Patents

Literature

3522results about How to "Will not deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

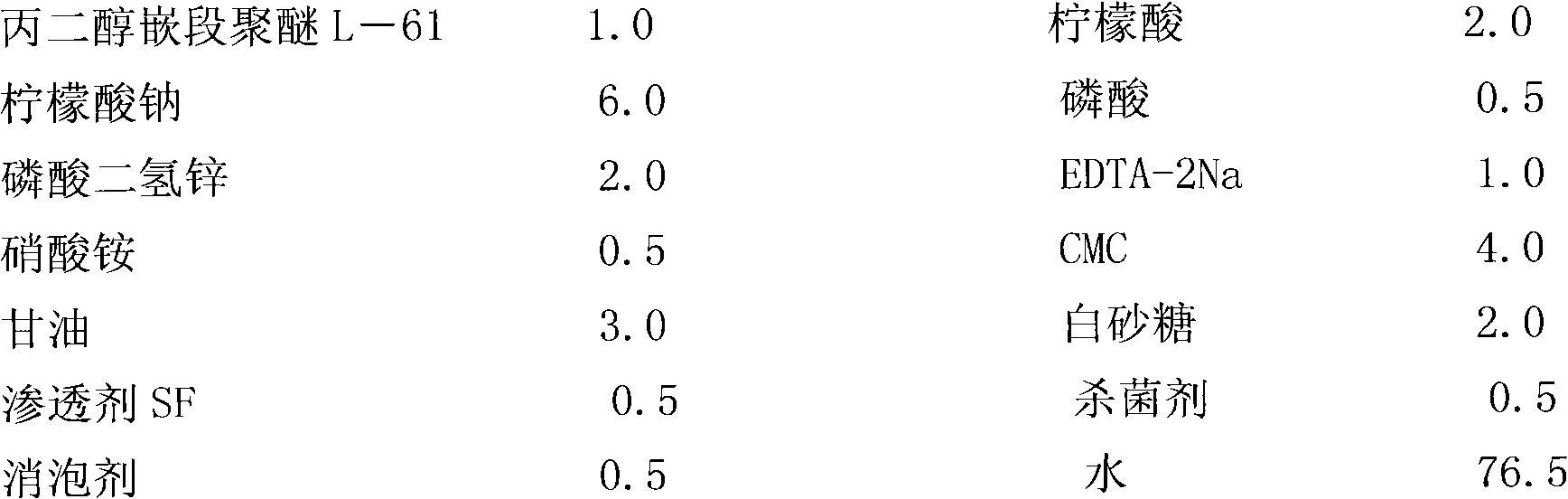

Alcohol-free concentrated fountain solution and preparation method thereof

InactiveCN102303465AStable concentrationPrint color difference is smallPrinting pre-treatmentAlcohol freePhysical well being

The invention provides an alcohol-free concentrated fountain solution and a preparation method thereof. The alcohol-free concentrated fountain solution is prepared from the following components based on 100 parts by weight: 0.5-5 parts of low-foam wetting agent, 8-20 parts of pH value regulator, 3-20 parts of printing plate protective agent, 5-10 parts of a water film regulator, 0.2-1.0 part of decontamination intensifier, 0.1-1.0 part of bactericide, 0.1-1.2 parts of defoamer and the balance of water. The concentrated fountain solution provided by the invention is environmentally-friendly, provides guarantee for the health of workers, and can improve the quality of the printing products.

Owner:冯星枢 +1

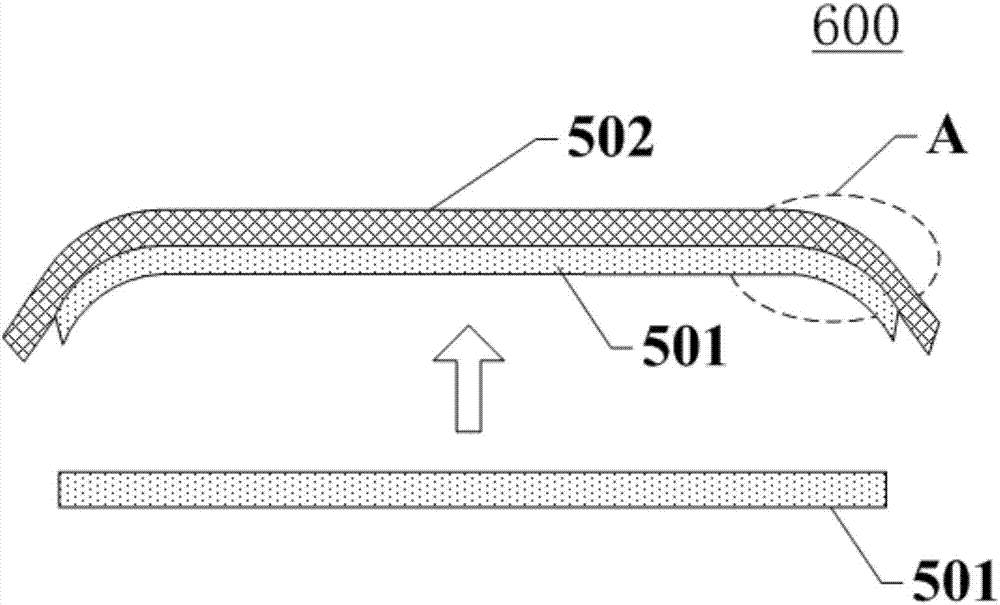

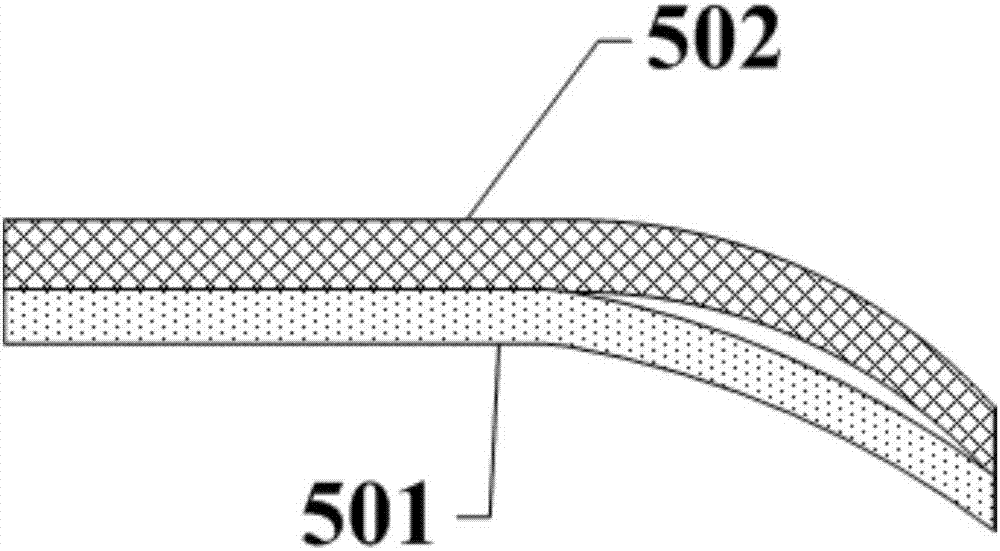

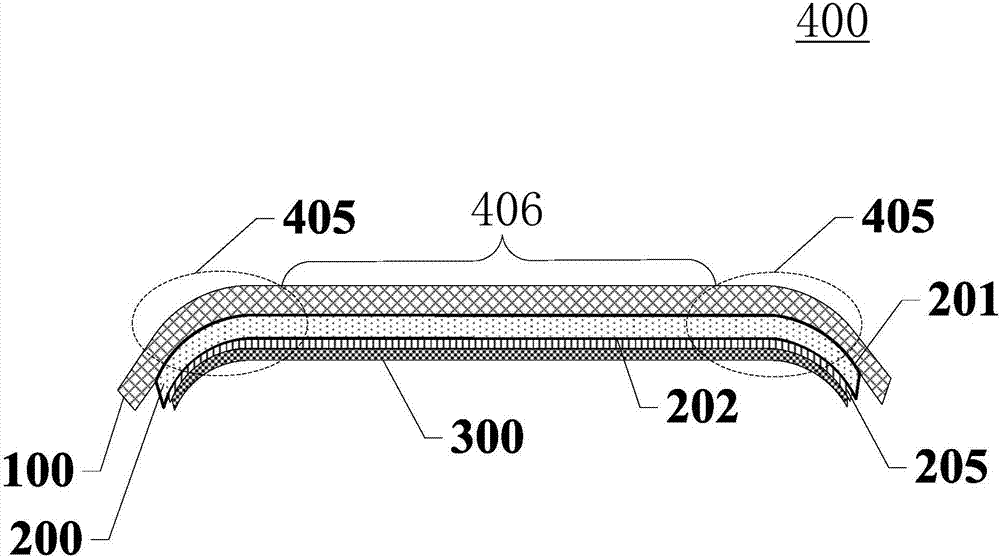

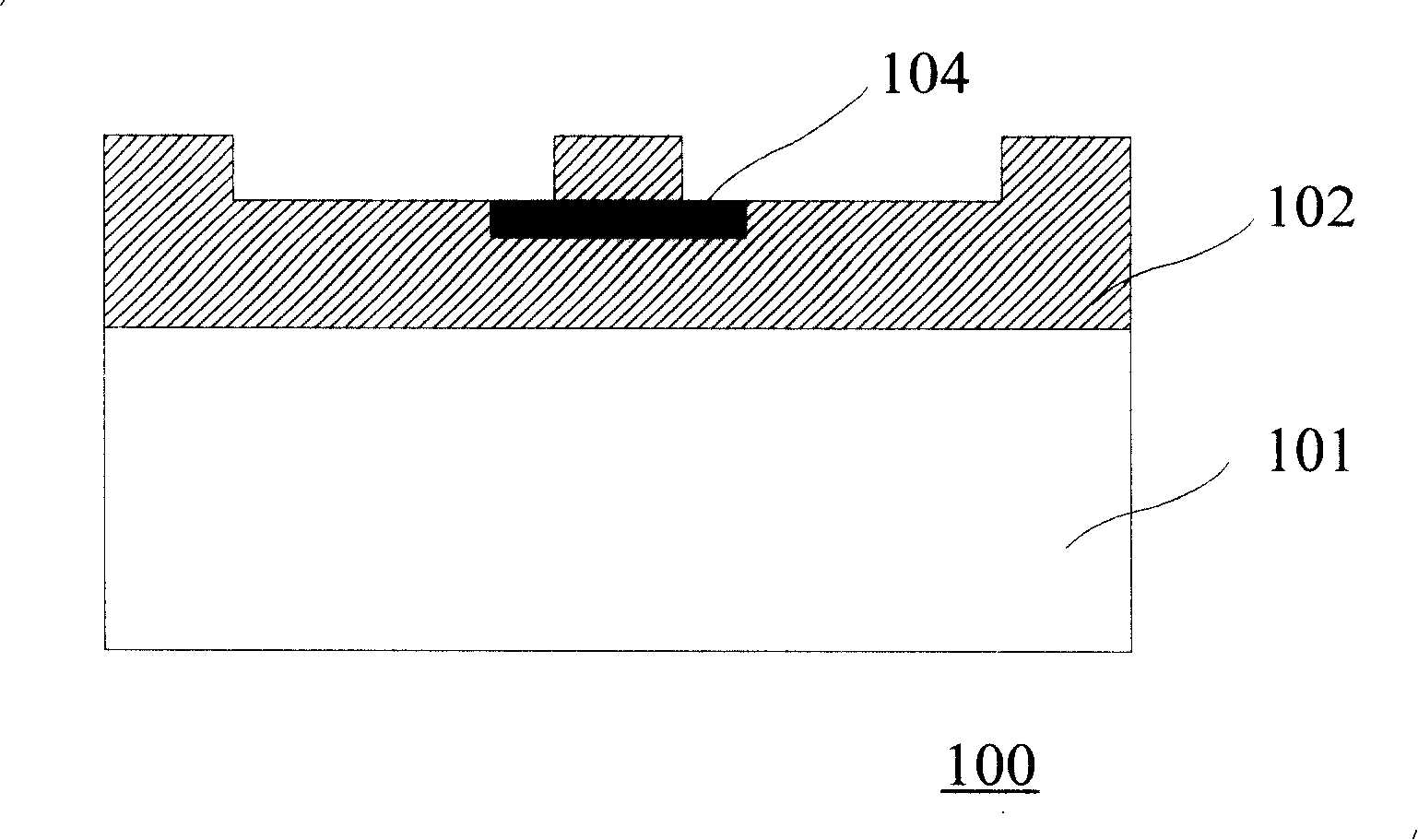

Display device

ActiveCN107978623AImprove production yieldExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display device and relates to the technical field of display. The display device comprises a cover plate, a flexible display panel and a support film arranged successively, the cover plate, the flexible display panel and the support film are all of curved-surface shapes, a first surface of the flexible display panel is attached to a first side of the cover plate, the support film is arranged in the side close to a second surface of the flexible display panel, the first surface is arranged opposite to the second surface, and the cover plate is positioned in a light output side of the flexible display panel; and within certain temperature range, the cover plate and the support film are of rigid structures. Thus, the flexible display panel positioned between the support film and the cover plate is fixed by the rigid support film and cover plate, deformation does not occur, the flexible display panel in a bending area of the display device is prevented from beingdisengaged from the cover plate and causing damage of the display device, the production yield rate of the display device is improved, and the service life of the display device is prolonged.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

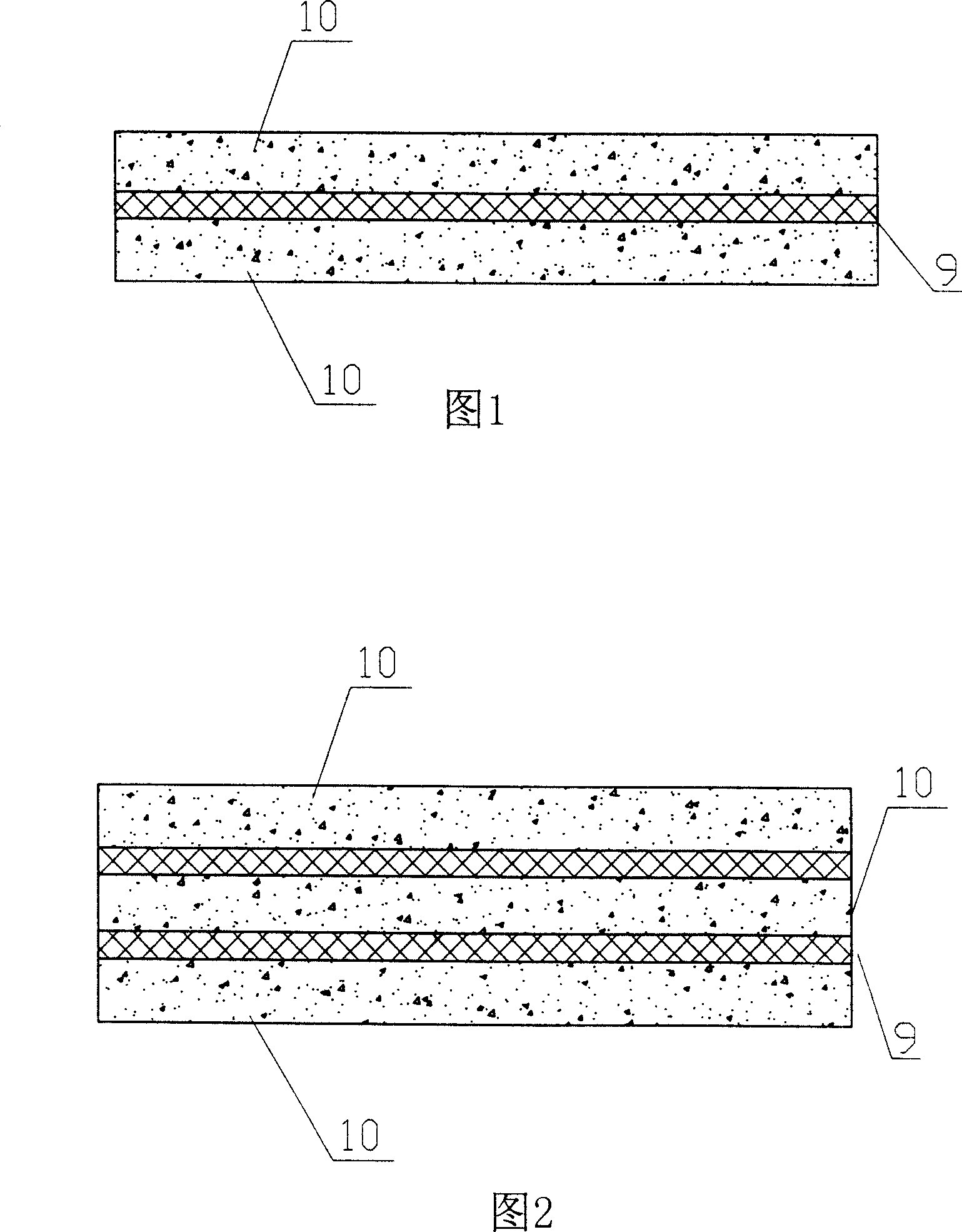

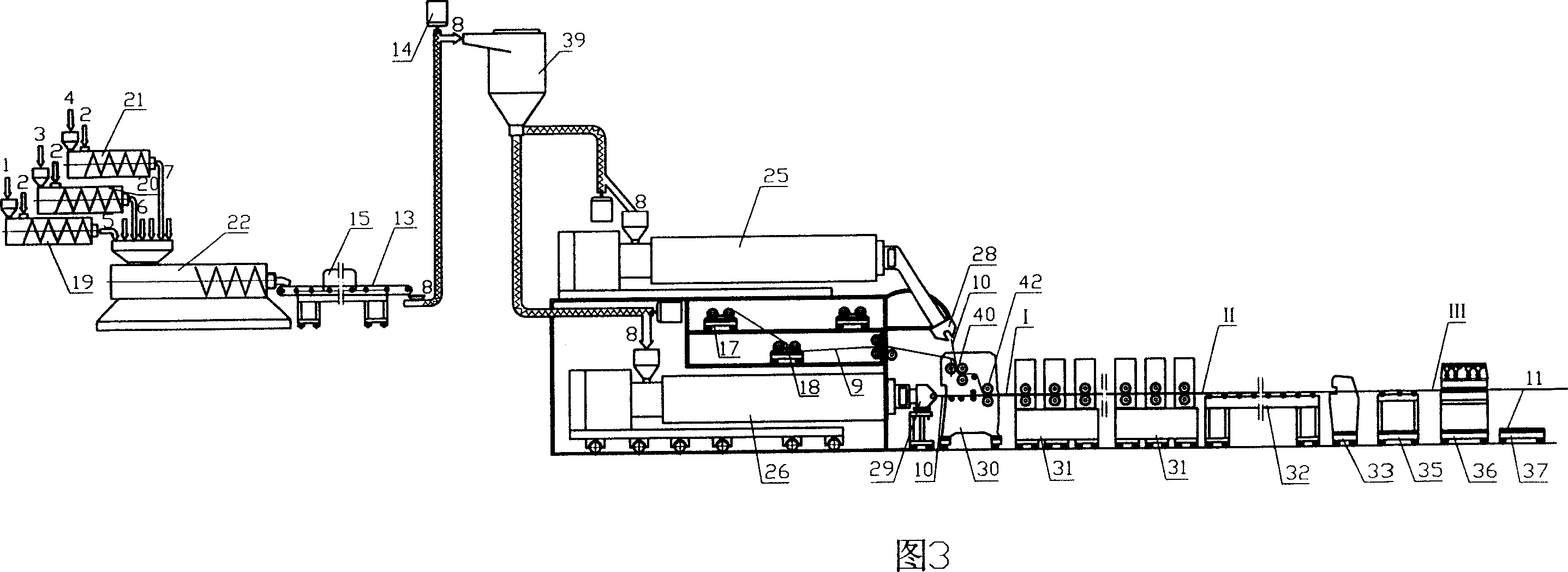

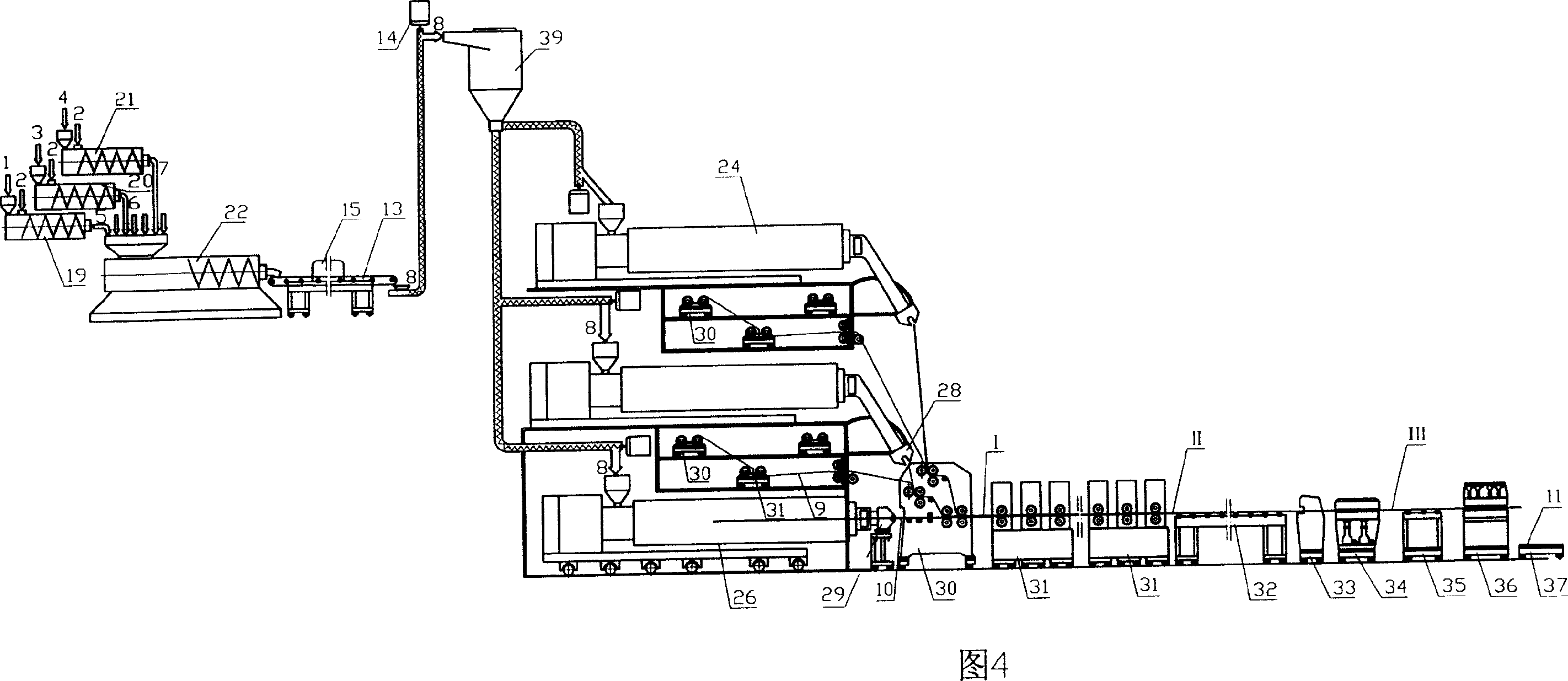

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

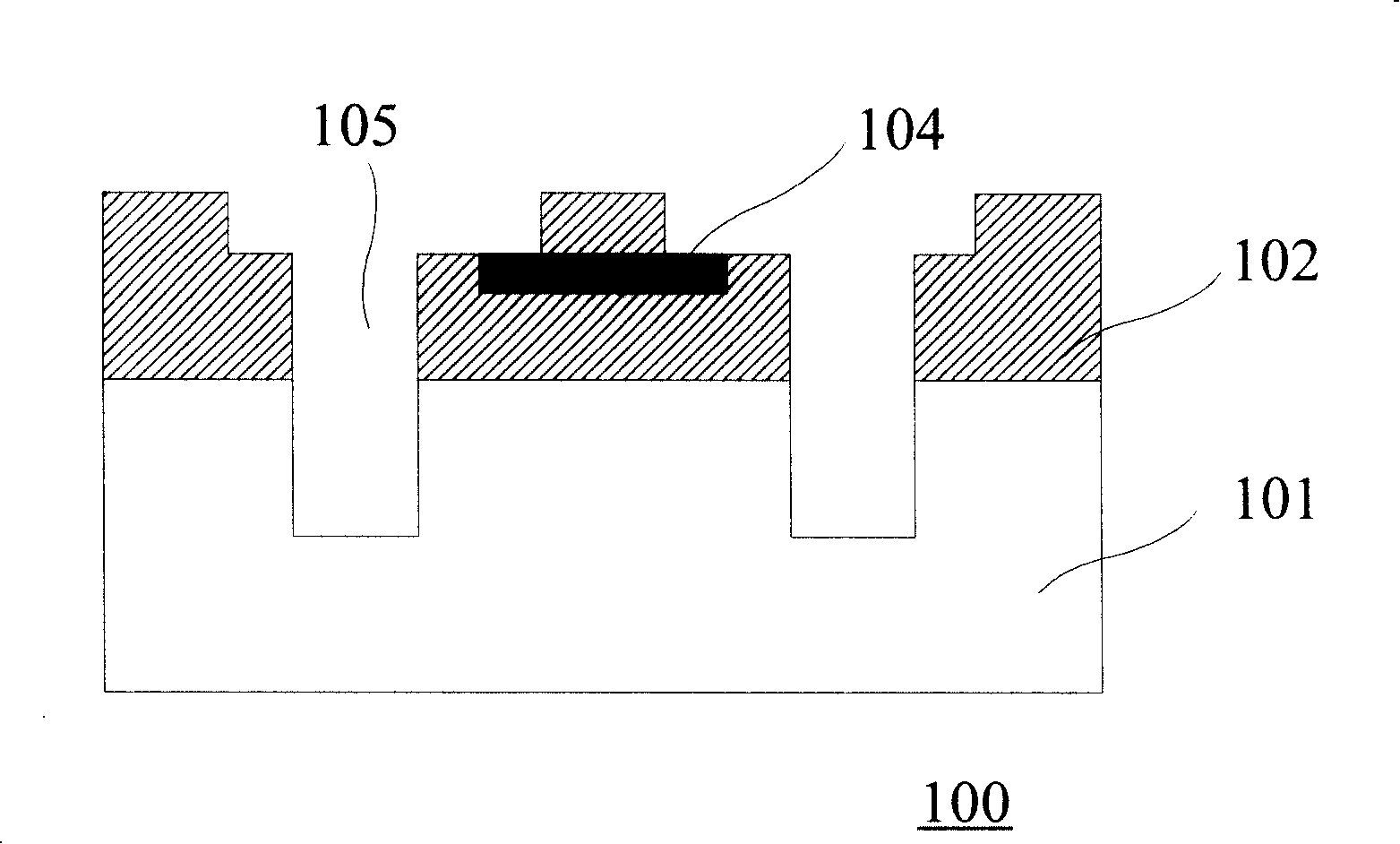

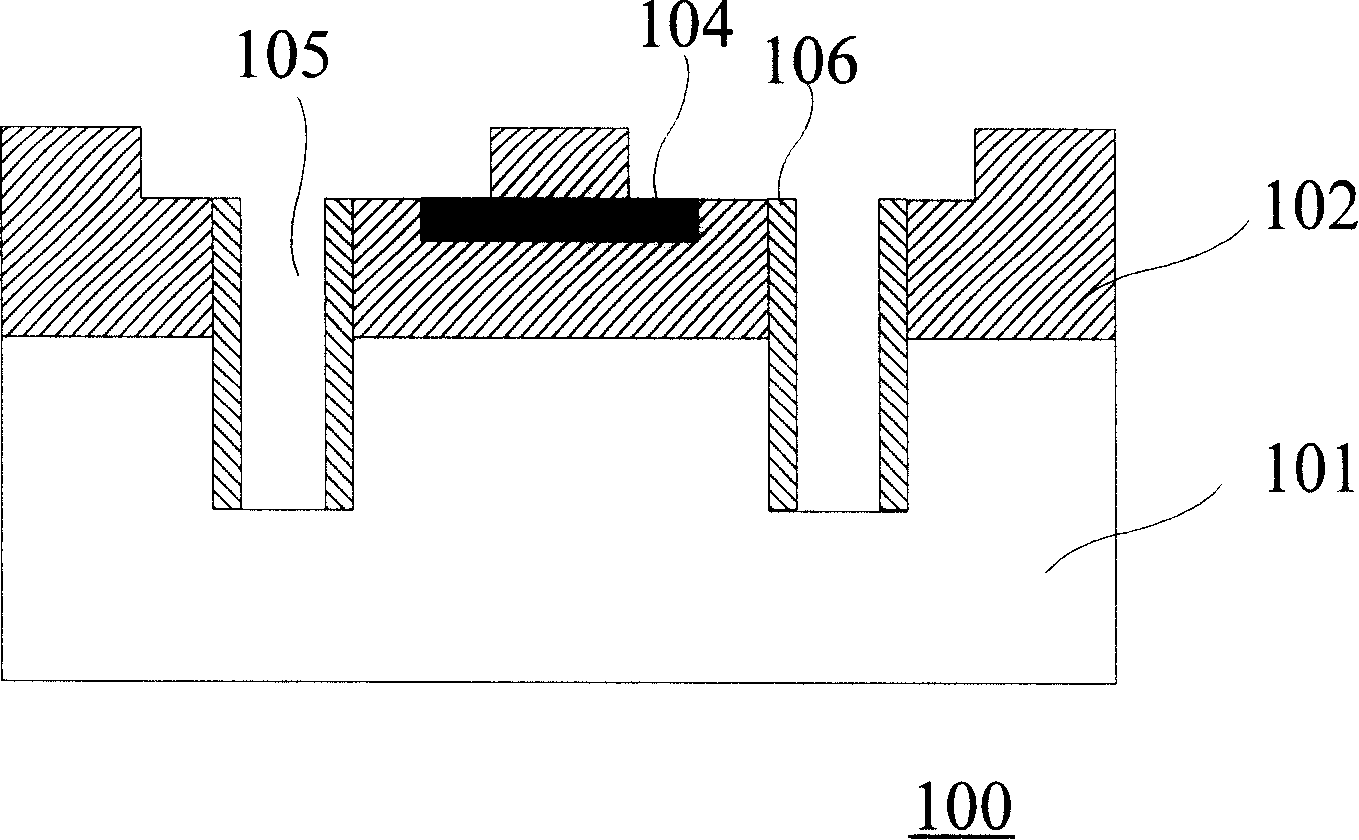

Wafer press welding and bonding method and structure thereof

ActiveCN101197297AWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

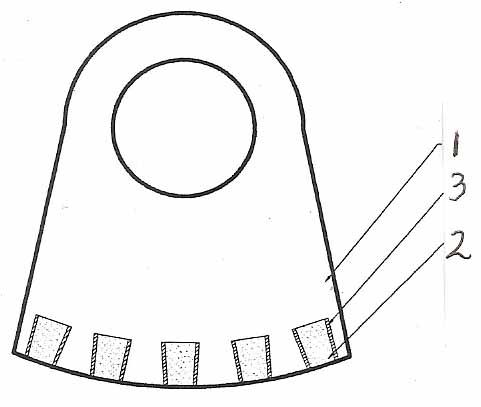

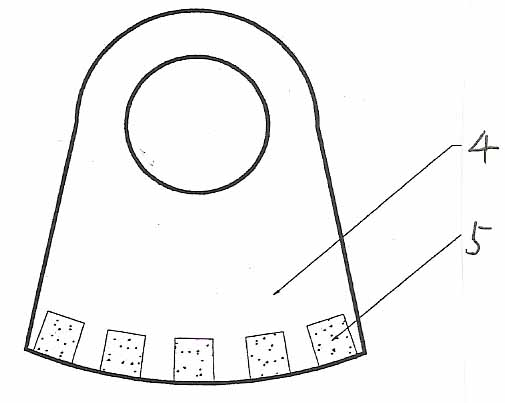

Ceramic reinforced metal matrix abrasion-resisting compound material and preparation method

