Patents

Literature

1108 results about "Organic Rankine cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

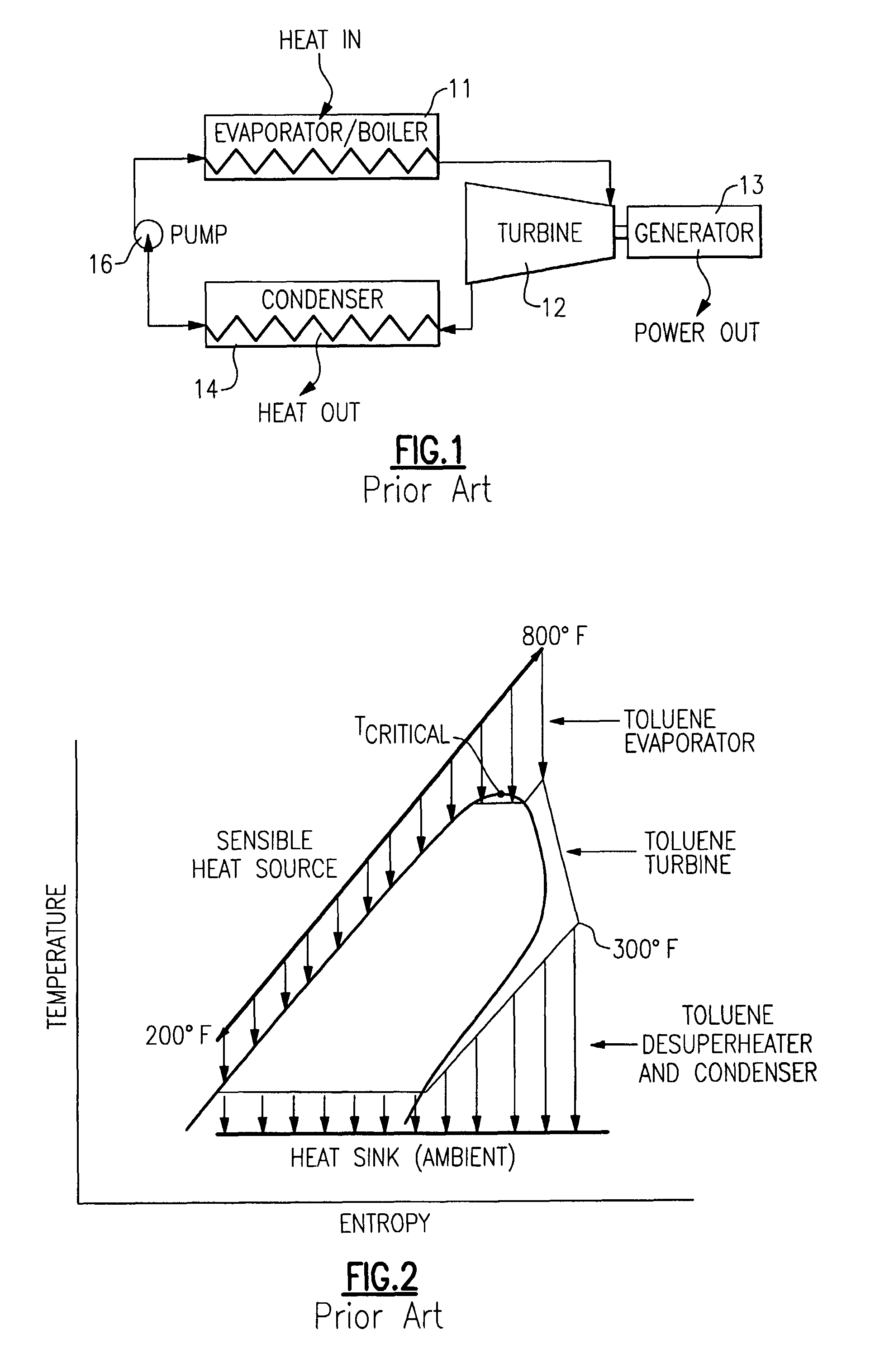

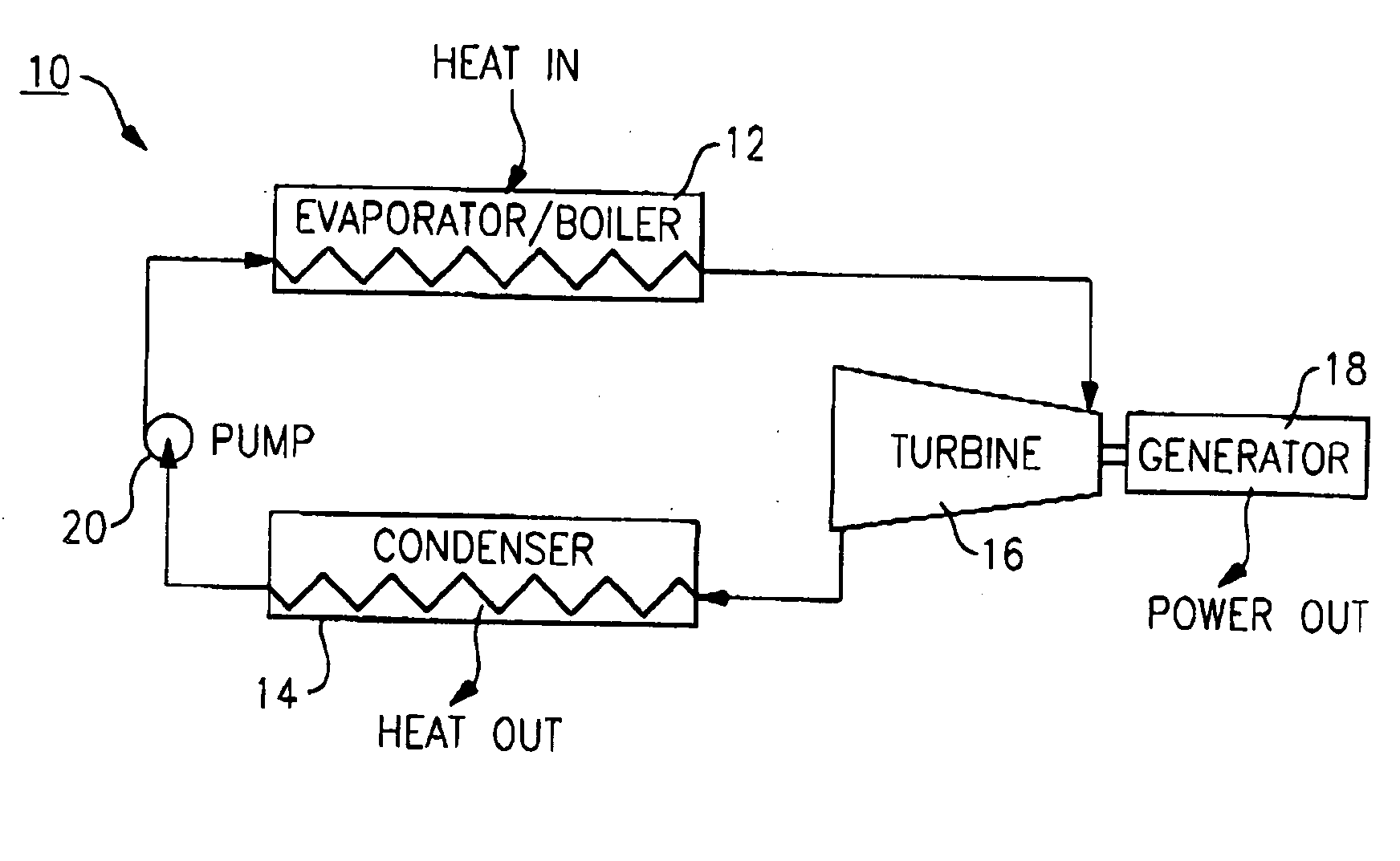

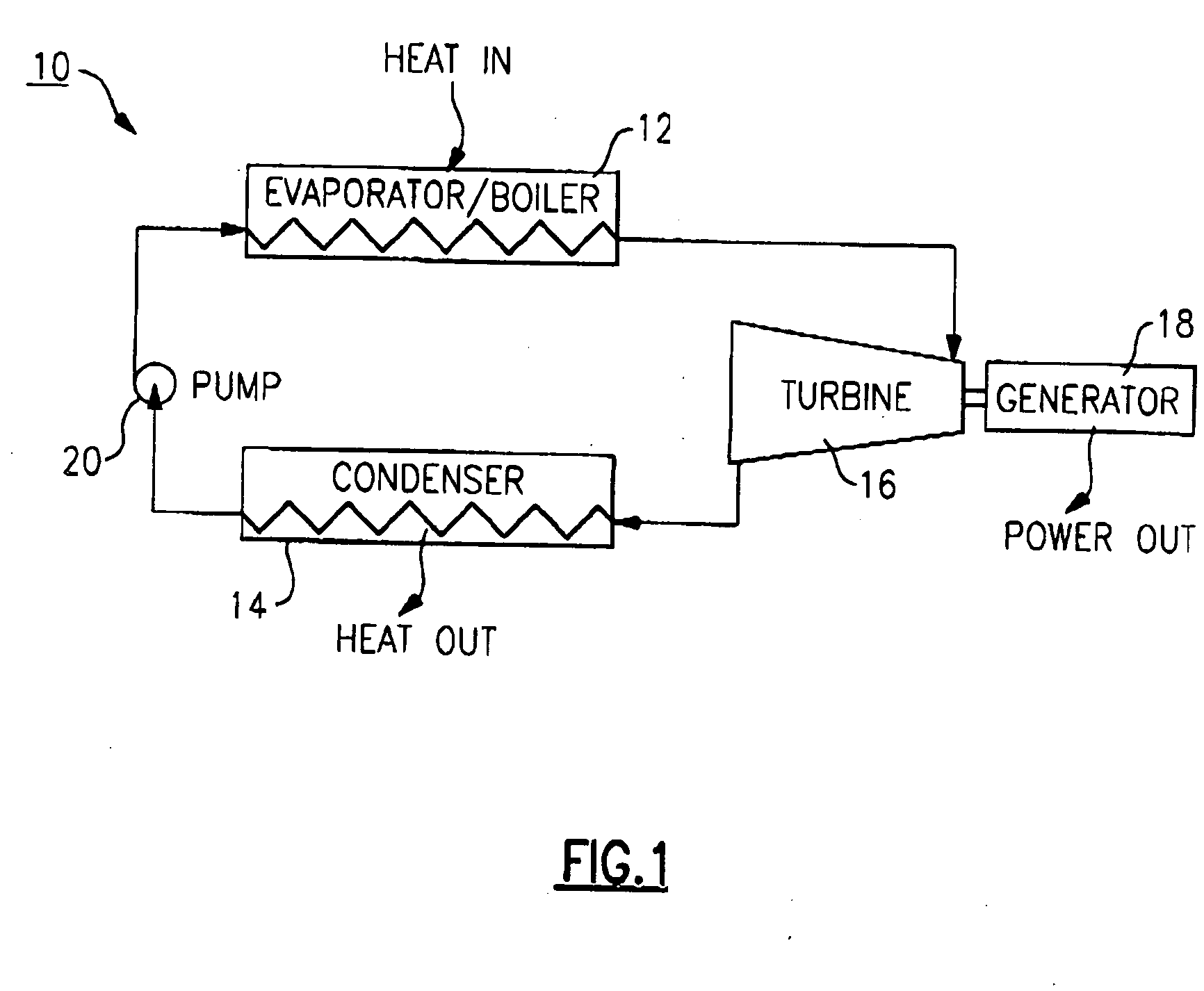

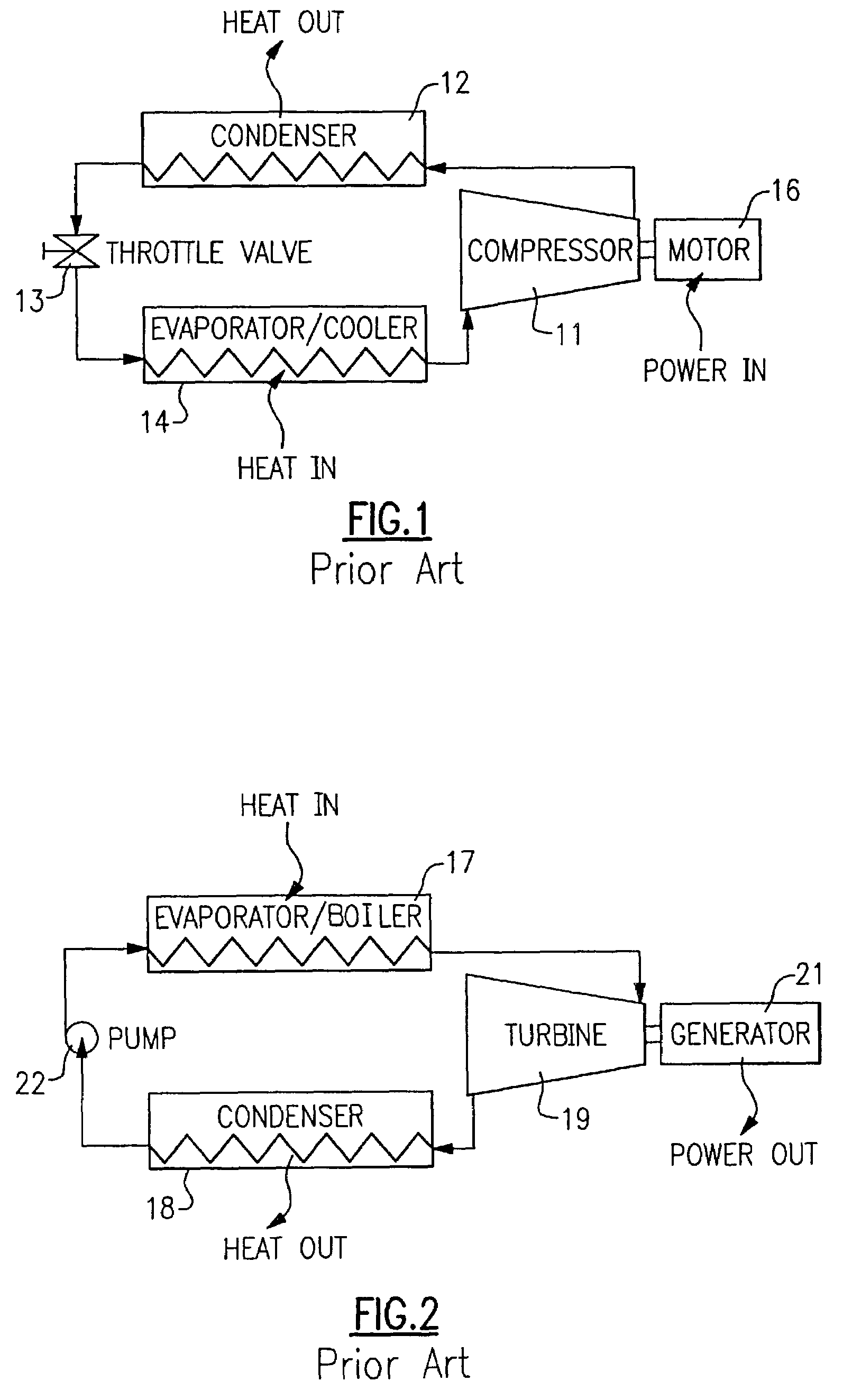

The Organic Rankine Cycle (ORC) is named for its use of an organic, high molecular mass fluid with a liquid-vapor phase change, or boiling point, occurring at a lower temperature than the water-steam phase change. The fluid allows Rankine cycle heat recovery from lower temperature sources such as biomass combustion, industrial waste heat, geothermal heat, solar ponds etc. The low-temperature heat is converted into useful work, that can itself be converted into electricity.

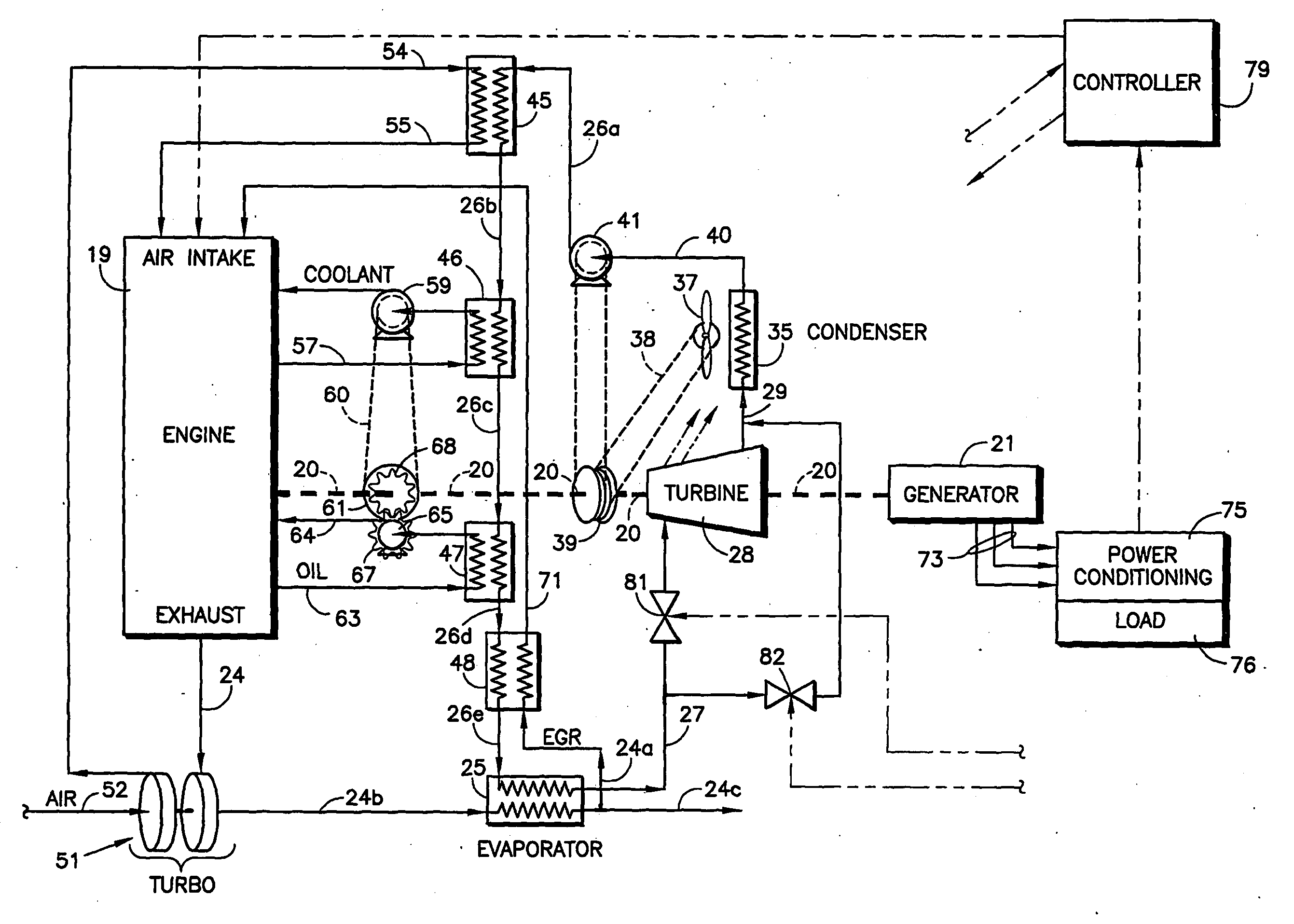

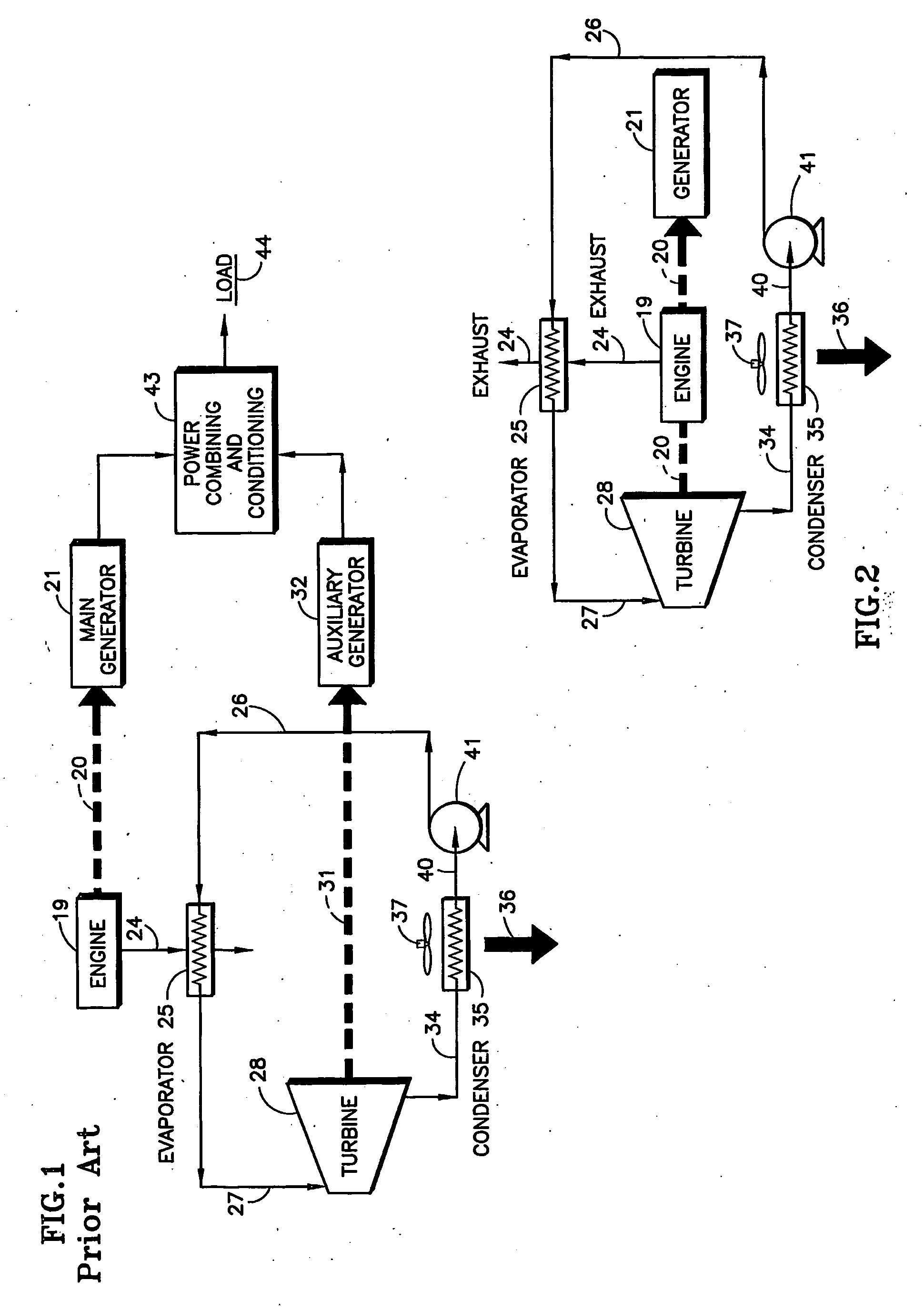

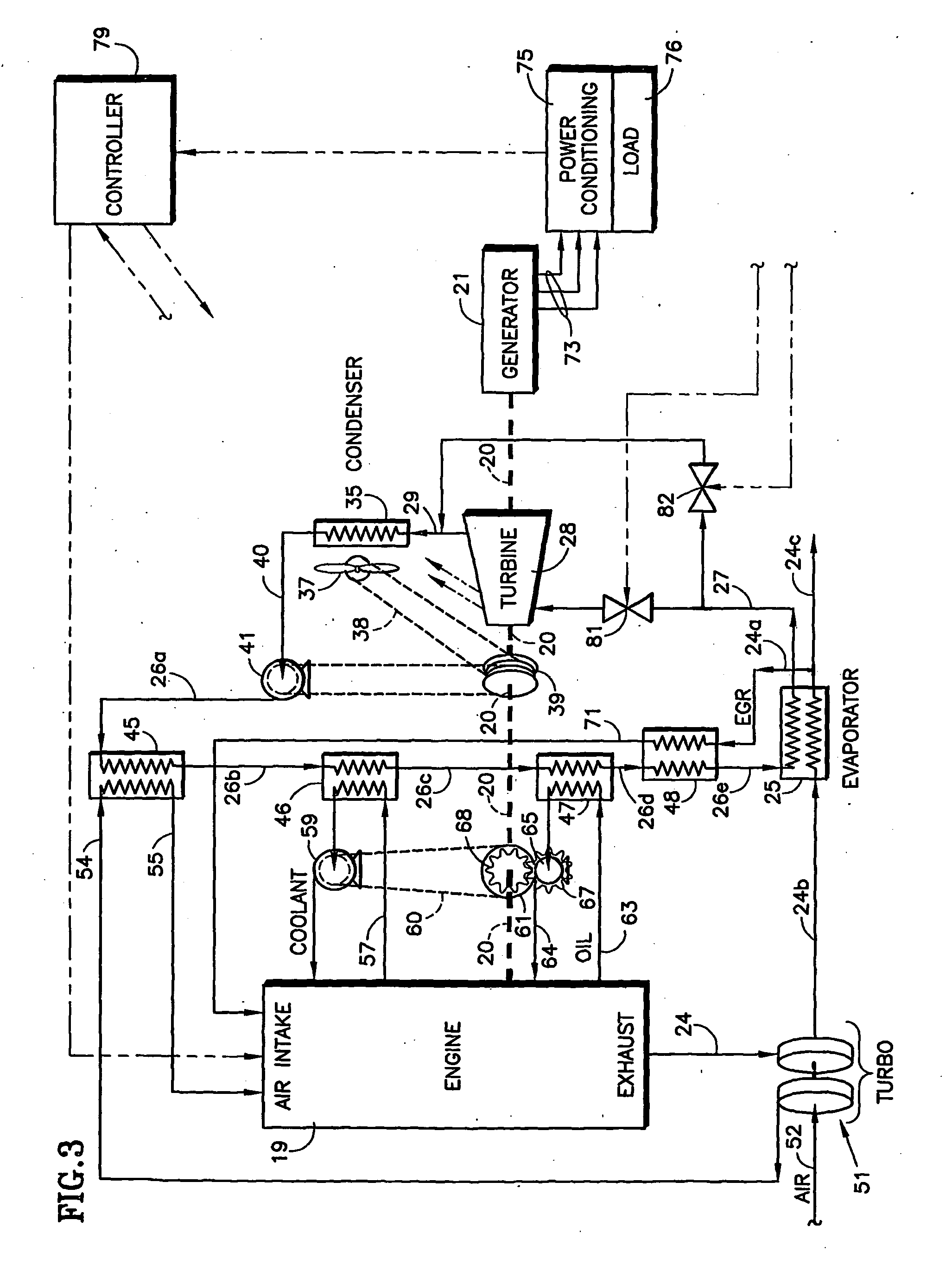

Organic Rankine Cycle Mechanically and Thermally Coupled to an Engine Driving a Common Load

InactiveUS20090211253A1Maximize efficiencyEngine componentsSteam engine plantsPtru catalystOrganic Rankine cycle

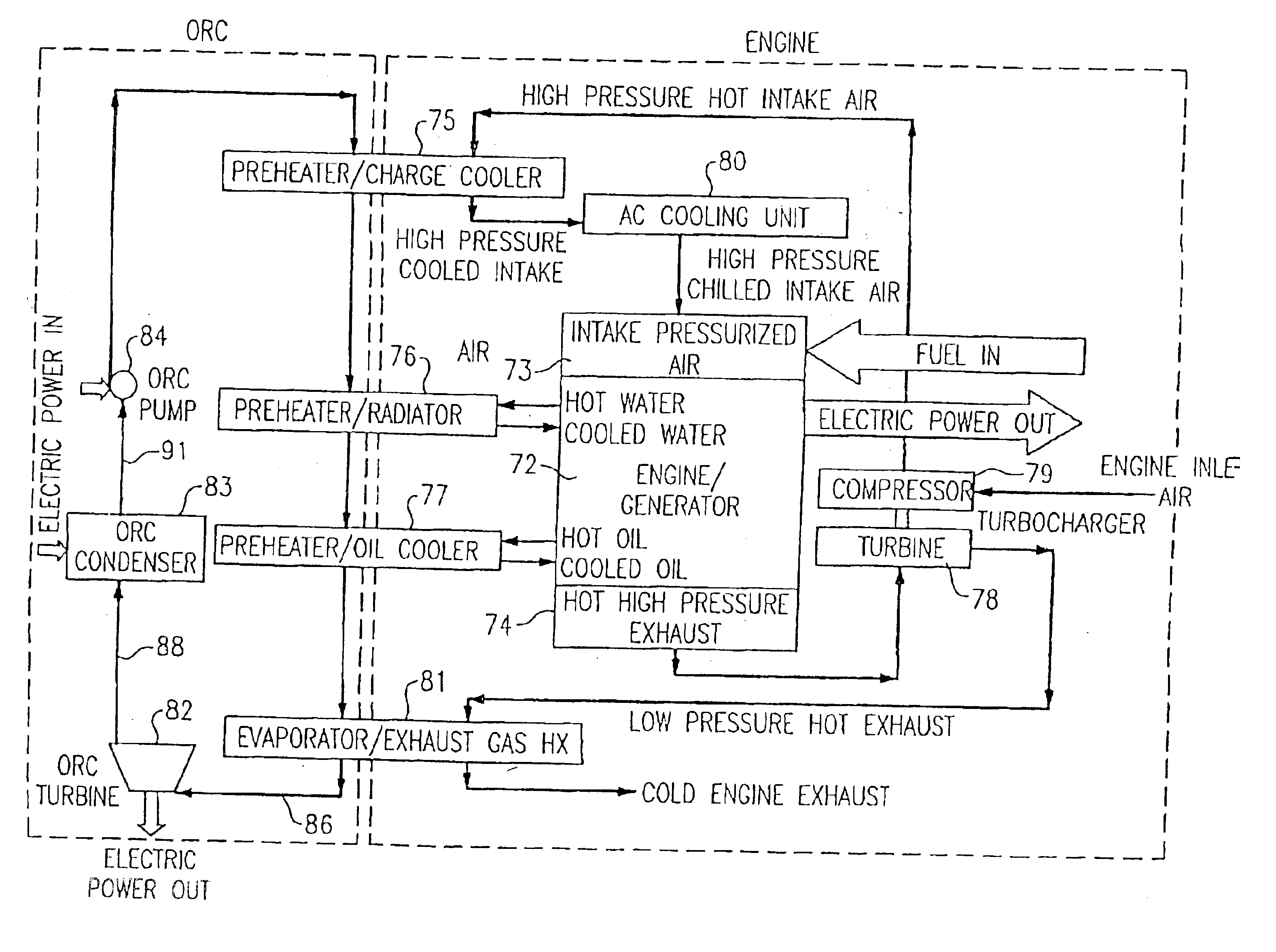

The shaft (20) of an engine (19) is coupled to a turbine (28) of an organic Rankine cycle subsystem which extracts heat (45-48, 25) from engine intake air, coolant, oil, EGR and exhaust. Bypass valves (92,94, 96, 99) control engine temperatures. Turbine pressure drop is controlled via a bypass valve (82) or a mass flow control valve (113). A refrigeration subsystem having a compressor (107) coupled to the engine shaft uses its evaporator (45a) to cool engine intake air. The ORC evaporator (25a) may comprise a muffler including pressure pulse reducing fins (121, 122), some of which have NOx and / or particulate reducing catalysts thereon.

