Patents

Literature

3495 results about "Chloride vinyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl chloride is an organochloride with the formula H2C=CHCl that is also called vinyl chloride monomer (VCM) or chloroethene. This colorless compound is an important industrial chemical chiefly used to produce the polymer polyvinyl chloride (PVC).

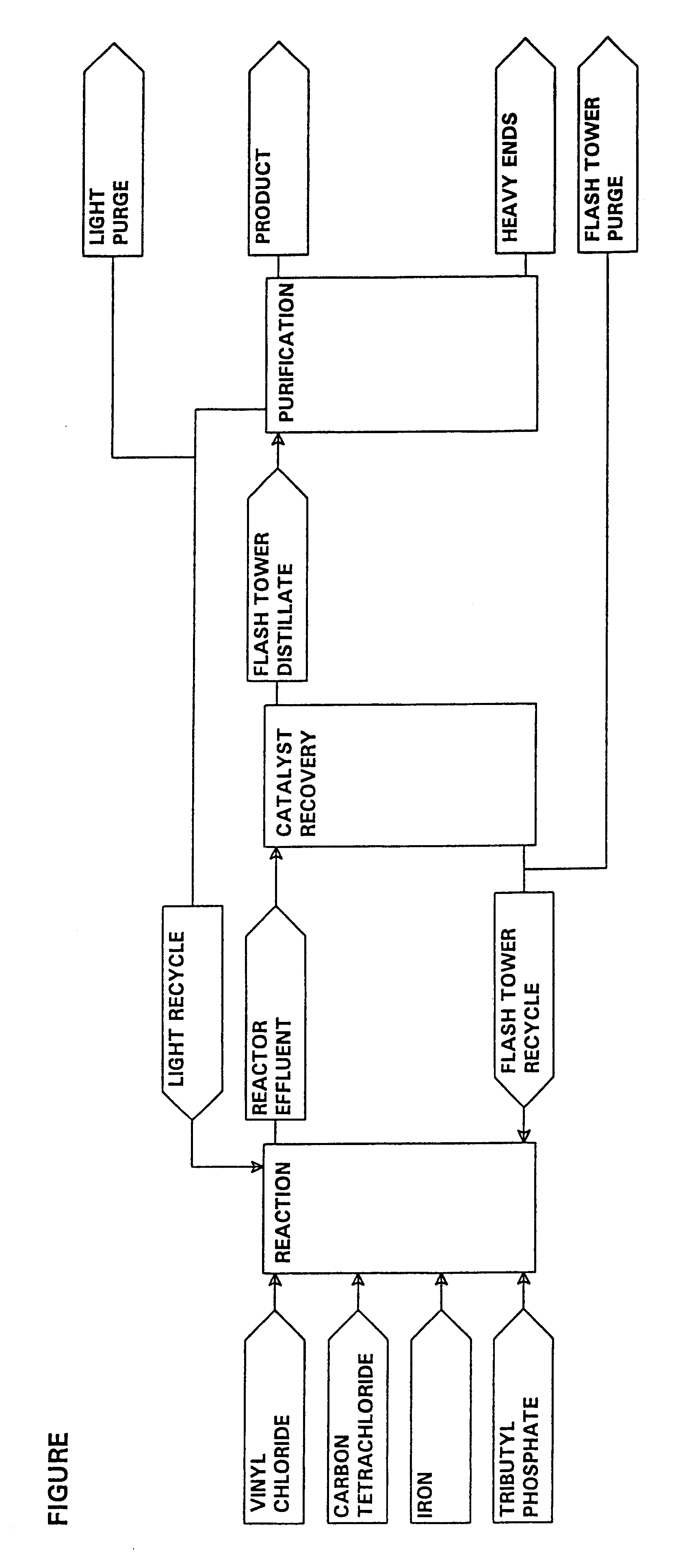

Process for the manufacture of 1, 1, 1, 3, 3-pentachloropropane

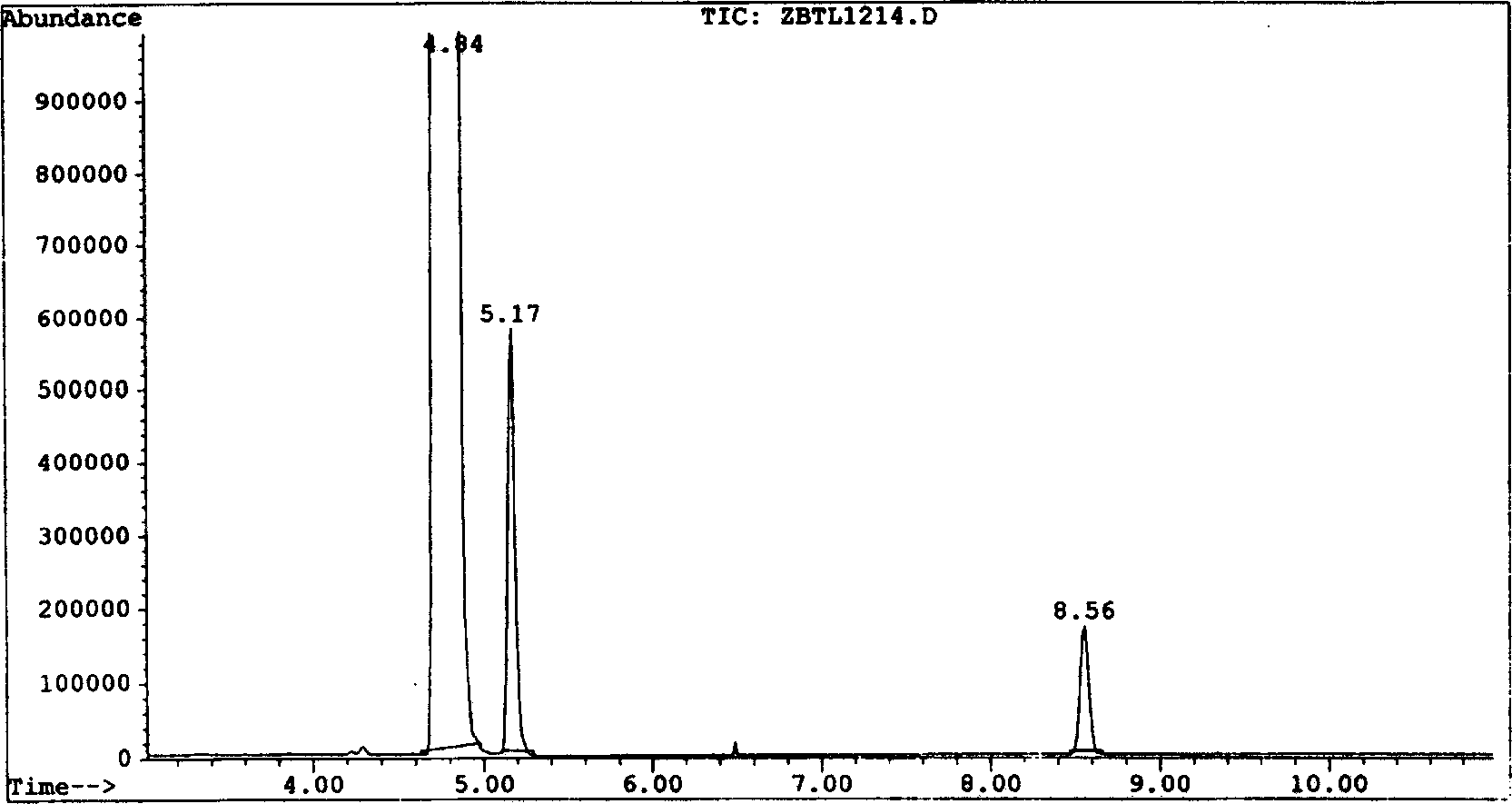

InactiveUS6313360B1Improve degradation rateShorten the timeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationChlorideOrganic phosphates

A process is provided for the production of 1,1,1,3,3-pentachloropropane. The process comprises: (a) producing a product mixture in a reactor by reacting carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture comprising organophosphate solvent, iron metal and ferric chloride under conditions sufficient to produce 1,1,1,3,3-pentachloropropane; (b) subjecting the 1,1,1,3,3-pentachloropropane containing product mixture from step (a) to evaporation such that a fraction enriched in 1,1,1,3,3-pentachloropropane is separated from the product mixture and a bottoms fraction results which comprises the iron metal / ferric chloride catalyst components and heavy end by-products; and (c) recycling at least a portion of the bottoms fraction from step (b) to the reactor.

