Patents

Literature

136 results about "Domestic production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate for low-temperature vessel and production method thereof

ActiveCN103540838AGood mechanical propertiesImprove organizationEconomic benefitsMechanical property

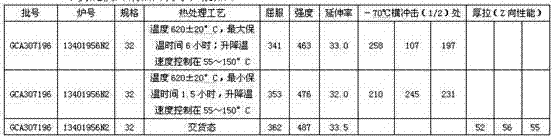

The invention relates to a steel plate for a low-temperature vessel and a production method thereof, belonging to the technical fields of special steel plates and steel plate production methods. The steel plate for a low-temperature vessel is produced by smelting the following components in percentage by weight: no more than 0.12% of C, 0.15-0.50% of Si, 1.2-1.6% of Mn, 0.3-0.8% of Ni, no more than 0.010% of P, no more than 0.005% of S, 0.020-0.045% of Al, no more than 0.040% of Nb and the balance of Fe and inevitable impurities. The invention develops a new steel plate for a low-temperature vessel and a production method thereof. The favorable mechanical property of the steel plate is ensured under the condition of low noble alloy consumption, so that the steel plate has good organization, comprehensive property and weldability, the low-temperature impact toughness of the steel plate in a delivery state and a die welding state is improved, and the requirements of the market for high-quality steel for a low-temperature vessel are met, thus making positive contributions for domestic production of large engineering low-temperature equipment and achieving remarkable economic benefits.

Owner:WUYANG IRON & STEEL +1

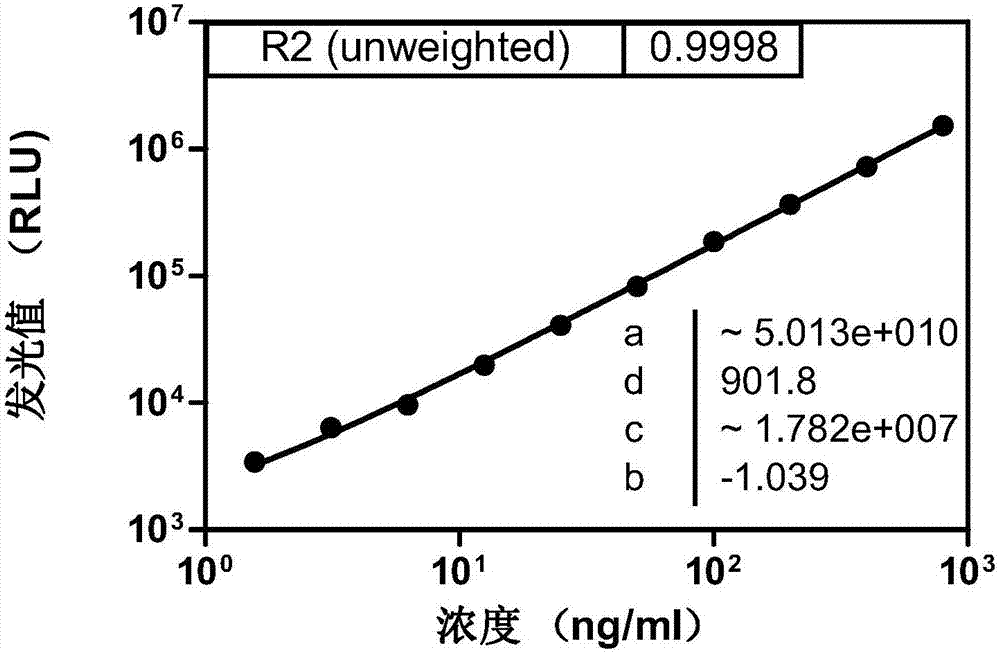

Hepatitis C virus antibody diagnostic kit and preparation method thereof

ActiveCN102072957AHigh sensitivityStrong specificityChemiluminescene/bioluminescenceSorbentQuality control

The invention belongs to the technical field of immunodiagnosis, in particular relates to a hepatitis C virus (HCV) antibody diagnostic kit adopting a micro particle chemiluminescence method, and a preparation method thereof. The kit consists of anti-HCV detecting magnetic micro particles, an anti-HCV detecting tracer conjugate, anti-HCV sample diluted solution and a quality control material. Theinvention also discloses the preparation method of the diagnostic kit, which adopts micro particle chemiluminescence immunoassay technology, has higher sensitivity and specificity than enzyme-linked immuno sorbent assay (ELISA), is suitable for clinical HCV auxiliary diagnosis and blood donor screening, and makes up the blank of the domestic production of the diagnostic kits for detecting the anti-HCV by the micro particle chemiluminescence method.

Owner:威海威高生物科技有限公司

Rubber softening agent and preparation method thereof

The invention discloses a rubber softening agent and a preparation method thereof. The rubber softening agent comprises the following raw material in part by weight: 10 to 30 percent of asphalt and 70 to 90 percent of naphthenic oil. The preparation method comprises: heating the asphalt to 80 to 100 DEG C till the asphalt is molten; fully stirring the molten asphalt, and keeping the temperature between 80 and 100 DEG C constantly for 50 to 70 minutes; adding naphthenic oil according to a corresponding ratio, heating the mixture at a constant temperature to 100 to 120 DEG C for 40 to 60 minutes with full stirring; and cooling, storing at room temperature for 24 to 27 hours and producing the rubber softening agent. The nontoxic asphalt-modified rubber softening agent which used to lack in China does not reach safety standards of European Union, thereby saving cost of China's tire manufacturers considerably.

Owner:TIANJIN HANKE LUBRICANT PRODS

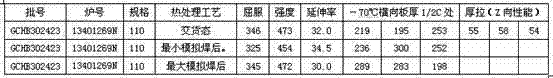

Underwater robot device for shallow water observation

InactiveCN103419915AHigh strengthImprove pressure resistanceUnderwater equipmentPropellerEngineering

The invention discloses an underwater robot device for shallow water observation. An electronic cabin is a body of the underwater robot device, transparent fairings are connected with the electronic cabin and mounted at two ends of the same, battery cabins are arranged on the electronic cabin, battery cabin sealing heads are connected with each battery cabin and mounted at two ends of the same, propeller and illuminating lamp cabins are arranged on the electronic cabin and mounted above the battery cabins bilaterally symmetrically, illuminating lampshades are connected with the illuminating lamp cabins, propellers are hermetically sleeved at the tail ends of the propeller and illuminating lamp cabins through O-rings, a handle is fixed on the electronic cabin, and an umbilical cable connecting port is formed in an electronic cabin body. The electronic cabin is made of PVC selectively, so that strength and pressure resistance of the electronic cabin are improved; through stability analysis of the electronic cabin, the illuminating lampshades, the handle, the umbilical cable connecting port, the propellers, the propeller and illuminating lamp cabins, the battery cabins, the battery cabin sealing heads and the transparent fairings, stability of a underwater robot is determined, and domestic production level is increased.

Owner:QINGDAO YUANCHUANG ROBOT AUTOMATION

Continuous production method of carboxymethylcellulose lithium for lithium batteries

The invention discloses a continuous production method of carboxymethylcellulose lithium for lithium batteries in order to solve the problems that a lithium ion battery adhesion agent pollutes the environment, is single in function and high in price. The production method includes the steps that sodium carboxymethyl cellulose is prepared, and the carboxymethylcellulose lithium is obtained after the sodium carboxymethyl cellulose is acidized, alkalinized and purified. The prepared carboxymethylcellulose lithium breaks the pattern that autonomous mass production of carboxymethylcellulose lithium cannot be achieved domestically, according to the current condition of domestic production, on the basis that the performance of the carboxymethylcellulose lithium is guaranteed, continuous and large-batch production of the carboxymethylcellulose lithium can be achieved, and production cost is greatly reduced. A series of product performance testing preparation parameters are summarized in the method, and the parameters are quality control indexes of carboxymethylcellulose lithium and can also provide a reference for establishing standards of industrialized carboxymethylcellulose lithium in future.

Owner:CHONGQING LIHONG FINE CHEM +1

Nano silver-bamboo-charcoal dispersing liquid and method for preparing nano silver-bamboo-charcoal fiber

InactiveCN101070632AImprove performanceOvercome the defects of general productionMonocomponent cellulose artificial filamentAnti bacteriaFar infrared

The invention relates to the nano-silver bamboo charcoal dispersed liquid and the method of making nano-silver bamboo charcoal fiber. The aim is conquer the current domestic production of antibacterial fabric general defects. The art is press the viscose fiber pulp after two filters and the nano-silver bamboo charcoal dispersed liquid into the spinning machine to weave. The fiber can take far infrared emission, anti bacteria, and has adsorption function. The particle diameter of the nano-silver is 20-60nm, and the particle diameter of the bamboo charcoal < 0.5mum.

Owner:广东拓扑中润科技发展有限公司

Coal and Biomass Conversion to Multiple Cleaner Energy Solutions System producing Hydrogen, Synthetic Fuels, Oils and Lubricants, Substitute Natural Gas and Clean Electricity

