Patents

Literature

738results about How to "Improve production pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

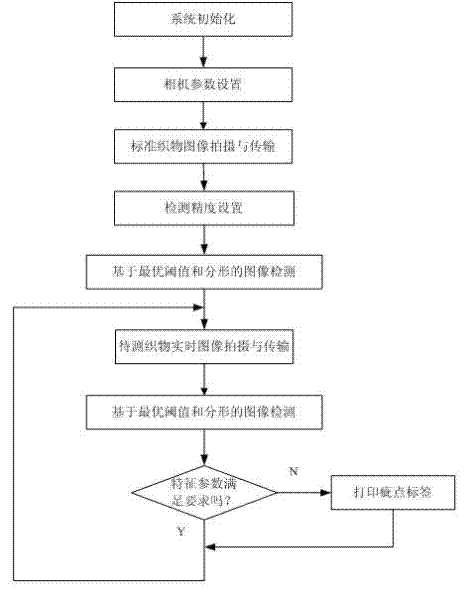

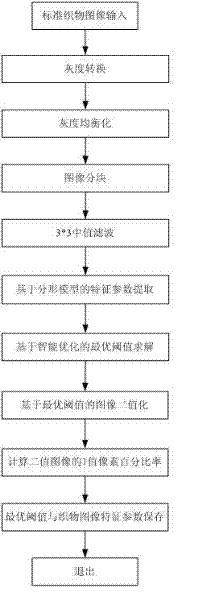

Online automatic detection method of fabric defects based on machine vision and device thereof

InactiveCN102221559AOvercome labor intensityOvercome visualInspecting textilesMaterial analysis by optical meansMachine visionFeature parameter

The invention relates to an online automatic detection method of fabric defects based on machine vision and a device thereof, wherein the clear and integral standard fabric images without the defects of the fabric are shot on a batching and burling machine as a standard image template by utilizing an industrial camera in order to solve the problems of great labor intensity and poor detection quality of the traditional manual detection method; the corresponding characteristic parameters are extracted and stored into a computer; the range of the fabric defect detection characteristic parameters is set according to the requirements of users; the fabric images which are shot in real time are transmitted to the computer to be compared with the standard image template by utilizing the industrial camera and compared with the standard characteristic parameters; if the fabric characteristic parameters are not in conformity with the set requirements, the alarm is started by detection software; the defects are analyzed; and the printing of defects labels is executed. The invention has the advantages of high detection accuracy and high speed; and the labor intensity is greatly reduced.

Owner:HOHAI UNIV CHANGZHOU

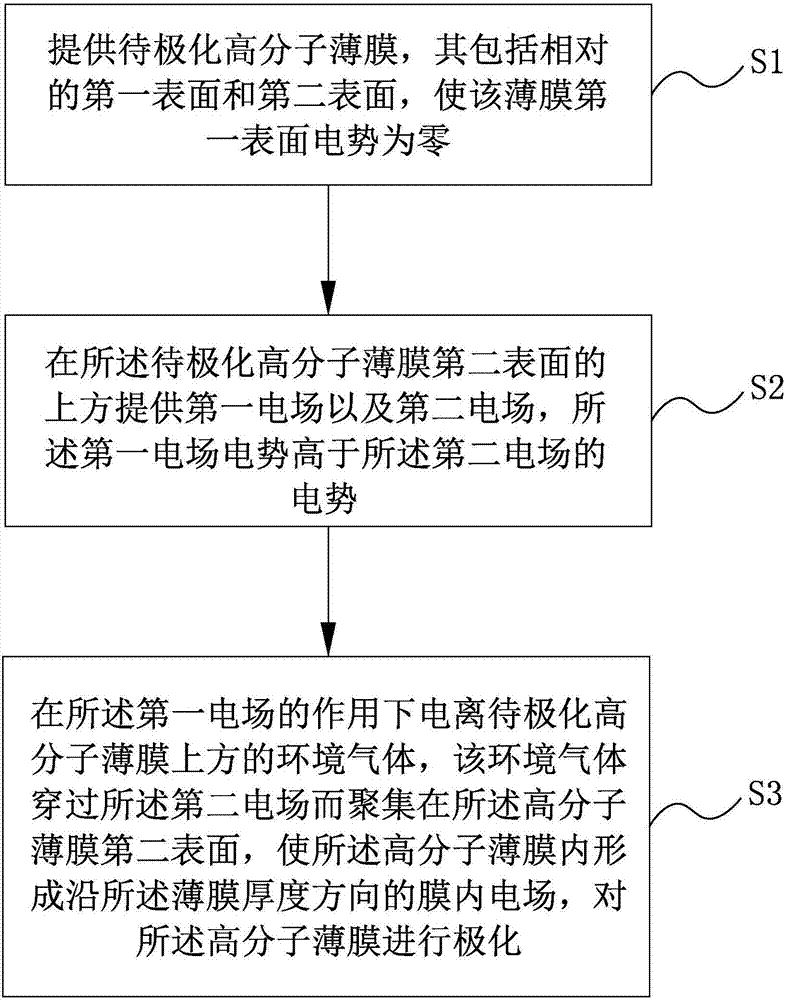

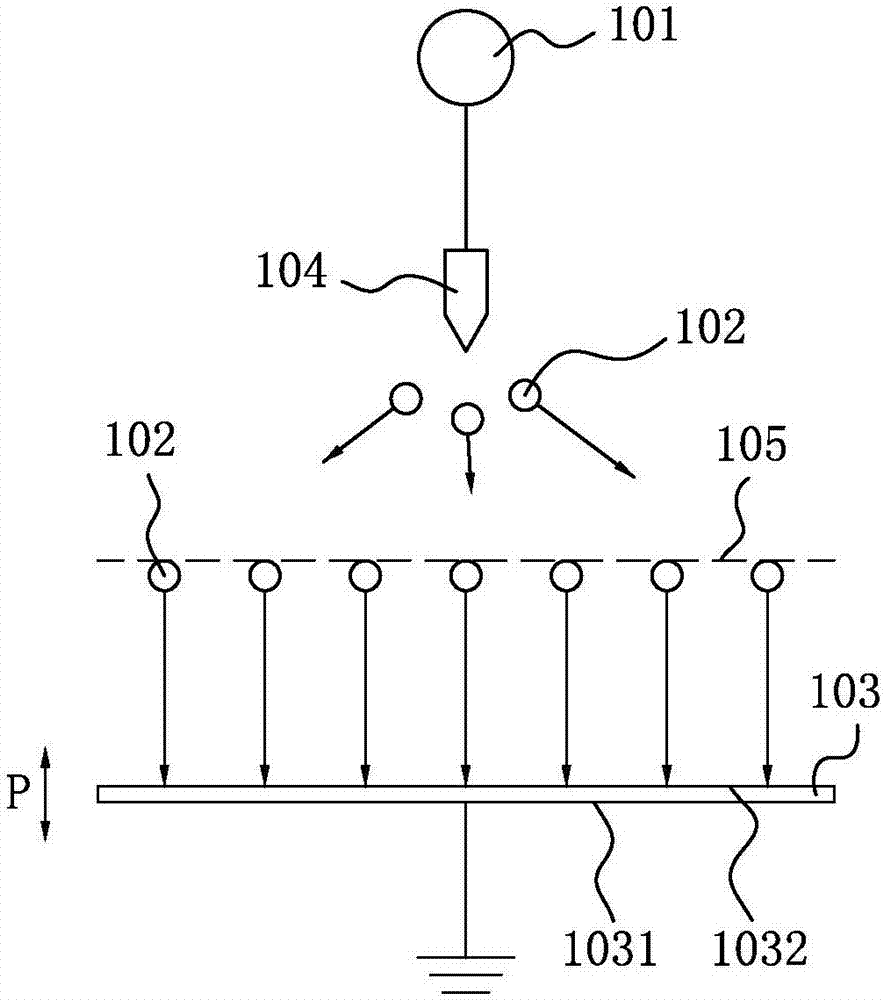

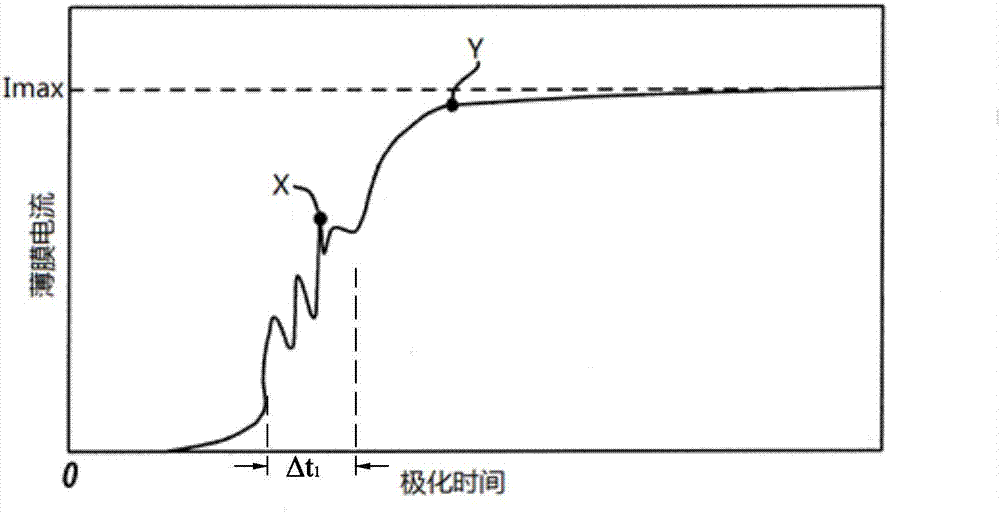

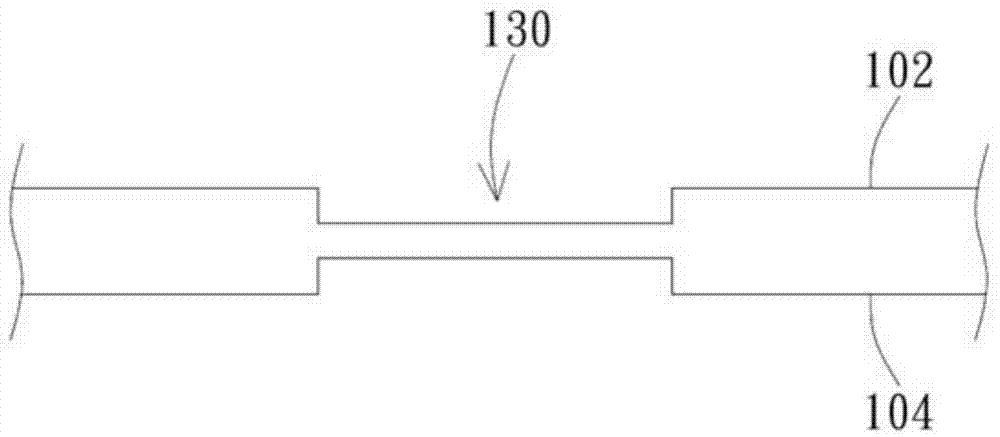

Polymeric thin film polarization method, polarizing film and electronic device

ActiveCN107104179APrevent breakdownImprove production pass ratePiezoelectric/electrostrictive devicesProduction rateElectricity

A method for polarizing a polymer film is disclosed. An ambient gas above a polymer film under the action of a first electric field is ionized, the ambient gas accumulates on the second surface of the polymer film through the second electric field, an organic electric field in the film thickness direction is formed in the molecular thin film, and the polymer film is polarized. The polymer film polarization method can avoid the breakdown of the polymer film, effectively improve the production rate of the polarized film, can achieve large-scale production; and the resulting polarized film has a strong piezoelectric effect and longer Service life. The present invention also provides a polarizing film prepared by the above-described method of polymer film polarization, which has a strong piezoelectric effect and a long service life. The present invention also provides an electronic device comprising a substrate and a polarizing film as described above.

Owner:科锐昇微系统(苏州)有限公司

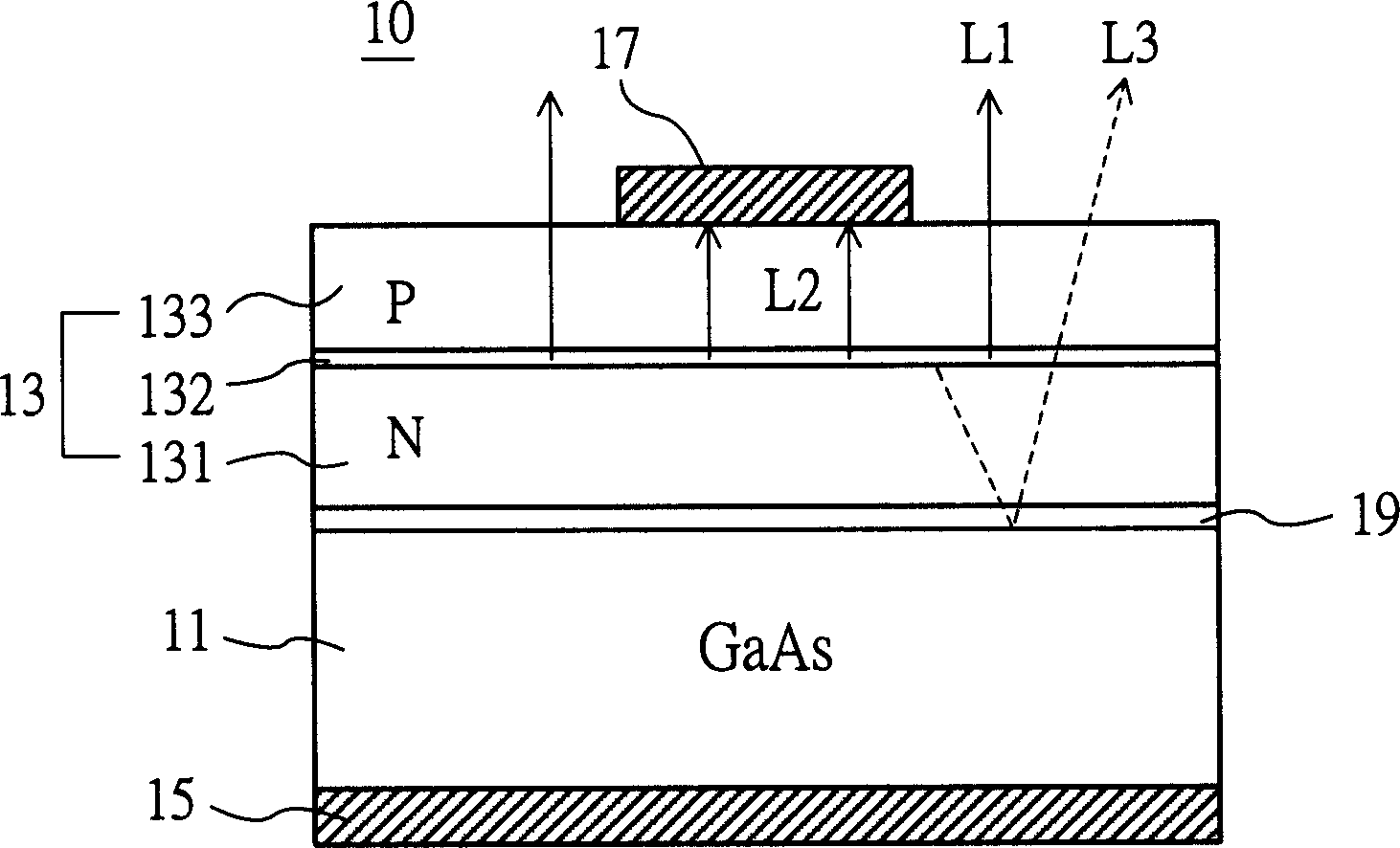

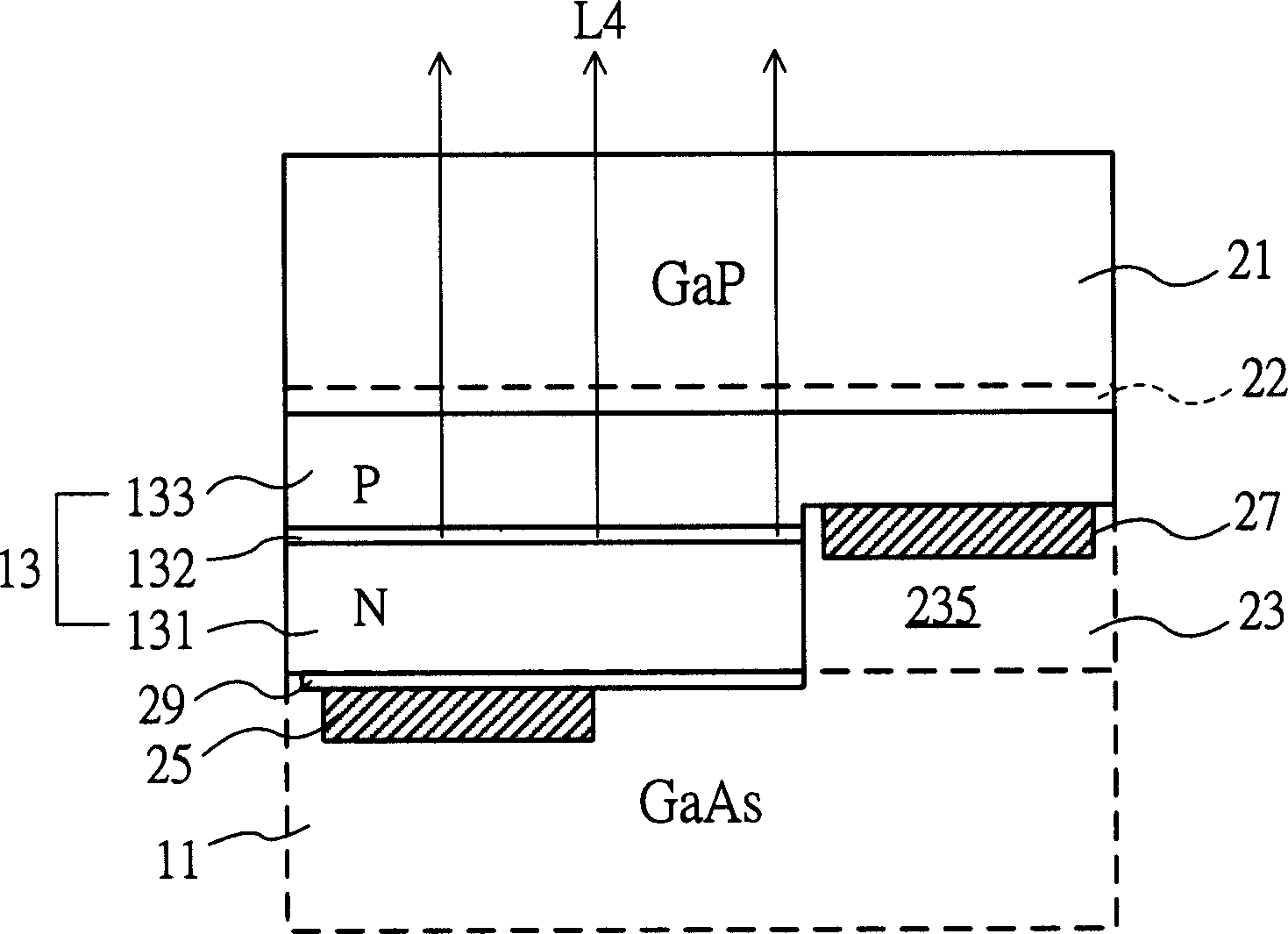

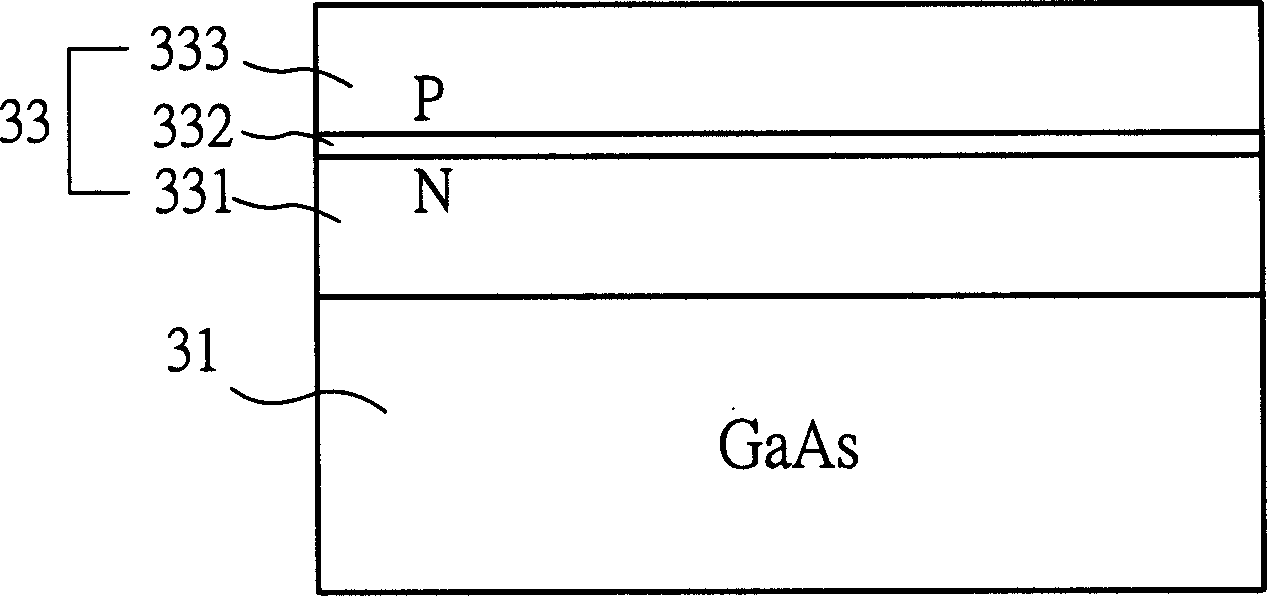

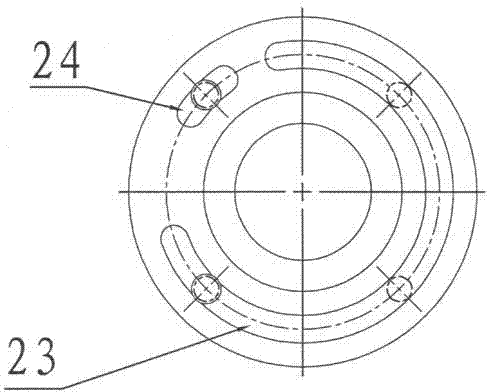

LED

InactiveCN1564333AUniform distribution of working current densityImprove efficiencySemiconductor devicesElectrical conductorEngineering

Quadreple epitaxial layer composed of first material layer, luminous layer and second material layer is formed on a semiconductor base plate. A euphotic base plate is fixed on surface of the second martial layer. With semiconductor base plate being removed, isolation groove and first extend groove are made under undersurface of first material to penetrate the first material layer and extend to part of volume of second material layer at least. First extend electrode is setup inside first extend groove. The first extend electrode is possible to connect with first electrode positioned at partial surface of the first material layer. Thus, the first electrode is located in nearly same level position to second electrode, which is on surface of other part of the first martial layer in order to carry out next processing easily. The invention increases luminescence are of PN interface, raises luminescence brightness and service life.