Owner:OCCIDENTAL CHEM CORP

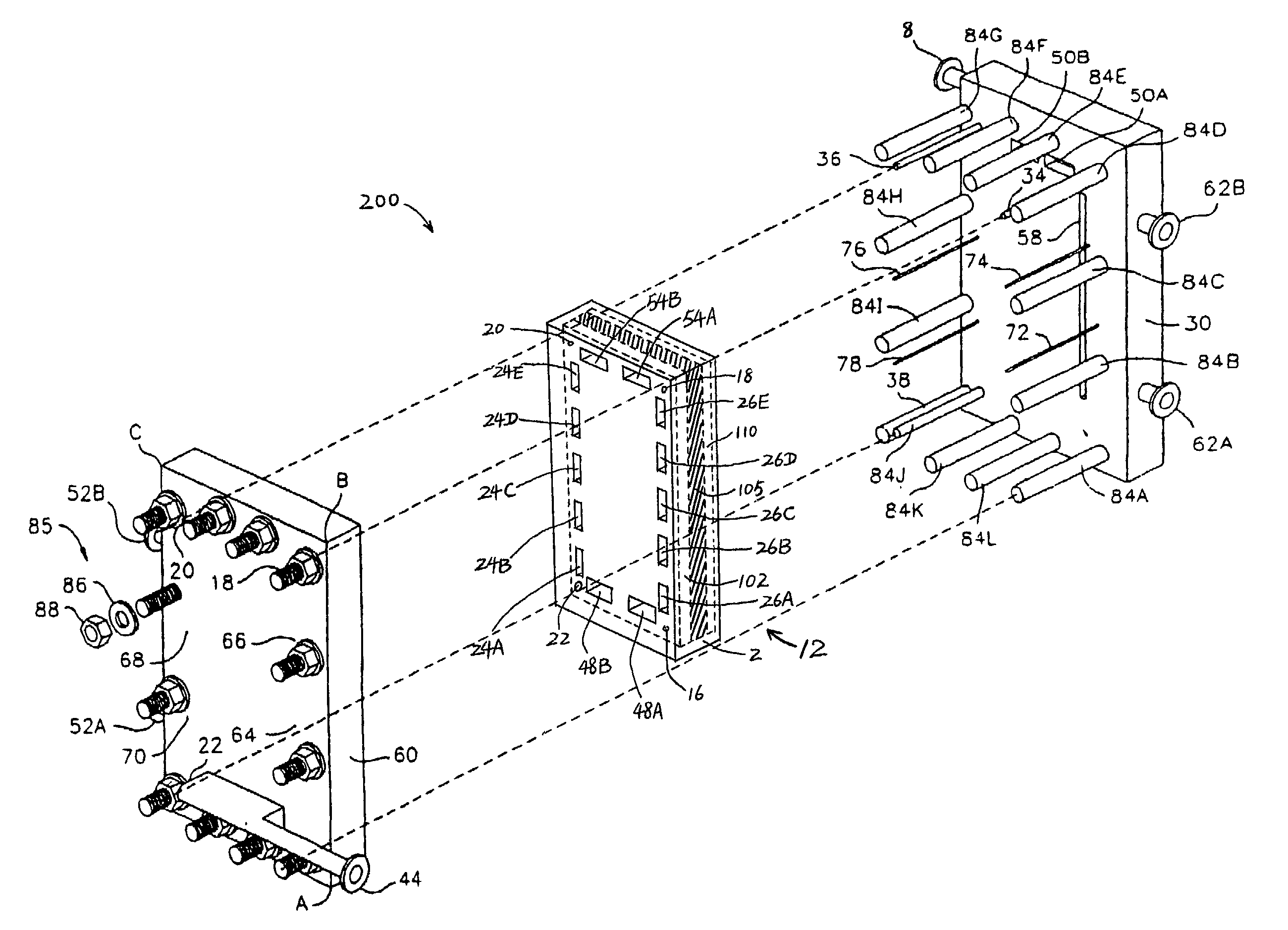

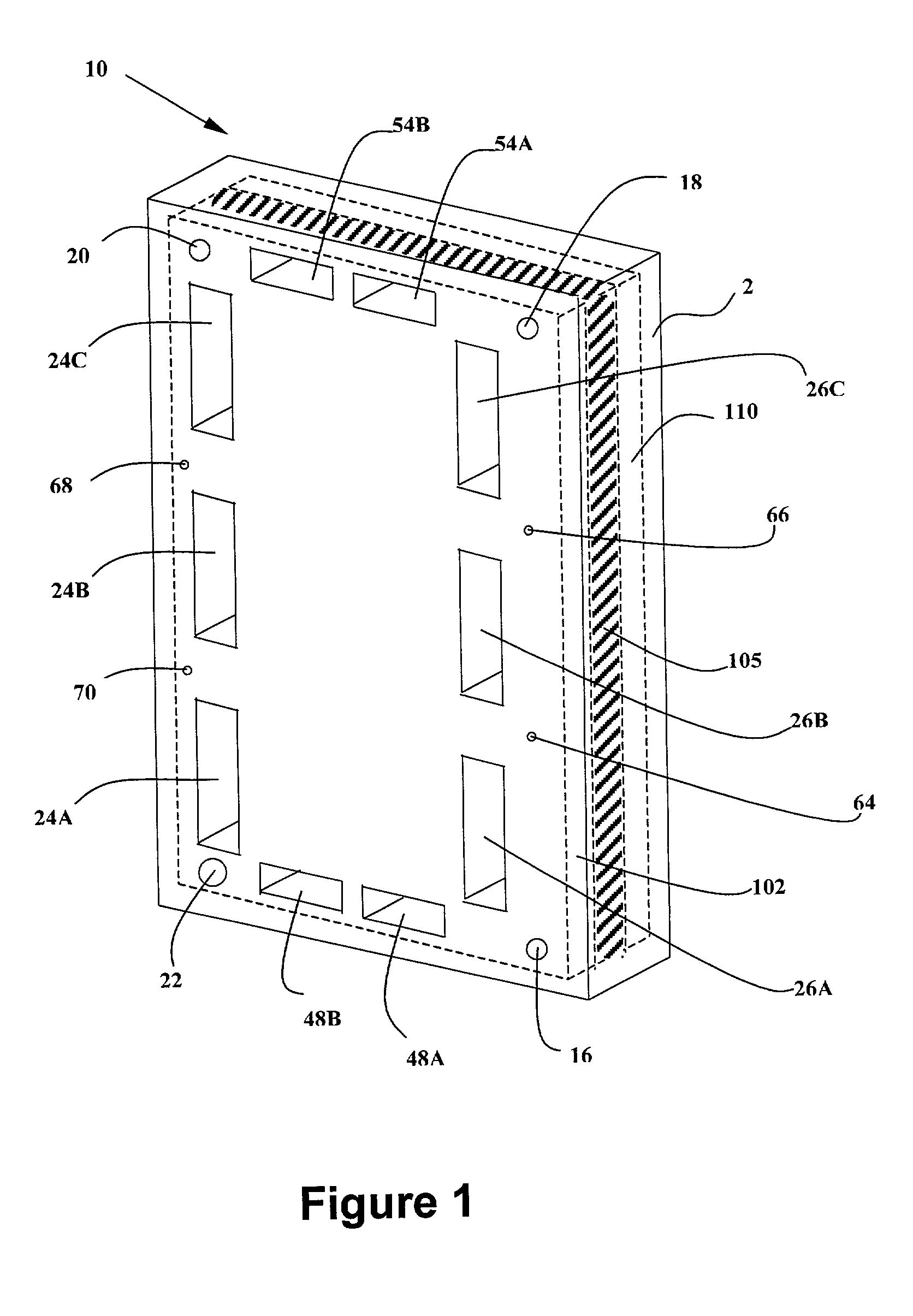

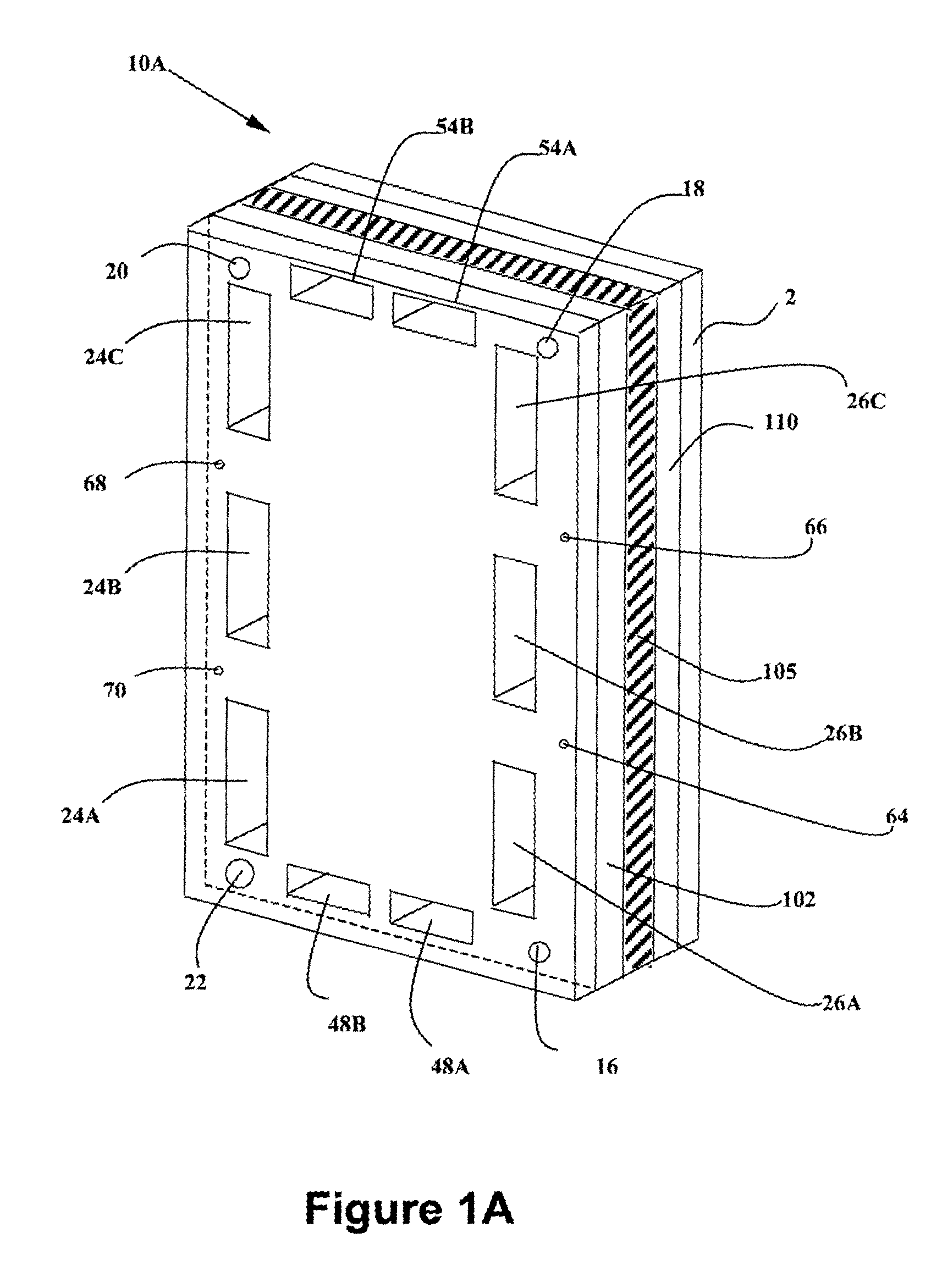

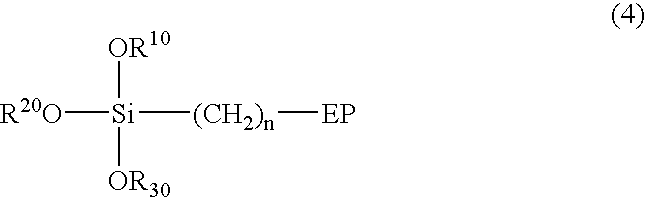

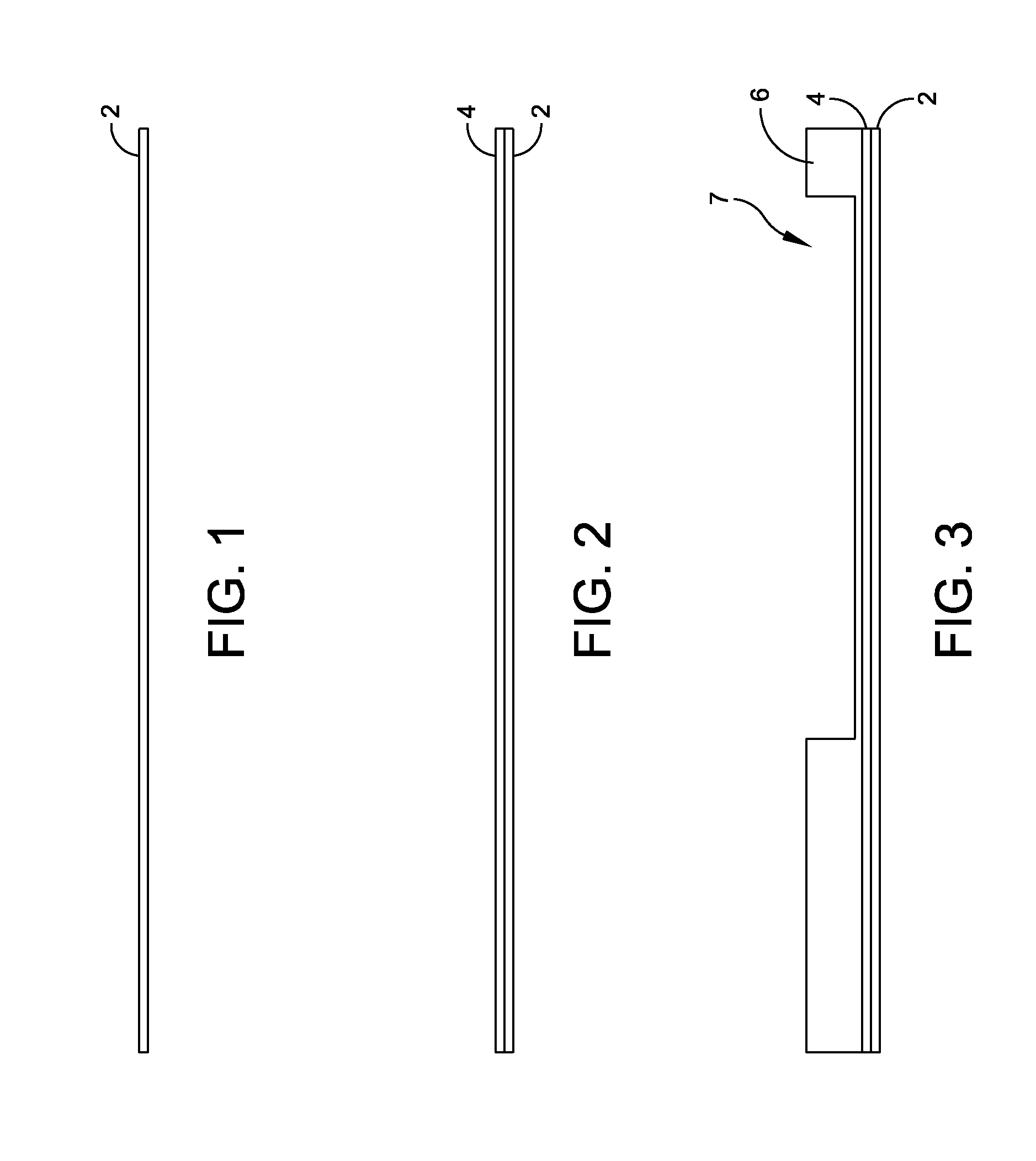

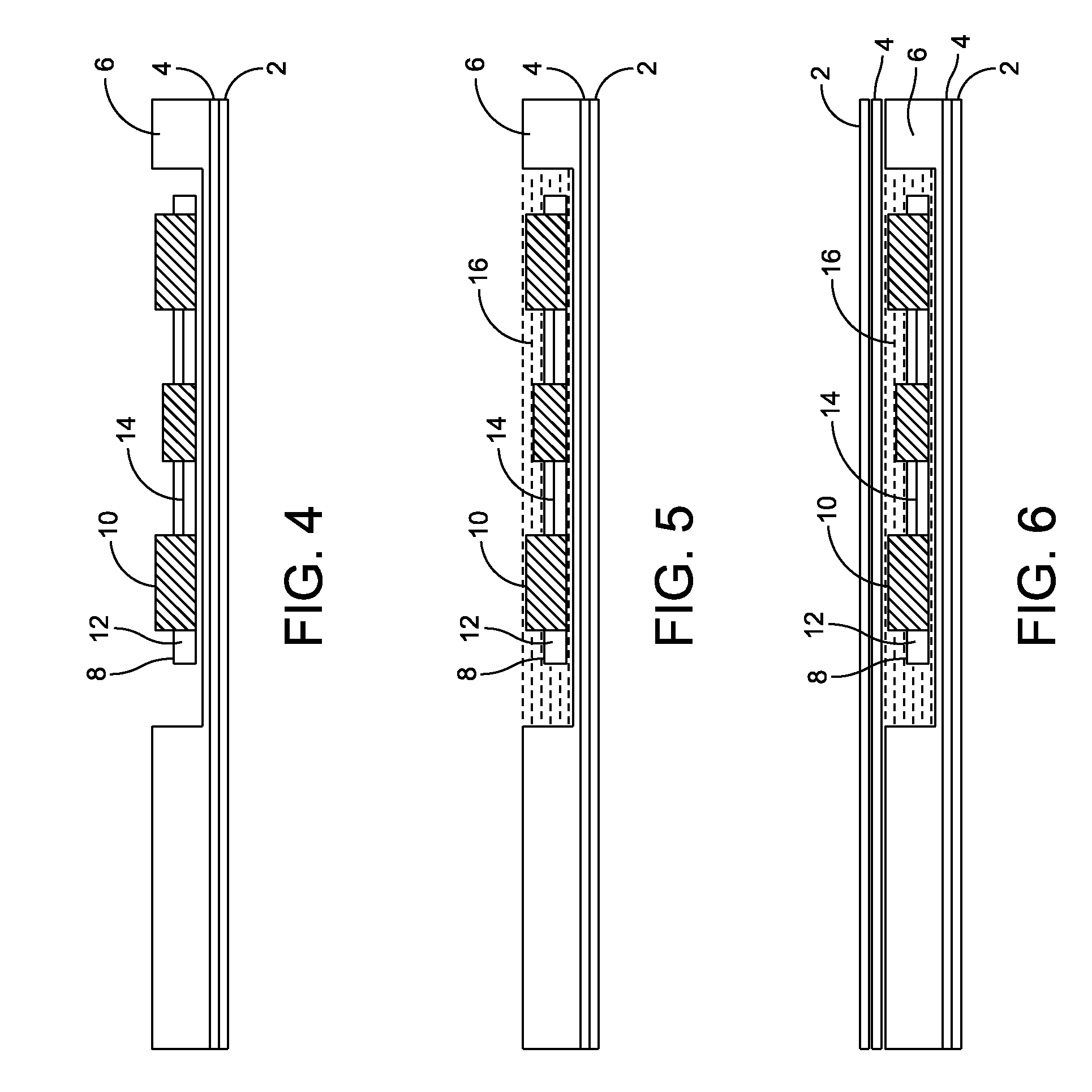

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Composite materials comprising polar polymers and single-wall carbon nanotubes

