Patents

Literature

5423results about How to "Smooth discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

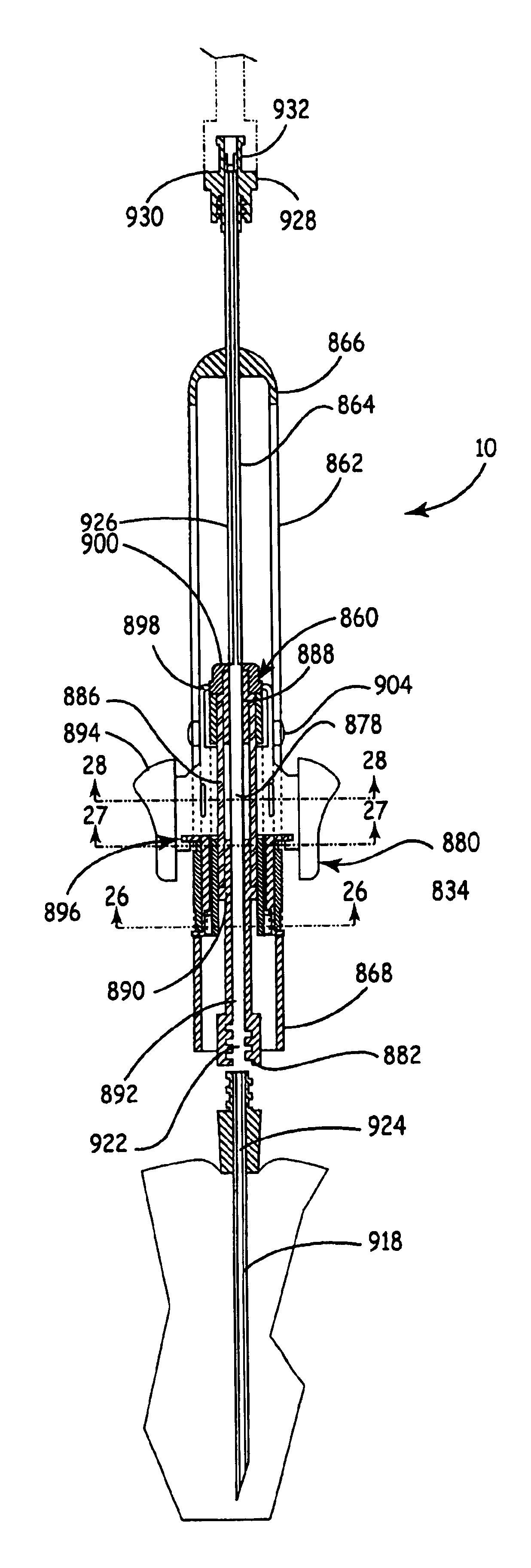

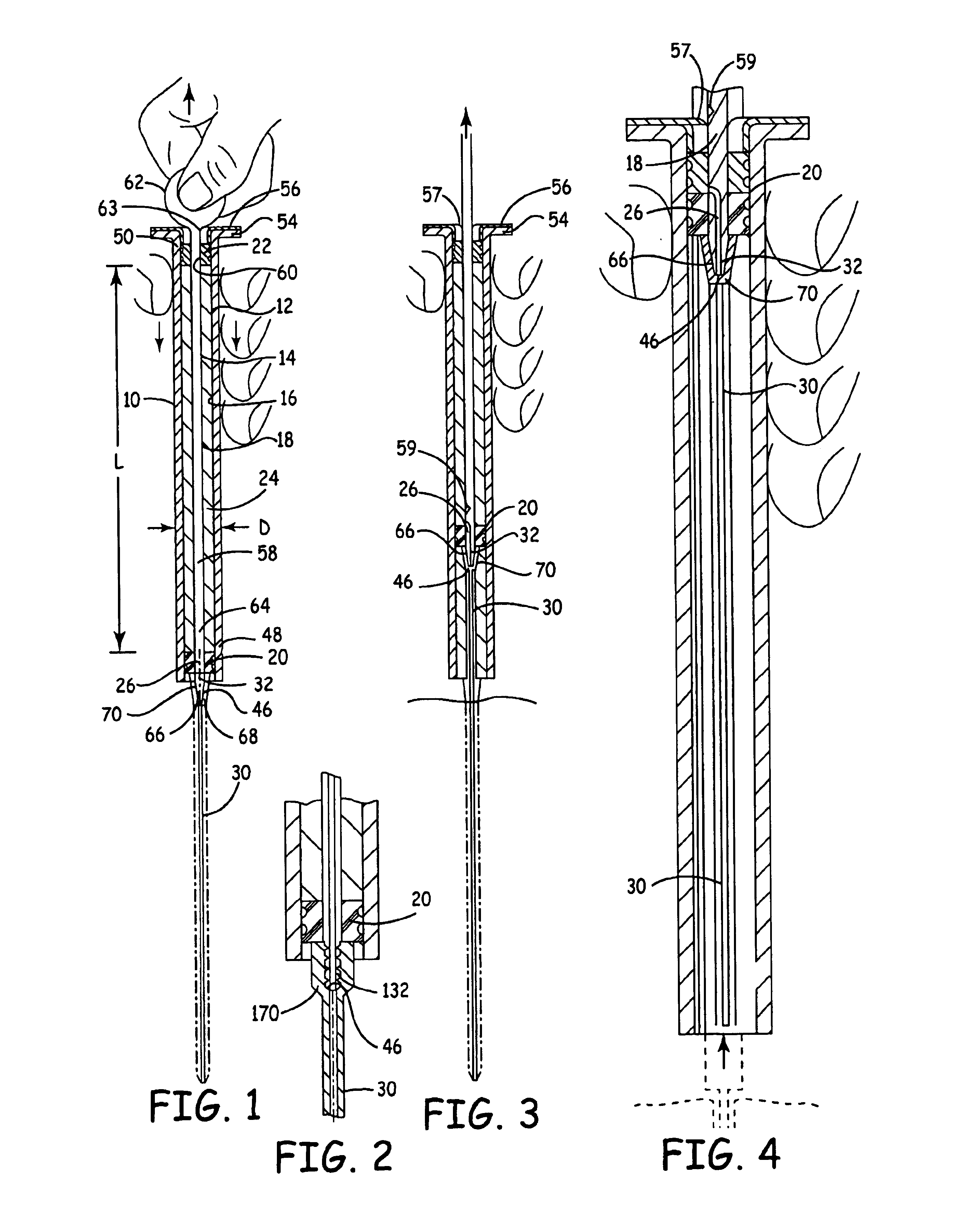

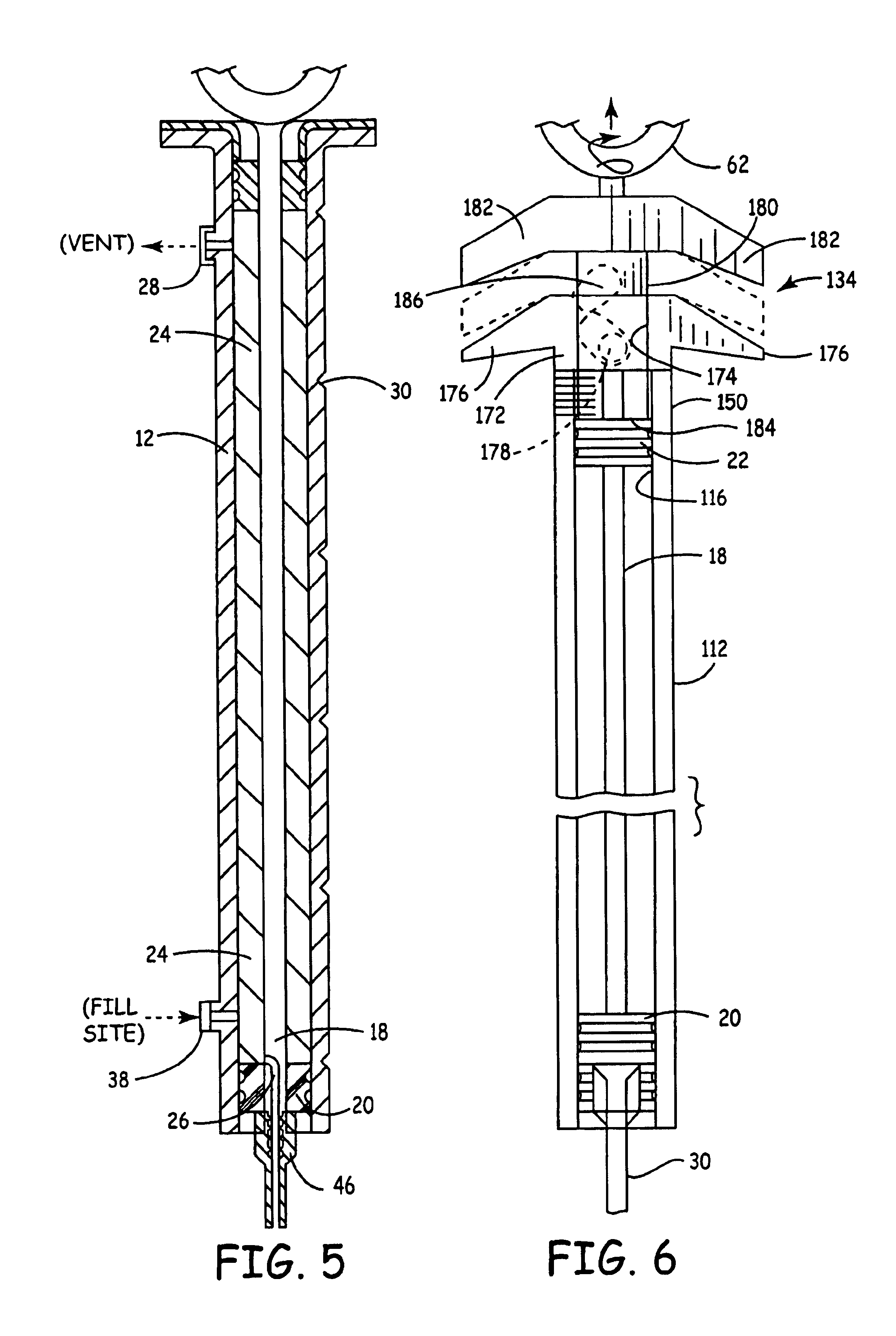

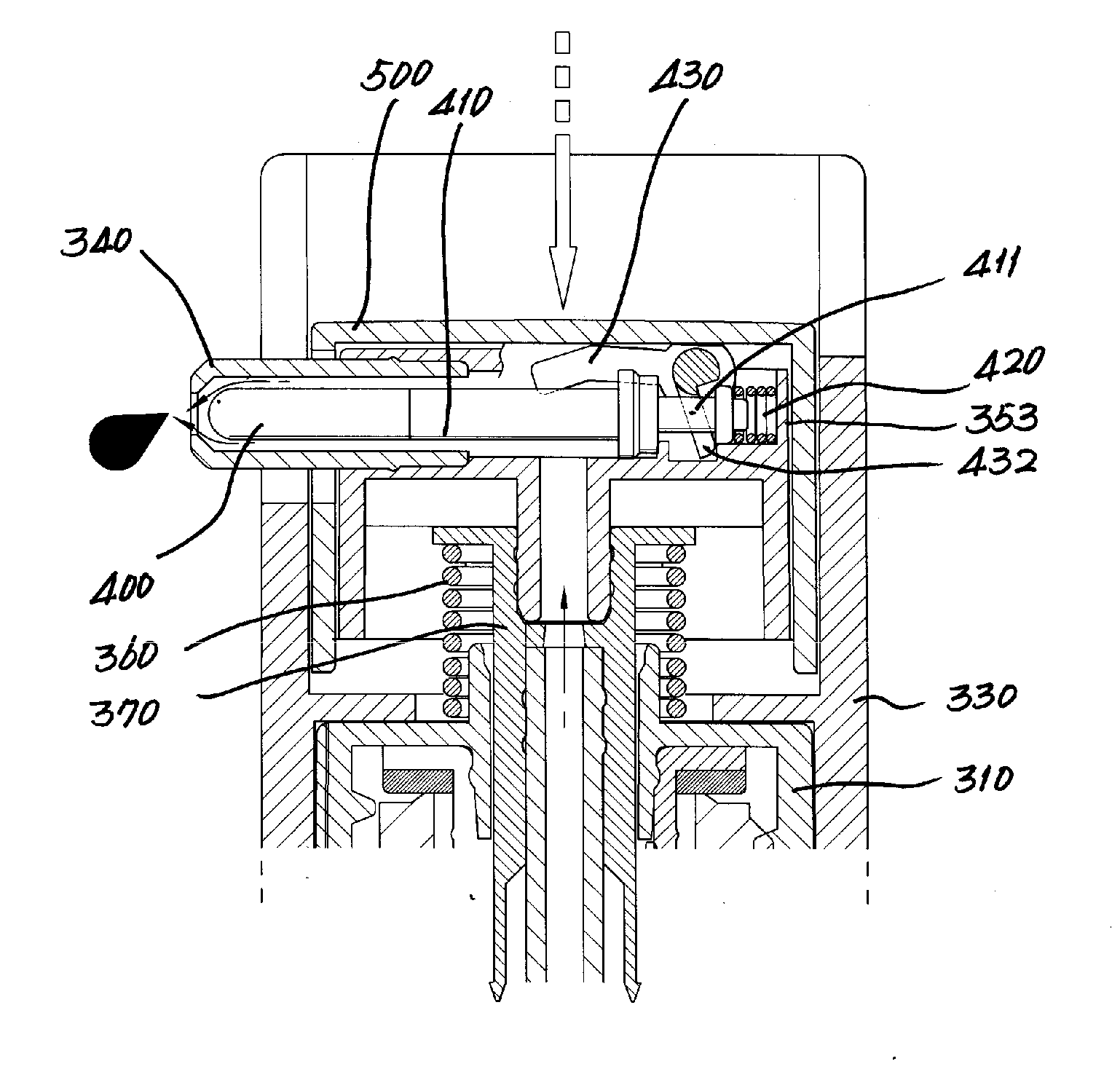

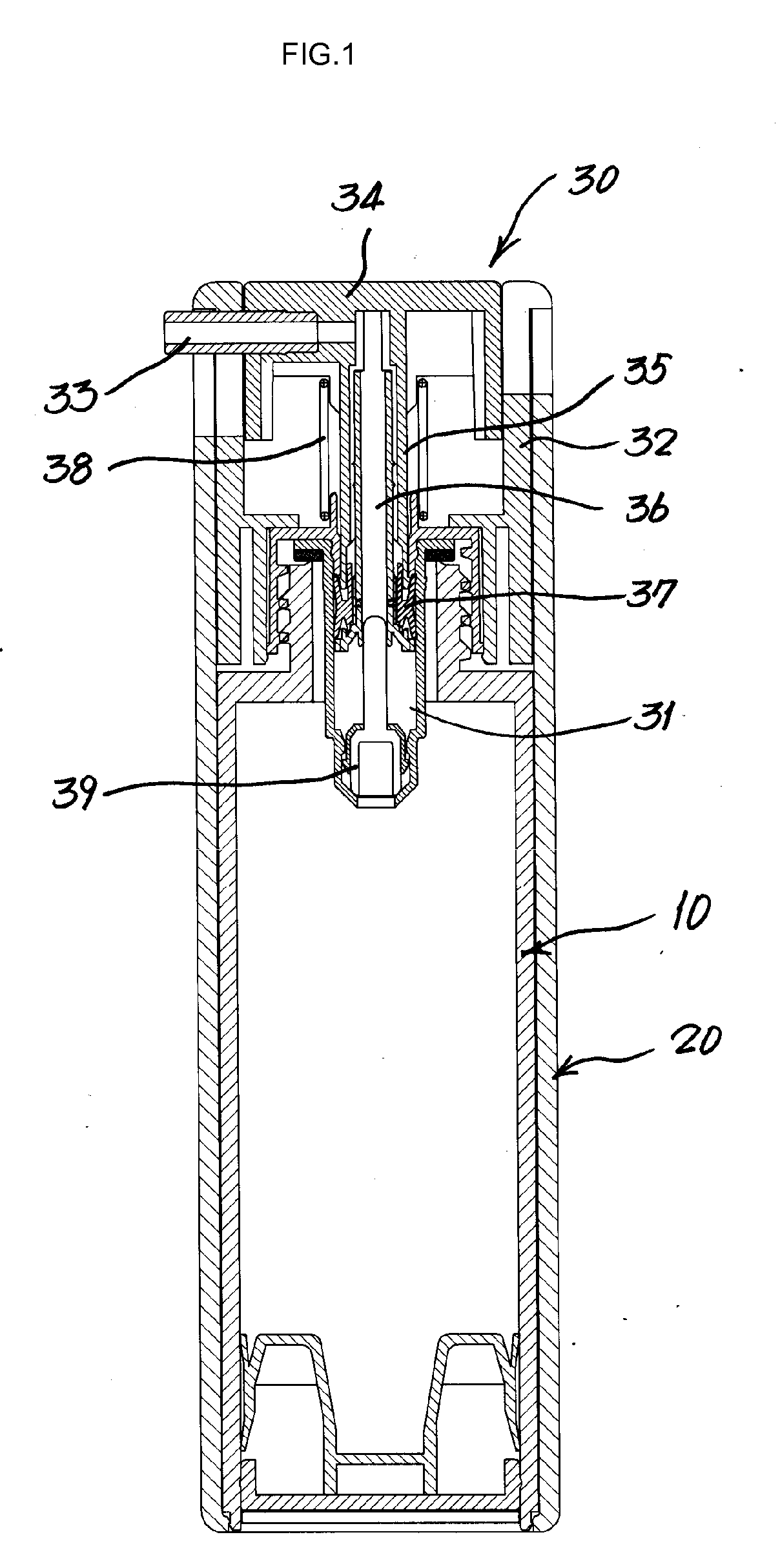

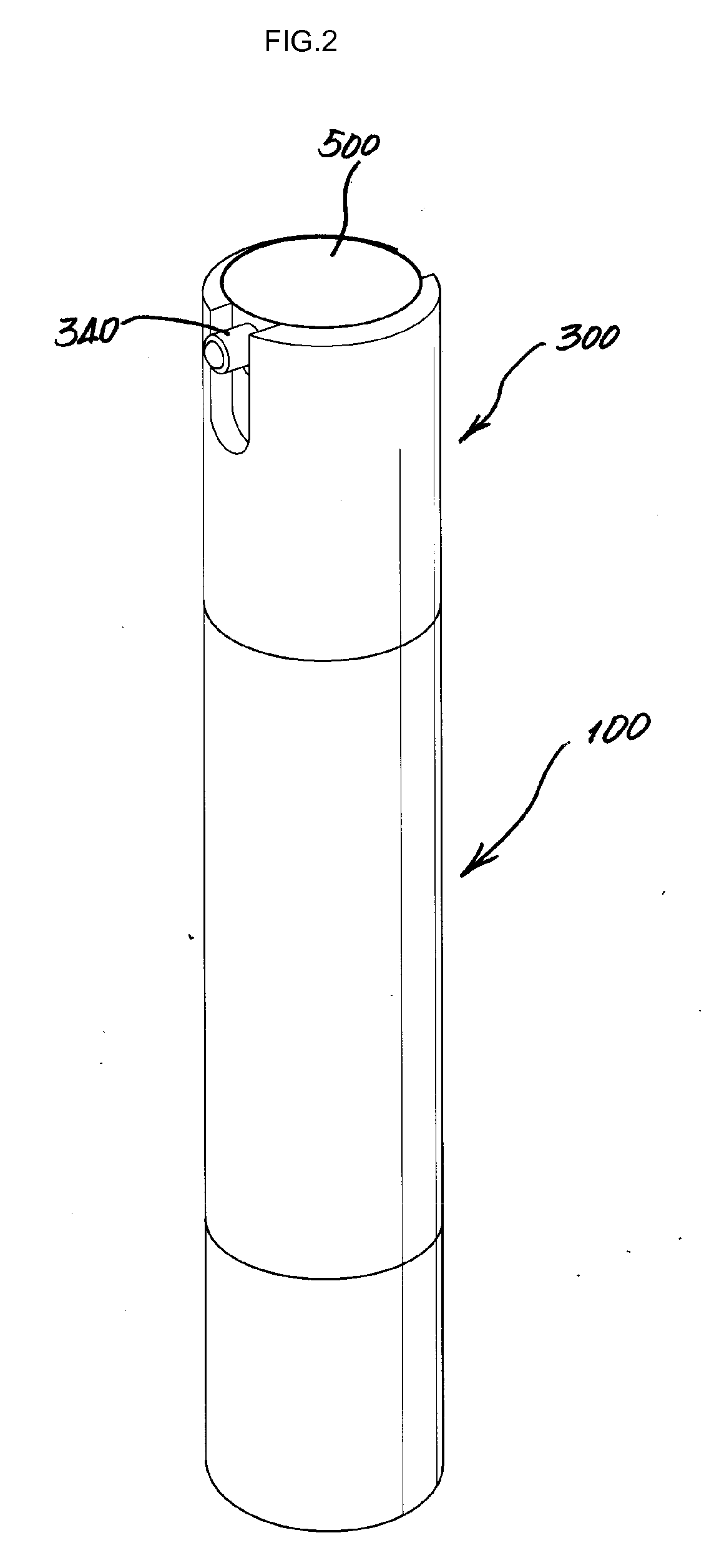

Tissue tract sealing device

InactiveUS6840952B2Smooth dischargeOvercome disadvantagesCatheterIntravenous devicesControl mannerGeneral surgery

A device and system for delivery of a flowable biocompatible material to a tissue tract in a controlled manner generally includes a reservoir adapted to be in fluid connection with a cannula, a discharging mechanism adapted to discharge the contents of the reservoir and a cannula retractor to withdraw the cannula. The cannula retractor is operably interconnected with the discharging mechanism so that a measured quantity of the reservoir contents is smoothly discharged to substantially fill at least a portion of the tissue tract.

Owner:SAKER MARK B

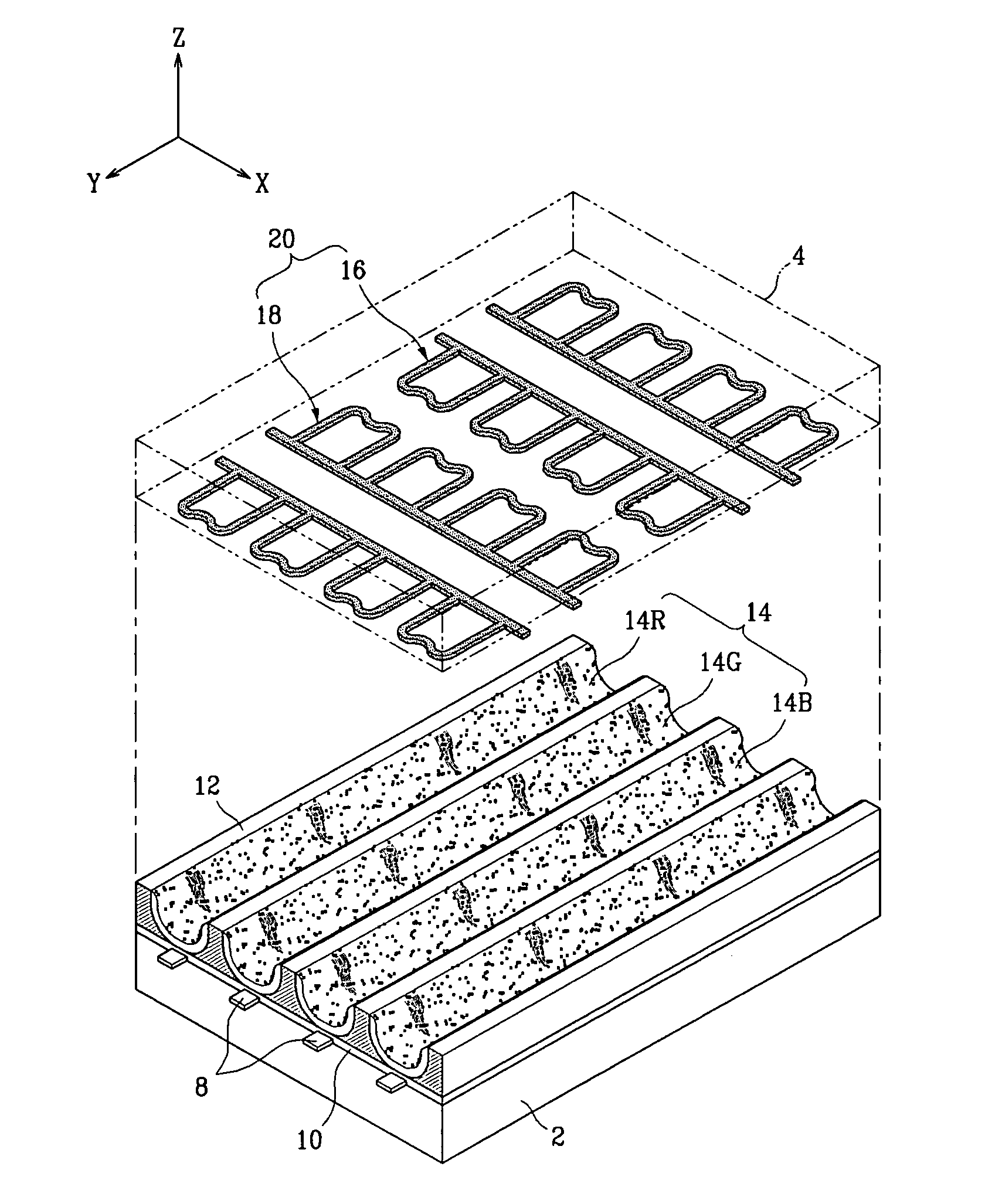

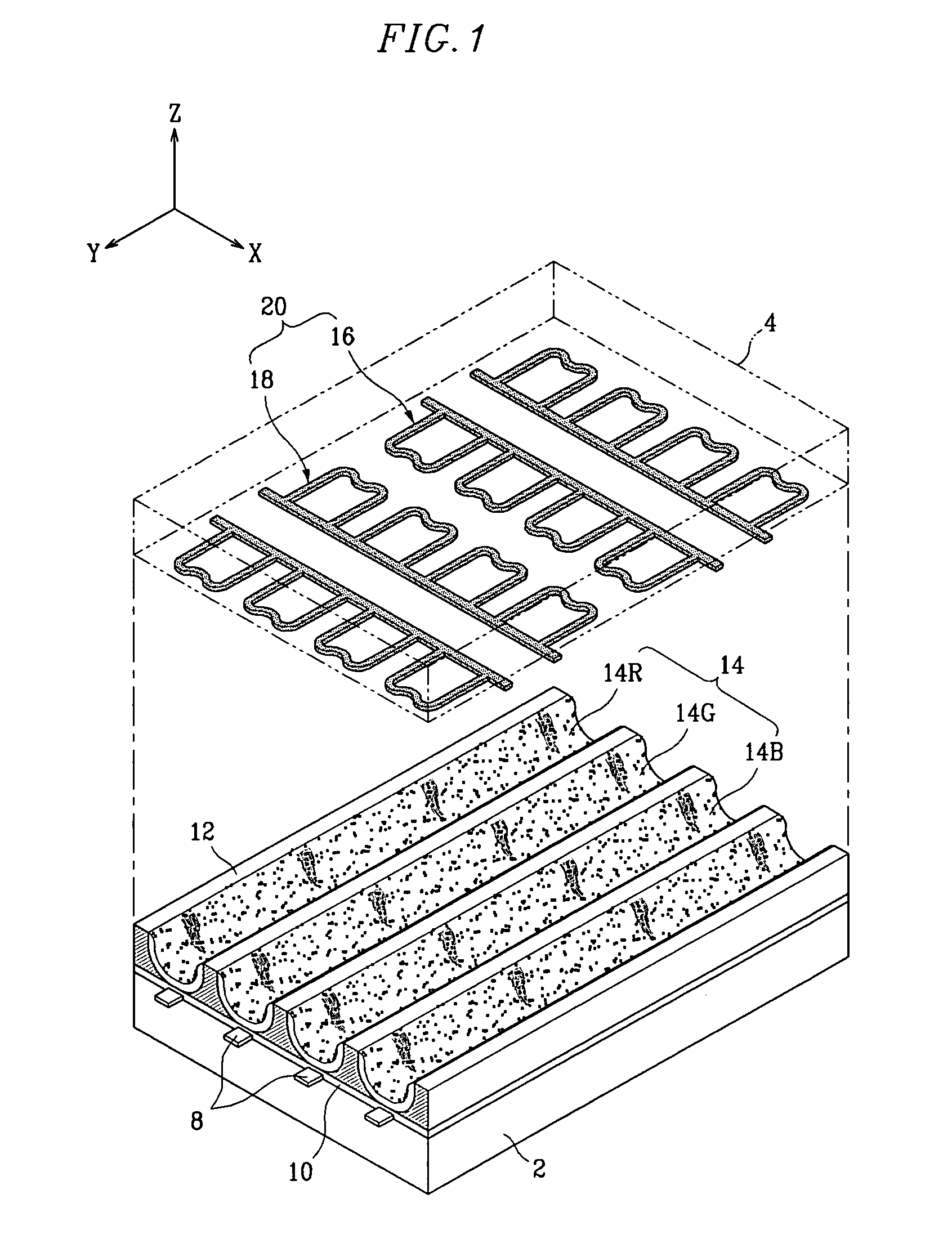

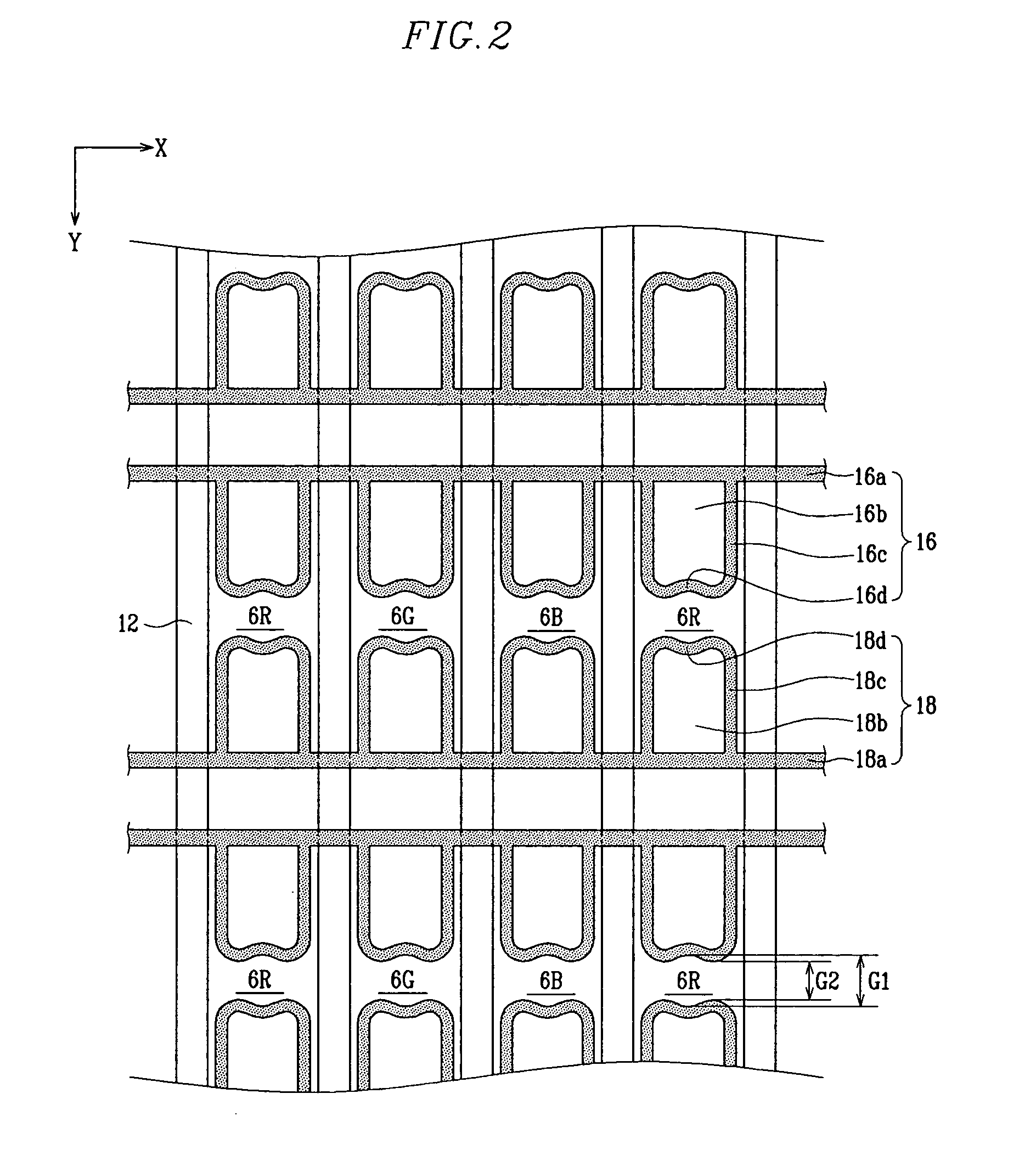

Plasma display panel

InactiveUS20050029941A1Reduce discharge firing voltageImprove illumination efficiencyAddress electrodesSustain/scan electrodesLine segmentEngineering

A plasma display panel (PDP) includes first and second substrates opposing one another with a predetermined gap therebetween. The PDP also includes address electrodes formed on a surface of the first substrate opposing the second substrate, and barrier ribs formed in the gap between the first and second substrates. The barrier ribs define discharge cells, and a phosphor layer is formed in each of the discharge cells. Further, discharge sustain electrodes made of a metal material are formed on a surface of the second substrate opposing the first substrate. The discharge sustain electrodes include line sections, each pair of which is formed corresponding to each discharge cell, and extensions are formed extending from the line sections into each of the discharge cells to define openings. Also, indentations are formed in distal ends of each of the extensions such that discharge gaps of differing sizes are formed between each pair of the extensions.