The invention discloses a ceramic reinforced metal matrix abrasion-resisting compound material and a preparation method. The compound material comprises a metal matrix abrasion-resisting component body, wherein a plurality of blind holes are formed on the surface of the metal matrix abrasion-resisting component body, and self-fluxing alloy powder metallurgically bonded with the metal matrix abrasion-resisting component body and ceramic sintering bodies are arranged in the blinding holes. At a sintering temperature of a vacuum furnace, the self-fluxing alloy powder is fused and is metallurgically bonded with the abrasion-resisting component body while the abrasion-resisting component body and the ceramic are not deformed. The process is simple and the prepared material with a required hardness can be acquired without being subjected to the heat treatment. By using the preparation method, the problem that the ceramic is difficult to be bonded with a metal substrate is solved and the defect caused by a pouring process is avoided. The ceramic, alloy and metal on the surface of the abrasion-resisting component are regularly distributed, the abrasion resistance of the abrasion-resisting component is ensured and the shock resistance is also ensured.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Self-cooling type conductive contact piece and connector

ActiveCN106887733AImprove cooling effectImprove thermal conductivitySoldered/welded conductive connectionsCoupling contact membersPower flowElectrical and Electronics engineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

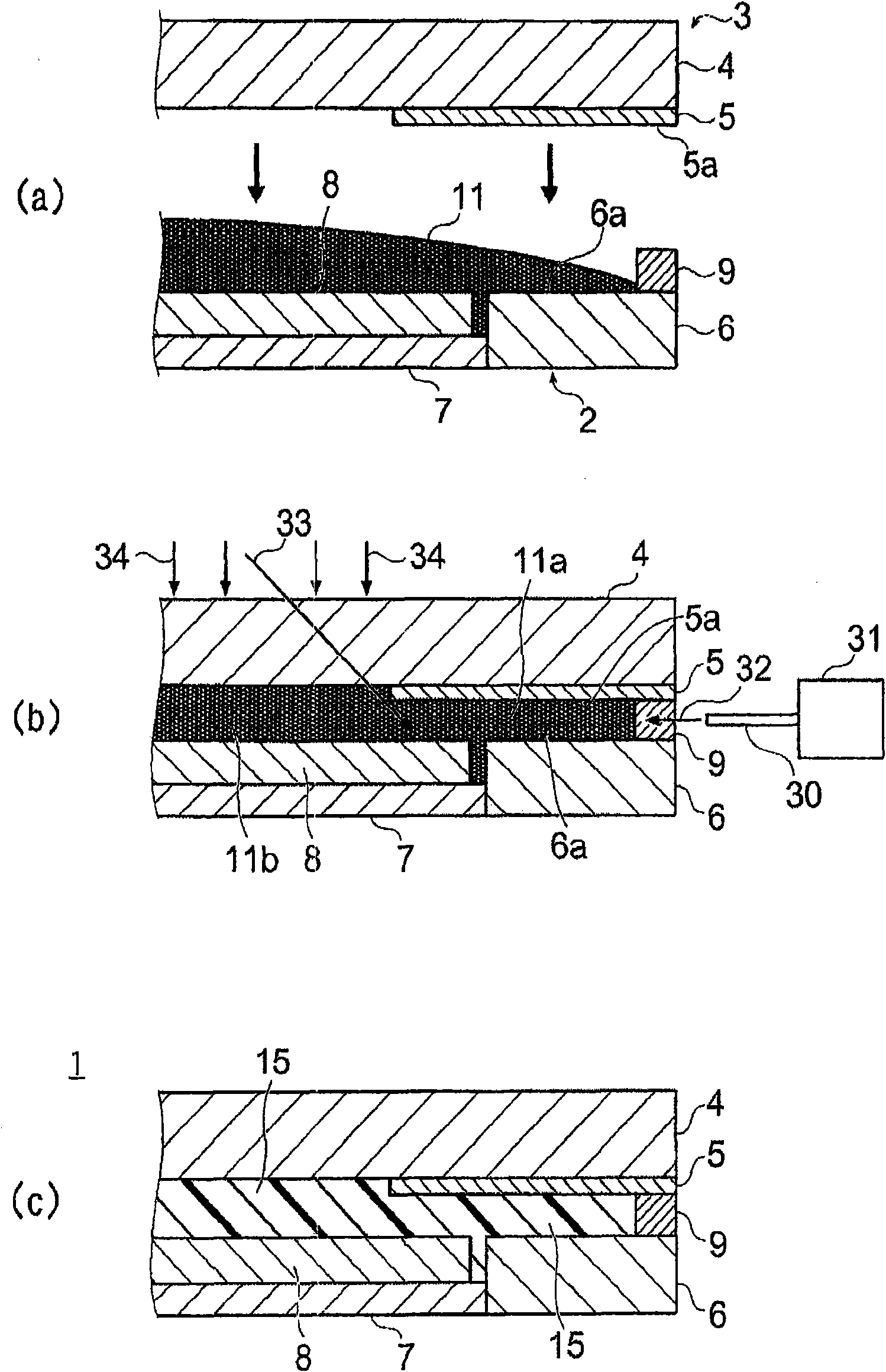

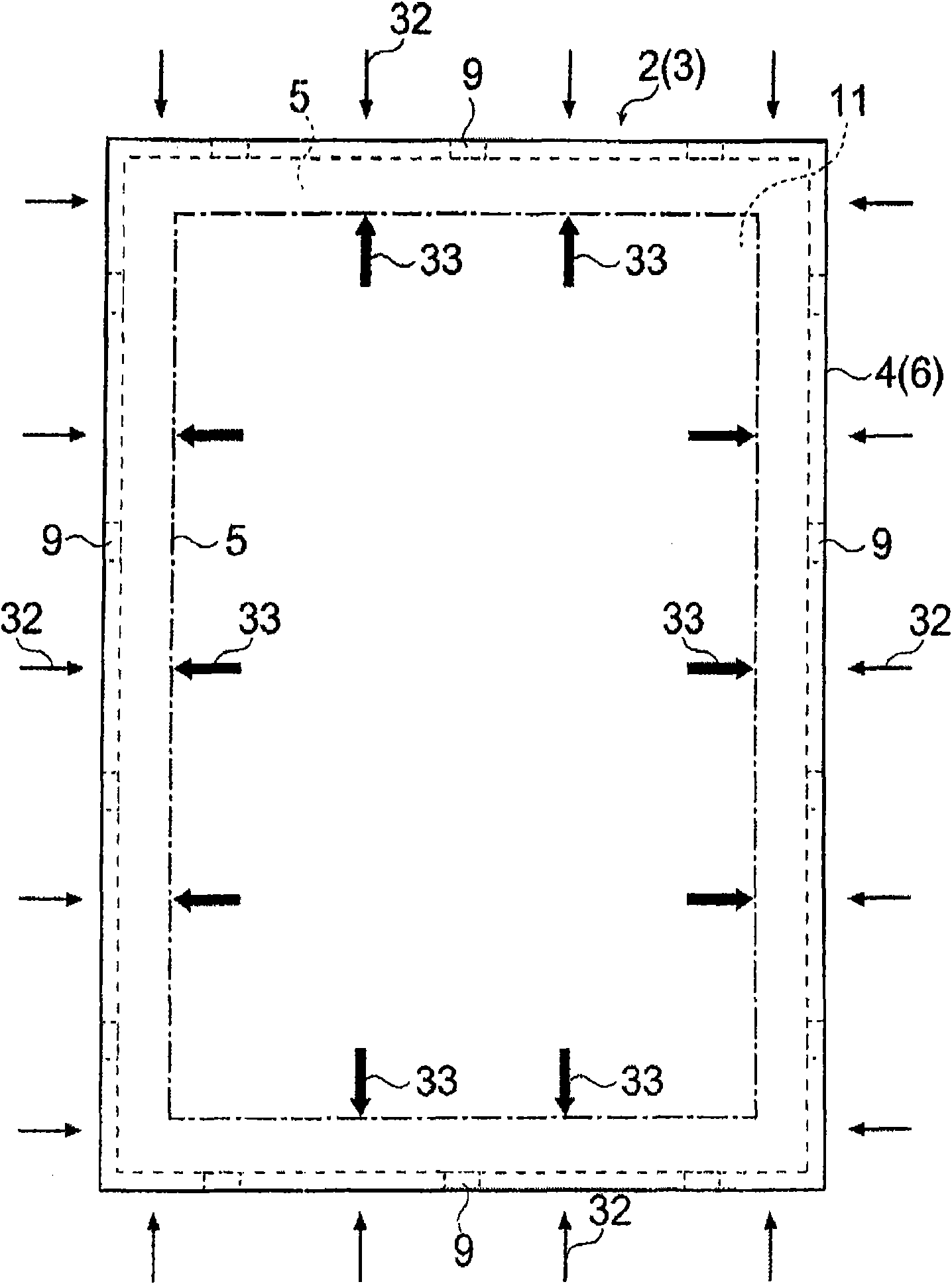

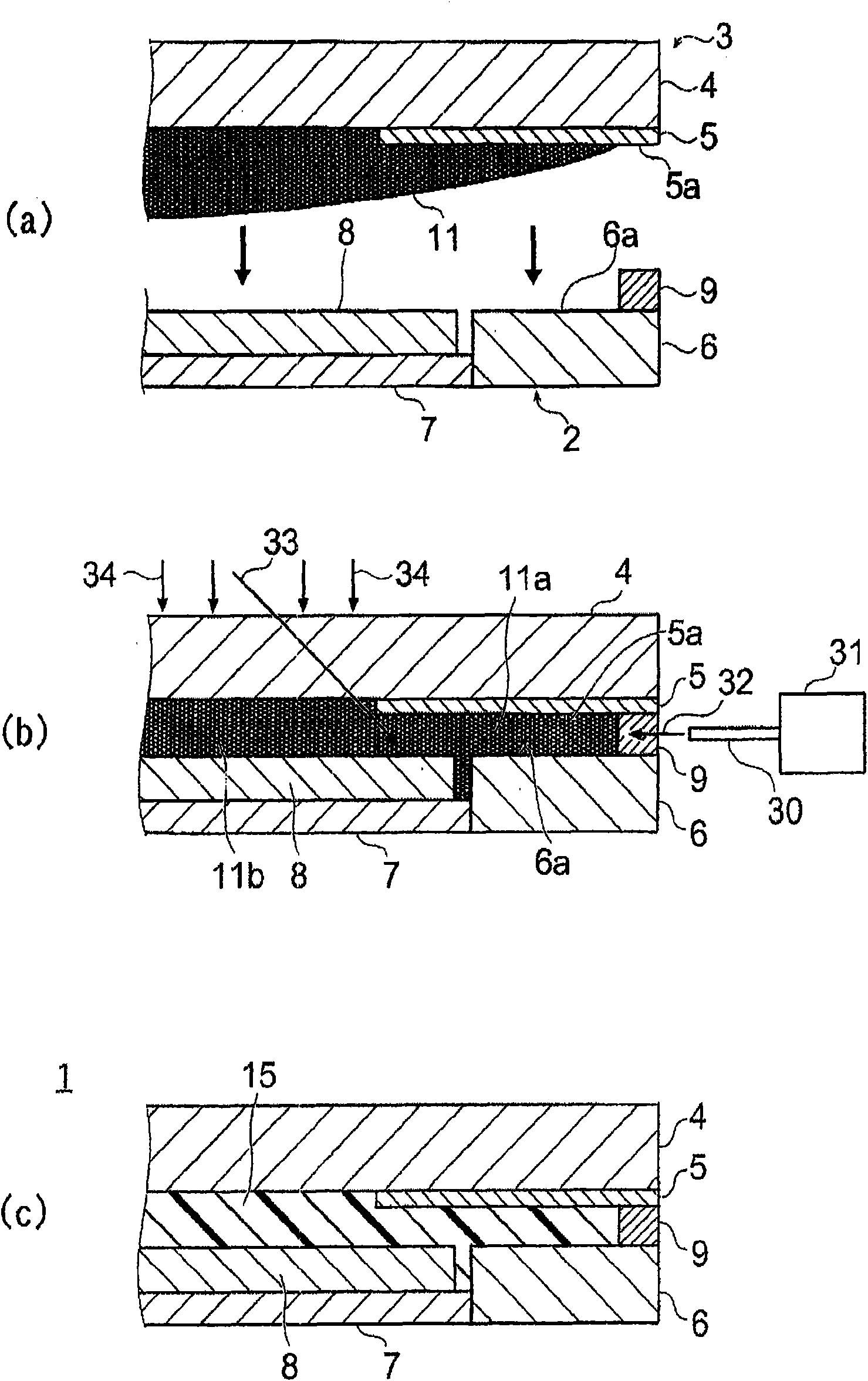

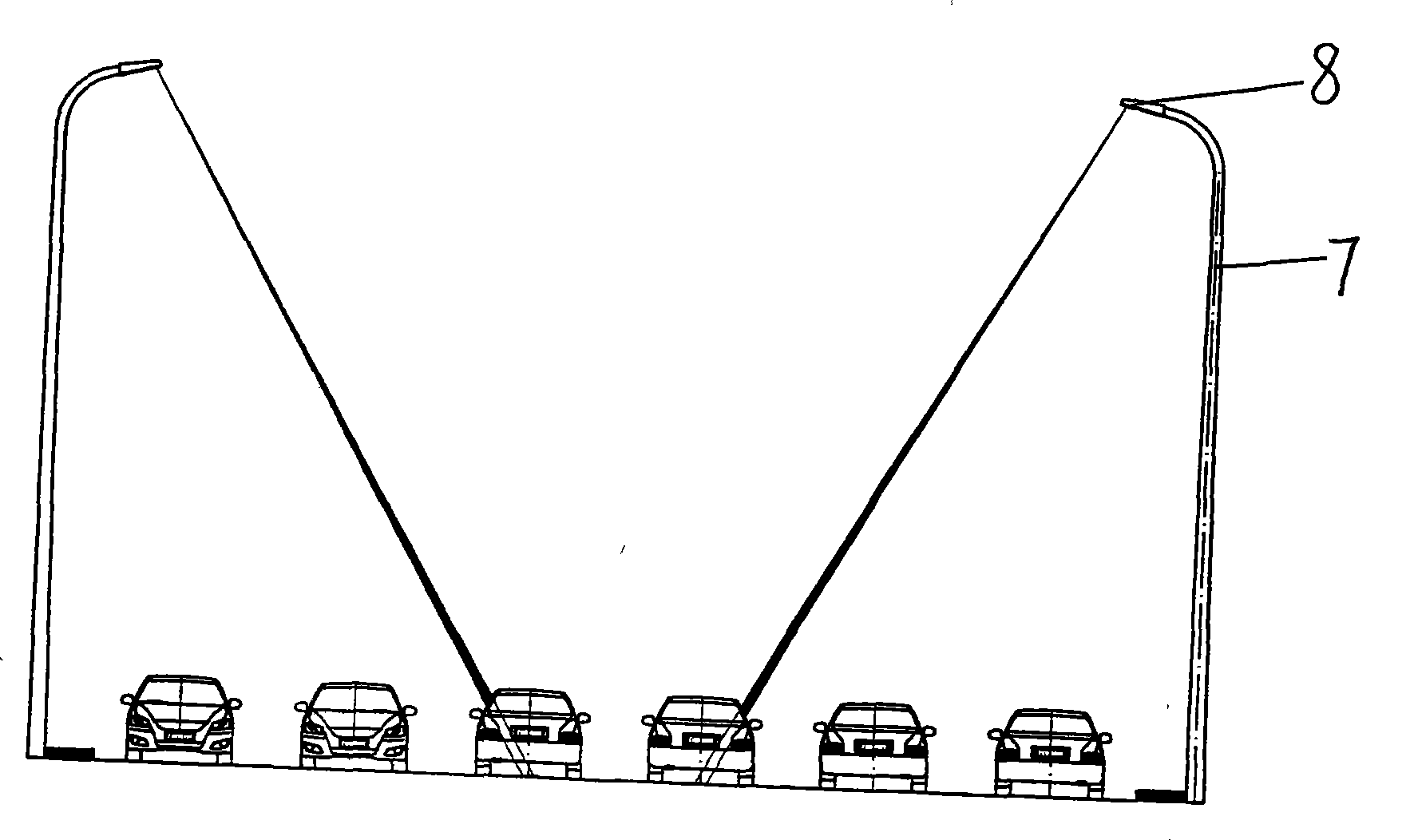

Method for manufacturing image display

ActiveCN101652803APrevent orientation confusionFully curedNon-linear opticsIdentification meansHigh contrastTransmittance

Disclosed is a method for manufacturing an image display (1), which comprises a step wherein a photocurable resin composition (11) is interposed between a base unit (2) having an image display unit such as a liquid crystal display panel (8) and a light-transmitting protective unit (3) having a light-shielding portion (5), and a cured resin layer (15) is formed by photocuring the resin composition(11). In this method, a resin composition having a curing shrinkage rate of not more than 5% and a storage modulus of the cured product at 25 DEG C of not more than 1.0 OE10<7> Pa, which enables to obtain a cured resin layer (15) having a visible light transmittance of not less than 90% is used as the photocurable resin composition (11). The method further comprises a step wherein a curable resincomposition (11a) containing a thermal polymerization initiator is interposed at least between the light-shielding portion (5) and the base unit (2) and then the curable resin composition (11a) is heated. Consequently, the resin in a forming-region of the light-shielding portion (5) is sufficiently cured, while attaining a high-luminance, high-contrast display without having display defects due todeformation of the image display unit (8), during manufacture of the thin image display (1) wherein the resin is interposed between the protective unit (3) having the light-shielding portion (5) andthe image display unit (8).

