Patents

Literature

66results about How to "Lower embrittlement temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

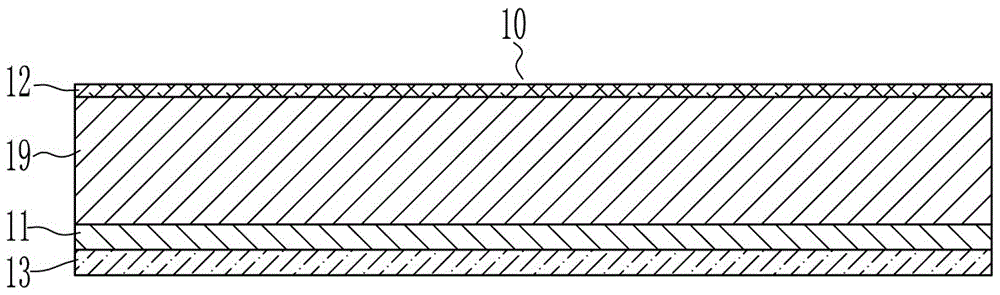

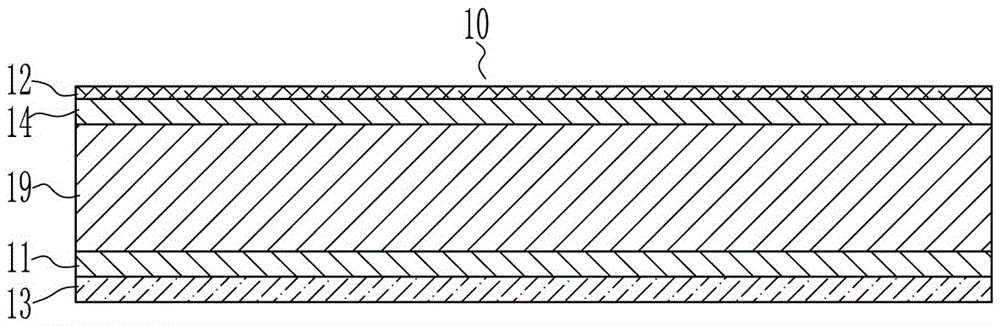

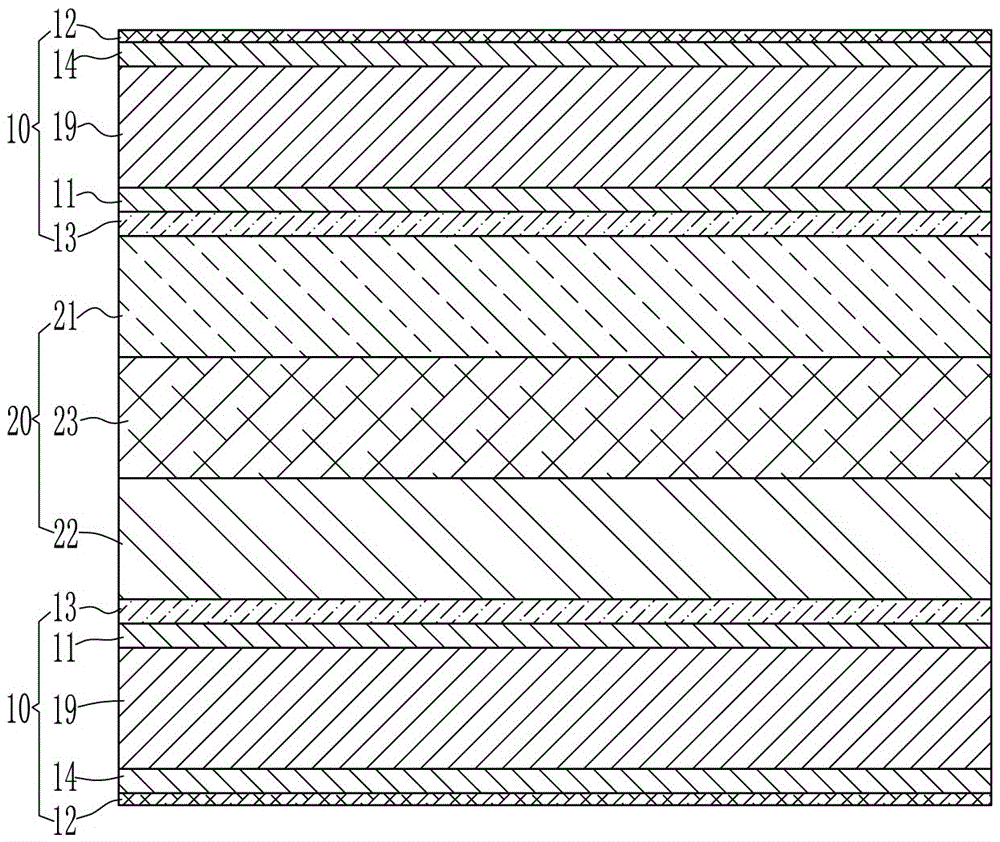

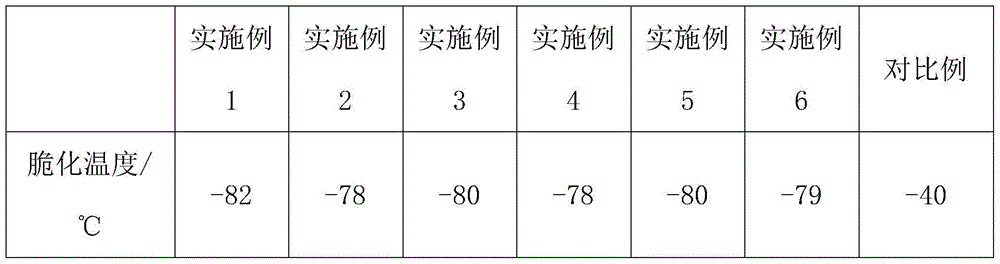

High-cold-resistant synthetic leather and preparation method of the high-cold-resistant synthetic leather

ActiveCN102168382AImprove performanceGive full play to the excellent characteristicsTextiles and paperFoaming agentThermoplastic polyurethane

