Patents

Literature

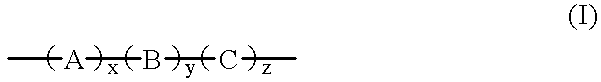

8824results about "Rubber layered products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

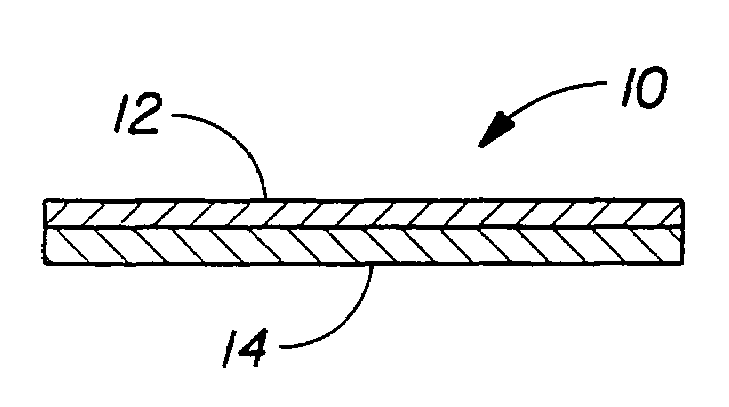

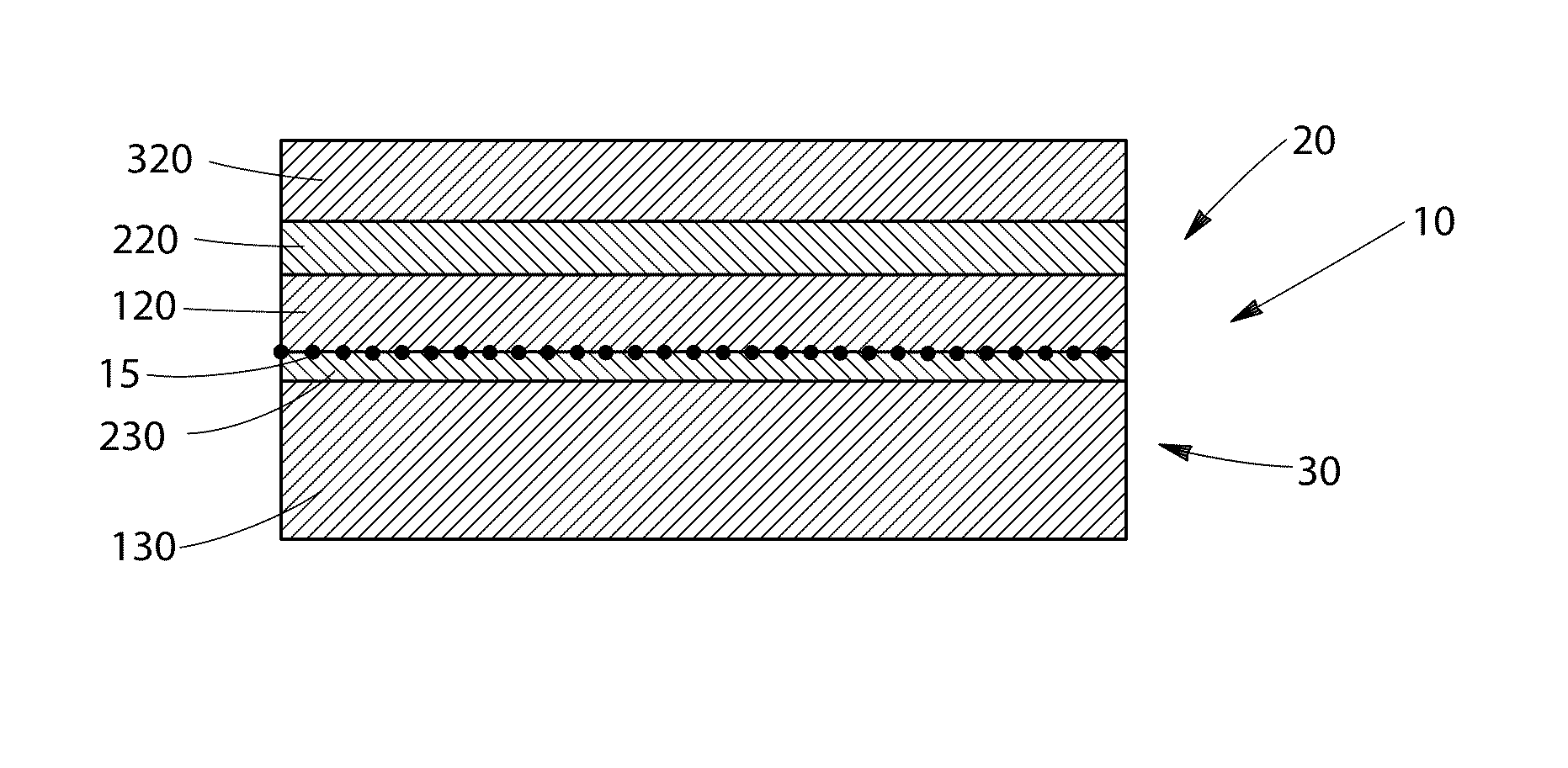

Ballistic fabric laminates

InactiveUS6846758B2Improved ballistic protectionImprove protectionSynthetic resin layered productsPersonal protection gearElastomerYarn

