Patents

Literature

420 results about "Elastomer composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

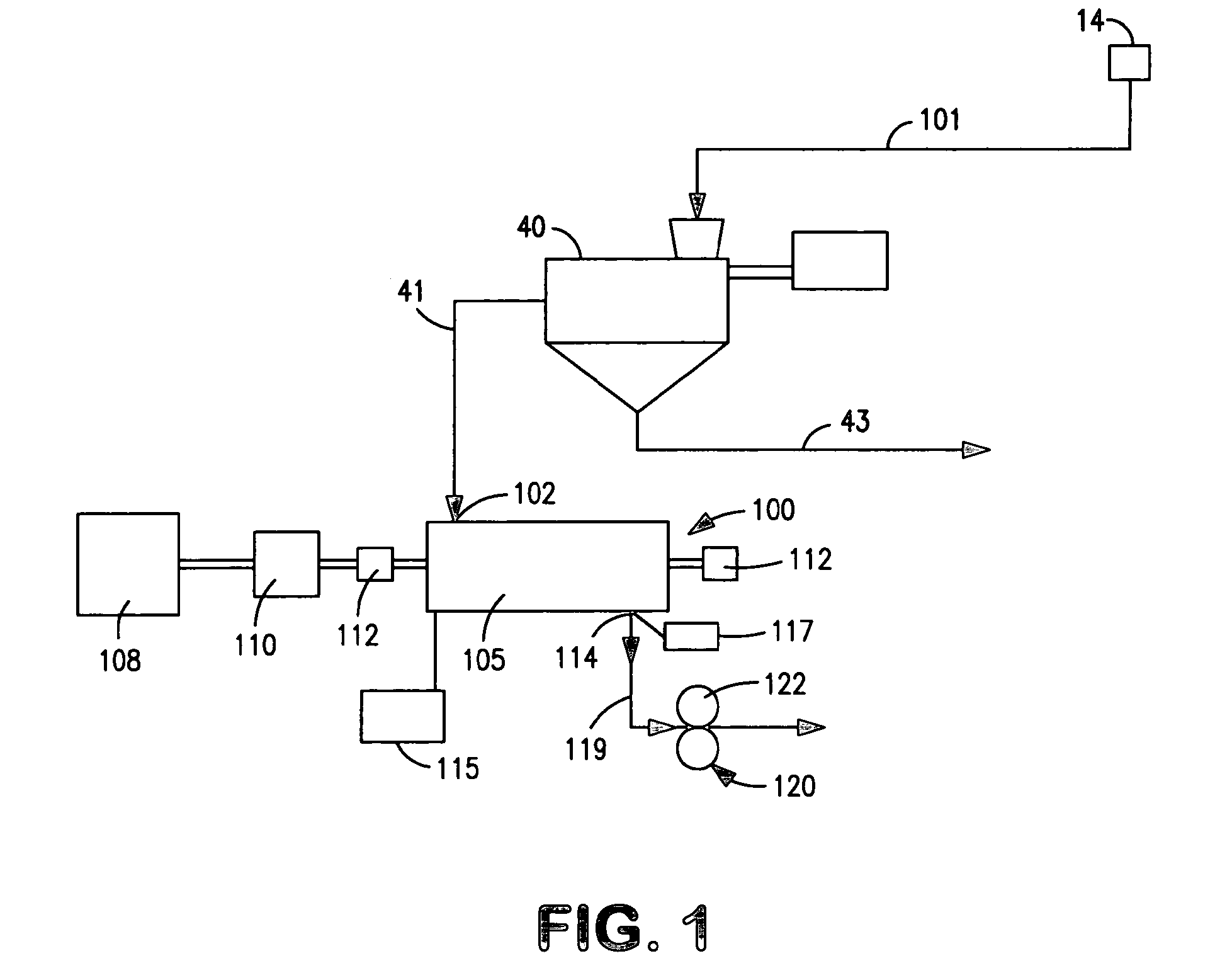

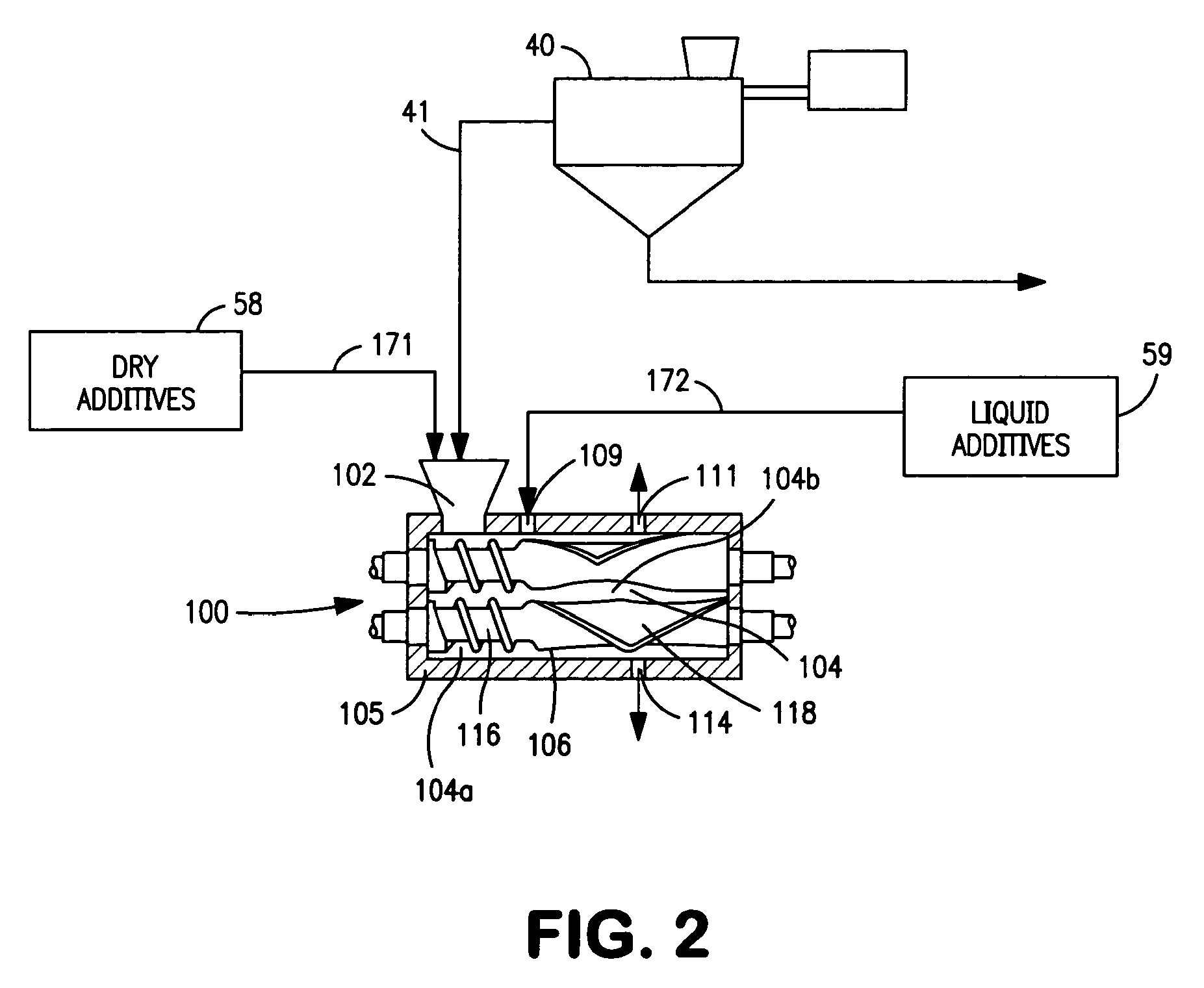

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

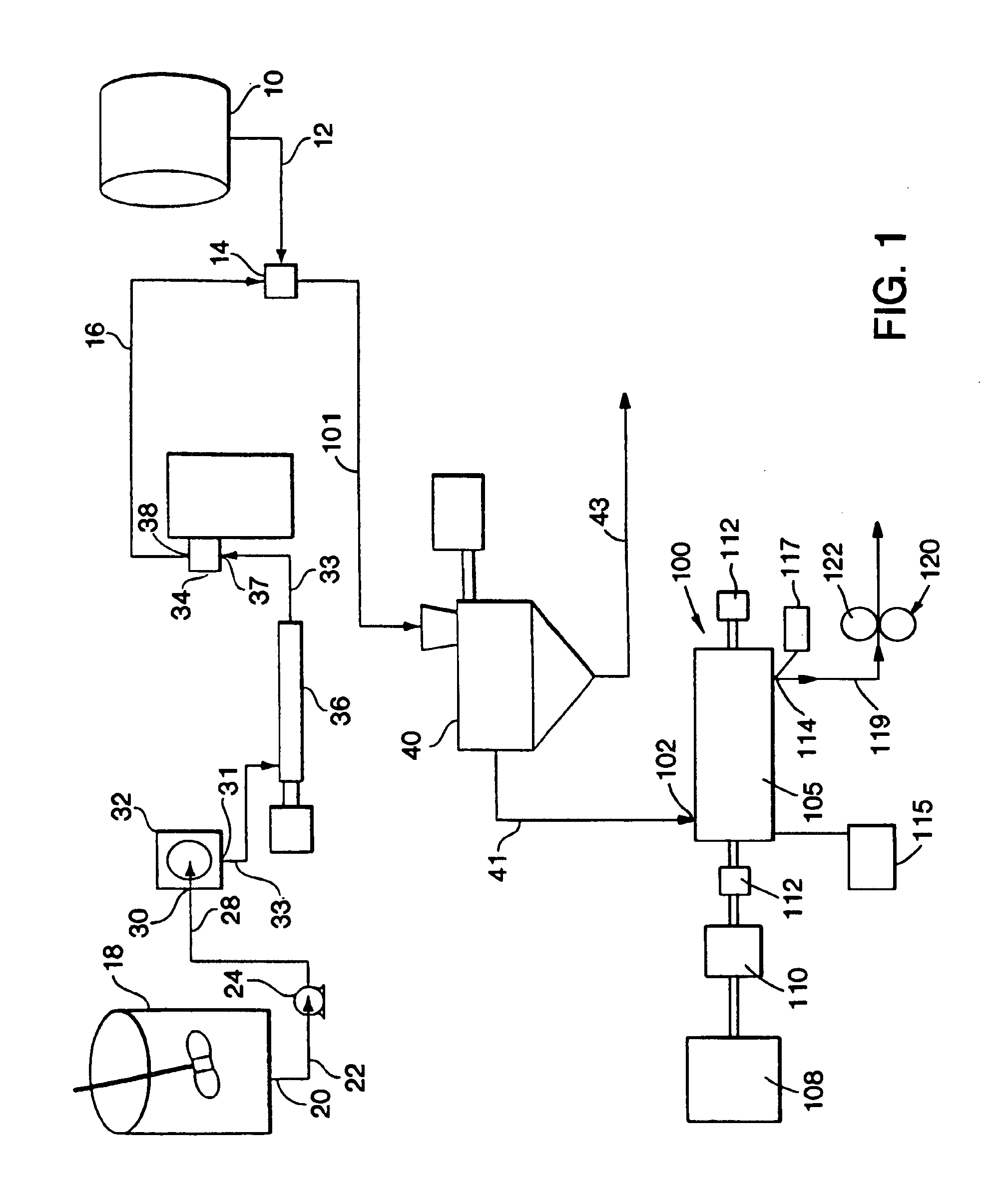

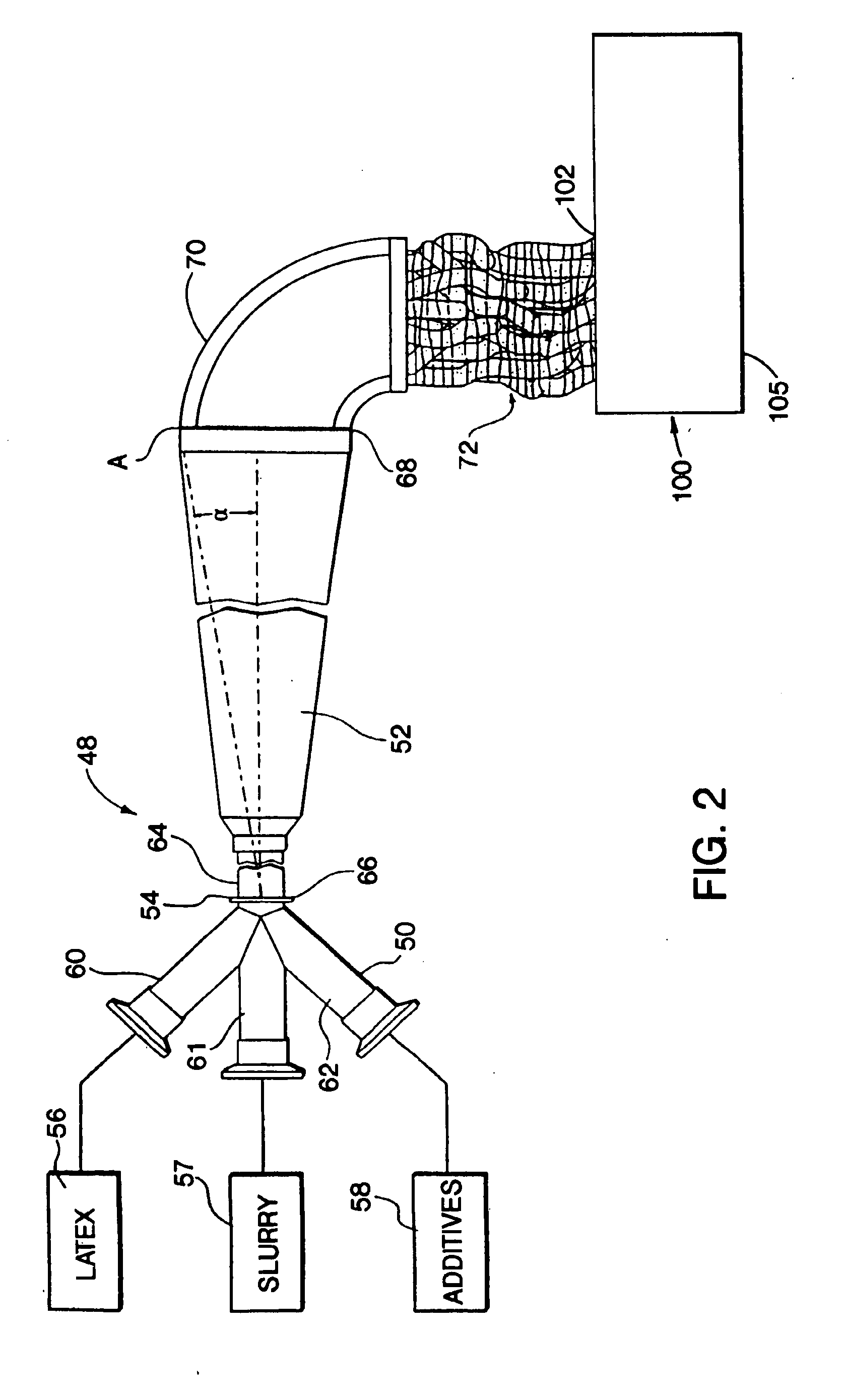

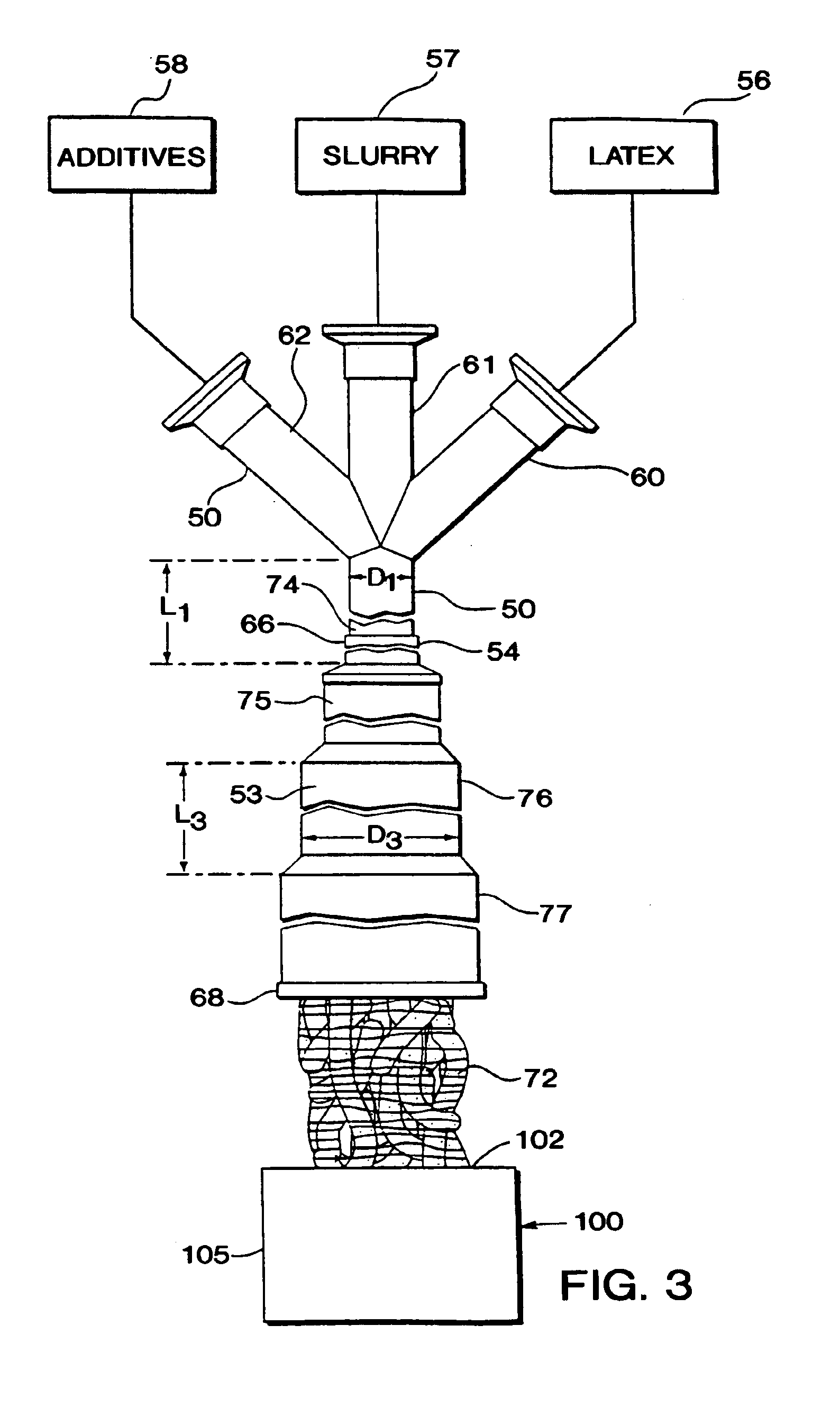

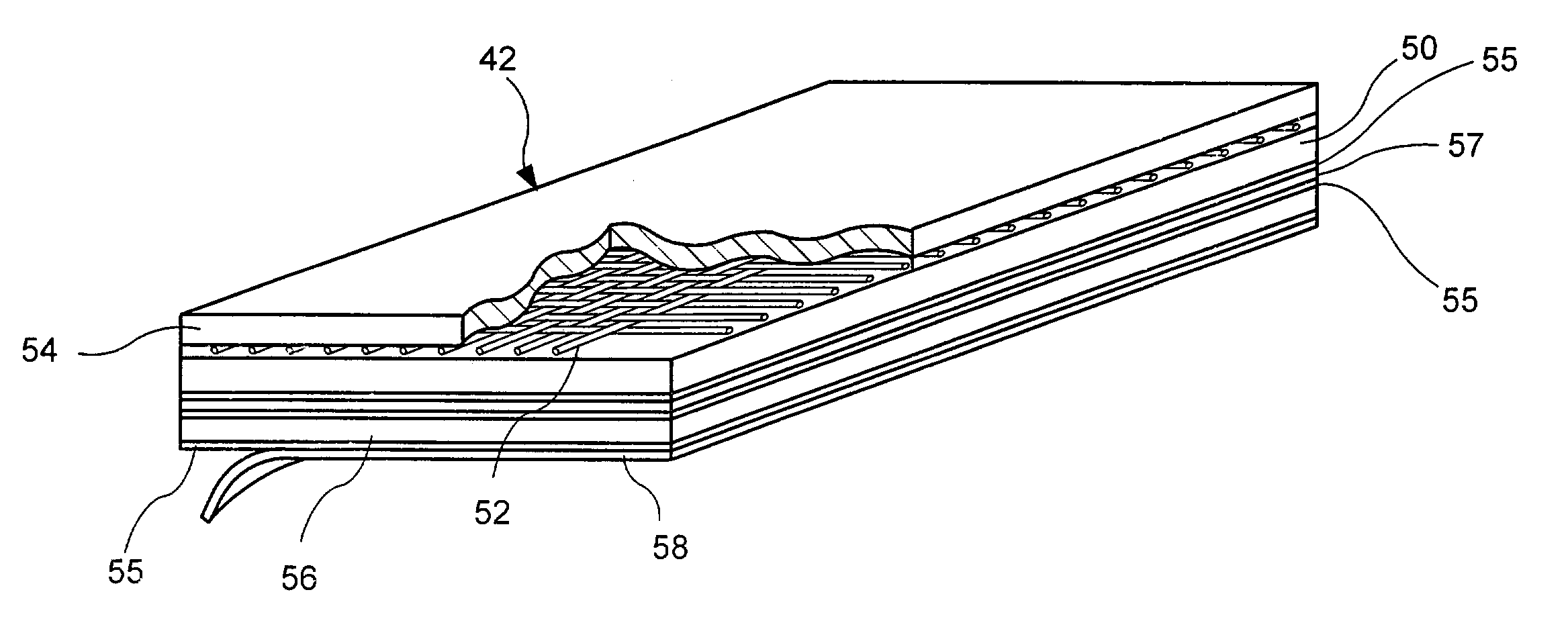

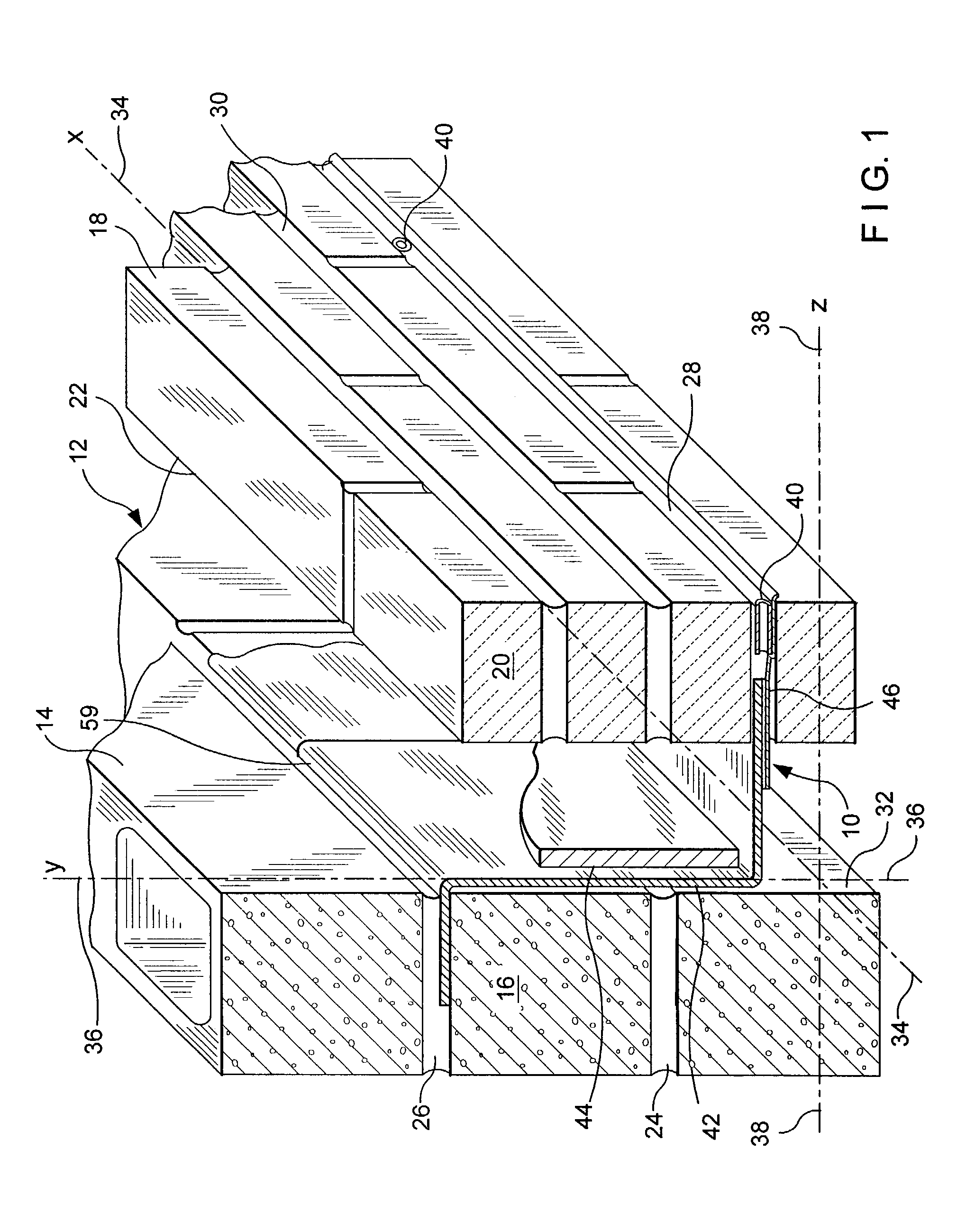

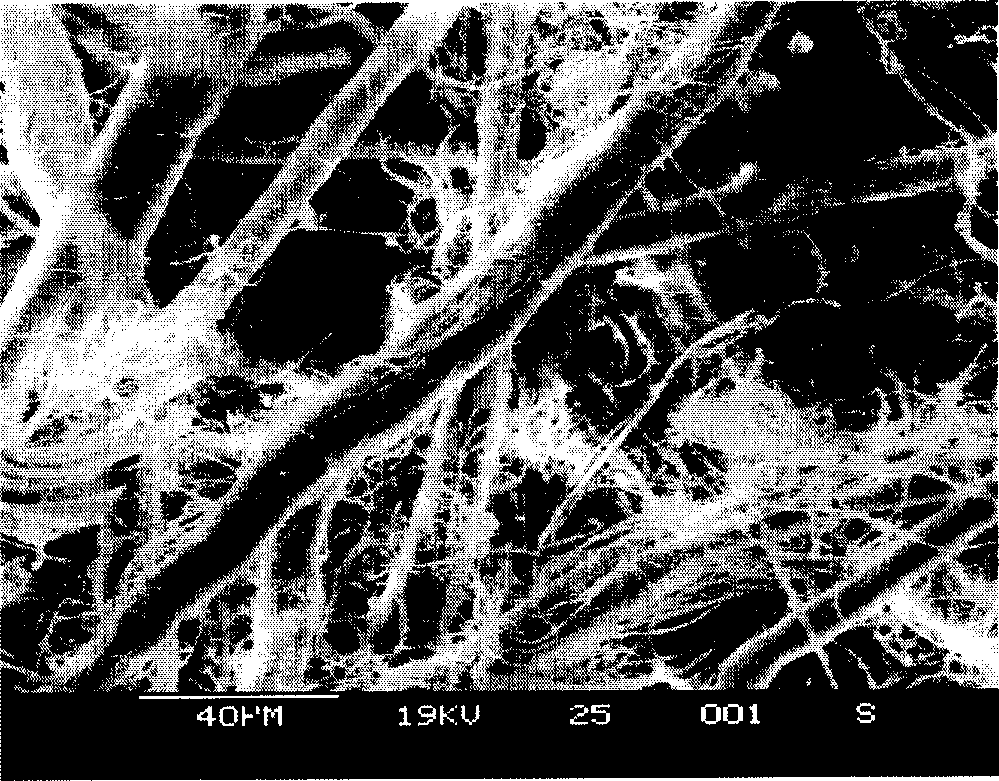

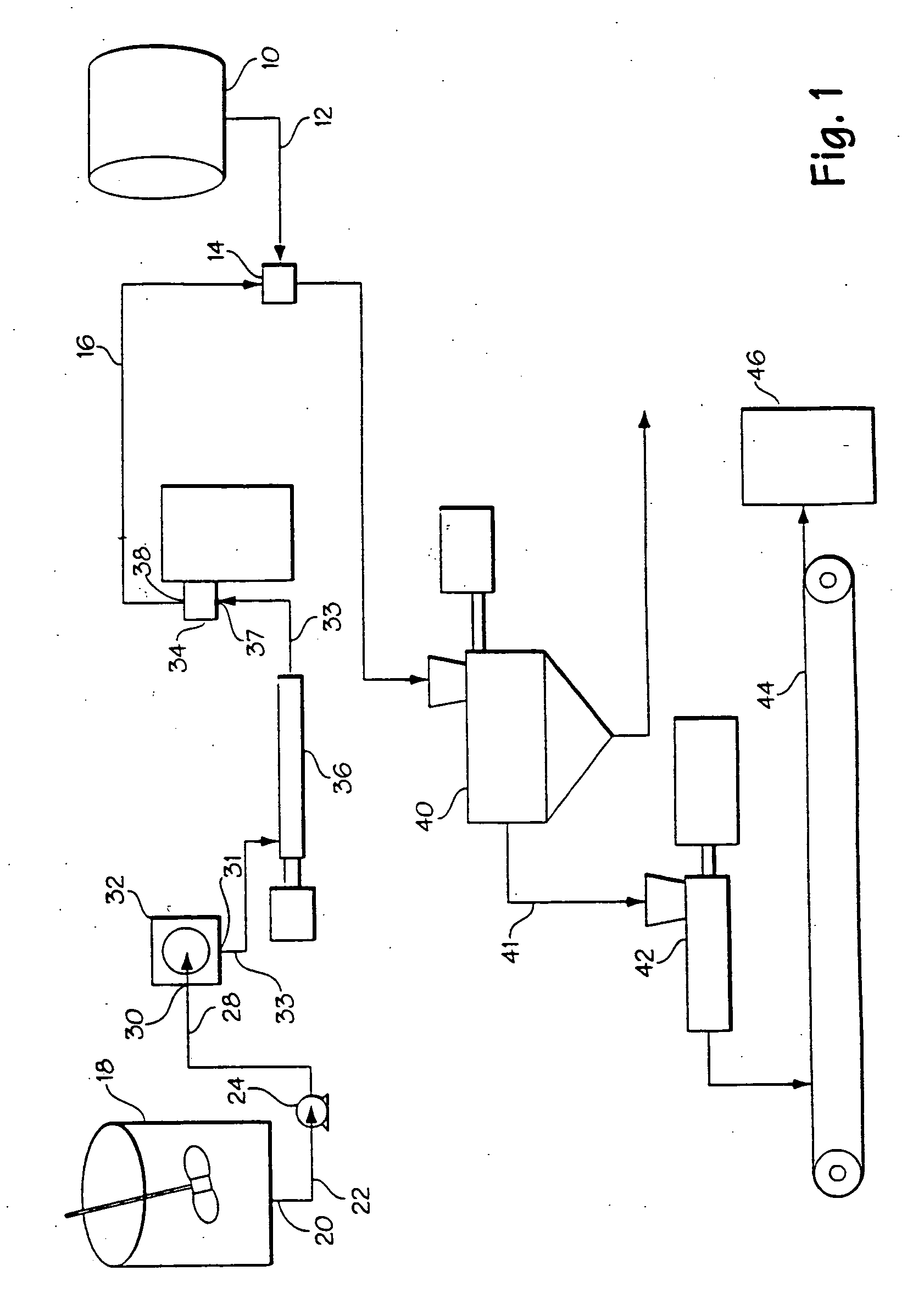

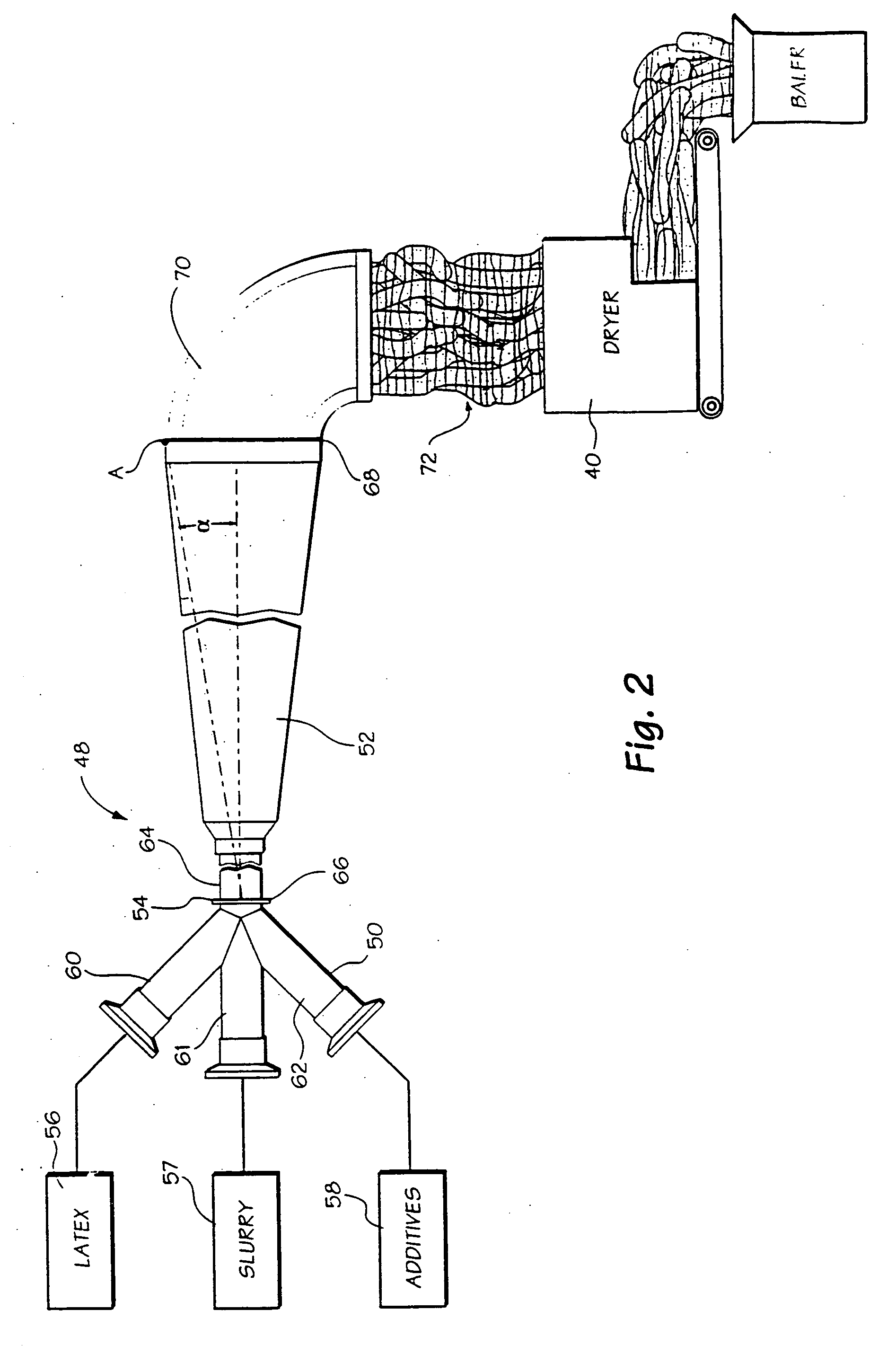

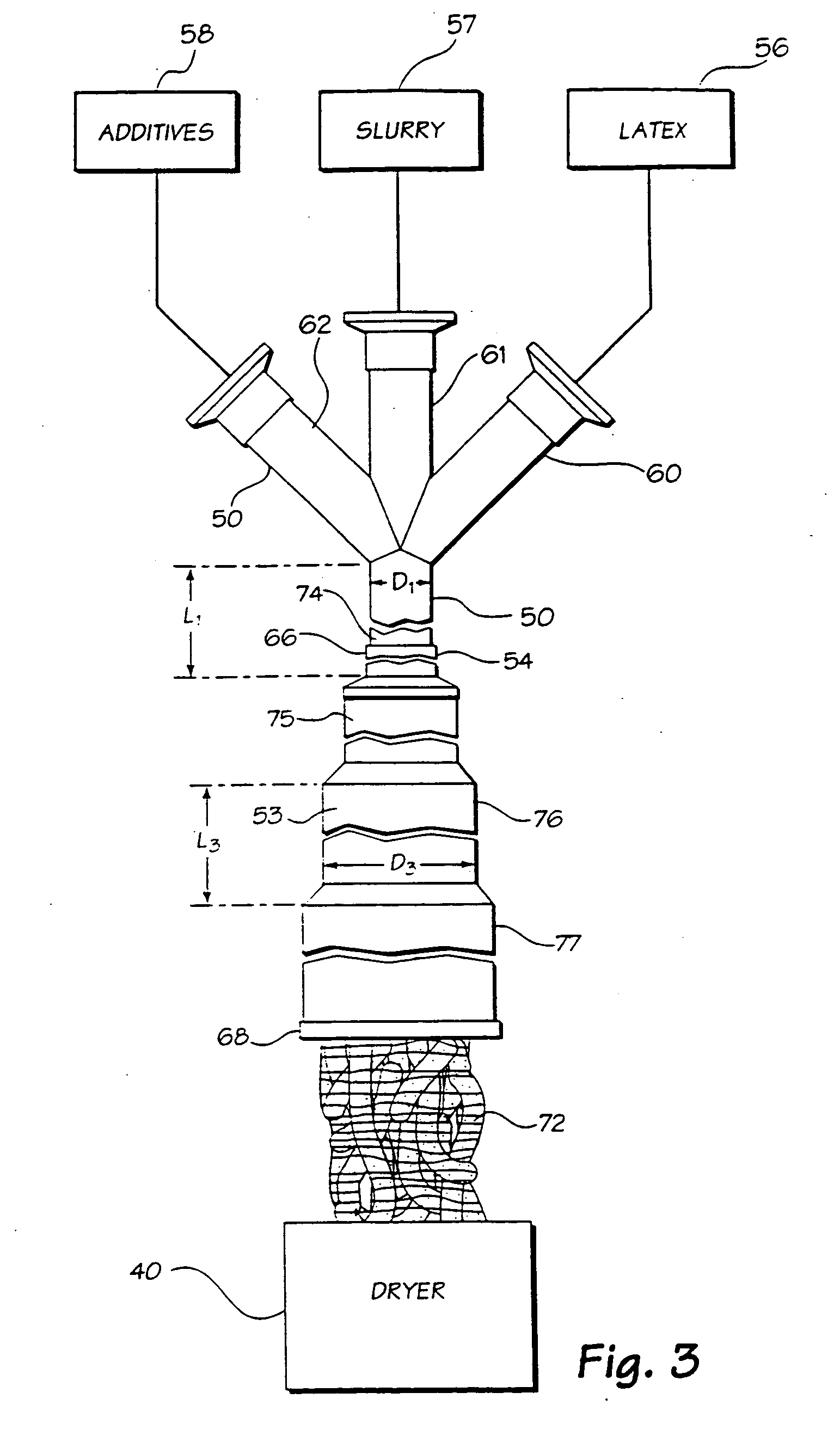

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

Thermoplastic and/or elastomeric composite based on carbon nanotubes and graphenes

The present invention relates to a composite of carbon nanotubes and of graphenes in agglomerated solid form comprising:a) carbon nanotubes, the content of which represents from 0.1% to 50% by weight, preferably from 10% to 40% by weight relative to the total weight of the composite;b) graphenes, the content of which represents from 0.1% to 20% by weight, preferably from 1% to 10% by weight relative to the total weight of the composite; andc) a polymer composition comprising at least one thermoplastic polymer and / or one elastomer.The present invention also relates to a process for preparing said composite, its use for the manufacture of a composite product, and also to the various applications of the composite product.

