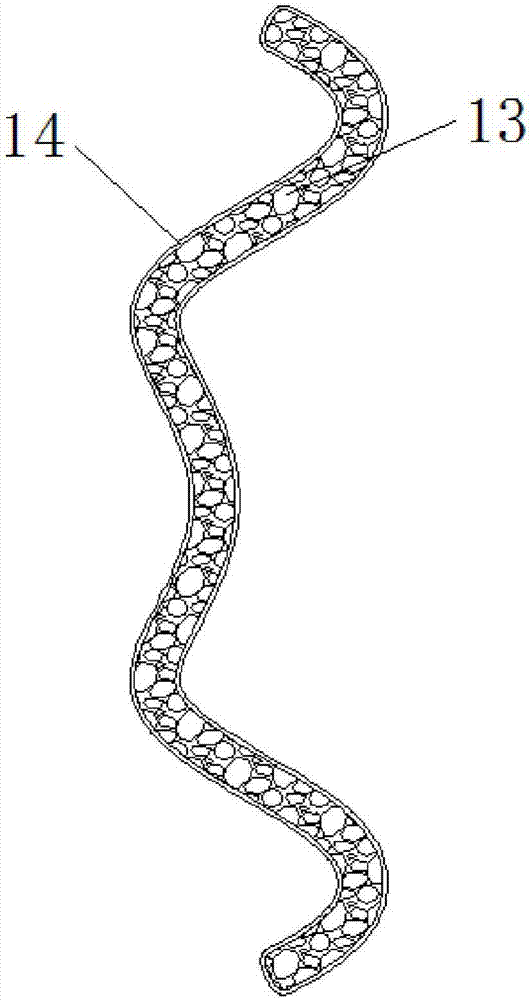

Pedestrian protection-based automobile energy absorption column A and optimization method thereof

ActiveCN106997417AImprove crashworthinessPlay a protective effectGeometric CADInternal combustion piston enginesFiberCarbon fibers

The invention discloses a pedestrian protection-based automobile energy absorption column A and an optimization method thereof. The automobile energy absorption column A comprises a left-side column A and a right-side column A, wherein the left-side column A and the right-side column A are symmetrically distributed on a vehicle center line, and respectively comprise an inner shell, an outer shell and an inner core; the inner shells, the outer shells and the inner cores of the left-side column A and the right-side column A are made of a carbon fiber material; and the inner cores are formed by three-dimensional indented hexagonal negative Poisson's ratio single-cell arrays. The invention furthermore discloses the optimization method of the automobile energy absorption column A; after optimization, two working conditions such as automobile-pedestrian collision and automobile front collision can be considered, so that the automobile crashworthiness and lightweight are ensured under the premise of reducing the pedestrian head injury.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

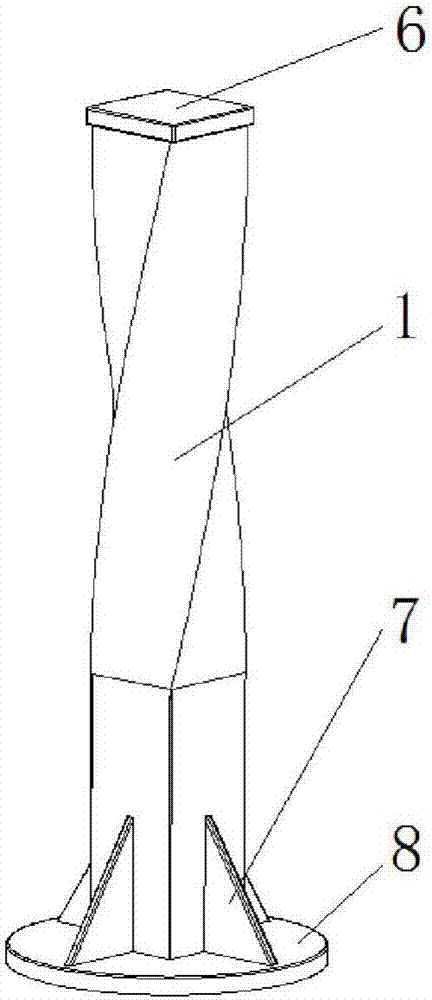

Corrugated sandwich road protection structure

ActiveCN106948294AEfficient energy absorption characteristicsImprove stabilityClimate change adaptationRoadway safety arrangementsArchitectural engineeringStructural engineering