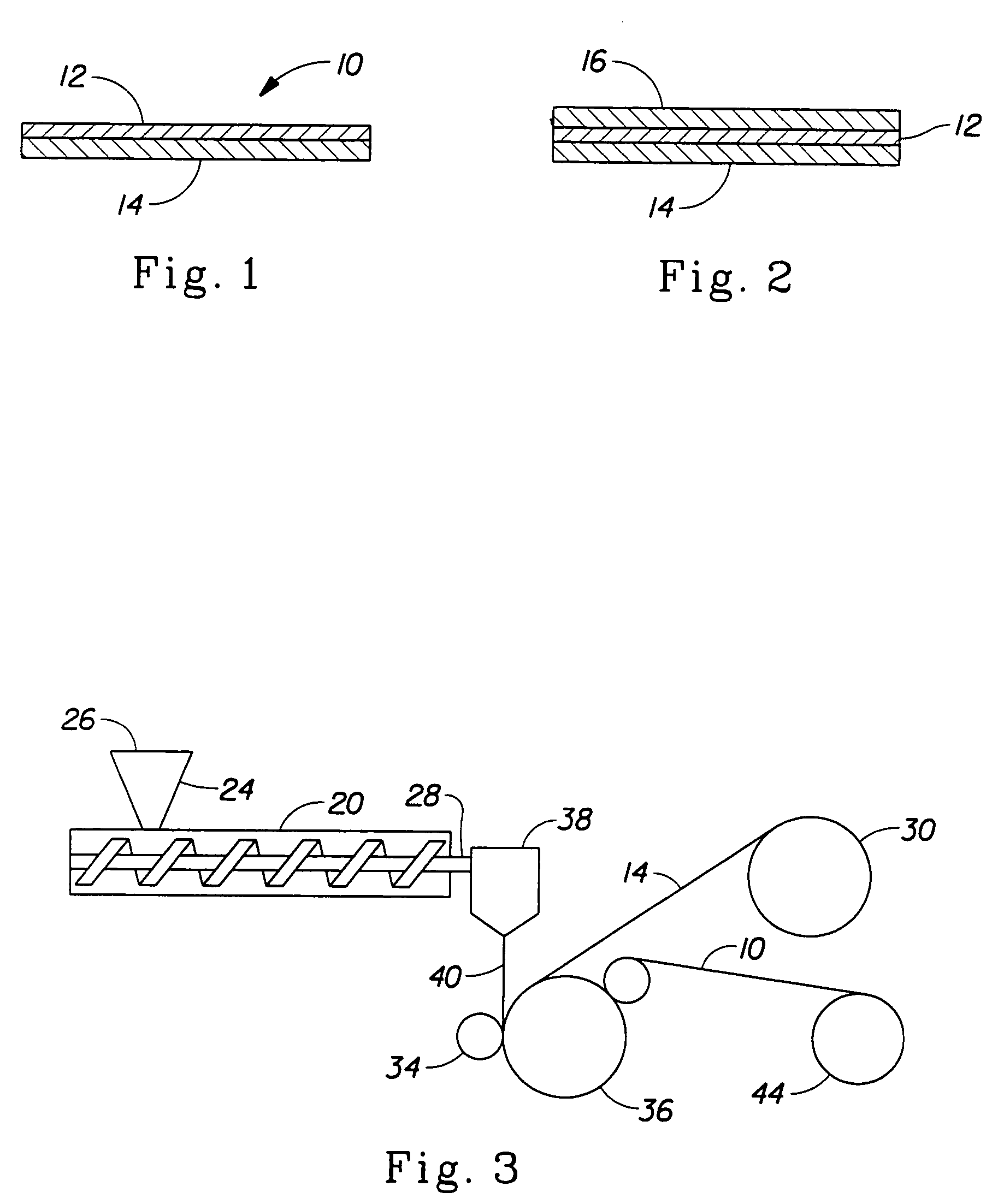

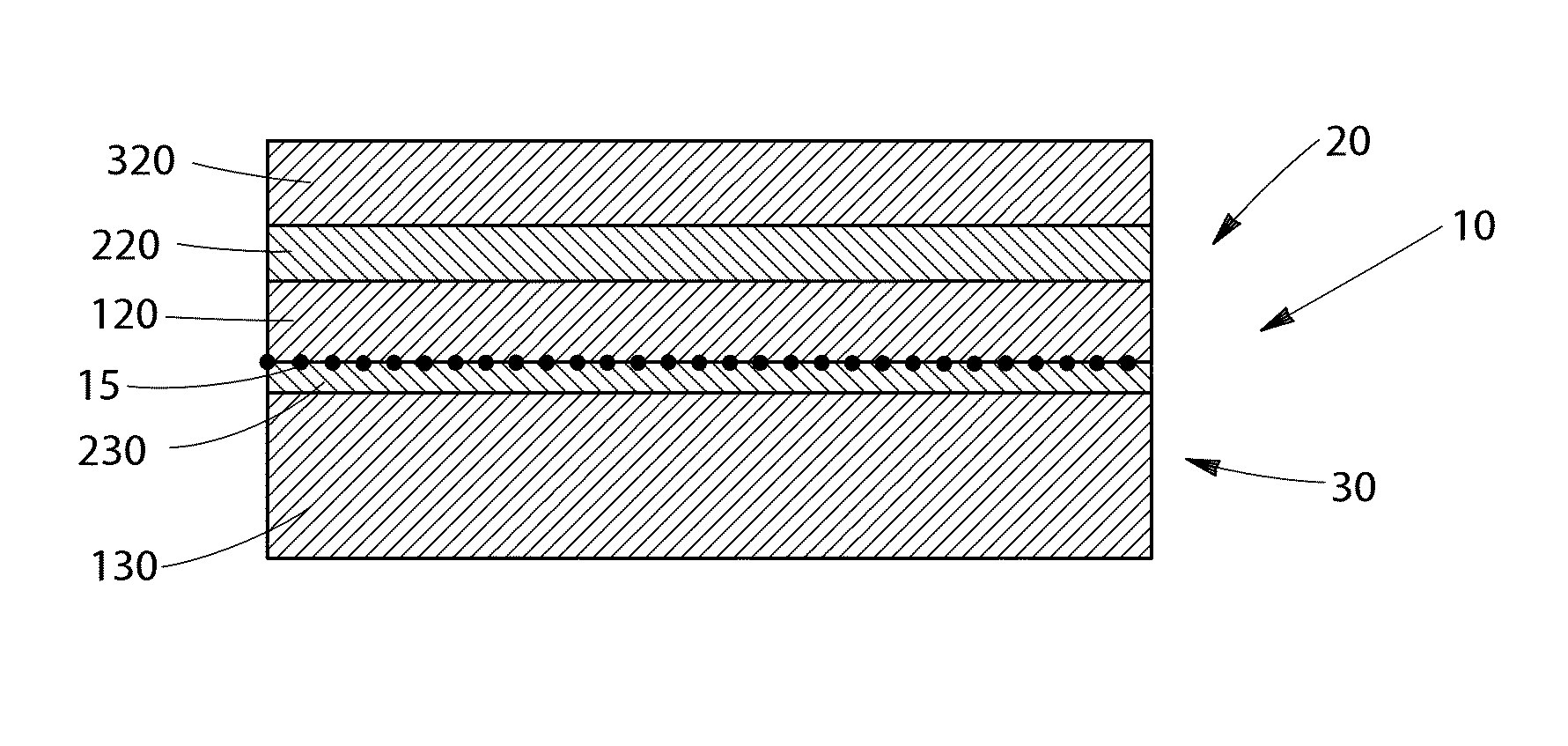

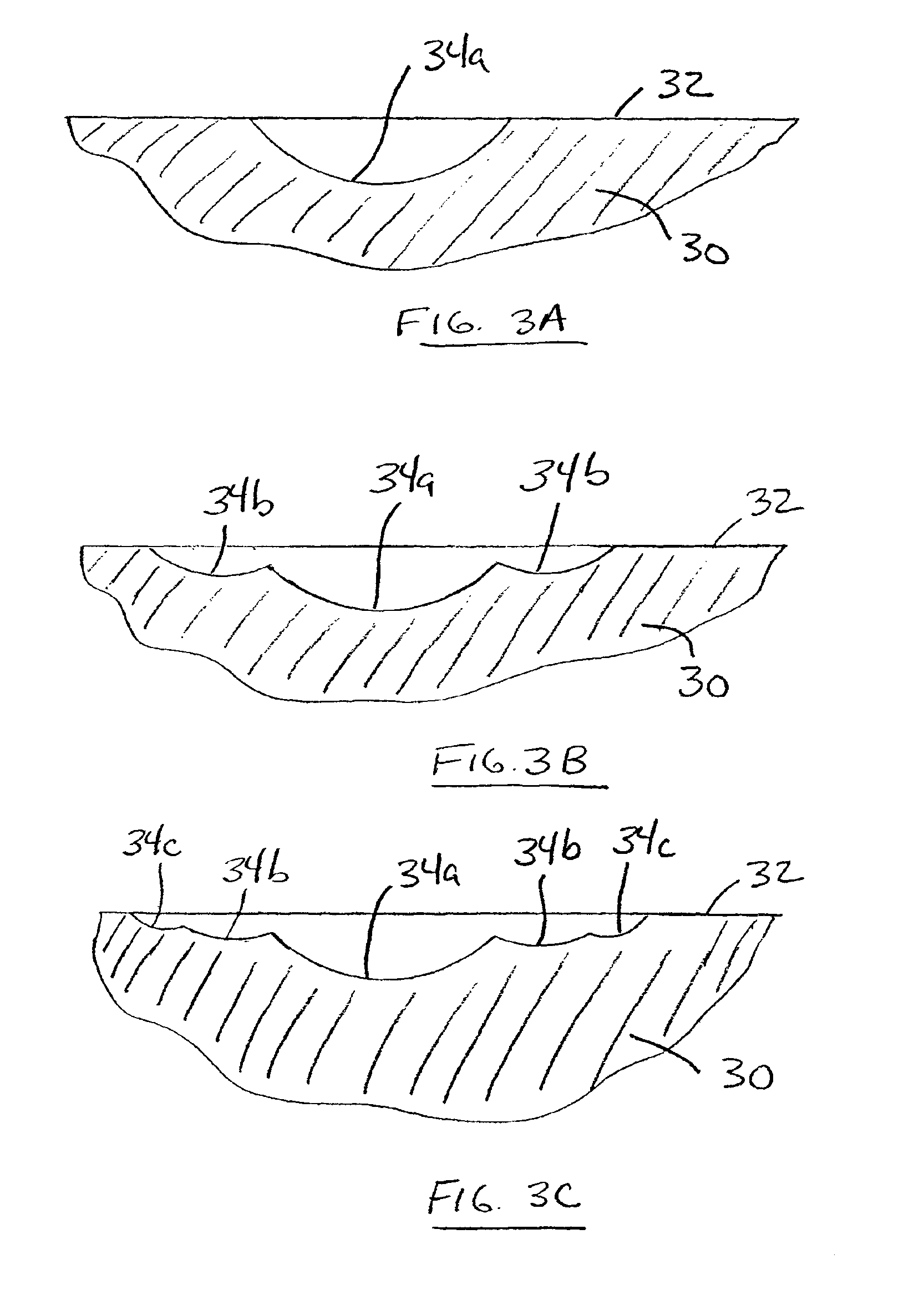

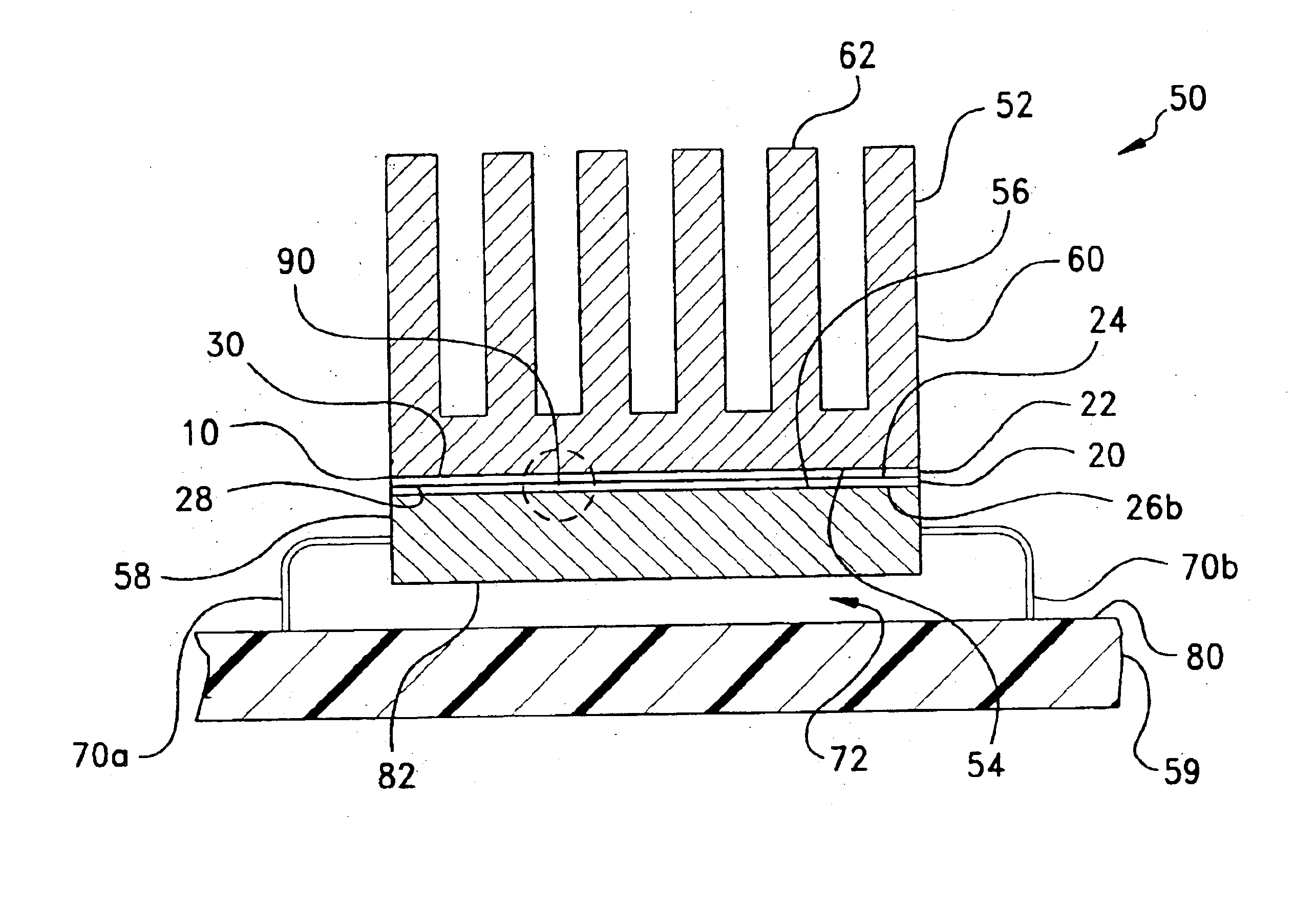

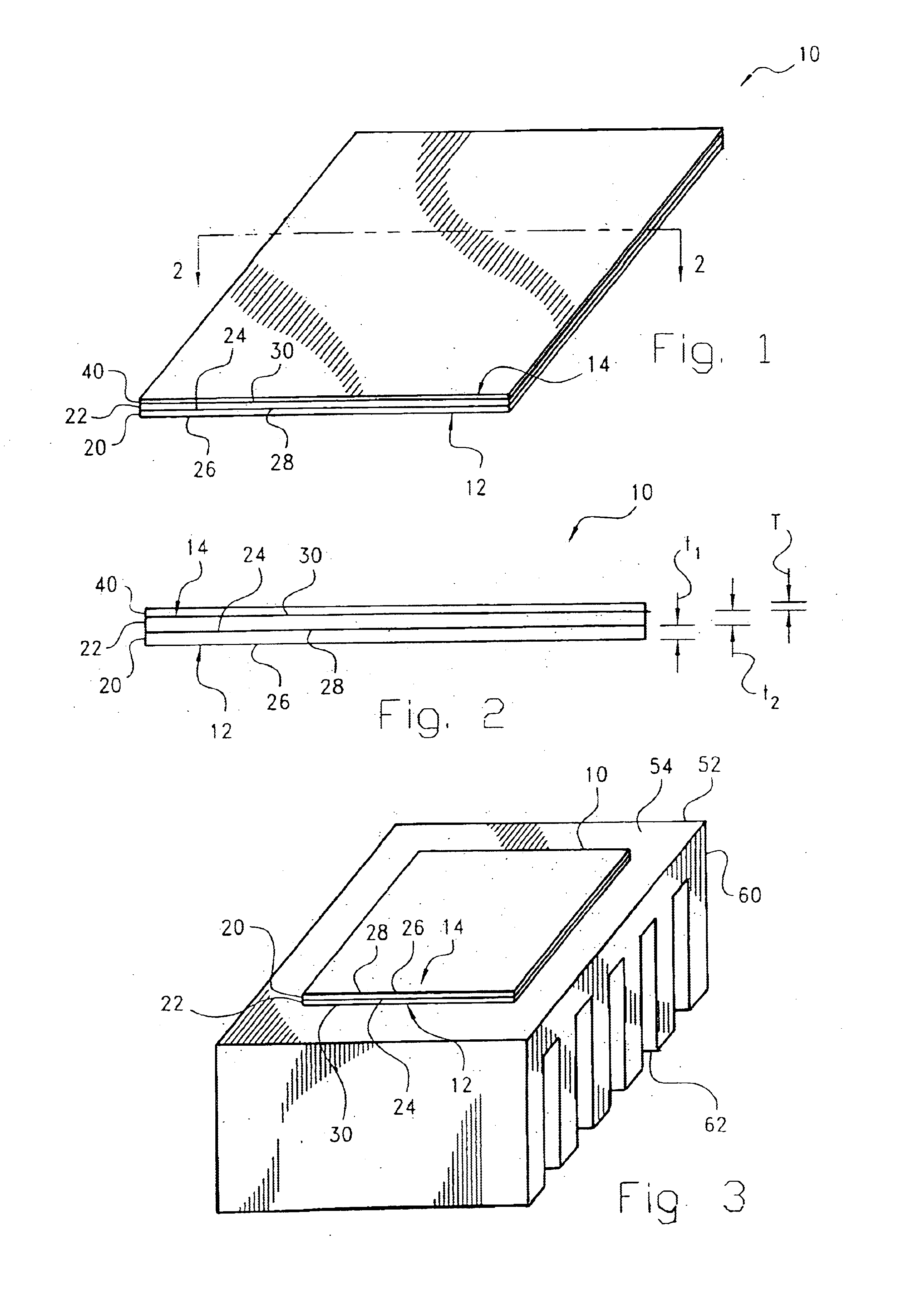

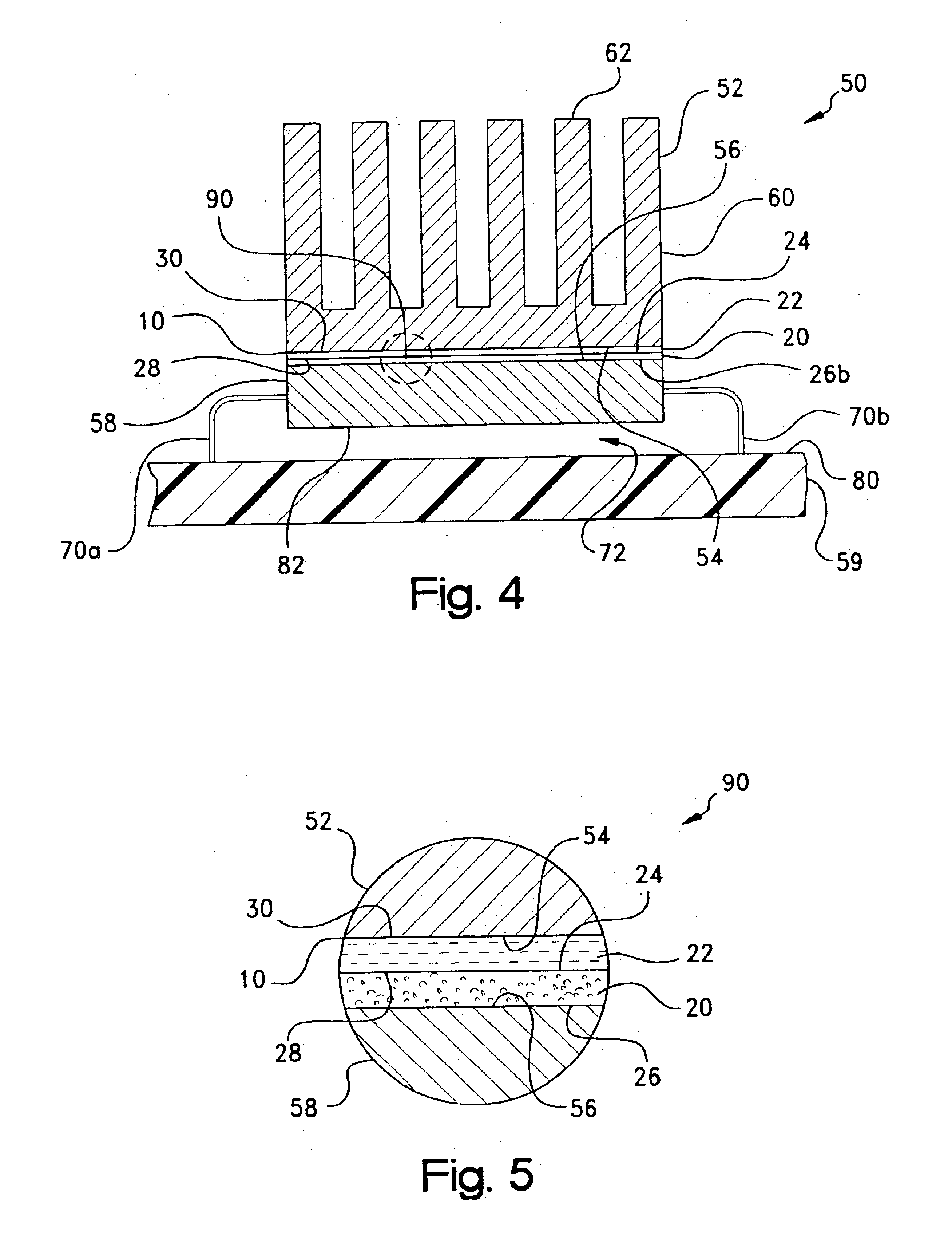

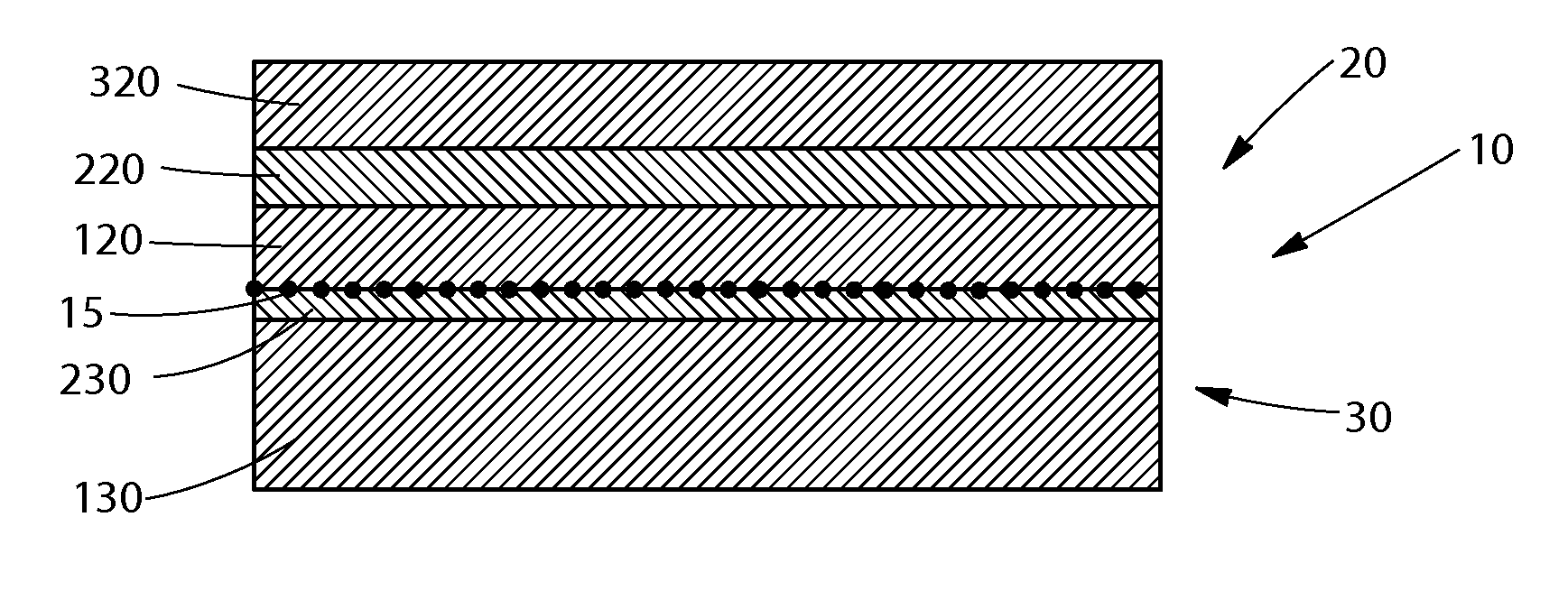

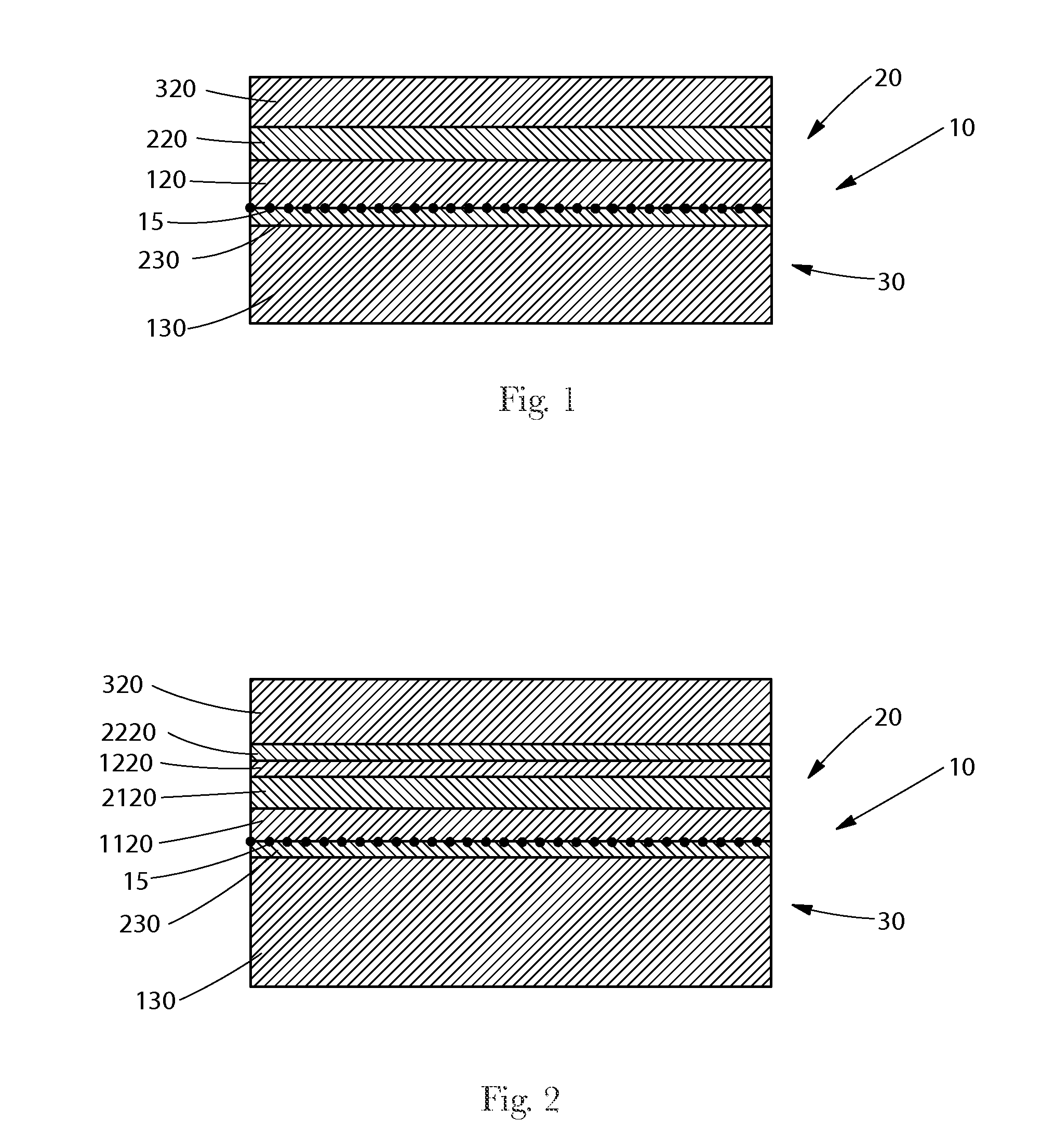

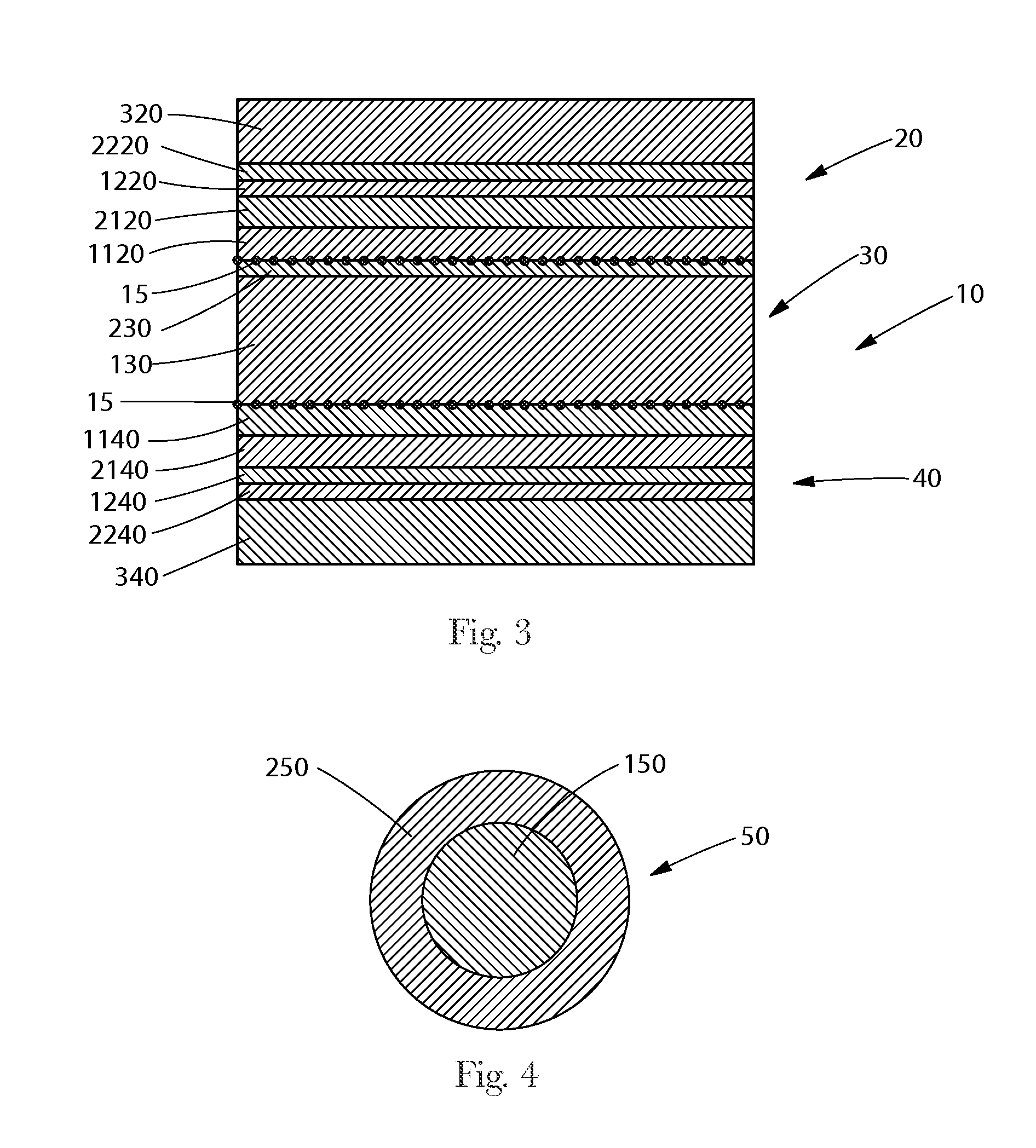

Woven fabric laminates having superior resistance to penetration by ballistic projectiles, assemblies thereof, and the method by which they are made. In one embodiment, among others, a laminate of the invention is comprised of a fabric woven from a high strength, high modulus yarn, a surface coating of a low modulus elastomer and a plastic film bonded to its elastomer-coated surface.

Owner:HONEYWELL INT INC

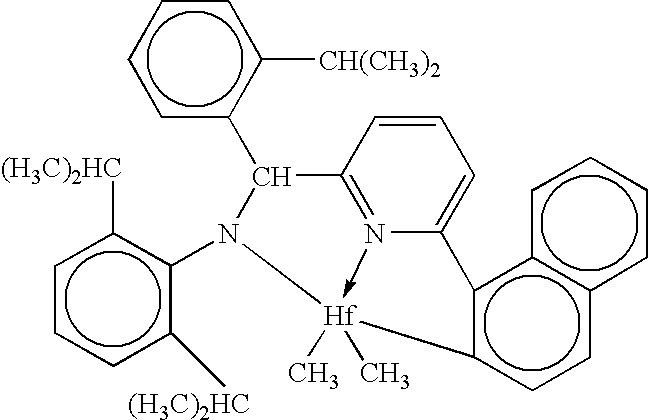

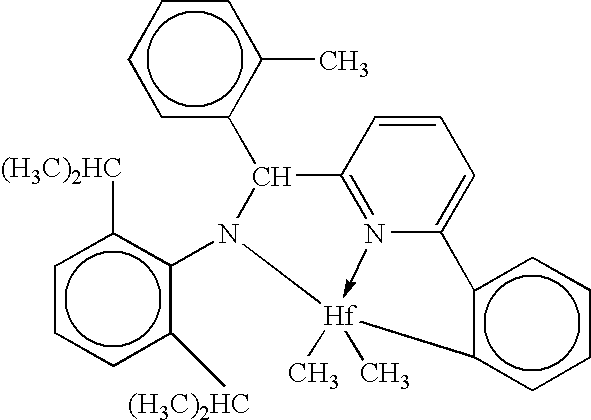

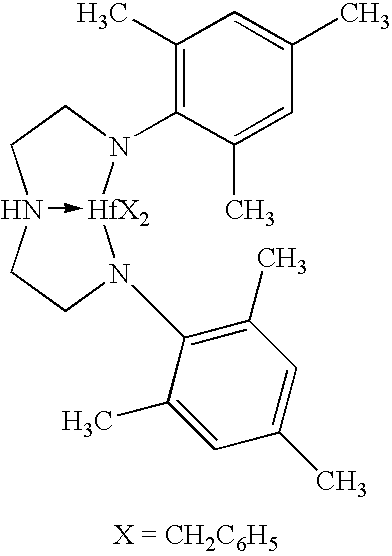

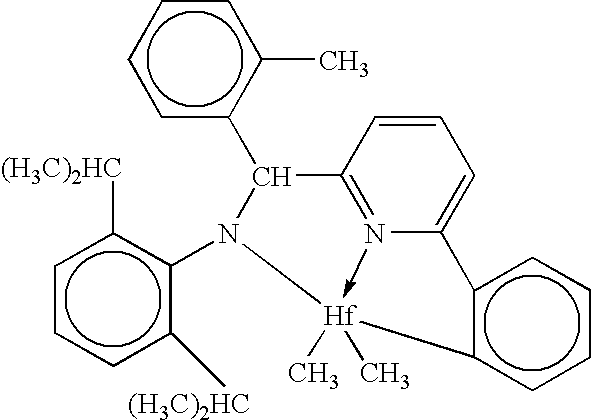

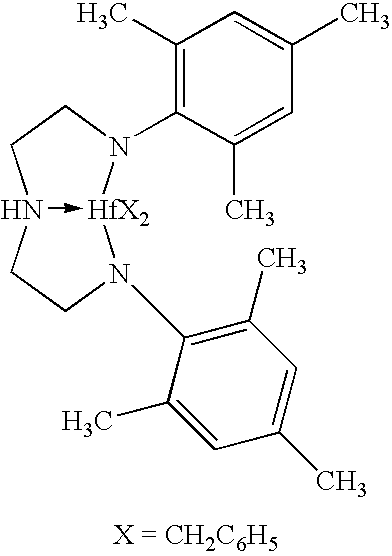

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS7504347B2Monocomponent synthetic polymer artificial filamentWoven fabricsFiberVolumetric Mass Density

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629 (d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

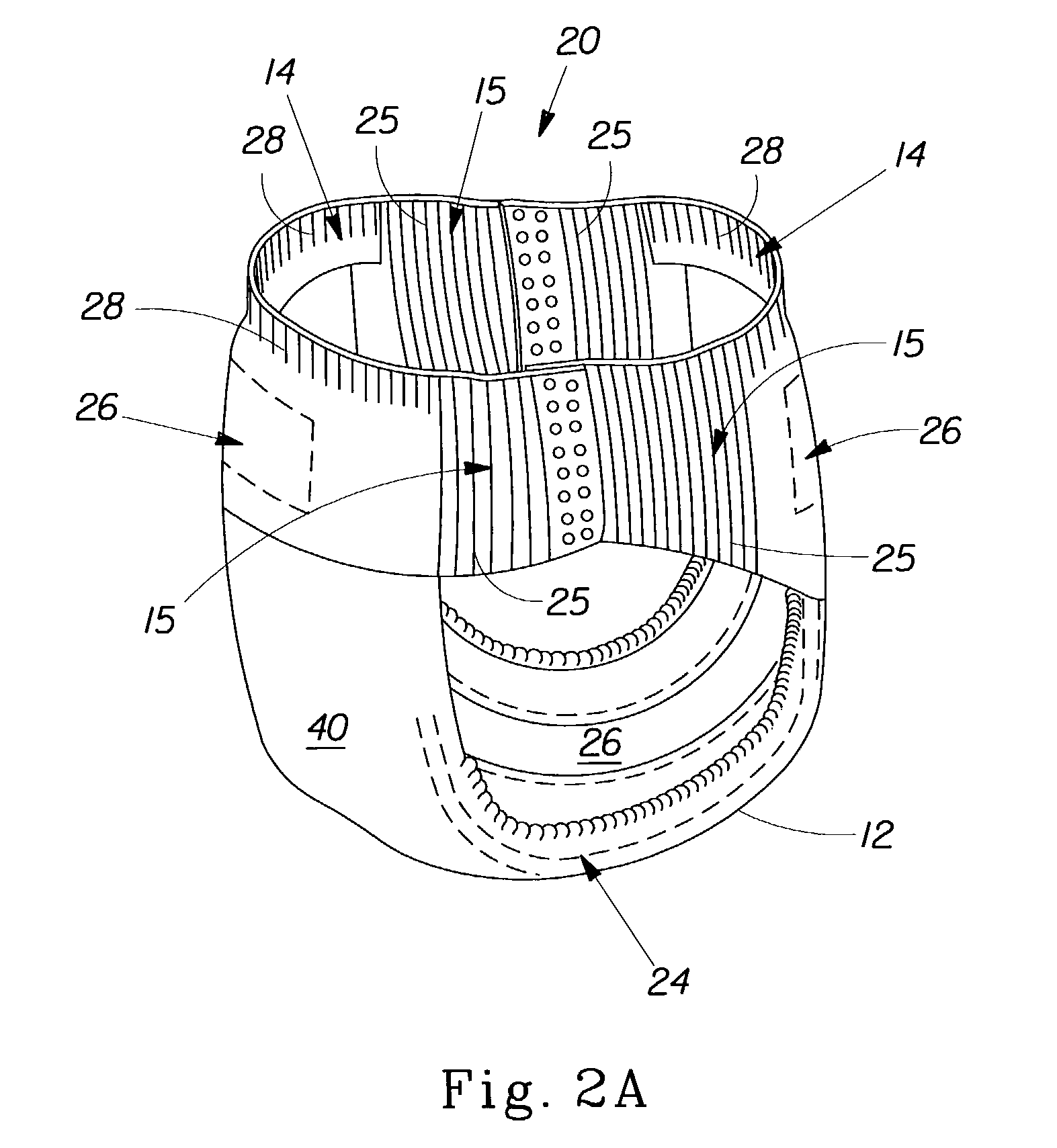

Breathable composite sheet structure and absorbent articles utilizing same

A breathable composite sheet material, a method for making such a sheet material, and an absorbent article utilizing the sheet material are provided. The composite sheet material is comprised of a thermoplastic film adhered directly to a fibrous substrate. The thermoplastic film comprises at least 50% by weight of a polymer material from the group of block copolyether esters, block copolyether amides and polyurethanes. The substrate comprises a fibrous web of at least 50% by weight of polyolefin polymer synthetic fibers. The composite sheet exhibits a peel strength of at least 0.1 N / cm, a dynamic fluid transmission of less than about 0.75 g / m2 when subjected to an impact energy of about 2400 joules / m2, and a moisture vapor transmission rate, according to the desiccant method, of at least 1500 g / m2 / 24 hr. The absorbent article comprises (a) a topsheet; (b) a backsheet; and (c) an absorbent core located between the topsheet and the backsheet; wherein the backsheet comprises the non-porous, substantially fluid impermeable, moisture vapor permeable composite sheet material described above. The composite sheet material is oriented such that the film layer of the composite sheet material faces toward the absorbent core. The absorbent article may comprise a disposable diaper.

Owner:THE PROCTER & GAMBLE COMPANY

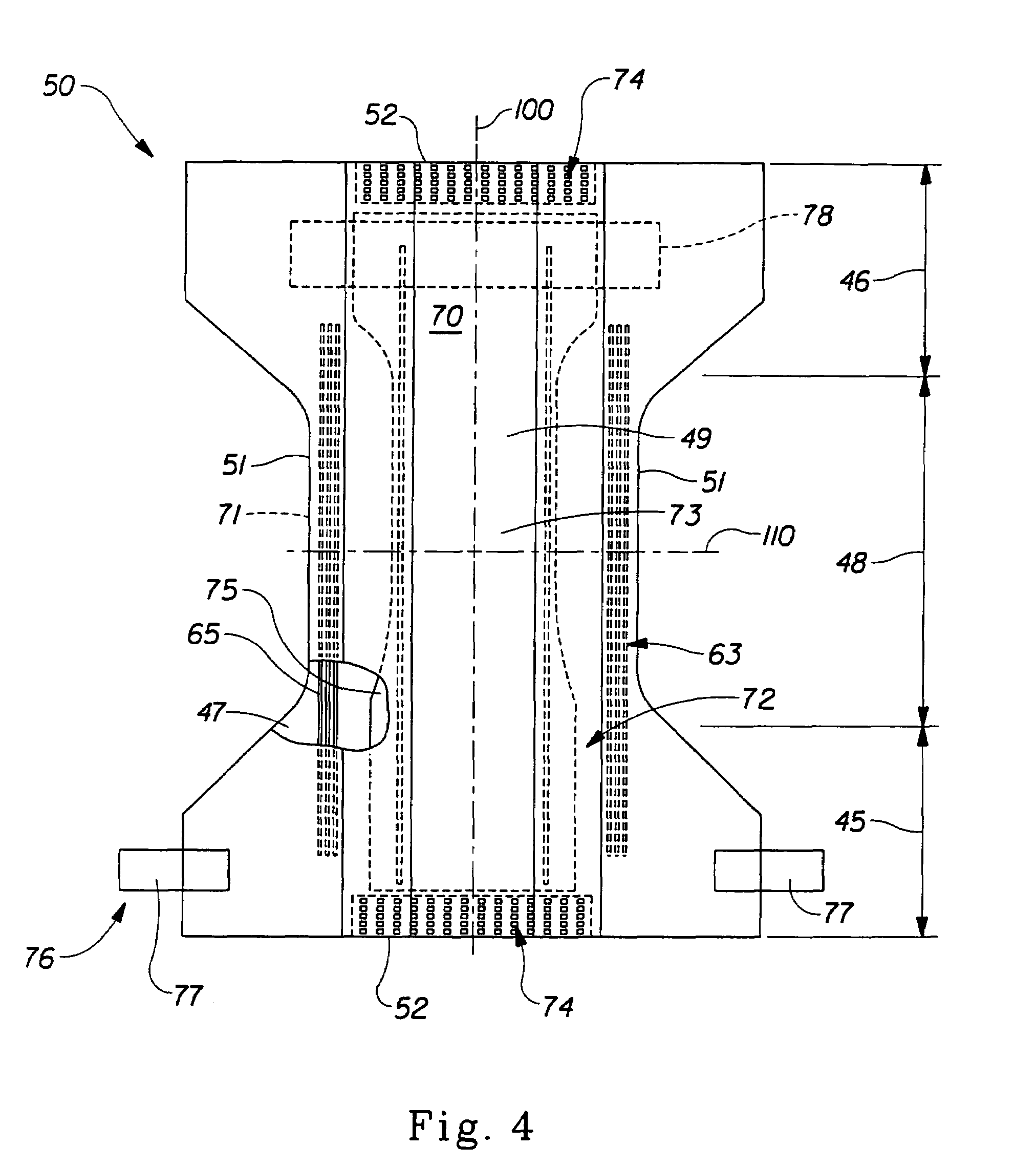

Elastic laminate including nonwoven layer formed from highly-oriented-component fibers and disposable garment employing the same

The present invention is directed to an elastic laminate which is elastically extensible in at least one direction. The elastic laminate includes an elastomeric material having a first surface and a second surface opposing the first surface; and a first nonwoven layer joined to the first surface of the elastomeric material. The first nonwoven layer is formed from component fibers having a primary fiber direction. The first nonwoven layer has a Fiber Orientation Ratio within about ±20 degrees from a primary fiber direction of at least about 65%. The present invention is also directed to a disposable garment employing such an elastic laminate.

Owner:THE PROCTER & GAMBLE COMPANY

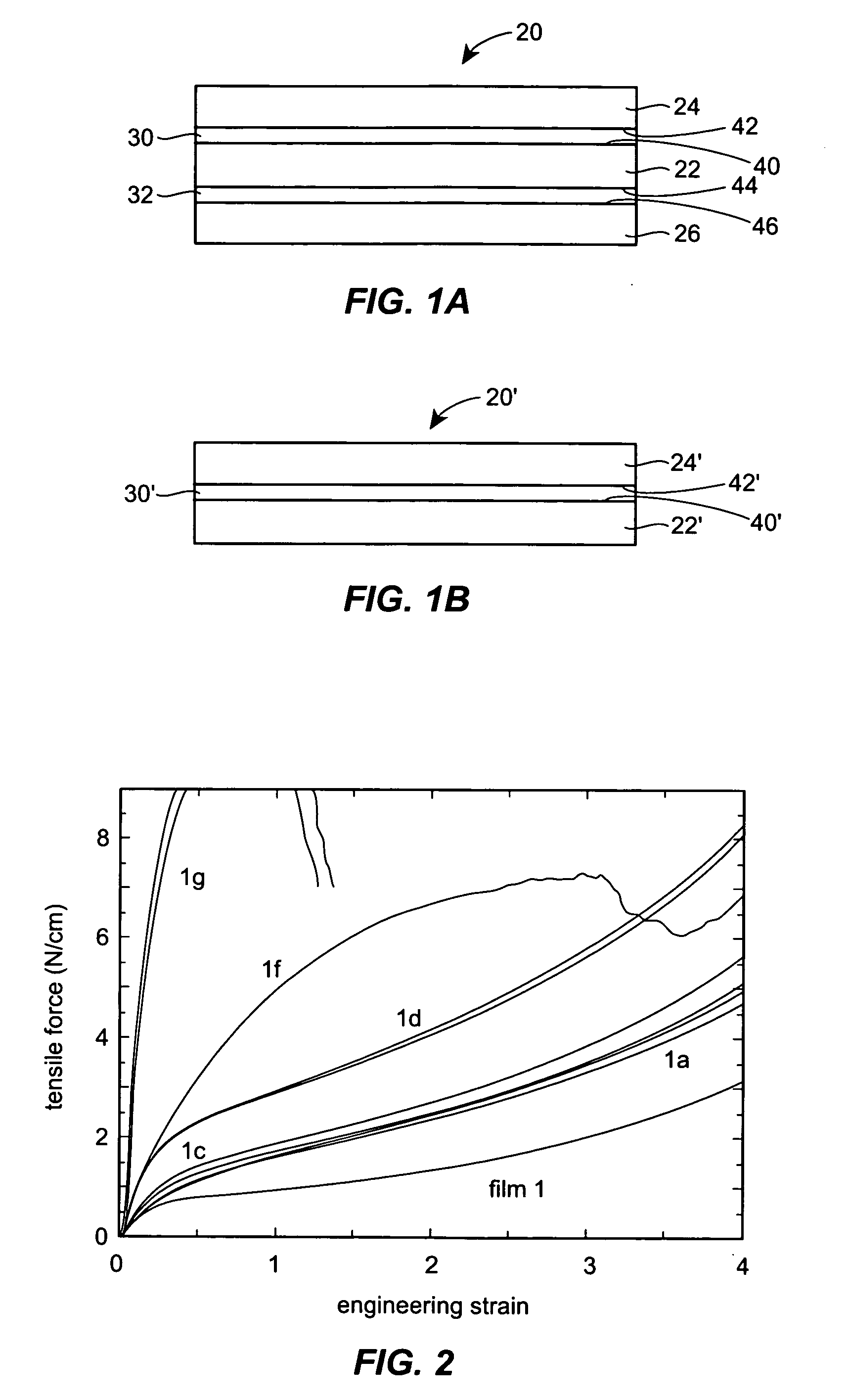

Stretch laminate, method of making, and absorbent article

A stretch laminate includes a first layer including an elastomer film, the first layer having a surface, and a second layer including a nonwoven material, the second layer having a surface that is attached to the surface of the first layer. The tensile behavior in the transverse direction of the stretch laminate is within about 2.5 N / cm of the tensile behavior in the transverse direction of the film at an engineering strain of about 1.5, and exists independent of mechanical activation. A method of making the stretch laminate and an absorbent article having at least one region defined by the stretch laminate are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

