Lightweight environment-friendly automobile interior material and preparation process thereof

A technology for automotive interior decoration and preparation technology, which is applied in the direction of chemical instruments and methods, lamination, superstructure sub-assembly, etc. It can solve the problems of low impact resistance, excessive filler addition, peeling, etc., and achieve good moisture resistance and antibacterial properties. The effect of low preparation cost and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

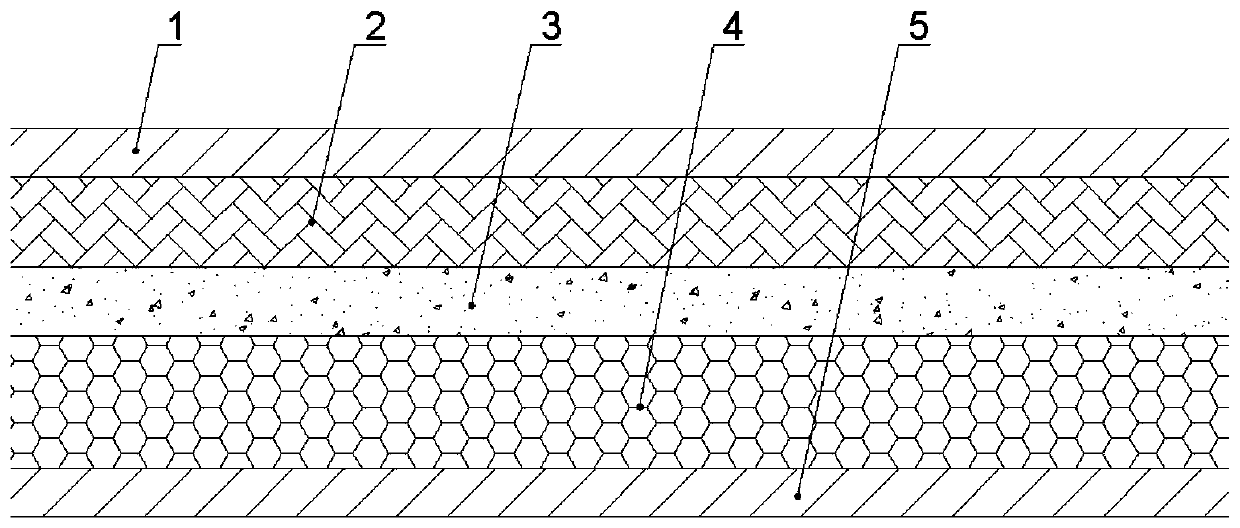

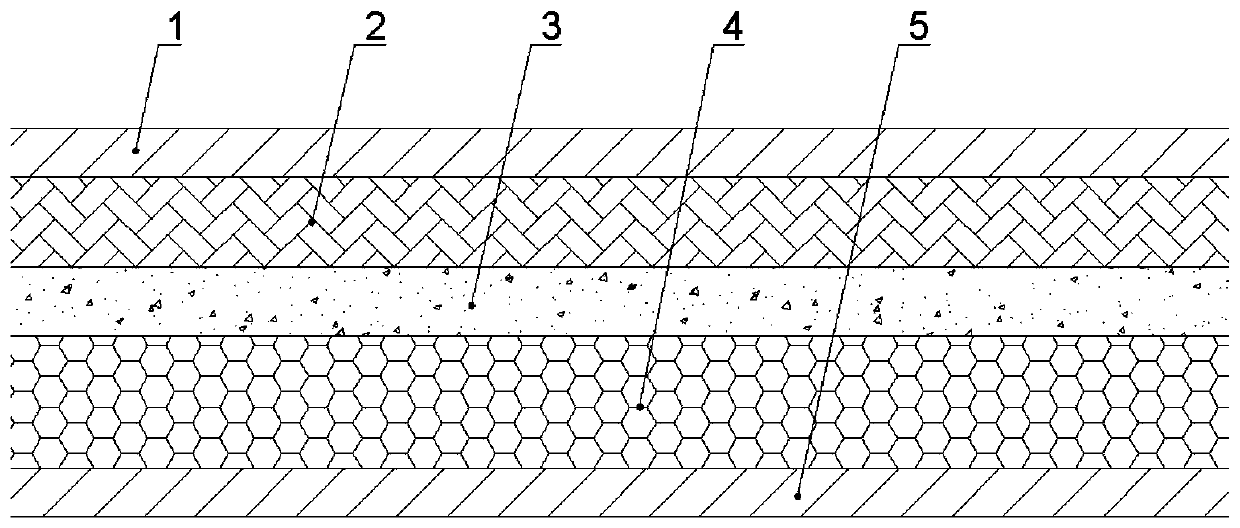

[0086] Such as figure 1 Shown 1, a kind of lightweight environment-friendly automobile interior material, is characterized in that: comprise upper surface treatment agent layer 1, TPO skin layer 2, sponge layer 3, base cloth layer 4, lower surface treatment agent layer 5; The top of the base cloth layer 4 is provided with a sponge layer 3; the bottom of the base cloth layer 4 is provided with a lower surface treatment agent layer 5; the top of the sponge layer 3 is provided with a TPO skin layer 2; the TPO skin layer 2 An upper surface treatment agent layer 1 is arranged above.

[0087] In addition, the TPO skin layer 2 is made of the following components in several parts by weight:

[0088] Semi-cross-linked TPO: 50 parts

[0089] Polyvinyl chloride resin: 40 parts

[0090] Polypropylene resin: 40 parts

[0091] Tackifying resin: 30 parts

[0092] Rubber: 90 parts

[0093] Filling: 12 servings

[0094] Olefin copolymer: 10 parts

[0095] Toughener: 10 parts

[0096] ...

Embodiment 2

