Patents

Literature

116results about How to "Has thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for the application of a conformal nanocoating by means of a low pressure plasma process

InactiveCN102821873ALow costCoating thicknessDielectric materialsElectric discharge tubesNanostructureNanometre

The invention relates to a conformal nanocoating applied by a low pressure plasma process. The invention also relates to a method for making such a conformal nanocoating on a three-dimensional nanostructure, in particular a three-dimensional structure containing electrically conductive and non-conductive elements.

Owner:EUROPLASMA

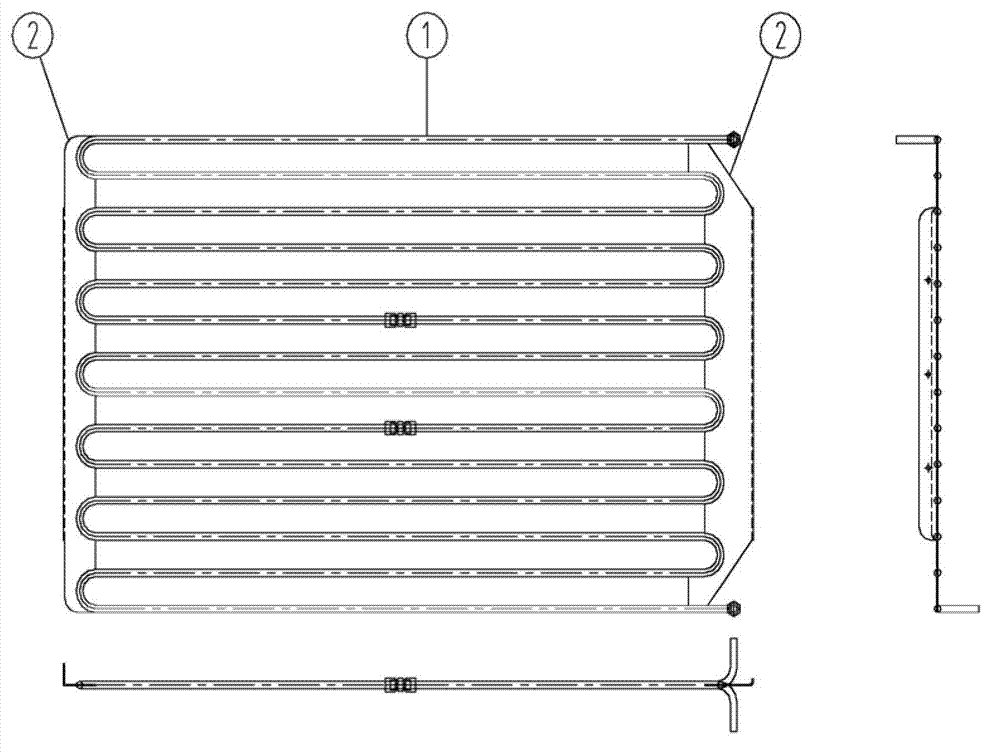

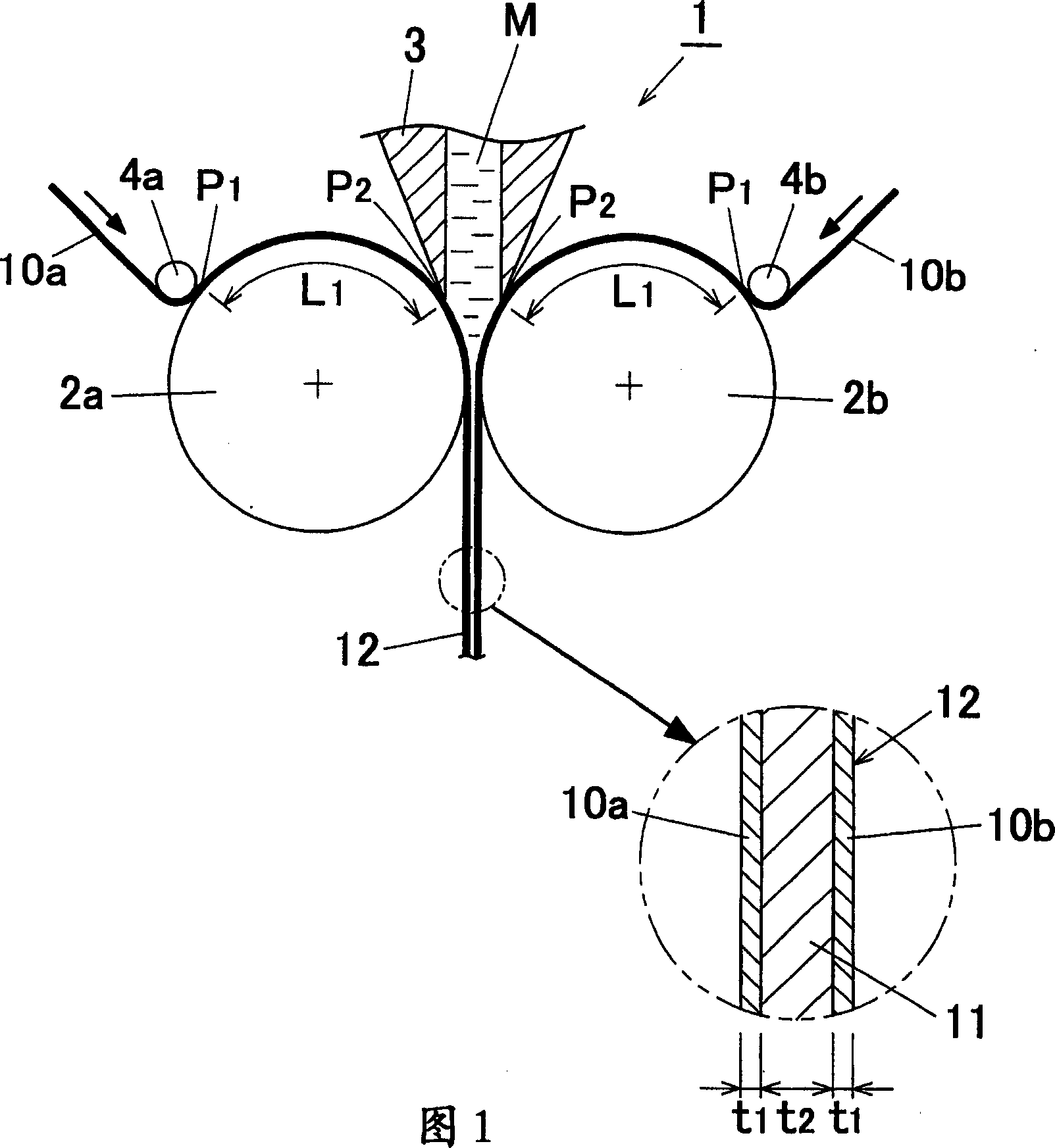

Clad material, method for manufacturing said clad material, and apparatus for manufacturing said clad material

InactiveCN1933928AControl tensionIncrease cooling rateHeat exchange apparatusMetal rolling arrangementsMeeting placeMolten metal

A method for manufacturing a clad material in which a core material is cast and skin materials are pressure-bonded thereon aims to prevent deterioration of adhesiveness of the core material and the skin materials while keeping sufficient cooling rate of the core material, prevent thickness variation and / or breakage of the skin materials during the manufacturing process, and keep the surface property of the cooling rolls constant. The method for manufacturing a clad material (11) includes the steps of continuously supplying molten metal (M) into a gap between a pair of cooling rollers (2a) (2b) to cast a core material, and cladding skin materials (10a) (10b) on both surfaces of the core material with hot rolling by continuously supplying the skin materials on peripheral surfaces of the cooling rollers so that the skin materials prevent direct contact between the cooling rollers and the molten metal, wherein the skin materials are supplied so as to come into contact with the peripheral surfaces of the cooling rollers, and wherein a contact distance (L1) from a contact starting point (P1) where the skin material begins to come into contact with the cooling roller to a meeting point (P2) where the skin material begins to come into contact with the molten metal is set to 100 times or more of a thickness (t1) of the skin material.

Owner:SHOWA DENKO KK

Decorative plate finishing paper and production method thereof

The invention aims to replace wood veneer and technical wood by using a piece of novel decorative plate finishing paper for artificial plate veneering. A piece of base paper which is 150-350g / m<2> is adopted, the upper layer of the base paper is printed with simulated natural and precious trees which are infrequent day by day, other artistic patterns can be also innovated and printed, and a vivid effect can be achieved after lamination. Due to adoption of chemical fiber in the decorative plate finishing base paper, the paper strength can be improved, and the paper is soft and tough. The decorative plate finishing paper is mainly applicable to veneering of artificial plates such as fiber boards and chipboards, and can replace veneering materials such as wood veneer and technical wood, and the finishing paper can have flame retardancy after being coated with a flame retardant adhesive.

Owner:SHANDONG LUNAN NEW MATERIALS

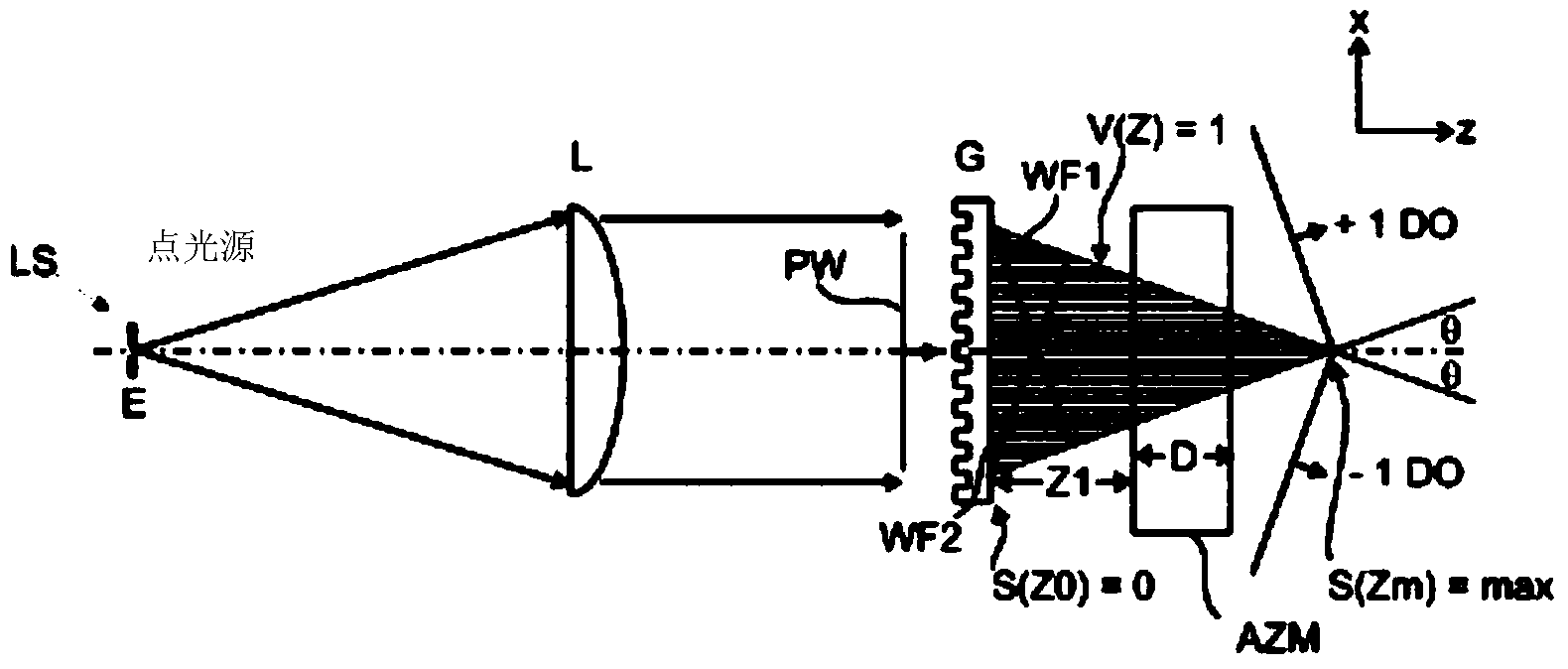

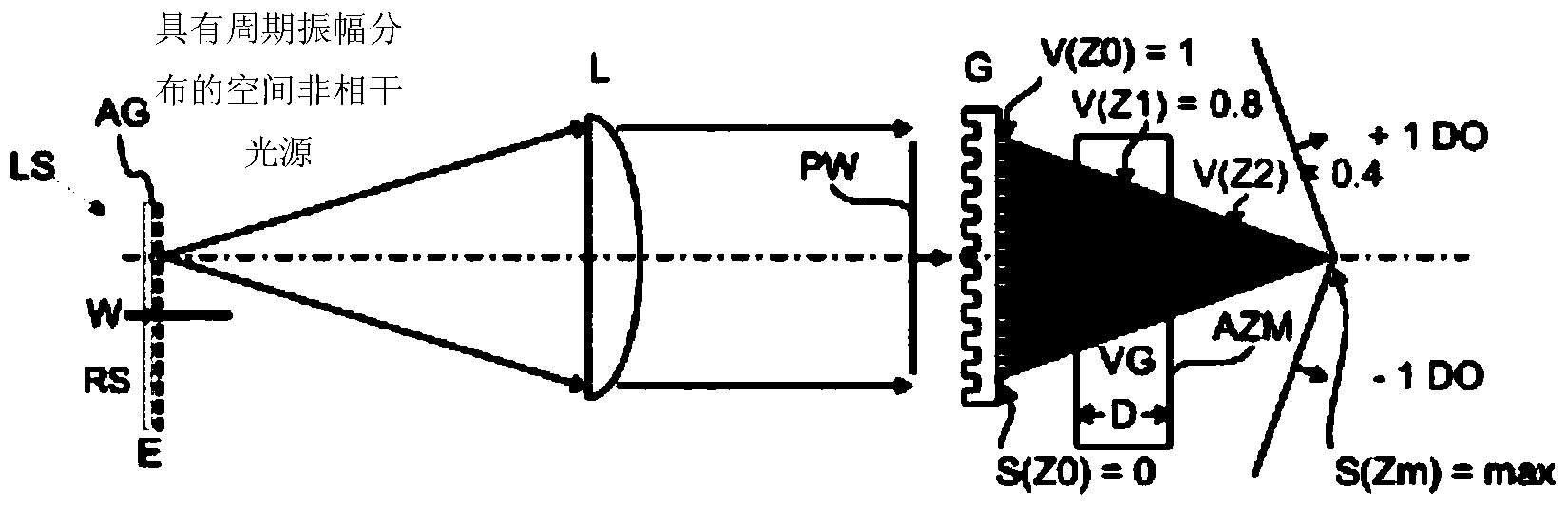

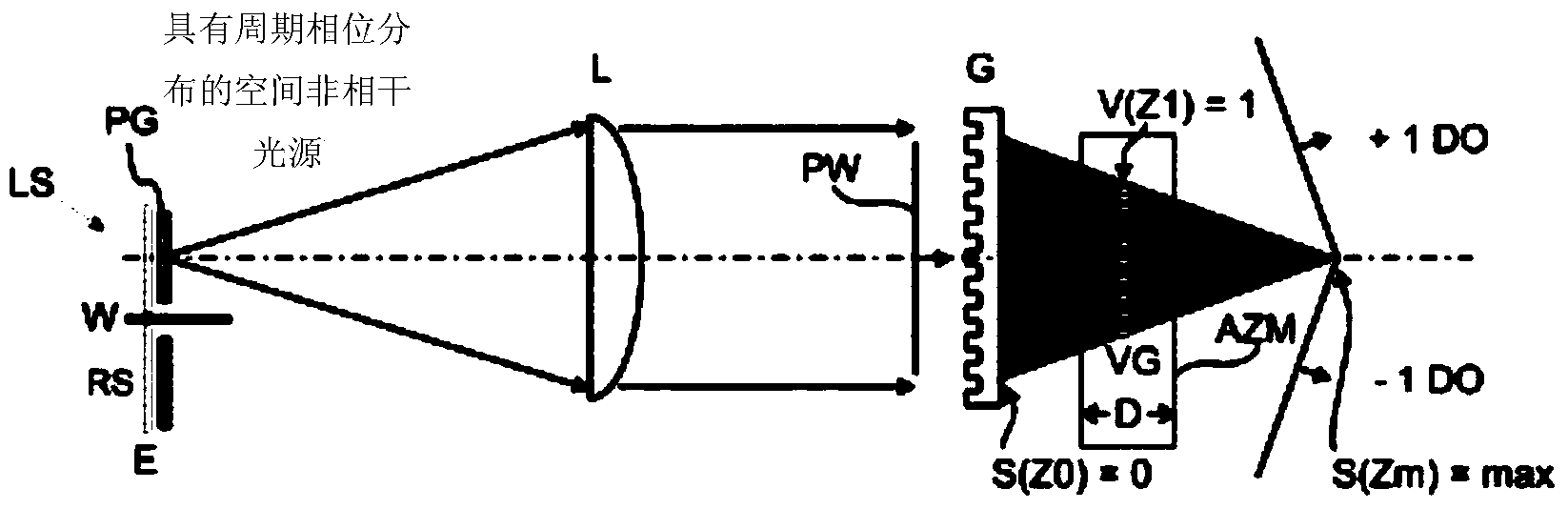

Method and device for the layered production of thin volume grid stacks, and beam combiner for a holographic display

ActiveCN103765329AHas thicknessHolographic light sources/light beam propertiesOptical articlesLight beamDepth dependent

The invention relates to a method and to a device for the layered production of at least one volume grid (VG) in a recording medium (AZM) by exposure to light, which comprises at least one light sensitive layer which is sensitized for a predeterminable wavelength (?) of the exposure light. Each volume grid (VG) is generated in the recording medium (AZM) by at least two interference capable wave fronts (WF1, WF2) of coherent light, which are superimposed at a predeterminable depth (z) at a predeterminable angle (2?) in the recording medium (AZM) with a predeterminable interference contrast V(z).; The depth (z) and the thickness of the refractive index and / or transparency modulation of a volume grid (VG) in the recording medium (AZM) are adjusted in the direction of light propagation (z) by a depth dependent control of the spatial and / or temporal coherence degree (?) of the interfering wave fronts (WF1, WF2). The invention further relates to a beam combiner for a holographic display and to a solar module having increased efficiency.

