Self-cooling type conductive contact piece and connector

A conductive contact, self-cooling technology, applied in conductive connections, contact parts, welding/welding connections, etc., can solve the problem that the current cannot pass a large current for a long time, the contacts cannot be used continuously for a long time, and the normal use of the contacts is affected, etc. The problem is to achieve the effect of simple and convenient structure, good cooling, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

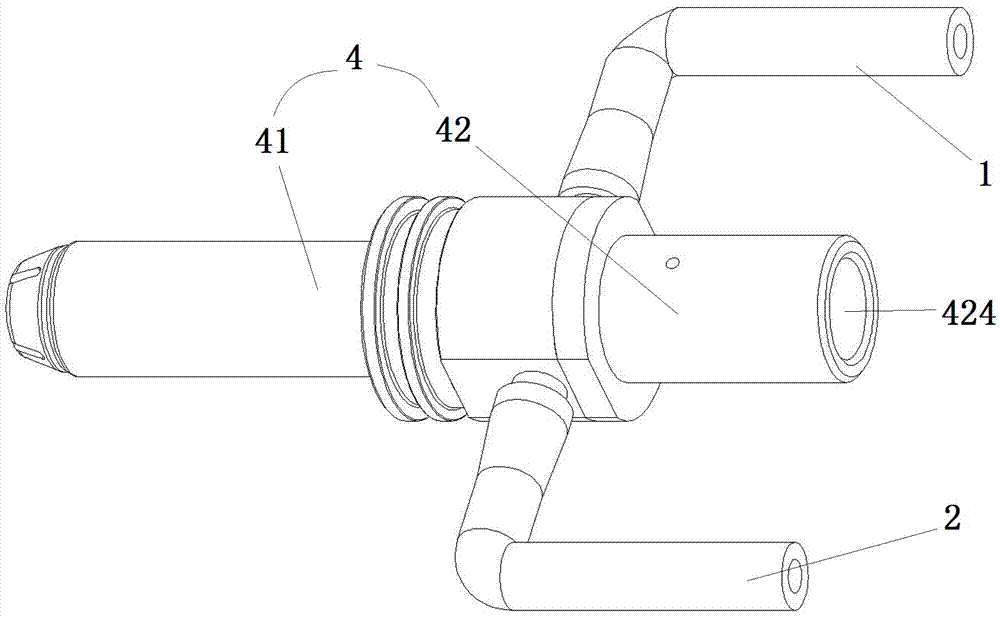

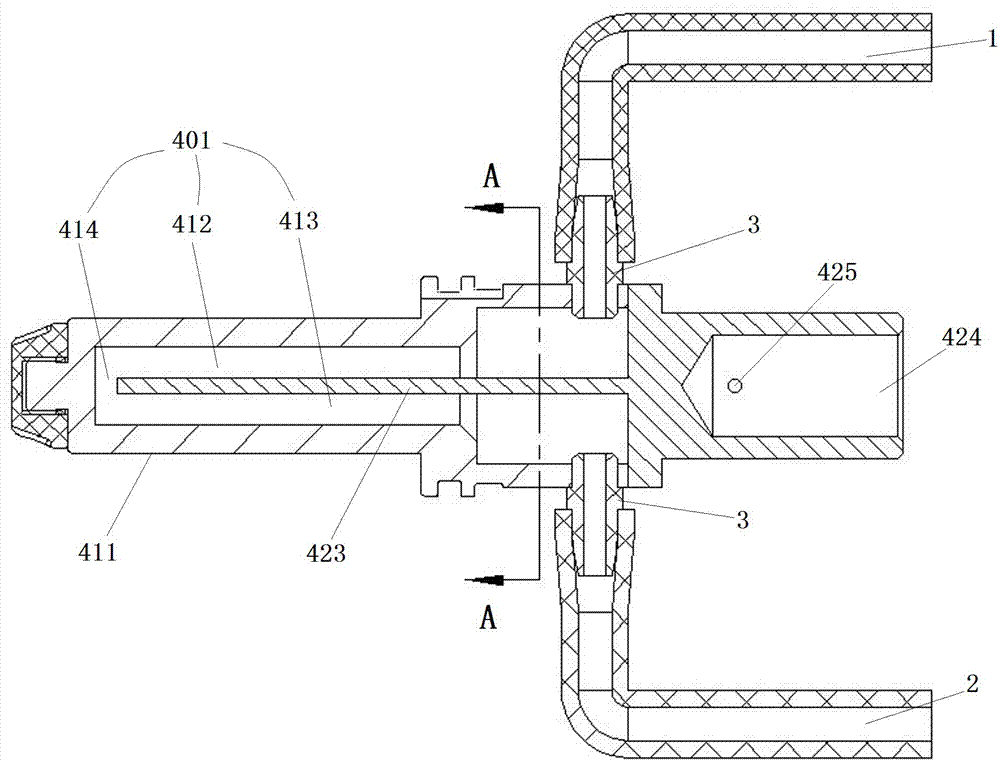

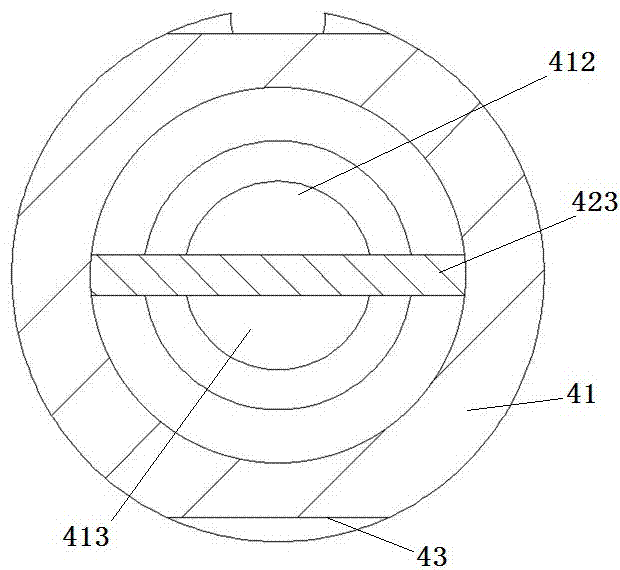

[0048] Specific embodiments of the connector of the present invention, such as Figure 1 to Figure 12As shown, the connector includes a connector housing on which conductive contacts are provided. The connector housing is the prior art, which is not shown in the figure and will not be described again. The conductive contact 4 includes a contact body. The contact body is welded by a pin end 41 and a crimping end 42. The pin end 41 has an inserting portion 411 that is adapted to be inserted into an adapted contact. The inserting portion 411 is used as a conductive part and is also a part that generates heat. The crimping end 42 has a crimping hole 424 for connecting with the cable. The side wall of the crimping hole 424 is provided with a screw hole 425 in the radial direction for inserting the cable. After the crimping hole 424, the cable is crimped and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com