Patents

Literature

4250 results about "Ethylene-propylene-diene-monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

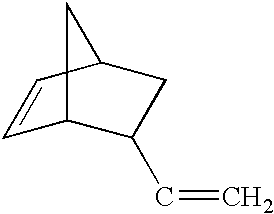

EPDM rubber (ethylene propylene diene monomer rubber), a type of synthetic rubber, is an elastomer characterized by a wide range of applications.

Hot melt sealant and foam-in-place gasketing material

ActiveUS20070042193A1Good balance of propertyImprove adhesionSynthetic resin layered productsOrganic dyesPolymer scienceSealant

A hot melt sealant and foam-in-place gasket composition based on a rubber such as ethylene propylene rubber (EPR) and / or ethylene propylene diene rubber (EPDM) and at least one semicrystalline olefinic polymer. The hot melt composition includes the rubber or a blend of rubbers in an amount of 5% to 50% by weight, at least one semicrystalline olefinic polymer in an amount of 5% to 40% by weight, at least one amorphous poly-α-olefin (APAO) polymer in an amount of 0% to 70% by weight, a compatible tackifier in an amount of 0% to 50% by weight, and a plasticizer in an amount of at least 30% by weight. The composition is particularly useful for foamed gasket applications as a replacement for pressure sensitive adhesive (PSA) coated foam tape.

Owner:BOSTIK INC

Polymerization process for olefin copolymers using bridged hafnocene compounds

InactiveUS6218488B1High Mooney viscosityIncrease pointsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerSide chain

The invention is a polymerization process for ethylene copolymers having a density less than 0.915 comprising contacting ethylene, one or more alpha-olefin monomer, and optionally one or more diene monomer, with a catalyst composition comprising the reaction product of at least one organometallic Group 4 metallocene compound derived from a bridged, fused-ring ligand containing biscyclopentadienyl hafnocene, said bridge being a substituted or unsubstituted carbon or silicon atom connecting the biscyclopentadienyl ligands, and a salt of a Group 13 element anionic complex having halogenated aromatic ligands in an essentially tetrahedral structure wherein the aromatic groups are polycyclic fused or pendant aromatic rings. The process is particularly suitable for the preparation of high comonomer content and high molecular weight ethylene-alpha-olefin plastomers and ethylene-propylene or ethylene-propylene-diene monomer elastomers.

Owner:EXXONMOBIL CHEM PAT INC

Non-crosslinking halogen-free flame-retardant cable insulating material or sheath material and preparation method thereof

ActiveCN103012941ACause damageReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerHalogen

The invention discloses a non-crosslinking halogen-free flame-retardant cable insulating material or sheath material, comprising the following components in part by weight: 100 parts of ethylene and ethylene copolymer and / or ethylene propylene diene monomer, 0-20parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0-40 parts of polymeric elastomer, 0-3 parts of coupling agent, and 0-20parts of color master batch, wherein the ethylene and ethylene copolymer are selected from one or more of the following materials: ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and the like. According to the halogen-free flame-retardant cable insulating material or sheath material, the insulating layer or the sheath layer prepared by the uncrosslinked halogen-free flame-retardant cable insulating material or sheath material can be adaptive to the environment at -40 to 80 DEG C, and the material can not generate poisonous gases such as halogen hydride in case of fire, so that harm to lives and property loss can not be caused by the poisonous gases such as halogen hydride; and besides, the production cost of the material is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

High temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material and method for preparing high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material

ActiveCN103012940AReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention discloses a high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material. The cable insulation material or sheath material comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-20 parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0.01-5 parts of peroxide crosslinking agent, 0-40 parts of polymer elastomer, 0-3 parts of coupling agent and 0-20 parts of color masterbatch; and the ethylene and the copolymer thereof are selected from one or a plurality of the following materials of ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate and the like. The high temperature peroxide crosslinking agent crosslinks under the temperature condition of above 150 DEG C only, during a cable material mixing extrusion and insulating layer or sheath layer formation process, chemical crosslinking or micro-crosslinking cannot be caused, but the high temperature peroxide crosslinking agent generates a crosslinking function when the temperature is higher than 150 DEG C in the case of fire, so that the production cost is lowered.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

Low smoke halogen-free flame retardant ethylene-propylene-diene rubber and preparation method by extrusion molding thereof

ActiveCN101704976AGood mechanical propertiesEasy extrusionEngine sealsVehicle sealing arrangementsPolymer scienceMechanical property

The invention relates to a low smoke halogen-free flame retardant ethylene-propylene-diene rubber and a preparation method by extrusion molding thereof; the preparation method comprises the following steps: firstly, raw rubber matrix is evenly mixed at 80-100 DEG C by an open mill or a banbury mixer, and then cooled down to the room temperature; carbon black, modified nanometer / micrometer hydroxide, plasticizer, flame retardant synergist, vulcanization accelerator and vulcanizing agent are added in sequence according to the proportion and evenly mixed. Mixed rubber is added into a single screw extrusion machine; the temperature of a machine body, a screw and a machine head is controlled to be 50-90 DEG C; the rotating speed of the screw is within 15-40 r / min to cause that glue stock is continuously squeezed out; and hot air (175-200 DEG C) or microwave (915-2450 MHz) is adopted to cause that the glue stock is continuously vulcanized and molded. The flame retardant ethylene-propylene-diene rubber has excellent mechanical property, low smoke halogen-free flame retardant performance and good extrusion performance, and is applicable to manufacturing of flame retardant gland strips used in doors and windows for building and vehicles.

