Miniature tilt-shift type optical anti-vibration voice coil motor structure facilitating production and assembling method

A voice coil motor and optical anti-shake technology, applied in optics, optical components, installation, etc., can solve problems such as the complex structure of voice coil motors, reduce mechanical and electronic connection processes, improve mechanical anti-collision performance, and reduce assembly hand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

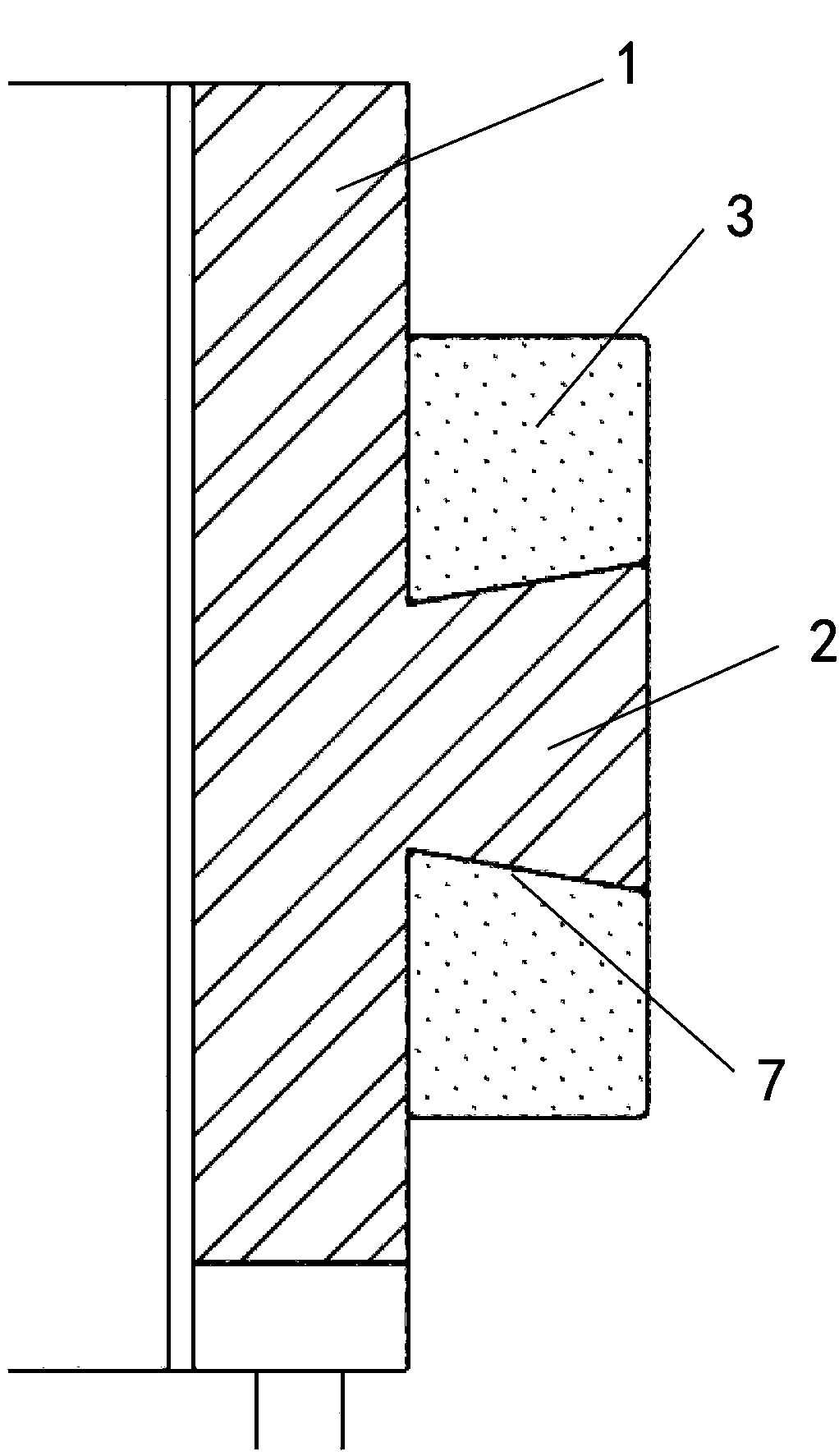

[0059] Embodiment two: Please refer to the attached Figure 7 And attached Figure 8 , the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that this embodiment contains two groups of elastic materials, namely the upper spring leaf 14 and the lower spring leaf 15, the upper spring leaf 14 and the lower spring leaf 15 are respectively located on the top and bottom of the lens carrier 10 .

Embodiment 3

[0060] Embodiment three: Please refer to the attached Figure 9 And attached Figure 10 , the basic structure of the present embodiment is the same as that of the first embodiment, the difference is that the coil 3 and the magnet 11 are arranged on the four sides of the coil carrier 1 in the first embodiment, and in this embodiment, the coil 3 and the magnet 11 are arranged on the coil At the four corners of the carrier 1, the rest of the structure is the same as in Embodiment 1.

Embodiment 4

[0061] Embodiment 4: The basic structure of this embodiment is the same as that of Embodiment 2. The difference is that in Embodiment 2, the coil 3 and the magnet 11 are arranged on the four sides of the coil carrier 1. In this embodiment, the coil 3 and the magnet 11 It is arranged at the four corners of the coil carrier 1, and the rest of the structure is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com