Patents

Literature

41results about How to "Conducive to follow-up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

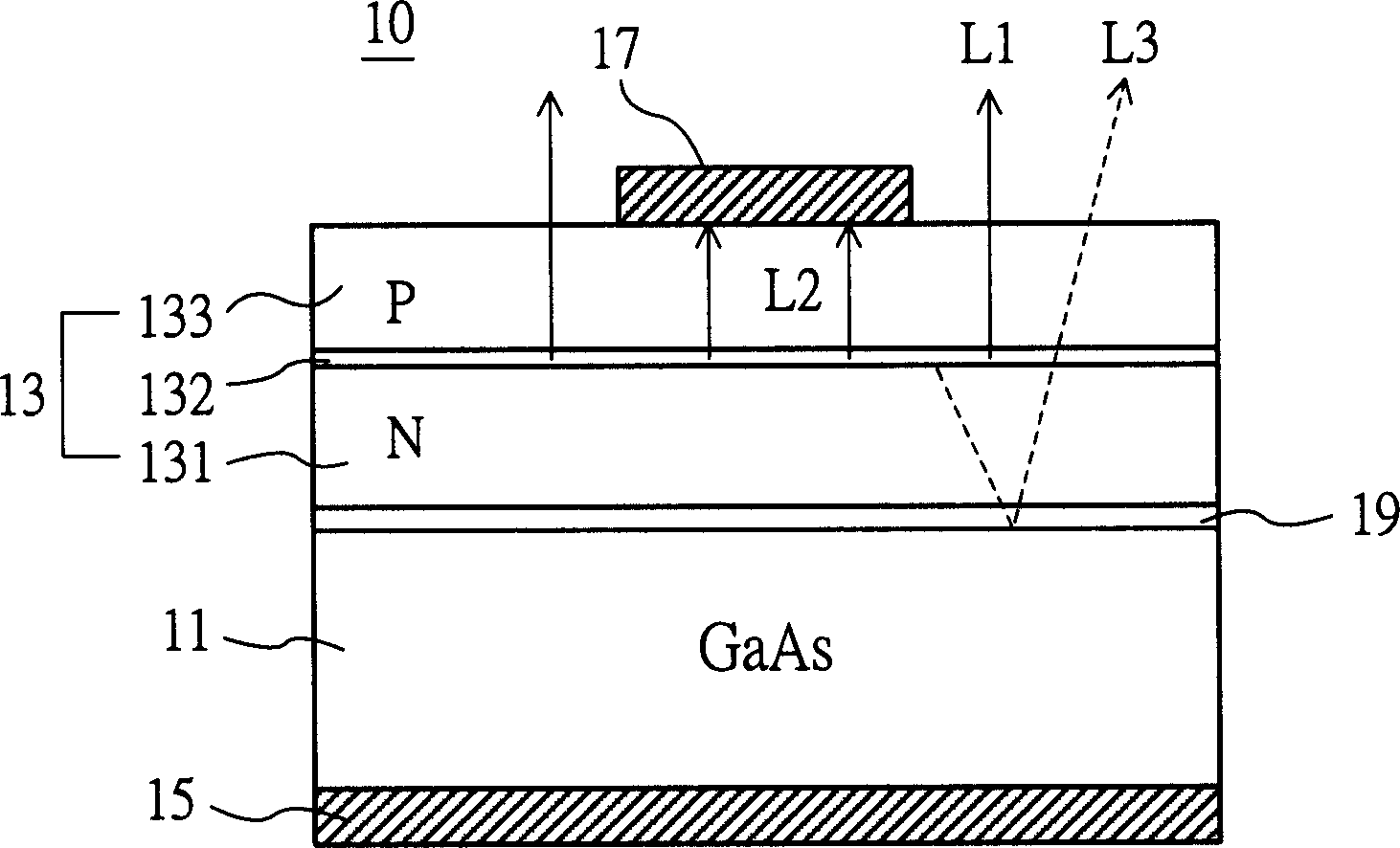

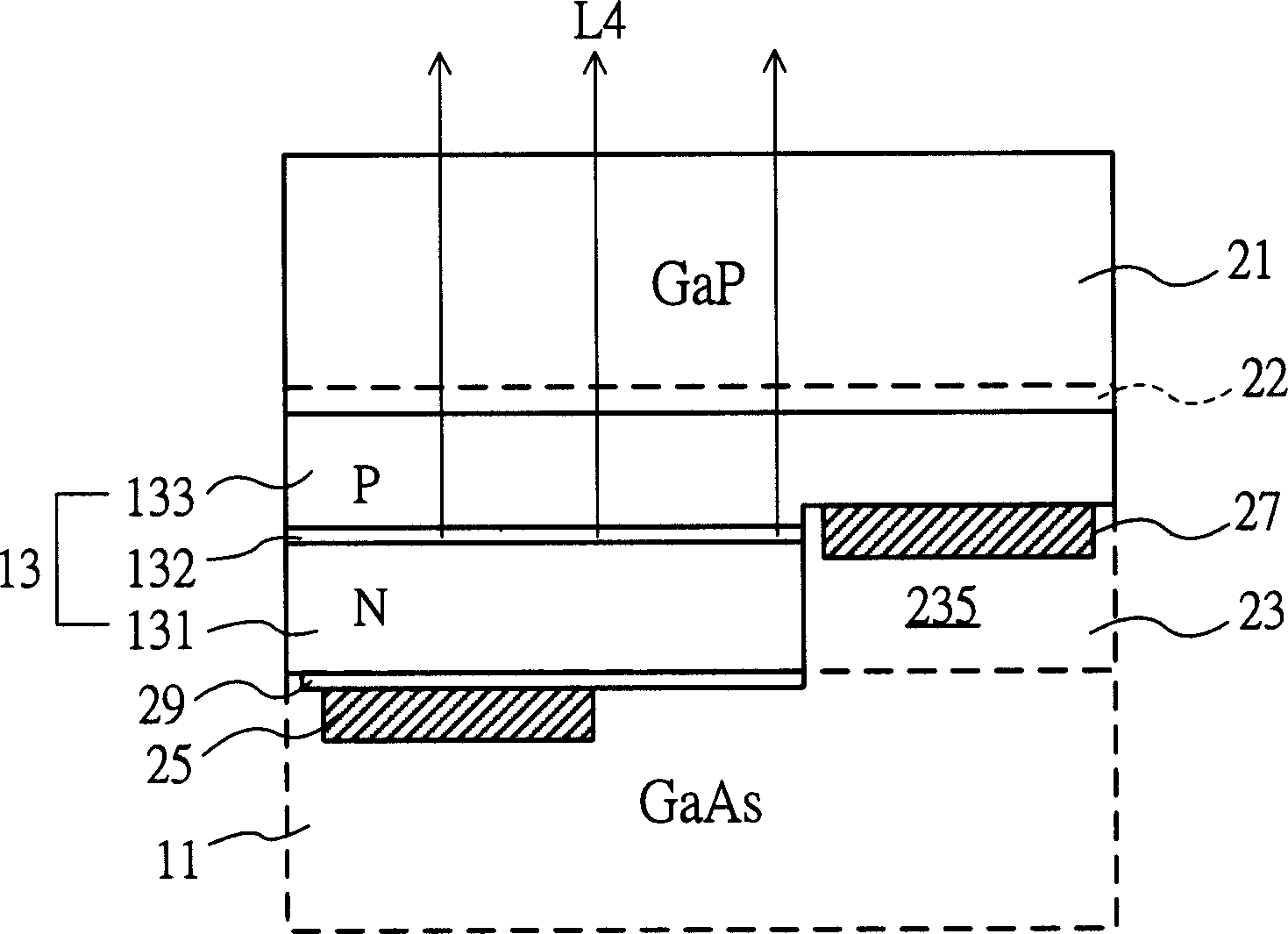

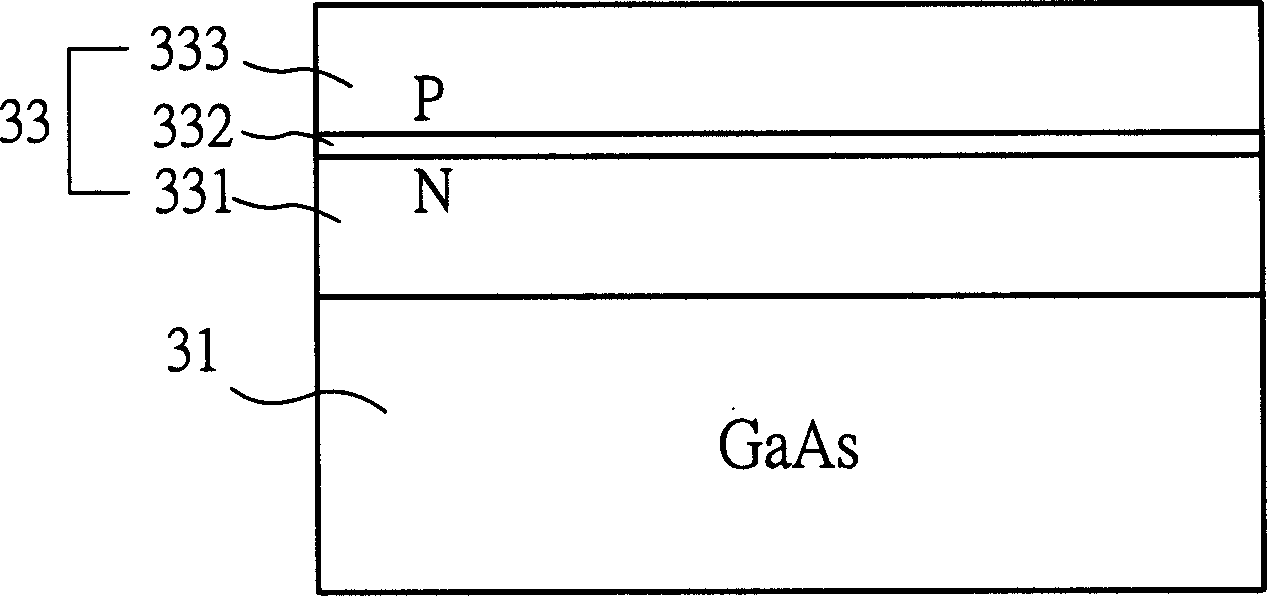

LED

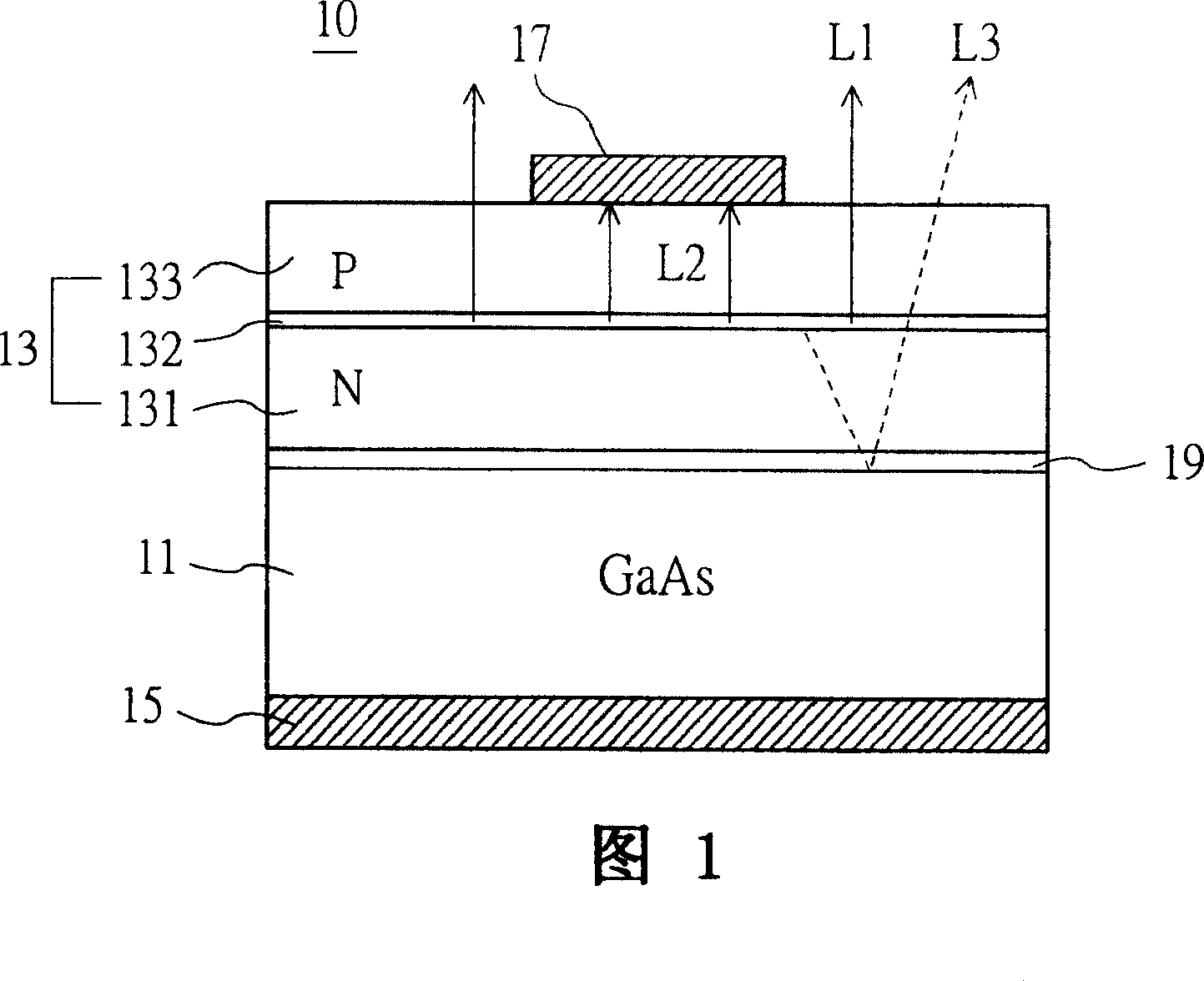

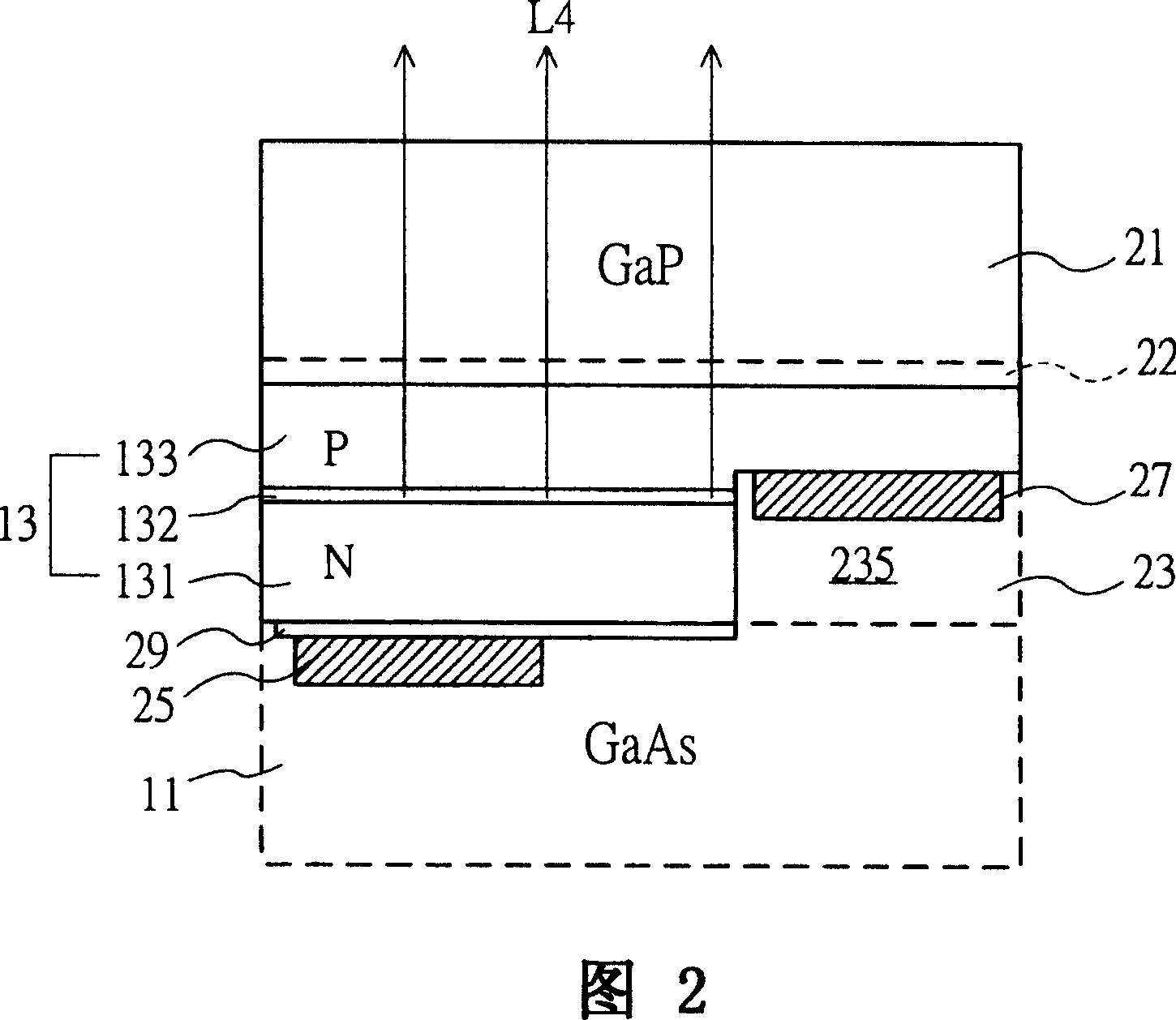

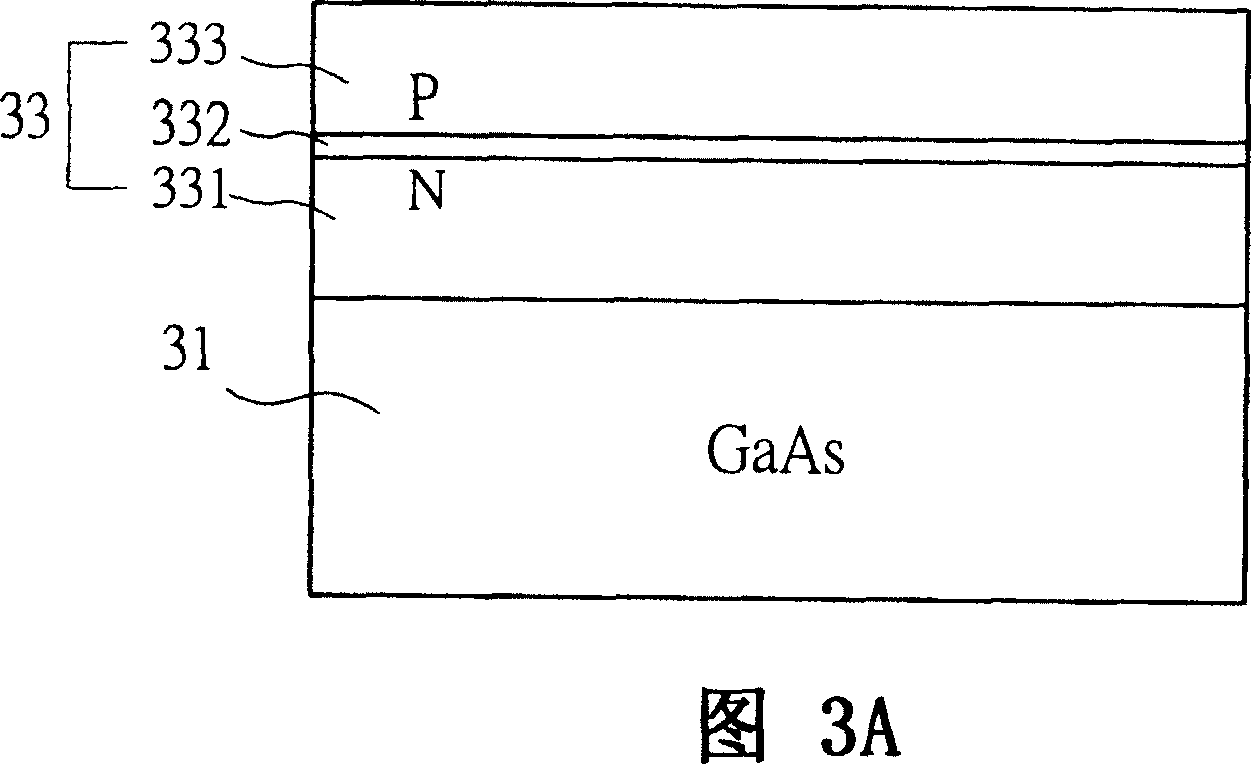

InactiveCN1564333AUniform distribution of working current densityImprove efficiencySemiconductor devicesElectrical conductorEngineering

Quadreple epitaxial layer composed of first material layer, luminous layer and second material layer is formed on a semiconductor base plate. A euphotic base plate is fixed on surface of the second martial layer. With semiconductor base plate being removed, isolation groove and first extend groove are made under undersurface of first material to penetrate the first material layer and extend to part of volume of second material layer at least. First extend electrode is setup inside first extend groove. The first extend electrode is possible to connect with first electrode positioned at partial surface of the first material layer. Thus, the first electrode is located in nearly same level position to second electrode, which is on surface of other part of the first martial layer in order to carry out next processing easily. The invention increases luminescence are of PN interface, raises luminescence brightness and service life.