Owner:SAMSUNG SDI CO LTD

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

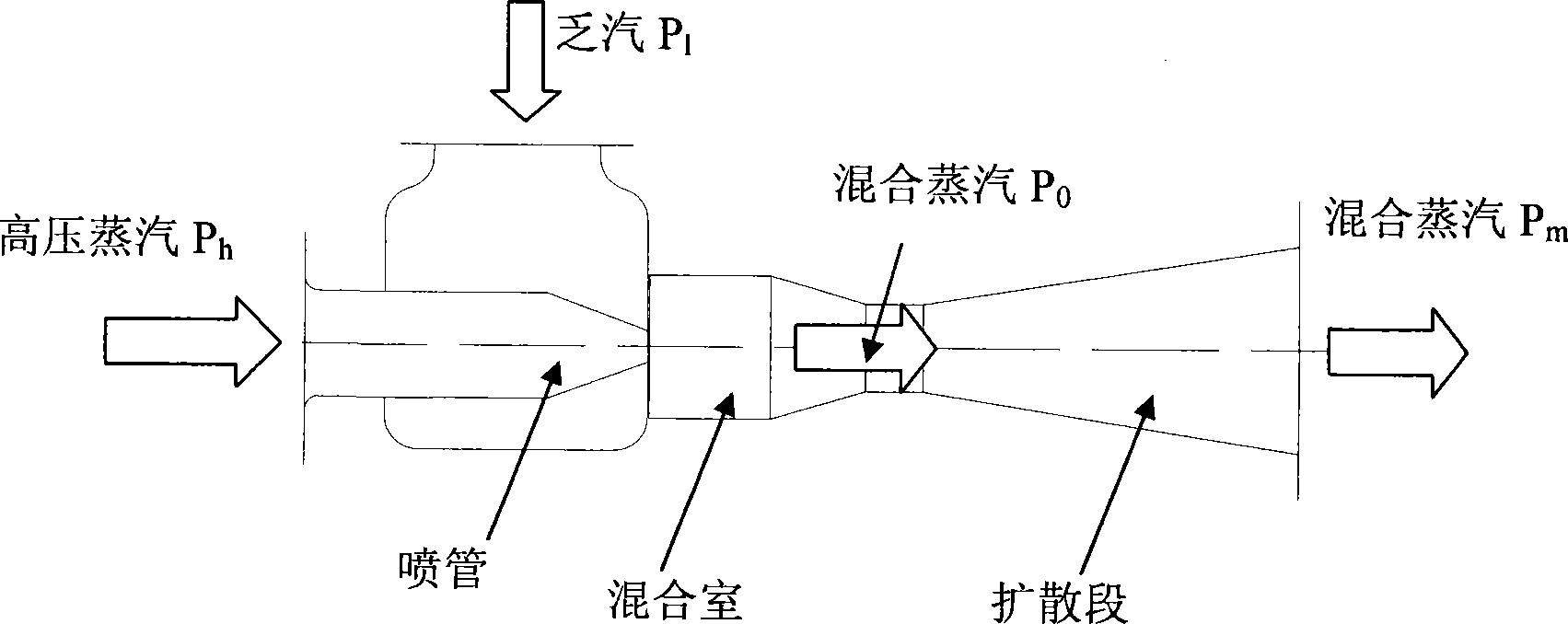

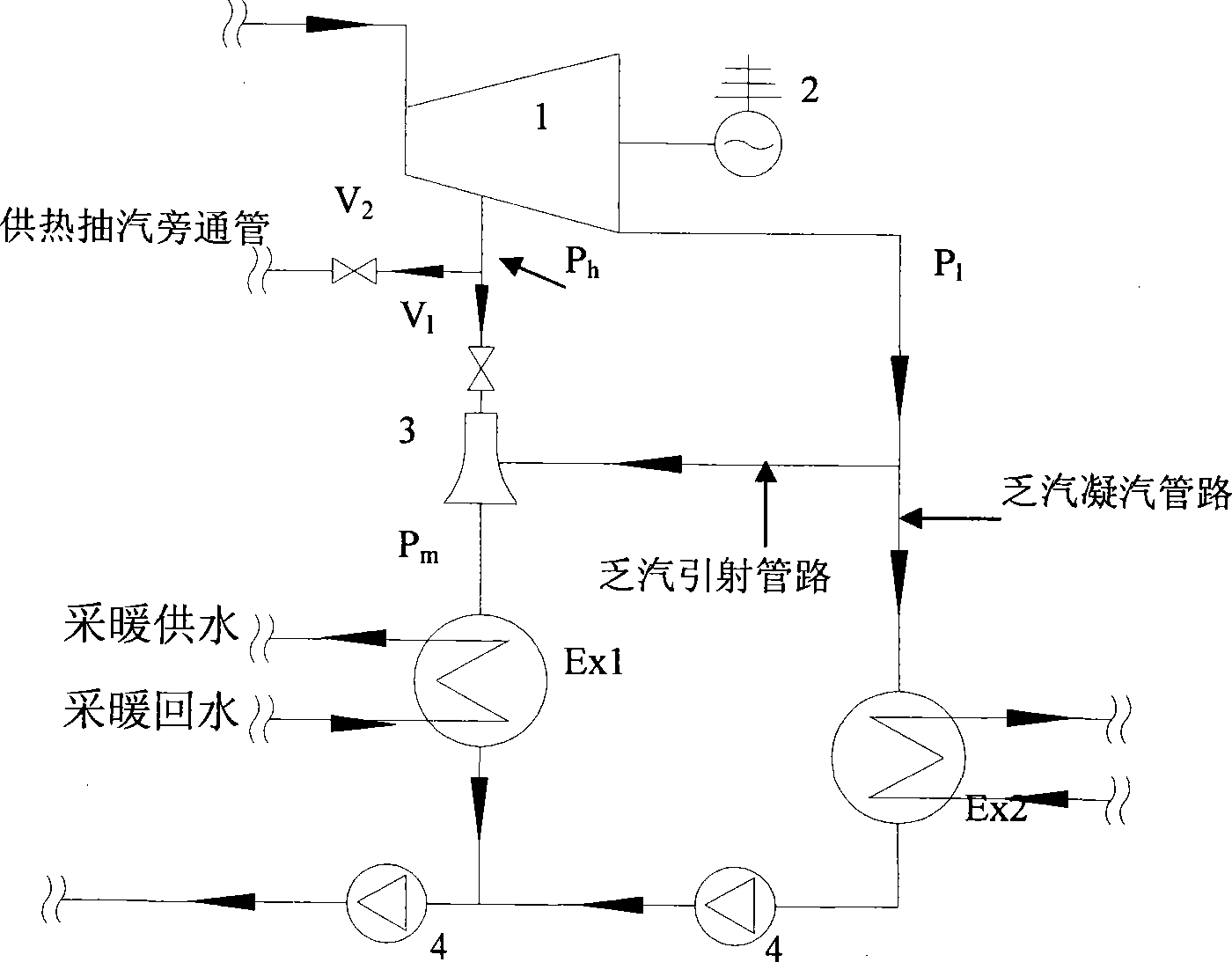

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

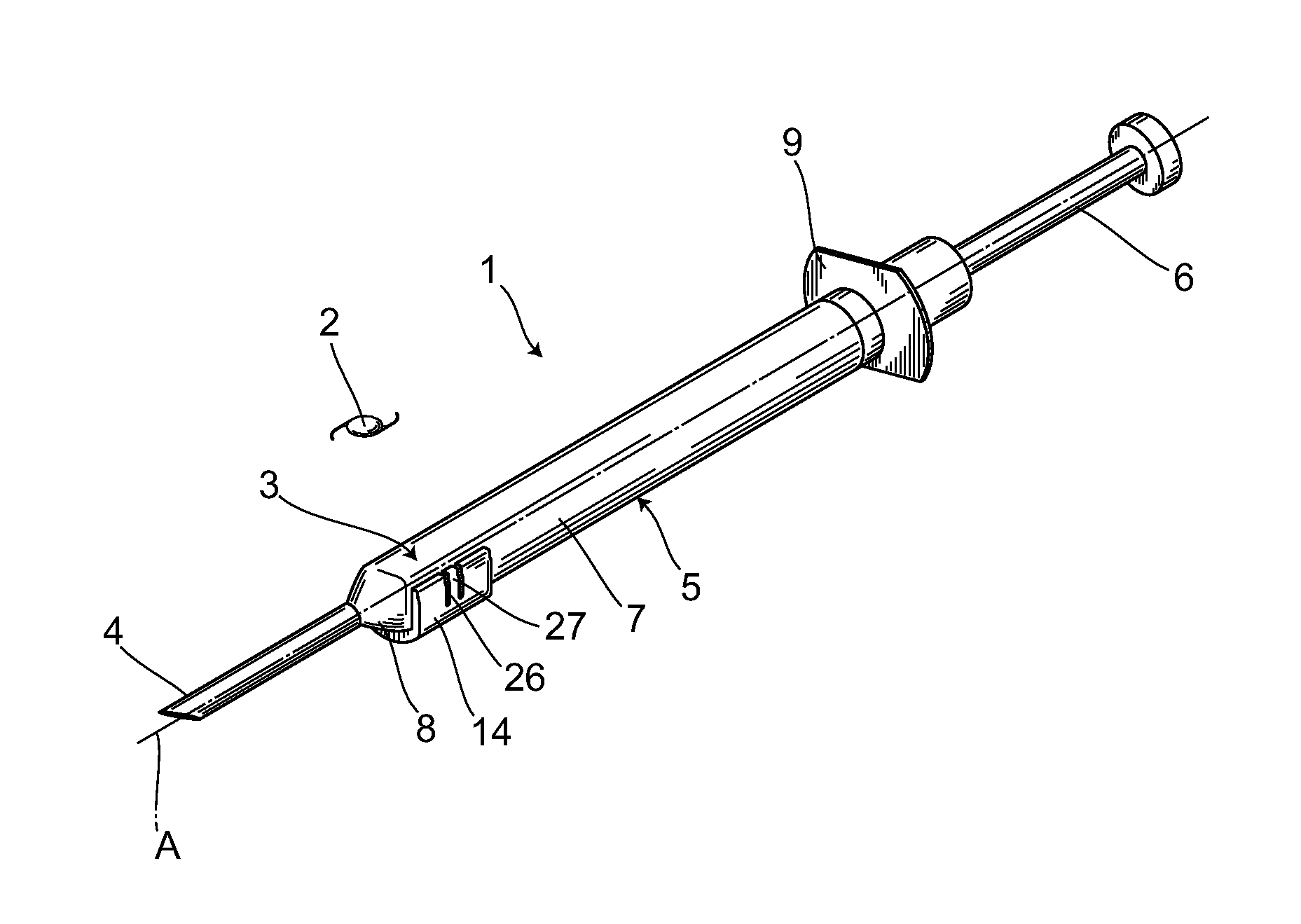

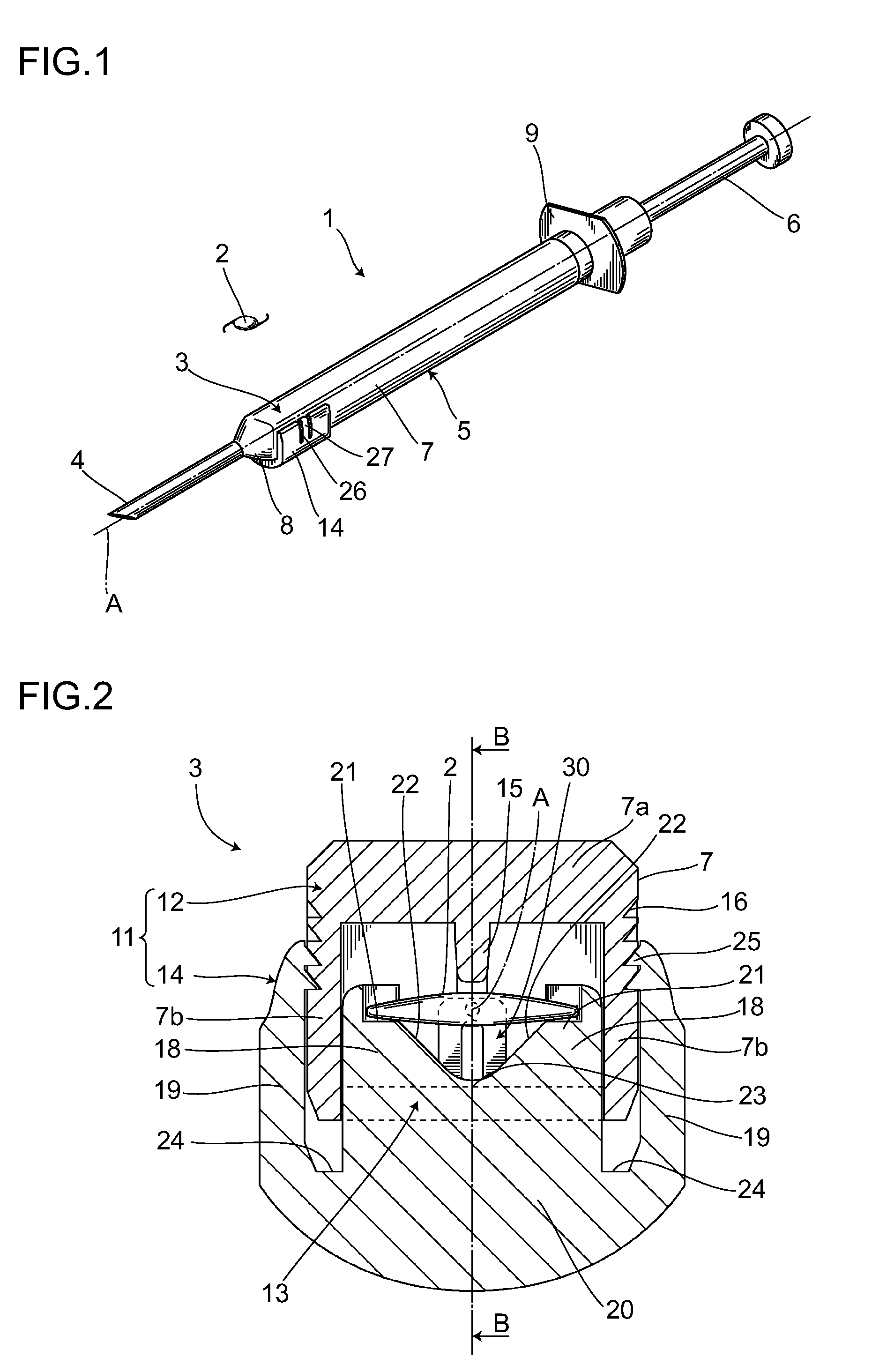

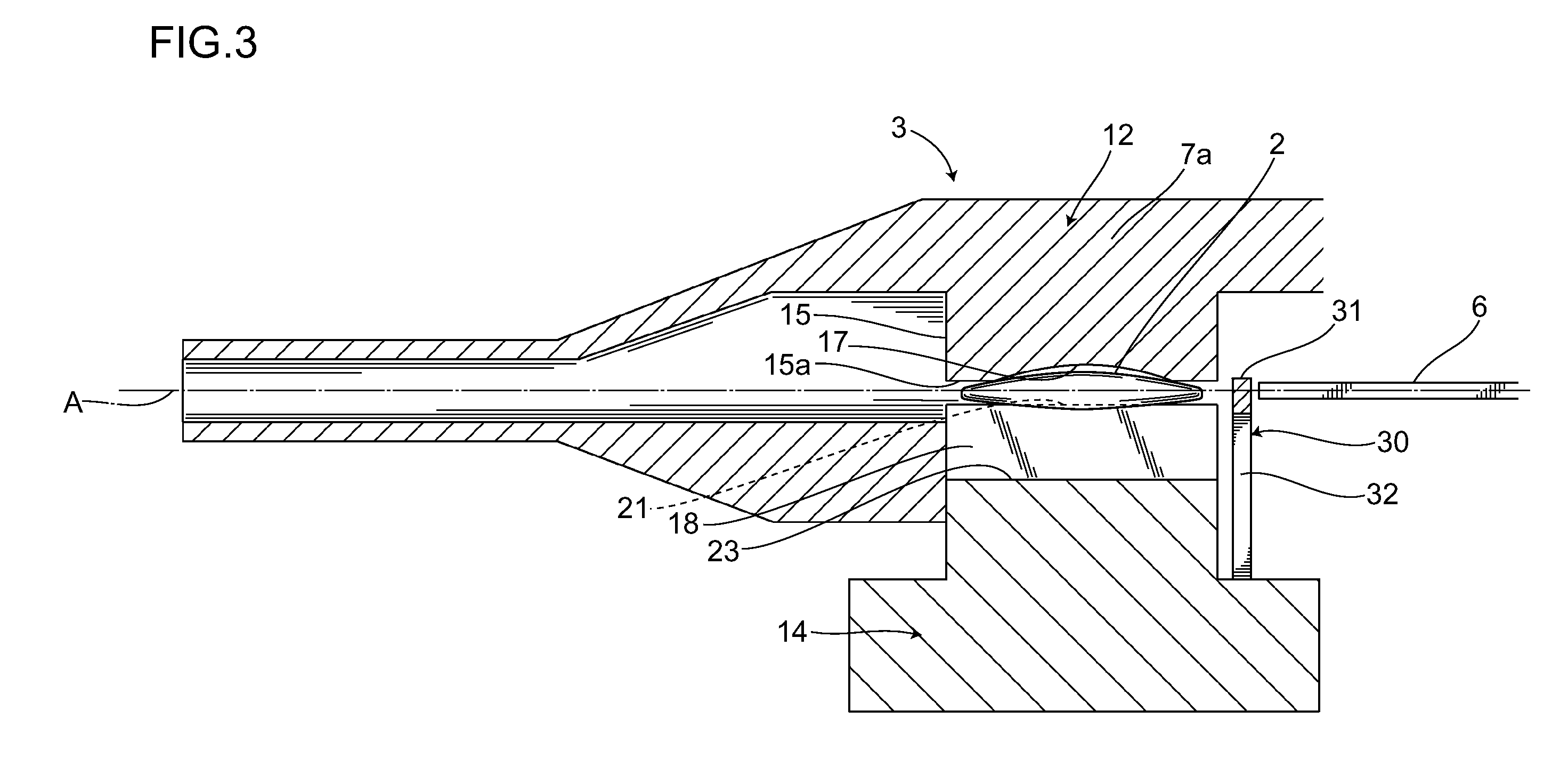

Intraocular lens insertion device

ActiveUS20090043313A1Smooth dischargeSimple wayEye surgeryIntravenous devicesIntraocular lens insertionInsertion device

An intraocular insertion device capable of safely performing discharge operation of a lens by a simpler construction. The intraocular lens insertion device has a body provided with a lens placement section where the lens is placed and a tube section for inserting the lens into an eye and has a plunger for discharging the lens placed on the lens placement section. The lens placement section has an upper holding member and a lower holding member. The upper holding member has a rib projecting on advancement axis A, to the lower side of the lens placement section. The lower holding member has a U-shaped cross-section and is constituted of a left and right pair of uprising sections and a pressing section uniting the uprising sections at their lower ends.

Owner:HOYA CORP

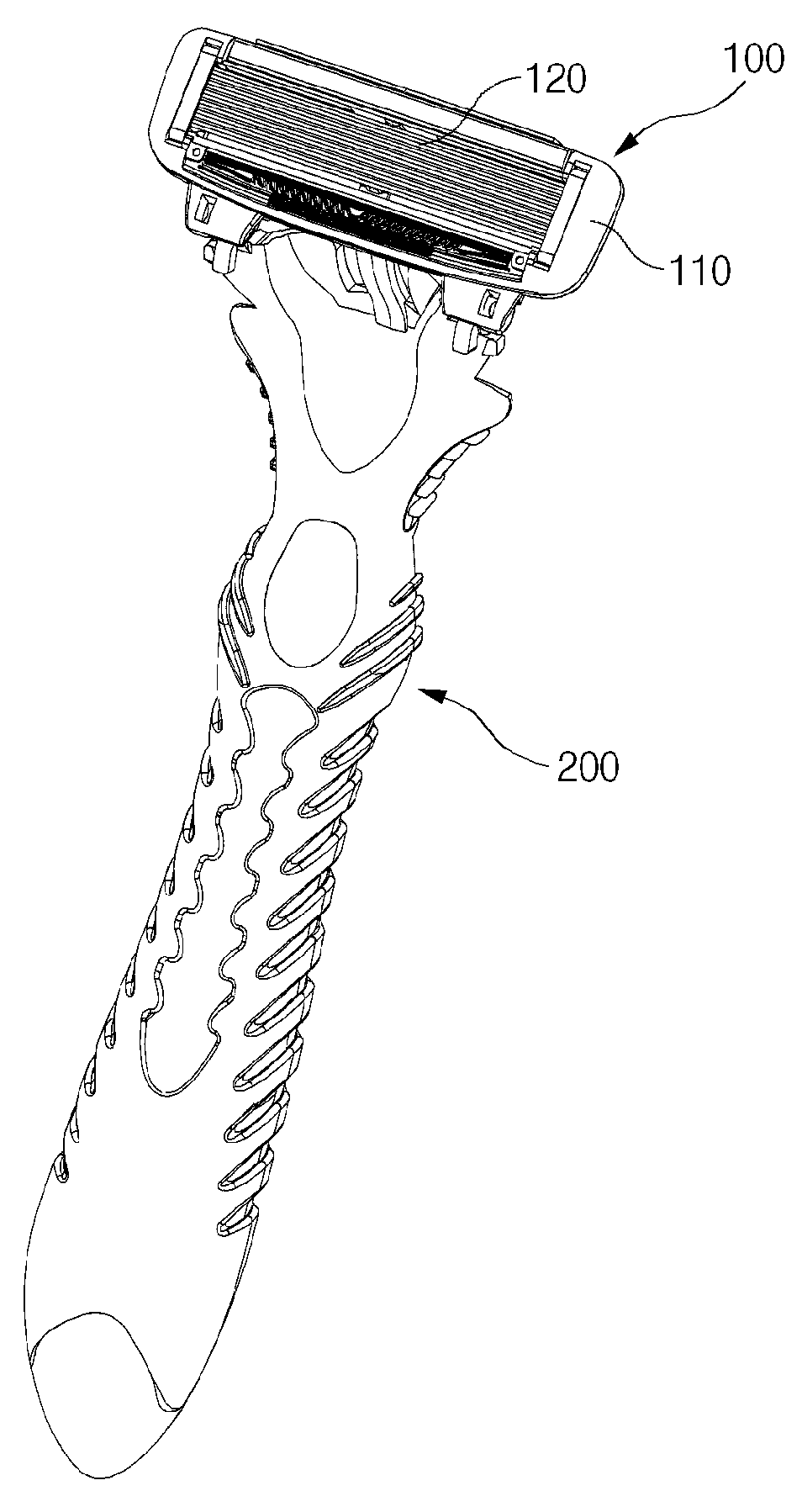

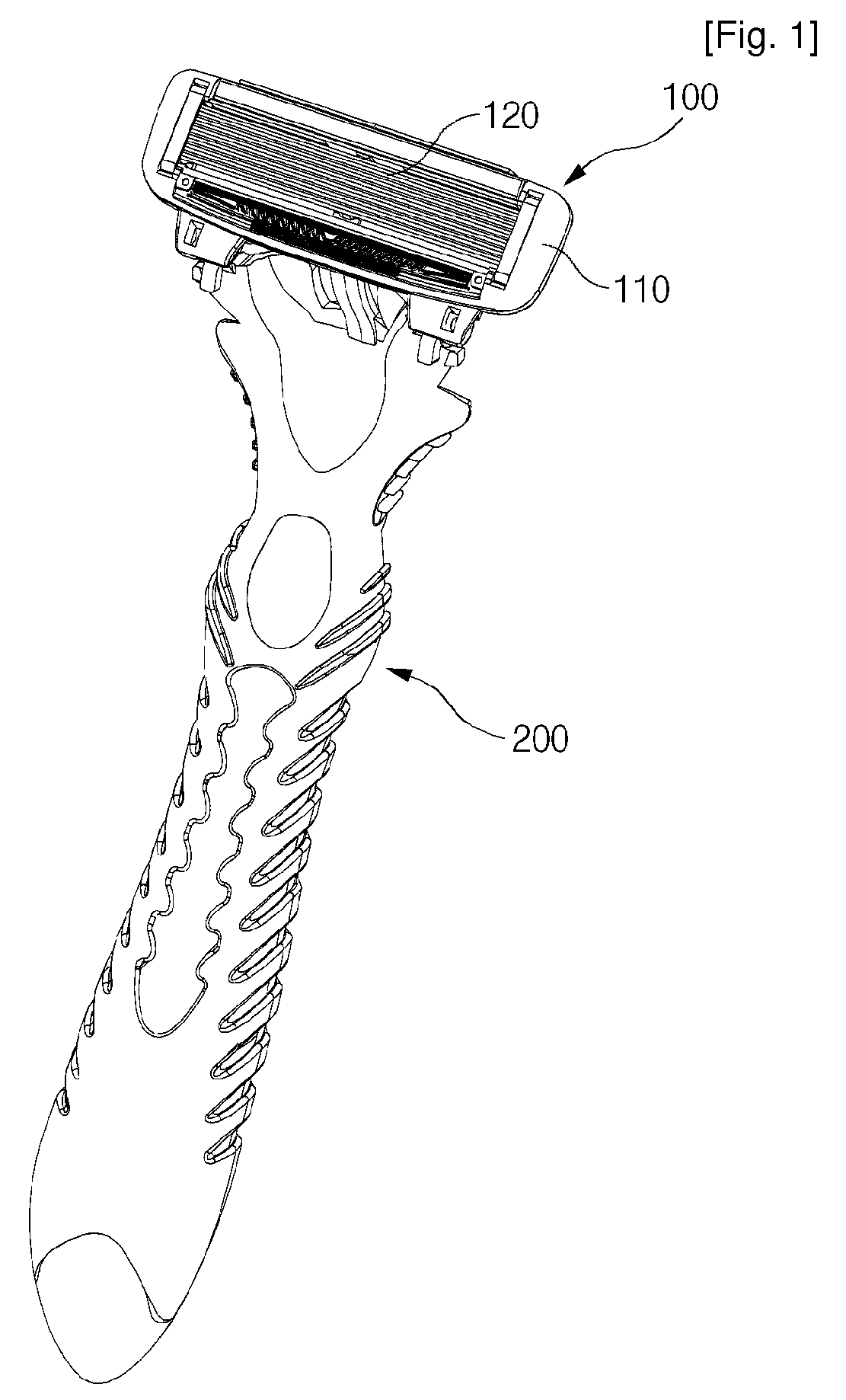

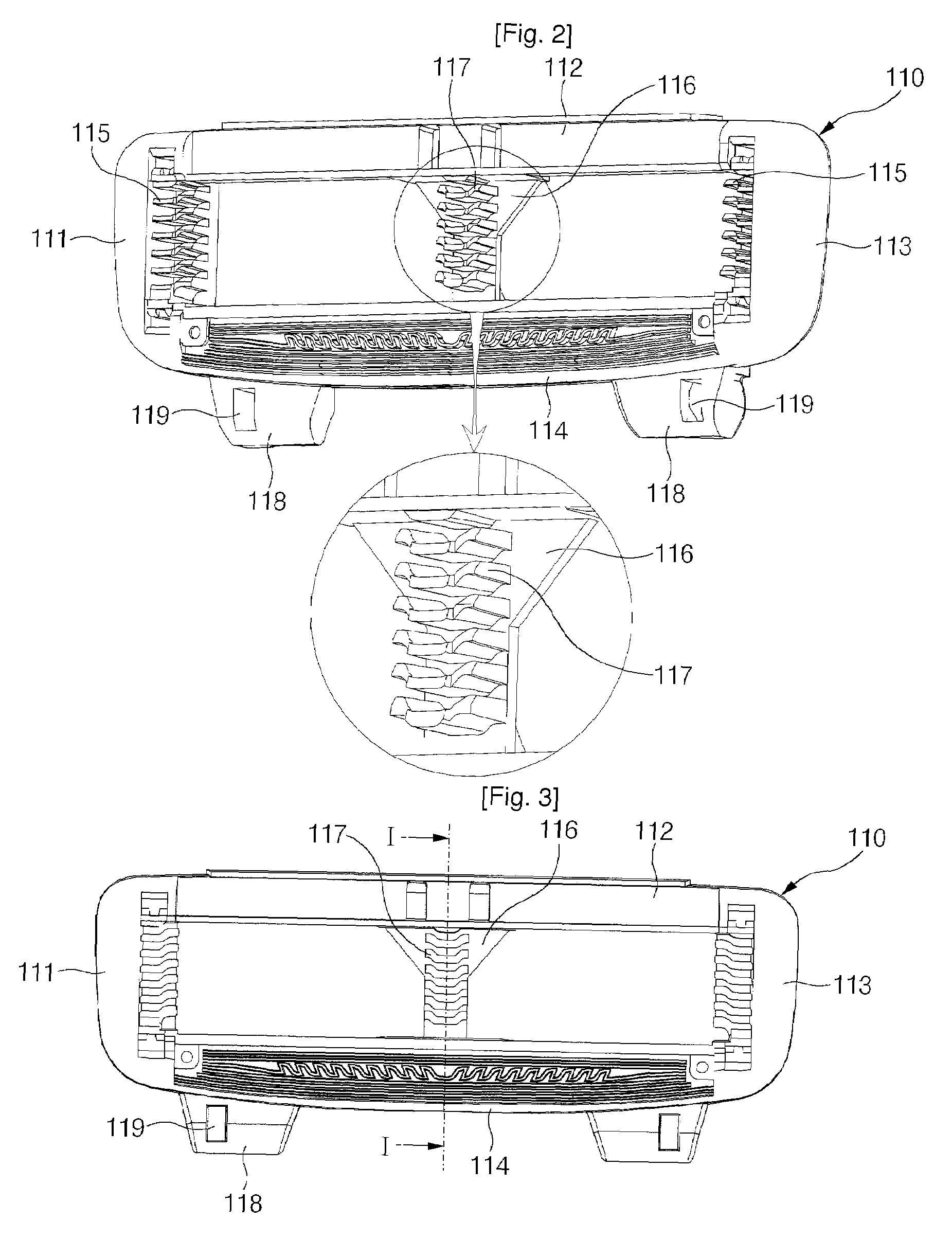

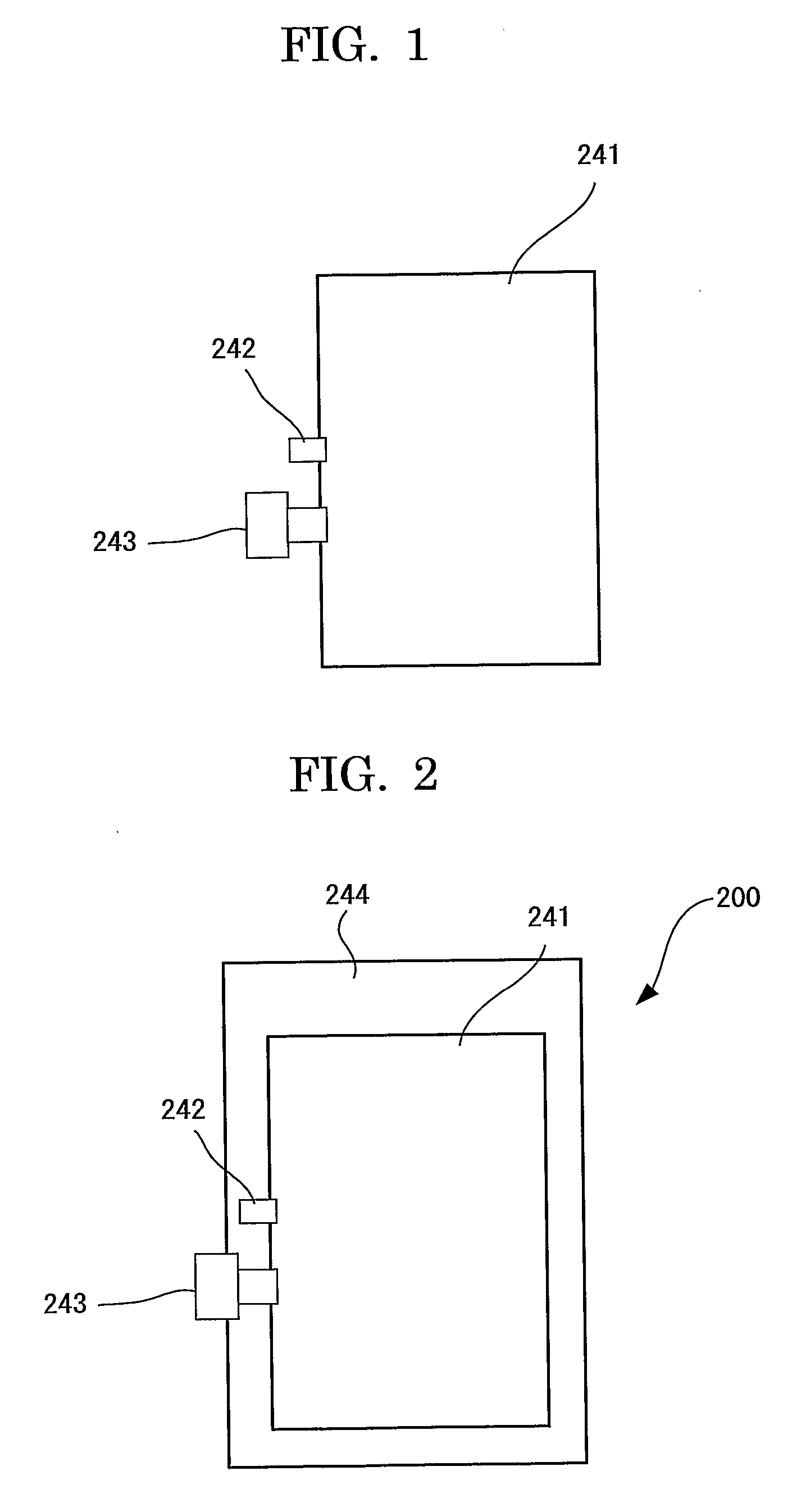

Shaver

ActiveUS20090193659A1Improve washabilitySmooth dischargeMetal working apparatusRazor stropEngineering

Provided is a shaver including a cartridge and a handle body. The cartridge includes a cartridge body formed in a rectangular frame shape; a plurality of blades installed in the cartridge body in the side-to-side direction of the cartridge body, each of the blades having a front portion bent downward; pair of side fixation slots formed on left and right frames of the cartridge body, respectively, so as to fix the left and right ends of each blade; a supporter connecting upper and lower frames of the cartridge body; and an inside fixation slot formed on the supporter so as to fix a portion of each blade. The handle body is coupled to the cartridge body.

Owner:DORCO CO LTD

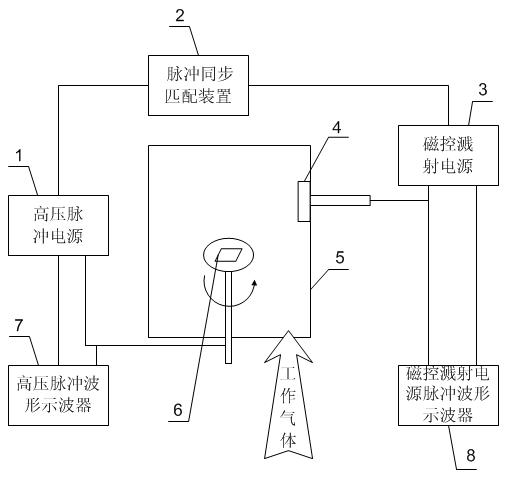

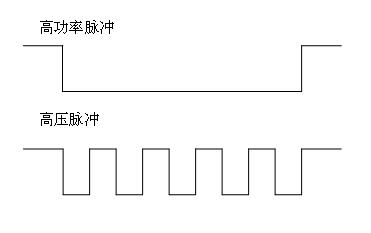

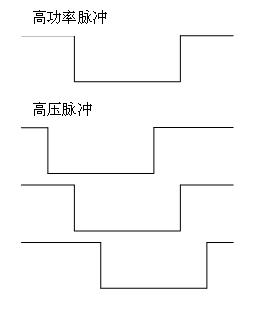

Ion implantation and deposit method of high-power composite pulse by magnetic control sputtering

ActiveCN101838795AIncrease ionization rateHigh bonding strengthVacuum evaporation coatingSputtering coatingPhase differenceHigh pressure

The invention discloses an ion implantation and deposit method of high-power composite pulse by magnetic control sputtering, which belongs to the field of material surface treatment technology and solves the problems of large particles and low film deposit efficiency in an adopted method in which negative high voltage pulse is applied to a workpiece. The method disclosed by the invention comprises the steps of: 1. placing the workpiece on a sample platform in a vacuum chamber, connecting the workpiece with a high-voltage pulse power supply, and connecting a magnetic control sputtering target source with a magnetic control sputtering power supply; and 2. implanting and depositing: when the vacuum degree in the vacuum chamber is lower than 10-2Pa, introducing working gas until the vacuum degree in the vacuum chamber reaching 0.011-10 Pa, starting up the high-voltage pulse power supply, adjusting the voltage value of output pulse of the high-voltage pulse power supply to 0.5-100kV, adjusting the pulse frequency to 0-1000Hz, adjusting the pulse width to 0-500 microseconds, starting up the magnetic control power supply, adjusting required process parameters by direct-current luminance pre-ionization, and controlling the voltage phase difference of the two power supplies to be -1000-1000 microseconds to perform the ion implantation and deposit.

