Patents

Literature

363 results about "Pentafluoropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1,1,1,3,3-Pentafluoropropane (HFC-245fa) is a hydrofluorocarbon used primarily for closed-cell spray foam insulation produced by Honeywell and in Asia by Sinochem. Honeywell markets HFC-245fa under the Enovate and Genetron 245fa brand names. HFC-245fa is also known as pentafluoropropane and by its chemical name 1,1,1,3,3,-pentafluoropropane. Unlike CFC and HCFC blowing agents formerly used for this purpose, it has no ozone depletion potential and is nearly non-toxic. Although it is intended to remain trapped within the foam insulation, it is practically non biodegradable with a lifetime of 7.2 years when it eventually does escape into the atmosphere. It does have a high global warming potential of 950 (950 times the global warming effect of CO2). Honeywell refers to this as "acceptable" in their literature, but they don't include the actual number.

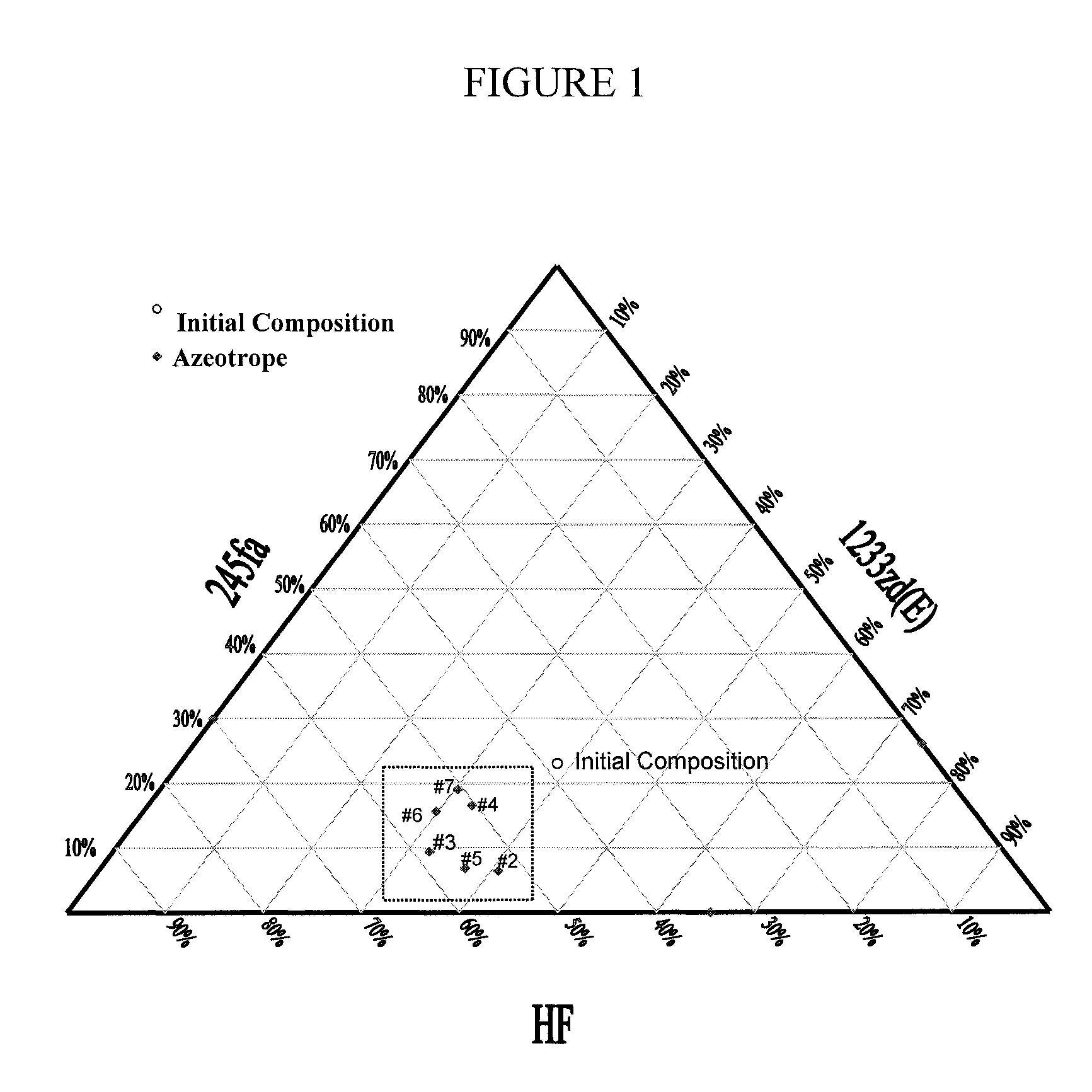

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS20050020862A1Physical/chemical process catalystsPreparation by hydrogen halide split-offPentafluoropropaneChemistry

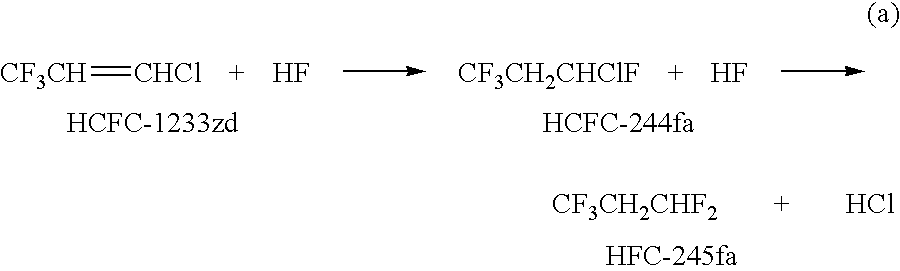

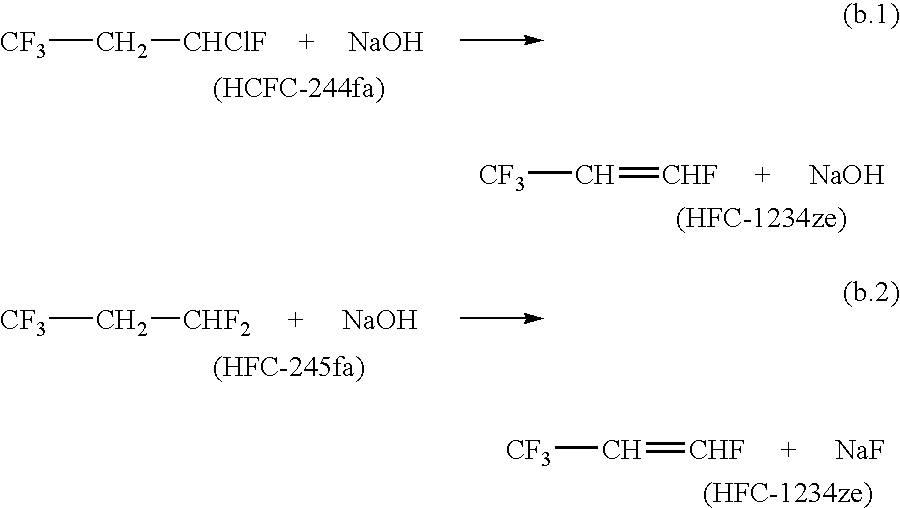

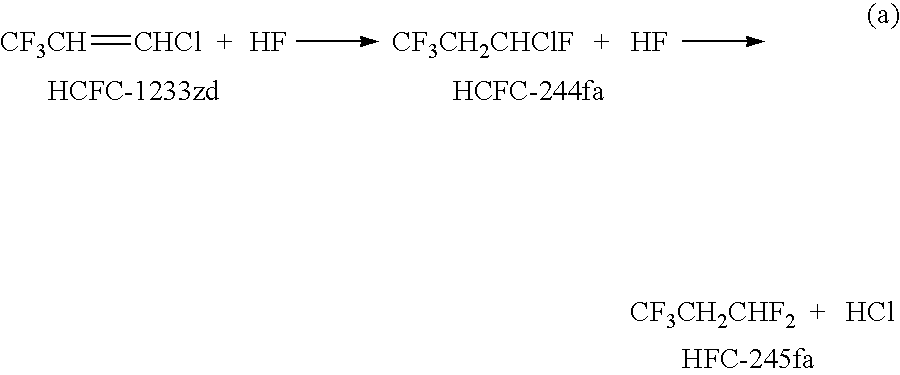

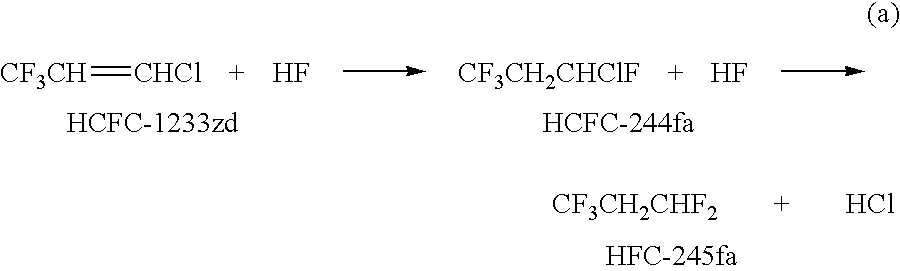

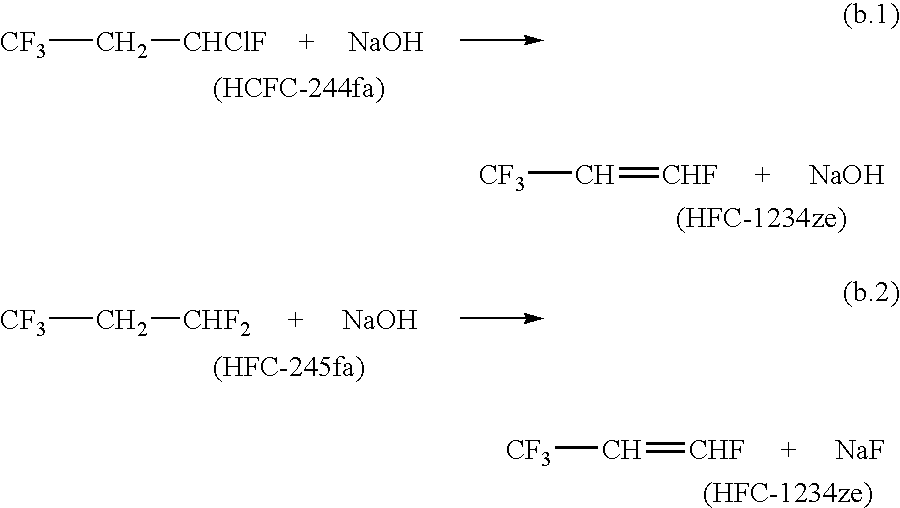

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

PROCESS FOR THE PRODUCTION OF HFO TRANS-1234ze FROM HFC-245fa

ActiveUS20080051611A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluoride1,3,3,3-Tetrafluoropropene