Owner:OPTO TECH

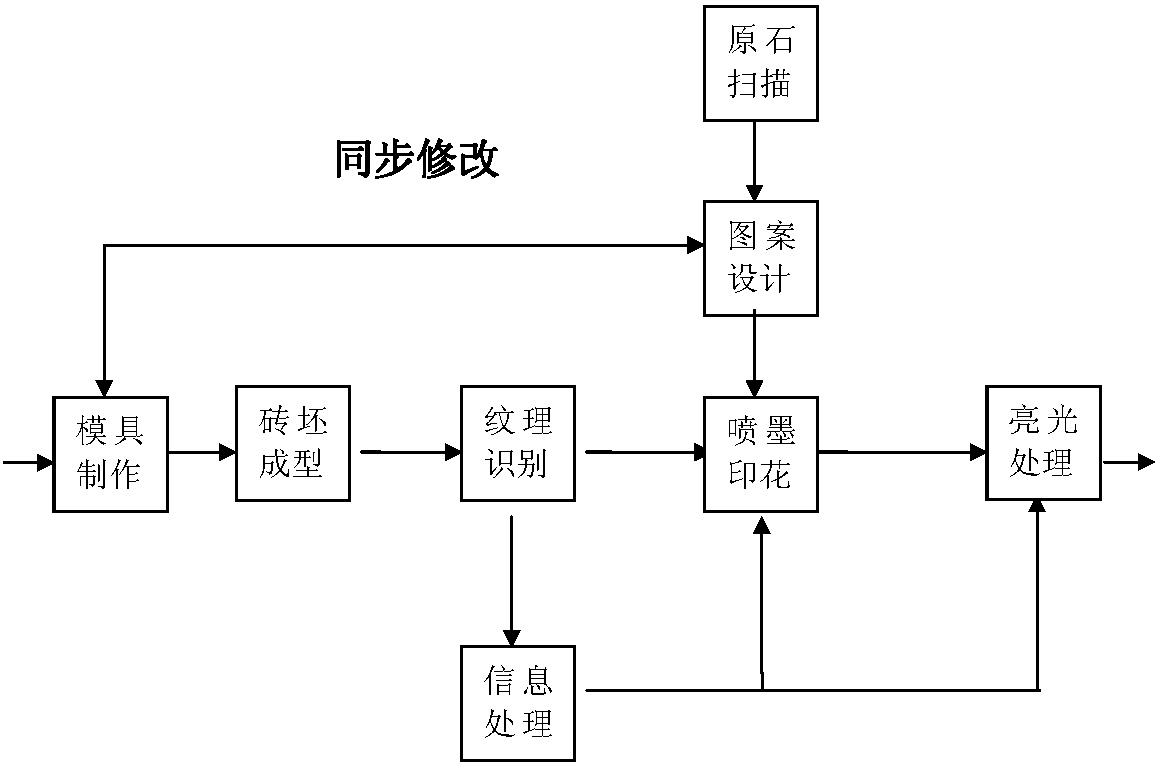

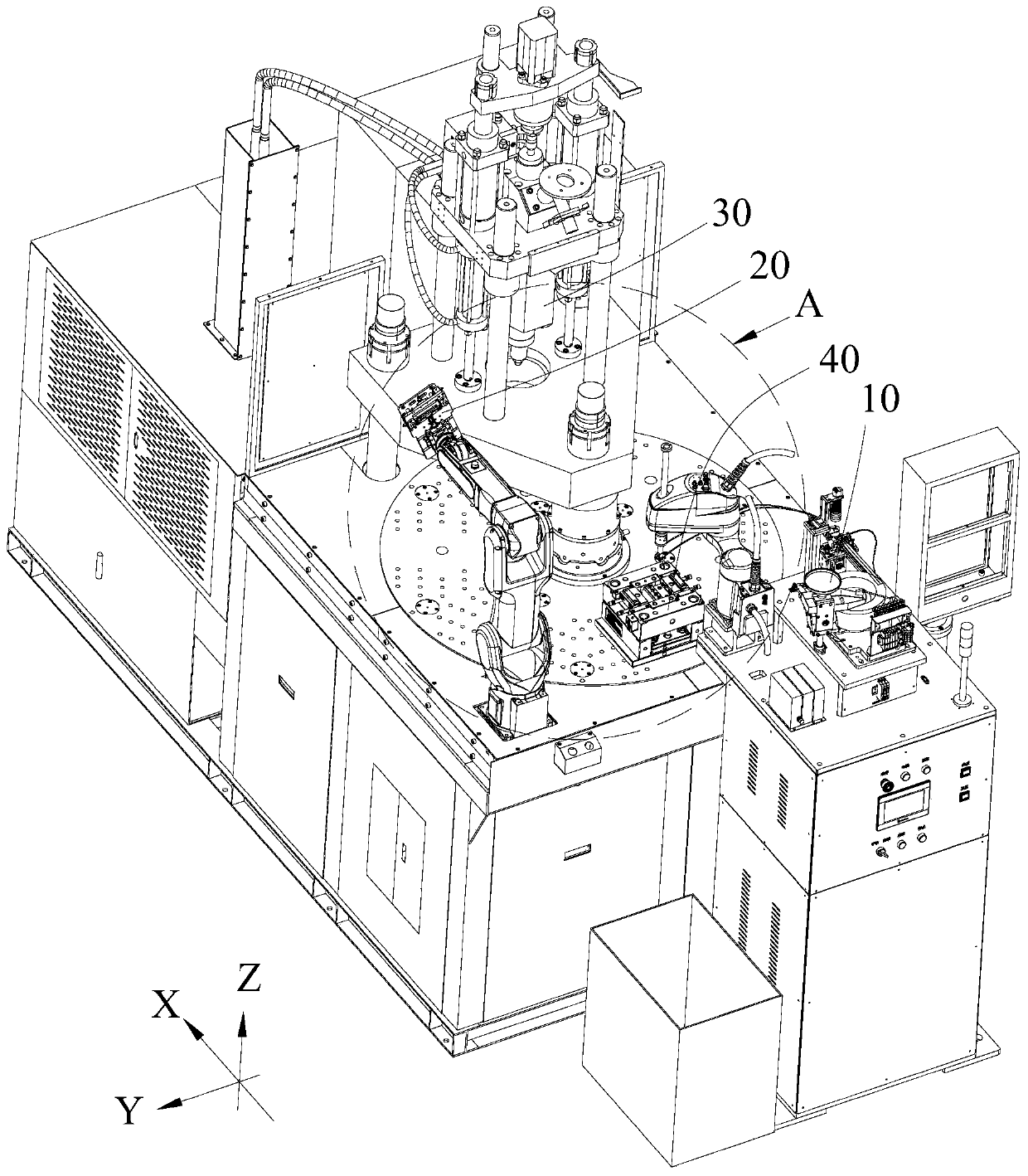

Tile preparing method and tile manufacturing system enabling ink jet patterns and die textures to be completely matched

ActiveCN103171039AInkjet processing facilitatesEfficient identificationCeramic shaping apparatusEngineeringBrick

The invention relates to a tile manufacturing method and a tile manufacturing system enabling ink jet patterns and die textures to be completely matched. Therefore, a vivid effect is achieved when tiles with a raw stone imitating effect are manufactured. The tile manufacturing method comprises the steps of scanning multiple kinds of natural raw stones to obtain multiple scanning patterns, manufacturing multiple dies with corresponding textures according to the multiple scanning patterns, adopting the multiple dies to carry out green brick molding to manufacture green bricks with textures corresponding to the textures of the dies, recognizing the textures of the green bricks to be jet with ink and generating recognition signals, generating multiple ink jet patterns based on the multiple scanning patterns, and selecting the corresponding ink jet patterns according to the recognition signals to carry out ink jet processing on the green bricks.

Owner:MONALISA GRP CO LTD

Decorative plate finishing paper and production method thereof

The invention aims to replace wood veneer and technical wood by using a piece of novel decorative plate finishing paper for artificial plate veneering. A piece of base paper which is 150-350g / m<2> is adopted, the upper layer of the base paper is printed with simulated natural and precious trees which are infrequent day by day, other artistic patterns can be also innovated and printed, and a vivid effect can be achieved after lamination. Due to adoption of chemical fiber in the decorative plate finishing base paper, the paper strength can be improved, and the paper is soft and tough. The decorative plate finishing paper is mainly applicable to veneering of artificial plates such as fiber boards and chipboards, and can replace veneering materials such as wood veneer and technical wood, and the finishing paper can have flame retardancy after being coated with a flame retardant adhesive.

Owner:SHANDONG LUNAN NEW MATERIALS

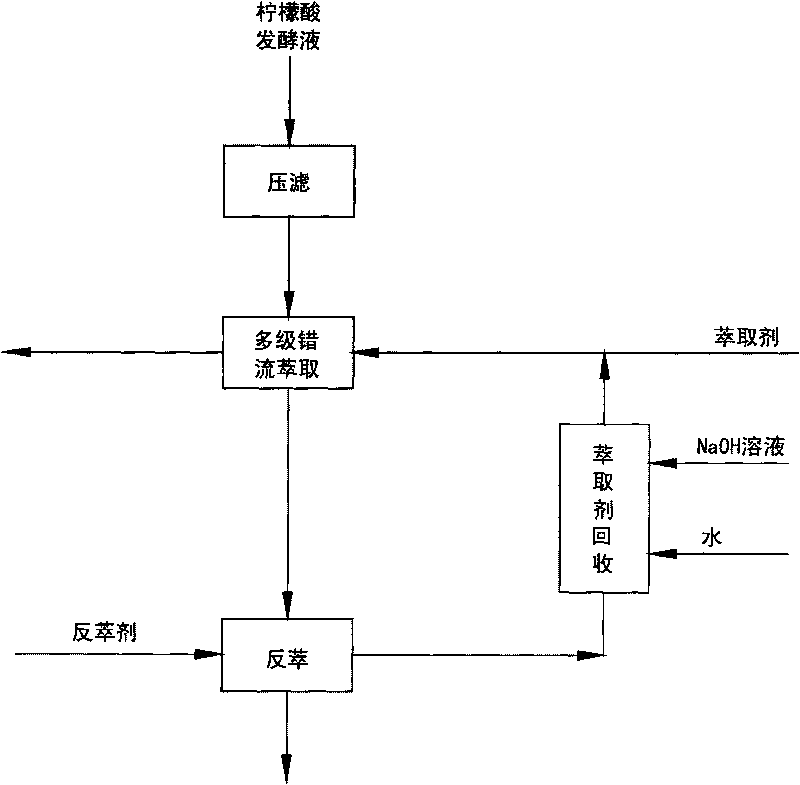

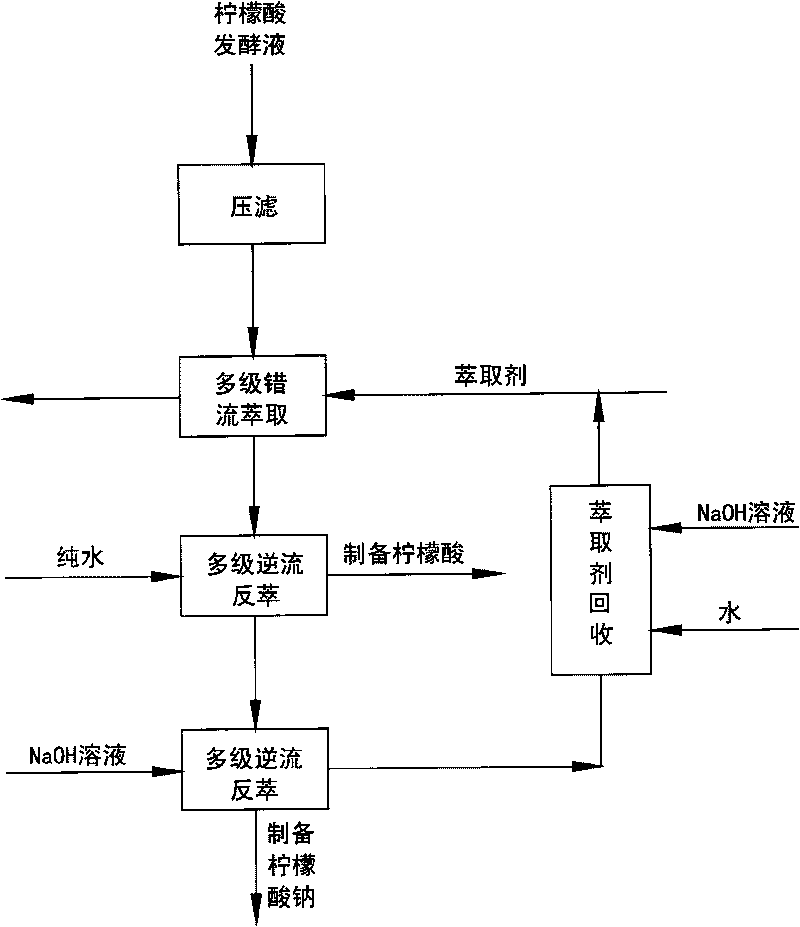

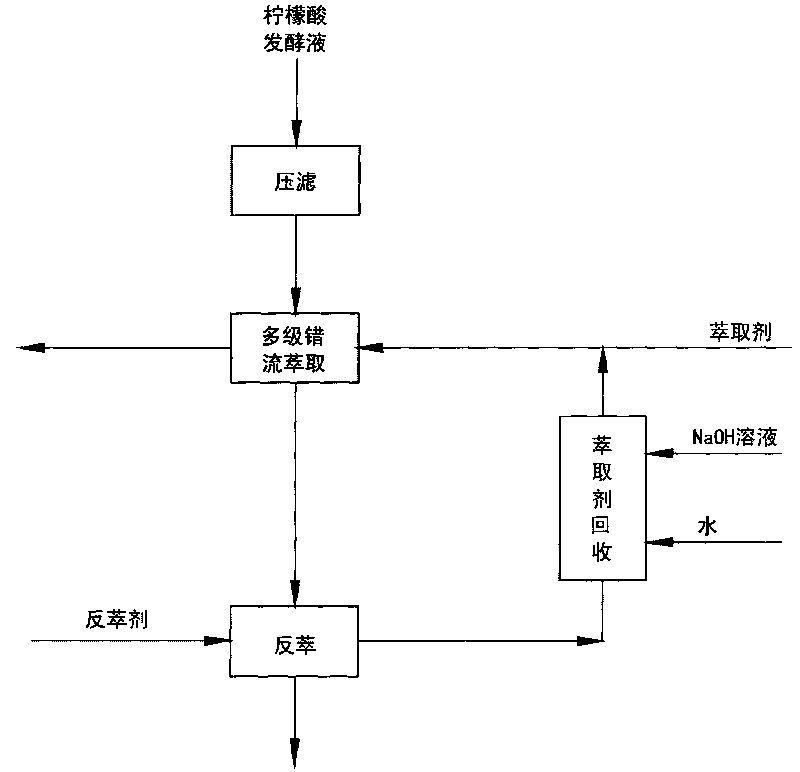

Method for extracting citric acid and/or sodium citrate from fermentation liquor by using extraction method

ActiveCN101704739AEasy to produceReduce the degree of emulsificationCarboxylic compound separation/purificationFilter pressSodium citrate

The invention provides a method for extracting citric acid and / or sodium citrate from fermentation liquor by an extraction method. In the method, a mixed solution of tertiary amine and high alcohol is used as a complex extracting agent for carrying out multilevel cross-flow extraction on citric acid fermentation liquor, and pure water and / or a NaOH aqueous solution is selected to carry out back extraction on an extraction phase. A more ideal extraction distribution coefficient can be reached by using the mixed extracting agent of the tertiary amine and the high alcohol to extract a filter-press clear citric acid solution, and the extraction yield by utilizing the multilevel cross-flow extraction can reach more than 98 percent. The extraction phase is back extracted by utilizing the pure water or the NaOH solution so as to prepare citric acid and sodium citrate aqueous solutions being suitable for concentration and crystallization.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Preparation method of graphene composite material

ActiveCN104577125AImprove high temperature resistanceImprove hydrophobicityMaterial nanotechnologyCell electrodesComposite filmHeat conducting

The invention relates to a preparation method of a graphene composite material. The preparation method comprises the following steps: adding polyethylene glycol monoperfluorononylene ether to prepare modified aqueous dispersion of graphene; preparing a graphene composite film from a sulfur-containing solution and a carbon nano tube; and carrying out gradient crystallization treatment on the graphene composite film. In the technical scheme, the graphene aqueous dispersion is good in stability and high in yield by adding the polyethylene glycol monoperfluorononylene ether; nano sulfur particles are evenly dispersed on the surface of the reduced graphene; full play of high electrical conductivity and stability of the graphene when the graphene composite material is used as a lithium battery anode material is facilitated; the energy density property of the graphene composite material as the anode of the lithium battery is improved; the power characteristics of the battery are improved; and in addition, the heat-conducting property, the conductivity and the strength performance of the graphene composite material can be improved by doping the carbon nano tube.

Owner:深圳特新界面科技有限公司

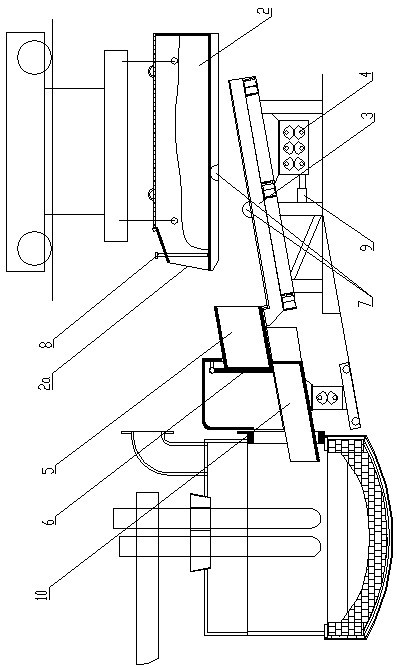

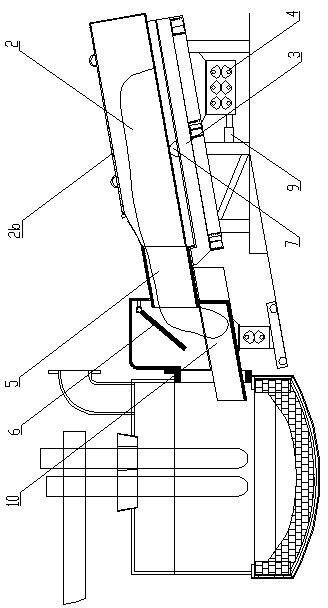

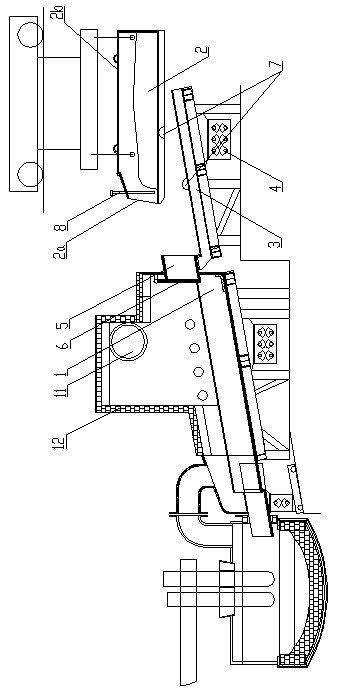

Quick feeding device for feeding waste steel into electric furnace and feeding method thereof

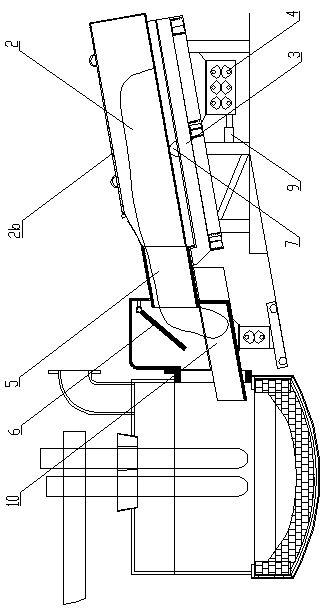

ActiveCN102183150ASimple structureFeeding speed can be controlledCharge manipulationPreheating chargesEnvironmental resistanceElectric arc furnace

The invention discloses a quick feeding device for feeding waste steel into an electric furnace. The device comprises a high-temperature connecting tank and a cold receiving material conveying device, wherein the high-temperature connecting tank is communicated with the electric furnace; the cold receiving material conveying device is used for loading the waste steel and comprises a feeding long tank which can be lifted to move; and the front end of the feeding long tank is provided with a discharge port which is hermetically communicated with a feed port of the high-temperature connecting tank. The device has a simple structure, is convenient to manufacture and easy and convenient to operate, has a good airtight effect, high reliability and high feeding speed, is environment-friendly andis convenient for maintenance of an entire system. In addition, a feeding process is performed under a sealed condition, so that air leakage can be effectively reduced, efficacy of a dust removing system of the electric furnace is improved, and a production environment is greatly improved; meanwhile, due to airtight production of the electric furnace, heat loss of a furnace body during productionof the electric furnace is also reduced and energy is saved. Compared with the prior art, feeding into the feeding long tank by using a bottom open type material tank is avoided, thickness of a laid material can be easily mastered and subsequent production can be facilitated, and the feeding long tank can be prevented from being damaged due to impact of the waste steel.

