Patents

Literature

929 results about "Composite laminates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, a composite laminate is an assembly of layers of fibrous composite materials which can be joined to provide required engineering properties, including in-plane stiffness, bending stiffness, strength, and coefficient of thermal expansion.

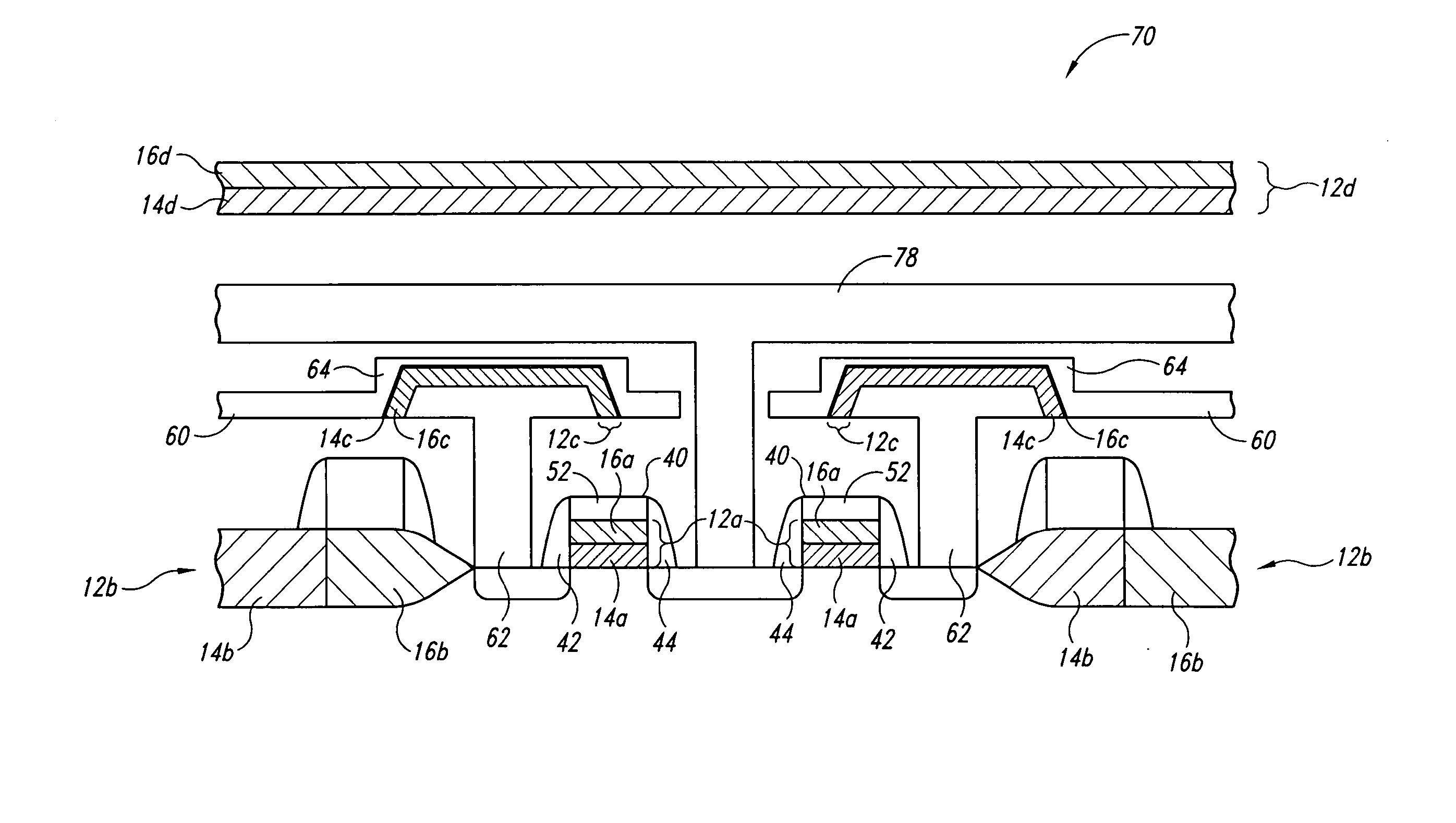

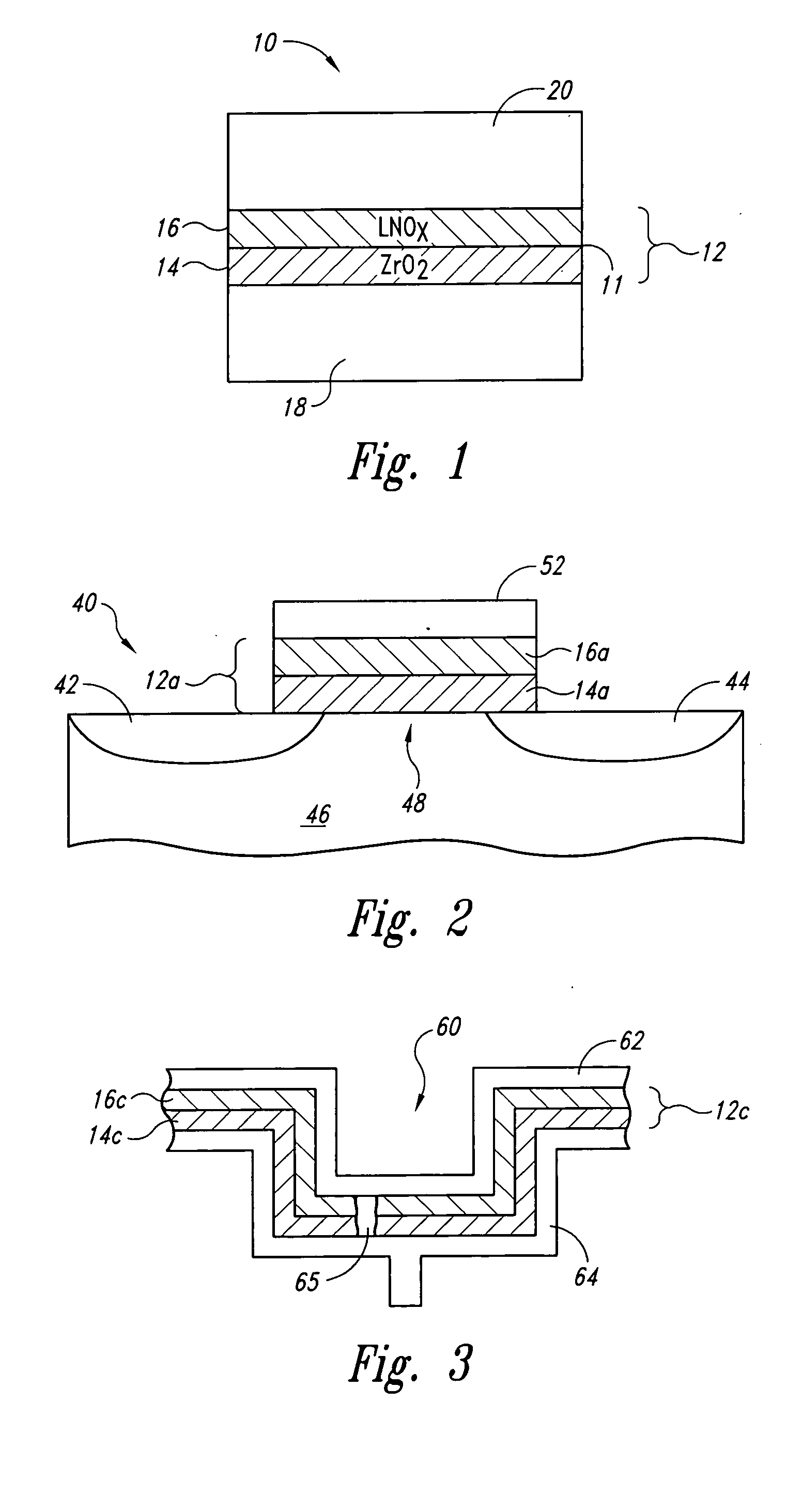

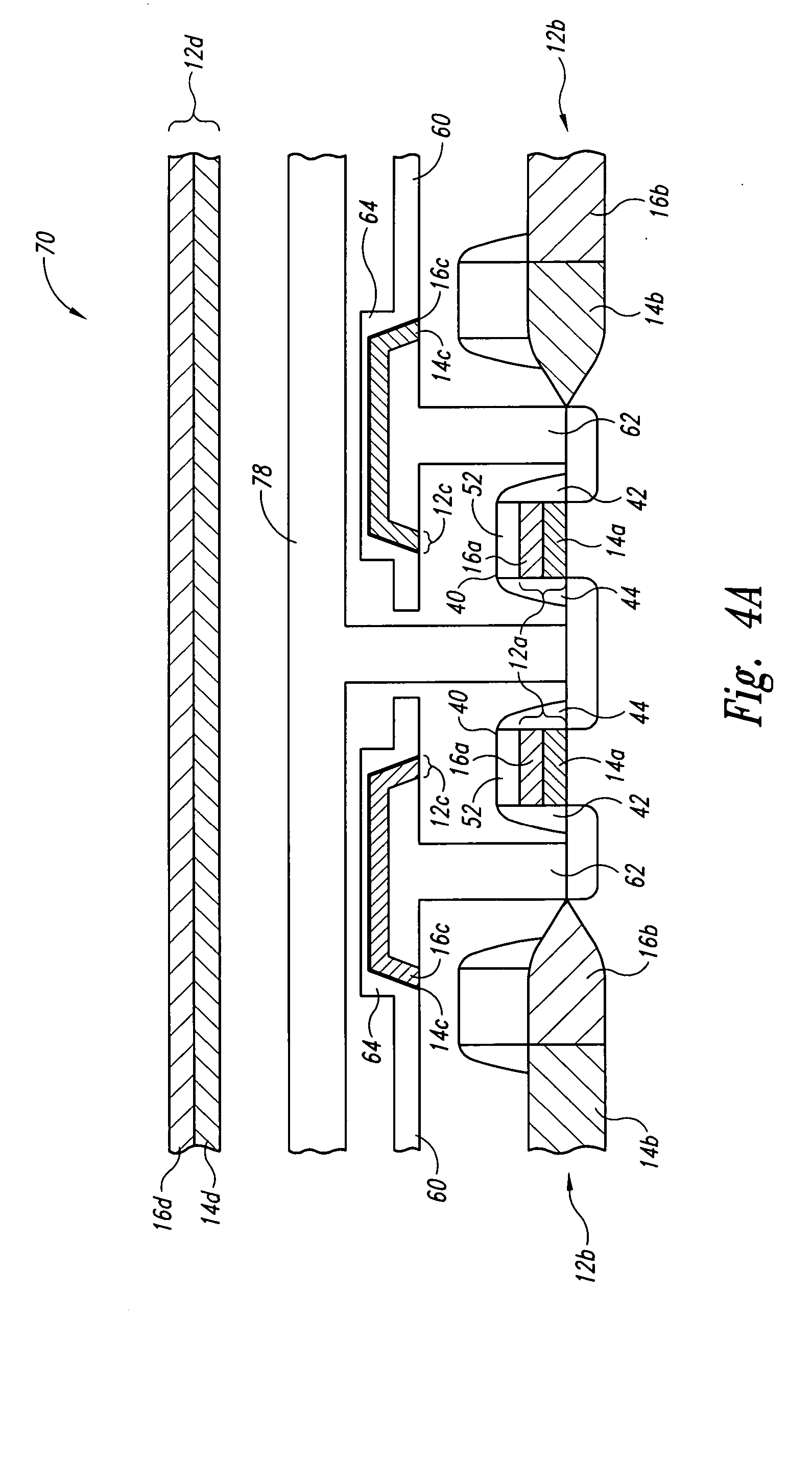

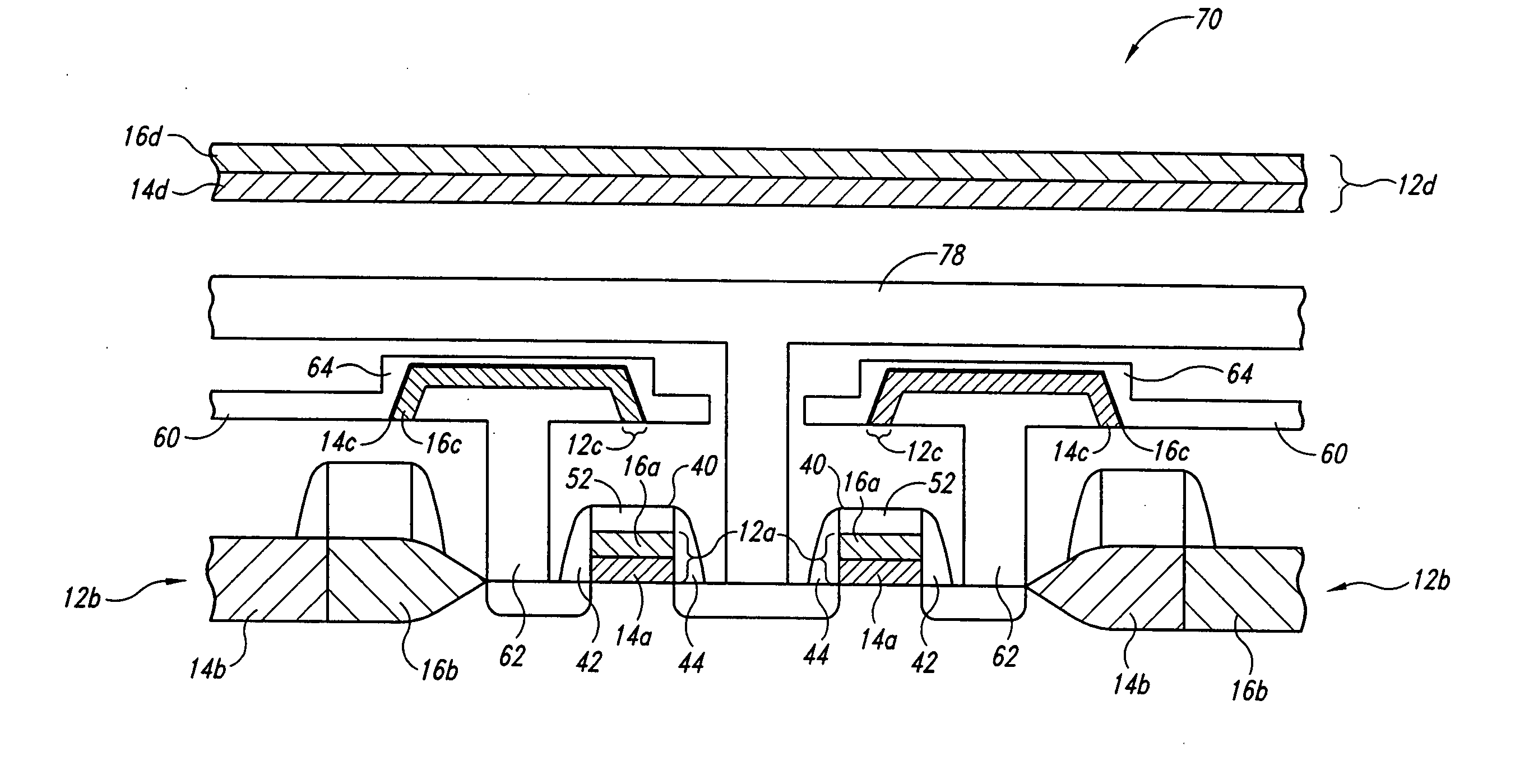

Lanthanide oxide/zirconium oxide atomic layer deposited nanolaminate gate dielectrics

The invention provides a laminated dielectric layer for semiconductor devices formed by a combination of ZrO2 and a lanthanide oxide on a semiconductor substrate and methods of making the same. In certain methods, the ZrO2 is deposited by multiple cycles of reaction sequence atomic layer deposition (RS-ALD) that includes depositing a ZrI4 precursor onto the surface of the substrate in a first pulse followed by exposure to H2O / H2O2 in a second pulse, thereby forming a thin ZrO2 layer on the surface. After depositing the ZrO2 layer, the lanthanide oxide layer is deposited by electron beam evaporation. The composite laminate zirconium oxide / lanthanide oxide dielectric layer has a relatively high dielectric constant and can be formed in layers of nanometer dimensions. It is useful for a variety of semiconductor applications, particularly for DRAM gate dielectric layers and DRAM capacitors.

Owner:MICRON TECH INC

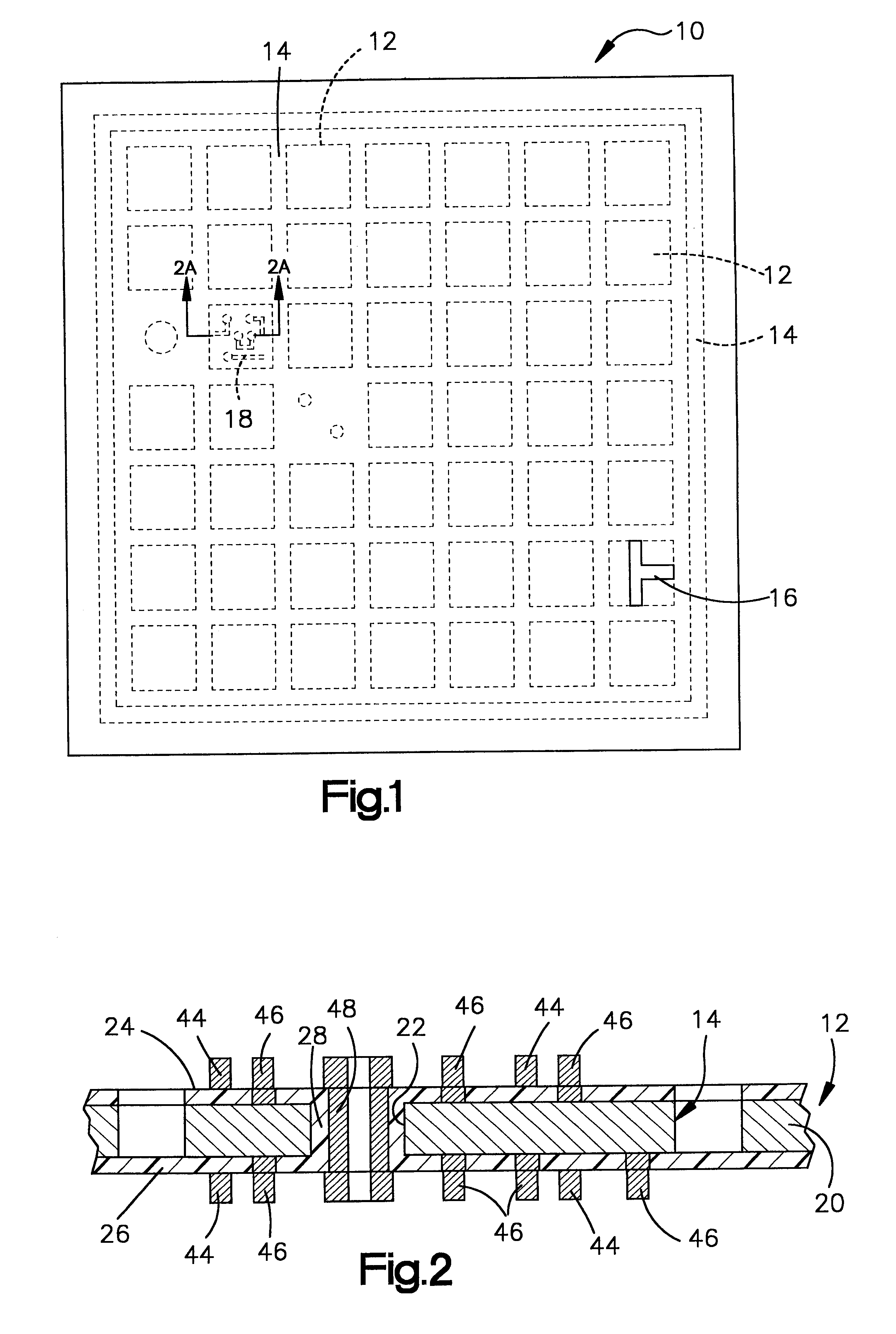

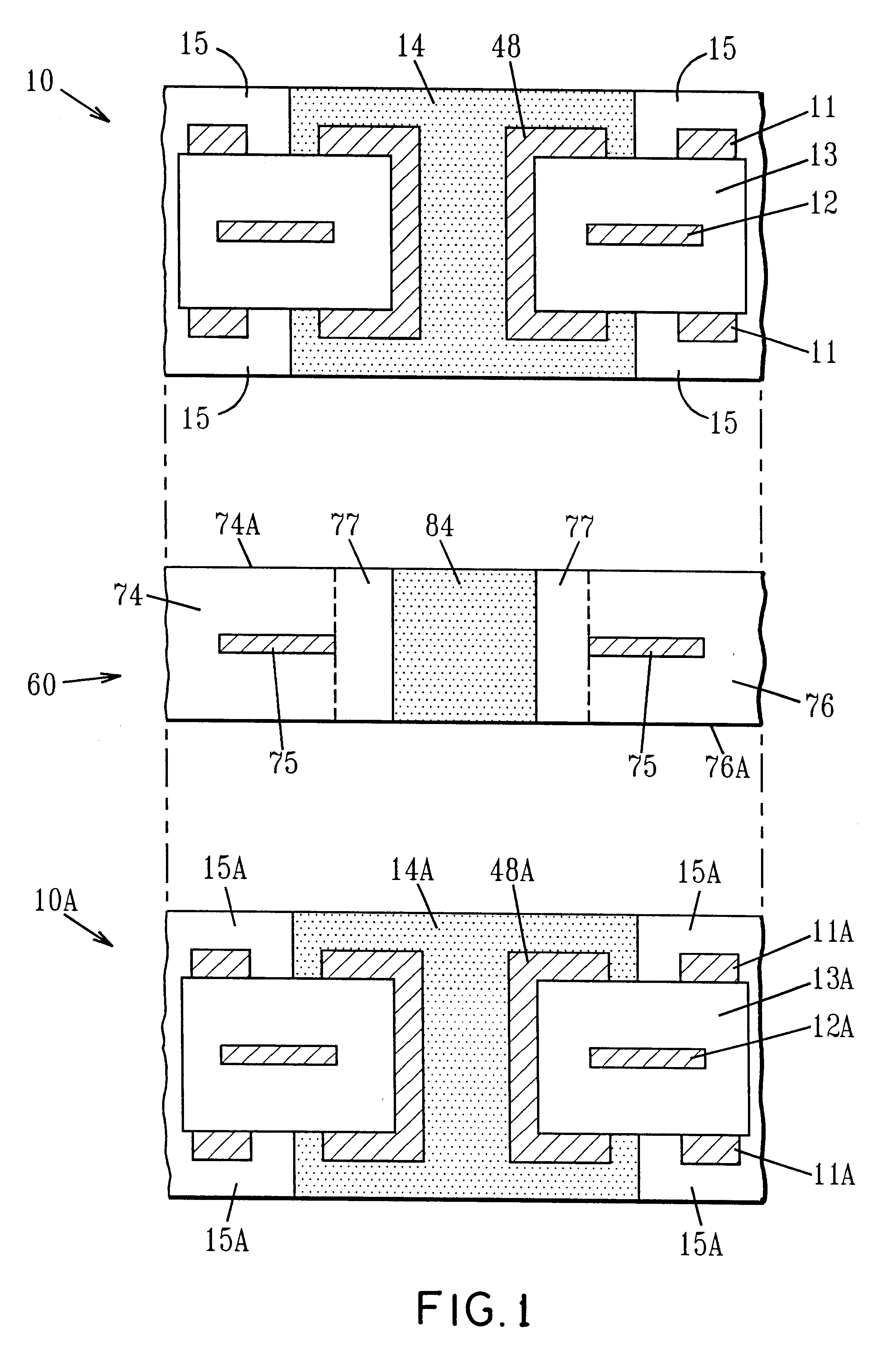

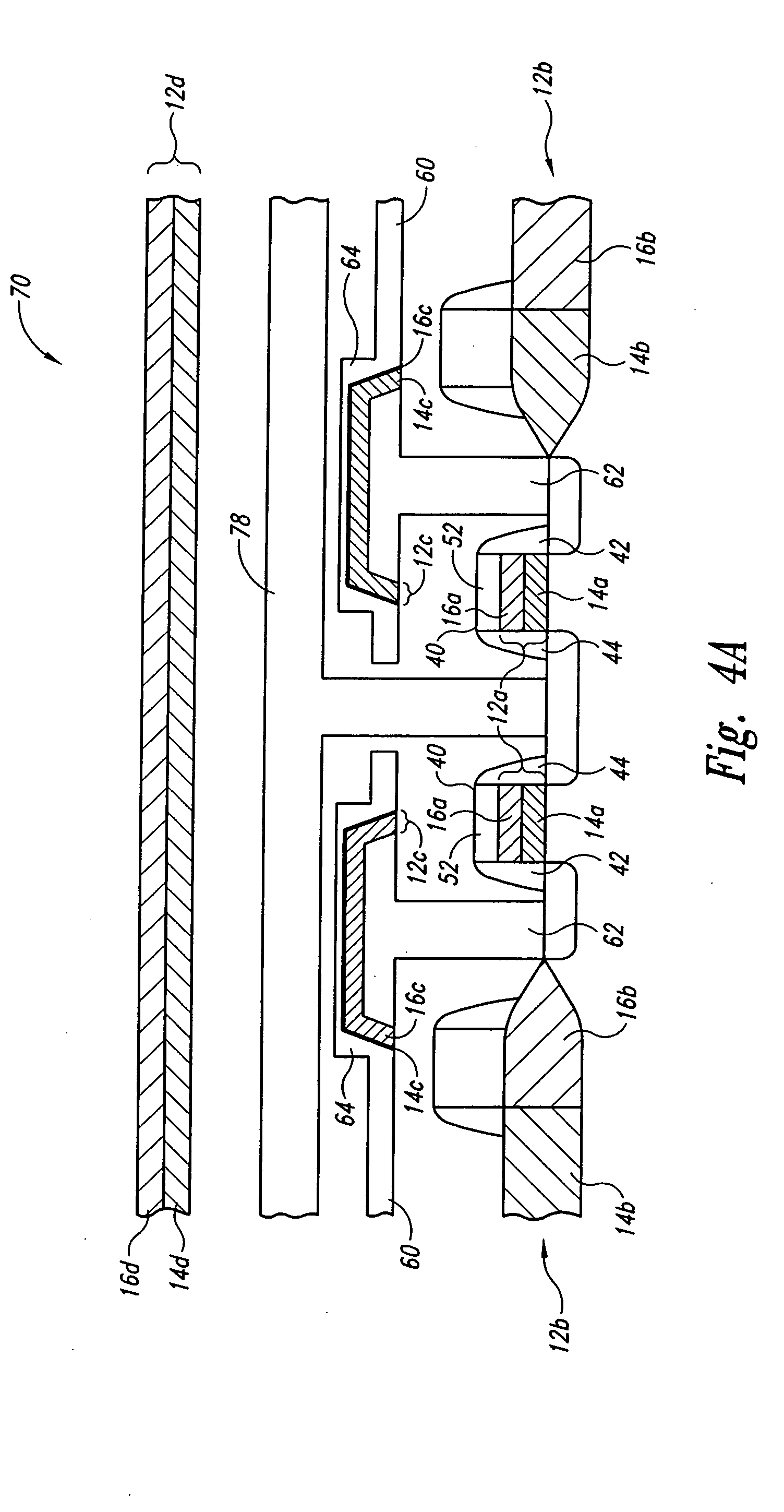

Composite laminate circuit structure and method of forming the same

InactiveUS6175087B1Printed circuit aspectsElectrical connection printed elementsComposite laminatesConductive materials

A method forming a composite laminate structure includes providing first and second circuit board element each having circuitry on at least one face thereof and plated through holes. A voltage plane element is provided having at least one voltage plane having opposite faces with layers of partially cured photodielectric material on each face. At least one hole is photopatterned and etched through the voltage plane element but completely isolated from the voltage plane. Each through hole in the voltage plane element is aligned with a plated through hole in each of the circuit board elements to provide a surface on the voltage plane element communicating with the plated through holes. The voltage plane is laminated between the circuit board elements and the photoimageable material on the voltage plane is fully cured. The surfaces of the voltage plane element communicating with the plated through holes in the circuit board elements are plated with a conducting material to establish a connection between the circuitry on the first and second circuit board elements.

Owner:GLOBALFOUNDRIES INC

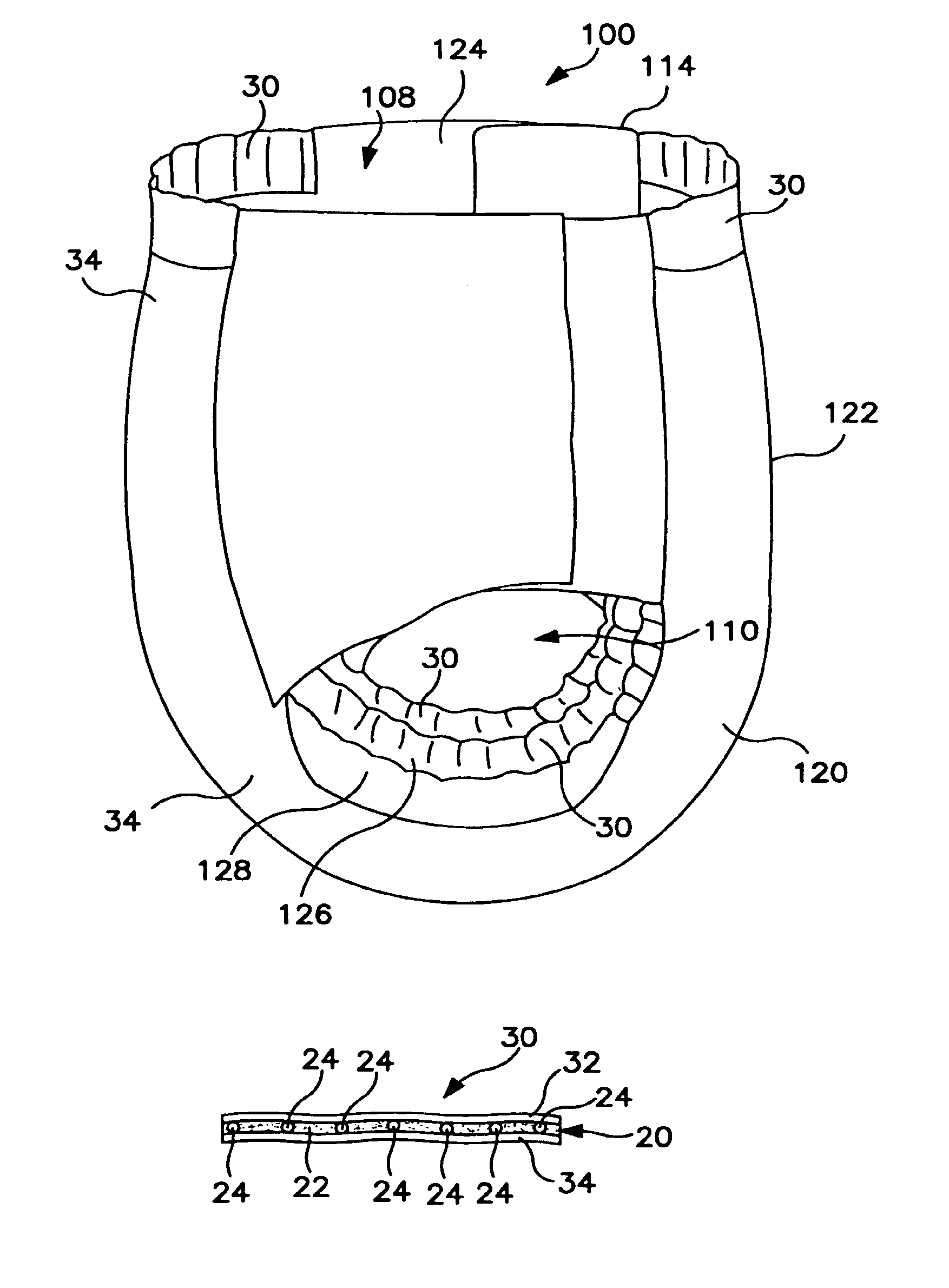

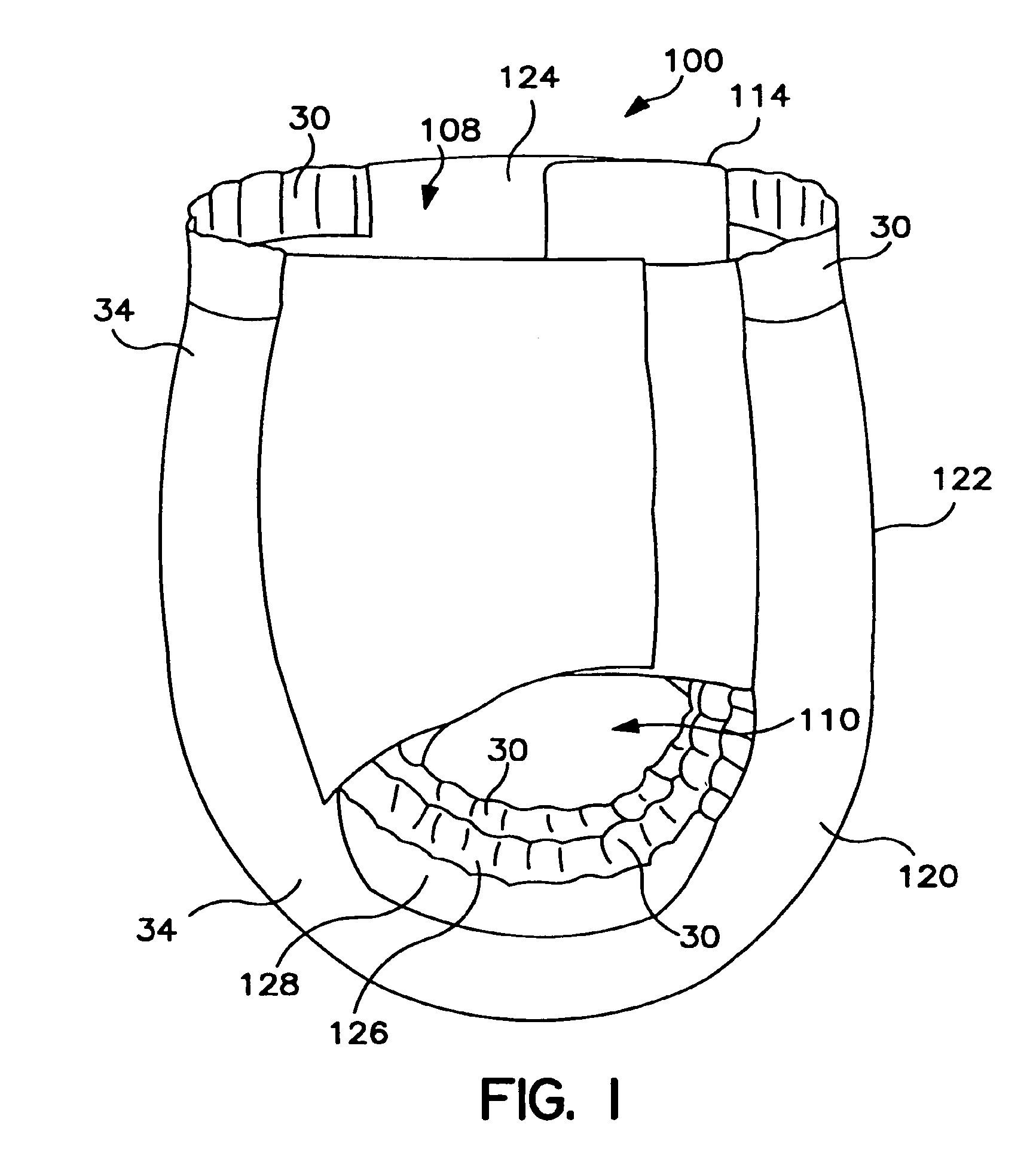

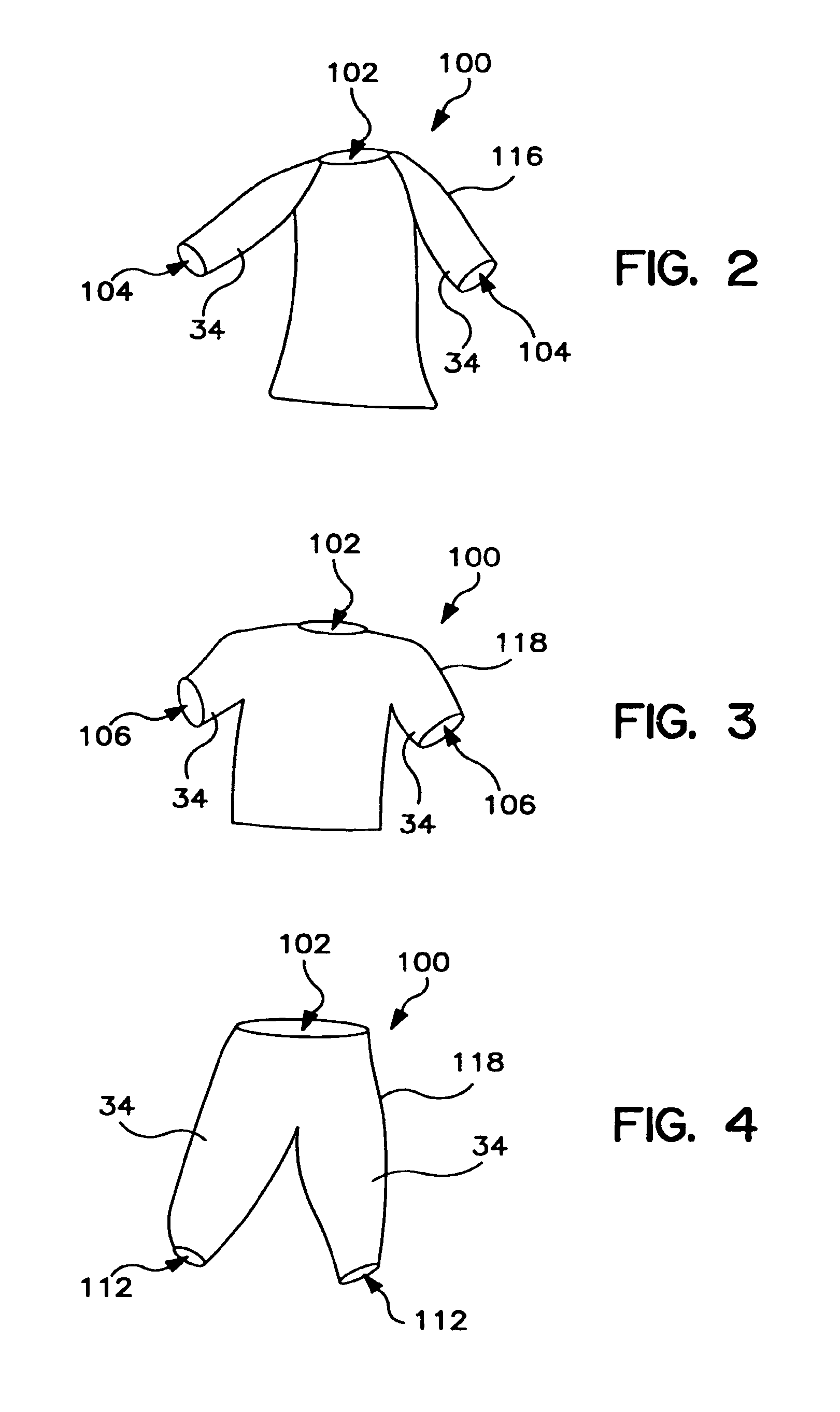

Garment including an elastomeric composite laminate

A garment including an elastomeric composite laminate around one or more openings for the legs, arms, waist, neck, or the like of a wearer. The garment includes a substrate defining the one or more openings, and an elastomeric composite laminate attached to the substrate adjacent the one or more openings. The elastomeric composite laminate includes reinforcement strands incorporated into an elastomeric adhesive film. In one embodiment, the garment is a pant-like garment with the elastomeric composite laminate adjacent each of the leg openings.

