Patents

Literature

421results about How to "Realize localization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

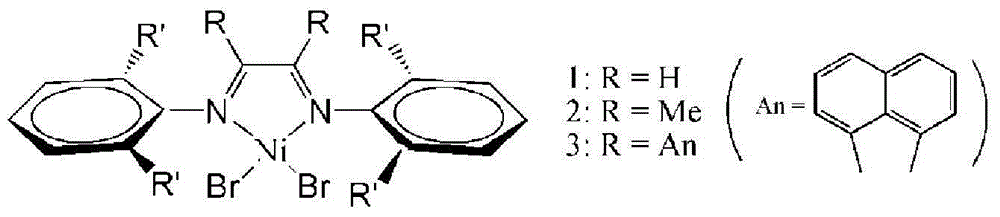

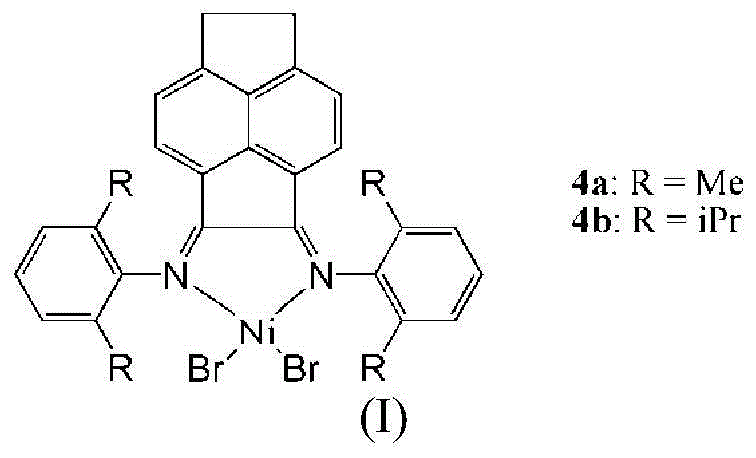

Ethylene acenaphthylene (alpha-diimine) nickel complex/alkyl aluminum chloride combined catalyst

The invention relates to the field of catalytic polymerization of olefins, aiming at providing an ethylene acenaphthylene (alpha-diimine) nickel complex / alkyl aluminum chloride combined catalyst. The combined catalyst consists of an ethylene acenaphthylene (alpha-diimine) nickel complex and alkyl aluminum chloride, wherein the molar ratio of aluminum in alkyl aluminum chloride to nickel in the ethylene acenaphthylene (alpha-diimine) nickel complex is 20-800:1. Compared with the prior art, the combined catalyst provided by the invention has higher activity and better stability in catalyzing polymerization of ethylene and propene. According to the invention, alkyl aluminum chloride is used as a cocatalyst. Compared with that of using methylaluminoxane or modified methyl aluminoxane, cost is significantly reduced, and in addition, localization of alkyl aluminum chloride is realized, saving the need of importing.

Owner:ZHEJIANG UNIV

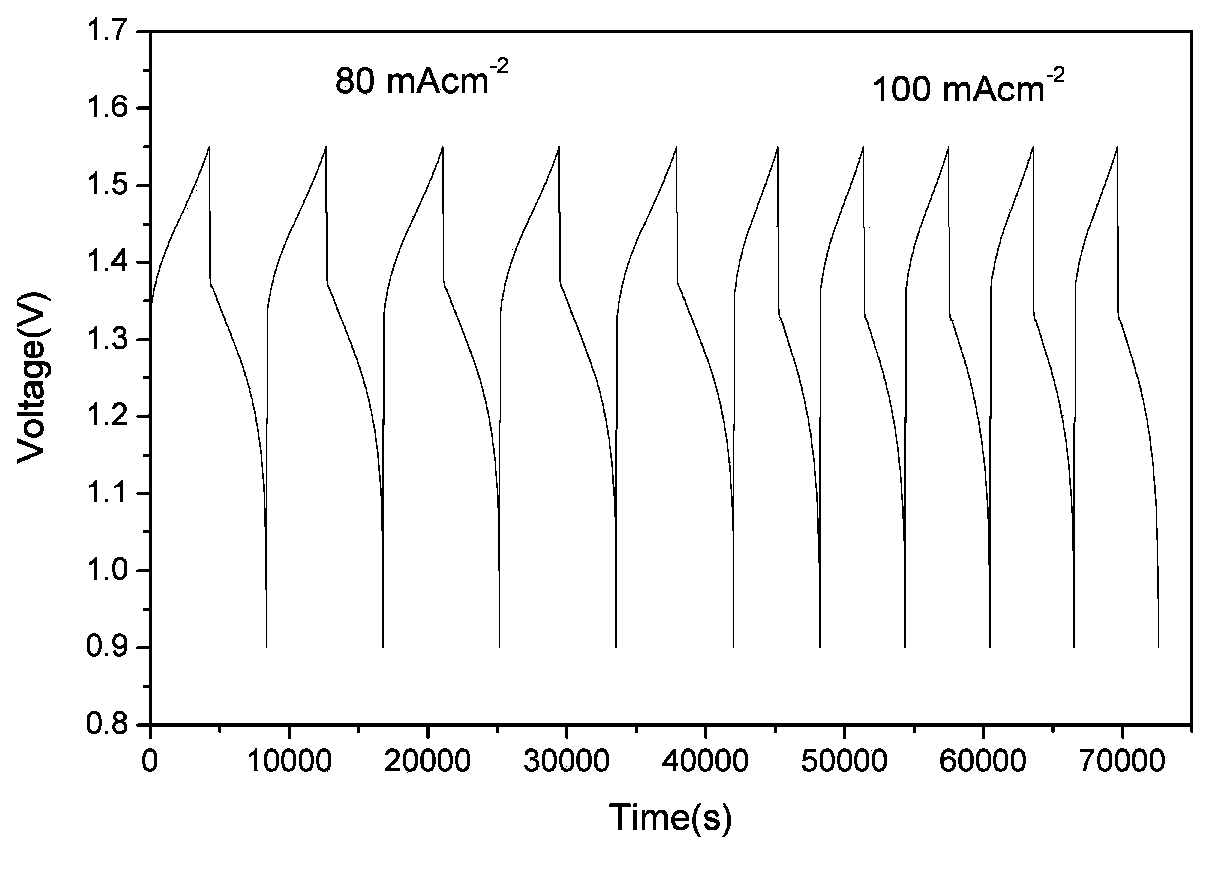

Bipolar plate for liquid flow energy storage battery and preparation method

ActiveCN103633336AEasy to buildReduce contact resistanceCell electrodesElectrical batteryInternal resistance

The invention relates to a bipolar plate for a liquid flow energy storage battery and a preparation method. The bipolar plate employs a carbon plastic composite plate with a thickness of 0.5-5mm as a matrix material. Conducting layers with a thickness of 1-1000 microns are coated on the surface of one side or surfaces of two sides of the matrix. The bipolar plate combines advantages of the carbon plastic composite plate and a graphite plate, decreases the contact resistance between an electrode and the bipolar plate, and finally decreases the Ohm internal resistance of the liquid flow energy storage battery. The bipolar plate raises the energy efficiency and the voltage efficiency of the liquid flow energy storage battery, and therefore the working current density is increased, thus weight, volume and cost of a battery with the same output power are all decreased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

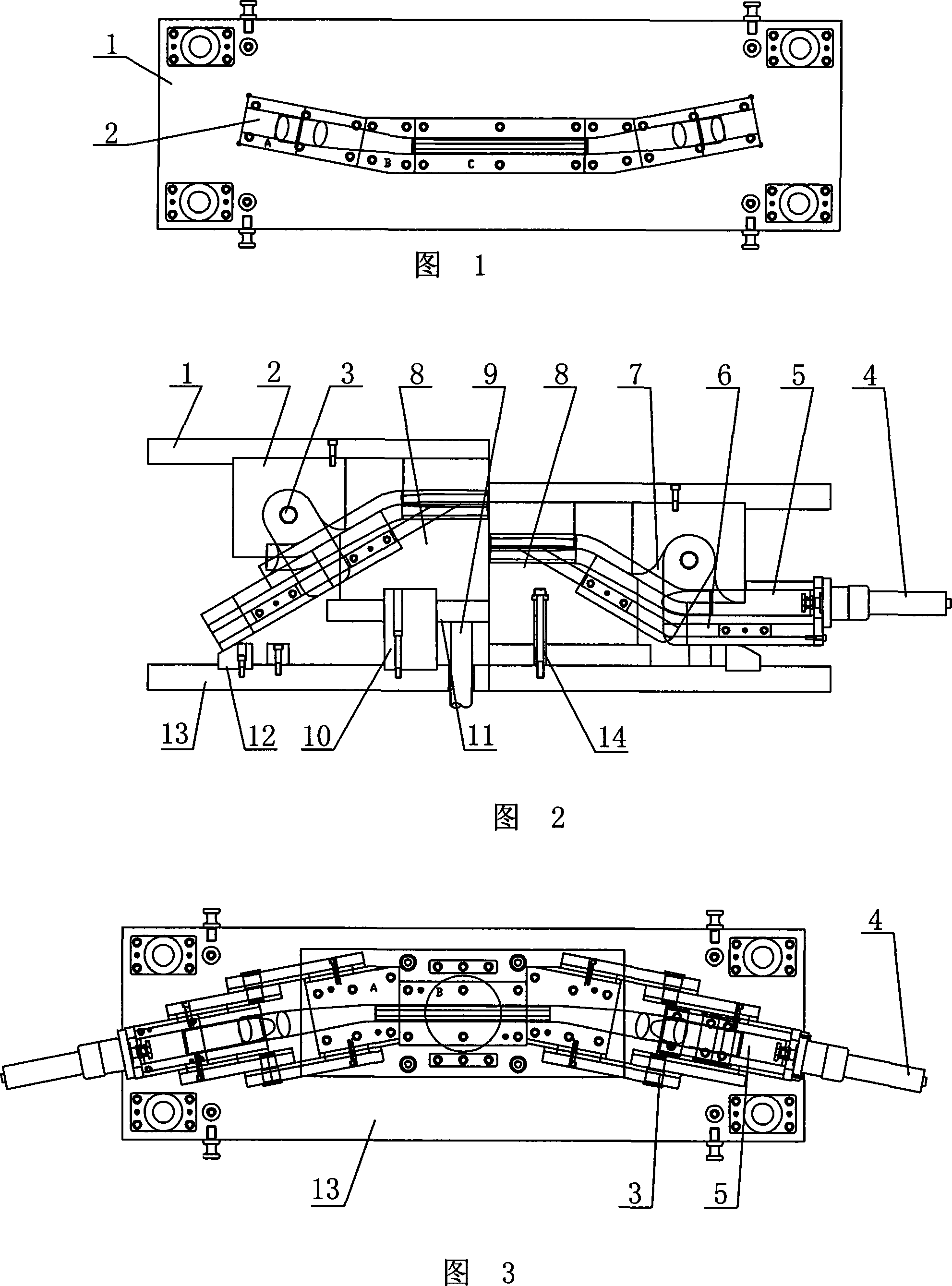

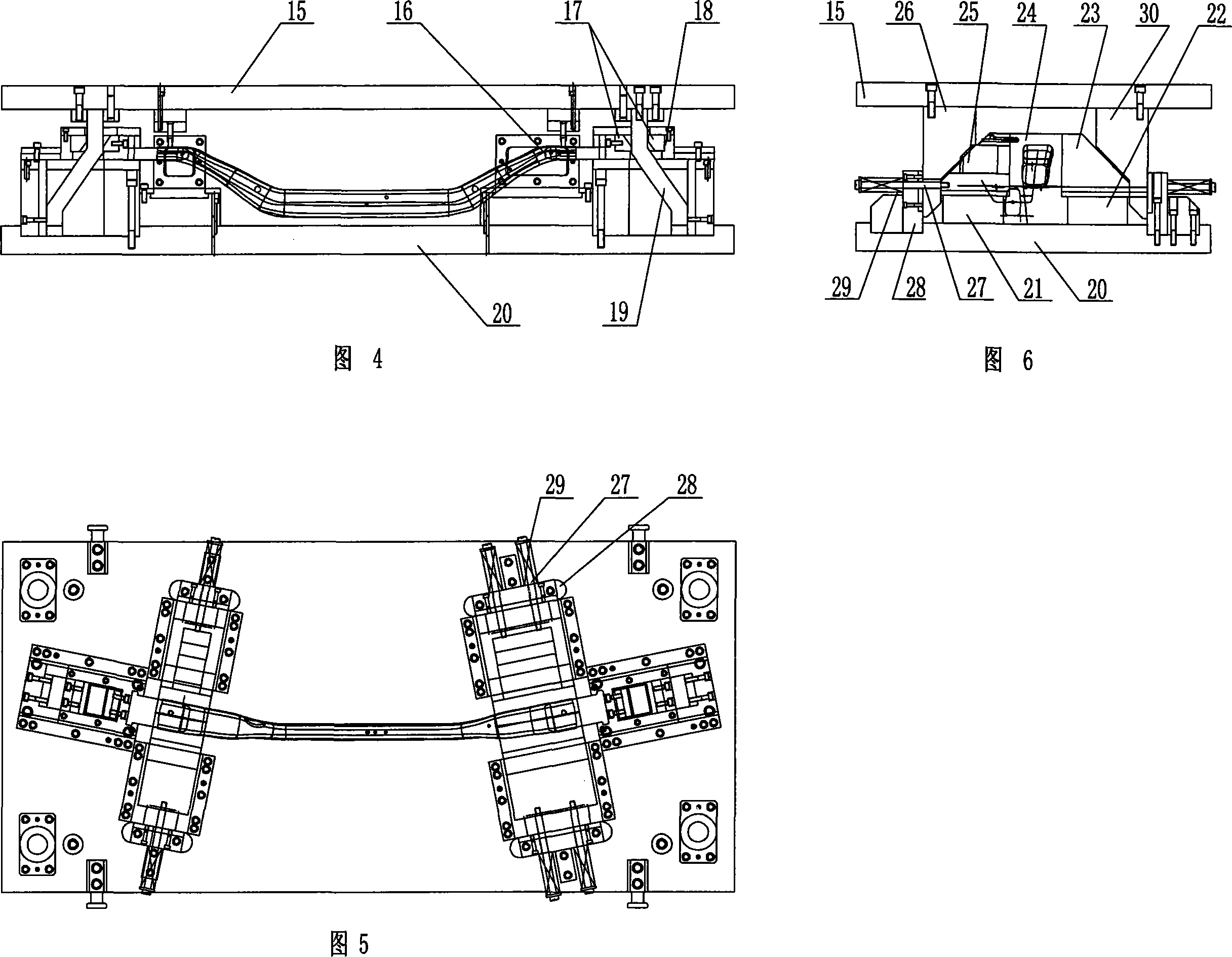

Vehicle rear axle assembly breast beam production method and special-purpose mold therefor

InactiveCN101234466AImprove performanceExtended service lifeShaping toolsVehicle componentsHydraulic cylinderPunching

The invention relates to a manufacturing method of a front beam of a vehicle rear axle assembly. The front beam of the vehicle rear axle assembly processed by the method is good in performance and long in service life. The invention also provides a special mould of the manufacturing method of the front beam of the vehicle rear axle assembly. The manufacturing method comprises the following steps: blanking, bending pipes, shaping of the middle part and local bending, shaping, reshape punching and drilling on heads of two ends of a workpiece. The special mould consists of a shaping mould and a local bending mould, while the local bending mould consists of an upper mould structure and a lower mould structure. The special mould is characterized in that a fixed stent is arranged on the lower mould; an overturn-board stent is arranged on the fixed stent through a shaft; a hydraulic core pulling device is arranged on the overturn-board stent and a core pulling stick is connected with a piston rod of a hydraulic cylinder through a universal joint; a special shaping mould which consists of an upper mould and a lower mould is characterized in that a wedge block is fixed on a slide block; a core stick is fixed on the slide block; a side-arranged Z-font oblique wedge punctures the wedge block, and the upper straight end part of the oblique wedge is connected with the upper mould while the lower straight end part of the oblique wedge extends into a through hole of the lower mould, which can guarantee the propulsion and the restoration of the core stick along the horizontal direction driven by the wedge block.

Owner:WUXI DAWN DIE & STAMPING

Electric locomotive pantograph copper-soaking carbon contact strip producing method

ActiveCN104774012AImprove conductivityHigh mechanical strengthPower current collectorsShock resistanceNitrogen gas

The invention discloses an electric locomotive pantograph copper-impregnated carbon contact strip producing method. The method comprises the steps that 1, pitch coke powder, graphite powder, siliconized graphite powder and high temperature pitch are mixed according to the proportion to be ground into powder; the mixed powder is prepressed into a stage stock column, and then the stage stock column is solidified and squeezed to be molded and roasted, so that a composite carbon contact strip is obtained; 2, the composite carbon contact strip is cleaned and dried, then is cooled and placed into a graphite crucible, and is placed in an electric furnace at temperature of 1300-1400 DEG C to be preheated; copper liquid is poured into the crucible to soak the composite carbon contact strip, then the crucible is placed in an oil press cover, nitrogen is led in, heat preservation is kept for 3-5 min under the specific intensity of pressure, and finally cooling is carried after pressure releasing. According to the electric locomotive pantograph copper-impregnated carbon contact strip producing method, the electroconductibility of the copper-impregnated carbon contact strip is improved, the electrical resistivity is lowered, the mechanical strength of the carbon contact strip and copper impregnated angle can be increased, then the carbon contact strip abrasive resistance and self-lubrication are improved, the copper-impregnated carbon contact strip is more resistant to abrasion, main line damage and block dropping are avoided, the shock resistance is high, and the service life of the copper-impregnated carbon contact strip is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