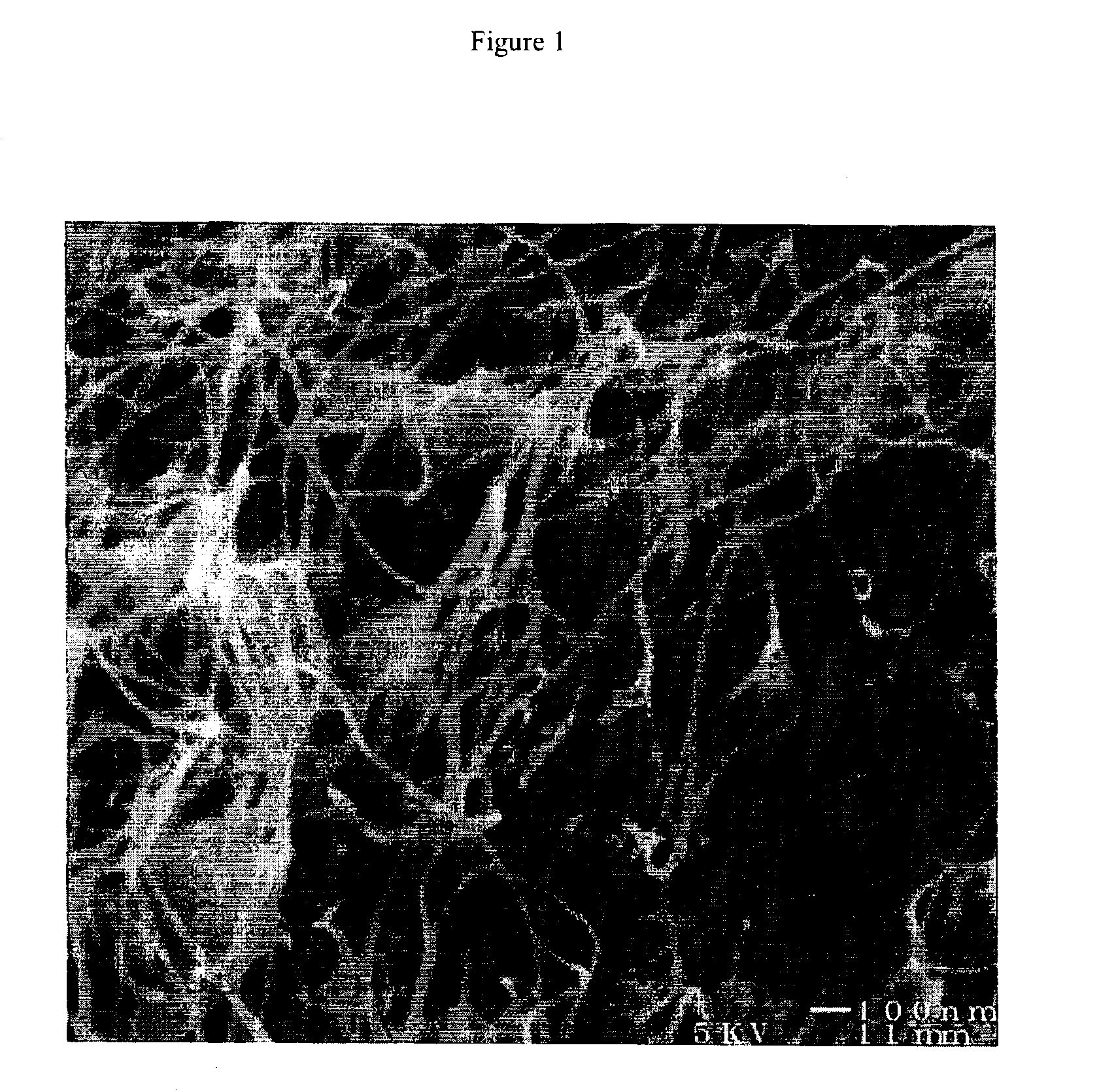

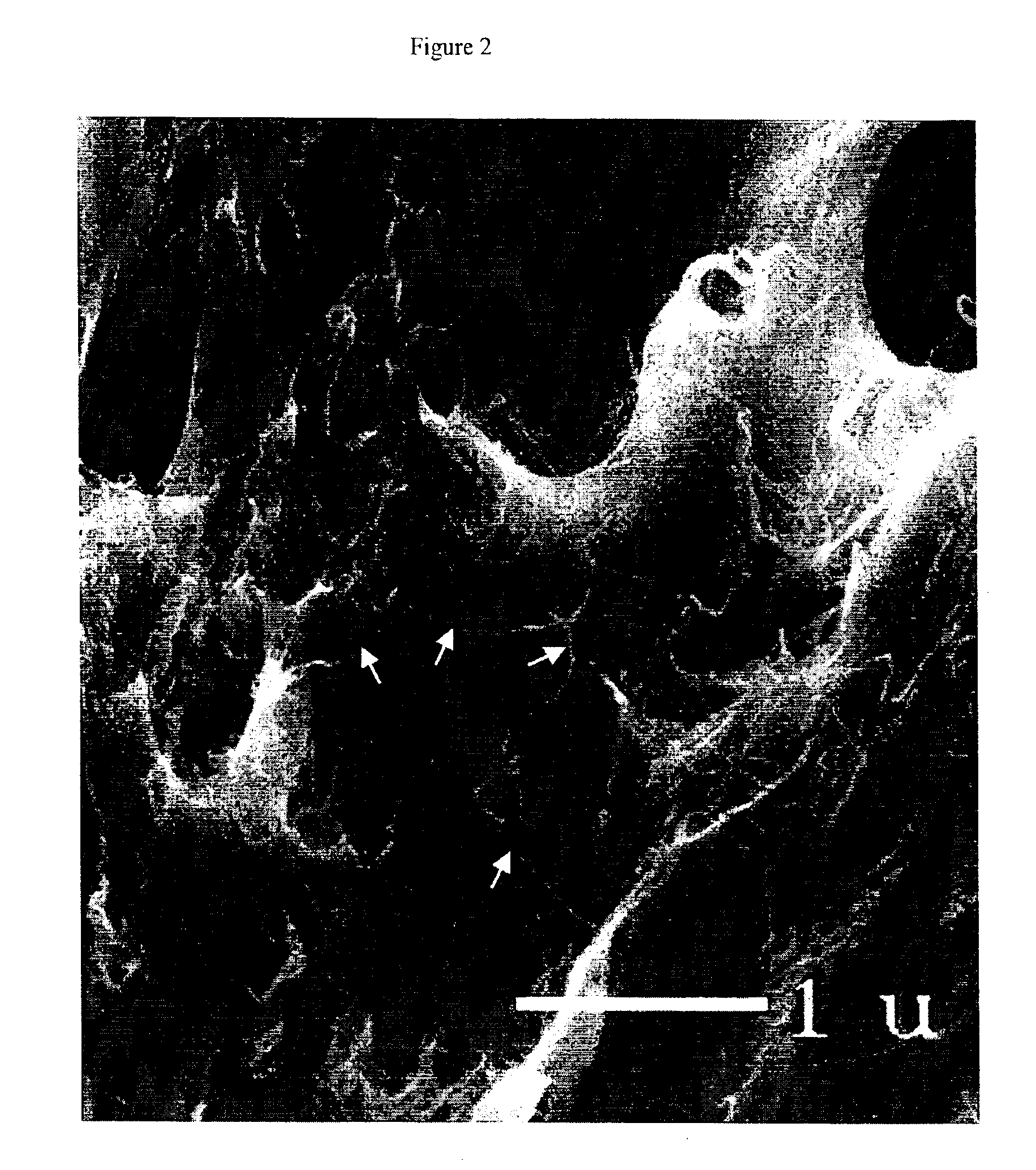

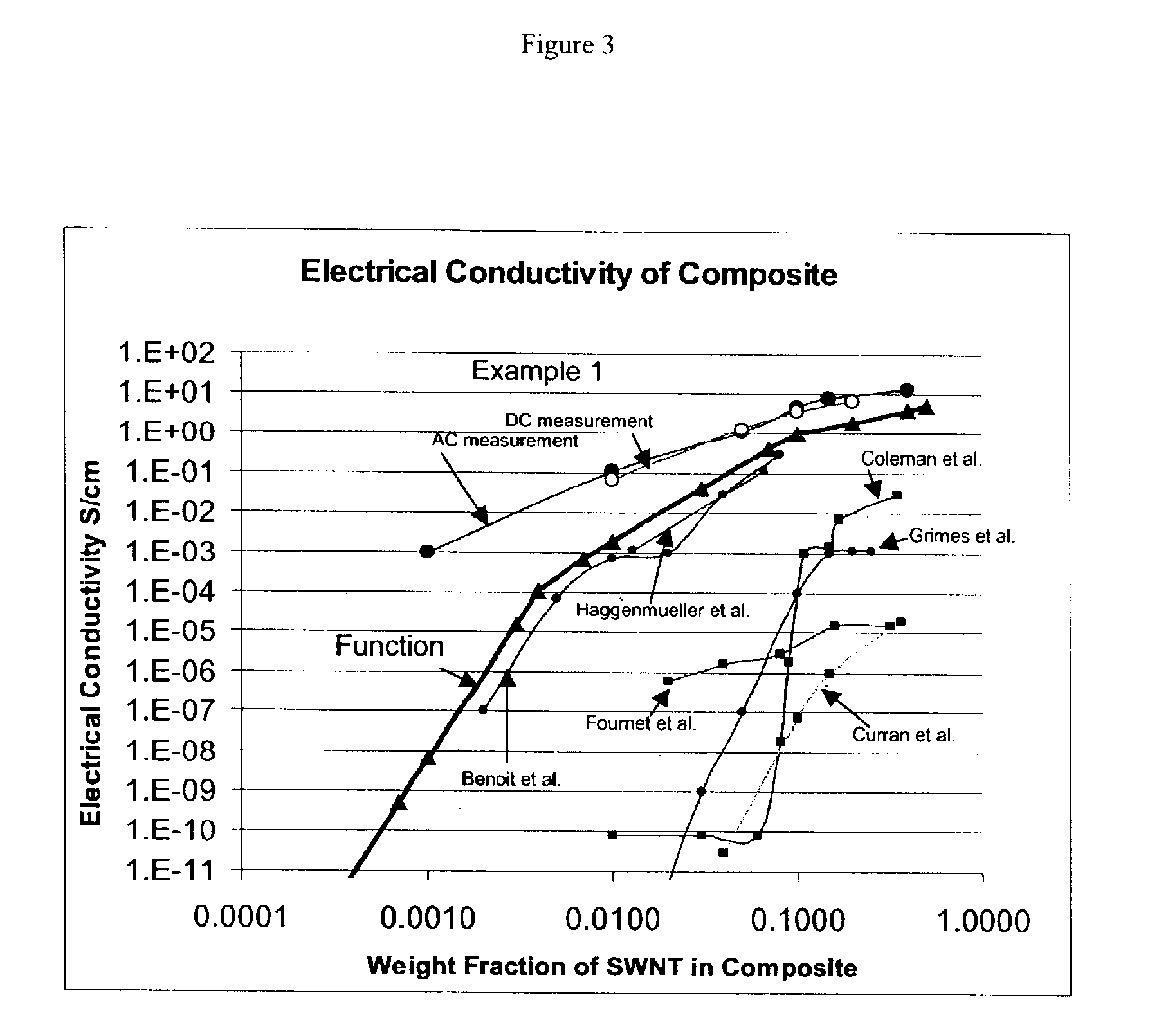

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

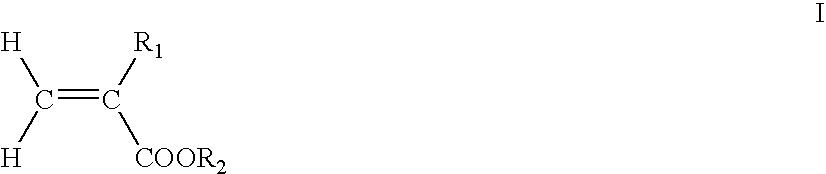

Polymer powders for SIB processes

A process of selective inhibition of bonding (SIB) to produce three-dimensional objects is used to obtain high-quality moldings. High-quality moldings can be produced by using pulverulent materials which have a median particle size of from 10 to 200 μm in which at least one polymer or copolymer selected from polyester, polyvinyl chloride, polyacetal, polypropylene, polyethylene, polystyrene, polycarbonate, polymethyl methacrylate (PMMA), PMMI, ionomer, polyamides, copolyester, copolyamides, terpolymers, or ABS, or a mixture of these, is present.

Owner:EVONIK DEGUSSA GMBH

Electrically Conductive Ink, Electrically Conductive Circuit, and Non-Contact-Type Medium

InactiveUS20080169122A1Improve conductivityWell formedConductive layers on insulating-supportsPrinted circuit aspectsHigh humidityContact type

Owner:TOYO INK SC HOLD CO LTD

Magnetic recording medium

InactiveUS20080057351A1High mechanical strengthImprove stabilityRecord information storageMagnetic recordingChloride vinylMagnetic layer

A magnetic recording medium, which comprises: a backcoat layer; a nonmagnetic support; a nonmagnetic layer; and a magnetic layer, in this order, wherein the backcoat layer has Tg of from 65 to 95° C., and the binder constituting the backcoat layer satisfies the