Owner:KIMBERLY-CLARK WORLDWIDE INC

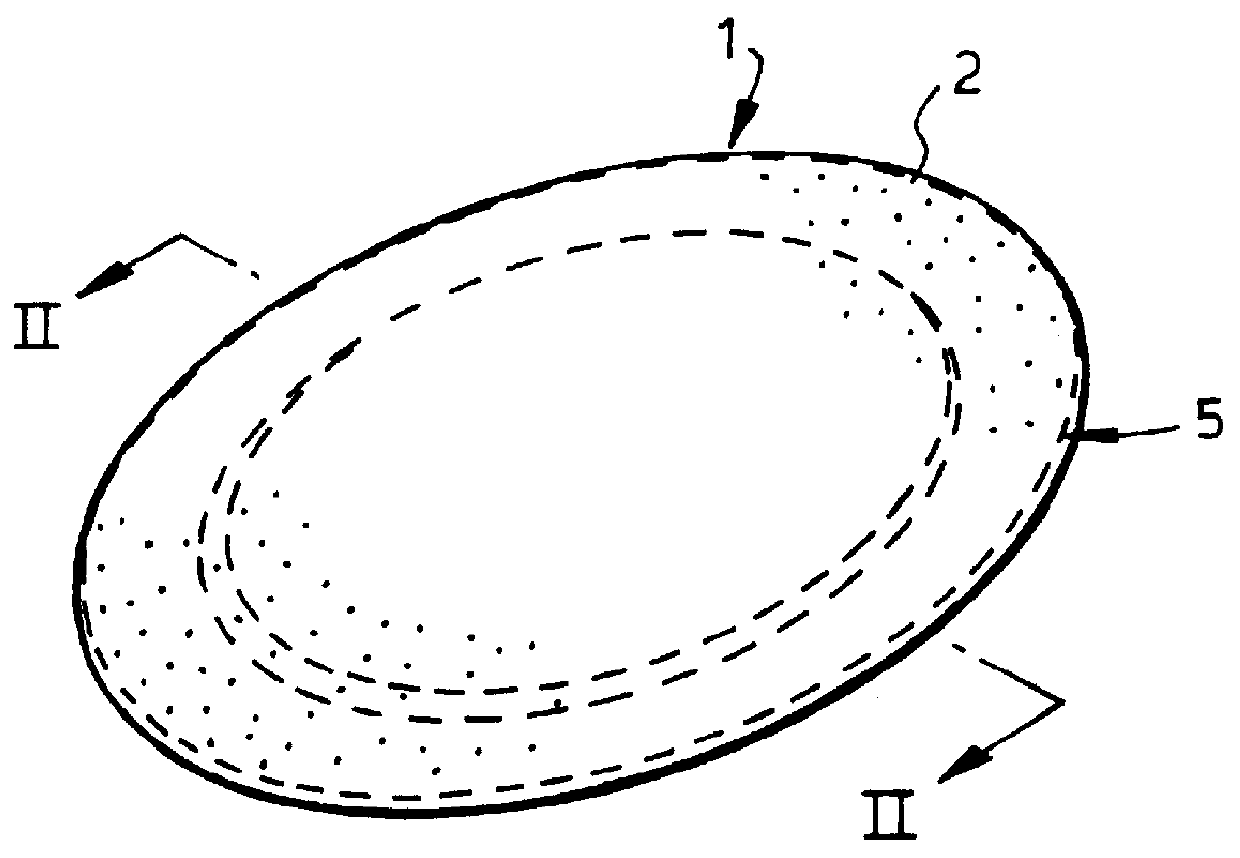

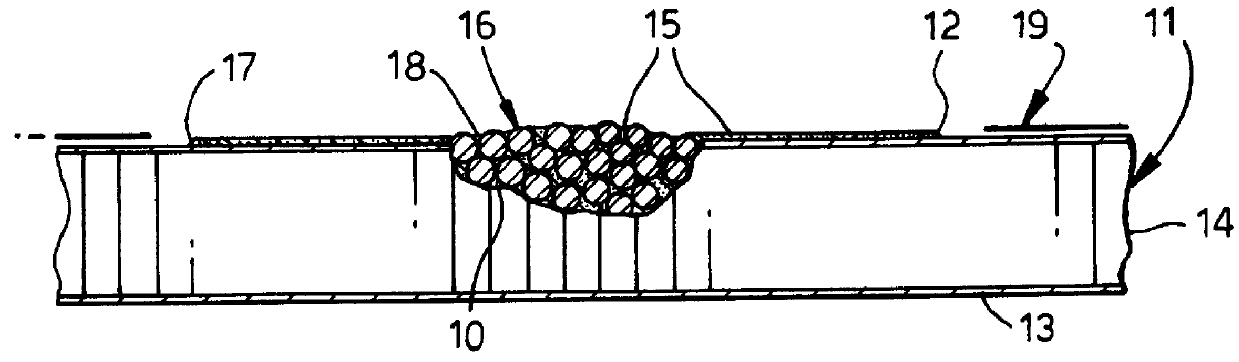

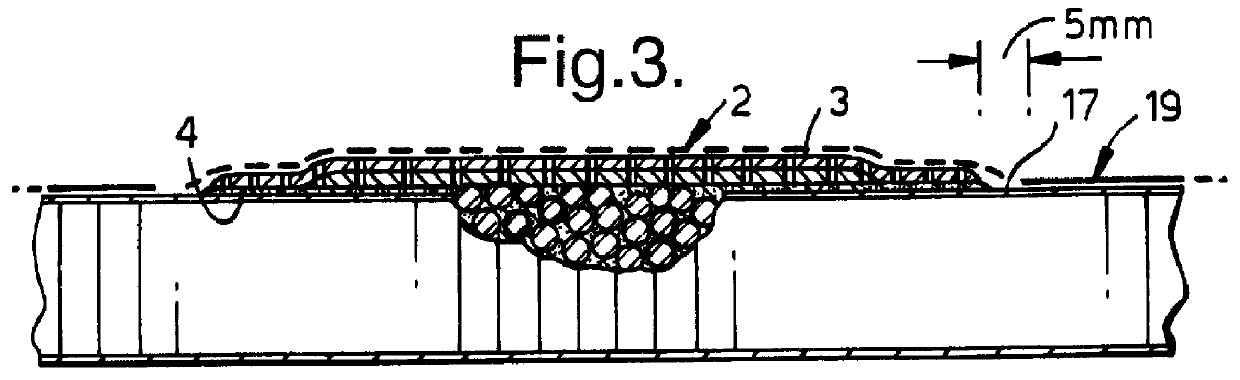

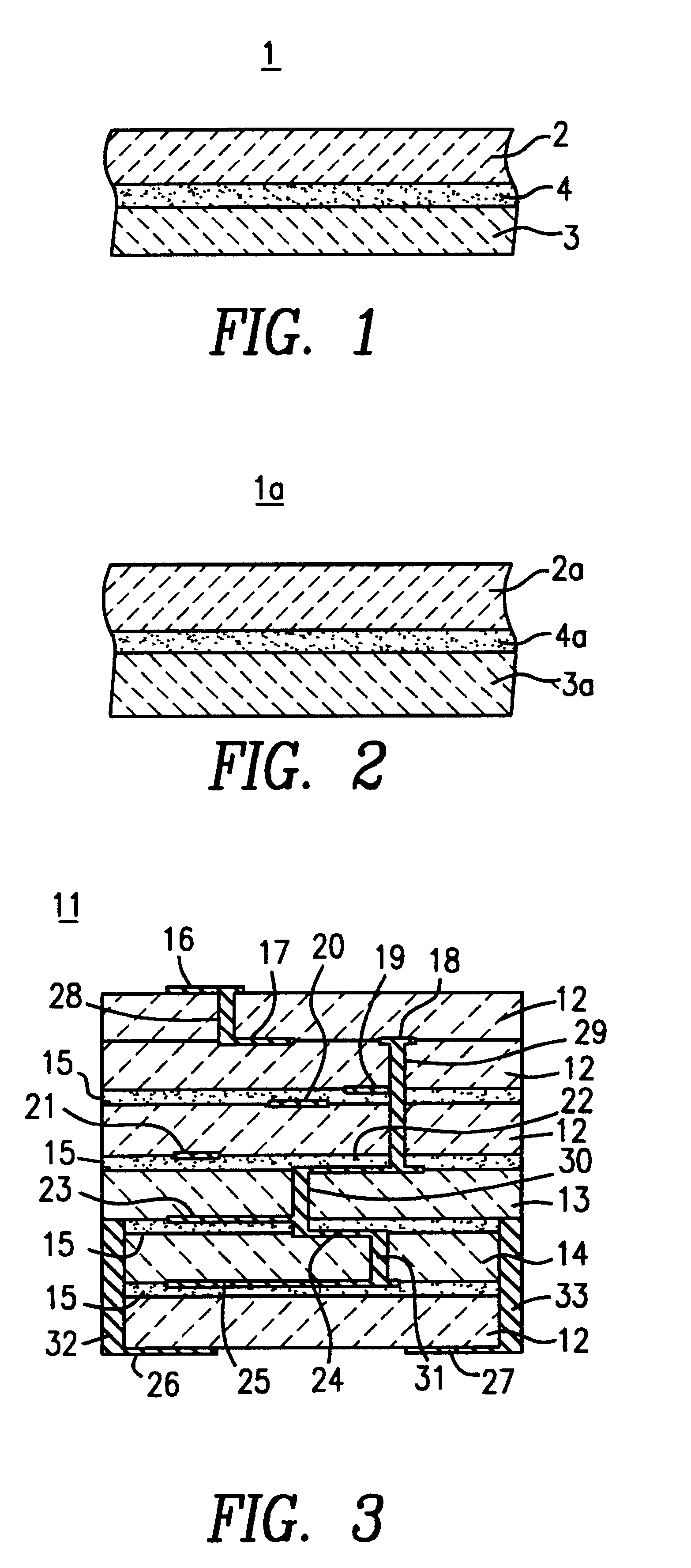

Repair of composite laminates

A patch of fibre reinforced plastics composite material, a repair kit including such a patch and a method of using such a patch and repair kit are provided. The patch (1) is for attachment to a surface (17) of a fibre reinforced plastics composite structure (11) over an area of damage (10) to the structure. The patch defines an outer surface (3), a bonding surface (4) opposed thereto and a peripheral edge. The patch includes fibre reinforcement and plastics matrix material with the latter being in a final state of hardness. The patch defines a series of small apertures (6) therethrough to allow the passage of gases and other matter through the patch to prevent entrapped air weakening the repair.

Owner:AIRBUS OPERATIONS LTD

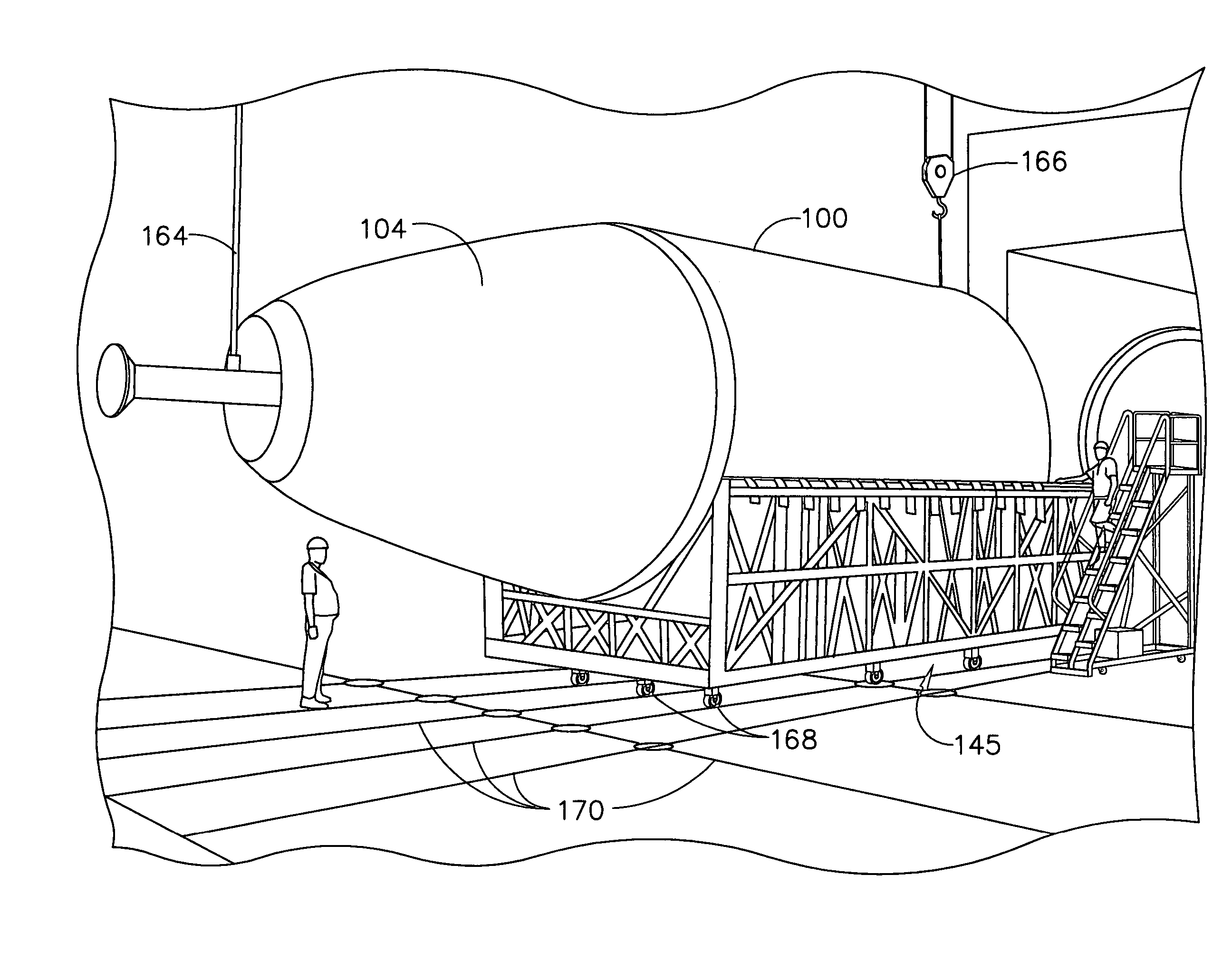

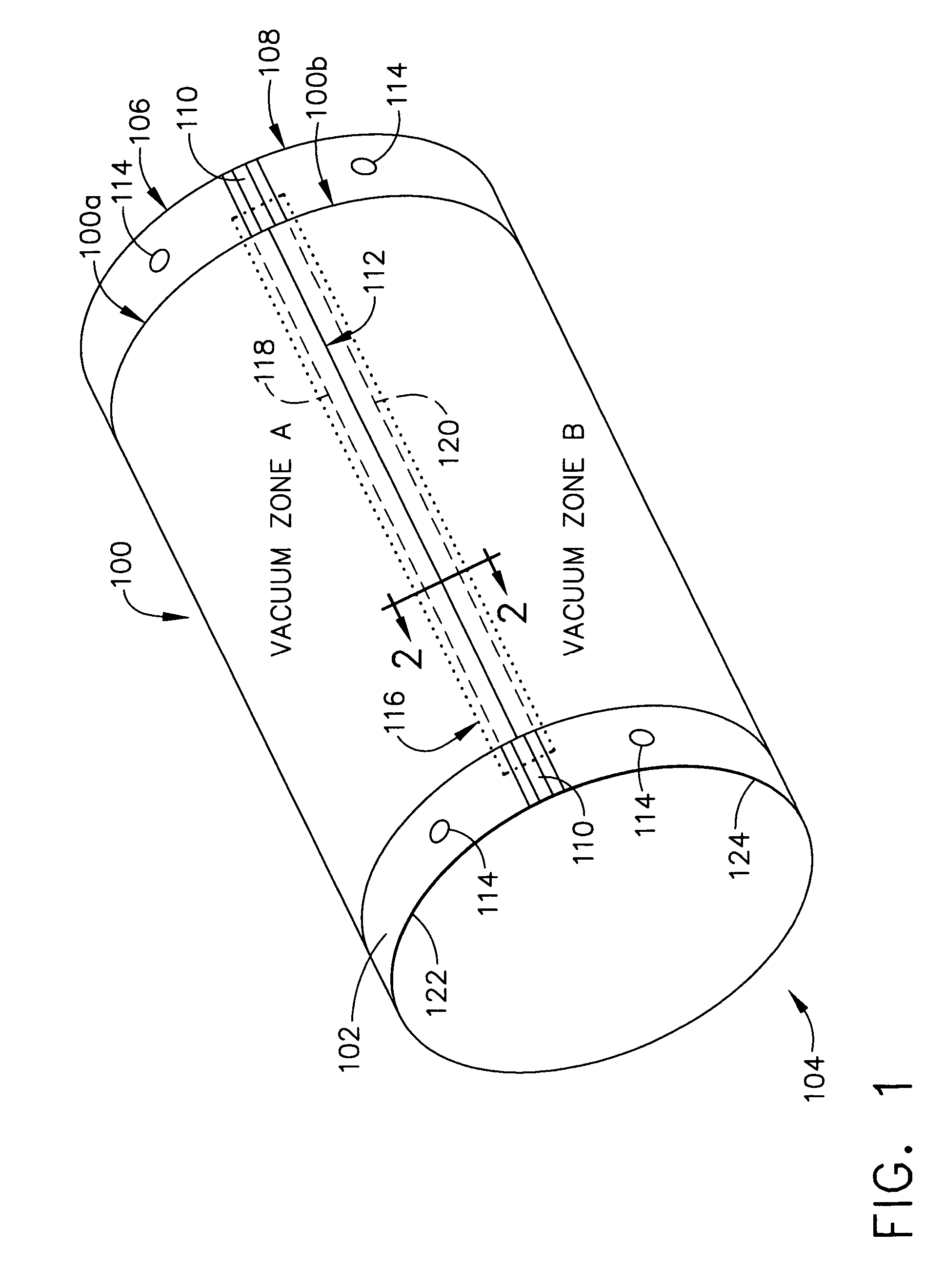

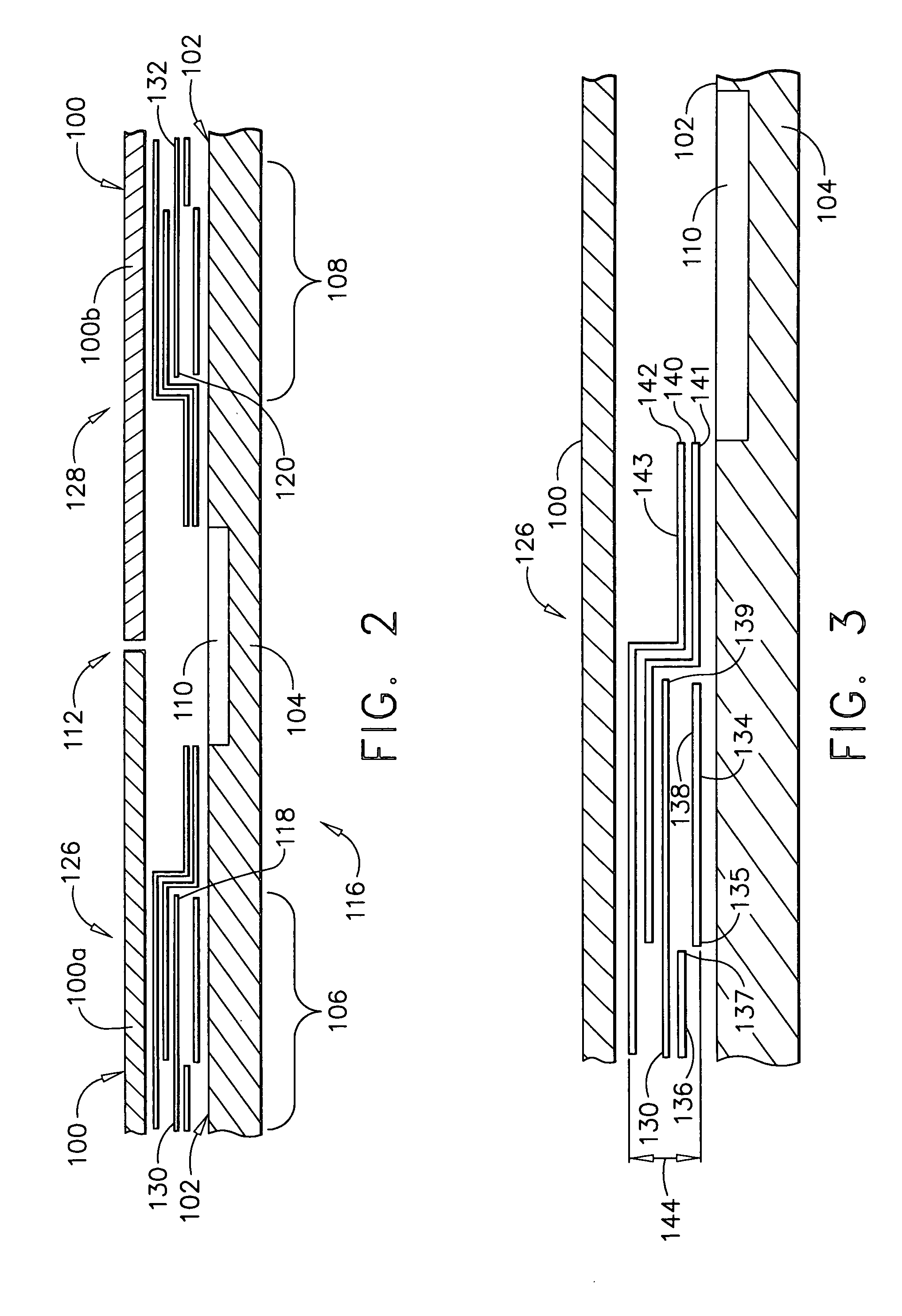

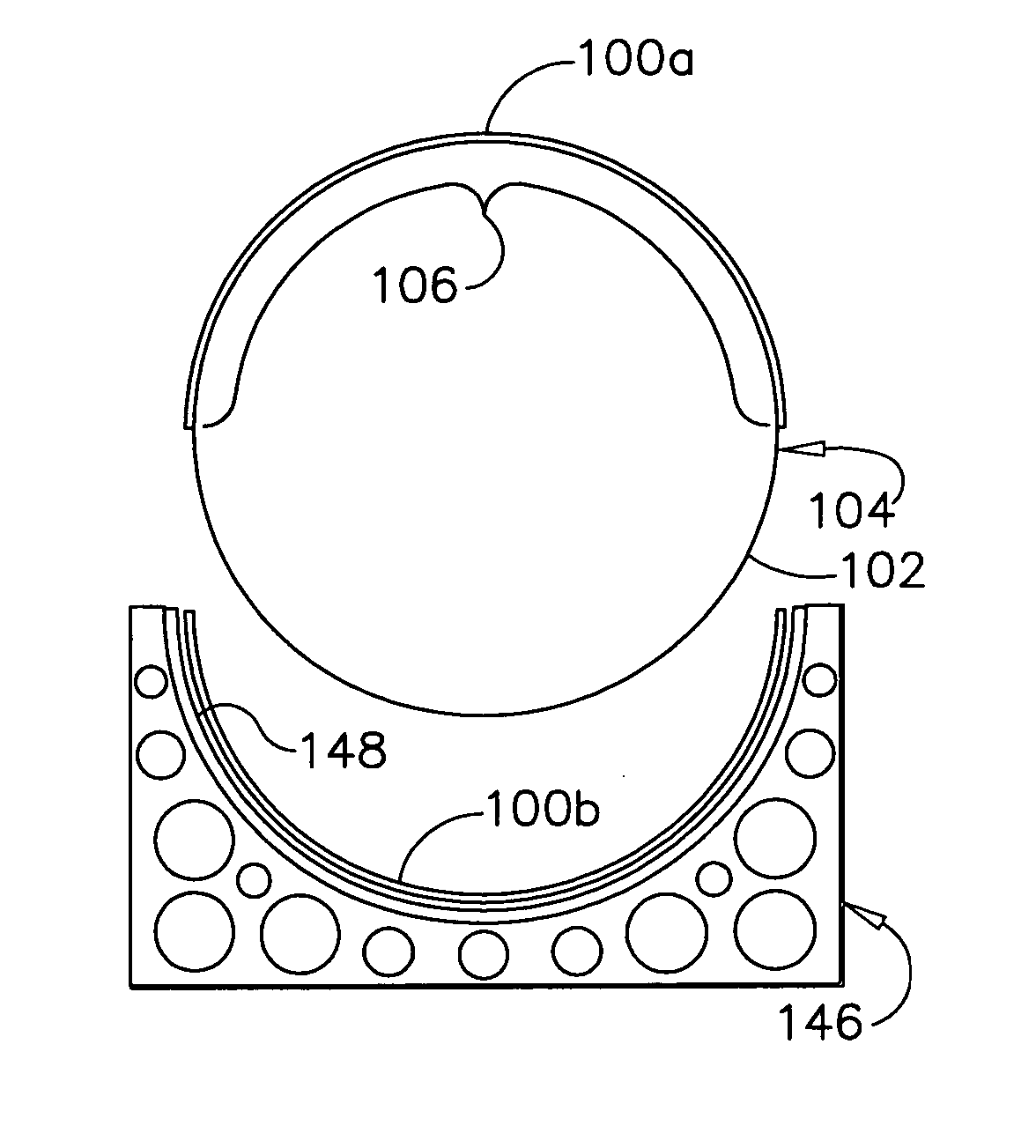

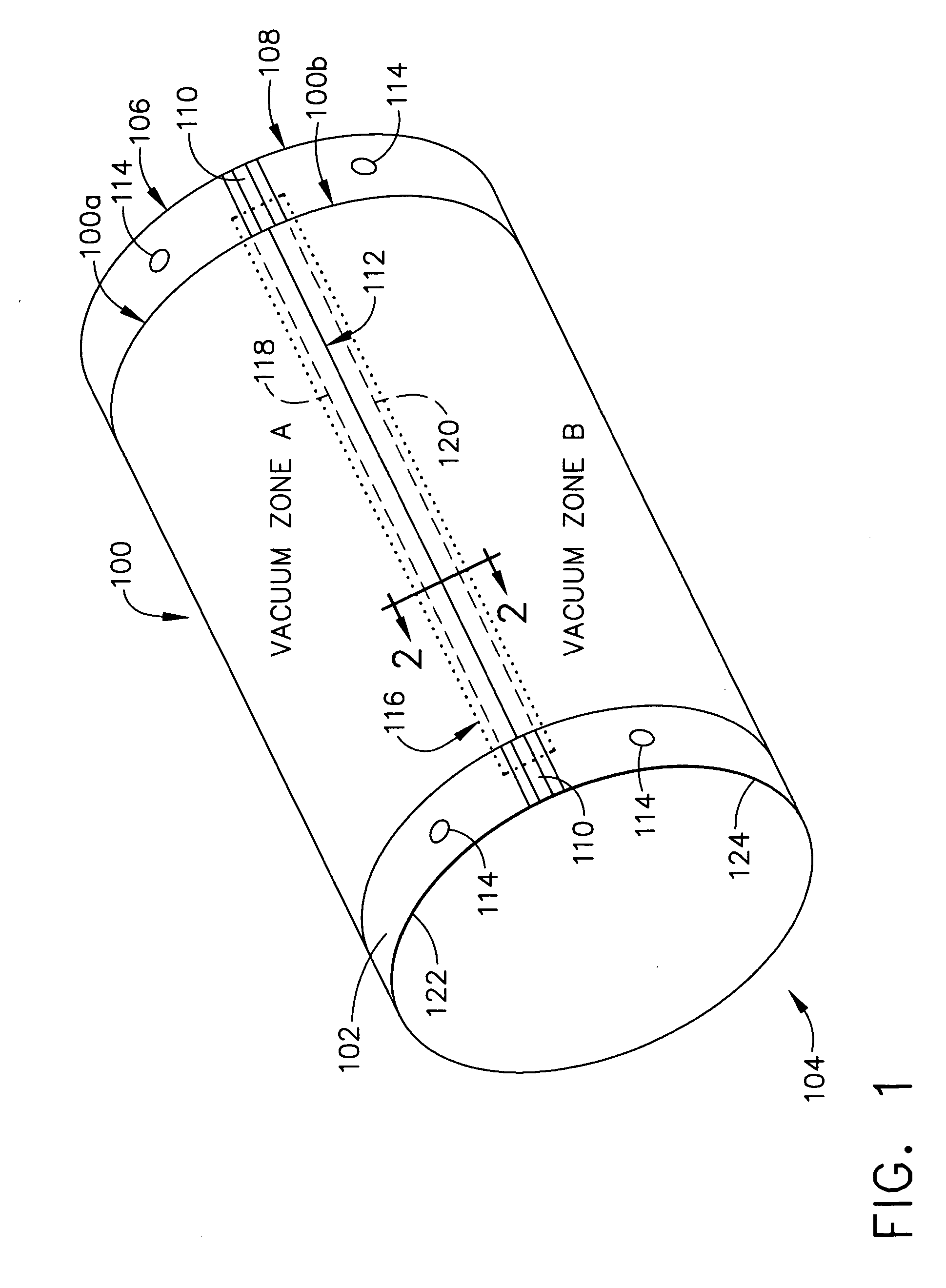

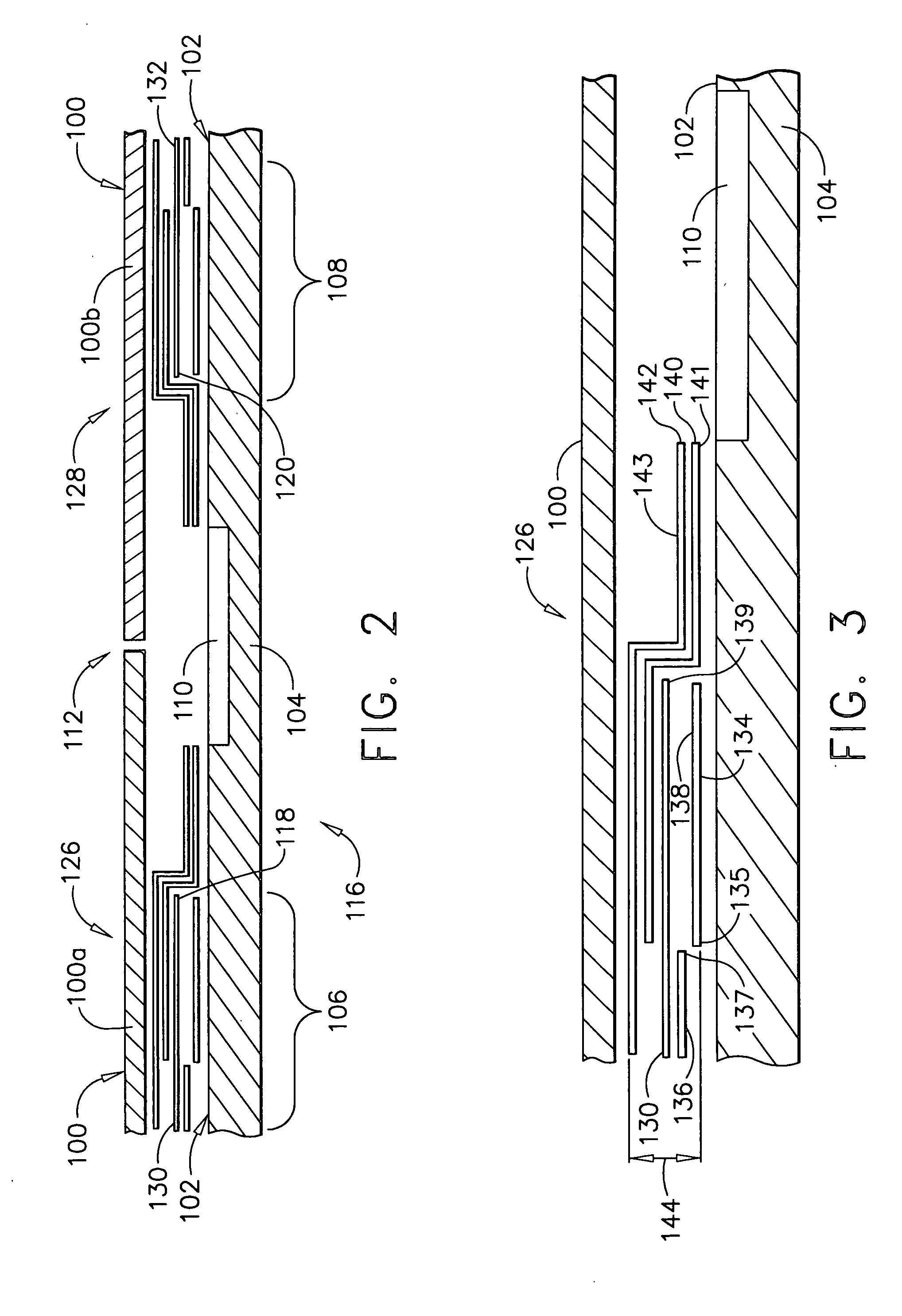

Method of transferring large uncured composite laminates

InactiveUS7228611B2Reduce investmentLaminationEfficient propulsion technologiesComposite laminatesEngineering

A method of transferring an uncured composite laminate skin from a lay-up surface of a male mandrel tool to a female cure tool includes defining multiple vacuum zones on the lay-up surface, each zone corresponding to one of a multiple of portions into which the skin is to be separated. For example, to separate the skin into two portions, a low profile seal of a first membrane to the lay-up surface is formed at a first vacuum zone and a second low profile seal for a second membrane is formed at a second vacuum zone. The method further includes laying up a composite laminate skin over all the vacuum zones; separating the composite laminate skin into portions, for example, a first portion over the first vacuum zone and a second portion over the second vacuum zone; and releasing the portions individually into cure tools having an outside mold line surface.

Owner:THE BOEING CO

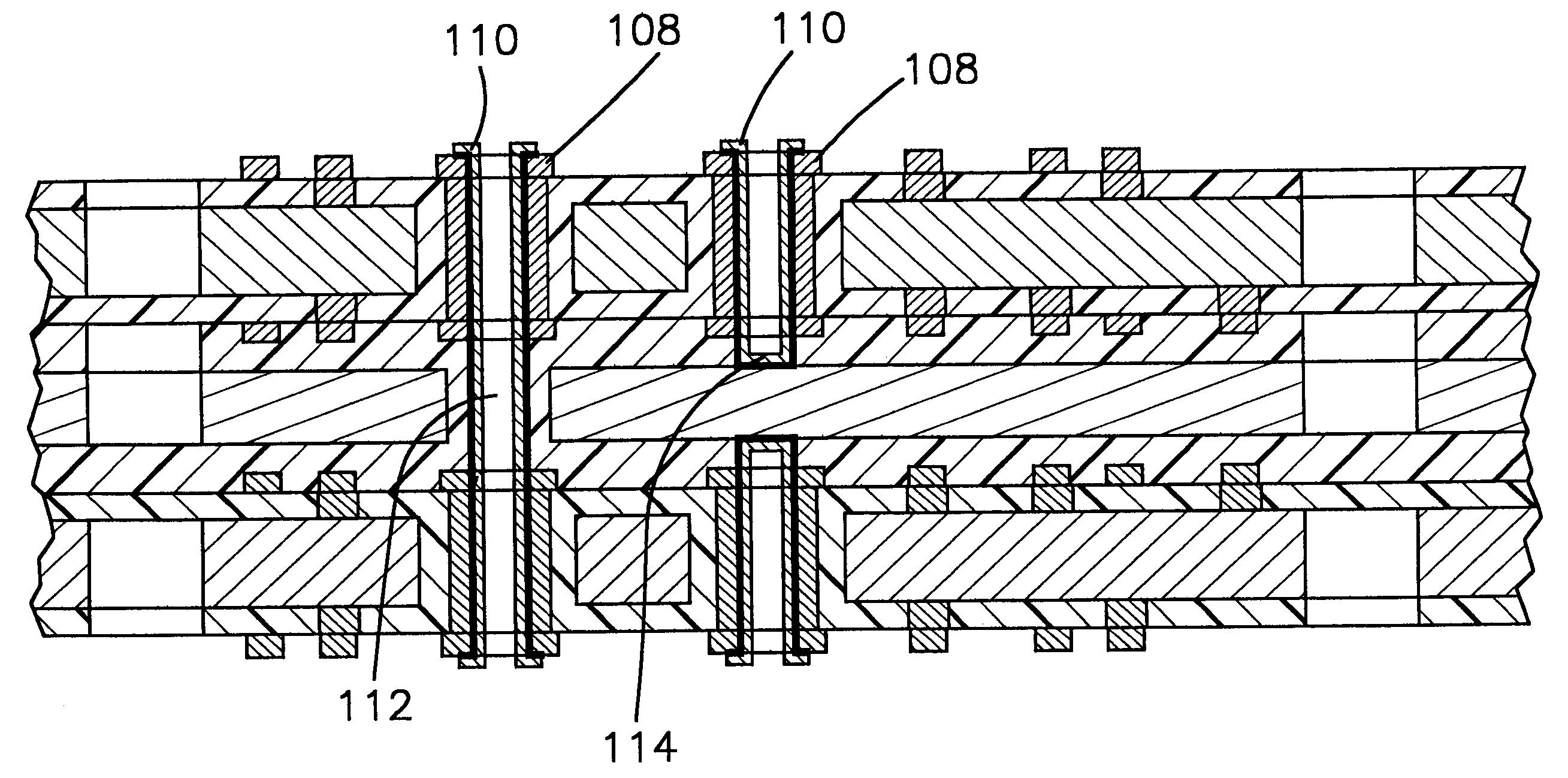

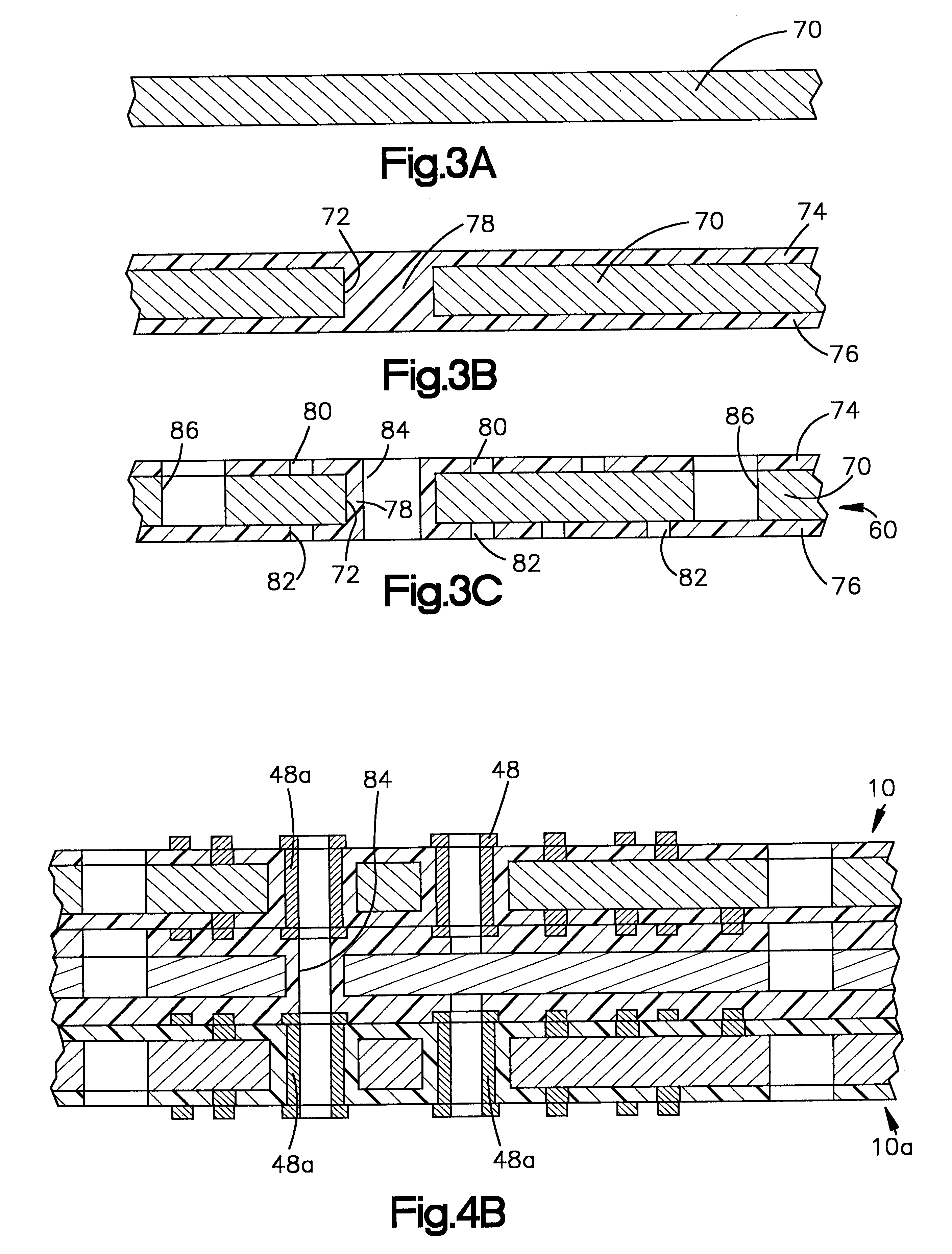

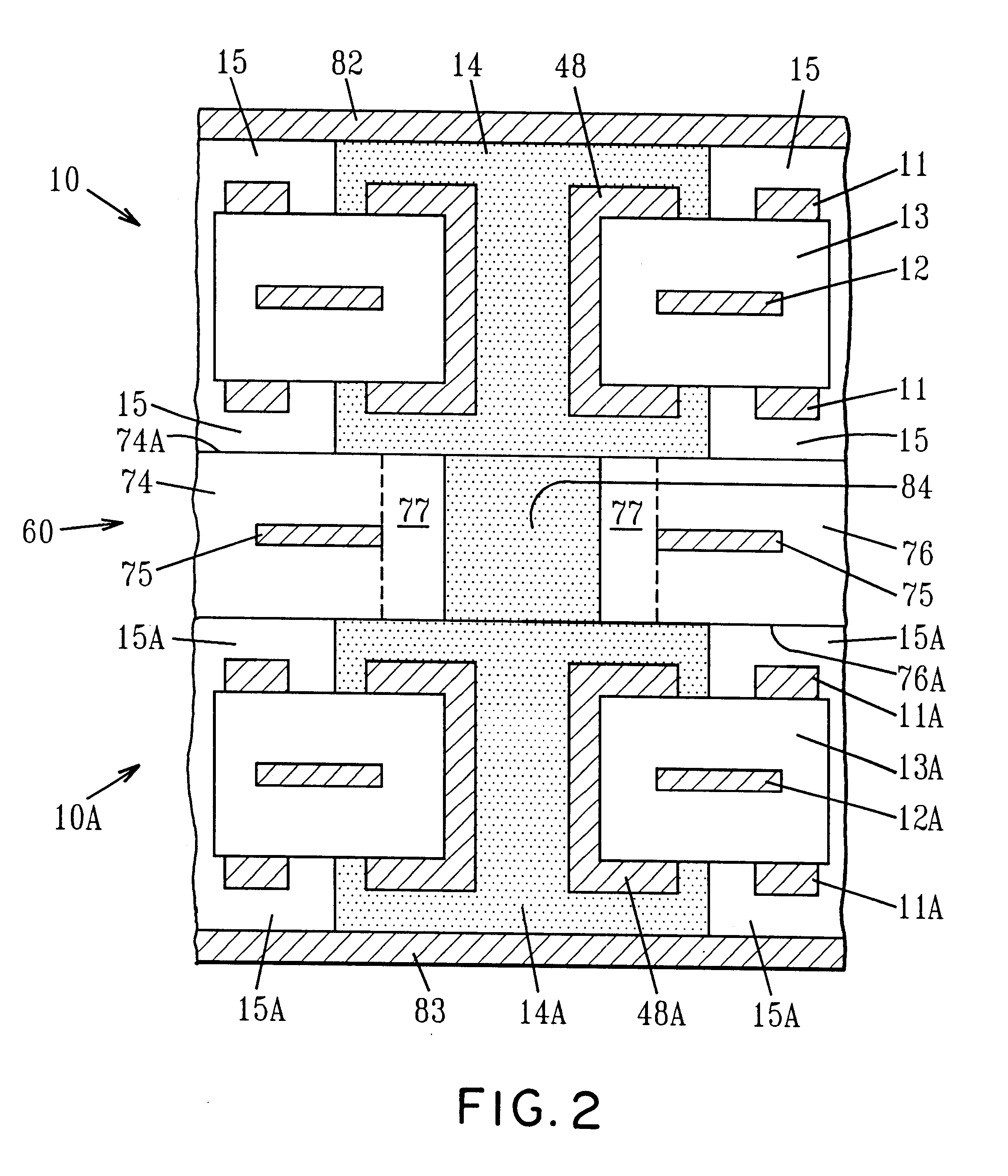

Composite laminate circuit structure and methods of interconnecting the same

InactiveUS6388204B1Low costLess costlyElectrically conductive connectionsPrinted circuit aspectsComposite laminatesConductive materials

A laminate circuit structure assembly is provided that comprises at least two modularized circuitized plane subassemblies; a joining layer located between each of the subassemblies and wherein the subassemblies and joining layer are bonded together with a cured dielectric from a bondable, curable dielectric. The subassemblies and joining layer are electrically interconnected with bondable electrically conductive material. The joining layer comprises dielectric layers disposed about an internal electrically conductive layer. The electrically conductive layer has a via and the dielectric layers each have a via of smaller diameter than the vias in the electrically conductive layer and are aligned with the vias in the electrically conductive layer. The vias are filled with electrically bondable electrically conductive material for providing electrical contact between the subassemblies.

