Electrochemical burring device and burring process thereof

A deburring and electrochemical technology, applied in electrochemical machining equipment, electric machining equipment, metal processing equipment, etc., can solve problems such as easy breakdown of workpieces and complex equipment, and achieve the effect of improving work efficiency and protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

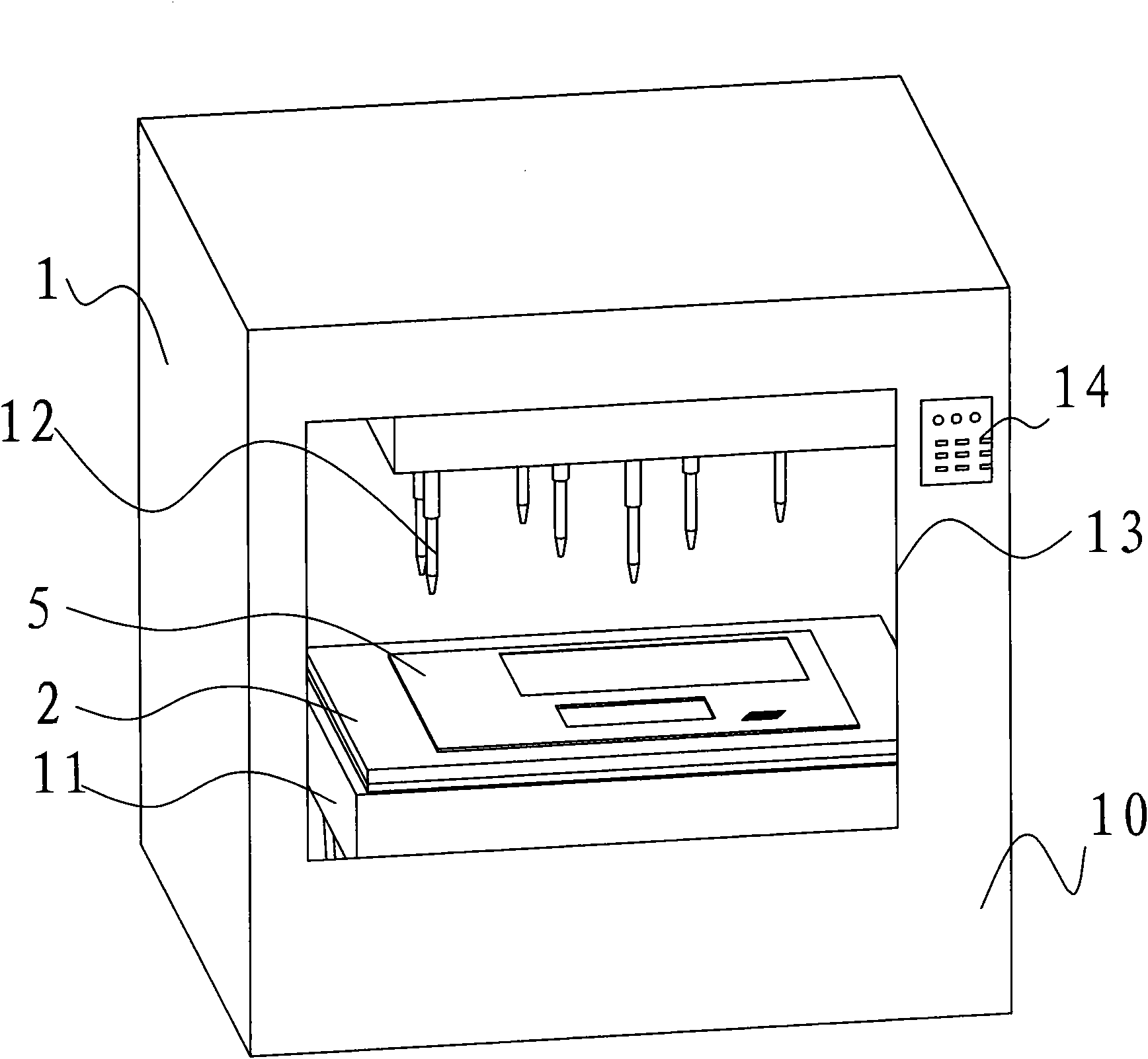

[0047]Electrochemical deburring equipment, including a workbench 1 and a freely movable tooling fixture 2;

[0048] Workbench 1, see figure 1 , including an operation window 13 for taking the tooling fixture 2, an electrical control system 14, an electrode 12 connected to the anode, and a wood glue base 11 capable of placing and supporting the tooling fixture 2. The operating window 13 is set on one of the workbench outer frames 10 On the side, the electrical control system 14, the electrodes 12 and the wood glue base 11 are all arranged inside the outer frame of the workbench, wherein the electrode 12 connected to the anode is arranged on the inner side of the top of the outer frame 10 and corresponds to the wood glue base 11, and the electrical control system 14 The man-machine interface is set on the outer side of the outer frame 10;