Owner:DEXERIALS CORP

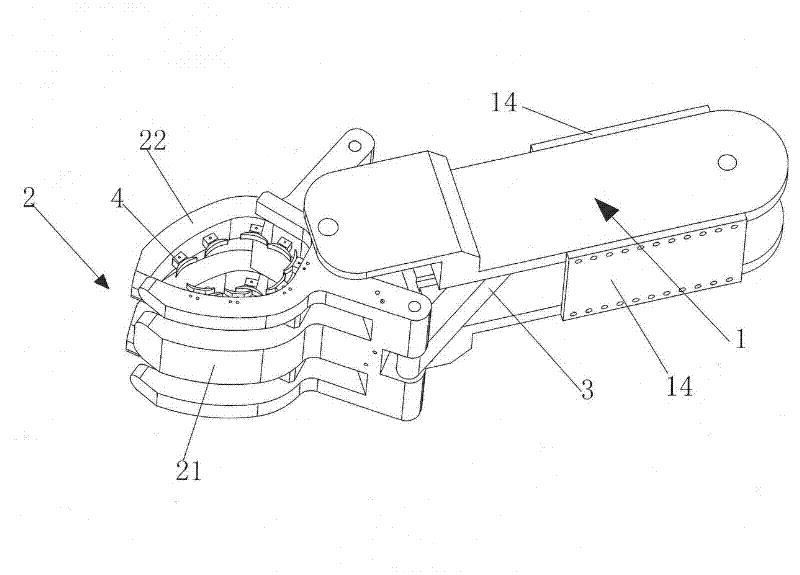

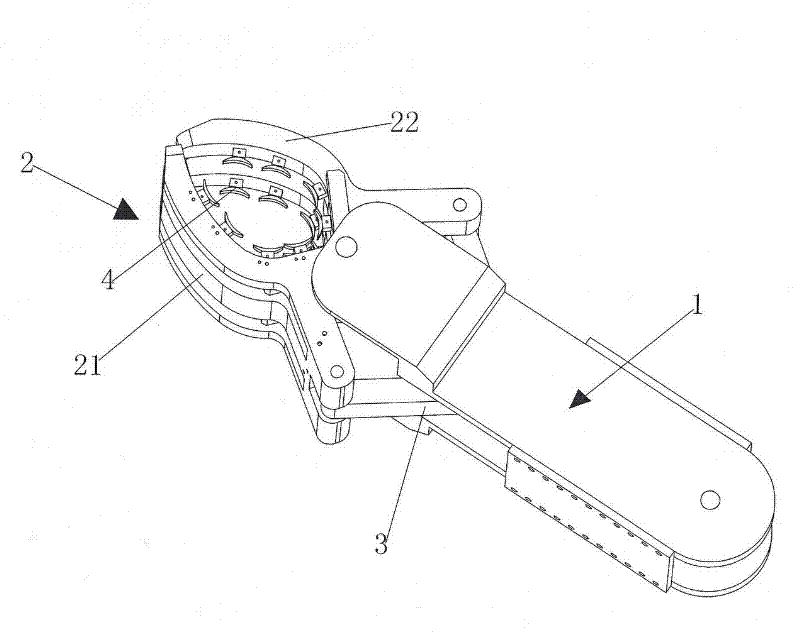

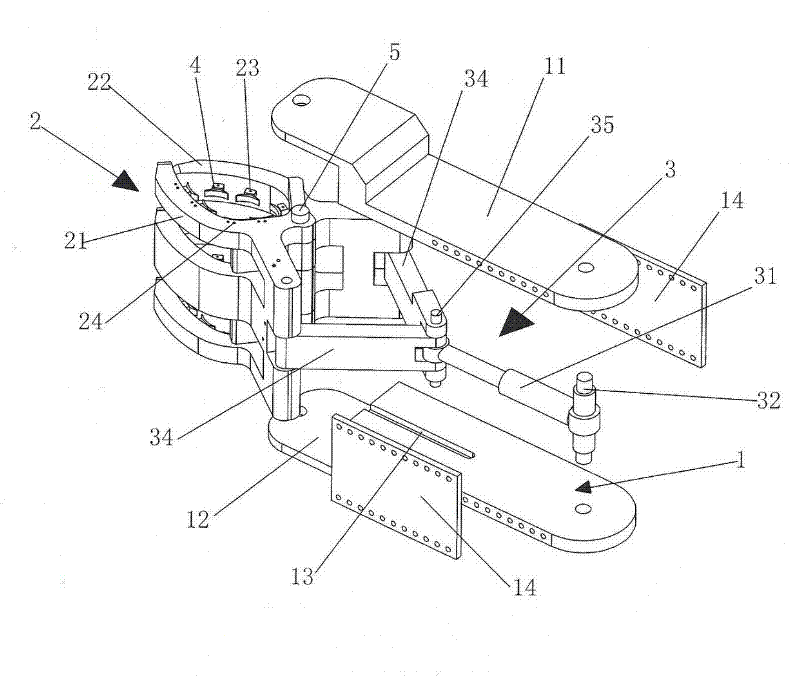

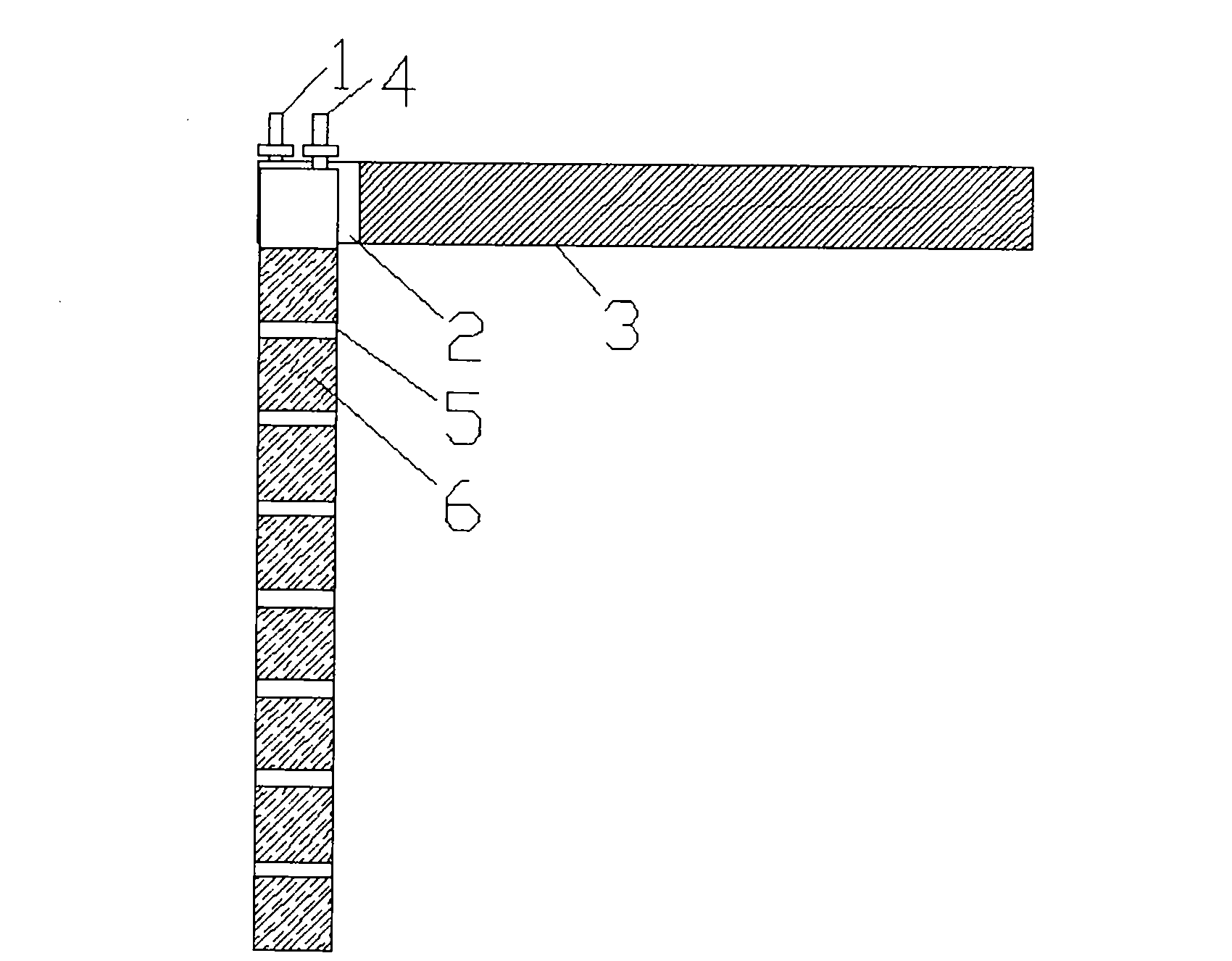

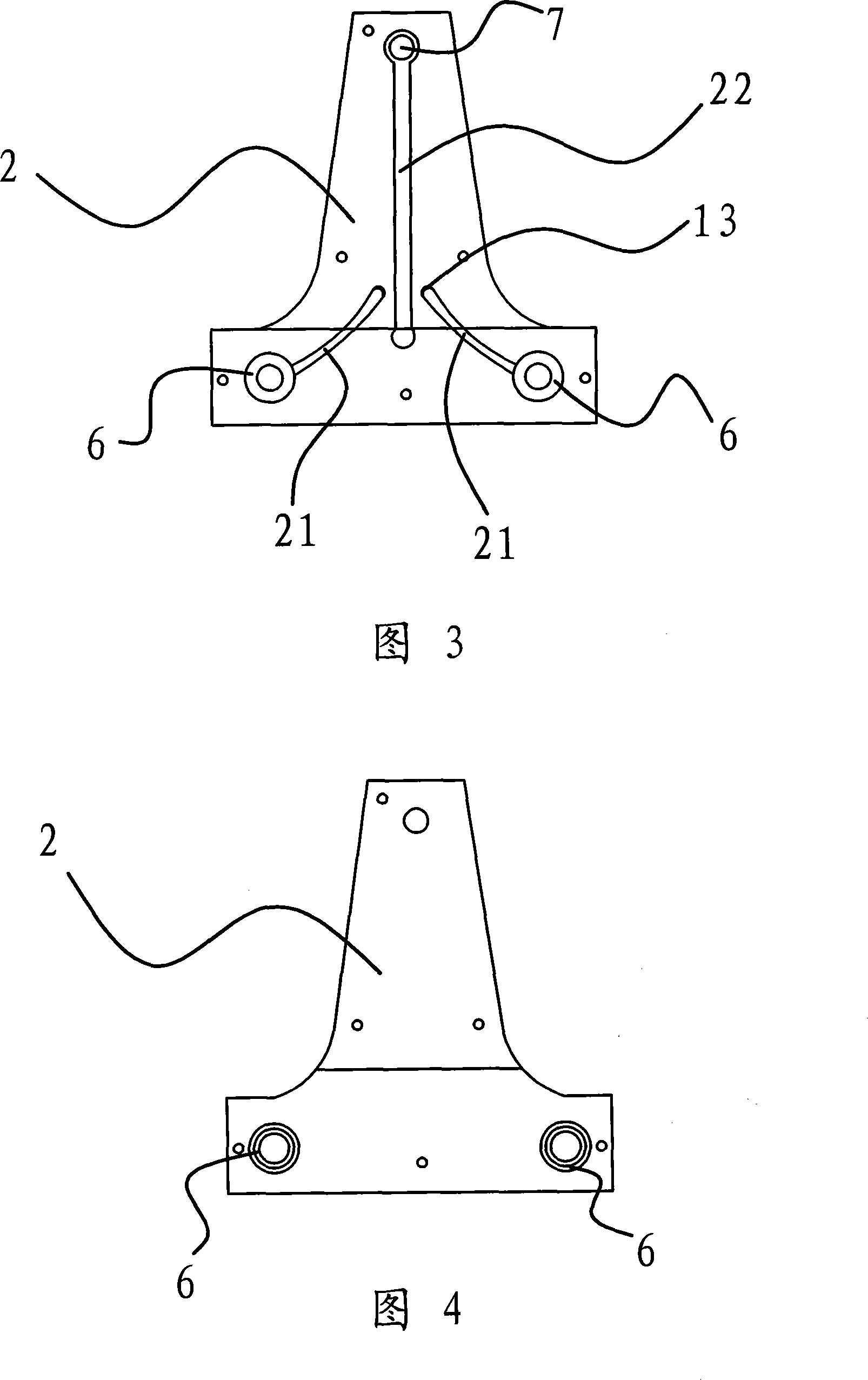

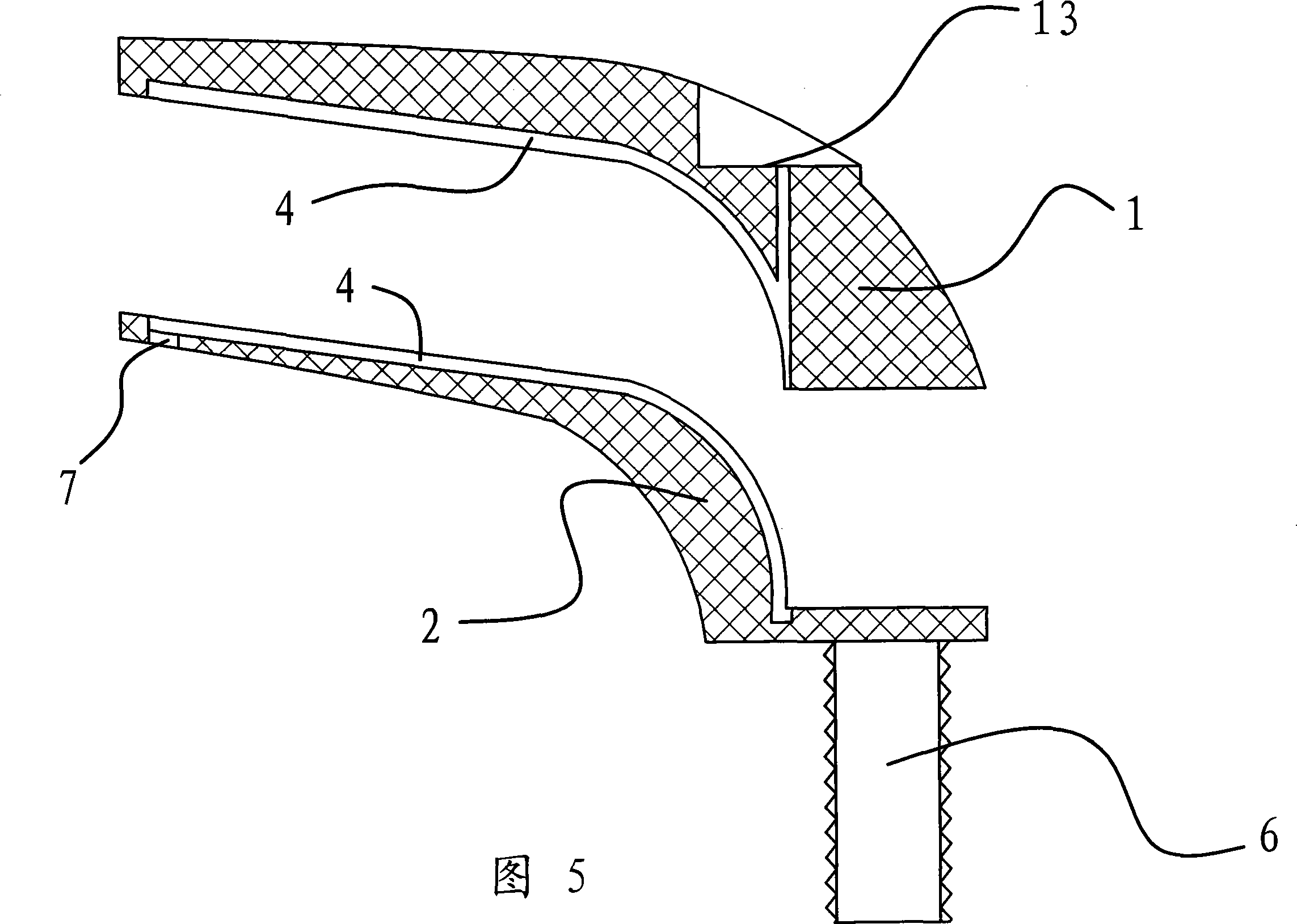

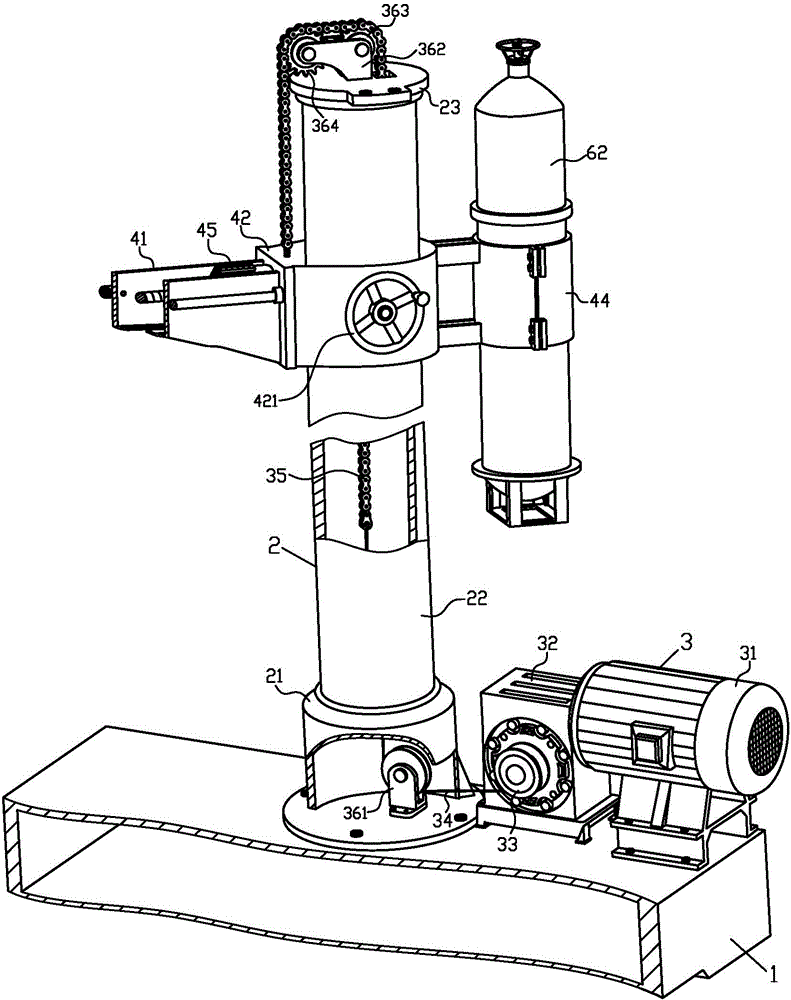

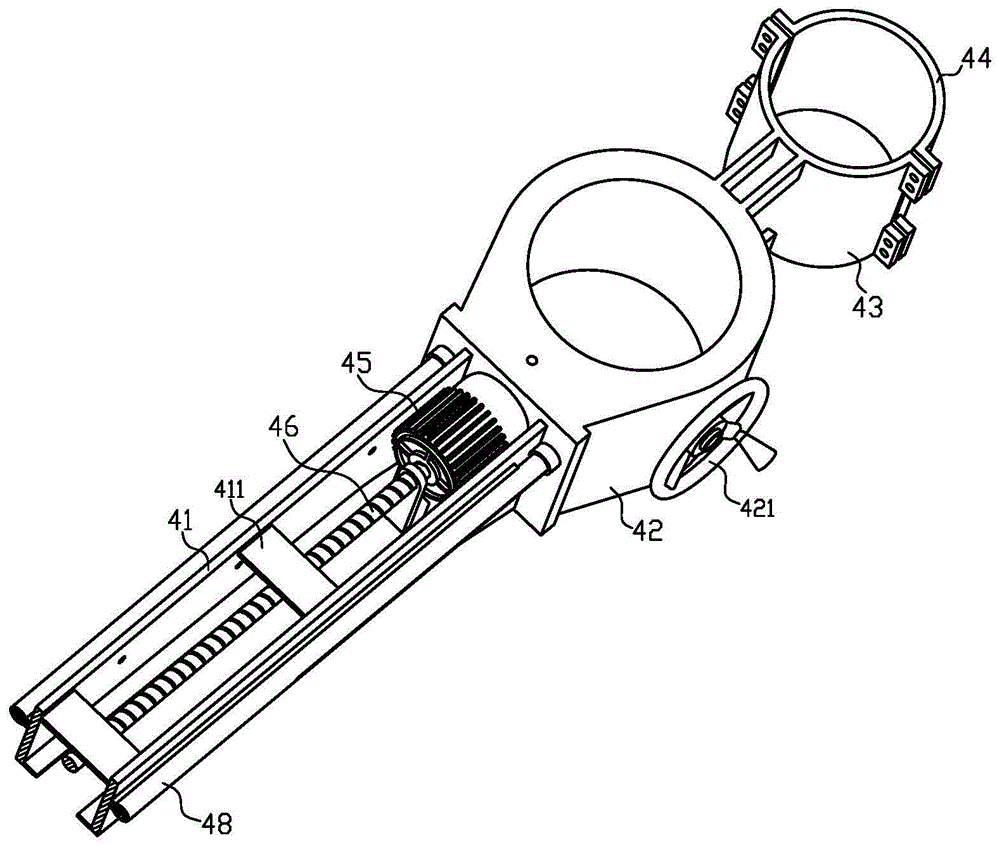

Multipoint mechanical hand for myriametre well drill

The invention discloses a multipoint mechanical hand for a myriametre well drill, which comprises an arm, a crossed hand, a hand driving mechanism and an elastic floating friction mechanism. The hand driving mechanism drives the crossed hand to open or close to clamp or release a tubular column, and the elastic floating friction mechanism is arranged on the inner side of the crossed hand. The crossed handle can be crossed to achieve grab of well casings with different pipe diameters, and one well drilling equipment only needs one handle. The elastic floating friction mechanism can automatically and slightly adjust angles to achieve a multipoint and force-equipotent clamping mode, and clamping points are evenly distributed around the well casing, so that too much clamping force is not required, and deformation of the well casing is avoided. An elastic friction sheet of the elastic floating friction mechanism is in a floating mode, so that friction area can be enlarged, the clamping force can be further reduced, and clamping can be reliable and safe.

Owner:JILIN UNIV

Lithium ion battery and combination method of pole pieces thereof

InactiveCN102664285AEnsure safetyReduce in quantityFinal product manufactureCell electrodesEngineeringPole piece

The invention relates to the technical field of lithium ion battery, in particular to a lithium ion battery, which comprises a battery cell, a packaging bag containing the battery cell, and an electrolyte filled in the battery cell and the packaging bag. The battery cell comprises positive pole pieces, negative pole pieces, and isolating films spaced between the positive pole pieces and the negative pole pieces, wherein head parts of the positive pole pieces and head parts of the negative pole pieces are mutually perpendicular and overlapping, and the positive pole pieces and the negative pole pieces are folded crosswise in a Z shape. Compared with the prior art, the lithium ion battery of the invention comprises a smaller amount of pole pieces, no multi-battery parallel structure with a lamination structure will be formed, and security performance of the battery is ensured; the positive pole pieces and the negative pole pieces are sequentially folded crosswise in a Z shape, layers of the pole pieces are arranged according to a feature which is similar to the lamination structure, same force is exerted on pole piece in each layer, internal stresses between the layers of the battery pole pieces are distributed uniformly, and the battery is not deformable. In addition, the invention further discloses a combination method of pole pieces of the lithium ion battery.

Owner:NINGDE AMPEREX TECH +1

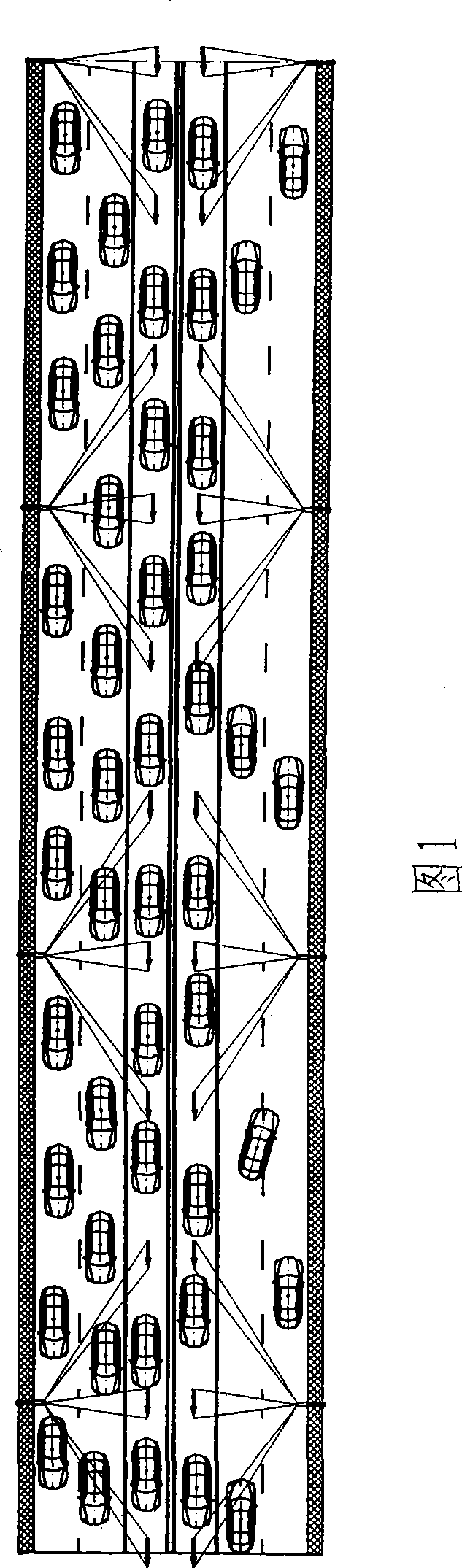

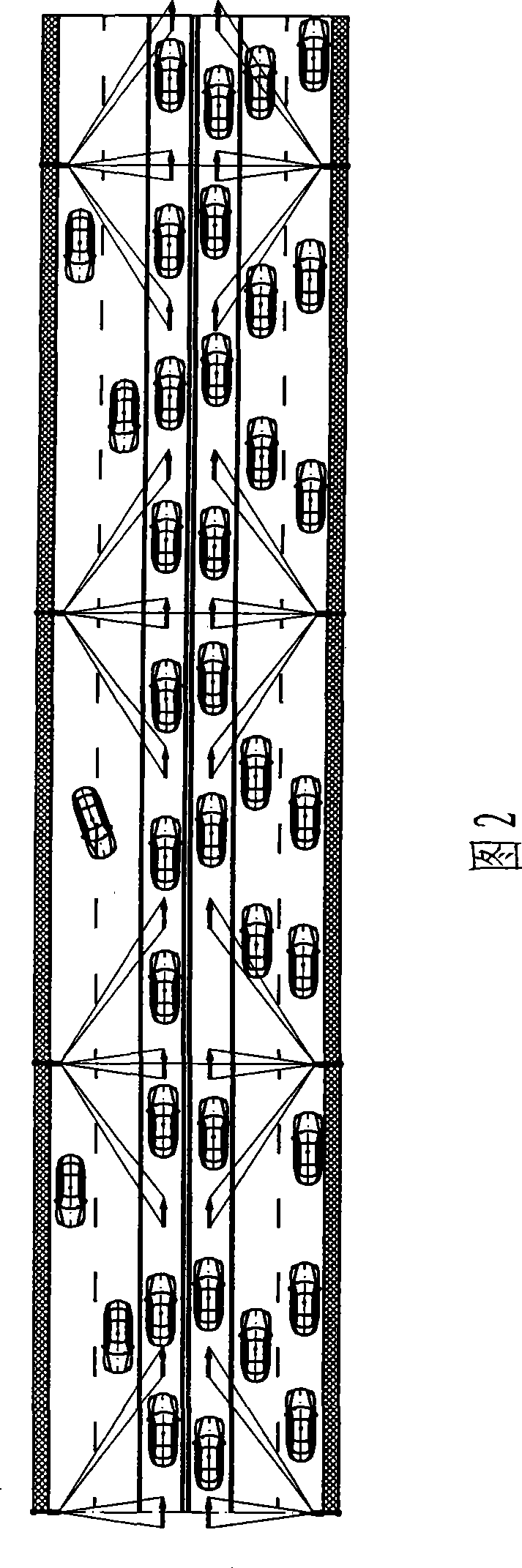

Traffic sign line labeling method and system thereof

InactiveCN101393688AIncrease brightnessImprove directionalityArrangements for variable traffic instructionsTraffic signalsLight beamEngineering

The invention relates to a method and a system for making a traffic sign marking. The traffic sign marking comprises a traffic sign and a traffic marking, and also traffic facilities; a laser generator is used for generating laser to form three-dimensional or two-dimensional traffic sign marking, and the laser beam generated by the laser generator can be adjusted to change the traffic sign marking. By adopting the method and the system, the vacant lane in the opposite direction can be utilized to relieve the pressure of traffic jam sections and solve the problem that traffic jam appears in the downtown direction and less cars go in the uptown direction when people go to work, and the traffic jam appears in the uptown direction and less cars go in the downtown direction when people get off work.