Owner:OPTO TECH

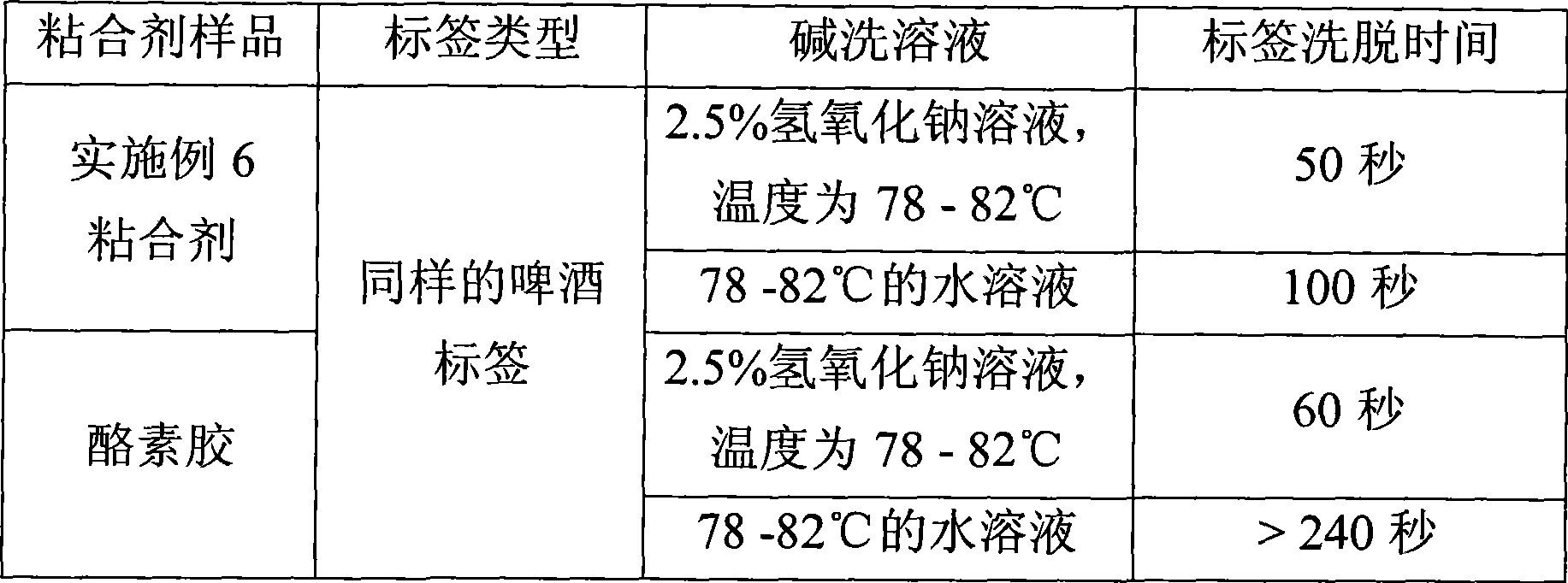

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

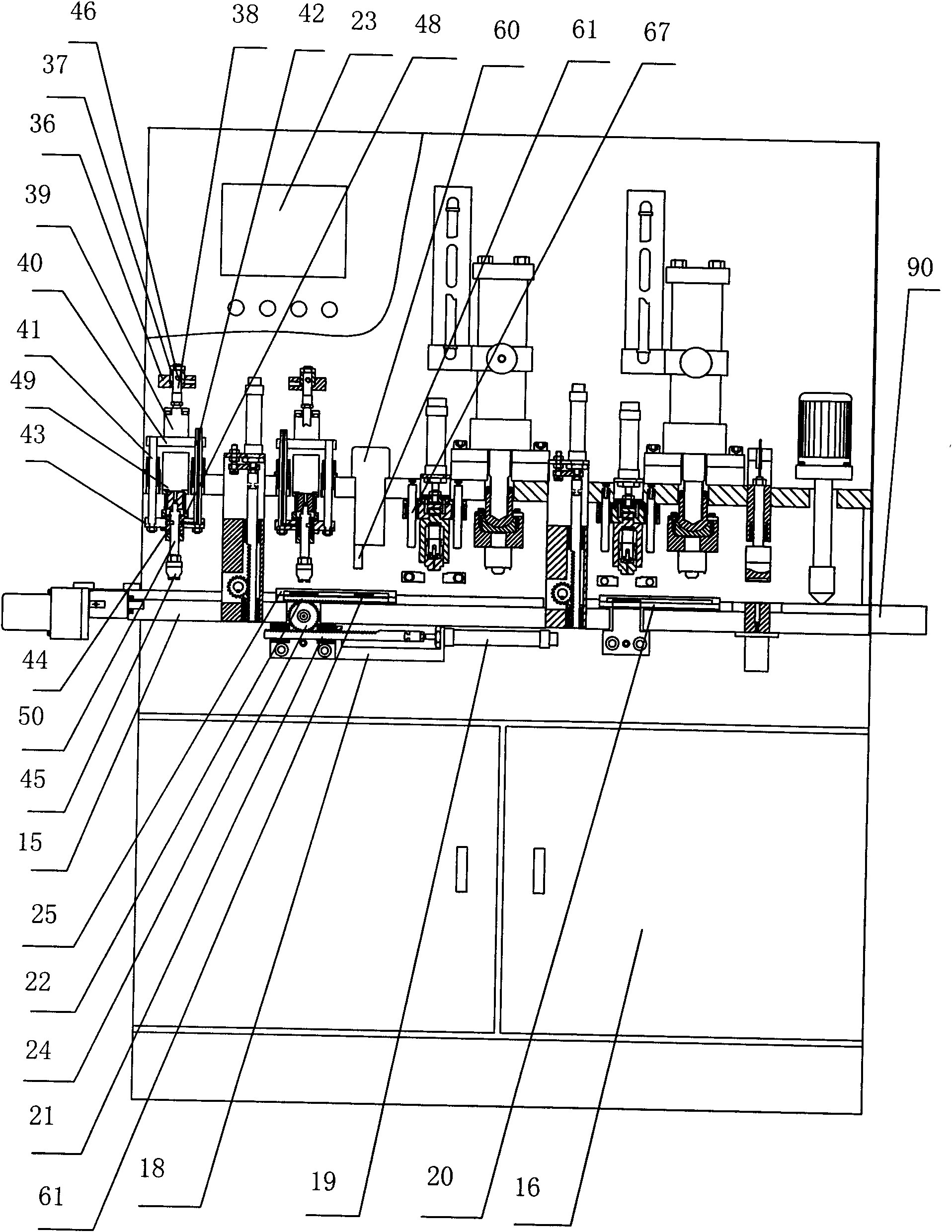

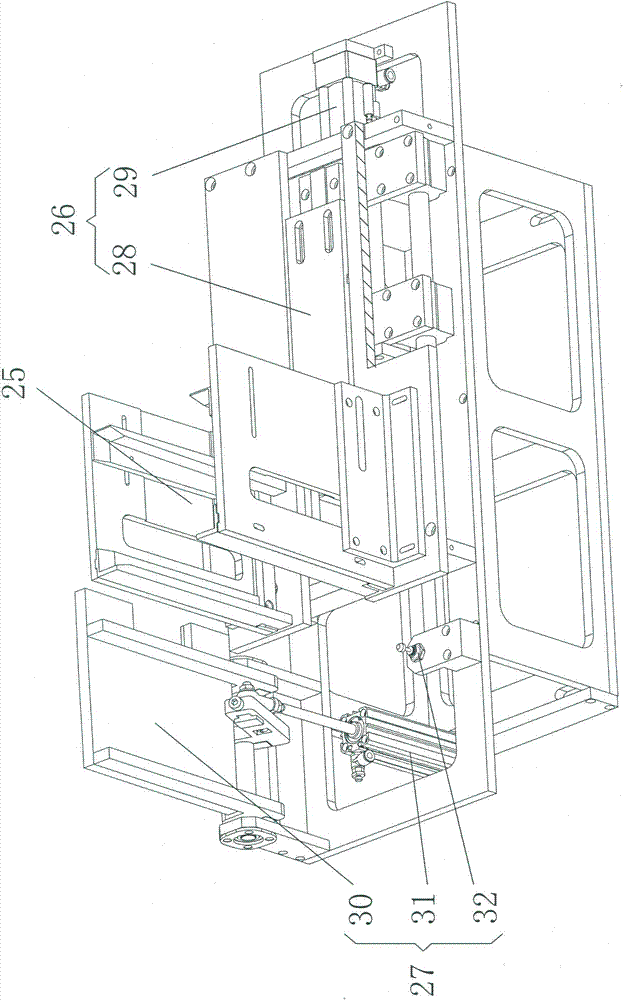

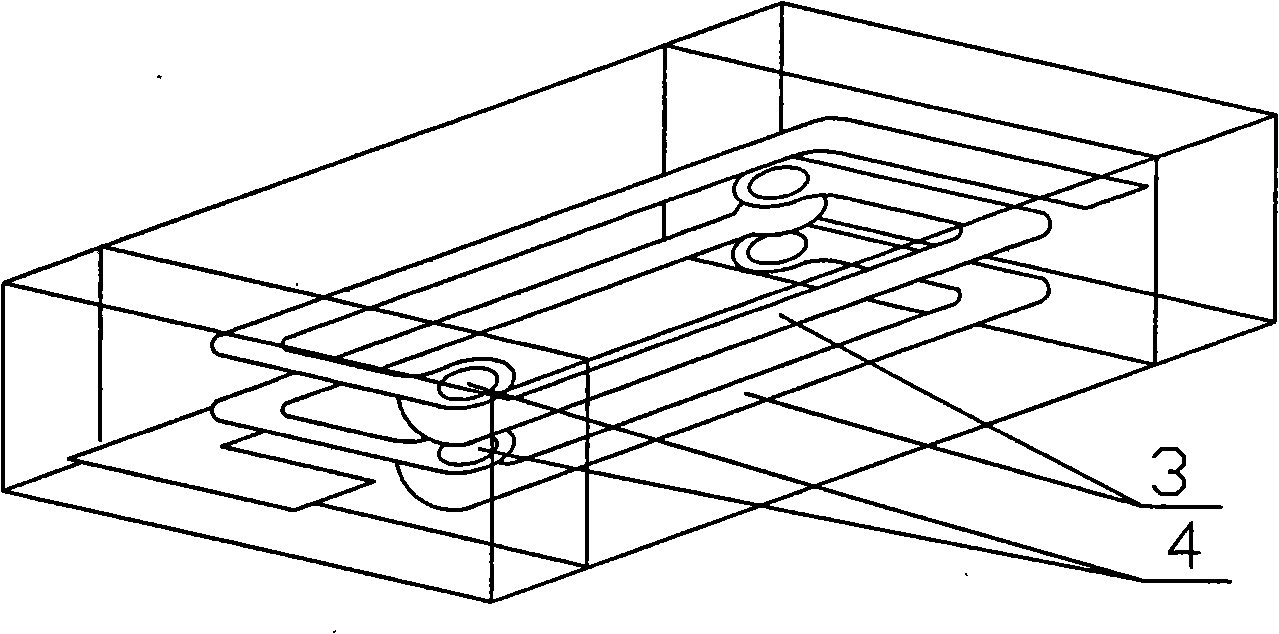

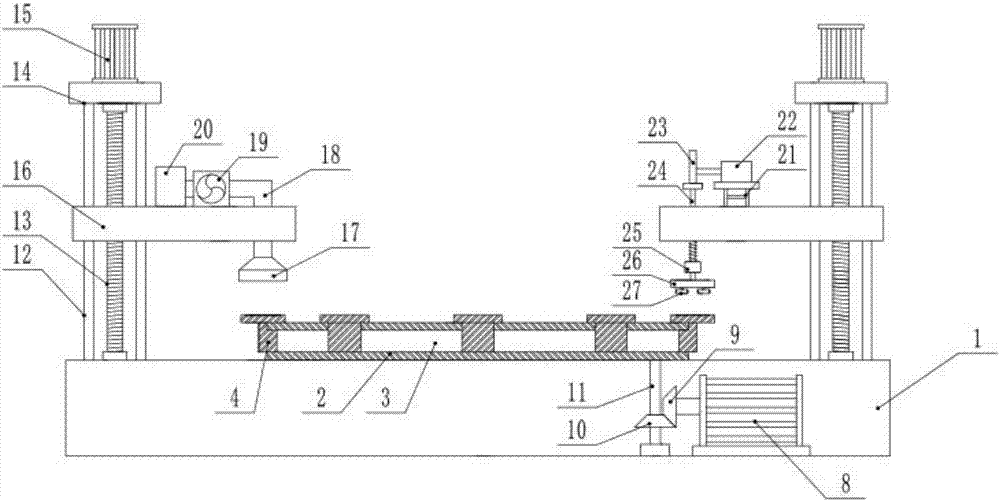

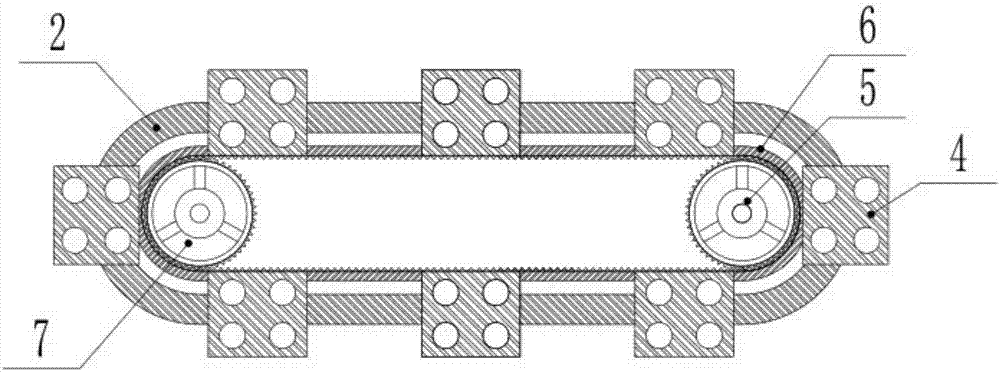

Full-automatic bearing greasing and capping machine

InactiveCN101982699ACompact structureEasy to debugProportioning devicesConveyorsFailure rateEngineering

The invention discloses a full-automatic greasing and capping machine, relating to a device for adding grease and a dust cap to a bearing. A workbench is fixed on a machine frame; a mounting base is fixed on the workbench; the front part of the mounting base is provided with a material support plate; the upper part of the mounting base is provided with a control device; the left side of the workbench is provided with a material conveyor, and the right side of the workbench is provided with an unacceptable product removing device; according to the processing sequence, two greasing devices, a grease quantity detection device, two capping devices, a dust cap height detection device and a grease equalizer are sequentially arranged on the mounting base from left to right; turning devices are respectively arranged between the two greasing devices and between the two capping devices; and a front reciprocating device and a rear reciprocating device are respectively arranged below the workbench. The full-automatic greasing and capping machine disclosed by the invention integrates the stations and the mounting base into a whole, is high in positioning accuracy and facilitates debugging and installation of a fixture mold; and the total seal shell is convenient for cleaning and maintenance, thus, the invention has the advantages of strong dustproof capacity, low danger coefficient, low failure rate and high product qualification rate.

Owner:SHANDONG XUNJIE PRECISION EQUIP

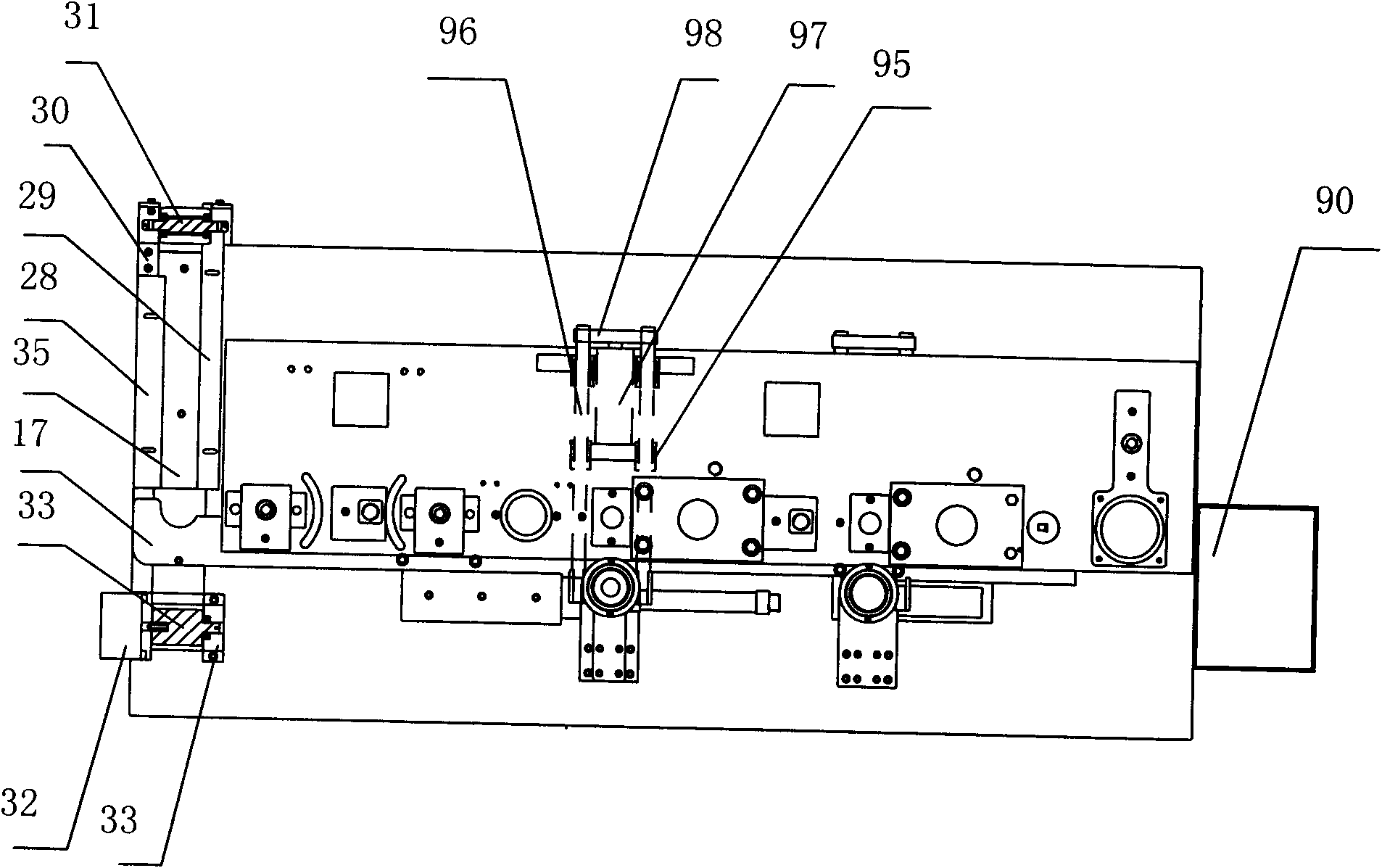

Carton forming machine

ActiveCN104842586AIncrease productivityImprove production pass rateBox making operationsPaper-makingCartonPaperboard

The invention discloses a carton forming machine. A three-opening edge covering mechanism comprises three-opening edge covering devices used for inwardly covering edges of surface paper, corresponding to three openings of a carton, of fed paperboards. A rotary plate mould mechanism comprises moulds, each mould is driven to rotate intermittently by a power source and sequentially passes through a bottom board feeding mechanism, a forming mechanism and a carton discharging mechanism, the outer lateral side of each mould is provided with an air hole which is communicated with an air passage formed in the corresponding mould, and each air passage is communicated with an air source control device. The bottom board feeding mechanism comprises bottom board feeding devices used for feeding bottom boards to the outer lateral sides of the moulds respectively; a paperboard transferring mechanism comprises paper board transferring devices used for transferring paperboards with three-opening edge covering finished to the carton forming mechanism; the carton forming mechanism comprises forming devices used for making the paperboards into cartons on the moulds; the carton discharging mechanism comprises carton discharging devices used for taking out the formed cartons from the moulds. The carton forming machine has the advantages that mechanization in forming of the cartons is realized, production efficiency and yield are improved, and automatic production can be realized by the aid of photoelectric eyes and a controller for controlling.

Owner:RUIAN JINGANG MACHINERY

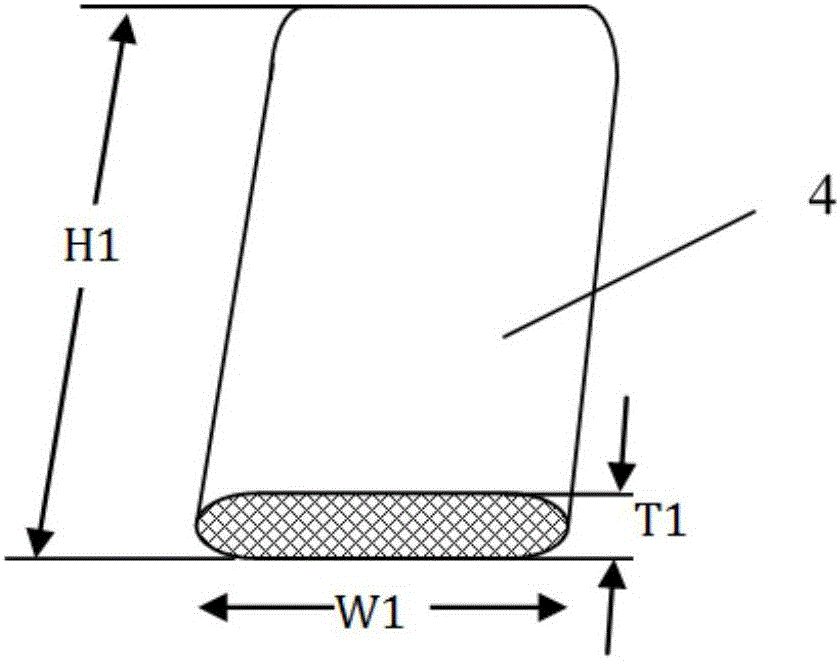

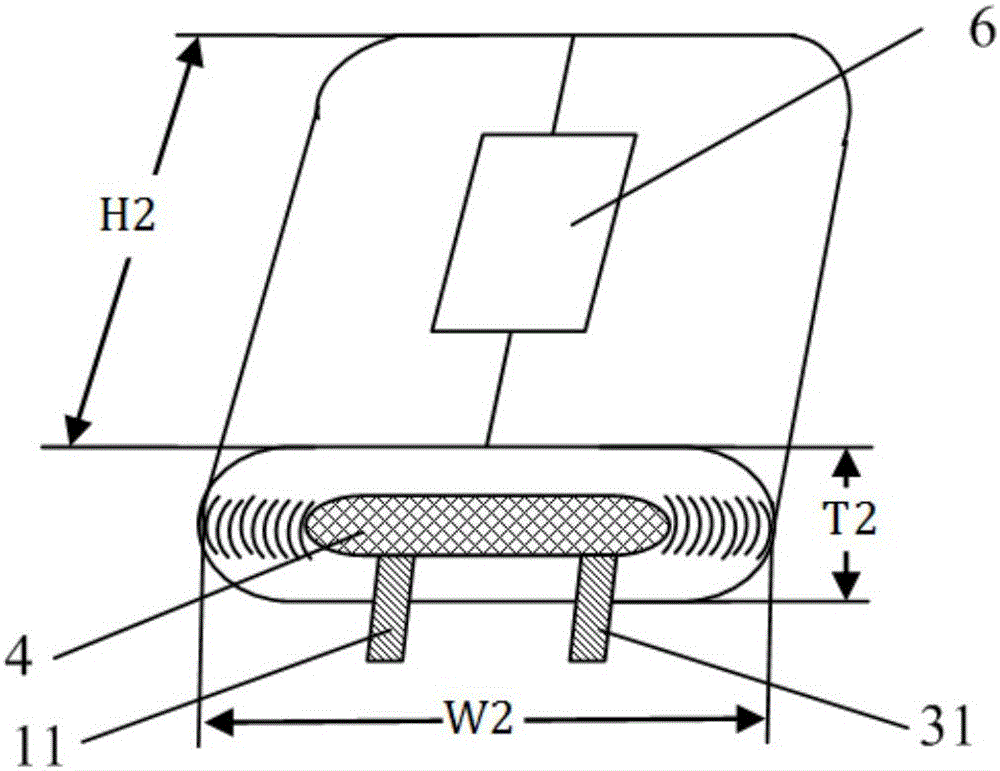

Method for manufacturing chip inductor and inductor thereof

InactiveCN101354948AImprove production pass rateReduce manufacturing costInductances/transformers/magnets manufactureFixed signal inductancesScreen printingLight sensing

The invention discloses a method for manufacturing a chip inductor, which comprises the steps of screen printing, casting, glue removal and sintering; in the step of screen printing, a conducting wire groove of a screen printing frame is between 0.5 and 0.85 circle; one end of the conducting wire groove is provided with a light sensing latex column; the screen printing frame is positioned on a substrate casting membrane; a line conductor sizing agent is printed on the conducting wire groove of the frame to form an inner electrode; a medium sizing agent is printed on the whole screen printing frame surface to form a medium membrane; pylomes are formed in the light sensing latex column; the screen printing frame is repeatedly positioned; the line conducting wire sizing agent and the medium sizing agent are printed to form a magnetic body of the chip inductor. The method reduces production cost and equipment input and improves production efficiency and the qualification rate of producing the inductor with ultra-small size. The inductor manufactured by the method has reliable performance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