Owner:CISDI ENG CO LTD

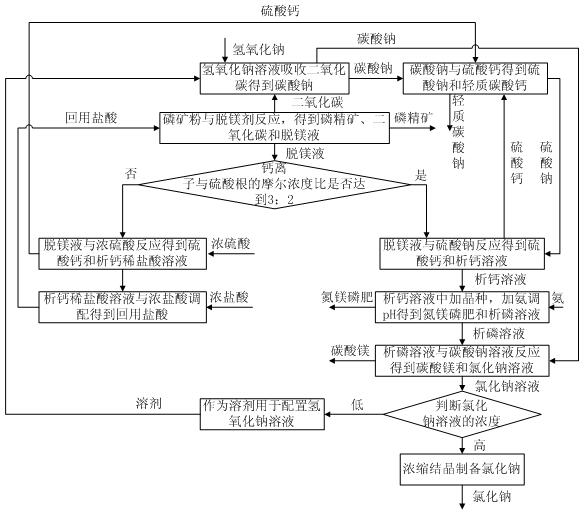

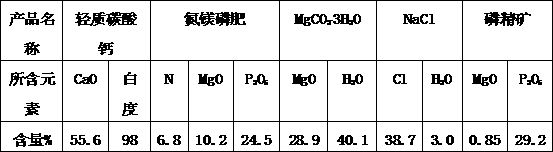

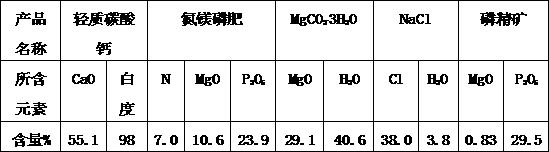

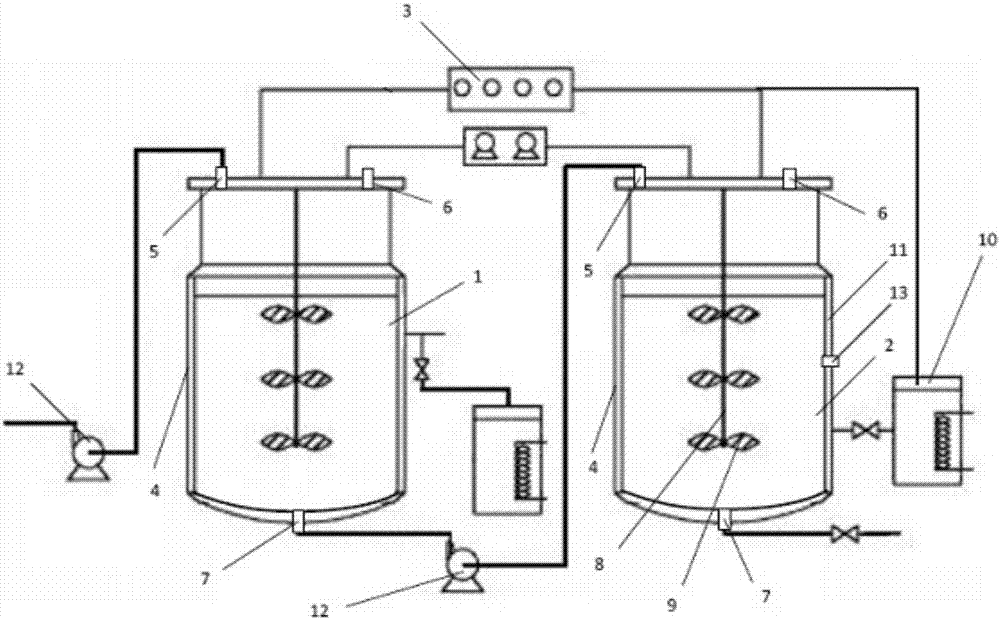

Chemical magnesium removal method for collophanite and free of tailings

ActiveCN112279227ANo emissionsImprove resource utilizationCalcium/strontium/barium carbonatesMagnesium carbonatesPhosphoric acidPrecipitated sulphur

The invention discloses a chemical magnesium removal method for collophanite and free of tailings, and belongs to the technical field of phosphorite magnesium removal. According to the method, dilutedhydrochloric acid is used for chemical magnesium removal, and phosphate concentrate, CO2 and magnesium removal liquid are obtained. The method comprises the steps: introducing CO2 into a NaOH solution to obtain a sodium carbonate solution; mixing the sodium carbonate solution with calcium sulfate for reaction to obtain a sodium sulfate solution and light calcium carbonate; adding sulfuric acid into the magnesium-removed solution to precipitate calcium sulfate to obtain calcium sulfate and a diluted hydrochloric acid solution containing phosphorus and magnesium, wherein the hydrochloric acid solution is used for preparing diluted hydrochloric acid and continuously used for removing magnesium from collophanite, and the process is repeated; when the molar concentration of calcium ions in themagnesium removal solution and the molar concentration of phosphate radicals reach 3: 2, precipitating calcium sulfate by using a sodium sulfate solution, adding ammonia water into the obtained filtrate to adjust the pH value, and precipitating to obtain a nitrogen-magnesium-phosphorus fertilizer and a phosphorus precipitation filtrate; adding a sodium carbonate solution into the phosphorus precipitation filtrate to obtain magnesium carbonate and a sodium chloride solution; and concentrating and crystallizing the sodium chloride solution to obtain sodium chloride.

Owner:HUBEI EZHONG ECOLOGICAL ENG CO LTD

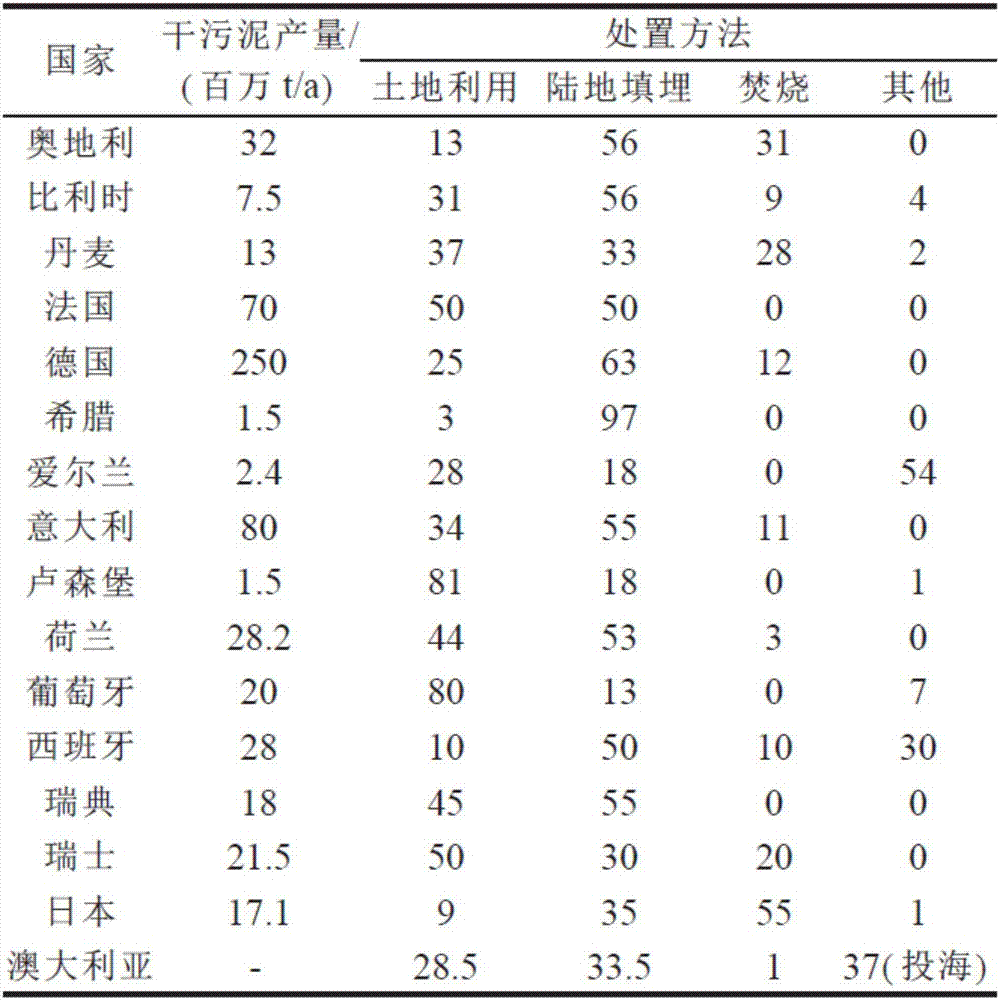

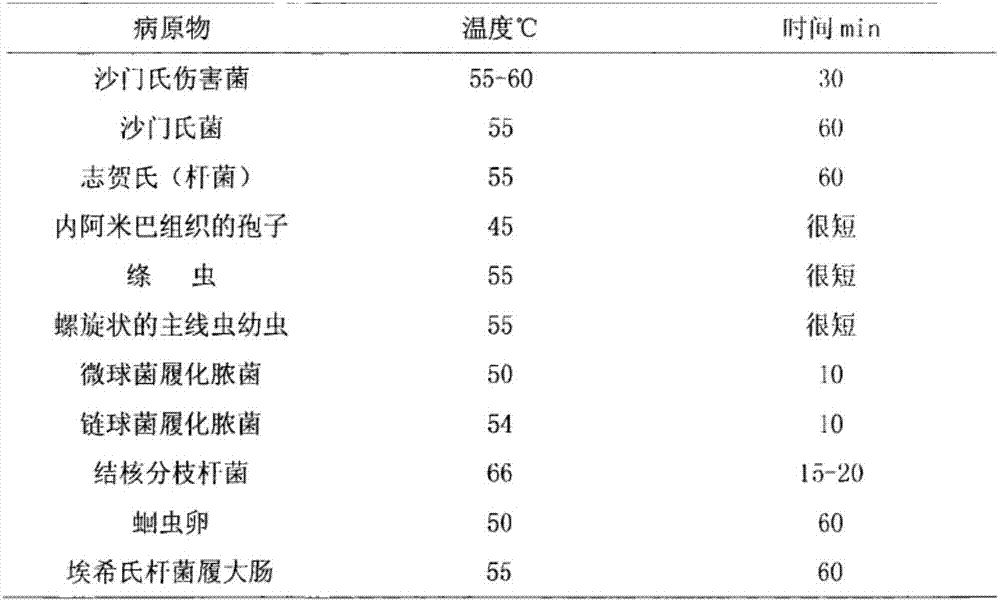

Organic treatment method of sludge

The invention discloses an organic treatment method of sludge. Firstly, wet sludge is dewatered until the moisture content of the sludge is reduced to 60%-65%; then, dewatered sludge is transported to a digestive treatment tank to be crushed and sieved, and a deodorant is sprayed during crushing and sieving; a carbon source / nitrogen source proportion modifier, an oxygen slow-release agent and a material containing beneficial strains are added; the obtained material is uniformly mixed and conveyed to an aerobic digestion bin for an aerobic digestion composting reaction of the sludge, and organic soil is obtained. With the adoption of the organic treatment method of the sludge, a large amount of moisture contained in the sludge and odors can be removed, harmful substances can be killed, and a foundation is laid for sludge for agriculture or forestry or other resource application.