Owner:ARKEMA FRANCE SA

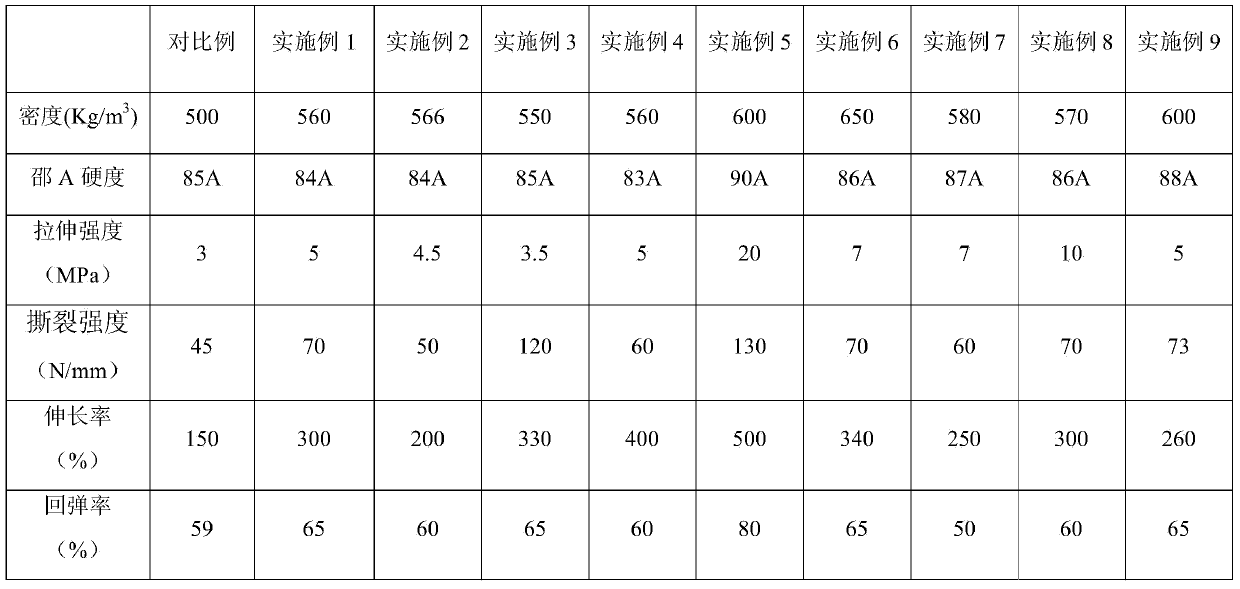

Enhanced polyurethane microcellular elastomer composite material and preparation method thereof

The invention discloses an enhanced polyurethane microcellular elastomer composite material and a preparation method thereof. The material is a reaction product of a polyol A component and a prepolymer B component, wherein the polyol A component is a mixture of 60-95 weight parts of polymer polyether polyol, 5-40 weight parts of polyether polyol I and auxiliaries; the prepolymer B component is a prepolymer prepared through the reaction of 35-70 weight parts of isocyanate and 30-50 weight parts of polyether polyol II; 0.1-7.5 weight parts of inorganic nanometer filler is added in the polyether polyol II; the NCO content of the prepolymer is 17-30wt.%. The preparation method the material is casting moulding process. The preparation method disclosed by the invention has the advantages that the material cost is reduced while the mechanical property of polyether polyurethane microcellular elastomers is increased at the same time; the application area of the material is greatly broadened. The material disclosed by the invention can be used for shoe parts, shoe sole materials, load-bearing tyres, automotive shock-absorbing buffering materials, bridge buffering shock-absorbing materials and the like.

