Patents

Literature

212 results about "Electric breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

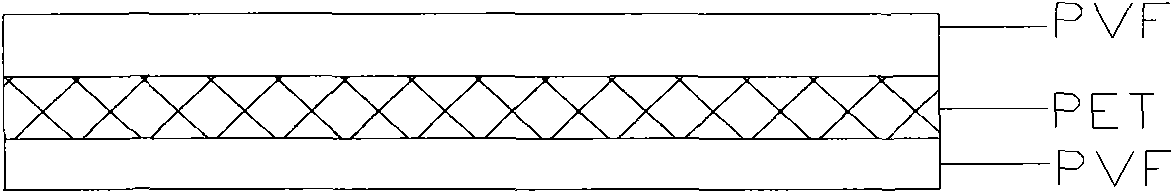

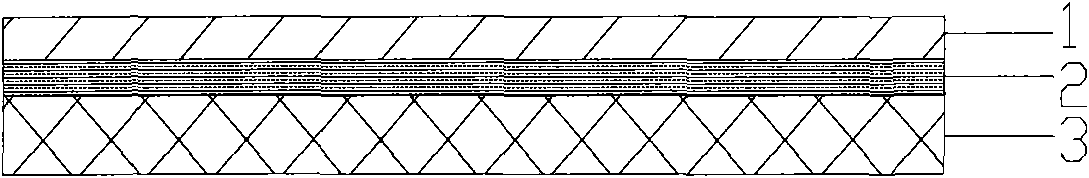

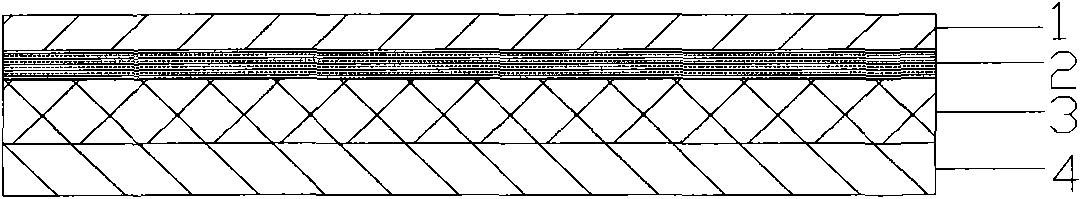

Solar battery back panel film and preparation method thereof

InactiveCN101997038AEasy to prepareGood weather resistanceLamination ancillary operationsFinal product manufactureAdhesiveElectric breakdown

The invention relates to a solar battery back panel film and a production method thereof. The solar battery back panel film comprises a PET (Polyethylene Terephthalate) thin film substrate layer and at least one polyvinylidene fluoride film layer, wherein the polyvinylidene fluoride film layer and the PET thin film substrate layer are compounded through an adhesive layer. The solar battery back panel film also comprises an EVA (Ethylene Vinyl Acetate Copolymer) film layer, and the EVA film layer and the PET thin film substrate layer are compounded by adopting a composite laminating process. The preparation method of the solar battery back panel film comprises the following steps of: carrying out surface corona treatment on the PET thin film substrate layer and the polyvinylidene fluoride film layer; coating an adhesive layer on the PET thin film substrate layer; and carrying out hot-pressing compounding on the adhesive-coated surface of the PET thin film substrate layer and the polyvinylidene fluoride film layer and then solidifying. The preparation method of the solar battery back panel film is simple, and the product has excellent weather fastness, higher lamination peel strength, good barrier property and good electric breakdown resistance.

Owner:NANJING NAQUAN HI TECH MATERIAL

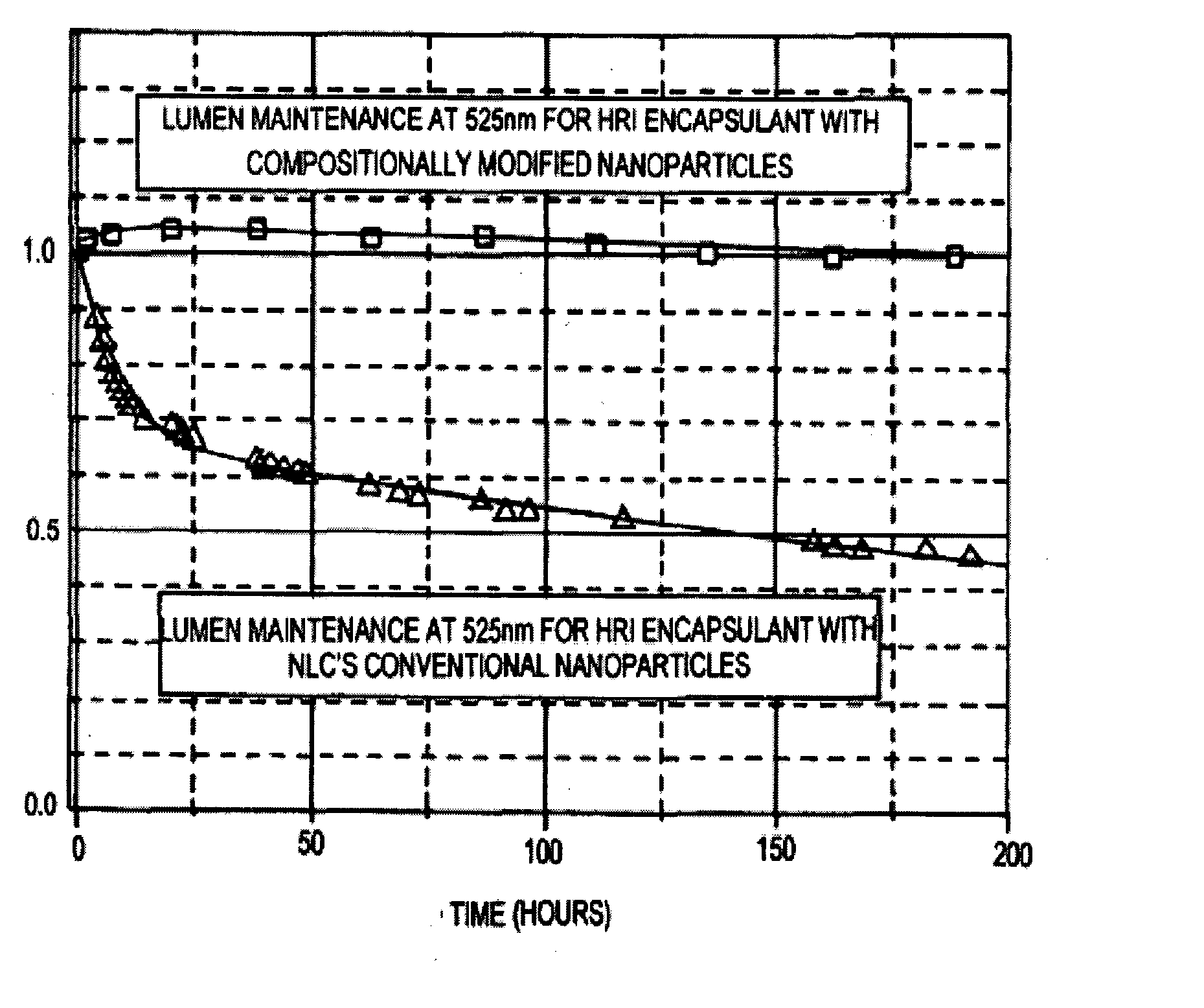

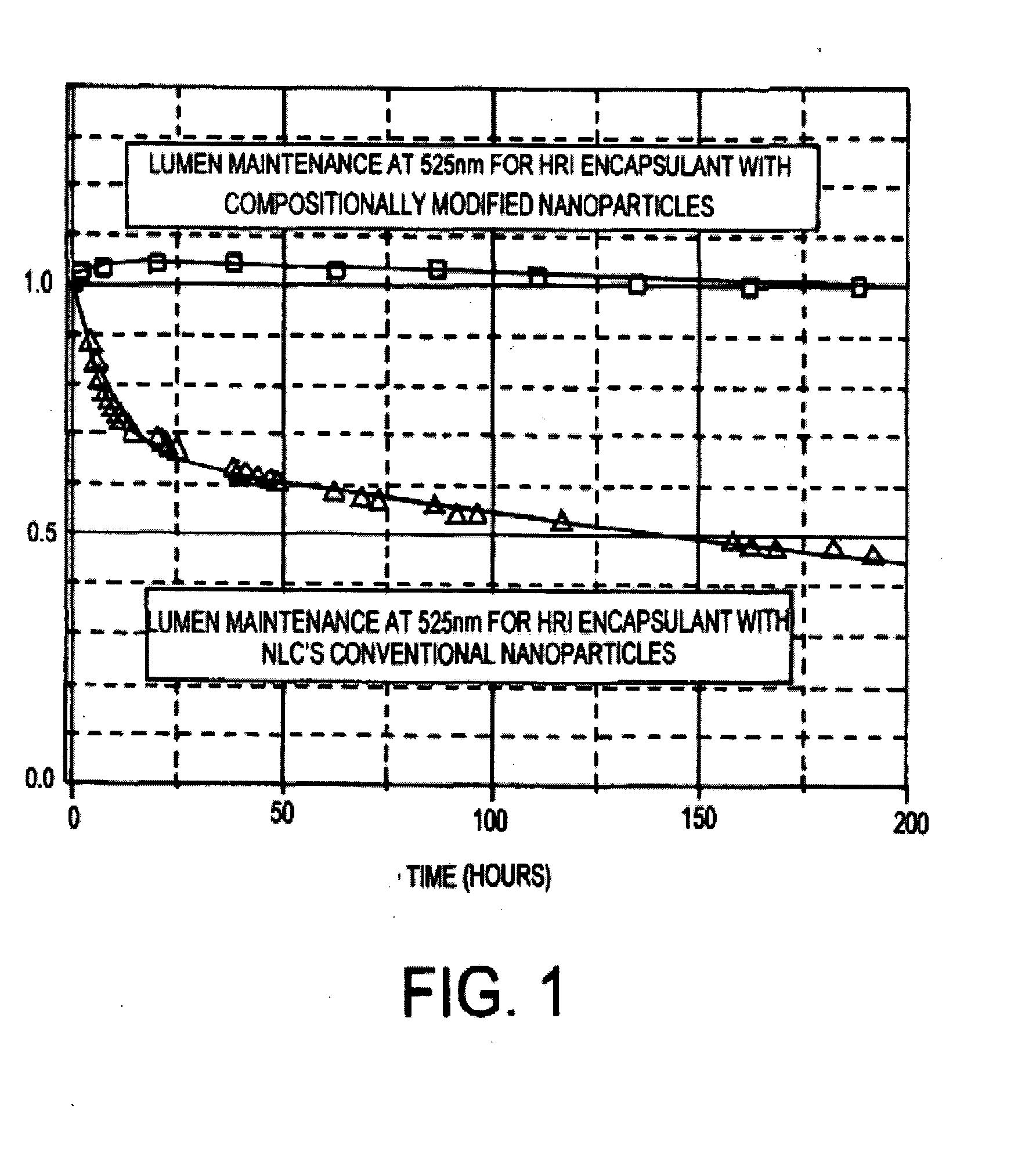

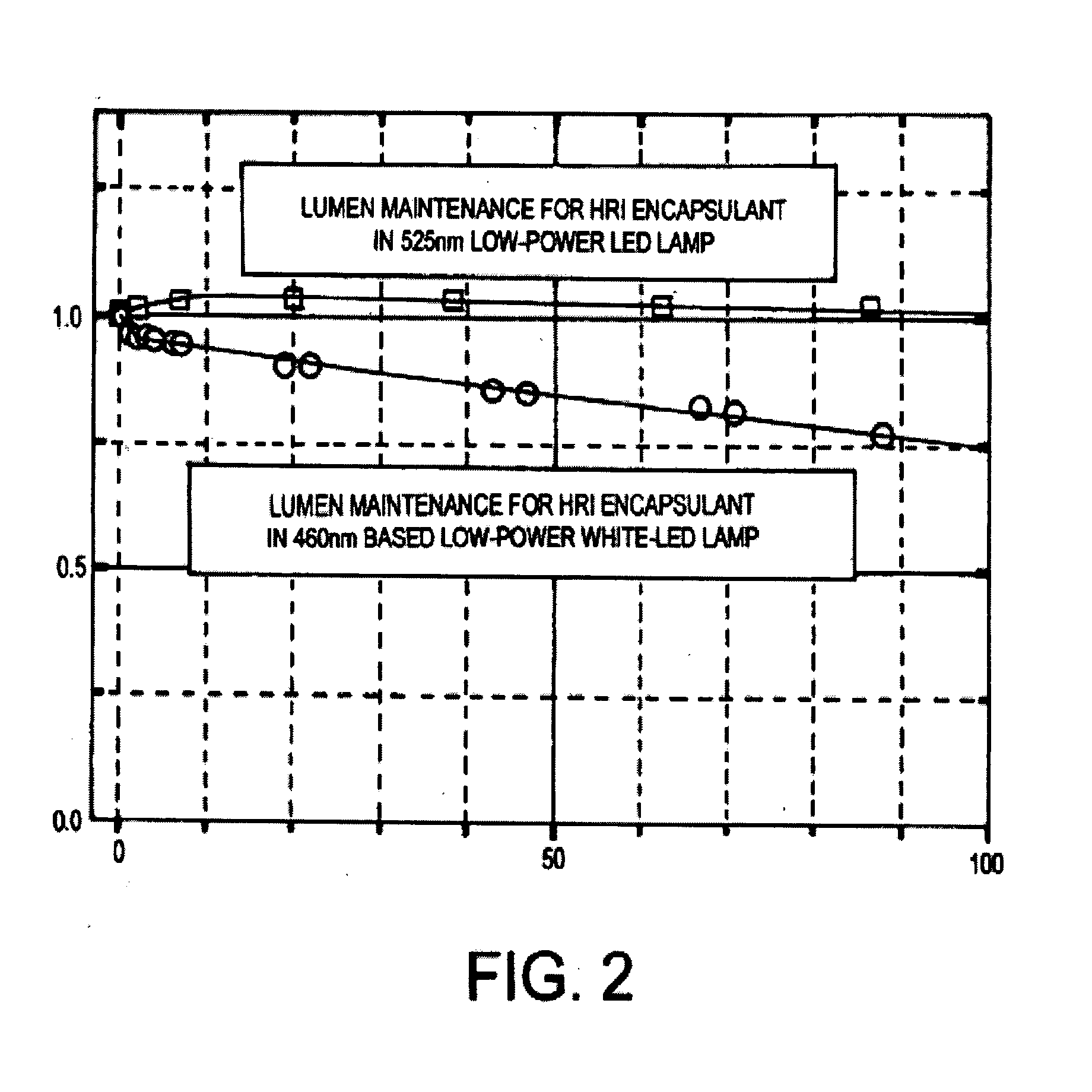

Optically reliable nanoparticle based nanocomposite HRI encapsulant, photonic waveguiding material and high electric breakdown field strength insulator/encapsulant

InactiveUS20070221939A1Good physical propertiesImprove photodegradation resistanceMaterial nanotechnologySemiconductor devicesEpoxyLight equipment

An optically reliable high refractive index (HRI) encapsulant for use with Light Emitting Diodes (LED's) and lighting devices based thereon. This material may be used for optically reliable HRI lightguiding core material for polymer-based photonic waveguides for use in photonic-communication and optical-interconnect applications. The encapsulant includes treated nanoparticles coated with an organic functional group that are dispersed in an Epoxy resin or Silicone polymer, exhibiting RI˜1.7 or greater with a low value of optical absorption coefficient α<0.5 cm−1 at 525 nm. The encapsulant makes use of compositionally modified TiO2 nanoparticles which impart a greater photodegradation resistance to the HRI encapsulant.

Owner:NANOCRYSTALS TECH

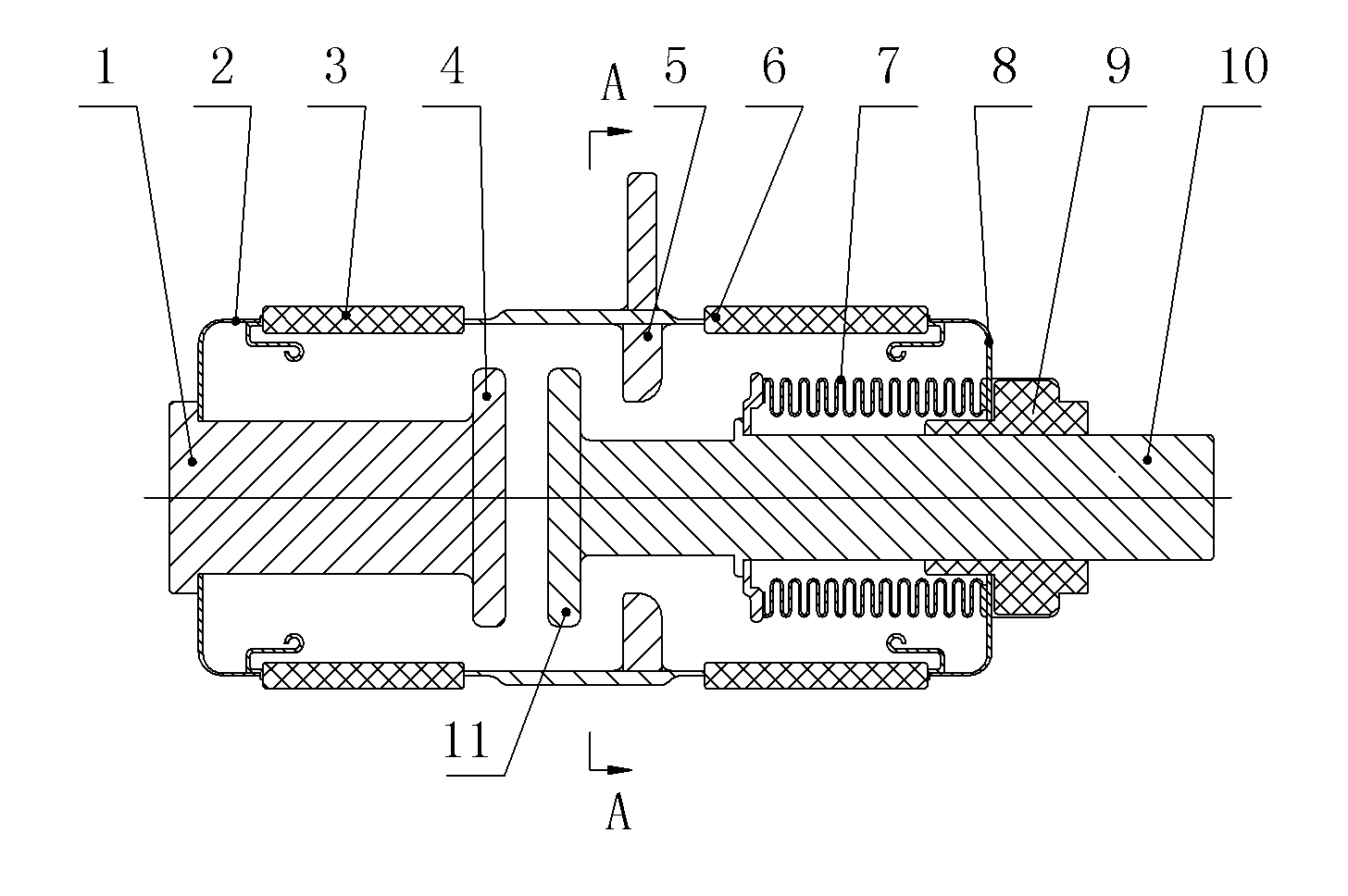

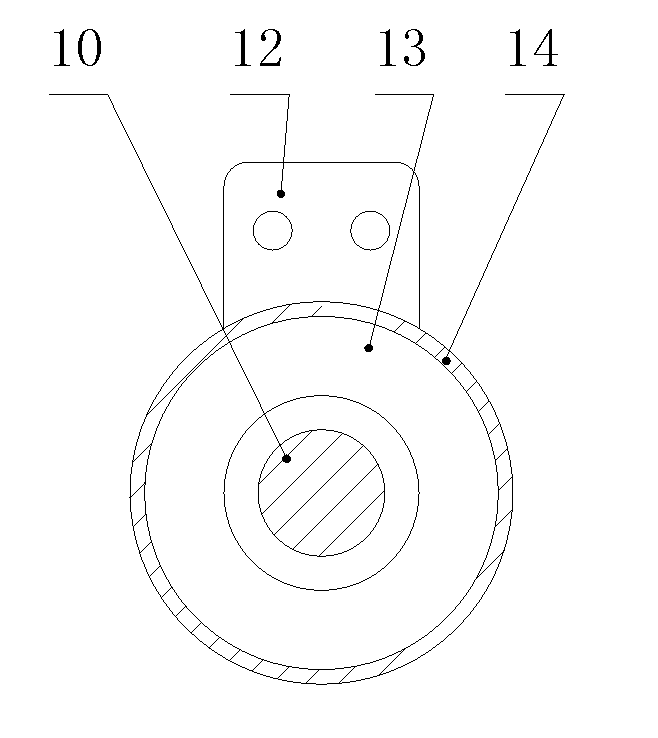

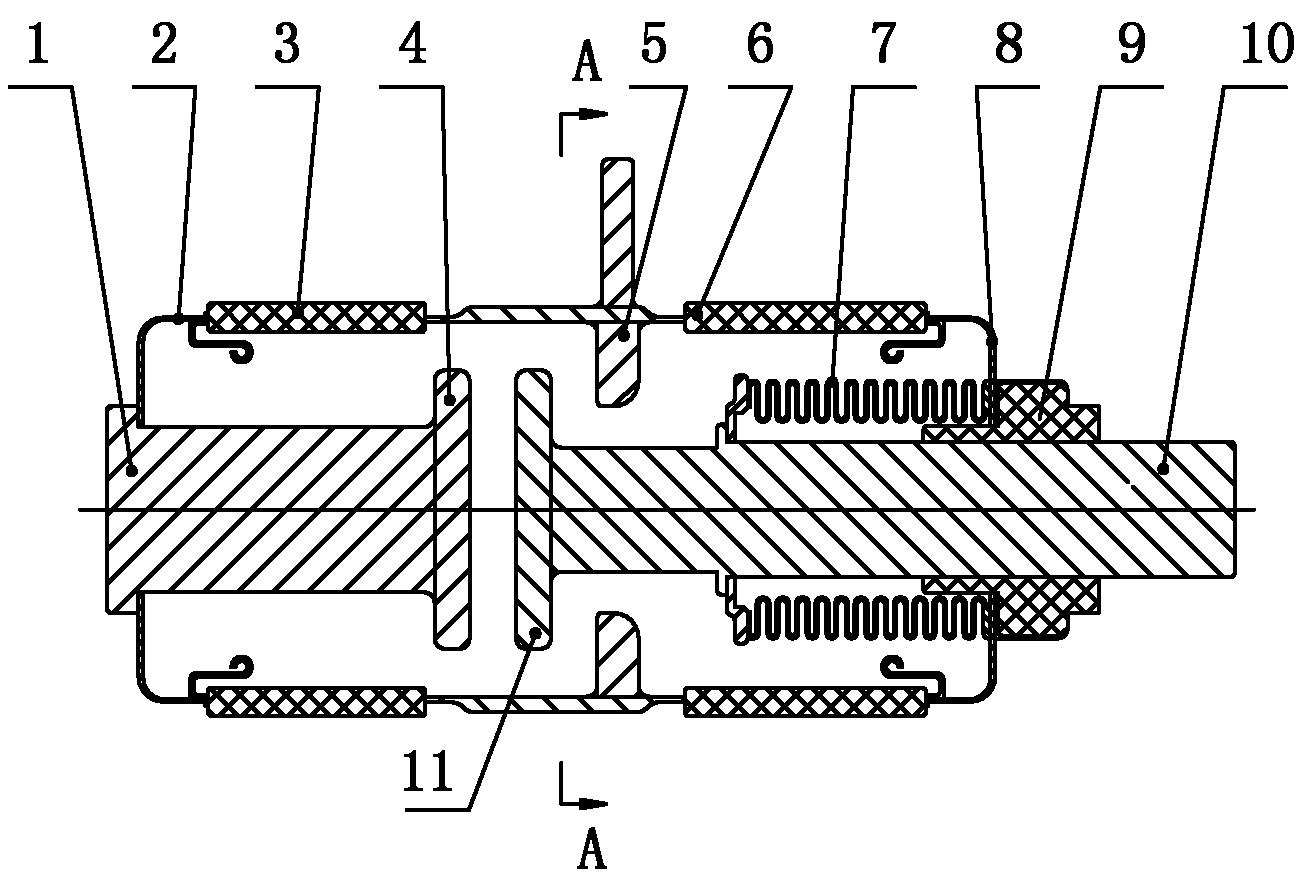

Three-station vacuum switch tube

ActiveCN102157297AAdvanced technologyReasonable designHigh-tension/heavy-dress switchesAir-break switchesElectricityGround contact