[0127] Such as figure 1 Shown 1, a kind of lightweight environment-friendly automobile interior material, is characterized in that: comprise upper surface treatment agent layer 1, TPO skin layer 2, sponge layer 3, base cloth layer 4, lower surface treatment agent layer 5; The top of the base cloth layer 4 is provided with a sponge layer 3; the bottom of the base cloth layer 4 is provided with a lower surface treatment agent layer 5; the top of the sponge layer 3 is provided with a TPO skin layer 2; the TPO skin layer 2 An upper surface treatment agent layer 1 is arranged above.

[0128] In addition, the TPO skin layer 2 is made of the following components in several parts by weight:

[0129] Semi-cross-linked TPO: 70 parts

[0130] Polyvinyl chloride resin: 50 parts

[0131] Polypropylene resin: 50 parts

[0132] Tackifying resin: 40 parts

[0133] Rubber: 100 parts

[0134] Filling: 20 servings

[0135] Olefin copolymer: 20 parts

[0136] Toughener: 20 parts

[0137]...

Embodiment 3

[0168] Such as figure 1 Shown 1, a kind of lightweight environment-friendly automobile interior material, is characterized in that: comprise upper surface treatment agent layer 1, TPO skin layer 2, sponge layer 3, base cloth layer 4, lower surface treatment agent layer 5; The top of the base cloth layer 4 is provided with a sponge layer 3; the bottom of the base cloth layer 4 is provided with a lower surface treatment agent layer 5; the top of the sponge layer 3 is provided with a TPO skin layer 2; the TPO skin layer 2 An upper surface treatment agent layer 1 is arranged above.

[0169] In addition, the TPO skin layer 2 is made of the following components in several parts by weight:

[0170] Semi-cross-linked TPO: 60 parts

[0171] Polyvinyl chloride resin: 45 parts

[0172] Polypropylene resin: 45 parts

[0173] Tackifying resin: 35 parts

[0174] Rubber: 95 parts

[0175] Filling: 16 servings

[0176] Olefin copolymer: 15 parts

[0177] Toughener: 15 parts

[0178] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com