Plastic tap and its manufacture method

A manufacturing method and faucet technology, which are applied in the field of faucets, can solve the problems affecting the water outlet flow of the faucet, the extrusion deformation of the connecting pipe, etc., and achieve the effects of good water outlet effect, low cost and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

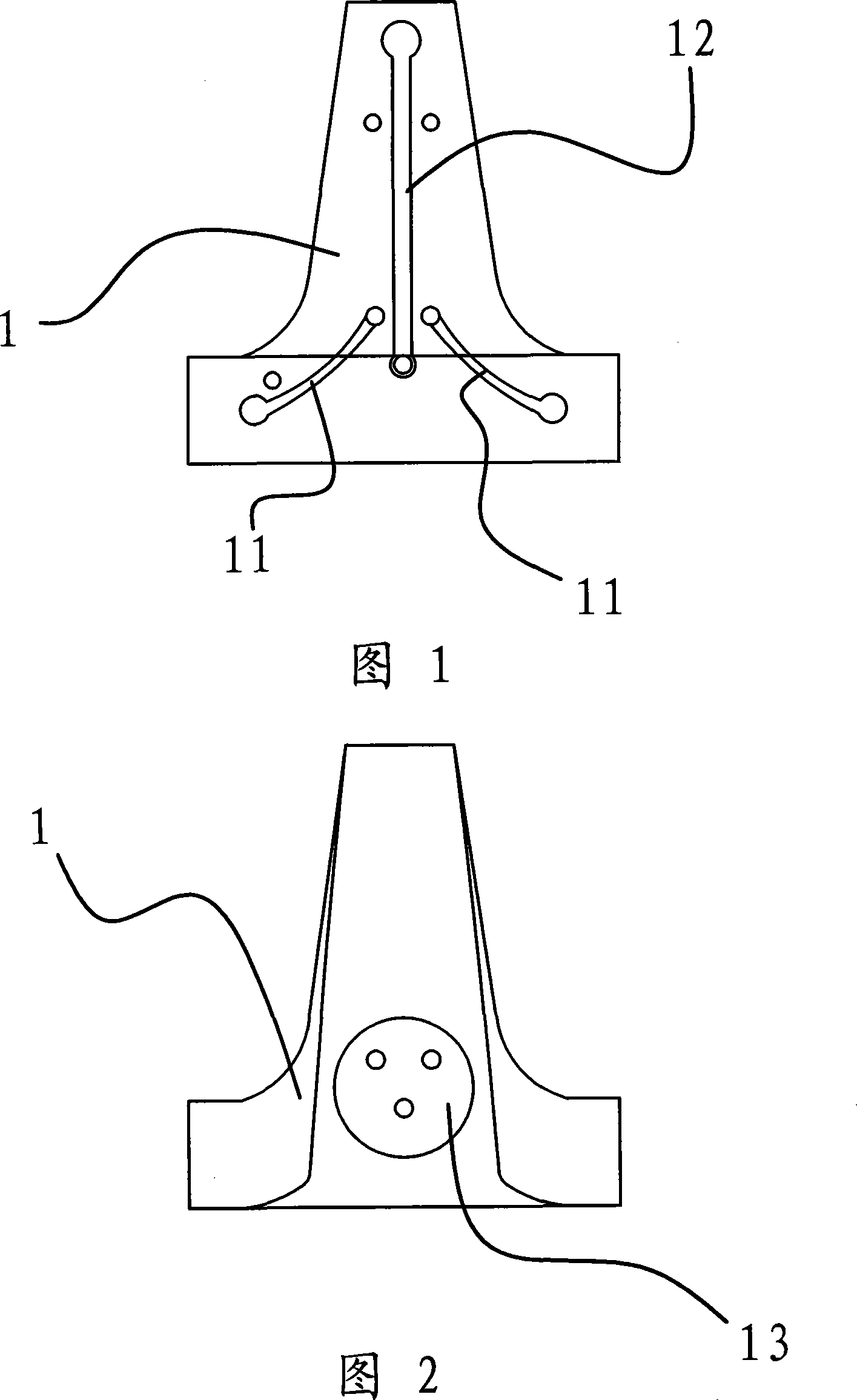

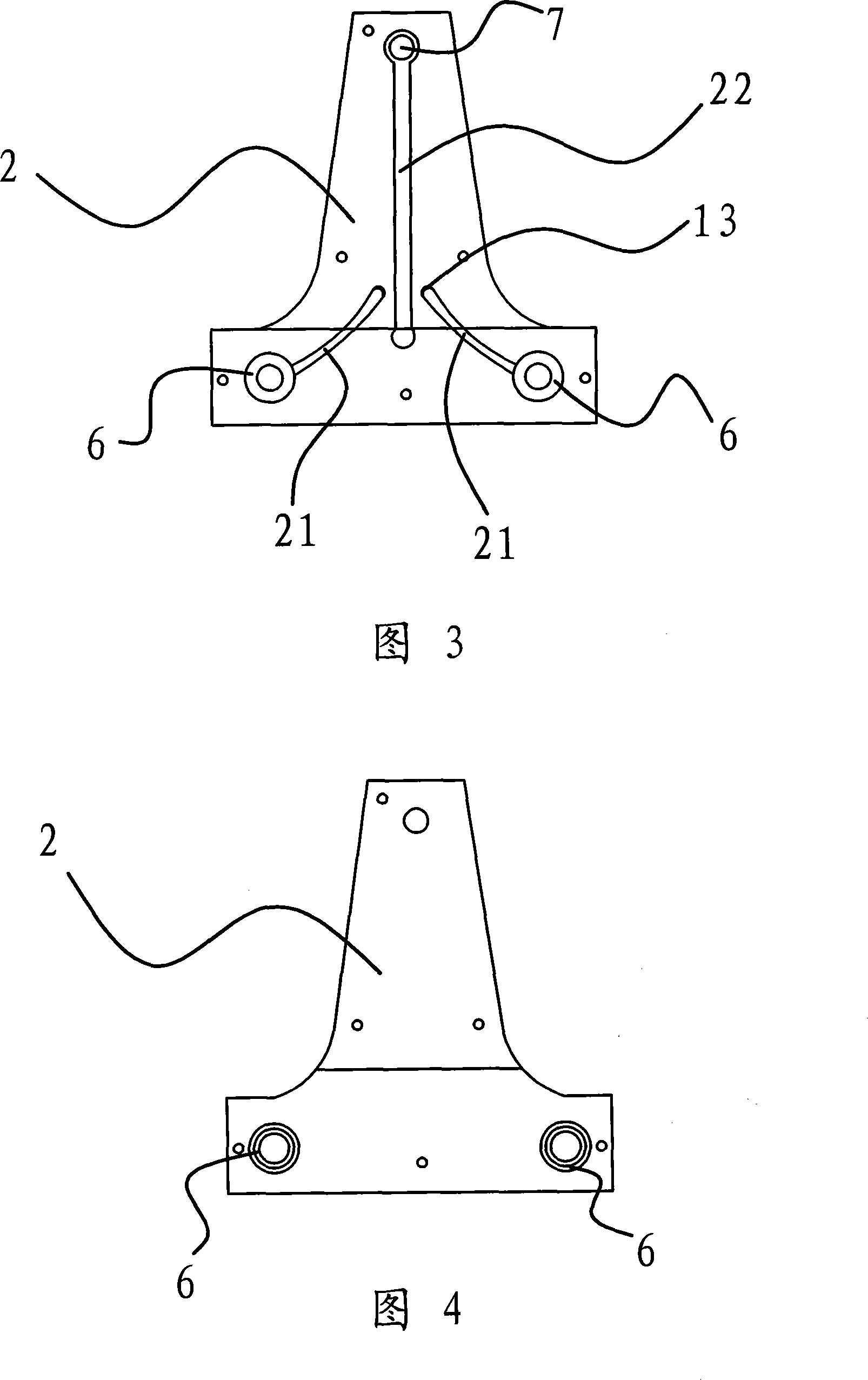

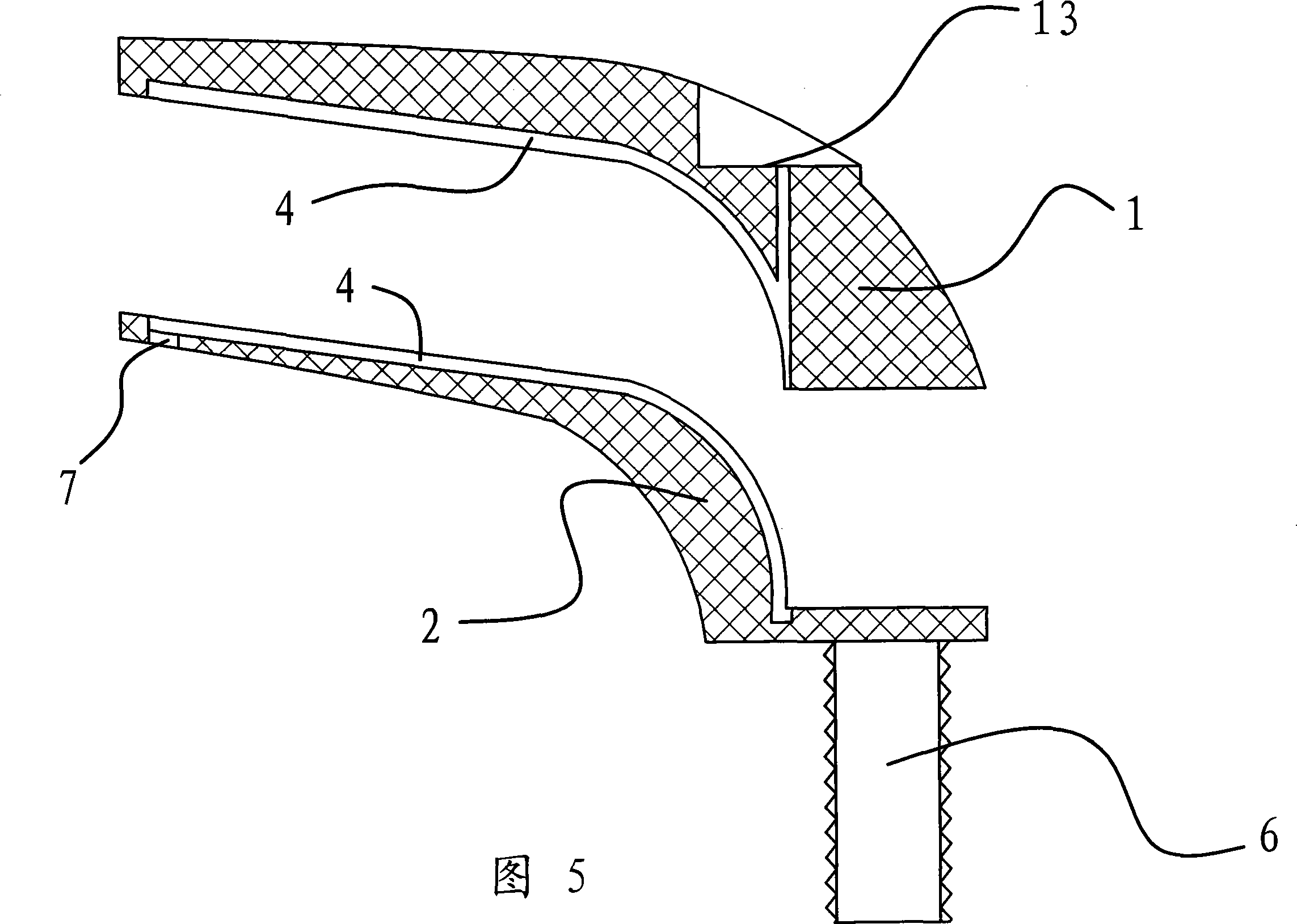

[0047] As shown in FIGS. 1 to 7 , the plastic faucet includes a body and a housing 5 tightly wrapped on the outside of the body.

[0048]As shown in Figure 1 and Figure 2 and Figure 3 and Figure 4, the body consists of an upper body 1 and a lower body 2 connected together, the upper body 1 is superimposed on the upper part of the upper and lower