The invention discloses a three-station vacuum switch tube comprising a vacuum chamber, a fixed contact assembly, a moving contact assembly and a grounding contact, wherein the grounding contact comprises a grounding contact ring and a grounding terminal, wherein the grounding terminal is electrically connected with the grounding contact ring, and a moving contact is driven by an operating mechanism to take linear back-and-forth movement between a fixed contact and the grounding contact ring; and when the moving contact, the fixed contact and the grounding contact ring are all in off states, the tolerance electric field intensity between the moving contact and the fixed contact is higher than that between the moving contact or the fixed contact and the grounding contact ring. The invention realizes the switch-on, isolation and grounding three-station functions, also not only has the advantages of compact structure, reasonable design, advanced technology, current relative standard accordance, long electrical life and mechanical life, wide application range, high safety and reliability, and the like, but also realizes that electric breakdown firstly generates between a loading terminal and a grounding terminal once vacuum degree is reduced, enables the leakage currents and the short-circuit currents to flow into earth and ensures the safety of maintenance personnel who possibly mistakenly contact the loading terminal.

Owner:西安森源开关技术研究所有限公司

Quantum energy storage or retrieval device

InactiveUS6501093B1Small leakageEliminate air pollutionSolid-state devicesPhotovoltaicsHigh energyBusbar

A solid state Quantum high Energy density Storage Or Retrieval device known as a quensor, and the trademark ENSOR(TM), having an energy density of about 1-15 kwhr / kg, comparable to gasoline, or more, is described. A fundamentally new principle is employed: A quensor film comprises oriented molecules with donor and acceptor groups and with metal layers on its surfaces. A dipole electric field may be established in the gap between a donor and an acceptor. Electric energy is stored in or retrieved from dipole electric fields throughout the volume of the quensor film. Electric energy is stored in the quensor film by charging the dipole electric fields from an electric energy source. Electric energy is retrieved from a quensor film by discharging the dipole electric fields and supplying the energy to a load. Electric breakdown in the film is avoided because positive and negative electric charges in the film are balanced everywhere. Busbars attached to the metal layers are connected to terminals for charging or discharging the device. The manufacture of a quensor film is described. A composite photovoltaic and quensor panel for the storage or retrieval of solar-electric energy day or night on demand is also described.

Owner:MARKS ALVIN M

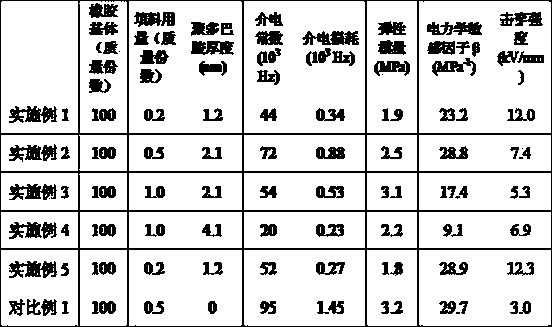

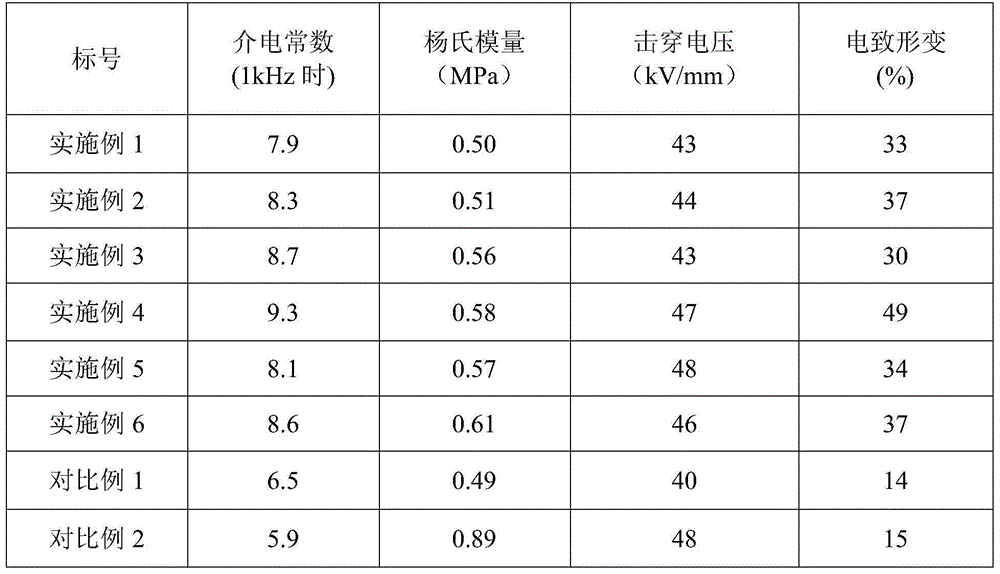

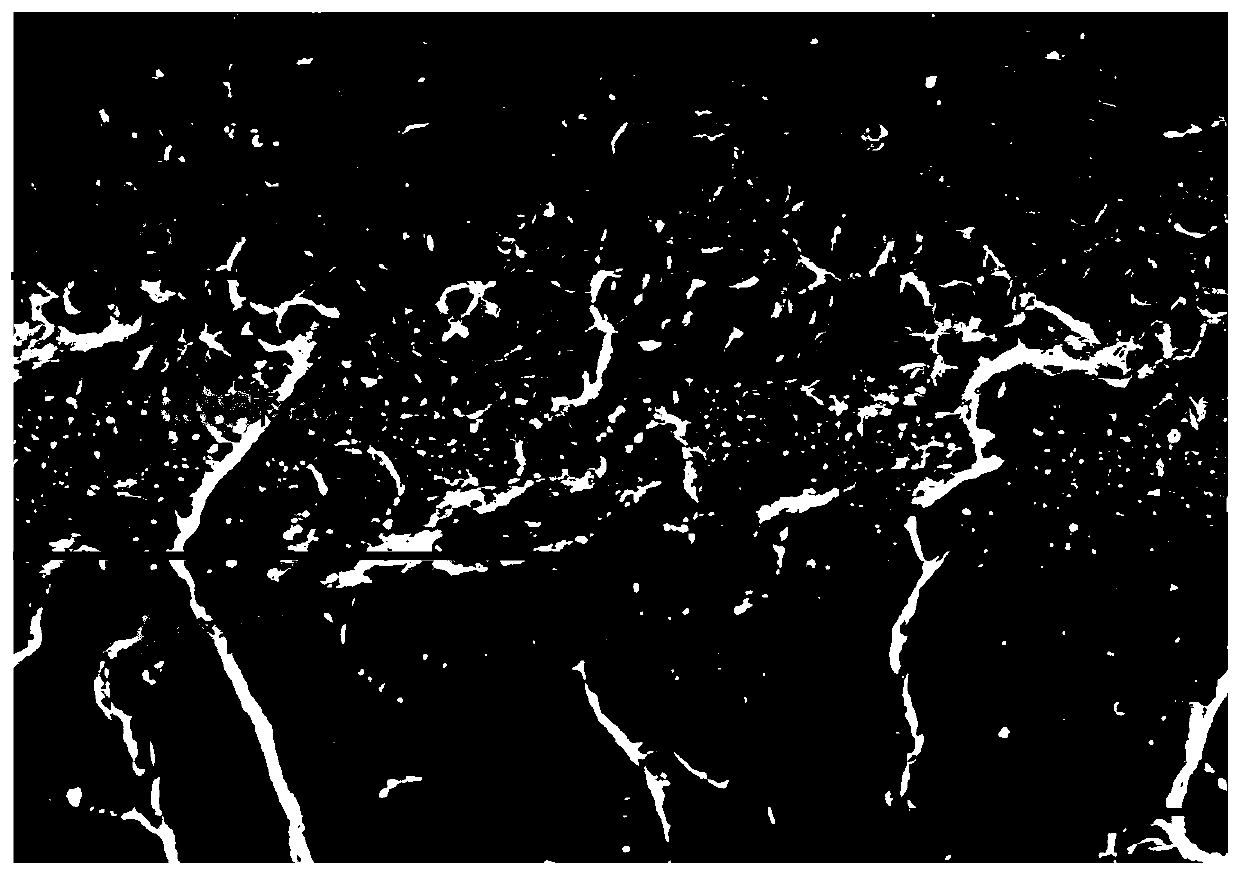

Graphene-based dielectric elastomer composite material and preparing method thereof

The invention relates to a graphene-based dielectric elastomer composite material and a preparing method thereof. The composite material comprises an elastomer matrix, graphene oxide dielectric padding and a crosslinking system, wherein the graphene oxide dielectric padding is oxidation graphene with the surface wrapped by a poly-dopamine organic layer and is scattered in the elastomer matrix in a nanometer horizontal layer mode, and an isolation network structure that an oxidized graphene slice layer which is wrapped by the poly-dopamine organic layer wraps latex particles. According to the preparing method, the dopamine bionic ornament oxidization graphene is adopted, the dielectric loss is obviously reduced, the electric breakdown strength is improved, the organic layer thickness of the poly-dopamine can be regulated through the parameters of the modification process of the dopamine, the dielectric constant, the dielectric loss and the electric breakdown strength of the composite material can be adjusted according to the demands, and the graphene-based dielectric elastomer composite material meeting the safety requirement in the biology medical field can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

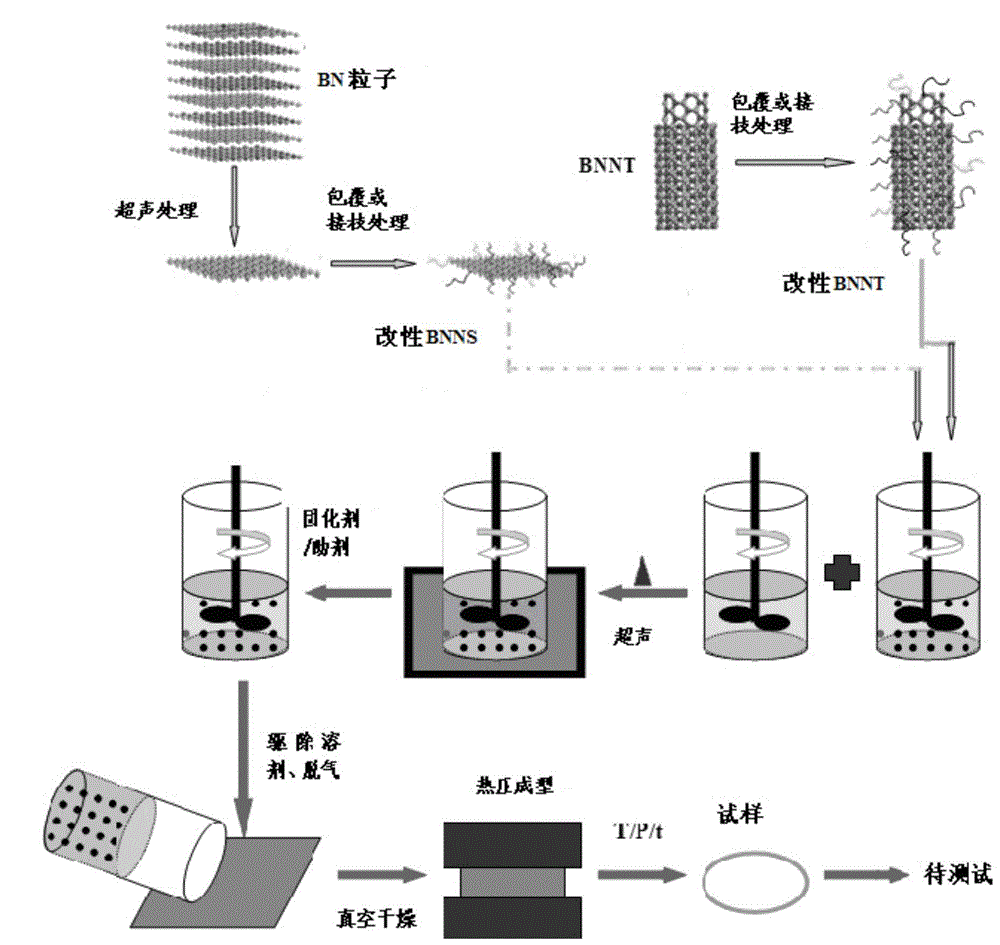

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

Preparing method of waterproof electric-breakdown-resisting coating

ActiveCN107058979AExtend power-on timeImprove electrical breakdown resistancePrinted circuit manufactureSpecial surfacesCross-linkHigh energy

The invention discloses a preparing method of a waterproof electric-breakdown-resisting coating, and belongs to the technical field of plasma chemical vapor phase deposition. According to the method, a base material is placed in a reaction cavity, continuous vacuum pumping is carried out, and inert gases or nitrogen is led in; monomer steam is led to start plasma discharge, the waterproof electric-breakdown-resisting coating is prepared on the surface of the base material; the monomer steam is a mixture of at least one kind of single-functional unsaturated fluorocarbon resin and at least one kind of polyfunctionality unsaturated hydrocarbon derivatives, wherein the mass percent of the polyfunctionality unsaturated hydrocarbon derivatives in the monomer steam ranges from 30% to 50%. Extra cross-linked points are led in by introducing of other monomer components with polyfunctional group cross-linked structures to form a cross-linked structure; plasma is broken by active base groups with high energy in the monomer components to form active points, the introduced extra active points are subject to cross-linking polymerization under the plasma environment to form a compact net-shaped structure, hydrophobicity of a thin film is ensured, and the property of corrosion resistance and underwater powering resistance of an electronic product is improved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

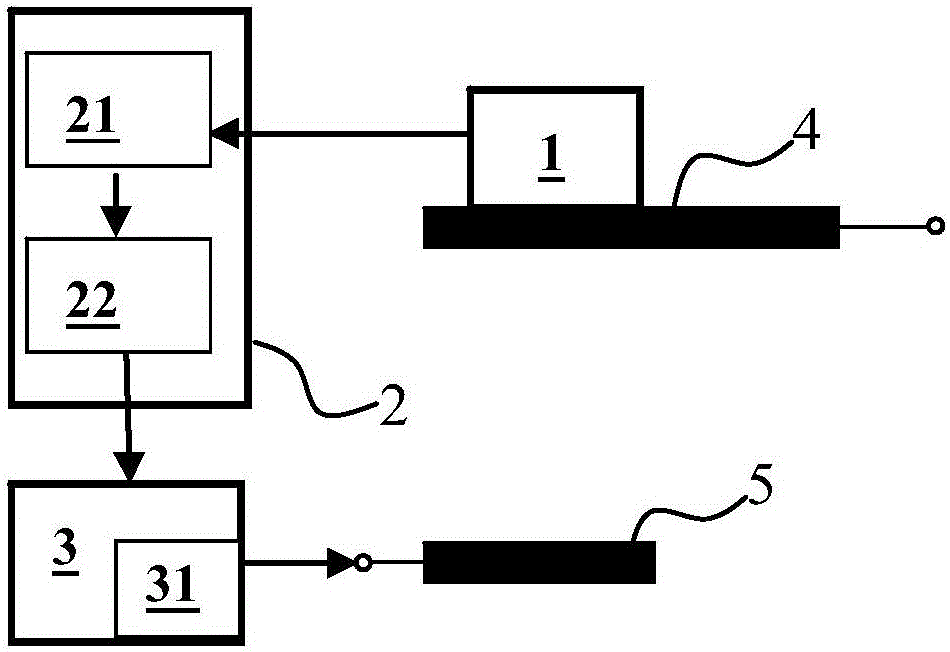

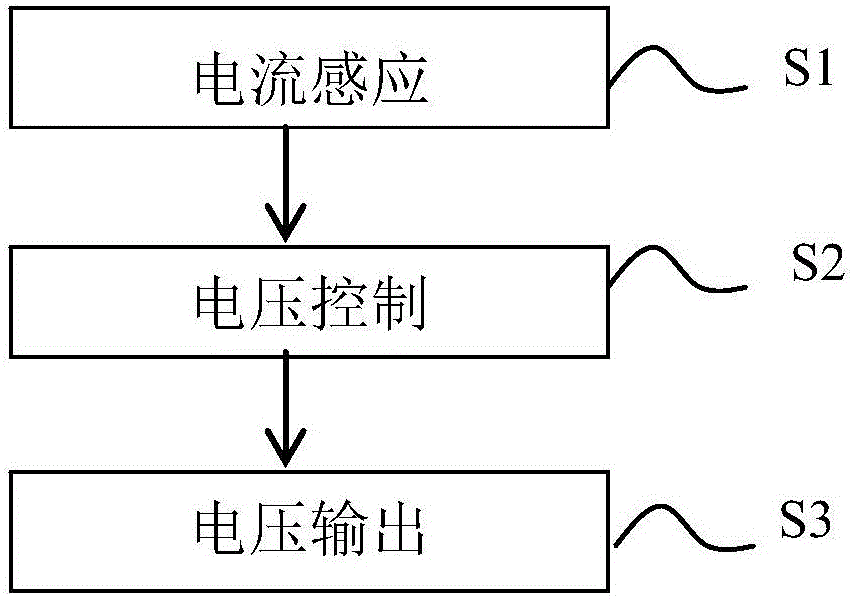

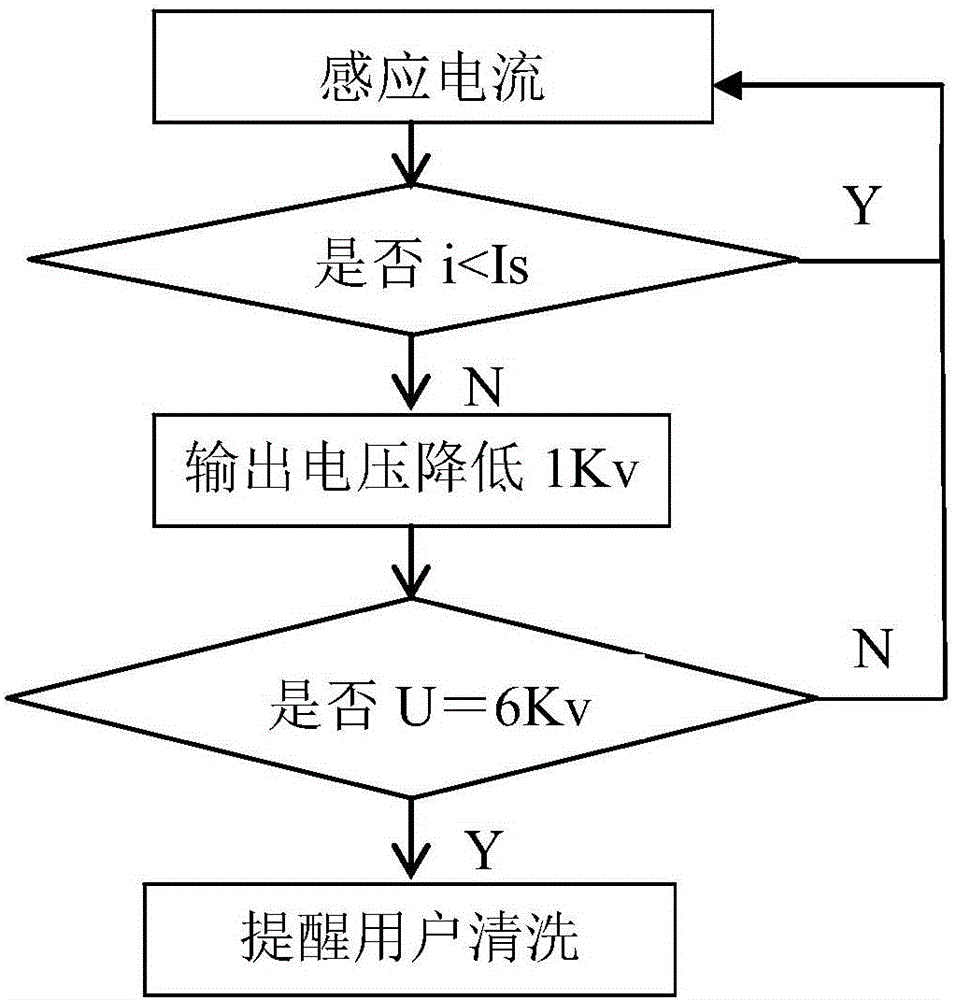

Air purifier, and dust deposition prevention device and method thereof

InactiveCN105750087AEasy to useAvoid electrical breakdownElectric supply techniquesPower flowControl signal

The invention provides an air purifier, and a dust deposition prevention device and method thereof. The dust deposition prevention device comprises a micro-current sensing module, a voltage control module and a voltage output module, wherein the micro-current sensing module is used for sensing current passing through a dust collecting electrode of the air purifier and outputting micro-current corresponding to the current passing through the dust collecting electrode; the voltage control module is used for comparing the magnitudes of the micro-current and a preset threshold value, and when the micro-current is more than or equal to the preset threshold value, a control signal indicating to reduce voltage applied to the dust collecting electrode is outputted by the voltage control module; the voltage output module is used for reducing the output voltage according to the control signal, so as to reduce voltage applied to a high voltage electrode of the air purifier. According to the scheme provided by the invention, the electric breakdown phenomenon between electrodes and the creepage phenomenon between electrodes and nearby materials, caused when much dust is accumulated on a dust collecting electrode after an air purifier runs for a long time, are prevented.