Owner:廖泽勋 +1

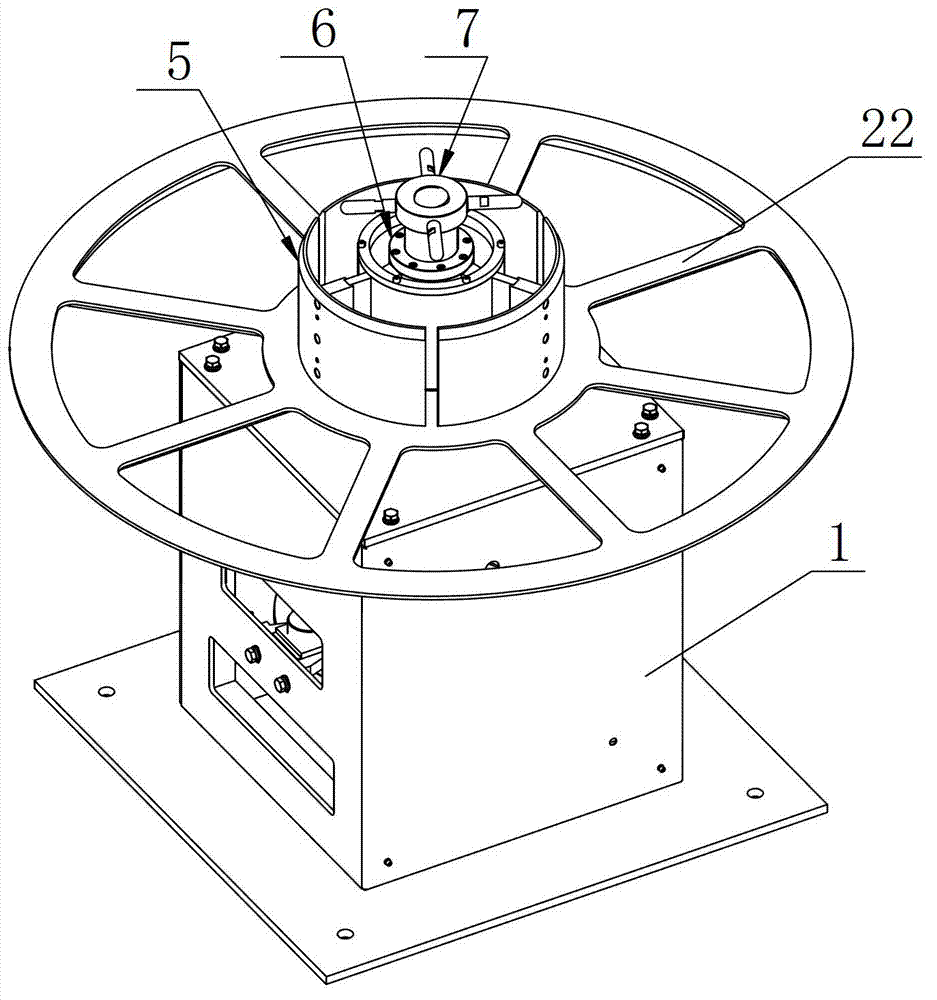

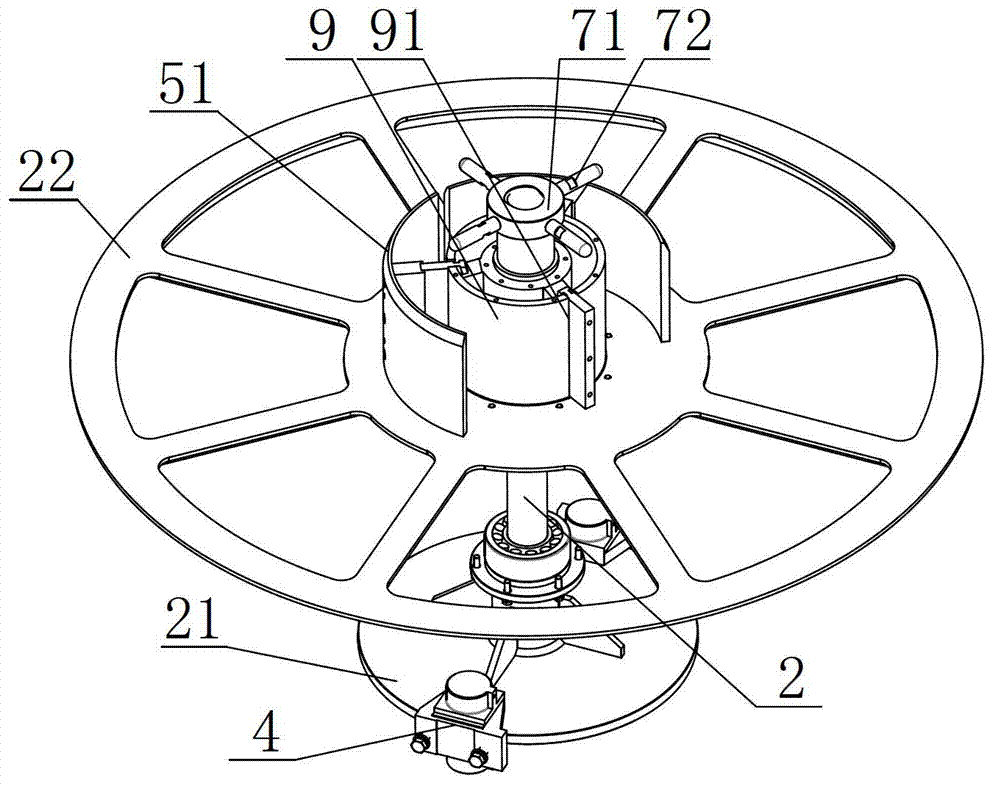

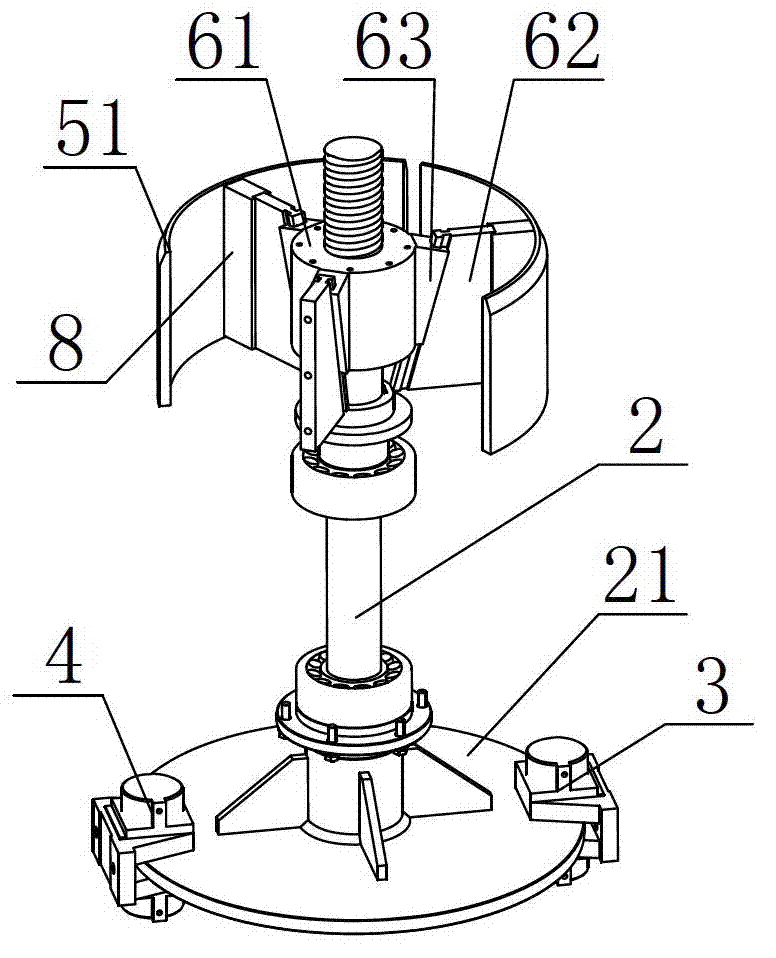

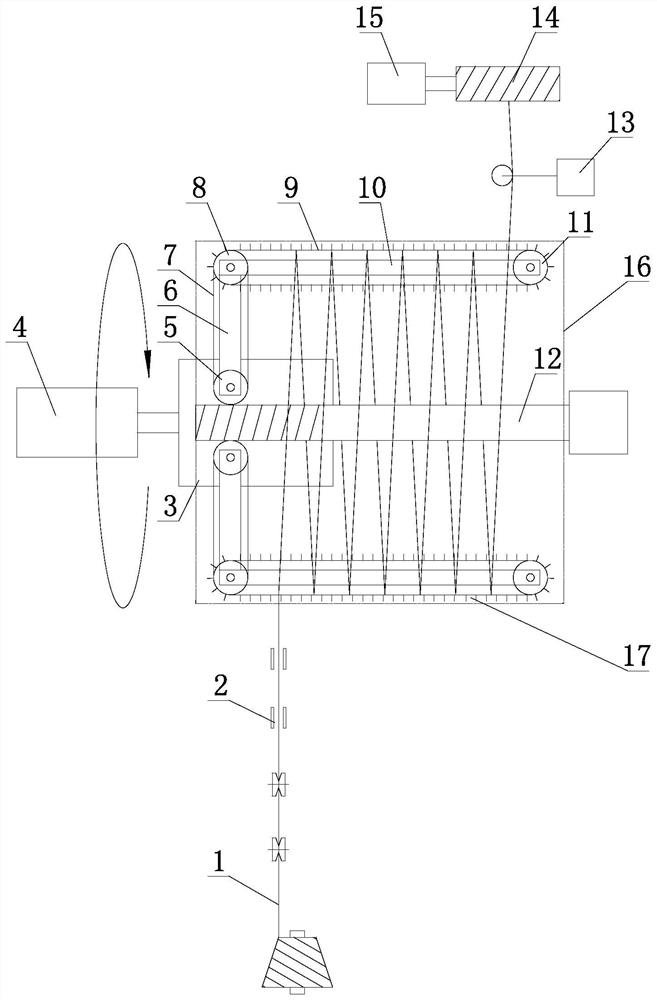

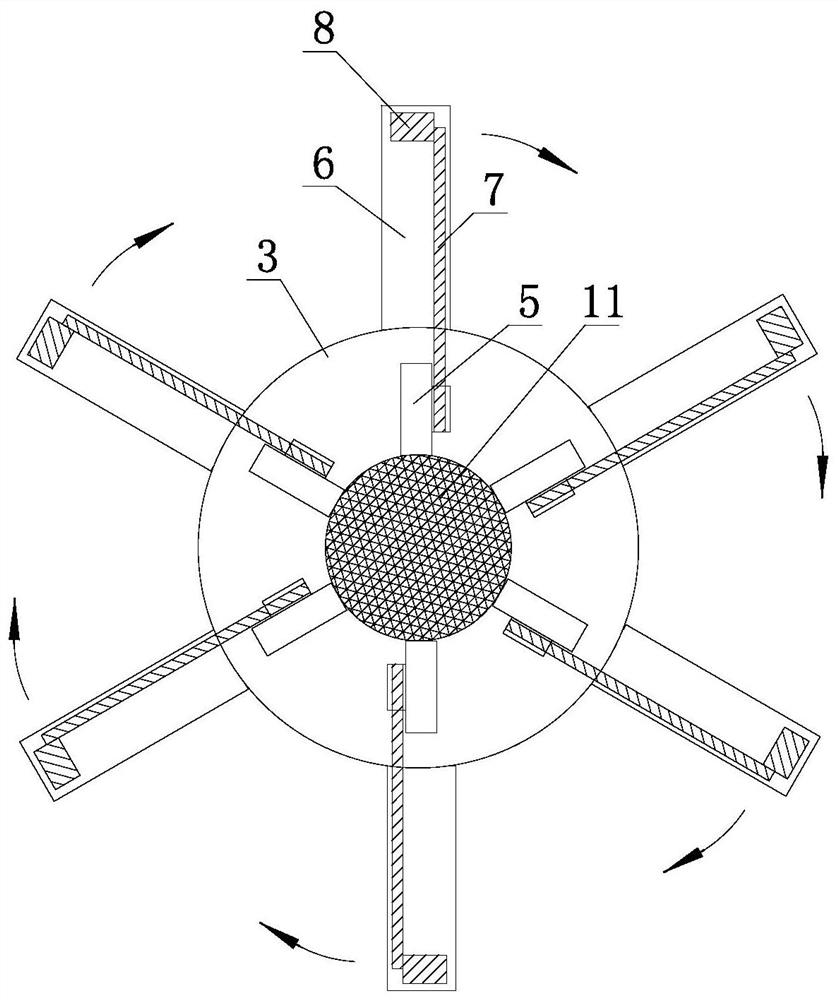

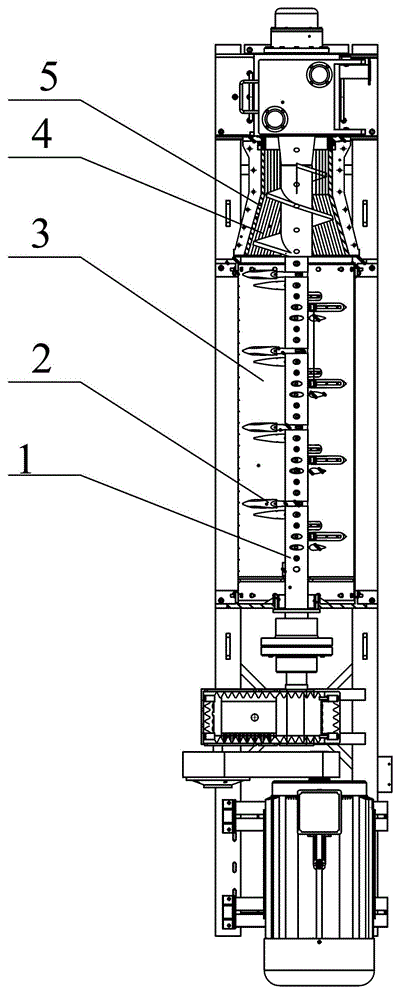

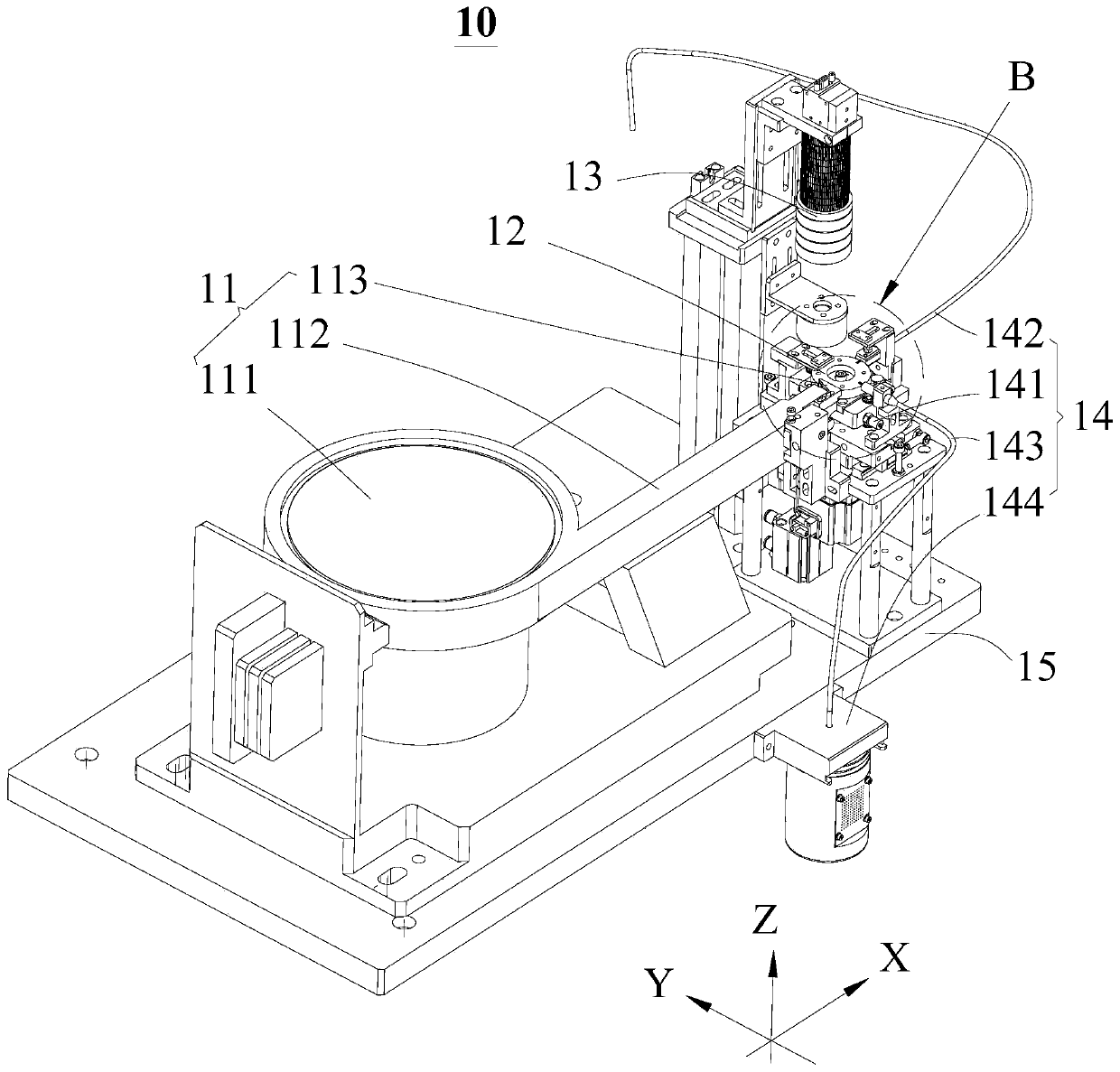

Flux-cored wire unwinding, supporting and rotating device

The invention relates to a flux-cored wire unwinding, supporting and rotating device, which comprises a base and a main transmission shaft. The middle part of the main transmission shaft is rotatably connected with the base. The main transmission shaft is vertically arranged. The lower part of the main transmission shaft is arranged in the inner chamber of the base. A brake disc is installed at the lower end of the main transmission shaft. At least one brake which is matched with the brake disc for conducting emergency braking is arranged on the base. At least one damper which is matched with the brake disc for controlling rotating speed is arranged on the base. The upper end of the main transmission shaft stretches out of the base and a tray is installed at the upper end of the main transmission shaft. A tensioning ring is installed on the tray and is provided with at least two groups of tensioning shoes. A driving device which is used for driving the tensioning shoes to be expanded or contracted is arranged on the main transmission shaft. The flux-cored wire unwinding, supporting and rotating device has the advantages that the design is novel, the device is easy to manufacture, the loading and the unloading are facilitated, the device is suitable for unwinding of I-shaped wheels with different inner diameters, the device is convenient to operate, the rotating speed is controllable and the precise unwinding is realized.

Owner:哈焊所华通(常州)焊业股份有限公司

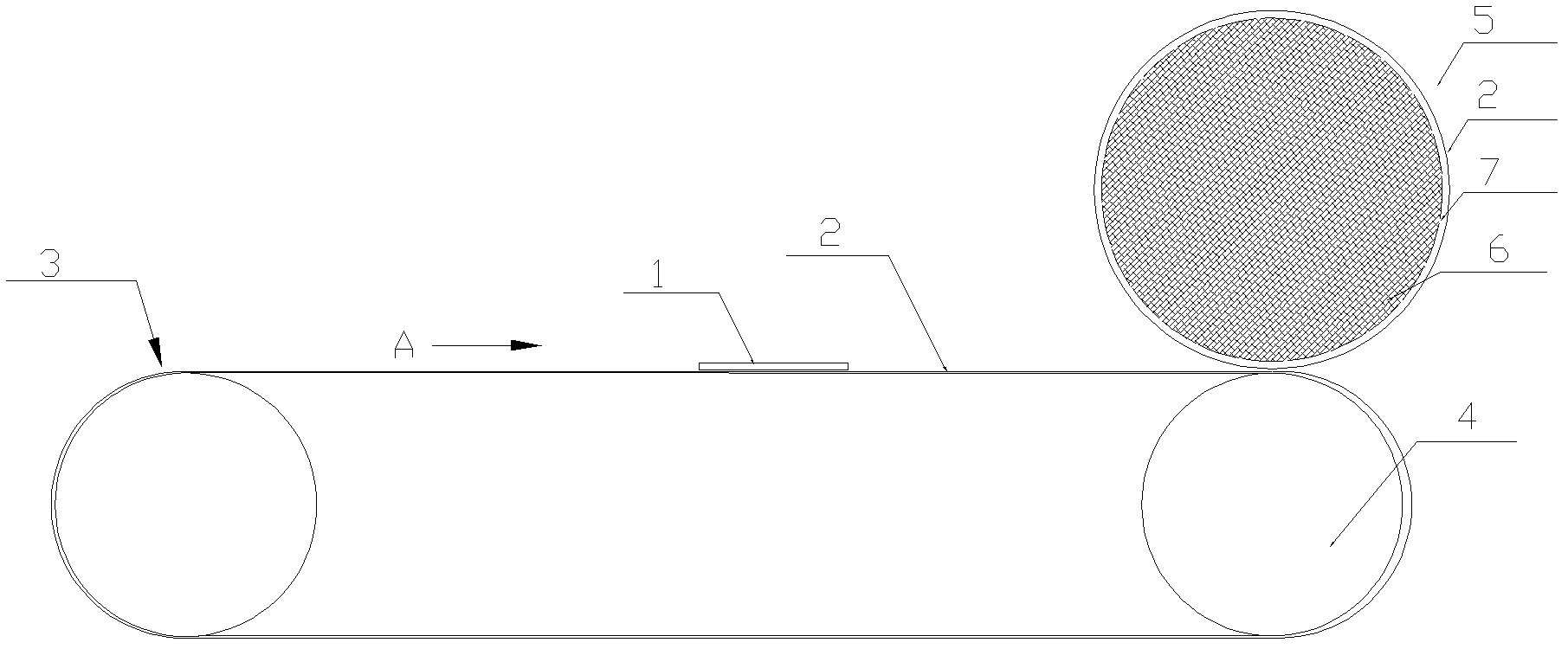

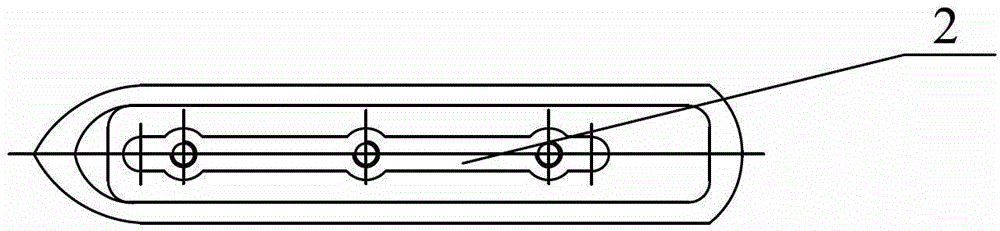

Production technology of steel wire ring for tires

The invention discloses a production technology of a steel wire ring for tires. The technology includes the steps of: steel wire unwinding, straightening, wiping cleaning, electric preheating, extrusion and rubber coating, cooling, coil forming, cutting, and isolation powder coating. During isolation powder coating, the surface of a shaped steel wire ring is coated with isolation powder through a coating powder conveyor so as to prevent sticking of the rubber coated shaped steel wire ring. The coating powder conveyor comprises a conveyer belt with a flannelette surface, and a roller above the conveyer belt. The isolation powder is disposed in the roller, the surface of which is provided with uniformly distributed holes and is wrapped by flannelette. The new technological method provided in the invention for a steel wire ring production process improves the steel wire ring sticking problem in current steel wire ring production. The employment of the flannelette equipped conveyer belt and the roller that make movement in opposite directions to coat the steel wire ring for tires with powder uniformly, and the efficiency is improved.

Owner:SICHUAN YUANXING RUBBER

Nuclear radiation shielding alloy lead fiber woven fabric

InactiveCN102650088AHas the function of shielding nuclear radiationWeave evenlyShieldingWoven fabricsYarnNuclear radiation

A nuclear radiation shielding alloy lead fiber woven fabric relates to the field of nuclear radiation protection biological shielding technology and is particularly applicable to the technical field of core materiasl for the production of nuclear radiation biological protection flexible shielding products. According to the nuclear radiation shielding alloy lead fiber woven fabric, nuclear radiation shielding alloy lead fiber yarns with the diameter of 0.01 mm-1 mm are arranged in the weft direction, and nuclear radiation shielding alloy lead fiber yarns with the diameter of 0.001 mm-1 mm and glass fiber yarns with the diameter of 0.05-0.5 mm are arranged in the warp direction. The nuclear radiation shielding alloy lead fiber woven fabric not only has a certain function of shielding nuclear radiation, but also ensures the weaving process to proceed smoothly by adopting the glass fiber yarns, meanwhile, the tensile strength of products is improved, and the follow-up production of light, thin and material-saving nuclear radiation shielding products is facilitated.

Owner:扬州锦沃科技有限公司

Yarn online continuous drying equipment and process

PendingCN113357895AEasy to dryReduce drying energy consumptionDrying gas arrangementsDrying machines with progressive movementsYarnTextile technology

The invention belongs to the technical field of textile, and particularly relates to a yarn online continuous drying equipment and process. The yarn online continuous drying equipment comprises a rotating cage, and yarn outlet equipment is connected to the front part of the rotating cage; a plurality of transverse moving belts moving in the same direction are distributed on the periphery of the rotating cage; single yarn is wound around the periphery of the rotating cage to rotate along with the rotating cage after being discharged from the yarn outlet equipment; and the single yarn continuously and transversely moves in the axial direction of the rotating cage under the action of the transverse moving belts. The yarn on-line continuous drying process comprises the steps that through high-speed rotation of the yarn on the rotating cage, the yarn makes contact with air in the rotating process, the yarn continuously and transversely moves on the rotating cage, the yarn is arranged in order but not overlapped, the air relatively flows to take away moisture on the yarn, and the dried yarn wound on the rotating cage is moved out of the rotating cage, and meanwhile, new wet yarns are continuously wound on the rotating cage; and therefore, the aim of continuously drying the wet yarns without heating and a high-frequency electric field is fulfilled.

Owner:LUTAI TEXTILE +1

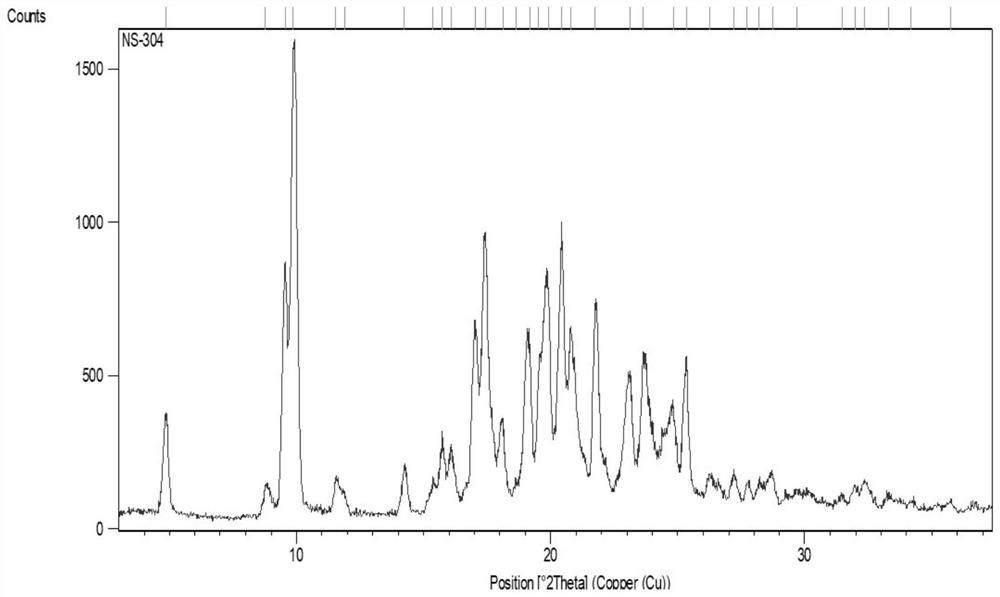

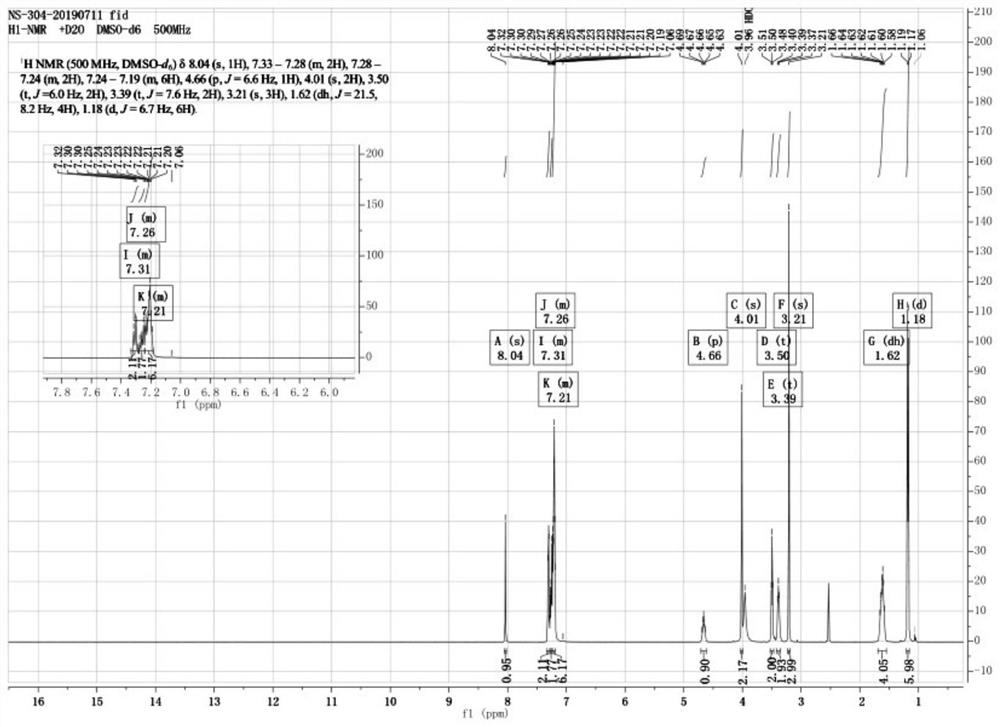

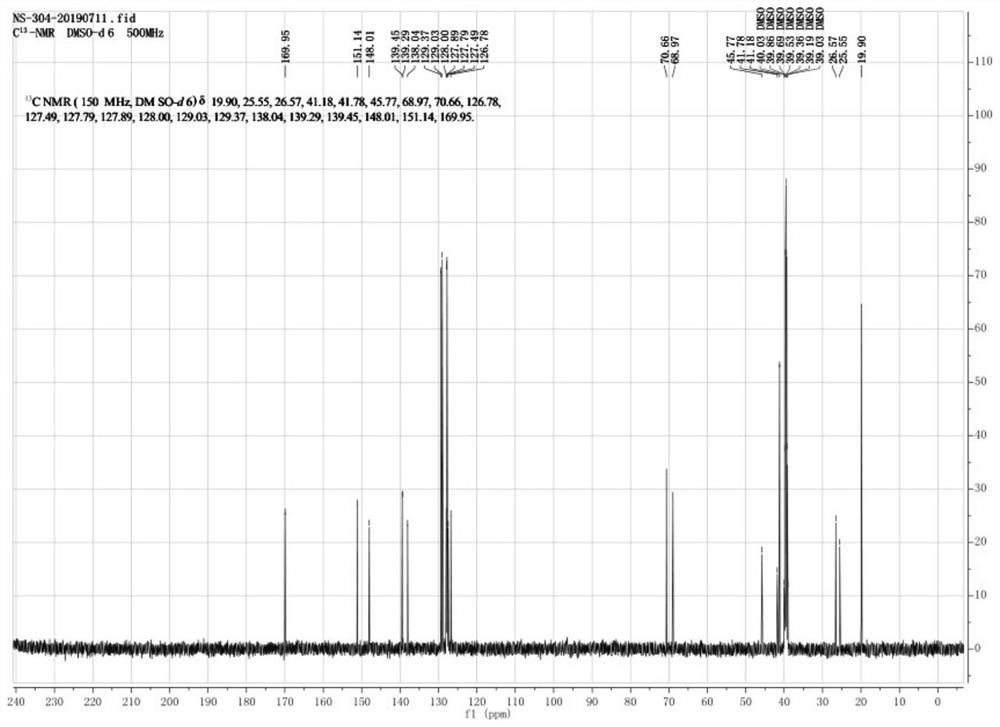

Synthesis method of diphenyl pyrazine derivative

The invention discloses a synthesis method of a diphenyl pyrazine derivative. The method is characterized in that benzil and glycinamide are used as raw materials, and a target product is prepared through five-step reaction. The obtained target product is high in purity, subsequent production of high-quality drugs is facilitated, and the synthesis method is reasonable in route design, mild in reaction condition, free of high-temperature reaction, good in safety and high in feasibility.