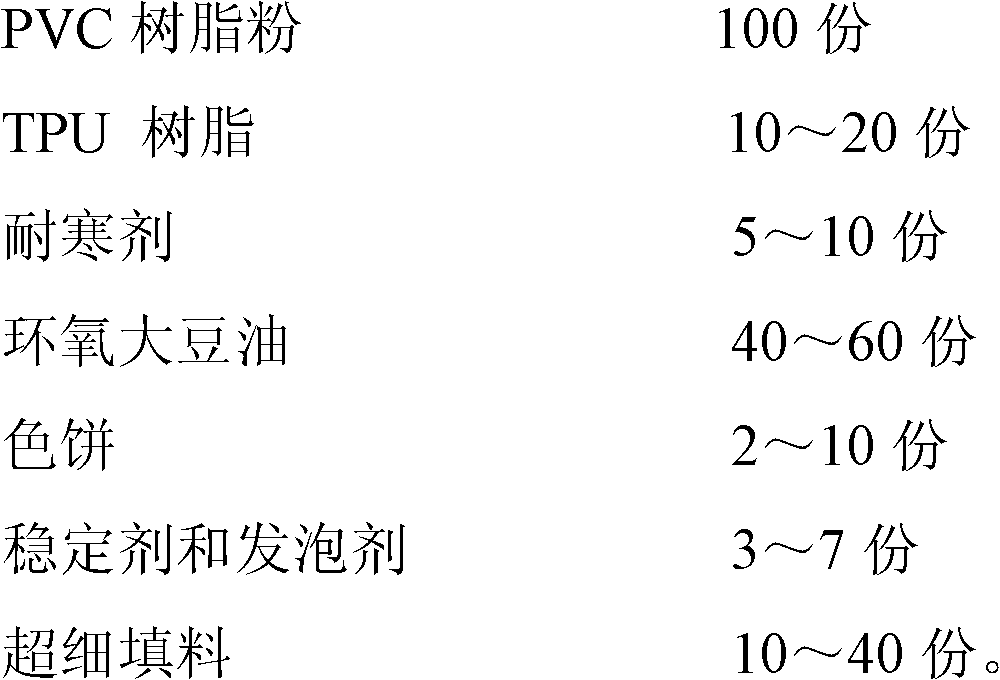

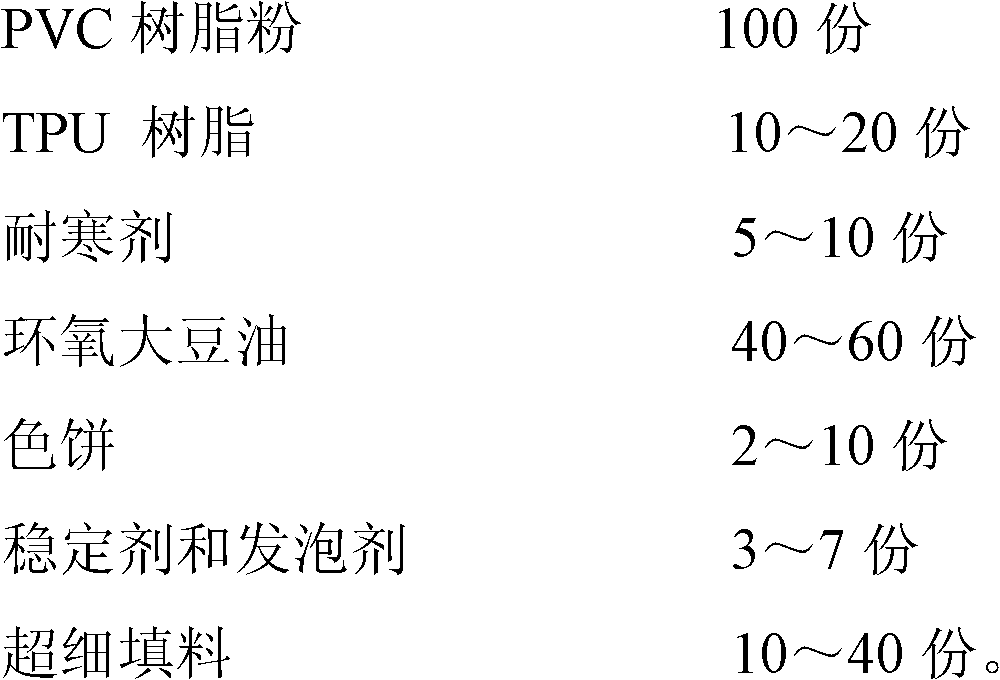

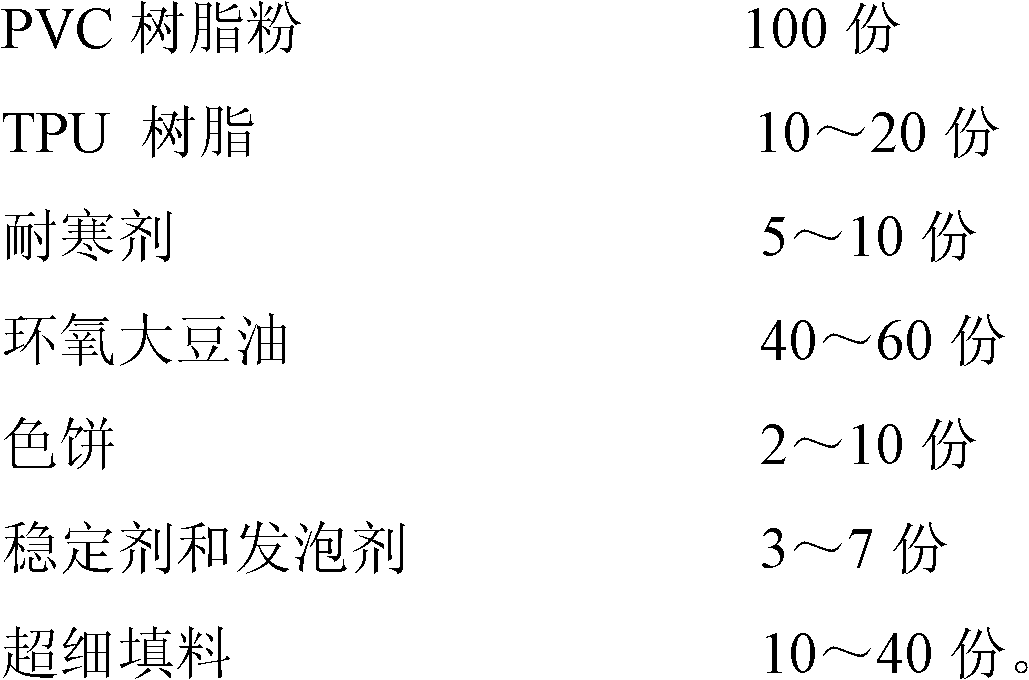

The invention discloses high-cold-resistant synthetic leather which is prepared by adding high-cold-resistant sizing agent and adopting a calendering method. The high-cold-resistant sizing agent is prepared by the following components in parts by weight: 100 parts of PVC (polyvinyl chloride) resin powder, 10-20 parts of TPU (Thermoplastic polyurethanes) resin, 5-10 parts of cold-resisting agent, 40-60 parts of epoxy soybean oil, 2-10 of color cakes, 3-7 parts of stabilizer and foaming agent, and 10-40 parts of ultra-fine filler. The synthetic leather has not only good mechanical properties, but also ultra-high cold-resisting characteristics, and can pass a minus 60 DEG C low temperature bending test.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

Polyethylene modified asphalt agglomerate and its making process

InactiveCN1468894AGood temperature sensitivityStriving for even distributionBuilding insulationsWeather resistancePolymer science

The present invention is polyethylene modified asphalt agglomerate and its making process. The material includes the components of polymer 50-85 wt%, asphalt 10-35 wt%, grafting modifier 0.5-3.0 wt%, chemical initiator 0.1-1.0 wt%, crosslinking agent 1.0-3.0 wt%, compatibilizer 1.0-4.0 wt% and assistant 0.1-8.0 wt%. The preparation process includes mixing the polymer and the assistant inside a mixer, heating to melt asphalt, and adding all the components into a double-screw extruder to prepare modified asphalt agglomerate. The modified asphalt agglomerate has high elasticity restoring rate, high strength, high weather resistance, simple preparation process, and low production cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Sizing material formulation of low-temperature resistant automobile constant velocity universal joint seal cover

ActiveCN101613497ALower embrittlement temperatureImprove low temperature resistanceYielding couplingEngineeringTemperature resistance

The invention relates to a sizing material formulation for manufacturing an automobile constant velocity universal joint seal cover, which takes chloroprene rubber as the main component and comprises the following component PHR (namely the adding quantity relative to 9,000 grams of the chloroprene rubber): 9,000 grams of the chloroprene rubber (domestic CR322), 1,000 grams of nitrile-butadiene rubber (N220S), 1,000 grams of semi-reinforcing furnace black, 1,000 grams of high abrasion furnace black, 1,000 grams of spray carbon black, 500 grams of titanate powder, 1,000 grams of zinc oxide, 1,000 grams of white carbon black, 1,500 grams of dioctyl sebacate, 500 grams of butyl oleate, 400 grams of magnesium oxide, 200 grams of 4010NI anti-aging agent, 90 grams of NA-22, 50 grams of TMTD, 66 grams of paraffin, 50 grams of stearic acid and 13 grams of sulfur, wherein the total weight is 18,369 grams. The quantity of the formulation can be increased and decreased in proportion. The automobile constant velocity universal joint seal cover prepared according to the sizing material formulation has the advantages of good low temperature resistance, low brittle temperature, good comprehensive performance and long service life.

Owner:NINGBO V SHINE AUTO PARTS

Modified polyvinyl chloride cable material with high cold resistance

InactiveCN104403228AImprove heat resistanceImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsFiberEpoxy

The invention discloses a modified polyvinyl chloride cable material with high cold resistance. The modified polyvinyl chloride cable material is prepared from the following raw materials: polyvinyl chloride, nitrile rubber, maleic anhydride-grafted polypropylene, ethylene-vinyl acetate-carbon monoxide terpolymer, bamboo fiber, modified kaolin, ultra-fine silica dioxide powder, triethyl citrate, acetyl-tri-n-butyl citrate, epoxy sunflower oil, eicosyl dehydroabietate, modified zinc borate, red phosphorus, nanometer aluminum hydroxide, maleopimaric acid lanthanum, methyl tin mercaptide, barium stearate, an antioxidant, and a lubricant. The modified polyvinyl chloride cable material with the high cold resistance disclosed by the invention is high in cold resistance, good in elasticity, good in impact resistance, and excellent in mechanical property; the cable prepared by the modified polyvinyl chloride cable material is long in service life in the cold environment.