Owner:SEEREAL TECHNOLOGIES

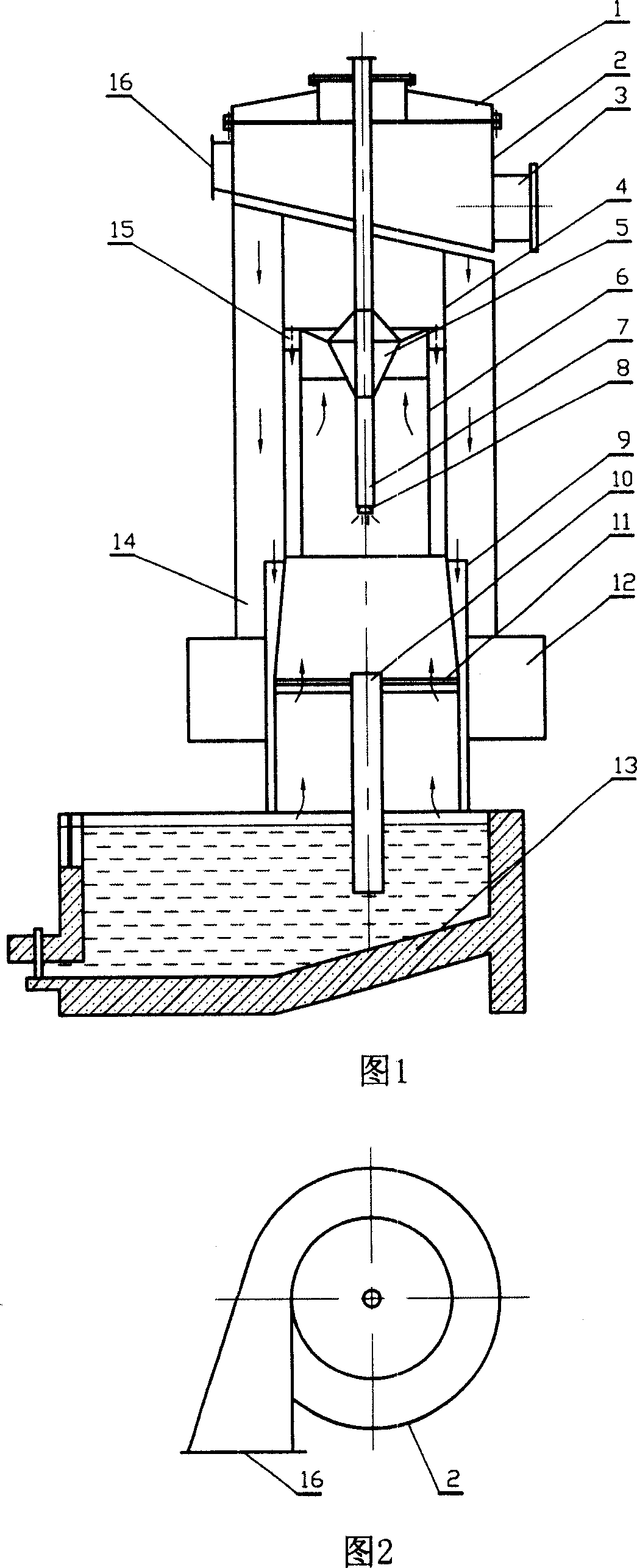

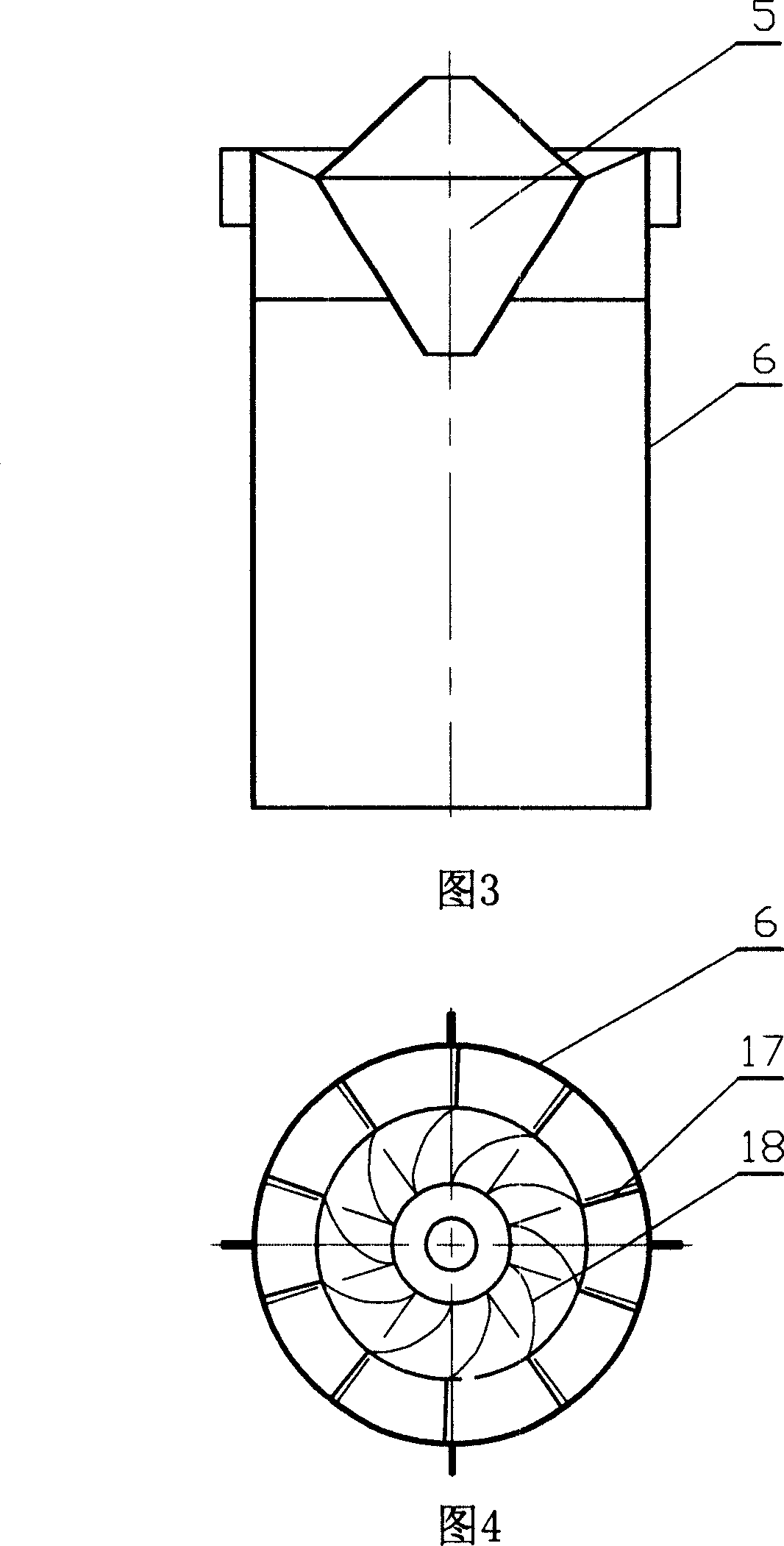

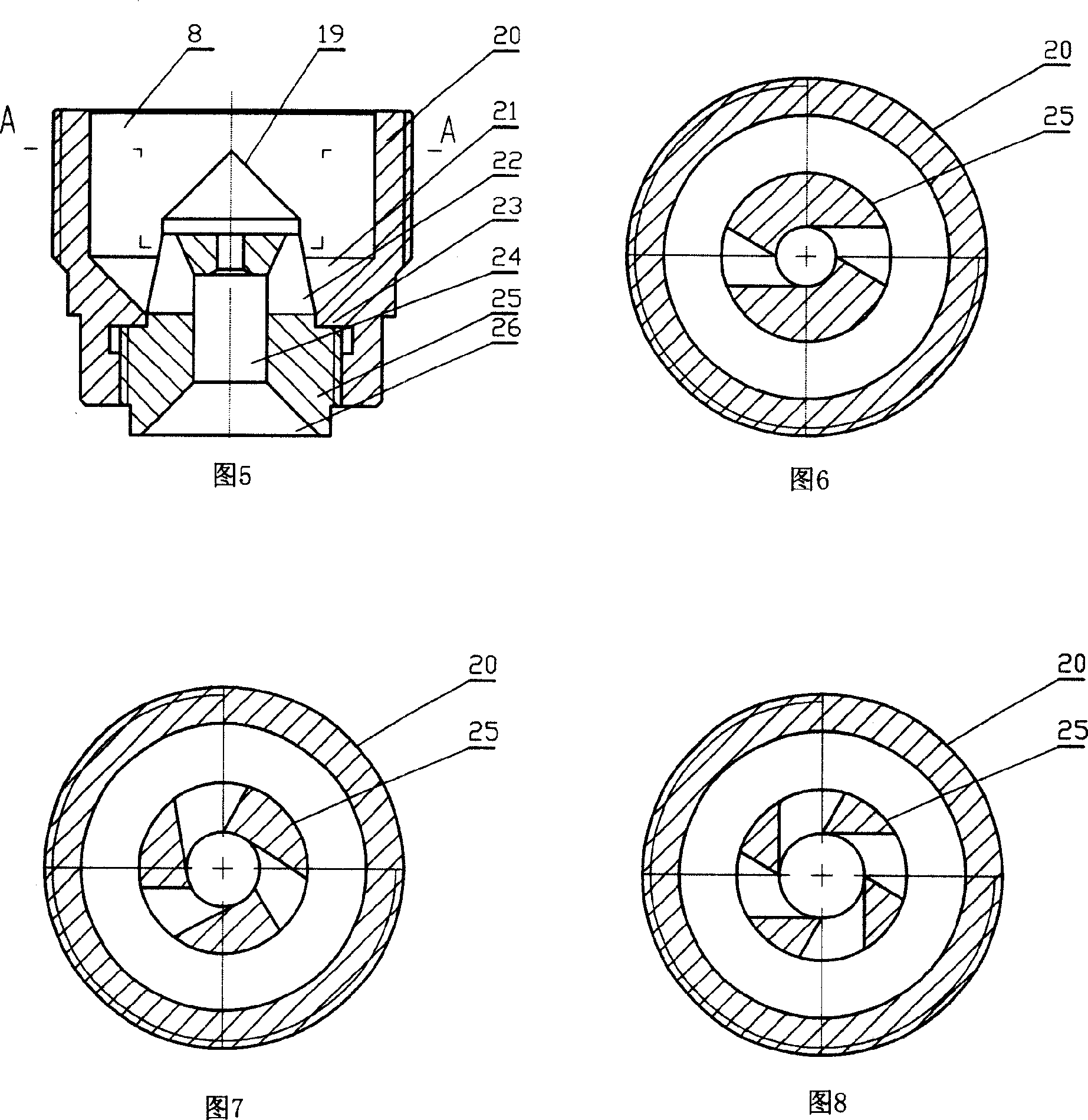

Integration dust-removing and desulfurizing device

InactiveCN101099920ACompact structureReasonable designUsing liquid separation agentSmall footprintEngineering

The present invention relates to integrated dedusting and desulfurizing apparatus and process. The integrated dedusting and desulfurizing apparatus one outer cylinder and one inner cylinder to form one sandwich with tangent air inlet and one air outlet, one sandwiched sleeve connected coaxially to the lower part of the inner cylinder and communicated to the sandwich between the outer cylinder and the inner cylinder, one water tank communicated to the sandwiched sleeve, one dewatering unit coaxially fixed inside the inner cylinder and with one axial water pipe, and one horizontal sieve plate in the middle part inside the sandwiched sleeve. The present invention has well combined cyclonic dedusting and spray dedusting and desulfurizing, possesses high dedusting and desulfurizing efficiency, and is suitable for purifying fume of small boiler.

Owner:王国华

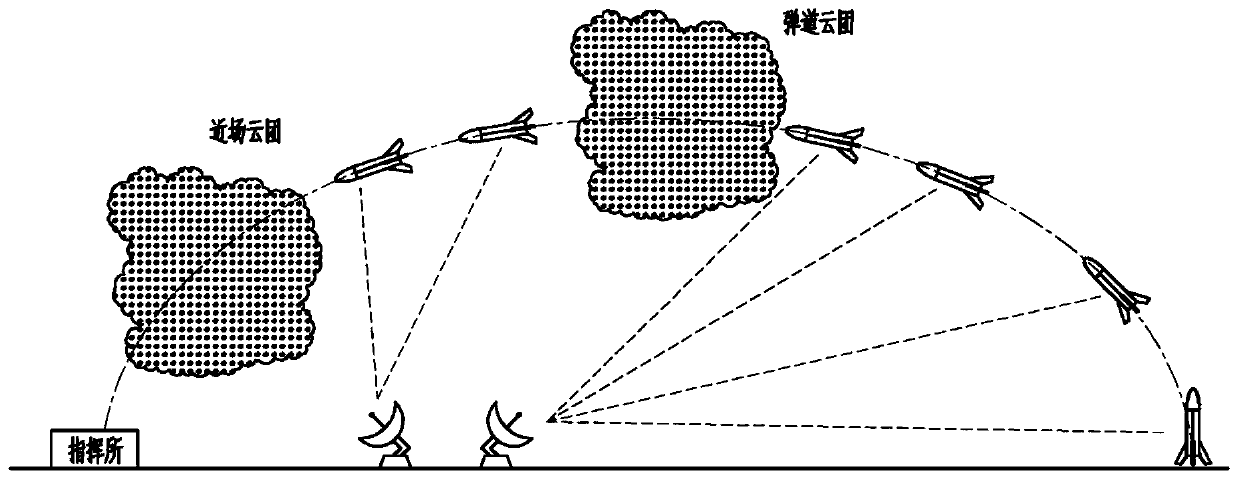

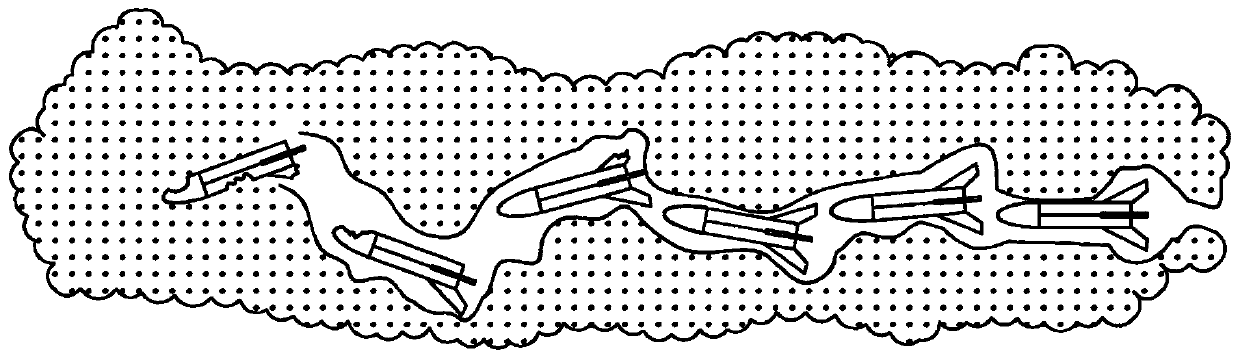

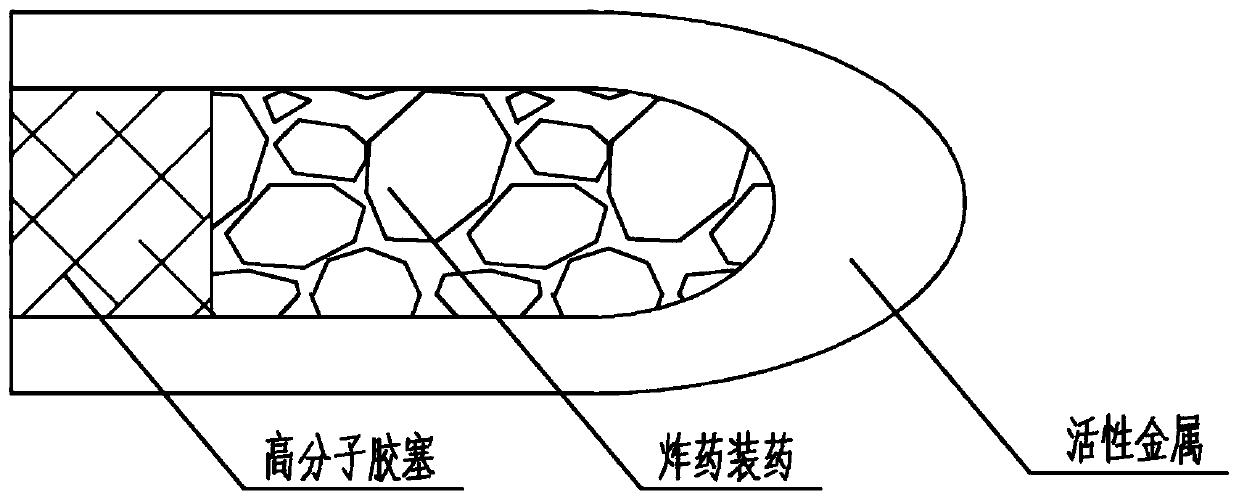

Preparation method for active metal micro-projectile loading high explosive

ActiveCN110360902AReduce predictive computing pressureImprove interception rateTransportation and packagingMetal-working apparatusAdhesiveMetal

The invention relates to a preparation method for an active metal micro-projectile loading a high explosive and belongs to the field of energetic material, damage and ammunition engineering. The active metal micro-projectile loading a high explosive prepared by the preparation method combines advantages of the active metal energetic material and the high explosive: an active metal micro-projectileprojectile cloud is formed by the projectile, a trajectory of an incoming missile is roughly resolved to give a substantial flight path, and the explosive is scattered around important targets on thetrajectory or the protected important targets. For a hypersonic vehicle, the trajectory resolving and trajectory predicting and calculating pressure is reduced without capturing and tracking, so thatthe intercepting probability is improved. A shell of the micro-projectile is prepared by compounding the active meal and an adhesive. An inner charge is an existing high molecular bonding explosive or a casted mixed explosive which is sophisticated in technology. Generally, the micro-projectile is easily available in raw material, simple in process, low in cost, convenient to prepare on a large scale and feasible.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Coloring and painting process for surface of hardware

InactiveCN102133570AReduce processing requirementsHas thicknessPretreated surfacesSpecial surfacesUV curingUltraviolet

The invention discloses a coloring and painting process for the surface of hardware, comprising the following work procedures: material cleaning, racking, electrostatic precipitation, prime coat spraying, top coat spraying and ultraviolet curing. In the process of top coat spraying, matte UV oil is adopted as coat, the matte UV oil is a liquid material formed by adding matte powder in highlight UV oil, the particle size of the matte powder in the liquid coat is 5-50mum, a high-pressure automatic spray gun uniformly covers the matte UV oil on the surface of hardware sprayed by prime coat, and due to drying, solvent in the liquid coat volatilizes completely so as to form finish paint with a matte effect. In the invention, the hardware has low requirement on polishing or other pretreatment, a paint vehicle film layer formed by the painting process is good in covering capability, can cover the small defects of sand holes, scratching and the like on the surface of the hardware, the effect of the matte fogging surface is indicated, the yield and the production rolled yield of the product are improved, and simultaneously, the product performances such as rotproofness, wearing resistance, scratch resistance and the like can be obtained.

Owner:SHENZHEN CHANGSHENGHUI PRECISION HARDWARE

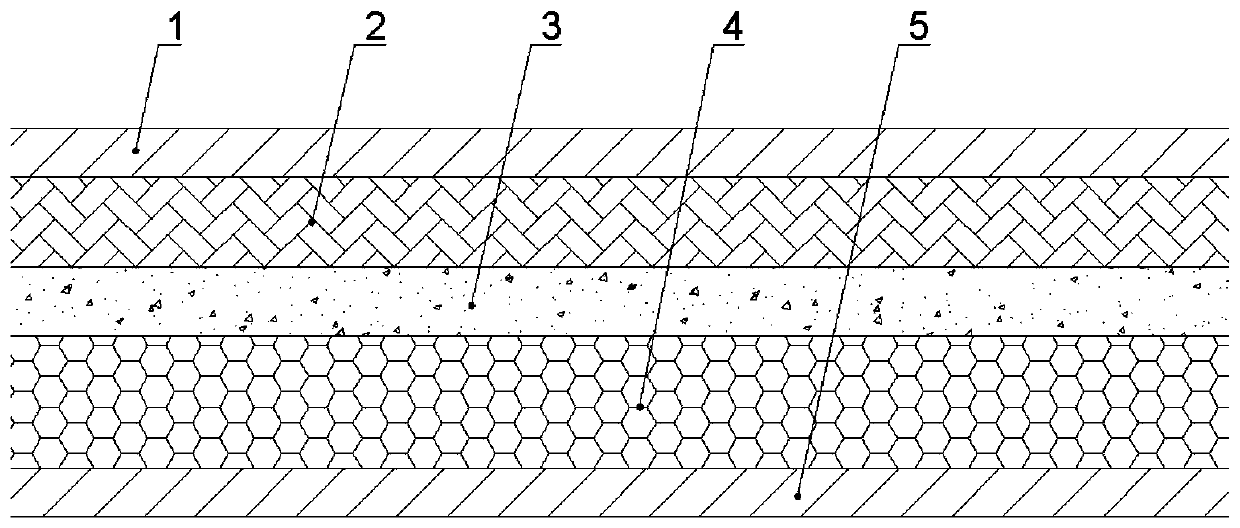

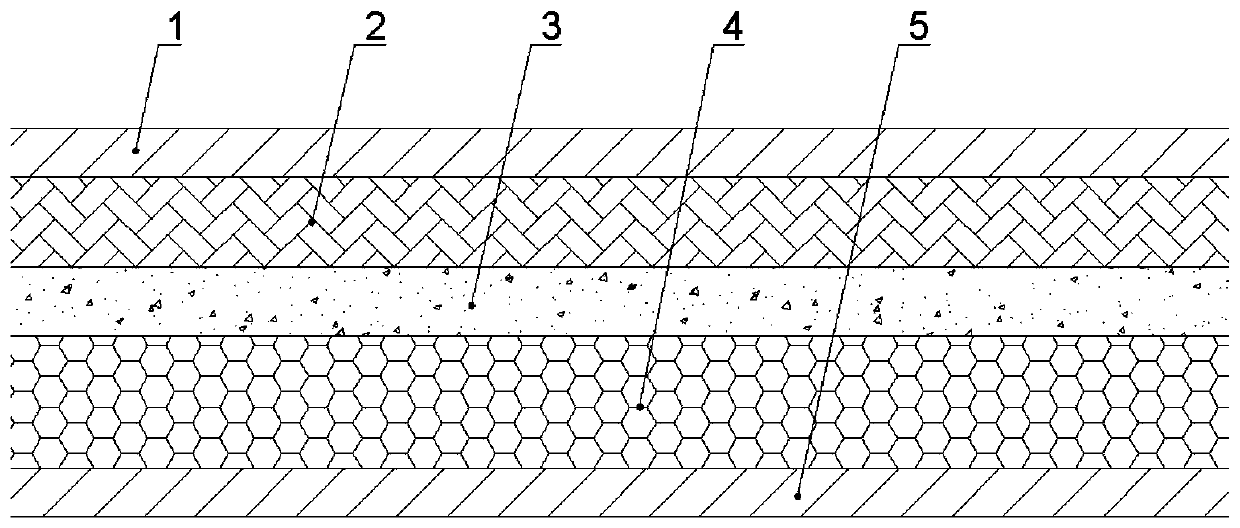

Lightweight environment-friendly automobile interior material and preparation process thereof

ActiveCN109910411AEasy to recycleSmall smellSynthetic resin layered productsLaminationCombustionSun protection

The invention discloses a lightweight environment-friendly automobile interior material and a preparation process thereof. The lightweight environment-friendly automobile interior material comprises an upper surface treatment agent layer, a TPO skin layer, a sponge layer, a base cloth layer and a lower surface treatment agent layer, wherein the sponge layer is arranged on the base cloth layer; thelower surface treatment agent layer is arranged below the base cloth layer; the TPO skin layer is arranged on the sponge layer; the upper surface treatment agent layer is arranged on the TPO skin layer. The TPO skin layer is easy to recover, resistant to high and low temperatures and low in odor and haze, produces hydrocarbons after combustion, and meets the requirement of environmental protection. The sponge layer enables automobile interior trim to have certain elasticity, and the base cloth layer enables the automobile interior trim to have certain thickness and has lower preparation costthan the TPO skin layer, the upper surface treatment agent layer and the lower surface treatment agent layer enable the prepared automobile interior trim to have certain bacteria and corrosion resistance, flame retardancy, abrasion resistance, oxidation resistance and sun protection.

Owner:TAICANG HONGEN ELECTRONIC TECH CO LTD

Full hemp liner for men's suits and manufacturing method thereof

InactiveCN101637319AStructural fitStrong three-dimensional senseGarmentsClothes making applicancesEngineeringFormaldehyde

The invention discloses a full hemp liner for men's suits, which comprises a bodice liner, a front chest liner, an armhole liner, an internal shoulder liner, an external shoulder liner and a bias chest liner. The invention also discloses a manufacturing method of the full hemp liner for men's suits, which comprises the following steps: putting the full hemp liner in a container, leading steam intothe container, and steaming the full hemp liner at the high temperature of 110-120 DEG C for 12-16 hours; then, taking out the full hemp liner, and cooling and airing the full hemp liner; and shrinking, expanding, shaping, pressing and ironing the full hemp liner to obtain a finished product. The full hemp liner for men's suits has the advantages of natural and neat wear and good air permeability, better joints the structure of a human body, does not contain formaldehyde and does not need a bonding liner. In addition, because the high-temperature steaming technology is adopted in the manufacturing process, the raw liner is made into a steamed liner, thus the liner is softer and can not be deformed by ironing.

Owner:NINGBO SHANSHAN +1

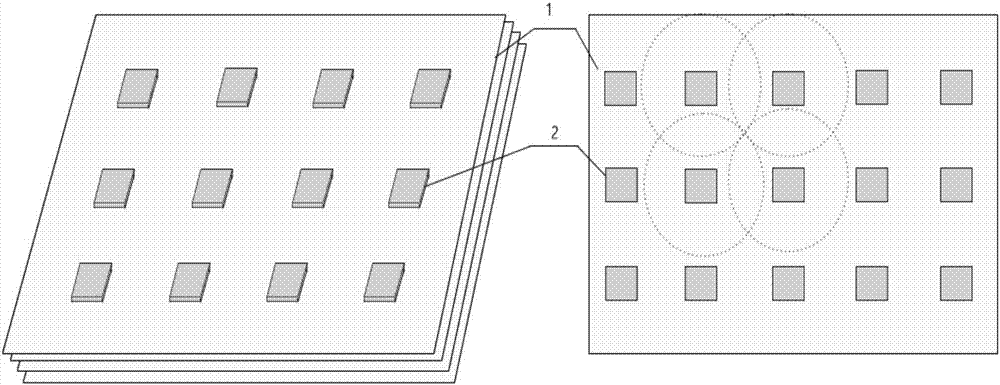

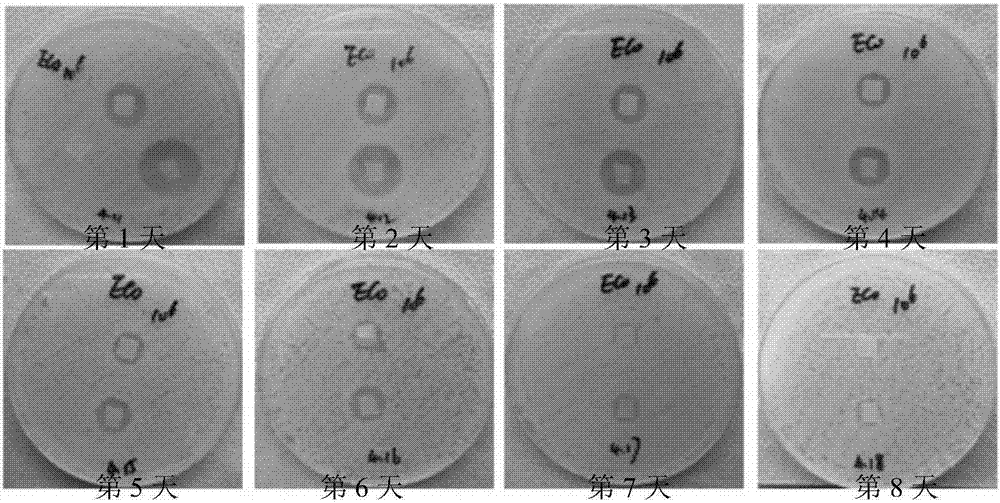

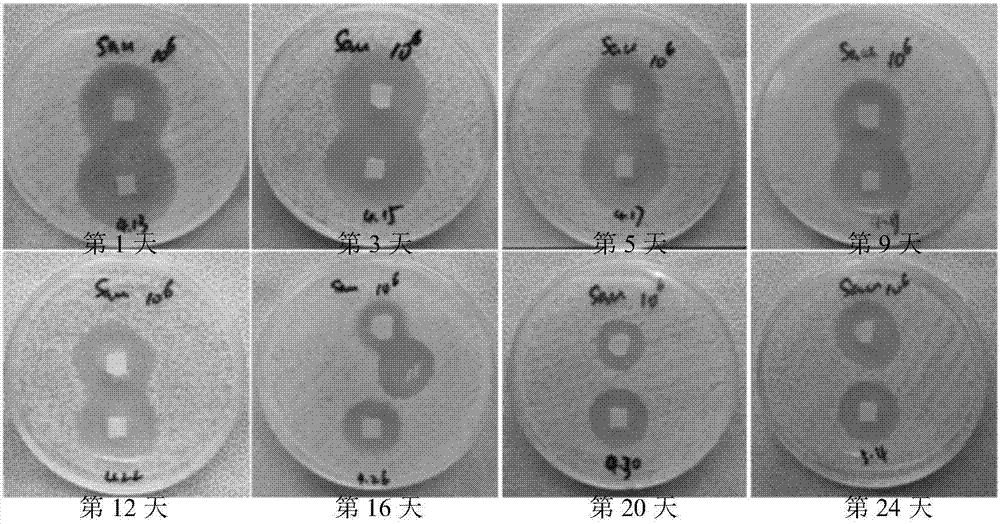

Slow-release and anti-infective composite soft tissue repair material and preparation method thereof

The invention relates to a slow-release and anti-infective composite soft tissue repair material and a preparation method thereof. The repair material is prepared from a biological material and media containing anti-infective components, wherein the media containing the anti-infective components are arranged between layers of the biological material or on the surface of the biological material at intervals according to the radius of an inhibition zone of a drug sensitive test, and a whole body is formed by the aid of a binding agent, suture lines or pressure. According to the slow-release and anti-infective composite soft tissue repair material and the preparation method thereof, the anti-infective components can be released effectively and continuously, meanwhile, biocompatibility of the biological material is not changed, the biological material is non-toxic and harmless, and the application prospect is good.

