Bracing steel sleeve flection restriction support component

A technology of supporting components and buckling constraints, which is applied to building components, earthquake resistance, etc., can solve the problems of unsuitable steel materials and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

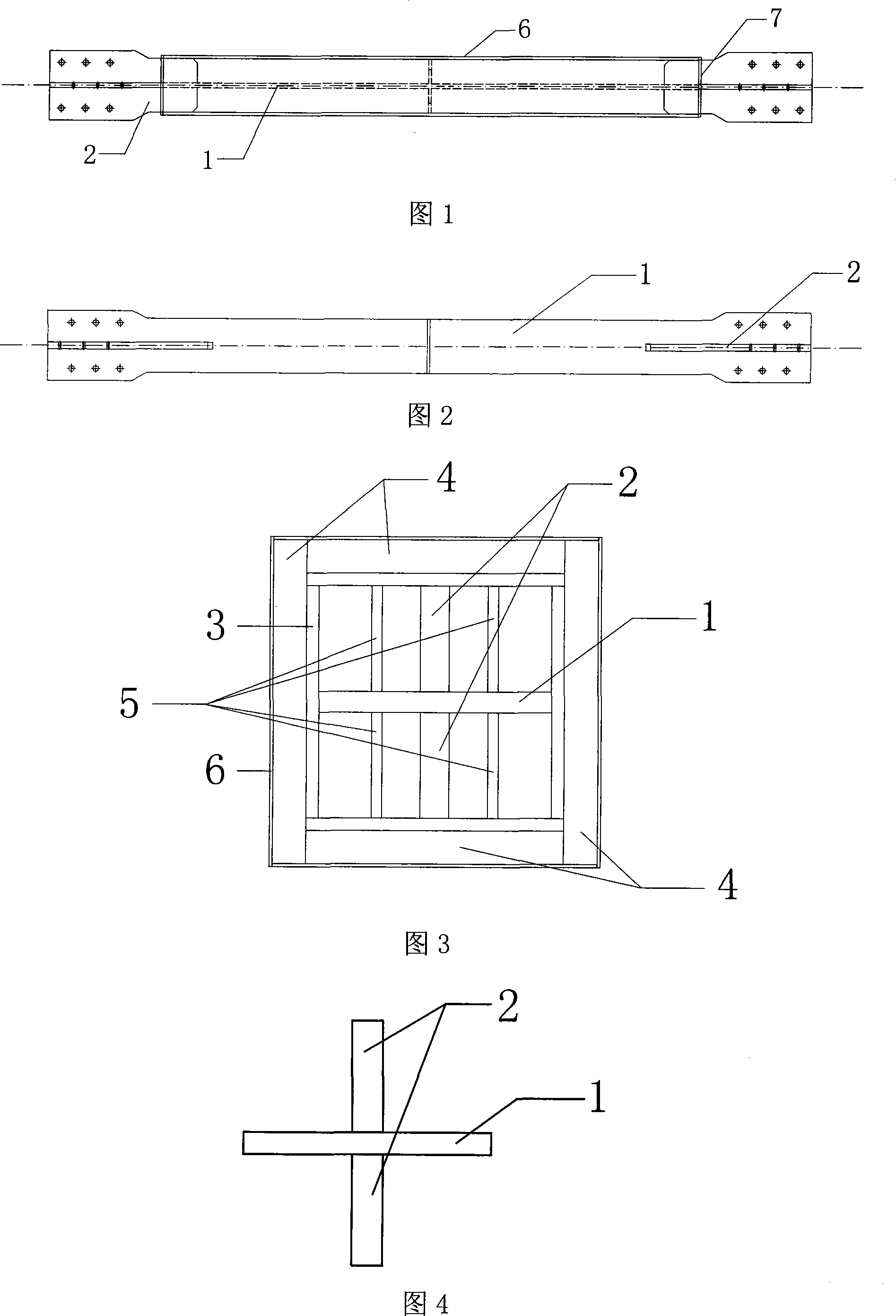

[0047] Please refer to Fig. 1-5, as can be seen from the figure, the present invention mainly comprises: core material part, inner sleeve part, outer sleeve, wherein core material part is made up of core plate 1 and core plate stiffener 2 (as shown in Fig. 2, 4 As shown), the inner sleeve part is composed of the inner sleeve wall plate 3, the inner sleeve stiffener 4 and the core plate constraint plate 5, and the outermost layer is the outer sleeve (as shown in Figure 5).