Owner:NANJING UNIV OF SCI & TECH

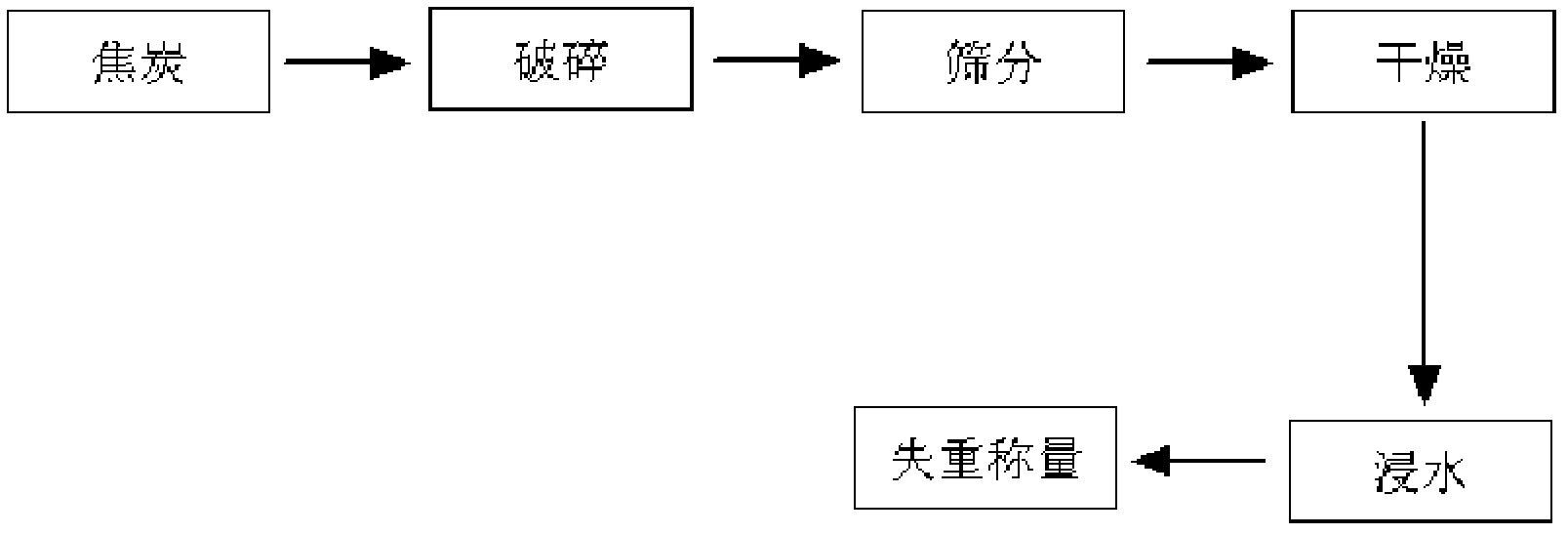

Method for determining saturated moisture of coke

ActiveCN102621028AQuality assuranceConducive to follow-up productionWeighing by absorbing componentEnvironmental engineeringForced-air

The invention discloses a method for determining saturated moisture of coke, comprising crushing treatment on the coke and drying treatment on the coke. The method comprises the following steps of: crushing appropriate amount of coke sample acquired from a production field, and screening the crushed coke according to different fractions within the particle size range of 5-30mm; placing the coke at different fractions into a drying box, and carrying out full forced air drying at the temperature of 95-115 DEG C; mixing the dried coke according to weight percentage of different fractions, and immersing the mixed coke into water to be fully soaked; and weighing the soaked coke on a balance, and calculating content of the saturated moisture of the coke when reading of the balance is stable. The invention provides a method for determining the saturated moisture of the coke for the coke with high moisture content in production, thus being beneficial to finding that whether excessive moisture is contained in the coke to judge whether excessive water is sprinkled into the coke, being beneficial to coke quality monitoring and improving use quality of the coke and being beneficial to reducing usage of the coke and production cost in a smelting reduction process.

Owner:XINJIANG BAYI IRON & STEEL

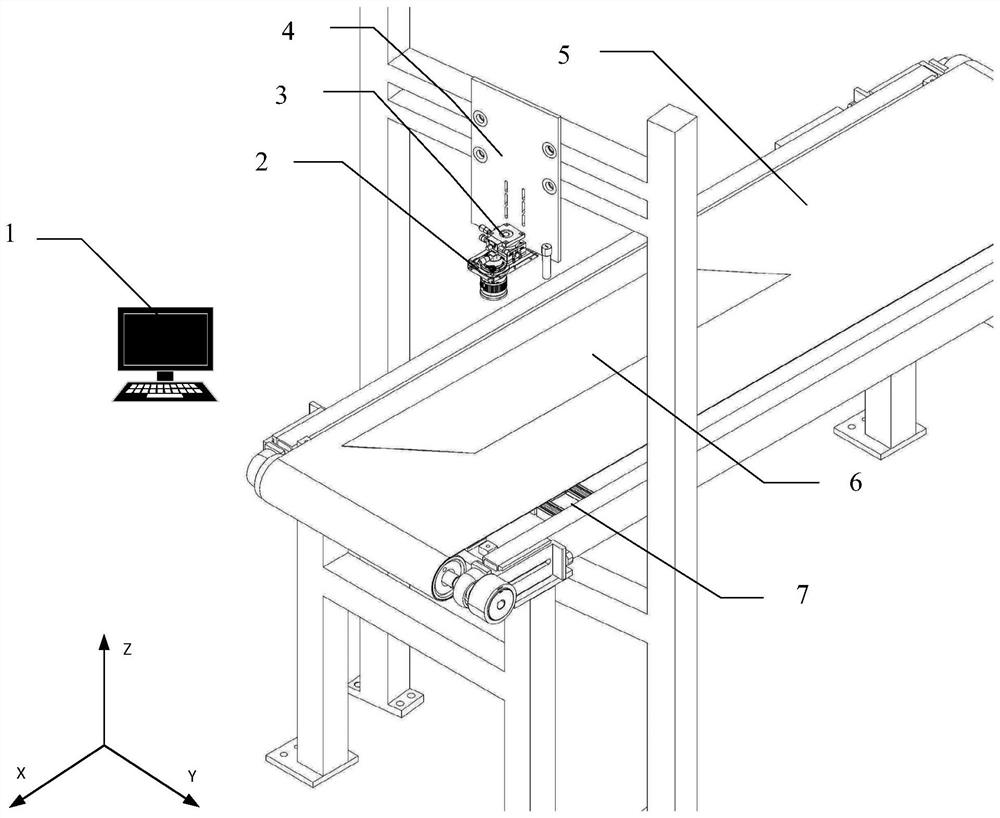

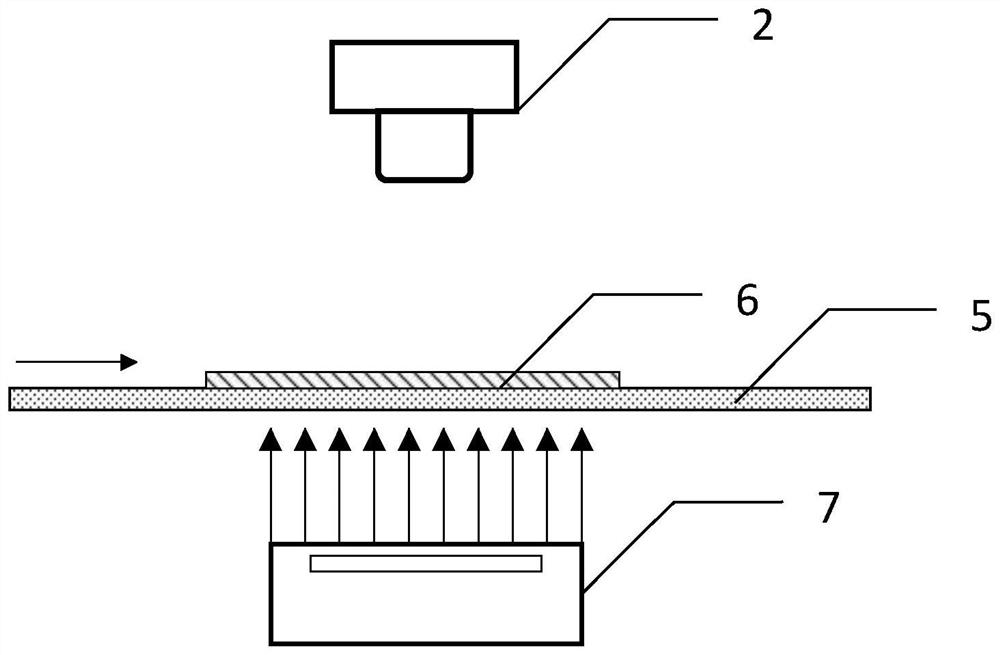

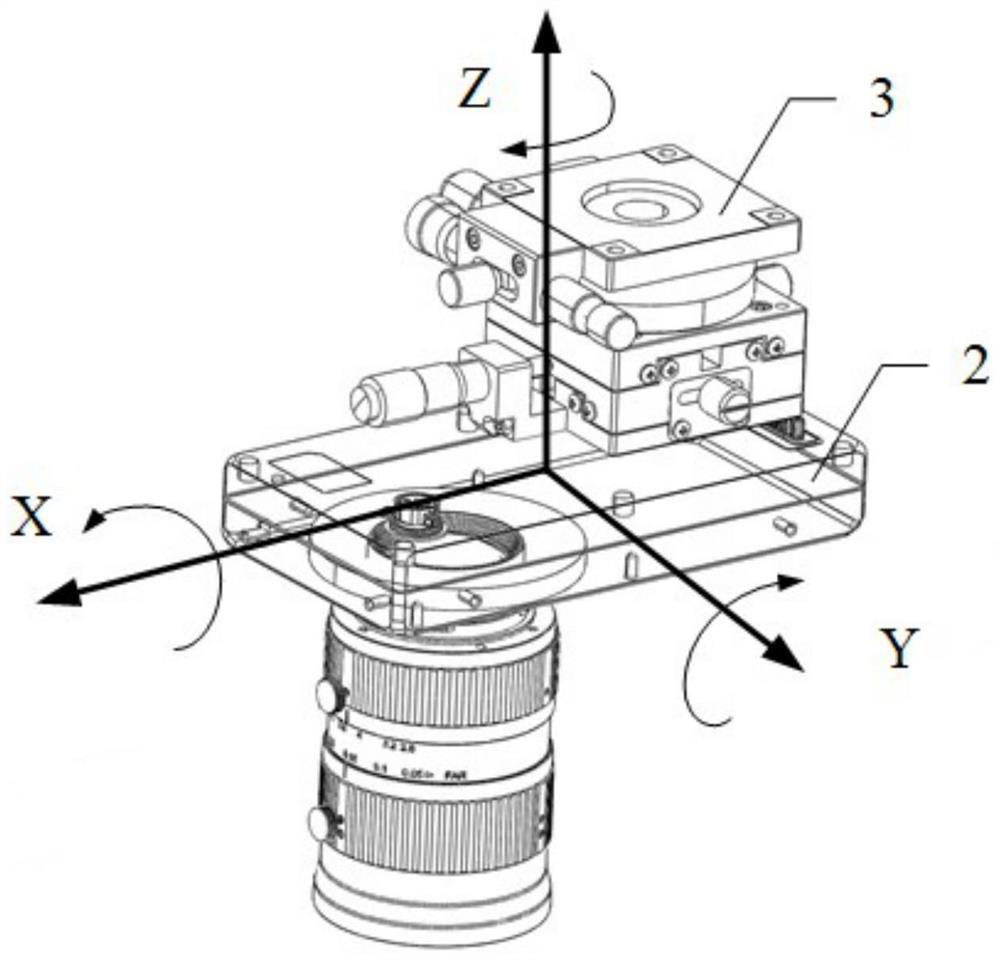

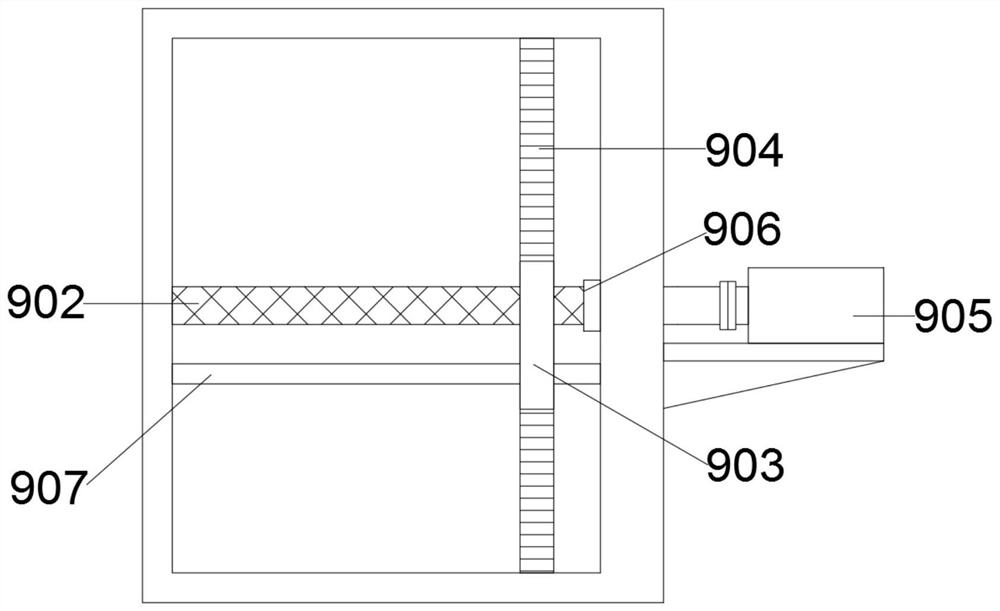

Visual measurement system for size of film on conveying belt and measurement method thereof

PendingCN114152199ARealize the need for real-time measurement of dimensionsRealize the need for real-time measurementUsing optical meansImaging qualityMechanical engineering

The invention provides a visual measurement system and method for the size of a film on a conveying belt, and the system comprises a main frame, a conveying belt assembly, an infrared LED backlight source, a camera, a precise sliding table, and a control device. The conveying belt assembly is installed on the main frame, the infrared LED backlight source is arranged under the conveying face of the conveying belt assembly, the camera is arranged over the conveying face of the conveying belt assembly and connected with the control device, the collecting portion of the camera is arranged right opposite to the conveying face and the infrared LED backlight source, the camera is installed on the precise sliding table, and the precise sliding table is connected with the control device. And the precise sliding table is mounted on the main frame. According to the measuring method, the measuring system is adopted for measurement, the measuring system is high in size measuring precision, more convenient and quicker to use and easy to operate, and the technical problems that in the prior art, the imaging quality of a detected film is poor, the measuring speed is low, and a calibration method is complex can be solved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