Owner:BEIJING UNIV OF CHEM TECH +1

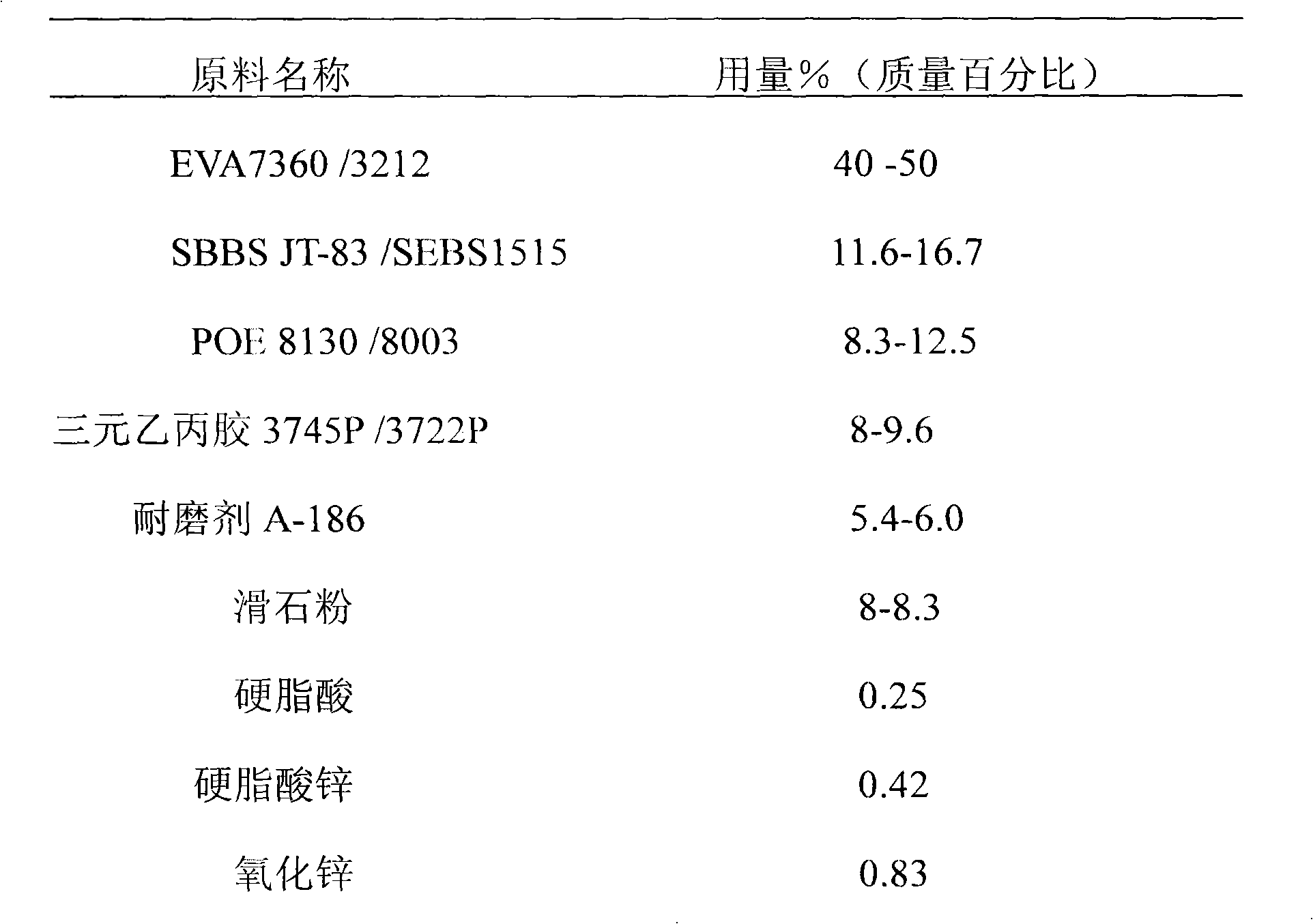

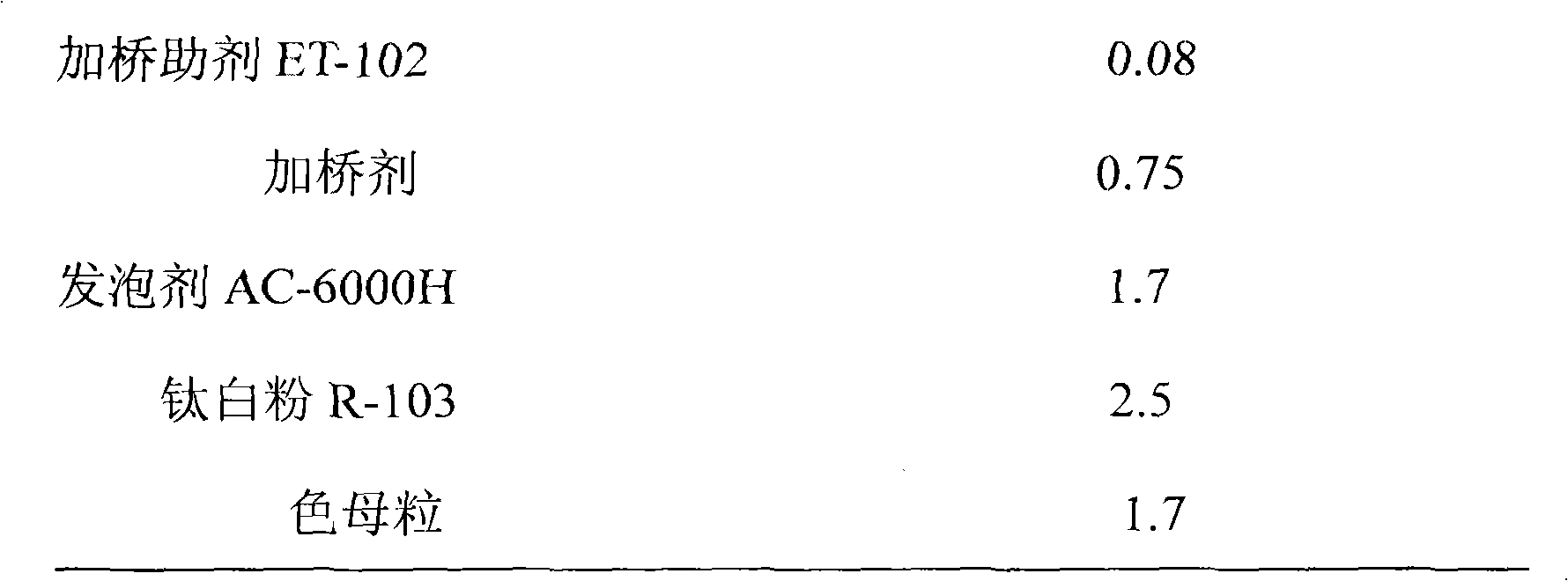

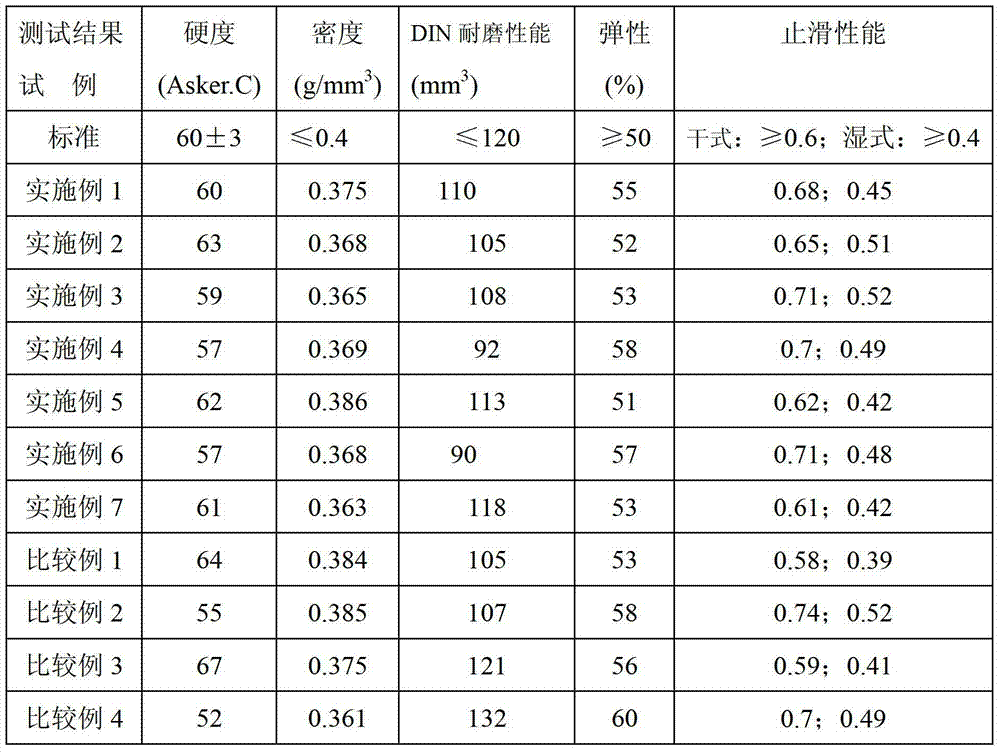

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Heat-conducting wire cable electric-insulation material or sheath material

InactiveCN104017267AImprove thermal conductivityImprove insulation performanceRubber insulatorsPlastic/resin/waxes insulatorsElastomerHeat conducting

The invention discloses a heat-conducting wire cable electric-insulation material or sheath material which comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-25 parts of compatilizer, 0-280 parts of flame retardant, 0.3-8 parts of antioxidant, 0.5-6 parts of lubricant, 0.01-10 parts of crosslinking assistant, 0-30 parts of polymer elastomer, 0-8 parts of coupling agent, 0-12 parts of color master batch and 1-35 parts of heat-conducting material. The heat-conducting wire cable electric-insulation material or sheath material has excellent heat conductivity and electric insulativity; and the cross network formed by piling the heat conducting material, the ethylene and copolymer thereof and other components can effectively perform heat conduction, so that the heat conductivity coefficient is up to 3.305-4.867 w / m.k, and the volume resistivity is 10<14> ohm*cm, thereby ensuring the electric-insulation effect and heat-conducting effect of the wire cable and the, and further ensuring the normal operation of the cable.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Open-cell foam of ethylene-propylene-diene rubber

InactiveUS20060142405A1Reduce impactImprove rendering capabilitiesFoaming agentEthylene-propylene-diene-monomer

Open-cell foam of ethylene-propylene-diene rubber that can convert to open-cell foams at the foaming of EPDM, rather than after the foaming of the same, and can produce low impact resiliency and improved filling capability. After 0.1-40 parts by weight of organic foaming agent, 2-40 parts by weight of inorganic foaming agent, and 2-40 parts by weight of foam auxiliary agent per 100 parts by weight of ethylene-propylene-diene rubber are mixed, the mixture is vulcanized and foamed to thereby produce open-cell foam of ethylene-propylene-diene rubber. This open-cell foam of ethylene-propylene-diene rubber has low impact resilience and good sealing performance so that it can be used as sealing materials of a variety of industrial products.

Owner:NITTO DENKO CORP

Tearing-proof high temperature resisting conveyer belt

InactiveCN101214880AImprove tear resistanceImprove high temperature resistanceConveyorsSteelmakingPolyester

The invention discloses an anti-tear and high temperature resistant conveyor belt, including a skeleton layer, a working face glue-covering layer, a non-working face glue-covering layer, a transverse reinforcement layer and a buffer glue layer. The transverse reinforcement layer is arranged between the skeleton layer and the buffer glue layer and is adjacent to the skeleton layer. The buffer glue layer is arranged between the transverse reinforcement layer and the working face glue-covering layer and is adjacent to the working face glue-covering layer. The skeleton layer adopts low hear shrinkage polyester canvas and the transverse reinforcement adopts polyester curtain net or metal wire. The material of the working face glue-covering layer is made by mixing ethylene propylene diene monomer with other filers with proper proportion. The material of the buffer glue layer is made by mixing the blend glue of ethylene-propylene-diene rubber and natural glue with other fillers of proper proportion. The invention improves the anti-tear and high temperature resistant performances and is widely applied to convey high temperature materials in such industrial enterprises as steelmaking plants, thermal power plants, cement plants, etc.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

All-steel giant-scale engineering tyre side glue and all-steel giant-scale engineering tyre using the same

The present invention relates to a tyre side rubber with perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, applying ethylene -propylene-diene rubber in single-layer huge full steel engineering tyre; the invention also relates to the full steel huge engineering tyre using the tyre side rubber. The full steel huge engineering tyre using the tyre side rubber of the present invention comprises usable sulfur and / or sulfur rubber mixture, the rubber mixture comprises: a. 10-30 parts by weight of ethylene -propylene-diene rubber; b. 50-90 parts by weight of caoutchouc; c. 0-20 parts by weight of butadiene rubber and / or styrene butadiene rubber; and the total content of the ethylene -propylene-diene rubber, caoutchouc, butadiene rubber and / or styrene butadiene rubber is 100 parts by weight compositions. The tyre side rubber produced according to the formula has perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, the rigidity of the rubber material of the tyre side rubber is 55-70 Shore A, the tension intensity is 15-25 Mpa, the flex crack resistance grade is less than or equal to 6 grade / 300000 times.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