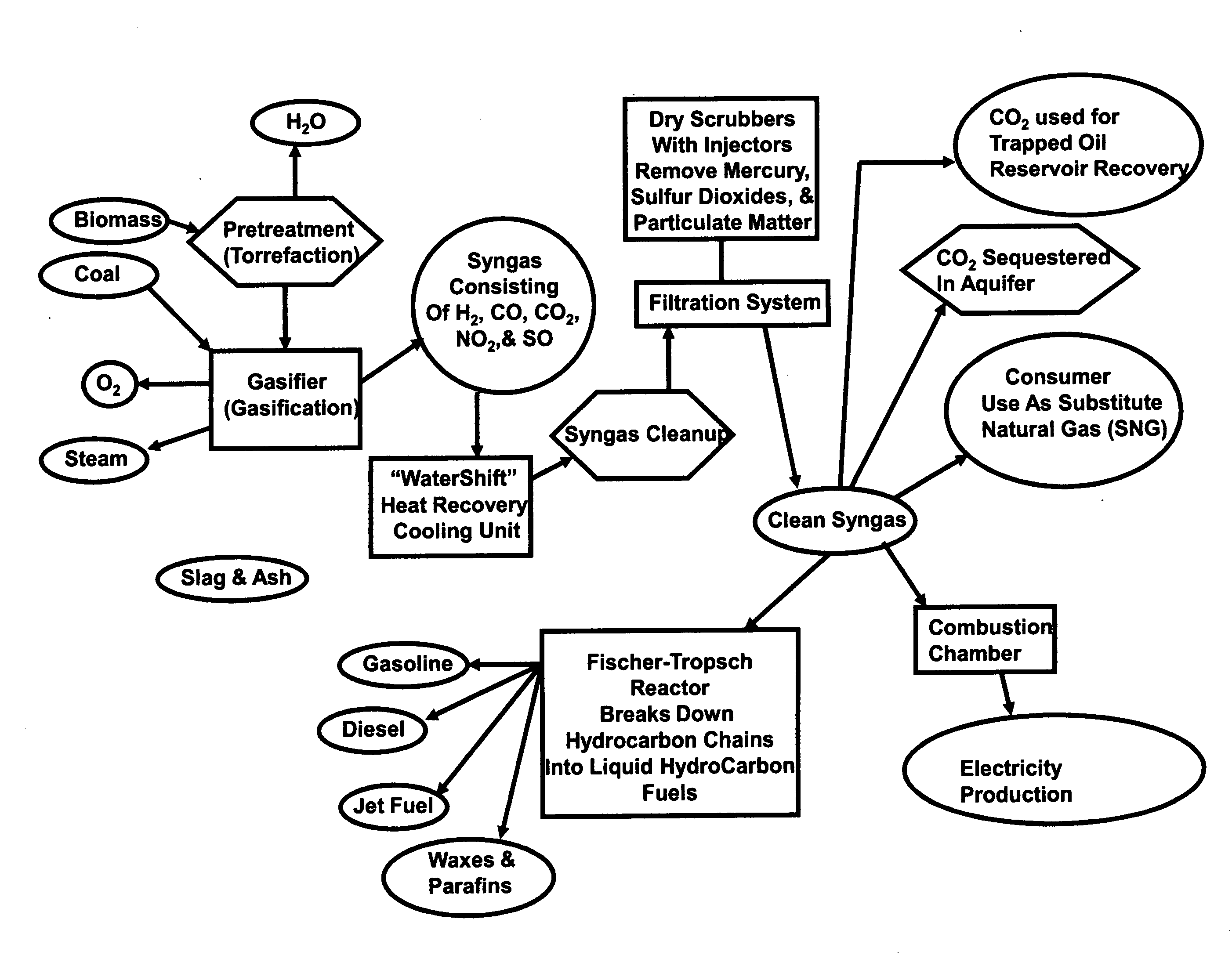

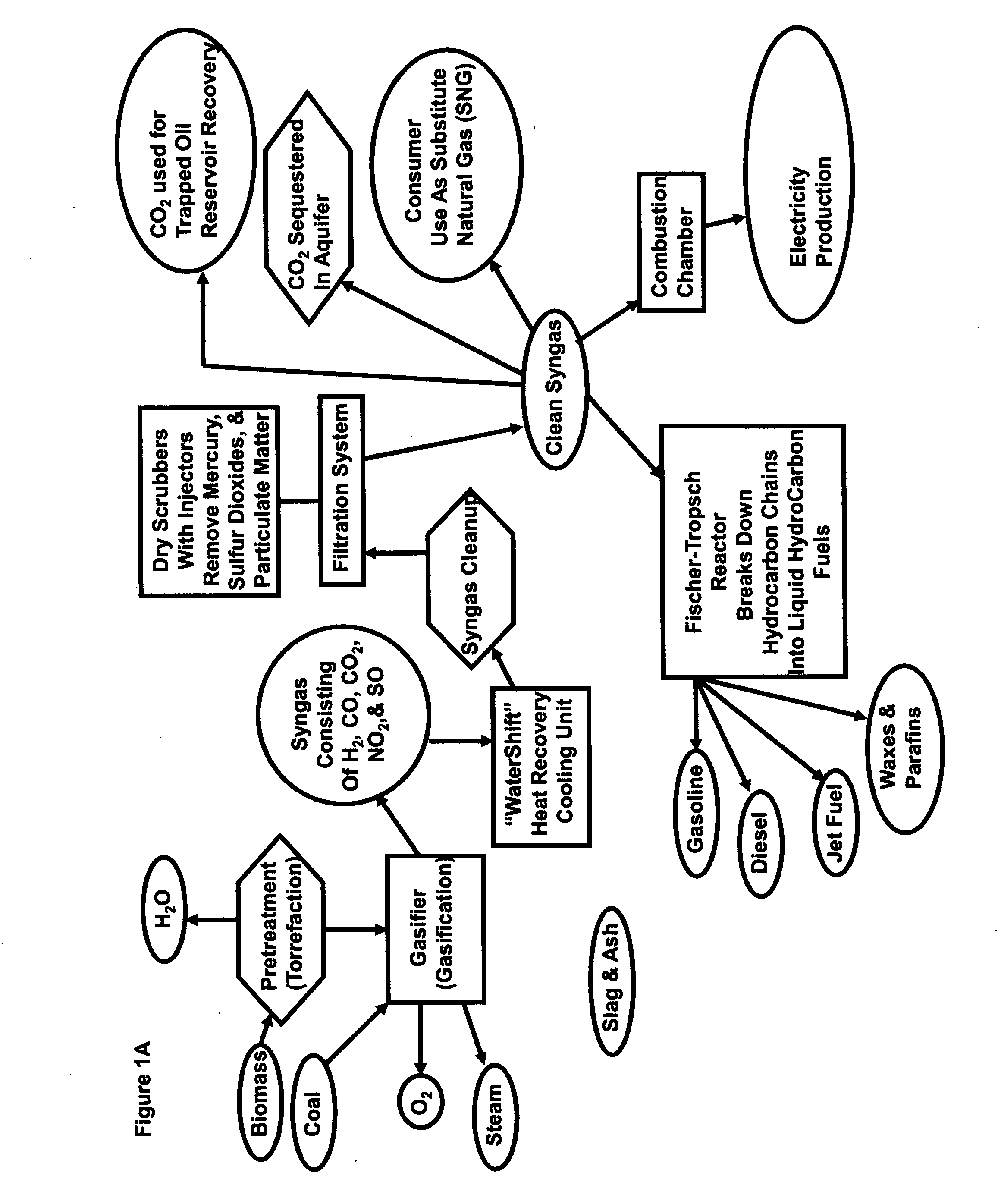

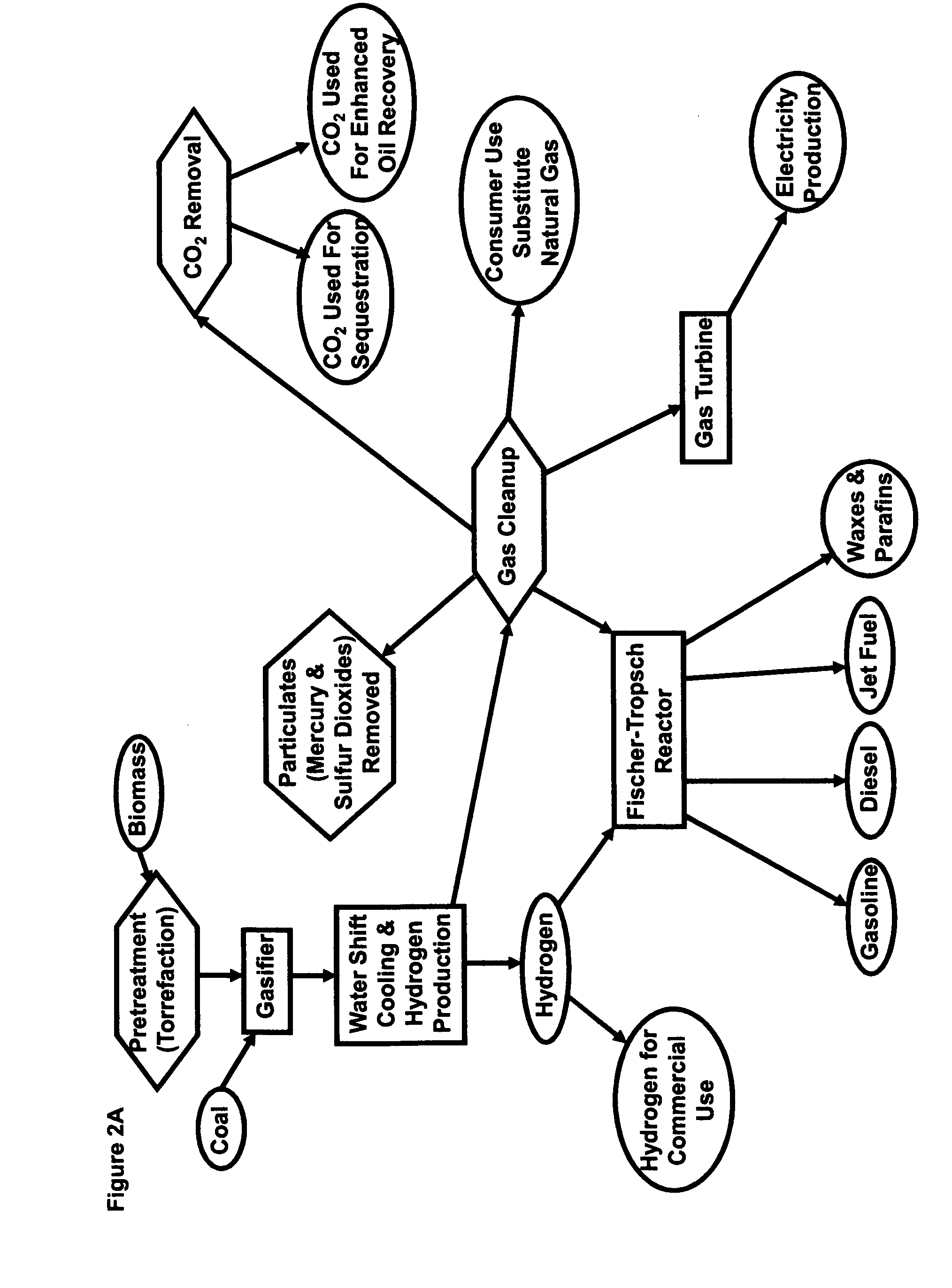

The system contained within this application for patent protection provides the ability to produce clean syngas, natural gas, synthetic fuels, electricity, hydrogen fuels, and oil substitutes using a variety of materials. These materials include, but are not limited to: coal, biomass (including but not limited to municipal solid wastes), and agricultural byproducts. The fuels and electricity generated by this system can immediately be utilized by existing power and transportation grids, and as such, allow for rapid integration into the nation's energy needs. The system also removes and sequesters carbon dioxide, creating a clean, environmentally responsible supply of multiple types of power. The overall process provides an alternative to current oil and power solutions, allowing for domestic production of various energy requirements, creating the possibility for the reduced dependence on foreign imports for energy needs.

Owner:KUKU MR LAI O

SST2 detection kit based on microparticle chemical luminescence immunity analysis

An sST2 detection kit based on microparticle chemiluminescence immunoassay relates to a chemiluminescence detection kit. The sST2 detection kit is equipped with reaction buffer, magnetic particles coated with sST2 monoclonal antibody, sST2 monoclonal antibody labeled with acridinium ester, luminescent solution, sST2 antigen standard solution, and concentrated washing solution. Prepare reaction buffer; prepare magnetic particles coated with sST2 antibody; prepare acridinium ester-labeled sST2 antibody; prepare sST2 antigen standard solution; prepare luminescent solution; prepare washing solution. It adopts microparticle chemiluminescence immunoassay technology, which has higher sensitivity and better stability than ELISA, filling the gap in the domestic production of microparticle chemiluminescence diagnostic reagents for human serum sST2 detection. It has the advantages of simple operation, high sensitivity, wide linear range, stable results, good safety, and easy automation. It has broad application prospects in clinical testing and other aspects.

Owner:ZHONGSHAN HOSPITAL XIAMEN UNIV

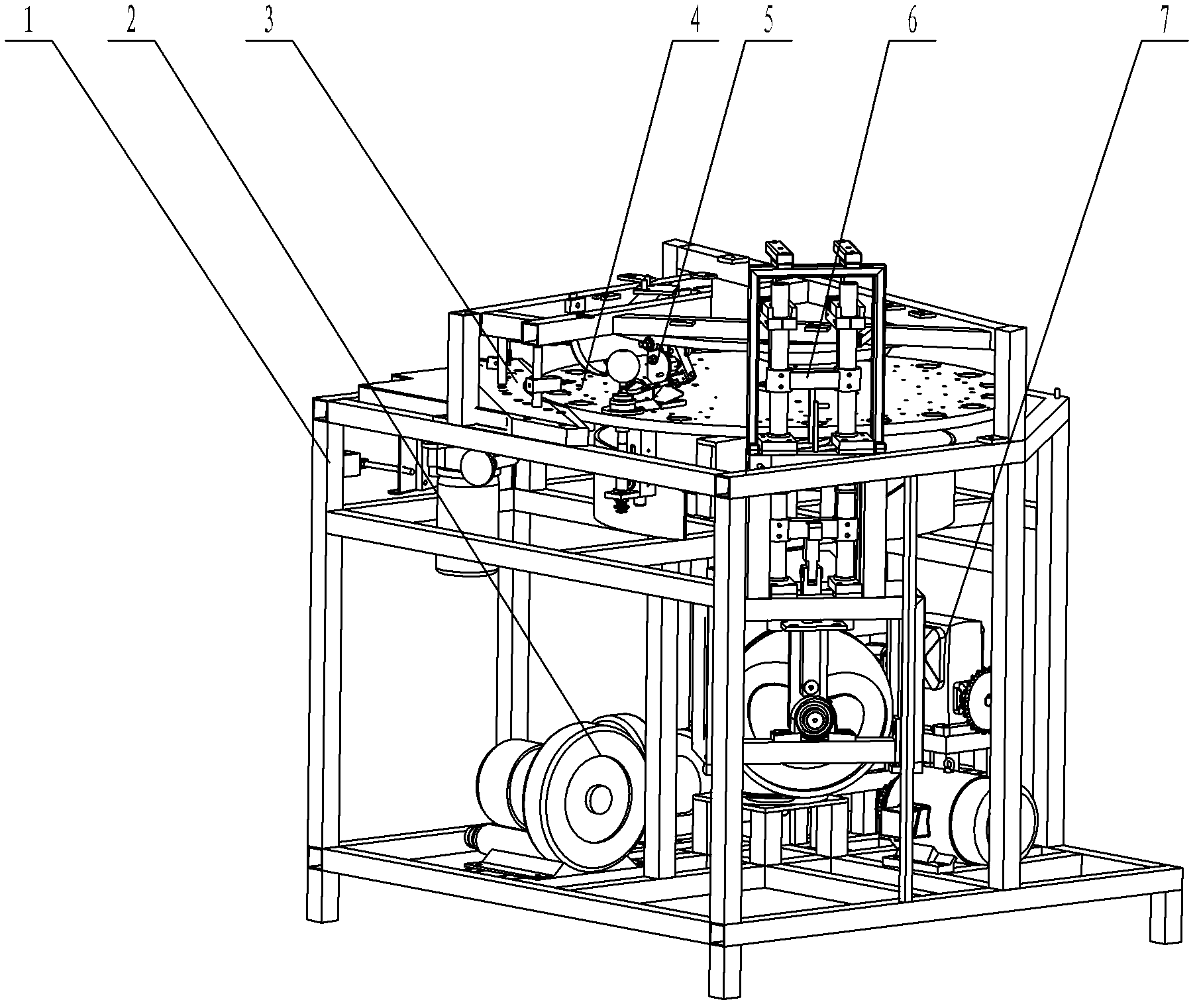

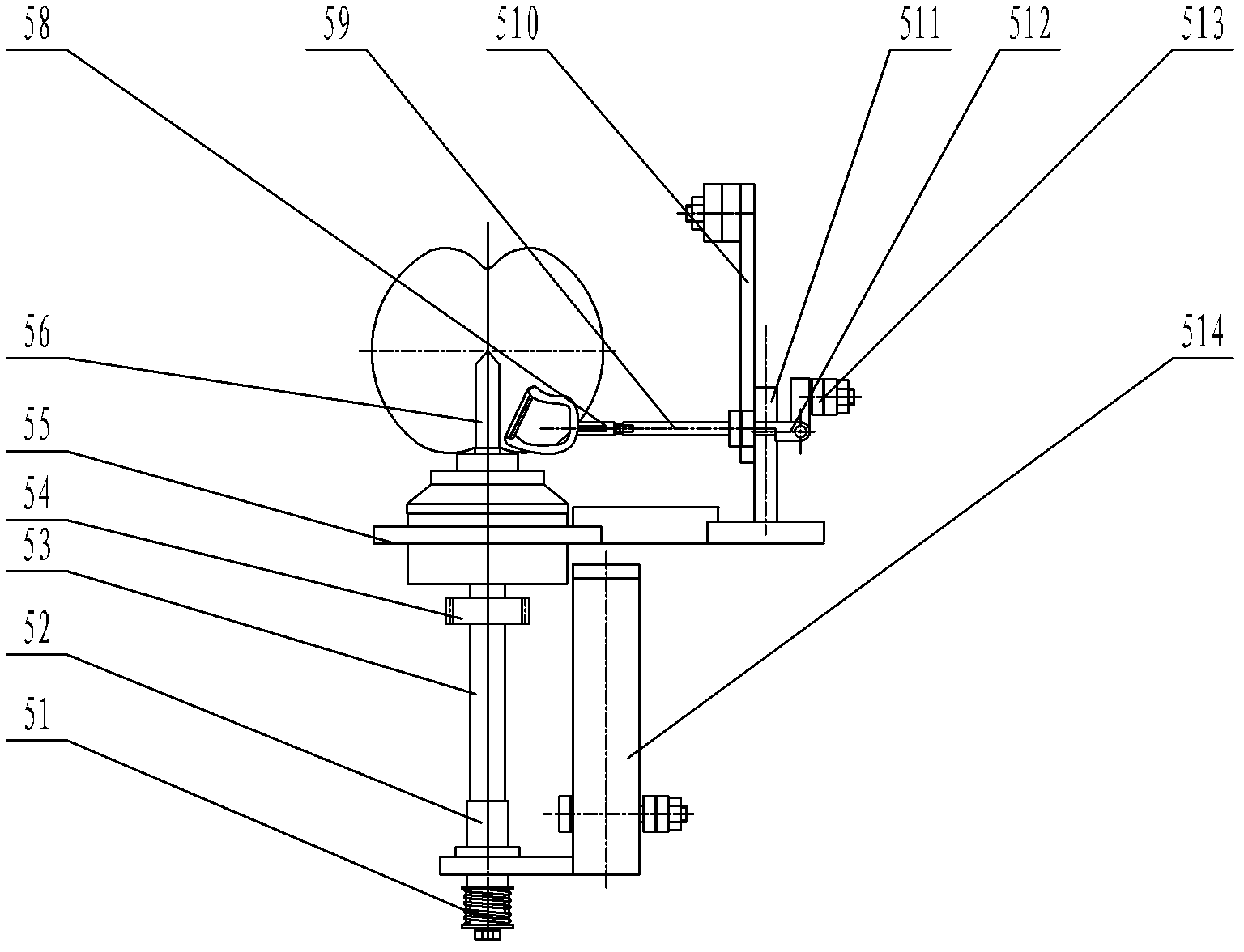

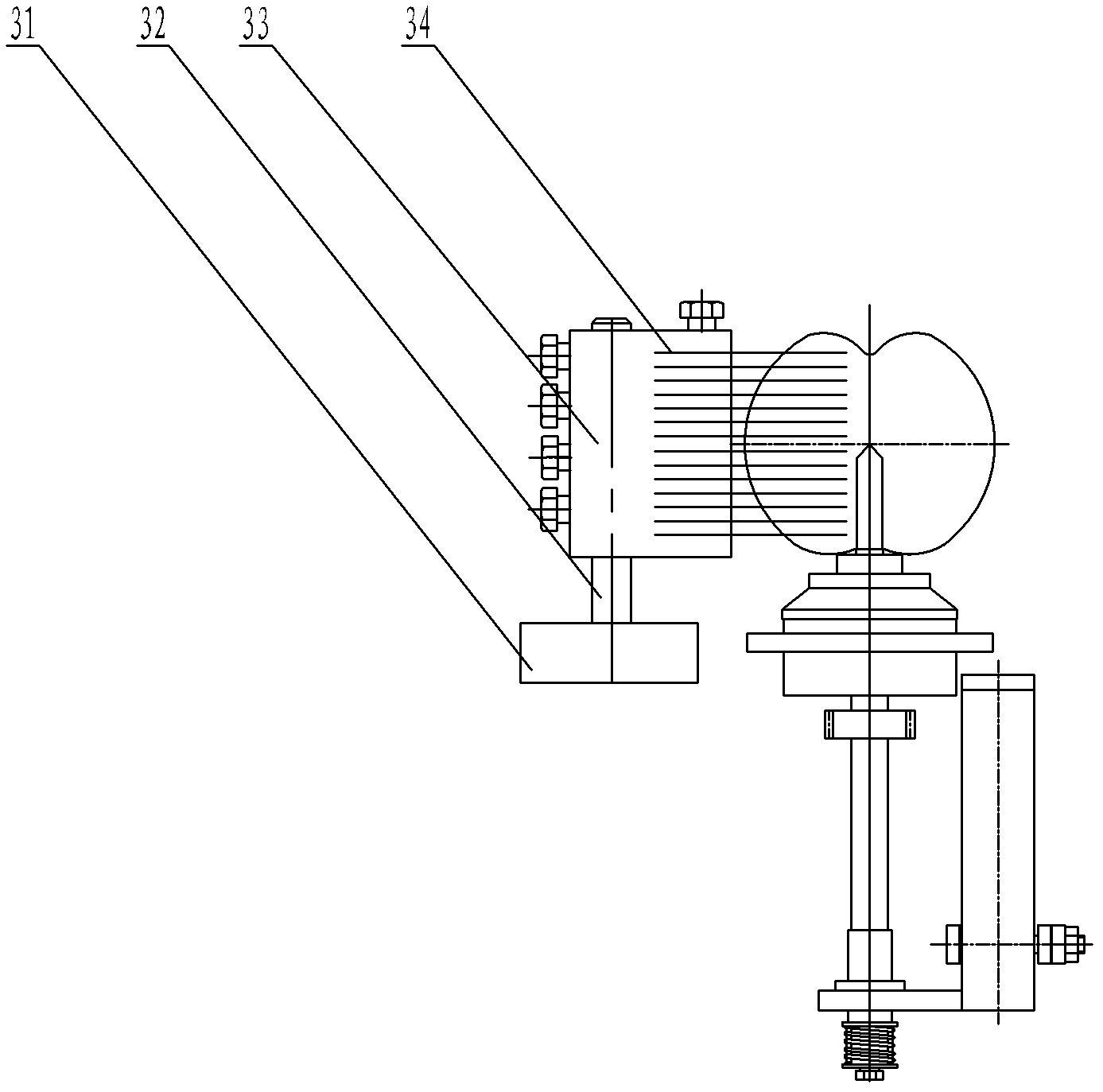

Multifunctional high-speed apple peeler

The invention relates to a multifunctional high-speed apple peeler, which comprises a framework. The multifunctional high-speed apple peeler is characterized in that a spindle is mounted on the framework, a main rotating disc is mounted on the spindle, a peeling mechanism is mounted on the edge of the main rotating disc, and a slicing mechanism and a core-removing and apple dividing mechanism aremounted on the framework on the outer edge of the main rotating disc. The multifunctional high-speed apple peeler has the following advantages that (1), the multifunctional high-speed apple peeler isreasonable in structure, simple in operation and high in efficiency; (2), multiple functions are combined in different ways, so that requirements of diversity of products are met, and an application range is quite wide; and (3), manual feeding and an automatic function are combined, accordingly, the multifunctional high-speed apple peeler is adaptive to current situations of domestic production of apples, and is high in adaptability to types, appearances and sizes of the apples, requirements on raw materials are reduced, and labor cost is lowered.