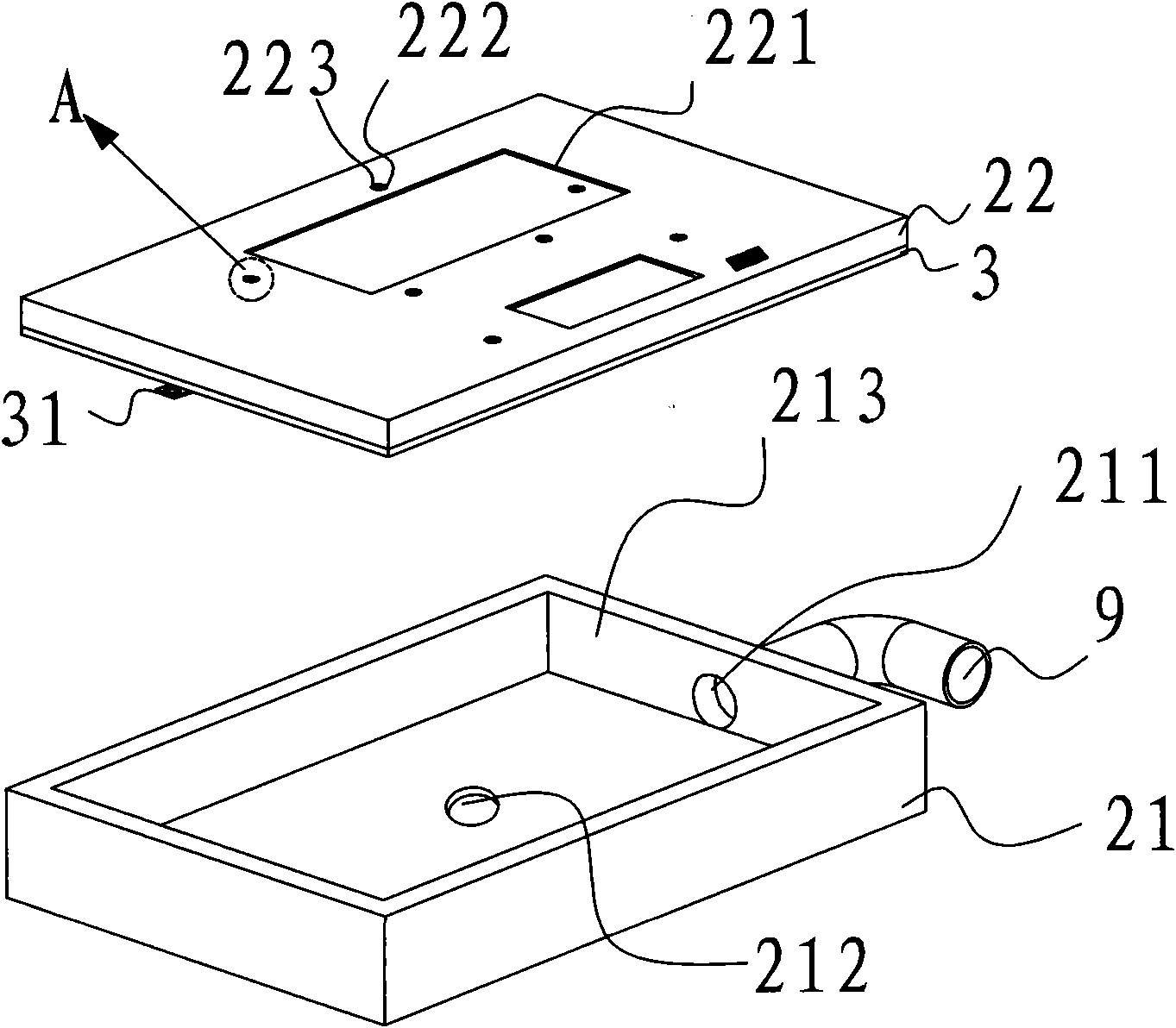

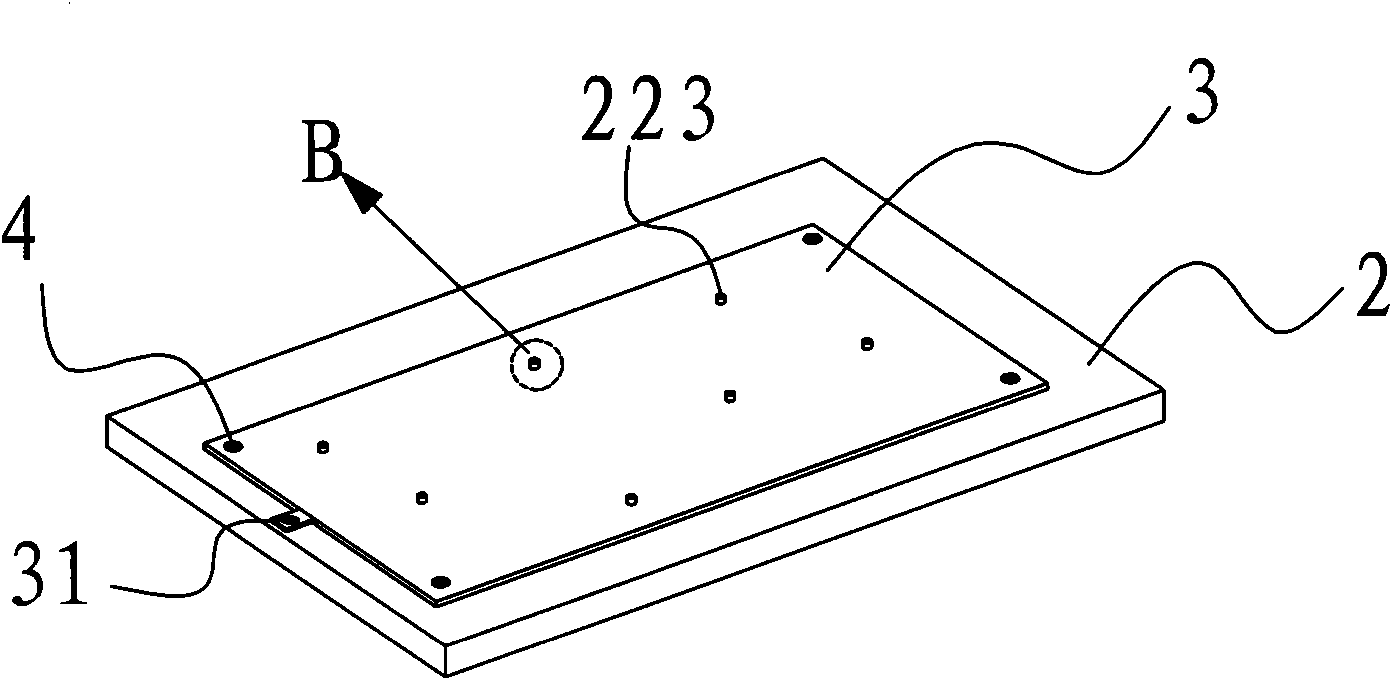

[0049] Fixture 2, see figure 2 , including a base jig 21, a conductive device 3 and a top cover jig 22 that can be fastened with the base...

Embodiment 2

[0060] Electrochemical deburring equipment, including a workbench 1 and a freely movable tooling fixture 2;

[0061] Workbench 1, see figure 1 , including an operation window 13 for taking the tooling fixture 2, an electrical control system 14, an electrode 12 connected to the anode, and a wood glue base 11 capable of placing and supporting the tooling fixture 2. The operating window 13 is set on one of the workbench outer frames 10 On the side, the electrical control system 14, the electrodes 12 and the wood glue base 11 are all arranged inside the workbench outer frame, wherein the electrode connected to the anode 12 is arranged on the inner side of the top of the outer frame 10 and corresponds to the wood glue base 11, and the electrical control system 14 The man-machine interface is set on the outer side of the outer frame 10;

[0062] Fixture 2, see figure 2 , including a base jig 21, a conductive device 3 and a top cover jig 22 that can be fastened with the base; the ...

Embodiment 3

[0073] Electrochemical deburring equipment, including a workbench 1 and a freely movable tooling fixture 2;

[0074] Workbench 1, see figure 1 , including the operation window 13 for taking the tooling fixture, the electrical control system 14, the electrode 12 connected to the anode, and the wood glue base 11 that can place the supporting tooling fixture. The operating window 13 is set on one side of the workbench outer frame 10, The electrical control system 14, the electrodes and the wood glue base 11 are all arranged inside the workbench outer frame 10, wherein the electrode 12 connected to the anode is arranged on the inner side of the top of the outer frame 10, and corresponds to the wood glue base 11, the people of the electrical control system 14 The machine interface is set on the outer side of the outer frame 10;

[0075] Fixture 2, see figure 2 , including a base jig 21, a conductive device 3 and a top cover jig 22 capable of fastening with the base; the base jig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com