Owner:EXCELLENCE MEDICAL TECH SUZHOU CO LTD +1

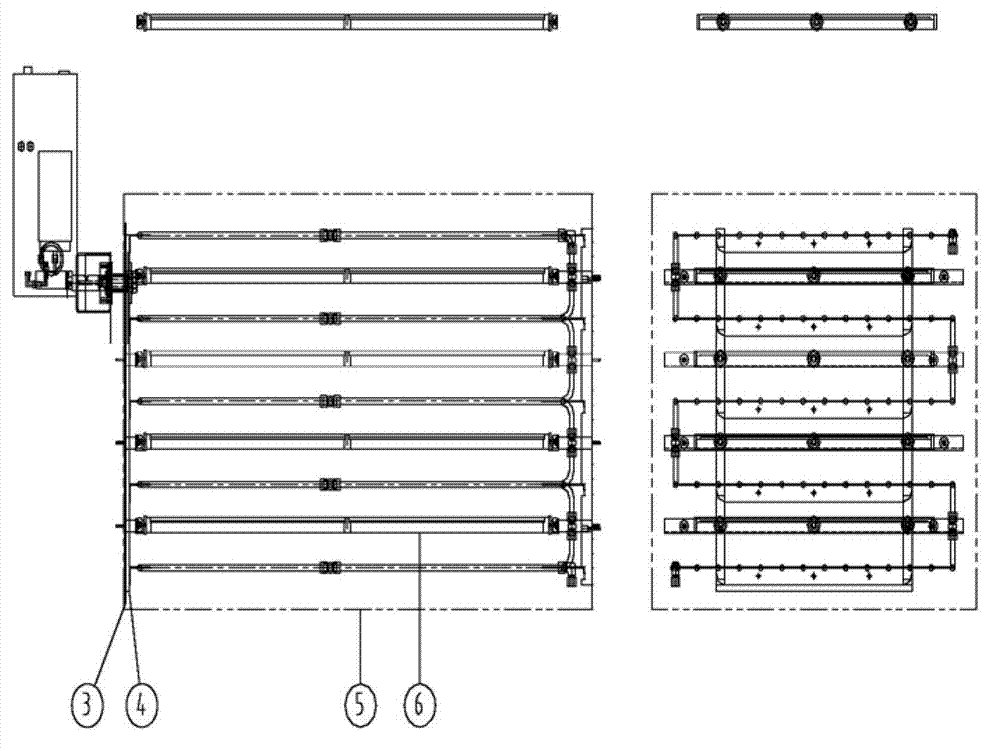

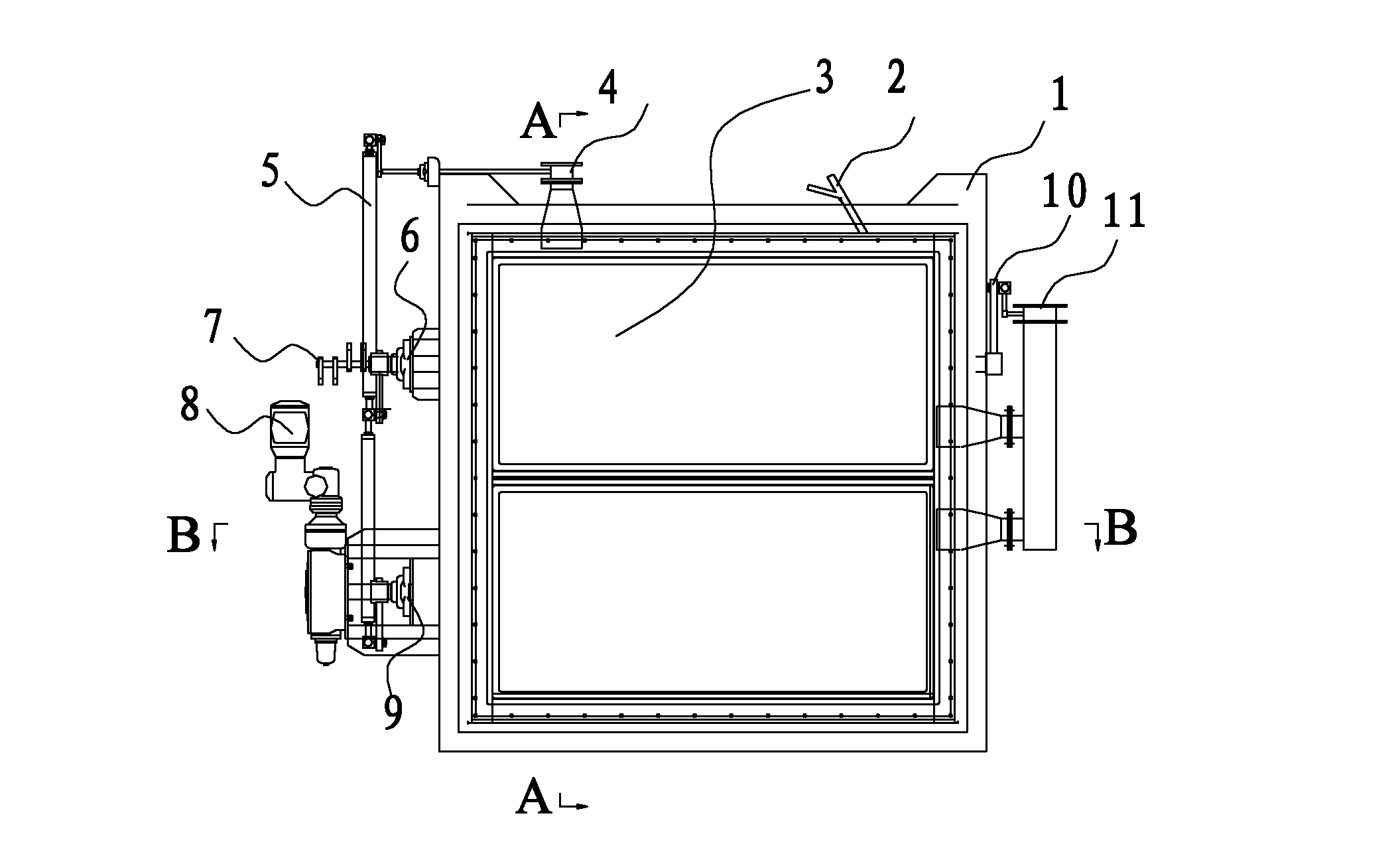

Shutter baffle door provided with sealing device

The invention discloses a shutter baffle door provided with a sealing device and belongs to the field of smoke gas treatment devices. The shutter baffle door comprises a door frame, at least one rotating shaft arranged on the door frame, and a baffle driven by the rotating shaft, wherein the inner edge of the door frame is wound with a flexible sealing piece; a cavity is defined between the flexible sealing piece and the inner edge of the door frame; the door frame is provided with a first air pipe communicated with the cavity; an open slot matched with the flexible sealing piece is arranged around the outer edge of the baffle; the door frame is provided with a second air pipe running through the flexible sealing piece and communicated with the open slot, and the second air pipe is tightly matched with the flexible sealing piece. The shutter baffle door is used in an air inlet flue, an air outlet flue and a bypass flue in a flue gas desulfurization device, and is good in sealing effect, simple in structure and convenient to operate.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

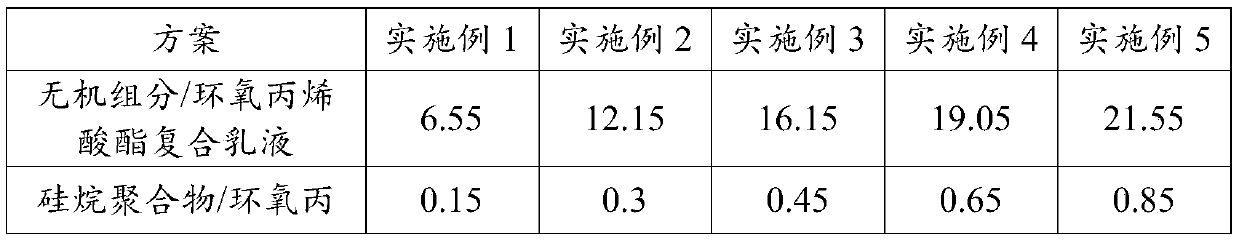

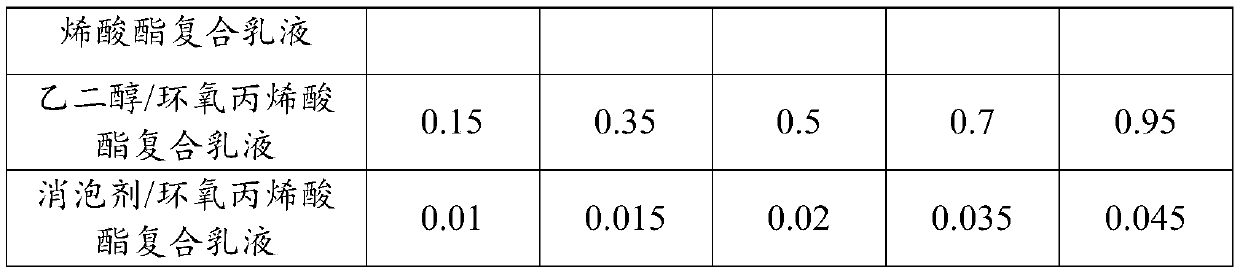

Energy-saving non-oriented silicon steel coating liquid, and preparation method and application thereof

InactiveCN110885571AUniform film formationHigh bonding strengthChemical industryAnti-corrosive paintsEmulsionCorrosion resistant

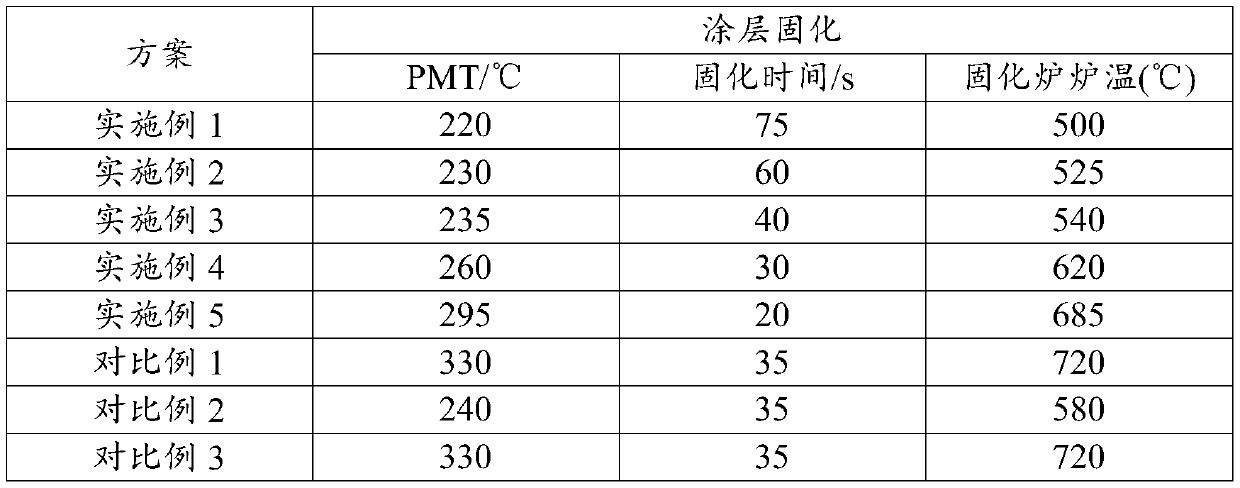

The invention discloses an energy-saving non-oriented silicon steel coating liquid, and a preparation method and an application thereof. The coating liquid is a semiorganic-semiinorganic silicon steelsheet coating liquid and comprises an inorganic component, an epoxy acrylate composite emulsion, a silane polymer, polyhydric alcohol and a defoaming agent according to a mass ratio of (6-22):1:(0.1-1.0):(0.1-1.0):(0.01-0.05); and the inorganic component comprises, by mass, 15-30 parts of silica sol, 14-28 parts of aluminum dihydrogen phosphate, 10-20 parts of chromium dihydrogen phosphate, 0.1-0.8 part of boric acid and 40-100 parts of water. A coating layer formed by the coating liquid has the advantages of good corrosion resistance, good adhesion, good glossiness, good hardness and uniformfilm forming quality, and reduces the temperature of a drying furnace by 150-200 DEG C under the same plate passing speed of similar continuous annealing units, and the preparation method has the advantages of great reduction of the combustion load and the energy consumption of the drying furnace, and great reduction of the consumption of unit devices and spare parts.

Owner:武汉钢铁有限公司

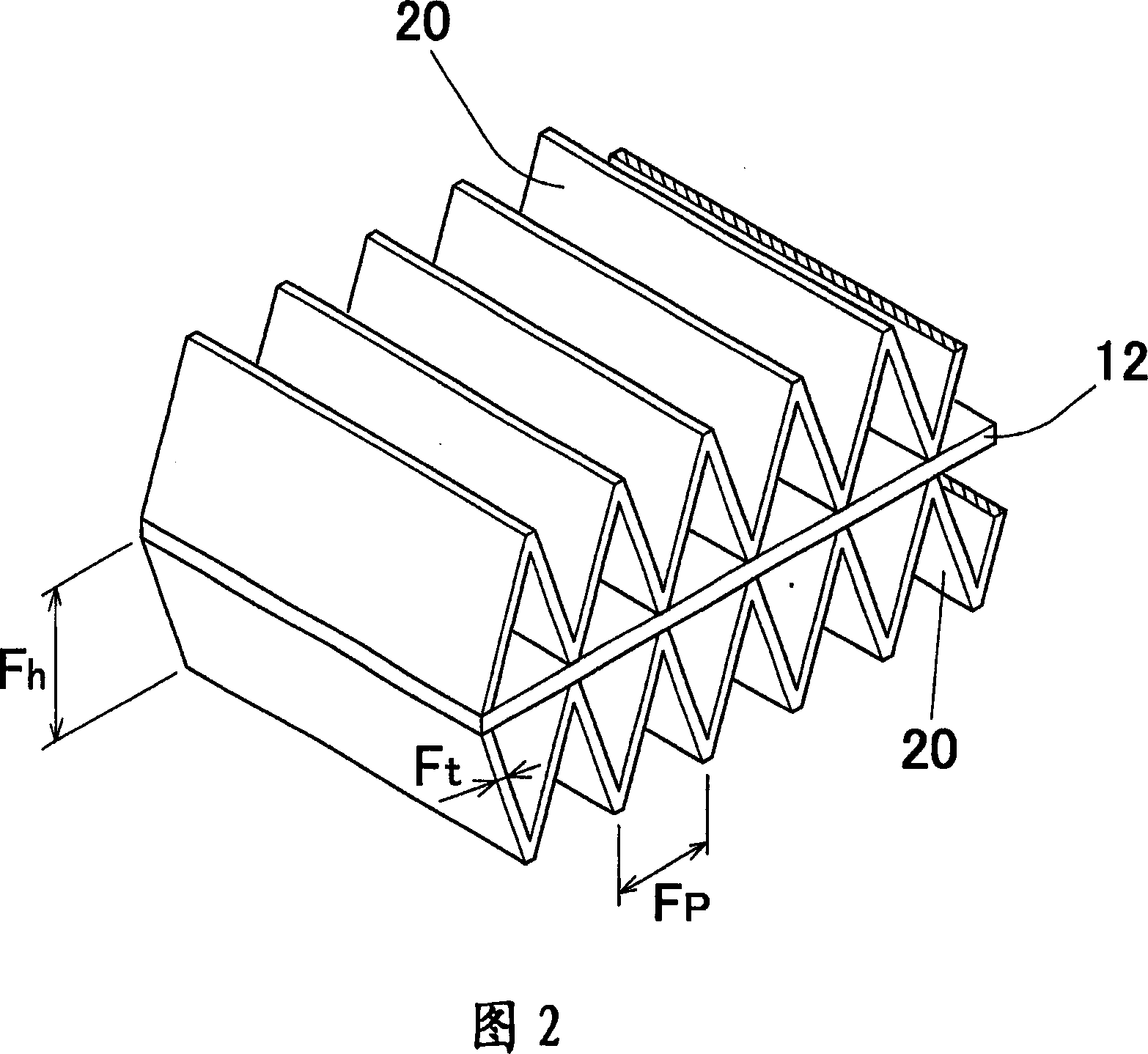

Trickling biofilter

ActiveCN102190374AAvoid cloggingAvoid backwashTreatment with aerobic and anaerobic processesMesh gridSewage treatment

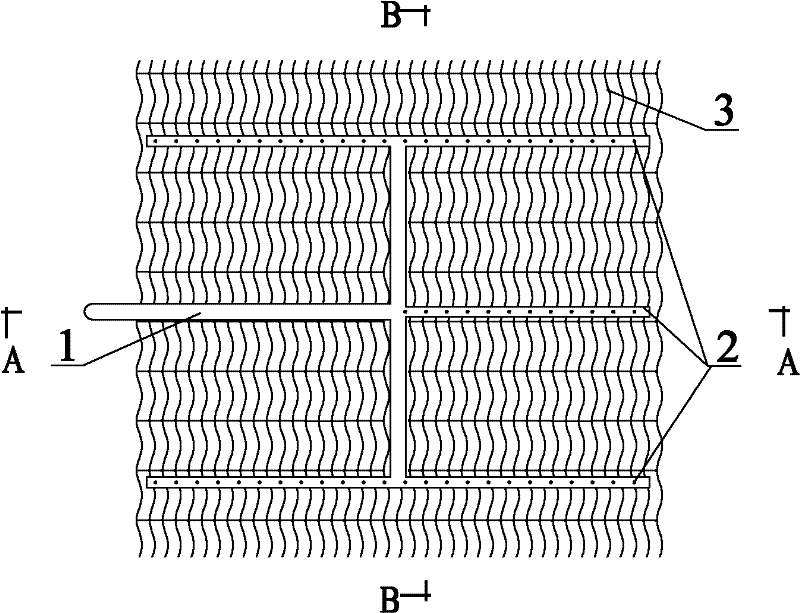

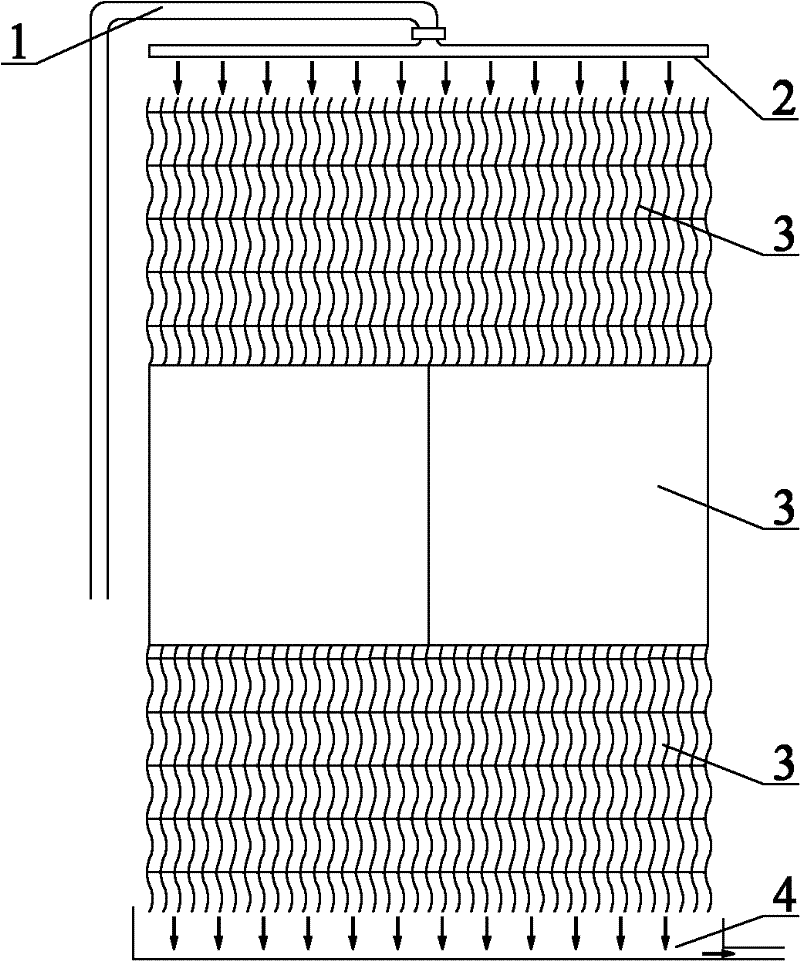

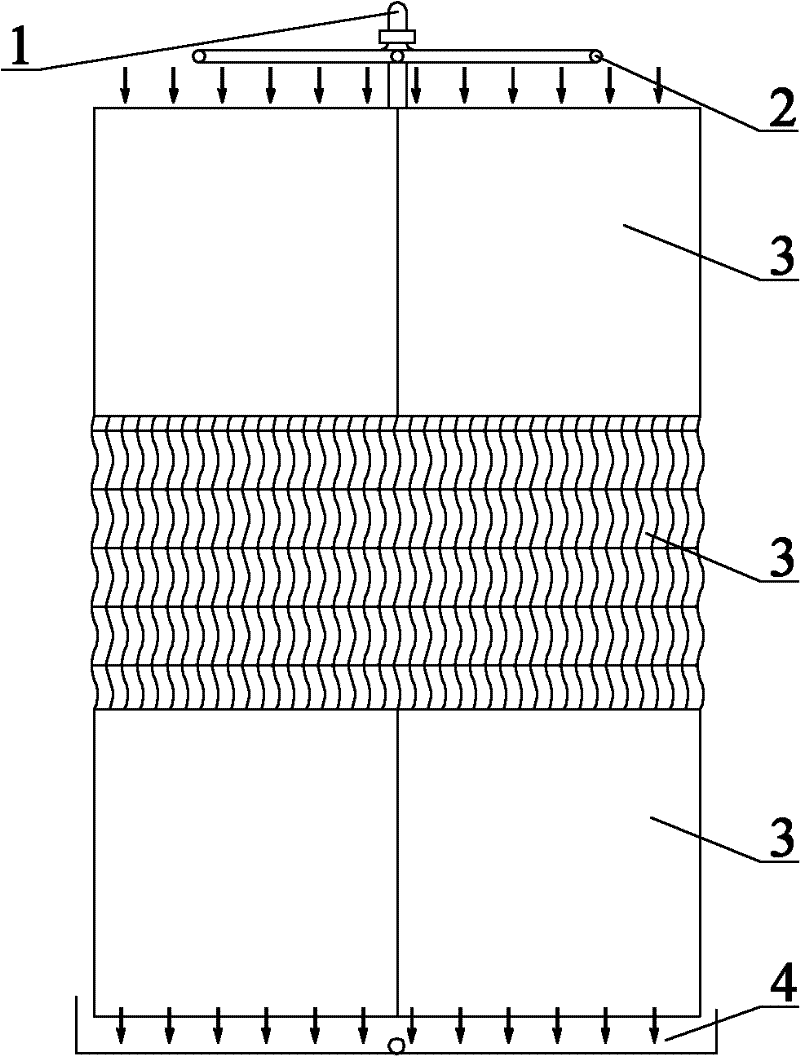

The invention relates to a trickling biofilter, which comprises a water inlet pipeline (1), a water distributing system (2), a material filling module (3) and a water outlet system (4). the water inlet pipeline (1) and the water distributing system (2) are provided on the upper of the trickling biofilter, inlet water is uniformly distributed in the material filling module (3), the material filling module (3) is arranged along a vertical direction, the water outlet system (4) is provided at lowest part of the trickling biofilter to collect, backflow and discharge treated water. Compared with the prior art, the material filling module is prepared by a combination of corrugated plate and a connecting rod or one-step injection molding, a gap of the material filling module can be increased, the screened large particle size materials in sewage can be prevented to intercept on a packed bed, sewage is degraded by biochemical action of biomembrane on the surface of the material filling during dropping, shed microbial biofilms can smoothly pass through the grid structure packed bed, clogging of the packed bed can be fundamentally prevented, backwashing can be avoided as well, an operation procedure for treating sewage can be simplified.