Owner:WUXI KEAN AUTOMATION EQUIP

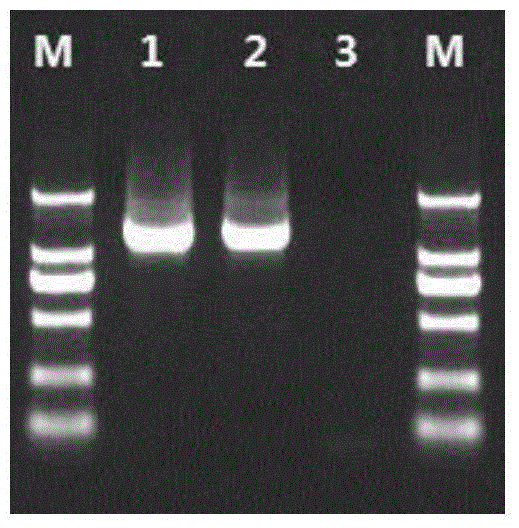

HIV-1 genotype and drug resistant mutation site detection kit and application thereof

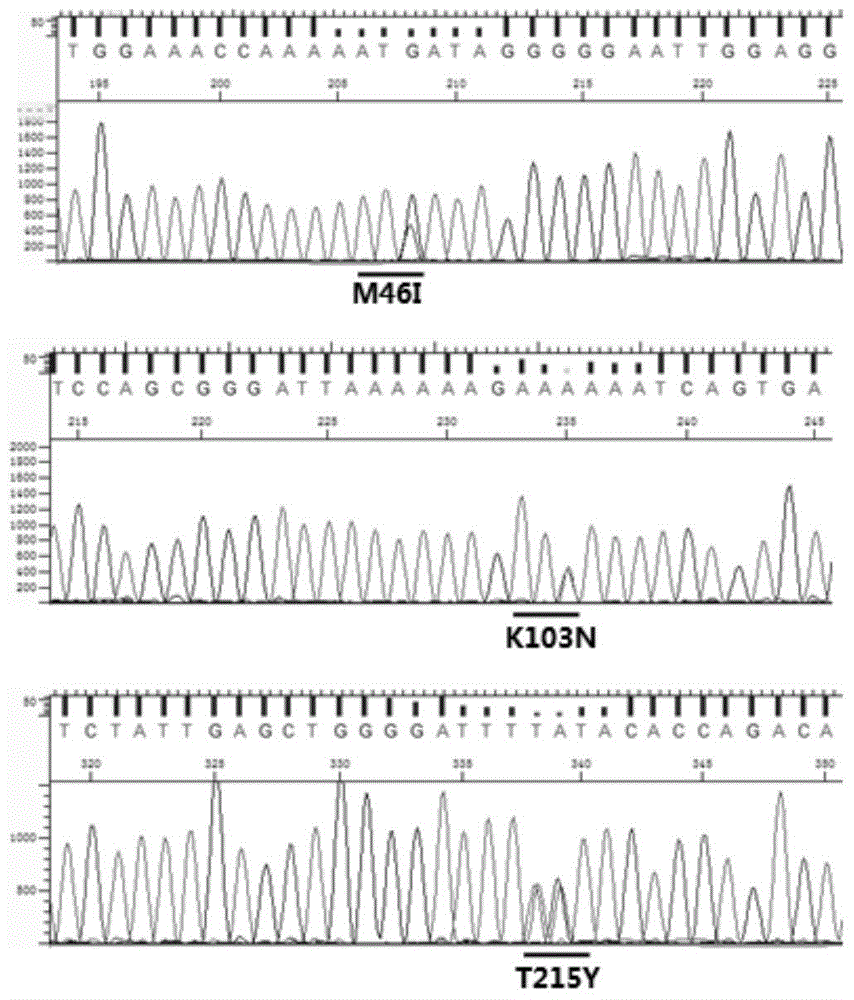

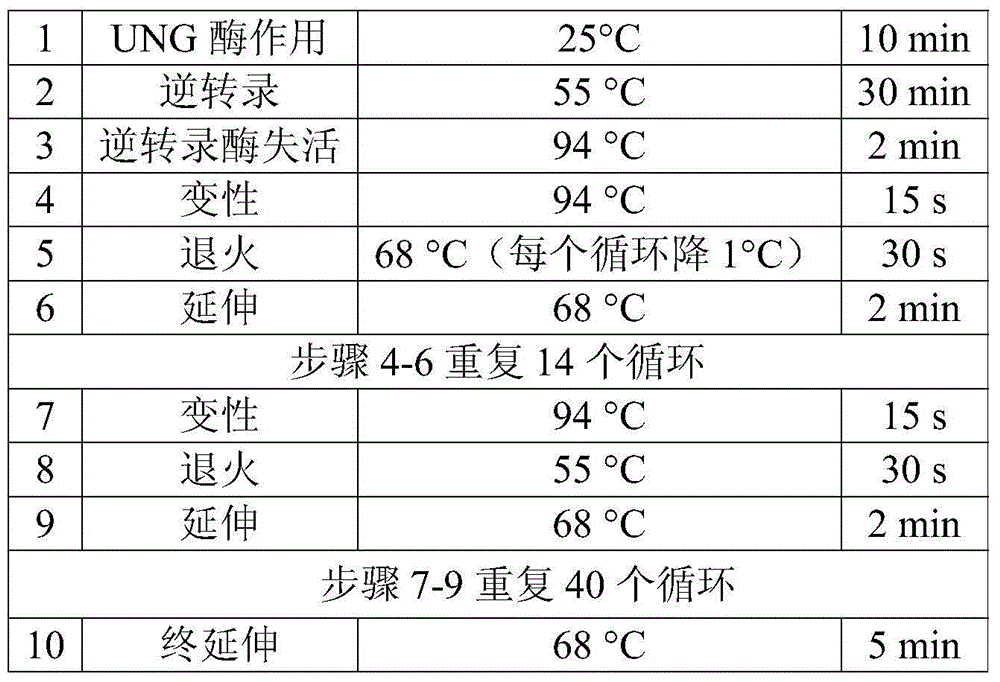

InactiveCN104946794AWide coverageStrong specificityMicrobiological testing/measurementDNA/RNA fragmentationVirus strainDetection rate

The invention discloses an HIV-1 genotype and drug resistant mutation site detection kit and application thereof. The kit comprises set of primers detecting to-be-detected HIV-1 genome's genotype and drug resistant mutation site. The set of primers include amplification primer pairs and sequencing primer sets. Experiments prove that the detection kit provided by the invention ensures the detection capability of low-frequency mutant strains, greatly makes up the disadvantages of poor amplification efficiency, low detection rate and low low-frequency mutation detection rate of similar kits imported from abroad to China HIV epidemic strains, has the characteristics of simple and fast operation, high efficiency, economical efficiency and high throughput, etc., not only lays a solid foundation for domestic production of HIV drug resistant detection reagents, but also opens up broad prospect for domestic large-scale detection of HIV virus strain drug resistant situation.

Owner:CAPITALBIO CORP +2

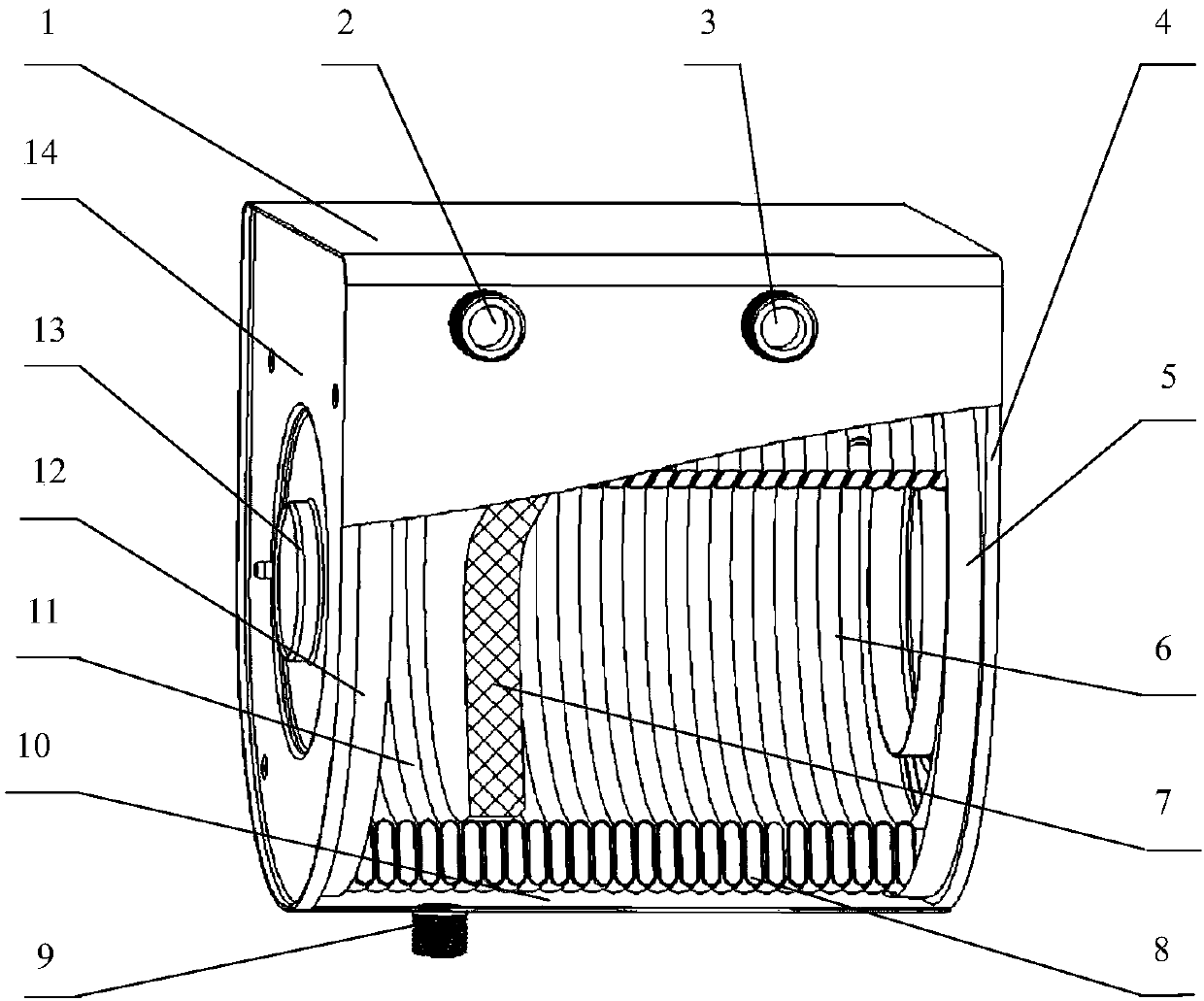

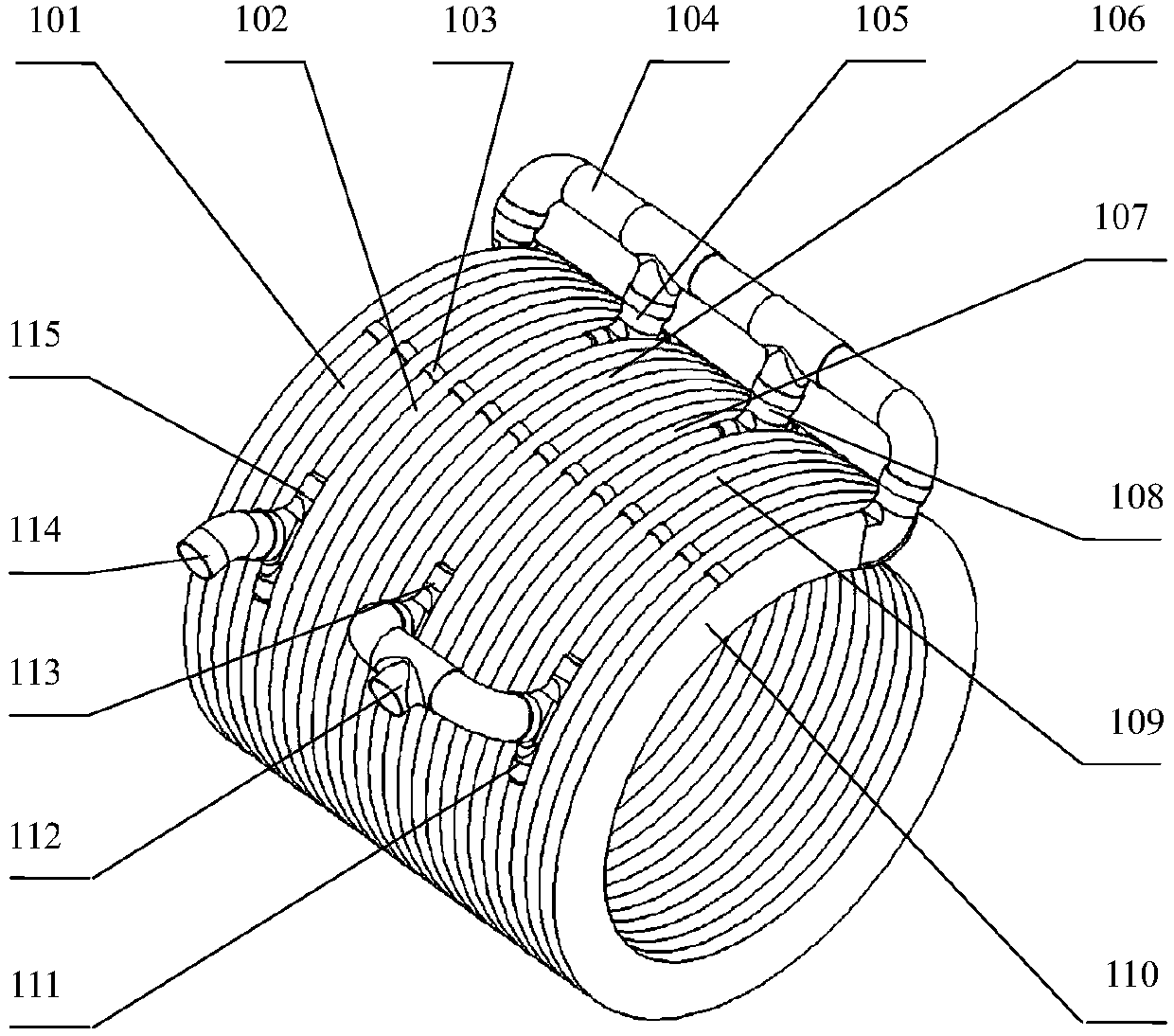

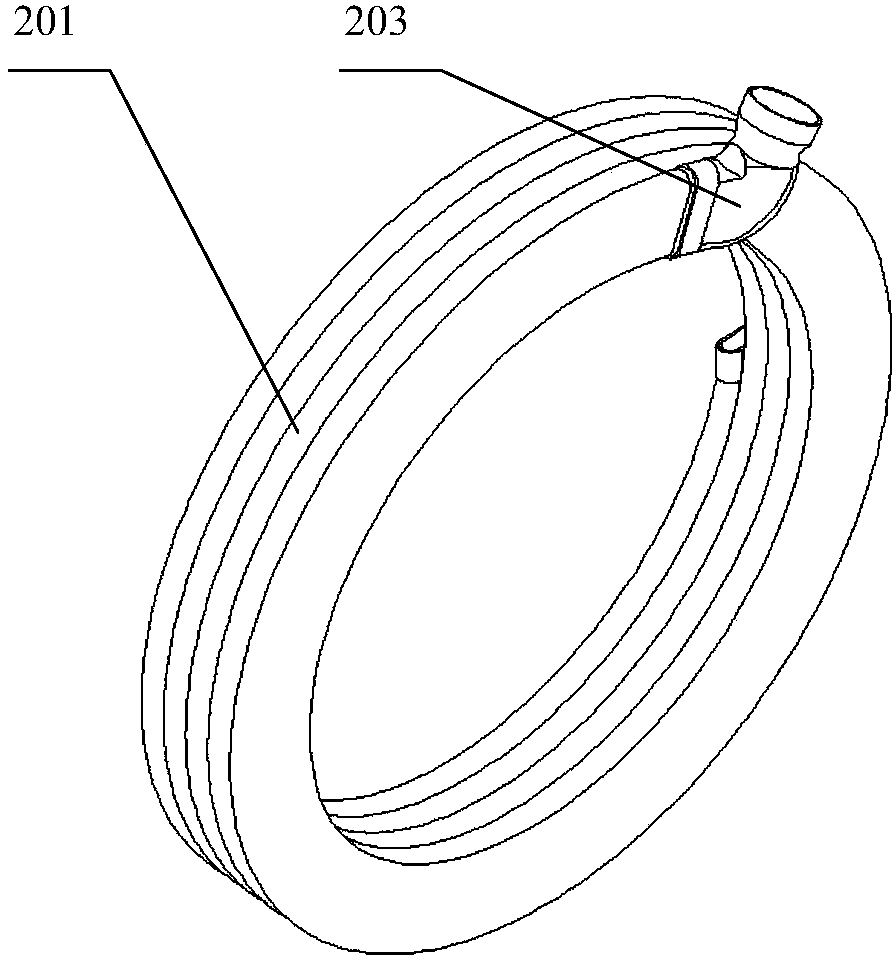

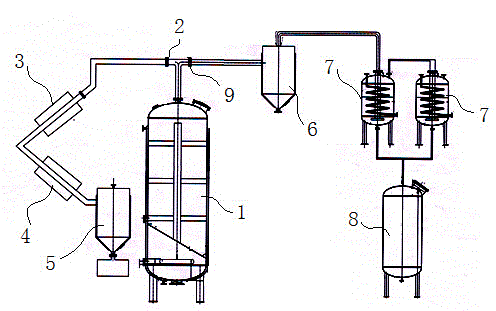

Heat exchanger structure

InactiveCN107869847AReduce lossUniform gapAir heatersStationary tubular conduit assembliesPlate heat exchangerWater flow

The invention provides a heat exchanger structure and particularly provides a heat exchanger structure for a fuel gas full pre-mixing condensation type wall-hung stove. A heat exchanger is the main component of the fuel gas full pre-mixing condensation type wall-hung stove and installed in the fuel gas full pre-mixing condensation type wall-hung stove. The heat exchanger is used for heating heating water. The heat exchanger is composed of a shell and an annular coiler group. The side face of the shell is provided with a water inlet and a water outlet, and a condensed water outlet is formed inthe bottom of the shell. An exhaust opening is formed in the back end cover. The annular coiler group is arranged in the shell and is provided with a plurality of spiral pipes, and the spiral pipes are coaxially connected in series to form a spiral entirety. Water flow in the spiral pipes are distributed through a communicating pipe, a confluence opening and a diversion opening. The gaps of the spiral pipes are kept through spacer sheets. Heat is fully absorbed, and the heat exchange efficiency can be guaranteed. The heat exchanger structure solves the problems of the prior art, and the heat exchanger structure is simple, convenient to produce and manufacture and capable of being manufactured by the adoption of existing domestic production equipment.