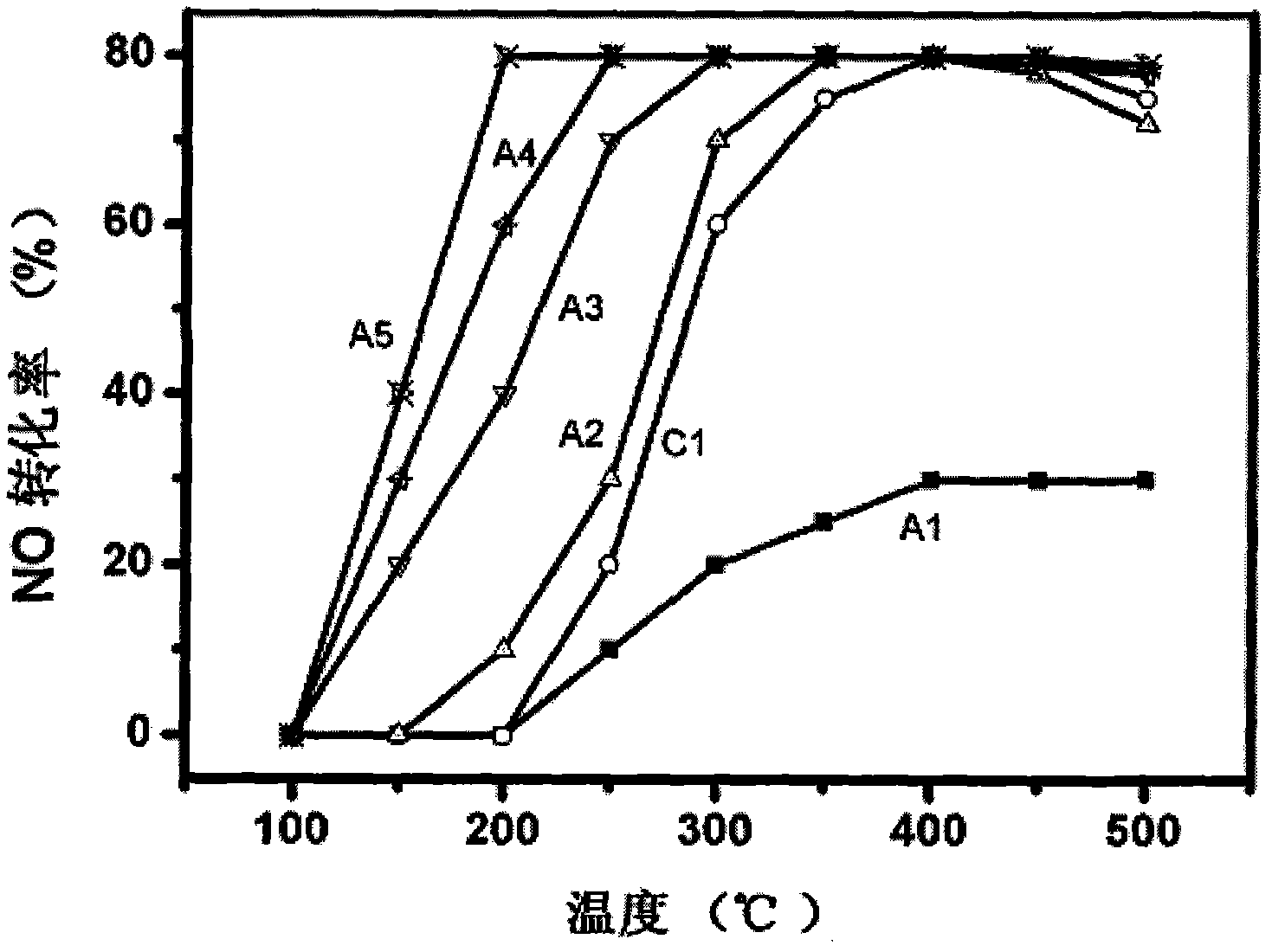

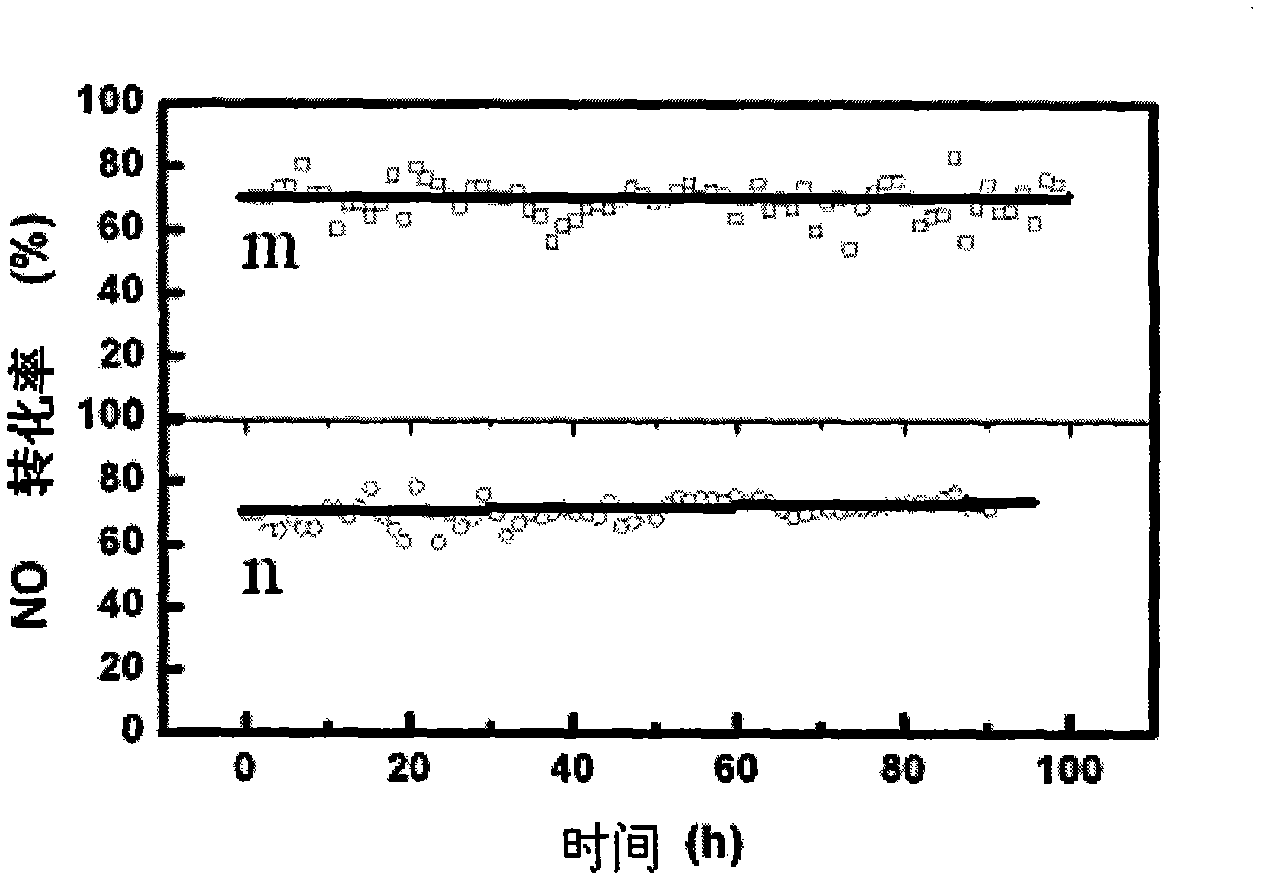

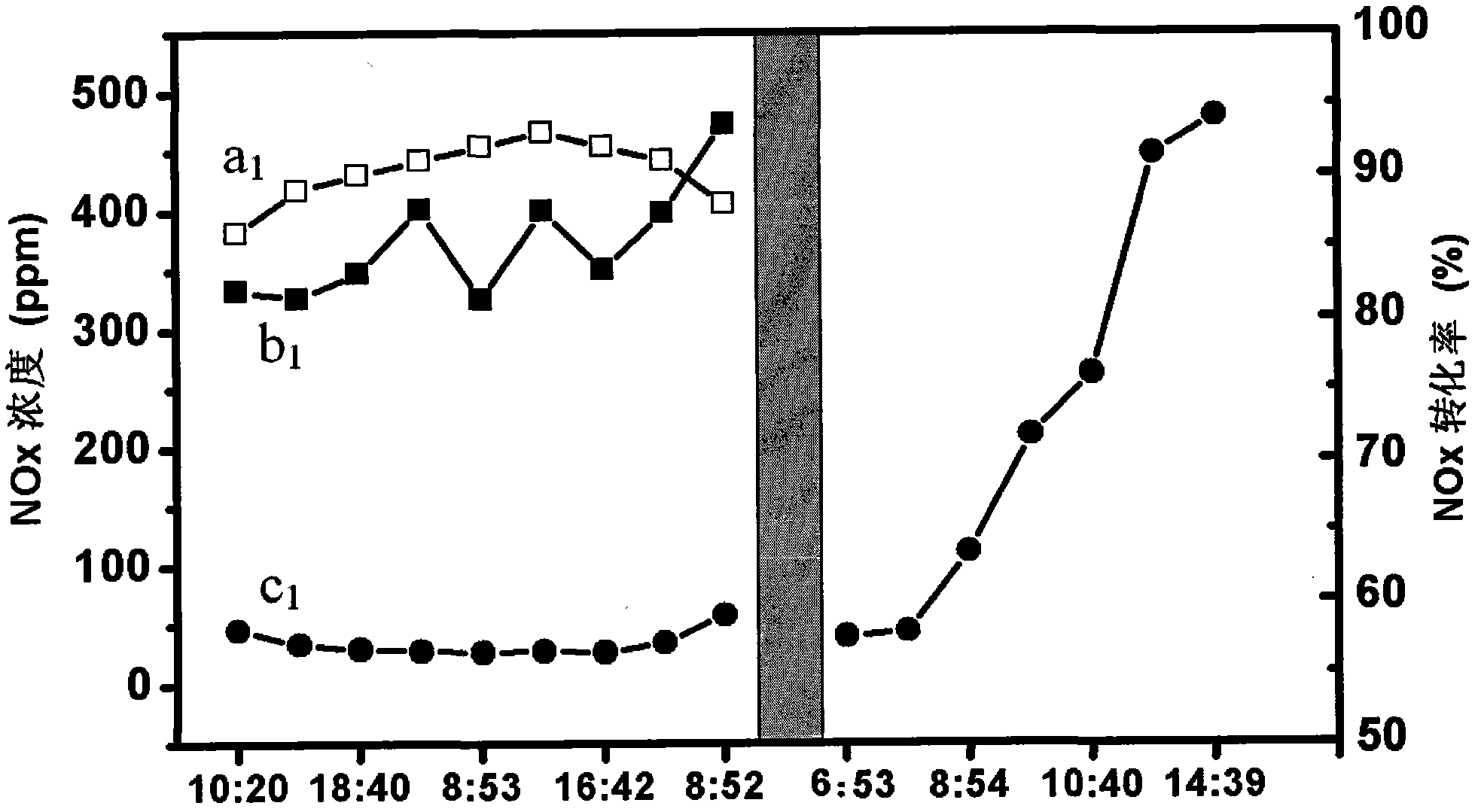

Preparation method of denitration catalyst

InactiveCN102463110ASmall grainReduce oxidationDispersed particle separationCatalyst activation/preparationSolventTungsten

The invention provides a preparation method of a denitration catalyst, comprising the following steps of: (1) dissolving or dispersing a titanium source precursor and a tungsten source precursor in water to obtain a precursor solution; (2) pouring the precursor solution into a solvent thermal autoclave with stirring for hydrothermal reaction; (3) filtering, washing and drying after the hydrothermal reaction so as to obtain the titanium-tungsten powdered denitration catalyst. According to the preparation method, the hydrothermal synthesis method is adopted to introduce an active component in the mode of in situ synthesis. As the active component is characterized by small crystal grain, low oxidizability and large specific surface, the component can maintain a monolayer dispersion state in a large range. By the titanium-tungsten powder hydrothermal synthesis technology provided by the invention, nationalization of key raw materials of the denitration catalyst can be realized, thus substantially reducing the manufacturing cost of present denitration catalysts.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

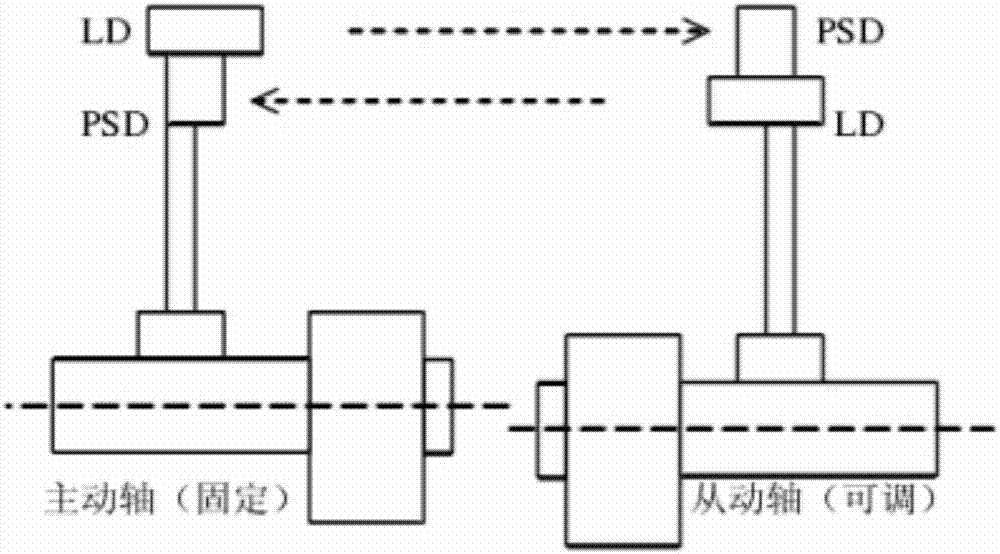

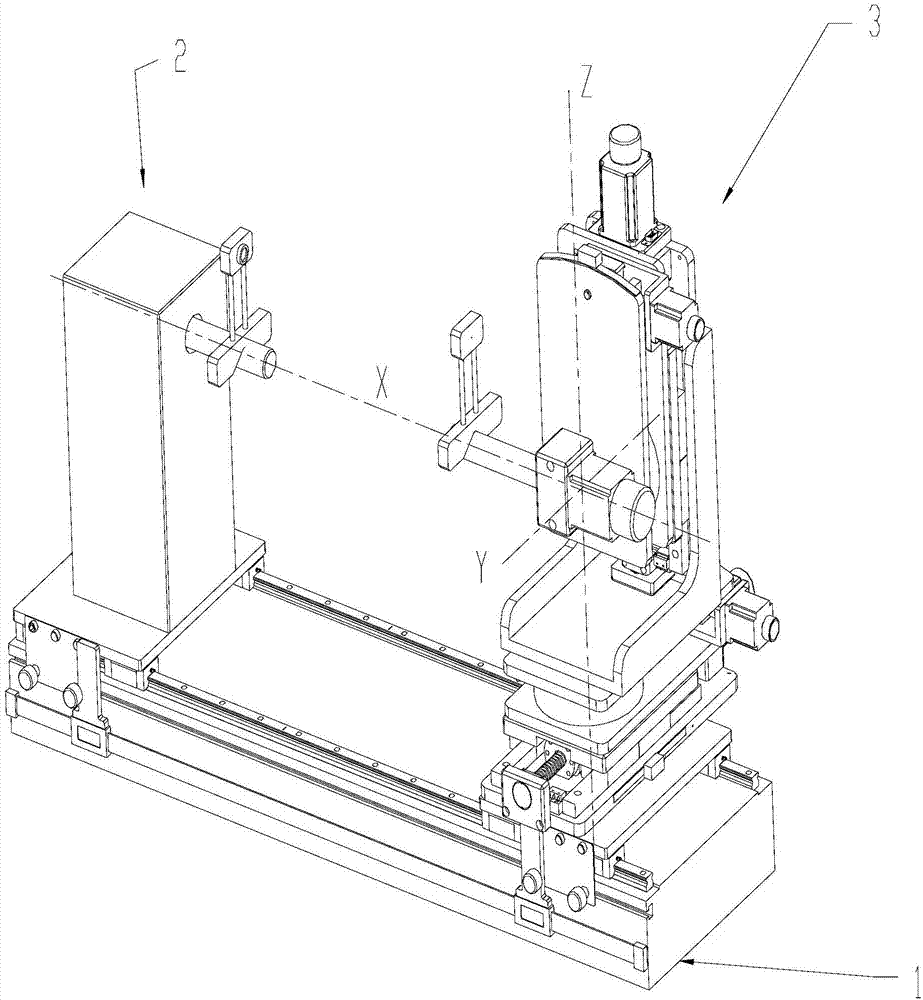

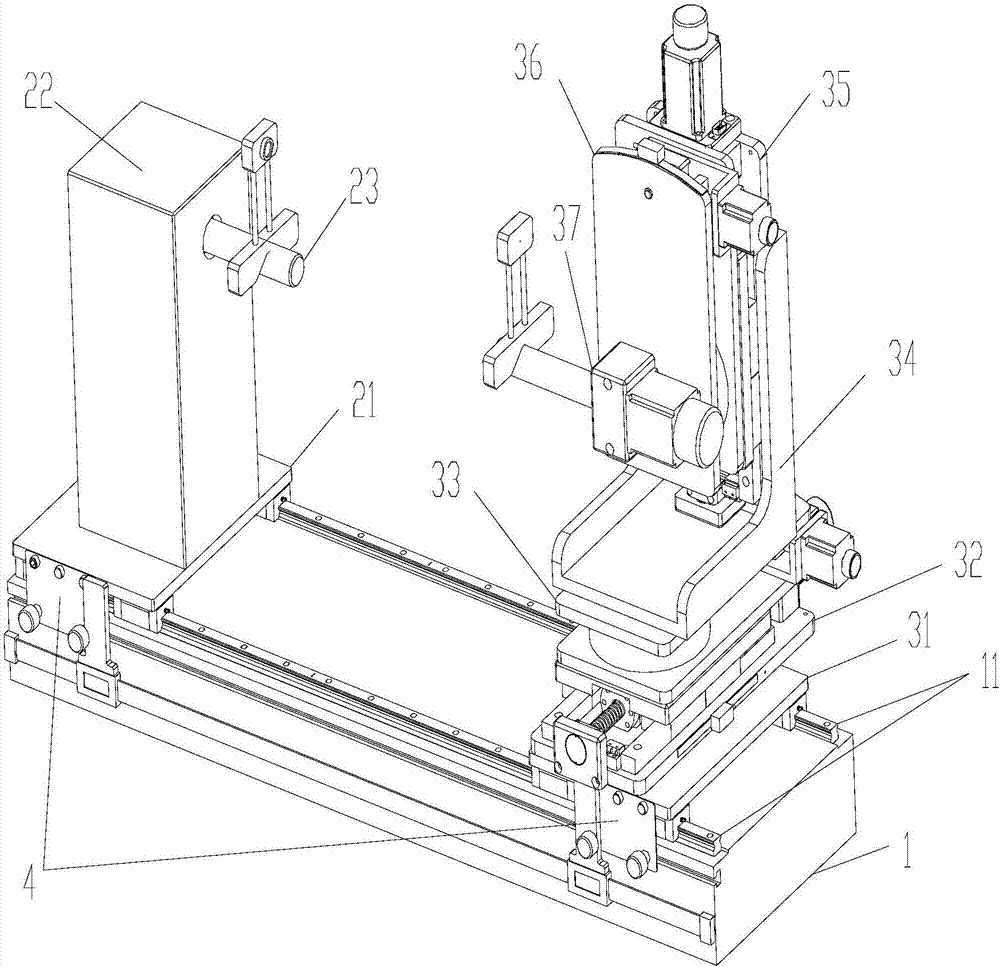

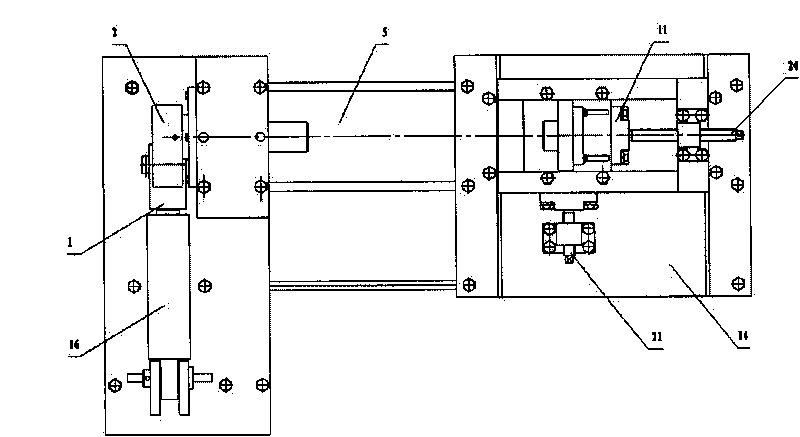

Calibration device of laser alignment device and method for measuring indication errors of laser alignment device through calibration device

The invention discloses a calibration device of a laser alignment device and a method for measuring indication errors of the laser alignment device through the calibration device. The calibration device comprises two mutually independent rotation shafts capable of rotating for 360 degrees. One of the rotation shafts is used as a reference shaft and the other rotation shaft is capable of moving, pitching and deflecting in the horizontal direction and vertical direction. By setting the rotation angles of the rotation shafts, and adjusting the horizontal and vertical displacement quantity, pitching quantity and deflection quantity of the other rotation shaft, measurement of the displacement quantity in the horizontal and vertical directions, the rotation angle quantity of an inclinometer and indication errors of alignment deviation of a position sensitive sensor of the laser alignment device can be achieved. According to the invention, operation states of the laser alignment device in actual working processes can be precisely simulated; the standard alignment deviation quantity of measurement shafts can be displayed in a real-time and direct manner; calibration results are quite precise; and operability of the measurement process is quite high.

Owner:广东省计量科学研究院(华南国家计量测试中心)

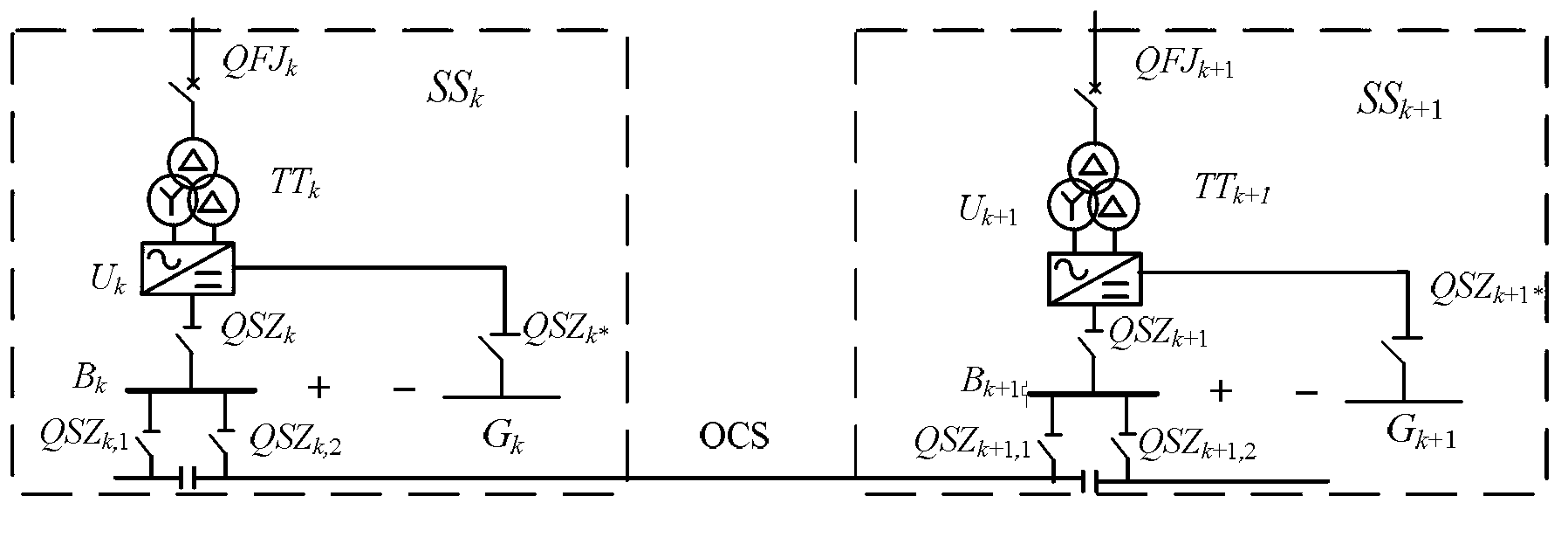

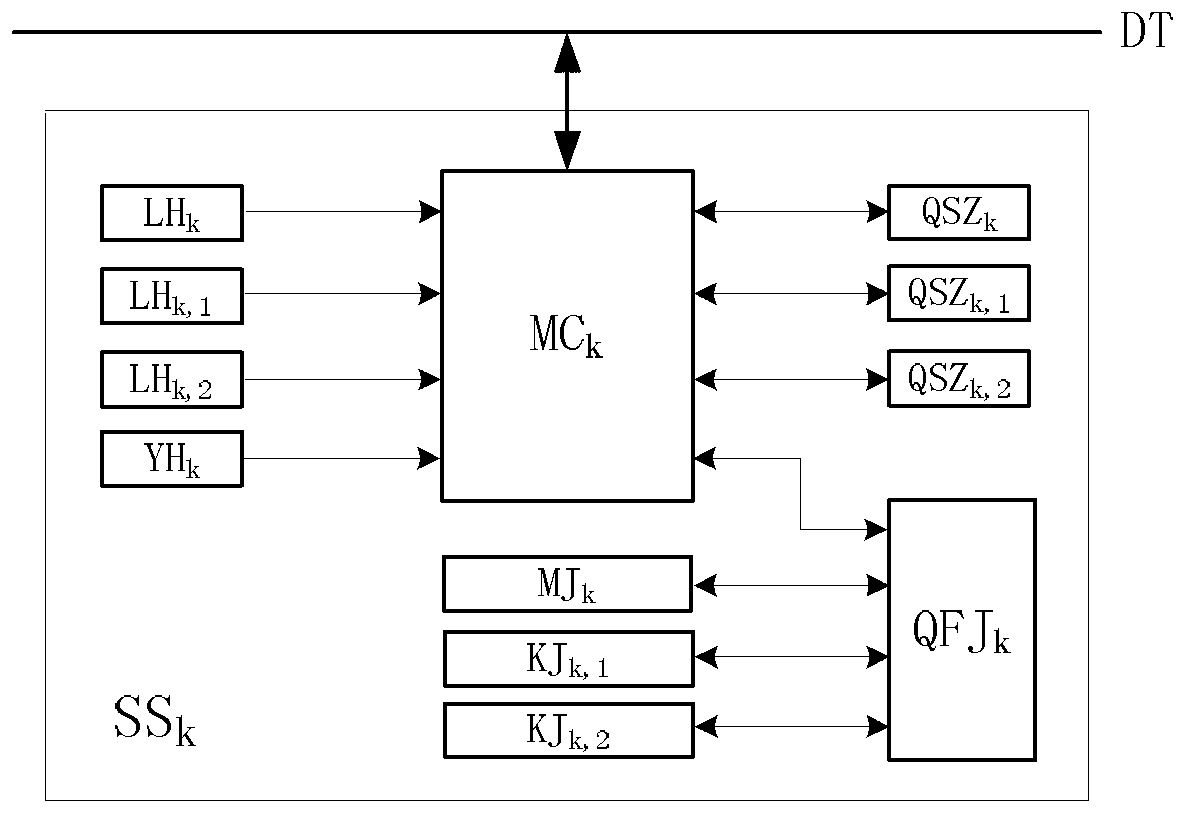

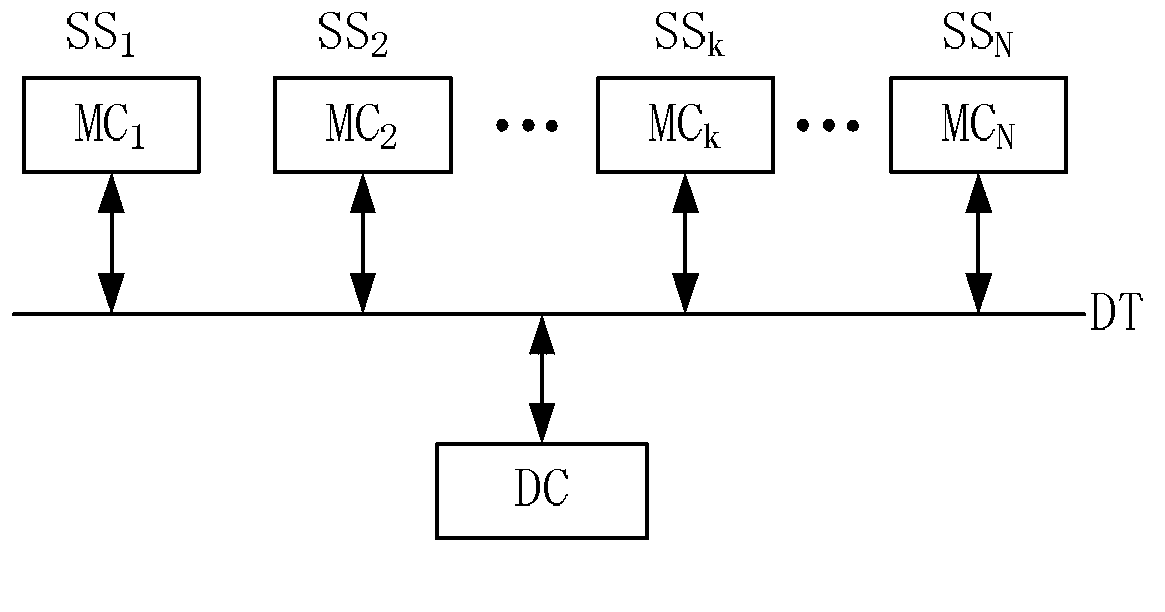

Direct current traction power supply system and protective method

ActiveCN103311910ARealize localizationAvoid serious consequences of breaking failureEmergency protective circuit arrangementsDc circuit breakerTraction power supply

The invention discloses a direct current traction power supply system and a protective method, and utilizes direct current protective device outlet information and a short circuit fault mark value as a criterion to judge various direct current short circuit faults. When the short fault occurs, an alternating current incoming line breaker closest to a fault element is subjected to brake separating; if the sum of the fault mark values of the element, measured and computed after the brake separating, is more than or equal to 1, permanent fault is determined, the alternating current incoming line breakers of other traction substations in the whole line are subjected to brake separating, and related direct current isolation switches are subjected to brake separating to enable the alternating current incoming line breakers of the traction substation in the whole line to be subjected to switching on, so the power supply of the system can be restored; and if the sum of the fault mark values of the element is smaller than 1, the fault is instant, and related breakers are switched on for restoring the power supply of the system. The direct current traction power supply system and the protective method are capable of omitting the direct current breakers and saving investment, convenient to implement, suitable for carrying out new line construction or old line transformation in occasions where the lines are not very long (for example in 20m and less than 10 traction substations). When the line is overlong, the traction power supply system can be subjected to partition by a small amount of direct current breakers.