Owner:上海浩为环境工程有限公司

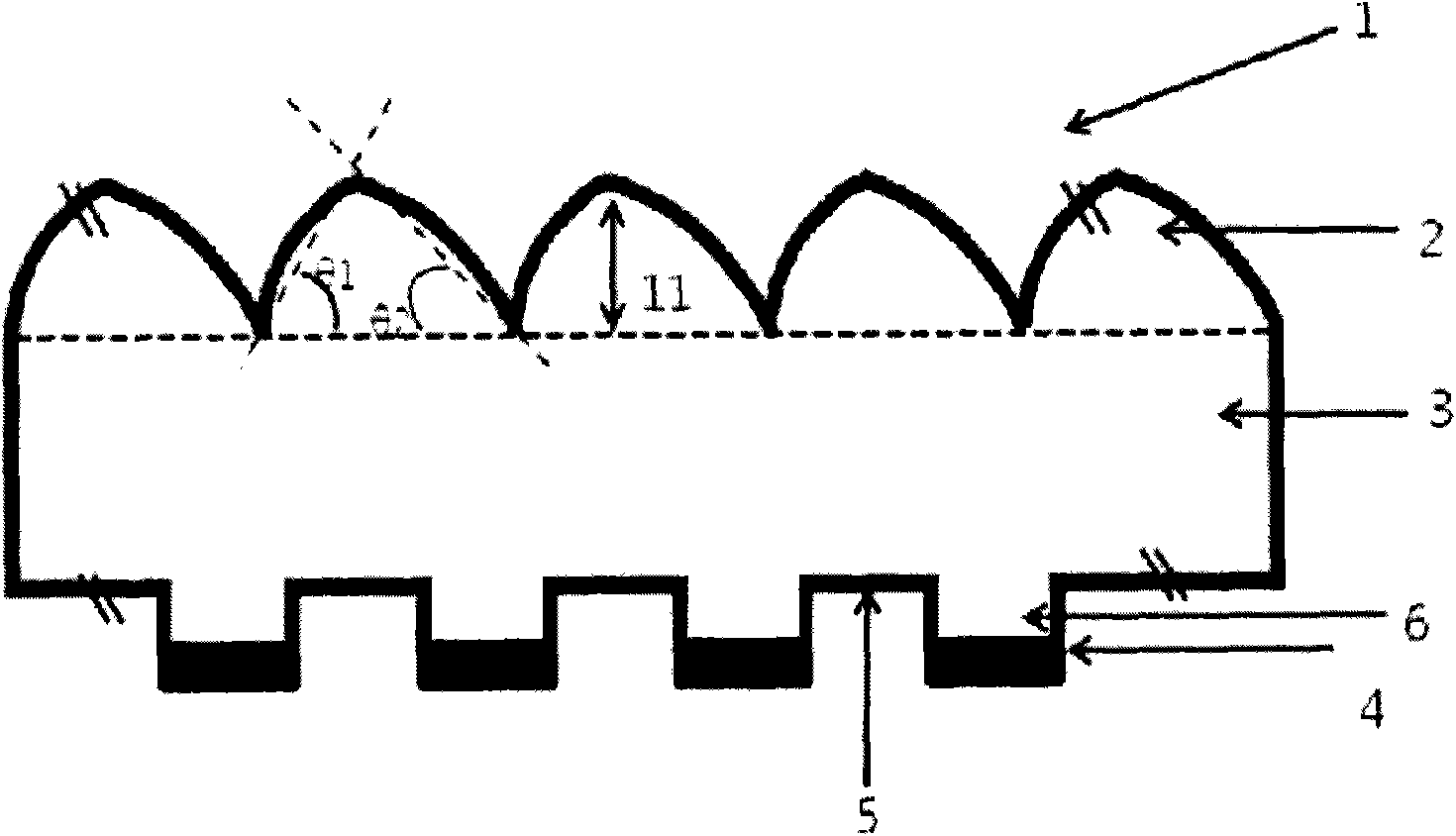

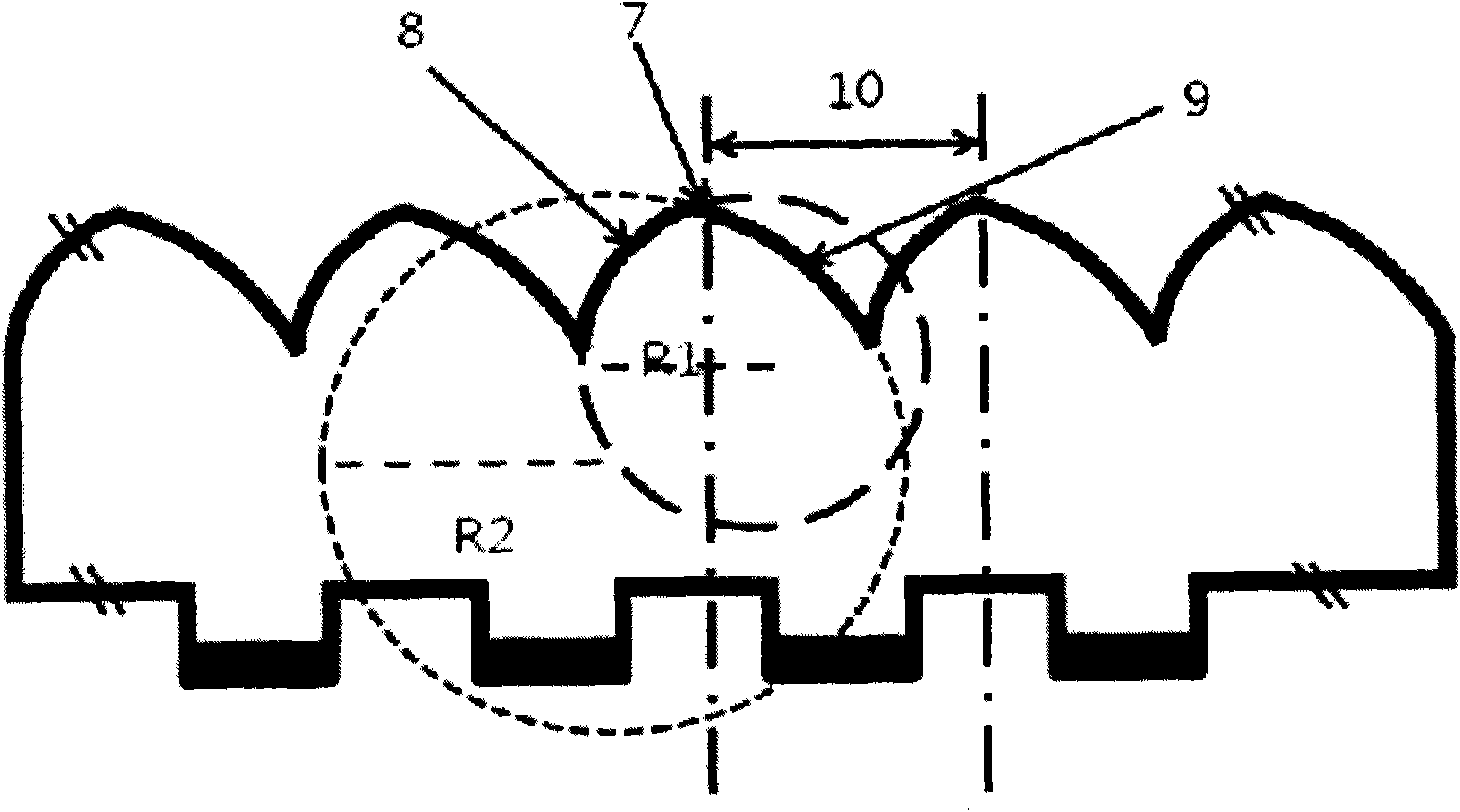

Optical sheet for controlling the direction of ray of light

InactiveCN101995595AHas thicknessIncrease brightnessPrismsDiffusing elementsComputer monitorLiquid-crystal display

The present disclosure relates to an optical sheet for controlling the direction of light rays which is used for manufacturing backlight units of TFT-LCDs for computer monitors and televisions, and more specifically to an optical sheet which can uniformly diffuse light, improve brightness, and adjust viewing angle. There is provided an optical sheet for controlling the direction of light rays comprising a substrate film; a microlens group arranged on a first face of the substrate film; and a plurality of protuberances formed on a second face of the substrate film, wherein each protuberance comprises a reflective layer at the bottom thereof, and the plurality of protuberances comprise an aperture formed therebetween, and wherein a unit microlens of the microlens group has a first side and a second side with different radii of curvature from each other with respect to a light emission control part thereof.

Owner:TORAY ADVANCED MATERIALS KOREA

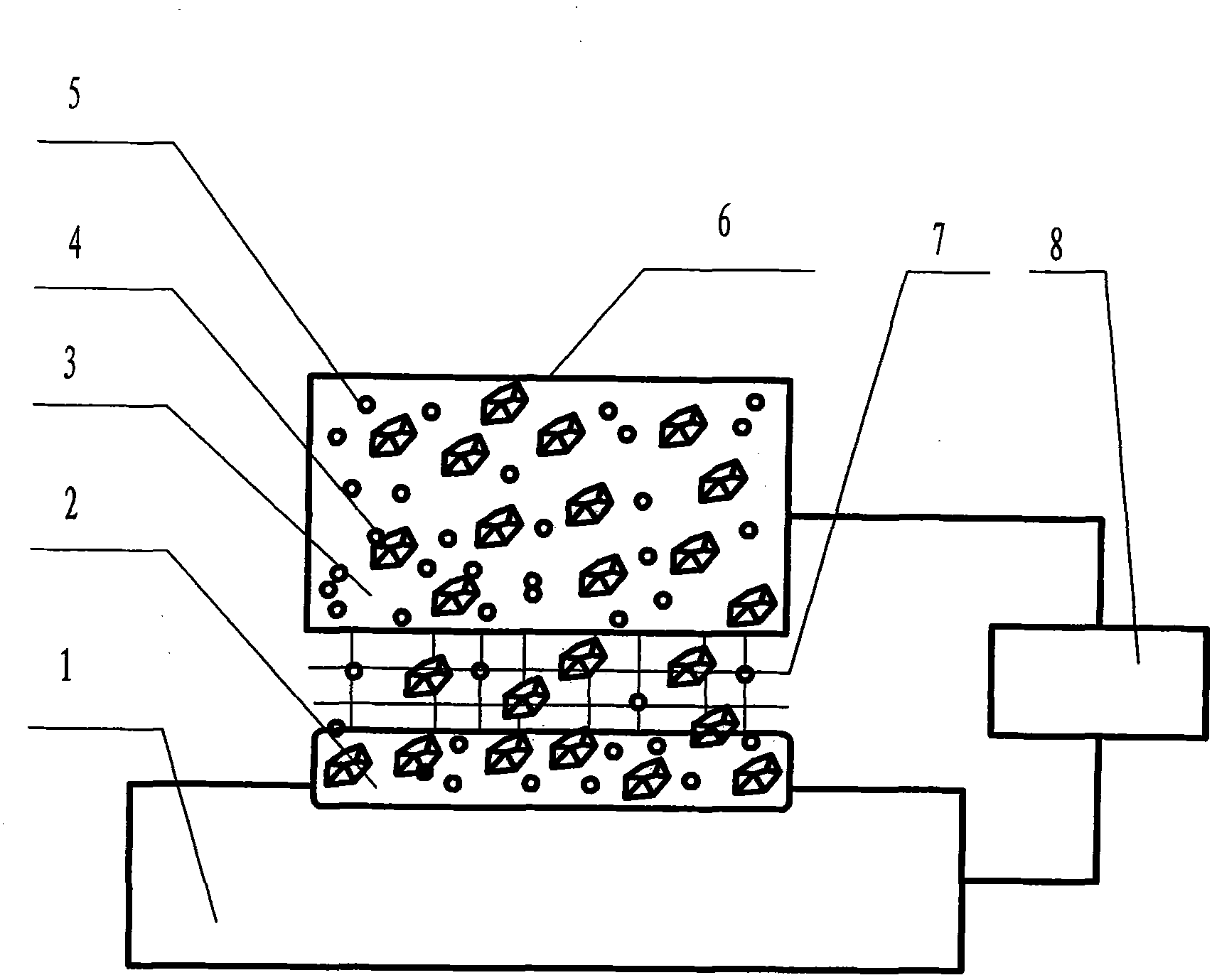

Electrospark deposition-based preparation method of diamond abrasive particle layer

InactiveCN102251206ASolve remanufacturingSolve the problem of green recyclingMolten spray coatingManufacturing technologyElectrical impulse

The invention discloses an electrospark deposition-based preparation method of a diamond abrasive particle layer. An electrode is arranged at a side of a workpiece. The workpiece is connected with a positive pole of a pulse power supply. The electrode is connected with a negative pole of the pulse power supply. Operating fluid is injected into a gap between the workpiece and the electrode during deposition. The electrode is a compression powder electrode. The method comprises the following steps that 1, the pulse power supply is turned on; a discharge voltage is maintained in a range of 70 to 90V; a discharge current is maintained in a range of 1.5 to 9 A; an electrical impulse width is maintained in a range of 20 to 60 microseconds; and a discharge impulse interval is maintained in a range of 25 to 90 microseconds, and 2, the operating fluid is sprayed to the gap; the pulse power supply produces discharge impulses; and compression powder of the compression powder electrode is deposited on the surface of the a workpiece to form an abrasive particle deposition layer. The method can prepare a diamond abrasive particle layer fast on an electrospark machine tool. Through the method, the circumferential surface of an old metal based grinding wheel is deposited with an abrasive particle layer, thus the problems of ultra-hard grinding wheel remanufacturing and green recycling are solved. The method is an economic and environmentally friendly remanufacturing technology.

Owner:湖南高创海捷工程技术有限公司

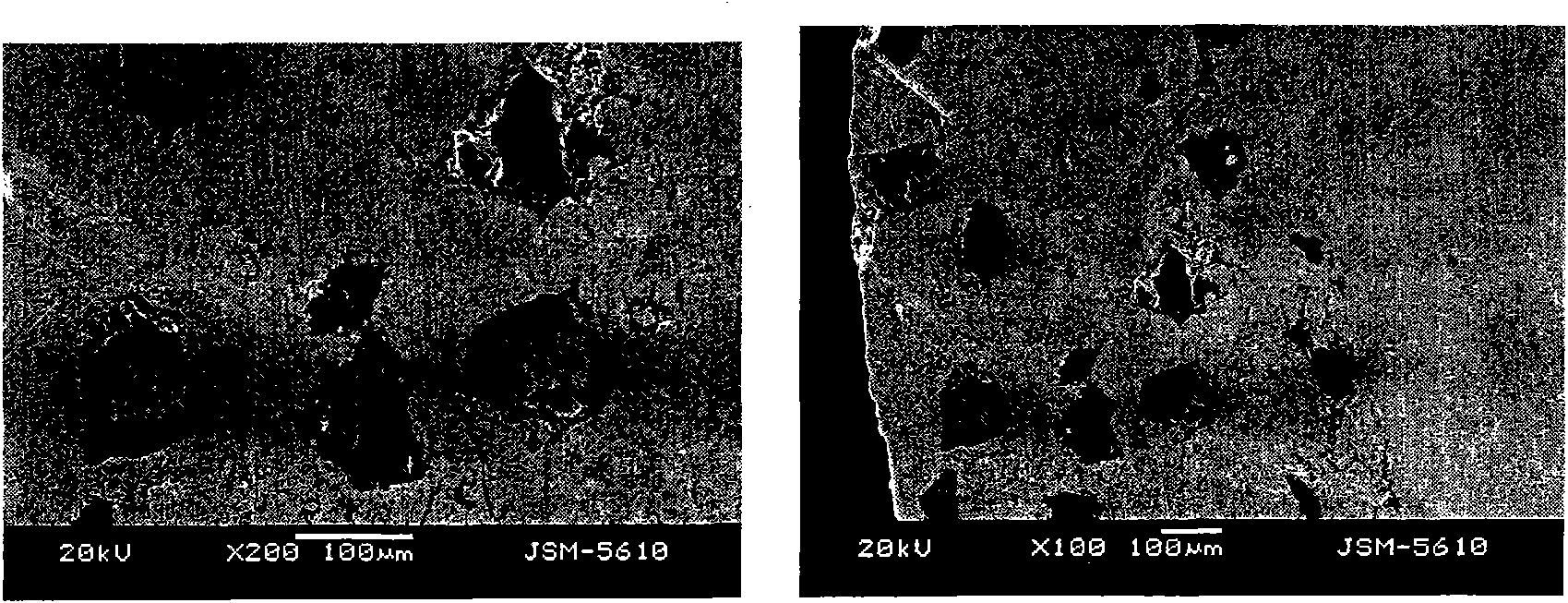

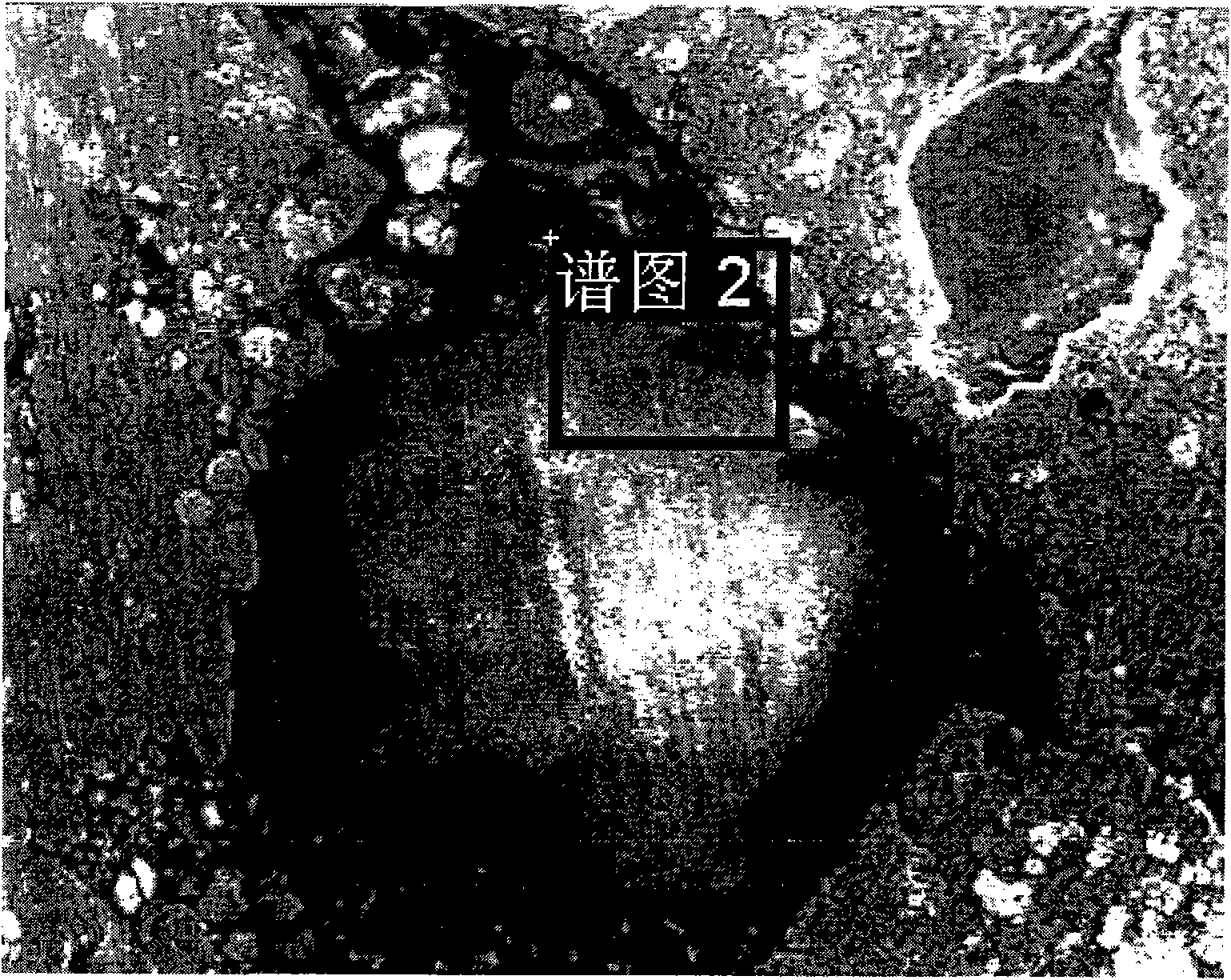

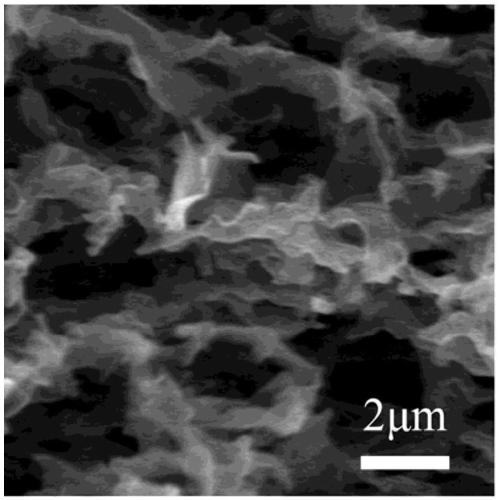

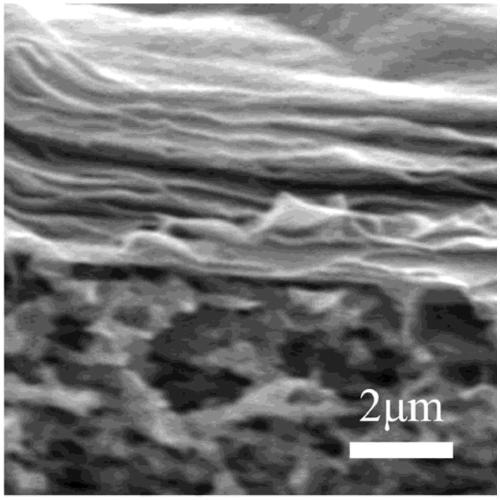

Method for preparing two-dimensional montmorillonite/cellulose composite filter membrane

ActiveCN109289544AEasy to prepareEase of industrial productionSemi-permeable membranesWater contaminantsCelluloseFiltration membrane

The invention relates to a method for preparing a two-dimensional montmorillonite / cellulose composite filtration membrane. The method comprises the following steps: (1) preparing a two-dimensional montmorillonite solution; (2) loading the two-dimensional montmorillonite solution onto a micro-porous cellulose filter membrane in a filtration manner; and (3) drying the two-dimensional montmorillonite-suported micro-porous cellulose filter membrane to obtain a two-dimensional montmorillonite / cellulose composite filter membrane, and closely stacking the two-dimensional montmorillonite on the surface of the micro-porous cellulose filter membrane to form a negatively-charged surface having a certain thickness. Compared with filter membranes in the prior art, the two-dimensional montmorillonite / cellulose composite filter membrane can effectively remove heavy metal ions and cationic dye pollutants in water. The preparation method has the advantages of simplicity, easiness in implementation, good repeatability and low product price, and the obtained two-dimensional montmorillonite / cellulose composite filter membrane can be used for removing heavy metal ions, cationic dyes and other pollutants in water.

