Patents

Literature

635 results about "Enhanced heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat exchangers were initially developed to use plain (or smooth) heat transfer surfaces. An Enhanced heat transfer surface has a special surface geometry that provides a higher thermal performance, per unit base surface area than a plain surface.

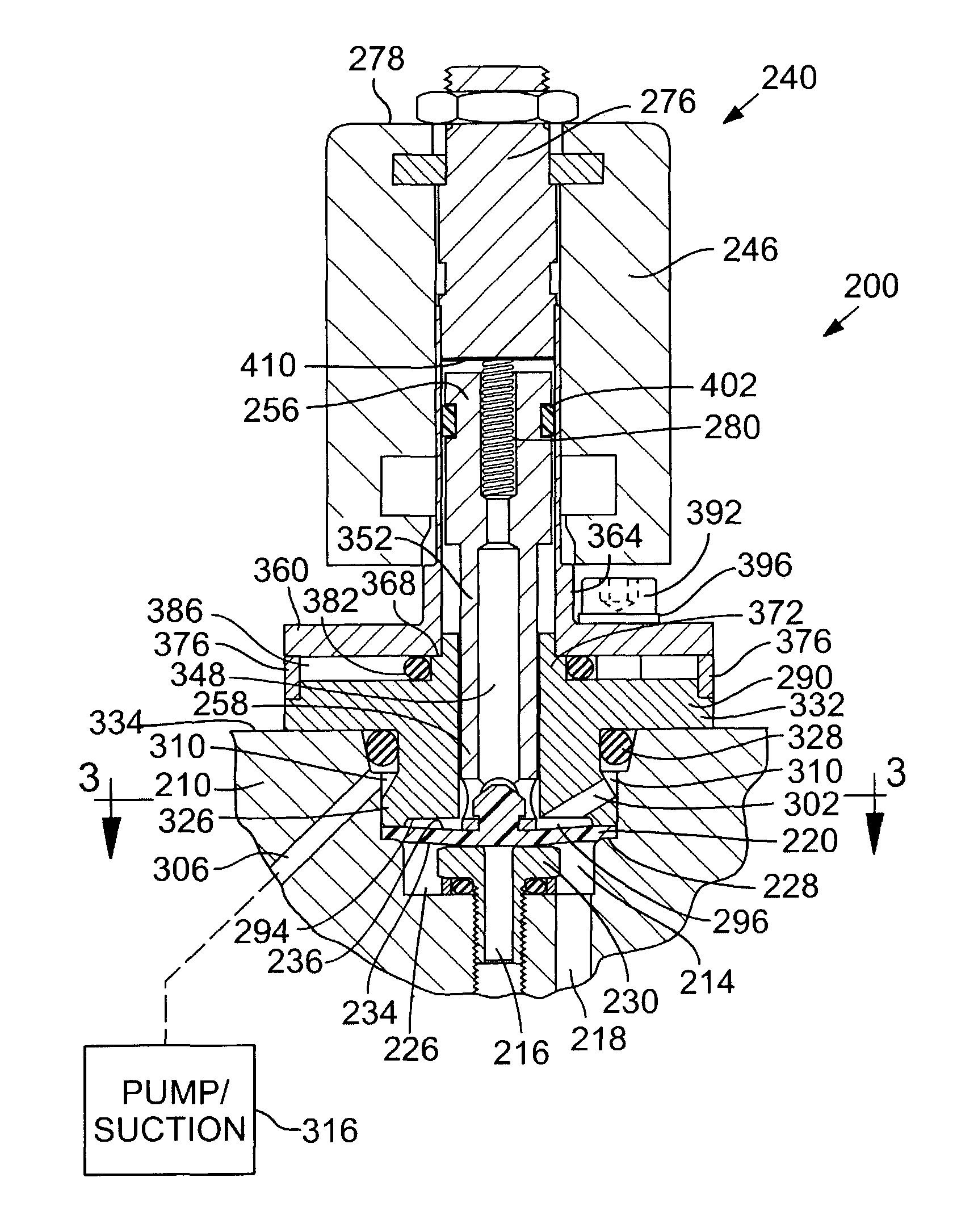

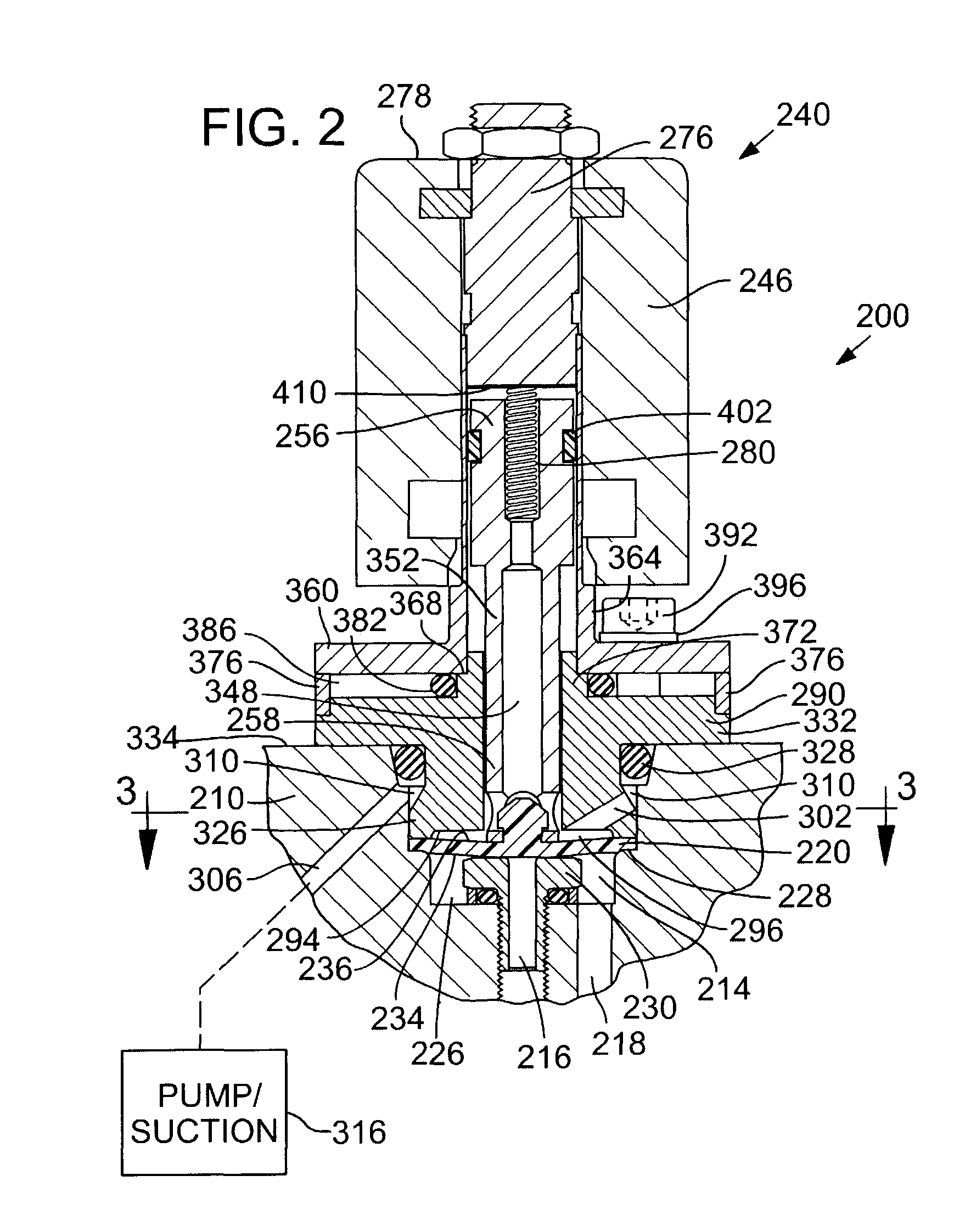

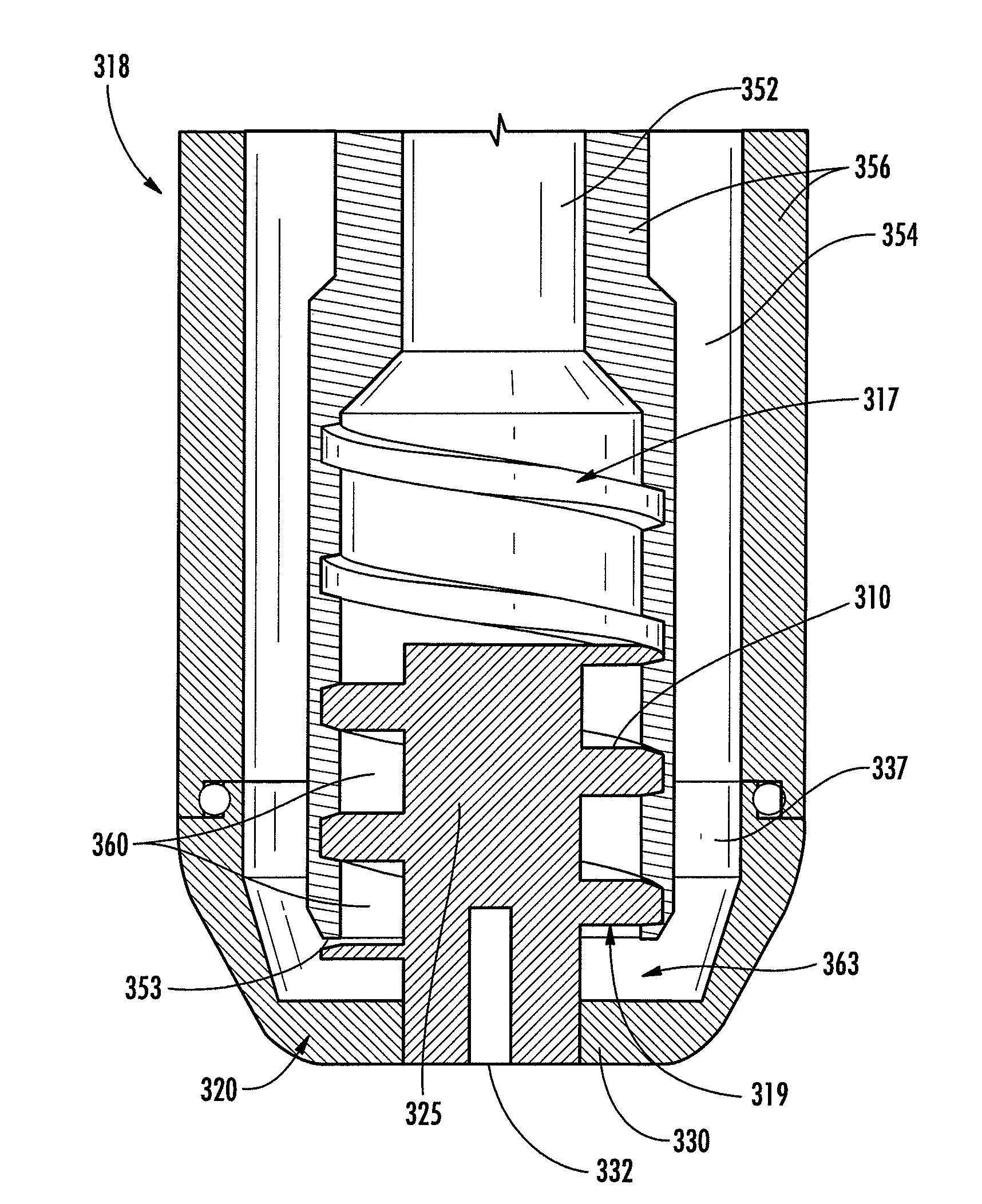

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

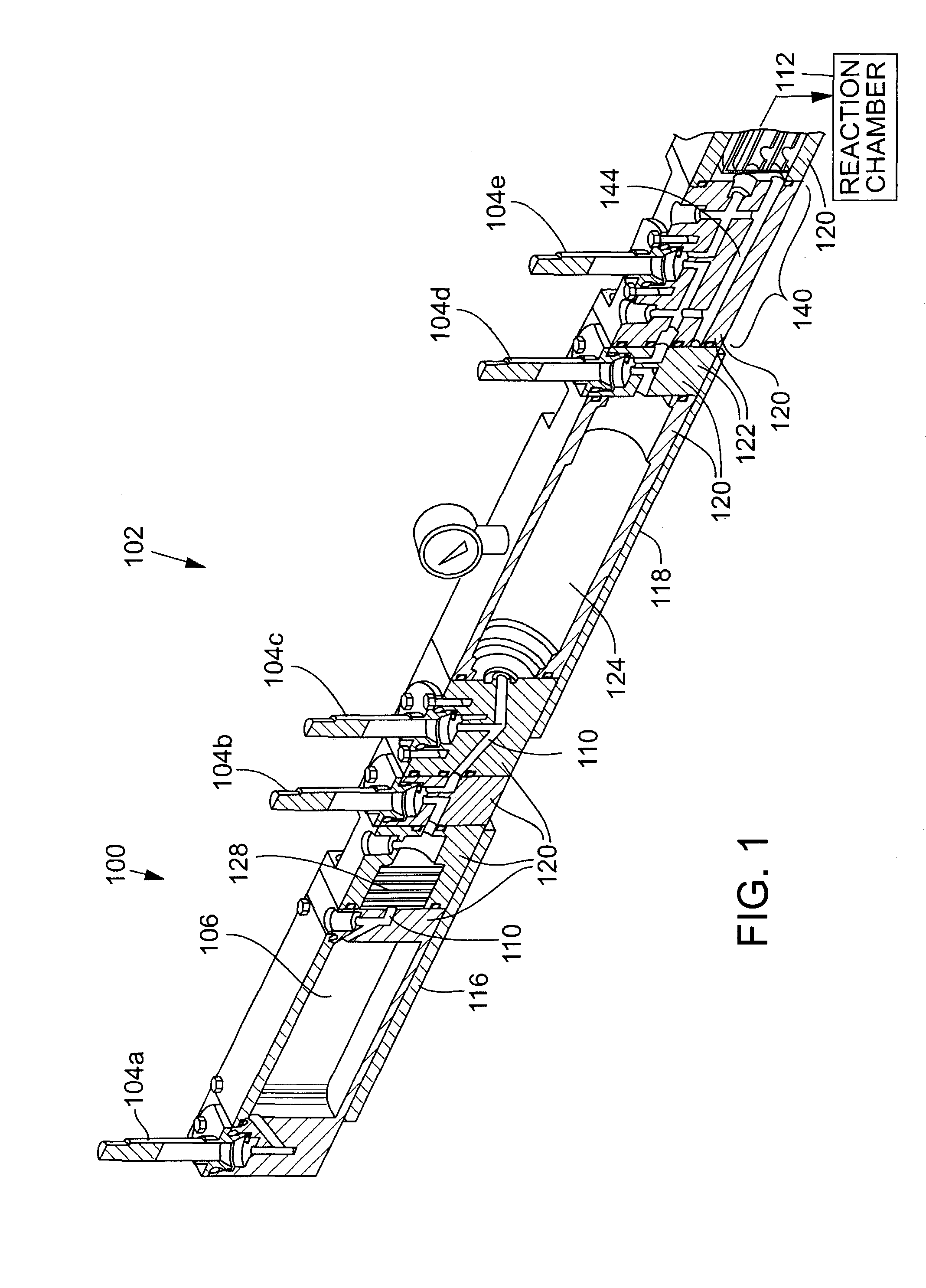

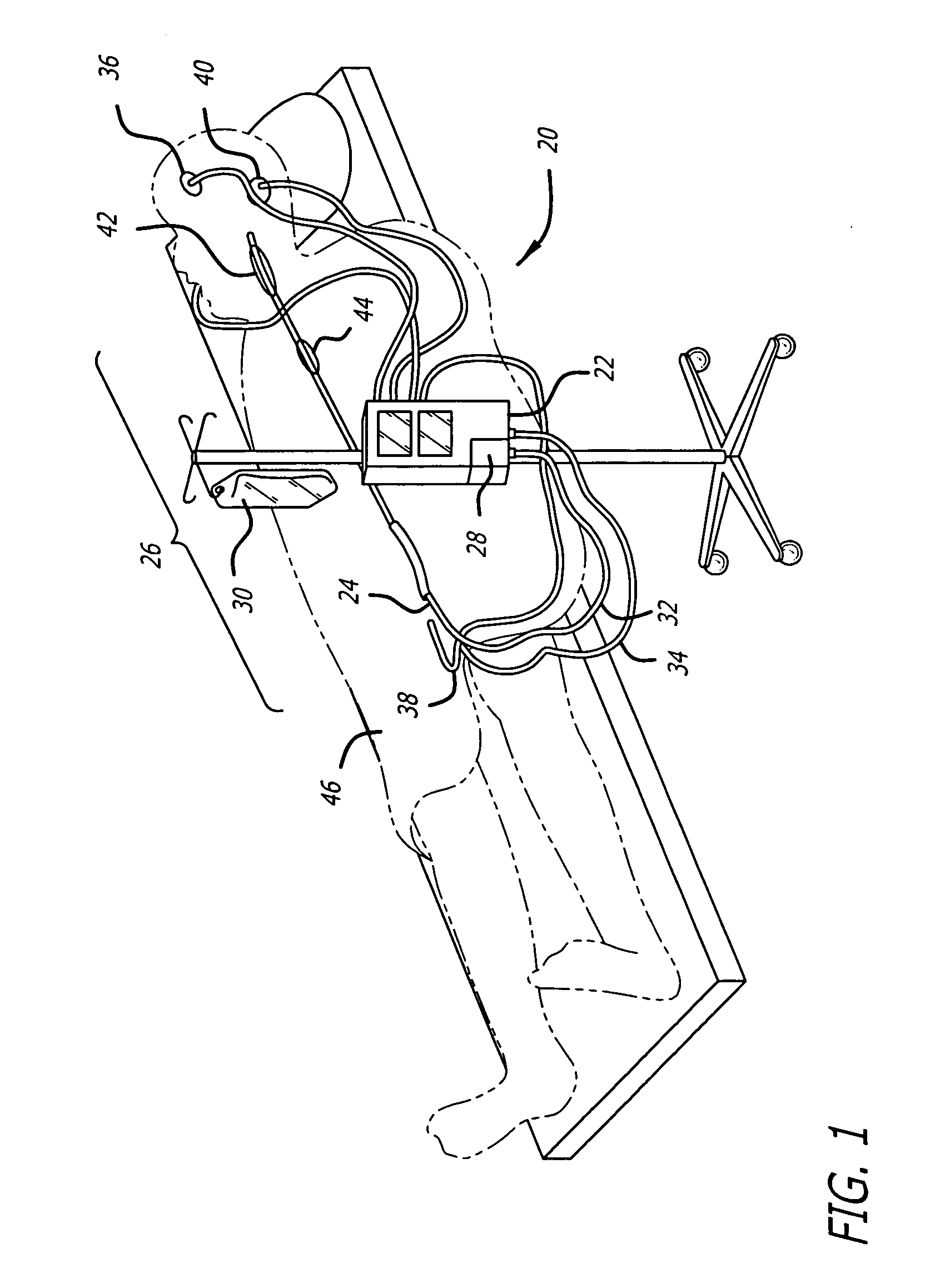

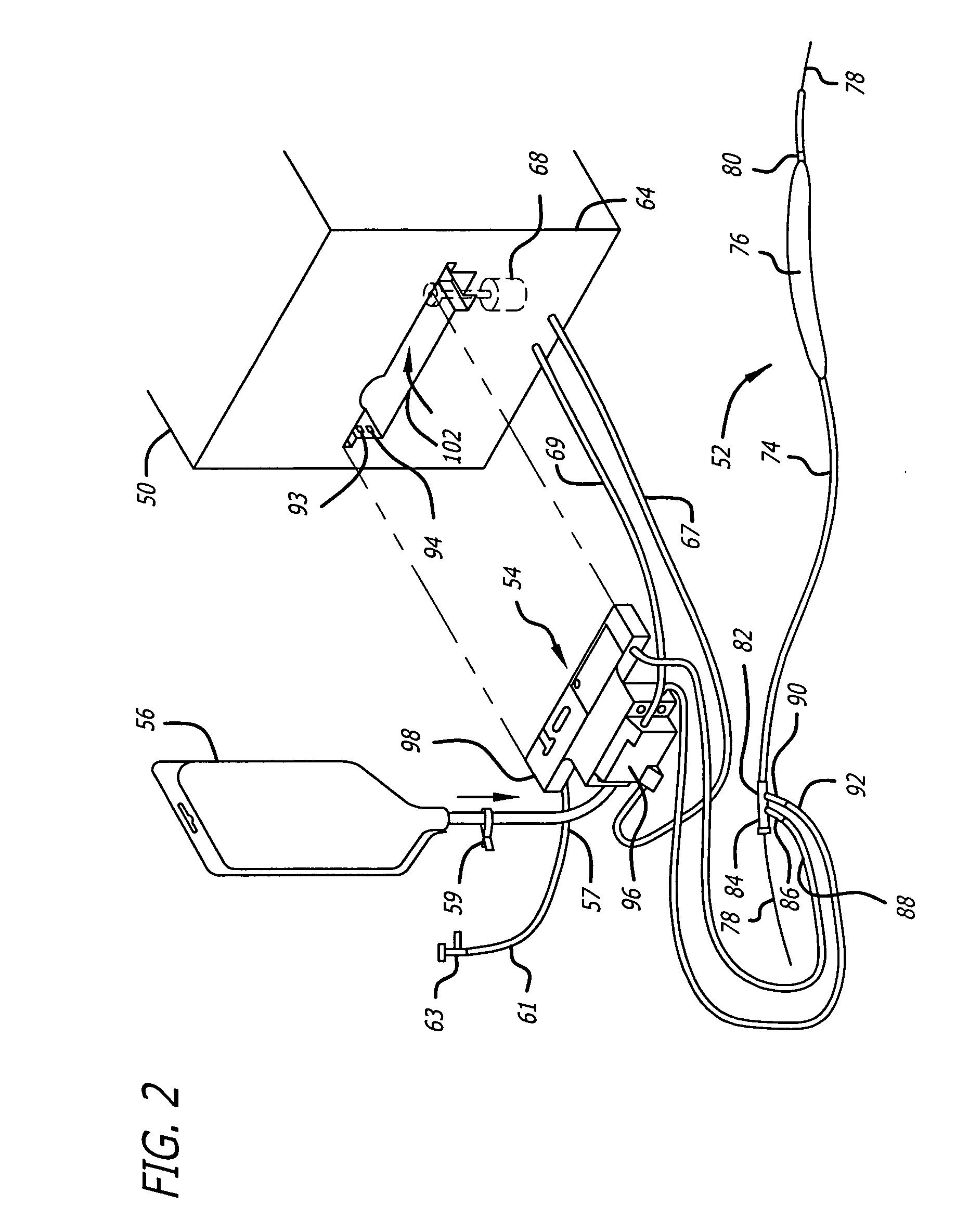

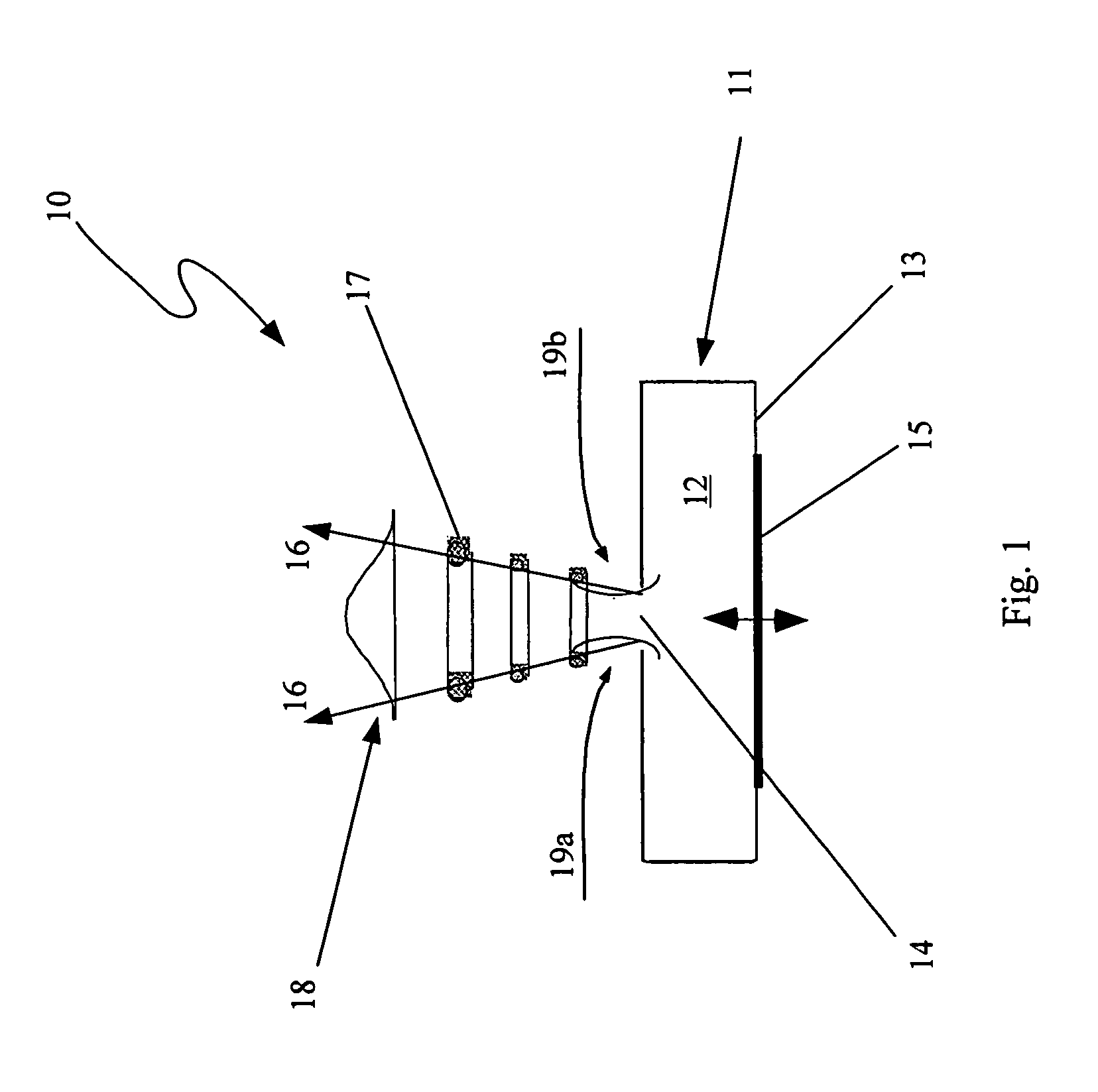

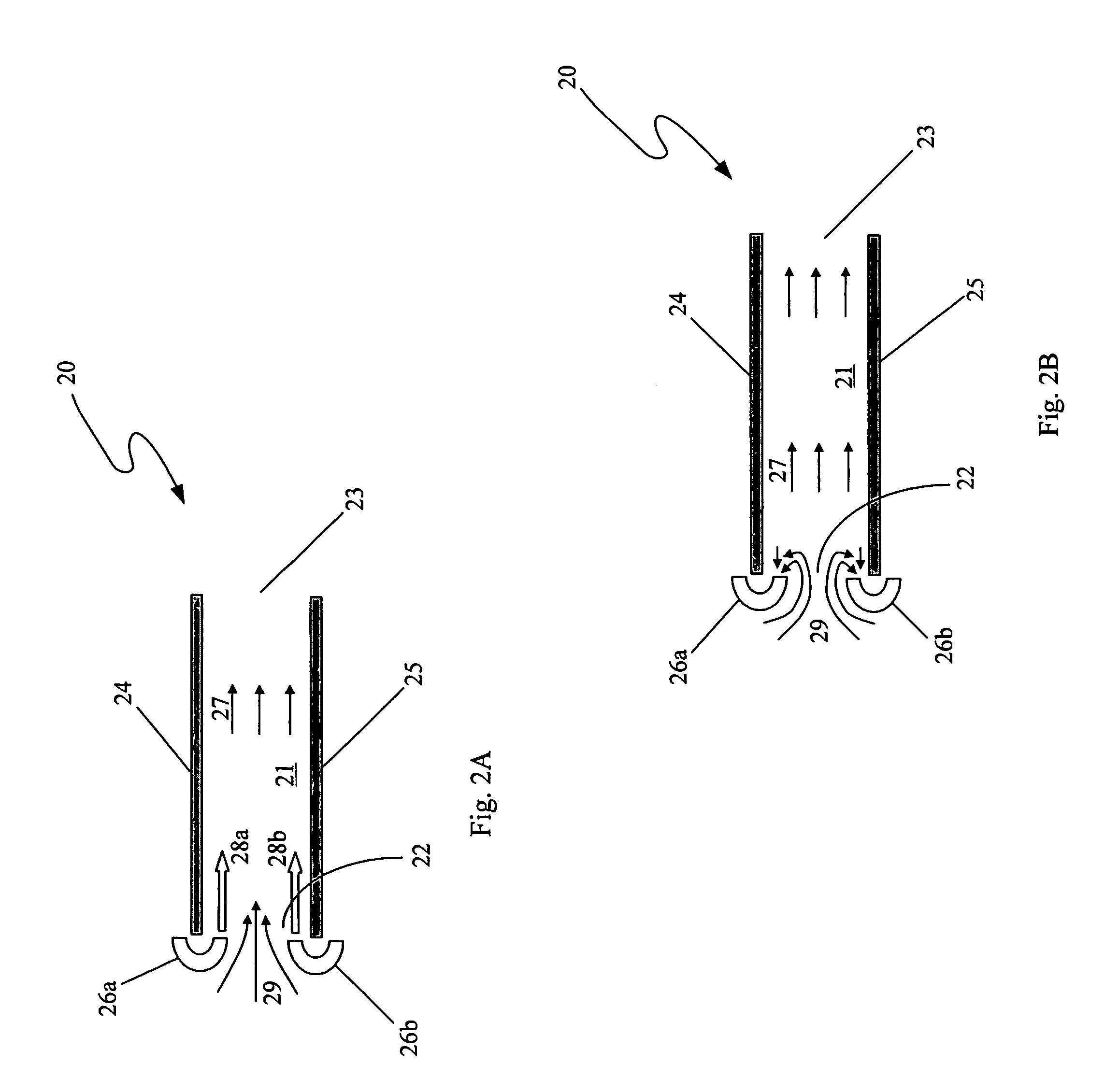

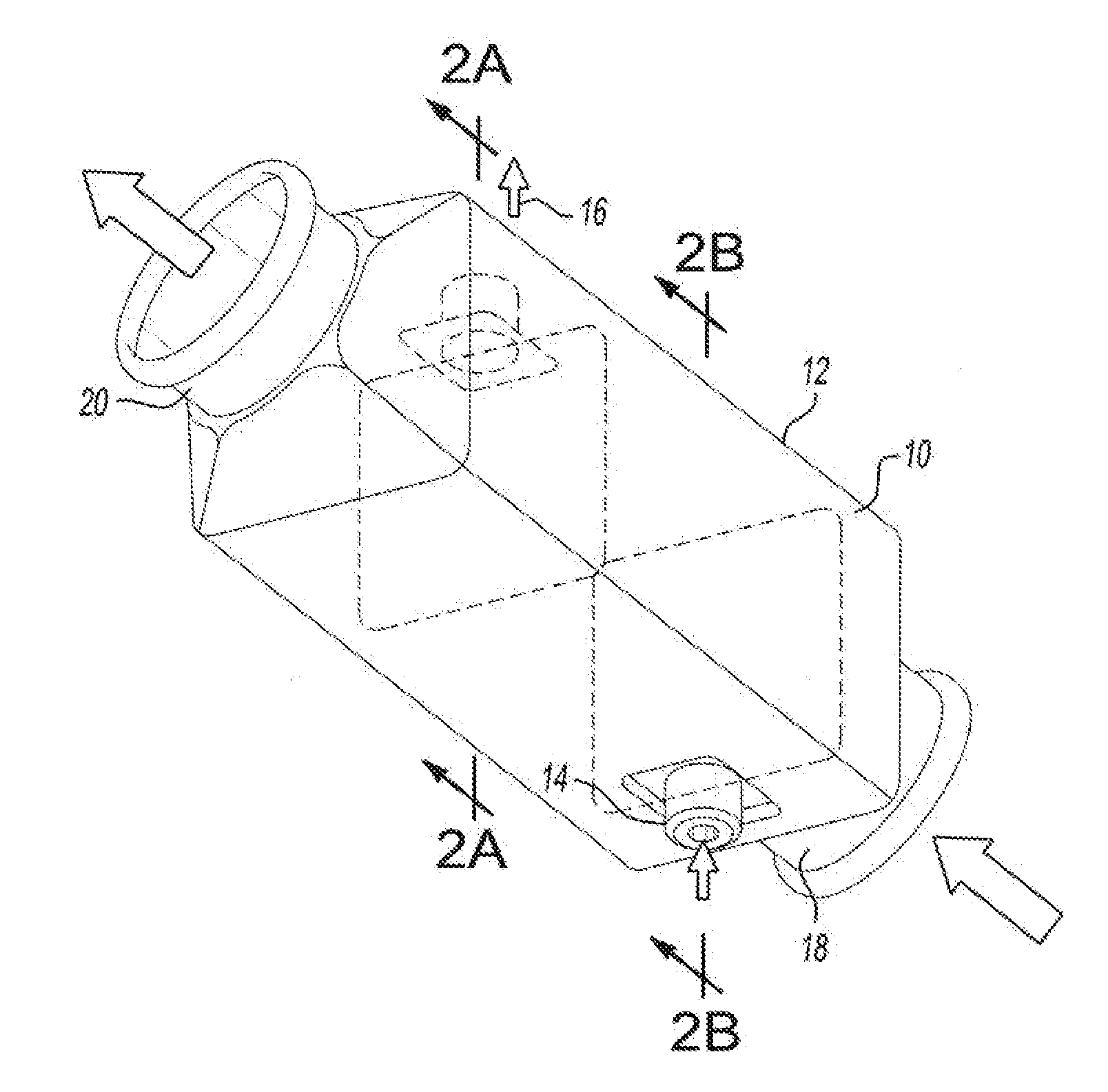

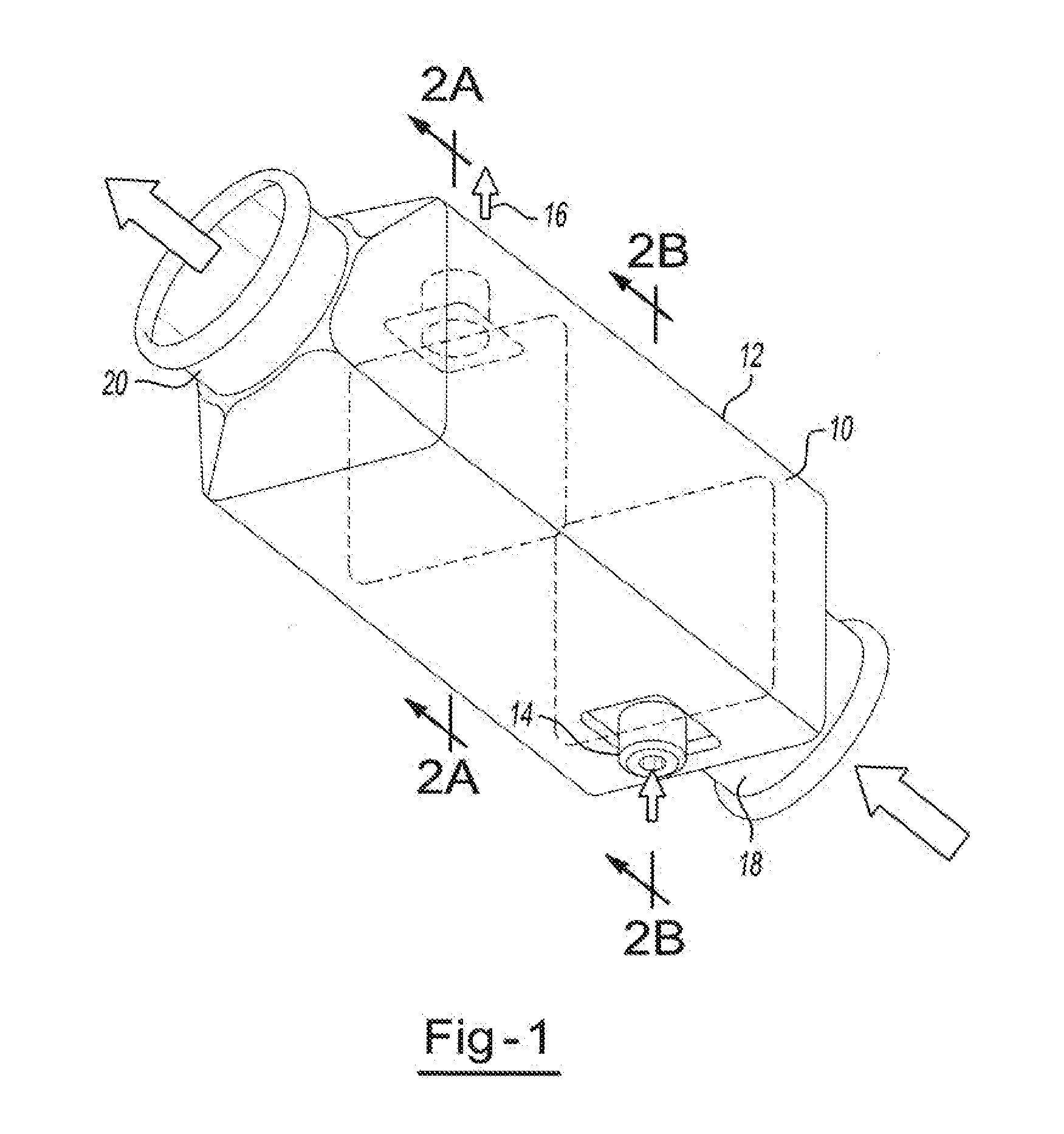