Owner:SOUTHWEST JIAOTONG UNIV +1

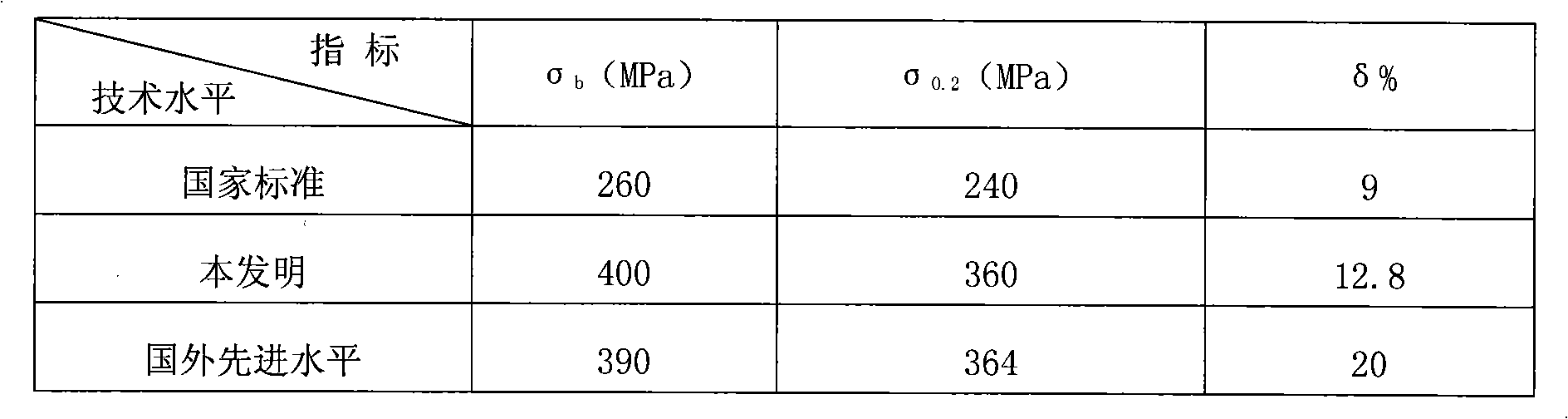

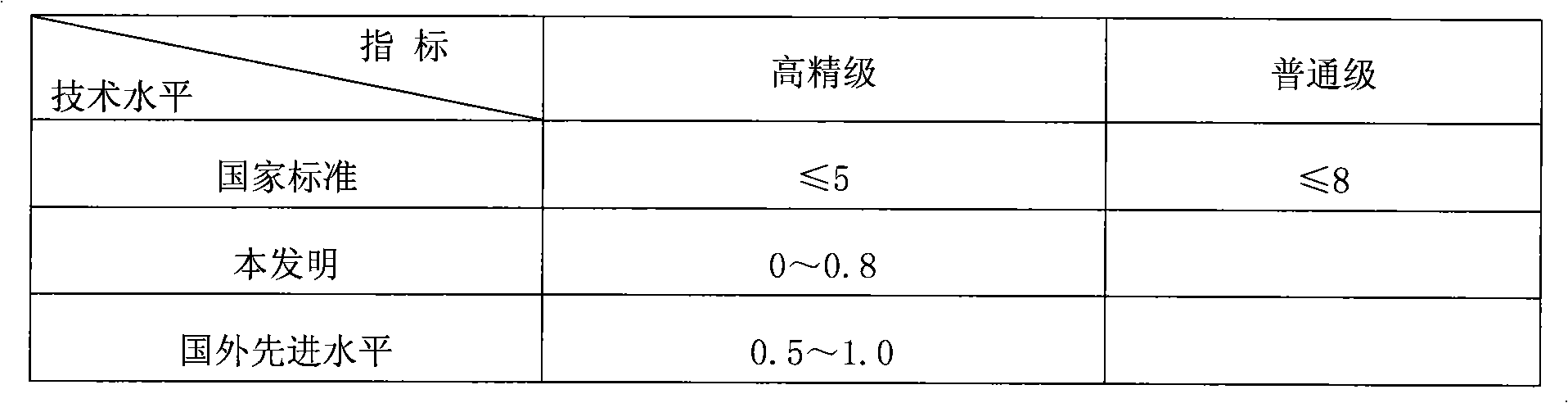

Production process of ABS valve body material for cars

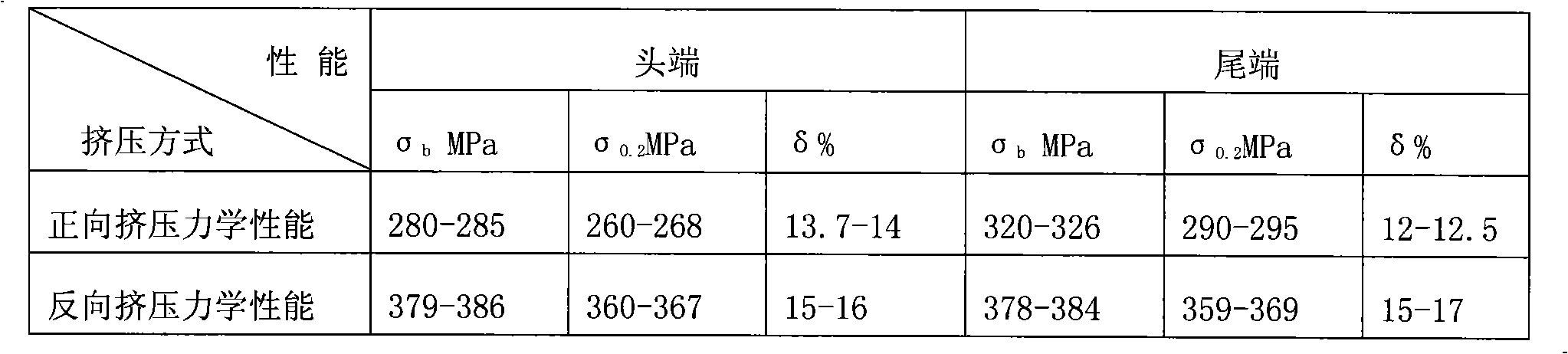

The invention provides a production process of the automobile ABS valve body material, which includes the following steps: preparing raw materials, melting, refining and standing, filtering and casting, homogenizing, ingot processing, ingot heating, indirect extruding, on-line water quenching, stretch rolling, artificial aging and finished product inspecting. By adopting the optimized alloy component in combination with indirect extrusion technology and on-line heat treatment technology, particularly the indirect extrusion technology, the inventive production process achieves the high uniformity of material structure, head-and-tail measures and mechanical property, thereby solving the problems of 6061 alloy coarse grain zone and mechanical property, increasing the production yield index, reducing the energy consumption of unit product, obtaining the material of which the mechanical property, metallographic structure, dimensional precision and the surface quality reach the advanced level of foreign similar products, achieving the import substitution of the material and laying the foundation of automobile localization.

Owner:西北铝业有限责任公司

Method and system for mobile robot to self-establish map indoors

InactiveUS20180172451A1Ensure effectivenessEasy accessInstruments for road network navigationNavigational calculation instrumentsComputer scienceMobile robot

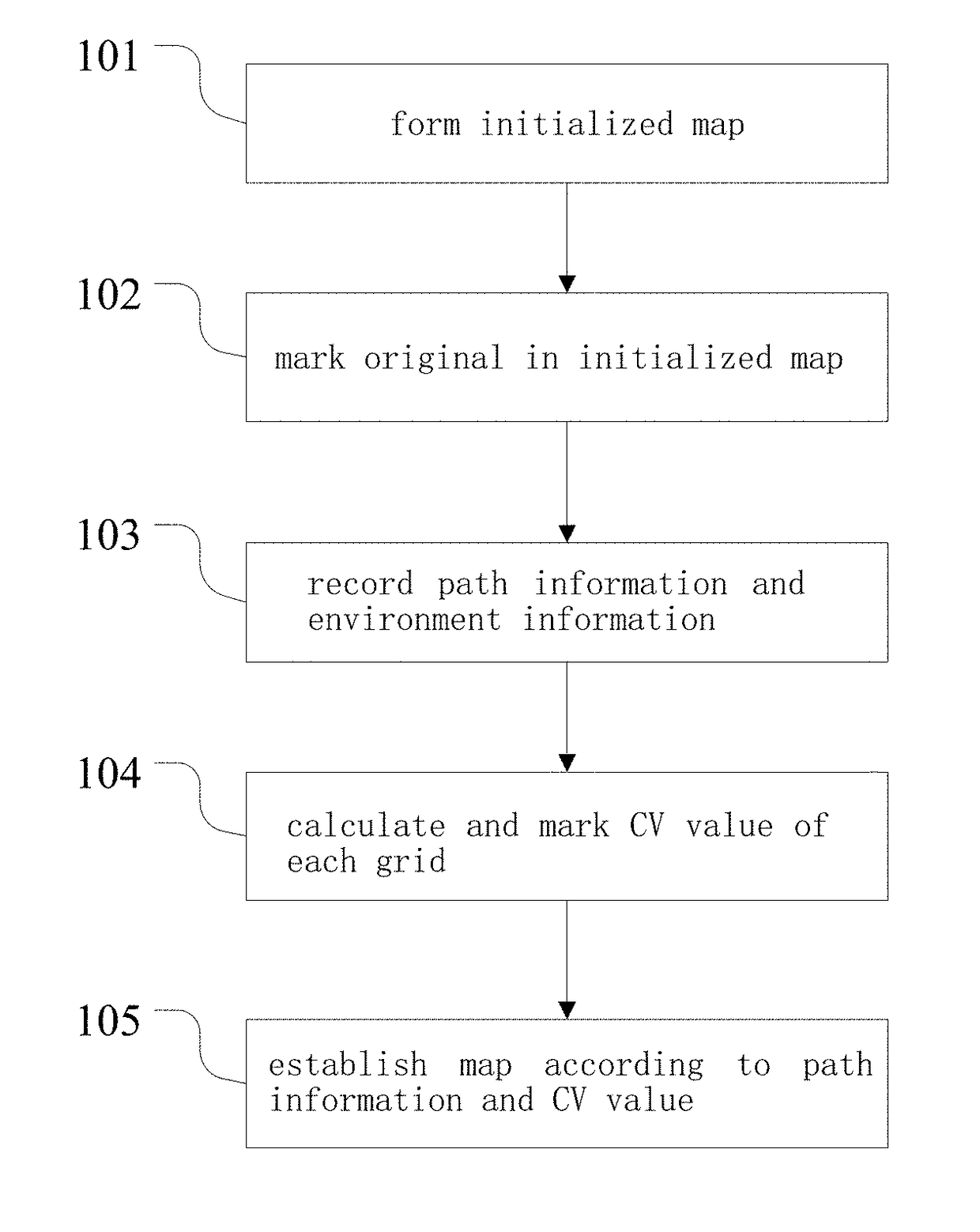

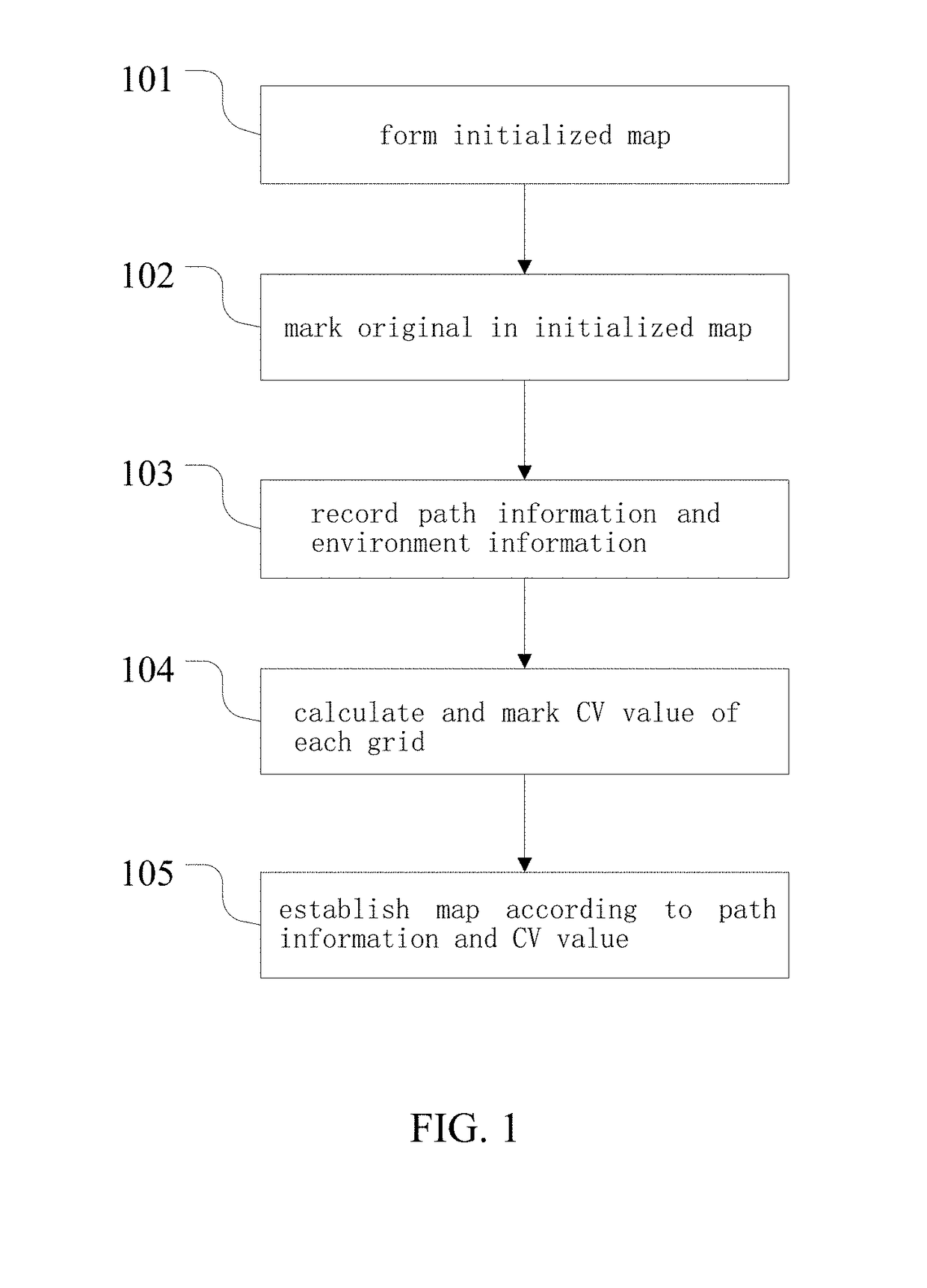

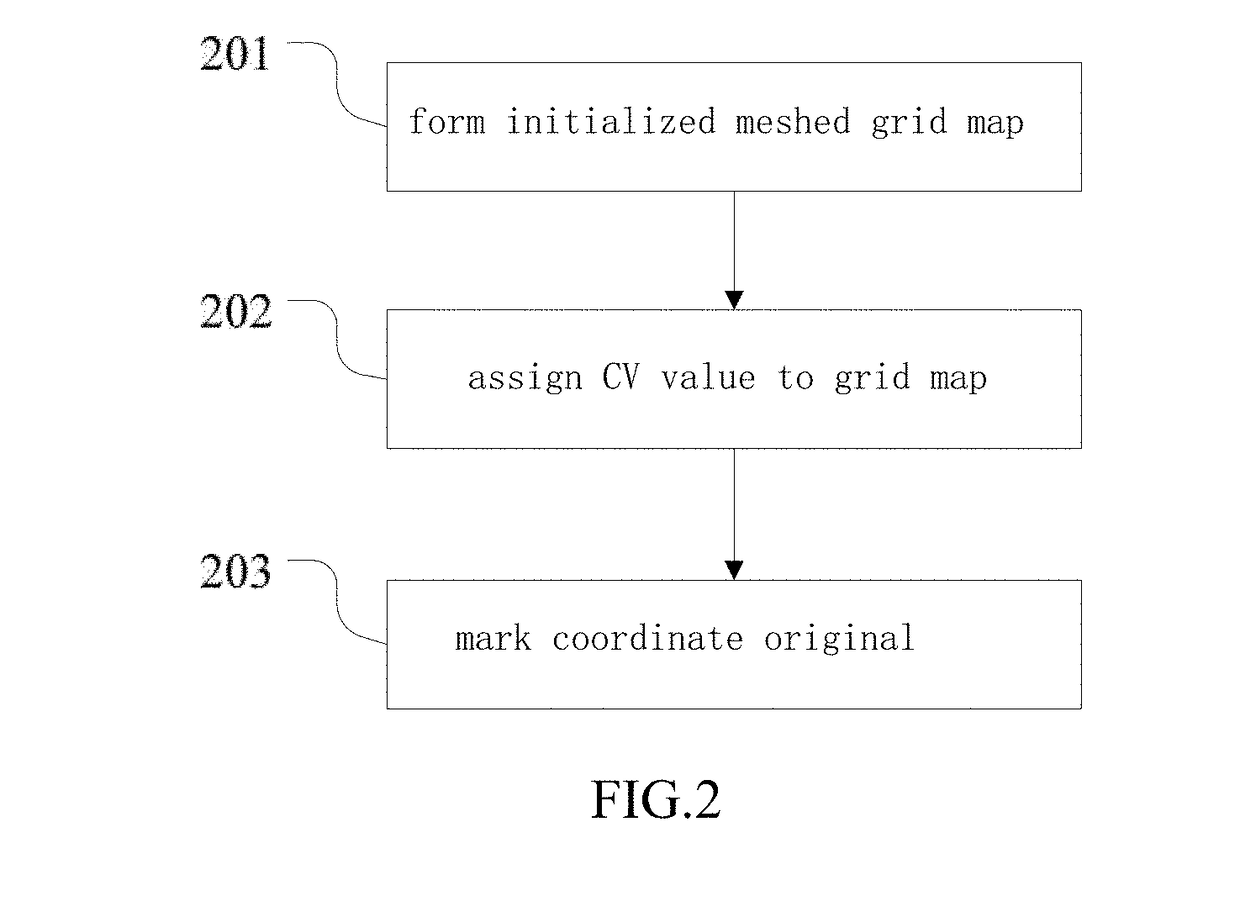

A method and a system for a mobile robot to self-establish a map indoors are provided, and the method comprises: forming an initialized map (101); marking a coordinate origin in the initialized map (102); causing the robot to travel throughout indoor accessible regions to record path information and environment information (103); causing the robot to calculate and mark a CV value of each grid in the map (104); and establishing the map according to the path information and the CV value (105), the path information and the CV value being obtained through calculation by using a mathematic algorithm. By adopting a grid map to perform modeling, real-time adjustment and correspondence of an indoor environment and grid information are realized and effectiveness of a map model is ensured; further, the grid map is easy to be maintained and is convenient for quick access of map data.

Owner:BEIJING EVOLVER ROBOTICS CO LTD

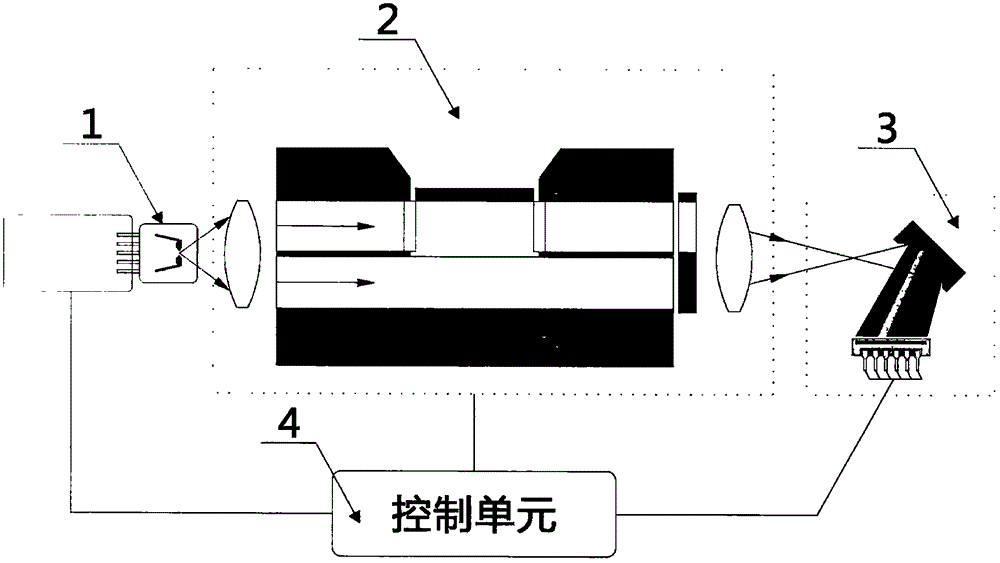

Online water quality monitoring device and method based on full spectra

ActiveCN106198424ARealize online monitoringRealize the localization of online monitoringColor/spectral properties measurementsAdditive ingredientTurbidity

The invention relates to an online water quality monitoring device and method based on full spectra. The device comprises a pulse xenon lamp, a cleaning module, a spectrum measuring module and a control unit. One end of the cleaning module is connected with the pulse xenon lamp, the other end of the cleaning module is connected with the spectrum measuring module, the control unit controls the pulse xenon lamp to emit pulse light, controls the cleaning module to clean a measuring surface as needed and carry out light path switching, and controls the spectrum measuring module to read the light signal intensity of each waveband. According to the online water quality monitoring device and method based on full spectra, ultraviolet visible full waveband absorbing spectra are adopted for measuring the water pollution condition, factors such as COD, BOD, TOC, nitrate, nitrite, the turbidity and chromaticity can be measured, and the online water quality monitoring device and method based on full spectra have the advantages of being high in measuring precision, short in measuring time, large in number of monitoring factors, free of a reagent and secondary pollution and the like; the changing condition of water pollution is reflected in real time, and corresponding chemical models can be established according to ingredients of field water samples to meet the demands for measuring different water bodies.