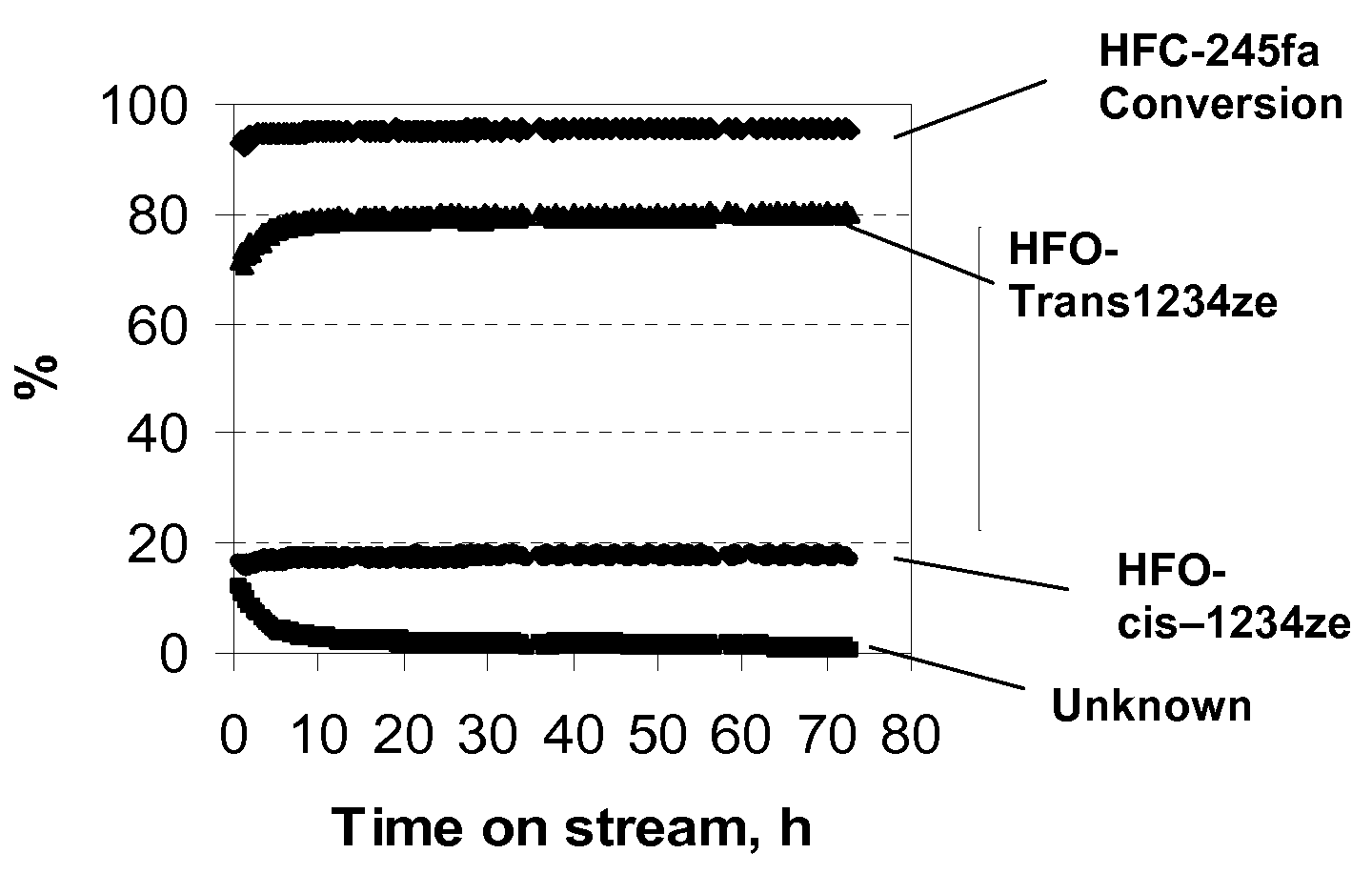

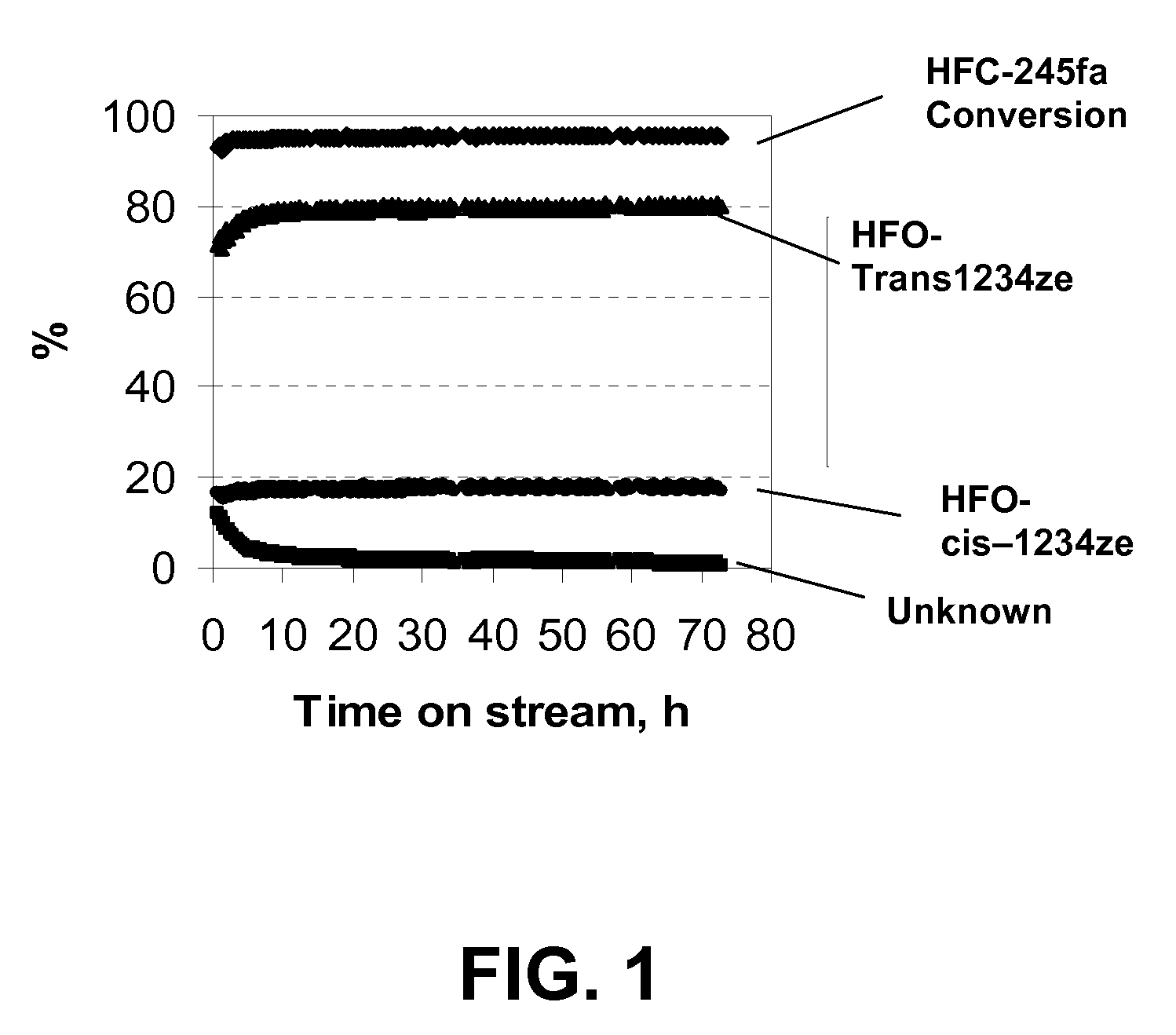

This invention relates a process for the manufacture of the HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze). More particularly, the invention pertains to a process for the manufacture of the HFO trans-1234ze by first dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride and then recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for preparing halogenated alkanes

InactiveUS7094936B1High selectivityBig advantagePreparation by hydrogen halide split-offPreparation by halogen replacementAlkaneLewis acid catalysis

Methods and materials are provided for the production and purification of halogenated compounds and intermediates in the production of 1,1,1,3,3-pentafluoropropane. In a preferred embodiment, the process steps include: (1) reacting carbon tetrachloride with vinyl chloride to produce 1,1,1,3,3-pentachloropropane; (2) dehydrochlorinating the 1,1,1,3,3-pentachloropropane with a Lewis acid catalyst to produce 1,1,3,3-tetrachloropropene; (3) fluorinating the 1,1,3,3-tetrachloropropene to produce 1-chloro-3,3,3-trifluoropropene; (4) fluorinating the 1-chloro-3,3,3-trifluoropropene to produce a product mixture containing 1,1,1,3,3-pentafluoropropane; and (5) separating 1,1,1,3,3-pentafluoropropane from by-products.

Owner:EI DU PONT DE NEMOURS & CO

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7829748B1Physical/chemical process catalystsPreparation by hydrogen halide split-offAlkaline earth metalOxidation state

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFO-1234ze) by a two stage process. A vapor phase hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and / or 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the thermal dehydrochlorination of HCFC-244fa and dehydro fluorination of HFC-245fa into HFO-1234ze in the presence of a catalyst which comprises one or more of alkali metal halides, alkaline earth metal halides, halogenated metal oxides, zero oxidation state metals, zinc halides, palladium halides, and activated carbon.

Owner:HONEYWELL INT INC

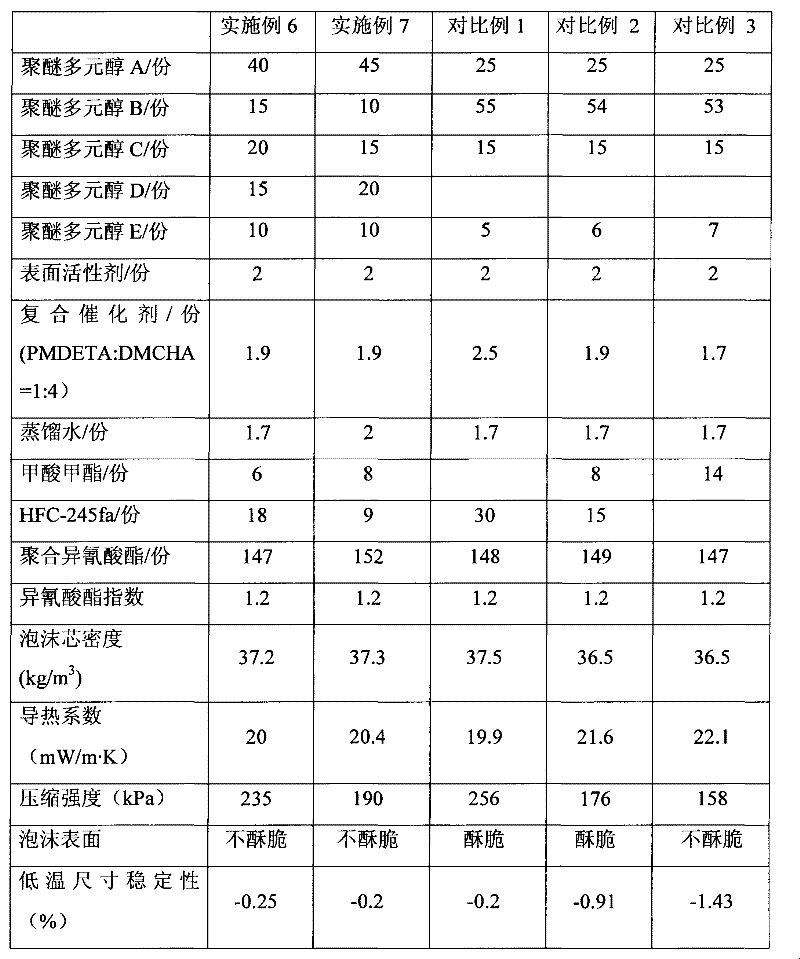

Azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride and uses thereof

ActiveUS20070100173A1Preparation by hydrogen halide split-offHydrogen fluorideHydrogen fluoride1,3,3,3-Tetrafluoropropene

Disclosed herein are azeotrope and near-azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride. These azeotrope and near-azeotrope compositions are useful in processes to produce E-1,3,3,3-tetrafluoropropene and in processes to purify E-1,3,3,3-tetrafluoropropene from mixtures of E-1,3,3,3-tetrafluoropropene with 1,1,1,3,3-pentafluoropropane and / or with hydrogen fluoride.

Owner:THE CHEMOURS CO FC LLC

Manufacturing method for 1,1,1,3,3-pentafluoropropane

InactiveUS6060628AImprove economyImprove efficiencyPreparation by dehalogenationOrganic chemistry methodsHydrogenHydrogen chloride