Owner:SHANGHAI SHUANGKAI GAS APPLIANCE

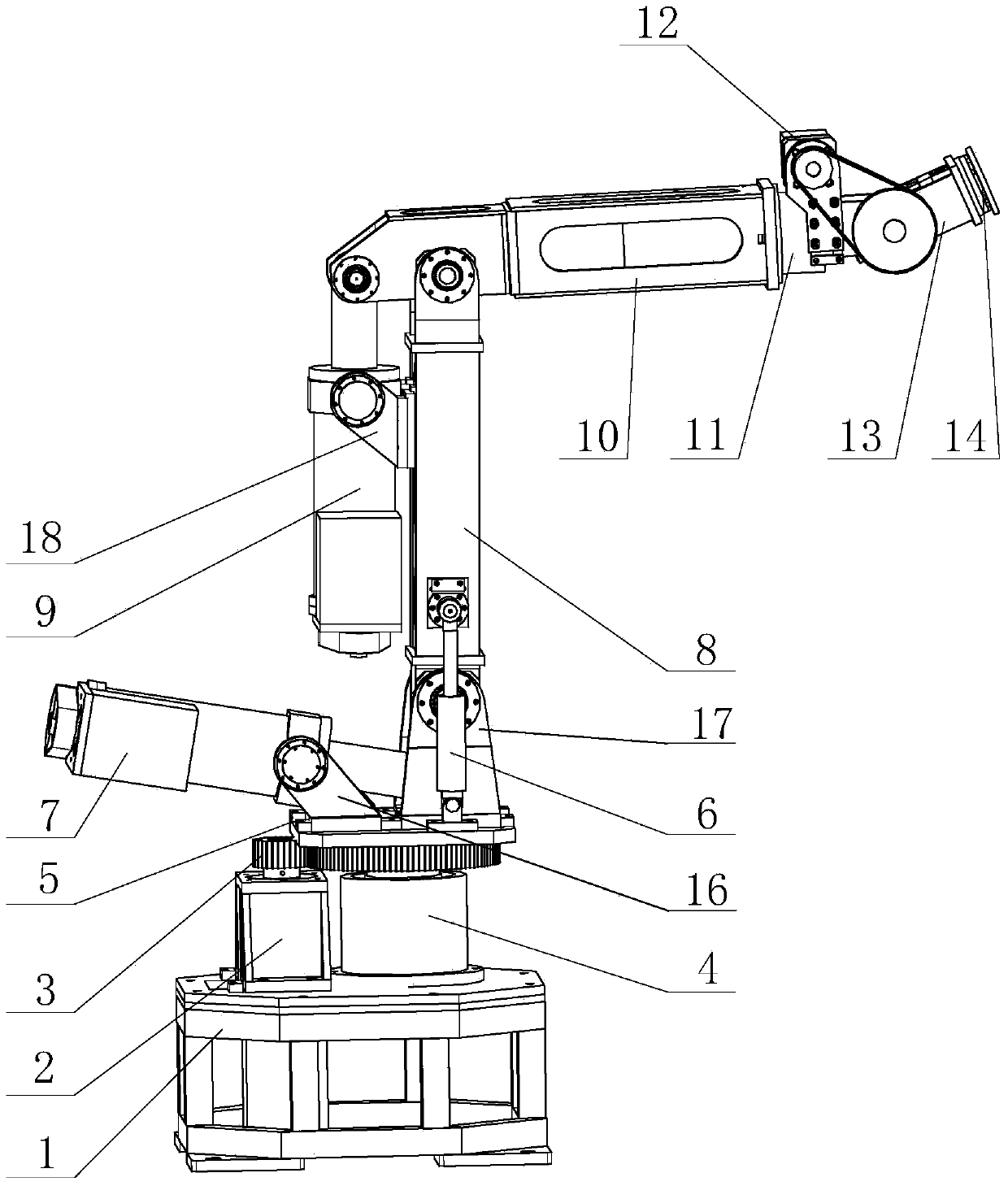

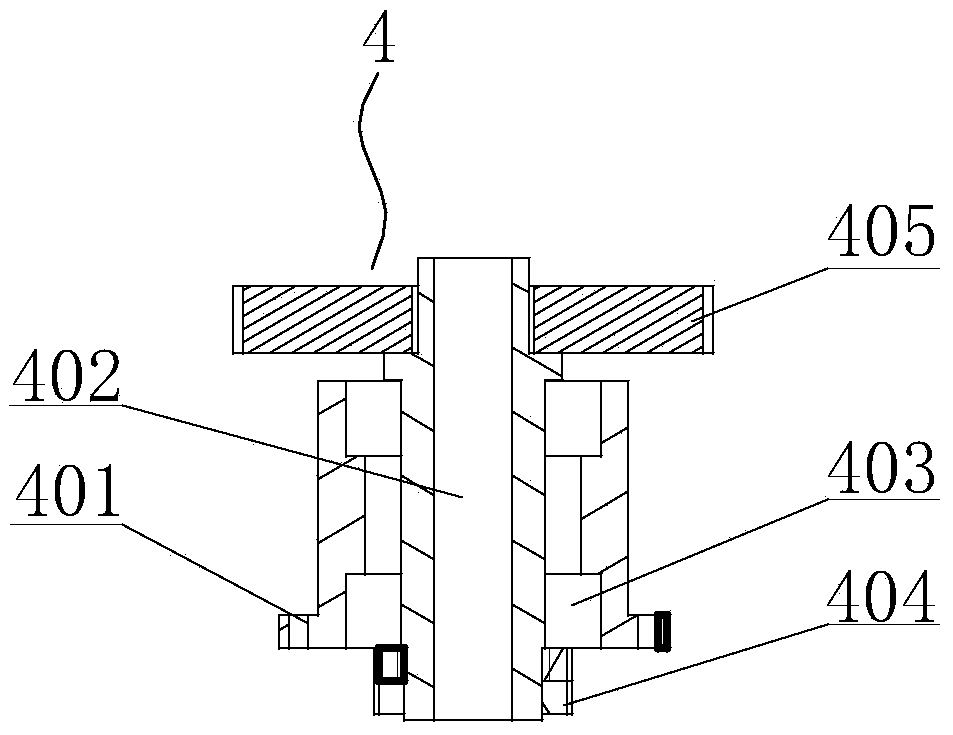

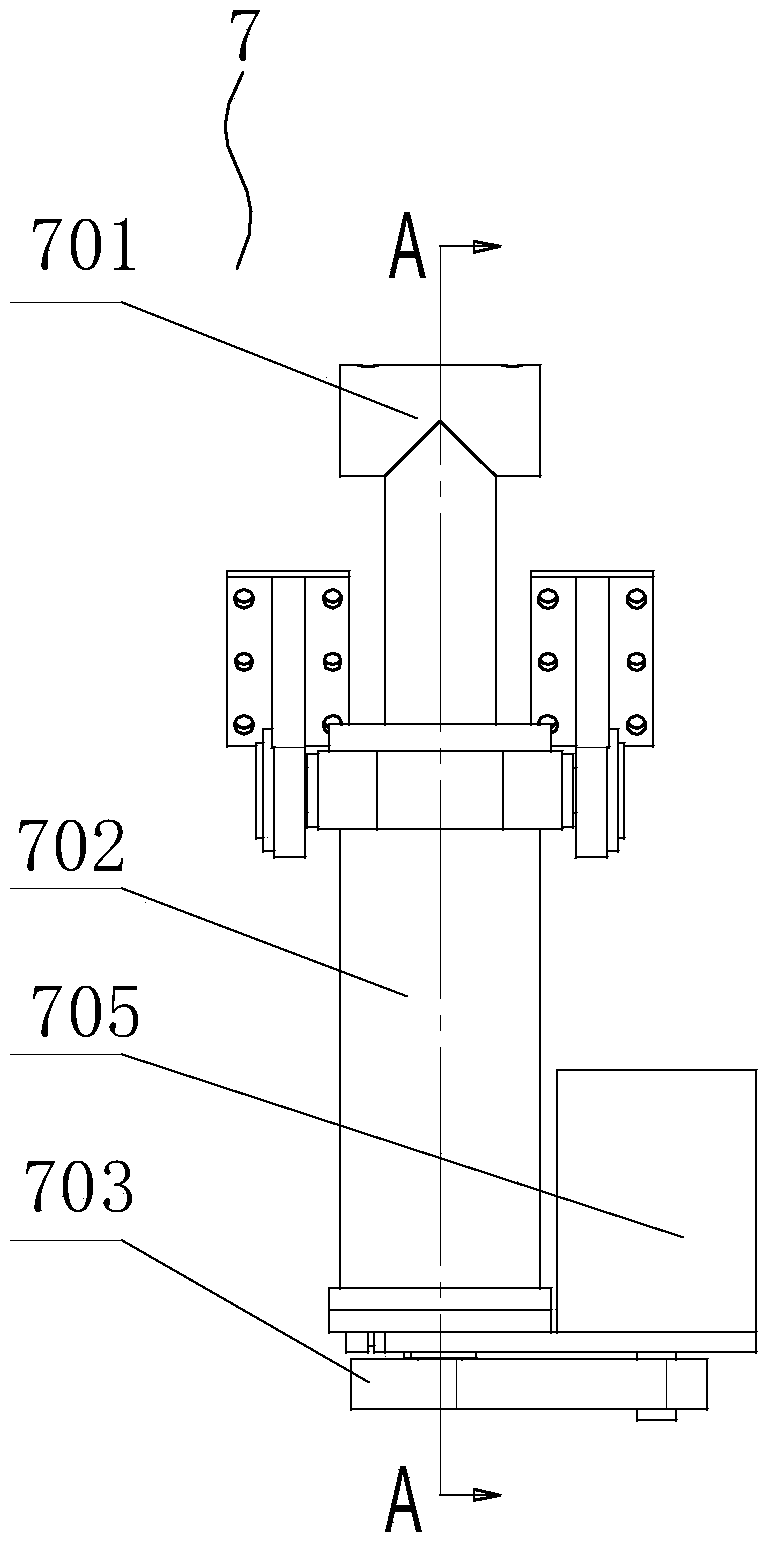

Six-shaft joint mechanical hand

InactiveCN103737607ALow costSimple structureProgramme-controlled manipulatorJointsControl systemIndustrial machine

The invention discloses a six-shaft joint mechanical hand and relates to the industry mechanical hand technology. The six-shaft joint mechanical hand comprises a mechanical hand body and a control system; the mechanical hand body is connected with the control system through a data line; the mechanical hand body comprises a base, a first shaft servo motor and a speed reducer thereof, a first shaft rotary shaft, a second shaft base, a lower hand servo cylinder, a lower arm, an upper arm servo cylinder, an upper arm, a fourth shaft rotary shaft, a fifth shaft servo motor and a speed reducer thereof, a fifth shaft rotary base, a sixth shaft rotary shaft and a sixth shaft servo motor and a speed reducer thereof; the control system comprises a programmable controller, a movement control module, a servo driver, an alarming device, a hand box, a touch screen, a limit switch and a sensor. The six-shaft joint mechanical hand has the advantages of achieving six-shaft joint control through the control system, being simple in structure, achieving domestic production, reducing products, shortening the purchasing cycle, being suitable for small and medium businesses to use and high in positioning accuracy, improving the production quality and the production efficiency and having a good application prospect in the industry mechanical hand technology field.

Owner:LIUZHOU GAOHUA MACHINE

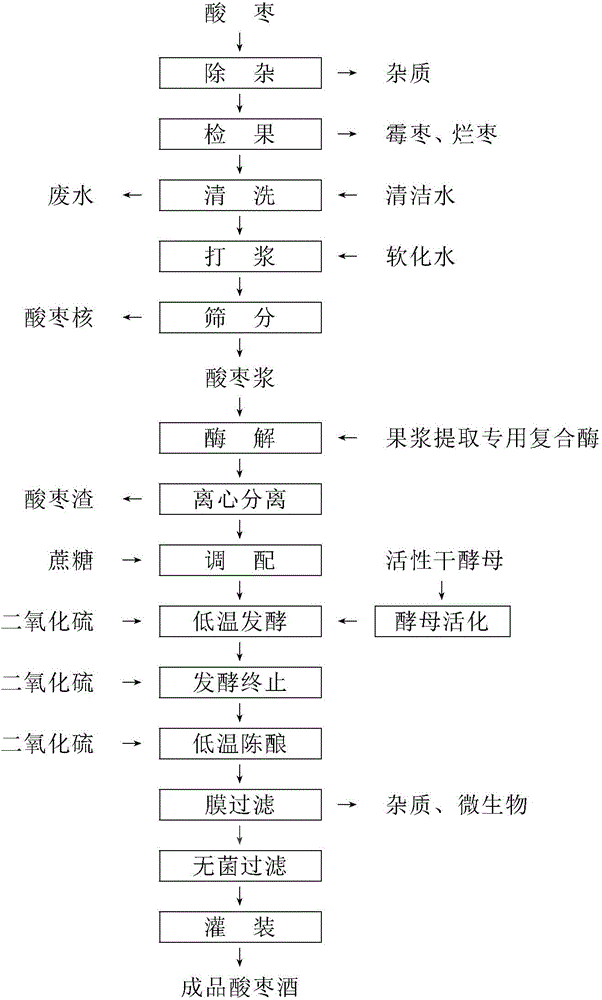

Production process of wild jujube wine

The invention relates to a production process of wild jujube wine. The production process comprises the following steps: impurity removal, fruit inspection, cleaning, beating, enzymatic hydrolysis, screening, centrifugal separation, blending, yeast activation, low-temperature fermentation, low-temperature ageing, filtration and filling. According to the invention, the produced wild jujube wine has unique natural fruit flavor of the wild jujube, is rich in nutrient, shows light purplish red, is clear and transparent in wine body, has rich and pure fragrance of wild jujube, and is soft and delicate in taste. The wild jujube wine can be drunk after being chilled, and shows neat fruit fragrance, refreshing taste and enjoyable taste. In addition to the typical characteristics of fruit wine, the wild jujube wine further has unique health care function. According to the production process, the production technology is reliable, has the domestic advanced level, fills the gap of domestic production and processing technology of high-quality wild jujube products, is domestic initiative, and fully meets the needs of industrial production.