Owner:深圳市七善科技有限公司

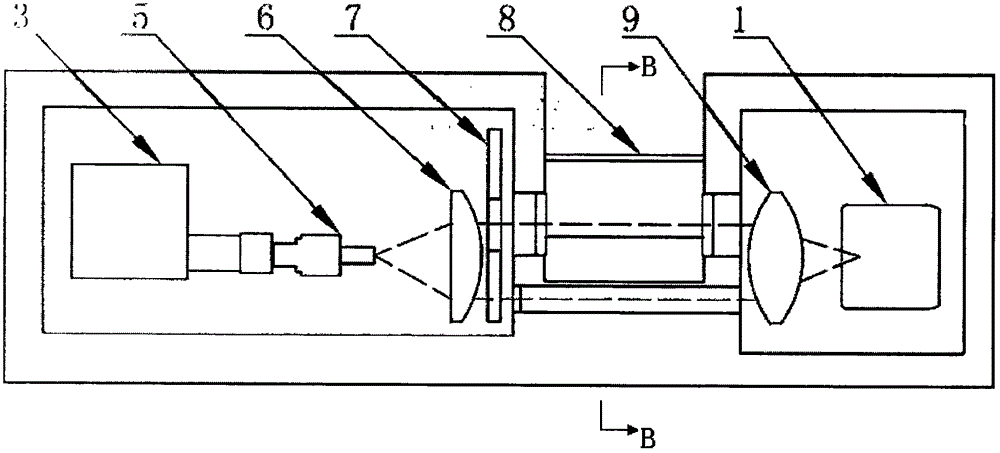

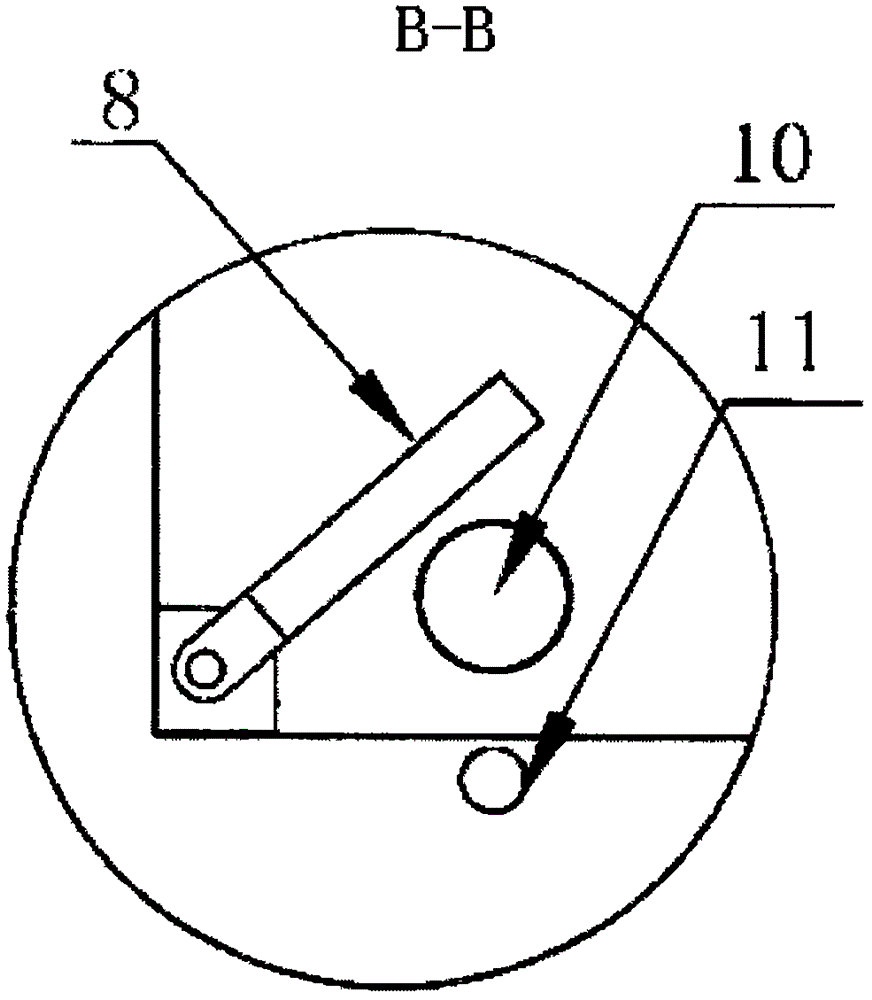

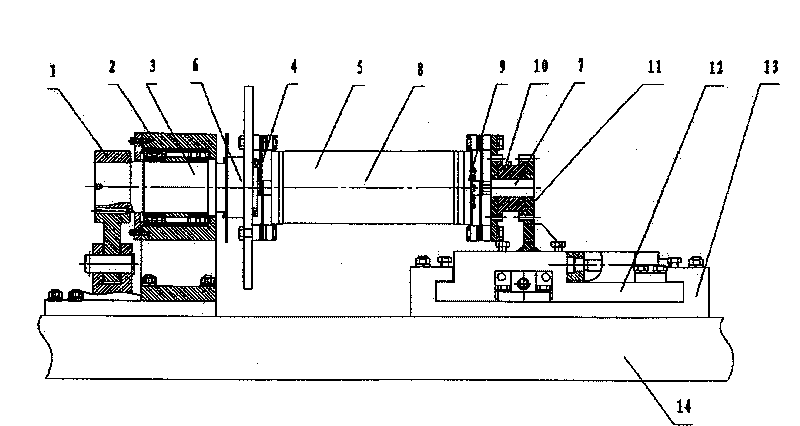

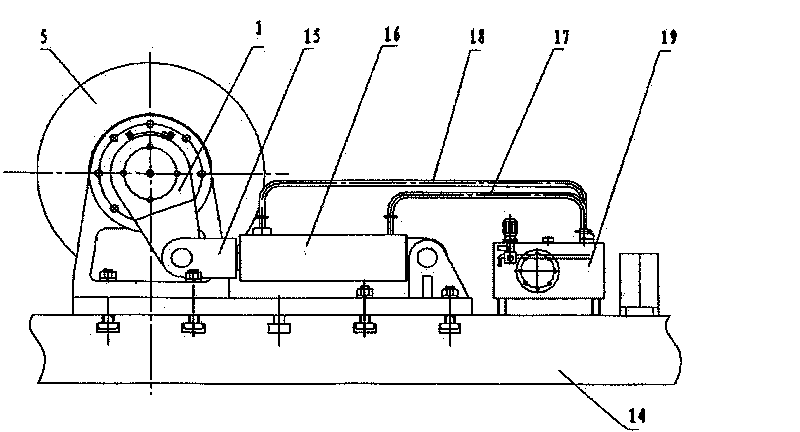

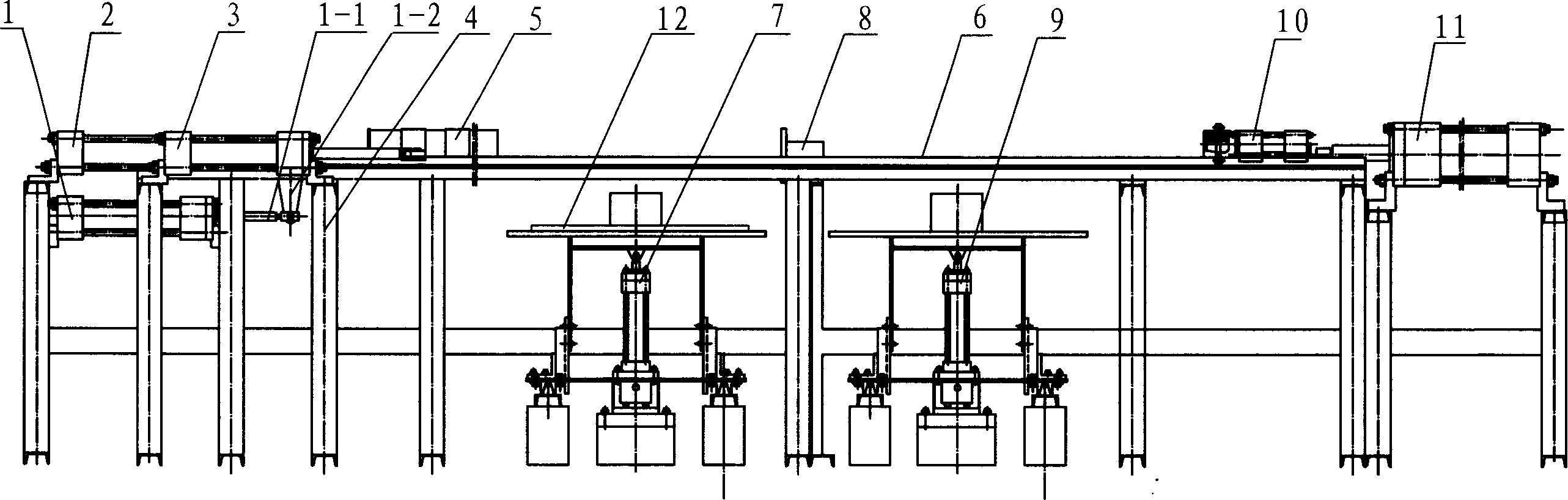

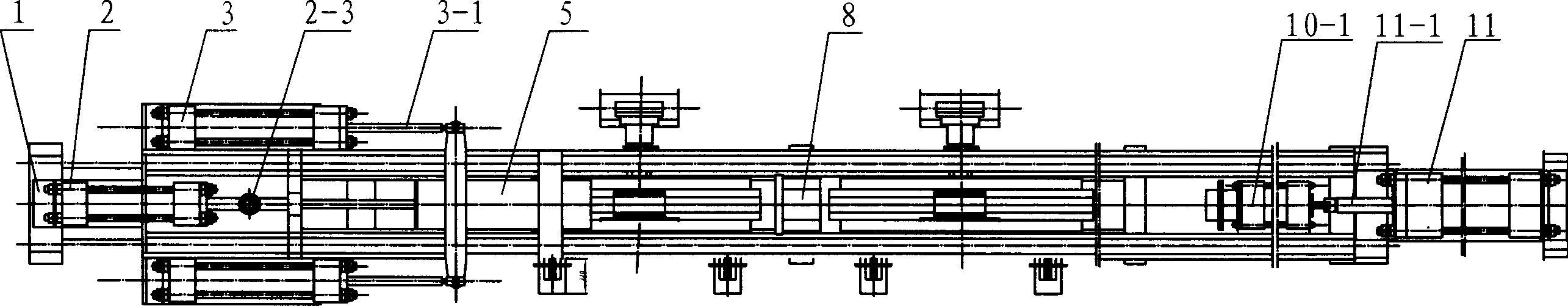

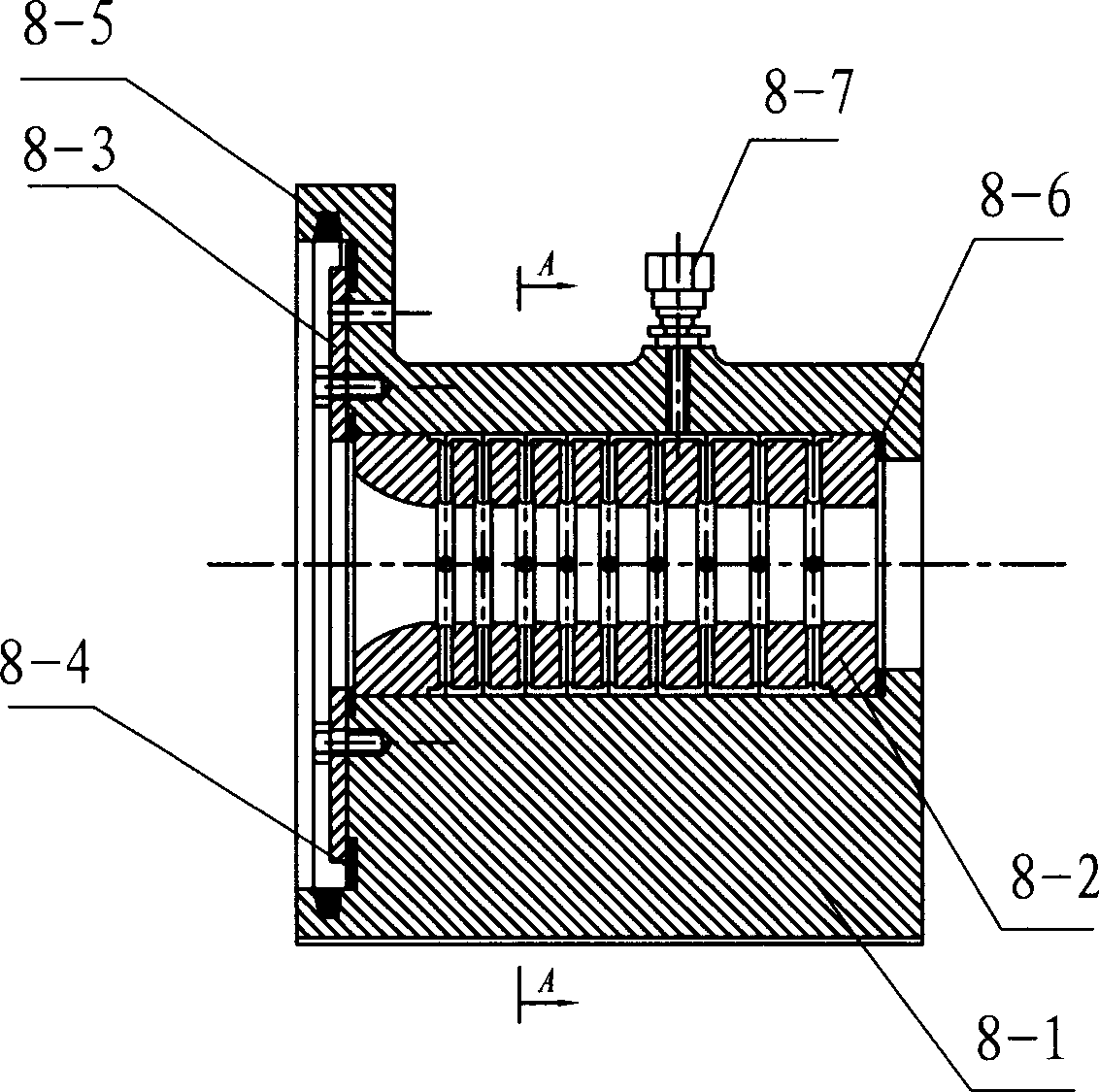

Wind driven generator coupler test-bed and test method

ActiveCN101726377AReasonable structureSimple and fast operationMachine part testingWork measurementElectricityWind driven

The invention relates to a wind driven generator coupler test-bed and a test method. The test-bed comprises a seat, a driving device and a display; a pair of left bracket and right bracket for installing the coupler is arranged on the seat; the left bracket is a bearing seat and internally provided with a torque input shaft, one end of the shaft is provided with a flange used for butt jointing with the input joint of the coupler; the right bracket is a composed of a torque sensor and a supporting board, the supporting board is arranged on the seat, the torque sensor is fixed on the supporting board and butt joints with the output joint of the coupler; the right bracket is provided with an axial, radial and angular displacement regulating mechanism; the driving device is arranged on the seat and connected with the torque input shaft of the left bracket and drives the shaft to rotate; the torque input shaft is provided with an angle sensor for measuring the angular displacement of the shaft; the display is used for displaying the set parameters and measurement parameters of the test. The invention can be used in test of skid torque calibration and largest load on the wind-electricity coupler.

Owner:DONGFANG TURBINE CO LTD

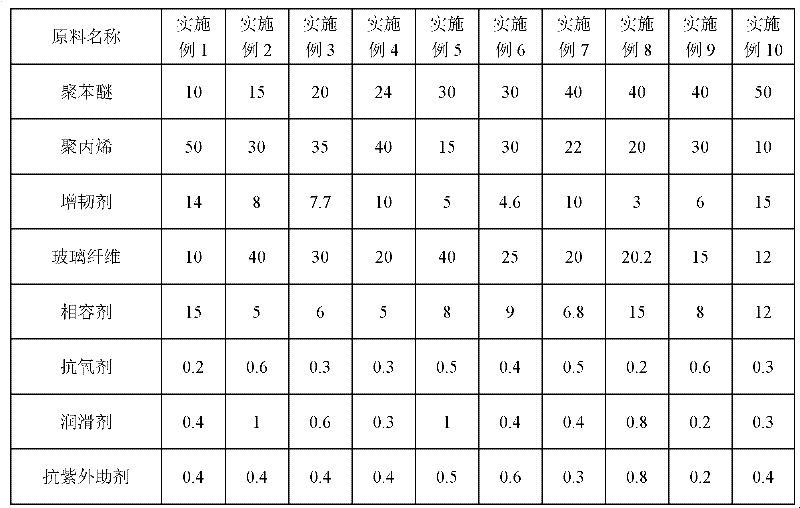

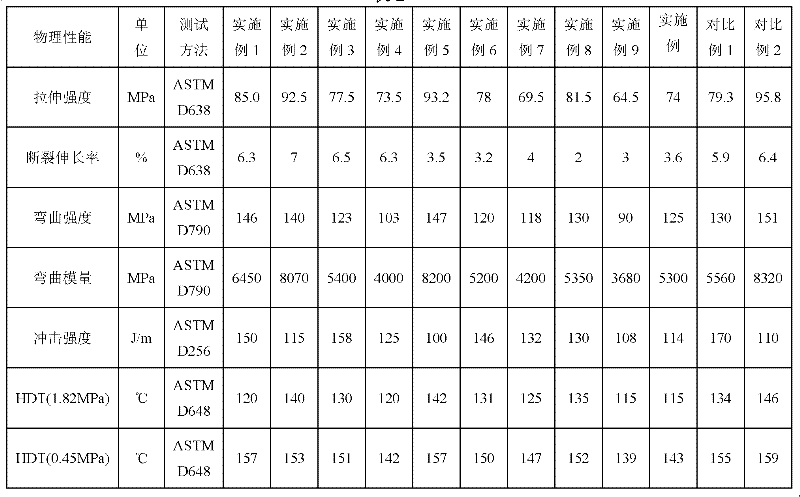

Glass fiber reinforcement polyphenyl ether/polypropylene alloy and production method thereof

InactiveCN102417718AImprove mechanical propertiesGood dimensional stabilityGlass fiberWeather resistance

The invention relates to a glass fiber reinforcement polyphenyl ether / polypropylene alloy and a production method thereof, wherein the alloy comprises the following component in part by weight: 10-50% of polyphenyl ether (PPO), 10-50% of polypropylene (PP), 3-15% of flexibilizer, 10-40% of glass fibre, 5-15% of polyphenyl ether-polypropylene compatilizer, 0.2-0.6% of antioxygen, 0.2-1% of lubricant and 0.2-0.8% of uvioresistant. The production technology comprises the following processes that: firstly, raw materials are mixed according to the proportion, and then are added into a double-screw extruder through a feeder, the long glass fibre is added from the glass fibre inlet of the double-screw extruder and is then granulated, the temperature is controlled between 220-250 DEG C, screws are controlled between 300-600r, so the glass fiber reinforcement polyphenyl ether / polypropylene alloy material can be obtained. The invention has the advantages of good stretching, bending and impacting performance, heat resistance, weather resistance, creep resistance, size stability, easiness in machine shaping and the like, and is applicable to automobile parts, pipe fittings, valve valves and the like.