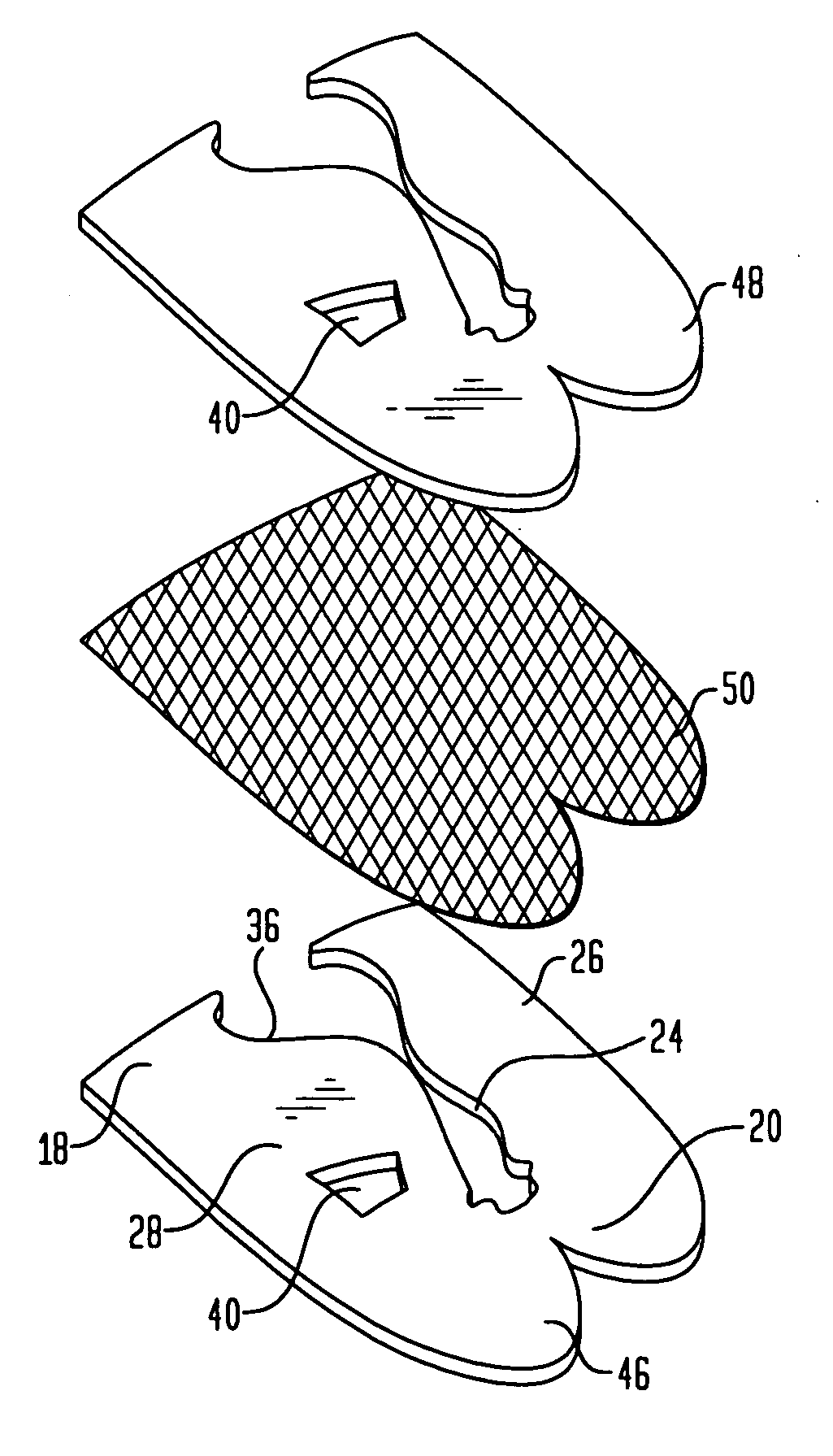

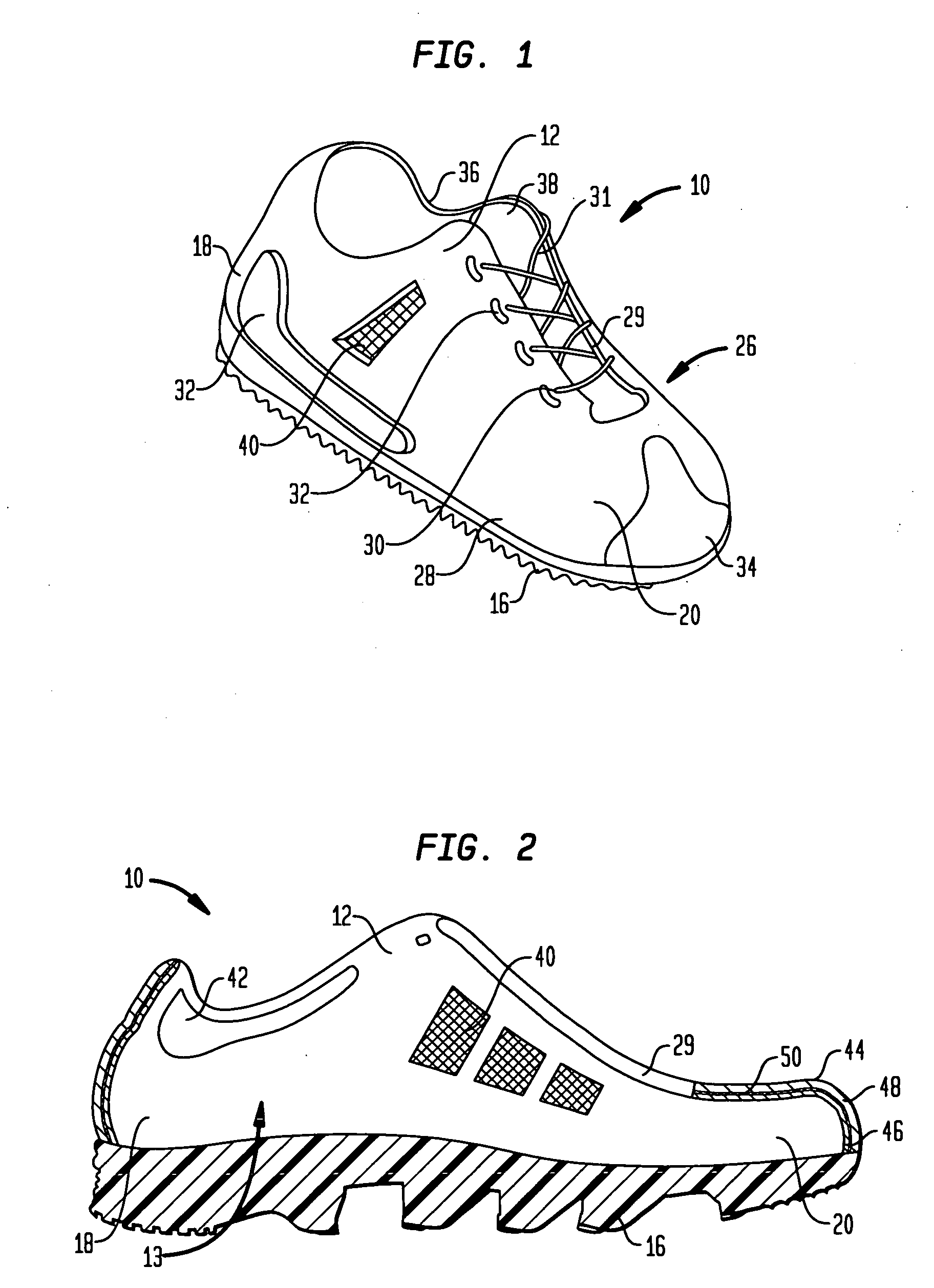

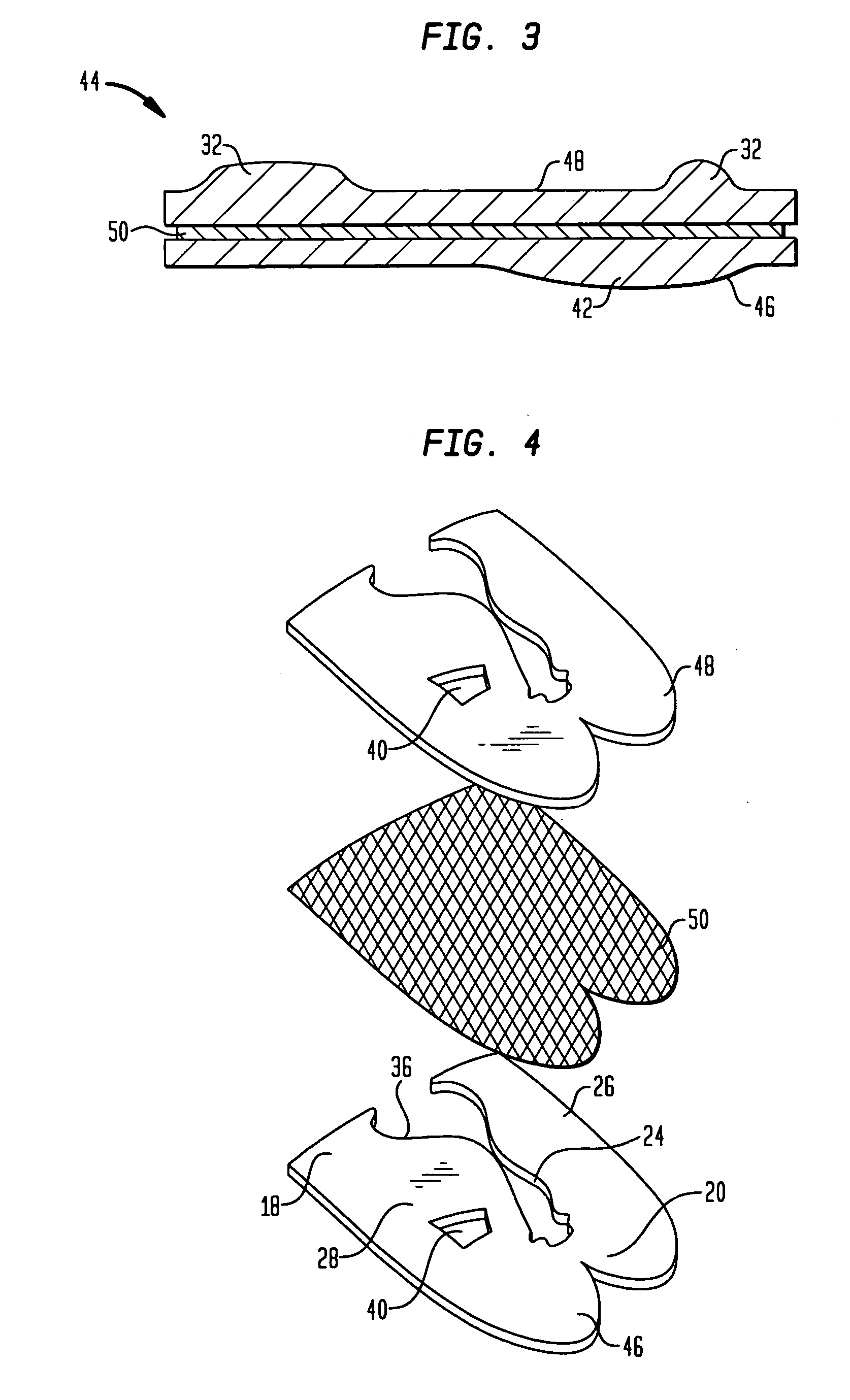

Compression molded footwear and methods of manufacture

Owner:THE TIMBERLAND COMPANY

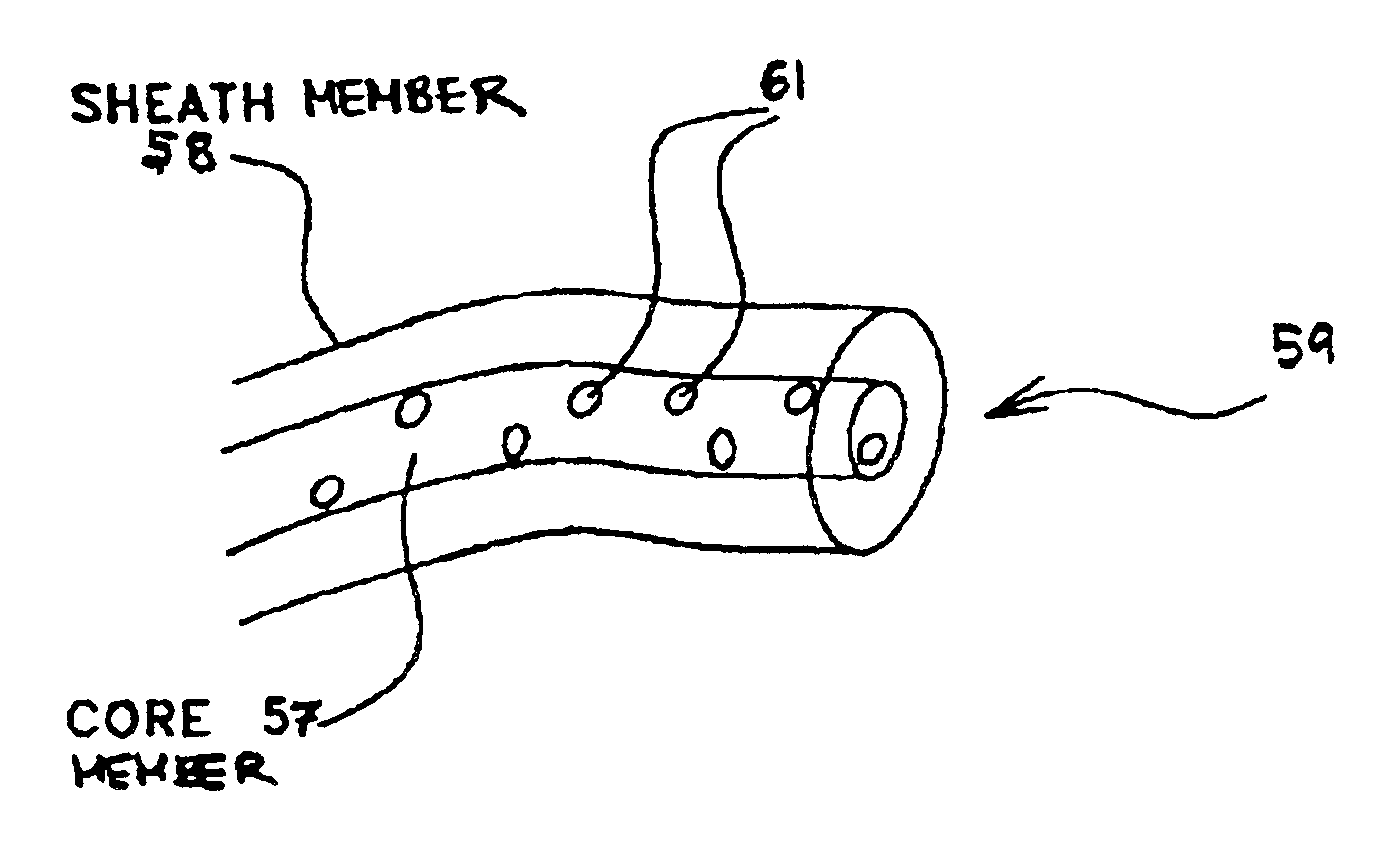

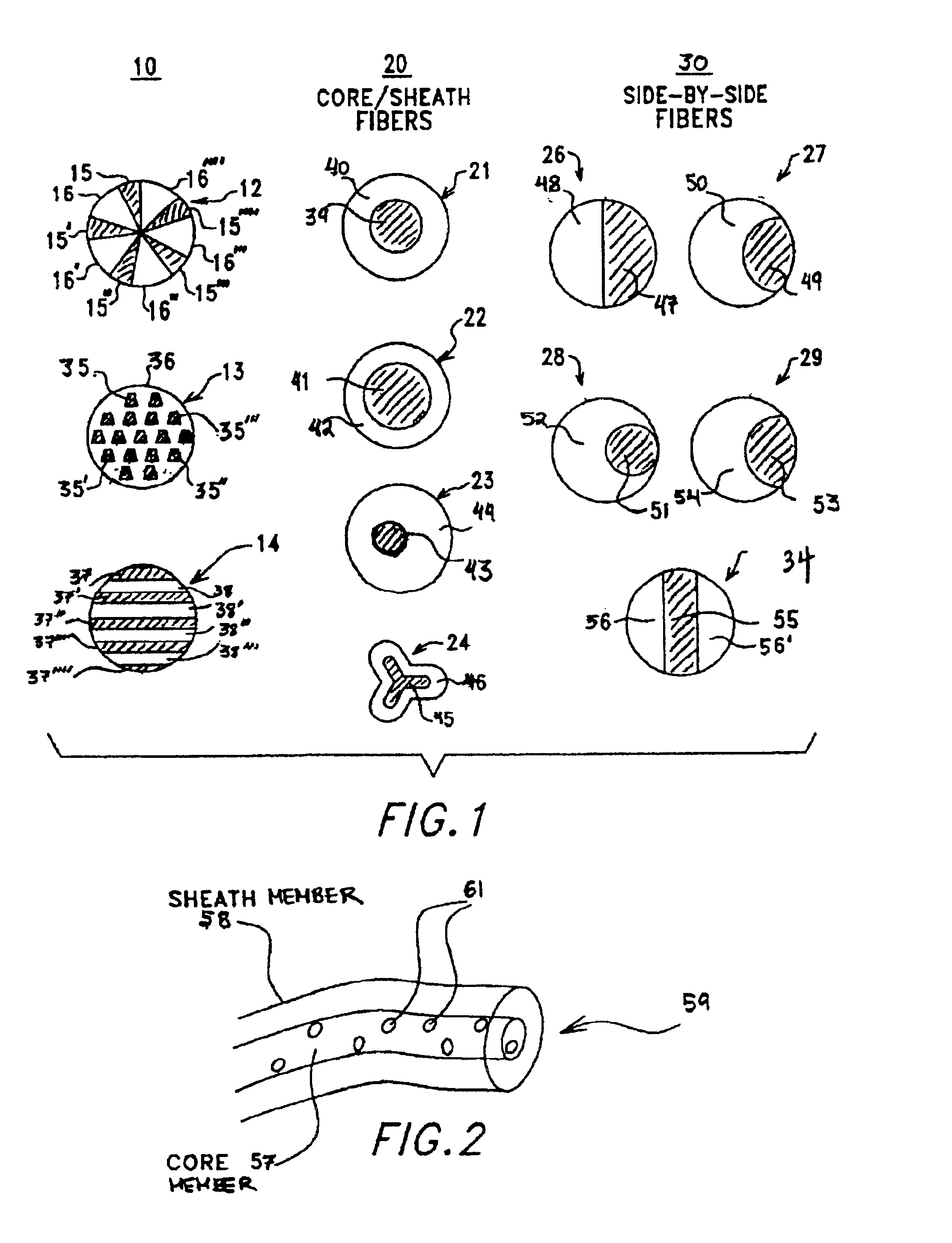

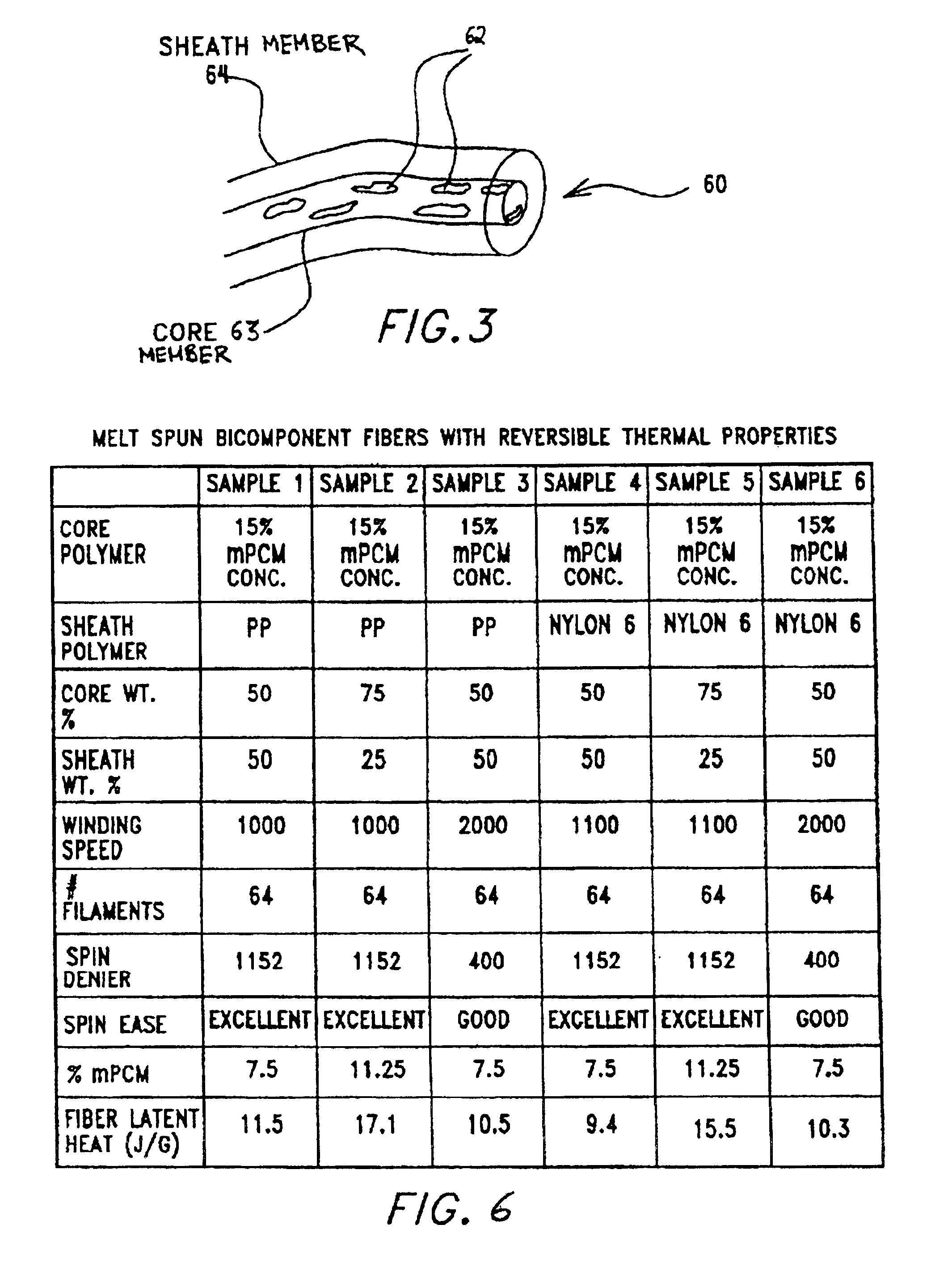

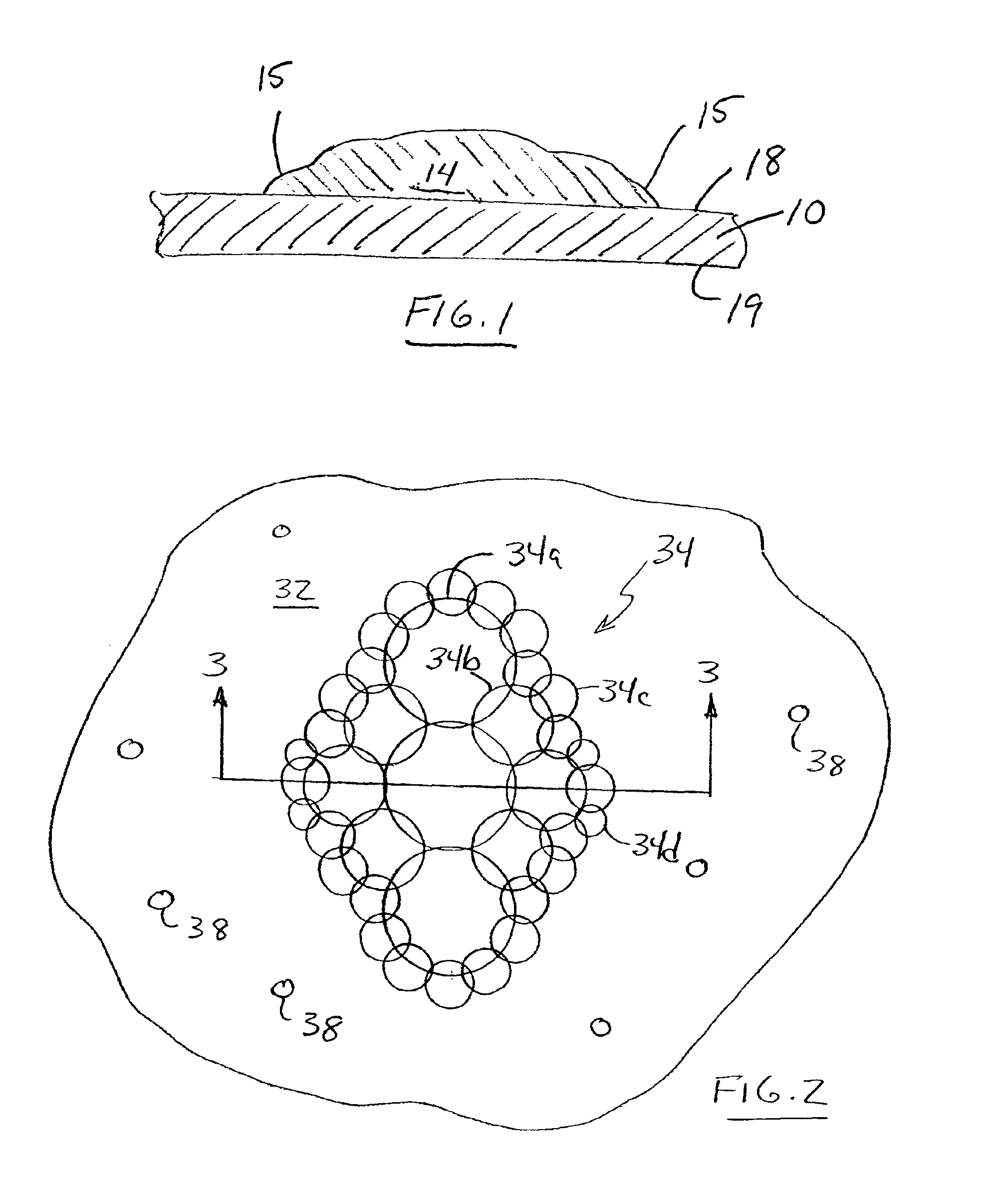

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

InactiveUS6855422B2Easy to processImprove propertiesHeat storage plantsWarp knittingMedical productPhase-change material

The invention relates to a multi-component fiber having enhanced reversible thermal properties and methods of manufacturing thereof. The multi-component fiber comprises a fiber body formed from a plurality of elongated members, at least one of the elongated members comprising a temperature regulating material dispersed therein. The temperature regulating material comprises a phase change material. The multi-component fiber may be formed via a melt spinning process or a solution spinning process and may be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber may be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

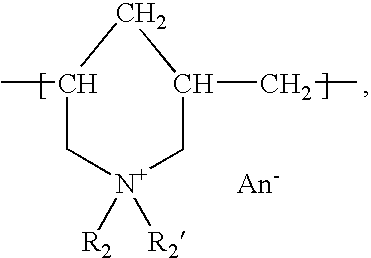

LbL-coated medical device and method for making the same

InactiveUS6926965B2Reduce charge densityImprove hydrophilicitySynthetic resin layered productsOptical articlesMedical deviceBiomedical engineering

The present invention provides a medical device, preferably an ophthalmic device, more preferably a contact lens, which comprises a core material and a biocompatible LbL coating non-covalently attached to said core material. The biocompatible LbL coating comprises at least one charge / non-charge bilayer, wherein said charge / non-charge bilayer is composed of, in no particular order, one layer of a charged polymeric material and one layer of a non-charged polymeric material which is capable of being non-covalently bond to the charged polymeric material.