Owner:重庆杰博科技有限公司

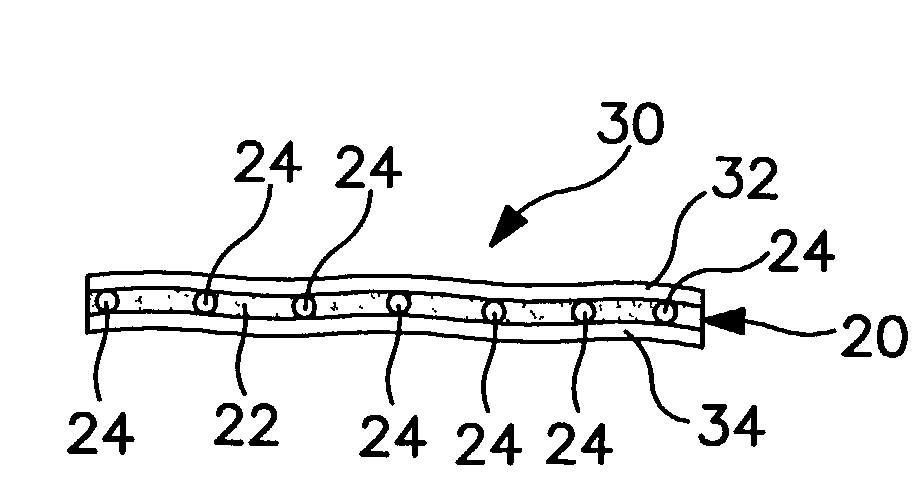

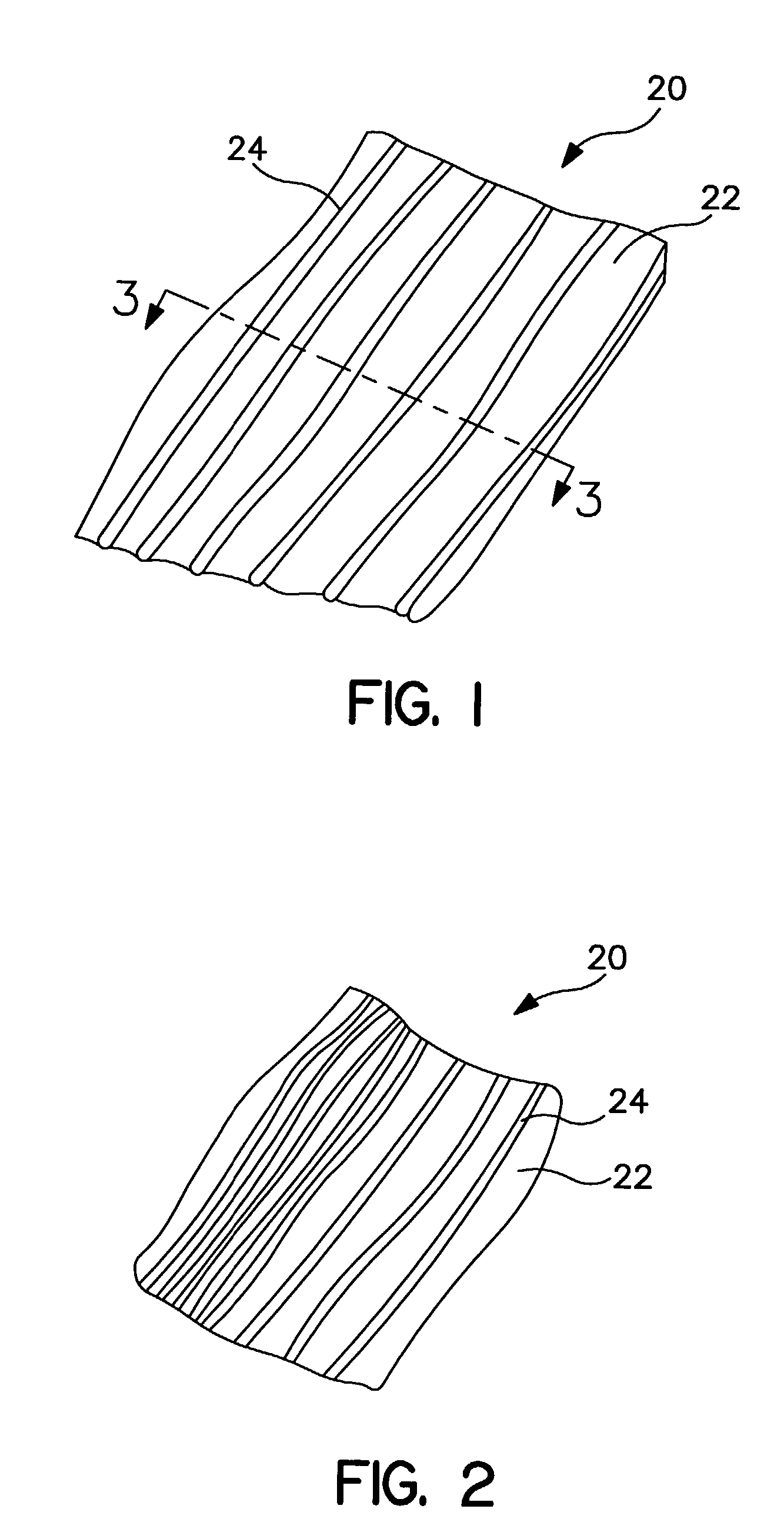

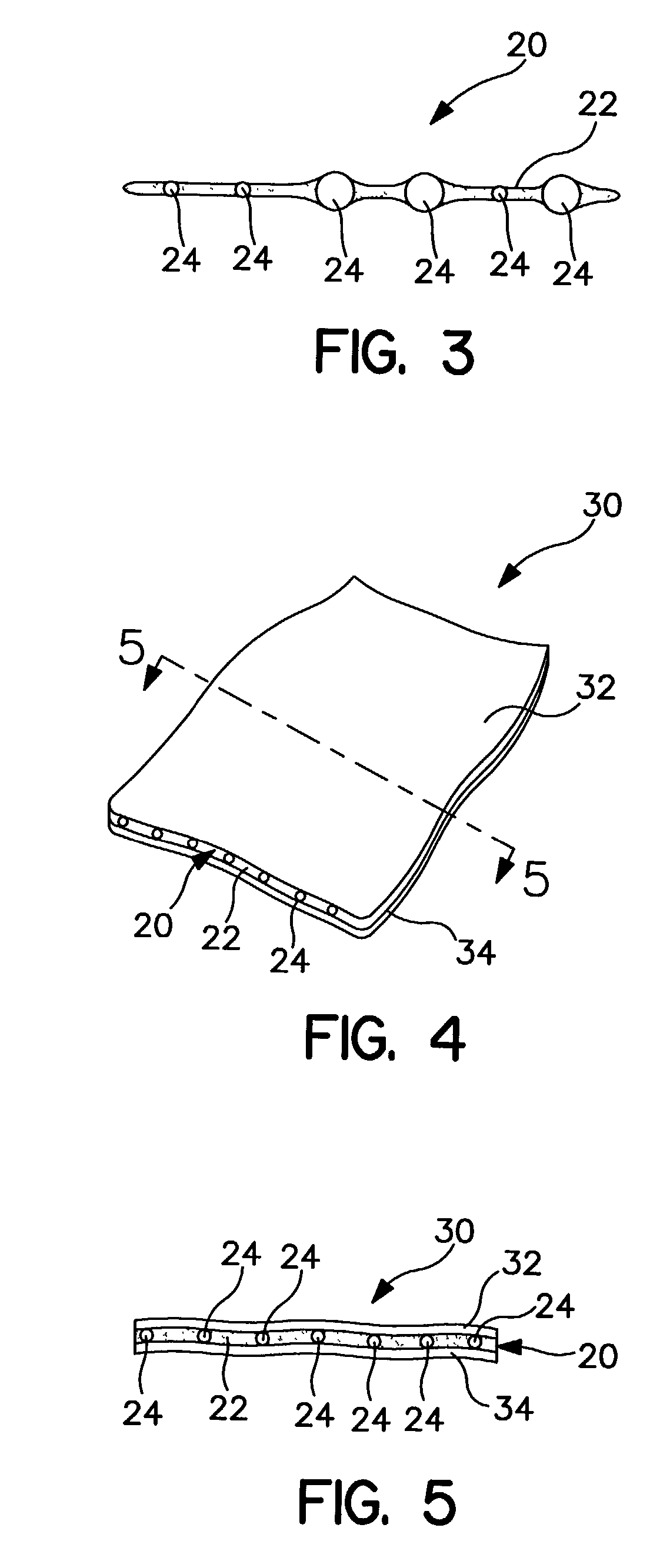

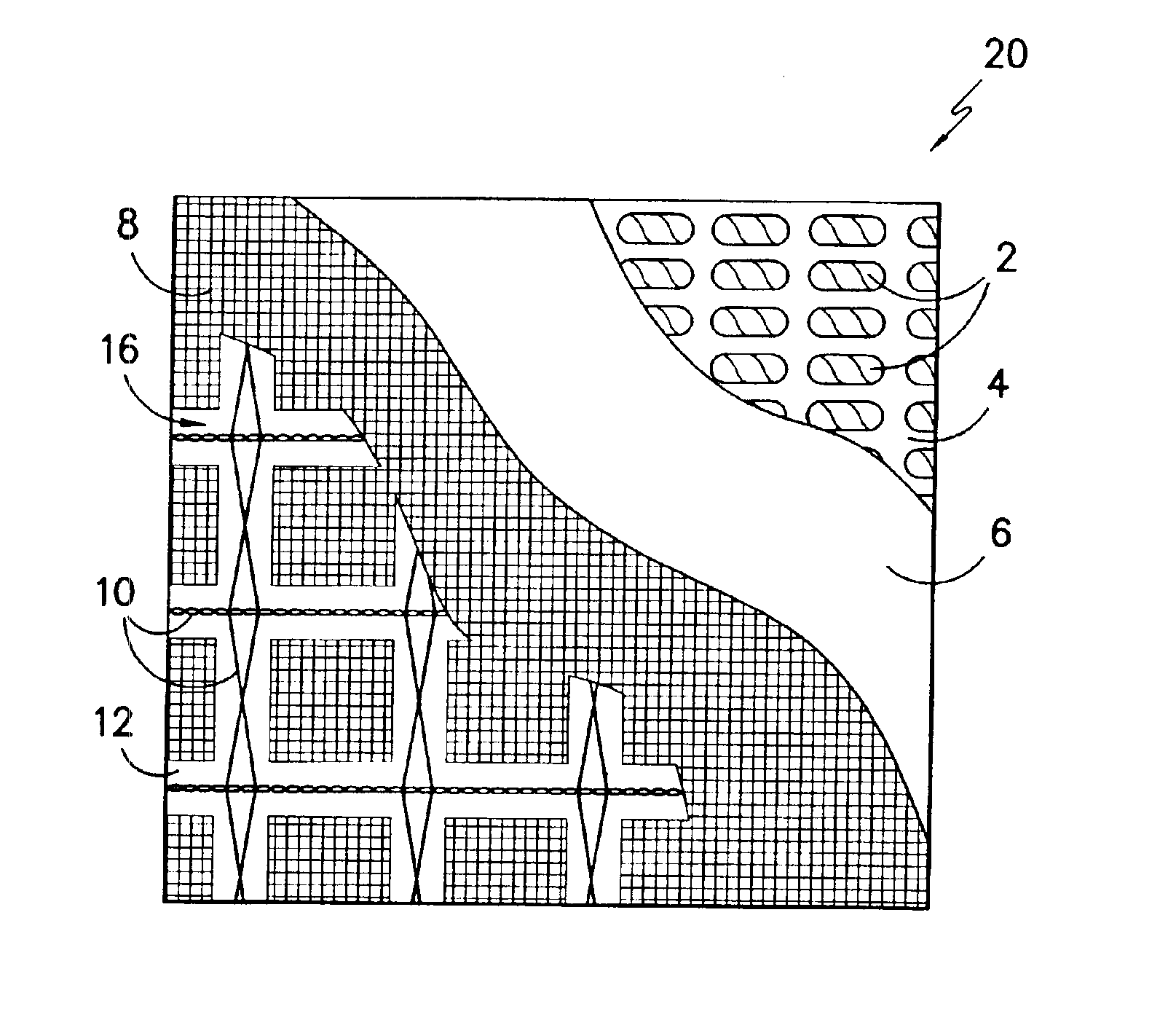

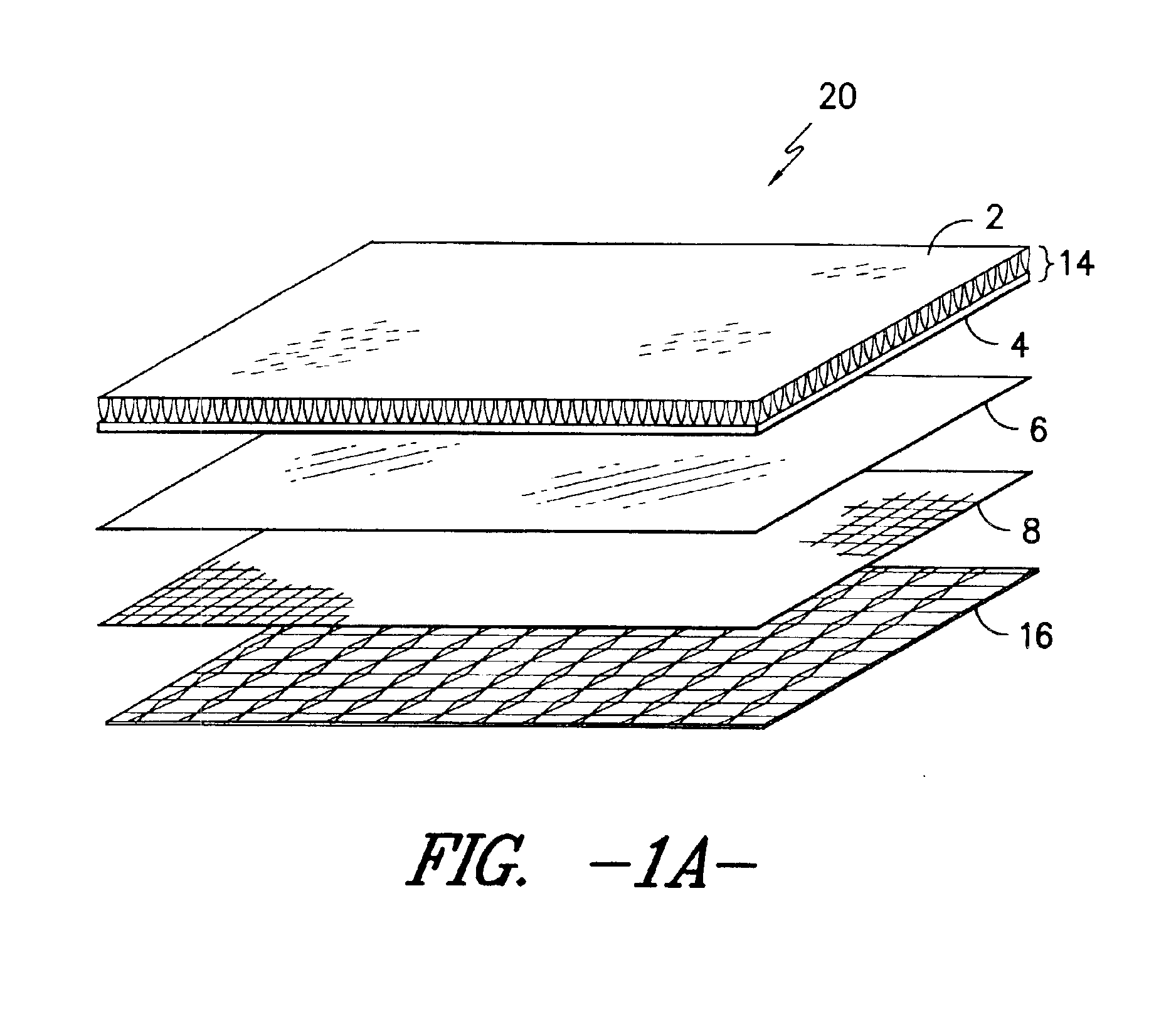

Strand-reinforced composite material

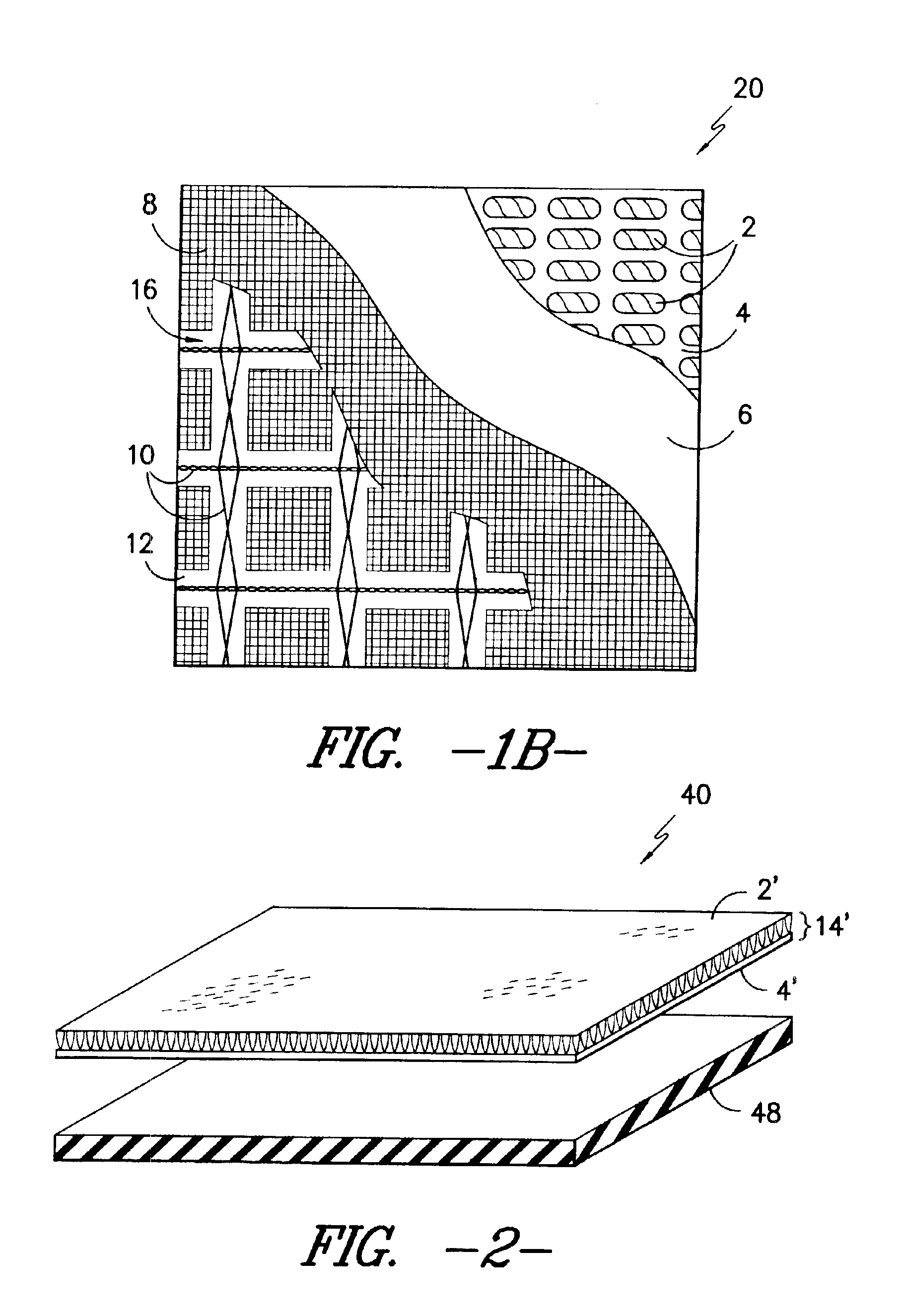

InactiveUS7316840B2Control tensionSynthetic resin layered productsLaminationElastomer compositesComposite laminates

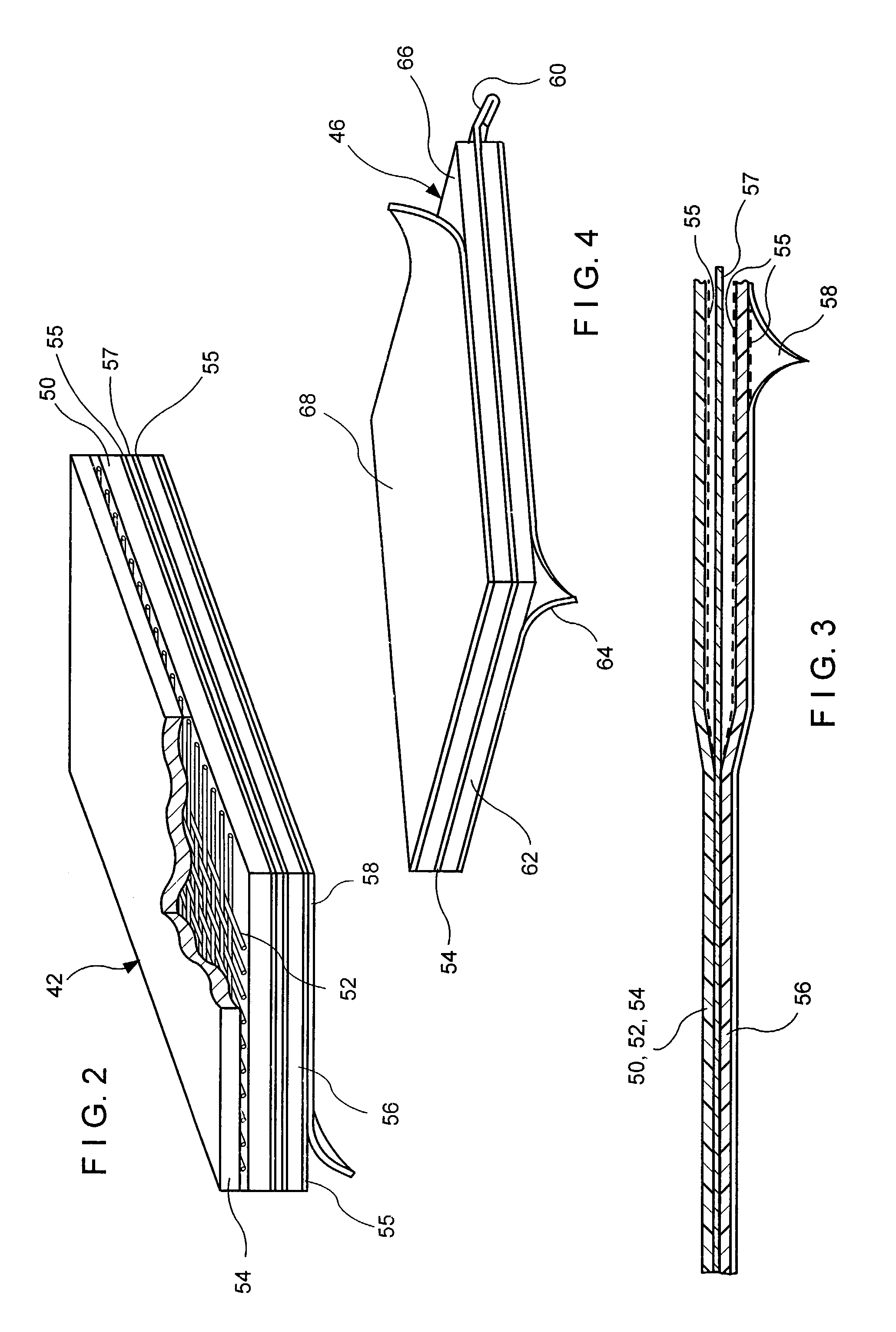

Elastomeric composites and elastomeric composite laminates including reinforcement strands incorporated into an elastomeric adhesive film. The strands may vary in terms of levels of tension. Facing layers, such as nonwoven webs, can be laminated to both surfaces of the elastomeric composite to form laminates. A method of making such composites and laminates involves adjusting tension among various elastic strands while extruding the elastic strands and incorporating the elastic strands into the elastomeric adhesive film.

Owner:KIMBERLY-CLARK WORLDWIDE INC

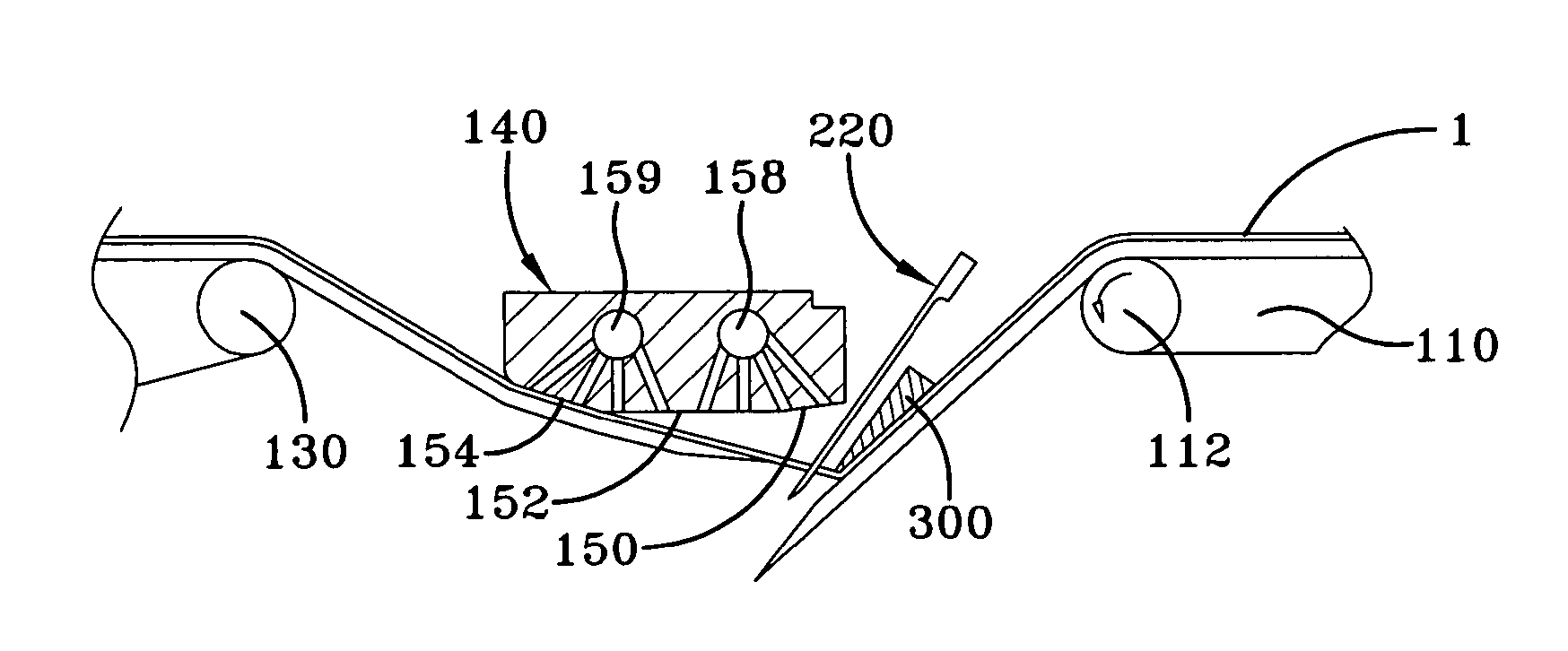

Anvil with vacuum width adjustment

A method and apparatus is provided for cutting an elastomeric laminate that may include a layer of reinforcement cords, into a desired length without cutting through the cords. The method includes the step of cutting through the gum portion of the elastomeric composite material at a desired skive angle, and then opening up the skived cut. Next, the cord reinforcement layer is cut without severing the reinforcement cords. An elastomeric composite strip cut to the desired length is produced and has cut ends. One of the cut ends has the gum portion cut at a desired skive angle adjacent an overhang portion of the reinforcement layer. The opposite end of the elastomeric composite segment also has a skived portion to mate with the skived portion of the first cut end, and a gap in the cord ply to mate with the cord overhang of the first end, resulting in a splice. An improved anvil having independently controlled vacuum zones and adjustable width vacuum zones is also provided, as well as improved cutting mechanisms.