Owner:ANHUI DUJIANG CABLE GROUP

Low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention and preparation method of low-temperature 3PE dry film hot melt adhesive

InactiveCN110028915AMeet construction needsSolve the needs of joint anticorrosion constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention. The low-temperature 3PE dry film hot melt adhesive is prepared by kneading a rubber elastomer, bonding resin, tackifying resin, a plasticizer, an antioxidant and a filler and conducting extruding, wherein the rubber elastomer is two or more of a styrene-isoprene-styrene block copolymer, a styrene-ethylene-butene-styrene block copolymer, butyl rubber and ethylene propylene diene monomer; the bonding resin is one or two of an ethylene-vinyl acetate maleic anhydride grafted modified material and an ethylene-acrylate-maleic anhydride terpolymer; the tackifying resin is one or more of terpene resin, C5 petroleum resin and rosin glyceride; and the plasticizer is polyisobutene or naphthenic oil. The low-temperature dry film hot melt adhesive disclosed by the invention is used for pipeline joint coating and corrosion prevention, meets the construction requirements in an extremely cold environment, and meets the pipeline joint coating and corrosion prevention construction requirements in cold regions; and the adhesive has the advantages of excellent adhesion and sealing property, good low-temperature flexibility, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

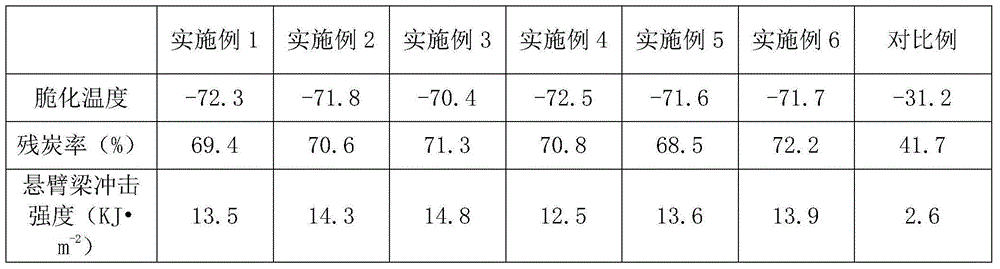

Carbon fiber reinforced epoxy resin composite and preparation method thereof

The invention provides a carbon fiber reinforced epoxy resin composite, comprising the components according to parts by weight: 45-60 parts of epoxy resin, 10-15 parts of a toughener, 4-5 parts of a smoothening agent, 15-20 parts of a solidifying agent, 1-2 parts of an accelerant, 5-10 parts of a thickener, 1-3 parts of a release agent, 5-10 parts of a compatibilizer, 10-15 parts of nano barium sulfate, 8-12 parts of UHMWPE (ultrahigh molecular weight polyethylene), and 10-16 parts of carbon fiber. The invention also discloses a preparation method of the carbon fiber reinforced epoxy resin composite. The carbon fiber reinforced epoxy resin composite has good scratch resistance.

Owner:泰安天成复合材料有限公司

High-strength low temperature resistant cable sheath material

InactiveCN103992581AEasy to useLower embrittlement temperaturePlastic/resin/waxes insulatorsInsulated cablesMethacrylateAntioxidant

The invention discloses a high-strength low temperature resistant cable sheath material which is prepared as follows: putting polyvinyl chloride, unitary ethylene propylene rubber, rubber and ethylene-propylene-diene monomer rubber into a plasticator for plastication; melting and mixing acrylic acid grafted high density polyethylene and bentonite in a flowing deformation instrument to obtain a second material, sending a first material and the second material into a mixing machine to mix evenly, when the temperature is increased to 80-85 DEG C, sequentially adding an antioxidant, N, N '-ethylene distearic amide, zinc stearate, microencapsulated red phosphorus and white carbon black, when the temperature is increased to 125-132 DEG C, adding gamma-aminopropyltrimethoxysilane, triallyl cyanurate and zinc methacrylate, mixing, then extrusion-molding and cutting to obtain the high-strength low temperature resistant cable sheath material. The high-strength low temperature resistant cable sheath material is excellent in low temperature resistant performance, high in mechanical strength and thermal deformation temperature, and good in thermal stability.

Owner:JINYUAN ELECTRIC GRP

Skin of stratospheric aerostat and preparation method thereof

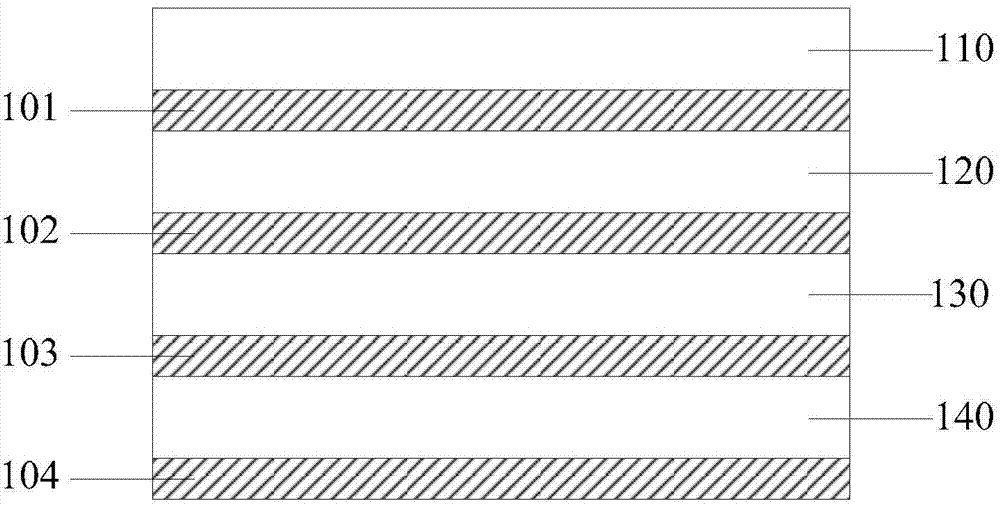

ActiveCN104742442AGood weather resistanceWide temperature rangeSynthetic resin layered productsLaminationWeather resistanceTetra

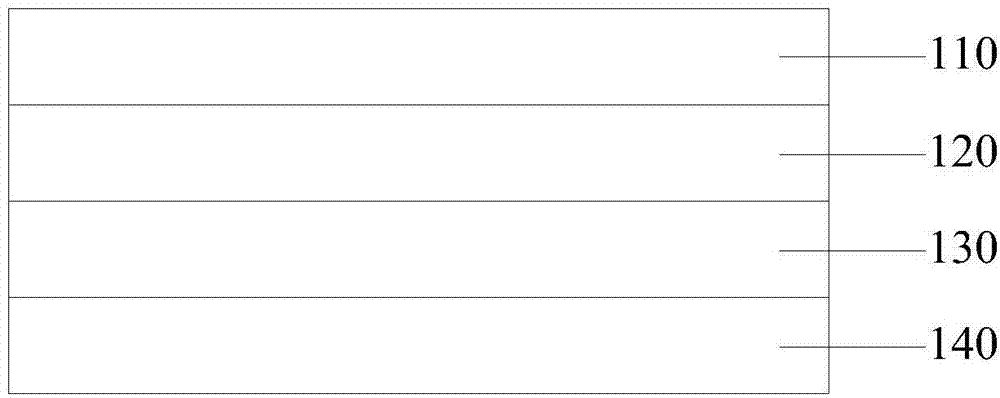

The invention provides a skin of a stratospheric aerostat and a preparation method thereof. The skin comprises a weather resistance layer, a first air barrier, a force bearing layer and a second air barrier, wherein the weather resistance layer is an ETFE (ethylene-tetra-fluoro-ethylene) layer; the using temperature range of ETFE is wide; the brittle temperature of ETFE is as low as minus 100 DEG C between minus 65 DEG C and minus 150 DEG C; ETFE has good radiation resistance and higher shear strength. The skin of the stratospheric aerostat uses the ETFE layer as the weather resistant layer, so that the weather resistance of the skin of the stratospheric aerostat can be substantially improved.

Owner:INSTITUTE OF SCIENCE & TECHNOLOGY INNOVATION DONGGUAN UNIVERSITY OF TECHNOLOGY

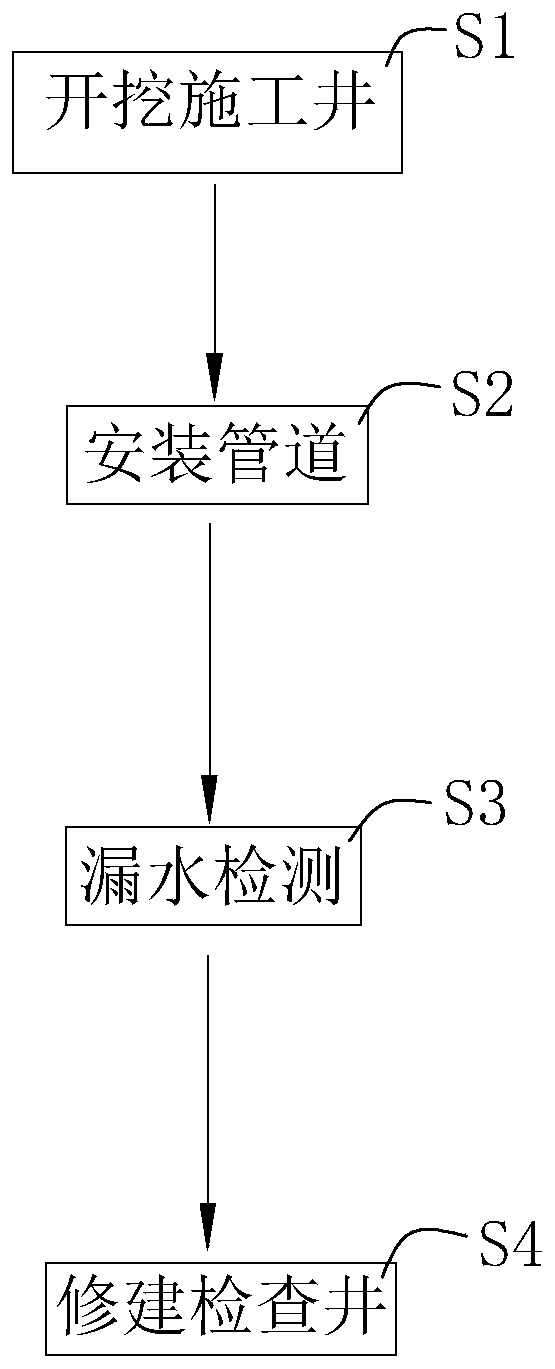

Construction method of sewage pipeline

ActiveCN110106960AImprove construction efficiencyNo need to overcome frictionSewer pipelinesPipeflowWater leakage

