Patents

Literature

2296 results about "Earthquake resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Earthquake Resistance. Earthquake-resistant structures are structures designed to withstand earthquakes. While no structure can be entirely immune to damage from earthquakes, the goal of earthquake-resistant construction is to erect structures that fare better during seismic activity than their conventional counterparts.

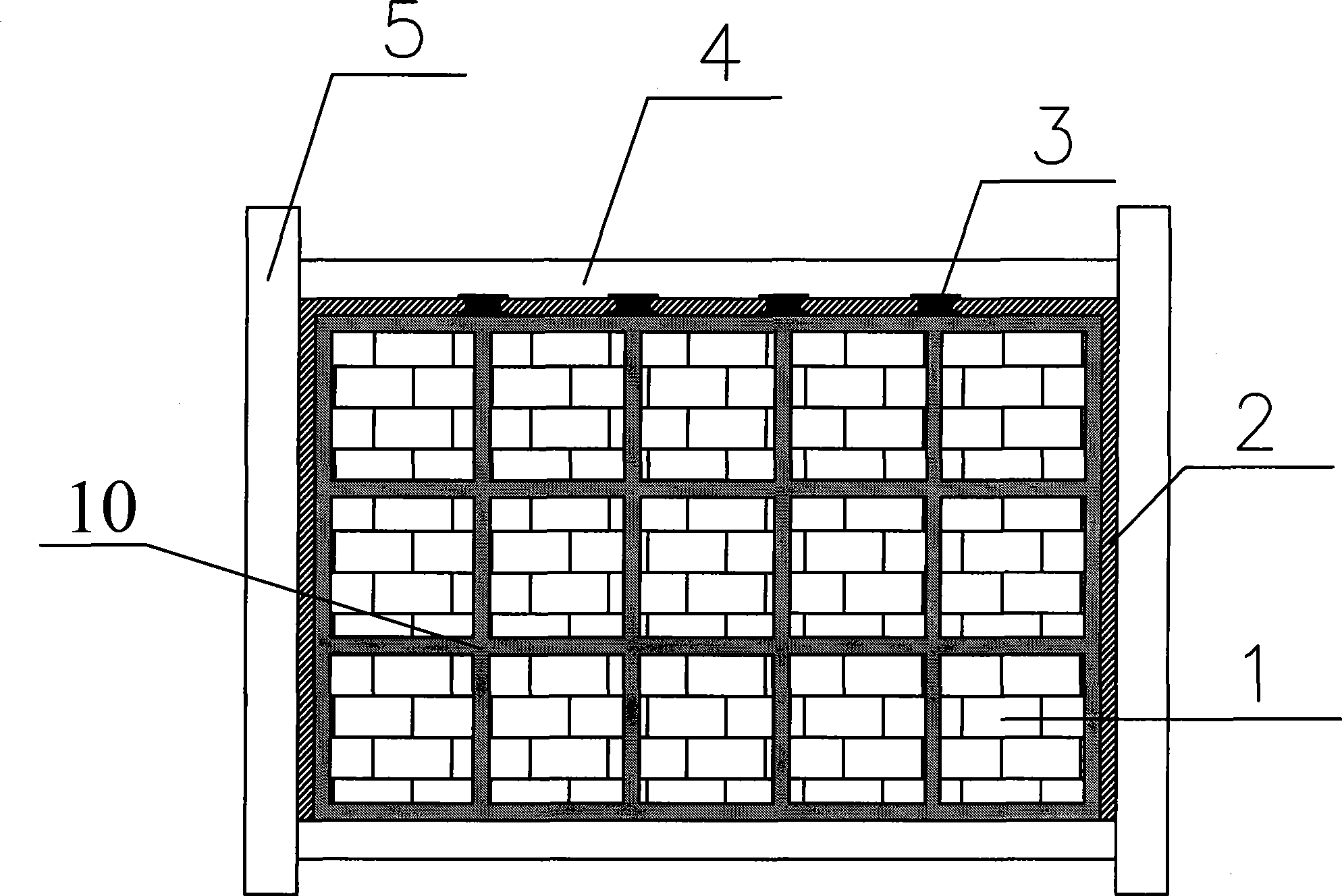

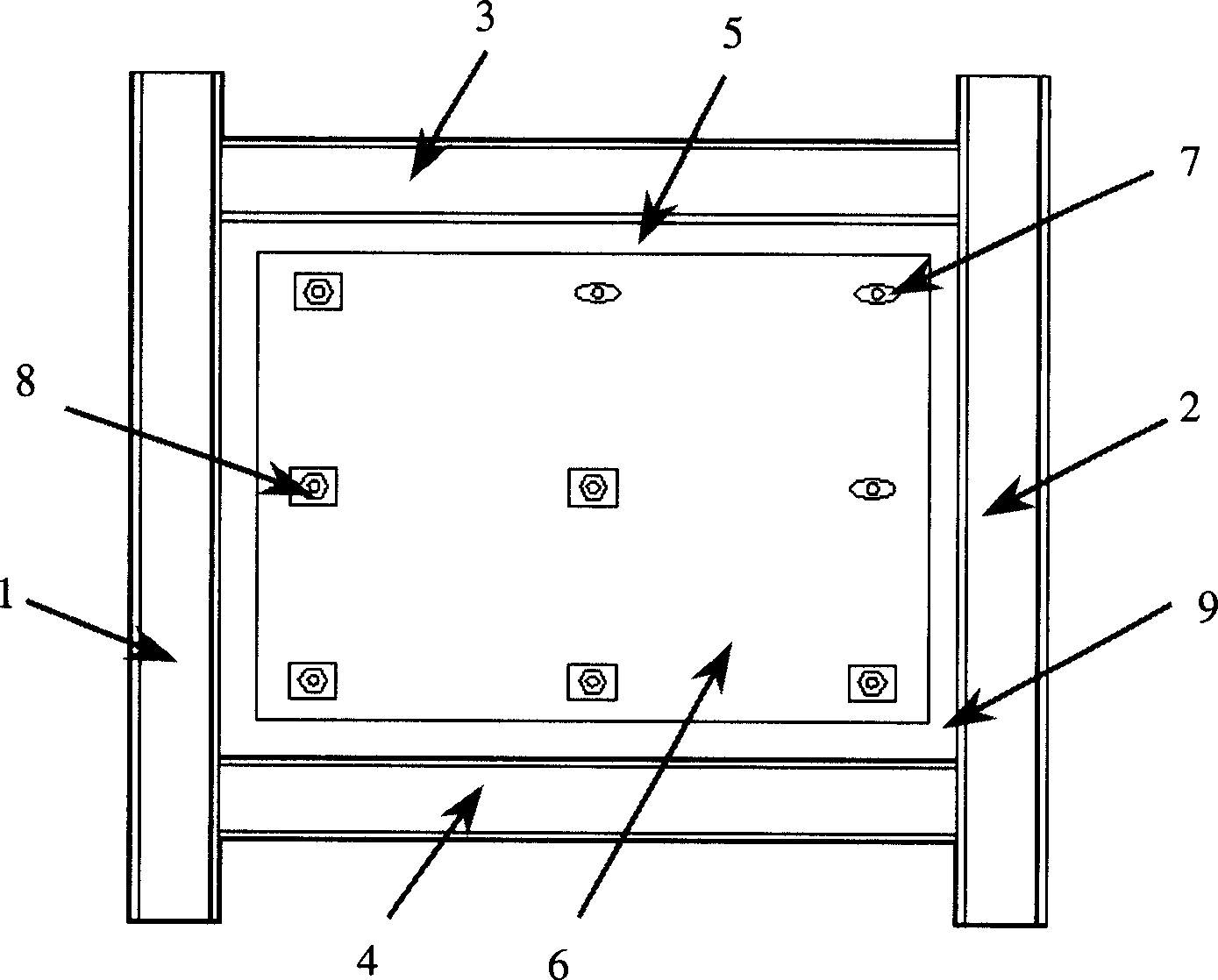

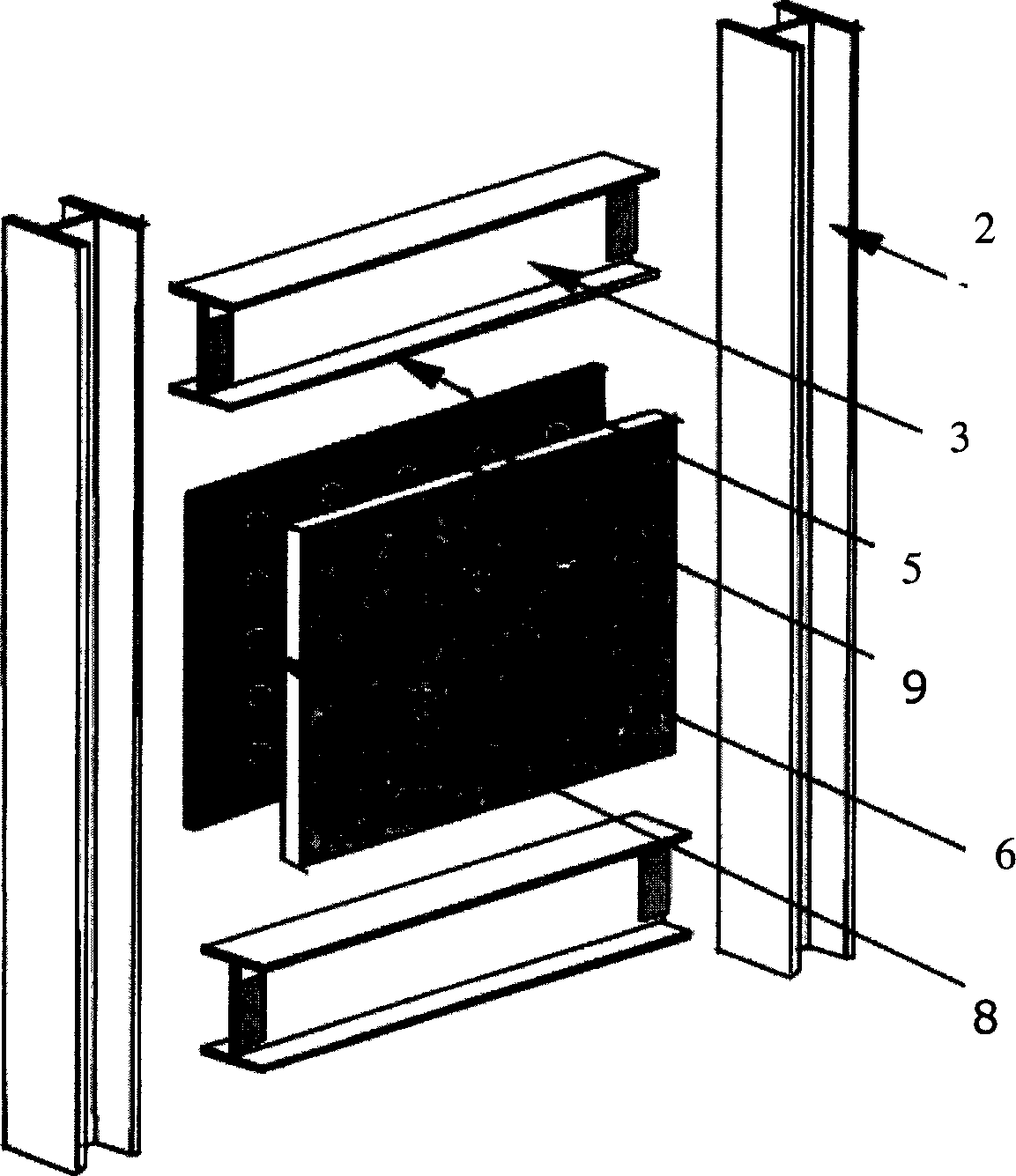

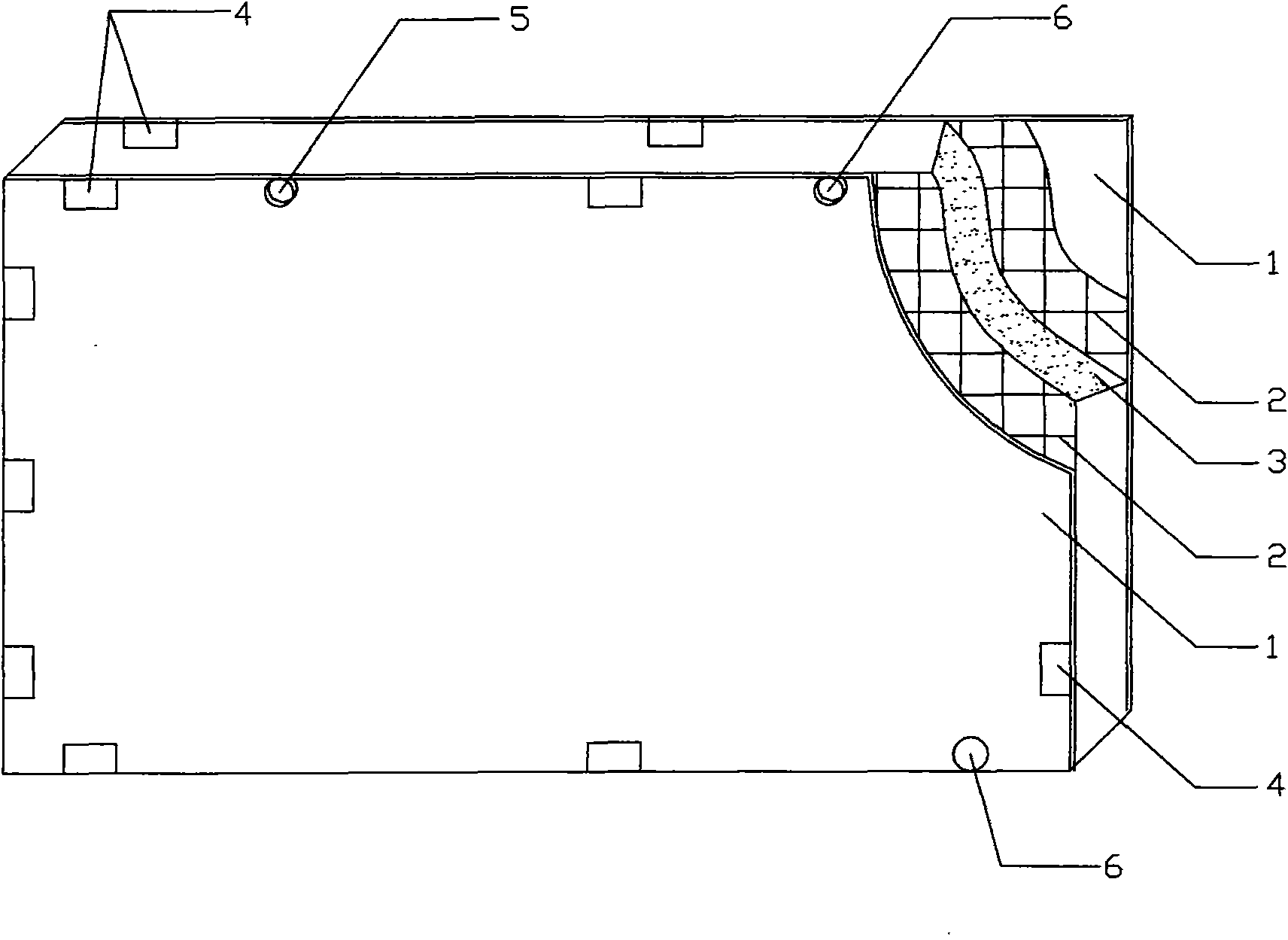

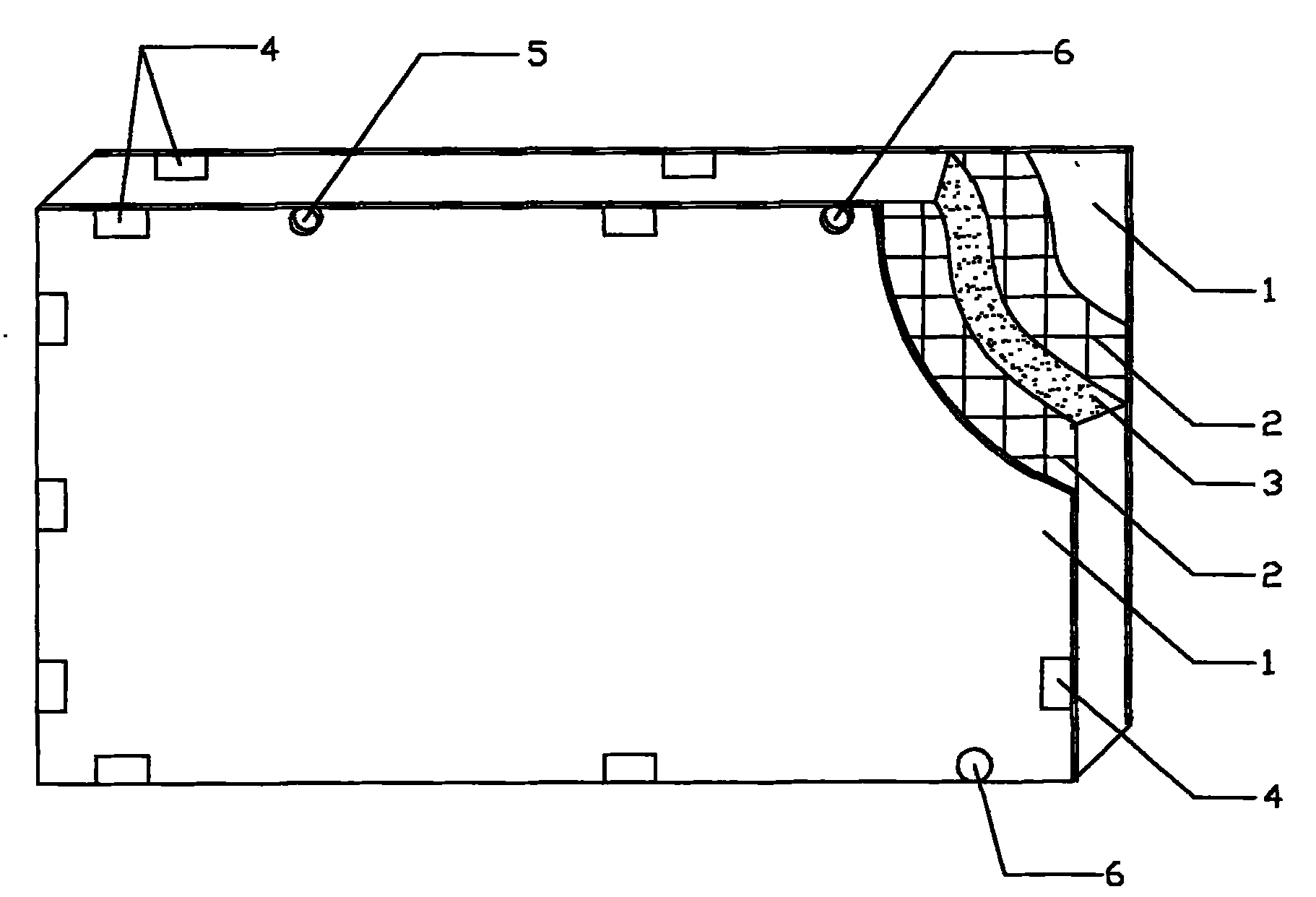

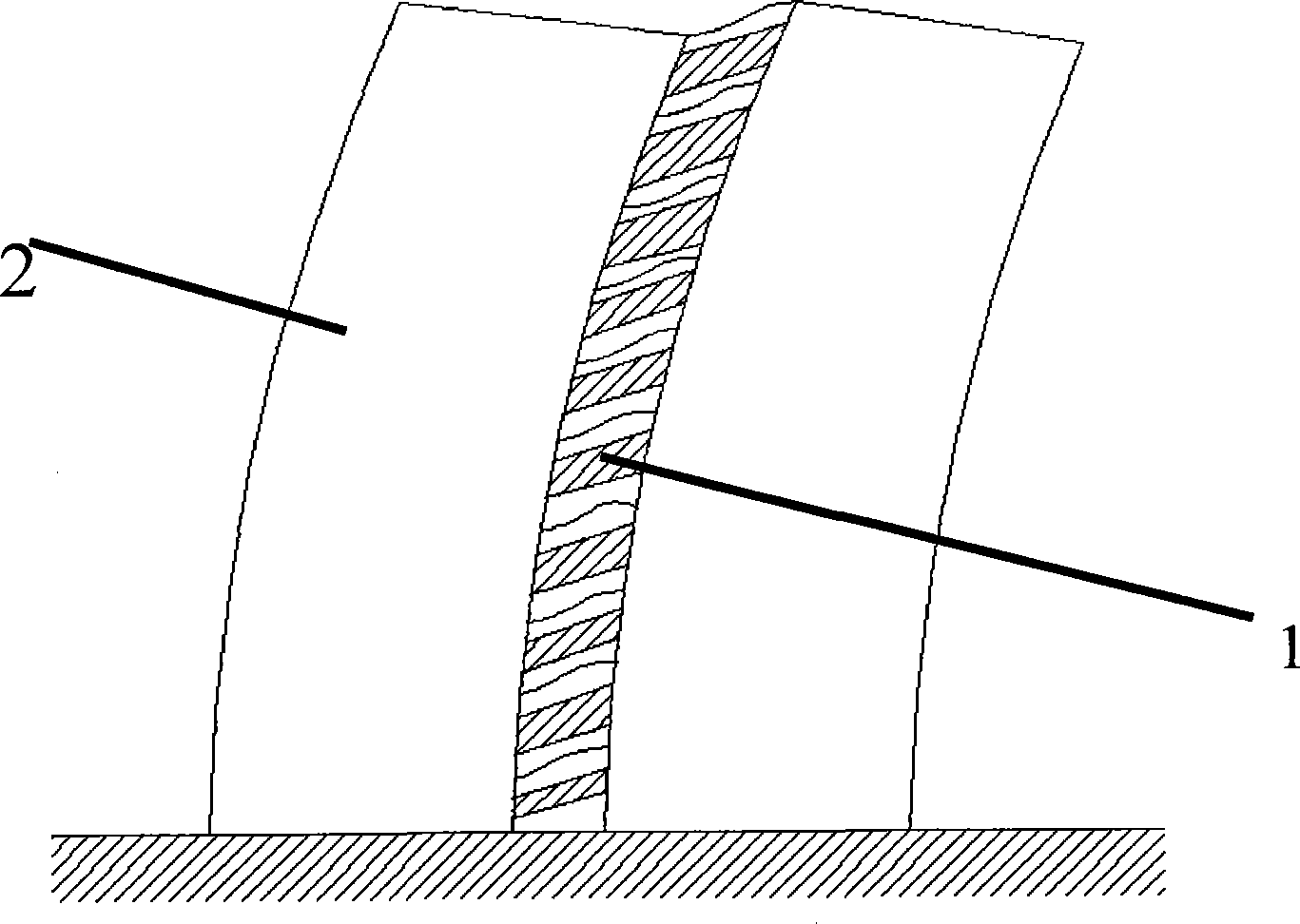

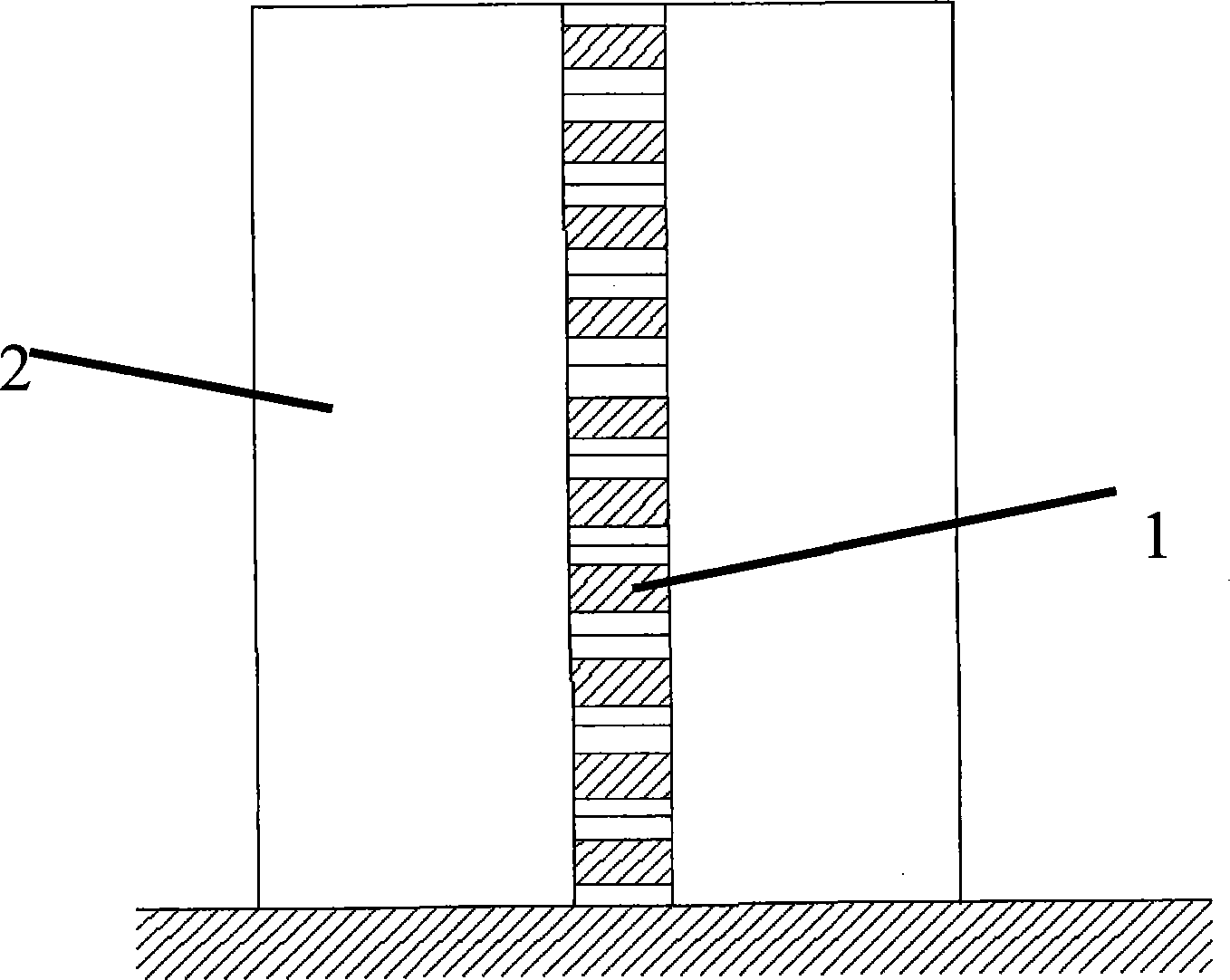

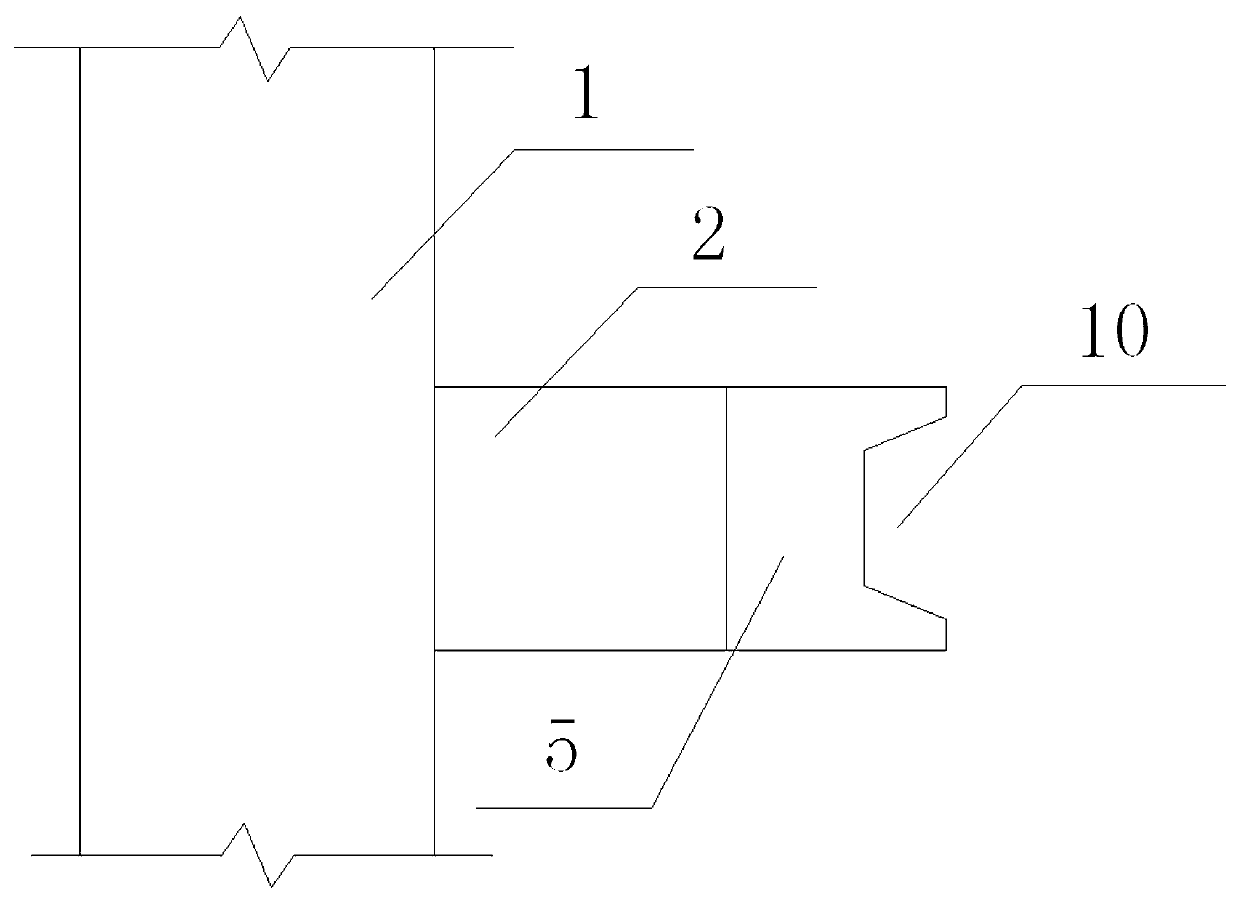

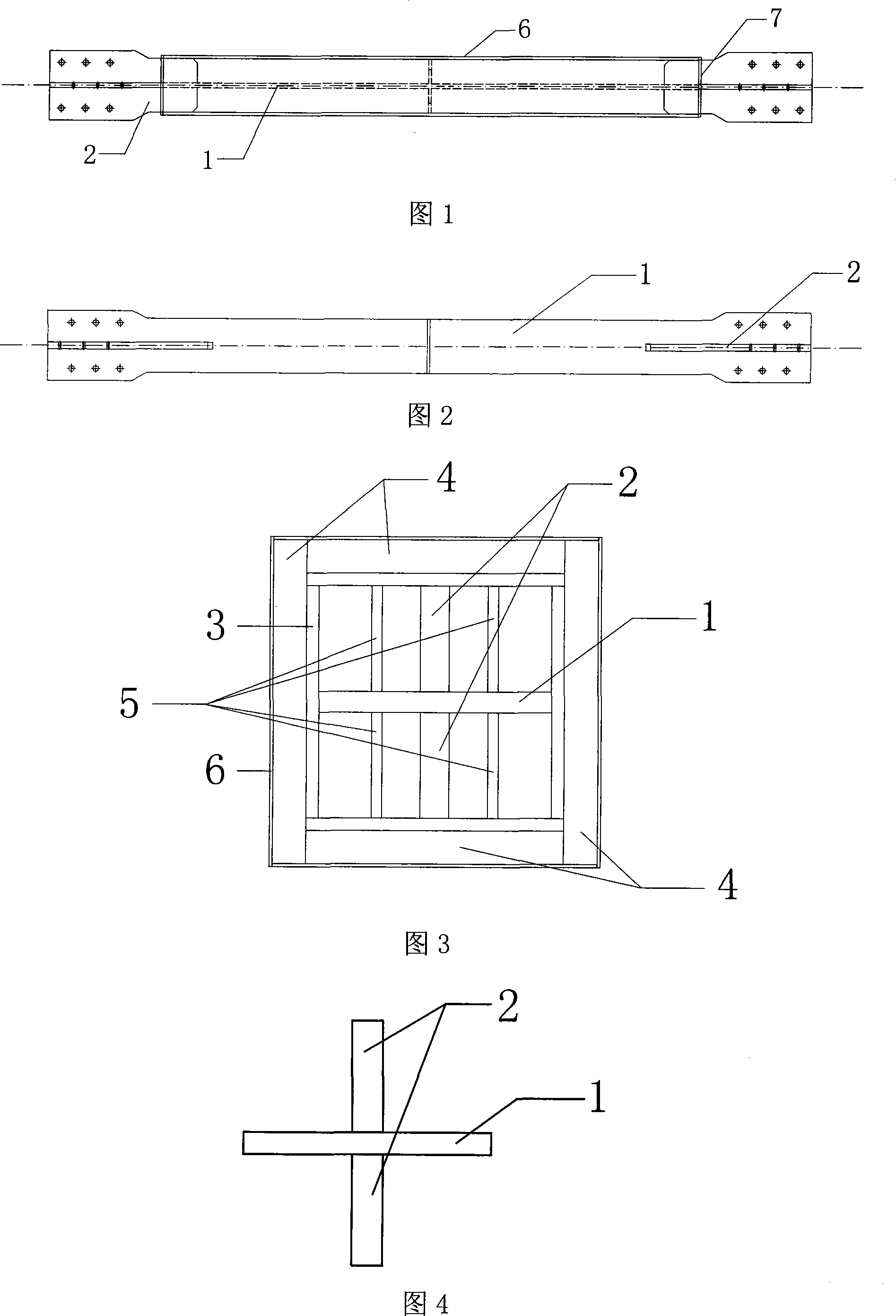

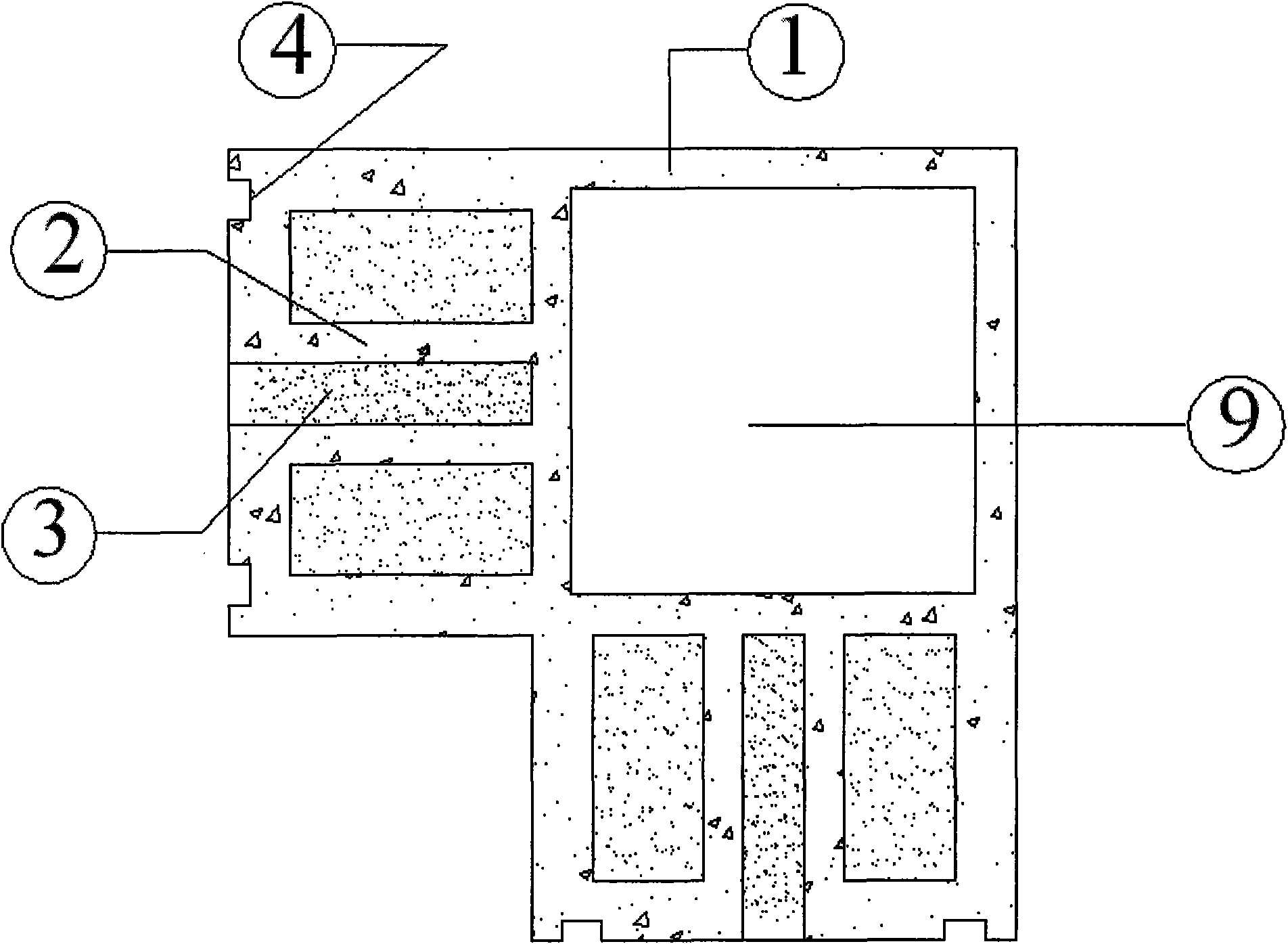

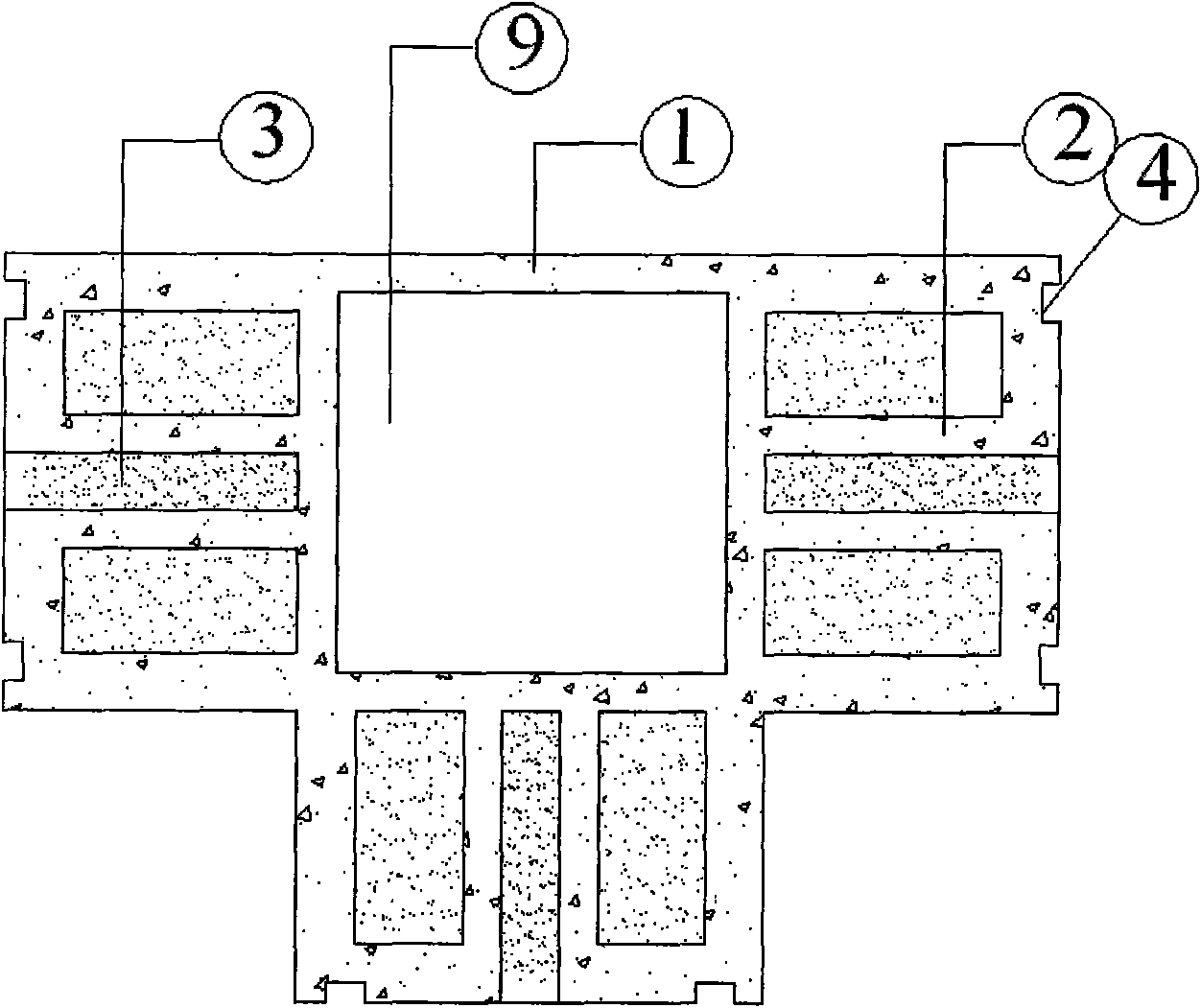

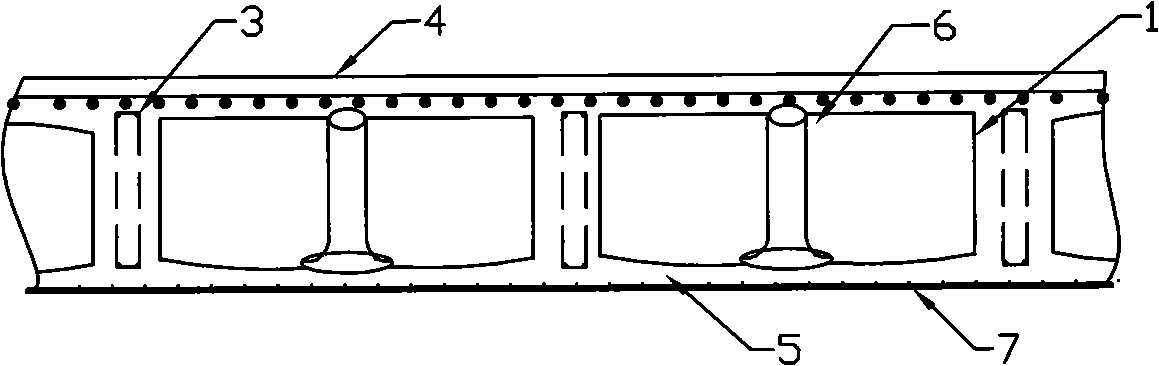