Owner:THE GOODYEAR TIRE & RUBBER CO

Microporous polyether urethane elastomer composite material and preparation method thereof

The invention relates to a microporous polyether urethane elastomer composite material and a preparation method thereof. The composite material is formed by the prepolymerization reaction of a polyhydric alcohol component A and a prepolymer component B, wherein the polyhydric alcohol component A comprises the following raw materials in the formula: 20 to 90 parts of polyoxytrimethyl-ene polyhydric alcohol, 5 to 50 parts of polyether polyol II, 5 to 50 parts of polymer polyether polyol, 2 to 30 parts of chain extender, 0.5 to 2 parts of nanometer graphene, 0.2 to 4 parts of foaming agent, 0.2 to 2 parts of foam homogenizing agent and 0.2 to 4 parts of catalyst; and the prepolymer component B comprises the following raw materials in the formula: 30 to 60 parts of diisocyanate, 4 to 20 parts of polyisocyanate modified by carbodiimide and 20 to 60 parts of polyoxytrimethyl-ene polyhydric alcohol. The polyether polyol II is formed by one or two of polyoxytrimethyl-ene epoxyethane copolyether polyol or / and polyethylene tetrahydrofuran polyol. The composite material provided by the invention is excellent in comprehensive mechanical property, antibacterial property and definite flame resistance.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

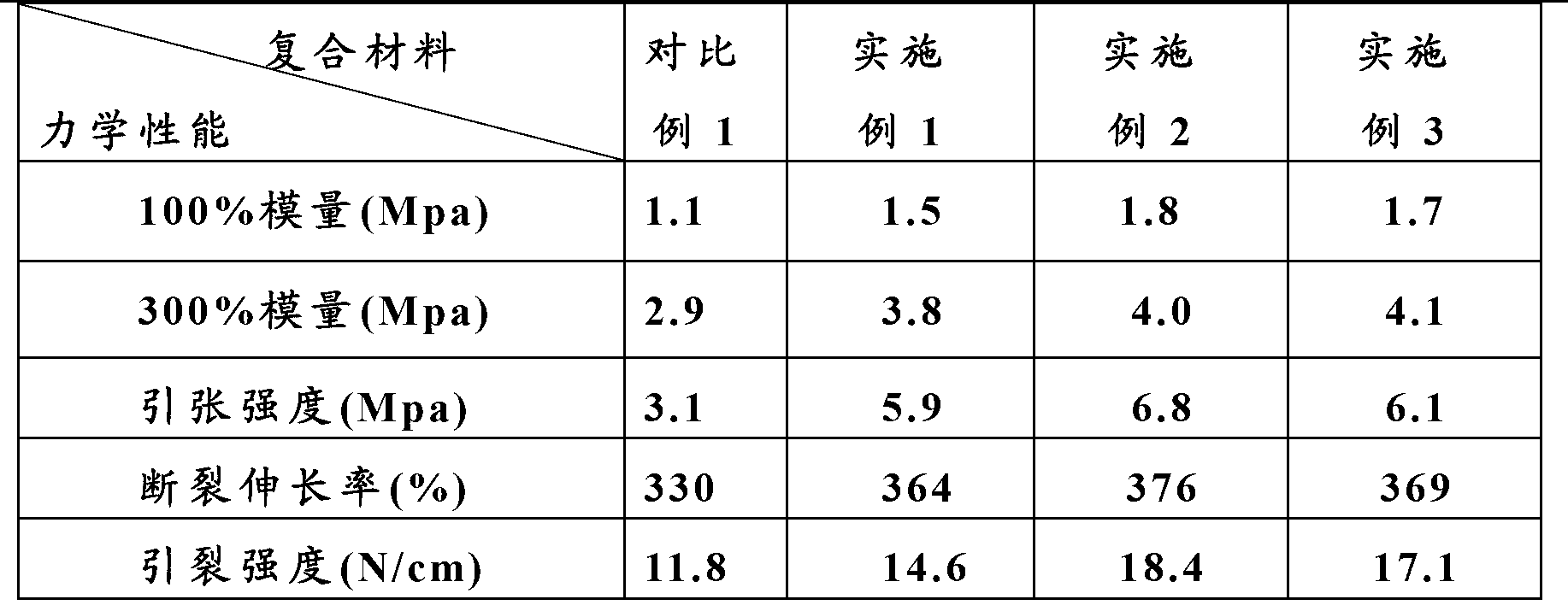

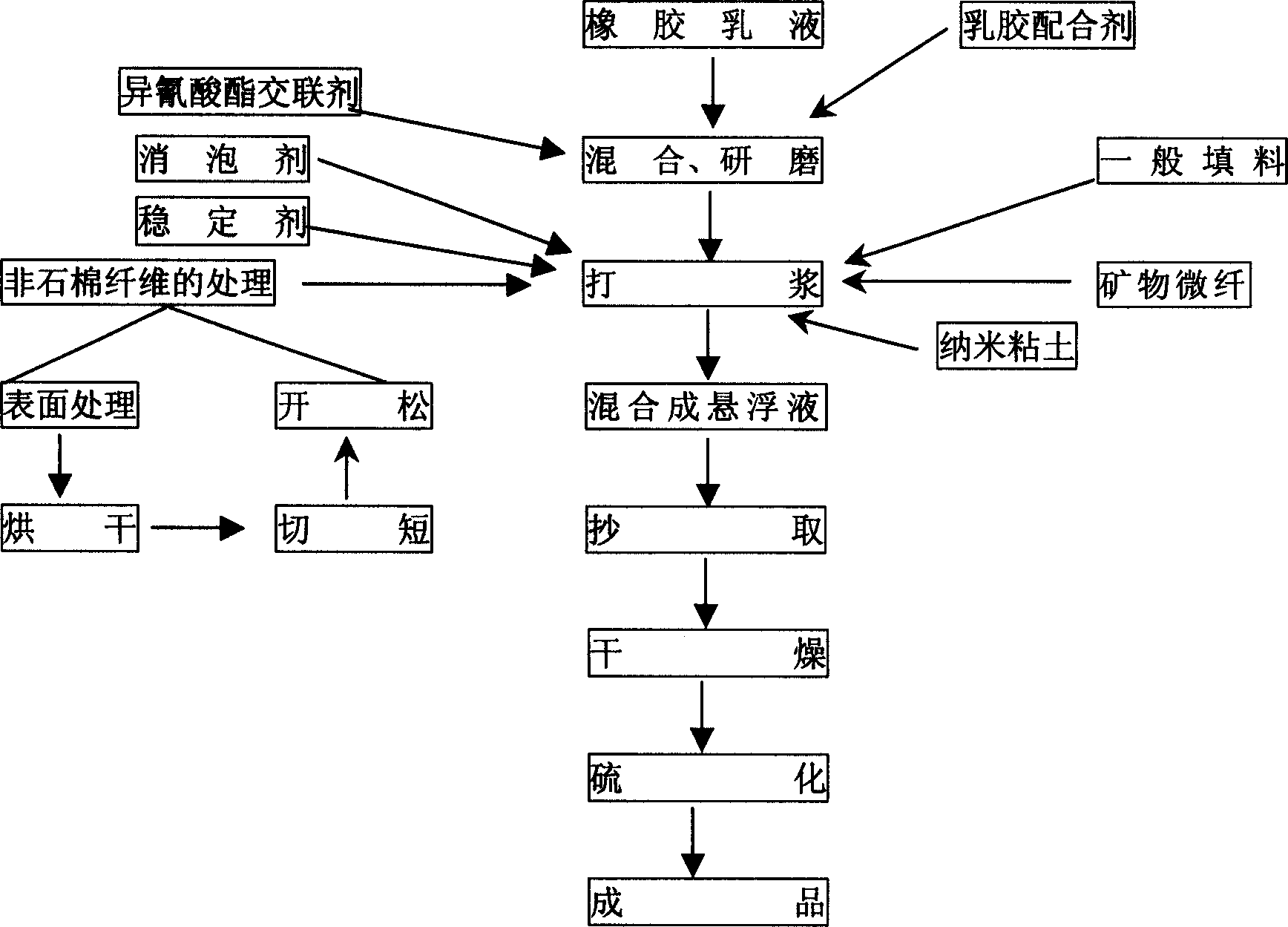

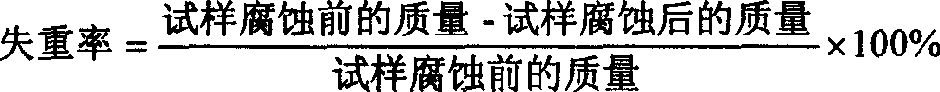

Process for preparation formation of nonasbestos fibre enhanced latex sealing plate

InactiveCN1557865AImprove mechanical propertiesMechanical properties such as good transverse tensile strengthEmulsionPolymer science

The present invention belongs to the field of fiber reinforced composite rubber elastomer material producing technology. The technological process includes preparing materials including non-asbestos fiber, rubber emulsion, cross-linking agent, stuffing, auxiliary additive, etc.; treating non-asbestos fiber; compounding emulsion; preparing suspension; forming; drying and rolling sulfurization. The present invention features the specific material proportion, traditional process and wet formation. The technological process is environment friendly and has no environmental pollution, and the sealing gasket plate of the non-asbestos fiber reinforced composite rubber elastomer material has relatively high mechanical performance and chemical corrosion resistance.

Owner:SHANGHAI UNIV

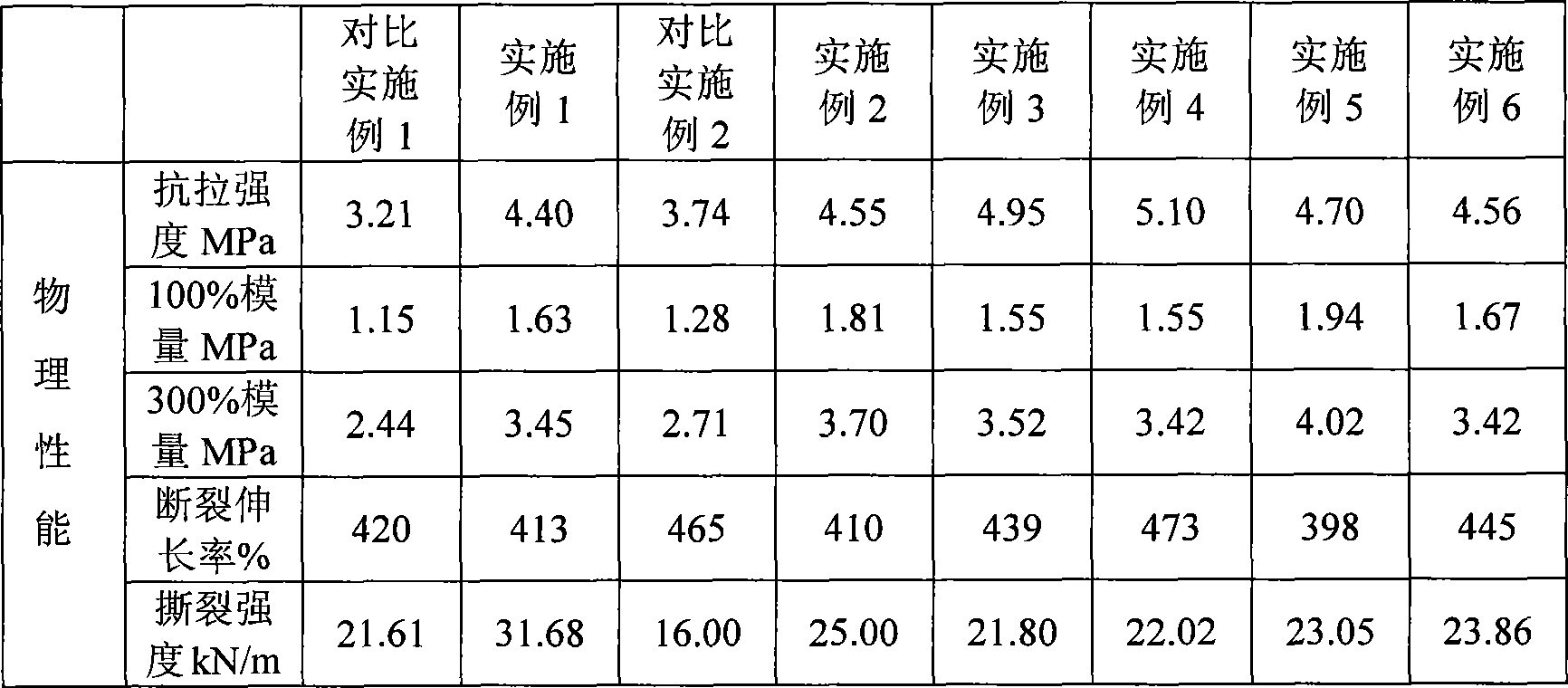

High performance nano polyurethane micropore elastomer composite material and preparation thereof

ActiveCN101486834AImprove mechanical propertiesHigh tensile strengthFoaming agentPolyether polyurethane

The invention discloses a high-performance nanometer polyurethane microcellular elastomer composite material and a preparation method thereof. Organic montmorillonite is added into polyether glycol I, heated and stirred, thus obtaining stably dispersed colloidal fluid; then polyether glycol II, an alcohols chain-extender, a foaming agent, a foam stabilizer and a catalyst are added, fully and evenly mixed, thus obtaining component A. B component is a performed polymer prepared by the reaction of the polyether glycol I, vulcabond or polyisocyanates at the temperature between 60 and 90 DEG C, with NCO percentage controlled between 17 and 26 percent by weight. The components A and B are mixed at high speed according to the weight mixture ratio that A:B equals to 0.5:1 to 3:1 by using a casting machine and at the temperature of 30-55 DEG C, and injected into a mould for injection moulding, consequently, the high-performance nanometer polyurethane microcellular elastomer composite material is obtained. With low cost, the invention improves a plurality of mechanical properties of a polyether polyurethane microcellular elastomer, such as the tensile strength, modulus and tear strength and the like, and broadens the application field of materials. The composite material can be used as shoe parts, bottom materials, bearing tires or shock absorption buffering materials, and the like. With a bi-component system and a casting moulding technology adopted simultaneously, the invention is simple and can be easily controlled, thus bringing convenience to production promotion.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

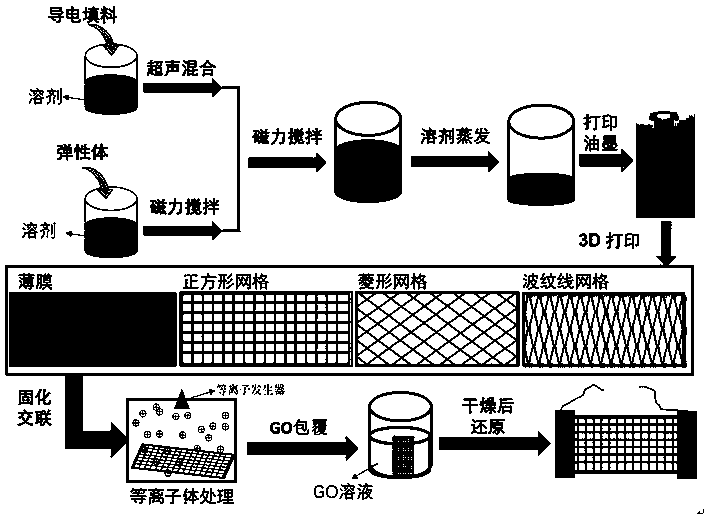

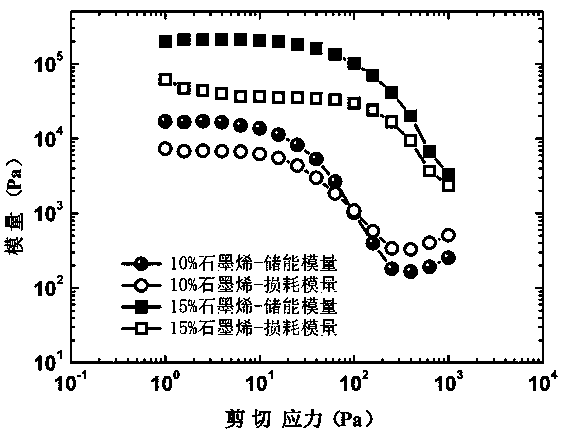

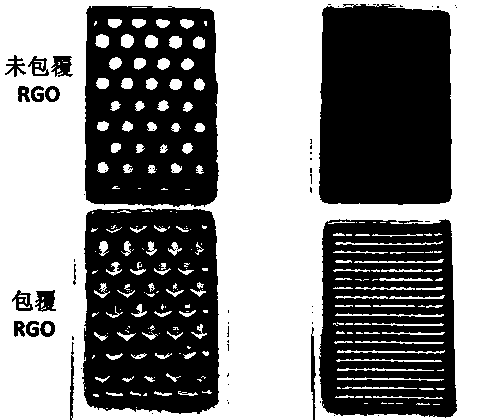

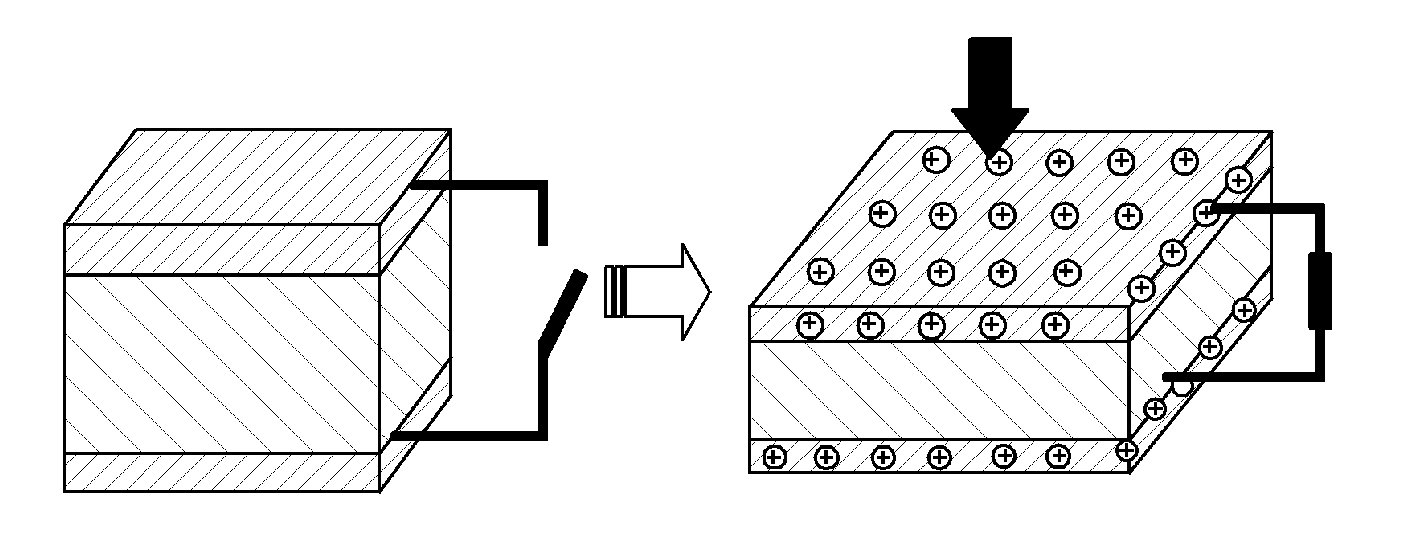

Highly-stretchable 3D printed graphene-based flexible sensor with high sensitivity and preparation method of graphene-based flexible sensor

ActiveCN108822548AImprove performanceEasy to operateAdditive manufacturing apparatusElectrical/magnetic solid deformation measurementElastomer compositesEngineering

The invention relates to a highly-stretchable 3D printed graphene-based flexible sensor with high sensitivity and a preparation method of the graphene-based flexible sensor. The graphene-based flexible sensor has two stages of sensing structures, wherein a first-stage sensing structure is formed by filling an elastomer composite with conductive filler, a second-stage sensing structure is formed bycoating the surface of the first-stage sensing structure with graphene, finally, the sensing material is encapsulated after being led out of an electrode, and the flexible sensor is formed. The controllable design of macroscopic shape of the first-stage sensing structure is realized with a 3D printing technology, the highly stretchable characteristic of the sensor is realized by means of construction of a macroscopic grid filling structure, and meanwhile, sensitivity of the sensor in a wide strain range is greatly improved by the two stages of sensing structures. The method is simple to operate, and the prepared graphene-based flexible sensor has high sensitivity and the highly stretchable characteristic, and has potential of being widely applied to the fields of medical wisdom, health monitoring, man-machine interaction and the like.