The invention relates to the technical field of pipelines, and provides a construction method of a sewage pipeline in order to solving the problem of low efficiency during water pipeline construction.According to the technical scheme, the construction method of the sewage pipeline comprises the following steps that S1, construction wells are excavated; S2, the pipeline is installed, specifically,sewage pipe installing holes communicating adjacent construction wells are formed by drilling through a drilling machine, advancing is carried out for every 1-5 m and is stopped when drilling is carried out, and sewage pipe mixtures are sprayed to the hole walls to form the pipe wall of a sewage pipe; S3, water leakage detection is carried out, specifically, the sewage pipe mixtures are sprayed to the water leakage positions for leak repairing according to the detection results; and S4, an inspection well is constructed. The sewage pipe installing holes are drilled, the sewage pipe mixtures are sprayed to the hole walls to form the pipe wall of the sewage pipe at the same time, so that drilling and pipeline preparation are carried out synchronously, soil frictional force does not need tobe overcome, and the construction efficiency of the sewage pipe is greatly improved.

Owner:广东隆建工程有限公司

Polystyrene resin-based composite material and preparation method thereof

The invention provides a polystyrene resin-based composite material. The polystyrene resin-based composite material comprises, by weight, 45 to 65 parts of polystyrene resin, 10 to 14 parts of chlorine ether rubber, 5 to 9 parts of uvarovite powder, 5 to 8 parts of a fire retardant, 2 to 5 parts of a light stabilizing agent, 1 to 2 parts of an antistatic agent, 2 to 7 parts of a plasticizer, 2 to 3 parts of a lubricant, 1 to 3 parts of a heat stabilizer, 2 to 5 parts of a compatilizer and 0.4 to 0.5 part of a nucleating agent. The invention further discloses a preparation method for the polystyrene resin-based composite material. The polystyrene resin-based composite material provided by the invention has good cold resistance, high temperature resistance, oxidizability and toughness.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

Novel pipeline suitable for non-excavation engineering

The invention provides a novel pipeline which is suitable for non-excavation engineering, and the product is prepared from the following components by weight ratio: 100 parts of B-85 type PVC resins, 3-5 parts of compound lead stabilizing agents, 3-5 parts of acrylic acid resins, 5-7 parts of chlorinated polyethylene or MBS resins, 1-3 parts of plasticizers, 0.5-2 parts of lubricants, 1.5-3 parts of fire retardants, 0.5-2 parts of anti-oxidants, 7-15 parts of alkali-free short glass fibers, and 0-5 parts of color masterbatch. The pipeline has good toughness and the fracture percentage elongation reaches more than 350, and the fracture yield strength reaches more than 50 MPa; the pipeline has good rigidity, and the wall is twice or three times as thick as the wall of pipeline made from polypropylene material; the product has good recovery rate and small permanent compression deformation; the product has good acid and alkali resistance capabilities, and the components mainly do not have inorganic filling materials, so the underground acid and alkali environment has little corrosion to the pipeline; the joint employs rivet or special-purpose glue, thereby the joint has high intensity and can be used for non-excavation engineering; the product has aging resistance with long usage life, and the can be better applied to non-excavation engineering.

Owner:ZHEJIANG FEILONG PIPE

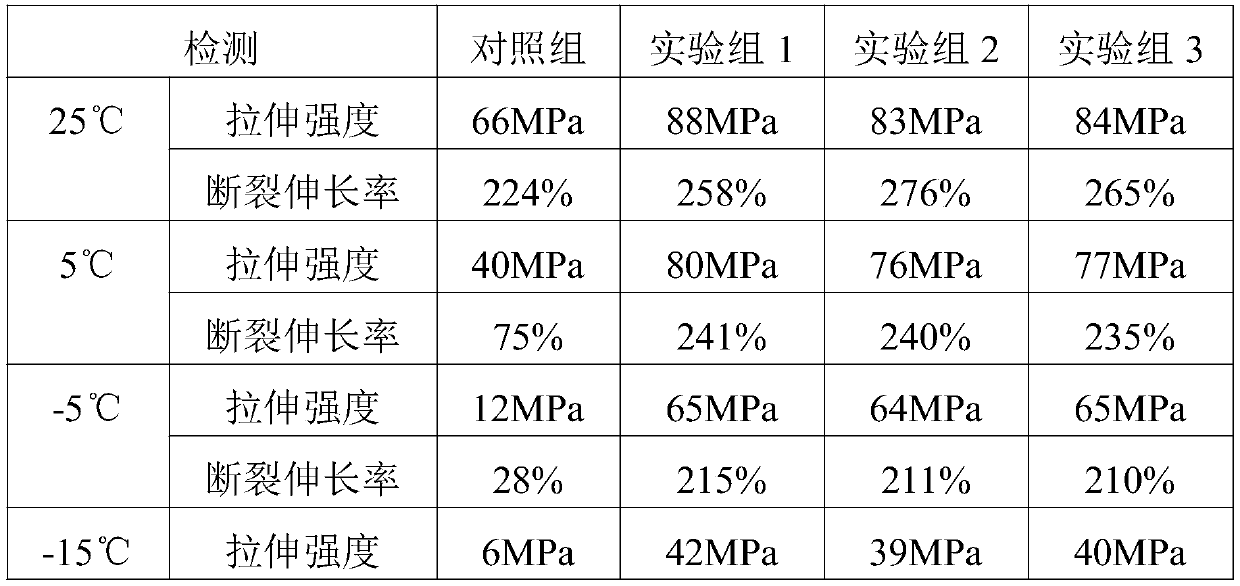

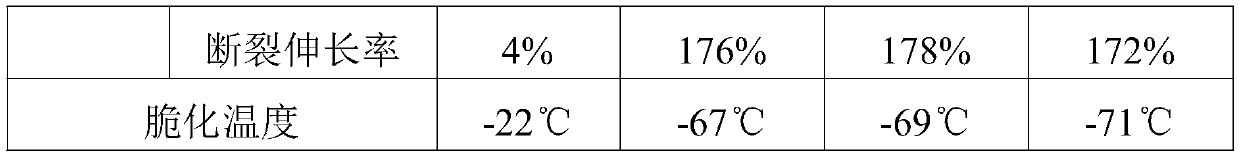

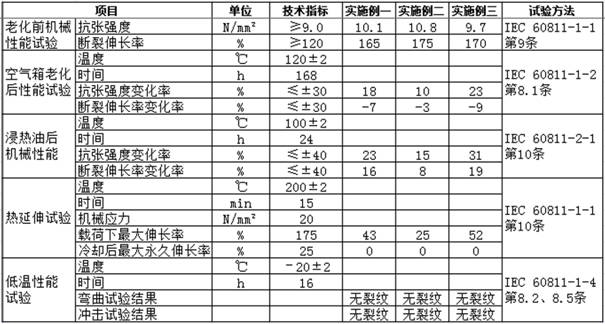

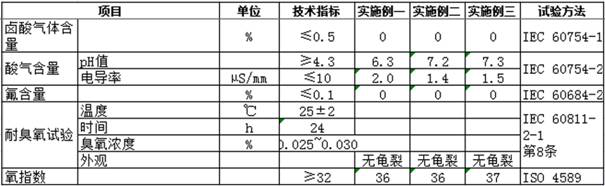

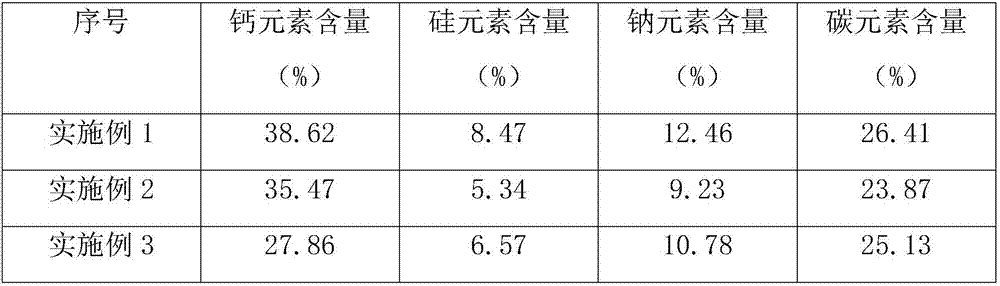

Insulated layer and sheath material of charging pile connecting cable and preparation method for insulated layer and sheath material