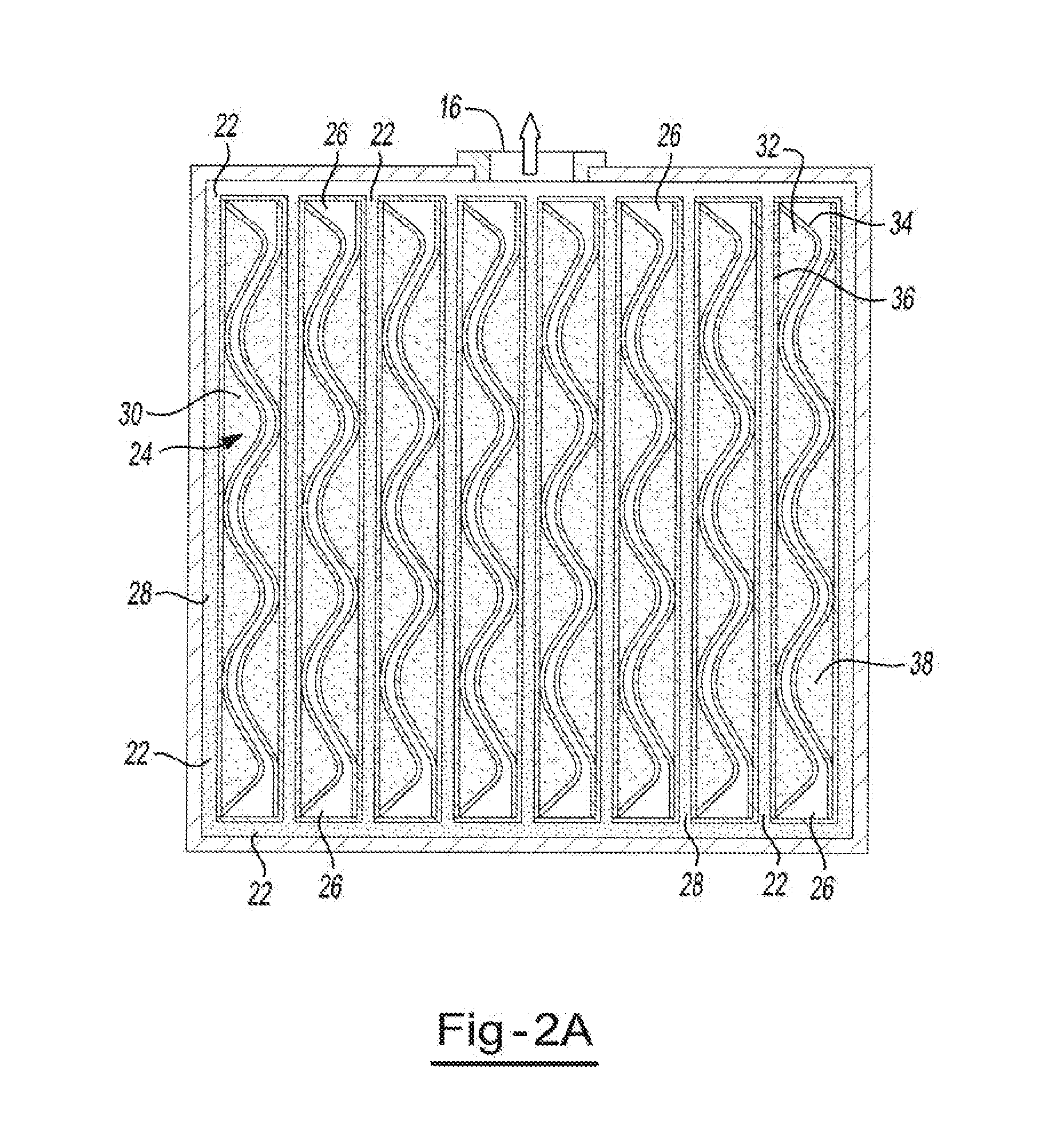

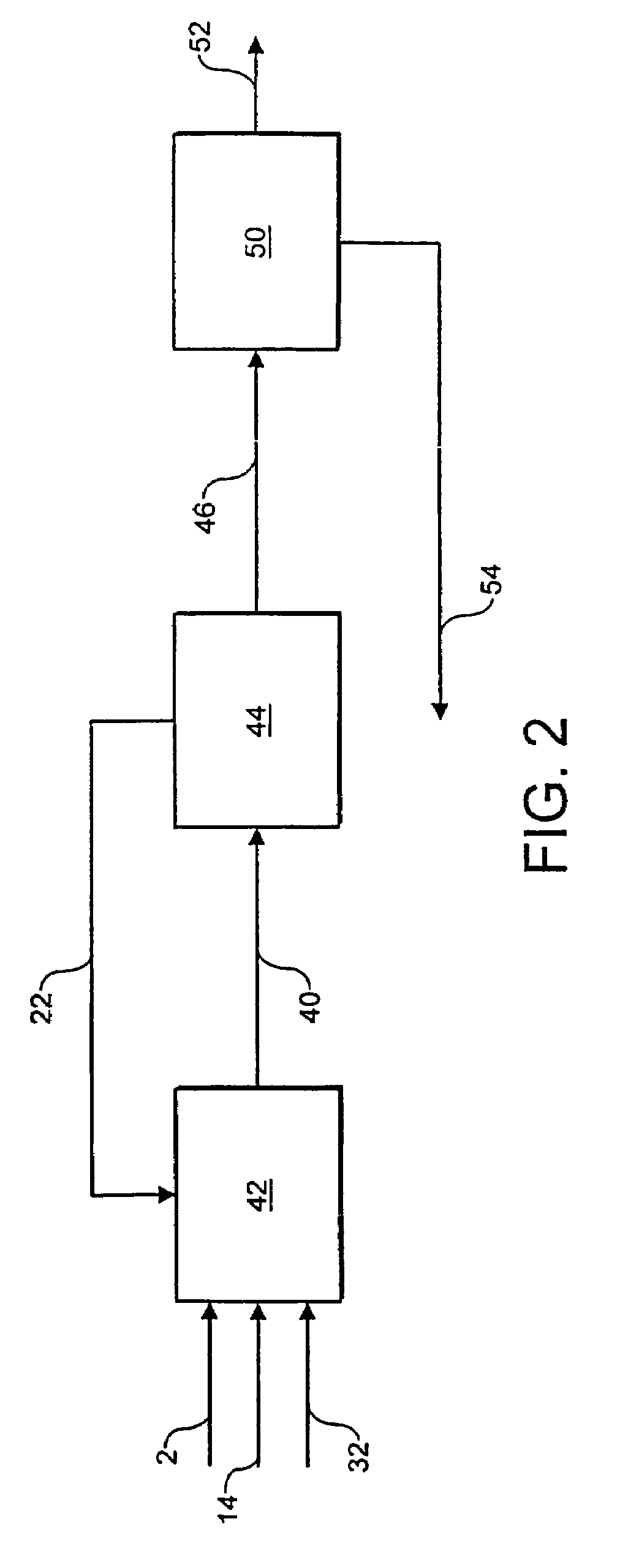

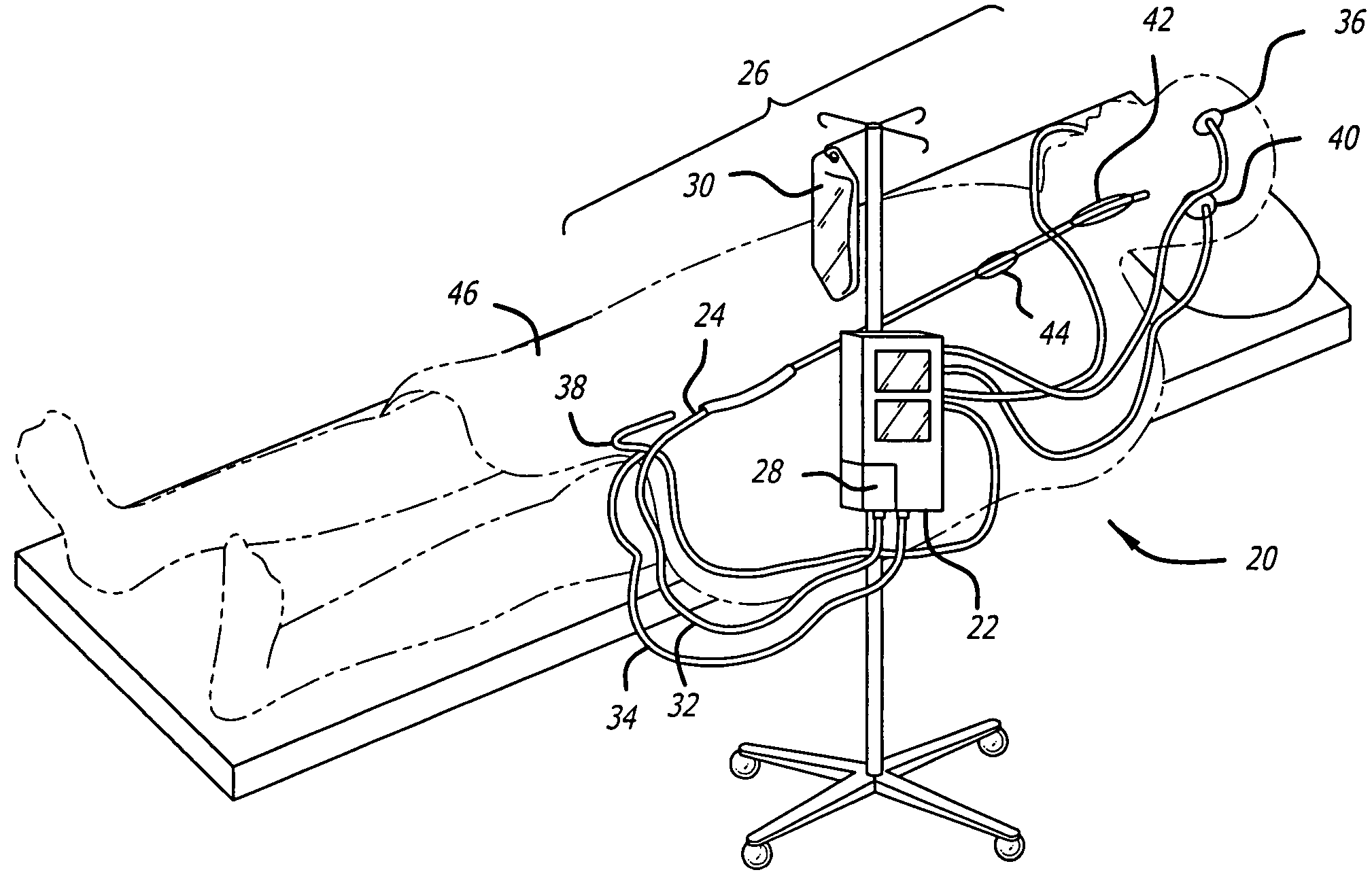

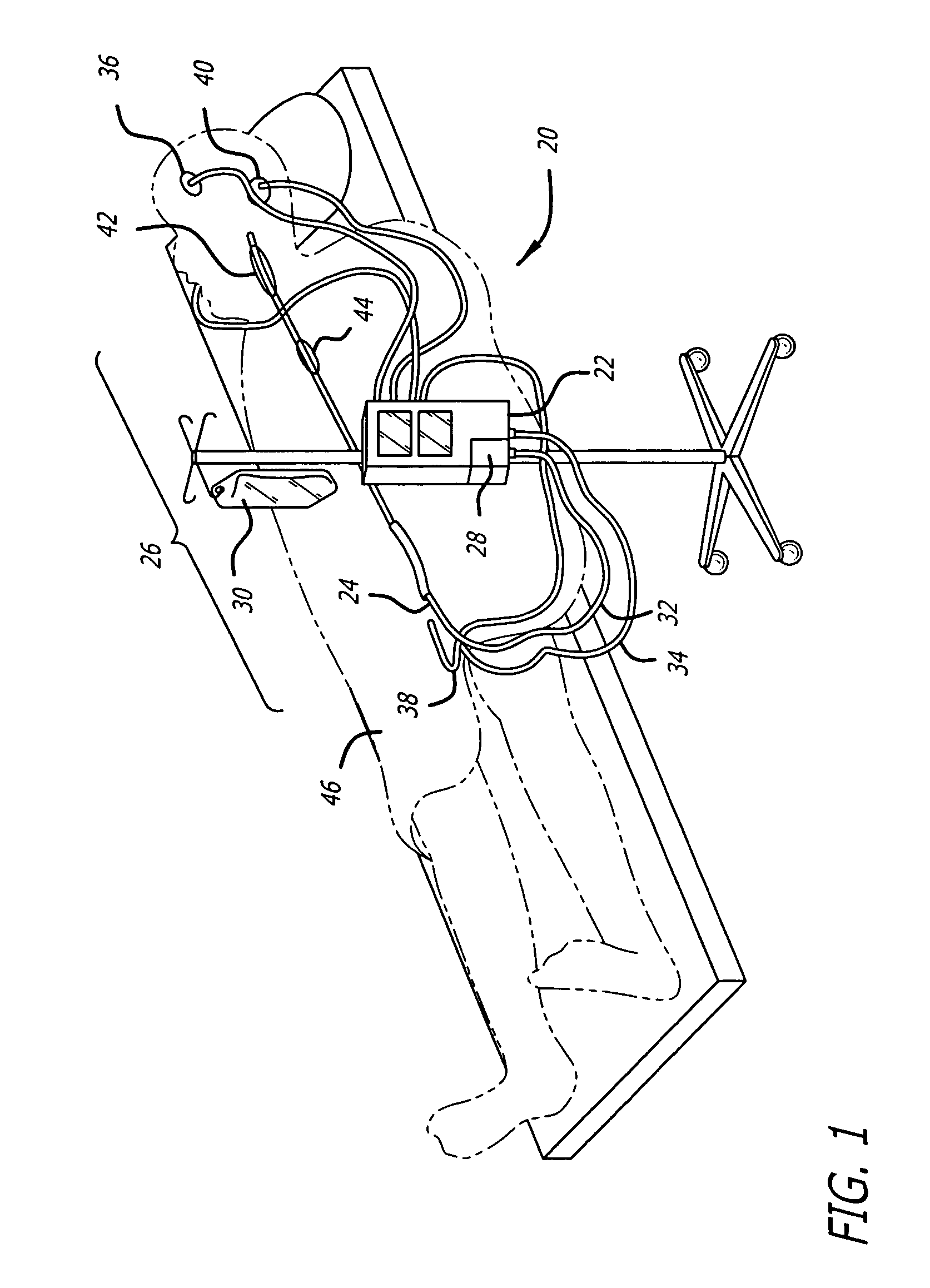

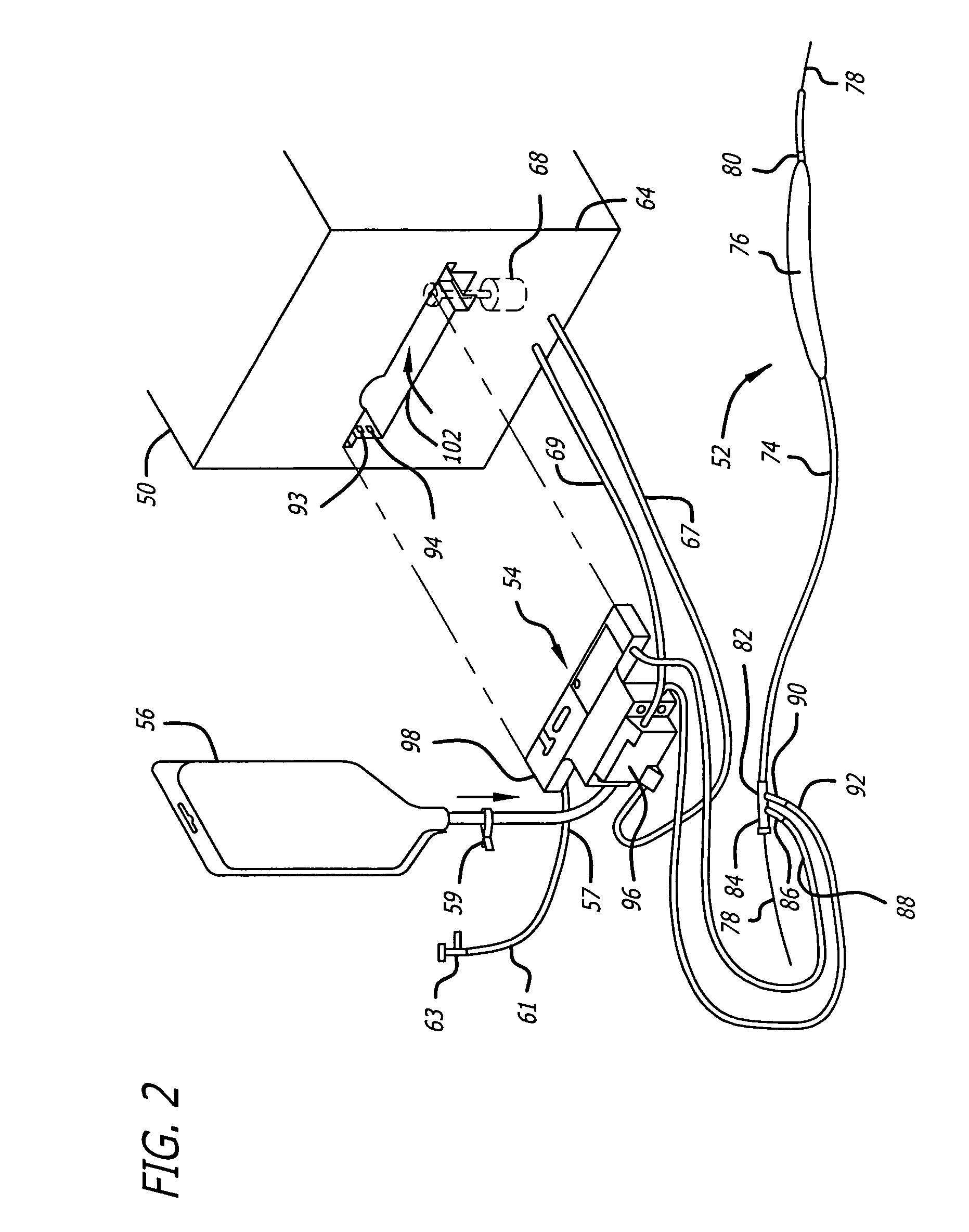

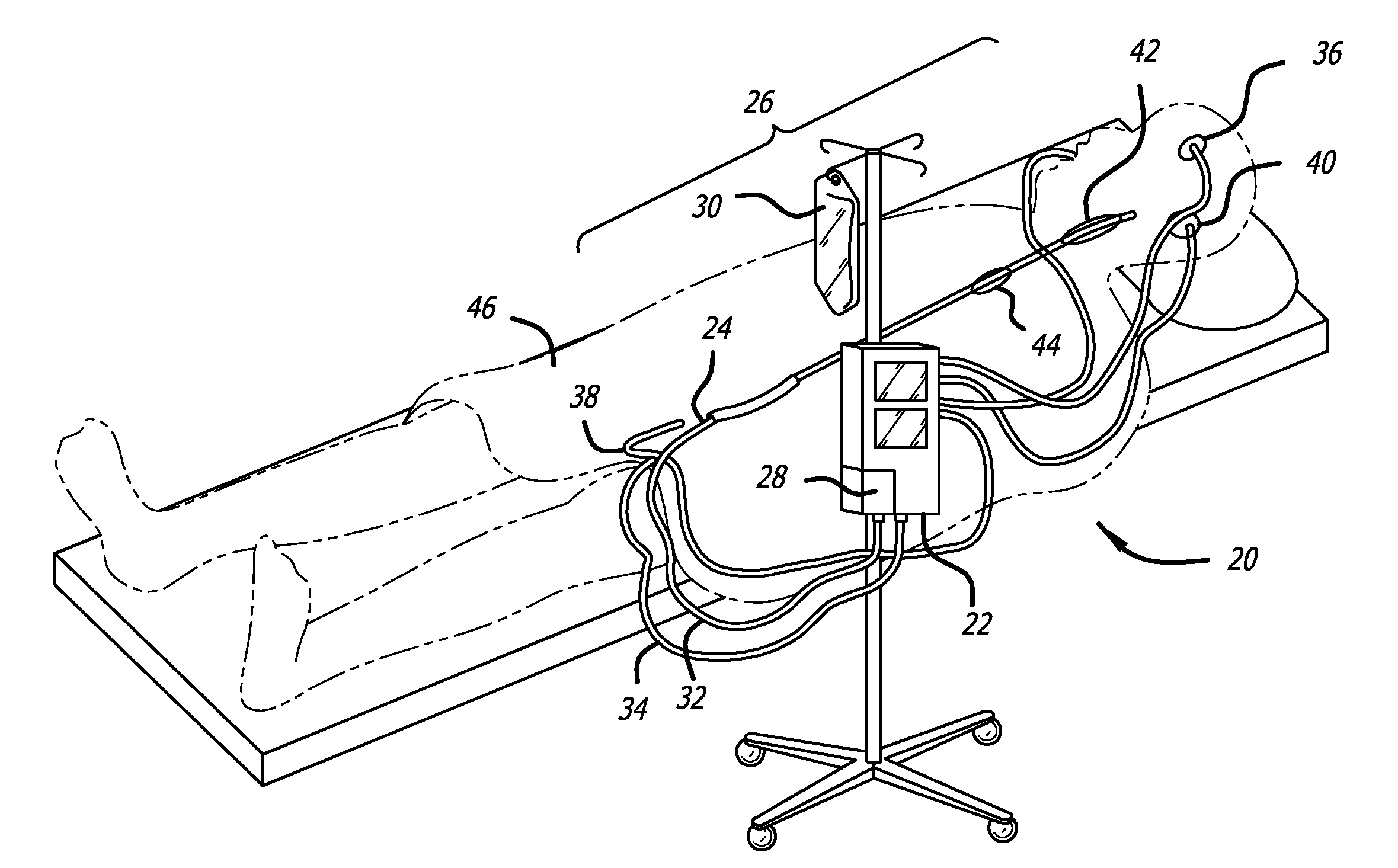

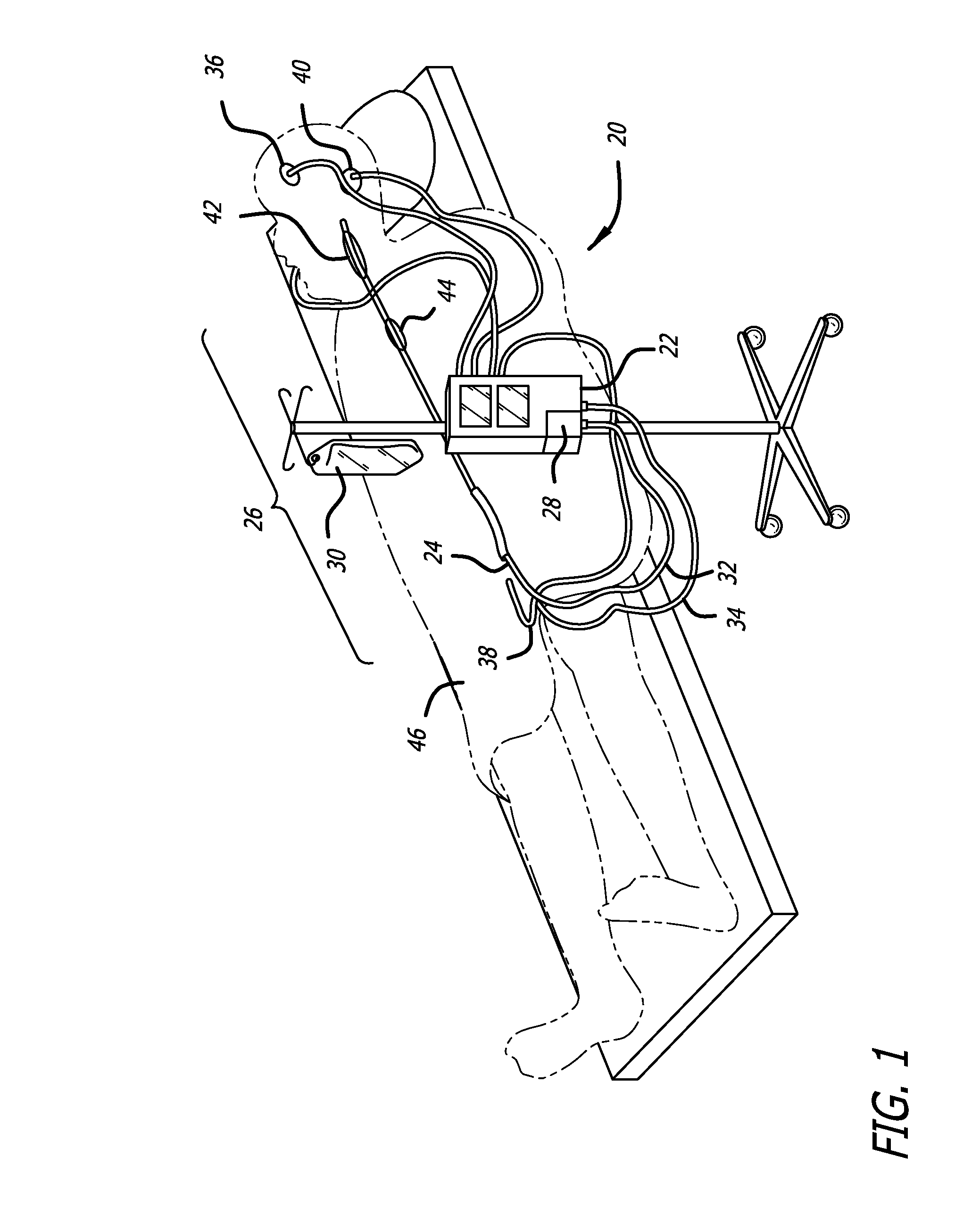

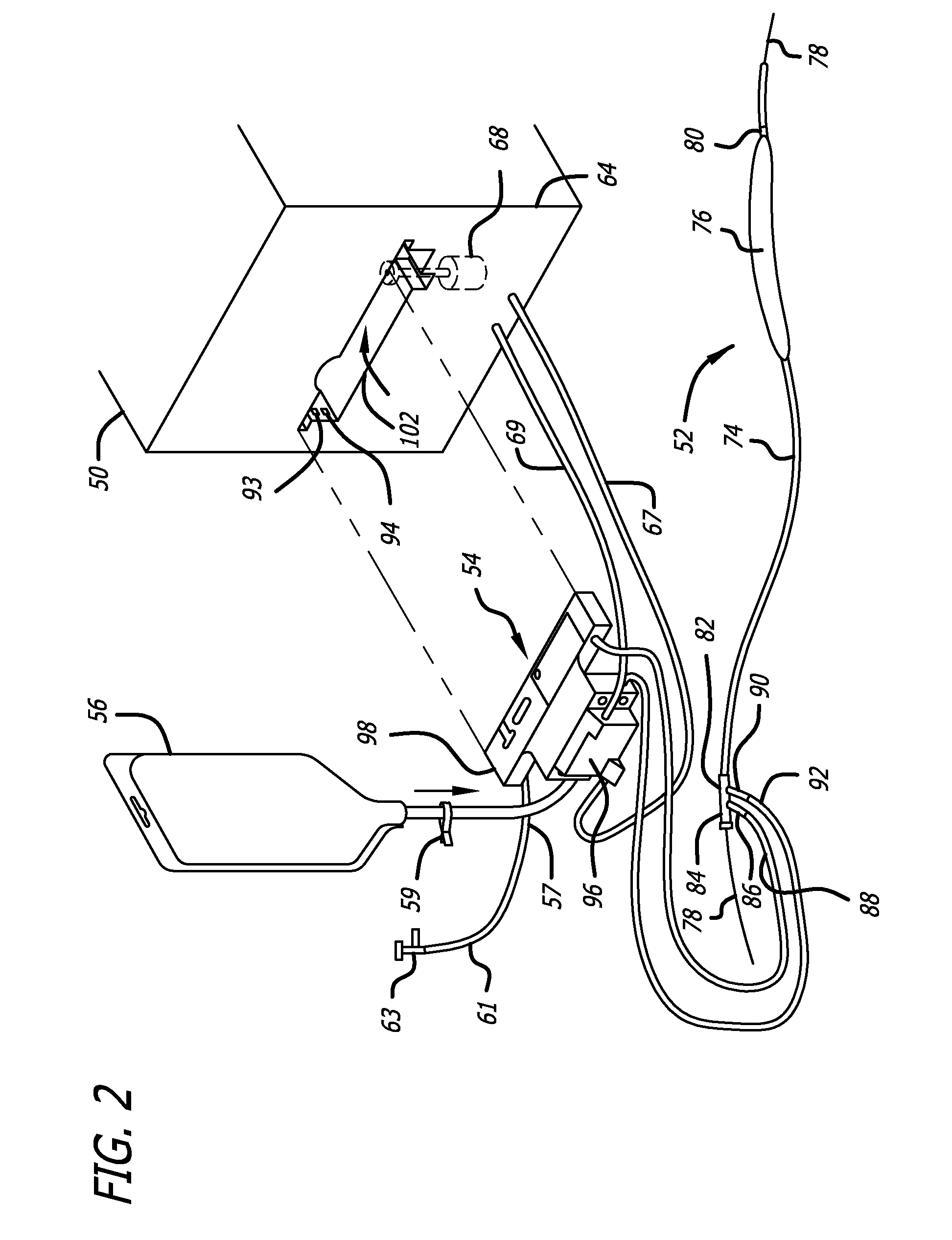

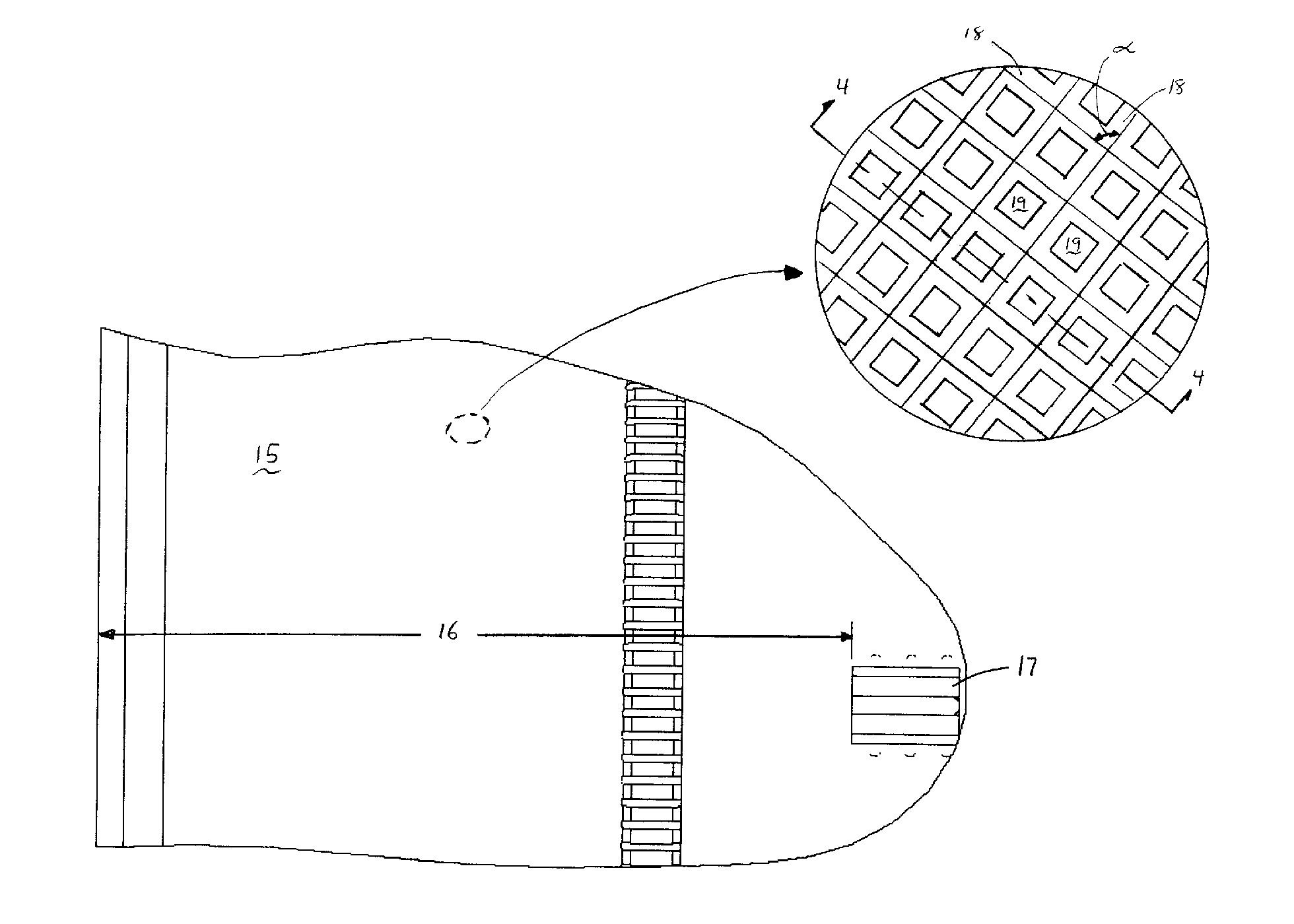

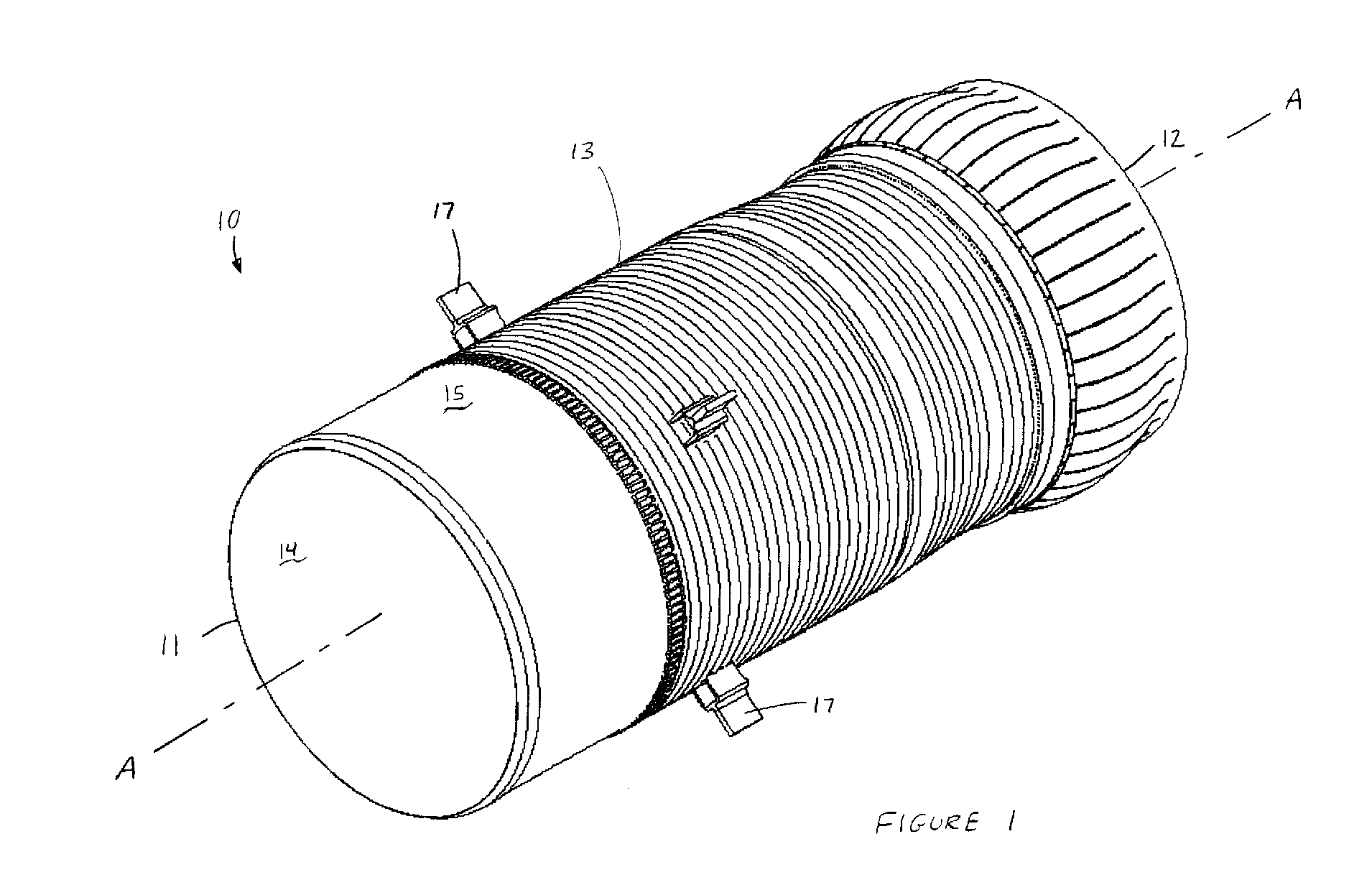

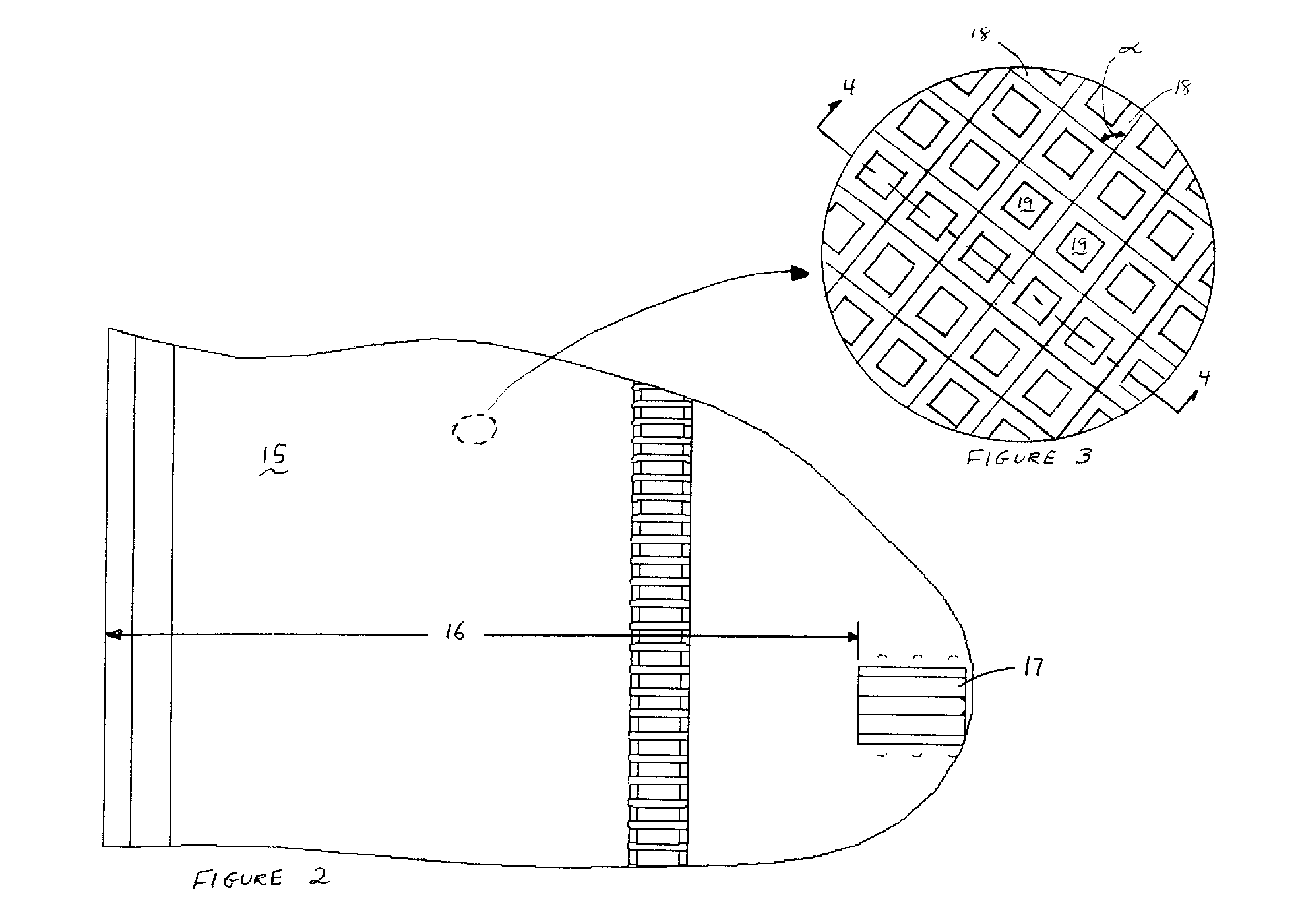

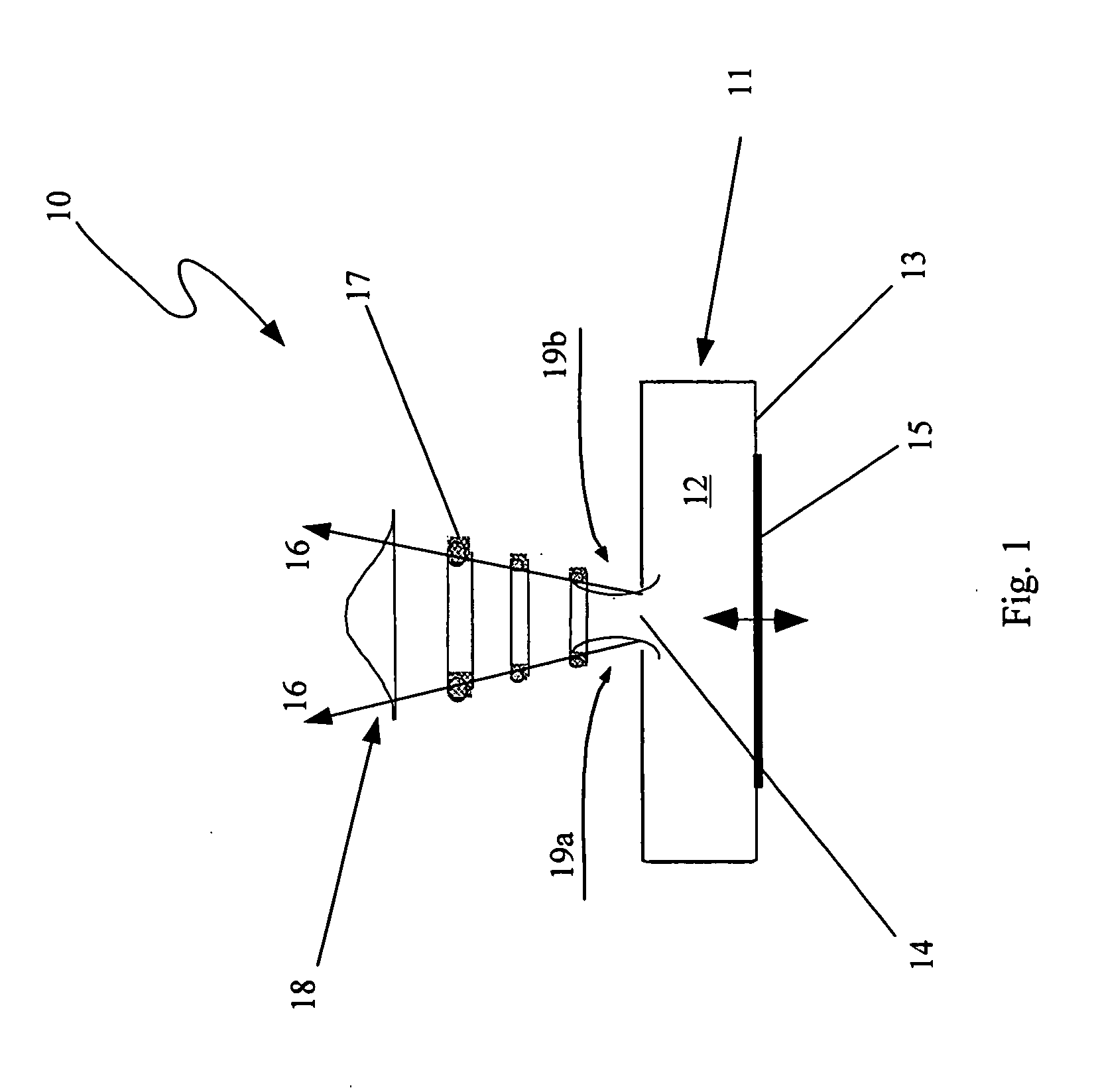

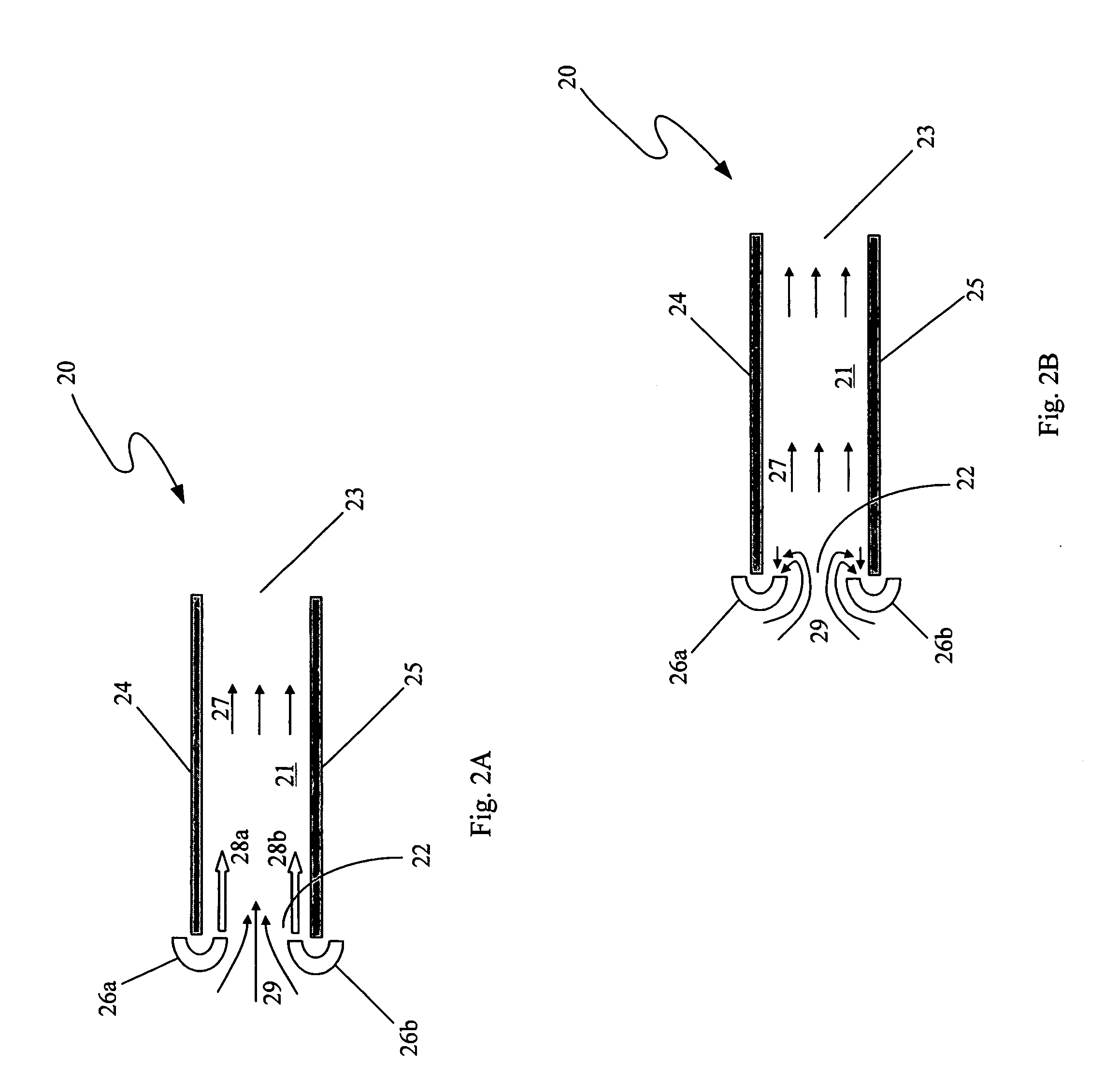

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS20060293734A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

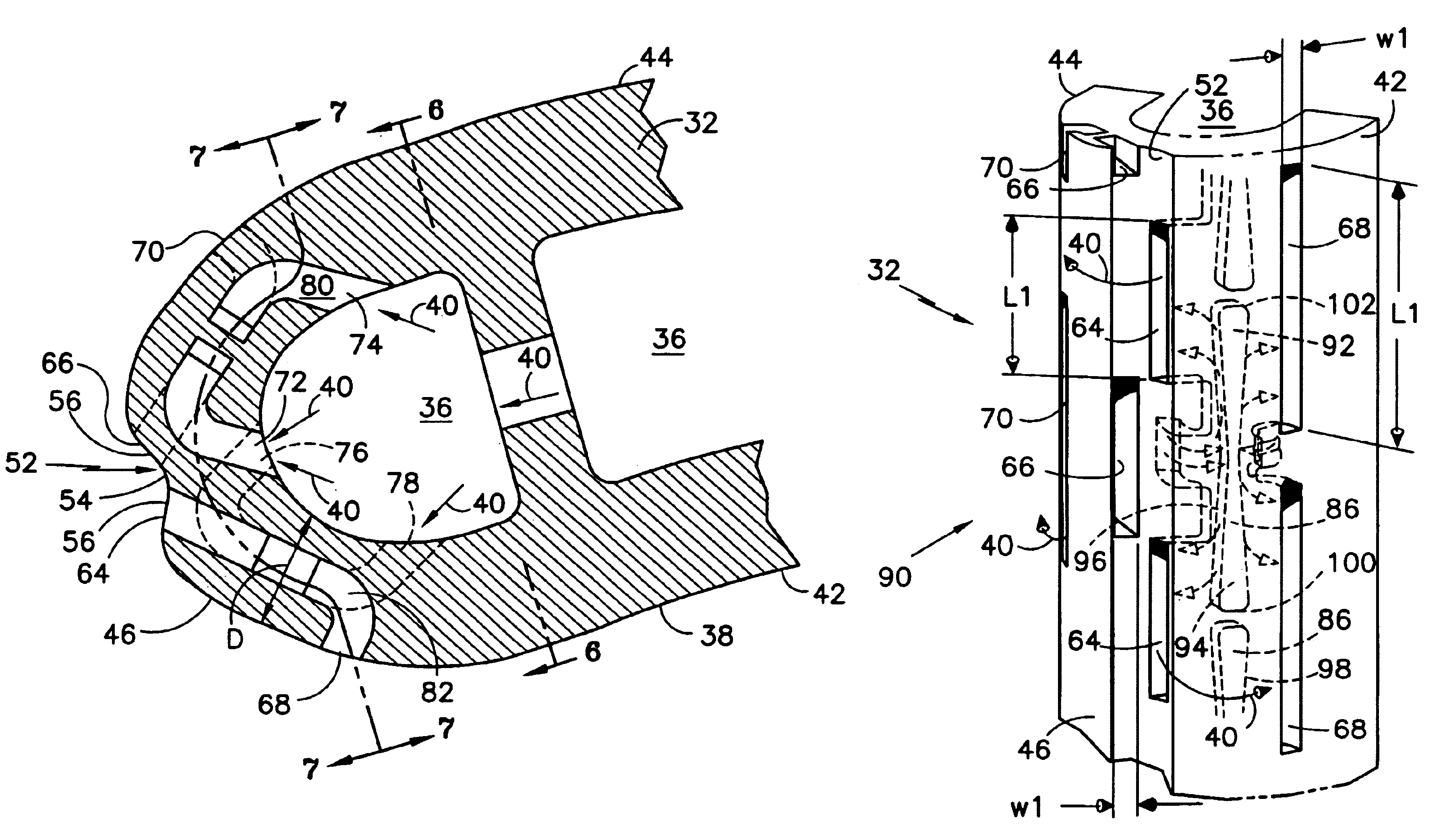

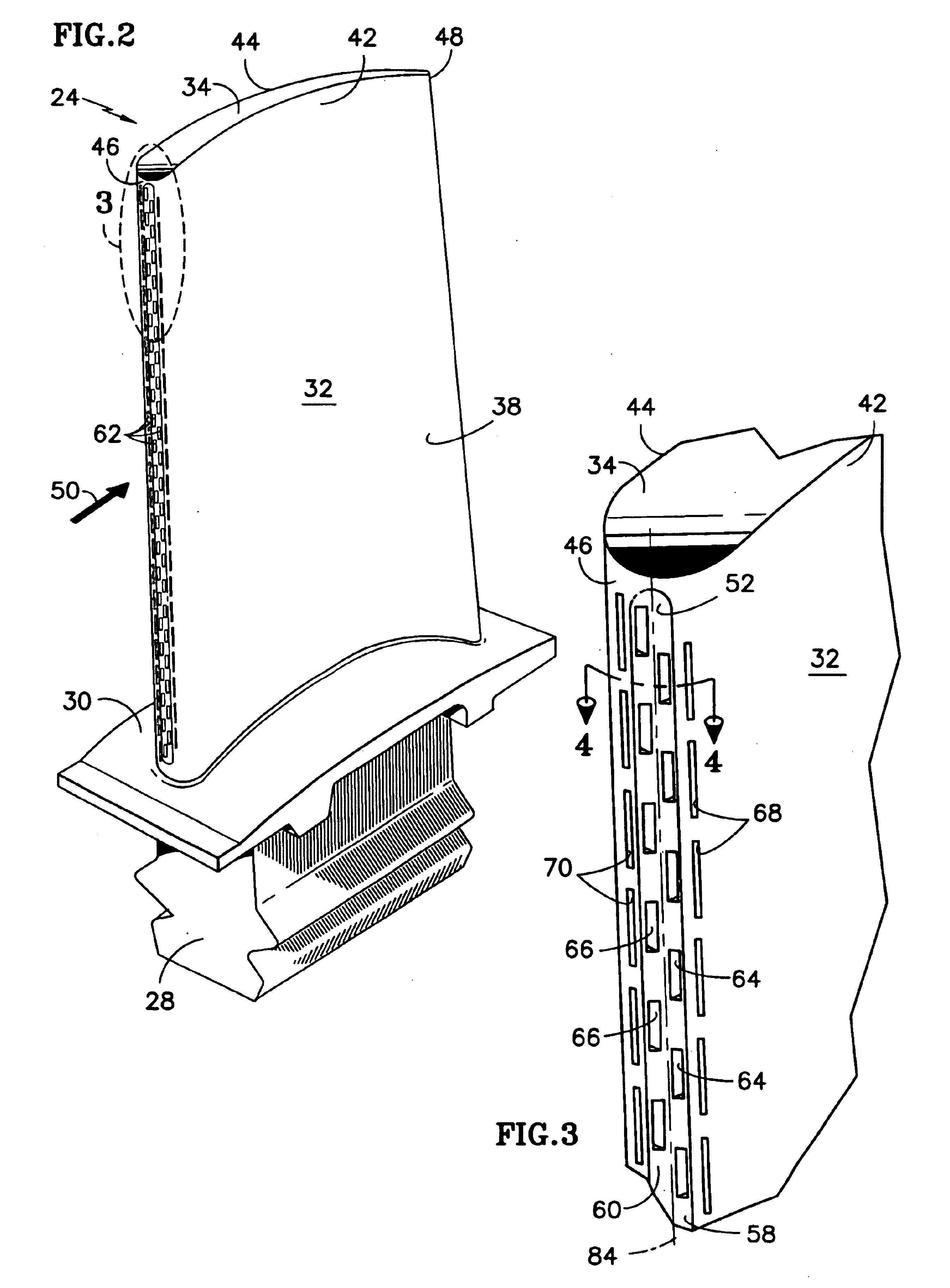

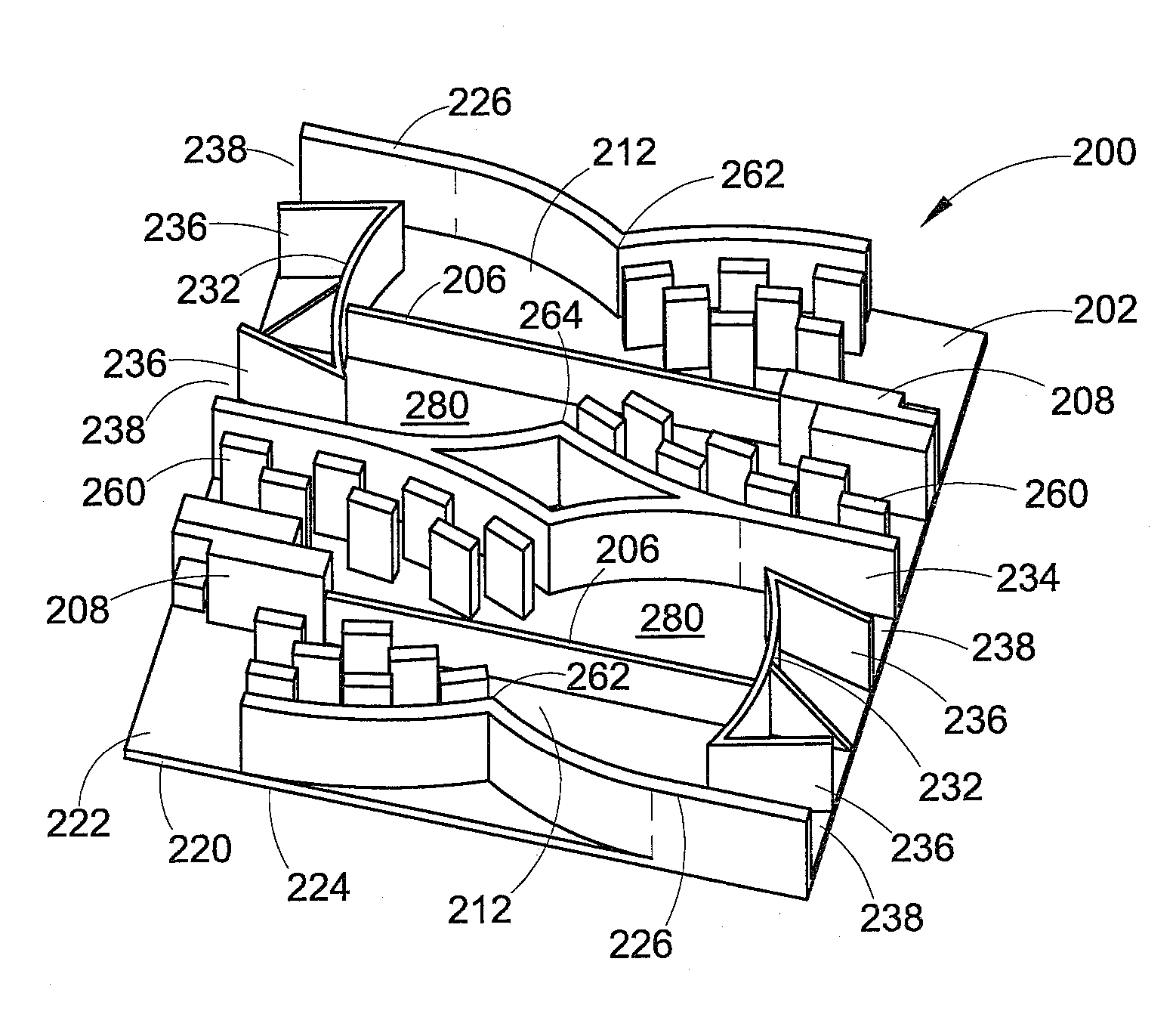

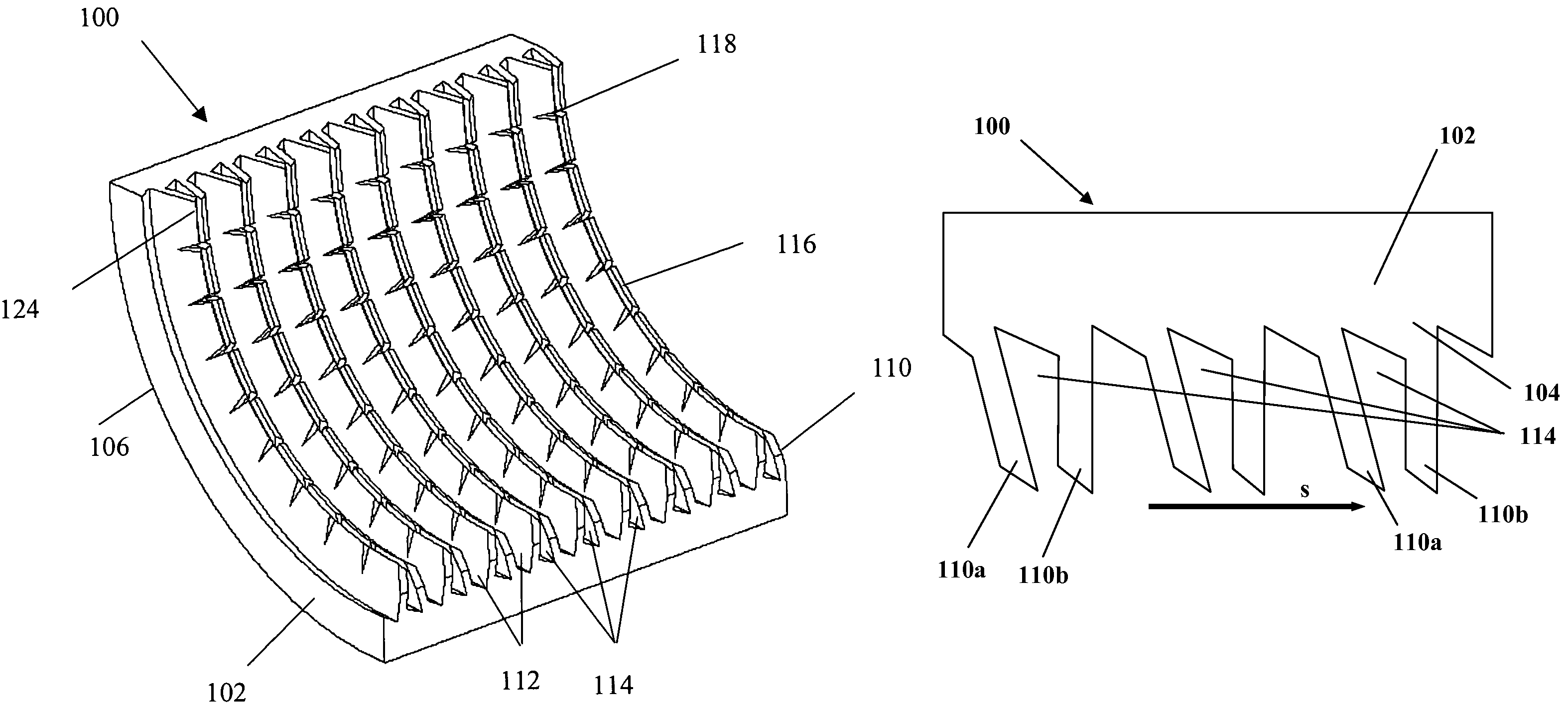

Method and apparatus for cooling an airfoil

ActiveUS6955522B2Increased uniformity and durabilityCooler leading edge designElectronic time-piece structural detailsPump componentsLeading edgeEnhanced heat transfer

An improved cooling design and method for cooling airfoils within a gas turbine engine is provided which includes a plenum longitudinally located within the leading edge of the airfoils. Within the plenum are positioned a plurality of turbulence promoters to provide enhance heat transfer within the leading edge. Also, the cooling design includes a plurality of inlets to receive cooling air from an internal cavity of the airfoil as well as a plurality of outlets located within a trench on the exterior surface of the leading edge through which the cooling air exits to film cool leading edge.