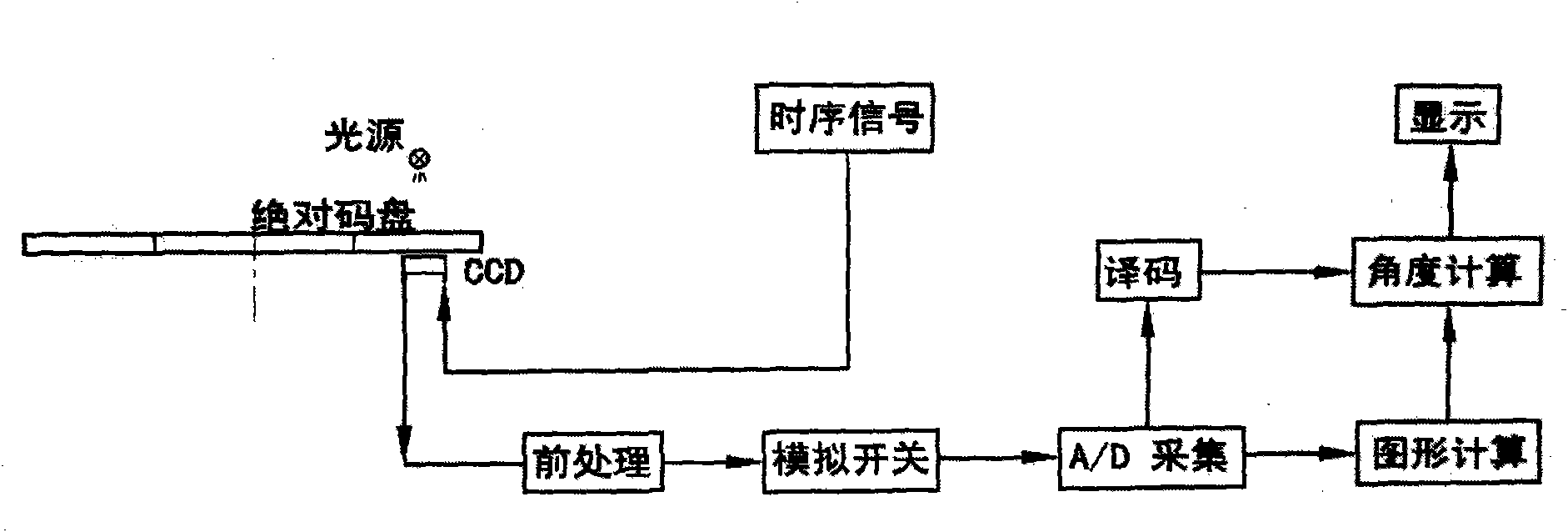

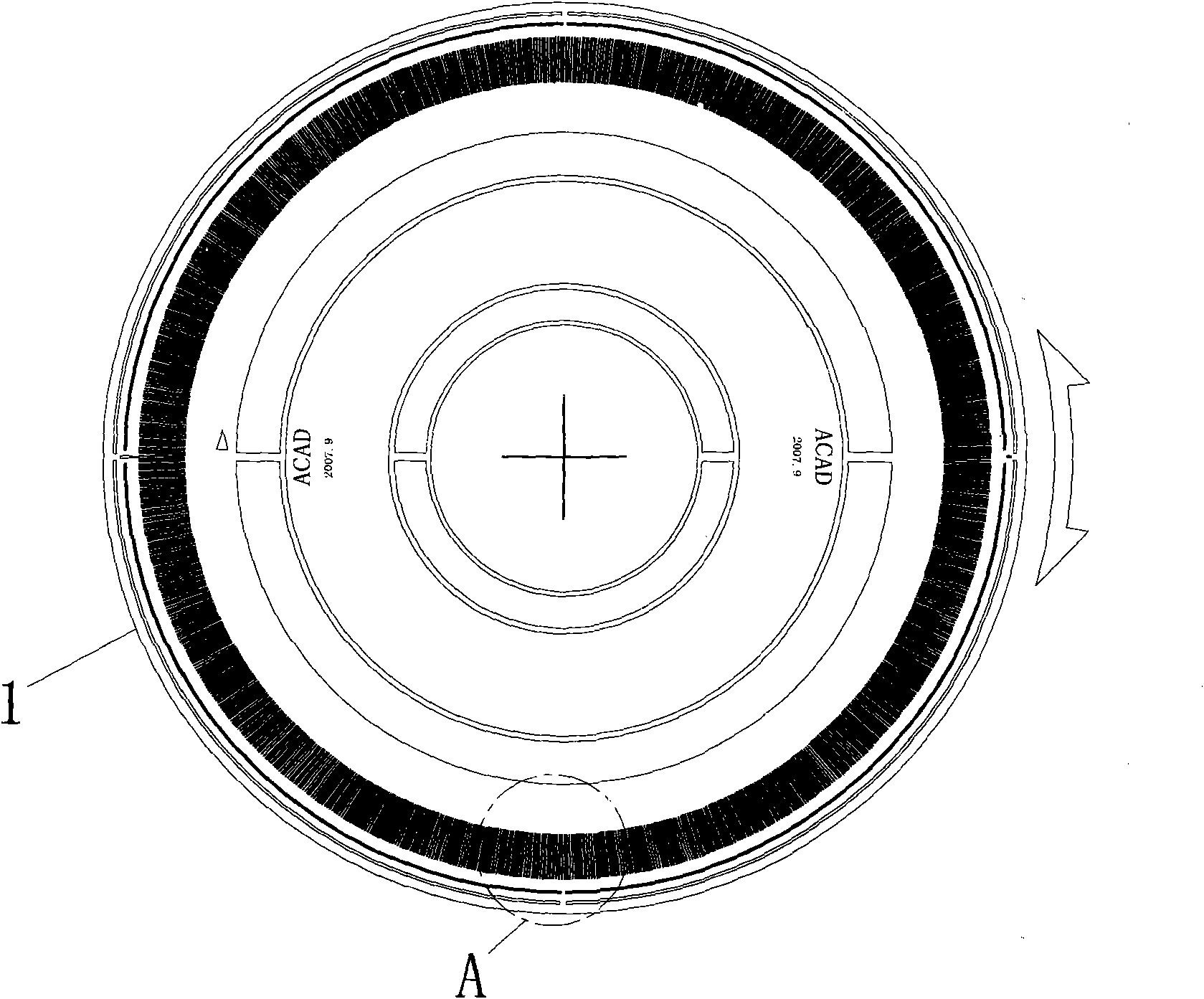

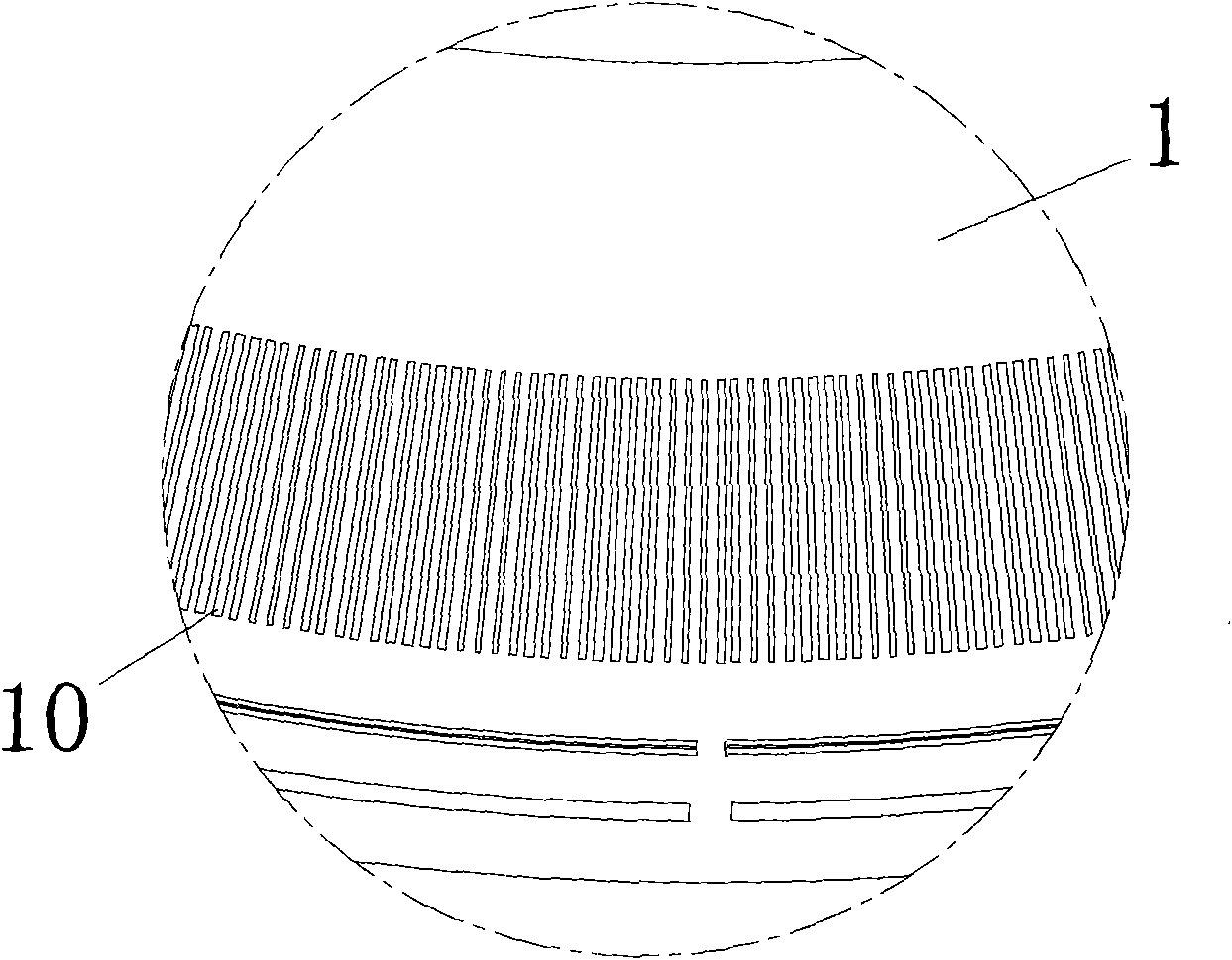

Method for highly accurately measuring absolute angle

InactiveCN102032924AEasy to manufactureConducive to simplificationConverting sensor outputData displayGreen-light

The invention discloses a method for highly accurately measuring an absolute angle, which facilitates the volume miniaturization and circuit simplification of measuring equipment to ensure that the measuring equipment is convenient to carry and can improve anti-interference performance and reliability. In the method, a green light source and a charge coupled device (CCD) linear array image sensor are correspondingly arranged on two sides of a single-code channel code disc; the code disc is provided with a position-fixed circular code channel; and codes for identifying angles are sequentially arranged along a circumference in the code channel. The method comprises the following steps of: acquiring image signals by using the CCD linear array image sensor, and performing decoding and image computation on the image signals respectively; obtaining the integer part of an angle value through decoding, and performing image computation by using a symmetric function fitting algorithm to obtain the decimal part of the angle value; and displaying the data. By the method, code channel codes 10 are more convenient to identify and cannot be repeated on the basis of a green light CCD highly subdivided digital single-code channel absolute coding disc 1; and received photoelectric signals have high quality and reliability, and an error code is difficult to generate.

Owner:朱勤

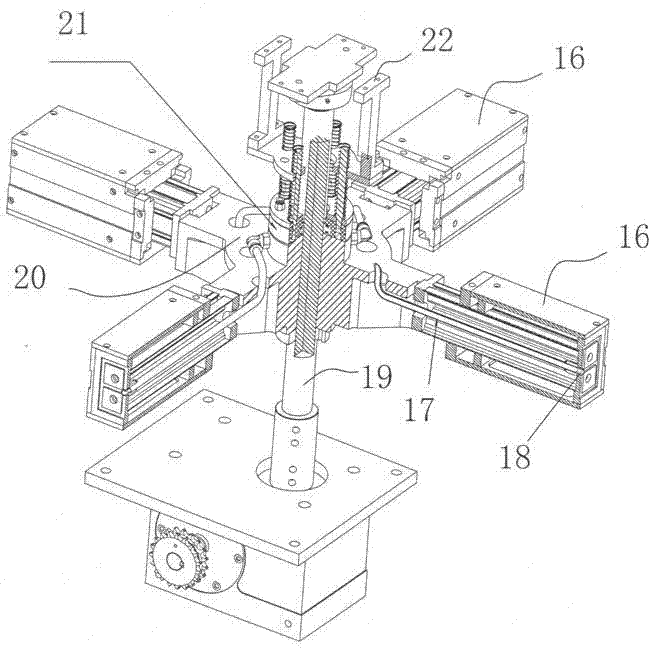

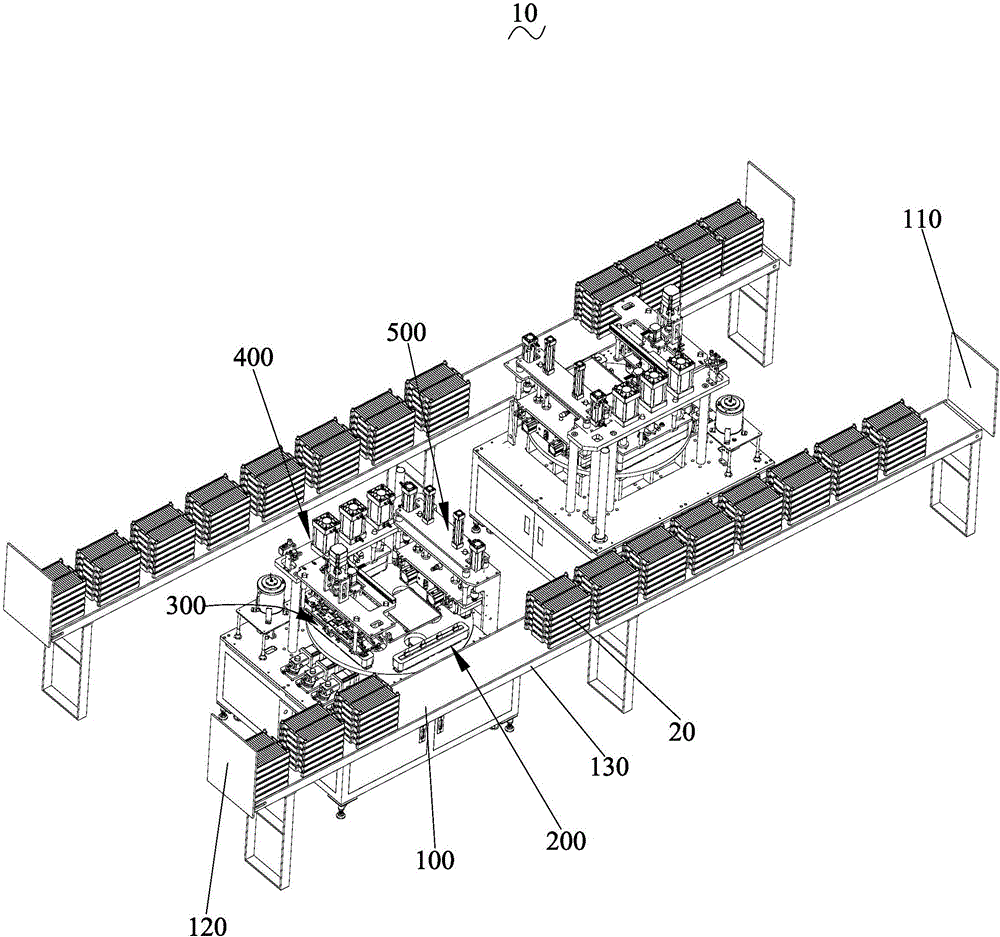

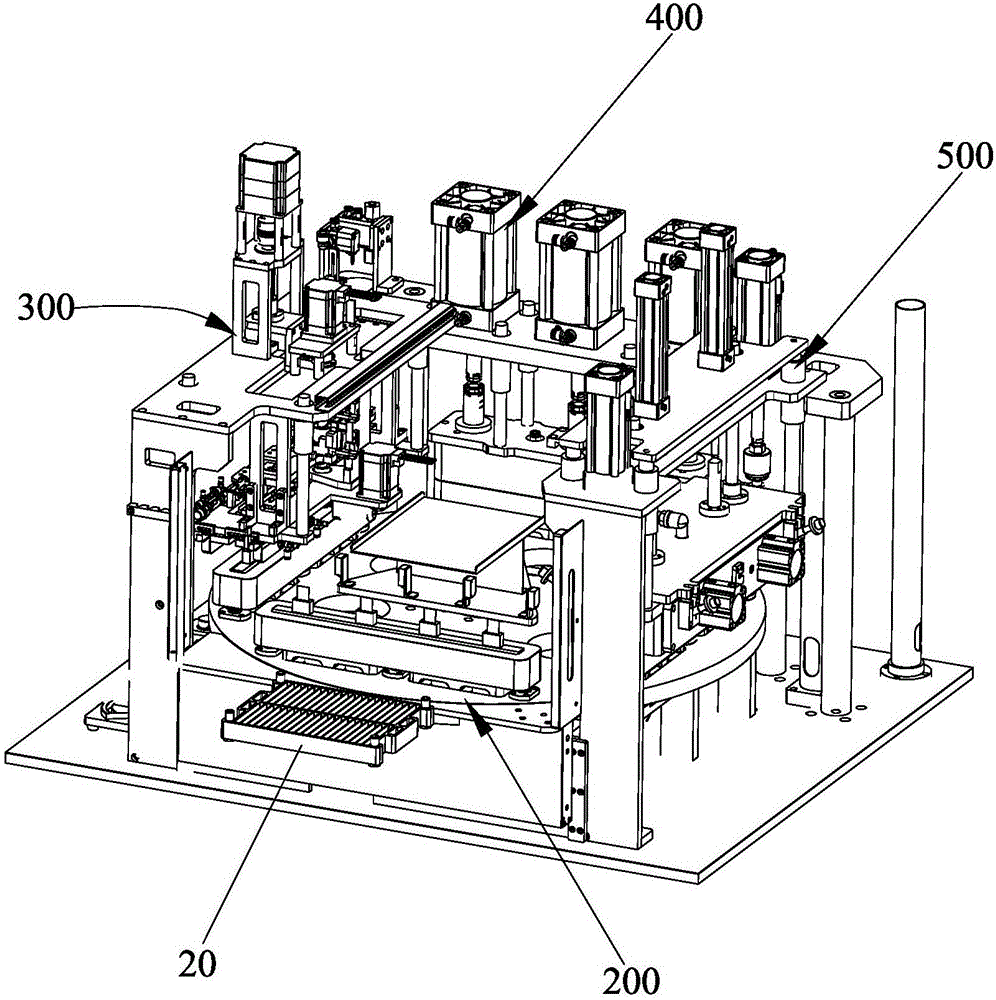

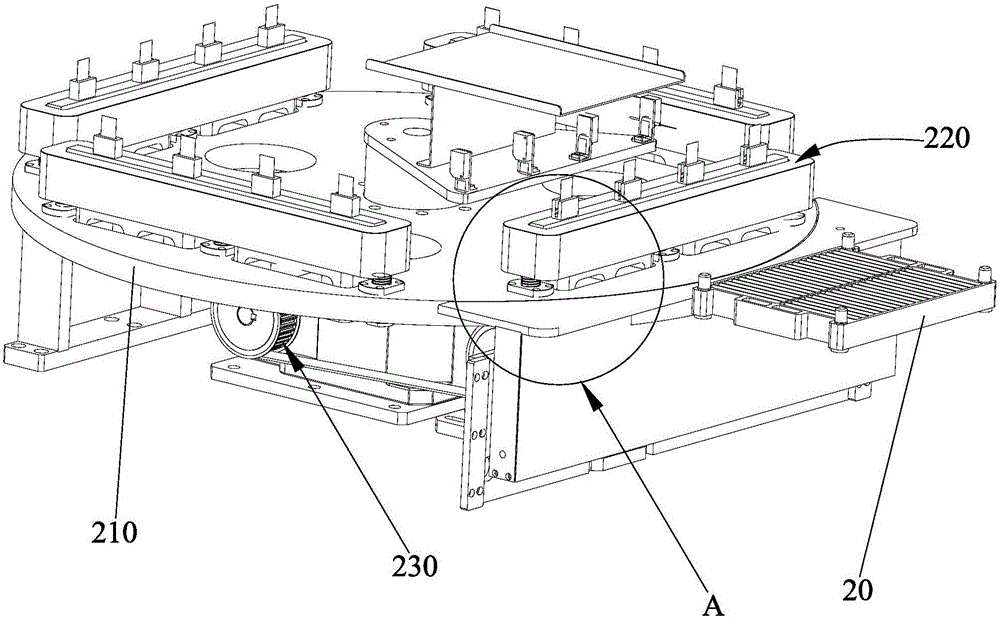

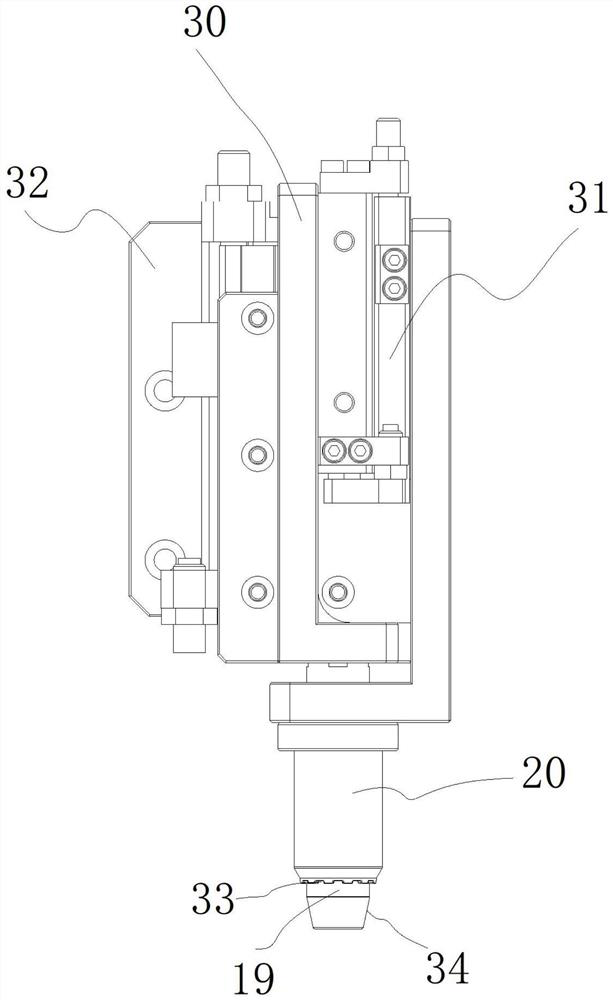

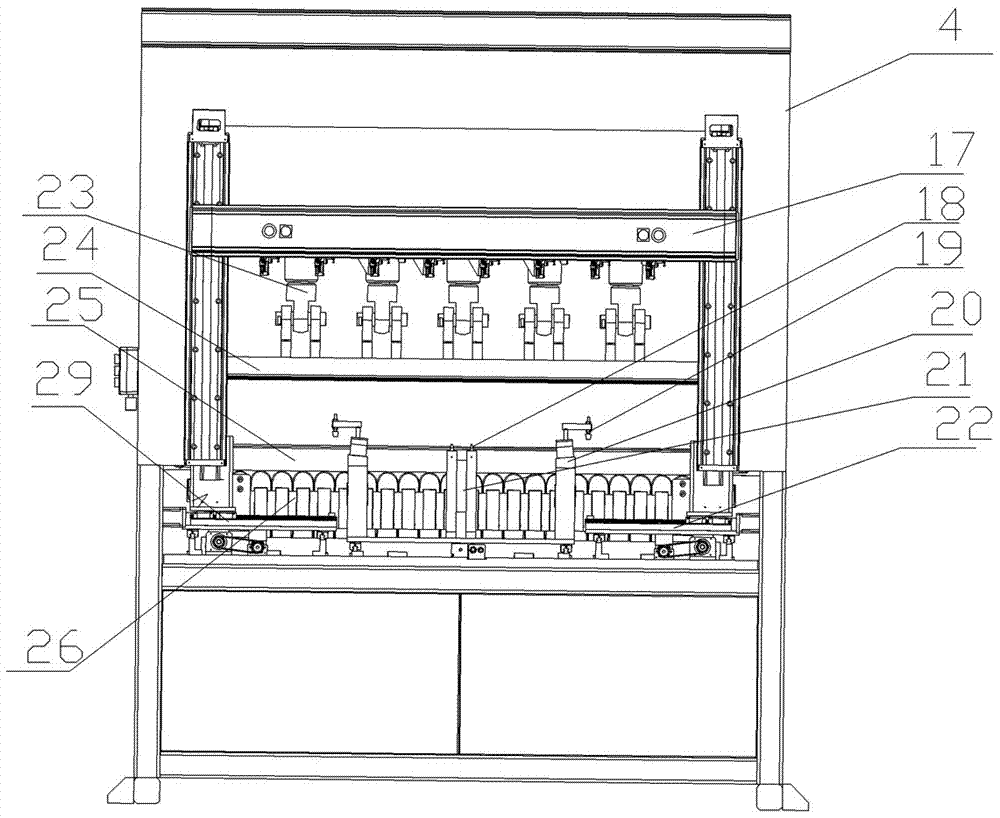

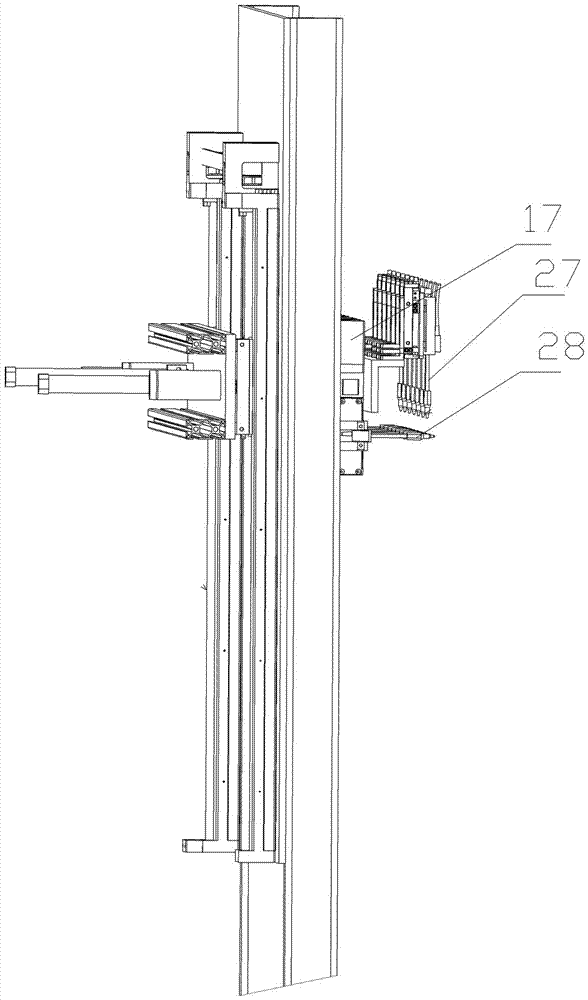

Battery liquid-injection mechanism and automatic production line of soft-package lithium ion batteries

ActiveCN106505177AIncrease productivityImprove production pass rateAssembling battery machinesFinal product manufactureProduction lineEngineering

The invention discloses a battery liquid-injection mechanism, which comprises a liquid-injection fixing support frame, a liquid-injection elevating gear and a liquid injection device. The liquid-injection elevating gear is installed on the liquid-injection fixing support frame, and the liquid injection device is installed on the liquid-injection elevating gear. The invention also discloses an automatic production line of soft-package lithium ion batteries. The automatic production line of soft-package lithium ion batteries comprises the above battery liquid-injection mechanism, a battery feeding assembly line, a battery processing swing-table, a battery standing mechanism and a battery packaging mechanism. According to the automatic production line of soft-package lithium ion batteries, by arranging the battery feeding assembly line, the battery processing swing-table, the battery liquid-injection mechanism, the battery standing mechanism and the battery packaging mechanism and through optimization design of each part, automatic production of soft-package lithium ion battery liquid-injection processing is realized. Therefore, production efficiency is enhanced, and qualified rate of products is raised.