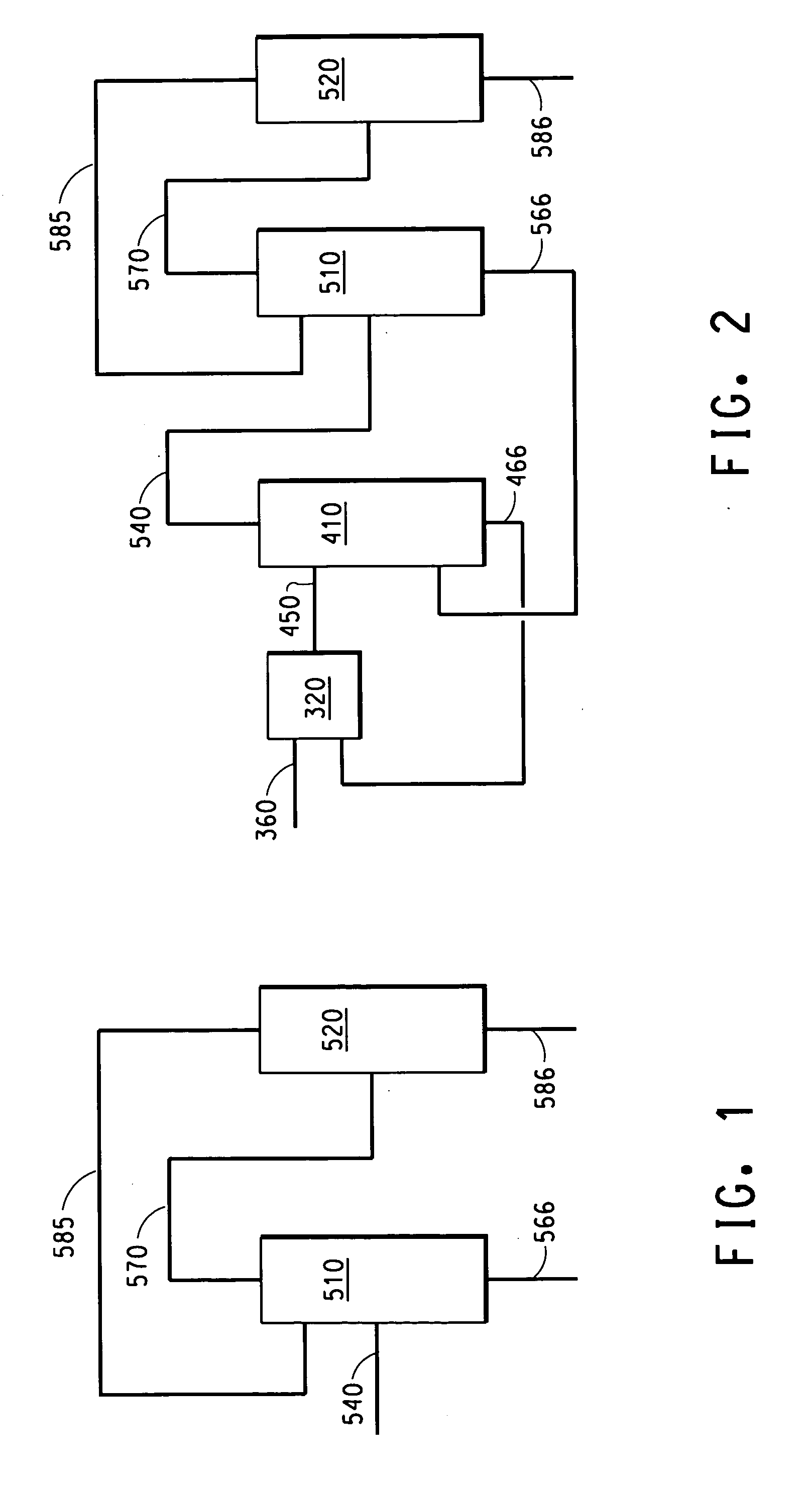

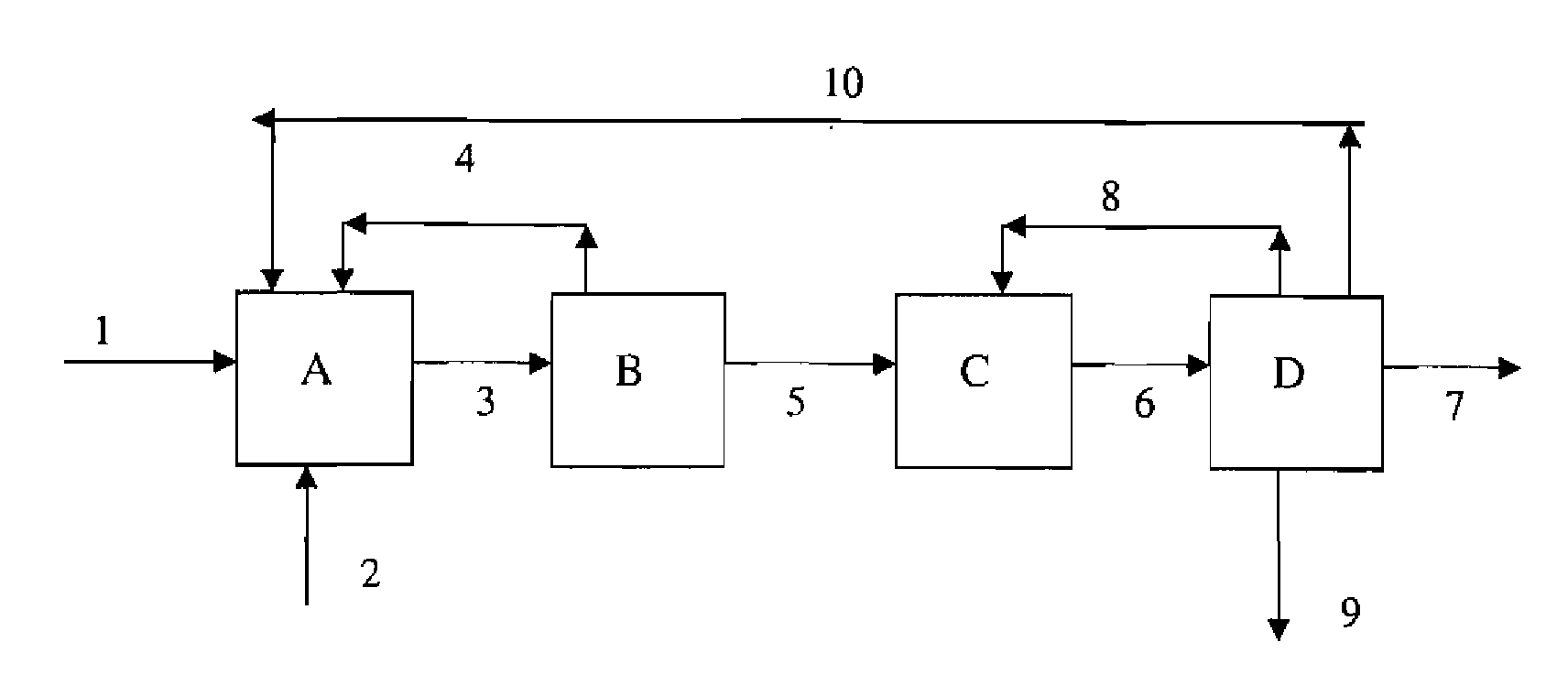

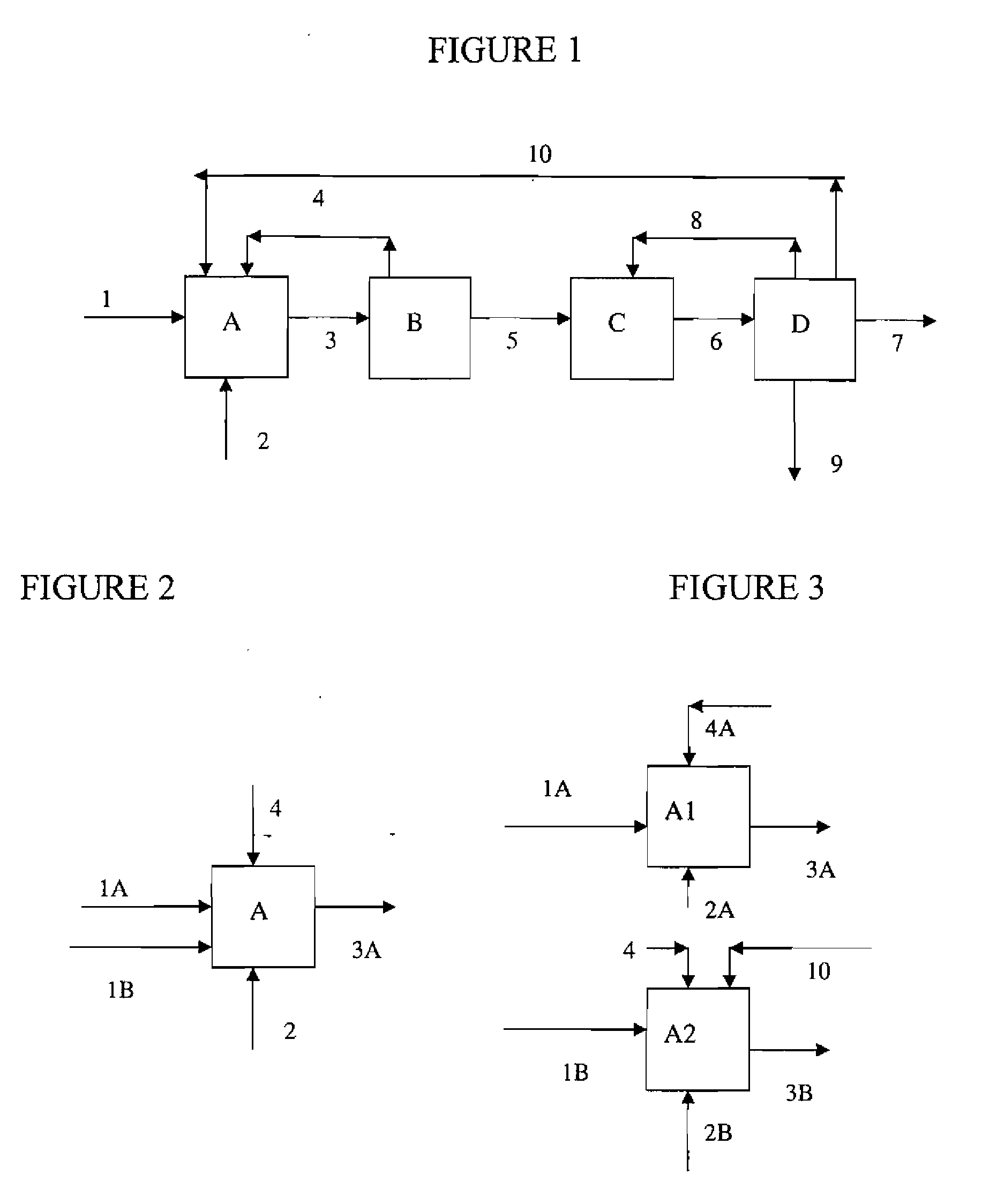

PCT No. PCT / JP96 / 00273 Sec. 371 Date Aug. 26, 1997 Sec. 102(e) Date Aug. 26, 1997 PCT Filed Feb. 8, 1996 PCT Pub. No. WO96 / 26914 PCT Pub. Date Jun. 9, 1996A manufacturing method for 1,1,1,3,3-pentafluoropropane in which the method is composed of: step A wherein 2,3-dichloro-1,1,1,3,3-pentafluoropropane is reduced with hydrogen under the presence of hydrogenation catalyst in gaseous phase; step B wherein all of the products of the said step A are introduced into a cooler condenser, so that either a component of hydrogen and hydrogen chloride as non-condensation component and another compoment of 1,1,1,3,3-pentafluoropropane as condensation components or a component of hydrogen as non-condensation component and another component of hydrogen chloride and 1,1,1,3,3-pentafluoropropane as condensation component are obtained; step C wherein hydrogen is separated from the non-condensation component of the said step B, and it is recycled to the said step A; and step D wherein 1,1,1,3,3-pentafluoropropane is separated from the condensation component of the said step B. The producing method based on a manufacturing process of 1,1,1,3,3-pentafluoropropane can be provided with good efficiency and economy in industrial scales.

Owner:DAIKIN IND LTD

Integrated HFC trans-1234ze manufacture process

ActiveUS7485760B2Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride and uses thereof

ActiveUS7423188B2Preparation by hydrogen halide split-offHydrogen fluorideHydrogen fluorideMedicinal chemistry

Disclosed herein are azeotrope and near-azeotrope compositions comprising E-1,3,3,3-tetrafluoropropene and hydrogen fluoride. These azeotrope and near-azeotrope compositions are useful in processes to produce E-1,3,3,3-tetrafluoropropene and in processes to purify E-1,3,3,3-tetrafluoropropene from mixtures of E-1,3,3,3-tetrafluoropropene with 1,1,1,3,3-pentafluoropropane and / or with hydrogen fluoride.

Owner:THE CHEMOURS CO FC LLC

Process for the manufacture of fluorinated olefins

ActiveUS20090234165A1Good economic advantagePreparation by dehalogenationSequential/parallel process reactionsHexafluoropropylenePentafluoropropane

A method for producing 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3 -pentafluoropropene using a single set of four unit operations, the unit operations being (1) hydrogenation of a starting material comprising hexafluoropropene and optionally recycled 1,1,1,2,3-pentafluoropropene; (2) separation of the desired intermediate hydrofluoroalkane, such as 1,1,1,2,3,3-hexafluoropropane and / or 1,1,1,2,3-pentafluoropropane; (3) dehydrofluorination of the intermediate hydrofluoroalkane to produce the desired 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3-pentafluoropropene, followed by another separation to isolate the desired product and, optionally, recycle of the 1,1,1,2,3-pentafluoropropene.

Owner:HONEYWELL INT INC

Integrated HFC trans-1234ZE manufacture process

ActiveUS20080051610A1Preparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoride1,3,3,3-Tetrafluoropropene

An integrated process for the manufacture of HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze) by first catalytically dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride, catalytically isomerizing cis-1234ze into trans-1234ze, and recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for the preparation of fluorine containing hydrohalocarbons

InactiveUS6187976B1Preparation by dehalogenationPreparation by halogen halide additionHydrogen fluorideHydrogen

The invention relates to the preparation of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa), useful as an intermediate in the production of 1,1,1,3,3-pentafluoropropane (HFC-245fa). The invention further relates to a process for the preparation of HFC-245fa comprising reacting HCFC-235fa with hydrogen in the presence of a reduction catalyst wherein the said HCFC-235fa is prepared by reacting CCl3CHCCl3 with hydrogen fluoride in the presence of fluorination catalyst in either the liquid phase or the vapor phase.

Owner:ALLIEDSIGNAL INC

Azeotropic composition, comprising 1, 1, 1, 3,3-pentafluoropropane and 1, 1, 1-trifluoro-3-chloro-2-propene, method of separation and purification of the same, and process for producing 1, 1, 1,3,3-pentafloropropane and 1, 1, 1-trifluoro-3-chloro-2-propene

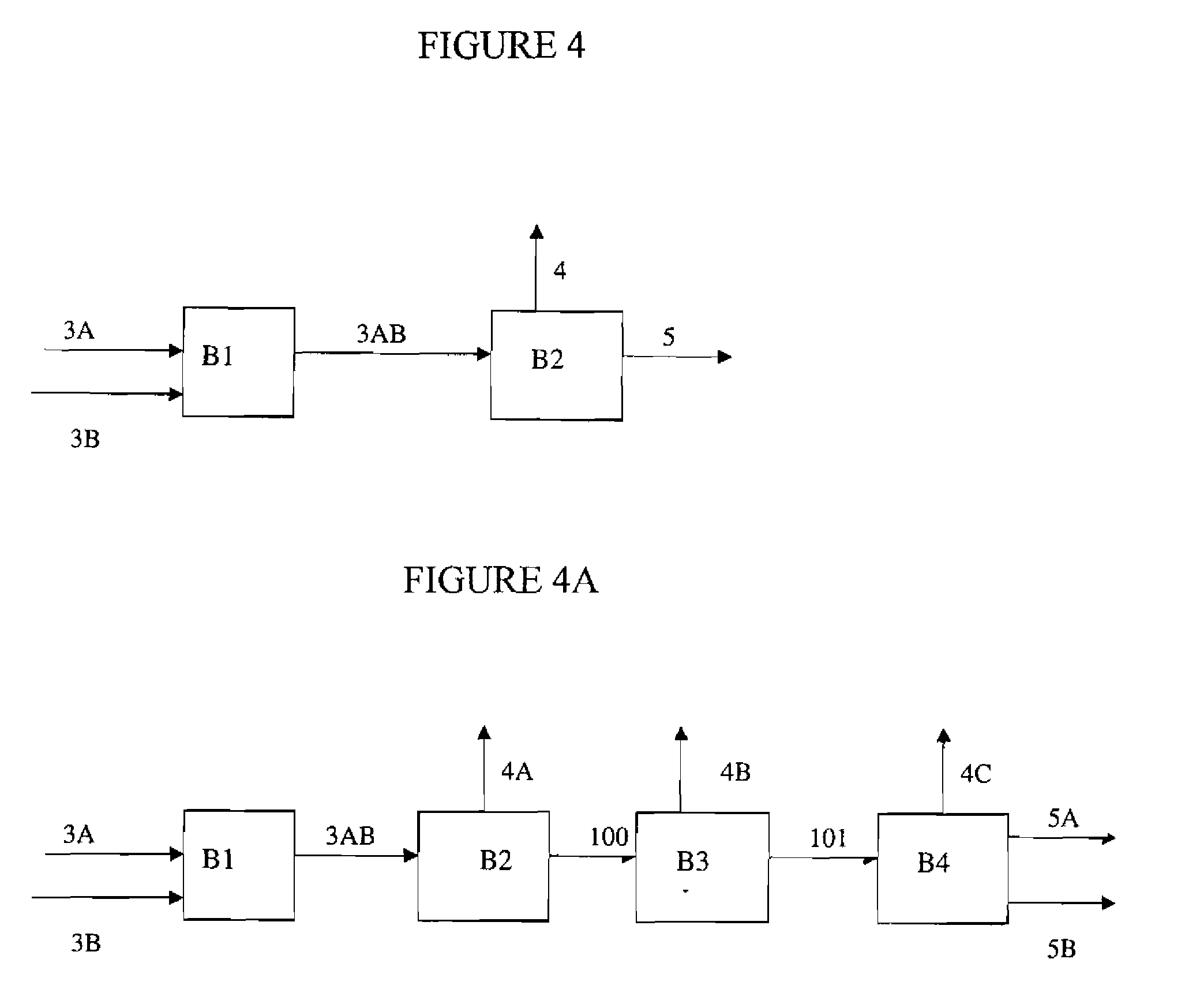

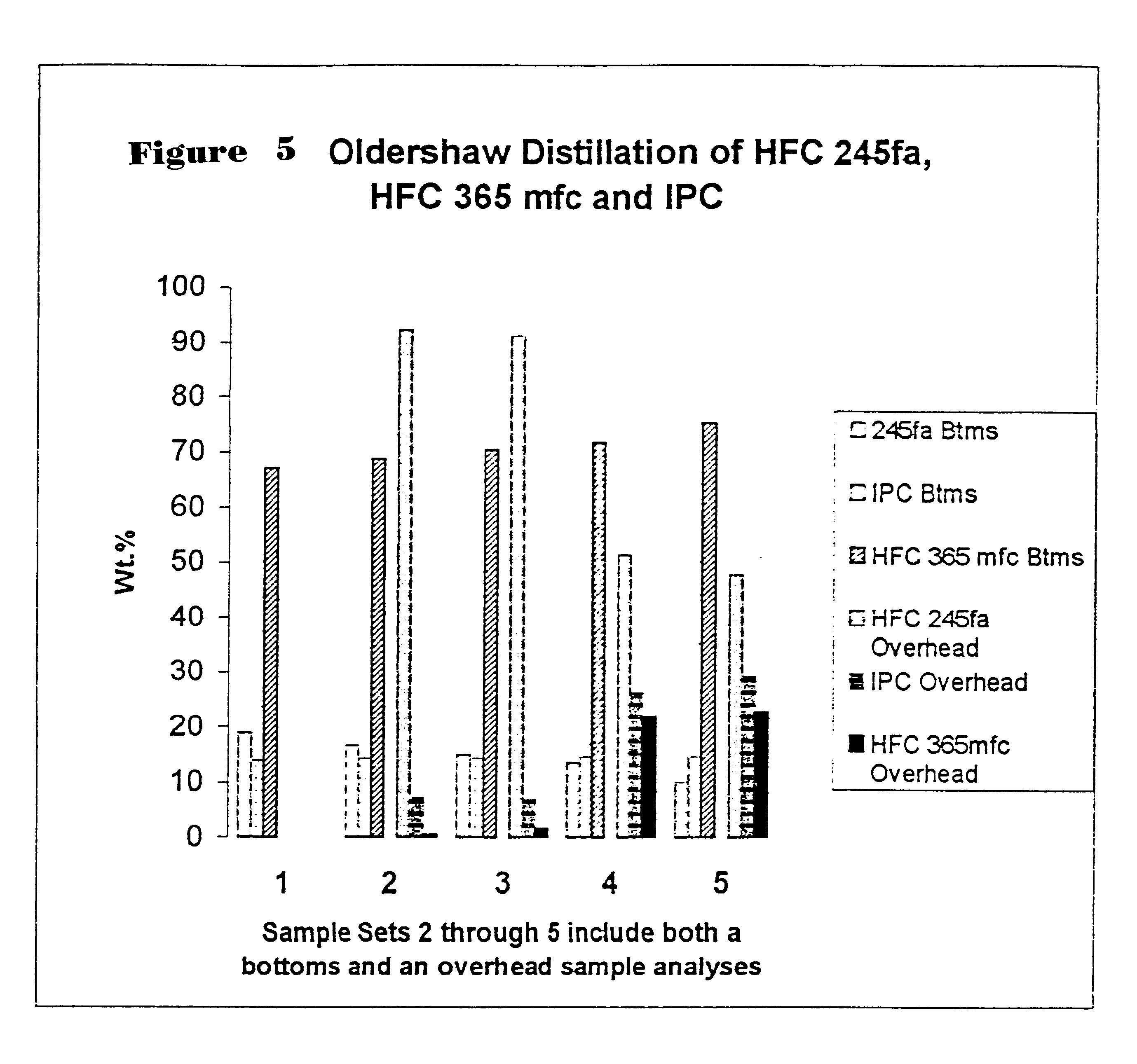

InactiveUS7183448B2Delayed recoveryIncrease production costPreparation by hydrogen halide split-offOther chemical processesDistillationPentafluoropropane

A mixture comprising at least 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is subjected to a distillation operation, and thereby, a distillate comprising an azeotropic composition consisting substantially of 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is obtained and a bottom product comprising 1,1,1,3,3-pentafluoropropane or 1,1,1-trifluoro-3-chloro-2-propene which each is separated and purified.