Owner:TONGJI UNIV

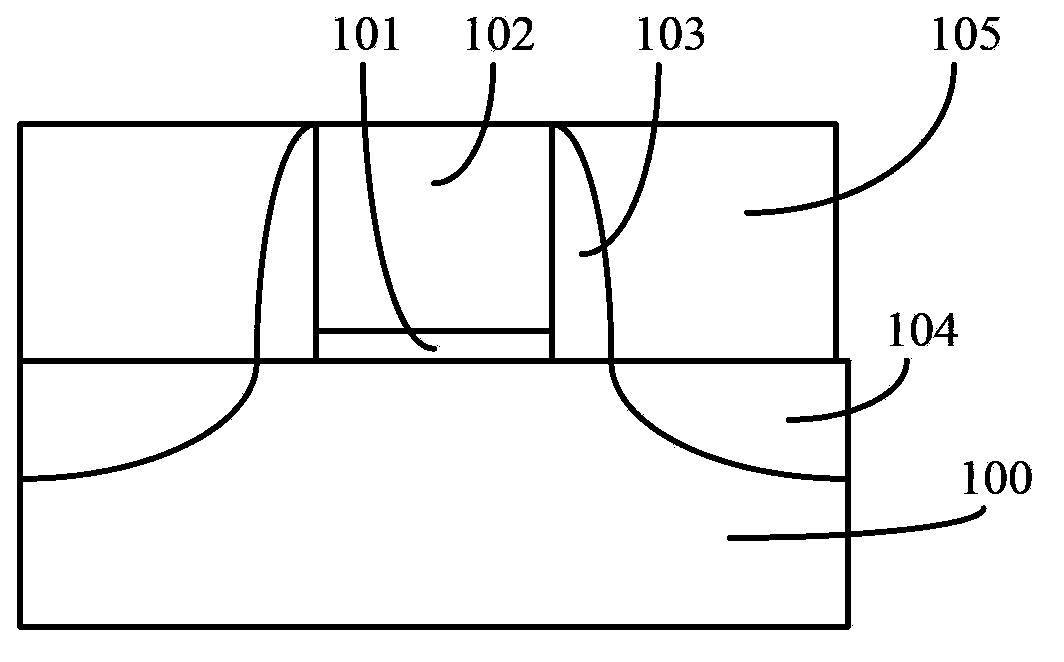

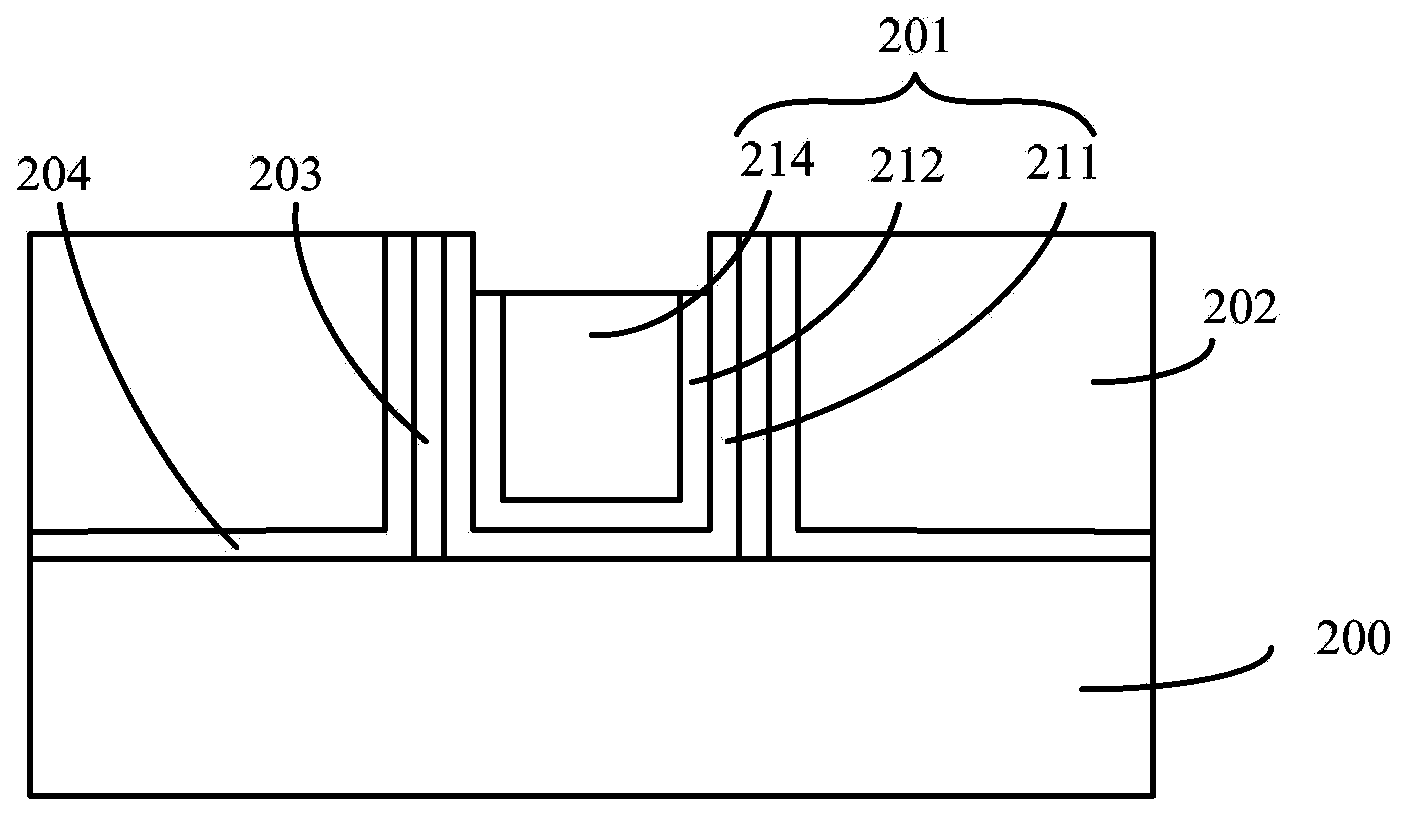

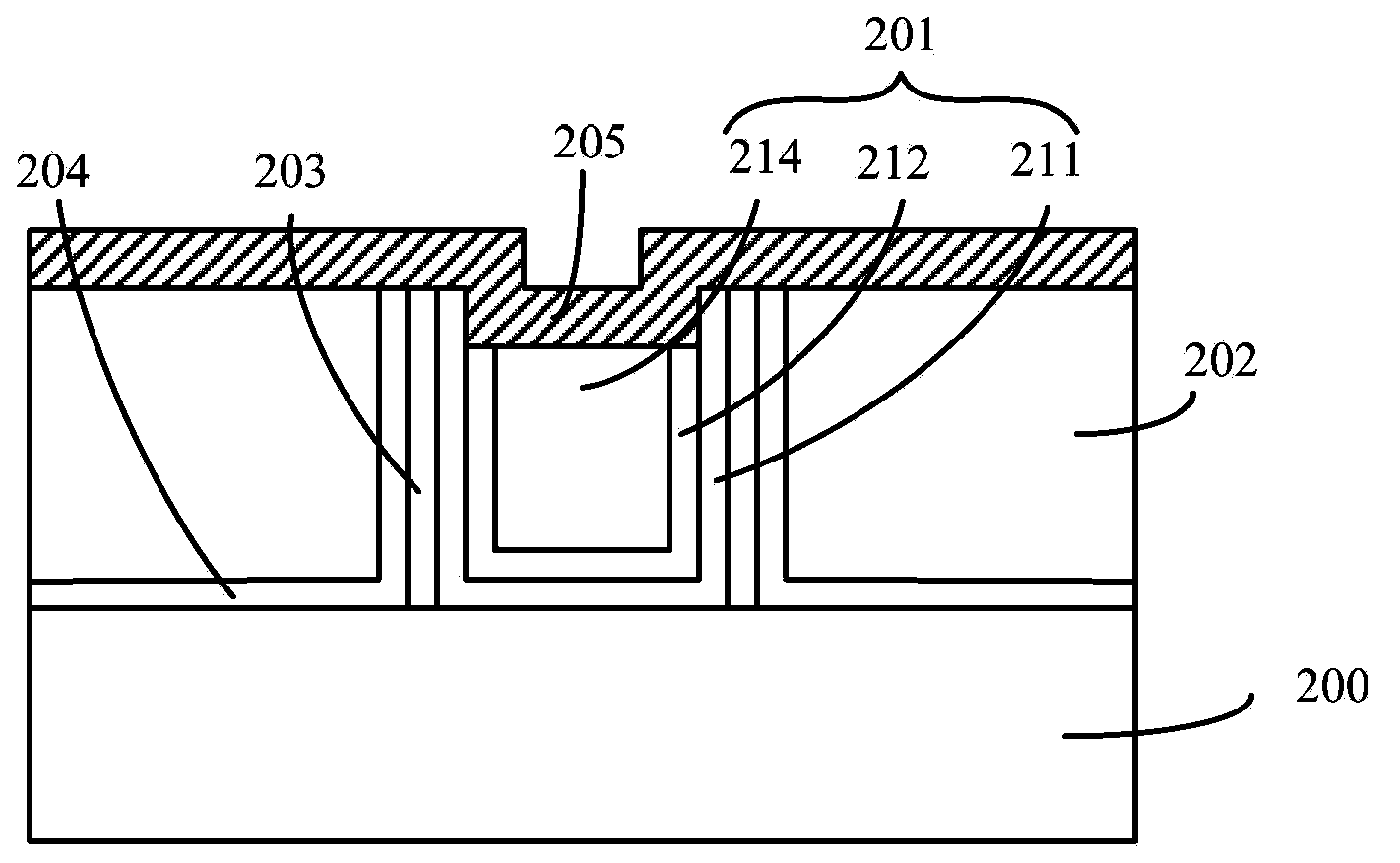

Transistor forming method

ActiveCN103794506APerformance improved and stableGood isolationTransistorSemiconductor/solid-state device manufacturingMetallic materialsSemiconductor

Provided is a transistor forming method which comprises: providing a semiconductor substrate, wherein a gate structure is disposed on the surface of the semiconductor substrate and comprises a gate dielectric layer and a gate electrode layer on the surface of the gate dielectric layer, the gate electrode layer is produced by metal material, and the surface of the semiconductor substrate also comprises a dielectric layer covering the sidewall of the gate structure; forming a sacrificial layer on the surfaces of the dielectric layer and the gate electrode layer, wherein the sacrificial layer comprises metal atoms different from the metal material of the gate electrode layer; diffusing the metal atoms in the sacrificial layer into the gate electrode layer by using thermal annealing technology in order to form a covering layer on the surface of the gate electrode layer; and removing the sacrificial layer residing at the surfaces of the covering layer and the dielectric layer. A formed transistor has excellent performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Environment-friendly artificial aggregate capable of degrading gas pollutants by photocatalysis and preparation method of environment-friendly artificial aggregate

InactiveCN103214202AHarm reductionReduce concentrationSolid waste managementHazardous substanceEnvironmental engineering

The invention relates to an environment-friendly artificial aggregate capable of degrading gas pollutants by photocatalysis and a preparation method of the environment-friendly artificial aggregate. The gas pollutant degrading aggregate is composed of a base material core and a photocatalysis aggregate coating layer. The production formula of the environment-friendly artificial aggregate includes a base material, photocatalysis aggregate coating pulp, organic dispersing agent and the like; the key components include a photocatalyst, functional additives (stabilizing additives, modifying additives, decorative additives), and the like. The preparation method of the environment-friendly artificial aggregate comprises the following steps of: (1), preparing base material particles; (2), preparing photocatalysis aggregate coating pulp; (3), packaging the surfaces of the base material particles; and (4), roasting and preserving the heat. The environment-friendly artificial aggregate is strong in practicability, energy-saving and environment-friendly and high in operability of the implementation method. The product is good in mechanical performances, safe and non-toxic, corrosion resistant, free of secondary pollution, capable of degrading and purifying main harmful substances of the gas pollutant under the excitation of natural light and efficient and lasting in purifying capacity. Besides, the environment-friendly artificial aggregate can be used as the material for being extensively applied to constructing the facilities including a road, a building, an ornament and the like rich in gas pollutants.

Owner:TONGJI UNIV

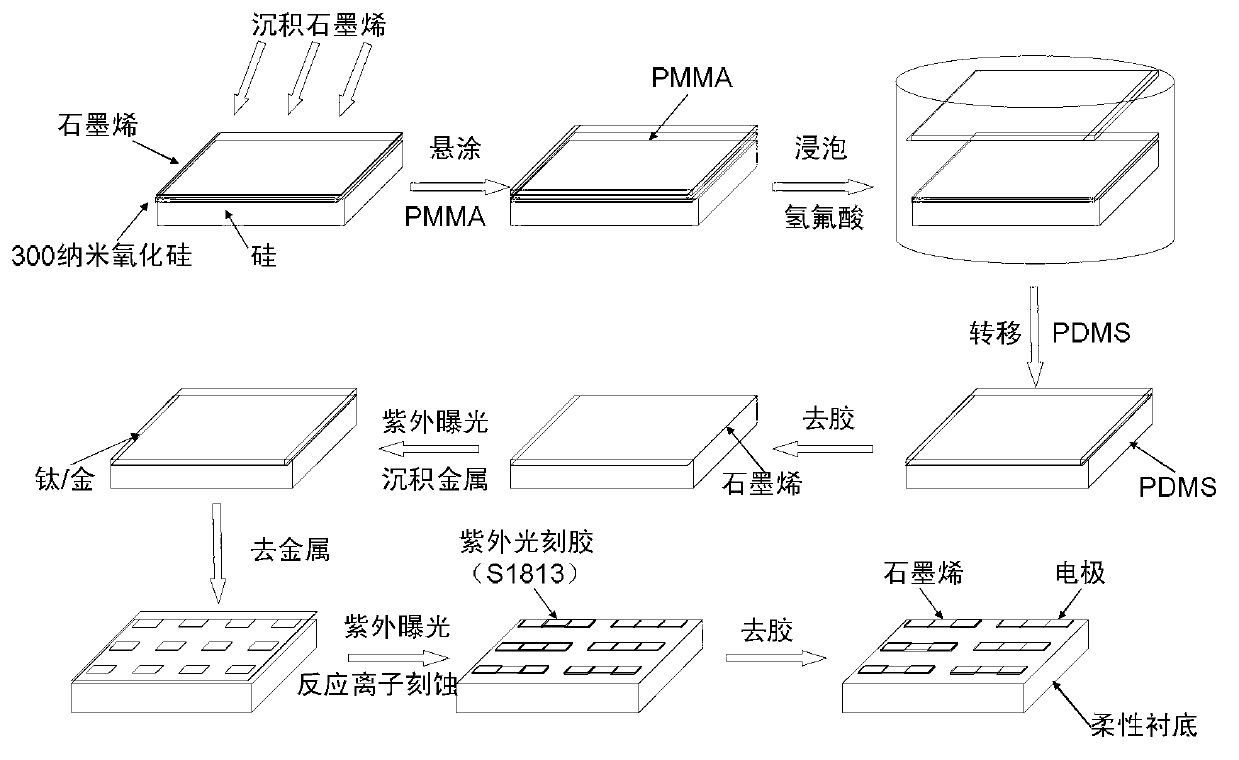

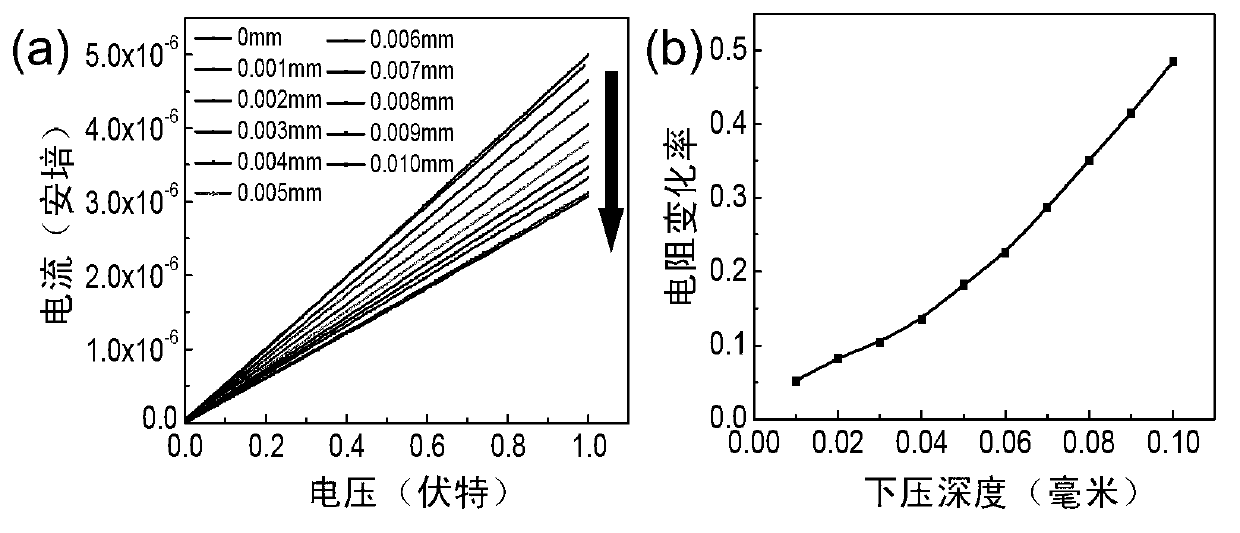

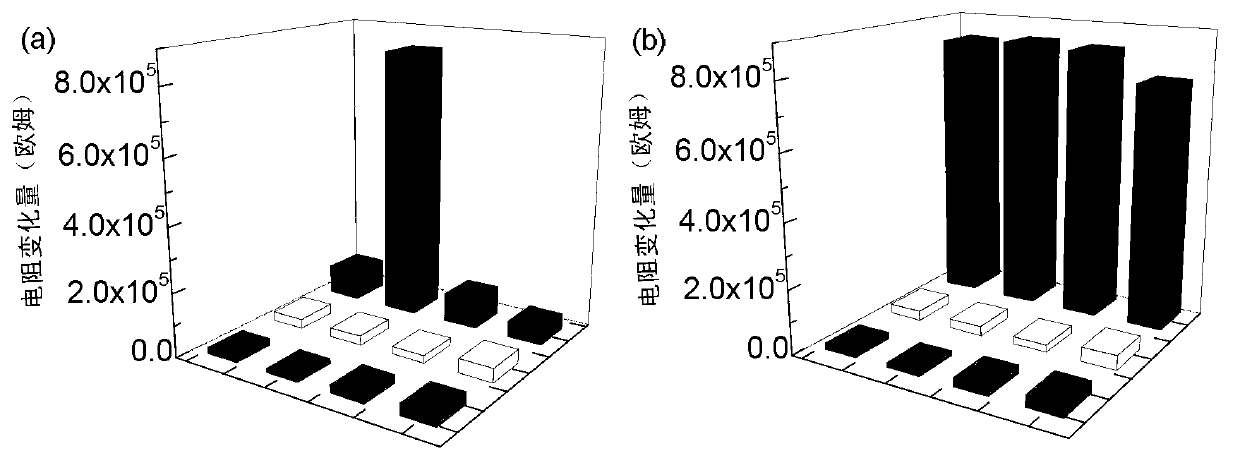

Nano graphene tunneling effect based artificial skin and preparation method thereof

The invention discloses a nano graphene tunneling effect based artificial skin and a preparation method thereof. The nano graphene tunneling effect based artificial skin comprises a flexible substrate, a graphene layer and a metal electrode, wherein a device which can sense stresses and is composed of the metal electrode and graphene is located on the flexible substrate. The artificial skin is provided with good features of the graphene and has the advantages of being good in monatomic layer thickness and malleability, high in crushing resistance, good in electrical property and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

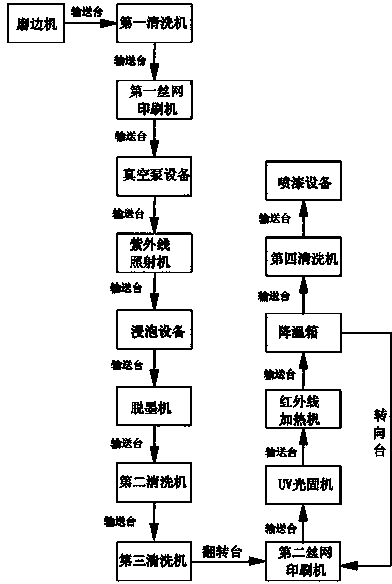

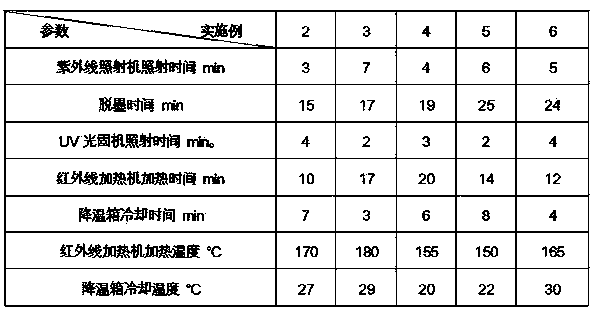

Manufacturing technology for glass with three-dimensional effect and corresponding production system

InactiveCN104163073AWith three-dimensional effectHas thicknessDecorative surface effectsSpecial ornamental structuresManufacturing technologyProcess engineering

The invention discloses a manufacturing technology for glass with a three-dimensional effect and a corresponding production system. The manufacturing technology comprises a cleaning working procedure, a front surface printing working procedure, a back surface multi-layer printing working procedure and a painting working procedure, which are carried out in sequence. According to the manufacturing technology, the front surface and the back surface of the glass are printed respectively to achieve an obvious layering effect on printed patterns; and the patterns have certain thicknesses, so that the glass has the three-dimensional effect. The manufacturing technology is suitable for manufacturing the glass with the three-dimensional effect.

Owner:永新县灵峰玻璃有限公司

Hollow two-sided embroidery technology

The invention discloses a hollow two-sided embroidery technology which includes the following steps: (1) selecting base cloth, wherein the base cloth comprises first bottom materials, a middle composite layer and second bottom materials, and the first bottom materials, the middle composite layer and the second bottom materials are sequentially and fixedly connected; (2) fixing the base cloth, wherein the base cloth is fixed in a fixing frame; (3) drawing embroidery patterns, (4) conducting embroidering according to the patterns, wherein embroidering is carried out with an embroidering needle and an embroidering thread according to actual requirements of the patterns, and the existing two-sided embroidery mode is adopted for conducting embroidering; (5) conducting glue adding processing, wherein after embroidering is completely carried out according to the patterns, one end of the fixing frame is opened, the other ends of the fixing frame are used for fixing the base cloth, hot melt glue is injected into the composite layer with a suction tube, on the basis that the base cloth is kept flat, the hot melt glue is naturally aired, and the hollow two-sided embroidering is completed. By means of the mode, the hollow two-sided embroidery technology enables embroideries to have certain thickness, the third-dimensional sense and the attractiveness of the embroideries are improved, and the patterns are more vivid and stereoscopic.