Owner:IBM CORP

Lanthanide oxide/zirconium oxide atomic layer deposited nanolaminate gate dielectrics

The invention provides a laminated dielectric layer for semiconductor devices formed by a combination of ZrO2 and a lanthanide oxide on a semiconductor substrate and methods of making the same. In certain methods, the ZrO2 is deposited by multiple cycles of reaction sequence atomic layer deposition (RS-ALD) that includes depositing a ZrI4 precursor onto the surface of the substrate in a first pulse followed by exposure to H2O / H2O2 in a second pulse, thereby forming a thin ZrO2 layer on the surface. After depositing the ZrO2 layer, the lanthanide oxide layer is deposited by electron beam evaporation. The composite laminate zirconium oxide / lanthanide oxide dielectric layer has a relatively high dielectric constant and can be formed in layers of nanometer dimensions. It is useful for a variety of semiconductor applications, particularly for DRAM gate dielectric layers and DRAM capacitors.

Owner:AHN KIE +1

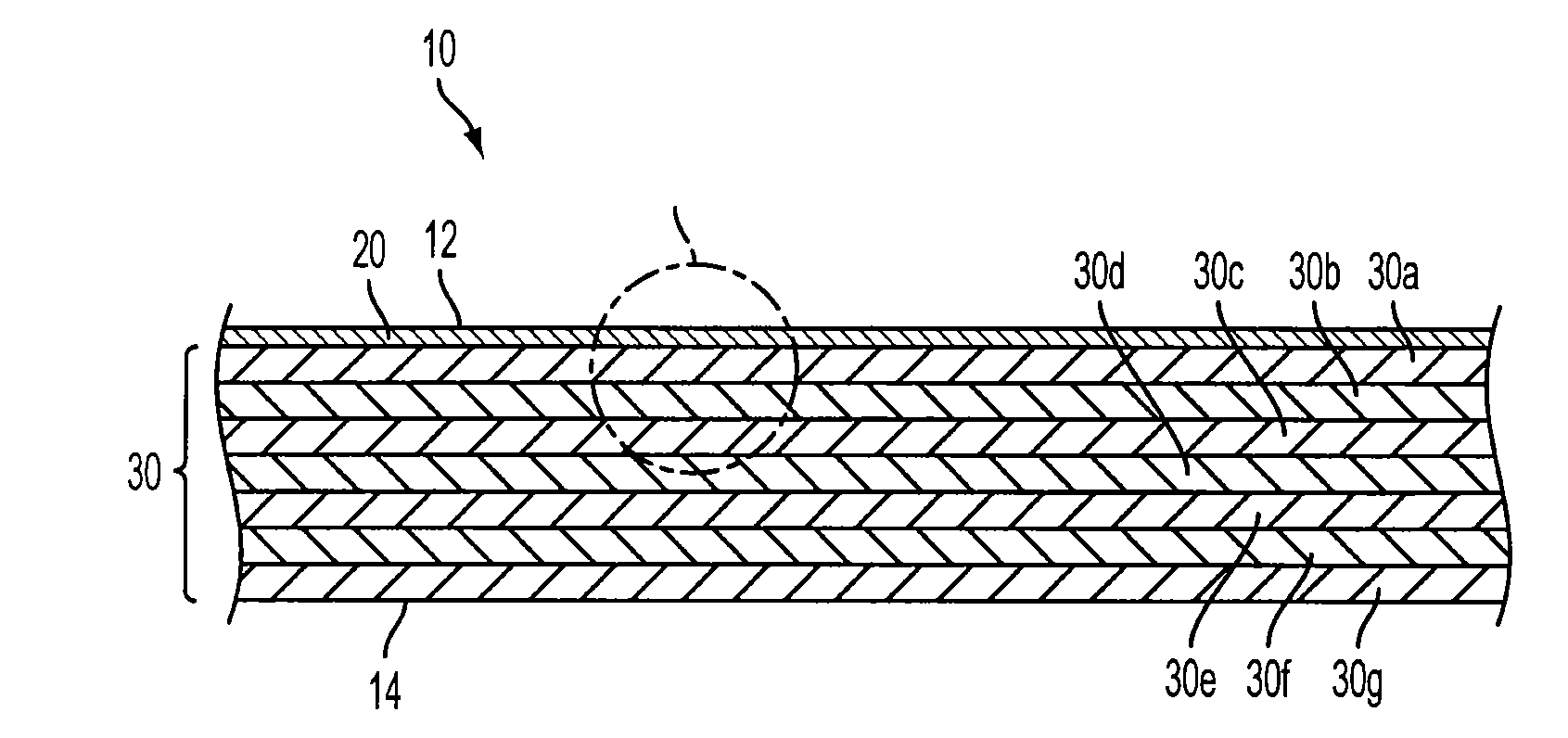

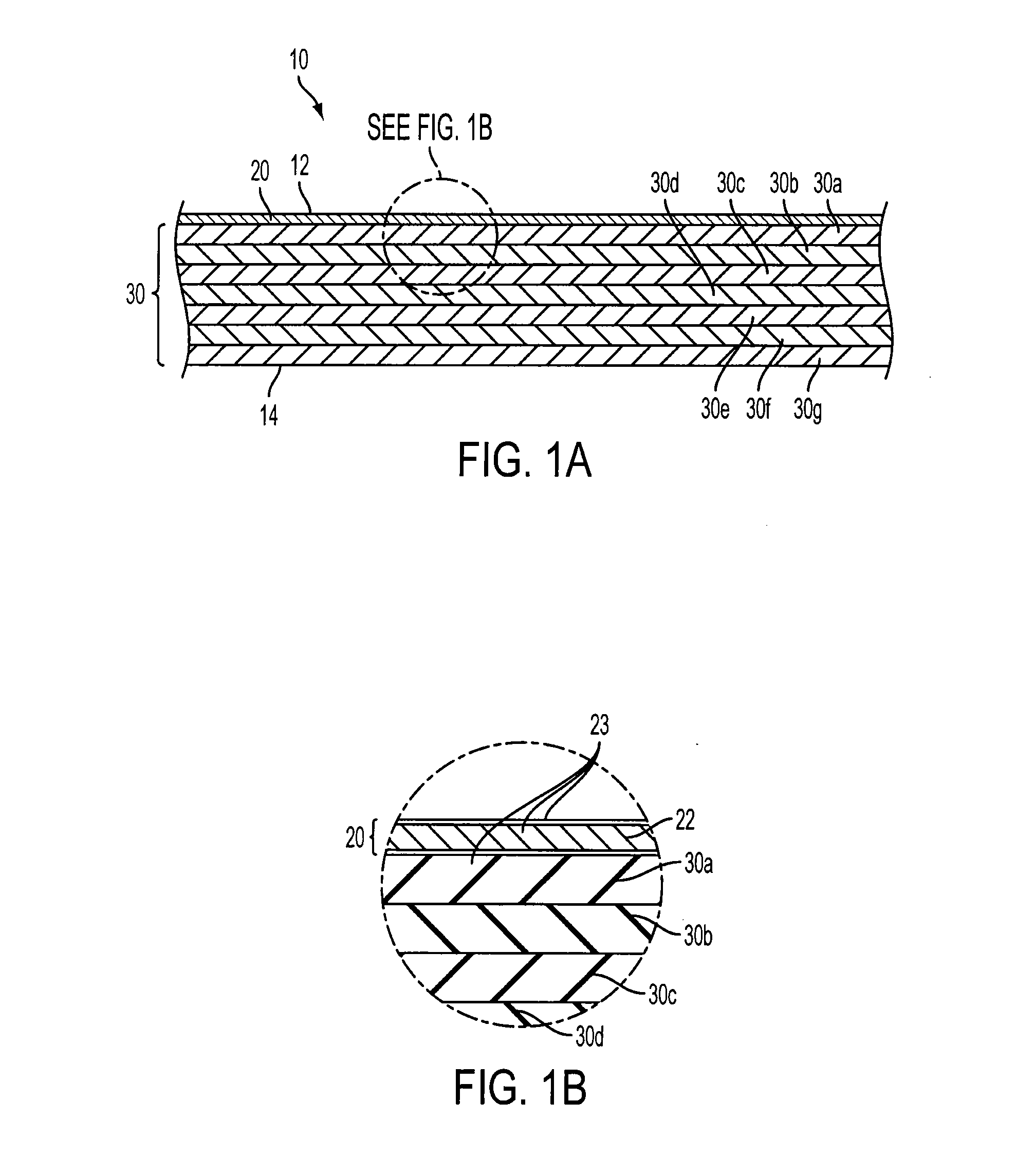

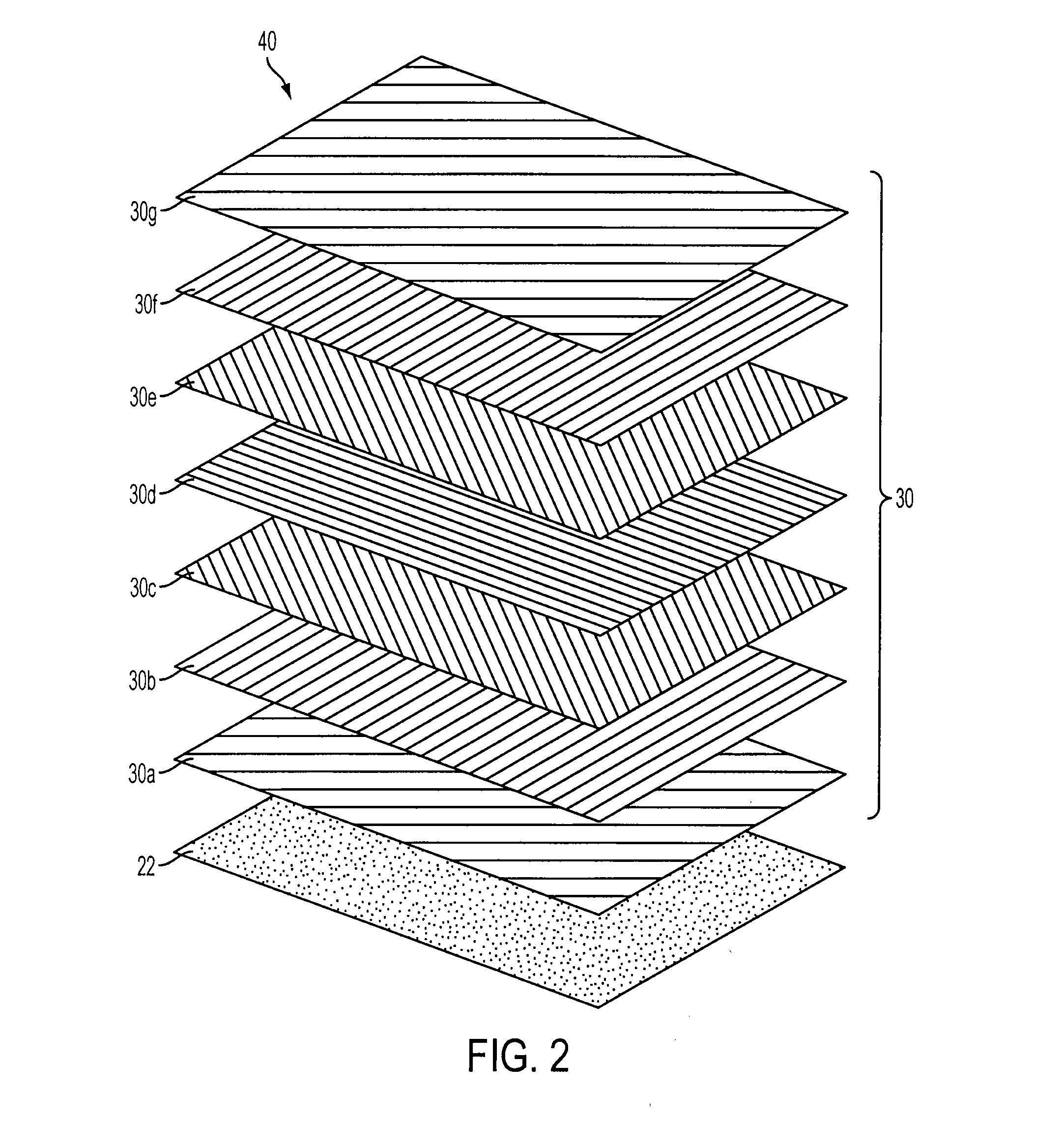

Multi-axial laminate composite structures and methods of forming the same

InactiveUS20060222837A1Synthetic resin layered productsEfficient propulsion technologiesFiberComposite laminates

Owner:THE BOEING CO

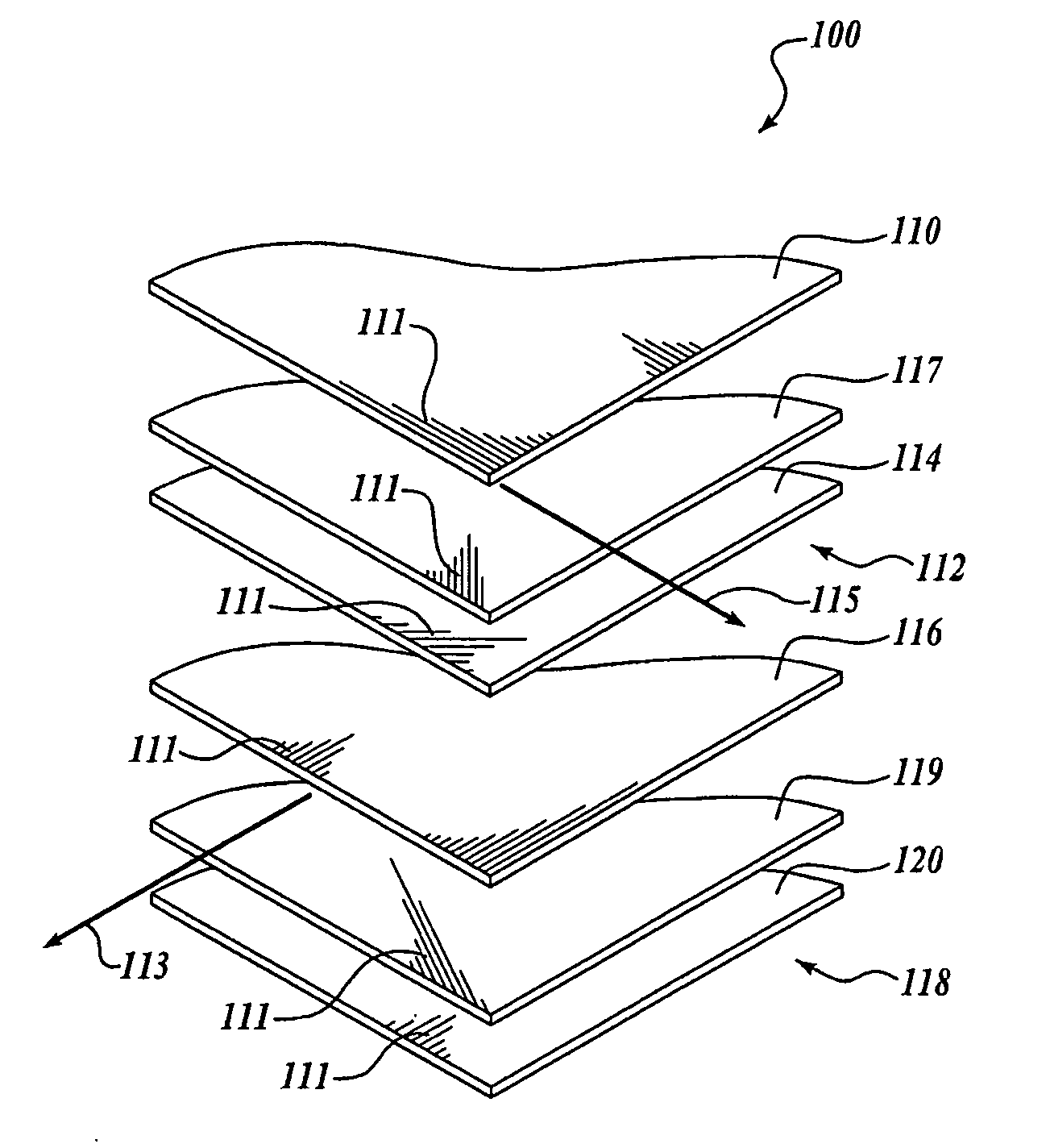

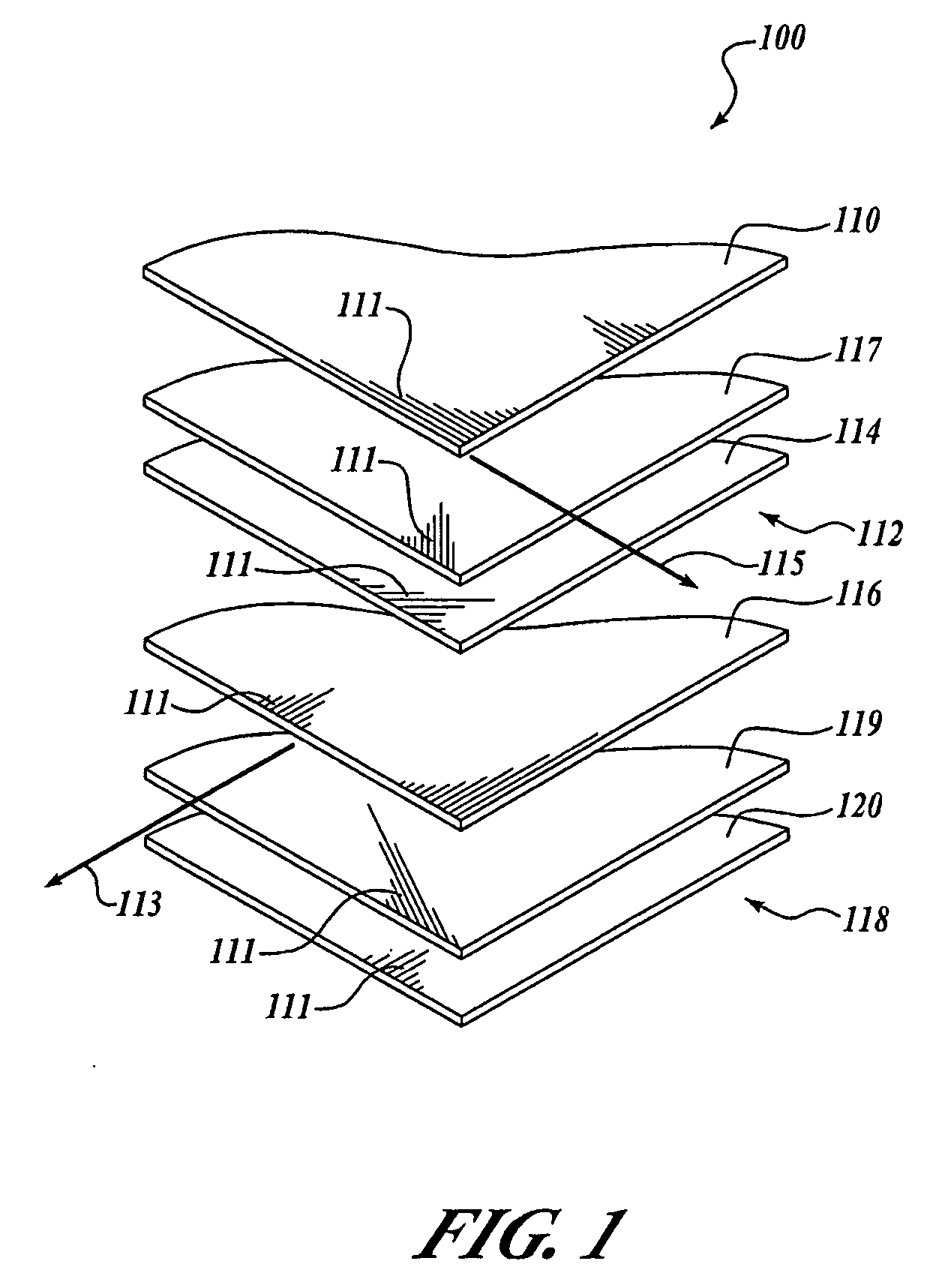

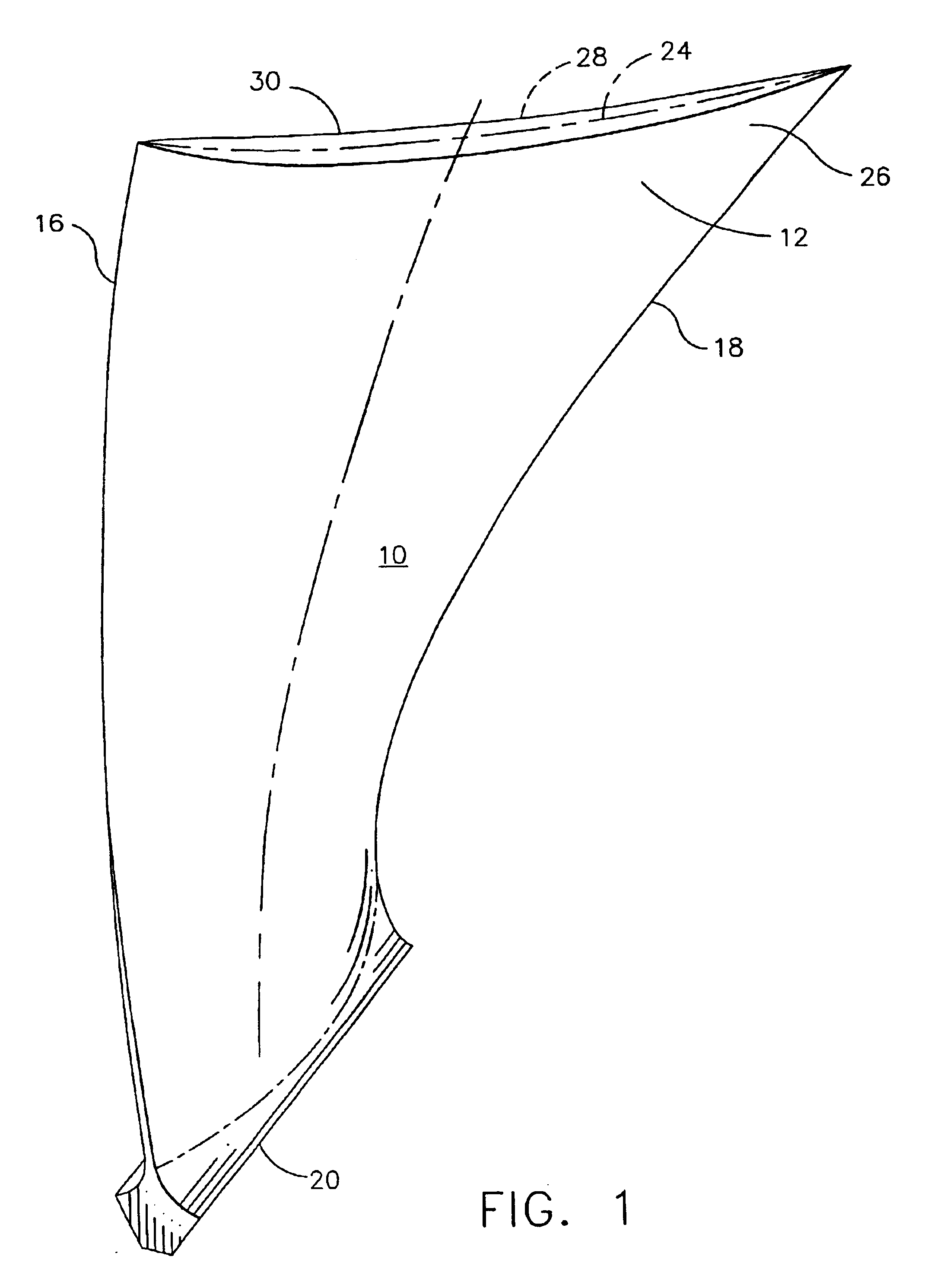

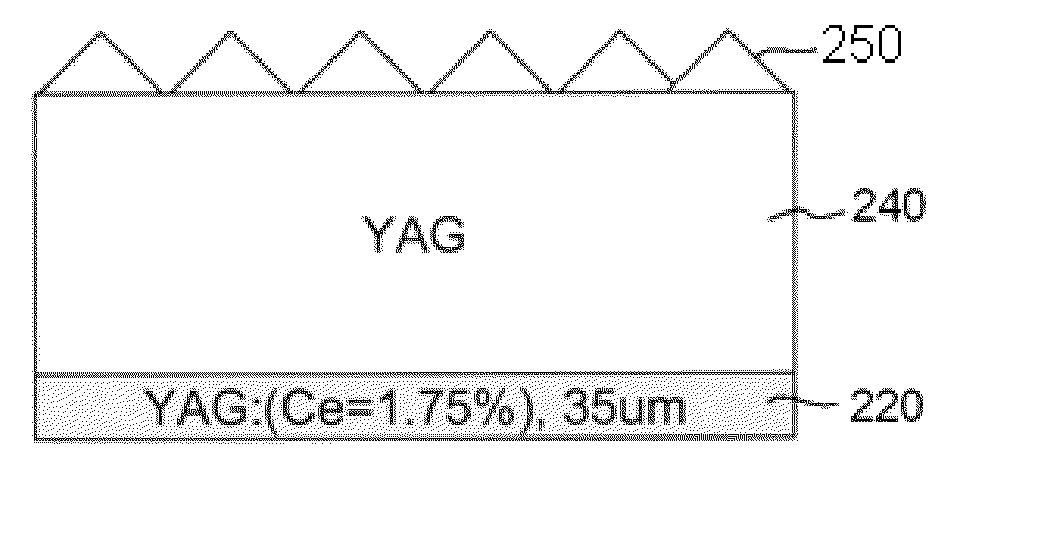

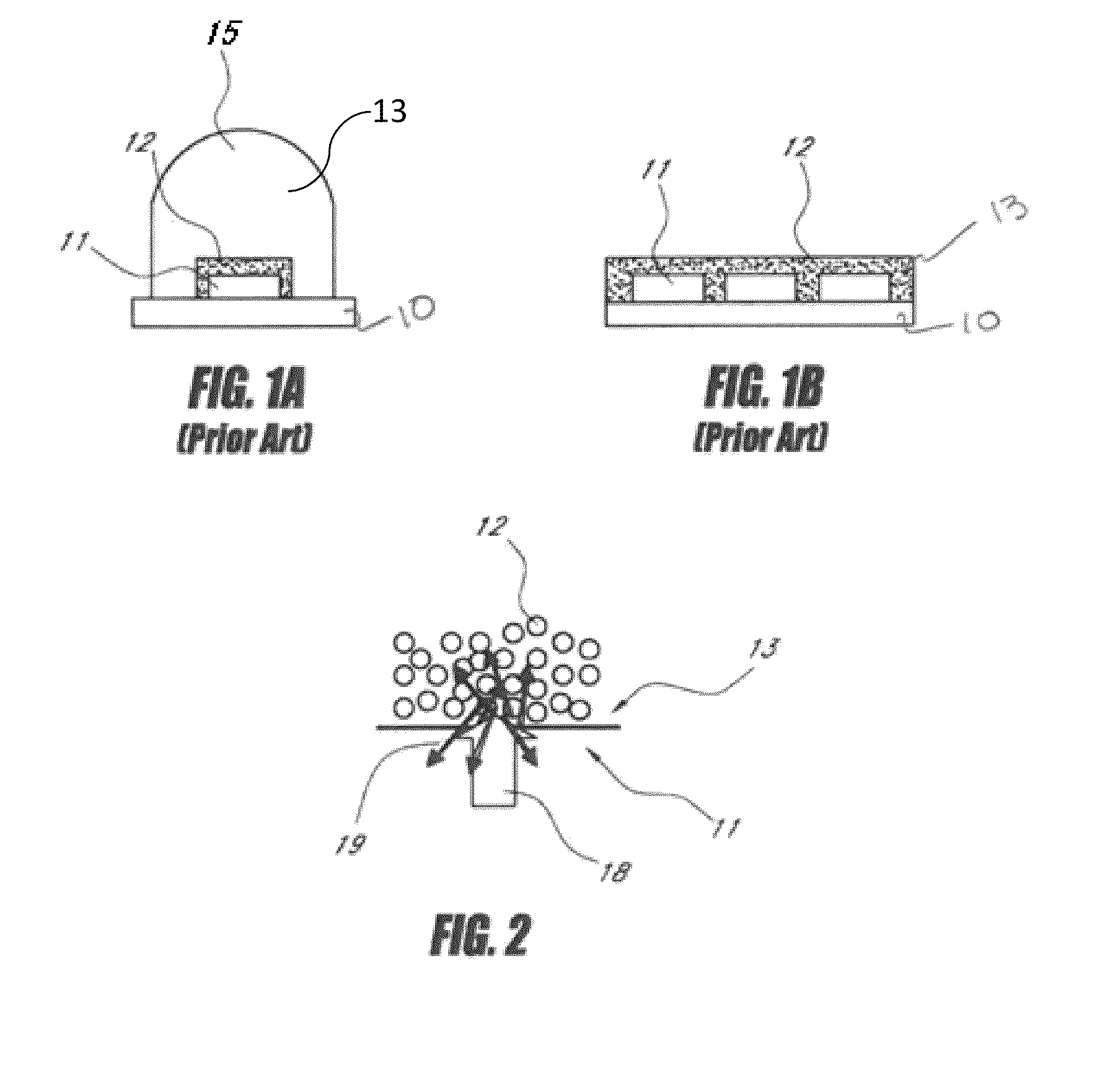

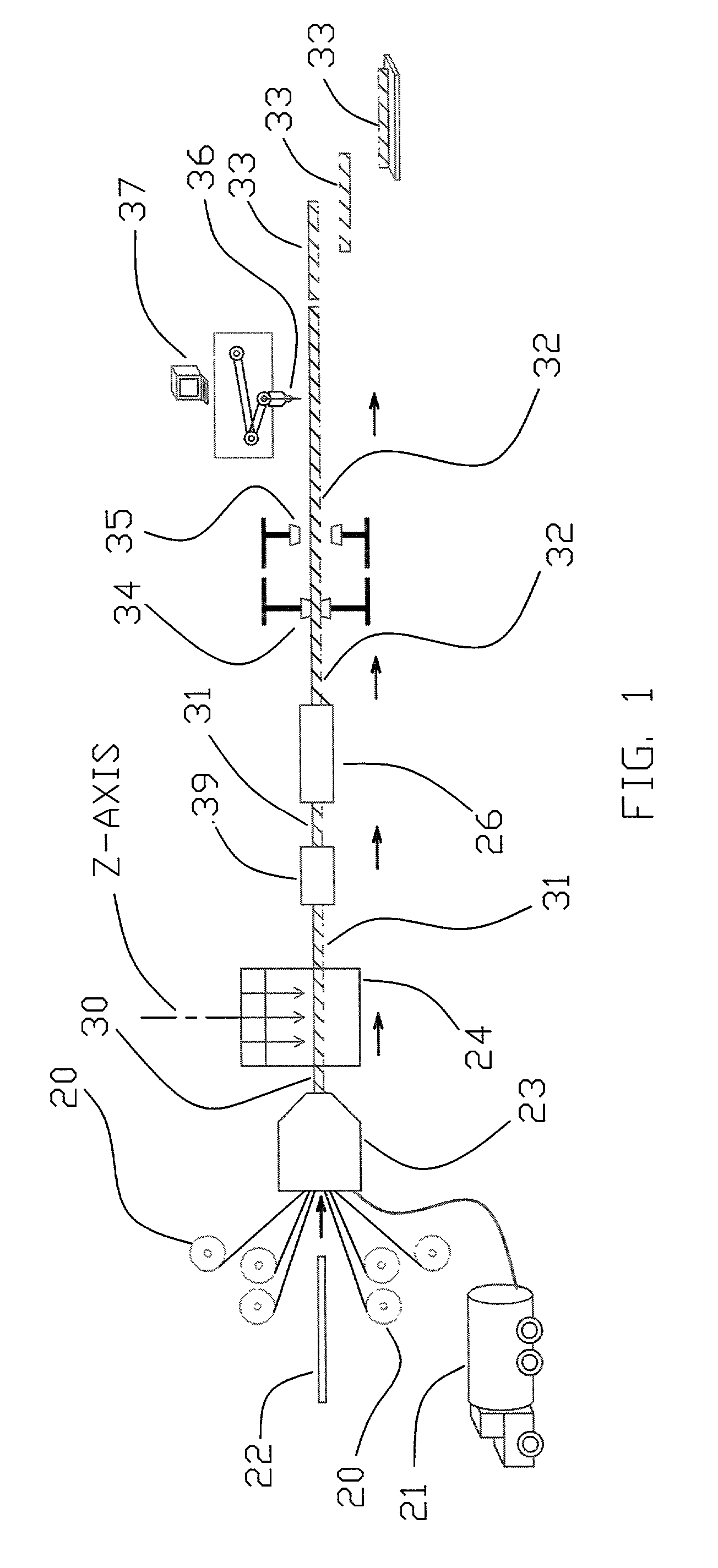

Laser projection system to facilitate layup of complex composite shapes

InactiveUS6843565B2Increased ply lay-up speedReduce morbidityBlade accessoriesProjectorsData setComposite laminates

The present invention provides a process for the lay-up of a composite laminate article, the article produced by this process, and the apparatus used to produce the composite laminate article. The composite laminate article may be, for example, an airfoil, particularly useful as a fan blade in a large high bypass ratio turbofan engine, wherein the blade is generally regarded as large and having a high degree of twist. In a preferred embodiment, the present invention provides a process for laying up a composite laminate article comprising a) reading a data set to enable the projection of an image of a ply section onto a work surface, the image indicating a ply section target point; b) laying up a ply section of composite laminating material within the image, wherein the ply section first contacts the work surface at the target point; and c) repeating steps (a)-(b) until the composite laminate article is complete. In a second preferred embodiment, the present invention provides for a lamination apparatus for use in making a composite laminate article comprising a work surface for receiving, in a predetermined sequence, a plurality of ply sections of composite laminating material; a laser projection system using predetermined projection points for outlining an image of a ply section onto the work surface, the image further indicating a ply section target point for making first contact of the ply section with the work surface; and a data set for providing the predetermined projection points to the laser projection system.