Owner:DAIKIN IND LTD

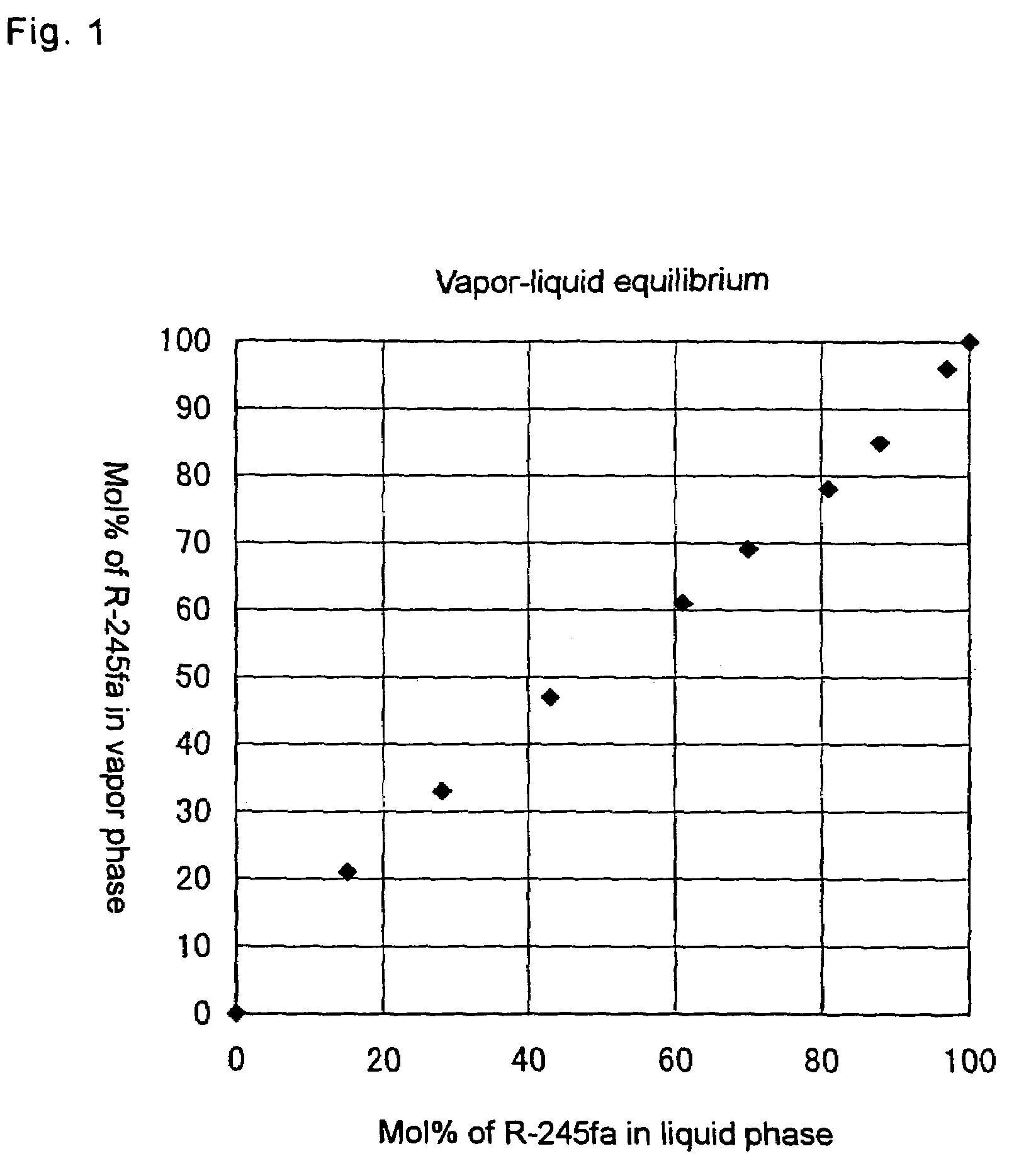

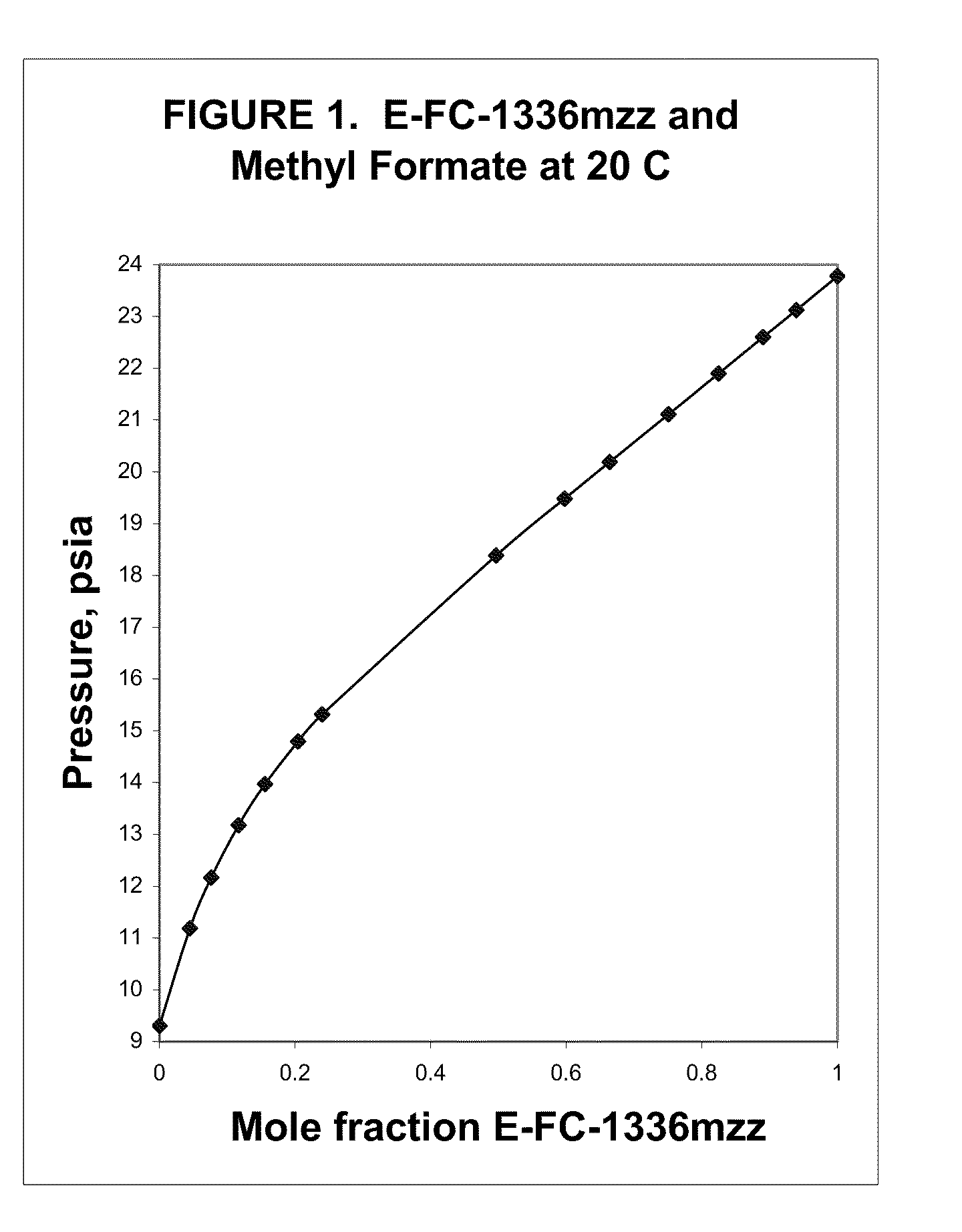

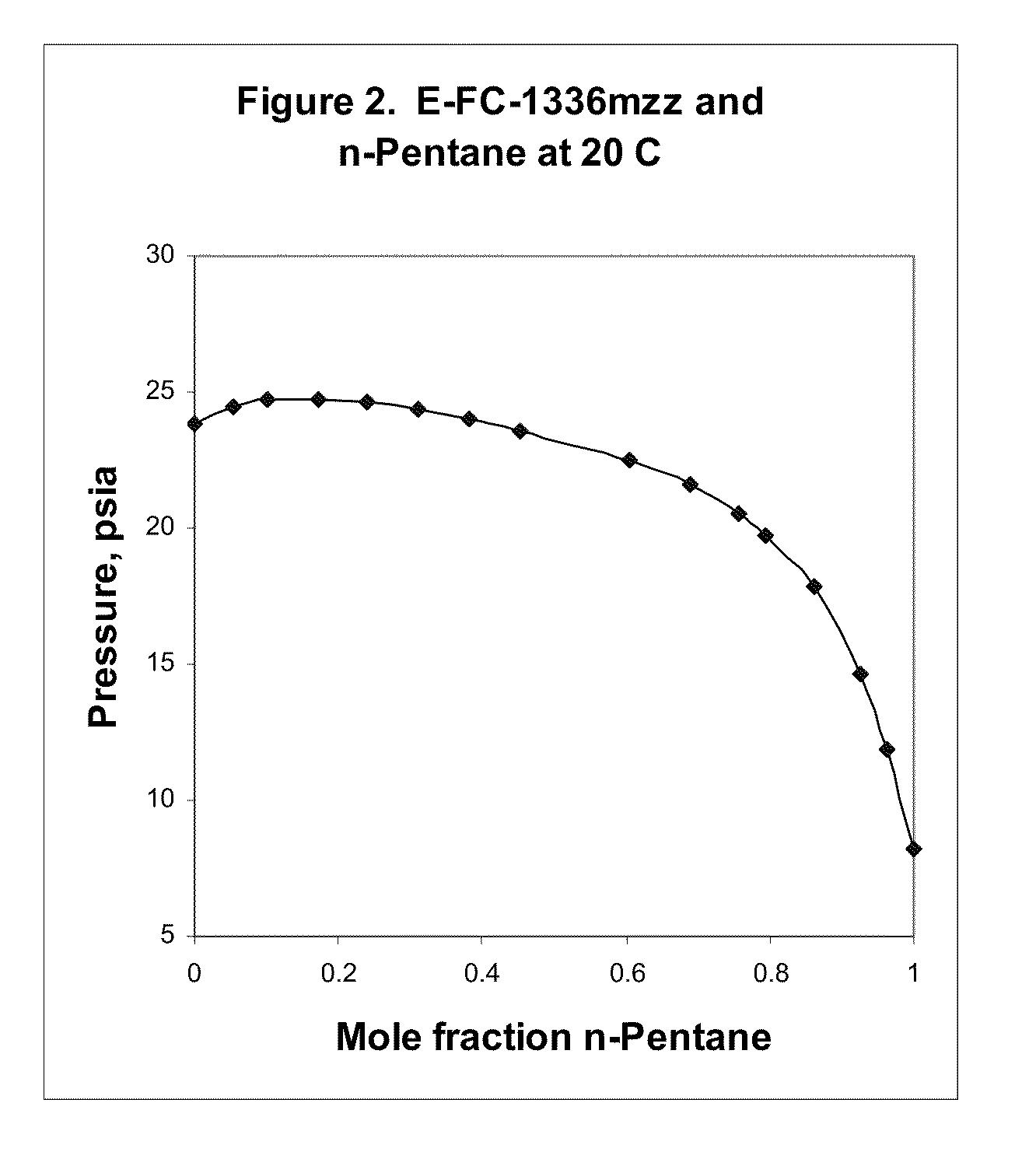

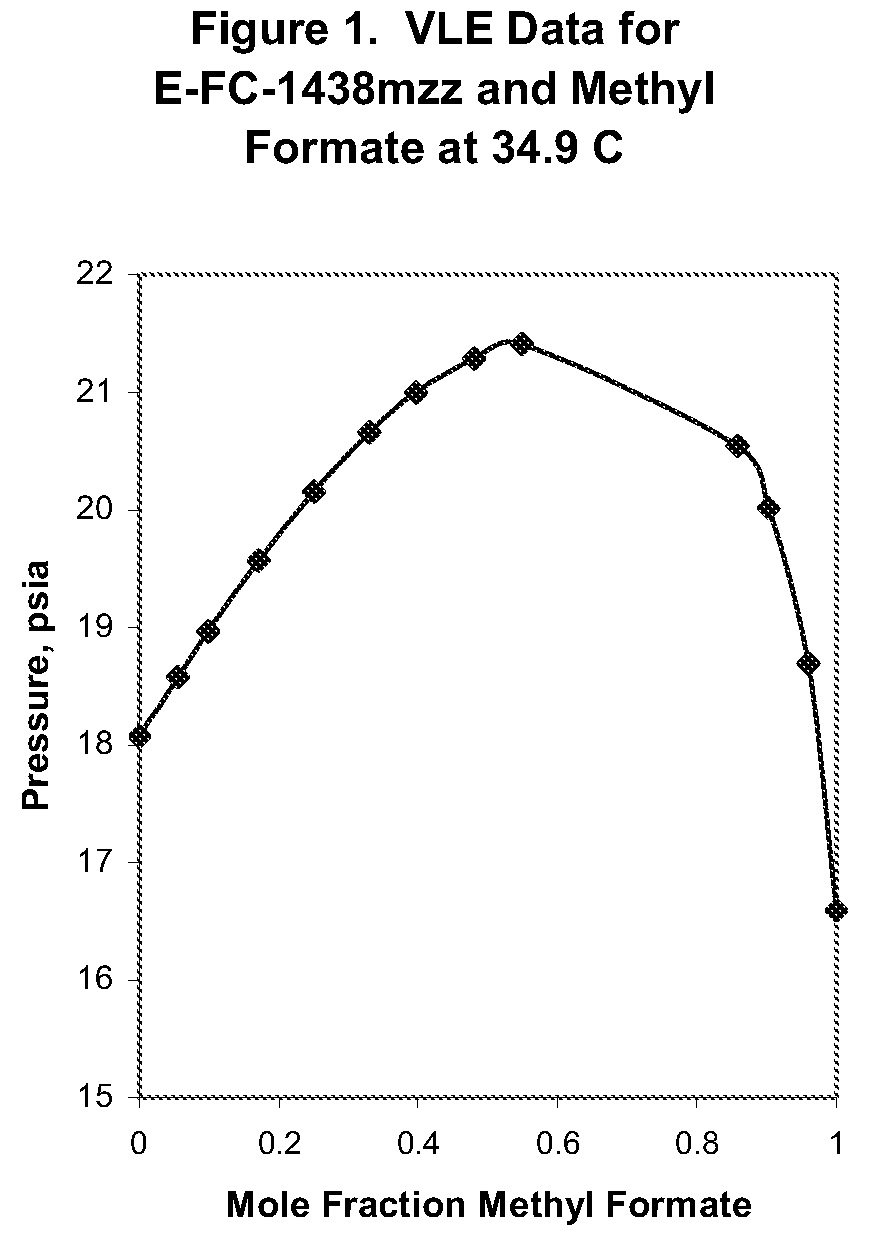

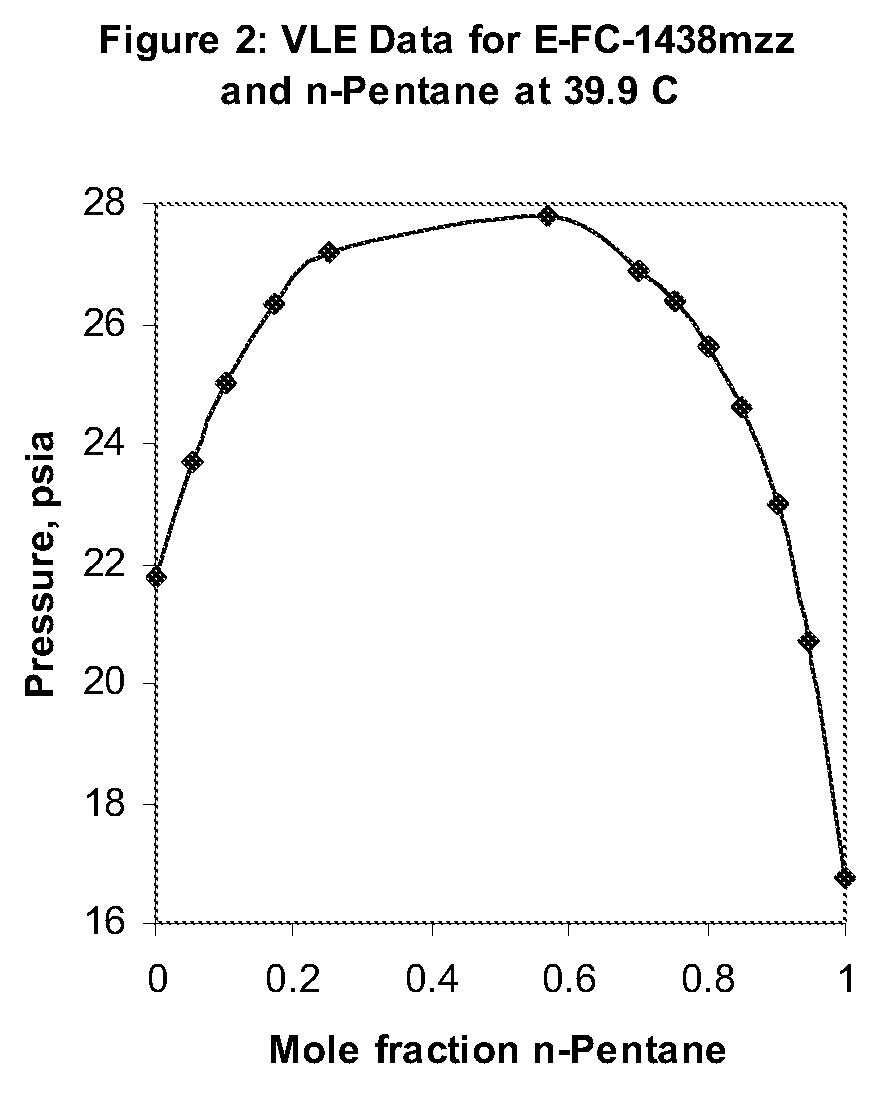

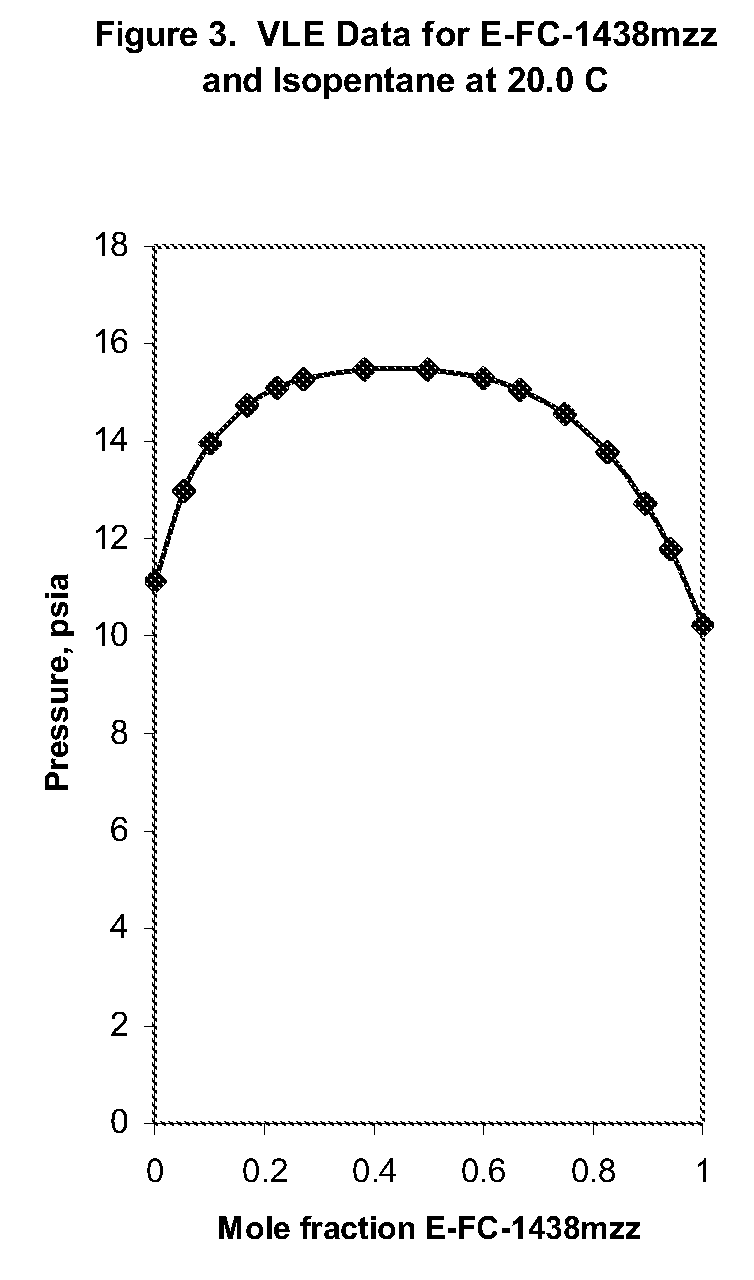

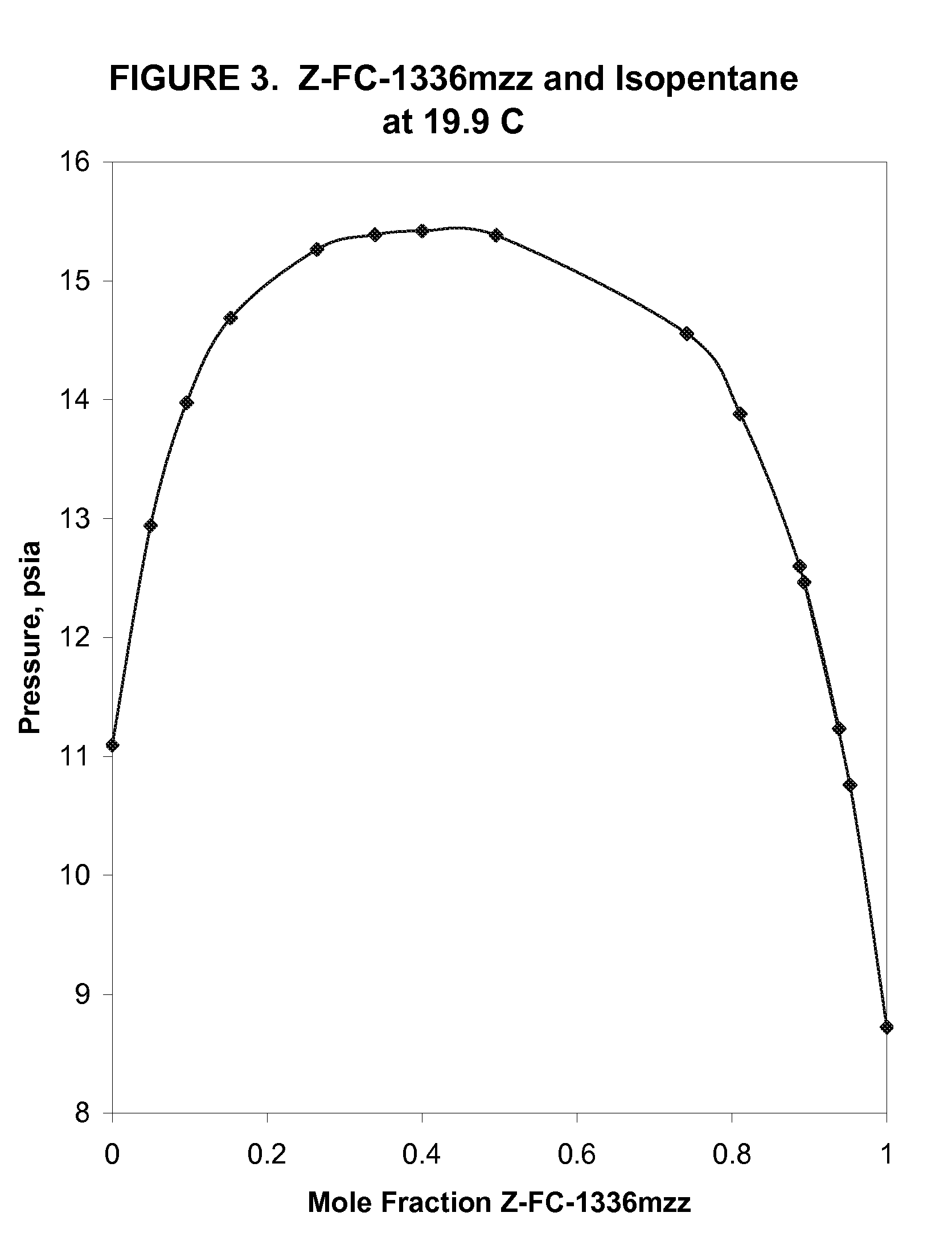

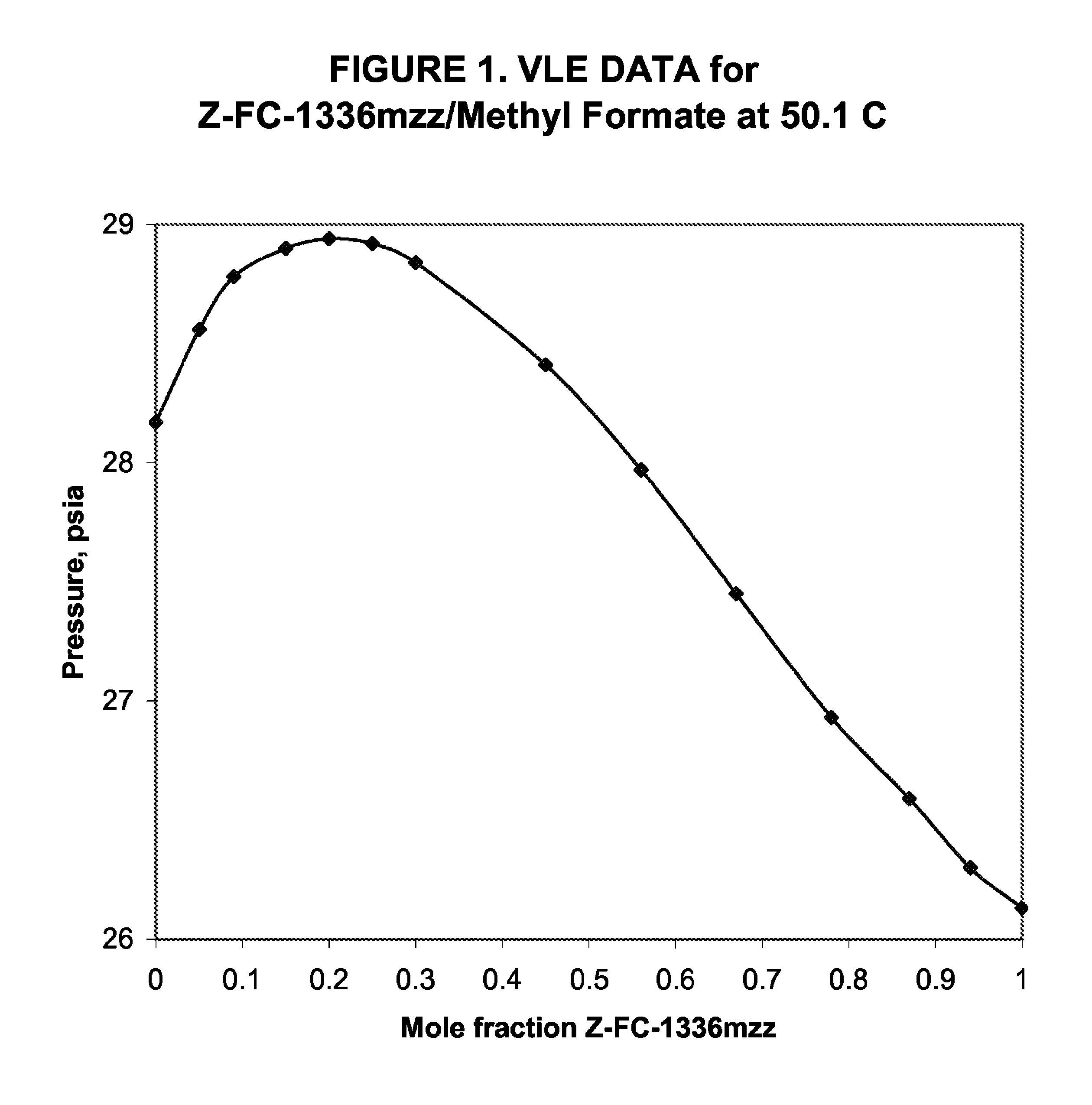

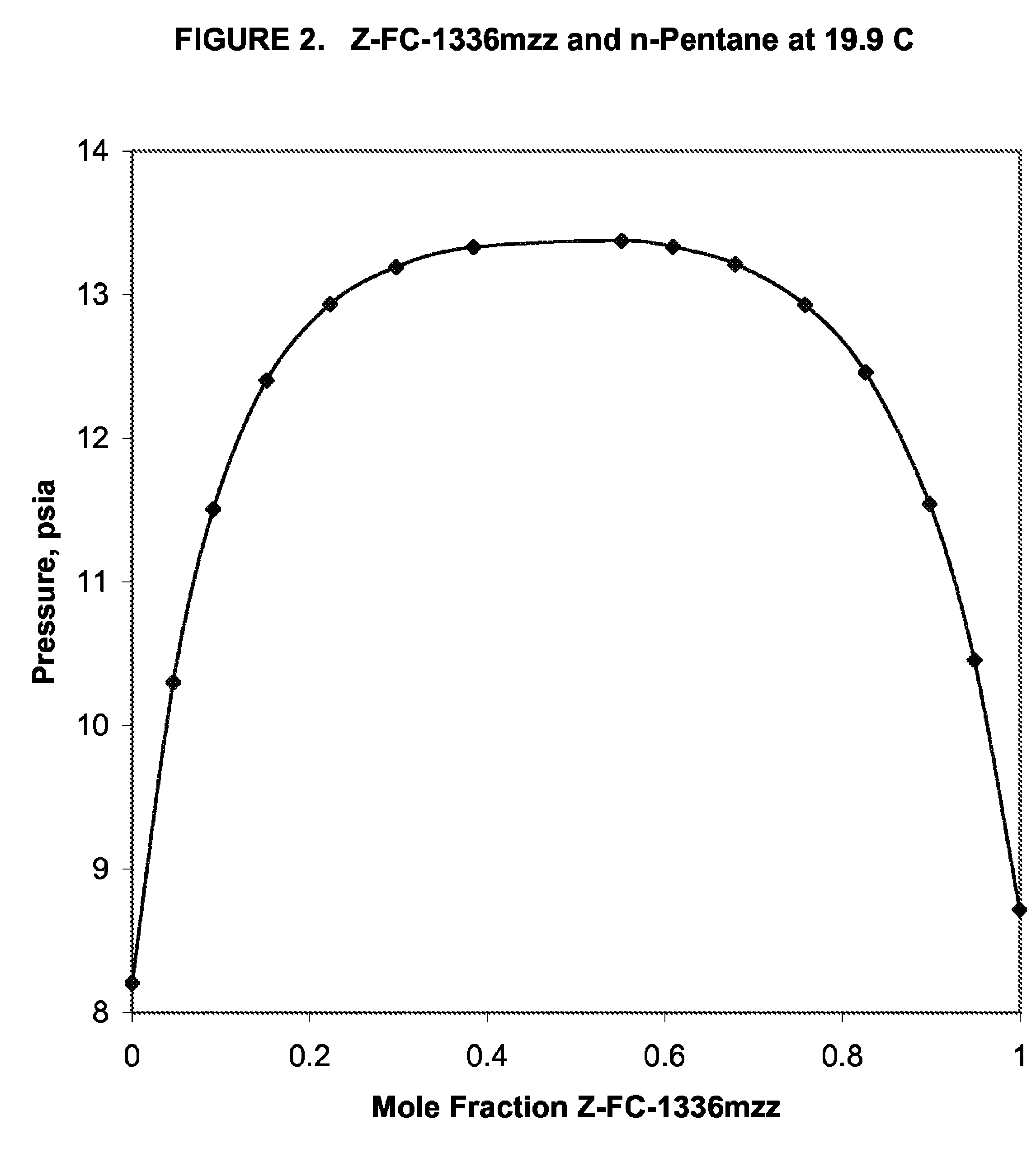

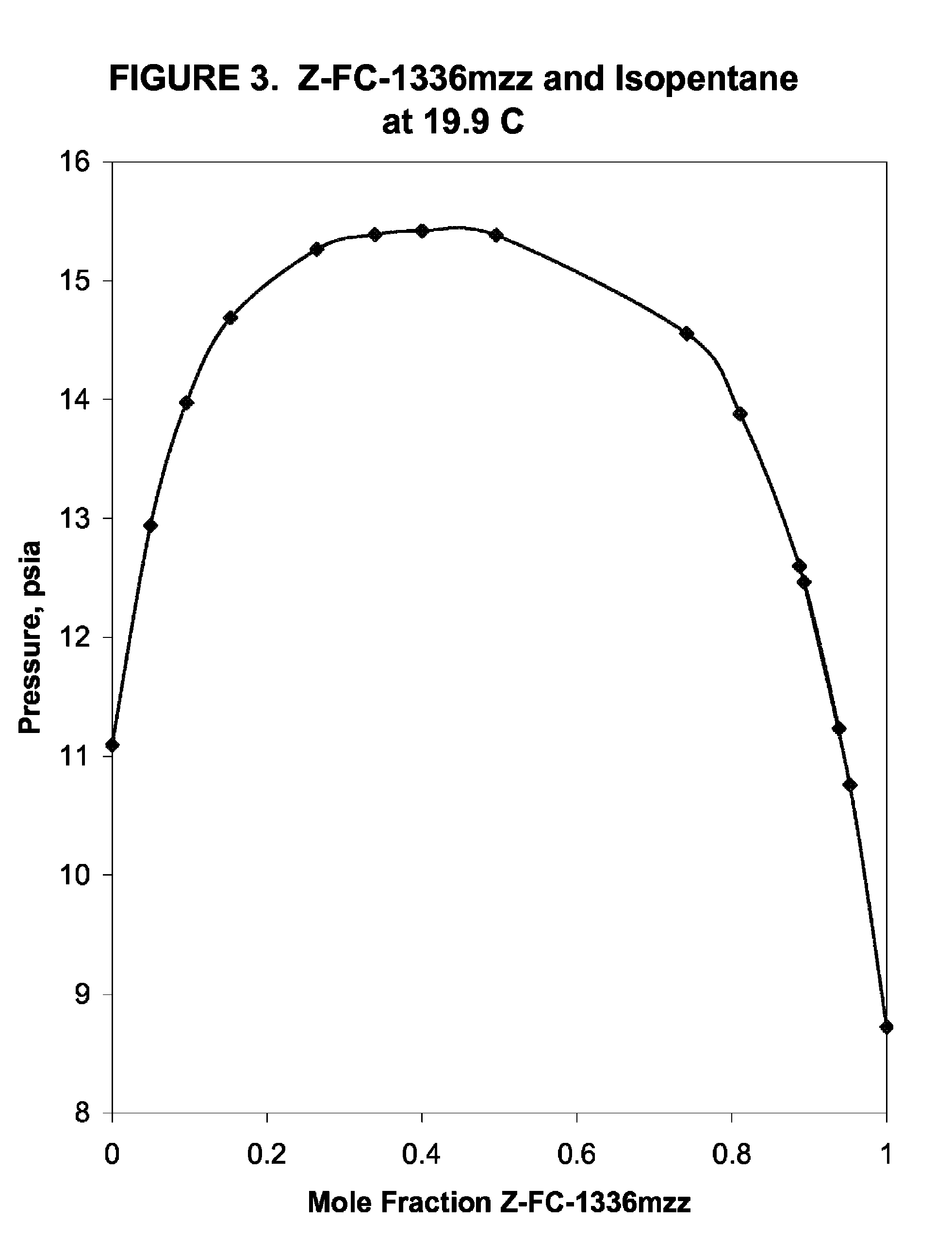

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Method of making 1,1,3,3,3-pentafluoropropene