Owner:SHANGHAI SUNNY

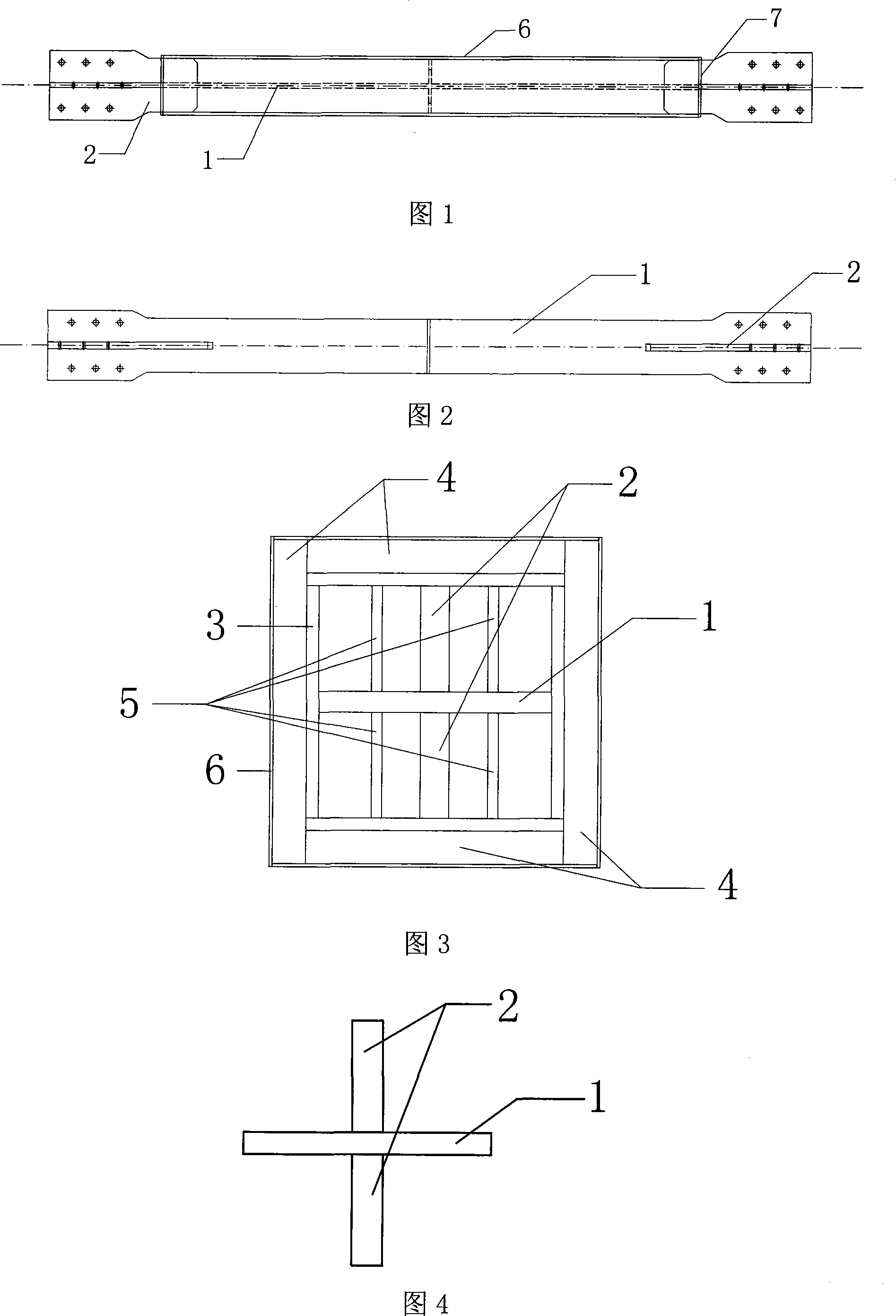

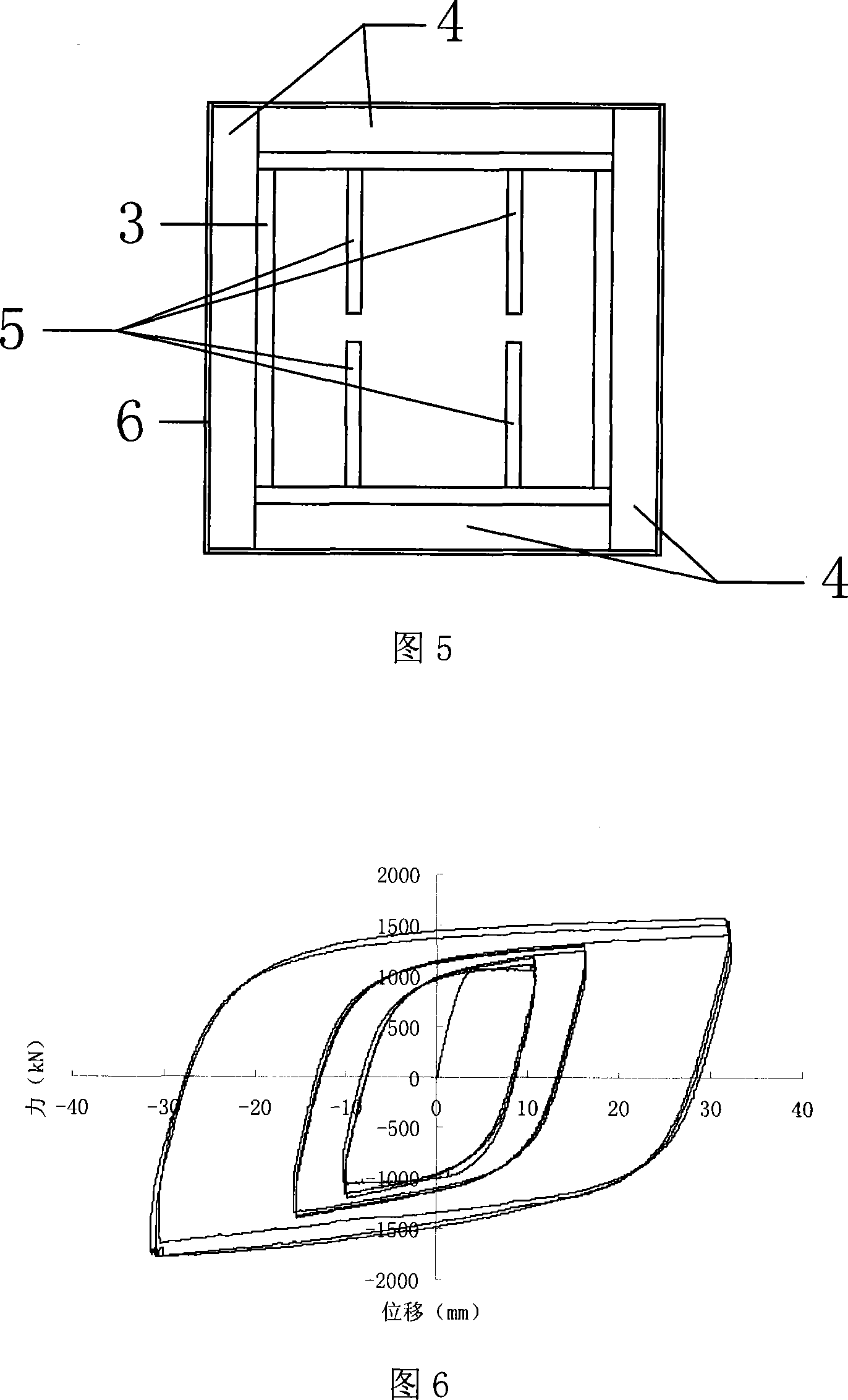

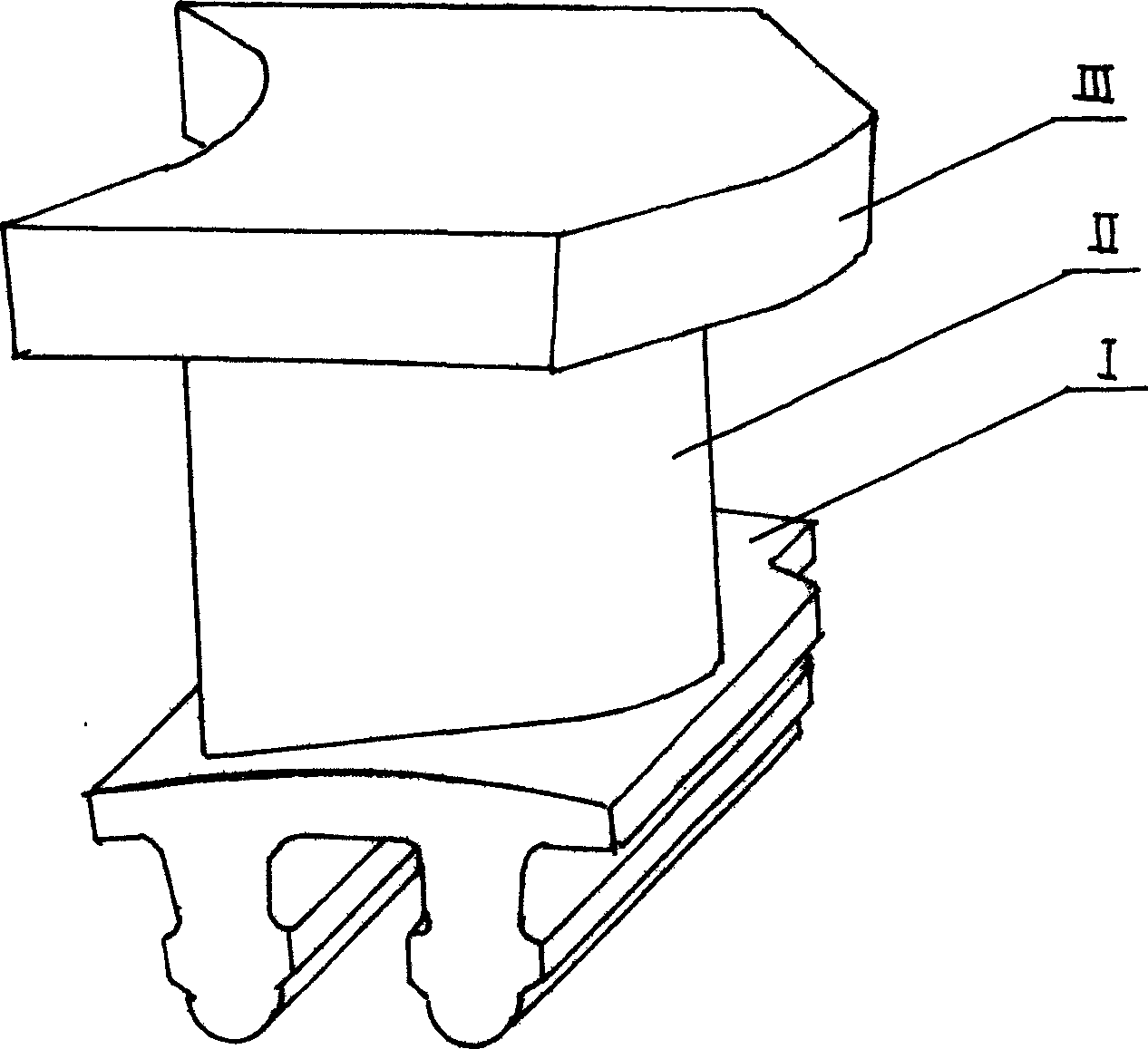

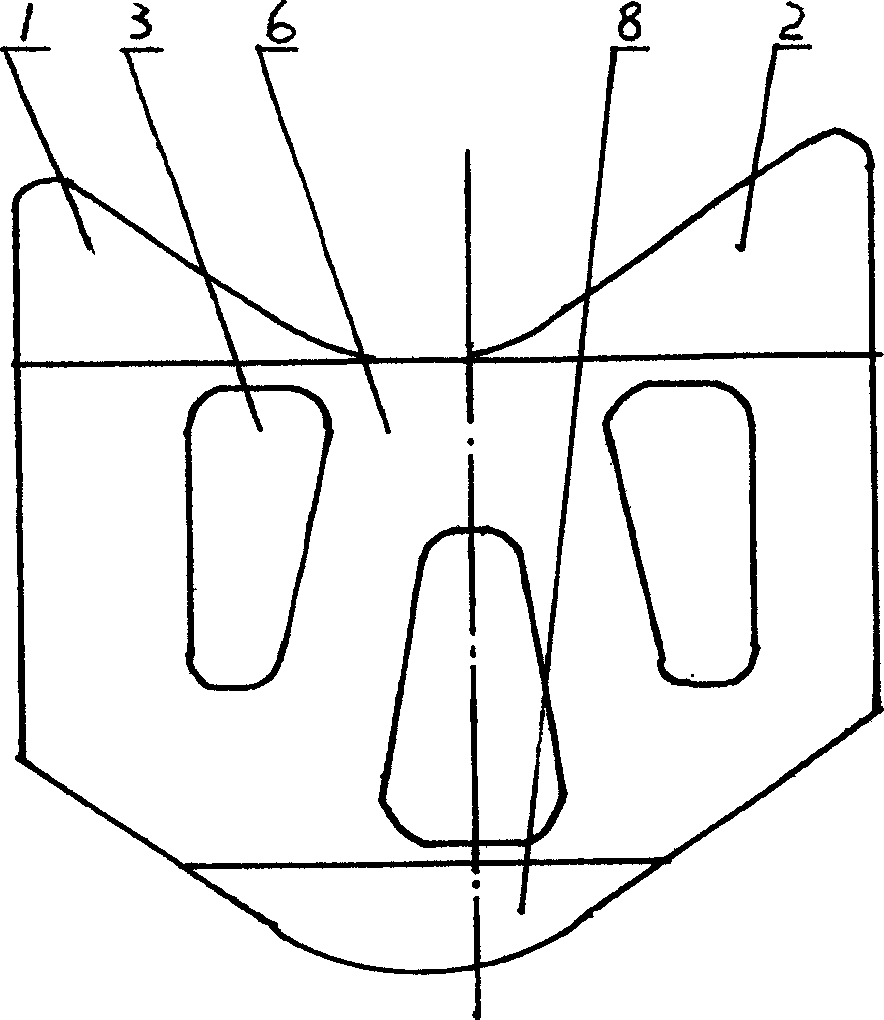

Bracing steel sleeve flection restriction support component

ActiveCN101220616AImprove featuresImprove energy consumptionShock proofingEarthquake resistanceBuckling-restrained brace

The invention relates to an improved flection-restraining support member which includes: a core part, an inner sleeve part, an outer sleeve; wherein, the core part consists of a core board and a ribbed stiffener for the core board; the inner sleeve part consists of an inner sleeve wallboard, an inner sleeve ribbed stiffener and a core board restraining board, the outermost layer is the outer sleeve; no clearance is left between the core board restraining board and the core board. The invention also provides a method for manufacturing the improved flection-restraining support member. The flection-restraining support has good returning-delaying characteristics and energy-consuming performance and is an effective energy-consuming member, which can reach 1 / 70 deformation amount, meet the 1 / 50 floor displacement distortion requirement of building under rarely-happen earthquake and can greatly improve the earthquake resistance of the building structure; furthermore, the material and manufacture are all realized in China, which greatly reduces the cost of the support and lays a foundation for generalization and application.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

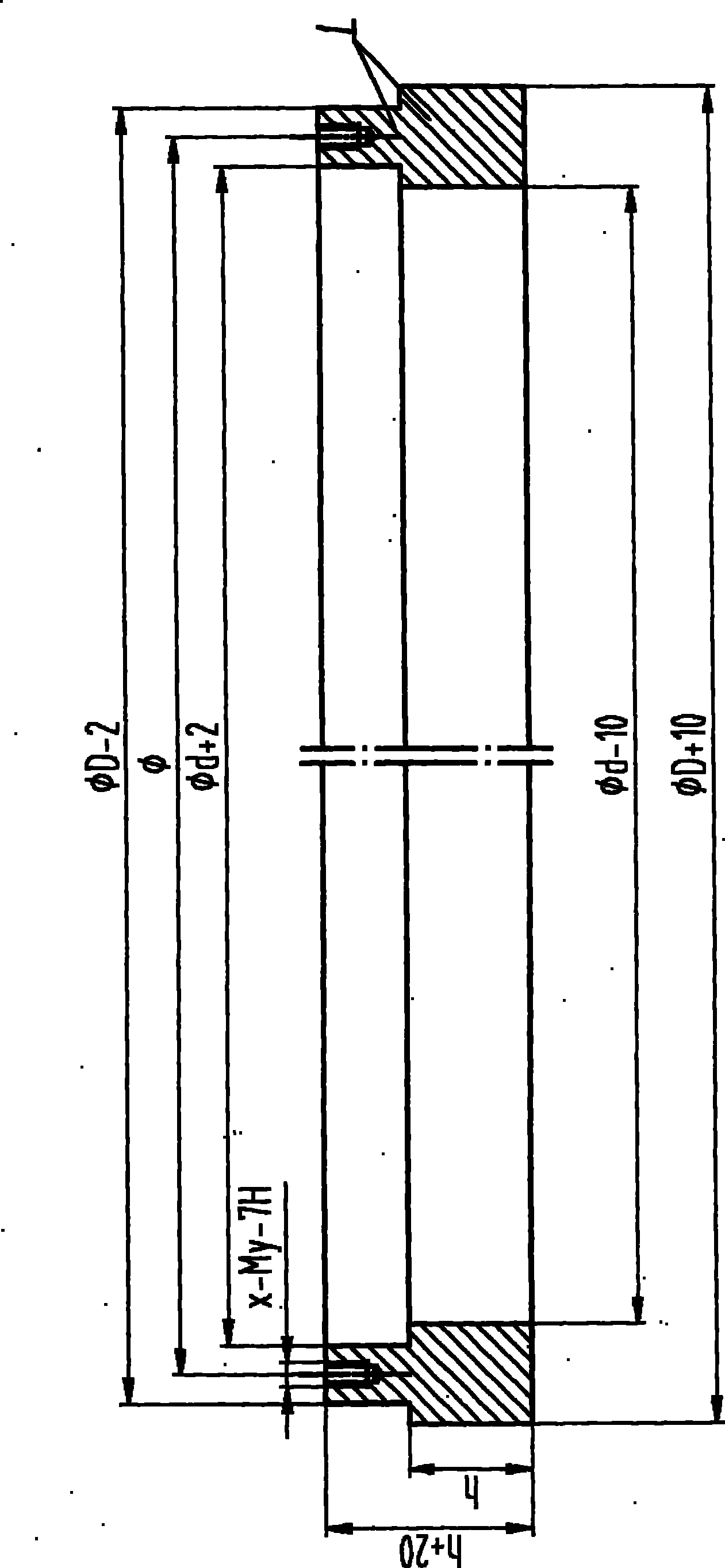

Processing method of ultra-thin annular pieces

InactiveCN101774111AImprove rigidityNo elasticityPositioning apparatusMetal-working holdersSheet steelWork in process

The invention relates to a processing method of ultra-thin annular pieces. The method comprises the following process flows of: (1) cutting a blank; (2) roughly turning; (3) drilling; (4) dividing single pieces; (5) manufacturing a tool clamp; (6) combining and fine turning; and (7) turning or grinding planes. 4-10 ultra-thin annular pieces are combined together, and meanwhile, steel plate flames are used for cutting and integrally blanking so as to improve the rigidity and ensure that no deformation occurs in the processing process. Semi-finished ultra-thin annular piece products to be processed, which are cut and blanked into single pieces, need to be combined together with the tool clamp, wherein the tool clamp is an annular piece with inner and outer steps between an upper section and a lower section. The circumference on the upper end surface of the tool clamp is uniformly provided with threaded holes according to the mounting hole sizes of the ultra-thin annular pieces, and then the single semi-finished products of the ultra-thin annular pieces to be processed are combined with the tool clamp into a whole by using bolts so as to enhance the rigidity of the semi-finished ultra-thin annular piece products, guarantee non-deformation during processing in subsequent working procedures, realize the localization of the ultra-thin annular pieces to replace imported pieces, greatly reduce the cost and meet the requirement of users.

Owner:MAANSHAN FANGYUAN SLEWING RING

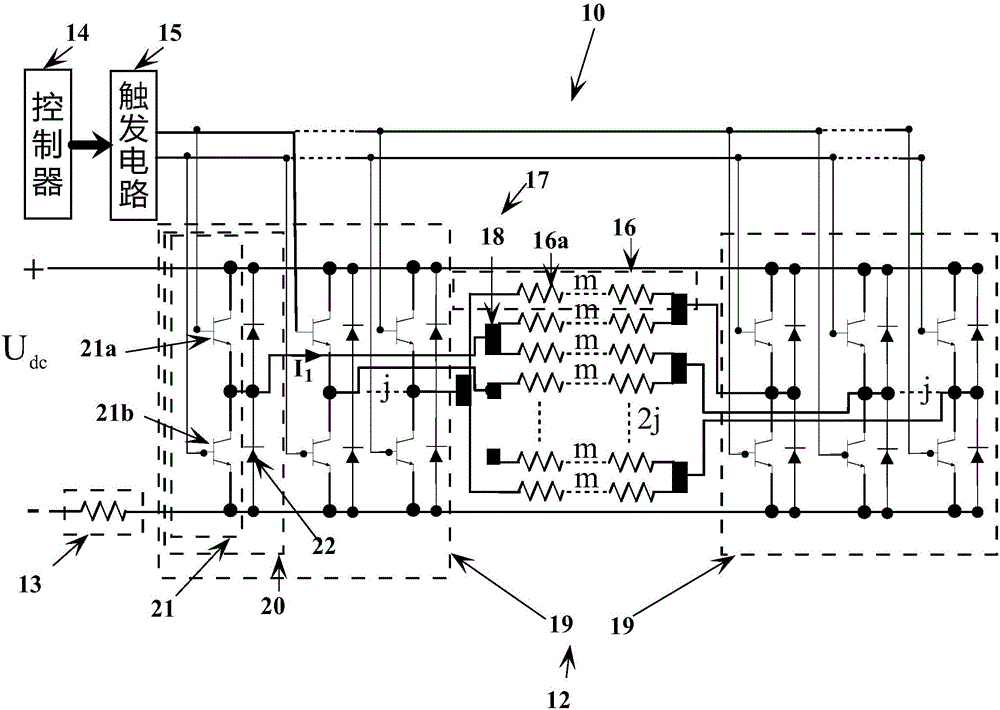

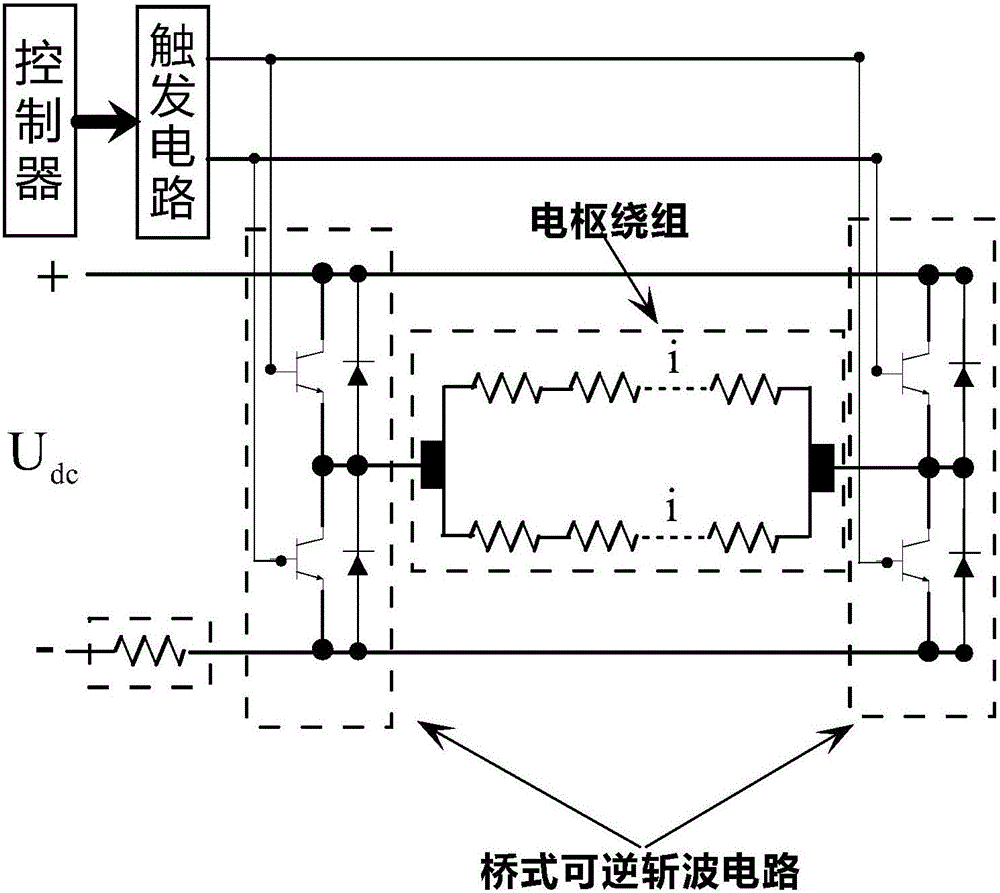

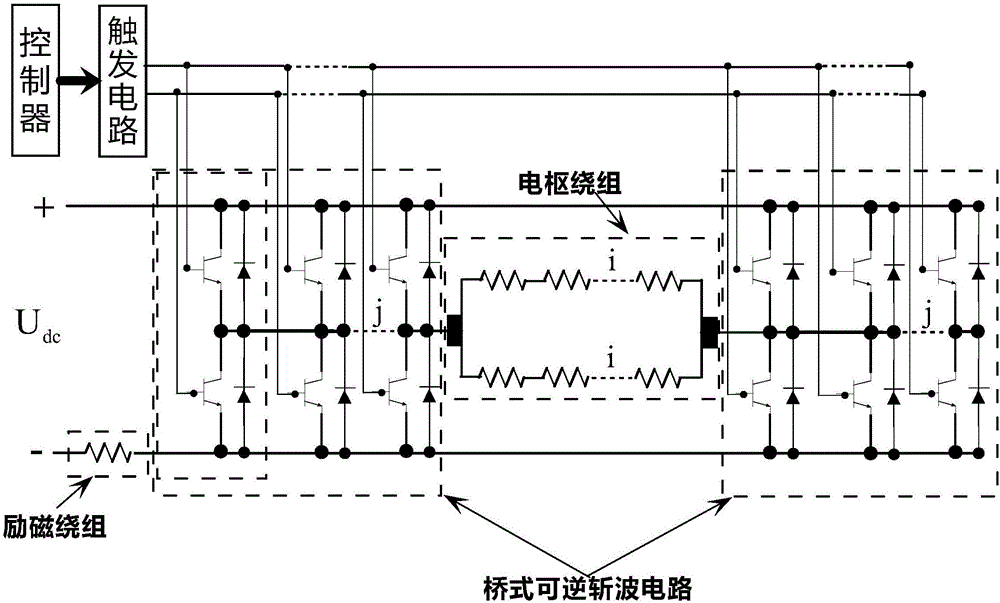

Electric driving unit, chopper circuit, DC motor and electric equipment

PendingCN106602947AReduced requirements for performance consistencyAvoid wasting human and financial resourcesAssociation with control/drive circuitsDC motor speed/torque controlEngineeringConductor Coil