Owner:GENERAL ELECTRIC CO

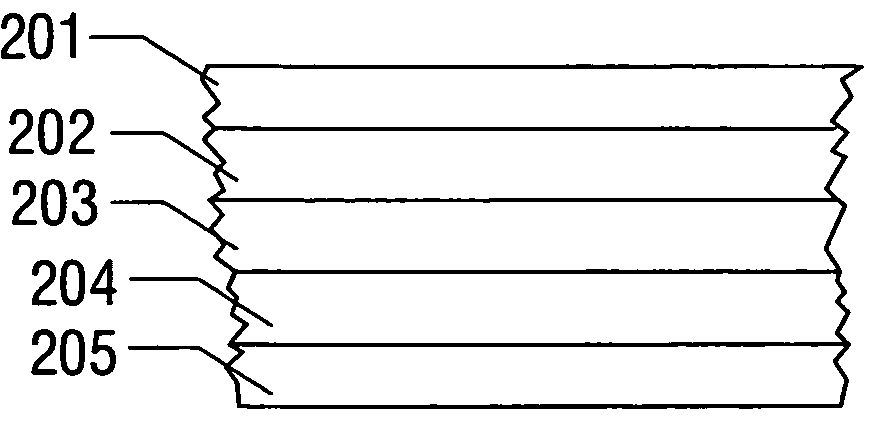

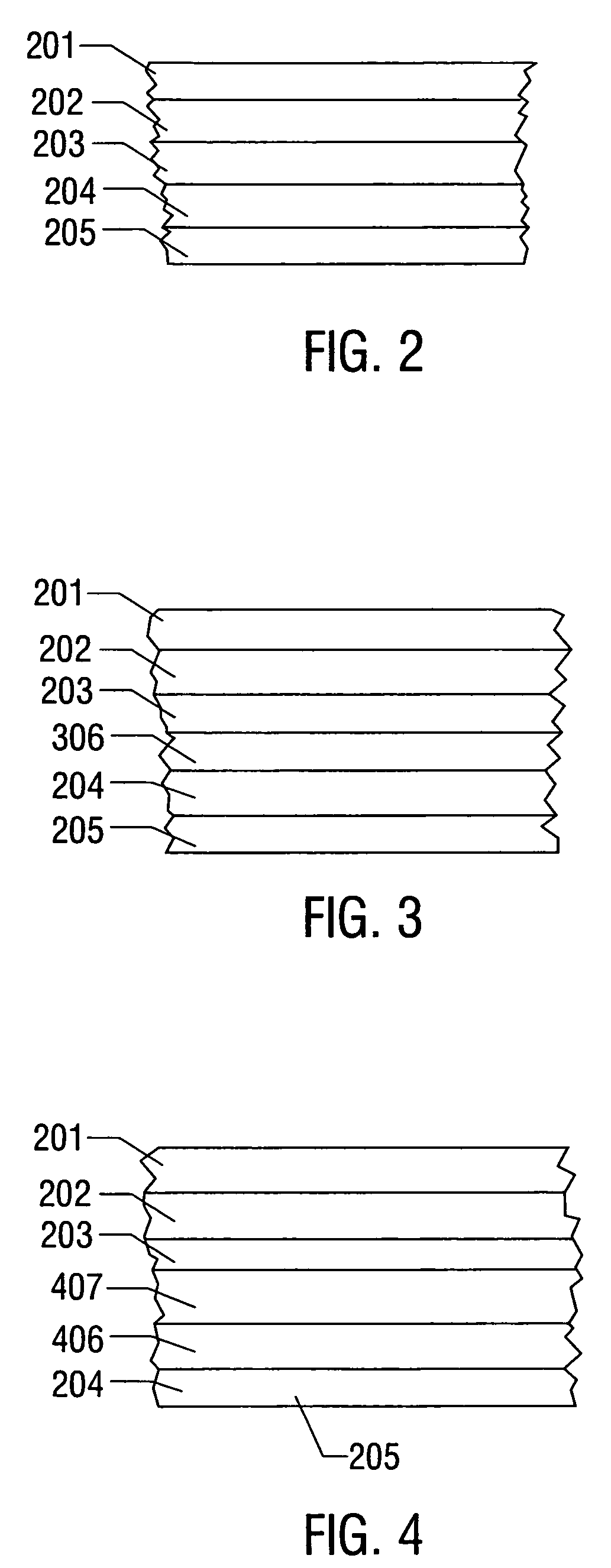

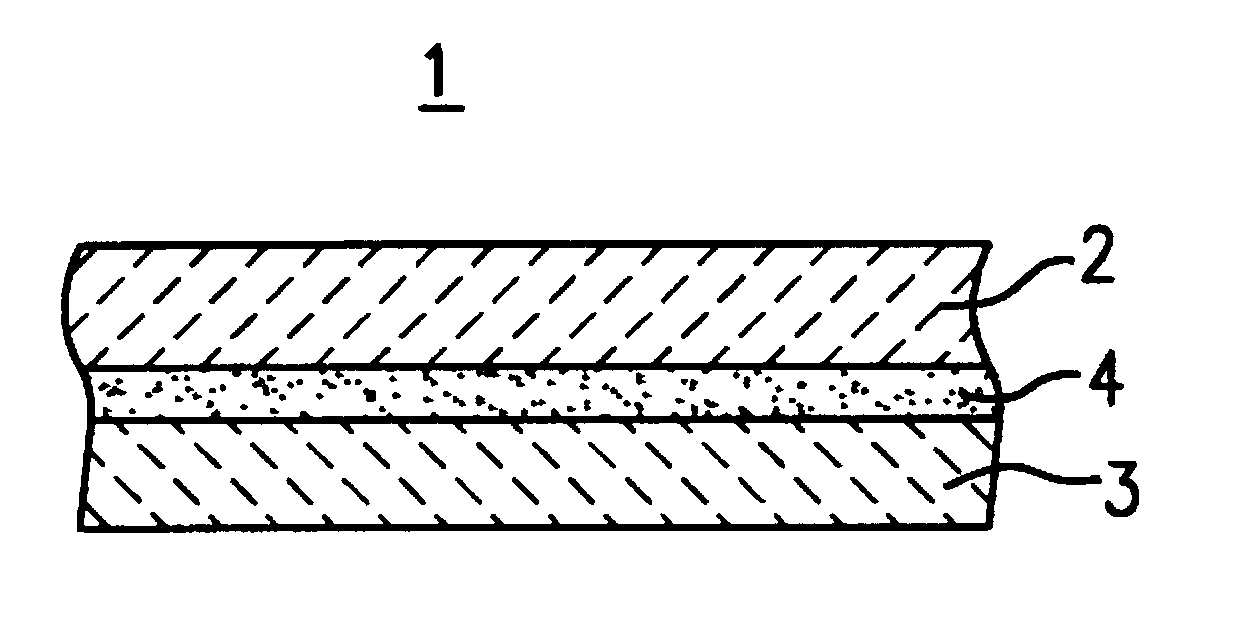

Composite Laminate Having An Improved Cosmetic Surface And Method Of Making Same

InactiveUS20090110872A1Improved cosmetic surfaceSynthetic resin layered productsLaminationGlass fiberFiber

A composite laminate includes a plurality of sheets of prepreg stacked one over another, and a scrim layer provided on an exterior surface of the sheets of prepreg. Each prepreg sheet is formed of fibers preimpregnated with resin. The scrim layer and the sheets of prepreg form a composite laminate whereby the scrim layer constitutes an outer, exposed surface of the composite laminate. The scrim layer may be a nonwoven carbon or glass fiber scrim that has absorbed resin from the sheets of prepreg. A method of making a composite laminate includes placing into a mold a scrim and a plurality of sheets of prepreg, with the scrim extending between an exterior surface of the sheets of prepreg and an inner surface of the mold; forming a composite laminate whereby the scrim is adhered to the sheets of prepreg; and removing the composite laminate from the mold. An outer layer of the composite laminate includes the scrim.

Owner:APPLE INC

Fabrication of interleaved metallic and intermetallic composite laminate materials

InactiveUS7188559B1Well formedLimit cracking and fracturingWeapon componentsDomestic articlesGramComposite laminates

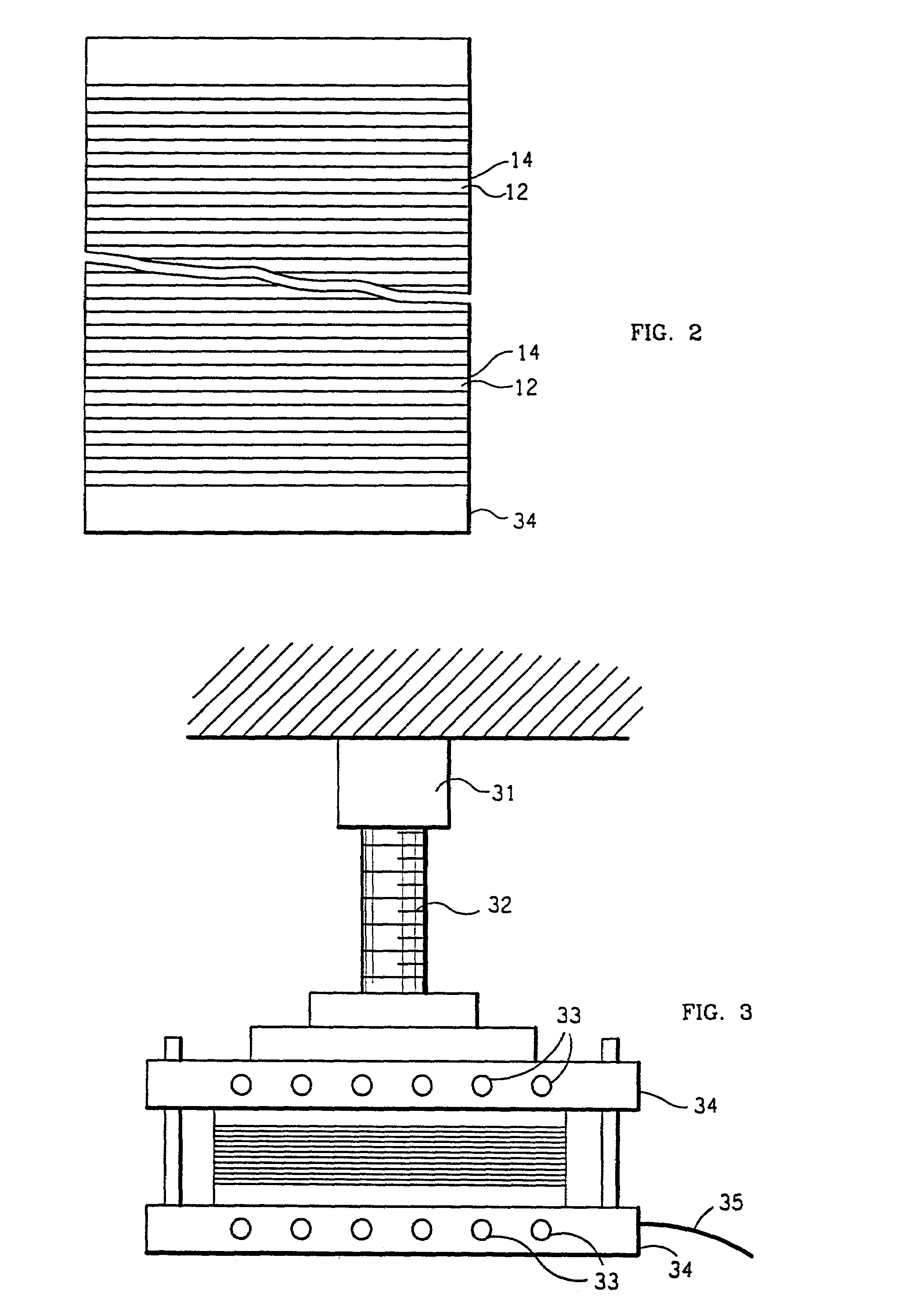

Typically 20–40 films of a tough first metal, normally 0.1–1.0 mm thick films of titanium, nickel, vanadium, and / or steel (iron) and alloys thereof, interleaved with a like number of films of a second metal, normally 0.1–1.0 mm thick films of aluminum or alloys thereof, are pressed together in a stack at less than 6 MPa and normally at various pressures 2–4 MPa while being gradually heated in the presence of atmospheric gases to 600–800° C. over a period of, typically, 10+ hours until the second metal is completely compounded; forming thus a metallic-intermetallic laminate composite material having (i) tough first-metal layers separated by (ii) hard, Vickers microhardness of 400 kg / mm2+, intermetallic regions consisting of an intermetallic compound of the first and the second metals. The resulting composite material is inexpensive, lightweight with a density of typically 3 to 4.5 grams / cubic centimeter, and very hard and very tough to serve as, among other applications, lightweight armor. Upon projectile impact (i) the hard intermetallic, ceramic-like, layers are confined by the tough metal layers while (ii) cracking and fracturing is blunted and channeled in directions orthogonal to the axis of impact.

Owner:RGT UNIV OF CALIFORNIA

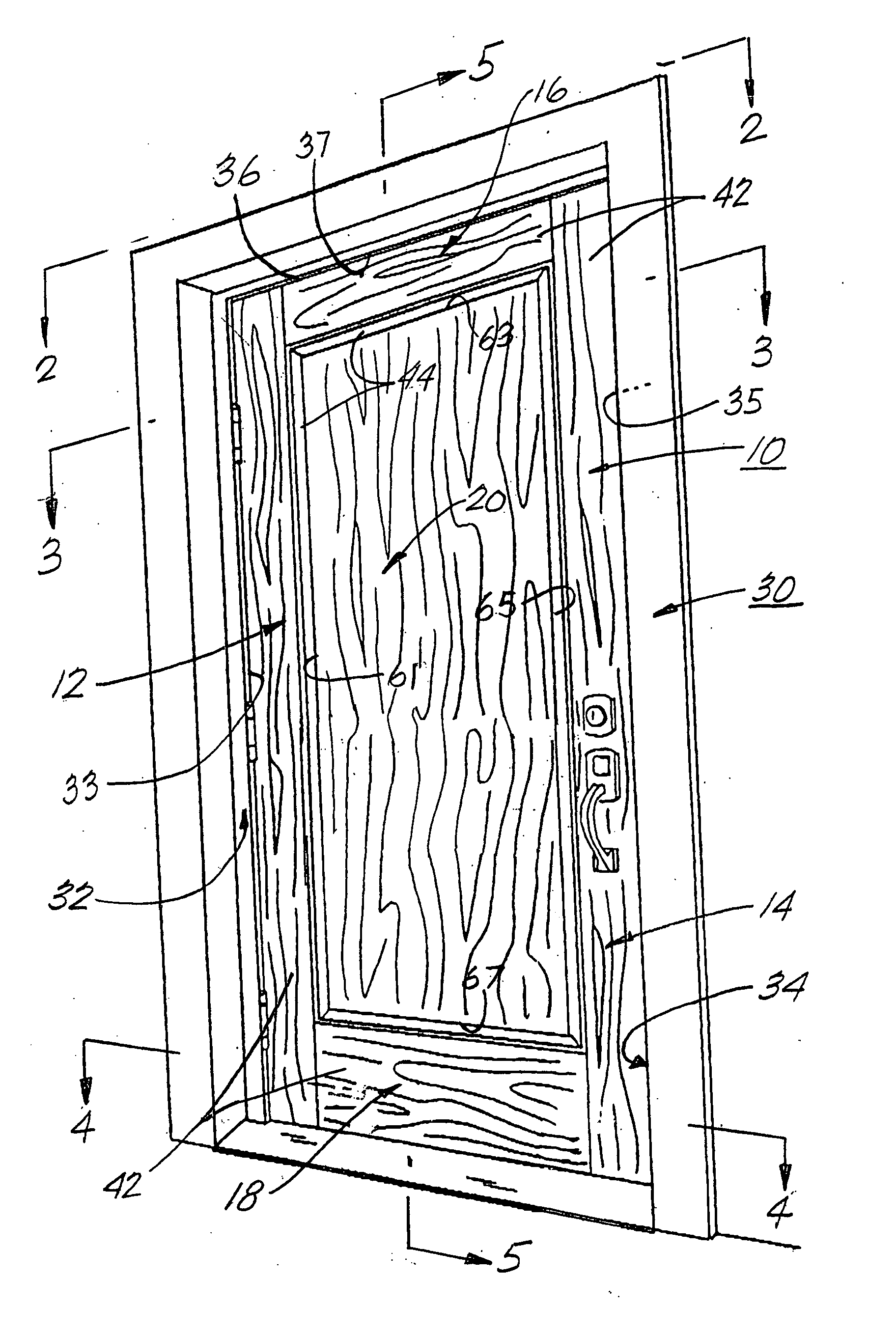

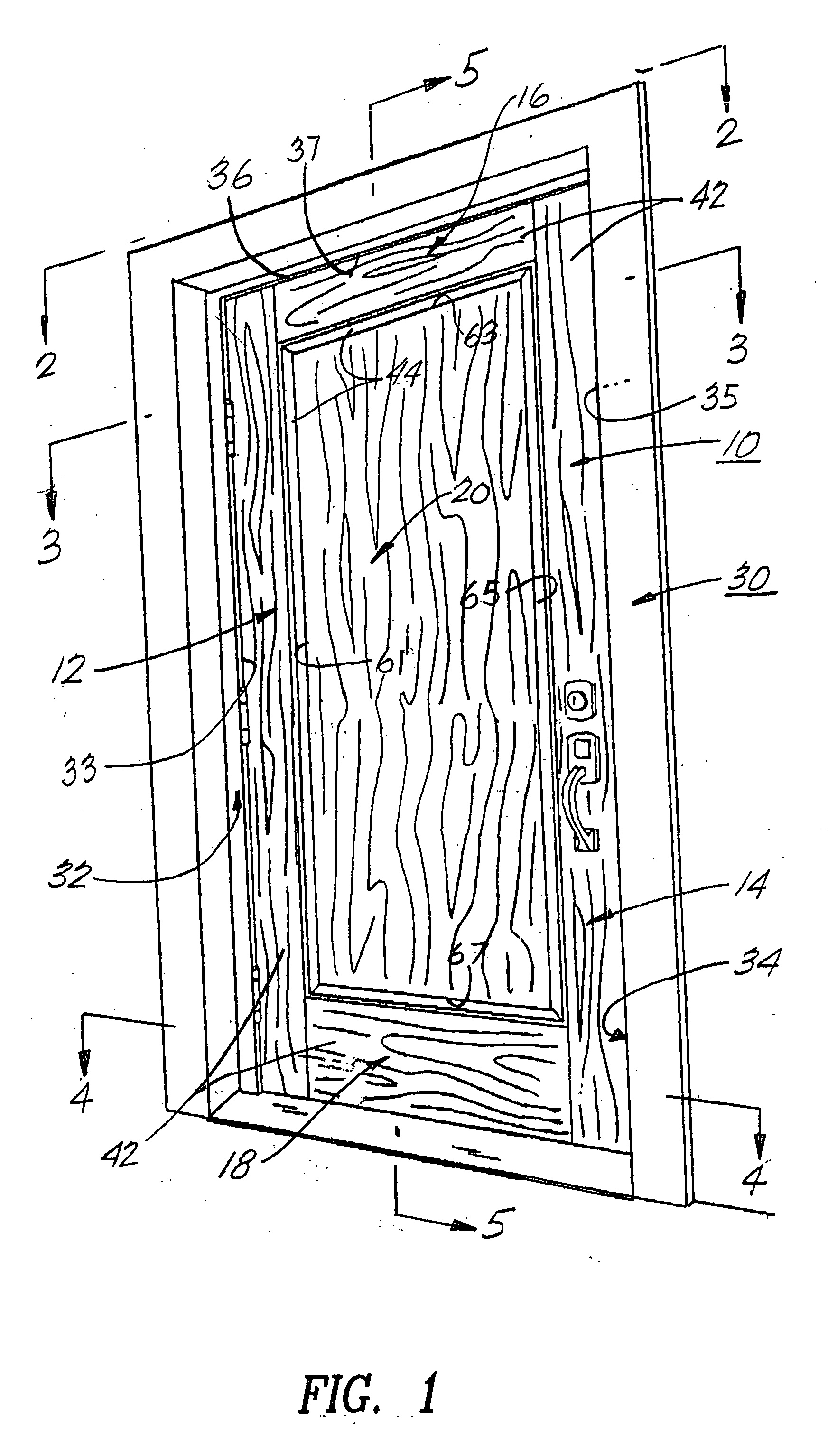

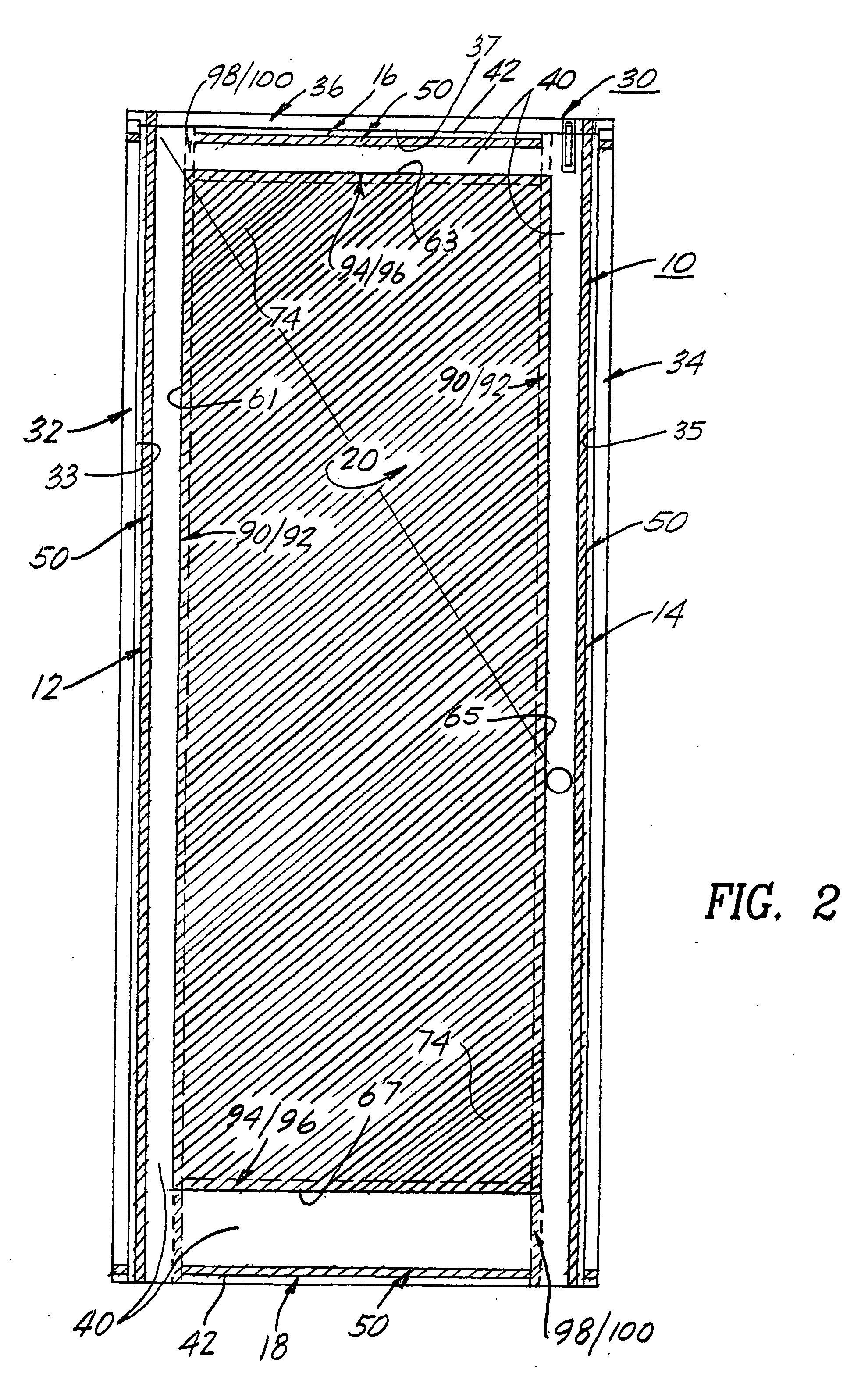

Fire retardant panel door and door frame having intumescent materials therein

InactiveUS20050284030A1Prevent the spread of fireFireproof doorsBuilding locksComposite laminatesRefractory

A fire retardant panel door and door frame that prevents the spread of fire through the door during a fire. The fire retardant panel door has at least one door panel and stiles and rails. The door panel includes an interior center composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a pair of outer sections formed of wood for enclosing the interior center composite section to form a composite laminated door panel. Each of the stiles includes a first center core formed of wood enclosed by a second plurality of layers of intumescent materials and a second plurality of layers of fire resistant materials; and the second layers of intumescent and fire resistant materials are enclosed by a first applique layer formed of wood to form a composite laminated stile. Each of the rails includes a second center core formed of wood enclosed by a third plurality of layers of intumescent materials and a third plurality of layers of fire resistant materials; and the third layers of intumescent and fire resistant materials are enclosed by a second applique layer formed of wood to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. At least one door panel is connected to the panel door by tongue and groove joints; and the tongue and groove joints have a fourth plurality of layers of intumescent materials and a fourth plurality of layers of fire resistant materials in the tongue and groove joints; and wherein the fourth plurality of layers of fire resistant materials in the tongue and groove joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ATRISTIC DOORS & WINDOWS

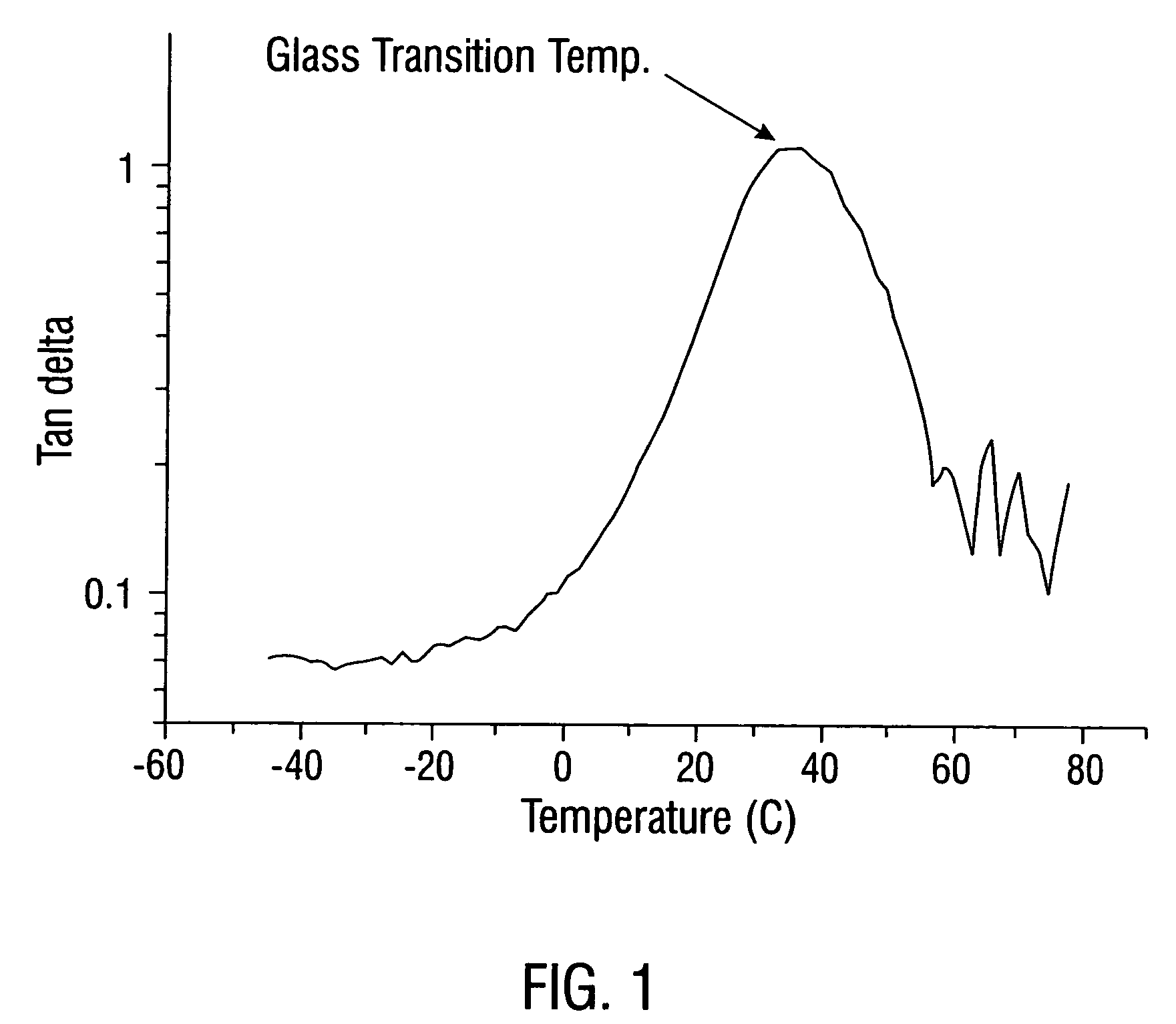

Intrusion resistant glass laminates

InactiveUS20050170160A1Increase stiffnessHigh stiffnessFilm/foil adhesivesSynthetic resin layered productsPolyvinyl butyralPolyethylene terephthalate

Composite laminate interlayers for adhering a glass laminate comprising a sheet of polyethylene terephthalate (PET) between layers of plasticized polyvinyl butyral (PVB) adhesive layers, wherein at least one of the PVB adhesive layers is stiffened, e.g. by reduction in the amount of plasticizer, and has a glass transition temperature greater than 35° C. The PET is preferably 0.075 to 0.25 mm (3-10 mils) thick and can have a functional coating for reducing radiation, e.g. UV or IR or visible light, transmission through the glass laminate. The laminate can also comprise at least one elastomeric layer adapted to reducing sound transmission through the glass laminate. The laminates exhibit enhanced maximum flexural modulus of greater than about 350 Newtons / centimeter.

Owner:SOLUTIA INC

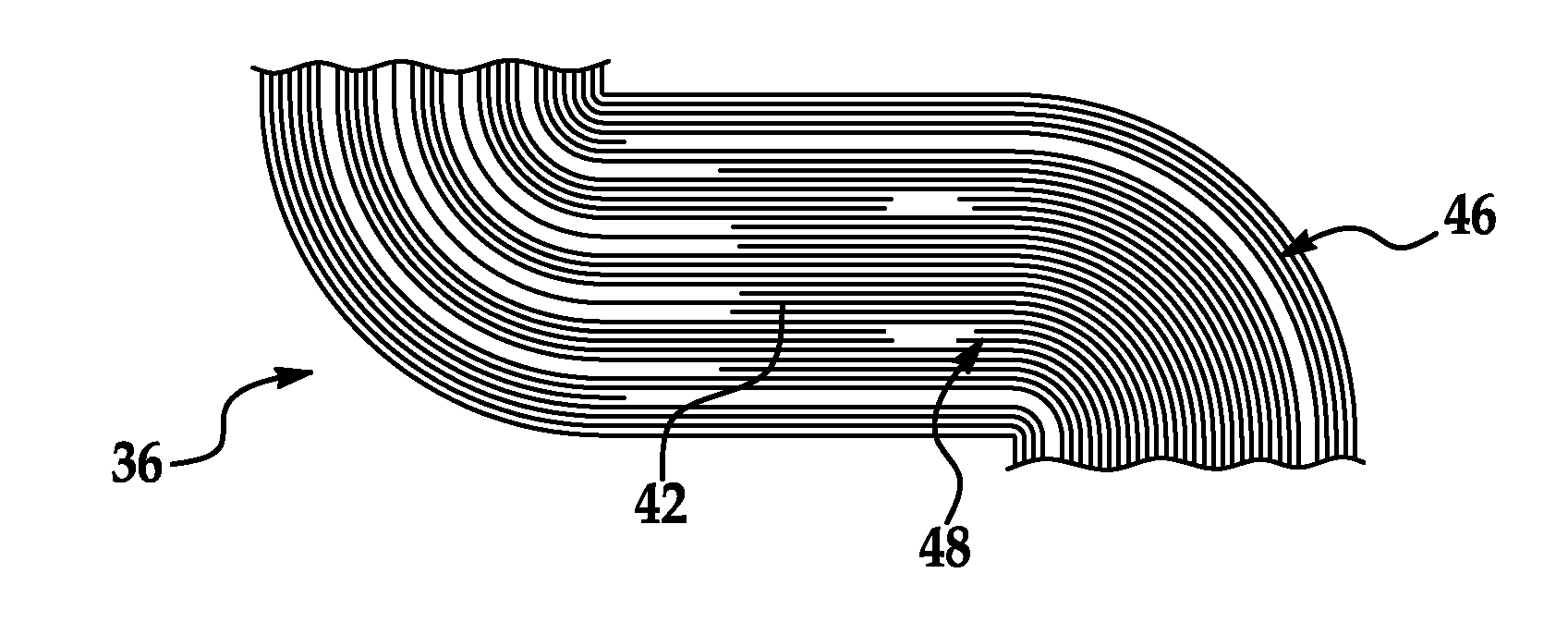

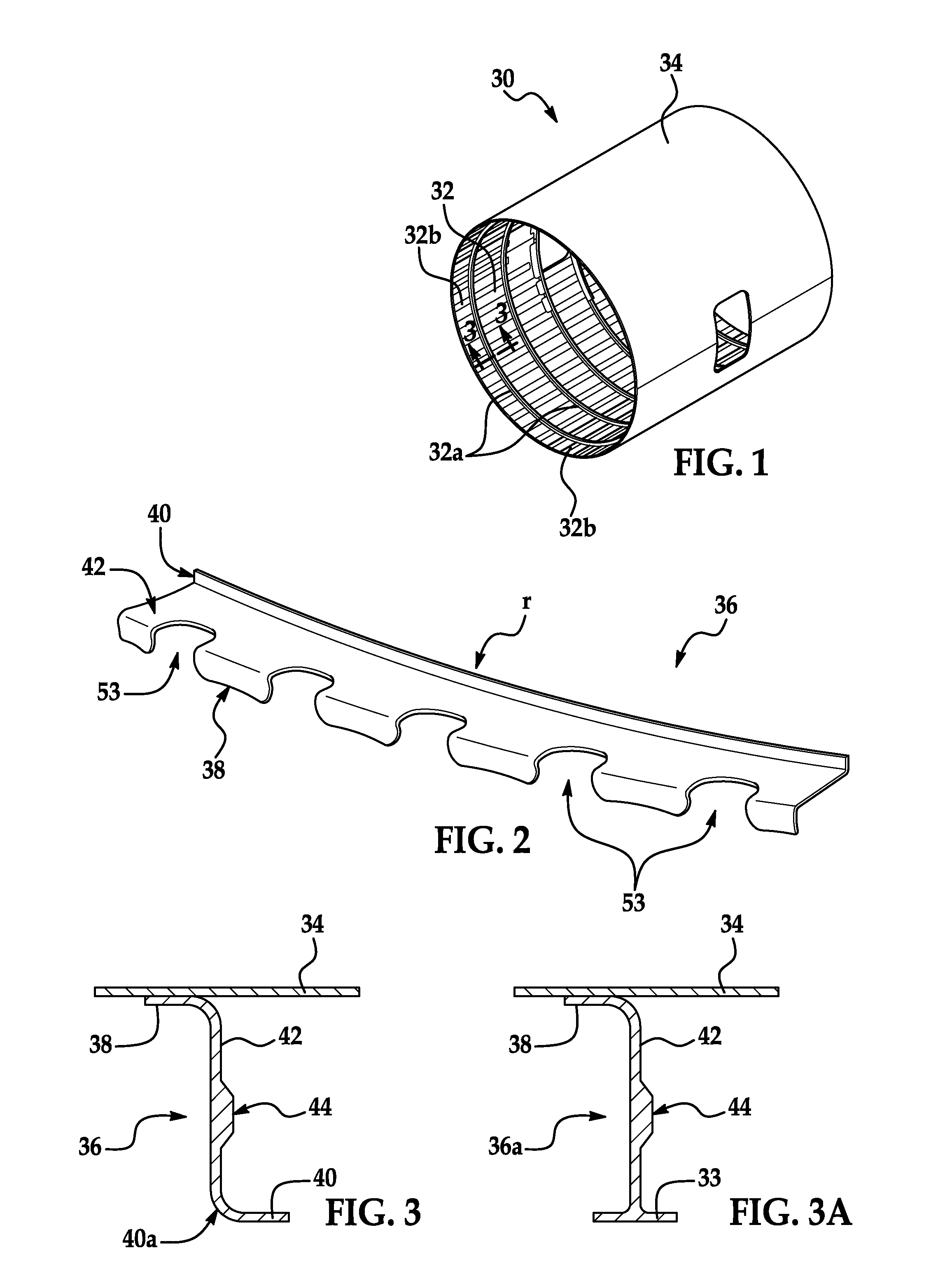

Curved composite frames and method of making the same

ActiveUS20110097554A1Improve structural efficiencyReduce weightLayered productsEfficient propulsion technologiesFiberComposite laminates

Owner:THE BOEING CO

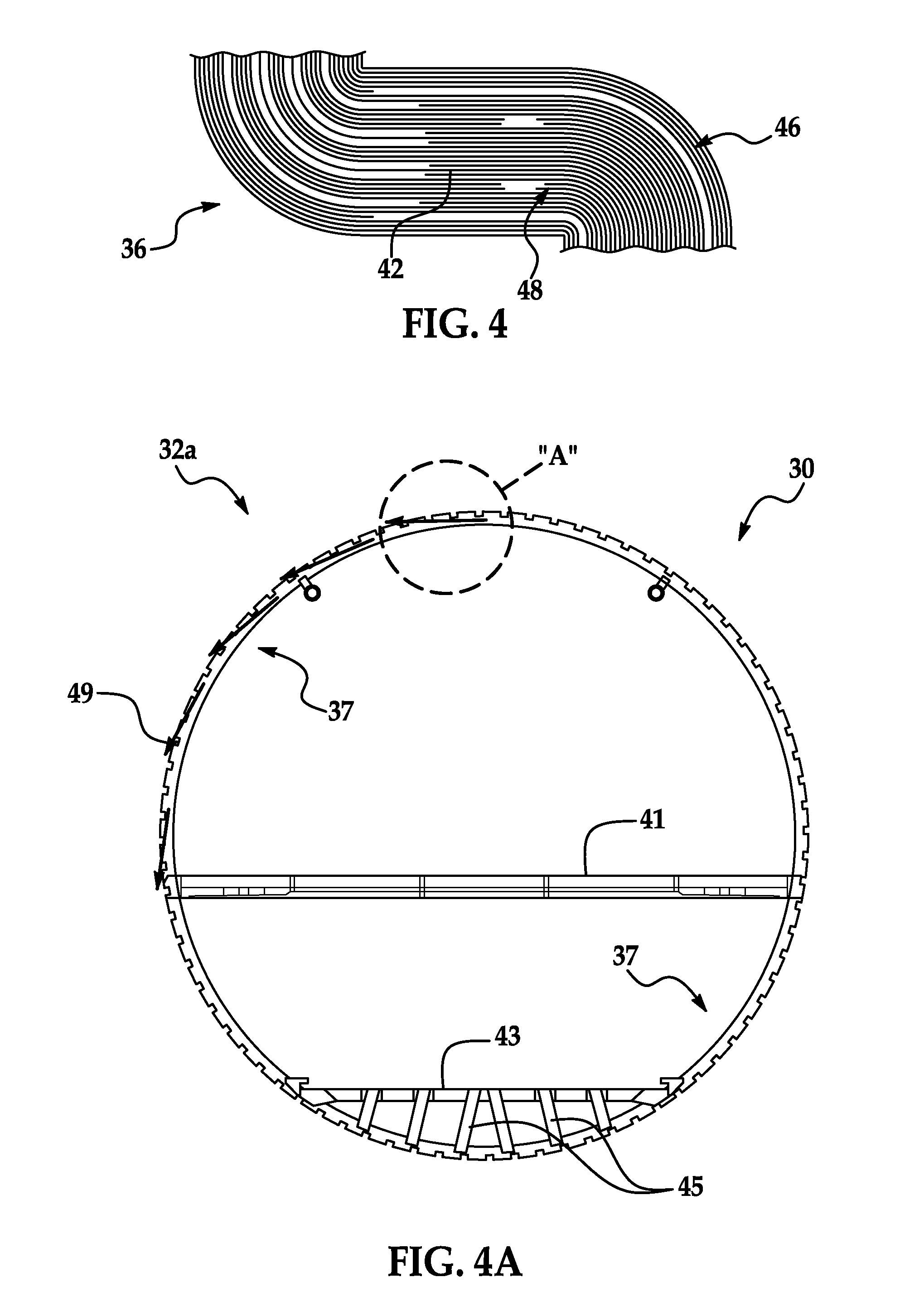

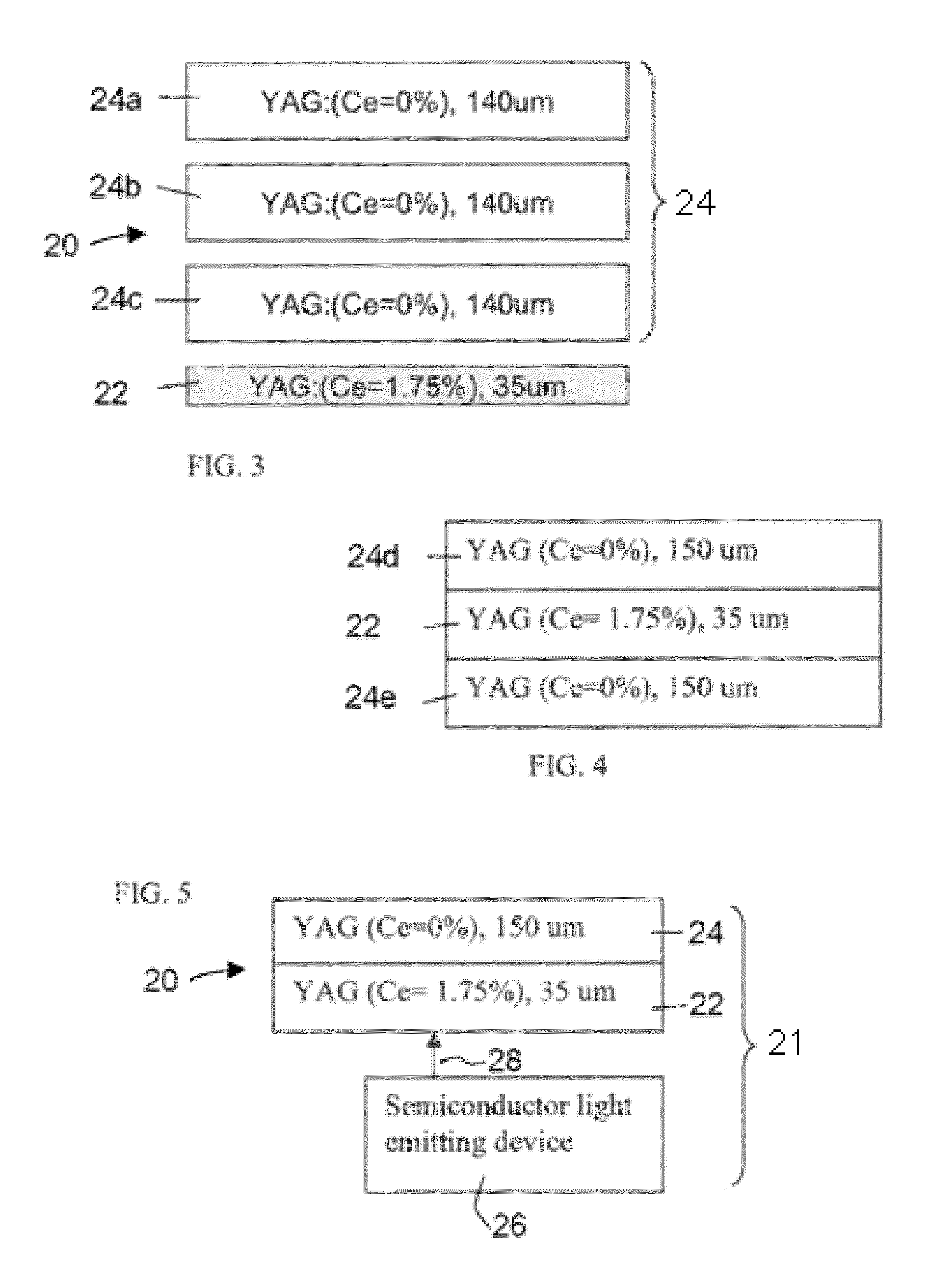

Light emissive ceramic laminate and method of making same

ActiveUS20110210658A1Incadescent screens/filtersElectric discharge tubesCeramic compositeComposite laminates

A ceramic composite laminate includes a wavelength-converting layer and a non-emissive layer, wherein the ceramic composite laminate has a wavelength conversion efficiency (WCE) of at least 0.650. The ceramic composite laminate can also include a wavelength-converting ceramic layer comprising an emissive material and a scattering material, wherein the laminated composite has a total transmittance of between about 40% to about 85%. The wavelength-converting layer may be formed from plasma YAG:Ce powder.