Owner:高玉宗

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

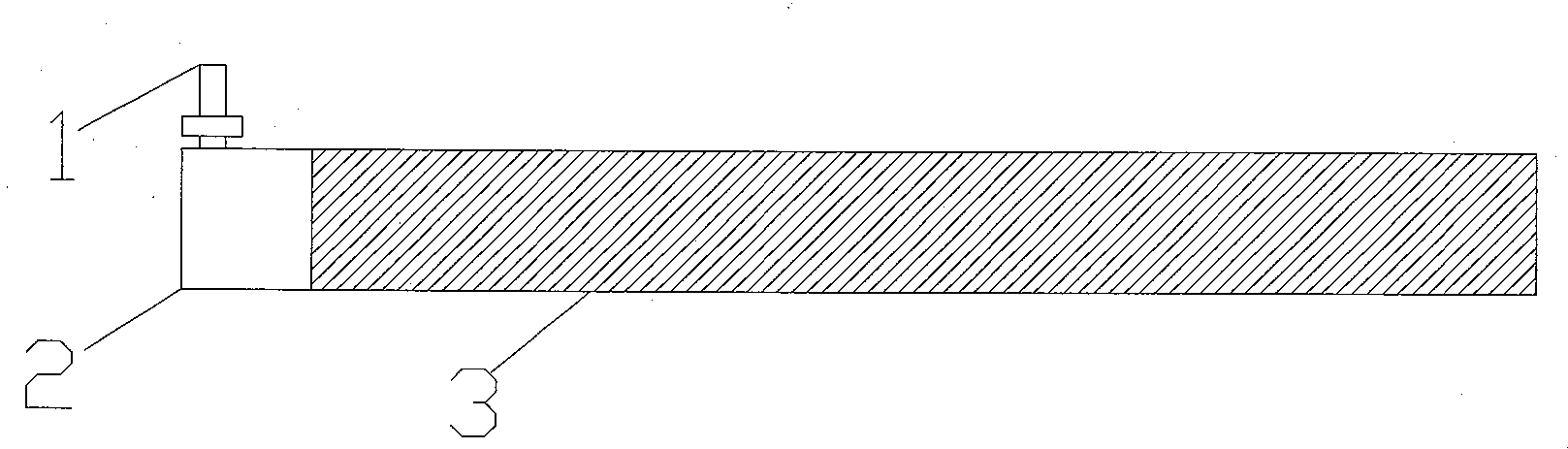

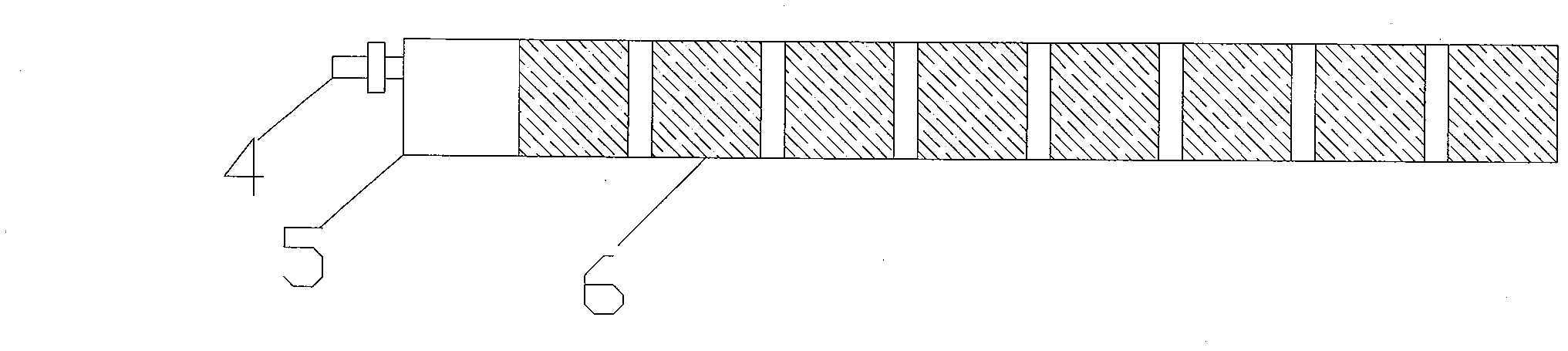

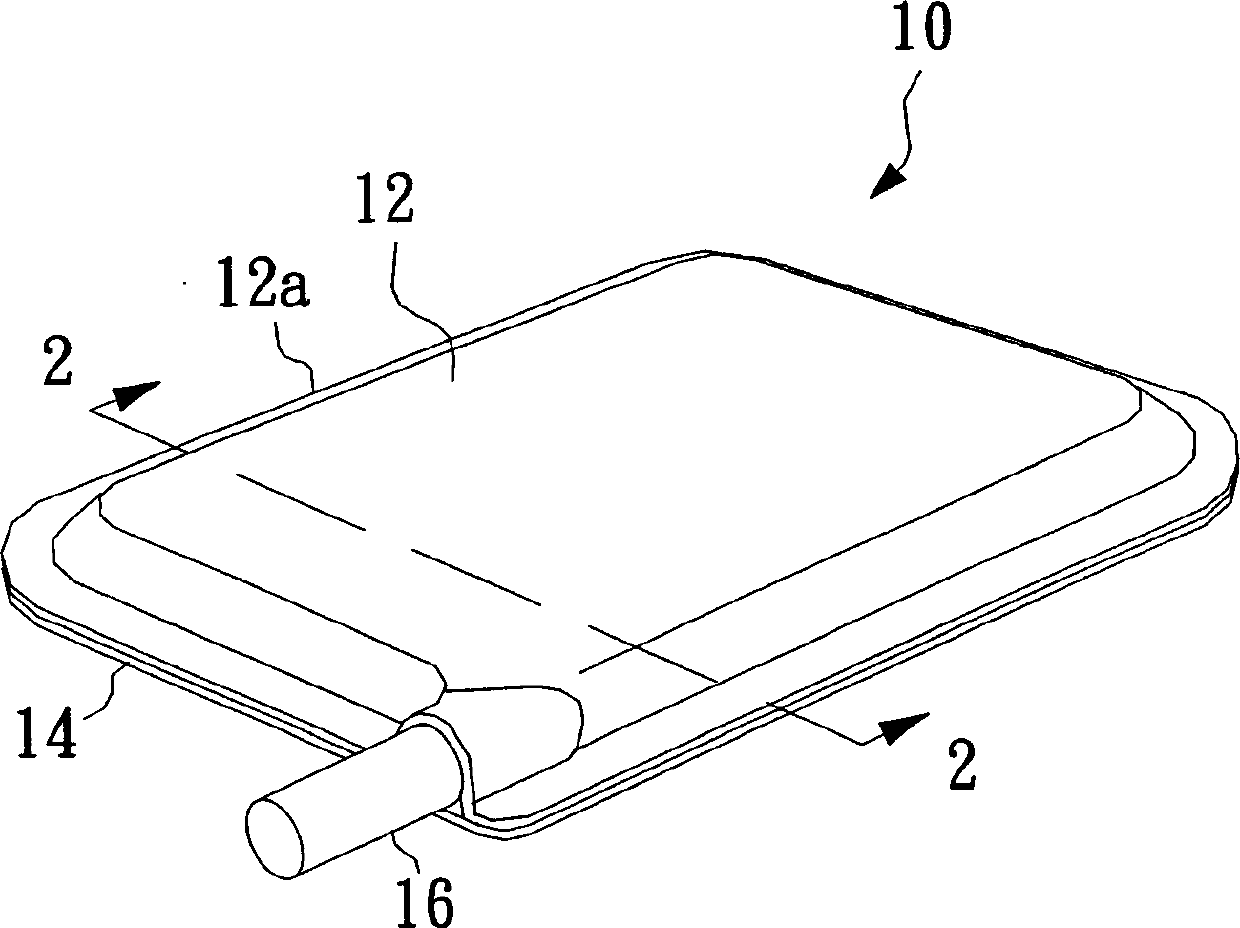

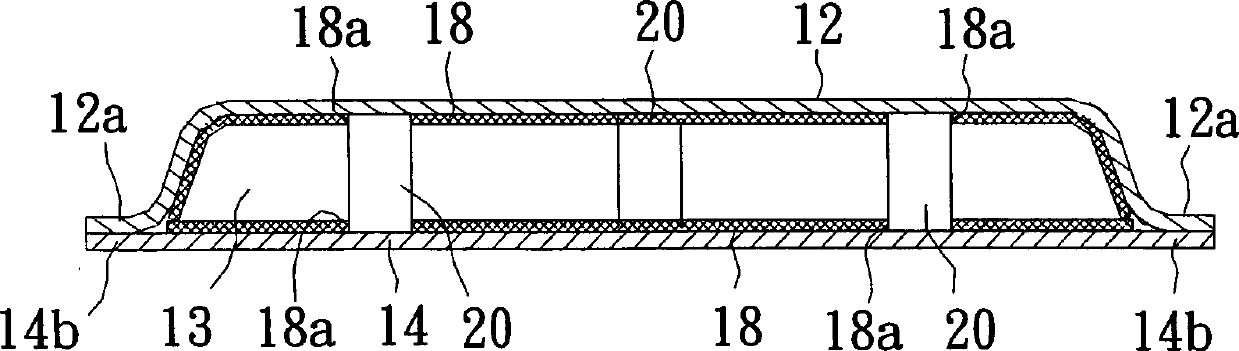

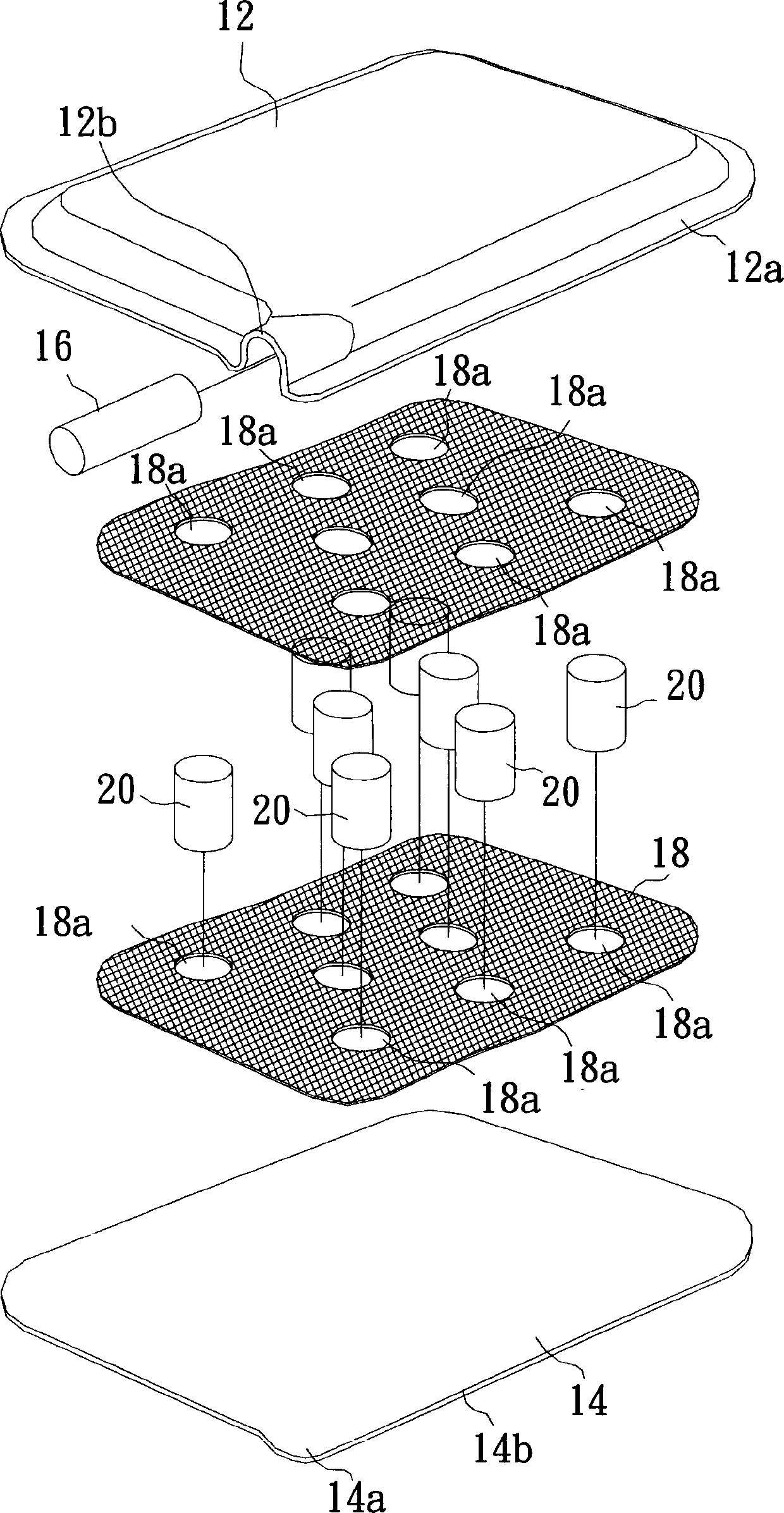

Winding carved heat equalizing plate with metal net micro structure and its producing method

InactiveCN1784137AEasy to form capillary structureWill not deformInstrumental cooling apparatusCooling/ventilation/heating modificationsMicro structureWorking fluid

A heat soaking board and method, which contains 1, providing metal piece upper cover and lower cover, 2, diffuse bonding metal net on inner surface of upper and lower cover to form capillary structure, 3, holding reinforced piece between upper and lower cover, 4, diffuse bonding upper, lower cover and reinforced piece to form a cavity, 5, vacuuming said cavity, 6, filling work fluid in the vacuumed cavity, 7, sealing said cavity. Said invention has low cost and less deformation.

Owner:TAIWAN MICROLOOPS CORP

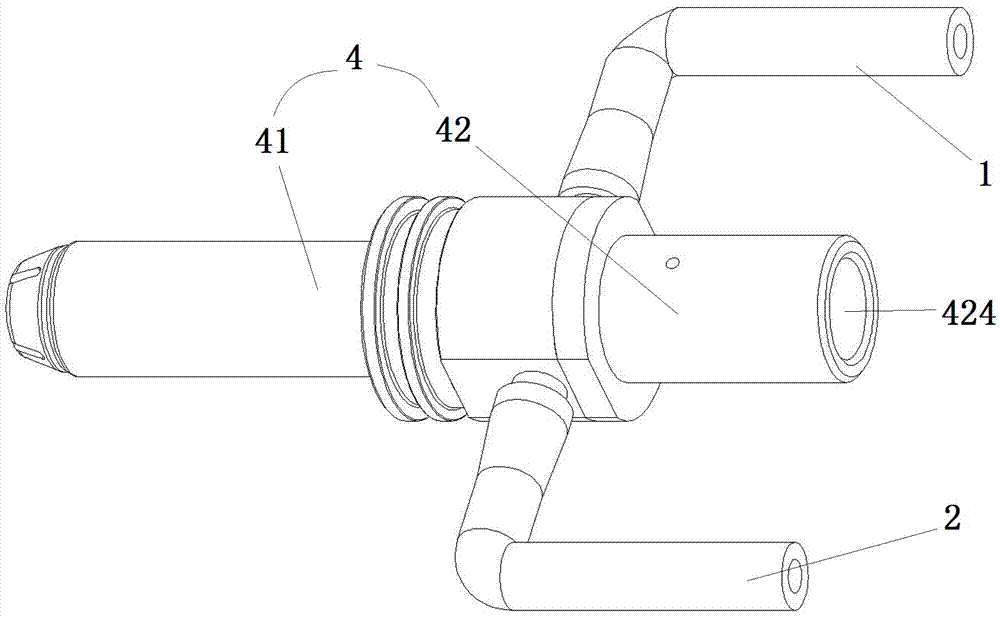

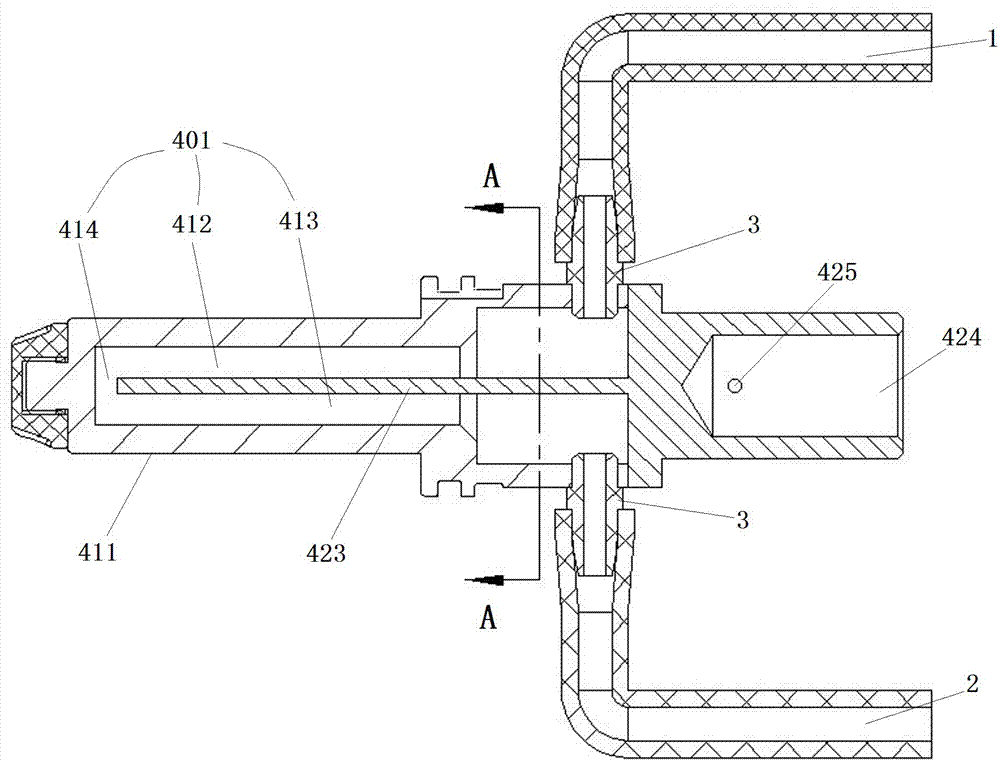

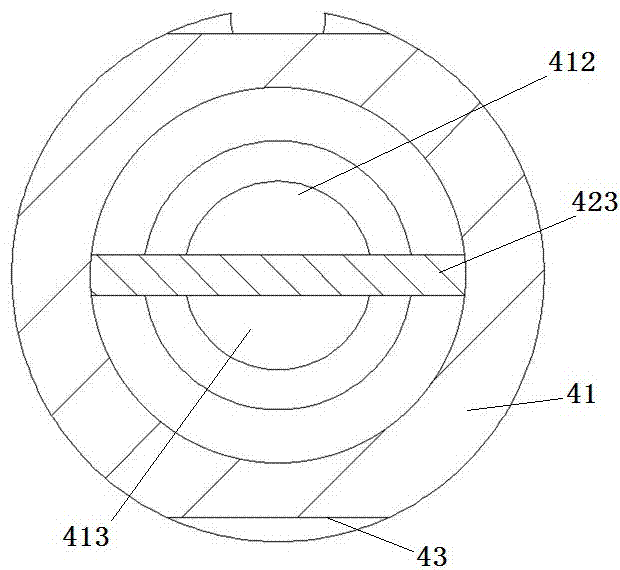

Plastic tap and its manufacture method

InactiveCN101216124ASmooth dischargeSimple structureMultiple way valvesSlide valvePlastic materialsEngineering

The invention provides a plastic faucet and a manufacturing method thereof, which belongs to the technical field of life necessaries and solves the problems of prior art, such as difficult fabrication, high cost and poor stability in water outlet. The plastic faucet comprises a main body and a valve core, which are made of plastic materials. The external end of the valve core extends outside the main body and then is connected with a handle. The main body is also provided with a water inlet pipe and a water outlet port. The main body consists of an upper body and a lower body, which are overlapped together. A shell is arranged outside the upper body and the lower body to tightly enclose the two bodies. An inlet water passage and an outlet water passage are arranged at the junction of the upper body and the lower body and communicated with the water inlet pipe and the water outlet port respectively. The manufacturing method of the plastic faucet comprises the following steps: A. parts fabrication; B. parts assembly; C. mould setting and closing; D. injection molding; E. surface treatment; and F. assembly finishing. The invention has the advantages of simple structure, low cost, good stability in water outlet, and convenient fabrication and use.

Owner:吴兵

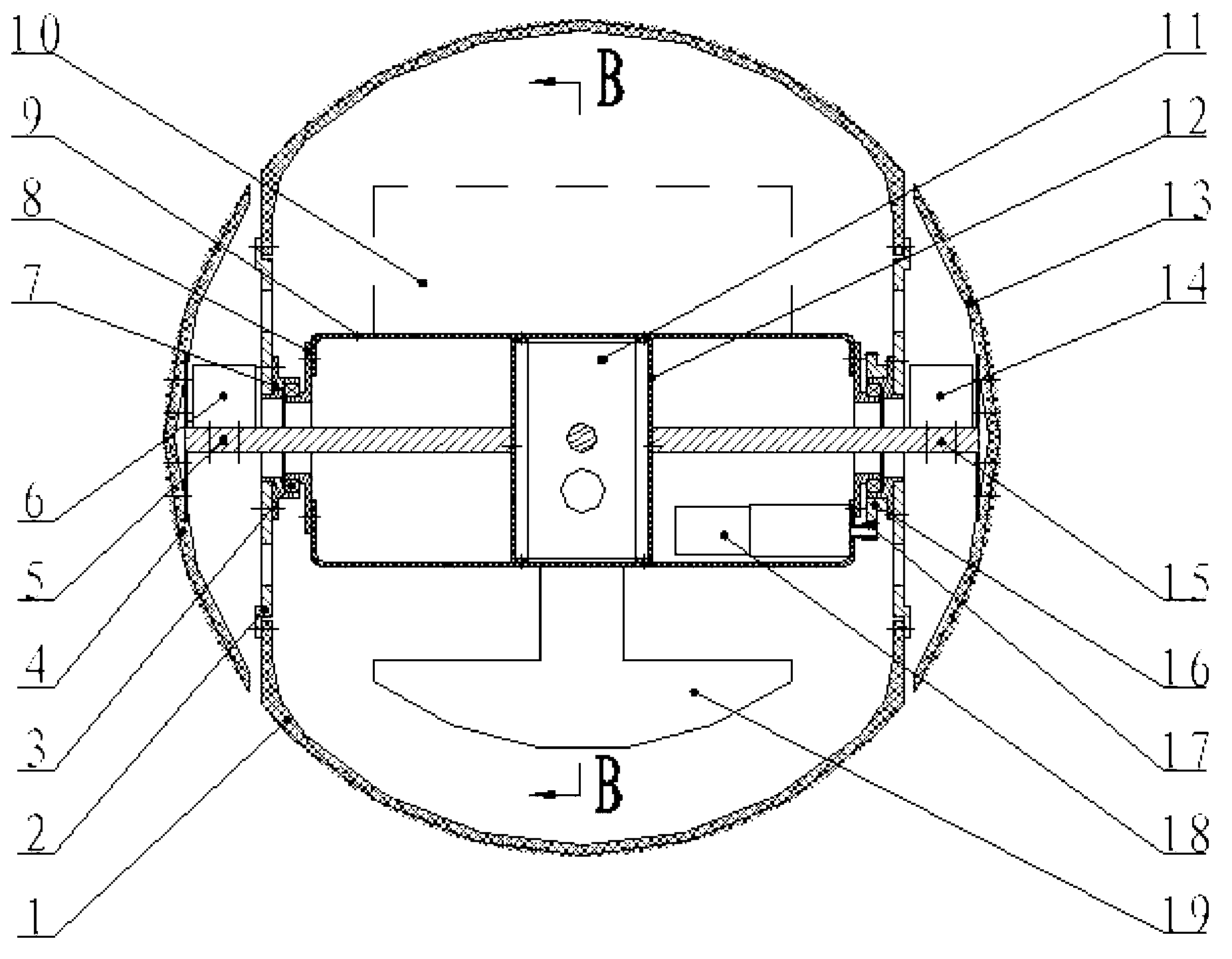

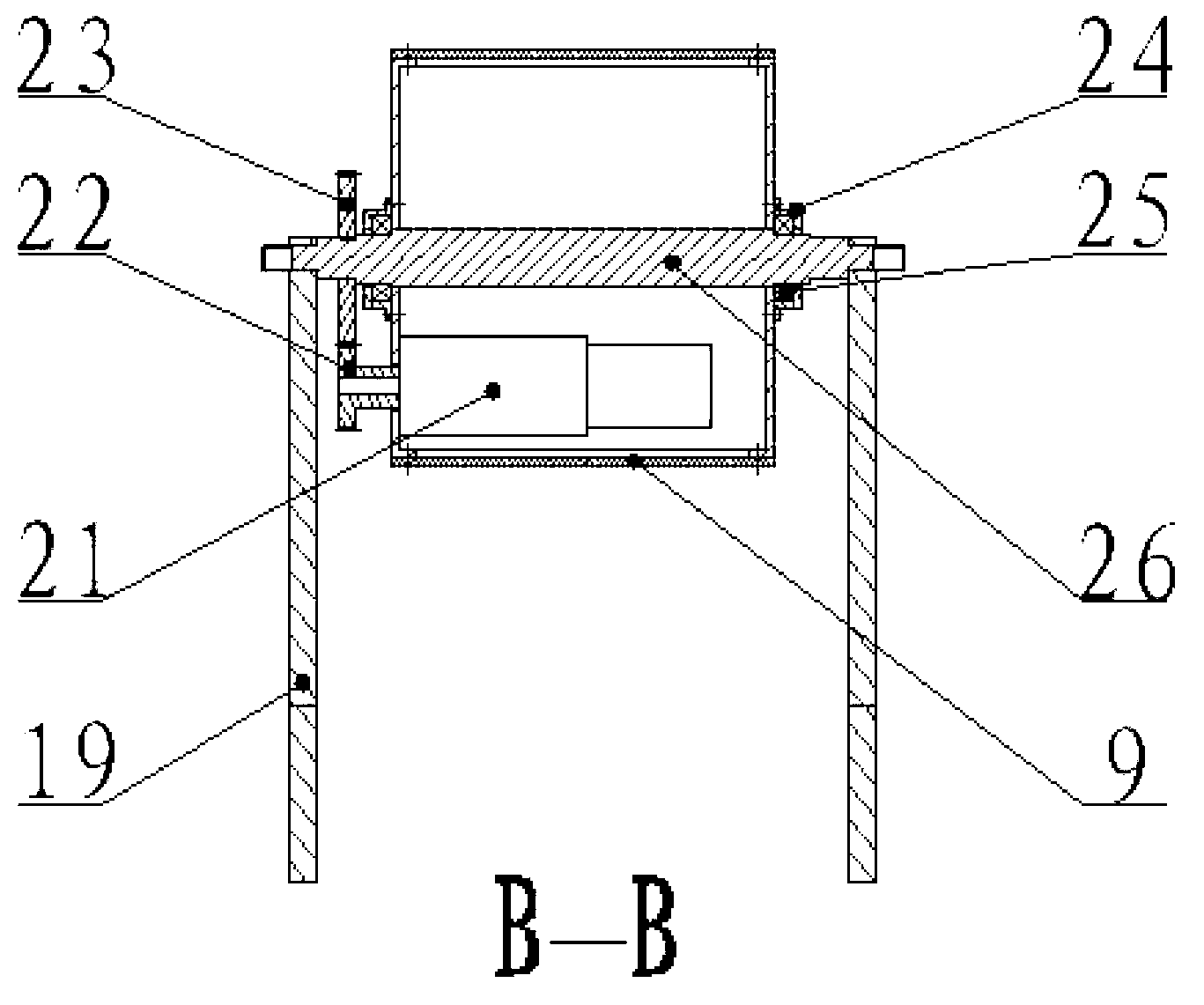

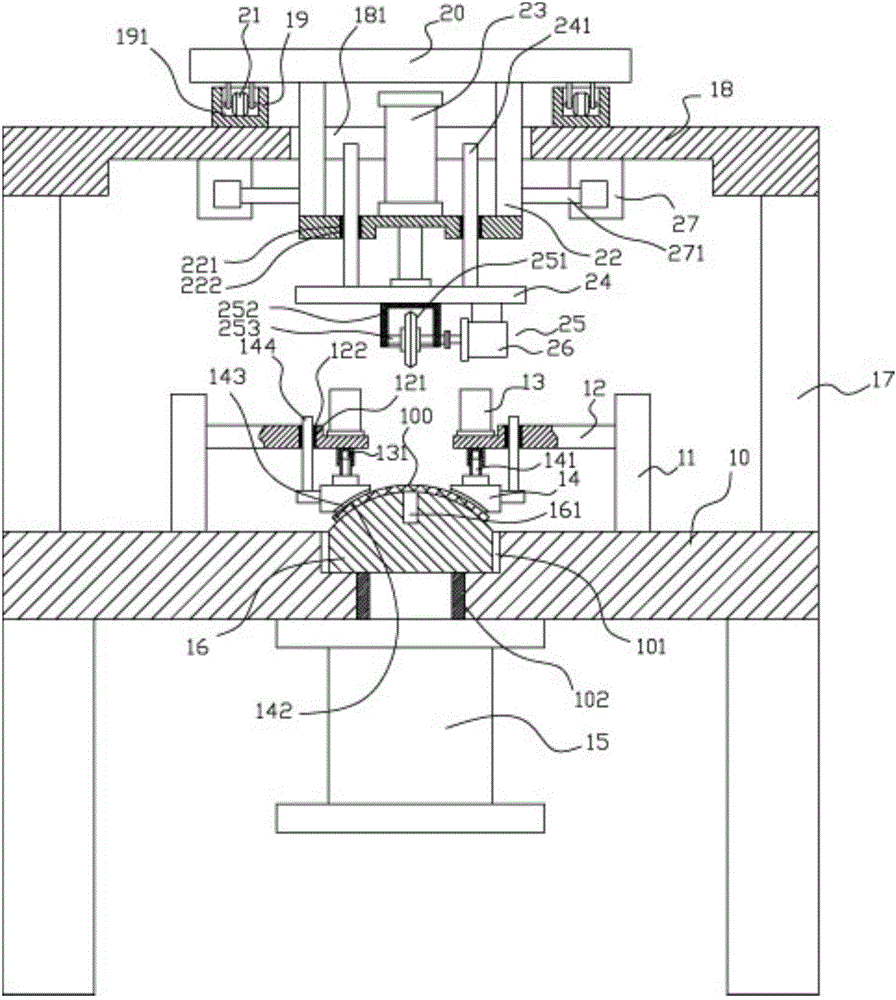

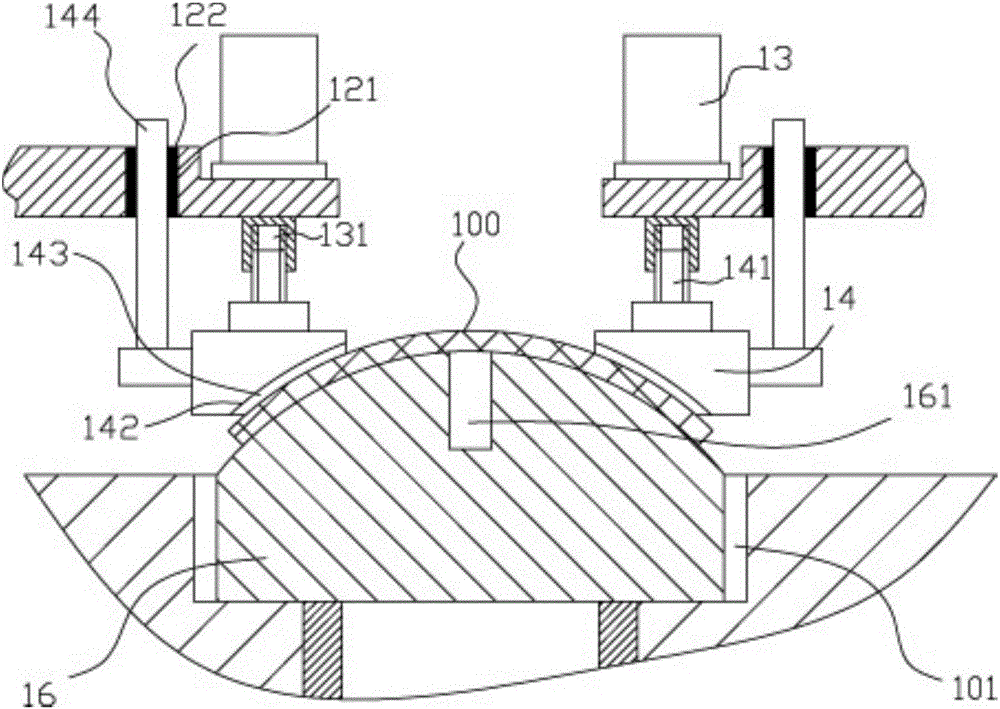

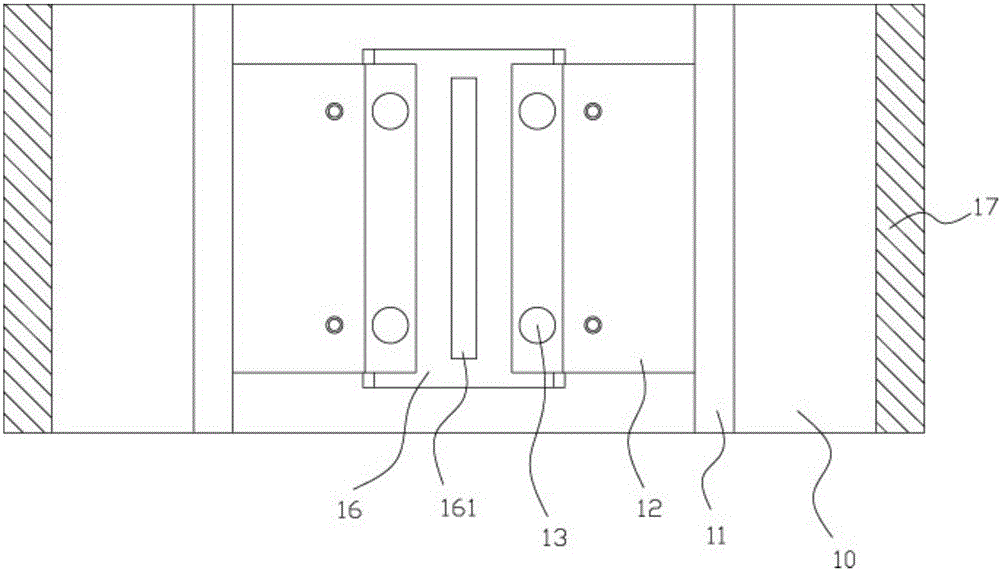

Spherical robot with binocular stereoscopic vision

InactiveCN103171638AWith binocular stereo visionAccurate collectionVehicle body stabilisationVehiclesBinocular distanceSpherical robot

The invention discloses a spherical robot with binocular stereoscopic vision. The spherical robot with the binocular stereoscopic vision comprises a visual camera support structure, a straight line and turning driving mechanism, a novel spherical shell and balance weights. The spherical shell is a whole formed by three portions, the spherical crowns of a left spherical shell and a right spherical shell are cut to form a through hole, a long shaft which cannot rotate with the spherical shell is arranged, the installation of a visual camera sensor is convenient, a visual camera can stretch out of the spherical shell through the through hole of the spherical shell, and the limitation of the spherical shell is avoided. A movement mechanism is provided to enable the spherical robot with the binocular stereoscopic vision to have the capacity of being flexible in turning.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Arc plastic plate grooving mechanism

ActiveCN105856296AEasy to processWill not deformMetal working apparatusMechanical engineeringEngineering

The invention discloses an arc plastic plate grooving mechanism which comprises a rack, wherein vertical plates are fixed on the two sides of a top plate of the rack; the two ends of the bottom surface of an upper support plate are fixed on the top surfaces of the two vertical plates; a moving through groove is formed at the middle part of the upper support plate; sliding groove bodies are fixed in the top surfaces of the upper support plates on the two sides of the moving through groove; multiple support rollers are arranged on the two end bottom surfaces of an upper moving block; the support rollers are inserted in the sliding groove in the top surface of the sliding groove body in a sleeving manner; a lower connection frame is fixed on the bottom surface of the upper moving block and inserted in the moving through groove in a sleeving manner; the lower end of the lower connection frame extends out of the moving through groove; a position adjusting air cylinder is fixed on the top surface of the bottom plate of the lower connection frame; the end part of a push rod of the position adjusting air cylinder goes through the bottom plate of the lower connection frame, and a connection plate body is fixed at the end part; and a cutting mechanism is arranged on the bottom surface of the connection plate body. An arc plastic plate can be automatically clamped, fixed and cut; and the arc plastic plate is supported by the bottom support block and prevented from deformation, and thus the processing effect is improved.