Owner:HARBIN INST OF TECH

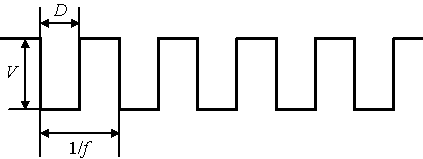

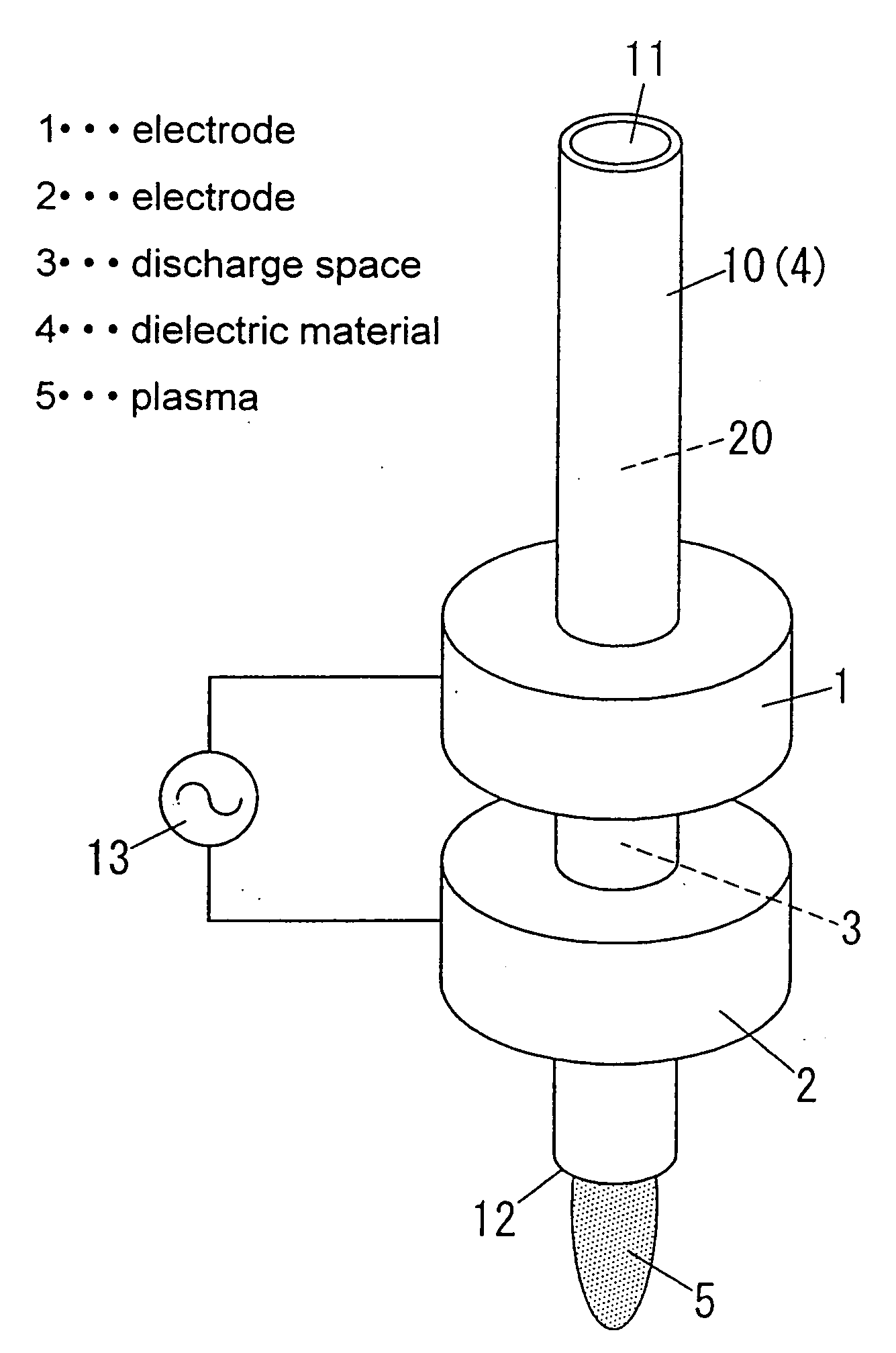

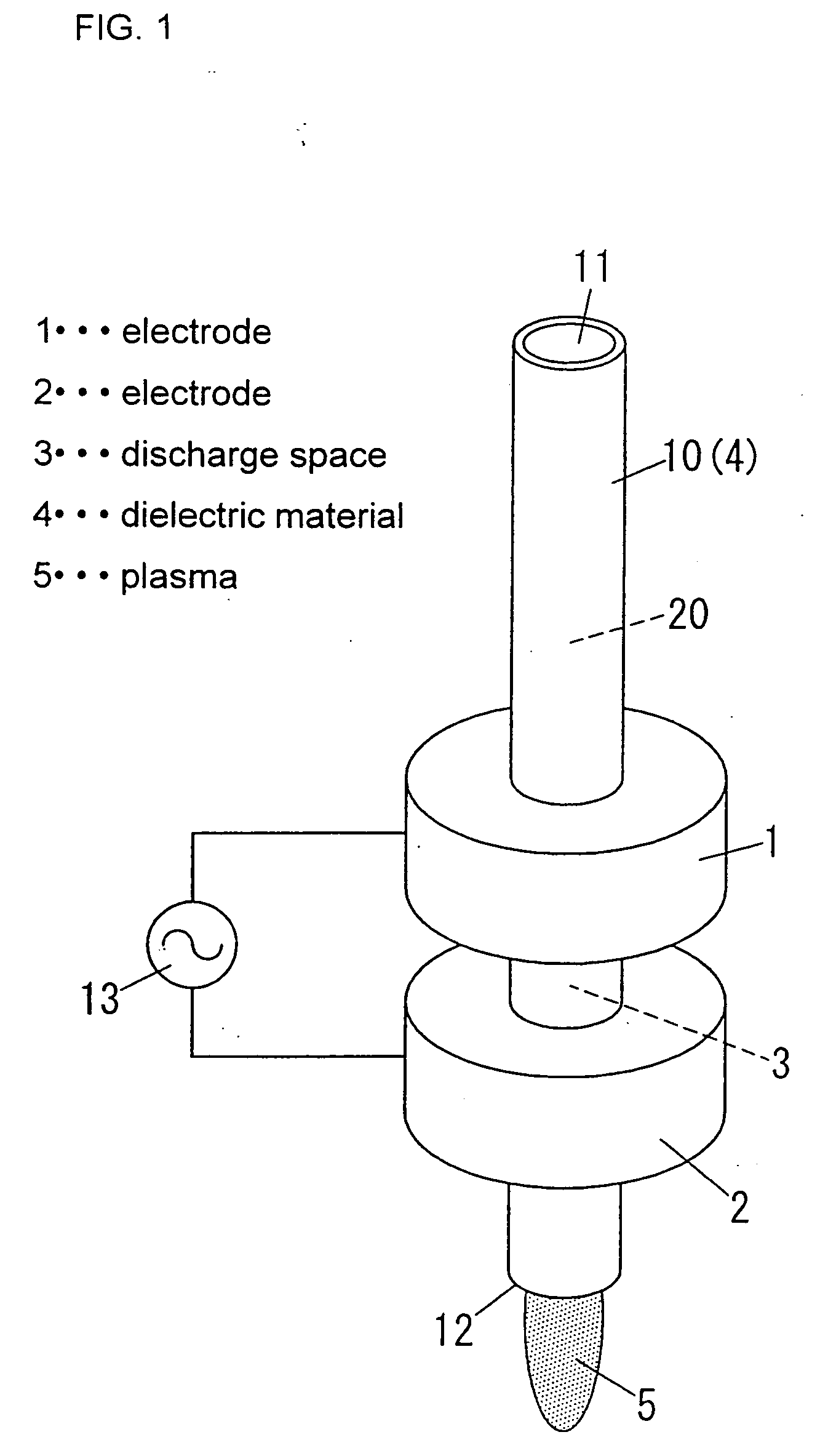

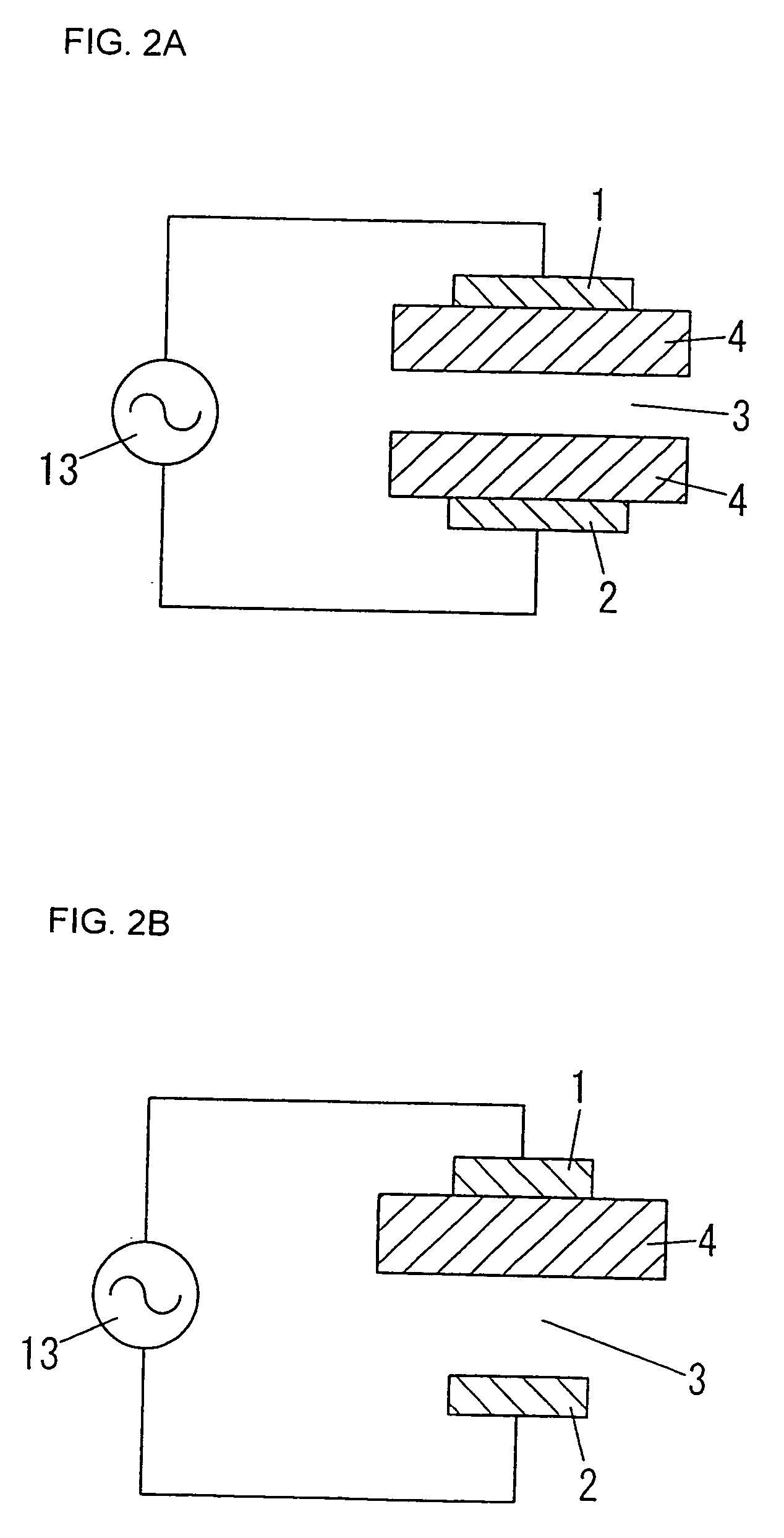

Plasma processing device and plasma processing method

InactiveUS20050016456A1Smooth dischargeSufficient treatment capabilityChemical vapor deposition coatingPlasma techniqueElectricityWave shape

A plasma treatment apparatus and method are provided, which have the capability of maintaining a stable discharge, achieving a sufficient plasma treatment, and reducing plasma temperature. In this apparatus, electrodes are arranged to define a discharge space therebetween, and a dielectric material is disposed at a discharge-space side of at least one of the electrodes. A voltage is applied between the electrodes, while a plasma generation gas being supplied into the discharge space, to develop the discharge in the discharge space under a pressure substantially equal to atmospheric pressure, and provide the plasma generated by the discharge from the discharge space. A waveform of the voltage applied between the electrodes is an alternating voltage waveform without rest period. At least one of rising and falling times of the alternating voltage waveform is 100 μsec or less. A repetition frequency is in a range of 0.5 to 1000 kHz. An electric-field intensity applied between the electrodes is in a range of 0.5 to 200 kV / cm.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

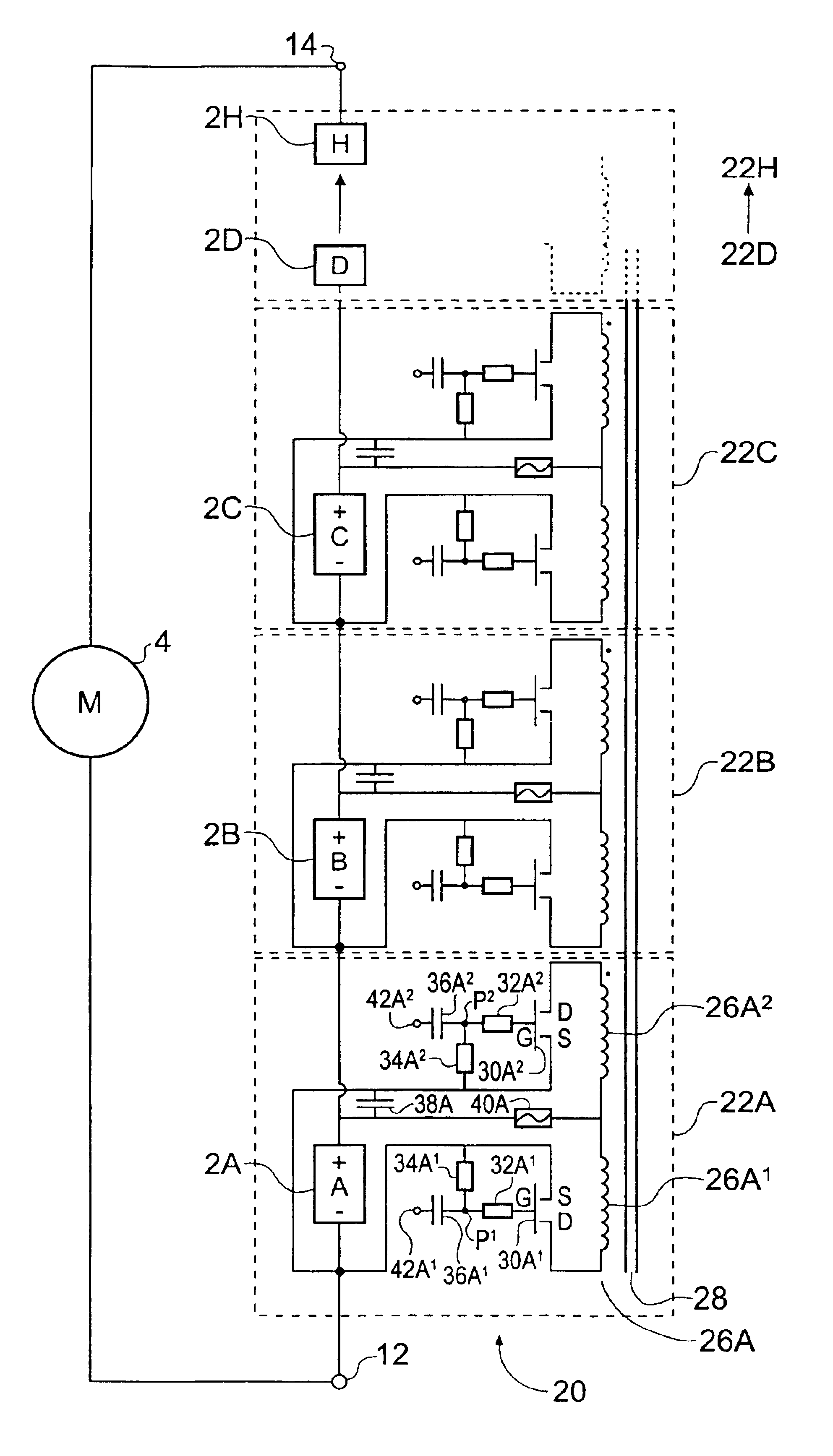

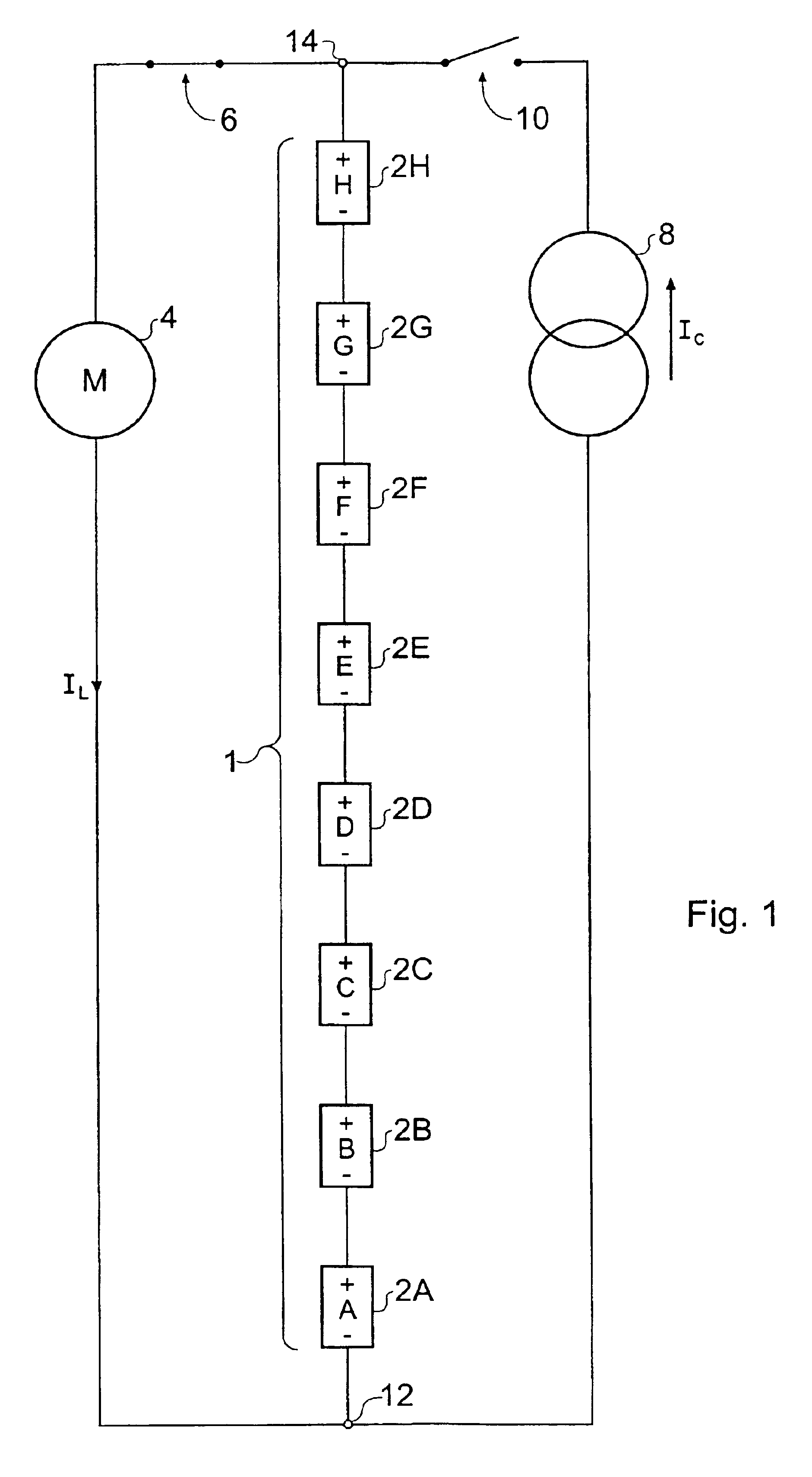

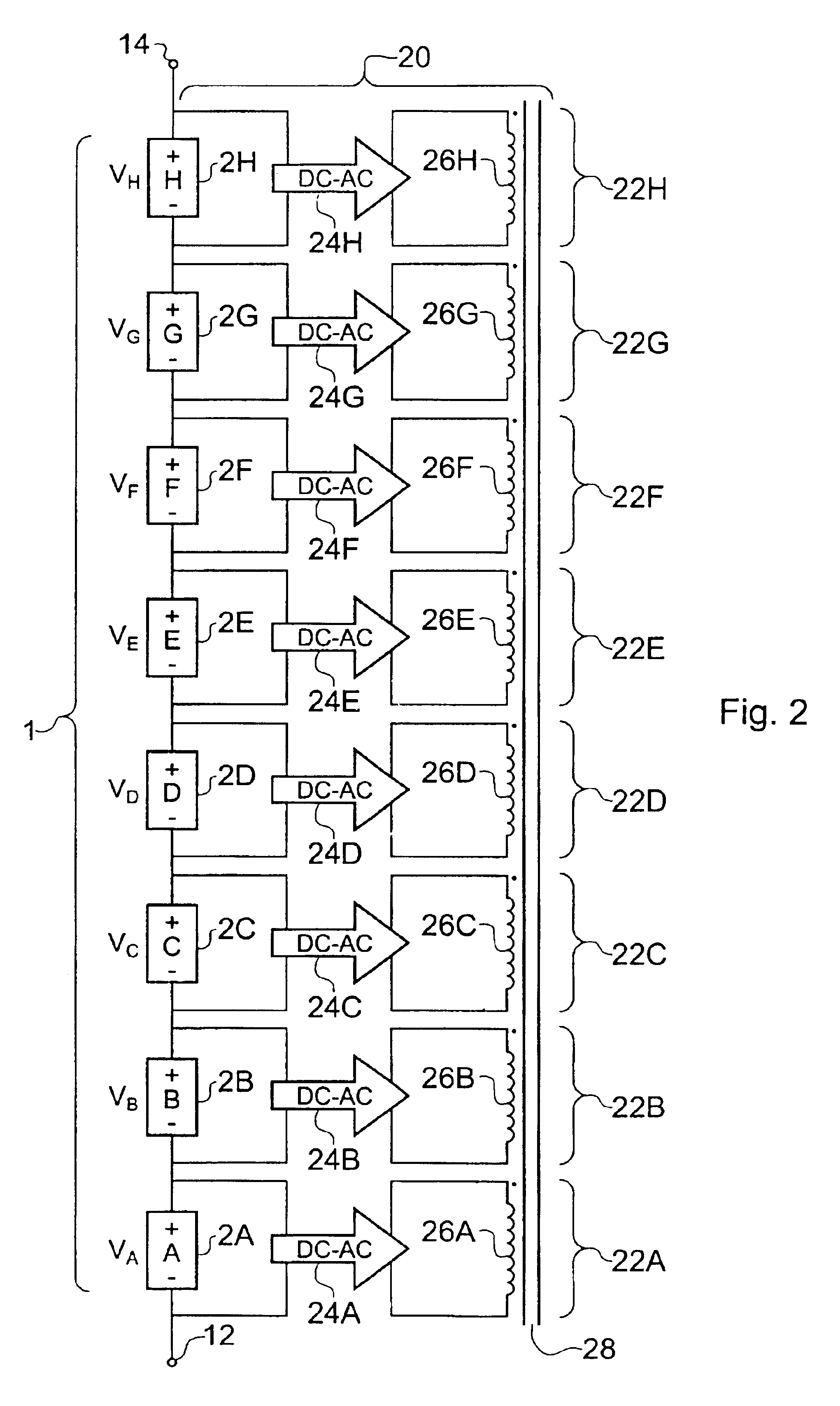

Cell equalizing circuit

InactiveUS7061207B2Guaranteed maximum utilizationMaximize battery lifeCharge equalisation circuitElectric powerLithiumCharge current

An electric circuit for equalizing voltages between serially arranged cells. The circuit is operable to generate AC voltages at amplitudes dependent on the DC voltages of the received cells. The AC voltages are all connected to an inductive coupling circuit. The inductive coupling allows higher-voltage cells to induce a recharging current flow in lower voltage cells and so equalize the cell voltages. The circuit also operates to ensure that cell voltages are maintained in equilibrium during charging or discharging of received cells, irrespective of the individual charging and discharging characteristics of the cells. The circuit thus prevents individual cells in a battery from being over-charged or over-discharged and allows more efficient use of the full capacity of a battery without risking damage to the individual cells. The cell equalizing circuit is thus especially useful for rechargeable cells, such as lithium-ion cells, which are sensitive to damage by over-charging and over-discharging.