The invention provides an electric driving unit, a chopper circuit, a DC motor and electric equipment equipped with the electric driving unit. The electric driving unit comprises the DC motor, a DC power supply, the chopper circuit used for providing a DC current to the DC motor according to a control signal, and an excitation portion used for providing a work magnetic field, wherein the DC motor has 2j mutually independent armature winding branches composed of M windings, 2j*m commutator segments connected with the windings, and 2 sets of electric brush sets which are respectively connected with two sets of power supply wires of the DC motor and at least contact with the 2j commutator segments, each electric brush set comprises j mutually independent electric brushes, the chopper circuit has 2 leg portions respectively corresponding to the 2 electric brush sets, each leg portion comprises leg units in one-to-one correspondence with the j electric brushes, each leg unit comprises a chopper leg providing a wire current to the corresponding electric brush and a freewheeling diode in reverse parallel connection, and the j and the m are both positive integers greater than 2.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

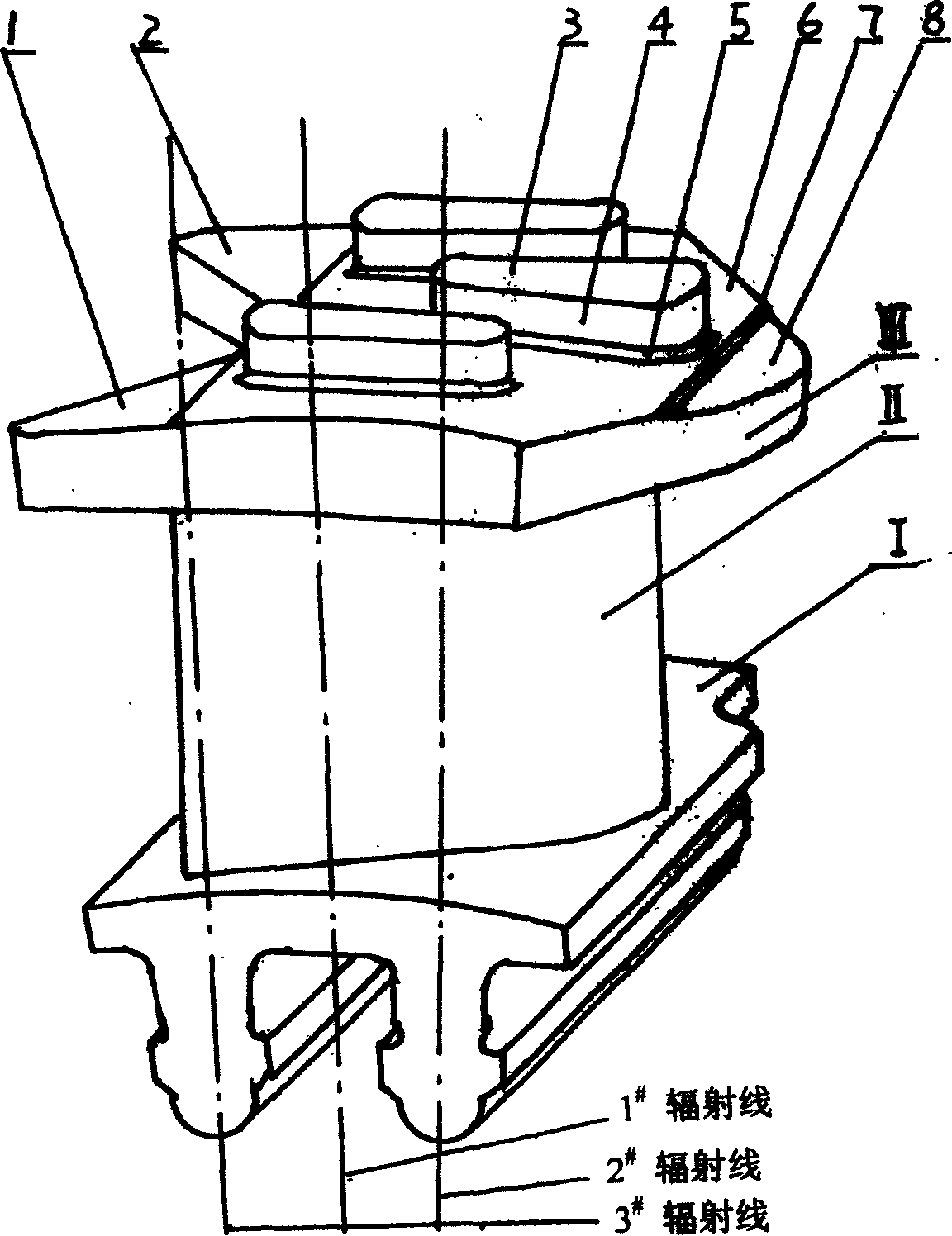

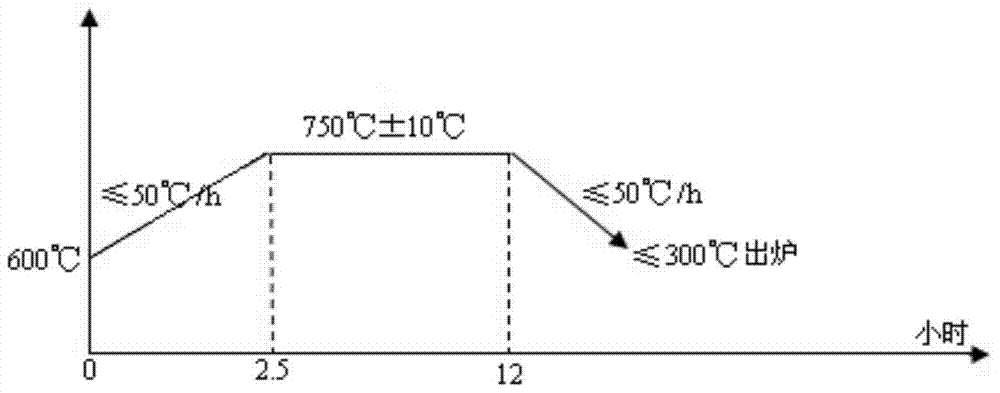

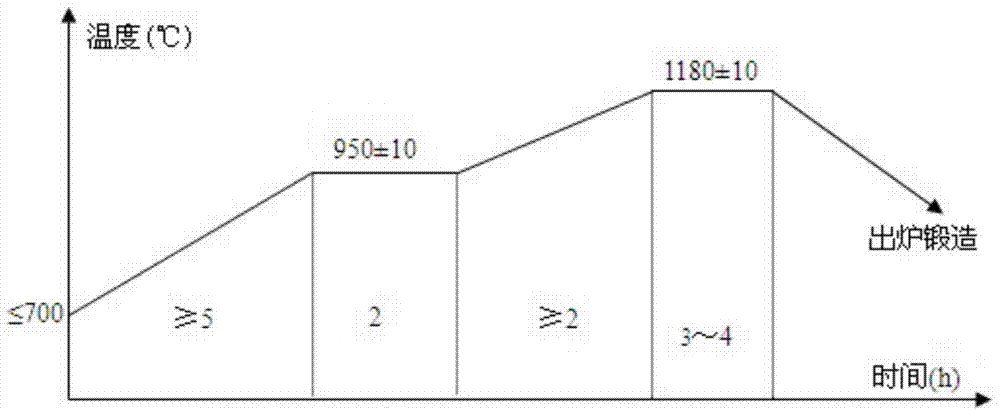

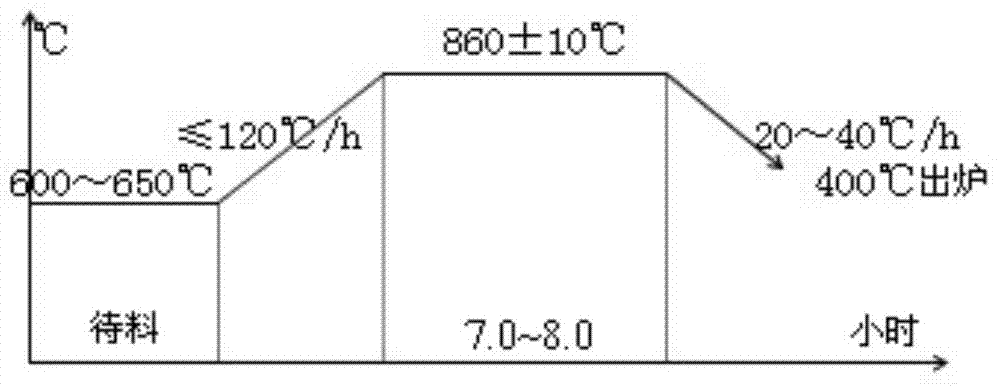

Hot-forming and forging method for large-sized high-temperature alloy turbine disc

ActiveCN1654140ARealize localizationReduce minimum loadWheelsHeating/cooling devicesIngotHot working

The hot forging process of high temperature large alloy turbine disc includes the following steps: 1) conventional upsetting and drawing to form cylindrical alloy blank of 730 mm diameter with electroslag ingot of 900 mm diameter; 2) low temperature heating the blank at 900 deg.c, coating the sides with diathermic cotton, further heating to stipulated temperature and maintaining for prolonged 5 hr; 3) upsetting the blank to intermediate blank of 1700 mm diameter through the first traditional process to machining limit of the press and then local deforming with rectangular upper anvil of width below 400 mm; 4) coating the lower surface of the circular cake blank and heating in furnace for 2 hr; and 5) final rotary forging for local deformation with upper anvil of width of 200 mm and rotating angle of 15 deg to forge the intermediate blank of 1700 mm diameter into finished product of 2000 mm diameter in the reducing amount of 25 mm and deformation amount of 35 %.

Owner:宝武特种冶金有限公司

Method of preparing medical high-precision titanium and titanium alloy rod bar

InactiveCN101157172ARealize localizationLess investmentHeat treatment process controlMetallurgyEconomic benefits

The invention relates to medical high precision titanium and the manufacture method of a titanium alloy rod with a diameter tolerance level between h9 to h8 and the length between 3 m to 3.5 m without any clearance after being arranged on operating platform. The main steps of the manufacture method comprises blank preparation, cogging and forging, distorting and processing, heat treatment, finishing operation, examination, and final product packaging. The invention greatly decreases the equipment investment, realizes the purposes that the localization and exportation of the medical high precision titanium rod can be utilized rapidly, the monopoly situation of the products in the China market by foreign countries can be broken, the international competition can be participated, the stronger market competence can be formed, and the good economic benefit can be created.

Owner:宝鸡市英耐特医用钛有限公司

Novel aluminum alloy welding wire and application thereof

ActiveCN103286472ASignificant grain refinement effectHigh strengthWelding/cutting media/materialsSoldering mediaWeld seamCorrosion

The invention relates to the field of welding materials, in particular to a novel aluminum alloy welding wire and application thereof. The novel aluminum alloy welding wire comprises, by mass percent, 5.50-7.0% of Mg, 0.80-1.0% of Mn, 0.25-0.35% of Ti, 0.05-0.20% of Zn, 0.10-0.20% of Cr, 0.25-0.35% of Zr, not more than 0.2% of Fe, not more than 0.2% of Si, not more than 0.05% of Cu, not more than 0.0005% of Be, not more than 0.1% of other single impurity element, not more than 0.15% of total other impurity elements, and the balance of Al. The hydrogen content of the aluminum alloy welding wire is not more than 0.03ml / 100g. The novel aluminum alloy welding wire is low in hydrogen, fine-grain, and even in internal structure. Product detecting and welding experiments show that welding seams are high in strength, high in plasticity, fine in solidification metal grains, low in thermal crack tendency, and good in corrosion resistance. The aluminum alloy welding wire is suitable for aluminum alloy section bar welding of various vehicles, aircrafts, and ships.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY +1

Production process of S-Al-N-controlled non-quenched and tempered steel

ActiveCN106148639AImprove purityUniform compositionProcess efficiency improvementElectric furnaceElectric arc furnaceMetal

The invention discloses a production process of S-Al-N-controlled non-quenched and tempered steel. The production process comprises the process flows of scrap steel and hot metal charging, electric arc furnace smelting, LF refining, VD vacuum degassing and bloom continuous casting (EAF-LF-VD-CCM process flows); the non-quenched and tempered steel respectively comprises the following components in percentage by mass: 0.020-0.055% of S, 0.015-0.055% of Alt and 0.070-0.150% of N. The S-Al-N-controlled high-grade non-quenched and tempered steel disclosed by the invention is high in purity, uniform in component and macrostructure and low in anisotropy, the bandwidth can be controlled within 4HRC for the steel with a hardenability requirement, and the produced automobile steel is not required to be subjected to quenching and tempering treatment, can be directly used for turning by a user, is good in cutting performance and also has excellent anti-fatigue performance.

Owner:NANJING IRON & STEEL CO LTD

Processing method and device for adjusting blade and integral shroud by turboset

ActiveCN1631593ARealize localizationAccelerate the pace of localizationMilling equipment detailsControl lineEngineering

The invention discloses a crown turbine set adjusting grade active fin crown processing technique and the processing device. Its features are: adopting special clamp, on the horizontal four coordinate lathes, with the surface milling method in the PRO / E software, picking the edge of the fin as control line, picking the outline of the clinch head as examining plane so to process the cylinder plane of the fin crown; process the clinch heat outline with the track milling method in the PRO / E software, processing roundabout contracting to the center; by using the rotor work bench on the lathe to let the fin crown step inclined plane perpendicular with the lathe main shaft, process the fin crown step inclined plane in plane milling way. The advantages of the invention are that all the processing planes is processed with one clamping, high processing accuracy, high efficiency and achieves home production of the fin no longer relying on import.

Owner:DONGFANG TURBINE CO LTD

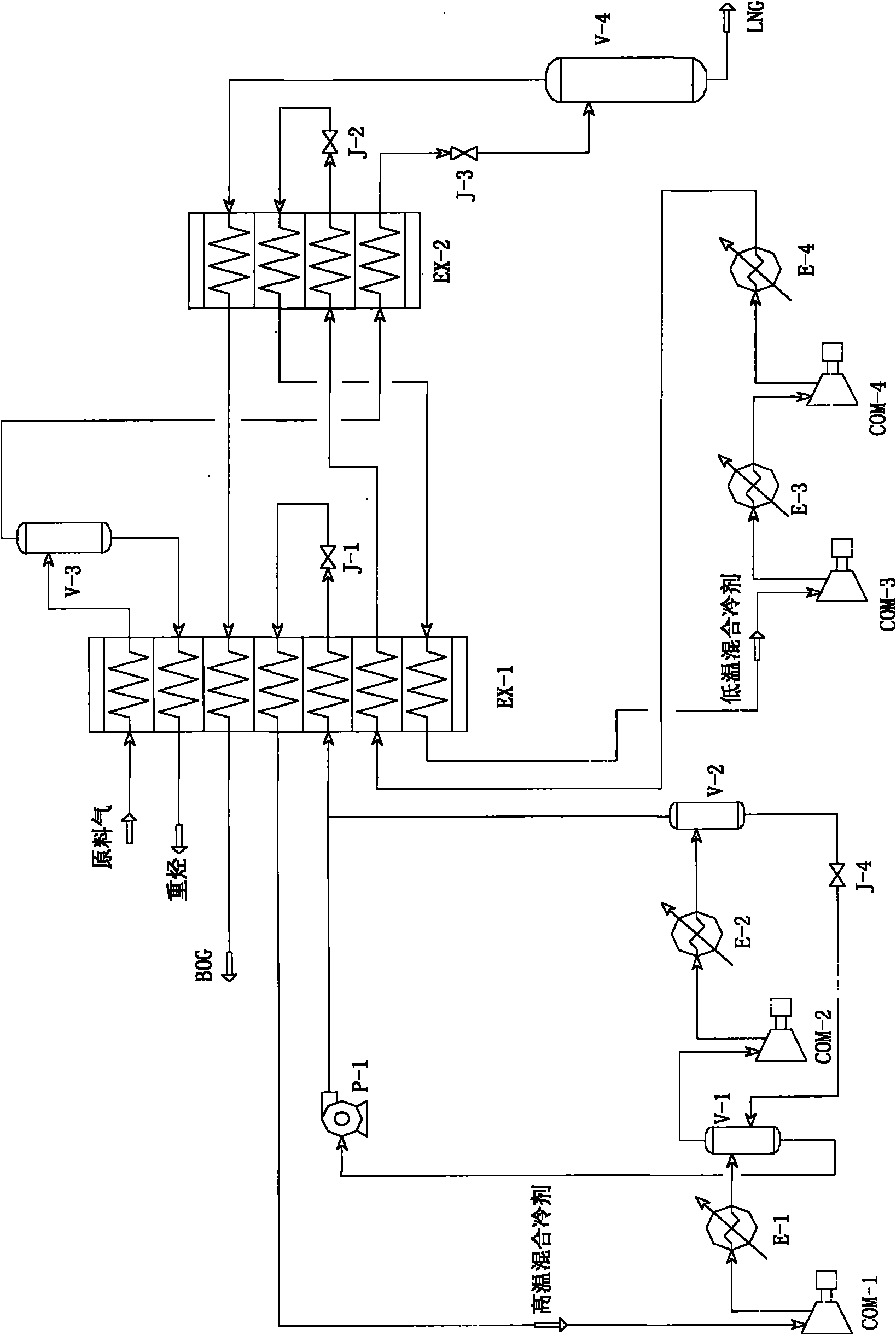

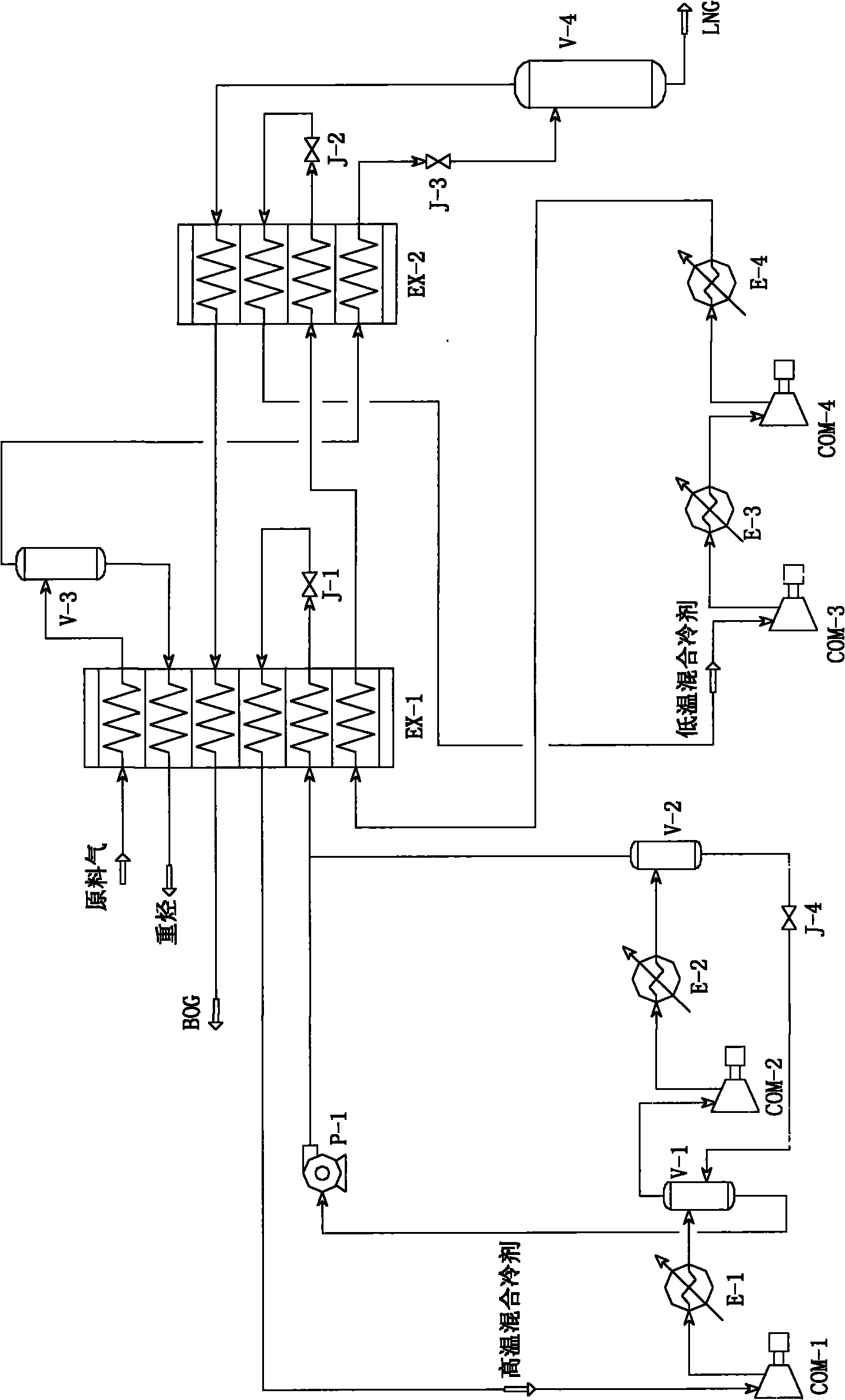

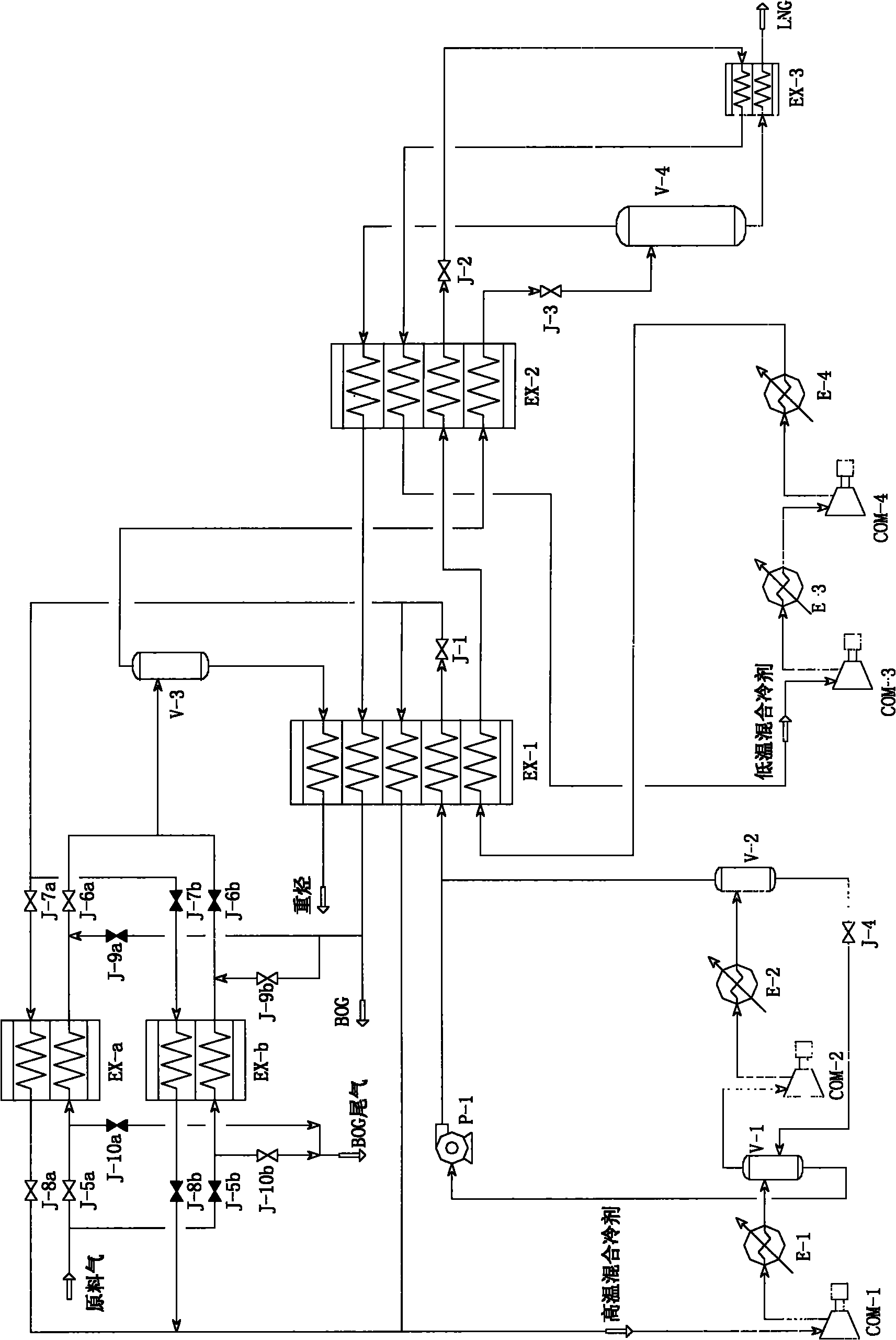

Method for producing liquefied natural gas

InactiveCN102115683ASimple designLower manufacturing requirementsCompression machines with non-reversible cycleGaseous fuelsLiquid stateRecuperator