InactiveUS20050070746A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offFoaming agentSolvent

The invention provides an economic process for the manufacture of the hydrofluorocarbon 1,1,3,3,3-pentafluoropropene (HFC-1225zc). HFC-1225zc can be made from the dehydrochlorination of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa). Alternatively, HFC-1225zc can also be made from the dehydrofluorination of 1,1,1,3,3,3-hexafluoropropane (HFC-236fa). HFC-1225zc) is a compound that has the potential to be used as a low Global Warming Potential refrigerant, blowing agent, aerosol propellant, or solvent.

Owner:HONEYWELL INT INC

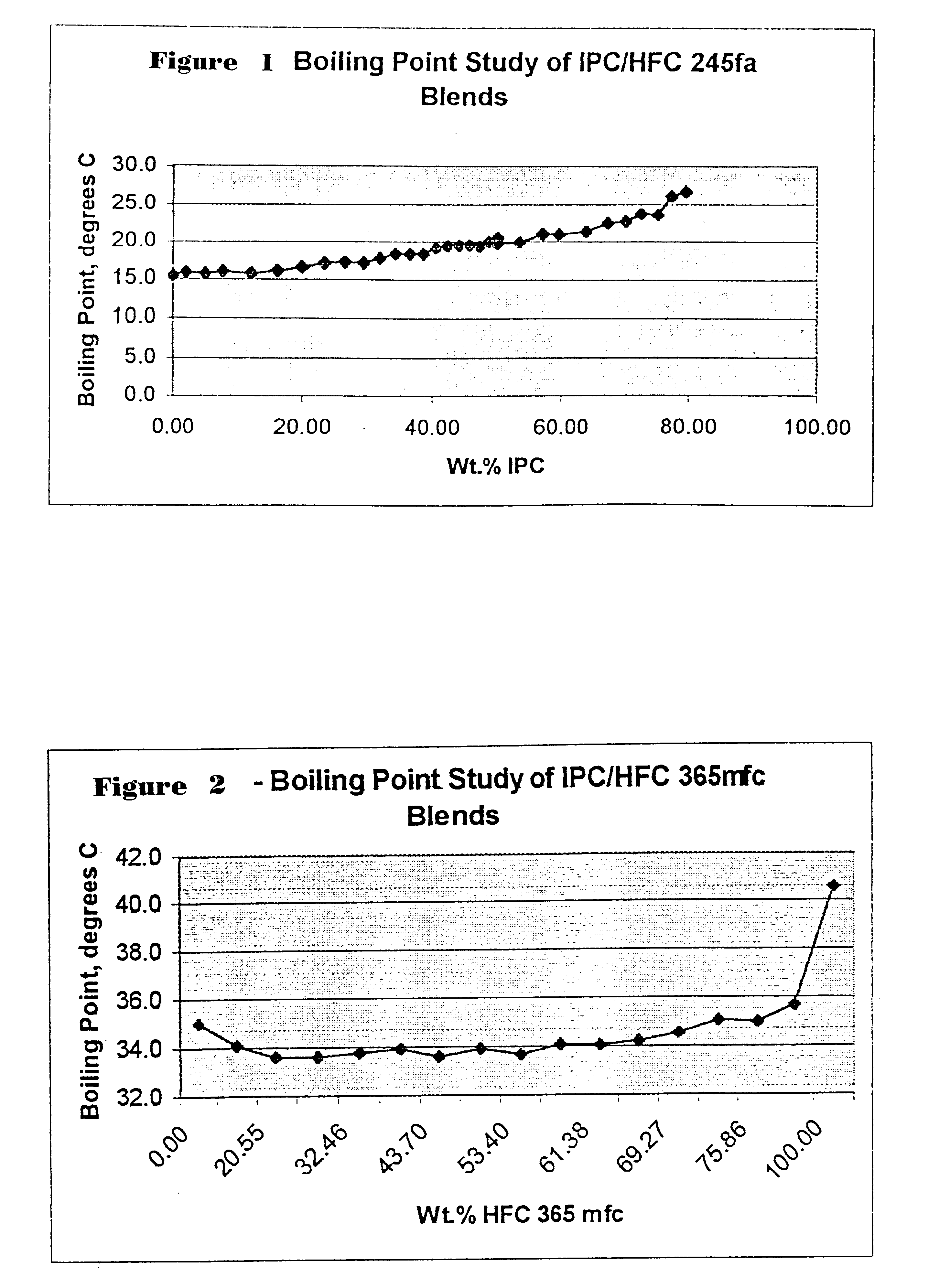

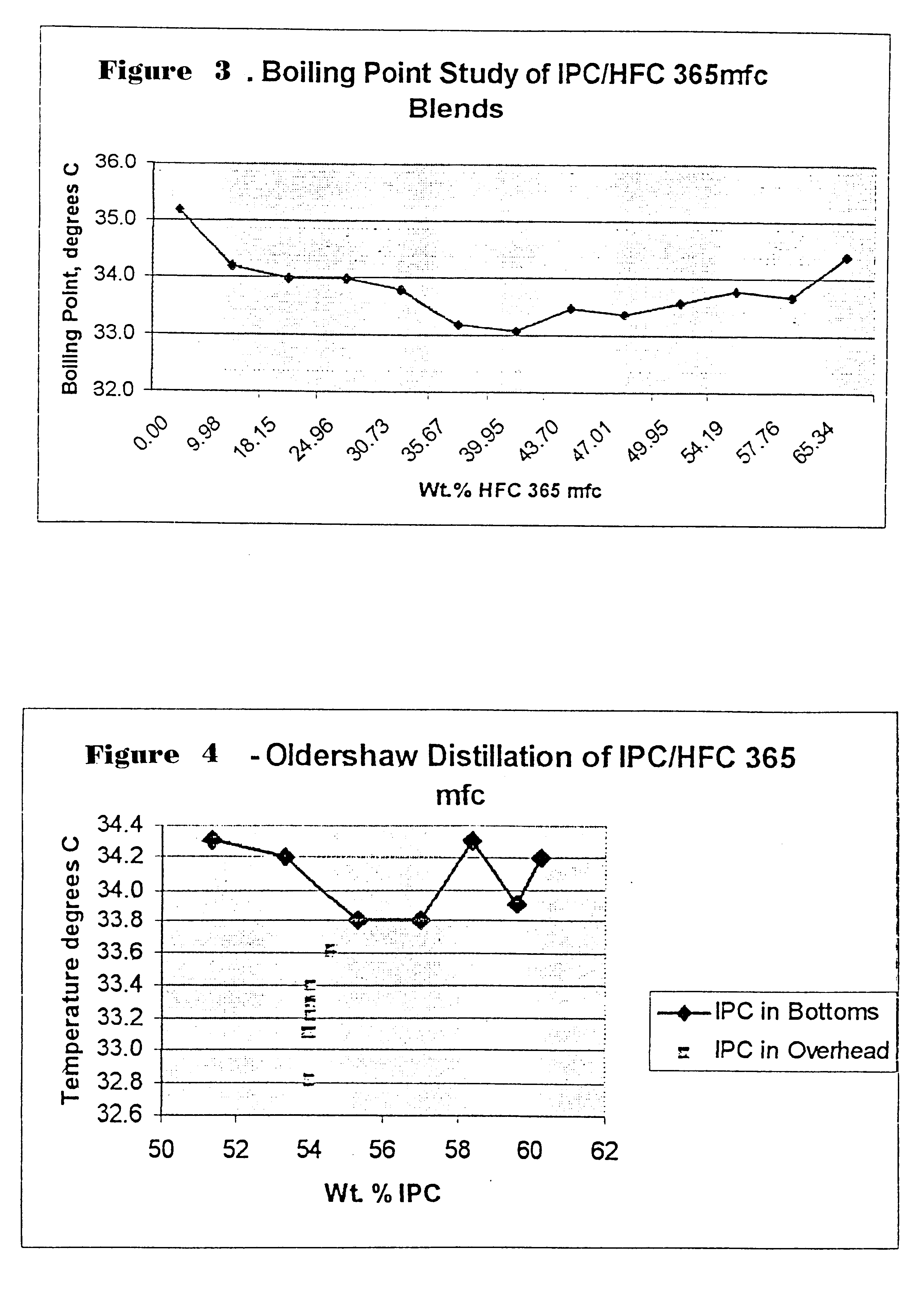

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7592494B2Physical/chemical process catalystsPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropenePentafluoropropane

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

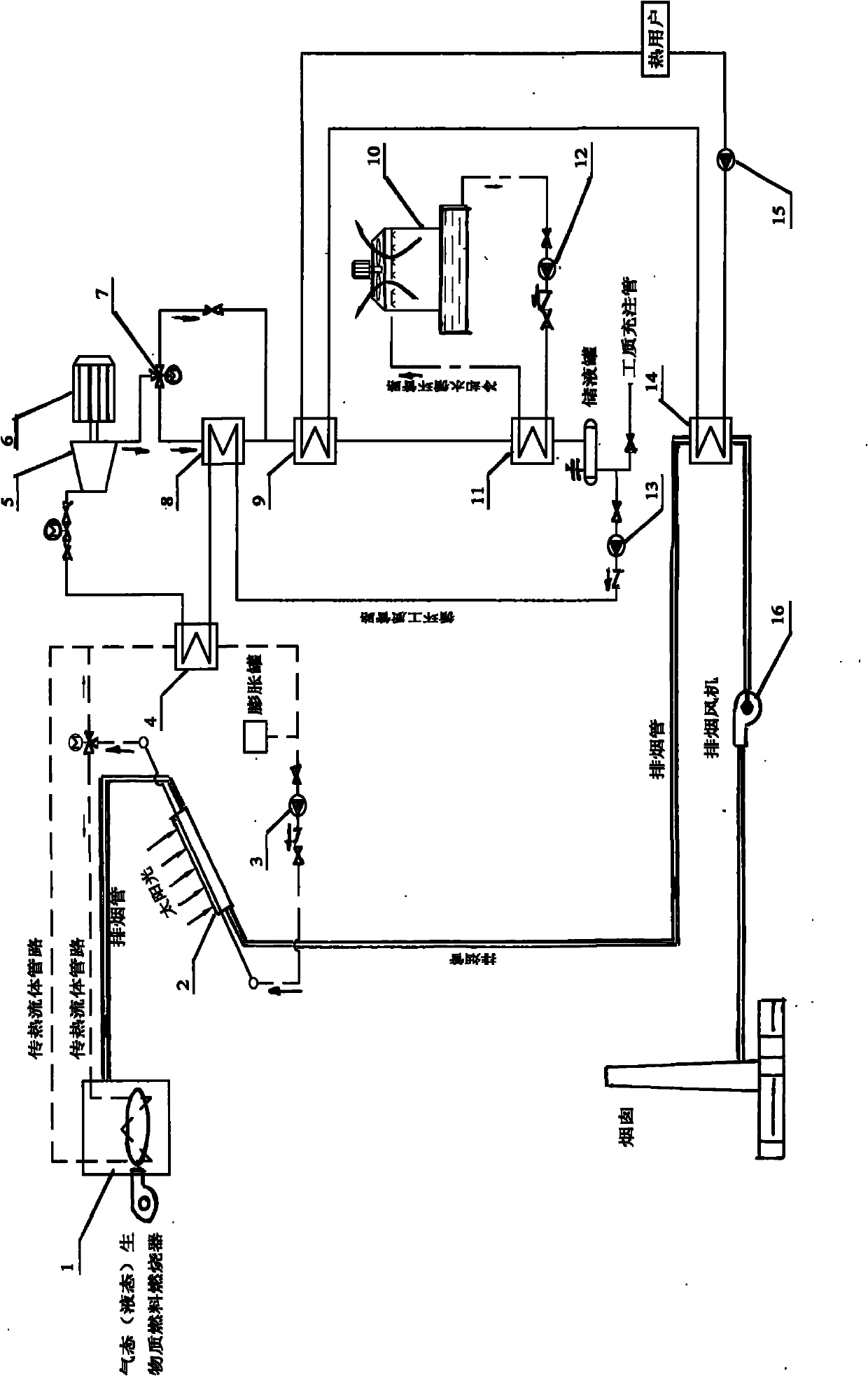

Low temperature solar energy-biomass energy combined heat and power system

InactiveCN101949369ARealize heatingReduce generationSolar heating energyFrom solar energyOrganic Rankine cycleEngineering