Owner:GREE ELECTRIC APPLIANCES INC

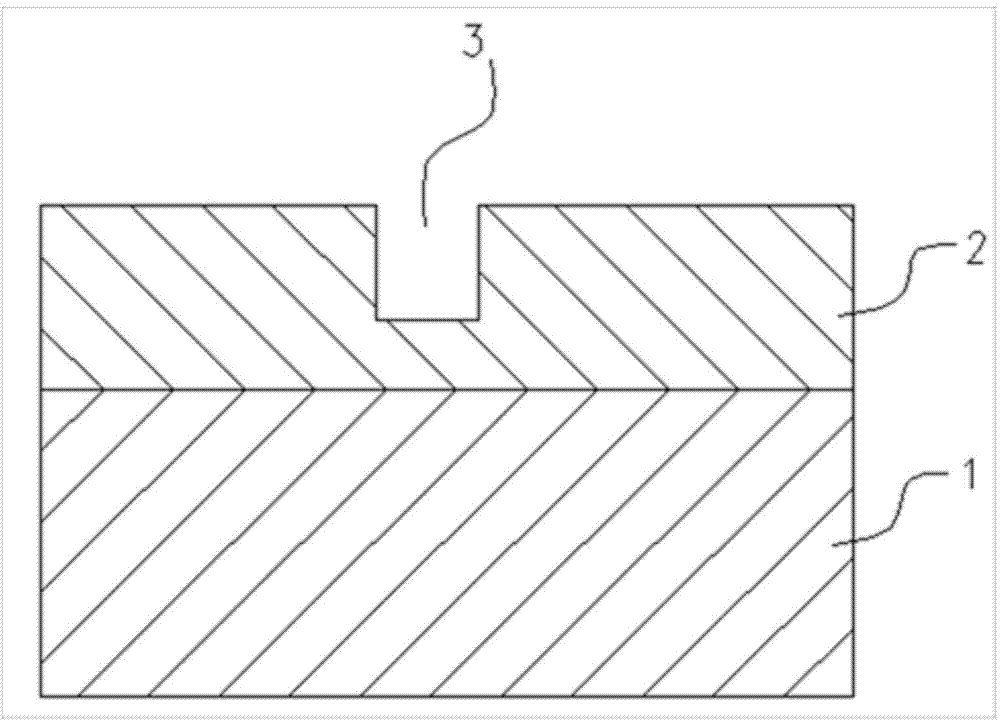

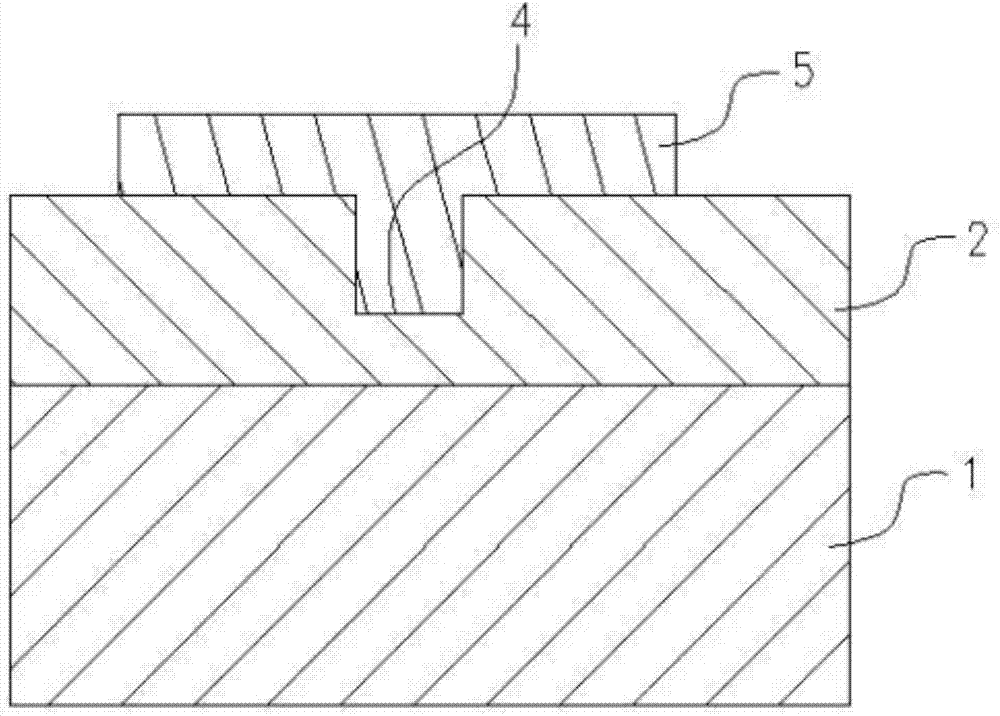

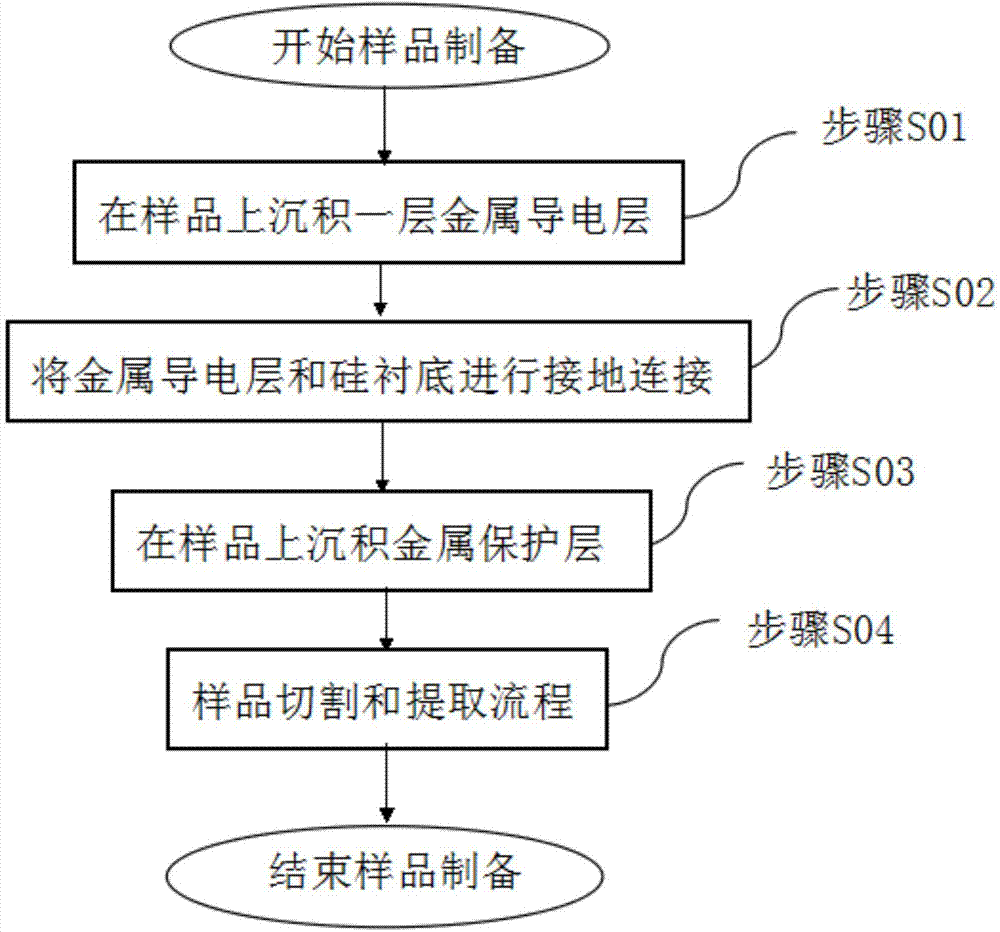

Preparation method of transmission electron microscope sample

ActiveCN104122130AAvoid accumulationAvoid buildup and breakdown insulation problemsPreparing sample for investigationIon beamElectric breakdown

The invention discloses a preparation method of a transmission electron microscope sample. The transmission electron microscope sample comprises a silicon substrate and an insulating layer, wherein a through-hole or groove type target structure is formed on the insulating layer. The preparation method comprises the following steps: firstly, depositing a metal conductive layer on the surface of the insulating layer; connecting the metal conductive layer with the silicon substrate, wherein the sample is directly arranged on a sample table in a focused ion beam system and the silicon substrate is grounded through the sample table; and then depositing a metal protective layer on a target structure part on the metal conductive layer. During sample cutting, electric charges generated by the metal protective layer can be conducted to the silicon substrate and then grounded through the sample table, so that the charge accumulation in the target structure is avoided and the problem that the target structure is damaged by electric breakdown is prevented; according to the method, the problems such as the charge accumulation in the target structure and the breakdown of the insulating layer are avoided during the sample cutting, so that real and intact information of the target structure is obtained.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

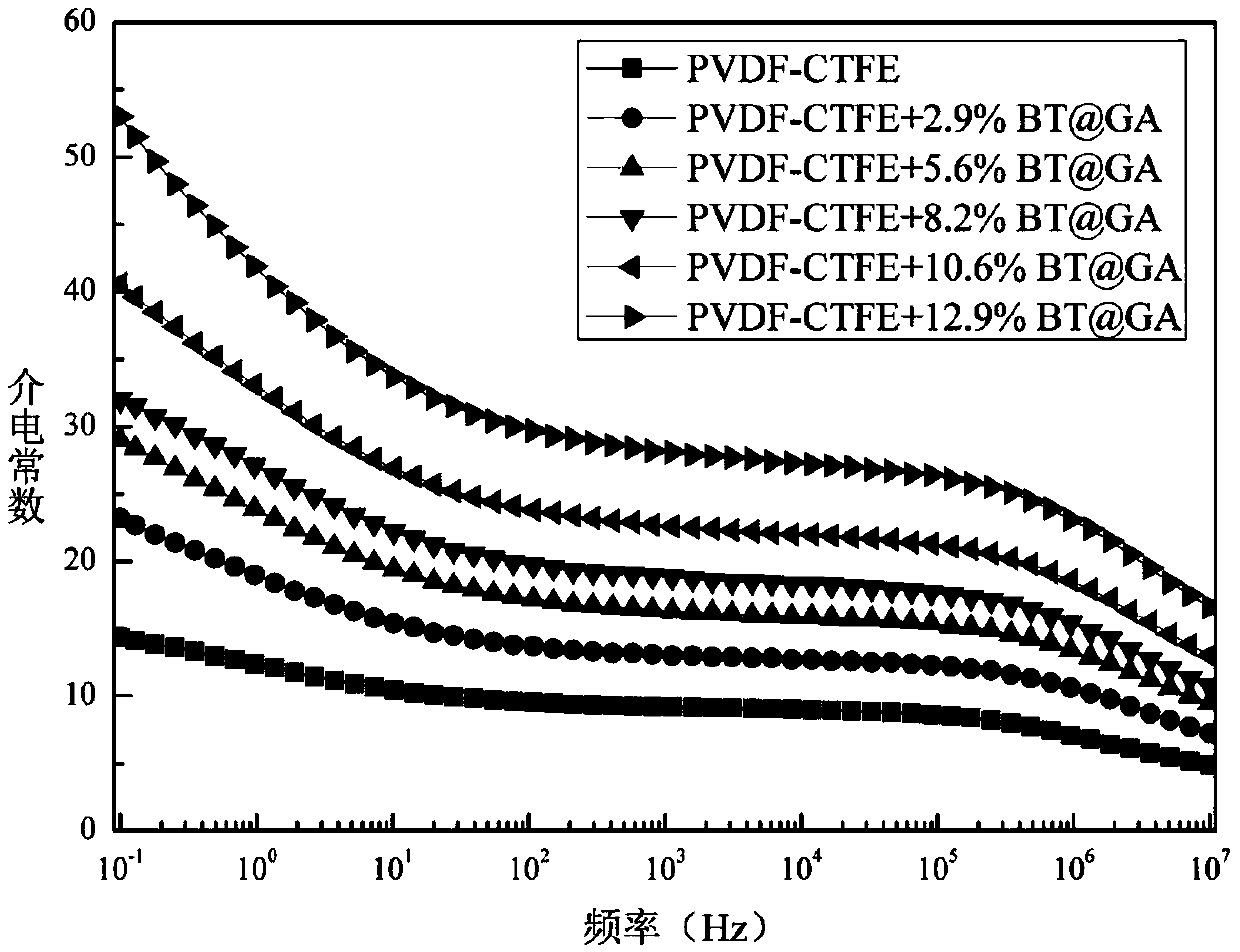

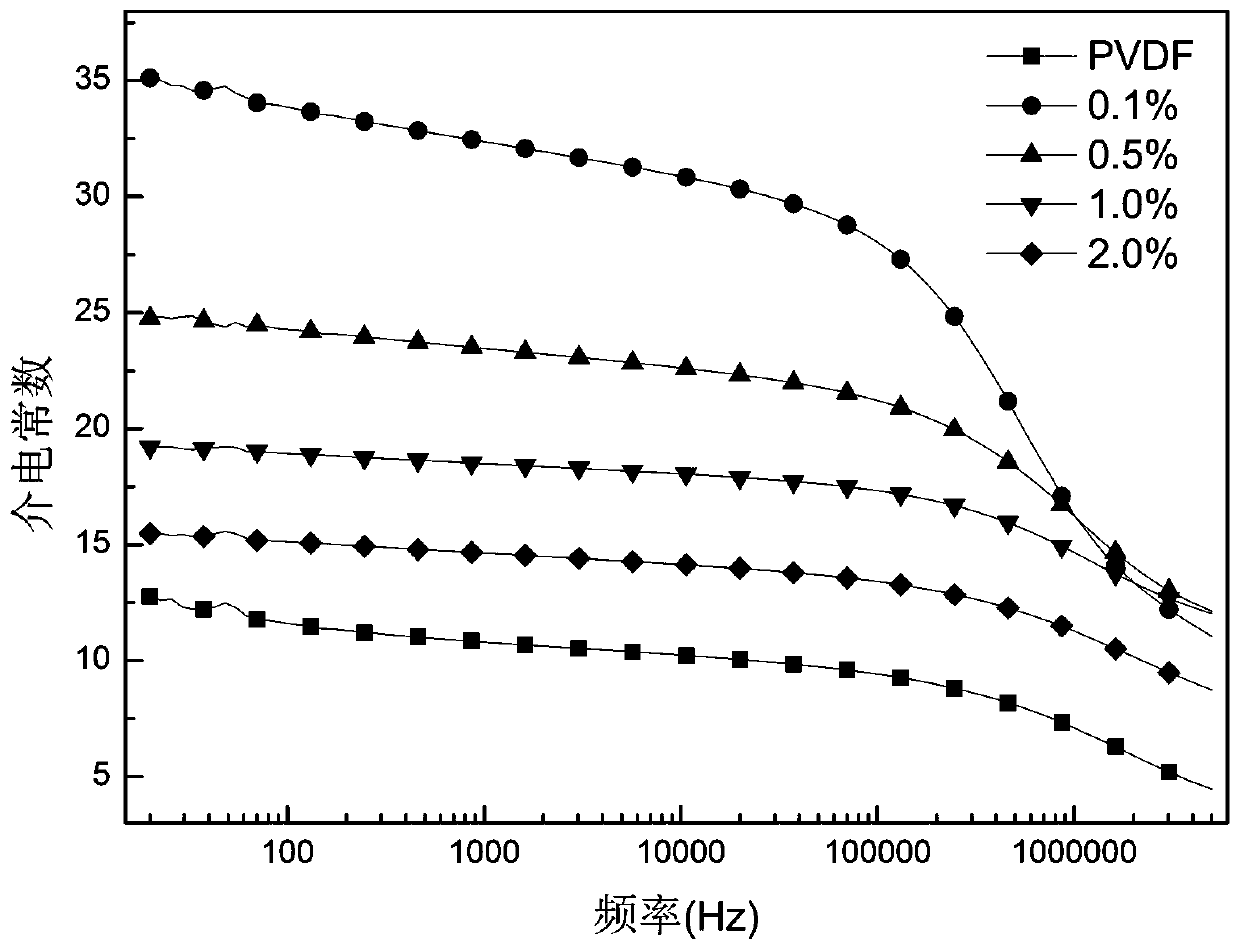

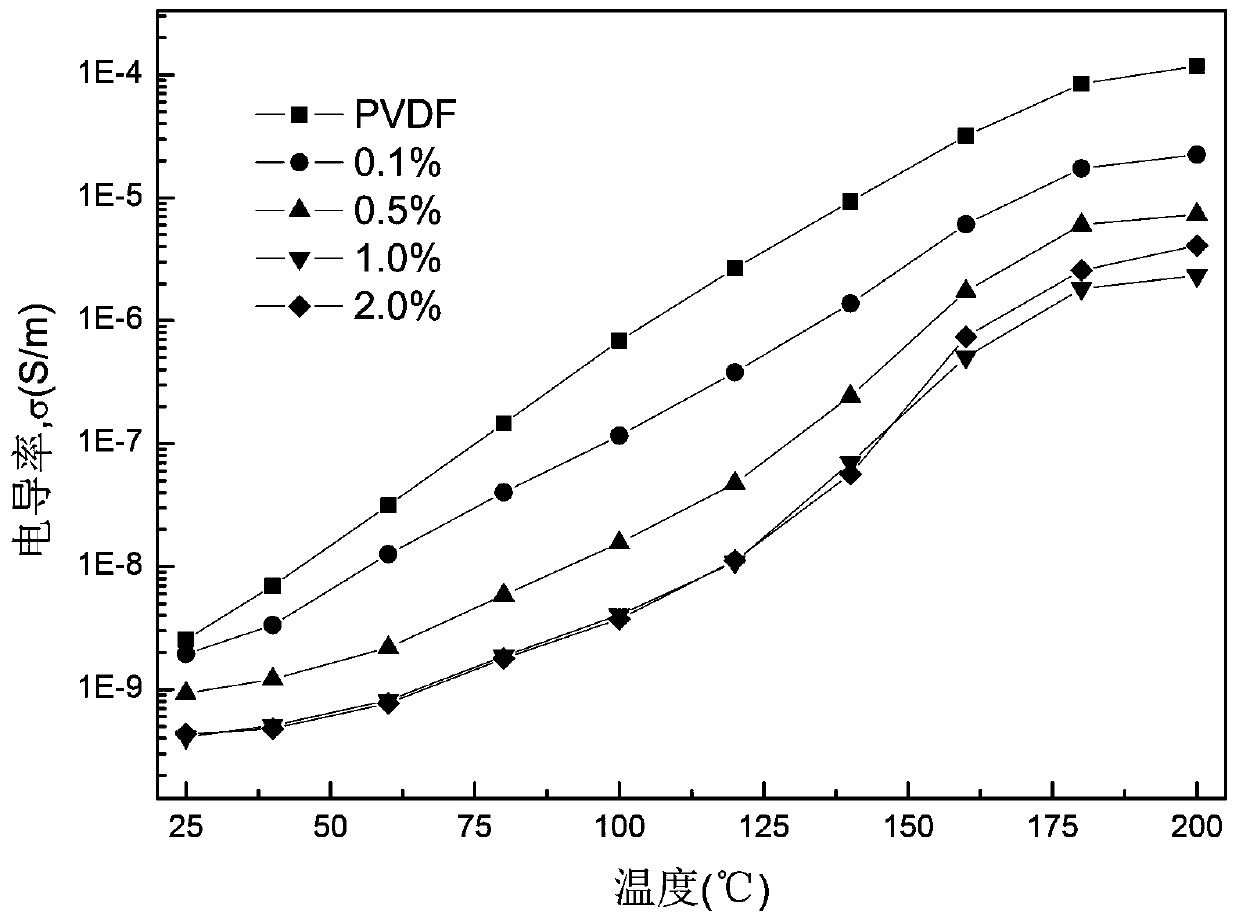

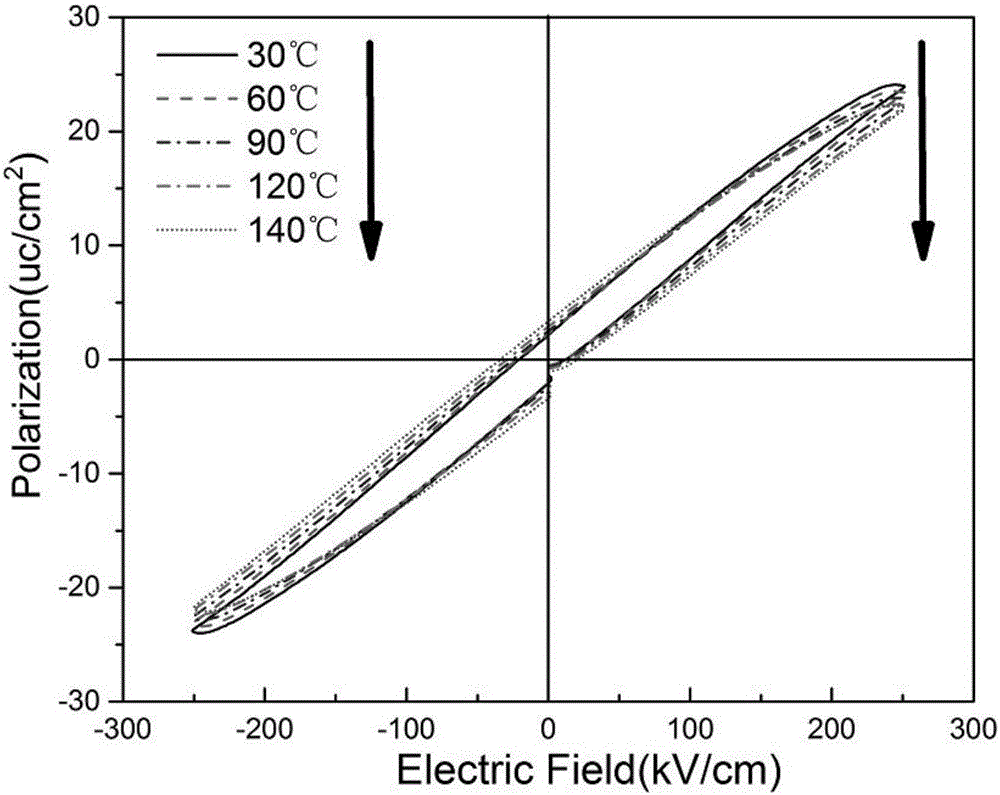

Carbonyl-containing material-coated barium titanate/polymer composite film and preparation method thereof and application

The invention discloses a carbonyl-containing material-coated barium titanate / polymer composite film and a preparation method thereof and application. The carbonyl-containing material-coated barium titanate / polymer composite film is prepared through the following method which comprises a step 1) of mixing dispersion liquid of nanometer barium titanate and a carbonyl-containing material, and obtaining composite nanoparticles coating the carbonyl-containing material; a step 2) of dispersing the composite nanoparticles coating the carbonyl-containing material into polymer composited solution, and obtaining mixed dispersion liquid; a step 3) of causing the mixed dispersion liquid in the step 2) to undergo tape casting, removing a solvent to form a film, and then causing the film to undergo hot pressing and cooling to obtain the carbonyl-containing material-coated barium titanate / polymer composite film. The carbonyl-containing material-coated barium titanate / polymer composite film can achieve high dielectric constant (30 or above), high electric breakdown strength (250 MV / m or above) and high discharge density are guaranteed, and the flexibility of the capacitor composite film is maintained. The carbonyl-containing material-coated barium titanate / polymer composite film is applied to the preparation of a flexible electronic device.