[0048] Construction of the present invention:

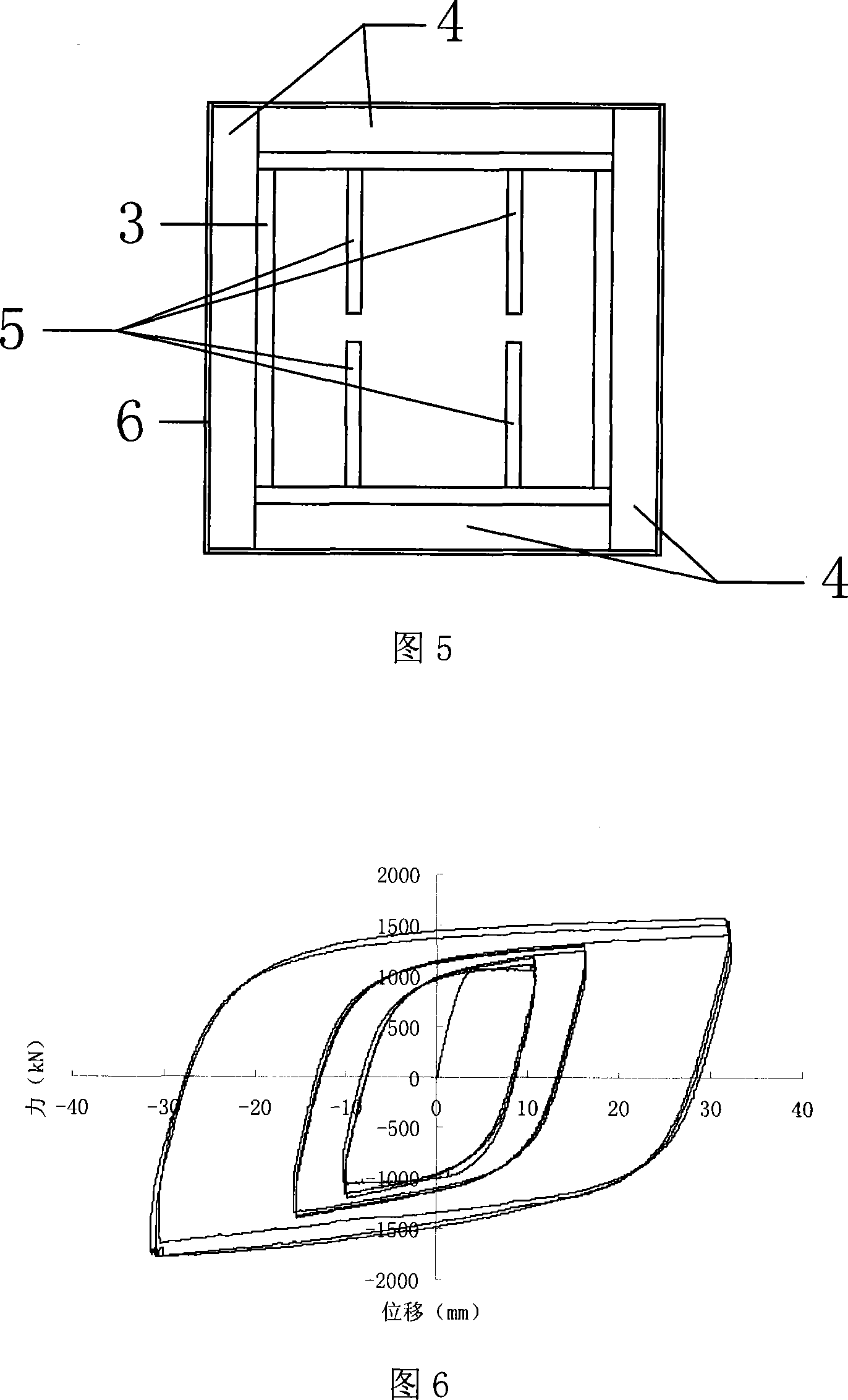

[0049] 1. Since the sleeve must be able to have a good restraint effect on the out-of-plane buckling of the core plate, the member of the present invention uses an inner sleeve and a ribbed plate to make the core plate restraint plate 5 and the core plate 1 tight (that is, make the core plate There is no gap between the plate restraint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com