Owner:UNITED TECH CORP

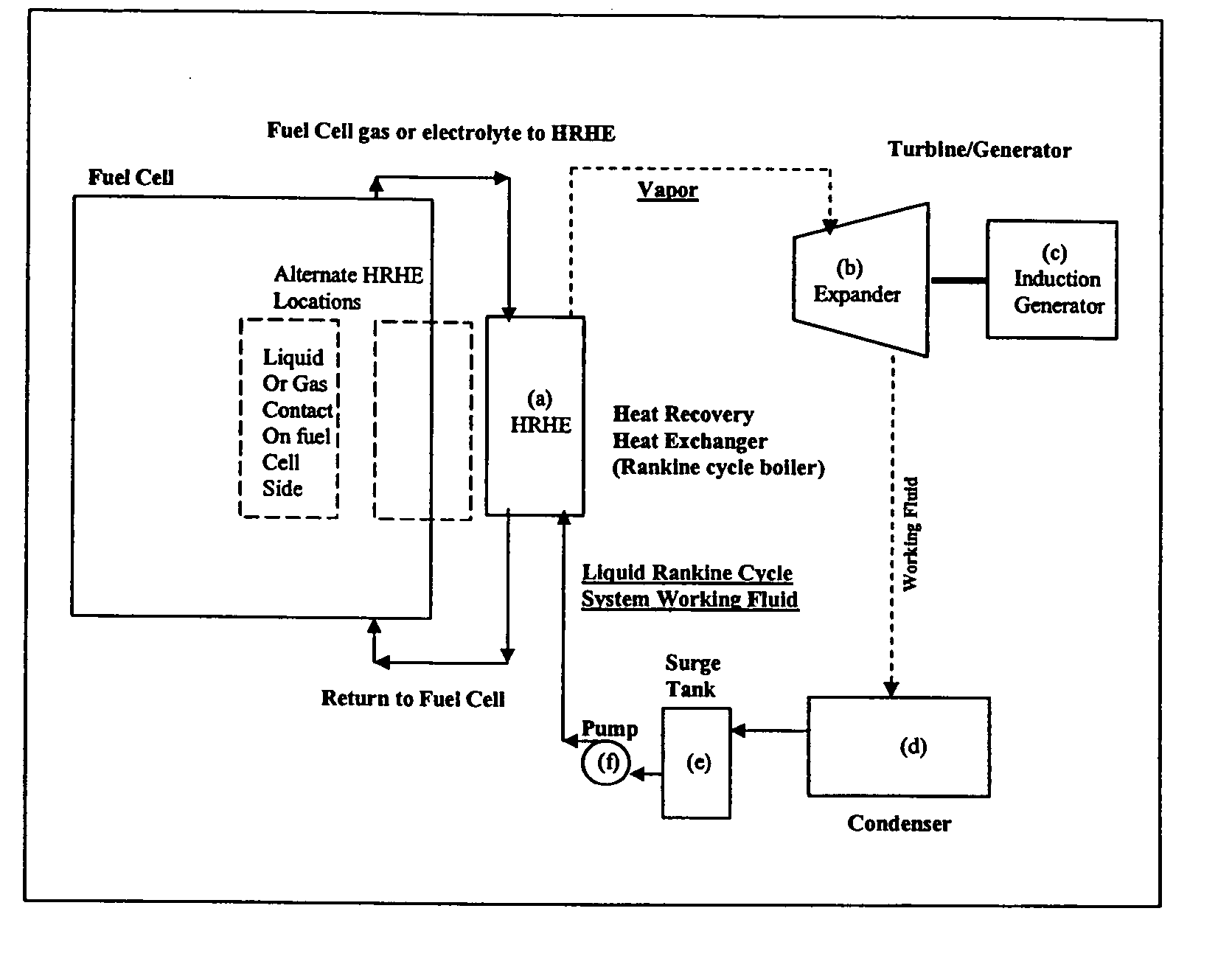

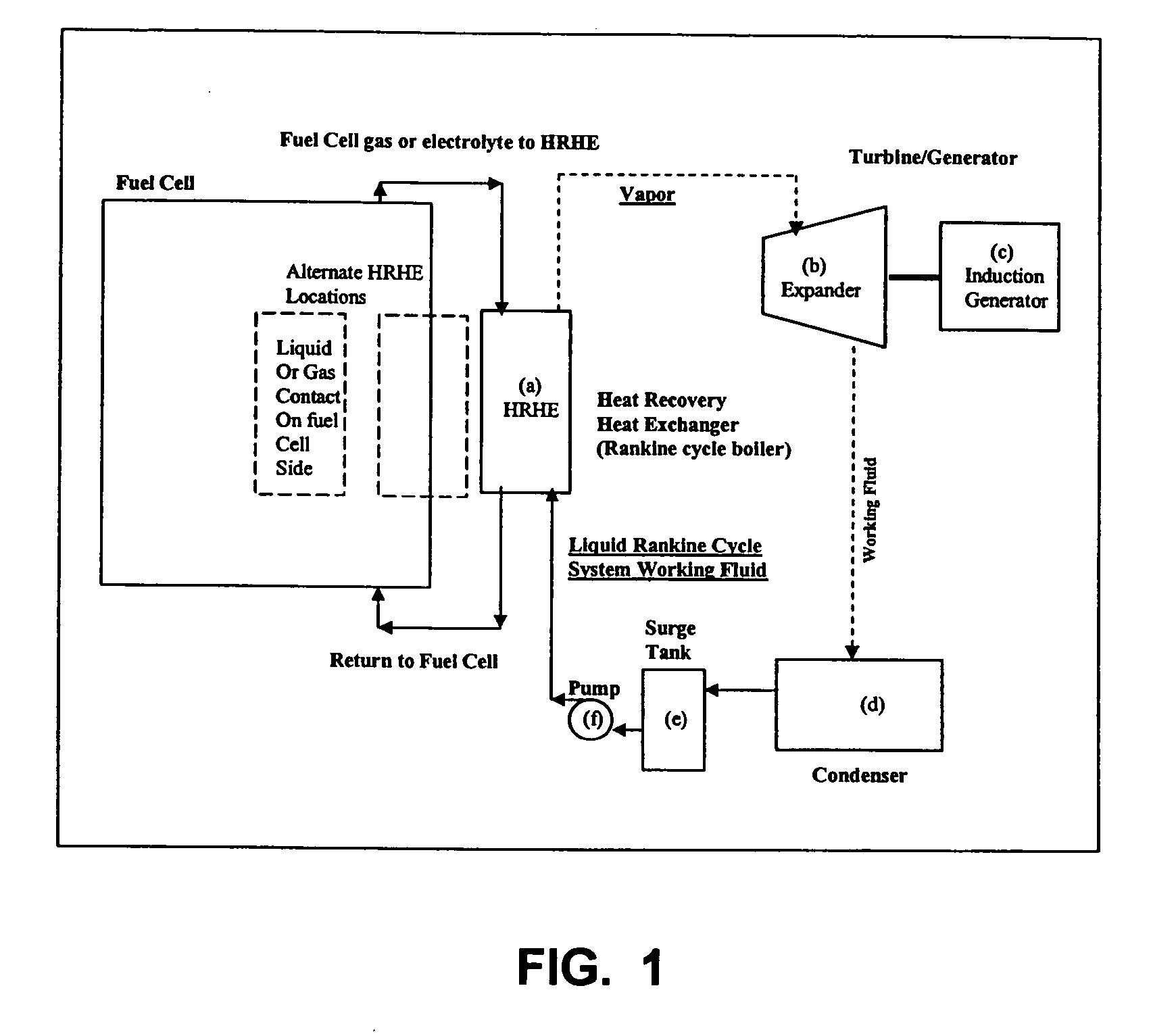

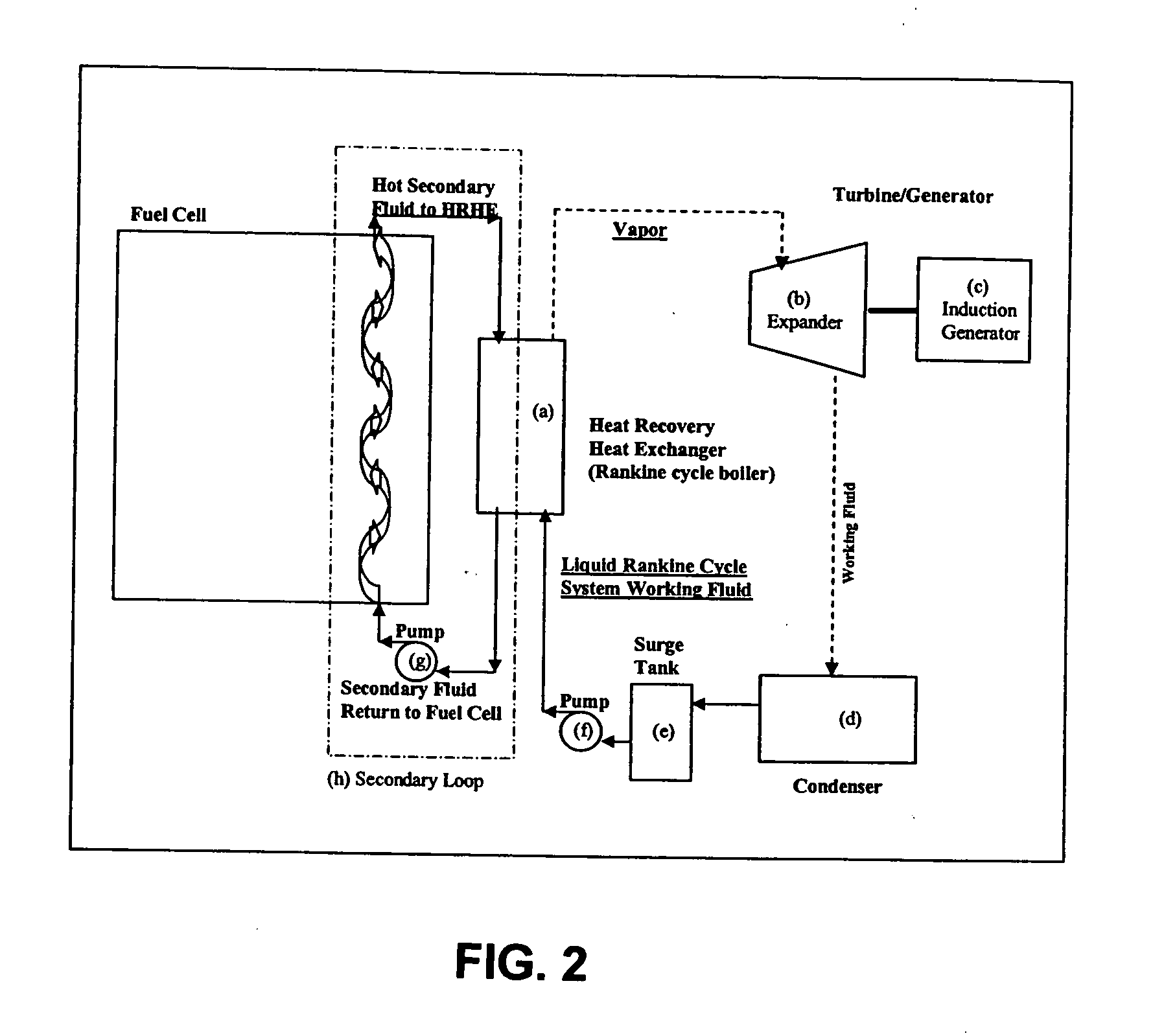

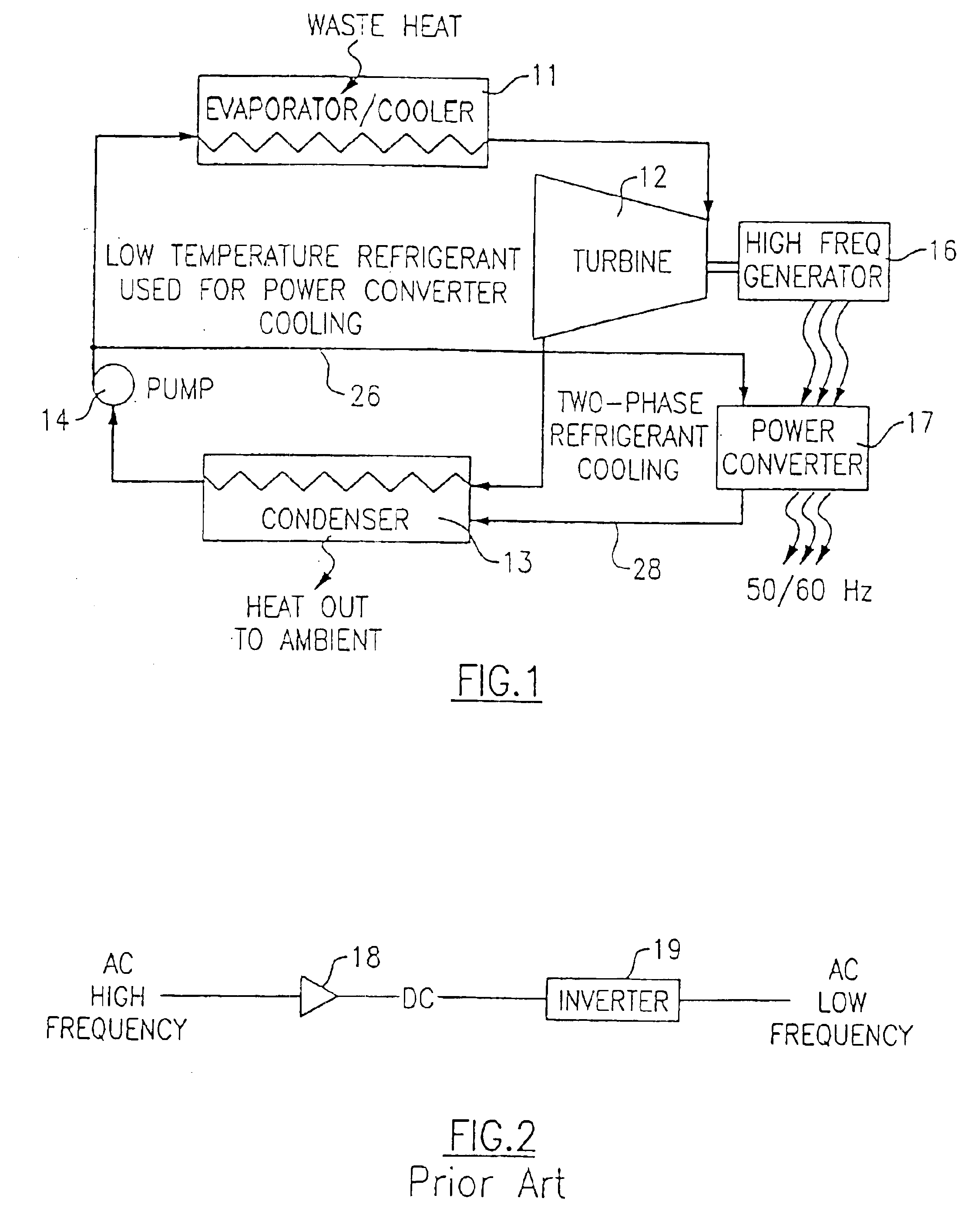

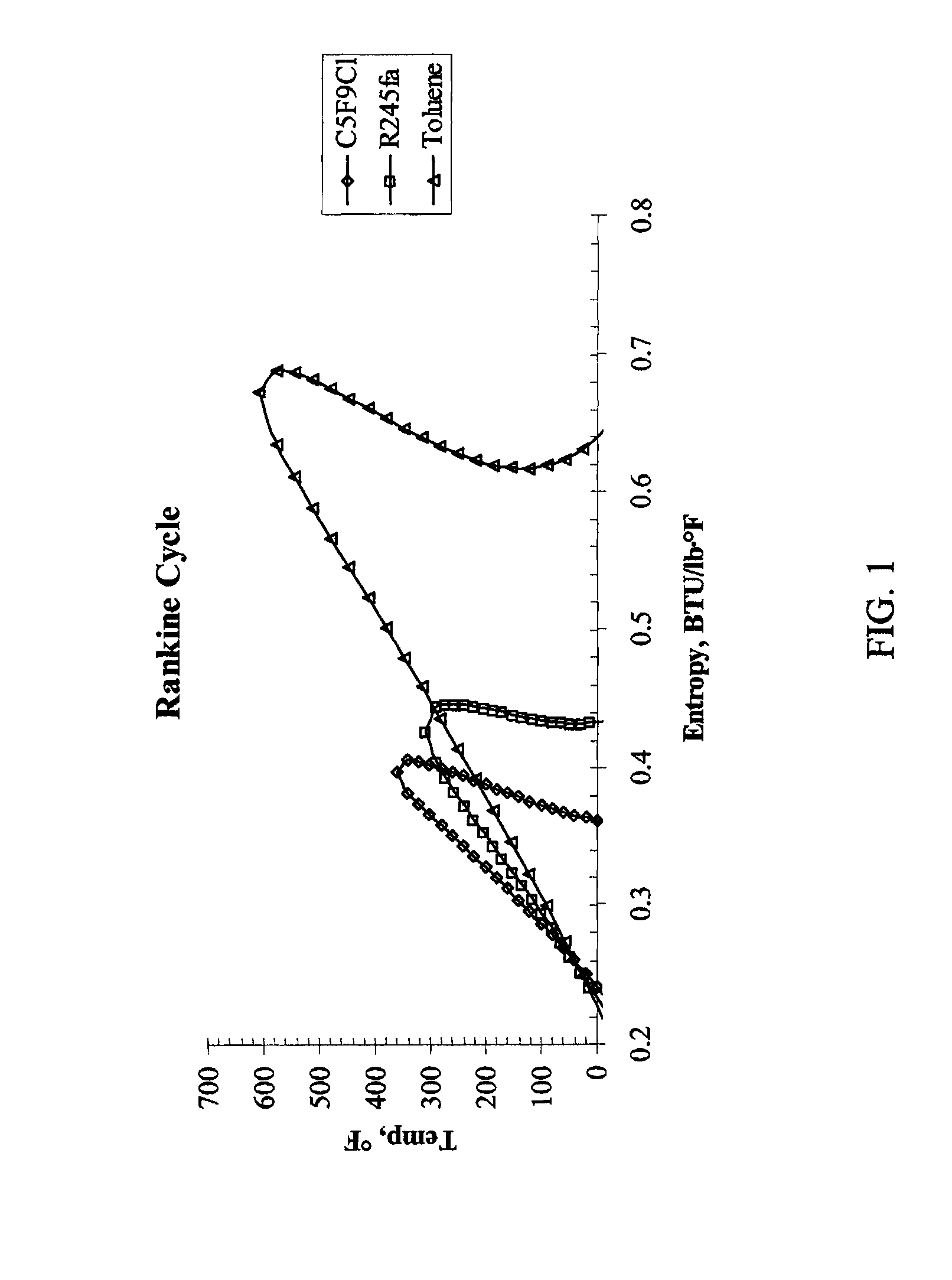

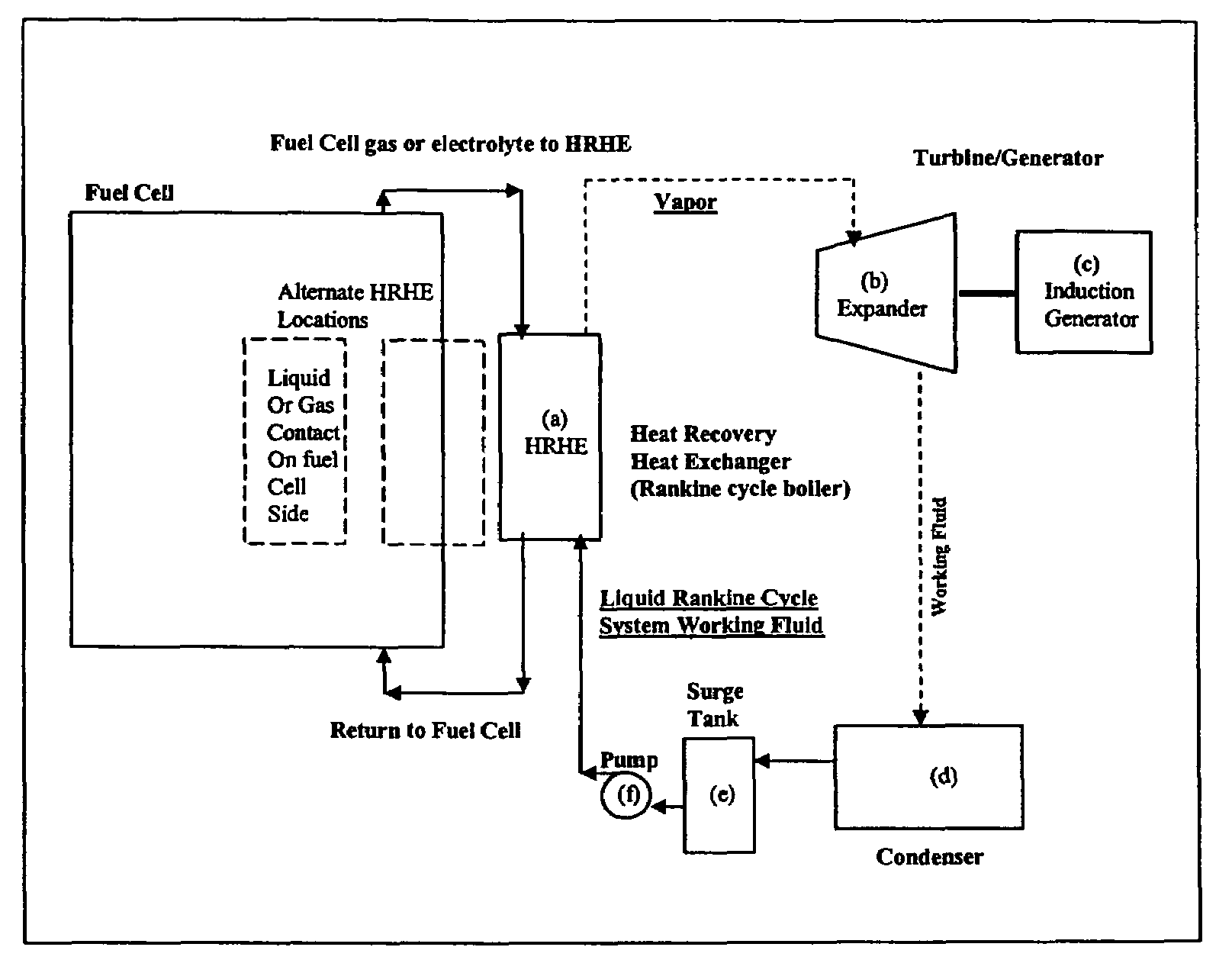

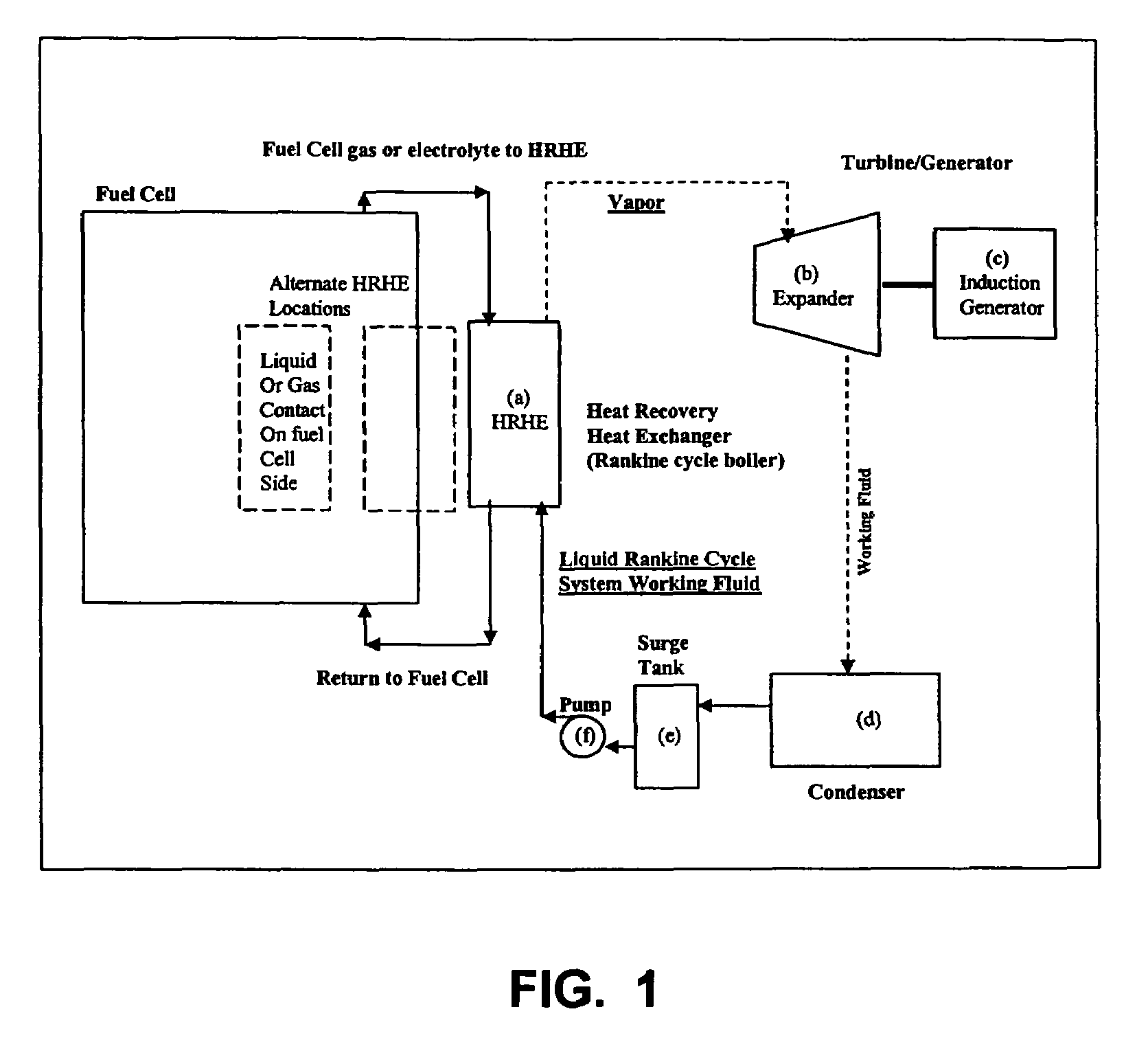

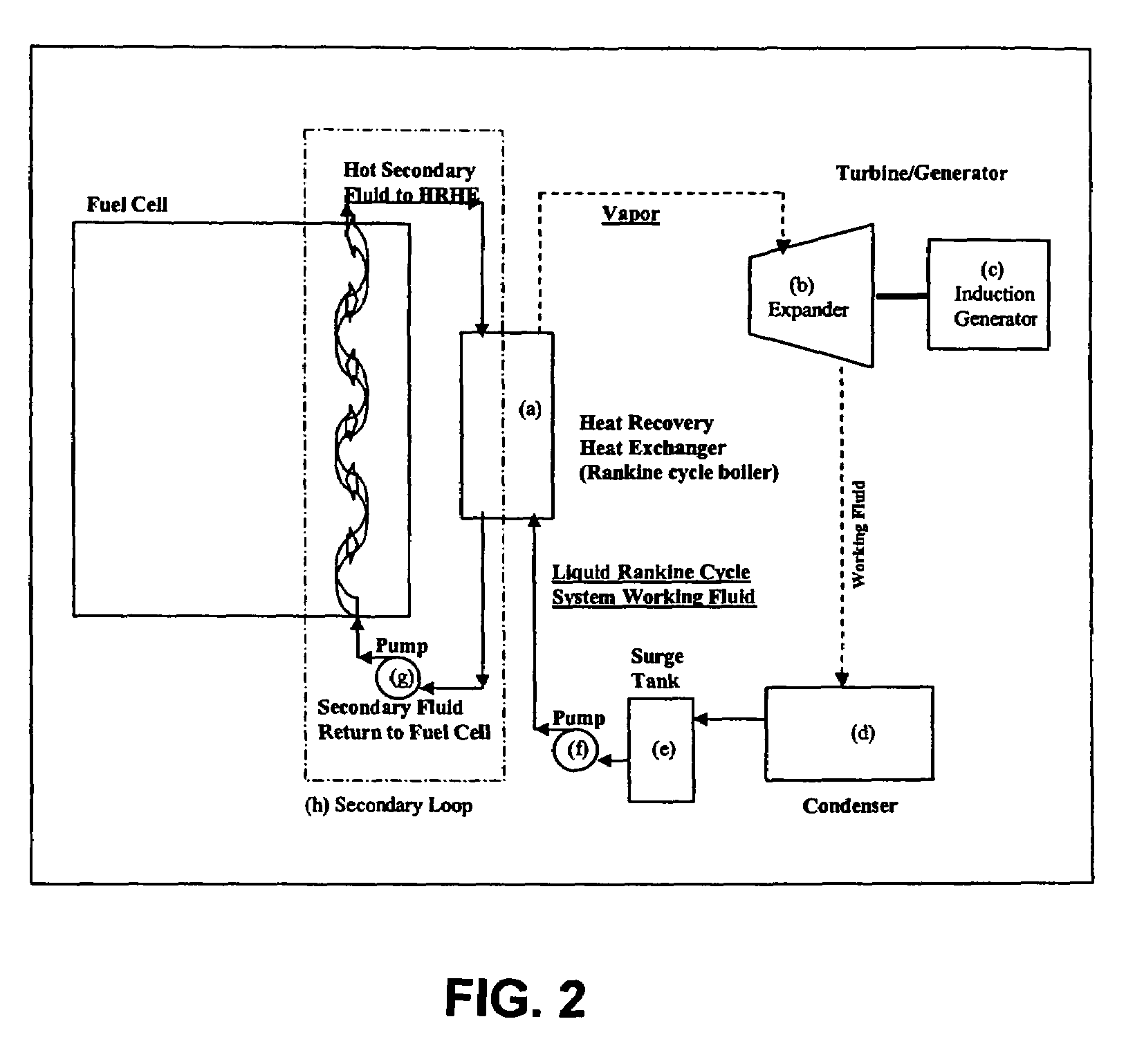

Working fluids for thermal energy conversion of waste heat from fuel cells using rankine cycle systems

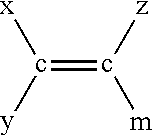

A process for recovering waste heat which comprises: (a) passing a liquid phase working fluid through a heat exchanger in communication with a process which produces the waste heat; (b) removing a vapor phase working fluid from the heat exchanger; (c) passing the vapor phase working fluid to an expander, wherein the waste heat is converted into mechanical energy; and (d) passing the vapor phase working fluid from the expander to a condenser, wherein the vapor phase working fluid is condensed to the liquid phase working fluid. The preferred working fluid is an organic Rankine cycle system working fluid comprising compounds having the following general structure: where x, y, z, and m are each selected from the group consisting of: fluorine, hydrogen, Rf, and R, wherein R and Rf are each an alkyl, aryl, or alkylaryl of 1 to 6 carbon atoms, and wherein Rf is partially or fully fluorinated.

Owner:HONEYWELL INT INC

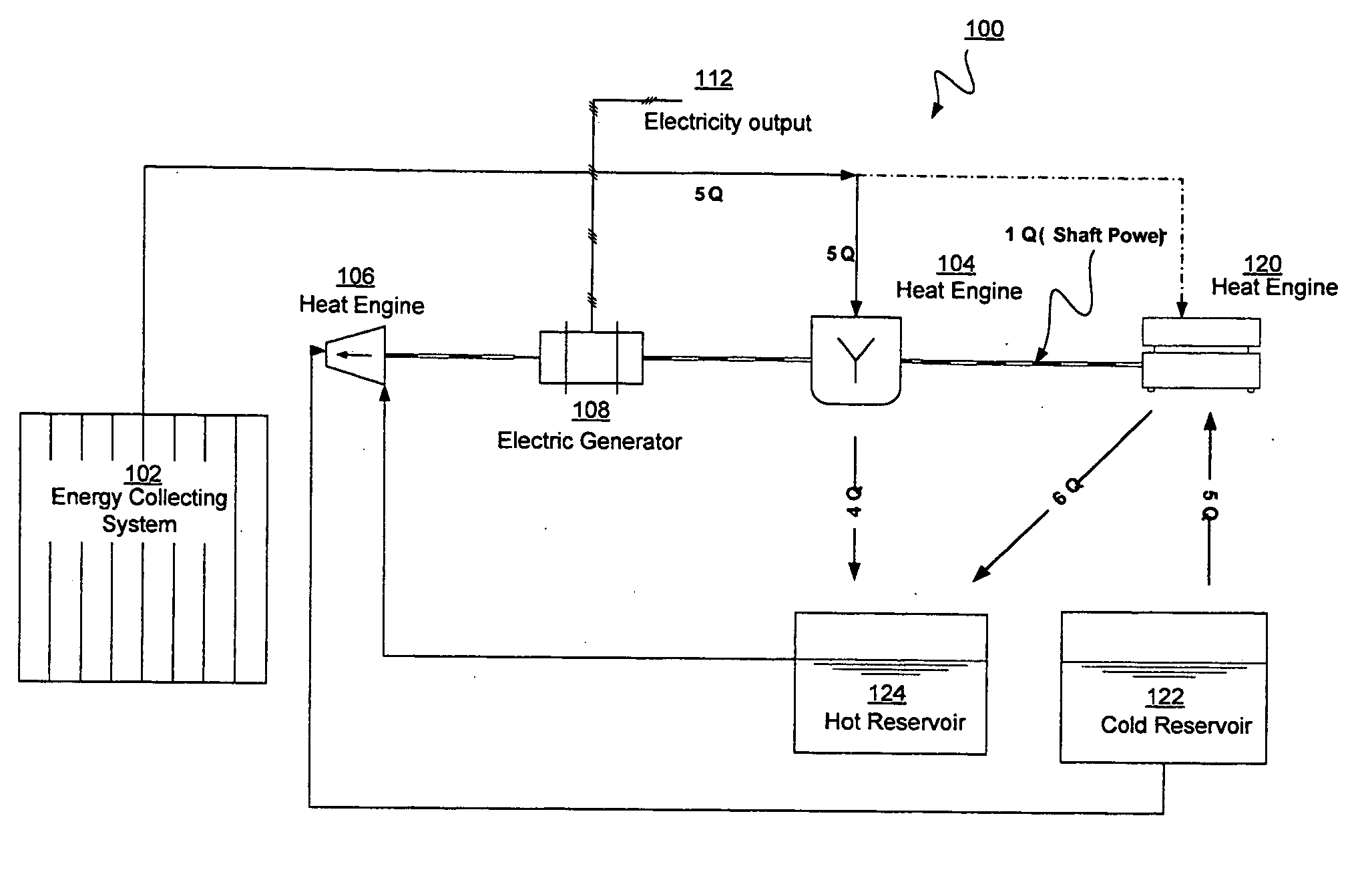

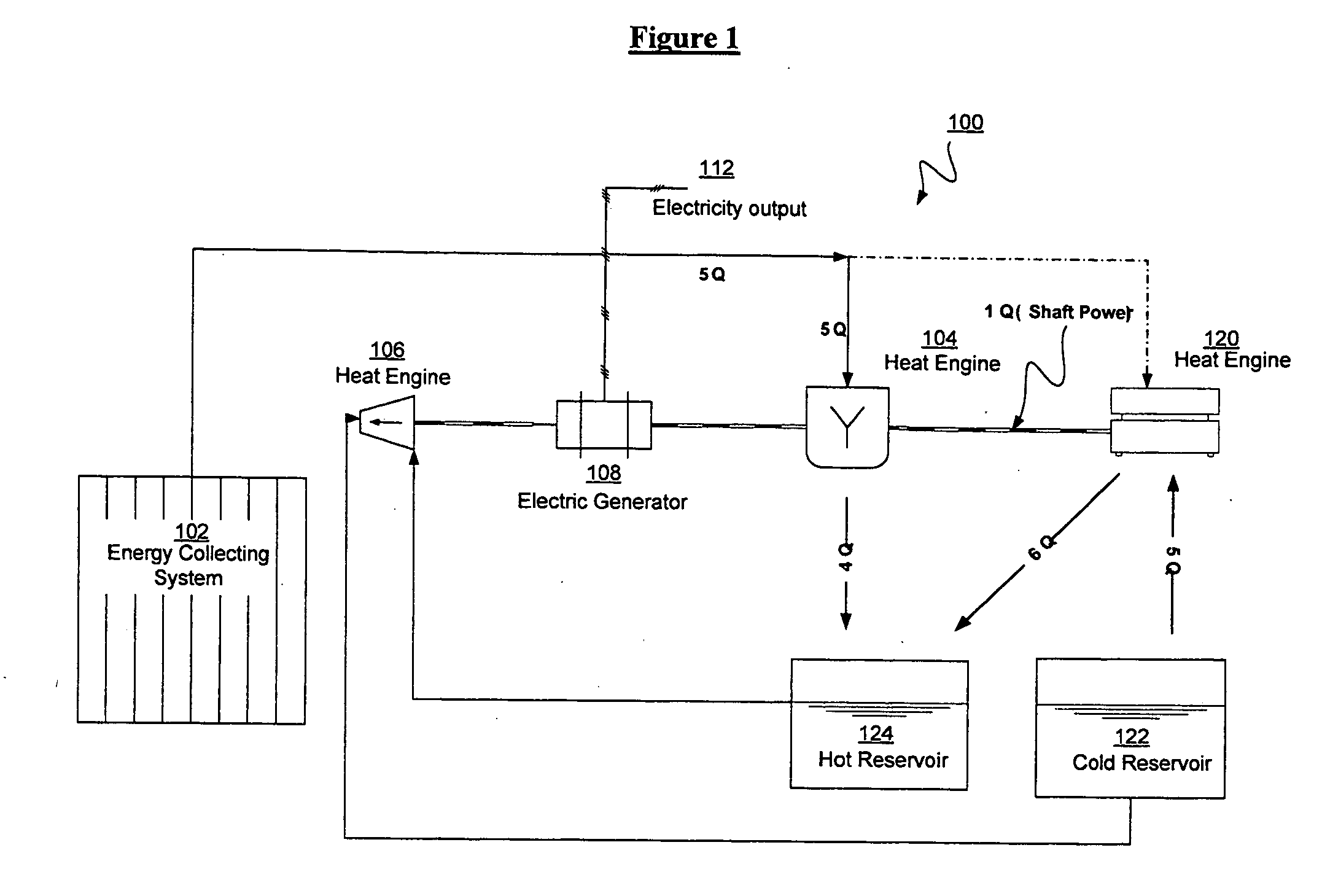

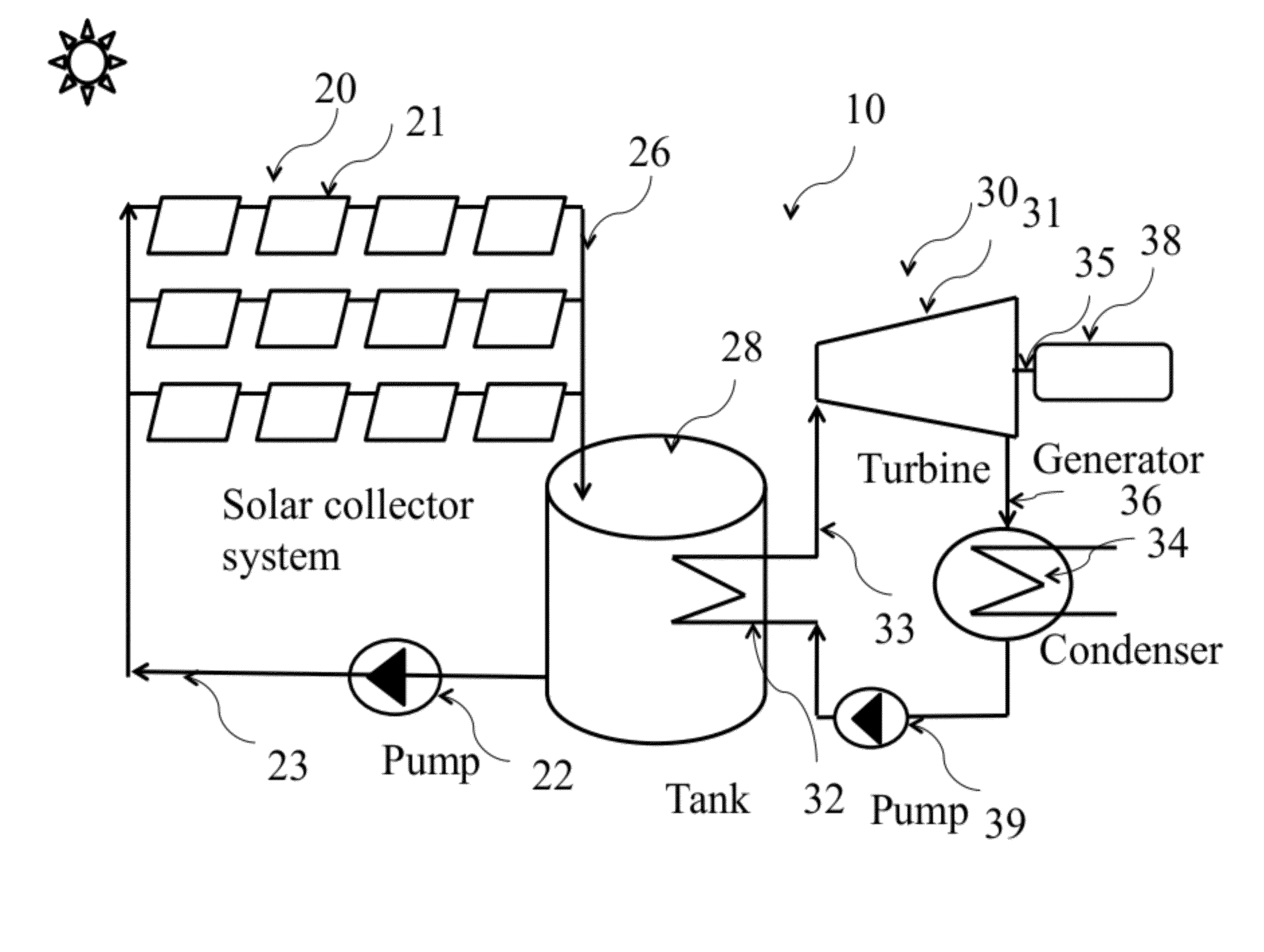

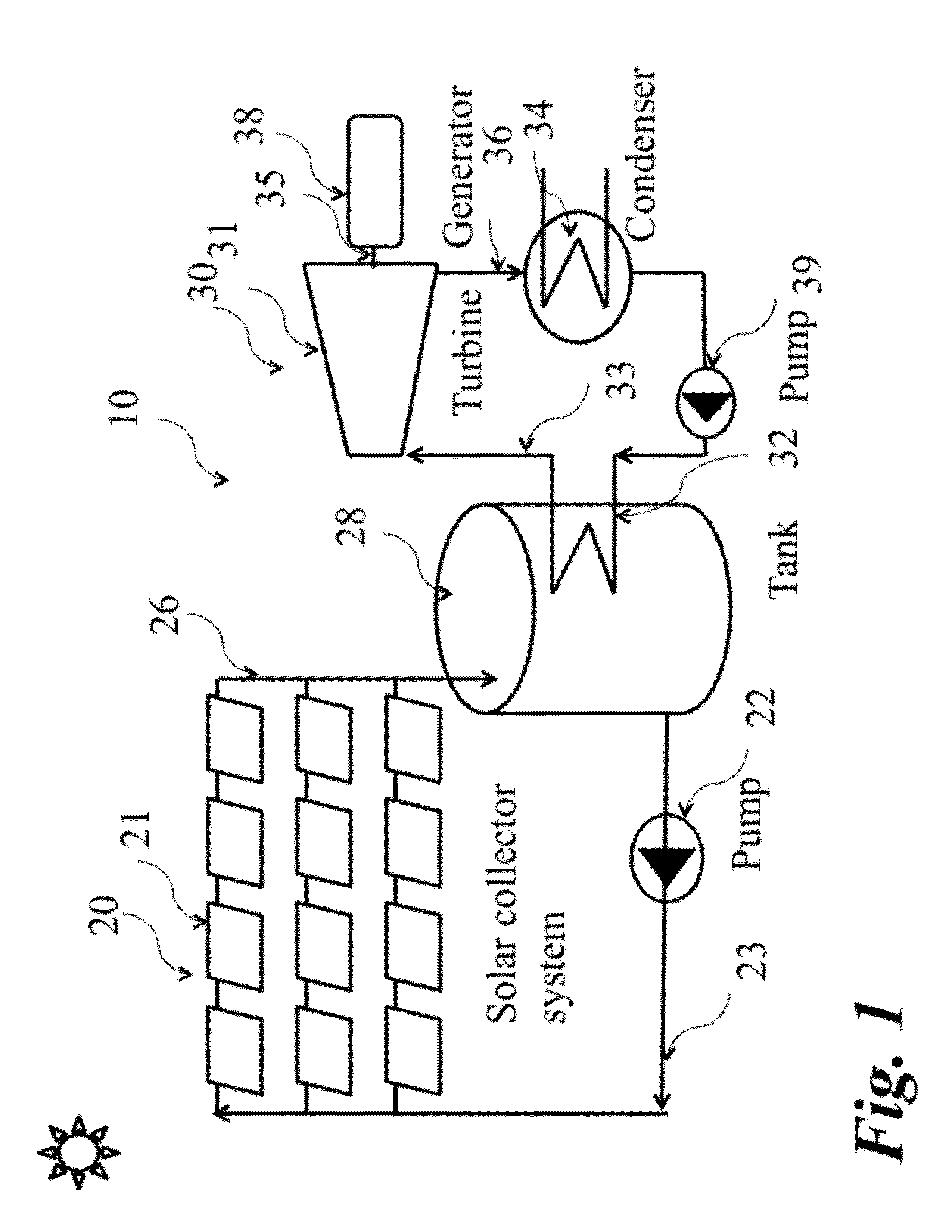

Efficient low temperature thermal energy storage

InactiveUS20090179429A1Improve heating efficiencyInternal combustion piston enginesFrom solar energyThermal energyWorking fluid

Thermal energy derived from a low temperature heat source is stored in one reservoir above ambient temperature and in another reservoir below ambient temperature for use in driving an organic Rankine cycle engine to produce electricity. The organic Rankine cycle engine may utilize an organic working fluid that boils below or near ambient temperature. Solar energy may be used to power a heat pump or chiller that provides the hot and cold storage fluids stored in hot and cold reservoirs for use in the organic Rankine cycle engine.