Owner:广东璐卡思服饰有限公司

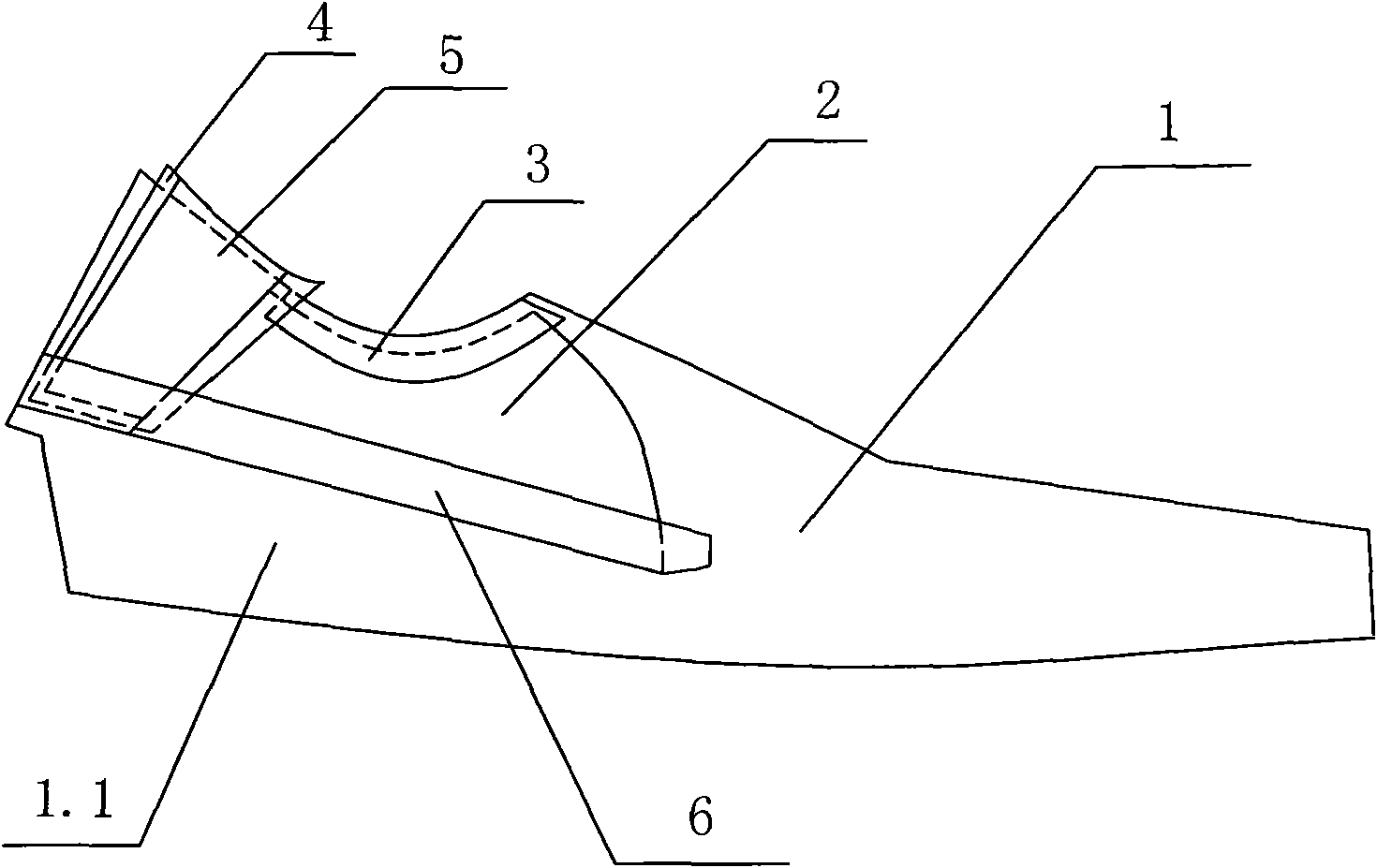

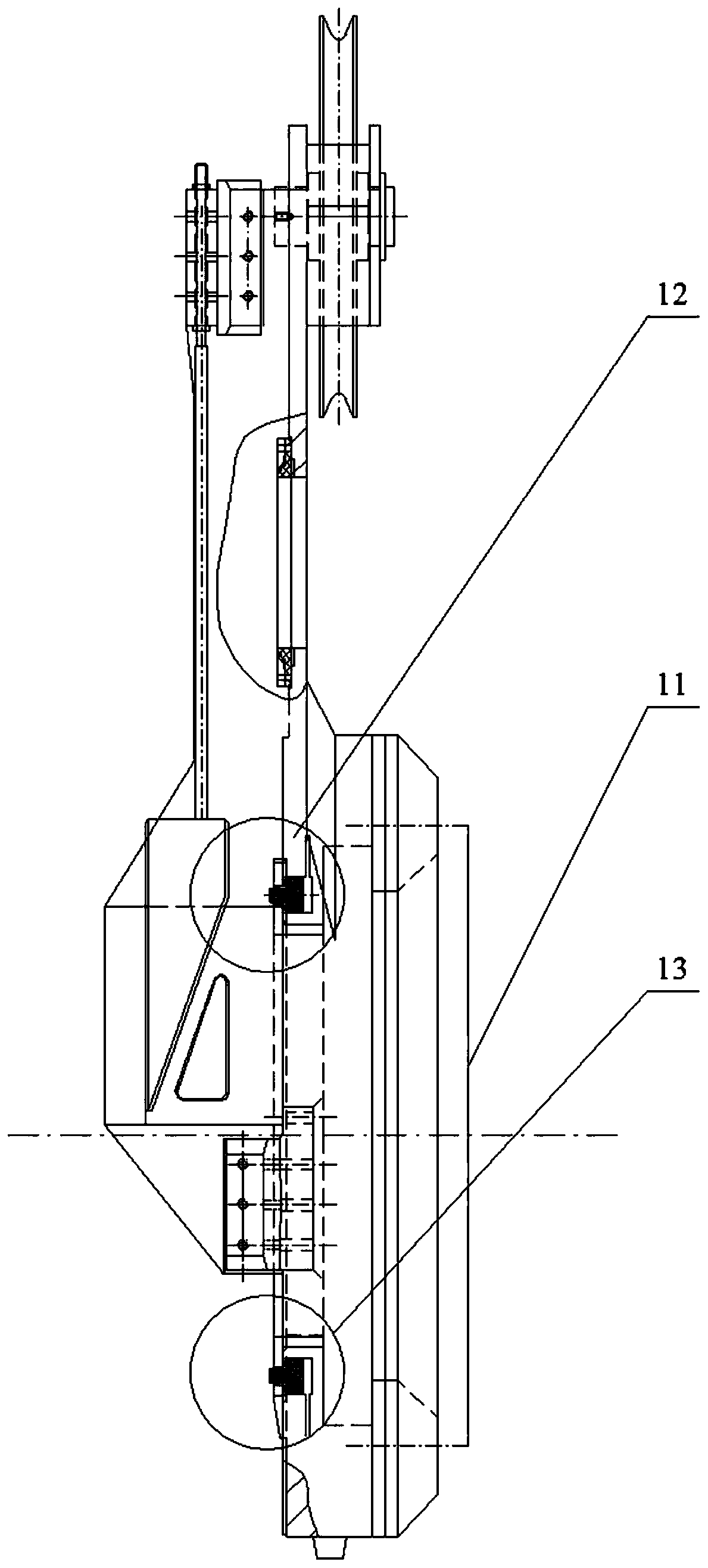

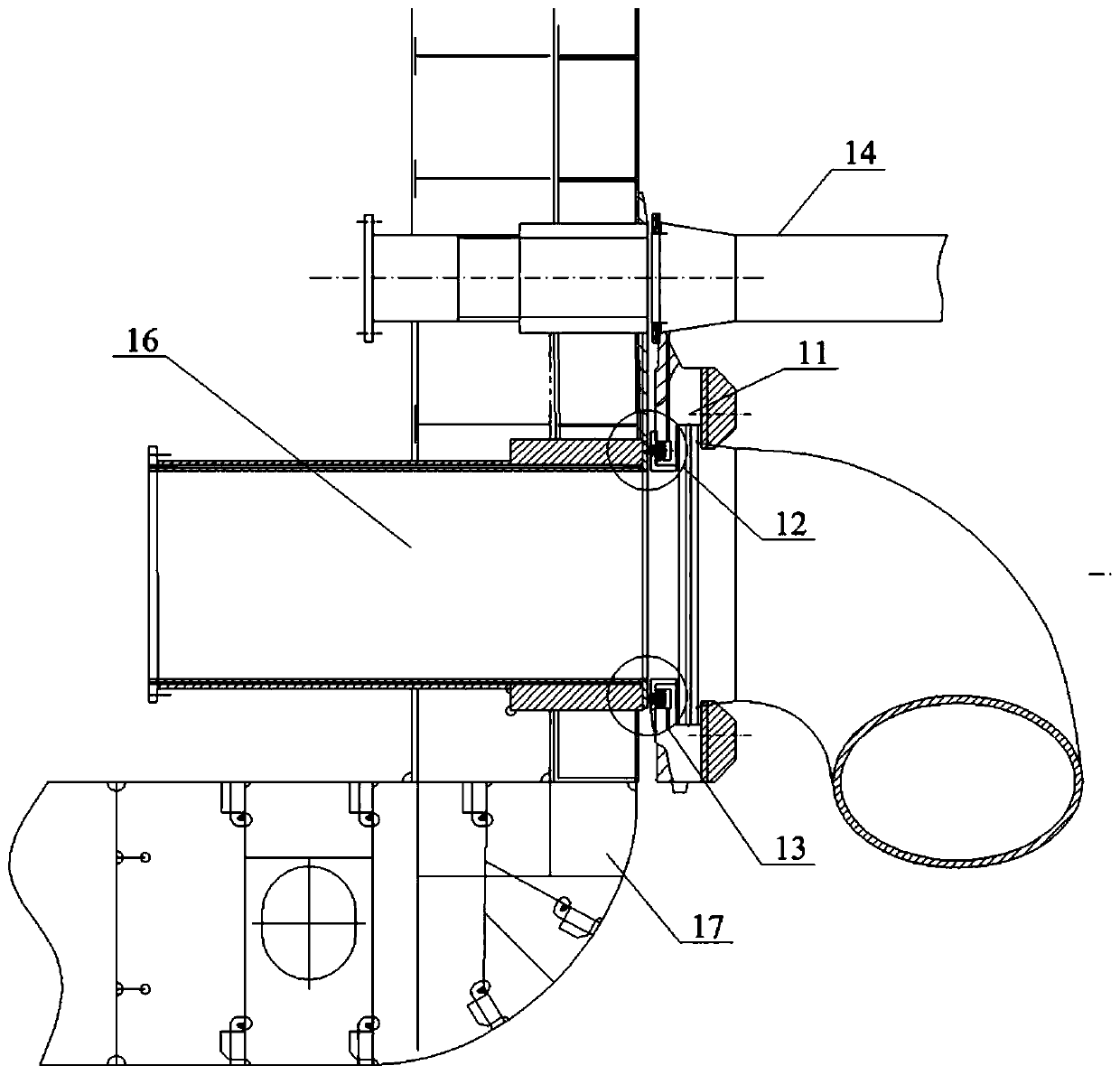

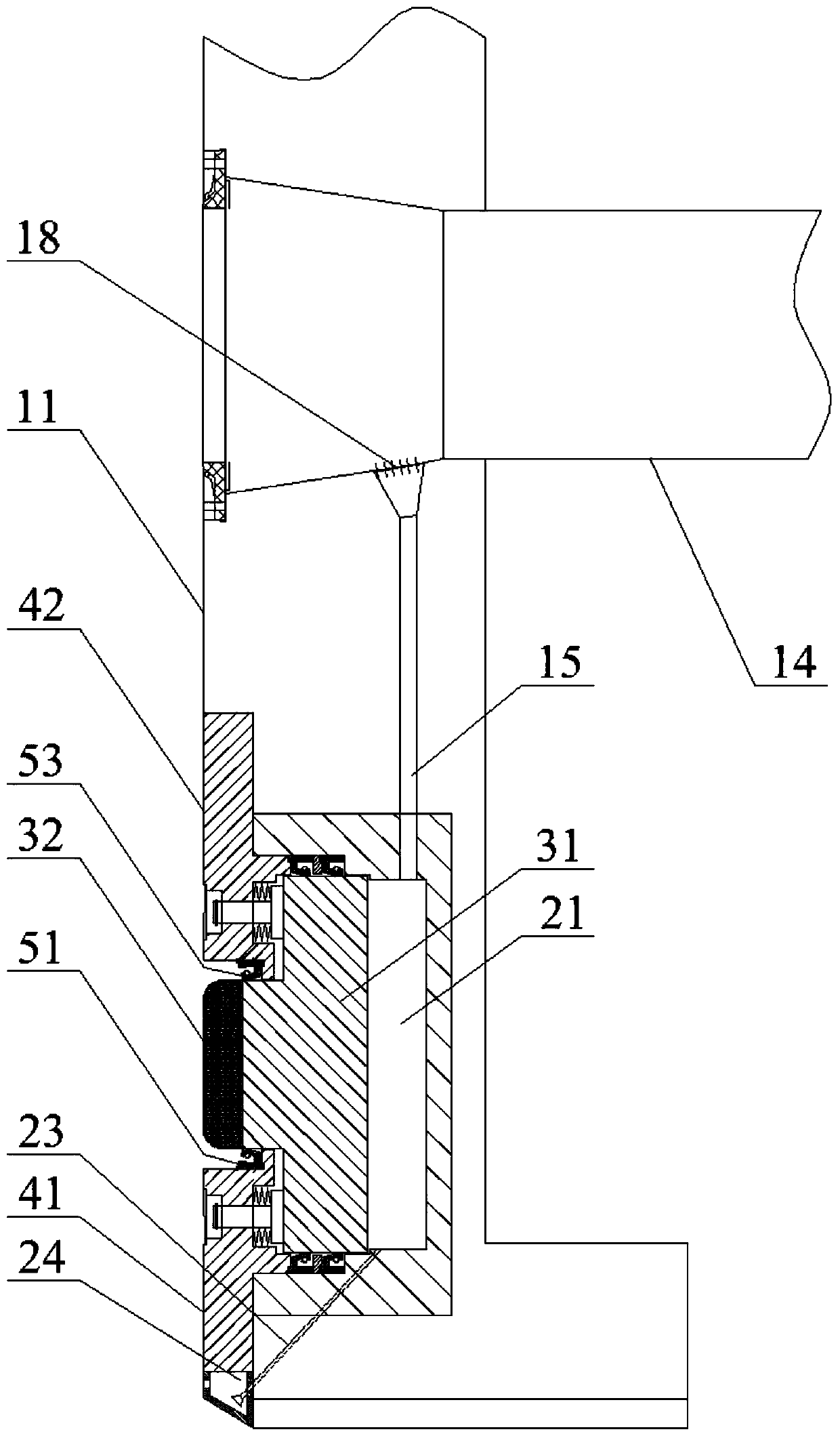

Trailing suction hopper dredger side suction port water acting piston-type sealing device

The invention relates to the technical field of dredging engineering machinery, and discloses a trailing suction hopper dredger side suction port water acting piston-type sealing device which includesa slider body, a water pressure chamber, a sealing ring, a gland, a return spring, a water inlet pipe, and a throttle tube; the water pressure chamber is arranged on the side, facing a hull, of the slider body, the water pressure chamber is connected to a high-pressure flush pipe through the water inlet pipe, the sealing ring is located in the water pressure chamber, and a protrusion at the top of the sealing ring faces the hull; and an elastic ring is fixed on the protrusion, the gland is fixed to a slider and presses the two sides of the protrusion of the sealing ring, and the return springis located between the inner side of the gland and the sealing ring. The trailing suction hopper dredger side suction port water acting piston-type sealing device has the advantages that the water pressure in the high-pressure flush pipe is used as the power to drive the sealing ring to move without additional power; the water pressure chamber and the seal ring are used to replace an air bag, andthe service life of the sealing device is prolonged; and the polymer elastic ring at the top of the sealing ring can be used for effectively reducing friction and can adapt to the relative movement between the slider and a suction port, and a good seal is maintained.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

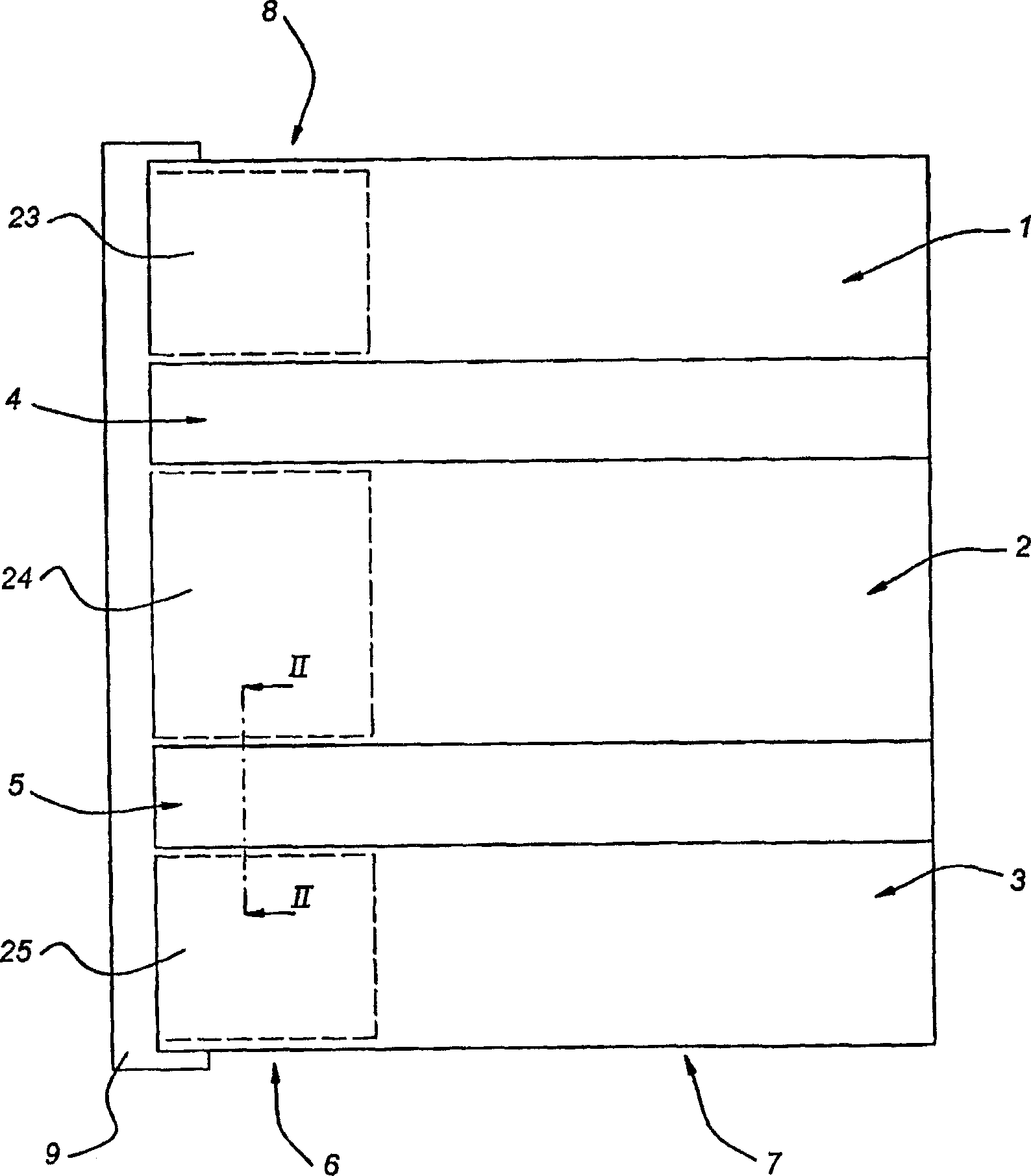

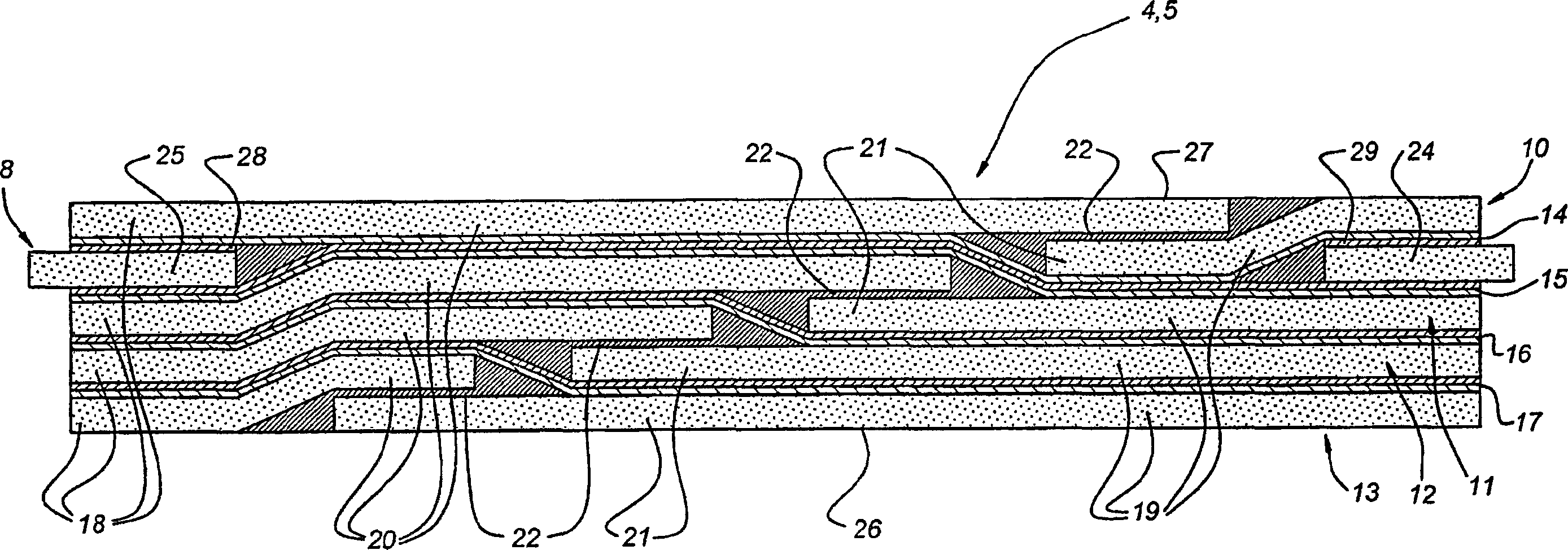

Laminate with fill layer

A laminate consisting of alternately offset metal layers and at least one plastic bonding layer, each metal layer comprising at least two metal layer portions having overlapping edges bonded to each other. In order to make the different parts uniform in thickness, a filler layer is provided, which has a thickness such that, at the location of the filler layer, the thickness of the laminate is equal to the thickness at the location of the overlapping edge.