Owner:H2EYE INT

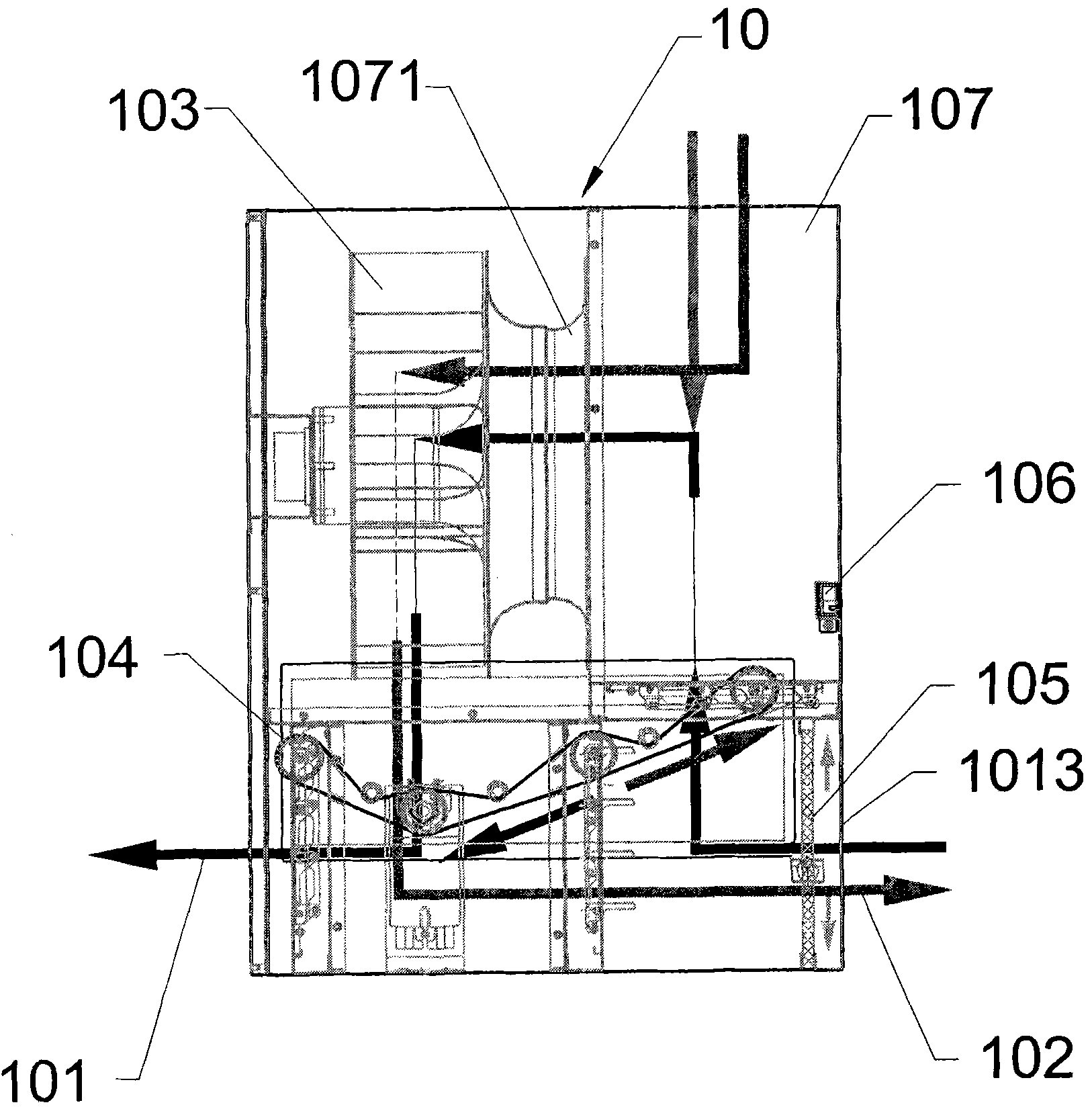

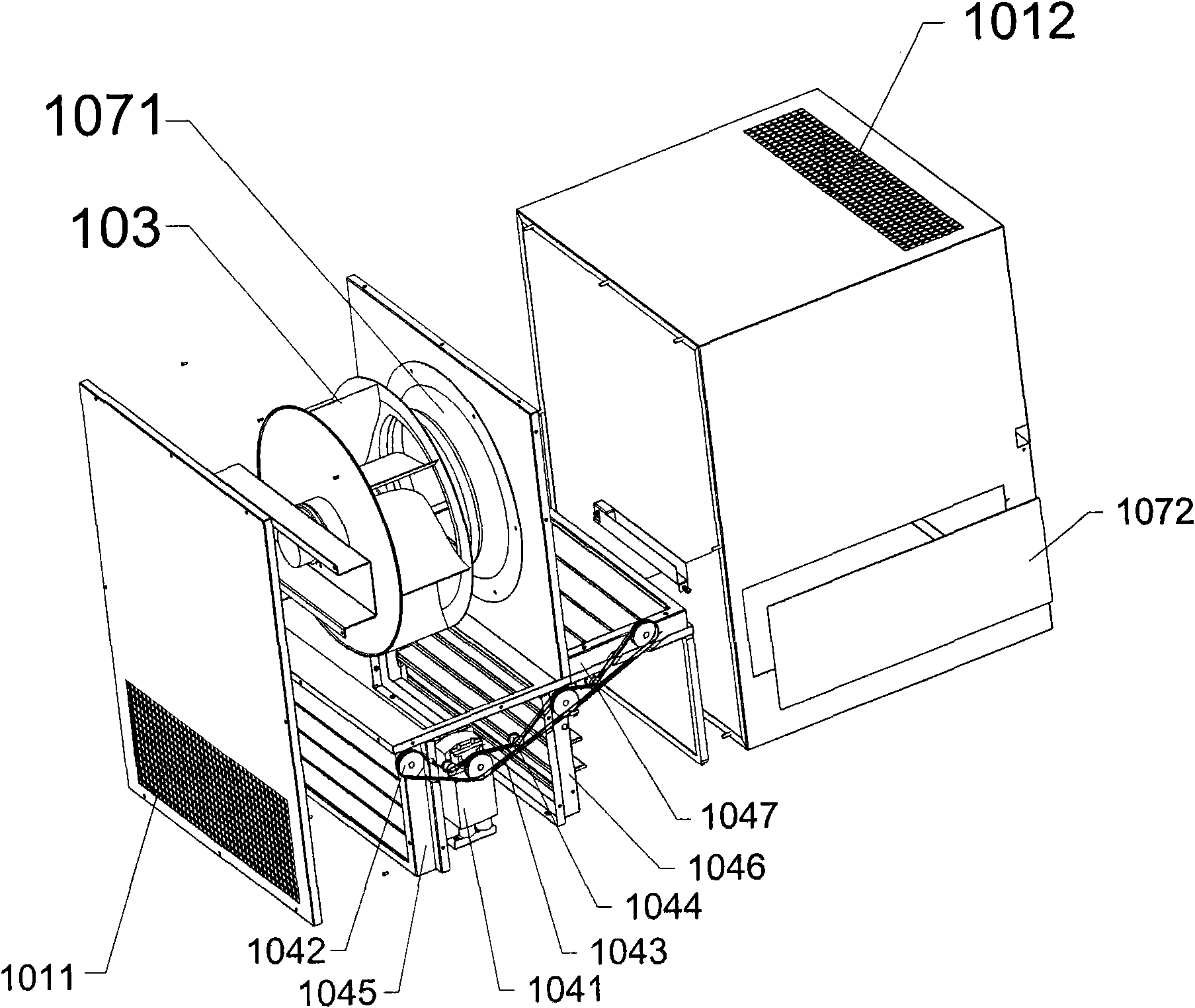

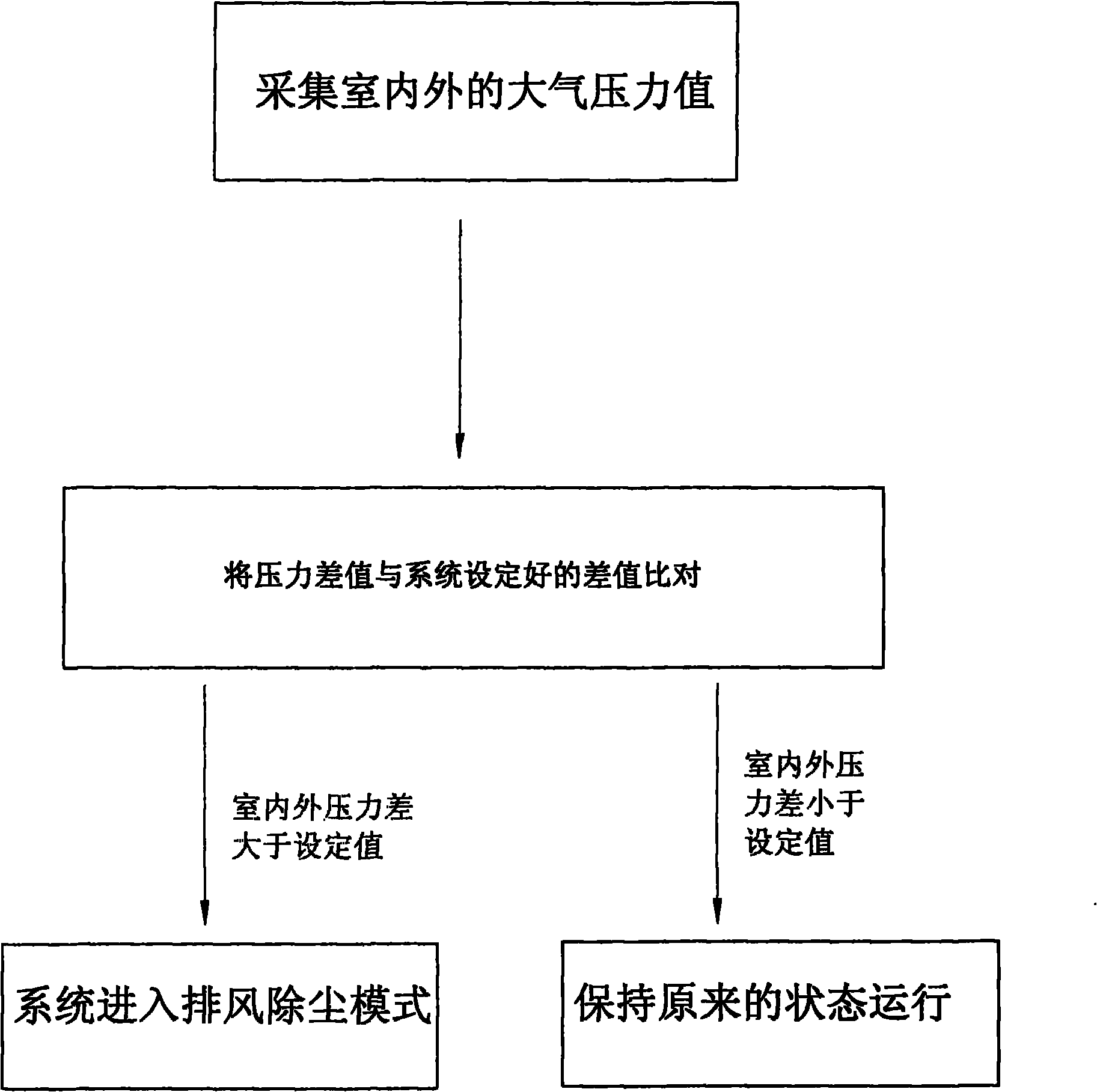

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

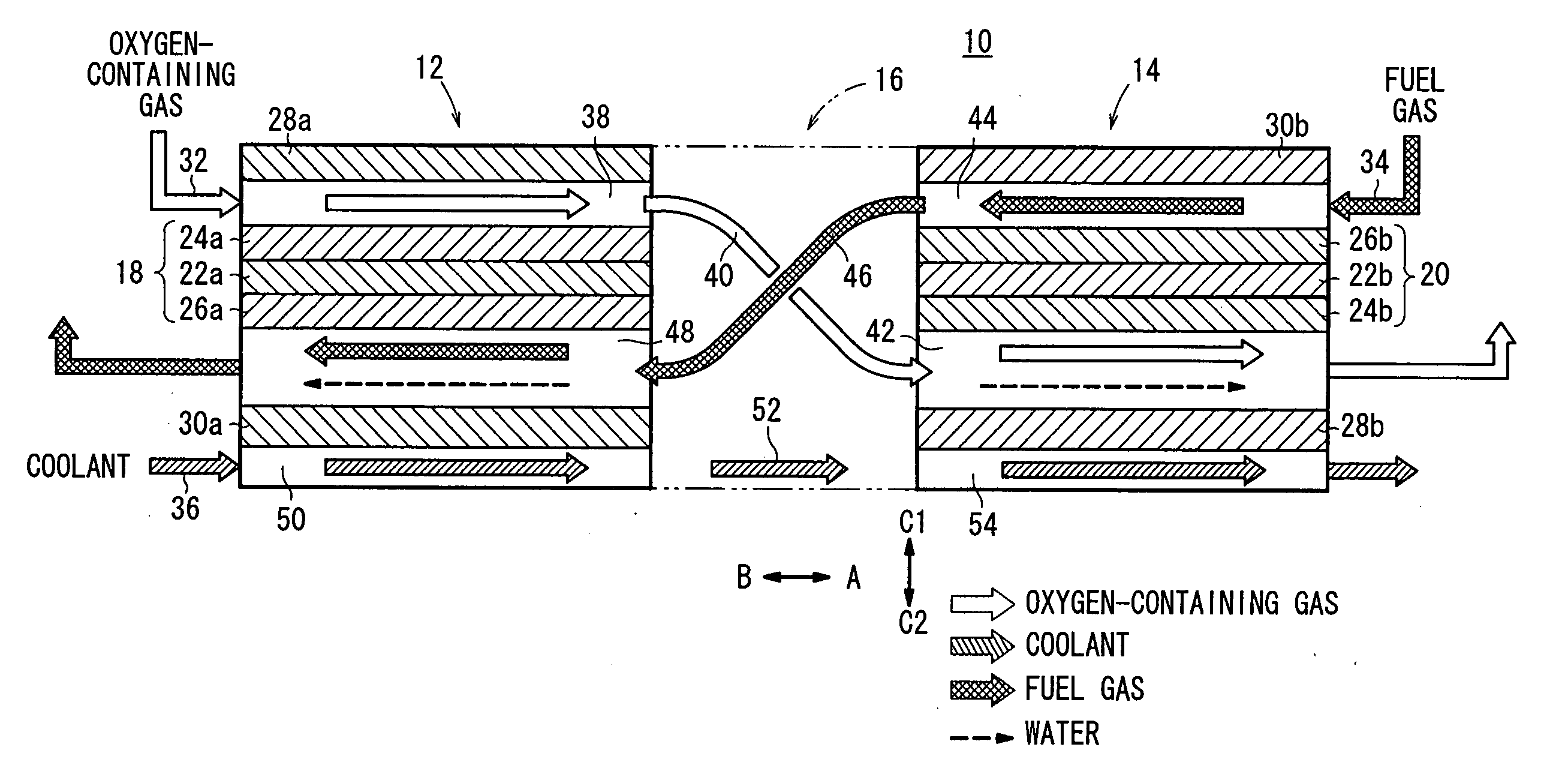

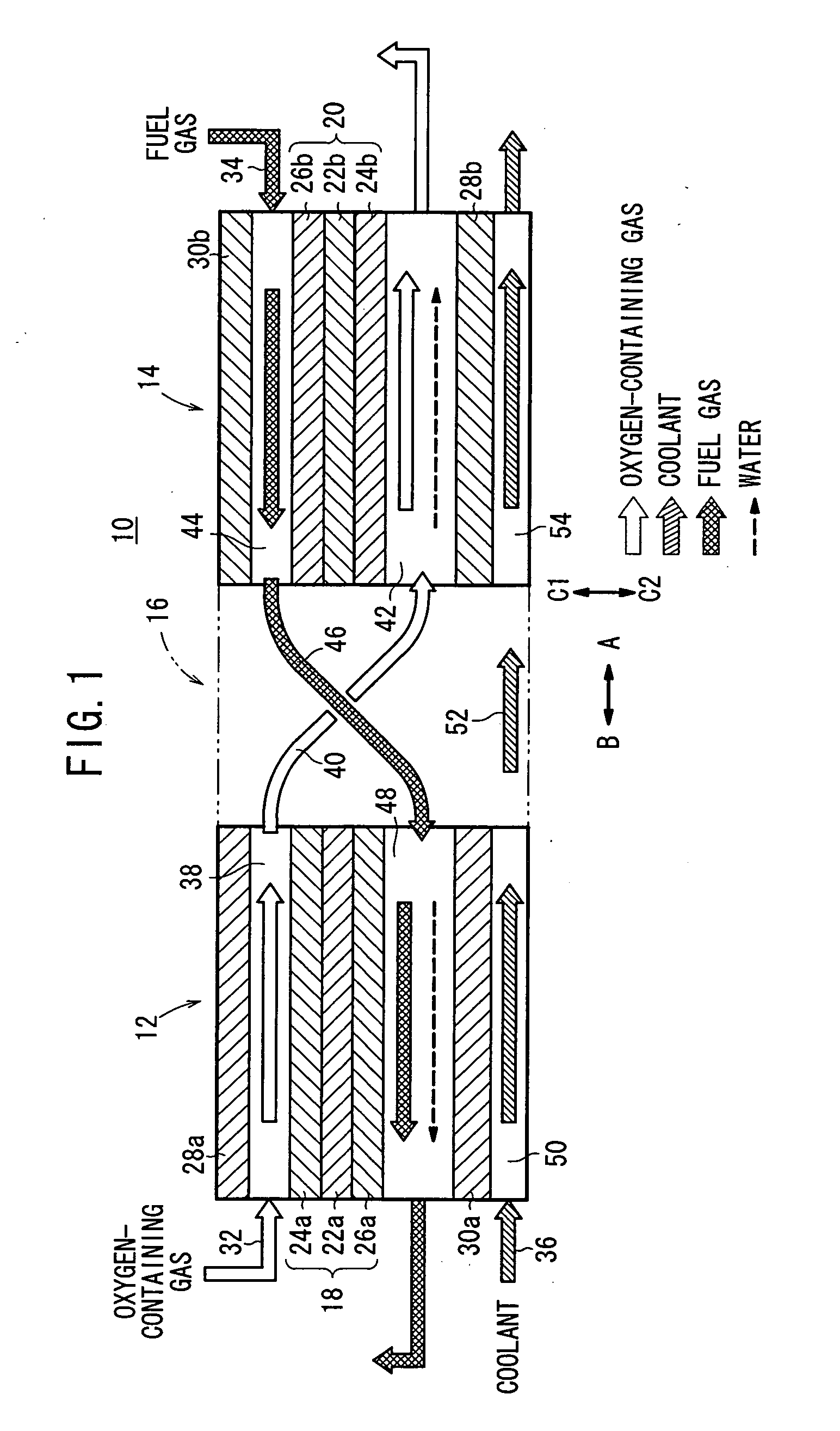

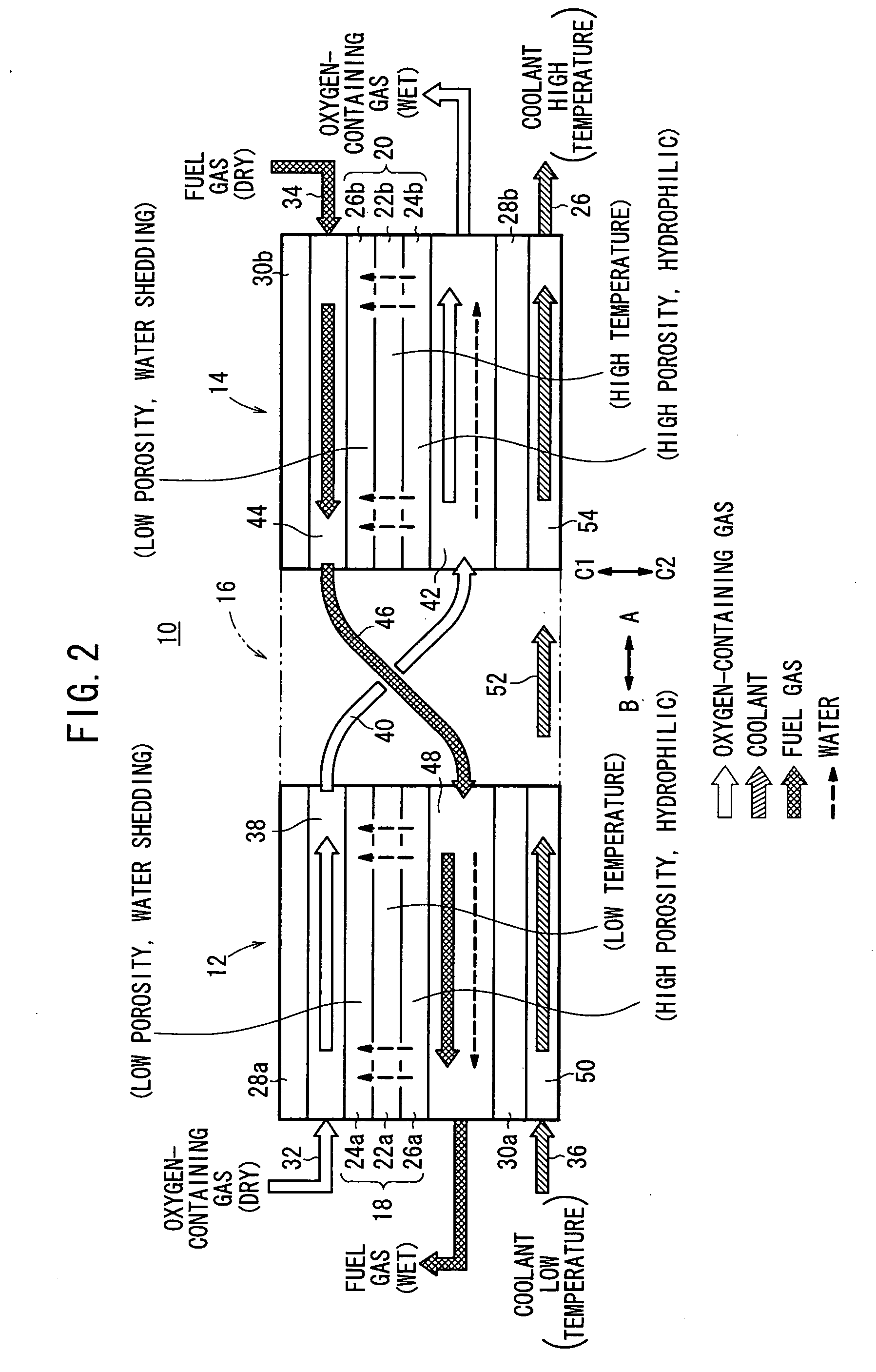

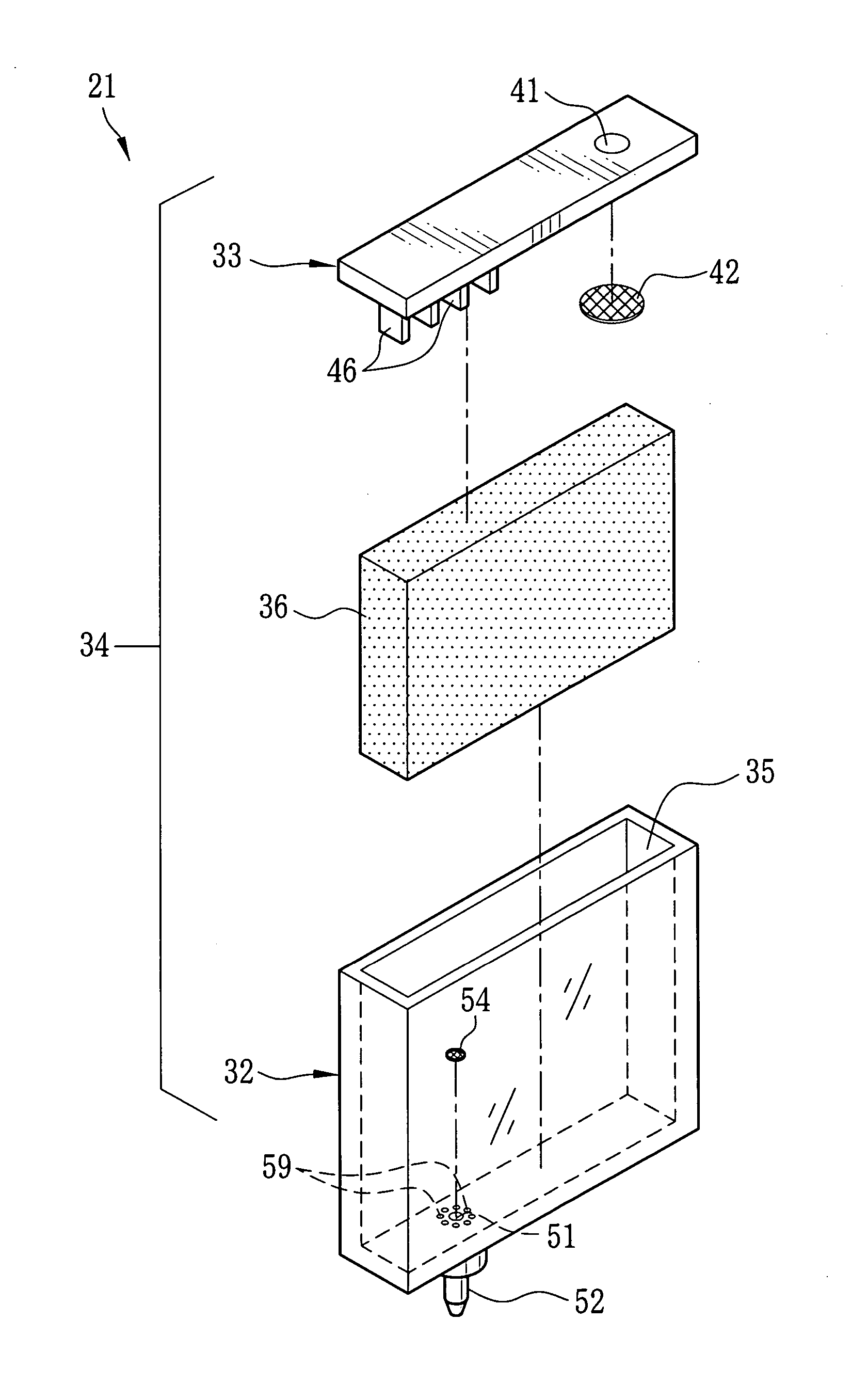

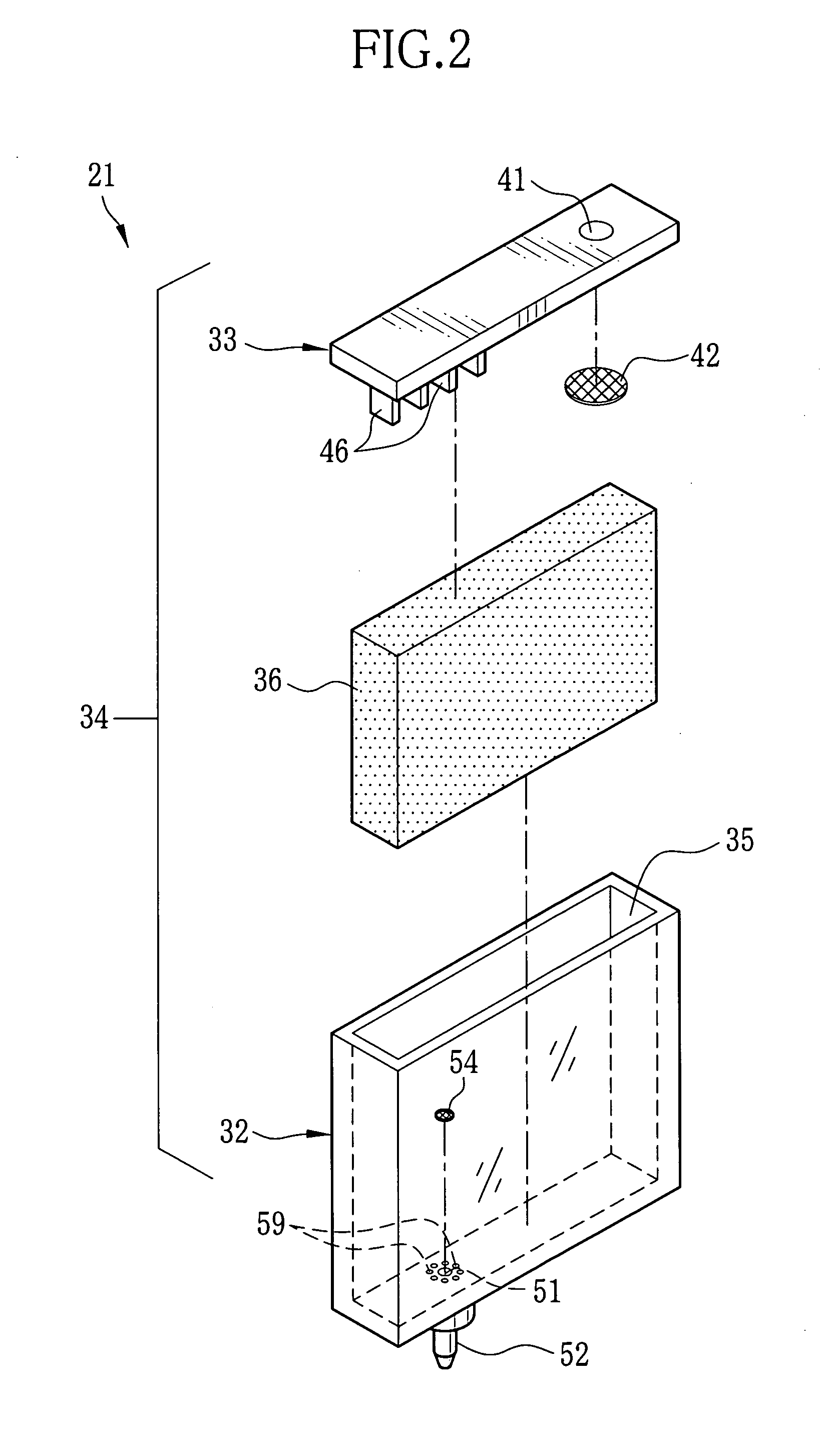

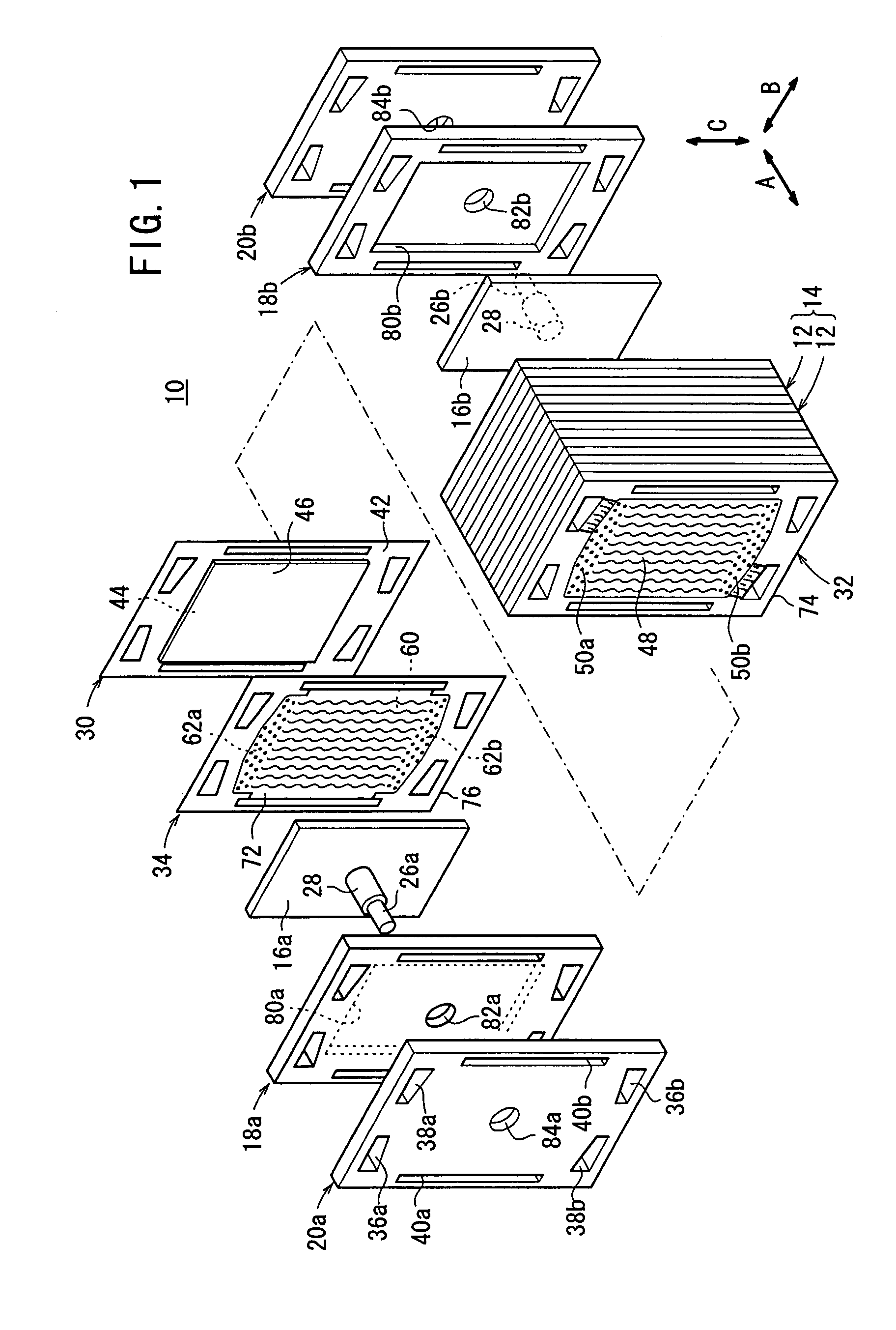

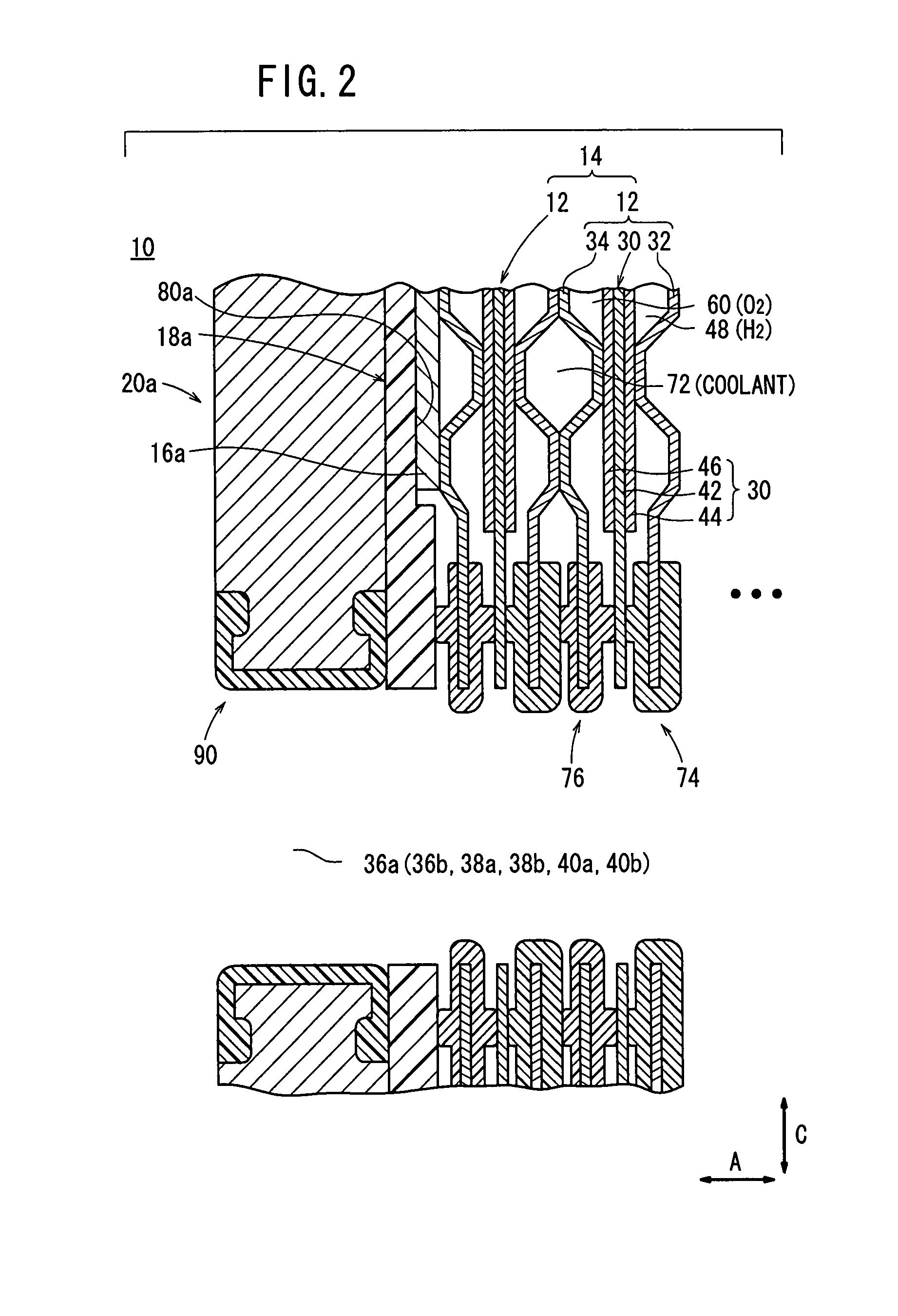

Solid high polymer type cell assembly

InactiveUS20050233181A1Increase flow rateReduce concentrationFuel cells groupingWater management in fuel cellsCell assemblyOxygen

A cell assembly (10) includes a first unit cell (12) and a second unit cell (14). The first unit cell (12) and the second unit cell (14) are juxtaposed such that electrode surfaces of the first unit cell (12) and electrode surfaces of the second unit cell (14) are aligned in parallel with each other. An oxygen-containing gas flow passage (32) includes a first oxygen-containing gas passage (38) in the first unit cell (12), an oxygen-containing gas connection passage (40) in a connection passage member (16), and a second oxygen-containing gas passage (42) in the second unit cell (14). The first oxygen-containing gas passage (38), the oxygen-containing gas connection passage (40), and the second oxygen-containing gas passage (42) are connected serially from the first unit cell (12) to the second unit cell (14).