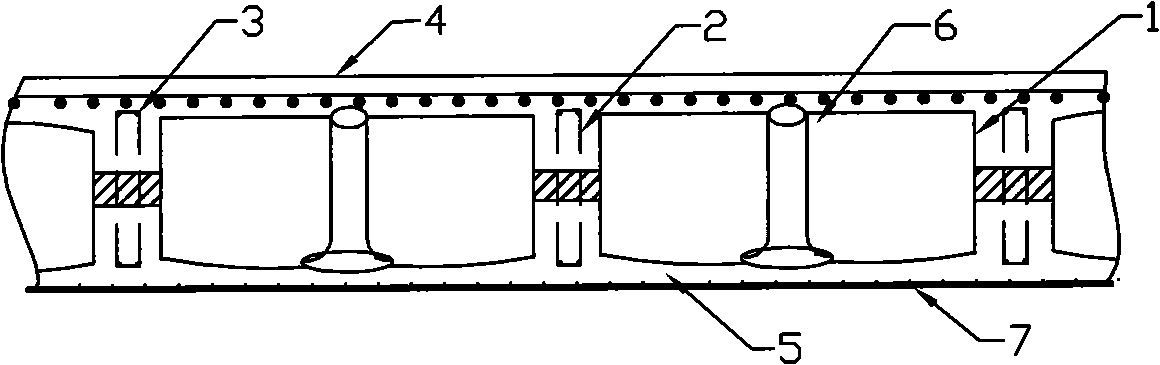

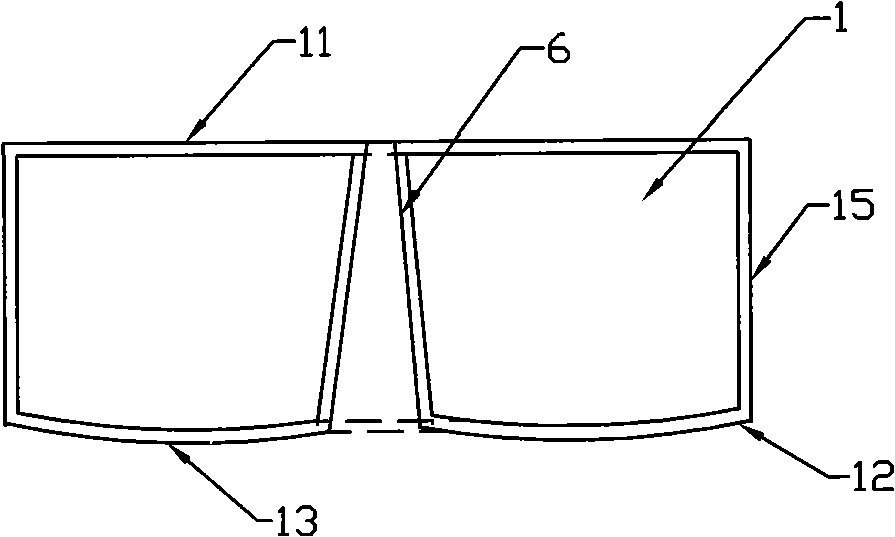

Novel energy-consumption shock-absorbing filling wall board used for frame structure

InactiveCN101476360ADynamic characteristics are not affectedAvoid detrimental effects on seismic performanceWallsShock proofingSlagReduction function

The invention belongs to the technical filed of building material, and in particular relates to a novel energy consumption and vibration reduction infilled wall board for a frame structure, wherein both sides of a ribbed composite wall board are connected with frame columns; flexible filling materials are arranged between the ribbed composite wall board and the frame columns; the top of the ribbed composite wall board is connected with frame beams through one or more than one slipping device; and the ribbed composite wall board is manufactured by taking a concrete sash as a framework and embedding gas-filling silicate building blocks which take furnace residue and fly ash as main raw materials. The novel energy consumption and vibration reduction infilled wall board for the frame structure has the advantages that the wall board does not participate in earthquake resistance under the condition of small earthquake, so that adverse effects of an infilled wall on the dynamic property and the anti-earthquake performance of the frame structure are avoided; the energy consumption and vibration reduction function of a ribbed composite wall is given full play under the condition of medium earthquake and large earthquake, and the anti-earthquake defense line and the safety margin of the frame structure under the condition of large earthquake are increased; and replacement of the whole wall body or local damaged building blocks can be performed according to the damage conditions after earthquake, so that the repair cost is low and the construction speed is quick.