Owner:RTX CORP

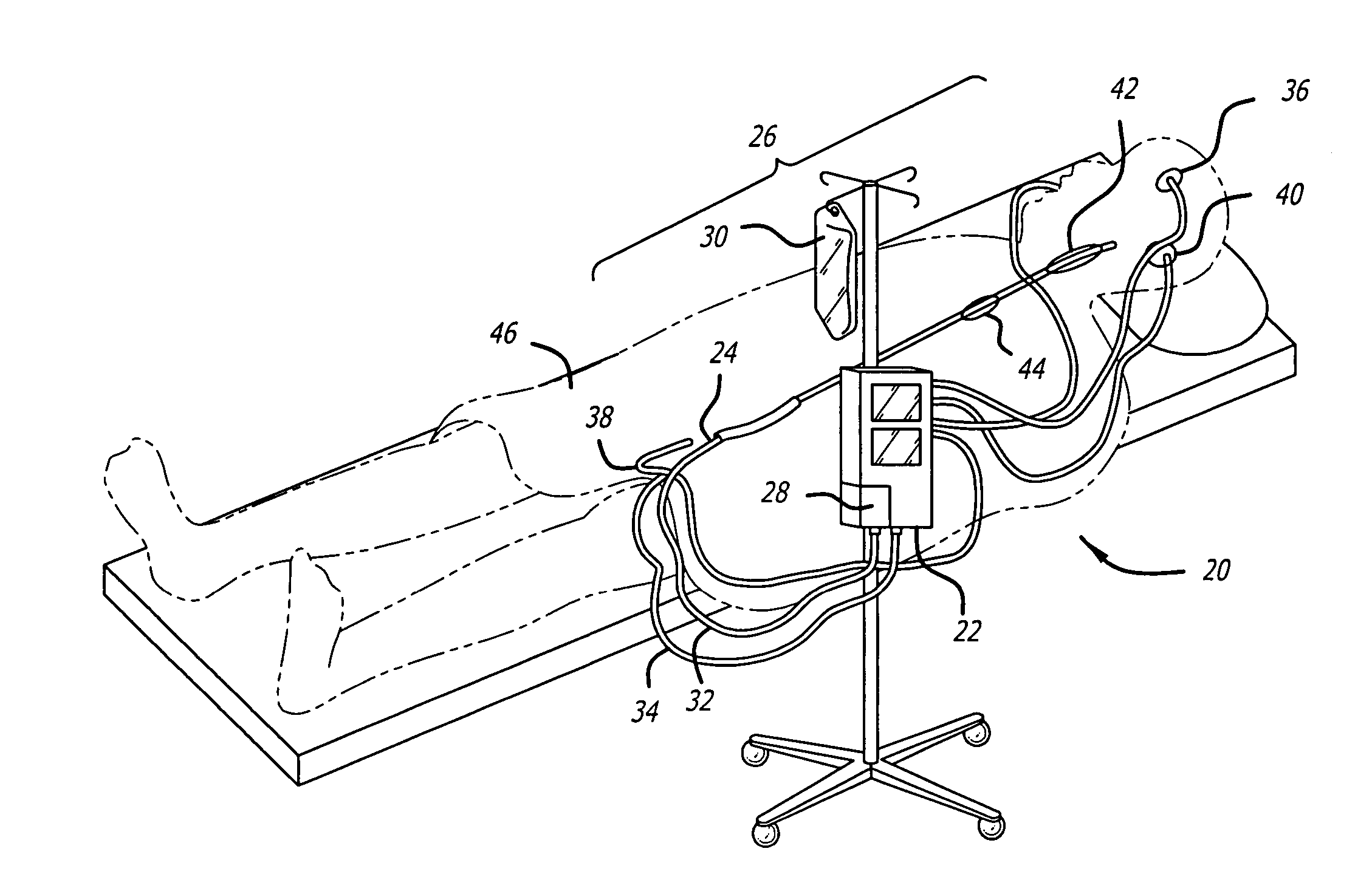

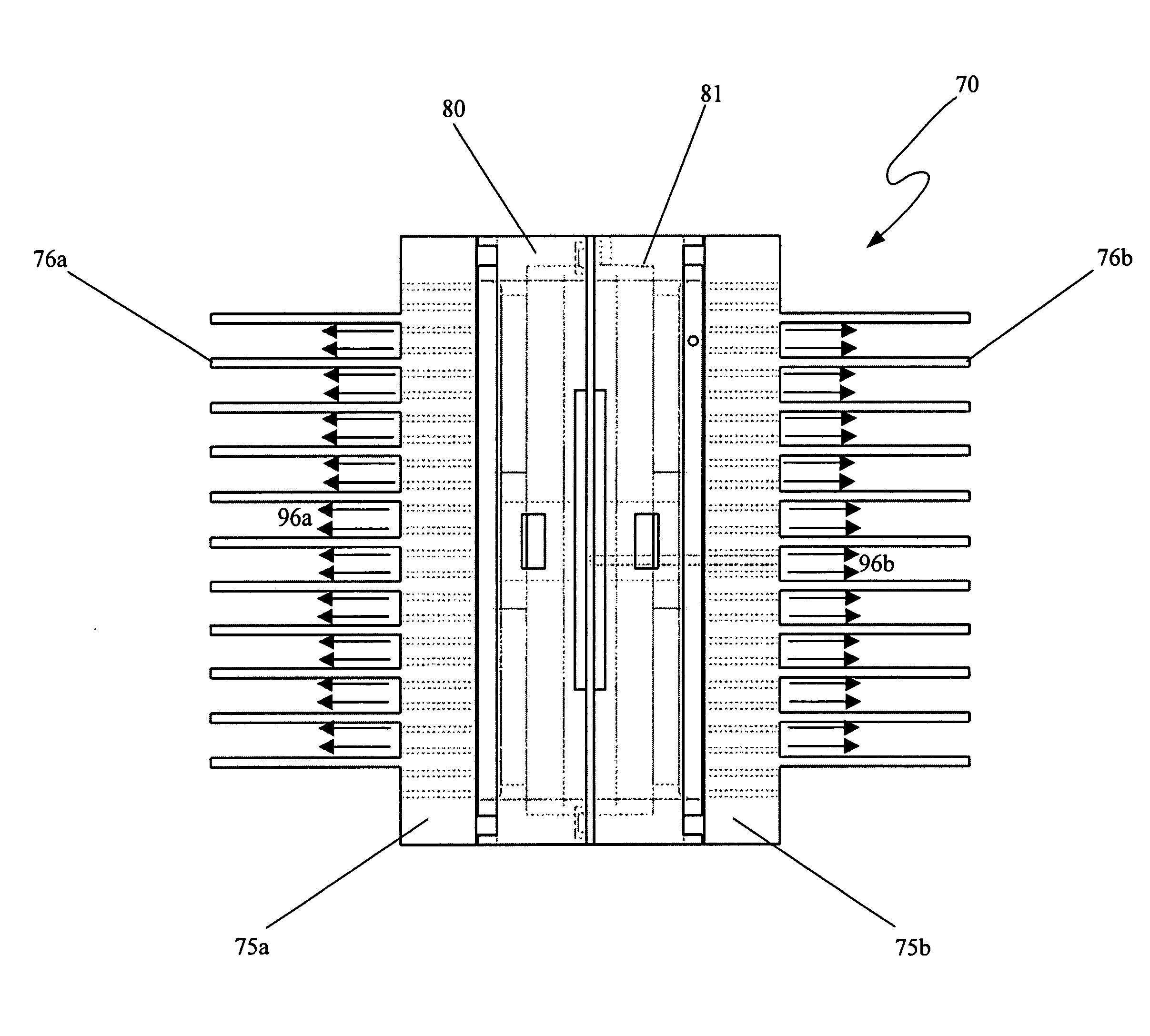

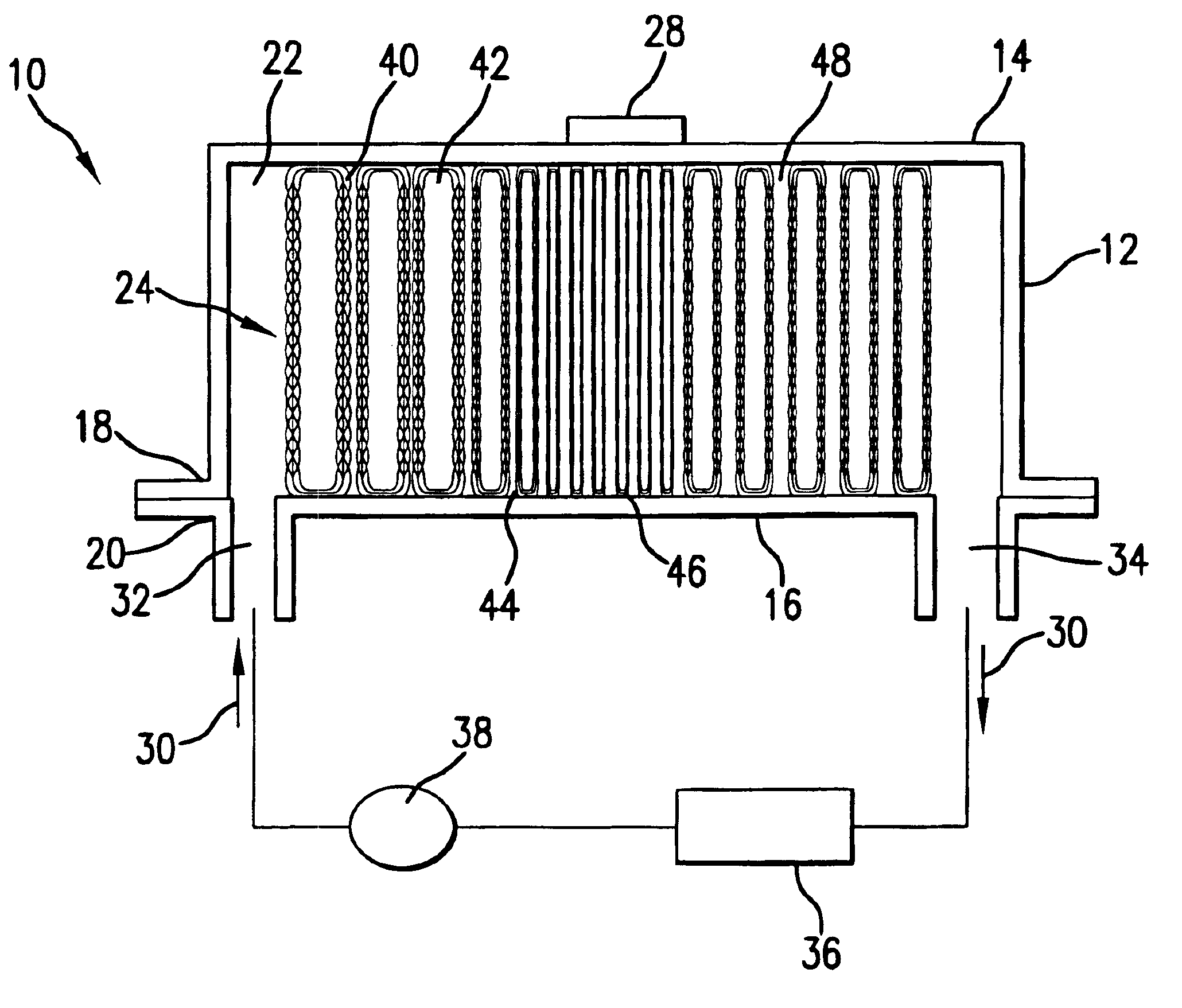

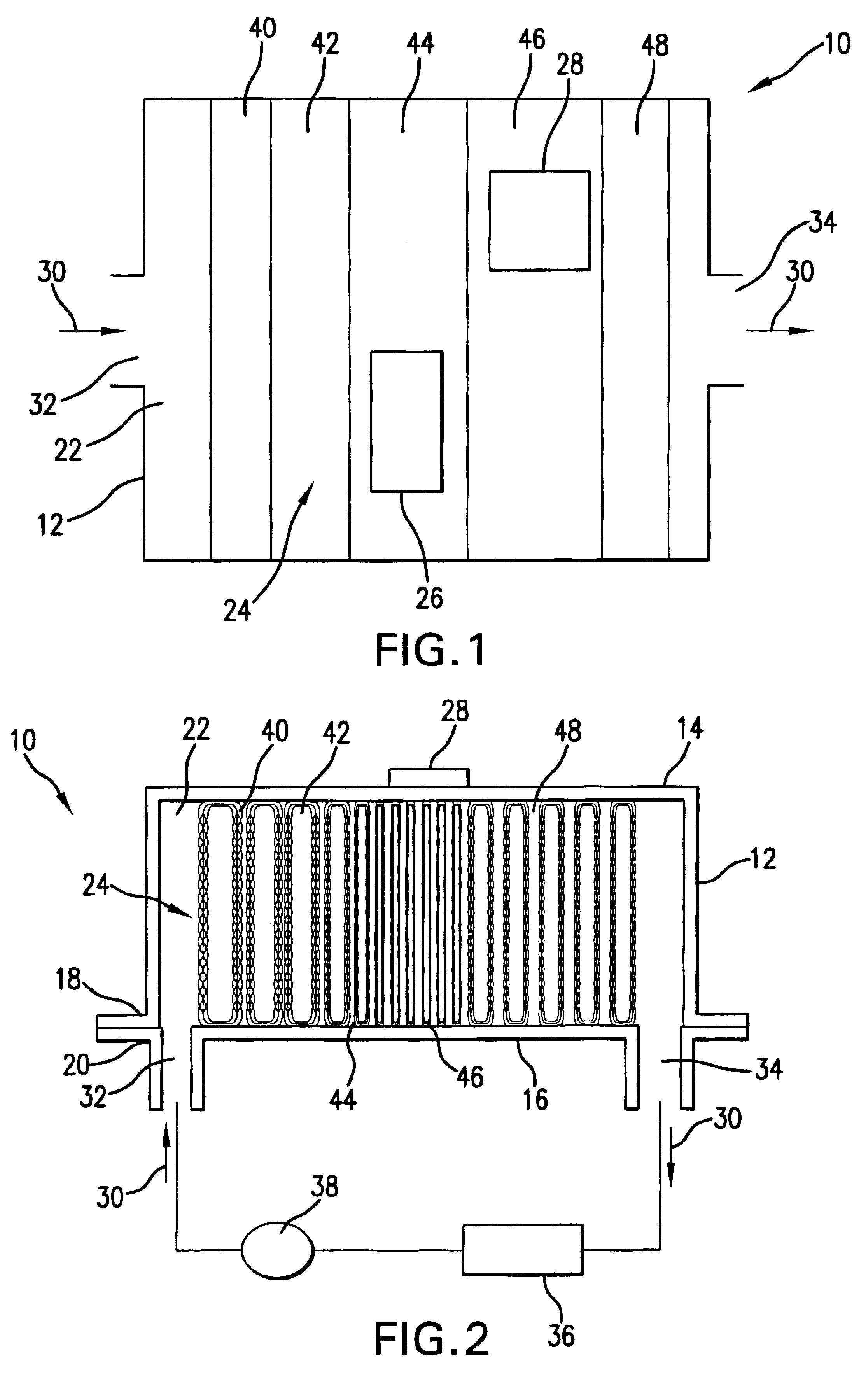

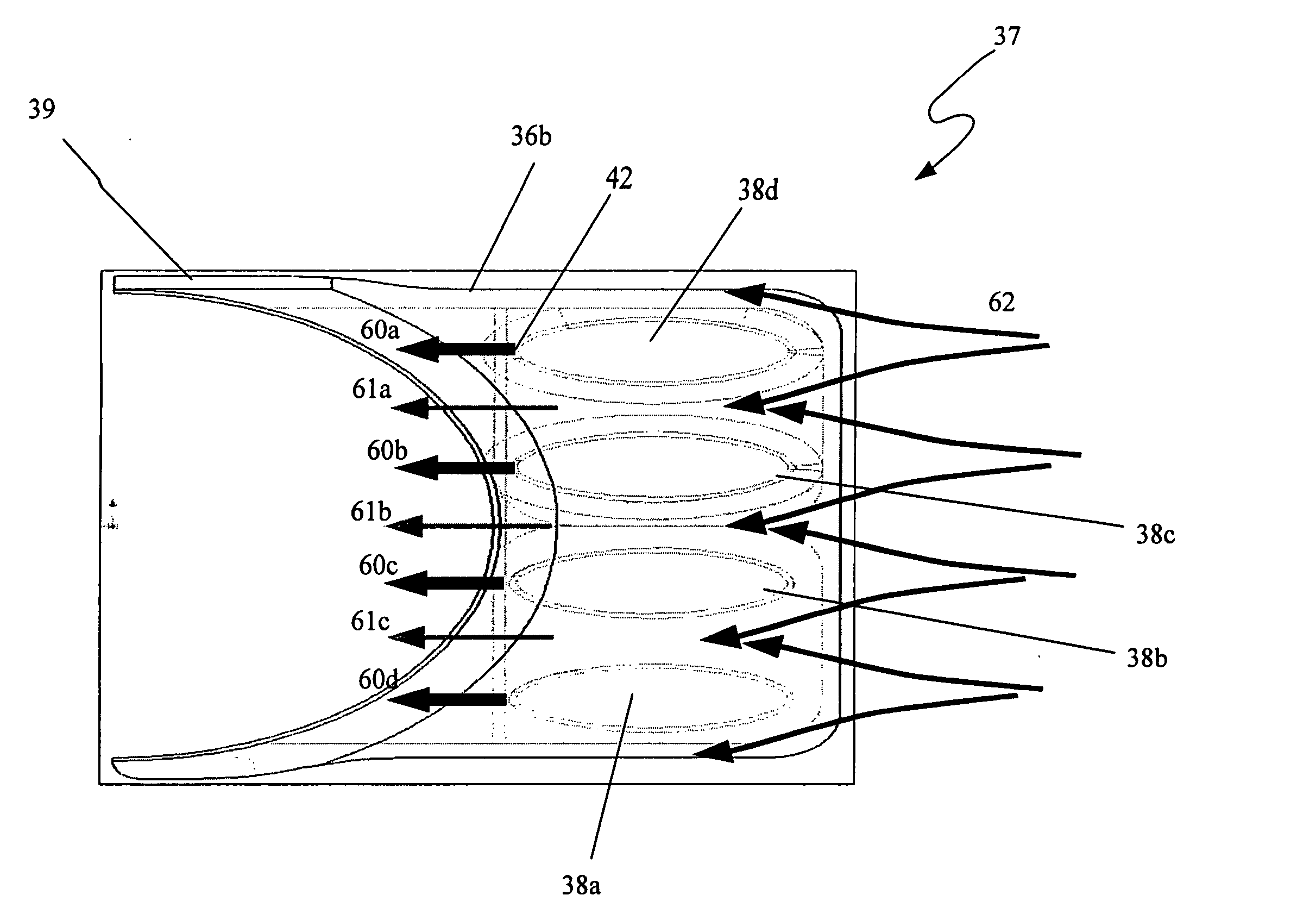

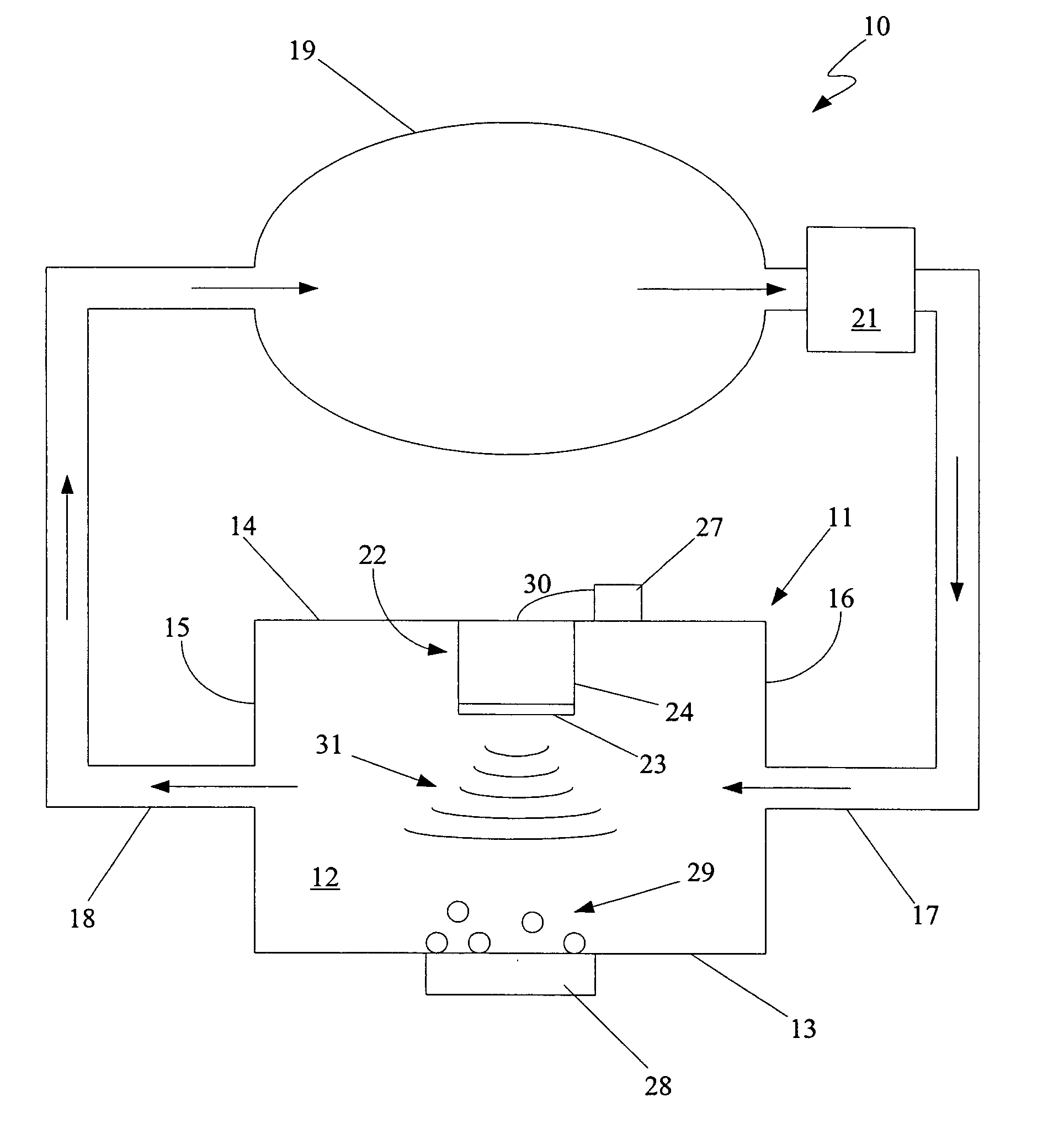

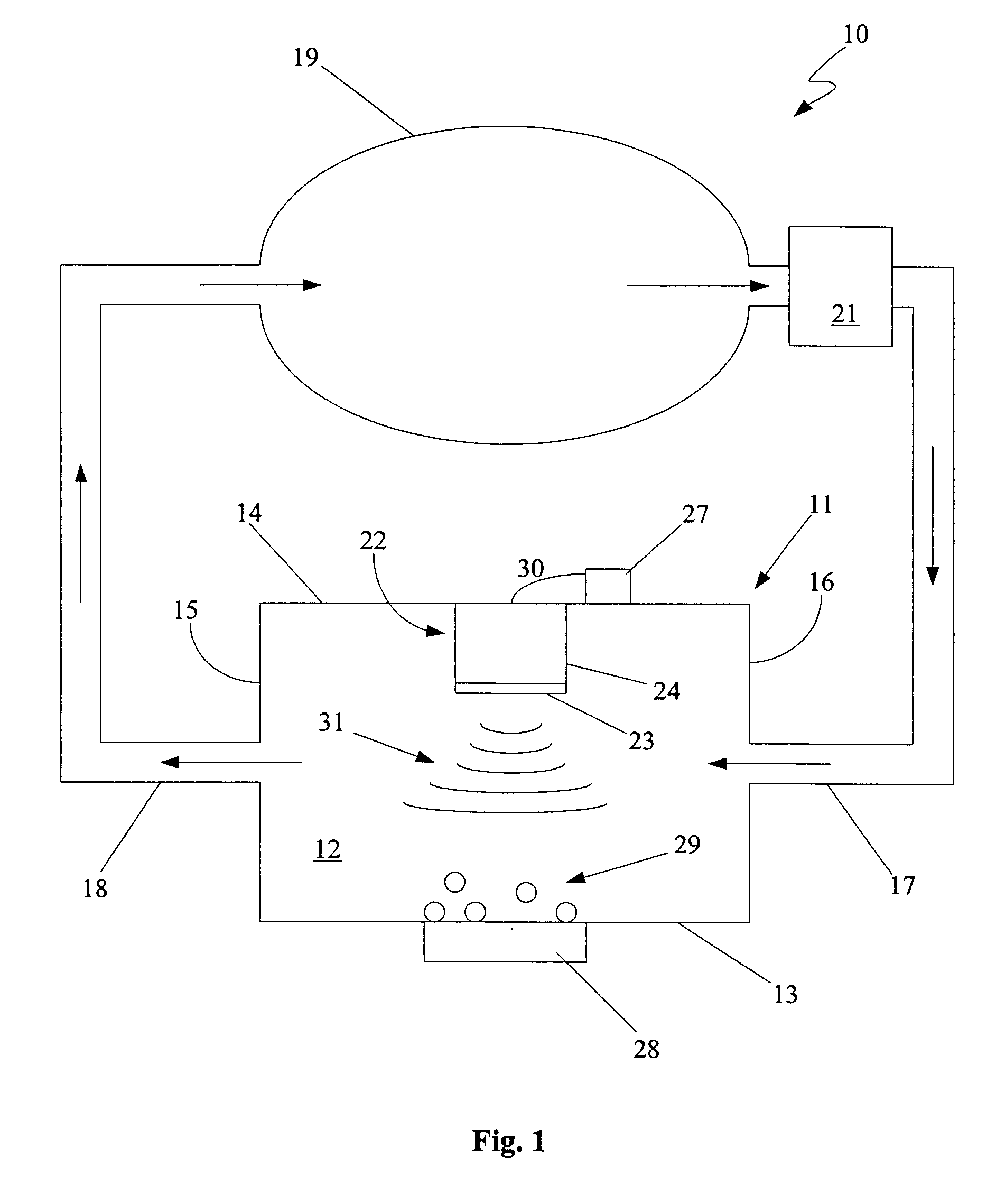

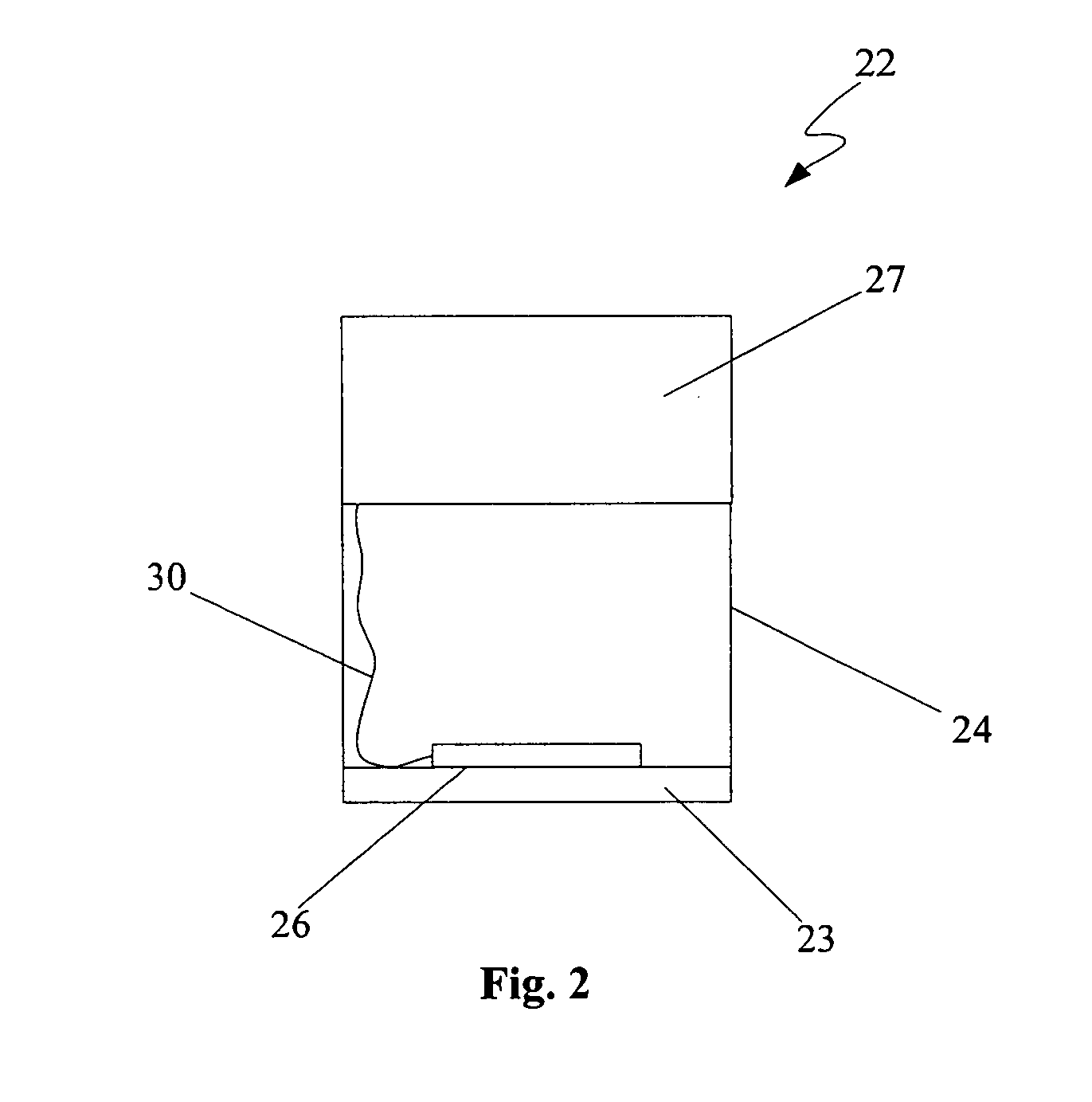

Apparatus and method for enhanced heat transfer

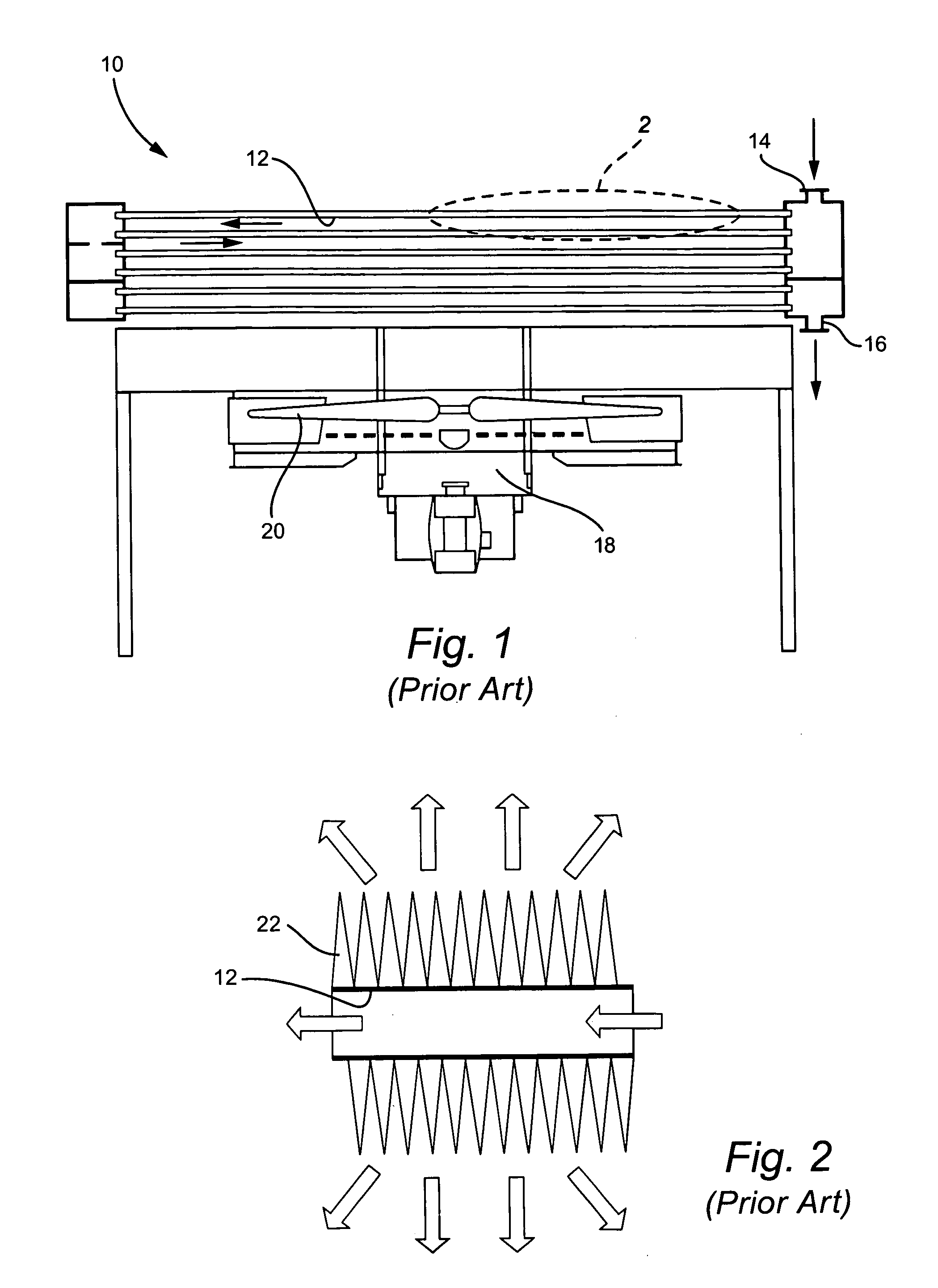

InactiveUS7252140B2Heat exchange apparatusCooling/ventilation/heating modificationsEnhanced heat transferDistribution system

One embodiment of the cooling module is implemented as a device having a heat sink and an integrated synthetic jet actuator. The heat sink is configured to have a channel and a jet distribution system associated with the synthetic jet actuator directs fluid flow into the channel of the heat sink. In operation, the fluid flow of this embodiment of the cooling module comprises a synthetic jet stream and ambient fluid entrained into the channel by the synthetic jet stream. The fluid flowing through the channel serves to a wall of the heat sink channel.

Owner:INNOVATIVE FLUIDICS +1

Nanometer sized phase change materials for enhanced heat transfer fluid performance

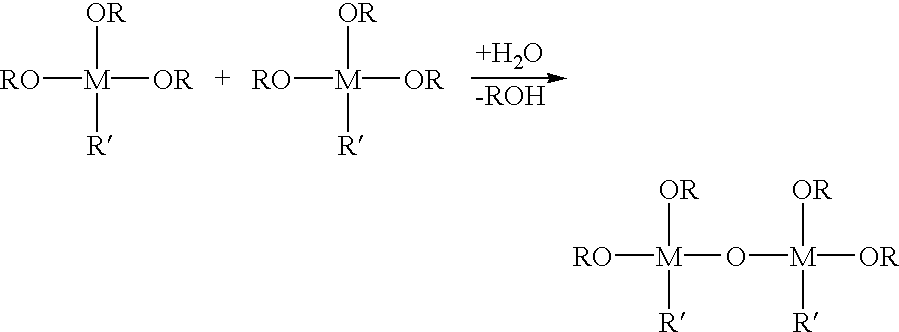

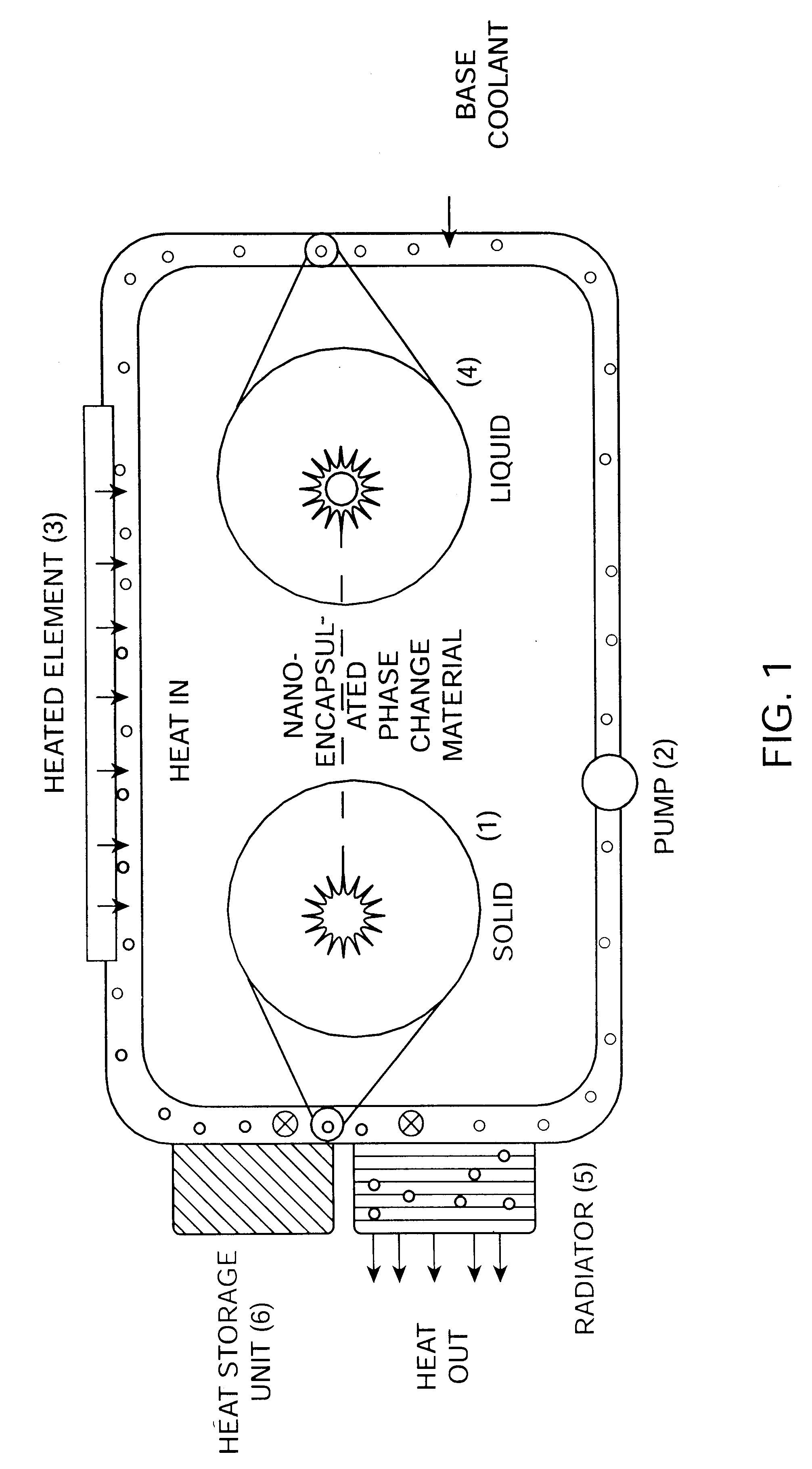

InactiveUS6447692B1Improve the heating effectIncrease heatNanotechOther chemical processesEnhanced heat transferEngineering

A composition for enhanced heat transfer fluid performance, comprising a base heat transfer fluid and a nanometer sized phase change material. Introduction of nanometer sized phase change material into the heat transfer fluid leads to improved, high reversible thermal transport properties at elevated temperatures while ensuring low viscosity of the fluid at sub-freezing temperatures. A method for preparing of the heat transfer fluid with enhanced heat transfer performance, comprising making nanometer sized capsules having the phase change material contained therein and dispersing the capsules into the base heat transfer fluid.