Owner:HONDA MOTOR CO LTD

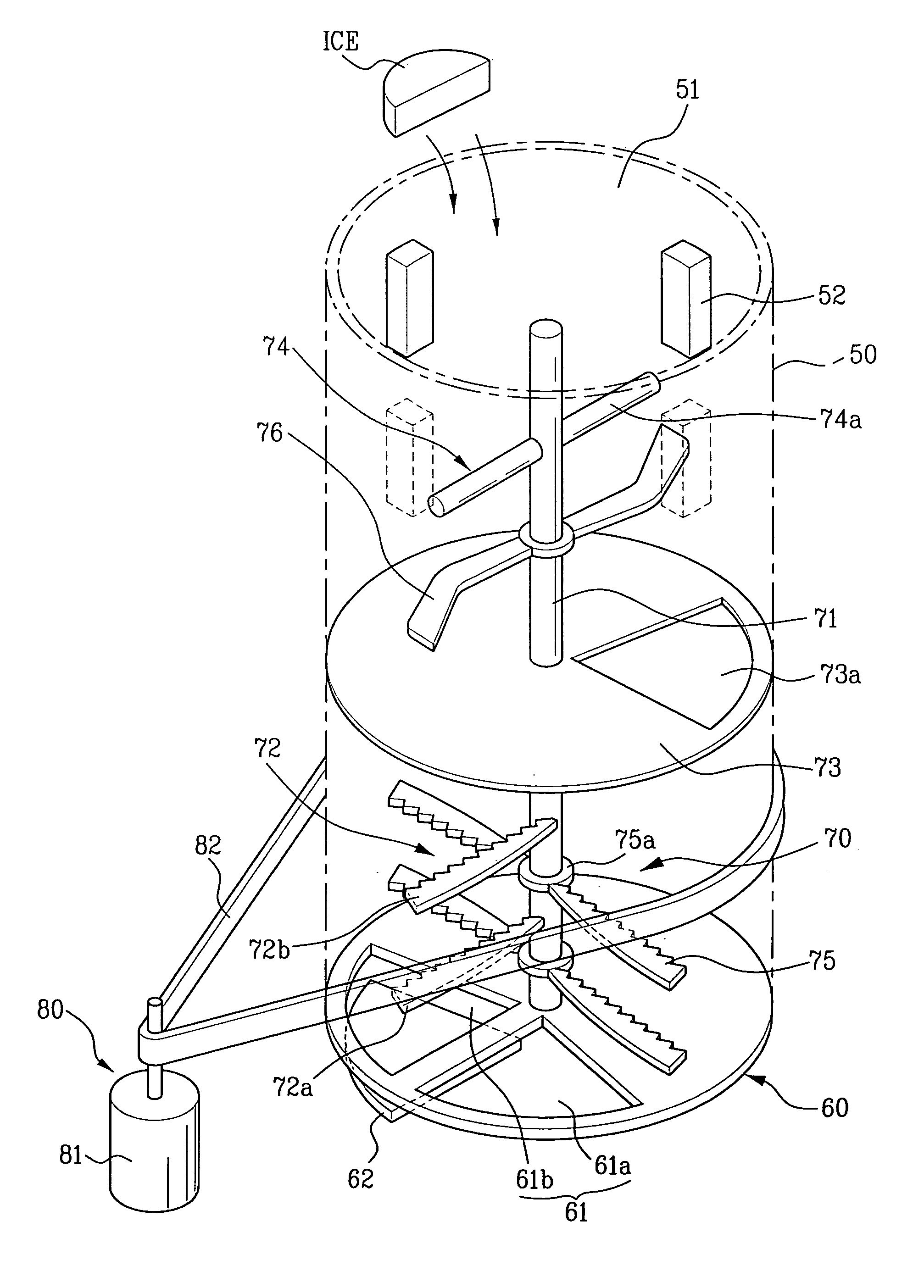

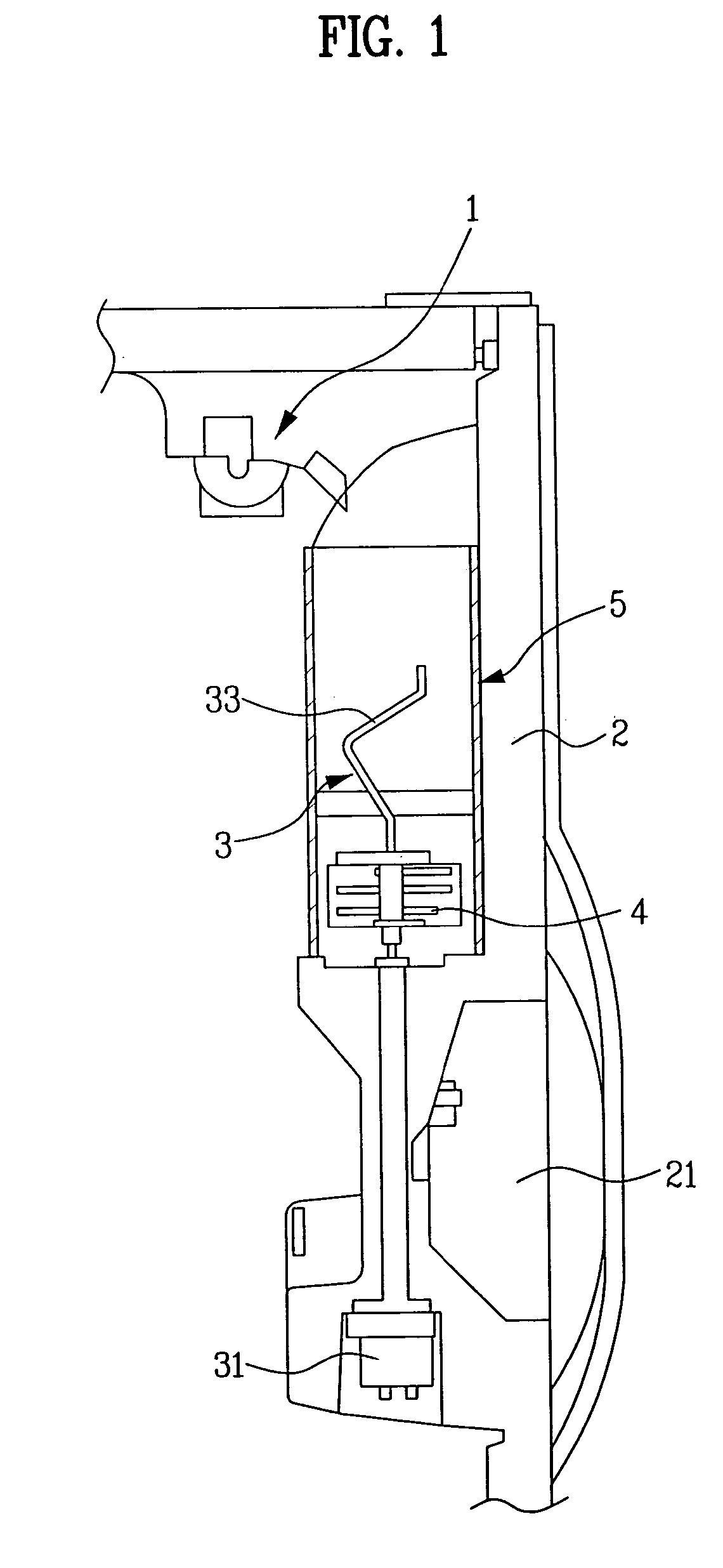

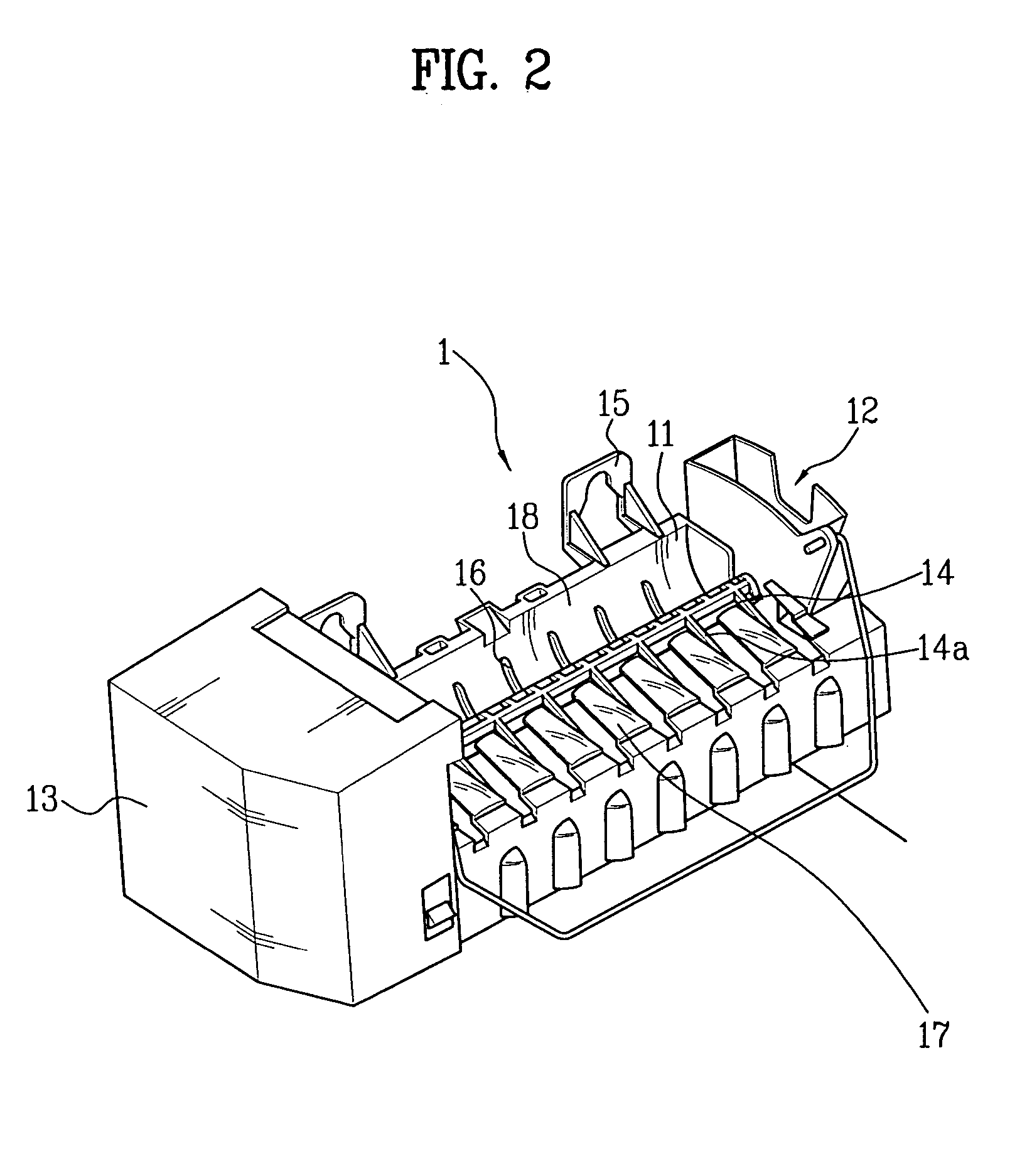

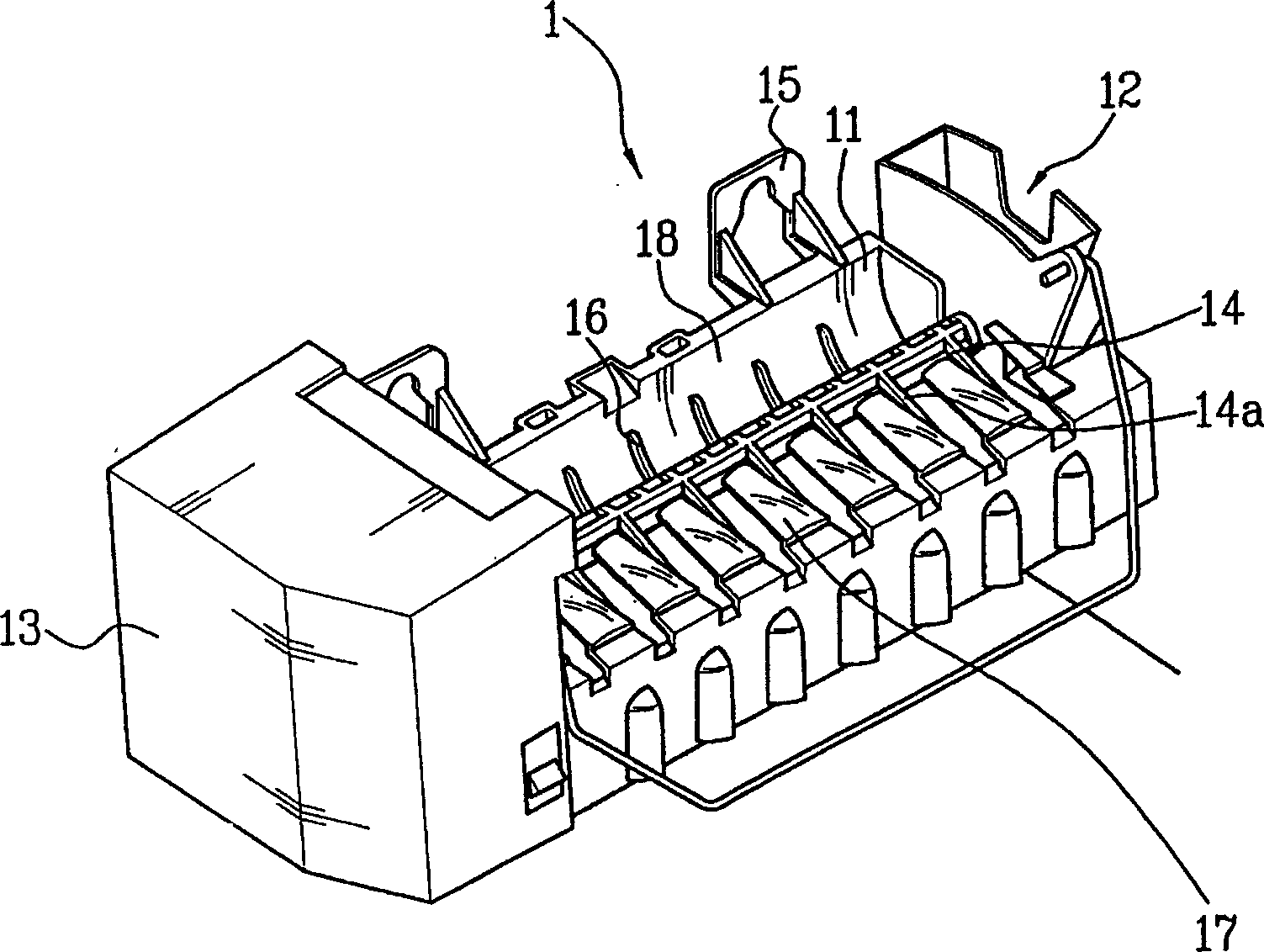

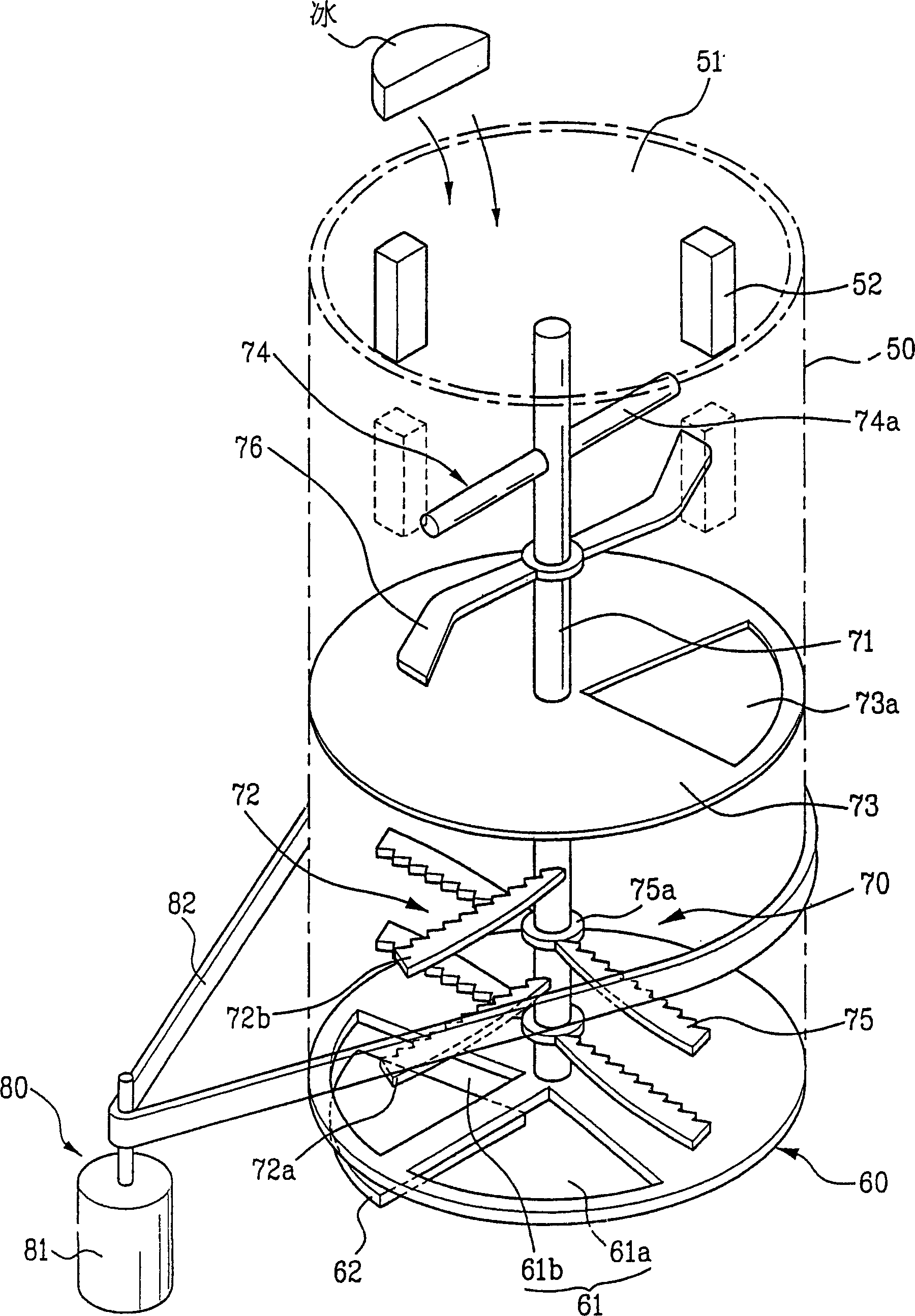

Ice bank of ice-making device for refrigerator

InactiveUS7111473B2Prevent fallingSmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

An ice bank of an ice-making device for a refrigerator is disclosed, for smooth crush and discharge of ice, which includes a housing for storing ice made in an icemaker, and provided rotatably to apply the power to the stored ice at a rotation direction; an ice discharger having at least one hole through which the ice is discharge to the external; a crusher provided in the inside of the housing, the crusher guiding the stored ice to the hole of the ice discharge and crushing the ice as a predetermined size before discharging the ice to the hole according to a user's select; and rotating means for rotating the housing. Also, the crusher includes fixed crushing means fixed to the inside of the housing, and rotation crushing means rotated for being synchronized with the housing so as to crush the ice before discharging the ice to the external according to a user's select.

Owner:LG ELECTRONICS INC

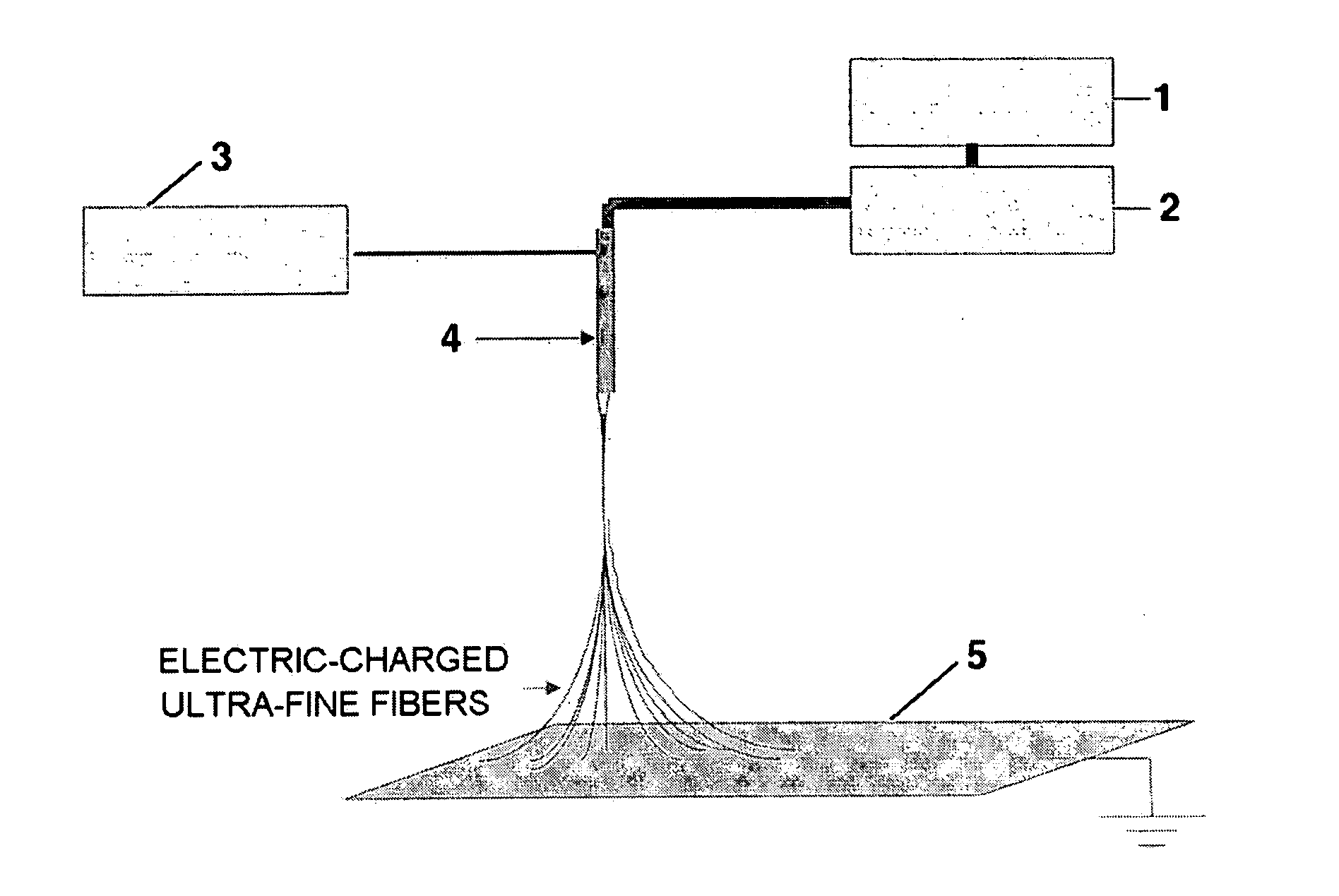

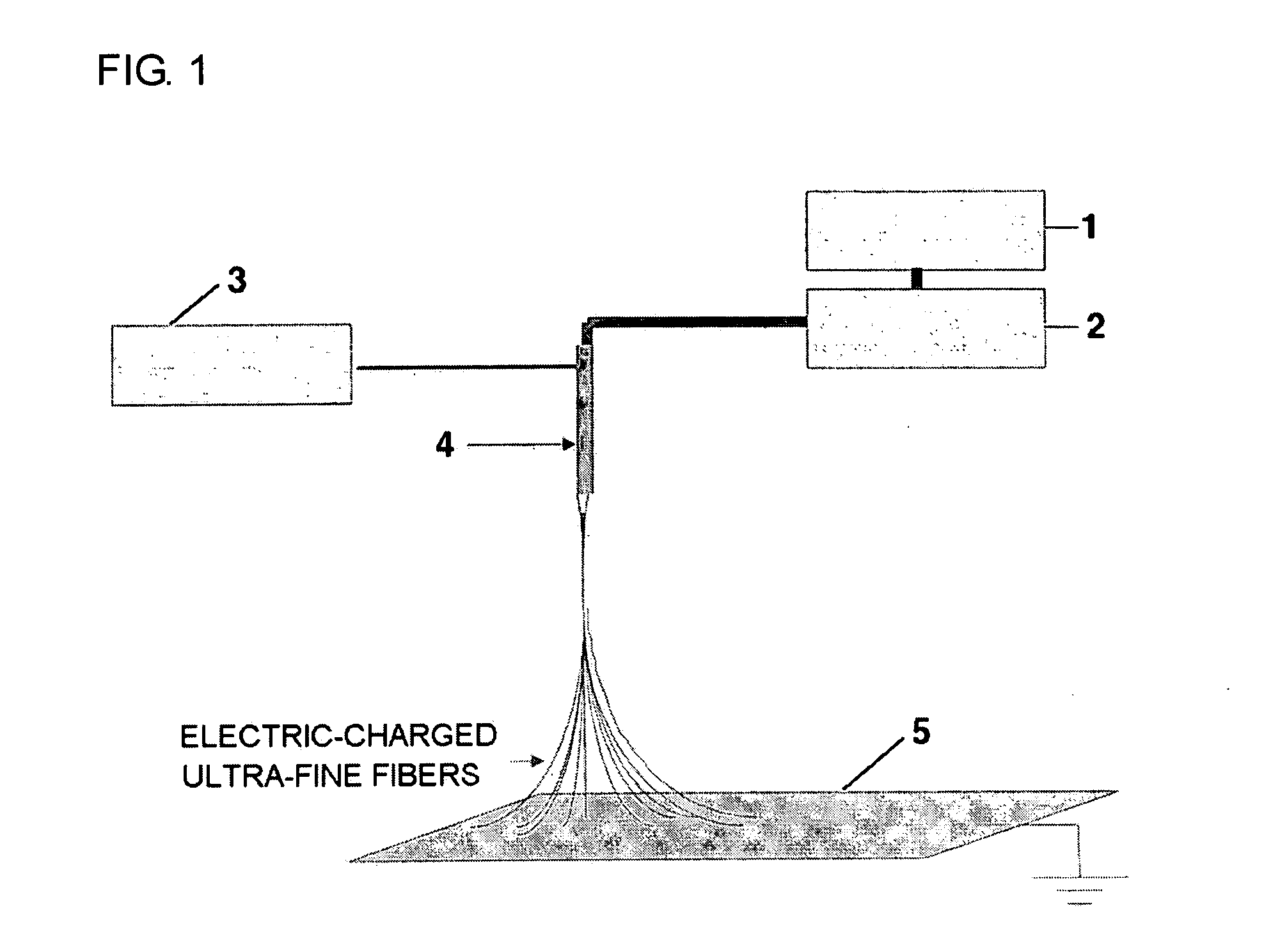

Lithium secondary battery comprising fine fibrous porous polymer membrane and fabrication method thereof

InactiveUS20050053840A1Simple processHigh suppression characteristicsMaterial nanotechnologyFinal product manufactureHybrid typeUltra fine

Disclosed are a lithium secondary battery comprising a fibrous membrane / electrode composite in which an ultra-fine fibrous porous polymer membrane is combined with an electrode into one body and a hybrid type polymer electrolyte in which pores of the ultra-fine fibrous porous polymer membrane is impregnated with an organic electrolyte solution or a polymer electrolyte; and a fabrication method thereof.

Owner:SAMSHIN CREATION

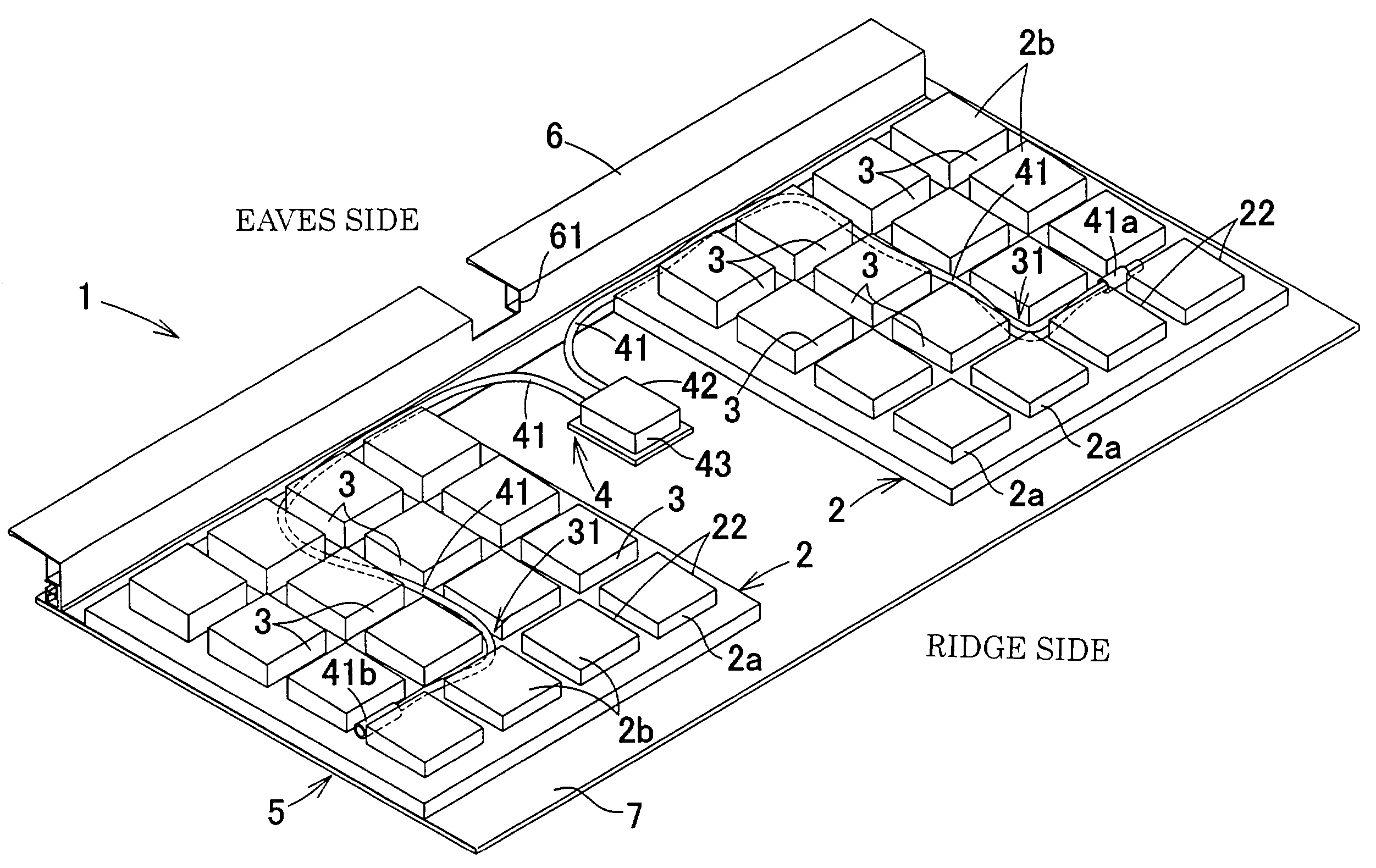

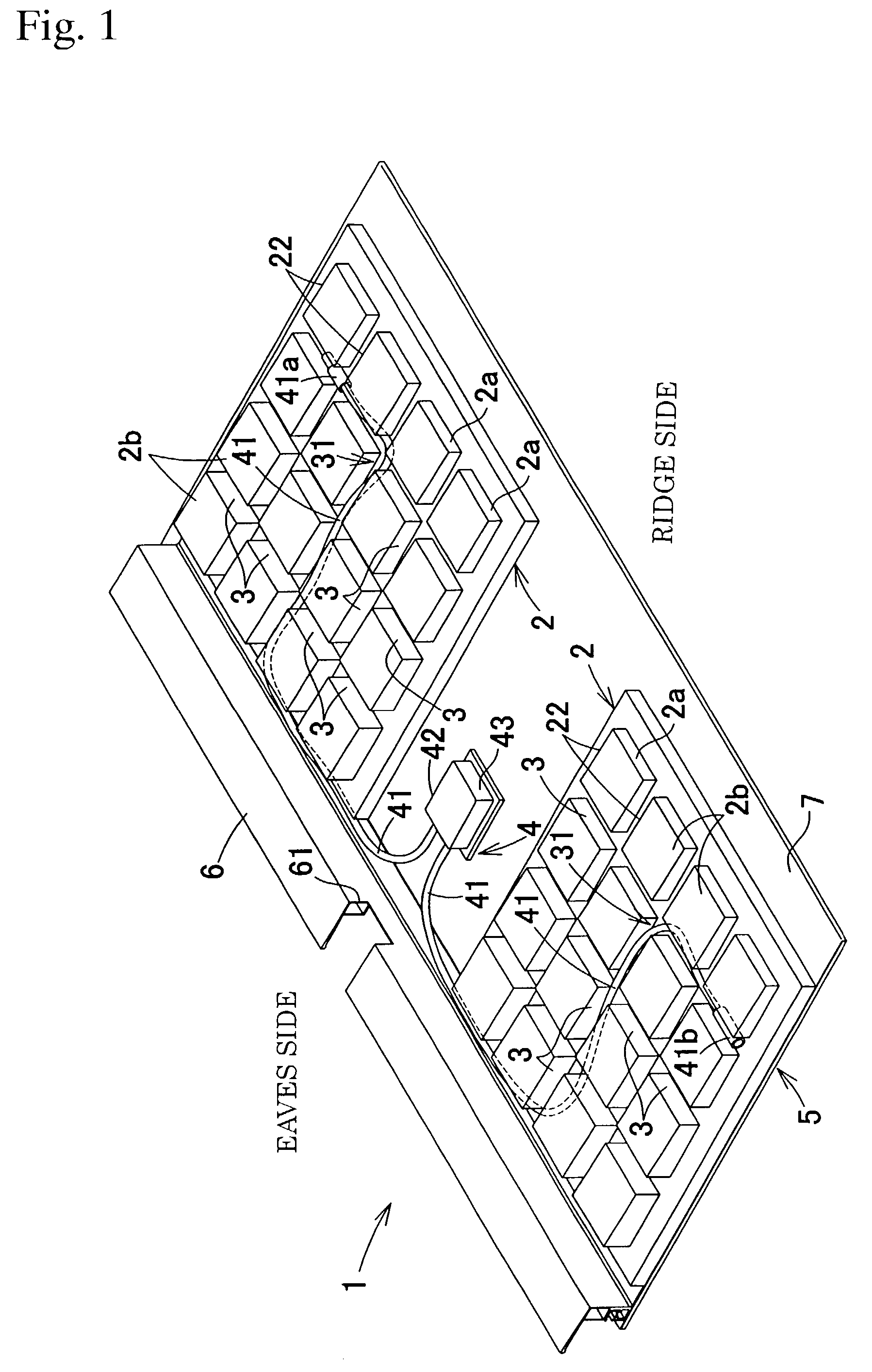

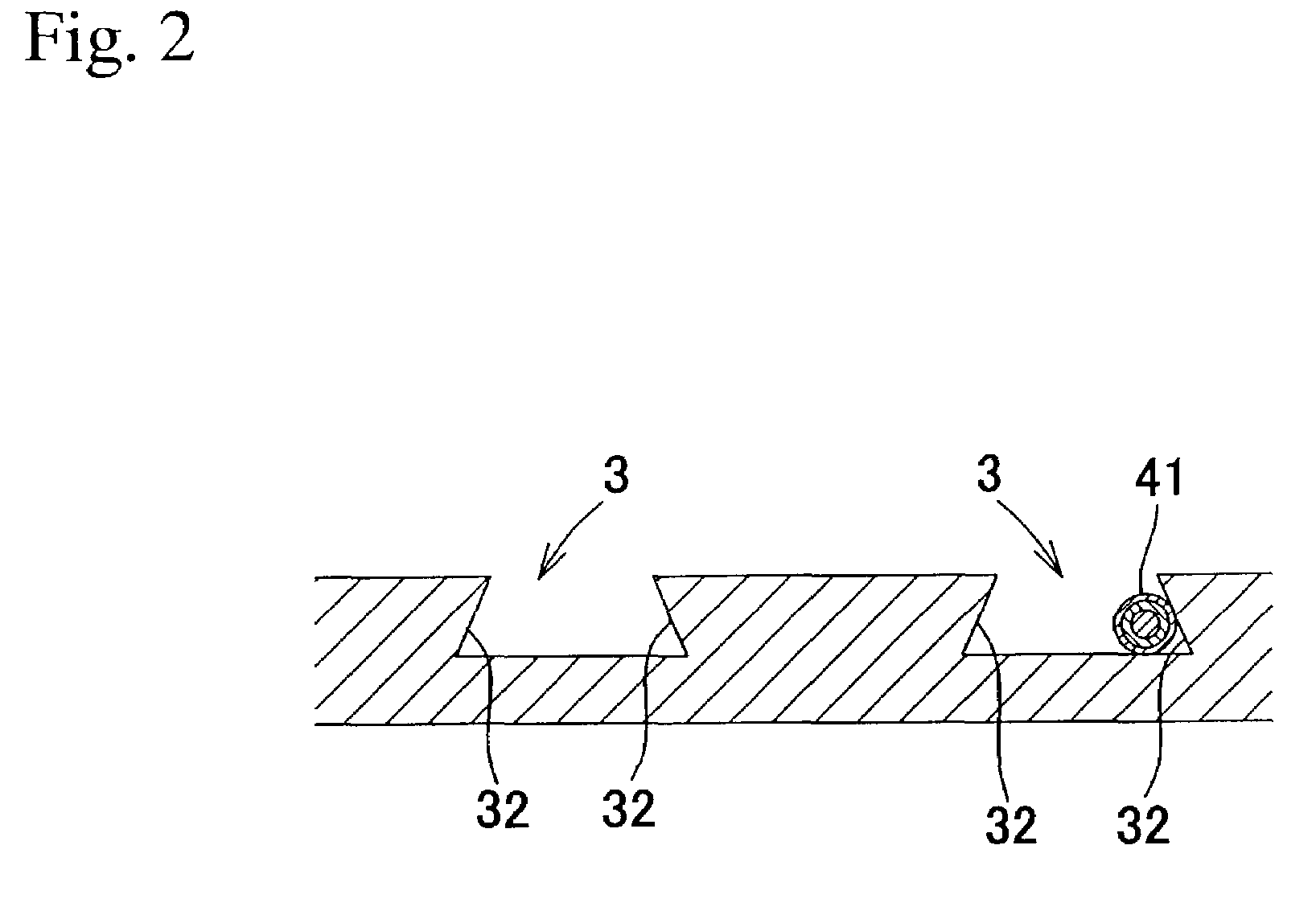

Solar cell module and roof equipped with power generating function using the same

InactiveUS6967278B2Stretch smoothlyPrevent water leakagePhotovoltaic supportsRoof covering using slabs/sheetsWater leakageElectrical battery

An object of the invention is to provide a solar cell module in which sufficient drainage and ventilation are ensured on the rear side, an output cable can be prevented from being caught during installation, and long term reliability is ensured by preventing bleed of the output cable, and another object of the invention is to provide a solar cell module integrated with building materials in which water leakage into the house and failure due to staying moisture can be avoided by imparting a waterproof function of a verge substrate water drip. A bottomed drain gutter opening to the abutting face of a heat insulating supporting material is provided to communicate with the side of the heat insulating supporting material, and a cable holding groove opening to the abutting face of a leg vertically provided on the heat insulating supporting material and deeper than the diameter of the laid cable is made to communicate with the side of the leg in order to hold the cable without projecting the cable from the opening. Furthermore, a plurality of geta members are arranged on the bottom of a supporting base and the thickness of each geta member is so set that the supporting base does not collapse the verge substrate water drip when the solar cell modules are laid on the verge substrate water drip.

Owner:KANEKA CORP

Ice bank of ice-making device for refrigerator

InactiveCN1576760ASmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

Owner:LG ELECTRONICS INC

High-temperature resistant semi-aromatic nylon and its preparation method

ActiveCN102477219AOvercome the disadvantages of high viscosity, poor fluidity and difficult dischargeHigh viscosityPresent methodPolymer science

The invention relates to semi-aromatic high-temperature resistant nylon and its preparation method. The preparation method provided by the invention comprises the following steps of: by weight, adding 75-95 parts of nylon salt, 0.2-0.8 part of an end-capping reagent, 0.1-0.6 part of a catalyst, 0.5-1 part of an antioxidant, 0.1-0.5 part of a lubricant and 30-50 parts of deionized water into a stirred polymerization autoclave, synthesizing a high-temperature resistant nylon prepolymer in a high-pressure stirred tank reactor, and carrying out melting extrusion on the prepolymer through a double screw extruder twice. According to the invention, devolatilization efficiency is raised, tackifying time is shortened, and simultaneously the high-viscosity polymer in the reaction vessel can be smoothly discharged. By different extrusion temperatures, high-temperature degradation of the prepolymer is prevented. Intrinsic viscosity of the high-temperature resistant nylon prepared by the method is higher than that of a polymer prepared by a present method. Therefore, the obtained nylon in the invention has better mechanical properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