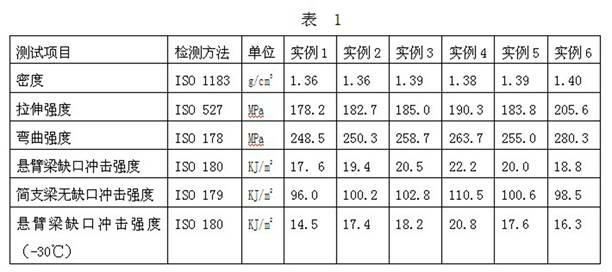

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

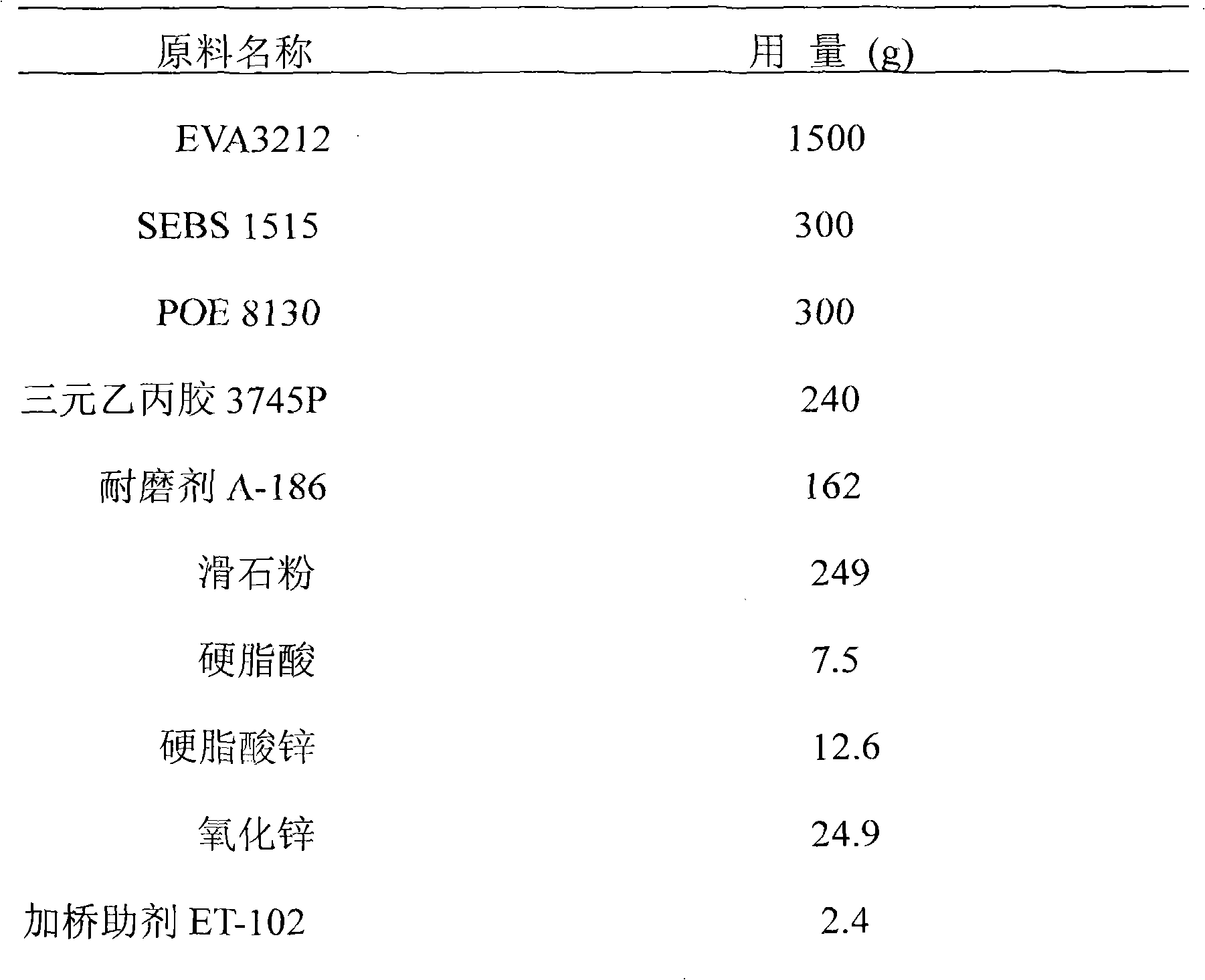

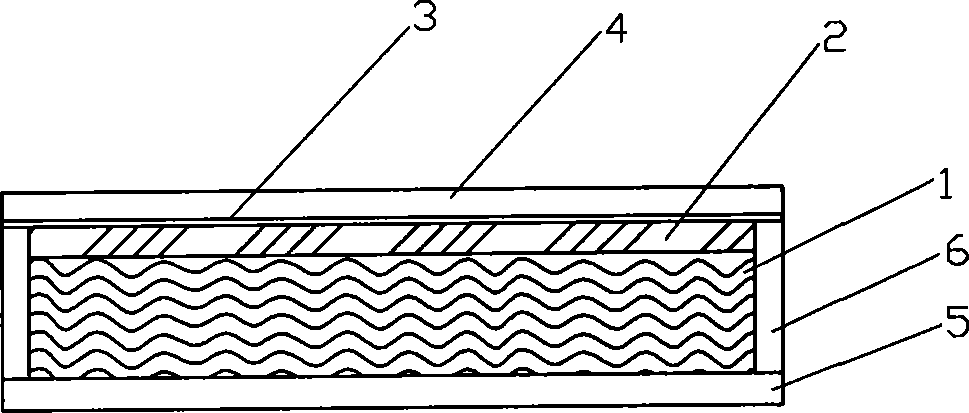

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

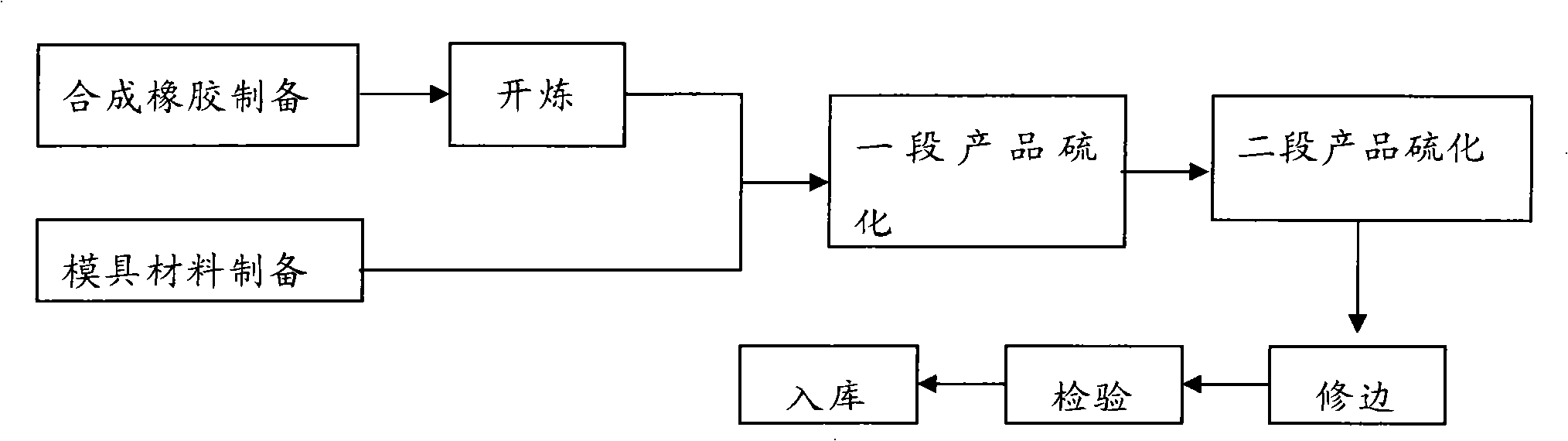

Rubber packing ring and manufacturing technology thereof

InactiveCN101315144AMedium resistantHigh tensile strengthFluid pressure sealed jointsPolymer scienceManufacturing technology

The invention provides a rubber sealing ring and a production method thereof. The rubber sealing ring is prepared from the following components of (by weight parts): ethylene propylene diene monomer (EPDM) 80-120, carbon black 55-75, paraffin oil 15-25, indirect process zinc oxide 4-6, stearic acid 0.2-1, anti-aging agent 2-4, sulfur S-80 0.1-0.35, vulcanizing agent dicumyl peroxide (DCP) 3-5, and lubricating agent 1-3. The production method comprises the steps of: synthesizing rubber with a Banbury mixer, forming the synthetic rubber with a mixing mill, first-stage vulcanizing in a mold of a vulcanizing device, second-stage the product from the first-stage vulcanization in an oven, trimming, testing, and storing. The inventive rubber sealing ring has improved tensile strength, extensibility, tear strength, self-lubrication effect, compression and deformation resistance, heat resistance and aging resistance, good medium resistance, and prolonged service life. The inventive production method is simple and reasonable.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