Owner:TSINGHUA UNIV

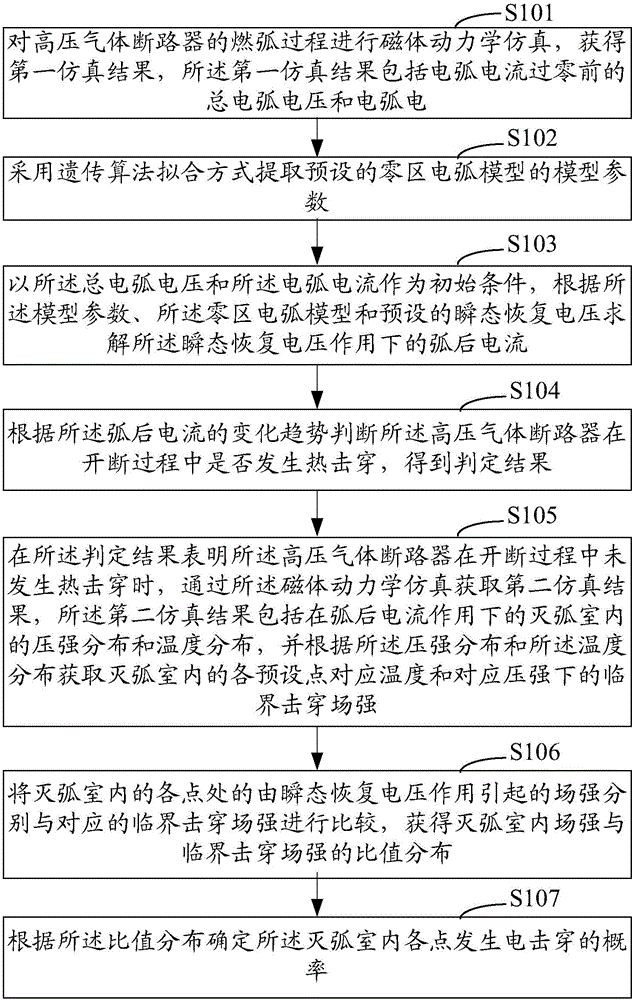

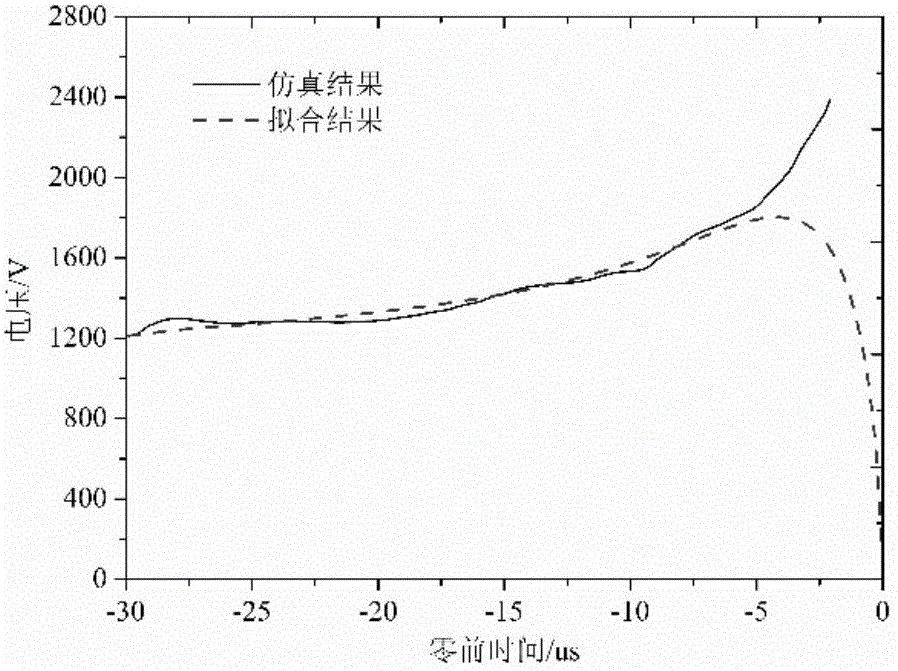

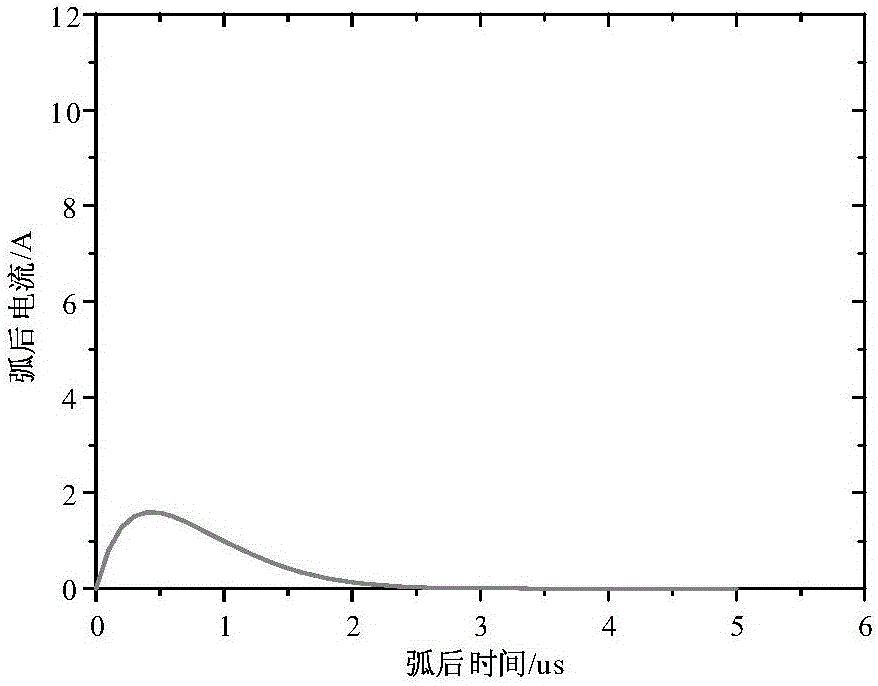

High-pressure gas breaker breaking performance assessment method and system

ActiveCN106407501ADesign optimisation/simulationSpecial data processing applicationsArc modelElectric breakdown

The invention relates to a high-pressure gas breaker breaking performance assessment method and system. The method comprises the following steps of: carrying out magnet dynamic simulation on an arcing process of a high-pressure gas breaker to obtain total arc voltage and arc current before the arc current crosses zero; extracting model parameters of a preset zero area arc model; taking the total arc voltage and the arc current as initial conditions to solve past-arc current under the action of transient recovery voltage on the basis of the zero area arc model; judging whether the high-pressure gas breaker causes thermal breakdown or not in the breaking process according to change trend of the past-arc current; obtaining pressure intensity distribution and temperature distribution in an arc extinction chamber under the action of the past-arc current through magnet dynamic simulation, comparing field intensity, caused by the action of the transient recovery voltage, at each point of the arc extinction chamber, corresponding temperature and critical breakdown field intensity, and assessing the probability of electric breakdown in the arc extinction chamber. By adoption of the method and system provided by the invention, the comprehensive assessment for the past-arc thermal breakdown and electric breakdown characteristics of the high-pressure gas breaker is realized.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

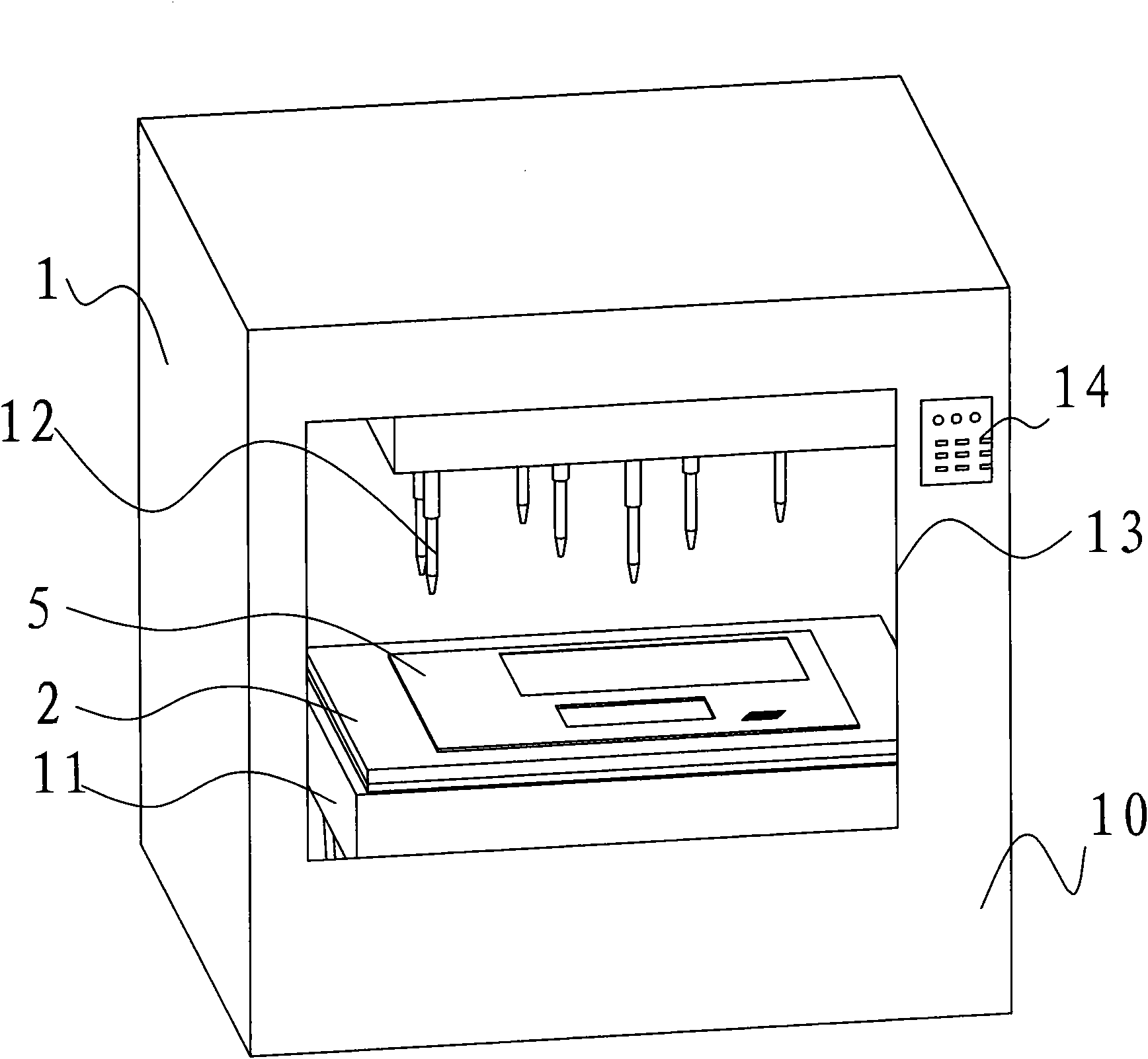

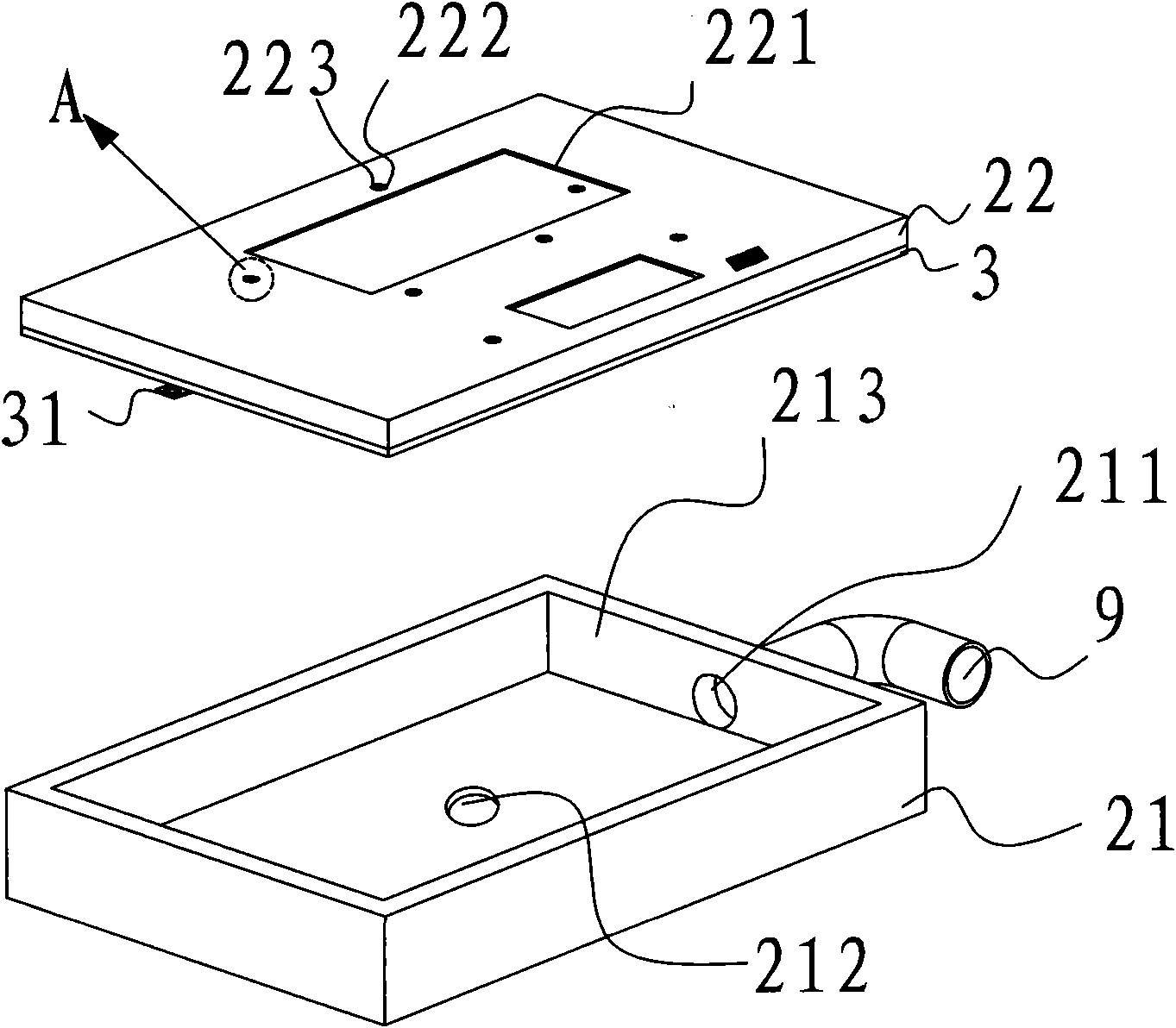

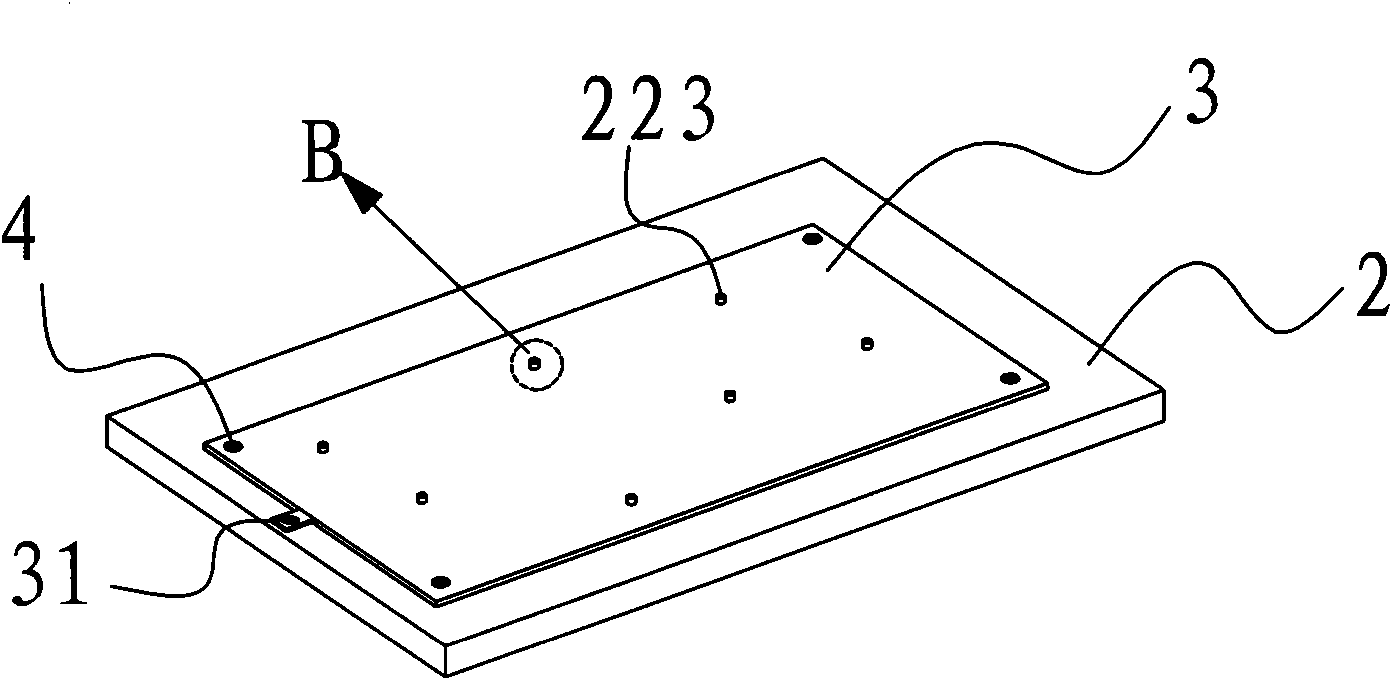

Electrochemical burring device and burring process thereof

InactiveCN101862871AImprove integrityNot corrodedMachining electrodesElectrical-based machining electrodesCopper electrodeElectric breakdown

The invention relates to the technical field of surface treatment, in particular to an electrochemical burring device and a burring process thereof. The invention mainly performs the burring of a casting through the electrochemical process, and the burring device comprises an operating platform and a tool fixture capable of moving freely. The operating platform comprises an operating window for fetching the tool fixture, and an electrode connected with an anode. The tool fixture comprises a base fixture and a top cap fixture capable of being buckled with the base. Due to that the tool fixture is connected with a cathode, the top of the operating platform is connected with the anode, the end top of the red copper electrode is of 0.2-1 mm lower than the top surface of the through hole on the side deviated from a conducting device of the top cap fixture, the invention can greatly enhance the work efficiency, save the labor cost, and the alloy-steel casting is hardly of electric breakdown during the burring of the alloy-steel casting, thereby protecting the integrity of the alloy-steel casting.