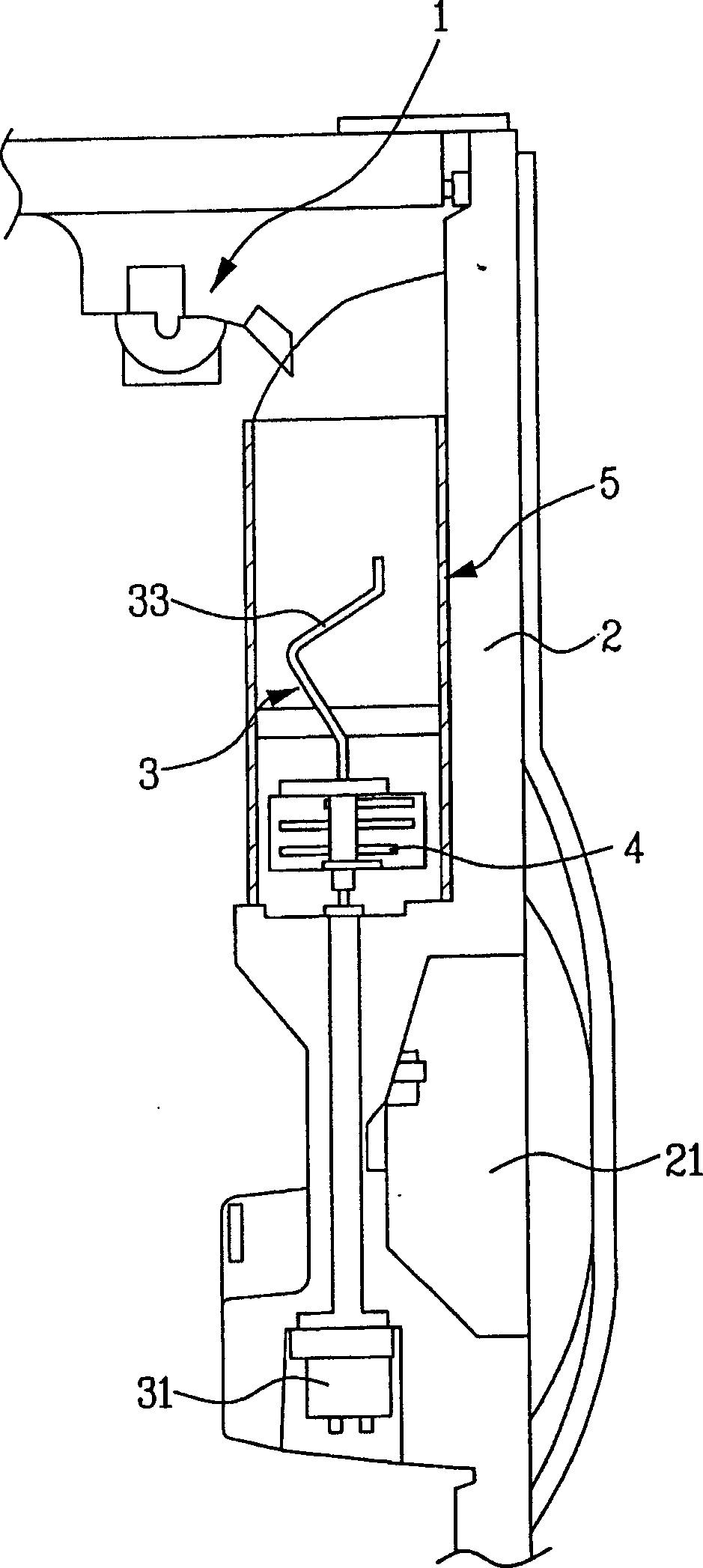

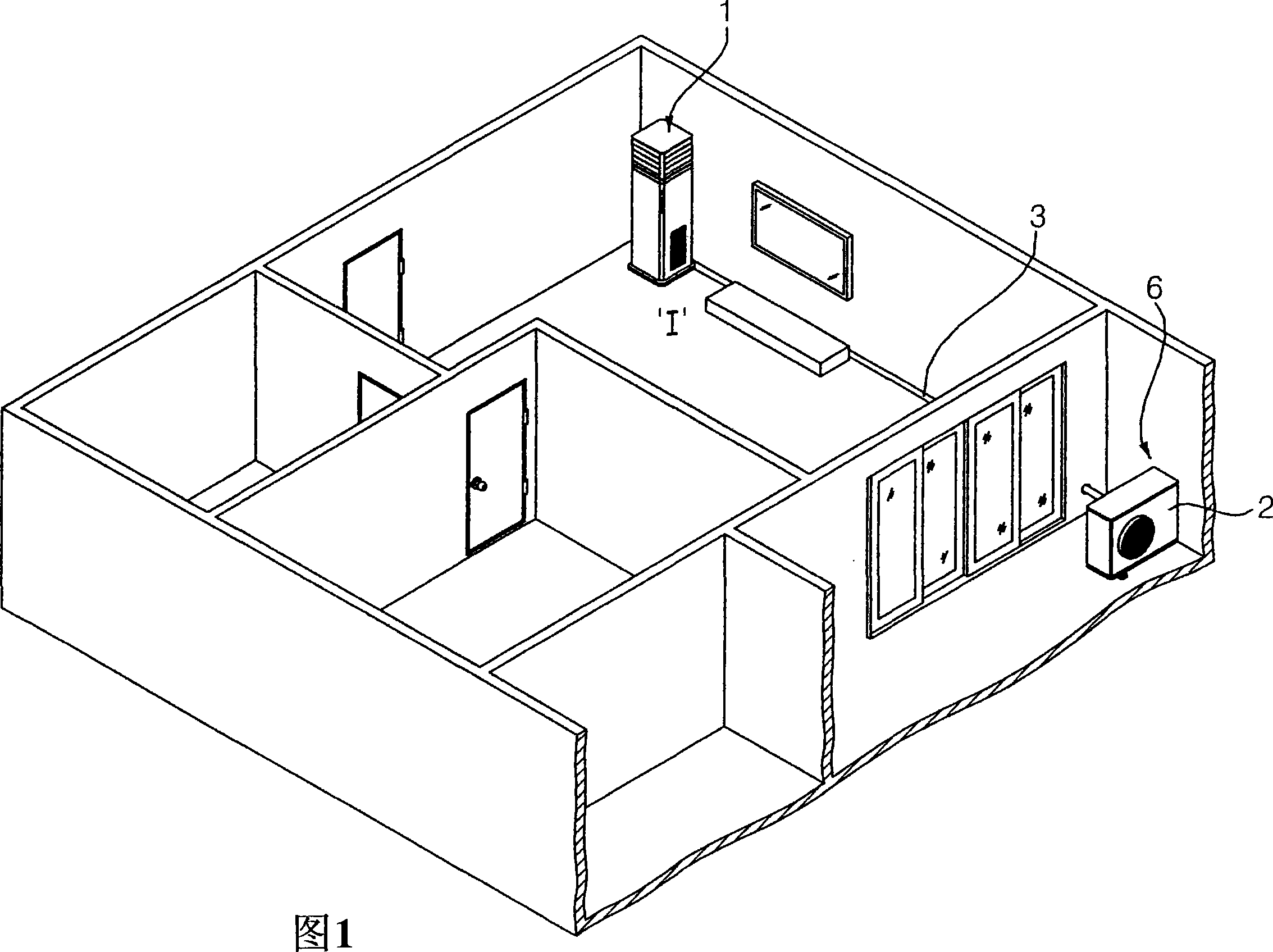

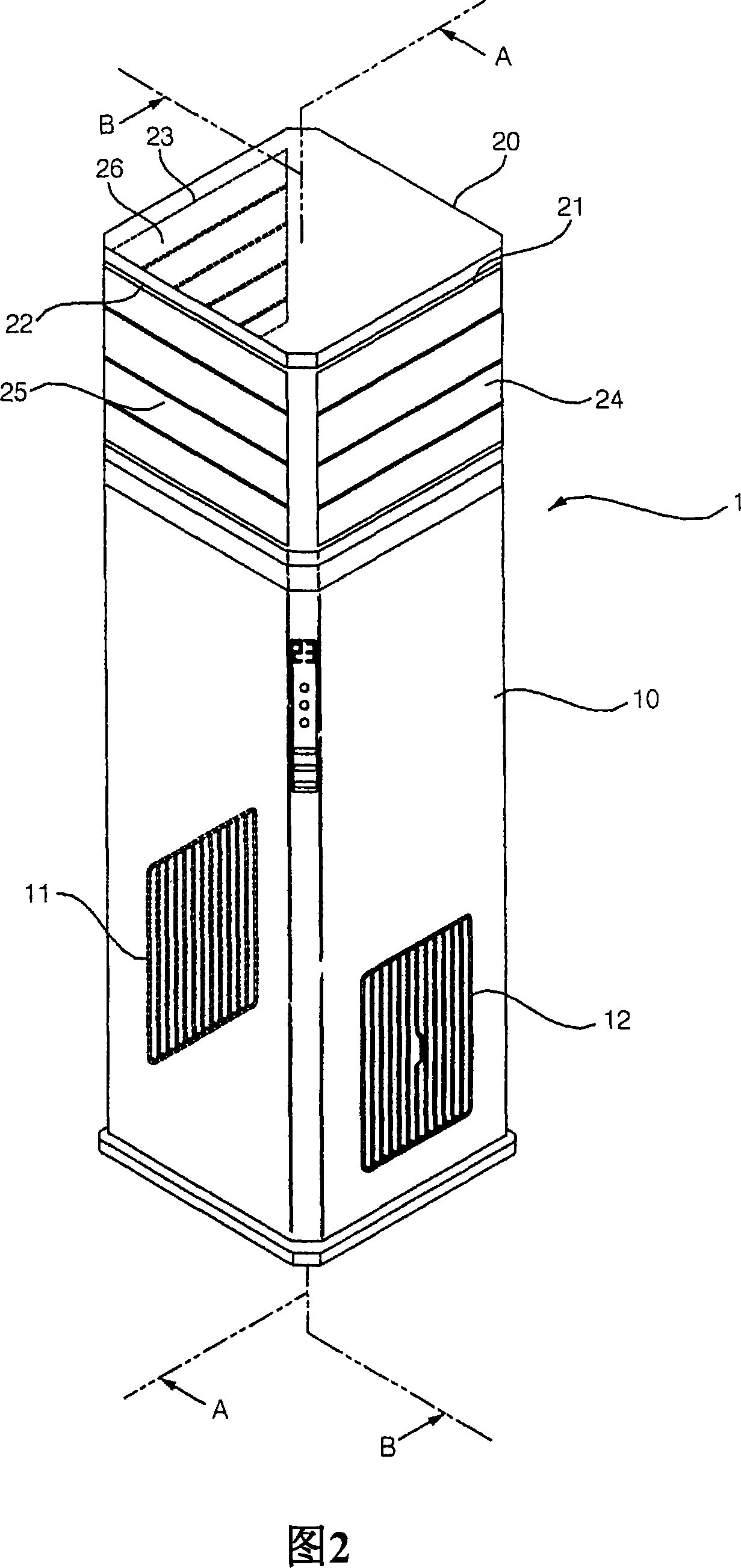

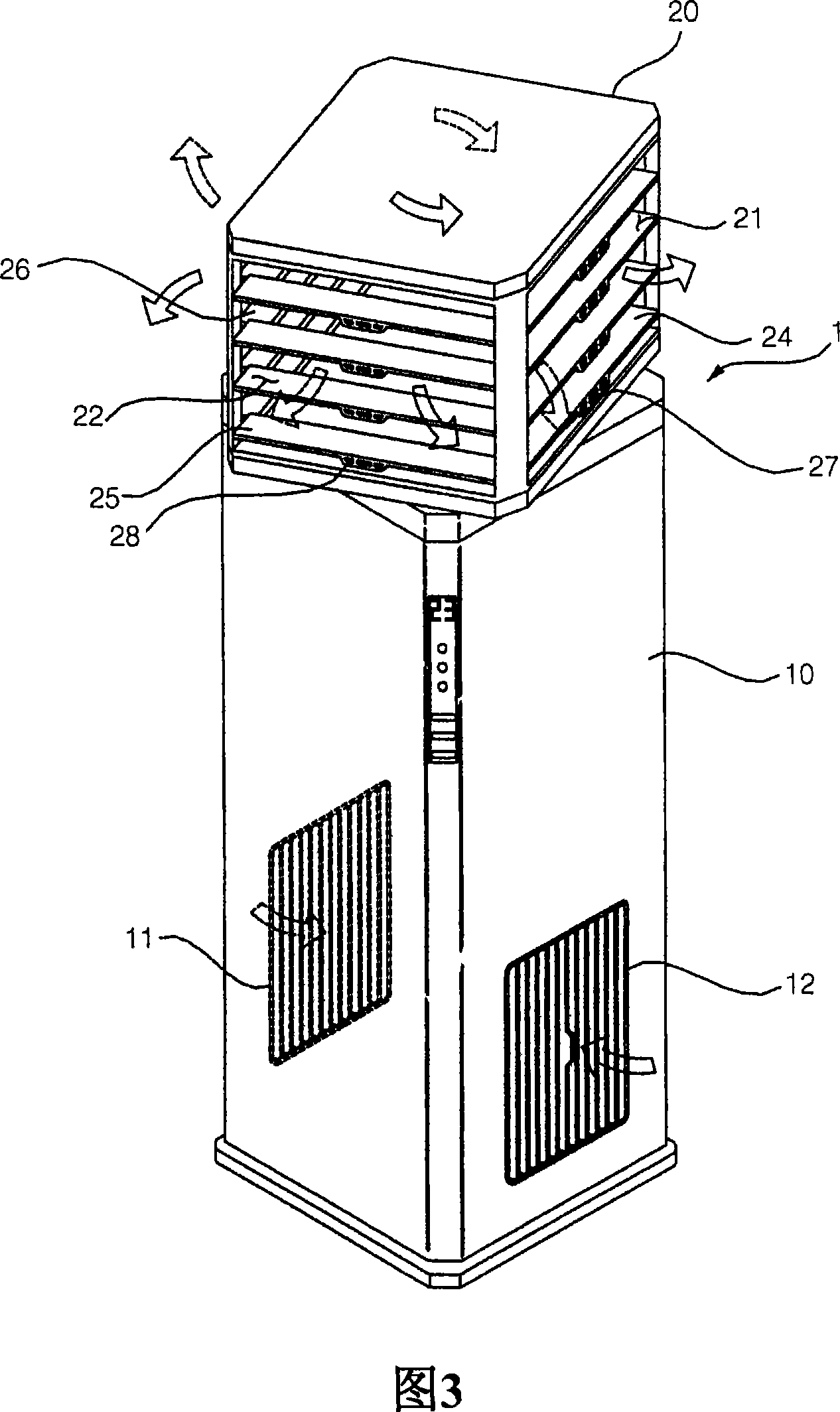

Air conditioner

InactiveCN101105307AEasy dischargeEfficient emissionsLighting and heating apparatusAir conditioning systemsPlate heat exchangerElectrical and Electronics engineering

The present invention discloses an air conditioner, including: a suction hole; a blower positioned to suck the air through the suction hole; a heat exchanger positioned to exchange heat with the air sucked by the blower; a passage extended to transfer the air from the suction hole to the blower and the heat exchanger, one end of the passage being opened; and at least one discharge hole positioned with a gap from the opened end, for discharging the air heat-exchanged in the heat exchanger, the at least one discharge hole being rotatable relatively to the opened end.

Owner:LG ELECTRONICS INC

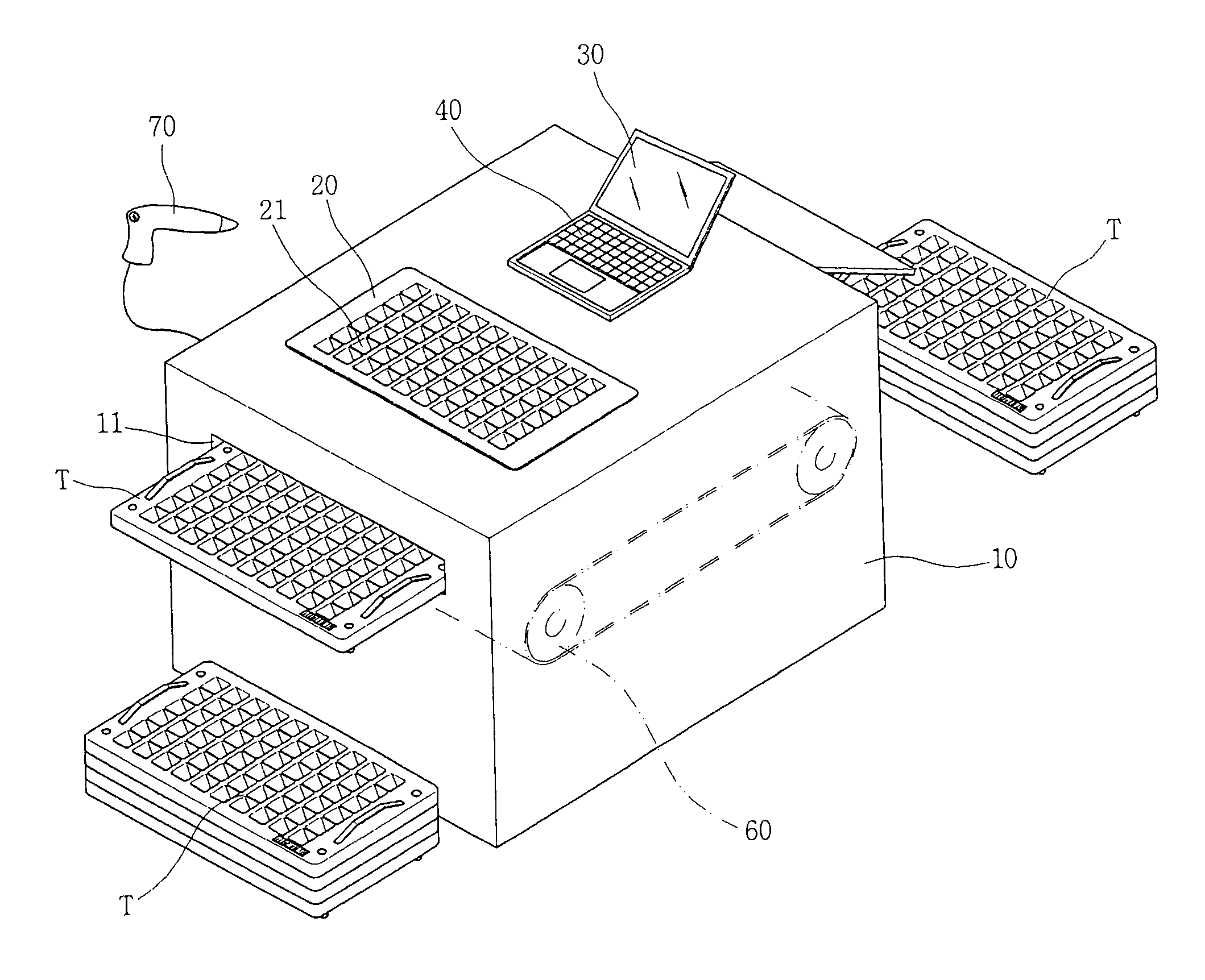

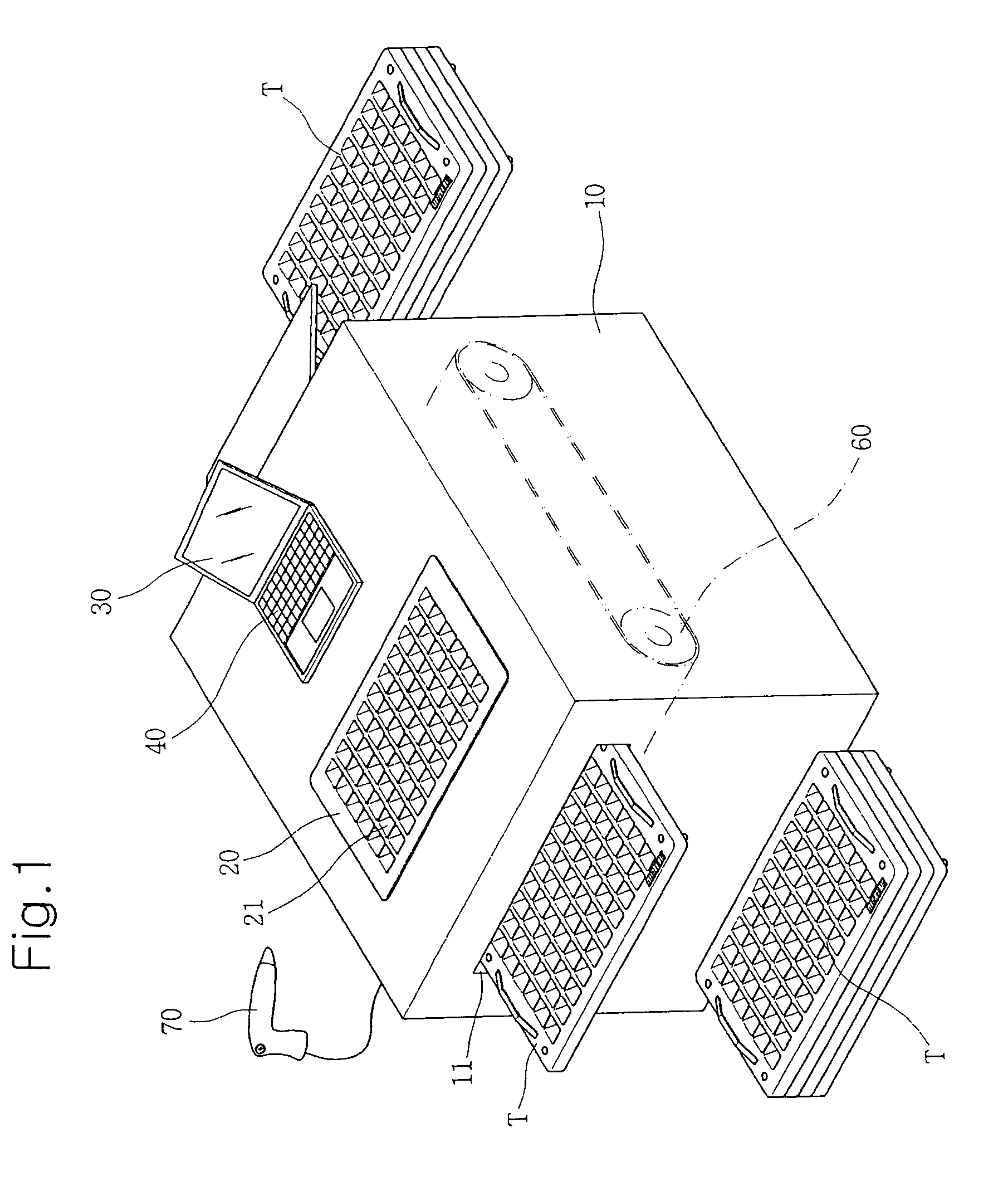

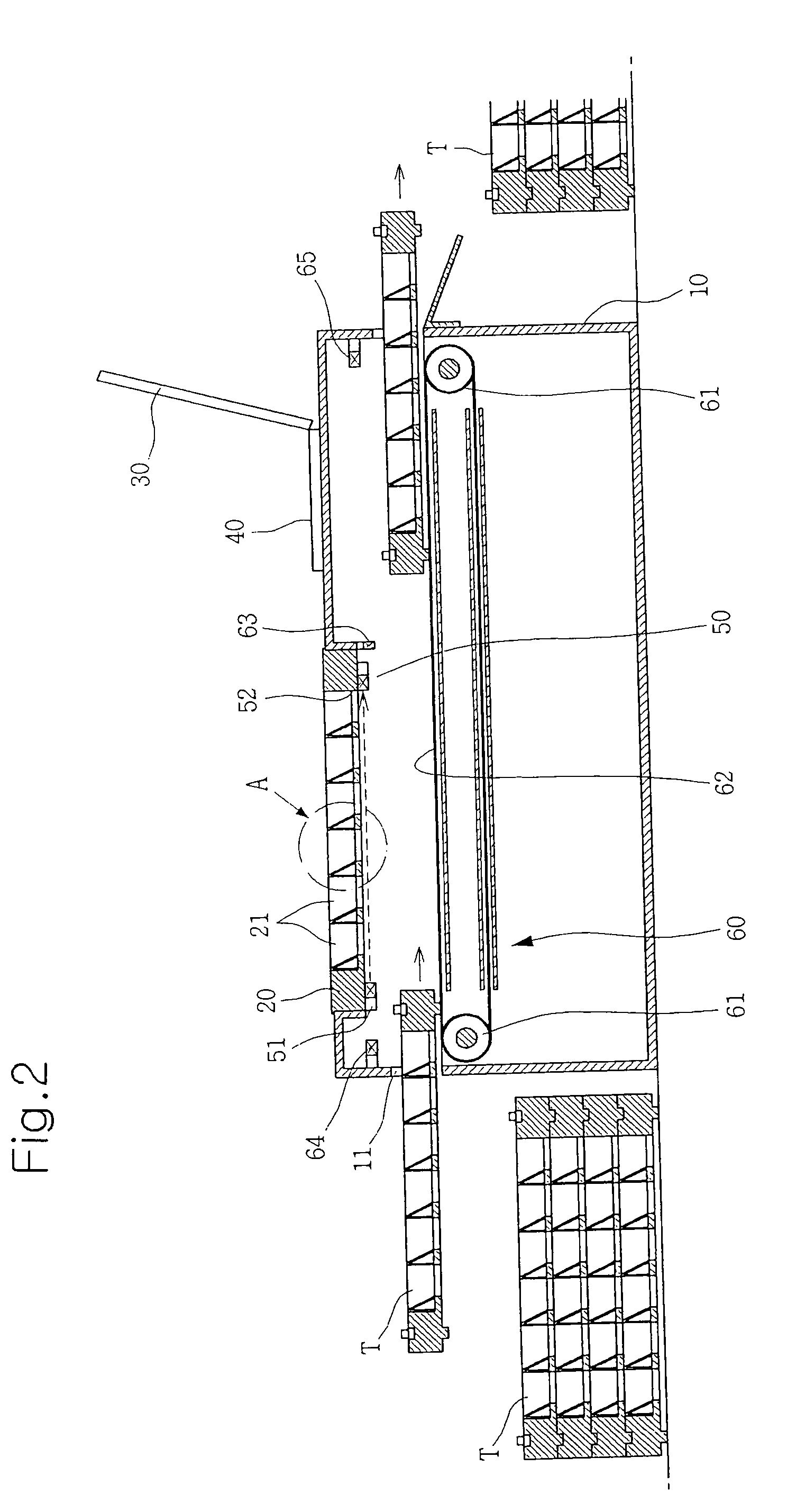

Tablet distribution apparatus for auxiliary trays and driving method thereof

InactiveUS20090188937A1Easily and accurately distributeAccurately and rapidly distributingSolid materialLiquid materialAuxiliary memoryServer

The tablet distribution apparatus includes an apparatus body having a pass-through channel through which an auxiliary tray is inserted into the pass-through channel, a distribution board mounted at the top of the apparatus body such that the distribution board vertically communicates with the pass-through channel, the distribution board having distribution through-holes of the same size and number as tablet receiving grooves of the auxiliary tray, each distribution through-hole being provided at the inside thereof with a lamp mounted therein, a display window mounted at the top of the apparatus body, and a control unit mounted at the apparatus body for selectively lighting the lamps depending upon the number of medicine packs to be prepared by patients according to the information of preparation inputted to a server computer.

Owner:JVM CO LTD

Nutrient meal-following food and producing method thereof

ActiveCN103053938AGuaranteed normal operationSmooth dischargeFood preparationPolygonum fagopyrumPlant cell

The invention discloses a nutrient meal-following food and a producing method thereof. The nutrient meal-following food is characterized by comprising the following components in parts by weight: 0.5-1.5 parts of polished round-grained rice, 0.5-1.5 parts of white rice, 0.5-1.5 parts of black rice, 0.5-1.5 parts of barley, 1.5-2.5 parts of buckwheat, 0.5-1.5 parts of wheat, 1.5-2.5 parts of oats, 1.5-2.5 parts of coix seeds, 1.5-2.5 parts of millets, 1.5-2.5 parts of corns, 1.5-2.5 parts of broomcorn and 1.6-2.4 parts of sesames. The producing steps are as follows: (1) mixing and cleaning the raw materials, and then soaking the mixture for 8-12 hours (2) steaming the raw materials thoroughly and then airing the raw materials to 30 DEG C; (3) adding fermentation strains and the raw material soaking water in the step (1) into the raw materials in the former step and mixing uniformly; (4) fermenting at a constant temperature of 30 DEG C for 30-35 hours; (5) repeating the step (3); (6) fermenting at a constant temperature of 30 DEG C for 24-30 hours; (7) grinding the well-fermented raw materials into paste; (8) drying the paste into powder and packaging the powder in a sealing manner. The nutrient meal-following food has rational allocation, results in no digestion discomfortableness to the intestines and stomach as the surfaces of the coarse grains are softened through biological fermentation, and is better for the absorption of an organism as the plant cell walls are destroyed by enzymes under the action of microorganisms.

Owner:姜桂英

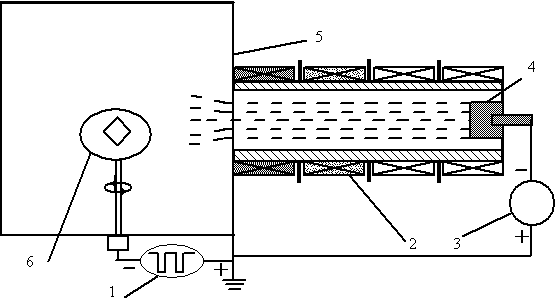

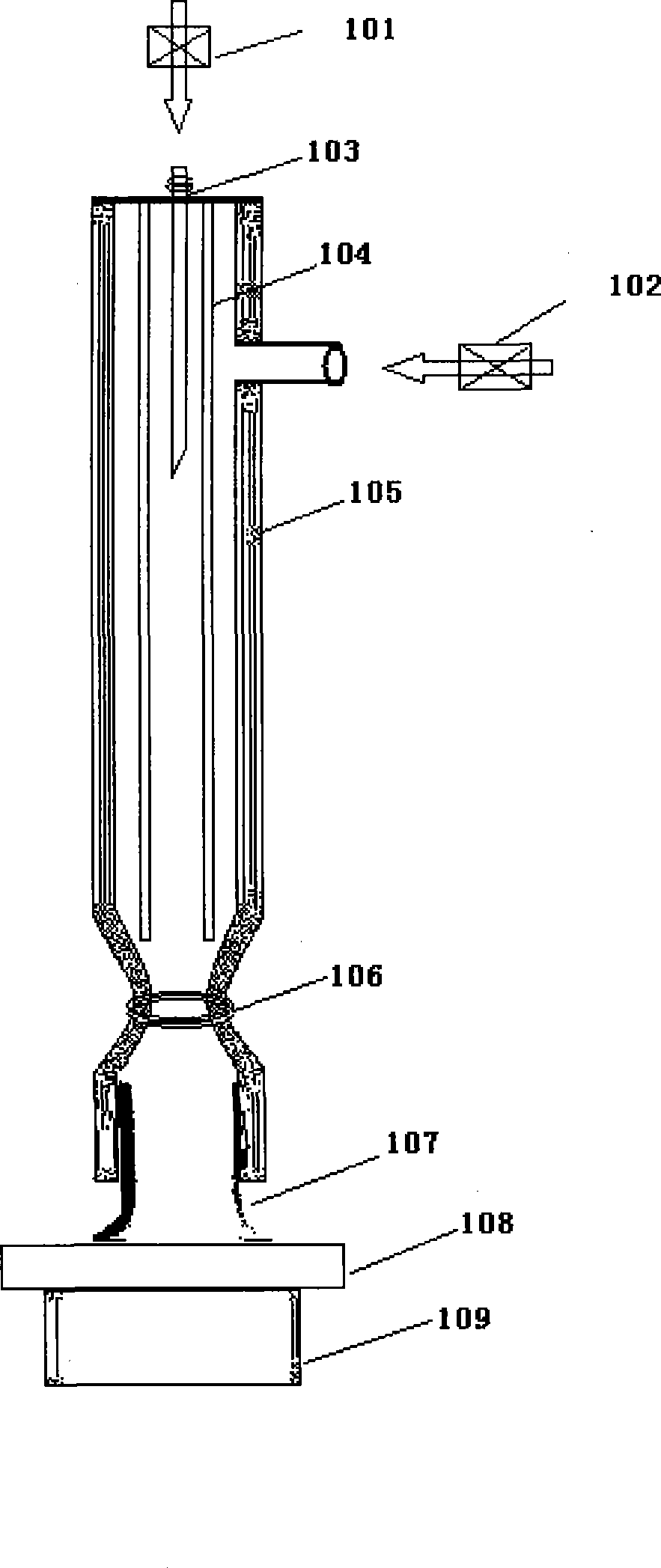

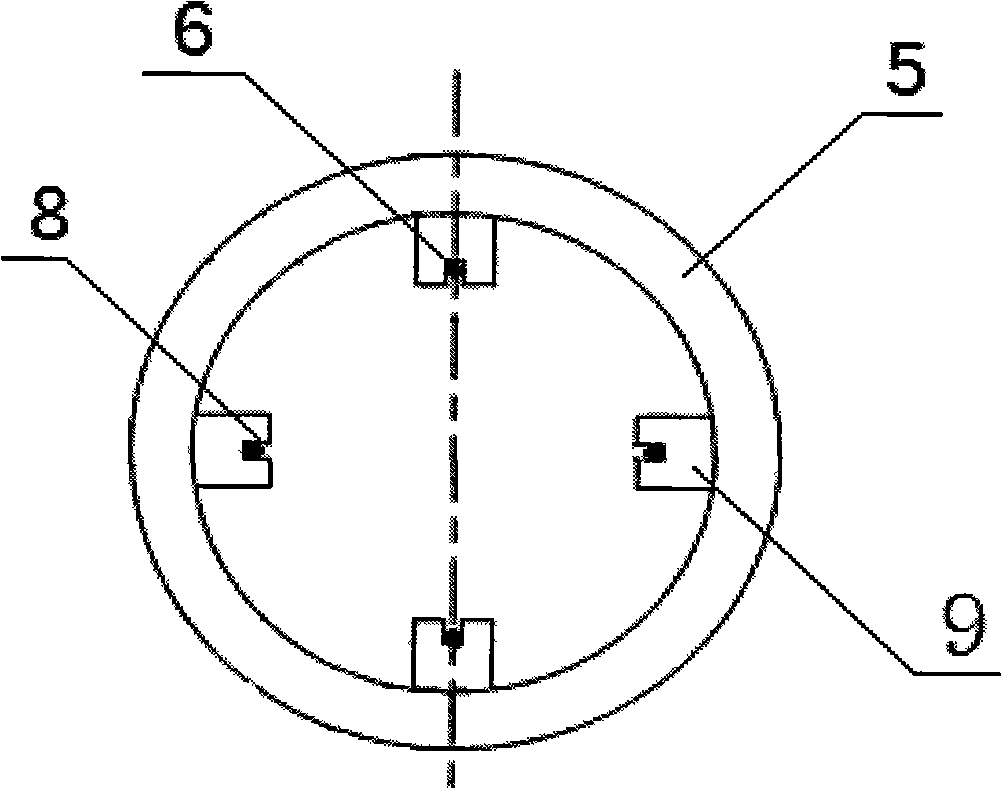

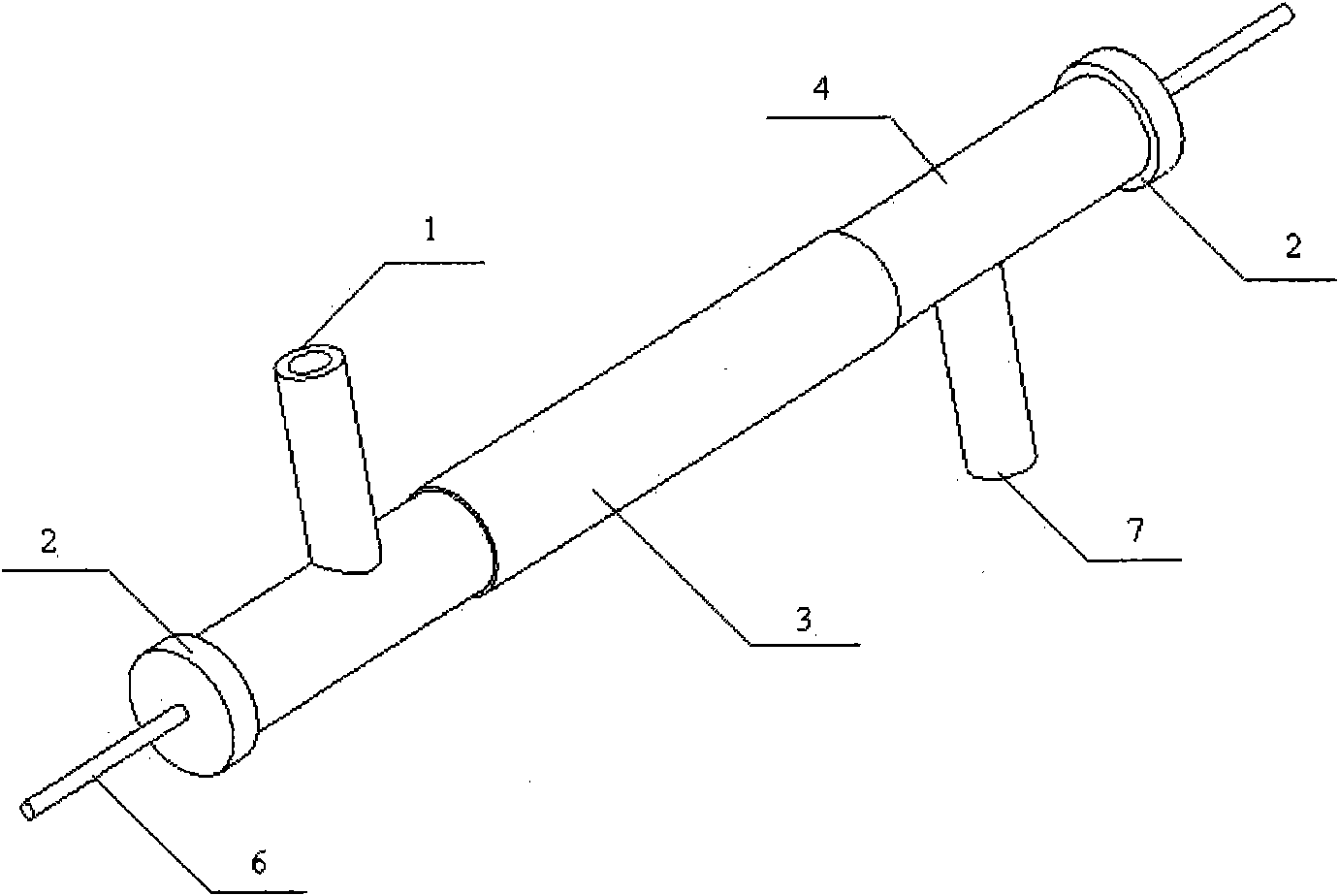

Preionization atmos low-temperature plasma jet generator

InactiveCN101466194AReduce breakdownIncrease discharge powerElectric discharge tubesPlasma techniquePlasma jetHigh concentration

The invention relates to an atmospheric pressure low-temperature plasma jet reactor with preionization structure, which belongs to plasma discharge reactor technical field, and the reactor is characterized in that: the device main body is a millimeter magnitude main silica tube with one open end; a part is arranged above the open end at the lower part with 15 to 25mm, and the part becomes the thinnest at 20mm part, and a ring-shaped electrode is wound on the part; a thin silica tube is connected at the closed end arranged in the inner part thereof through the closed end arranged at the upper part of the silica tube; and a needle electrode is arranged in the thin silica tube. An earthing electrode is arranged below the open end of the main silica tube; and the argon gas is filled into the needle electrode, and the oxygen gas is filled into the main silica tube. The needle electrode and the ring-shaped electrode can be exerted with the same high voltage; the needle electrode discharge can supply the seed electrons for the ring-shaped electrode discharge, and a stable glowing discharge plasma jet is arranged between the ring-shaped electrode and the earthing electrode. The reactor has the beneficial effects that the obtained plasma jet can generate high-concentration chemical activity species, and the reactor has practical value.