The invention provides a process for producing liquefied natural gas, which comprises the following steps of: introducing purified feed gas into a first heat exchanger for precooling; introducing the precooled feed gas into a heavy hydrocarbon separator for gas-liquid separation; introducing the separated gaseous fluid into a second heat exchanger, and liquefying to obtain liquid-state fluid; and depressurizing and throttling to obtain the liquefied natural gas, wherein a refrigeration cycle consists of two independent mixed working medium refrigeration cycles in a high temperature area and a low temperature area; the feed gas can pass through a reversing heat exchanger to enter the first heat exchanger; and the separated heavy hydrocarbons and BOG return to the heat exchanger for reheating. In the process, the energy consumption is low; each mixed working medium refrigeration cycle is controlled by only one throttle valve in a cold box, and the operation is simpler; due to the reversing heat exchanger, the production process is more stable and safe; and the cold quantity of the separated heavy hydrocarbons and BOG is fully recycled and discharged out of the cold box, and the energy consumption is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

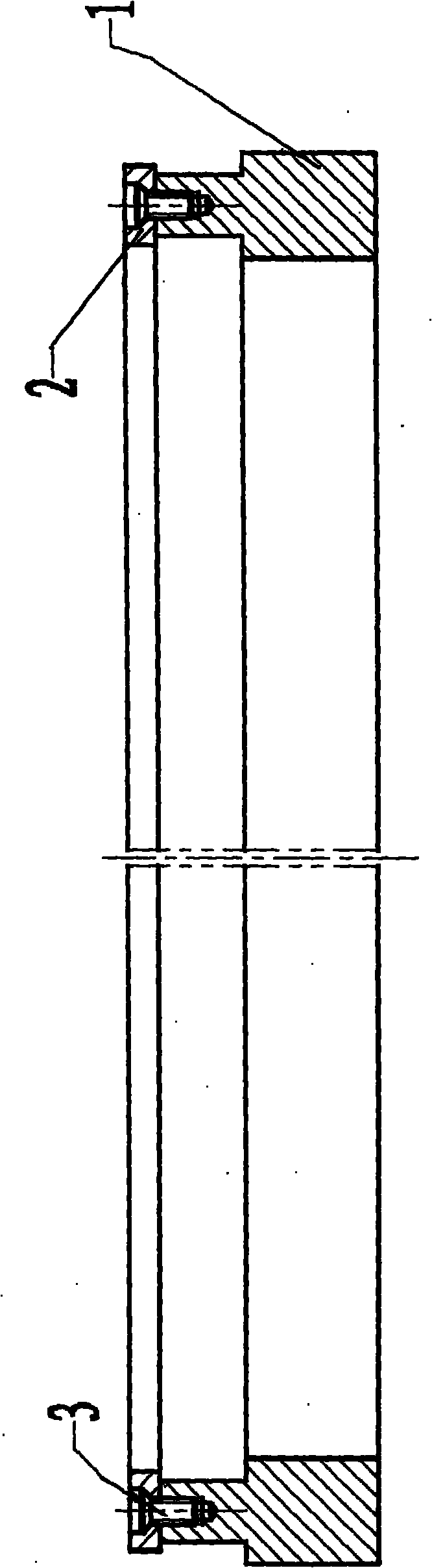

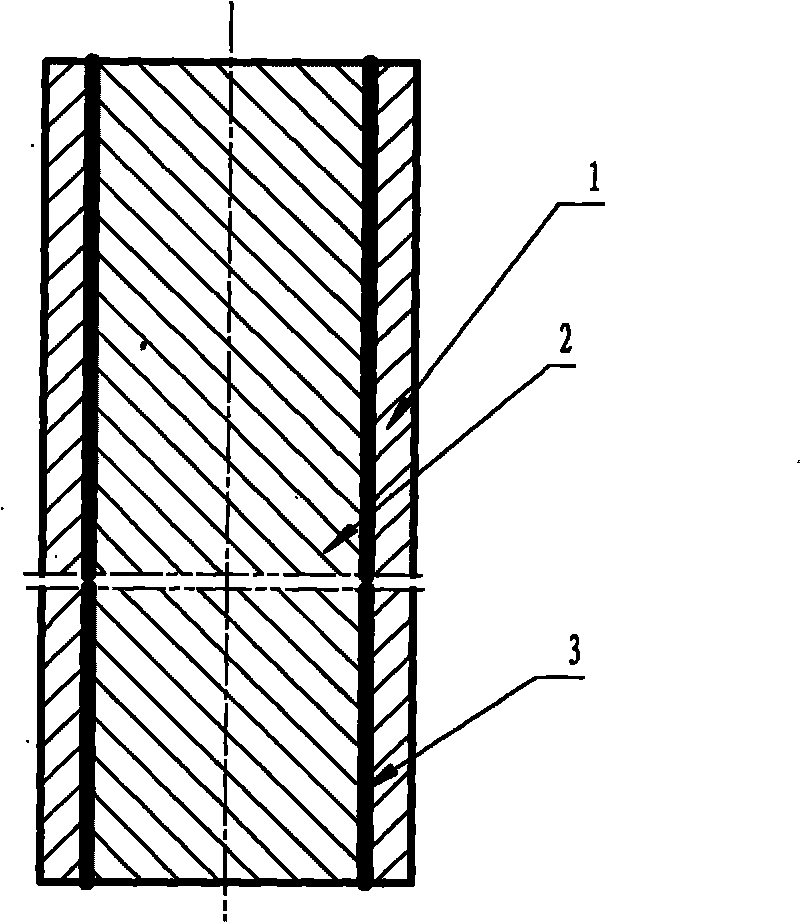

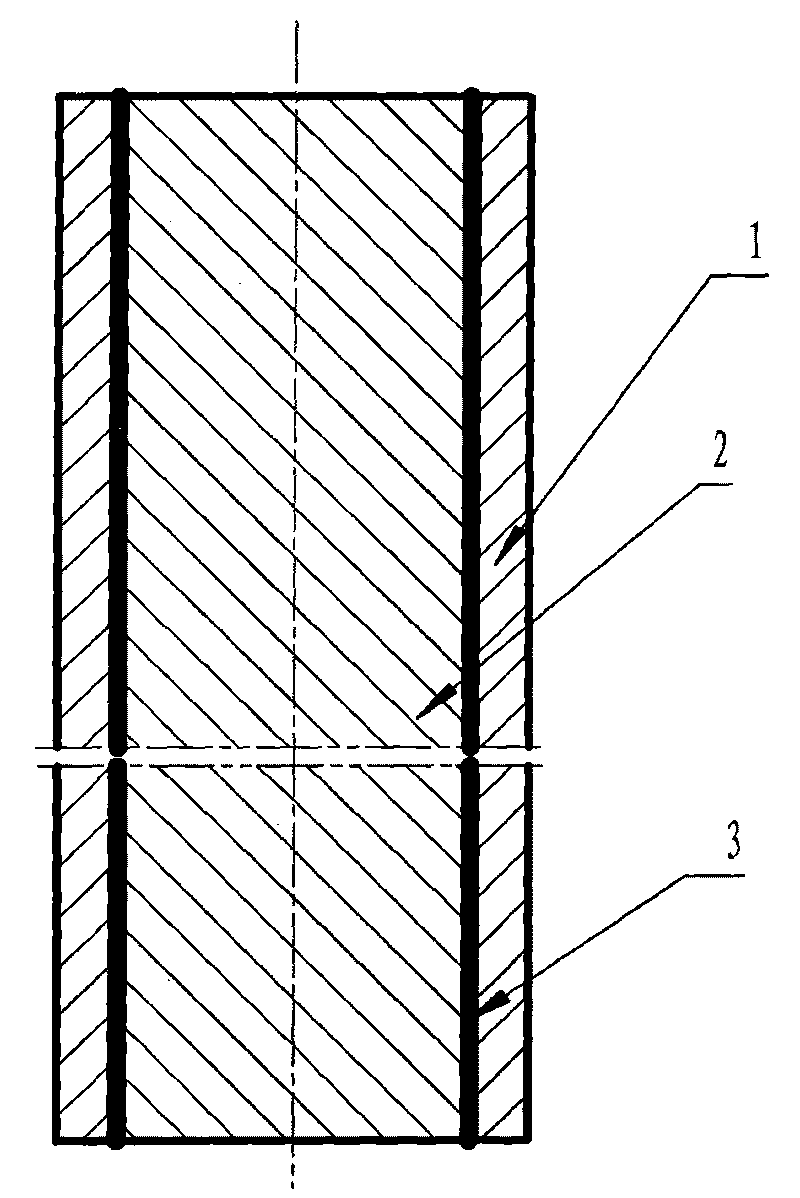

Technique for producing titanium-copper compound wire

ActiveCN101698206ARealize localizationFit tightlyTemperature control deviceSurface finishEconomic benefits

The invention relates to the field of a technique for producing a titanium-copper compound wire. The invention has the technical proposal that the technique comprises the following steps: selecting a titanium or titanium alloy pipe in proper dimensions meeting the national standard as a sleeve pipe (1); selecting a copper rod matching the dimensions of the titanium pipe as a rod material (2); penetrating the rod material (2) into the sleeve pipe (1), and attaching the rod material (2) to the sleeve pipe (1) by using an explosion compounding method to make a titanium-copper compound rod and form a titanium-base compound layer (3); and swaging the titanium-copper compound rod, and drawing to make the titanium-copper compound wire. The titanium-copper compound wire has the advantages of high bond strength, high surface smoothness and high quality of finished products. The invention changes the current unfavorable situation that the high-quality titanium-copper compound wire in China still highly depends on import, and enjoys favorable economic benefits.

Owner:宝鸡巨成钛业股份有限公司

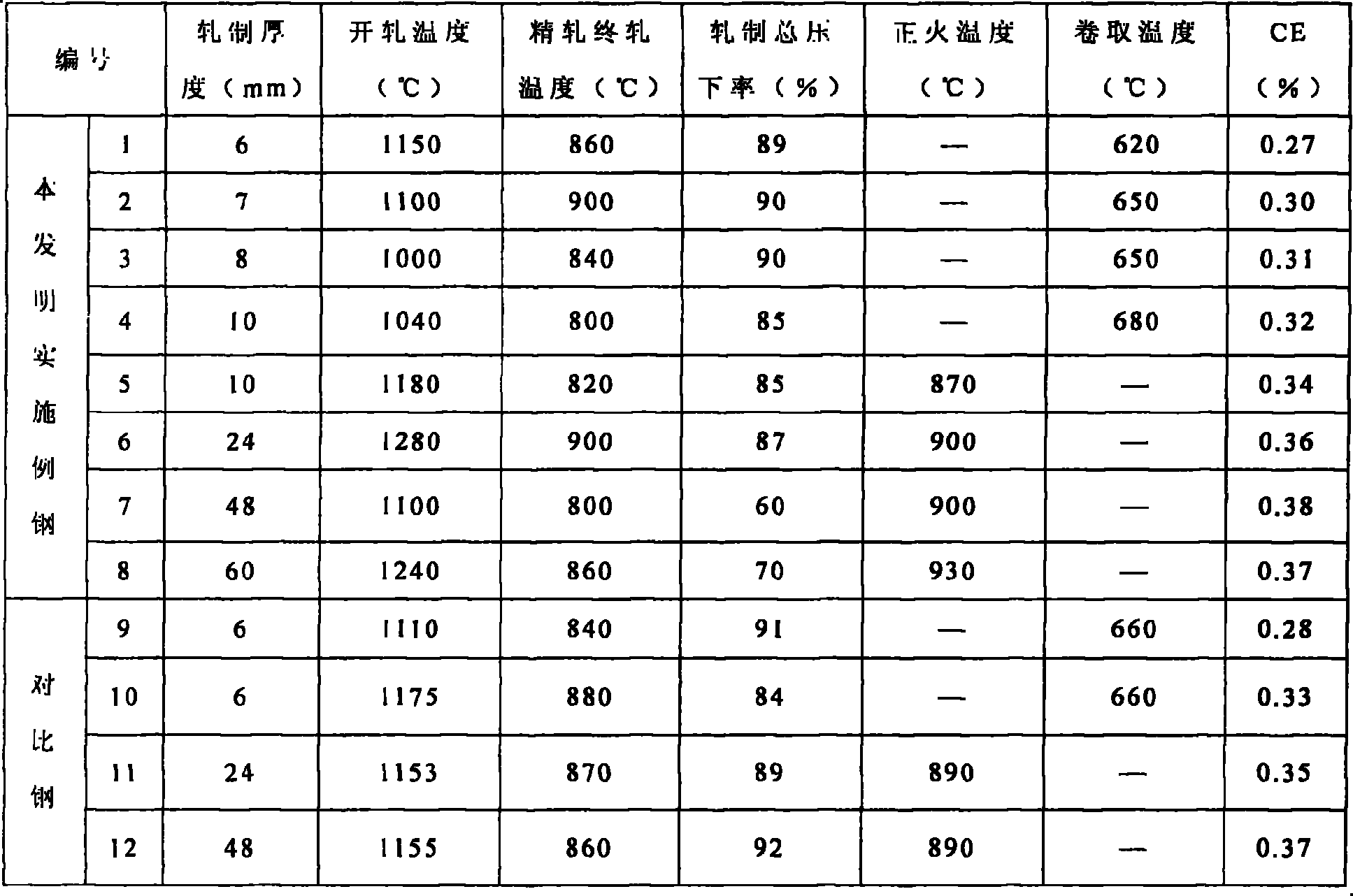

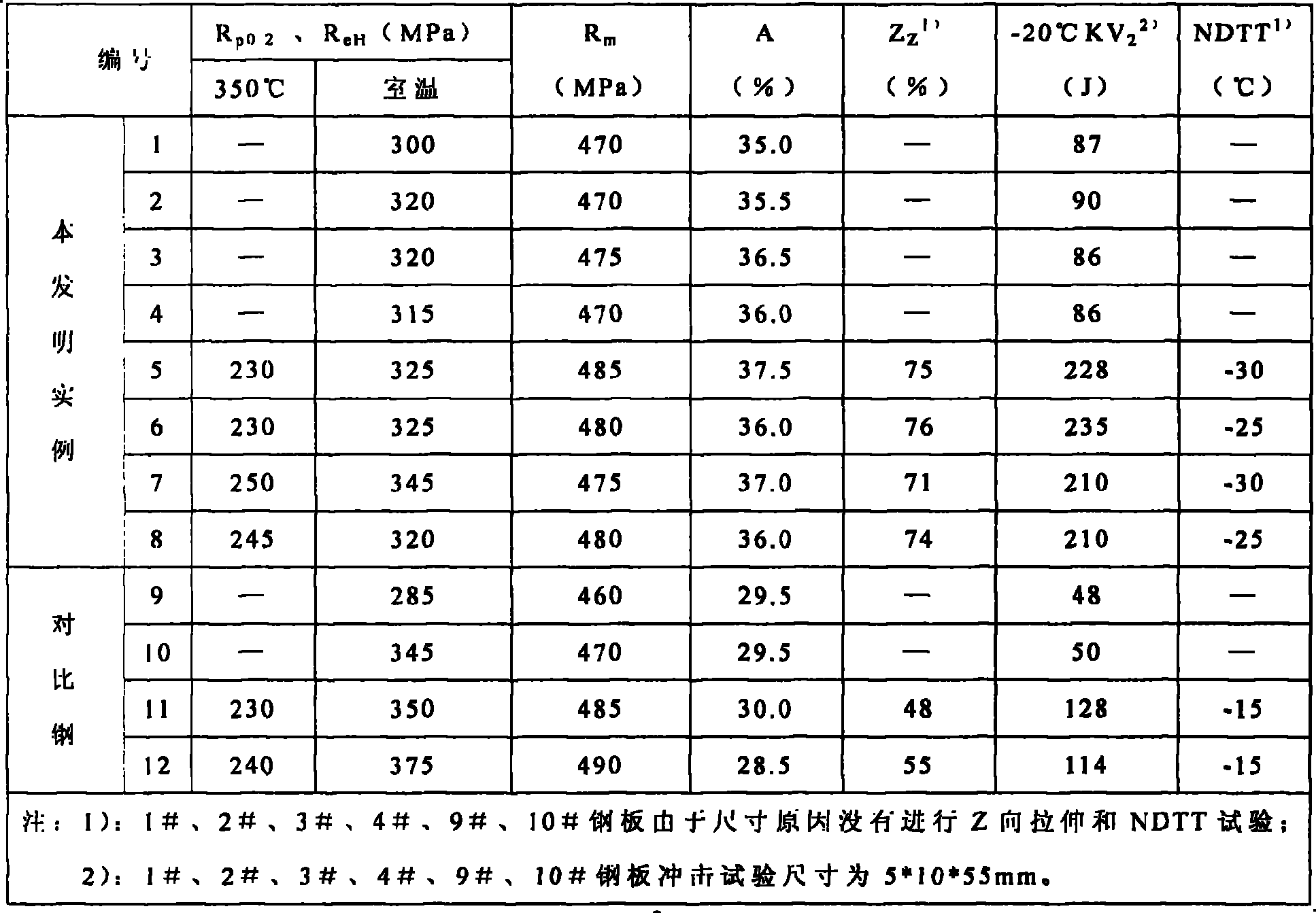

Steel for nuclear power pressure equipment with high toughness, high ductility and low irradiation embrittlement and making method thereof

InactiveCN101892442AImprove toughnessImprove ductilityTemperature control deviceChemical compositionNuclear power

The invention discloses a steel for nuclear power pressure equipment with high toughness, high ductility and low irradiation embrittlement and a making method thereof. The steel comprises the following chemical compositions in percentage by weight: 0.08-0.15 percent of C, 0.20-0.35 percent of Si, 0.80-1.60 percent of Mn, P no more than 0.012 percent, S no more than 0.005, 0.01-0.05 percent of Alt, 0.08-0.015 percent of Ti, N no more than 0.010 and the balance of Fe and unavoidable impurities. The chemical compositions of the steel also satisfy that Ni+Cr+Mo+Cu is no more than 0.70, Alt / N is no less than 2.0, Cu+6Sn is no more than 0.30 and Sn+Sb+As+Pb no more than 0.020. In the invention, the making method in a controlled rolling state and a normalized state is designed according to the requirements of different delivery states of steel products and different steel thicknesses, has the advantages of simple rolling technology and high product qualified rate of steel plates and can towel meet the requirements of mass production. The steel can be widely used for making second generation nuclear power pressure equipment, second generation improved nuclear power pressure equipment and third generation nuclear power pressure equipment.

Owner:武钢集团有限公司

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584ASolve processabilitySolve product problemsWelding/cutting media/materialsSoldering mediaAlloyGraphite

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Hydraulic flexible method for producing cold-drawn pipe and apparatus

InactiveCN1803328ALow manufacturing costAvoid vibrationDrawing mandrelsDrawing diesPiston cylinderLubricant

The invention discloses a hydraulic flexible cold-drawing method and equipment in the metallurgical mechanic pipe moulding technique, which comprises the following parts: pushing piston cylinder, pushing core bar cylinder, pushing assembly cylinder, assembly, rail, feeding structure, mould, blanking structure, clamp structure and drawing cylinder. The mould doesn't touch the deformation metal to form the flexible deformation state of mould-hydraulic oil-hollow billet-hydraulic oil-core head, which improves the precision of cold-drawing pipe.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for raising glutathion yield by fermentation of tornla yeast

InactiveCN1450168ASignificant economic and social benefitsRealize localizationFermentationFermentation brothCysteine

The method for preparing glutathione by utilizing fermentation method includes the following steps: adopting torula yeast as fermentation strain, after slant culture and seed culture, inoculating into fermentation culture medium to make share-flask culture or fermentation tank culture, adding L-cysteine into fermentation culture medium, increasing supply of L-cysteine in fermentation liquor so asto raise the synthesis speed and yield of the product glutathione. Said invention can be greatly favorable for implementing industrial production for preparing glutathione by using fermentation method.