Owner:BEIJING JIAOTONG UNIV

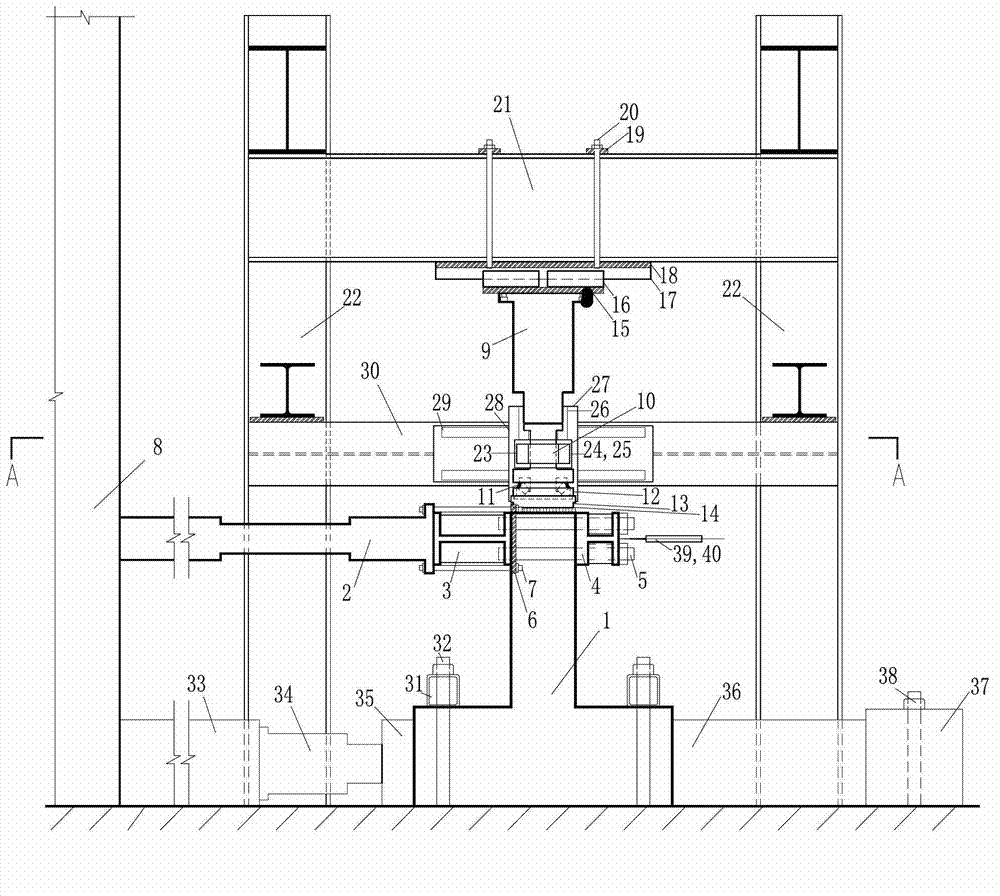

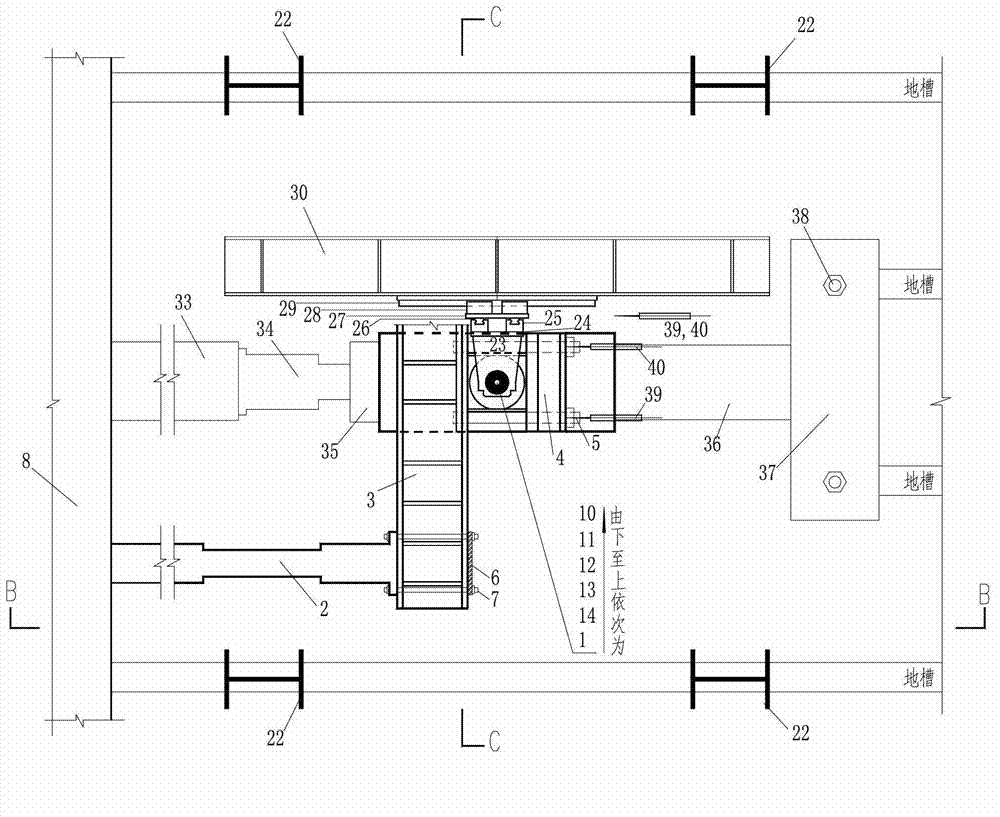

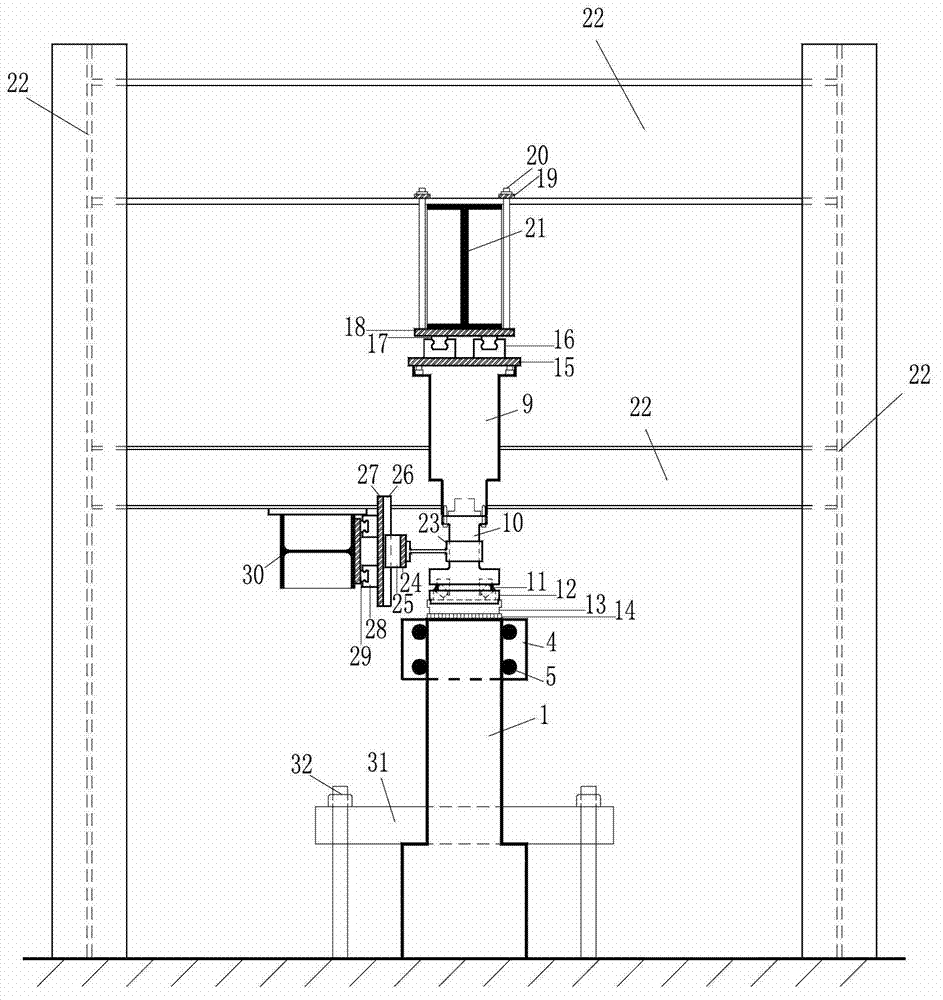

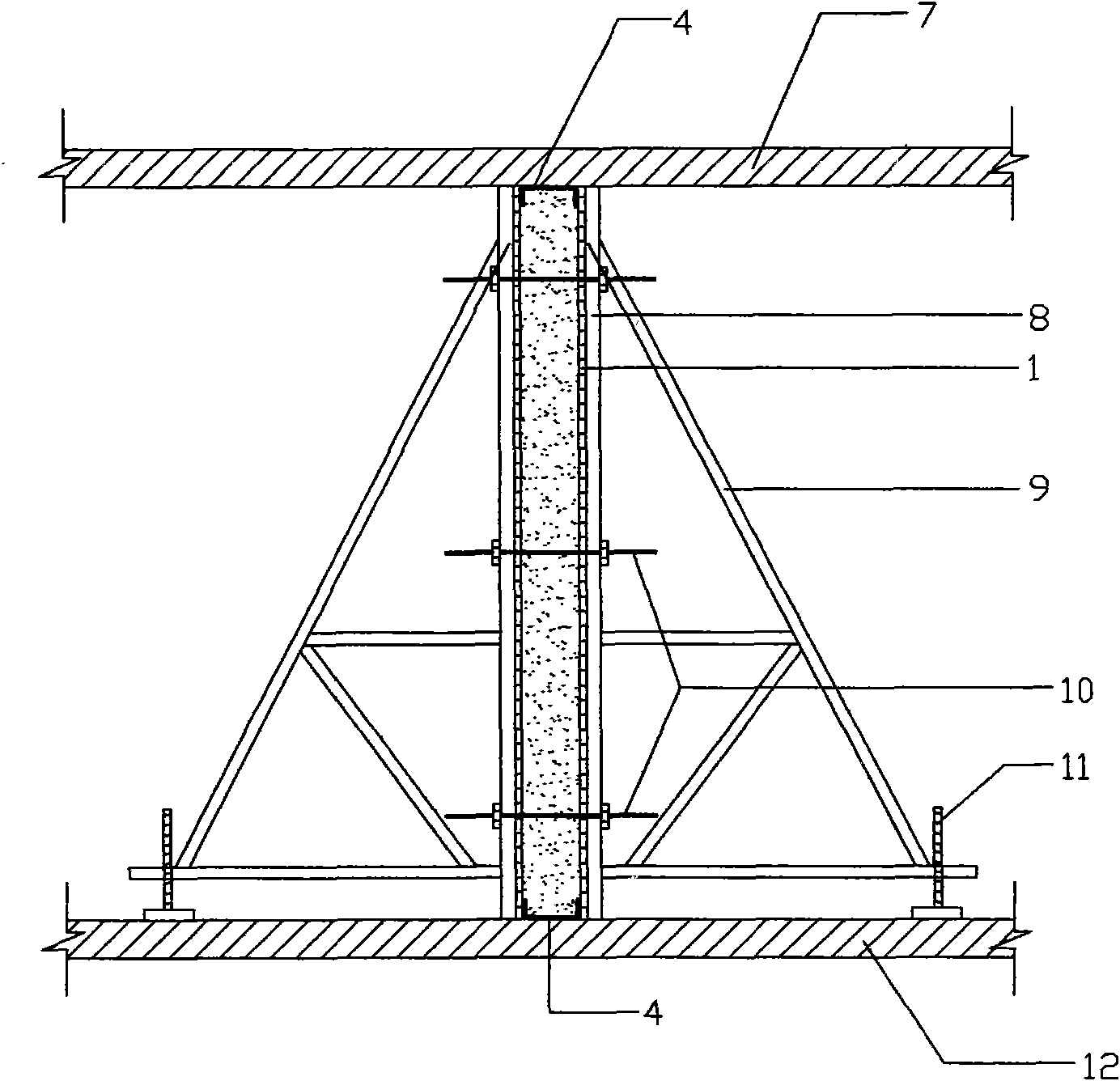

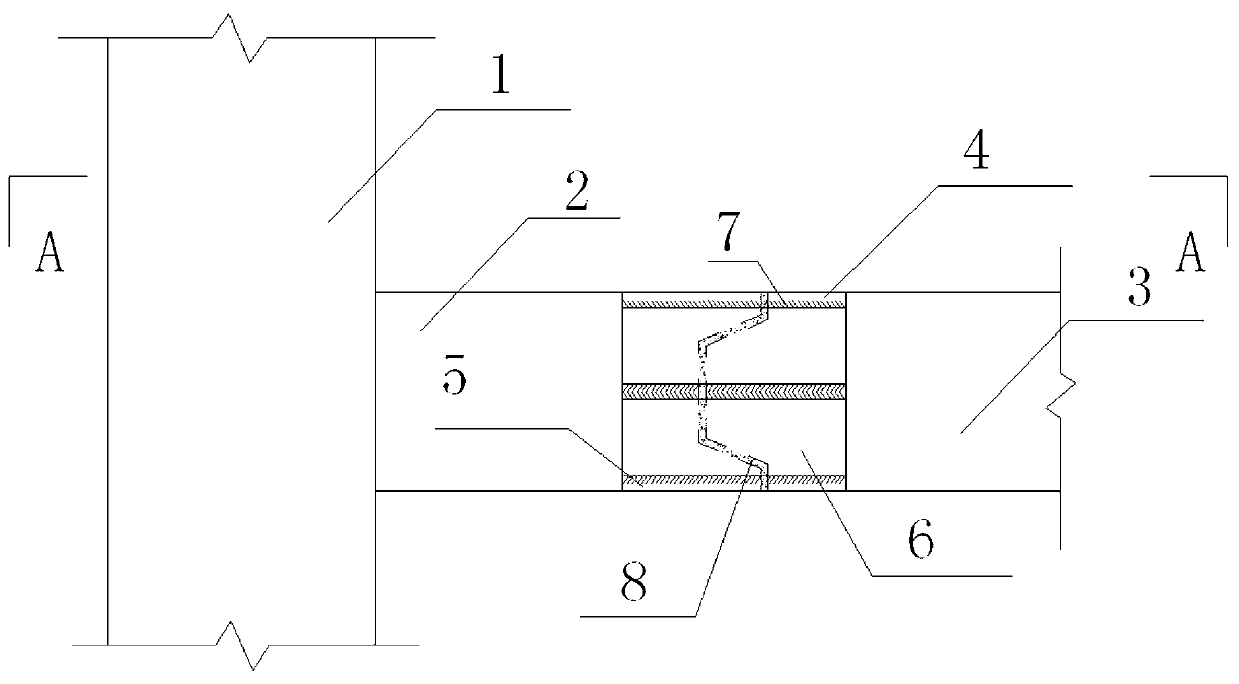

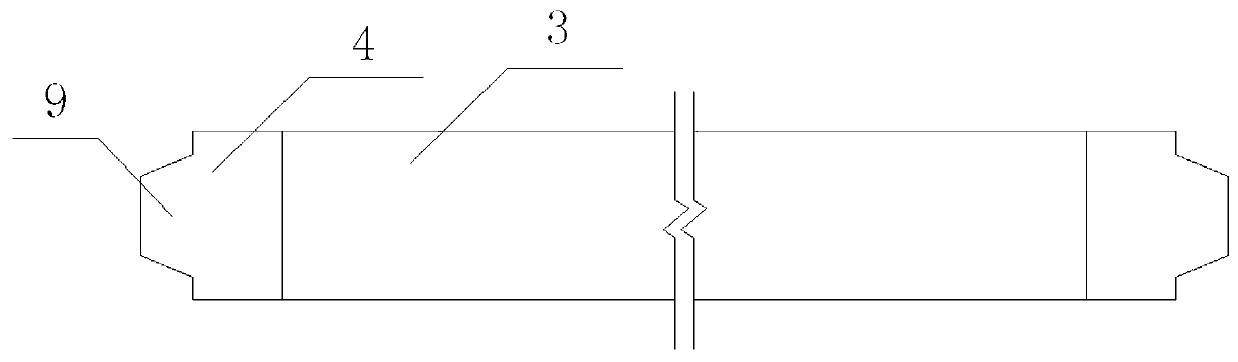

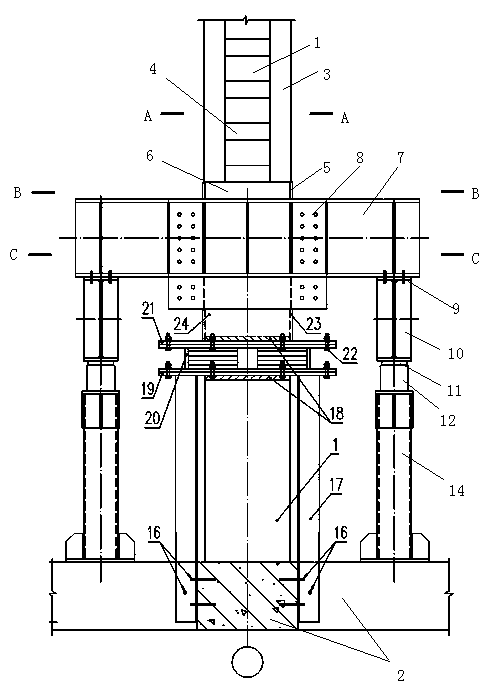

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

Buckling and energy consumption preventing steel plate shear wall

The invention involves a kind of data organization project area of technology to guard against the flexure to consume energy the steel plate shearing force wall. Its characteristic causes to state the shearing force wall to inlay the steel plate and two sides periphery concrete lap by in is composed; In states inlays the steel plate to use the low yield point high ductility steel products or the high strength high ductility steel products; States the periphery concrete lap to use the common concrete slab; States the edge component is composed by the marginal beam and the edge column; In states inlays the steel plate with to state between the concrete lap through to penetrate three blocks the bolts or the pre-stressed bold fastening, in states on the concrete lap to open the ellipse hole in order to the bolt passed through also has the enough slipping space; In states the concrete lap to open the hole site with to bury the trough section to give strengthens. And is strengthening the channel steel the corresponding position to open oval hole. The invention provides guards against the flexure steel plate shearing force wall is the high-rise construction structure or other structures a kind of new anti- lateral force components, it has the earthquake resistance performance well, the ductility is high, consumes energy stagnates winds full and so on the characteristic, is a kind of superior earthquake resistance consumes energy the component.