Owner:CHINA LIGHT IND INT ENG CO LTD

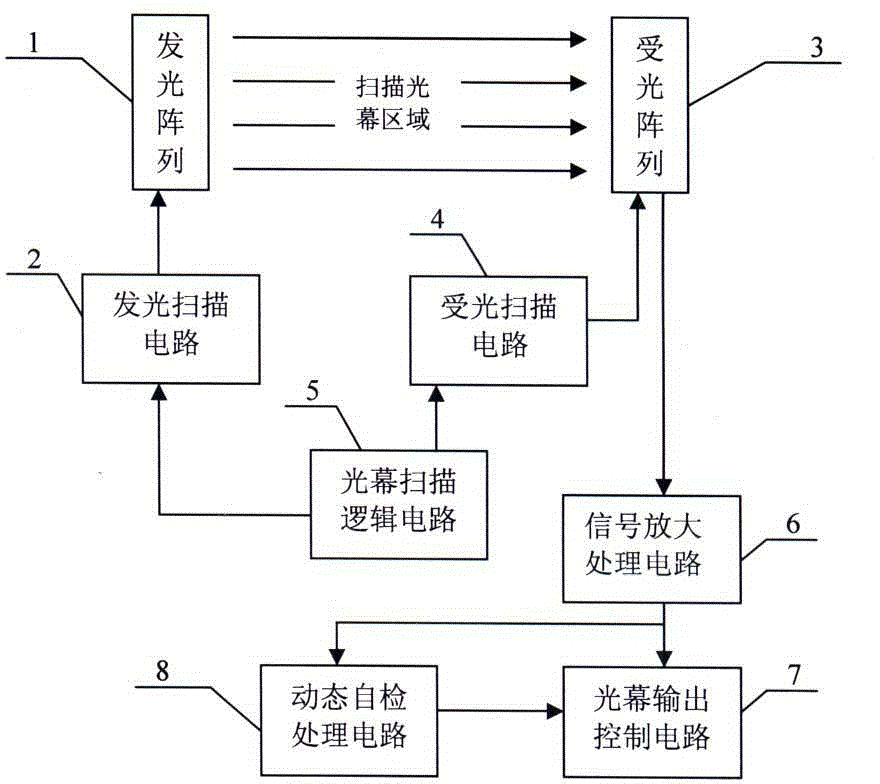

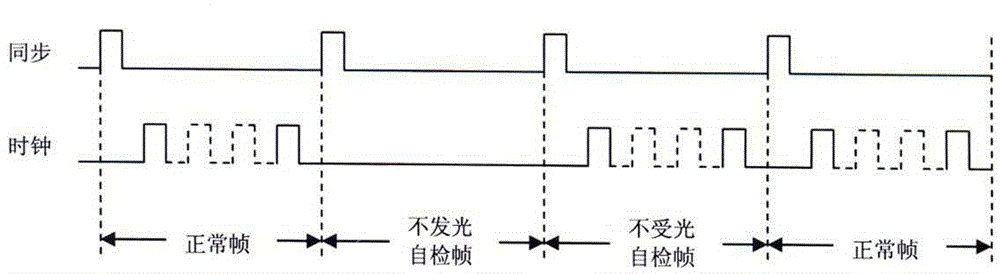

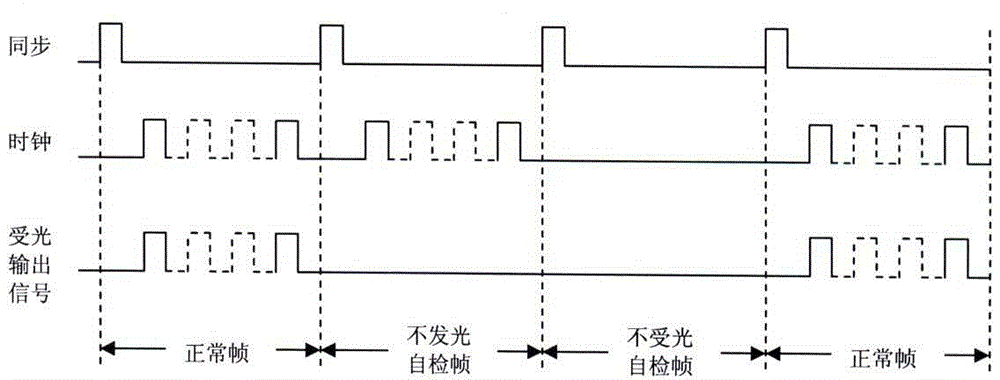

Dynamic self-check method of safety light curtain

ActiveCN102744346ARealize localizationImprove anti-interference abilityForging press drivesAnti jammingEngineering

The invention discloses a dynamic self-check method of a safety light curtain. The method comprises a photoelectric protection sensor circuit composed of a luminous array, a luminous scanning circuit, a light receiving array, a light receiving scanning array, a light curtain scanning logic circuit, a signal amplifying processing circuit, a light curtain output control circuit and a dynamic self-check processing circuit, wherein the dynamic self-check processing circuit is connected with an output end of the signal amplifying processing circuit and connected into the light curtain output control circuit; in the response time of photoelectric protection, a non-luminous scanning self-check frame and a non-receiving scanning self-check frame are inserted into a normal photoelectric scanning frame array; and when the dynamic self-check processing circuit analyzes and processes the light receiving output signal between the two self-check frames, the aim of detecting the status of the whole scanning circuit is achieved. Through the invention, various faults covering all luminous and light receiving circuits can be diagnosed by adding a few circuits and control logics; the anti-jamming capability is strong; and the structure is simple and reliable and can be realized by a general logic device, being favorable for realizing domestic production of 4-level safety photoelectric protectors or safety light curtains so as to break foreign monopoly.

Owner:JINING KELI PHOTOELECTRIC IND CO LTD

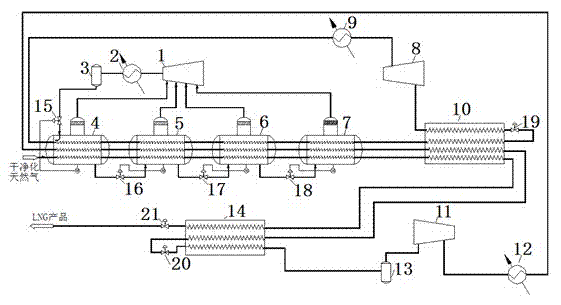

Dual compounding cryogen refrigeration system with a precooling function and method

InactiveCN102927791AEmbody adaptabilityRich adjustment meansSolidificationLiquefactionProcess engineeringRefrigeration

The invention discloses a dual compounding cryogen refrigeration system with a precooling function and a method. The temperature of purified natural gas is gradually decreased in four evaporators and two heat exchangers until that the purified natural gas is liquefied, the cold quantity required by the liquefaction process is provided by three systems, namely, a precoolant system, a mixing cryogen MR1 and a mixing cryogen MR2, system adjustment means are abundant so as that the cold quantity can be fully provided for the natural gas liquefaction process, and the flexibility of the system on the aspects of the operation and the adaptability to a raw material are shown. According to the refrigeration system and the method provided by the invention, the energy consumption during the natural gas liquefaction process is low, the domestic production for a large-scale liquification factory is free from the mode limitation by a main heat exchanger, the large-scale refrigeration compression can be realized, and an LNG (liquefied natural gas) device with ten millions tons can be realized to the greatest degree..

Owner:CHINA GASOLINEEUM ENG

Method for coarsely extracting natural borneol from cinnamomum camphora

ActiveCN104693008AEmission reductionReduce extraction timeHydroxy compound separation/purificationCinnamomum camphoraVaporization

The invention discloses a method for coarsely extracting natural borneol from cinnamomum camphora. The method for coarsely extracting the natural borneol from the cinnamomum camphora includes steps that 1) smashing cinnamomum camphora branches and leaves, wherein the granule length is less than or equal to 10 centimeters after smashing; 2) adding the smashed cinnamomum camphora branches and leaves to an extracting tank, using high-pressure super-heated steam to directly act on the branches and leaves, controlling the temperature to guarantee the vaporization sublimation for the natural borneol in the cinnamomum camphora, and extracting for 35 to 40 minutes; 3) using a condenser to condense the gasified natural borneol, and gathering. The method for coarsely extracting the natural borneol from the cinnamomum camphora enables the extraction time to be shortened by a half, enables the yield to be improved by 10% and enables the energy consumption to be lowered by 65%, the waste water emission can be reduced by 99% through using steam, and the domestic production capacity technology is amplified by 20 times.

Owner:江苏金叶子生物科技有限公司

Method for preparation of high-purity pseudo-boehmite adhesive

InactiveCN107720791ASimple preparation processEasy to controlAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesSolubilityAlcohol

The invention provides a method for preparation of a high-purity pseudo-boehmite adhesive, and belongs to the technical field of inorganic functional materials. The product prepared by the method is high in purity, the gel solubility index and the thixotropy are easily controlled, and the requirements for pseudo-boehmite used in the adhesive in domestic and overseas catalyst fields can be met. Nowaste is discharged in the whole preparation process, and the method is an environment-friendly technology; at the same time, the preparation process is simple, the operation process is simple and thecost is low. The method shows significant competitive advantages and profit space in terms of the manufacturing cost and environmental friendliness, especially is of great significance in the aspectof achieving domestic production of the seudo-boehmite adhesive used in catalysts. Moreover, the adopted raw materials are low-carbon-alcohol aluminum alkoxide, and compared with the process using long-chain aluminum alkoxide, the high-purity pseudo-boehmite adhesive prepared by the method has the advantages of being low in toxicity and easy to purify.

Owner:DALIAN UNIV OF TECH

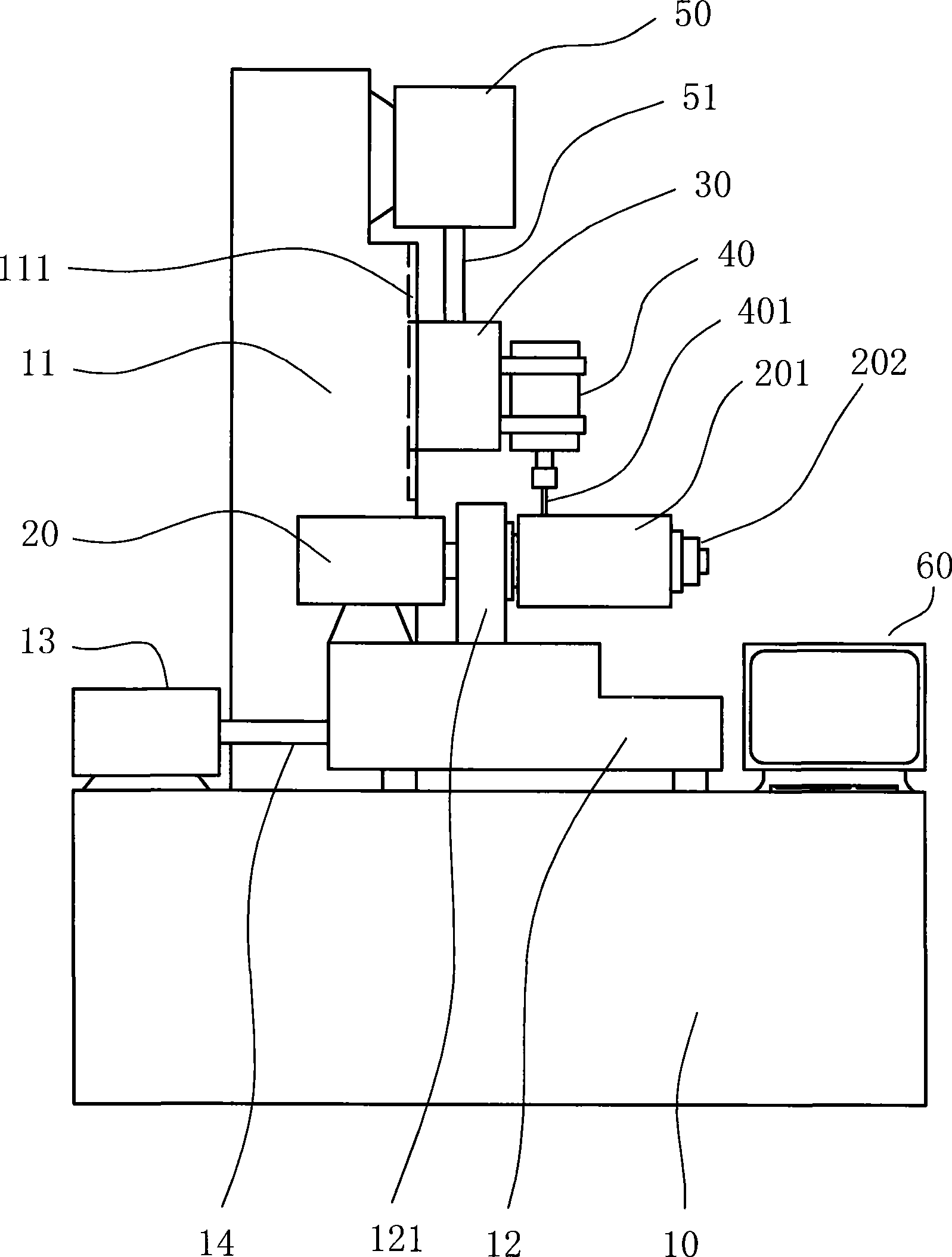

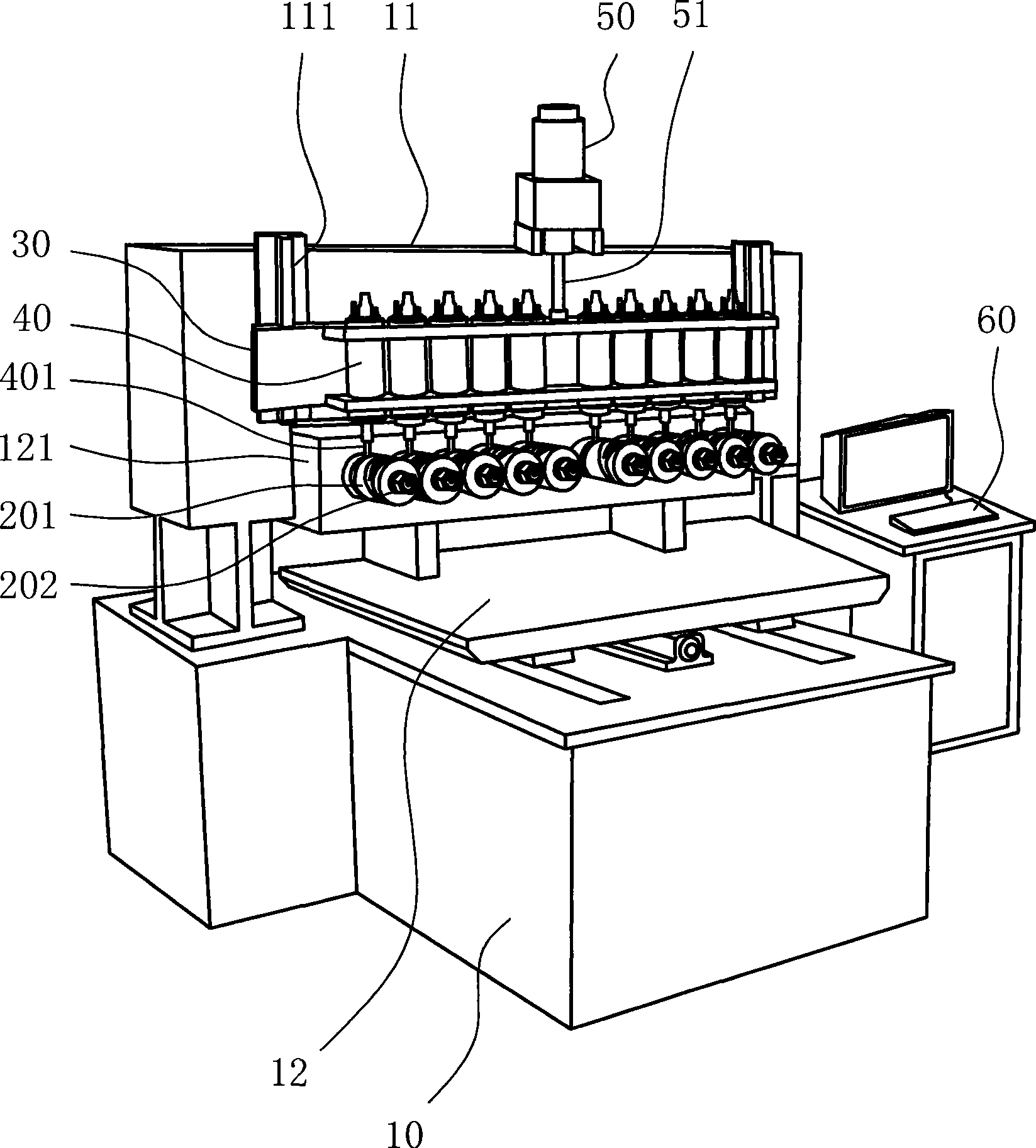

Production equipment special for numerical control groove drum

InactiveCN101391316AAccelerate the pace of scientific and technological progressLocalization realityFilament handlingMilling machinesWinding machineNumerical control

The invention provides a special production equipment of a numerical control grooved drum, which belongs to the technique field of numerical control milling machines, wherein, a sliding platform and a transmission mechanism are arranged on a frame, a grooved drum support and more than two sets of grooved drum motors and grooved drum jigs are disposed at the upper part of the sliding platform, a mounting rack is fixed at the middle and rear part of the frame, a jacking motor, a milling cutter motor mounting rack, a milling cutter motor and a milling cutter are arranged on the mounting rack, and the movement of the invention is controlled by a controller according to the edited program and the corresponding servo motor, and the invention has the advantages that: the production efficiency of the equipment is ten times higher than the existing equipment, but the price is only one eighth of that of the existing equipment, the lifetime of the metal grooved drum manufactured by the equipment is 8 to 10 years, the winding speed is 1300m / min, and the time of not-in-place at both ends is zero, and the invention can meet the requirements of domestic production as well as new situations of energy saving, consumption reduction and emission reduction, and enhance the competitive power of the national textile industry, and the equipment is used to manufacture various cone winding machines and parallel winding machines with different angles of taper.