body 2, and the upper body 1 is provided with an upper body Groove one 11, the lower body 2 is provided with a lower groove one 21, and the position of the upper groove one 11 is corresponding to the position of the lower groove one 21. At the same time, the upper body 1 is also provided with an upper groove 2 12, and the lower body 2 is also provided with a lower groove 2 22, and the positions of the upper groove 2 12 and the lower groove 2 22 are corresponding. Obviously, such a structure makes the upper groove one 11 and the lower groove one 21 form the water inlet channel 3 , and the upper groove two 12 and the lower groove two 22 ...

Embodiment 2

[0067] This embodiment is basically the same as Embodiment 1, except that the water inlet channel 3 is a through hole drilled directly on the lower body 2, and one end of the through hole communicates with the water inlet pipe 6 and the other end communicates with the valve core seat 13. Since the through hole is drilled directly, a straight hole-shaped water inlet channel 3 is formed, as shown in FIGS. 8 and 9 . Of course, according to the actual situation, the water outlet channel 4 can also be formed by drilling.

[0068] As shown in FIG. 8 , FIG. 9 , FIG. 10 and FIG. 11 and FIG. 12 , the upper body 1 is further provided with a card slot 14 , and the lower body 2 is provided with a card head 23 matching the shape of the card slot 14 . As shown in Figure 12, during the connection process of the upper body 1 and the lower body 2, the clamping head 23 can be matched directly through the slot 14, so that the positions of the upper body 1 and the lower body 2 are aligned, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com