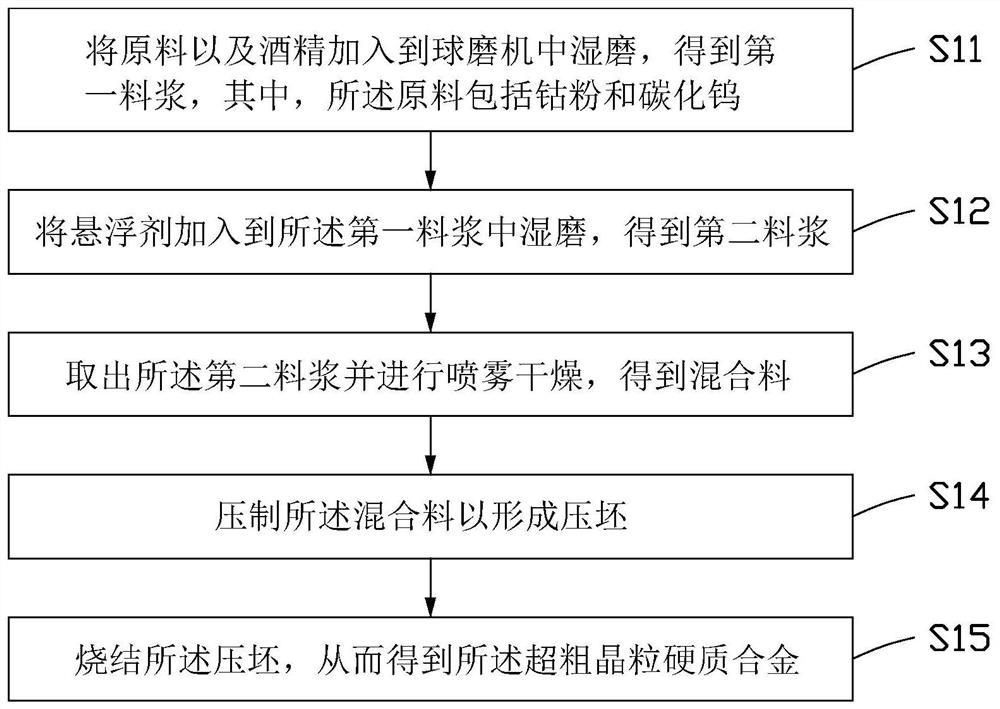

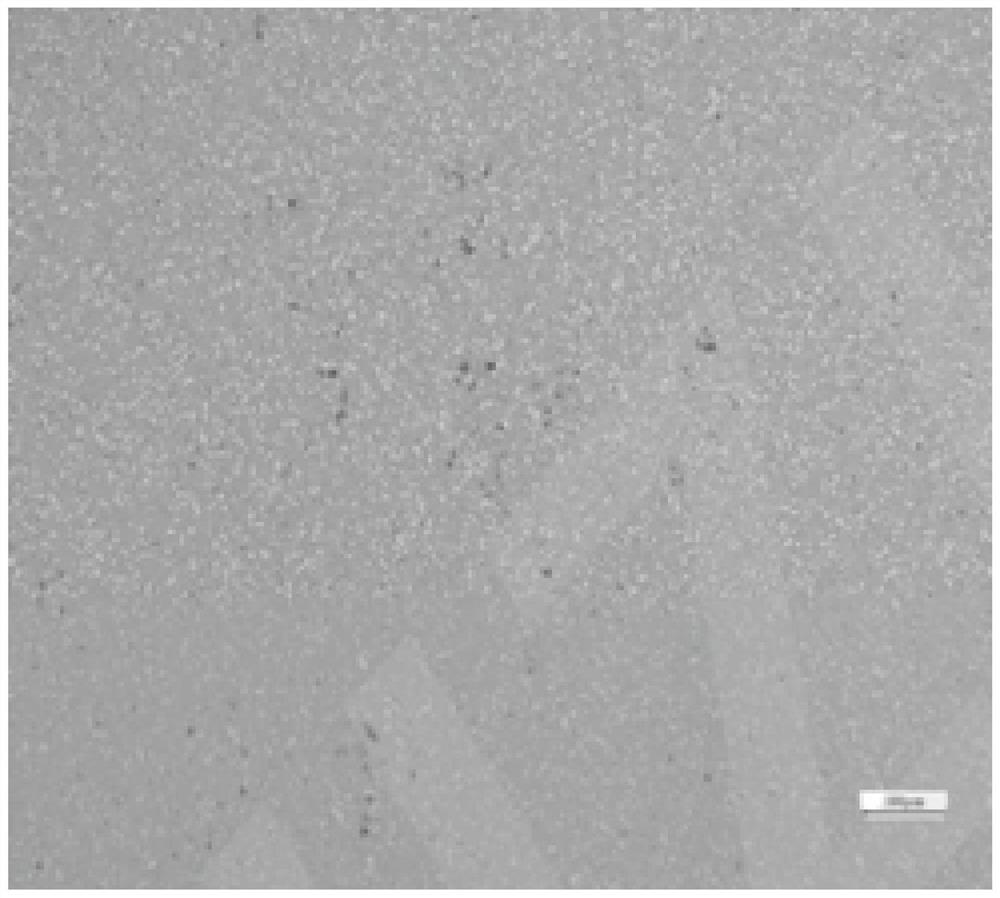

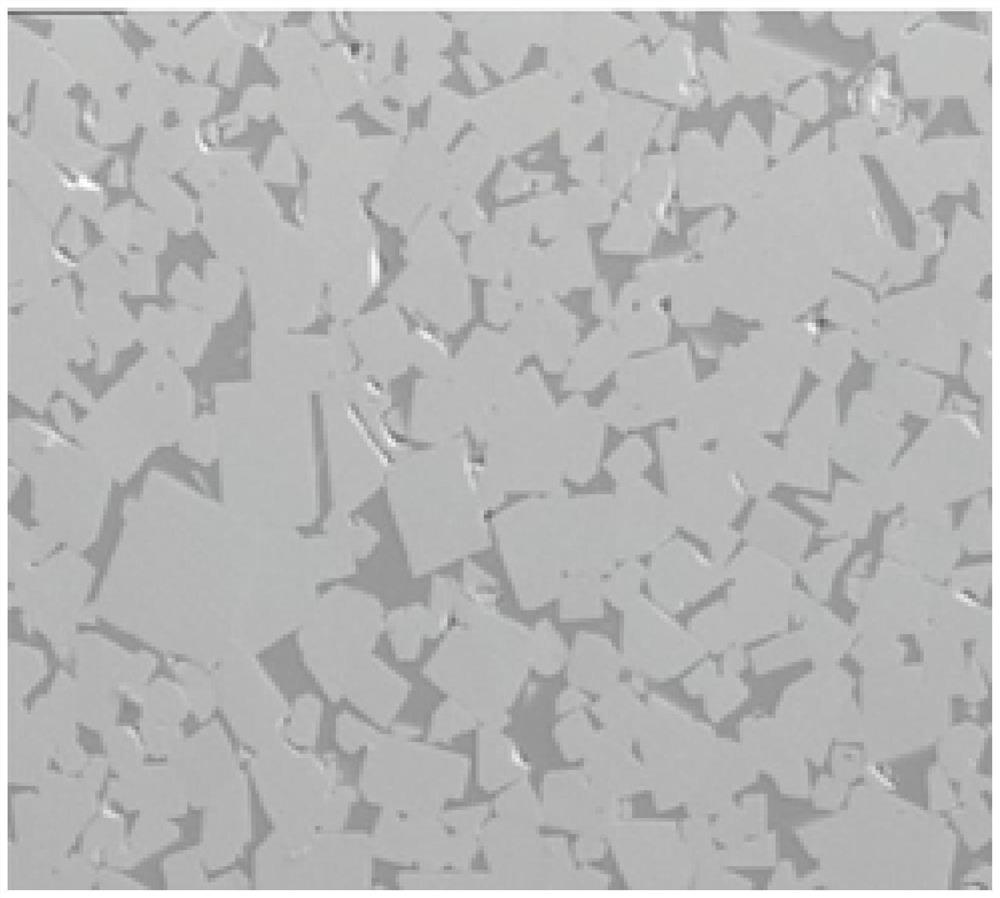

Preparation method of ultra-coarse-grain hard alloy

InactiveCN112921198ALow viscosityPrevent precipitationTransportation and packagingMetal-working apparatusSpray driedSlurry

The invention provides a preparation method of an ultra-coarse-grain hard alloy, which comprises the following steps that raw materials and alcohol are added into a ball mill for wet milling to obtain first slurry, wherein the raw materials comprise cobalt powder and tungsten carbide; a suspending agent is added into the first slurry for wet milling to obtain second slurry; the second slurry is taken out and subjected to spray drying to obtain a mixture; the mixture is pressed to form a green compact; and the green compact is sintered to obtain the ultra-coarse-grain hard alloy. According to the preparation method provided by the invention, the problems of slurry precipitation and gun blockage during spray drying of the ultra-coarse-grain hard alloy can be solved.

Owner:晋城富联鸿刃科技有限公司

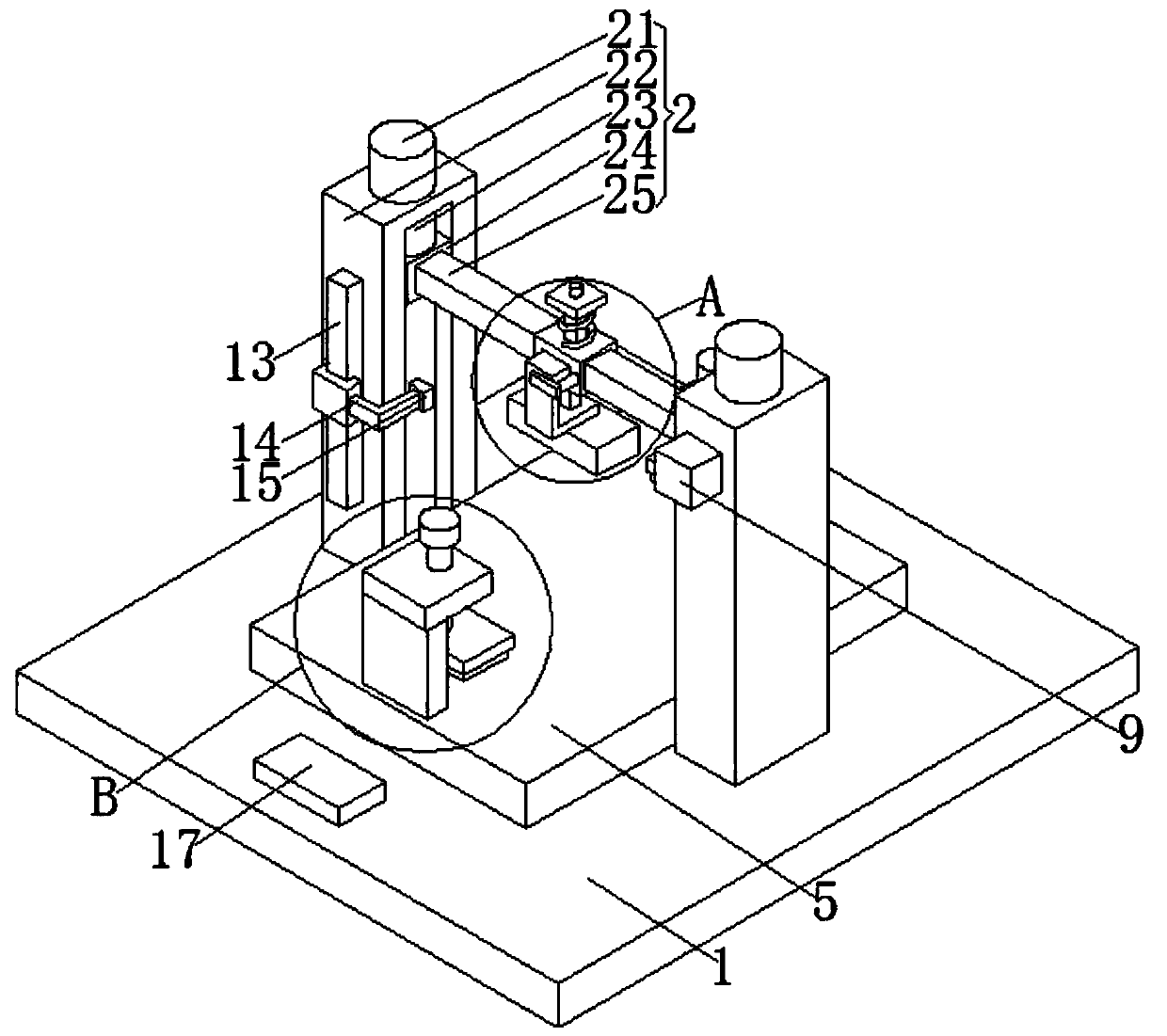

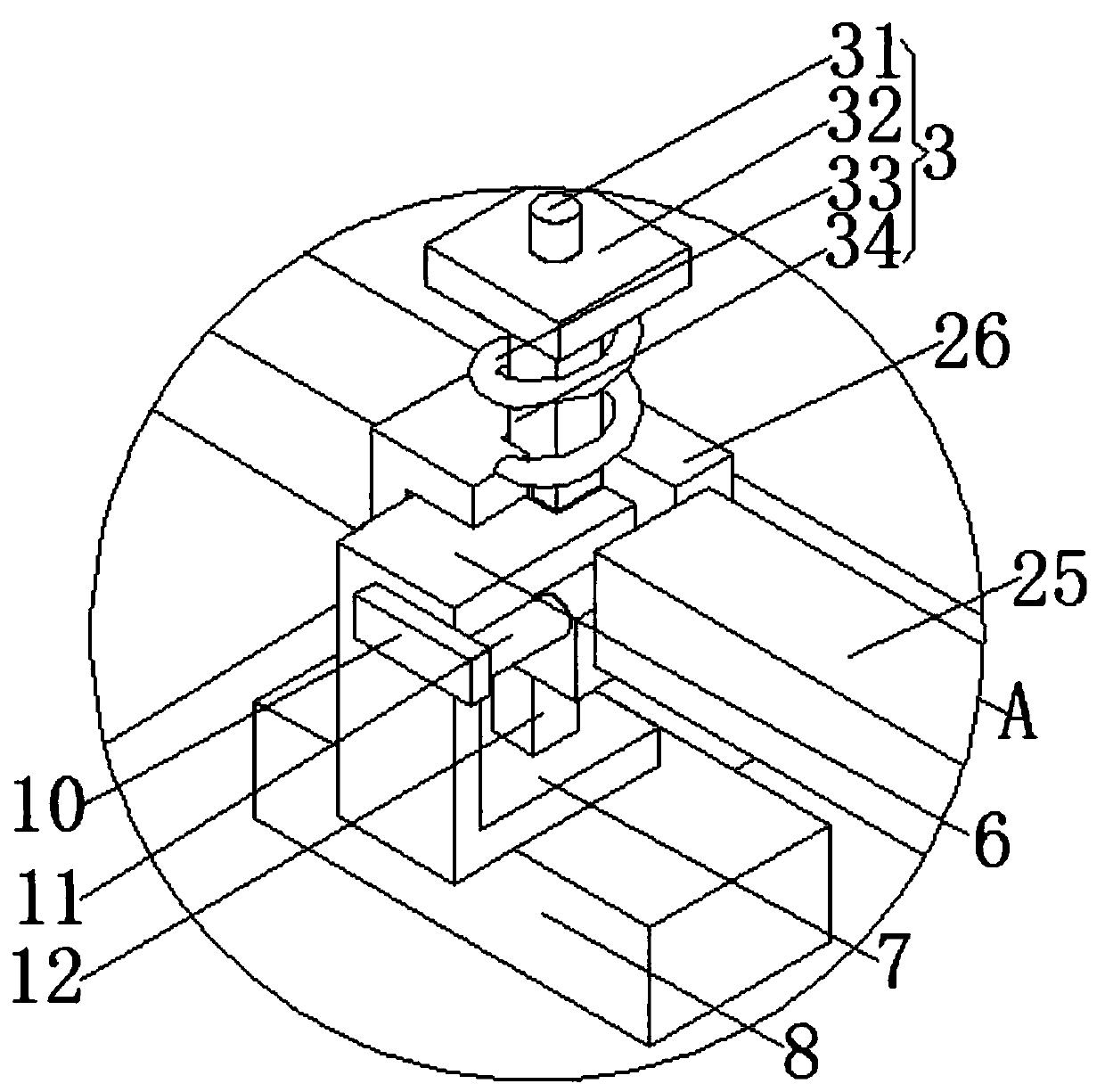

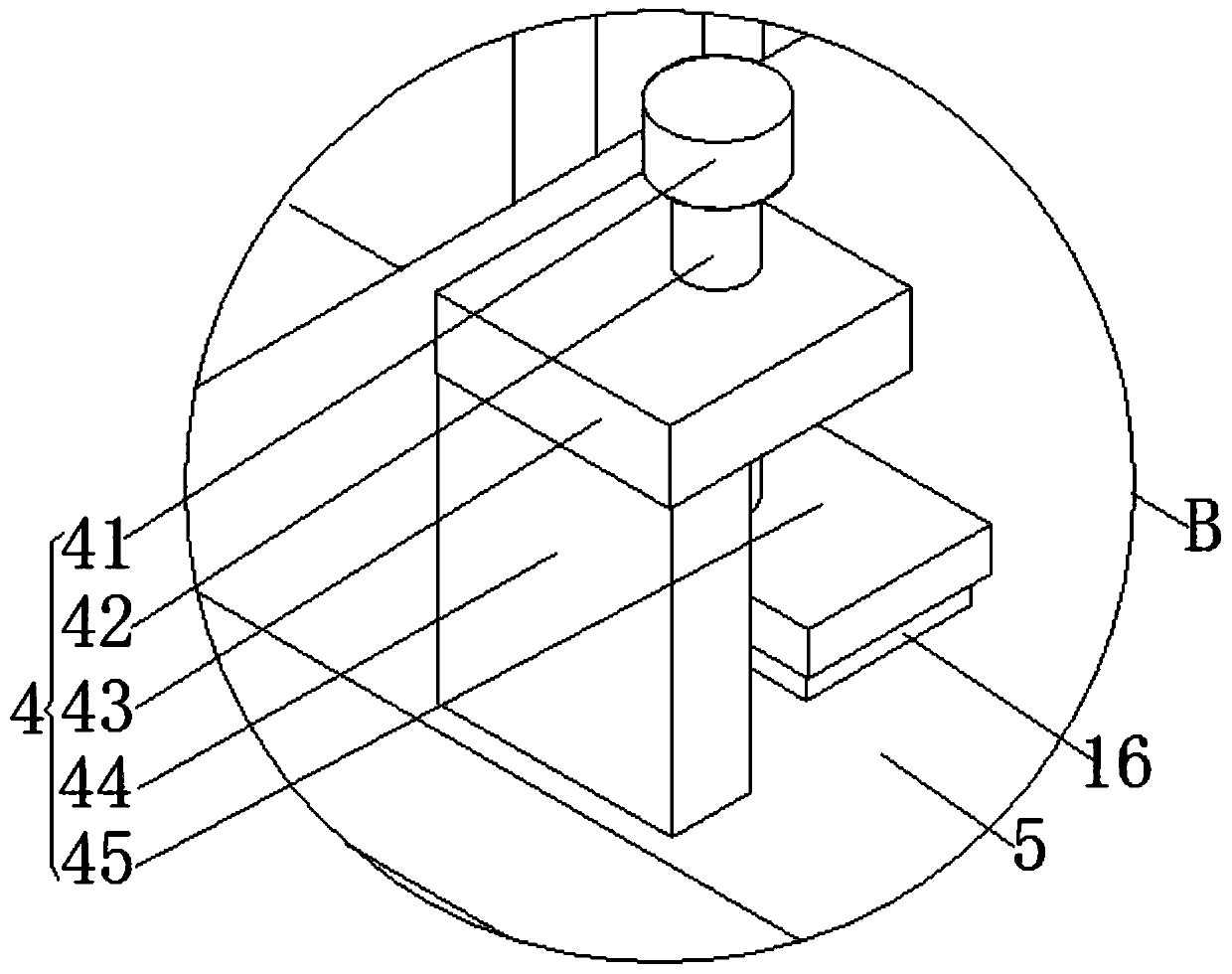

Automatic test tool for simulating manual stepping

InactiveCN111024532AConducive to follow-up productionPromote improvementMaterial strength using repeated/pulsating forcesElectric machineryStructural engineering

The invention discloses an automatic test tool for simulating manual stepping. The automatic test tool comprises a bottom plate, a test unit, a replacement unit and a containing plate, wherein the containing plate is arranged in the middle of an upper surface of the bottom plate, fastening units are arranged on the left side and the right side of a top end of the containing plate, the test unit comprises motors, fixed blocks, a lead screw, a movable block, connecting rods and an installation block, the two fixed blocks are arranged at a front end and a rear end of the upper surface of the bottom plate correspondingly, grooves are formed on inner side surfaces of the two fixed blocks, the lead screw is rotationally connected into the groove, the two motors are arranged at top ends of the two fixed blocks correspondingly, output shafts of the motors are connected with a top end of the lead screw, screw holes in the side faces of the movable blocks are in threaded connection with the leadscrew, the number of the connecting rods is two, and outer side ends of the connecting rods are connected with inner side faces of the two movable blocks respectively. The automatic testing tool forsimulating manual stepping is convenient to use, firm in fixation, convenient to disassemble and assemble and good in testing effect.

Owner:JIANGSU HAOSAI TECH CO LTD

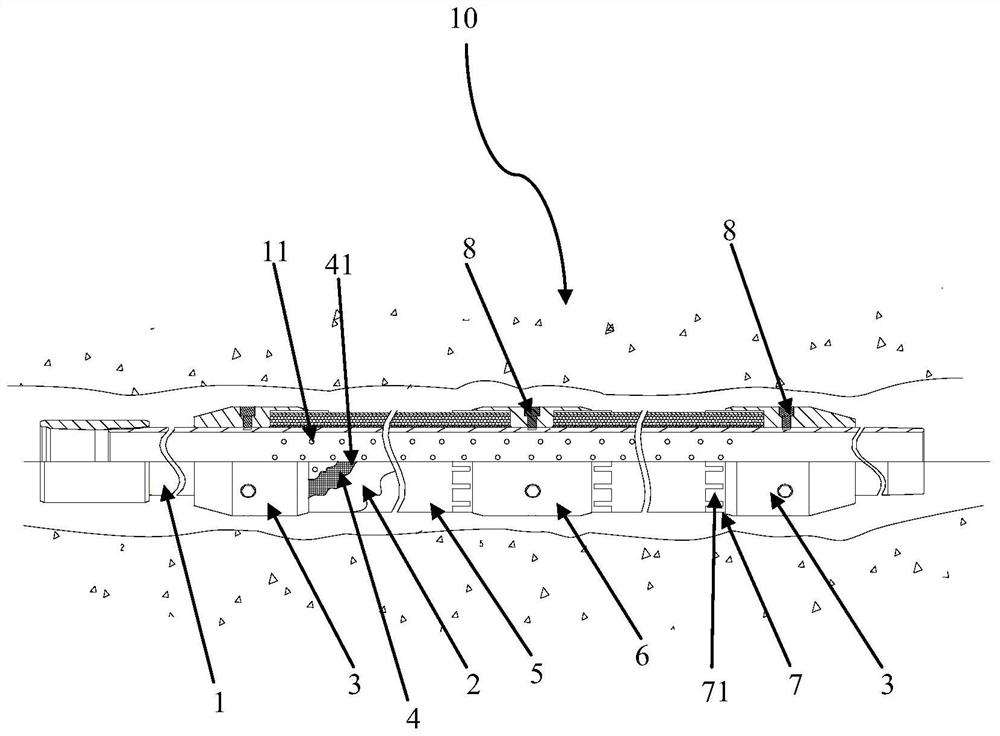

Annular self-filling sand control screen

The invention provides an annular self-filling sand control screen. The annular self-filling sand control screen comprises a base tube, sand blocking layers and clamping rings, wherein the sand blocking layers are arranged on the base tube in a sleeving mode and fixed to the two ends of the base tube through the clamping rings. First circulating holes are evenly formed in the base tube, and gaps used for fluid circulation are formed between the sand blocking layers and the base tube. Each sand blocking layer comprises a framework material made of polyurethane foam and a hot melt adhesive material repeatedly soaked in the framework material, and therefore compressible composite foam is formed. The annular self-filling sand control screen is good in sand control effect, simple in construction process and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