following requirements: (1) the binder comprises a vinyl chloride-based resin (PVC) and a polyurethane resin (PU); (2) PVC has a solubility parameter of from 9 to 11 (cal·cm3)1 / 2, Tg of from 65 to 95° C. and Mw of from 5000 to 25000; (3) a ratio of PVC to the total mass of PVC and PU is from 10 to 60% by mass; (4) PU has a solubility parameter of from 9.5 to 11.5 (cal·cm−3)1 / 2, Tg of from 80 to 110° C. and Mw of from 20000 to 60000; and (5) a ratio of PU to the total mass of PVC and PU is from 90 to 30% by mass.

Owner:FUJIFILM CORP

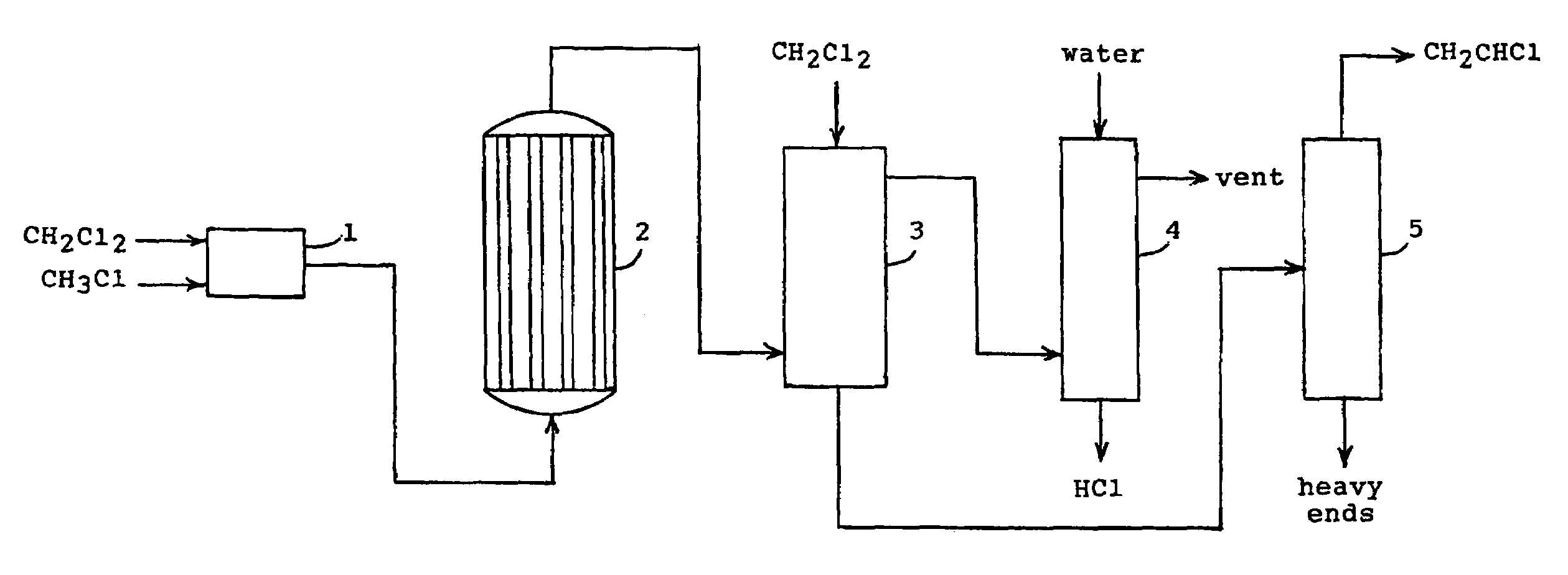

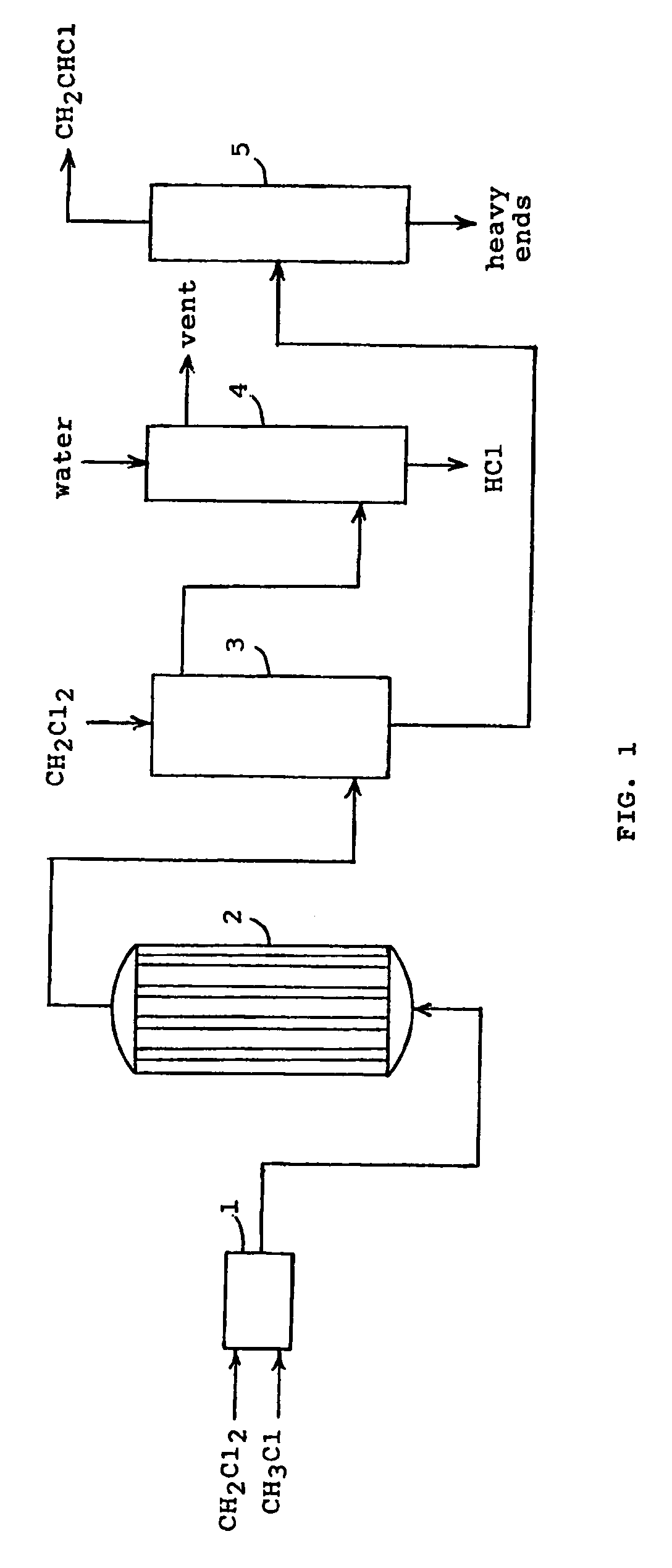

Process for preparing halogenated alkanes

InactiveUS7094936B1High selectivityBig advantagePreparation by hydrogen halide split-offPreparation by halogen replacementAlkaneLewis acid catalysis

Methods and materials are provided for the production and purification of halogenated compounds and intermediates in the production of 1,1,1,3,3-pentafluoropropane. In a preferred embodiment, the process steps include: (1) reacting carbon tetrachloride with vinyl chloride to produce 1,1,1,3,3-pentachloropropane; (2) dehydrochlorinating the 1,1,1,3,3-pentachloropropane with a Lewis acid catalyst to produce 1,1,3,3-tetrachloropropene; (3) fluorinating the 1,1,3,3-tetrachloropropene to produce 1-chloro-3,3,3-trifluoropropene; (4) fluorinating the 1-chloro-3,3,3-trifluoropropene to produce a product mixture containing 1,1,1,3,3-pentafluoropropane; and (5) separating 1,1,1,3,3-pentafluoropropane from by-products.