Owner:EVE ENERGY CO LTD

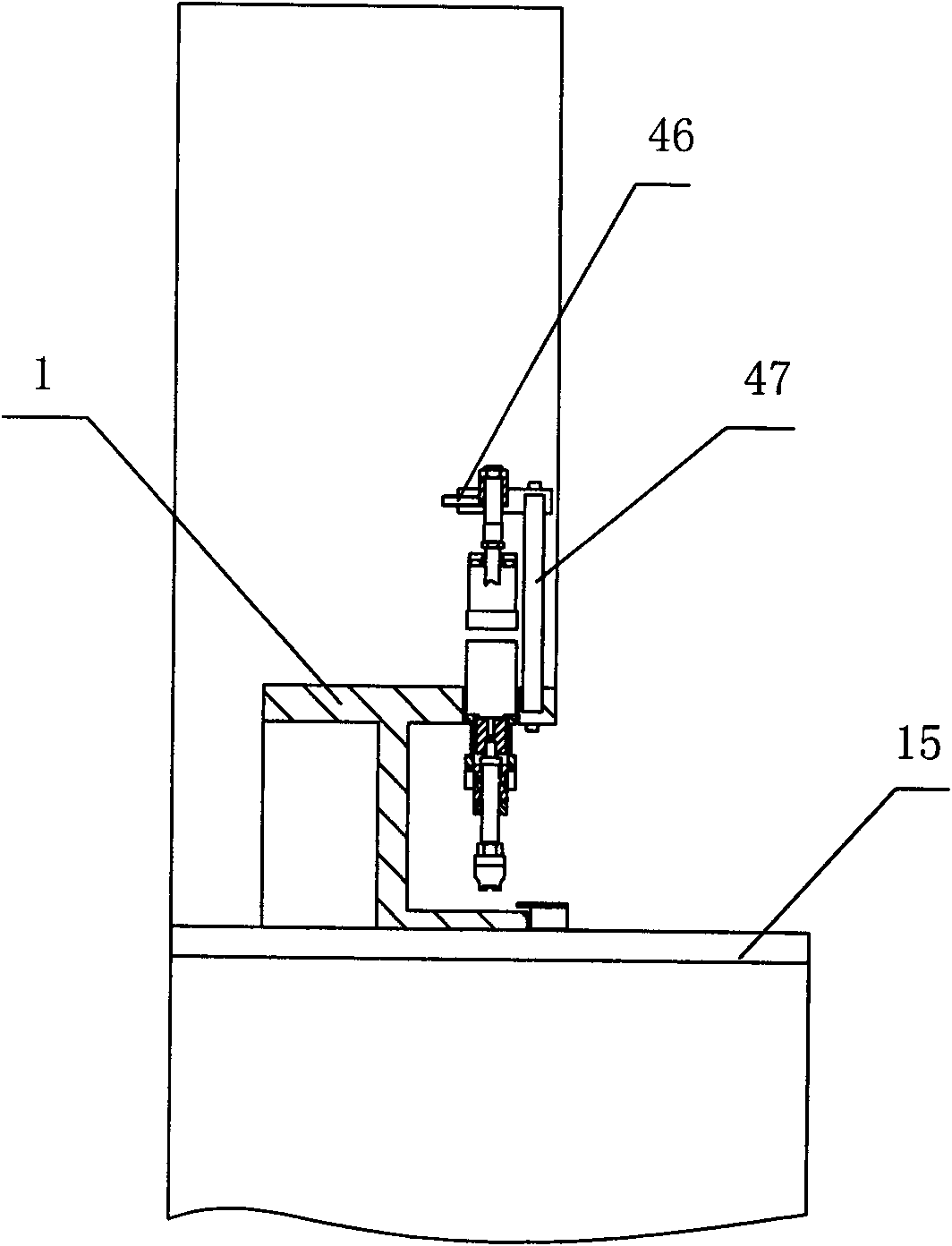

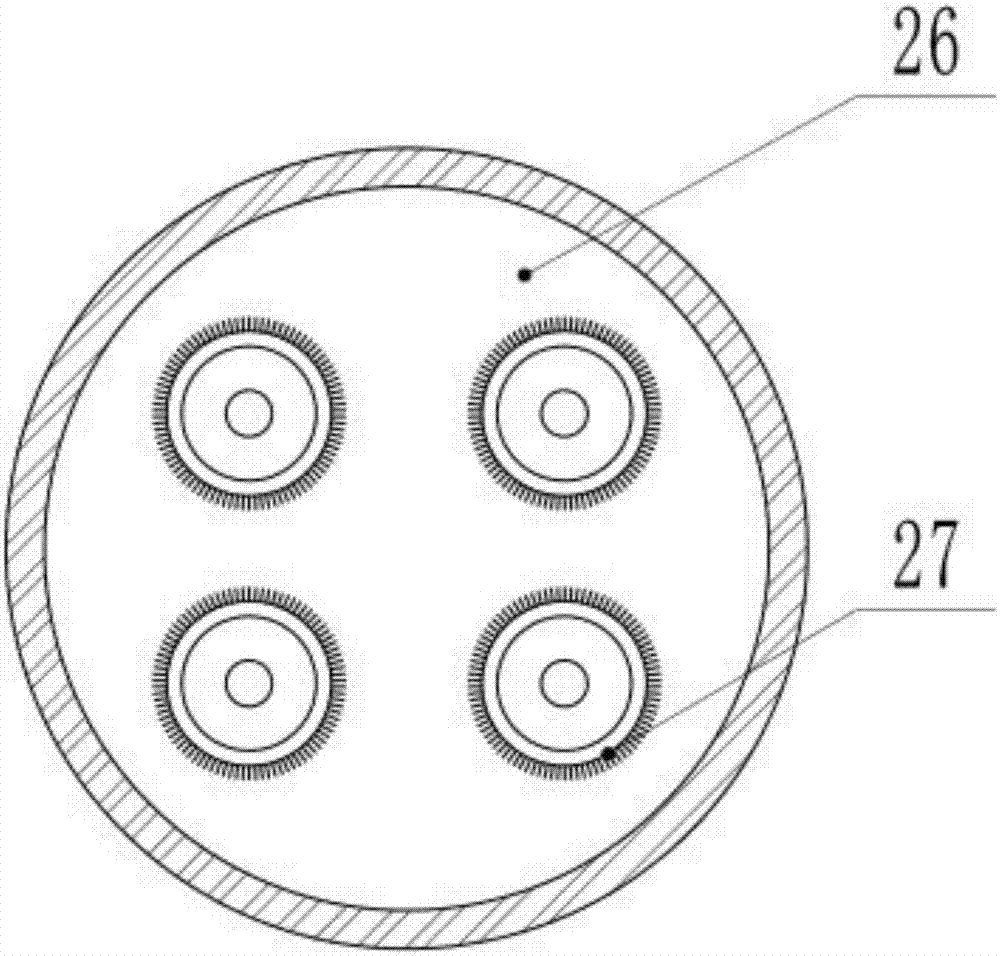

Ironclad motor cast-aluminum rotor end surface burr cleaning device

InactiveCN107370306AMeet clean upPrevent adhesionEdge grinding machinesGrinding drivesCouplingDrive motor

The invention discloses an ironclad motor cast-aluminum rotor end surface burr cleaning device, which comprises a slideway, a driving gear, a toothed belt, a driven gear, a driving motor A, a screw rod, a driving motor B, a lifting table, a high-pressure suction fan, a circular wheel and grinding heads, wherein a plurality of groups of sliding blocks are arranged on a sliding groove in a sliding mode; a rotor placement groove is opened in the upper surface of each sliding block; the output shaft of the driving motor B is connected with the screw rod through a coupler; the lifting table is arranged on the screw rod in a threaded mode; the lower side of the lifting table is provided with a fan cover; the upper side of the lifting table is provided with the high-pressure suction fan; the output shaft of a rotation motor is provided with the circular wheel in a rotating mode; and the lower side of the circular wheel is fixedly provided with a plurality of groups of grinding heads. While the device grinds rotor end surface burrs, the ground burrs can also be absorbed, burr scrap can be prevented from being attached to the surface of the rotor as much as possibly, the problem of single motor noise caused by various friction noise in the case of final assembly can be effectively avoided, and the production qualification rate of the motor can be improved.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

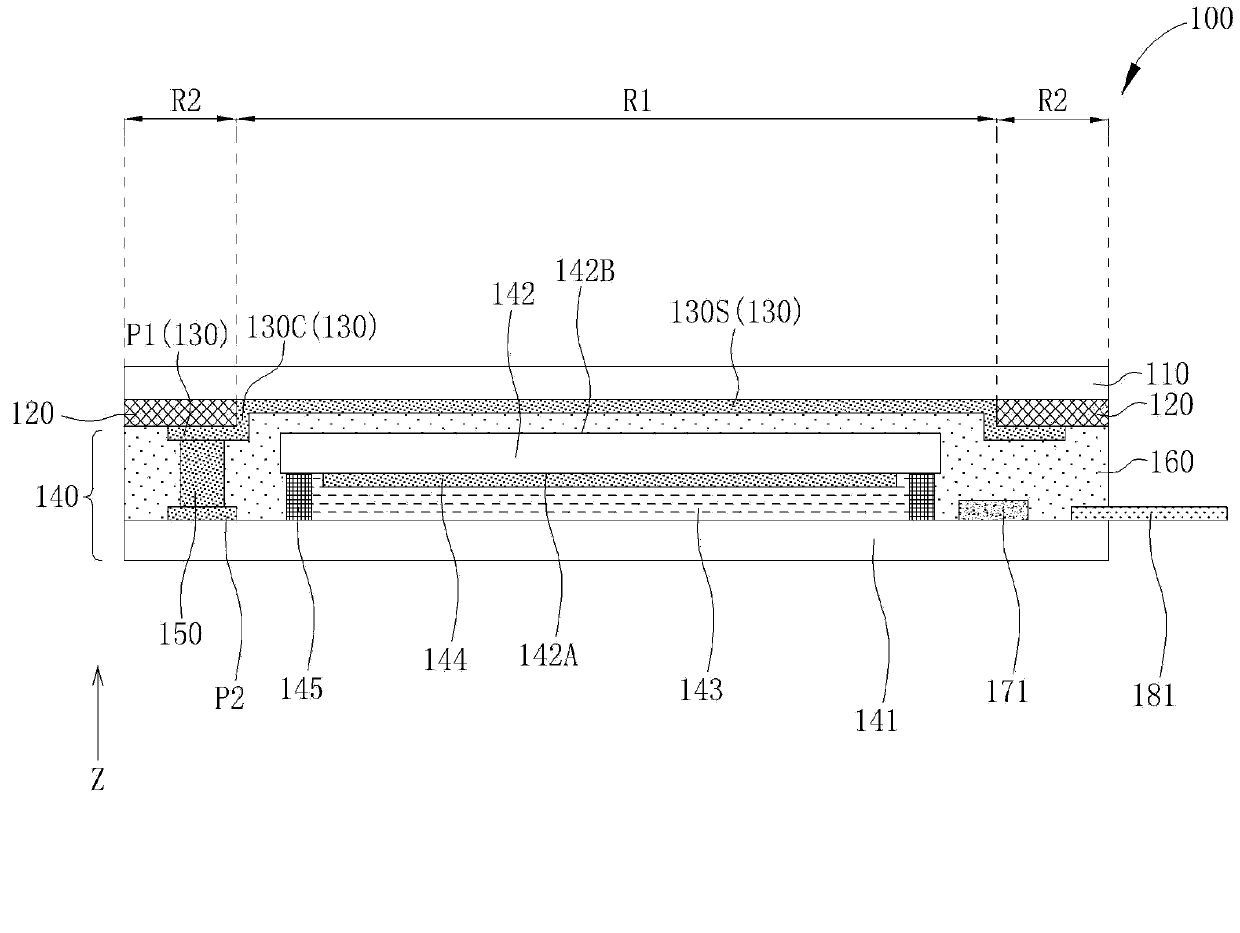

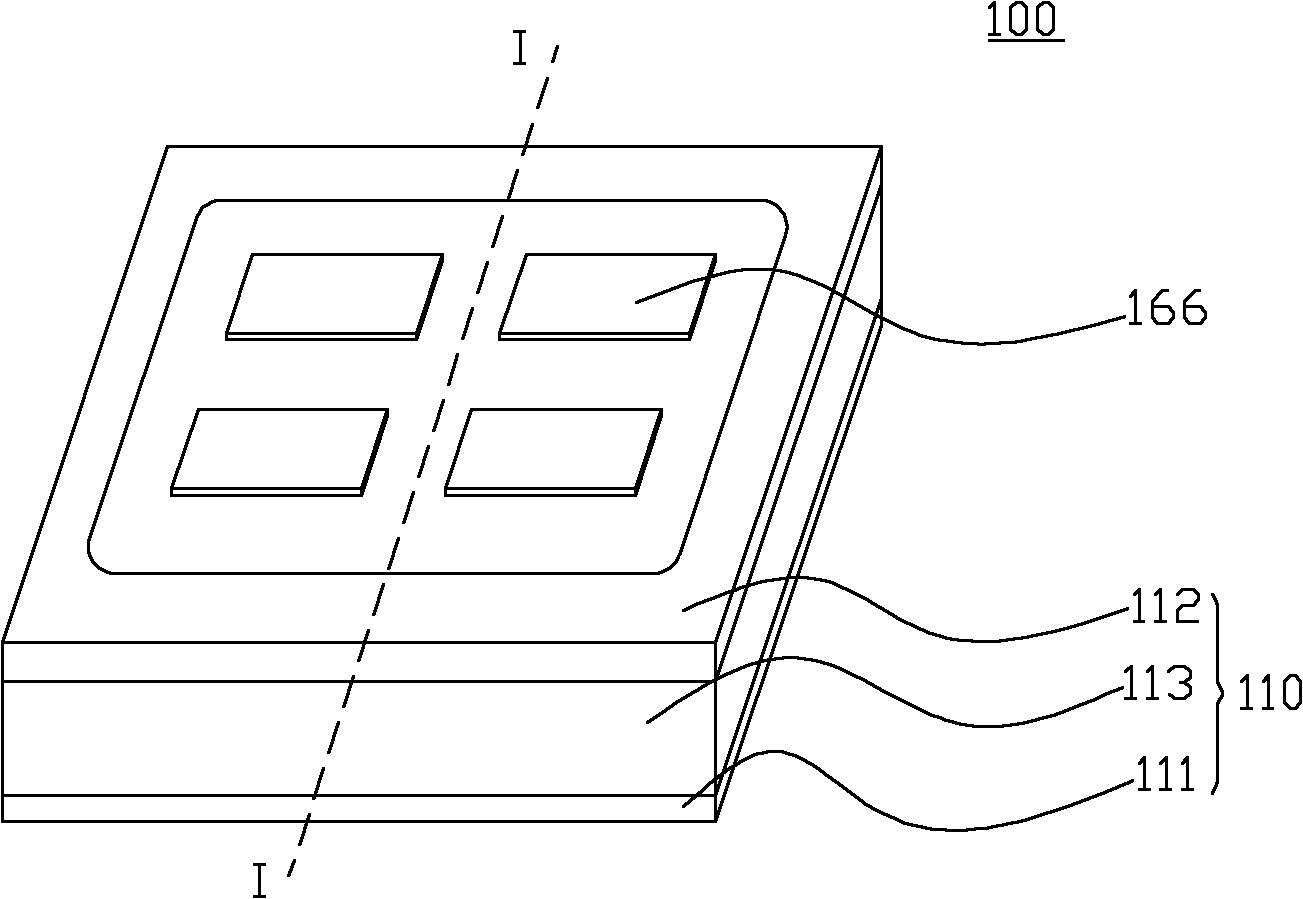

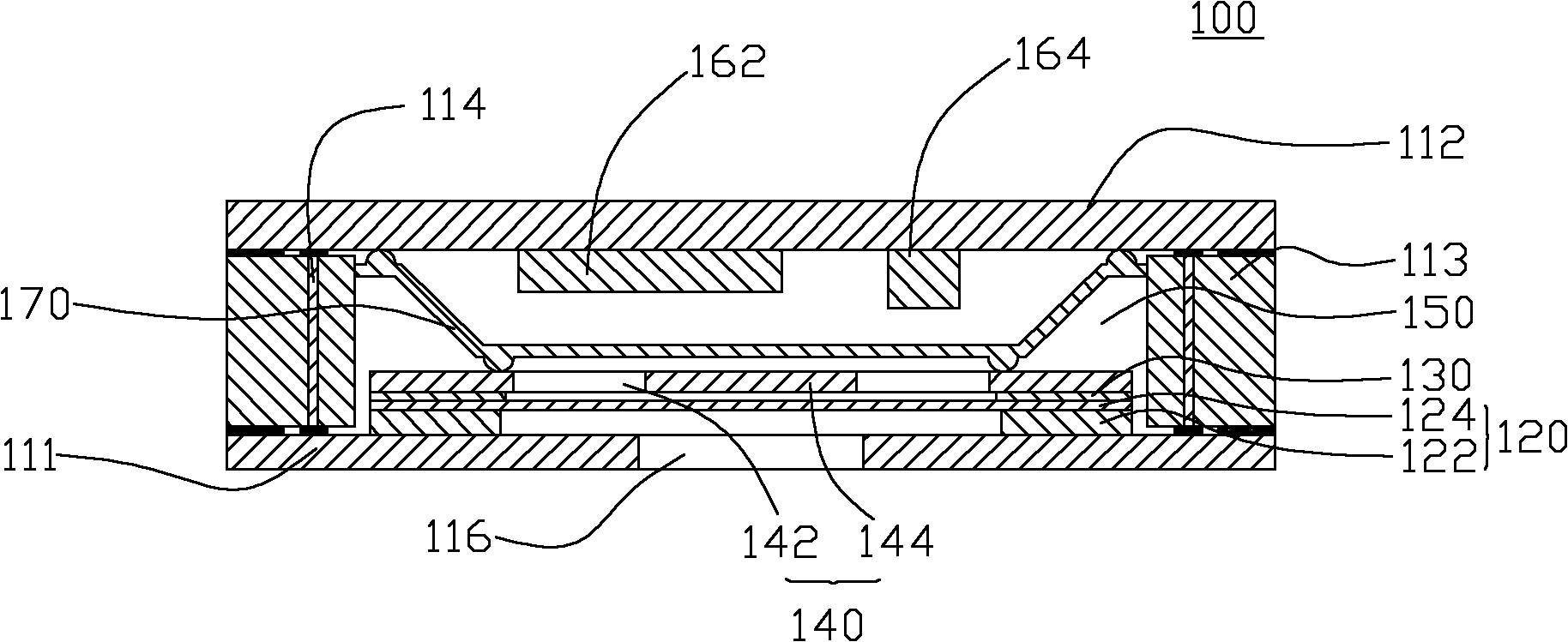

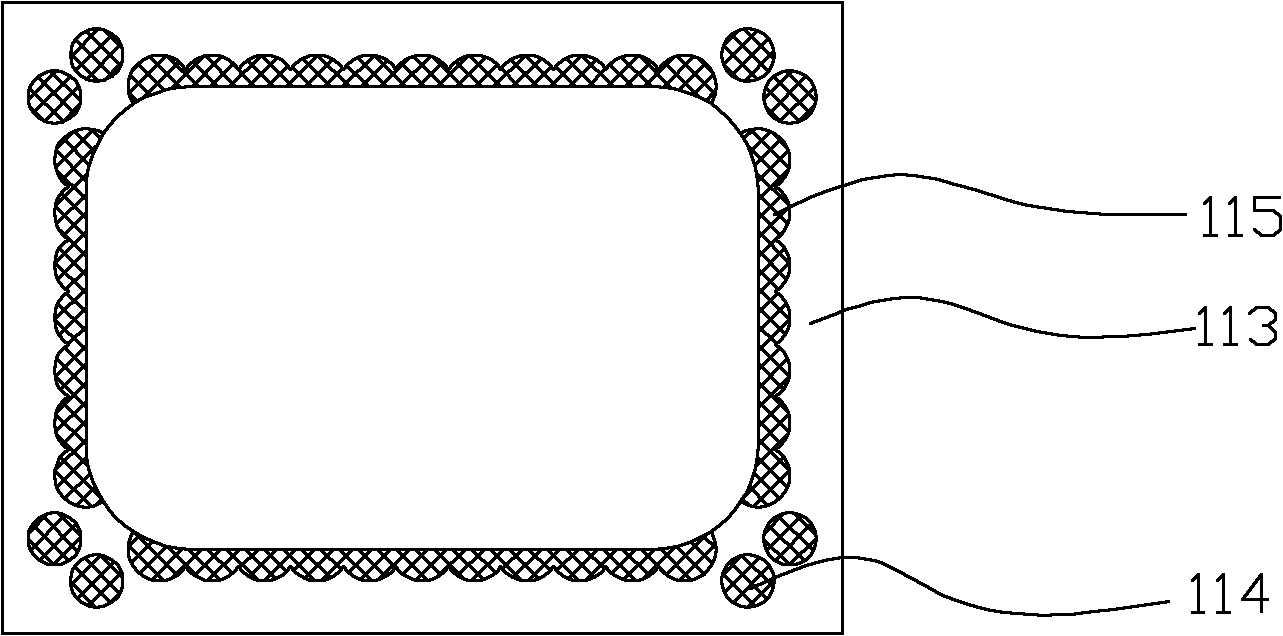

Touch display device

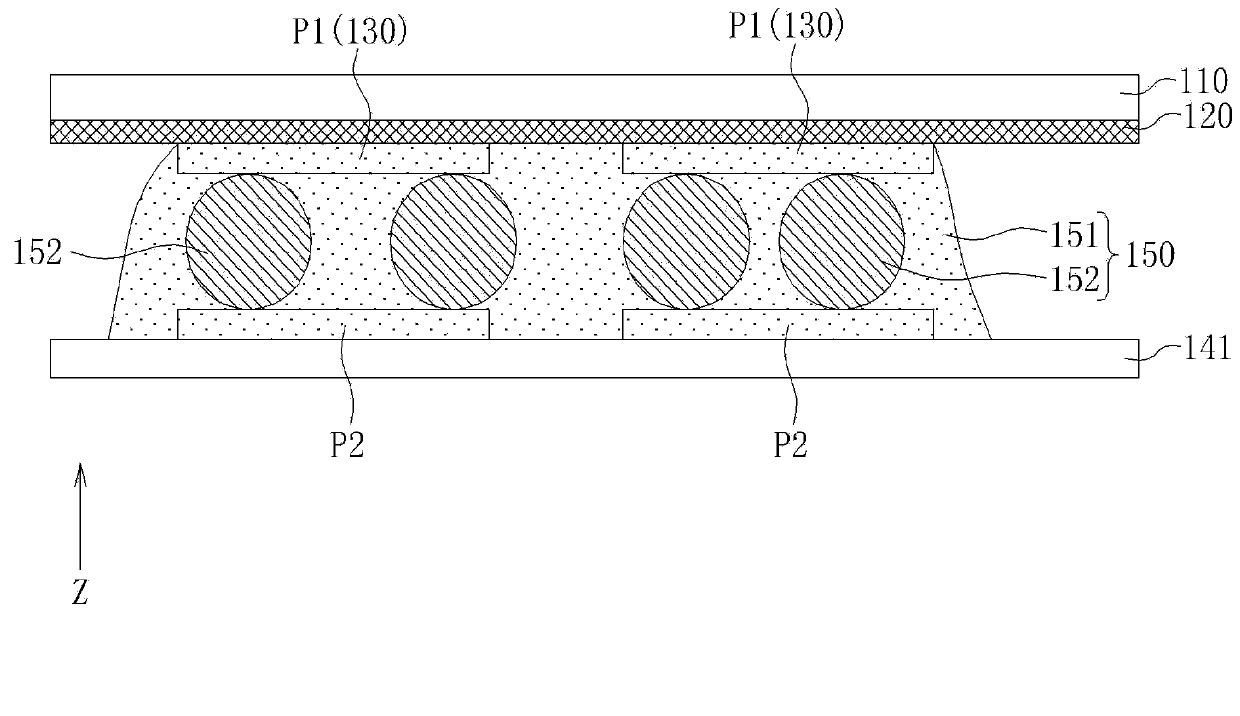

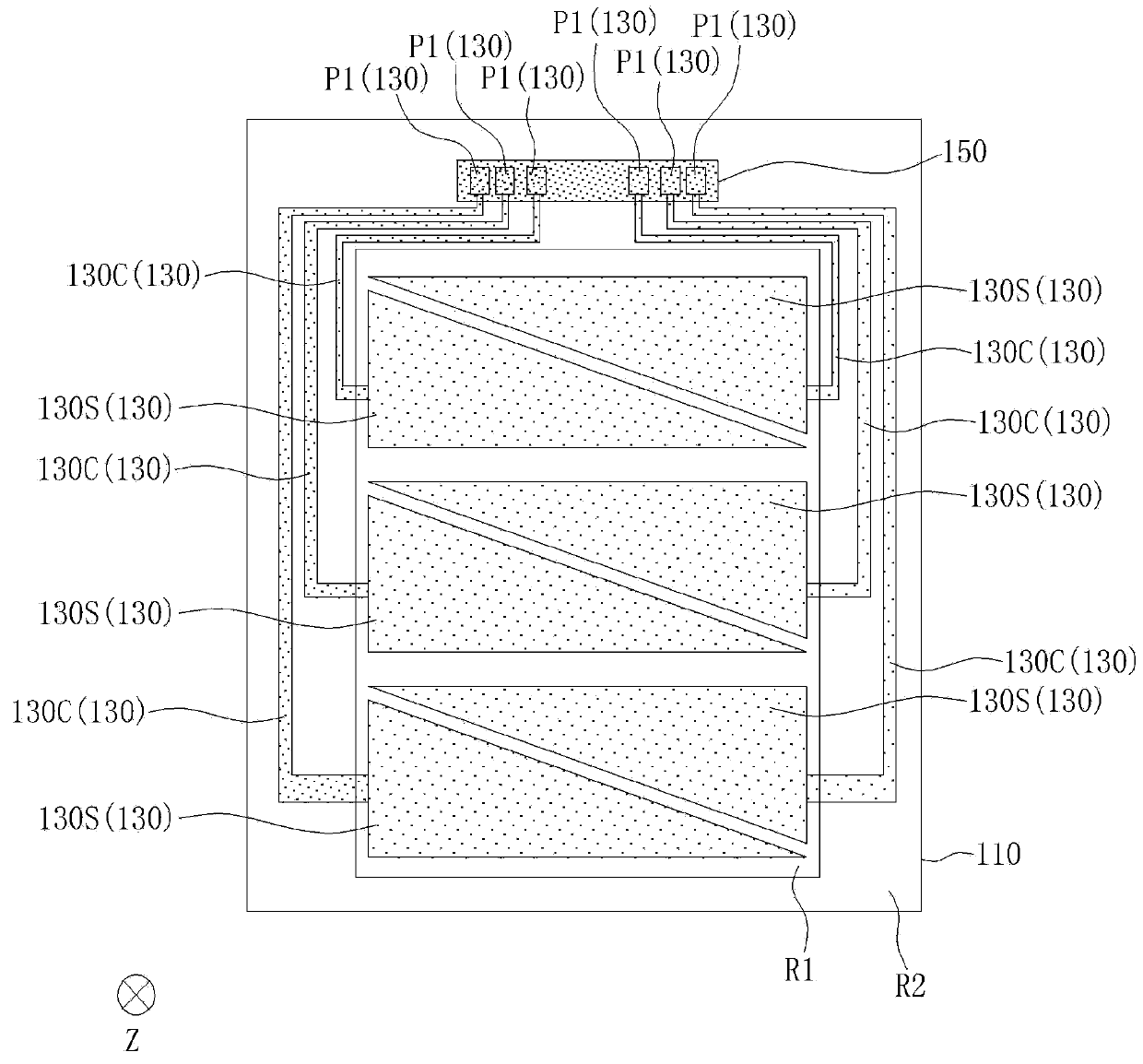

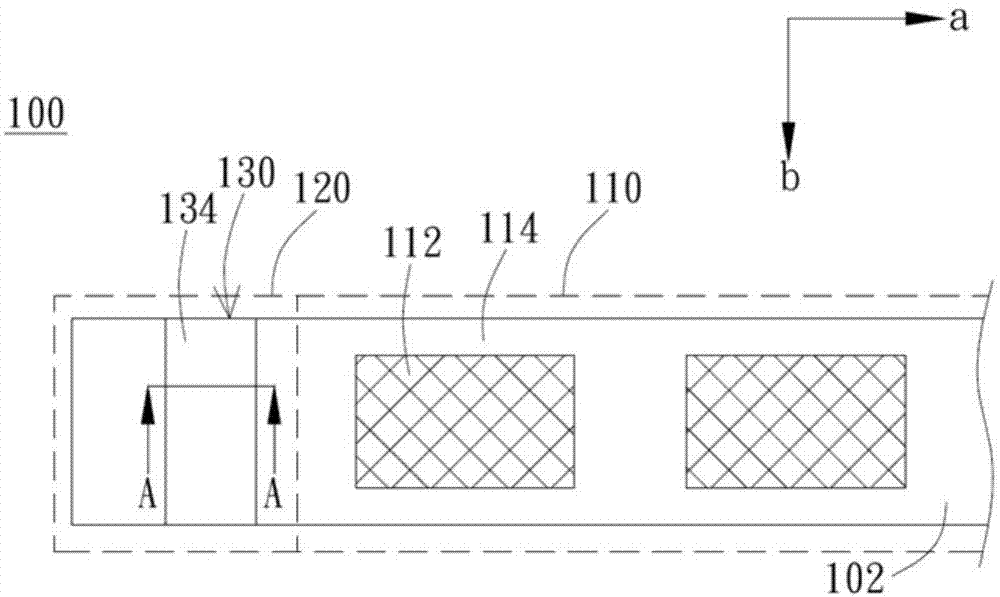

ActiveCN103970312AImprove production pass rateSimple manufacturing methodInput/output processes for data processingTouch SensesDisplay device

The invention discloses a touch display device. The touch display device comprises a cover plate, a display panel, a plurality of first touch sensing electrodes, a plurality of first connecting cushions and a first conductive adhering material, wherein the cover plate is defined with a visible area and a peripheral area; the peripheral area is arranged on at least one side of the visible area; the display panel comprises an upper substrate, an array substrate and a display medium; the upper substrate is arranged between the cover plate and the array substrate; the display medium is arranged between the upper substrate and the array substrate; the first touch sensing electrodes are at least arranged in the visible area; the first connecting cushions are arranged in the peripheral area, and electrically connected with the corresponding first touch sensing electrodes; the first conductive adhering material is arranged between the cover plate and the array substrate, and is used for electrically connecting the first connecting cushions and the array substrate.