Owner:东莞东运镁业有限公司

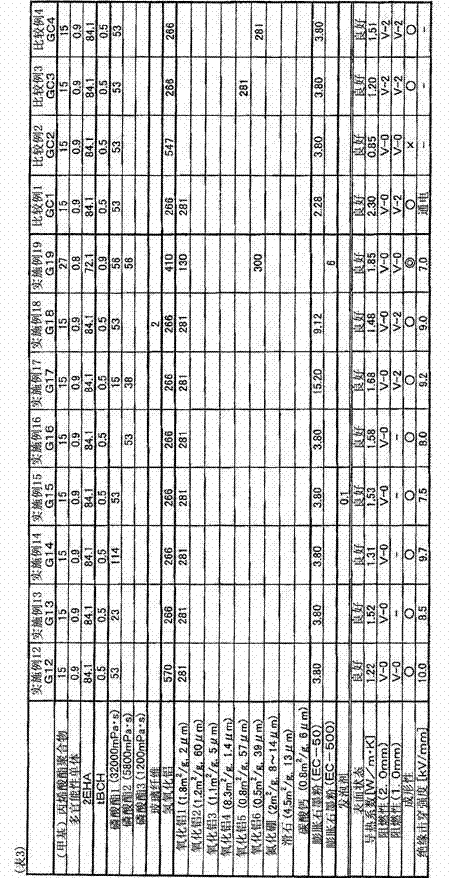

Thermally conductive pressure-sensitive adhesive composition,thermally conductive pressure-sensitive adhesive sheet,and electronic component

InactiveCN102741372AImprove uniformityImprove thermal conductivityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPhosphoric Acid EstersInorganic compound

Disclosed are a thermally conductive pressure-sensitive adhesive sheet which has a high thermal conductivity,a good flame retardancy and a high electric breakdown strength in a well-balanced manner,a thermally conductive pressure-sensitive adhesive composition to be used as a base of said sheet,and an electronic component provided with said sheet. Specifically disclosed are:a thermally conductive pressure-sensitive adhesive composition (F) which comprises 100 parts by mass of at least one kind of a polymer (S),1.8-18 parts by mass inclusive of an expanded graphite powder (B),20-130 parts by mass inclusive of a phosphoric acid ester (C) which has a viscosity at 25oC of 3000 mPa.s or above and exists as a liquid within a temperature range of 15-100oC inclusive under atmospheric pressure,100-1000 parts by mass inclusive of alumina (E) having a BET specific surface area of 1 m2 / g or above, and 160-600 parts by mass inclusive of flame-retardant thermally conductive inorganic compound(s) (D) excluding the expanded graphite powder (B) and the alumina (E) having a BET specific surface area of 1 m2 / g or above;a thermally conductive pressure-sensitive adhesive sheet (G) comprising said thermally conductive pressure-sensitive adhesive composition (F);and an electronic component provided with said sheet.

Owner:ZEON CORP

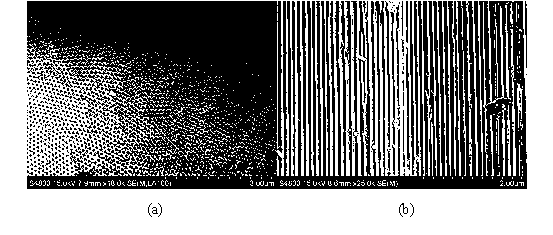

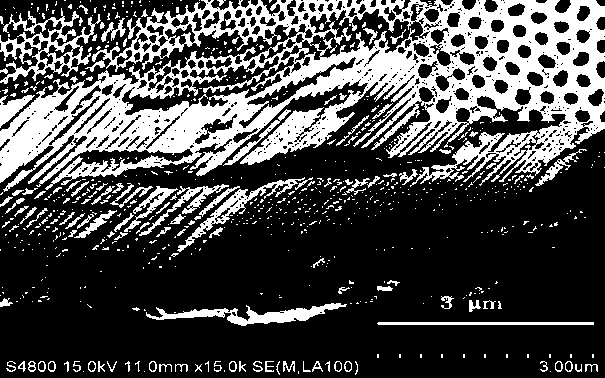

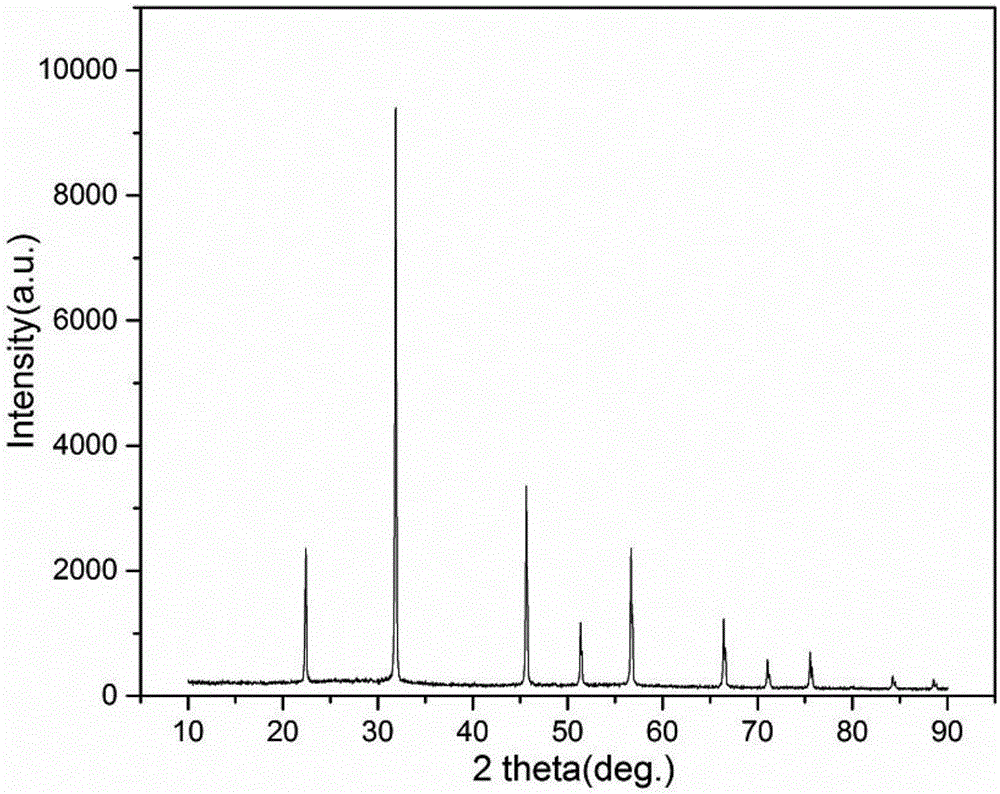

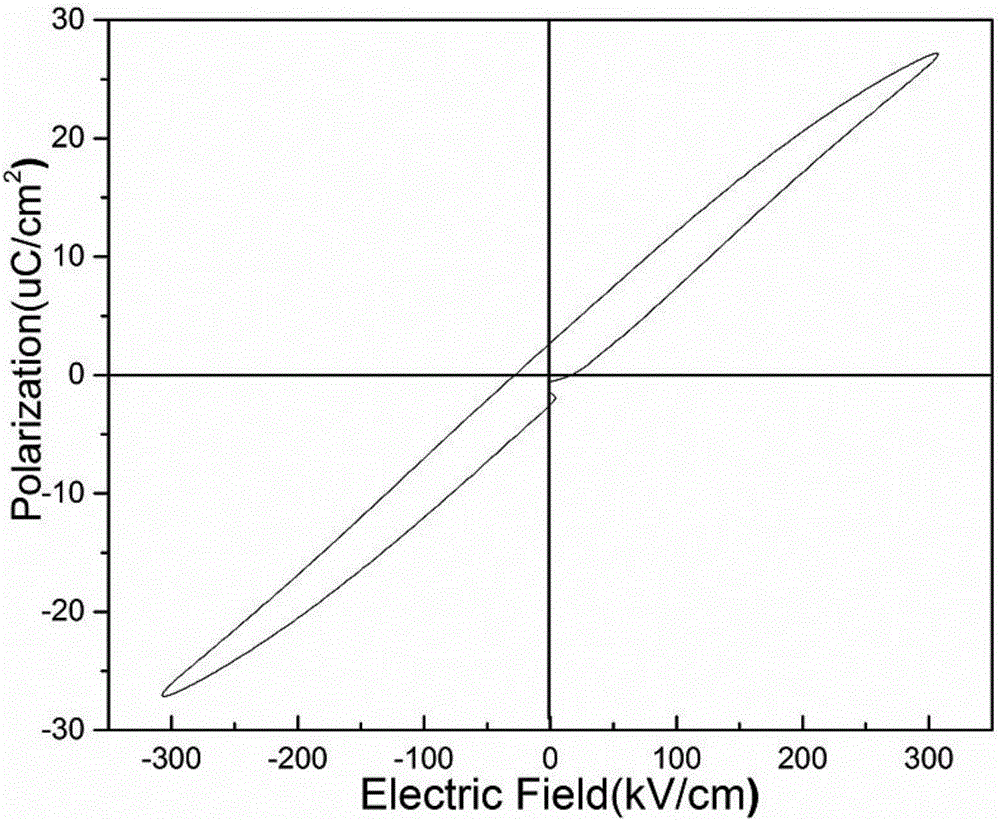

Method for preparing polycrystal texture ceramic material

InactiveCN1850725AQuality improvementImprove performanceElectromechanical coupling coefficientElectric breakdown

This invention relates to polycrystal texture ceramic material preparation method, it includes preparation technique principle and corresponding technique method. Diffusion route of ion and polar particle in high temperature field can be affected by electrostatic field, the characteristic is used to induct crystal nucleus growth process and reinforce anisotropy growth to form texture polycrystal material. Different strength orientation electric field is applied, and the strength is related to material system different component, core forming and crystal growth speed, anisotropy radius-thickness ratio expected, and electric breakdown strength of environment and materials. The anisotropy growth of polusrystal texture made is appreciable, polyspinal deformity is uniform, breaking tenacity and fracture toughness of material on wishful direction can be improved. Directed dielectric property can be great improved, and material piezoelectric constant and electromechanical conpling factor can be improved, dielectric loss can be reduced.

Owner:QINGDAO UNIV

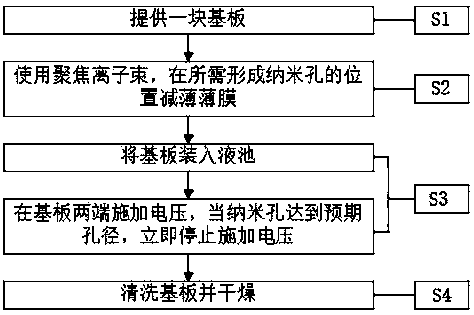

Accurately controllable nano-hole manufacturing method

InactiveCN108706543ASimple manufacturing methodAchieve precise positioningNanotechnologyElectricityComposite film

The invention relates to the technical field of nanofabrication, in particular to an accurately controllable nano-hole manufacturing method which includes the steps: firstly, providing a substrate andthinning a film at a position needing to form nano-holes by a focusing ion beam; secondly, placing the substrate into a liquid tank; applying voltage to two ends of the substrate and stopping applying the voltage when the nano-holes reach expected hole diameters; finally, cleaning and drying the substrate to obtain the nano-holes with accurately controllable positions and sizes. The nano-holes can be formed in a micron-sized or nano-sized multilayer composite film, and the applicable range is wide. The film is thinned at the position needing to form the nano-holes by the focusing ion beam, sothat the nano-holes are formed in the thinned position and can be accurately positioned. Moreover, the nano-holes with the hole diameters smaller than 10nm are finally formed by electric breakdown, the hole diameters of the nano-holes are continuously enlarged along with continuous voltage application and can be accurately controlled according to real-time voltage and real-time current, and the nano-holes with the needed hole diameters are accurately manufactured.

Owner:GUANGDONG UNIV OF TECH

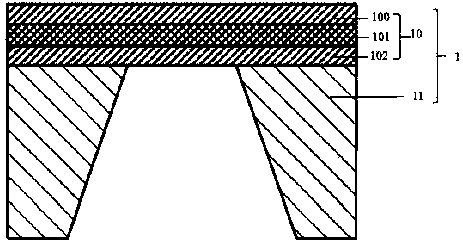

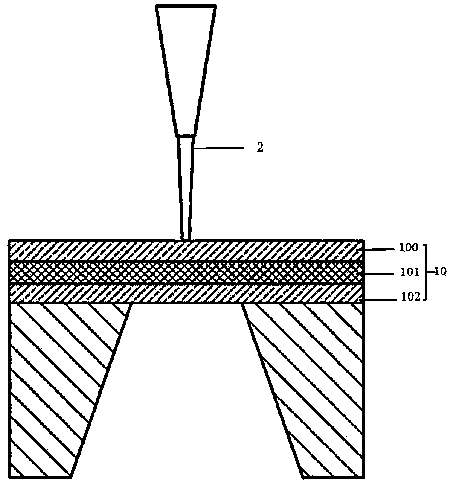

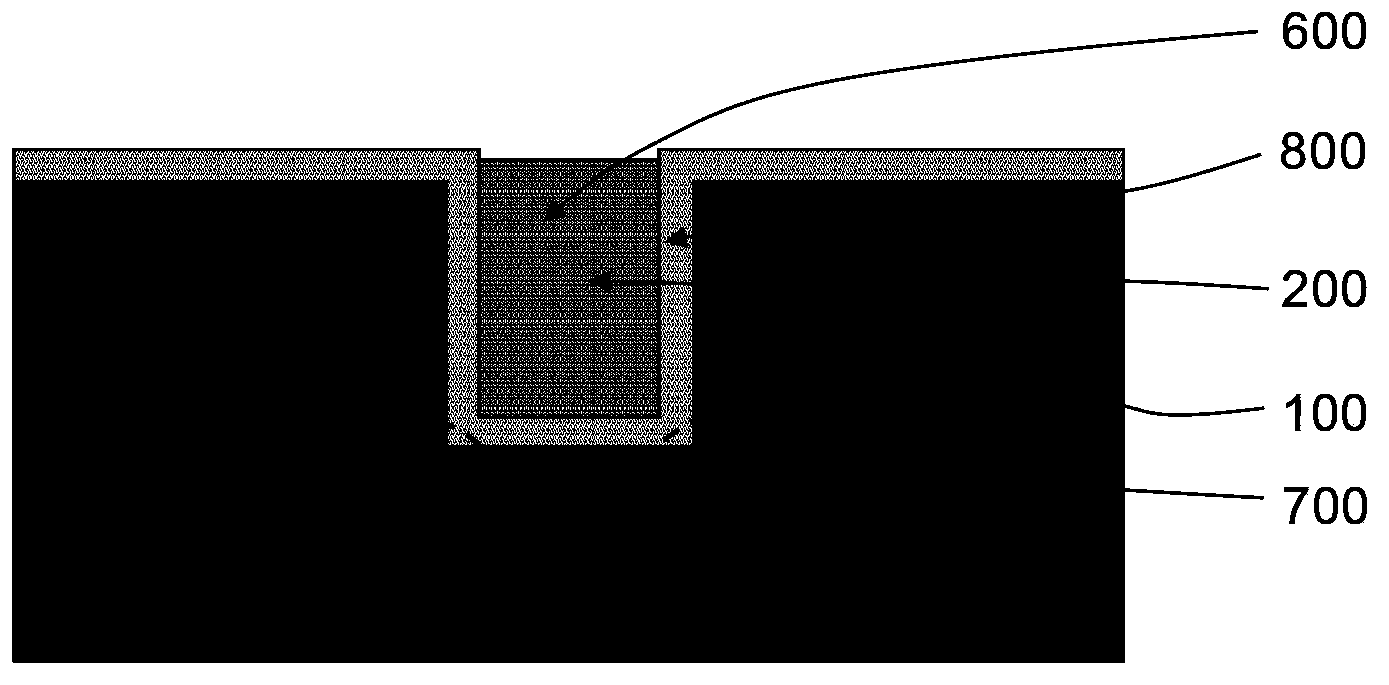

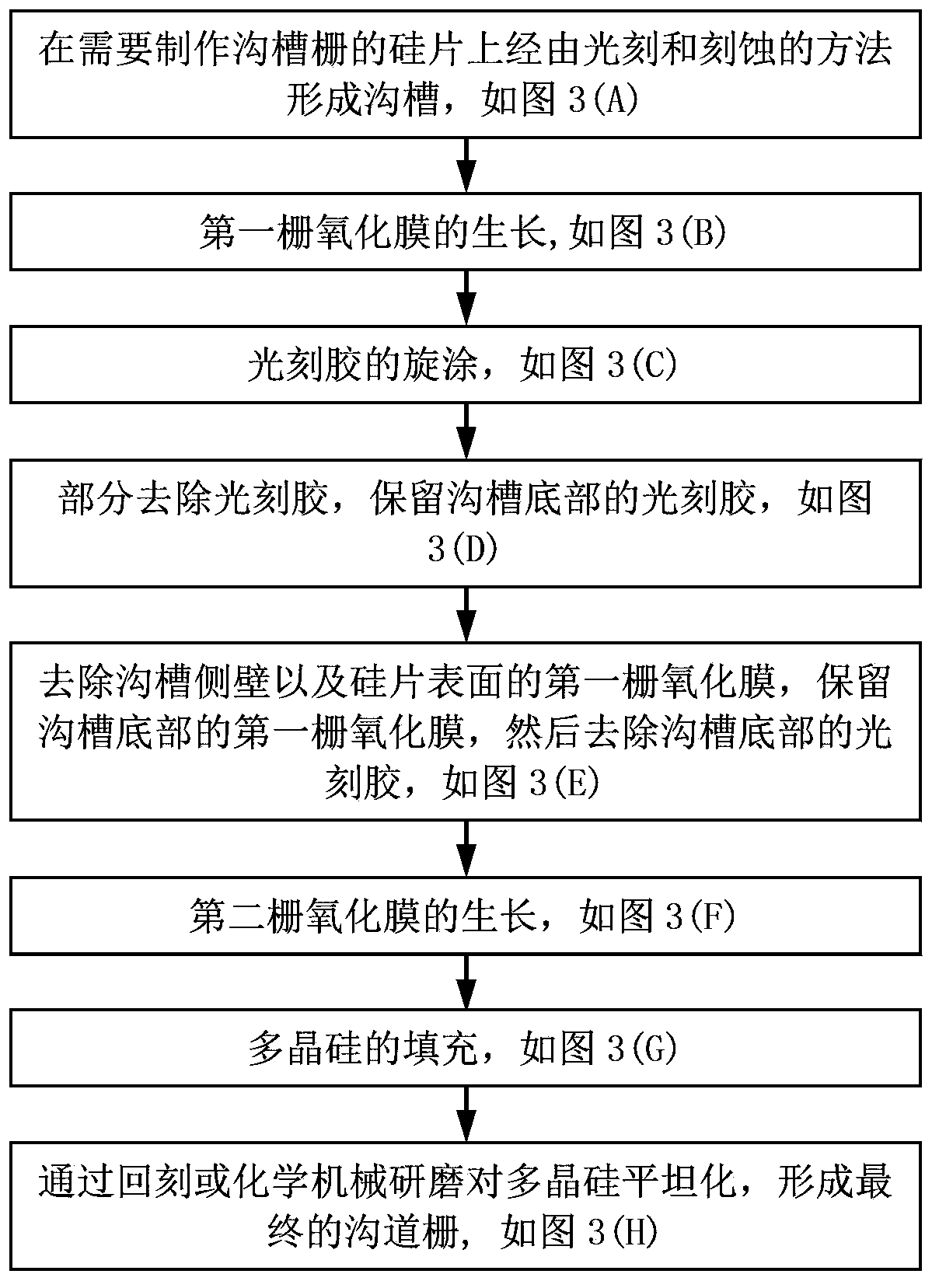

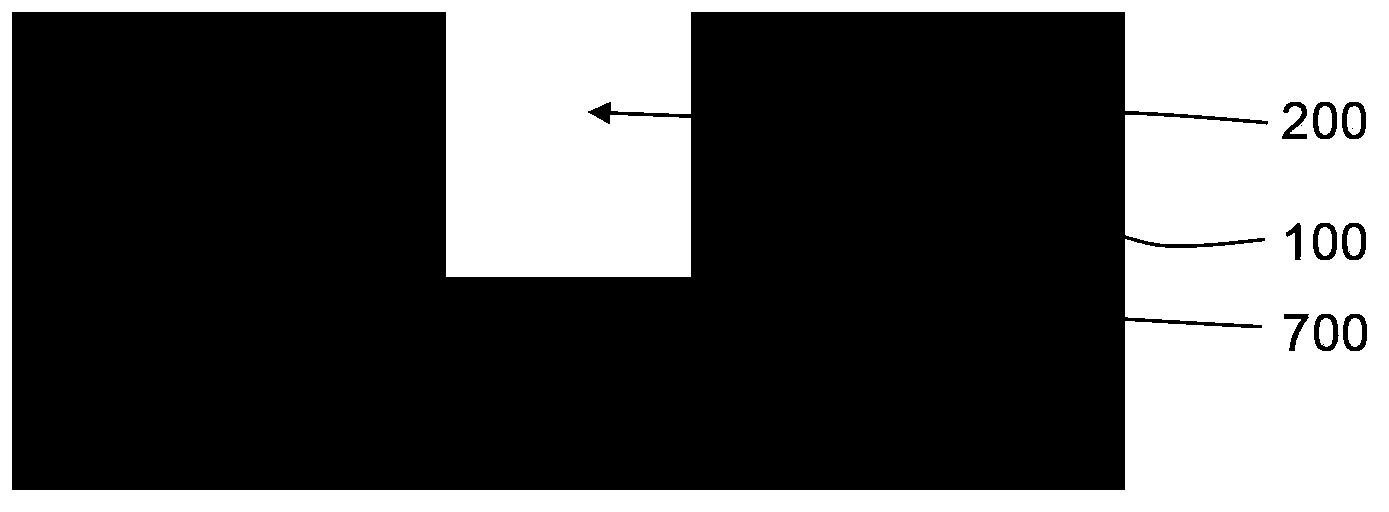

Preparation method of trench gate in trench MOS device

InactiveCN103824764AFast switching speedSolve the problem of prone to electrical breakdownSemiconductor/solid-state device manufacturingSemiconductor devicesParasitic capacitanceElectric breakdown

The invention discloses a preparation method of a trench gate in a trench MOS device. The preparation method of the trench gate in the trench MOS device is characterized in that the thickness of a gate oxidation film at the bottom of a trench is larger than the thickness of a gate oxidation film at the sidewall of the trench. The preparation method includes the following steps that: 1, a trench is formed on a silicon wafer through photo-etching and etching, and a trench gate is required to be produced on the silicon wafer; 2, a first gate oxidation film is grown; 3, spin coating of photoresist is performed; 4, the photoresist is removed partially, and part of the photoresist, which is located at the bottom of the trench, is reserved; 5, a part of the first gate oxidation film, which is located at the sidewall of the trench and the surface of the silicon wafer, is removed, and a part of the first gate oxidation film, which is located at the bottom of the trench, is reserved, and part of the photoresist, which is located at the bottom of the trench, is removed; 6, a second gate oxidation film is grown; polycrystalline silicon is filled; 8, planarization is performed on the polycrystalline silicon through etch-back or chemical mechanical lapping, and the final trench gate can be formed. With the preparation method of the trench gate in the trench MOS device of the invention adopted, parasitic capacitance between a gate and a drain can be reduced, and the switching speed of the trench MOS device can be improved, and switching loss can be decreased, and at the same time, the problem of proneness to electric breakdown at the bottom of the trench of the trench MOS device can be solved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