Owner:佛山市顺德区金业华橡塑有限公司

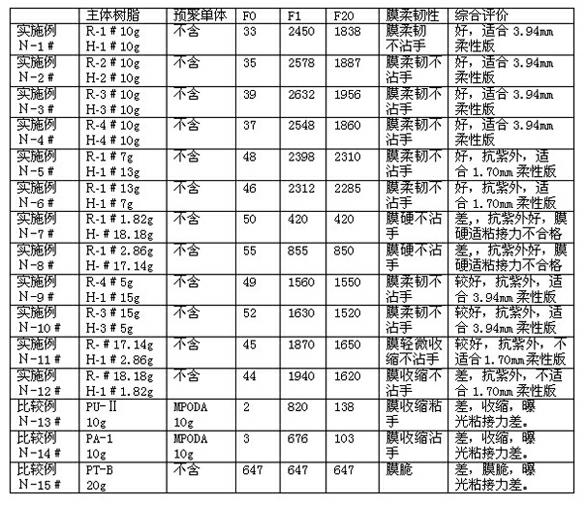

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

Paper deacidification method

ActiveCN101538816ALow viscosityIncrease the diffusion coefficientOld paper after-treatmentOrganic solventPulp and paper industry

The invention discloses a paper deacidification method by using a supercritical fluid technology. The method comprises the following steps: placing paper (particularly ancient books) in a supercritical CO2 treatment device, extracting and purifying before adding a deacidification agent and an entrainer for treatment so that the paper approaches to neutral. The invention applies the supercritical fluid technology to the paper deacidification method to save time and labor and avoid organic solvent pollution, and the treated paper is not bent and deformed and has no phenomena, such as color diffusion, ink diffusion, conglutination, and the like.

Owner:GUANGDONG UNIV OF TECH +1

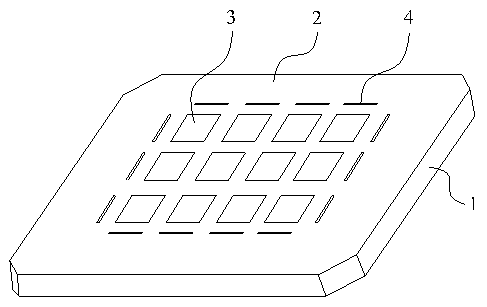

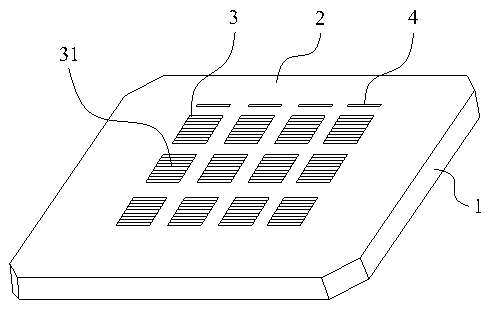

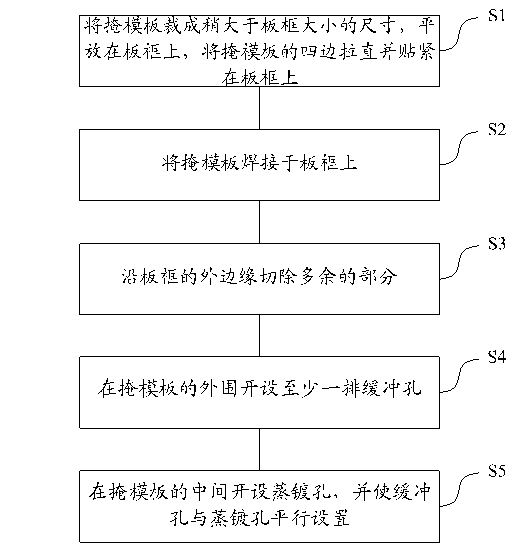

Mask plate used for evaporation and manufacturing method thereof

InactiveCN103014618AGood effectImproved accuracy and stabilityVacuum evaporation coatingSputtering coatingEngineeringManufacturing cost reduction

The invention relates to a mask plate used for evaporation and a method manufacturing method thereof. The mask plate comprises a plate frame and a mask plate that are fixed on the plate frame. A plurality of deposition holes are regularly arranged in the mask plate. The deposition holes are disposed in the centre of the mask plate. At least a row of cushion holes are disposed outside of the deposition holes. The cushion holes are parallel to the deposition holes. According to the manufacturing method, the deposition holes in the mask plate do not deform after a manufacturing process of the mask plate used for evaporation is completed. The effect is more remarkable when the method is used for producing a large-size mask plate used for evaporation, so that precision of the mask plate can be increased effectively, a manufacturing precision of an OLED display screen particularly a large-size OLED display screen is increased significantly and manufacturing cost is reduced.

Owner:南京澄超光电科技有限公司

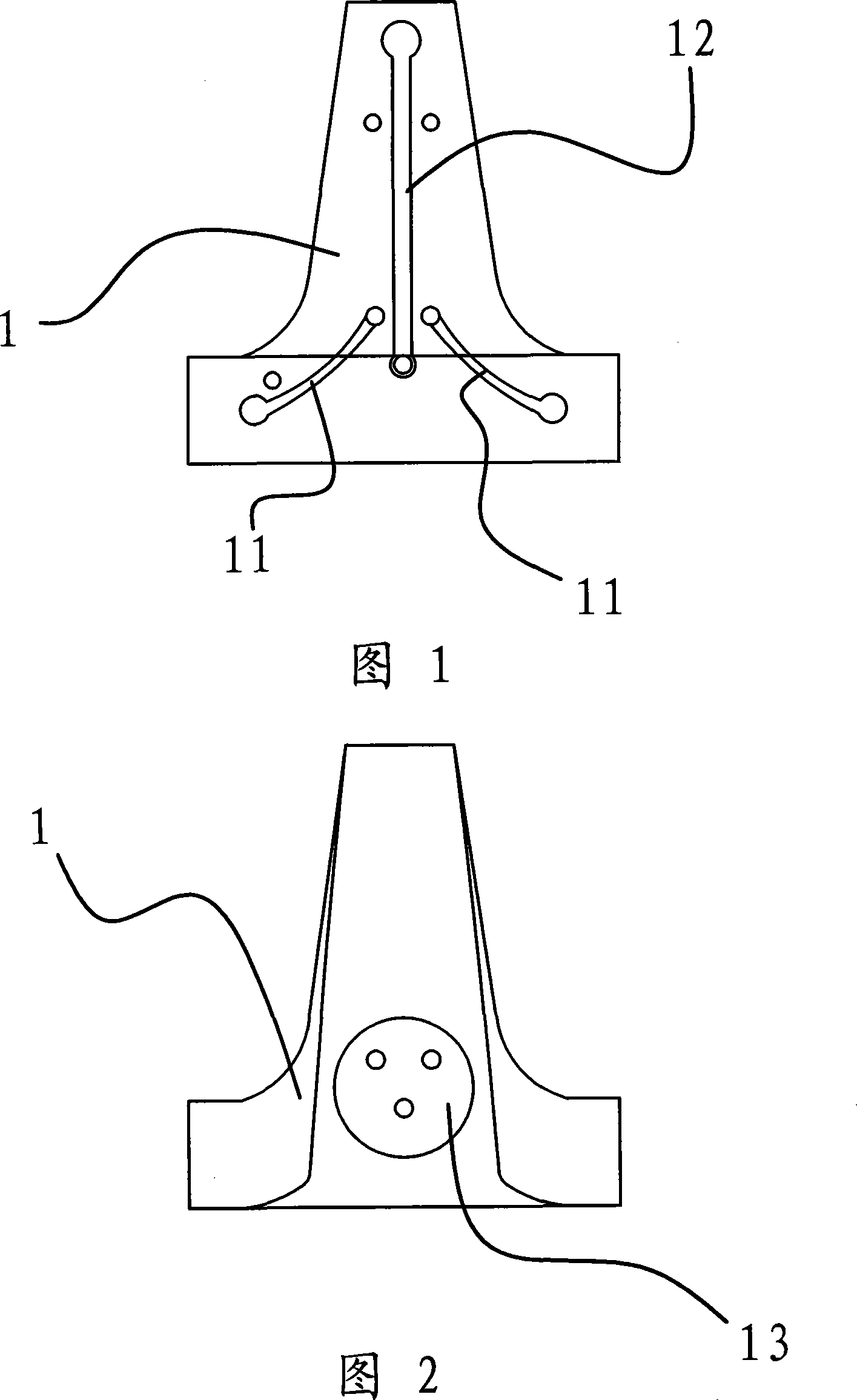

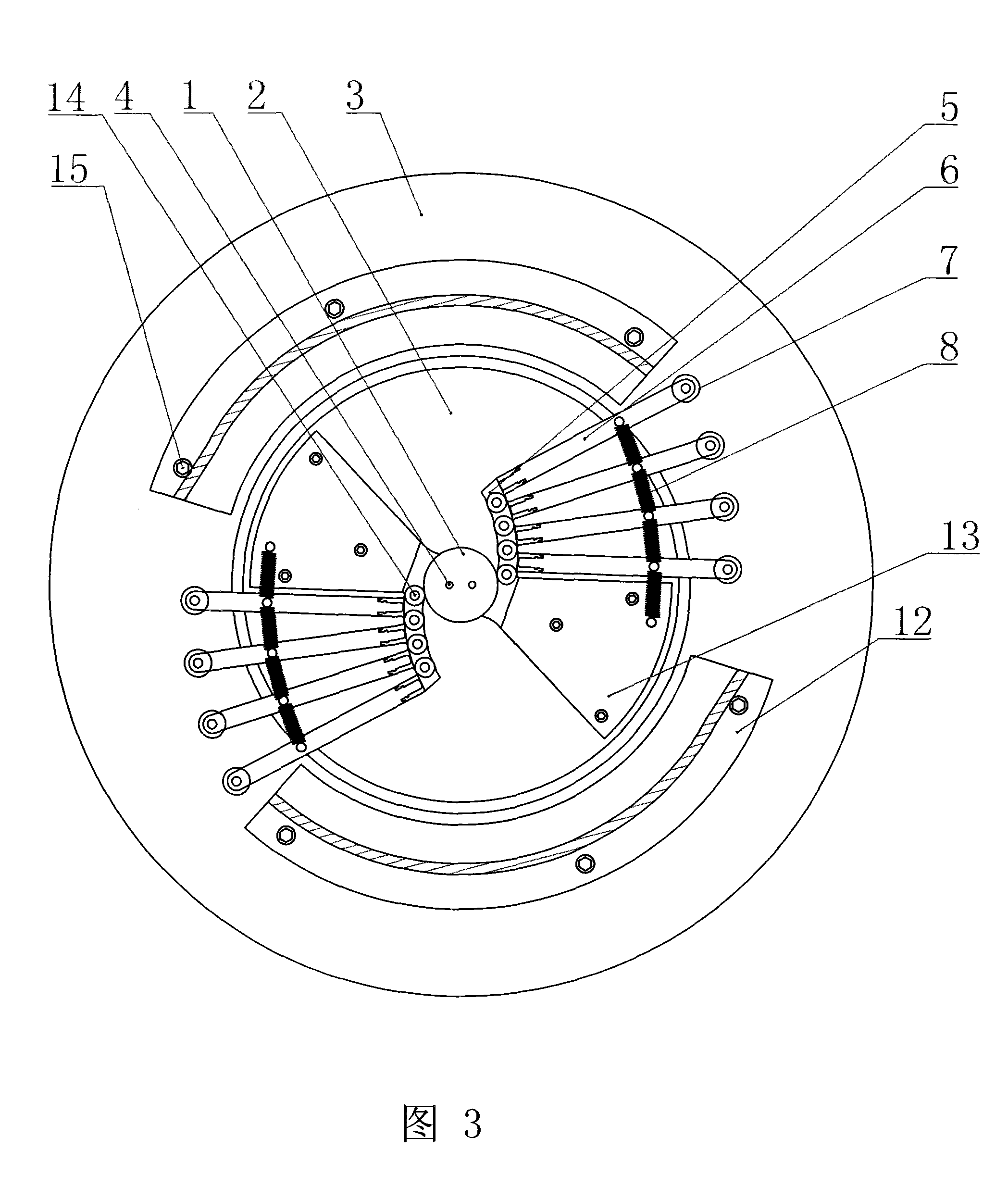

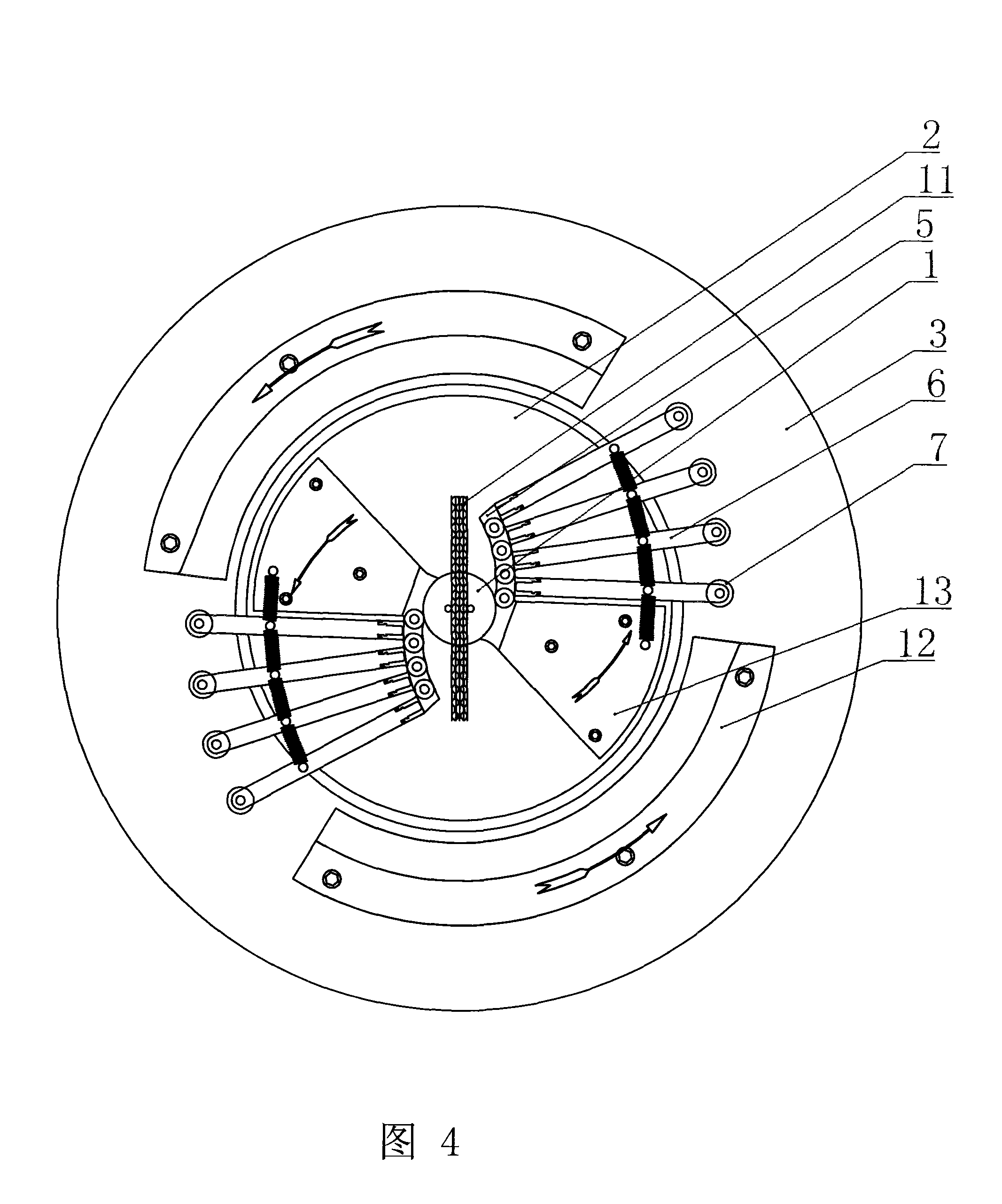

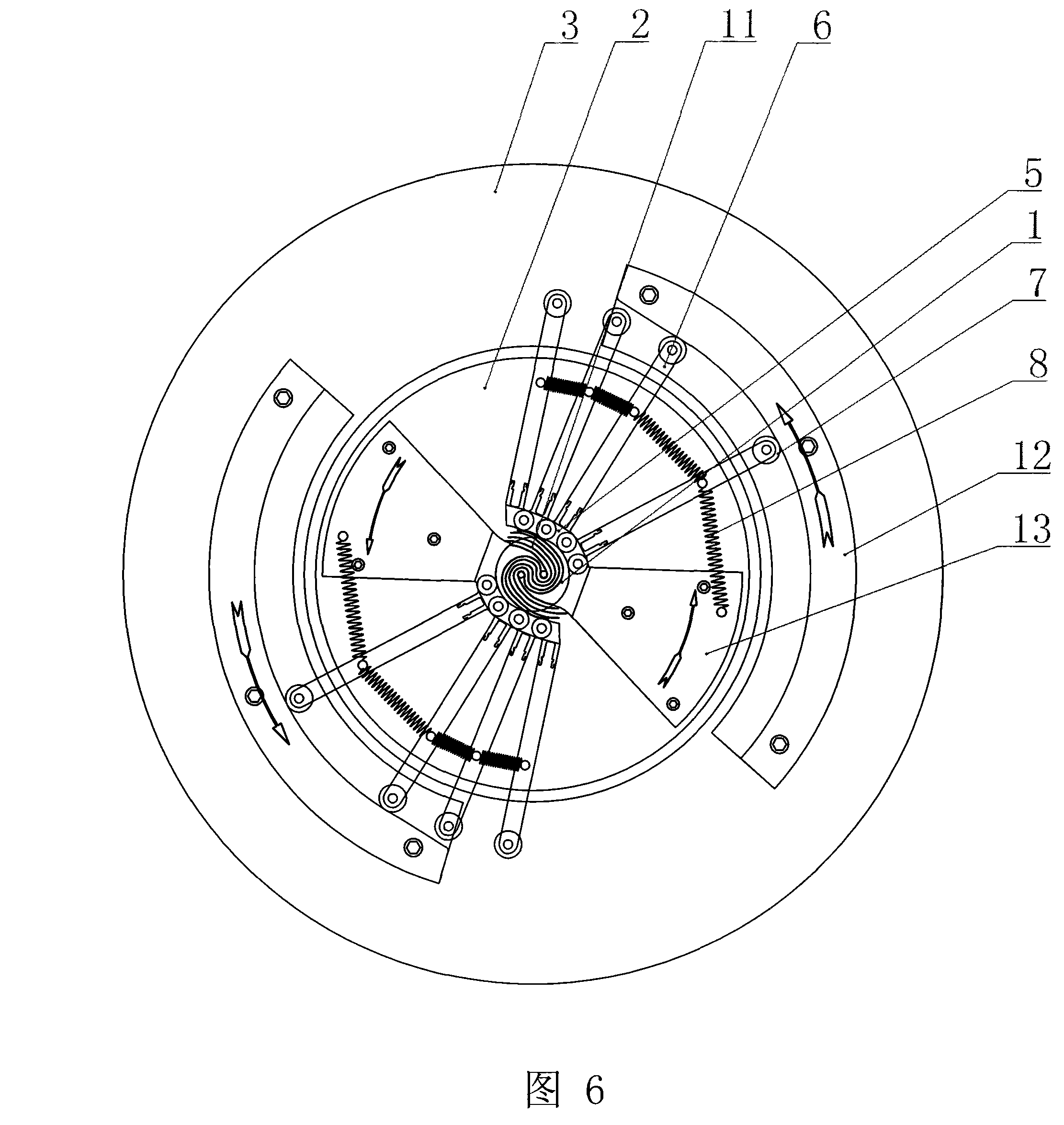

Apparatus for preparing S type metallic honeycomb

ActiveCN101251036AWill not deformImprove molding qualityPhysical/chemical process catalystsExhaust apparatusChain structureHoneycomb

The invention relates to a device for preparing an S-shaped metal beehive, comprising a fixed pole (1) and two groups of forming sections (5) which can be mutually closed section by section to form a section mould, wherein, two coaxial fixed rods (4) are arranged on the top of the fixed pole (1). The invention is characterized in that: each group of forming sections (5) consist of at least three sections; a chain structure is hinged between each section by utilization of a pin pole; the forming sections (5) can be gradually deformed from a straight line or a curve with small curvature to a curve with large curvature; the two groups of forming sections (5) are closed to form the section mould the cross section of which is round, obround or elliptical. Due to adoption of the technical proposal, the metal stack fixed rods (namely the S-shaped center) are immobile during the rolling process; corrugated tooth profiles can be straightened by the sectional closed section mould during the rotation process even an inner core material piece is slightly longer, and residual tooth profiles can be straightened into flat sheets and then attached to the circumference of an inner core of the beehive; moreover, an S-shaped central tooth profile is always immobile and then can not be deformed, thereby the forming quality and the finished product rate are improved.

Owner:南京亿达高科环保技术有限公司 +1

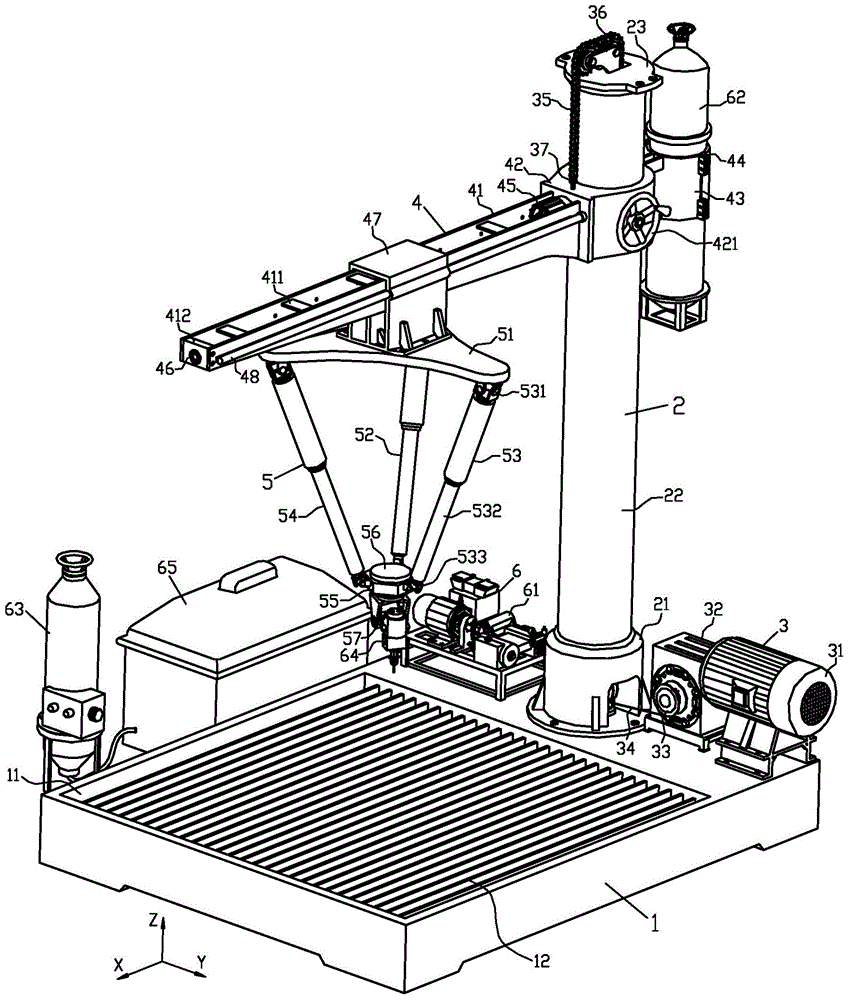

Series-parallel water jet carving robot with six degrees of freedom

InactiveCN104827405AReduce forceNot volatileBlast gunsAbrasive feedersThree degrees of freedomEngineering

The invention discloses a series-parallel water jet carving robot with six degrees of freedom. The robot comprises a mount, a vertical column component, a lifting device, a rocker with six degrees of freedom, a parallel cutter rack with three degrees of freedom and a jet carving device, wherein a water tank is arranged in the mount, the rocker can move upwards and downwards along the vertical column under the driving of the lifting device; and the parallel cutter rack with three degrees of freedom sleeves the rocker with two degrees of freedom and can translate along the rocker with two degrees of freedom; a spraying gun in the jet carving device is arranged on the parallel cutter rack and has six spatial movement degrees of freedom. According to the carving robot, the processing operations such as blanking and cutting, carving, chamfering, routing and trimming of an acrylic product can be realized; the action force of the robot during carving operation is small; a work piece is low in temperature and keeps the shape; the influence of the acrylic material bonding on a cutter or the work piece to the precision and quality of the work piece can be avoided; and the robot further has the advantage of being compact in device structure, stable and reliable in work, convenient and fast to operate and maintain, low in entire machine cost and high in processing precision.