Owner:SCHOTT AG

Method of transferring large uncured composite laminates

InactiveUS20050102814A1Desired aero-smoothnessLow capital equipment investmentLaminationEfficient propulsion technologiesComposite laminatesEngineering

A method of transferring an uncured composite laminate skin from a lay-up surface of a male mandrel tool to a female cure tool includes defining multiple vacuum zones on the lay-up surface, each zone corresponding to one of a multiple of portions into which the skin is to be separated. For example, to separate the skin into two portions, a low profile seal of a first membrane to the lay-up surface is formed at a first vacuum zone and a second low profile seal for a second membrane is formed at a second vacuum zone. The method further includes laying up a composite laminate skin over all the vacuum zones; separating the composite laminate skin into portions, for example, a first portion over the first vacuum zone and a second portion over the second vacuum zone; and releasing the portions individually into cure tools having an outside mold line surface.

Owner:THE BOEING CO

Stretch bonded laminate including an elastic member containing an adhesive composition

InactiveUS20070135008A1Monocomponent polyurethanes artificial filamentDecorative surface effectsComposite laminatesEngineering

Elastic composite laminates are disclosed. The laminates include an elastic member bonded to at least one facing material. In accordance with the present disclosure, an adhesive composition is coextruded with an elastomeric material to form the elastic member. In this manner, the elastic member can be bonded to the facing material in a stretched state without having to apply a separate adhesive layer between the two materials. In one embodiment, the elastic member can be bonded to the facing material according to a pattern that includes bonded areas and non-bonded areas.

Owner:KIMBERLY-CLARK WORLDWIDE INC

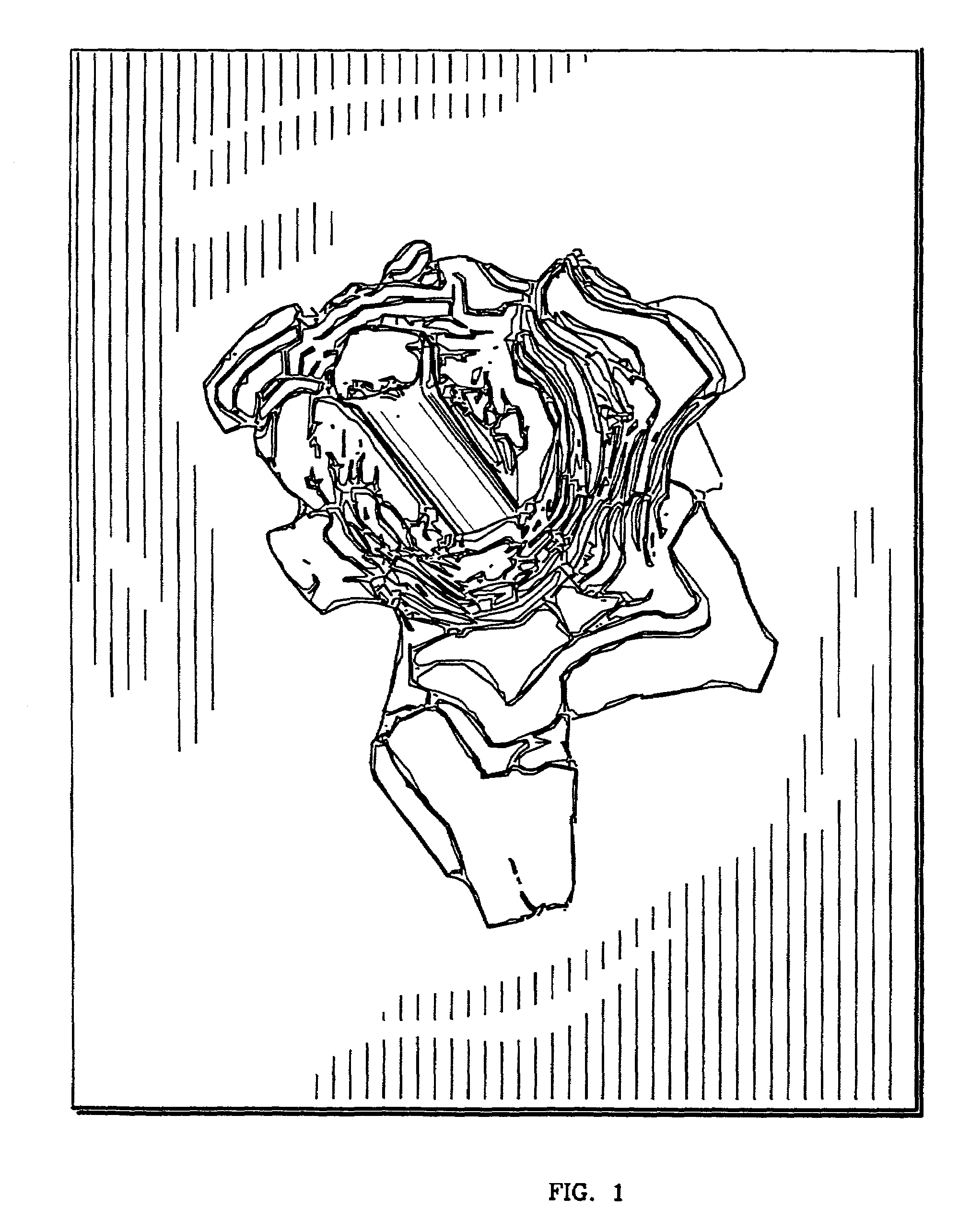

Automated Production and Installation of Patches for Reworking Structures

ActiveUS20150090392A1Reduce decreaseImproved size controlProgramme controlLamination ancillary operationsComposite laminatesEngineering

An area of a composite laminate structure is reworked by scarfing the area, generating a 3-D map of the scarfed area, and installing a rework patch that is built based on the 3-D map.