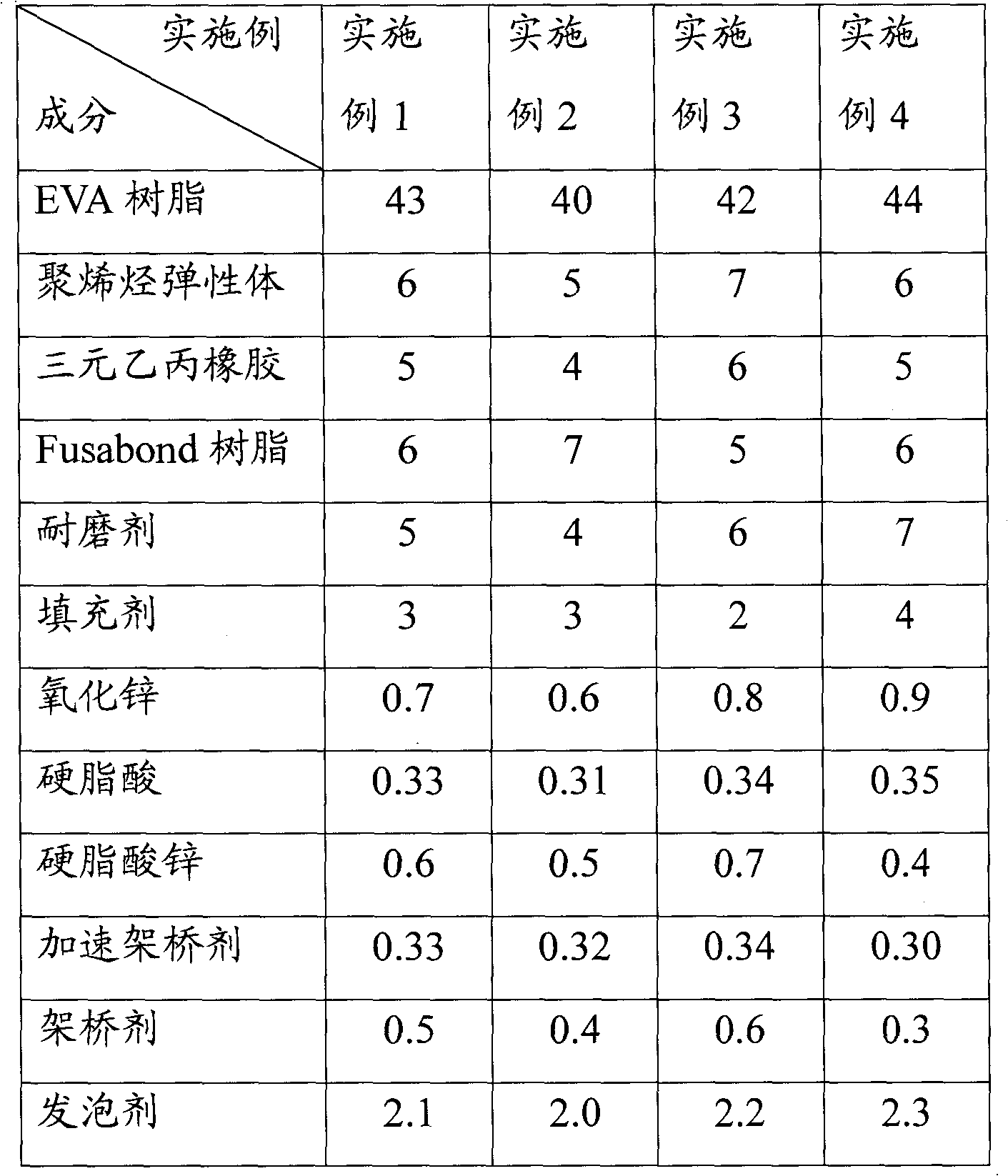

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

High temperature resistant conveyor belt

ActiveCN102275712AImprove adhesionGood burning resistanceConveyorsNatural rubber adhesivesEthylene-propylene-diene-monomerMetallic materials

The invention provides a high-temperature resistant conveyer belt which comprises a framework layer and a covering glue layer which covers the surface of the framework layer, wherein the framework layer is made of a metal material; the covering glue layer is mainly made of ethylene propylene diene monomer rubber and chloroprene rubber and is added with a fire retardant agent, trichloroethyl phosphate, a binding agent and a binding improver apart from a main cross-linking agent, an auxiliary cross-linking agent, an activating agent, an anti-aging agent, a reinforcing agent, a dispersing agent and a softening agent, wherein the binding agent comprises phenolic resin and hexakis(methoxymethyl)melamine; and the binding improver comprises maleic anhydride complexing butadiene and liquid natural rubber. The high-temperature resistant conveyer belt provided by the invention can be used at a temperature of 300 DEG C and has good firing bonding performance and firing resistant performance.

Owner:YANKUANG GRP CO LTD +1

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

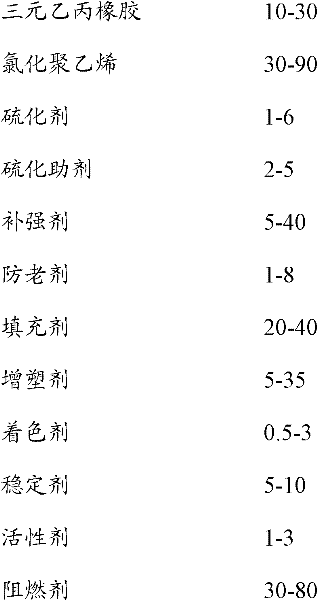

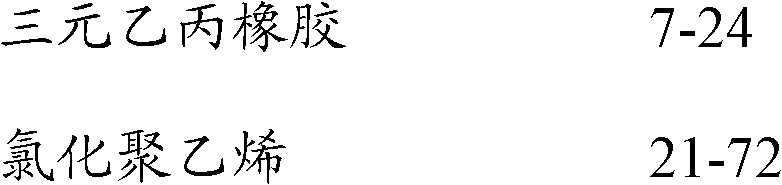

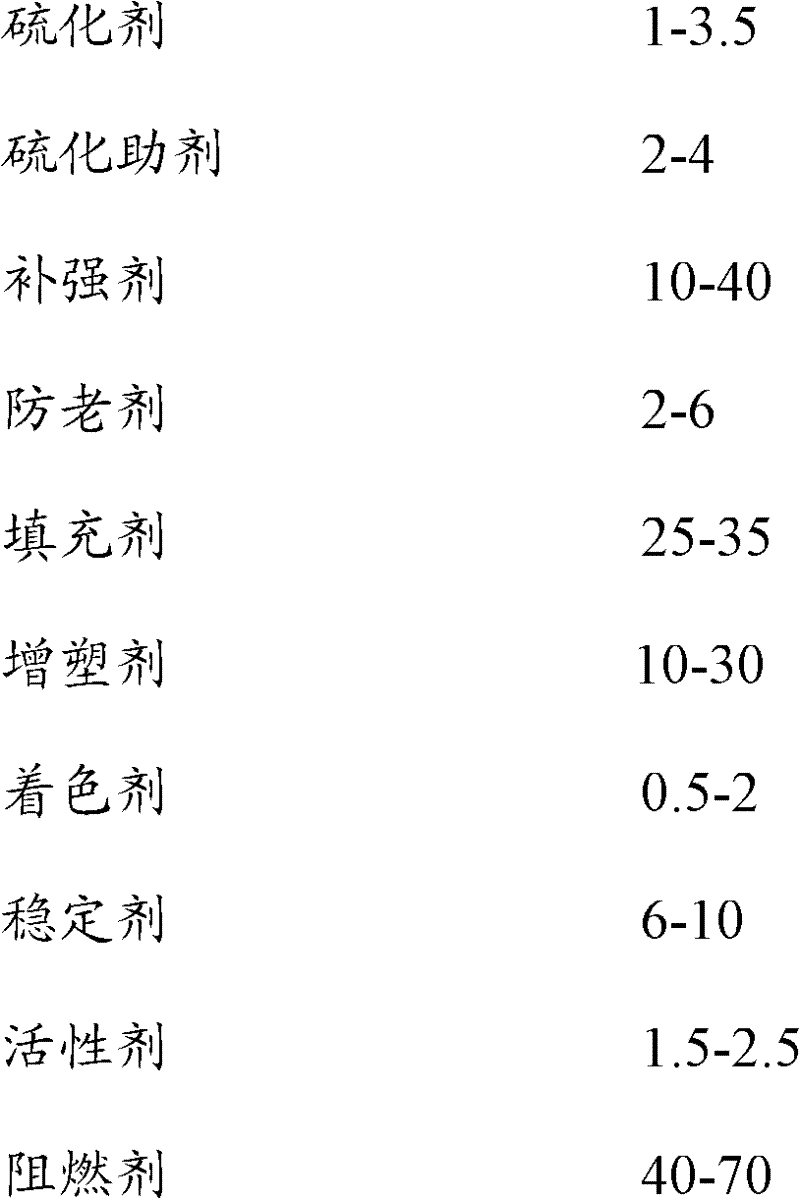

Mining cable rubber sheath glue

InactiveCN102516675AAccelerated vulcanizationImprove tear resistanceInsulated cablesInsulated conductorsPolymer sciencePlasticizer

The invention relates to a mining cable rubber sheath glue, which comprises the following raw material components according to parts by weight: 10-30 parts of ethylene propylene diene monomer rubber, 30-90 parts of chlorinated polyethylene, 1-6 parts of vulcanizing agent, 2-5 parts of vulcanizing auxiliary agent, 5-40 parts of reinforcing agent, 1-8 parts of anti-aging agent, 20-40 parts of filling agent, 5-35 parts of plasticizer, 0.5-3 parts of coloring agent, 5-10 parts of stabilizing agent, 1-3 parts of active agent and 30-80 parts of fire retardant, wherein the mass ratio of the ethylene propylene diene monomer rubber to the chlorinated polyethylene is 1:3. In the mining cable rubber sheath glue, the chlorinated polyethylene is adopted to replace parts of ethylene propylene diene monomer rubber, the formula of the raw material is regulated, and the use cost of the prepared mining cable rubber sheath glue is lowered on the premise of satisfying the use standard of the mining cable.