Owner:EI DU PONT DE NEMOURS & CO

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

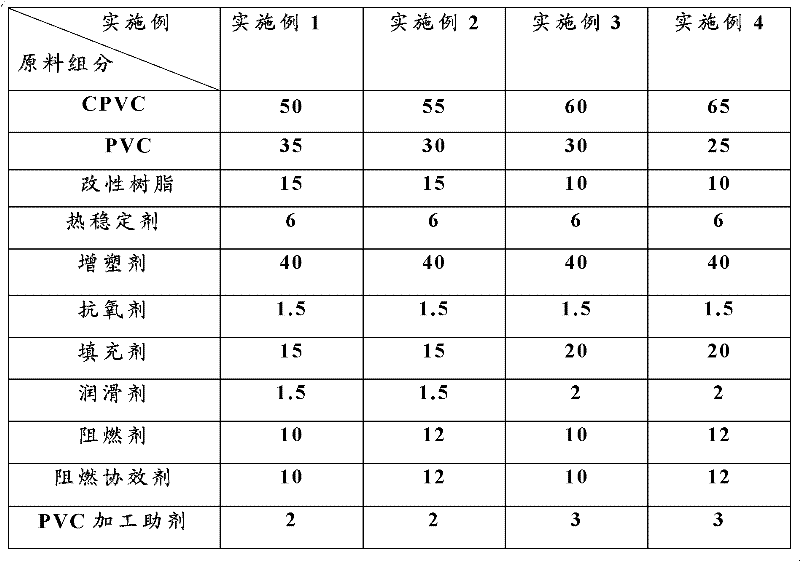

Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

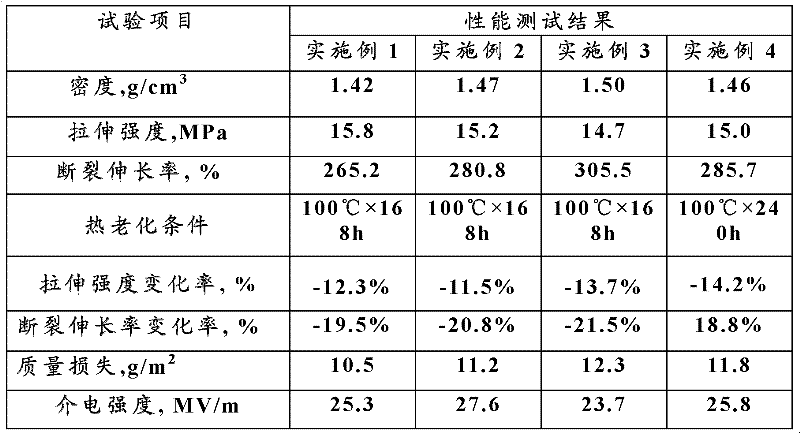

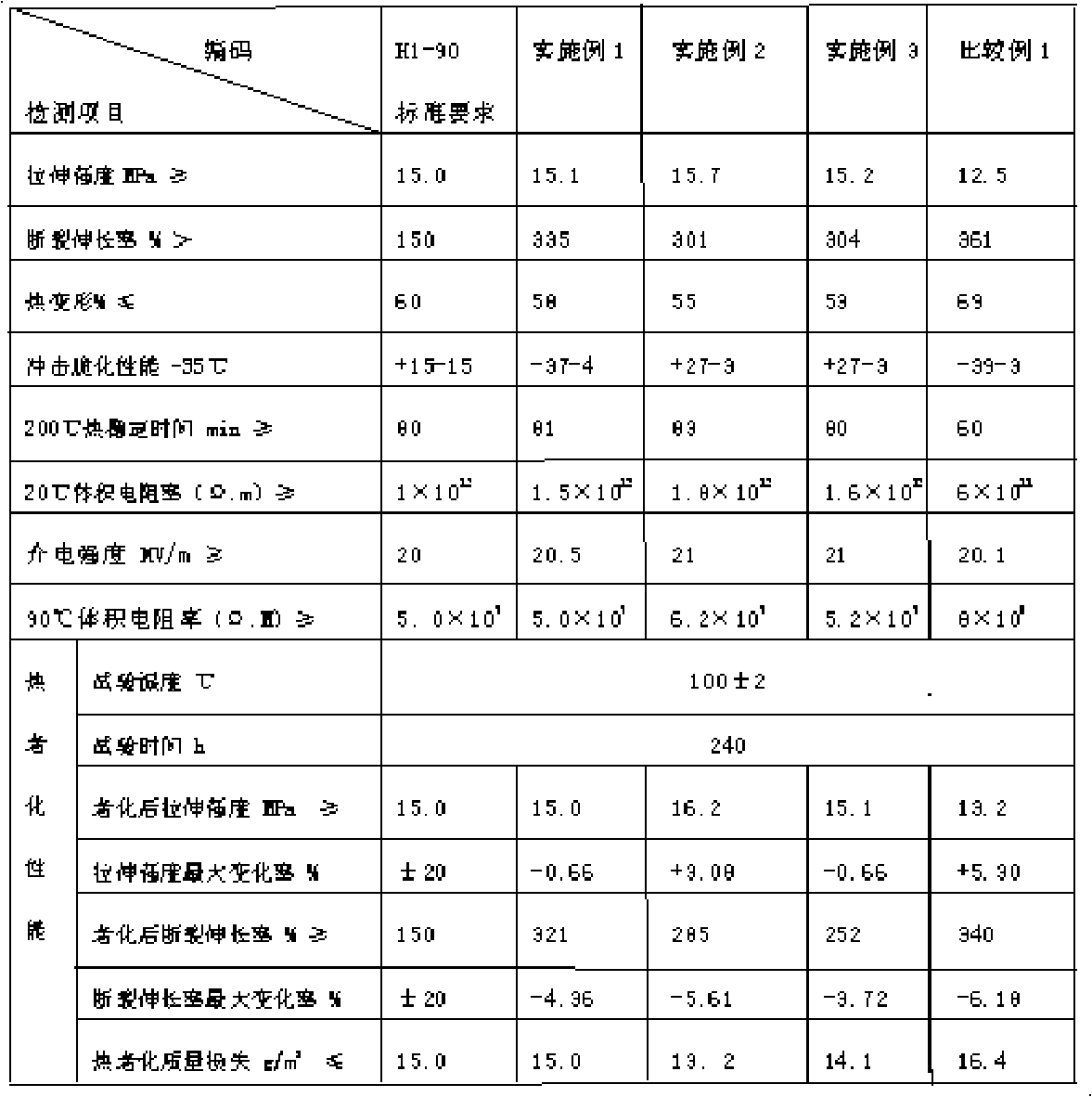

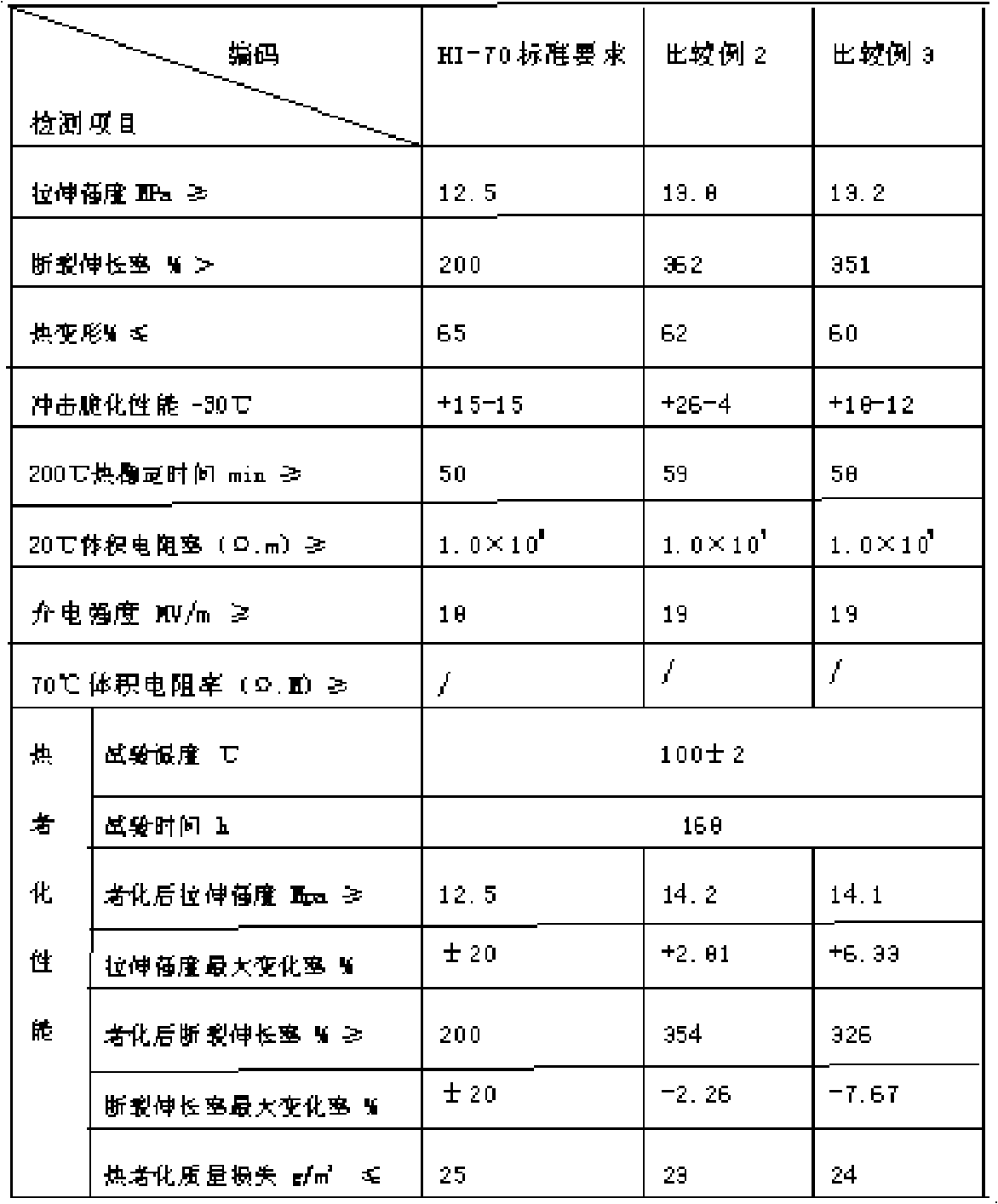

ActiveCN102532763AGood physical and mechanical propertiesImprove brittlenessInsulated cablesInsulated conductorsAntioxidantShock resistance

The invention relates to a chlorinated polrvinyl chloride modified material as well as a preparation method and application thereof. The raw material formula of the chlorinated polrvinyl chloride modified material comprises the following components in parts by weight: 40-90 parts of chlorinated polrvinyl chloride, 20-70 parts of polrvinyl chloride, 5-30 parts of modified resin, 1.5-10 parts of heat stabilizing agent, 20-60 parts of plasticizer, 1-10 parts of antioxidant, 1-10 parts of lubricating agent, 5-40 parts of filling agent, 8-40 parts of fire retardant, 8-40 parts of flame retardant synergist and 1-20 parts of polrvinyl chloride processing aid. Compared with the known CPVC (chlorinated polrvinyl chloride) modified plastic, the CPVC modified plastic disclosed by the invention is more excellent in physical and mechanical properties and is relatively reduced in cost; and compared with the known CPVC modified plastic, the CPVC modified material disclosed by the invention is obviously improved in heat resistance and flame retardant property (oxygen index can reach about 45%, and simple root of CPVC modified material can be vertically burnt) besides more excellent processabilityand obviously improved material brittleness and shock resistance. Thus, the CPVC modified material disclosed by the invention is suitable for being used as a wire and cable sheath material.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

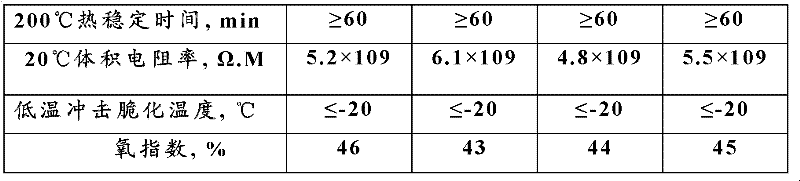

Antimicrobial coatings for medical applications

InactiveUS20050008763A1Broaden applicationEasy to preparePharmaceutical containersPretreated surfacesArylAdditive ingredient

The invention generally is related to preventing or inhibiting microbial infections on live tissues or in relation to the use of medical articles. In one embodiment, the invention is directed to a method for forming an antimicrobial coating on live tissue or a medical article, such as, for example, a catheter. The method includes applying to a live tissue or a surface of a medical article an aqueous or non-aqueous composition that includes at least one silane of the general formula R1nSi(OR2)4-n wherein, n is an interger of 1 or 2, R1 generally is a lower alkyl group, a C6-C8 aryl group, or a functional group, such as vinyl, acrylic, amino, mercapto, or vinyl chloride functional group, and R2 generally is a lower alkyl group. A partial condensate of a silanol of the formula R1Si(OH)3 also can be used. The composition includes one or more additional ingredients. The method also includes reacting and / or curing the silane, in the presence of the one or more ingredients, thereby forming the antimicrobial coating.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