The invention relates to a low temperature solar energy-biomass energy combined heat and power system and a generating process. The system comprises a heat transfer fluid (such as heat transfer oil, ionic liquid, and water) circulation loop, a working medium circulation loop of an organic Rankine cycle, a heating furnace smoke discharge pipeline, a hot water heating loop and a cooling water loop. A heating furnace is used for supplementing heat for the heat transfer fluid or used as a standby heat source, and the heating surface uses dimethyl ether, heavy oil, biomass or low-grade cheap fuel made from the biomass; propane (R290), pentafluoropropane (R245fa) and the like are used as circulation working media; the exhaust heat regeneration quantity of the organic Rankine cycle can be adjusted according to the heating demand of a user; and a solar concentrator of the system is a solar concentration and waste heat recovery integrated vacuum flat-plate concentrator with a heat regenerating measure at the bottom, and the waste heat of exhaust smoke of the heating furnace can be recovered while fully using solar energy. The system can directly and efficiently convert a large quantity of low-grade biomass fuel and low-density solar energy into electric energy and supplies heat to users at the same time.

Owner:KUNMING UNIV OF SCI & TECH

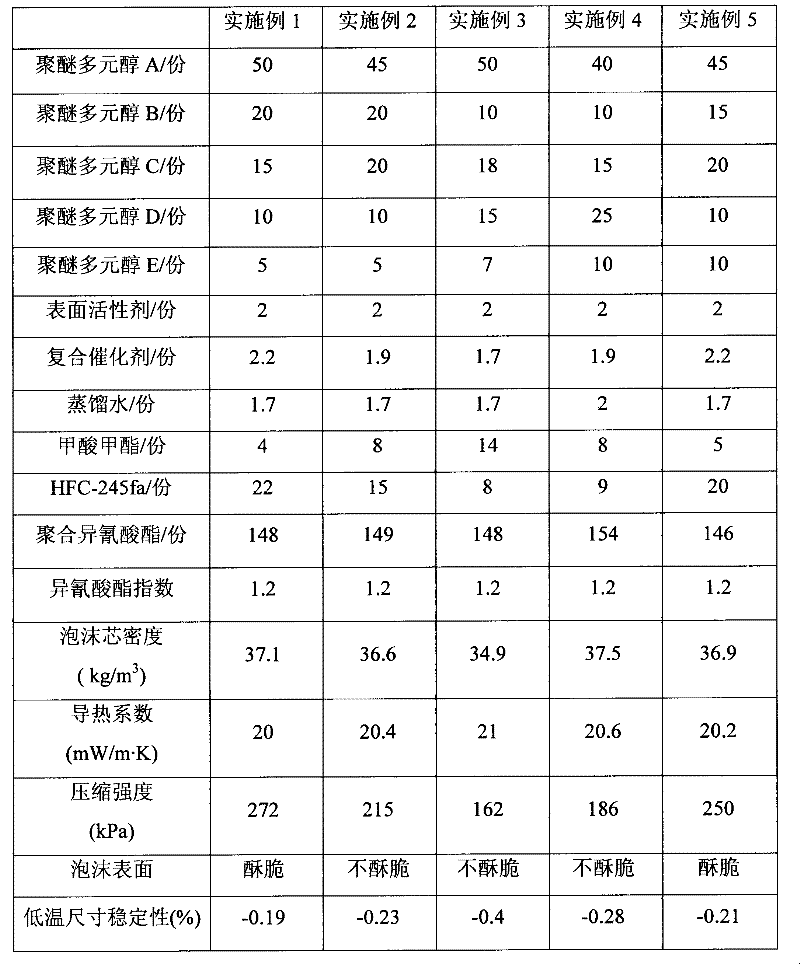

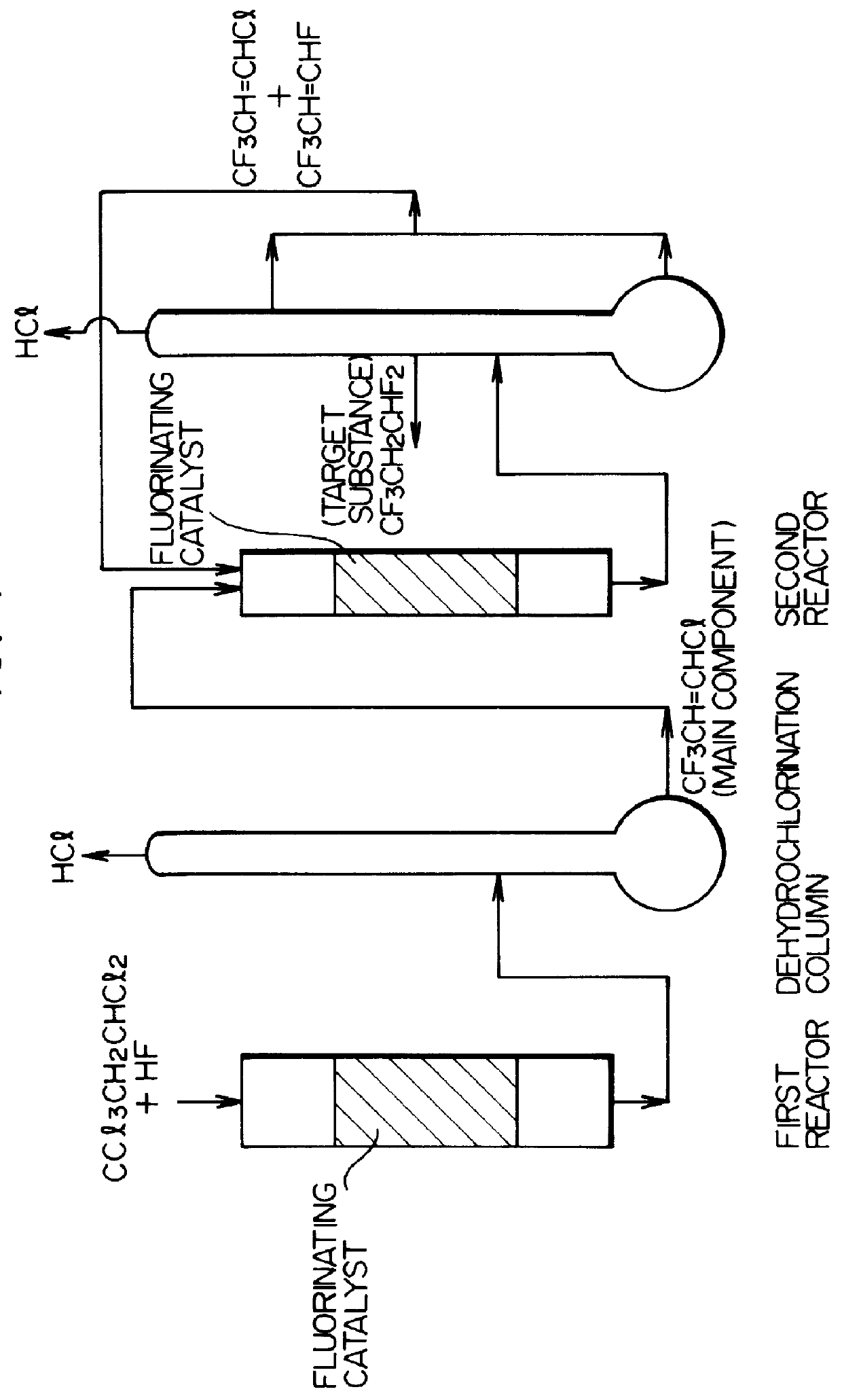

Polyurethane rigid foam and preparation method thereof

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

Azeotrope-like compositions of pentafluoropropane, chlorotrifluoropropene, and hydrogen fluoride

ActiveUS20100237279A1Preparation by hydrogen halide split-offOther chemical processesHydrogen fluoridePentafluoropropane

The invention is directed to a ternary azeotrope-like mixture consisting essentially of effective amounts of 1,1,1,3,3-pentafluoropropane, 1-chloro-3,3,3-trifluoropropene, and hydrogen fluoride.

Owner:HONEYWELL INT INC

Process for producing 1,1,1,3,3-pentafluoropropane

InactiveUS6018084AHigh yieldHigh selectivityPreparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluorideHydrogen

PCT No. PCT / JP96 / 02942 Sec. 371 Date Jun. 25, 1998 Sec. 102(e) Date Jun. 25, 1998 PCT Filed Oct. 8, 1996 PCT Pub. No. WO97 / 24307 PCT Pub. Date Jul. 10, 1997A manufacturing method for 1,1,1,3,3-pentafluoropropane comprises a first process, in which 1,1,1-trifluoro-3-chloro-2-propene is obtained by inducing a reaction between 1,1,1,3,3-pentafluoropropane and hydrogen fluoride in the vapor phase, and a second process, in which the 1,1,1,3,3-pentafluoropropane is obtained by inducing a reaction between 1,1,1-trifluoro-3-chloro-2-propene and hydrogen in the vapor phase, and 1,1,1-trifluoro-3-chloro-2-propene obtained in the first process is supplied to the second process after removing the HCl by-products. This invention can provide a new economic manufacturing method of 1,1,1,3,3-pentafluoropropane with high yield and selectivity.

Owner:DAIKIN IND LTD

Method for producing 1,1,1,3,3-pentafluoropropane

InactiveUS6316681B1High yieldContinuous productionPhysical/chemical process catalystsPreparation by halogen halide additionHydrogen fluorideGas phase

The present invention relates to a method for producing 1,1,1,3,3-pentafluoropropane. This method includes a first step of fluorinating 1-chloro-3,3,3-trifluoropropene in a liquid phase by hydrogen fluoride in the presence of an antimony compound as a catalyst, or a second step of fluorinating 1-chloro-3,3,3-trifluoropropene in a gas phase by hydrogen fluoride in the presence of a fluorination catalyst. If the first step is taken, 1,1,1,3,3-pentafluoropropane can be produced with a high yield. If the second step is taken, 1,1,1,3,3-pentafluoropropane can continuously be easily produced. Therefore, the second step is useful for an industrial scale production thereof. According to the invention, 1-chloro-3,3,3-trifluoropropene may be produced by a method including a step of reacting 1,1,1,3,3-pentachloropropane with hydrogen fluoride in a gas phase in the presence of a fluorination catalyst. This method is useful, because yield of 1-chloro-3,3,3-trifluoropropene is high.