Owner:AREVA SOLAR

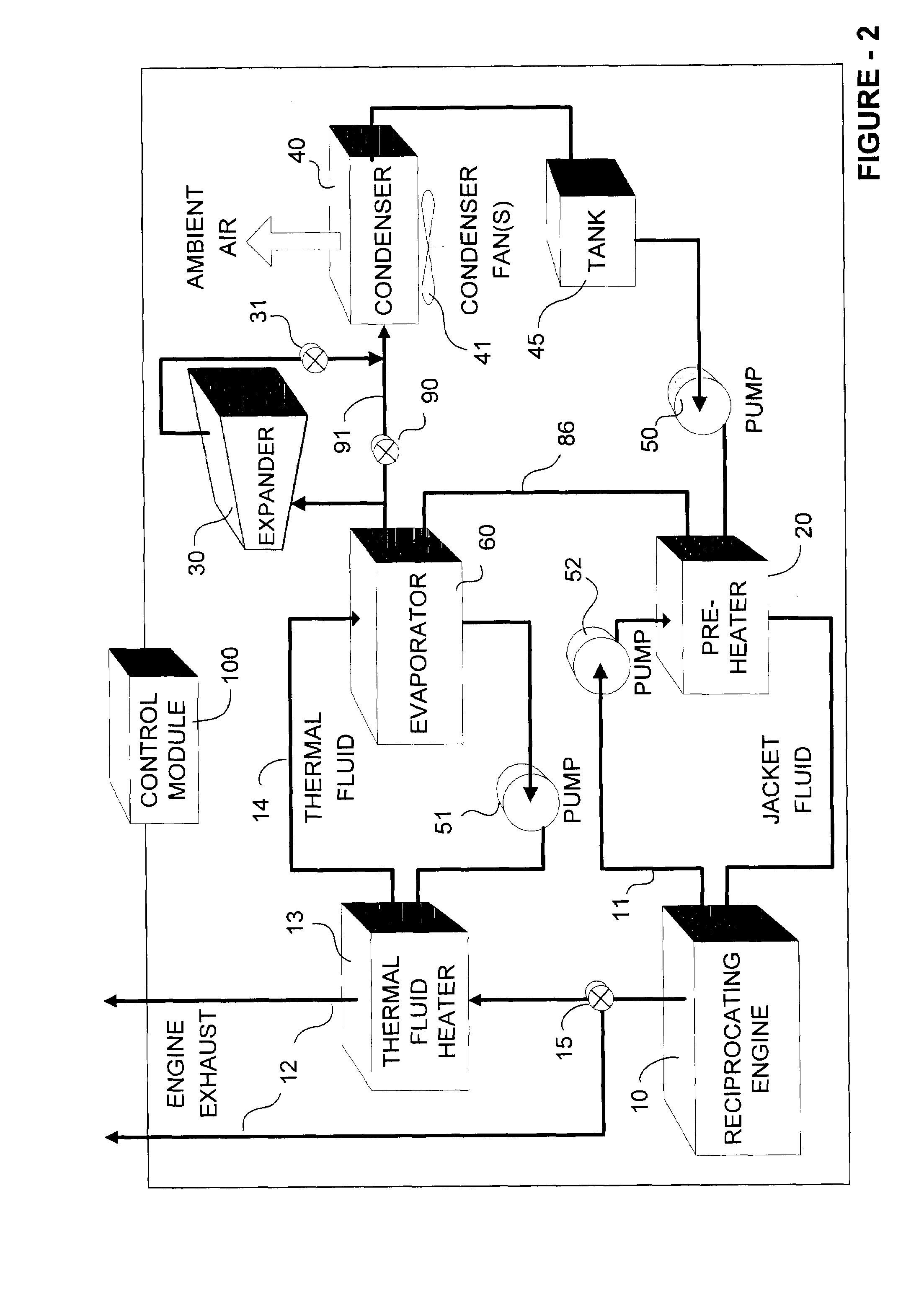

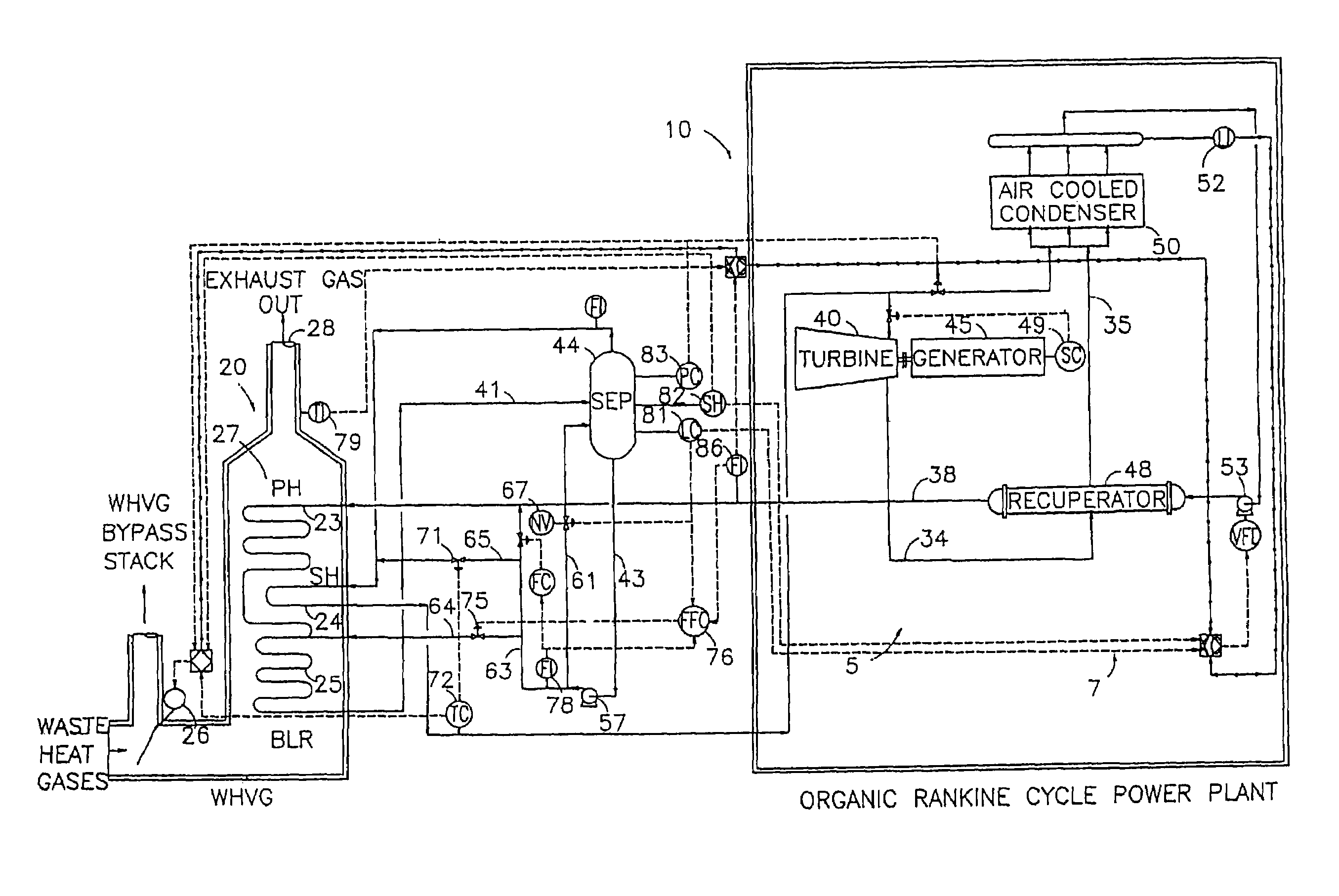

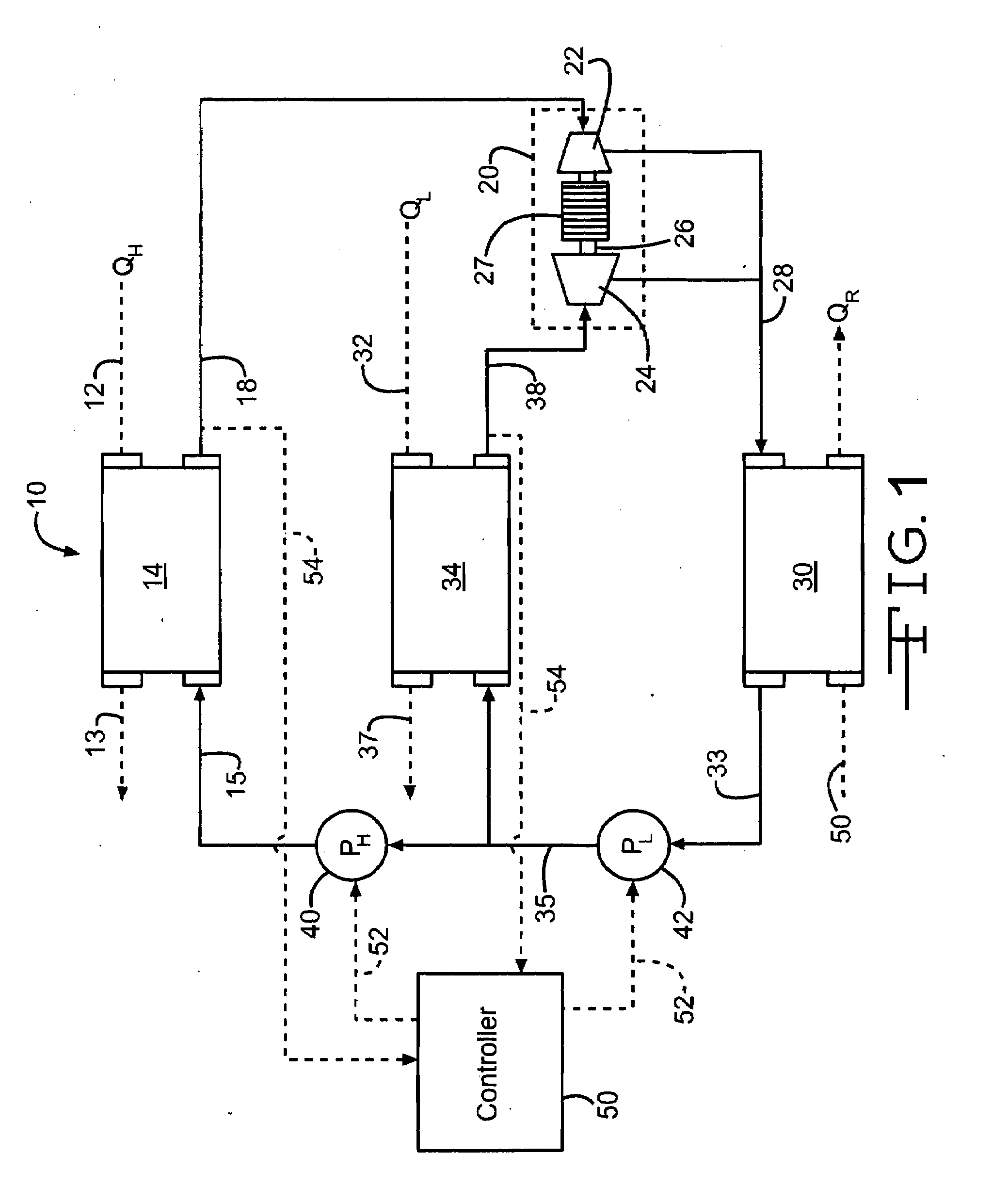

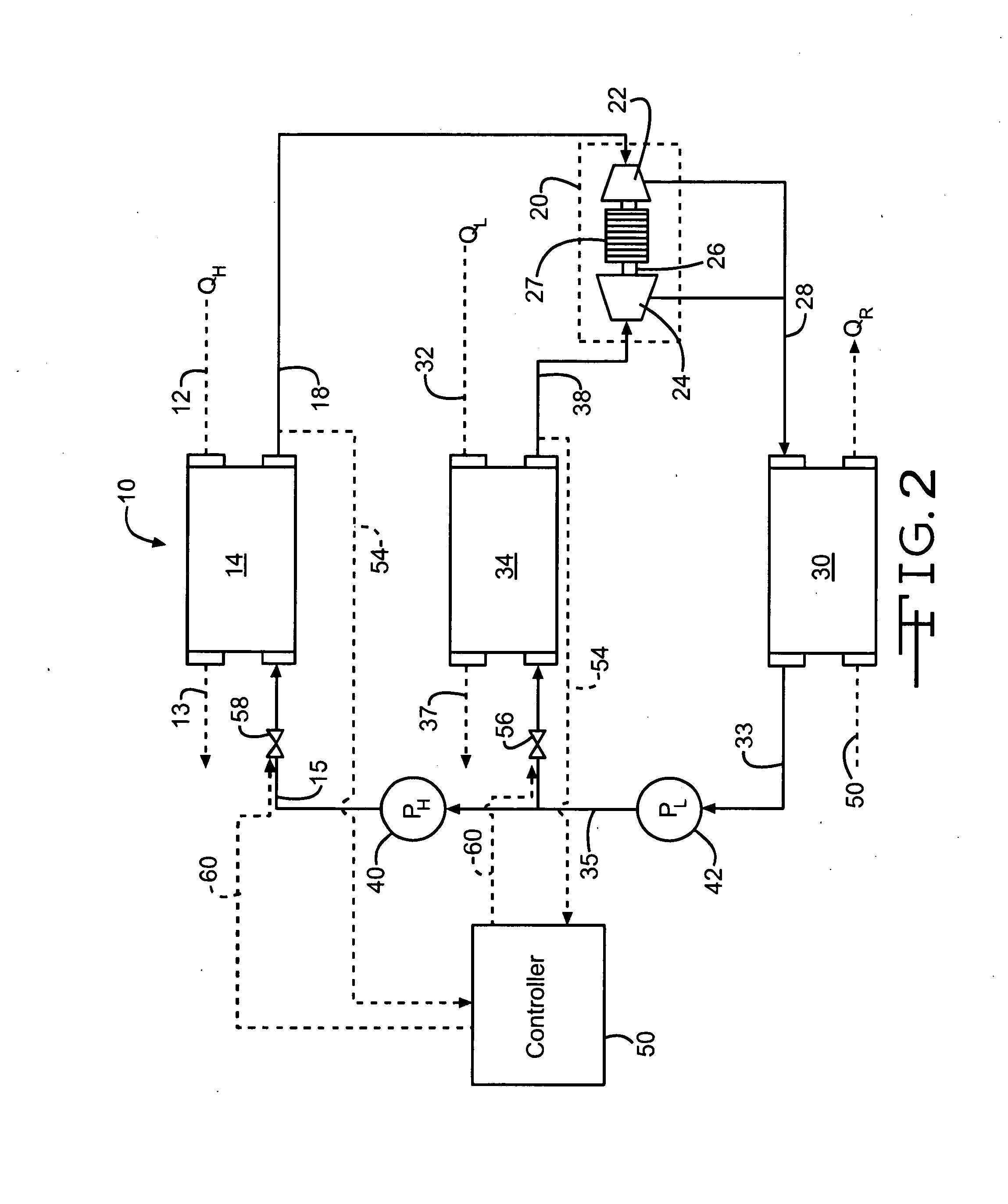

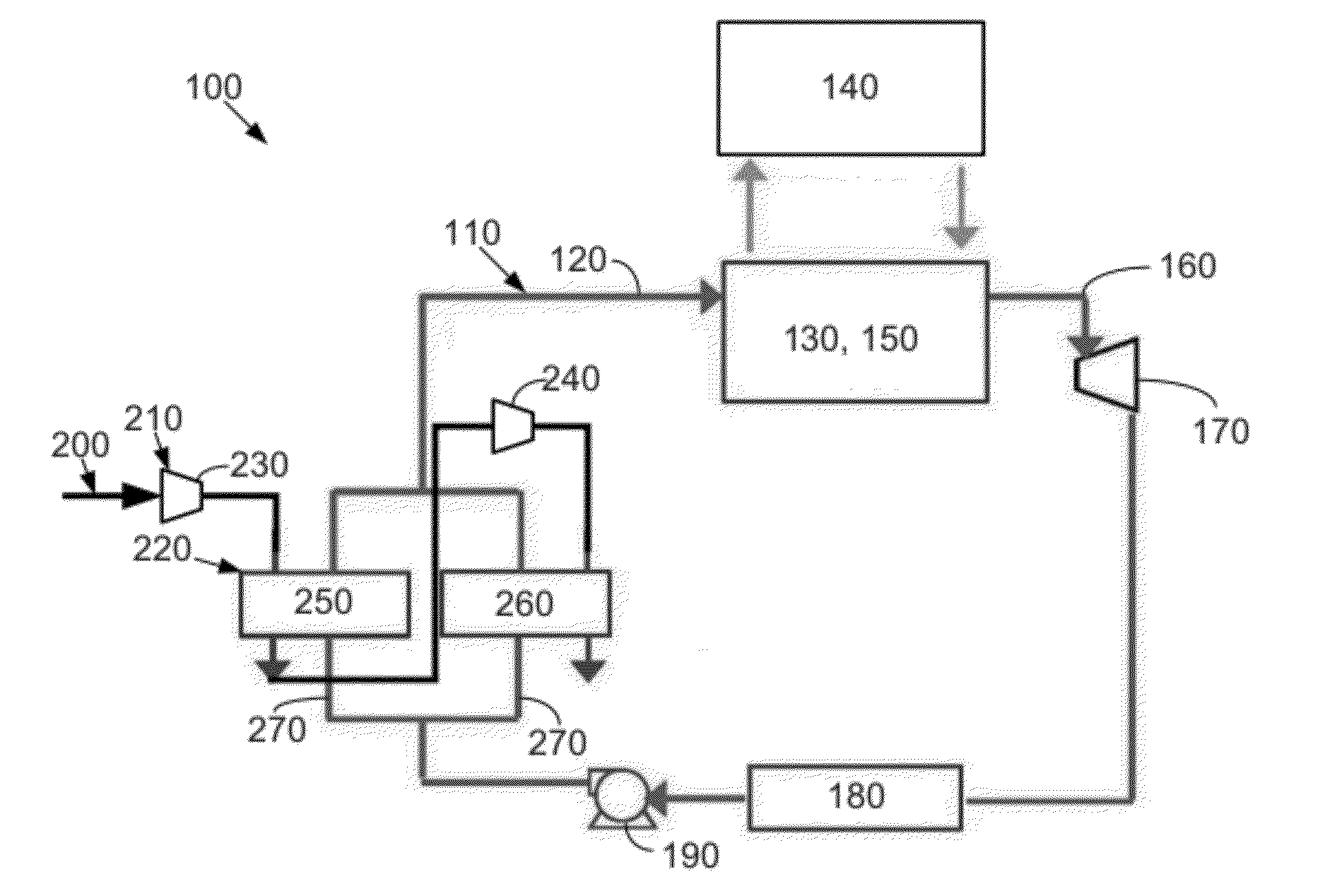

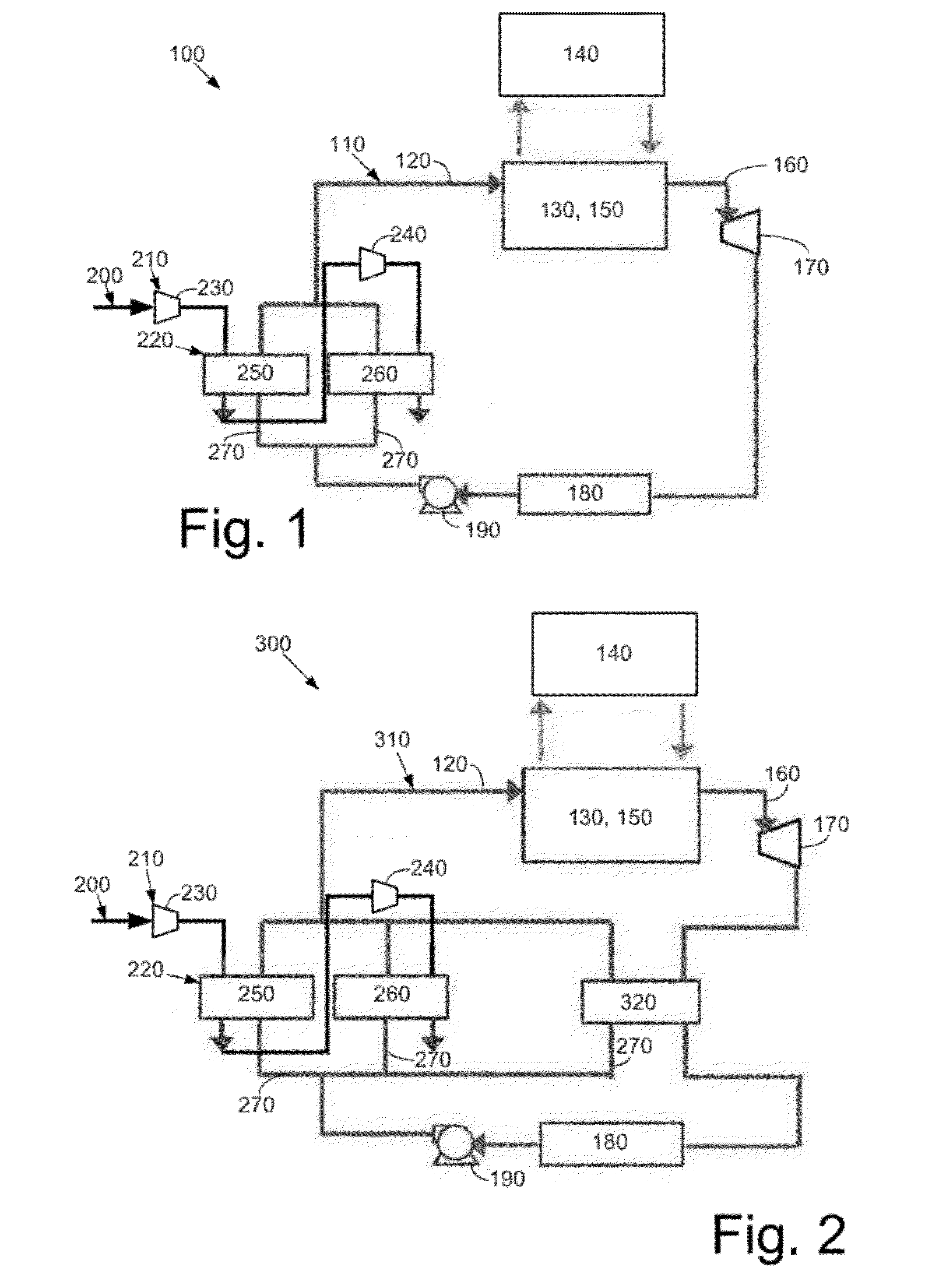

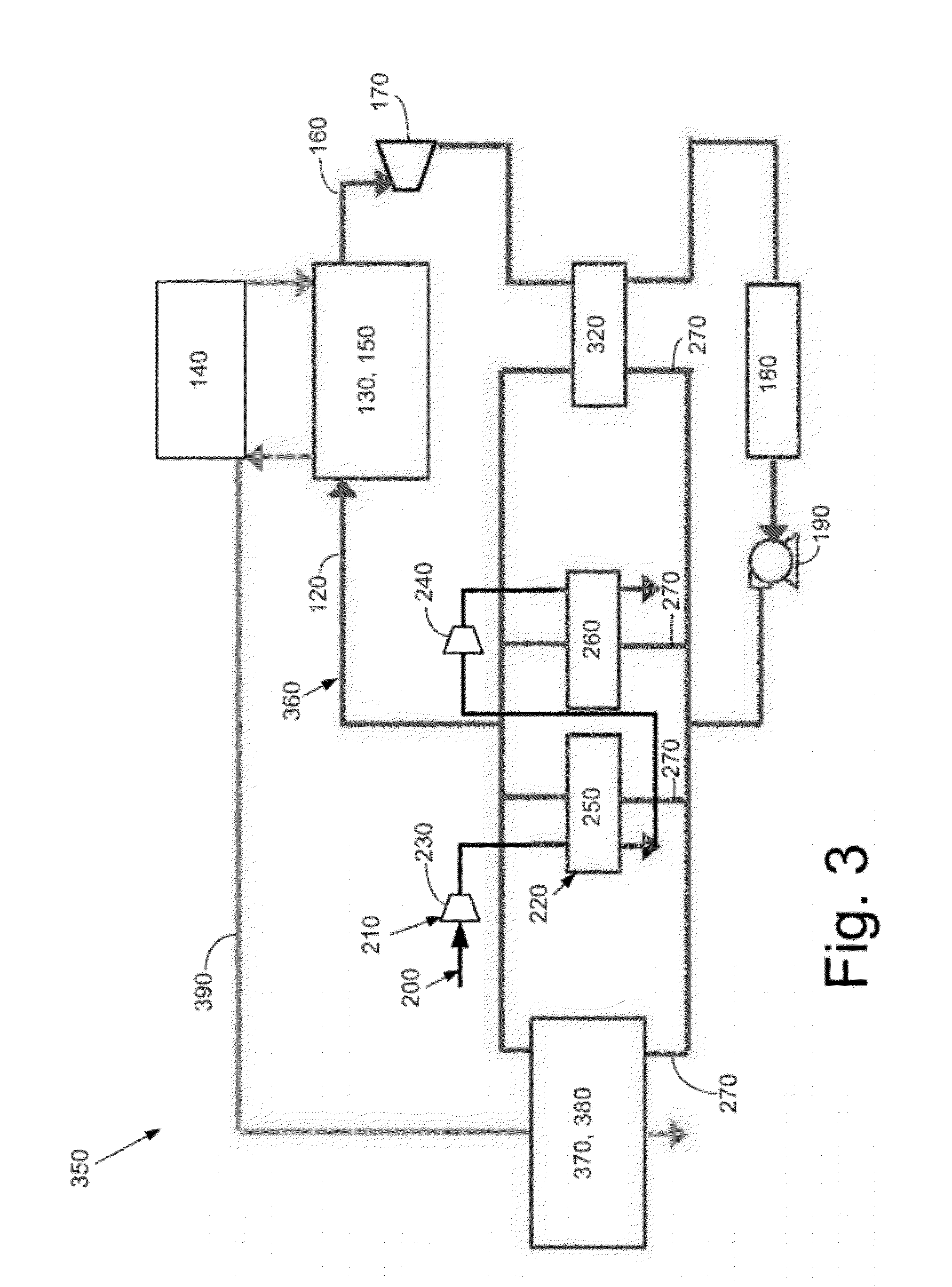

Controlled Organic Rankine Cycle System for Recovery and Conversion of Thermal Energy

A system for controlled recovery of thermal energy and conversion to mechanical energy. The system collects thermal energy from a reciprocating engine, specifically from engine jacket fluid and / or engine exhaust and uses this thermal energy to generate a secondary power source by evaporating an organic propellant and using the gaseous propellant to drive an expander in production of mechanical energy. A monitoring module senses ambient and system conditions such as temperature, pressure, and flow of organic propellant at one or more locations; and a control module regulates system parameters based on monitored information to optimize secondary power output. A tertiary, or back-up power source may also be present. The system may be used to meet on-site power demands using primary, secondary, and tertiary power

Owner:JUCHYMENKO VICTOR

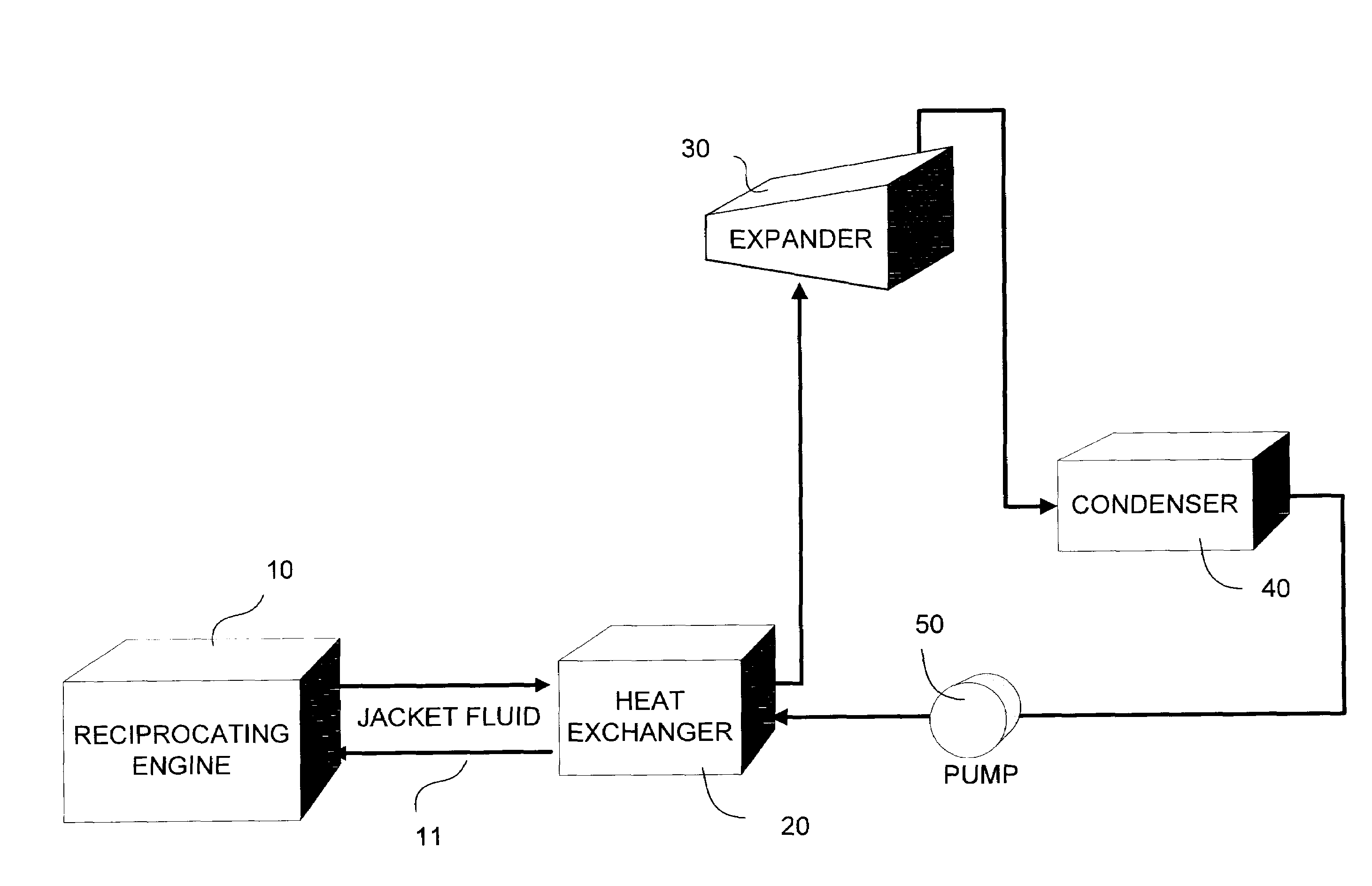

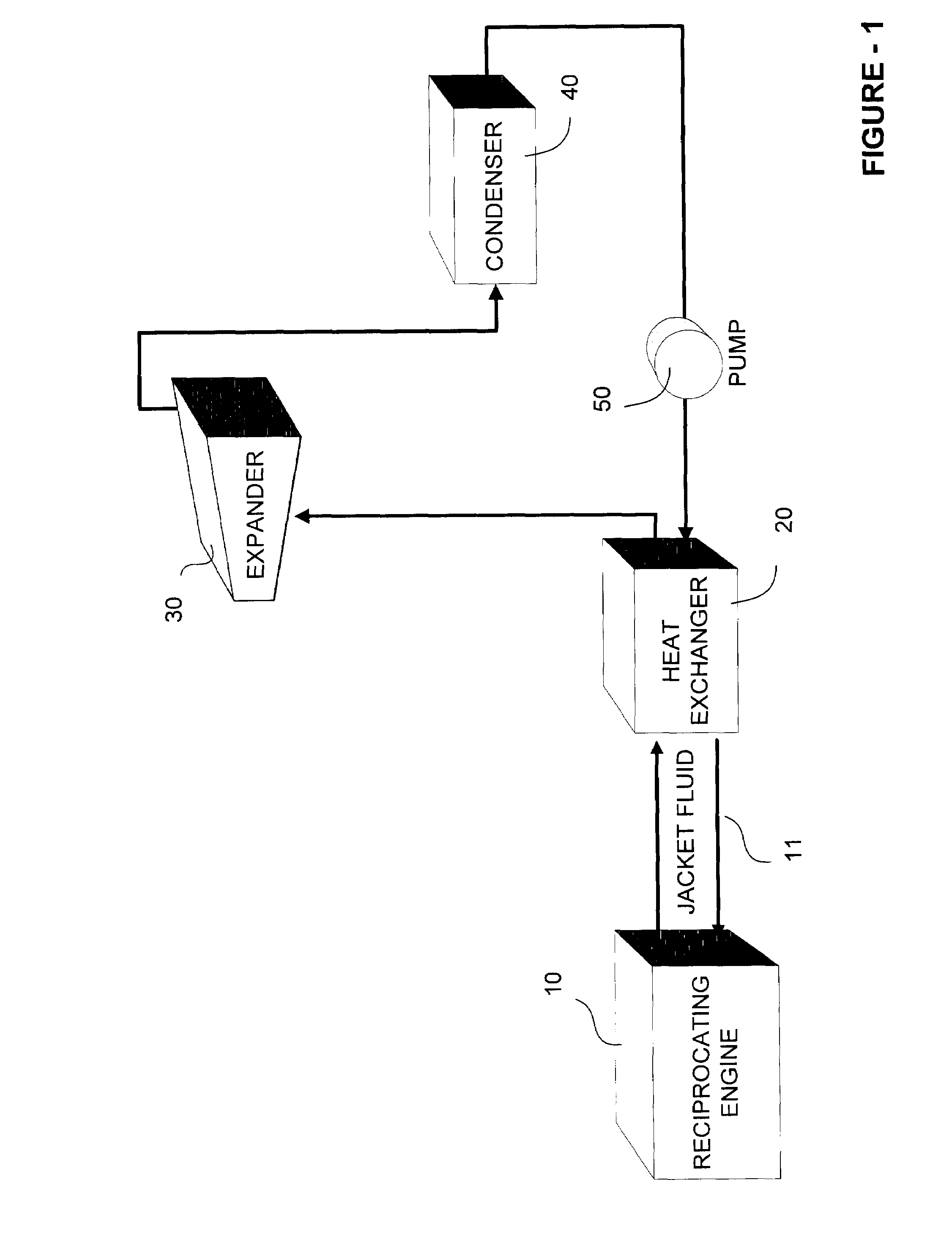

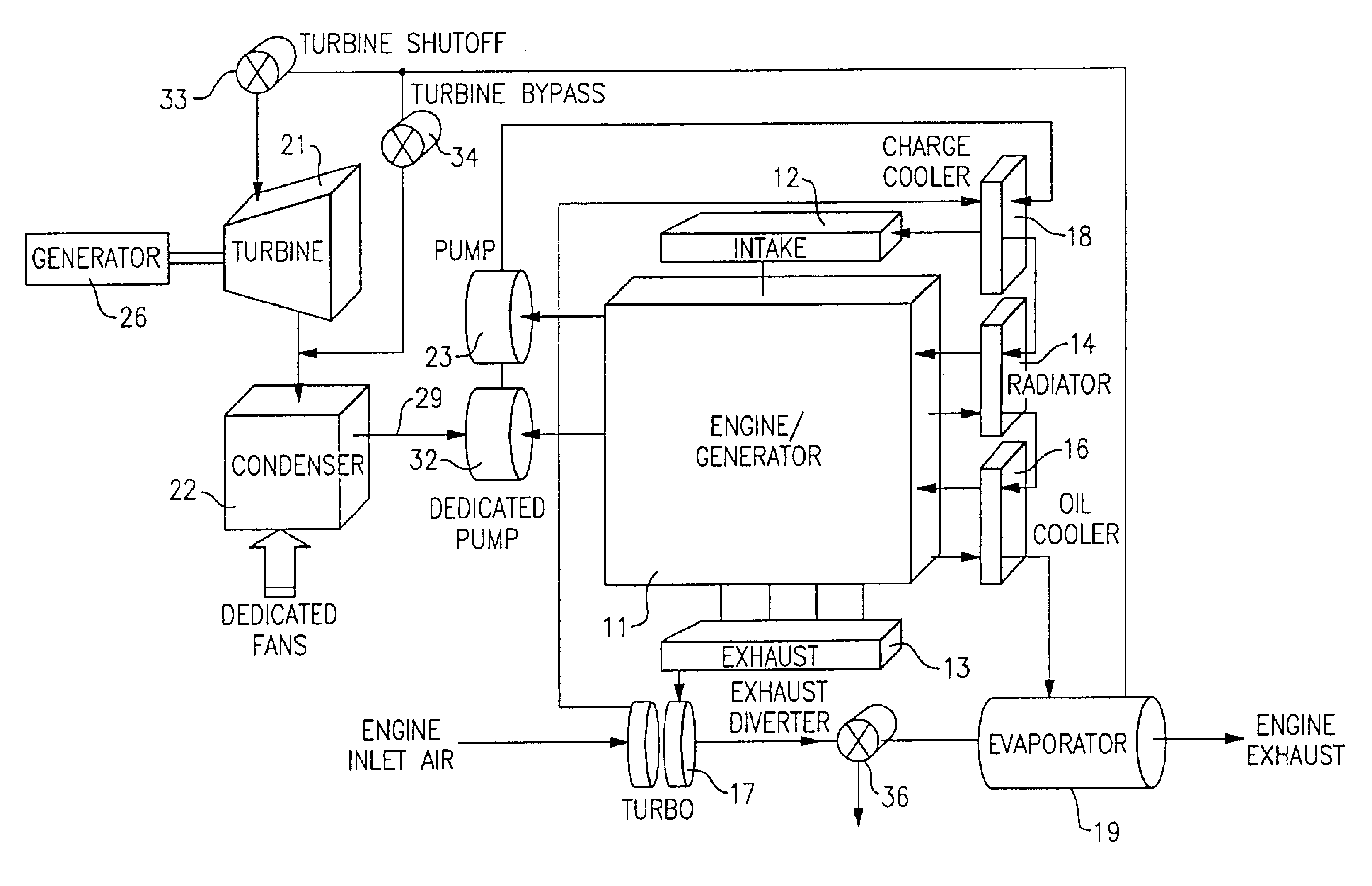

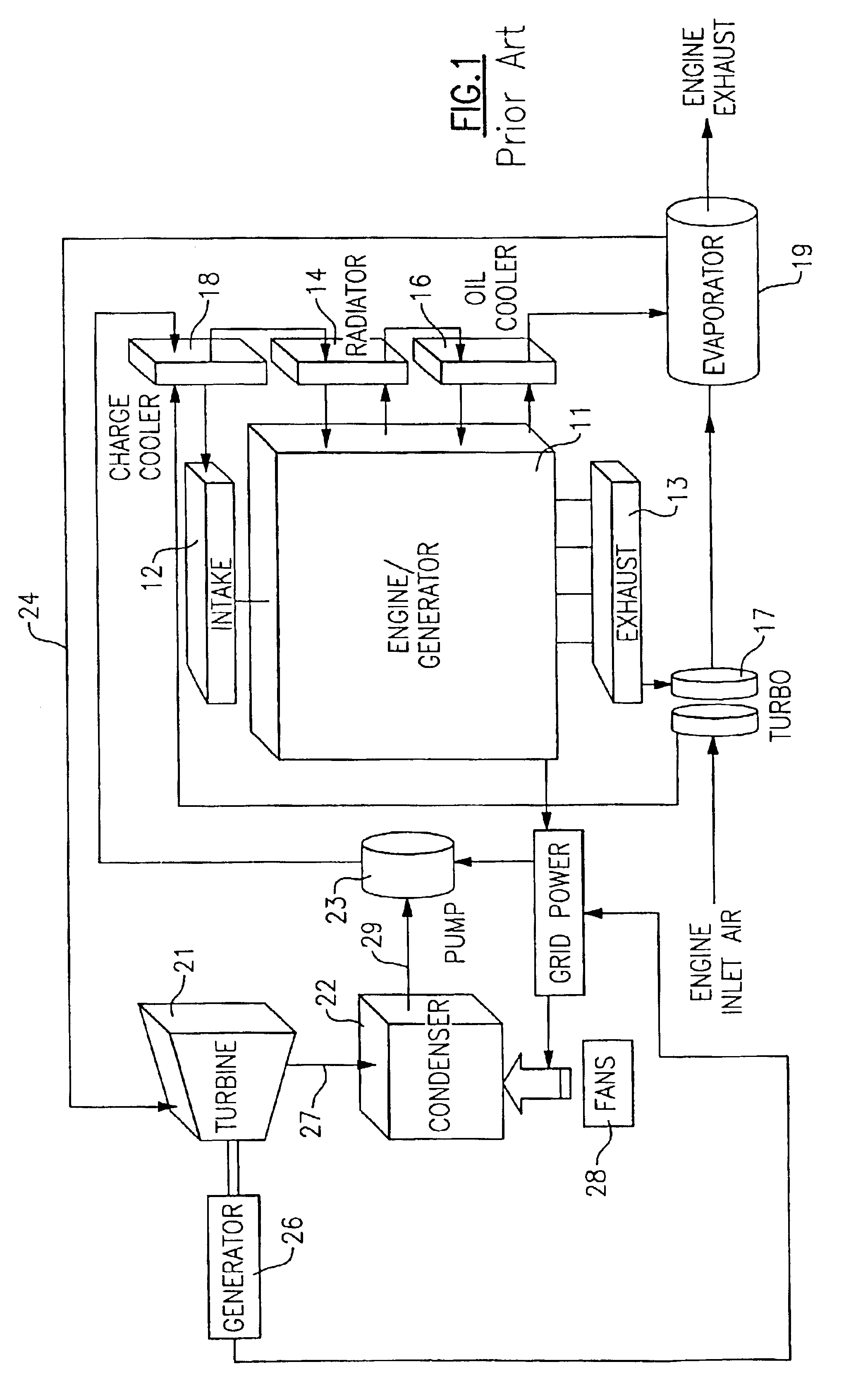

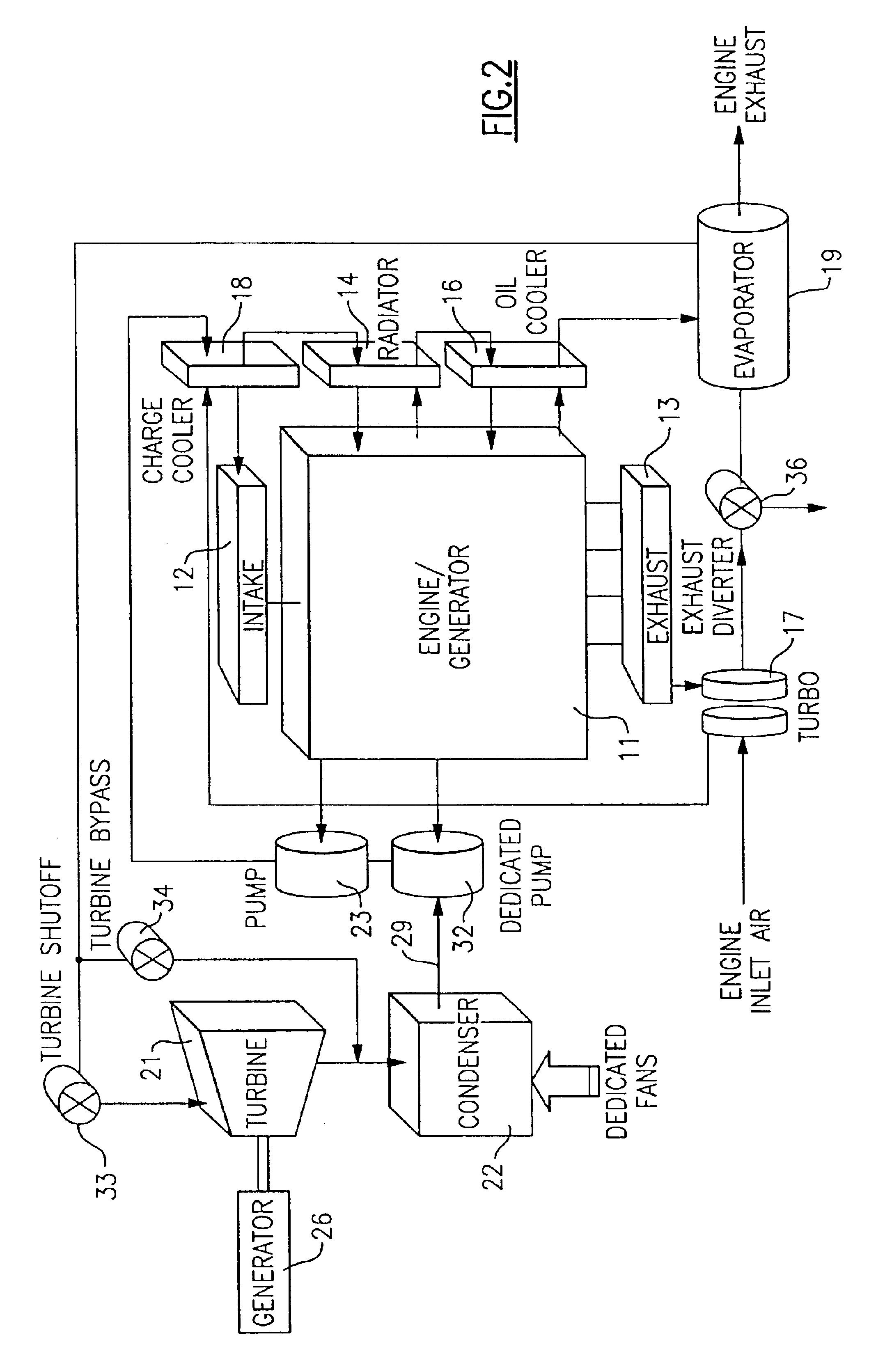

Organic rankine cycle system for use with a reciprocating engine

InactiveUS6986251B2Reduce heatShorten speedSteam engine plantsMechanical power devicesLow speedCavitation

In a waste heat recovery system wherein an organic rankine cycle system uses waste heat from the fluids of a reciprocating engine, provision is made to continue operation of the engine even during periods when the organic rankine cycle system is inoperative, by providing an auxiliary pump and a bypass for the refrigerant flow around the turbine. Provision is also made to divert the engine exhaust gases from the evaporator during such periods of operation. In one embodiment, the auxiliary pump is made to operate simultaneously with the primary pump during normal operations, thereby allowing the primary pump to operate at lower speeds with less likelihood of cavitation.