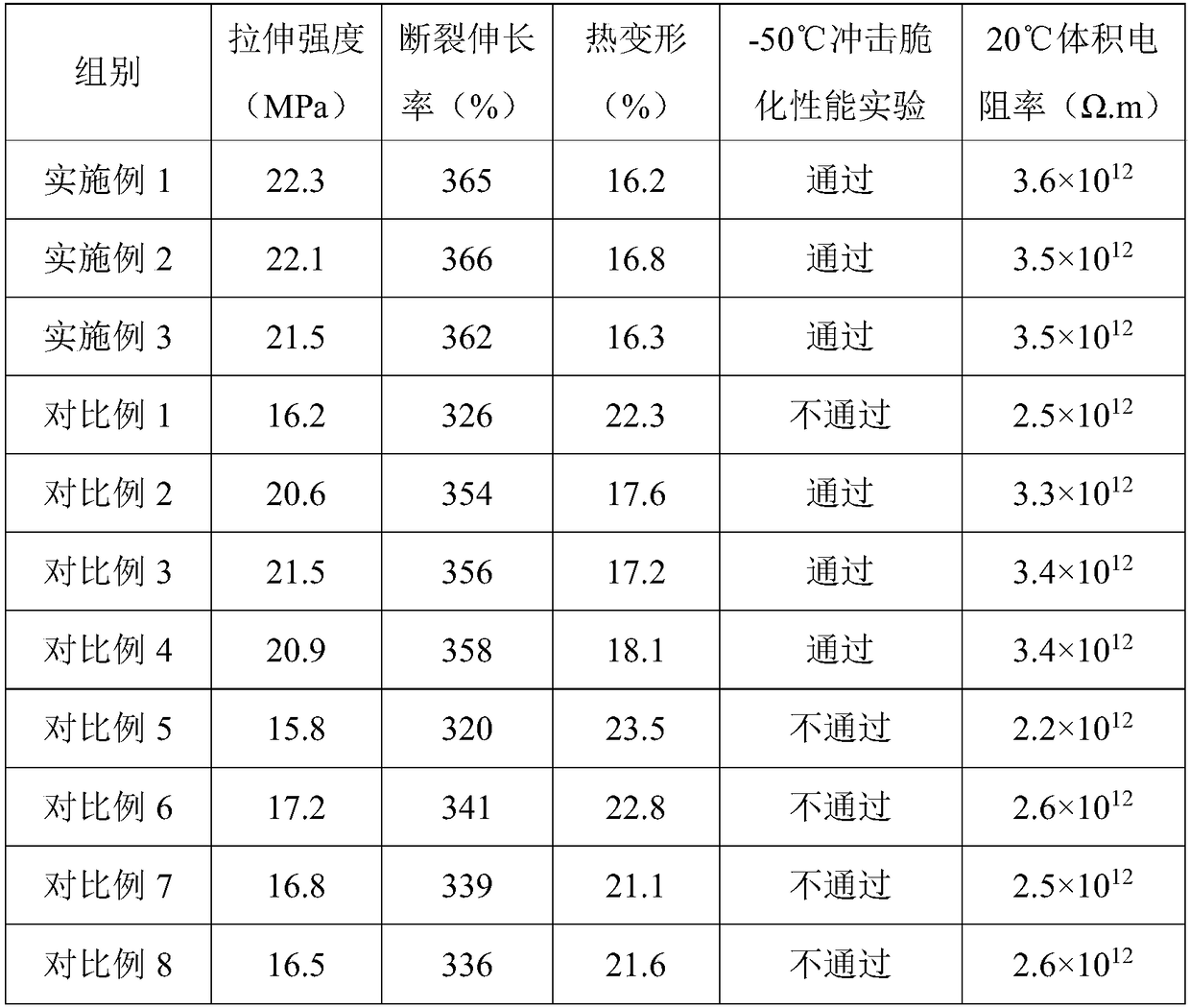

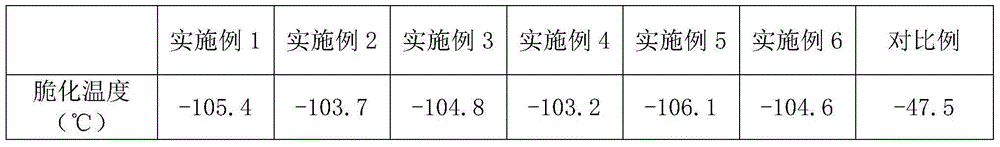

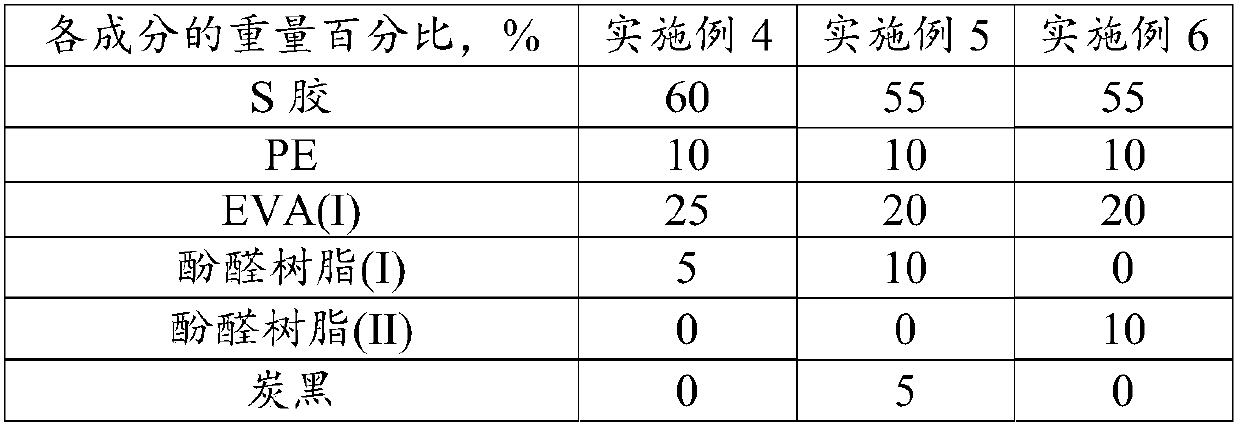

InactiveCN108359172AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesCross-linkAcrylonitrile

The invention discloses an insulated layer and sheath material of a charging pile connecting cable, and belongs to the technical field of preparation. The insulated layer and sheath material of the charging pile connecting cable is prepared from the following raw materials: polyvinyl chloride resin, ethylene vinyl acetate copolymer, hydrogenated butadiene-acrylonitrile rubber, acrylate rubber, a cross-linking agent, a flame retardant, a scorch retarder, an accelerant, an anti-oxidant, an anti-ageing agent, a plasticizer, a stabilizer, a high molecular weight compatibilizer, a coupling agent, naphthenic oil, polytrifluorochloroethylene, and polyethylene wax. Tensile strength, elongation at break and electrical resistivity of the cable insulated layer and sheath material are improved througha reinforcing system which is prepared from naphthenic oil, polytrifluorochloroethylene and polyethylene wax, and reduces thermal deformation.

Owner:金龙电缆科技有限公司

Low-temperature-resistant silicone sealant and preparing method thereof

InactiveCN105086921ABarrier damageImprove low temperature toughnessNon-macromolecular adhesive additivesOther chemical processesMicrospherePlasticizer

The invention provides low-temperature-resistant silicone sealant. The silicone sealant is prepared from, by weight, 100 parts of end-capped polydimethylsiloxane, 5-10 parts of plasticizers, 15-20 parts of filler, 3-10 parts of cross-linking agents, 1-2 parts of catalysts, 0.5-1 part of coupling agent, 1-2 parts of stabilizers, 1.5-2 parts of antiager, 2-6 parts of tackifier, 4-5 parts of solubilizer PE-g-MAH, 10-12 parts of polysulfone and 14-15 parts of hollow calcium carbonate microspheres. The invention further provides a preparing method of the silicone sealant. The silicone sealant is high in low temperature resistance.

Owner:DONGGUAN XINXING ORGANIC SILICON TECH

Low-temperature-resistant insulation cable sheath material

A disclosed low-temperature-resistant insulation cable sheath material is prepared as follows: putting polyvinyl chloride, ethylene-propylene-diene monomer and ethylene-vinyl acetate copolymer in a plasticizing machine for plasticizing and obtaining a first material; performing fusion mixing on methacrylic acid-grafted high-density polyethylene and bentonite in a rheometer to obtain a second material; sending the first material and the second material to a mixer for uniform mixing, then heating to 80-85 DEG C, successively adding an anti-oxidant, dioctyl sebacate, N,N'-ethylene bis(stearamide), zinc stearate, microencapsulated red phosphorus and modified kaolin, heating to 125-135 DEG C, adding a coupling agent titanate and gamma-aminopropyltrimethoxysilane, continuing to stir and mix until no powder attaches to a hand when a hand touches the powder, and after mixing is finished, performing plastic extrusion and pelletizing to obtain the low-temperature-resistant insulation cable sheath material. The above low-temperature-resistant insulation cable sheath material is excellent in cold resistance, high in mechanical strength and thermal distortion temperature and good in thermal stability.