Owner:WINTEK CHINA TECH LTD +1

Casting process method of integrated water cooling circulation motor casing

The invention discloses a casting process method of an integrated water cooling circulation motor casing. The method includes the steps that a, a water channel sand core is manufactured first; b, the water channel sand core is placed in a die; c, then, die assembling is conducted on the die through hydraulic pressure stations on the periphery, and the water channel sand core is fixed through set compressing points; d, afterwards, pressure is applied to molten aluminum in a crucible through an air pressure filling control system of a low pressure casting machine; e, the height of the molten aluminum is increased slowly through a liquid rising tube, air pressure is increased when the molten aluminum arrives at the die bottom of the die, and accordingly an entire cavity is filled with the molten aluminum at the speed of 0.9-1.3 m / s; f, pressurization is conducted continuously, and the motor casing is condensed and solidified under certain pressure; g, the cast motor casing is taken out from the cavity of the die, and after complete cooling, the water channel sand core is removed through sand burning, heat treatment and sand shaking; h, a feeder head and burrs are removed ultimately. By the adoption of the casting process method, the production efficiency and the percent of pass can be improved, the labor intensity of workers is lowered, and the production cost is lowered.

Owner:GUANGDONG LIHAO TECH

Metal shield

ActiveCN103572205AChange stress distributionDifferent thicknessLiquid surface applicatorsVacuum evaporation coatingEngineeringMetal

The invention provides a metal shield comprising a shielding segment and an end part segment. The shielding segment is provided with a shielding body and an external frame part, which is connected with the shielding body in an encircled manner. The end part segment is connected with one end of the shielding segment. At least one of the shielding segment and the end part segment is provided with a concave part, which is disposed on the outer side of the shielding body. The ratio between the volume sum of the concave part and the volume sum of the shielding segment and the end part segment is in a range from 0.087 to 0.667.

Owner:DARWIN PRECISIONS CORP

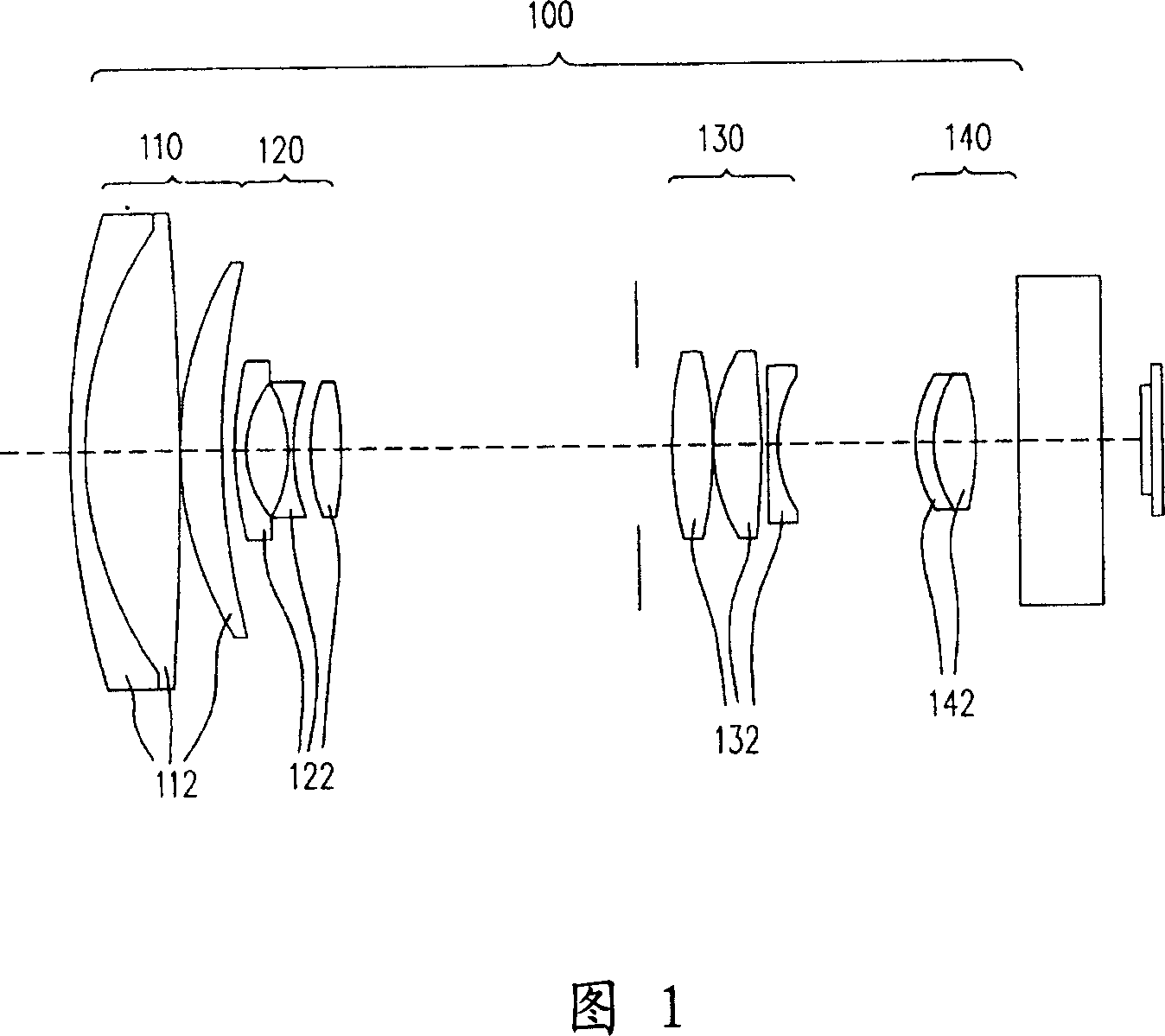

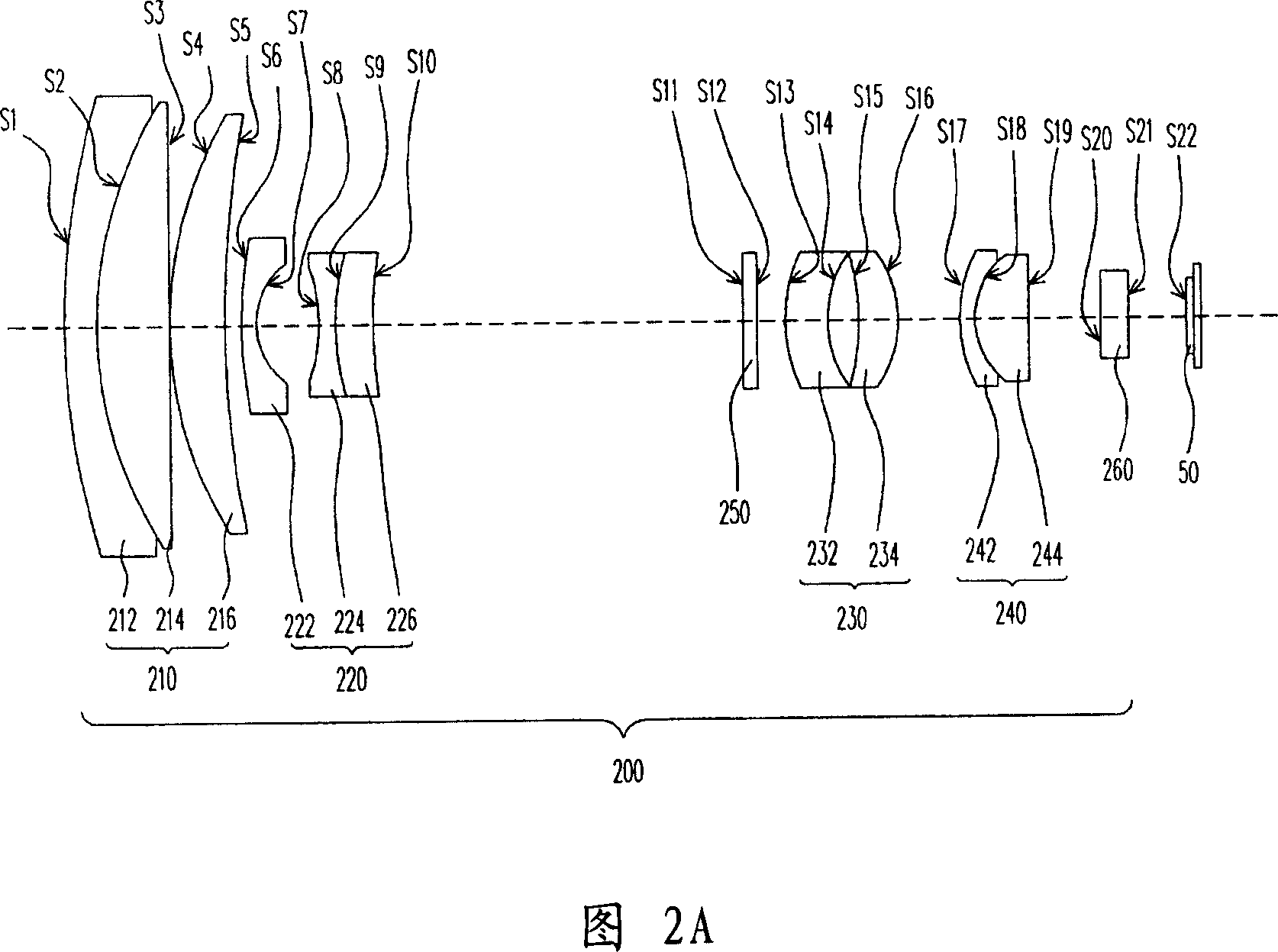

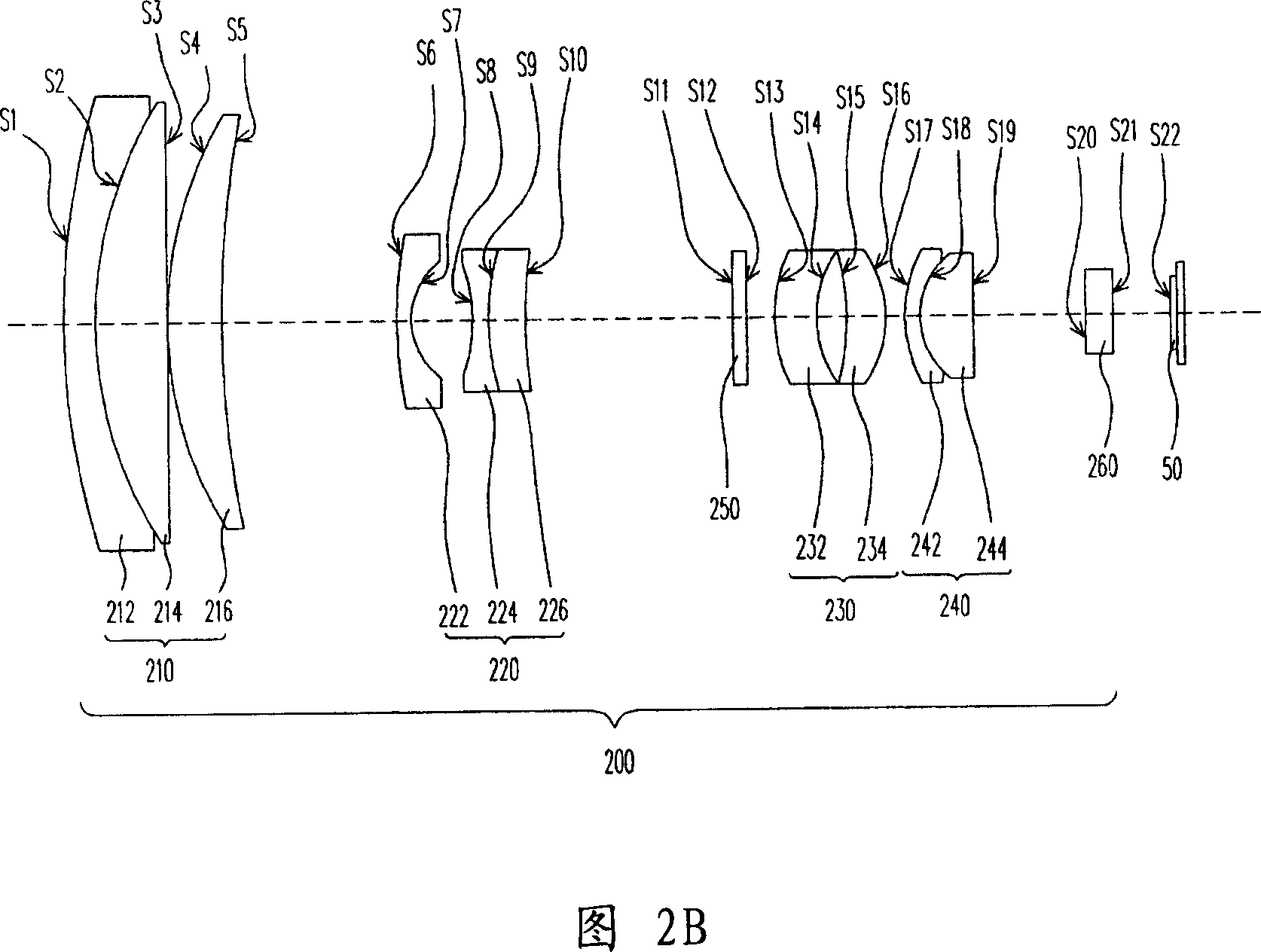

Zoom lens

InactiveCN101051113AReduce material costsImprove production pass rateOptical elementsCamera lensOptoelectronics

Owner:YOUNG OPTICS

Electret microphone

ActiveCN102075838AReduce difficultyLow costElectrets selectrostatic transducerEngineeringElectret microphone

The invention relates to an electret microphone. The electret microphone comprises a shell, a membrane component, an insulating gasket and a back electret component which are arranged in the shell in sequence, wherein the shell comprises a square bottom plate, a square circuit board and a square column-shaped support body arranged between the bottom plate and the circuit board; an inner cavity for accommodating the membrane component, the insulating gasket and the back electret component is arranged in the support body, and both ends of the support body are sealed by the bottom plate and the circuit board; and the back electret component is electrically connected with the circuit board. The top part of the electret microphone is directly sealed by the flat panel-type circuit board, and the smoothness of the top part of the electret microphone is much higher than that of shell edges curled by the traditional method, so that the SMT difficulty of the electret microphone is lowered, and the qualification rate of products is improved.

Owner:SHENZHEN HORN AUDIO

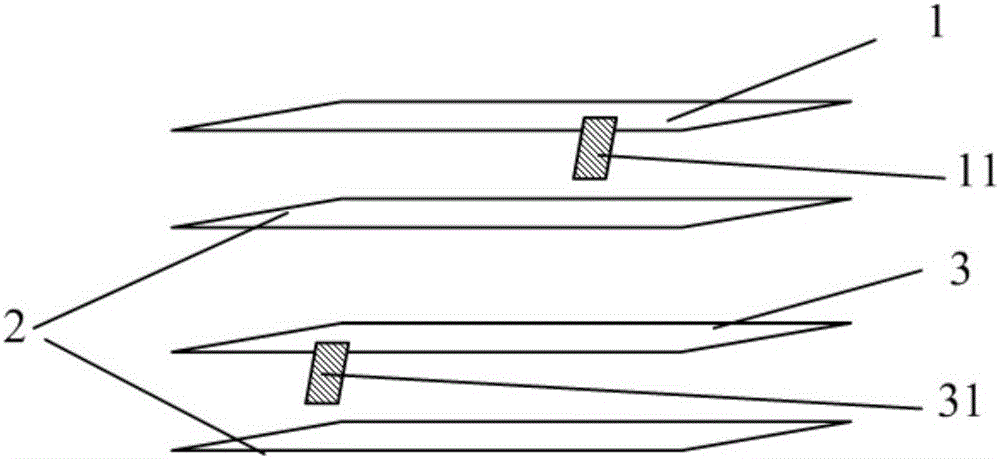

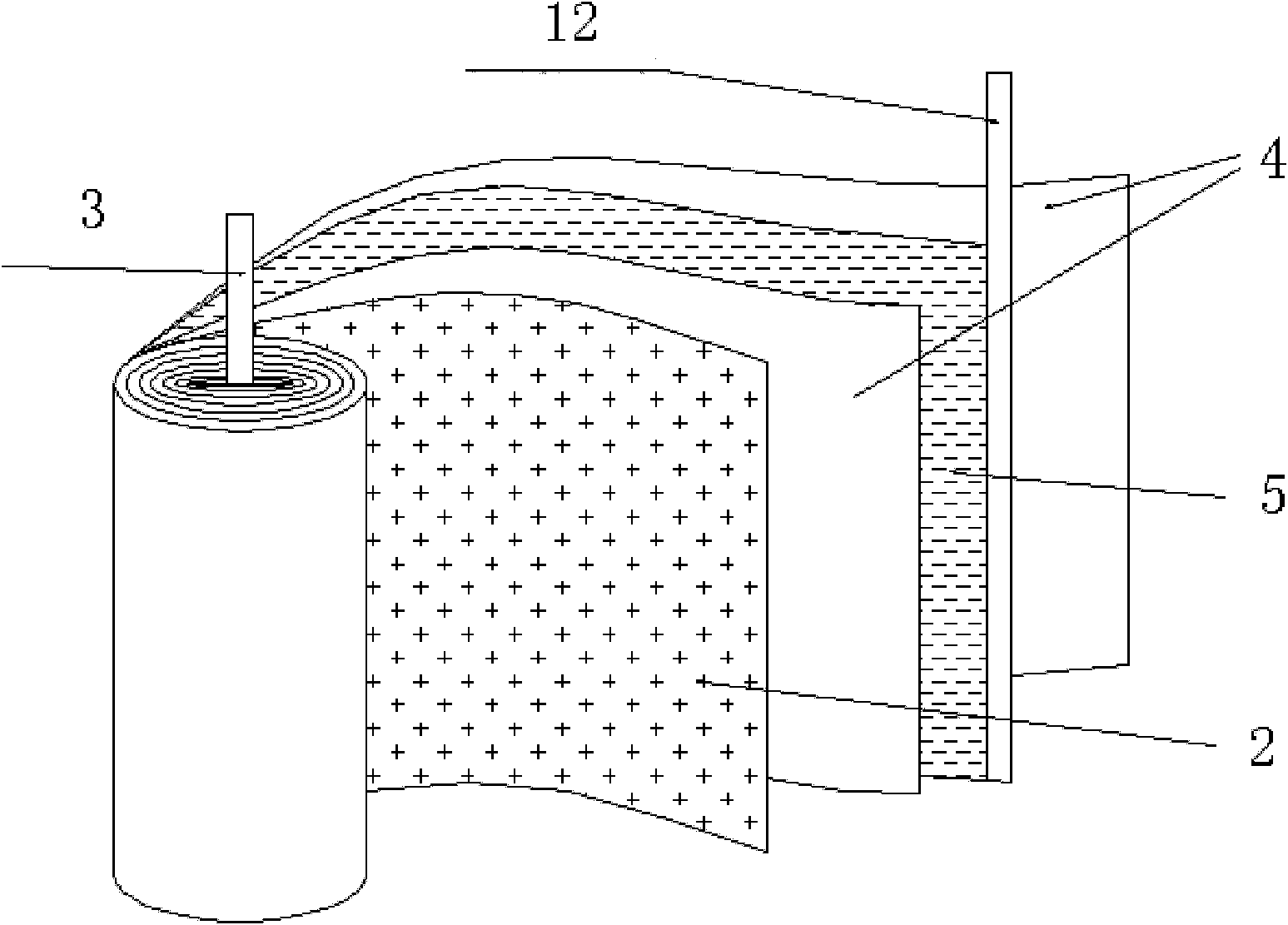

Square lithium ion battery winding cell and manufacturing method for same

ActiveCN104966852ASolve the deformationReduce deformation and wrinkleFinal product manufactureSecondary cellsPower batteryElectrical battery

The invention provides a square lithium ion battery winding cell and a manufacturing method for the same. The square lithium ion battery winding cell comprises a positive pole piece, a diaphragm and a negative pole piece, wherein the positive pole piece is provided with a positive tab; the negative pole piece is provided with a negative tab; an internal supporting frame is arranged in the center of the square lithium ion battery winding cell. By the adoption of the technical scheme, the problems of easy deformation of pole pieces of a conventional square winding cell in charge-discharge cycles and easy disengagement of materials at semicircular positions of the bent pole pieces are solved, the consistency of a square lithium ion battery in a static state and a charge-discharge cycle dynamic state is maintained to the greatest extent, the production qualification rate of winding cells and the safety of the square lithium ion battery are improved, and conditions are created for reliable application of the square winding cell to the field of power batteries.

Owner:李震祺 +1

Method for forging Cr-Ni-Mo stainless steel blades

InactiveCN103878292AImprove production pass rateIncreased stress relief annealingEngine componentsStress reliefSlow cooling

The invention discloses a method for forging Cr-Ni-Mo stainless steel blades, relates to the field of technologies for forging blades, and particularly relates to the technical field of technologies for forging Cr-Ni-Mo stainless steel blades. The method has the advantages that air cooling implemented after free forging and die forging are completed is adjusted on the basis of the original forging process and is replaced by slow cooling implemented by the aid of heat-insulation cotton or heat-insulation tanks, a forged crude shape is added, stress relief annealing implemented after die forging is completed is additionally carried out, integral die forging for the crude shape is adjusted and is replaced by a die forging process including integral die forging and sectional die forging, accordingly, cracks of the Cr-Ni-Mo stainless steel blades are reduced in forging procedures, a cavity of a die can be completely filled with the forged crude shape during die forging, and the production qualified rate of forged piece blanks for manufacturing the blades can be increased.

Owner:SHAANXI HONGYUAN AVIATION FORGING

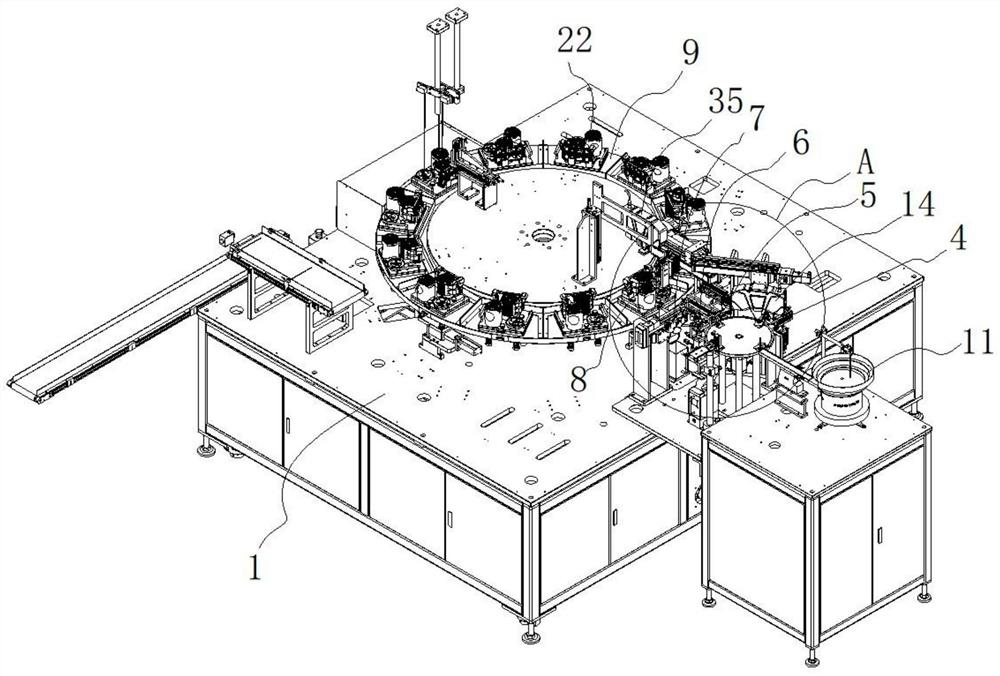

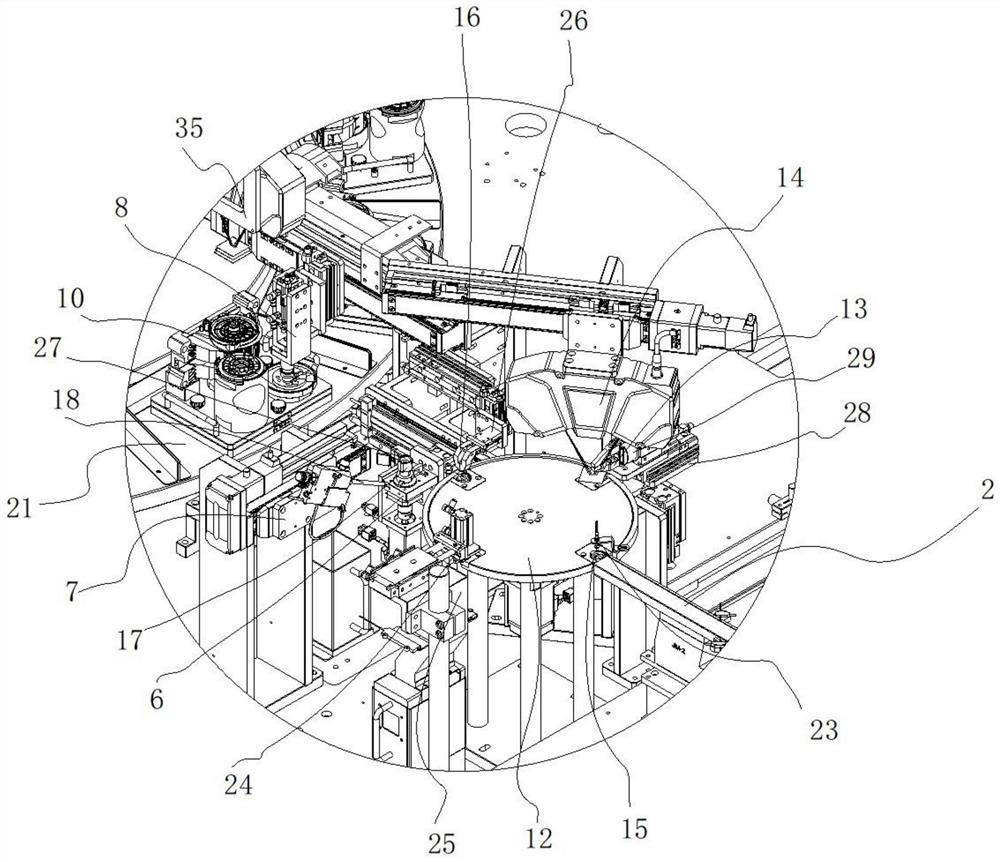

Automatic assembling and detecting mechanism for X-shaped sealing ring and operation method thereof

ActiveCN112475845AAchieve Assembly ConsistencyImprove pass rateSpraying apparatusSortingStructural engineeringMechanical engineering

The invention relates to an assembling and detecting mechanism, and particularly relates to an automatic assembling and detecting mechanism for an X-shaped sealing ring and an operation method thereof. The automatic assembling and detecting mechanism comprises a rack and the sealing ring, wherein a feeding assembly, a detecting and overturning assembly, a carrying assembly, a rotary oiling jig, anoiling jig, a material taking and pressing-in assembly and a rotary disc jig are arranged on the upper portion of the rack; the sealing ring enters the detecting and overturning assembly through thefeeding assembly; the detecting and overturning assembly detects and overturns the sealing ring; the sealing ring which is detected to be qualified is conveyed into the rotary oiling jig through the carrying assembly; the rotary oiling jig drives the sealing ring to rotate; the oiling jig conducts oiling operation on the rotating sealing ring; and the sealing ring with the front face and the backface oiled is placed in a valve deck of the rotary disc jig through the material taking and pressing-in assembly. The structure compactness is high, the machining efficiency is further improved, and the assembling quality is further improved.