Owner:ALCON INC

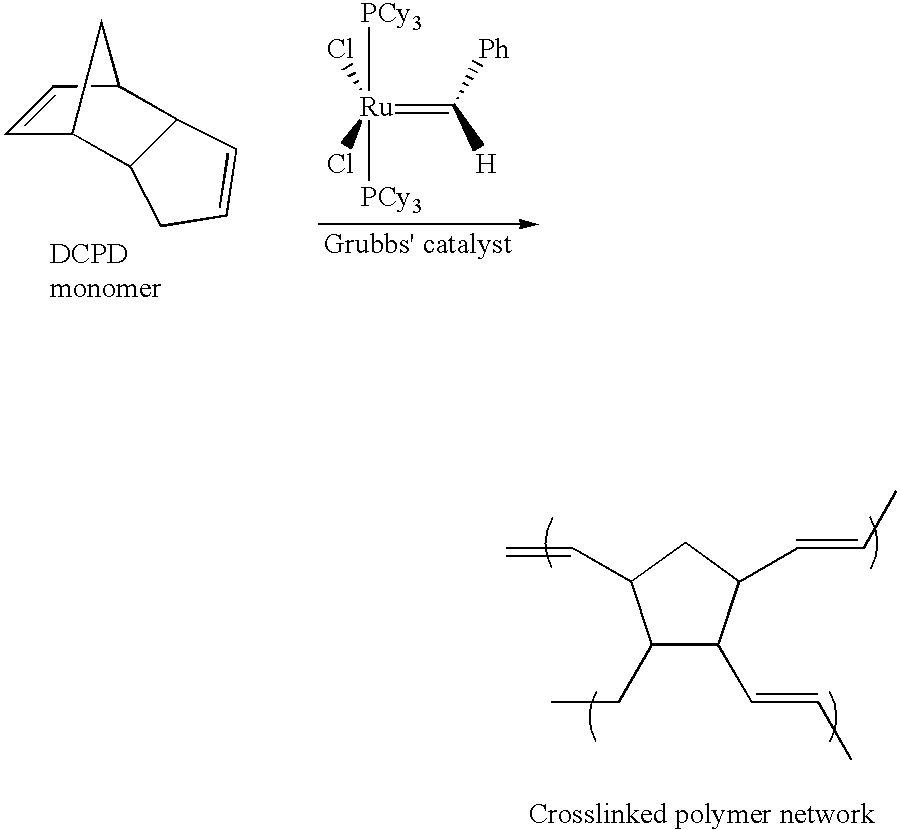

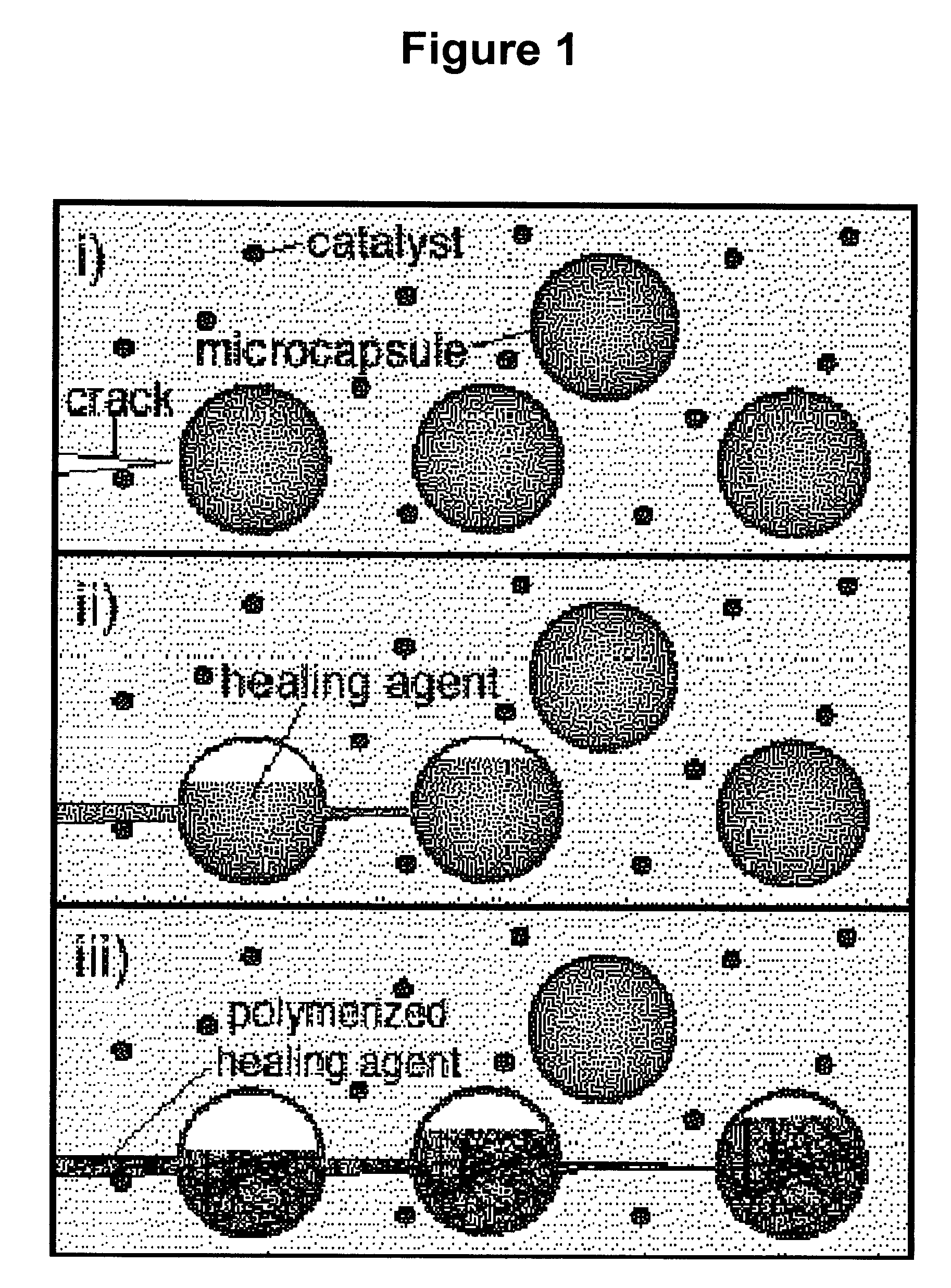

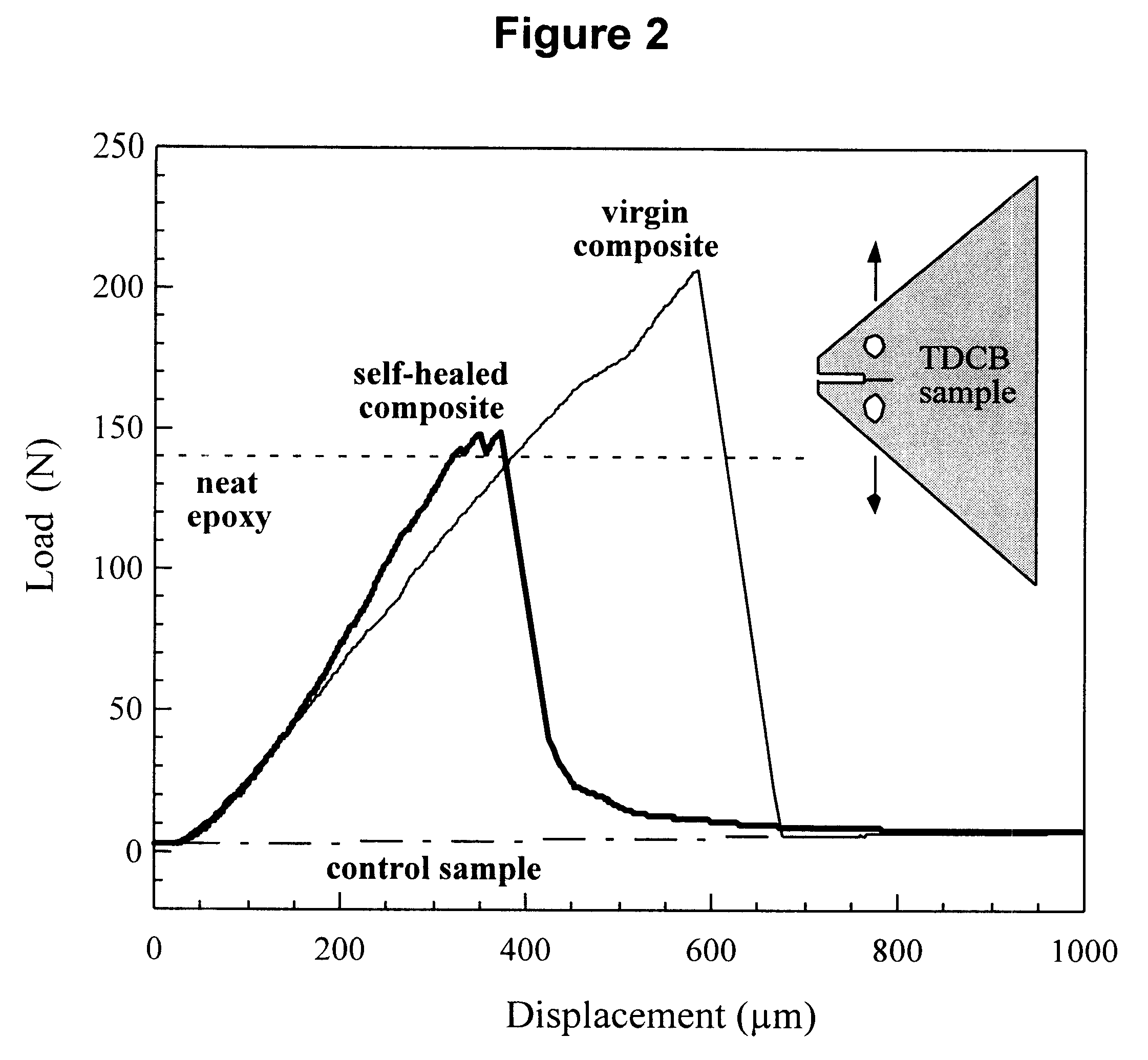

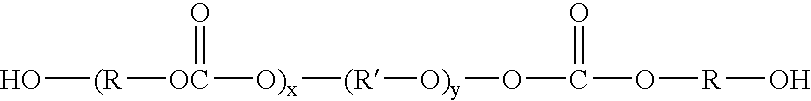

Multifunctional autonomically healing composite material

InactiveUS6518330B2Improve adhesionSynthetic resin layered productsCellulosic plastic layered productsSelf-healingPolymer

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

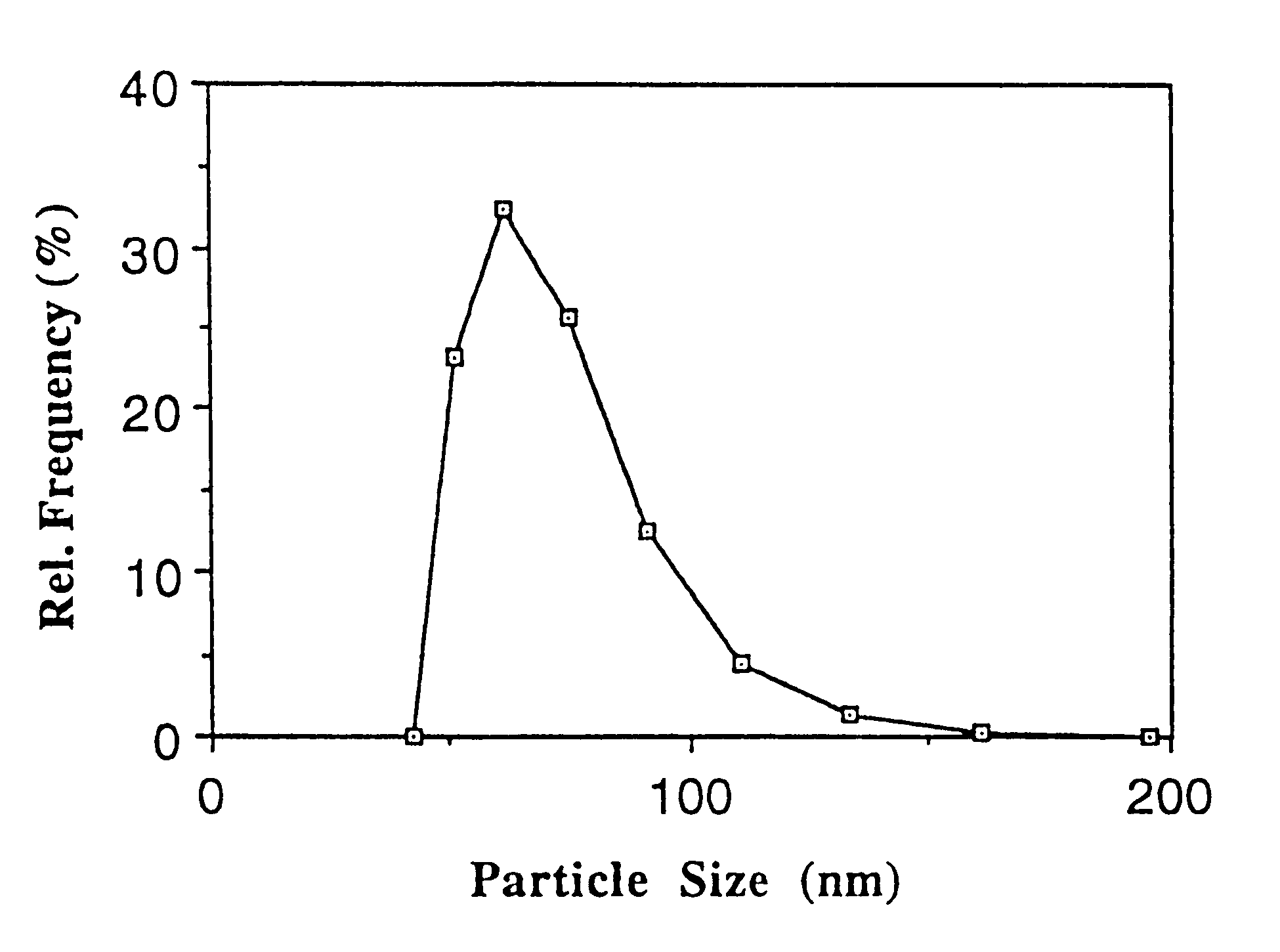

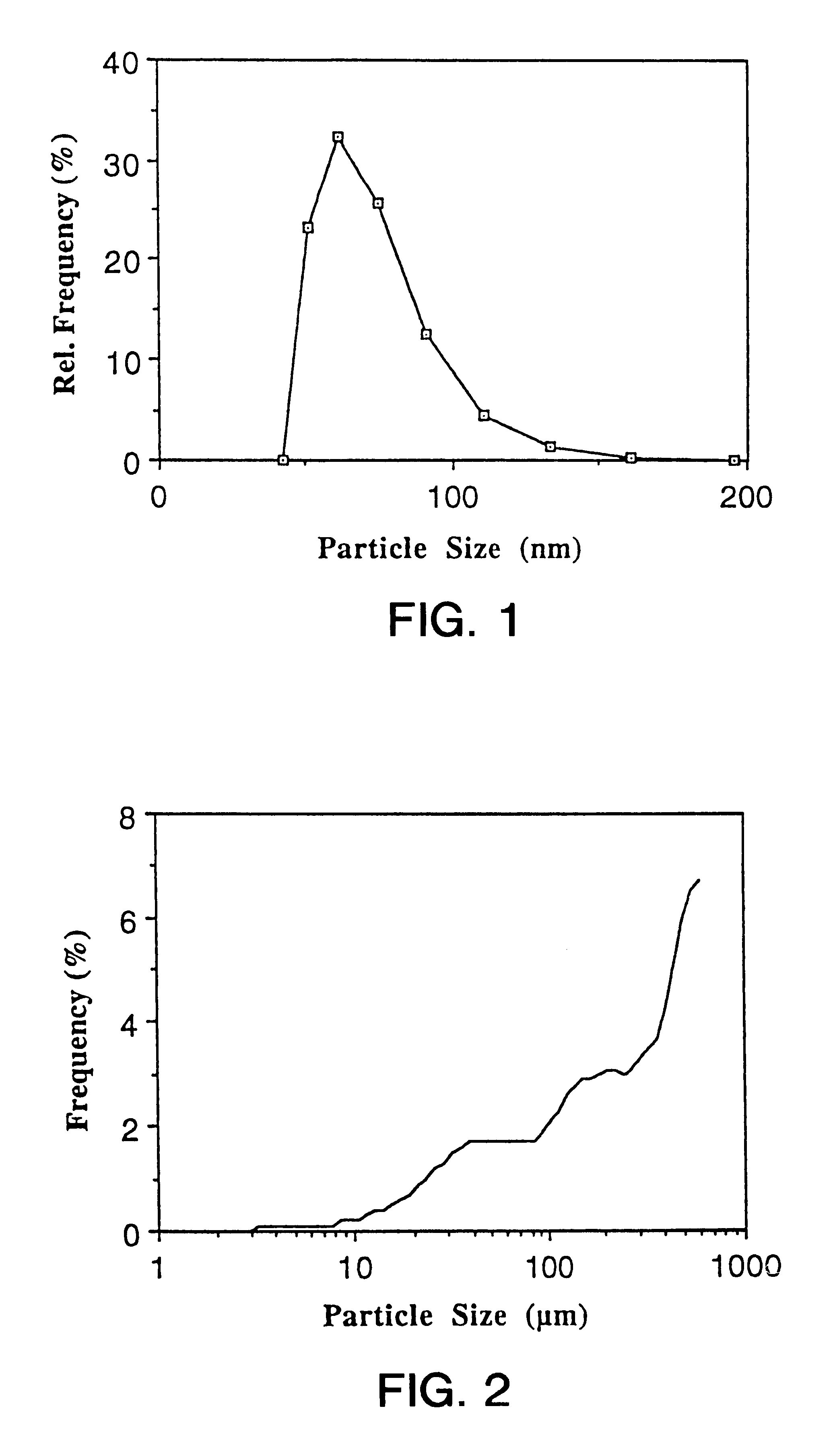

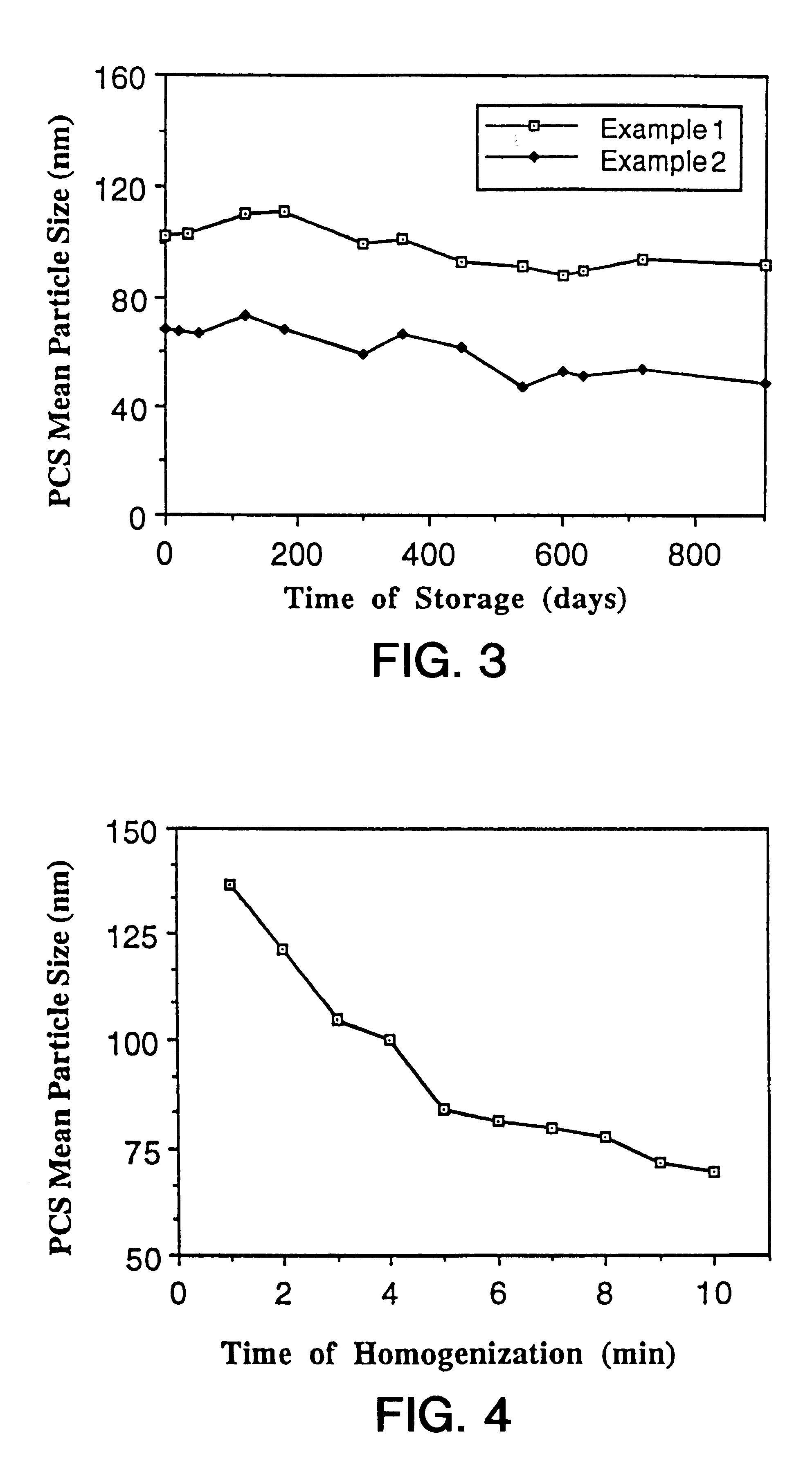

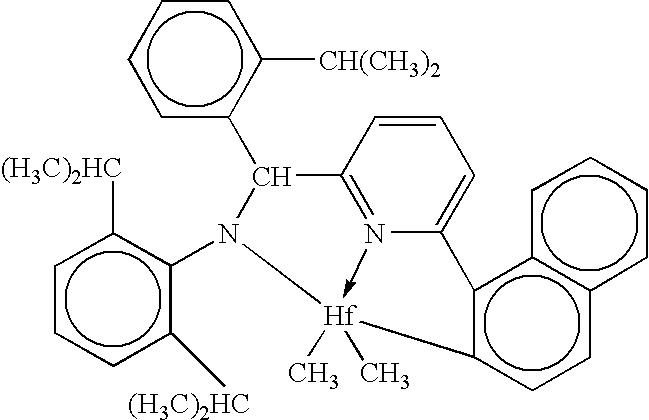

Particles with modified physicochemical properties, their preparation and uses

InactiveUS6197349B1Easy to handleImprove bioavailabilityPowder deliveryOrganic active ingredientsActive agentDelivery system

Particles comprising(a) a supercooled melt of a poorly water-soluble substance and(b) a stabilizing agent,which have a mean particle size of between 30 and 500 nm, and disperse compositions containing them, as administration forms and delivery systems for drugs, vaccines and other biologically active agents such as herbicides, pesticides, insecticides, fungicides, fertilizers, vitamins, nutrition additives and cosmetics.

Owner:MSE PHARMA

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

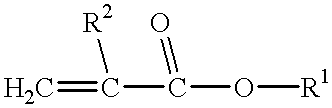

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS20060199006A1Monocomponent synthetic polymer artificial filamentWoven fabricsFiberAlpha-olefin

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

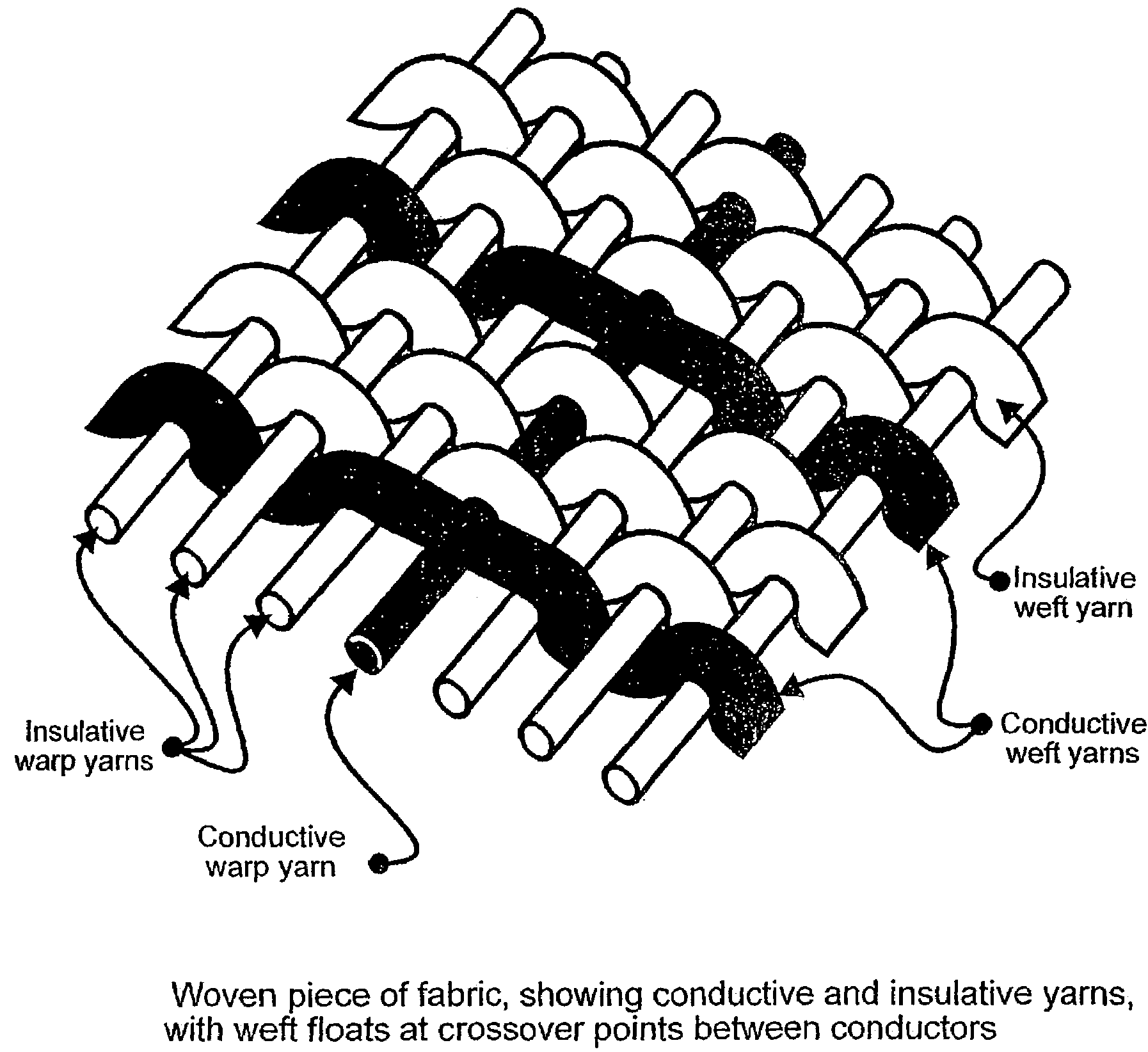

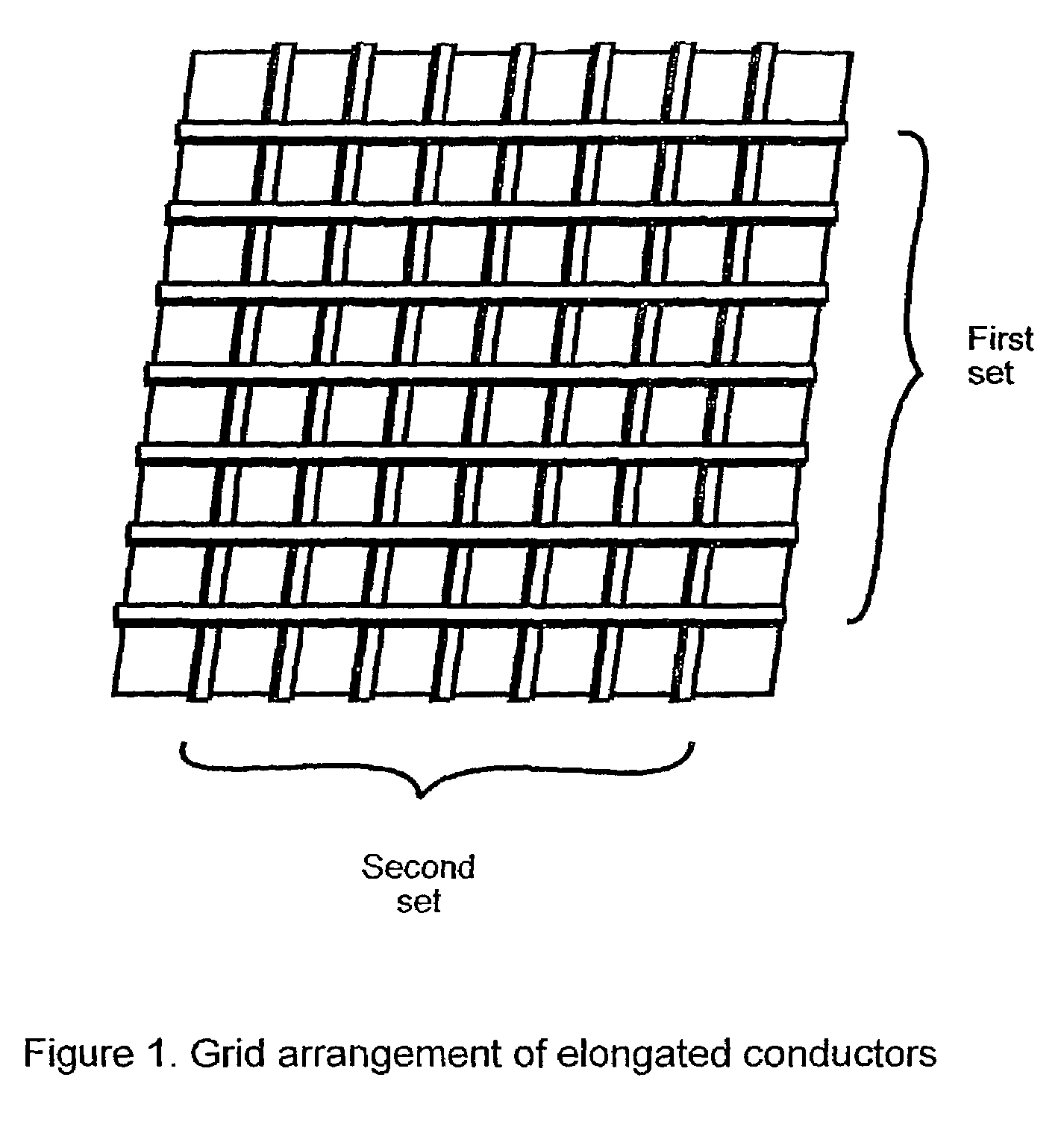

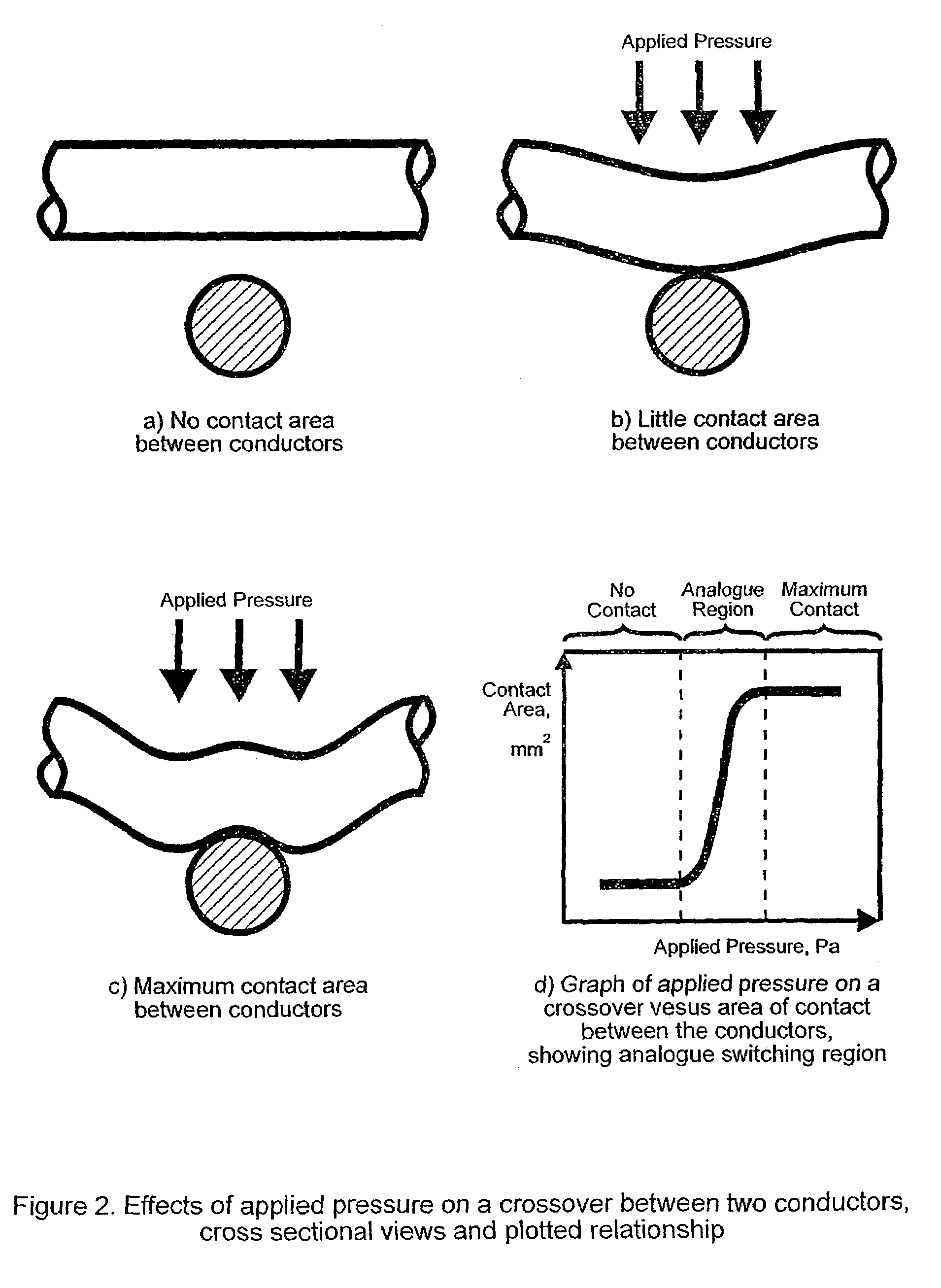

Conductive pressure sensitive textile

InactiveUS7365031B2Low production costReduce edge effectsForce measurementInsulated cablesElectrical conductorEngineering

A fabric including within its construction a first elongated electrical conductor crossed by a second elongated electrical conductor, the conductors being normally biased apart at a crossover point of said fibres with an air gap between them, whereby application of pressure in a direction substantially normal to a plane of the fabric causes the conductors to make contact. The fabric may be woven, knitted, non-woven or plaited. The fabric can be used as a pressure sensor, switch or other sensor.