Owner:台州宇硕自络槽筒有限公司

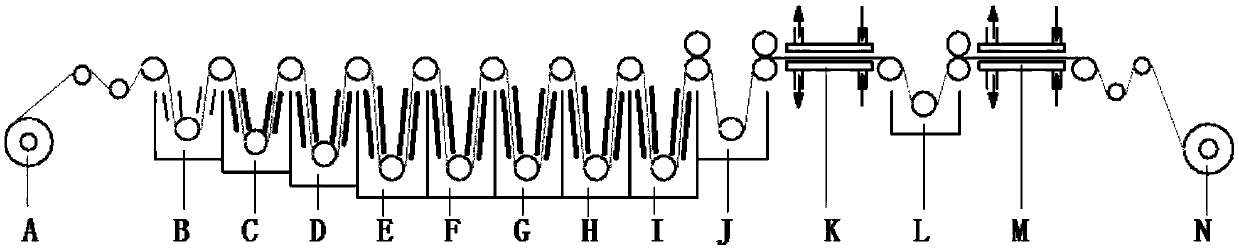

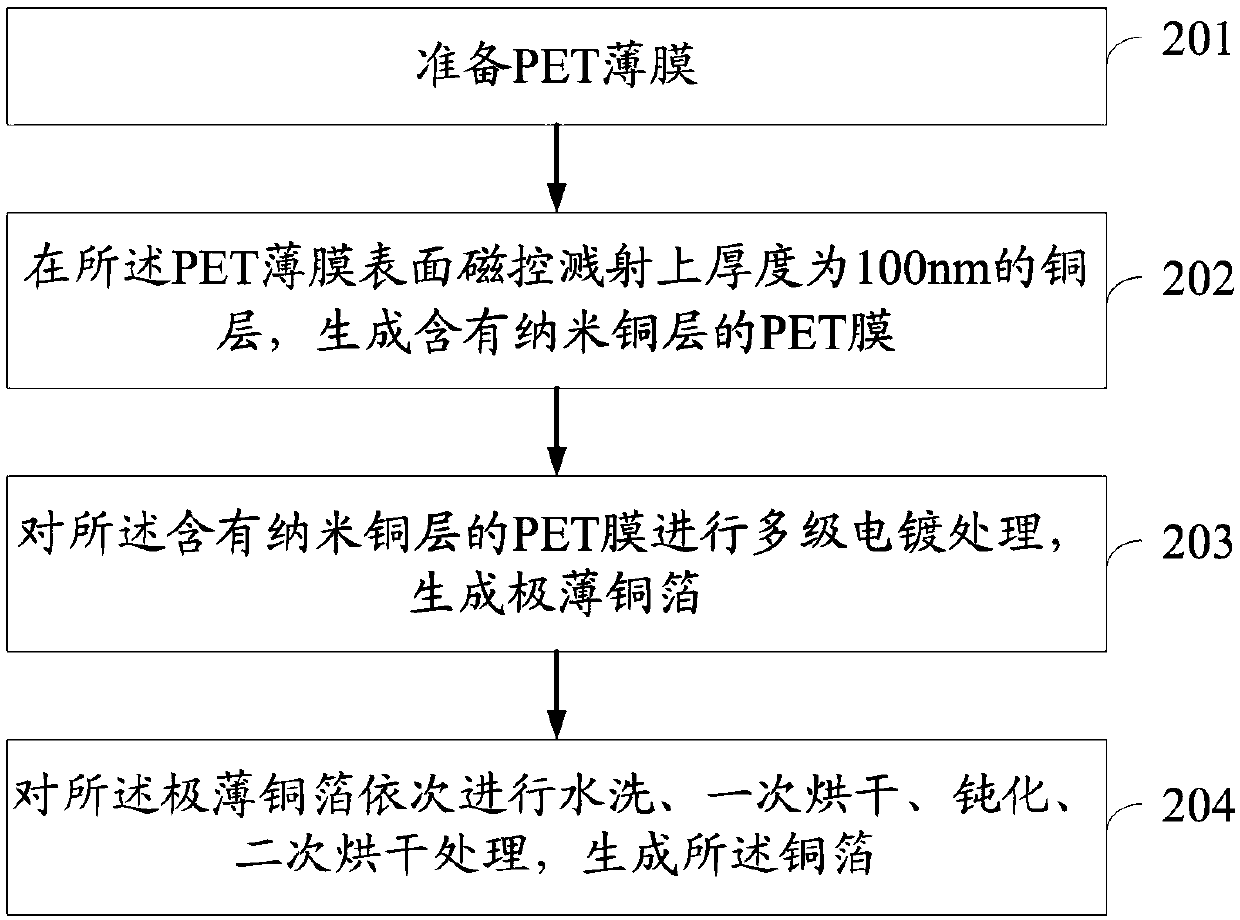

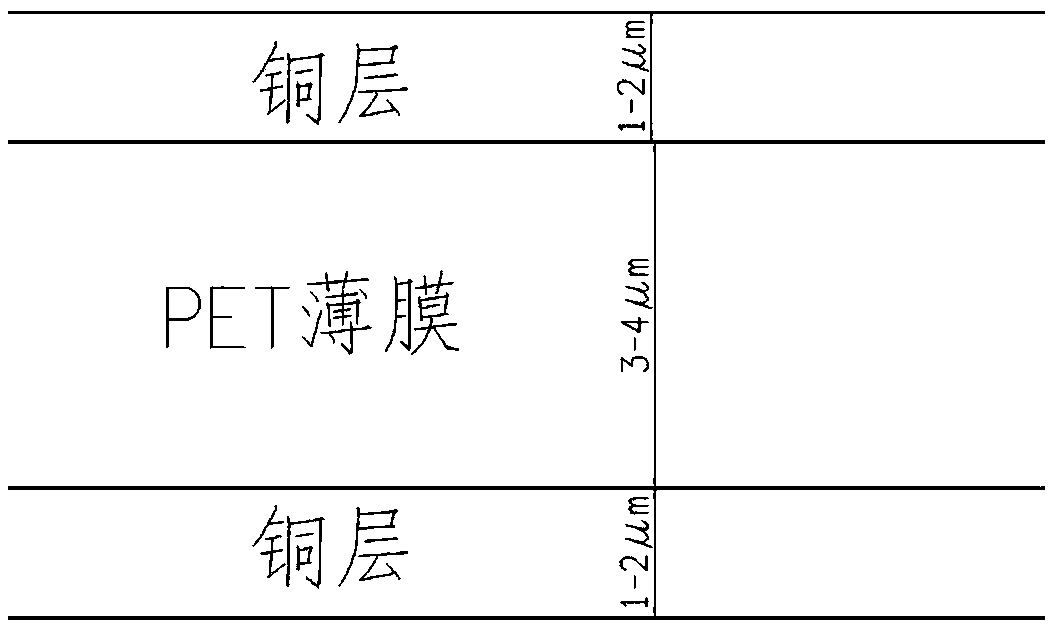

Lithium ion battery negative pole copper foil production equipment and method

InactiveCN109554738ANo edge tearingThere will be no problems such as broken foilElectrolysis componentsVacuum evaporation coatingElectrolysisElectrical battery

The invention discloses lithium ion battery negative pole copper foil production equipment and method. PET films containing nanometer copper layers are unwound from an unwinding mechanism to enter anelectroplating tank B for electroplating to enter an electroplating tank C, are continuously electroplated by all stages of electroplating tanks D-I, are fed in a water washing tank for water washing,are dried in first drying equipment after water extrusion, are passivated in a passivating tank, are dried, and are finally wound by a winding mechanism. Ultrathin copper foils produced by the production equipment and method effectively reduce the weight of lithium ion batteries, provide light negative pole materials for realization of 300 Wh / kg power battery specific energy, meanwhile, solve thedefects of existing domestic technologies and equipment, and fill up the blank in domestic production field of ultrathin copper foils. In addition, the ultrathin electrolytic copper foil production method and equipment replace expensive and huge negative pole roller equipment in the electrolytic copper foil production, reduce the enterprise production cost, and are easier to operate and convenient for large-scale enterprise production.

Owner:胡旭日

Process for manufacturing coarse denier high-strength nylon 6 stretching industrial thread

A process of manufacturing fully drawn nylon6 industrial yarns with heavy denier and high strength. It is characterized in, heating and melting nylon6 chips in a screw extruder with 40í½50r / min, at 310degree Cí½320degree C, maintaining the melts in pipes by gaseous biphenyl at 295degree Cí½300degree C, the spinning nozzle ejecting the melts at high pressure through the yarn metering pump and forming threadlines, cooling threadlins and molding, fatliquoring, drafting and winding. The drafting process is divided into three sections with heat drafting. The drafting multiple factor is 4.96í½5.1, the spinning rate is 2210í½2400m / min, the viscosity of nylon6 chips is 3.5í½3.6. The produced fully drawn industrial yarns with heavy denier and high strength have the following properties: the breaking tenacity of 2100dtex / 316F is í¦86CN / tex which is at least 5CN / tex higher than the existing domestic products, the breaking extensibility is íœ23úÑ which is 1í½3úÑ smaller than the existing domestic products, the constant load extensibility is 11.5úÑ which is 1úÑ smaller than the existing domestic products, the spinning rate is 200í½ 300M / MIN higher than the existing domestic products.

Owner:中国石油化工股份有限公司巴陵分公司

Forging method of relatively-large-size fine-grained austenitic gas valve steel SNCrW

ActiveCN110935827ARealize localizationMeet needsFurnace typesHeating/cooling devicesChemical compositionSmelting process

The invention discloses a forging method of relatively-large-size fine-grained austenitic gas valve steel SNCrW. The forging method aims to solve the problems of serious primary carbide segregation ofas-cast structures of steel ingots, the large amount of secondary carbide precipitation of billet corners and thick and large core structures. According to the technical scheme, an EAF / non-vacuum induction furnace + LF + VOD / VHD + ESR smelting process is adopted to produce electroslag ingots with qualified chemical compositions, a radial rapid forging combining forging method is adopted, and through high-temperature homogenization treatment before forging and control over the heating temperature of billets, billet reburning time, upsetting amount, drawing reduction amount, deformation amountand a deformation mode per firing and length of radial forging billets, the problems of the as-cast structures of the ingots are solved. The forging method has the beneficial effects that macrostructures of relatively-large-size fine-grained austenitic stainless steel SNCrW bar products are qualified, the grain size is above 6 grade, and the flaw detection reaches the grade A required by GB / T 4162, the needs of domestic gas valve manufacturers are met, and the domestic production of SNCrW bars is realized.

Owner:FUSHUN SPECIAL STEEL SHARES

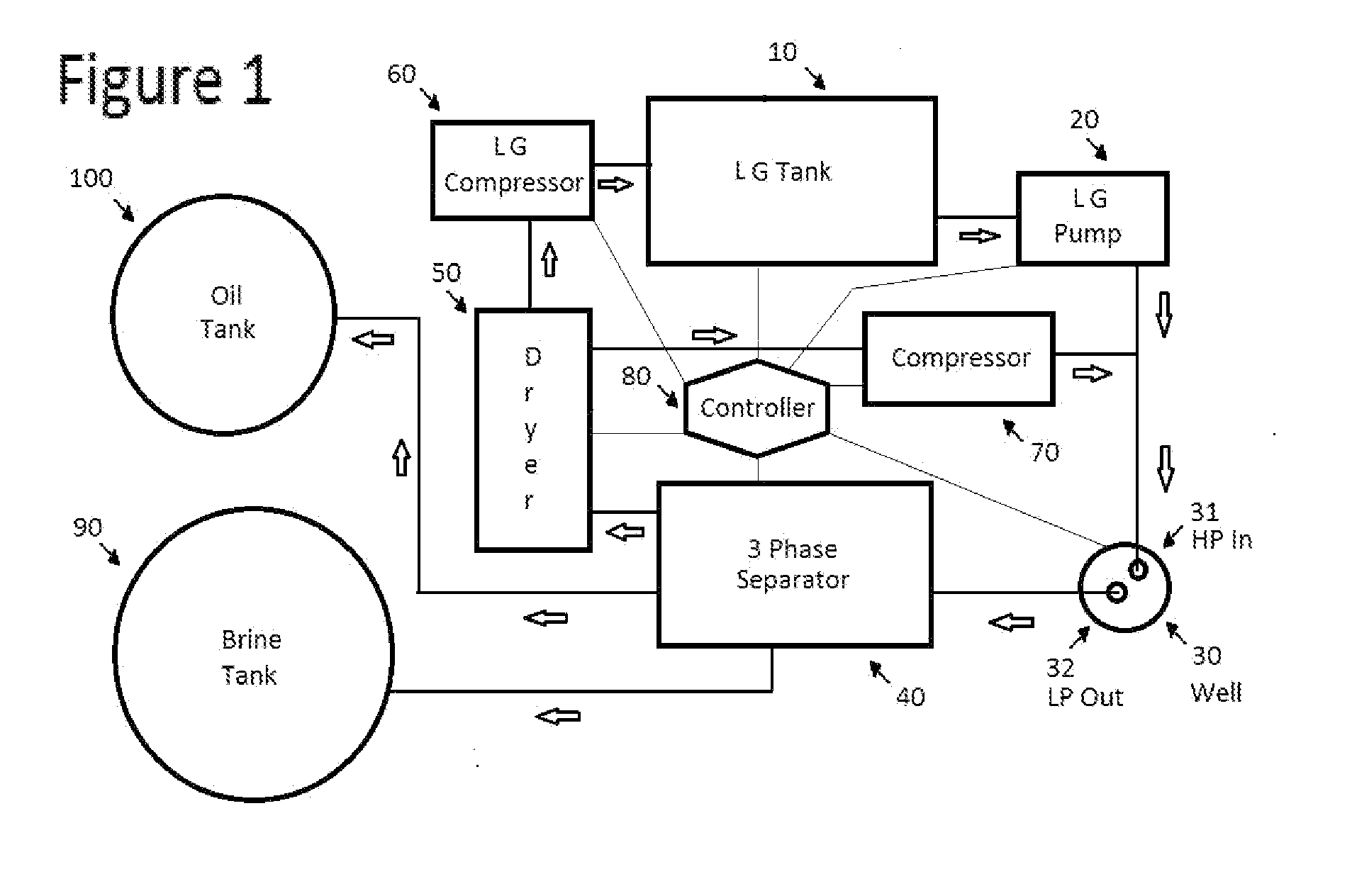

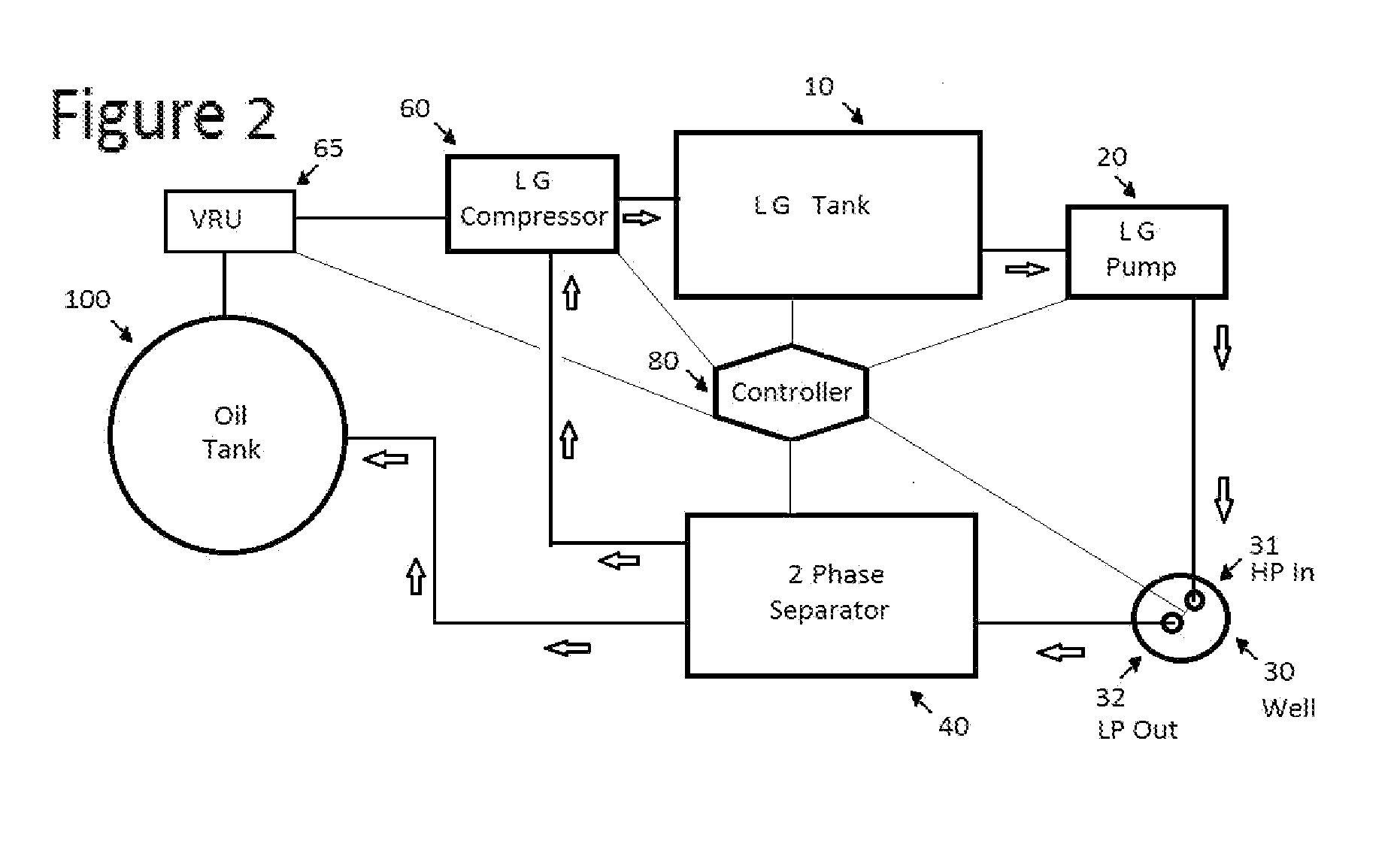

Liquid or Hydrate Power System Applied To A Single Point Injection Gas Lift System

InactiveUS20150377000A1Efficient unloadingProduce efficientlySurveyDrilling rodsElectricityChemical reaction

This system stores and uses as needed Compressed Gas, Hydrates, or Liquified Gas to unload and add power in order to produce a well or transfer fluids from one place to another. It can also supply gas to run the system, or generate electricity or various other auxiliary functions. It has been proven successful and could increase production in America and the world by bringing back into production wells that are not economical any other way. One well at a time, or entire fields can be produced with a single compressor. Stripper wells account for 40% of total domestic production. There are 1000s of wells not being produced. Huge production OPEC type wells could be produced with this system better, faster, and less expensive than any other system. This is also environmentally cleaner as very little gas will escape to the atmosphere. I believe that generators and other engines could be operated with this expanding vapor renewable physical reaction which seems close to the level of energy created during the expansion of a diesel chemical reaction.