Owner:DALIAN UNIV OF TECH

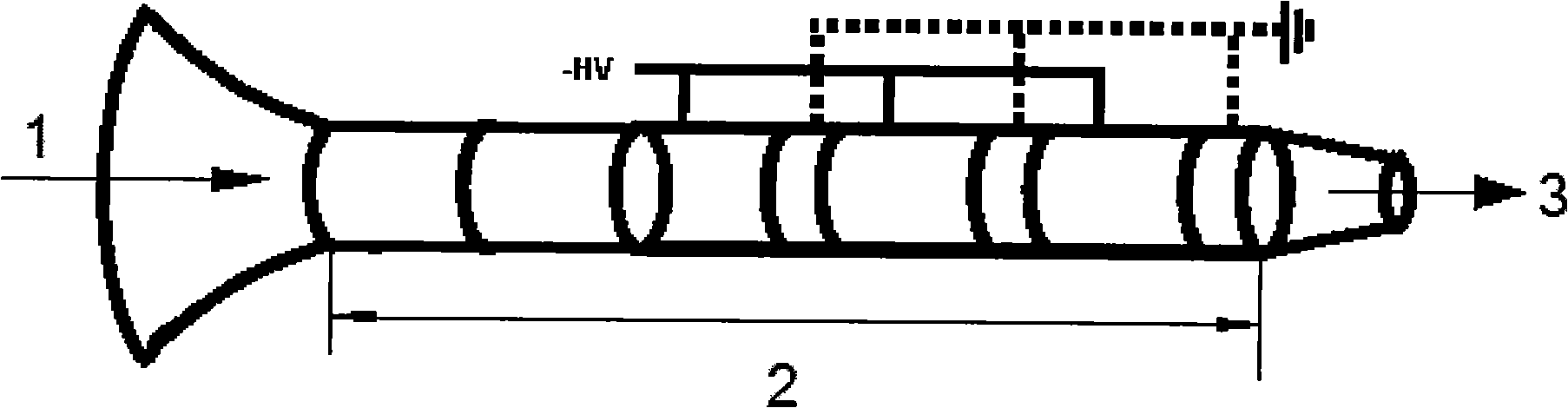

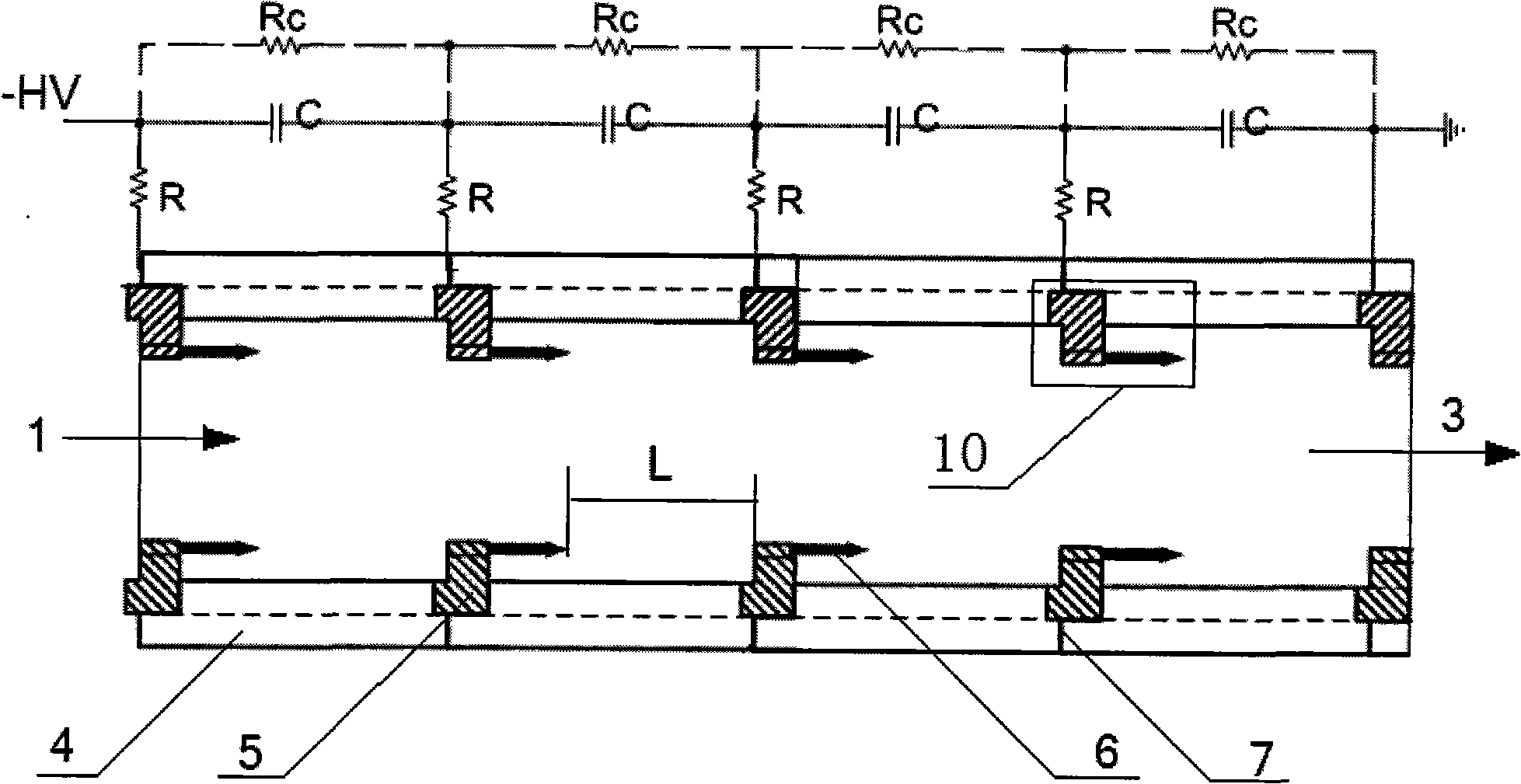

Device for exciting high-speed and large-area ionic wind

InactiveCN101577397AExpand the scope of actionHigh ion wind speedCorona dischargeElectrical conductorEnhanced heat transfer

The invention discloses a device for exciting high-speed and large-area ionic wind, which comprises an ionic wind exciting area cylinder body, an inlet and an outlet at two ends. Multiple-stage series needle-ring electrodes are arranged in the cylinder body. The device is characterized in that a needle electrode of a post stage and a ring electrode of a previous stage are combined to form an integral multi-needle ring electrode, and the needle electrode and the ring electrode of the multi-needle ring electrode of each two stages form an electrode spacing; the ring electrodes of the multi-needle ring electrode of each two stages are connected in series with a current-limiting resistor outside the cylinder body through a conductor respectively, and then are connected in parallel with a voltage-dividing capacitor to form a discharge loop; and the voltage-dividing capacitors are mutually connected in series, the voltage-dividing capacitor connected with the ring electrode close to the inlet is connected with a direct-current high voltage source, the voltage-dividing capacitor connected with the ring electrode close to the outlet is grounded, and the ring electrode close to the outlet is not provided with a needle electrode and is grounded directly through a conductor. The device can obtain high-speed and large-area ionic wind, and can be applied in various fields of enhanced heat transfer, micro air pumps, air purification and the like.

Owner:XI AN JIAOTONG UNIV

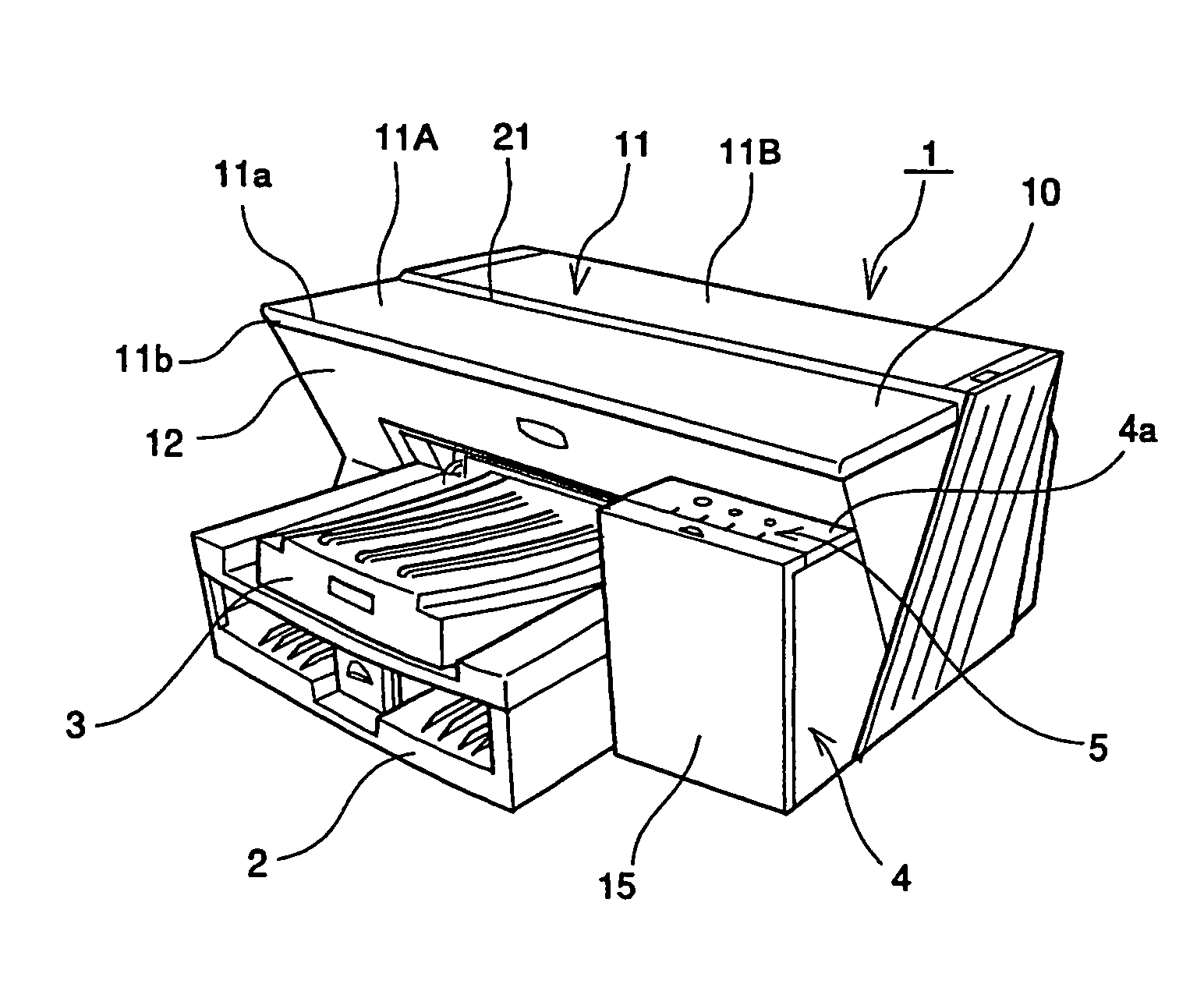

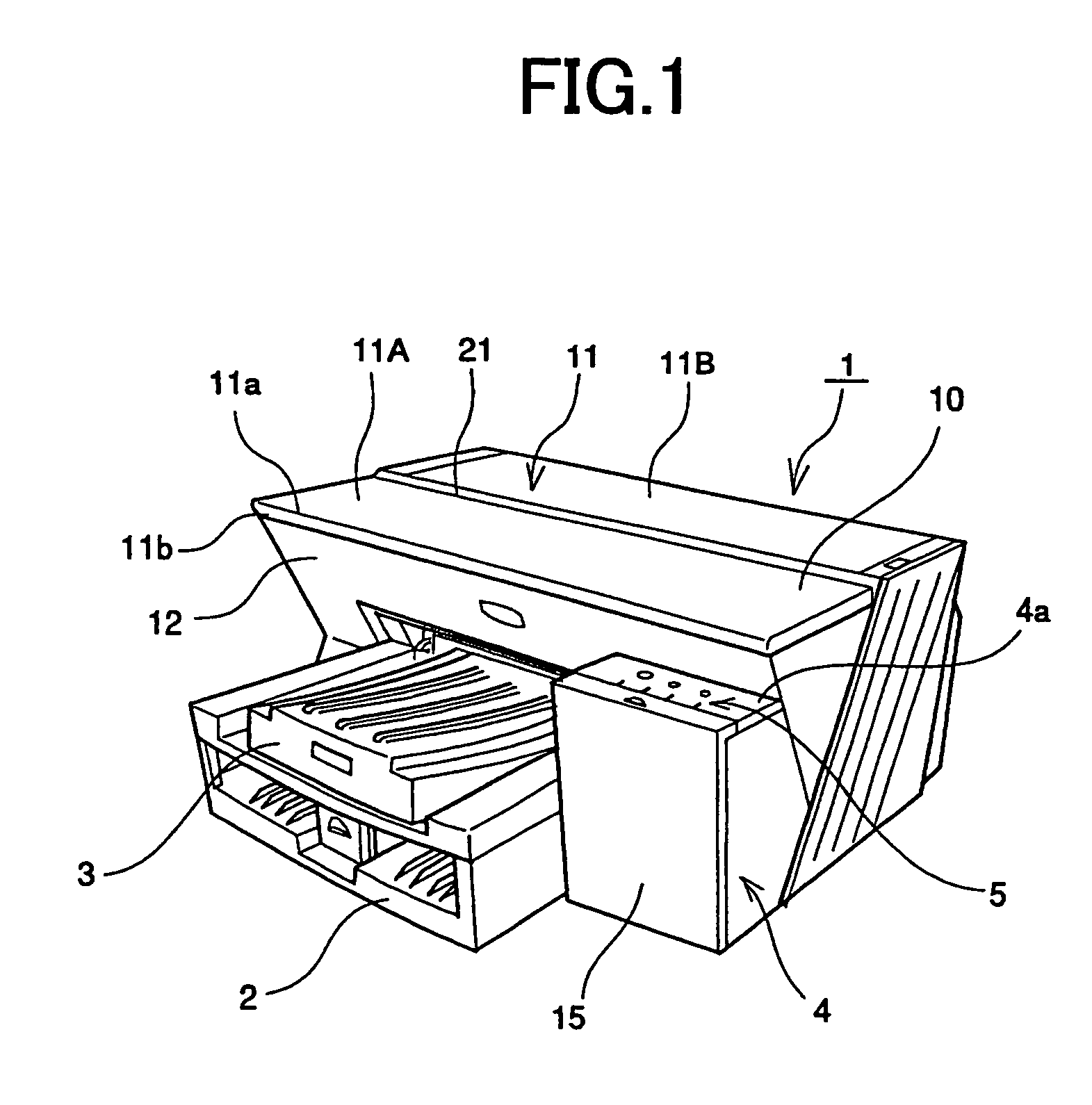

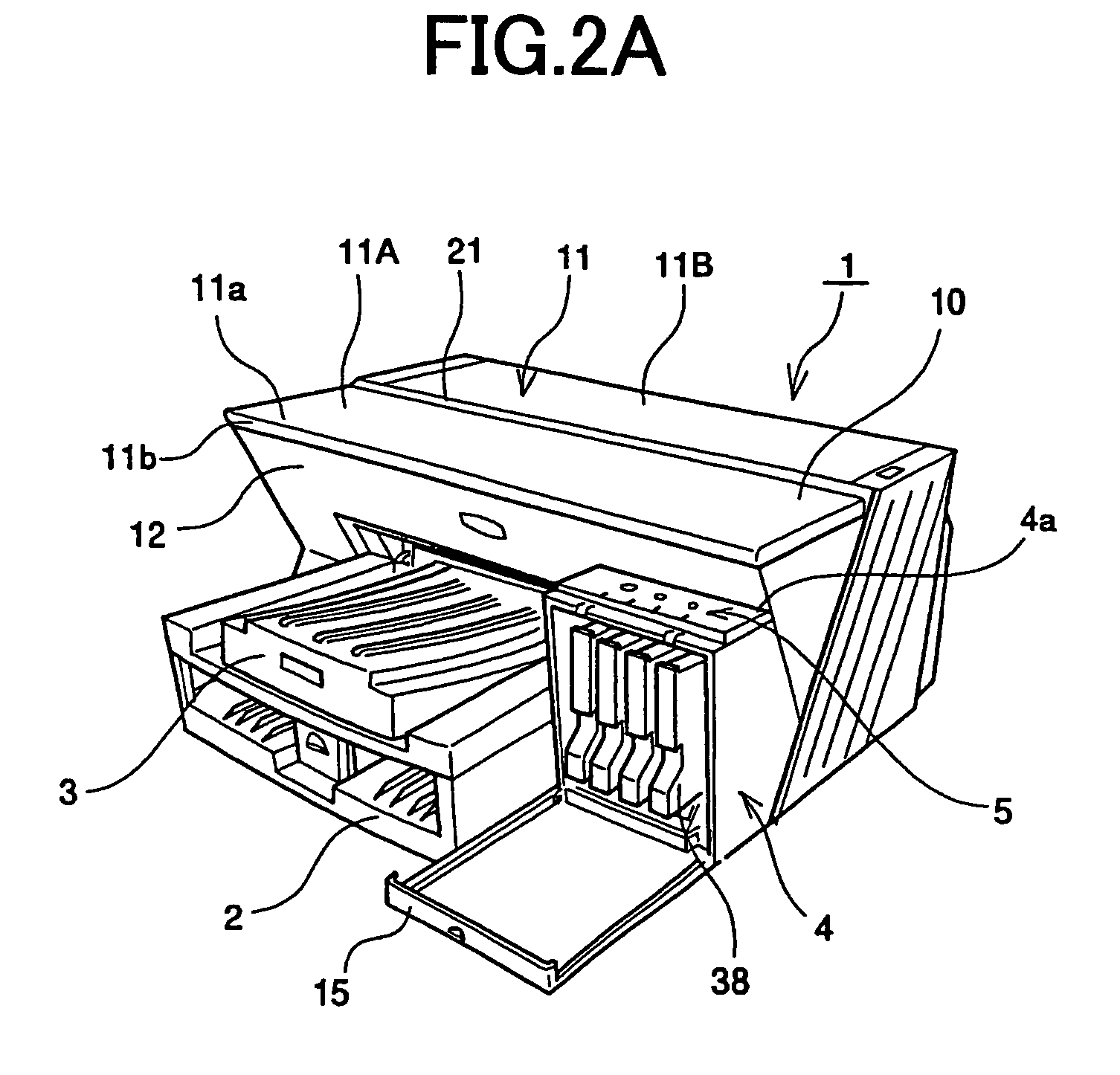

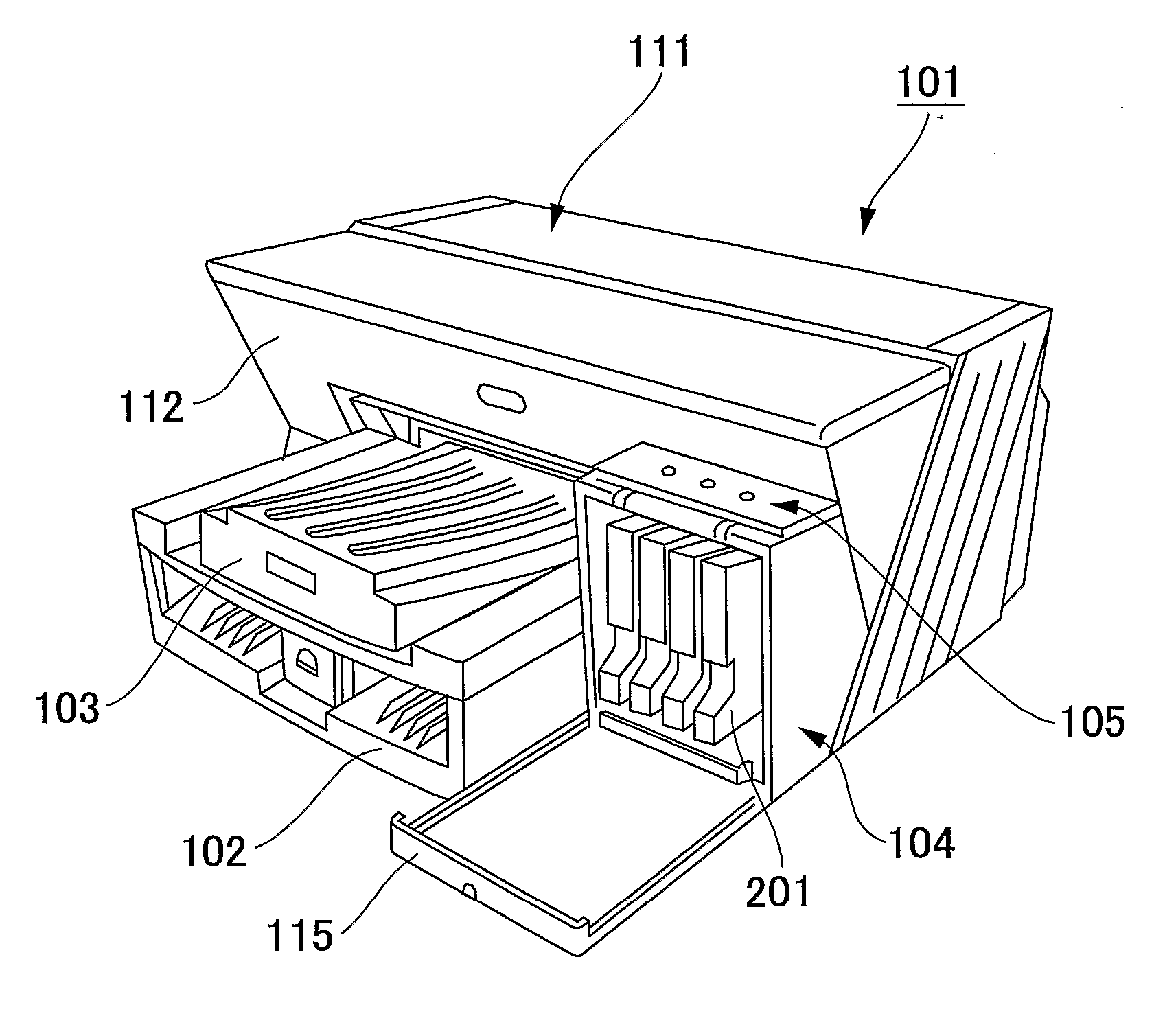

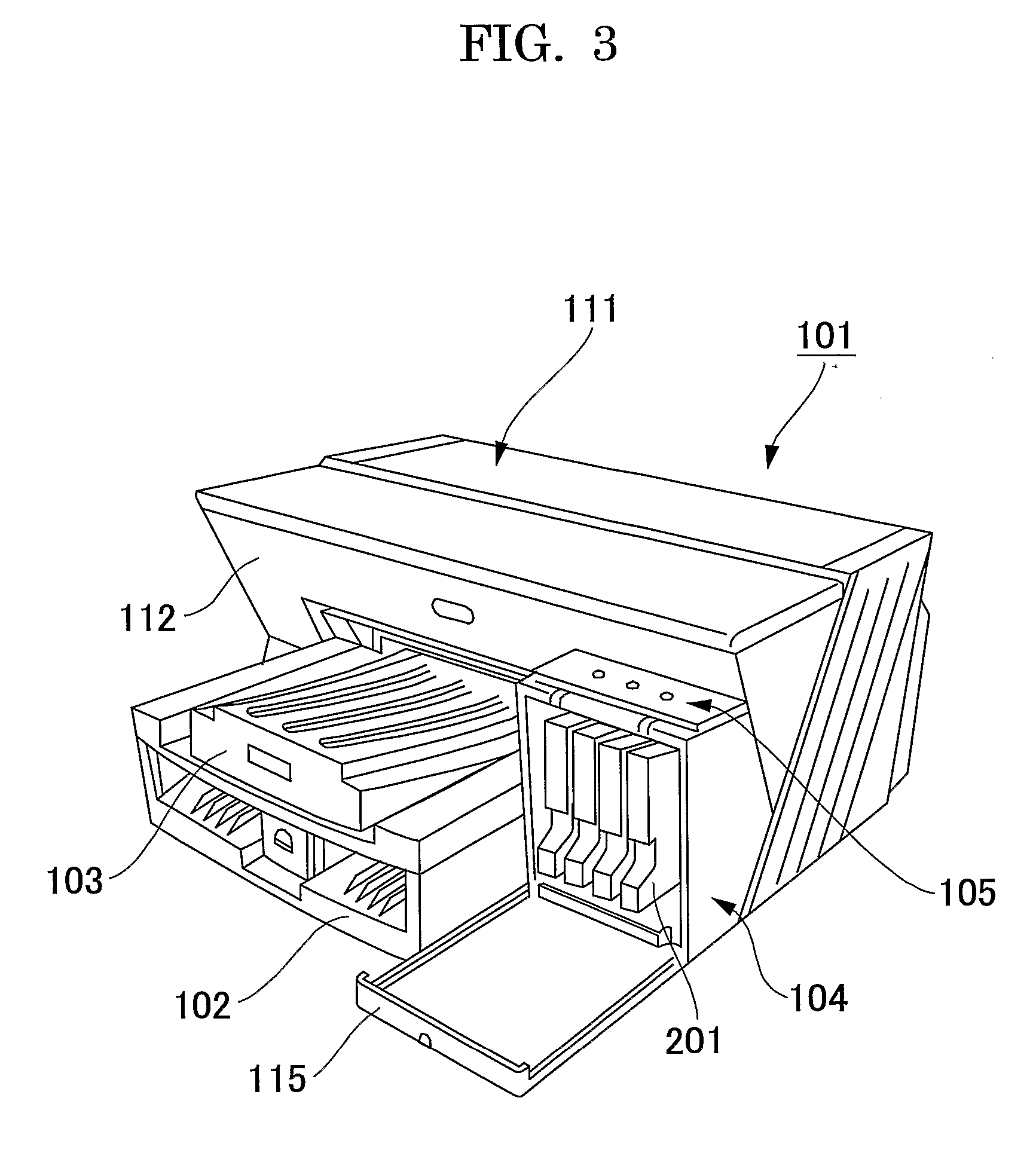

Compact front-operable image forming apparatus

InactiveUS7469981B2Easily replenished with paperStable outputRecording apparatusElectrographic process apparatusImage formationEngineering

An image forming apparatus is disclosed that includes a substantially flat top face and a slanted front face, the bottom side of which recedes backward. The image forming apparatus may includes a paper discharge tray disposed at a lower portion of the slanted front face, the paper discharge tray protruding forward. The paper discharge tray may be tiltable upward and downward. Because the bottom side of the slanted front face recedes backward, the flat top face can be provided, and simultaneously, enough space for the feeding and discharging of paper can be secured.

Owner:RICOH KK

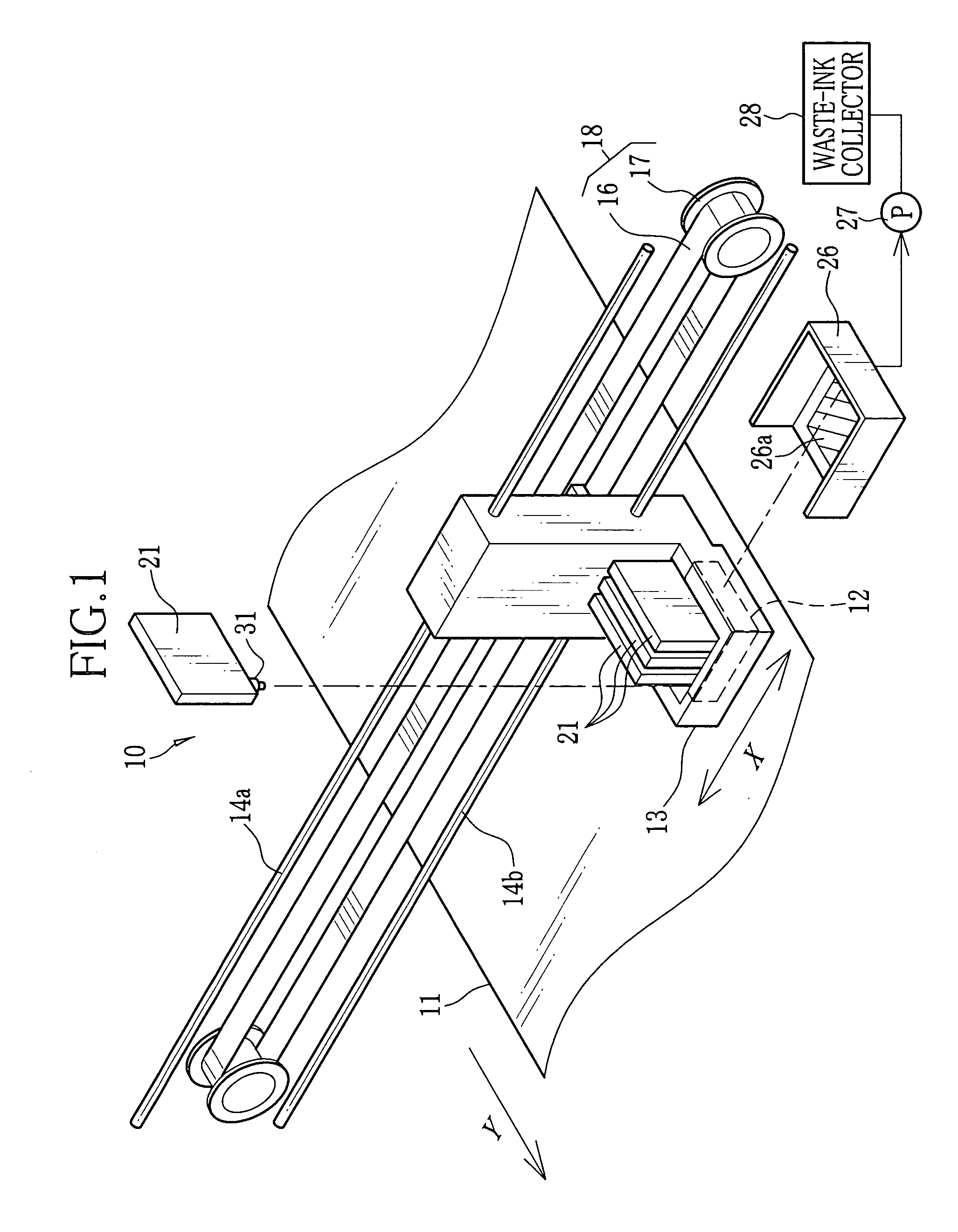

Ink container, ink jet recording apparatus, ink filling method, and ink filling device

InactiveUS20070046742A1Prevent chokeAvoid suffocationOther printing apparatusRecording headEngineering

An ink cartridge is formed with an ink outlet, which is connected to an ink jet type recording head through an ink supply path. Ink filling openings are formed around the ink outlet. To refill the ink cartridge with ink, the ink filling openings are connected through an ink filling tube to an ink supply tank. A pump mechanism first reduces pressure inside the ink supply tank, to suck ink residue out of the ink cartridge through the ink filling openings and collect the ink residue into the ink supply tank. Thereafter, the pump mechanism applies pressure to ink in the ink supply tank, to send the ink from the ink supply tank through the ink filling tube and the ink filling openings into the ink cartridge.

Owner:FUJIFILM CORP

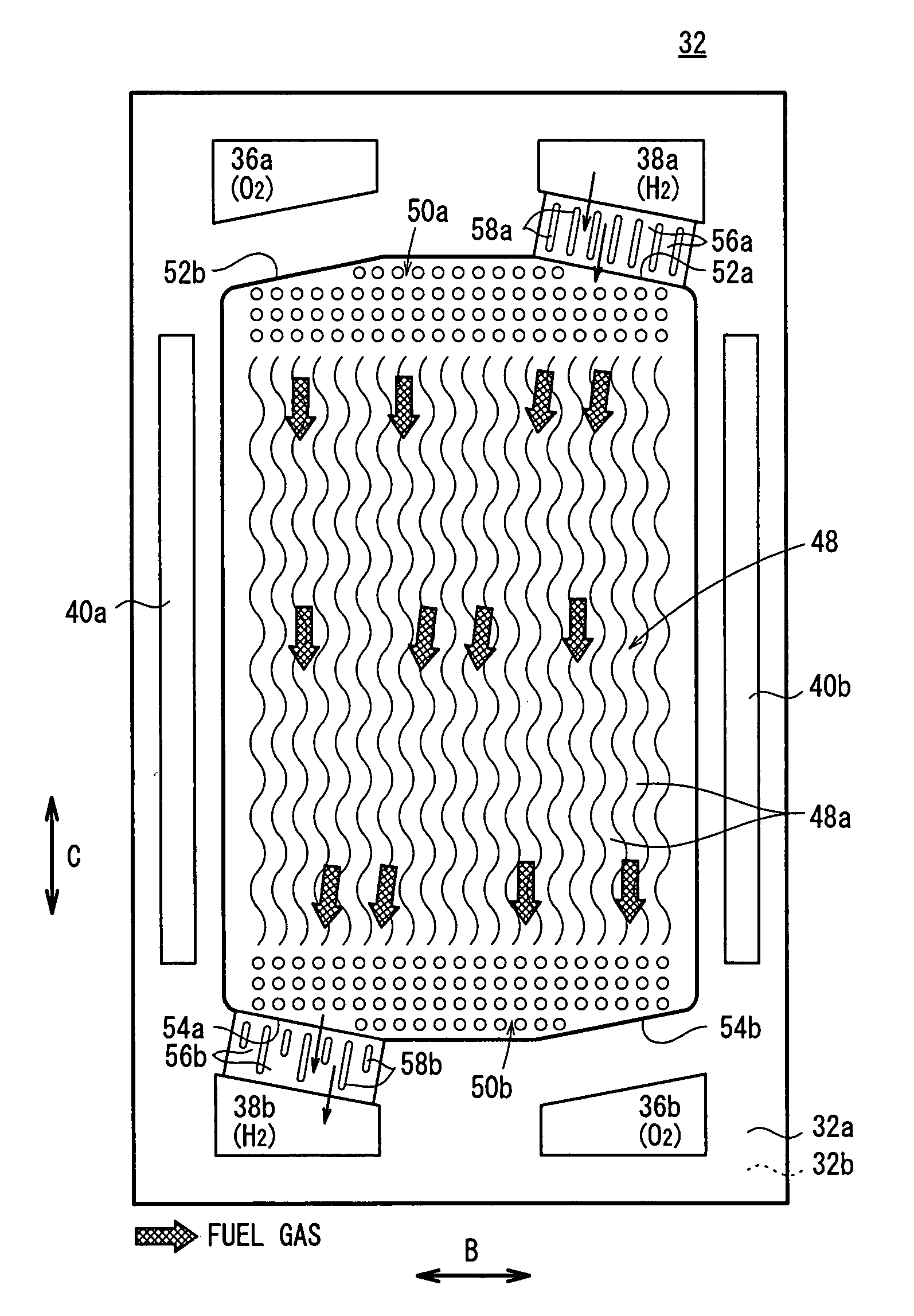

Fuel cell

ActiveUS20070207372A1Simple structureMaintain durabilityFuel cells groupingFuel cell auxillariesEngineeringFuel gas

A fuel gas flow field is formed on a surface of a rectangular first metal separator. The fuel gas flow field includes flow grooves extending in the direction of gravity. An outlet buffer is provided at a lower end of the fuel gas flow field. The outlet buffer includes an inclined surface inclined toward a fuel gas discharge passage. The fuel gas discharge passage is positioned below the outlet buffer. Outlet channel grooves are formed by ridges provided between the fuel gas discharge passage and the outlet buffer. Lower ends of the ridges are arranged in a zigzag pattern.