Owner:ANHUI LAND GRP

High performance rubber sheath rubber material

ActiveCN102796293AExcellent ozone resistanceGood weather resistanceRubber insulatorsInsulated cablesRubber materialNitrile rubber

The invention discloses a high performance rubber sheath rubber material, which comprises the following raw materials by weight part: 30-60 of ethylene propylene diene monomer rubber, 30-70 of nitrile rubber, 25-60 of a reinforcing filler, 5-10 of active agents, 3-5 of anti-aging agents, 0.5-10 of a vulcanizing agent, 0.5-3 of a promoter and 5-20 of plasticizers. The raw materials are subjected to mixing by an open mill and an internal mixer to produce a mixed rubber compound, which is then prepared into a semi-finished product extruder extrusion. The rubber material not only has good ozone resistance and weathering aging resistance, but also has excellent oil resistance and bonding performance. And under the premise of satisfying comprehensive performance, the service life of the rubber material is further improved.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

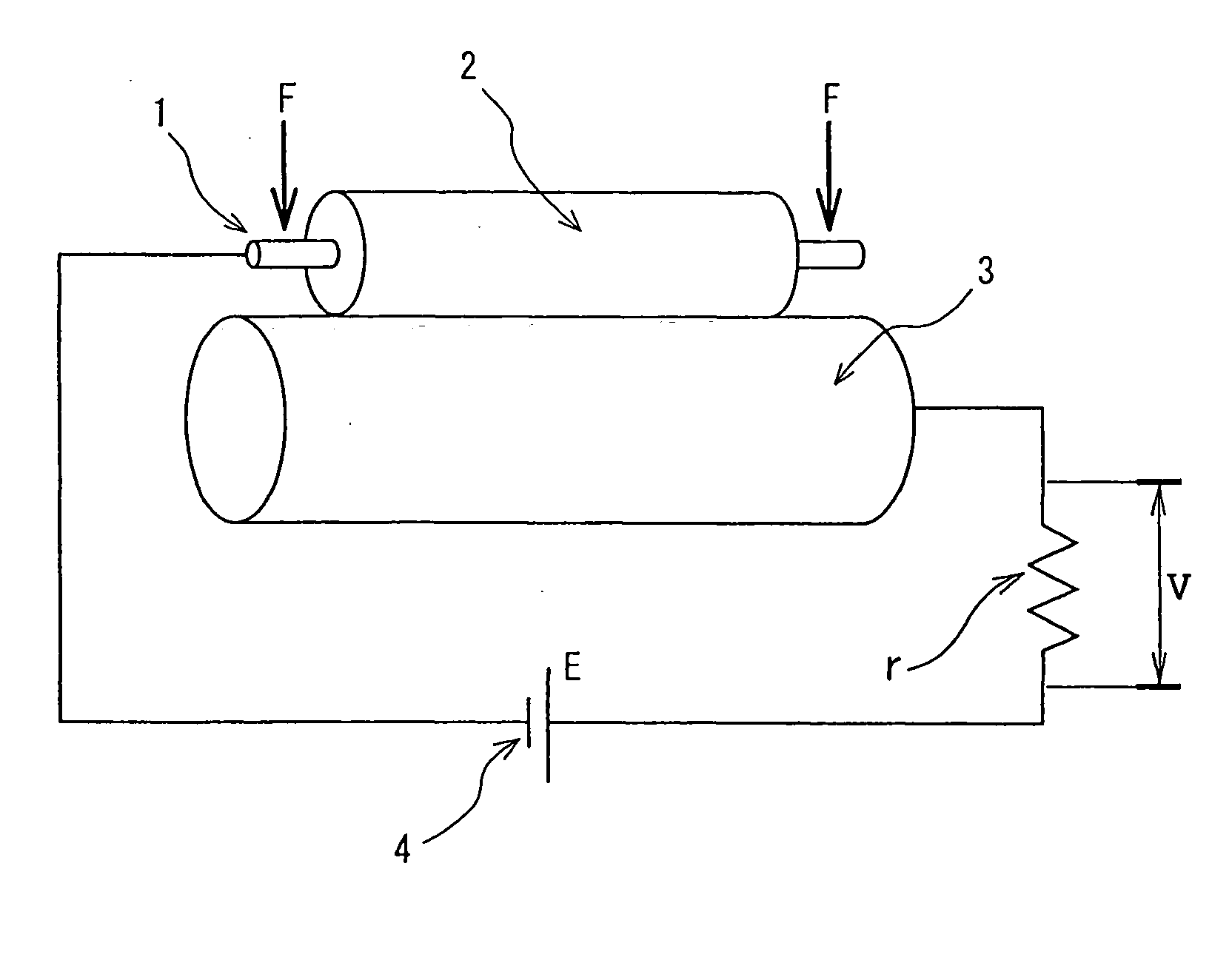

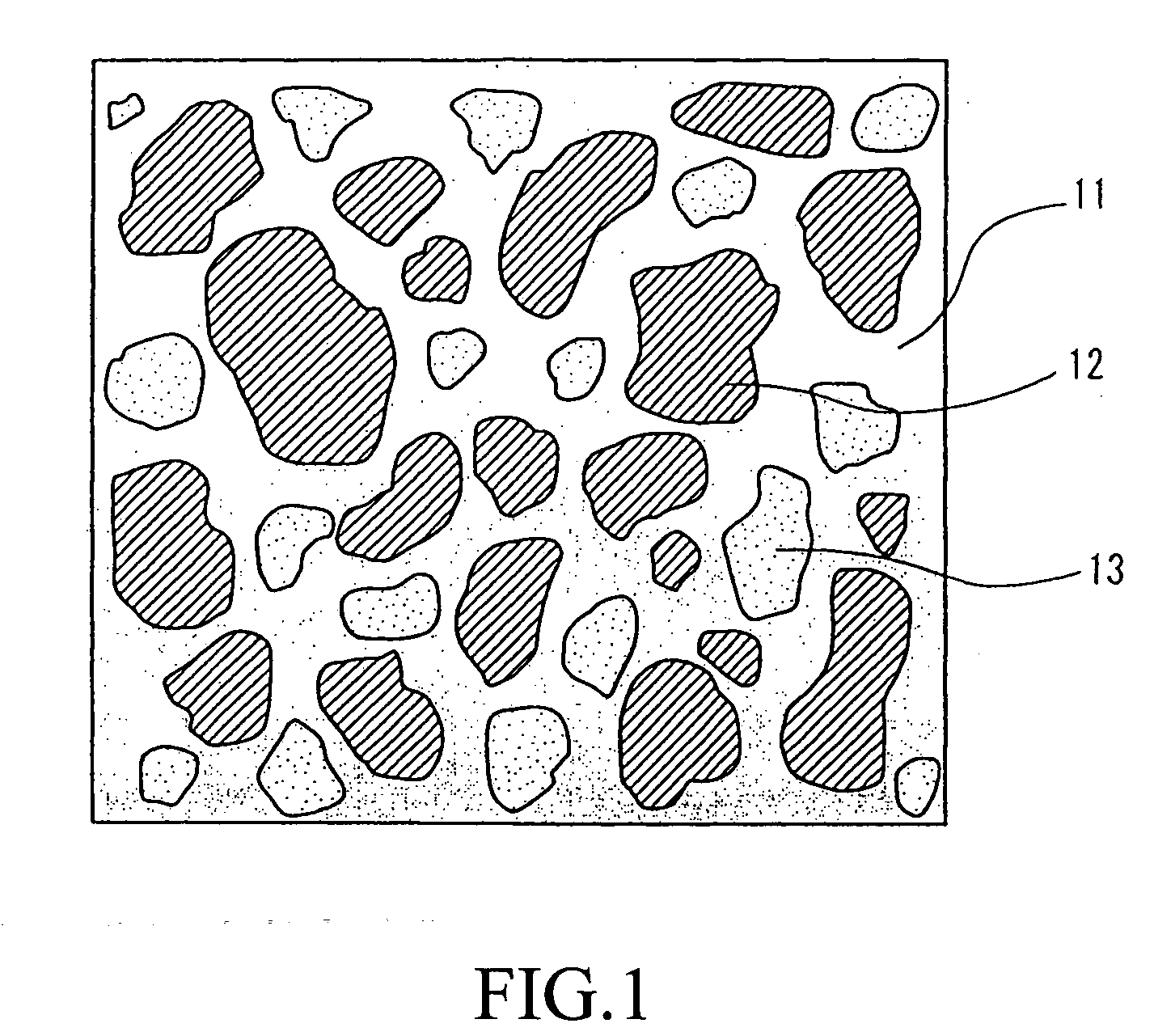

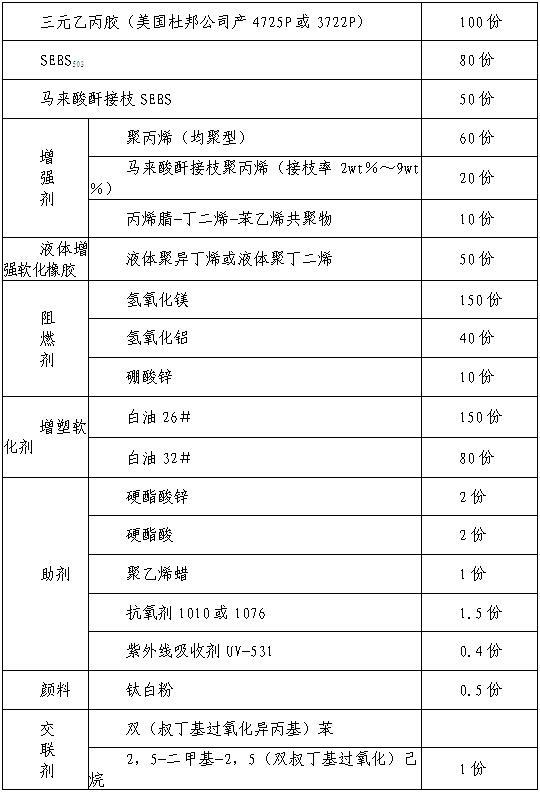

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

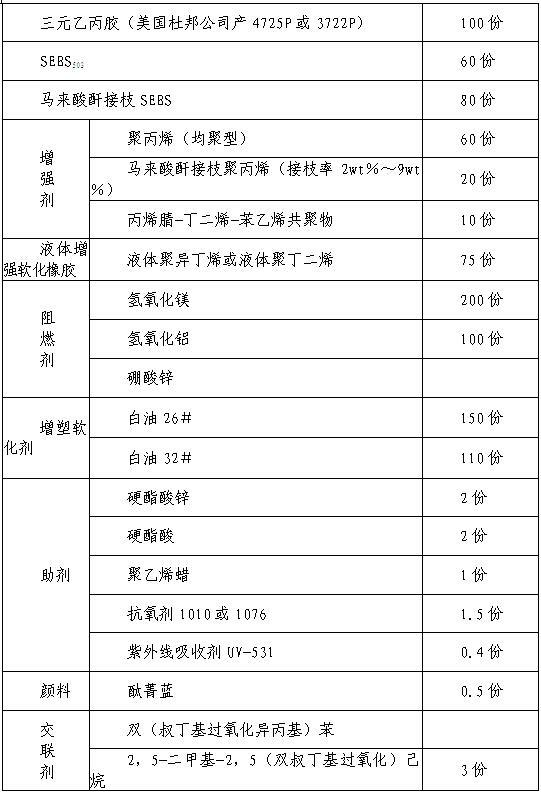

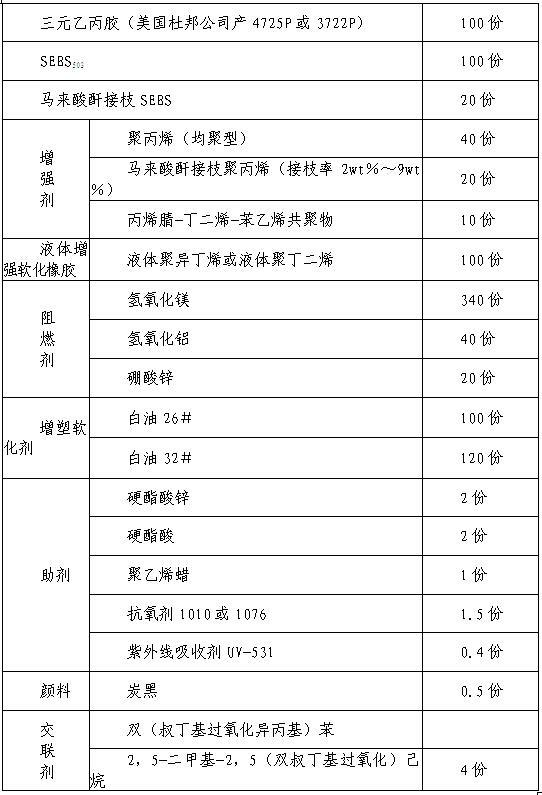

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437AChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

Production method for chloroprene rubber adhesive