Owner:HRL LAB

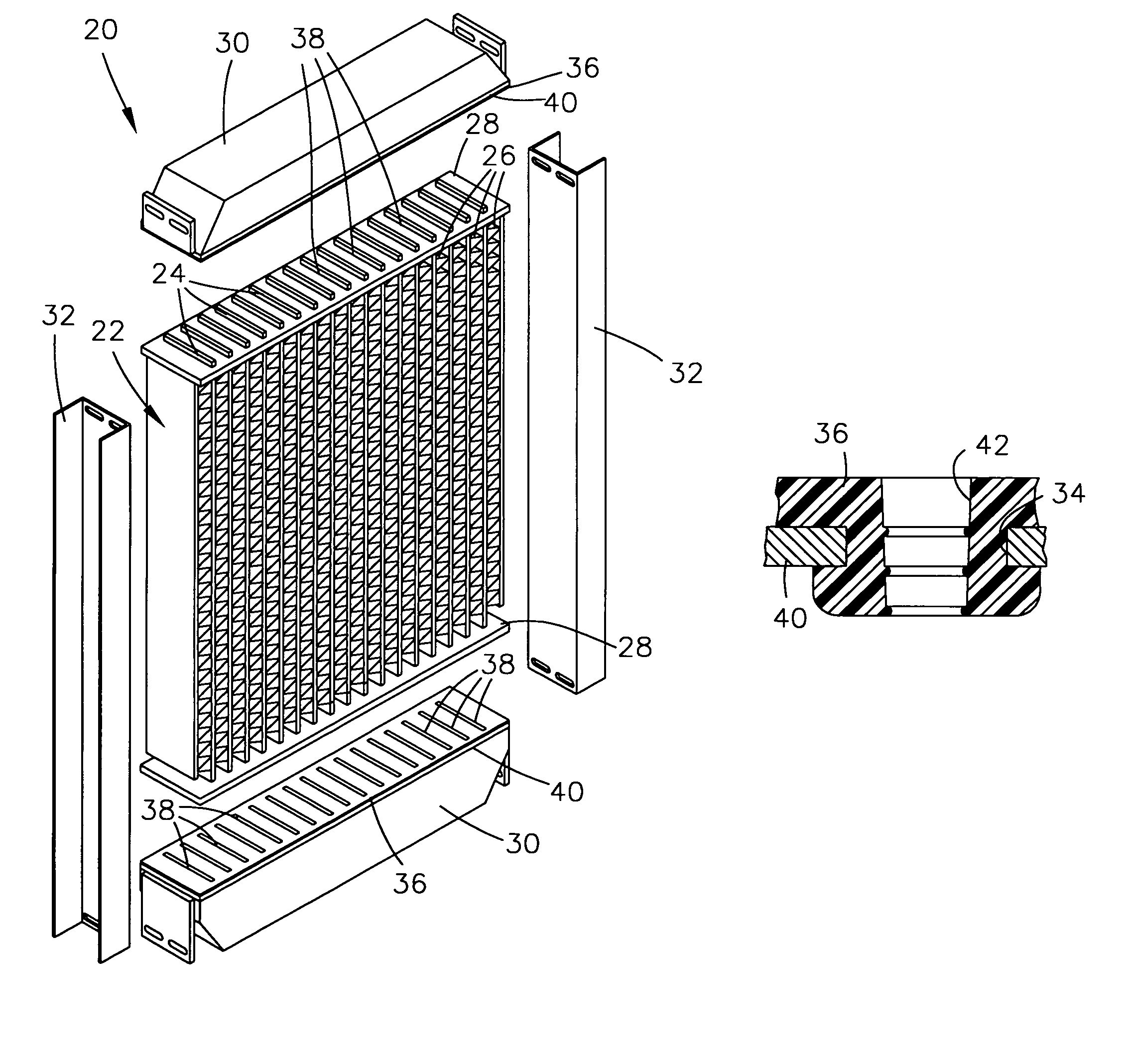

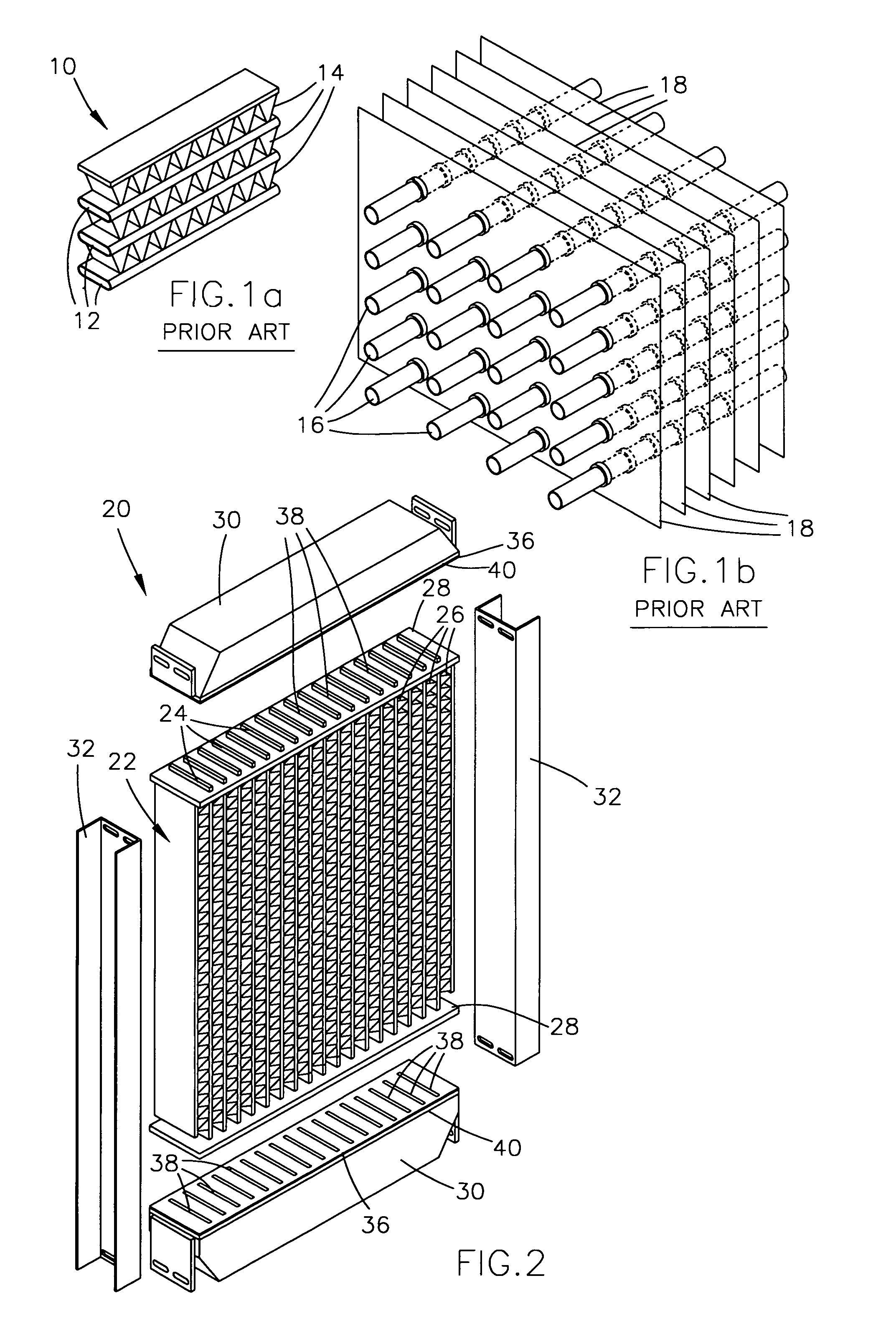

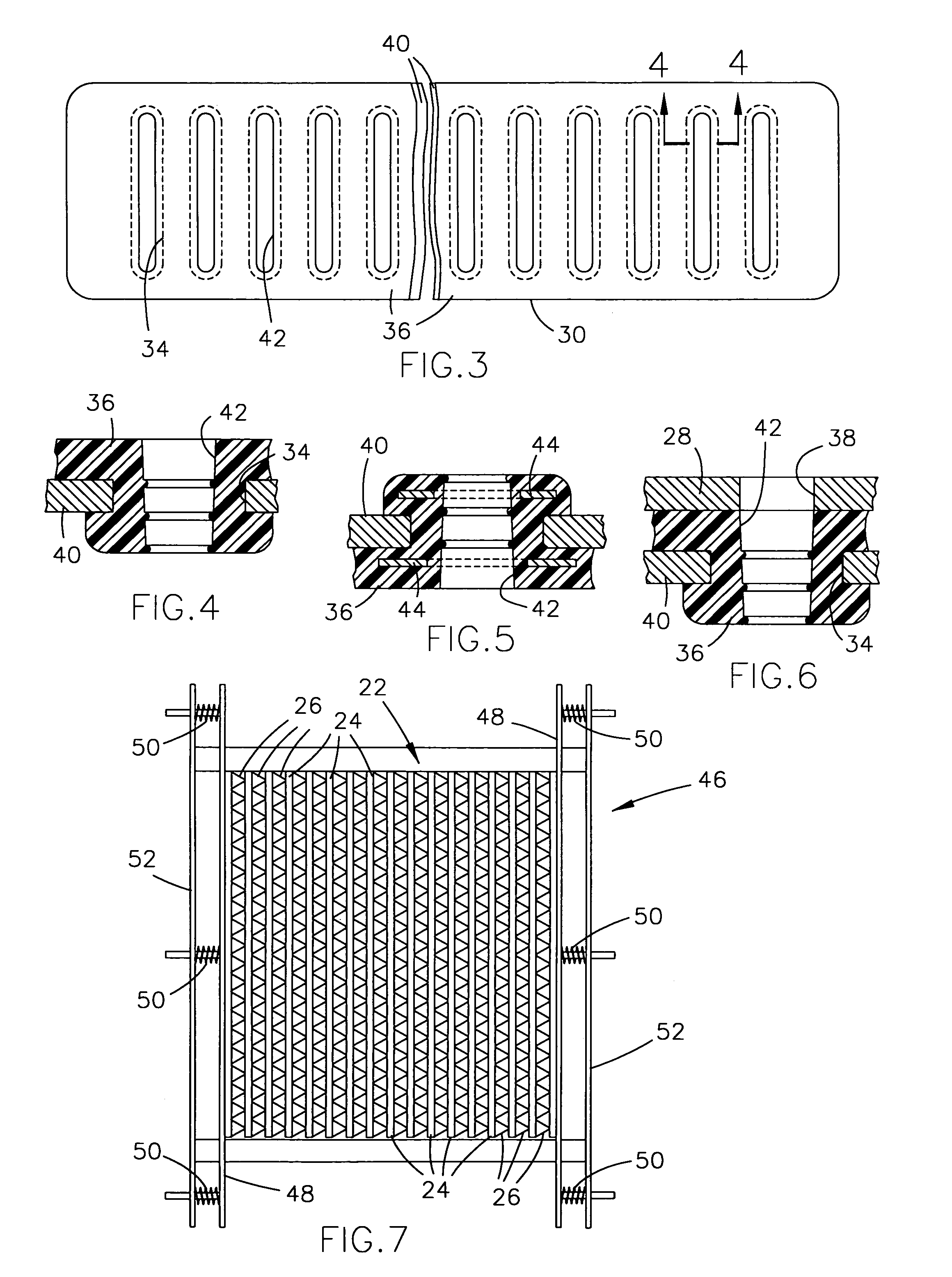

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

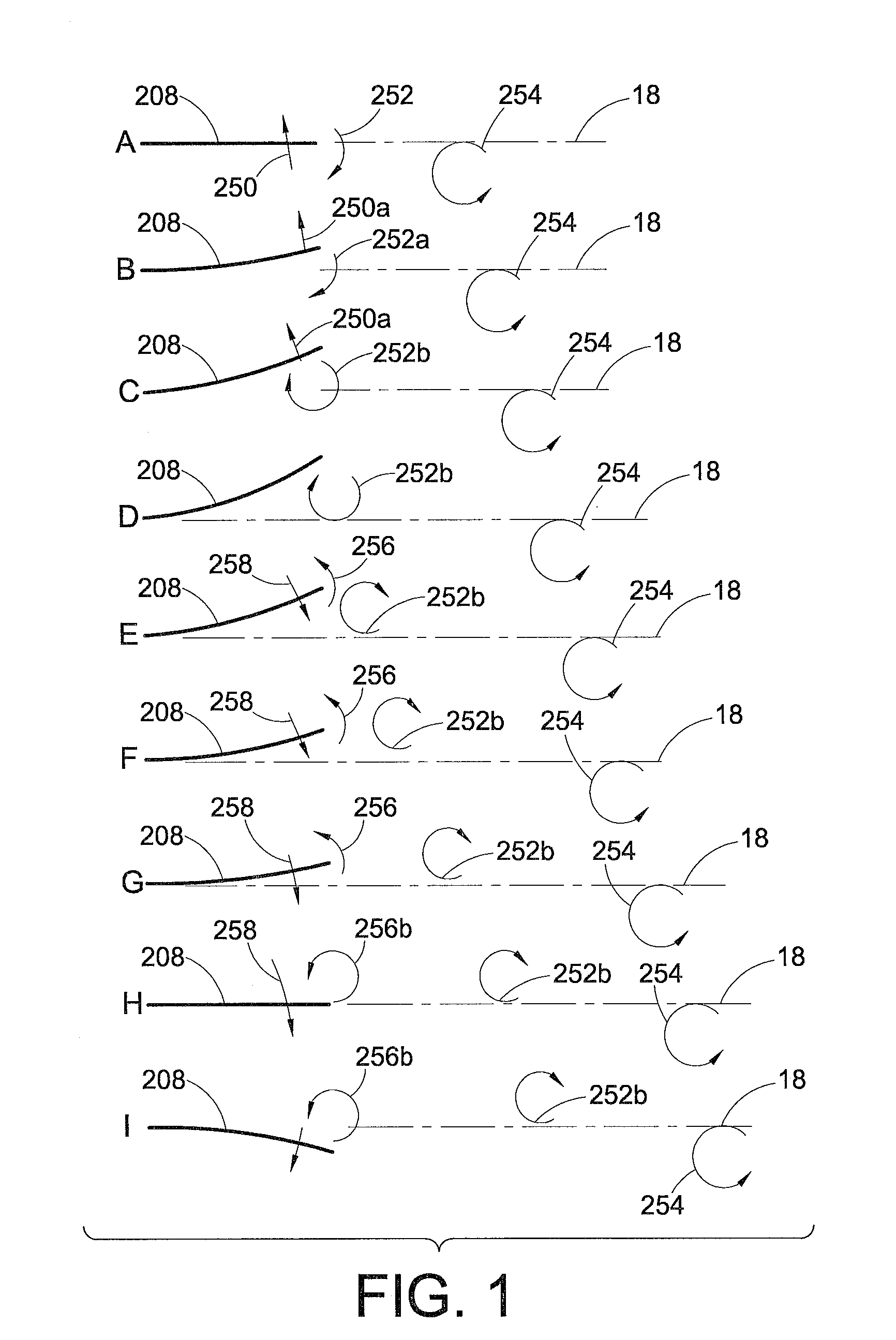

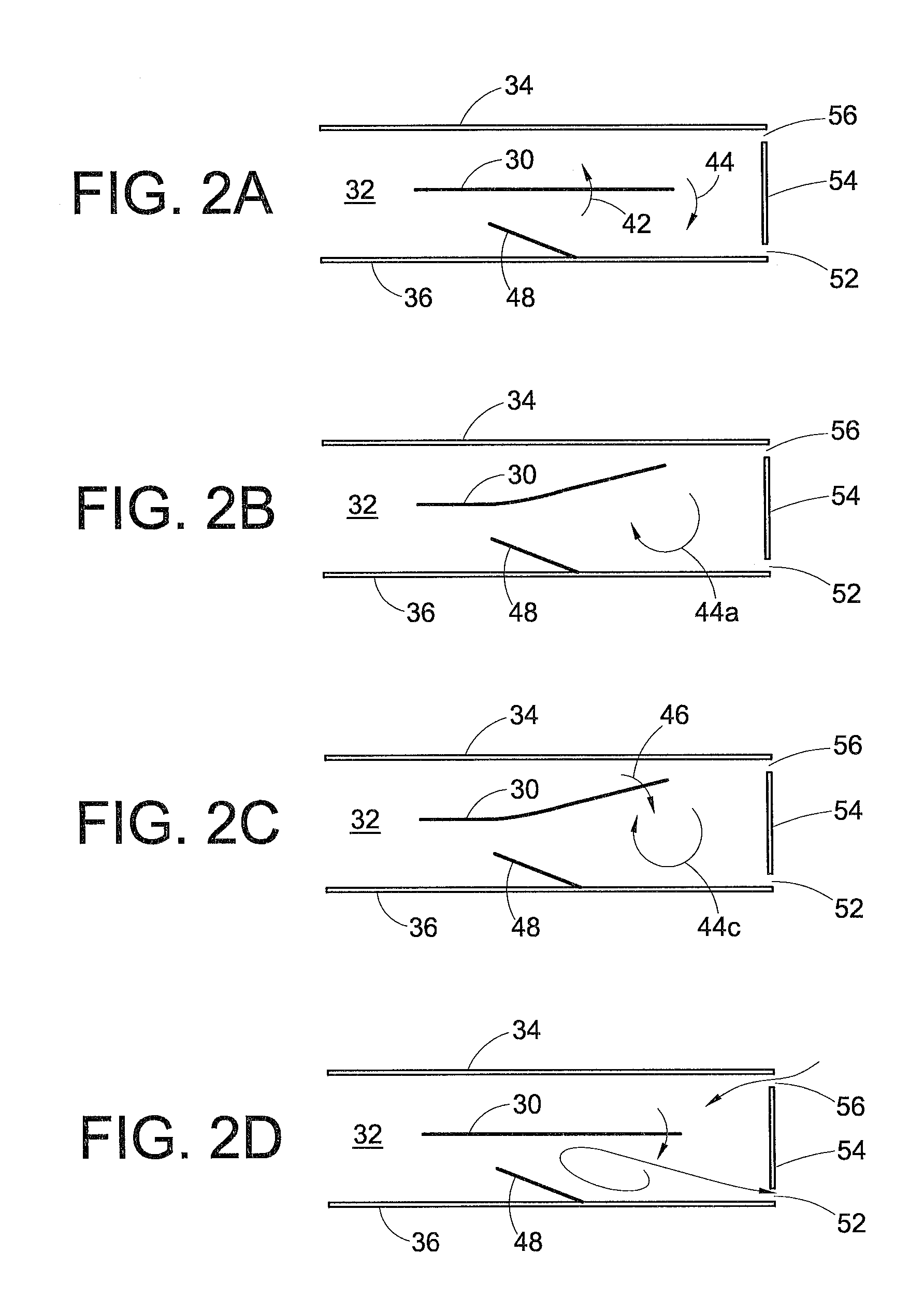

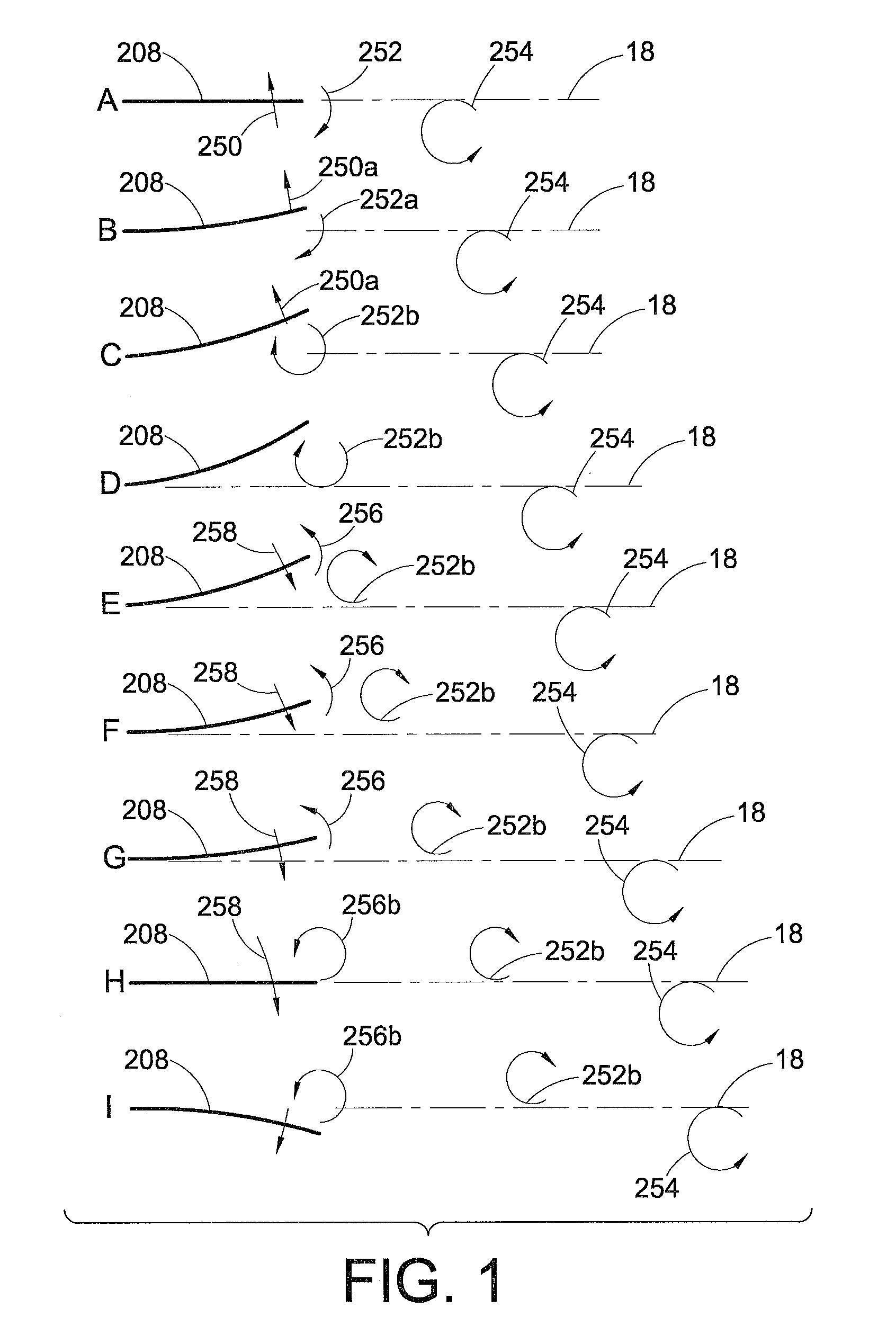

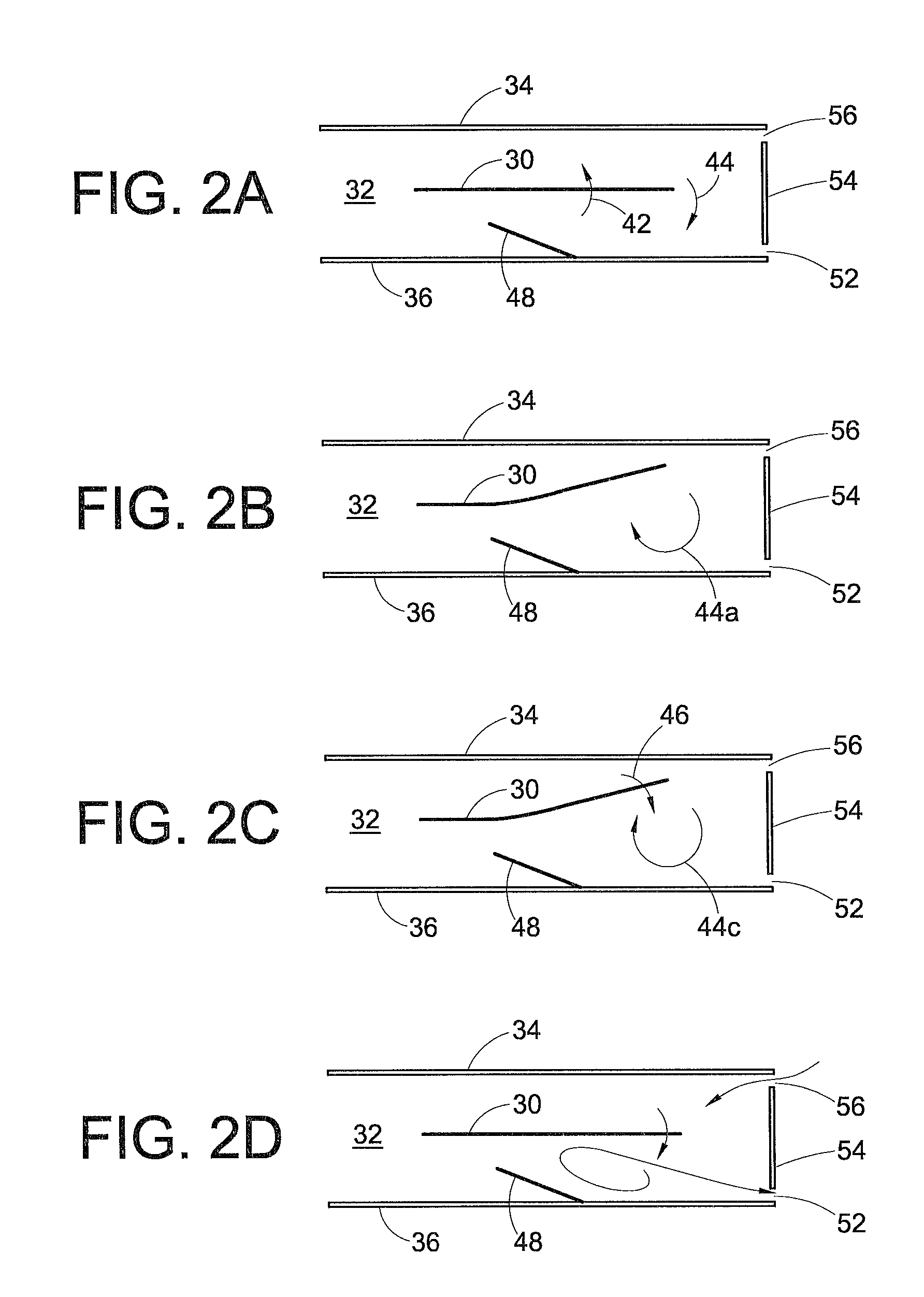

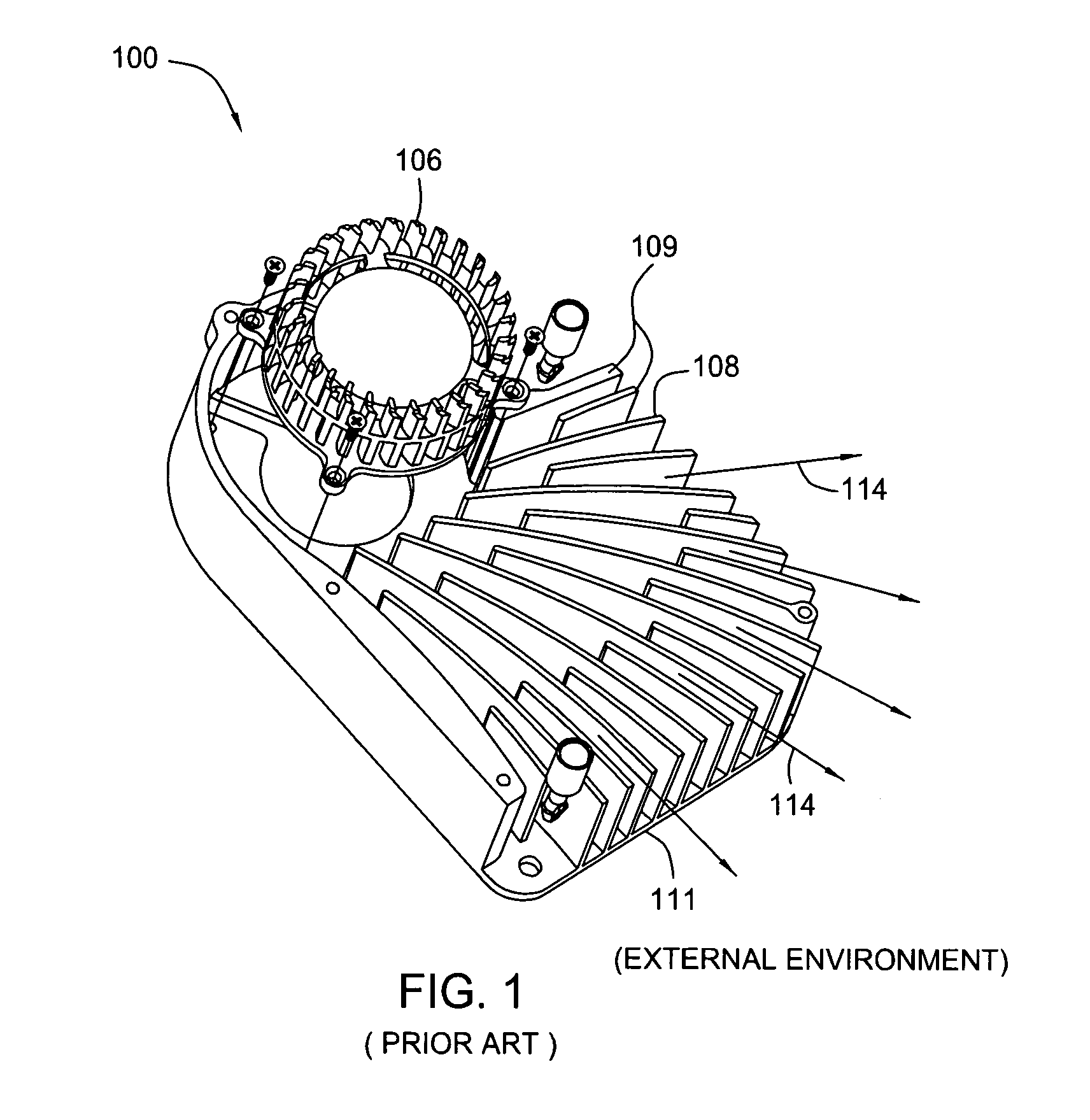

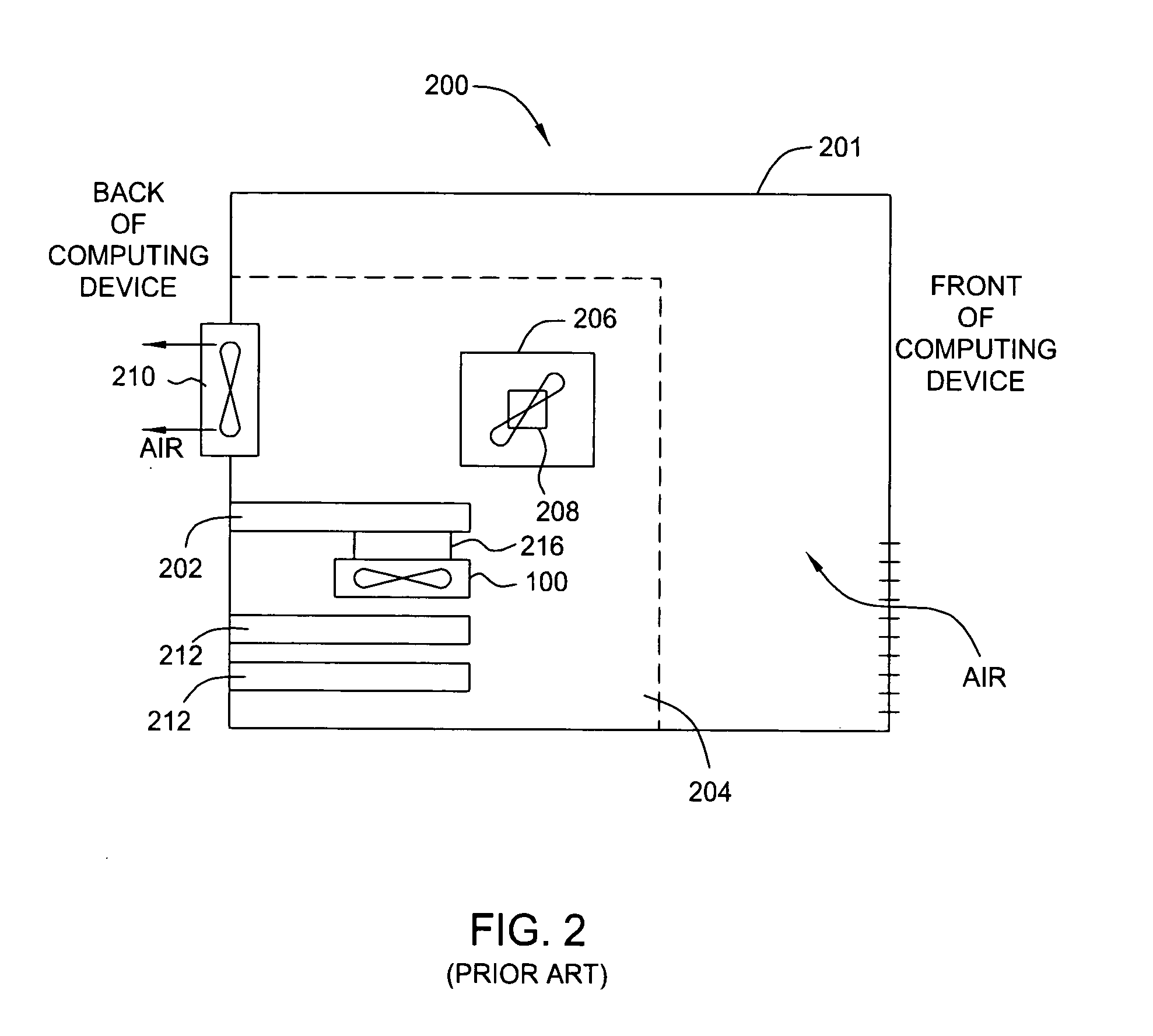

Piezofan and heat sink system for enhanced heat transfer

An electronic device having enhanced heat dissipation capabilities includes an electronic device, a heat sink, a channel, a piezoelectric element, and a blade. The heat sink is in thermal communication with the electronic device. The channel includes an inlet, an outlet and a constriction disposed along the channel between the inlet and the outlet. The heat sink defines at least a portion of the channel. The blade includes a free end and an attached end. The blade is disposed in the channel and connected to the piezoelectric element. The piezoelectric element is activated to move the blade side to side in the channel to create air vortices. The constriction in the channel and the blade cooperate with one another such that a vortex that is generated as the blade moves toward a first side of the channel is compressed against the first side of the channel and expelled towards the outlet of the channel.

Owner:CONSUMER LIGHTING (U S) LLC

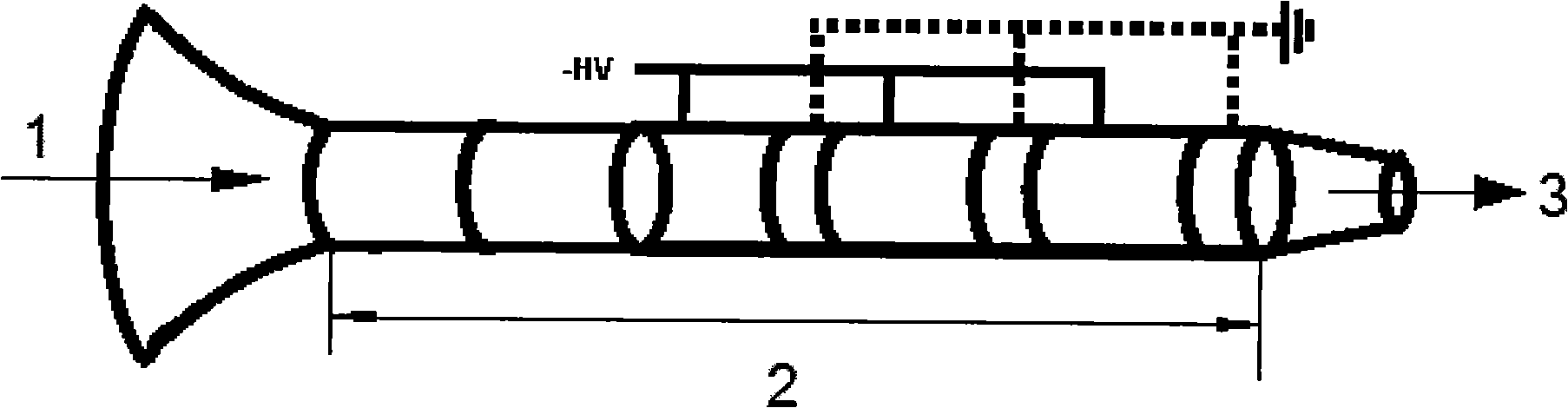

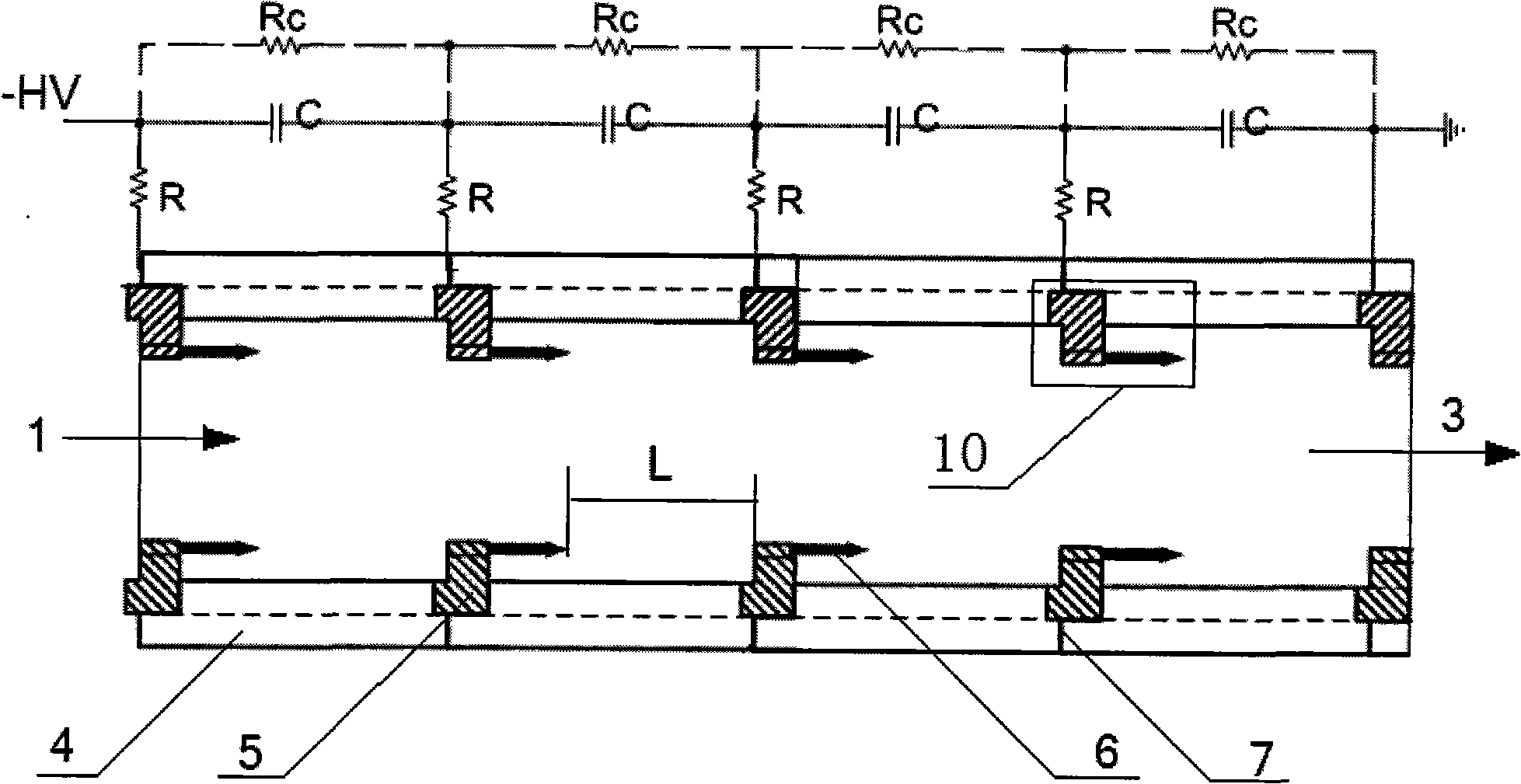

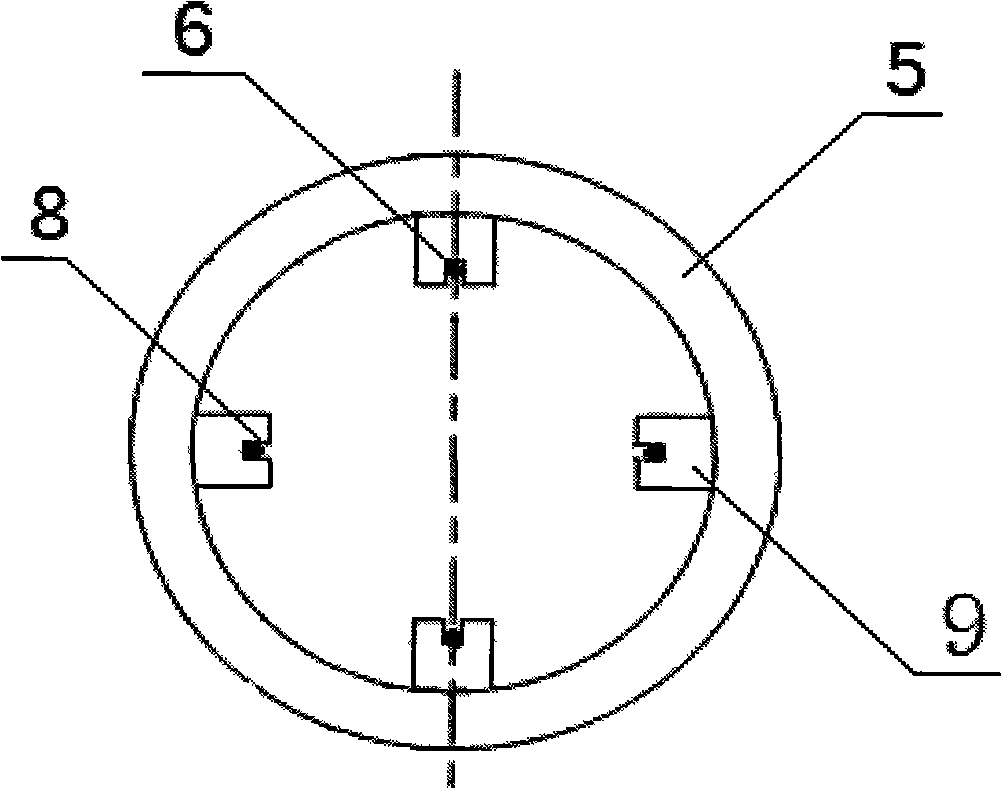

Device for exciting high-speed and large-area ionic wind

InactiveCN101577397AExpand the scope of actionHigh ion wind speedCorona dischargeElectrical conductorEnhanced heat transfer

The invention discloses a device for exciting high-speed and large-area ionic wind, which comprises an ionic wind exciting area cylinder body, an inlet and an outlet at two ends. Multiple-stage series needle-ring electrodes are arranged in the cylinder body. The device is characterized in that a needle electrode of a post stage and a ring electrode of a previous stage are combined to form an integral multi-needle ring electrode, and the needle electrode and the ring electrode of the multi-needle ring electrode of each two stages form an electrode spacing; the ring electrodes of the multi-needle ring electrode of each two stages are connected in series with a current-limiting resistor outside the cylinder body through a conductor respectively, and then are connected in parallel with a voltage-dividing capacitor to form a discharge loop; and the voltage-dividing capacitors are mutually connected in series, the voltage-dividing capacitor connected with the ring electrode close to the inlet is connected with a direct-current high voltage source, the voltage-dividing capacitor connected with the ring electrode close to the outlet is grounded, and the ring electrode close to the outlet is not provided with a needle electrode and is grounded directly through a conductor. The device can obtain high-speed and large-area ionic wind, and can be applied in various fields of enhanced heat transfer, micro air pumps, air purification and the like.

Owner:XI AN JIAOTONG UNIV

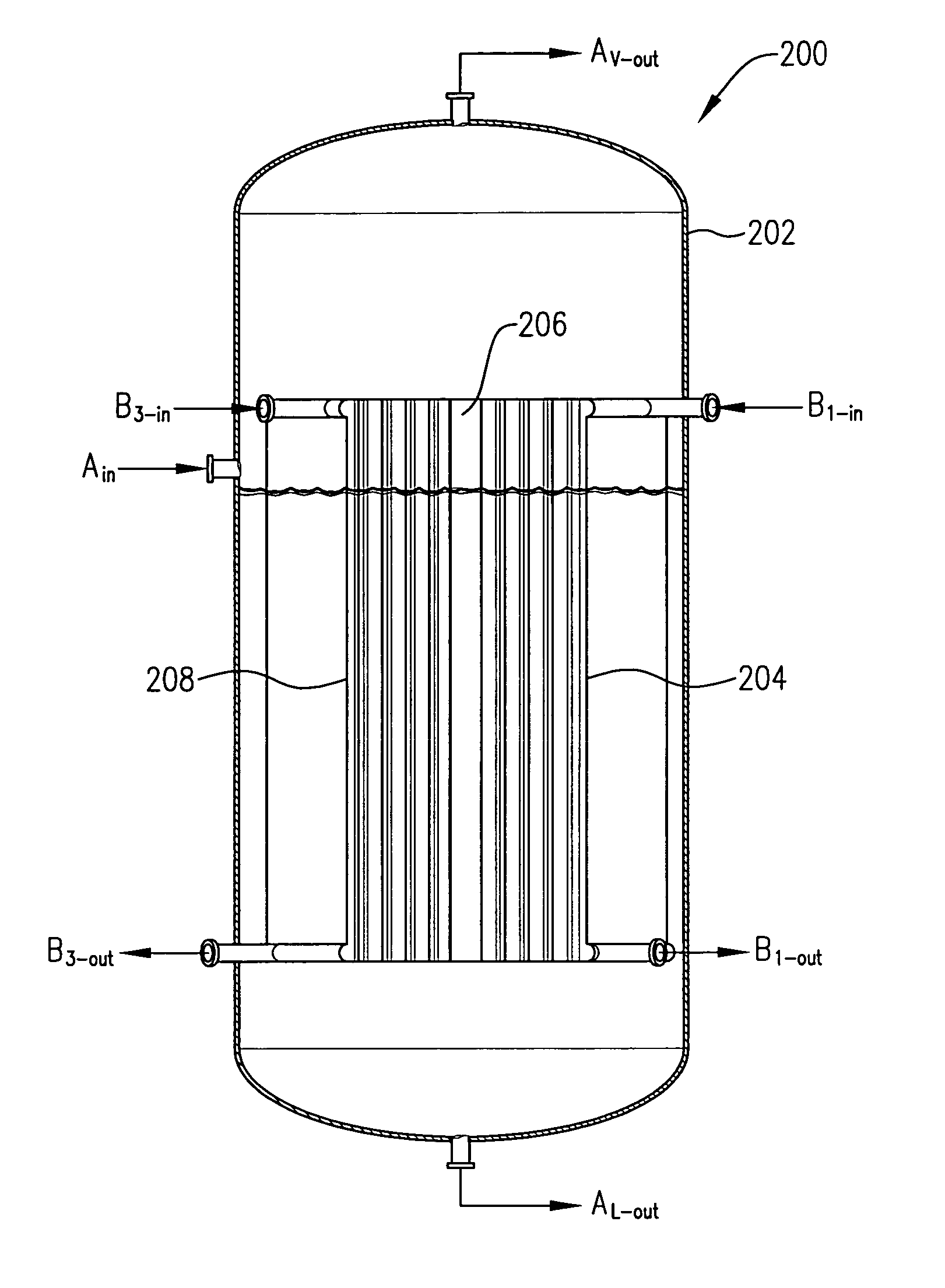

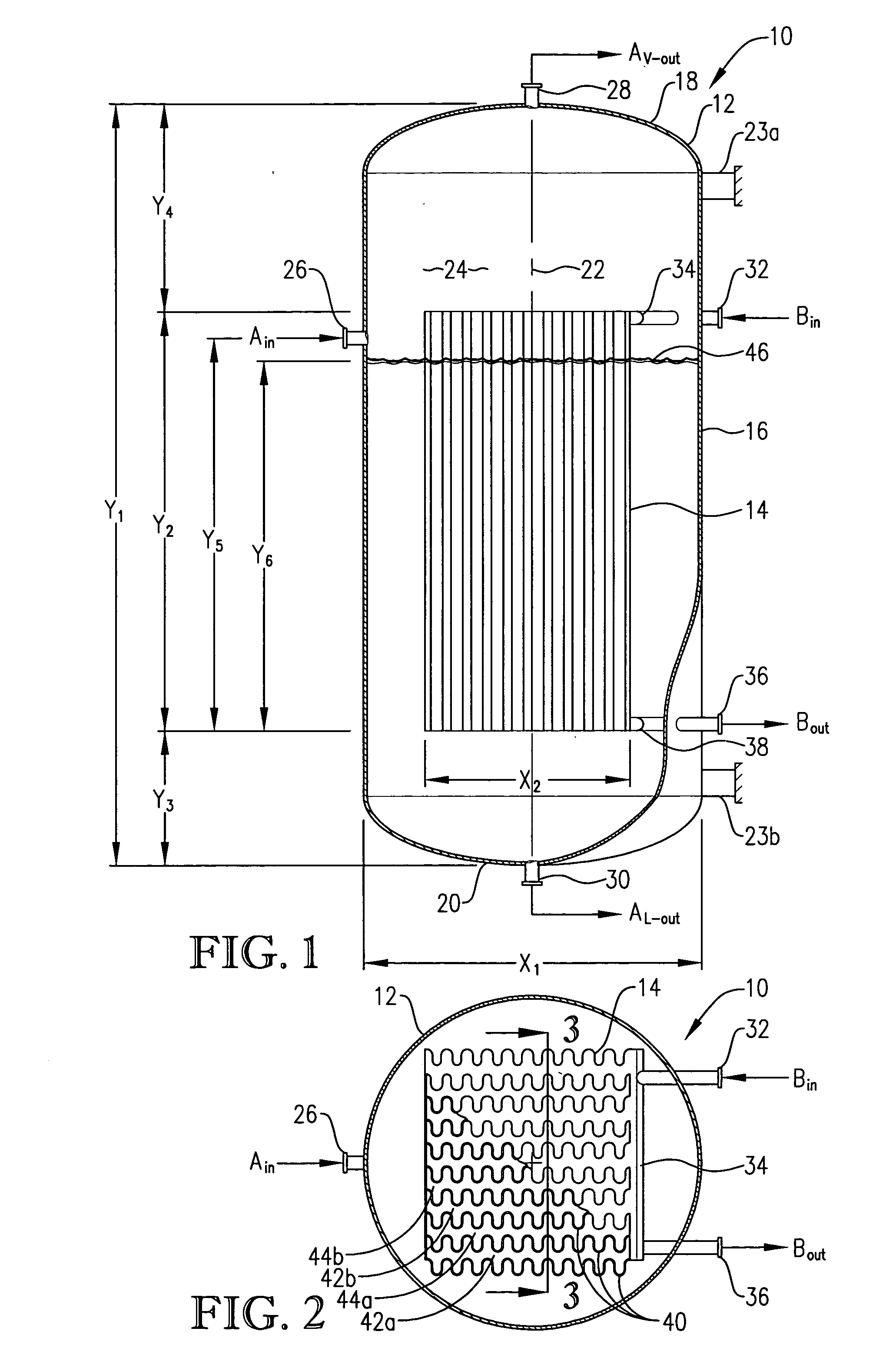

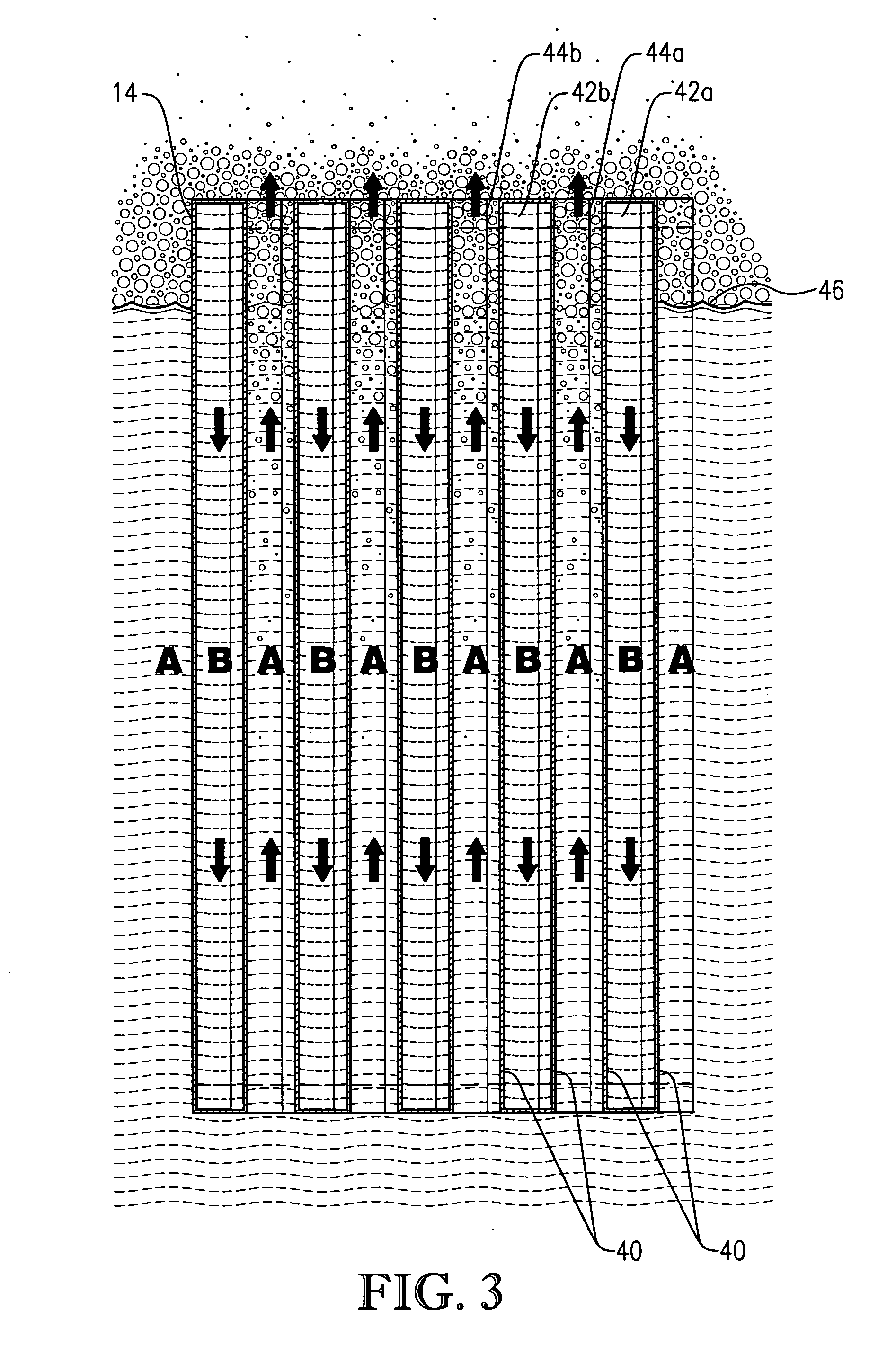

Vertical heat exchanger configuration for LNG facility

LNG facility employing one or more vertical core-in-kettle heat exchangers to cool natural gas via indirect heat exchange with a refrigerant. The vertical core-in-kettle heat exchangers save plot space and can be use to reduce the size of cold boxes employed in the LNG facility. In addition, vertical core-in-kettle heat exchangers can exhibit enhanced heat transfer efficiency due to improved refrigerant access to the core, improved refrigerant circulation around the core, and / or improved vapor / liquid disengagement above the core.

Owner:CONOCOPHILLIPS CO

Heat transfer system utilizing thermal energy storage materials

An enhanced heat transfer between stored thermal energy and a heat recipient via a capillary pumped loop. The devices, systems and methods employ a thermal energy storage material having a solid to liquid phase transition at a temperature and a structure having a plurality of capillaries.