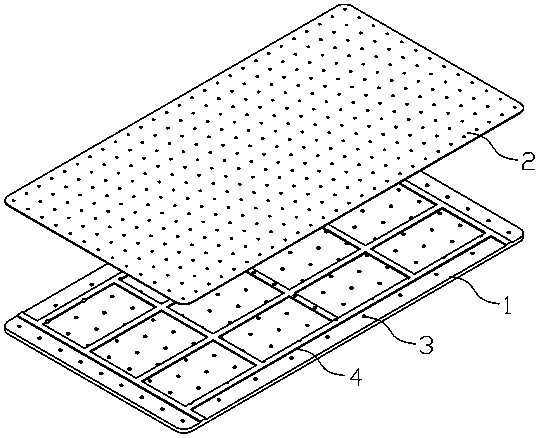

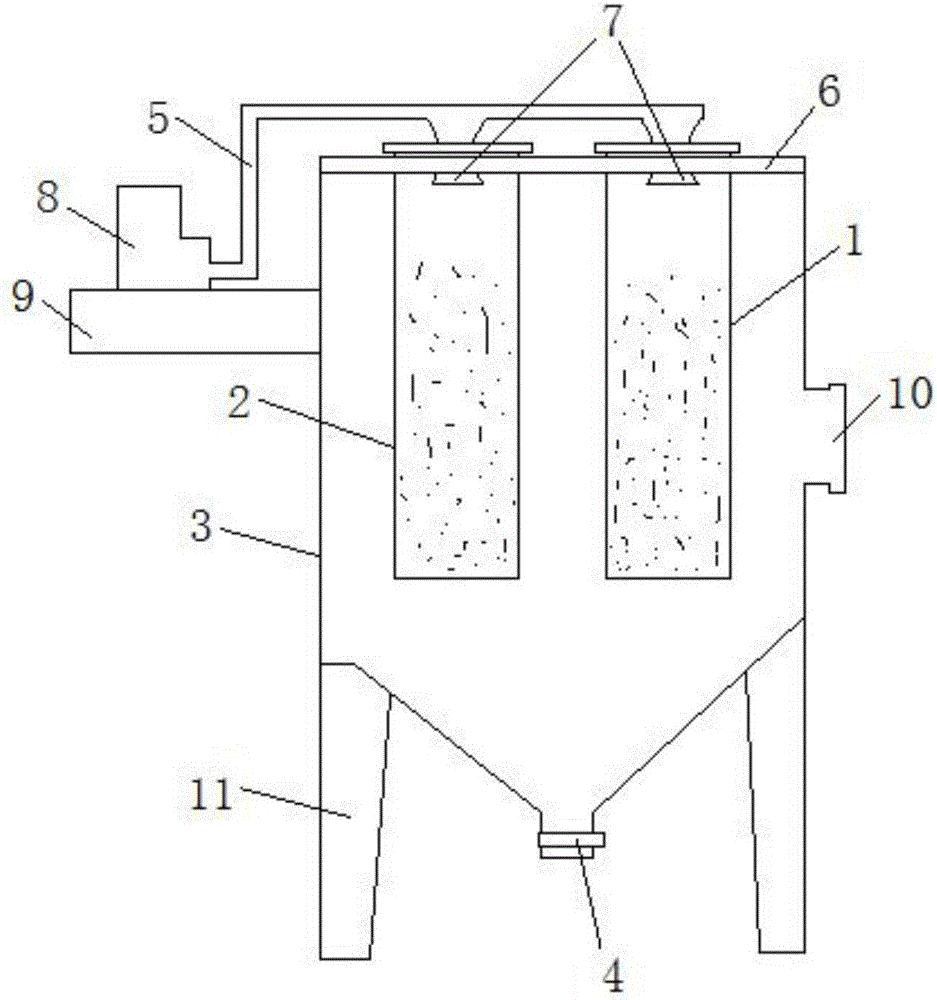

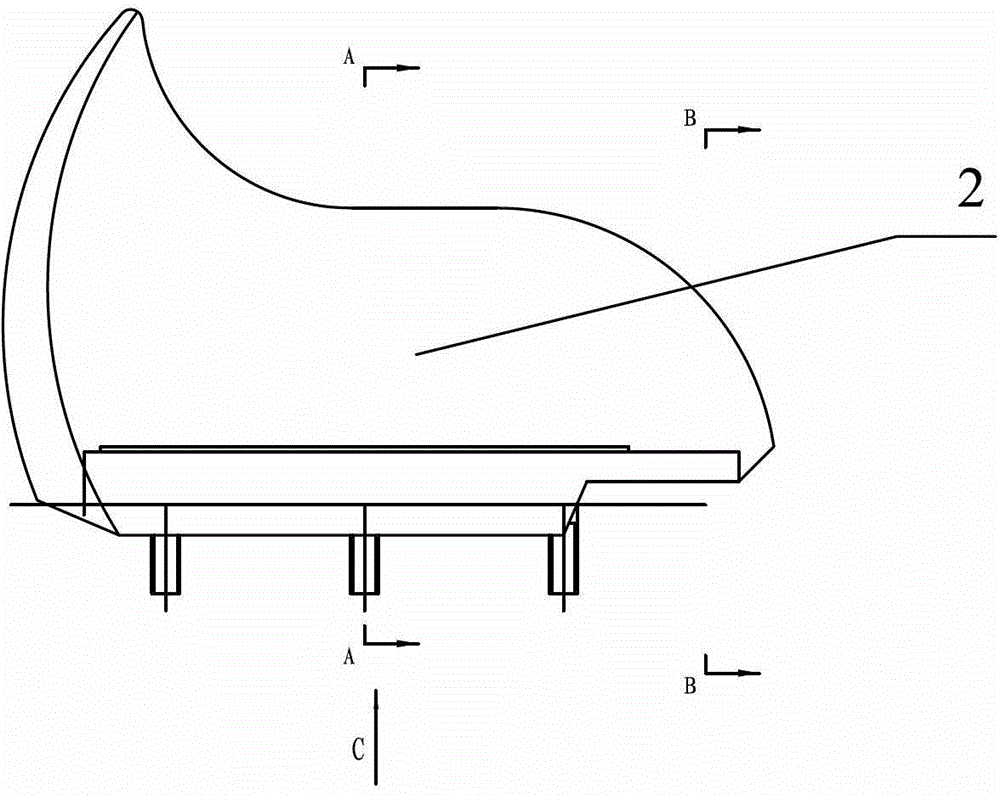

Flat-plate simplified seedling raising tray

InactiveCN109168771AEasy to grow seedlingsSeedling suitableCultivating equipmentsPlant rootsIsolation layer

A flat-plate simplified seedling raising tray relates to the technical field of agricultural production. The flat-plate simplified seedling raising tray comprises a nutrient base layer (1) made of fermented straws. The nutrient base layer (1) is a rectangular plate. An isolation layer (2) is arranged on the back of the nutrient base layer (1). The flat-plate simplified seedling raising tray has the advantages of being simple in structure, loose and breathable, and capable of simplifying the production process and the seedling raising procedure. The isolation layer isolates the roots of seedlings from the ground and makes the roots grow regularly. The flat-plate simplified seedling raising tray is conducive to the growth of plant roots, is suitable for raising the seedlings of rice and other crops, is conducive to follow-up production, and has better growth advantages than seedling raising based on nutrient soil.

Owner:湘潭县双桥农机服务专业合作社

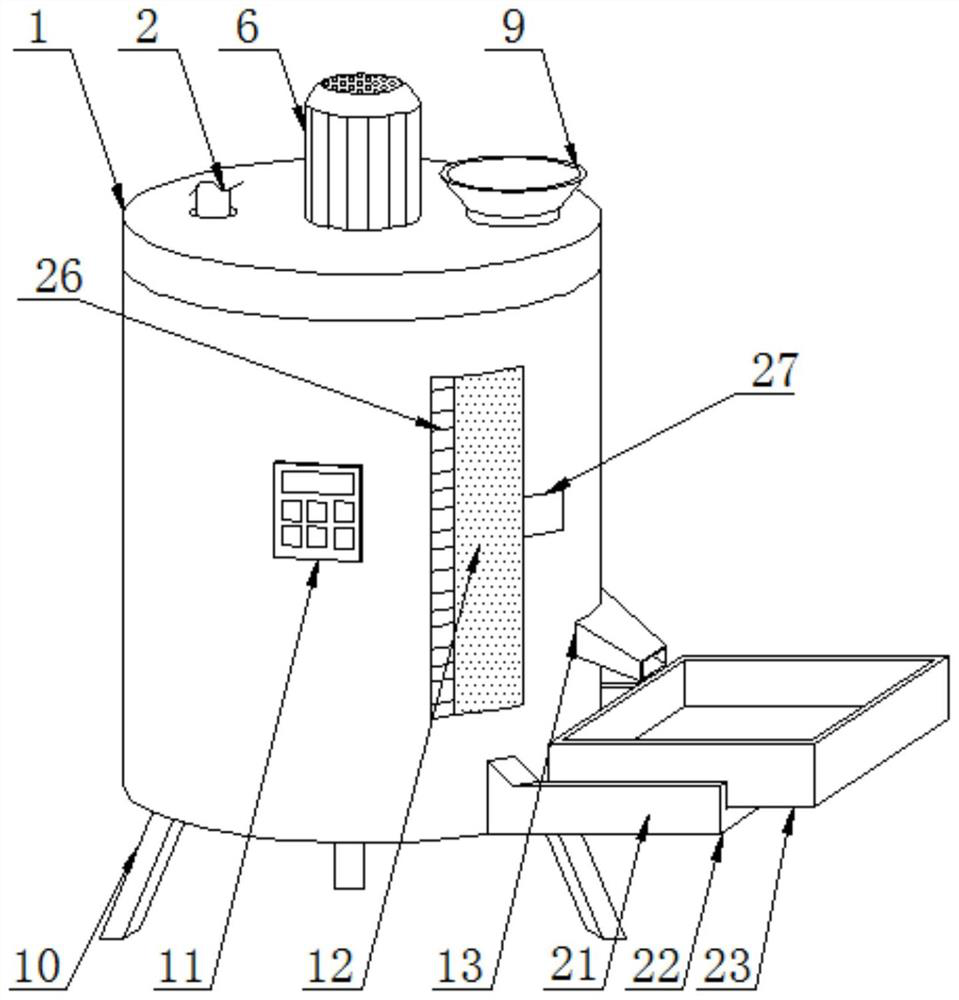

Pigment preparation device for drawing oil paintings

PendingCN112123995AReduce wasteImprove formulation qualityHollow article cleaningOther artistic work equipmentsPolymer sciencePolymer chemistry

The invention discloses a pigment preparation device for drawing oil painting. Through cooperative use of a heat preservation layer, a heating layer and a temperature controller, the interior of a machine body is kept at a stable temperature all the time, and the pigment preparation quality can be improved; through the arrangement of a weighing device, after the pigment is prepared, the prepared pigment can be directly weighed and equally divided, subsequent production is facilitated, and the production efficiency is improved; and through the arrangement of a cleaning device, after the pigmentis prepared, the interior of a preparation cylinder can be conveniently cleaned, the pigment can be conveniently used when the pigment is prepared again, and the labor intensity of workers is reduced. According to the pigment preparation device for drawing the oil paintings provided by the invention, a fine ingredient adding assembly and a cleaning assembly are integrally installed together and extend into the machine body, space is saved, meanwhile, holes on a machine cover can be reduced, and through the arrangement of a visual window, a colorimetric bar and a control panel, colors can be accurately compared, the comparison effect is improved, and the accuracy of the prepared pigment is guaranteed.

Owner:宿州学院

A decorative board facing paper and its production method

Owner:SHANDONG LUNAN NEW MATERIALS

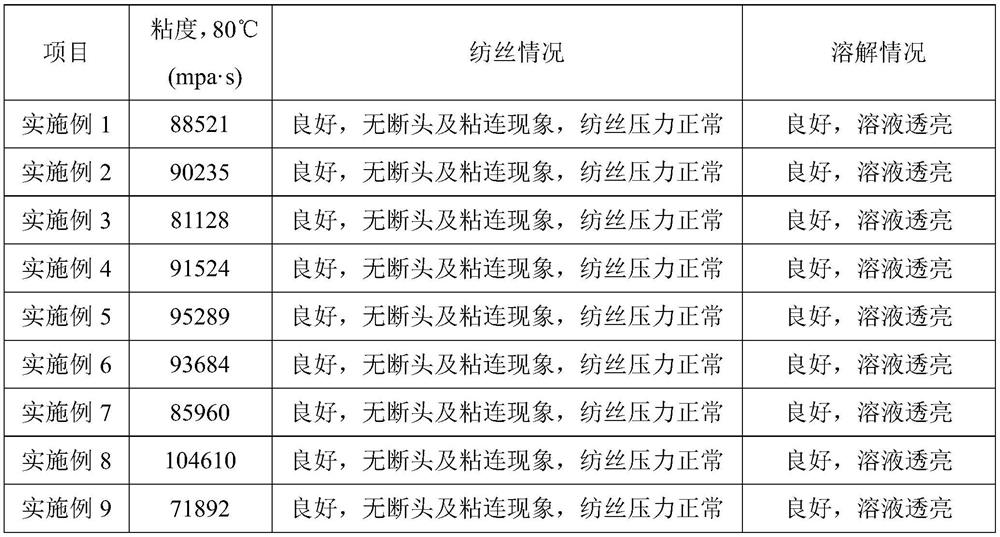

Method for improving dissolving property of high molecular weight polyacrylonitrile produced by dry method

ActiveCN114457448AIncrease concentrationSolve the difficulty of dissolutionTextile/flexible product manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention relates to the technical field of high molecular weight polyacrylonitrile, in particular to a method for improving the solubility of high molecular weight polyacrylonitrile produced by a dry method. The method for improving the dissolving property of the high molecular weight polyacrylonitrile produced by the dry method comprises the following steps: mixing solvents dimethylacetamide and dimethylformamide, heating to a set temperature, then adding polyacrylonitrile powder into the mixed solvent, stirring for dissolving, then adding a dimethyl sulfoxide solvent, heating to 65-80 DEG C, stirring for 1-2 hours, and cooling to room temperature to obtain the high molecular weight polyacrylonitrile. The uniform polyacrylonitrile solution is formed. The method for improving the solubility of the high-molecular-weight polyacrylonitrile produced by the dry method is easy to implement, solves the problem of poor solubility of the high-molecular-weight polyacrylonitrile on the premise of ensuring higher concentration of the solution, improves the stability of a spinning process and improves the product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

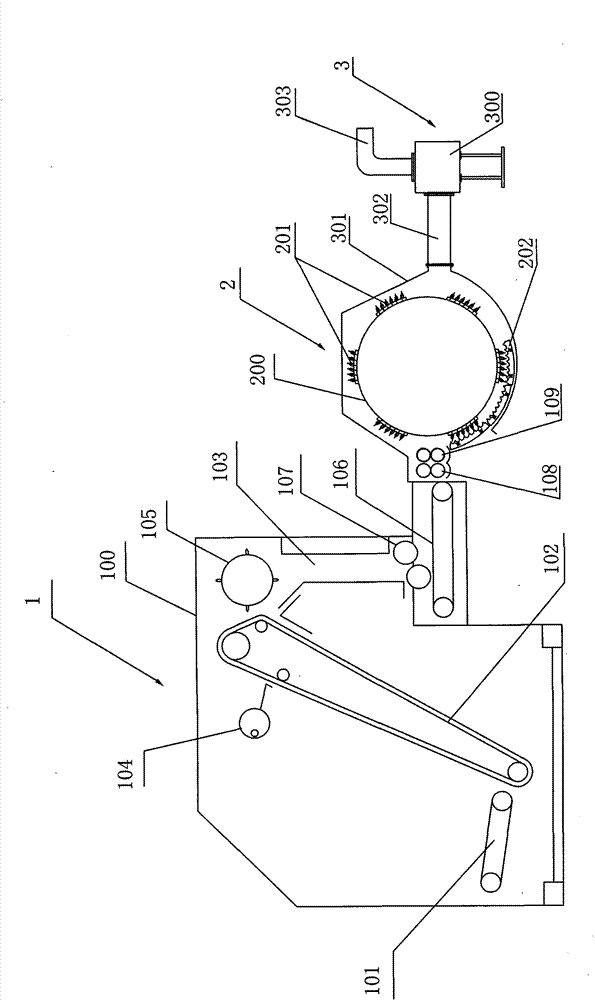

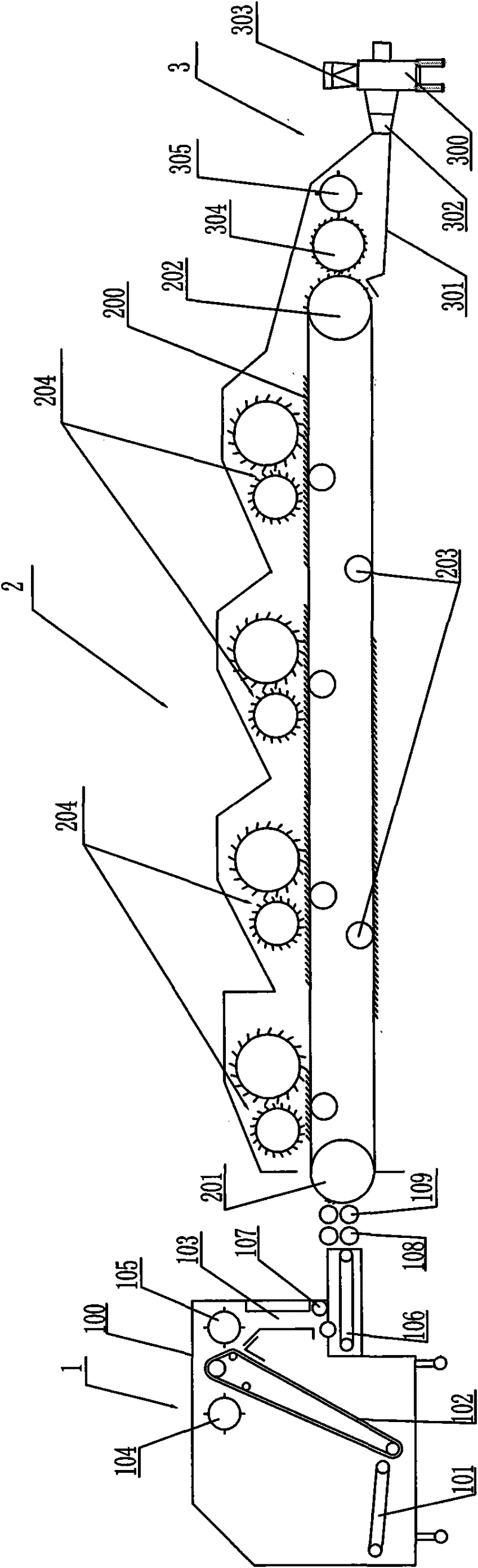

Fine opener with under screen and card clothing

ActiveCN101736446BImprove performanceReasonable useFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention discloses a fine opener with an under screen and card clothing, which comprises a feeding mechanism, an opening and carding mechanism, and an opened fiber output mechanism. The opening and carding mechanism is provided with a opening roller, a plurality of opening roller fallers are arranged in the circumferential direction of the opening roller, a card wire is arranged on each teasing roller faller, and the under screen is arrange below the opening roller. The fine opener is characterized in that the under screen comprises a supporting light panel, a plurality of under screen faller strips are arranged on the upper supporting surface of the supporting light panel, and each of the under screen faller strips is provided with the card clothing, and an opening and carding region is formed among the opening roller fallers and the under screen faller strips. The invention has a production efficiency increased by more than 20% by verification on condition that the rotating speed of the opening roller and the number of the opening roller fallers are not increased and the opening and carding effect is ensured.

Owner:青岛东佳纺机(集团)有限公司

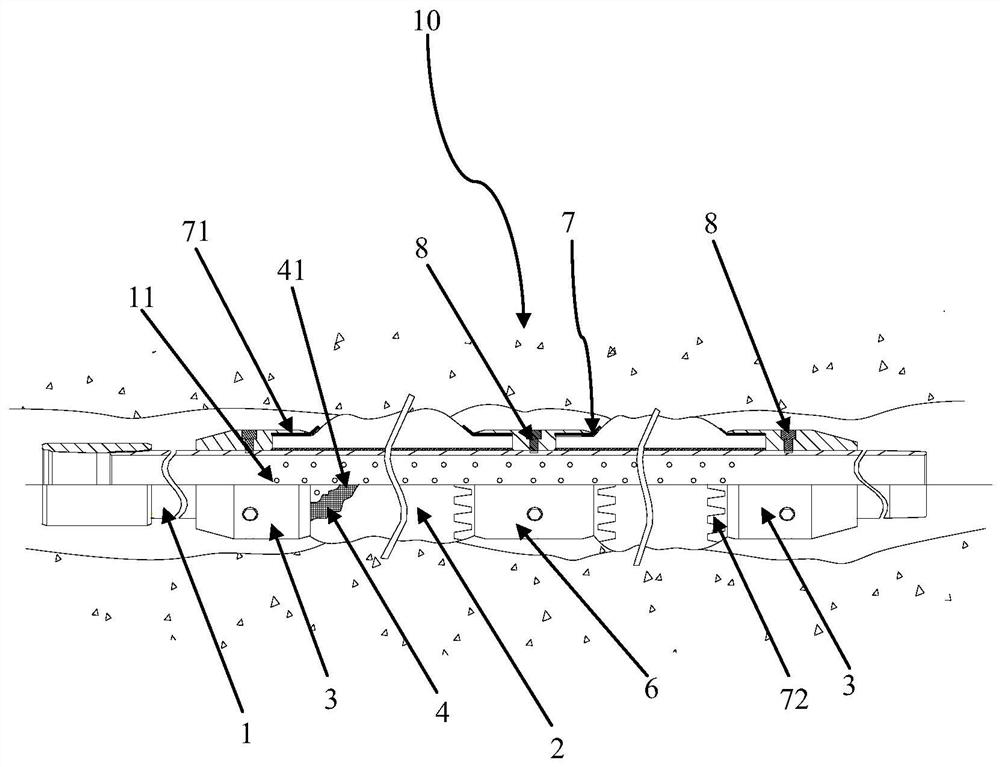

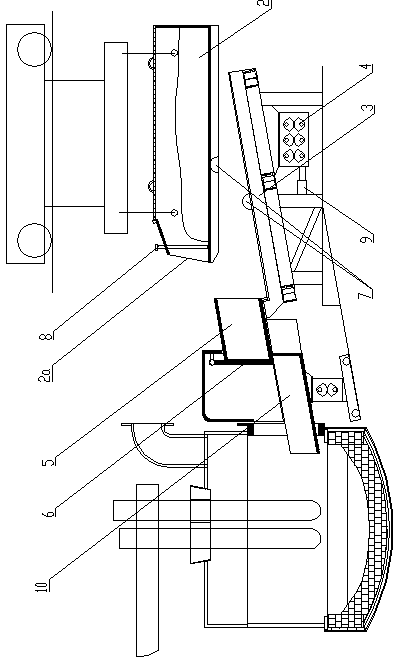

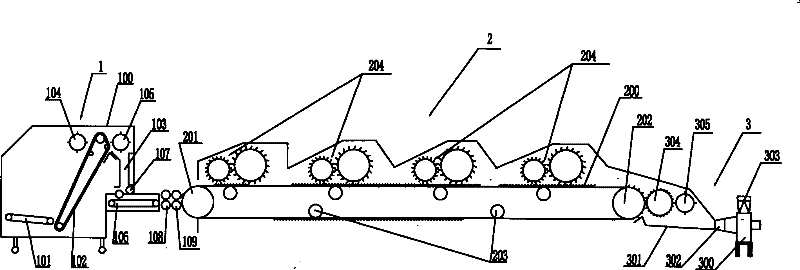

Quick feeding device for feeding waste steel into electric furnace and feeding method thereof

ActiveCN102183150BSimple structureFeeding speed can be controlledCharge manipulationPreheating chargesAir volumeElectric arc furnace

Disclosed are a rapid feeding device and a feeding method for feeding scrap steel into an electrical furnace. The rapid feeding device comprises a high temperature coupling tank (10) in communication with the electrical furnace, and a cold material-receiving device for feeding in the scrap steel. The cold material-receiving device comprises a long feeding groove (2) that can be hoisted. The long feeding groove (2) has a discharge port (2a) made at its front end, that can be in sealed communication with a feeding port of the high temperature coupling tank (10). The rapid feeding device has good air tightness and a high feeding speed. The feeding is carried out in closed conditions, which can effectively reduce air leakage, and improve the performance of the electrical furnace dedusting system. The discharge port is made at the front end of the long feeding groove so that the thickness of the spread material can be easily controlled.