Owner:INT FUEL CELLS +1

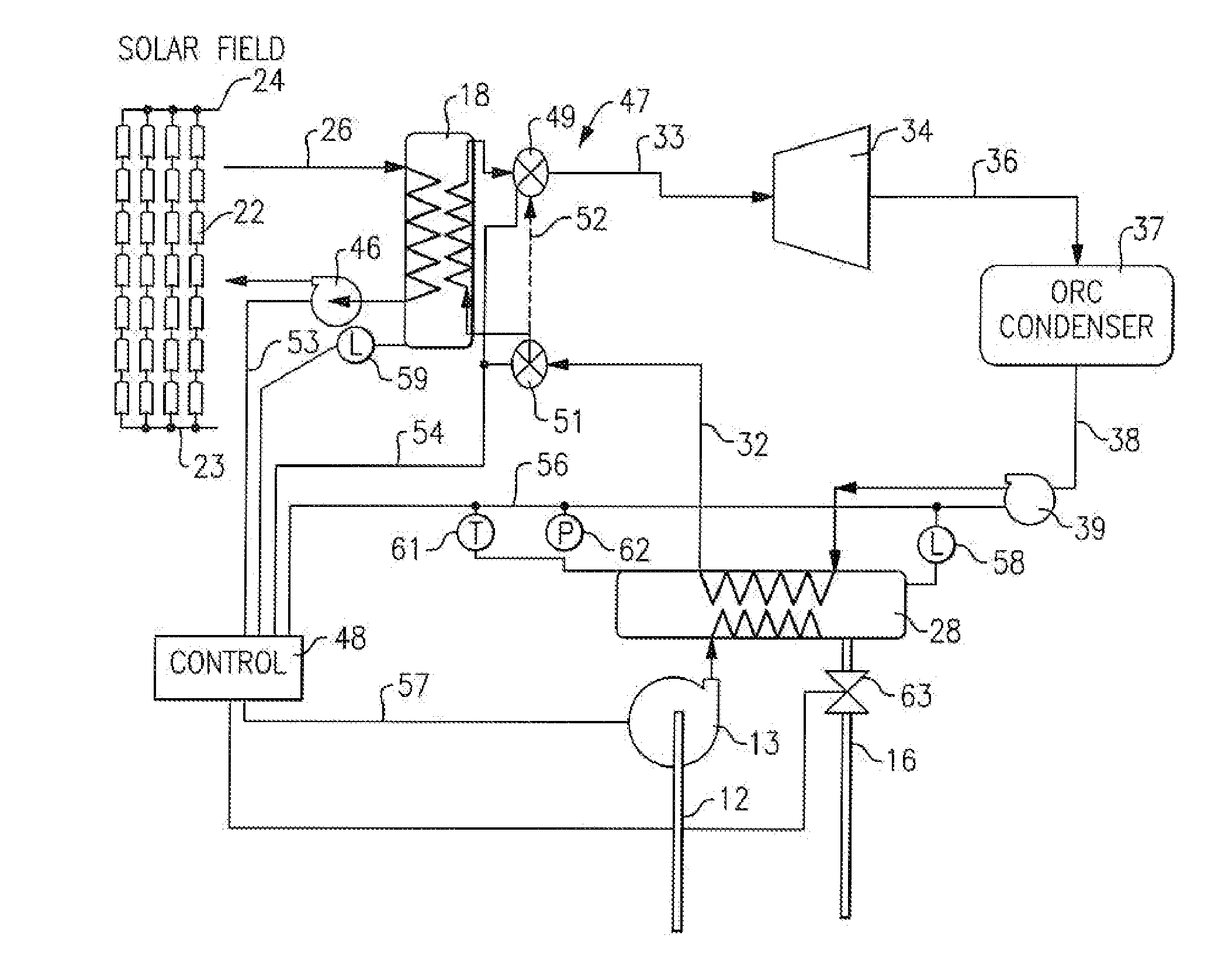

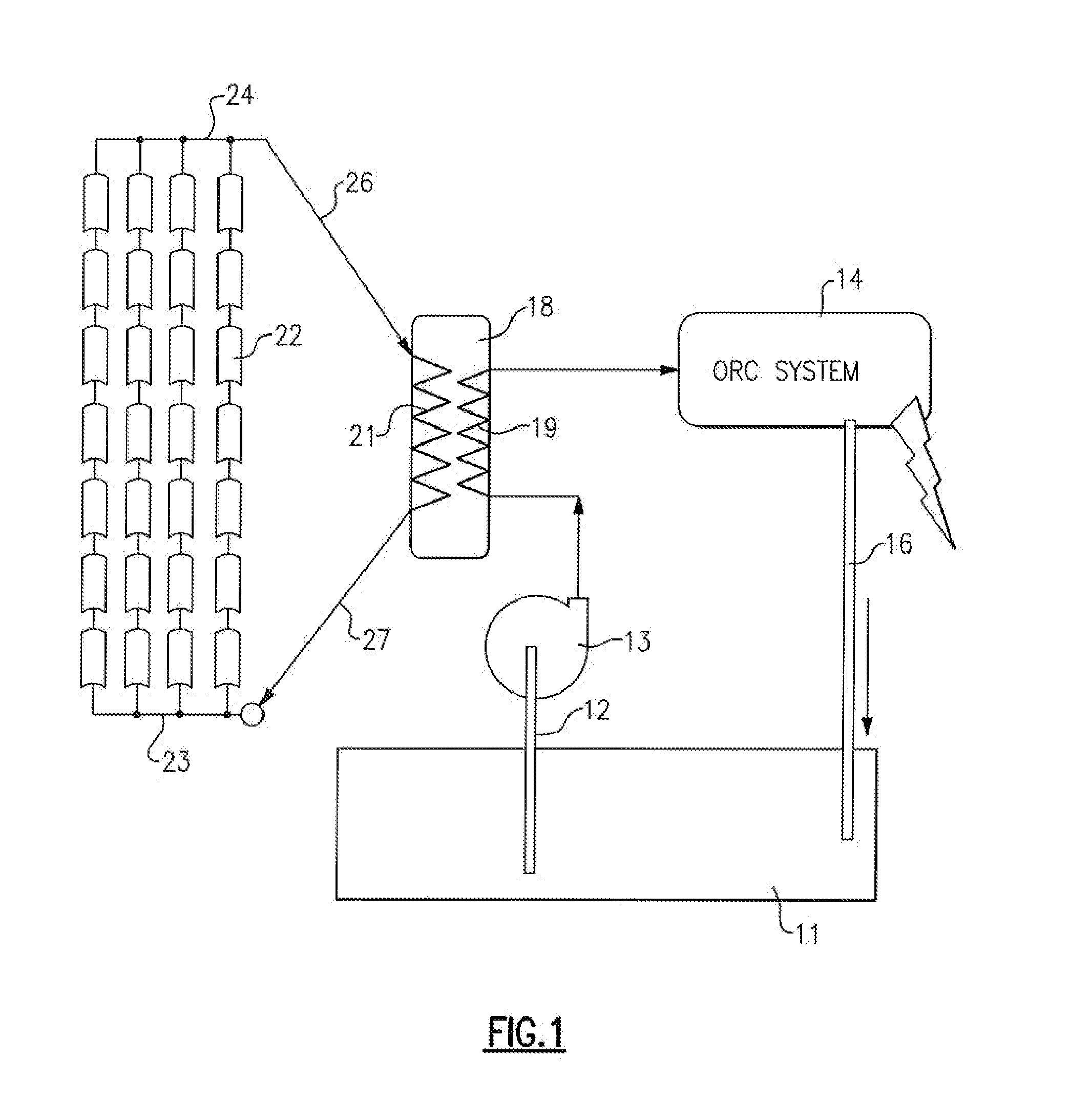

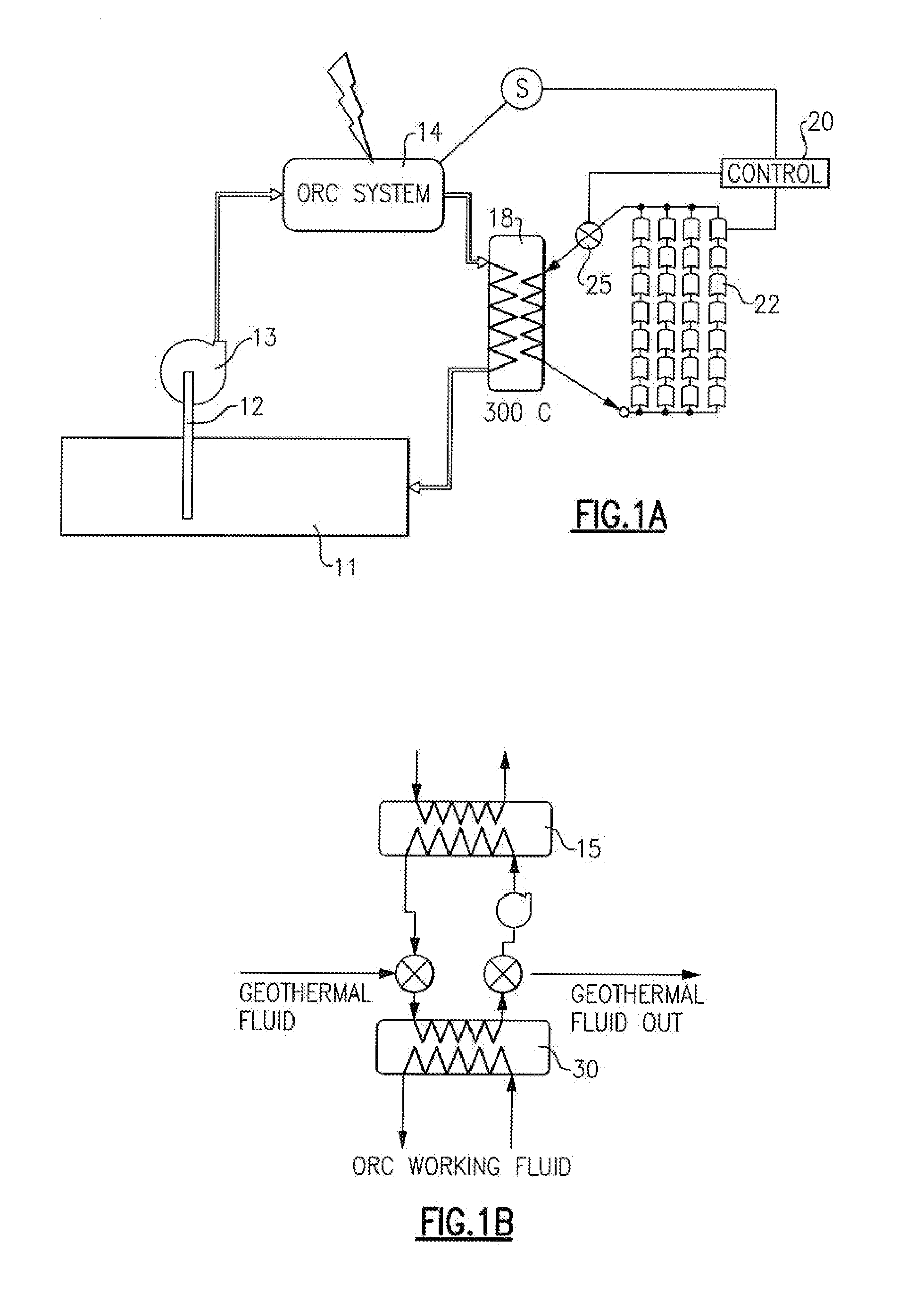

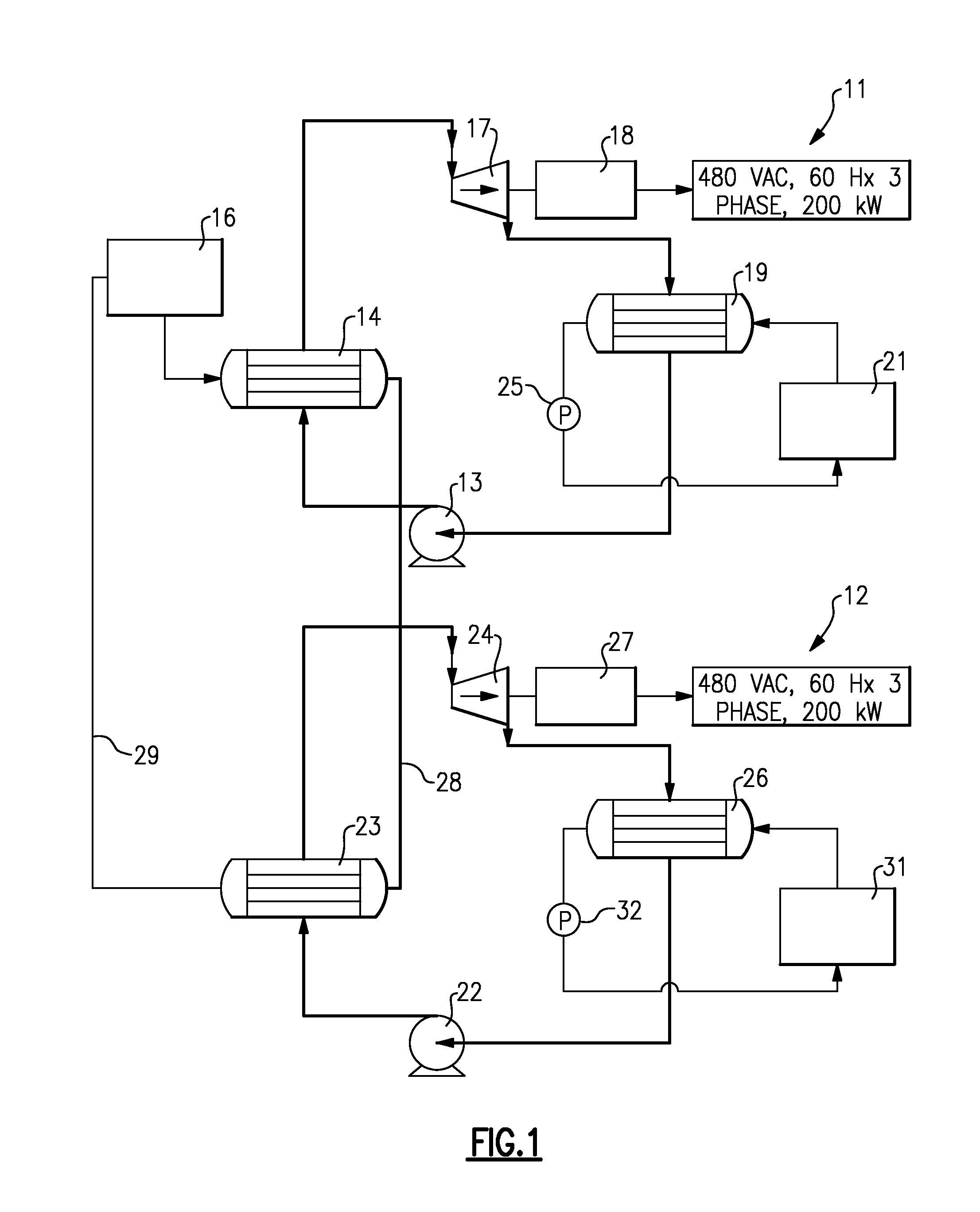

Combined geothermal and solar thermal organic rankine cycle system

In a system where the thermal energy of a geothermal fluid is applied to an ORC system, the energy is enhanced by the use of solar energy to thereby increase the temperature of the fluid being applied by the ORC system. A single heat exchanger version provides for direct heat exchange relationship with the geothermal and solar fluids, whereas a two heat exchanger version provides for each of the geothermal and solar fluids to be in heat exchange relationship with the working medium of the ORC system. Control features are provided to selectively balance the various fluid flows in the system.

Owner:UNITED TECH CORP

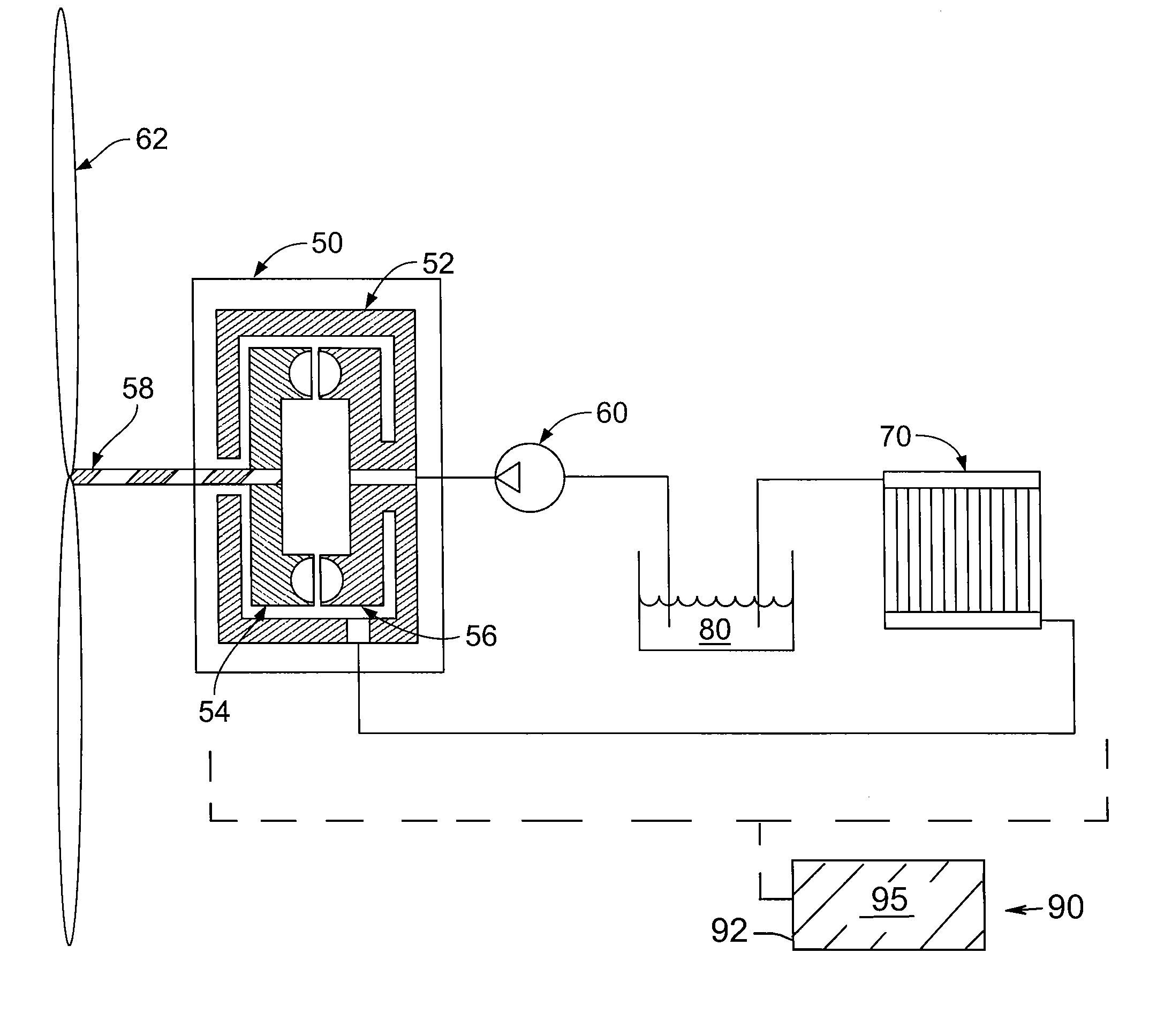

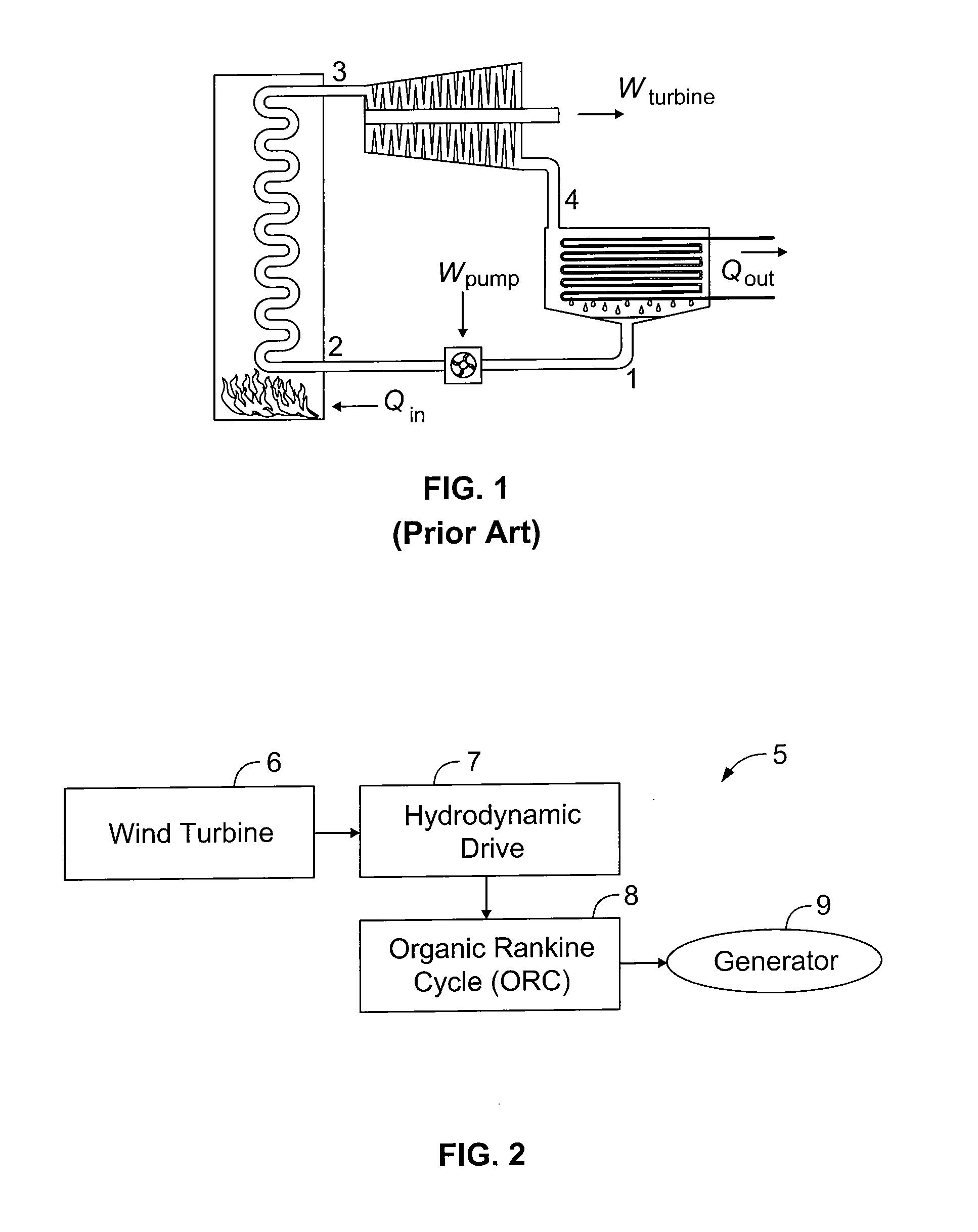

Power generator using a wind turbine, a hydrodynamic retarder and an organic rankine cycle drive

InactiveUS20120001436A1Facilitates easy inspectionEasy maintenanceWind energy with garvitational potential energyEnergy industryElectricityOrganic Rankine cycle

An electric power generating system is provided that uses a wind turbine to generate waste-heat that is utilized in an organic Rankine Cycle drive that converts heat energy into rotation of a generator rotor for generating electricity. A hydrodynamic retarder may be provided that dissipates heat into a hot fluid by directing the flow of the fluid through the hydrodynamic retarder in a manner that resists rotation of blades of the wind turbine. The hot fluid circulating in the hydrodynamic retarder is a thermal heat source for vapor regeneration of organic heat exchange fluid mixture(s) used in the Rankine cycle, expansion of the organic heat exchange fluid being converted into rotation of the generator rotor.

Owner:SAMI SAMUEL DR

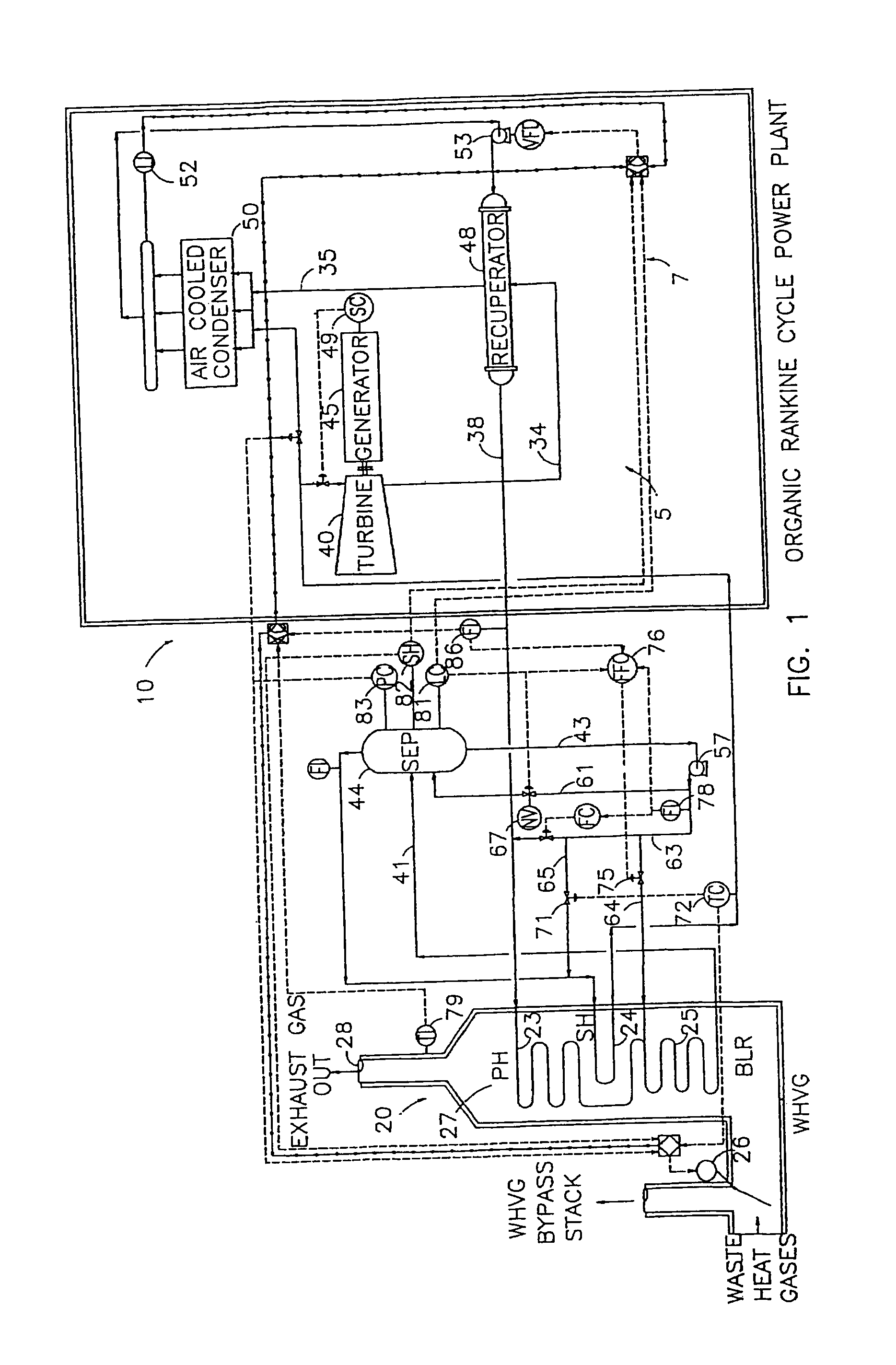

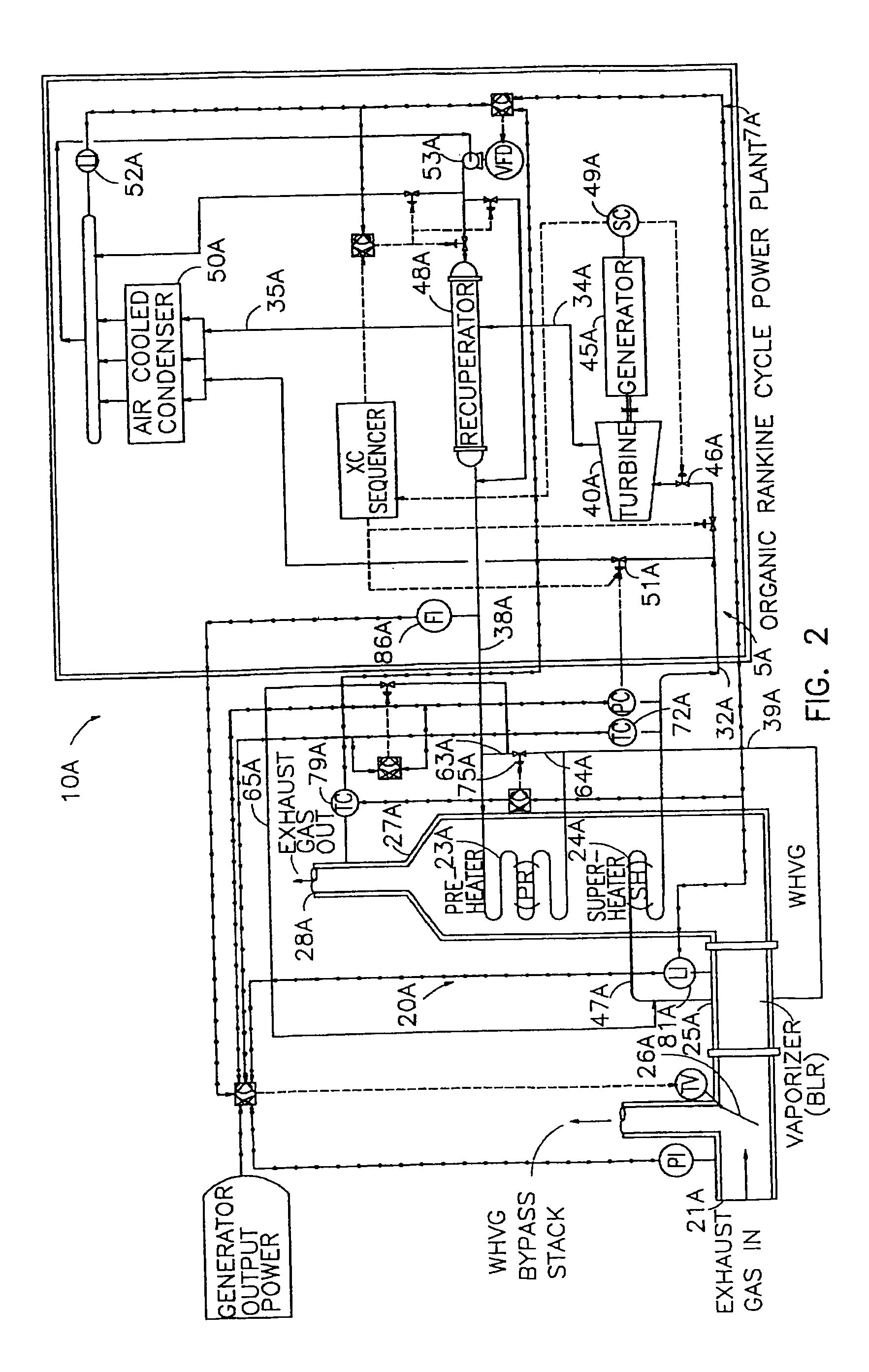

Direct heating organic rankine cycle

ActiveUS20080289313A1Suppress temperature increaseGas turbine plantsSteam engine plantsOrganic Rankine cycleProcess engineering

The present invention provides an organic Rankine cycle power system, which comprises means for superheating vaporized organic motive fluid, an organic turbine module coupled to a generator, and a first pipe through which superheated organic motive fluid is supplied to the turbine, wherein the superheating means is a set of coils through which the vaporized organic motive fluid flows and which is in direct heat exchanger relation with waste heat gases.

Owner:ORMAT TECH INC

Combined rankine and vapor compression cycles

InactiveUS6880344B2Effective use of wasteEasy to useInternal combustion piston enginesBiofuelsOrganic Rankine cycleEngineering

An organic rankine cycle system is combined with a vapor compression cycle system with the turbine generator of the organic rankine cycle generating the power necessary to operate the motor of the refrigerant compressor. The vapor compression cycle is applied with its evaporator cooling the inlet air into a gas turbine, and the organic rankine cycle is applied to receive heat from a gas turbine exhaust to heat its boiler within one embodiment, a common condenser is used for the organic rankine cycle and the vapor compression cycle, with a common refrigerant, R-245a being circulated within both systems. In another embodiment, the turbine driven generator has a common shaft connected to the compressor to thereby eliminate the need for a separate motor to drive the compressor. In another embodiment, an organic rankine cycle system is applied to an internal combustion engine to cool the fluids thereof, and the turbo charged air is cooled first by the organic rankine cycle system and then by an air conditioner prior to passing into the intake of the engine.

Owner:NANJING TICA AIR CONDITIONING CO LTD

Chloro- And Bromo-Fluoro Olefin Compounds Useful As Organic Rankine Cycle Working Fluids

Aspects of the present invention are directed to working fluids and their use in processes wherein the working fluids comprise compounds having the structure of formula (I):wherein R1, R2, R3, and R4 are each independently selected from the group consisting of: H, F, Cl, Br, and C1-C6 alkyl, at least C6 aryl, at least C3 cycloalkyl, and C6-C15 alkylaryl optionally substituted with at least one F, Cl, or Br, wherein formula (I) contains at least one F and at least one Cl or Br, provided that if any R is Br, then the compound does not have hydrogen. The working fluids are useful in Rankine cycle systems for efficiently converting waste heat generated from industrial processes, such as electric power generation from fuel cells, into mechanical energy or further to electric power. The working fluids of the invention are also useful in equipment employing other thermal energy conversion processes and cycles.

Owner:HONEYWELL INT INC

Working fluids for thermal energy conversion of waste heat from fuel cells using Rankine cycle systems

A process for recovering waste heat which comprises: (a) passing a liquid phase working fluid through a heat exchanger in communication with a process which produces the waste heat; (b) removing a vapor phase working fluid from the heat exchanger; (c) passing the vapor phase working fluid to an expander, wherein the waste heat is converted into mechanical energy; and (d) passing the vapor phase working fluid from the expander to a condenser, wherein the vapor phase working fluid is condensed to the liquid phase working fluid. The preferred working fluid is an organic Rankine cycle system working fluid comprising compounds having the following general structure:where x, y, z, and m are each selected from the group consisting of: fluorine, hydrogen, Rf, and R, wherein R and Rf are each an alkyl, aryl, or alkylaryl of 1 to 6 carbon atoms, and wherein Rf is partially or fully fluorinated.

Owner:HONEYWELL INT INC

Organic working fluids

ActiveUS7225621B2Improve thermal stabilityStable compoundAuxillary drivesFrom solar energyHuman useAlkane