Owner:HANGZHOU TAISHANG INTELLIGENT EQUIP CO LTD

Prepn of polygelatine peptide injection

InactiveCN1387912AImprove production pass rateControl product qualityPeptide/protein ingredientsBlood disorderPeptideChemistry

The polygelatin peptide injection is prepared with gelatin of ox bone, pig bone, etc. and through dissolving, hot degradation in controlled condition, cross-linking with non-toxic cross-linking agent, mixing with electrolyte, adsorption, clarification and stepped filtering to separate cross-linked spherical molecule. During the preparation, the molecular weight of the cross-linked matter is well controlled.

Owner:武汉华龙生物制药有限公司

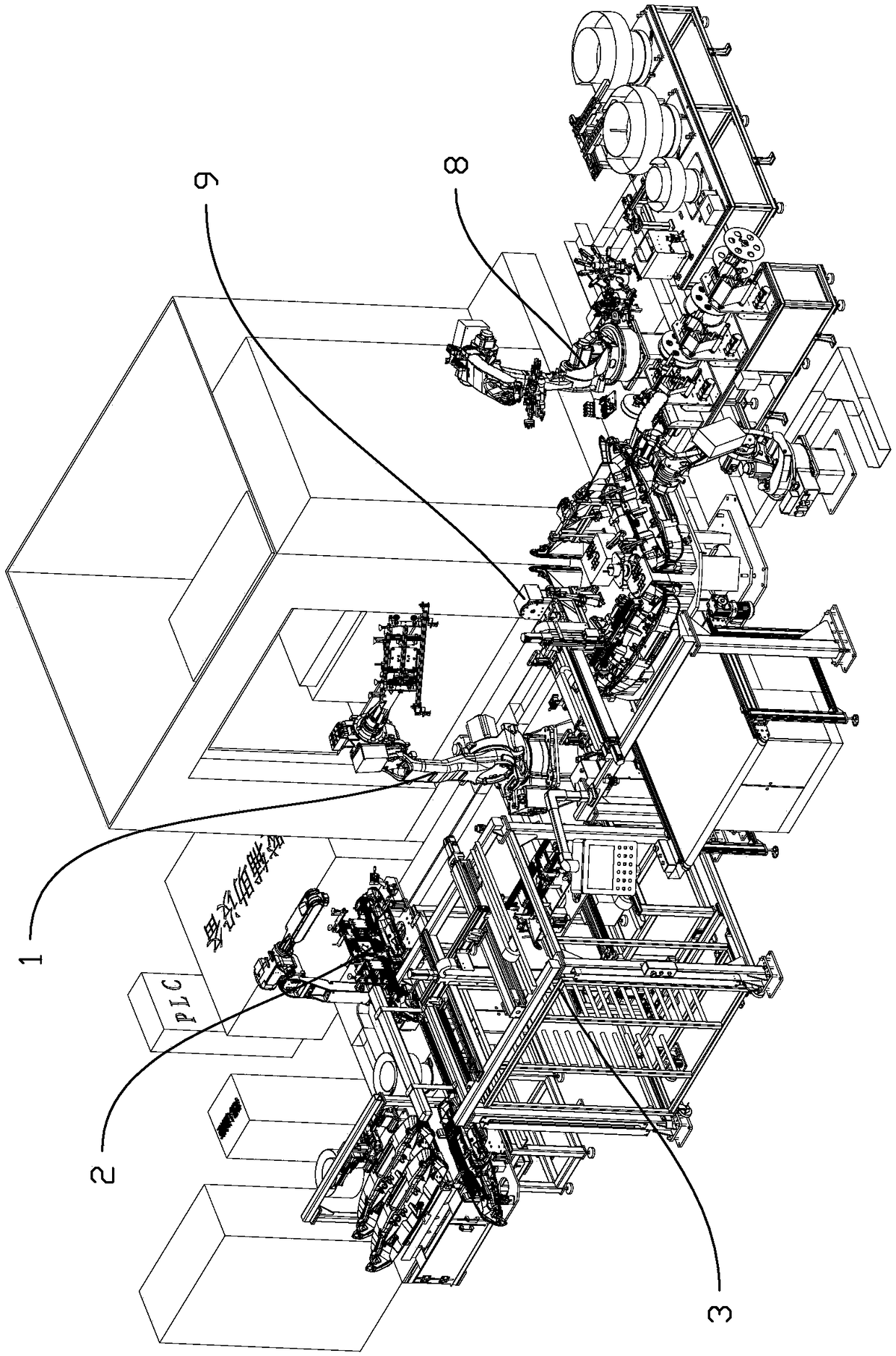

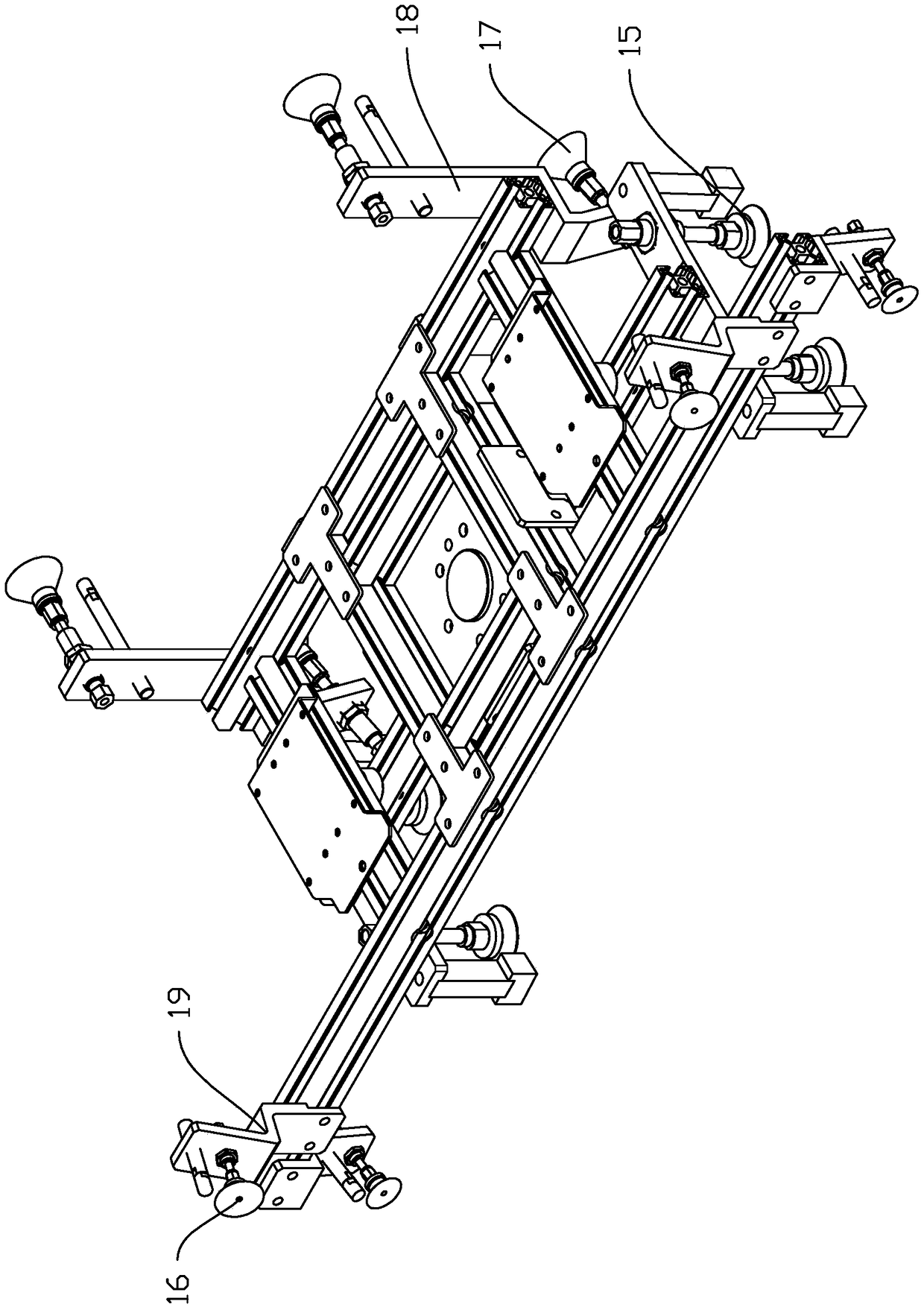

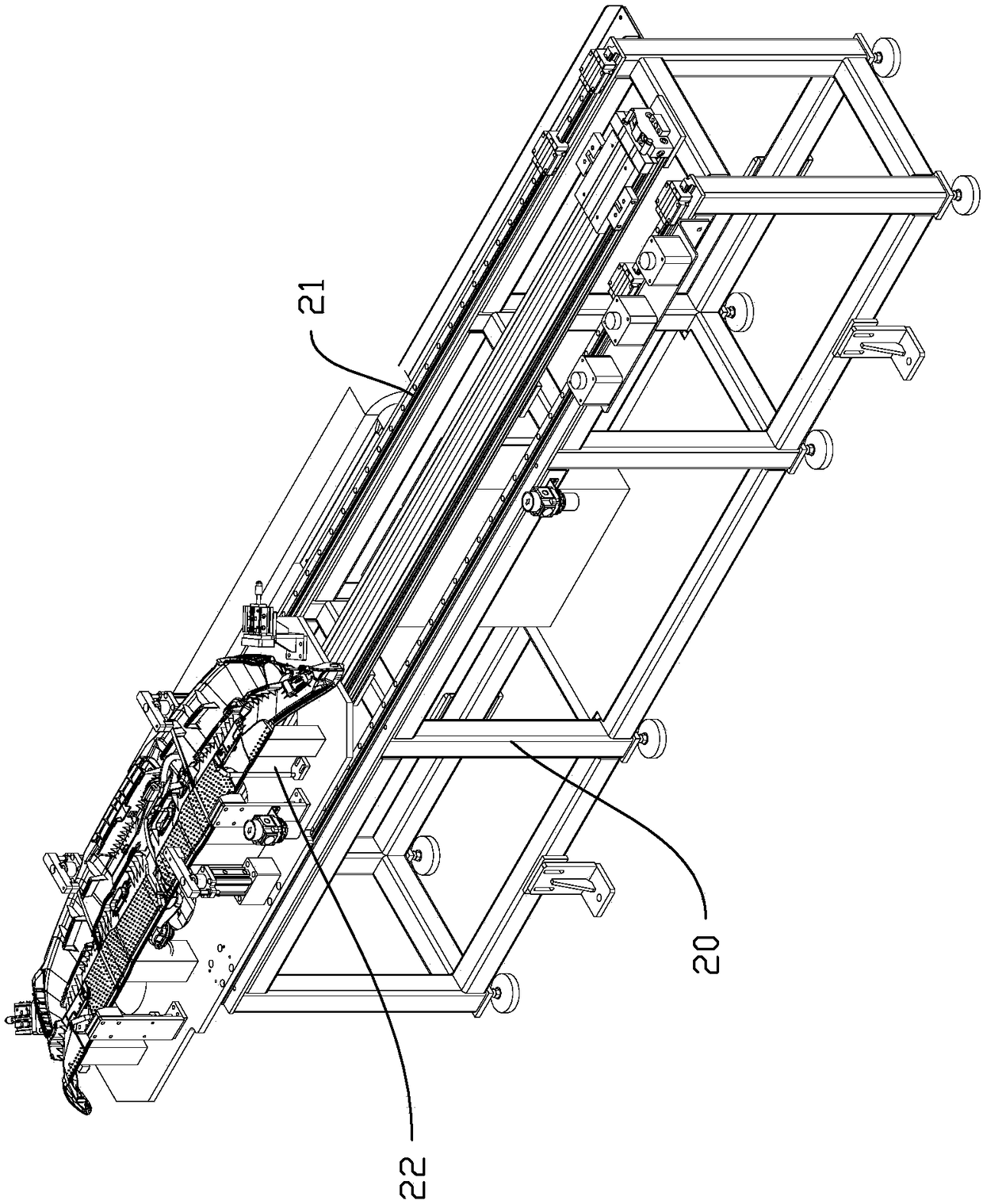

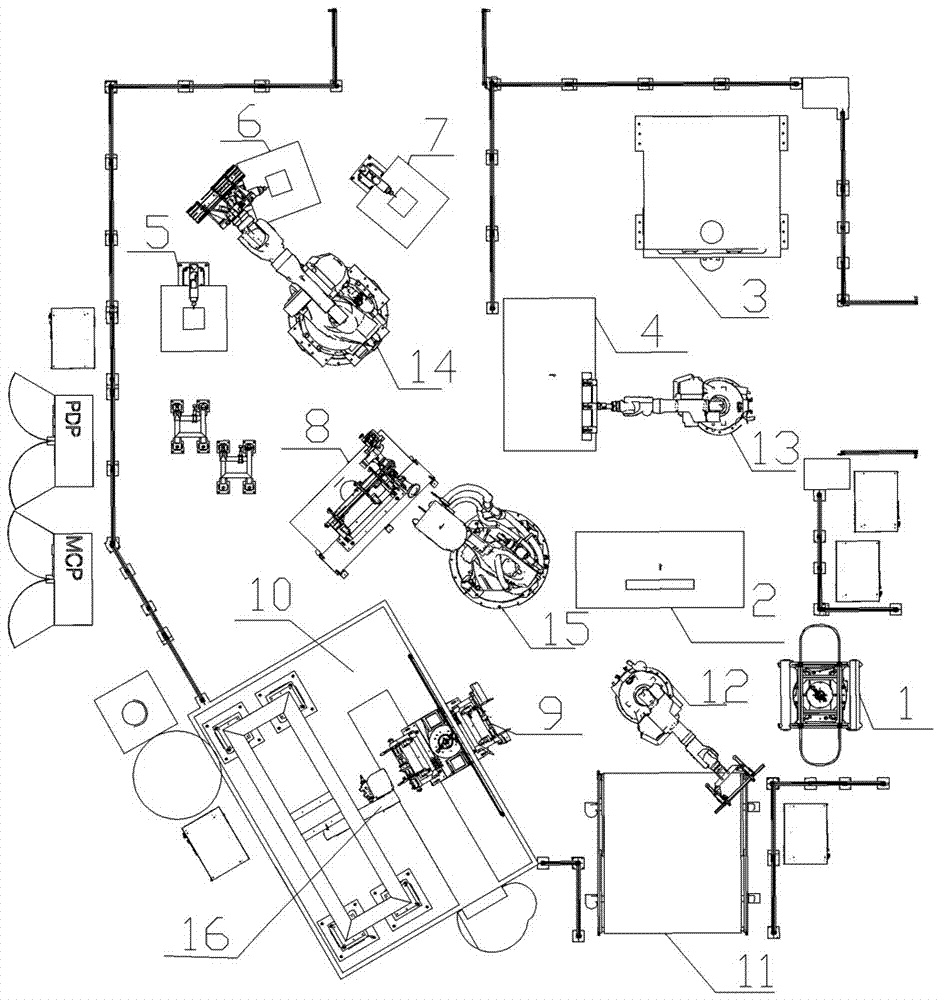

Gluing, welding and assembling production line for car spoiler

PendingCN108857410AReduce labor intensityAutomate installationLiquid surface applicatorsOther manufacturing equipments/toolsProduction lineControl system

The invention discloses a gluing, welding and assembling production line for a car spoiler. The production line comprises a transfer robot, a spoiler glue tape sticking unit and a control system. A bottom shell gluing feeding unit, an outer shell feeding unit, a turnover unit and a welding unit are installed around the transfer robot, and the turnover unit is located between the transfer robot andthe spoiler glue tape sticking unit. The transfer robot comprises a transfer mechanical arm, a transfer rotating block installed at the tail end of the transfer mechanical arm and a transfer disc installed on the transfer rotating block, a transfer mounting frame is installed on the transfer disc, and a bottom shell adsorption mechanism, an outer shell adsorption mechanism and a turnover adsorption mechanism are arranged on the transfer mounting frame. The production line realizes gluing and welding of a bottom shell and an outer shell and also realizes automatic installation of foam, bucklesand nuts; three operators are reduced, and the labor cost is greatly reduced; the production efficiency is improved; the percent of pass of production of products is improved; the labor intensity ofoperation personnel is relieved; and the influences of gluing on human health are reduced.

Owner:GUANGZHOU LASEN INTELLIGENCE TECH CO LTD

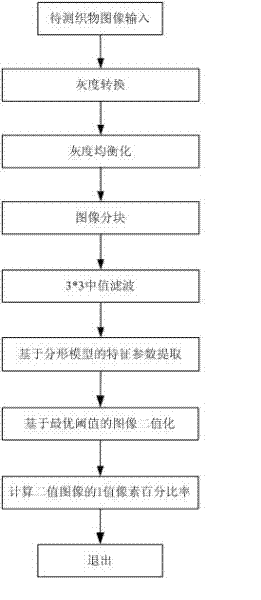

Machine vision based cloth inspection device and method

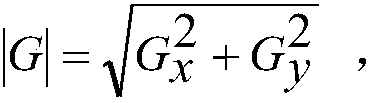

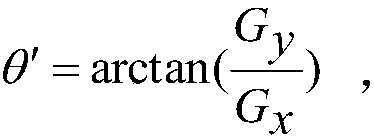

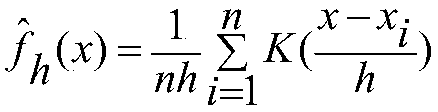

ActiveCN108921819ATake advantage of generalizationThe result is obviousImage enhancementImage analysisGrey levelHistogram equalization

The invention discloses a machine vision based cloth inspection method. The machine vision based cloth inspection method includes: adopting an industrial camera to focus on and shoot a finished fabricto be inspected after heat-setting, and acquiring a real-time image; and then using the first and second methods to calculate the longitudinal density and the transverse density of the fabric; and obtaining the actual density of the fabric according to the longitudinal density and the transverse density obtained by the first and second methods. The invention also discloses a machine vision basedcloth inspection device. An output end of an image acquisition unit is connected with an input end of an image processing unit; an output end of the image processing unit is connected with an input end of a density detection unit; the image acquisition unit acquires a reflective image of a fabric surface; the image processing unit is used for performing image Fourier transformation, grey level transformation, histogram equalization and image binarization; and the density detection unit uses the edge detection algorithm, Hough transform, and the kernel density estimation algorithm to analyze the inclination of the fabric, the number of ridge lines, and the number of circular columns according to the processed image, and calculates out the density of the fabric.

Owner:LIMING VOCATIONAL UNIV

Anti-cracking machining method of small axial surface carburizing and hardening stepped shaft with end face provided with groove

The invention discloses an anti-cracking machining method of a small axial surface carburizing and hardening stepped shaft with an end face provided with a groove. The groove is arranged in an end face of a shaft section B of the stepped shaft, a shaft section A and a side face, close to the shaft section A, of the shaft section B have carburizing and hardening requirements, other parts have no hardness requirements, 20Cr steel serves as blanks of the stepped shaft, the procedures of blanking, rough machining, carburizing treatment, semi finish machining, hardening, fine machining, cutting and groove milling are sequentially carried out on the blanks, and then the stepped shaft with different shaft sections having different mechanical properties are machined. The anti-cracking machining method is simple in structure and convenient to achieve; a protective step is arranged before carburizing, the protective step before the hardening is machined to be a fillet, and cracking caused by oversize stress when the carburizing and hardening are carried out on the root portion of the step can be effectively avoided; a shaft section B carburized layer is milled off before the hardening, the hardness of the shaft section B after the hardening is reduced, and machining efficiency of following steps is improved.

Owner:HEBEI HUABEI DIESEL ENGINE

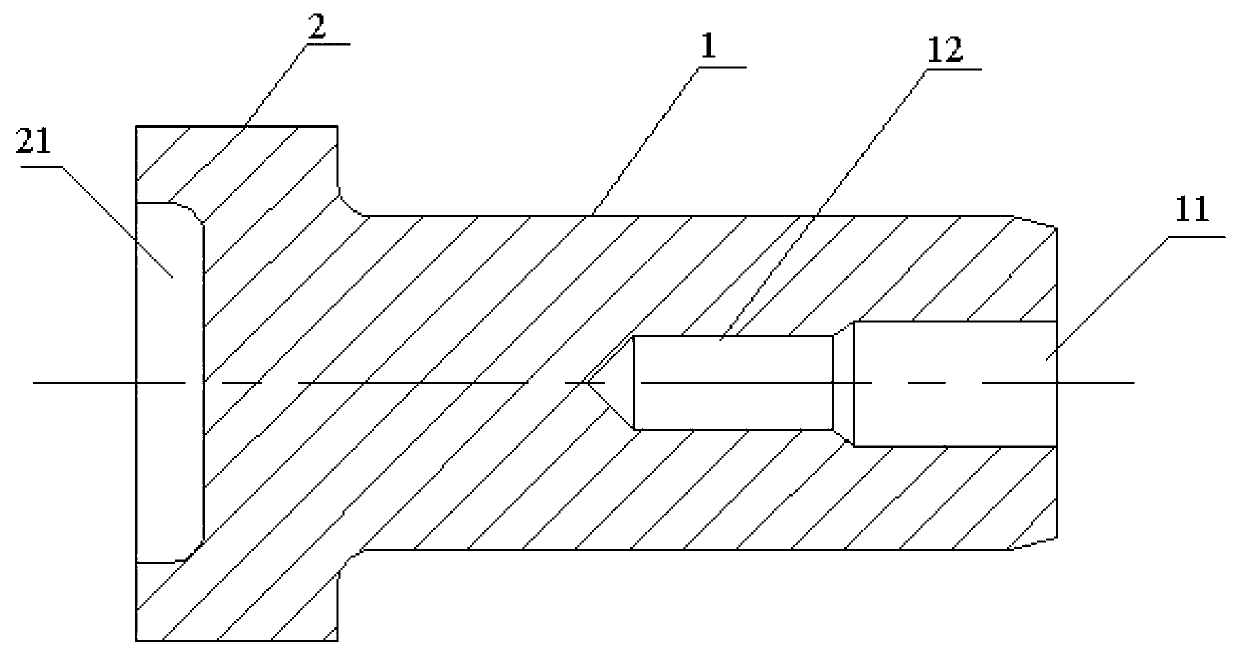

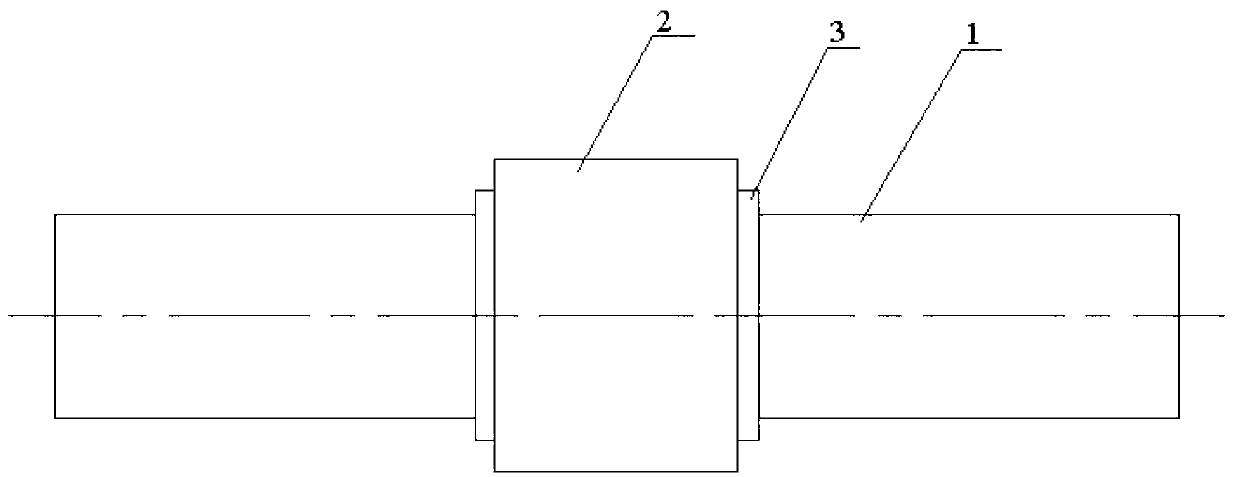

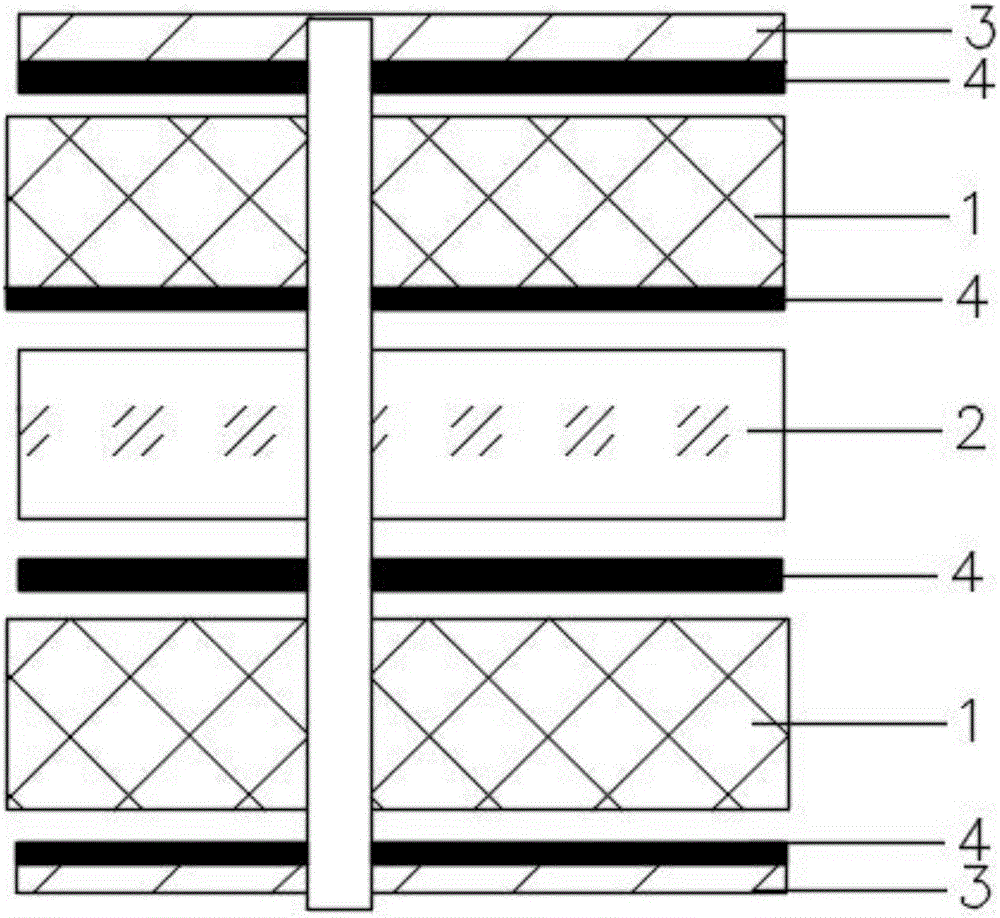

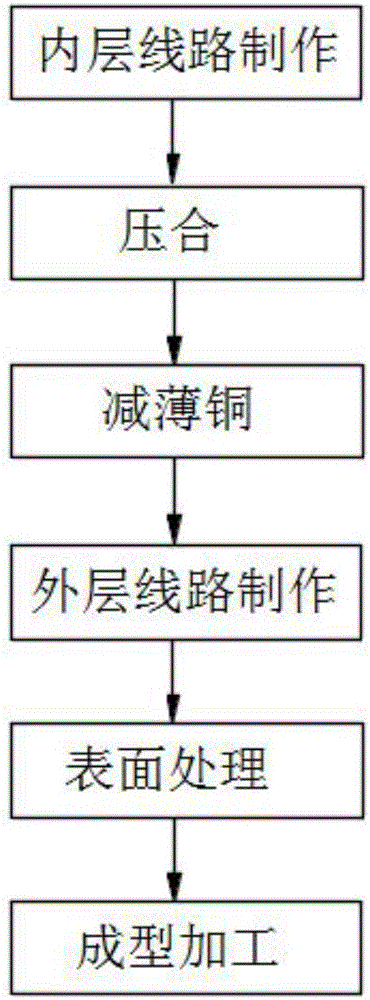

Multi-layer line board structure and manufacturing method thereof

InactiveCN106341939AReduce overlayReduce over etchCircuit susbtrate materialsMultilayer circuit manufacturePower flowCopper foil

