Double-dielectric barrier discharge low-temperature plasma generator

A technology of low-temperature plasma and blocking discharge, which is applied in the field of plasma, can solve the problems that are not suitable for the treatment of harmful gas pollutants, and achieve the effects of stable discharge, ensuring stability and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

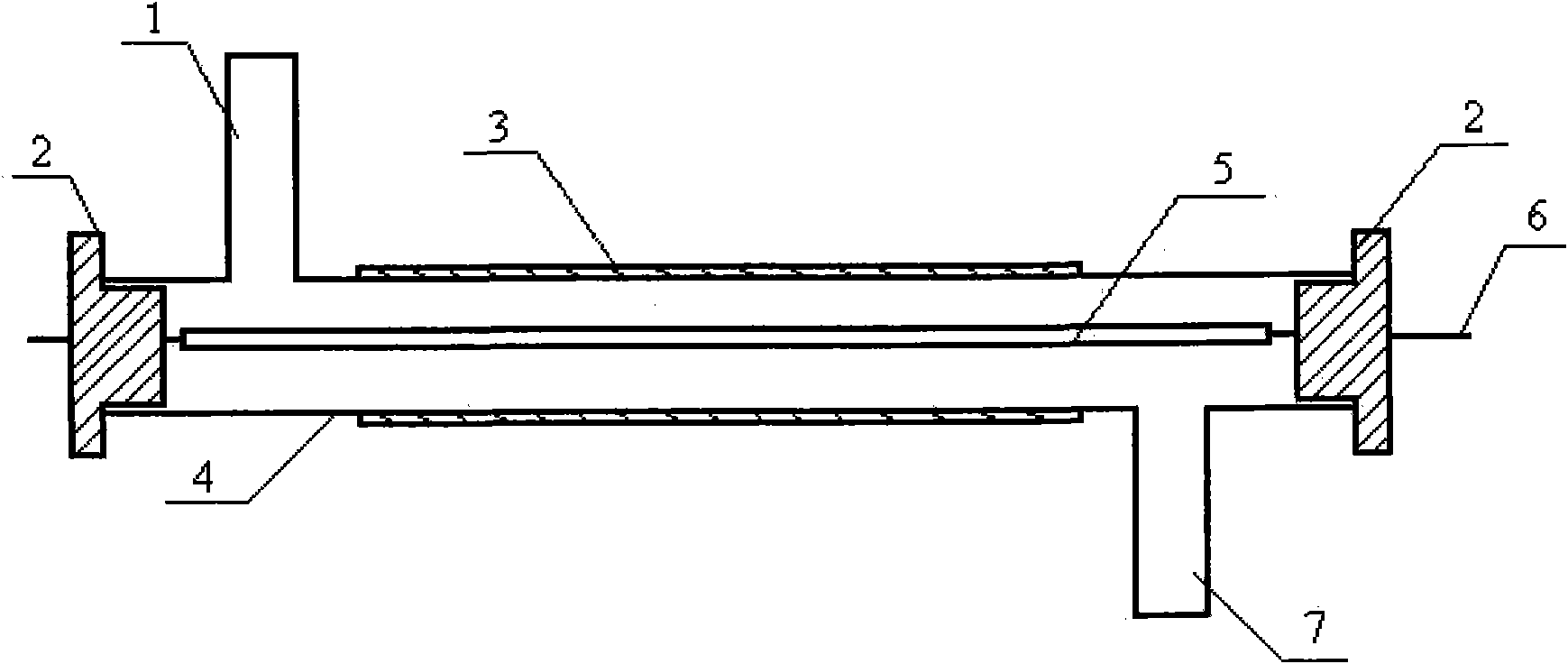

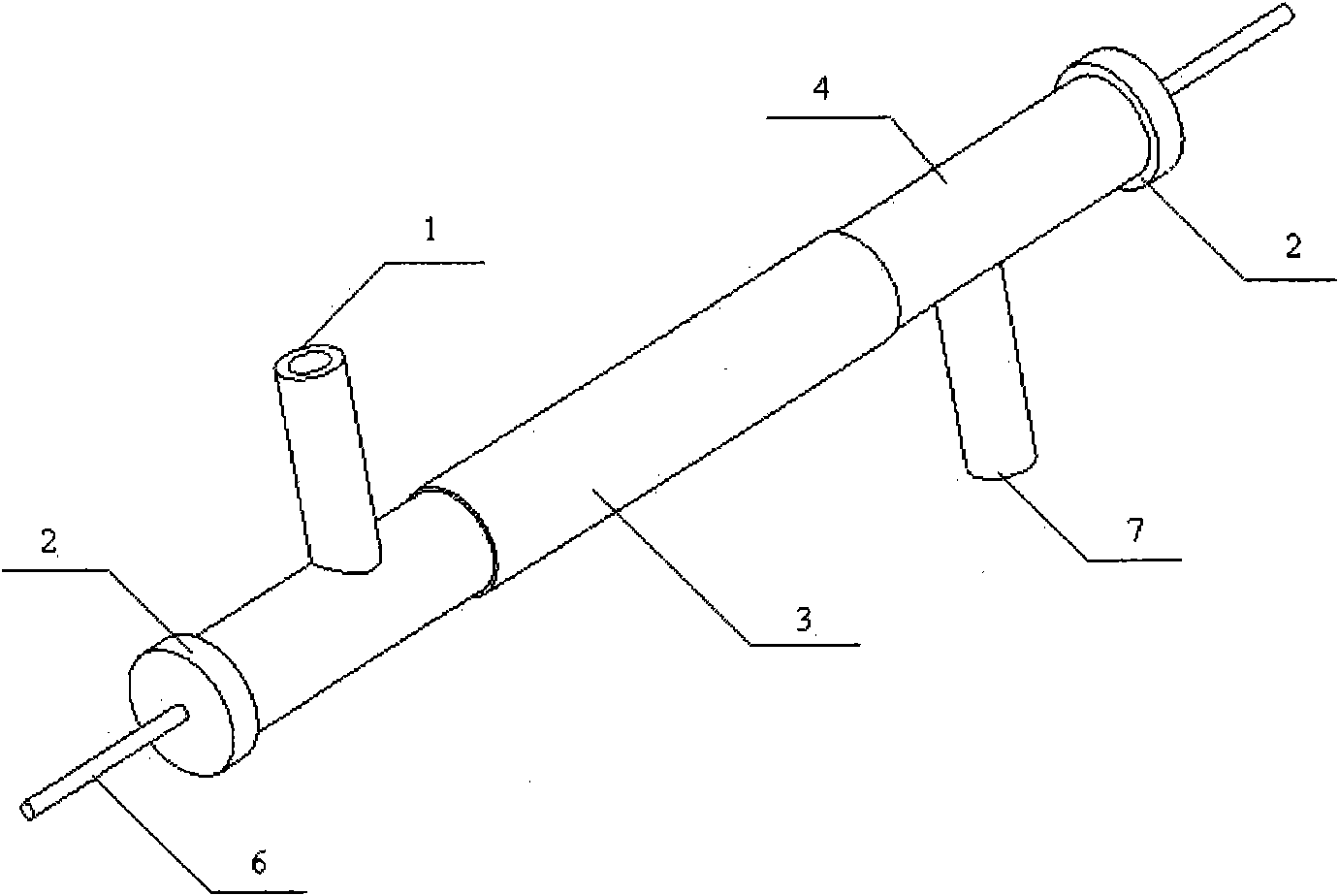

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

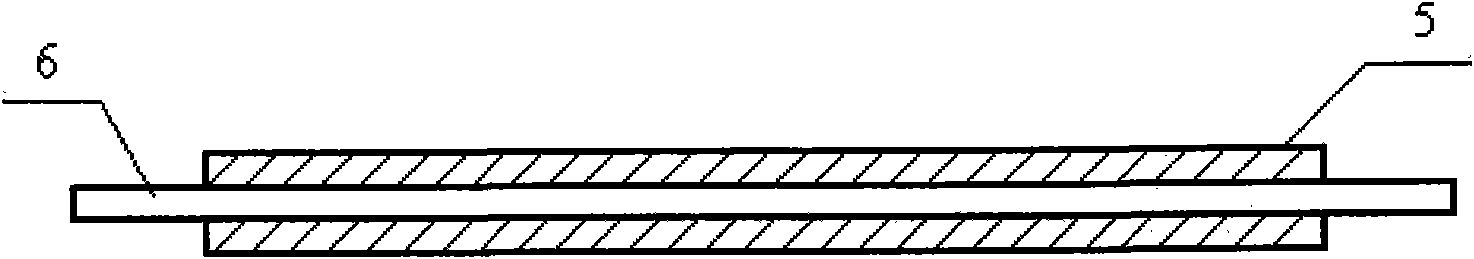

[0016] The dual-dielectric barrier discharge low-temperature plasma device of the present invention connects the high-voltage electrode 6 to a variable-voltage variable-frequency plasma power supply and the low-voltage electrode 3 to ground to generate low-temperature plasma discharge between the two dielectrics. The outer layer of the high-voltage electrode 6 is covered with a quartz glass tube B5, which can prevent the harmful gas from corroding the electrode during the discharge process, protect the discharge performance of the electrode, make the work of the low-temperature plasma generator more stable, and effectively extend the service life. The present invention adopts a double-dielectric barrier discharge structure, and the gas enters the gas phase reaction zone of the low-temperature plasma generator through the gas inlet 1 and is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com