Owner:BOLLINGHAM LEONARD ALAN

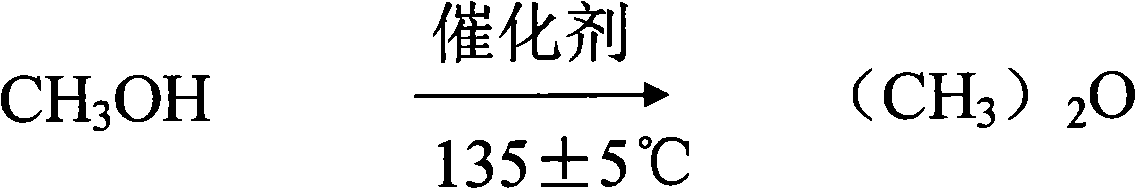

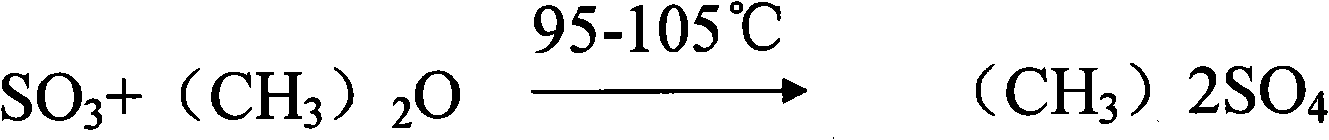

Production process for preparing dimethyl sulfate by composite acid through catalytic dehydration

InactiveCN101654420AReduce pollutionImprove efficiencySulfuric acid esters preparationDistillationSulfur trioxide

The invention relates to a production process for preparing dimethyl sulfate by composite acid through catalytic dehydration, which solves the problems of high consumption of sulphuric acid and methanol during production and more serious production pollution in the prior domestic production of dimethyl sulfate due to the adoption of conventional sulphuric acid-methanol method. The production process is characterized in that composite acid catalyst is adopted to carry out dehydrated etherealization of vaporized methanol to generate dimethyl ether gas; after purification, dimethyl ether gas reacts with dimethyl sulfate rich solution absorbing sulfur trioxide to generate a crude product of dimethyl sulfate; and an eligible finished product of dimethyl sulfate is obtained through reduced pressure distillation. The production process is suitable to be used in small and medium-sized methanol production enterprises or sulphuric acid production enterprises taking dimethyl sulfate as a downstream product.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

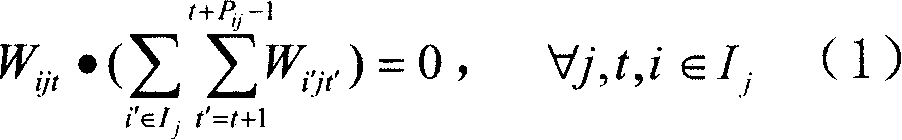

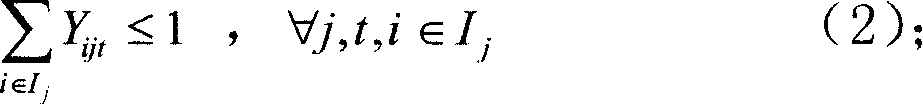

A simulation validation method for virtualization dispatching optimization in process industry

The invention relates to a simulative validation method used for the simulative scheduling-optimization of process industry, belonging to the advanced manufacturing and automatization technical field and aiming at solving the problem that the actual scheduling problem is not solved despite certain development of present domestic production scheduling model, arithmetic and calculation capability. The method of the invention includes the following steps: the generation of a scheduling plan, the prediction of potential production abnormity by calculation, simulation by virtue of visible ESCPetri-Nets technique of a graph and the generation and the storage of process data. An actual result indicates that the adoption of the method of the invention can dramatically enhance the execution quality of the scheduling plan and enhance the utilization rate of raw material and manufacturing equipment with dramatic economical benefit.

Owner:HANGZHOU DIANZI UNIV

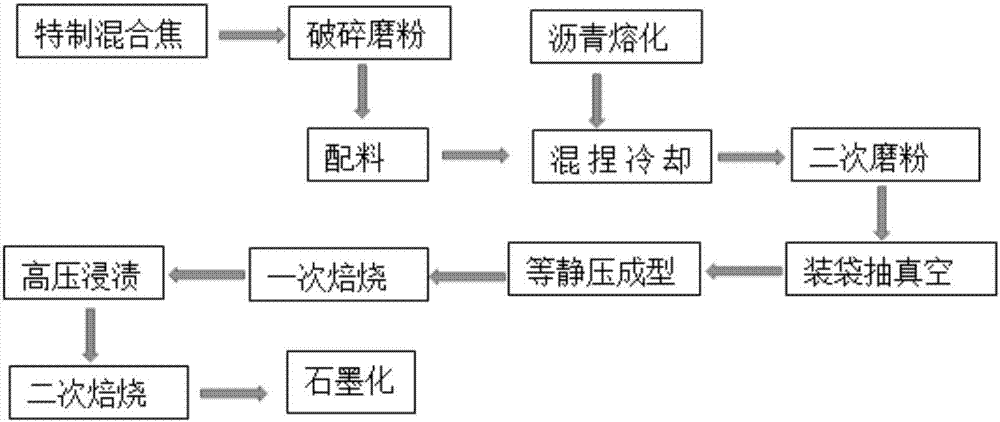

Method for short-term production of isotropic superfine structure isostatic pressing formed graphite

InactiveCN106892428AReduce production processShorten the production cycleGraphiteAdhesivePositive pressure

The invention relates to a method for short-term production of isotropic superfine structure isostatic pressing formed graphite. The method comprises the following steps: crushing mixed coke, performing primary powder milling, blending materials, melting asphalt, kneading and cooling, performing secondary powder milling, bagging and vacuuming, performing isostatic pressing formation, performing primary roasting, performing high-pressure soaking, performing secondary roasting, and performing graphitization, wherein the step of melting asphalt refers to that high-temperature modified asphalt is adopted as an adhesive. The preparation procedures of the method are greatly shortened, the production period is shortened by 90 days when being compared with that of a conventional domestic production procedure, and a short-term process is achieved. Unique positive pressure roasting of a bogie hearth furnace is adopted for the primary roasting, the temperature uniformity of the positive pressure roasting is greatly improved when being compared with that of conventional negative pressure roasting of an annular furnace, the pass percentage of the primary roasting is as high as 99.5%, and meanwhile the yield of the primary roasting is up to 94% or greater.

Owner:辽宁丹炭科技集团有限公司

Production process for full-sealing automatic production line for fluid sealant for construction

ActiveCN101402841AGood dispersionGood mixing effectOther chemical processesChemical industryProduction lineSealant

The invention discloses a production method of a seal glue full-seal automatic production line used for construction, which mainly comprises the steps of: conveying materials, feeding materials, dispersing and mixing materials, cooling and reducing temperature, adding accessory ingredients, discharging byproducts, cushioning and storing, mixing with a color paste and split charging, and the like. The production method overcomes the defects of domestic production technique; and the full-automatic configuration software industrial control system is adopted in the production process for continuously producing the products under completely sealed state.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

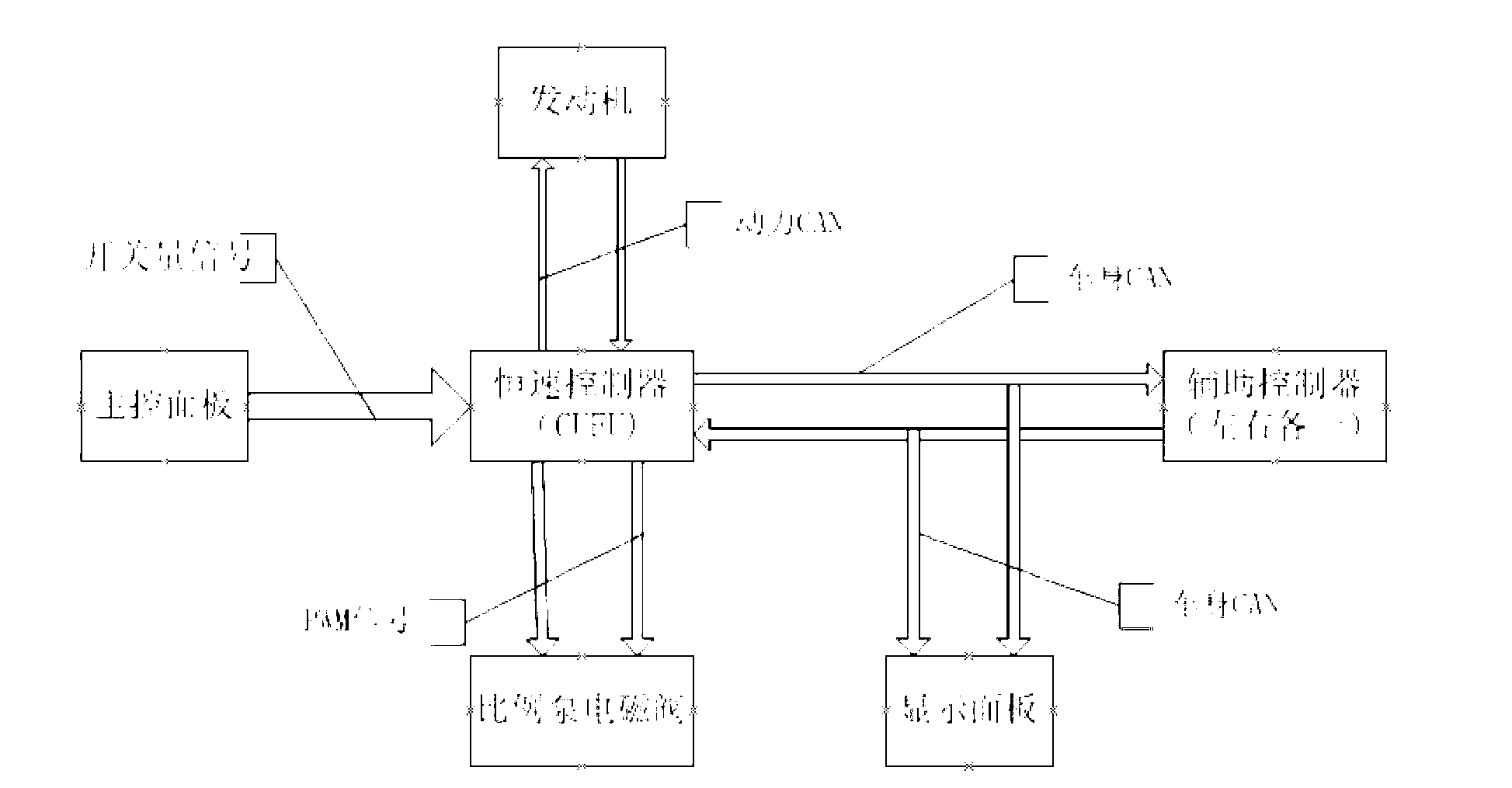

Constant speed control system of concrete mixing and transporting vehicle

ActiveCN102794823AGuaranteed homogeneityReduce manufacturing costCement mixing apparatusControl apparatusSolenoid valveControl system

The invention discloses a constant speed control system of a concrete mixing and transporting vehicle. The constant speed control system comprises a constant speed controller connected with a motor by a power bus, a main control unit connected with the constant speed controller, an auxiliary control unit connected with the constant speed controller, a display unit for displaying an operation situation of the main control unit at the real time, a variable discharge pump electromagnet valve connected with the constant speed controller, a hydraulic drive unit controlled by the variable discharge pump electromagnet valve and a rotation speed sensor used for detecting the rotation speed of a stirring cylinder. The constant speed control system facilitates the domestic production of whole electronic devices of the concrete mixing and transporting vehicle in our country, the production cost of the constant speed electronic speed control system is reduced, simultaneously the uniformity of the concrete is ensured and the energy consumption is reduced.

Owner:西安智源电气有限公司

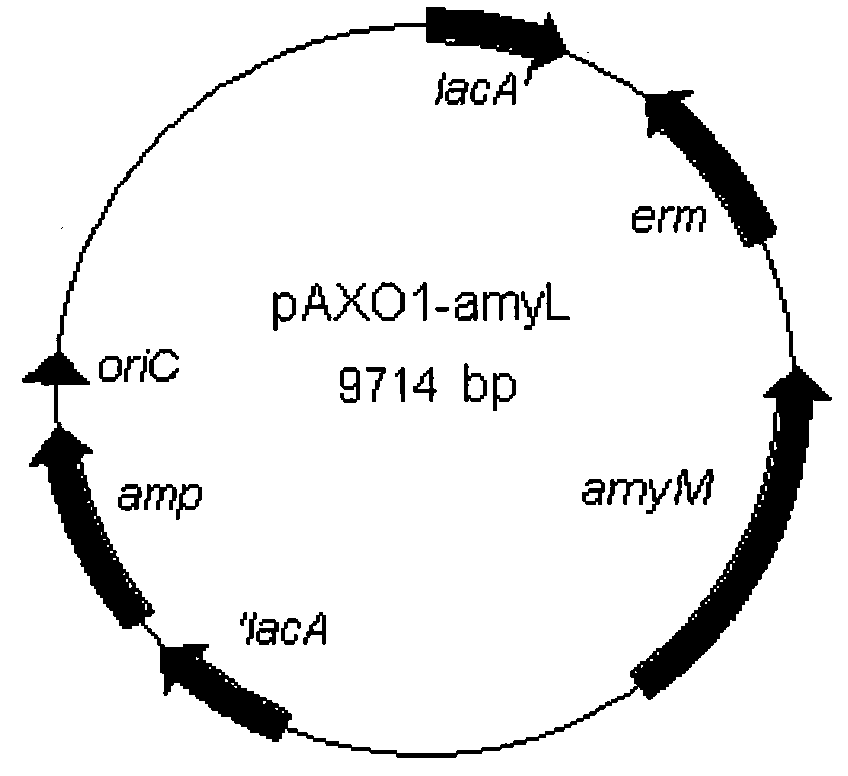

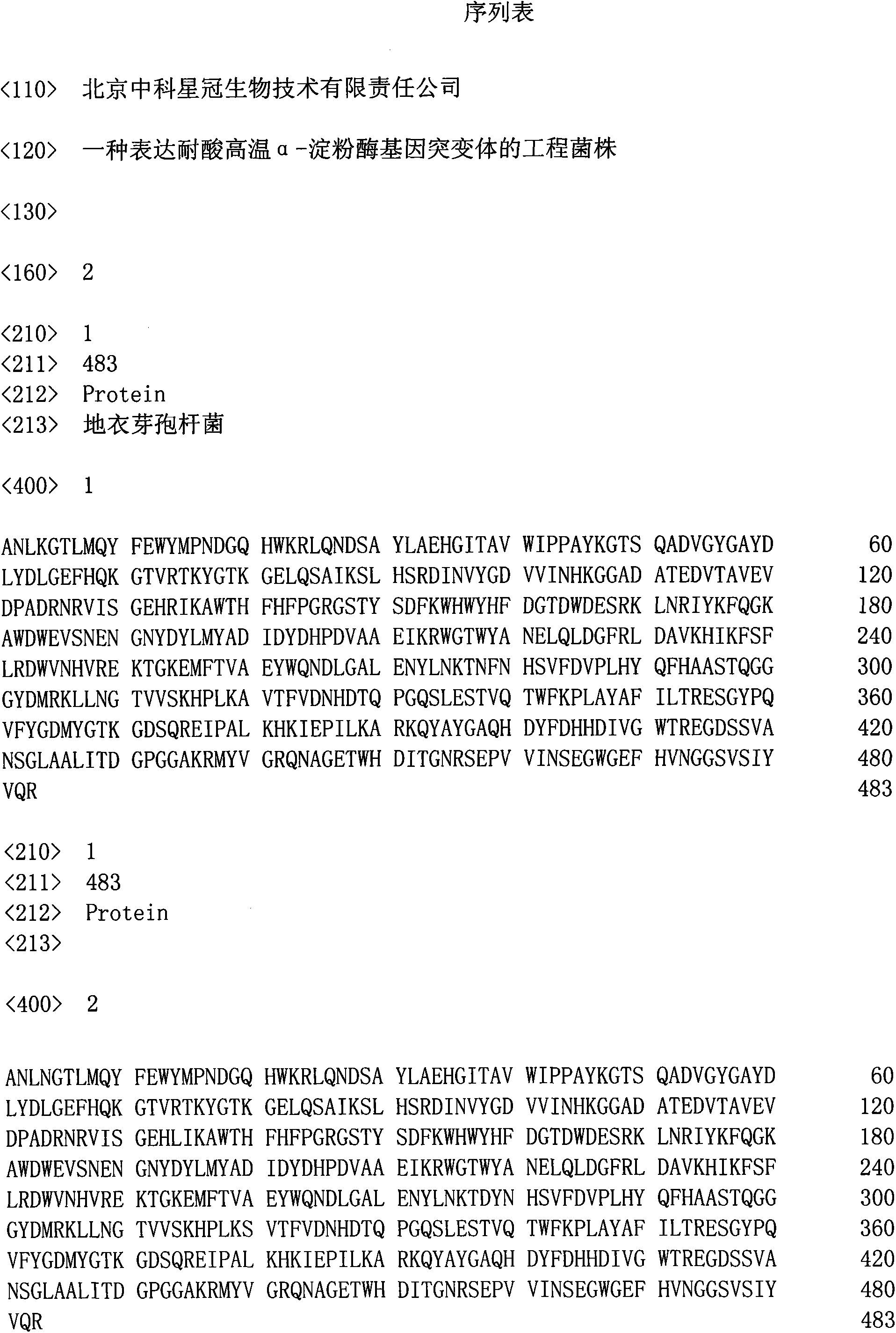

Engineering strain expressing acid-resistant high-temperature alpha-amylase gene mutants

