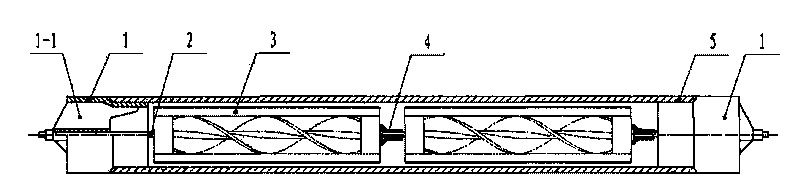

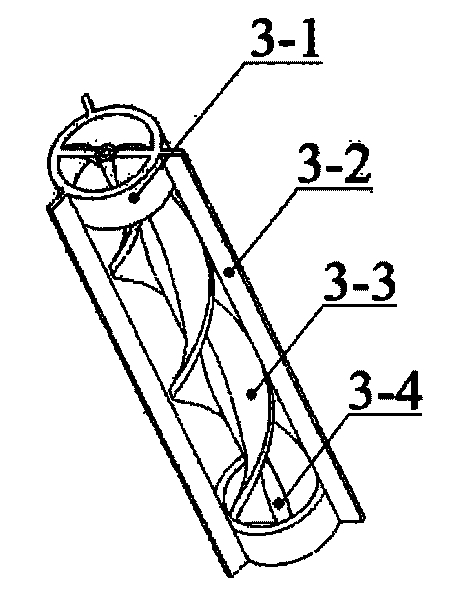

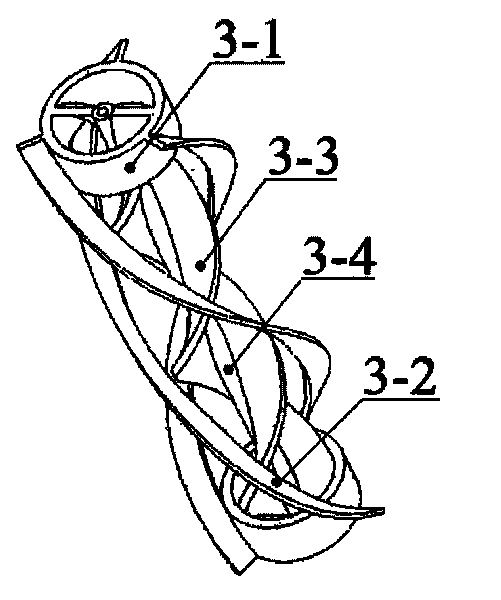

Inner boundary layer cutting disturbing radial mixed flow device of heat exchange pipe

A technology of heat exchange tubes and inner boundaries, which is applied in the direction of cleaning heat transfer devices, heat transfer modification, heat exchange equipment, etc., and can solve the problems of large gap in heat transfer performance and insufficient shear disturbance of fluid boundary layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: The main parameters of the heat exchange tube inner boundary layer shear disturbance radial mixed flow device are: the length of the heat exchange tube 5 is 2000mm, its inner diameter is Φ23mm, the outer diameter of the rotor 3 is Φ22mm, and the rotor is injection molded from POM (polyoxymethylene). The disturbance fin is a straight fin with a height of 3 mm, the diameter of the driving fin is 14 mm, the helix angle is 72°, the thickness of the support ring is 1 mm, and the length of the rotor is 50 mm. According to the experimental test, under the condition of lower Reynolds number (1000-3000), the heat transfer performance of the device of the present invention is about twice that of the existing rotor, while the resistance is only 1.2 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com