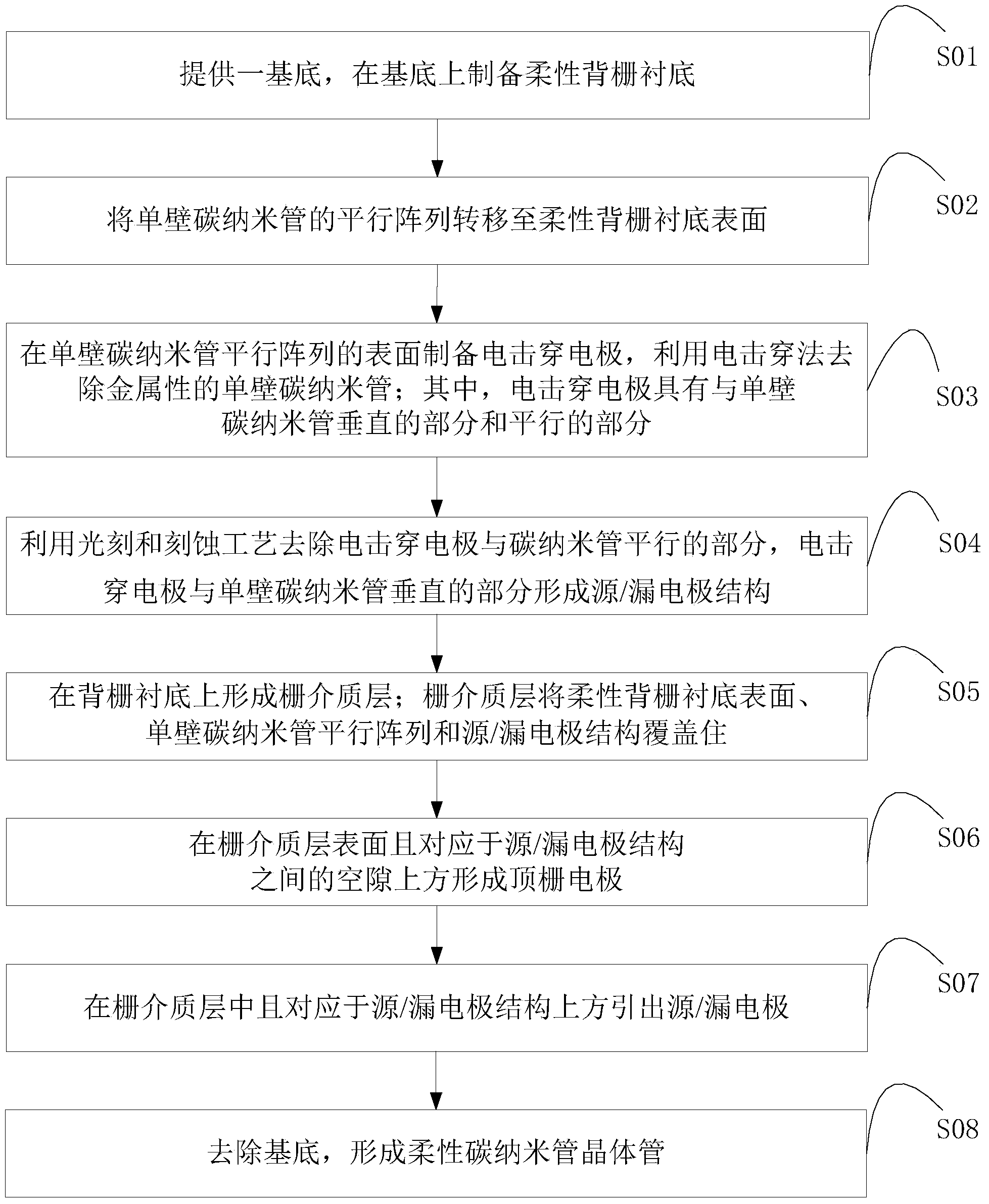

Method for manufacturing flexible carbon nano-tube transistor

ActiveCN103996624AImprove performanceSimple designTransistorNanoinformaticsGate dielectricCarbon nanotube

The invention provides a method for manufacturing a flexible carbon nano-tube transistor. The method comprises the following steps that a flexible back gate substrate is manufactured on a substrate; a single-wall carbon nano-tube parallel array is transferred to the surface of the flexible back gate substrate; metallic single-wall carbon nano-tubes are remoted through an electric breakdown method; a part of electric breakdown electrodes are removed through photoetching and etching processes, so that a source / drain electrode structure is formed; a gate dielectric layer is formed on the flexible back gate substrate; the surface of the flexible back gate substrate, the single-wall carbon nano-tube parallel array and source / drain electrode patterns are covered with the gate dielectric layer; top gate electrodes are formed on the surface of the gate dielectric layer; source / drain electrodes are led out of the source / drain electrode patterns; the substrate is removed, and the flexible carbon nano-tube transistor is formed. According to the method, the intrinsic characteristic that semiconductor single-wall carbon nano-tubes are high in migration rate is brought into full play, the electric breakdown electrodes are directly improved to be capable of serving as the following source / drain electrode structure, the process steps are simplified, and device performance is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

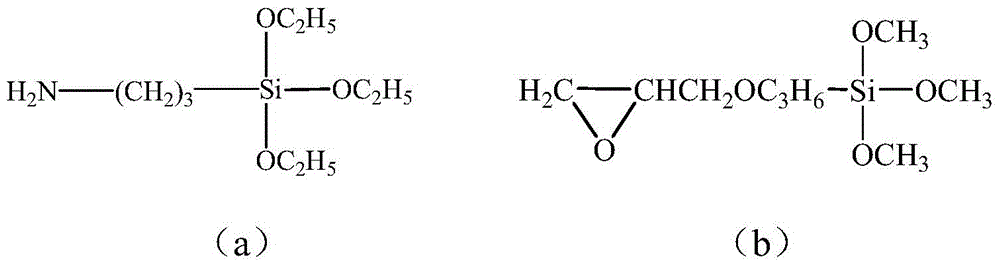

Fluorinated silicone rubber dielectric elastomer composite material and preparation method thereof

InactiveCN104830072ASolve the problem of adding fillers to reduce material stabilityHigh dielectric constantCross-linkElectricity

The invention relates to a fluorinated silicone rubber dielectric elastomer composite material and a preparation method thereof. The cross-linking density is changed, the amount of a high-dielectric semiconductor filler is regulated and controlled, and thus the composite material with good dispersion is obtained. The obtained composite material can obtain high dielectric constant with relatively low filling of the semiconductor filler, at the same time, the elastic modulus has no obvious improvement, the electric breakdown strength remains unchanged, and eventually relatively large electrodeformation is produced.

Owner:BEIJING UNIV OF CHEM TECH

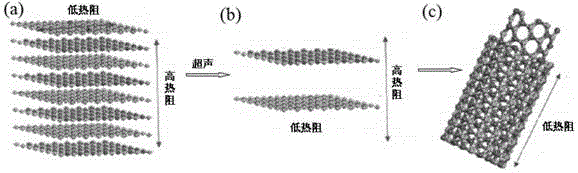

Sandwich-structure high-energy-storage low-conductivity polymer-based composite film manufacturing method

InactiveCN110556247AImprove performanceHigh breakdown strengthFixed capacitor dielectricDielectricComposite film

The invention provides a method for manufacturing polymer-based dielectric composite film with a sandwich structure, high energy storage and low conductivity by taking novel fluorinated graphene as afunctional filler. In the method, the fluorinated graphene is uniformly dispersed in a polymer through a solution ultrasonic dispersion method so as to be served as a middle layer, a pure polymer is taken as an outer layer, and a polymer-based composite film of a sandwich structure is obtained through a layer-by-layer solution flow delay casting method and high-temperature annealing treatment. Byintroducing the fluorinated graphene / polymer composite film which is taken as the middle layer, a dielectric constant is improved, the pure polymer layers on upper and lower outer layers improve electric breakdown strength, and advantages of the two materials are considered. Besides, due to fluorine atoms on a surface of the fluorinated graphene and an interface effect between layers, stacking ofthe fluorinated graphene and formation of a conductive network are hindered, and therefore, energy storage density of the composite film is integrally improved. The dielectric composite film manufactured in the method is simple in process and excellent in performance, and the method can be widely applied to the fields of pulse electromagnetic devices, high-energy-storage-density capacitors and thelike.

Owner:HANDAN COLLEGE

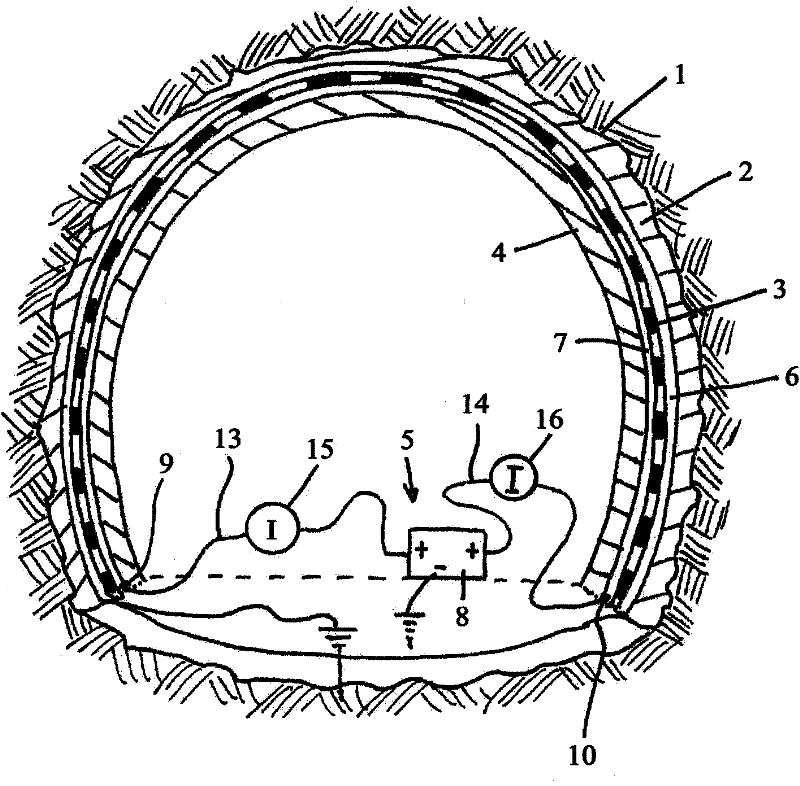

Method and device for checking the seal of structural seals

InactiveCN102099531AEasy to detectRealize monitoringProtective foundationElectric breakdownEngineering

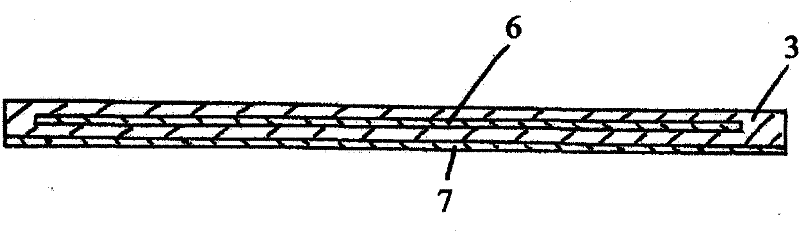

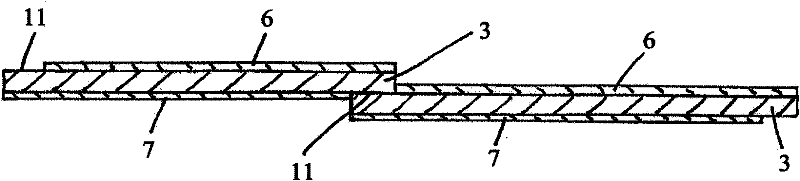

The invention relates to a method for determining weak points with a reduced material thickness in a structural seal (3) having a high electrical dielectric strength in comparison to air, said seal provided with an electrically conducting layer (6, 7) disposed inside or outside of the structural seal (3), the electrically conducting layer (7) that is electrically separated from the electrically conducting layer (6) by the structural seal and that two all extend substantially over the entire surface of the structural seal. The level of the test voltage between the electrically conducting layers (6, 7) under voltage is selected such that the weak point is present in the structural seal, the electrical dielectric strength is surpassed and an electric arc or spark forms at the location of the damaged, faulty and / or weak point, wherein the test voltage is selected to be less than a destructive test voltage at which an electric breakdown would result in an undamaged and / or un-weakened structural seal corresponding to the structural seal (3) to be tested, thereby forming an electric arc or spark. Also claimed is a correspondingly designed structural seal (3).

Owner:普罗吉欧监控技术有限公司

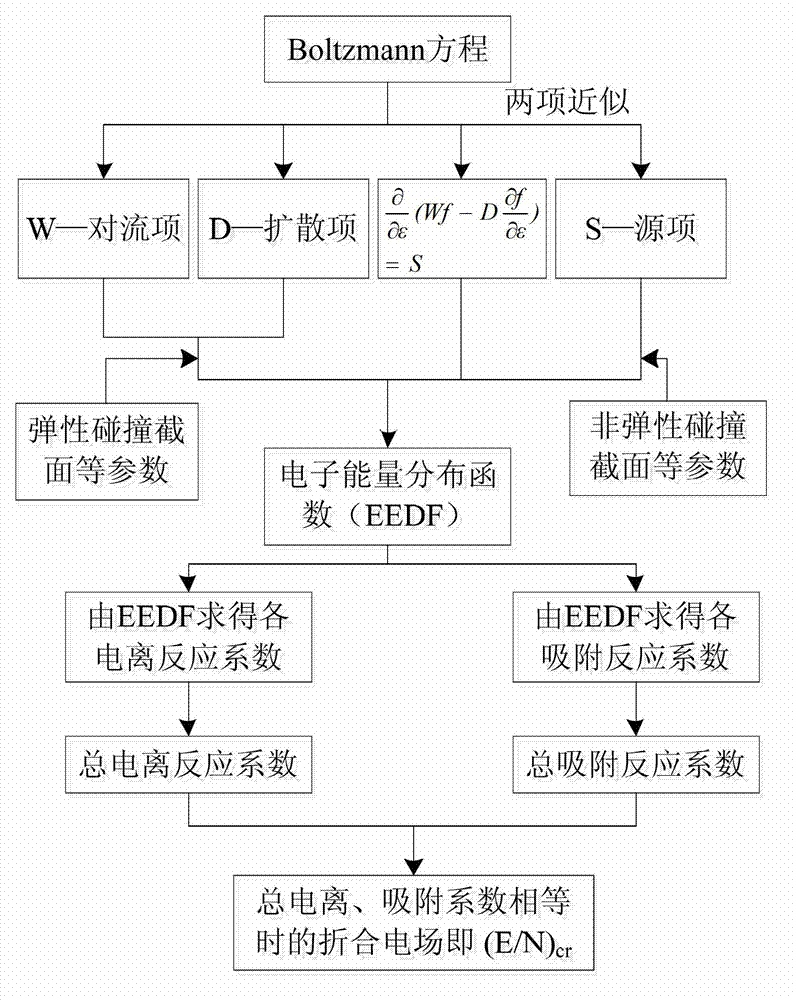

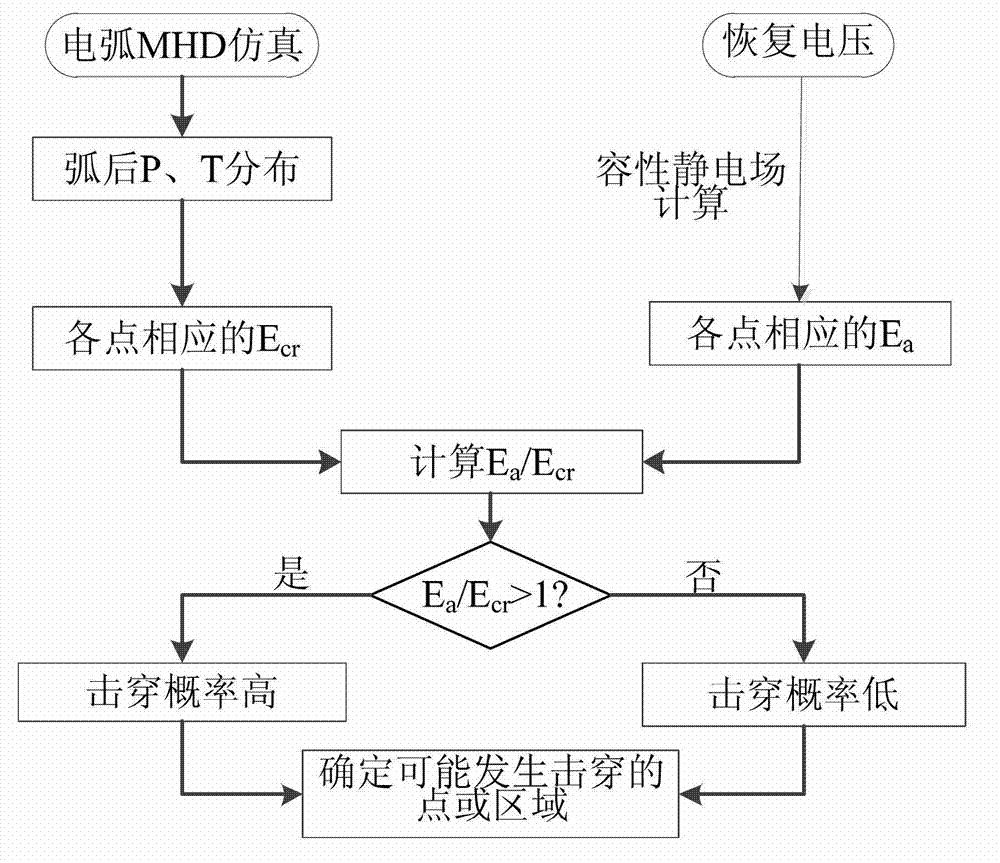

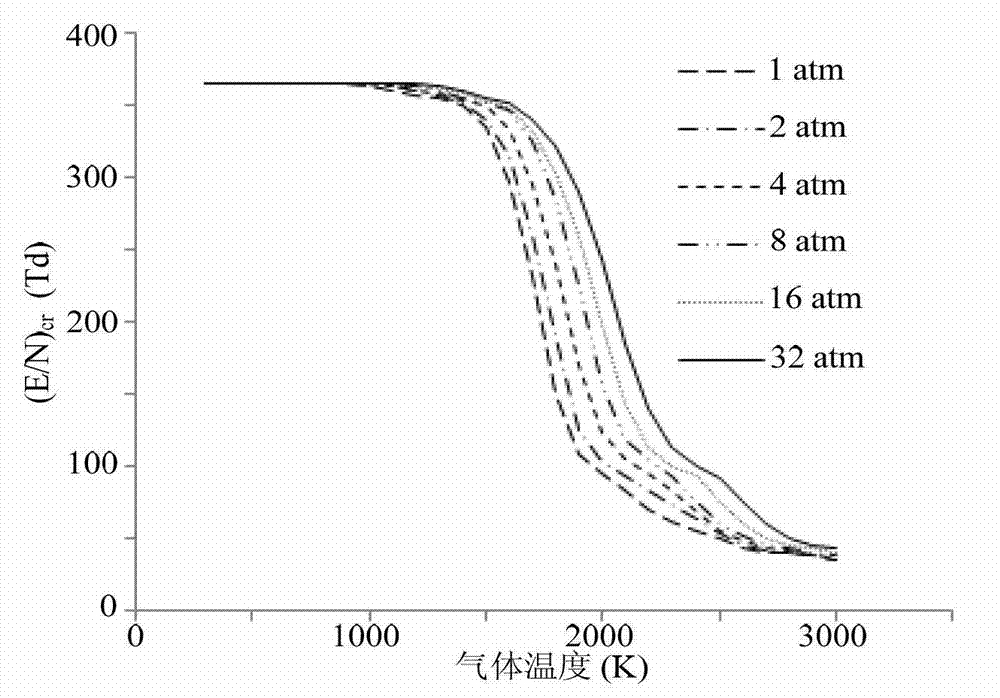

Method for assessing probability of occurrence of back-arc electric breakdown of hot gas of SF6 breaker

ActiveCN102789548ASpecial data processing applicationsElectric breakdownElectron energy distribution function

The invention provides a method for assessing probability of occurrence of back-arc electric breakdown of hot gas of an SF6 breaker. The method is characterized by comprising the following steps: 1), obtaining an electron energy distribution function (EEDF) by solving a Boltzmann equation to further determine the critical breakdown field strength Ecr of the SF6 gas under different temperatures and pressures; 2), determining the back-arc distribution of temperature and pressure in an arc extinguishing chamber by means of MHD simulation analysis of the SF6 electric arc; and 3), comparing field strength Ea caused by recovery voltage of each point in the arc extinguishing chamber with the Ecr of the SF6 under the corresponding temperature and pressure, and assessing the probability of occurrence of electric breakdown of each point in the arc extinguishing chamber. The method is applicable to the assessment of back-arc electric breakdown features of all SF6 breakers, whether the SF6 breakers are made of polytetrafluoroethylene (PTFE) nozzle material or not; and therefore, an effective method is provided for assessing the back-arc electric breakdown features of the SF6 high-voltage breaker.