Owner:ANHUI UNIV OF SCI & TECH +1

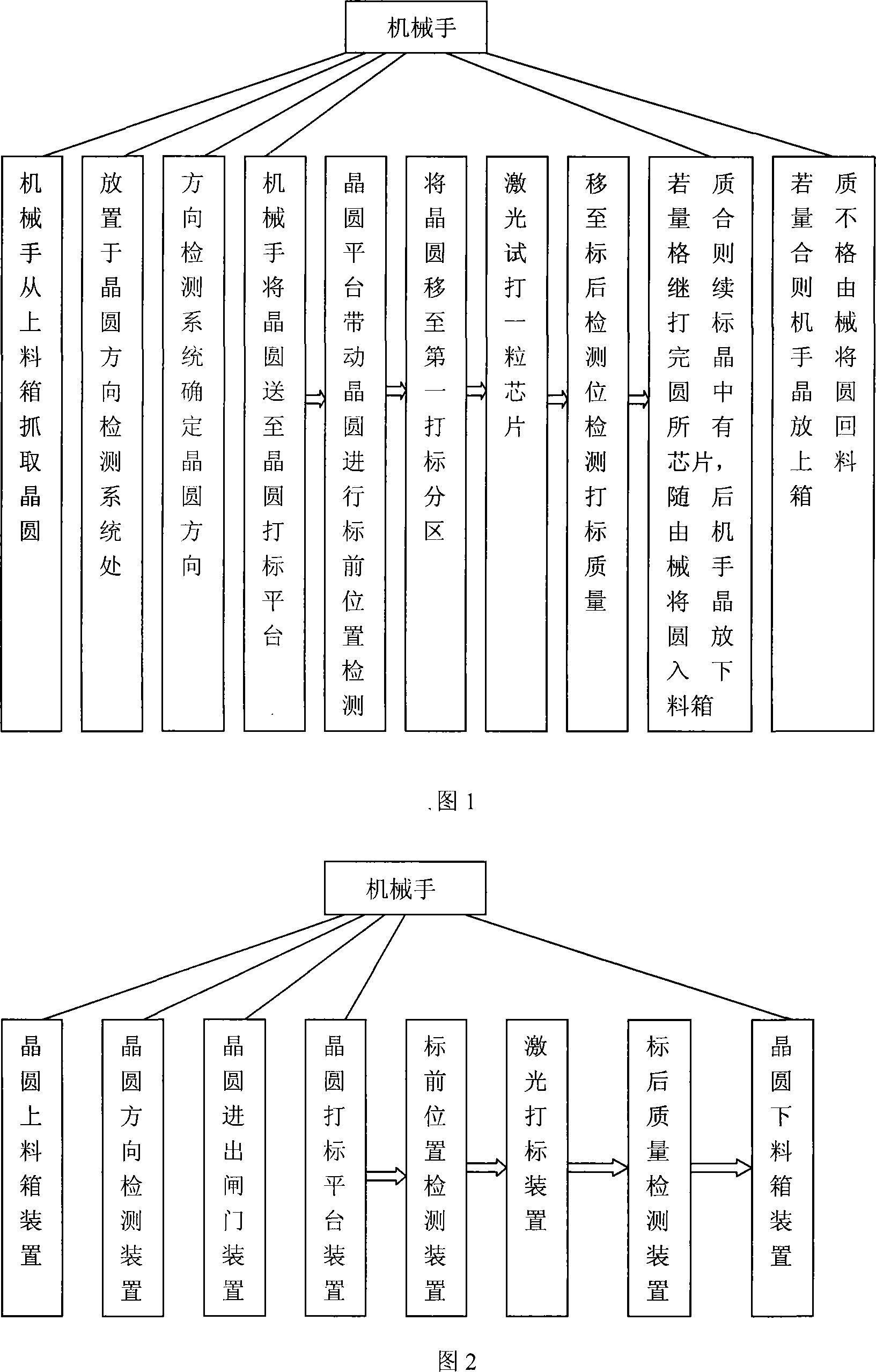

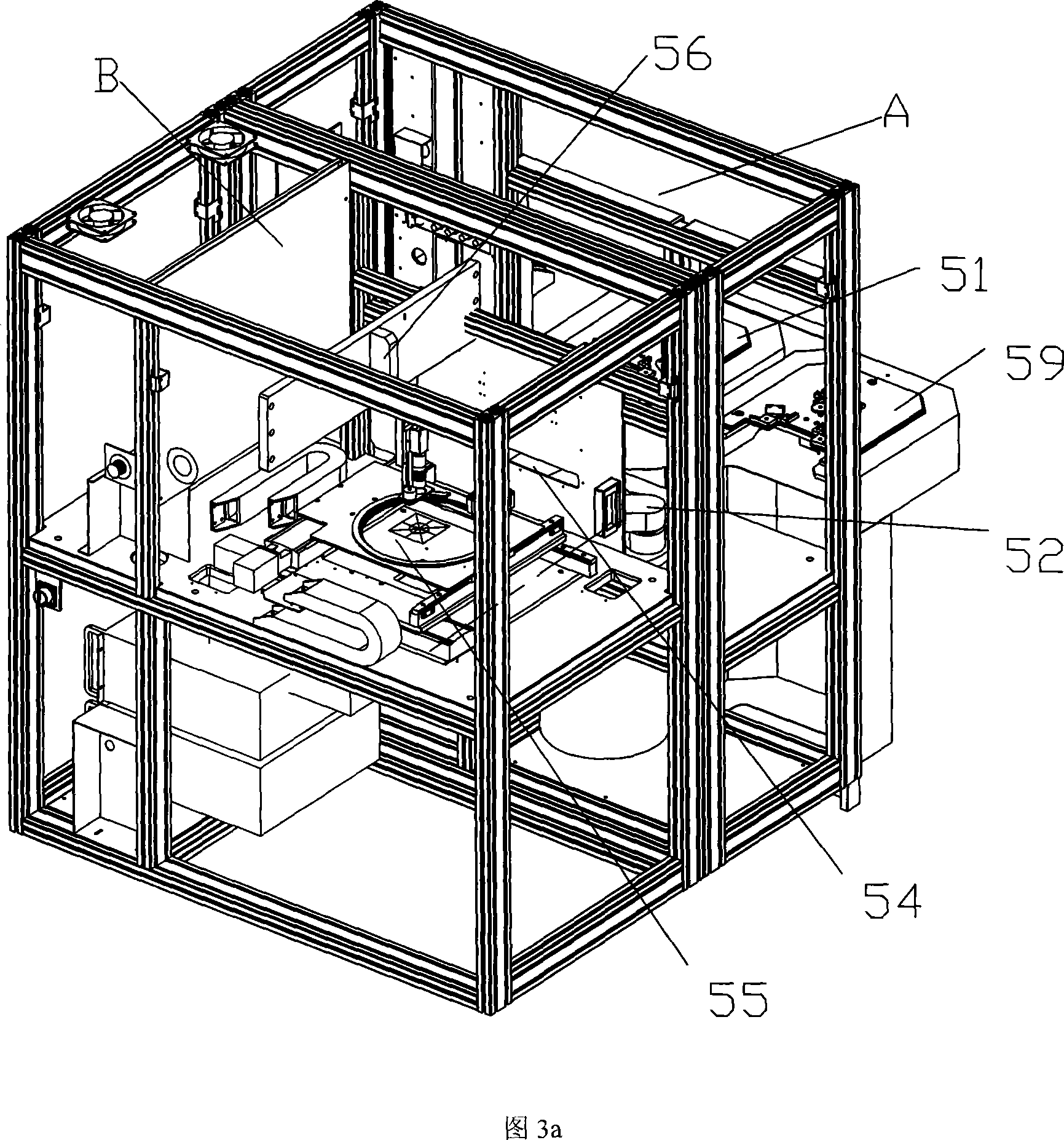

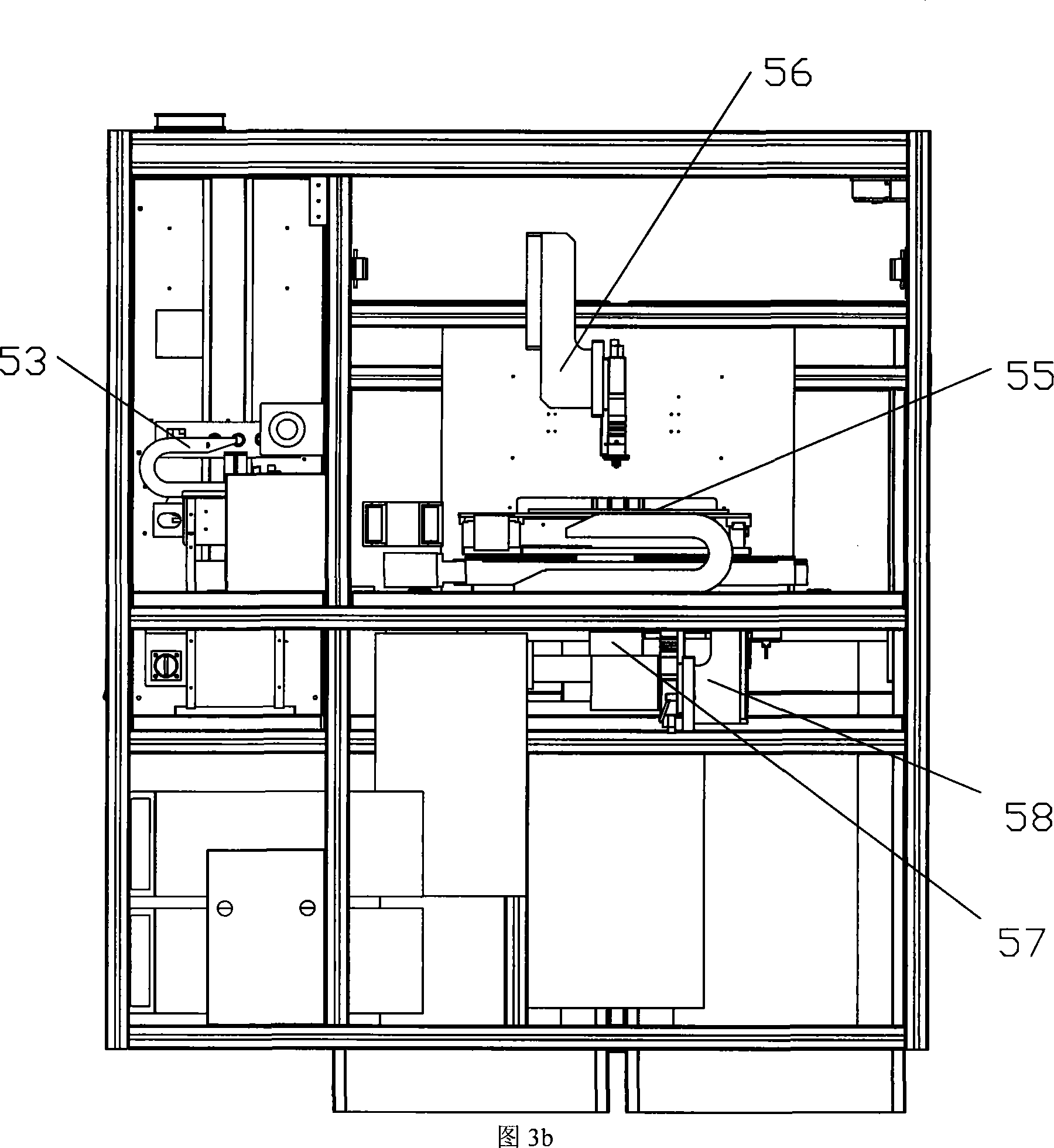

Full-automatic wafer rear marking machine

InactiveCN101097848AWill not deformMeet deformationSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention relates to a novel device for marking IC crystal, in particular to a full-automatic crystal back marking machine, which uses a mechanical hand to take out crystal from a material feeding box to be sent to a crystal direction checker, a crystal marking platform or the like, to be marked and checked to be taken off by a mechanical hand to be put into a material outputting box. The invention is composed of a front area and a back area, wherein the front area is arranged with an electric controller and a PC, a baffle plate is arranged between the front and back areas, the baffle plate is arranged with a gate entrance, the outer side of the front area is arranged with a material feeding box and a material discharging device, the front area is arranged with a mechanical hand and a crystal direction checker inside, the back area is arranged with a crystal marking platform inside, the marking platform is respectively arranged with a before-marking checker and an after-marking checker above and under.