Owner:FUDAN UNIV

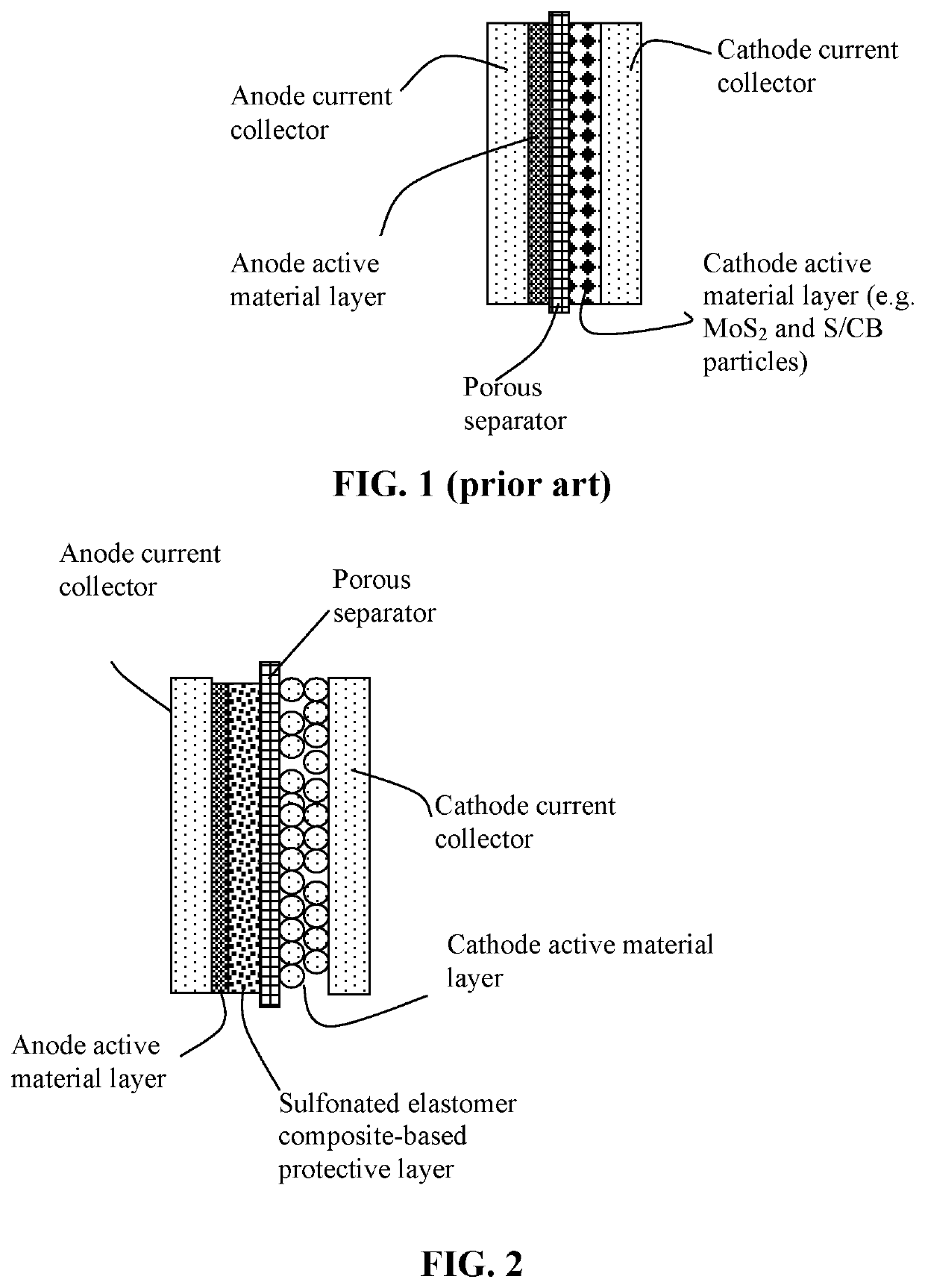

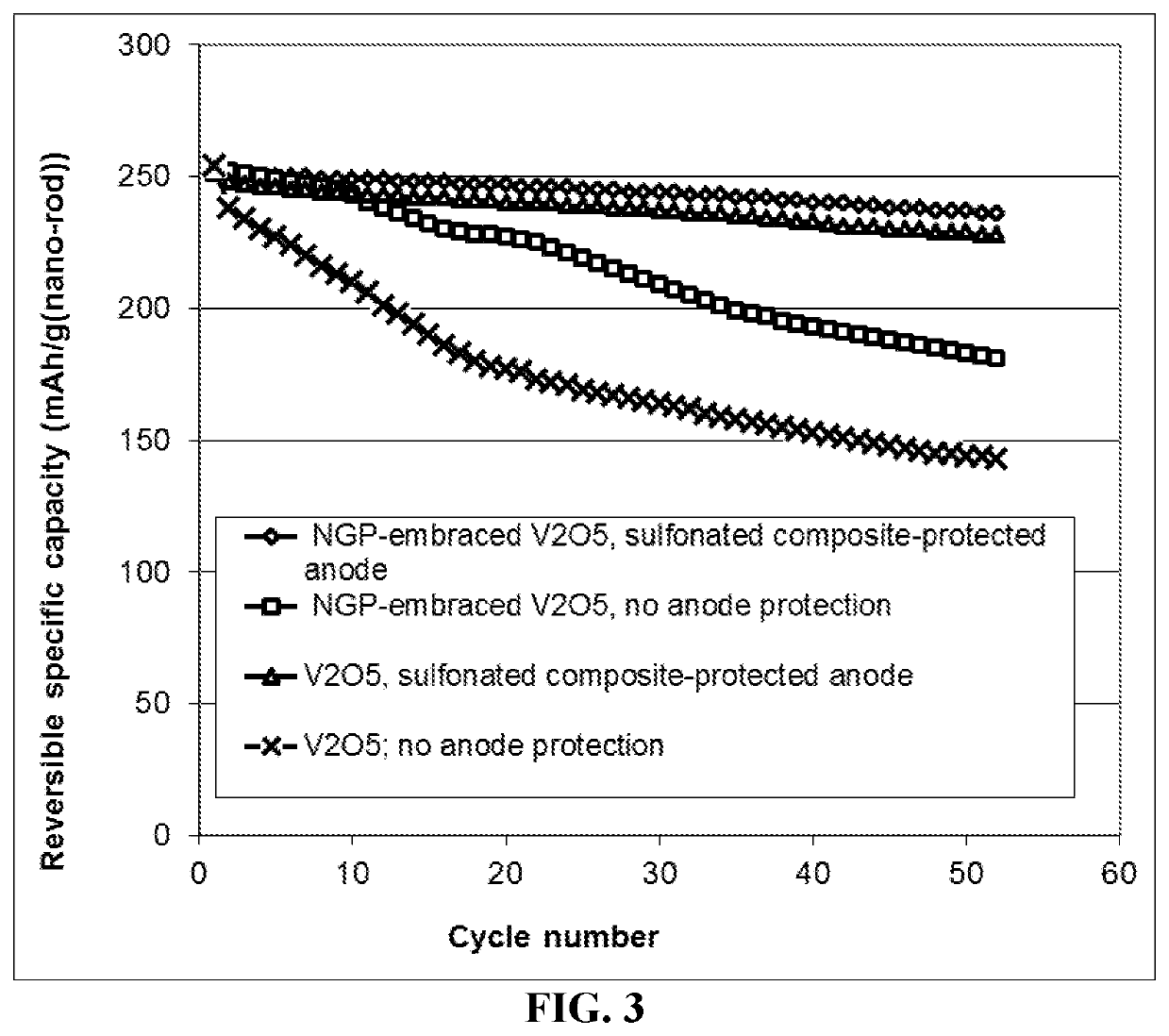

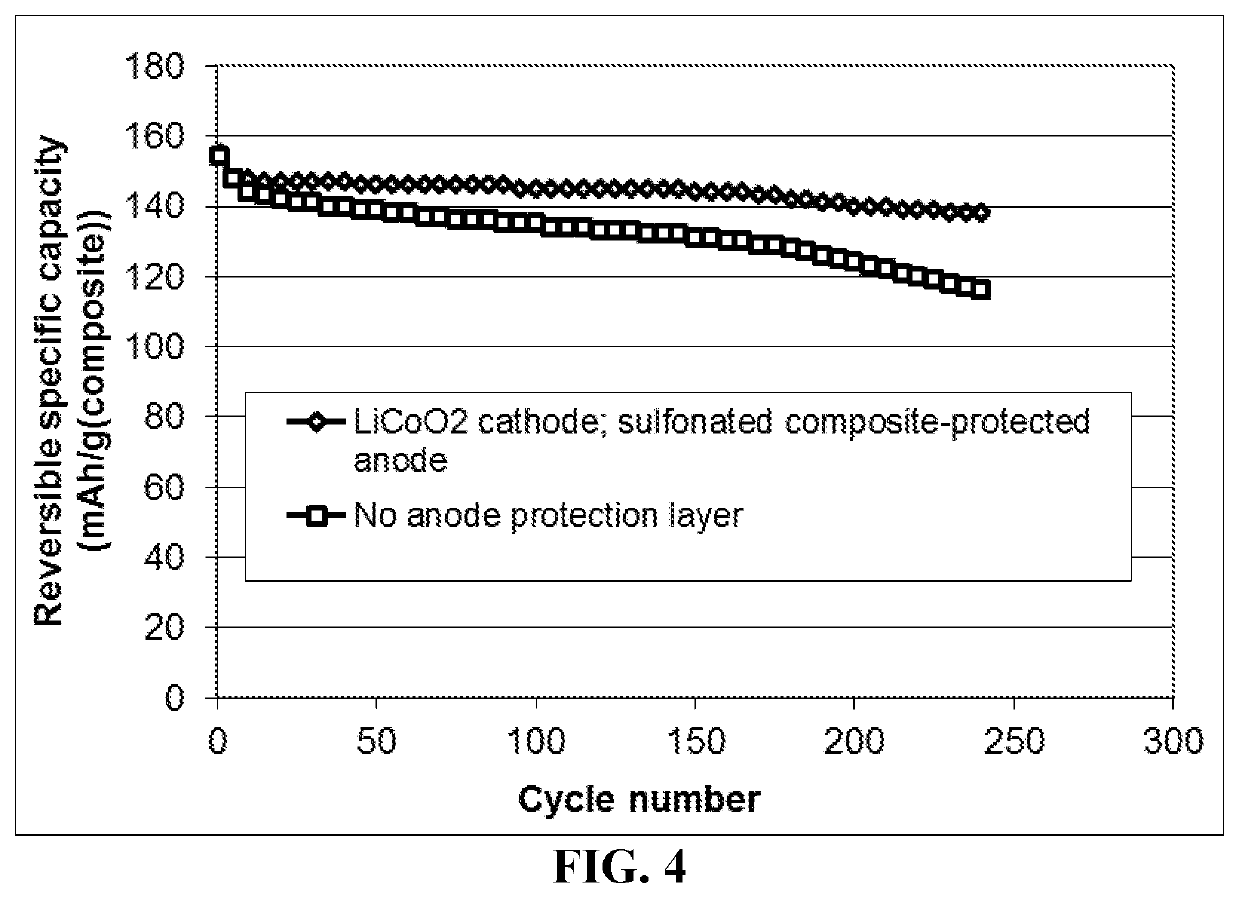

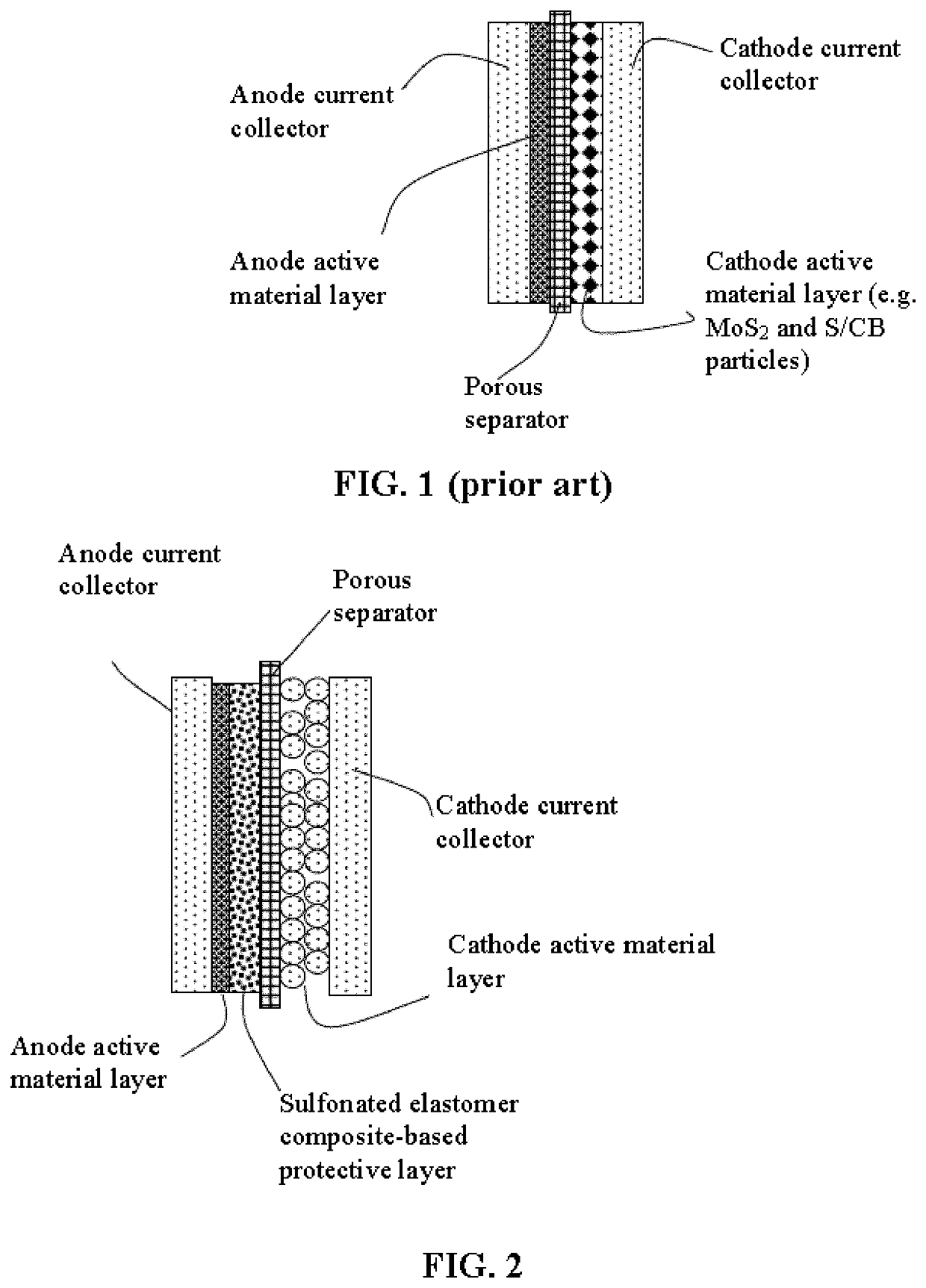

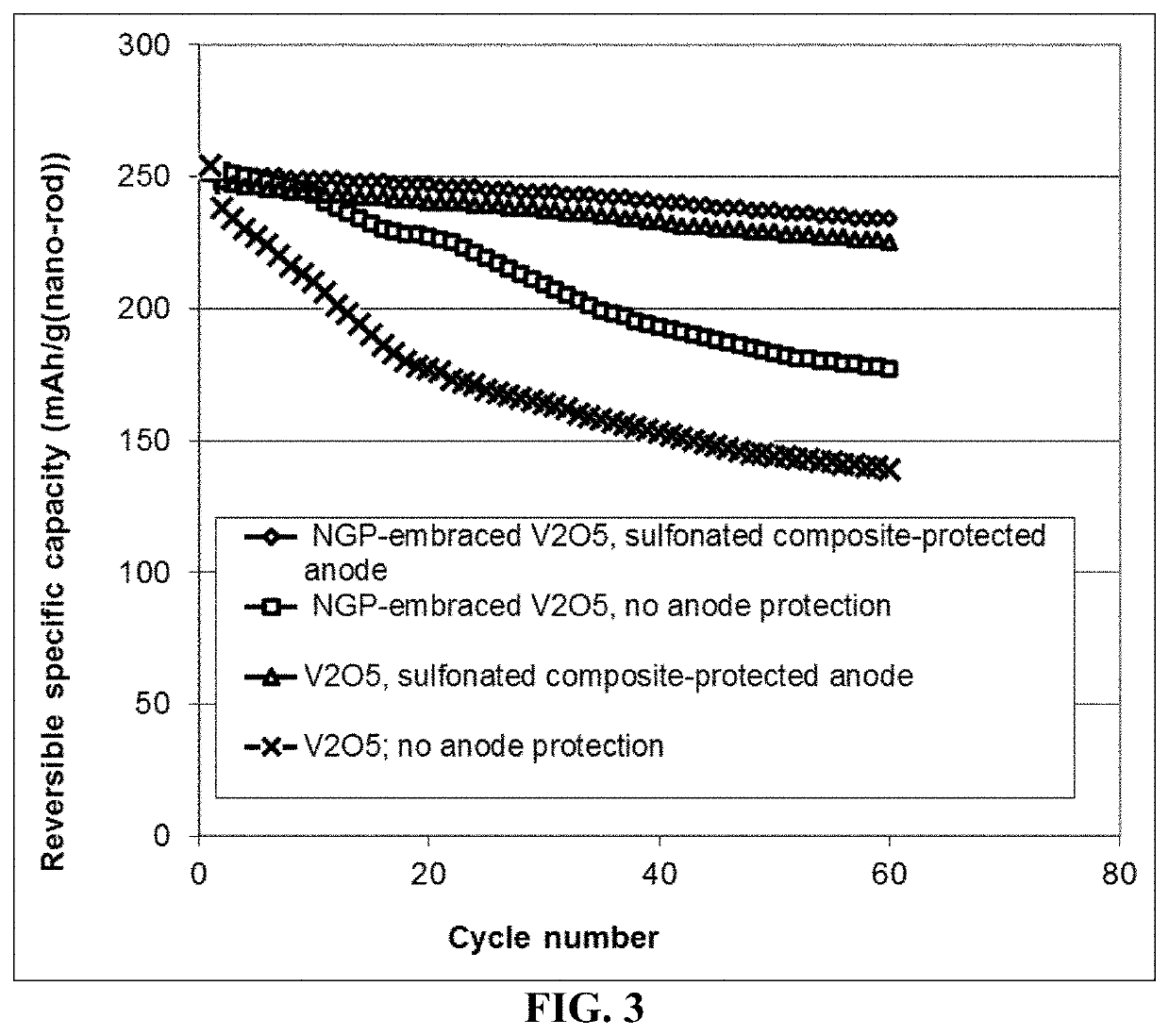

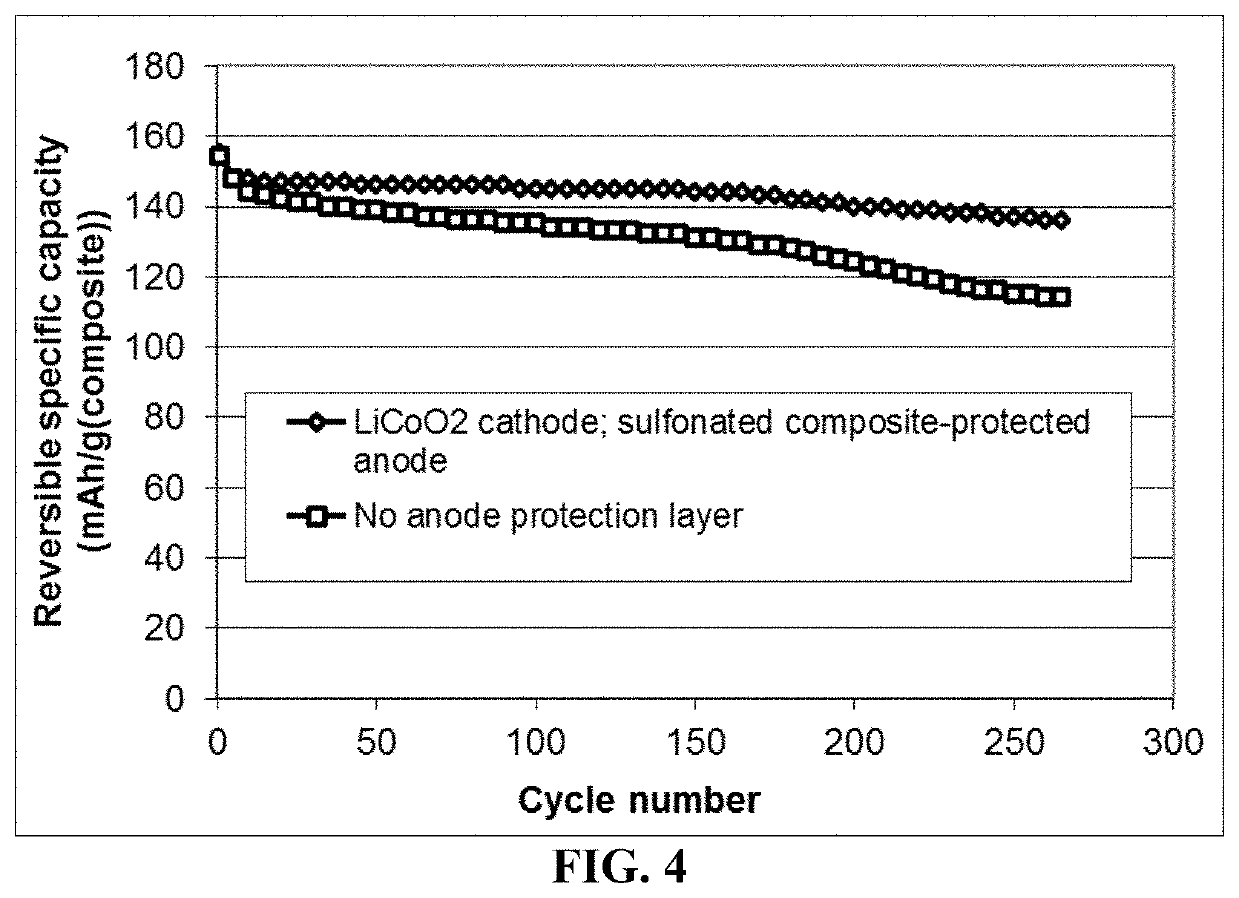

Lithium metal secondary battery featuring an anode-protecting layer

ActiveUS20190393543A1Reduce eliminatePromotes uniform depositionCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsTensile strainLithium metal

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte disposed between the cathode and the anode, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; and (b) an anode-protecting layer of a conductive sulfonated elastomer composite, disposed between the anode active layer and the separator / electrolyte; wherein the composite has from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

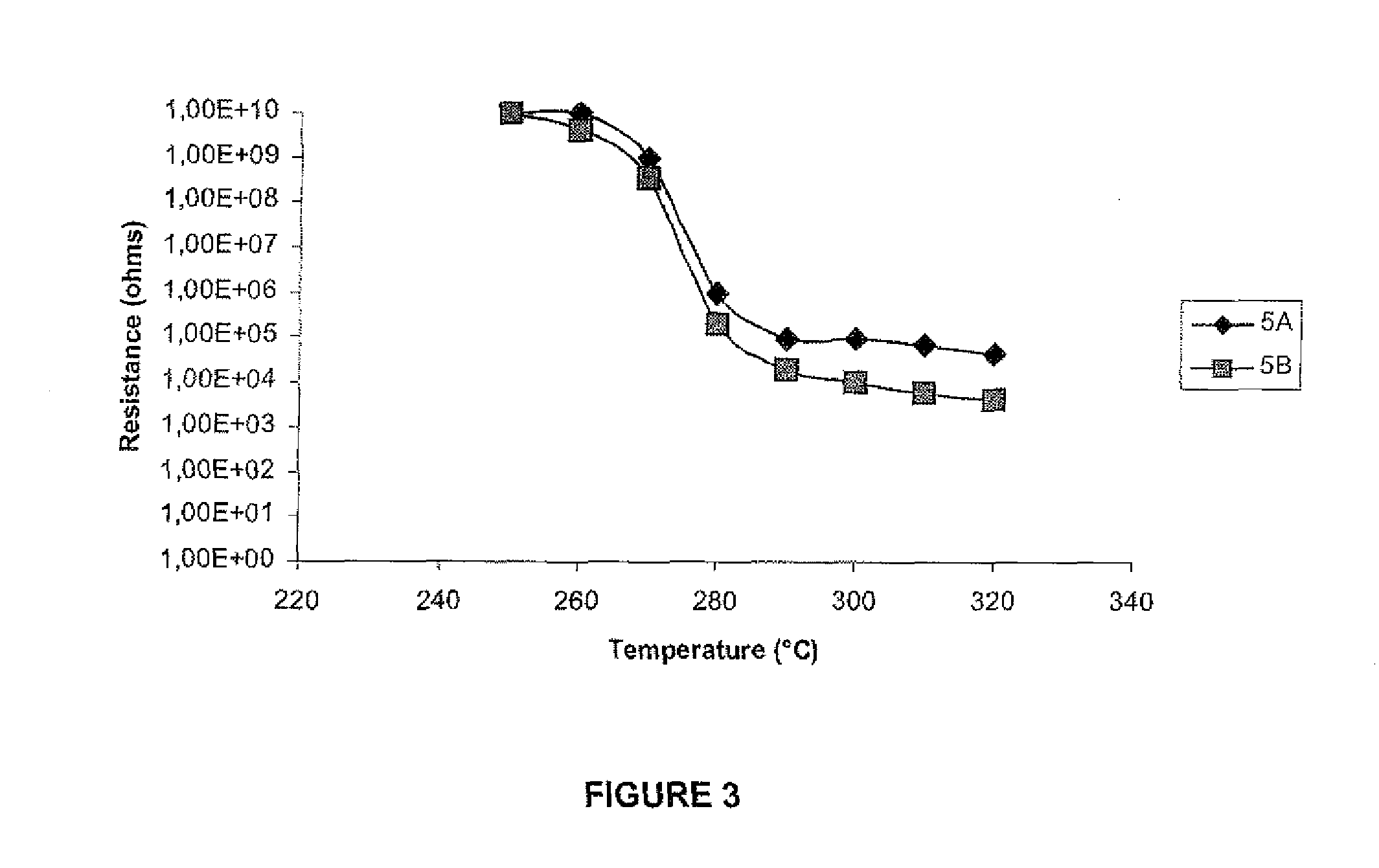

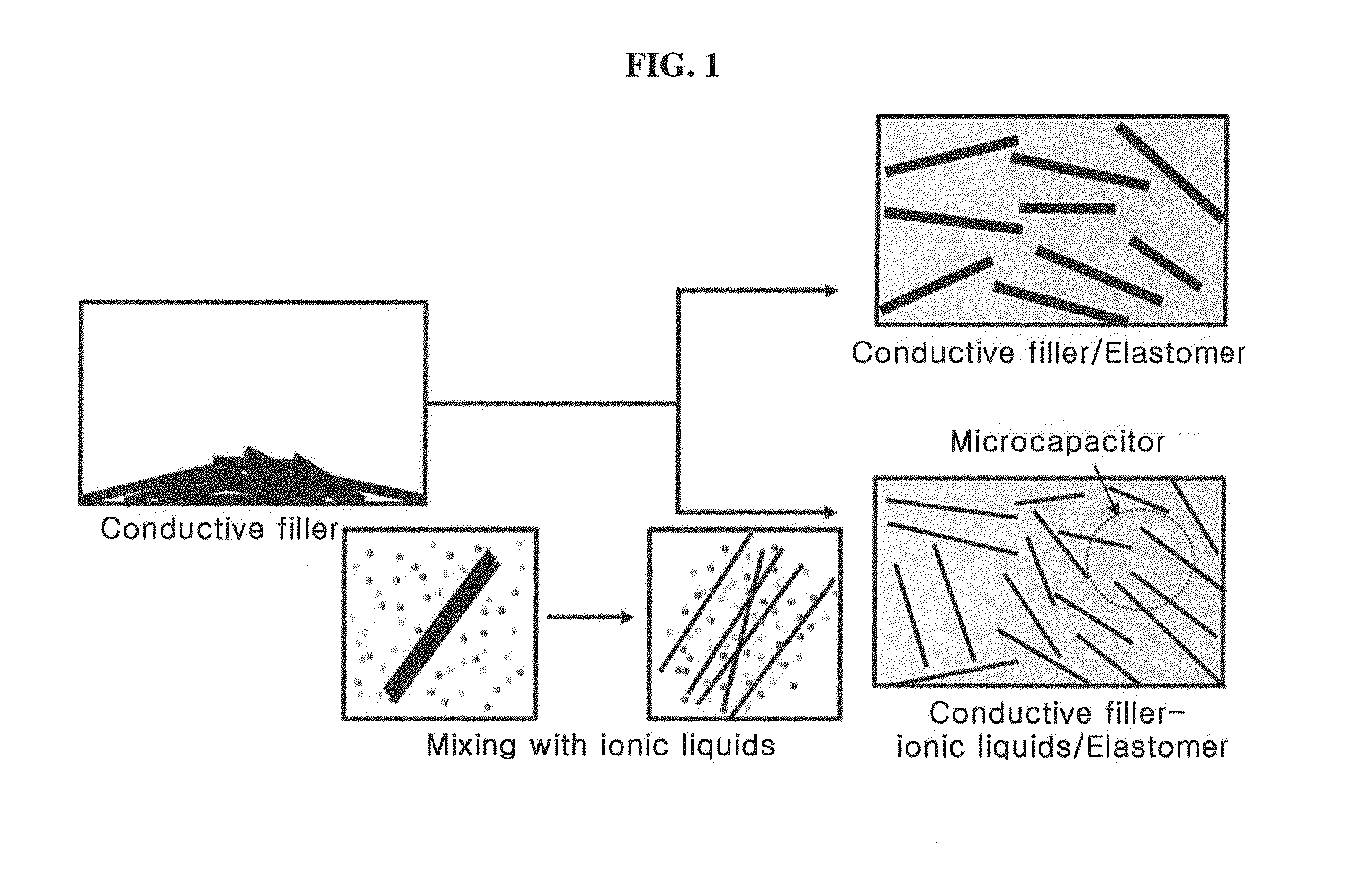

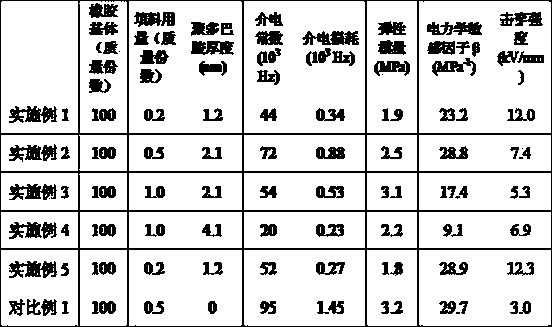

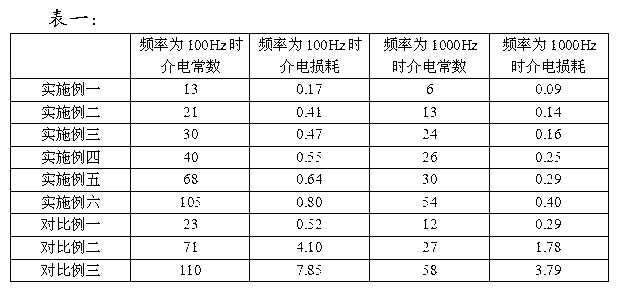

Elastomer composite with improved dielectric properties and production method thereof