Owner:TSINGHUA UNIV

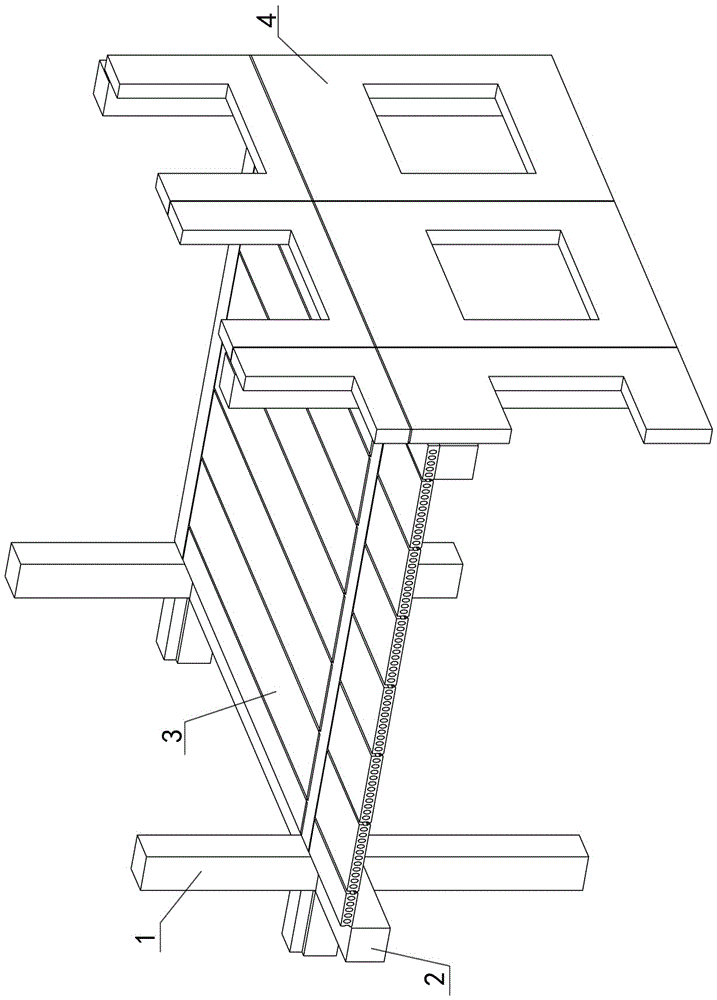

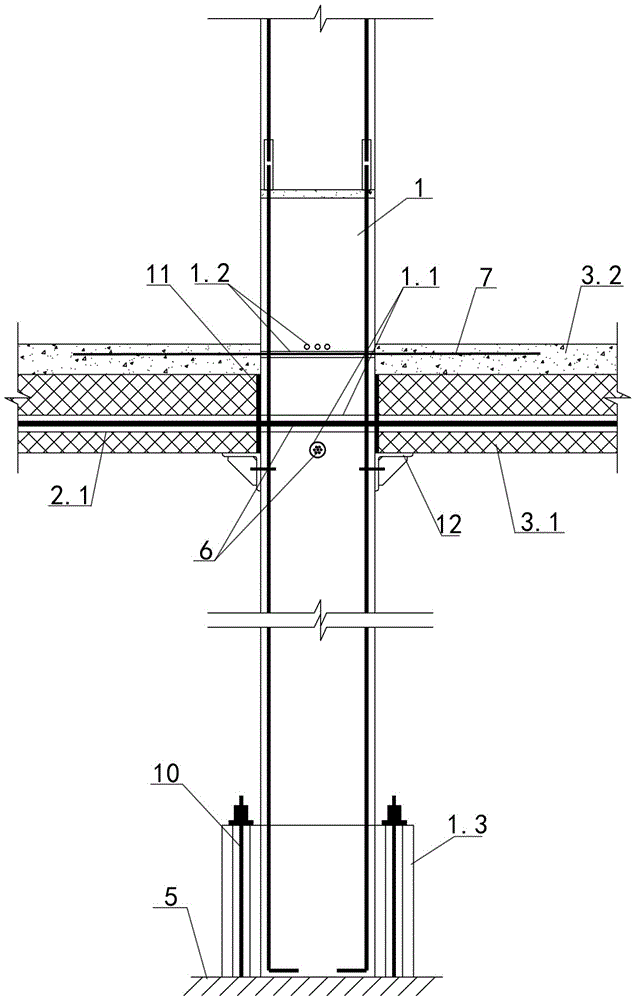

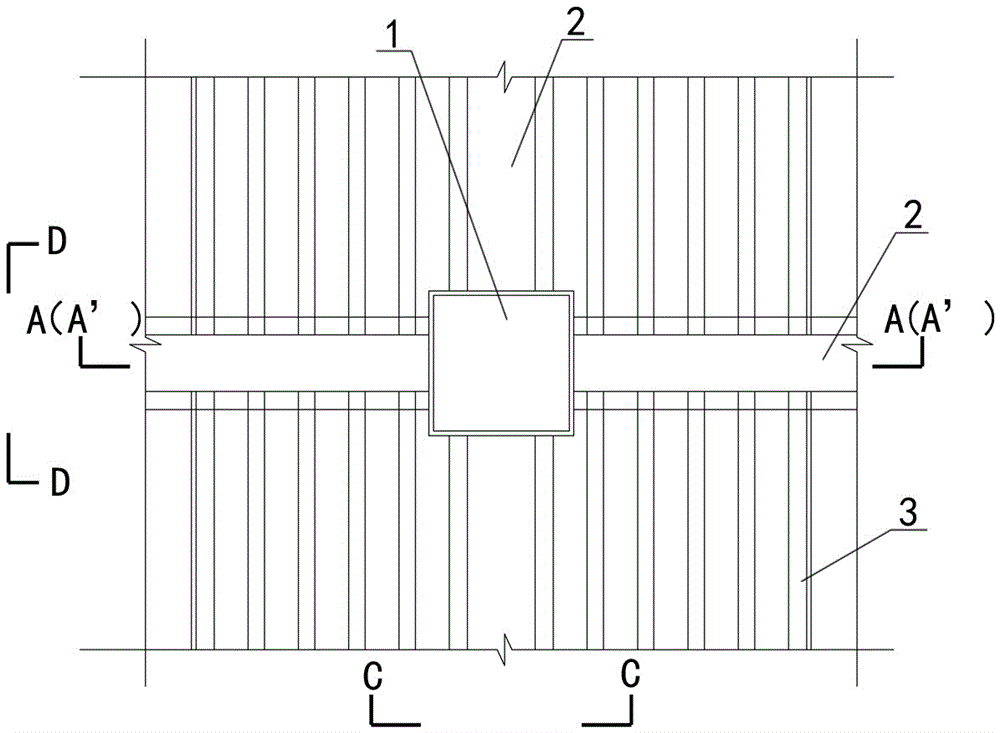

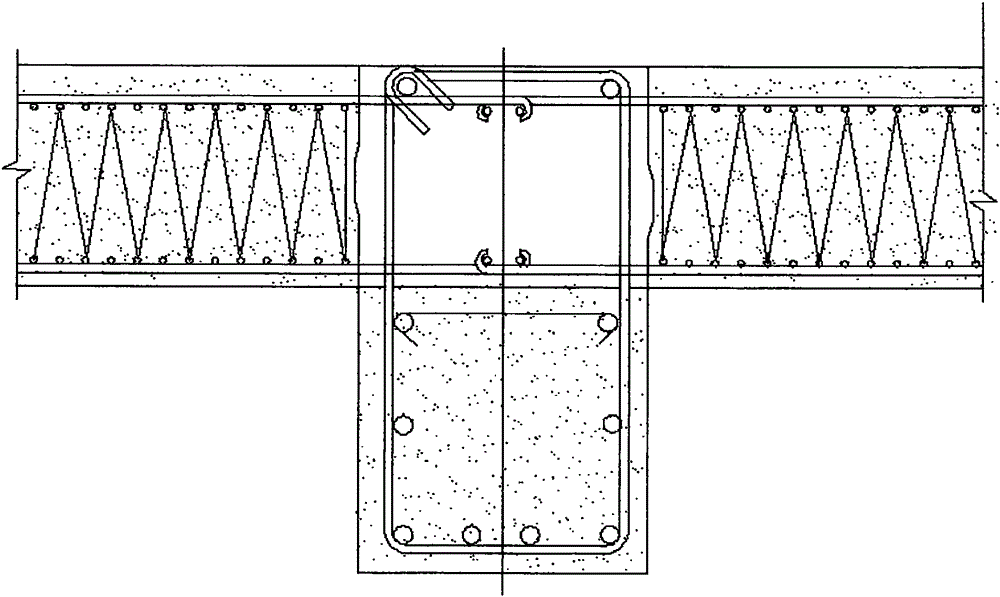

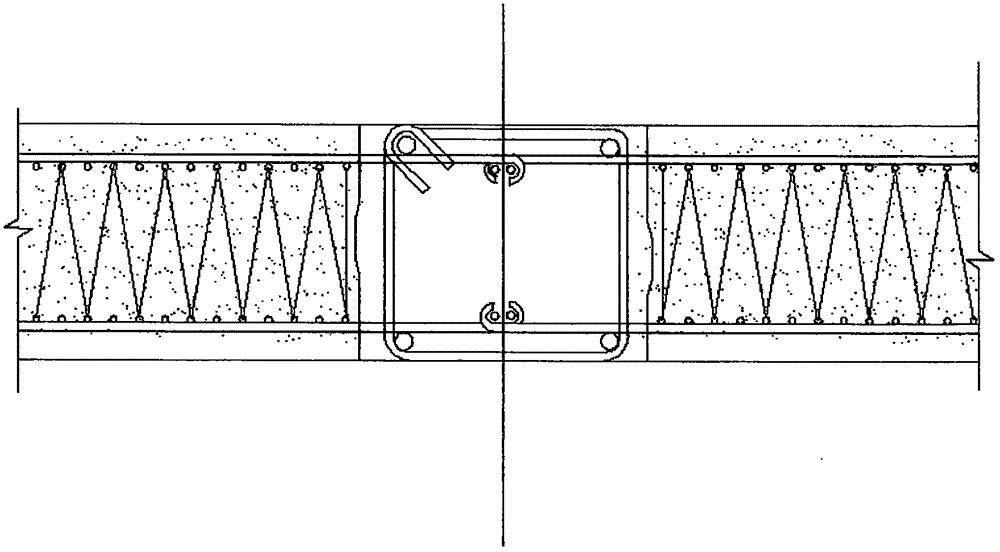

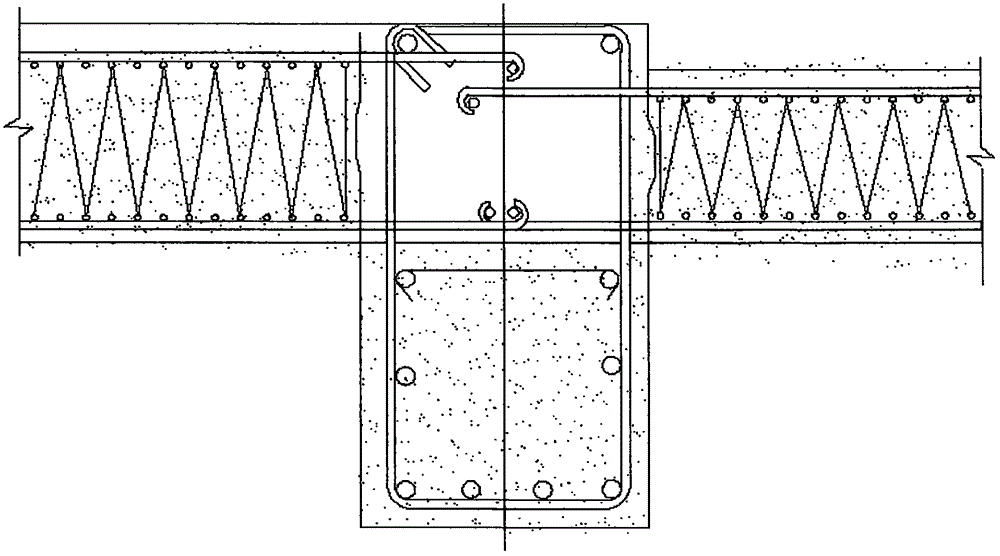

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

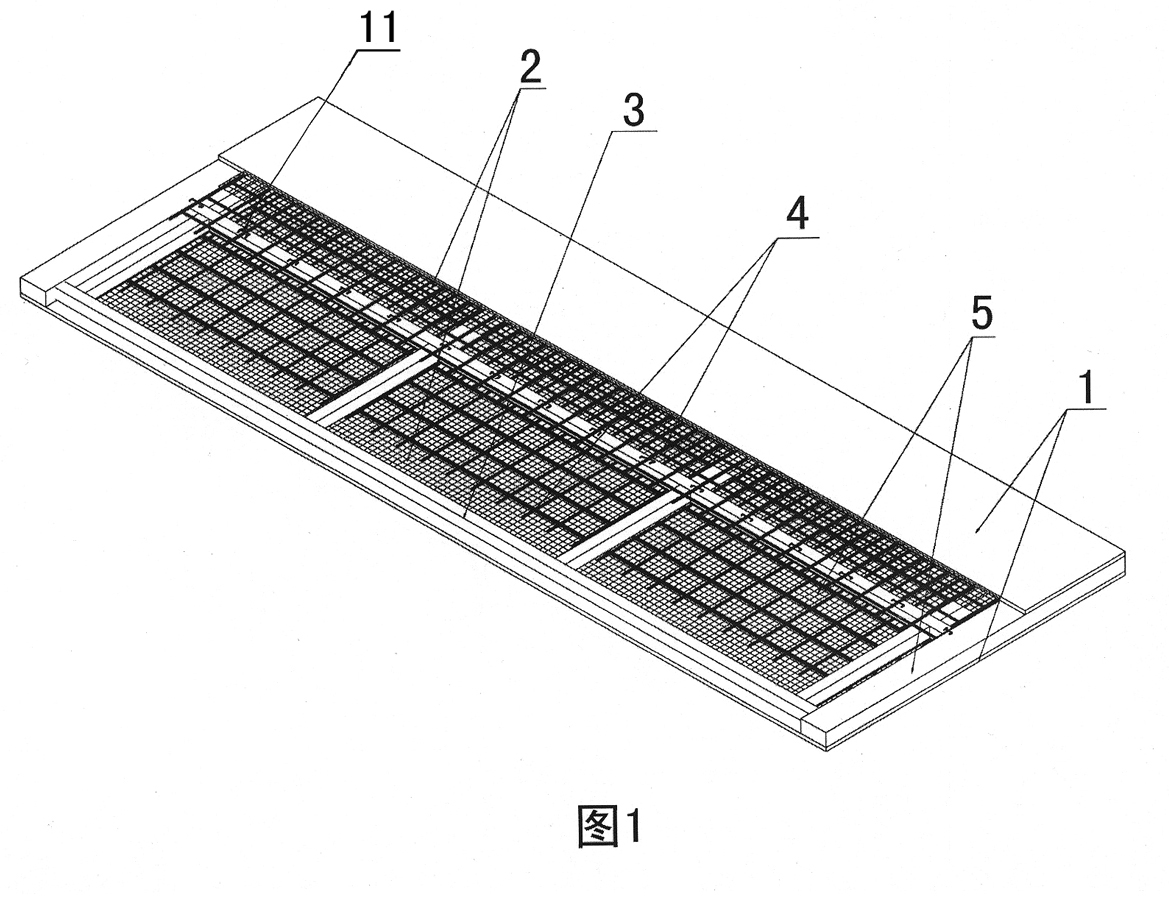

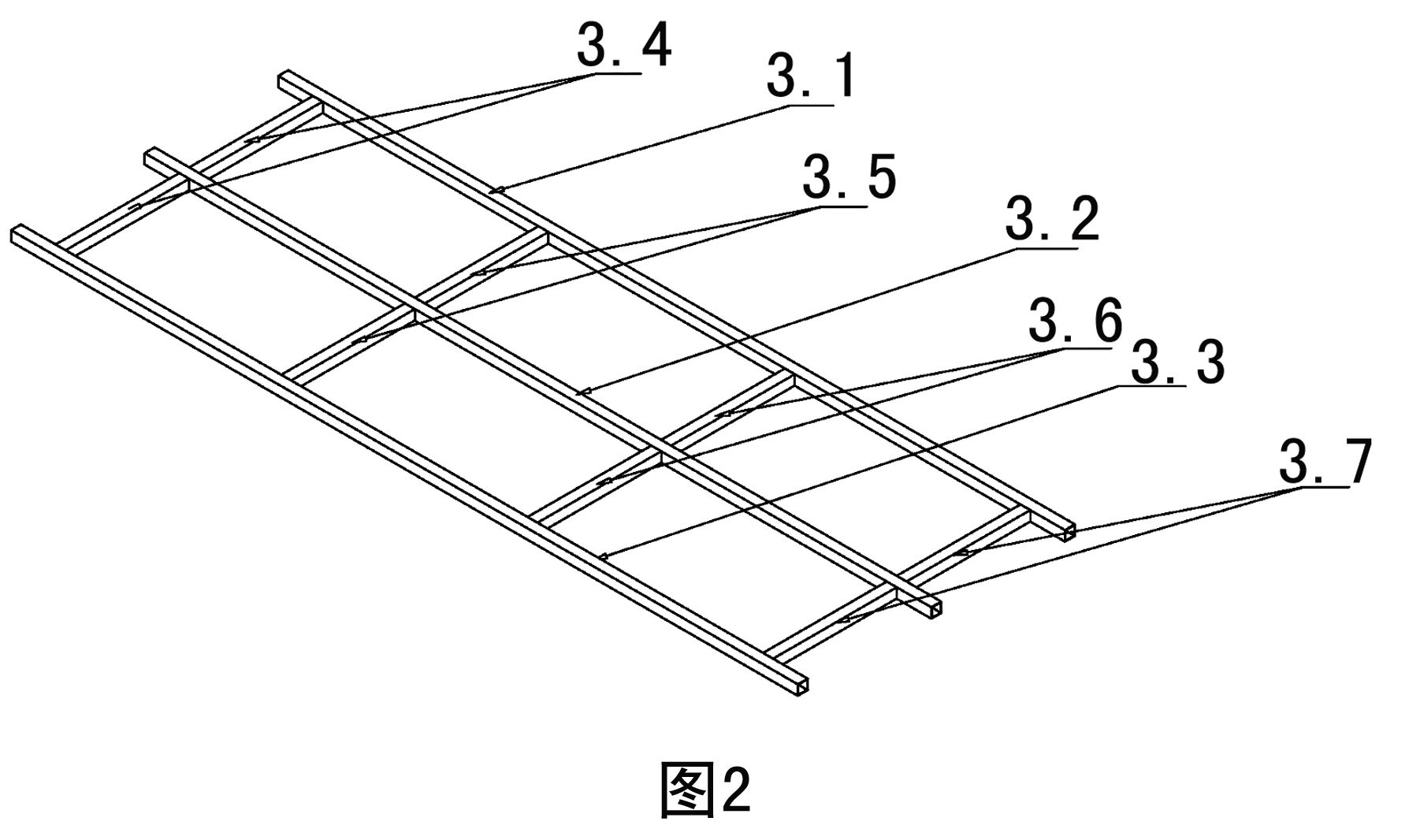

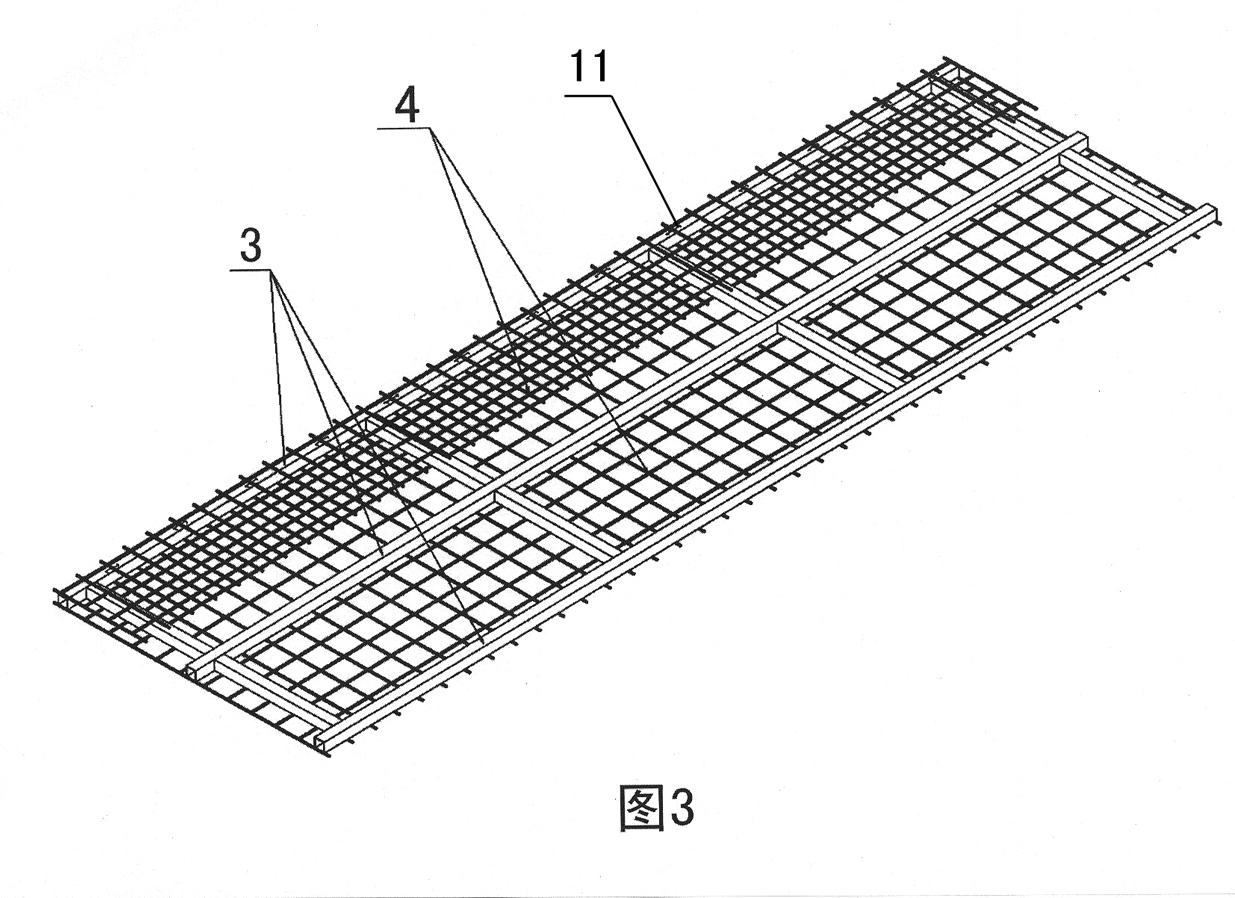

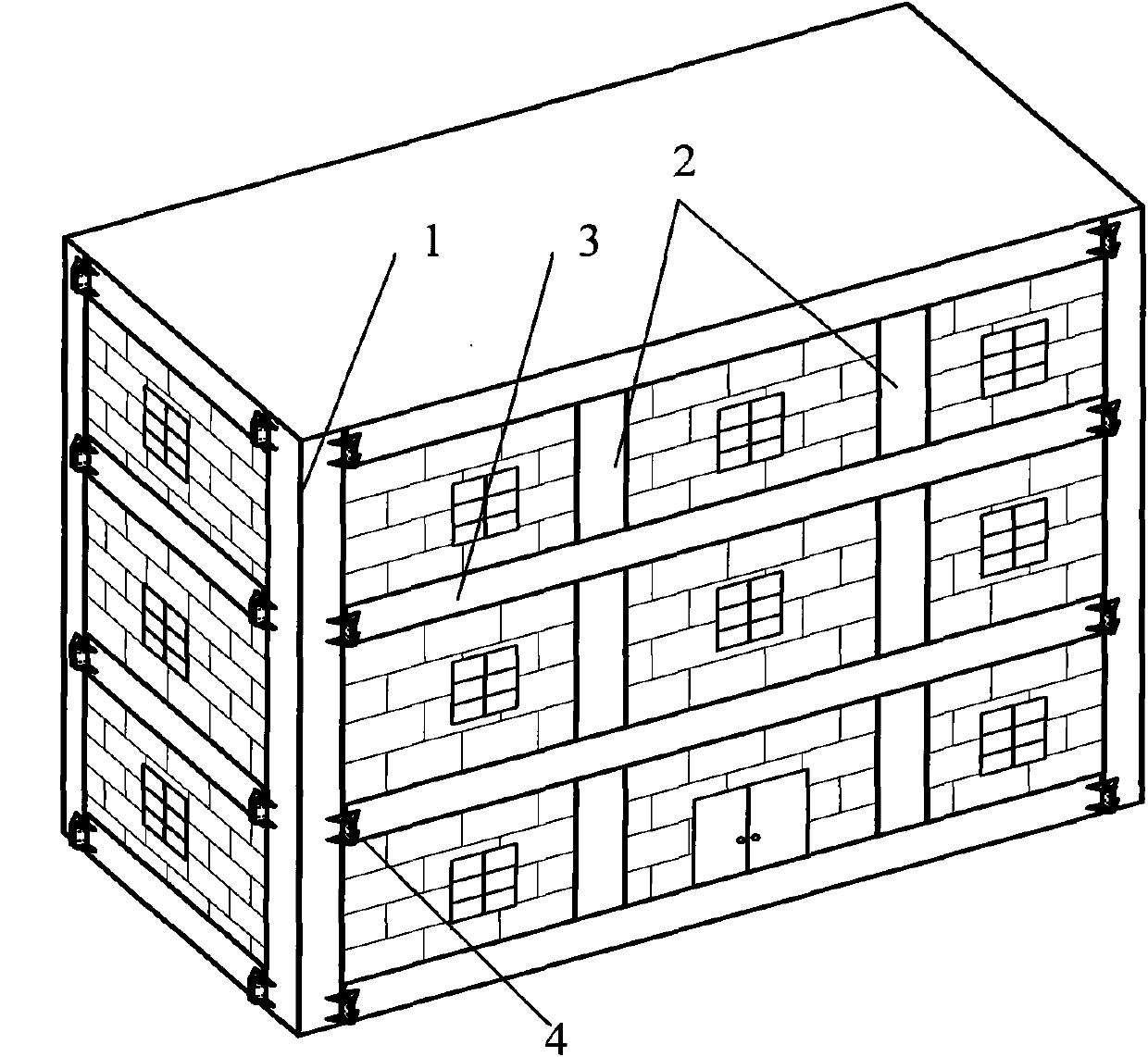

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

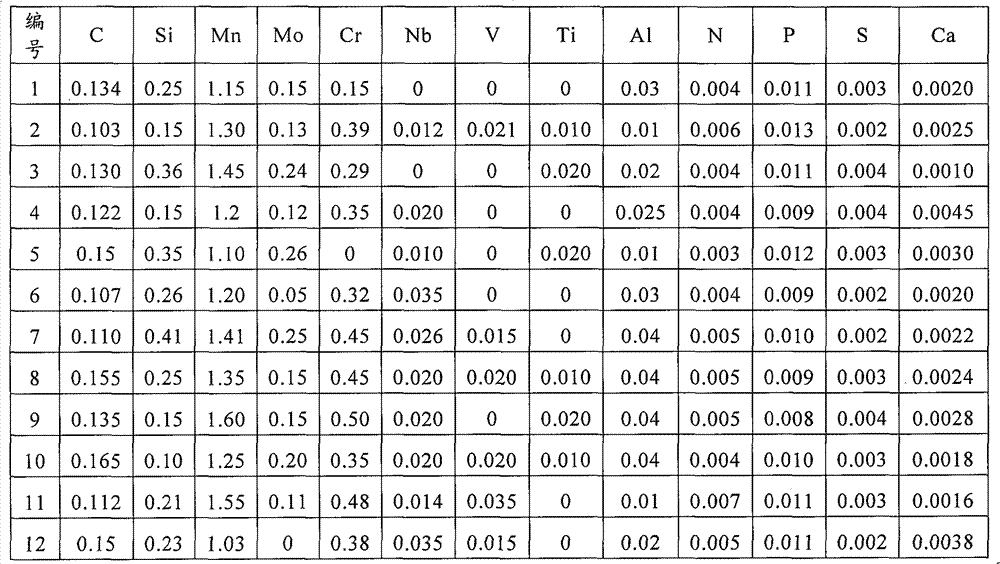

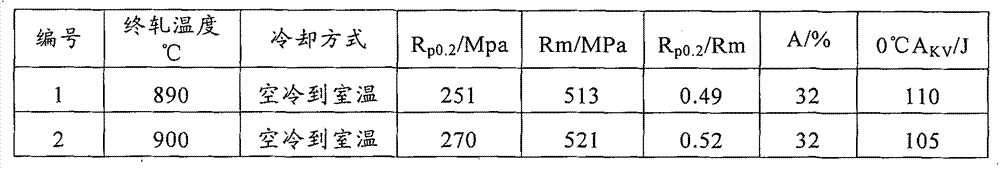

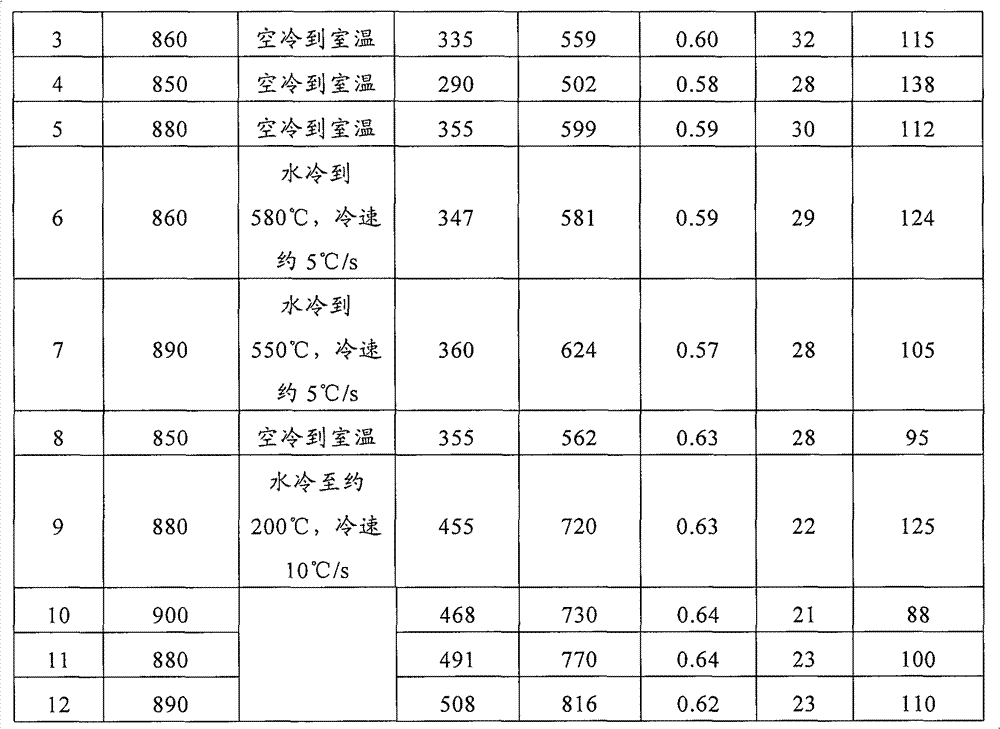

Fire-resistant and earthquake-resistant steel for construction and production method thereof

ActiveCN102952994AImprove fire resistanceSimple mechanical propertiesReduction rateEarthquake resistance

The invention relates to a fire-resistant and earthquake-resistant steel for construction. The steel comprises the following components by weight percent: 0.1-0.18 % of C, 0.1-0.50 % of Si, 1-1.80 % of Mn, less than or equal to 0.025 % of P, less than or equal to 0.015 % of S, less than or equal to 0.50 % of Cr, less than or equal to 0.30 % of Mo, less than or equal to 0.04 % of Al, less than or equal to 0.007 % of N, less than or equal to 0.006 % of Ca, one or two or more of less than or equal to 0.050 % of Nb, less than or equal to 0.055 % of V and less than or equal to 0.035 % of Ti, with Nb+V+Ti being <= 0.055 %, and the balance being Fe and unavoidable impurities. A production method comprises heating under a temperature of 1180 DEG C, insulating for 3 hours, rolling with a starting temperature of not less than 1180 DEG C, an accumulated reduction rate of last three controlled rolling being not less than 35 %, and a terminating temperature of 860 to 900 DEG C, and then directly air-cooling to a room temperature or cooling with a rate of 5 to 15 DEG C per second to the room temperature. The obtained steel is excellent in fire resistance, low in yield ratio (Rp0.2 / Rm <= 0.75), and good in earthquake-resistance performance, with Rp0.2 (yield strength at 600 DEG C) / Rp0.2 (yield strength at the room temperature) >= 2 / 3.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