The invention relates to a corrugated sandwich road protection structure. The corrugated sandwich road protection structure comprises spiral columns, a sandwich corrugated plate, main corrugated taper pipe assemblies, and subsidiary corrugated taper pipe assemblies; the sandwich corrugated plate comprises a corrugated shell, and fillers arranged in the corrugated shell; the upper portion of each spiral column rotates along the axis and forms warped surfaces; and each main corrugated taper pipe assembly and each subsidiary corrugated taper pipe assembly are connected with the sandwich corrugated plate and the upper portion of corresponding spiral column, the main corrugated taper pipe assemblies are obliquely connected with the sandwich corrugated plate, and the subsidiary corrugated taper pipe assemblies are vertically connected with the sandwich corrugated plate. The corrugated sandwich road protection structure solves the problems that protective fences of a general road and an expressway are not strong enough in crashworthiness, single in energy-absorbing form, and poor in buffering effects, and cannot effectively prevent vehicles off the road. The corrugated sandwich road protection structure has the beneficial effects of having a characteristic of high energy absorption; being safe and reliable with high stability, strong in crashworthiness, and high in adaptability of impact angle; and being easy to mount, convenient to replace, and high in sustainable use.

Owner:HUAQIAO UNIVERSITY

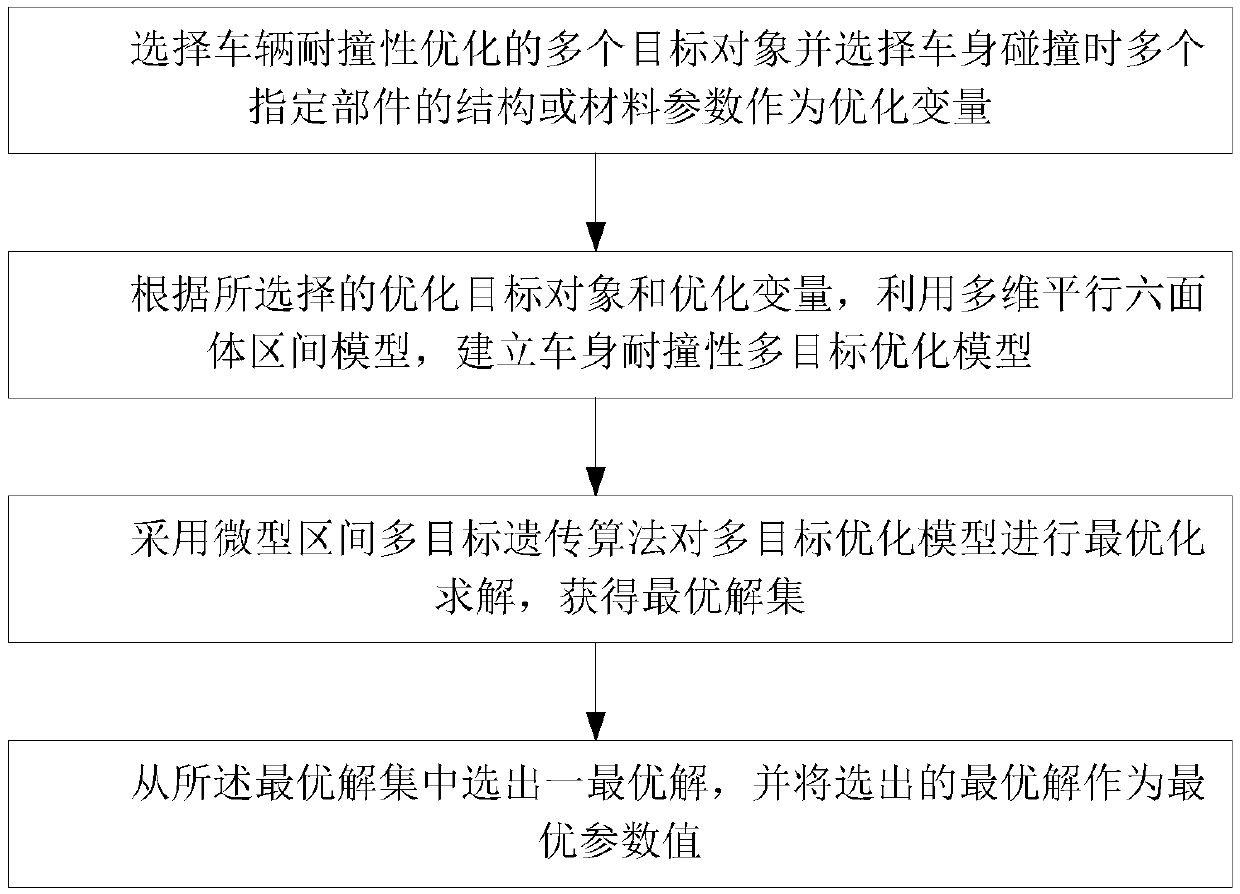