The invention relates to the multi-layer line board field and particularly relates to a multi-layer line board structure and a manufacturing method thereof. The multi-layer line board structure mainly comprises multiple inner-layer substrates which are sequentially laminated, light core boards are arranged among adjacent inner-layer substrates, outer-layer copper foils are arranged both above the first inner-layer substrate and below the last inner-layer substrate, and prepregs are respectively arranged among the inner-layer substrates and the adjacent light core boards or the outer-layer copper foils. According to the multi-layer line board structure, through combination of the light core boards and the prepregs, lamination of the multiple prepregs is reduced, and problems of board sliding and interlayer offset during stitching of the multiple prepregs are avoided. According to the method, small-current long-time electroplating technological parameters are employed, uniformity of electroplating copper thickness is improved, a copper thickness range value is reduced, and manufacturing precision of an etching line is improved; dense lines and isolate lines are designed in a segment compensation mode, line etching excess and under etching rates are reduced, and a line making qualified rate is improved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

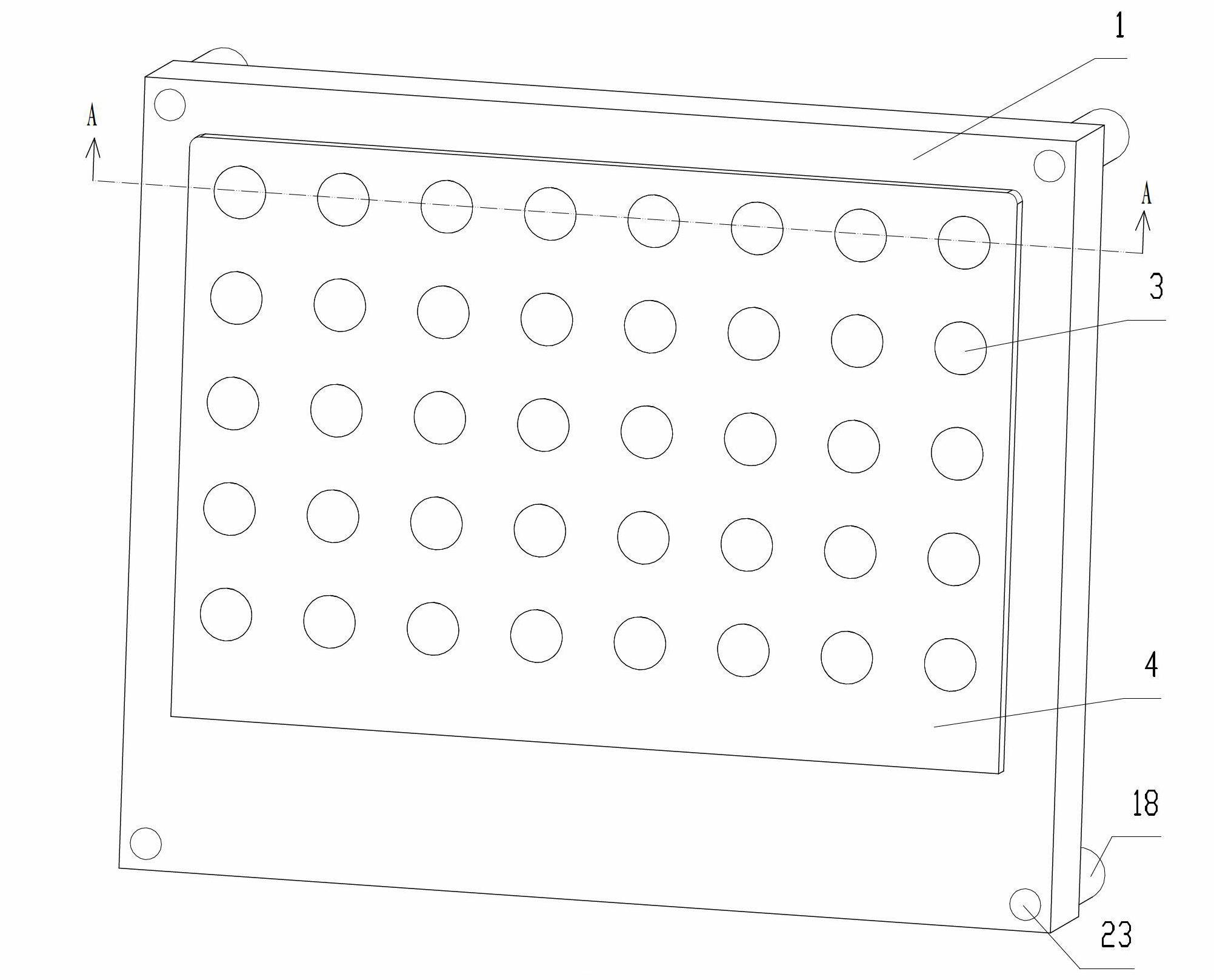

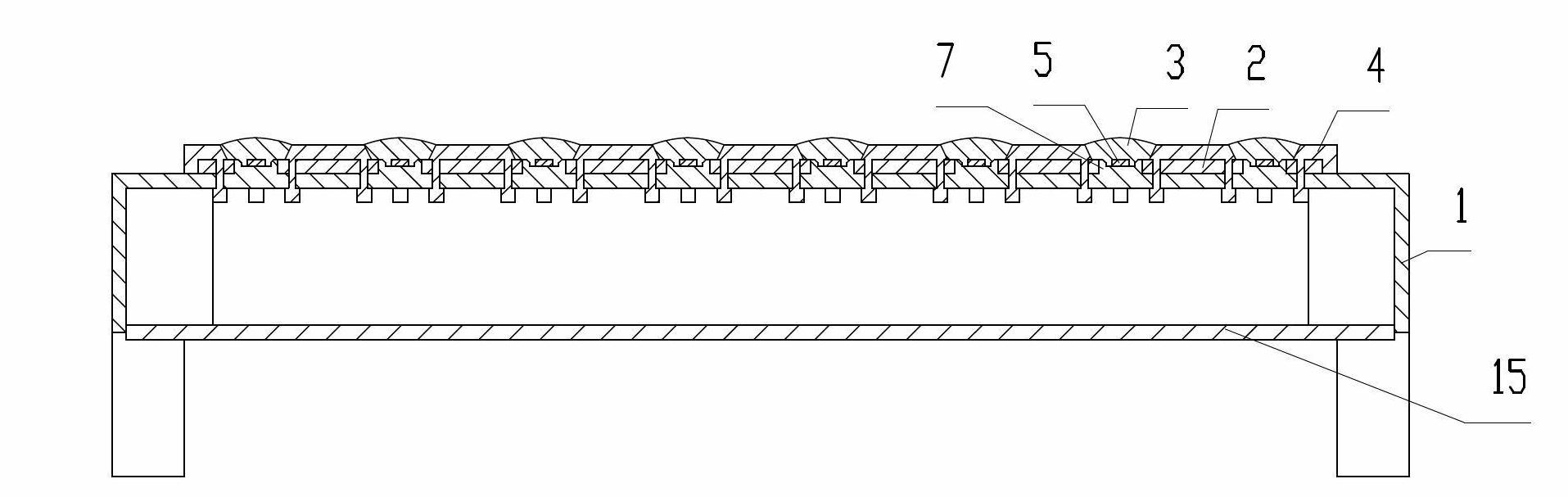

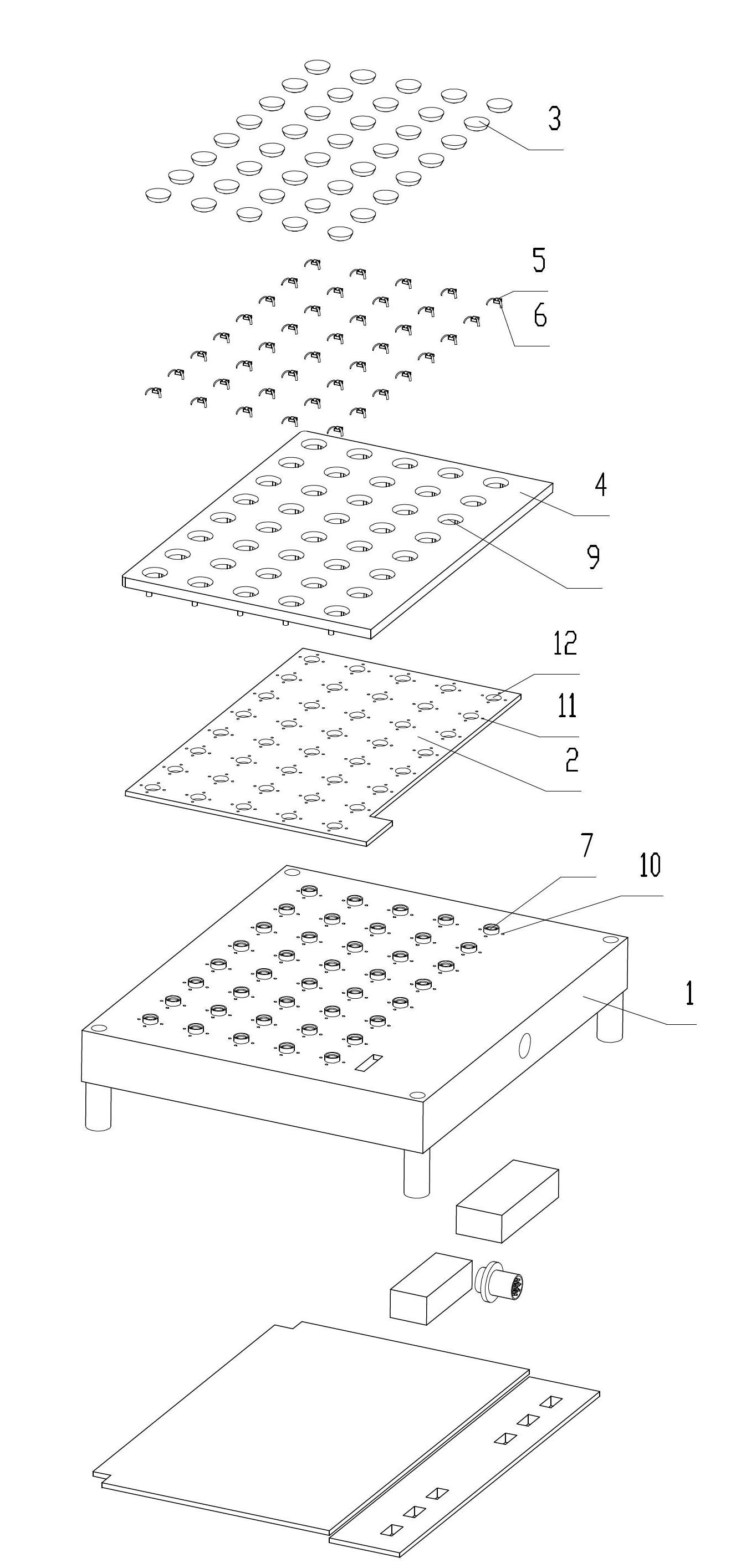

LED (light-emitting diode) dot matrix display screen and combined dot matrix display screen

InactiveCN102682671ACause material deteriorationExtend your lifeCooling/ventilation/heating modificationsIdentification meansDot-matrix displayColloid

The invention discloses an LED (light-emitting diode) dot matrix display screen and a combined dot matrix display screen. The dot matrix display screen comprises a heat-dissipating substrate, a PCB (printed circuit board), an uniformly-arrayed LED light-emitting unit, an imaging controller, a layout circuit conducting layer, a pervious-to-light packaging colloid for packaging LED chips, and a plastic plate forming the pervious-to-light packaging colloid for packaging the LED chips, wherein the LED light-emitting unit comprises more than one LED chips, guide lines and the pervious-to-light packaging colloid; the guide lines electrically connect the LED chips with the layout circuit conducting layer, and the pervious-to-light packaging colloid is used for packaging the LED chips; a hermetically-sealed outer cavity side wall which is hermetically connected with the plastic plate and the heat-dissipating substrate is arranged between the plastic plate and the heat-dissipating substrate; the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate defines a hermetically-sealed cavity, and the PCB is accommodated in the hermetically-sealed cavity; and the heat-dissipating substrate, the plastic plate and the pervious-to-light packaging colloid are directly contacted with the outside air. The dot matrix display screen disclosed by the invention has the advantages that of being simple in structure and low in cost and having good waterproof and heat-dissipating effects since the PCB is accommodated in the hermetically-sealed cavity formed by the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate.

Owner:东莞市万兴智能科技有限公司

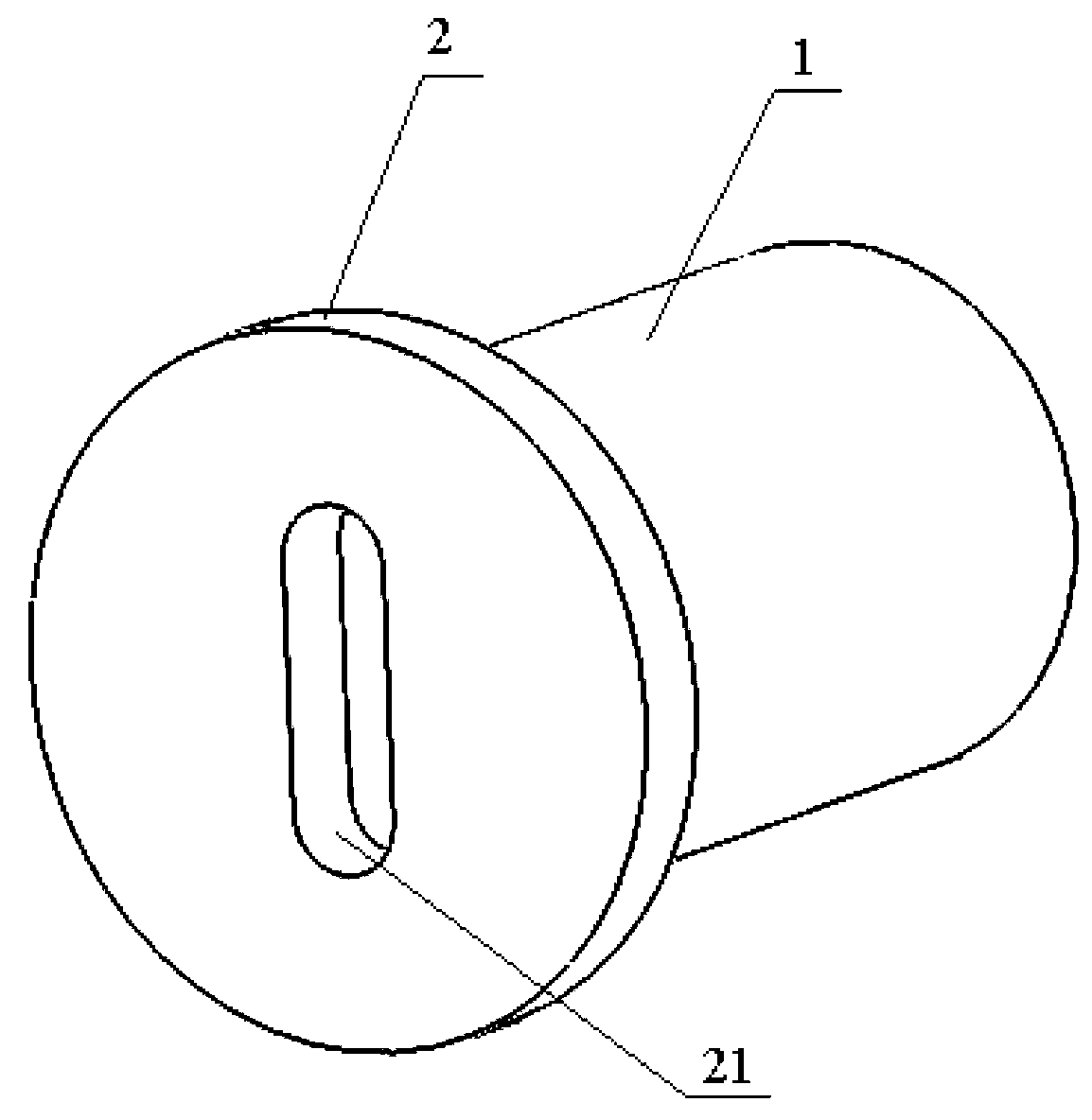

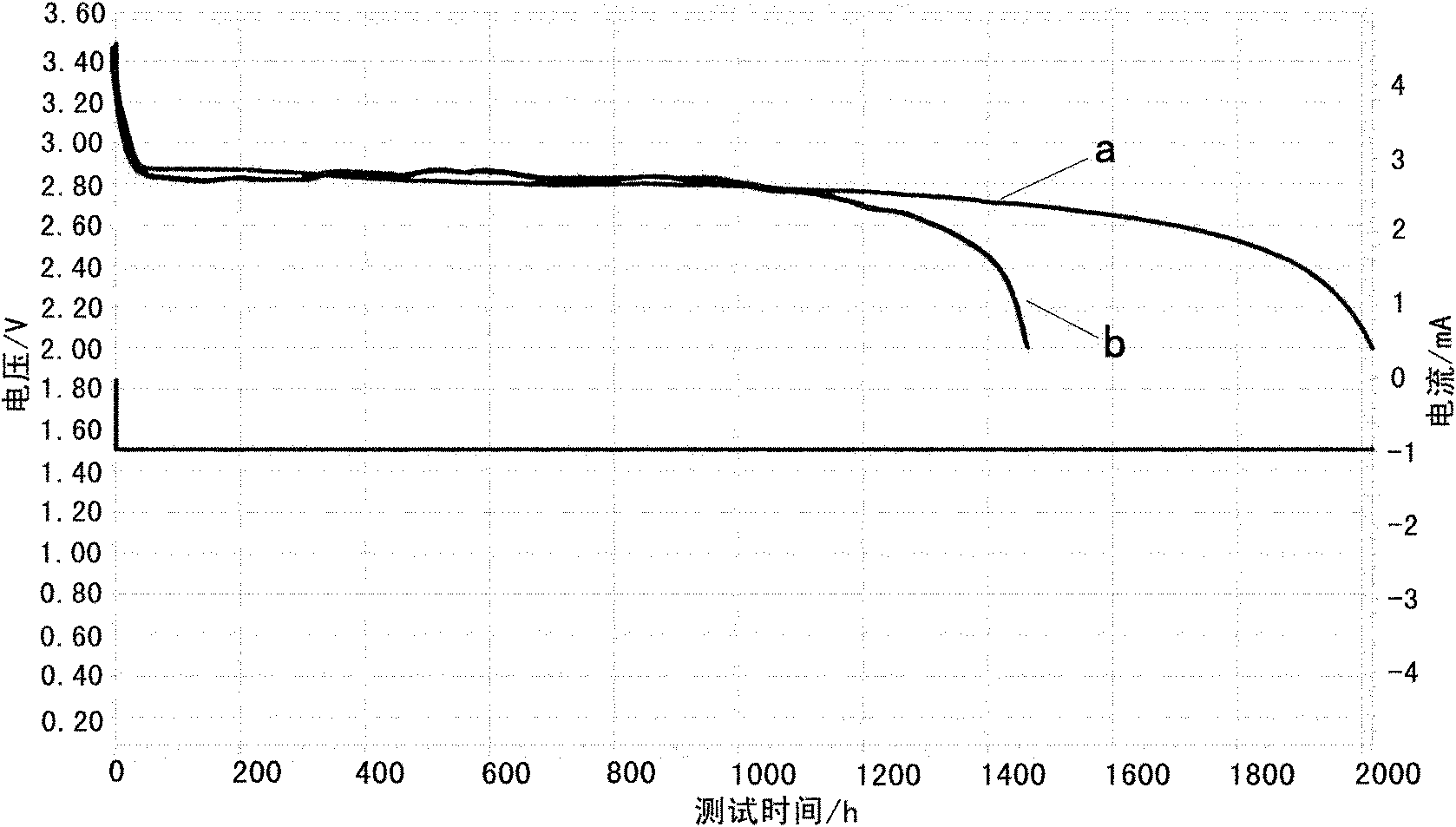

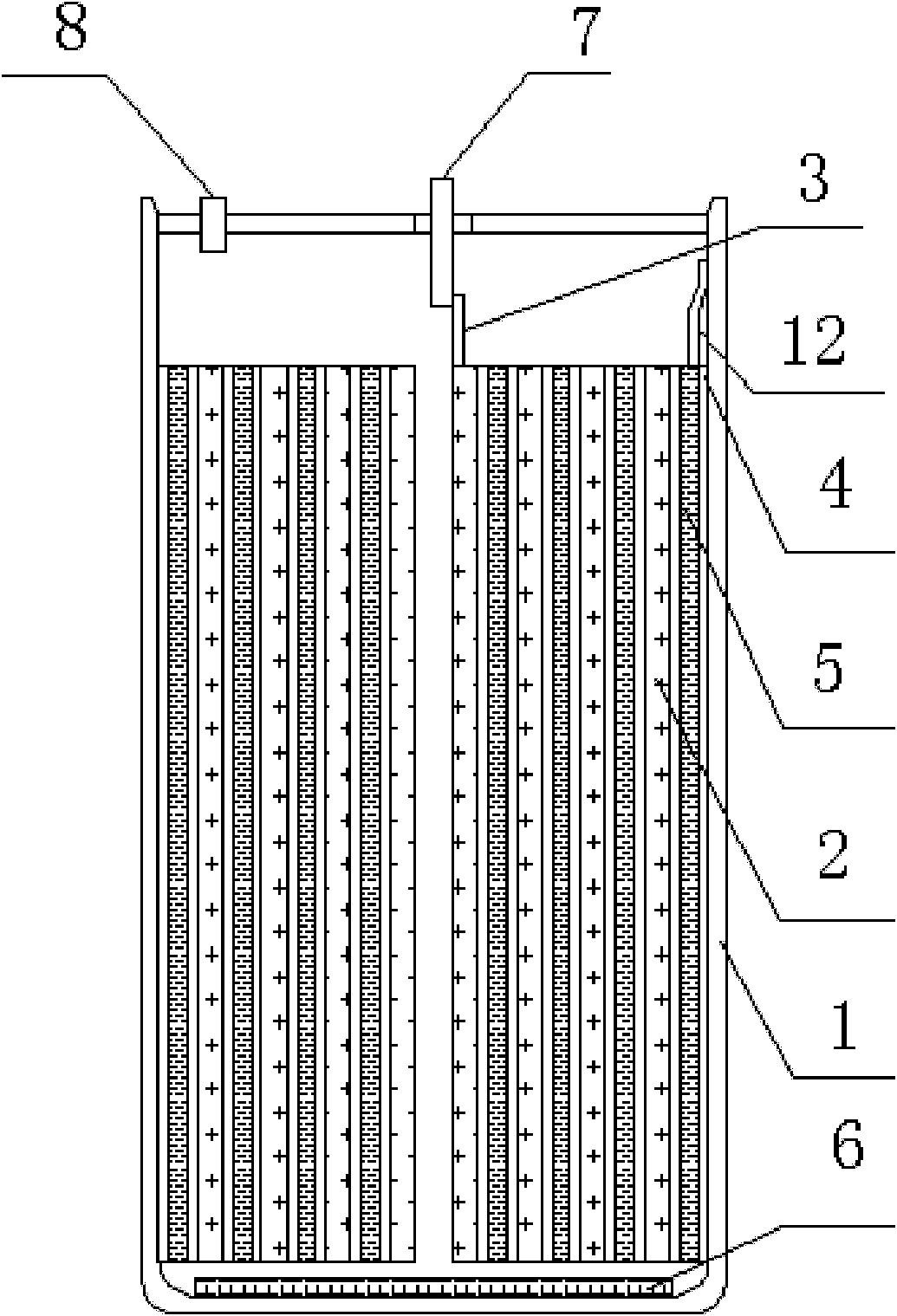

Cylindrical lithium-manganese dioxide battery structure with high capability and preparation method thereof

ActiveCN101916879AReduce contact areaFull use of spaceFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithiumEngineering

The invention relates to a cylindrical lithium-manganese dioxide battery structure with high capability, wherein a ring of diaphragm (4) is wrapped on an outer surface of an anode electrical core (3), a lithium band (5) is arranged between the diaphragm (4) and a steel shell (1), a cover assembly (9) is located on the inner upper end of the steel shell (1), an anode core post (7) is located in the middle of the cover assembly (9), a metal connecting strip (10) is connected with the anode core post (7), the cover assembly (9) is provided with a liquid injection hole (11) and a sealing pin (8) for sealing the liquid injection hole (11), and an insulation sheet (6) for isolating an anode piece (3) from the lithium band (5) is arranged at the inner bottom of the steel shell (1). By adopting the cylindrical lithium-manganese dioxide battery structure, the capability of the battery is increased by 25.0%-36.4%, and the cost of materials is reduced. The invention further discloses a method for assembling the cylindrical lithium-manganese dioxide battery structure with high capability.