Owner:XI AN JIAOTONG UNIV +1

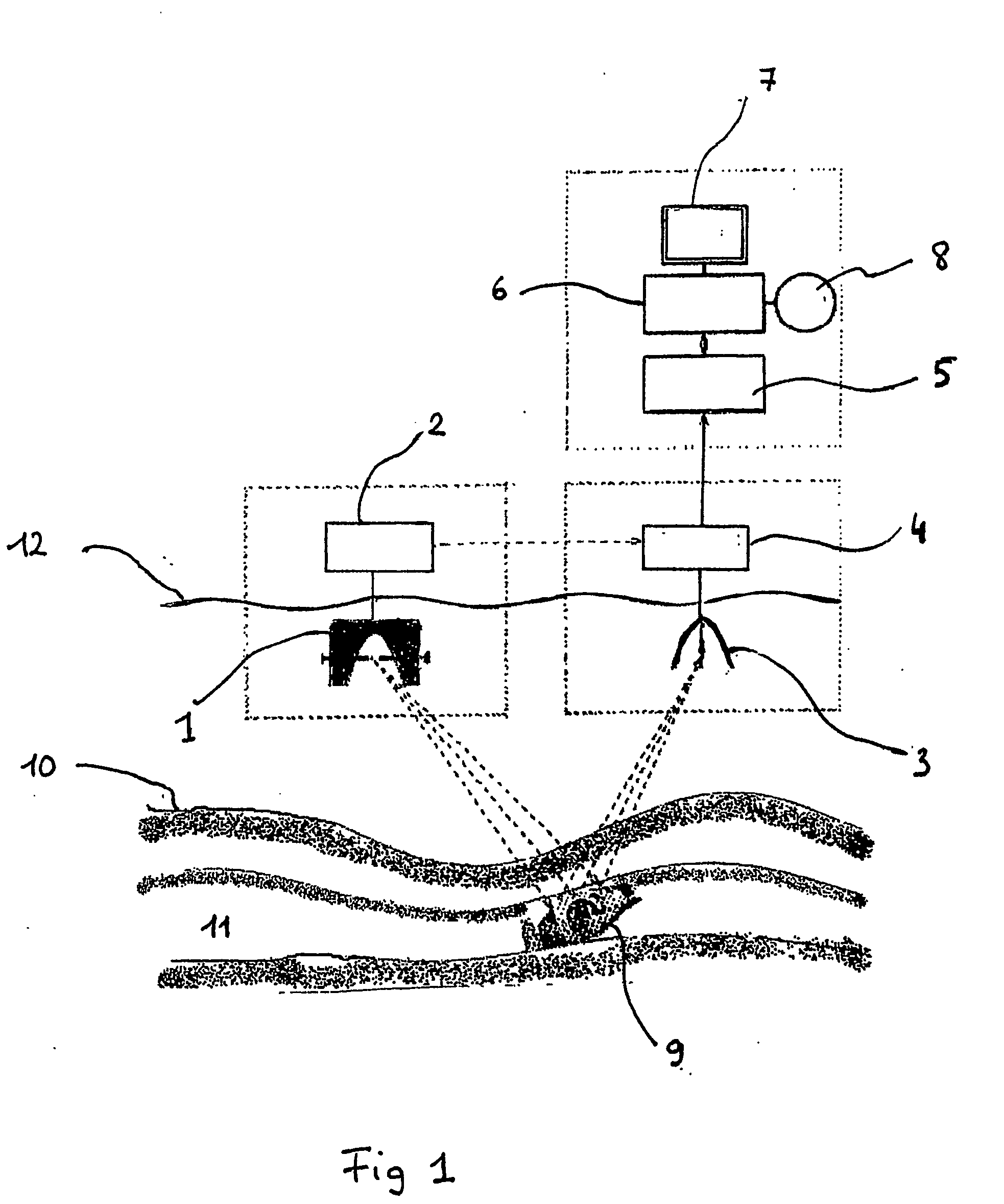

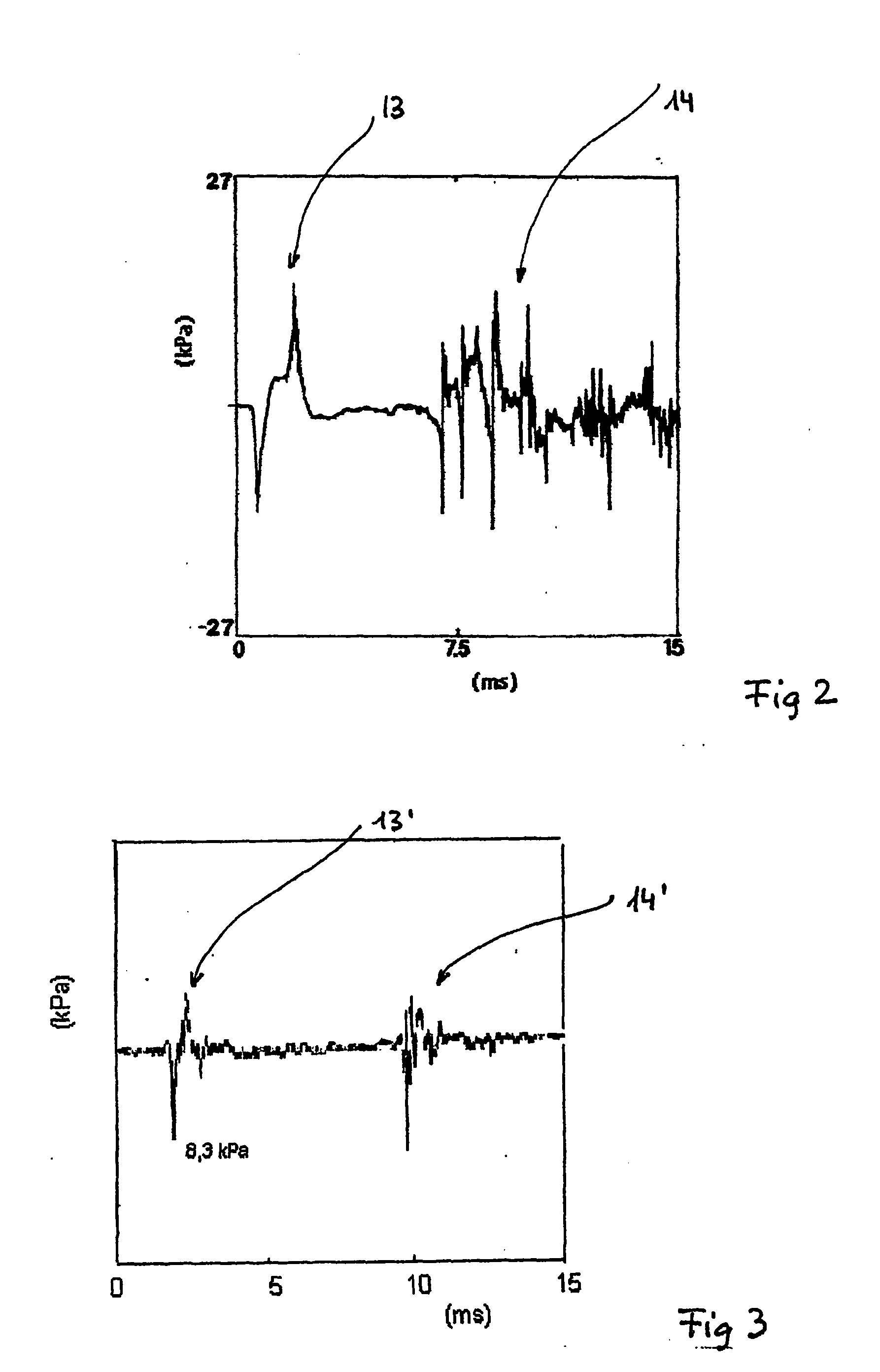

High-resolution and high-power ultrasound method and device, for submarine exploration

A method for underwater exploration which makes use of a parabolic transmitter (1) and a parabolic receiver (3), the transmitter (1) and the receiver (3) being both open at their lower side and immersed below the seawater surface. The electric breakdown discharge occurring between both electrodes (15) of the transmitter (1) generates a primary signal and a pulse which is called “cavitation bubble pulse.” The method consists in enhancing the signal (23) produced by the implosion of the cavitation bubble, to the detriment of the primary signal (13″), by appropriately adjusting the value of the “spark gap” (distance d between the electrodes) so as to optimize the delay time (t) and consequently the acoustic efficiency of the transmitter, by transferring the electrostatic energy to the bubble implosion signal.

Owner:CONSIGLIO NAT DELLE RICERCHE

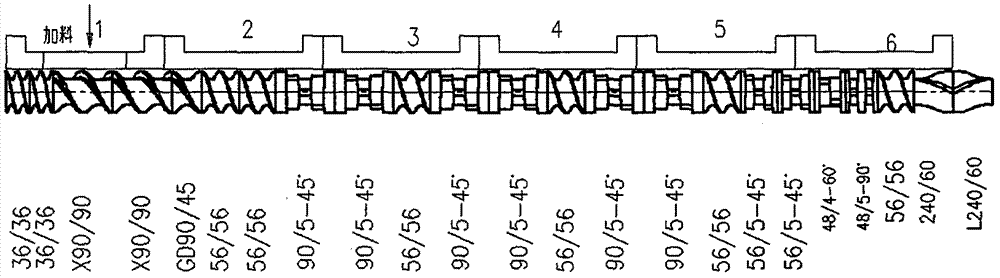

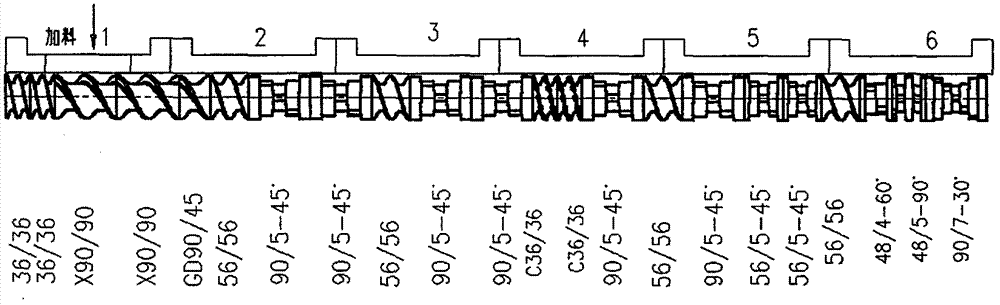

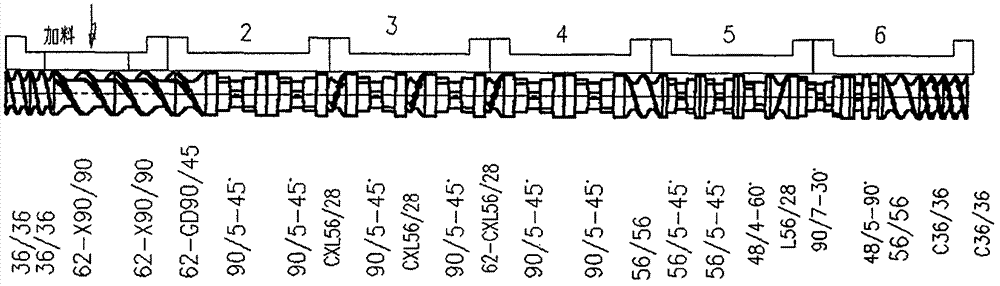

Preparation method of polypropylene material

InactiveCN107141686ALow dielectric constantImprove electrical breakdown resistanceFlat articlesAntioxidantElectric breakdown

The invention provides a special fiber-reinforced polypropylene material and a preparation method and application thereof. The special fiber-reinforced polypropylene material comprises 50-90 parts of polypropylene, 1.0-2.0 parts of a compatilizer, 0.3-0.5 part of a coupling agent, 0.5-1.0 part of an antioxidant, 0.5-0.8 part of doped silicon dioxide, 0.5-3.0 parts of nano-montmorillonite and 0.5-2.0 parts of a micro-foamed polymer. A twin-screw extruder is adopted to extrude, and the polypropylene material which is low in dielectric constant and excellent in electric breakdown resistance is prepared by means of a special screw combination and a fiber adding position technology. A polypropylene film with a special application is prepared from the material. Meanwhile, plasma treatment is performed on the surface of the film. The film can be applied to special parts in special fields such as military industry and micro-electronic industry.

Owner:温州市赢创新材料技术有限公司

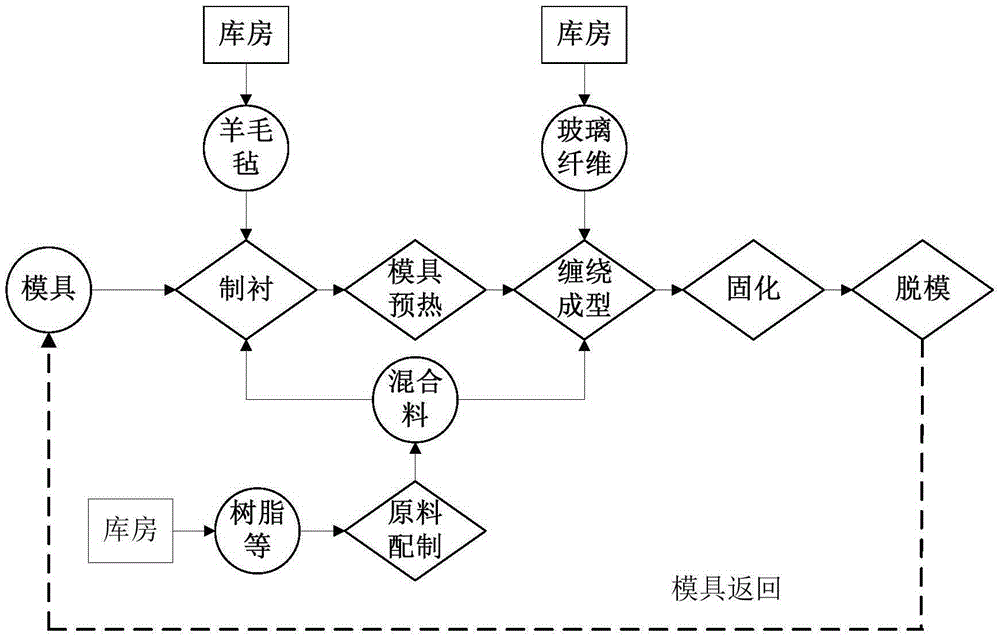

Winding pipe for hollow composite insulator and preparation method of winding pipe for hollow composite insulator

The invention discloses a winding pipe for a hollow composite insulator and a preparation method of the winding pipe for the hollow composite insulator. The winding pipe is formed by winding and curing of epoxy resin adhesive impregnated glass fibers. An epoxy resin adhesive is prepared from, by weight, 80-120 parts of epoxy resin, 50-80 parts of a curing agent, 5-10 parts of a diluting agent, 2-5 parts of an accelerating agent and 0.1-0.5 part of a defoaming agent, wherein epoxypropane butyl ether serves as the diluting agent. The content of the epoxy resin adhesive in the winding pipe is 25%-30%. The winding pipe for the hollow composite insulator has the advantages that the epoxy resin adhesive is appropriate in viscosity and fluidity and excellent in performance of adhesion to the glass fibers, multiple strands of the epoxy resin adhesive impregnated glass fibers are easy to coat with the adhesive and can form fiber yarns, and winding efficiency is improved; the winding pipe formed by the cured epoxy resin adhesive and the glass fibers is high in strength, compactness and air tightness and has an excellent insulation performance; since the content of the epoxy resin adhesive in the winding pipe is appropriate, the winding pipe is excellent in mechanical performance and electric breakdown resistance.

Owner:PINGGAO GRP +1

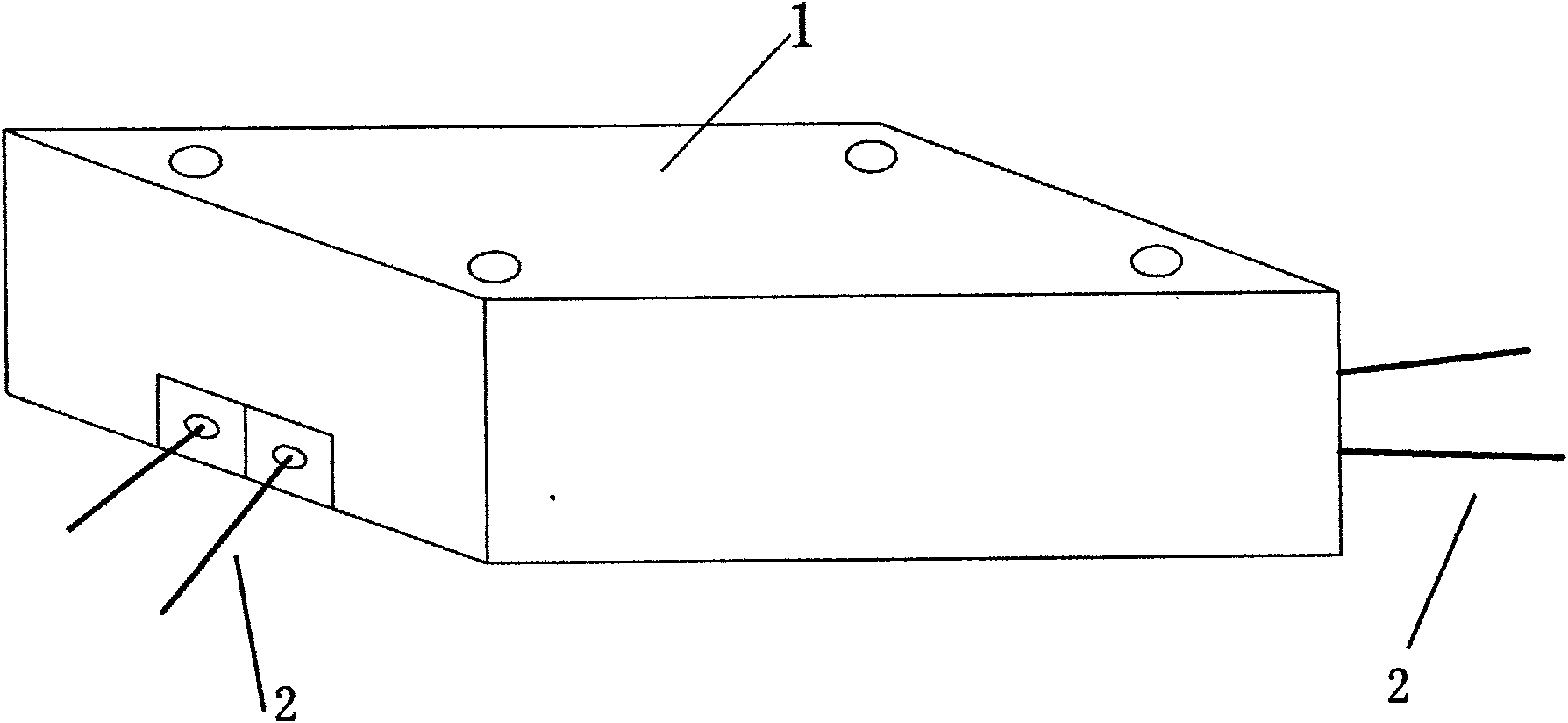

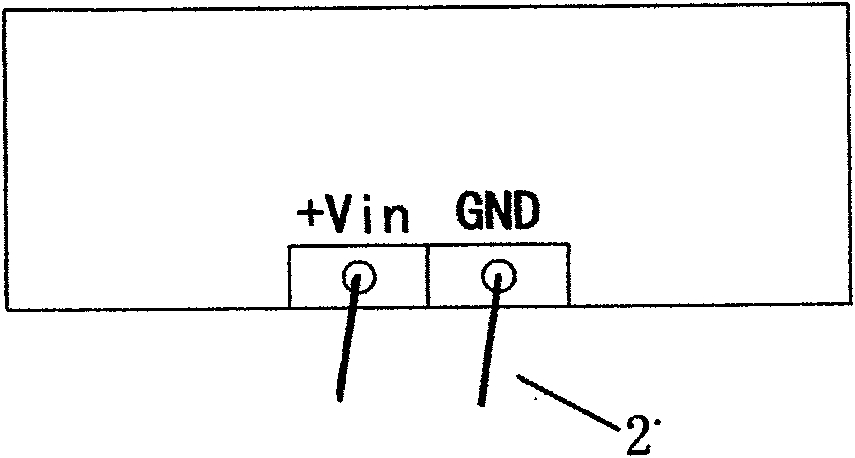

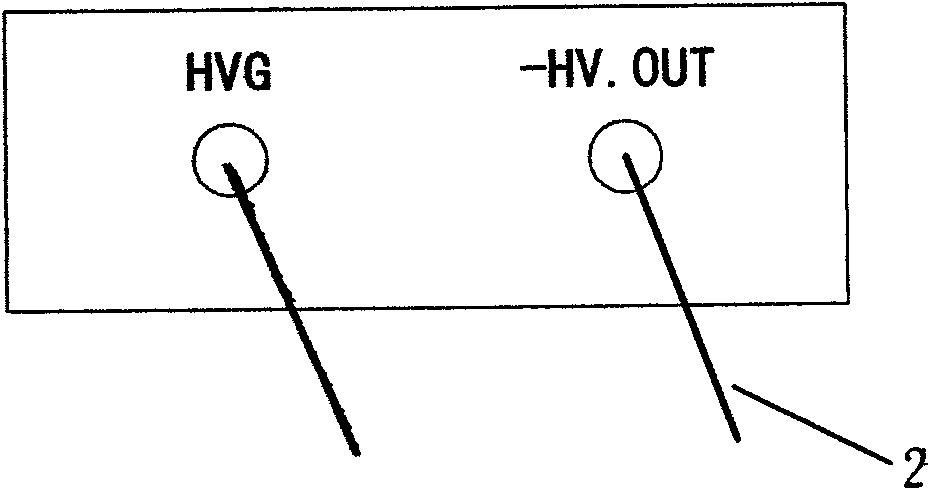

Negative output fixed constant-current type electric breakdown high-voltage module power supply

InactiveCN101834528AEasy to installEasy to useEmergency protective circuit arrangementsDc-dc conversionElectricityOvervoltage

The invention relates to a negative output fixed constant-current type electric breakdown high-voltage module power supply which comprises a power supply circuit packaged in a shell. A plurality of lead wires are welded on the power supply circuit, and the power supply circuit comprises a control circuit, a drive circuit, a voltage-stabilizing circuit, a high-voltage feedback circuit, a current feedback circuit and a combined high-voltage output circuit, wherein the voltage-stabilizing circuit is connected with the drive circuit through the control circuit, the drive circuit is respectively connected with the high-voltage feedback circuit, a current feedback circuit and the combined high-voltage output circuit, and the combined high-voltage output circuit is respectively connected with the high-voltage feedback circuit and the current feedback circuit. The invention has the advantages that ignition and maintenance of two high voltages are combined to output so that the use is convenient; output overvoltage protection is available; after a load is ignited, the output current is fixed and constant so that long-term stability is good; and the invention has small appearance size, light weight and easy installation of a PCB.

Owner:天津市东文高压电源厂

Preparation method of large-area high-order porous anodised aluminium film

InactiveCN102888642AIncrease concentrationIncrease temperatureAnodisationHigh concentrationHigh current density

The invention discloses a preparation method of a large-area high-order porous anodised aluminium film. Based on a principle of generating electric breakdown, an acidic electrolyte with high concentration is adopted for carrying out high-current-density constant-current anodic oxidization under a high temperature, so that the anodised aluminium film can uniformly and stably grow without causing the electric breakdown, an aluminum foil is only subjected to a process of simply removing a natural oxide film by using sodium hydroxide without a complex pretreatment process and electrochemical polishing, a strong cooling system is not needed, the electrolyte do not need to be stirred, and under a normal temperature, the large-area high-order porous anodised aluminium film rapidly and stably grows with the growth speed rate reaching 4mu m.min<-1>.