Owner:JIANGNAN UNIV

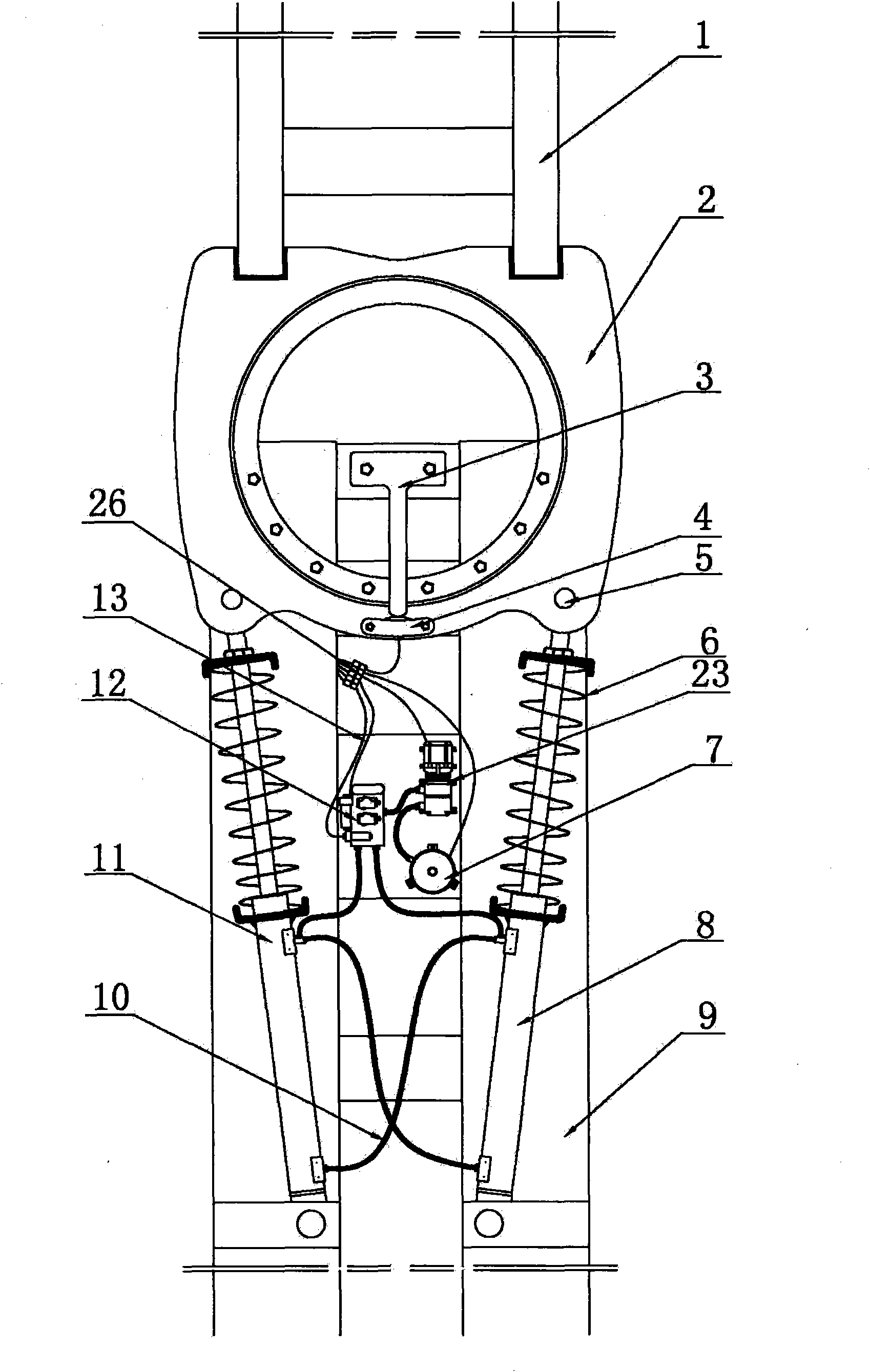

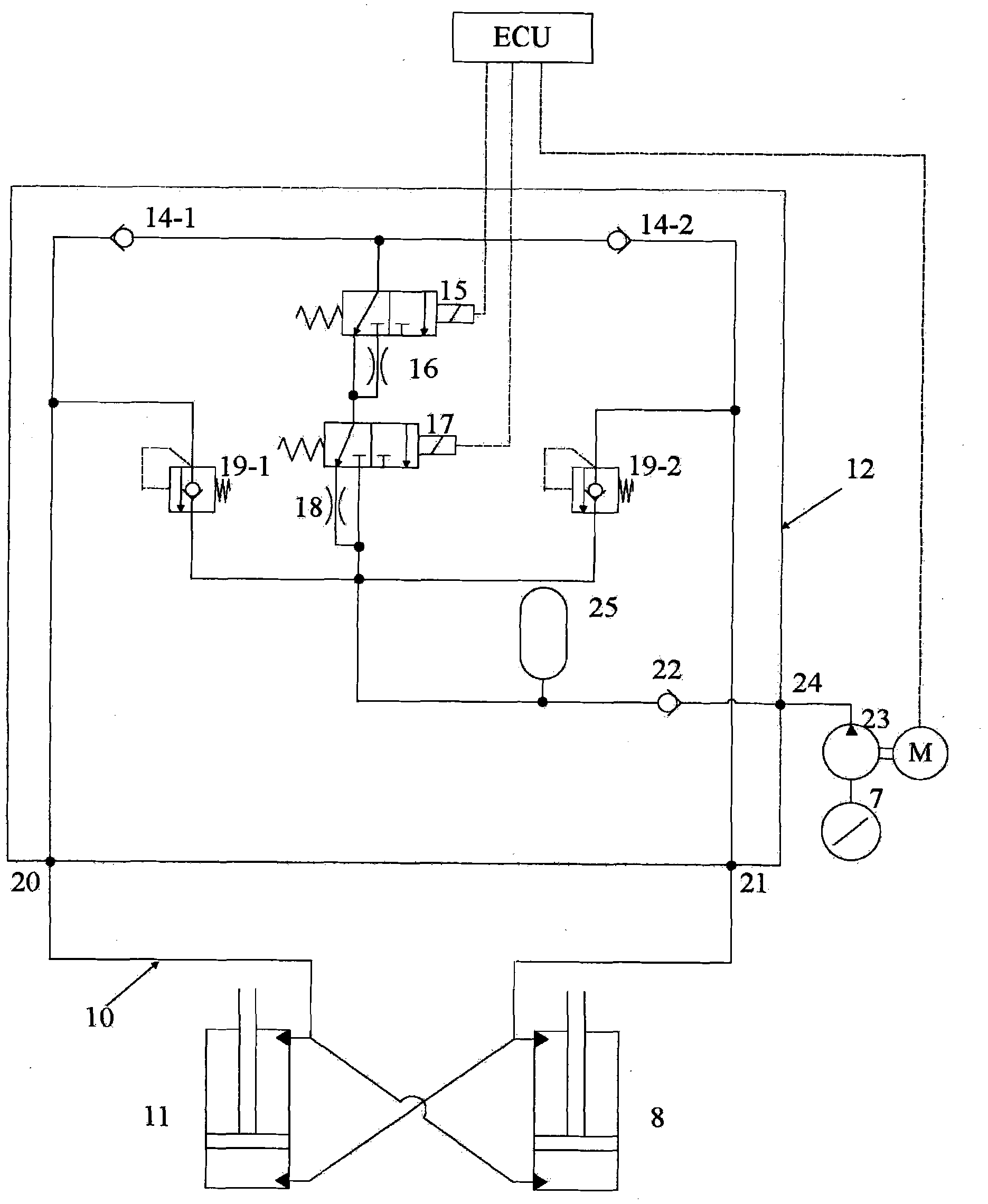

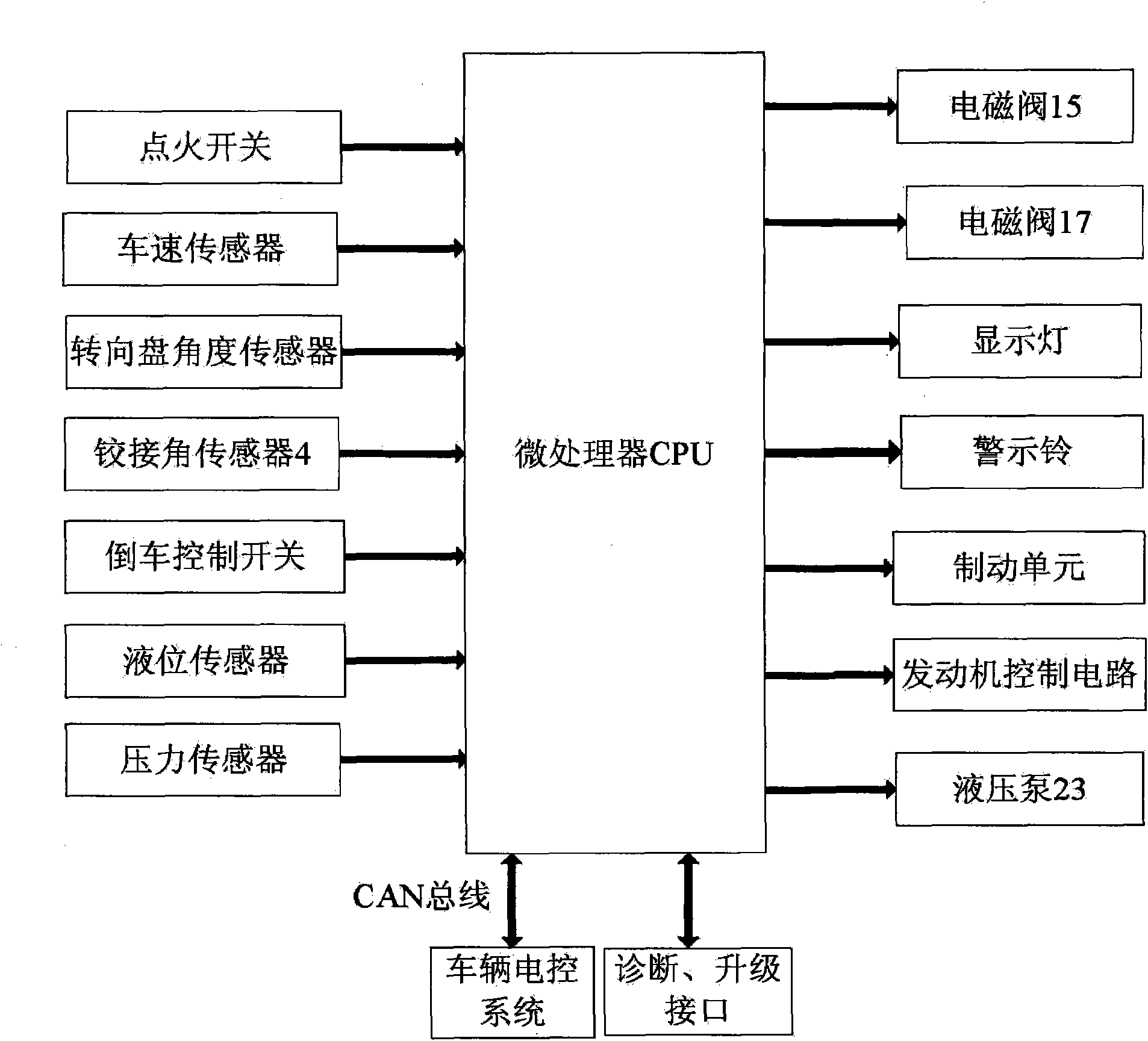

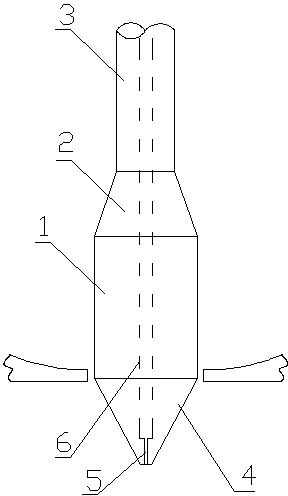

Bus chassis articulated system for urban bus rapid transit system and working method thereof

InactiveCN101934819ARealize localizationReduce manufacturing costFluid steeringElectrical steeringCross connectionHydraulic pump

The invention discloses a bus chassis articulated system for a urban bus rapid transit system and a working method thereof. The bus chassis articulated system consists of a turntable device, a hydraulic system and a system control unit ECU, wherein the turntable device comprises a turntable connected between a front turntable frame and a rear turntable frame; the central position of the turntable is movably connected with a mandril positioned in a vertical center line of the turntable; the upper free end of the mandril is connected with an articulated angle sensor; the hydraulic system comprises a left hydraulic cylinder, a right hydraulic cylinder, a hydraulic integrated block, a hydraulic pump and an oil tank which are arranged on the rear turntable frame and rotate together with the rear turntable frame; hydraulic arms of the left and right hydraulic cylinders are respectively sleeved with a cylindrical helical compression spring; front and rear cavities of the left and right hydraulic cylinders are in crossed connection and oil ways are communicated through the hydraulic integrated block; and the system control unit ECU comprises a microprocessor CPU. The bus chassis articulated system provides a larger torque during large-angle turning, realizes the self-locking function on the maximum articulated angle, and prevents a second axle from laterally sliding and front and rear bus bodies from shearing.

Owner:JIANGSU UNIV

Preparation method of optical fiber covering quartz capillary perform and continuous melting furnace equipment

The invention discloses a method of an optical fiber covering quartz capillary perform. The method comprises the following steps: firmly, preparing high-purity quartz sand with SiO2 content not less than 99.9999%; then, melting, drawing and forming through a continuous melting furnace, wherein a special former is formed by combining a middle cylindrical section and a lower frustum-shaped section; the drawn and formed optical fiber covering quartz capillary perform is 0.1-0.2mm in inner hole diameter, 0.05mm in outside diameter tolerance and 0.02mm in thickness deviation, and the perform, after being treated by dehydroxylation, is not more than 1ppm in hydroxyl value. By rice natural crystal raw materials in China, the preparation method realizes domestication of optical fiber covering pipes; the excellent high-quality and high-purity optical fiber covering quartz capillary perform produced by the method completely achieves a quality standard of international similar products.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

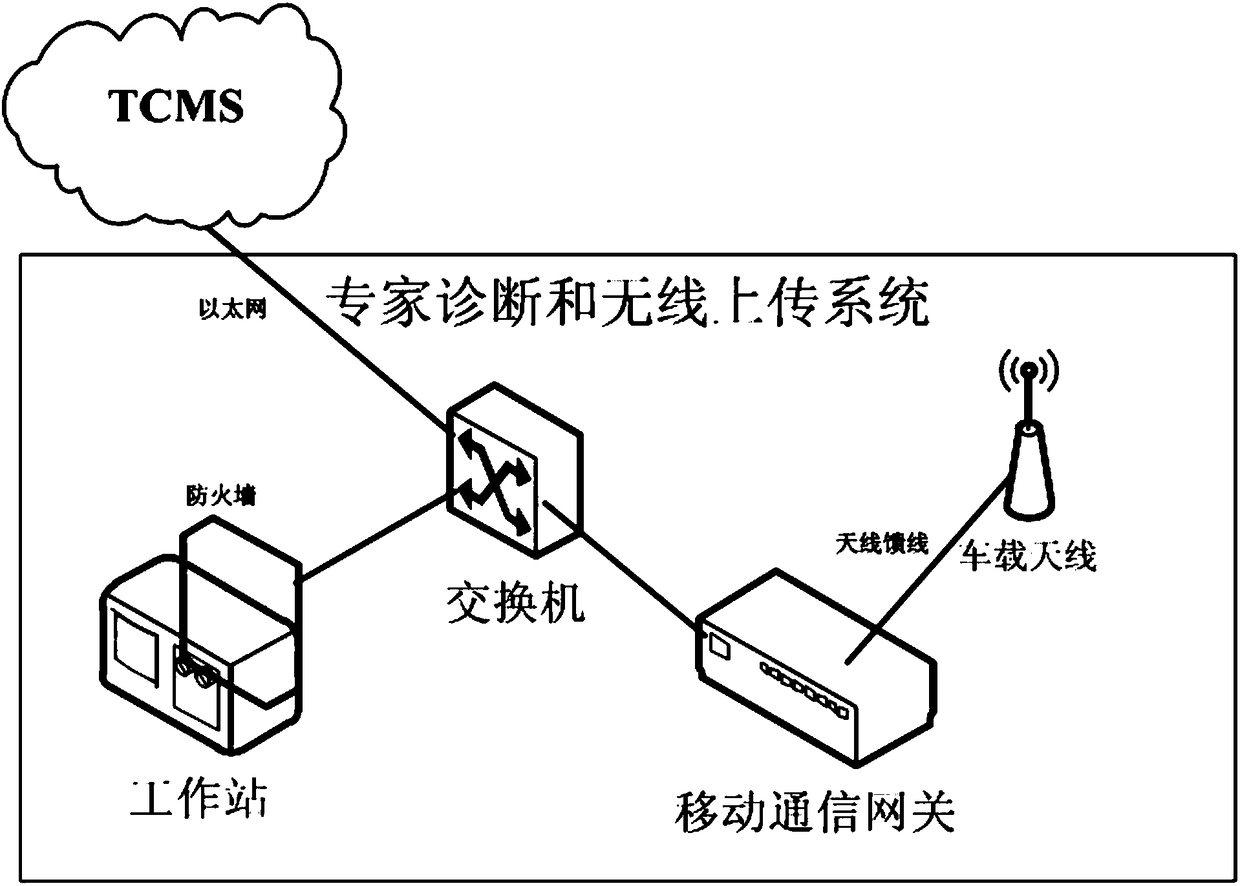

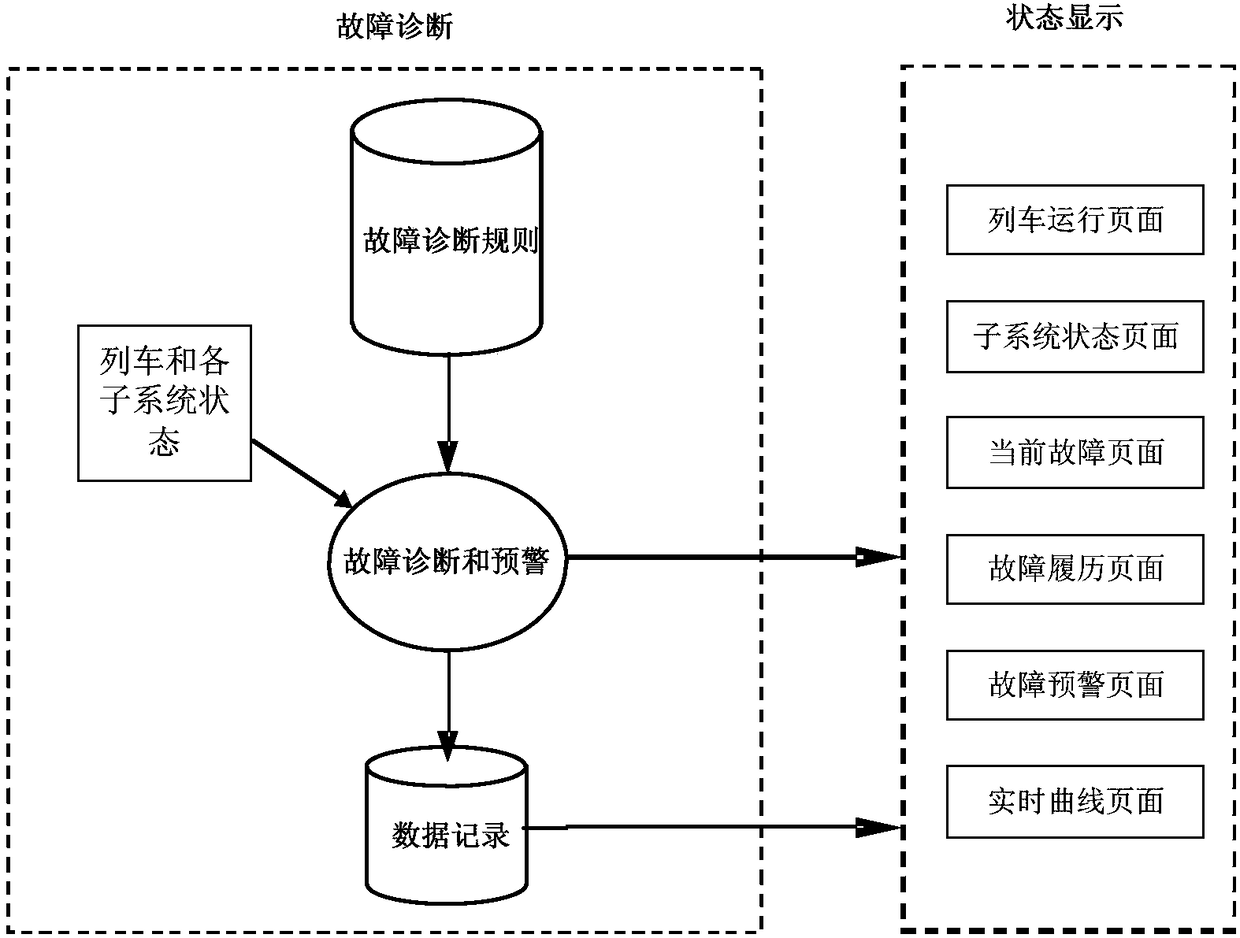

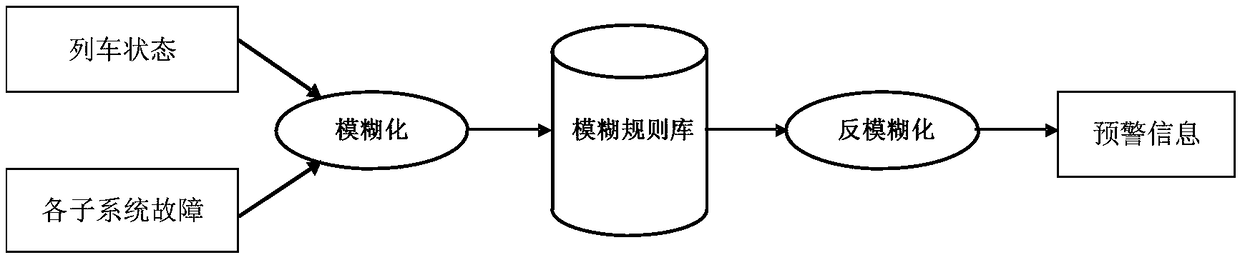

Wireless uploading and expert diagnosis system for medium and lower speed magnetic levitation train based on TRDP (Train Real-time Data Protocol) protocol

InactiveCN108173929AMonitoring operationImprove securitySignalling indicators on vehicleData switching networksReal-time dataLow speed

The invention discloses a wireless uploading and expert diagnosis system for an intermediate and low speed magnetic levitation train based on a TRDP (Train Real-time Data Protocol) protocol. The system comprises an expert diagnosis system and a wireless uploading system. The expert diagnosis system is used for carrying out real-time monitoring, fault smart diagnosis and fault early warning and isisolated with a train control and management system (TCMS) through utilization of a firewall based on the TRDP protocol, thereby preventing a network attack. The wireless uploading system is used forcommunicating with the TCMS and the expert diagnosis system through utilization of the Ethernet, obtaining train fault, state and early warning information and uploading the information to a ground server through utilization of wireless network. According to the system, vehicle operation is monitored visually in forms such as a chart and a curve, information such as vehicle states and faults is wirelessly uploaded, an operation control center (OCC) and a vehicle depot control center (DCC) can monitor train states remotely in real time, and the train operation security and train maintainabilityare improved.

Owner:CRRC DALIAN CO LTD

Driving rod of driving mechanism of nuclear power station control rod and preparation method thereof

InactiveCN103789684AReach mechanicalMeet the requirementsNuclear energy generationReactors manufactureElectricityNuclear power

The invention discloses a driving rod of a driving mechanism of a nuclear power station control rod and a preparation method of the driving rod. The preparation method comprises the following steps: 1) selecting raw materials, smelting by using an electric furnace, refining in AOD (Argon Oxygen Decarburization) and refining by using an LF (Low Frequency) furnace so as to obtain molten iron; 2) casting the molten iron into an electrode; 3) remelting the electroslag of the electrode to obtain a steel ingot, wherein the steel ingot comprises the following components in percentage by weight: less than or equal to 0.150% of C, less than or equal to 1.00% of Mn, less than or equal to 1.00% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 0.50% of Ni, 11.50-13.50% of Cr, less than or equal to 0.06% of Co, less than or equal to 0.001% of B and the balance of Fe; 4) fogging the steel ingot into a tube blank, hot-rolling and hot-drilling the tube blank so as to obtain a pierced billet; and 5) processing the pierced billet into the driving rod of the driving mechanism of the nuclear power station control rod. When being used in a CRDM (Control Rod Drive Mechanism), the CRDM driving rod prepared according to the method disclosed by the invention is ideal in wear-resistance and free of deflection or deformation and has certain rigidity when being meshed with a hook claw and can be safely operated under the condition of load, the service life meets the CRDM design provision and the national standard requirements, the quality also meets the advanced level of similar products in other countries, and domestication of the CRDM driving rod is achieved.

Owner:中广核工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com