Owner:GRAND TECH SHENZHEN

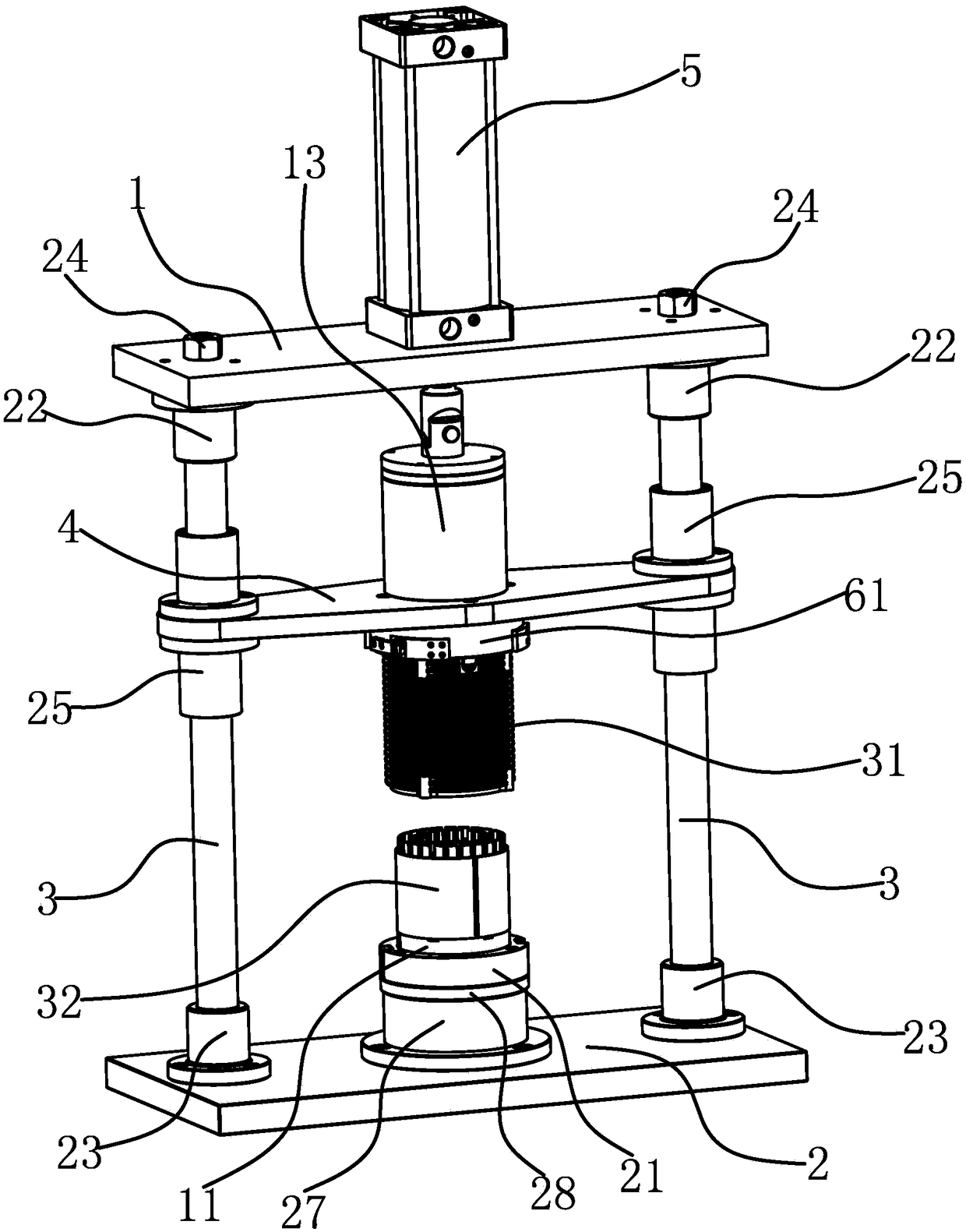

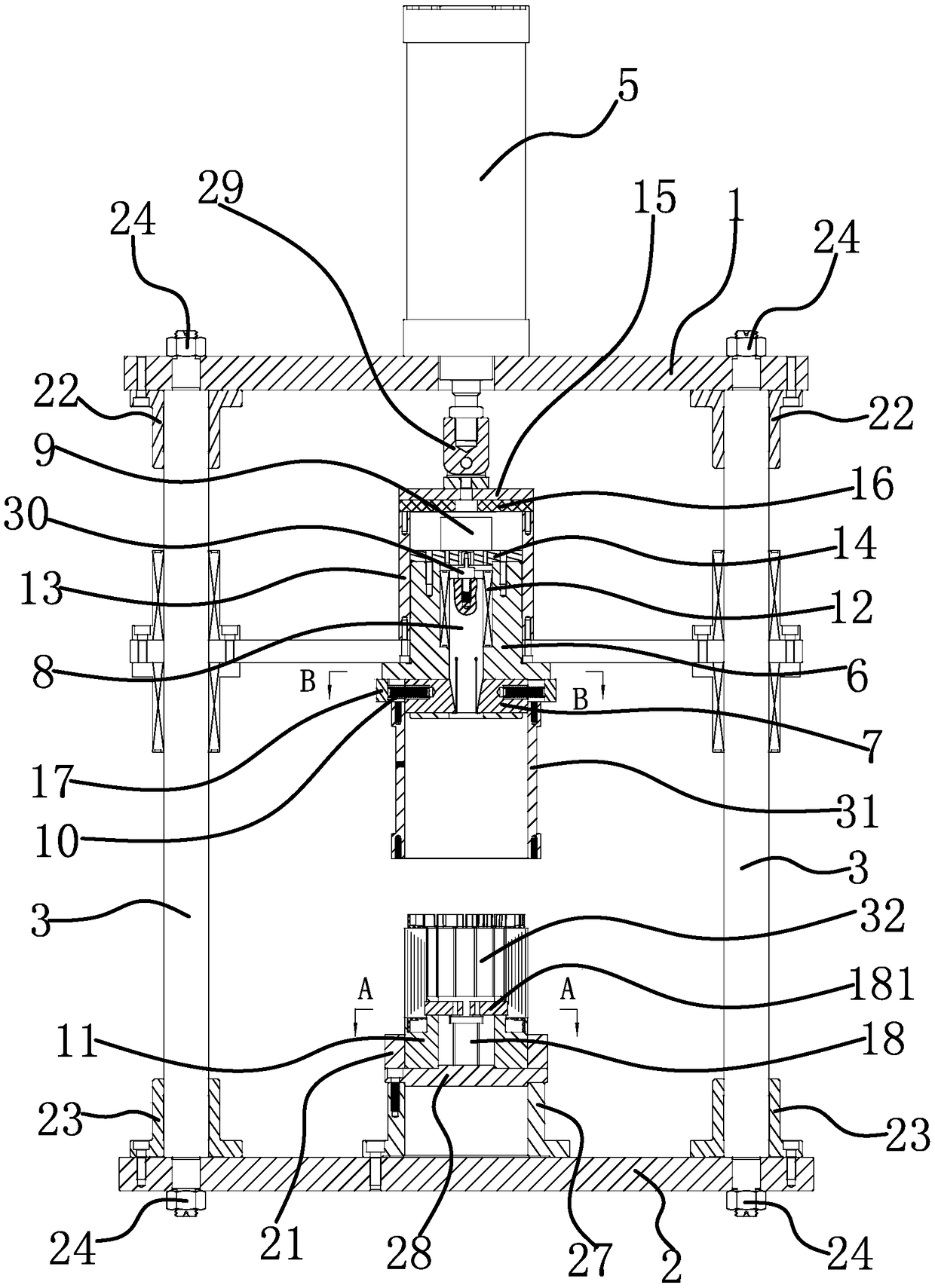

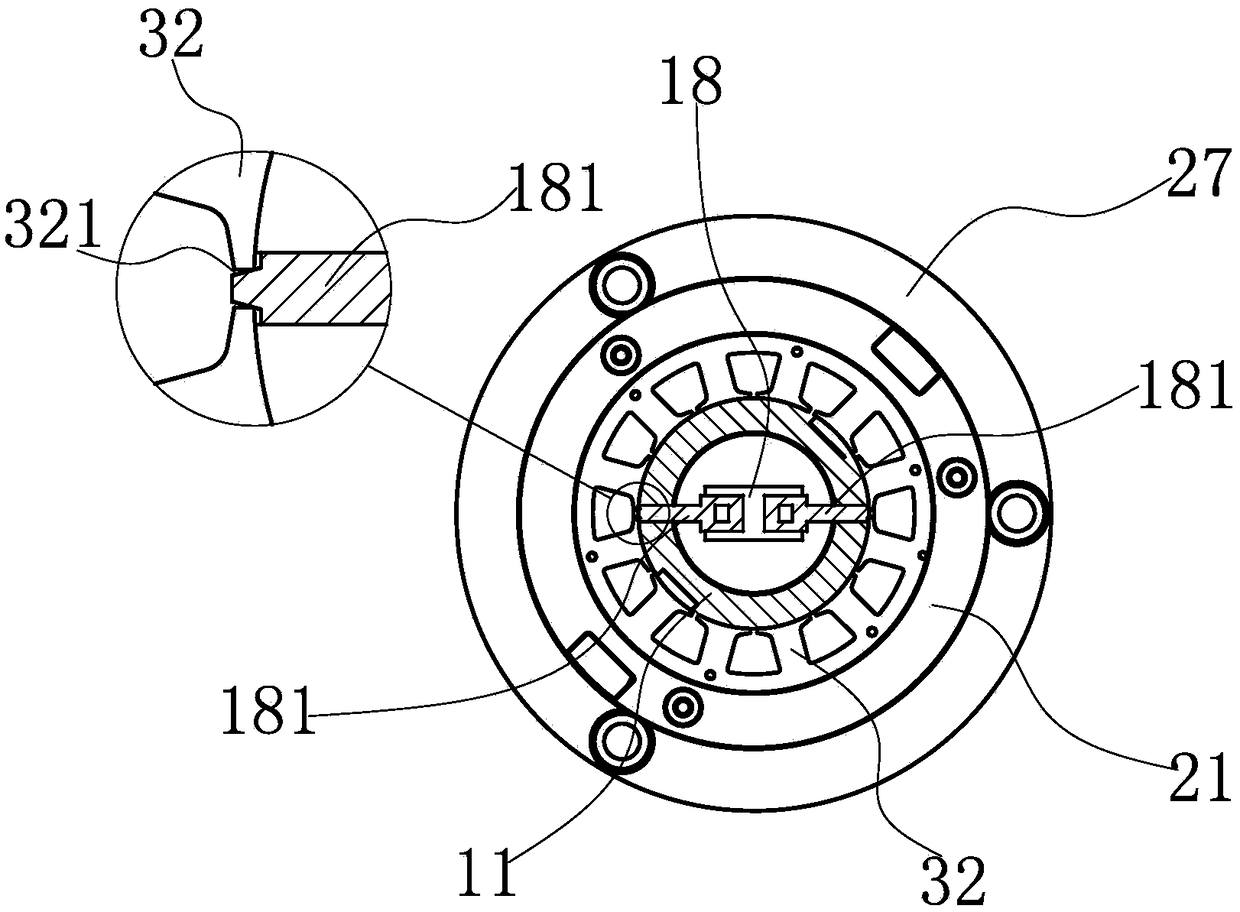

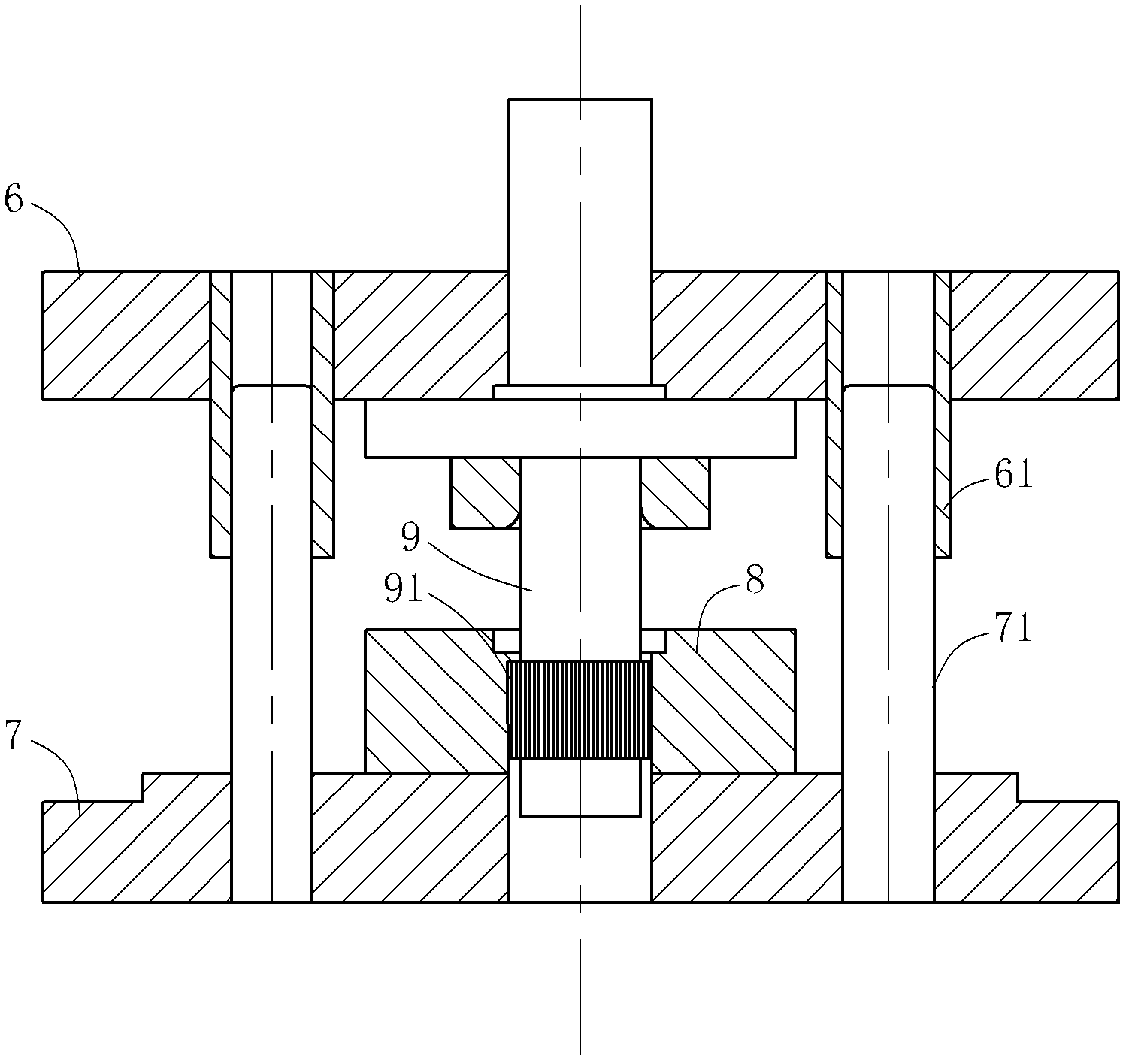

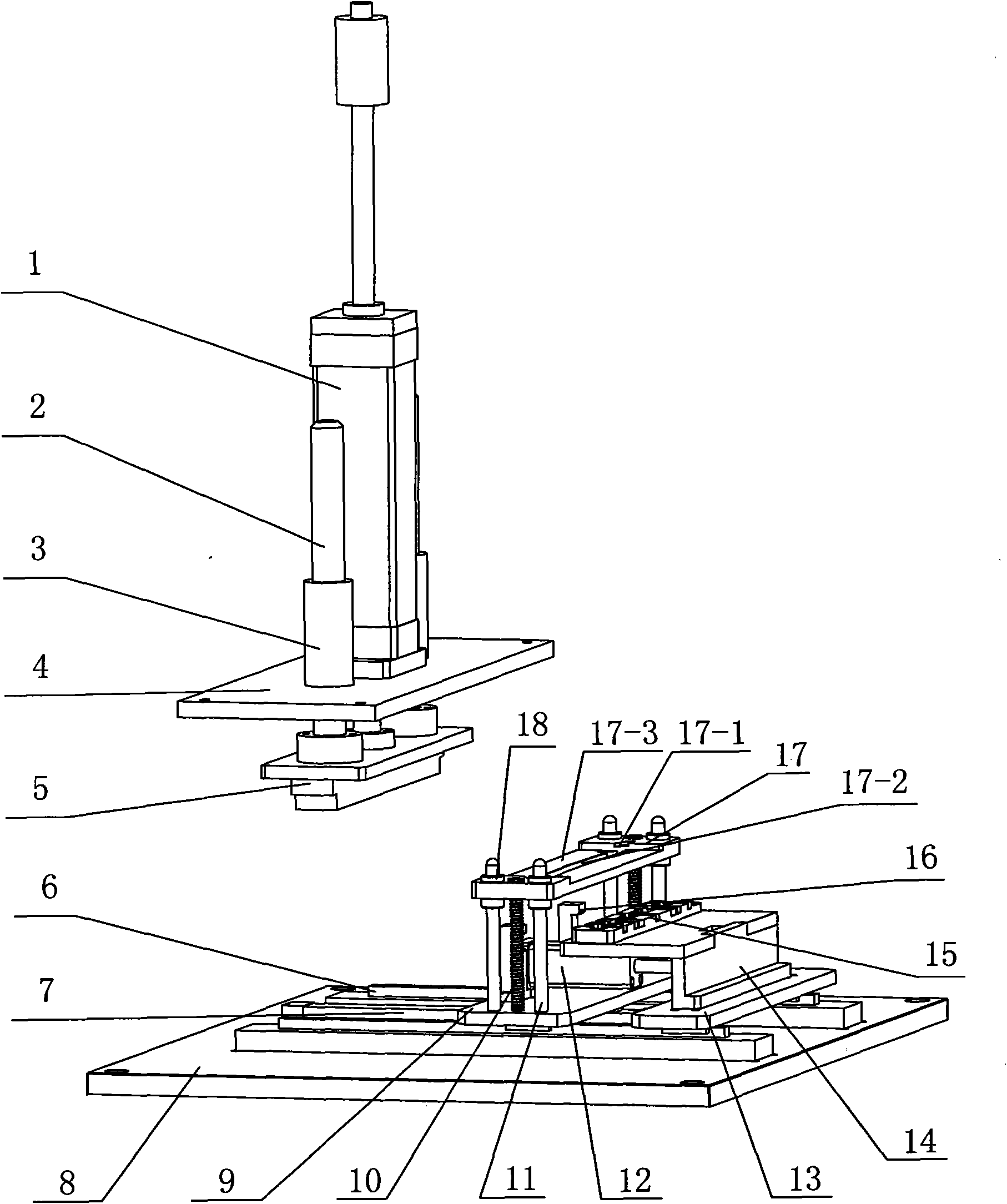

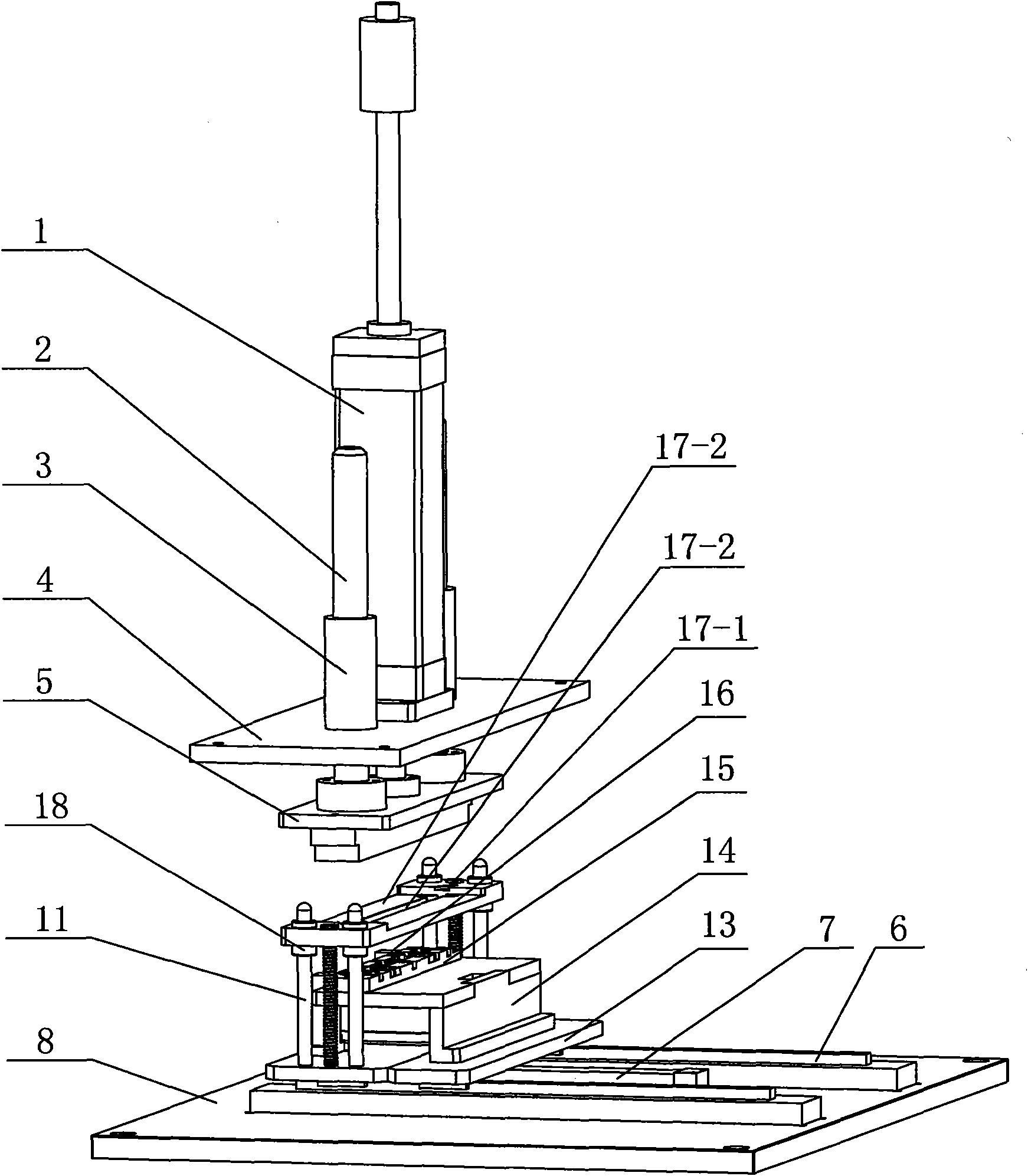

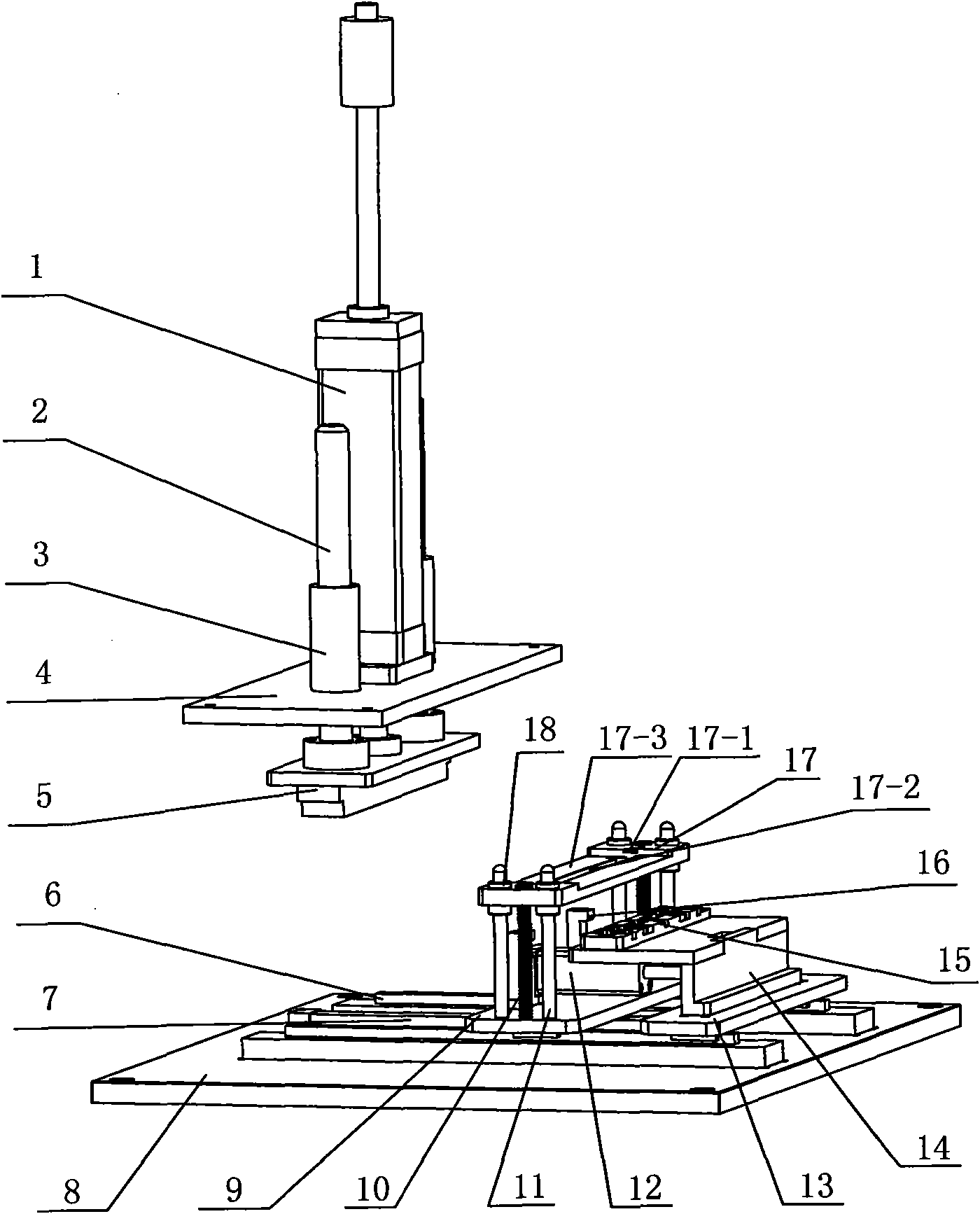

Shrinkage fit and positioning tool for stator core and casing

PendingCN108723699APrecise positioningImprove concentricityManufacturing stator/rotor bodiesMetal working apparatusStatorEngineering

The invention provides a shrinkage fit and positioning tool for a stator core and a casing, belonging to the technical field of machinery. Therefore, a conventional shrinkage fit and positioning toolcan reliably position. The shrinkage fit and positioning tool for the stator core and the casing comprises an upper base, a lower base and at least two columns. A support panel is slidably connected onto the columns. An elevating driving source is arranged on the upper base. A downward installing seat is arranged on the support panel. The bottom of the installing seat is equipped with a positioning boss allowing the casing to sleeve. The center of the installing seat is provided with a perforating hole. The positioning boss is equipped with at least three sliding channels extending in a radialdirection to communicate with the perforating hole in circumferential direction. Each sliding channel is slidably connected with an internally-supporting sliding block. A telescopic guide rod is arranged in the perforating hole in a penetrating manner. The top of the installing seat is provided with a telescopic driving source. The installing seat is further equipped with a limiting structure. The lower base is fixed with a positioning seat which is coaxial to the installing seat. A positioning structure capable of positioning the stator core is arranged on the positioning seat. The shrinkagefit and positioning tool has better circumferential positioning accuracy and stability.

Owner:WENLING JIUZHOU ELECTROMECHANICAL

Fabric gold stamping technological method

InactiveCN101457492AHigh fastnessDoes not affect the feelDecorative surface effectsTextile decorationMaterials scienceNanotechnology

The invention discloses a gold stamping method of a surface fabric, comprising the following steps: 1: gold stamping film rubberizing; 2: compound of the gold stamping film and the surface fabric; 3: heat preservation; 4: parting; the gold stamping surface fabric produced by the invention retains previous feel after gold stamping, as heat preservation provides the gold stamping surface fabric produced by the method with very good fastness and the gold stamping surface fabric does not fade or deform after going through washing or high temperature, therefore, seen from any angle, the gold stamping surface fabric reflects different colors and has colorful and diverse designs and patterns.

Owner:WUJIANG LINGTONG TEXTILE FINISHING

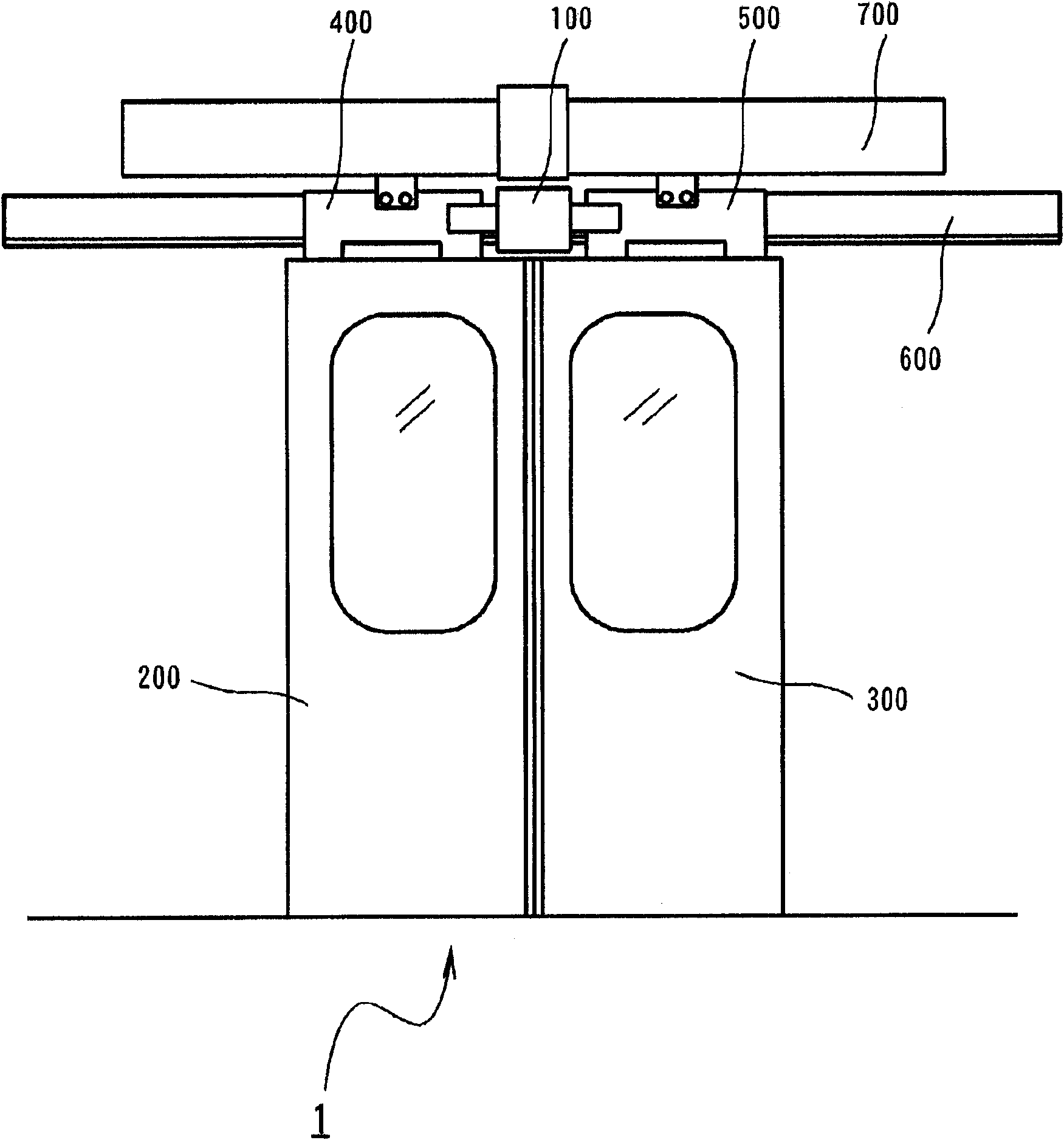

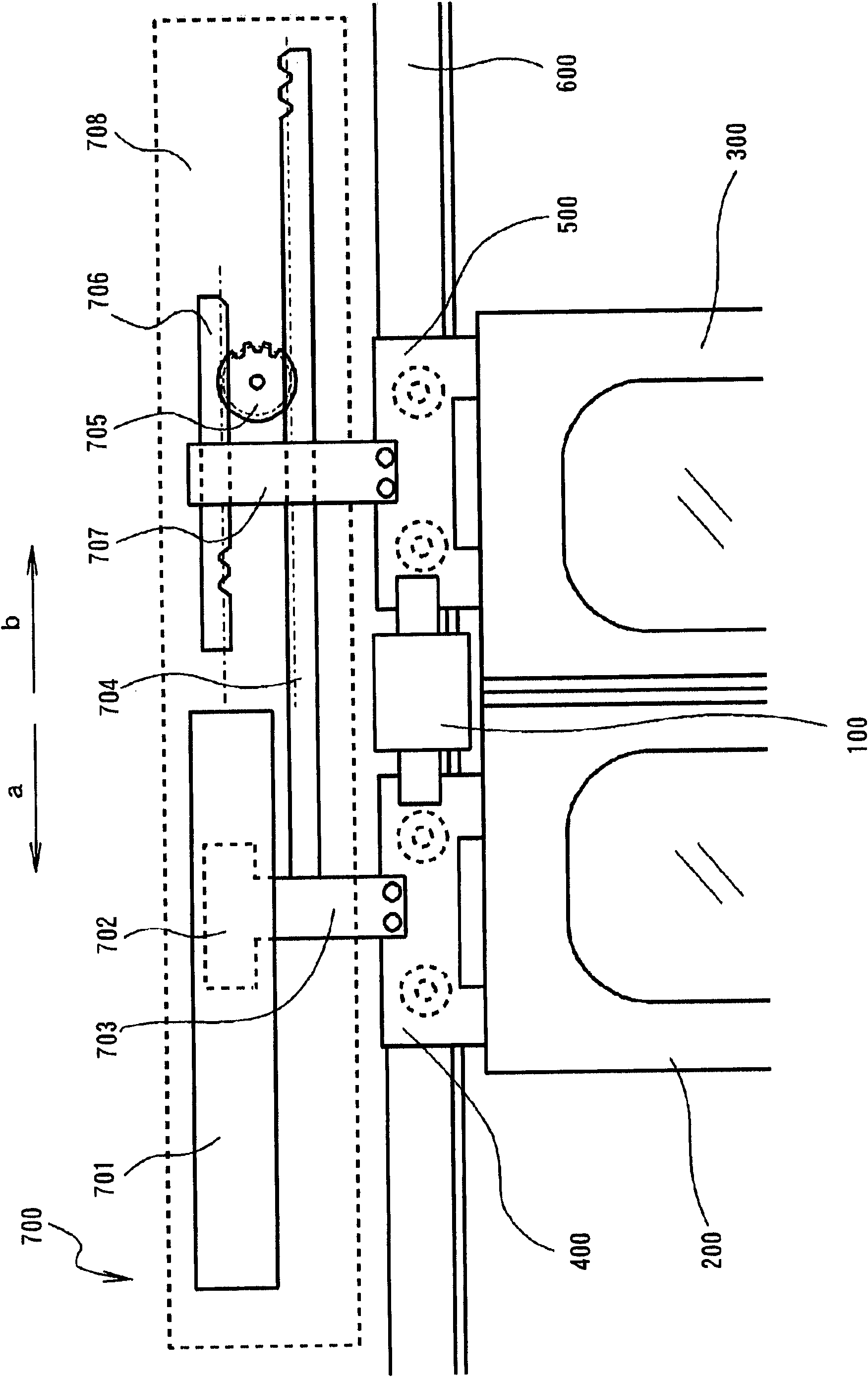

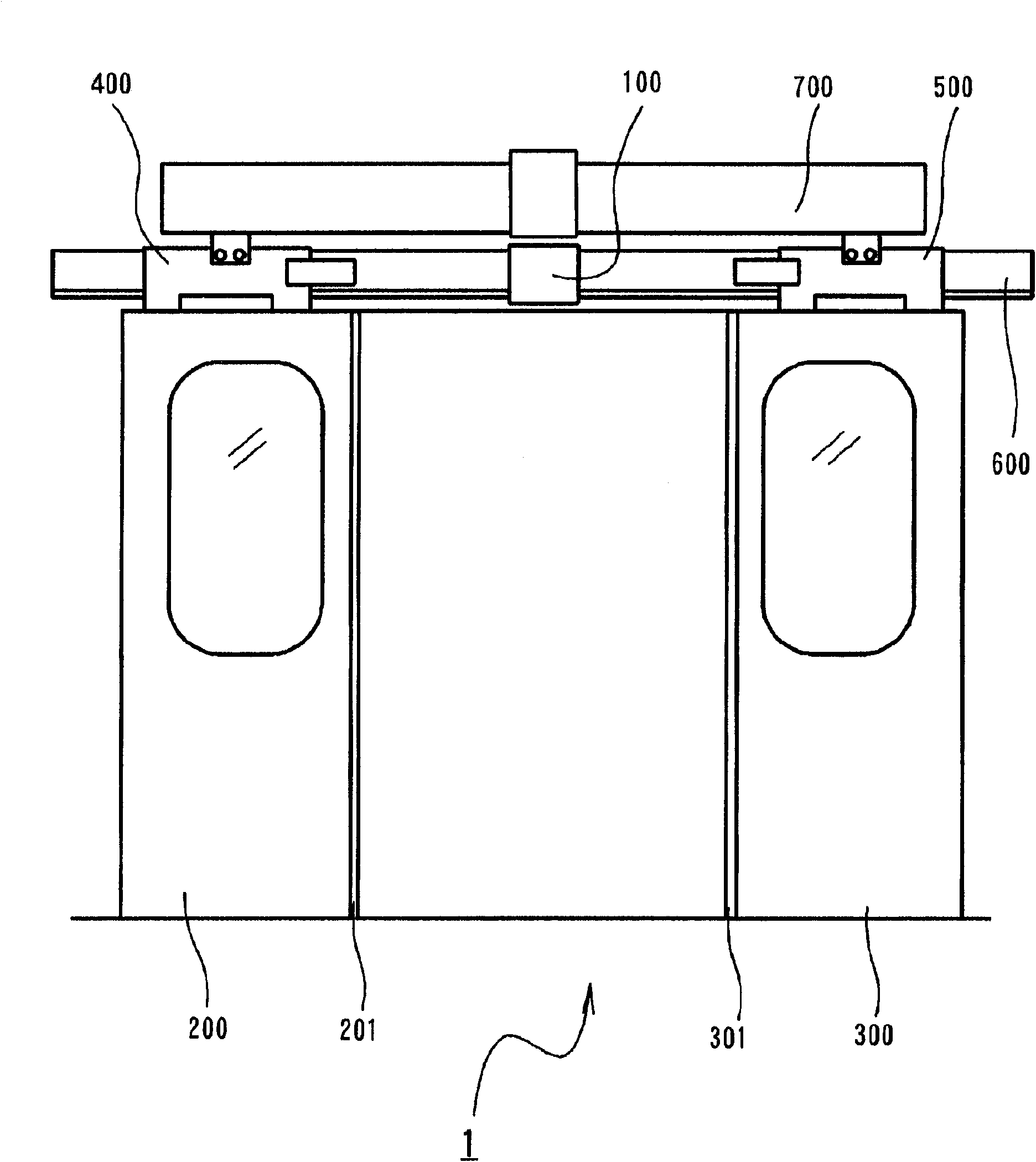

Sliding door opening/closing device for vehicle

InactiveCN101787827AEasy and reliable releaseWill not deformNon-mechanical controlsWing fastenersMagnetic tension forceOperability

The present invention provides a sliding door opening / closing device for a vehicle that applies a sufficient opening / closing drive force to the left and right sliding doors and reduces a force necessary to lock and unlock the latch, despite a simple configuration of the device, and that facilitates the manufacturing process, improves operability and safety, and reduces noise. A lock device, against both sides of which locking portions abut, rotates a columnar permanent magnet so as to form magnetic locking circuits and fixes the locking portions by magnetic forces of the locking magnetic circuits. The rotational operation of the columnar permanent magnet is converted into the downward operation of a latch, and the lowered latch restrains the locking portions with respect to the lock device.