InactiveCN103834606AStrong acid resistanceBacteriaMicroorganism based processesBacillus licheniformisBiotechnology

The invention discloses an engineering strain expressing acid-resistant high-temperature alpha-amylase gene mutants. The engineering strain is obtained by introducing a recombinant vector expressing acid-resistant high-temperature alpha-amylase genes into bacillus licheniformis, and performing screening to obtain the engineering strain with improved acid-resistant high-temperature alpha-amylase expression level; the acid-resistant high-temperature alpha-amylase has an amino acid sequence as shown in sequence 2 in the sequence table. The engineering strain has stronger capability of producing acid-resistant high-temperature alpha-amylase than current domestic production strains, has a unique identification label, and is a bacillus licheniformis production strain of acid-resistant high-temperature alpha-amylase that has great production and application value.

Owner:BEIJING ZHONGKE XINGGUAN BIOLOGICAL TECH

Hot-rolled rod online EDC water bath toughening treatment method for high-strength bridge cable galvanized steel wire

ActiveCN108165716ALargest production sizeWide range of production specificationsFurnace typesHeat treatment furnacesWater bathsHigh intensity

The invention relates to a hot-rolled wire rod online EDC water bath toughening treatment method for a high-strength bridge cable galvanized steel wire. After rolled materials are rolled through high-speed wire rods, and after spinning, the wire rods are subjected to linear thermal relaxation, and EDC water bath toughening heat treatment and on-line heat collection and heat preservation are carried out; the thermal relaxation temperature is 820 DEG C-880 DEG C, and the thermal relaxation time is 10s-60s; after water bath cooling is carried out on the wire rods after online wire heat relaxation, the water bath temperature is 93 DEG C-100 DEG C, and the water bath cooling time is 30s-90s; the temperature of the water outlet of the wire rods after being cooled through EDC water bath is controlled to be 520 DEG-600 DEG C; and after water is discharged from the wire rods, heat collection is carried out, the heat collection temperature is 200 DEG C-400 DEG C, and the heat collection and heatpreservation time is 30min-2h. The hot-rolled wire rod online EDC water bath toughening treatment method is suitable for producing the wire rods with the diameter of phi 12.0mm-phi 16.0mm for the bridge cable galvanized steel wires, the specification range of the wire rods is wider, the diameter of the wire rods is larger, the tensile strength of the galvanized steel wires for a bridge cable by the wire rods is larger than or equal to 1960MPa, the number of twisting times is larger than or equal to 15 times, and the cable galvanized steel wire with the performance fills the domestic production blank.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

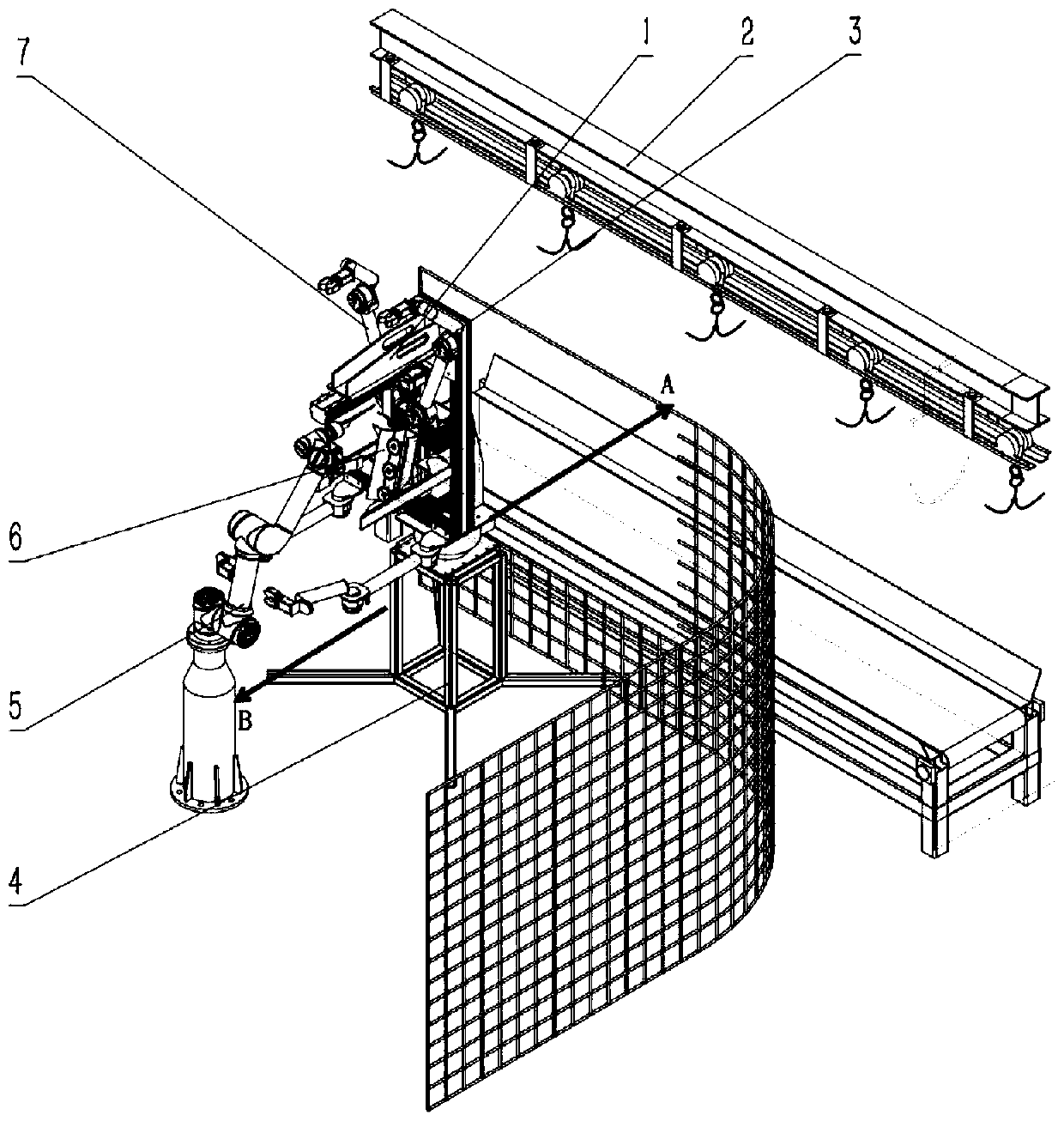

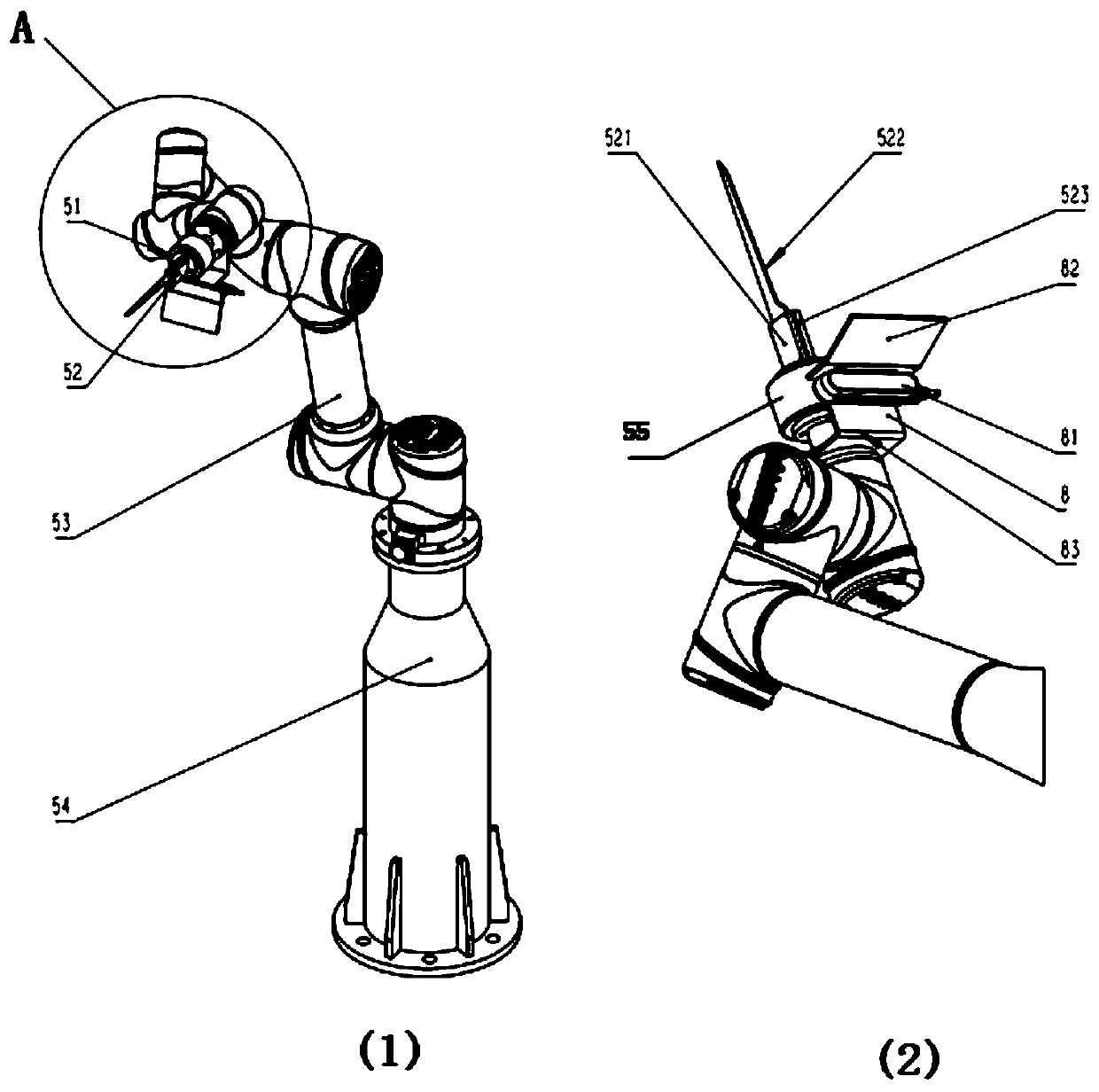

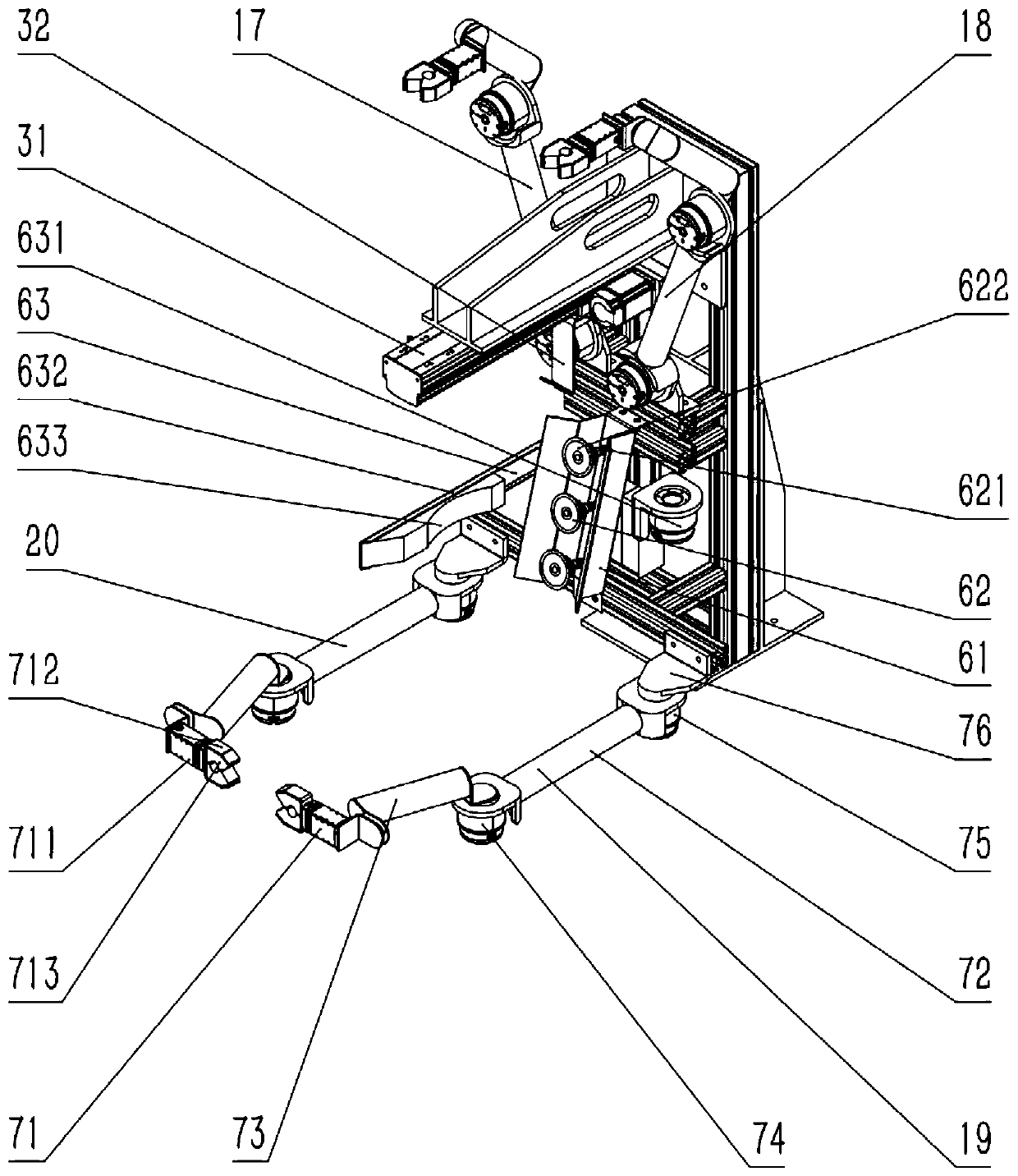

Livestock carcass leg-removing device

InactiveCN111096350AImprove securityEasy loadingMeat shaping/cuttingAnimal scienceAgricultural science

The invention belongs to the technical field of slaughtering and segmentation, and relates to a livestock carcass leg-removing device. The device comprises a mounting frame, a feeding mechanism, a rotary frame, a segmentation mechanism, a carcass clamp, a limb clamping mechanism, a machine vision device and an upper computer. According to the invention, four limbs are segmented from a complete livestock carcass, and the cutting part is accurately scanned in a segmentation process, so that the device has the advantages of small cutting force and rapid and accurate segmentation, and meets integration requirements of a domestic production line. Therefore, efficiency of segmenting four limbs is improved, and meat loss in a segmentation process is reduced.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com