Owner:INTELLIGENT TEXTILES

Silane copolymer coatings

InactiveUS6908681B2Maintain good propertiesImprove adhesionMale contraceptivesSurgerySilanesMedical device

Owner:CR BARD INC

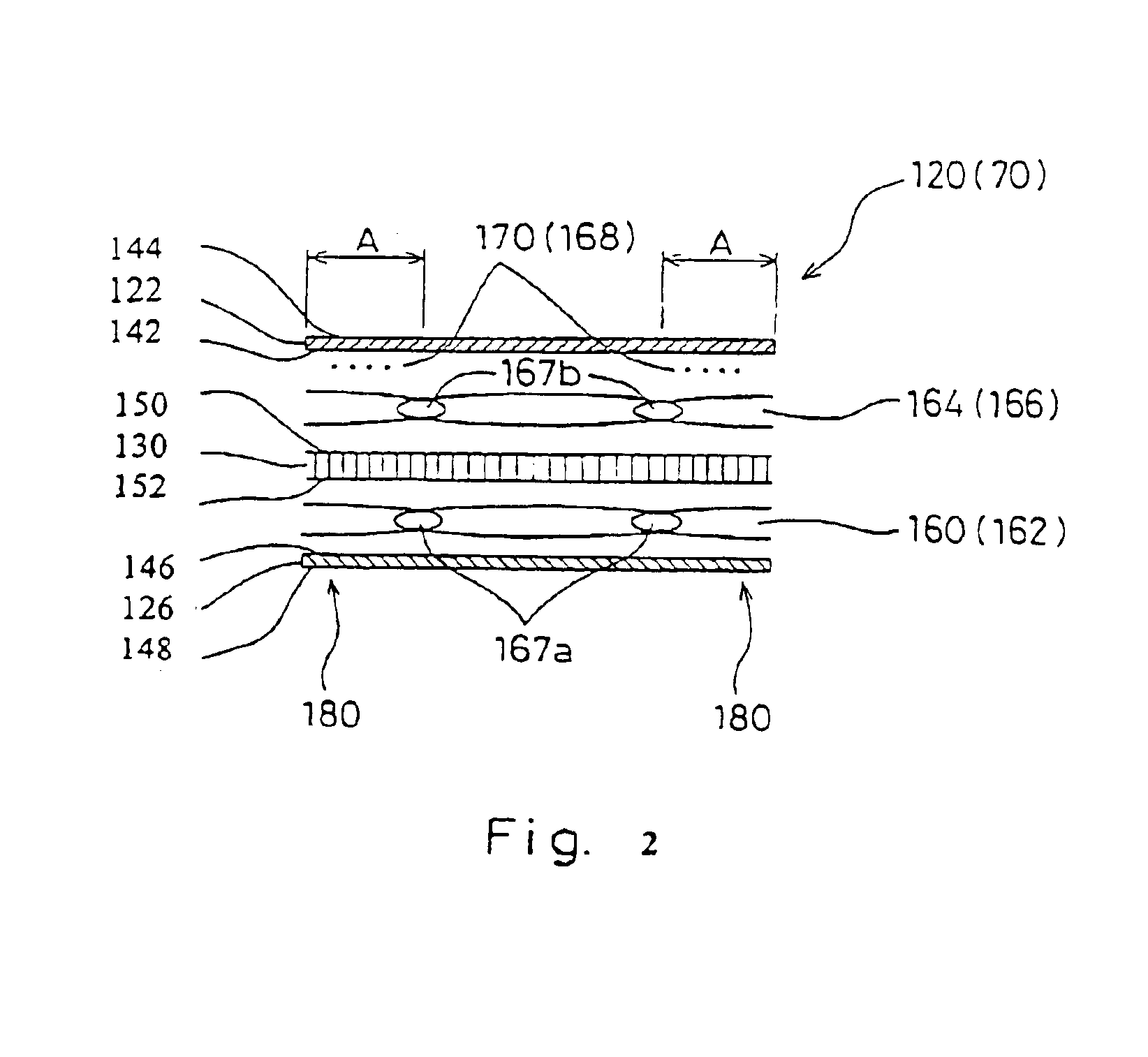

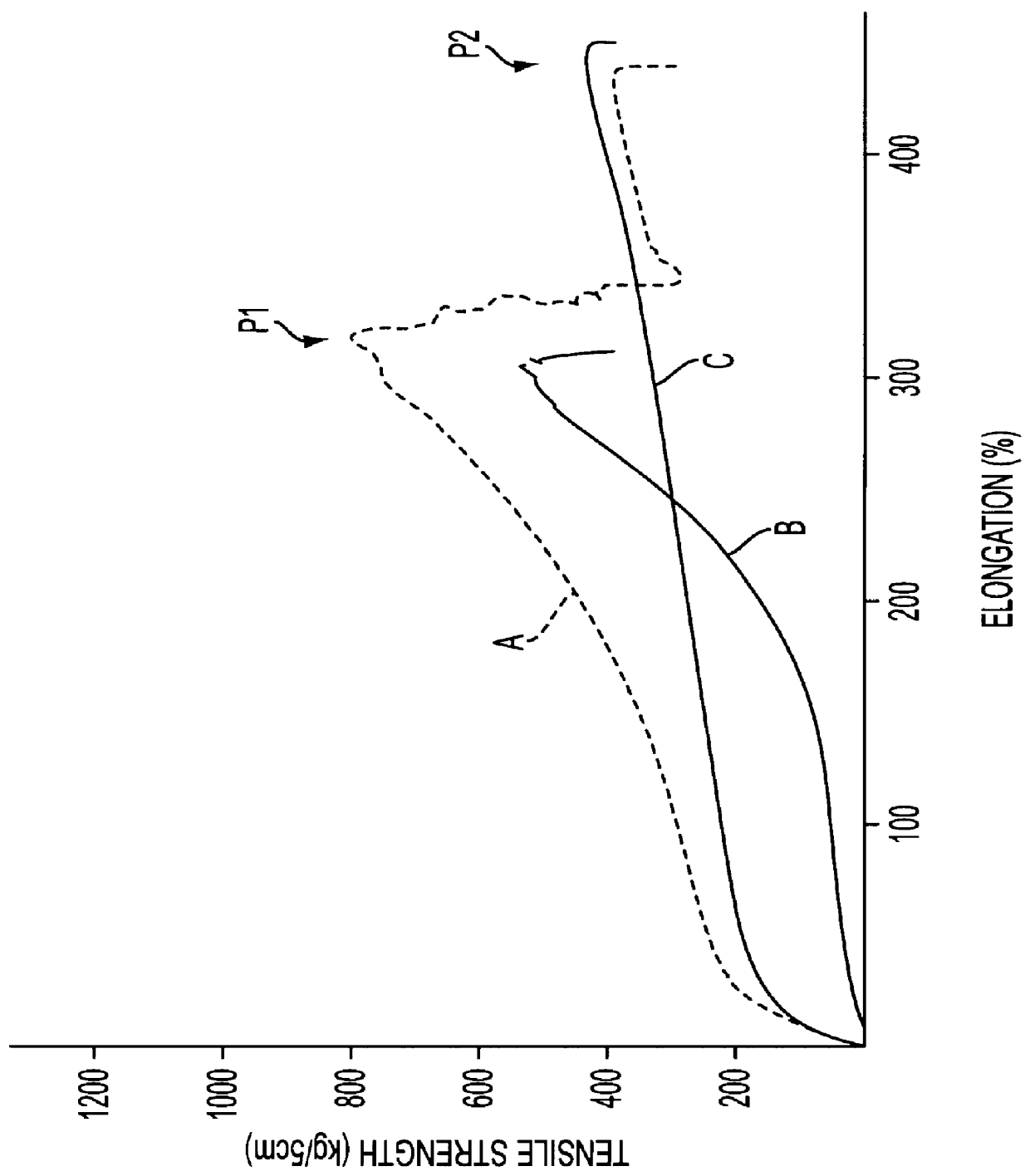

Composite elastic material having multistage elongation characteristics and method of manufacturing the same

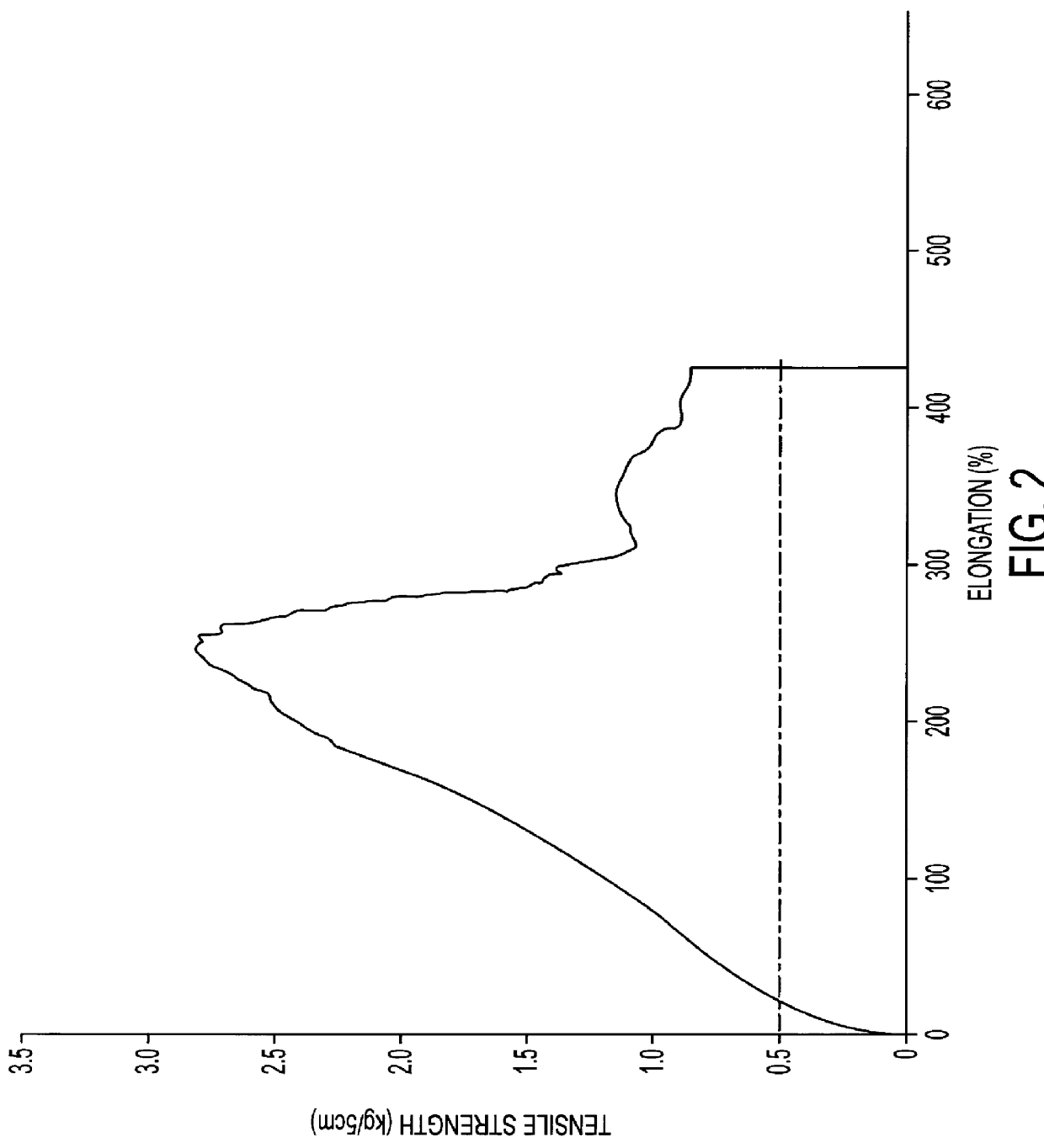

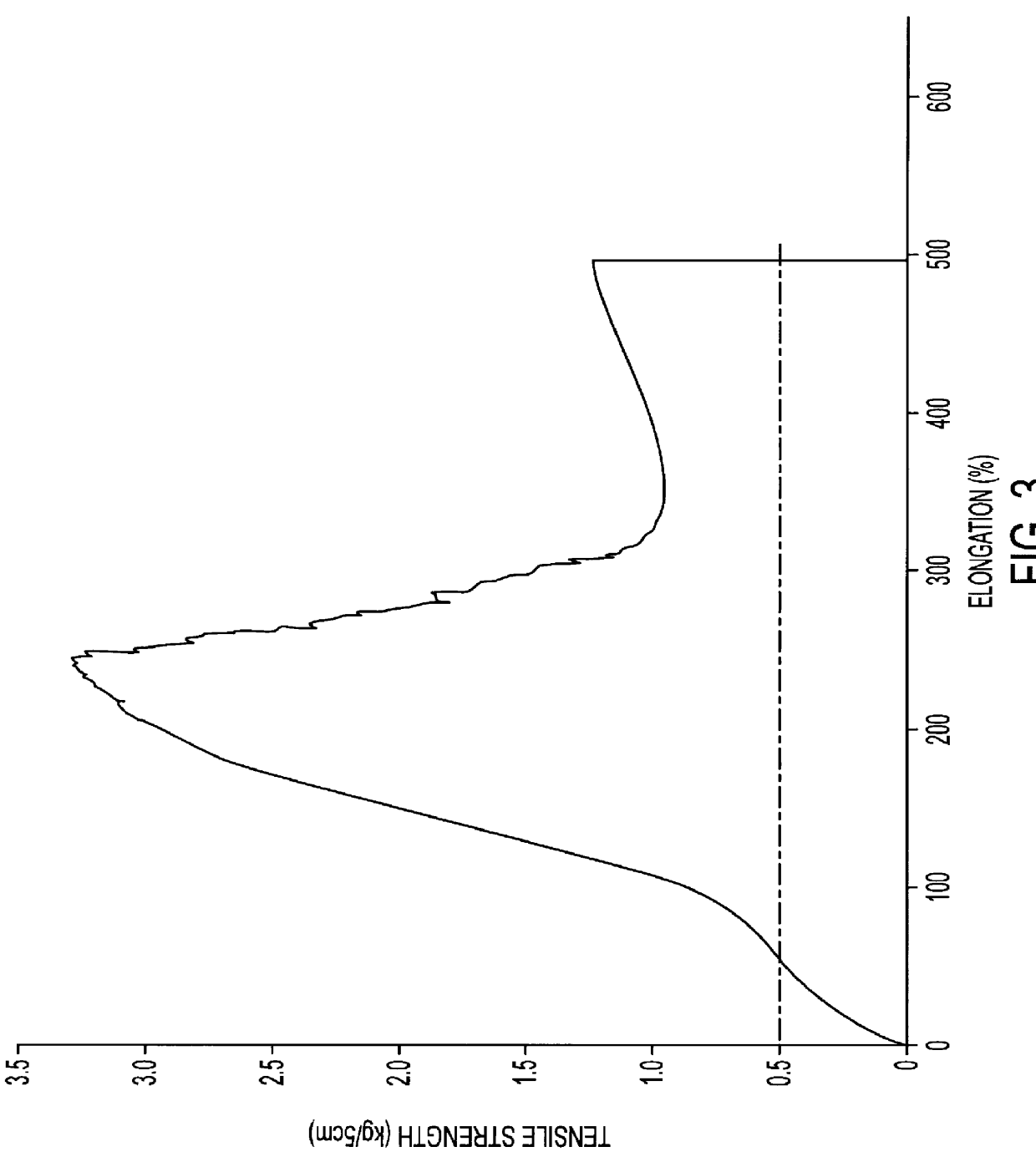

PCT No. PCT / JP96 / 00041 Sec. 371 Date Sep. 16, 1997 Sec. 102(e) Date Sep. 16, 1997 PCT Filed Jan. 12, 1996 PCT Pub. No. WO96 / 21760 PCT Pub. Date Jul. 18, 1996A composite elastic material comprises a non-woven fabric secured to an elastic member. The non-woven fabric is elastically stretchable by about 100% or more. The sheet-like elastic member has an elastic recovery of about 60% or more and a break-down elasticity of about 200% or more. The elastic member and the non-woven fabric are secured together at a plurality of points in the stretchable direction of the non-woven fabric. The composite elastic material has multiple-stage elongation characteristics including a first stress lowering point caused by changes in the structure of the non-woven fabric, and a second stress lowering point occurring at an elongation larger than that of the first stress lowering point, caused by the fracturing of the sheet-like elastic member. The elastic material clearly shows a break-down point when stretched, and increases the flexibility of designing various products.

Owner:PARAGON TRADE BRANDS

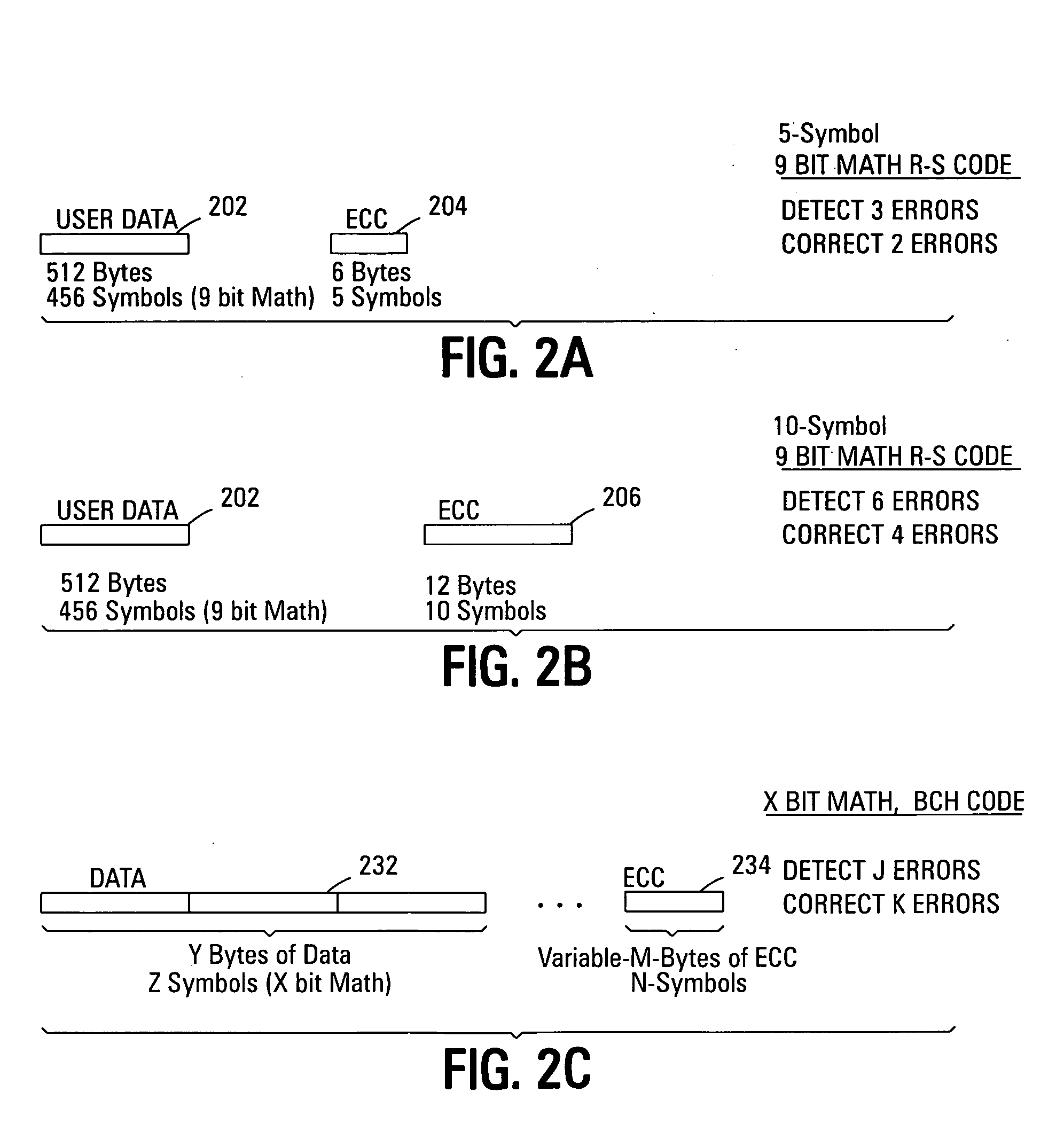

Variable Strength ECC

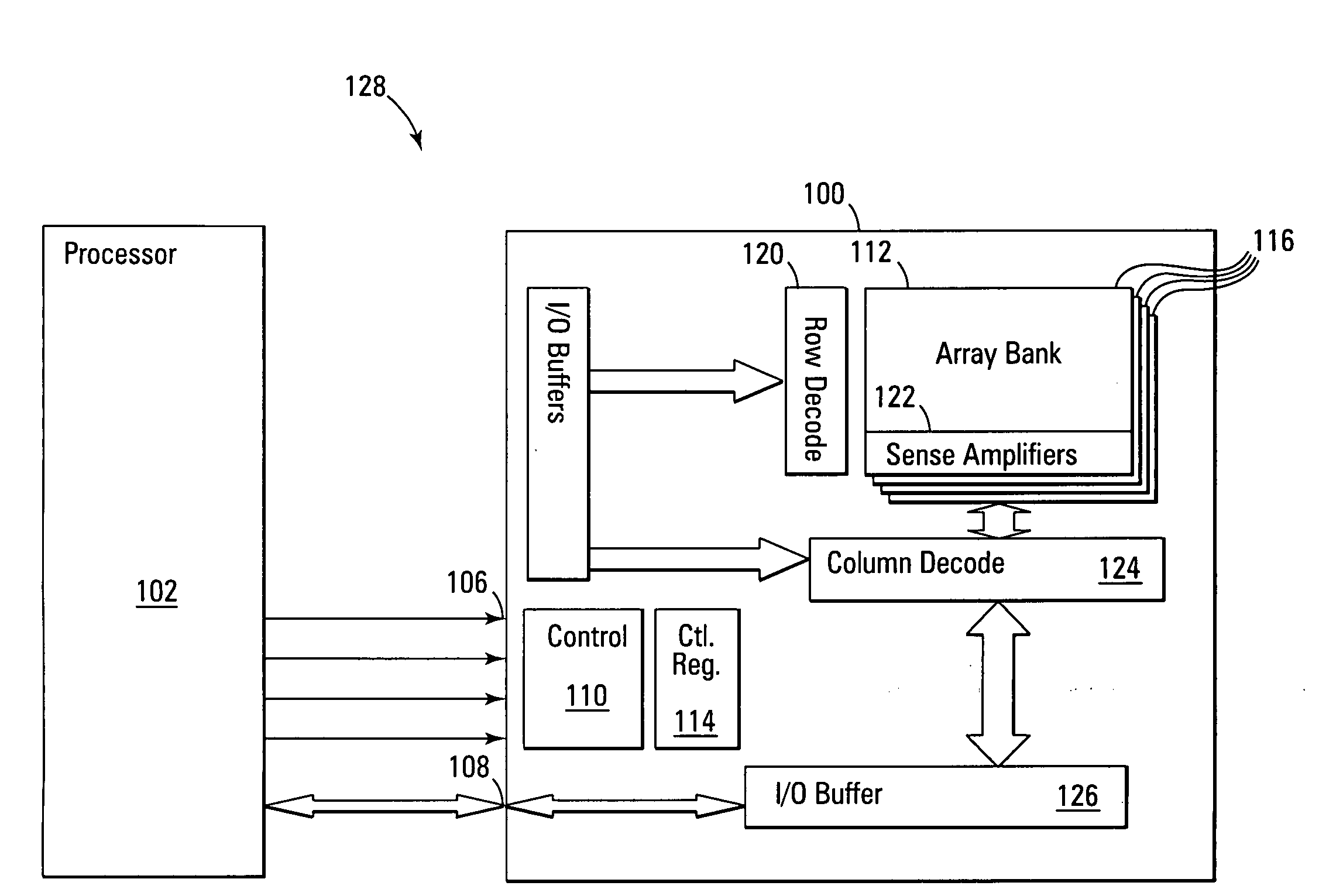

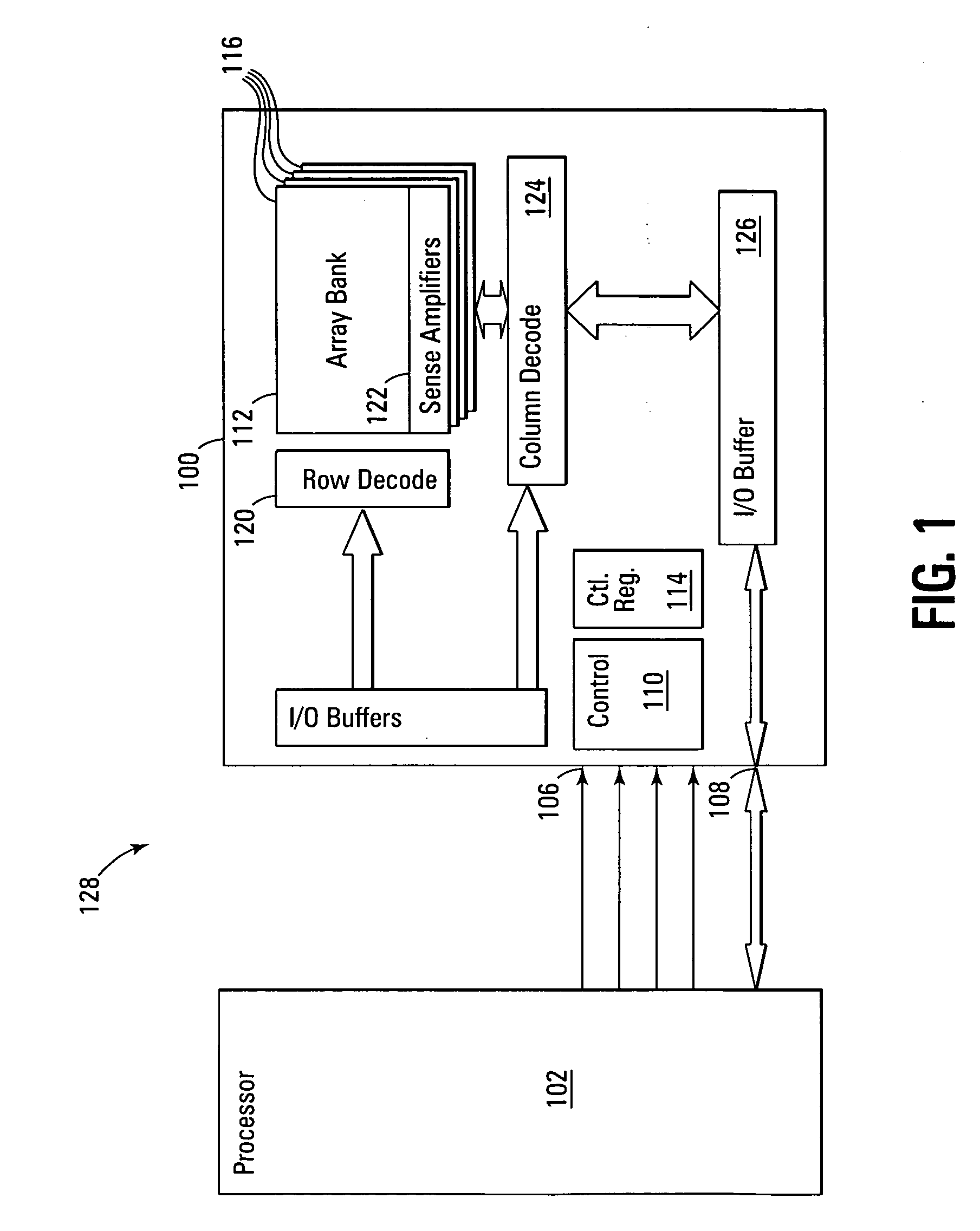

Memory devices, circuitry, and data methods are described that facilitate the detection and correction of data in memory controllers, memory systems, and / or non-volatile memory devices by allowing the number of ECC check bytes being utilized to be varied to increase or decrease the ECC check depth. This allows the depth of the ECC coverage (the overall number of bit errors detectable and / or correctable in each sector by the stored ECC check bytes) to be selected based on the application, the amount of available data storage for ECC check bytes in the overhead / spare area associated with the sector, the version of memory device or controller being utilized, or the number of errors being seen in the memory system, device, bank, erase block, or sector (the error incidence rate), while the base data size of the area (sector) covered by the ECC check bytes stays the same.