Owner:HONDA MOTOR CO LTD

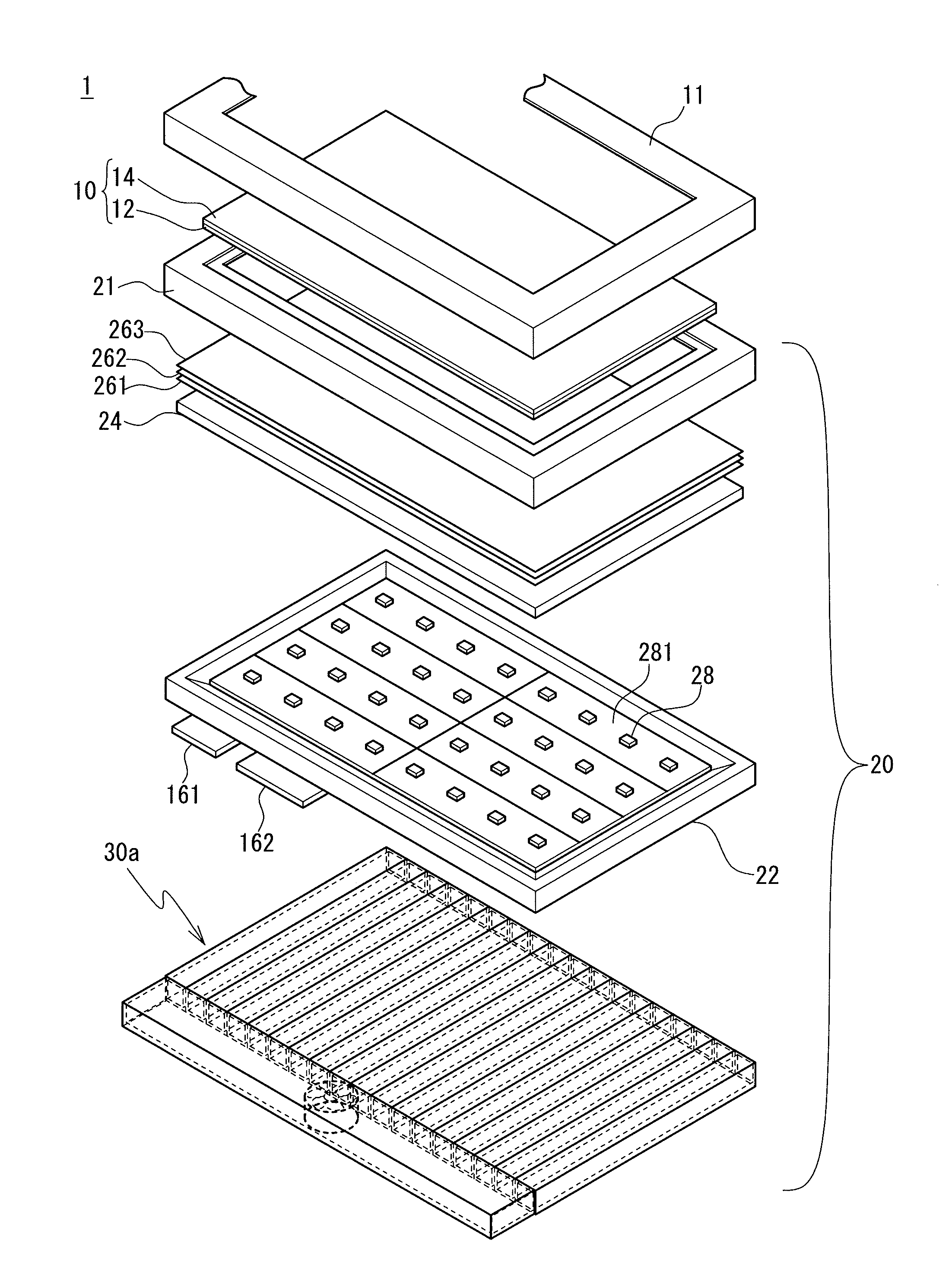

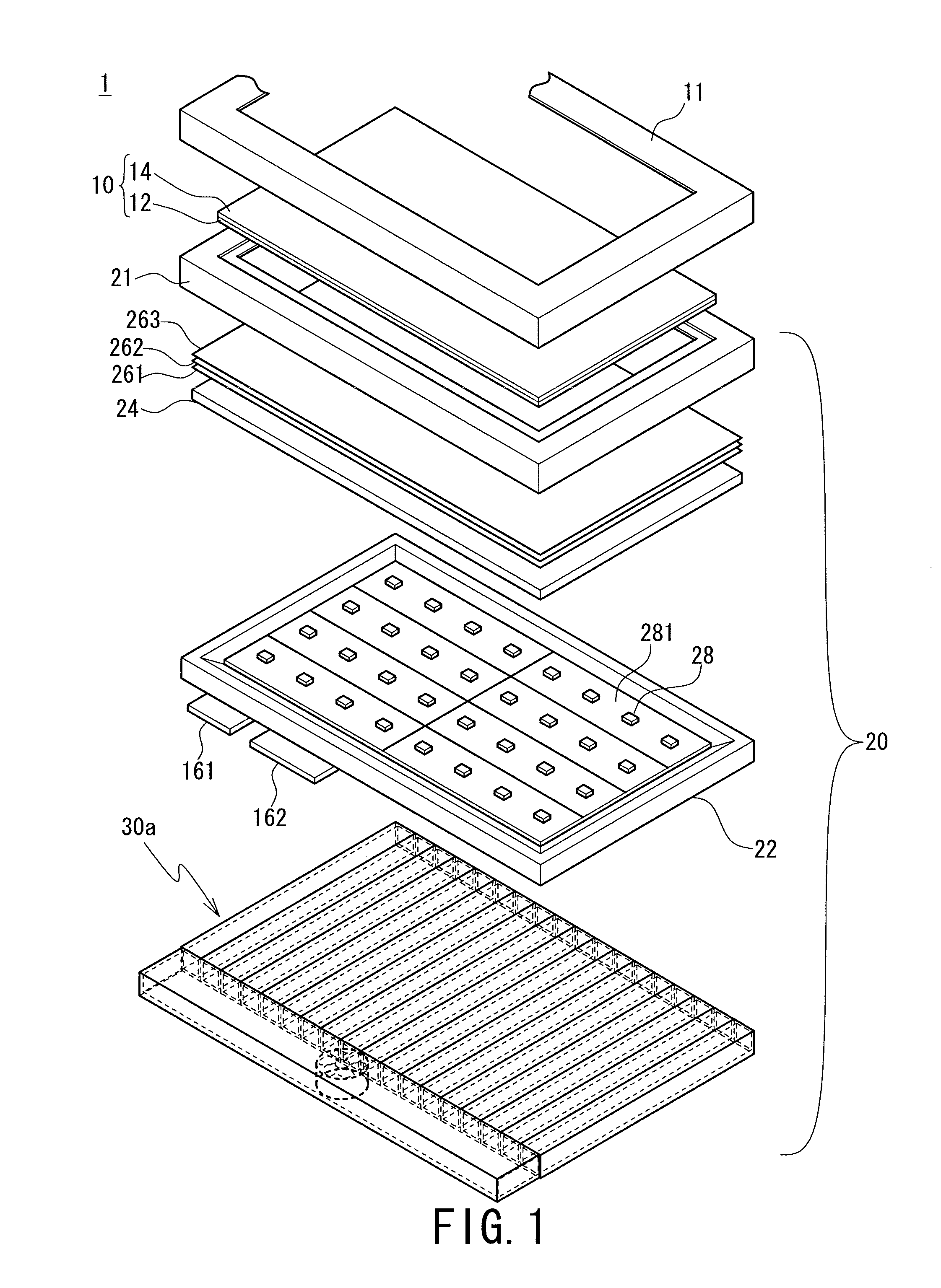

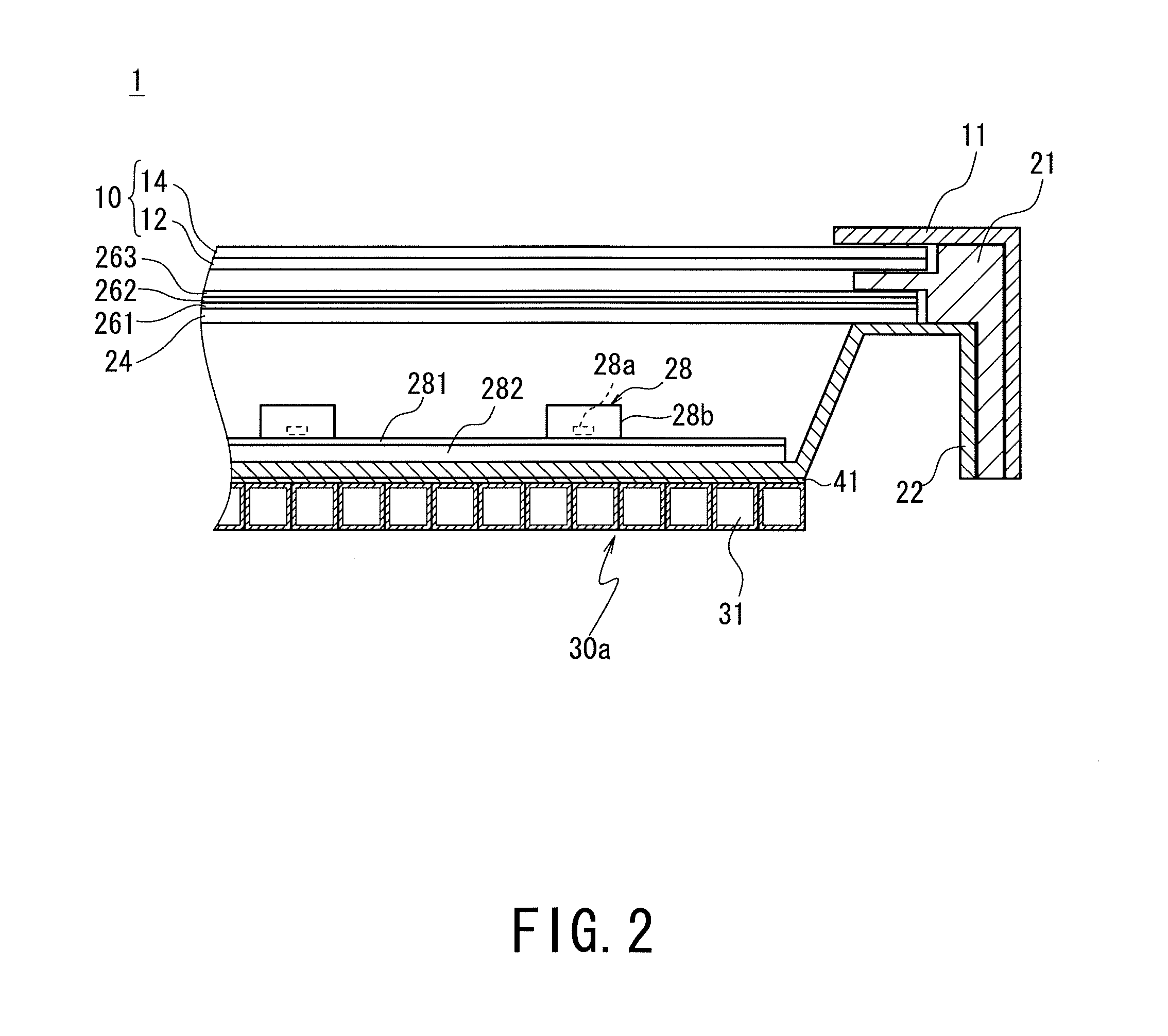

Liquid crystal display device, and LED backlight unit

InactiveUS20120320566A1Improve cooling effectUnnecessary to provideLighting heating/cooling arrangementsIlluminated signsLiquid-crystal displayEngineering

Provided is a liquid crystal display device and a backlight unit that are of high quality and have a simple configuration that a mechanism cooling a cooling medium is not included. Included are a liquid crystal display panel and an LED backlight unit including an LED light source emitting light toward the panel, and a chassis plate on which the light source is disposed, the plate including a through flow path for cooling air dissipating heat from the light source, wherein the path includes a main duct introducing the cooling air and disposed along one side of the panel, and a branch duct branching off from the main duct, aligned along a disposed direction of the light source, and including an exhaust port disposed at an end of the branch duct and discharging the cooling air to outside of the device.

Owner:SHARP KK

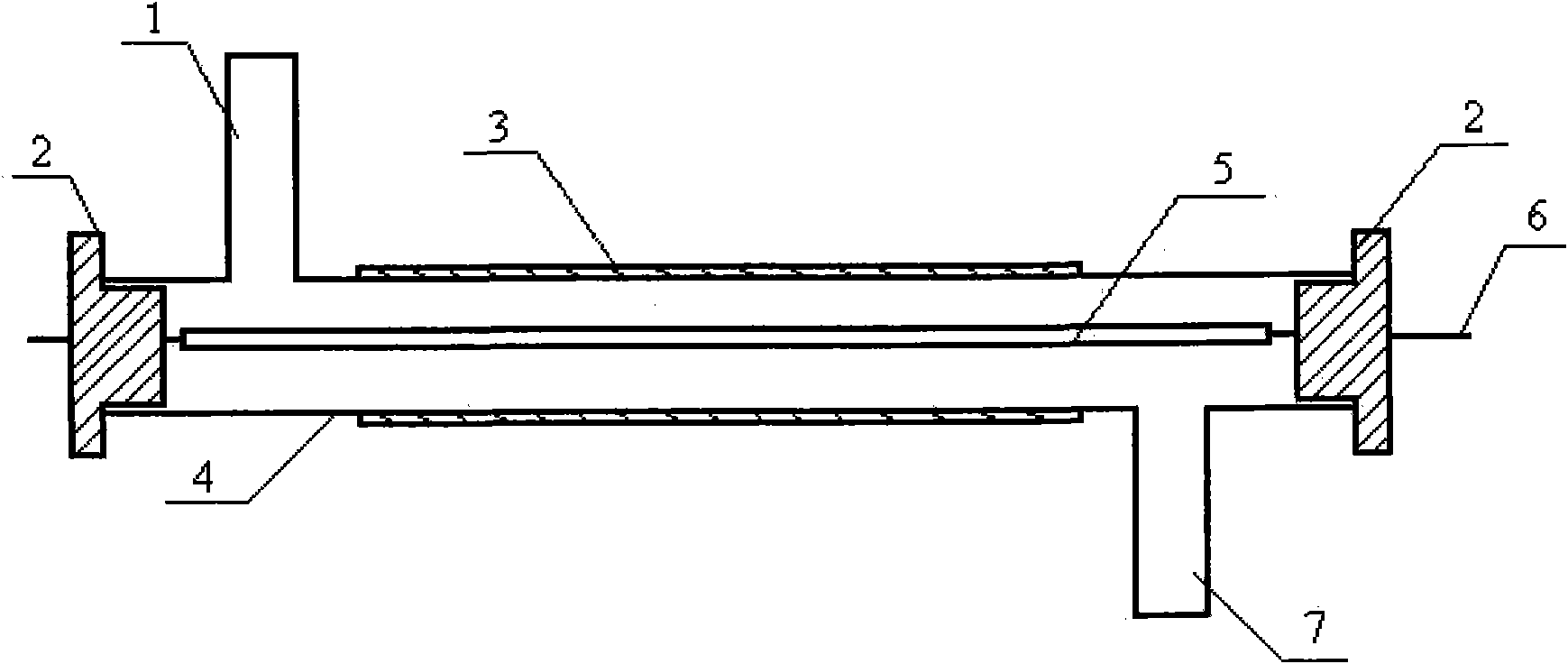

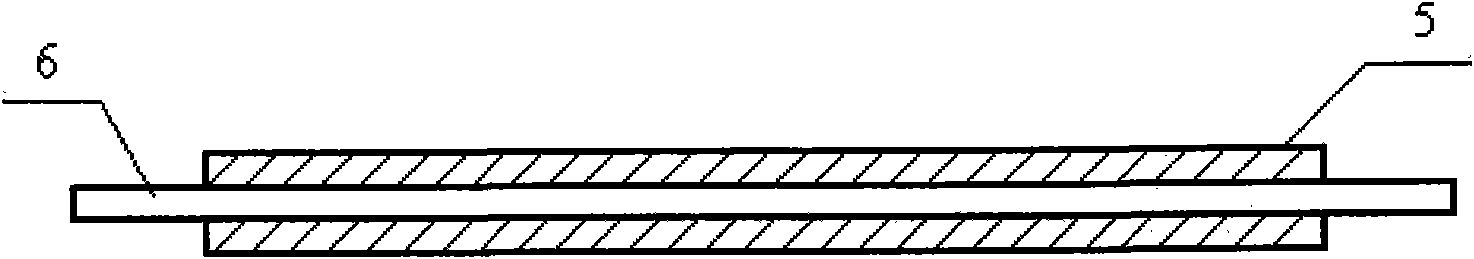

Double-dielectric barrier discharge low-temperature plasma generator

InactiveCN101835336AEvenly distributedImprove conversion efficiencyPlasma techniqueHigh energyLow voltage

The invention discloses a double-dielectric barrier discharge low-temperature plasma device, and belongs to the field of low-temperature plasma technology. The plasma device comprises an air inlet (1), a polytetrafluoroethylene plug (2), a low voltage electrode (3), a quartz glass tube A (4), a quartz glass tube B (5), a high voltage electrode (6) and an air outlet (7), wherein the outer layer of the high voltage electrode (6) is the quartz glass tube B (5), and the low voltage electrode (3) consists of constantan sheets and is led out by a lead wire and grounded. In the process of treating pollutant gas, the low-temperature plasma generator can effectively reduce the corrosion of air on the high voltage electrode and avoid generating arc discharge and further damaging or breaking down discharge dielectric layers. The formed double-dielectric barrier discharge has high stability and high energy density utilization rate. The low-temperature plasma device can stably work under normal pressure and is applied to the discharge of automotive noxious pollutant gas.

Owner:JIANGSU UNIV

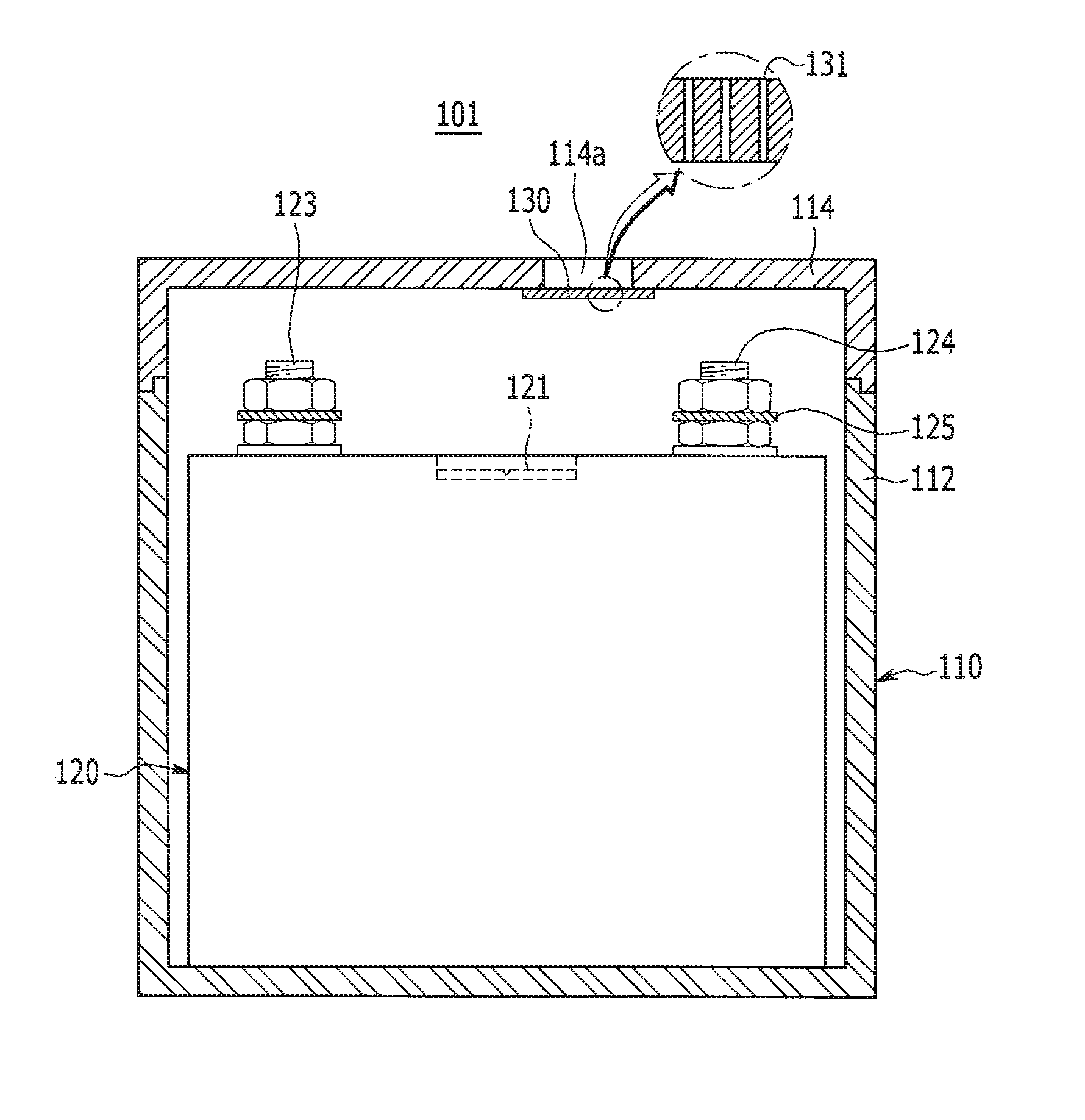

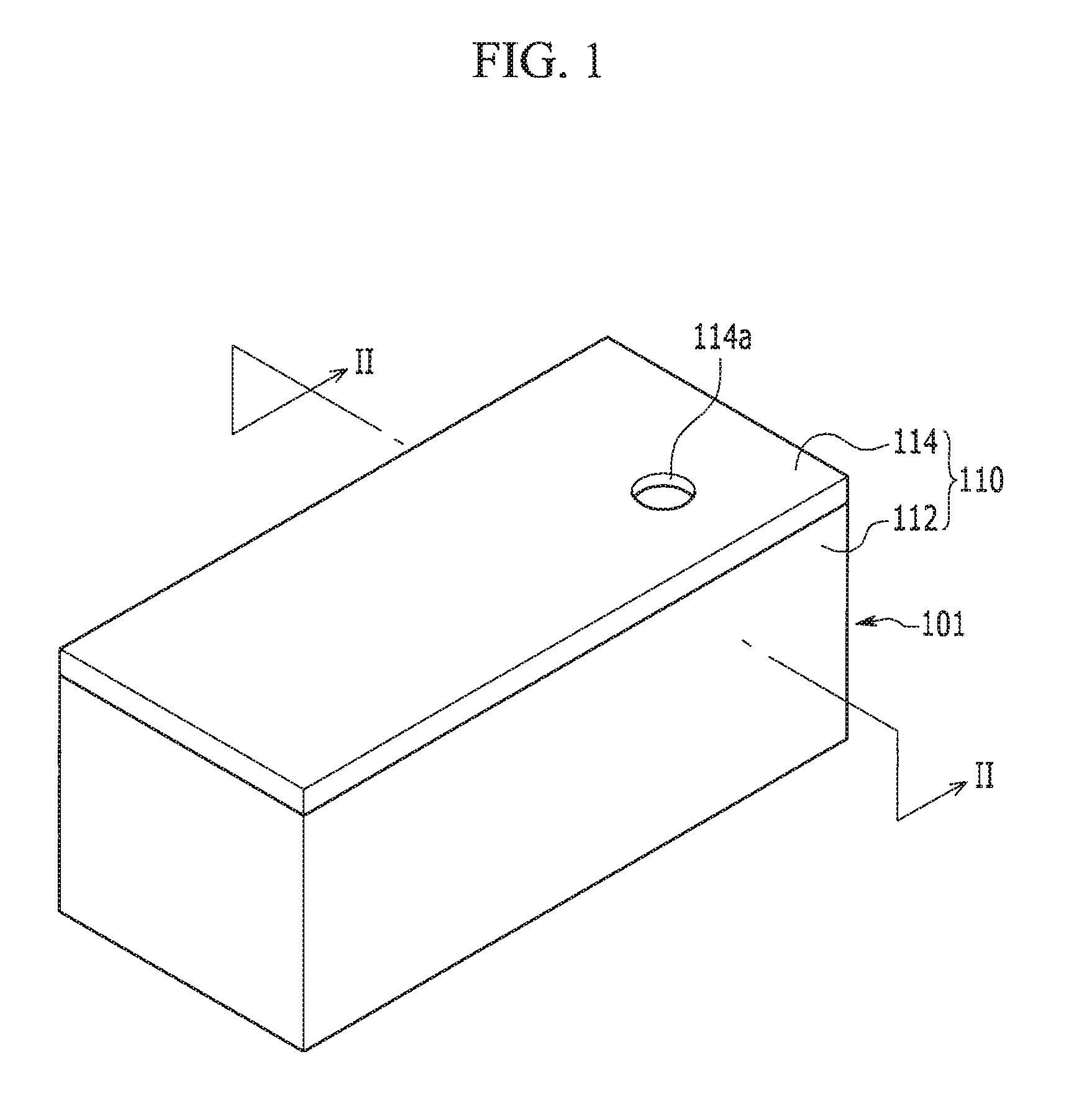

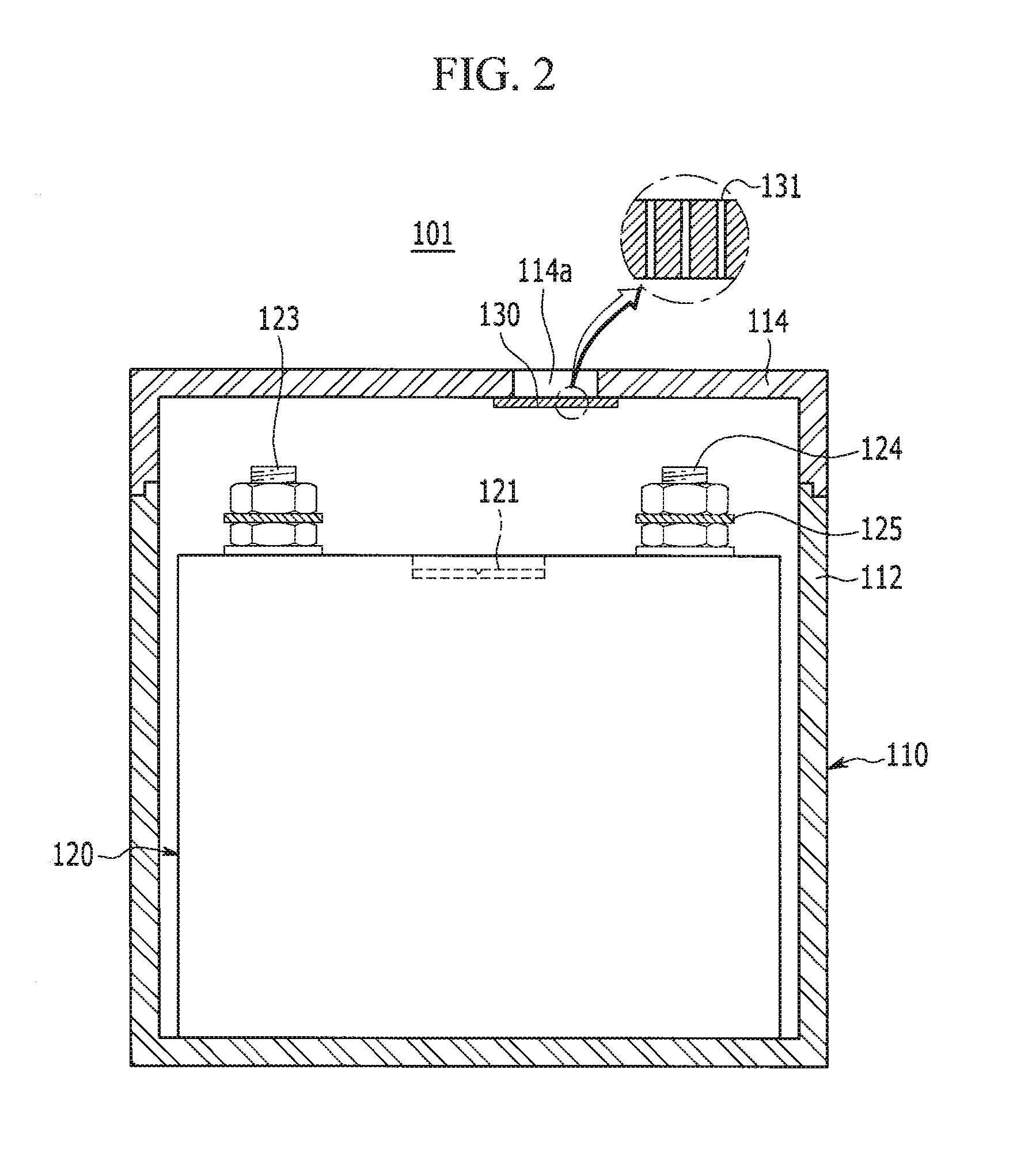

Battery module

ActiveUS20120015218A1Improve securitySmooth dischargeVent arrangementsLi-accumulatorsRechargeable cellWater particle

A battery module includes a plurality of rechargeable batteries and a housing configured to receive the rechargeable batteries, wherein the housing has a vent opening; and a valve configured to close the vent opening, wherein the valve includes a porous film with pores having a diameter larger than that of gas molecules and smaller than that of water particles.

Owner:ROBERT BOSCH GMBH +1

Recording Ink, Ink Catridge, Ink Record, Inkjet Recording Apparatus, and Inkjet Recording Method

ActiveUS20080070008A1Good colorSmooth dischargeMeasurement apparatus componentsDecorative surface effectsOrganic solventWater soluble

The recording ink having a water, a water-soluble organic solvent, a colorant, and at least one fluorochemical surfactant selected from the following Structural Formulae (1) to (3). Structural Formula (1): where, Rf is a fluorine-containing group; and m, n, and p are integers in the Structural Formula (1). Structural Formula (2): where, Rf is a fluorine-containing group; X is a cationic group; Y is an anionic group; and q is an integer in the Structural Formula (2). Structural Formula (3): where, Rf is a fluorine-containing group; X is a cationic group; Y is an anionic group; and q is an integer in the Structural Formula (3).

Owner:RICOH KK

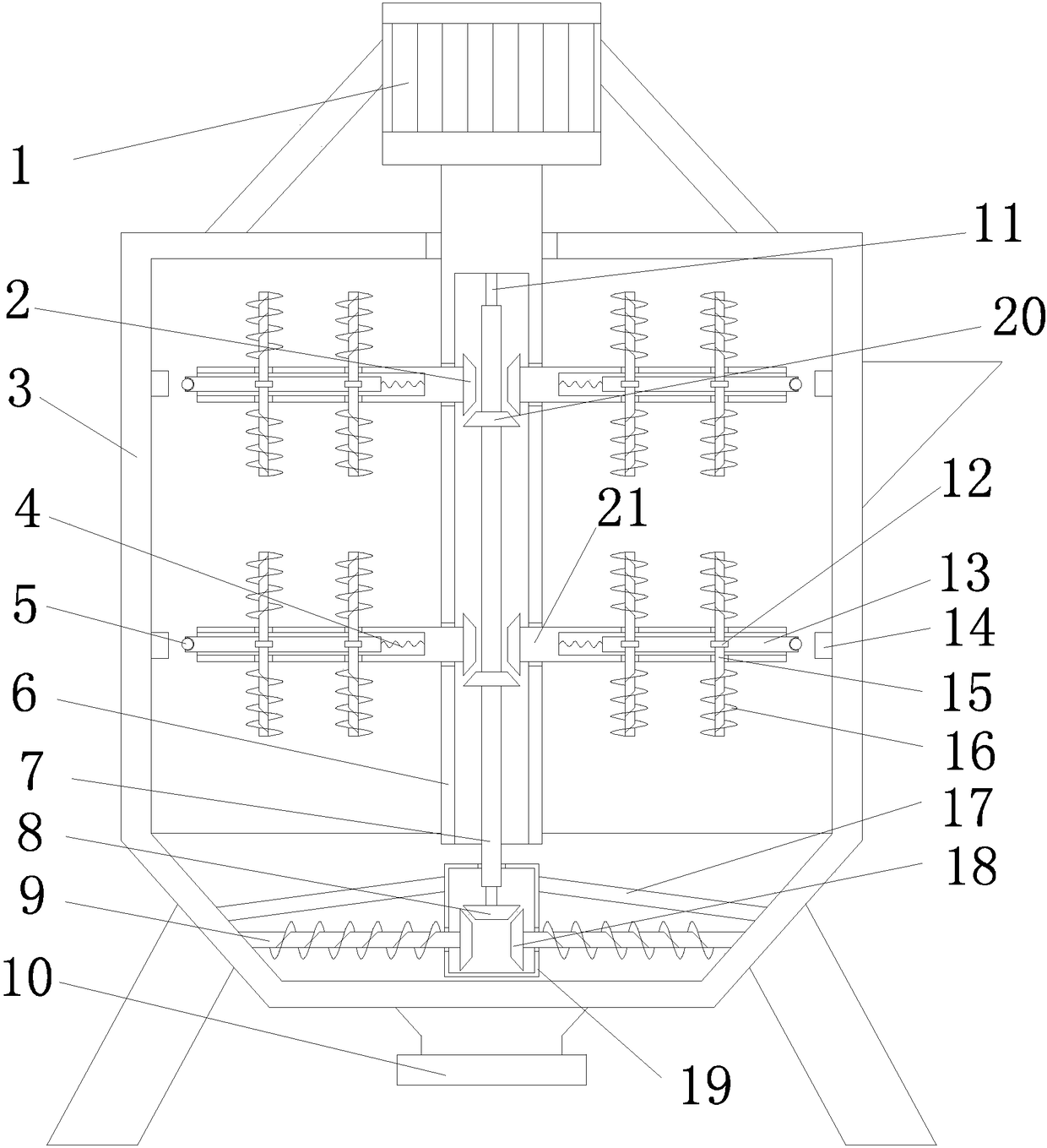

Method for producing fine sand concrete gel containing waste stone dust through concrete mixing device

ActiveCN108394027ASimple structureRaw materials are mixed evenlyCement mixing apparatusEngineeringMotor drive

The invention discloses a method for producing fine sand concrete gel containing waste stone dust through a concrete mixing device. The concrete mixing device comprises a mixing tank and supporting legs fixed to the bottom of the mixing tank. One side of the mixing tank communicates with a feed hopper. The bottom of the mixing tank communicates with one end of a discharge pipe. The concrete mixingdevice is simple in structure. A motor drives a hollow shaft to rotate. The hollow shaft and a fixed shaft rotate relatively to drive mixing shafts to rotate to conduct mixing on a raw material for the first time. A first bevel gear is engaged with a fourth bevel gear to drive the mixing shaft to rotate and then drive rotary shafts and spiral blades to conduct mixing on the raw material for the second time. When the rotary shafts revolve around the hollow shaft, under the action of springs, racks abut against corresponding arc-shaped blocks intermittently and are driven to do reciprocation motion. The racks are engaged with spur gears to drive the rotary shafts and the spiral blades to do reciprocating rotation to conduct mixing on the raw material for the third time. The raw material ismixed more evenly through three combined mixing, and the strength of concrete is guaranteed. Meanwhile, the hollow shaft drives the spiral blades to rotate through a connecting shaft, and the concretecan be discharged smoothly to prevent blockage.

Owner:FUJIAN HONGGAO STONE POWDER COMPREHENSIVE UTILIZATION CO LTD

Device for opening and shutting nozzle of cosmetic case

InactiveUS20100224652A1Smooth dischargeAvoid introducingClosuresLiquid flow controllersEngineeringSupport point

A device for opening a nozzle during use of a cosmetics case and closing the nozzle during non-use has an operation button and a guide pipe with a rod-shaped pin for opening and closing the nozzle and a push pin with a ring-shaped engagement recess parallel to the rod-shaped pin. A rear side of the push pin is engaged with a spring enabling the pin for opening and shutting the nozzle and the push pin to move forward. The support axis of the operation button is provided with an operation lever that is pivoted about a hinge hole which is a support point and is in engagement with the push pin for opening and closing the nozzle when the button is pressed. The nozzle is opened before a pumping operation for smoothly discharging the cosmetics. Thereafter and until the next use of the case, the nozzle is closed by the elastic force of the spring.

Owner:TOLY KOREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com