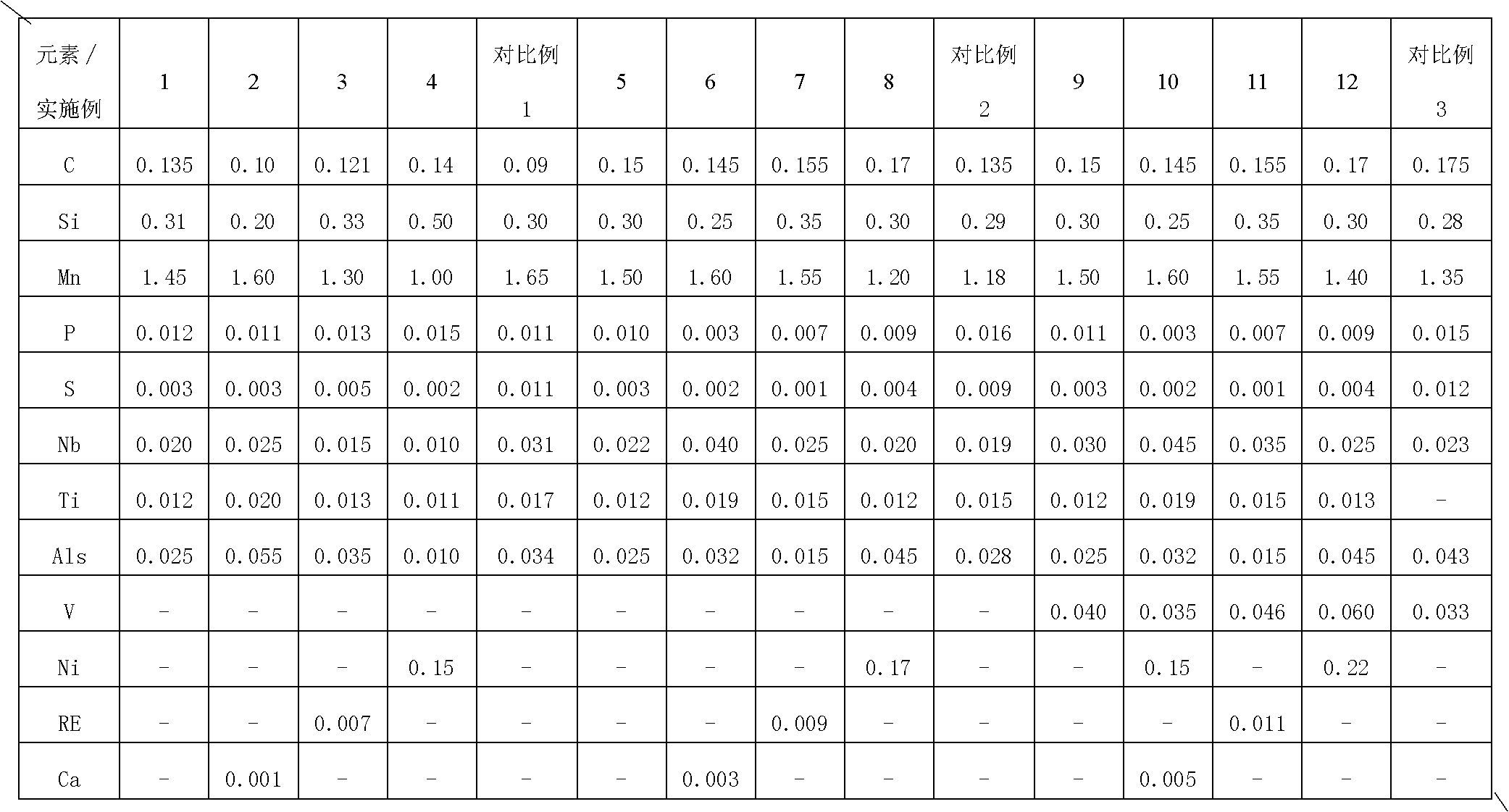

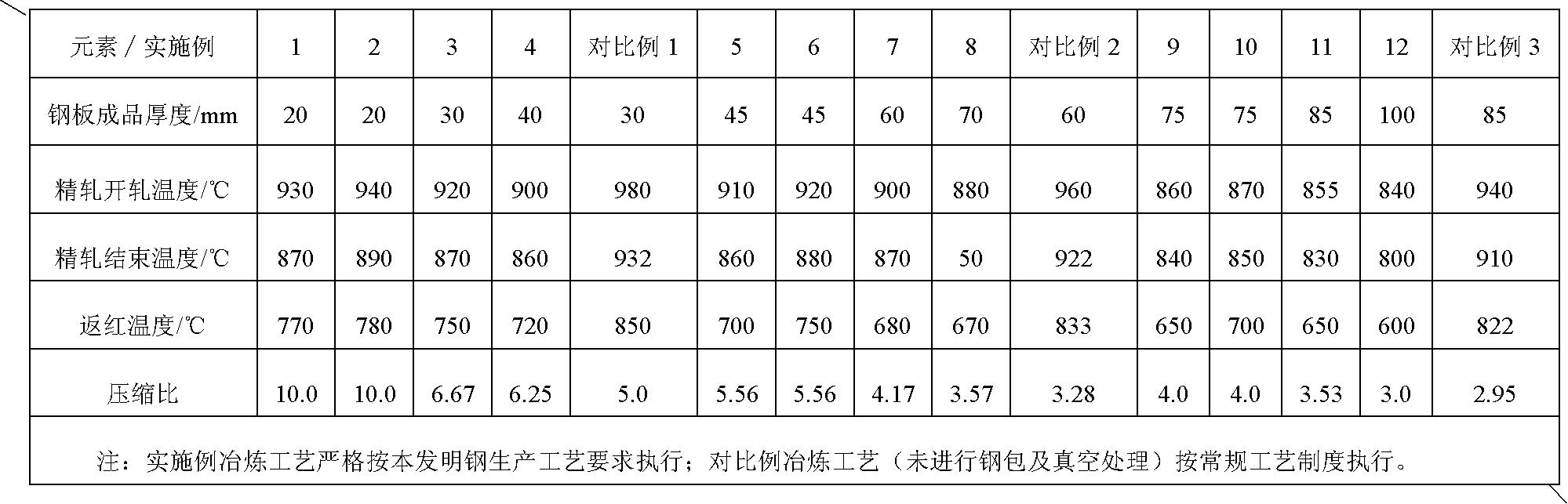

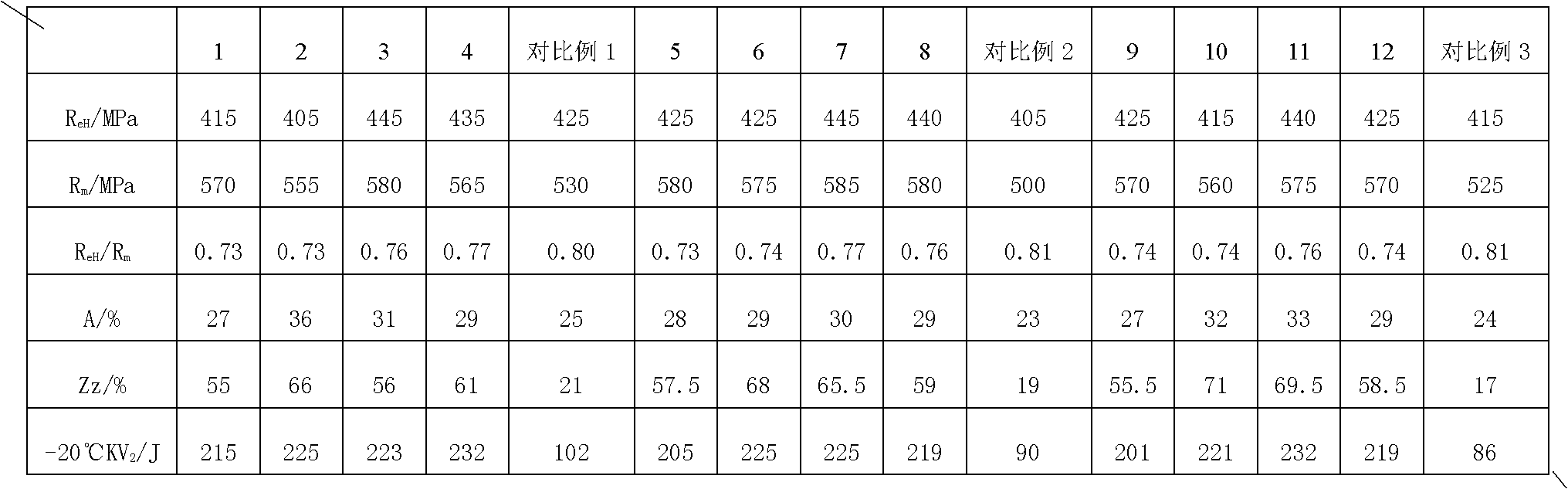

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

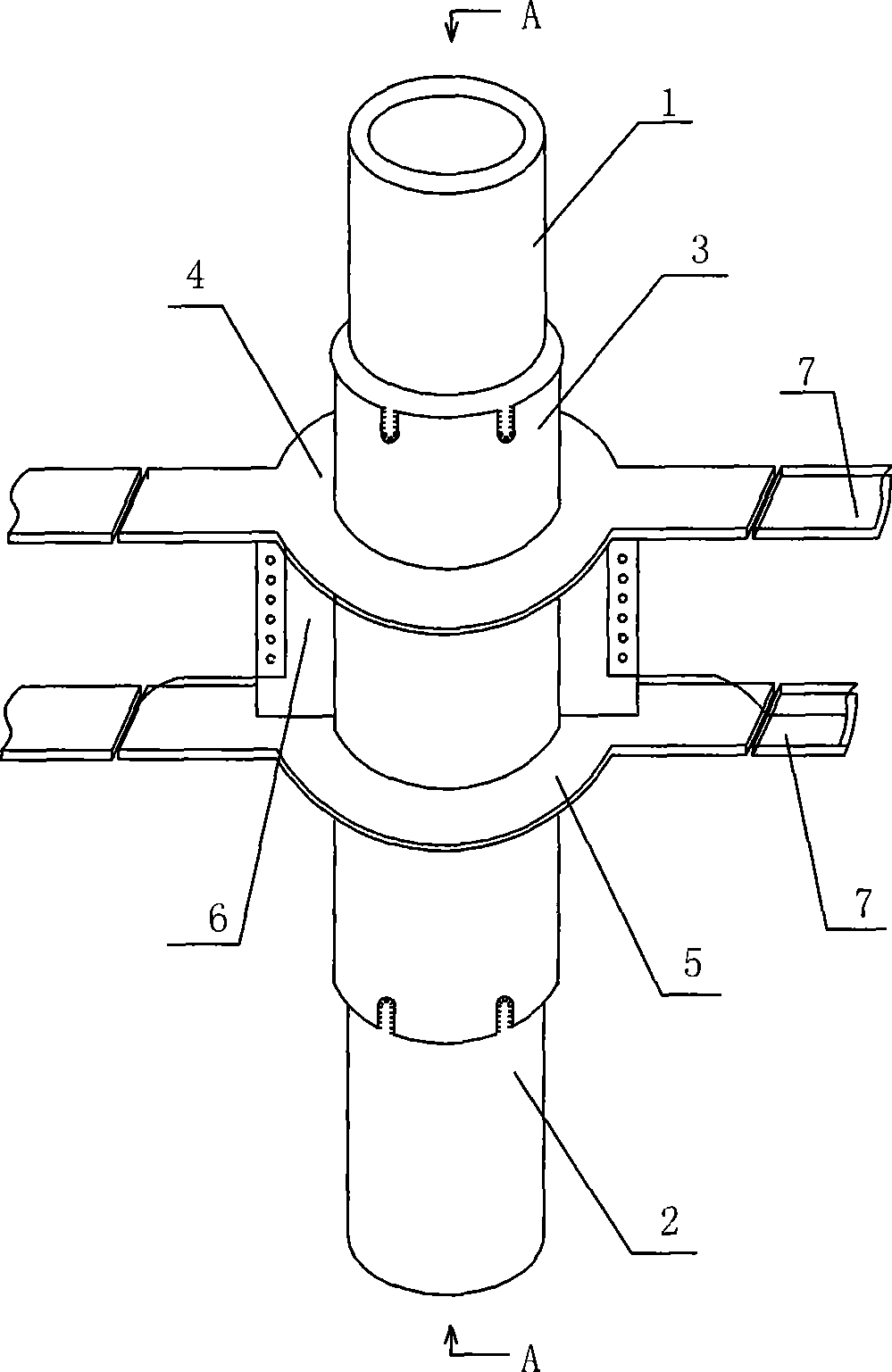

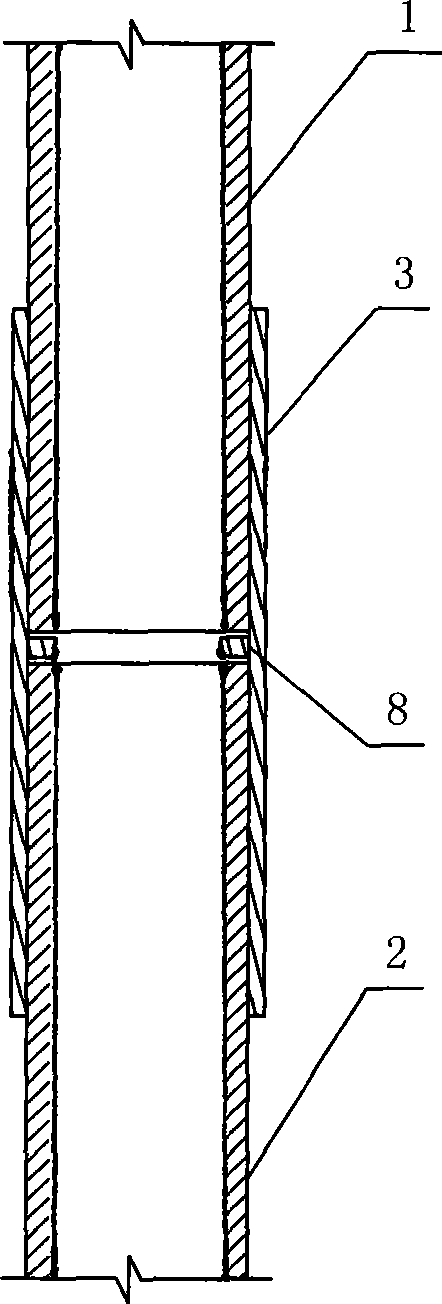

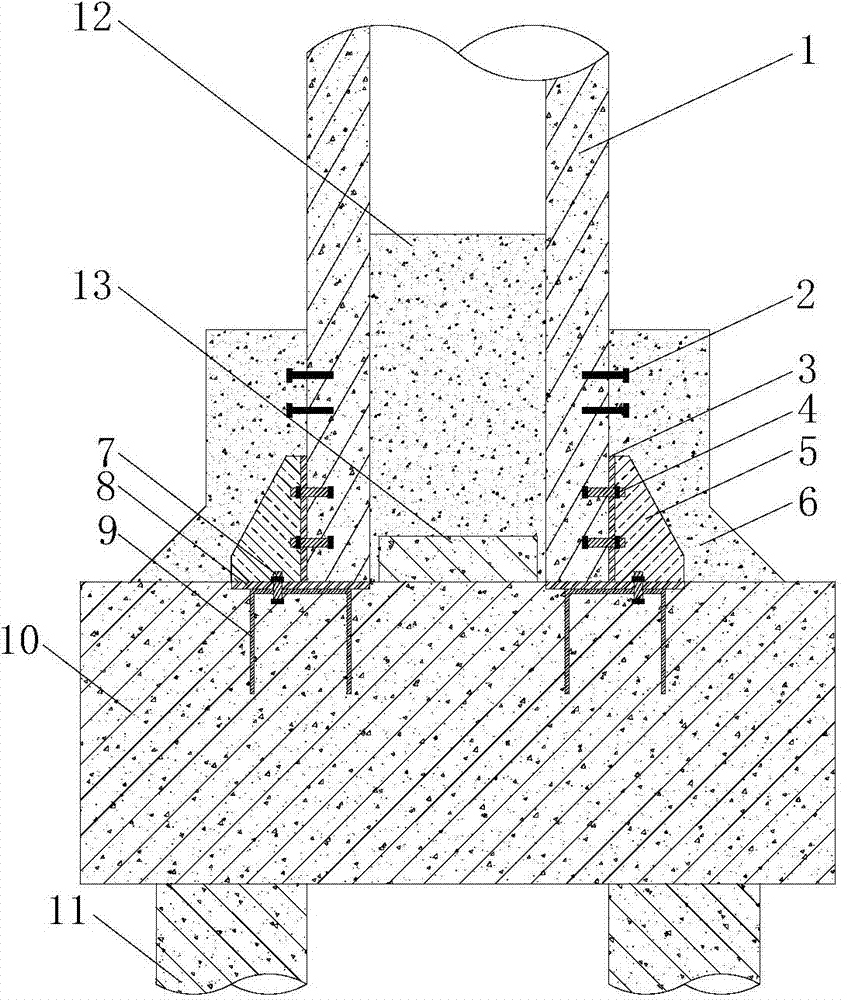

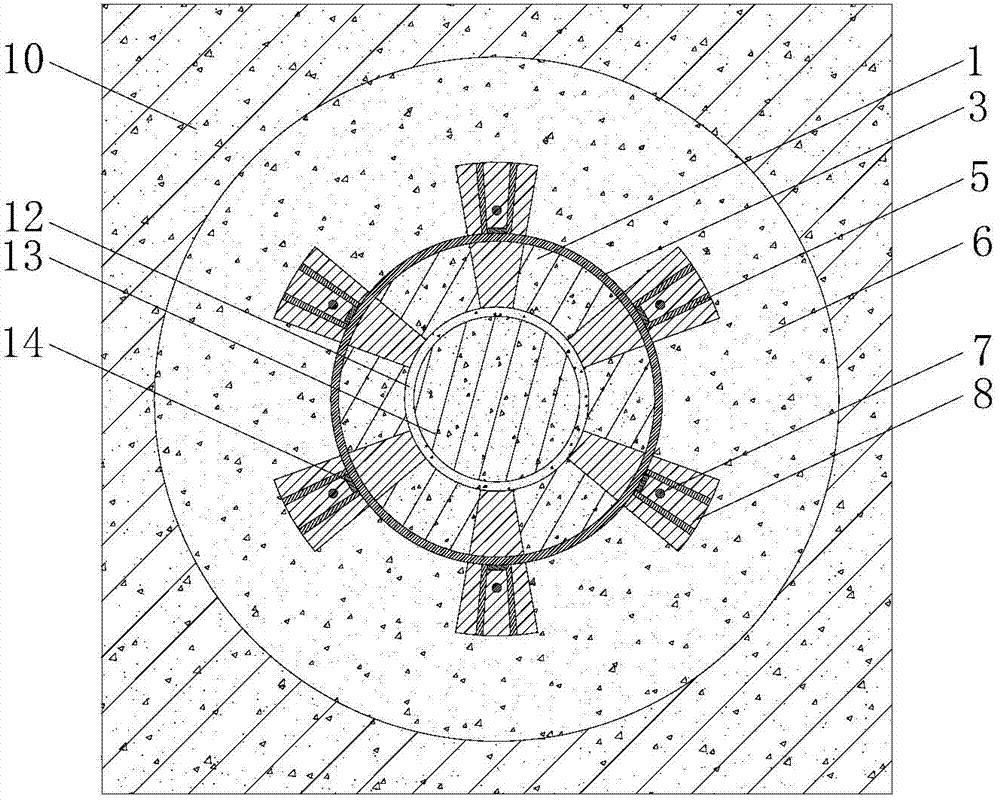

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

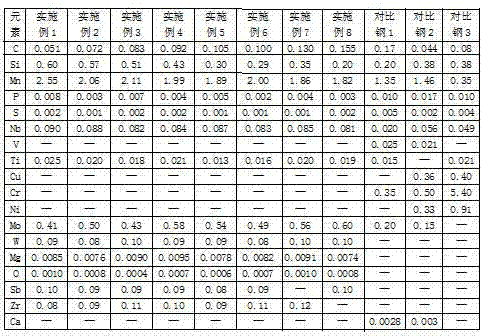

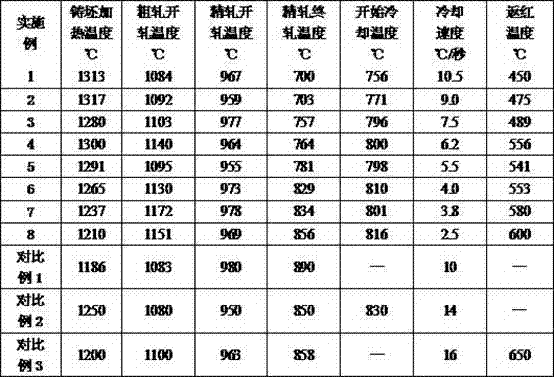

690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695773AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.051-0.155% of C, 0.20-0.60% of Si, 1.82-2.55% of Mn, at most 0.008% of P, at most 0.002% of S, 0.081-0.090% of Nb, 0.010-0.025% of Ti, 0.41-0.60% of Mo, 0.08-0.10% of W, 0.0071-0.0095% of Mg and at most 0.0010% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 690-850MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

Bridge prefabricated hollow pier column post-poured connecting structure and construction method

InactiveCN104746422AGood connection performanceFast constructionBridge structural detailsFoundation engineeringEarthquake resistanceArchitectural engineering

The invention relates to a bridge prefabricated hollow pier column post-poured connecting structure. The bridge prefabricated hollow pier column post-poured connecting structure is characterized by comprising a prefabricated hollow pier column, a pier column foundation and a post-poured concrete pier wall, wherein connecting steel plates are pre-buried in the top surface of the pier column foundation, and an installation limiting block limiting the installation position of the prefabricated hollow pier column is arranged at the center of the pier column foundation; the prefabricated hollow pier column is fixed on the pier column foundation through the connecting steel plates; the prefabricated hollow pier column is wrapped by a steel protecting barrel, and a steel rib plate is arranged on the outer wall of the steel protecting barrel; the concrete pier wall is poured on the periphery of the bottom of the prefabricated hollow pier column, and the hollow position in the prefabricated hollow pier column is filled with a concrete filling core section formed by micro-expansion concrete. As the prefabricating process is adopted for the structure, the construction speed is high, connection strength is high, overall stress performance is good, anti-seismic performance is strong, and technological and economical benefits are good. The invention further discloses a construction method for the bridge prefabricated hollow pier column and foundation connecting structure.