Owner:MICRON TECH INC

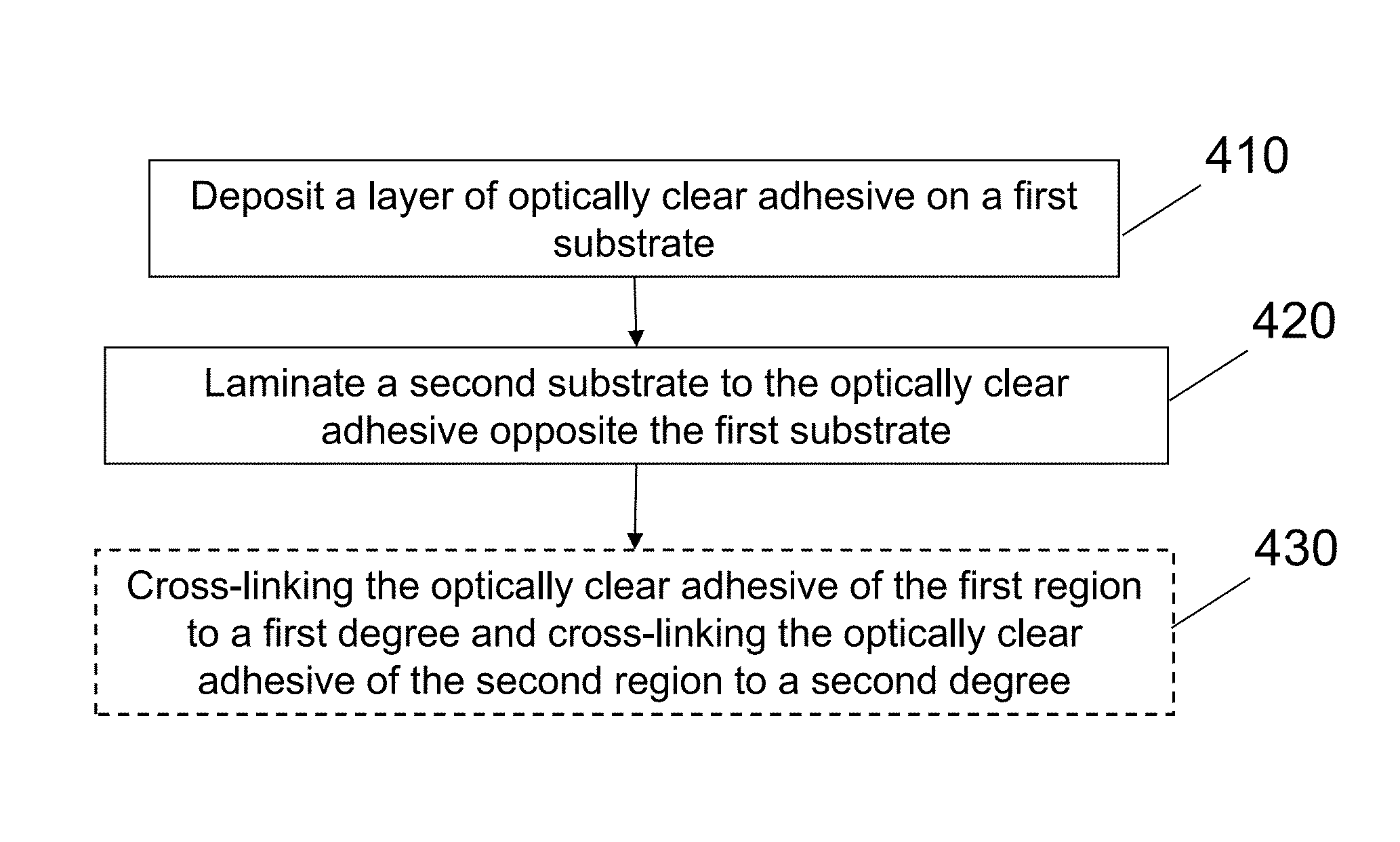

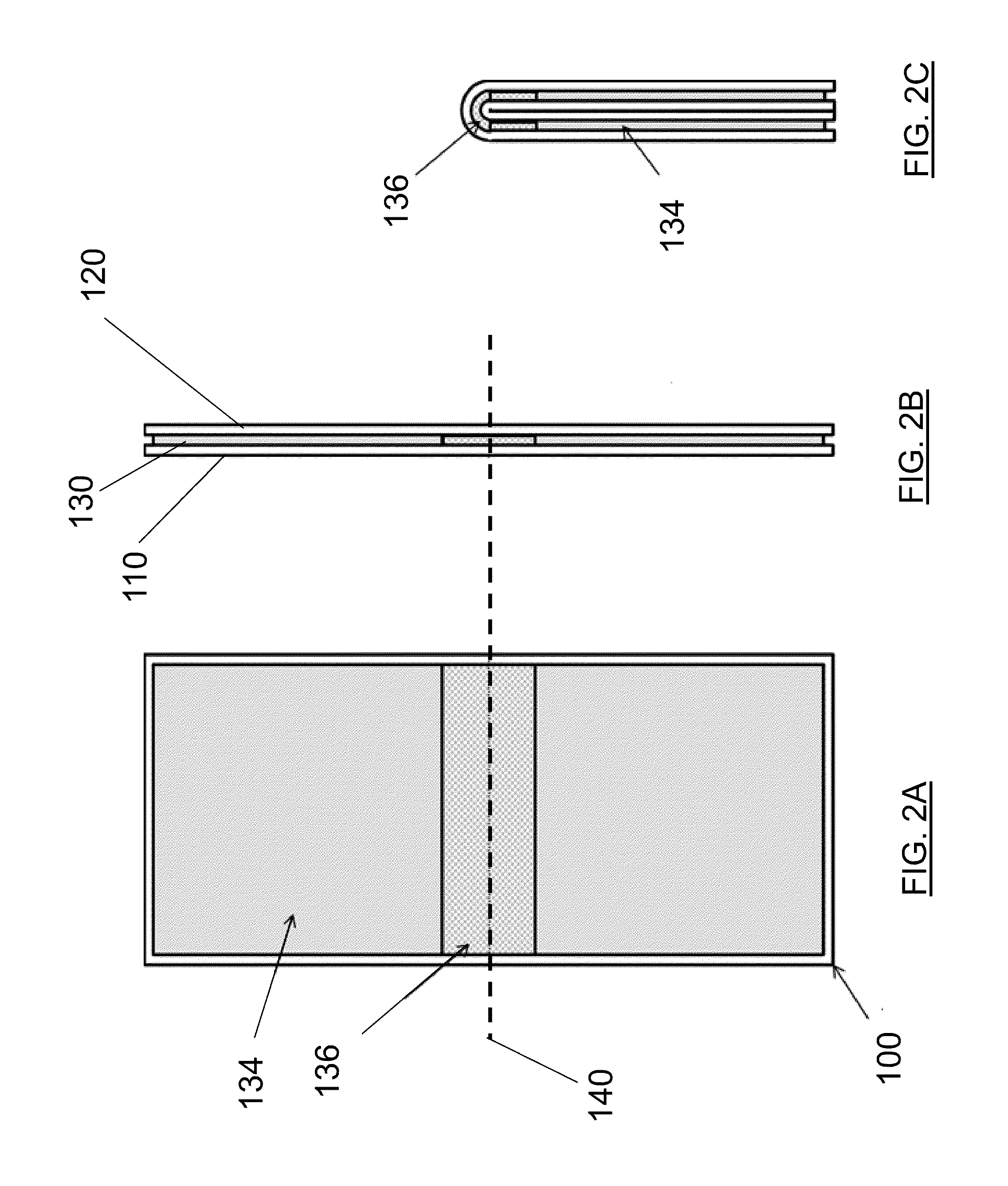

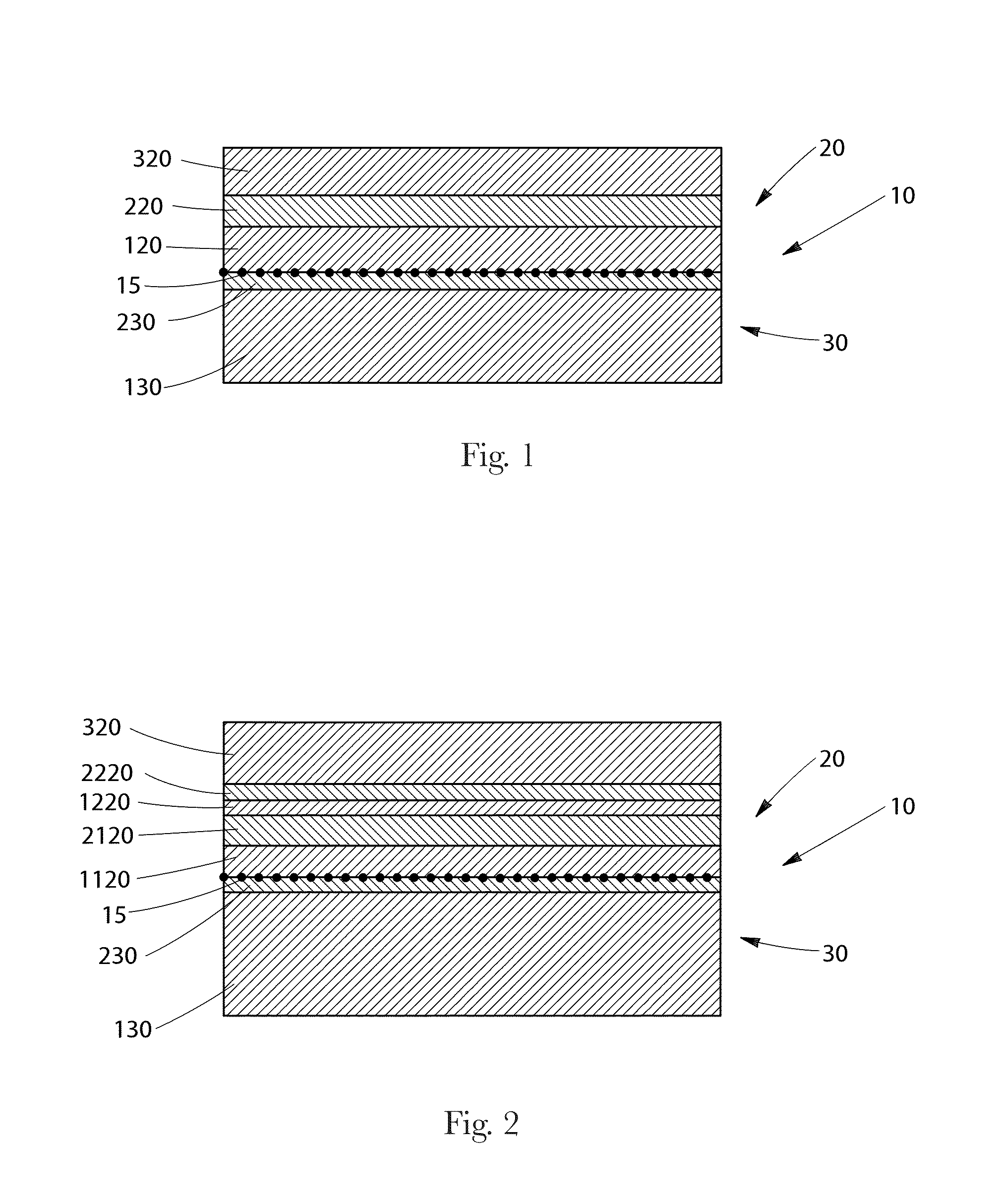

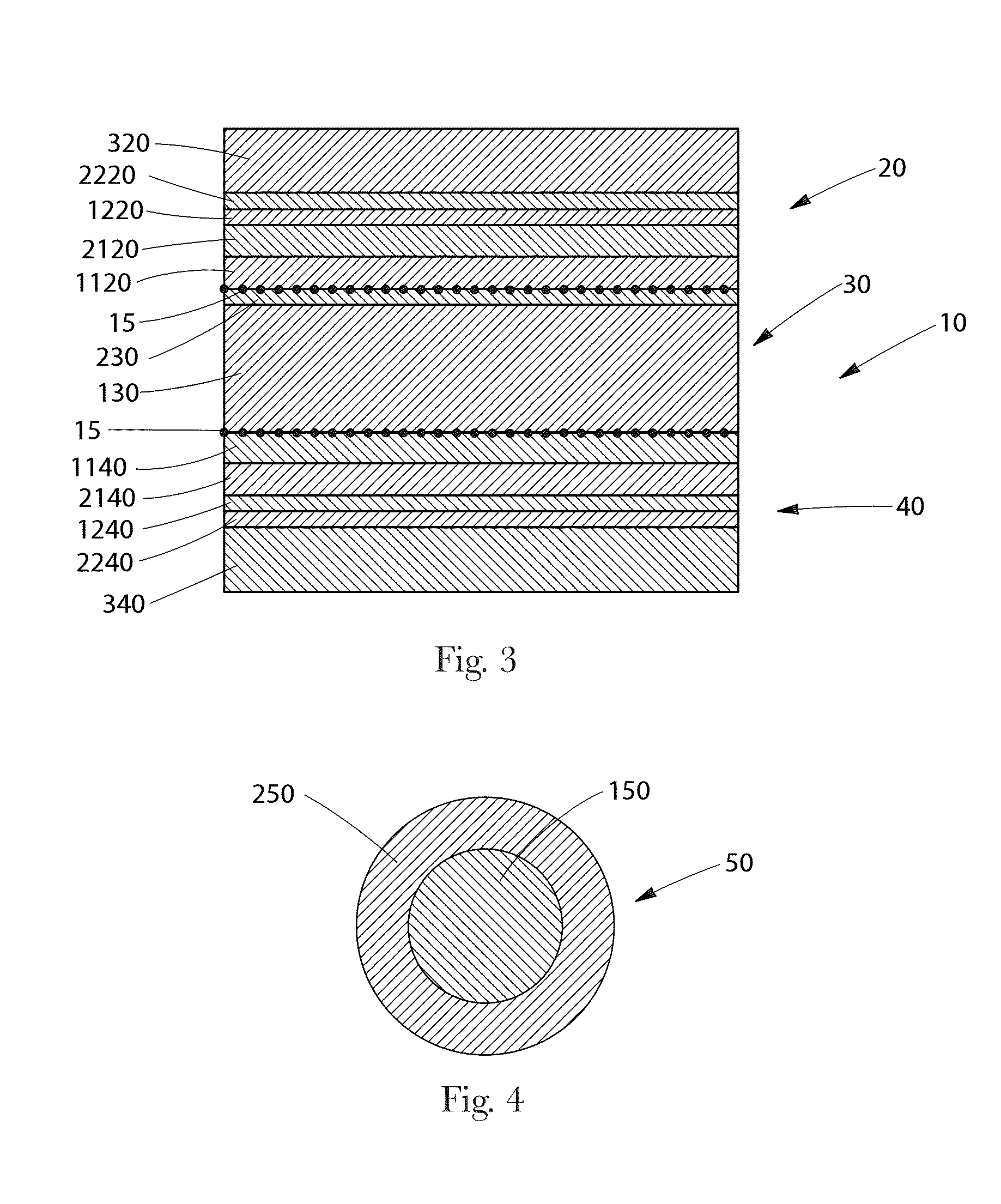

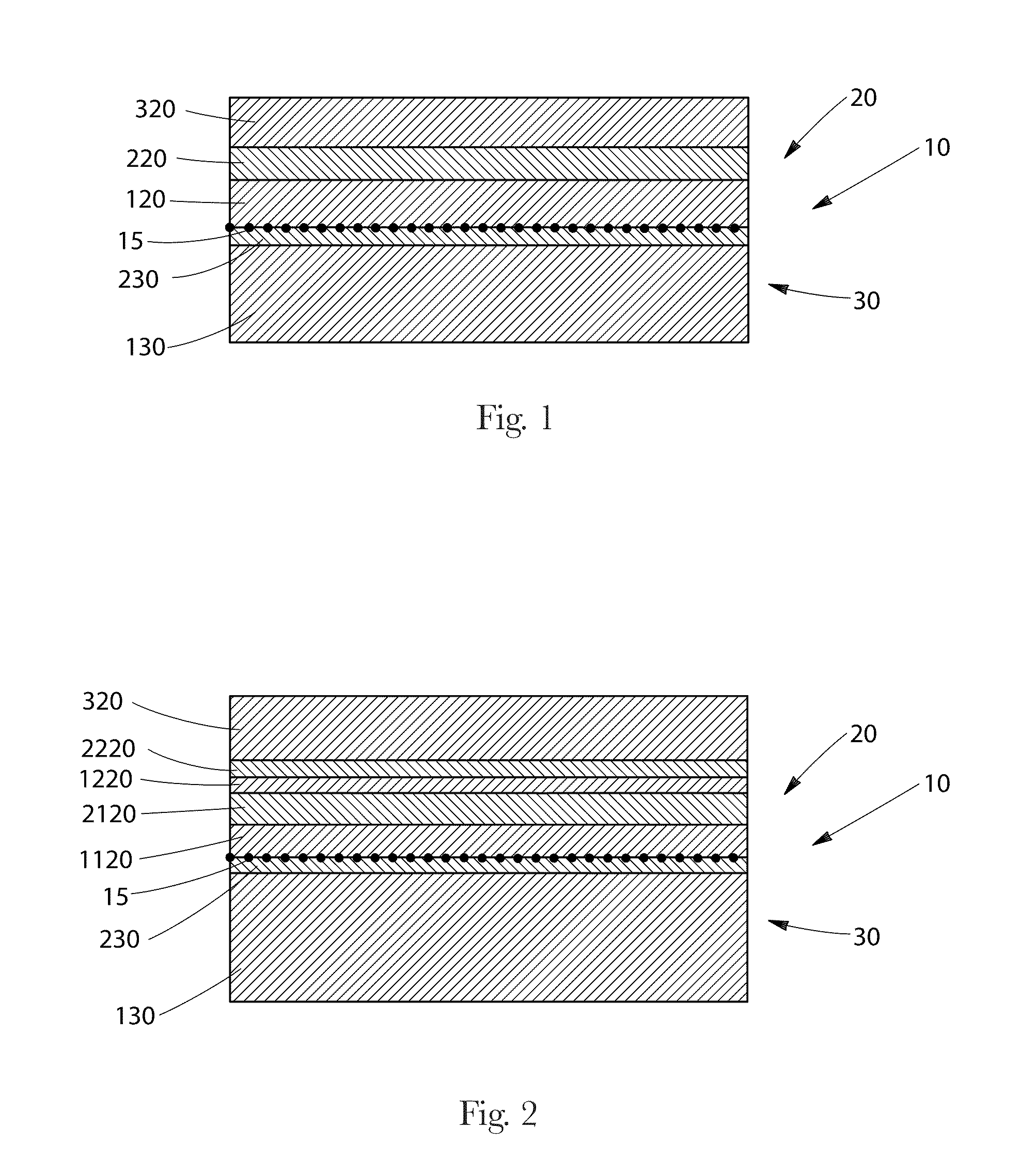

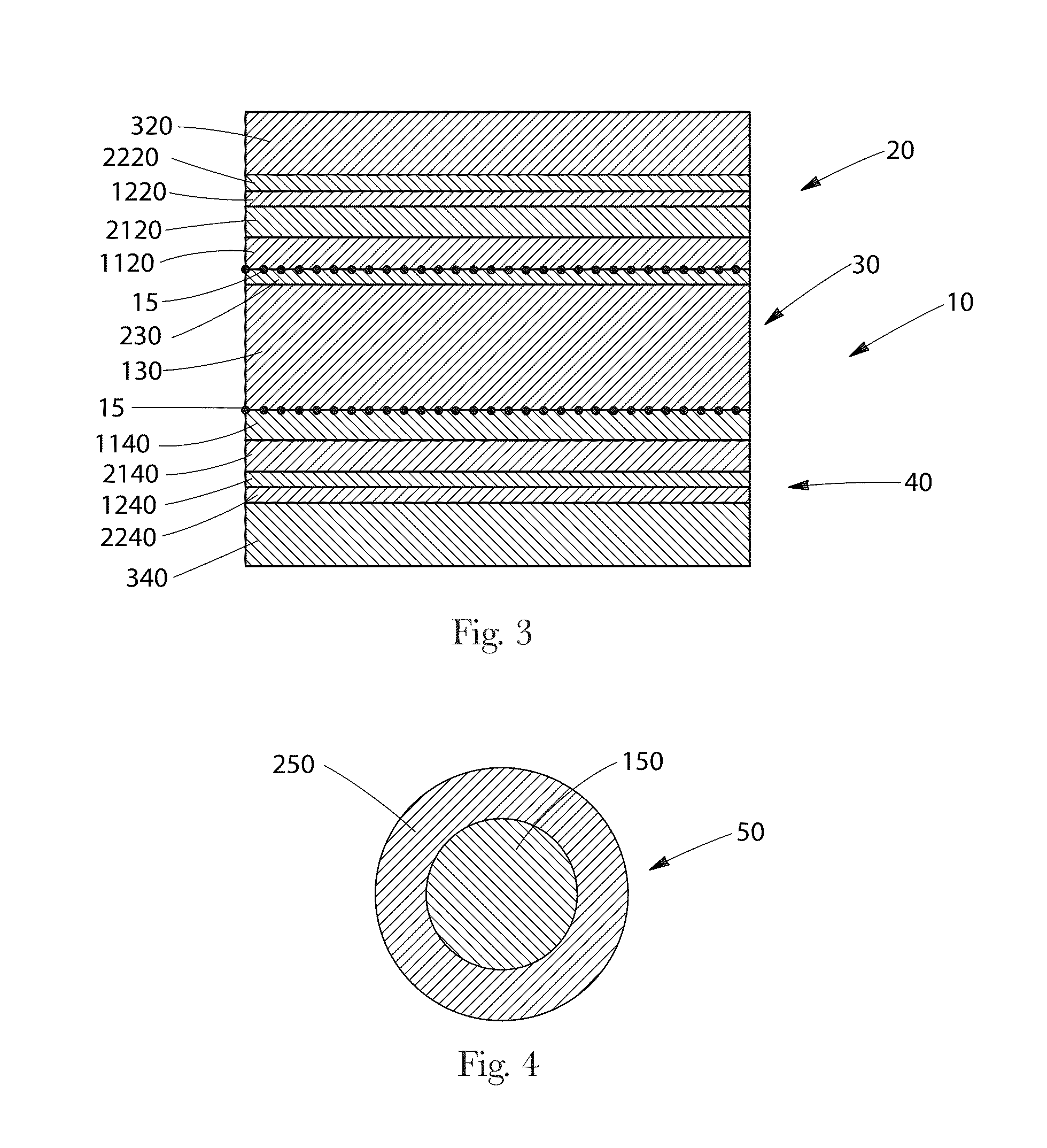

Method and apparatus for joining together multiple functional layers of a flexible display

ActiveUS20140295150A1Increase flexibilityIncrease display flexibilityFinal product manufactureFilm/foil adhesives without carriersOptical propertyAdhesive

The present invention may relate to provision of a mechanism to join together the various substrate layers of a flexible display with optically clear adhesives that permit improved flexibility of the substrate layer stack and may also optically guide images to locations on a display surface that are not aligned with the display layer of a substrate layer stack. Embodiments of the present invention may provide for an improved user interface which may include enhanced flexibility and enhanced optical characteristics.