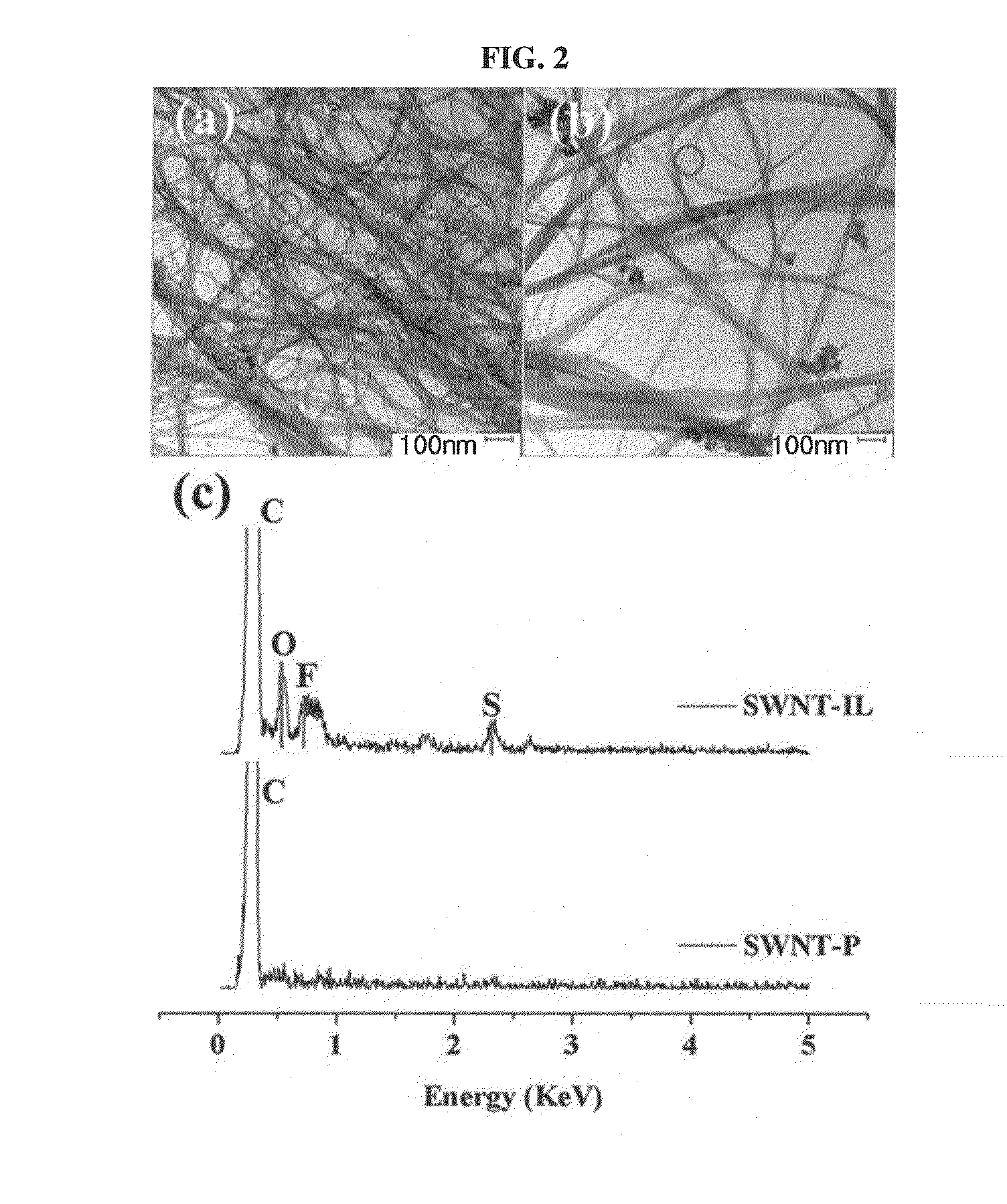

ActiveUS20130310495A1Good dispersionHigh dielectric constantMaterial nanotechnologyInorganic insulatorsElastomer compositesConductive polymer

Disclosed is an elastomer-conductive filler composite with improved dielectric properties. The composite includes conductive fillers and an ionic liquid dispersing the conductive fillers. The ionic liquid is used as a dispersant to effectively enhance the dispersion of the conductive fillers, achieving a high dielectric constant and a low dielectric loss of the composite without deteriorating the physical properties of the conductive fillers. The use of the ionic liquid can reduce the number of processing steps and the presence of the conductive fillers at a low concentration in the composite can minimize deterioration of the physical properties of the elastomer. Further disclosed is a method for producing the composite.

Owner:KOREA INST OF SCI & TECH

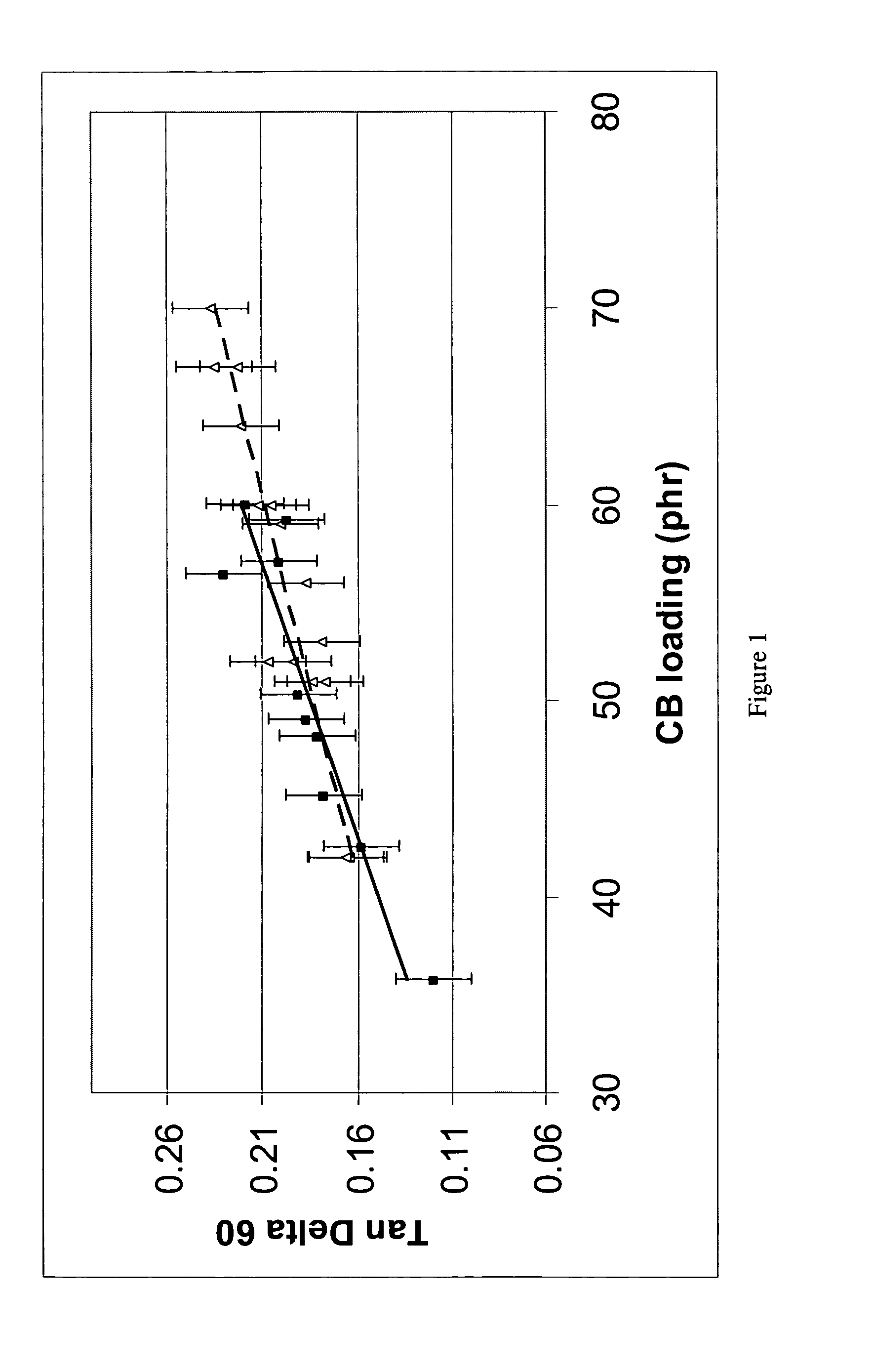

Preparation of reinforced elastomer, elastomer composite, and tire having component thereof

InactiveUS20030119946A1High viscosityGood dispersionSpecial tyresOrganic dyesMasterbatchPolymer science

This invention relates to the preparation of a silica reinforced elastomer via preparation of a silica-elastomer masterbatch as a composite of synthetic silica and an emulsion polymerization prepared synthetic elastomer. Such masterbatch is prepared by introducing such silica and a silane into a latex of the synthetic elastomer and recovering the composite thereof The invention further includes a rubber composition of at least two elastomers wherein at least one of said elastomers is such masterbatched composite. A tire having a component of such rubber composition, particularly a tire tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

Elastomer composite and method for producing it

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

Self-skinning microporous elastomer composite for polyurethane foam tire

ActiveCN102250313AGood mechanical propertiesIncrease elasticitySpecial tyresInflatable tyresPolyesterPolymer science

The invention relates to a self-skinning microporous elastomer composite for a polyurethane foam tire. The composite is composed of a component A and a component B, wherein the component A comprises polyether polyol, polymer polyol, a cross-linking agent or / and a chain extender, a foam stabilizer, a catalyst and a foaming agent; the component B is alcohol-modified isocyanate with -NCO content of 18.0-20.0% by mass; and the mass ratio of the component A to the component B is 100: (70-100). The microporous elastomer material prepared from the composite has excellent mechanical performance, and can be used for replacing the existing conventional polyester sole raw material liquid to prepare the polyurethane foam tire.

Owner:SHANDONG INOV POLYURETHANE

Lithium metal secondary battery containing an electrochemically stable anode-protecting layer

ActiveUS20190393495A1Reduce eliminatePromotes uniform depositionNegative electrodesPositive electrodesElectrical batteryLithium metal

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; and (b) an anode-protecting layer of a conductive sulfonated elastomer composite, disposed between the anode active layer and the separator / electrolyte; wherein the composite has from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an inorganic filler dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

Urethane micro-pore elastomer composite material adapated for insole and preparation method thereof

The microporous polyurethane elastomer composition material suitable for insole consists of one component A and one component B in the weight ratio of 100 to 60-80. The component A consists of polyether polyol, polymer polyol, cross-linking agent, foam stabilizer, foaming agent and catalyst; and the component B is pre-polymer of polyether polyol and isocyanate. When it is used, the two components are mixed in the said weight ratio at normal temperature to form microporous polyurethane elastomer. The normal temperature production process of insole is simple and has easy operation, no waste, stable product quality and low production cost.

Owner:SHANDONG INOV POLYURETHANE

Metal foil masonry flashings and termination bar therefor

InactiveUS6945000B1Precise positioningImprove sealingRoof covering using slabs/sheetsRoof covering using tiles/slatesElastomer compositesMetal foil

A metal-foil-containing flashing laminate is disclosed which laminate is for flashing cavity walls. The laminate has at least one layer of an elastomeric composite over which is placed a hot melt adhesive layer, a metal foil lamina, and another hot melt adhesive layer. In this embodiment the metal foil is encapsulated by the adhesive layers. In application this laminate used with a release paper forms a peel-and-stick product and is suitable for surface mounting. Also to the basic laminate an additional elastomeric composite layer is placed above the metal foil lamina sandwiching the foil and forming a through-wall mountable product. A termination bar for use with surface mounted flashing with a polymeric foam coating is also disclosed. The peel-and-stick flashing may be lap-mounted at the seams between adjacent strips without caulks or sealants.

Owner:HOHMANN & BARNARD INC

Poly-fibre slurry cake pretreatment

InactiveCN1896369AGood dispersionUnleash the full enhancement potentialFibre typesPretreatment methodElastomer composites

The aramid pulp pretreatment process in the present invention relates to a pretreatment process insulating the surface of aramid pulp fibres with isolation medium. The used isolation medium contains inorganic isolation powder and lubricant, the inorganic isolation powder is mixed with incompact aramid pulp mixture and then with lubricant to prepare aramid pulp composite. In every 100 weight parts of aramid pulp composite, there are 20-30 parts of aramid pulp, 37.5-62.5 parts of inorganic isolation powder, and 10-40 parts of lubricant. The inorganic isolation powder is hollow glass microbeads of 1250- 5000 mesh and the lubricant is phthalate ester compound. The prepared aramid pulp composite is a homogeneous and stable fibre composite, the aramid pulp fibres in it disperse well in the elastomer matrix facilitating the enhancement of the performance of the elastomer composite materials.

Owner:BEIJING UNIV OF CHEM TECH

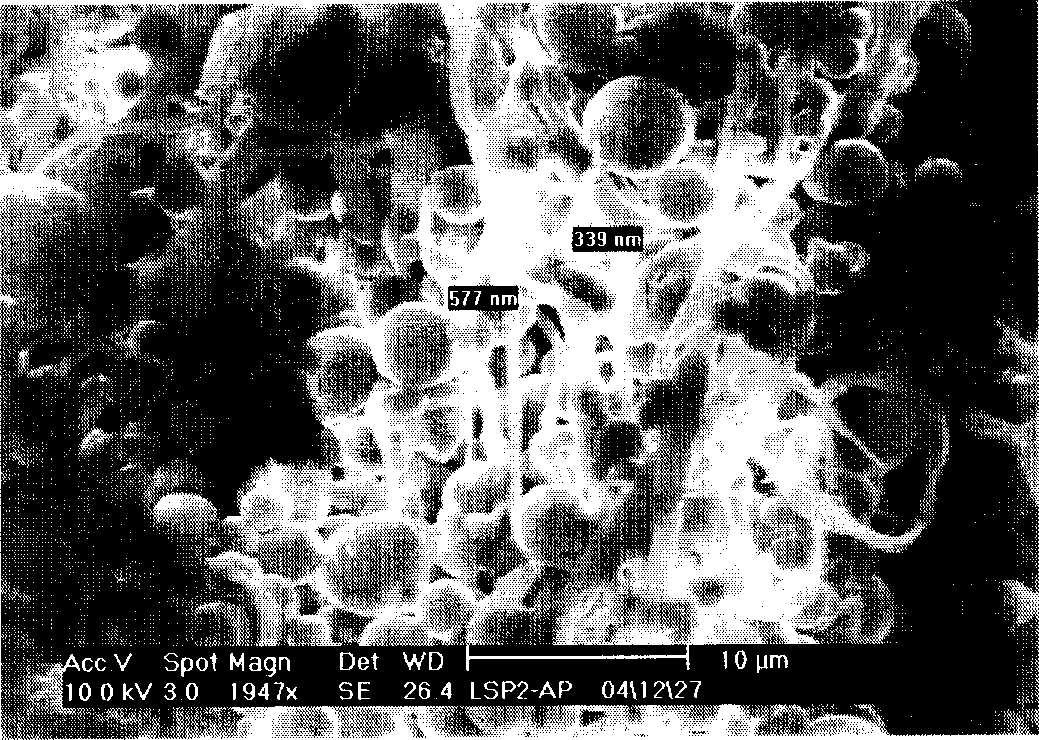

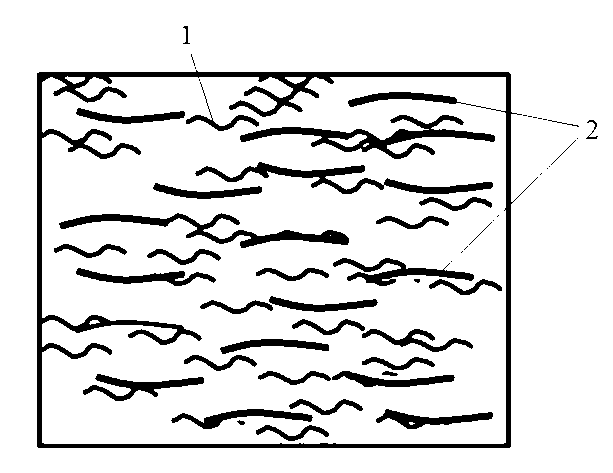

Graphene-based dielectric elastomer composite material and preparing method thereof

The invention relates to a graphene-based dielectric elastomer composite material and a preparing method thereof. The composite material comprises an elastomer matrix, graphene oxide dielectric padding and a crosslinking system, wherein the graphene oxide dielectric padding is oxidation graphene with the surface wrapped by a poly-dopamine organic layer and is scattered in the elastomer matrix in a nanometer horizontal layer mode, and an isolation network structure that an oxidized graphene slice layer which is wrapped by the poly-dopamine organic layer wraps latex particles. According to the preparing method, the dopamine bionic ornament oxidization graphene is adopted, the dielectric loss is obviously reduced, the electric breakdown strength is improved, the organic layer thickness of the poly-dopamine can be regulated through the parameters of the modification process of the dopamine, the dielectric constant, the dielectric loss and the electric breakdown strength of the composite material can be adjusted according to the demands, and the graphene-based dielectric elastomer composite material meeting the safety requirement in the biology medical field can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

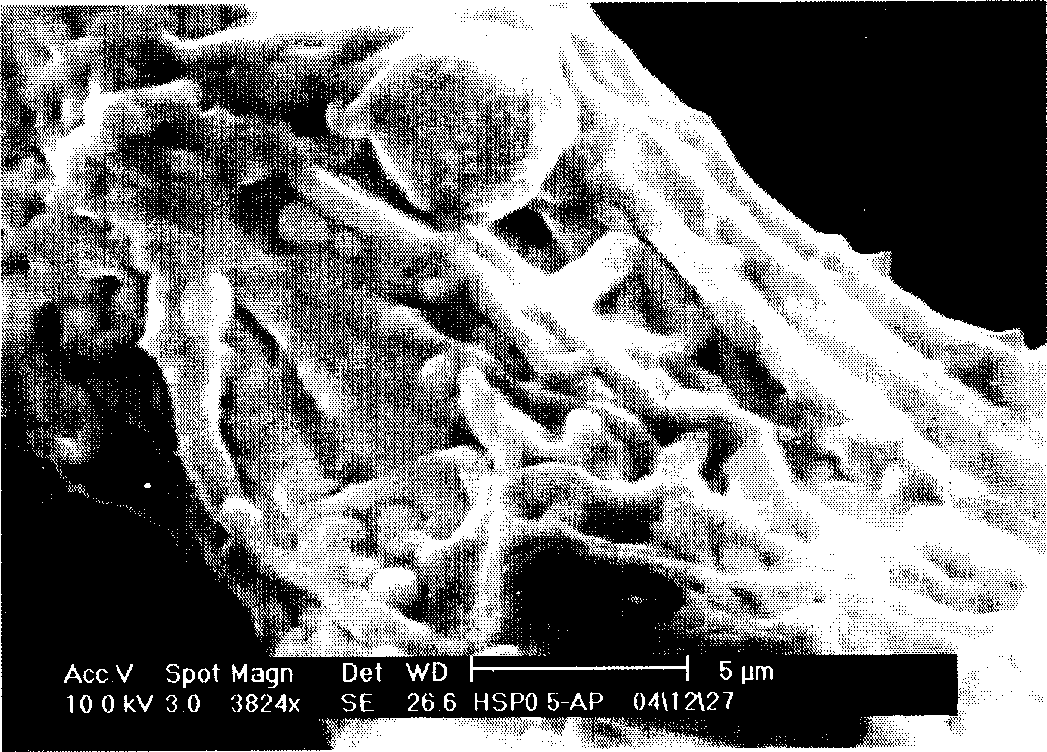

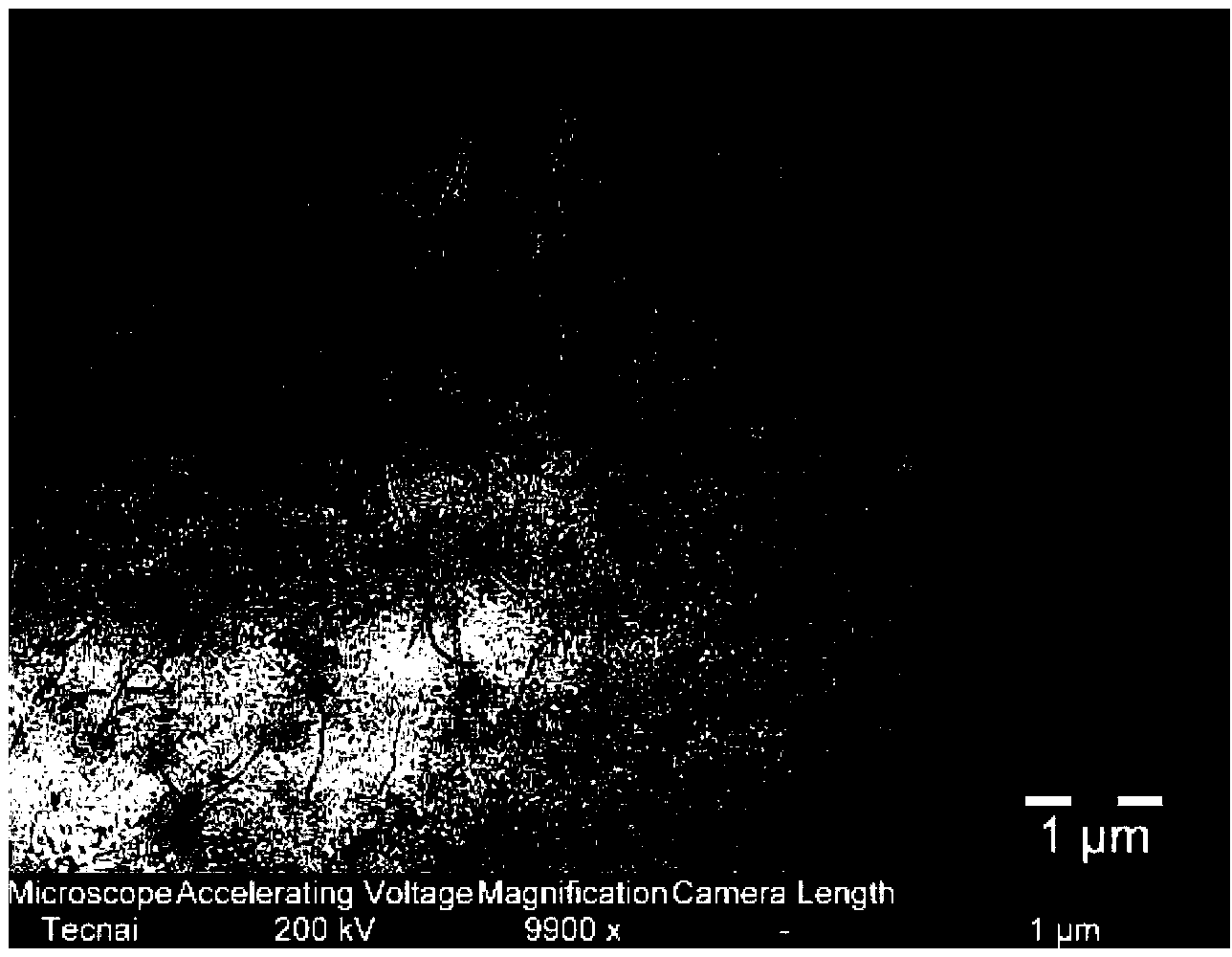

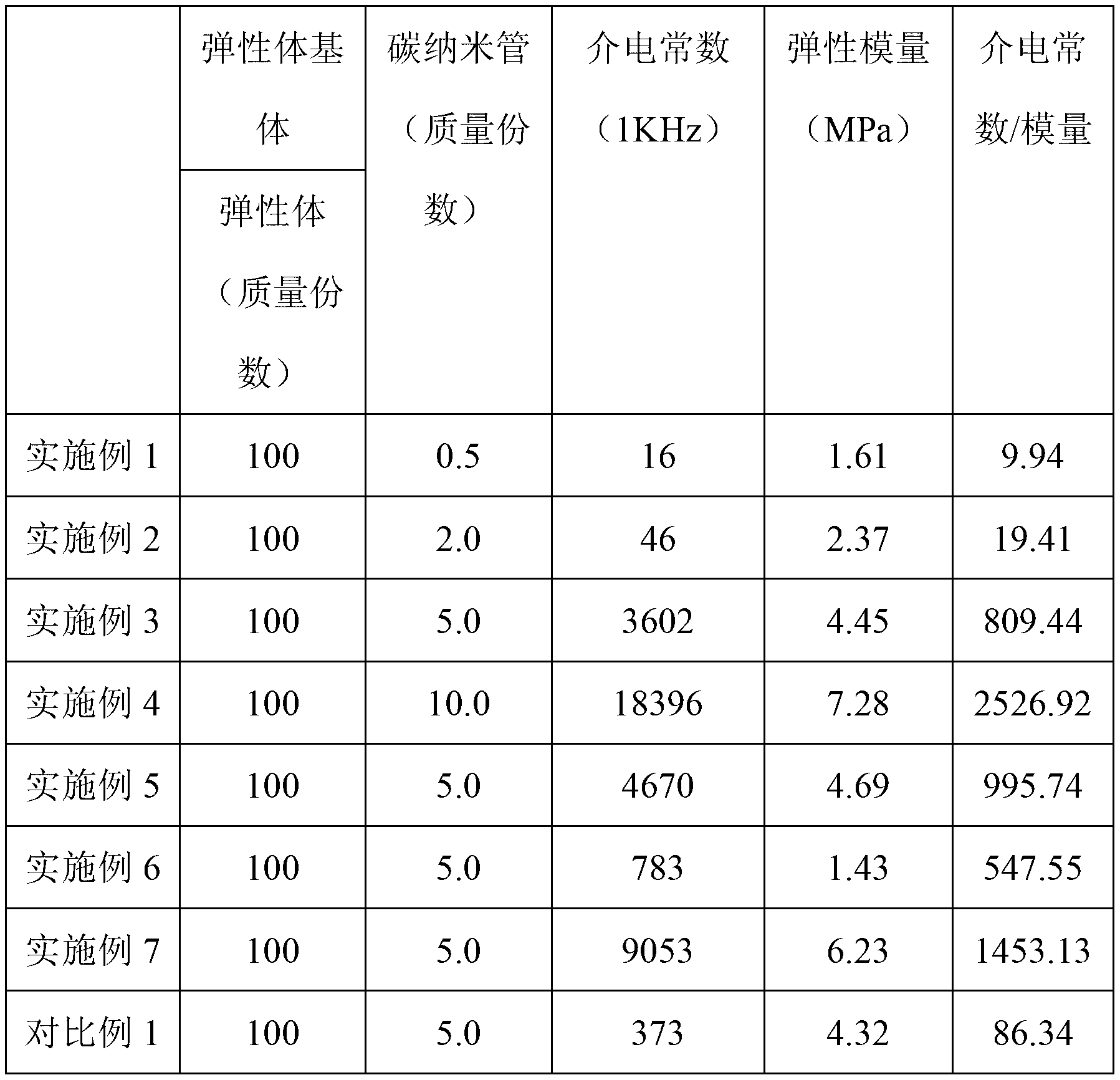

High-dielectric elastomer composite material with low content of carbon nanometer tubes and preparation method of composite material