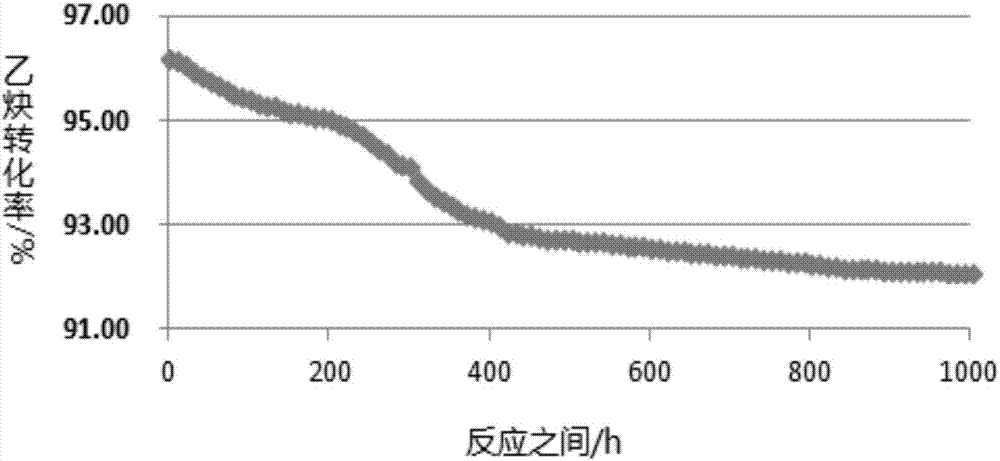

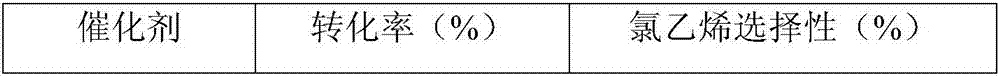

Catalyst system of chloroethylene prepared by hydrochlorinating acetylene and preparation method and application thereof

ActiveCN101716528AEasy to prepareImprove conversion ratePreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPt elementIonic liquid

The invention discloses a catalyst system of chloroethylene prepared by hydrochlorinating acetylene and a preparation method and application thereof. The catalyst system comprises a catalyst carrier and a catalyst, wherein the catalyst carrier is imidazole ion liquid and the catalyst is any combination of one or more of gold, platinum, palladium, tin, mercury, copper or rhodium chlorides. The preparation method of the catalyst system is to dissolve the catalyst into the catalyst carrier. Acetylene and chlorine hydride are mixed and react in the presence of the catalyst system. The preparation process realizes a liquid phase reaction for preparing chloroethylene by hydrochlorinating acetylene, avoids the loss of the catalyst system, is more environment-friendly and safer, and improves the conversion rate of the acetylene and the selectivity of the chloroethylene.

Owner:于志勇

Information carrying card comprising a cross-linked polymer composition, and method of making the same

The disclosure provides a cross-linkable polymer composition, a core layer for an information carrying card comprising such cross-linked composition, resulting information carrying card, and methods of making the same. A crosslinkable polymer composition comprises a curable base polymer resin in a liquid or paste form, and a particulate thermoplastic filler. The base polymer resin is selected from the group consisting of urethane acrylate, silicone acrylate, epoxy acrylate, urethane, acrylate, silicone and epoxy. The particulate thermoplastic filler may be polyolefin, polyvinyl chloride (PVC), a copolymer of vinyl chloride and at least another monomer, or a polyester such as polyethylene terephthalate (PET), a compound or blend thereof.

Owner:X CARD HLDG

Non-mercury catalyst for acetylene hydrochlorination and method of preparing the same

InactiveCN101249451AEasy to prepareHigh selectivityPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonHydrogen chloride

The invention discloses a non-mercury catalyst used in the acetylene hydrochlorination and preparation method thereof. The method includes the following steps: (1) dissolving noble metal chloride 0.5-3 parts by weight and base metal chloride 1-10 parts by weight into 2-4 mol / L hydrochloric acid solution to obtain a 0.01-0.05mol / L noble metal chloride solution; (2) adding the activated carbon 100 parts by weight into the solution at room temperature for 5-12 hours; (3) evaporating the immersion liquid on the activated carbon at 80-100 DEG C, drying at 70-80 DEG C for 2-4 hours and calcining at 120-140 DEG C for 4-12 hours; (4) and activating in hydrogen chloride atmosphere for 0.5-3 hours. The inventive catalyst can be used for green synthesis of vinyl chloride monomer to reach a conversion rate of acetylene up to 95-98% and selectivity of vinyl chloride greater than 99%.

Owner:SICHUAN UNIV

Process for production of cross copolymers, cross copolymers obtained by the process, and use thereof

InactiveUS20090263604A1Excellent in heat resistance and compatibilityExcellent transparencySynthetic resin layered productsFoundry mouldsCrystallinityAlkene

To provide a novel cross copolymer and resin composition which are improved in heat resistance and compatibility over conventional ethylene / aromatic vinyl compound copolymers and which have low crystallinity, are excellent in softness, transparency and compatibility and show mechanical properties similar to soft vinyl chloride resins, as compared with conventional cross copolymers.A process for producing a cross copolymer, which comprises a coordination polymerization step and a subsequent anionic polymerization step, wherein in the coordination polymerization step, copolymerization of an olefin monomer, an aromatic vinyl compound monomer and an aromatic polyene is carried out by using a single-site coordination polymerization catalyst to synthesize an olefin / aromatic vinyl compound / aromatic polyene copolymer, and then, in the anionic polymerization step, polymerization is carried out in the coexistence of such an olefin / aromatic vinyl compound / aromatic polyene copolymer and an anionic polymerizable vinyl compound monomer by using an anionic polymerization initiator.

Owner:DENKA CO LTD

Heat shrinkable multilayer film and tube with improved adhesion after orientation

Multilayer laminated shrink films that have good interlayer adhesion comprise at least three layers, a first layer comprising a polymer selected from the group consisting of polyamides, ethylene vinyl alcohol copolymers and mixtures thereof, a second adhesive layer consisting essentially of a blend of a functionalized polymer component, an ethylene copolymer component and a tackifier and a third layer comprising a polymer selected from the group consisting of polyethylene homopolymers, ethylene copolymers, polypropylene homopolymers, propylene copolymers, polyesters, polyamides, polyvinyl chloride, polycarbonates, and mixtures thereof The adhesive layer is positioned between and contacts the first and third layers.

Owner:EI DU PONT DE NEMOURS & CO

Heat-Sealing Compound For Sealing Aluminium Foil And Polyethlene Terephthalate Film To Polypropylene, Polyvinyl Chloride and Polystyrene Containers

ActiveUS20080057205A1High bonding strengthImprove thermal stabilitySynthetic resin layered productsPretreated surfacesSolventPolypropylene

The invention relates to a heat-sealing system consisting of an olefin polymer or olefin copolymer A, a methacrylate copolymer B, a graft polymer AB that is composed of the aforementioned components, a polyester C and an optional polymer D or an optional polymer blend DA, in addition to a solvent or solvent mixture L. The heat-sealing system is characterised by a high heat resistance, excellent barrier properties and short sealing times in relation to various plastics and aluminium foil or PET film.

Owner:EVONIK OPERATIONS GMBH

Method for producing vinyl chloride monomer

Owner:STAUFFER VALERIE +1

Low-mercury catalyst for acetylene hydrochlorination

InactiveCN102380407AEasy to makeLow costPhysical/chemical process catalystsPreparation by halogen halide additionO-Phosphoric AcidPtru catalyst

Disclosed is a low-mercury catalyst for acetylene hydrochlorination. Mercuric chloride is carried on activated carbon. Raw materials comprise, by weight, 100 parts of activated carbon, 4-5 parts of mercuric chloride, 8-10 parts of total essential assistant, 1-5 parts of total non-essential assistant, wherein the essential assistant comprises 2-5 parts of bismuth chloride, 1-5 parts of cerium chloride, 1-5 parts of barium chloride and 2-5 parts of copper chloride; and the non-essential assistant comprises at least one of potassium chloride, phosphoric acid, zinc chloride and cuprous chloride. After being subjected to surface subtraction and drying on acid and oxidizing conditions, activated carbon is in reflux treatment with urea solution; and the catalyst can be prepared by soaking the treated activated carbon with HgC12 dissolved in hydrochloric acid and assistant solution sufficiently after urea is removed by steps of heating, washing the activated carbon with hydrochloric acid and finally drying the same. The carrying capacity of mercuric chloride in the catalyst is lower so that cost for the catalyst is reduced and consumption of mercury resources is decreased. Furthermore, activity and stability of the low-mercury catalyst are much higher than those of the existing high-mercury catalyst, and reforming rate and selectivity of reaction of vinyl chloride can be 99.7% and be higher than 99.8%. Accordingly, the low-mercury catalyst for acetylene hydrochlorination is suitable for industry production and is environment-friendly.

Owner:CHENGDU HUIEN FINE CHEM

Catalyst system for preparing vinyl chloride by hydrochlorinating acetylene and preparation and application thereof

ActiveCN101879464AEasy to prepareImprove conversion rateCatalyst carriersPreparation by halogen halide additionManganeseIonic liquid

The invention discloses a catalyst system for preparing vinyl chloride by hydrochlorinating acetylene, and preparation and application thereof. The catalyst system comprises a catalyst carrier and a catalyst, wherein the catalyst carrier is pyridine ionic liquid, and the catalyst is one or any combination of more than two of tin, palladium, gold, copper, manganese, bismuth, mercury and rhodium. The preparation method for the catalyst system comprises a step of dissolving the catalyst in the catalyst carrier. Acetylene gas and hydrogen chloride gas are mixed and then reacted in the presence of the catalyst system. The preparation process realizes a liquid phase reaction for preparing the vinyl chloride by hydrochlorinating the acetylene, avoids the loss of the catalyst system, is more environment-friendly and safer, and improves the conversion rate of the acetylene and the selectivity of the vinyl chloride.

Owner:于志勇

Electrically-conducting paint, preparation method and uses thereof

ActiveCN101314680AImprove adhesionAvoid damagePretreated surfacesPolyurea/polyurethane coatingsConductive coatingLacquer

The invention discloses a conductive coating and the preparation method thereof and a method for forming film on material surface. The preparation method comprises the following steps: wetting and dispersing metal powder; uniformly mixing film-forming resin, chloride-vinyl acetate resin and conductive coating additive, adding diluting agent, stirring at high speed, dispersing to form a conductive paint base material, adding into the wetted and dispersed metal powder, and uniformly stirring; and sieving, removing impurities to obtain conductive coating, adding curing agent, and spraying or applying on material. The conductive coating has the advantages of smooth surface and high adhesion of film-forming substance, and good conductivity, and can be adhered on the surface of any materials.

Owner:ZHAOQING CITY CAIXIN DECORATION MATERIALS

Novel mercury-free catalyst and application of mercury-free catalyst in synthesis of vinyl chloride

ActiveCN104289246AGood catalytic performanceImprove catalytic performancePreparation by hydrogen halide split-offPhysical/chemical process catalystsIonPyrrole

The invention discloses a novel mercury-free catalyst, and application of the mercury-free catalyst in synthesis of vinyl chloride. The novel mercury-free catalyst is prepared by a method comprising the steps of pickling and drying active carbon, and then taking the active carbon as a carrier for later use; dissolving a nitrogen-containing compound in deionized water so as to prepare impregnation liquid, wherein the nitrogen-containing compound is selected from one or several of ammonia water, ammonia gas, pyridine, pyrrole, imidazole, acrylamide, polyacrylamide and polyvinylpyrrolidone; adding the pickled active carbon into the impregnation liquid containing the nitrogen-containing compound, and impregnating, wherein the content of the nitrogen-containing compound and the active carbon is 0.01-20% by weight part; and completely drying the impregnated active carbon at 60-140 DEG C, then calcining the active carbon at 400-800 DEG C for 4-6 hours in the nitrogen atmosphere to prepare the novel mercury-free catalyst. The prepared catalyst shows good catalytic performance in the aspect of catalyzing the reaction of synthesis of vinyl chloride by 1,2-dichloroethane and acetylene.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and preparation method and application thereof

ActiveCN106944151AEasy to prepareLow costPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsSolventActive carbon

The invention relates to a mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, dissolving alkali metal salt and an amide solvent in water to prepare a mixed solution; 2, adding active carbon into the mixed solution obtained in step 1, and dipping the active carbon; and 3, filtering the active carbon obtained in step 2, draining the filtered active carbon, and heating and drying the drained active carbon to obtain the catalyst. The concentration of raw gas on the surface of the catalyst is increased through using the synergism of the alkali metal salt and the amide solvent and the adsorbing and dissolving ability of the amide solvent to raw materials comprising acetylene and hydrogen chloride, and the amide solvent is a high-polarity aprotic polar solvent, and has a polarization effect on reactants, so the reaction efficiency is further improved, the low temperature activity of the catalyst is high, and the selectivity and the stability are good.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

Polyvinyl chloride heat stabilizer and preparation method thereof

ActiveCN102898741ASimple preparation processApplication productivity is reliablePolyvinyl chlorideStearic acid

The invention discloses a novel environment-friendly type PVC heat stabilizer comprising 1,3-dimethyl-6-Aminouracil as a main stabilizing agent. The novel environment-friendly type PVC heat stabilizer comprises the following ingredients: 1-5weight parts of 1,3-dimethyl-6-Aminouracil, 10-100 weight parts of epoxy soybean oil, 3-10 weight parts of calcium stearate, 3-10 weight parts of zine stearate, and 2-15 weight parts of organic auxiliary agent. According to the invention, the heat stabilizer disclosed herein significantly raises the stability of PVC materials in the processing process; and compared with traditional stabilizing agents, the heat stabilizer disclosed herein contains no heavy metal, and is an environment-friendly efficient novel heat stabilizer.

