Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

A thermoplastic elastomer, flame-retardant and fire-resistant technology, applied in the field of wire and cable materials, can solve the problems of high scrap rate, large production consumption, complex equipment, etc., and achieve the effects of excellent flame-retardant and fire-resistant performance, outstanding cold resistance, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

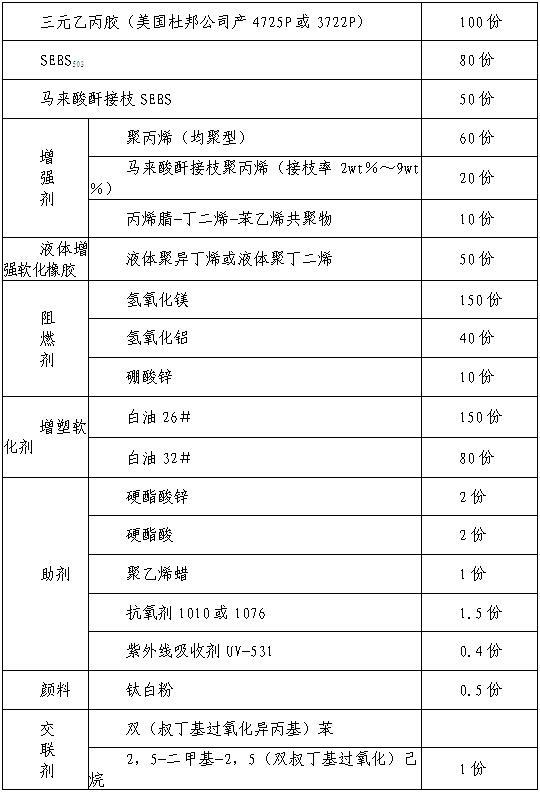

[0034] The low-smoke halogen-free thermoplastic elastomer flame-retardant and fire-resistant wire material of this embodiment contains the components shown in Table 1 by weight:

[0035] Table 1. Example 1 product components

[0036]

[0037] The production method of the above-mentioned low-smoke halogen-free thermoplastic elastomer flame-retardant and fire-resistant wire material, the steps of which include:

[0038] A. Preparation of thermoplastic elastomer masterbatch:

[0039] A-1, first take SEBS 503 Mix and stir 50 parts of SEBS grafted with maleic anhydride. During the stirring process, add plasticizer and softener in batches. SEBS 503 And / or the grafted SEBS of maleic anhydride is fully and uniformly absorbed; wherein, the plasticizer is specifically 100 parts of 26# white oil and 50 parts of 32# white oil;

[0040] A-2. Add the remaining plasticizing softener, reinforcing agent, and pigment, and mix evenly; wherein, the reinforcing agent is specifically 40 part...

Embodiment 2

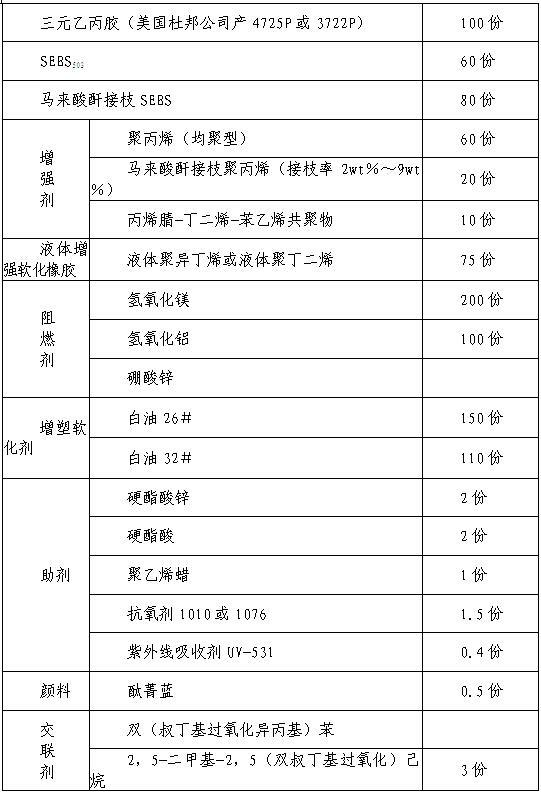

[0047] The low-smoke halogen-free thermoplastic elastomer flame-retardant and fire-resistant wire material of this embodiment contains the components shown in Table 2 by weight:

[0048] Table 2. Example 2 product components

[0049]

[0050] Its preparation method is similar to that of Example 1.

Embodiment 3

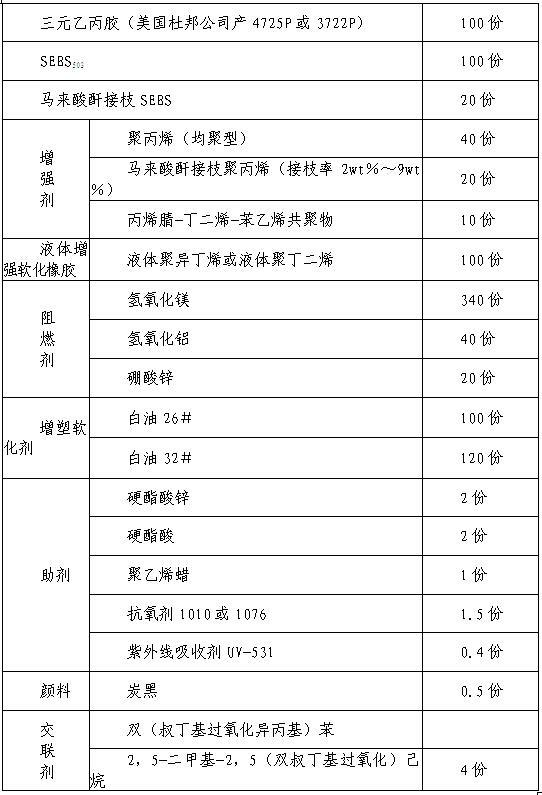

[0052] The low-smoke halogen-free thermoplastic elastomer flame-retardant and fire-resistant wire material of this embodiment contains the components shown in Table 3 by weight:

[0053] Table 3. Example 3 product components

[0054]

[0055] Its preparation method is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com