ActiveCN103214707AHigh dielectric constantHigh dielectric constant/modulus ratioDielectricElastomer composites

The invention discloses a high-dielectric elastomer composite material with low content of carbon nanometer tubes and a preparation method of the composite material and belongs to an elastomer composite material. The high-dielectric elastomer composite material contains the following components in parts by weight: 100 parts of elastomers, 0.5-10 parts of array carbon tubes, 0 or 0.5-12 parts of a vulcanizing agent, and 0 or 1-7 parts of a vulcanizing-assisting agent, wherein when the elastomers are rubber matrixes, the vulcanizing agent and the vulcanizing-assisting agent are needed; and when the elastomers are thermoplastic elastomer matrixes, the vulcanizing agent and the vulcanizing-assisting agent are not needed. The composite material is prepared by a mechanical blending method. The composite material with good dispersing performance is obtained by means of adding the array carbon tubes with a one-dimensional orientation arrangement structure, the dielectric constant of the elastomer can be enhanced greatly under the condition of a low stuffing content, simultaneously the modulus of the elastomer is not increased remarkably and a high ratio value of dielectric constant / modulus is obtained.

Owner:BEIJING UNIV OF CHEM TECH

Prepared reinforced elastomer, elastomer composite and tire having component thereof

InactiveUS6156822AReduction of mixing energySpeed up the processSpecial tyresWheelsPolymer scienceElastomer composites

Preparation of an elastomer which contains a dispersion of filler reinforcement by forming a filler reinforcement in-situ within the elastomer host, the resulting elastomer / filler composite and tire having component which contains such reinforced elastomer. The invention includes a rubber composition of at least two elastomers wherein one of said elastomers is a pre-formed composite of elastomer and in-situ formed filler reinforcement. A tire having a component of such rubber composition, particularly a tire tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

Modular area rug and process of manufacture

There is provided a modular area rug having a plurality of individual floor covering elements positioned in an aesthetically pleasing tiled configuration. The modular area rug may include a plurality of similar repeating sub-units, each of which may comprise multiple floor covering elements. The modular area rug is free-standing, requiring no contact with a wall to maintain its monolithic nature. Further, the individual floor covering elements may be easily repositioned to satisfy user needs or whims. Each floor covering element has a textile upper surface and a skid-resistant backing of either a sheet material or a fabric-elastomer composite.

Owner:MILLIKEN & CO

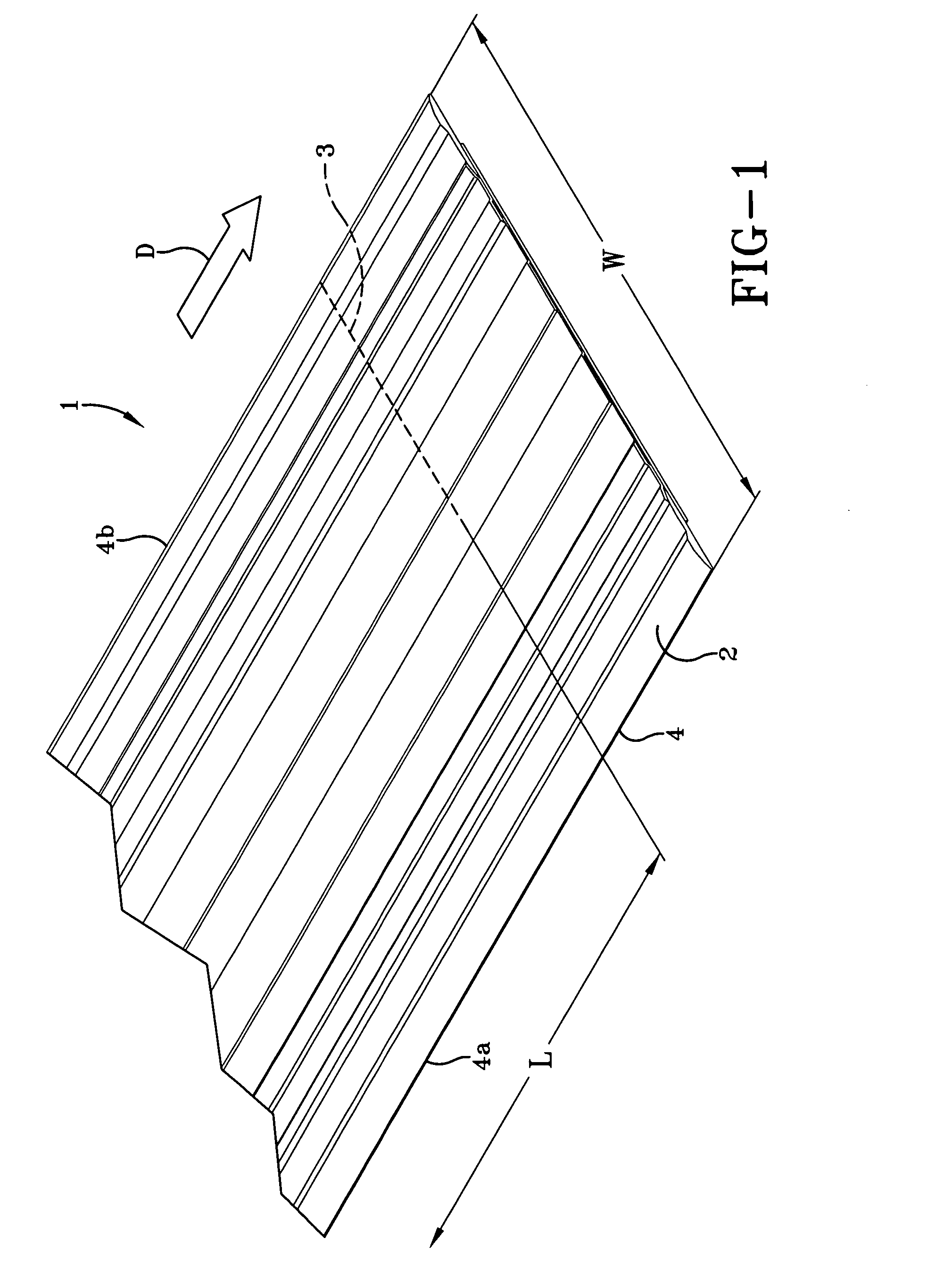

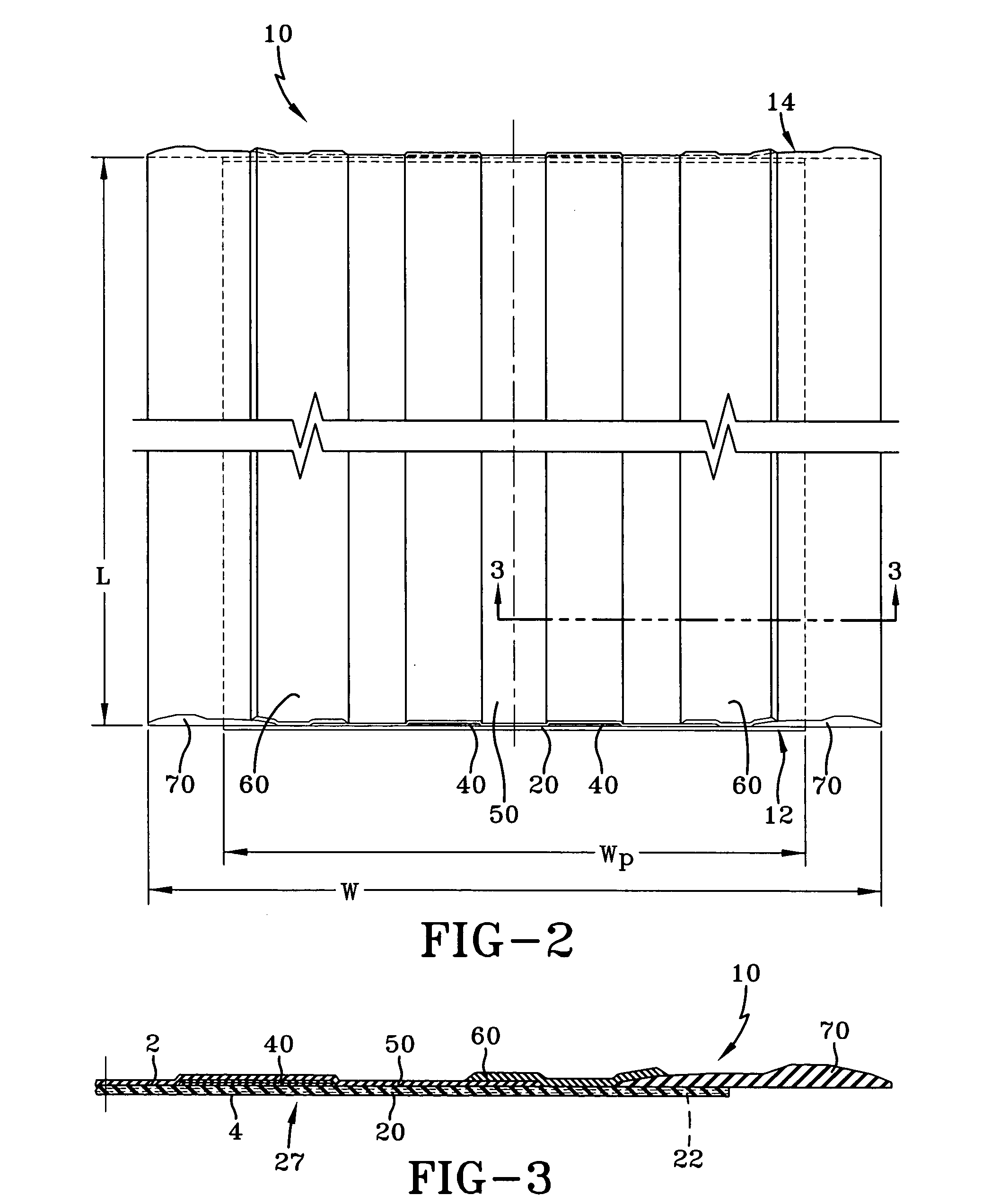

Novel elastomer composites, method and apparatus

InactiveUS20060111475A1Increase the cross-sectional areaEasy to collectFlow mixersSpecial tyresParticulatesElastomer composites

Elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end. Highly efficient and effective elastomer coagulation is achieved without the need for a coagulation step involving exposure to acid or salt solution or the like. Novel elastomer composites are produced. Such novel elastomer composites may be cured or uncured, and combine material properties, such as choice of filler, elastomer, level of filler loading, and macro-dispersion, not previously achieved.

Owner:CABOT CORP

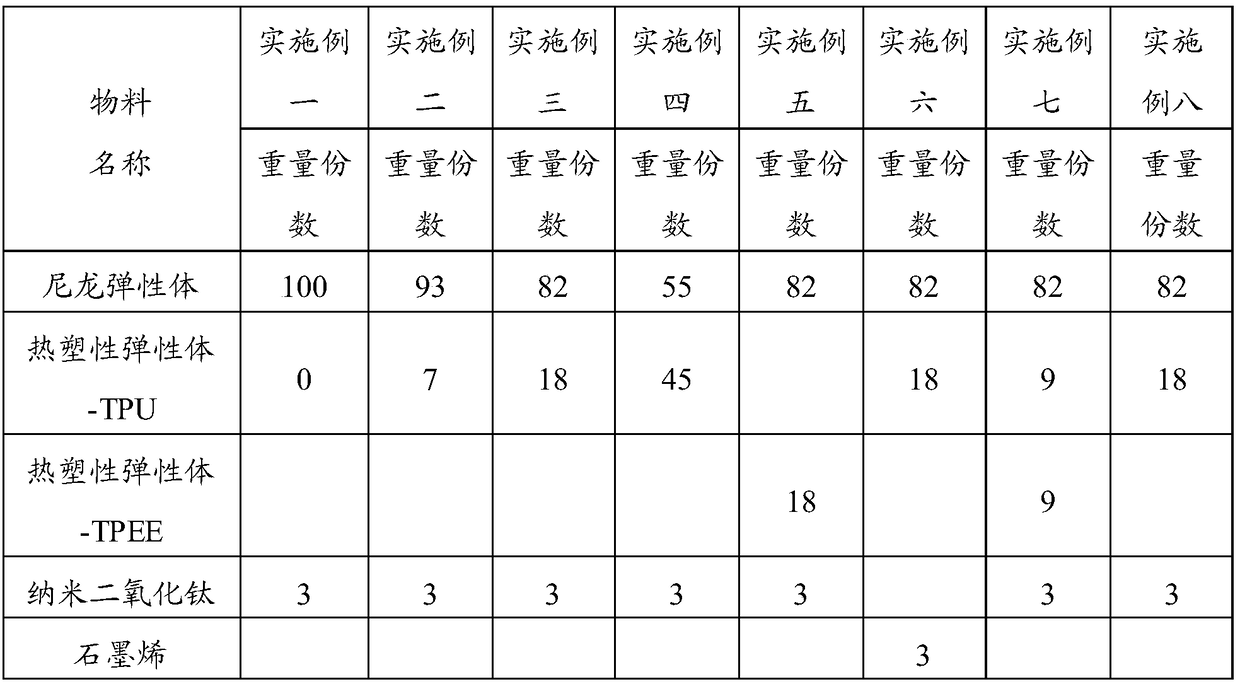

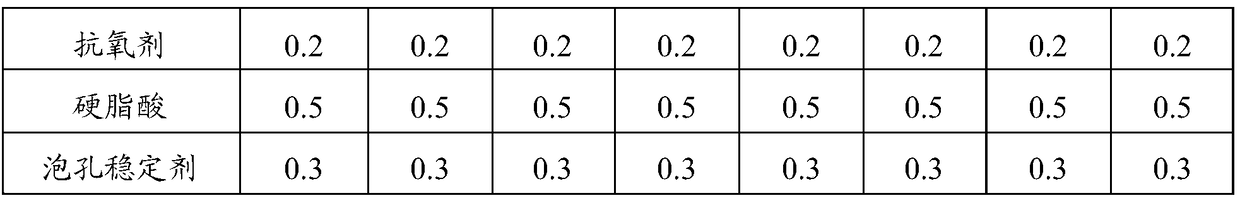

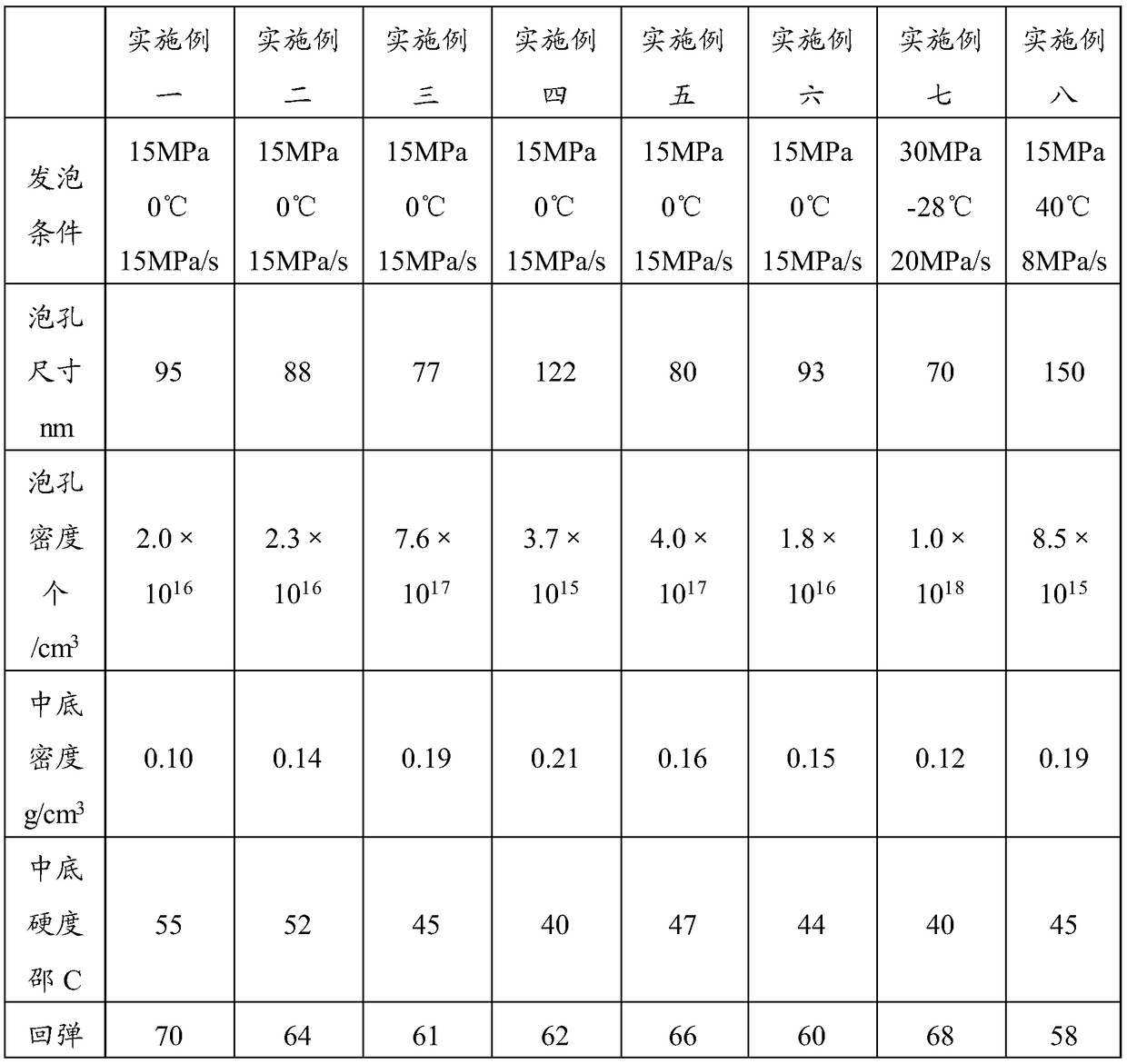

Foam material for shoe, preparation method and application of foam material

The invention provides a foam material for a shoe, a preparation method and application of the foam material. The foam material is prepared by sequentially performing the processes of injection molding and supercritical fluid foaming molding on a nylon elastomer composite material, and the nylon elastomer composite material comprises the following components in parts by mass: 50-100 parts of nylonelastomer resin, 0-50 parts of thermoplastic elastomer resin, 0.5-3 parts of a nanometer nucleating agent, 0-0.6 part of an antioxygen, 0-1.2 parts of stearic acid and 0-0.6 part of a foaming stabilizer. The foam material for the shoe has nanopores, is relatively light in weight, is endowed with relatively high hardness, further has the advantages of high resilience, low compressive deformation,relatively high tensile strength and the like, greatly reduces the weight of a sneaker and also is also relatively excellent in mechanical property and durability when used as an insole material of the shoe. In addition, the insole material of the shoe is prepared by rapidly releasing the pressure and foaming after dipping in supercritical fluid, the preparation flow is shorter, and the efficiencyis higher.

Owner:ANTA CHINA

Silicon rubber based porous dielectric elastomer composite material and preparation method thereof

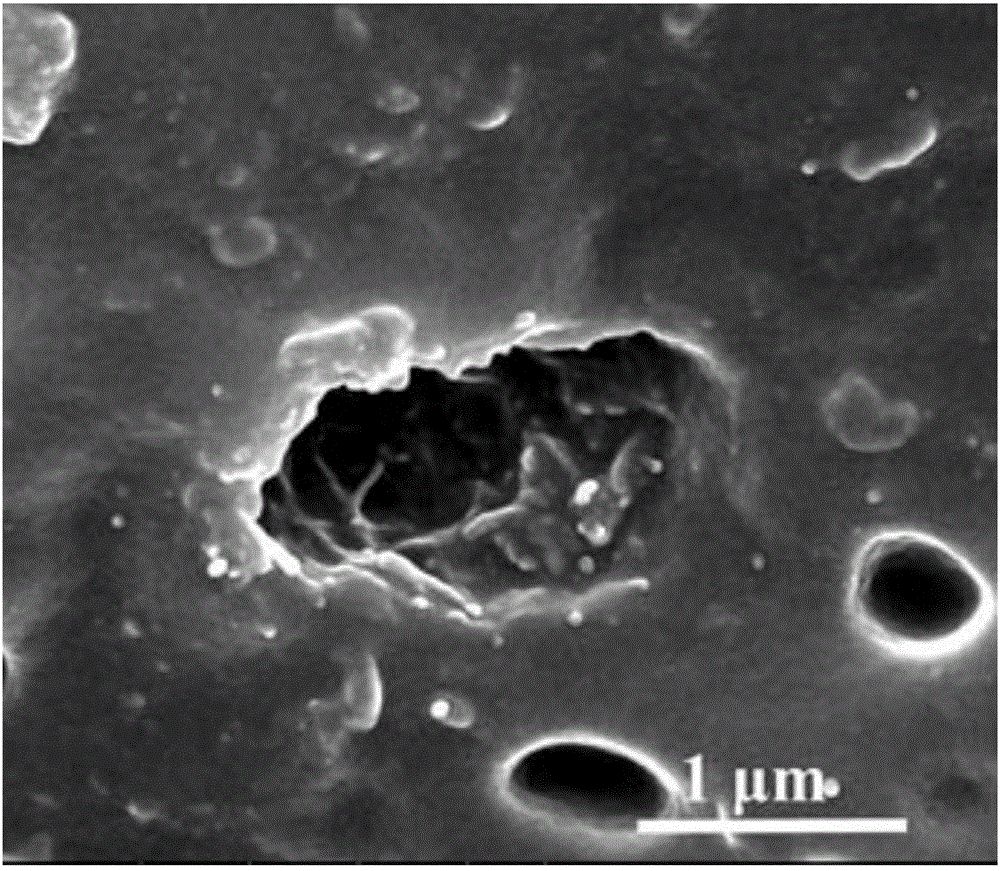

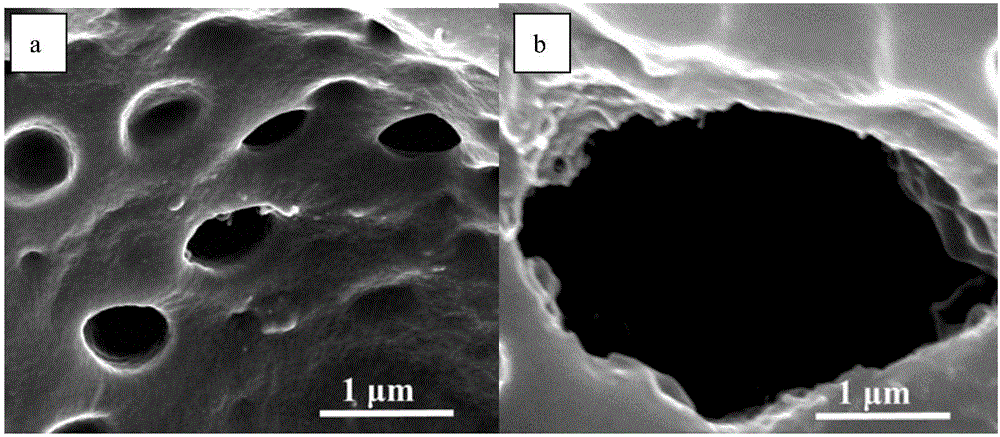

The invention relates to a silicon rubber based porous dielectric elastomer composite material, in particular to a silicon rubber based porous dielectric elastomer composite material having high dielectric constant, low dielectric loss and low Young modulus and a preparation method thereof. The silicon rubber based porous dielectric elastomer composite material comprises polydimethylsiloxane, curing agent, polyethylene glycol and conductive filler, a mass ratio of polydimethylsiloxane to the curing agent is 5:1-40:1, a mass ratio of polydimethylsiloxane to polyethylene glycol is 17:10-88:1, and the conductive filler accounts for higher than 0 and lower than or equal to 2.7% of total mass of polydimethylsiloxane / polyethylene glycol / curing agent. The composite material has a uniform microporous structure, and the conductive filler is selectively distributed at an interface of polydimethylsiloxane and polyethylene glycol. The silicon rubber based porous dielectric elastomer composite material has the advantages of high dielectric constant, low dielectric loss and low Young modulus.