Owner:JINYUAN ELECTRIC GRP

Hot melt adhesive, preparation method and application of hot melt adhesive, and heat shrinkable sleeve

InactiveCN107892887AExcellent performance indexImprove performanceNon-macromolecular adhesive additivesBituminous material adhesivesHeat-shrinkable sleevePolymer science

The invention discloses a hot melt adhesive, a preparation method and an application of the hot melt adhesive, and a heat shrinkable sleeve. The hot melt adhesive is prepared from the following main components in percentages by weight: 30 to 80% of asphalt mastic, 15 to 50% of thermoplastic resin, 5 to 40% of thickening resin, 0 to 5% of an antioxidant and 0 to 20% of a filling material. The preparation method for the hot melt adhesive comprises the following steps: weighing of raw materials in a formula proportion, mixing under heating, cooling and molding. The invention alleviates problems like poor binding properties, narrow application range and no resistance to low temperature for a conventional hot melt adhesive. The hot melt adhesive provided by the invention has excellent binding properties and high peel strength to PE, steel and epoxy primer; meanwhile, the preparation method for the hot melt adhesive provided by the invention has the advantages of convenience in operation andcontrol, low energy consumption, low cost, easy implementation of large-scale production, and facilitation of further promotion of industrial development.

Owner:NITTO QINGDAO TECH RES INST CO LTD

Low temperature resistant environmentally-friendly sealant and preparation method thereof

InactiveCN108753245AWith low temperature resistanceFlexibleNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkSealant

The invention discloses a low temperature resistant environmentally-friendly sealant. The low temperature resistant environmentally-friendly sealant comprises the following raw materials in parts by weight: 42 to 46 parts of blocking polydimethylsiloxane, 28 to 32 parts of modified epoxy resin, 14 to 18 polytetrafluoroethylene, 16 to 22 parts of silica fume, 8 to 14 parts of a cross-linking agent,6 to 10 parts of a binder, 5 to 9 parts of a king sundew, 6 to 10 parts of epoxidized soybean oil, 1 to 3 parts of p-phenylenediamine and 2 to 6 parts of butyl cellosolve. According to the low temperature resistant environmentally-friendly sealant provided by the invention, compared with the prior art, the low temperature resistance of the sealant is greatly improved, and the sealant has preferable use value and good application prospect.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

Road asphalt

The invention discloses road asphalt. The road asphalt is prepared from the following components by weight percentage: 80-100 parts of asphalt, 3-15 parts of styrene butadiene rubber, 2-5 parts of neoprene, 2-5 parts of isoprene rubber, 2-6 parts of polystyrene, 0.3-3 parts of N-isopropyl-N-phenyl-p-phenylenediamine, 0.5-5 parts of dimethyl phthalate, 0.1-1 part of p-tolualdehyde, 3-10 parts of mica powder, 1-7 parts of sodium alkyl benzene sulfonate, 3-8 parts of polyvinyl alcohol and 1-3 parts of caustic soda. The road asphalt has a good interlayer bonding degree, the high-temperature stability performance of the asphalt can be effectively improved, and meanwhile, the brittleness temperature is decreased so that the low-temperature anti-cracking performance of the asphalt can be improved; the asphalt is high in viscosity, resistant to high temperature and good in waterproof property, and has high ability of resisting high-temperature and rainy weather, and thus, the damage rate of roads is greatly decreased.

Owner:海宁新业新材料科技有限公司

Card protective film, manufacturing method, and payment card

InactiveCN106497443AMeet the technical performance requirements of surface tensionMeet technical requirementsLamination ancillary operationsProtective equipmentTectorial membraneHot stamping

The invention relates to a card protective film, a manufacturing method, and a payment card. The card protective film includes a core layer formed by a bi-oriented stretching polyester thin film, a first connection layer, a printing adhesion layer which is connected to a printing layer of a card base material, and a surface process layer which has the functions of hot-lamination release, thermal-lamination and / or hot-stamping. The printing adhesion layer is connected to one surface of the core layer through the first connection layer. The surface process layer is connected to the other one surface of the core layer. The card protective film can satisfy the technical performance demands of surface tension in surface processing of the payment card and release and process temperature during the surface processing of lamination of the card. The card protective film can protect the payment card as well as other cards better. The payment card or other cards have higher transparency, higher surface and entire strength and higher temperature resistant level and further has longer service life.

Owner:TIANJIN BOYUAN NEW MATERIALS

High-strength anti-fall remote controller shell material and preparation method thereof

The invention provides a high-strength anti-fall remote controller shell material and a preparation method thereof, which relates to the technical field of remote controller processing. The remote controller shell material is made of the following raw materials in parts by weight: 30-40 parts of polyvinyl chloride, 8-10 parts of petroleum resin, 15-20 parts of polycarbonate, 8-12 parts of phenolicresin, 6-8 parts of glass fiber, 2-3 parts of talc powder, 3-5 parts of metallocene polyethylene, 2-3 parts of polyimide, 2-4 parts of cyclohexanone peroxide, 1-1.4 part of a coupling agent, 1-3 parts of carbon fiber, 1-2 parts of dimethylsiloxane, 1-1.2 part of isononyl isononanoate, 0.4-0.8 part of hydroxyl silicone oil, 4-5 parts of filler, 0.3-0.5 part of plasticizer. The invention overcomesthe shortcomings of the prior art, improves the impact resistance performance of the outer shell material of the remote controller, enhances the strength of the outer shell material, effectively prevents the remote controller from falling and cracking and the like in the use process, prolongs the service life of the product, enhances the economic benefit, and is suitable for popularizing production and use.

Owner:天长市富达电子科技股份有限公司

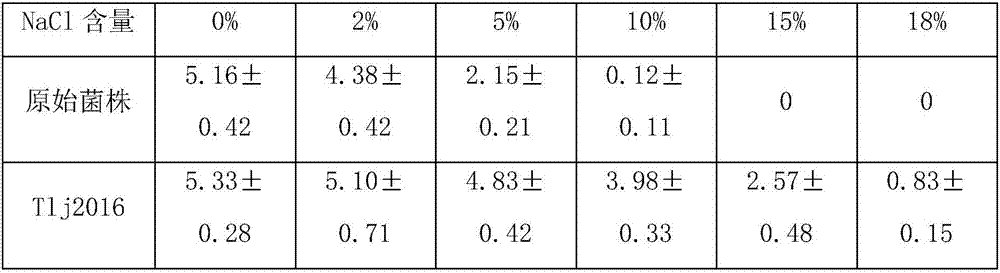

Low temperature resistant EPDM (ethylene-propylene-diene monomer) cable material and preparation method thereof

ActiveCN104861309AImprove low temperature resistanceReduced low temperature resistanceRubber insulatorsEthylene-propylene-diene-monomerEngineering

The present invention provides a low temperature resistant EPDM (ethylene-propylene-diene monomer) cable material comprising the following components by weight: 100 parts of EPDM, 9-14 parts of ECO rubber, 4-5 parts of MMA, 0.3-0.5 parts of a crosslinking agent, 8-12 parts of EVA, 3-8 parts of a compatilizer, 2.5-4.5 parts of a vulcanizing agent, 1.5-3 parts of a co-vulcanizing agent, 70-90 parts of a packing, 0.1-0.2 part of a coupling agent and 1-2 parts of an antiager. The present invention also provides a preparation method of the cable material. The low temperature resistant EPDM (ethylene-propylene-diene monomer) cable material has good low temperature resistance.

Owner:王鸳

Cable sheath material for coal mine

ActiveCN101538380BImprove stabilityEasy to useInsulated cablesInsulated conductorsPolyvinyl chlorideStearic acid

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusionperformance and low cost.