The invention discloses a production method for a chloroprene rubber adhesive. The product produced by the production method is a high-performance adhesive. The adhesive is produced by using chloroprene rubber as a main body and using raw materials including styrene, silicon dioxide, magnesium oxide, zinc oxide, polyisocyanates, polyester resin, vinyl trisilane, antiaging agent D and the like and by a certain process. The product is mainly used in the building industry for adhering ethylene propylene diene monomer rubber waterproof coiled material, chlorinated polyethylene-rubber blended waterproof coiled material, chlorinated polyethylene waterproof coiled material, sulfurized rubber plastic waterproof coiled material, chlorinated polyethylene plastic floorings and calcium plastic plates with concrete, cement, asbestos boards, wood and other materials.

Owner:张耀华

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Formula of sole material

InactiveCN102250407AGuaranteed wear resistanceGuaranteed compression performanceSolesElastomerPolyolefin

The invention discloses a formula of a sole material. The sole made of the sole material can be formed in one piece to save cost, and the sole does not contain heavy metal and is light and breathable. The sole material comprises the following substances in percentage by weight: 1, 11.6 to 52.4 percent of ethylene vinyl acetute (EVA); 2, 7 to 13 percent of polyolefin elastomer (POE); 3, 1.4 to 2.6percent of ethylene-propylene-diene monomer; 4, 12.6 to 23.4 percent of standard rubber; 5, 12.6 to 23.4 percent of cis-polybutadiene; 6, 3.5 to 6.5 percent of butylbenzene; 7, 2.8 to 5.2 percent of talc powder; 8, 2.1 to 3.9 percent of white carbon black; 9, 2.1 to 3.9 percent of stearic acid; 10, 0.7 to 1.3 percent of modifier; 11, 1.05 to 1.95 percent of zinc oxide; 12, 1.4 to 2.6 percent of cross-linking agent; and 13, 0.35 to 0.65 percent of sulfur.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