Owner:SICHUAN UNIV

Low-gloss polyolefin elastomer composite material and preparation method thereof

The invention discloses a low-gloss polyolefin elastomer composite material and a preparation method thereof. The low-gloss polyolefin elastomer composite material is composed of polypropylene, polyethylene, a delustering agent, a toughening agent, an antioxidant, a lubricant, a light stabilizer and an aid. The composite material disclosed by the invention has the characteristics of low surface gloss, good toughness, excellent heat resistance and the like, the raw materials are easily available, and the cost is low; and moreover, toxic and harmful substances such as vulcanizing agent and a vulcanizing aid are not added, secondary pollution is avoided, the preparation technology is simple, and the production cost is low.

Owner:HEFEI GENIUS NEW MATERIALS

Halogen-flame retardant and application thereof

ActiveCN109836817AReduce the difficulty of productionReduce dosageCost ControlsInorganic fluorine compounds

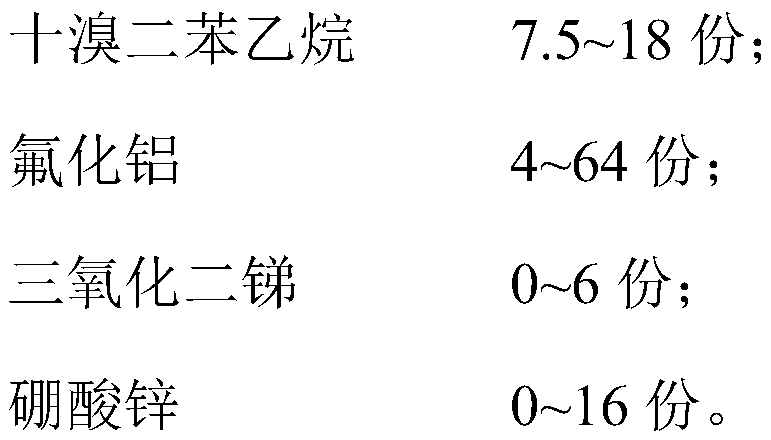

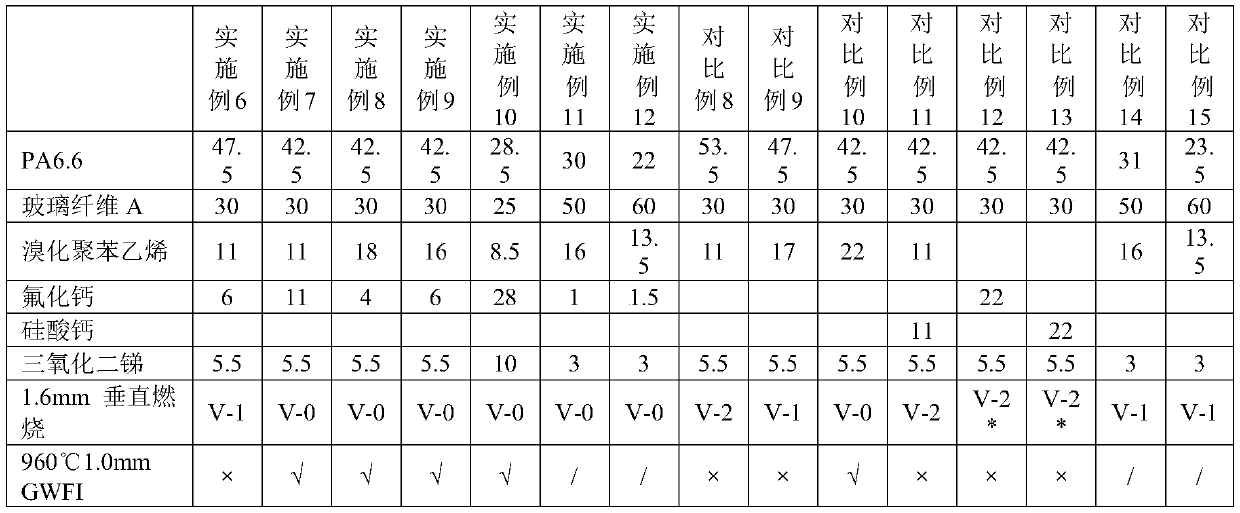

The invention belongs to the field of flame retardant technology and provides a halogen-frame retardant. The halogen-flame retardant comprises a first component and a second component. The first component is composed of a main flame retardant and an auxiliary flame retardant. The main flame retardant is selected from a brominated flame retardant and a chlorinated flame retardant; and the auxiliaryflame retardant is a fluorine compound. The second component is a flame-retardant synergistic compound, selected from metal oxides of the group IIIA, IVA, VA metals in the periodic table of the elements or salt thereof, transition metal oxide, a silicon-based flame retardant, a phosphorus-based flame retardant and a nitrogen-based flame retardant. The invention also provides a resin composite material, an elastomer composite material and a relative formed body containing the halogen-frame retardant, a coating medium and related part or structural body, and an impregnated material. The invention has the following beneficial effects: the technical bias that fluoride cannot effectively perform the flame-retardant effectiveness and then cannot be used or is hard to be used as a flame retardant is corrected; the actual usage of the brominated flame retardant and / or the chlorinated flame retardant is reduced, and then the production difficulty of the flame retardant and the environmental pollution are reduced, and the color matching and cost control difficulty is reduced.

Owner:BENSONG ENG PLASTICS HANGZHOU

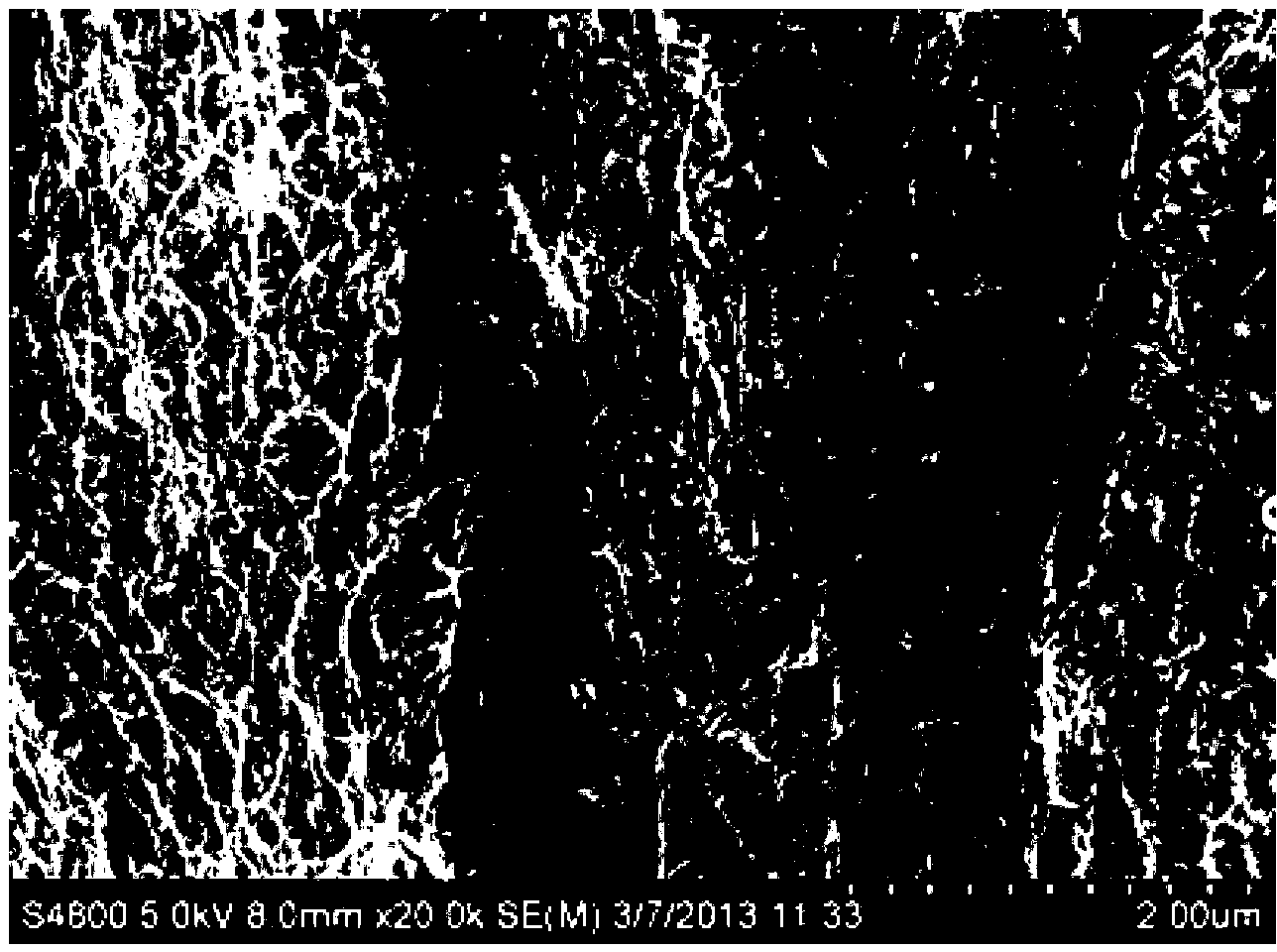

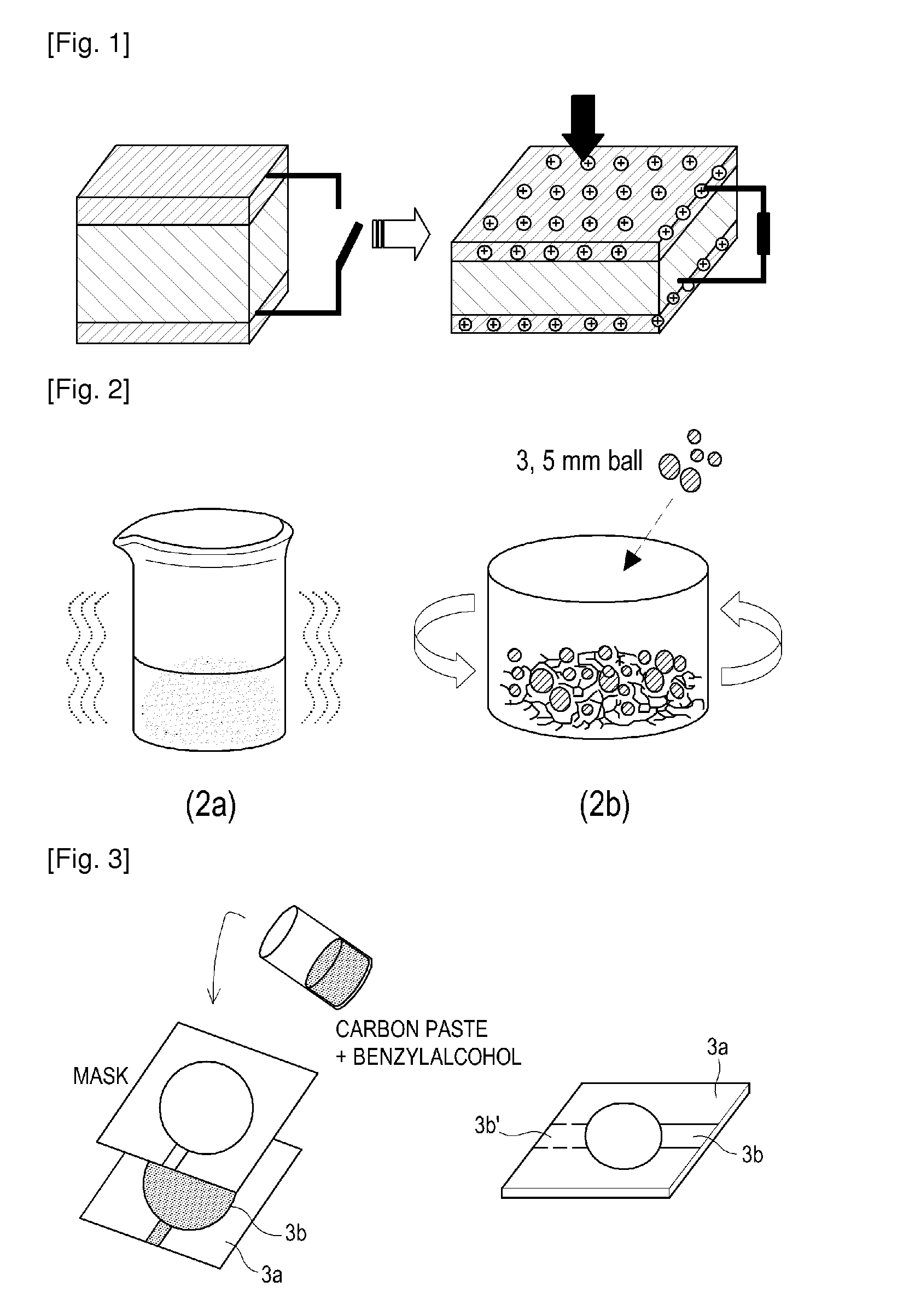

Elastomer composite with high dielectric constant and low dielectric loss and preparation method thereof

ActiveCN103194858AIncrease contentIncrease percolation valueSolvent-treatmentFilament/thread formingElectricityElastomer composites

The invention relates to elastomer composite with high dielectric constant and low dielectric loss and a preparation method thereof. The preparation method includes the steps of suspension allocation, electrospinning and post-treatment. Percolation value of the composite is increased by controlling directional arrangement of carbon nanotubes in substrate, so that dielectric constant of the composite is increased by increasing the content of the carbon nanotubes, the dielectric loss is kept low, and the problem that the high dielectric constant and the low dielectric loss are not balanced for the dielectric composite is solved.

Owner:BEIJING UNIV OF CHEM TECH

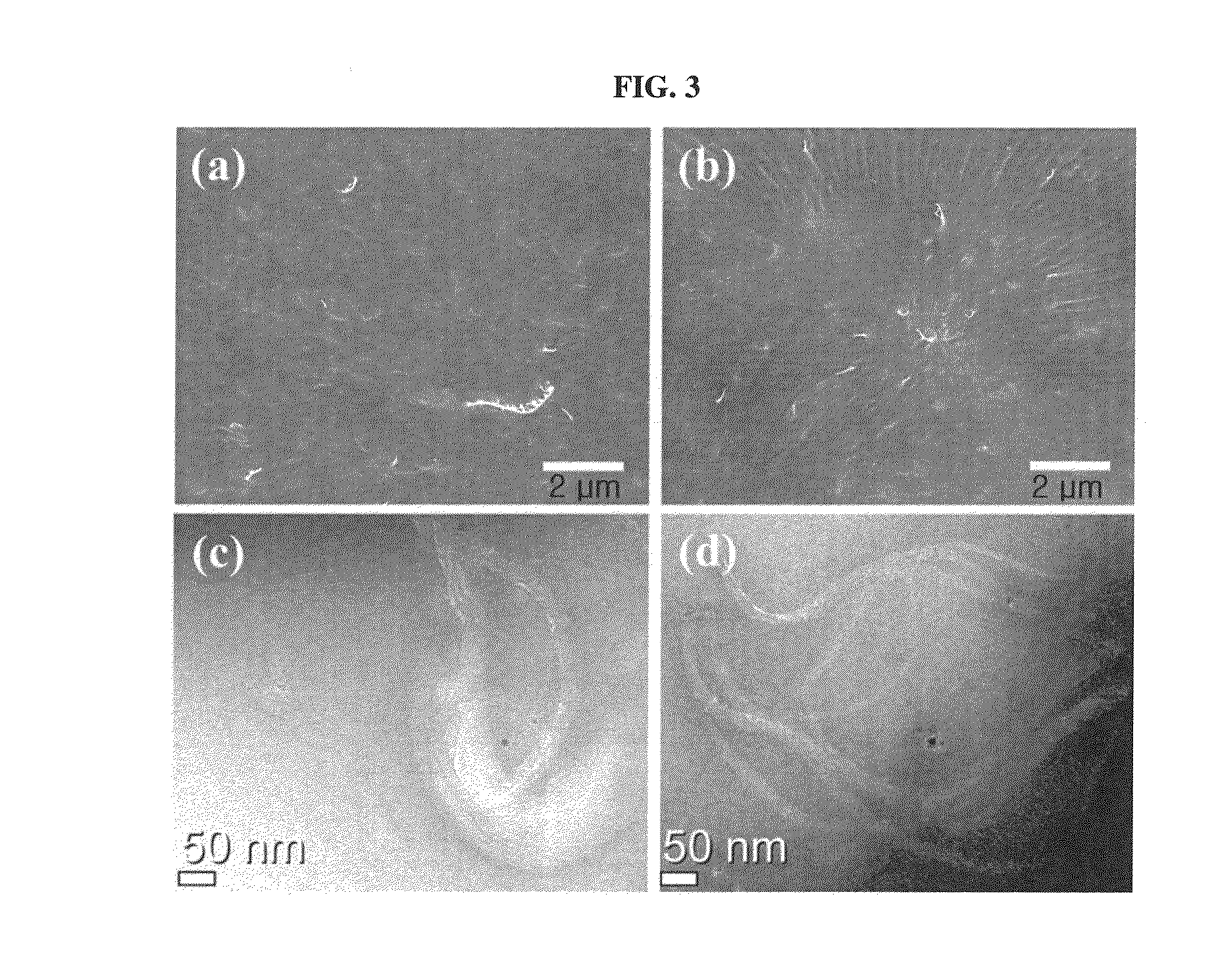

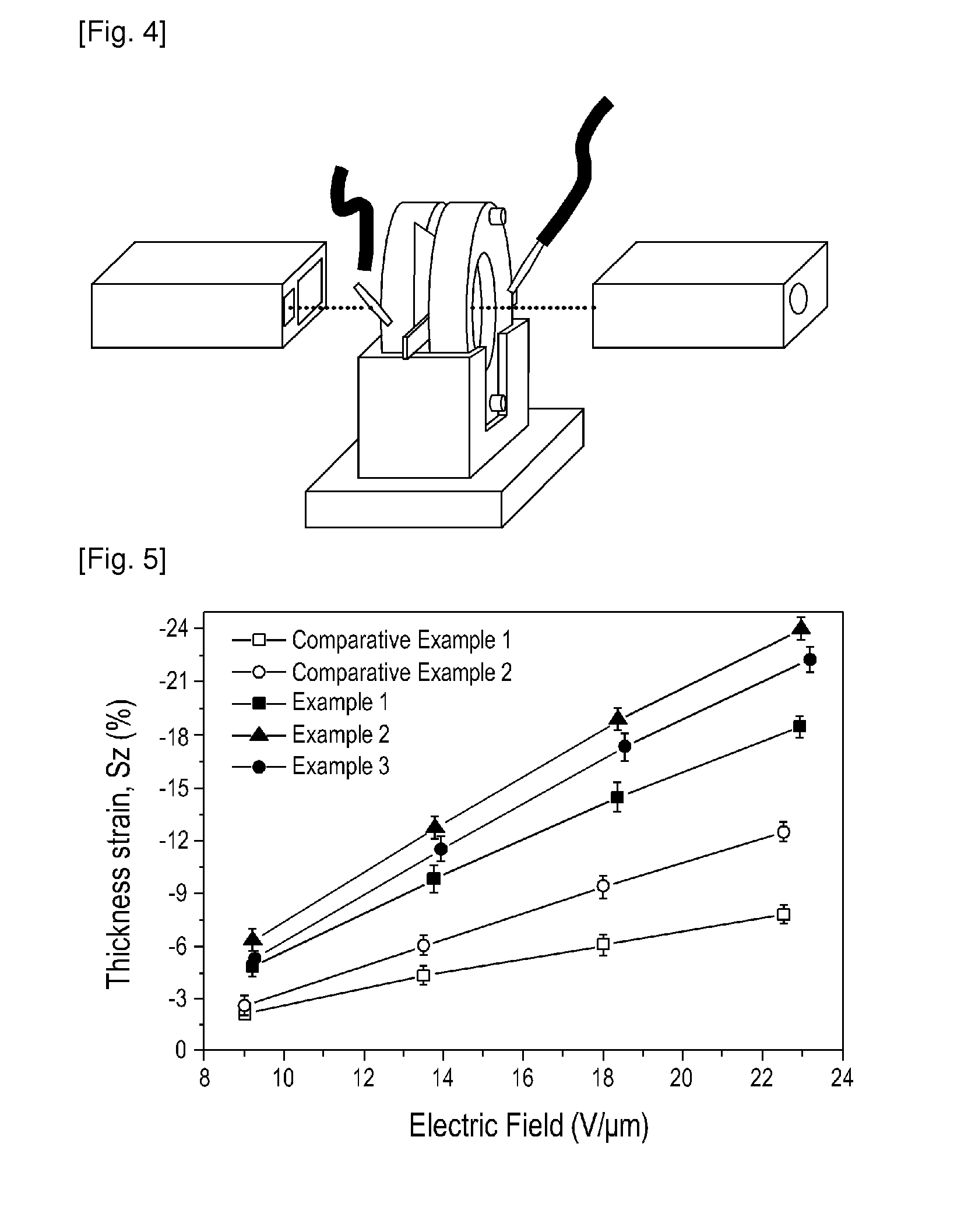

Dielectric elastomer composites and actuators using the same

InactiveUS20130049530A1Improve propertiesEnhancing dispersibility of fillerPiezoelectric/electrostrictive device manufacture/assemblyNanotechnologyPolymer scienceBarium titanate

The present invention relates to an actuator which is one of the energy conversion devices, and is characterized by improving the ability to convert electrical energy into mechanical energy by way of using a dielectric elastomer composite comprising a filler with an efficient dispersibility. In case of using a conventional resilient dielectric layer, there was a problem in that the operating voltage is high, while advantageously exhibiting a fast response and a high strain. The present invention can provide dielectric elastomer composite actuators that show excellent electromechanical conversion properties, by adding a dispersing agent such as a pyrene derivative or a polymeric compound having an amine end group when preparing the composite wherein carbon-based conductive fillers such as carbon blacks, single-walled carbon nanotubes (SWCNTs), double-walled carbon nanotubes (DWCNTs), multi-walled carbon nanotubes (MWCNTs) and graphenes, or high dielectric fillers such as copper phthalo-cyanine (CuPc), MOFs (metal organic frameworks) and barium titanate (BaTiO3) are comprised in a thermoplastic resilient dielectric layer to enhance the dispersibility of the fillers.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com