Owner:阳谷新太平洋电缆有限公司

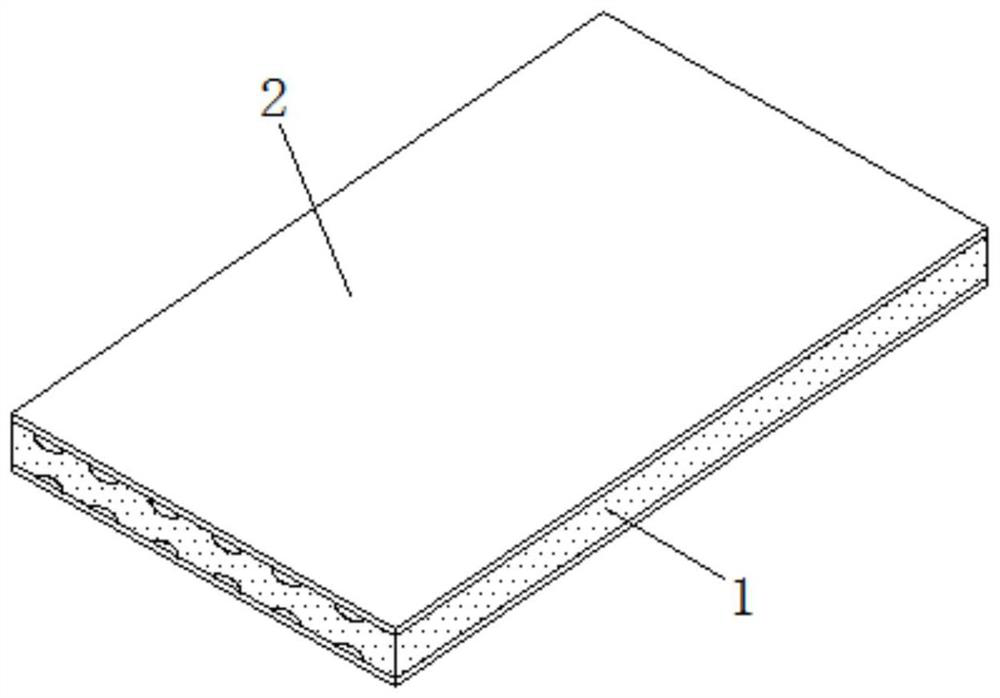

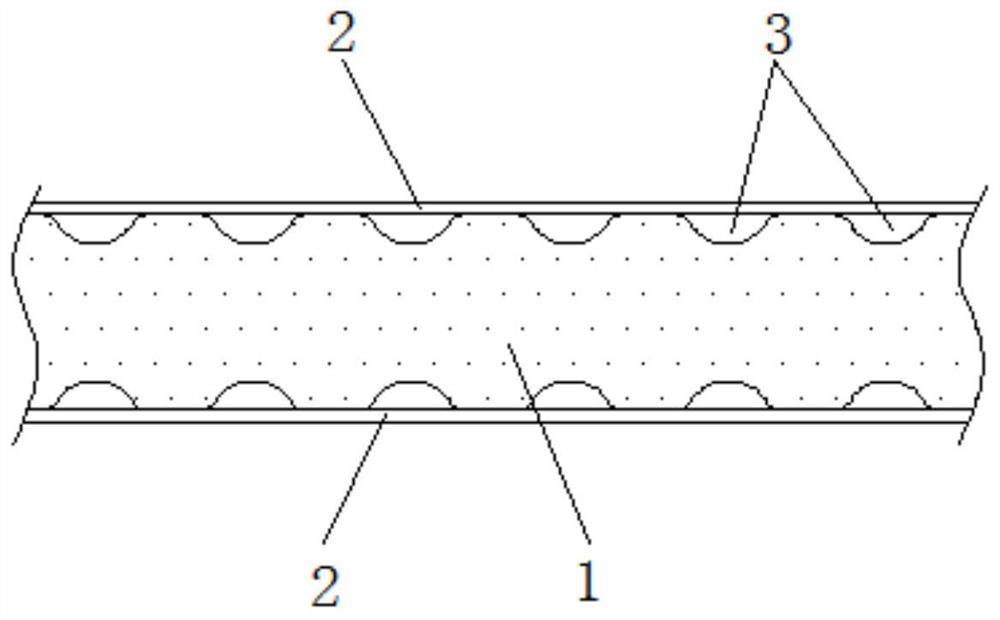

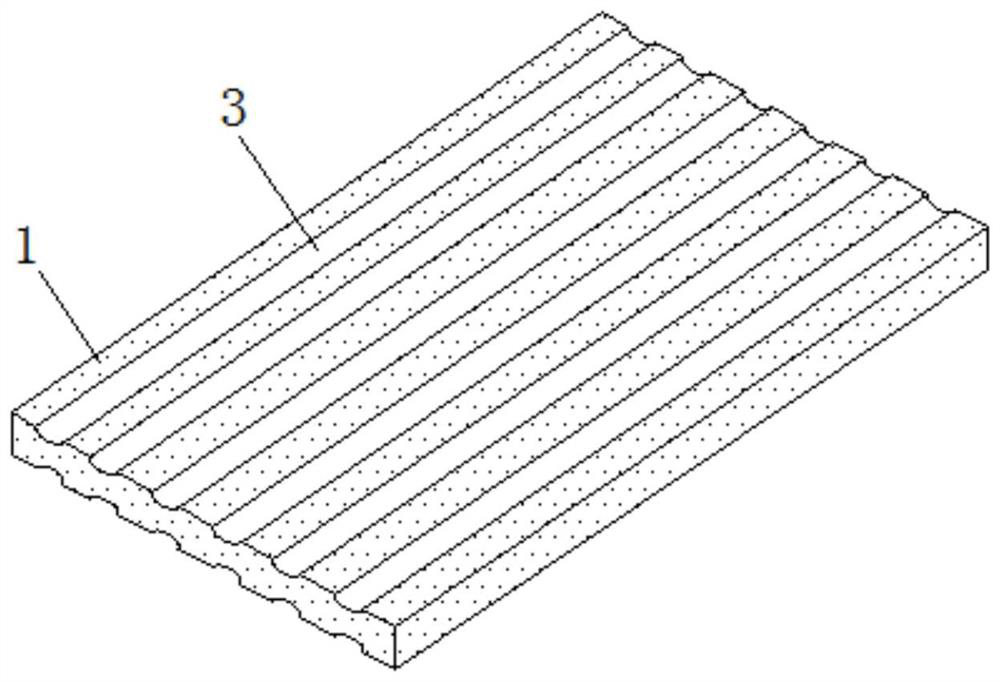

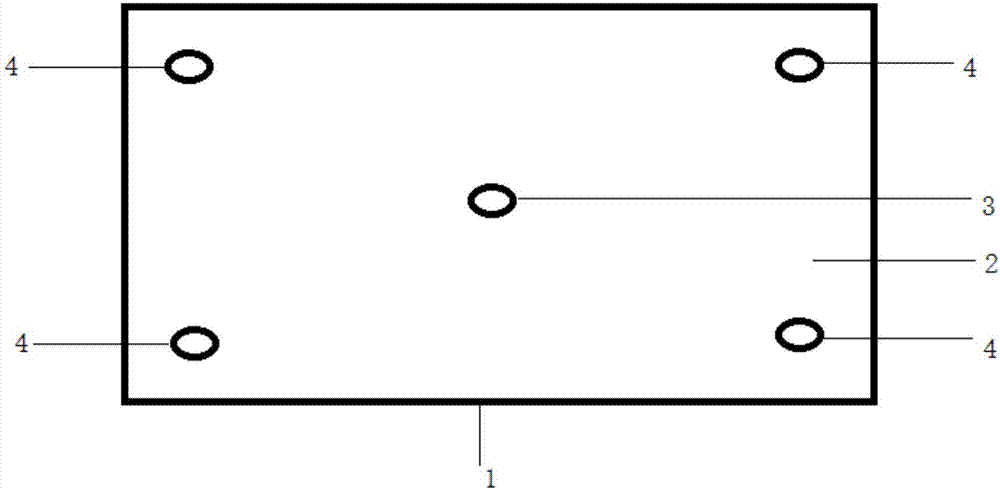

High-impact-resistance glass fiber reinforced polypropylene material and manufacturing process thereof

The invention discloses a high-impact-resistance glass fiber reinforced polypropylene material and a manufacturing process thereof, and belongs to the field of polymer modified materials. The high-impact-resistance glass fiber reinforced polypropylene material is a composite material and comprises a modified PP material of a middle main body part and glass fiber gridding cloth glued to the upper face and the lower face of the modified PP material. The modified PP material is prepared from the following components: 5 parts of a polypropylene raw material, 4 parts of glass fiber powder, 0.7 part of butadiene rubber, 0.01 part of a nucleating agent, 0.01-0.02 part of a coupling agent and 0.27-0.28 part of a toughening agent. The glass fiber reinforced polypropylene material with high impact resistance is low in manufacturing cost, has high-strength impact resistance and toughness, can replace traditional tempered glass to intercept objects falling from high altitudes, and effectively prevents the objects falling from high altitudes from hurting people.

Owner:泗阳联欣塑业有限公司

Method for producing plastic tray by utilizing hollow blow molding machine

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

Glue for TPR material sole and preparation method thereof

InactiveCN109233691AHigh softening temperatureLower embrittlement temperatureNon-macromolecular adhesive additivesWax adhesivesCresolParaffin oils

The invention discloses a glue for a TPR material sole. The glue is prepared from the following raw materials in parts by weight: 90-110 parts of ethylene-vinyl acetate interpolymer, 25-35 parts of butyl rubber, 20-30 parts of coumarone-indene resin, 5-8 parts of synthetic paraffin resin, 15-25 parts of talcum powder, 4-6 parts of calcium carbonate and 0.5-1.5 parts of 2,6-di-tert-butyl-p-cresol.The glue product provided by the invention has a high softening temperature and a low brittle temperature, can be used at most temperatures without losing viscosity, and has good adhesive bonding performance for various materials; and nitrile-butadiene rubber is added to improve the flexibility and elasticity of the glue solution, improve the adhesive bonding strength and shorten the curing time.