Owner:CENT GLASS CO LTD

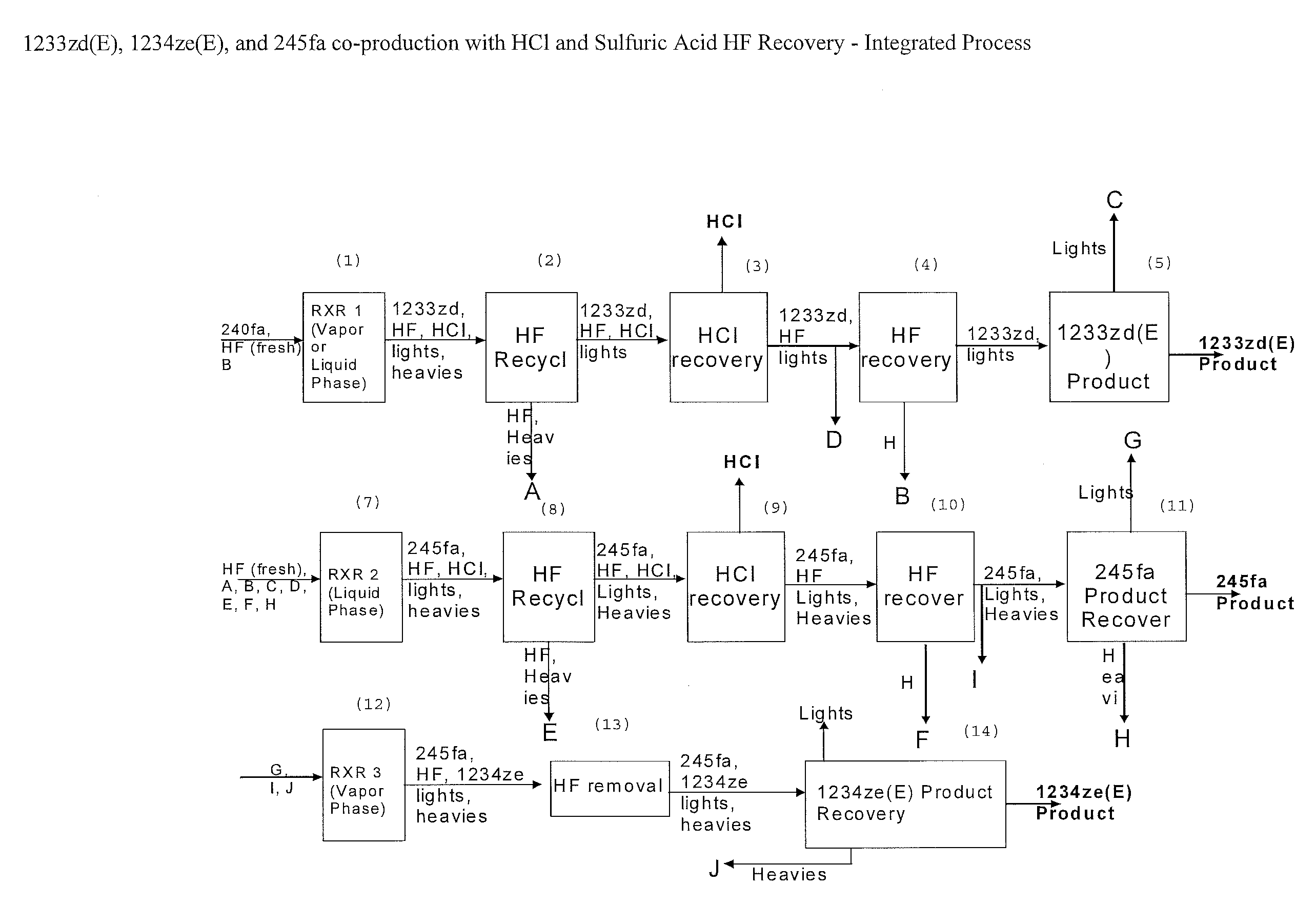

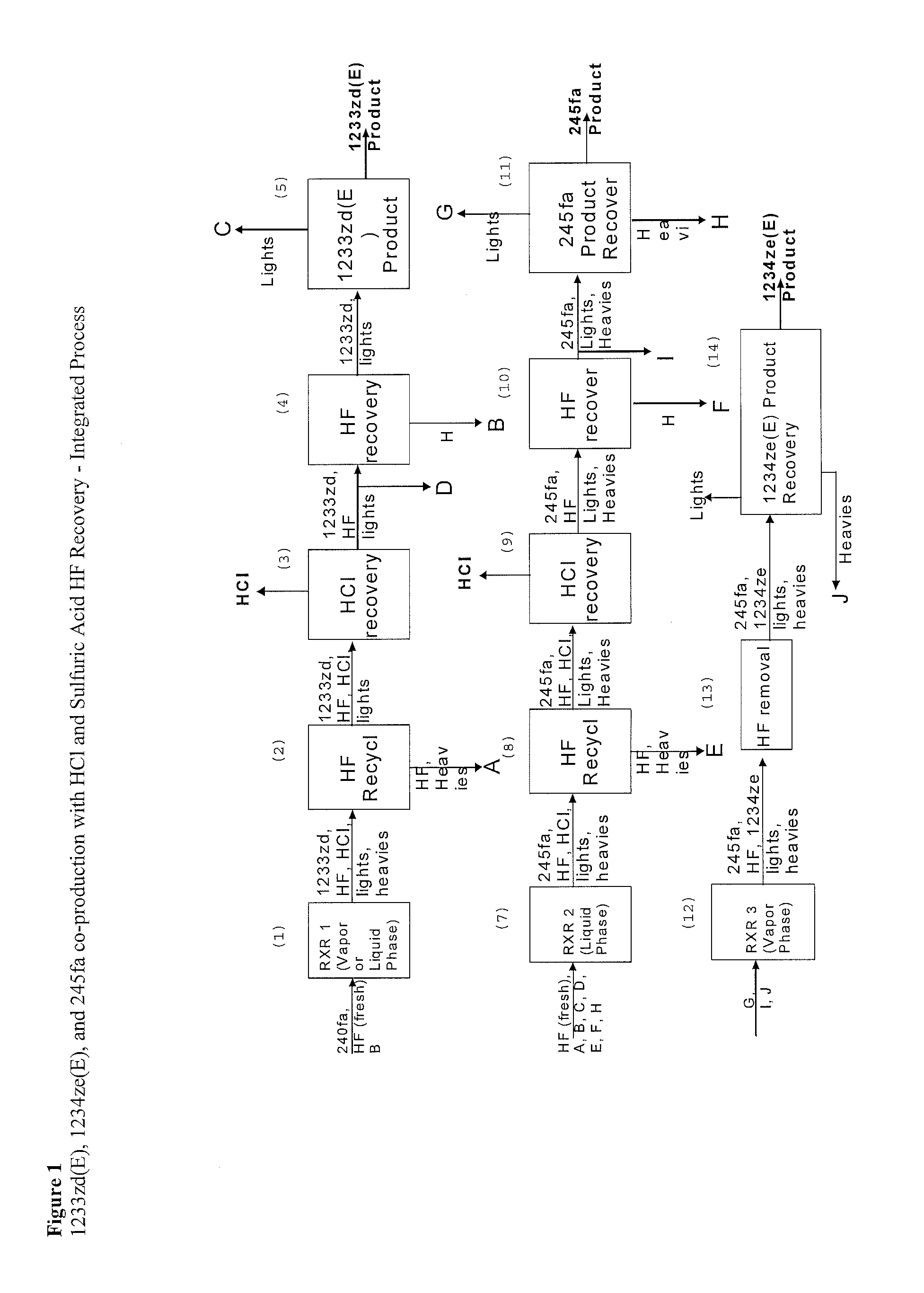

Integrated Process to Coproduce Trans-1-Chloro-3,3,3-Trifluoropropene, Trans-1,3,3,3-Tetrafluoropropene, and 1,1,1,3,3-Pentafluoropropane

ActiveUS20120059200A1High selectivityImprove production yieldPreparation by dehalogenationHydrocarbon from carbon oxidesGas phase1,3,3,3-Tetrafluoropropene

Disclosed is an integrated manufacturing process to co-produce (E)1-chloro-3,3,3-trifluoropropene, (E)1,3,3,3-tetrafluoropropene, and 1,1,1,3,3-pentafluoro-propane starting from a single chlorinated hydrocarbon feed stock, 240fa. The process includes a combined liquid or vapor phase reaction / purification operation which directly produces (E)1-chloro-3,3,3-trifluoropropene (1233zd(E)) from 240fa. In the second liquid phase fluorination reactor 1233zd(E) is contacted with HF in the presence of catalyst to produce 1,1,1,3,3-pentafluoropropane (245fa) with high conversion and selectivity. A third reactor is used for dehydrofluorination of 245fa to produce (E)1,3,3,3-tetrafluoropropene (1234ze(E)) by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrofluorination catalyst. This operation may be followed by one or more purification processes to recover the 1234ze(E) product.

Owner:HONEYWELL INT INC

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

Hfo-1234ze mixed isomers with hfc-245fa as a blowing agent, aerosol, and solvent

A composition which is a blowing agent which comprises from about 75% to about 90% by weight trans-1,3,3,3-tetrafluoropropene, from about 1% to about 15% by weight cis-1,3,3,3-tetrafluoropropene, and from about 1% about 15% by weight 1,1,3,3,3-pentafluoropropane.

Owner:HONEYWELL INT INC

Method for producing tetrafluoropropenes

ActiveUS20110270000A1Increase reactionHigh yieldPreparation by dehalogenationPreparation by hydrogen halide split-offReagentPentafluoropropane

The current invention relates to a process for making a tetrafluoropropene using a tetrafluorochloropropane and / or a pentafluoropropane as starting or intermediate reagents. More specifically, though not exclusively, the present invention relates to a novel method for preparing a tetrafluoropropene by dehydrohalogenating a starting or intermediate tetrafluorochloropropane and / or pentafluoropropane material in the presence of a caustic solution at a temperature range greater than 40° C. and less than or equal to 80° C.

Owner:HONEYWELL INT INC

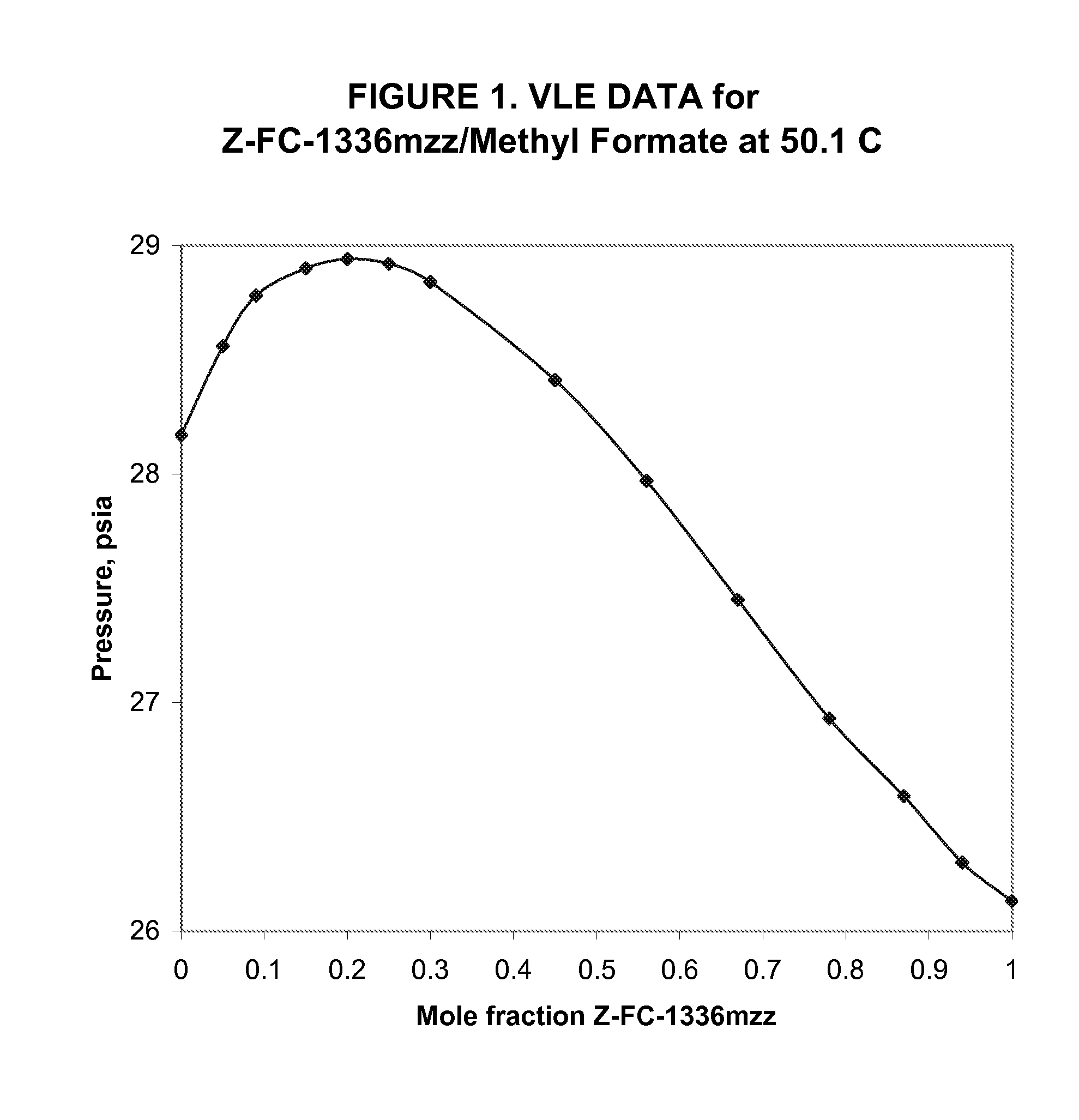

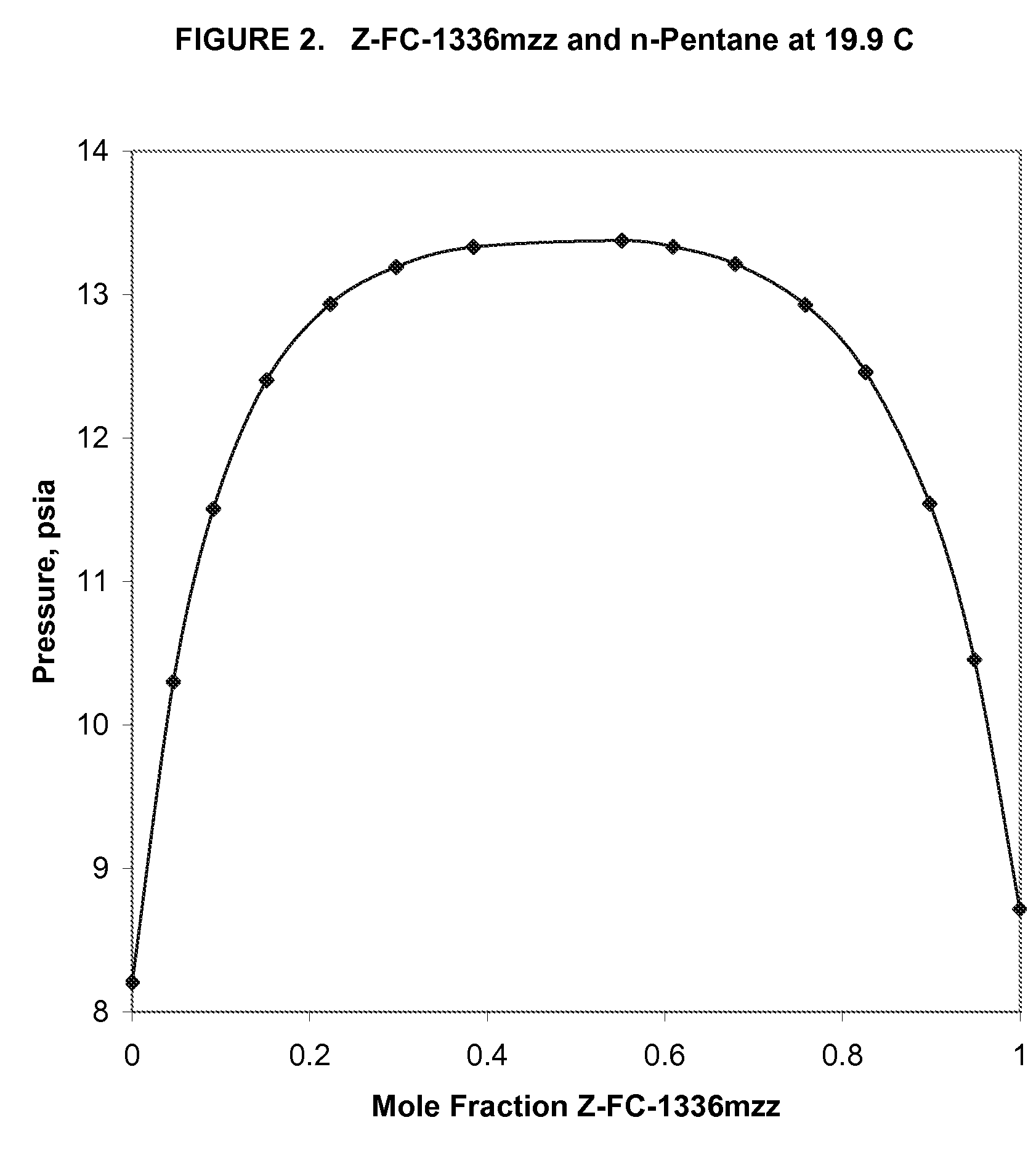

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Azeotropic and azeotrope-like compositions of Z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Coproduction of hydrofluoroolefins

InactiveUS7687670B2Preparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationCeriumCobalt

Disclosed is a process for the co-manufacture of the hydrofluoroolefins HFC-1225ye and HFC-1234yf. The process comprises contacting a blend of 1,1,1,2,3,3-hexafluoropropane and 1,1,1,2,3-pentafluoropropane at a temperature of from about 200° C. to about 500° C. with a catalyst, optionally in the presence of an inert gas. The catalyst includes, but is not limited to, aluminum fluoride; fluorided alumina; metals on aluminum fluoride; metals on fluorided alumina; oxides, fluorides, and oxyfluorides of magnesium, zinc and mixtures of magnesium and zinc and / or aluminum; lanthanum oxide and fluorided lanthanum oxide; chromium oxides, fluorided chromium oxides, and cubic chromium trifluoride; carbon, acid-washed carbon, activated carbon, three dimensional matrix carbonaceous materials; and metal compounds supported on carbon. The metal compounds are oxides, fluorides, and oxyfluorides of at least one metal selected from the group consisting of sodium, potassium, rubidium, cesium, yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, chromium, iron, cobalt, rhodium, nickel, copper, zinc, and mixtures thereof. The product hydrofluoroolefins are separated from unreacted hydrofluorocarbons and hydrogen fluoride. In another embodiment, the unreacted hydrofluorocarbons optionally may be recirculated back through the process.

Owner:EI DU PONT DE NEMOURS & CO

1,3,3,3-tetrafluoropropene process azeotropes with hf

The present invention pertains to azeotropic and azeotrope-like compositions of the following three blends:1. Trans-1,3,3,3-tetrafluoropropene (HFO-1234ze(E)), cis-1,3,3,3-tetrafluoropropene (HFO-1234ze(Z)) and hydrogen fluoride (HF);2. HFO-1234ze(E), 1,1,1,3,3-pentafluoropropane (HFC-245fa) and HF; and3. HFO-1234ze(Z), HFC-245fa and HF.These azeotropic and azeotrope-like compositions are useful as intermediates in the production of HFO-1234ze(E).

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com