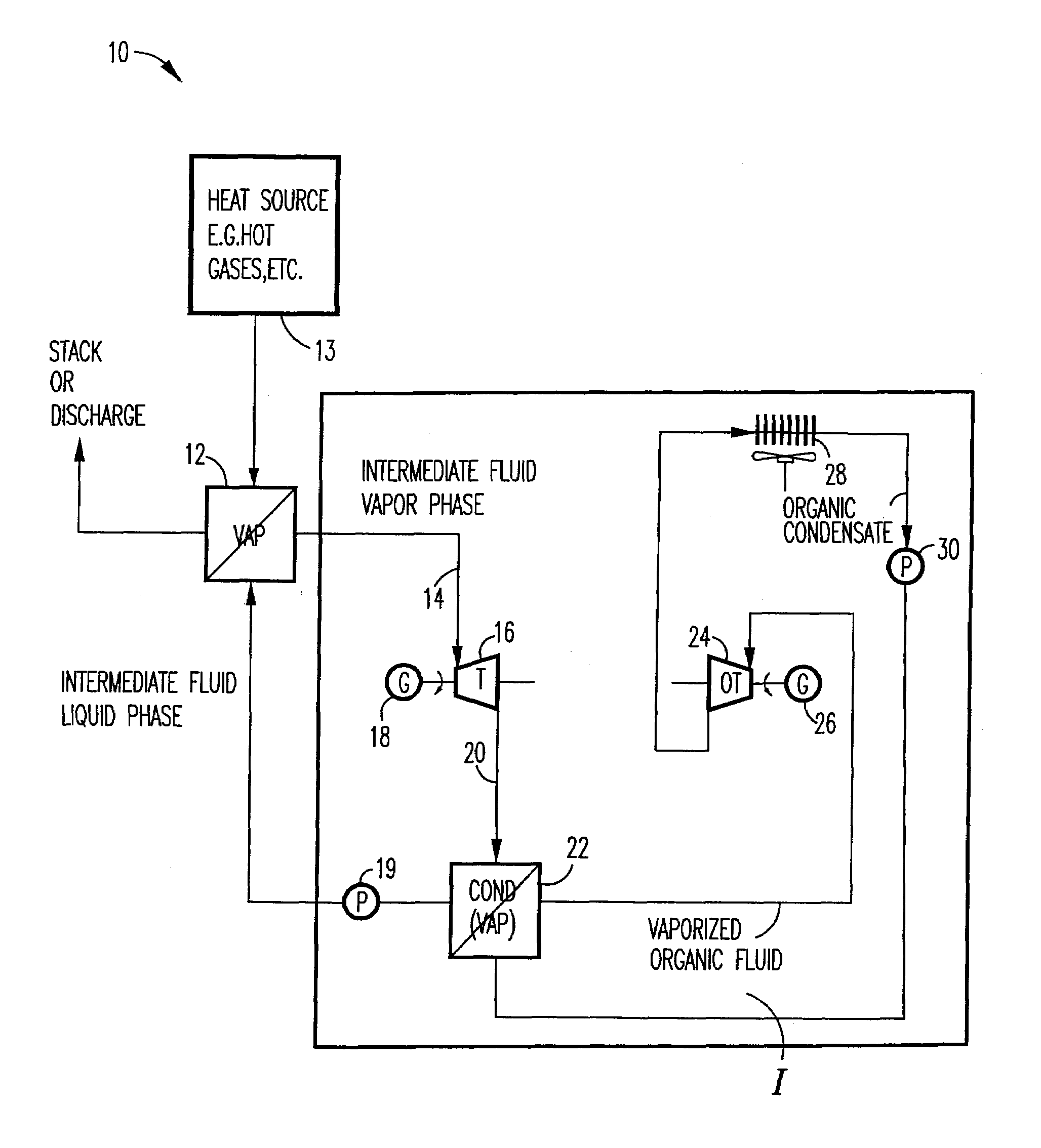

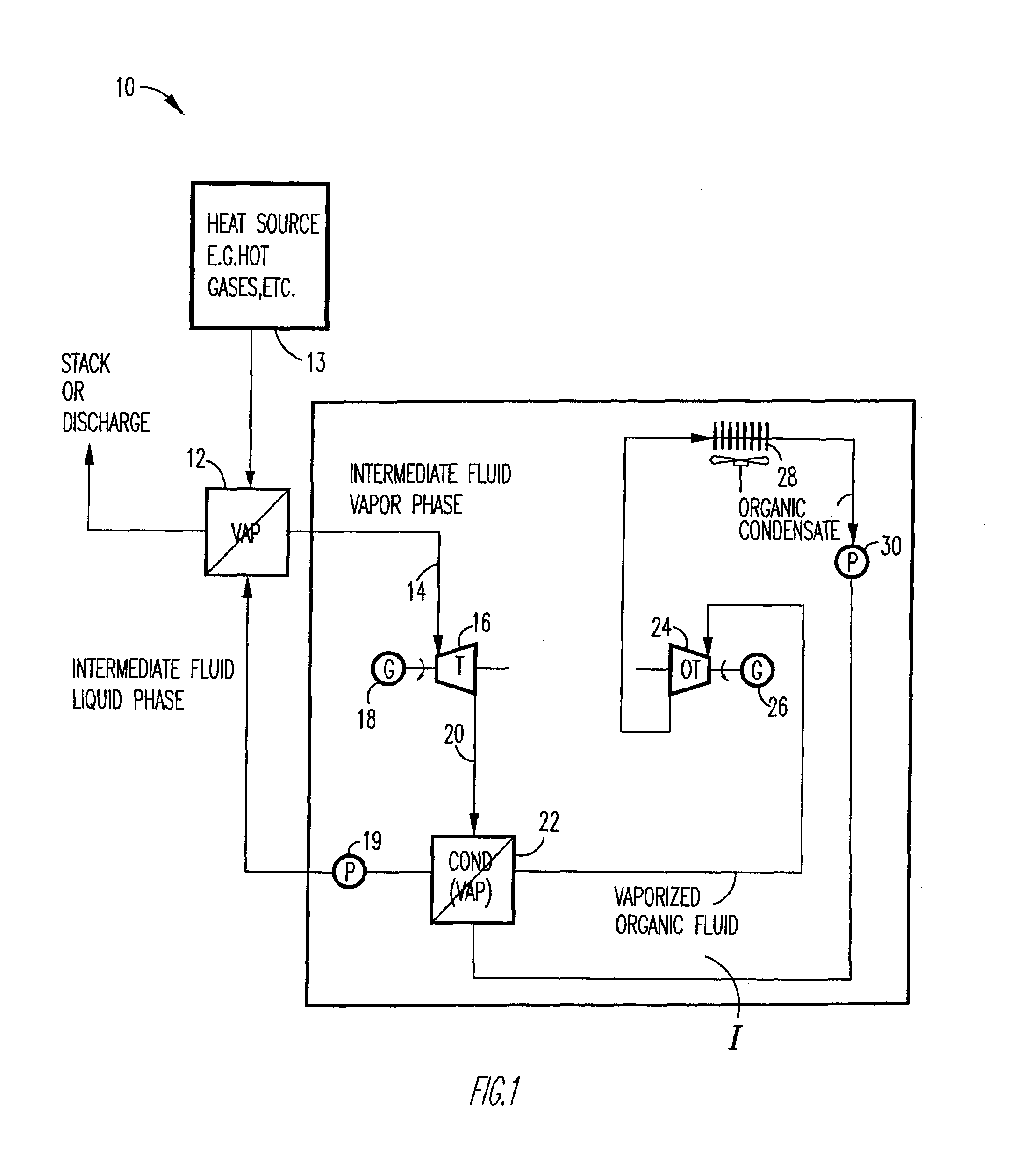

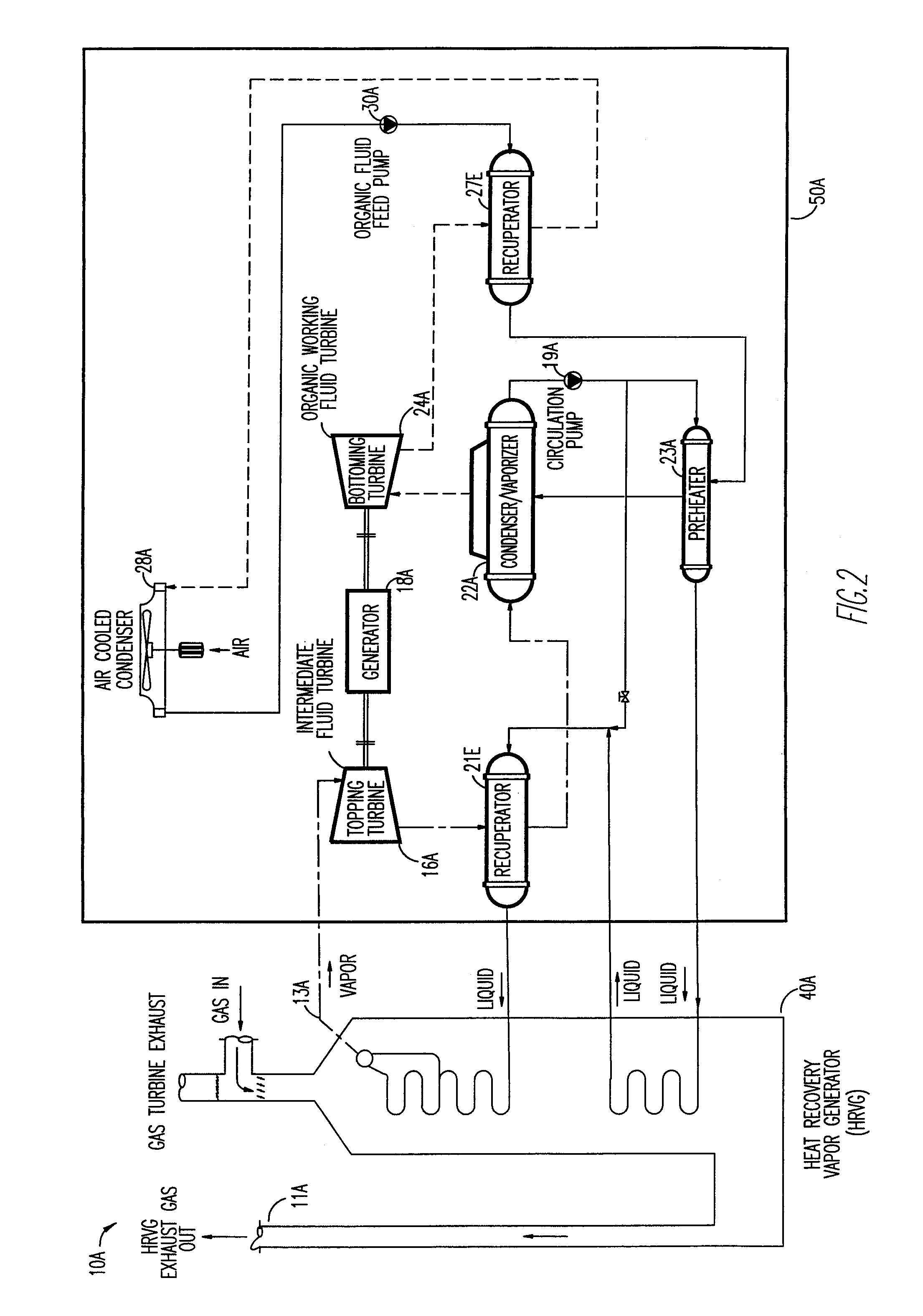

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECH INC

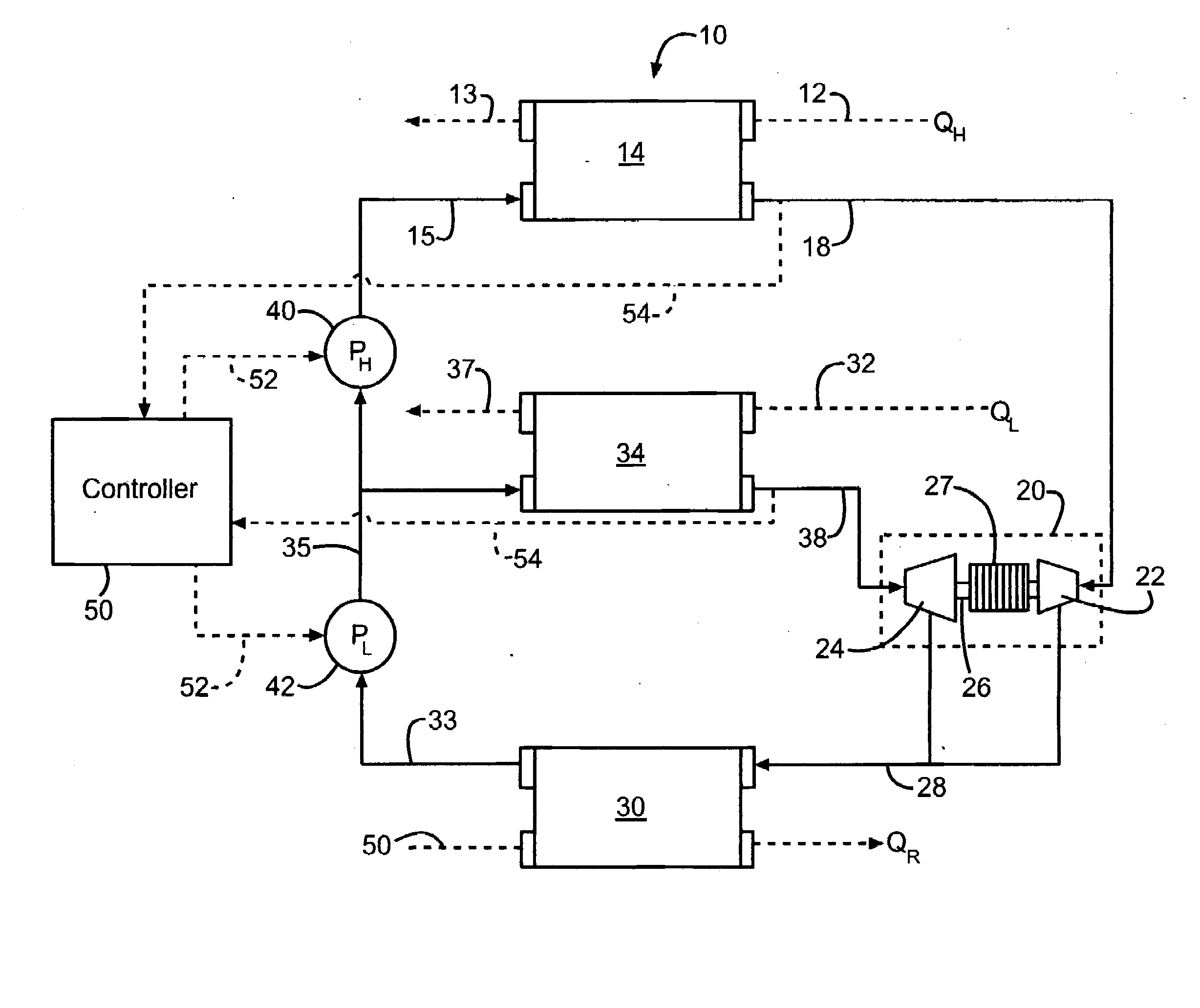

Energy recovery system using an organic rankine cycle

ActiveUS20110016863A1Improve energy recoveryDifferent temperatureSteam useGas turbine plantsThermal energyHeat flow

A thermodynamic system for waste heat recovery, using an organic rankine cycle is provided which employs a single organic heat transferring fluid to recover heat energy from two waste heat streams having differing waste heat temperatures. Separate high and low temperature boilers provide high and low pressure vapor streams that are routed into an integrated turbine assembly having dual turbines mounted on a common shaft. Each turbine is appropriately sized for the pressure ratio of each stream.