Owner:LYTEN INC

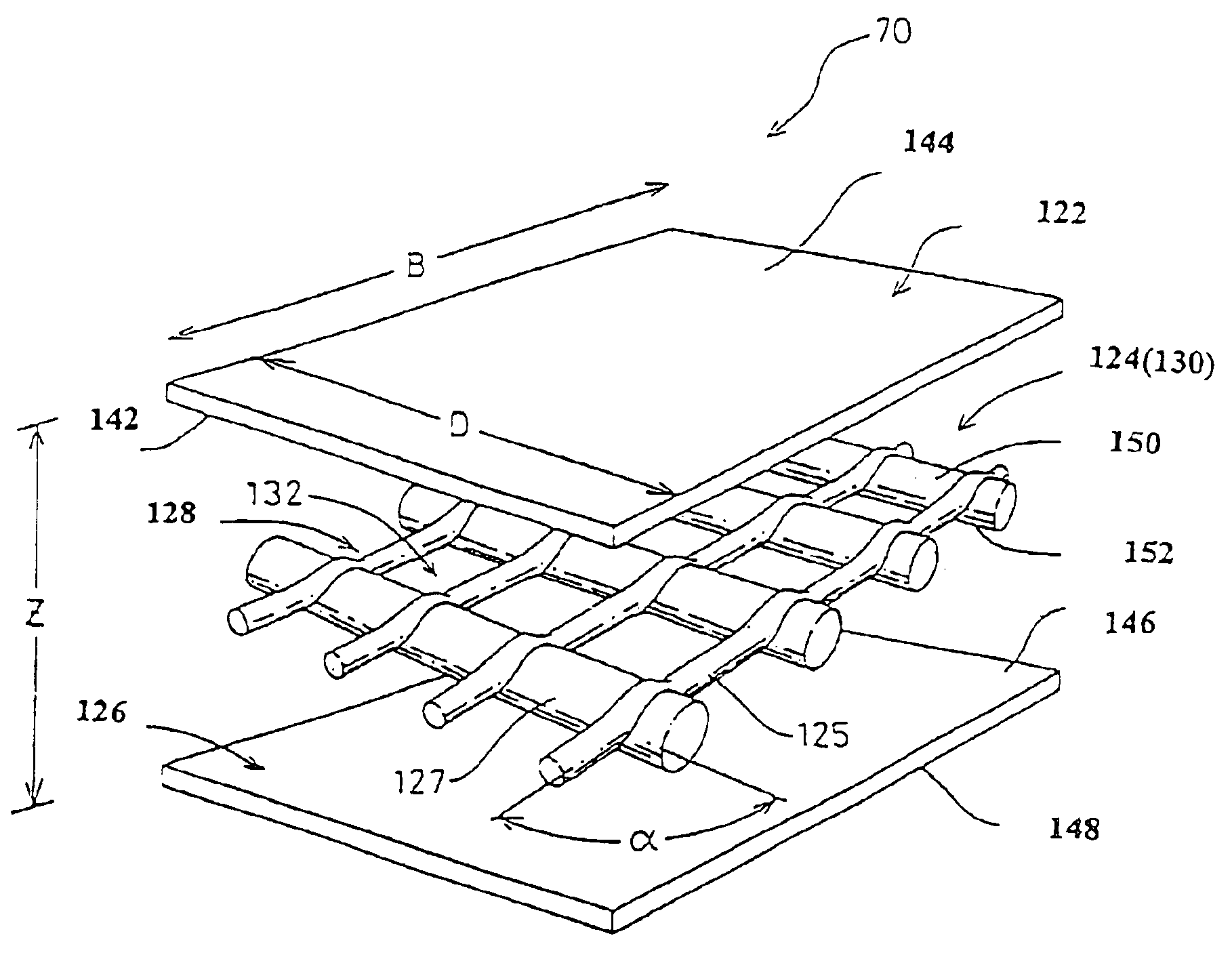

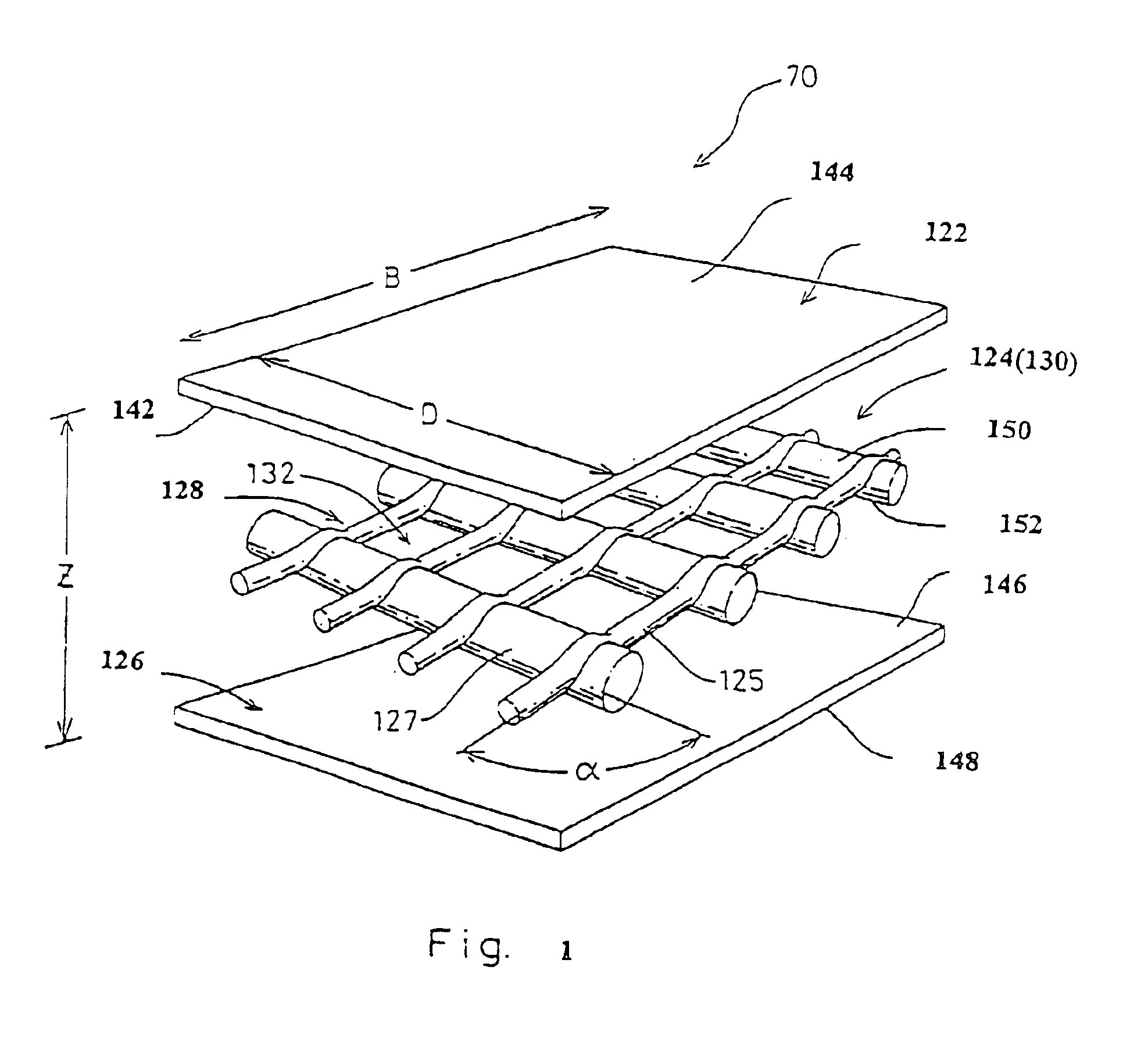

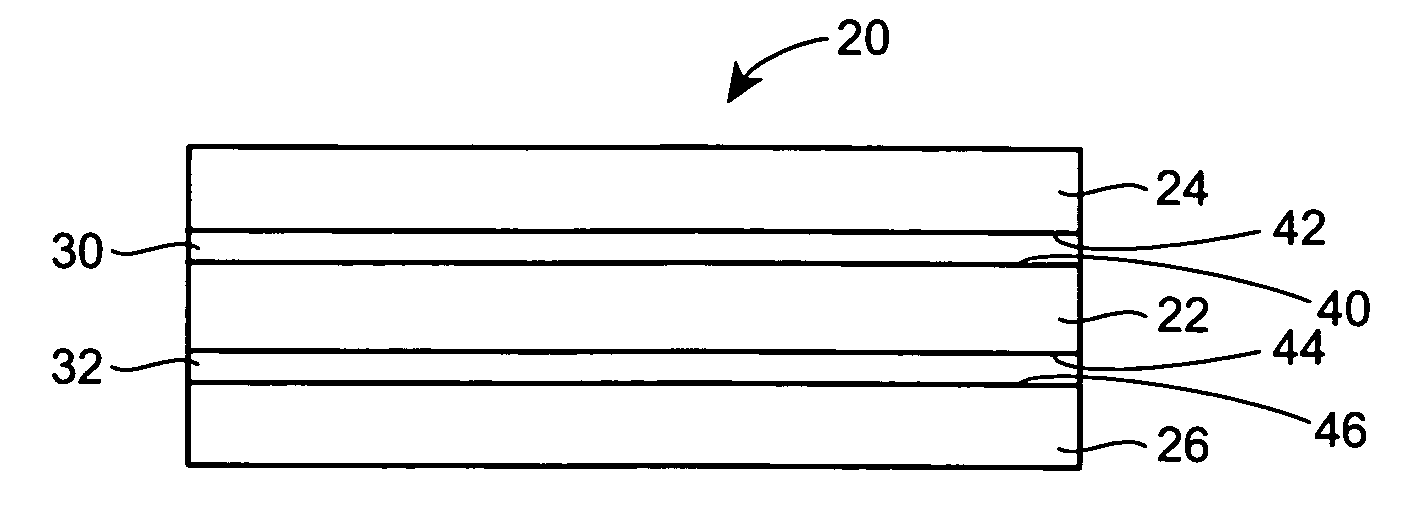

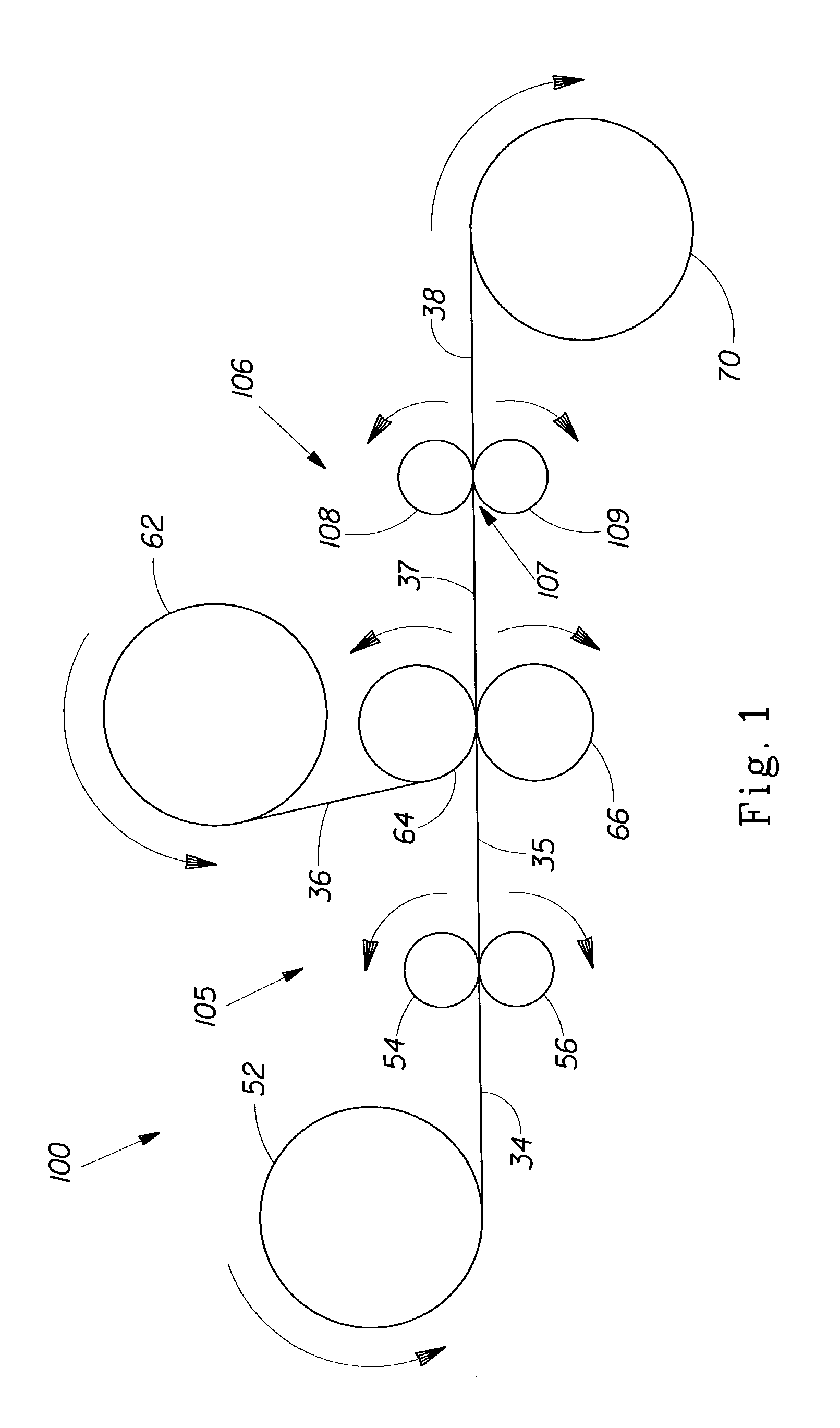

Stretchable laminates of nonwoven web(s) and elastic film

A stretchable laminate, a process of making a stretchable laminate and a disposable absorbent article that includes a stretchable laminate are disclosed. The stretchable laminate includes a nonwoven web and a web of elastomeric material. The nonwoven web includes three layers of spunbond fibers and two layers of meltblown fibers. The side of the nonwoven web that includes two layers of spunbond fibers is attached to the elastomeric material.

Owner:PROCTER & GAMBLE CO

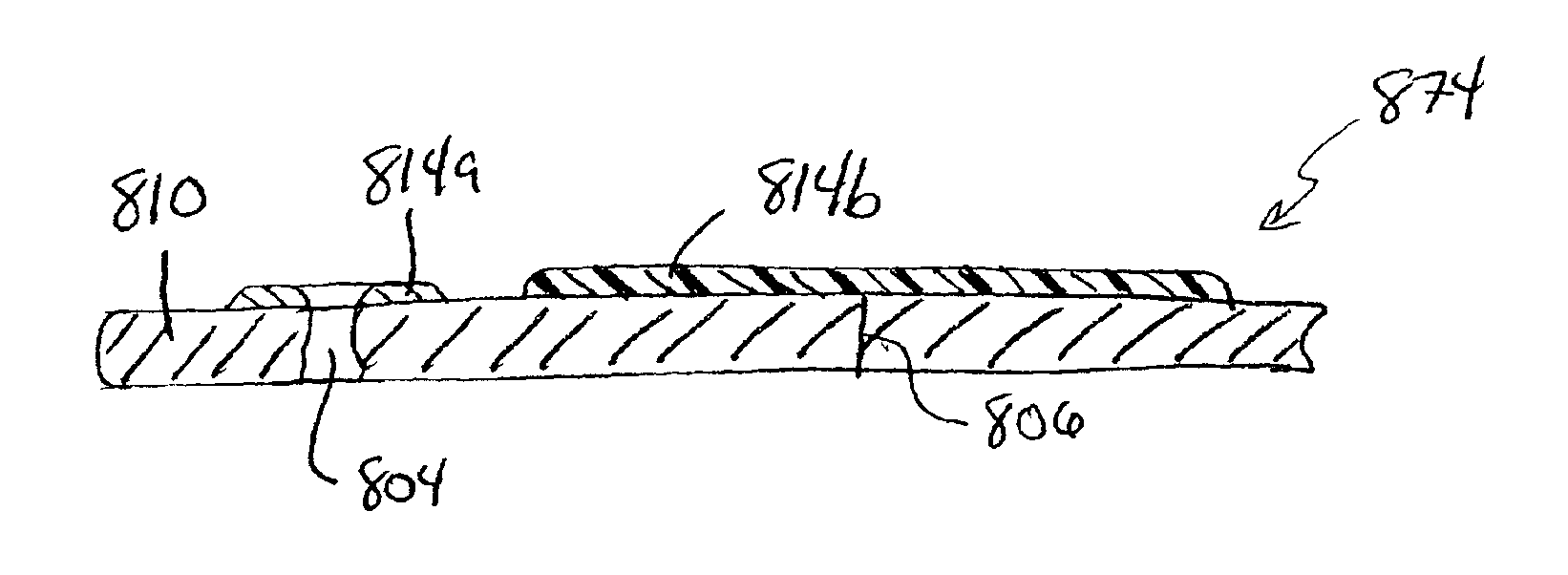

Elastomerically impregnated ePTFE to enhance stretch and recovery properties for vascular grafts and coverings

This invention relates to an elastomerically recoverable PTFE material that includes a longitudinally compressed fibrils of ePTFE material penetrated by elastomeric material within the pores defining the elastomeric matrix. The elastomeric matrix and the compressed fibrils cooperatively expand and recover without plastic deformation of the ePTFE material. This invention was used for various prosthesis, such as a vascular prosthesis like a patch, a graft and an implantable tubular stents. Furthermore, this invention discloses a method of producing the elastomerically recoverable PTFE material which include the steps of: providing the specified ePTFE, defined by the nodes and fibrils, to meet the desired end use; longitudinally compressing the fibrils of the ePTFE, the pore size sufficiently enough to permit penetration of the elastomeric material; applying the elastomeric material within the pores to provide a structurally integral elastomerically recoverable PTFE material defining an elastomeric matrix. The elastomeric material is applied to the ePTFE by dip, brush or spray coating techniques. The compression step and the application steps are interchangeable to produce the desired properties for the end use material. Finally, the elastomeric material is dried within the pores of the longitudinally compressed ePTFE to solidify the elastomeric matrix.

Owner:LIFESHIELD SCI

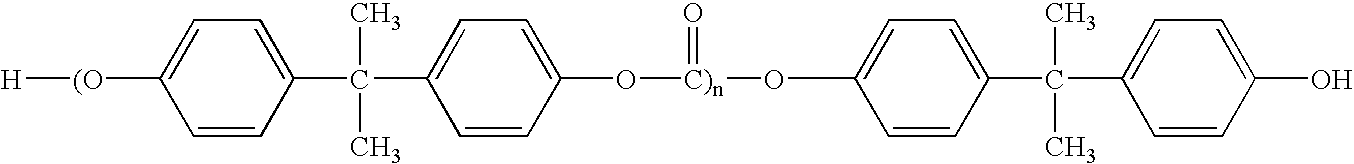

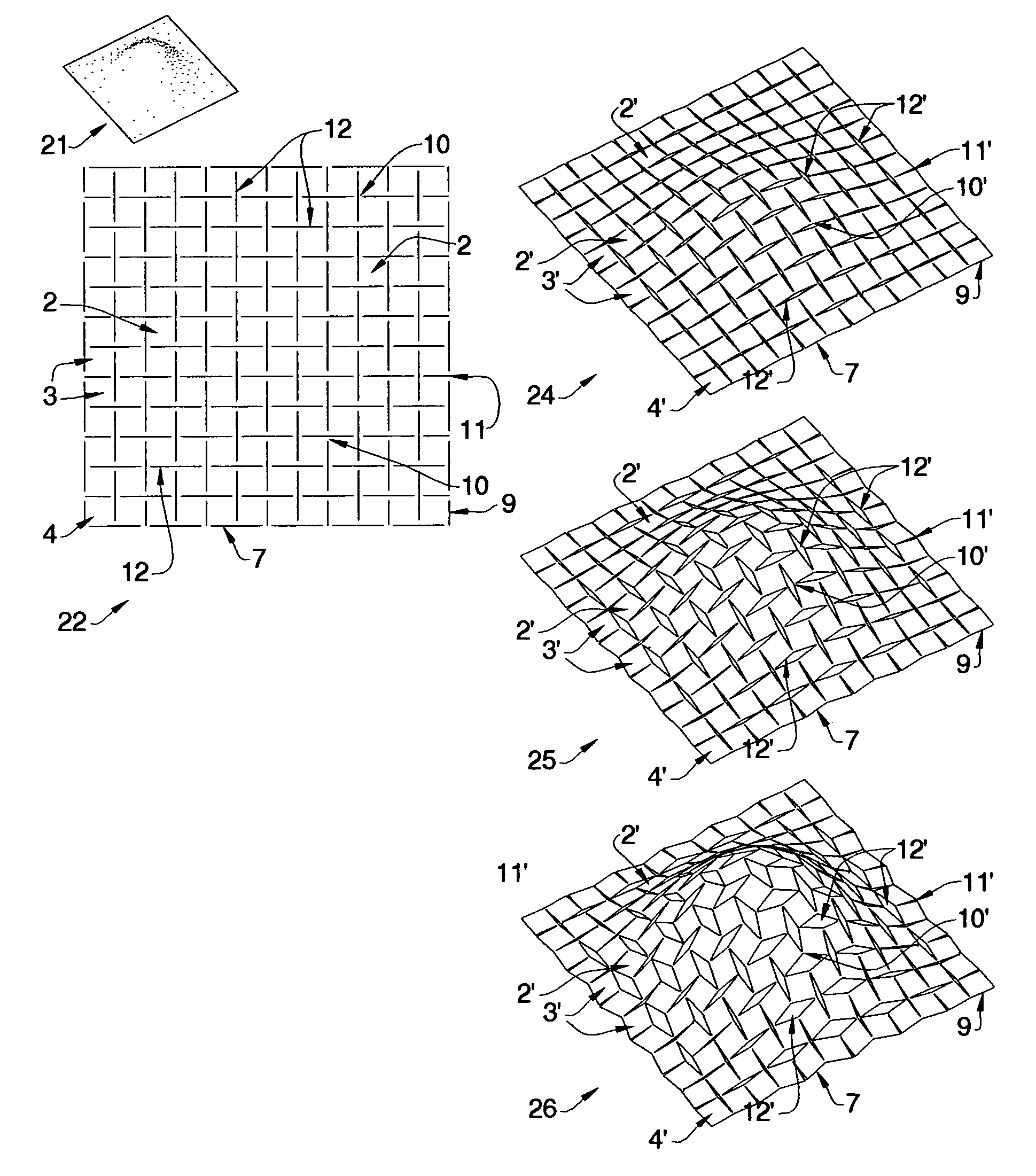

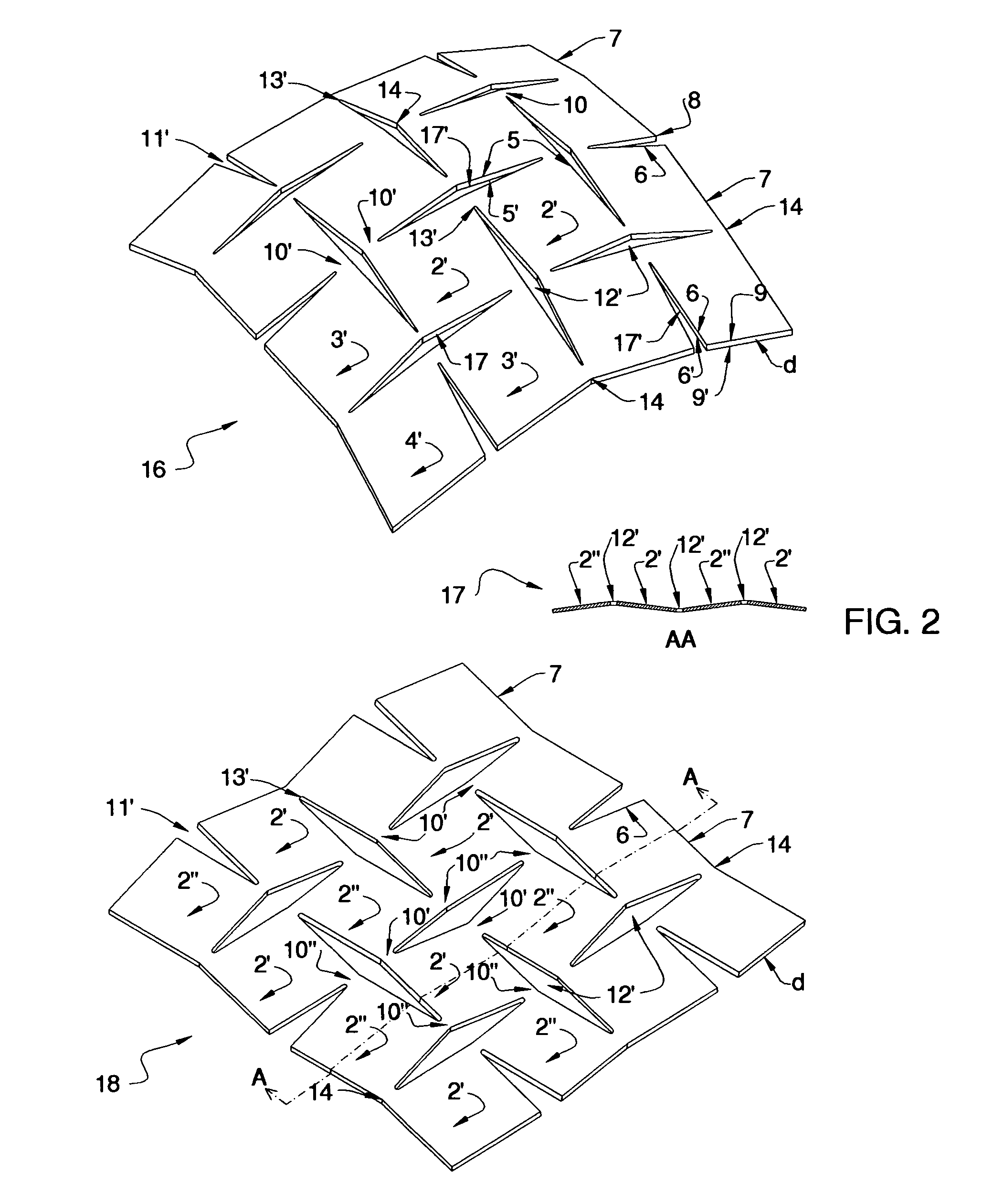

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

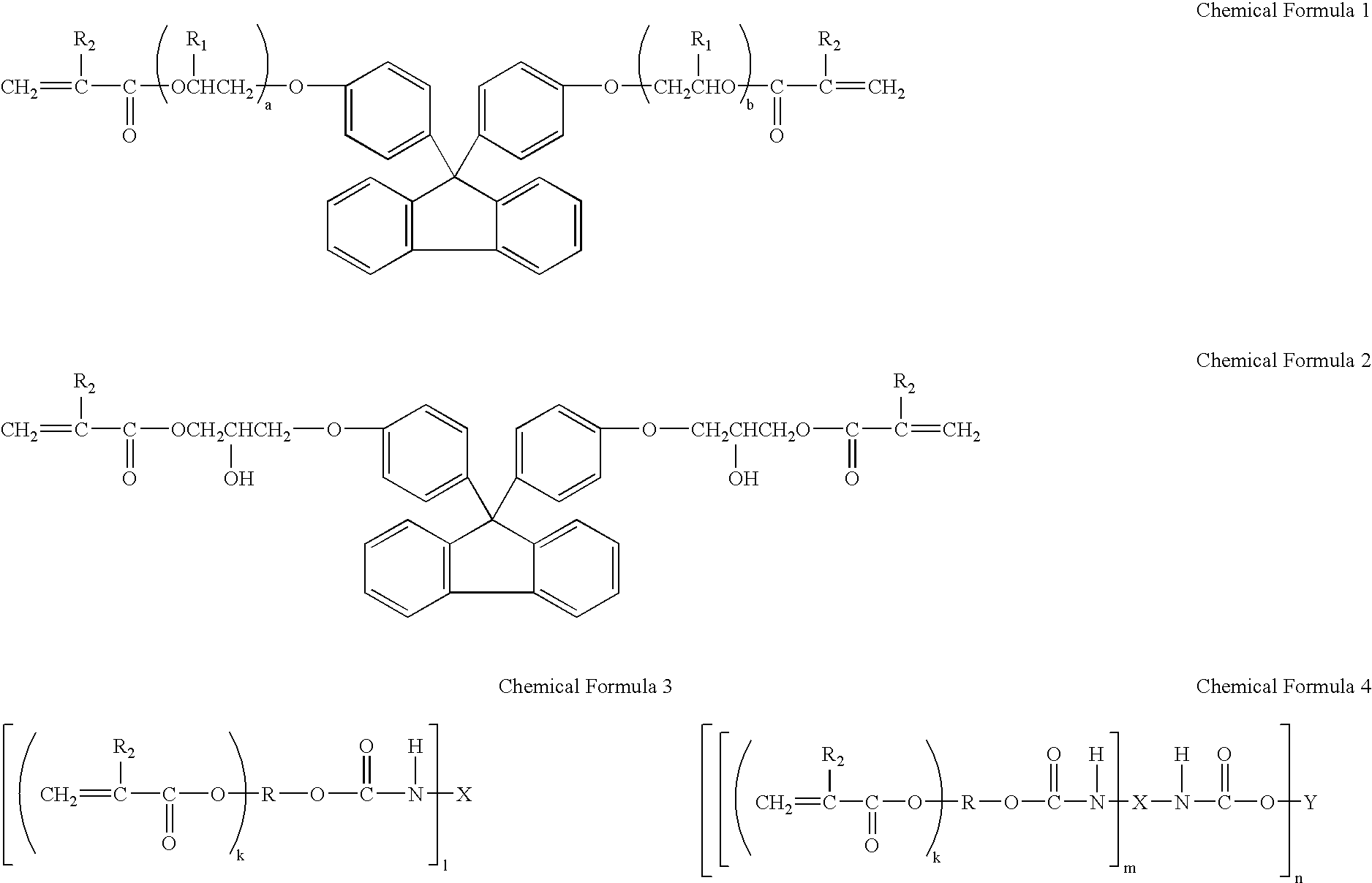

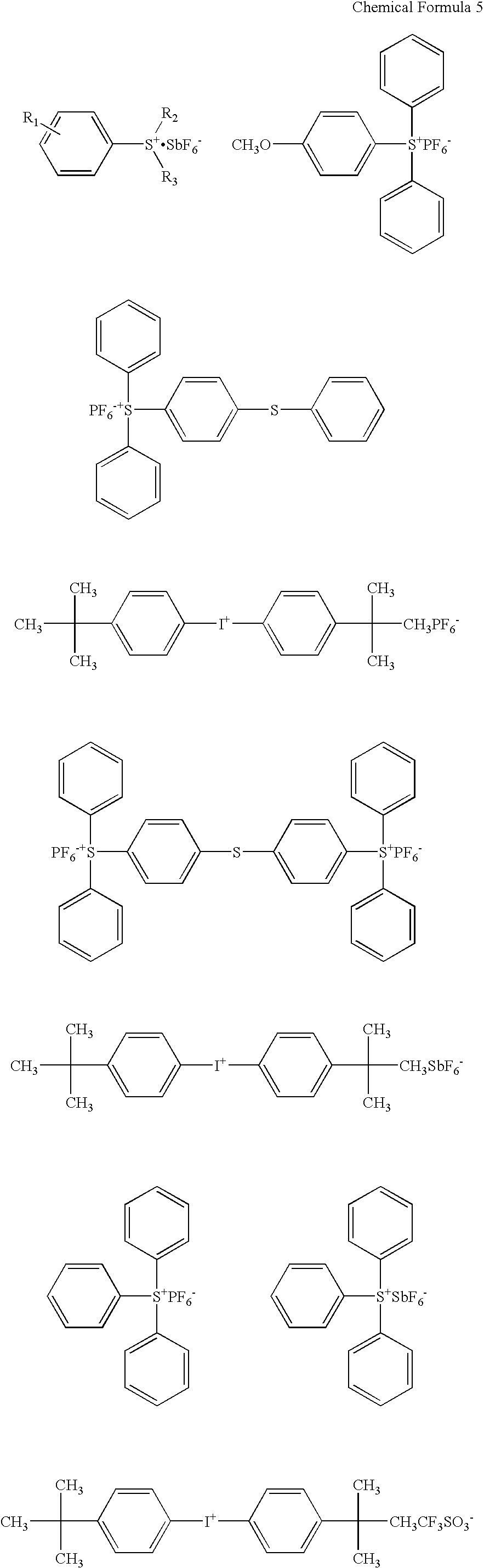

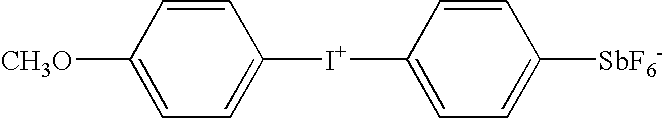

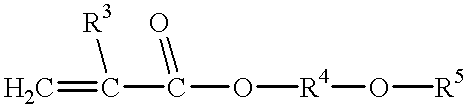

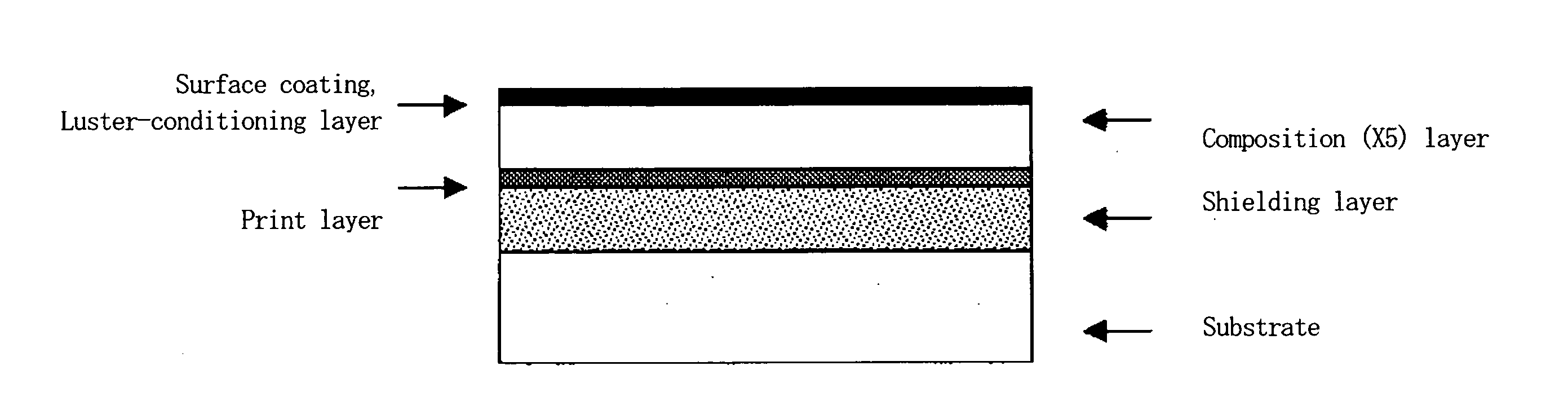

Antireflection material and polarizing film using the same

InactiveUS6777070B1Improve anti-reflection effectReduce image contrastSynthetic resin layered productsCoatingsRefractive indexDisplay device

An anti-reflection material and a polarization film which exhibit superior anti-reflection properties by preventing external light such as sunlight, fluorescent light, etc., from being reflected on a display, which yield a clear image without sparkling and reduces image contrast, and which exhibit superior wear resistance, chemical resistance, and contamination resistance, as well as exhibit optical stability. A hard coat layer is provided on one surface or two surfaces of a transparent substrate directly or via another layer, and an anti-reflection film having a lower refraction index than the hard coat layer is further provide on the hard coat layer. The hard coat layer consists of at least {circle around (1 a polymer polymerizing (metha)acrylate compound having a fluorene structure; {circle around (2 a polymer polymerizing urethane (metha)acrylate compound and ultrafine particles having a high refraction index; and {circle around (3 radiation and / or thermosetting resin and surface-treated titanium oxide ultrafine particles.