Owner:CISDI ENG CO LTD

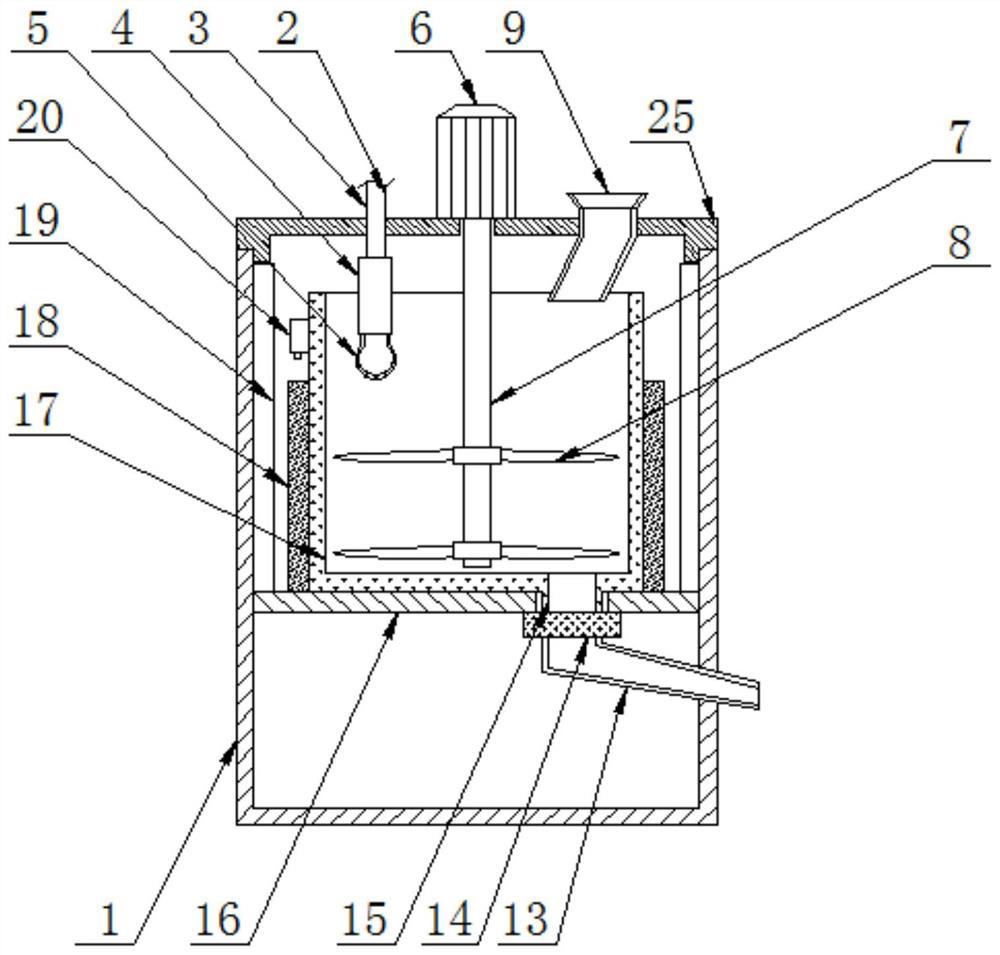

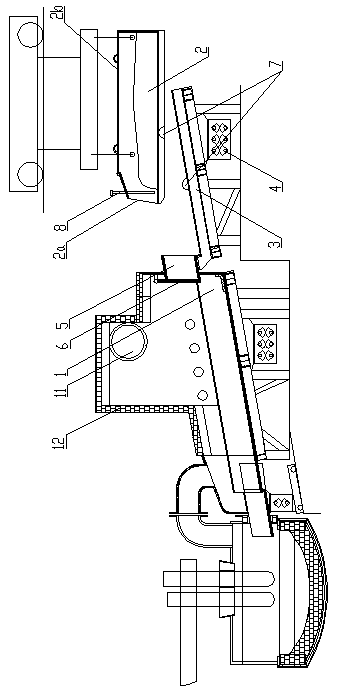

Efficient powder-like material separating device

The invention discloses an efficient powder-like material separating device. The efficient powder-like material separating device comprises a separating barrel installed on a stand column, a sealing cover is arranged at the upper end of the separating barrel, a distributing opening is formed in the lower end of the separating barrel, and a glass window is arranged on the circumferential side wall; the sealing cover is provided with not less than two round holes, and a first filter bag and a second filter bag are contained into the separating barrel through the round holes; and a bearing plate is fixedly welded to the circumferential side wall of the separating barrel, a draught fan is installed on the bearing plate, a flow guide pipe is connected to the position above the sealing cover through an air outlet of the draught fan, and the positions, corresponding to the first filter bag and the second filter bag, of a pipe body of the flow guide pipe are each communicated with a taper opening, and the taper openings extend into bag bodies of the first filter bag and the second filter bag correspondingly. The efficient powder-like material separating device is compact in structure and reasonable in design, and rapid separating of powder is facilitated; and different from conventional vibration separation, material machining is more even, and follow-up production is facilitated.

Owner:安徽清水岩生态科技有限公司

Linear refined opener

InactiveCN101705544BPerformance improvements and enhancementsOvercome constraintsCarding machinesState of artFiber

The invention discloses a linear refined opener, which comprises a feed mechanism, an opening and carding mechanism and an opened fiber output mechanism. The opener is characterized in that: the opening and carding mechanism is provided with a rotary annular card flat and at least more than three work roll sets, wherein each work roll set consists of a work roll and a wiper roll, all the work roll sets are arrayed in a row over the rotary annular card flat from the front to the back, and an opening and carding area is formed between each work roll set and the rotary annular card flat. The linear refined opener can better overcome a plurality of limiting factors in the prior art, and is favourable for freely designing the number of added work roll sets according to actual need; and the performance of the refined opener can be greatly improved.

Owner:青岛东佳纺机(集团)有限公司 +1

Single-shaft powerful stirring and kneading machine

ActiveCN103042599BFull power outputEasy to shapeCement mixing apparatusPulp and paper industryHead shape

The invention relates to a single-shaft powerful stirring and kneading machine, which comprises a mud stirring homogenizing and kneading section, and is characterized in that a single stirring shaft is arranged in a mud box of the mud stirring homogenizing and kneading section and a plurality of hook head-shaped stirring and kneading knives are arranged on the single stirring shaft in a staggered way. The single-shaft powerful stirring and kneading machine is reasonable in structure and convenient to use; the single stirring shaft is higher in power output; the mud stirring refining recovering and forming capability is further improved in combination with proper stirring knives; and not only is the working efficiency improved, but also the subsequent formability of mud is good, thereby facilitating subsequent production.

Owner:GONGLI MACHINE CO LTD

LED

InactiveCN1324719CUniform distribution of working current densityImprove efficiencySemiconductor devicesElectrical conductorEngineering

Quadreple epitaxial layer composed of first material layer, luminous layer and second material layer is formed on a semiconductor base plate. A euphotic base plate is fixed on surface of the second martial layer. With semiconductor base plate being removed, isolation groove and first extend groove are made under undersurface of first material to penetrate the first material layer and extend to part of volume of second material layer at least. First extend electrode is setup inside first extend groove. The first extend electrode is possible to connect with first electrode positioned at partial surface of the first material layer. Thus, the first electrode is located in nearly same level position to second electrode, which is on surface of other part of the first martial layer in order to carry out next processing easily. The invention increases luminescence are of PN interface, raises luminescence brightness and service life.

Owner:OPTO TECH

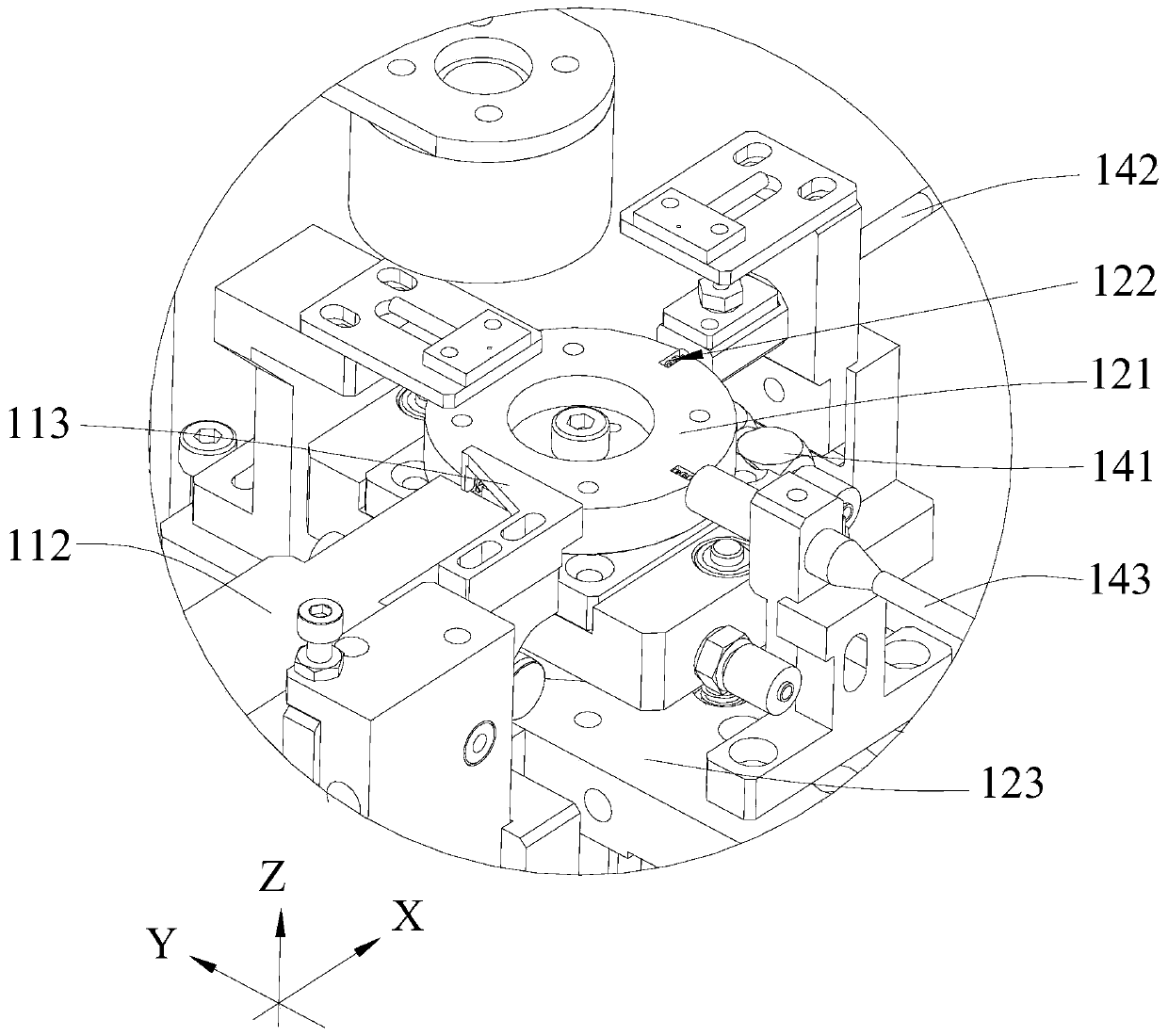

Implantation device and implantation method

PendingCN110370533AHigh precisionImplanted accuratelySortingImplanted deviceInjection molding machine

The invention is applicable to the field of implantation equipment and methods, and provides an implantation device and an implantation method. The implantation equipment comprises a screening mechanism, an implantation mechanism and an injection molding mechanism, wherein the screening mechanism is used for screening out fine materials with correct orientation in a batch of fine materials; the implantation mechanism is used for pressing the screened fine materials into an implantation hole of a receiving object; and the injection molding mechanism is used for carrying out film injection molding on the fine materials. The implantation device can ensure that the fine materials entering a discharging pipe are in the same direction, so that the subsequent production is facilitated; and meanwhile, the alignment difficulty is reduced, the precision of placement of the fine materials is improved, and the implantation efficiency is improved.

Owner:现代精密自动化(深圳)有限公司

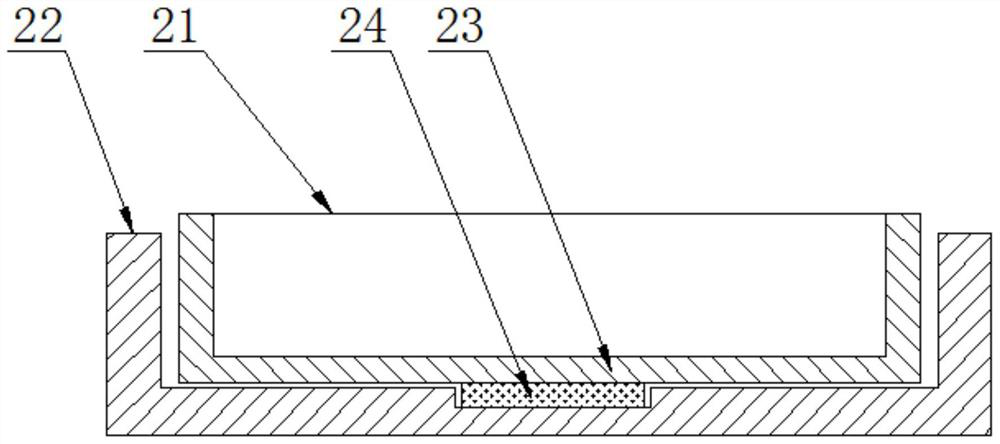

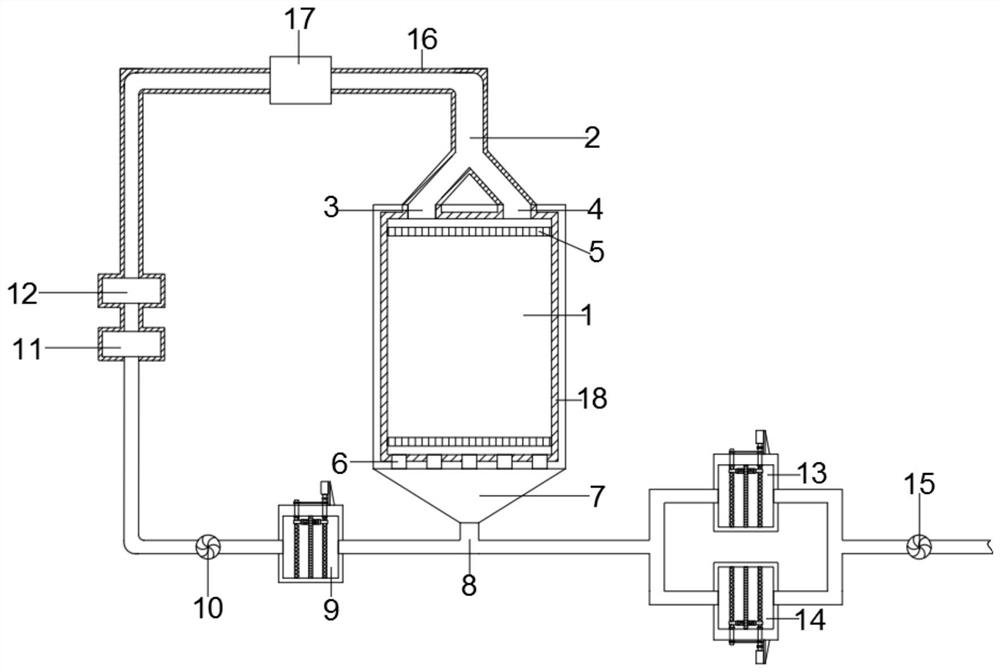

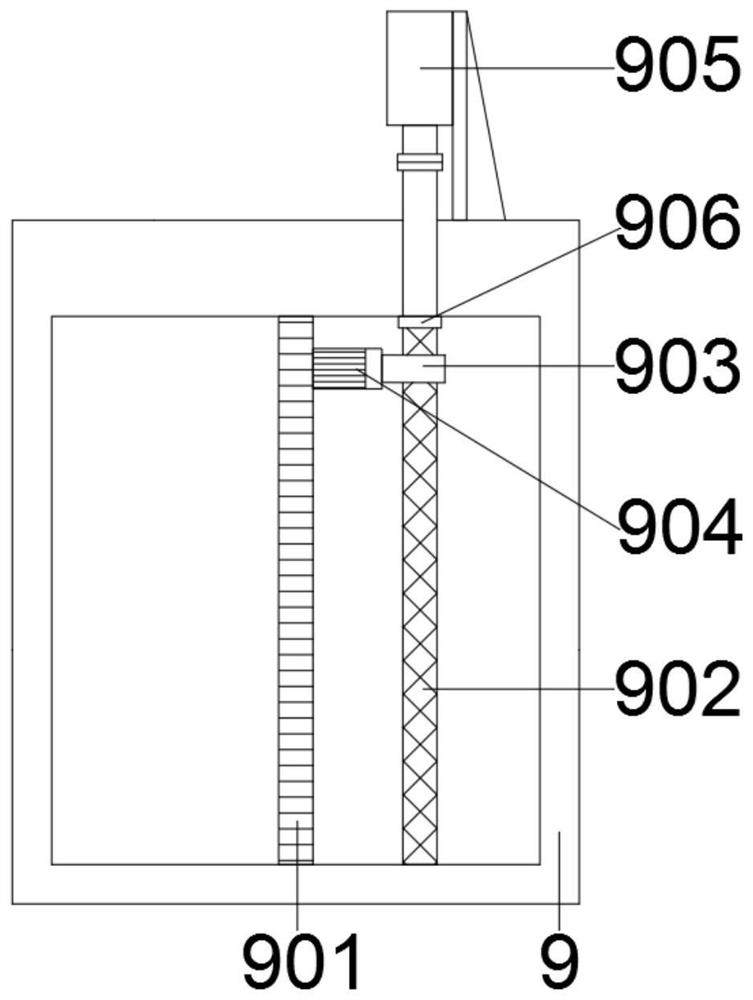

Spinning thread gel tank with internal circulation pipeline

InactiveCN112746341AReasonable structural designConducive to follow-up productionArtificial thread manufacturing machinesWet spinning methodsYarnFiber

The invention discloses a spinning thread gel tank with an internal circulation pipeline. The gel tank comprises a gel tank body; one side of the gel tank body communicates with a Y-shaped pipe; a water outlet channel is formed in the other side of the gel tank body; mesh plates are fixed to the positions, close to a first water inlet and the water outlet channel, in the gel tank body; a water collecting chamber is fixed to the gel tank body and located on the outer side of the water outlet channel; the other side of the water collecting chamber is connected with a three-way pipe; an inner circulating pipeline is arranged between one water outlet of the three-way pipe and the water inlet of the Y-shaped pipe; and another water outlet of the three-way pipe communicates with a second filter and a third filter. According to the invention, the Y-shaped water inlet pipe can enable water flow to uniformly enter the gel tank, the water flow uniformly flows out after passing through the mesh plates, no flow velocity difference exists, the water flow with the uniform flow velocity ensures that fiber yarns in the gel tank have the same performance characteristics, and subsequent production is facilitated.

Owner:江苏关怀医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com