Owner:DOW GLOBAL TECH LLC

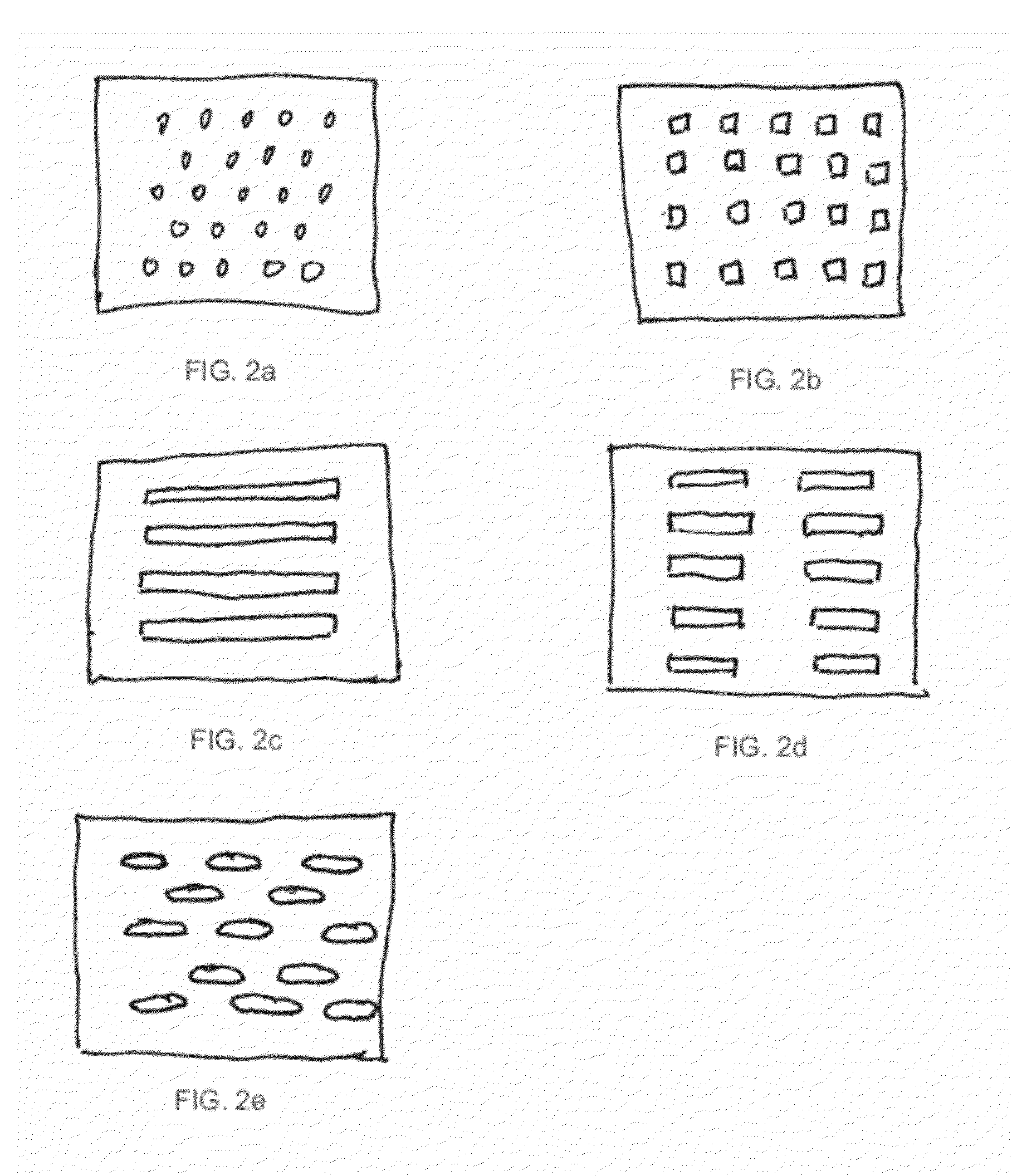

Systems and methods for heat transfer utilizing heat exchangers with carbon nanotubes

InactiveUS20120090816A1Material nanotechnologySemiconductor/solid-state device detailsMultiwalled carbonEnhanced heat transfer

A heat exchanger with mini channels or micro channels provides enhanced heat transfer abilities. One or more surfaces of the channels may be covered with a nanostructure, such as single walled carbon nanotubes or multiwalled carbon nanotubes. The nanostructures may fully cover the entire surface of the channel or a selected surface area of the channel. Further, the nanostructures may be arranged into multiple patterned bundles covering the surface of the channel.

Owner:RICE UNIV

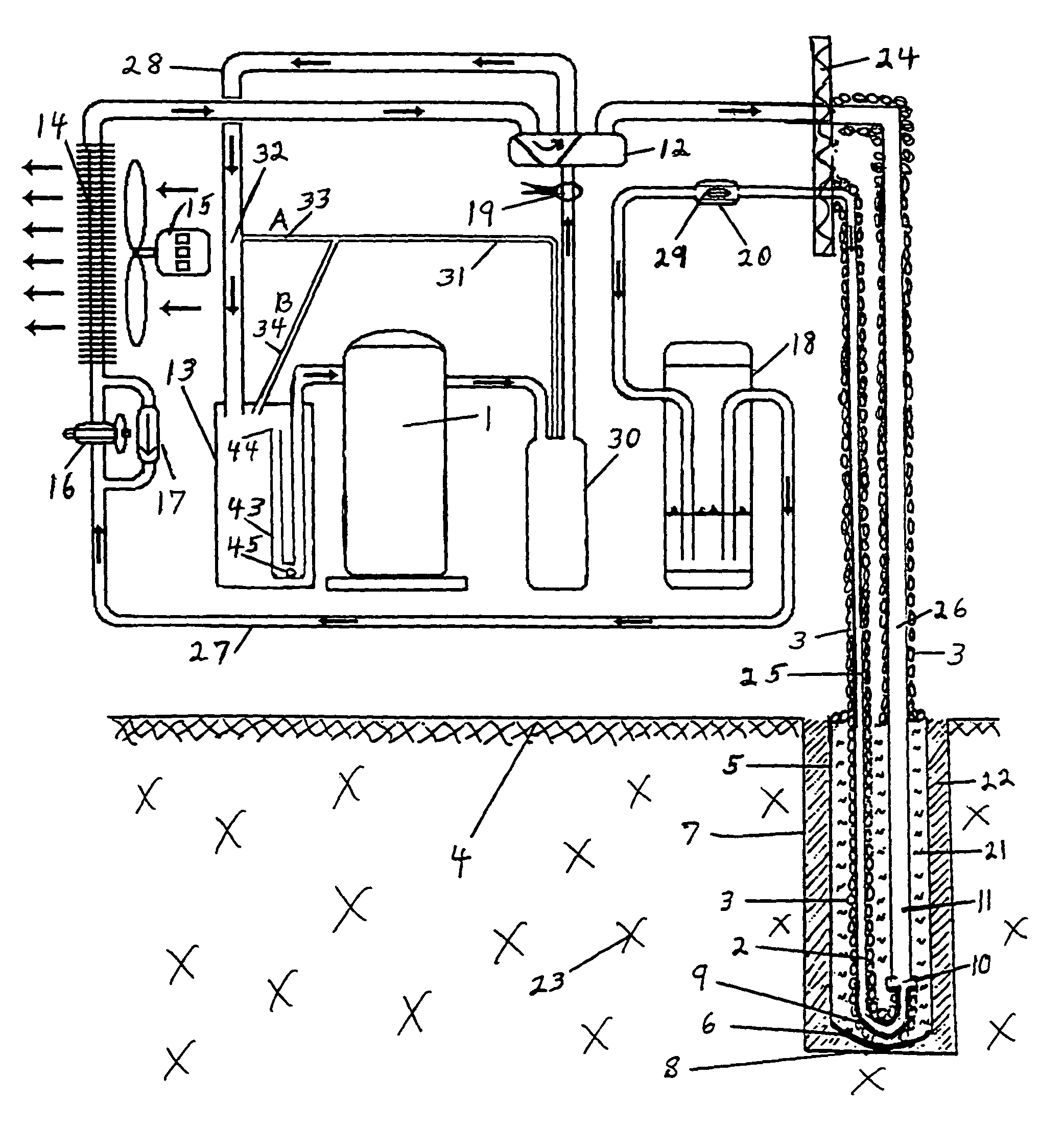

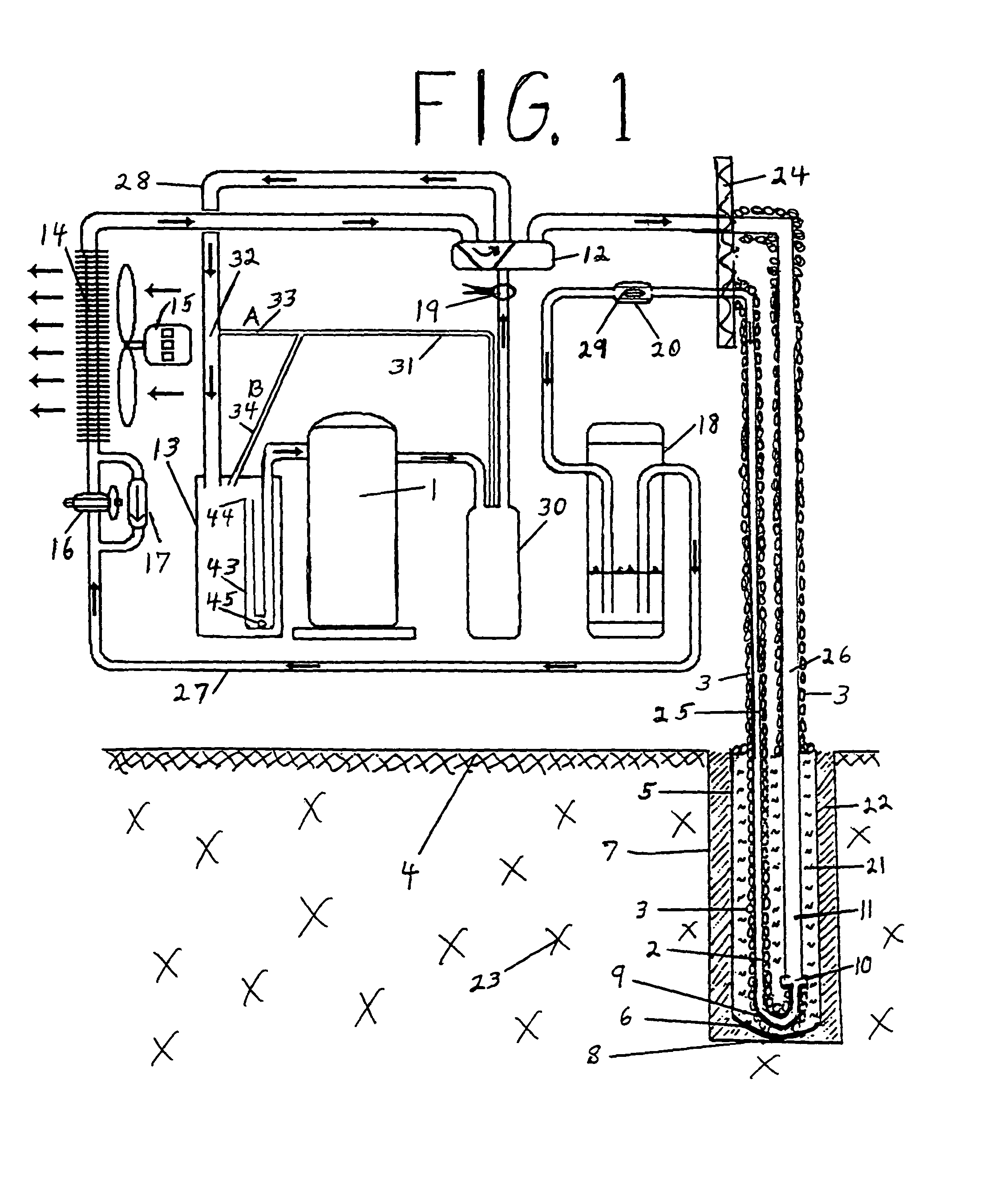

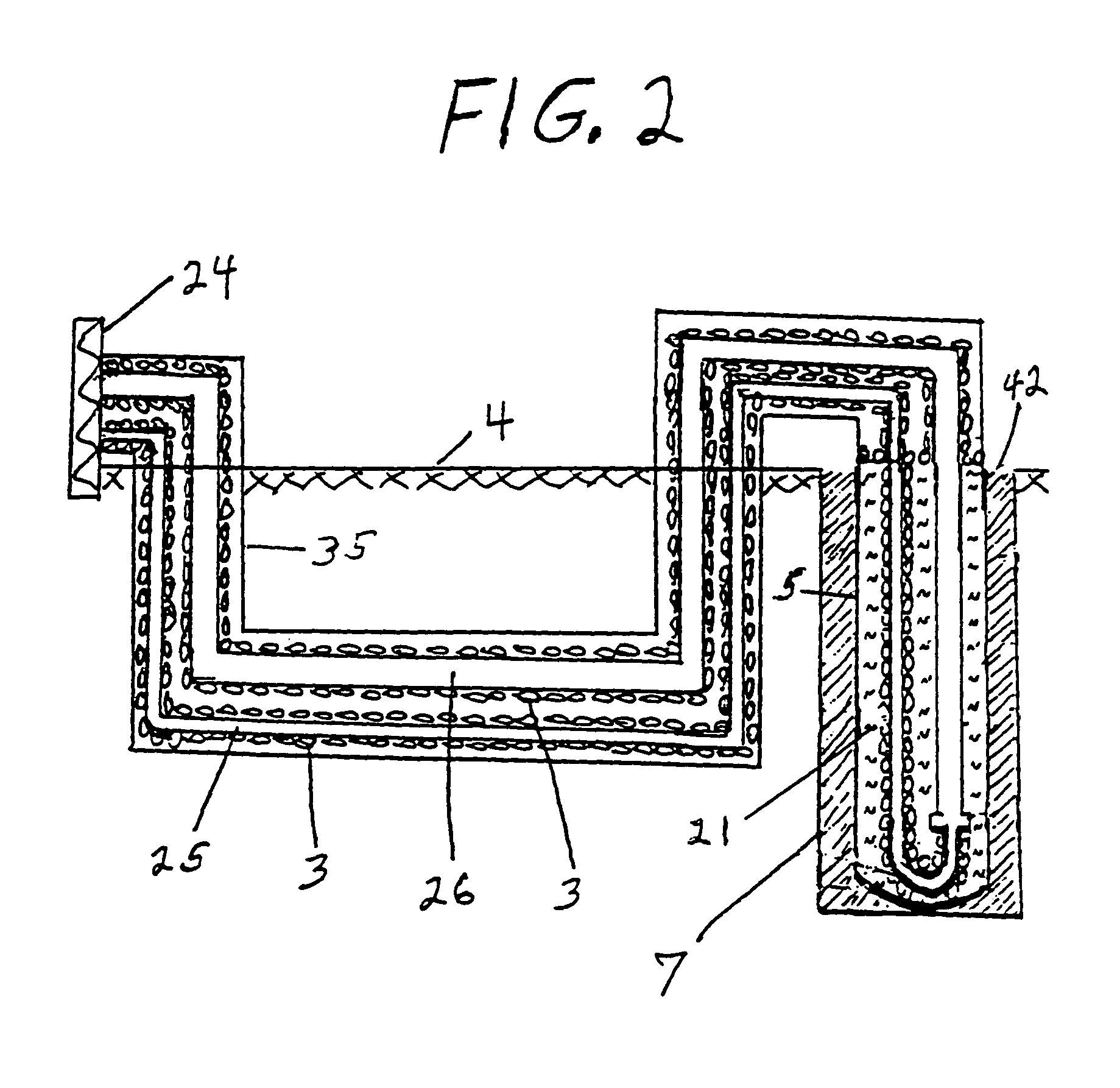

Deep well direct expansion heating and cooling system

A direct expansion geothermal heat exchange system including certain requisite heating / cooling load calculations, certain operational refrigerant pressures, refrigerant tubing design lengths in varying soils, refrigerant tubing sizing per ton of system design capacity, refrigerant tubing sizing at varying sub-surface installation depths, lowering refrigerant tubing into a borehole via rope, encasing the lower segment of refrigerant tubing within a solid encasement, providing a bar for rope attachment, using a winch to raise and lower refrigerant tubing, certain sizing of the compressor, certain air handler sizing, certain accumulator sizing, certain sizing of metering devices in the heating mode and in the cooling mode, parameters for charging the system, certain sizing of the receiver, utilizing certain grout for corrosion protection and for enhanced heat transfer, providing a fluid filled pipe within a borehole to contain accessible refrigerant tubing, providing a certain fluid fill for the pipe, one of providing a certain time delay on the low pressure cut off switch and of eliminating the switch, providing a certain oil separator return line location, and providing a certain amount of lubricating oil.

Owner:EARTH TO AIR SYST

Piezofan and heat sink system for enhanced heat transfer

An electronic device having enhanced heat dissipation capabilities includes an electronic device, a heat sink, a channel, a piezoelectric element, and a blade. The heat sink is in thermal communication with the electronic device. The channel includes an inlet, an outlet and a constriction disposed along the channel between the inlet and the outlet. The heat sink defines at least a portion of the channel. The blade includes a free end and an attached end. The blade is disposed in the channel and connected to the piezoelectric element. The piezoelectric element is activated to move the blade side to side in the channel to create air vortices. The constriction in the channel and the blade cooperate with one another such that a vortex that is generated as the blade moves toward a first side of the channel is compressed against the first side of the channel and expelled towards the outlet of the channel.

Owner:CONSUMER LIGHTING (U S) LLC

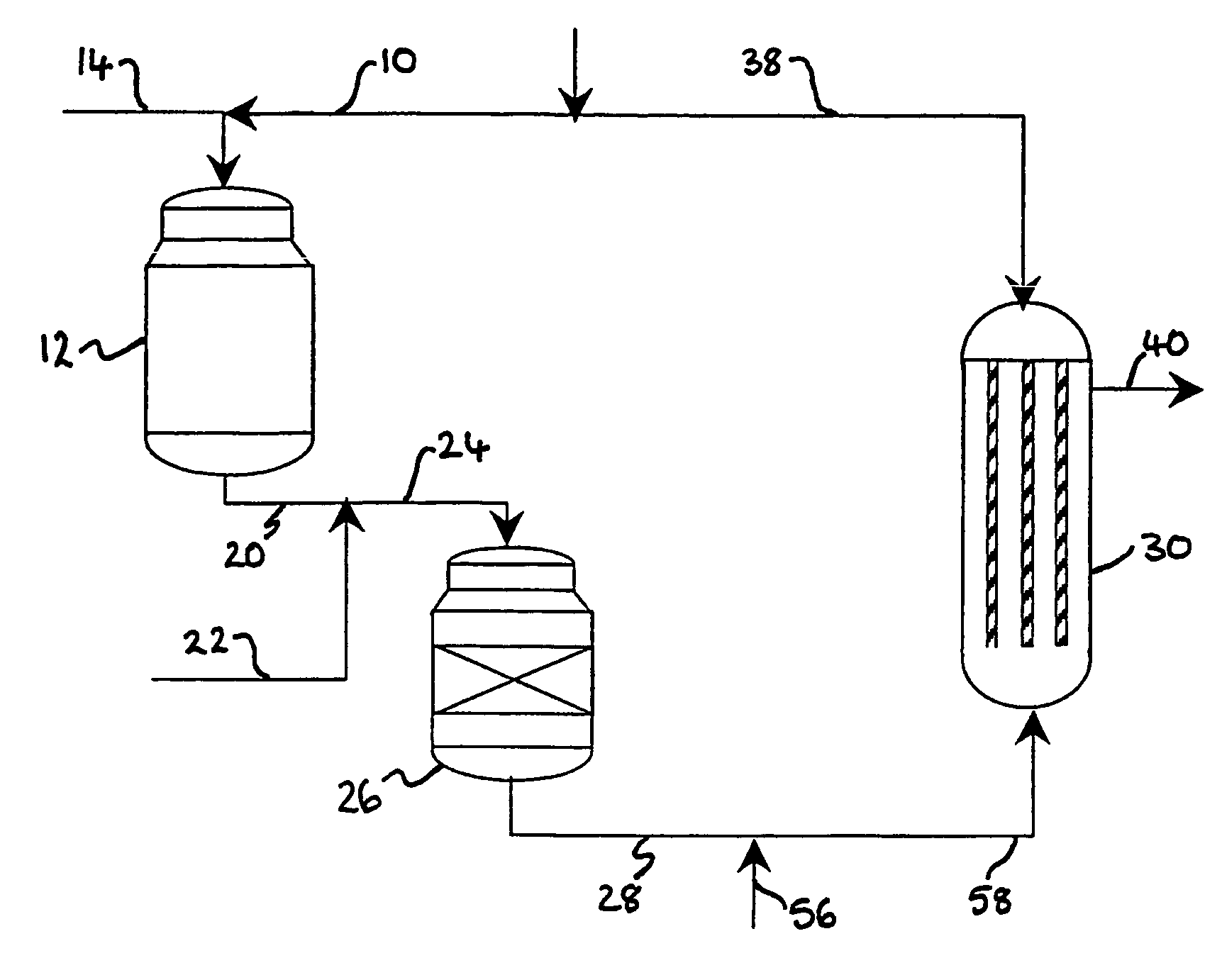

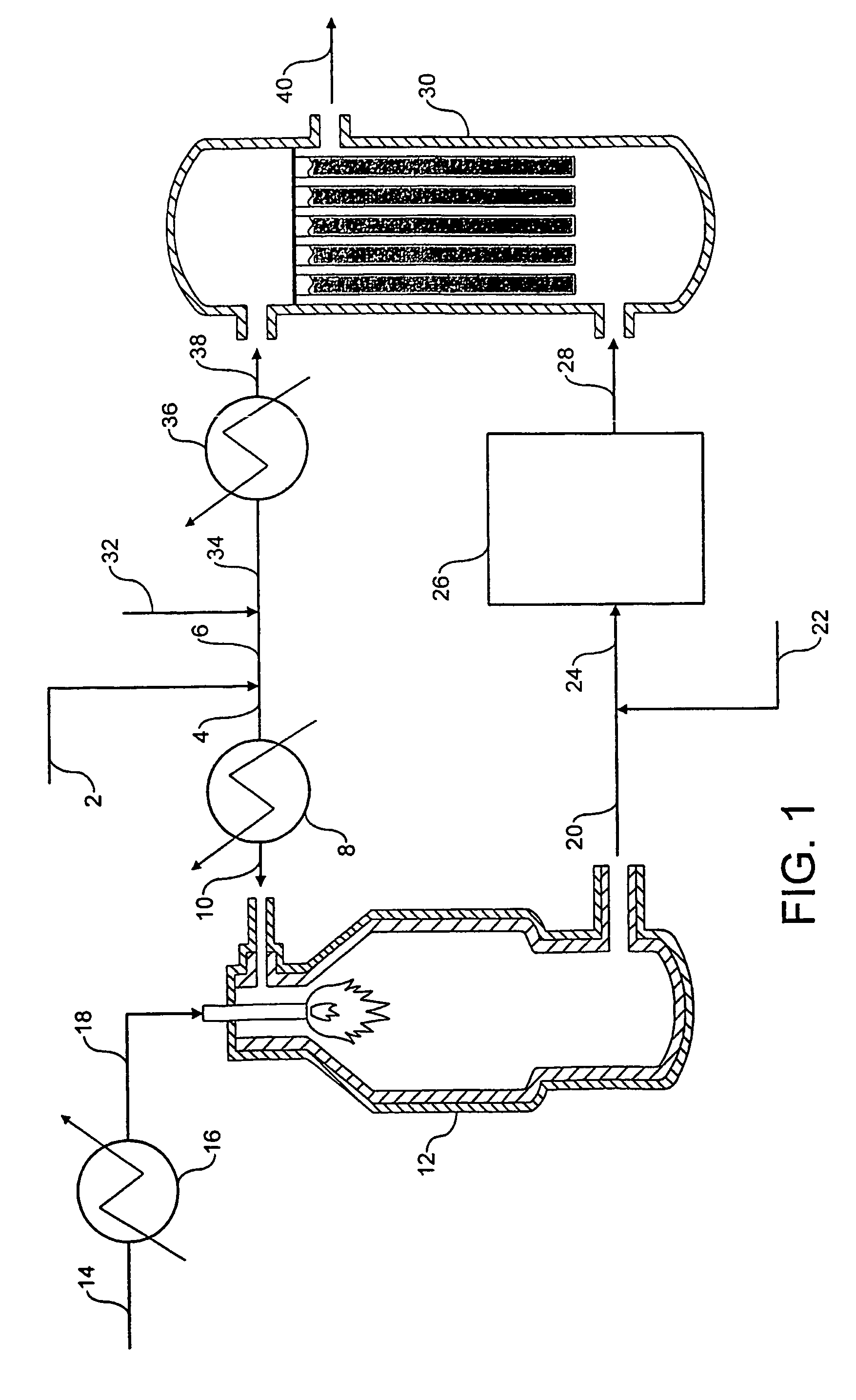

Process and apparatus for the production of synthesis gas

ActiveUS7670586B2Avoiding negatively affecting the mechanical integrity of the secondary unit.Lower Level RequirementsUsing liquid separation agentHydrogen productionSolid carbonSyngas

Owner:KANSAS STATE UNIV INST FOR COMMLIZATION +1

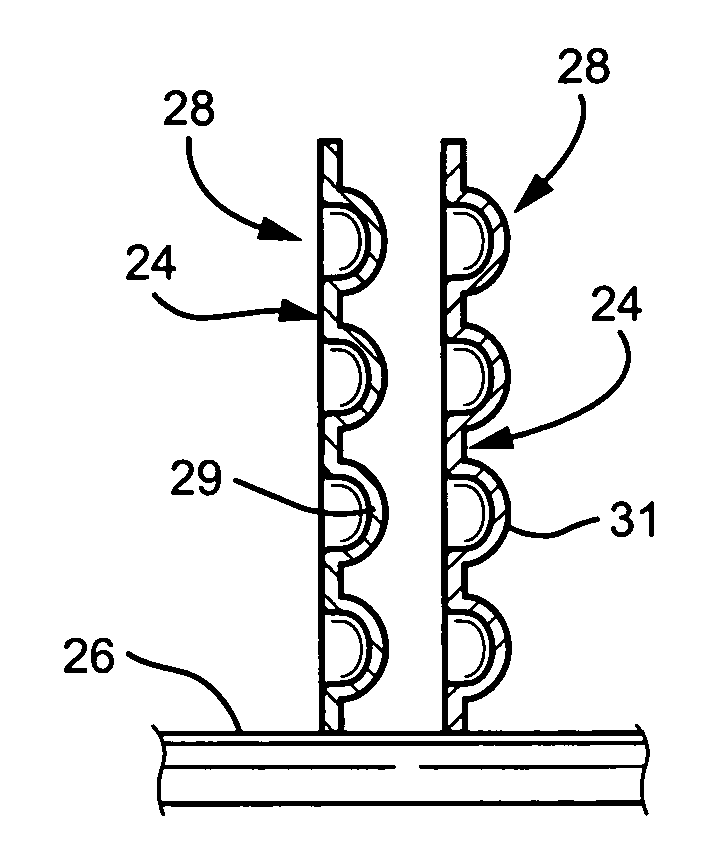

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS7806915B2Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

Apparatus and method for providing enhanced heat transfer from a body

InactiveUS20110022136A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlMedicine

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

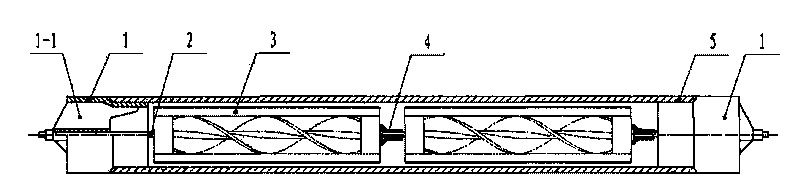

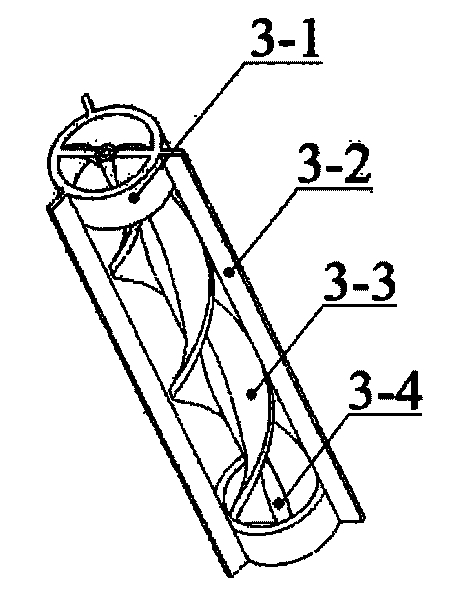

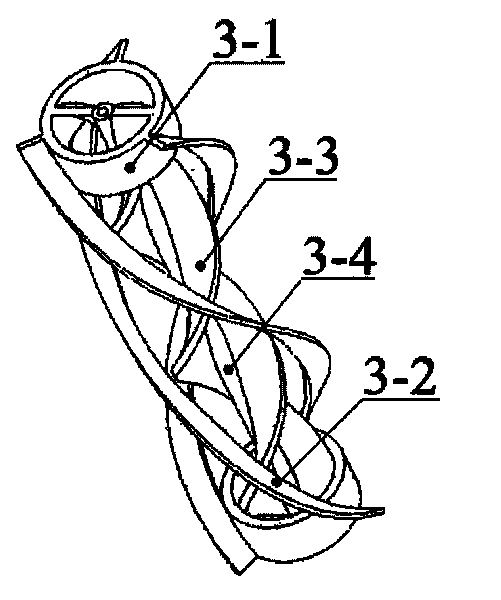

Inner boundary layer cutting disturbing radial mixed flow device of heat exchange pipe

InactiveCN101762203AImprove heat transfer effectEasy to useHeat transfer modificationRotary device cleaningMixed flowEnhanced heat transfer

The invention relates to an inner boundary layer cutting disturbing radial mixed flow device of a heat exchange pipe, which belongs to an inner insertion element enhanced heat transfer device of a heat exchange pipe of pipe type heat exchange equipment. The device consists of a rotor (or a plurality of rotors), pipe end hanging elements, a support shaft and position limiting rivets, wherein two pipe end hanging elements are respectively fixed at both ends of the heat exchange pipe, one or a plurality of rotors are arranged in the heat exchange pipe, the rotors can be ranged in groups, each group is separated through the position limiting rivets, the support shaft passes through shaft holes of the rotors and the position limiting rivets, and both ends of the support shaft are fixed on the pipe end hanging elements. Each rotor consists of a driving wing, a disturbing wing, a support ring and a shaft hole, the fluid in the heat exchange pipe can be divided into two parts: a driving region and a cutting disturbing region, the disturbing wings can be straight wings or spiral wings in the opposite direction to the rotating direction of the driving wings, and in addition, small gaps are formed between the pipe walls and the disturbing wings for realizing the sufficient cutting disturbing on the boundary layer of the fluid. The device per se has the double functions of on-line cleaning and enhanced heat transfer in the heat exchange pipe through the enhanced fluid boundary layer cutting disturbing and radial mixed flow effect.

Owner:BEIJING UNIV OF CHEM TECH

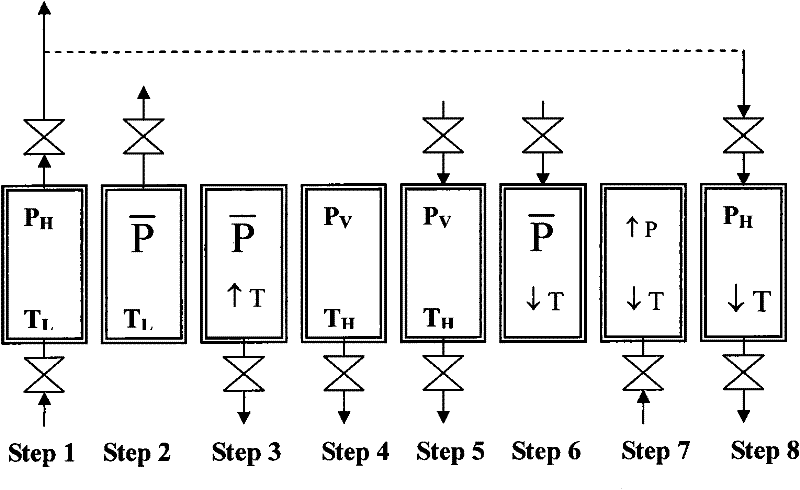

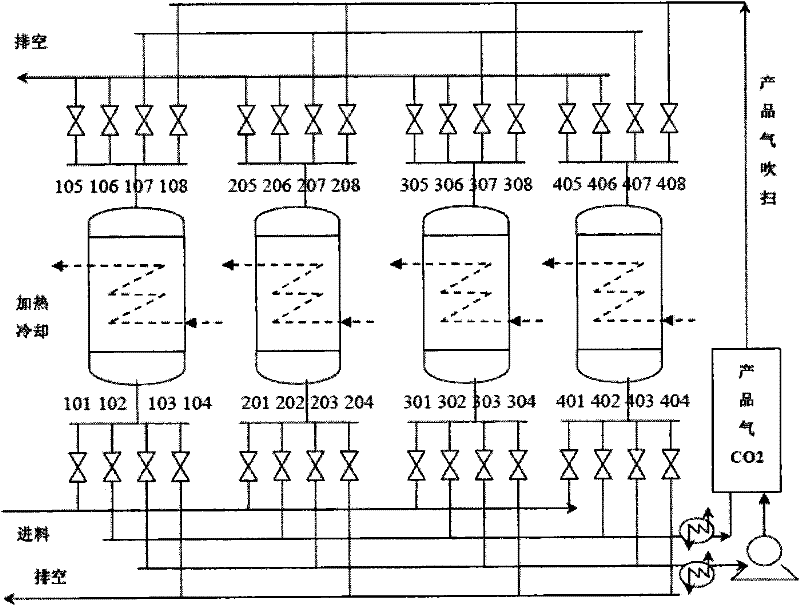

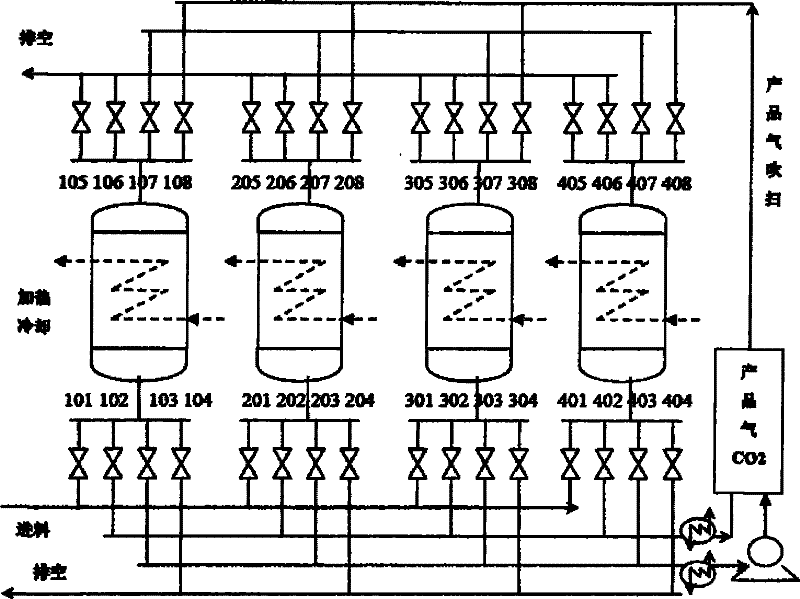

Method for vacuum pressure and temperature varying coupling adsorbing and trapping carbon dioxide in flue gas

The invention relates to a trapping method of carbon dioxide, namely a method for multi-tower vacuum pressure and temperature varying coupling adsorbing and concentrating the carbon dioxide. The method comprises the following main steps: (a) under the conditions of 10-50 DEG C of temperature and 1.1-5.0 atm of pressure, adopting an adsorbent for adsorbing the carbon dioxide to adsorb the carbon dioxide in flue gas; (b) under the conditions of 80-150 DEG C of temperature and 1-10 kPa of vacuum, desorbing the adsorbent in step (a), and cooling the obtained gas containing the carbon dioxide to enter a gas collector. The method has the advantages that under the auxiliary condition of heating temperature rising, the adsorbent is desorbed in vacuum, and the power consumption and the cost of vacuum equipment are reduced; pipe-shell absorbers or the absorbers of enhanced heat transfer elements of tower inbuilt fin type, coils, and the like to increase the indirect heating and cooling efficiency; and adopting low-temperature exhaust gas discharged from the top end of an adsorption tower to directly regenerate a post adsorbent in a bed to shorten the cooling time. Compared with the prior art, the method reduces the trapping and post processing cost of the carbon dioxide.

Owner:EAST CHINA UNIV OF SCI & TECH

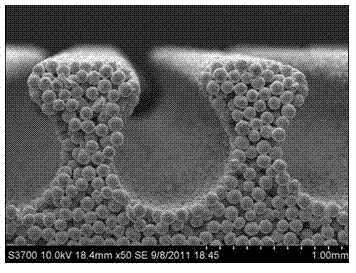

Inner groove porous strengthened boiling micro-channel structure, manufacture method and application

InactiveCN102878845AHigh transmission frequencyHigh porosityIndirect heat exchangersHeat flowEnhanced heat transfer

The invention discloses an inner groove porous strengthened boiling micro-channel structure, which includes a metal sintered felt formed by sintering metal powder and provided with uniformly-distributed particles, wherein a plurality of inner grooves are uniformly distributed in the metal sintered felt. The porous surface of the inner groove porous strengthened boiling micro-channel structure has excellent capillary characteristics, can keep the wall surface to be sufficiently damp, avoids the local scabbing and polymer deposit caused by hot spot and local drying, improves the heat transfer coefficient and critical heat flux density by adopting the porous structure for strengthened boiling heat transfer, and has excellent strengthened heat transfer effect.