Owner:THE BOEING CO

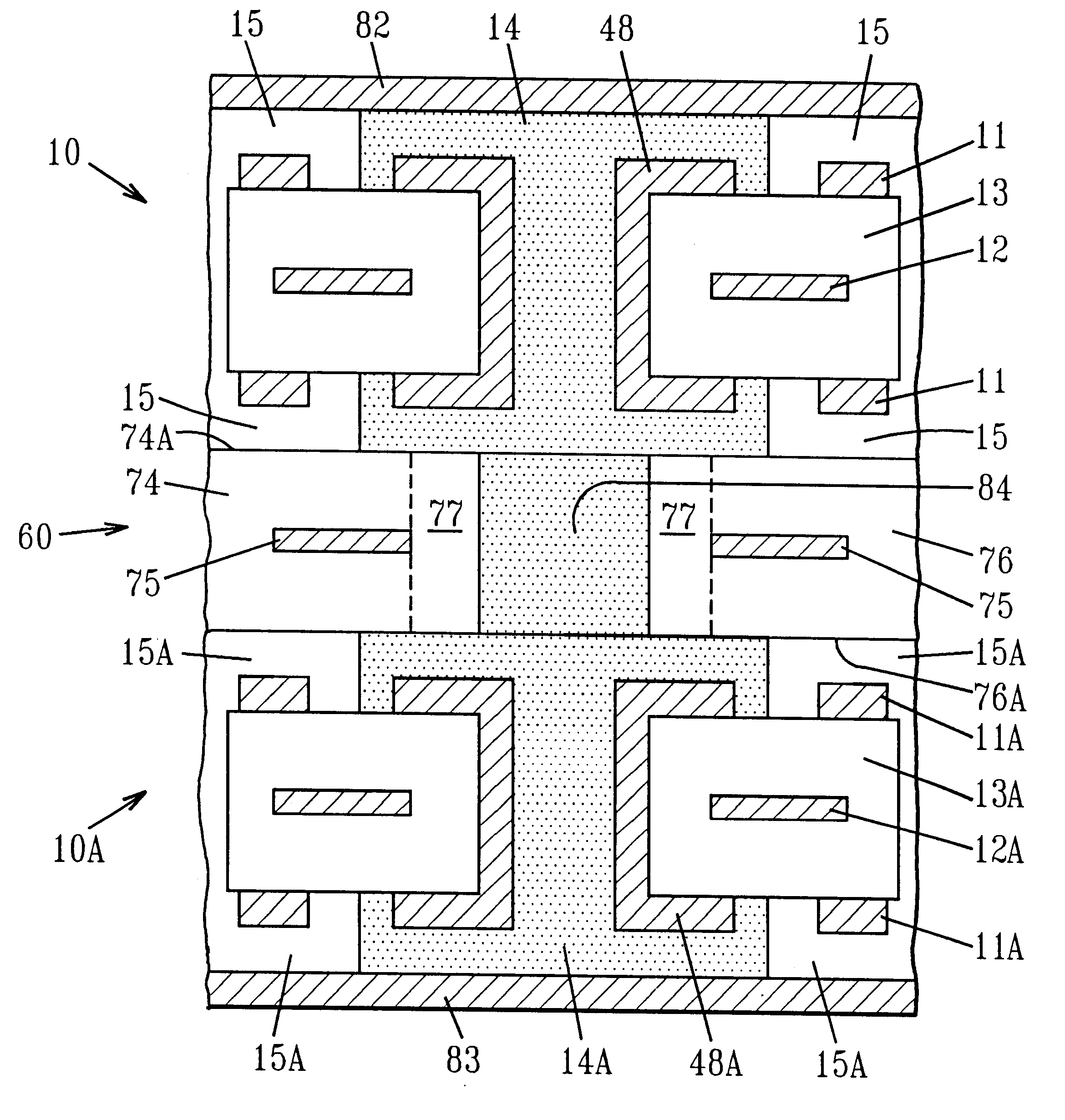

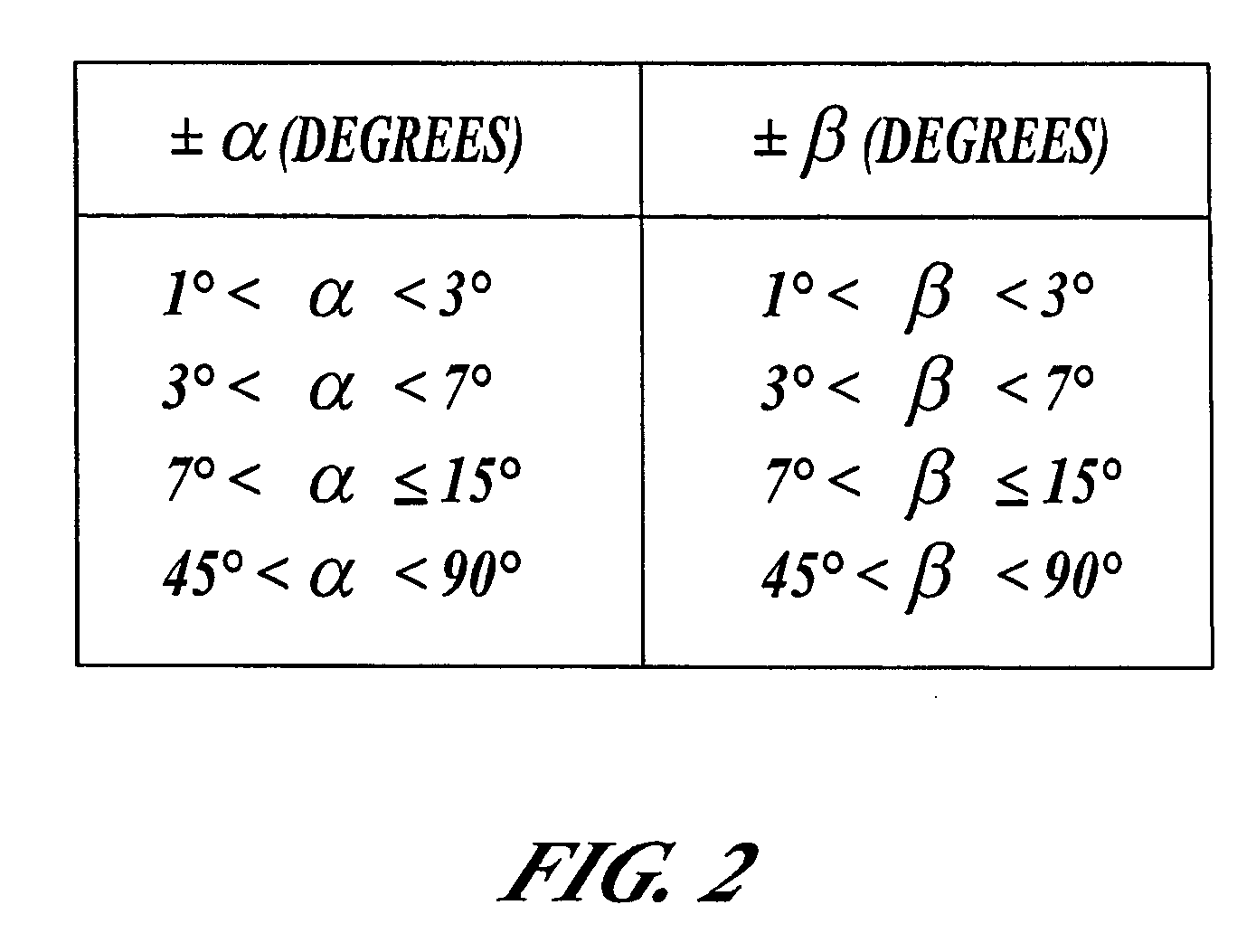

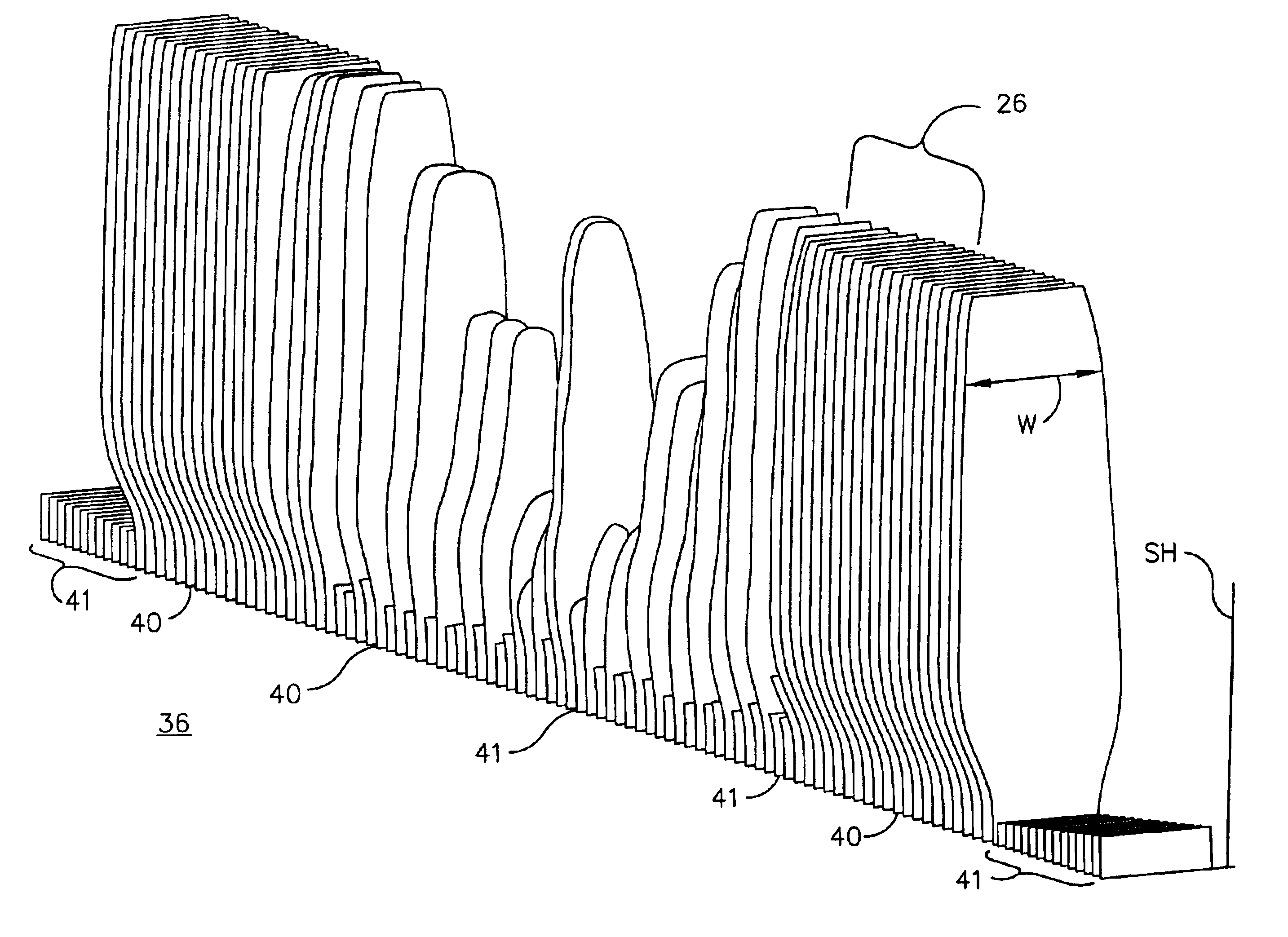

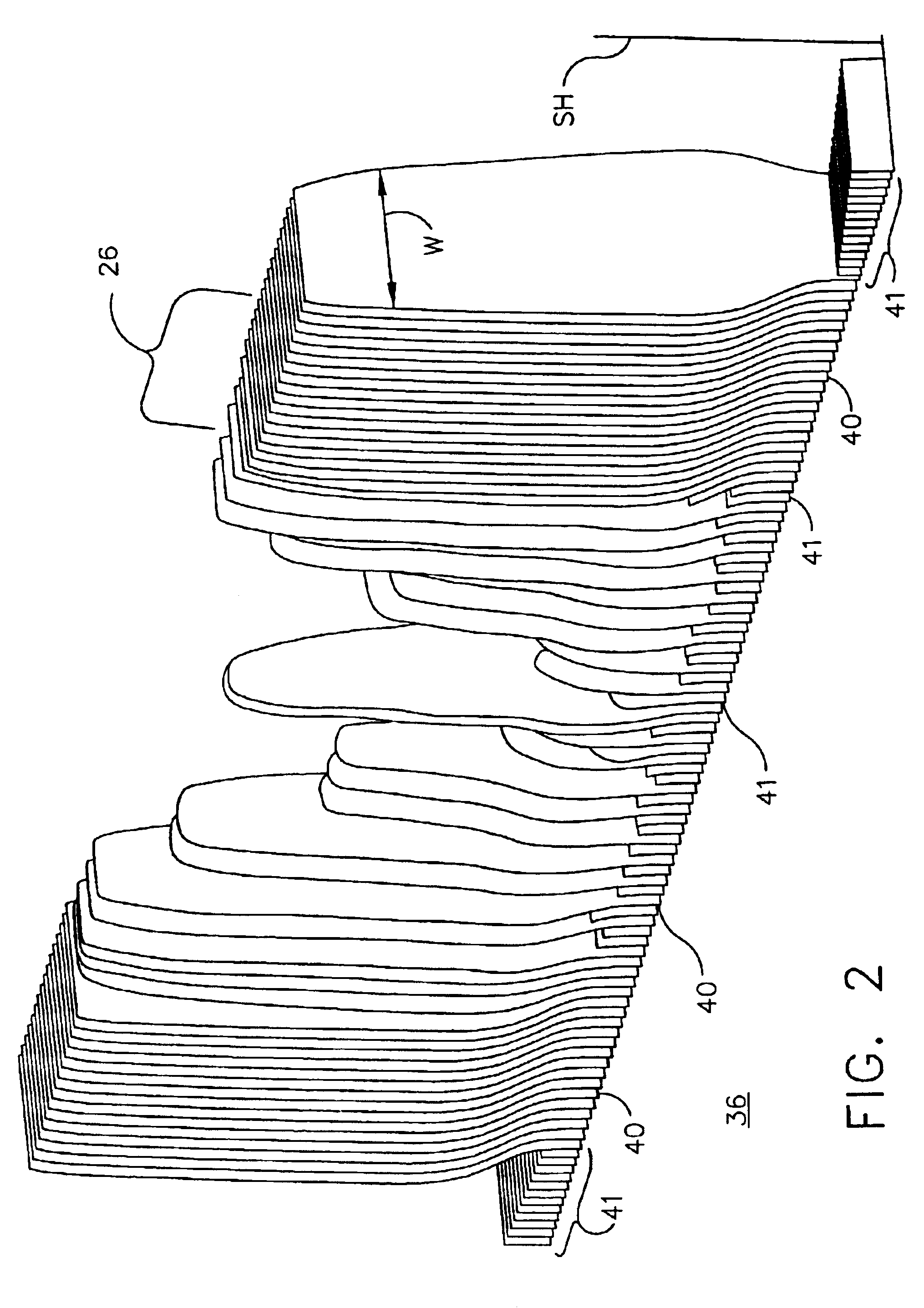

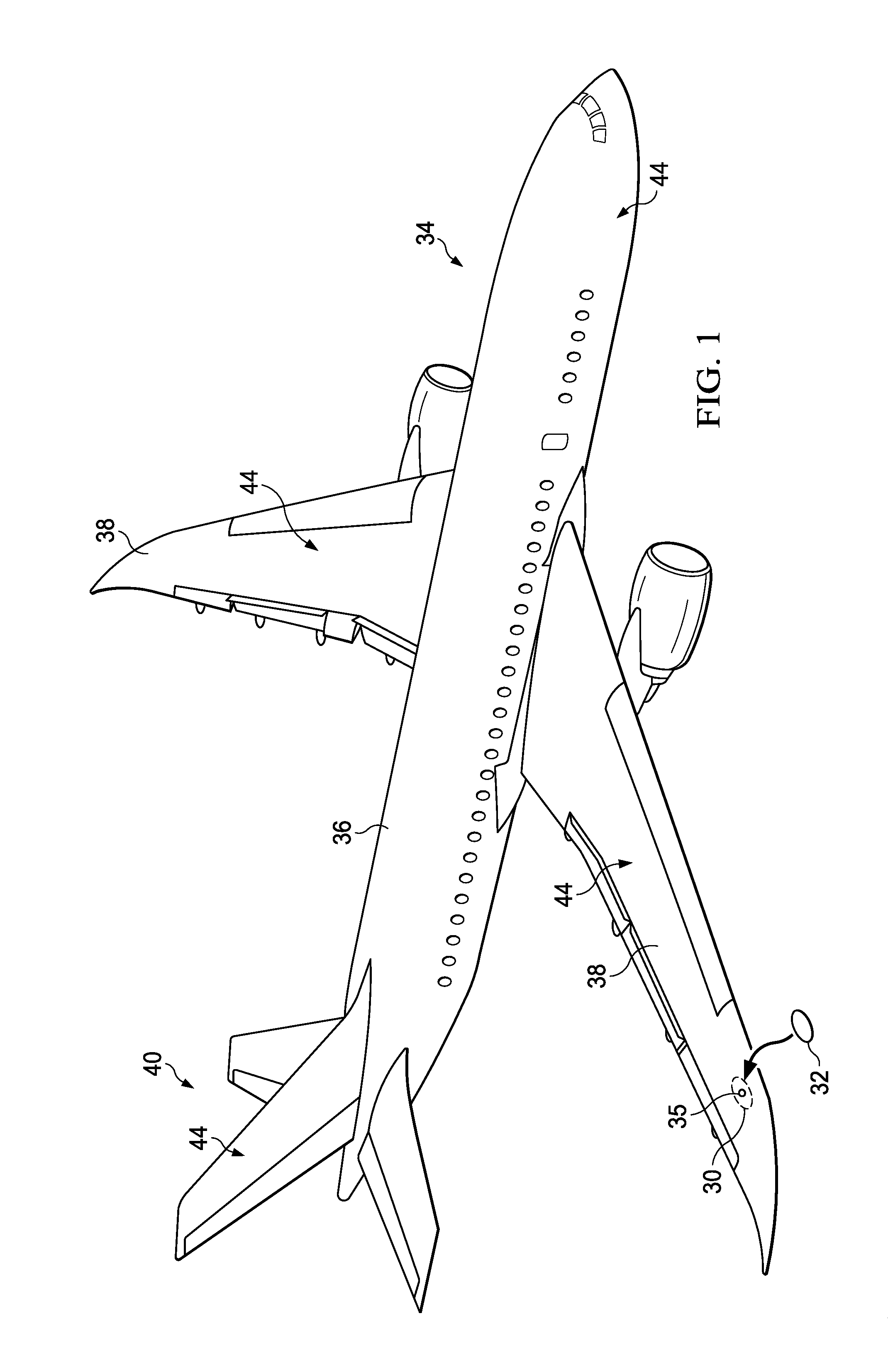

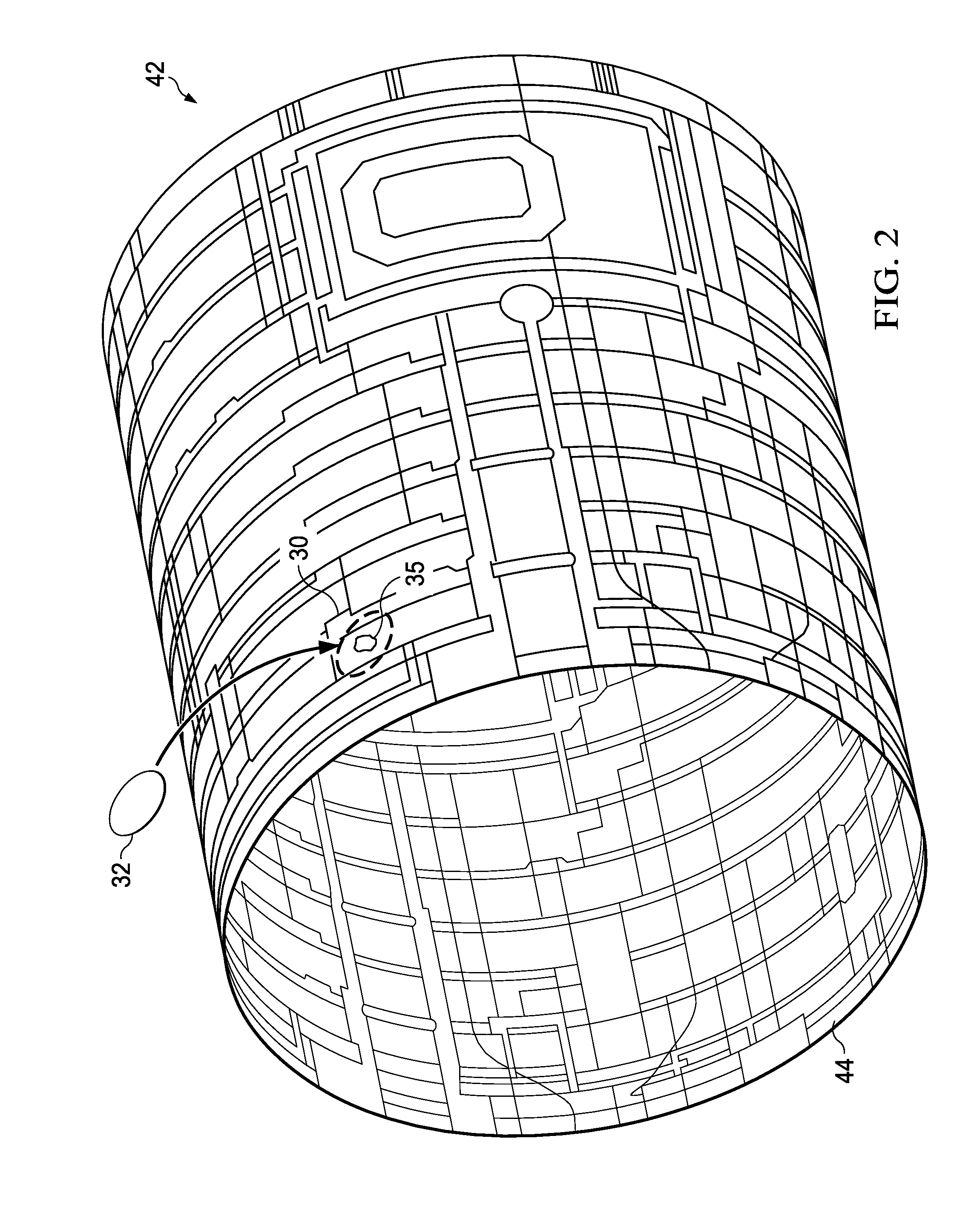

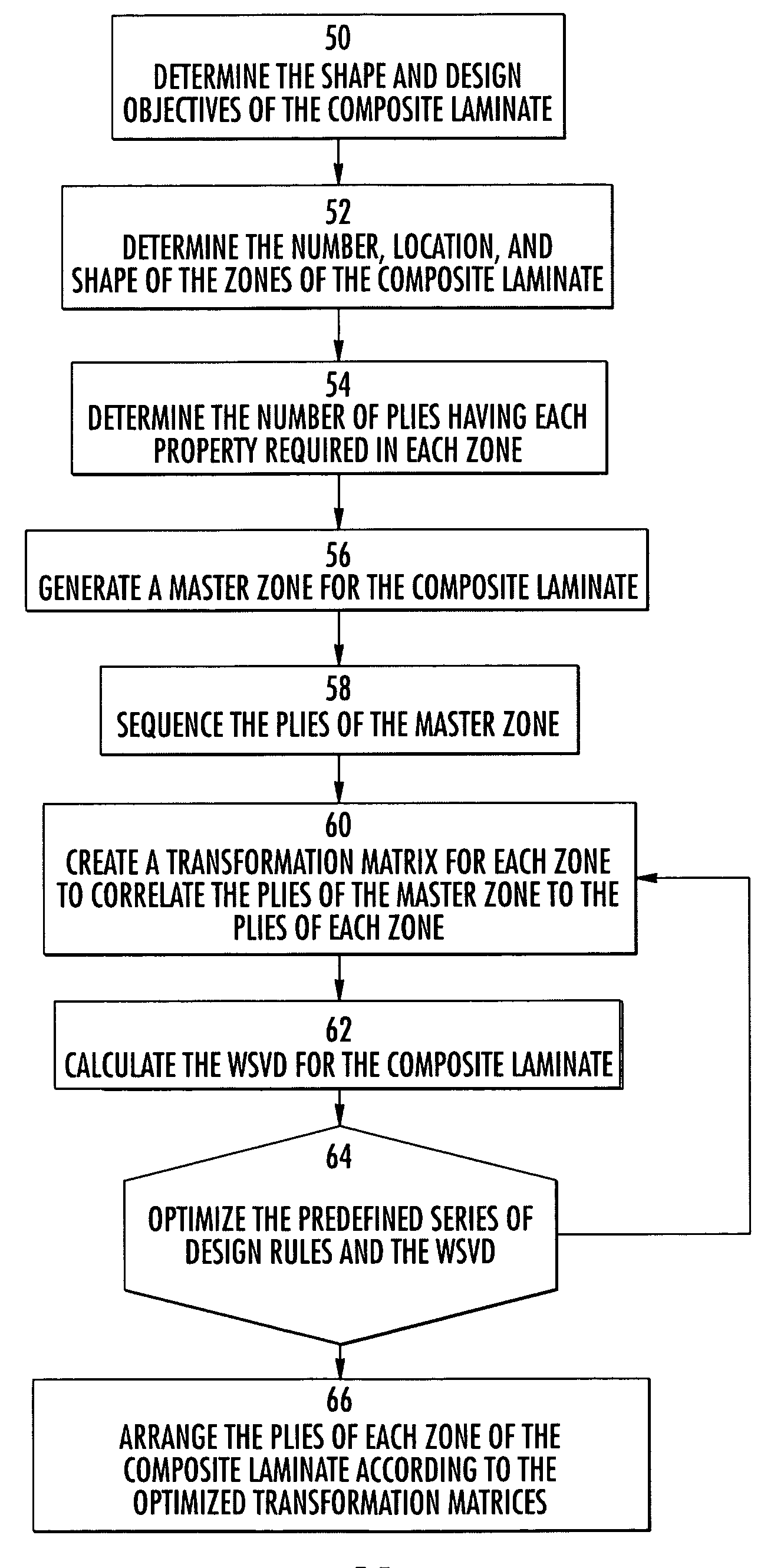

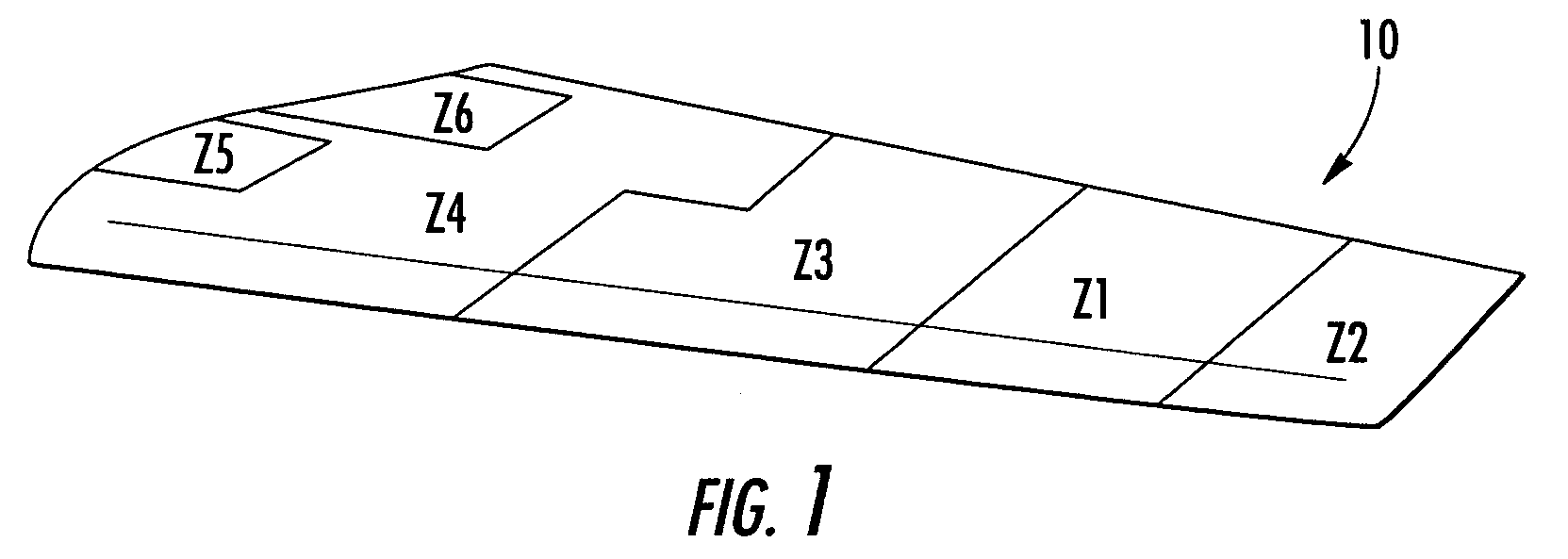

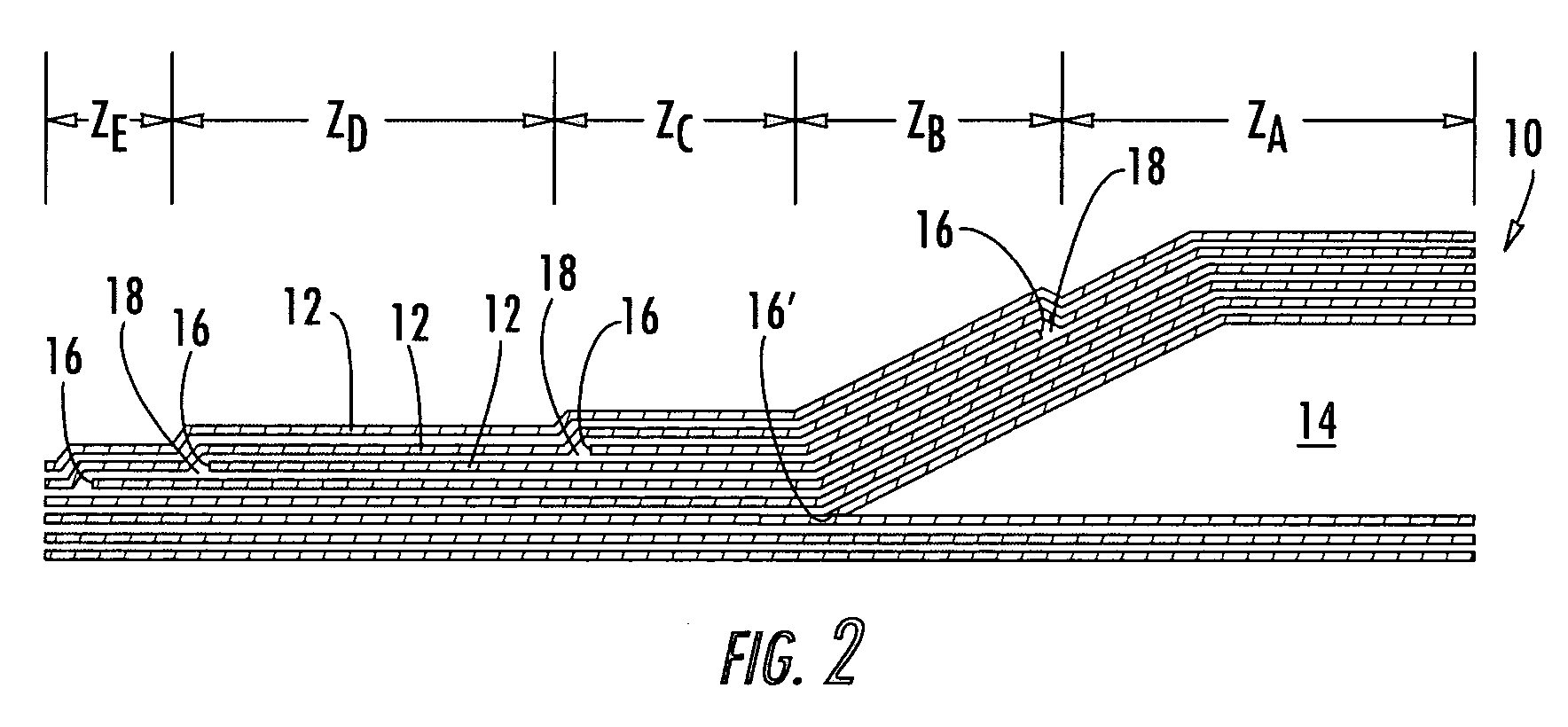

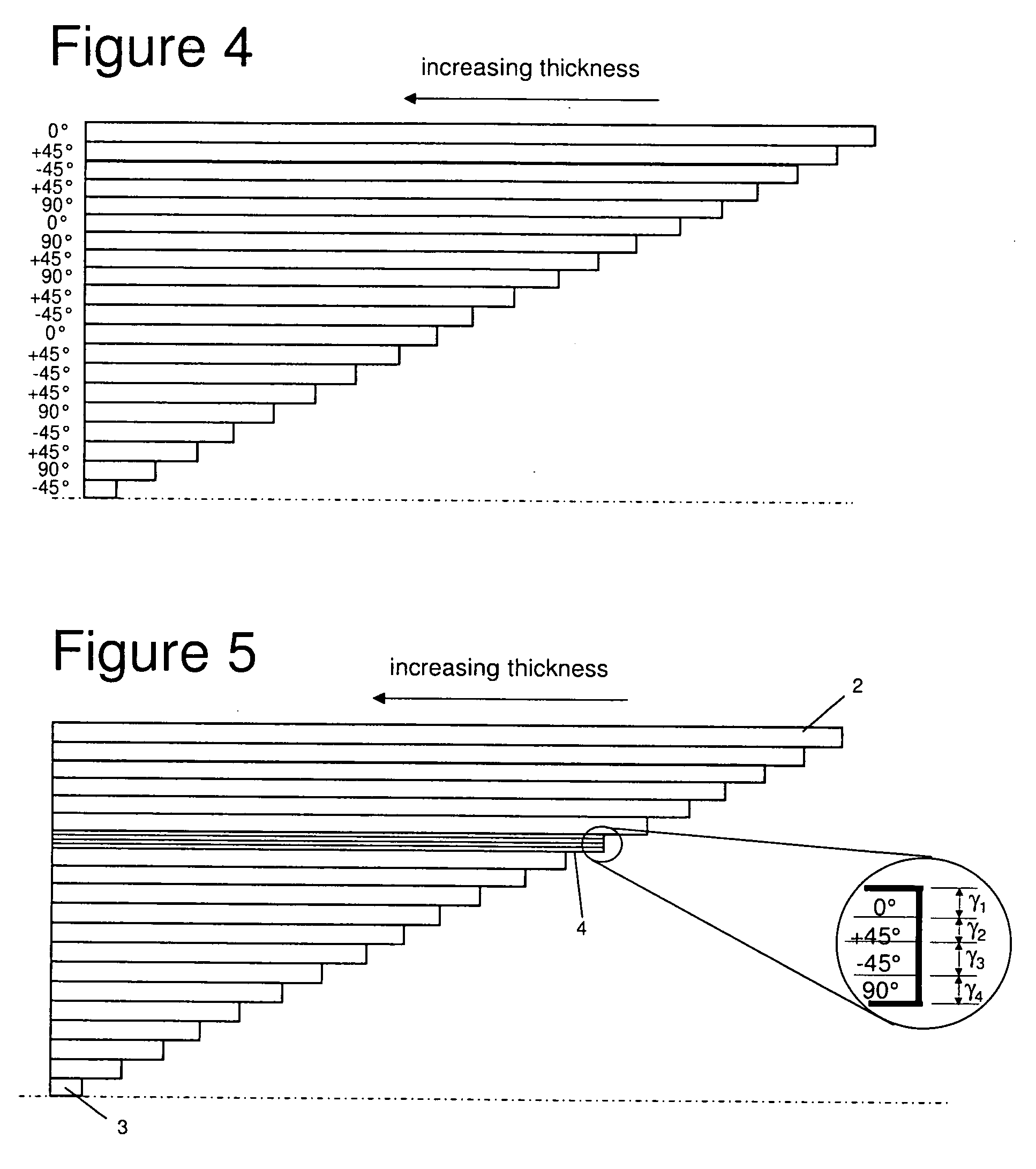

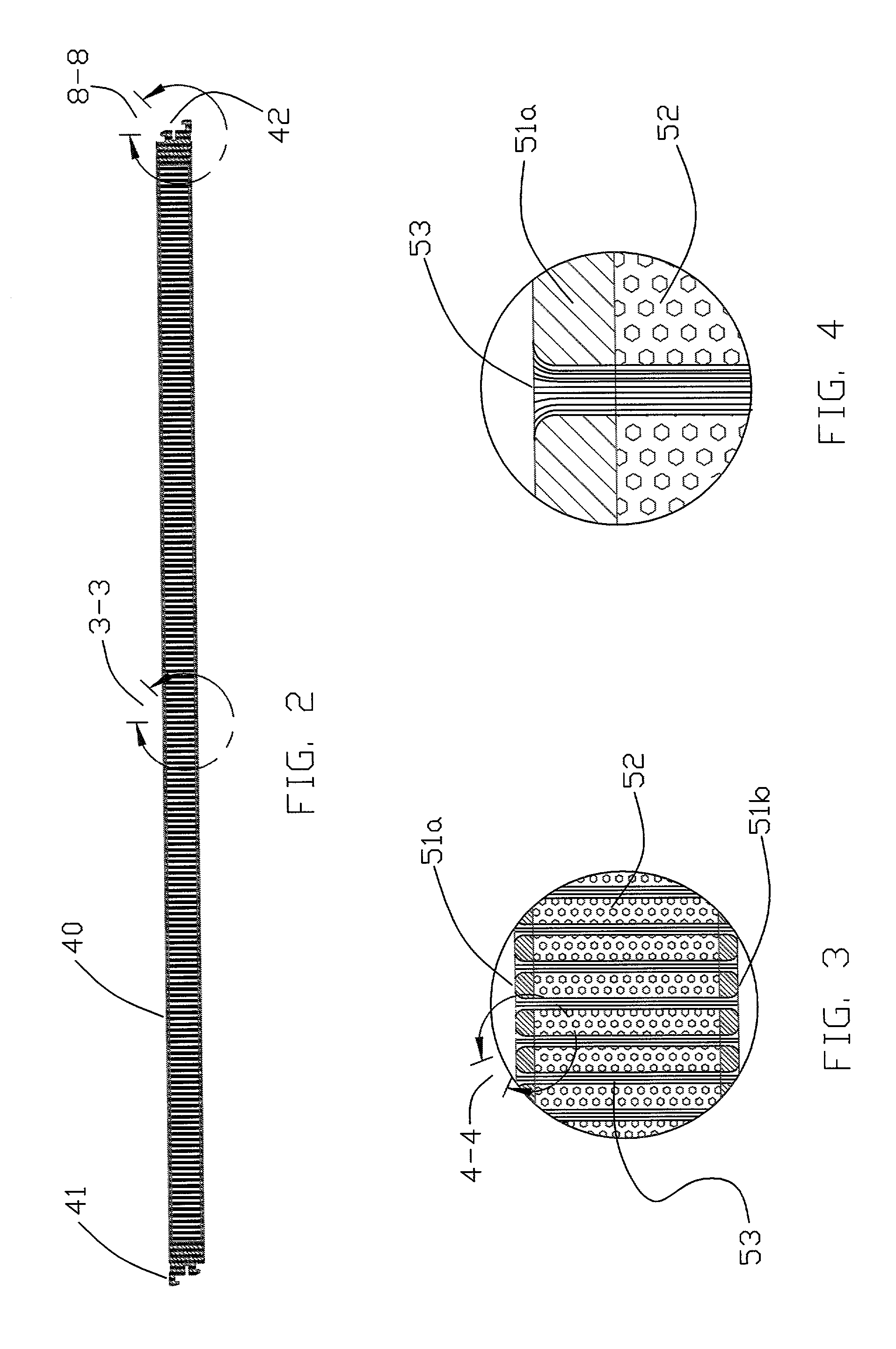

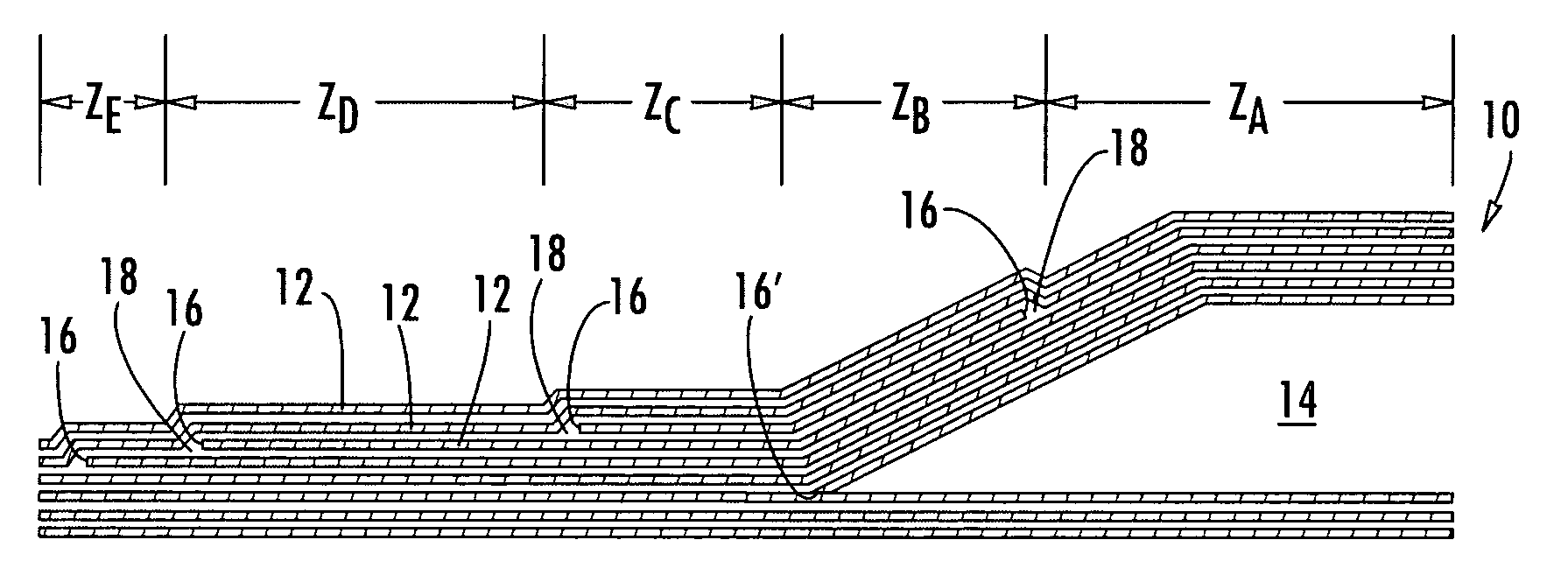

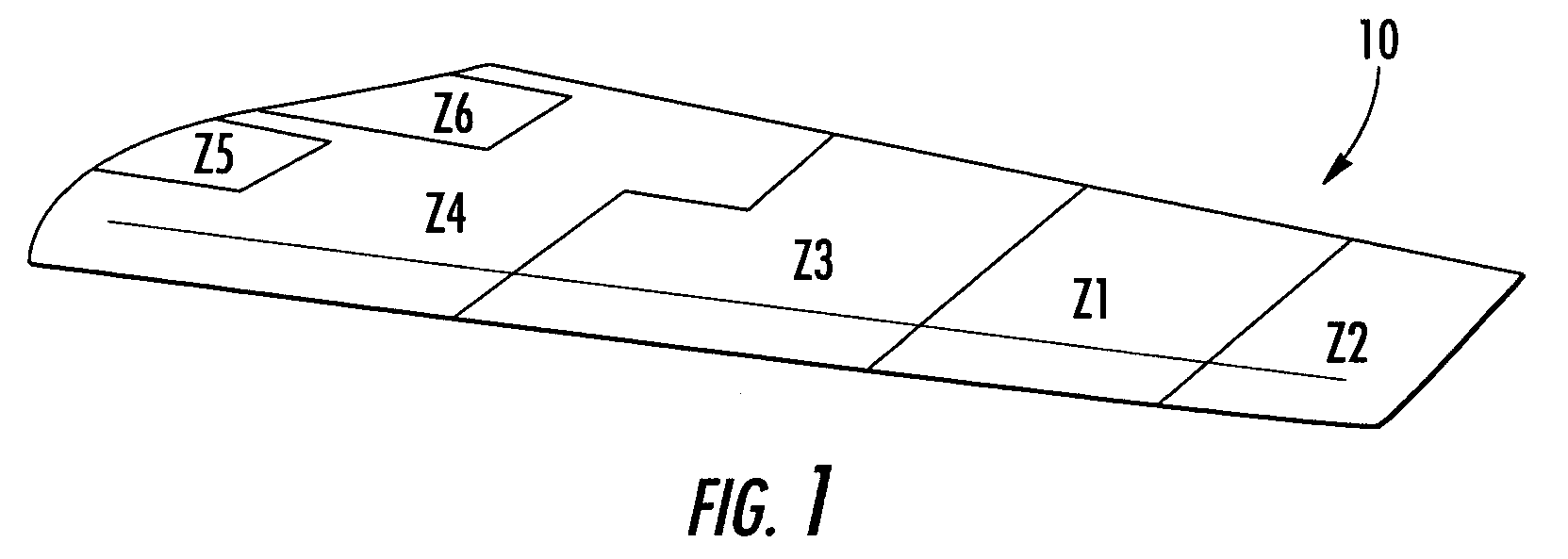

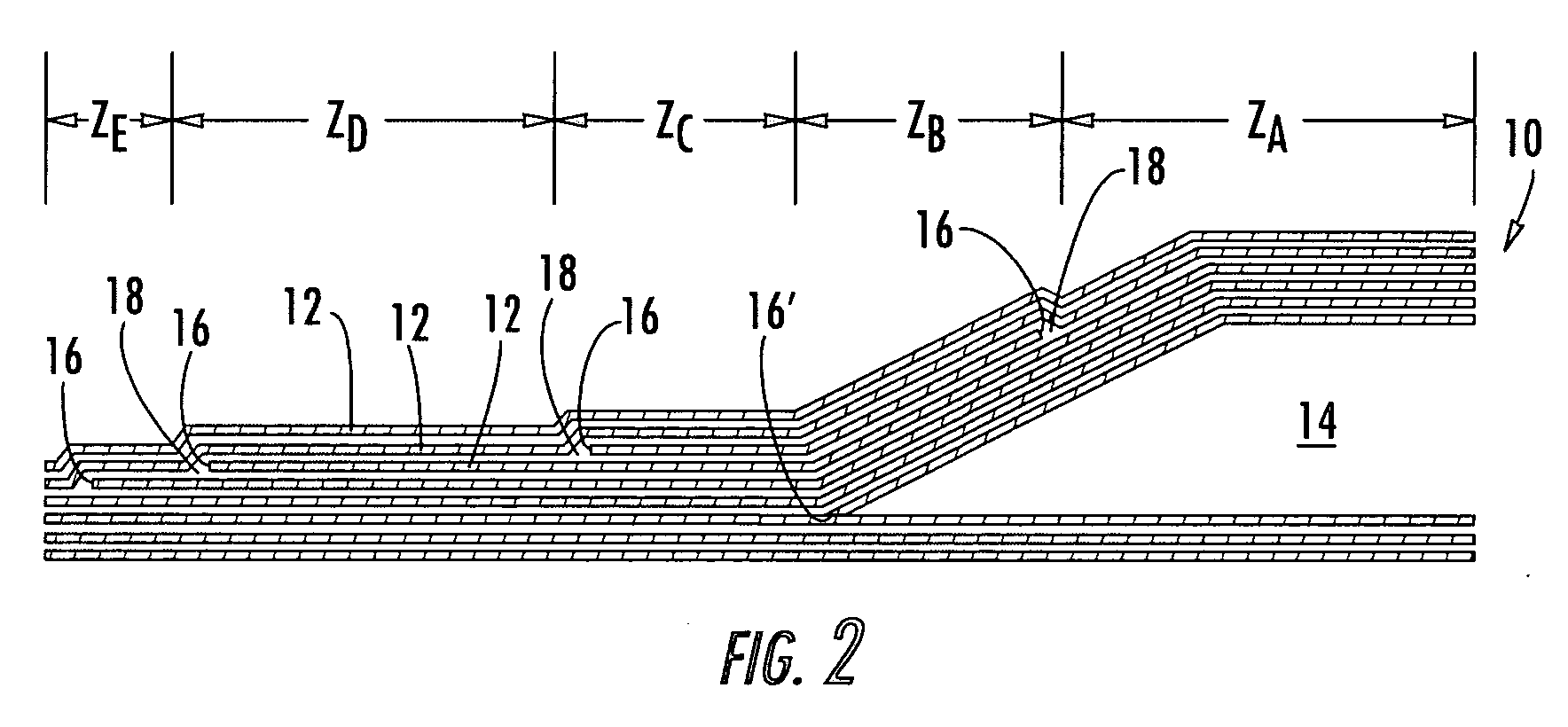

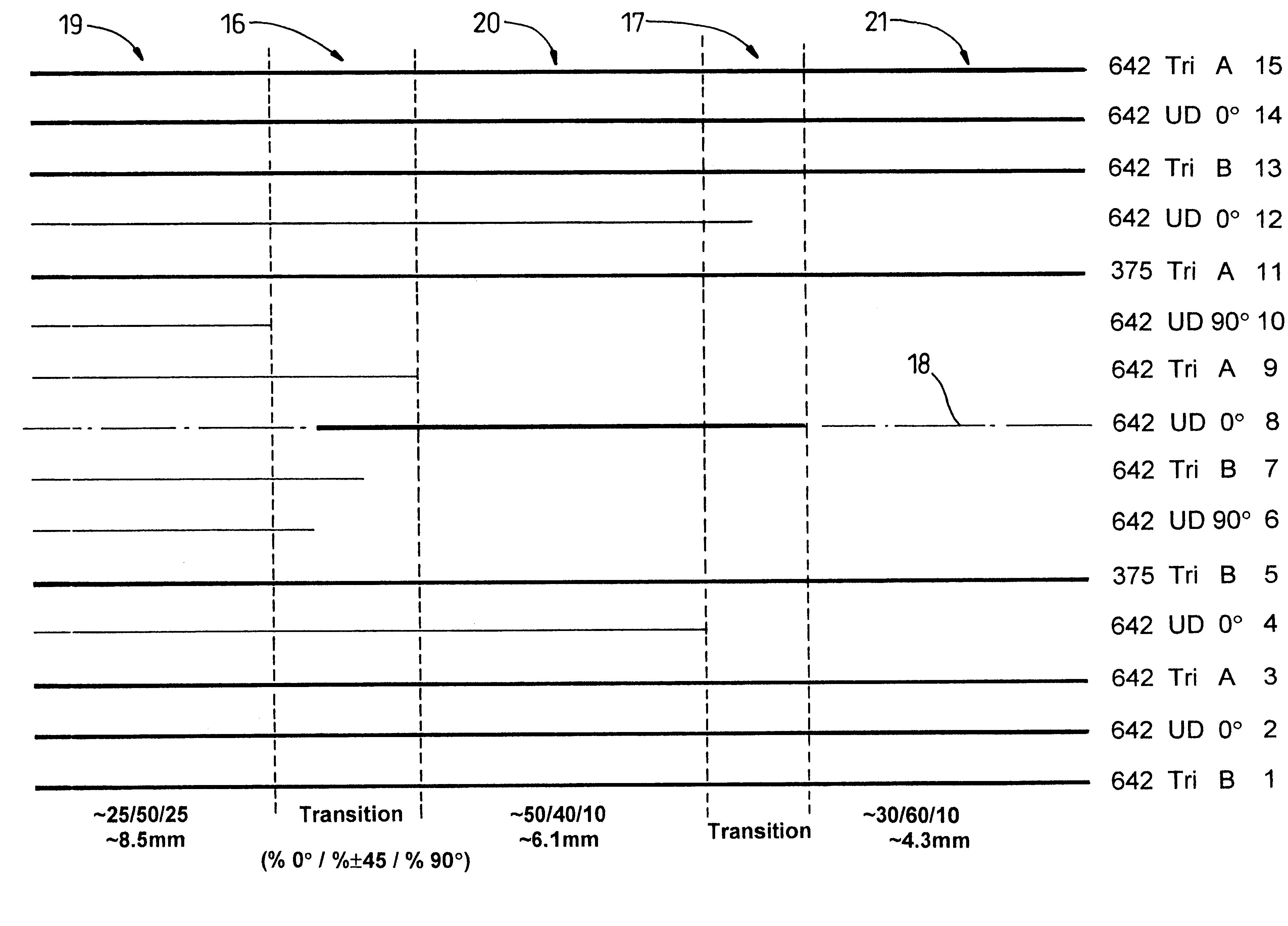

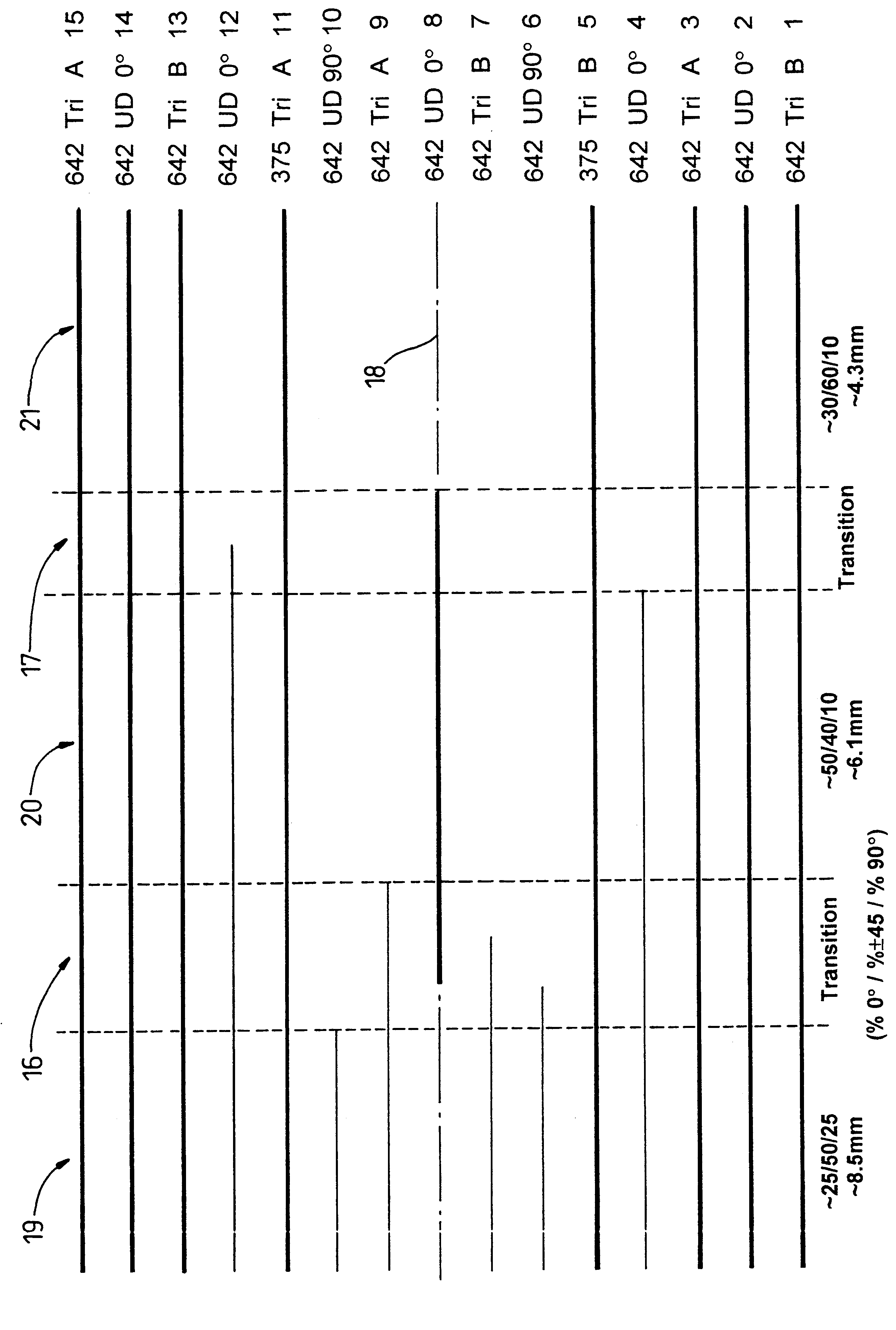

Composite stacking sequence optimization for multi-zoned composites

ActiveUS7243055B2Shorten the lengthReduce the numberCellulosic plastic layered productsComputation using non-denominational number representationComposite laminatesStructural engineering

Method, apparatus, and computer program products are provided for optimizing a stacking sequence for a composite laminate having multiple zones to reduce the number or length of internal ply edges in the composite laminate with the most design rule compliant sequences. Once the number and location of the zones and the number of plies having different properties required for each zone have been determined for the composite laminate, a master zone is generated. Advantageously, the property of the plies may be fiber orientation, though alternative properties such as material may be considered when determining the number of required plies. The master zone notionally includes the maximum number of plies having a respective property required by any one zone, and the plies of the master zone are sequenced using a predefined series of design rules. The plies of each zone are then arranged based upon the stacking sequence of the master zone. A transformation matrix, a second predefined series of design rules, and a weighted solid / void differential may be used when arranging the plies of each zone based upon the stacking sequence of the master zone.

Owner:THE BOEING CO

Multilayered ceramic substrate and method of producing the same

InactiveUS6337123B1Prevent of changePrevent of deteriorationSemiconductor/solid-state device detailsSolid-state devicesMetallurgyComposite laminates

A multilayered ceramic substrate which includes at least two types of ceramic layers respectively containing different ceramic materials, and which can be produced by simultaneous firing without causing layer peeling is described. A green composite laminated product is prepared in a state in which two substrate green sheets respectively contain different types of low-temperature sintered ceramic materials, and a shrinkage inhibiting green sheet containing an inorganic material which is not sintered at the sintering temperature of each of the low-temperature sintered ceramic material is arranged between the two substrate green sheets, followed by firing. In the firing step, the low-temperature sintered ceramic materials are sintered while inhibiting shrinkage of the substrate green sheets in the direction parallel to the main surfaces thereof by the shrinkage inhibiting green sheet, while the inorganic material remains unsintered and is fixed by glass supplied by firing the low-temperature sintered ceramic materials.

Owner:MURATA MFG CO LTD

Fire resistant flexible ceramic resin blend and composite products formed therefrom

InactiveUS20100304152A1Improve fire performanceConducive to lightweightSynthetic resin layered productsCellulosic plastic layered productsAdhesiveComposite laminates

High heat resistant elastic composite laminates, sealants, adhesives, and coatings developed from a resin blend. The resin blend is made up of methyl and optionally phenyl silsequioxane resins selected to produce silanol-silanol condensation silicone polymers formed in a slowly evolving reaction mass containing submicron boron nitride, silica and boron oxide fillers. The required ratio of submicron boron nitride to silica has been discovered for assuring the formation of a high temperature resistant elastic composite blend that will form intermediate flexible ceramic products up to 600 deg C., then continue to form preceramic then dense ceramic products from 600 to 1000 deg C. The thermal yield of the composite is generally greater than 90 wt. % at 1000 deg C. Composite products with different levels of heat transformation can be fabricated within the same product depending upon the thickness of the layers of reinforcement.

Owner:FLEXIBLE CERAMICS

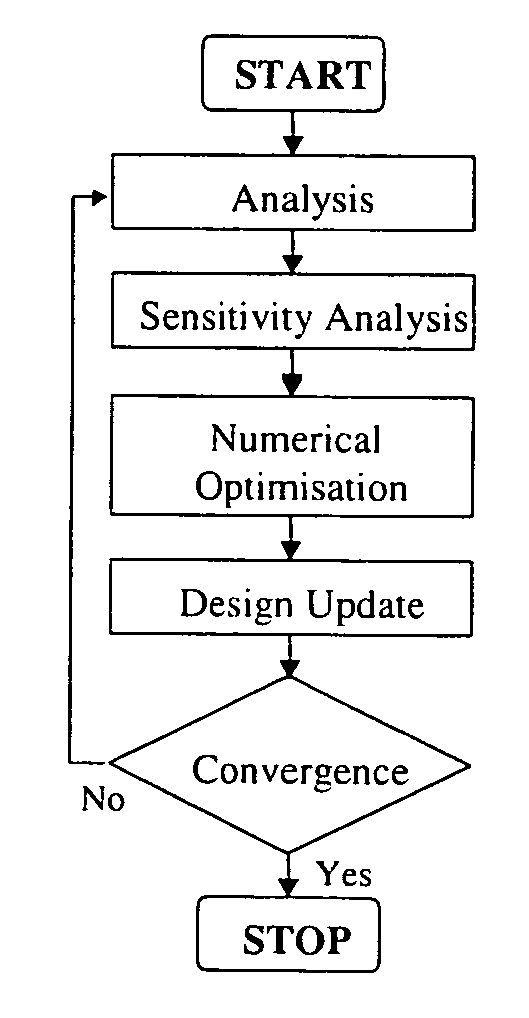

Method of designing a composite laminate

InactiveUS20100121625A1Sufficient capabilityHigh strengthGeometric CADComputation using non-denominational number representationComposite laminatesEngineering

A method of designing a composite laminate, the laminate comprising a plurality of zones, each zone comprising a plurality of plies of composite material, each ply in each zone having a respective ply orientation angle. A global stacking sequence is determined for the laminate, the global stacking sequence comprising a sequence of stacking sequence elements. A local laminate thickness is determined for each zone. A local stacking sequence is then determined for each zone by extracting a subsequence of stacking sequence elements from the global stacking sequence. The global stacking sequence and the local laminate thicknesses are determined together in an optimisation process in which multiple sub-ply selection variables are assigned to each stacking sequence element, each sub-ply selection variable representing the density or sub-ply thickness for a respective candidate ply orientation angle. Optimal values are determined for the sub-ply selection variables and the local laminate thicknesses. A single one of the sub-ply selection variables is assigned to each stacking sequence element thereby forcing a discrete choice of global ply orientation angle for each stacking sequence element.

Owner:AIRBUS OPERATIONS LTD

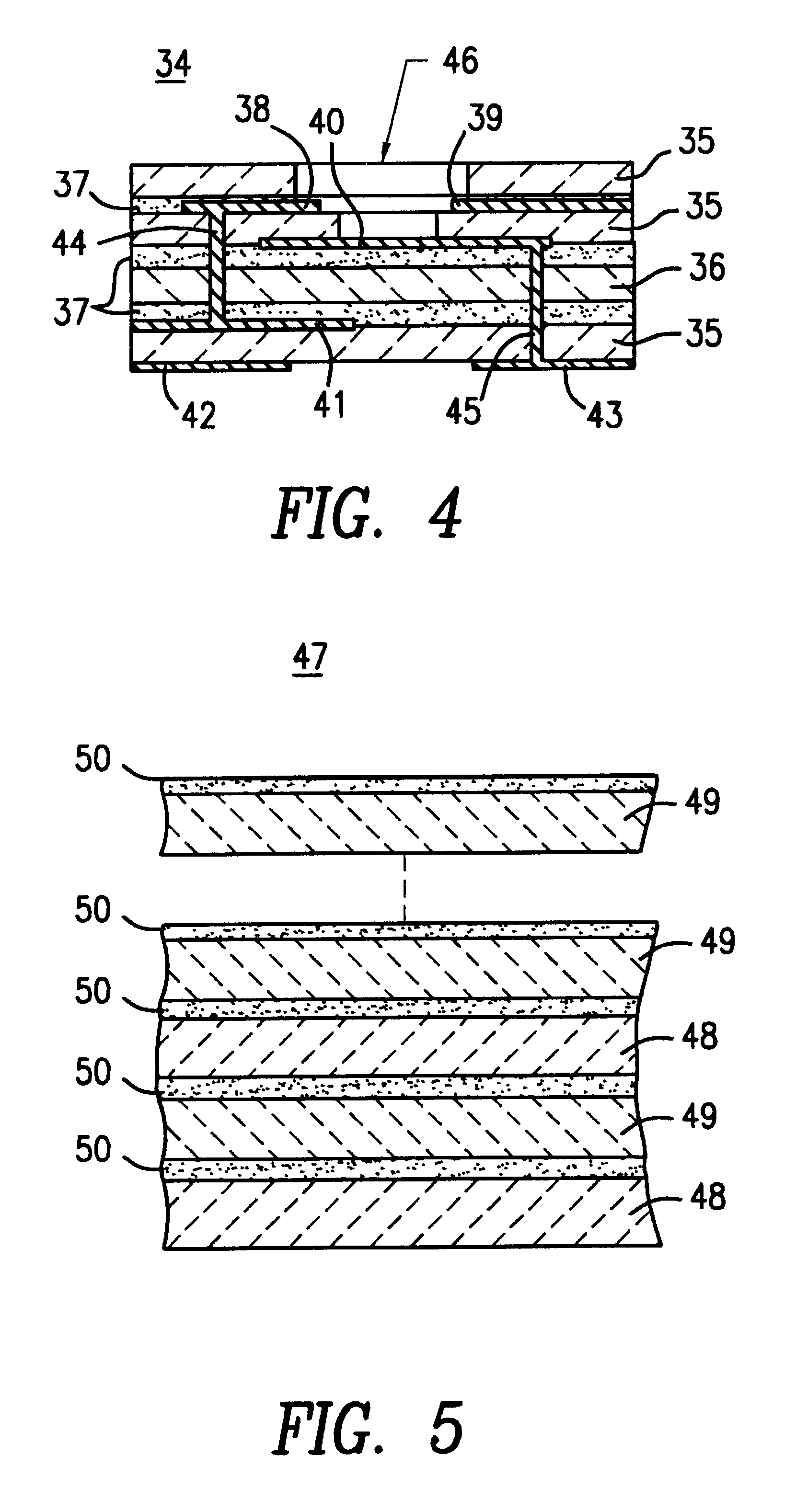

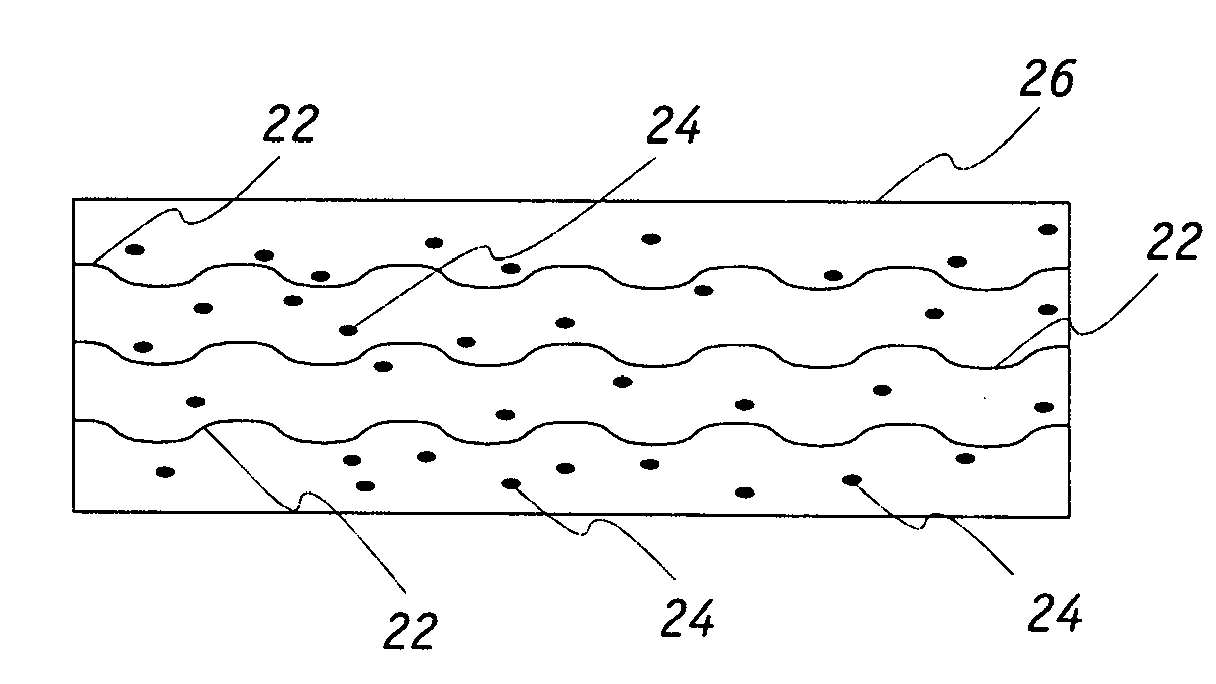

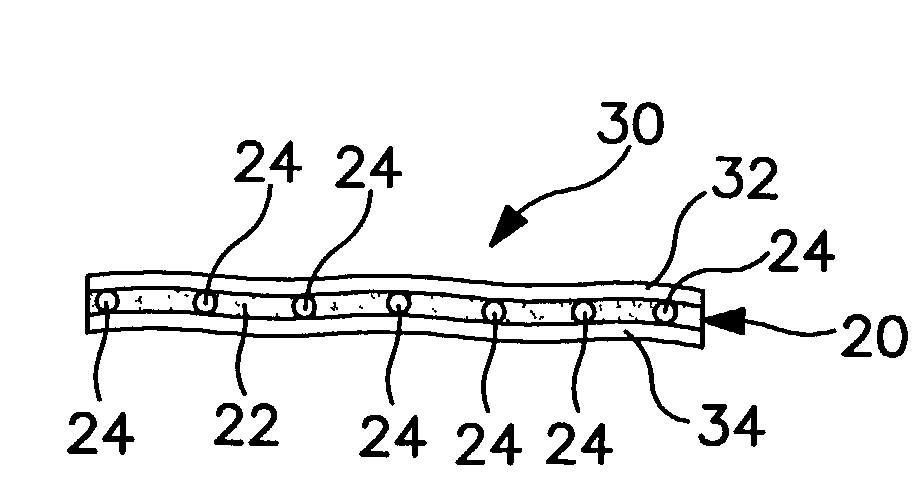

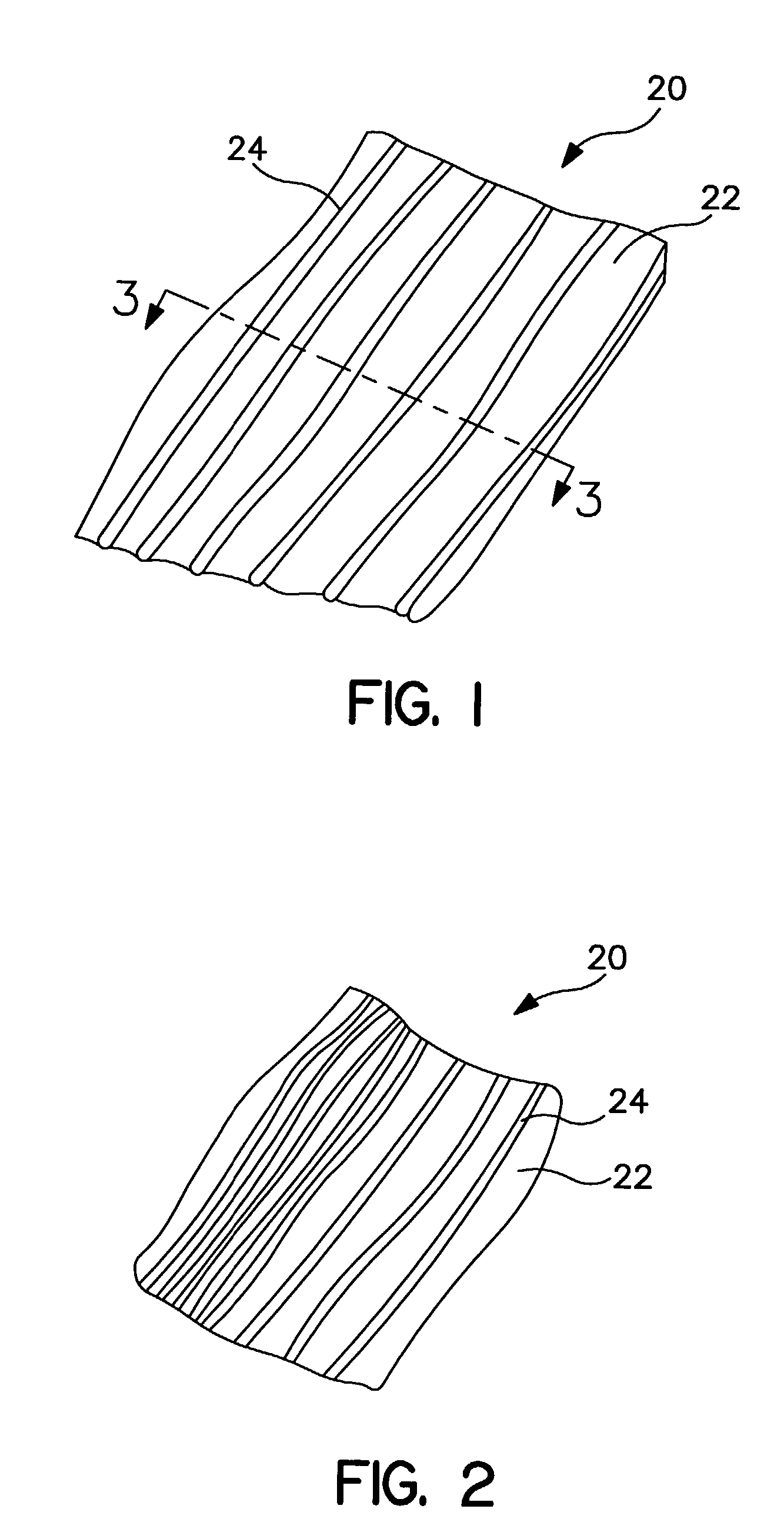

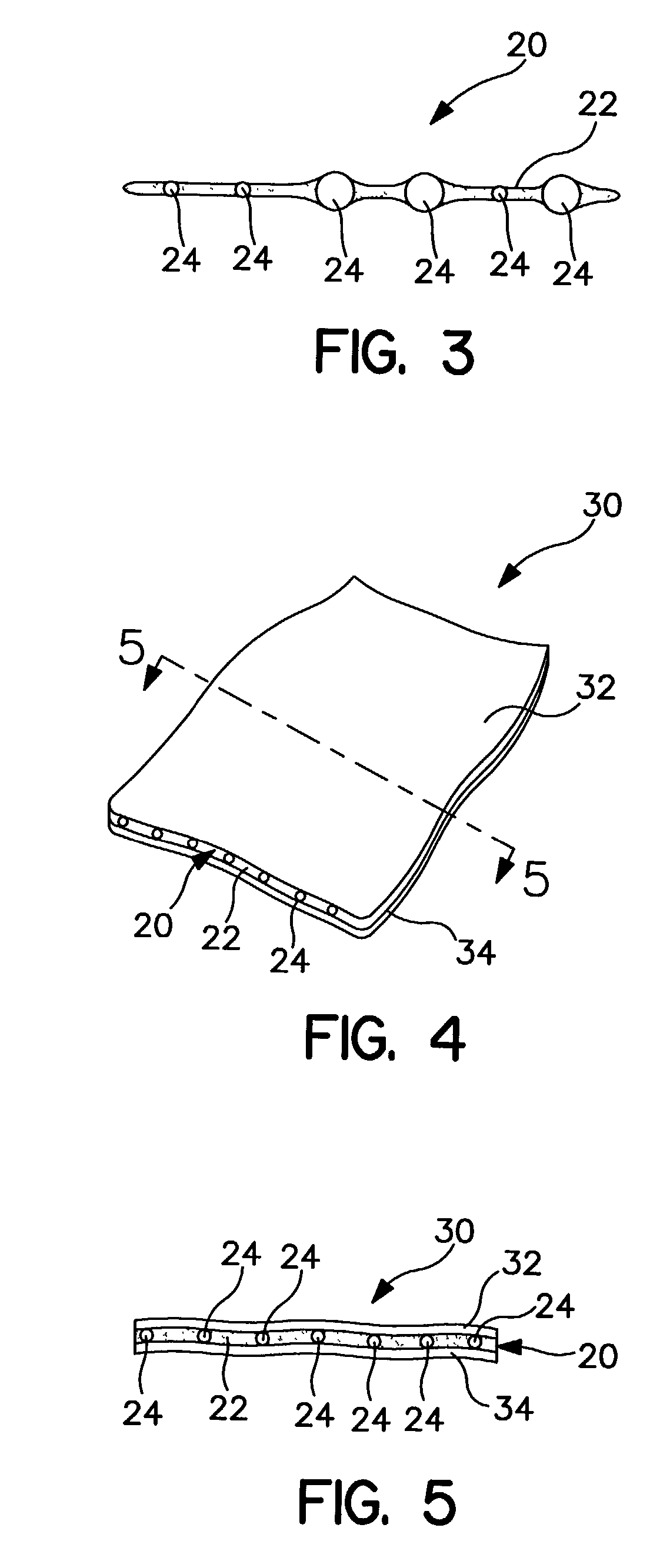

Strand-reinforced composite material

InactiveUS7316840B2Control tensionSynthetic resin layered productsLaminationElastomer compositesComposite laminates

Elastomeric composites and elastomeric composite laminates including reinforcement strands incorporated into an elastomeric adhesive film. The strands may vary in terms of levels of tension. Facing layers, such as nonwoven webs, can be laminated to both surfaces of the elastomeric composite to form laminates. A method of making such composites and laminates involves adjusting tension among various elastic strands while extruding the elastic strands and incorporating the elastic strands into the elastomeric adhesive film.