Owner:CUMMINS INTPROP INC

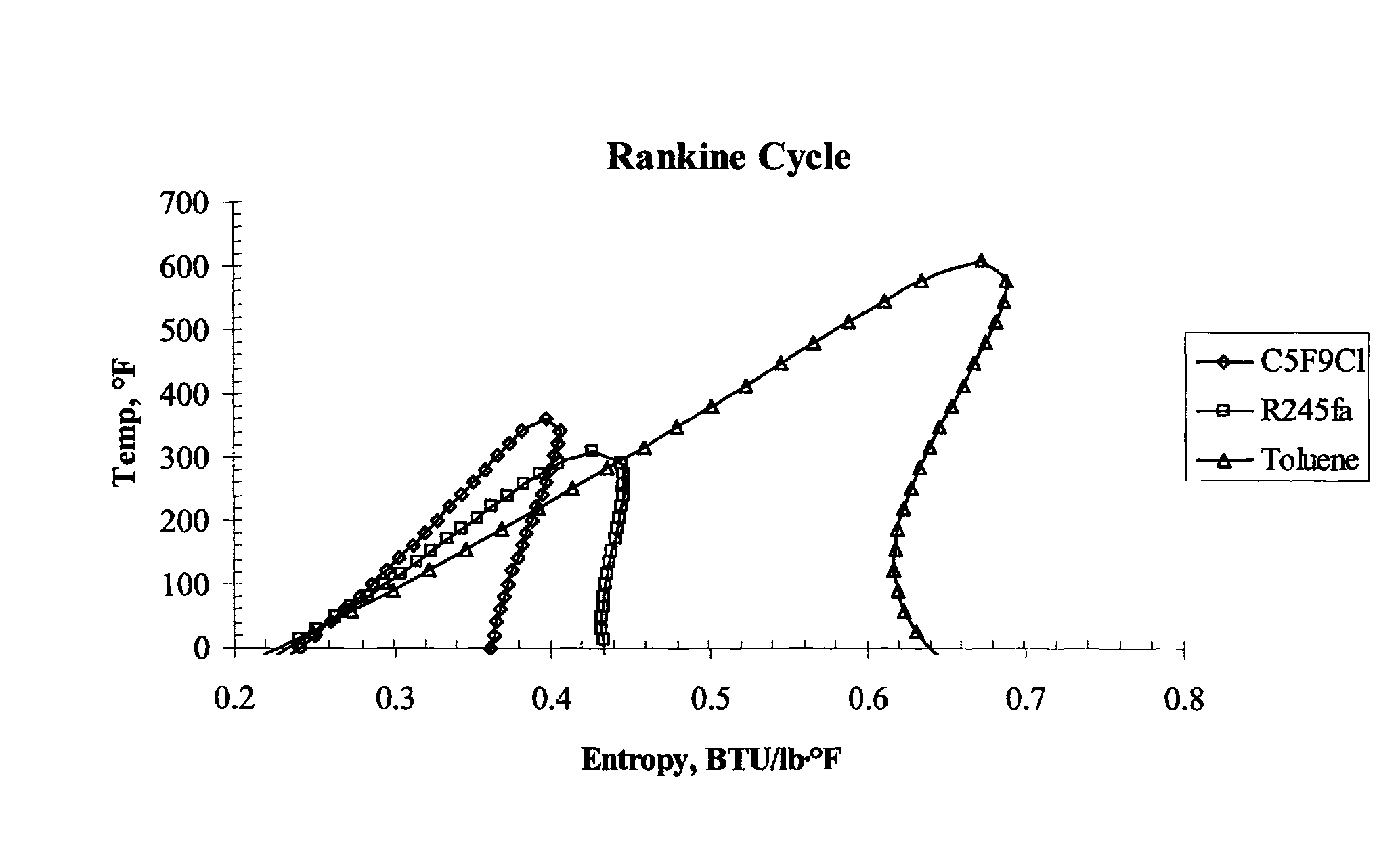

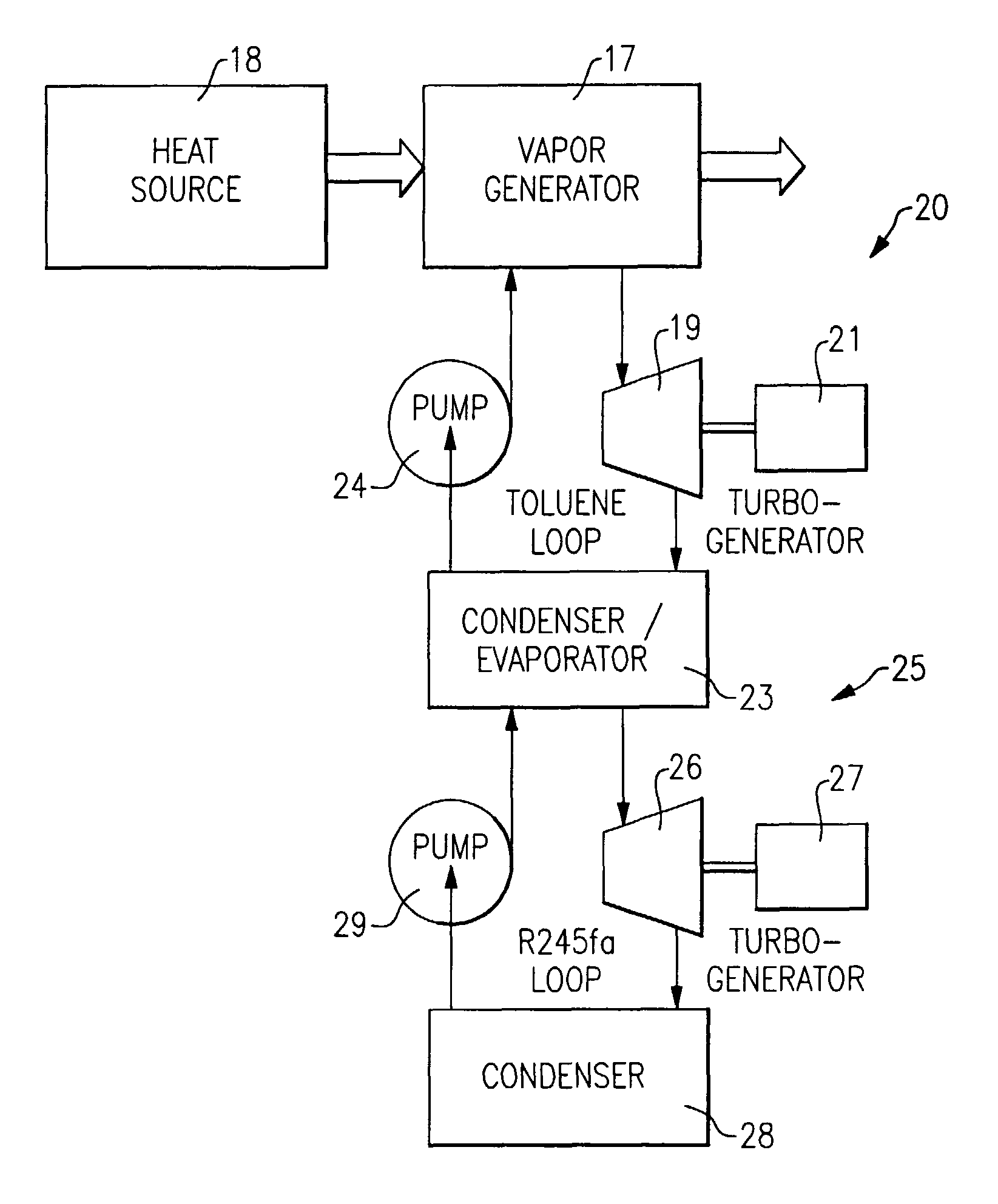

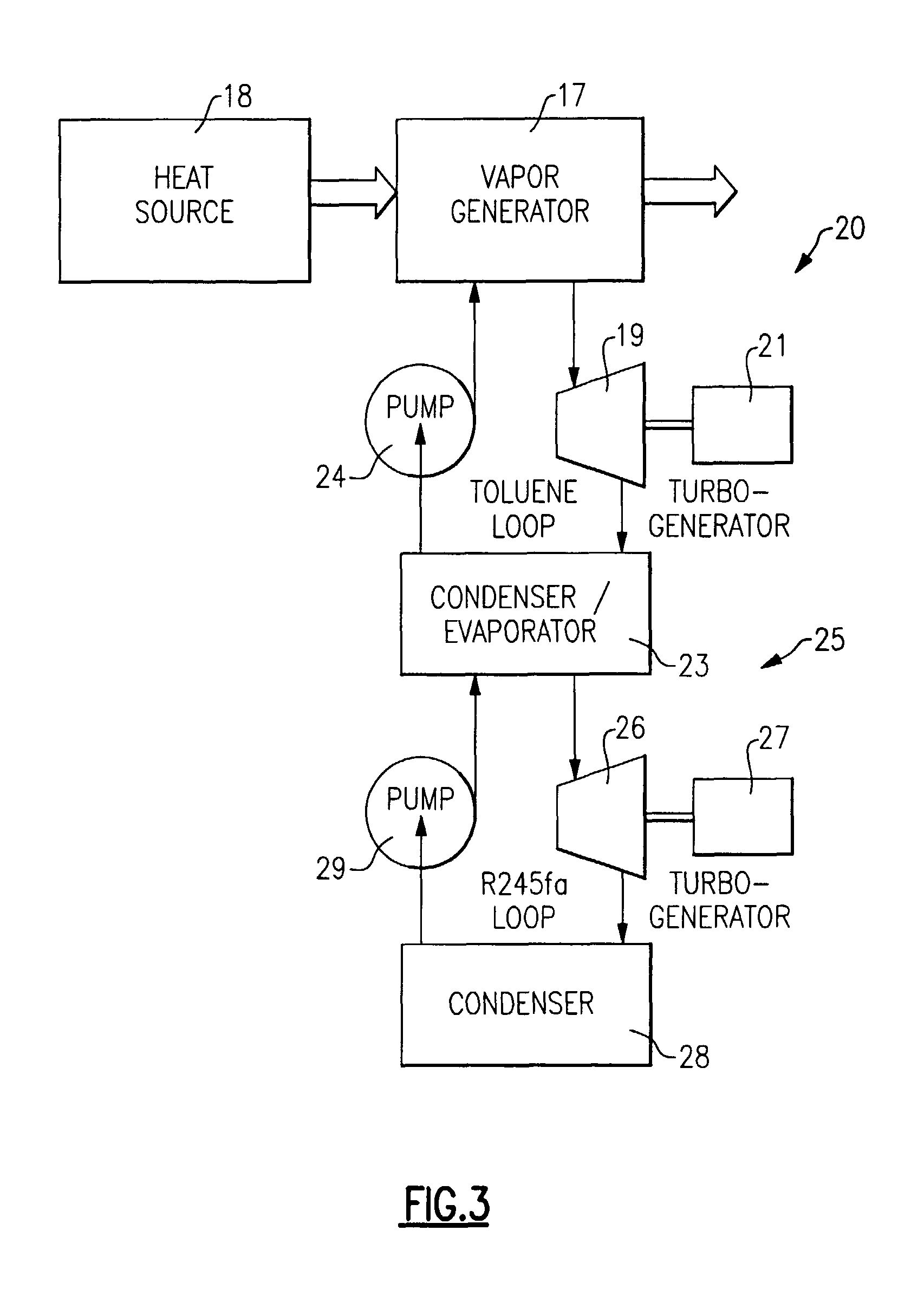

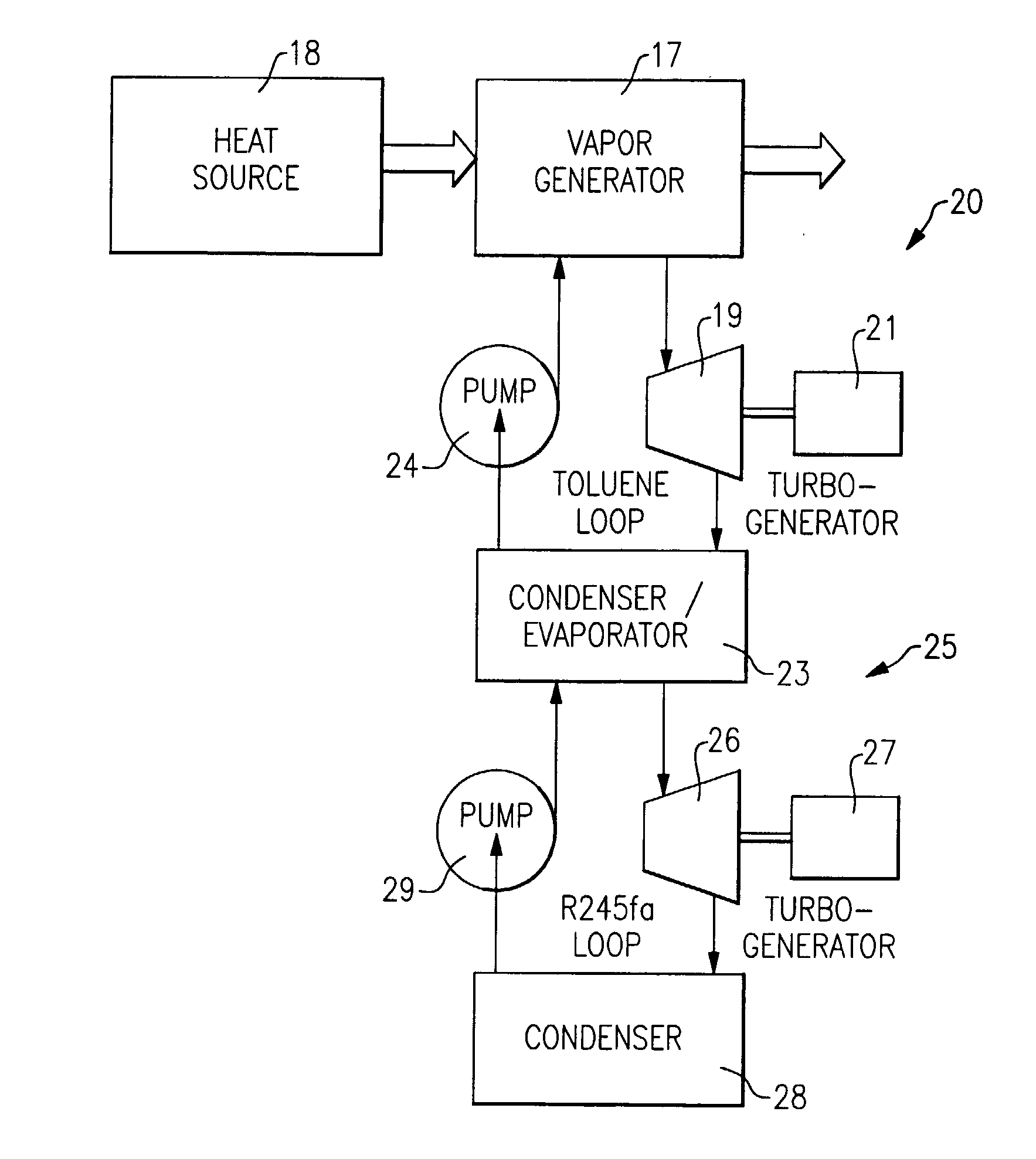

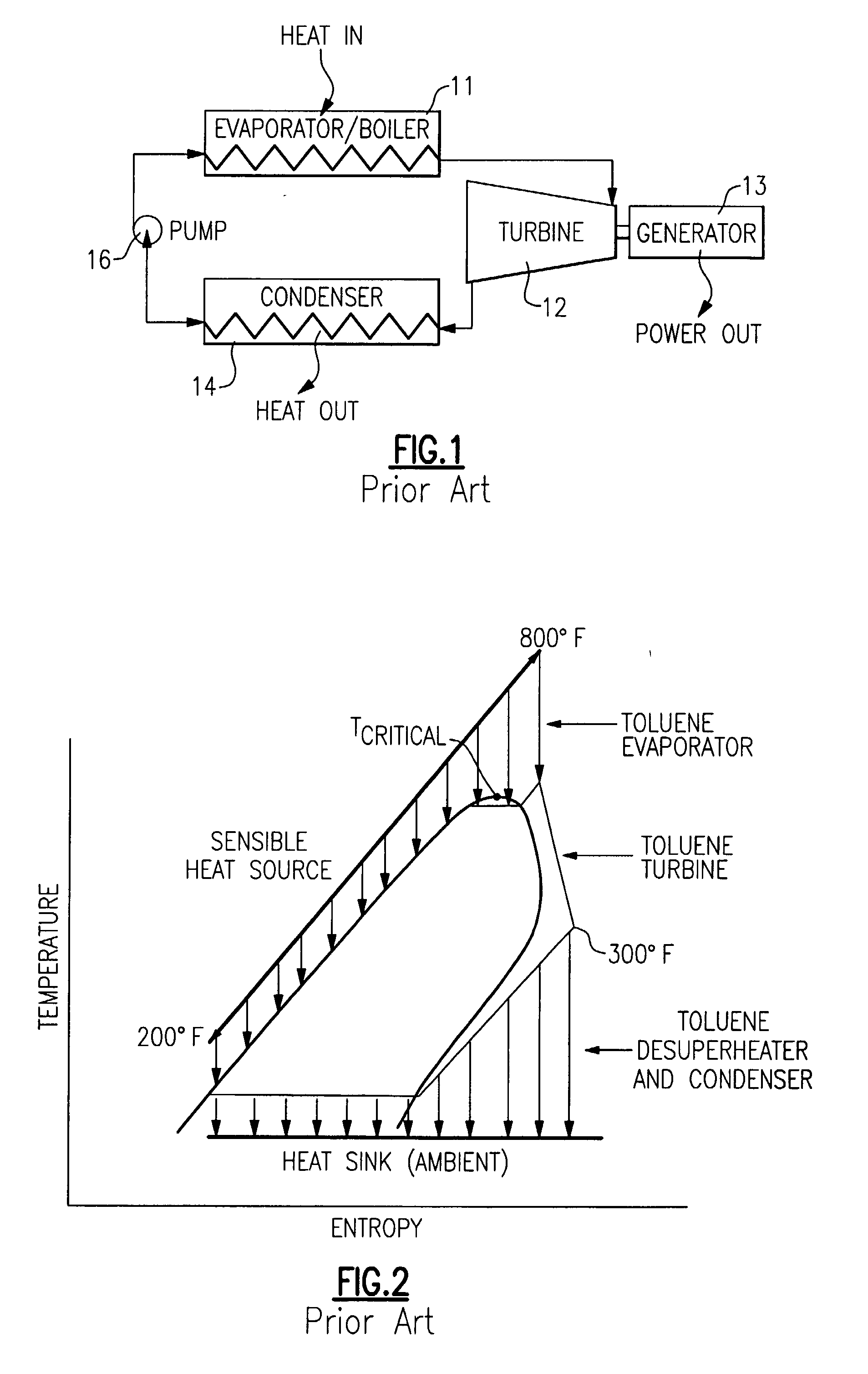

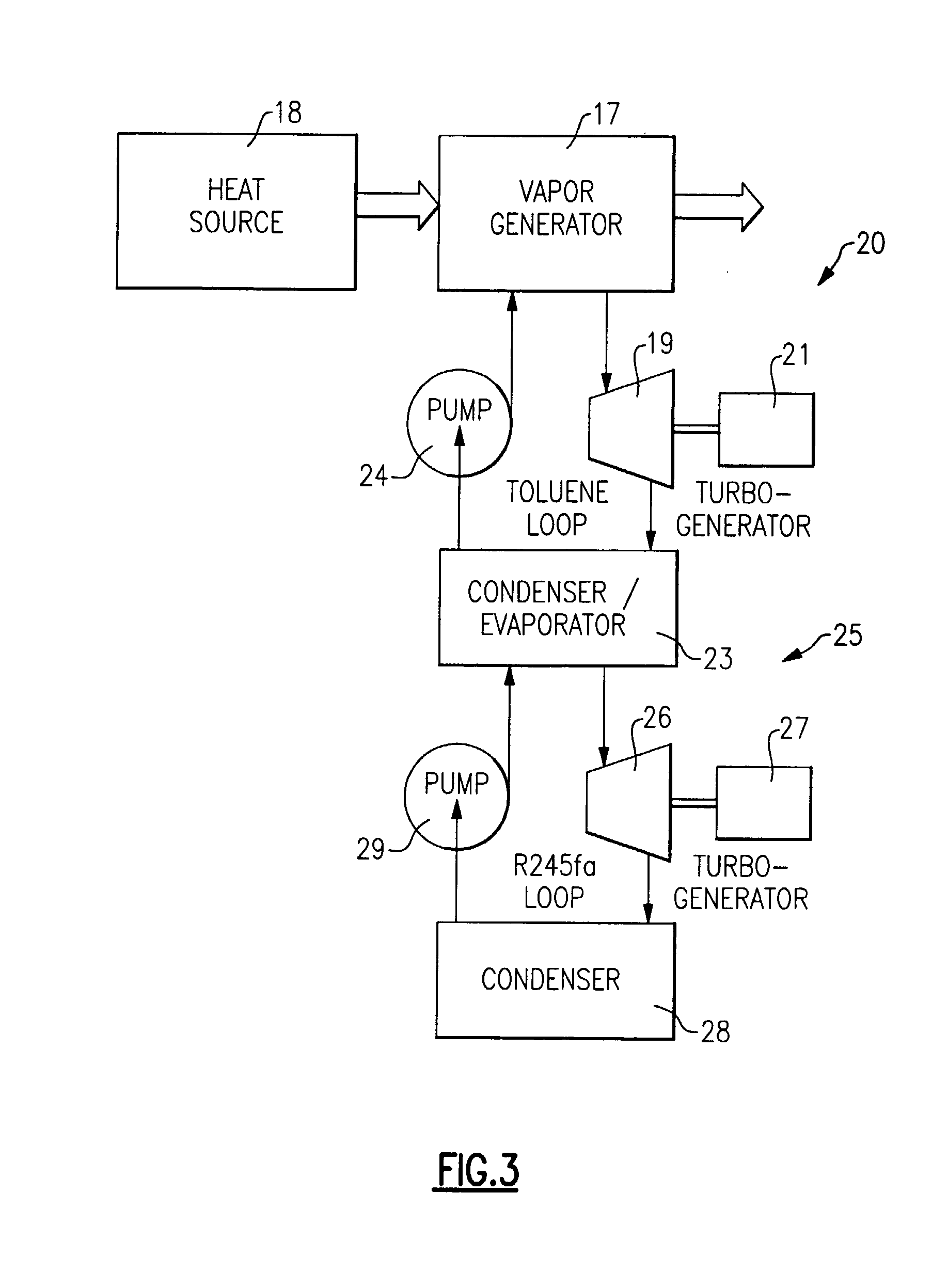

Cascaded organic rankine cycles for waste heat utilization

InactiveUS7942001B2Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

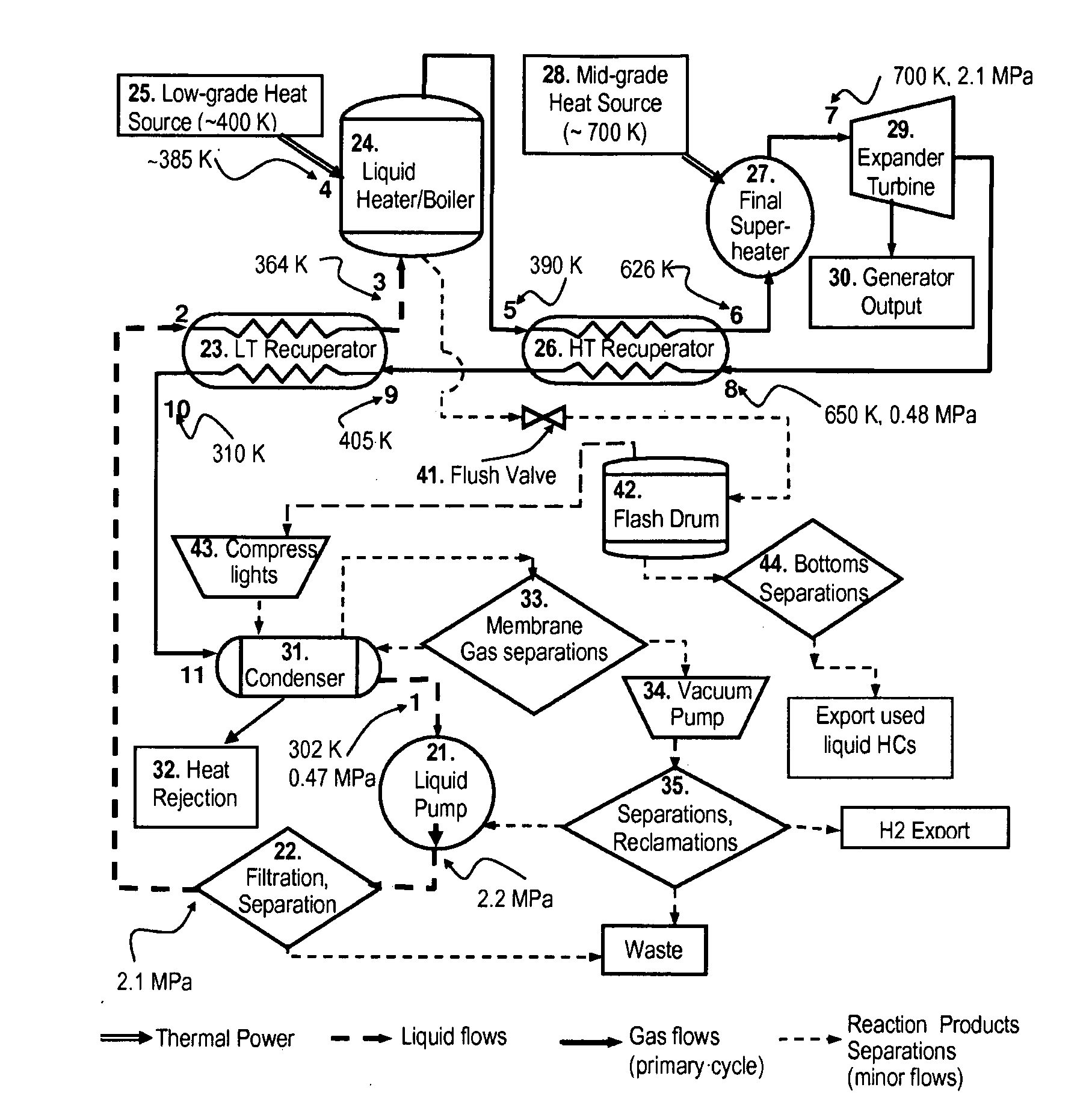

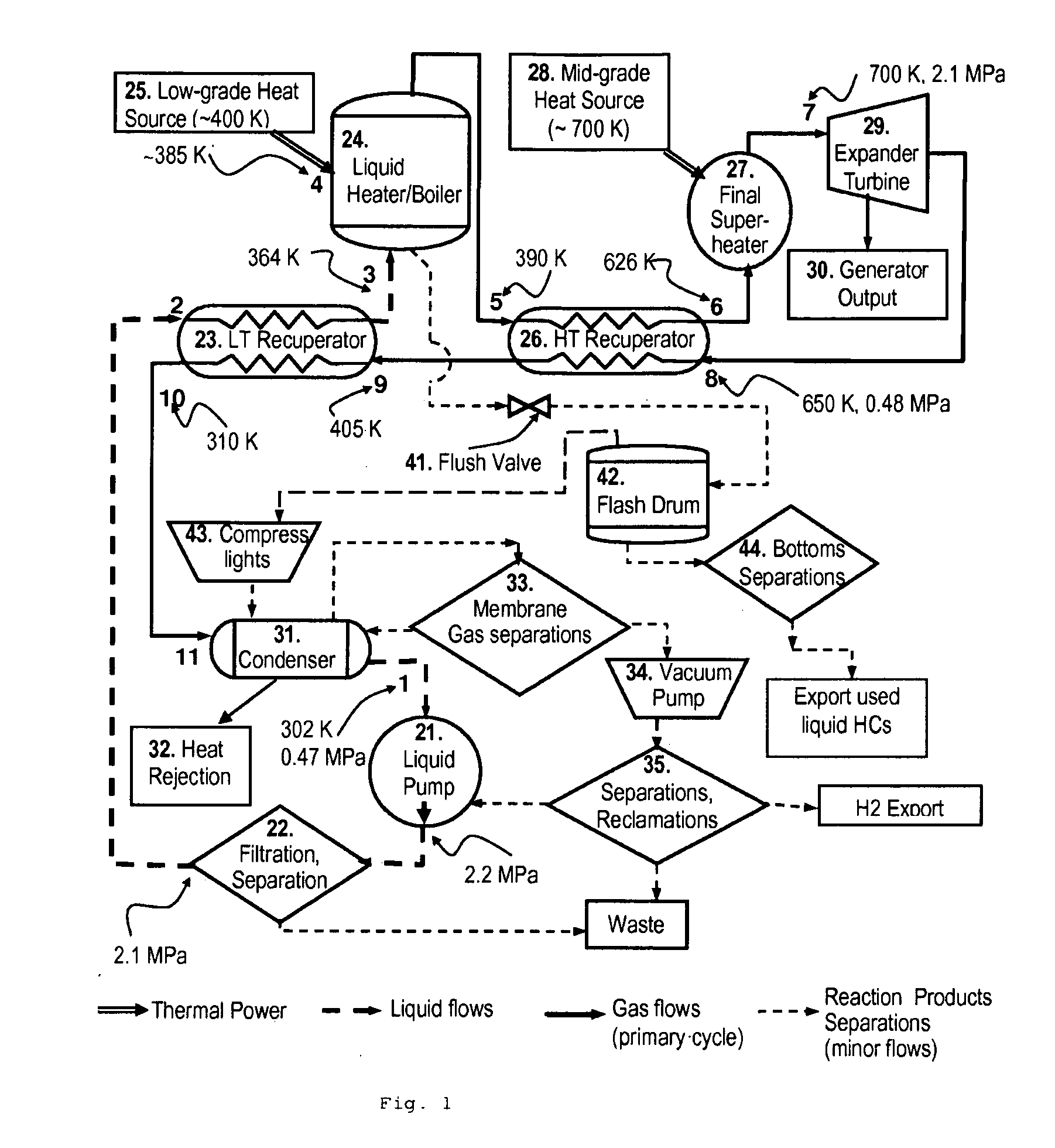

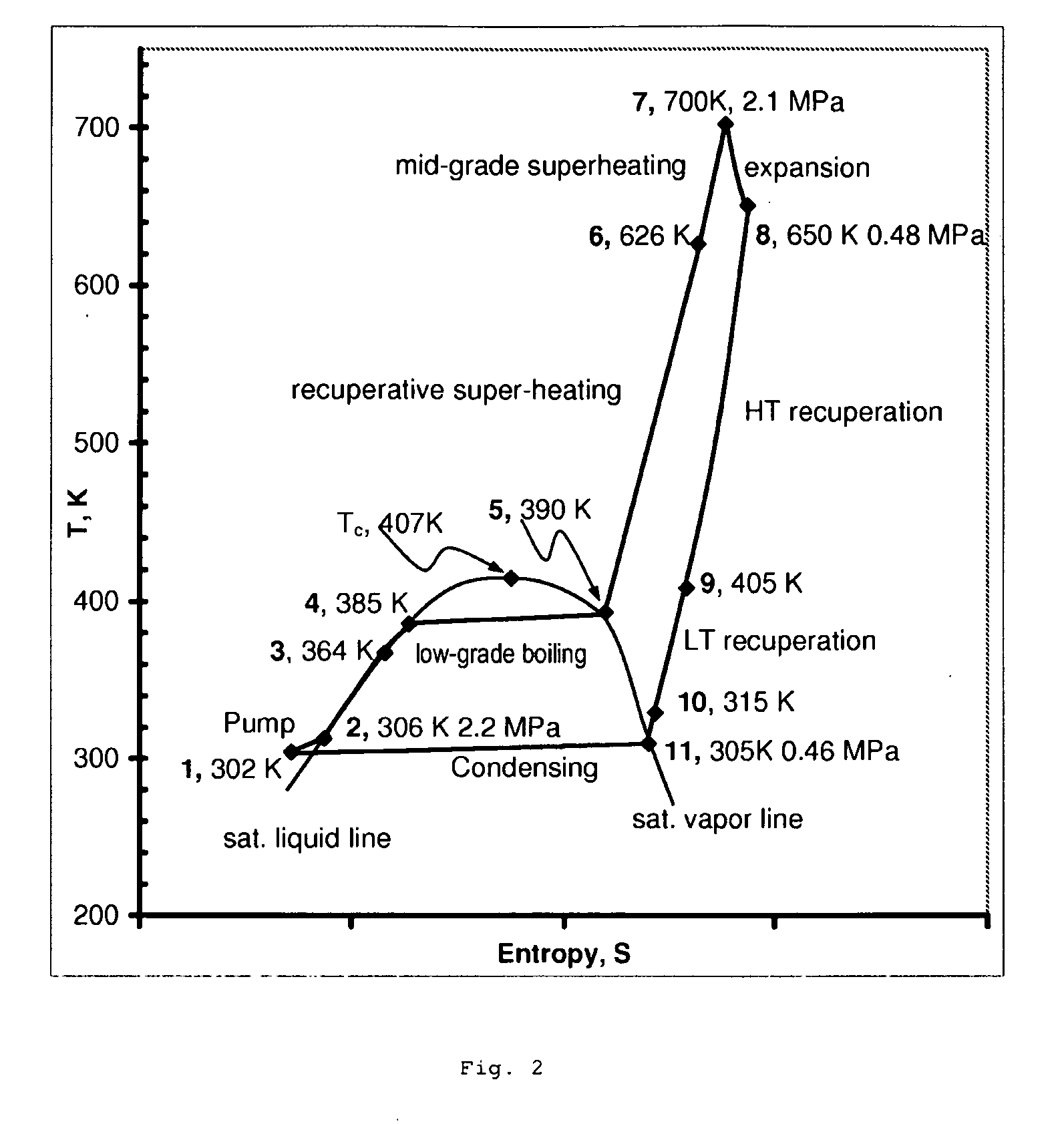

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

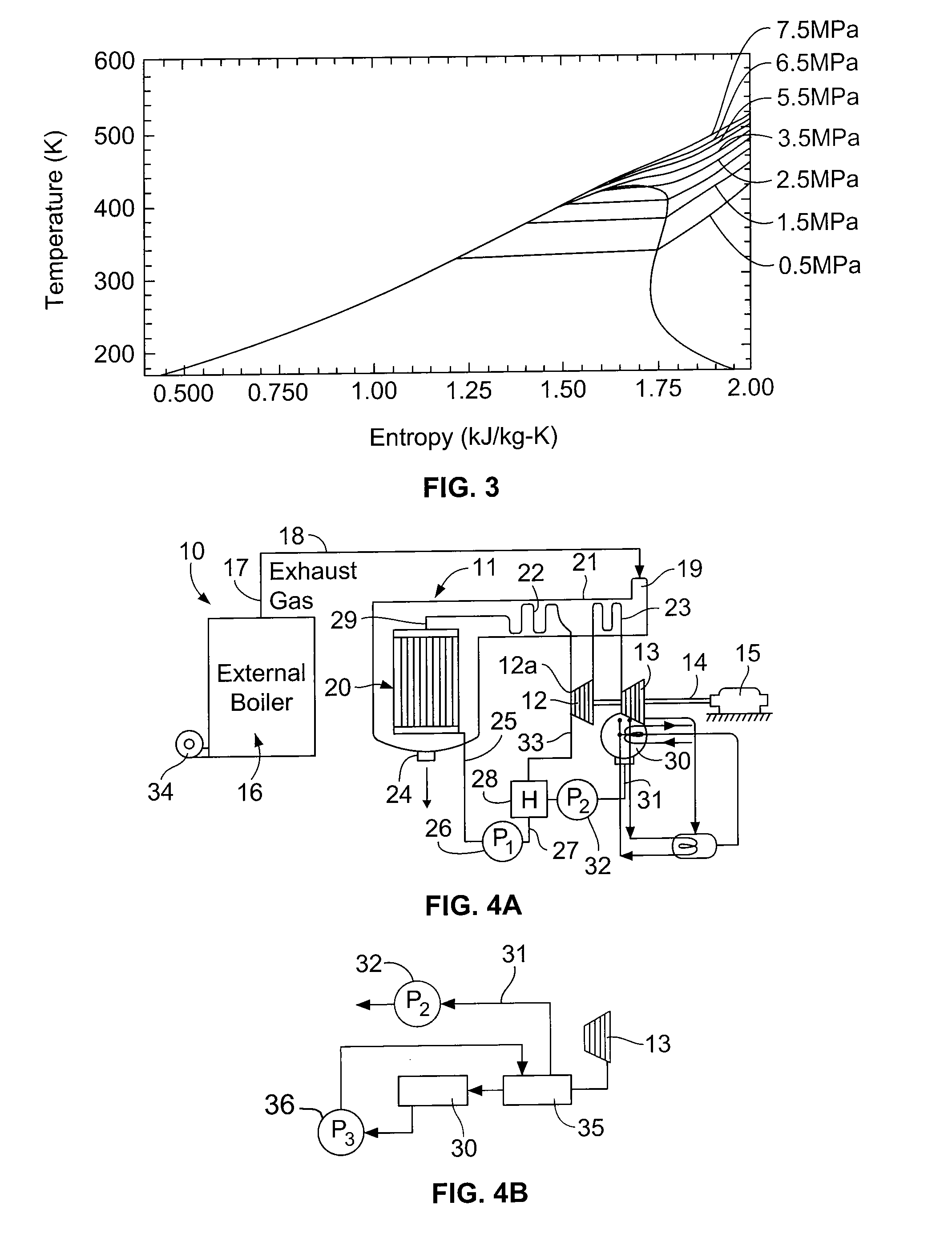

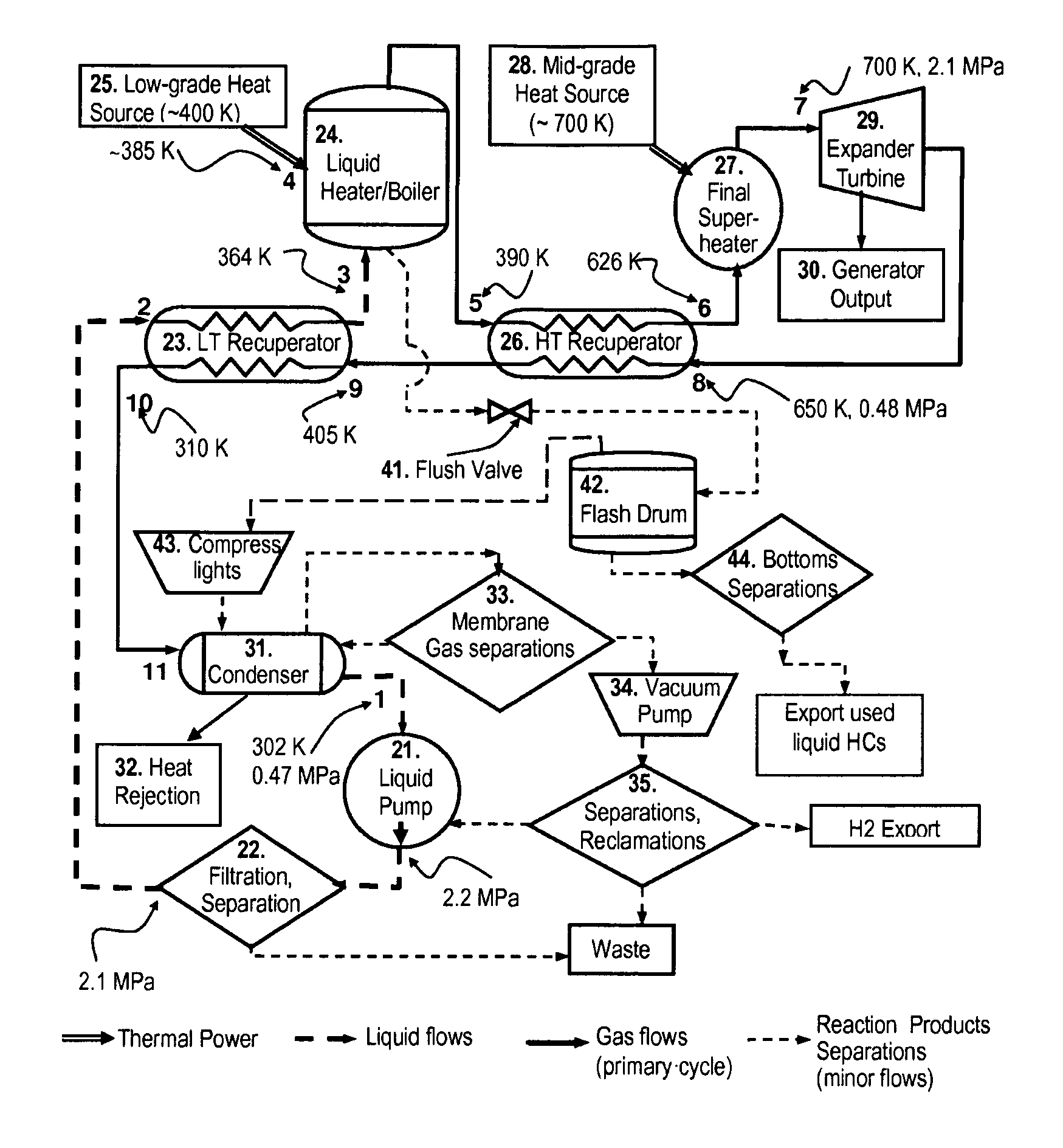

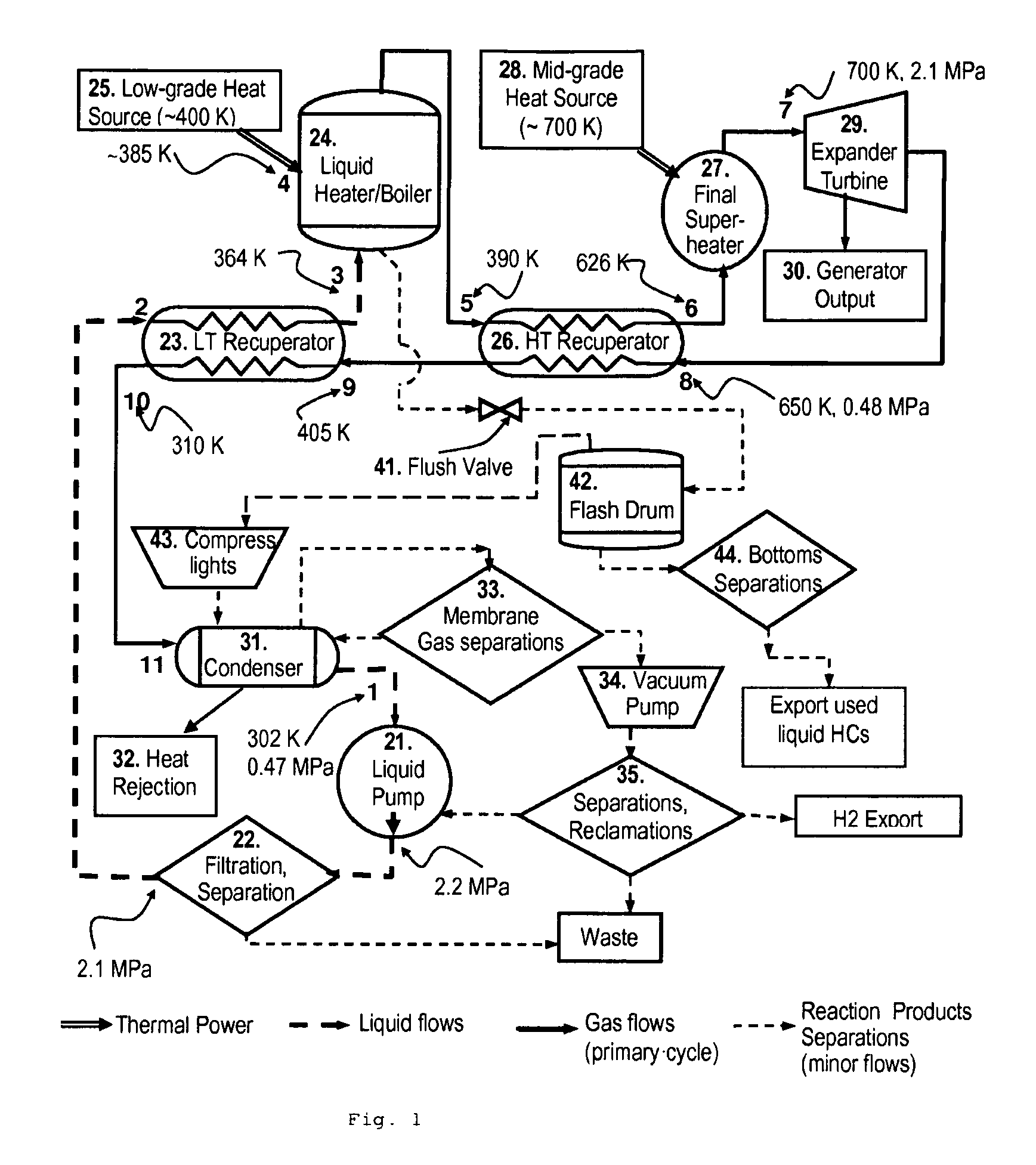

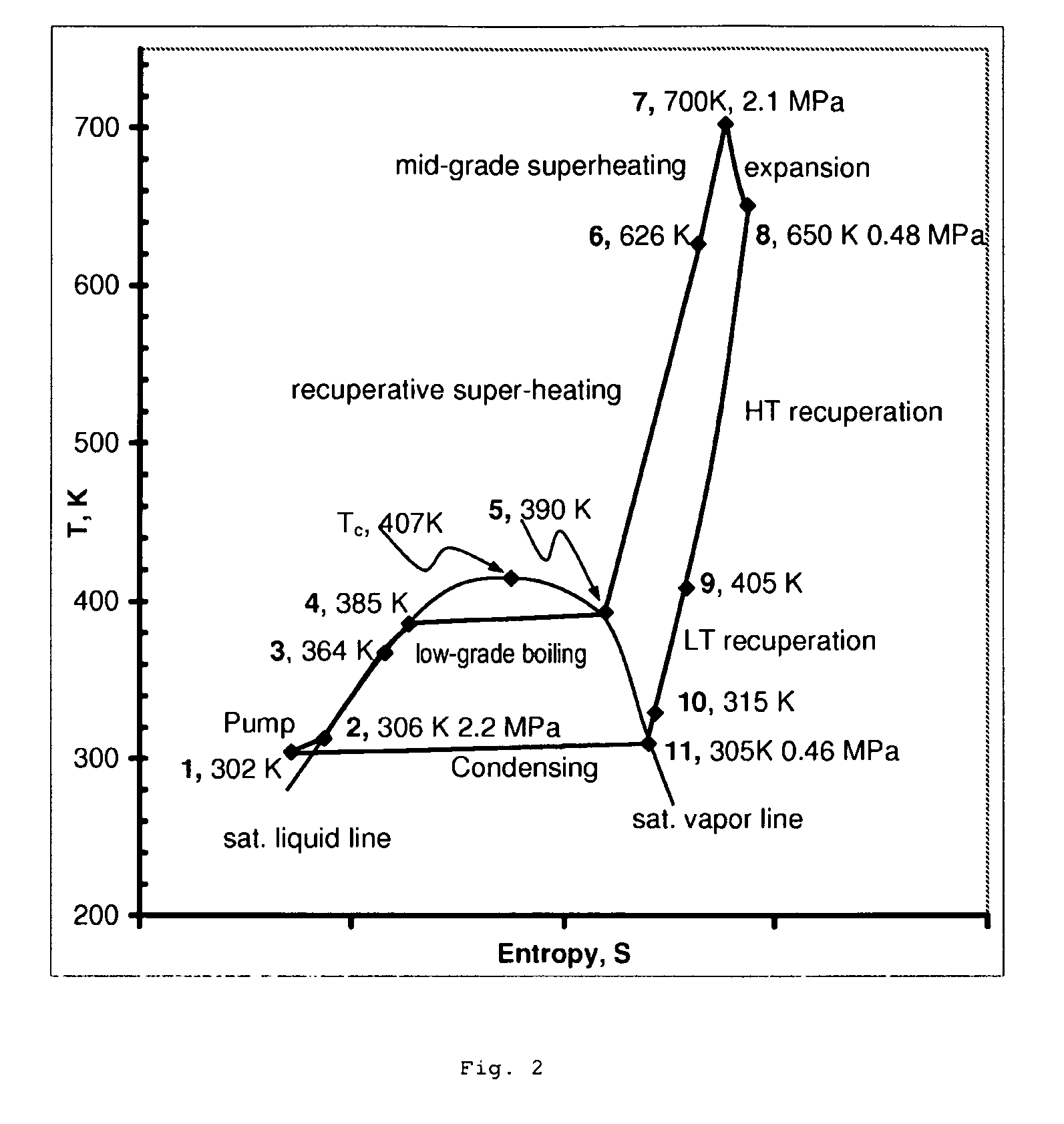

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

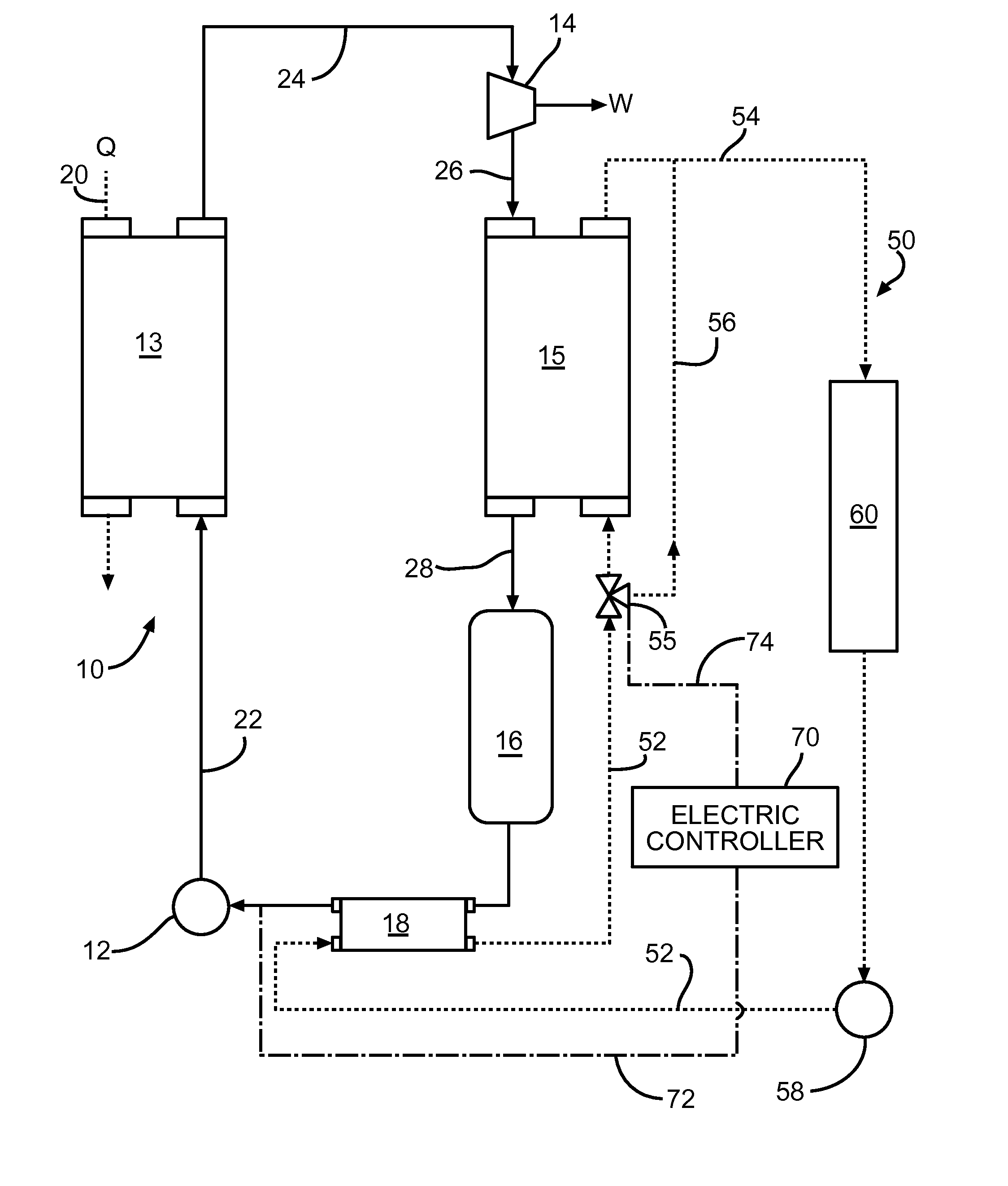

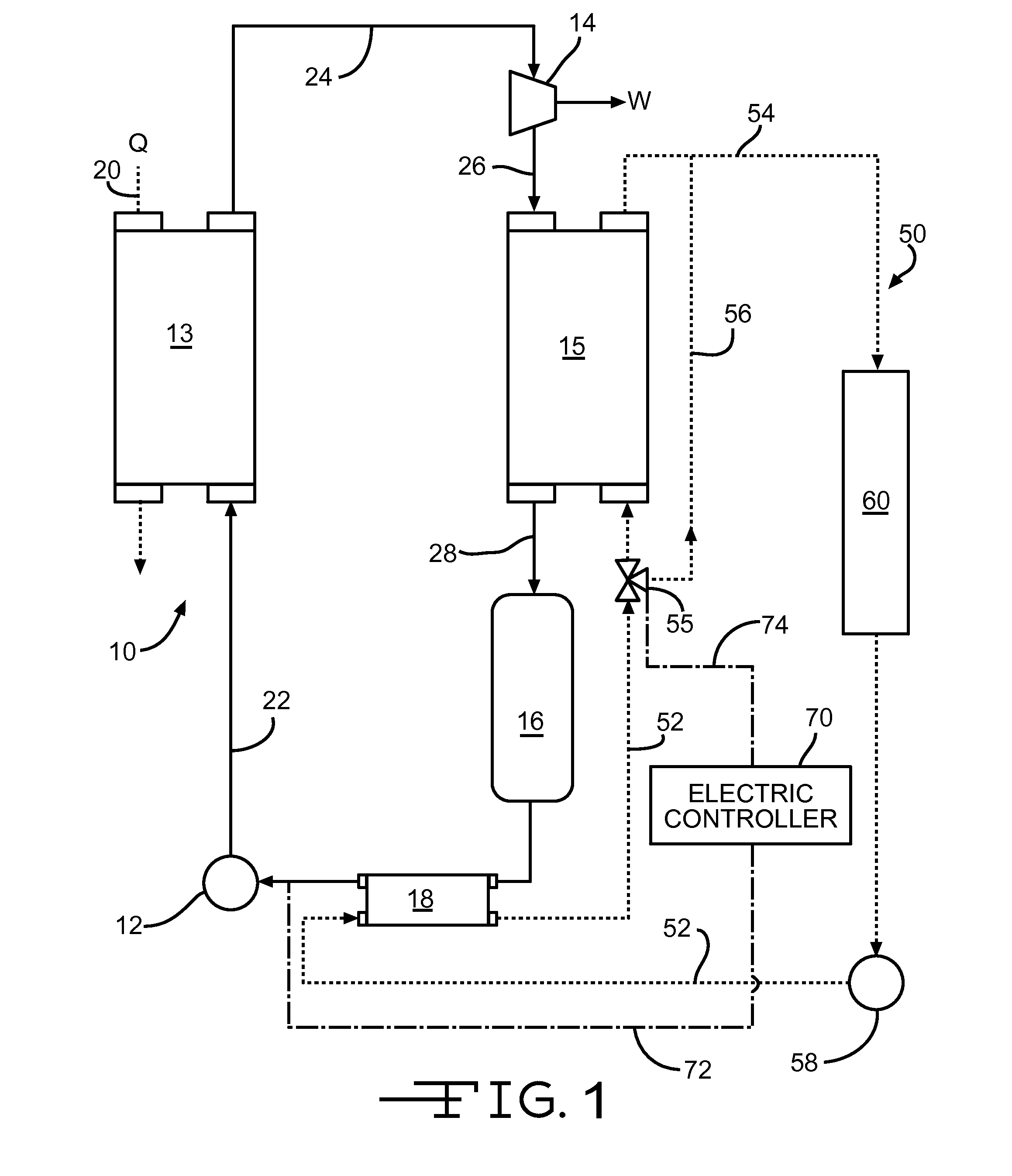

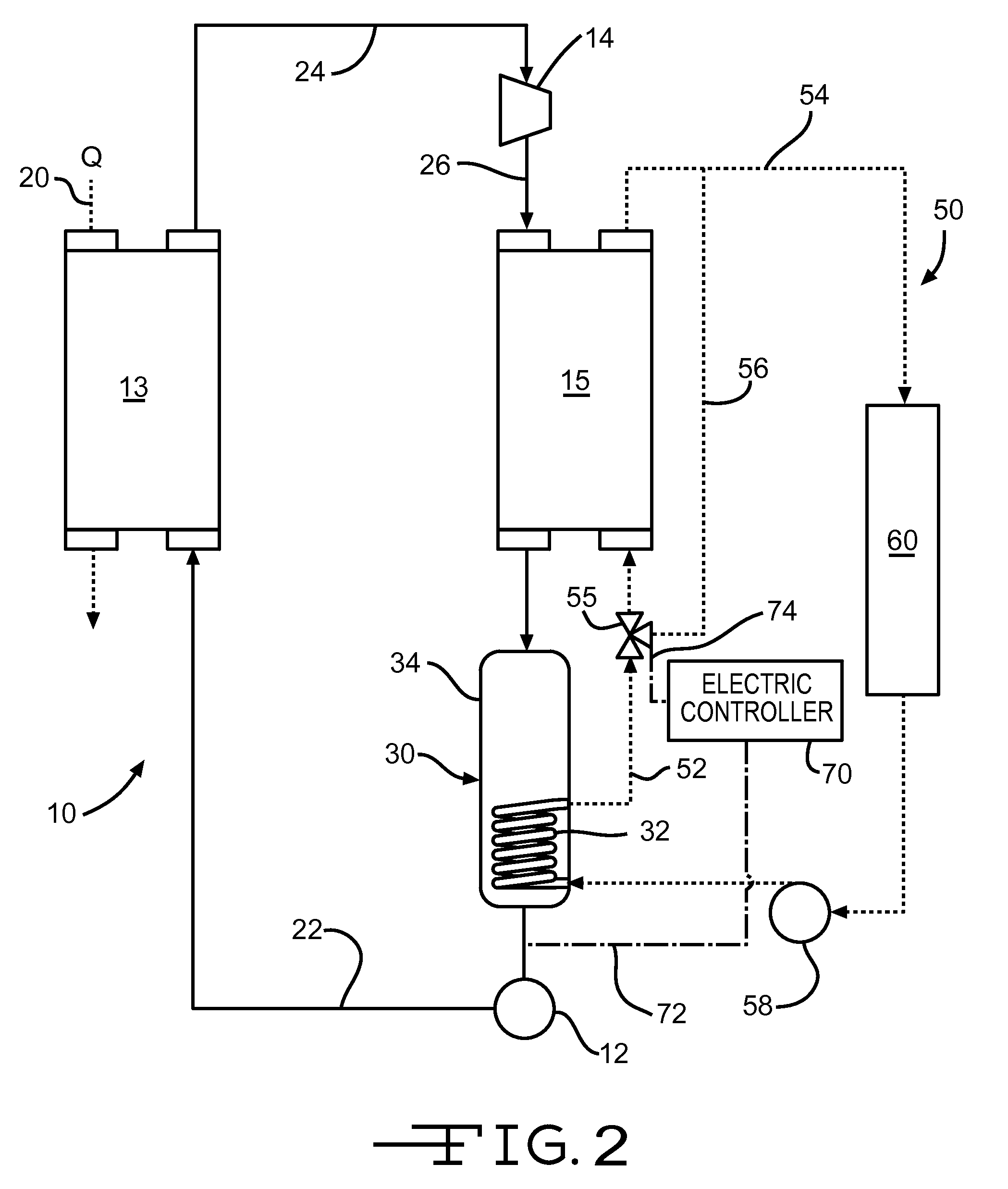

Energy recovery system and method using an organic rankine cycle with condenser pressure regulation

An energy recovery system and method using an organic rankine cycle is provided for recovering waste heat from an internal combustion engine, which effectively controls condenser pressure to prevent unwanted cavitation within the fluid circulation pump. A coolant system may be provided with a bypass conduit around the condenser and a bypass valve selectively and variably controlling the flow of coolant to the condenser and the bypass. A subcooler may be provided integral with the receiver for immersion in the accumulated fluid or downstream of the receiver to effectively subcool the fluid near the inlet to the fluid pump.

Owner:CUMMINS INTPROP INC

Energy Conversion Using Rankine Cycle System

InactiveUS20120047889A1Reduce the temperatureEnergy industrySteam engine plantsWorking fluidPlate heat exchanger

A process for recovering waste heat in an organic Rankine cycle system which comprises passing a liquid phase working fluid through heat exchange in successive communication with two or more process streams which thus heat the working fluid, removing a vapor phase working fluid from the heat exchanger, passing the vapor phase working fluid to an expander wherein the waste heat is converted into mechanical energy, and passing the vapor phase working fluid from the expander to a condenser wherein the vapor phase working fluid is condensed into the liquid phase working fluid.

Owner:UOP LLC

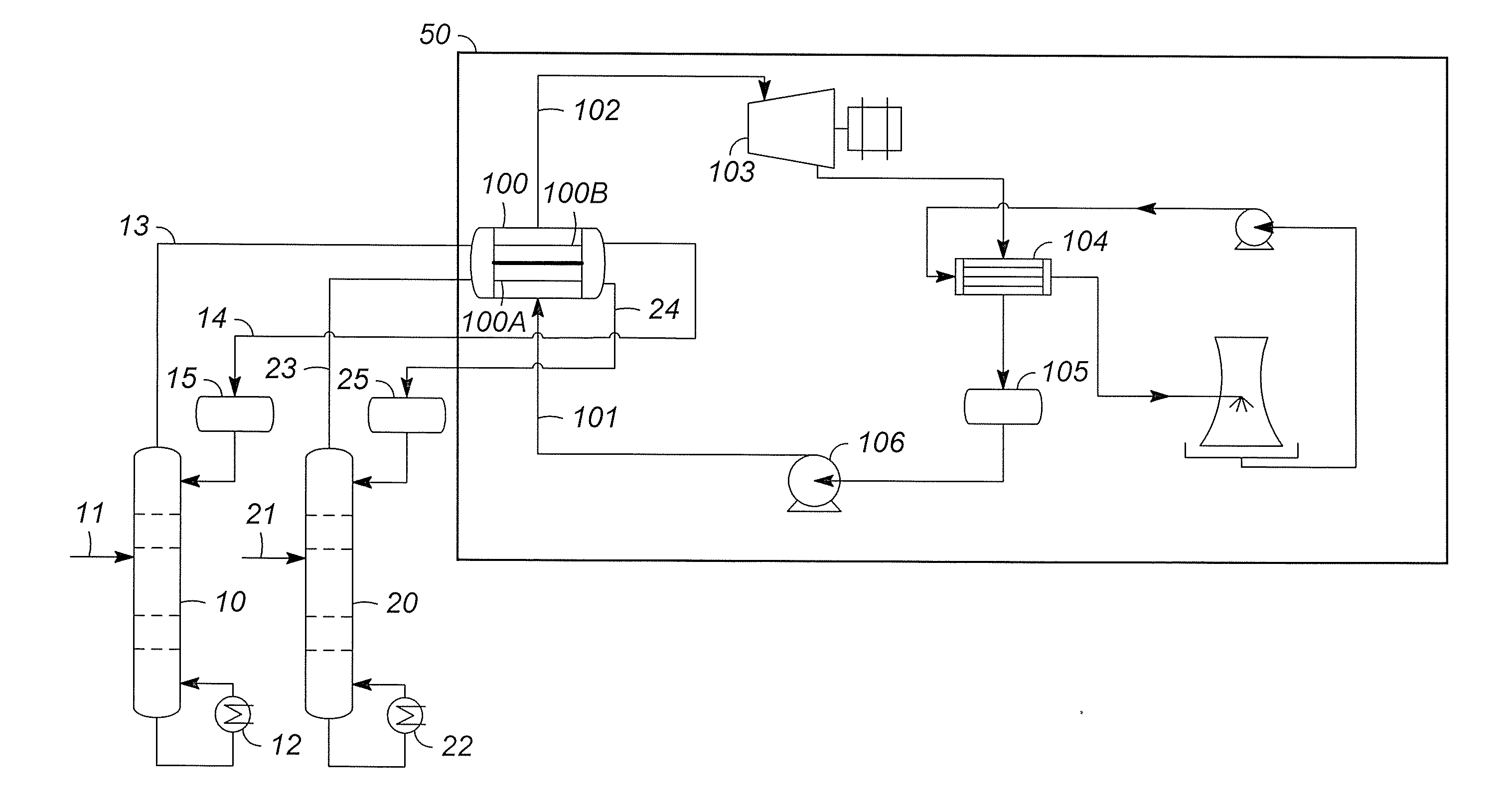

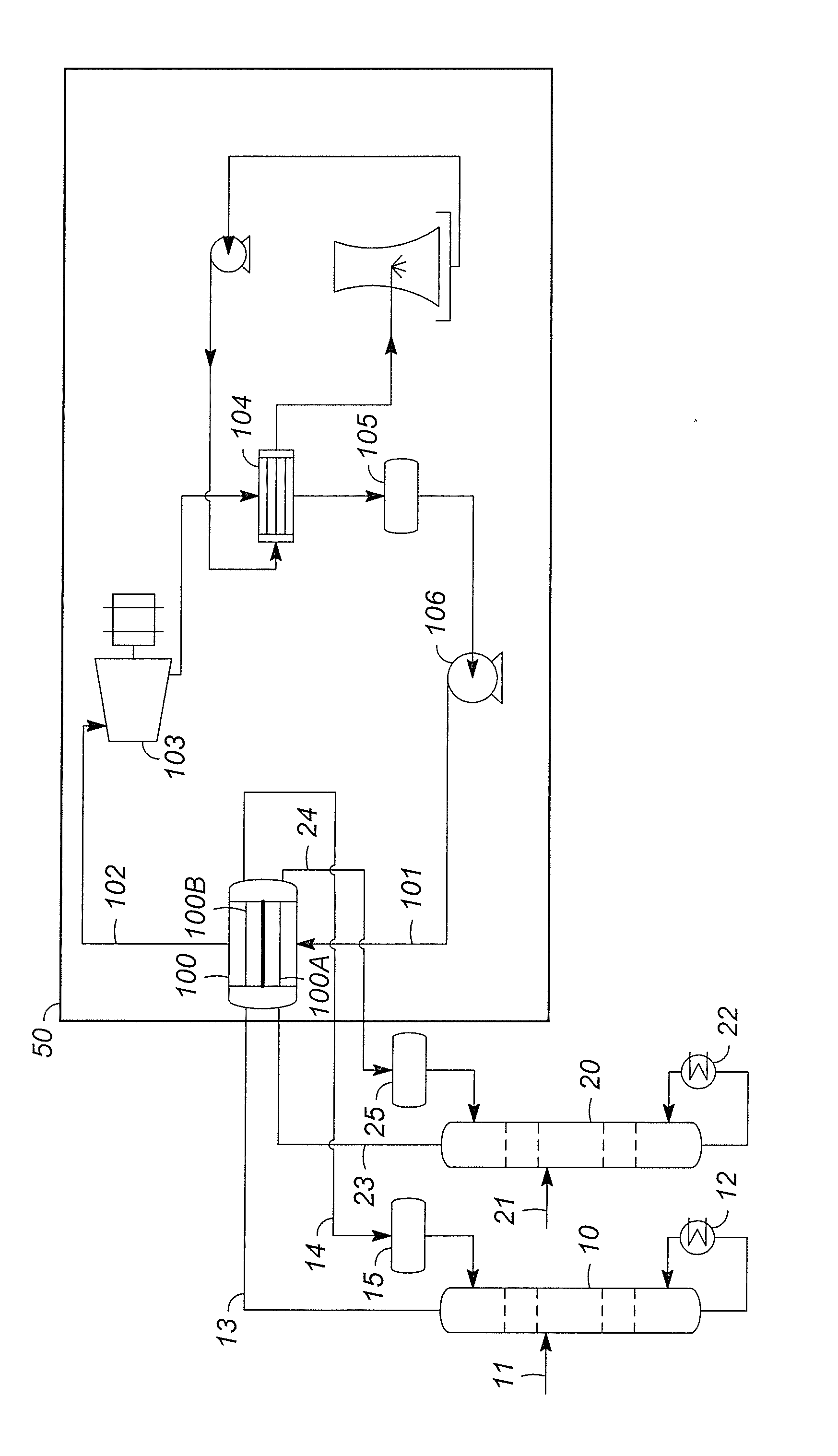

Cascaded Organic Rankine Cycles for Waste Heat Utilization

InactiveUS20080168772A1Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

Organic rankine cycle systems using waste heat from charge air cooling

InactiveUS20120285169A1Internal combustion piston enginesExhaust apparatusWaste heat recovery unitOrganic Rankine cycle

The present application and the resultant patent provide a waste heat recovery system for recovering heat from a number of turbocharger stages. The waste heat recovery system may include a simple organic rankine cycle system and a number of charge air coolers in communication with the turbocharger stages and the simple organic rankine cycle system. The charge air coolers are positioned in a number of parallel branches of the simple organic rankine cycle system.