Owner:NANJING UNIV OF SCI & TECH

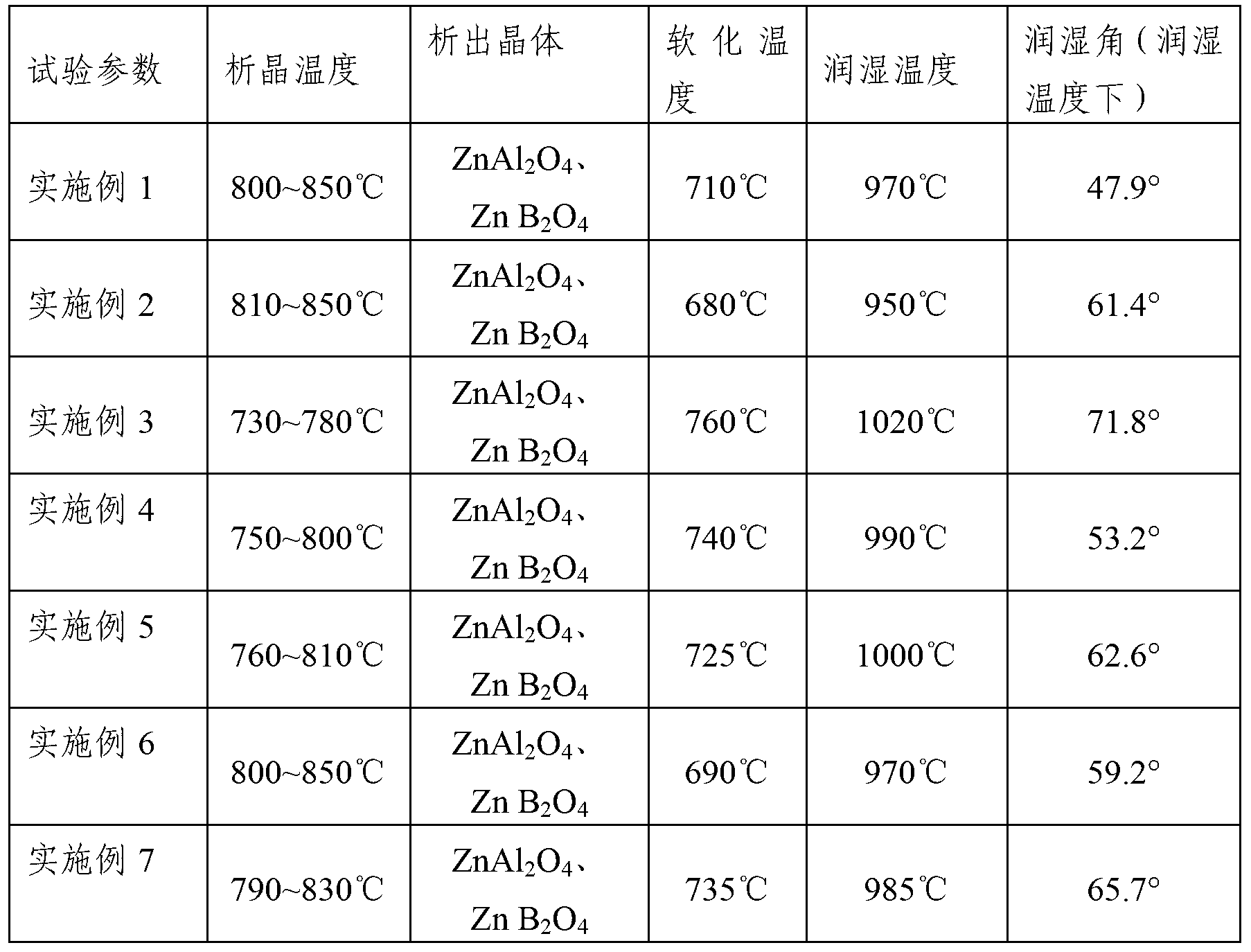

Ceramic material high in energy storage density and energy storage efficiency and preparation method of ceramic material

The invention relates to the technical field of dielectric energy storage ceramic materials and discloses a ceramic material high in energy storage density and energy storage efficiency. A chemical formula of the ceramic material is (1-x) (K0.5Na0.5)NbO3-xBi(Mg0.5Ti0.5)O3, wherein x is larger than or equal to 0 and smaller than or equal to 0.2. Due to addition of Bi(Mg0.5Ti0.5)O3, crystal grains of (K0.5Na0.5)NbO3 ceramic are reduced; by regulation of a ceramic phase inversion temperature interval, electric breakdown strength of the ceramic is improved, and high storage density, high energy storage efficiency and high energy storage temperature stability of the ceramic material are achieved. In addition, technical simplicity in preparation, low preparation cost and high practicality are realized.

Owner:AIR FORCE UNIV PLA

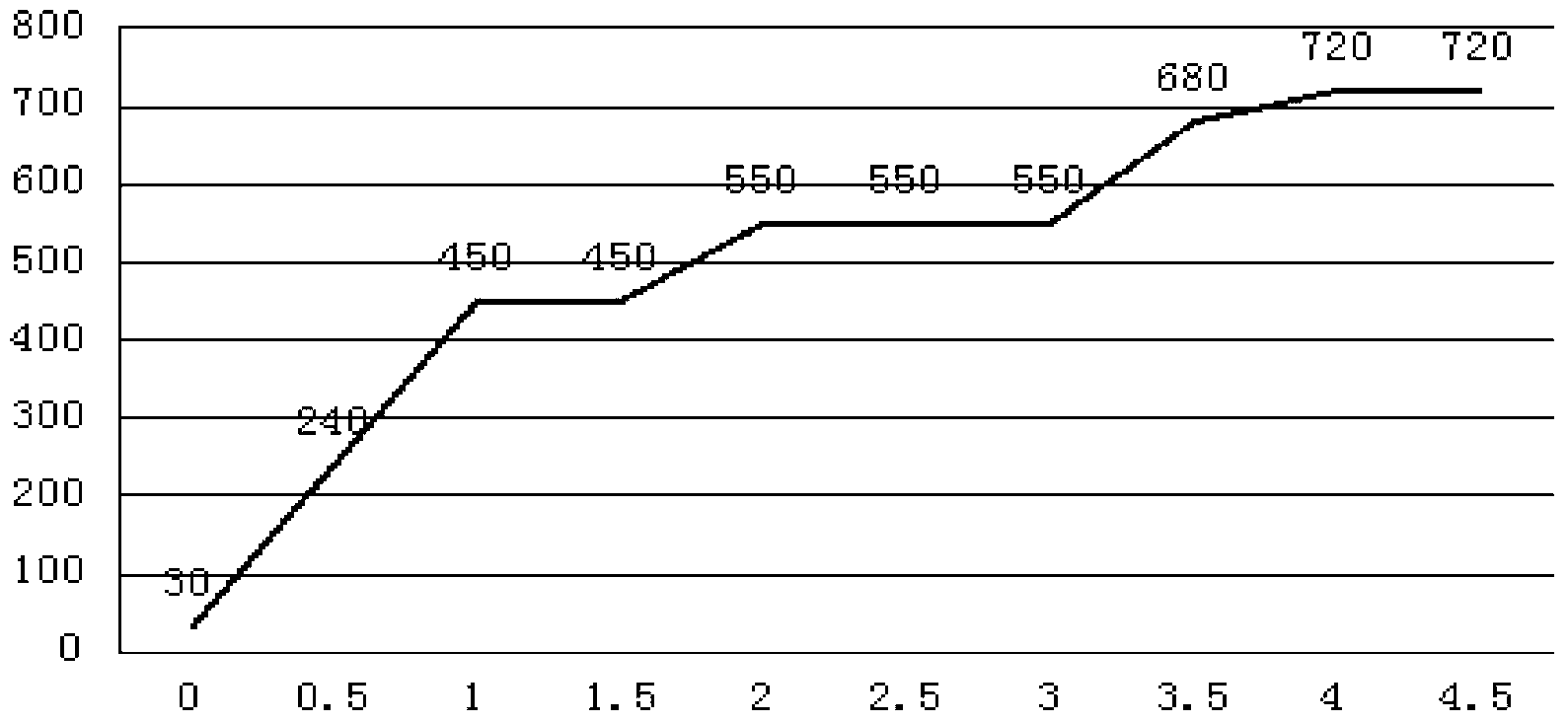

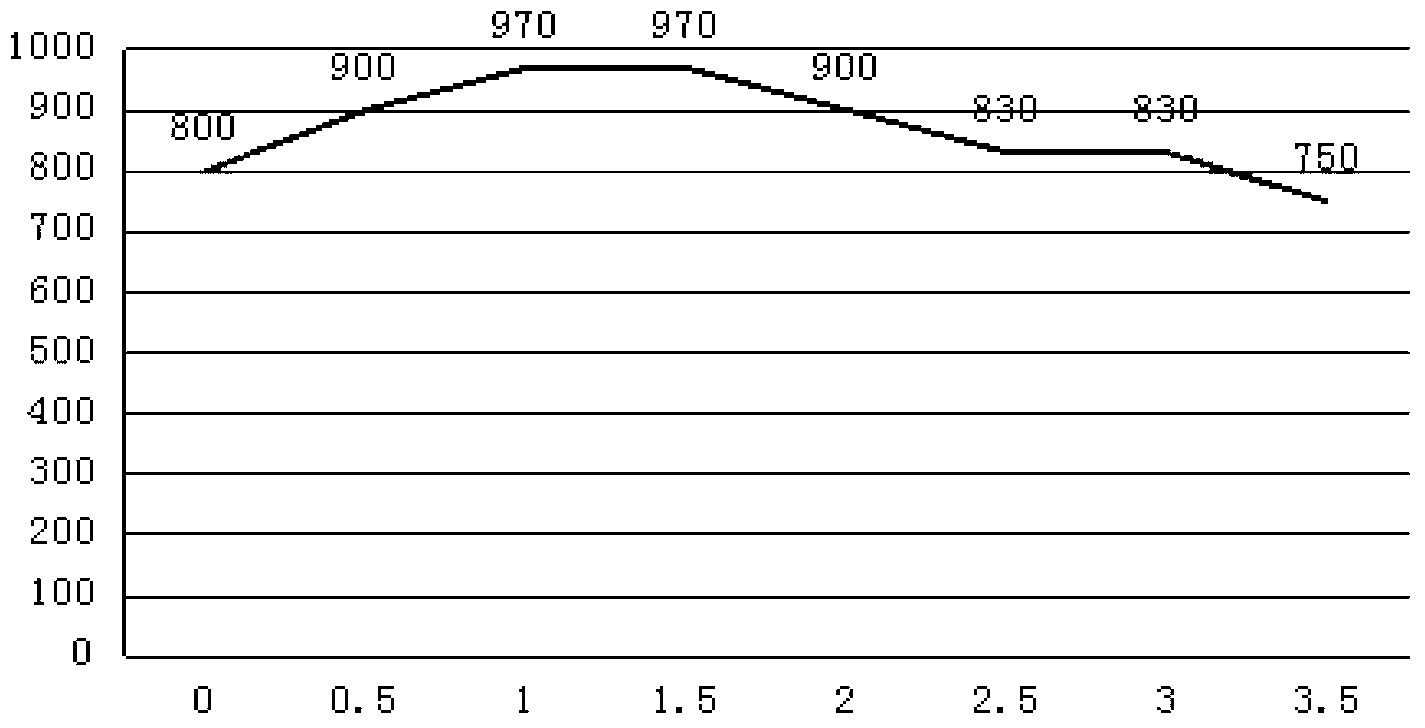

Sealing microcrystalline glass, and sealing method and application thereof

The invention relates to sealing microcrystalline glass which comprises the following raw materials: SiO2, ZnO, Al2O3, B2O3, Na2CO3, K2CO3, ZrO2, TiO2, Li2CO3 and P2O5. The invention also relates to a sealing method of the microcrystalline glass and application of the microcrystalline glass in sealing of a metal shell of an electronic component. For the sealing microcrystalline glass provided by the invention, the components and consumptions thereof of the common microcrystalline glass are changed; the microcrystalline glass having excellent sealing performance is obtained by using new complex nucleator; after sealing, the microcrystalline glass has favorable thermal expansion compatibility, realize compact air-tight seal, is high in dielectric loss electric breakdown voltage and can meet the requirements of higher standards. The sealing method provided by the invention is simple in process, can realize automatic crystallization without subsequent nucleation and crystallization process, ensures the strength of the glass and has wide application prospects.

Owner:天津北旭新材料有限公司

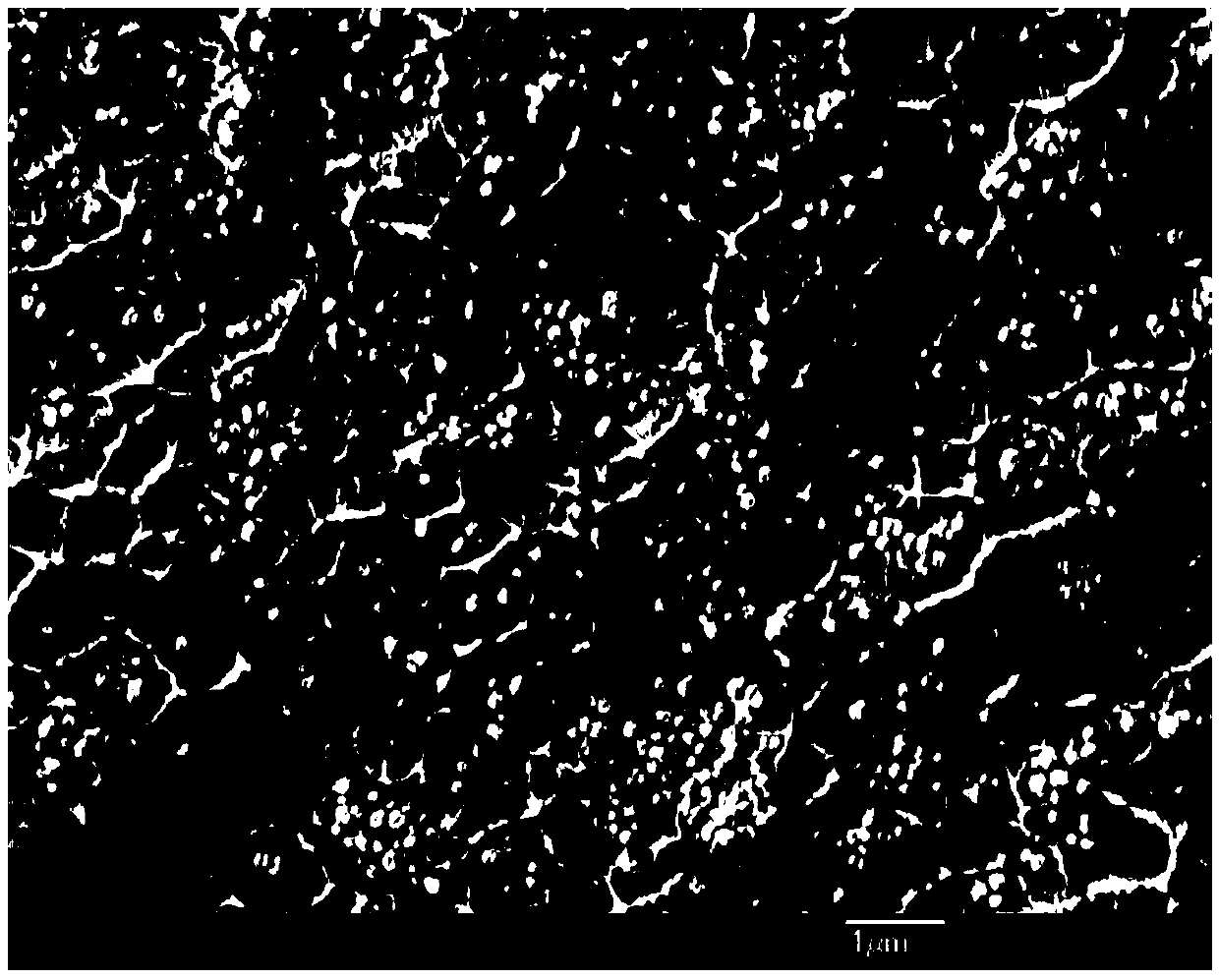

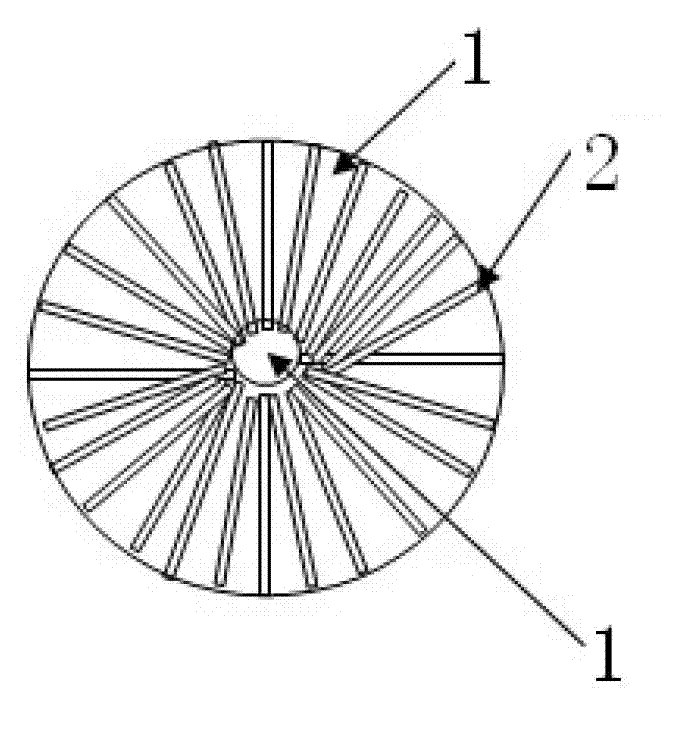

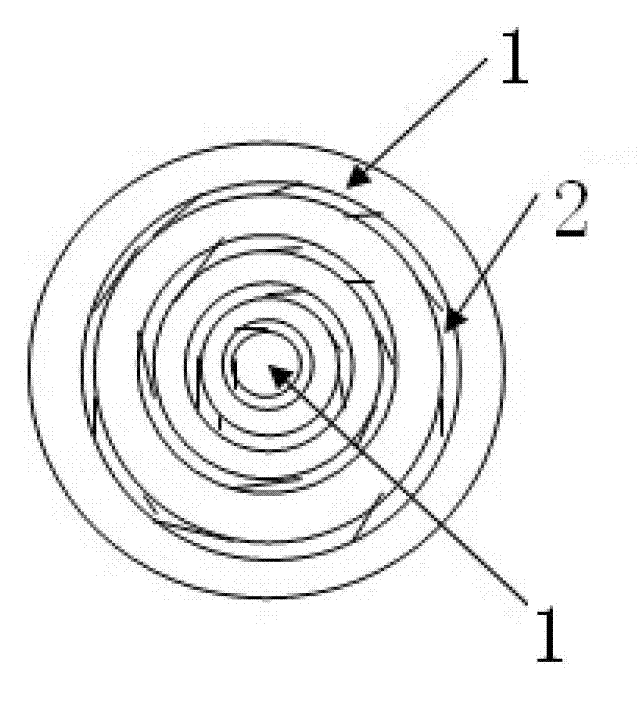

Contact with function of controlling directional extension movement of vacuum arc

ActiveCN102881511AReduce arc ablationImprove breaking capacityContact surface shape/structureHigh-tension/heavy-dress switchesElectric breakdownAlloy

The invention discloses a contact with a function of controlling directional extension movement of a vacuum arc. Second phases or mixtures of the second phases and copper-based alloy, which are easily subjected to electric breakdown are distributed in the contact, the second phases and the mixtures of the second phases and the copper-based alloy form continuous arrangement areas from the center of the contact, and the continuous arrangement areas are radiating, annular or spiral from the center of the contact, so that the arc can be induced to perform directional continuous extension movement along the areas rich in the second phases. The continuous arrangement areas are radiating, annular or spiral from the center of the contact. Similar to the function of a horizontal magnetic field, the second phase continuously arranged areas can provide the arc with a channel for directional continuous extension movement, so that the arc ablation on the surface of the contact can be relieved, and the breaking capacity of a switch is improved.

Owner:宁波建锡新材料有限公司

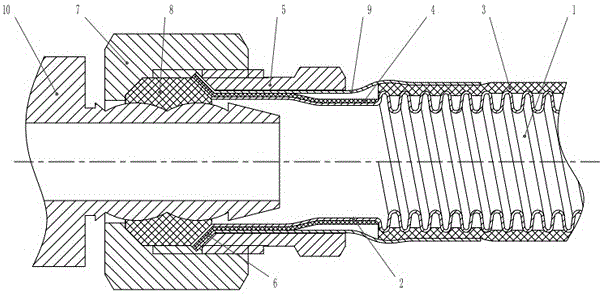

Joint connecting device of corrugated stainless steel hose for connection of gas appliance

ActiveCN105090648APrevent leakageImprove sealingPipe-jointsHose connectionsElectric breakdownEngineering

The invention discloses a joint connecting device of a corrugated stainless steel hose for connection of a gas appliance. The joint connecting device comprises the hose. The hose comprises a corrugated section and a straight pipe section located at the end of the corrugated section and connected with the corrugated section into a whole. The outer surface of the corrugated section is coated with a plastic jacket. The outer surface of the straight pipe section is coated with a thermal shrinkage insulation sleeve sleeved with a fastening ring. A port of the fastening ring is provided with a conic face. Outer ports of the straight pipe section and the thermal shrinkage insulation sleeve are provided with a horn opening matched with the conic face. A nut is screwed to the fastening ring and internally provided with a rubber sleeve, wherein the two side faces of the rubber sleeve are outer conic faces, one outer conic face on one side is matched with an inner conic face in the nut, and the one outer conic face on the other side is matched with the horn opening. The joint connecting device has the following beneficial effects that due to the fact that the straight pipe section is sleeved with the thermal shrinkage insulation sleeve and a metal sleeve, even though the straight pipe section is broken down through an electric arc, the thermal shrinkage insulation sleeve cannot be broken down, danger generated by electric breakdown is eliminated fundamentally, and meanwhile the strength of a joint cannot be affected.

Owner:HANGZHOU WANQUAN METAL HOSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com