Owner:扬州朗劲塑胶实业有限公司

Long-acting cold-resistant cable material and preparation method thereof

InactiveCN110372985AImprove stabilityImprove cold resistancePlastic/resin/waxes insulatorsCross-linkGas phase

The invention provides a long-acting cold-resistant cable material and a preparation method thereof, and relates to the technical field of cable processing. The long-acting cold-resistant cable material is prepared from the following raw materials in parts by weight: 15-20 parts of ABS resin, 8-12 parts of ethylene propylene diene monomer, 10-15 parts of polytetrafluoroethylene, 6-8 parts of fluororubber, 2-3 parts of dimethyl silicone polymer, 3-5 parts of hexanedioic acid dibutyl diglyceride, 2-4 parts of ethoxyethoxyethyl acrylate, 1-2 parts of dodecanedioic acid, 2-4 parts of basalt powder, 2-4 parts of gas phase white carbon black, 1-1.2 parts of a cross-linking agent, 1-1.6 parts of a lubricating agent, and 0.8-1.2 parts of an antioxidant.

Owner:安徽上华电缆有限公司

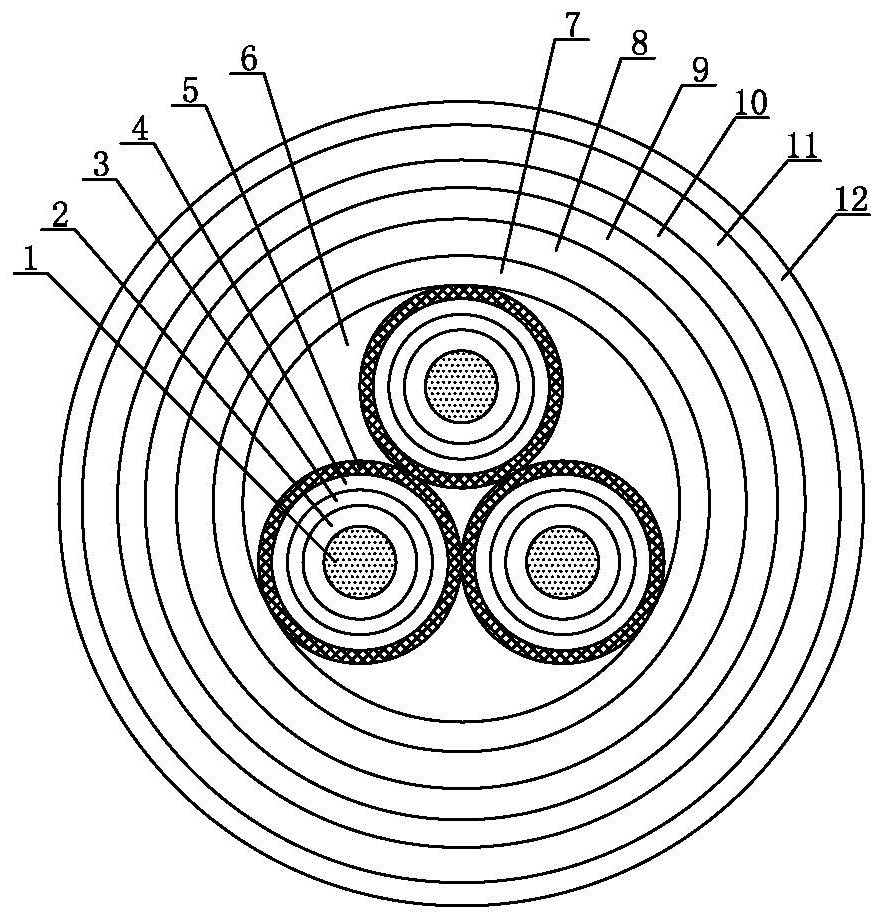

Jet flame and hydrocarbon flame resistant medium-voltage cable for offshore oil platform and manufacturing method thereof

ActiveCN112466536AEasy to slideSmall outer diameterClimate change adaptationInsulated cablesCopper conductorPolyolefin

The invention relates to a jet flame and hydrocarbon flame resistant medium-voltage cable for an offshore oil platform and a manufacturing method thereof. A semi-conductive conductor shielding layer,an insulating layer and a semi-conductive insulating shielding layer wrap the periphery of a stranded tin-plated annealed copper conductor from inside to outside in a three-layer co-extrusion mode; atinned copper wire shielding layer is woven on the periphery of a semi-conductive insulation shielding layer to form a shielding wire core, a plurality of shielding wire cores are twisted to form a cable core, an inner silicone oil layer is extruded on the periphery of the cable core, an inner lining layer is extruded on the periphery of the inner silicone oil layer, a fireproof wrapping tape is wrapped on the periphery of the inner lining layer, and an armor layer is wrapped on the periphery of the fireproof wrapping tape; the periphery of the armor layer is extruded with an outer silicone oil layer, the periphery of the outer silicone oil layer is extruded with a jet flame and hydrocarbon flame resistant inner sheath, and the periphery of the jet flame and hydrocarbon flame resistant inner sheath is extruded with a slurry resistant cross-linked polyolefin outer sheath. The cable adopts a double-layer composite sheath, can bear high-temperature flame of 1300 DEG C for 120 minutes under rated voltage, and does not have a grounding fault or a short circuit.

Owner:WUXI MINGZHU CABLE

Sheath material used for coal mine cable

The invention discloses a sheath material used for a coal mine cable. The sheath material used for the coal mine cable is characterized by being prepared from, by weight, the raw materials of 55-100 parts of elastomeric chlorinated polyethylene, 45-80 parts of resin type chlorinated polyethylene, 35-65 parts of white carbon black, 10-20 parts of magnesium oxide, 9-20 parts of magnesium hydroxide, 25-55 parts of chlorinated paraffin, 35-45 parts of cable powder, 1-3 parts of silane coupling agents A-172, 10-20 parts of dioctyl phthalate, 15-30 parts of flame retardant CM80AT, 10-20 parts of flame retardant TCEP, 1-3 parts of paraffin, 2-5 parts of polyethylene wax and 6-18 parts of vulcanizing agents. The sheath material has good thermo-oxidative ageing resistance and flame retardancy and has the advantages of being good in elasticity, high in tensile strength, good in tear resistance and calendaring performance, low in cost and the like.

Owner:山东太平洋橡缆股份有限公司

Resin material for high-toughness urine bag catheter, and preparation method thereof

The invention provides a resin material for a high-toughness urine bag catheter, and a preparation method thereof, and relates to the technical field of urethral catheterization bag processing, wherein the resin material is prepared from the following raw materials by weight: 45-55 parts of a PVC resin, 18-22 parts of polyformaldehyde, 4-8 parts of polyphenylene sulfide, 10-12 parts of polycarbonate, 6-8 parts of carboxylated nitrile rubber, 1-3 parts of nanometer dilanthanum trioxide, 2-3 parts of hydroxyapatite, 1-1.8 parts of 1,2-dimethoxybenzene, 4-6 parts of maleic anhydride, 2-2.5 partsof N,N'-di-tert-butylethylenediamine, 3-5 parts of benzoguanamine, 1-1.2 parts of a vulcanizing agent, 1-2 parts of an antioxidant, and 1-1.8 parts of a dispersing agent. According to the present invention, the deficiencies in the prior art are overcome, the toughness and the tensile strength of the resin material for the conventional urine bag catheter are improved, the embrittlement temperatureis reduced, the softness is increased so as to be conveniently used, and the method is suitable for popularization and production.

Owner:天长市佳诺医疗器械有限公司

Concrete formula for bridge construction and preparation method thereof

InactiveCN107572939ALow softening pointLower embrittlement temperatureCeramicwareSlagPolyvinyl chloride

The invention discloses a concrete formula for bridge construction and a preparation method thereof. The concrete formula comprises the following components by weight percent: 40-50% of cement, 20-50%of sand, 3-10% of coal ash, 3-5% of aggregates, 3-5% of slag, 3-5% of silicon powder, 2-5% of polyvinyl chloride, 2-5% of sodium silicate, 1-3% of a foaming agent and 0.3-0.6% of a foam stabilizing agent; polyvinyl chloride is added and the characteristics of polyvinyl chloride are utilized to reduce the crystallization of soluble salts in concrete, so that the salt tolerance of the concrete is greatly promoted; the sodium silicate is added, the silica gel and solid are the main components after the sodium silicate is hardened, and the specific surface area is large, so that the adhesion force is higher and the concrete is capable of resisting against almost all the inorganic acids and organic acids except for hydrofluoric acid, heat phosphoric acid and higher aliphatic acid.

Owner:韩为国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com