Owner:SOUTH CHINA UNIV OF TECH

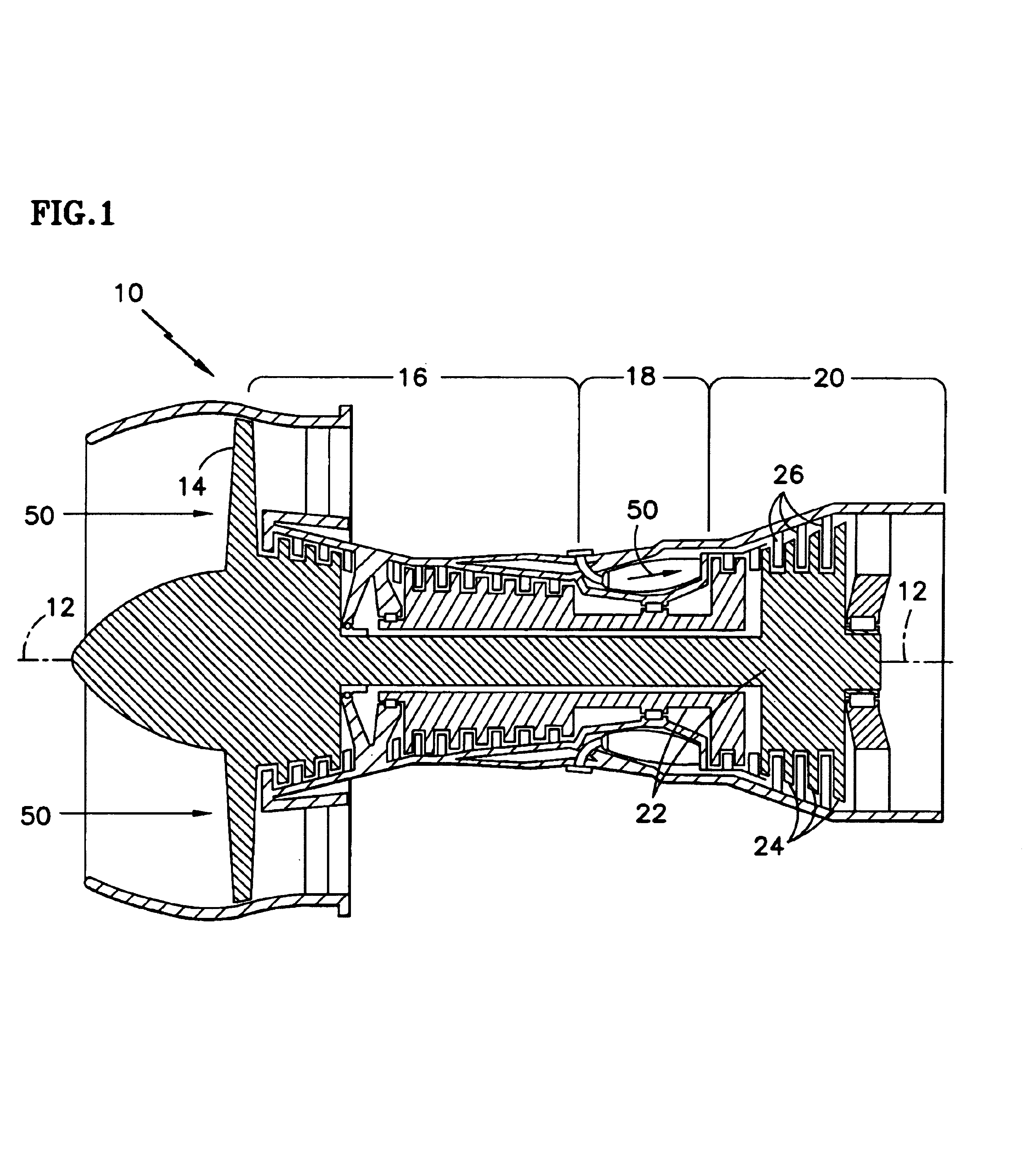

Combustion liner with enhanced heat transfer

ActiveUS7386980B2Improve heat transfer performanceIncrease surface areaContinuous combustion chamberGas turbine plantsCombustionEnhanced heat transfer

Owner:H2 IP UK LTD

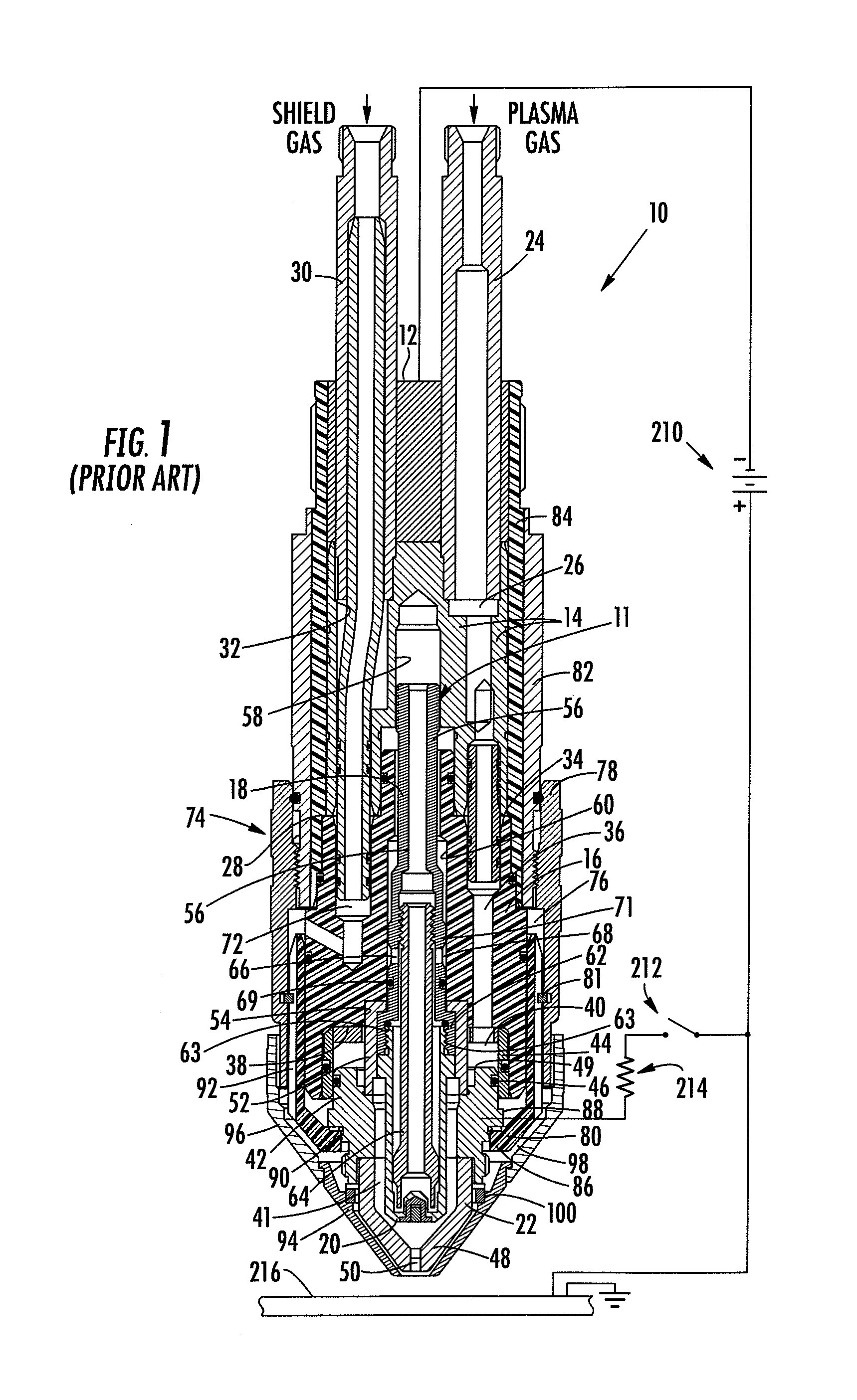

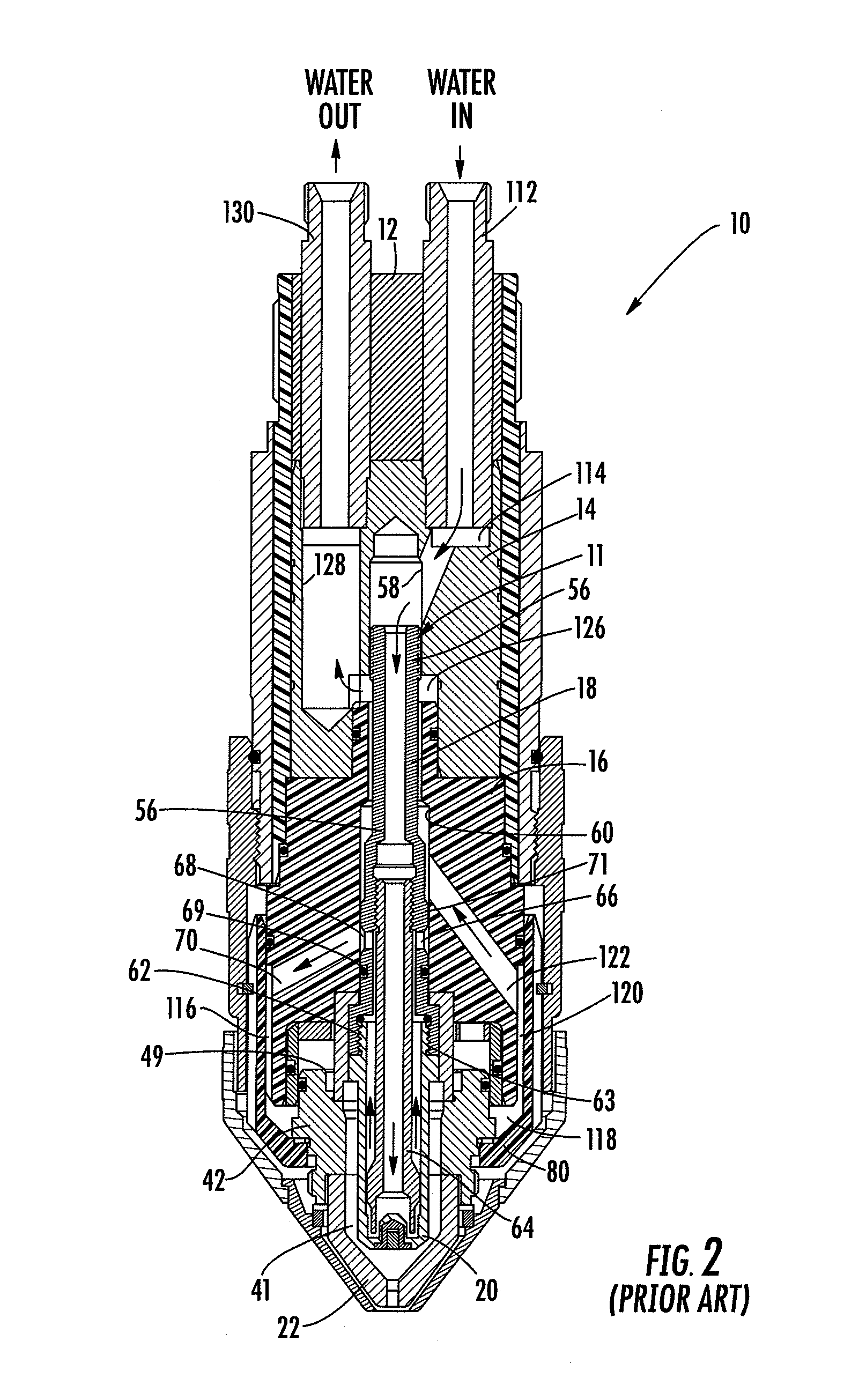

Electrode for plasma torch with novel assembly method and enhanced heat transfer

ActiveUS8633417B2Long electrode lifeReduce manufacturing costOhmic-resistance electrodesElectrode featuresEnhanced heat transferEngineering

Embodiments of the present invention are related to an electrode for a plasma arc torch, the electrode comprising a generally tubular outer wall, an end wall, and a protrusion. The end wall is joined to a distal end of the outer wall and supports an emissive element in a generally central region. The protrusion extends from the generally central region of the end wall and is configured to connect with an electrode holder by a releasable connection, wherein the protrusion is configured such that at least one coolant passage forms between the protrusion and the electrode holder when the electrode is connected with the electrode holder. In some embodiments, the releasable connection comprises a threaded connection, wherein the protrusion is threaded to releasably connect to a threaded coolant tube of the electrode holder. In other embodiments, at least one coolant passage is defined by the threaded connection.

Owner:THE ESAB GROUP

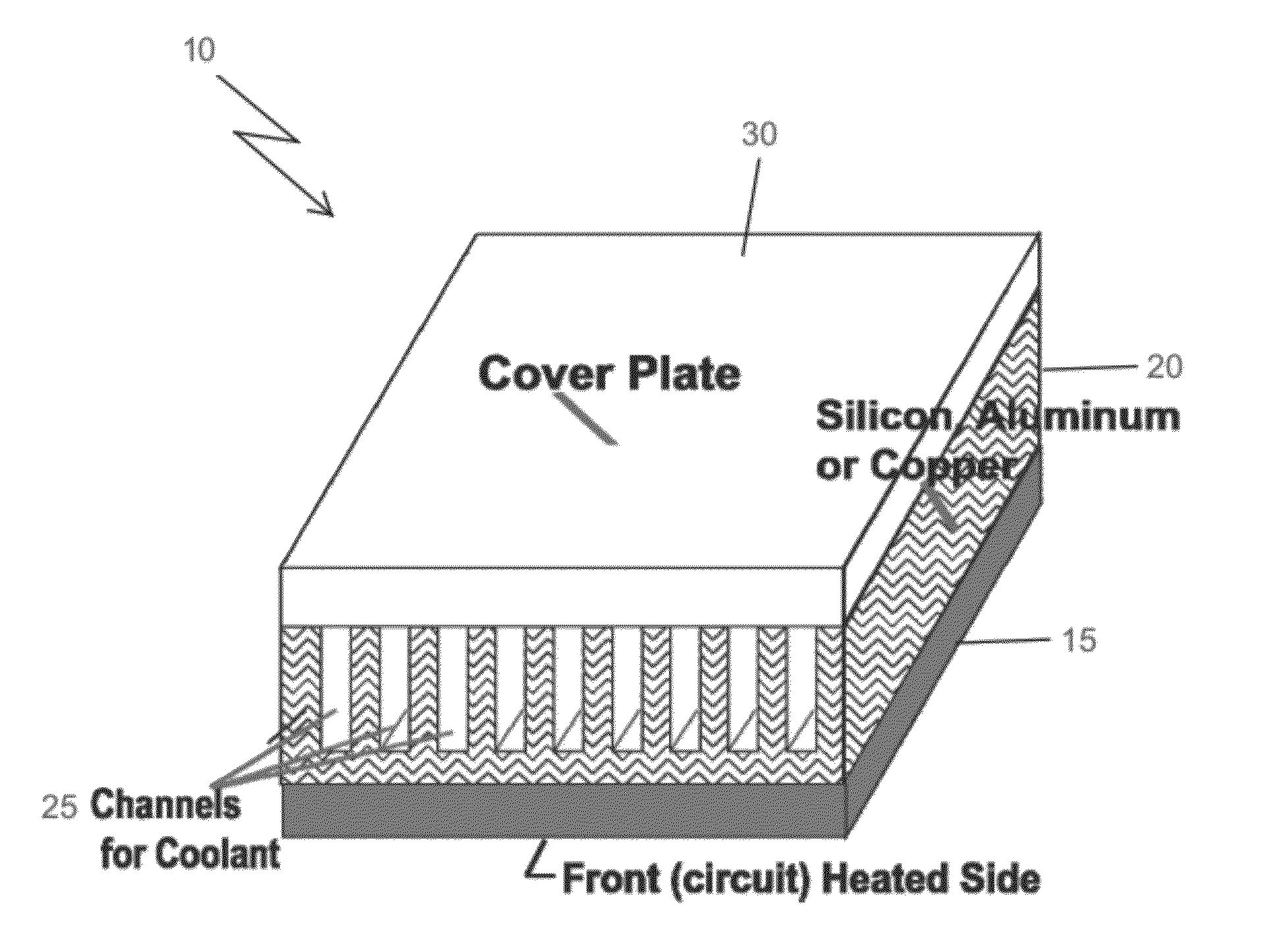

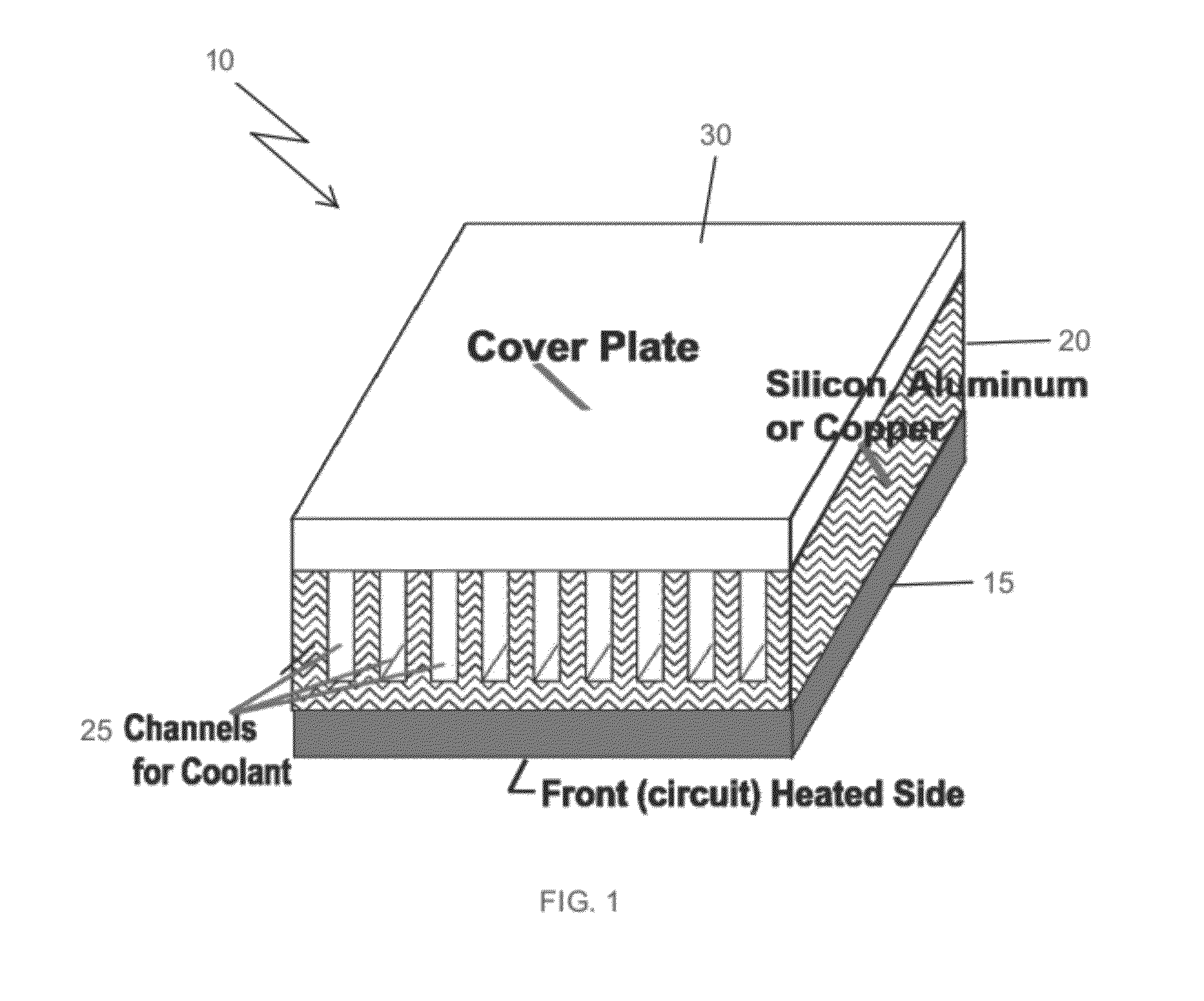

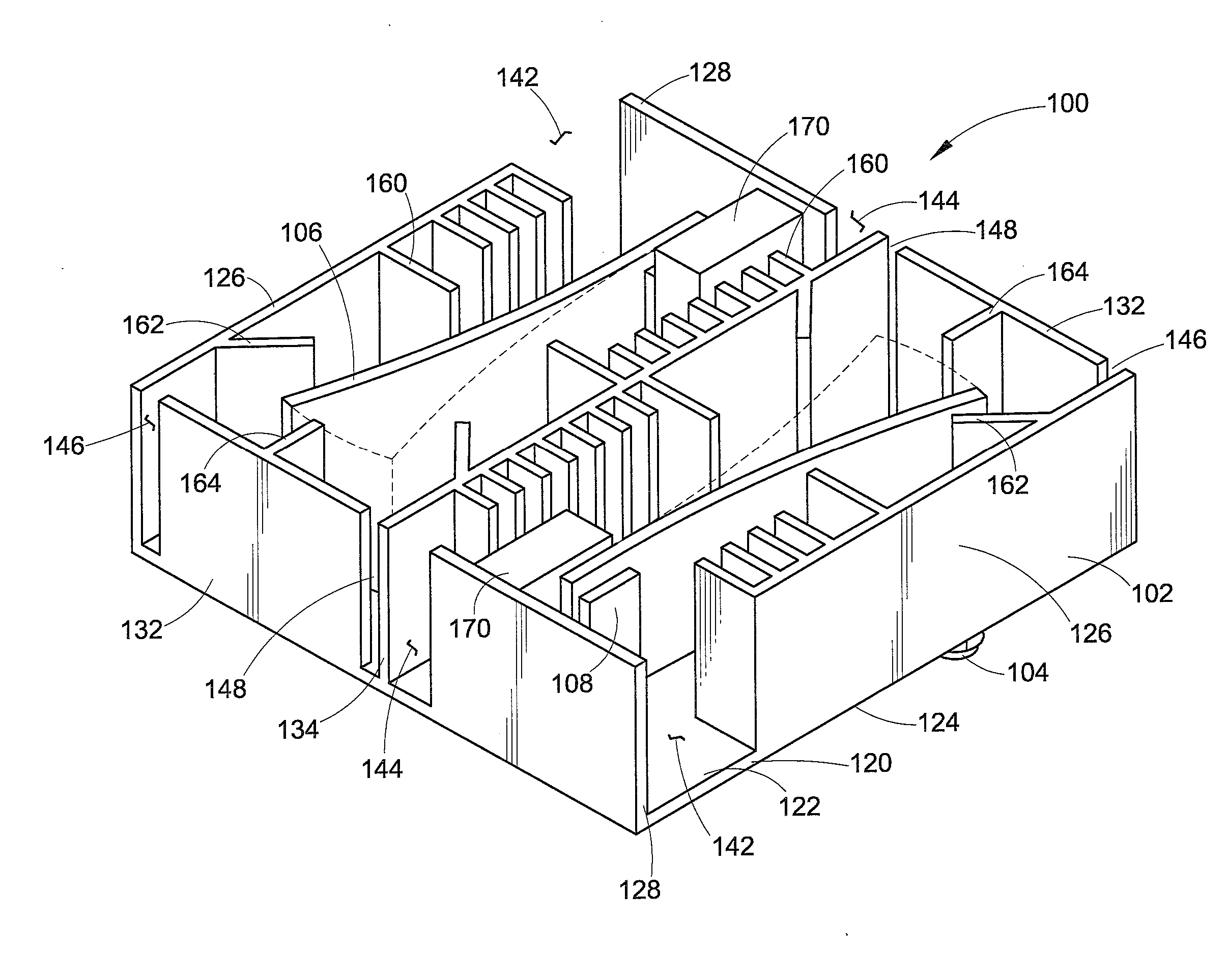

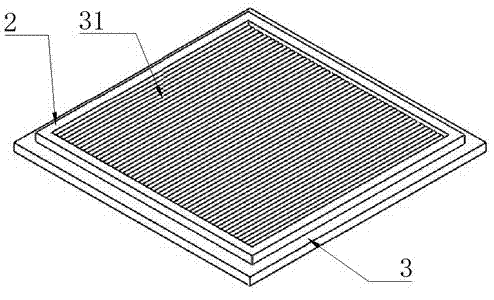

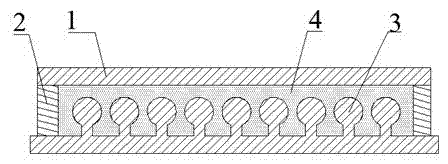

Enhanced heat transfer structure with heat transfer members of variable density

InactiveUS6898082B2Efficient heat transferAvoid easy cloggingSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEnhanced heat transfer

A heat transfer structure includes a heat transfer module having a plurality of heat transfer members in the duct chamber with the density increased in the direction of the flow of the coolant and having a greatest density adjacent to the position of a heat source attached in thermal contact with the heat transfer module. The profile of the duct chamber is adjusted to the position of the heat source to increase the velocity of coolant directly under the heat source and to partially or completely block the coolant flow to the areas which do not need to be temperature adjusted. The heat transfer members may be formed as pin fins fabricated from springs compressed to a predetermined density in a direction perpendicular to the longitudinal axis of the spring (and / or in parallel to the longitudinal axis of the heat transfer module).

Owner:DESSIATOUN SERGUEI V +1

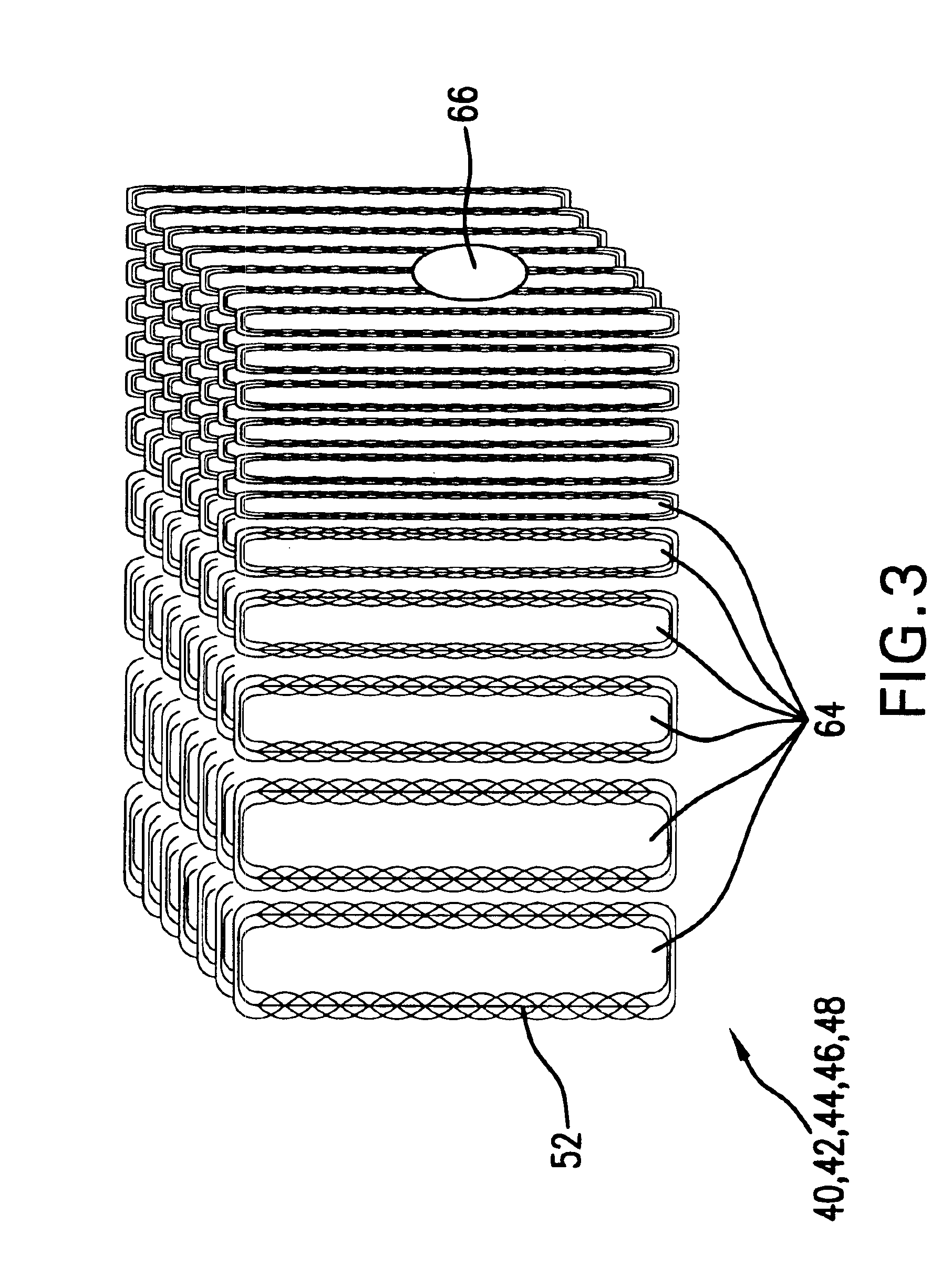

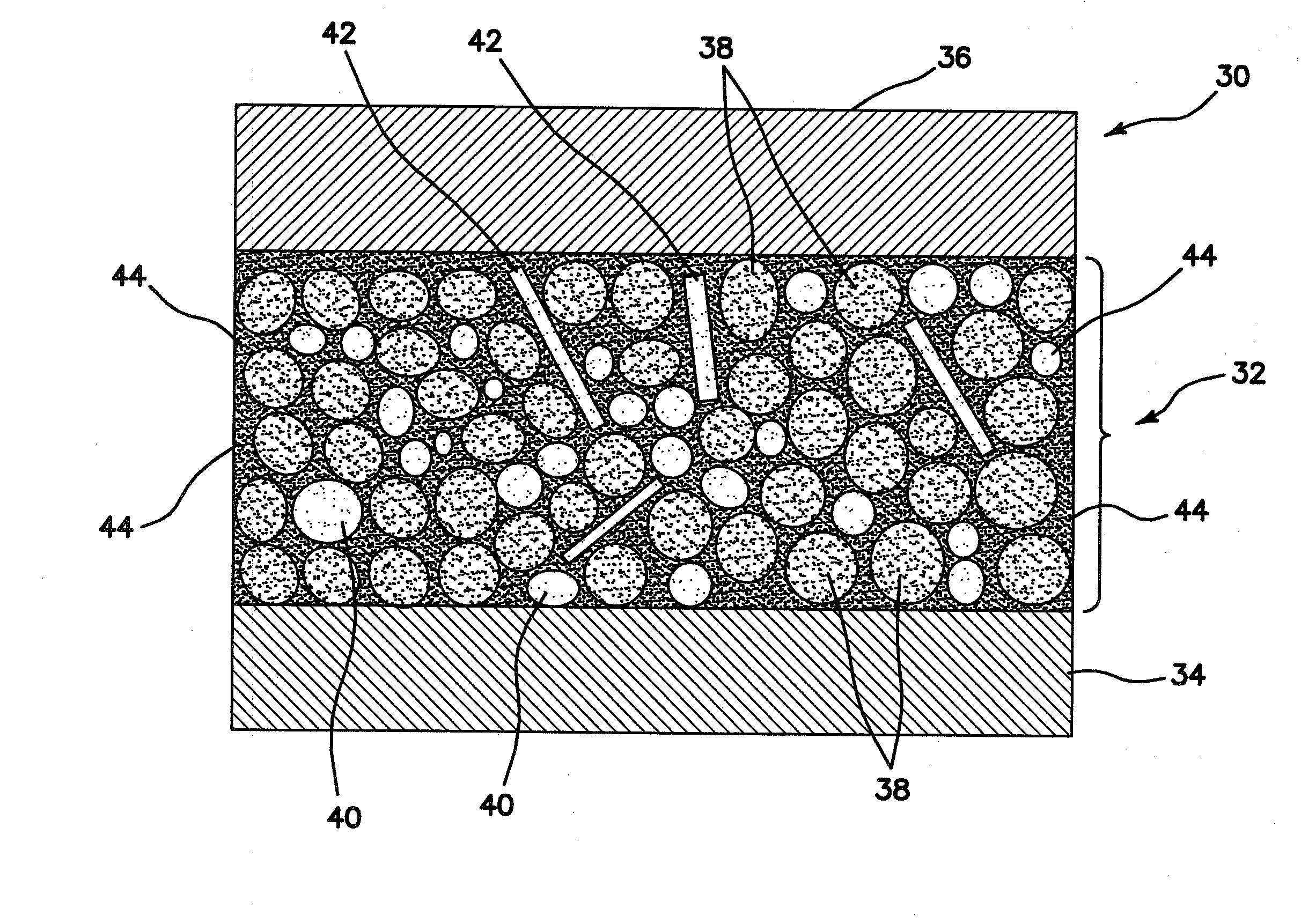

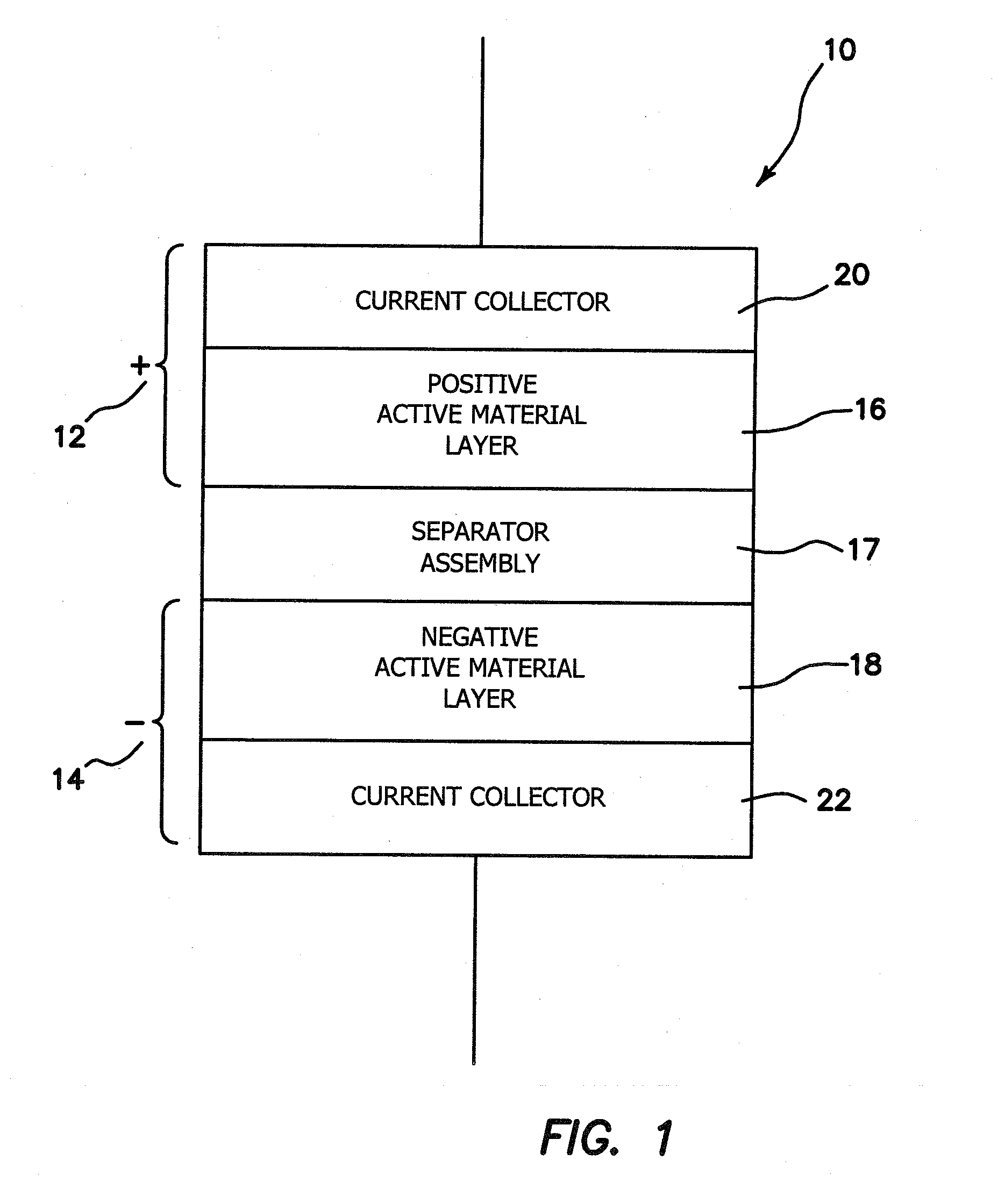

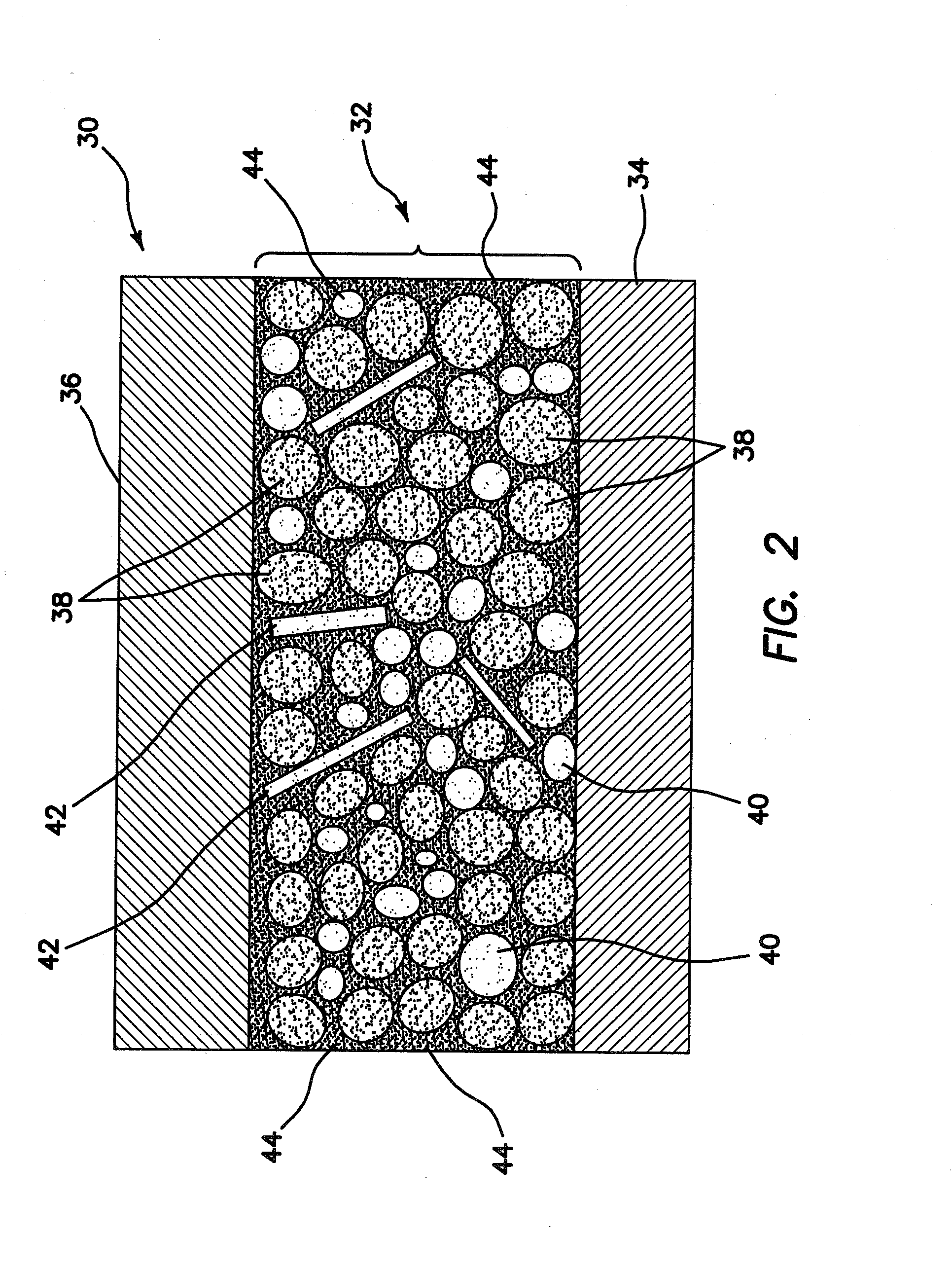

Enhanced Electrolyte Percolation in Lithium Ion Batteries

InactiveUS20100035141A1High porosityImprove abilitiesCell seperators/membranes/diaphragms/spacersActive material electrodesPorosityPresent method

New lithium ion batteries and methods useful in making lithium ion batteries and / or components thereof are provided. The present lithium ion batteries and / or components thereof are structured to allow enhanced ion diffusion into and out of an active material through an electrolyte and to provide enhanced heat transfer out of the active material. The present methods provide electrodes with enhanced porosity without employing a separate porosity additive or a separate electrolyte percolation additive.