Owner:FUJI ELECTRIC CO LTD

Aqueous adhesive for binding rubber and metal and preparation thereof

The invention discloses a water-based adhesive used for the bonding between rubber and metal; according to the parts by weight, the adhesive comprises 60-90 parts of soft monomer, 30-60 parts of hard monomer, 2-8 parts of functional monomer, 3-10 parts of emulsifier, 0.4-0.8 part of initiator, 0.6-1.0 part of pH buffer, 100 parts of deionized water or distilled water, 0.05-0.1 part of anticorrosive bactericide, and 1.4-1.6 parts of pH regulator. The invention also discloses a preparation method for preparing the water-based adhesive. The adhesive can replace the existing solvent-typed adhesive, effectively realizes the bonding between the rubber and the metal, has no poison, no combustion and no explosion, is safe and protects the environment. The preparation method which applies the seed latex polymerization has simple preparation process and high production efficiency and is beneficial for the industrial production.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

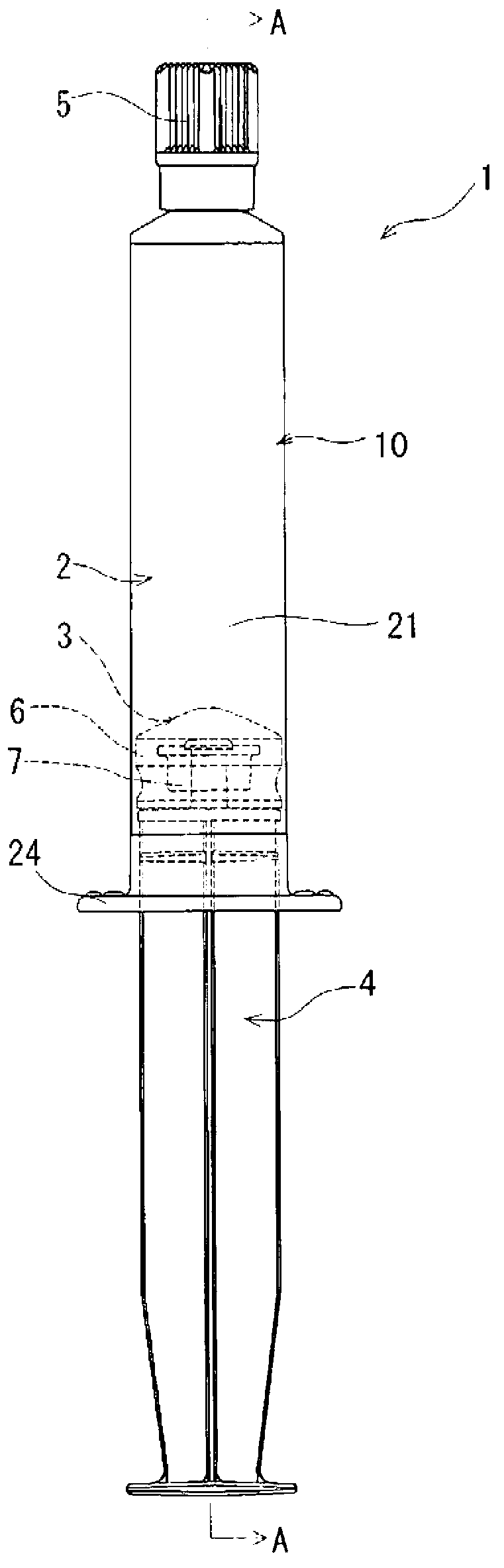

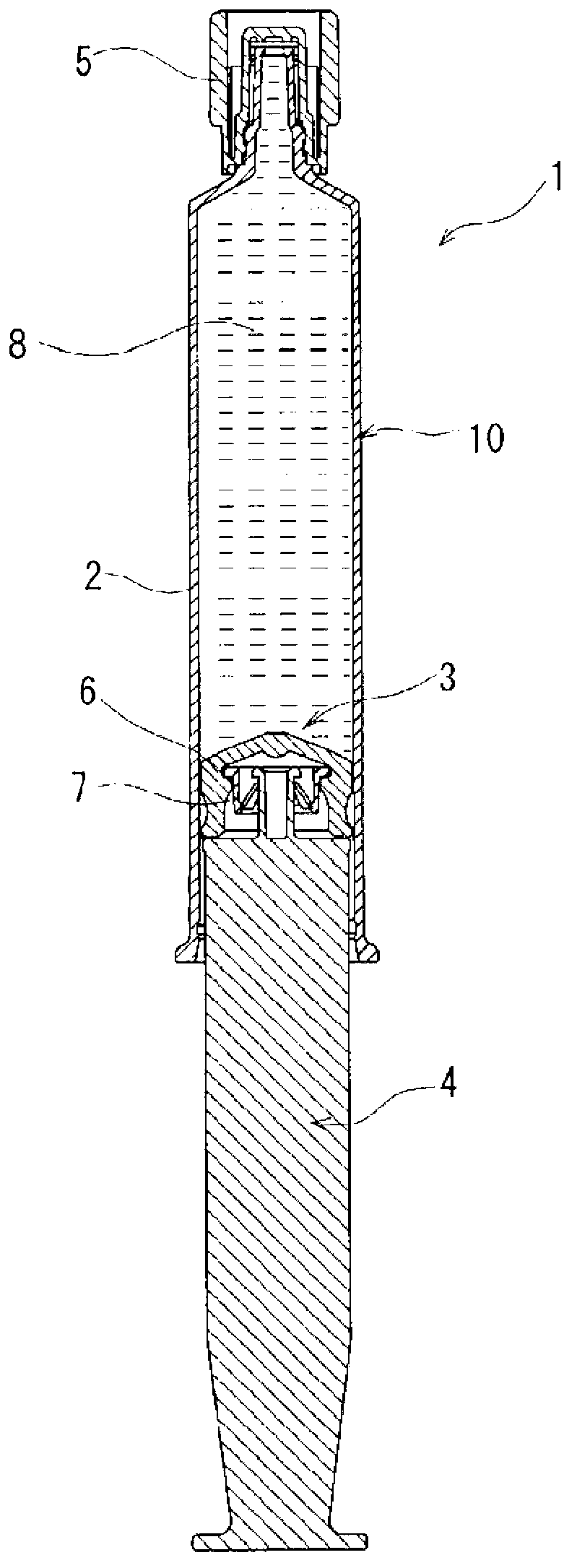

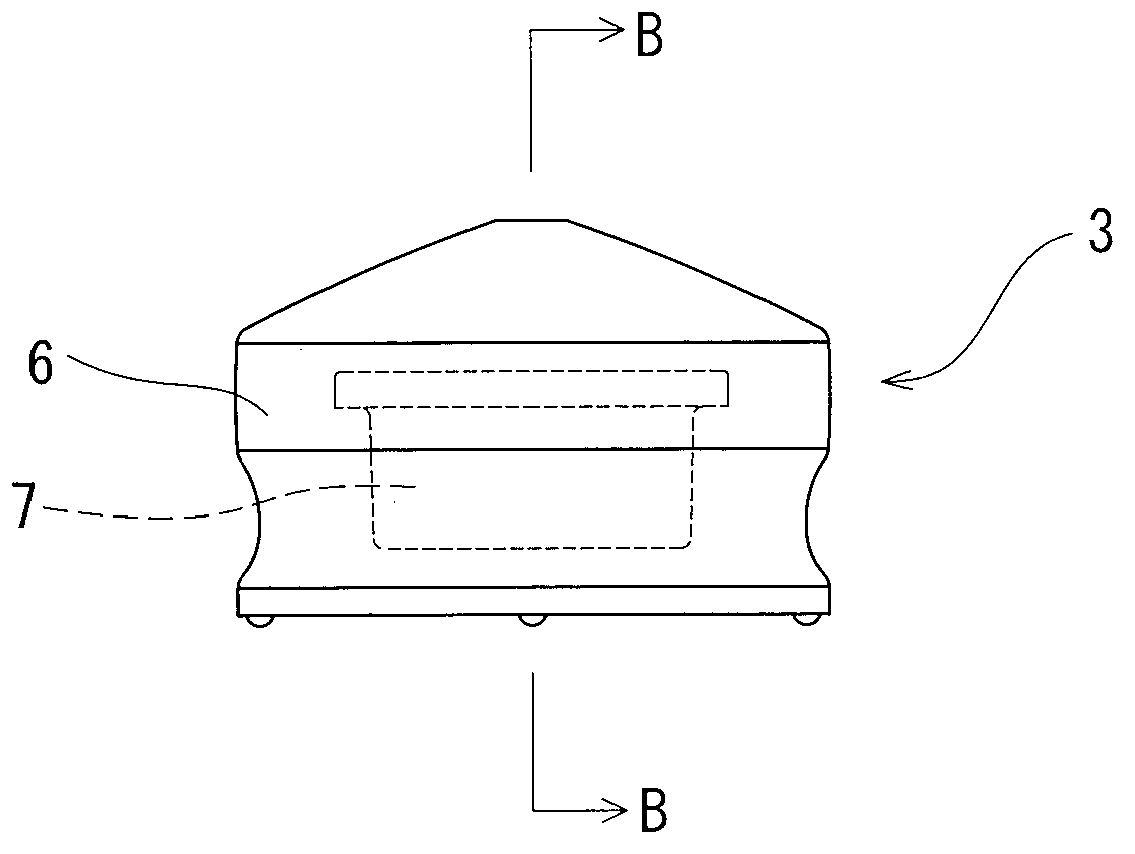

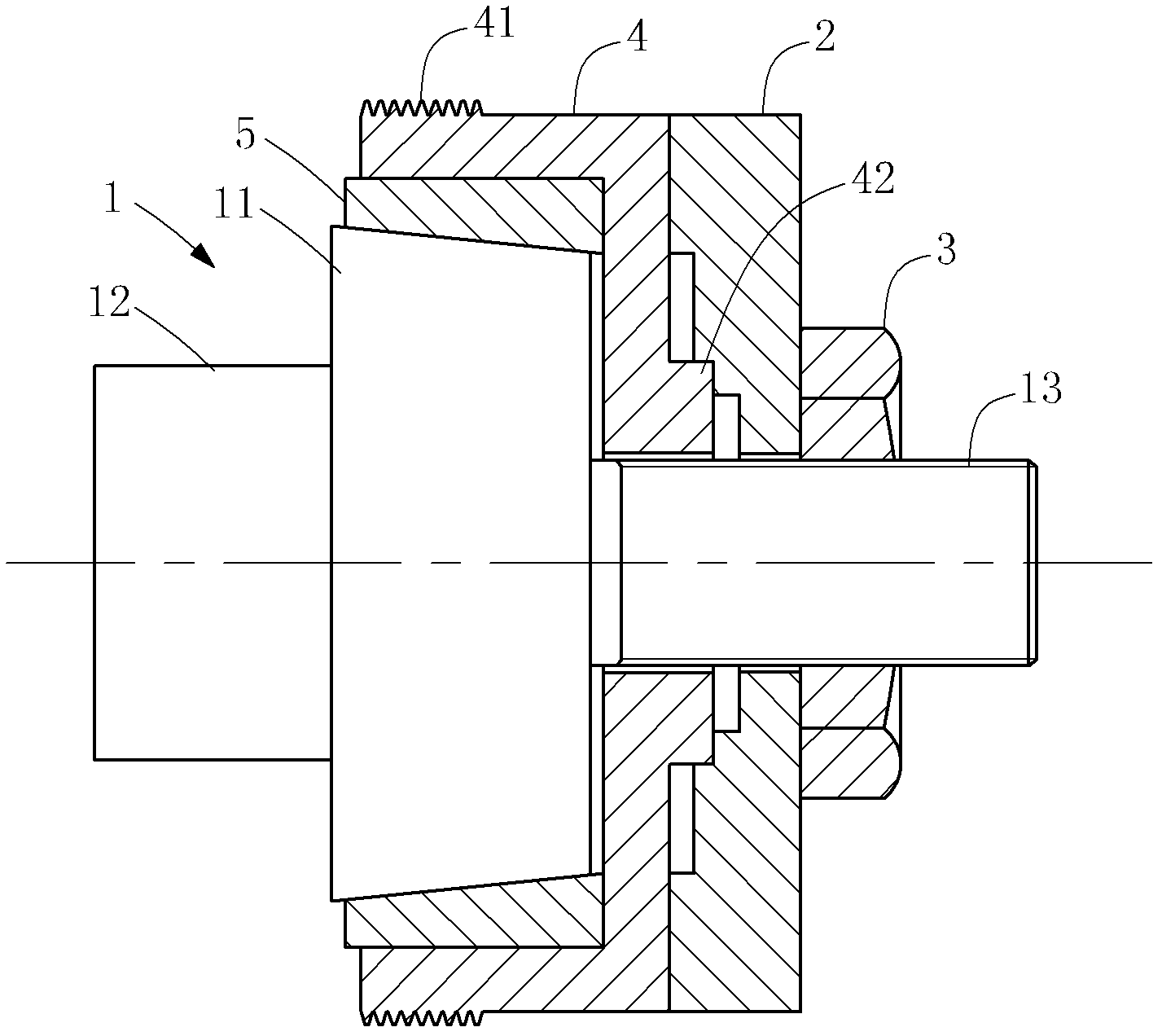

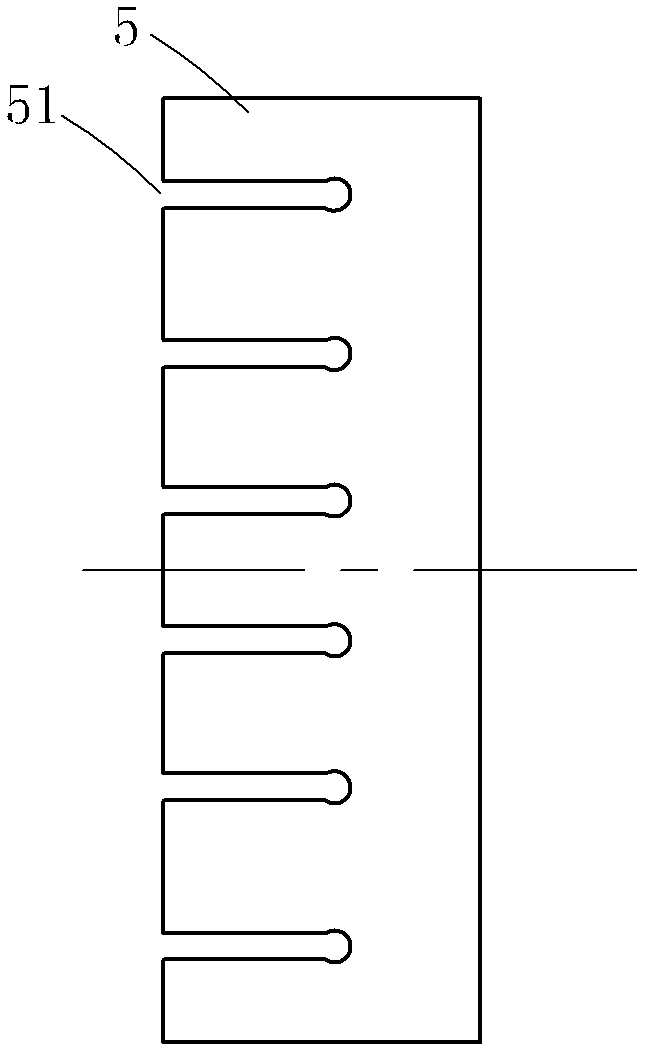

Prefilled syringe

ActiveCN102821803APrevent disengagementWill not deformInfusion syringesIntravenous devicesPrefilled SyringeBiomedical engineering

A gasket (3) for a prefilled syringe (1) comprises a gasket body (6) and a member (7) which is adapted for mounting on the plunger. The gasket body (6) has formed on the inner surface thereof a rib (62) for retaining the member for mounting on the plunger. The member for mounting on the plunger is provided with: an outer surface protrusion section (73) engaging with the rib (62) of the gasket body (6), the rib (62) retaining the member for mounting on the plunger; elastically deformable inside protrusion sections (75) extending obliquely, from an inner section on the rear end side of the member (7) for mounting on the plunger, in the direction toward the center of the member (7); and plunger retaining engagement sections (76) respectively formed at the free ends of the inside protrusion sections. The plunger (4) is provided with: a tubular front end section (42) capable of entering the inside of the member (7) for mounting on the plunger; and an outer surface protrusion section (43) engaging with the plunger retaining engagement sections of the member (7) for mounting on the plunger.

Owner:TERUMO KK

Method for manufacturing harmonic reducer of robot

The invention discloses a method for manufacturing a harmonic reducer of a robot, which belongs to the technical field of harmonic reducer processing and includes the steps of manufacturing flexible gears and the steps of manufacturing rigid gears. The steps of manufacturing the flexible gears include: forging solid billets of the flexible gears; performing heat treatment for the solid billets of the flexible gears to reach the hardness of HRC (Rockwell hardness) 38-40; turning the solid billets of the flexible gears after heat treatment into thin-wall semi-finished flexible gears; supporting inner cavities of the semi-finished flexible gears by a flexible gear tensioning fixture; and grinding the supported semi-finished flexible gears to form external gear rings of the flexible gears on a grinder. By the method, the efficiency and the precision of machining the flexible gears and the rigid gears are improved, the hardness of the flexible gears is enhanced, the service life of the harmonic reducer is prolonged, and the method is widely applied to production of harmonic reducers.

Owner:SHANDONG SHKE MACHINERY MFG

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

Lamp crimping and assembling mechanism

The invention relates to a lamp crimping and assembling mechanism, which comprises an upper crimping assembly and a lower crimping assembly, wherein a lower connecting base of the lower crimping assembly is provided with two linear guide tracks and a first cylinder in the transverse direction; a first sliding plate and a second sliding plate are arranged on the two linear guide tracks and are movable; the piston of the first cylinder is connected with the first sliding plate; at least two springs arranged on the first sliding plate are supported to a first limiting plate; the first limiting plate is provided with a mounting surface for mounting parts, a positioning groove and an H-shaped discharge notch arranged on the mounting surface; a second cylinder arranged on the first sliding plate is connected with a supporting plate arranged on the second sliding plate; a second limiting plate is arranged on the supporting plate; the second limiting plate is provided with a mounting surface for mounting parts and more than two spacing grooves; and the first sliding plate is provided with a positioning block for height positioning of the second limiting plate, and the positioning block is provided with a side positioning notch. The lamp crimping and assembling mechanism ensures that two parts can be placed in a staggered mode, can improve the assembly efficiency, and has accurate positioning, and safe and convenient operation.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

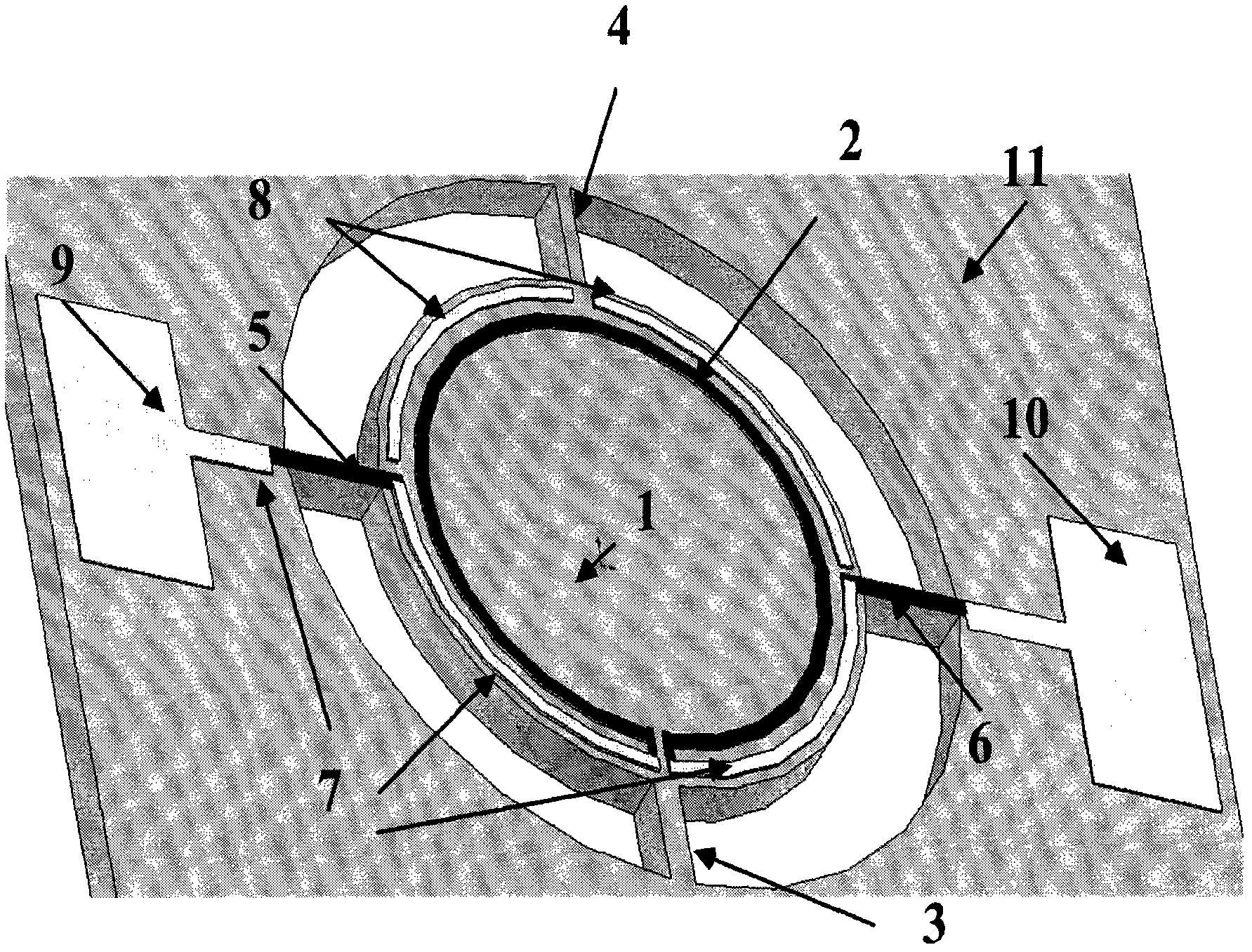

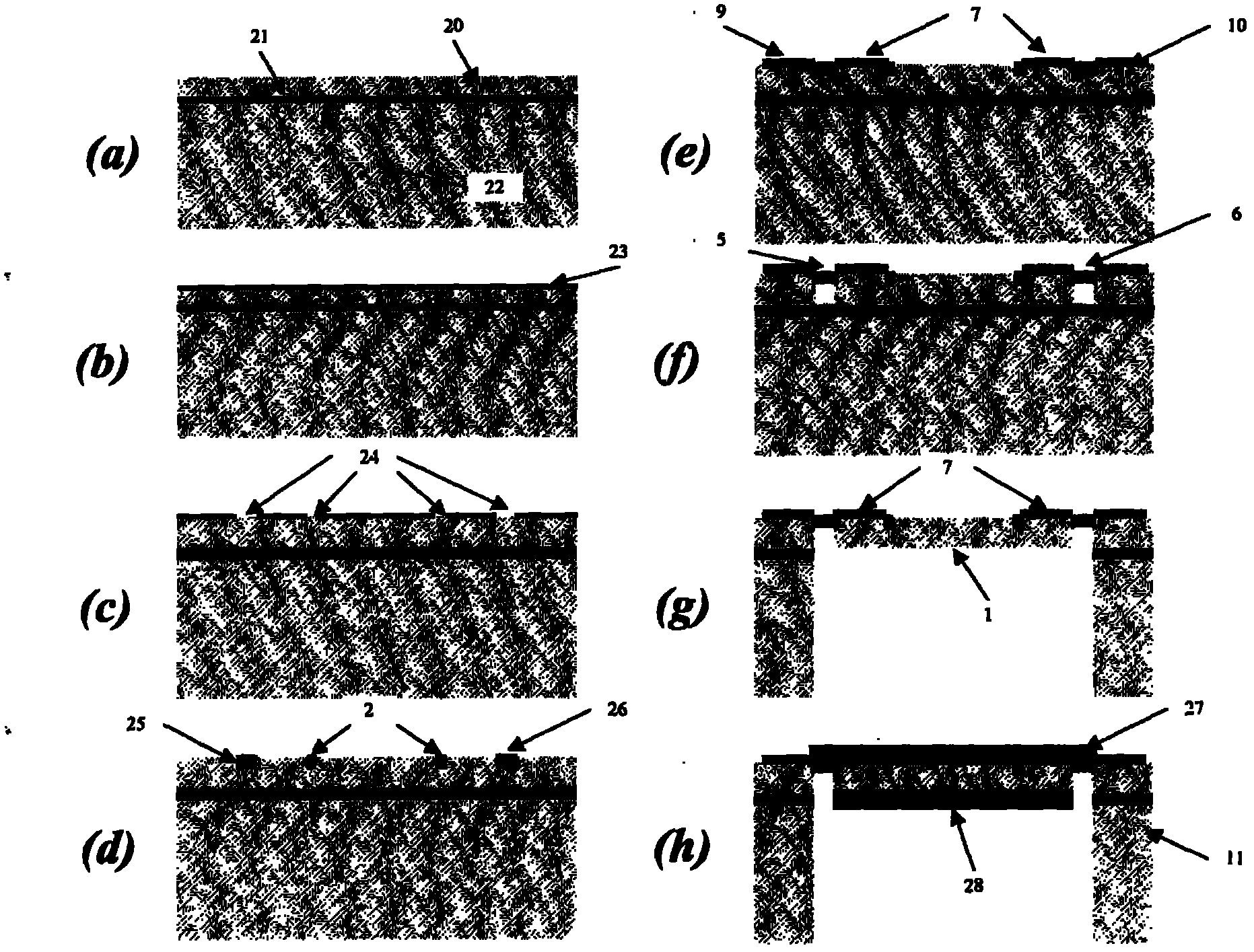

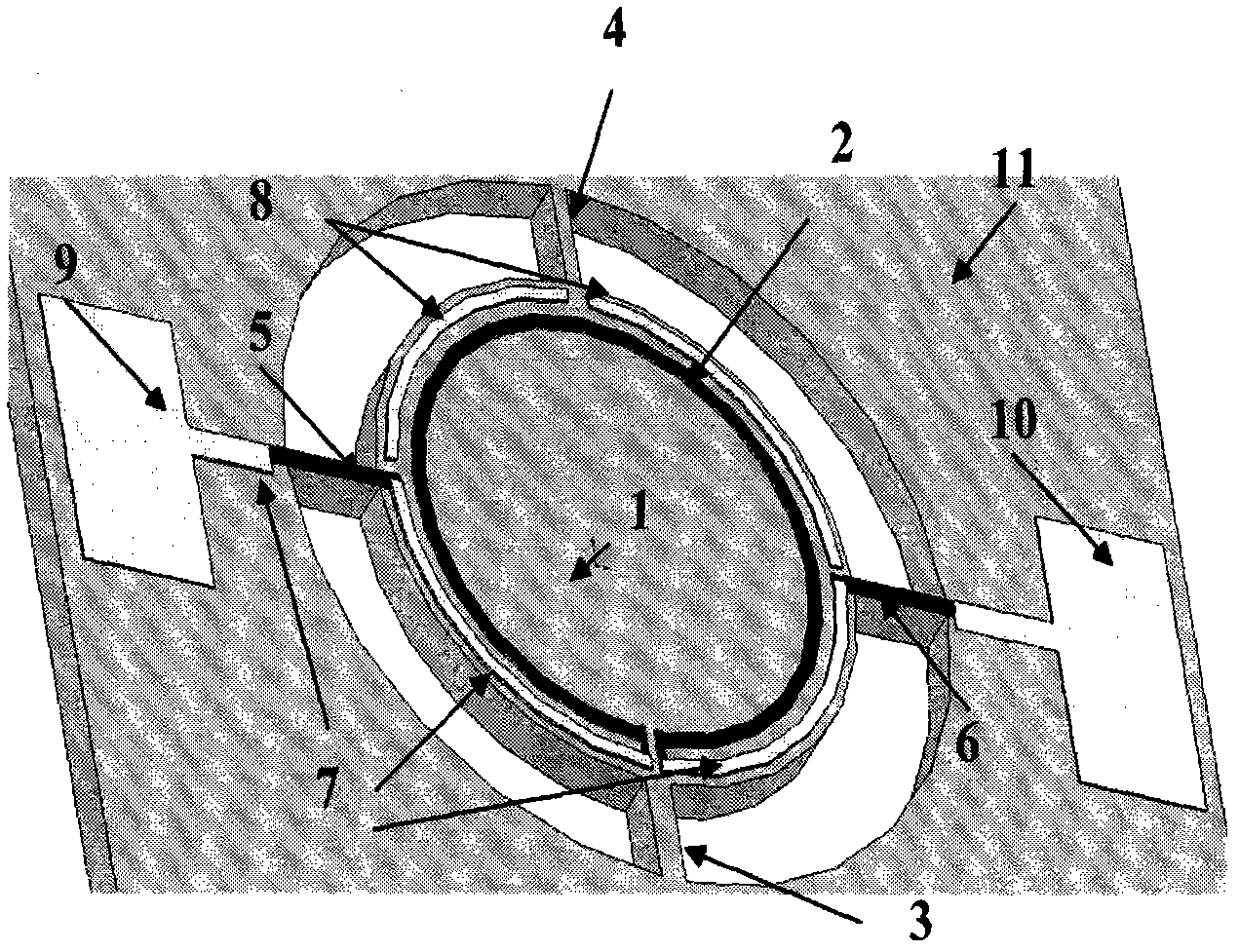

Silicone tunable optical filter and making method thereof

The invention provides a silicone tunable optical filter, comprising a silicone tuning cavity, a highly-doped silicone resistance heater, a lower cantilever beam, an upper cantilever beam, a left surface highly-doped cantilever beam, a right highly surface doped cantilever beam, a metal lead, a stress balancing metal lead, a left lead region, a right lead region and an SOI (Silicon-on-Insulator) supporting silicon substrate 11. The silicone tunable optical filter is obtained by using an SOI wafer with high resistance and a silicone machining process. A making method provided by the invention comprises the following steps of: (a) making a highly doped region on the surface of an SOI wafer device layer; (b) sputtering metal on the surface of the wafer device layer and making a metal structure; (c) making the silicone tuning cavity and each cantilever beam structure on the surface of the wafer device layer; (d) releasing the silicone tuning cavity and the cantilever beam structure from asubstrate layer of the lower surface of the silicon wafer; and (e) making high reflective films on the upper and lower surfaces of the silicone tuning cavity to form an optical F-P interference cavity body. The made filter has the advantages of very good optical performance, simple making process and high structural reliability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com