Owner:TOMOEGAWA PAPER CO LTD

Thermoplastic elastomer composition, process for the preparation there of, hose made by using the composition, and process for the production thereof

InactiveUS6179008B1Improvement of hose flexibilityLow production costSynthetic resin layered productsFlexible pipesElastomerVulcanization

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:YOKOHAMA RUBBER CO LTD

Variable stretch composites and methods of making the composite

InactiveUS7056411B2Little strengthImprove comfortLamination ancillary operationsLaminationElastomerMechanical engineering

Owner:THE PROCTER & GAMBLE COMPANY

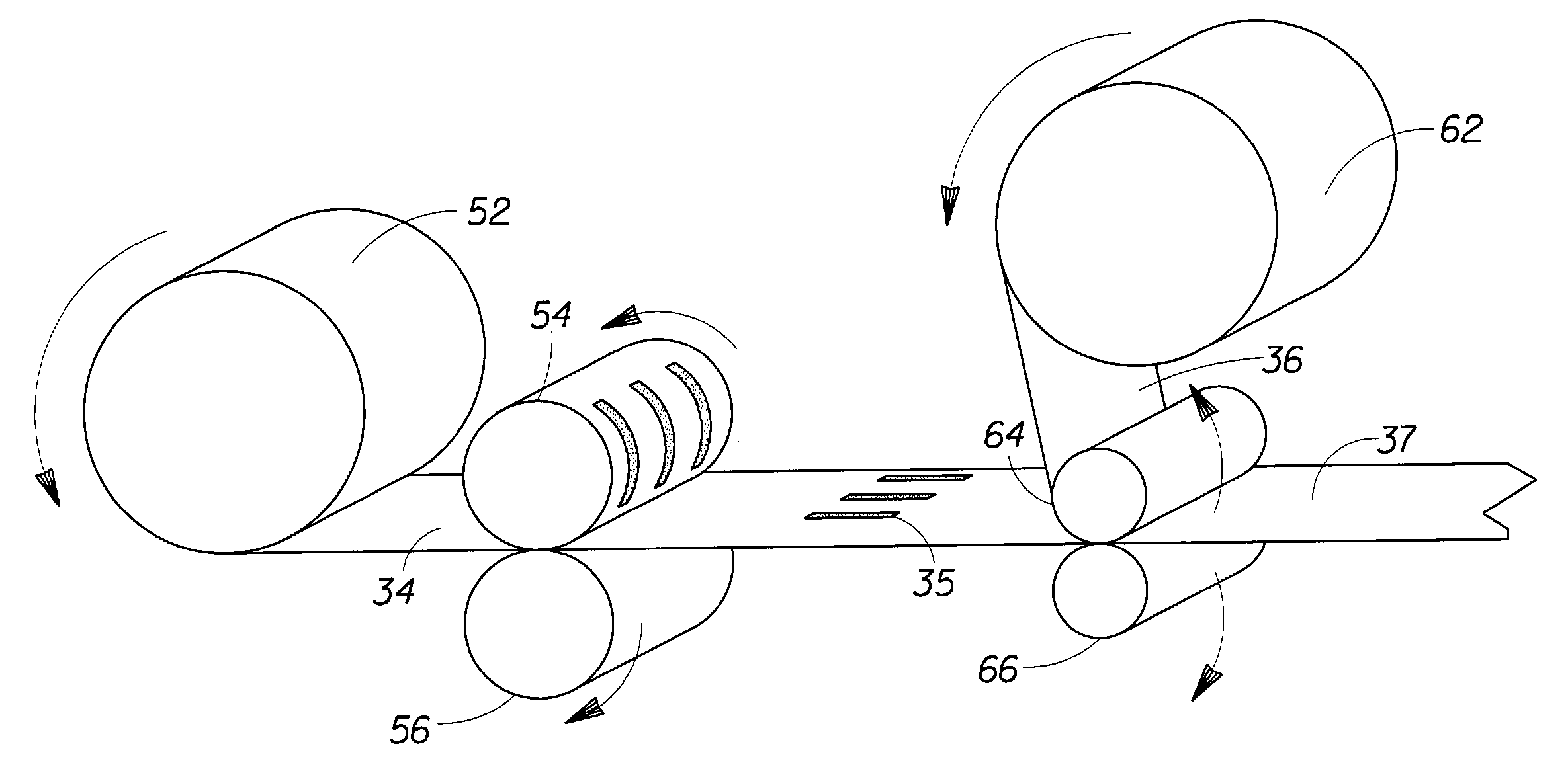

Composite webs with reinforcing polymeric regions and elastic polymeric regions

InactiveUS6875710B2Increased formationRaise transfer toPersonal careSynthetic resin layered productsFiberPolymer

Methods of manufacturing composite webs including a substrate with one or more reinforcing discrete polymeric regions located on or within the composite web are disclosed. Molten nonelastomeric thermoplastic material of the discrete polymeric region is forced against the substrate by a transfer roll. If the substrate is porous, fibrous, etc., a portion of the nonelastomeric thermoplastic composition may infiltrate the substrate and / or encapsulate fibers of the substrate. The composite webs also include elastomeric thermoplastic material in discrete polymeric regions on or within the composite web.

Owner:3M INNOVATIVE PROPERTIES CO

Clean release, phase change thermal interface

InactiveUS6835453B2Improve efficiencyIncrease ratingsSemiconductor/solid-state device detailsSynthetic resin layered productsGraphitePhase change

A laminar, thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermally-conductive pathway therebetween. The interface includes a first layer formed of a flexible, lamellar graphite or tin foil material, and a second layer formed of a thermally-conductive phase-change material.

Owner:PARKER INTANGIBLES LLC

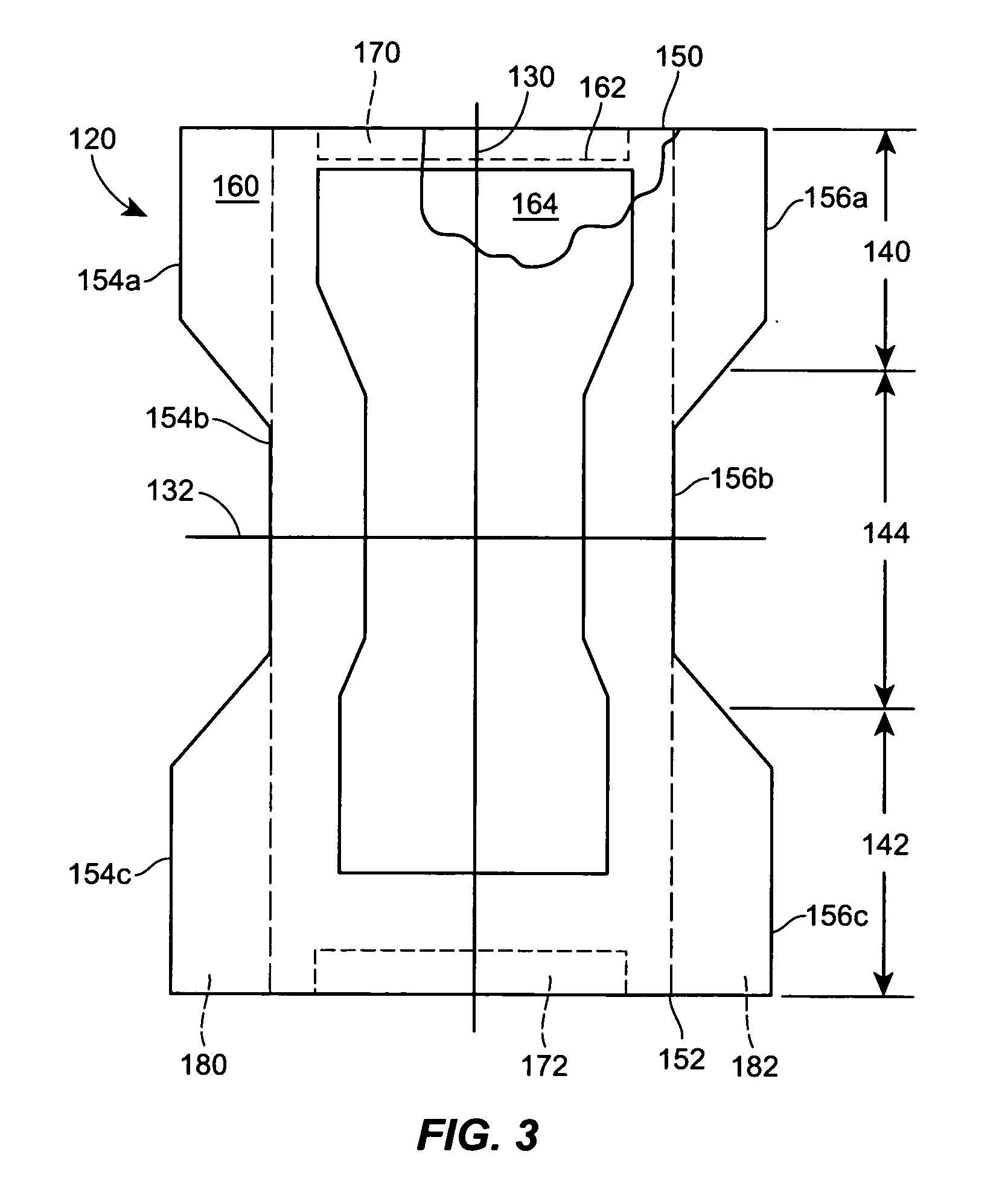

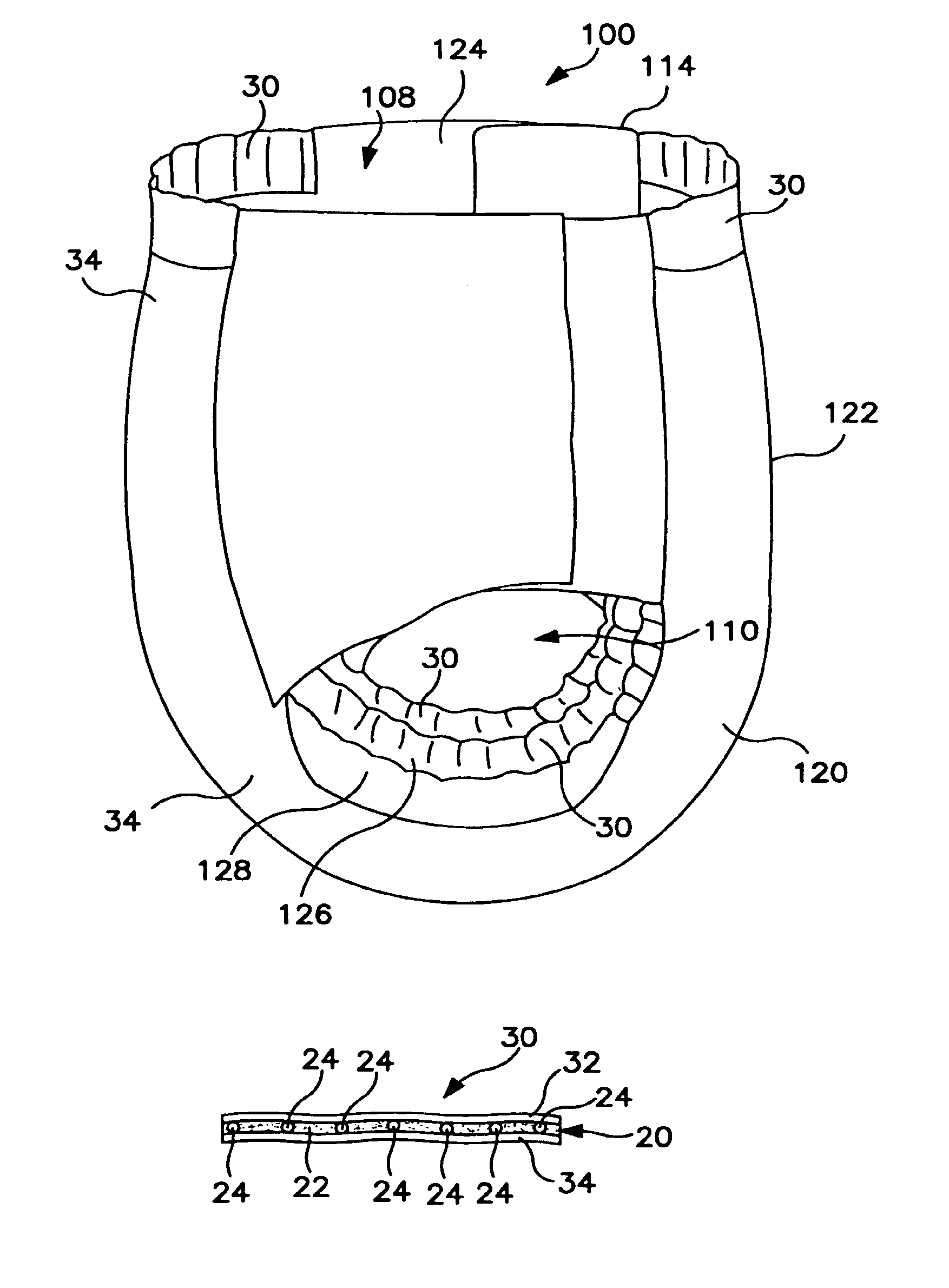

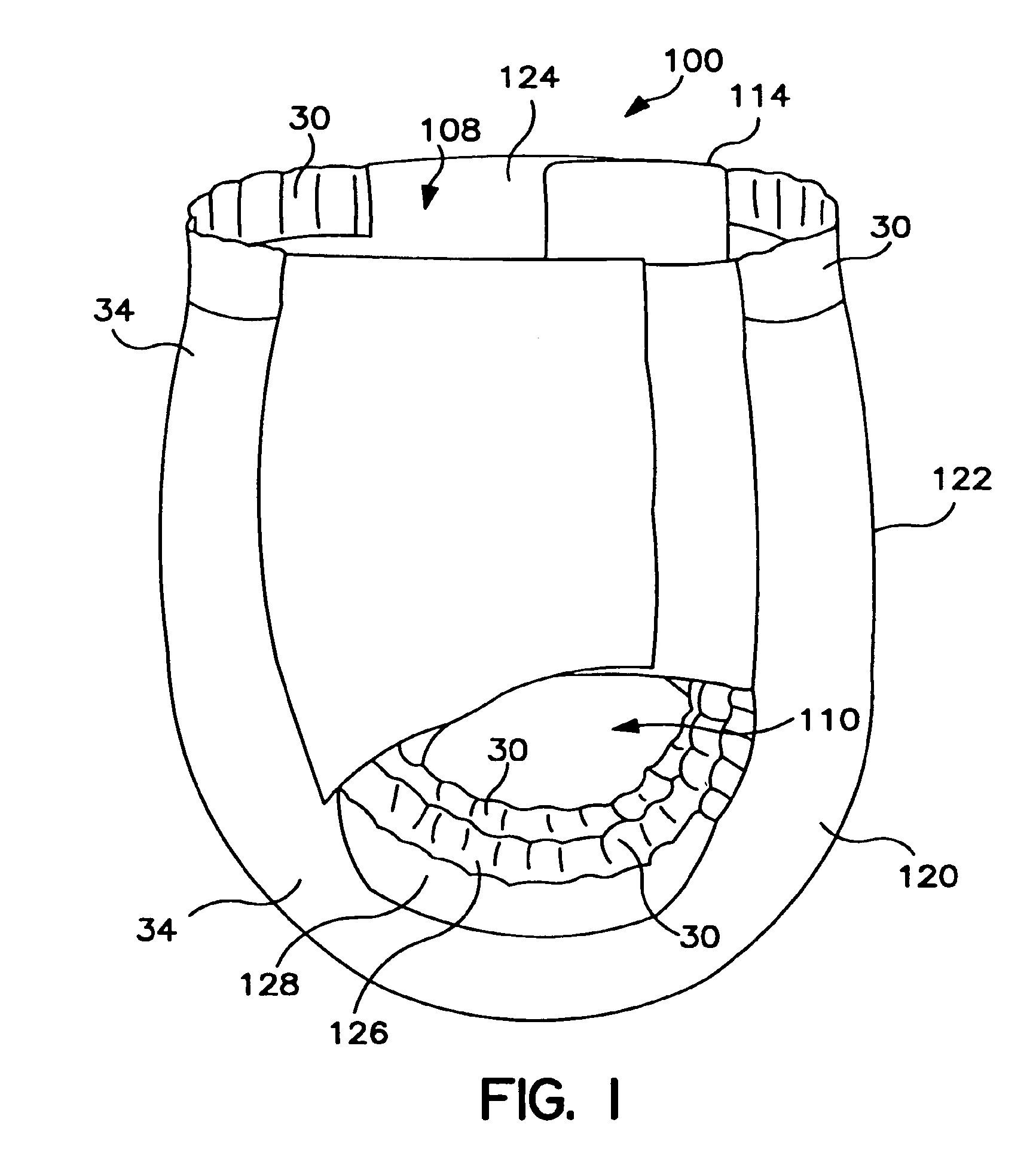

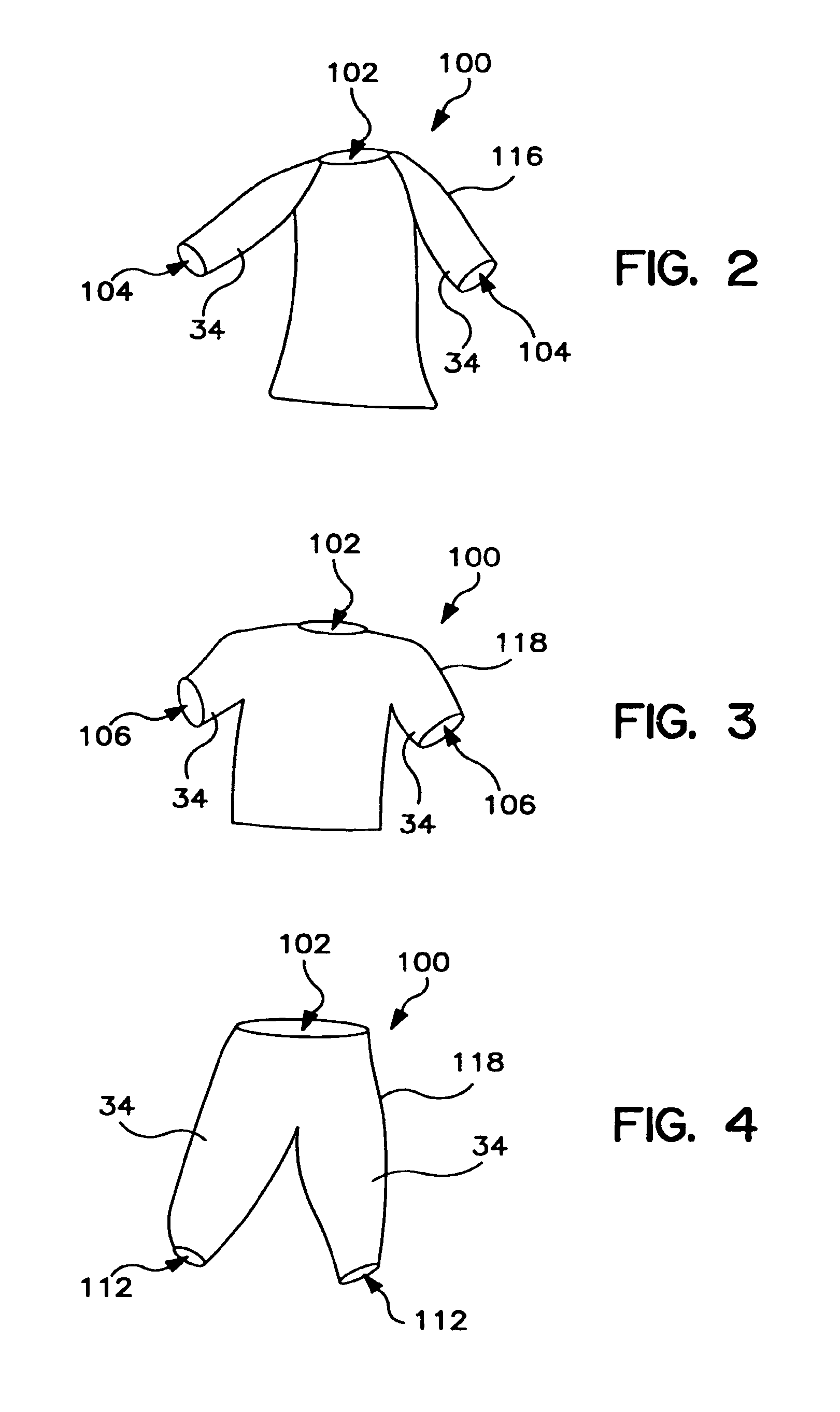

Garment including an elastomeric composite laminate

A garment including an elastomeric composite laminate around one or more openings for the legs, arms, waist, neck, or the like of a wearer. The garment includes a substrate defining the one or more openings, and an elastomeric composite laminate attached to the substrate adjacent the one or more openings. The elastomeric composite laminate includes reinforcement strands incorporated into an elastomeric adhesive film. In one embodiment, the garment is a pant-like garment with the elastomeric composite laminate adjacent each of the leg openings.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Stretchable laminates of nonwoven web(s) and elastic film

A stretchable laminate, a process of making a stretchable laminate and a disposable absorbent article that includes a stretchable laminate are disclosed. The stretchable laminate includes a nonwoven web and a web of elastomeric material. The nonwoven web includes two layers of spunbond fibers and one layer of meltblown fibers. Some of the meltblown fibers are present in the interstices formed by the spunbond fibers of one of the layers.

Owner:PROCTER & GAMBLE CO

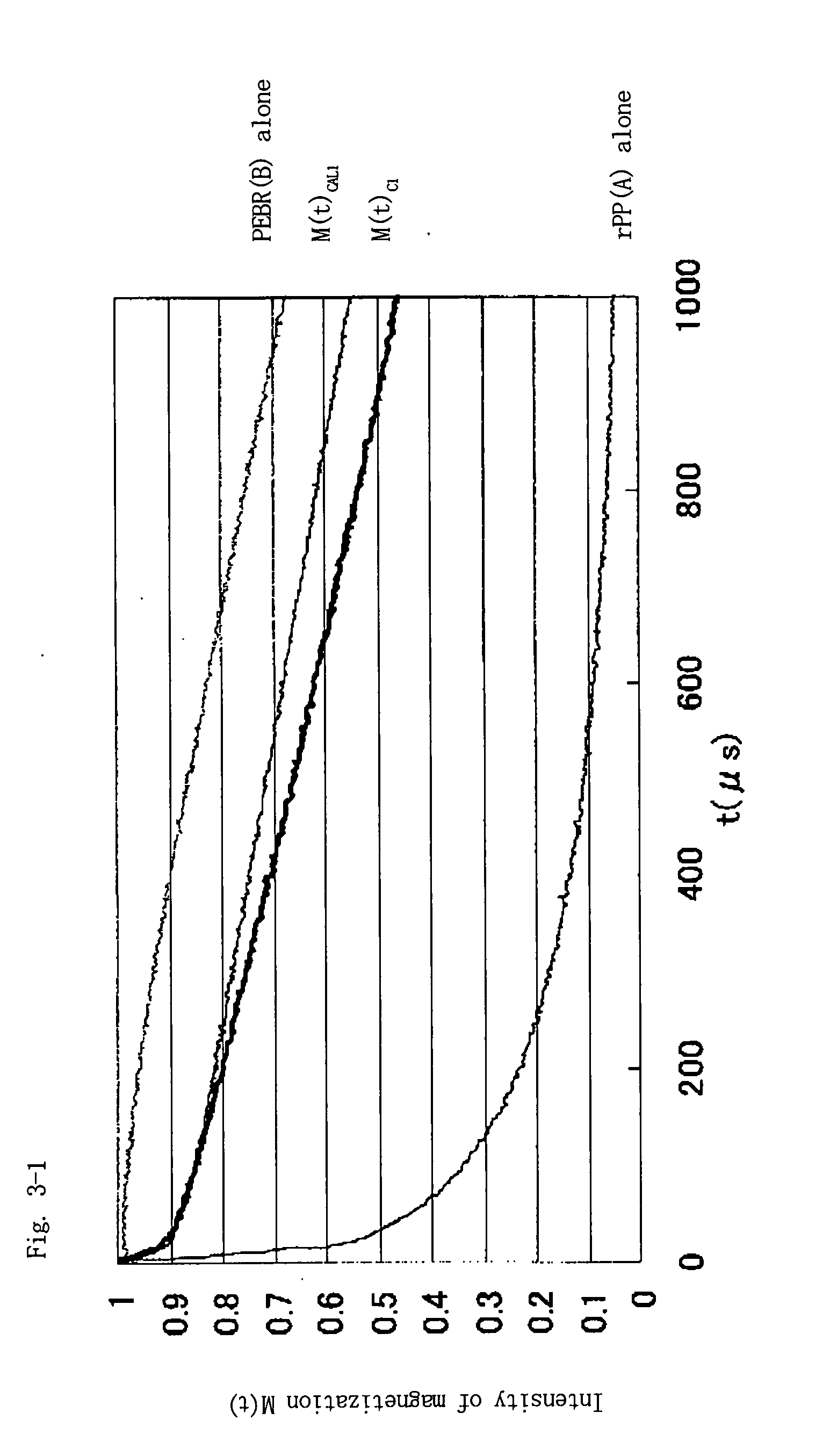

Propylene resin composition and use thereof

ActiveUS20070251572A1Improve mechanical propertiesGood rubber elasticitySolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (Xi) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below: 1 to 90 wt % of an isotactic polypropylene (A1); 9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol% of propylene-derived structural units, 10 to 25 molt of ethylene-derived structural units, and optionally, 0 to 30 mol% of C4-C20 α-olefin-derived structural units (a1); 1 to 80 wt % of a styrene-based elastomer (C1); and 0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

High performance elastic laminates made from high molecular weight styrenic tetrablock copolymer

An elastic laminate is provided which has an elastic layer and one or two outer facing layers. The elastic layer is formed from an improved styrene-(ethylene-butylene)-styrene-(ethylene-butylene) tetrablock copolymer, or a blend of the copolymer. The copolymer has a number average molecular weight of at least about 70,000. The two ethylene-butylene blocks have number average molecular weights which together constitute more than 75% of the number average molecular weight of the copolymer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Stretchable laminates of nonwoven web(s) and elastic film

A stretchable laminate, a process of making a stretchable laminate and a disposable absorbent article that includes a stretchable laminate are disclosed. The stretchable laminate includes a nonwoven web and a web of elastomeric material. The nonwoven web includes two layers of spunbond fibers and one layer of meltblown fibers. Some of the meltblown fibers are present in the interstices formed by the spunbond fibers of one of the layers. As a result of activation of the stretchable laminate, the nonwoven web has a Residual Maximum Peak Force of at least 0.3 N / cm.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com