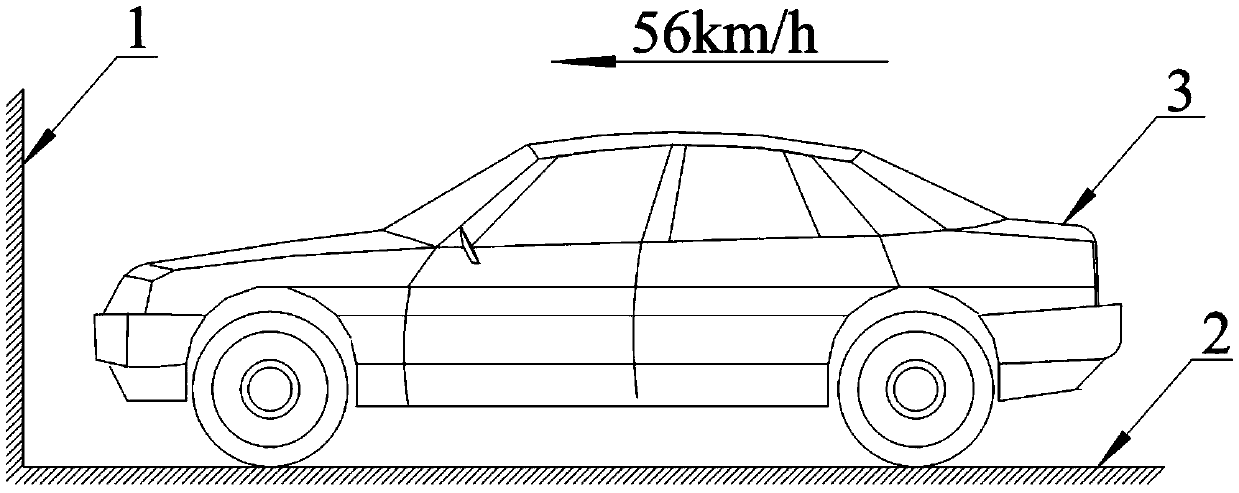

A vehicle body crashworthiness optimization method

PendingCN108984901AHigh precisionImprove efficiencyGeometric CADDesign optimisation/simulationGenetic algorithmAutomobile safety

The invention relates to a vehicle body crashworthiness optimization method, belonging to the technical field of automobile safety optimization. The vehicle body crashworthiness optimization method includes selecting a plurality of objective objects for optimizing the crashworthiness of the vehicle and selecting structural or material parameter of a plurality of specified components as optimization variables when the vehicle body collides, wherein the structural or material parameters of the plurality of specified components are uncertain parameters; according to the selected optimization object and optimization variable, establishing a multi-objective optimization model of vehicle body crashworthiness by using the multi-dimensional parallelepiped interval model; solving the multi-objective optimization model by using the micro-interval multi-objective genetic algorithm, obtaining an optimal solution set, selecting the optimal solution from the optimal solution set, and taking the selected optimal solution as the optimal parameter value. The method effectively improves the precision and efficiency of the crashworthiness optimization of the automobile body, improves the safety of the automobile product, and achieves the purpose of reducing the development cost.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com