Owner:KIMBERLY-CLARK WORLDWIDE INC

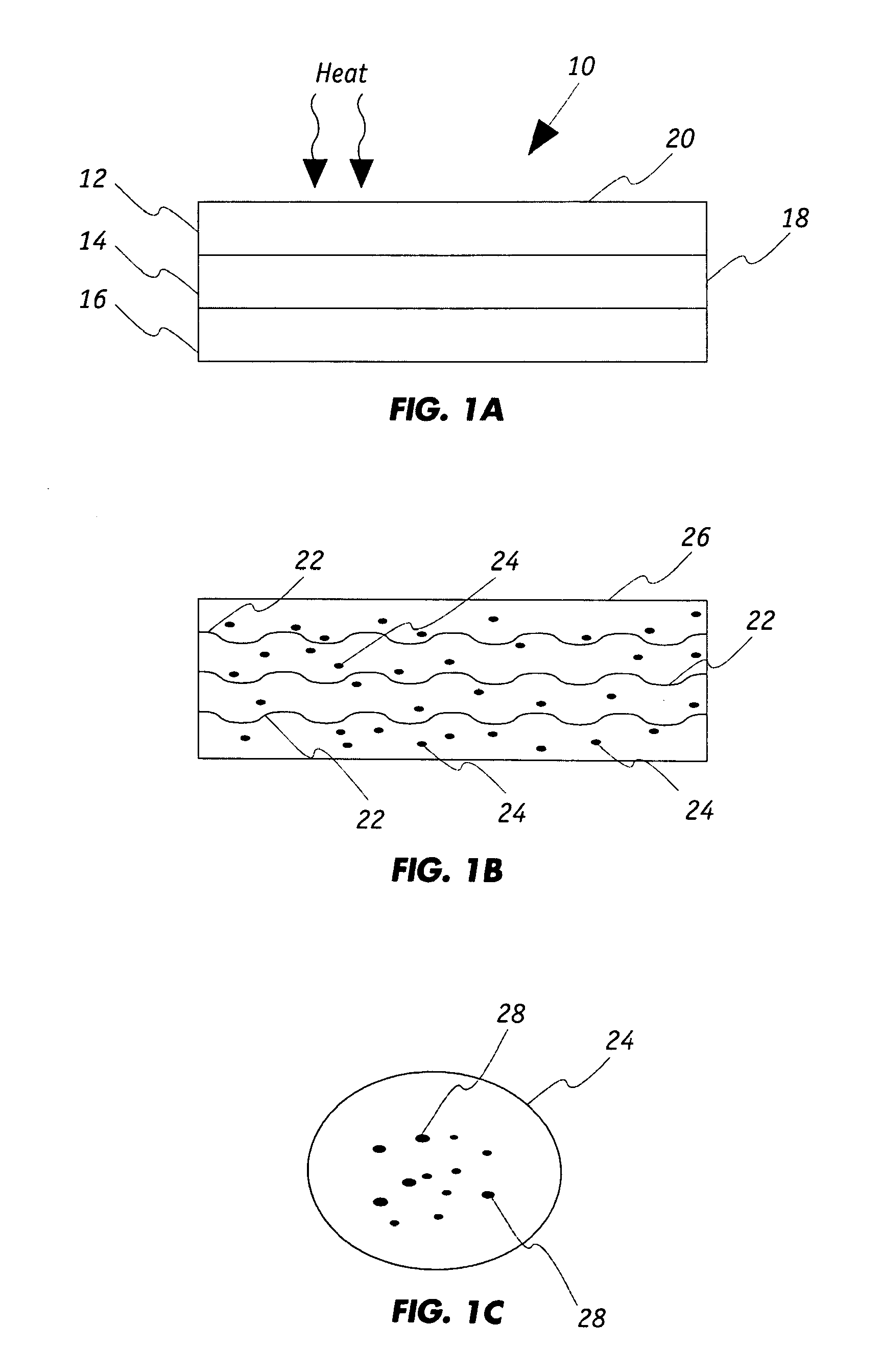

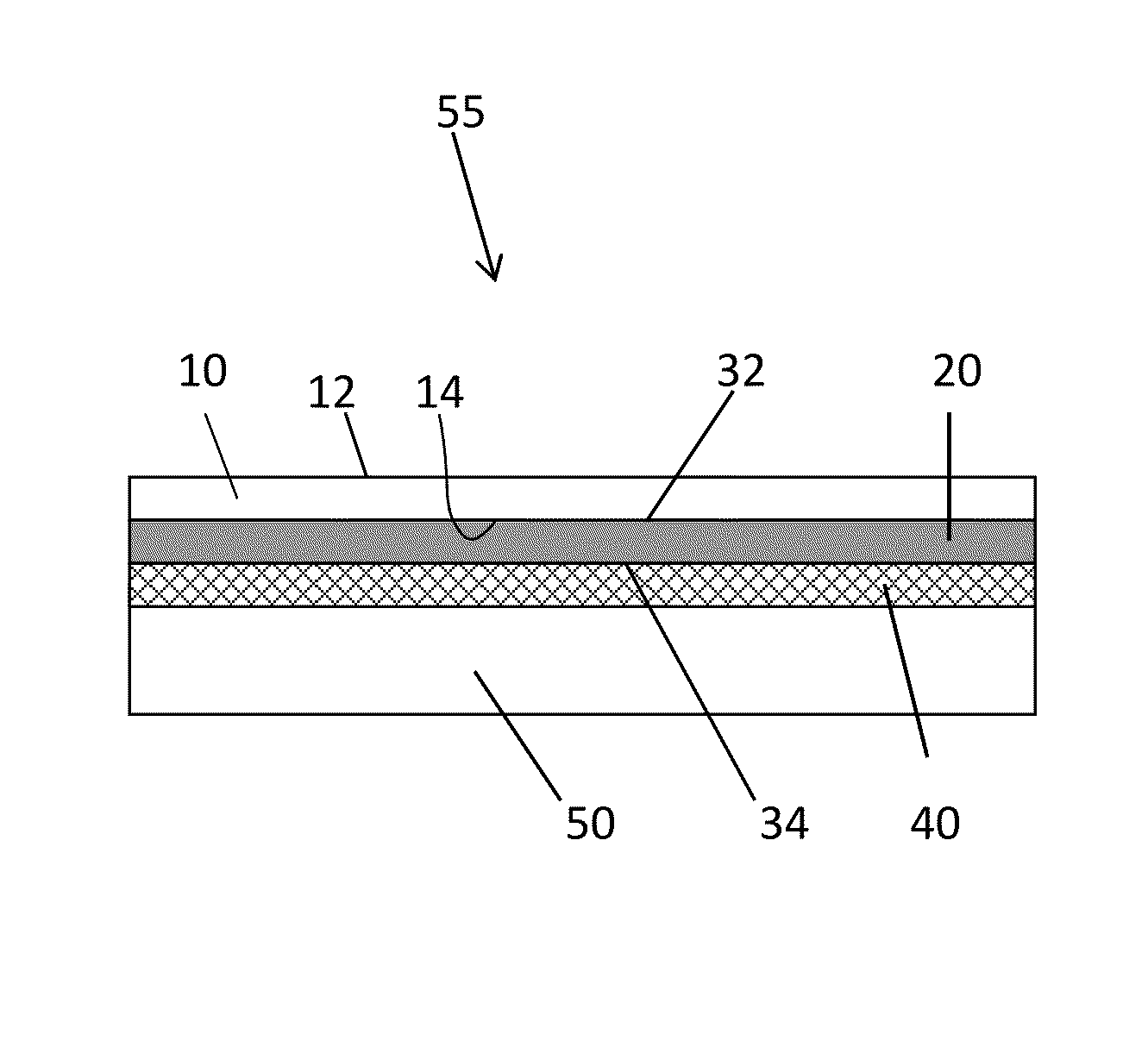

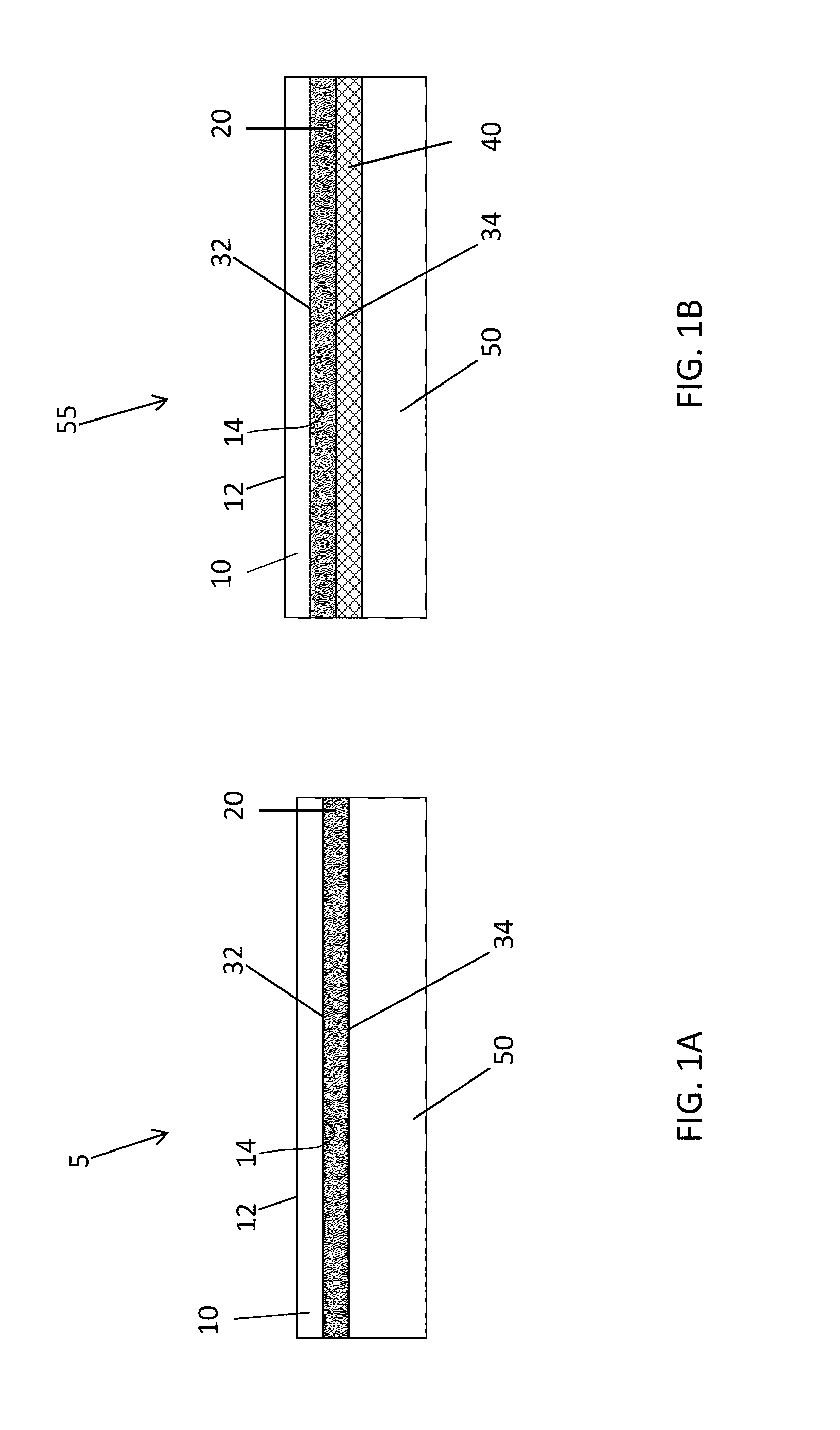

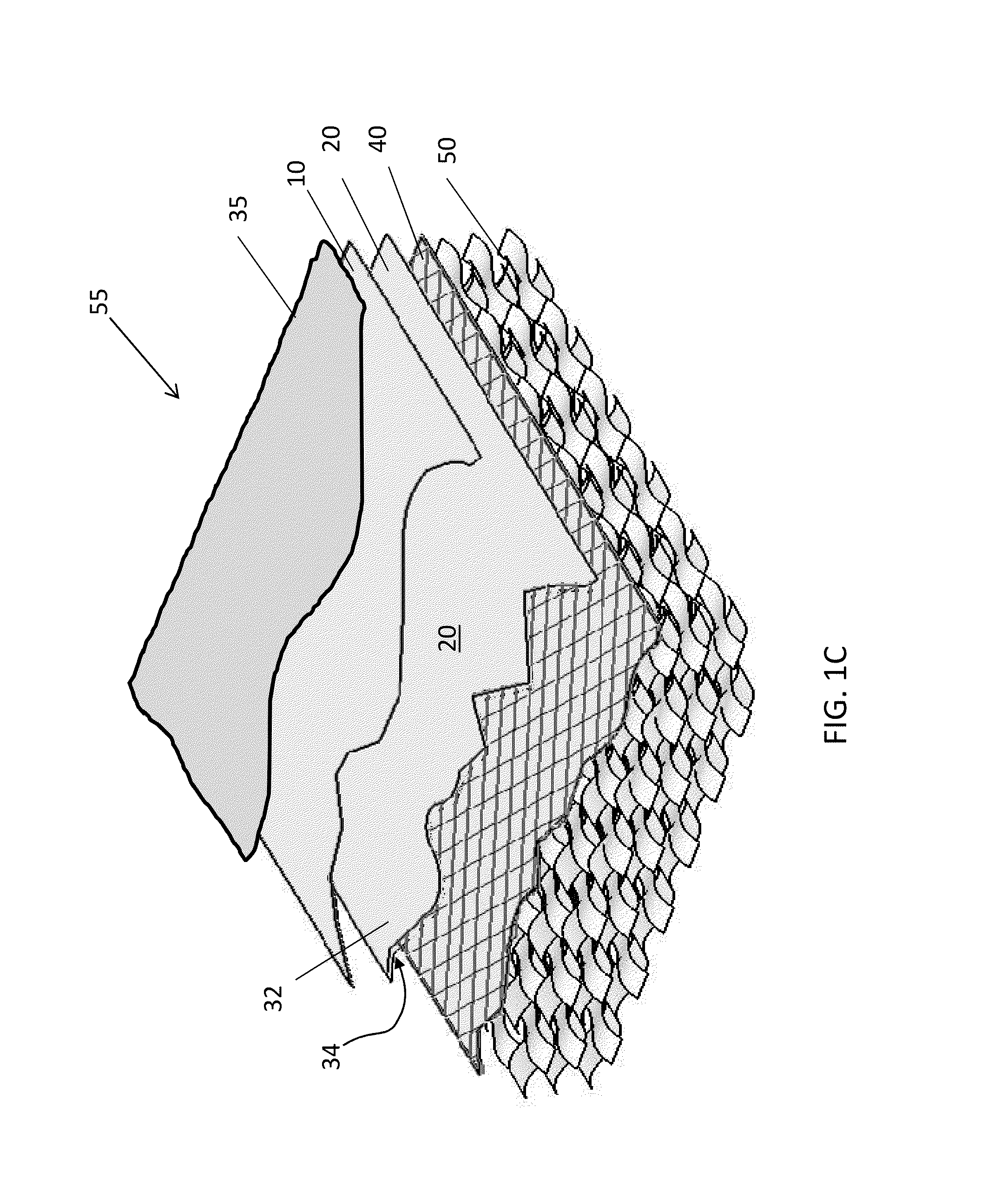

Nanoreinforced films and laminates for aerospace structures

ActiveUS20140011414A1Improved ultraviolet resistance and resistance to microcrackingMaterial nanotechnologyWarp knittingPolymer resinNanofiber

A composite laminate for use on an external part of an aerospace vehicle has improved ultraviolet resistance and resistance to microcracking from thermal cycling. The laminate comprises a nanoreinforcement film, a support veil, and a composite layer. The laminate also can have a lightning strike protection layer and an external paint and primer. The nanoreinforcement film can comprise carbon nanomaterial and a polymer resin, and the composite layer has one or more layers of a reinforcement and a polymer resin. The carbon nanomaterial can be carbon nanofibers, and the nanoreinforcement film can have an areal weight of less than about 100 g / m2. The carbon nanomaterial can also comprise carbon nanofibers and carbon nanotubes.

Owner:ROHR INC +1

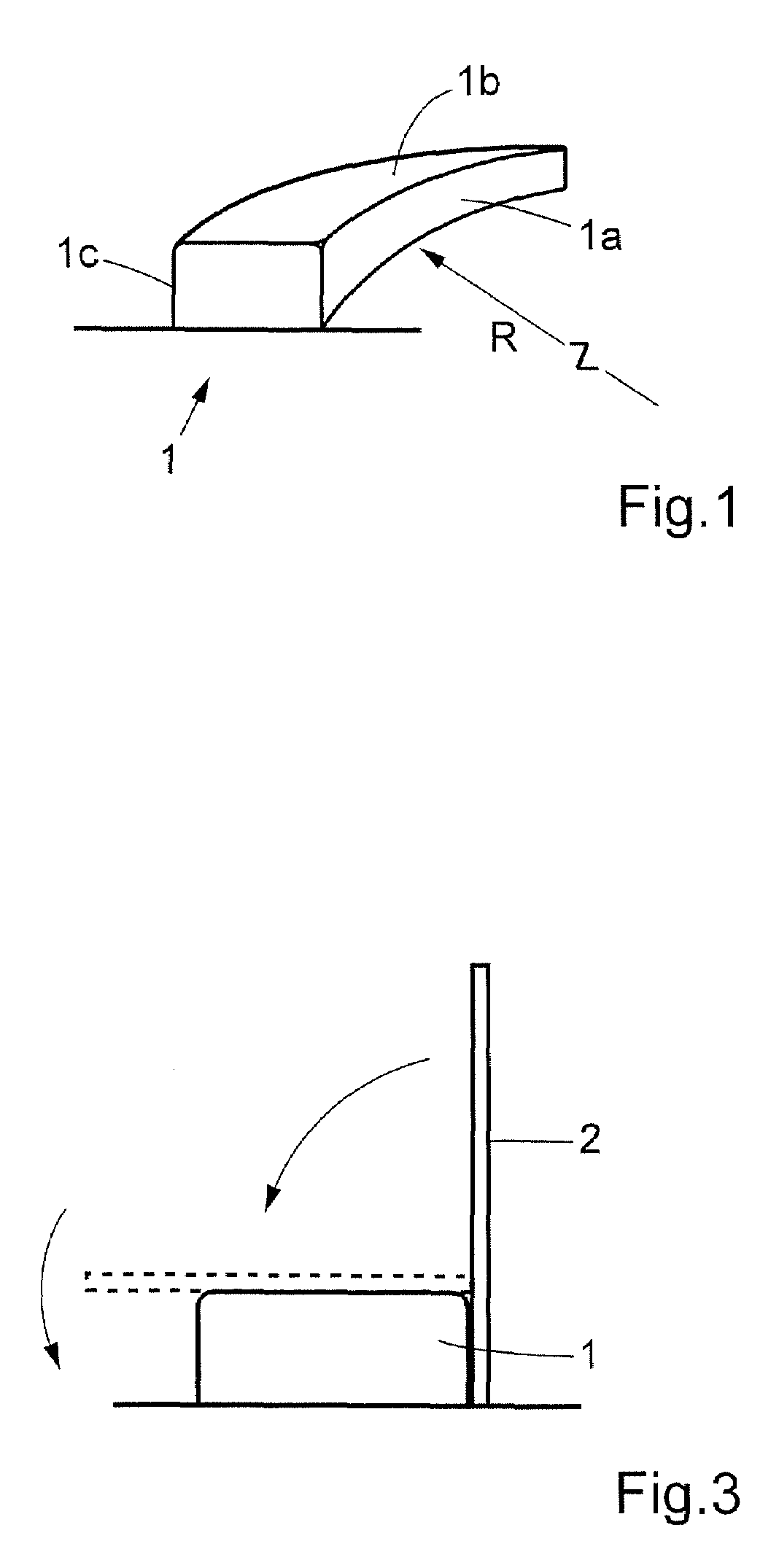

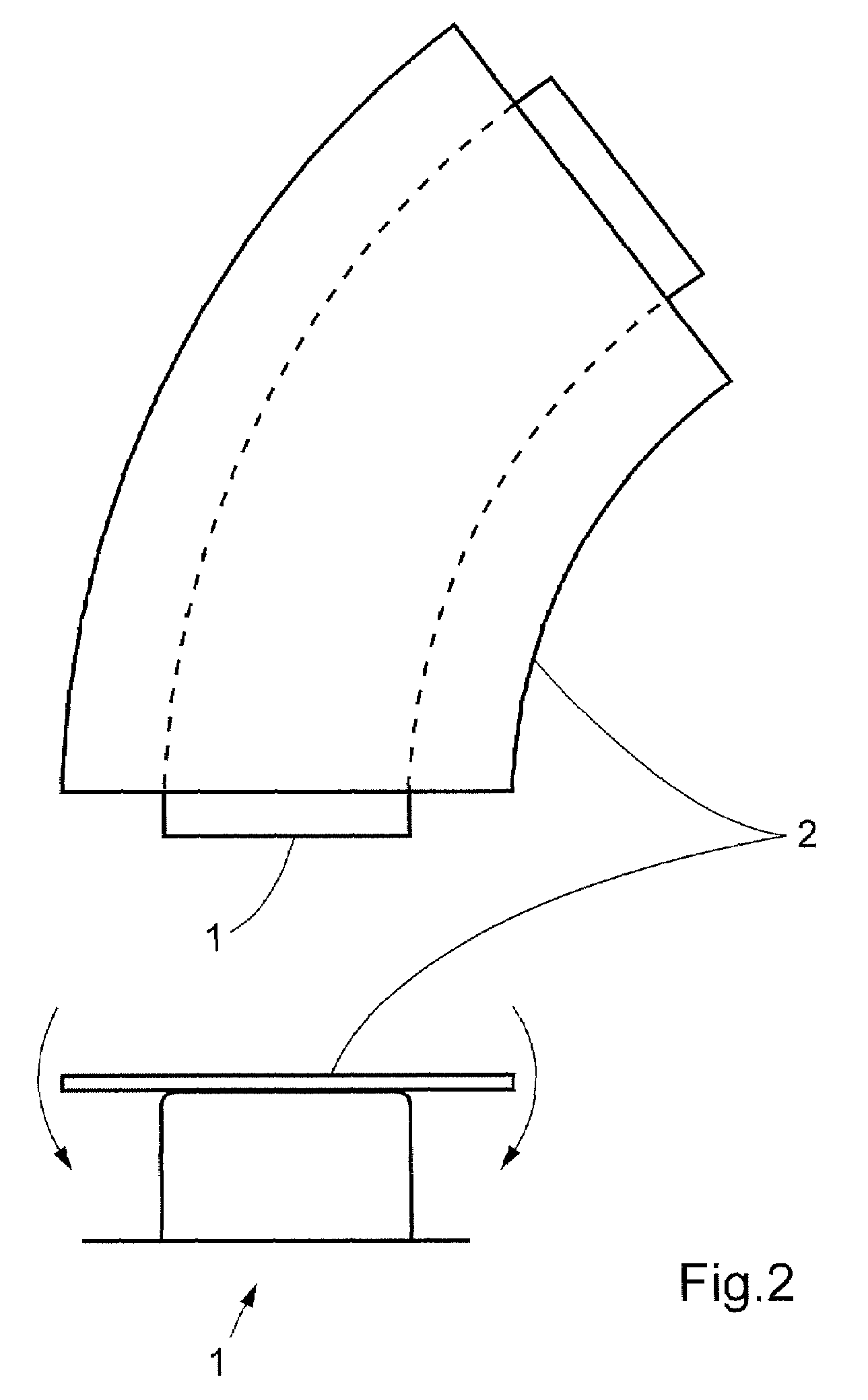

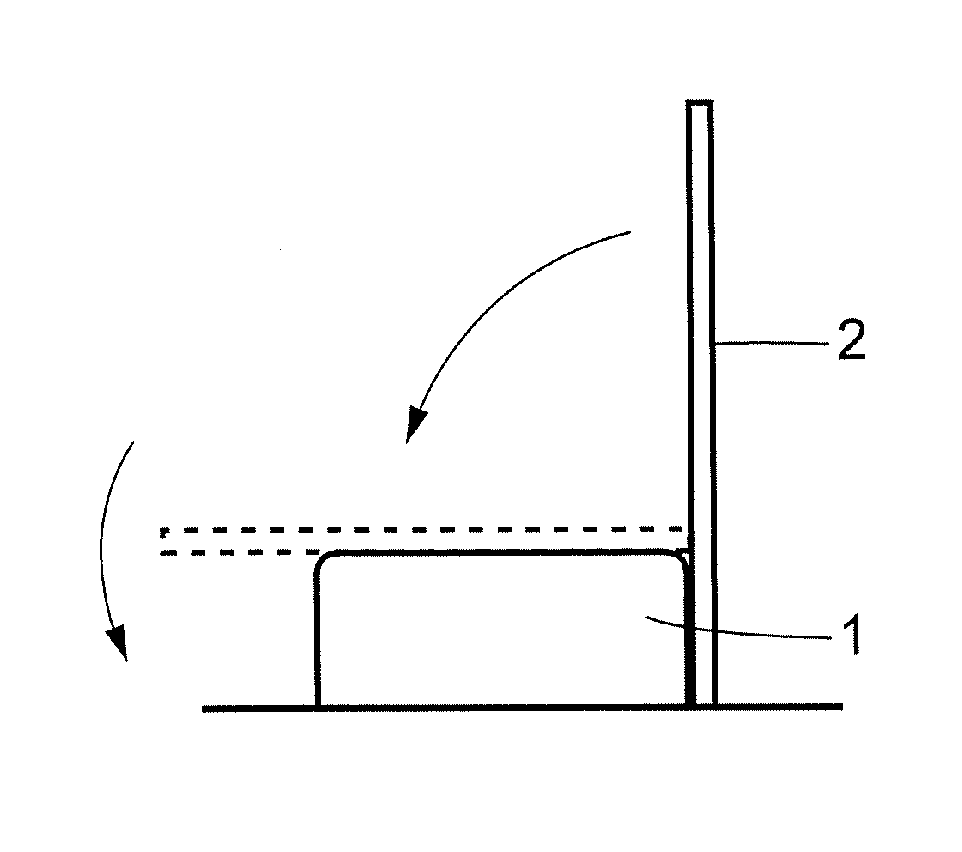

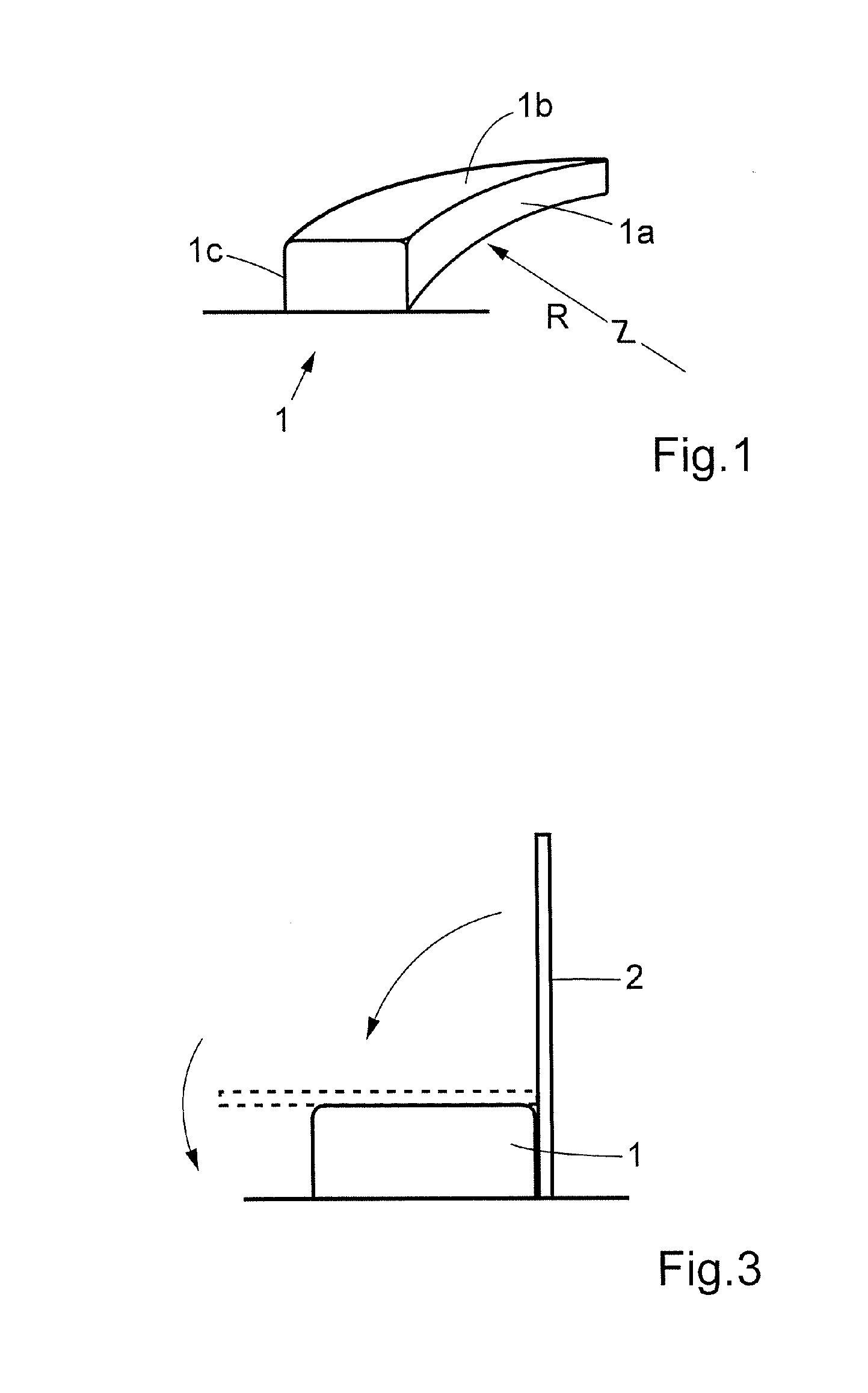

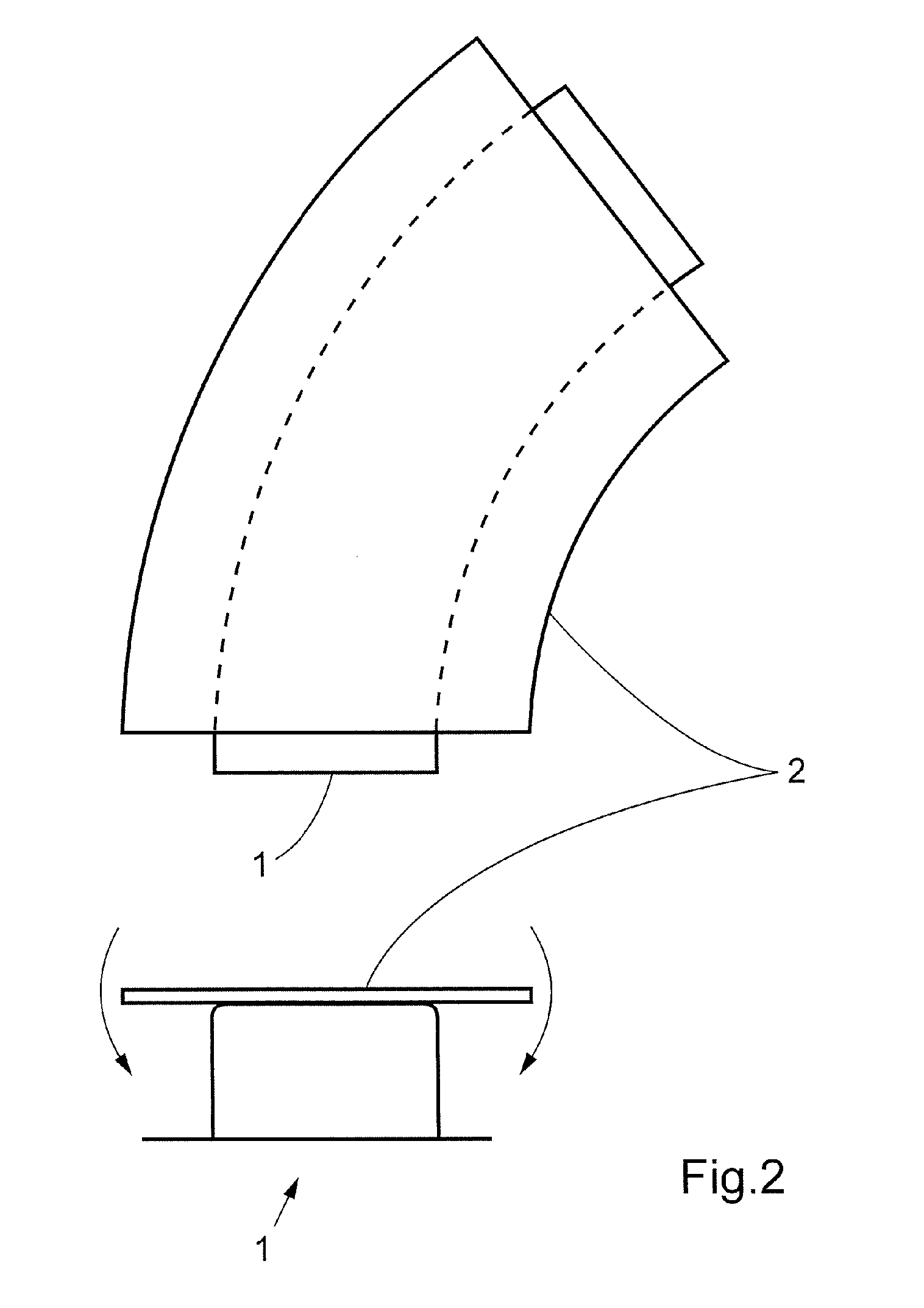

Method for fabricating a curved beam from composite material

InactiveUS7670525B2Avoid huge wasteGood strength performanceMouldsWood working apparatusComposite laminatesEngineering

A method for fabricating a curved beam from fiber composite material. A flat fiber composite laminate including a plurality of layers and at least two different fiber directions is formed. The fiber composite laminate is disposed in contact with a male tool includes a first flange, a second flange and an intermediate web. The male tool is curved in its longitudinal direction with a radius of curvature in such a way that the first flange has a shorter longitudinal extent than the second flange. The fiber composite laminate is brought into contact with and secured to the first flange of the male tool. The male tool and the fiber composite laminate are then rotated relative to one another so that the fiber composite laminate is brought into contact with the intermediate web of the male tool in a first rotational movement, and brought into contact with the second flange of the male tool in a second rotational movement. The fiber composite laminate hardens on the male tool, and the finished beam is separated from the tool. Also a beam of fiber composite material fabricated according to the method.