Owner:武汉昊诚锂电科技股份有限公司 +1

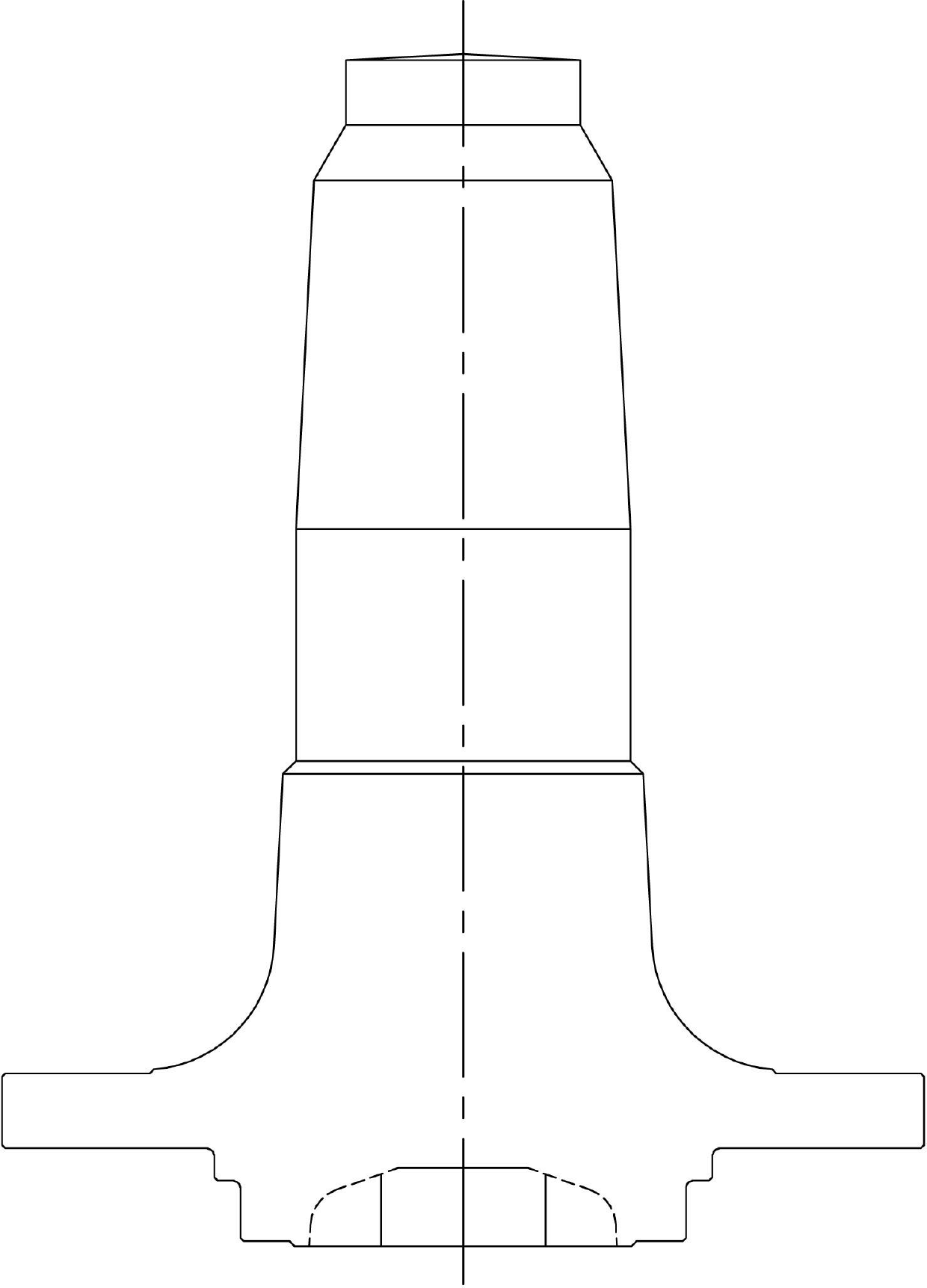

Manufacturing process of automobile half shaft

The invention discloses a manufacturing process of an automobile half shaft. The manufacturing process comprises the following steps of (1) preparing raw materials, (2) conducting finish machining on a flange, (3) conducting friction and crimping, (4) conducting half shaft machining and (5) conducting half shaft finish turning grinding and rustproof packaging. Hole drilling, chamfering and center hole drilling of a flange rough blank are carried out before a flange blank and a rod shaft are crimped, and the crimping is carried out after machining is finished. The manufacturing process solves the problem of location degree deviation of a flange coordinate and the hole position of the whole automobile half shaft, and accuracy is accurate. The flange shape is small before crimping, a common center machine can meet requirements for the flange to drill the hole, cost of equipment is reduced, simultaneously, material feeding and discharge are fast, and production efficiency and percent of pass can be greatly improved.

Owner:大永精机(福州)有限公司

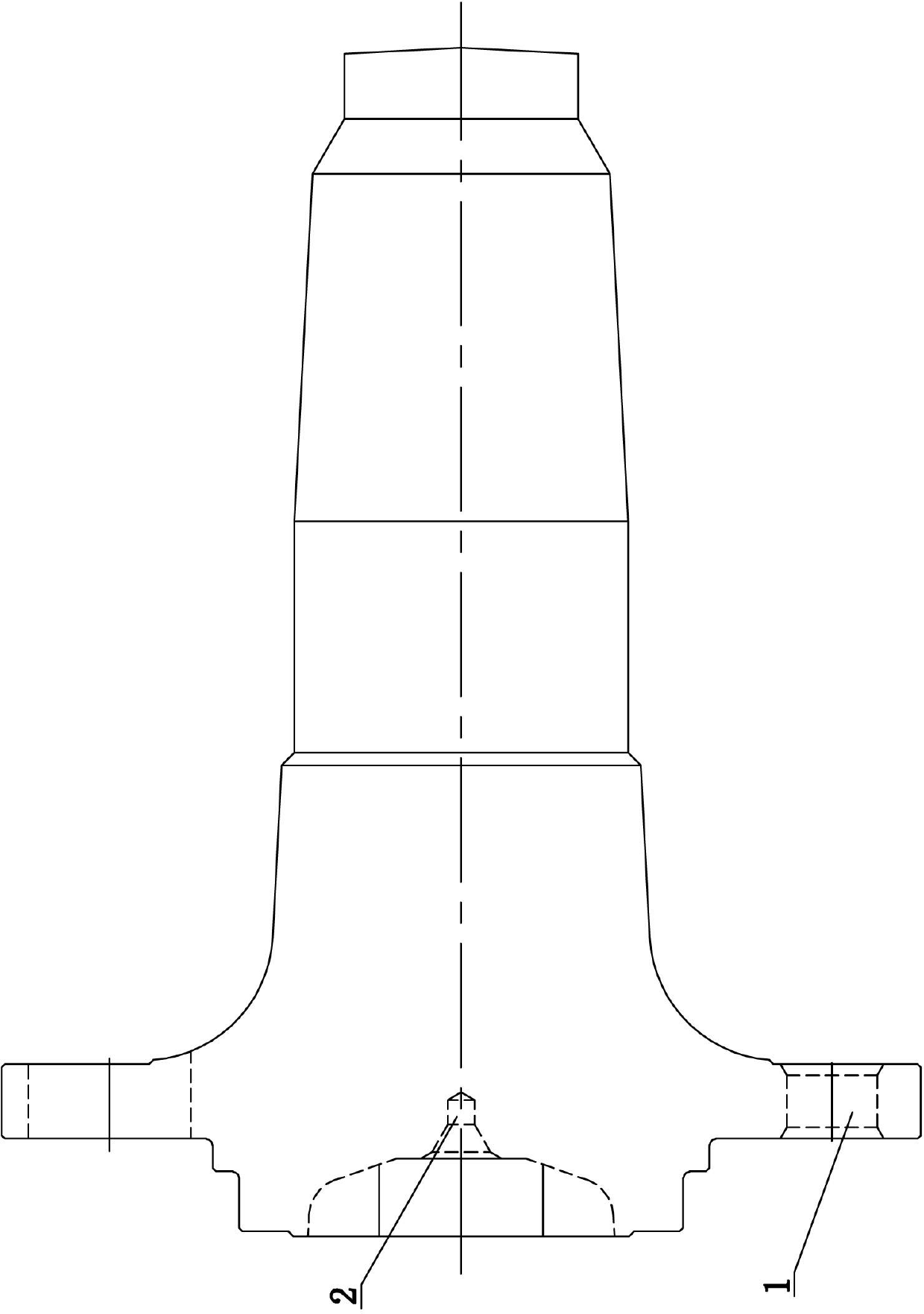

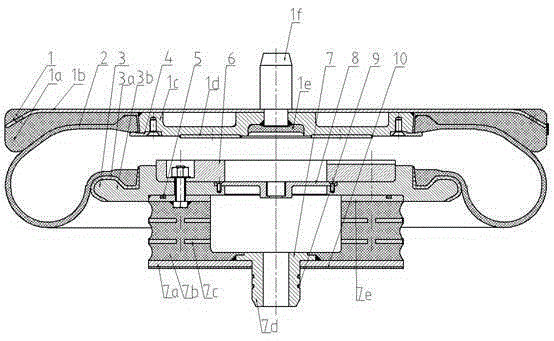

Air spring for railway passenger vehicle and production method of air spring

ActiveCN105202103AImprove production and manufacturing process control capabilitiesReduce manufacturing costSpringsBogie-underframe connectionsAir springAgricultural engineering

The invention discloses an air spring for a railway passenger vehicle and a production method of the air spring. The air spring comprises an upper cover plate assembly, an air bag, a rubber seat, an auxiliary spring assembly and a throttling flange which is located in the middle of the rubber seat and connected with the rubber seat, wherein the rubber seat is mounted above the auxiliary spring assembly; the air bag is located above the rubber seat, and the upper cover plate assembly is located above the air bag; the upper cover plate assembly comprises an upper cover plate flat plate, an upper cover plate locating pin, upper cover plate vulcanized rubber, upper cover plate sealing rubber and an upper cover plate support plate connected to the lower side of the upper cover plate flat plate. The production method of the air spring for the railway passenger vehicle comprises the following steps: producing the upper cover plate assembly; producing the air bag; producing the rubber seat; producing the auxiliary spring assembly; assembling the components to form the air spring for the railway passenger vehicle. The air spring can provide high bearing capacity under the condition of smaller mounting height and provide proper vertical and horizontal stiffness values. The air spring manufacturing process control capacity is improved, and the manufacturing cost of the air spring is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Guide rail machining technology for automobile skylight

ActiveCN107309360AFast tempoReduce manufacturing costOther manufacturing equipments/toolsVehicle componentsEngineeringSkylight

The invention relates to a guide rail machining technology for an automobile skylight. Parts are grasped and conveyed to different stations through a robot and different operations are carried out. A whole guide rail production technology flow and equipment are improved, so that the production pace is reduced, the yield of production is improved and a process of producing and detecting synchronously is realized. The guide rail machining technology can be switched through one key according to different project guide rails, different radians and pre-adjusted parameters.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

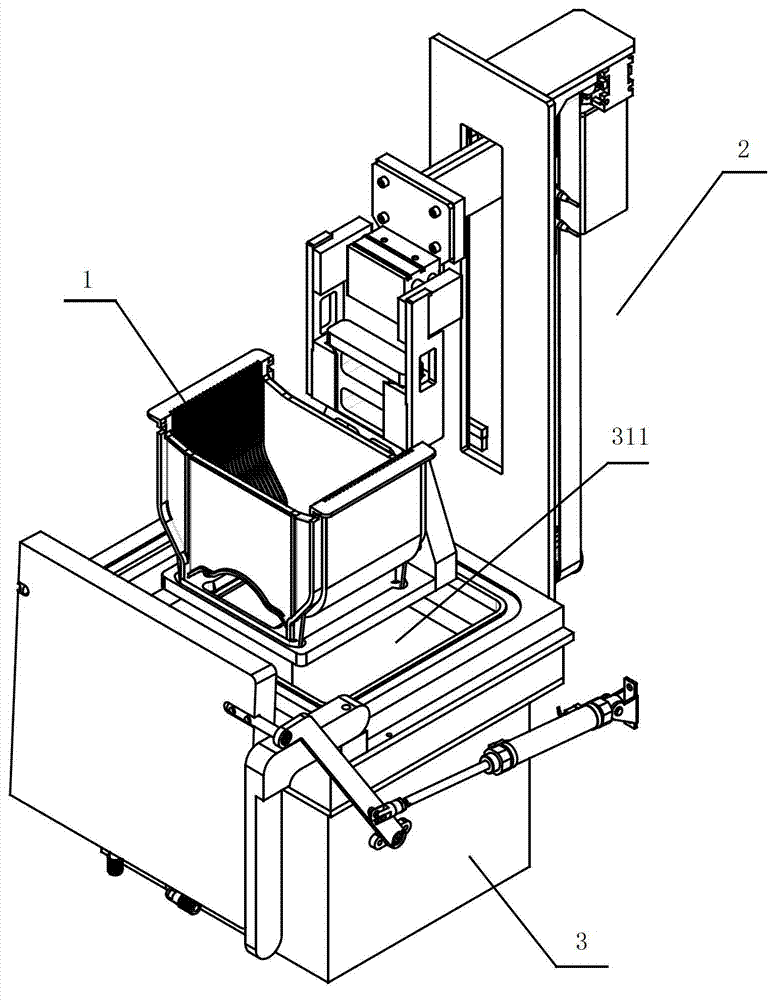

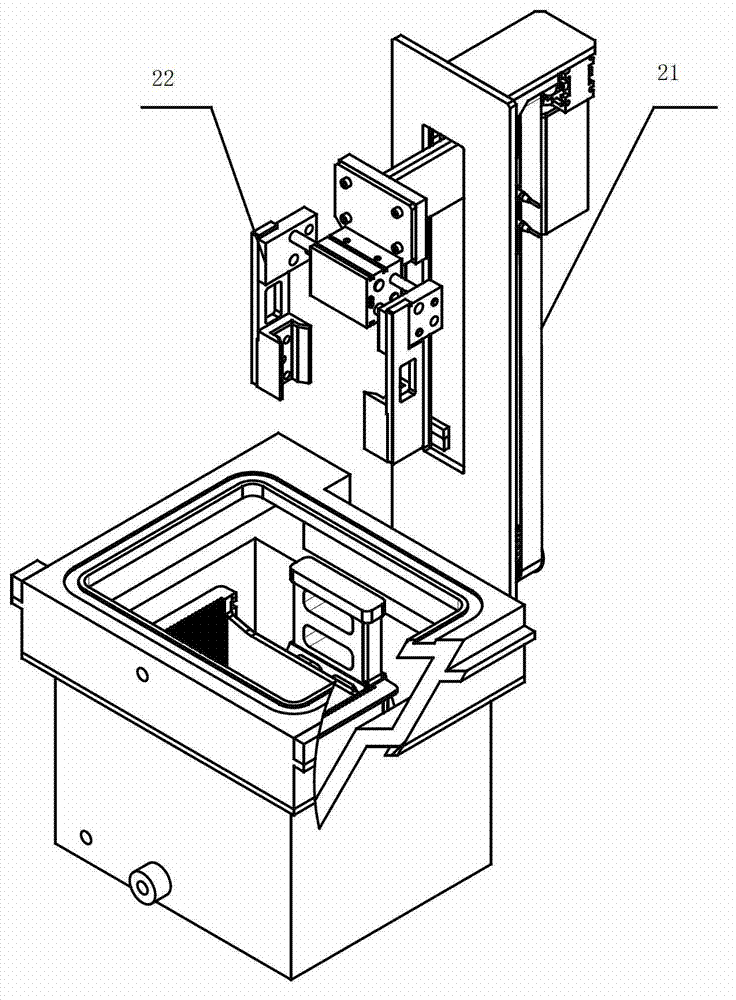

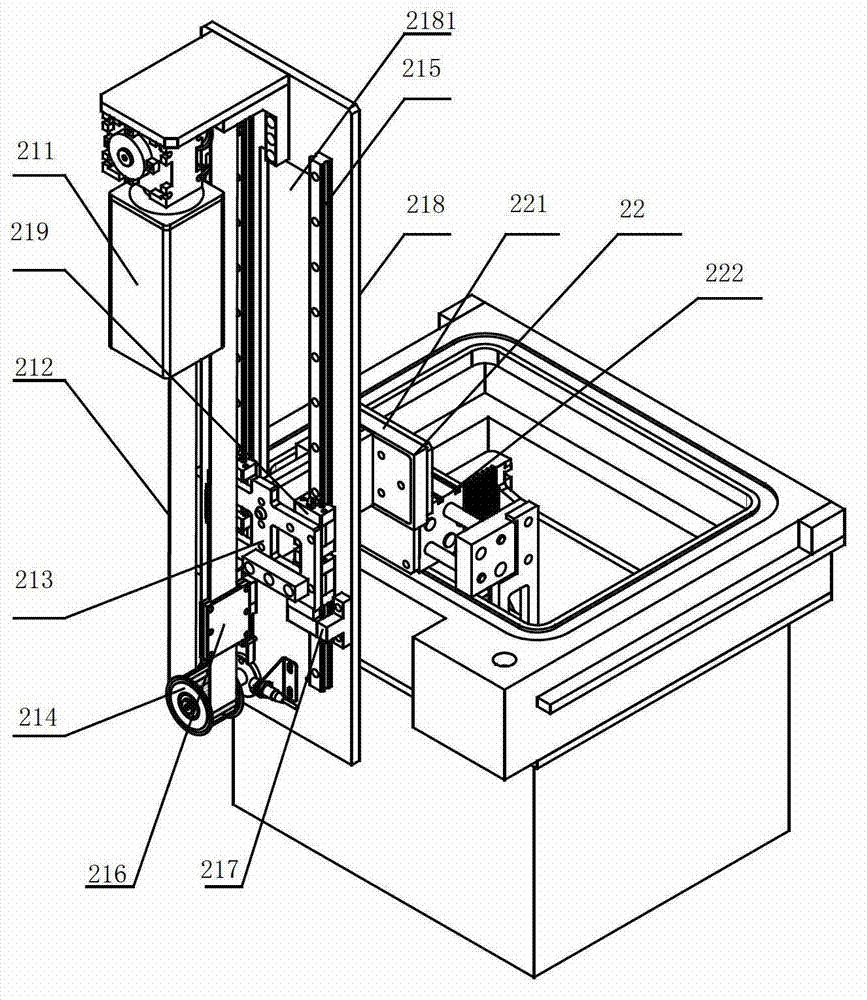

Wafer processing device

ActiveCN103046097AAvoid damageImprove work efficiencyCellsSemiconductor devicesIndustrial engineering

The invention discloses a wafer processing device, which is characterized by comprising a processing tank and provided with an accommodating cavity which can be sealed, wherein the accommodating cavity is used for accommodating treatment fluid to process wafers; and a grabbing and lifting device, arranged on one side of the processing tank for conveying the wafers to the accommodating cavity of the processing tank. According to the wafer processing device provided by the invention, the automatic operation of a series of working procedures is achieved by the combination of the grabbing and lifting device and the processing tank, the work efficiency is greatly enhanced, the labor cost is saved, and the qualified rate is improved.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

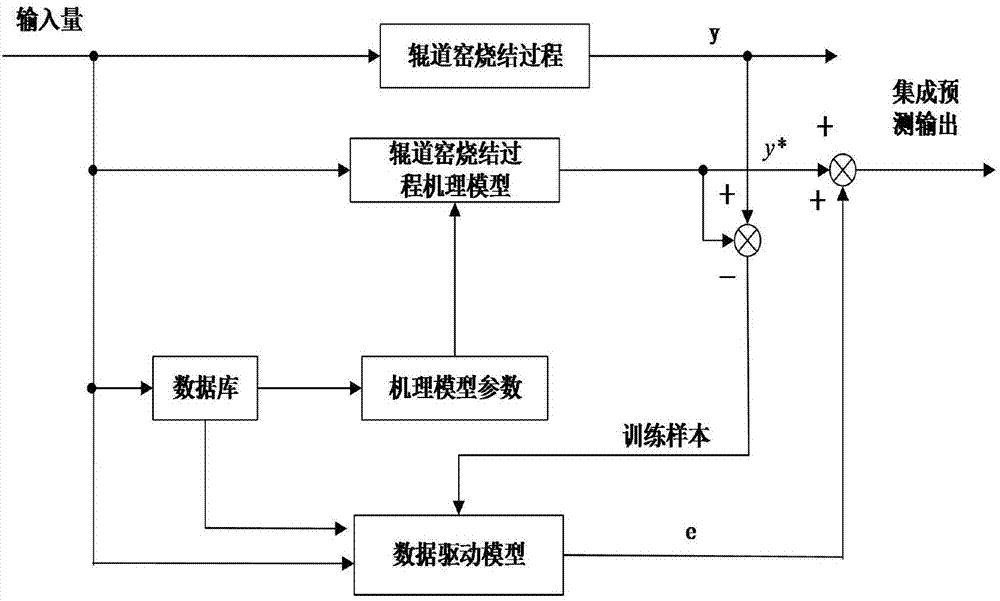

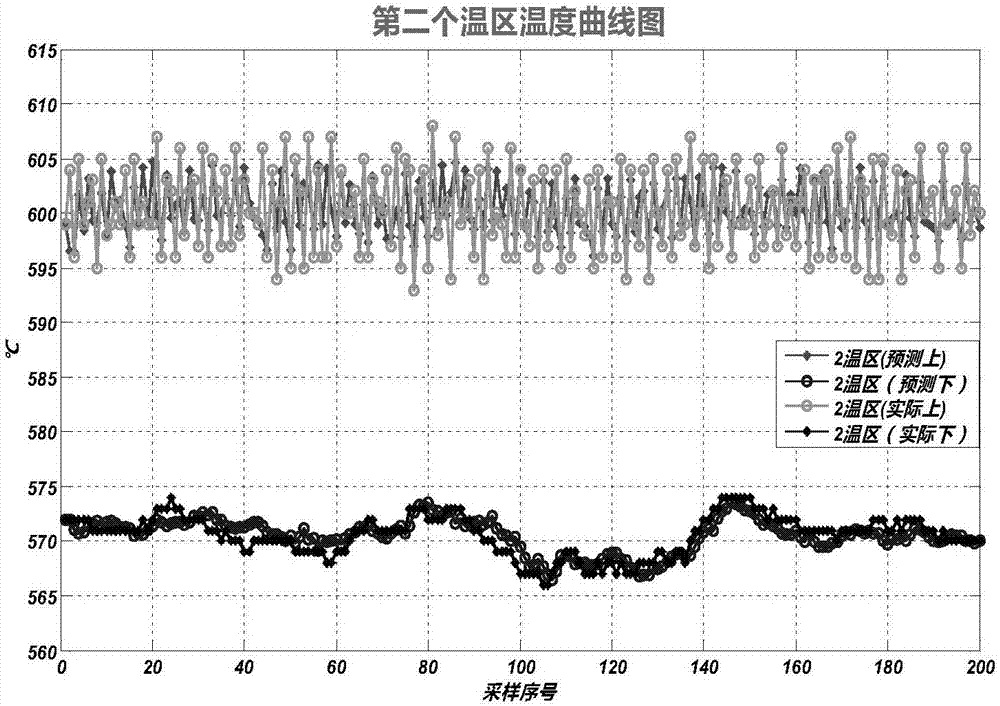

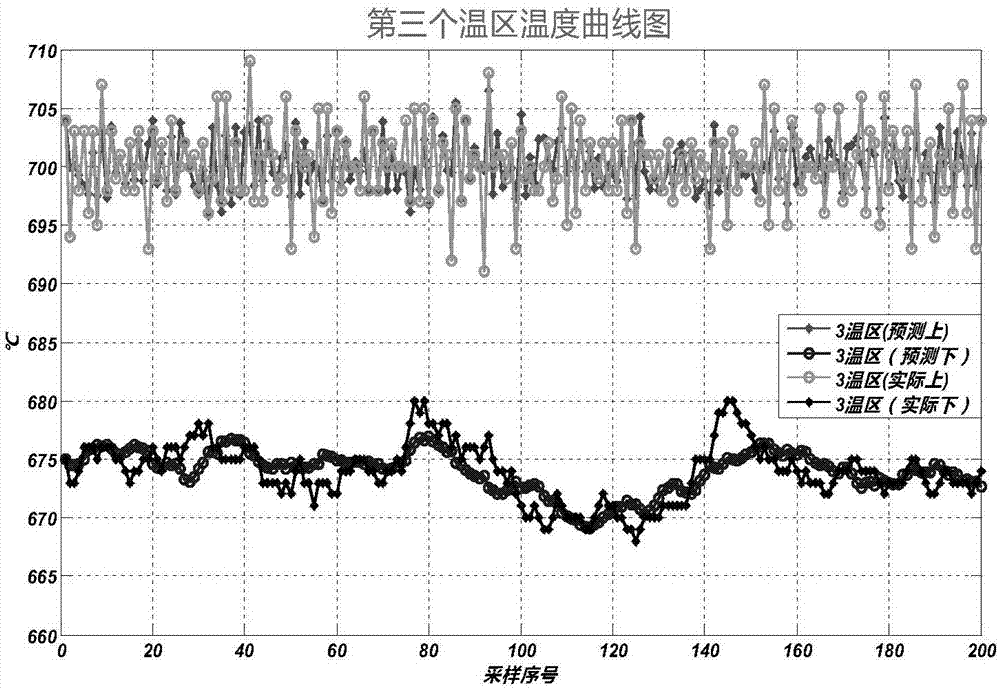

Roller kiln temperature prediction integrated modeling method capable of combining mechanism with data

ActiveCN107038307AThe result is close to realityOptimize forecast resultsDesign optimisation/simulationSpecial data processing applicationsTemperature controlPrincipal component regression

The invention discloses a roller kiln temperature prediction integrated modeling method capable of combining a mechanism with data. The method comprises the following steps that: through the analysis of factors which affect temperature change, from a perspective of the temperature change and energy, establishing a mechanism model; then, considering situations that roller kiln sintering is a very complex process, a whole sintering process can not be described through a single mechanism model and the mechanism model has model errors through simplification, establishing a data model to predict model errors so as to make up mechanism output, i.e., utilizing errors to serve as a training sample to establish an error prediction model of a nonlinear time-varying process based on local weighted kernel principal component regression; and finally, combining the mechanism model with the data model to establish a roller kiln temperature prediction integration model. By use of the model, the state change of a process can be better tracked, and a good guidance function is provided for roller kiln temperature control so as to improve the production quality and the percent of pass of a product.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com