Owner:FOKKER AEROSTRUCTURES

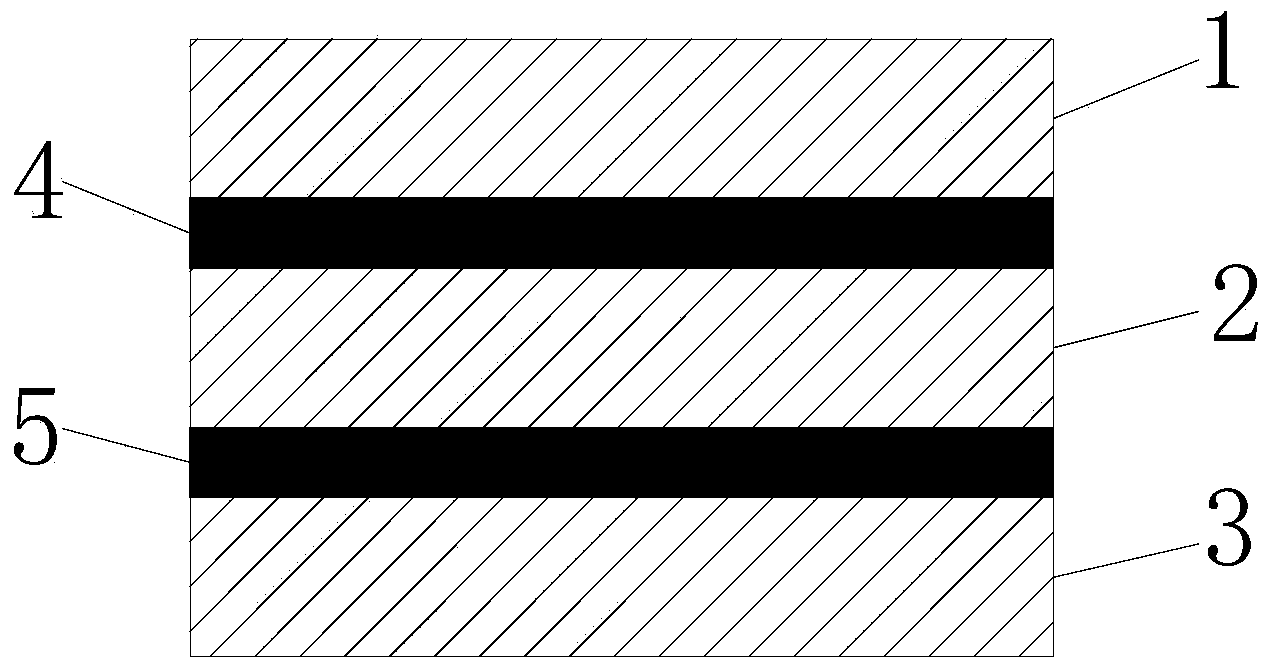

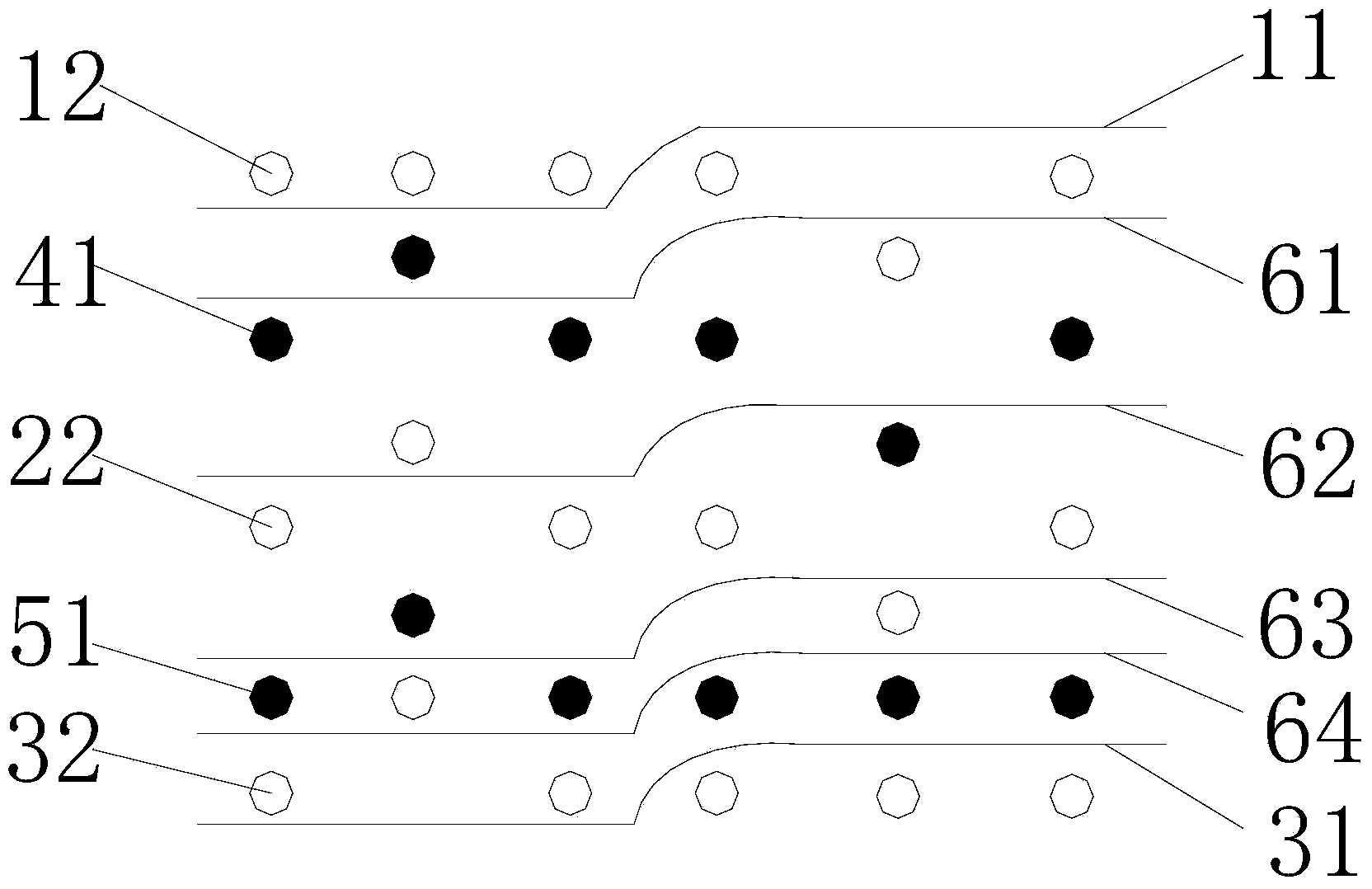

High-density yarn-dyed jacquard fabric with various colors and figures on double faces

The invention discloses high-density yarn-dyed jacquard fabric with various colors and patterns on double faces. The high-density yarn-dyed jacquard fabric with the various colors and patterns on the double faces comprises a first structural layer, a second structural layer and a third structural layer, wherein the first structural layer is formed by weaving first warps and first wefts; the first warps and the first wefts are mutually interwoven to form a first organizational structure; the second structural layer consists of a plurality of second wefts; the third structural layer is formed by weaving third warps and third wefts; the third warps and the third wefts are mutually interwoven to form a second organizational structure; a first black yarn layer is arranged between the first structural layer and the second structural layer; a second black yarn layer is arranged between the second structural layer and the third structural layer. By the adoption of the high-density yarn-dyed jacquard fabric with the various colors and patterns on the double faces, not only is the appearance attractive, but also the effect of light shading can be realized; the fabric has certain thickness and larger density; the structure is compact; the attractiveness and the light shading performance are integrated; the patterns are rich and strong in three-dimensional sense; moreover, the effect of full light shading is realized.

Owner:ZHEJIANG BOYING TEXTILE

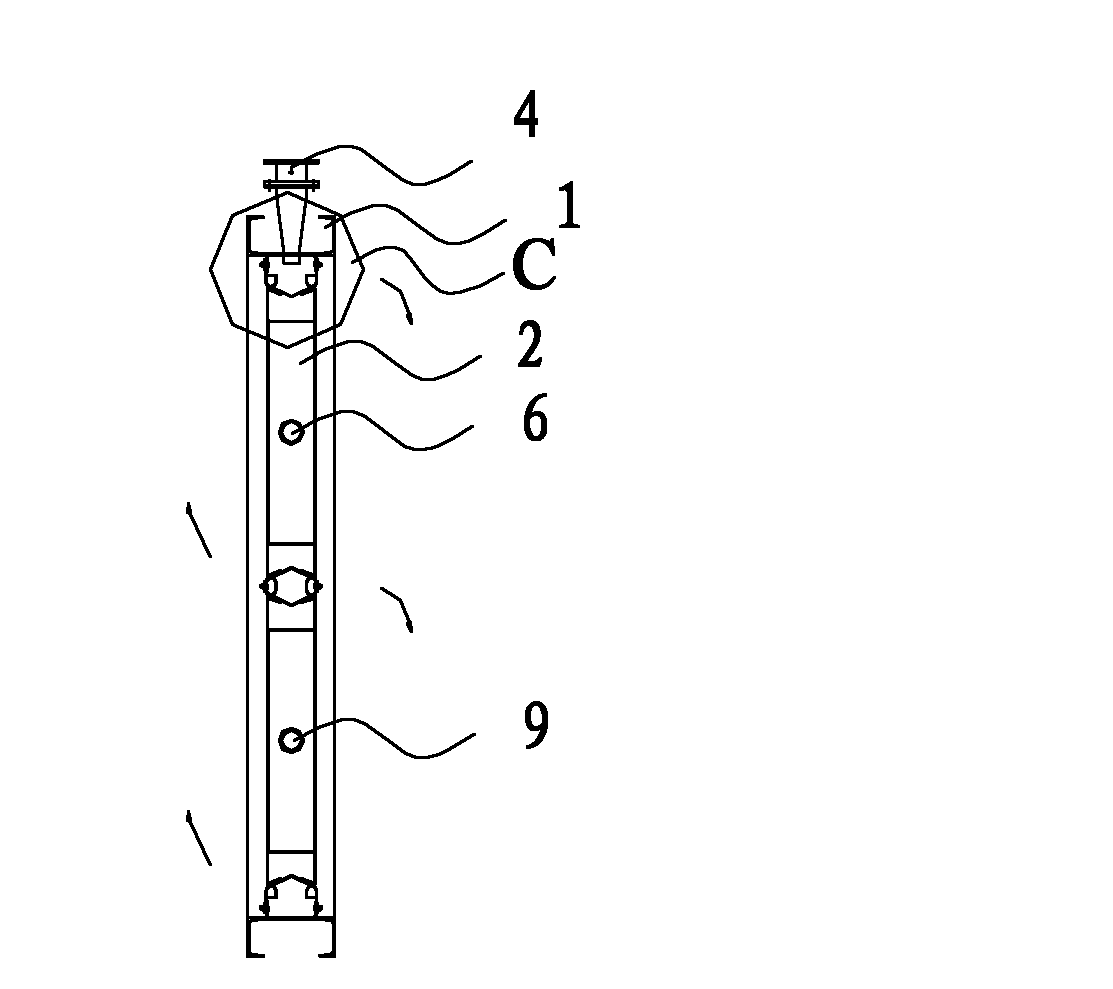

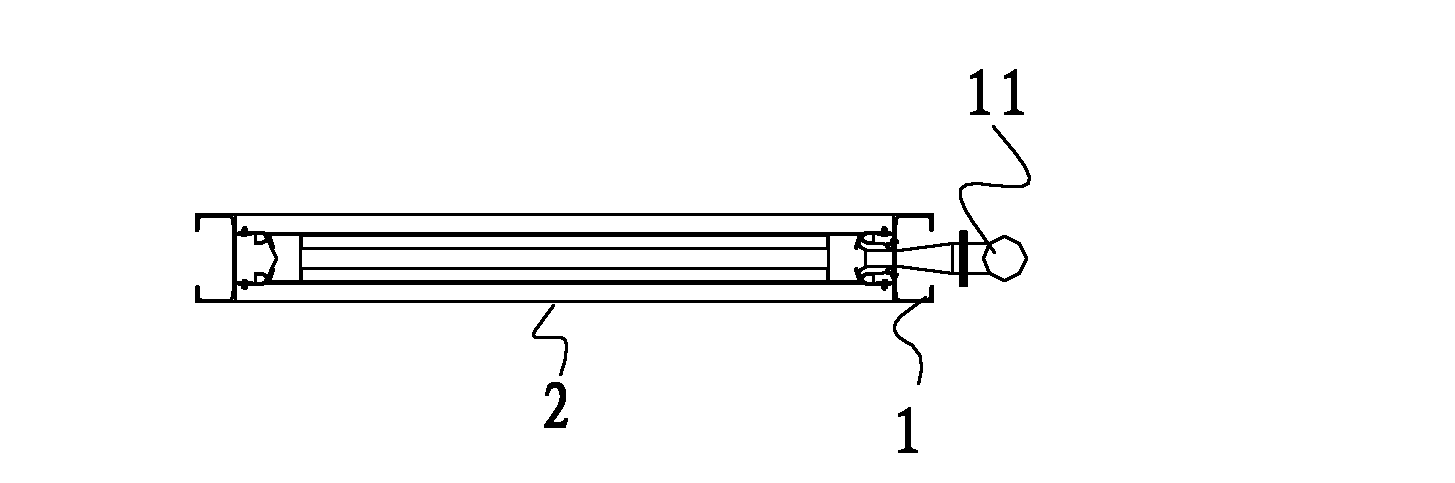

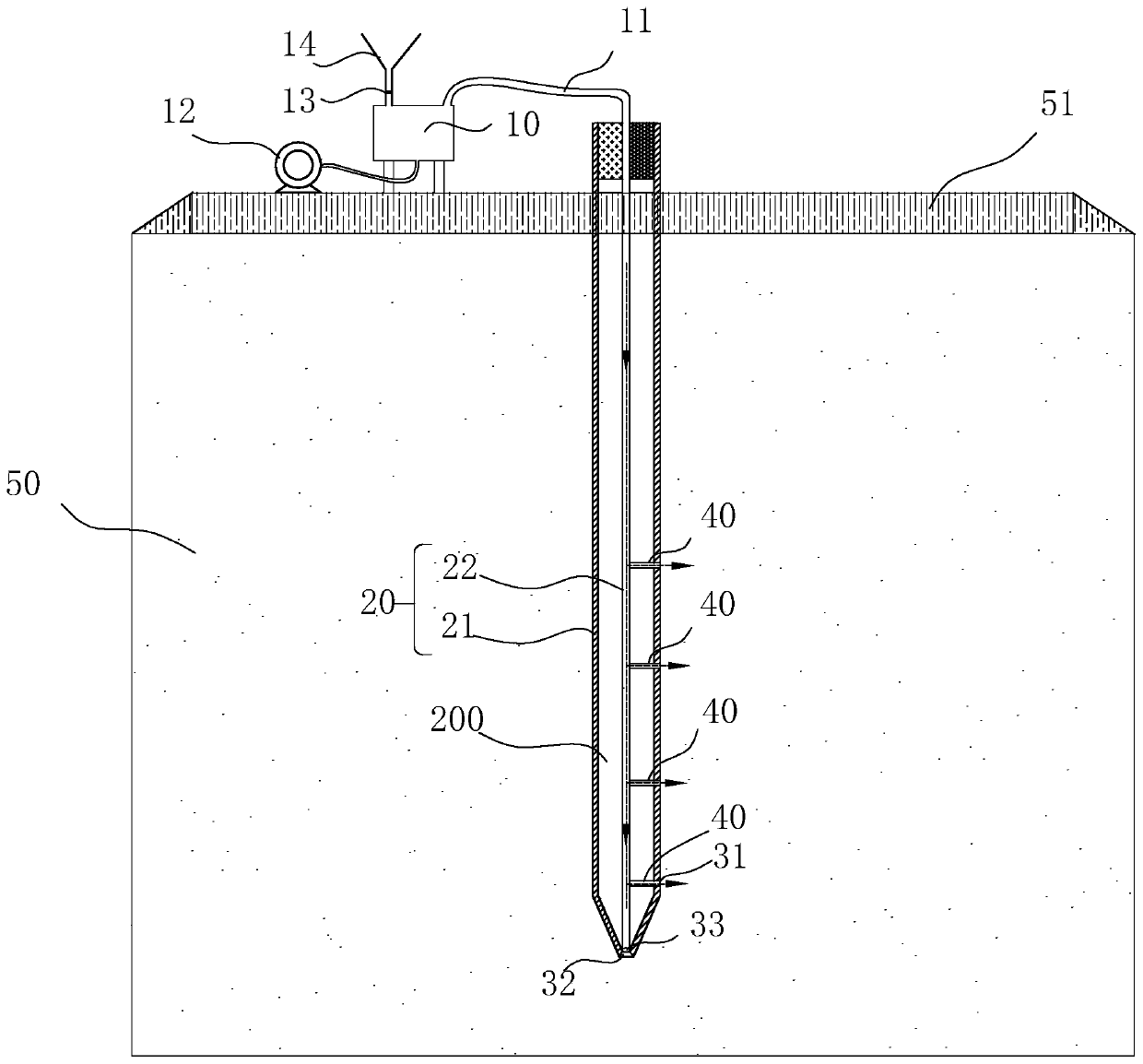

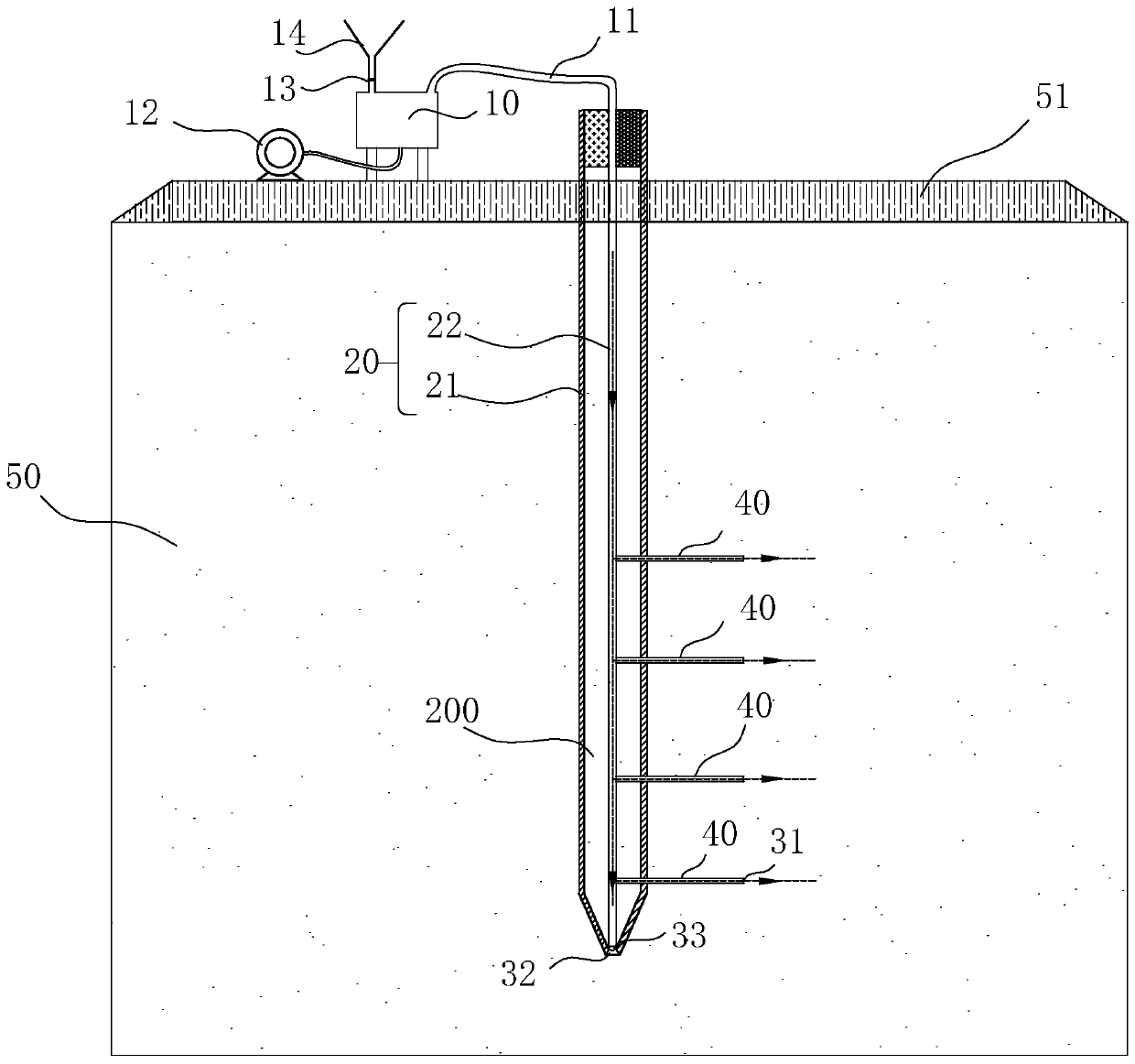

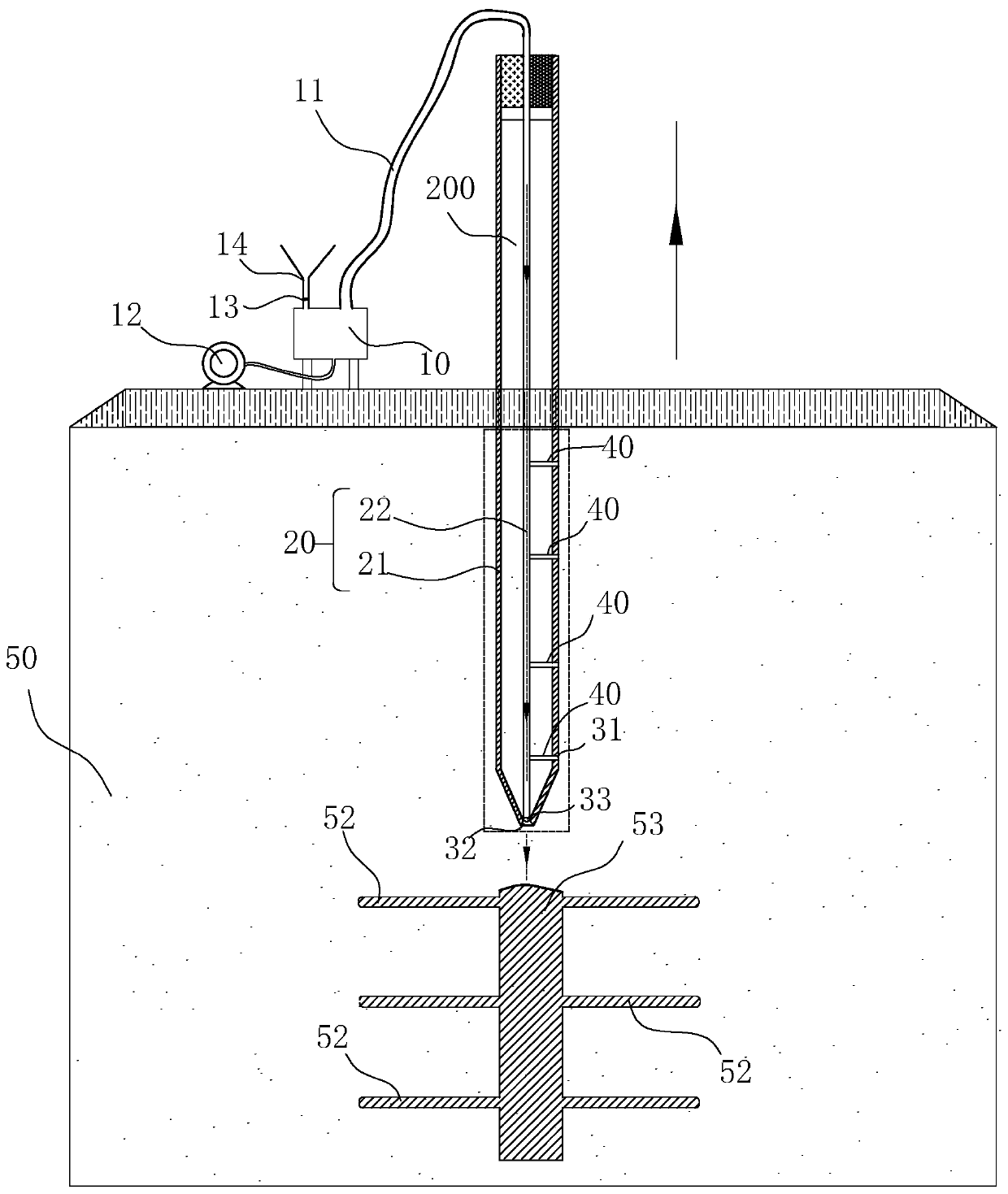

Soft soil foundation treatment device and method

PendingCN110847150AWith strengthHas thicknessDrilling rodsLiquid/gas jet drillingSoil scienceGeotechnical engineering

The invention relates to a soft soil foundation treatment device and method. The soft soil foundation treatment device comprises a gas-sand mixed conveying device, a gas-sand spraying device and a power device, wherein the gas-sand mixed conveying device comprises a mixing chamber used for fluidizing sand materials to form gas-sand mixed fluid and a gas generating device; the gas-sand spraying device comprises a drill rod assembly used for being inserted into a soft soil layer downwards, the drill rod assembly communicates with a material conveying pipe, and the drill rod assembly is providedwith a first spraying hole used for spraying the gas-sand mixed fluid outwards; and the power device is used for driving the drill rod assembly to move up and down and driving the drill rod assembly to rotate around the axis of the drill rod assembly. The soft soil foundation treatment device can spray the gas-sand mixed fluid into the soft soil layer to form a horizontal drainage sand layer withgood water permeability, the horizontal drainage sand layer formed by laying under the action of pneumatic force has certain strength and thickness, deformation is not prone to occur, so that a drainage channel is not blocked, and uneven settlement of soft soil can be coordinated; and due to the existence of the horizontal drainage sand layer, additional stress in a soil body is increased, and thedrainage uniformity and the drainage efficiency are improved.