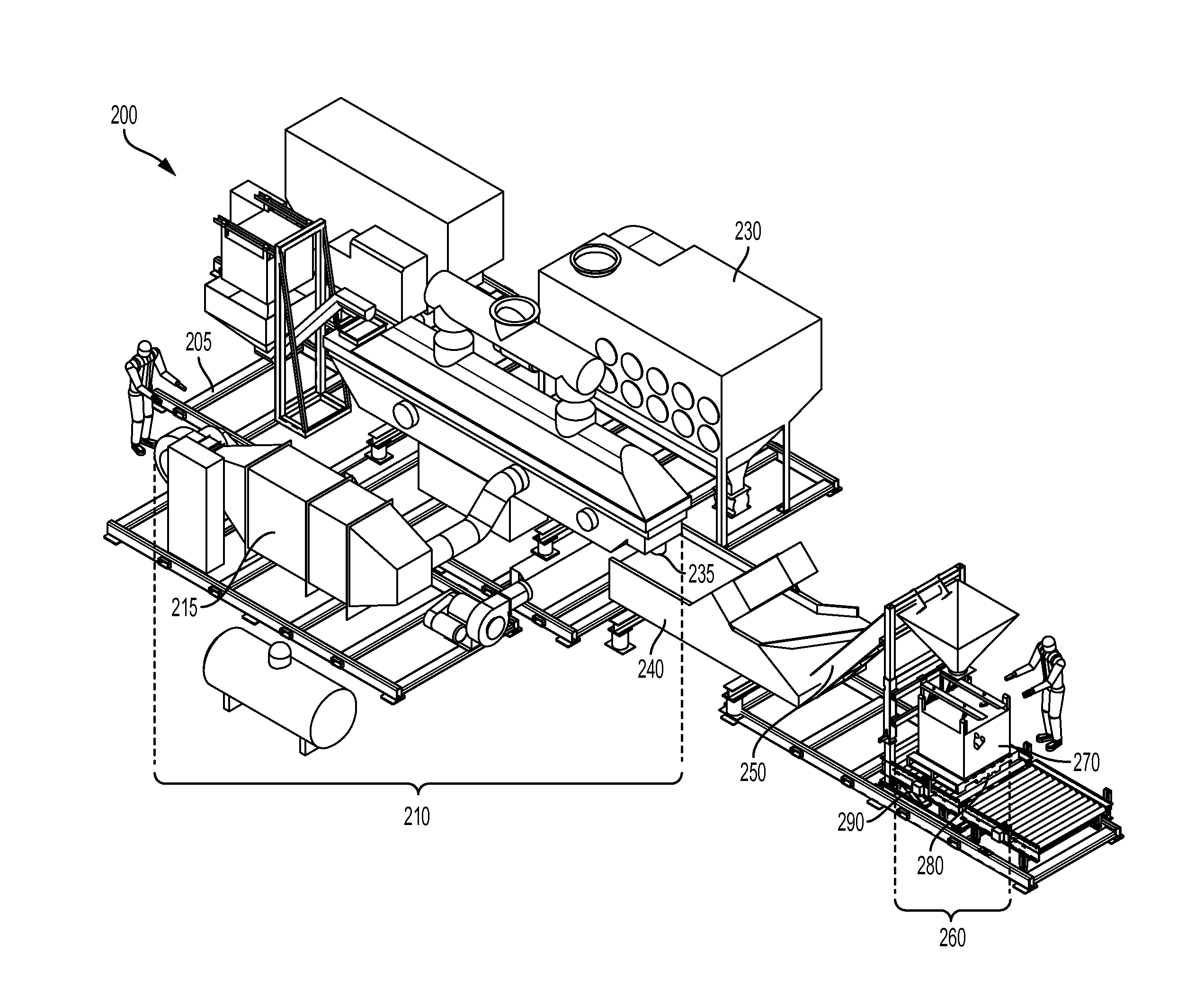

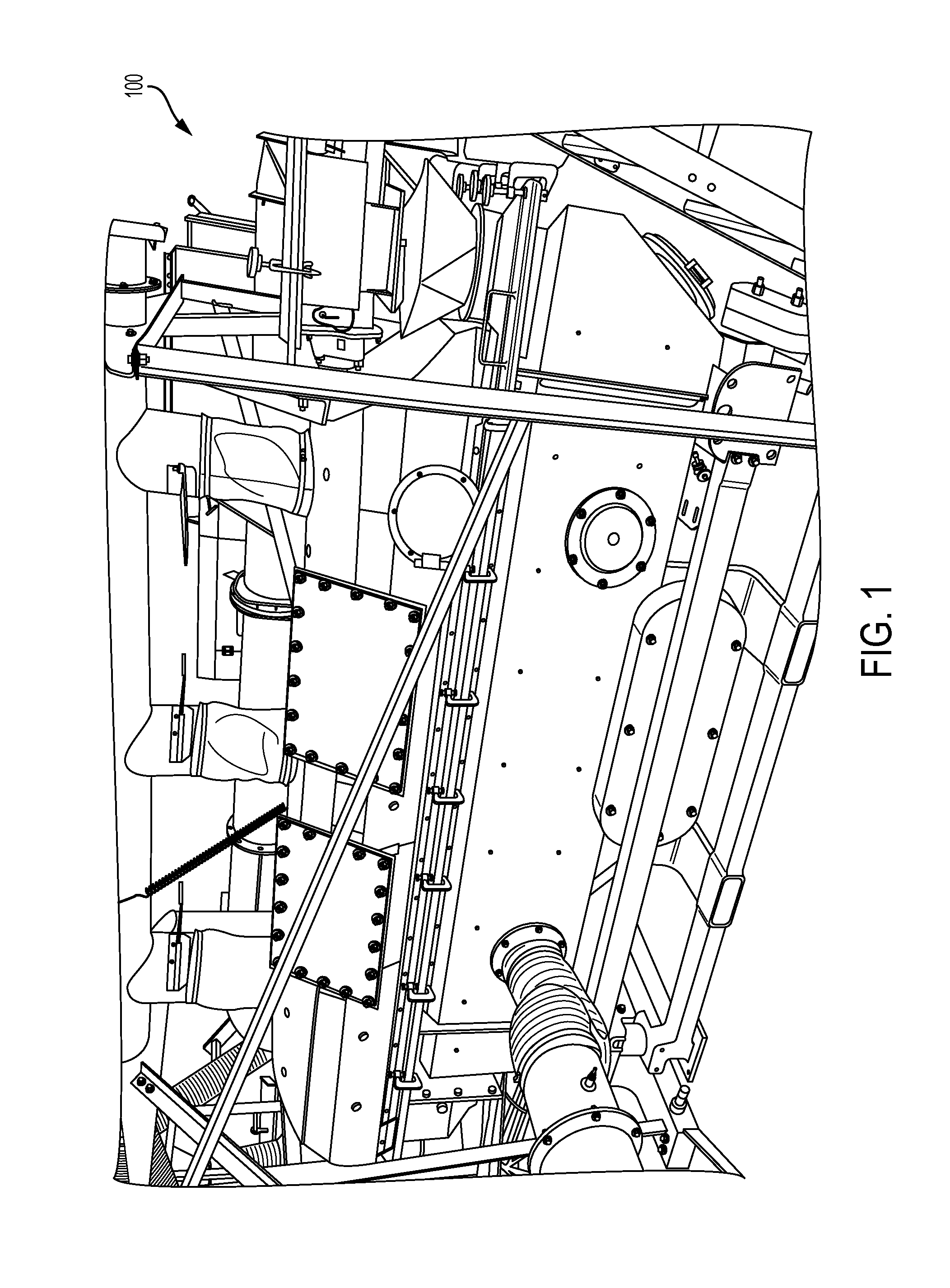

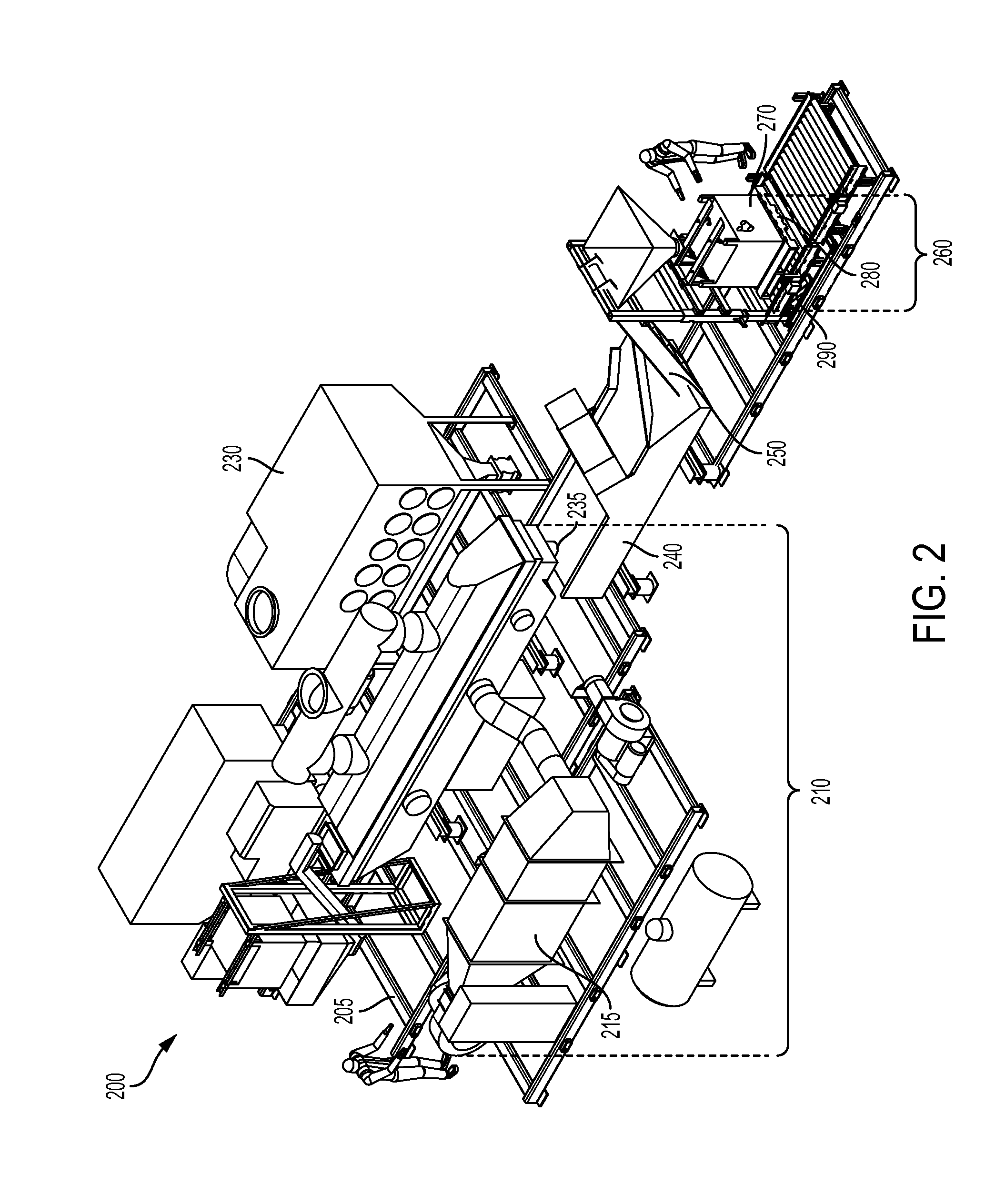

Method and system for processing and recycling infill material of artificial turf

ActiveUS20150209830A1High strengthEasy to set upDrying solid materials with heatGas current separationFluidized bed dryingEngineering

A method and system for processing and recycling infill material of artificial turf. The invention includes drying extracted infill material through a fluid bed dryer, the fluid bed dryer passes a process gas through a bed of solids via a perforated plate. The dried infill material is processed using a plurality of vibrating screens to remove excessively large or small particles from the infill material. The plurality of vibrating screens may be a set of progressively finer mesh screens. The processed infill material is separated by density. The density of the infill material may be determined by a high intensity, uniform sheet of laminar airflow. The separated infill material is discharged and is ready to be used again in another artificial turf. In one embodiment, the infill material includes at least one of graded sand, granulated styrene-butadiene rubber, cork, organic infill, thermoplastic elastomers, or ethylene propylene diene monomers.