Owner:AI ALPINE US BIDCO INC

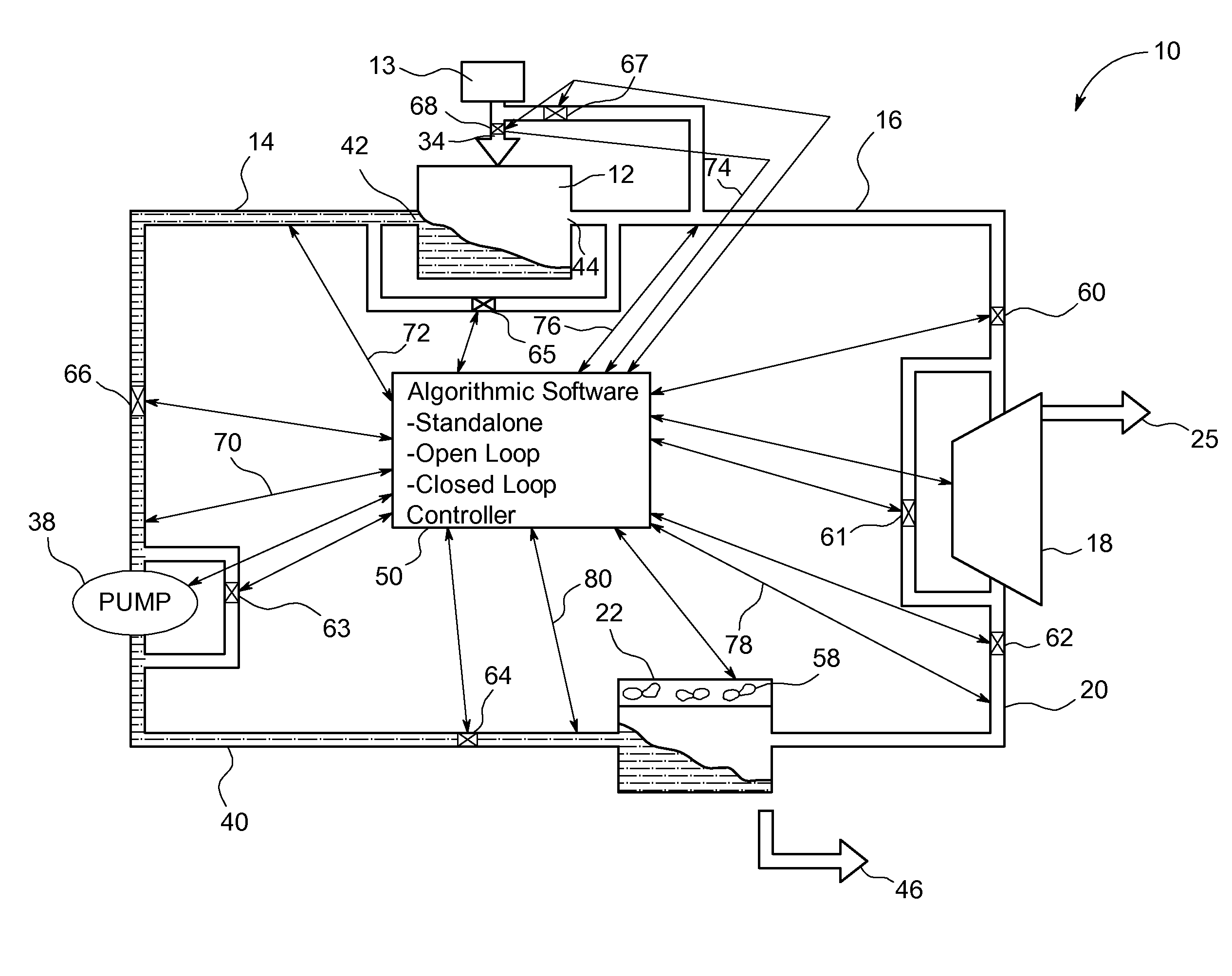

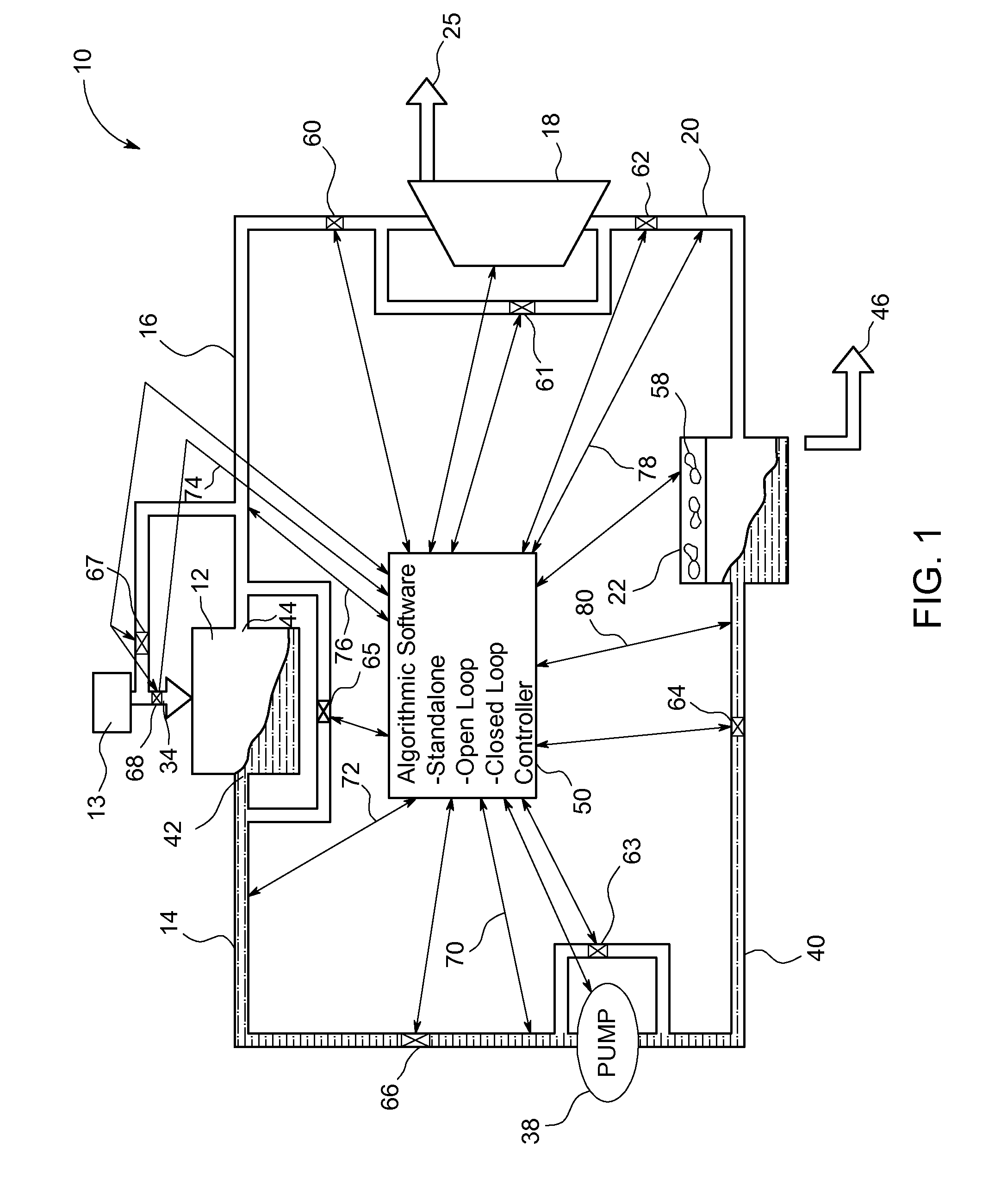

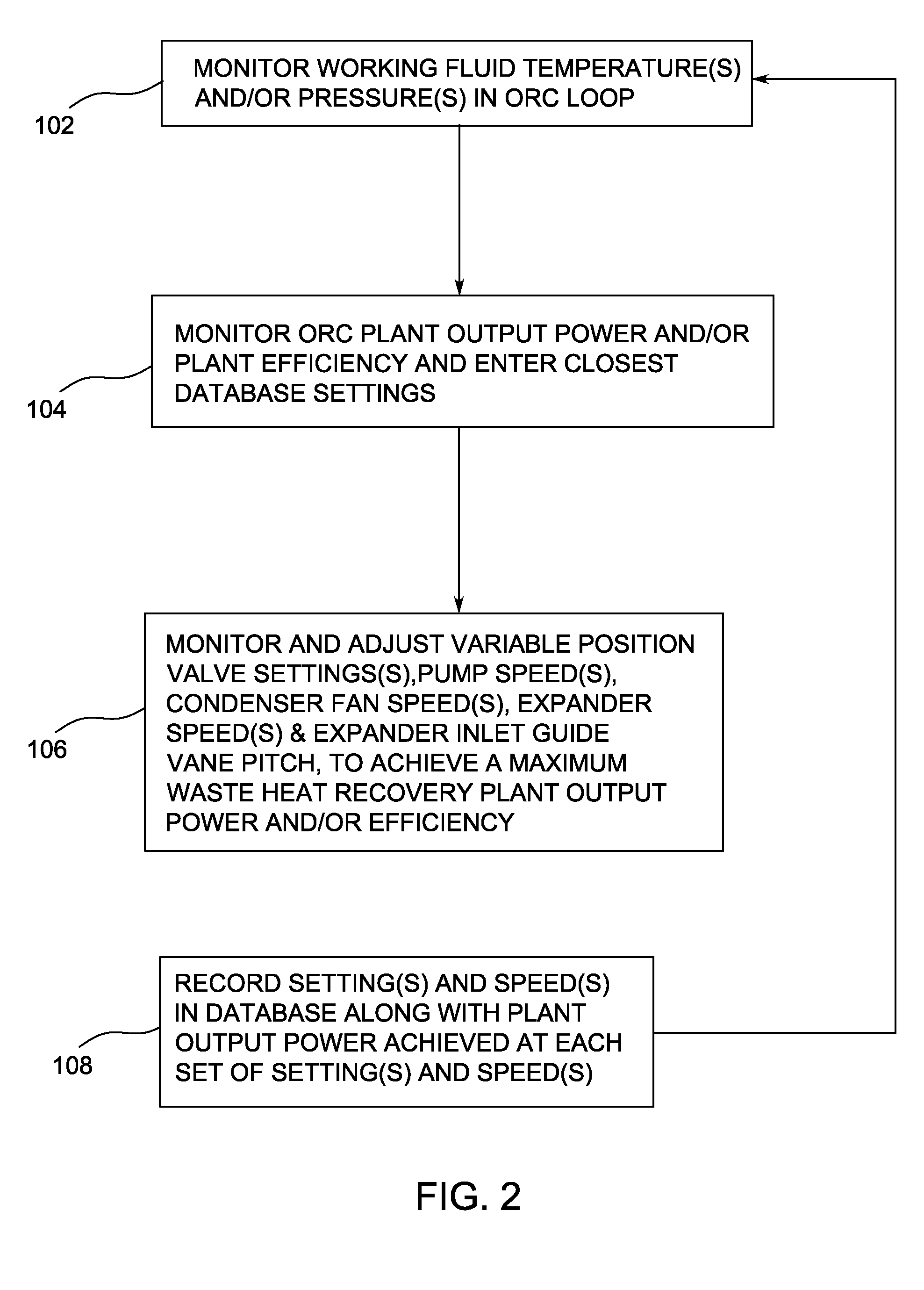

Auto optimizing control system for organic rankine cycle plants

InactiveUS20110203278A1Maximize efficiencyOutput maximizationWind motor controlPump componentsWorking fluidOrganic Rankine cycle

A waste heat recovery plant control system includes a programmable controller configured to generate expander speed control signals, expander inlet guide vane pitch control signals, fan speed control signals, pump speed control signals, and valve position control signals in response to an algorithmic optimization software to substantially maximize power output or efficiency of a waste heat recovery plant based on organic Rankine cycles, during mismatching temperature levels of external heat source(s), during changing heat loads coming from the heat sources, and during changing ambient conditions and working fluid properties. The waste heat recovery plant control system substantially maximizes power output or efficiency of the waste heat recovery plant during changing / mismatching heat loads coming from the external heat source(s) such as the changing amount of heat coming along with engine jacket water and its corresponding exhaust in response to changing engine power.

Owner:AI ALPINE US BIDCO INC

Organic rankine cycle fluid

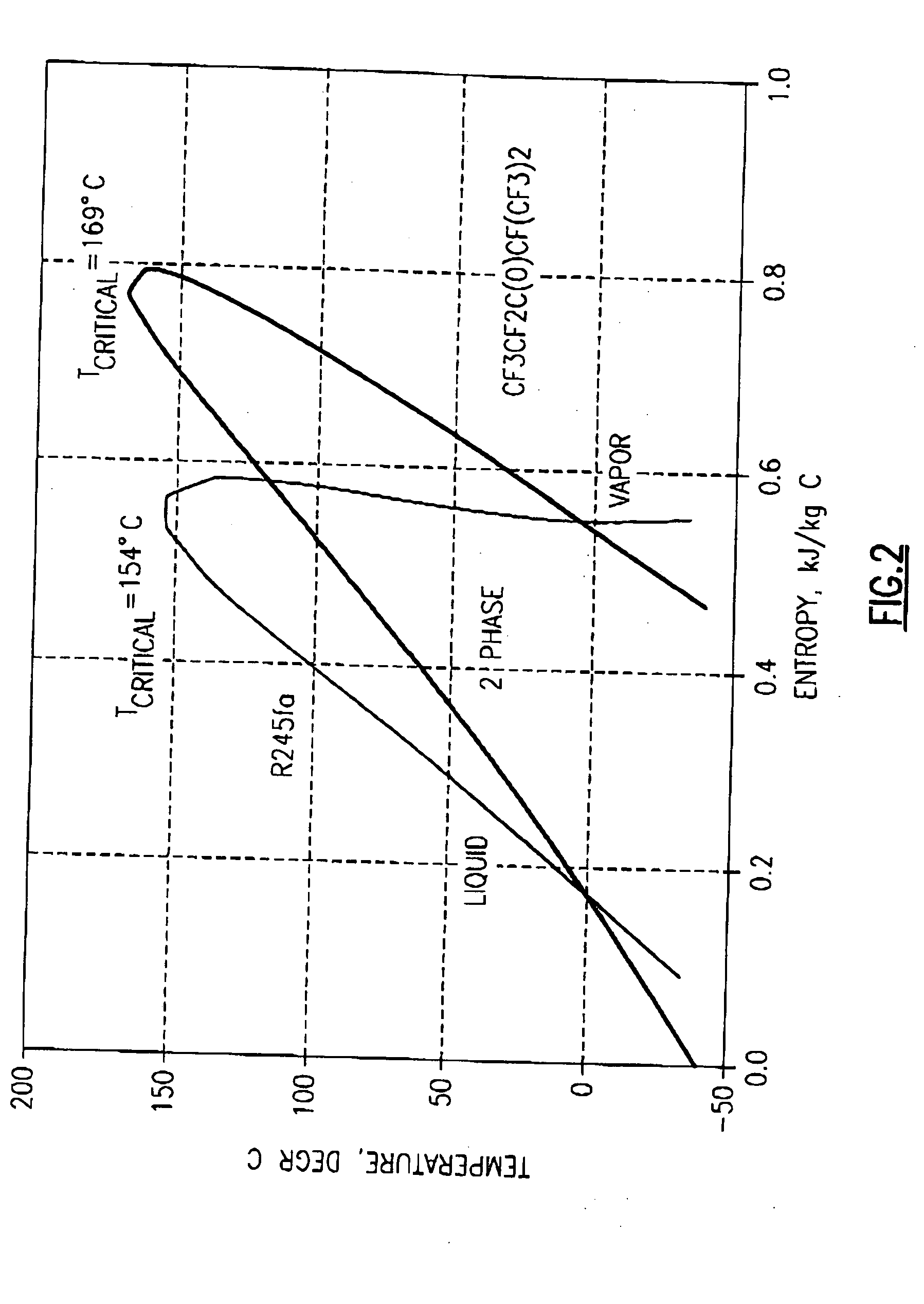

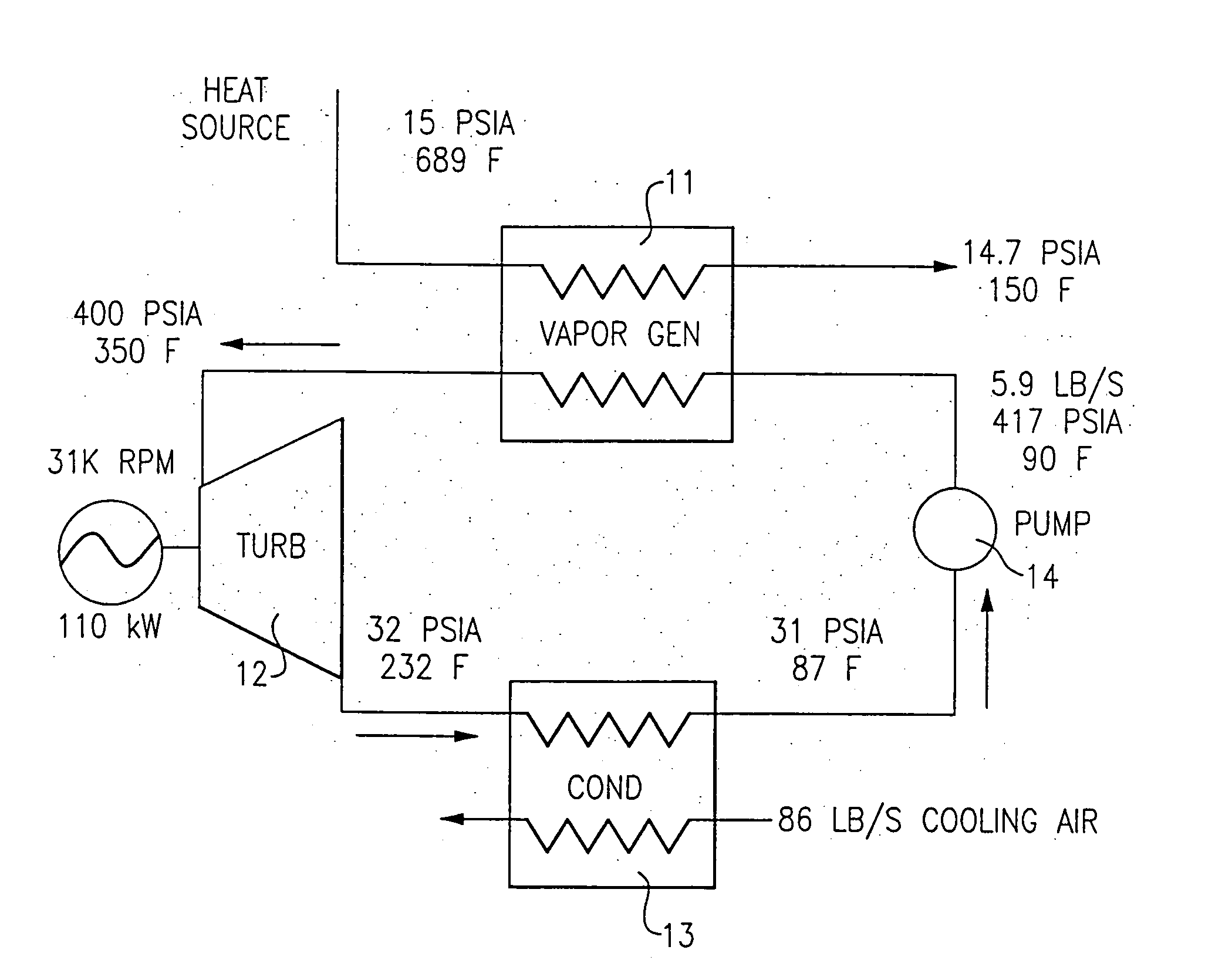

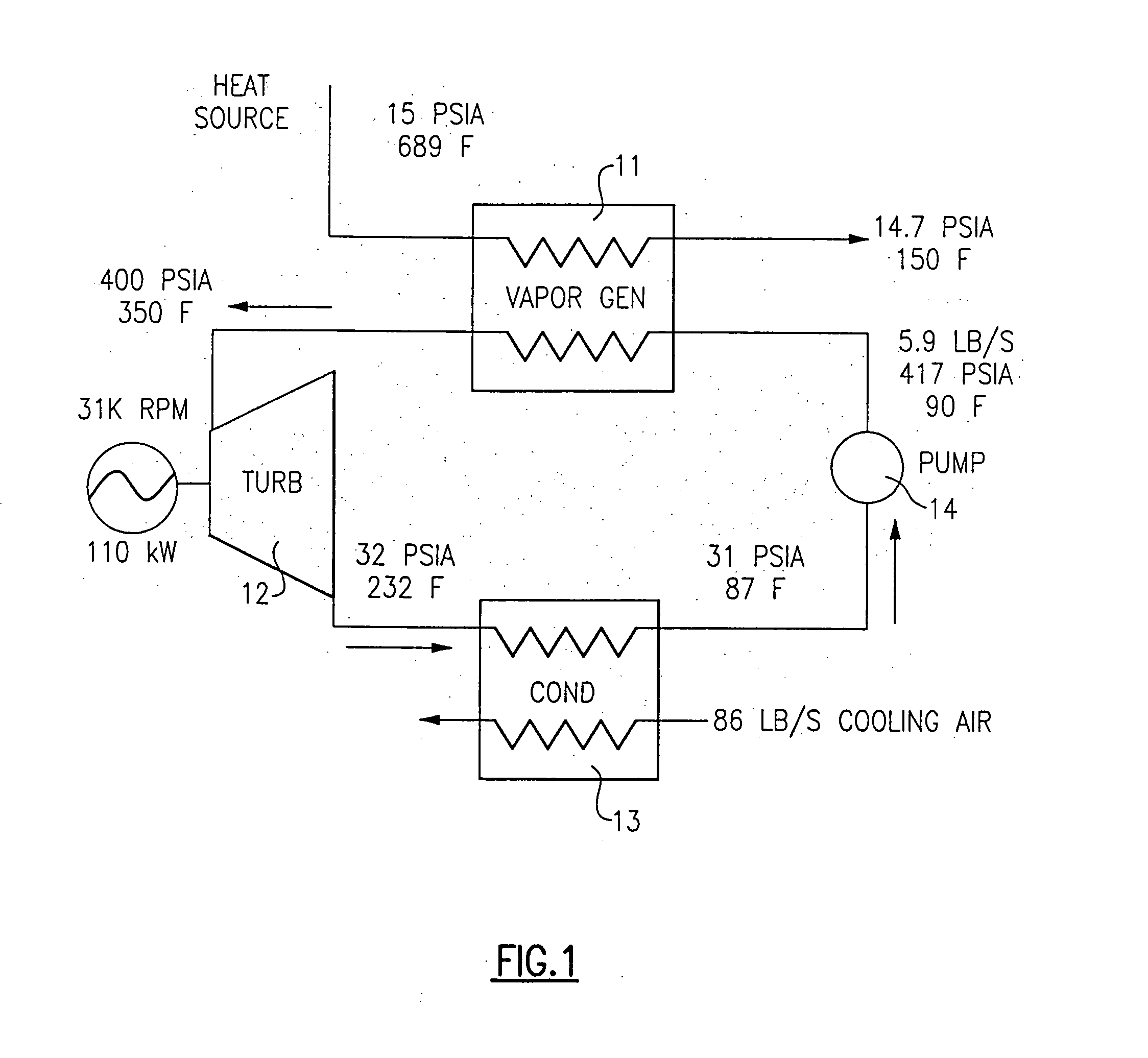

ActiveUS20050166607A1Reduce stressReduce speedCompression machines with non-reversible cycleHeat-exchange elementsOrganic Rankine cycleProcess engineering

A method of operating an organic rankine cycle system wherein a liquid refrigerant is circulated to an evaporator where heat is introduced to the refrigerant to convert it to vapor. The vapor is then passed through a turbine, with the resulting cooled vapor then passing through a condenser for condensing the vapor to a liquid. The refrigerant is one of CF3CF2C(O)CF(CF3)2, (CF3)2 CFC(O)CF(CF3)2, CF3(CF2)2C(O)CF(CF3)2, CF3(CF2)3C(O)CF(CG3)2, CF3(CF2)5C(O)CF3, CF3CF2C(O)CF2CF2CF3, CF3C(O)CF(CF3)2.

Owner:NANJING TICA AIR CONDITIONING CO LTD

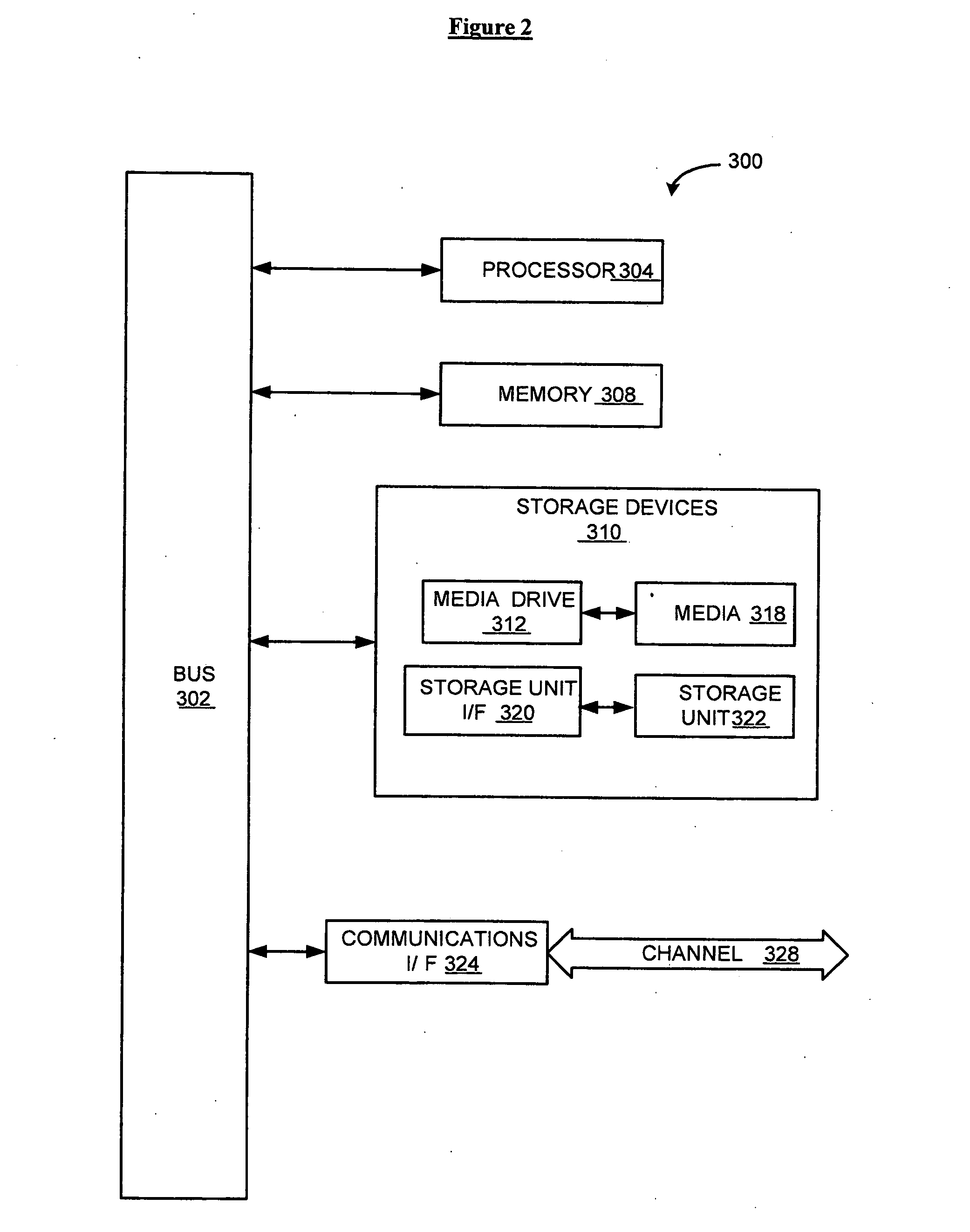

Health monitoring and diagnostic/prognostic system for an ORC plant

InactiveUS20050171736A1Vibration measurement in solidsFlow propertiesDigital signal processingAccelerometer

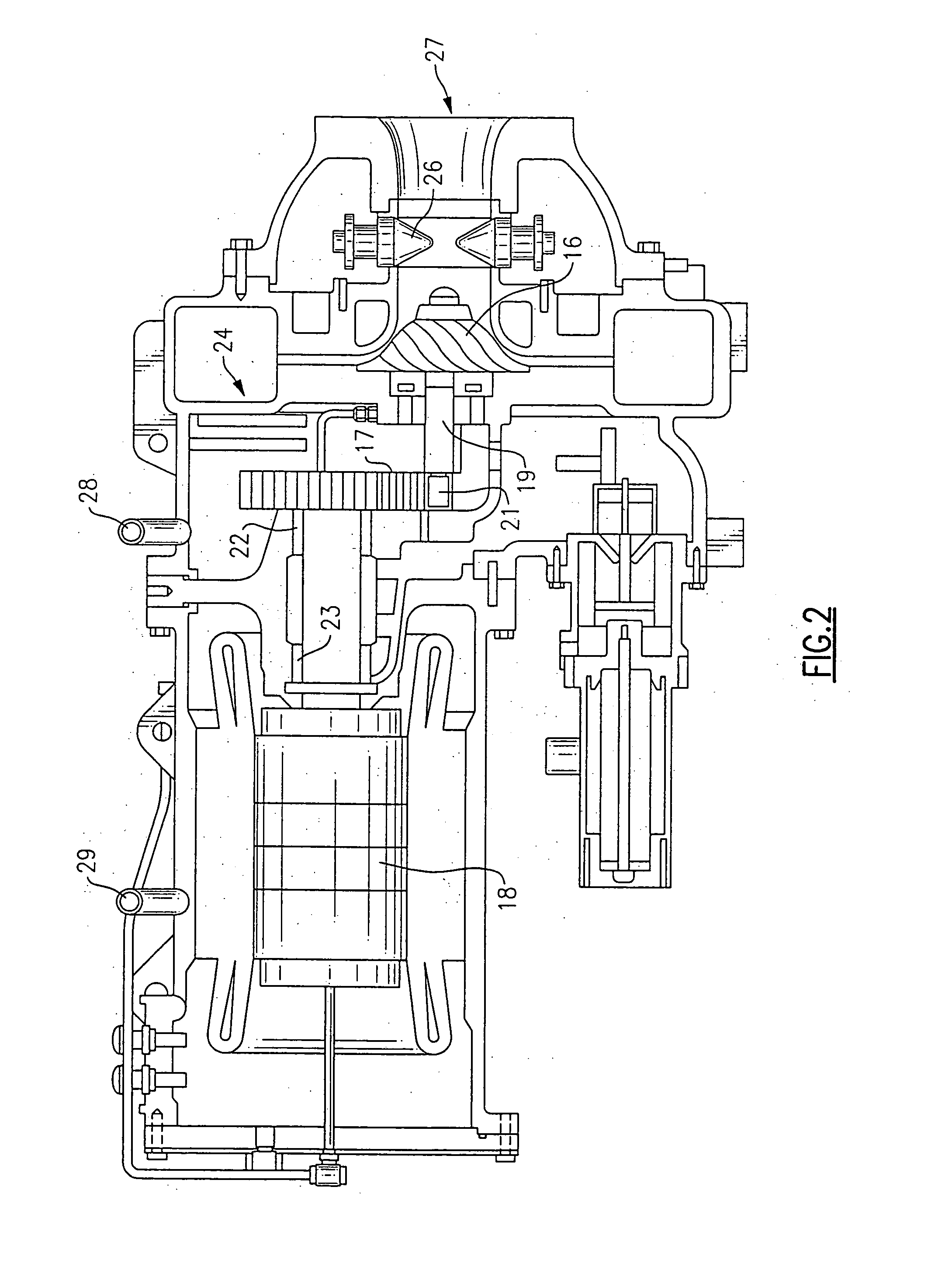

An organic rankine cycle turbine generator includes one or more embedded sensor devices that incorporate both a 3-axis accelerometer and a digital signal processing board. The device monitors, processes, analyses and stores vibrational data to determine whether and when the defect occurs in a turbine or generator component so that appropriate action may be taken. Prognostic analysis is also performed to determine the life of a faulty component.

Owner:UNITED TECH CORP

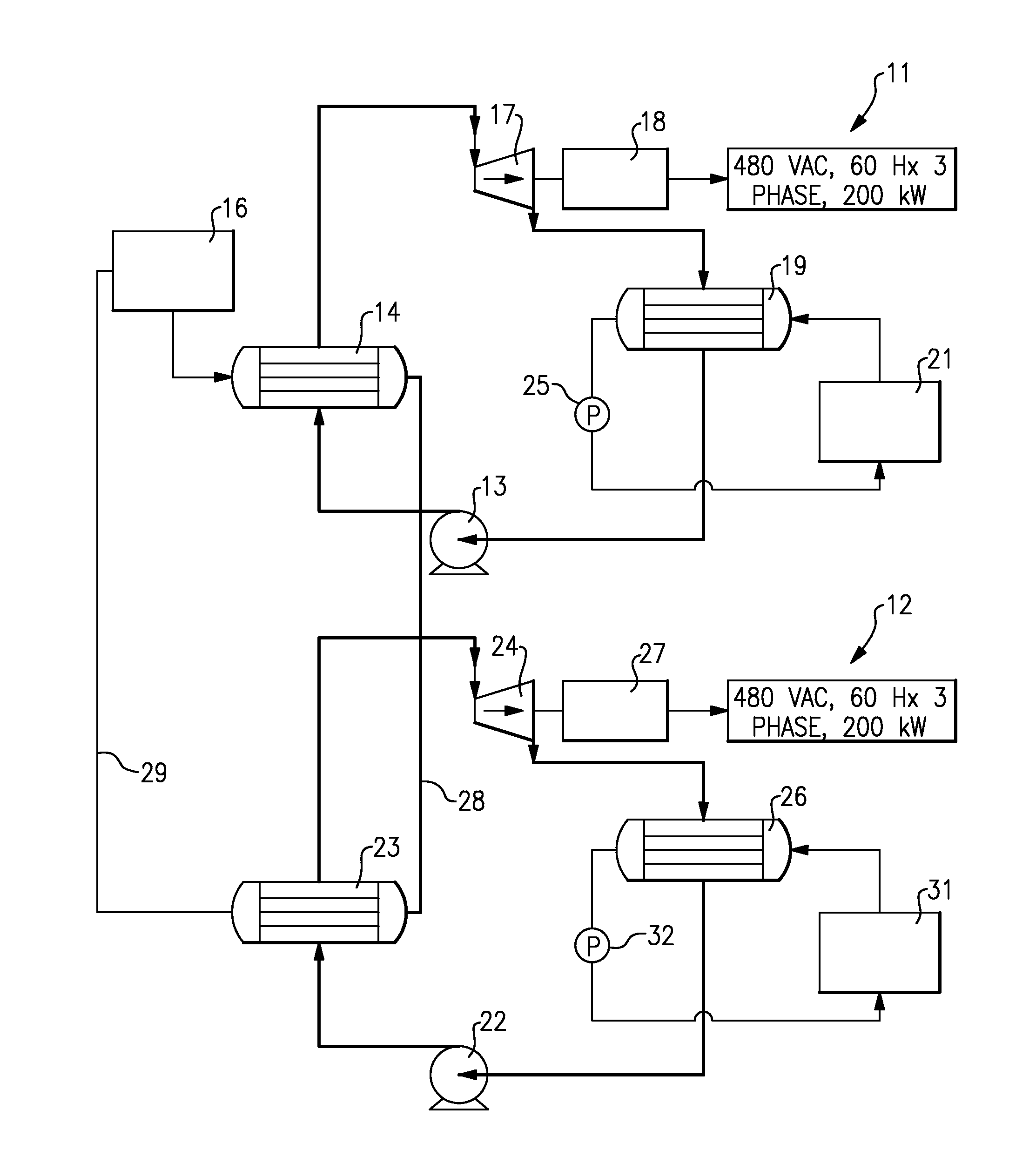

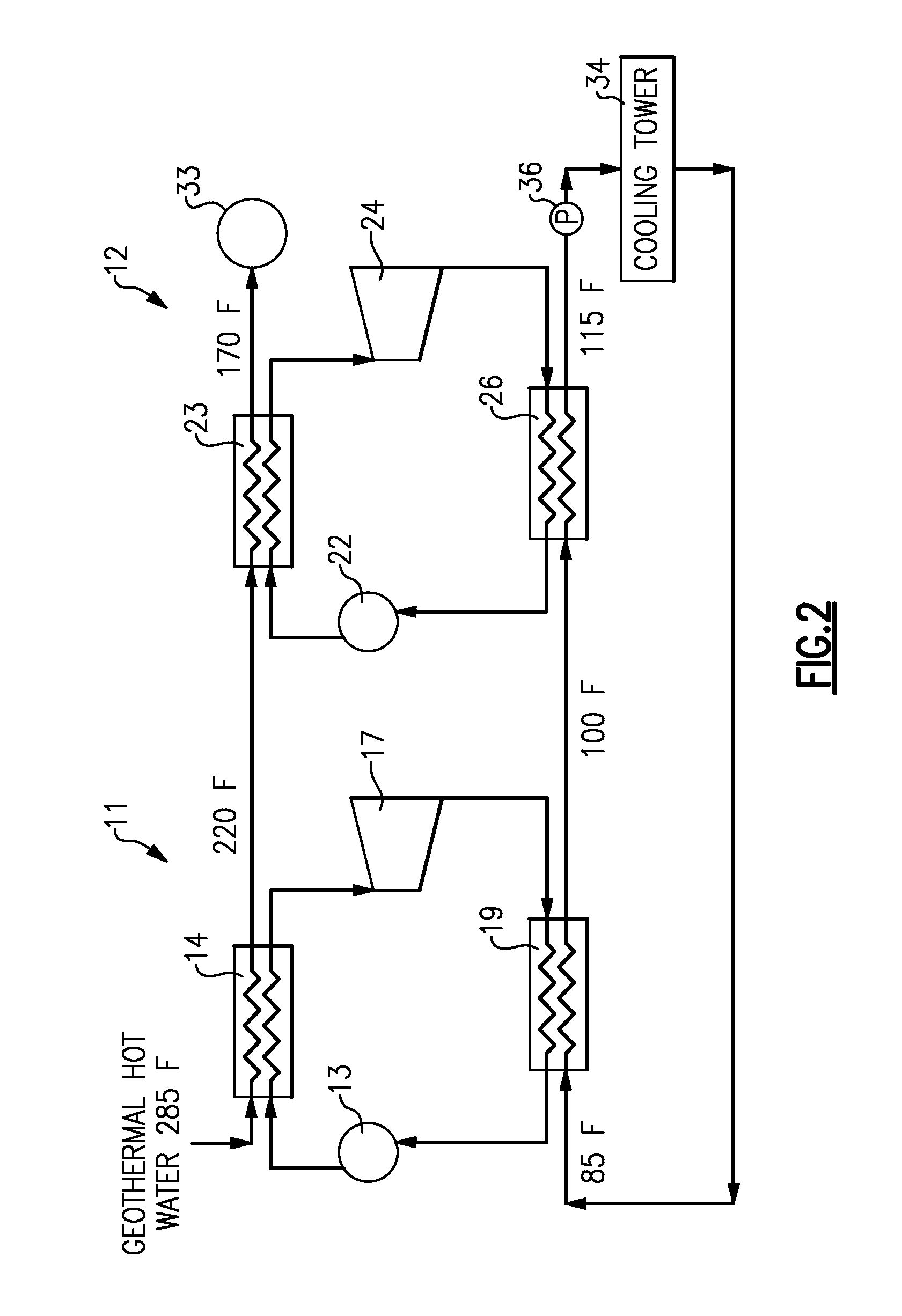

Cascaded condenser for multi-unit geothermal orc

A pair of organic rankine cycle systems are connected in series with the geothermal fluid passing first through an evaporator of the first system and then through an evaporator of the second system before returning to a sink. Similarly, the cooling tower is arranged to provide cooling water to pass first through the condenser in one system and then through the condenser of the other system, to reduce the total flow required and the size of associated cooling hardware.

Owner:UNITED TECH CORP

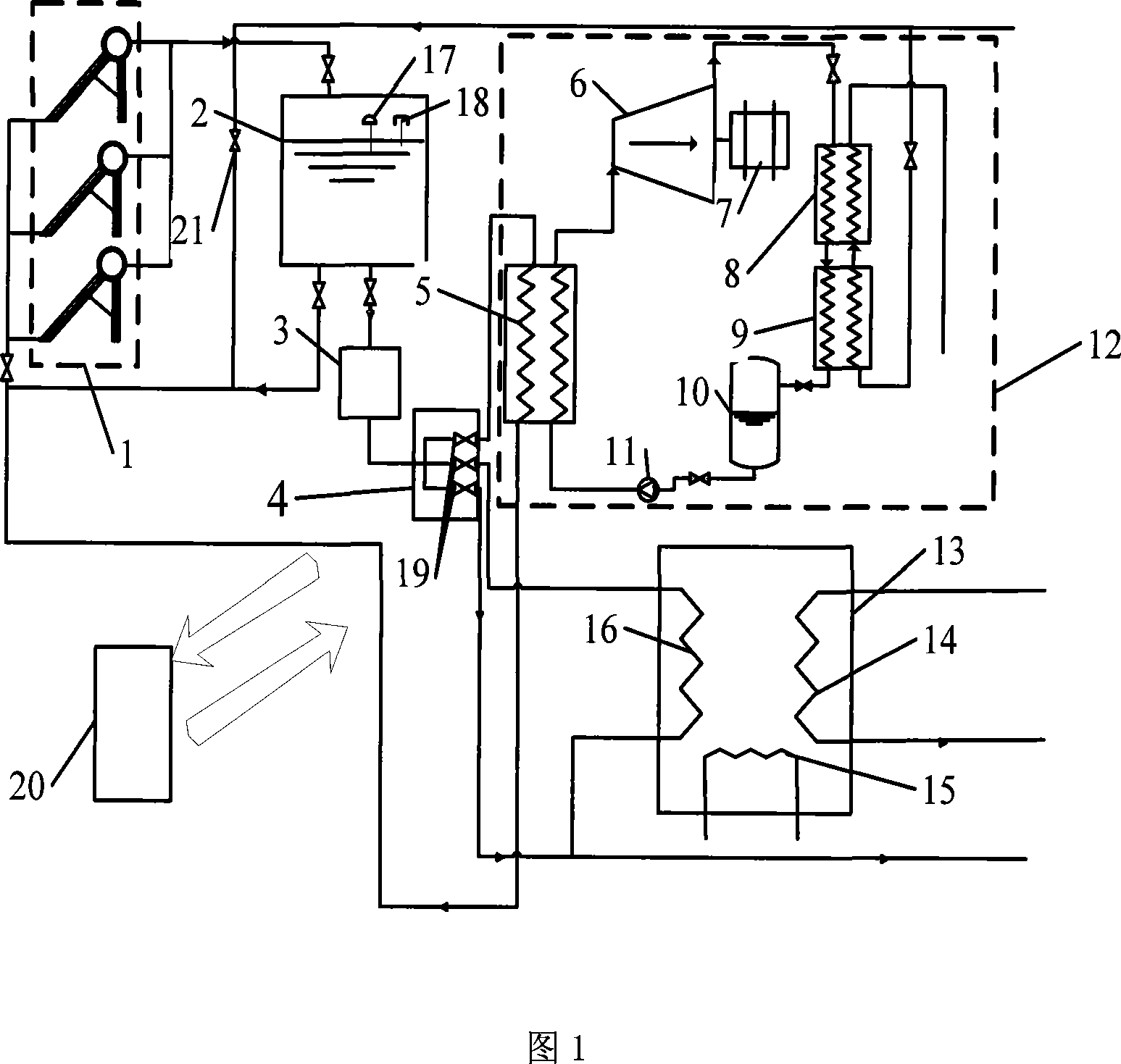

Minisize distributed type solar energy driven combining system for supplying cool, hot energy and electricity

InactiveCN101055121AGreen and environmentally friendly distributed energy supplyEfficient recyclingSolar heat devicesEnergy efficient heating/coolingWater useAdsorption refrigeration

The invention relates to micro distributed solar-driven combined cooling heating and power system belonging to field of energy technology. The invention includes: solar collection system, organic Rankine cycle thermal power generation system, adsorption refrigeration system, heating and hot water system, hot water distribution system, control system, secondary combustion device. The solar collection system is connected to the pipe of the hot water distribution and control system via the secondary combustion device, and the organic Rankine cycle thermal power generation system and the adsorption refrigeration system and the heating and hot water system are parallel connected to downstream of the hot water distribution and control system via pipes. The invention provides hot water by employing the vacuum tube solar water heater, and provides electricity by using ORC generation system, and provides cold water used by air conditioner and hot water by using the adsorption refrigeration system; the regulation and control on the hot water distribution system is user-oriented, and the system generates electricity, refrigerates, heats based on user requirement, and the system prepares the secondary combustion device to suffice the requirement when illumination is inadequate or user requirement is overlarge.