Owner:GROSVENOR VICTOR

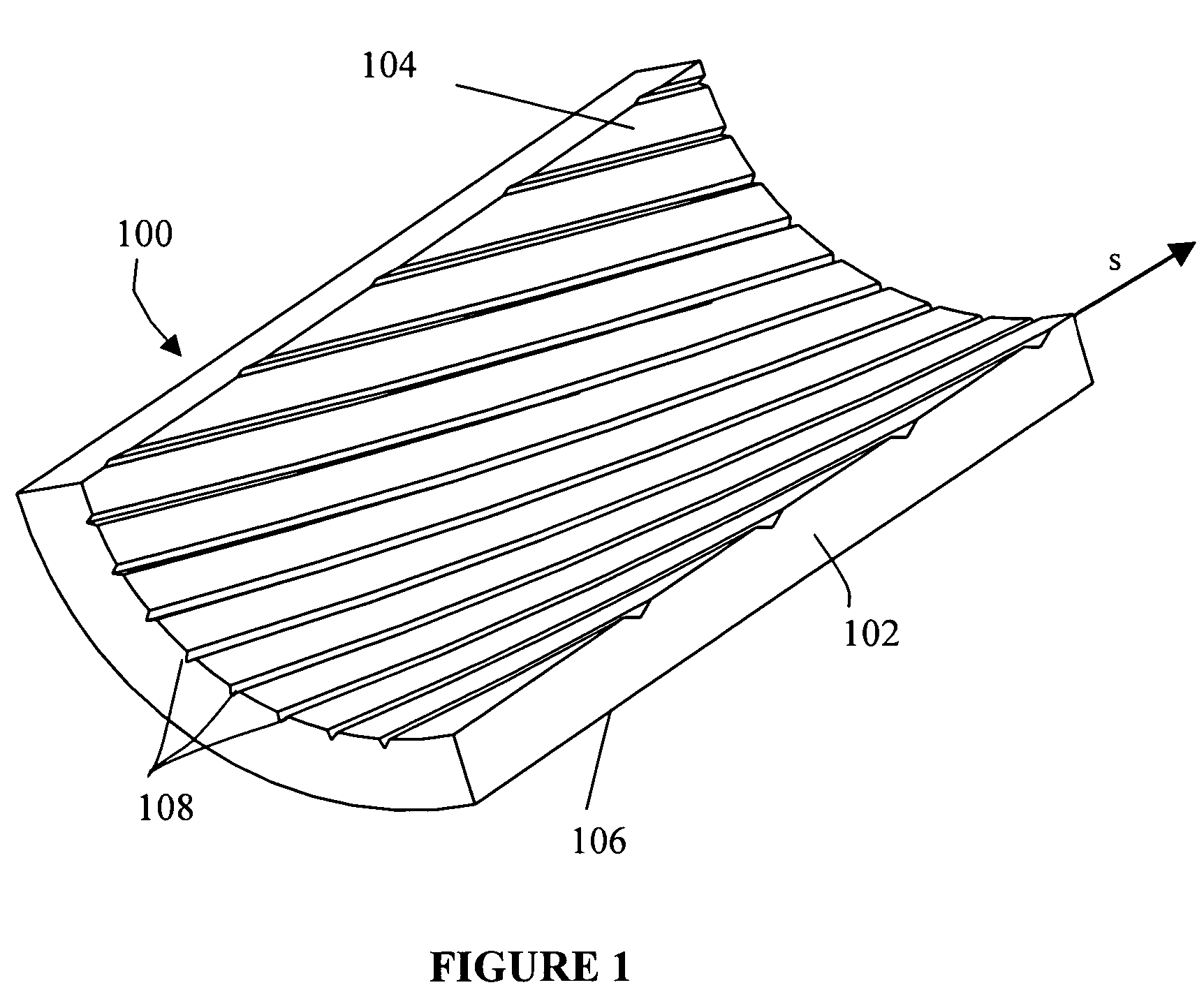

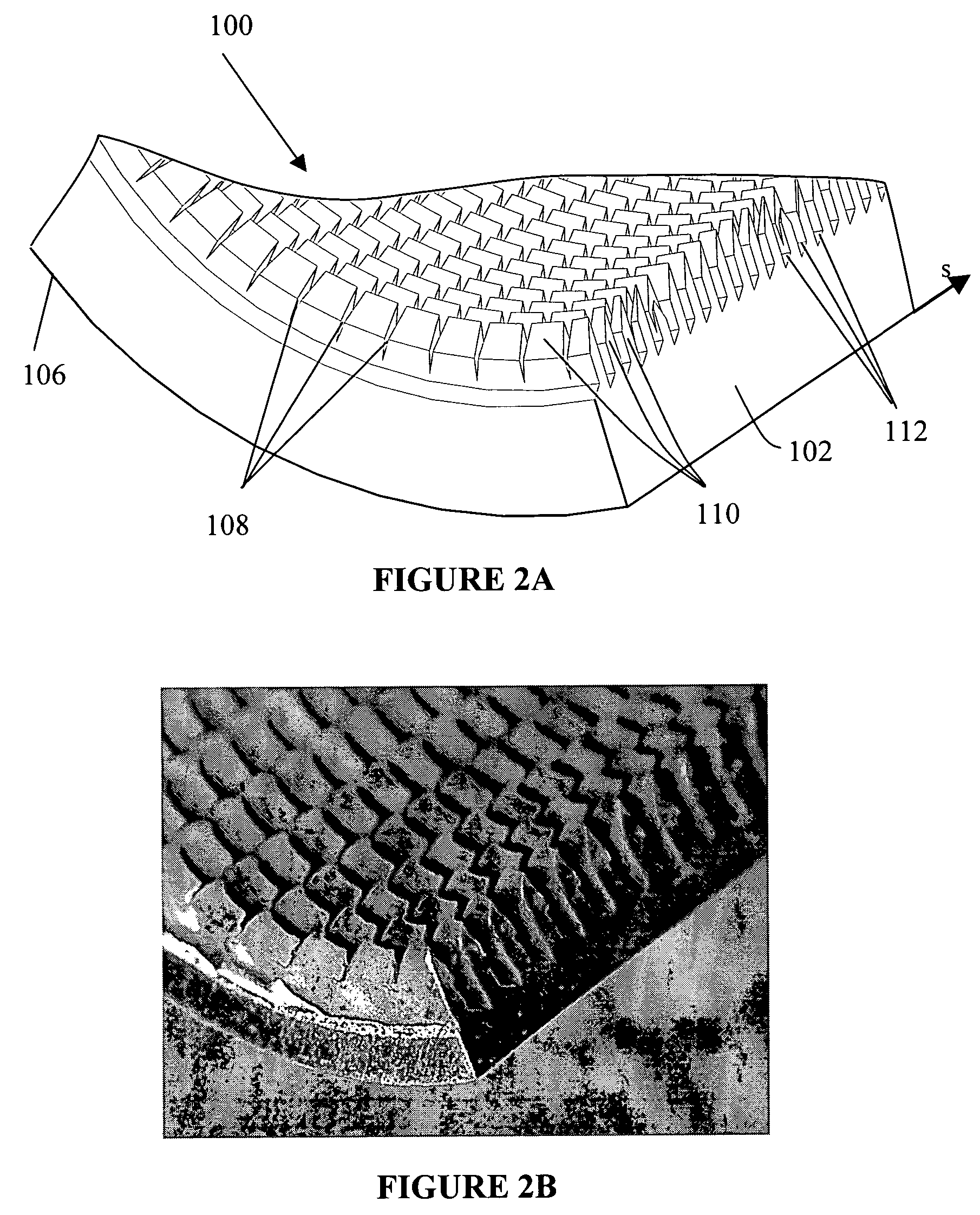

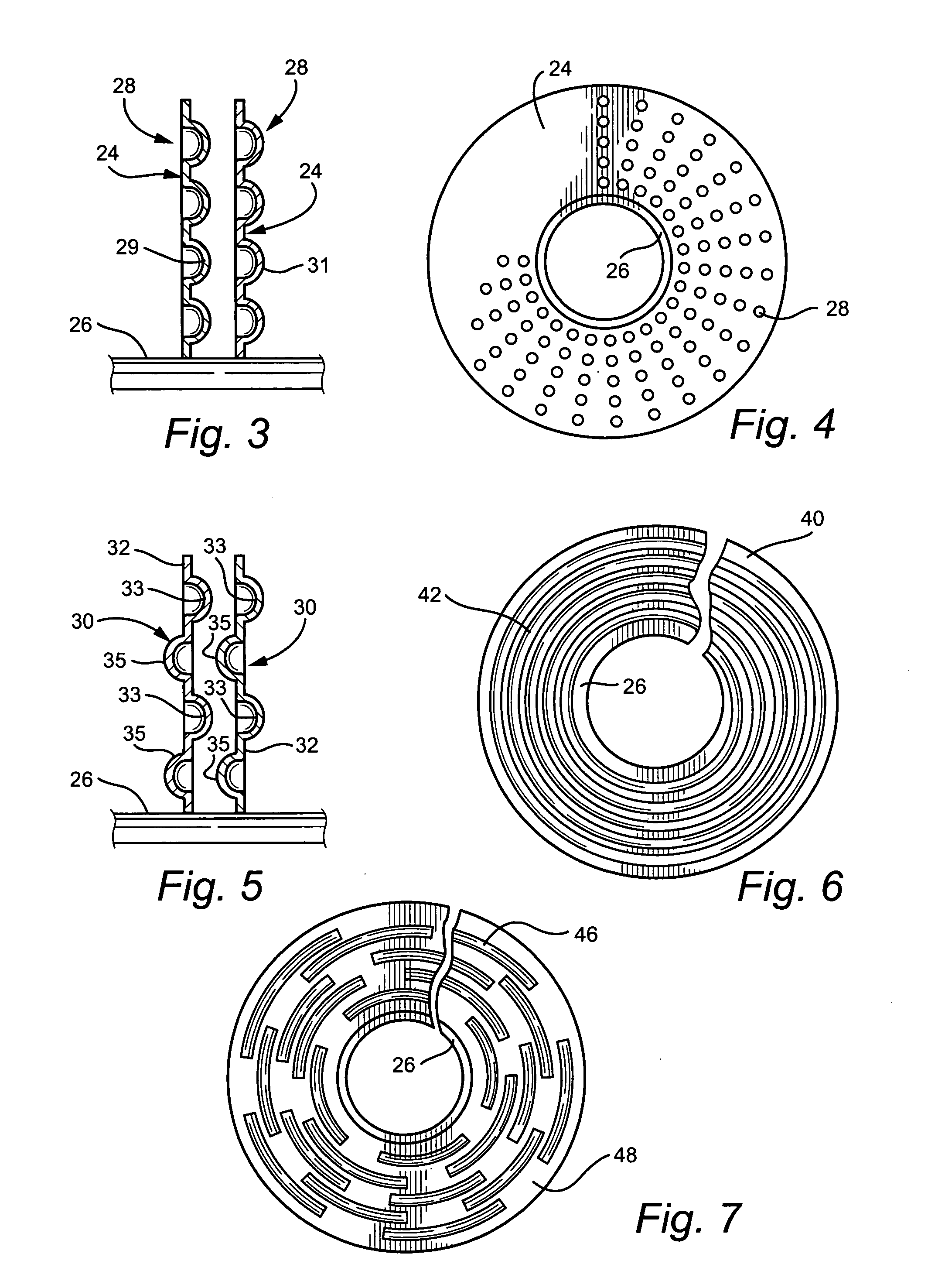

Heat transfer tube including enhanced heat transfer surfaces

InactiveUS7311137B2Improve heat transfer performanceIncreased turbulenceMetal-working apparatusCorrosion preventionEnhanced heat transferBiomedical engineering

The invention relates to enhanced heat transfer surfaces and methods and tools for making enhanced heat transfer surface. Certain embodiments include a boiling surface that include a plurality of primary grooves, protrusions and secondary grooves to form boiling cavities. The boiling surface may be formed by using a tool for cutting the inner surface of a tube. The tool has a tool axis and at least one tip with a cutting edge and a lifting edge. Methods for making a boiling surface are also disclosed, including cutting through the inner surface of a tube to form primary grooves, then cutting and lifting the inner surface to form protrusions and secondary grooves.

Owner:WIELAND WERKE AG

Air cooled heat exchanger with enhanced heat transfer coefficient fins

ActiveUS20080023180A1Heat transferMinimum pressure lossHeat transfer modificationTubular elementsEnhanced heat transferEngineering

The heat exchanger includes a tube having axially spaced fins or a continuously spirally wound fin about the tube. One or more of the fins are dimpled, mechanically or molded, to provide concavities and projections on opposite sides of the fins or alternating concavities and projections on opposite side of the fins. The dimples improve the heat transfer between the fluid flowing through the tubes and the air circulating about the tubes and through the fins. The dimples create vortices and turbulent flow between the fins and effectively increase the heat transfer rate.

Owner:NUOVO PIGNONE TECH SRL

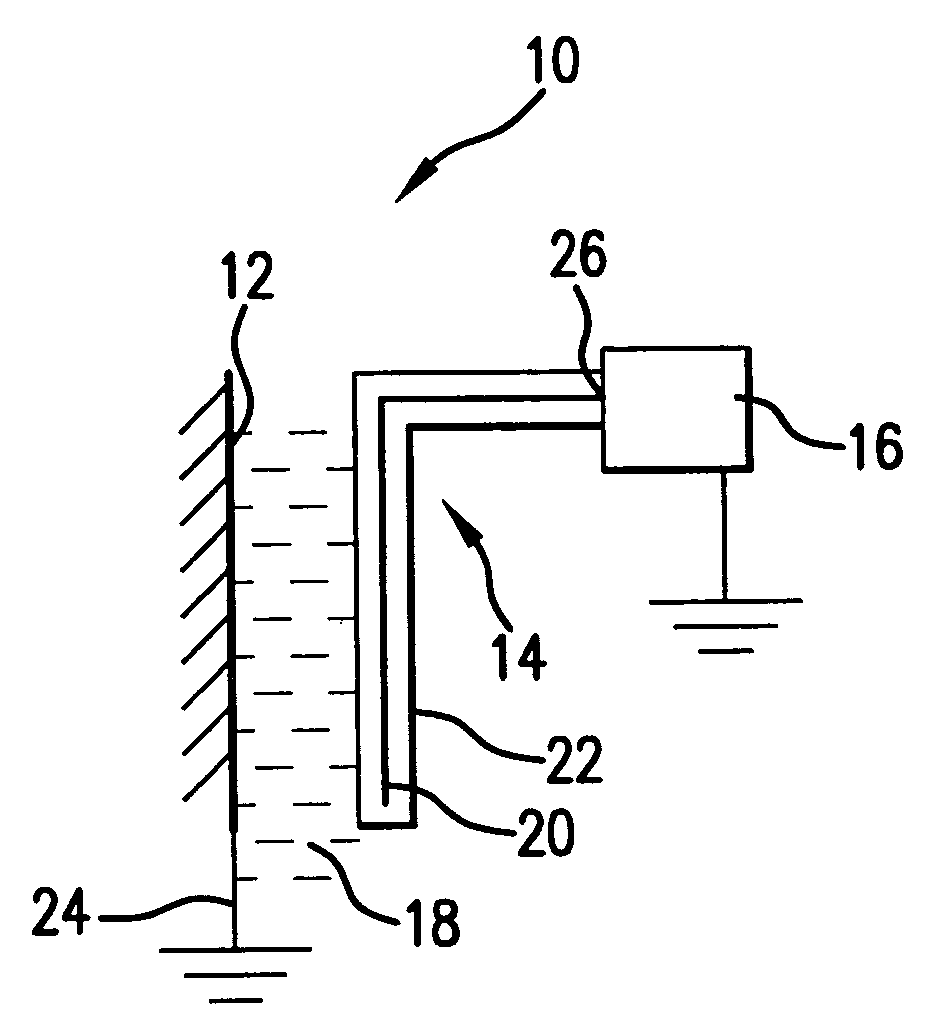

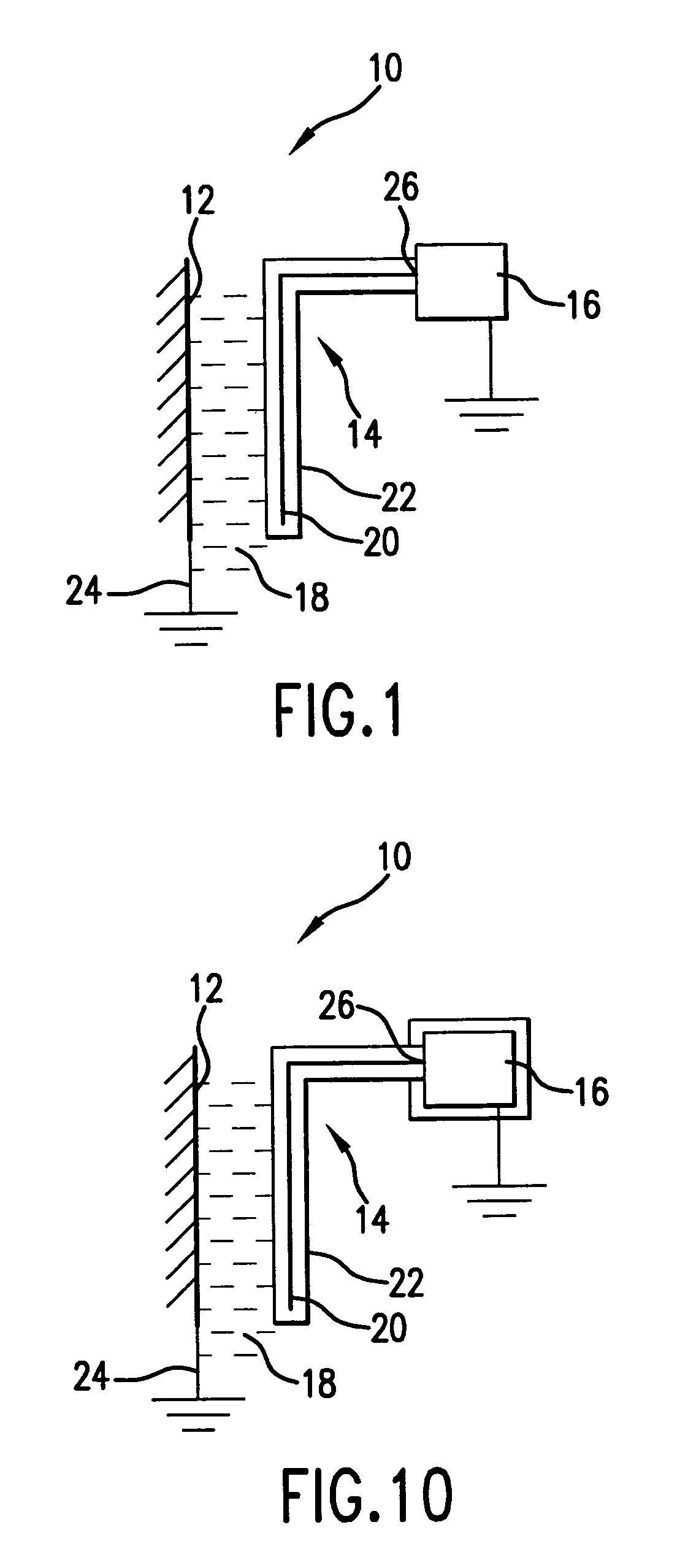

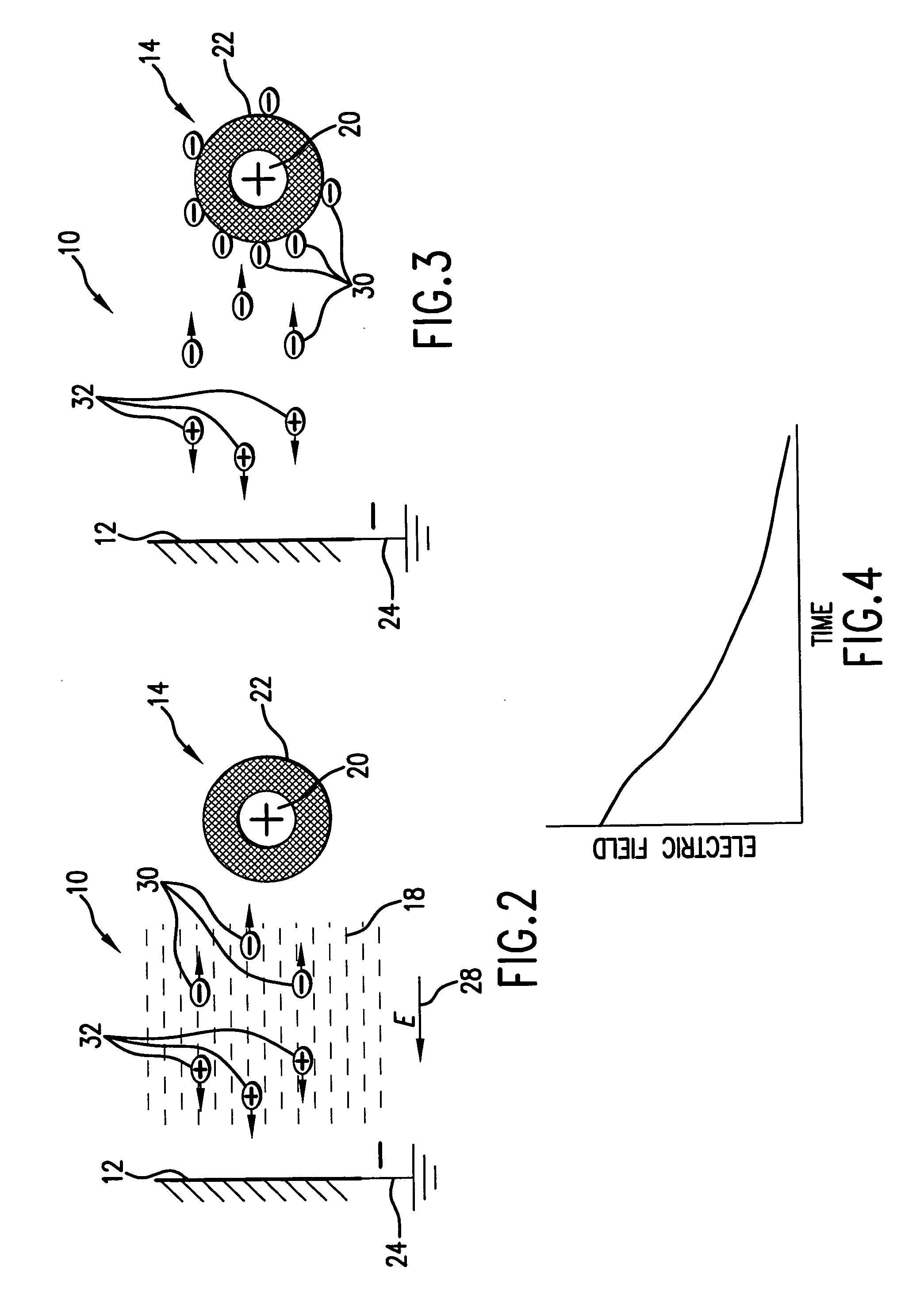

Electrohydrodynamically (EHD) enhanced heat transfer system and method with an encapsulated electrode

InactiveUS7159646B2Improve efficiencyReduce power consumptionIndirect heat exchangersHeat transfer modificationFrostEnhanced heat transfer

An electrohydrodynamically enhanced heat transfer system (EHD) includes an electrode completely encapsulated in an insulating material and coupled to a power supply to generate an electric field between a heat transfer surface and the encapsulated electrode when energized for interacting with the heat exchange surface and the working media to reduce frost formation on the heat transfer surface and to enhance heat transfer. The power supply may be completely encapsulated and immersed into the working media. In order to reduce accumulation of condensed liquid onto the electrode, the surface of the insulating material of the encapsulated electrode is either covered with a water repellent, or heated a few degrees above the dew point temperature of the air surrounding the heat transfer surface. The encapsulated electrode can be energized by an AC or DC electric field through a controlling switch.

Owner:UNIV OF MARYLAND

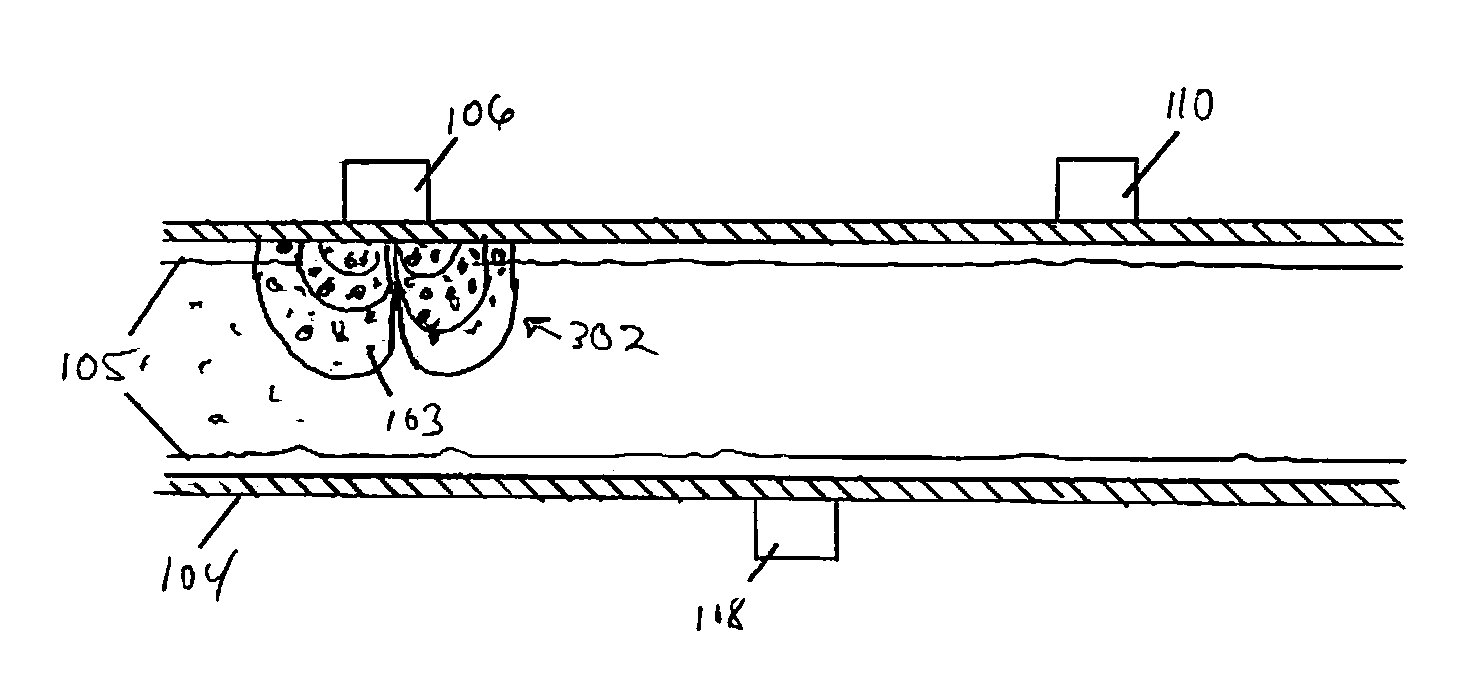

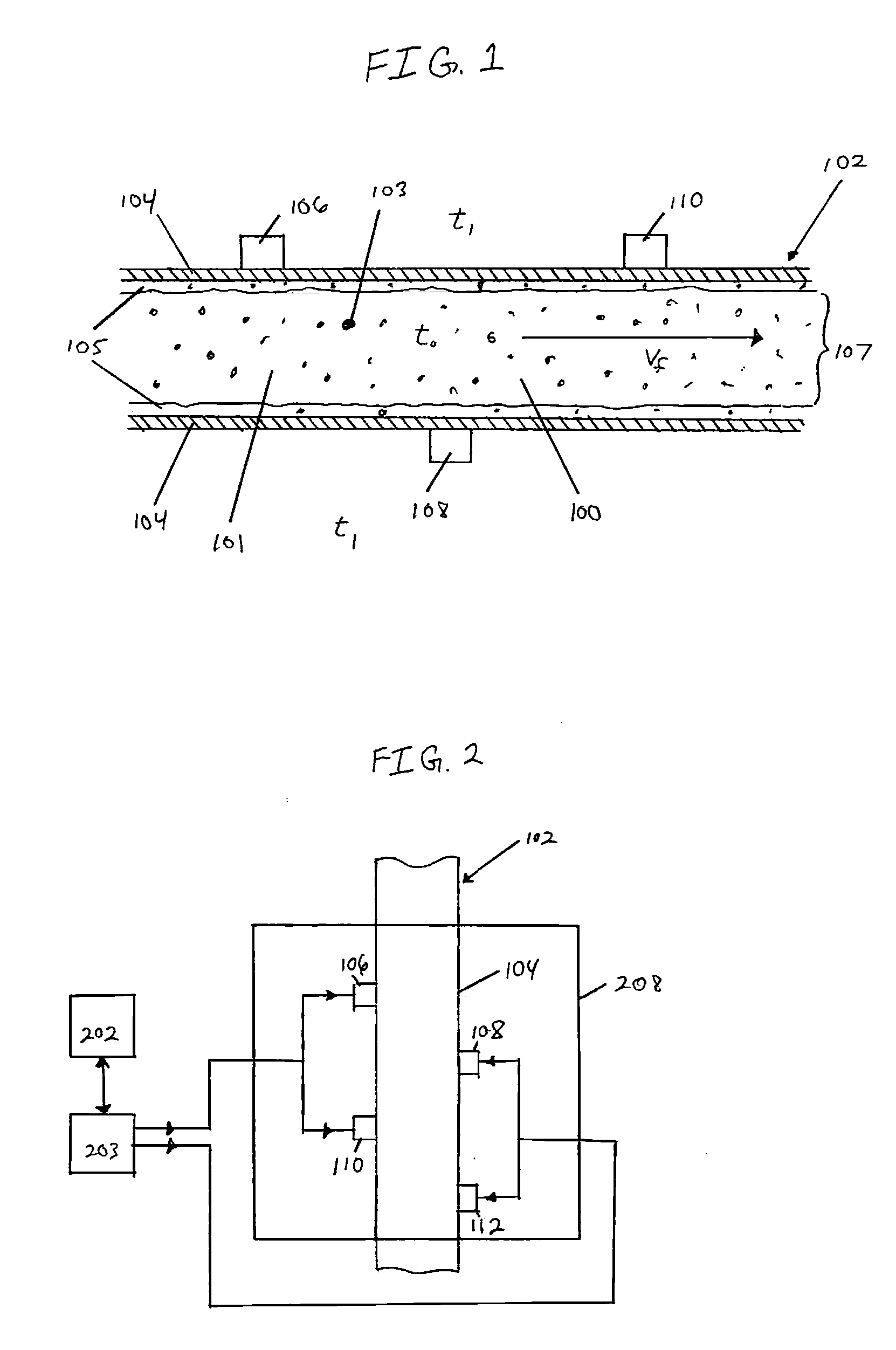

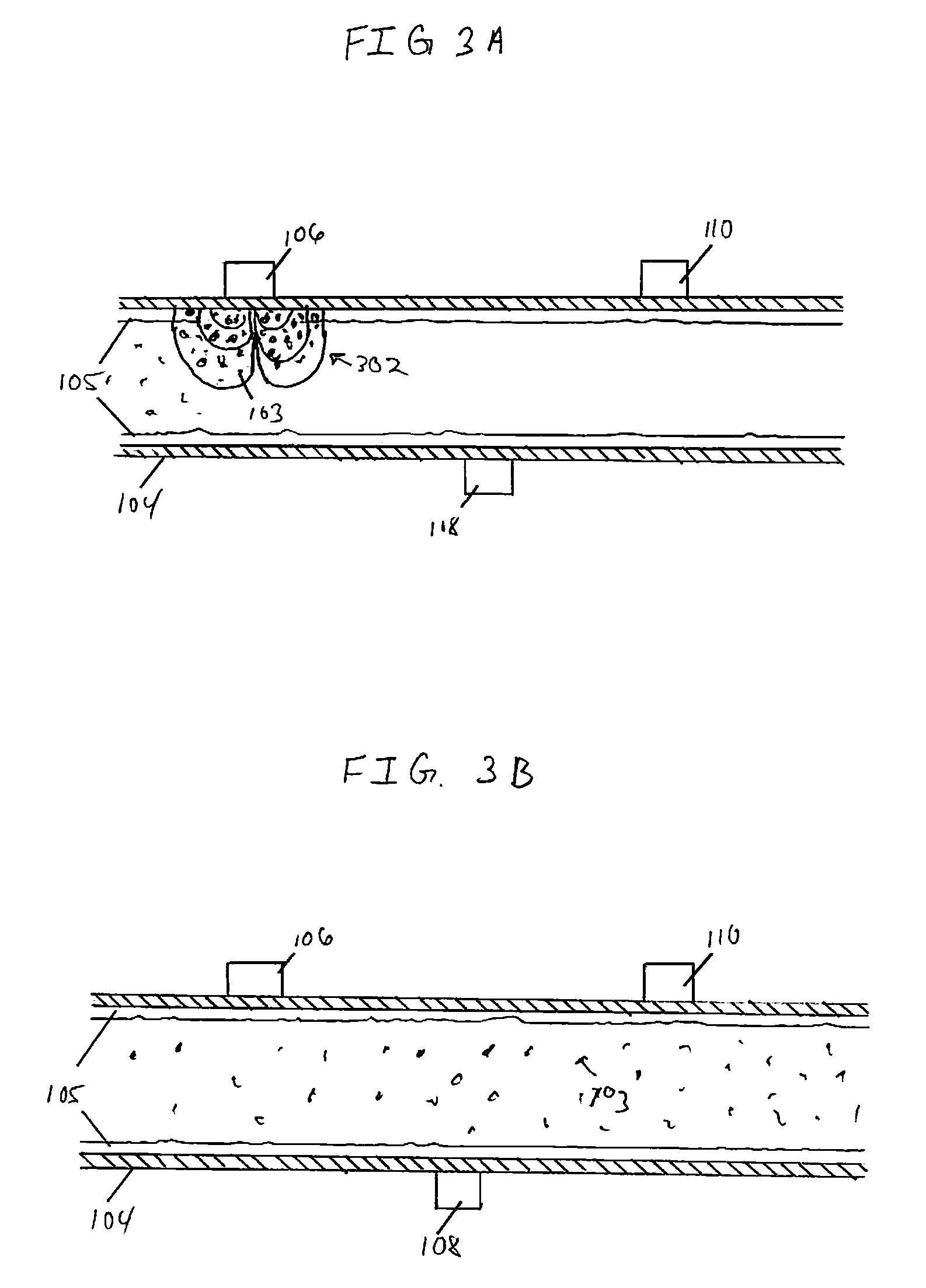

System and method for convective heat transfer utilizing a particulate solution in a time varying field

InactiveUS20070039721A1Improve thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesEnhanced heat transfer

A system combines the thermal conductivity characteristics of certain solids with the high specific heat values of appropriate fluids to enhance the overall heat transfer characteristics of a heat exchanger. The system comprises a fluid channel disposed in a heat exchanger unit with a slurry as the convective heat transfer medium. The slurry comprises an appropriate fluid with field reactive particles suspended therein. Field emitters are located along the walls of the fluid channel whereby the distribution of particles within the slurry is manipulated to achieve enhanced heat transfer characteristics.

Owner:UNITED STATES OF AMERICA

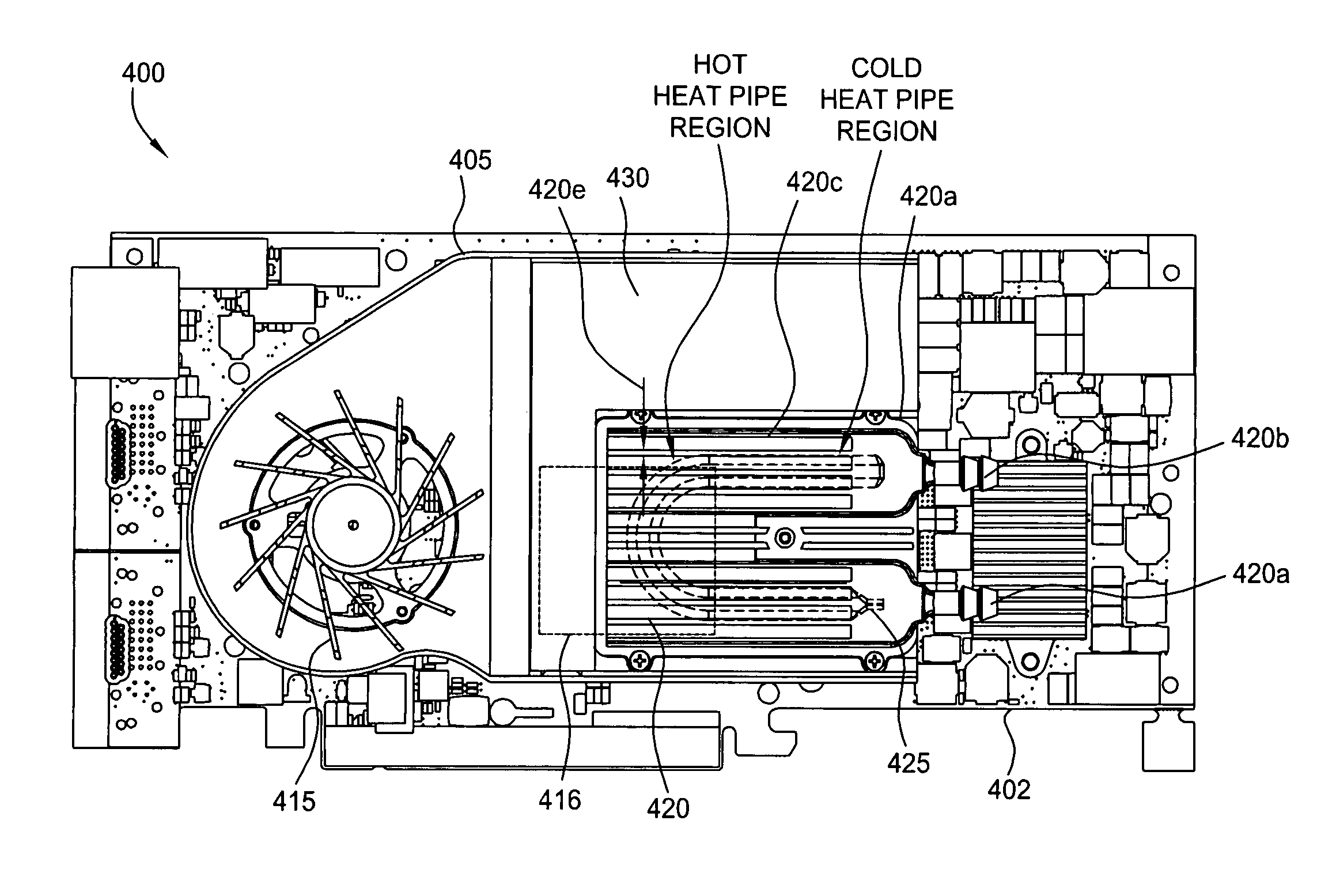

Embedded heat pipe in a hybrid cooling system

ActiveUS20070125522A1Remove heatIncrease the heat transfer surface areaSemiconductor/solid-state device detailsSolid-state devicesEnhanced heat transferEngineering

One embodiment of a system for cooling a heat-generating device includes a base adapted to be coupled to the heat-generating device, a housing coupled to the base, a liquid channel formed between the base and the housing, where a heat transfer liquid may be circulated through the liquid channel to remove heat generated by the heat-generated device, and a heat pipe disposed within the liquid channel, where the heat pipe increases the heat transfer surface area to which the heat transfer liquid is exposed. Among other things, the heat pipe advantageously increases the heat transfer surface area to which the heat transfer liquid is exposed and efficiently spreads the heat generated by the heat-generating device over that heat transfer surface area. The result is enhanced heat transfer through the liquid channel relative to prior art cooling systems.

Owner:NVIDIA CORP

Apparatus and method for enhanced heat transfer

InactiveUS20060050482A1Heat exchange apparatusCooling/ventilation/heating modificationsEnhanced heat transferDistribution system

One embodiment of the cooling module is implemented as a device having a heat sink and an integrated synthetic jet actuator. The heat sink is configured to have a channel and a jet distribution system associated with the synthetic jet actuator directs fluid flow into the channel of the heat sink. In operation, the fluid flow of this embodiment of the cooling module comprises a synthetic jet stream and ambient fluid entrained into the channel by the synthetic jet stream. The fluid flowing through the channel serves to a wall of the heat sink channel.

Owner:INNOVATIVE FLUIDICS +1

Apparatus and method for enhanced heat transfer

InactiveUS20060060331A1Consume energyExceeding performanceSemiconductor/solid-state device detailsSolid-state devicesVapor bubbleEnhanced heat transfer

One embodiment of the system is implemented as a device for two-phase heat transfer. This device comprises a chamber containing a fluid, where a heated wall makes up a portion of the chamber. The device also comprises an actuator that emits pressure vibrations. The pressure vibrations dislodge vapor bubbles that form at the heated wall due to the heat in the wall.

Owner:INNOVATIVE FLUIDICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com