Owner:太原市塑料研究所

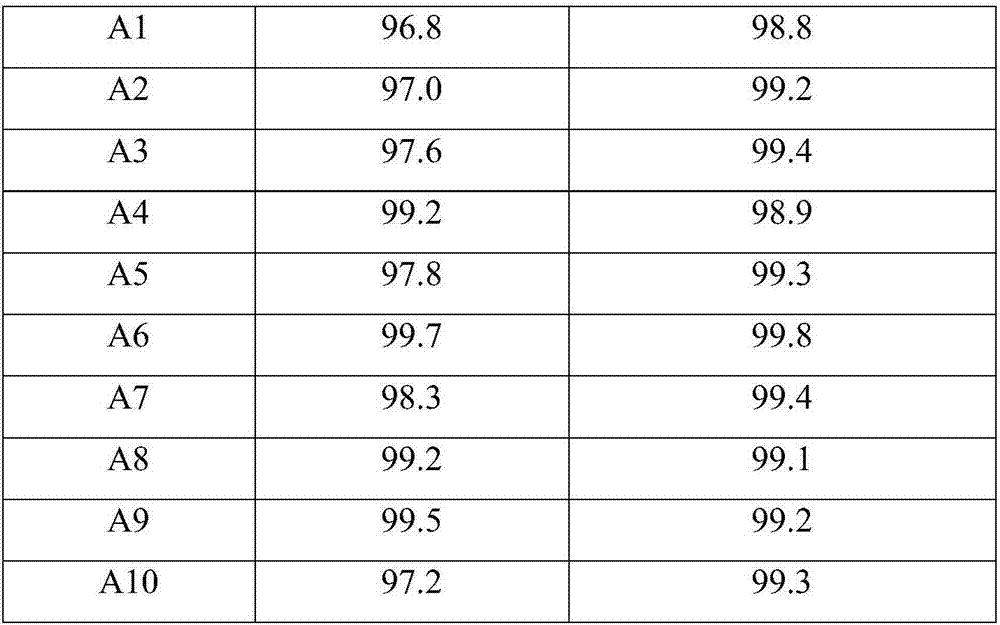

Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof

ActiveCN101875747ALower embrittlement temperatureMeet construction requirementsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention discloses an ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material, belonging to the field of materials. The cable material is mainly prepared from the following raw materials in percentage by weight: 45-50% of PVC resin, 15-20% of plasticizer, 20-25% of filler, 1-3% of electrical property modifier, 9-15% of impact resistant and high and low temperature resistant modifier, 0.4-2.2% of lubricant, 1.0-2.0% of stabilizer and 0.1-0.3% of antioxidant, wherein the plasticizer is a mixture of more than two of phthalate, terephthalate or trimellitate; and the lubricant is a mixture of a composite lubricant and oxidized polyethylene wax. The invention also provides a preparation method of the cable material. The cable material provided by the invention has the advantages of low brittle temperature and good insulating property, wherein the brittle temperature can reach -35 DEG C; and simultaneously, the preparation method of the cable material is simple and is convenient for industrialized production.

Owner:ZHEJIANG DEYU TECH

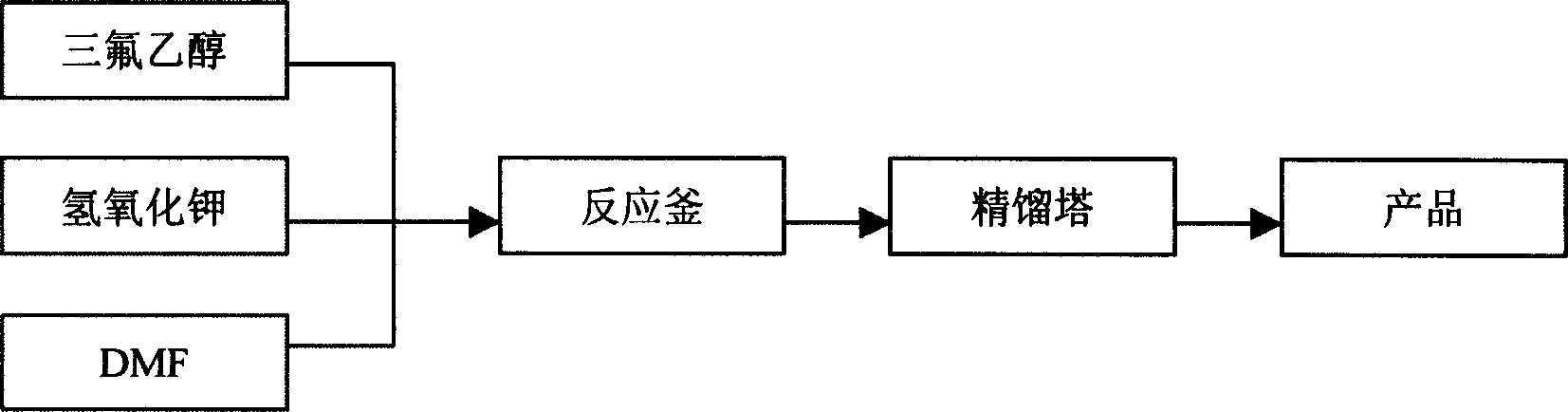

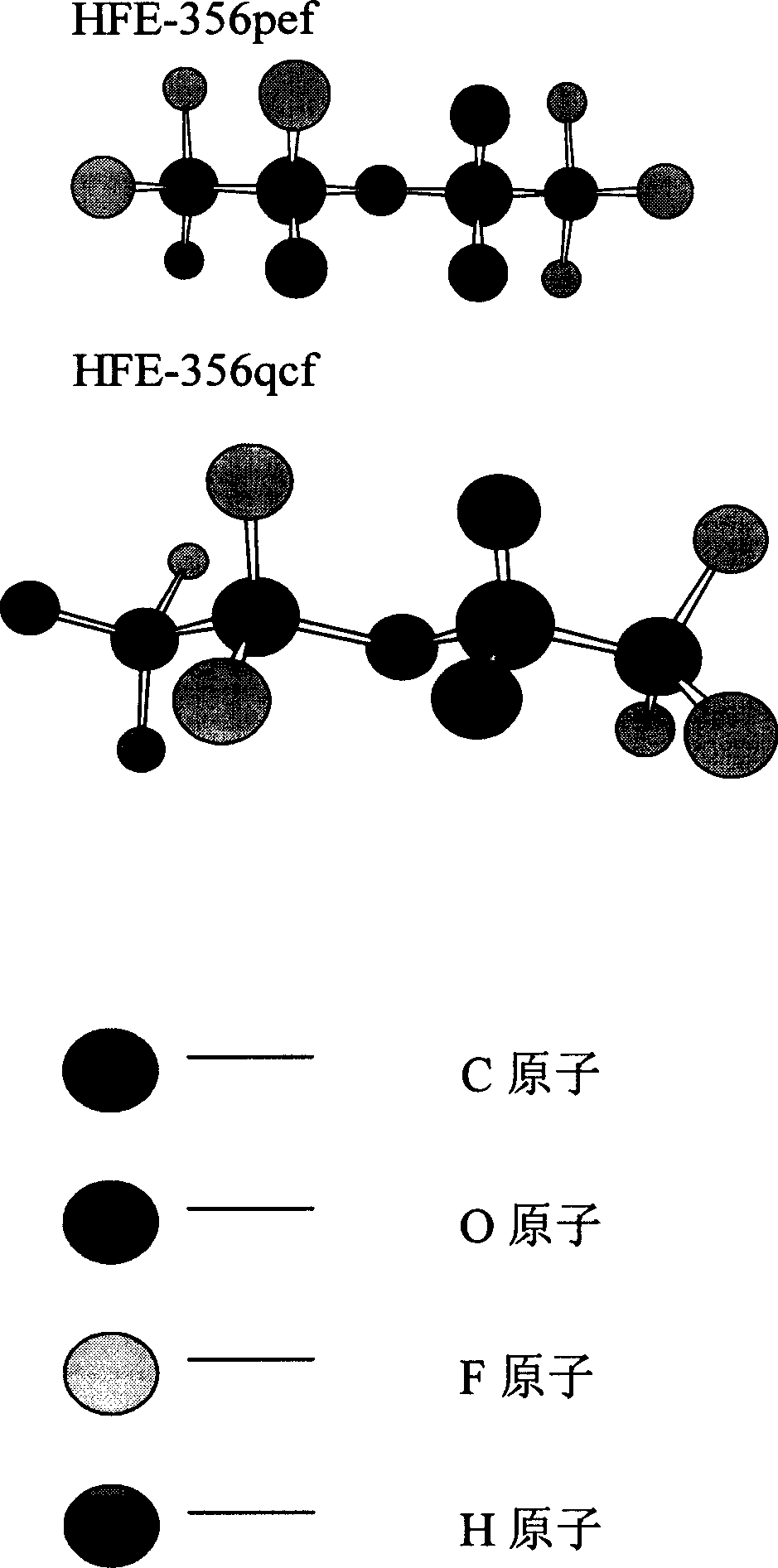

New hydrofluoro ether and its preparation method

InactiveCN1651378AHigh yieldEasy to separate and purifyEther preparationFoaming agentOrganic solvent

A process for preparing hydrofluoroether features the reaction between one of trifluoroethene, tetrafluoroethene, hexafluoro propene, etc and one of trifluoroethanol, trifluoropropanol, metanol, etc in organic solvent (DMF or DMSO). Its advantages are high output rate and easy purifying and separating.

Owner:大连振邦氟涂料股份有限公司

Single coating transfer aluminum plating coating, and preparation and use thereof

InactiveCN101407689AAppropriate molecular weight rangeHigh viscosityCoatings with pigmentsCoatingsCelluloseHigh surface

The invention relates to a single-coated transfer aluminium-plated coating, a preparation method and an application thereof, wherein, the coating takes the following components with the contents (weight percent) as raw materials: 0 to 16 weight percent cellulose resin; 0 to 6 weight percent vinyl chloride-vinyl acetate resin; 4 to 20 weight percent polyacrylate resin; 0 to 1 weight percent auxiliary agent and 70 to 87 weight percent solvent. Compared with the prior art, the invention has the following advantages: (1) the single-channel coating is adopted, compared with two times of coating, the process is simple, the production efficiency is high, the energy consumption is less, the emission is less, the coating amount is less and the cost is low; (2) the product has good technological adaptability and is applicable to the different technological conditions of different manufacturers; (3) a coating layer has excellent comprehensive performance, great peeling performance, good adhesion with aluminium, wear resistance, temperature resistance, solvent resistance, good flexibility, high surface luminance brightness and good adaptability with ink printing; and (4) the coating and the coating layer have no triphenyl or other solvents which are prohibited by the industry, thereby being safe and environment-friendly.