Owner:冯清波

Production technology and application of calcium hydrophosphate

InactiveCN102992292AComplete crystal formRegular crystal formPhosphorus compoundsLuminescent compositionsSlurryDigestion

The invention relates to a production technology and application of calcium hydrophosphate. The production technology comprises the following steps of: by using an ammonium dibasic phosphate and a calcium chloride solution as raw materials, carrying out double liquid phases to obtain hydryoxyapetite by stirring at a certain temperature and flow rate, then dewatering through a belt filter to separate and washing a mother liquid till chloride ions reach 500PPM, thus obtaining hydryoxyapetite; adding a certain amount of deionized water to hydryoxyapetite, adjusting a slurry ratio to be in line with technological requirements, adding a certain amount of acid, carrying out high-temperature digestion after adjusting a pH value, observing the state of the slurry after raising the temperature to 90 DEG C, stopping heating when the slurry is expanded and solidified, and removing two crystal water after settling for 30 minutes, thereby obtaining calcium phosphate dibasic anhydrous; carrying out washing chlorine, dewatering, drying and sieving, thus obtaining the calcium hydrophosphate finished product. The production technology has the advantages that the synthetic technology is simple, raw materials are easily obtained, by-products can be recycled, and the environmental pollution is little.

Owner:LIAONING GOLDEN ANCHOR IND

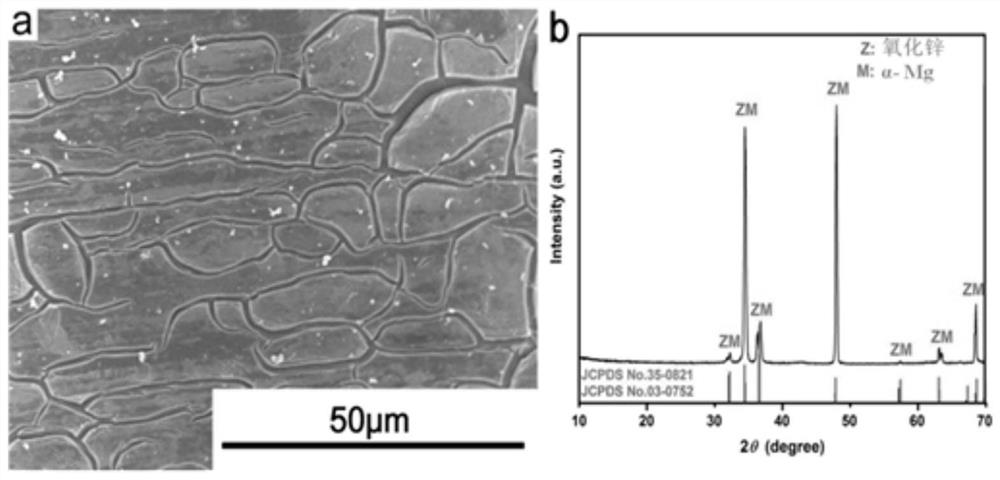

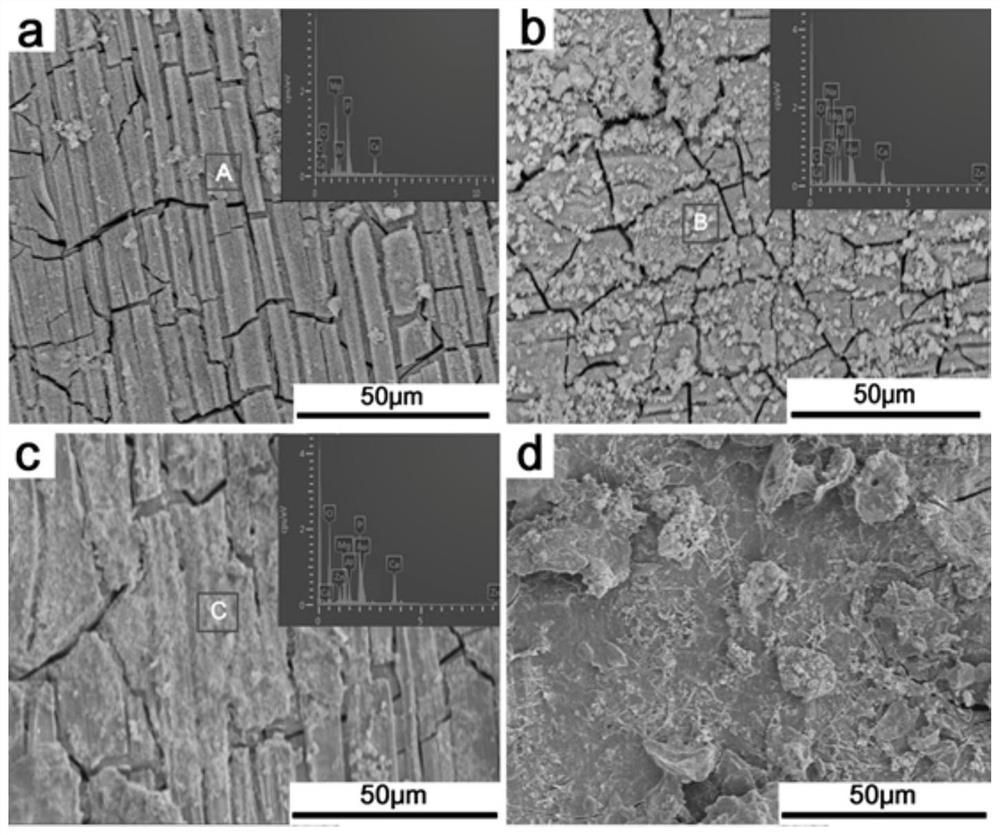

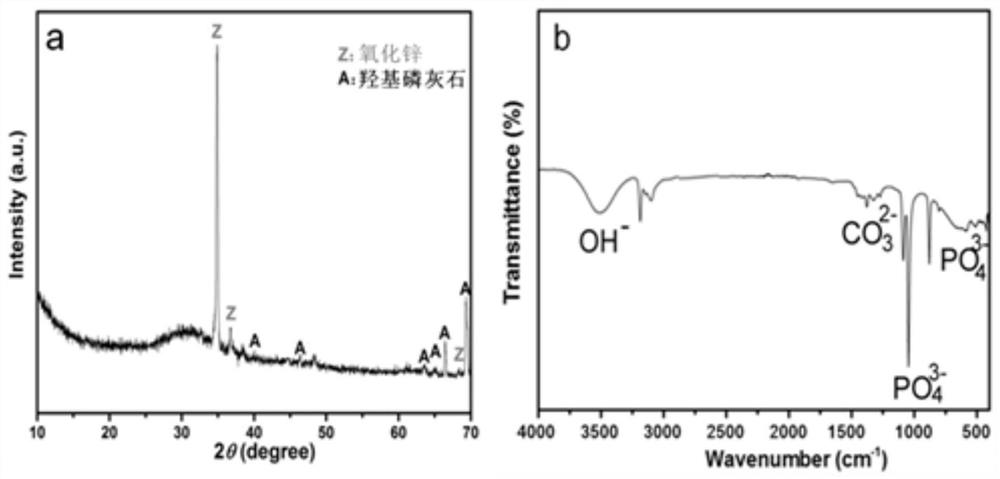

Zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial property as well as preparation method and application thereof

ActiveCN113082290AHigh antibacterial activityImprove interface binding statePharmaceutical delivery mechanismMetallic material coating processesUltraviolet lightsOxide coating

The invention discloses a zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial property as well as a preparation method and an application thereof. The zinc oxide coating-hydroxyapatite coating comprises an alkaline zinc oxide coating and a hydroxyapatite coating, the alkaline zinc oxide coating is excited by ultraviolet light to generate .OH on the surface to form a zinc oxide coating-hydroxyapatite coating with the hydroxyapatite coating; and the preparation method comprises the following steps: exciting the surface of the alkaline zinc oxide coating to generate. OH, and reacting with SBF simulated body fluid to form the zinc oxide coating-hydroxyapatite coating. The zinc oxide coating-hydroxyapatite coating is used for preparing an orthopedic implant. The method is low in cost, high in efficiency, simple and easy to implement and environmentally friendly, and the zinc oxide coating-hydroxyapatite coating prepared through the method has good biological activity and antibacterial performance and has high commercial popularization value.

Owner:北京科技大学天津学院

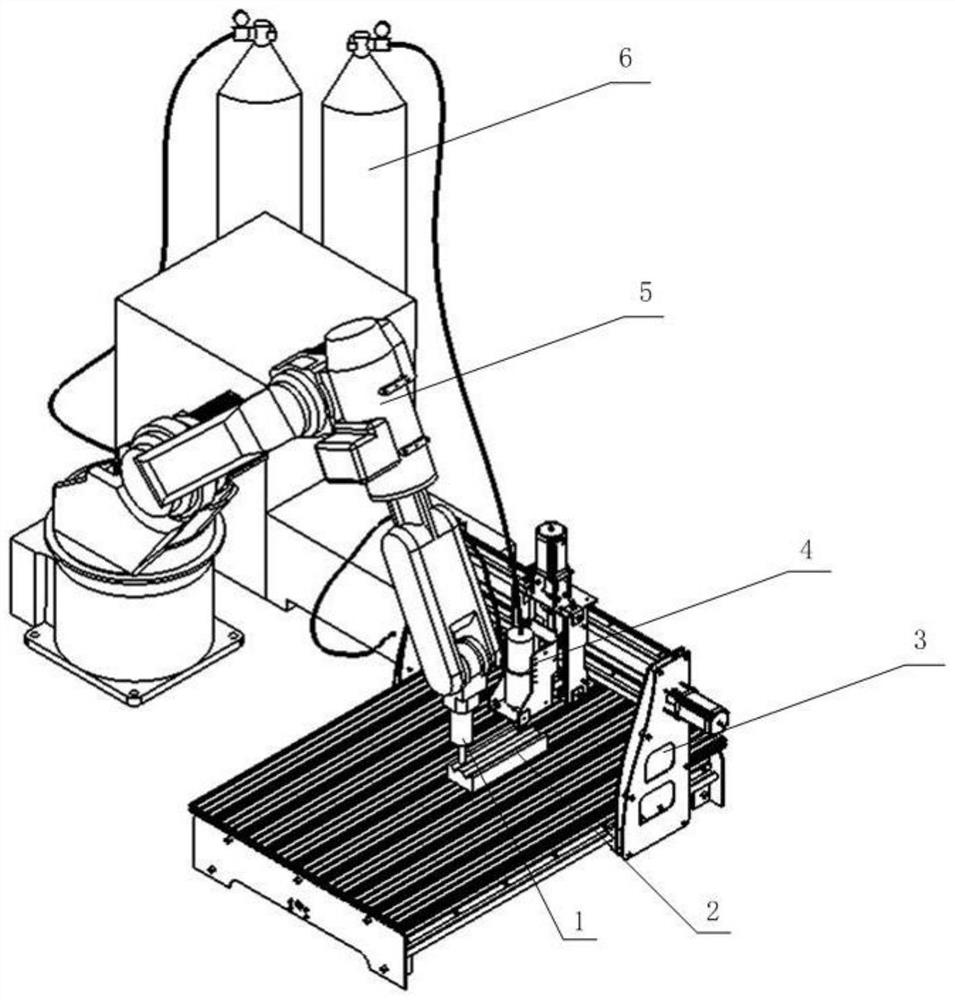

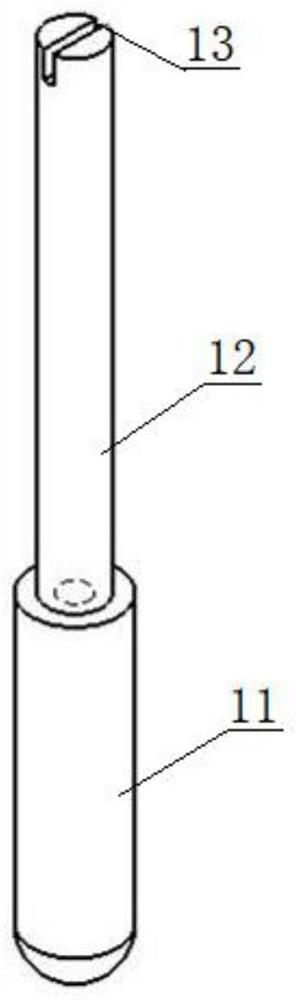

Device and method for enhancing steel-based surface composite structure or steel-based surface repair

ActiveCN112059530AImprove preparation efficiencyExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesComposite structureEngineering

The invention discloses a device and method for enhancing steel-based surface composite structure or steel-based surface repair. The device comprises micro impact heads, an ultrasonic impact tool head, an ultrasonic amplitude-change pole and an air pressure auxiliary type ultrasonic impact module. The lower ends of the micro impact heads are convex curved surfaces, the multiple micro impact headsare densely arranged, and enveloping surfaces formed by the lower ends of the micro impact heads are matched with the shape of the bottoms of grooves to be reinforced; the upper ends of the micro impact heads are fixed to the ultrasonic impact tool head; the ultrasonic impact tool head is fixed to the ultrasonic amplitude-change pole; and the ultrasonic amplitude-change pole is installed on the air pressure auxiliary type ultrasonic impact module, and the air pressure auxiliary type ultrasonic impact module is used for adjusting the posture of the ultrasonic amplitude-change pole. Compared with the prior art, the shape of the micro impact heads of the invention can be adjusted at any time according to the actual situation, so that it is guaranteed that ultrasonic impact strengthening can be fully conducted on the surface to be machined every time, and fine and regular ultrasonic impact strengthening holes are formed.

Owner:NANCHANG HANGKONG UNIVERSITY

Novel blanket for children and production method thereof

The invention discloses a novel blanket for children, which belongs to the textile field. The novel blanket for the children is characterized in that the blanket adopts an upper layer of weave construction, a middle layer of weave construction and a lower layer of weave construction; the upper layer and the lower layer adopt the plain cloth tissue layers of ordinary cotton yarn respectively; and the middle layer adopts the pile tissue layers by adopting untwisted yarn with good bulkiness as wool warps. The invention also provides a production method of the novel blanket for the children. The blanket for the children produced in the production method has the following characteristics: firstly, the product has the thickness of a woolen blanket; secondly, the novel blanket feels comfortable and the water absorbability is good; and thirdly, the depilating rate is greatly reduced.

Owner:LOFTEX INDS

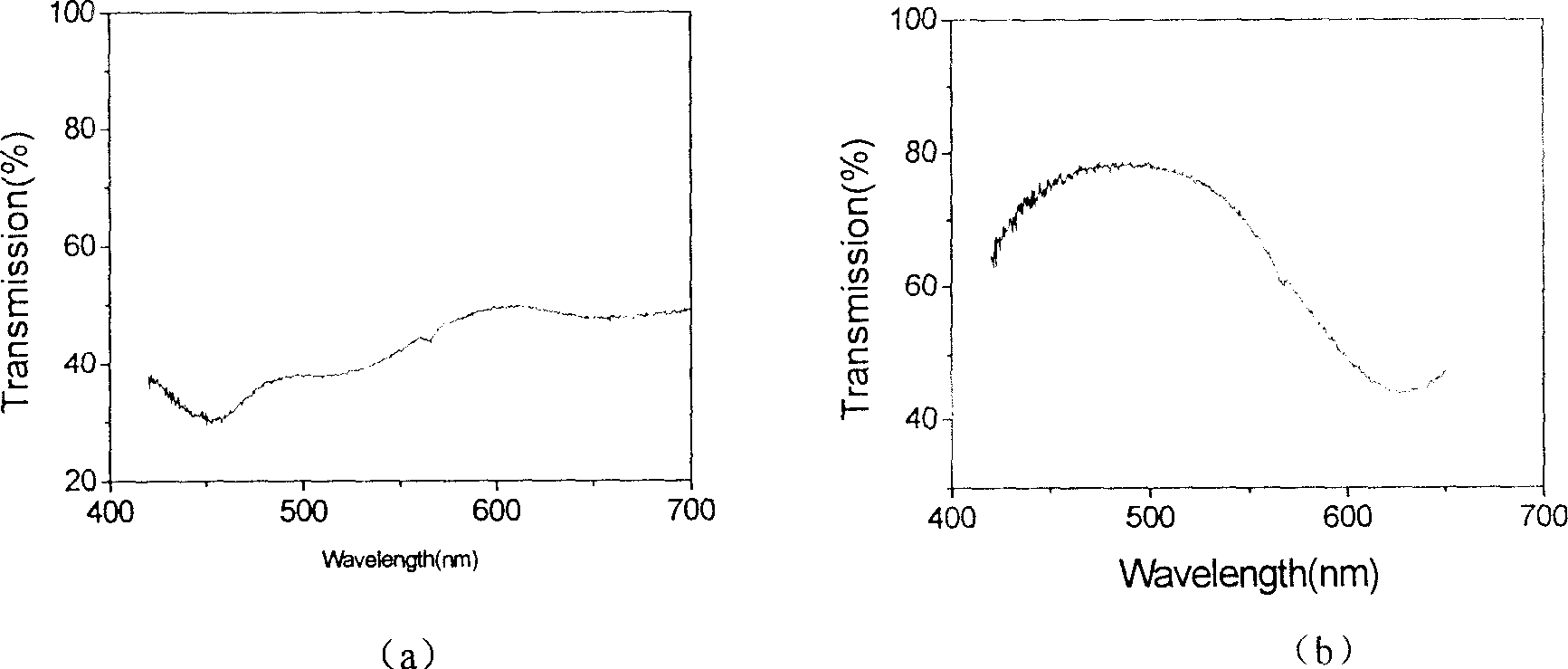

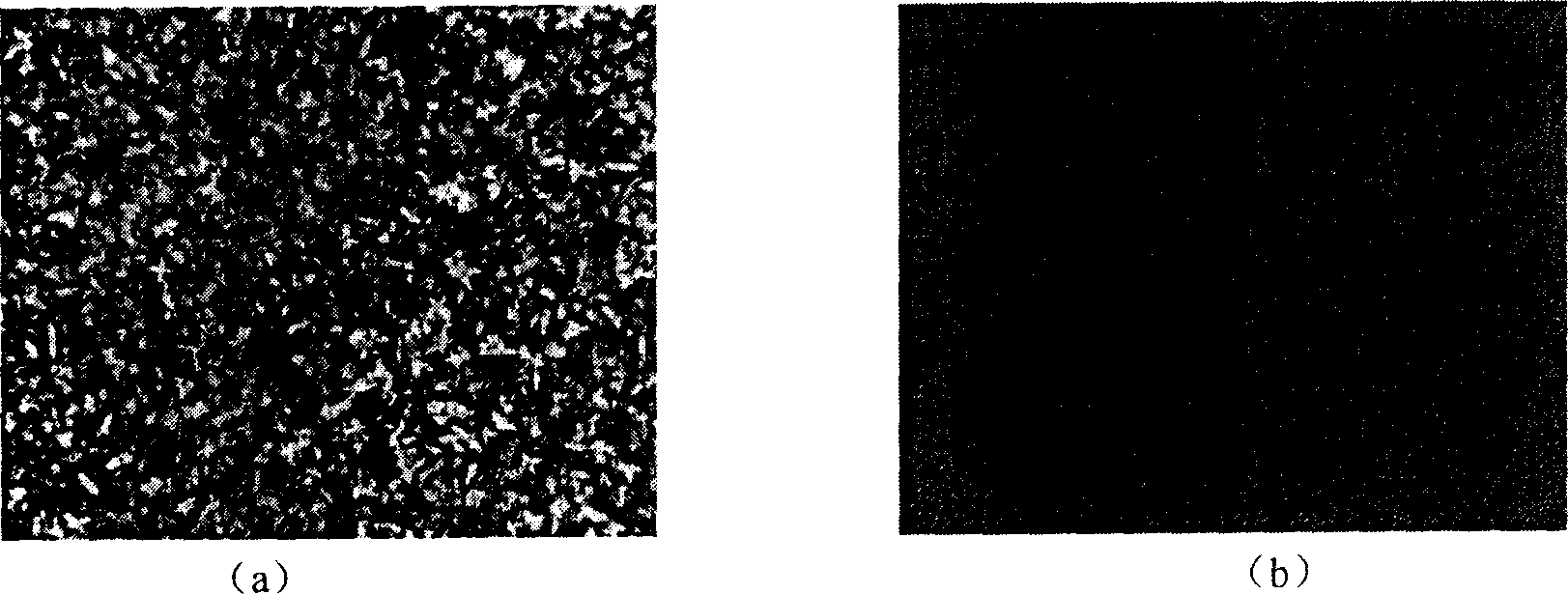

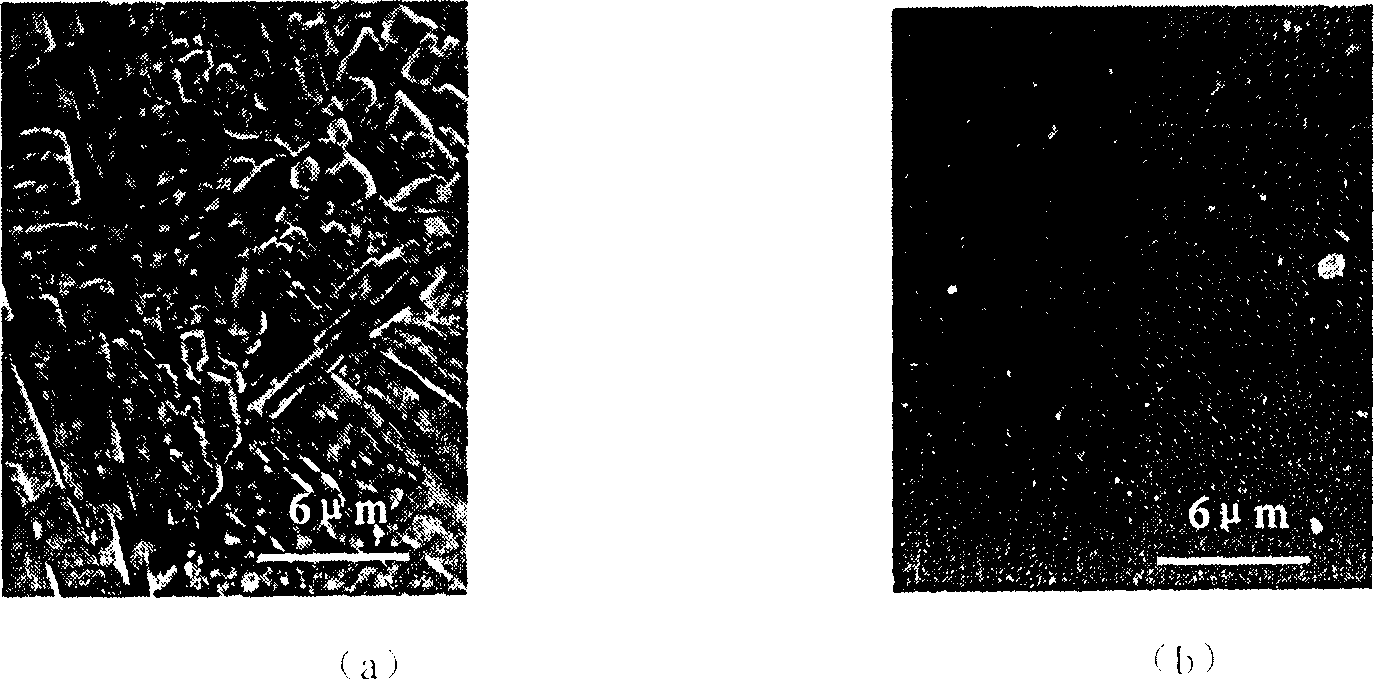

Process for preparing metal-organic complex electric bistable film

InactiveCN1523130AHas thicknessUniform surfaceVacuum evaporation coatingSputtering coatingGas phaseElectron

The present invention relates to a method for preparing metal-organic complex MTCNQ electric bistable film. Said method includes the following steps: firstly, adopting physical gas phase deposition method to deposit metal M and TCNQ mixed film, and using chemical electroplating process to prepare MTCNQ film. Said invented product can be extensively used for preparing microelectronic device, molecular electronic device and mass memory.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com