Owner:TARKETT INC

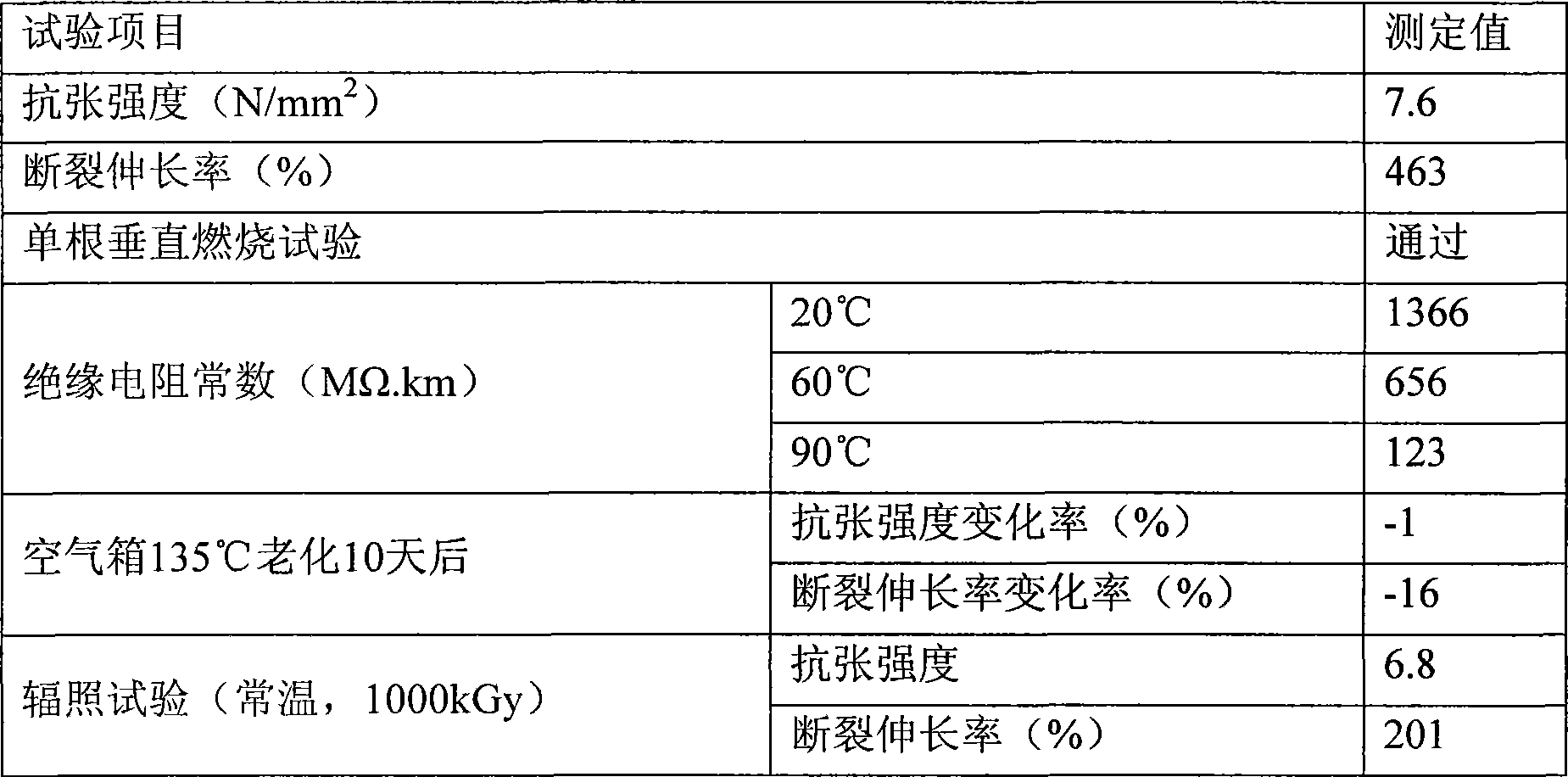

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Blends of epdm and metallocene plastomers for wire and cable applications

Power cable coating compounds are disclosed, the coating compounds including an ethylene alpha-olefin diene elastomeric terpolymer, and an ethylene alpha-olefin copolymer having a Melt Index Ratio I10 / I2 of at least 7 and / or a Melt Index Ratio I21 / I2 of at least 20. In various embodiments, the ethylene alpha-olefin copolymer can be present in the coating compound in amounts up to 90 percent by weight, based on the weight of the ethylene alpha-olefin diene elastomeric terpolymer and the ethylene alpha-olefin copolymer. Also disclosed are electrical devices including extruded coating compounds, the extruded compounds having low surface roughness at high extrusion rates.

Owner:EXXONMOBIL CHEM PAT INC

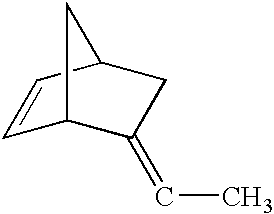

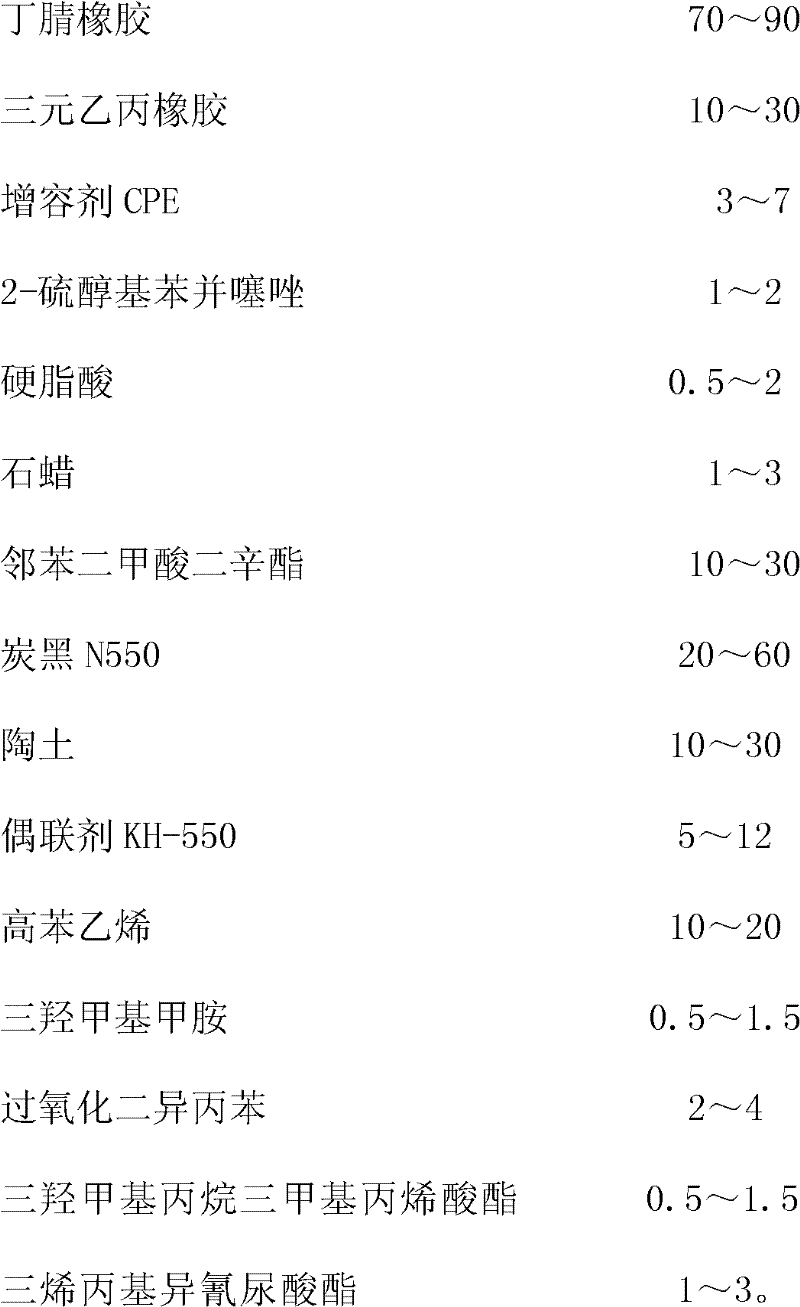

Nitrile/EPDM for ozone and low temperature resistant seals

The invention relates to a nitrile rubber / ethylene-propylene-diene rubber used for an ozone resistant and low temperature resistant sealing ring. The rubber comprises the following components of: a nitrile rubber, an ethylene-propylene-diene rubber, a compatibilizer CPE, an anti-aging agent MB, stearic acid, paraffin wax, a plasticizer DOP, carbon block N550, pottery clay, a coupling agent KH-550, high styrene, a neutralizer TRA, a cross-linking agent DCP, a cross-linking aid TMPTMA and a cross-linking aid TAIC, wherein the nitrile rubber and the ethylene-propylene-diene rubber are used together to make up deficiencies of each other so that the poor ozone resistance, poor low temperature resistance and narrower heat resistant temperature range of the nitrile rubber can be improved and theuse temperature range of the product can be also expanded. After a small quantity of EPDMs (Ethylene-Propylene-Diene Monomers) are added to the nitrile rubber, the ozone resistance, the low temperature resistance and the heat resistance of the blended rubber product can be improved; meanwhile, the rubber product obtains wider use temperature range, better process performance and lower raw material and production cost while being compared with the nitrile rubber and the chloroprene rubber; and the requirements on the performance of domestic parts are satisfied.

Owner:TIANJIN PENGYI GRP CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com