Owner:SAAB AB

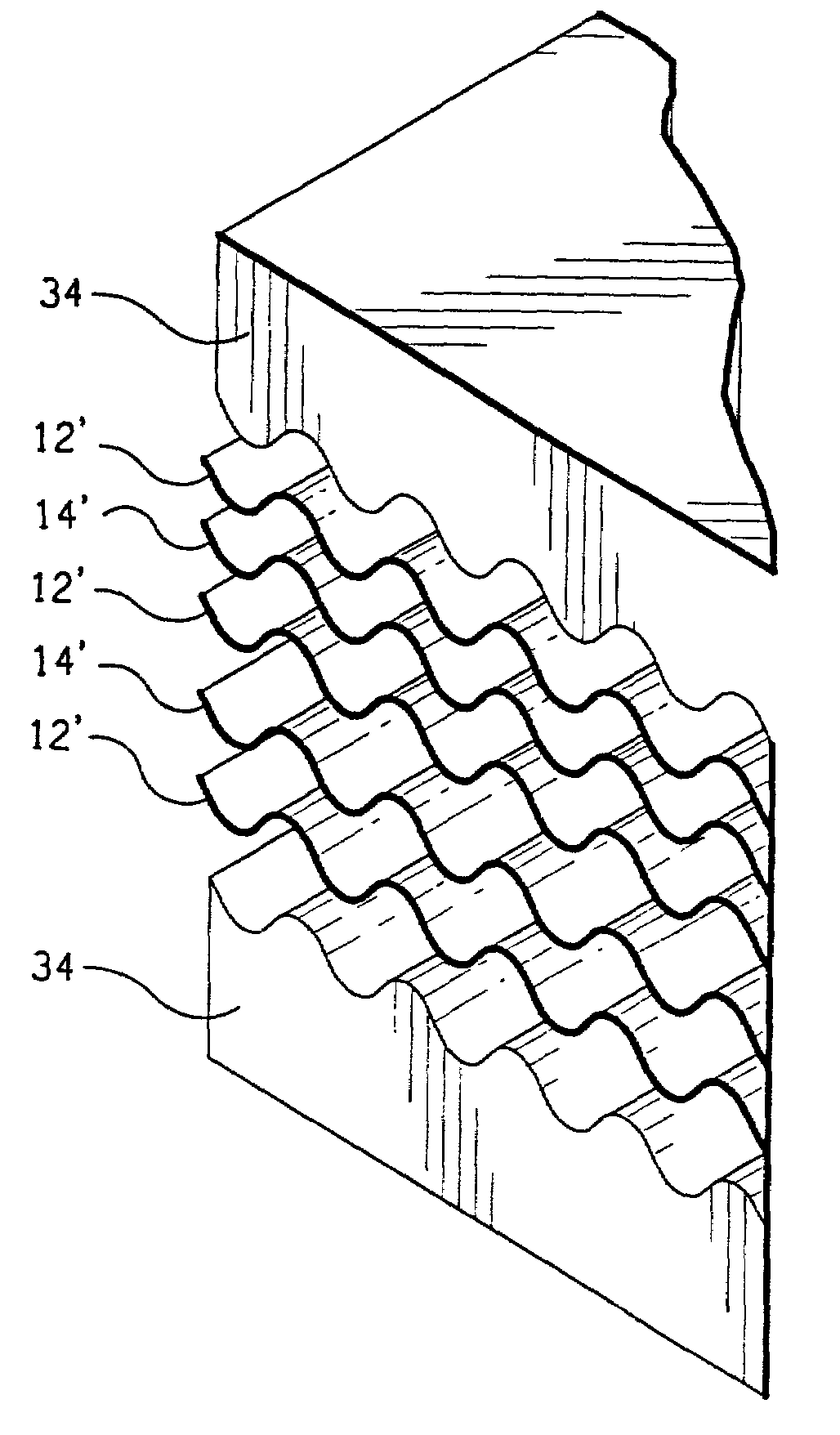

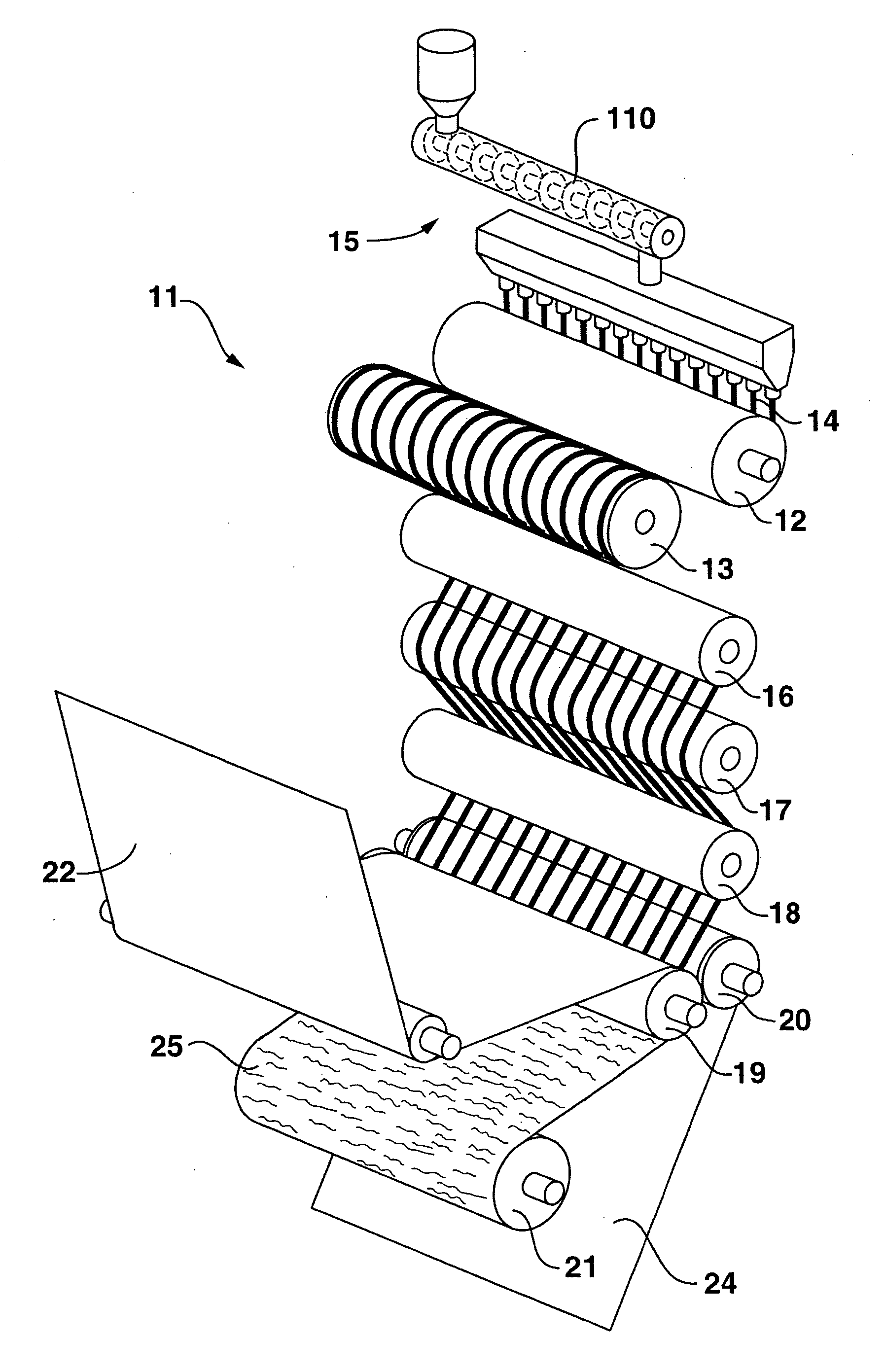

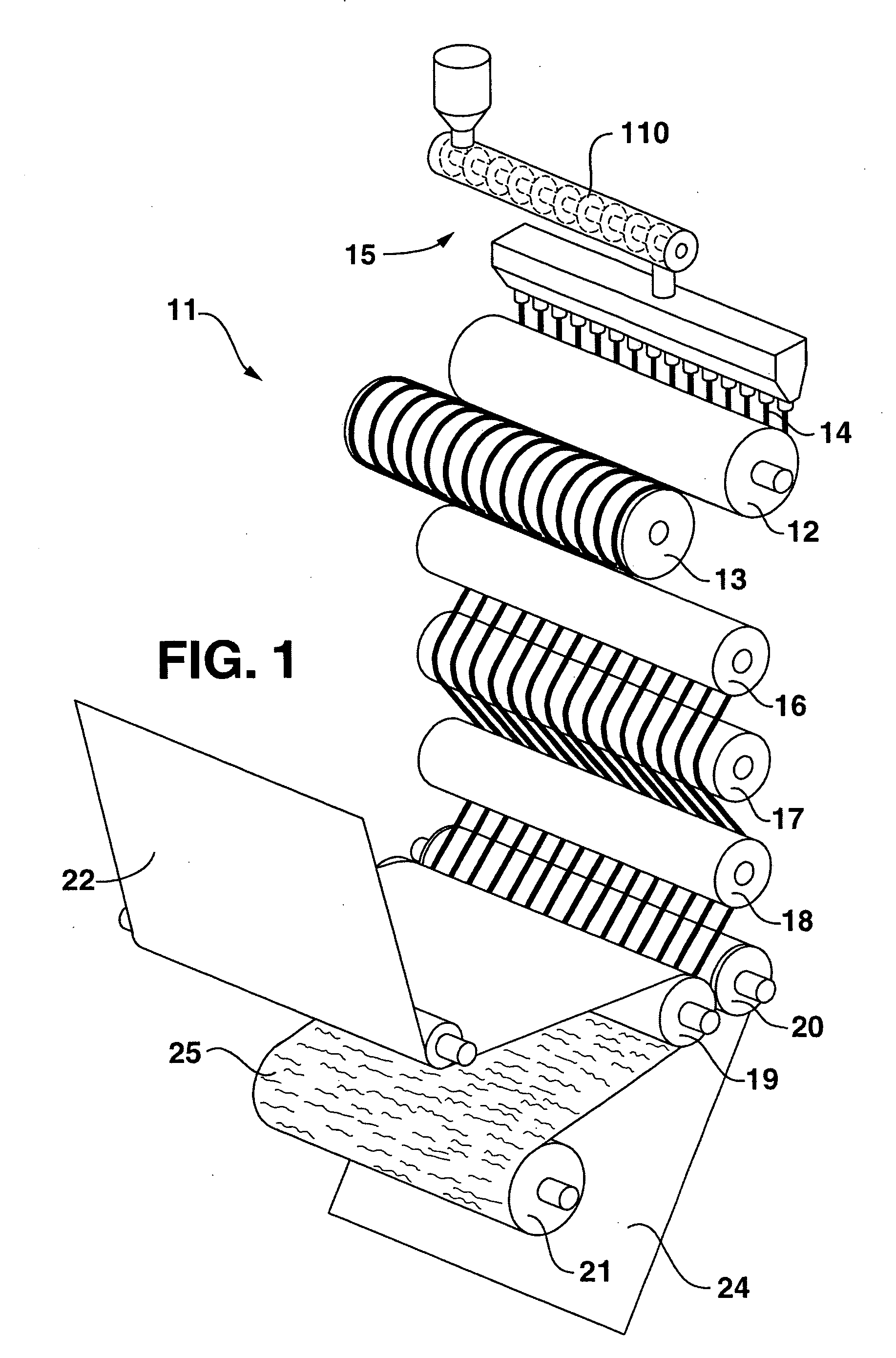

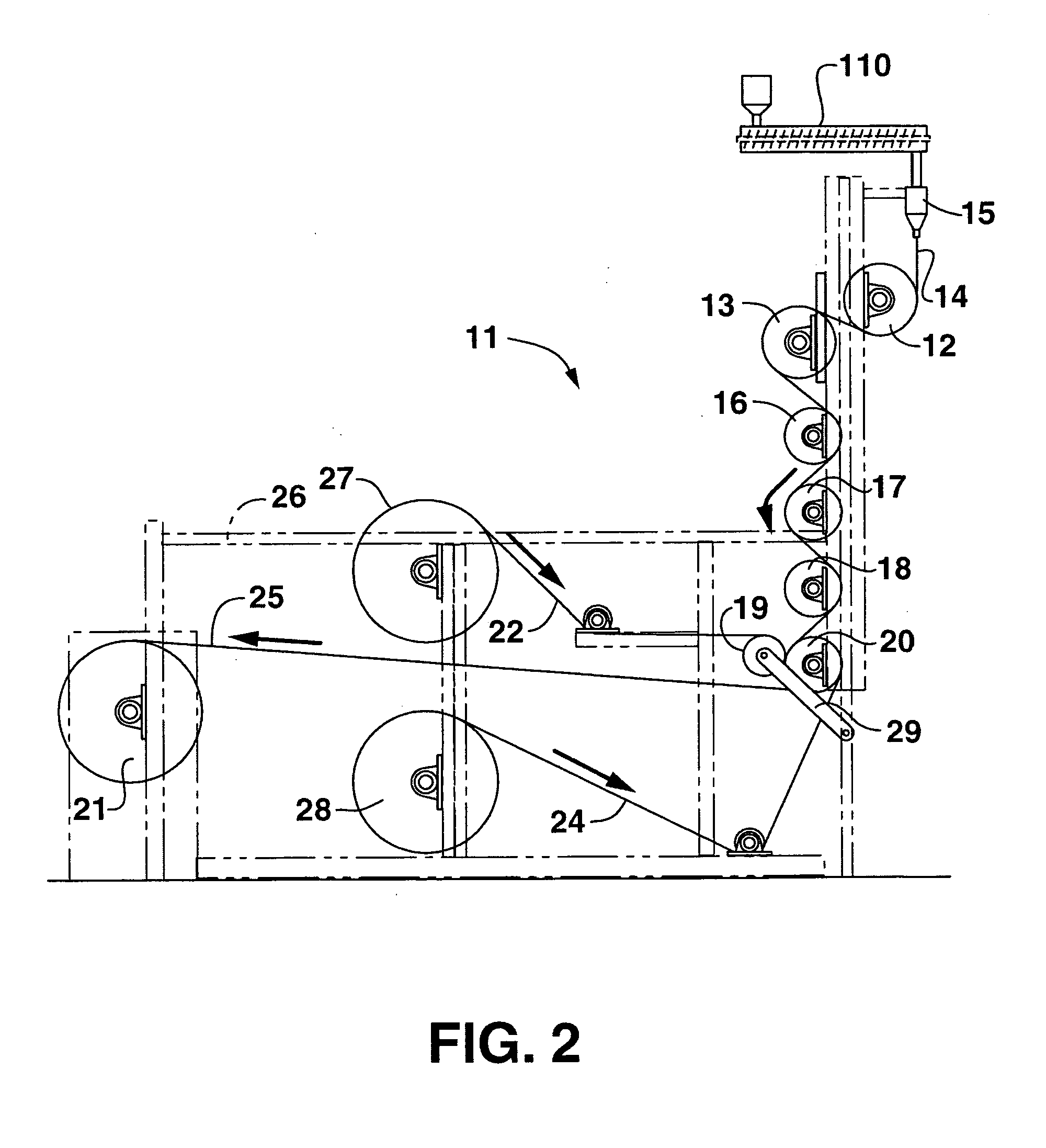

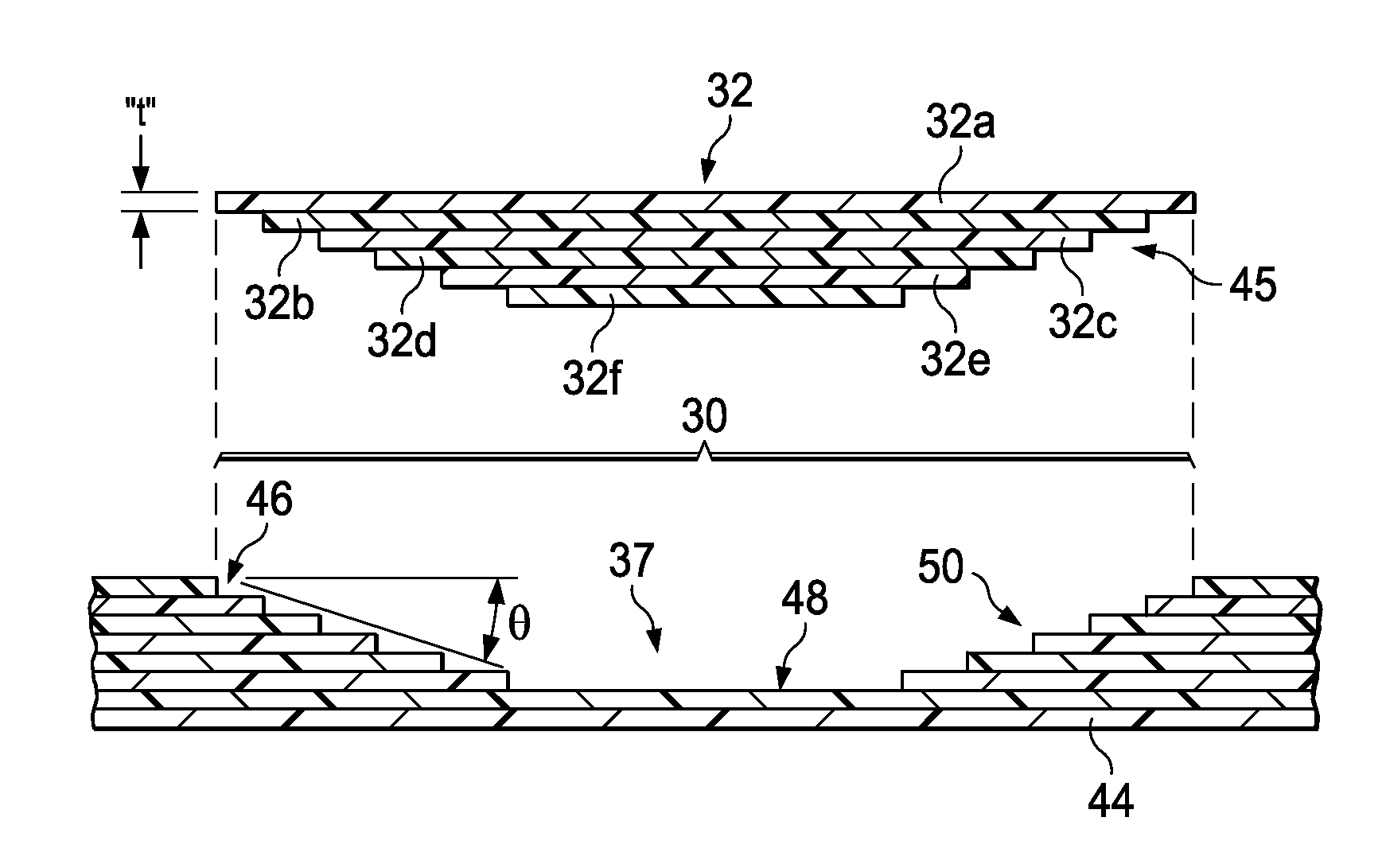

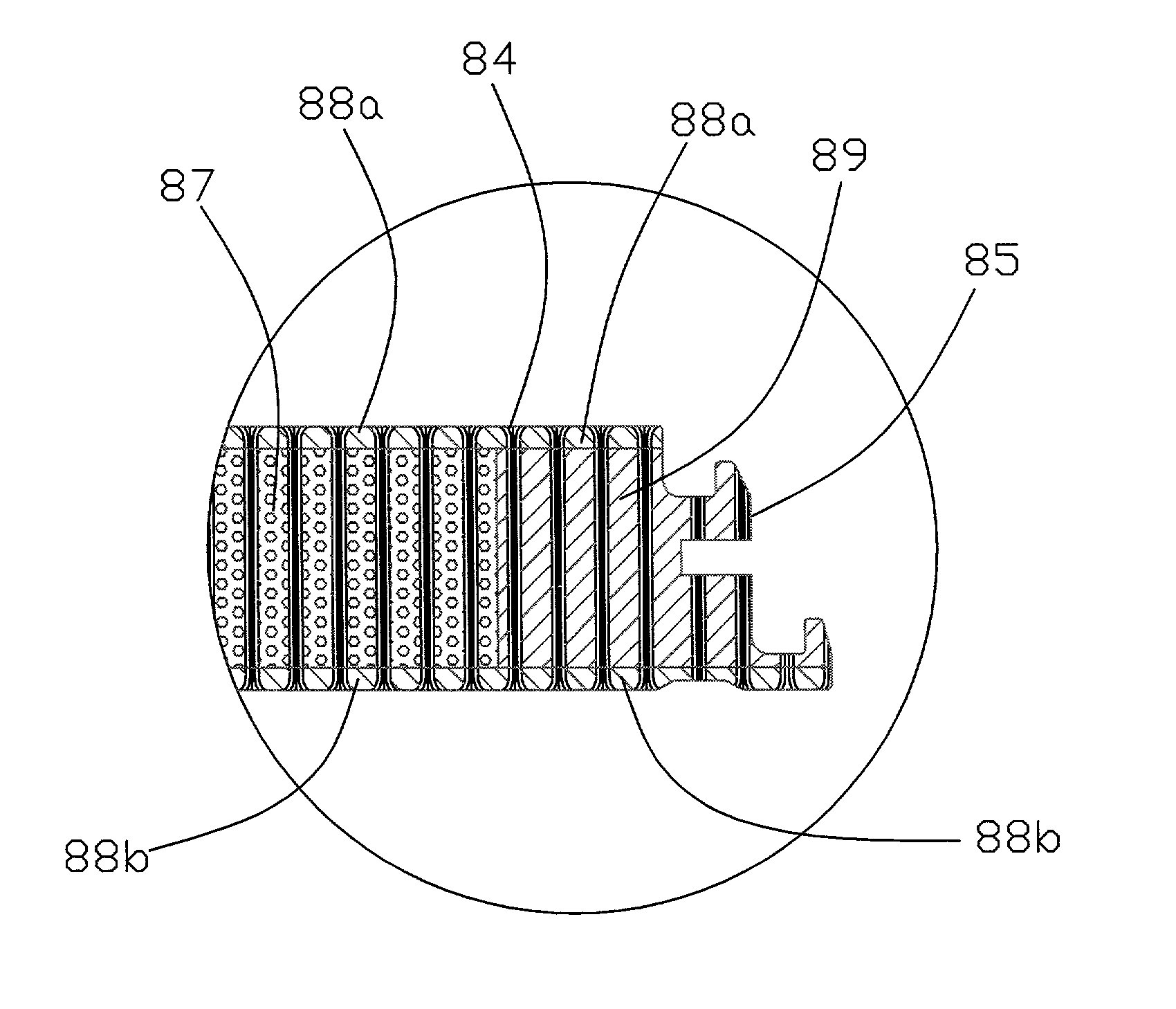

Method of clinching the top and bottom ends of Z-axis fibers into the respective top and bottom surfaces of a composite laminate

InactiveUS20020144767A1Improve the immunityEasy to assembleLayered productsTemporary pavingsComposite laminatesFiber-reinforced composite

A method and apparatus for forming an improved pultruded and clinched Z-axis fiber reinforced composite laminate structure. The upper and lower skins and the core are pulled automatically through tooling where the skin material is wetted-out with resin and the entire composite laminate is preformed in nearly its final thickness. The preformed composite laminate continues to be pulled into an automatic 3-dimensional Z-axis fiber deposition machine that deposits "groupings of fiber filaments" at multiple locations normal to the plane of the composite laminate structure and cuts each individual grouping such that a extension of each "grouping of fiber filaments" remains above the upper skin and below the lower skin. The preformed composite laminate then continues to be pulled into a secondary wet-out station. Next the preformed composite laminate travels into a pultrusion die where the extended "groupings of fiber filaments" are all bent over above the top skin and below the bottom skin producing a superior clinched Z-axis fiber reinforcement as the composite laminate continues to be pulled, catalyzed, and cured at the back section of the pultrusion die. The composite laminate continues to be pulled by grippers that then feed it into a gantry CNC machine that is synchronous with the pull speed of the grippers and where computerized machining, drilling, and cutting operations take place. This entire method is accomplished automatically without the need for human operators.

Owner:EBERT COMPOSITES

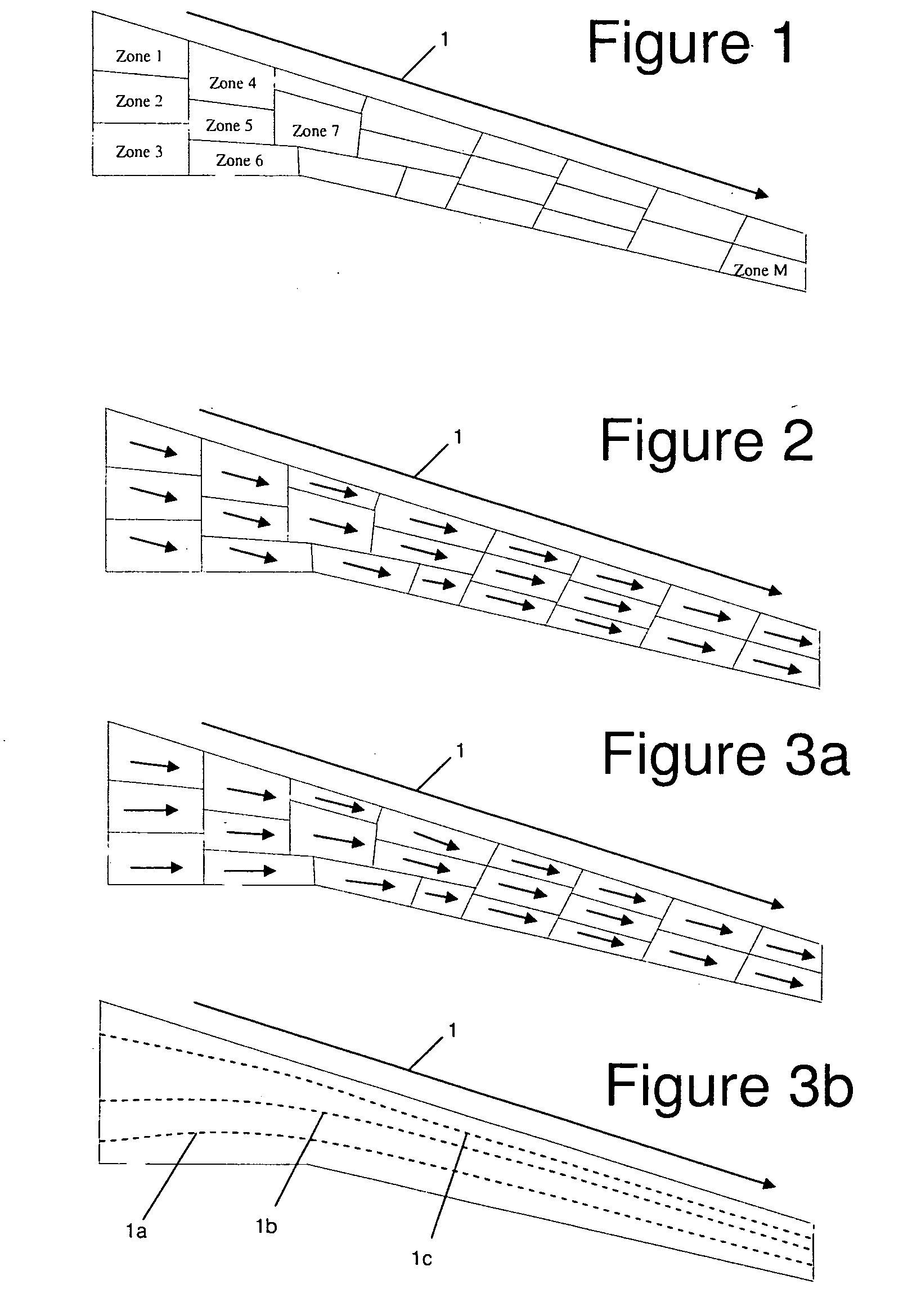

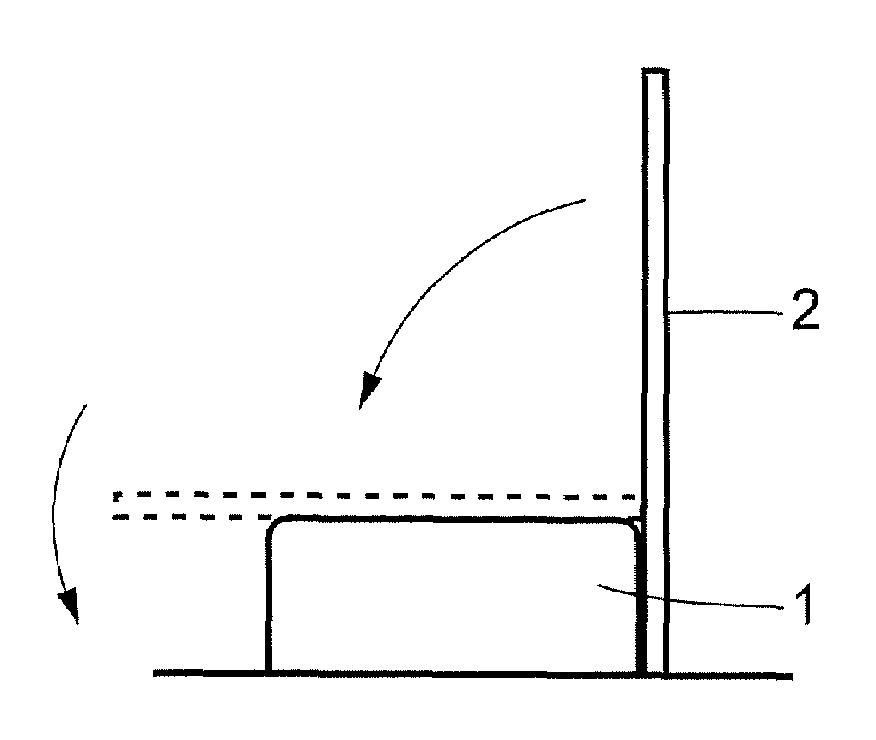

Method For Fabricating A Curved Beam From Composite Material

InactiveUS20060216480A1Avoid huge wasteGood strength performanceMouldsLayered productsComposite laminatesEngineering

This invention concerns a method for fabricating a curved beam from fiber composite material. A flat fiber composite laminate (2) comprising a plurality of layers and at least two different fiber directions is formed. The fiber composite laminate (2) is disposed in contact with a male tool (1) comprised of a first flange (1a), a second flange (1c) and an intermediate web (1b), which male tool (1) is curved in its longitudinal direction with a radius of curvature R in such a way that the first flange (1a) has a shorter longitudinal extent than the second flange (1c). The fiber composite laminate (2) is brought into contact with and secured to the first flange (1a) of the male tool (1). The male tool (1) and the fiber composite laminate (2) are then rotated relative to one another so that the fiber composite laminate (2) is brought into contact with the intermediate web (1b) of the male tool (1) in a first rotational movement, and brought into contact with the second flange (1c) of the male tool (1) in a second rotational movement. The fiber composite laminate (2) hardens on the male tool (1), and the finished beam is separated from the tool (1). The invention also relates to a beam of fiber composite material fabricated according to the method.

Owner:SAAB AB

Composite stacking sequence optimization for multi-zoned composites

ActiveUS20050163975A1Shorten the lengthReduce the numberCellulosic plastic layered productsComputation using non-denominational number representationComposite laminatesEngineering

Method, apparatus, and computer program products are provided for optimizing a stacking sequence for a composite laminate having multiple zones to reduce the number or length of internal ply edges in the composite laminate with the most design rule compliant sequences. Once the number and location of the zones and the number of plies having different properties required for each zone have been determined for the composite laminate, a master zone is generated. Advantageously, the property of the plies may be fiber orientation, though alternative properties such as material may be considered when determining the number of required plies. The master zone notionally includes the maximum number of plies having a respective property required by any one zone, and the plies of the master zone are sequenced using a predefined series of design rules. The plies of each zone are then arranged based upon the stacking sequence of the master zone. A transformation matrix, a second predefined series of design rules, and a weighted solid / void differential may be used when arranging the plies of each zone based upon the stacking sequence of the master zone.

Owner:THE BOEING CO

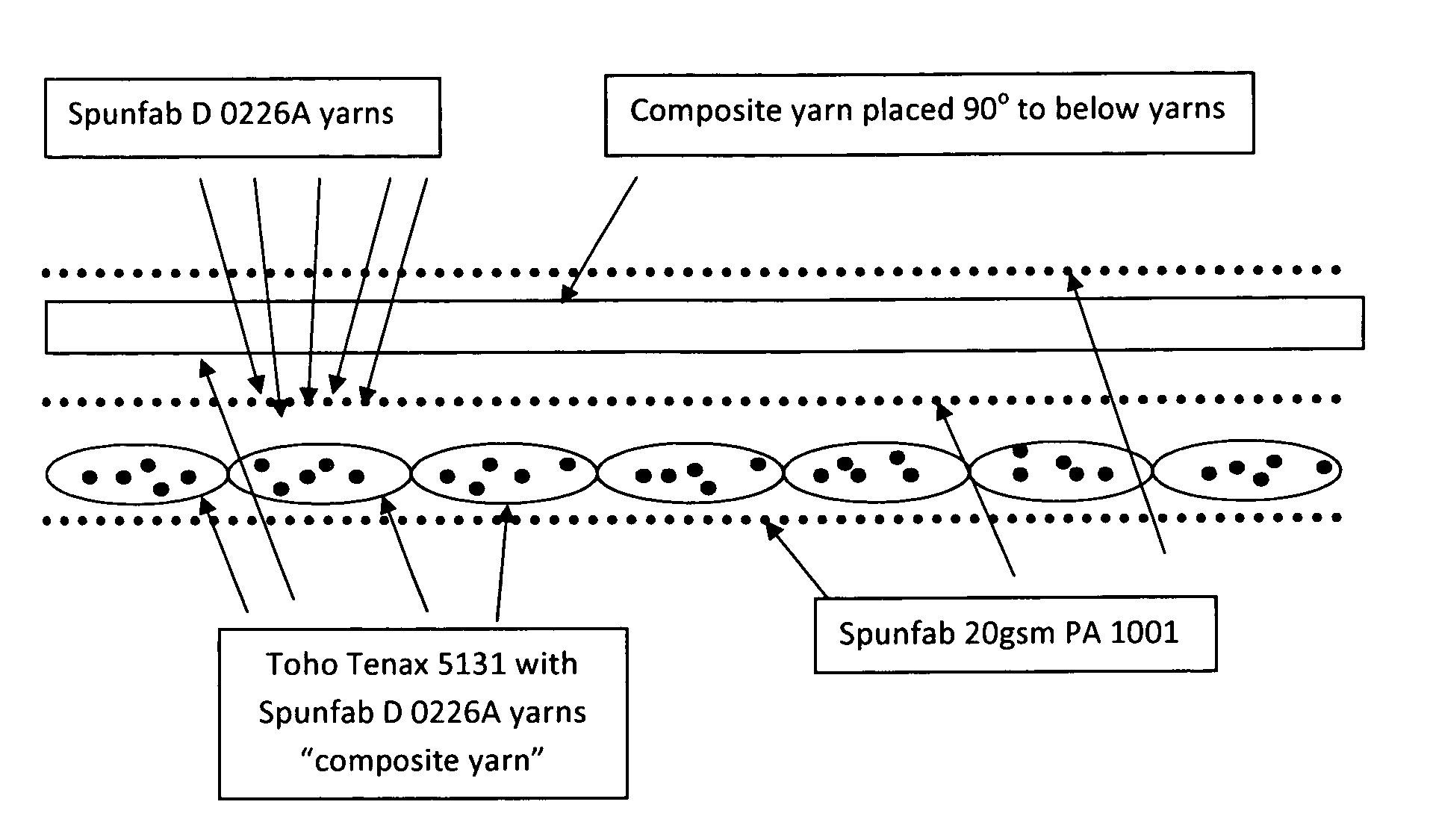

Method of delivering a thermoplastic and/or crosslinking resin to a composite laminate structure

The present invention provides a process for producing a prepreg of high modulus reinforcing fibers, the process comprising the steps of: a) providing a reinforcing fiber bundle layer wherein such bundle contains a thermoplastic and / or crosslinking resin within the fiber bundle; b) providing a layer of a thermoplastic and / or crosslinking material layer on at least one side of the high modulus fiber layer of step a); c) compressing the layers from step b) under an appropriate amount of heat and pressure, and thereby producing a prepreg of high modulus reinforcing fibers.

Owner:KEUCHEL KENNETH HERBERT

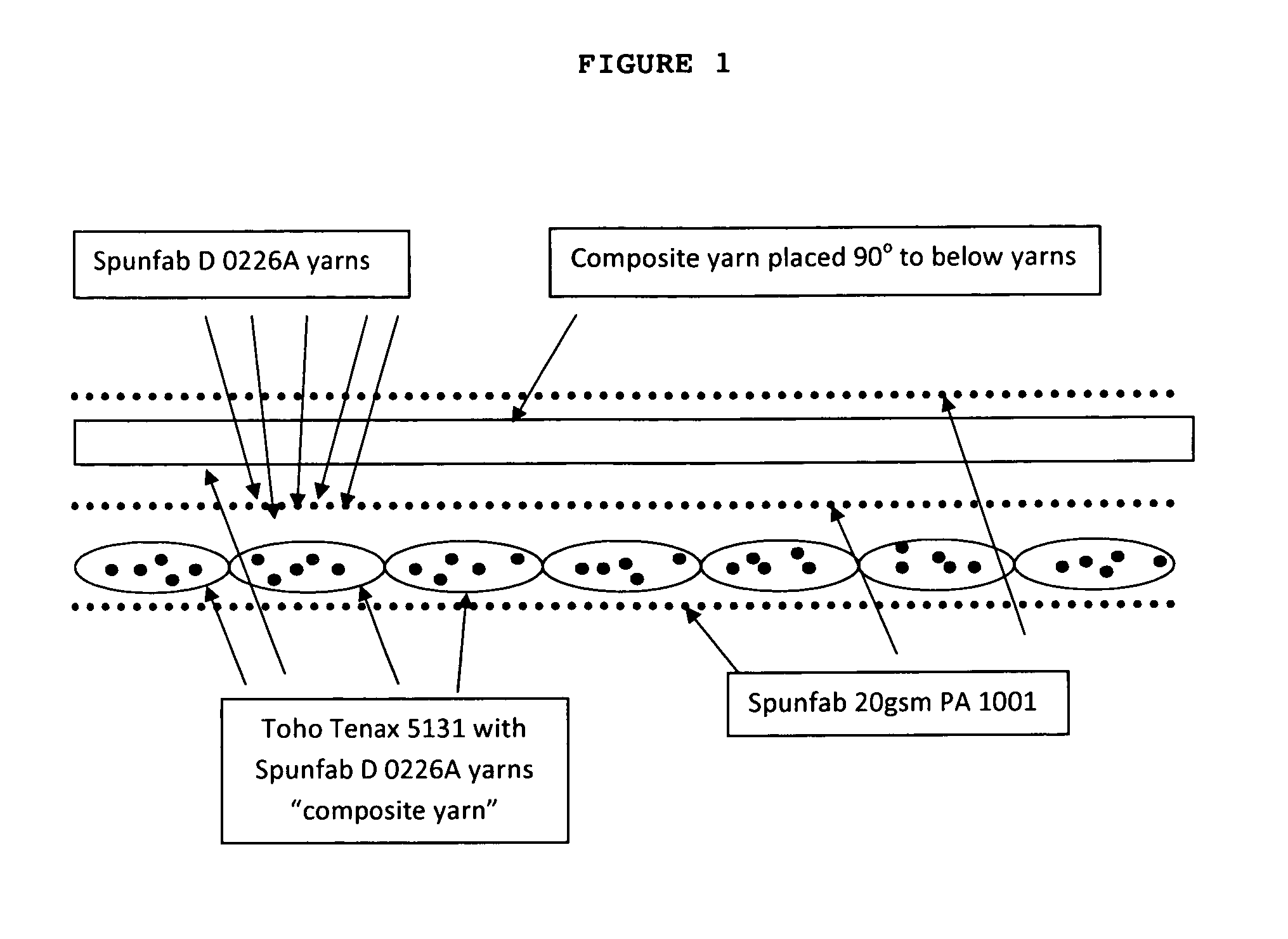

Composite laminate manufacture with multiaxial fabrics

Owner:AIRBUS OPERATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com