Owner:SHANGHAI JIAO TONG UNIV

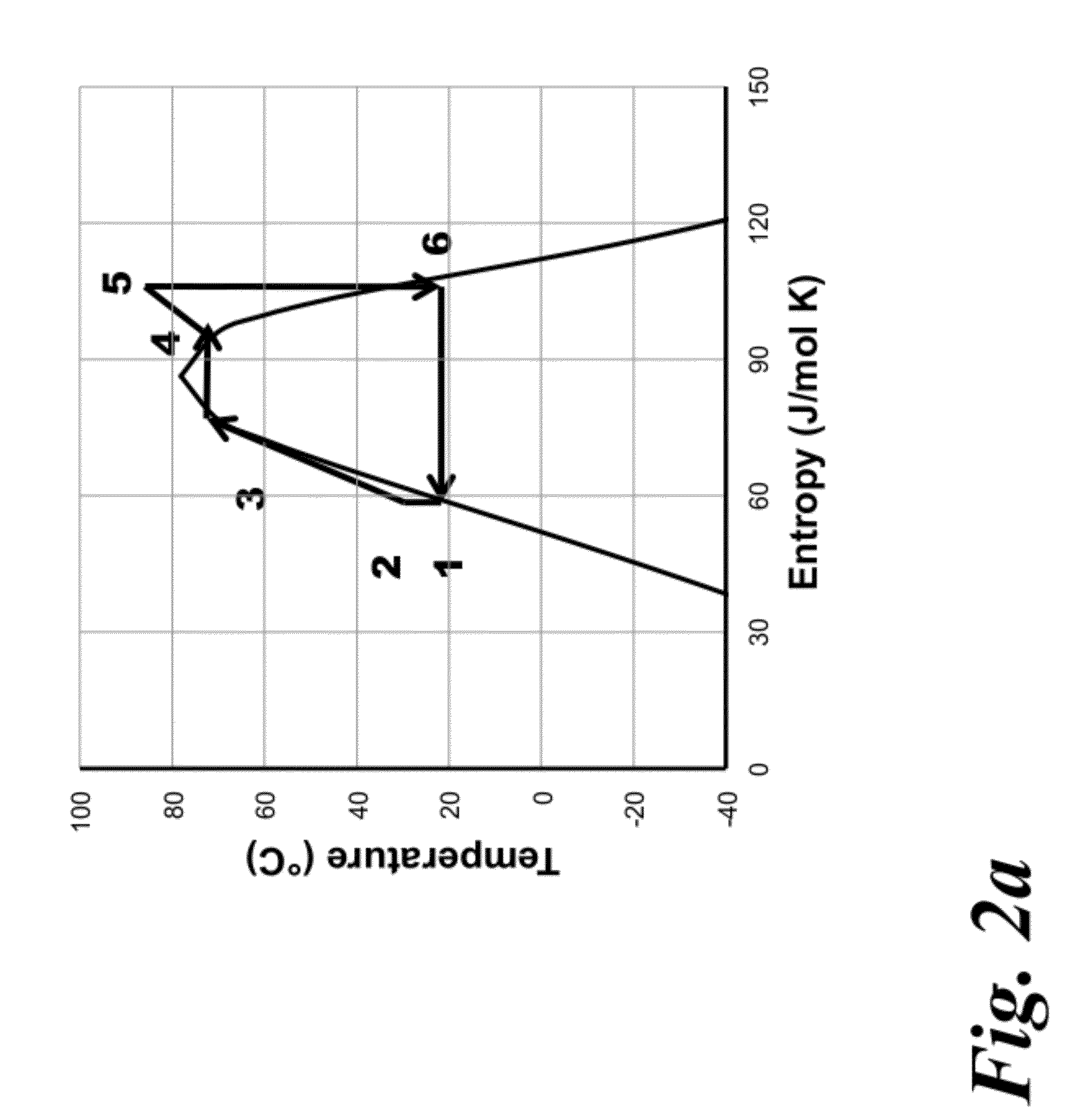

Low temperature rankine cycle solar power system with low critical temperature hfc or hc working fluid

InactiveUS20120291433A1Reliable and cost-effective wayLong-term problemSolar heating energyAuxillary drivesThermal energyWorking fluid

This invention relates to a low temperature solar thermal power system, which combines the solar hot water collectors with the organic Rankine cycle system using the low critical temperature hydrofluorocarbons (HFC) or hydrocarbons (HC) working fluid for converting solar energy to electrical energy. This invention also relates to systems and methodology for conversion of low temperature thermal energy, wherever obtained, to electrical energy using the low critical temperature hydrofluorocarbons (HFC) or hydrocarbons (HC) working fluid for organic Rankine cycle system to drive an electrical generator or do other work in a cost effective way.

Owner:NING MENG

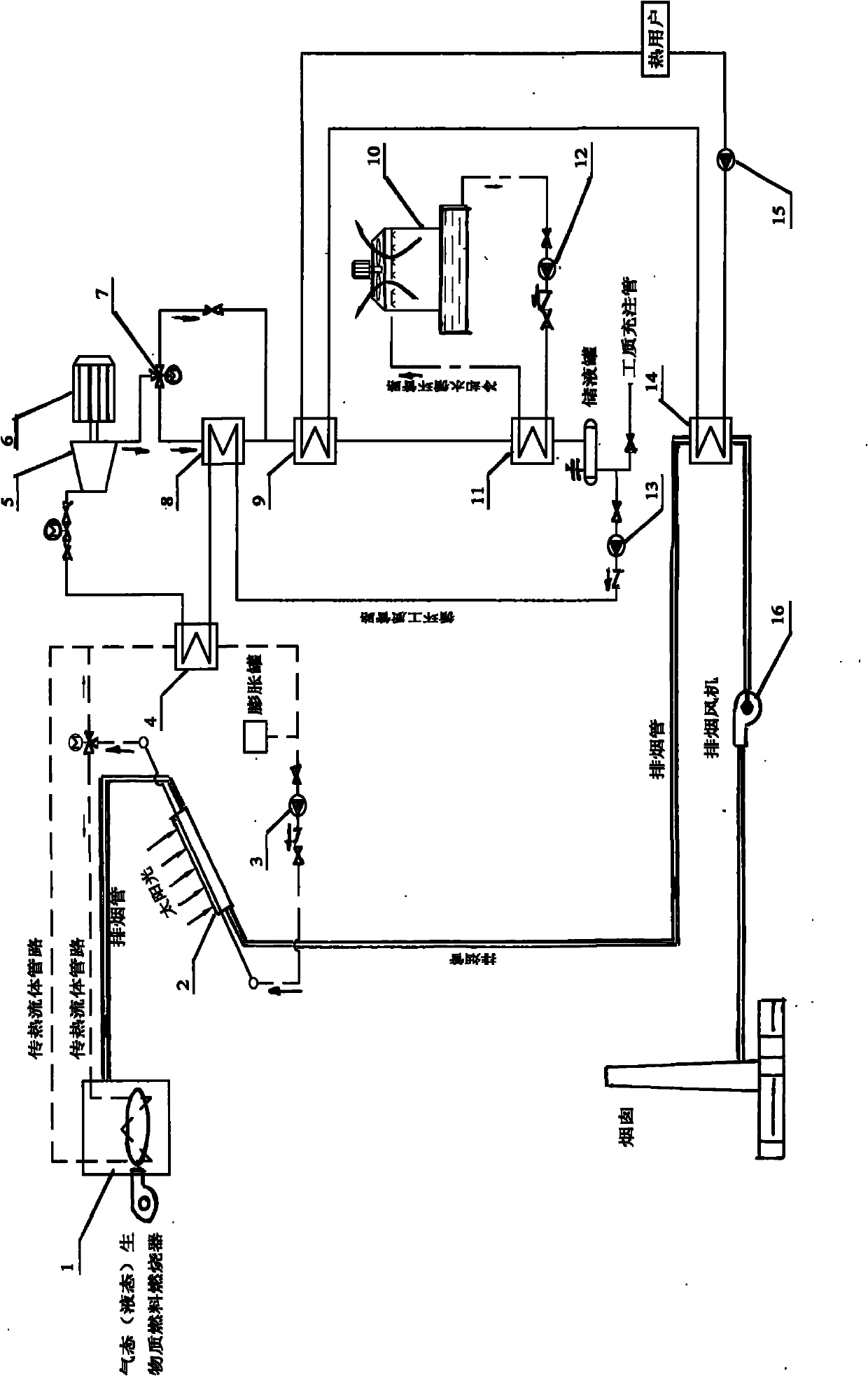

Low temperature solar energy-biomass energy combined heat and power system

InactiveCN101949369ARealize heatingReduce generationSolar heating energyFrom solar energyOrganic Rankine cycleEngineering

The invention relates to a low temperature solar energy-biomass energy combined heat and power system and a generating process. The system comprises a heat transfer fluid (such as heat transfer oil, ionic liquid, and water) circulation loop, a working medium circulation loop of an organic Rankine cycle, a heating furnace smoke discharge pipeline, a hot water heating loop and a cooling water loop. A heating furnace is used for supplementing heat for the heat transfer fluid or used as a standby heat source, and the heating surface uses dimethyl ether, heavy oil, biomass or low-grade cheap fuel made from the biomass; propane (R290), pentafluoropropane (R245fa) and the like are used as circulation working media; the exhaust heat regeneration quantity of the organic Rankine cycle can be adjusted according to the heating demand of a user; and a solar concentrator of the system is a solar concentration and waste heat recovery integrated vacuum flat-plate concentrator with a heat regenerating measure at the bottom, and the waste heat of exhaust smoke of the heating furnace can be recovered while fully using solar energy. The system can directly and efficiently convert a large quantity of low-grade biomass fuel and low-density solar energy into electric energy and supplies heat to users at the same time.

Owner:KUNMING UNIV OF SCI & TECH

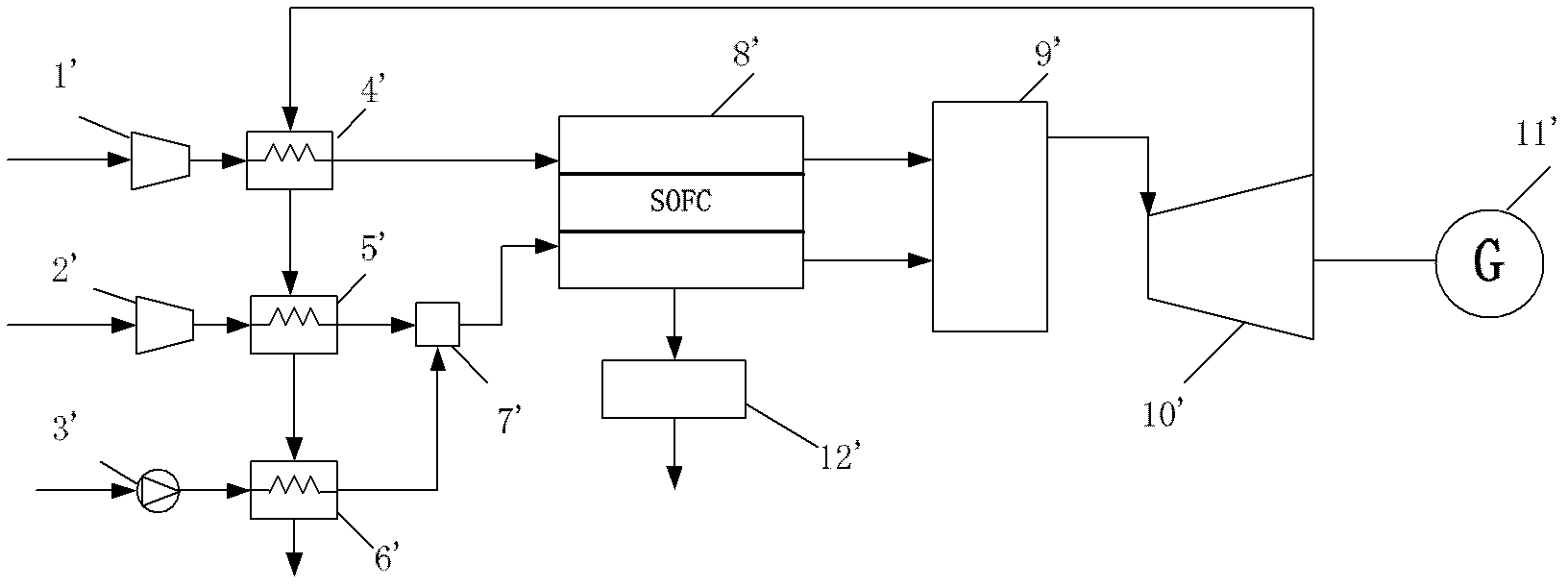

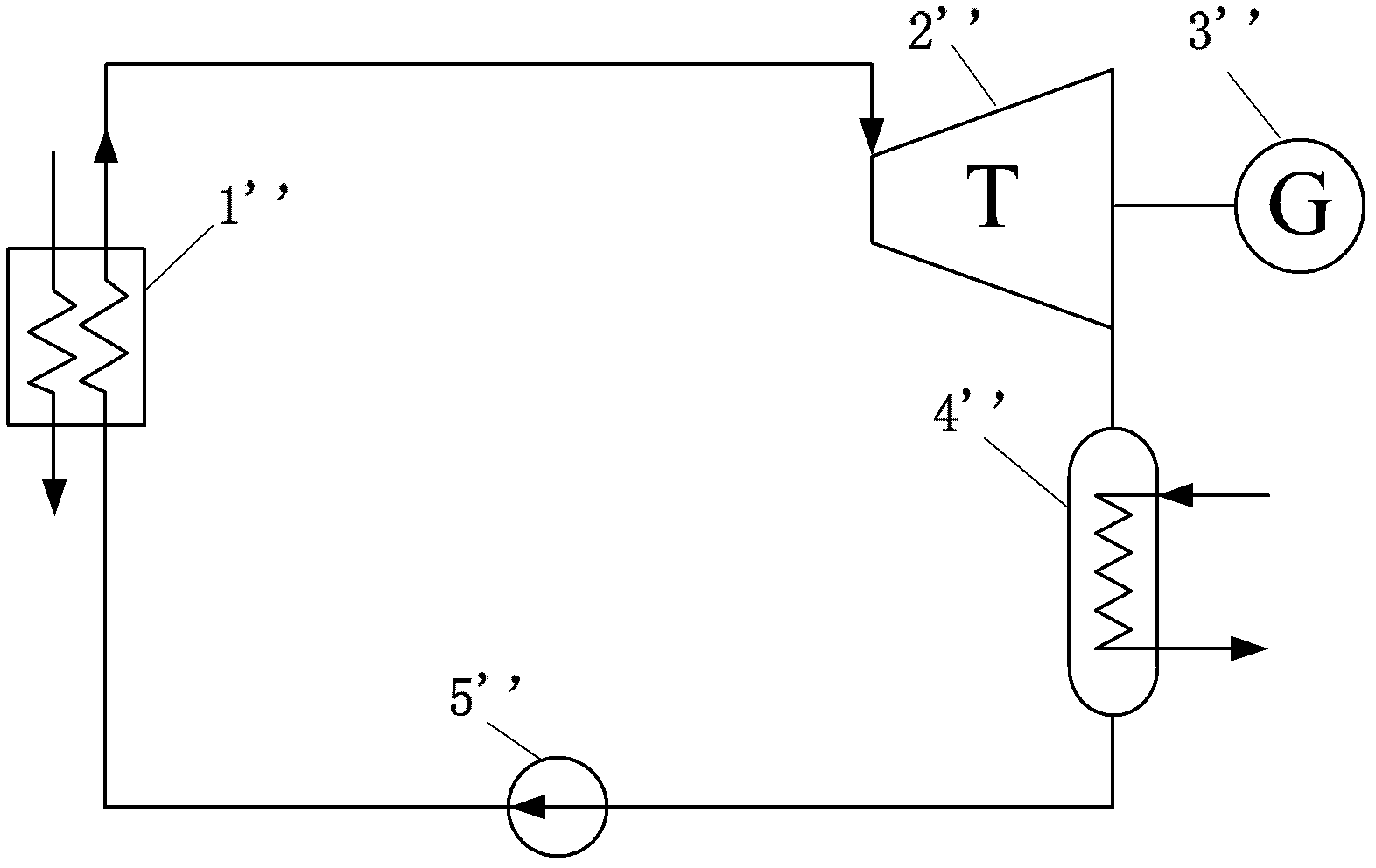

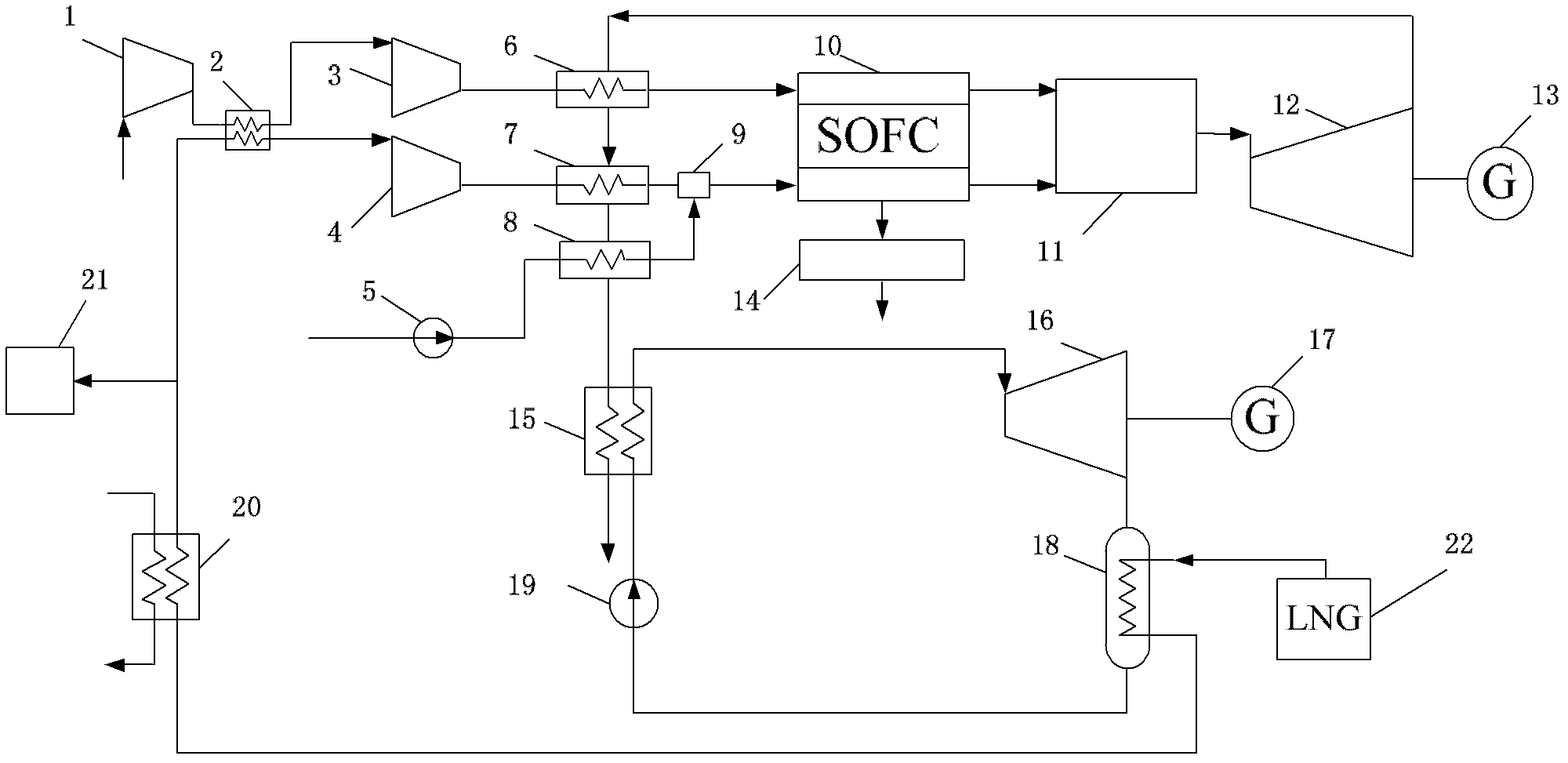

Fuel cell and organic Rankine cycle combined power generating system based on LNG (Liquefied Natural Gas) cold energy utilization

InactiveCN102628402AImprove conversion efficiencyEmission reductionFuel cell heat exchangeGas turbine plantsCombustion chamberOrganic Rankine cycle

The invention discloses a fuel cell and organic Rankine cycle combined power generating system based on LNG (Liquefied Natural Gas) cold energy utilization. The fuel cell and organic Rankine cycle combined power generating system comprises a solid oxide fuel cell and gas turbine combined cycle system, an organic Rankine cycle system and an LNG cold energy source, wherein un-reacted fuel in an SOFC (Solid Oxide Fuel Cell) and air combust in a rear combustion chamber to generate a high-temperature and high-pressure gas which enters the gas turbine for doing work and outputting electric energy; high-temperature exhaust gas in the gas turbine sequentially preheats the air, fuel and water; the organic Rankine cycle system is used for recycling low-temperature flue gas waste heat which is left after being used for preheating the air, the fuel and the water; the low-temperature flue gas waste heat is converted into electric energy for outputting, so that the cascade utilization of energy is realized; the LNG cold energy source as a cold source of organic Rankine cycle is used for condensing exhausted gas of an organic working medium turbine, so that back pressure of the organic working medium turbine is remarkably reduced and power output of the organic Rankine cycle is increased; and meanwhile, the cold energy of the LNG is recycled. According to the fuel cell and organic Rankine cycle combined power generating system disclosed by the invention, the conversion efficiency of energy source can be remarkably improved, the discharge of pollutants is reduced and the performances of the system are improved.

Owner:XI AN JIAOTONG UNIV

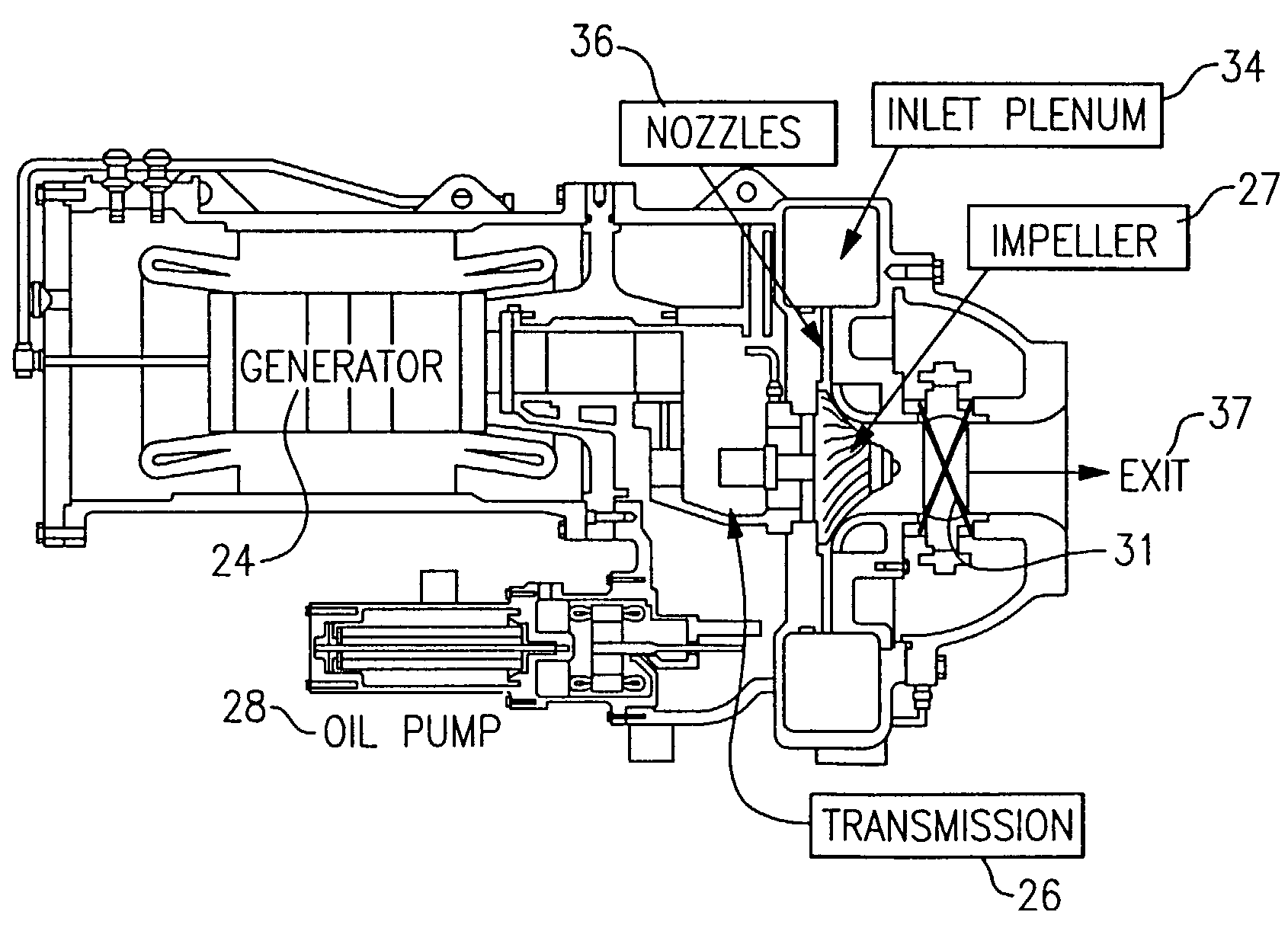

Turbine with vaned nozzles

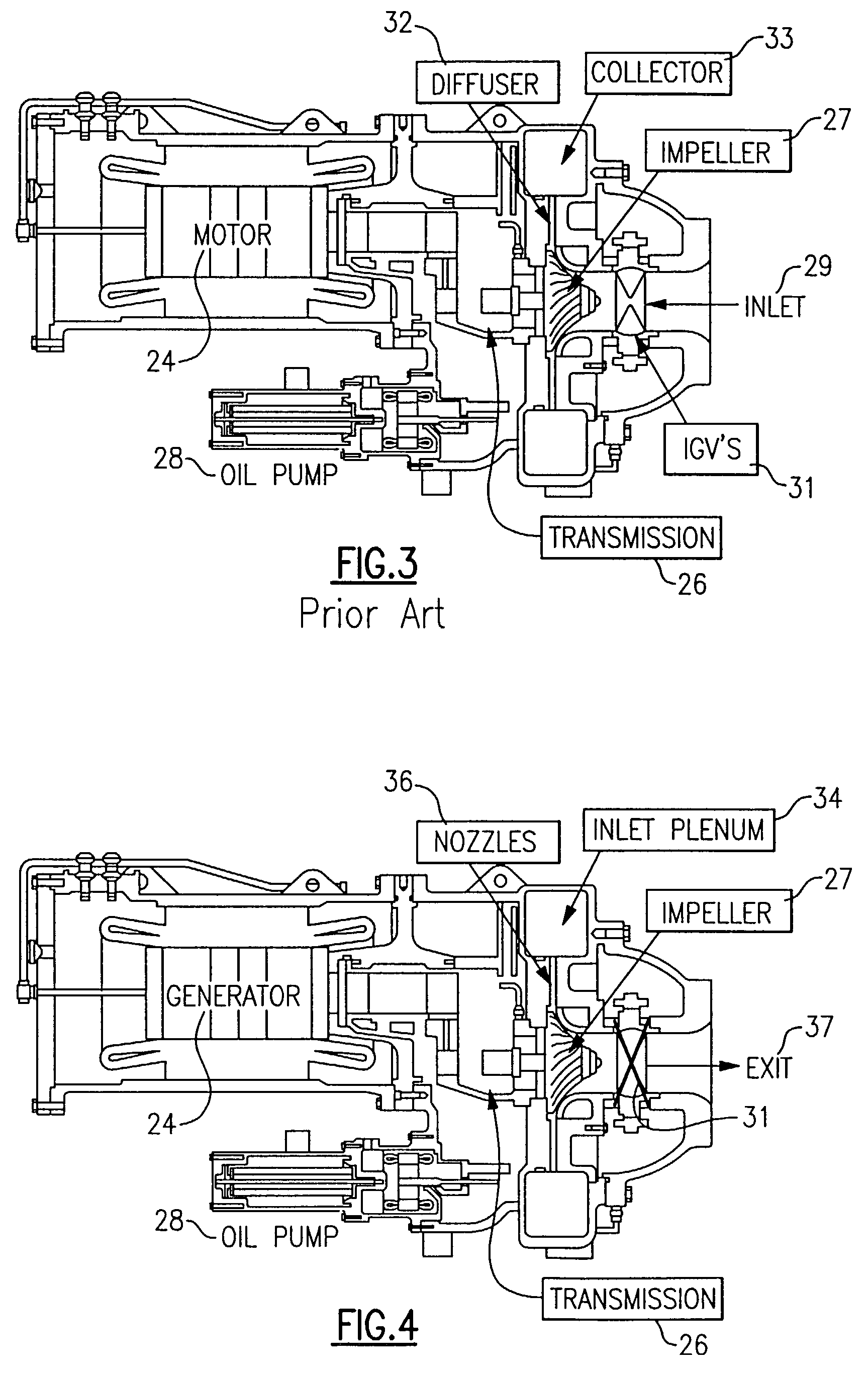

InactiveUS7254949B2Efficient use ofEasy to useEngine manufacturePump componentsOrganic Rankine cycleProcess engineering

A machine designed as a centrifugal compressor is applied as an organic rankine cycle turbine by operating the machine in reverse. In order to accommodate the higher pressures when operating as a turbine, a suitable refrigerant is chosen such that the pressures and temperatures are maintained within established limits. Such an adaptation of existing, relatively inexpensive equipment to an application that may be otherwise uneconomical, allows for the convenient and economical use of energy that would be otherwise lost by waste heat to the atmosphere.

Owner:UNITED TECH CORP

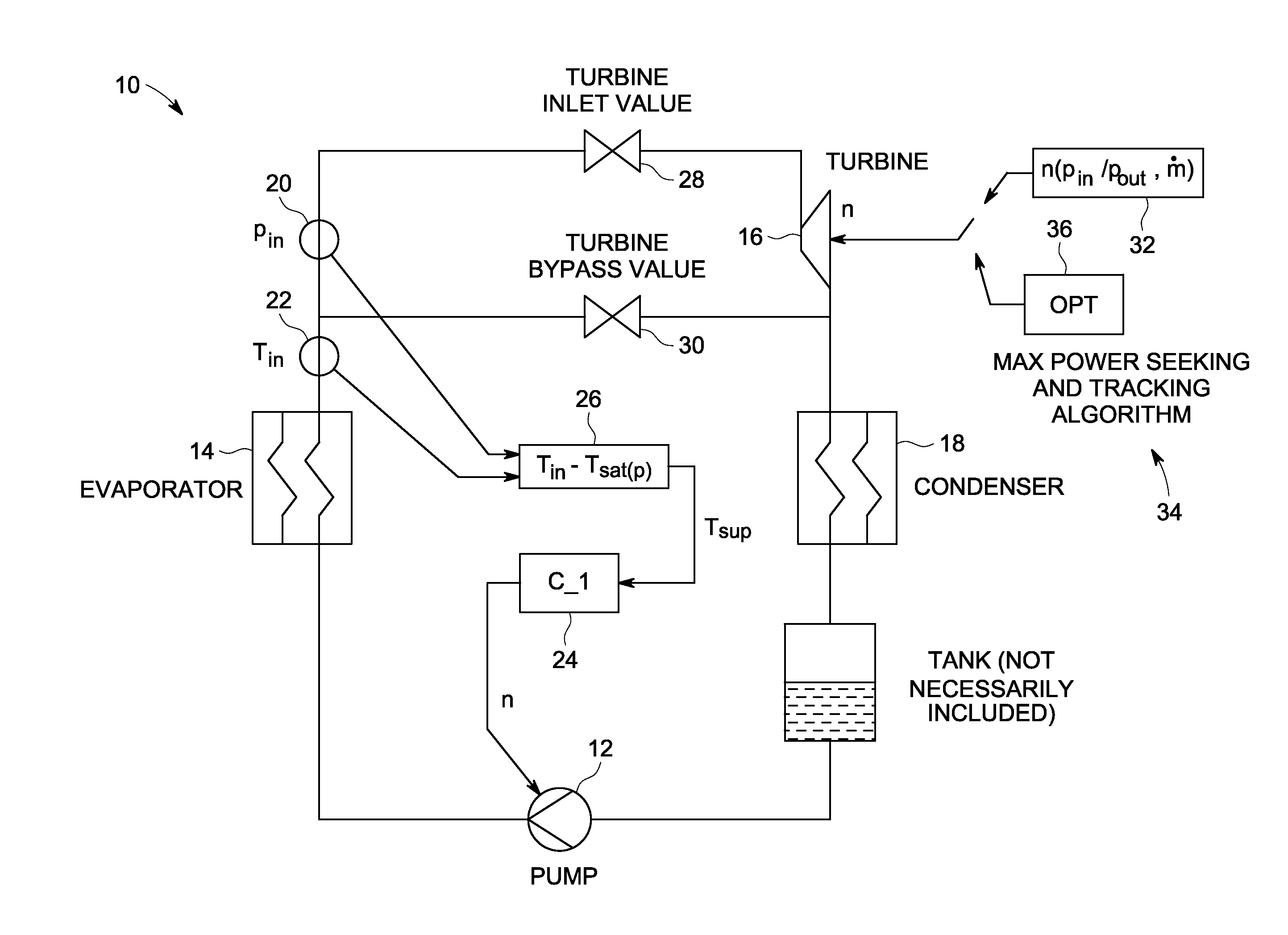

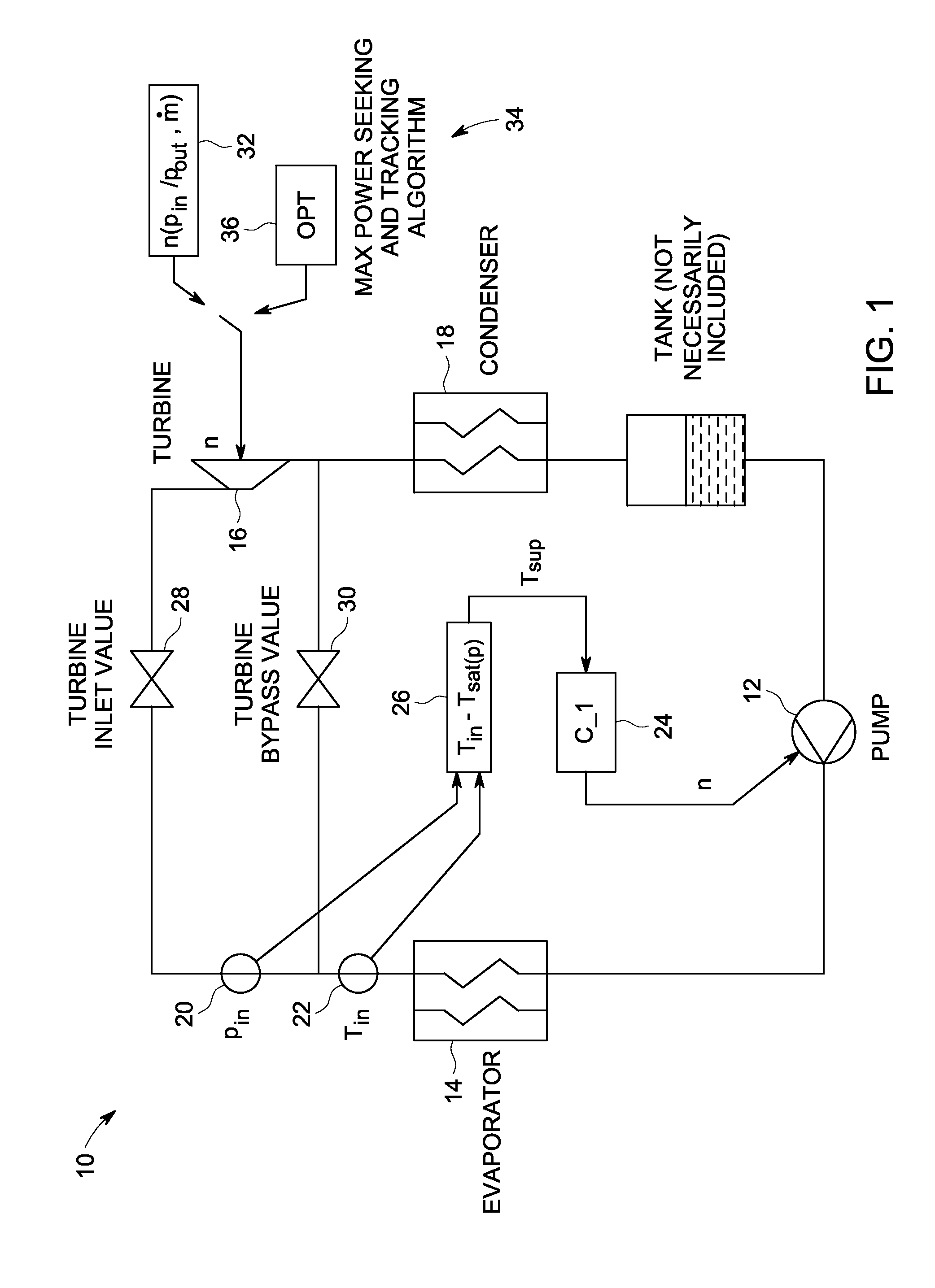

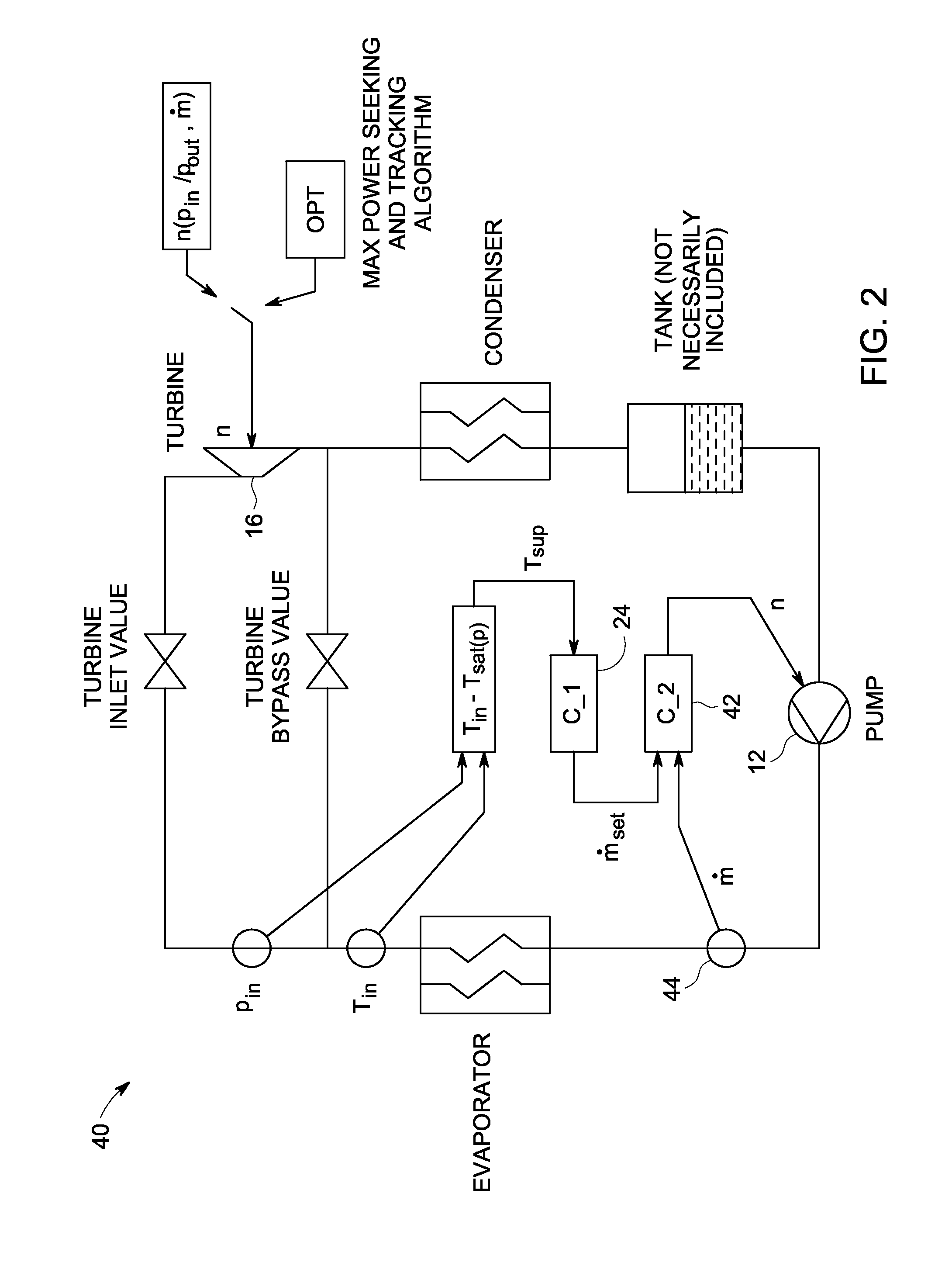

Turbine inlet condition controlled organic rankine cycle

A pressure sensor measures an organic Rankine cycle (ORC) working fluid pressure in front of a radial inflow turbine, while a temperature sensor measures an ORC working fluid temperature in front of the radial inflow turbine. A controller responsive to algorithmic software determines a superheated temperature of the working fluid in front of the radial inflow turbine based on the measured working fluid pressure and the measured working fluid temperature. The controller then manipulates the speed of a working fluid pump, the pitch of turbine variable inlet guide vanes when present, and combinations thereof, in response to the determined superheated temperature to maintain the superheated temperature of the ORC working fluid in front of the radial inflow turbine close to a predefined set point. The superheated temperature can thus be maintained in the absence of sensors other than pressure and temperature sensors.

Owner:AI ALPINE US BIDCO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com