Owner:SHANGHAI WEIKAI CHEM

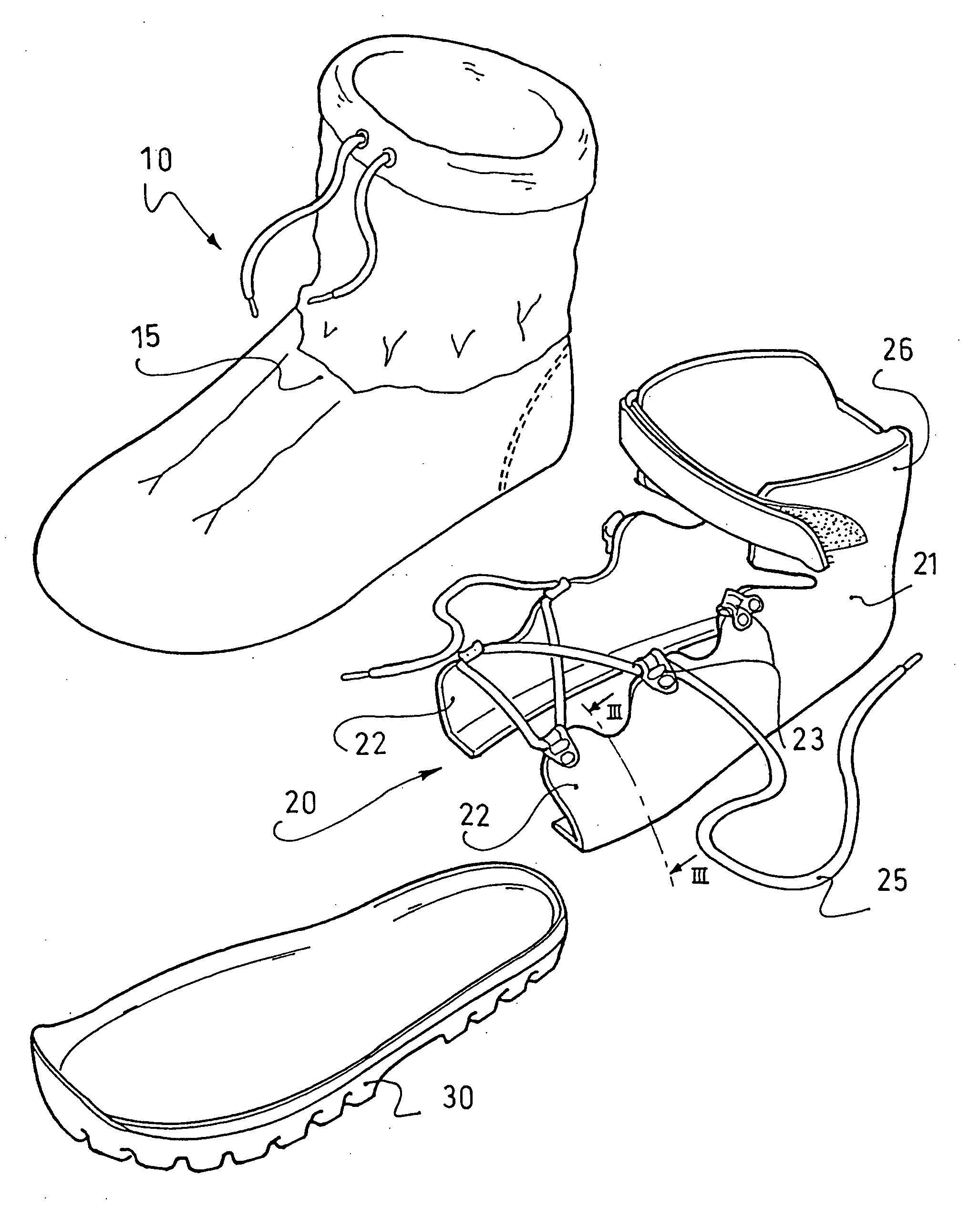

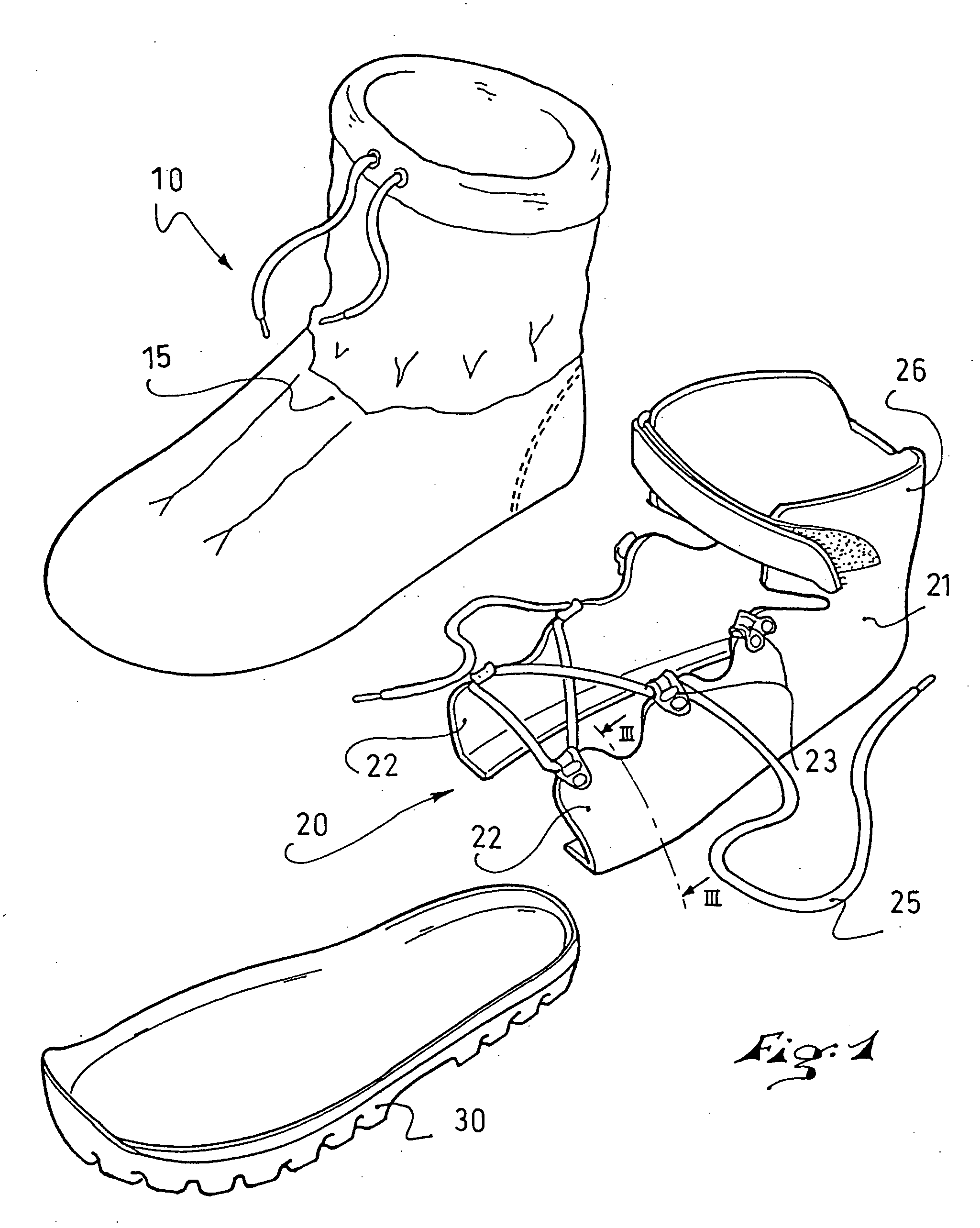

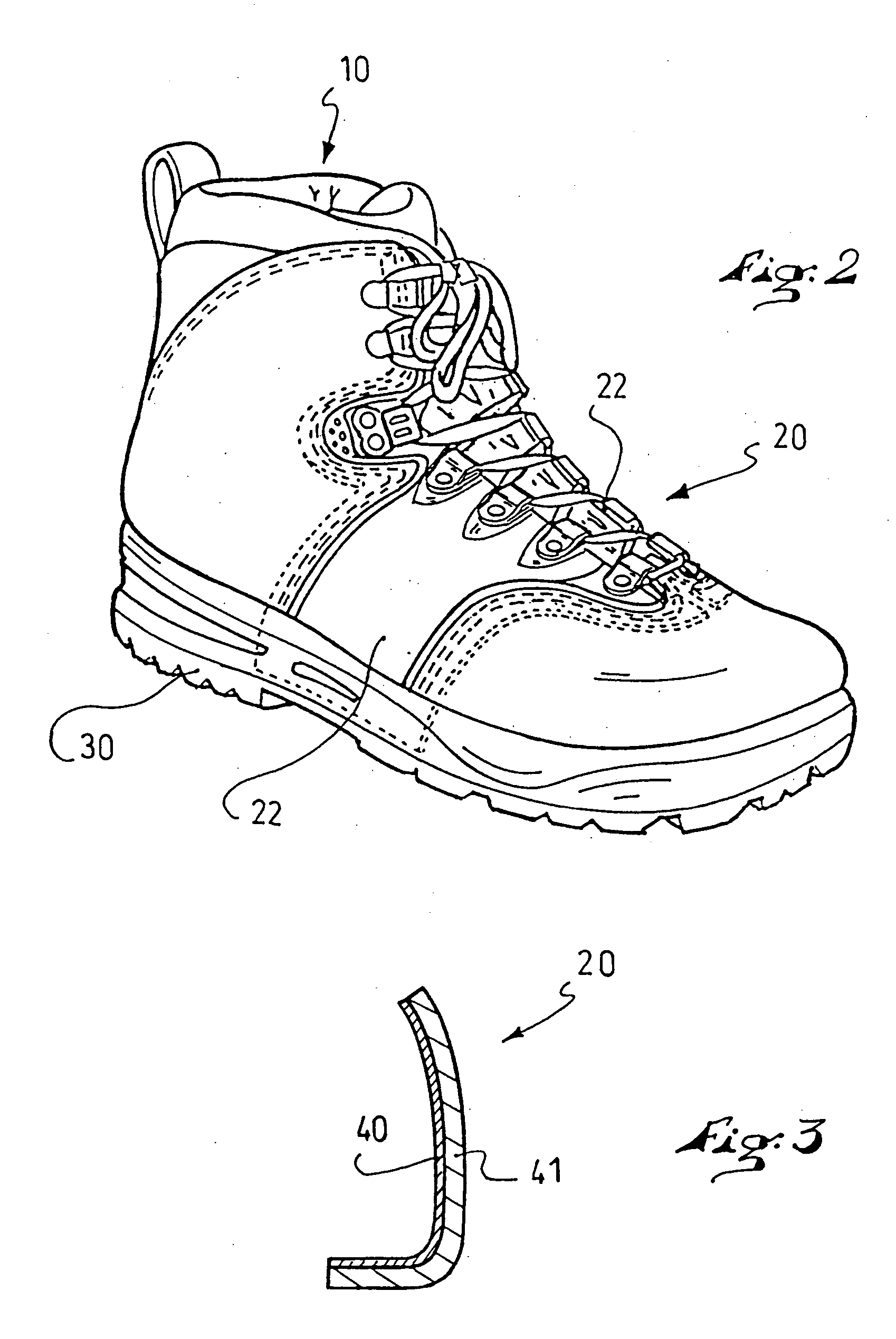

Composite reinforcement element, a boot and a binding incorporating such element, and a method of manufacturing same

InactiveUS20050188564A1Low implementation costSame property of mechanical strengthSolesSnowboard bindingsGlass fiberPolyester

Reinforcement element made of a composite material constituted of a layer of inextensible textile material and a layer of polymeric material assembled to the layer of textile material during a molding or vulcanizing step. The textile material is a woven or mesh material, and the textile material is a polyester, polyamide, polypropylene or glass fiber based material. The polymeric material can be a thermosetting material, such as rubber or silicone, or an injected thermoplastic, such as polyurethane, polyvinyl chloride, or polypropylene. Advantageously, the polymeric material is at least partially transparent. The composite material can be incorporated in a boot or a binding, such as a snowboard binding, in the form of a tightening strap. The invention also relates to a method of manufacturing such reinforcement element.

Owner:SALOMON SA

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN101081653AReduce consumptionReduce thicknessFlexible coversWrappersPolyesterPolymer science

The present invention discloses one kind of multilayer high blocking film for packing liquid material, the multilayer high blocking film includes polyethylene-based heat sealing layer(s), blocking polymer layer(s) preferably of ethylene-vinyl alcohol copolymer, PVA or polyvinylidene dichloride; and protecting layer(s) of polypropylene, polyester, etc. It has the total thickness below 80 micron, preferably of 55-65 micron. The present invention discloses also the making process of the multilayer high blocking film.

Owner:刘建林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com