Owner:柳州市建筑工程集团有限责任公司

Mounting method of prefabricated building

ActiveCN106013811AImprove air tightnessImprove water tightnessFoundation engineeringBuilding material handlingEarthquake resistanceSewage

The invention discloses a mounting method of a prefabricated building, comprising the following steps: base level treatment, binding of basic steel bars, mounting of first level vertical members, pouring of basic concrete, mounting of first level top horizontal members, pouring of concrete, mounting of second level vertical members, pouring of concrete, mounting of second level horizontal members, pouring of concrete and sequential cyclic operation according to the mounting operation flow. The method disclosed by the invention has the advantages of good integrity of structural connection, good safety and earthquake resistance, good environmental friendliness and energy-saving performance, reliable quality and convenience of quality inspection; the prefabrication rate reaches over 95%; secondary large area pouring, leveling blanket, masonry and other field operation procedures are saved; labor and materials are saved; by virtue of continuous mounting, the efficiency is improved, and the construction period is shortened; precise mounting and one-step positioning can be realized; the safety risk is reduced, and the quality is upgraded; waste water, waste materials, garbage, dust and noise generated by site construction and pollution of transportation to the air environment are reduced; and the prefabricated building is safe, durable, energy-saving, efficient, green, environment-friendly, economical and applicable.

Owner:李藏柱

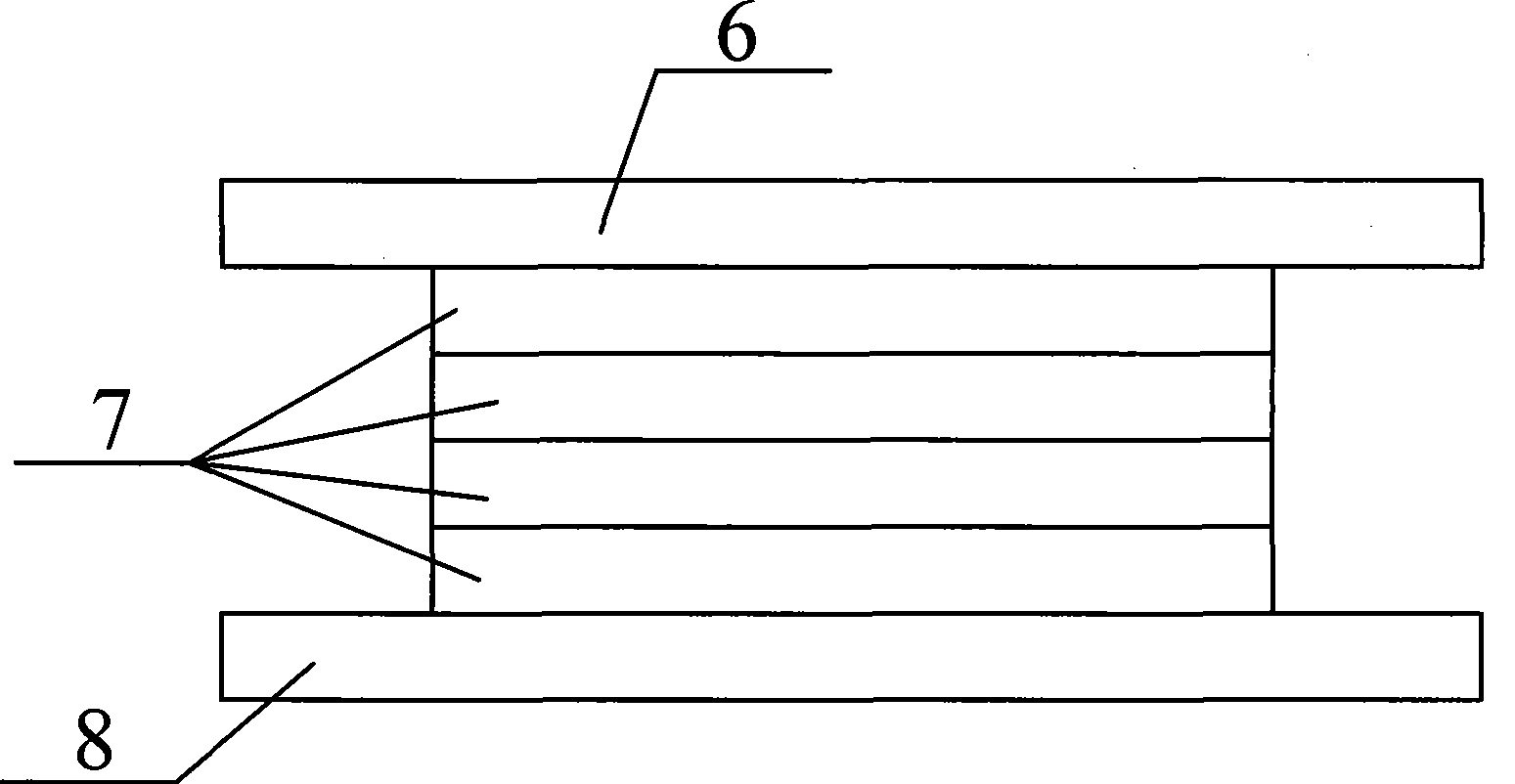

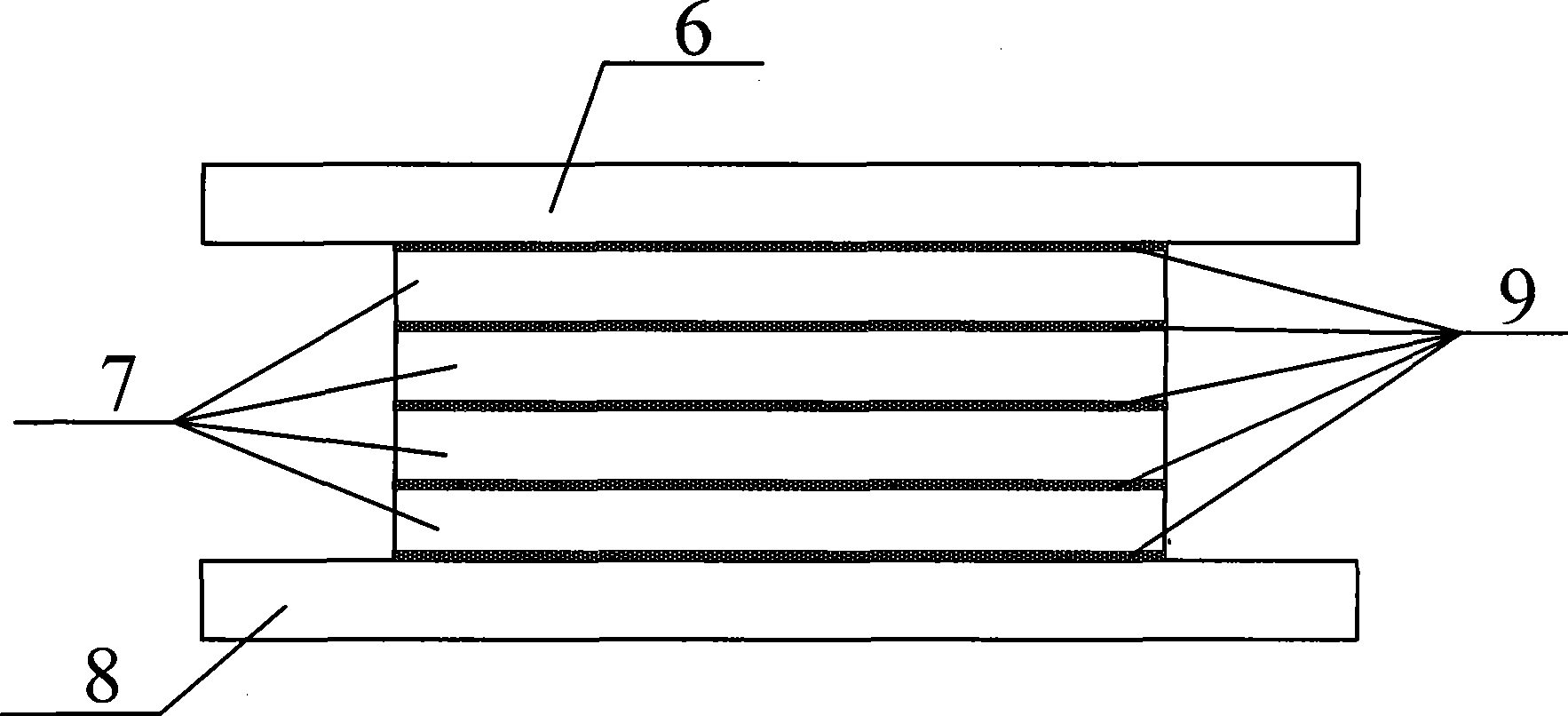

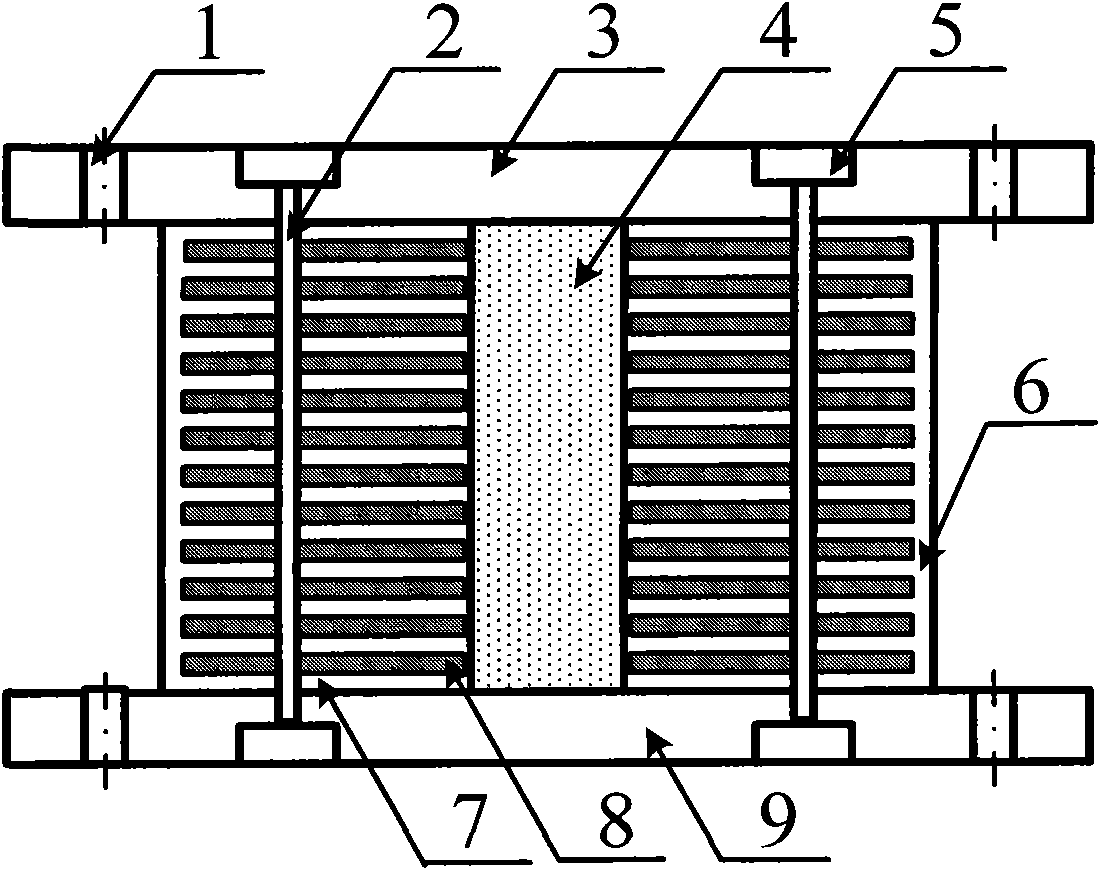

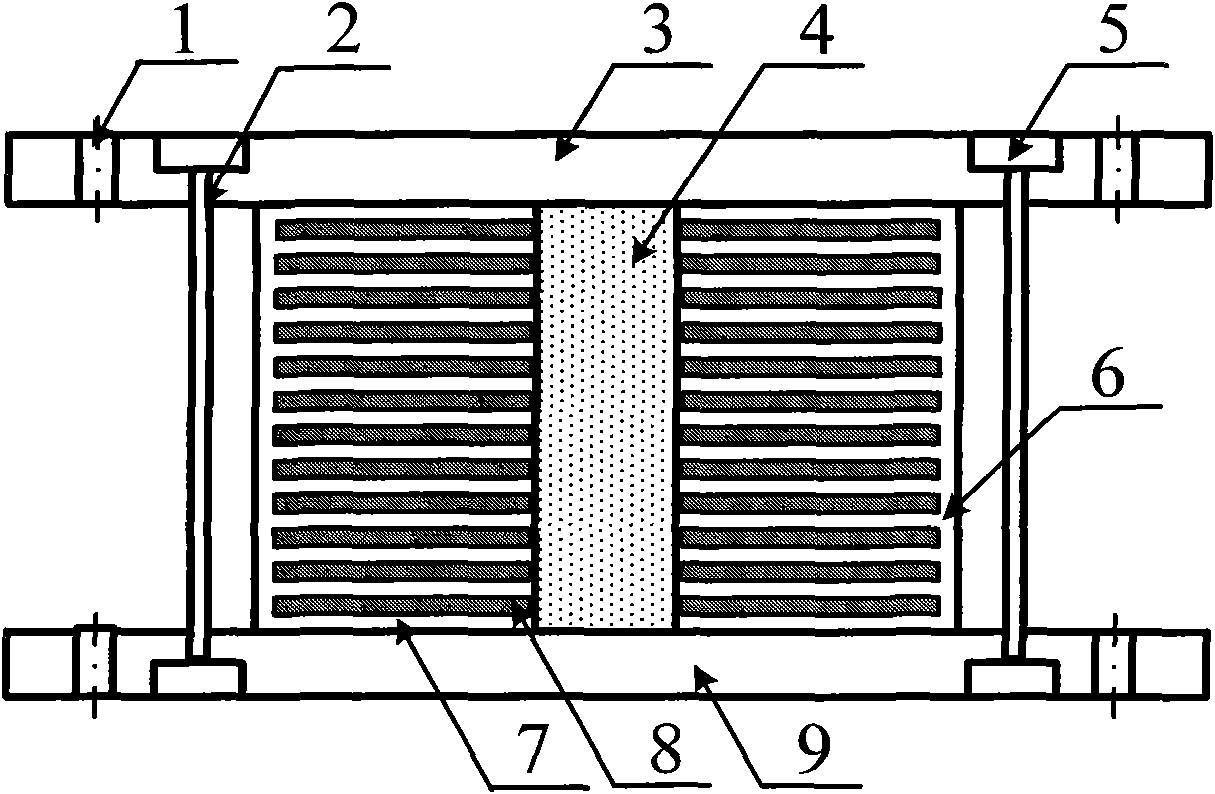

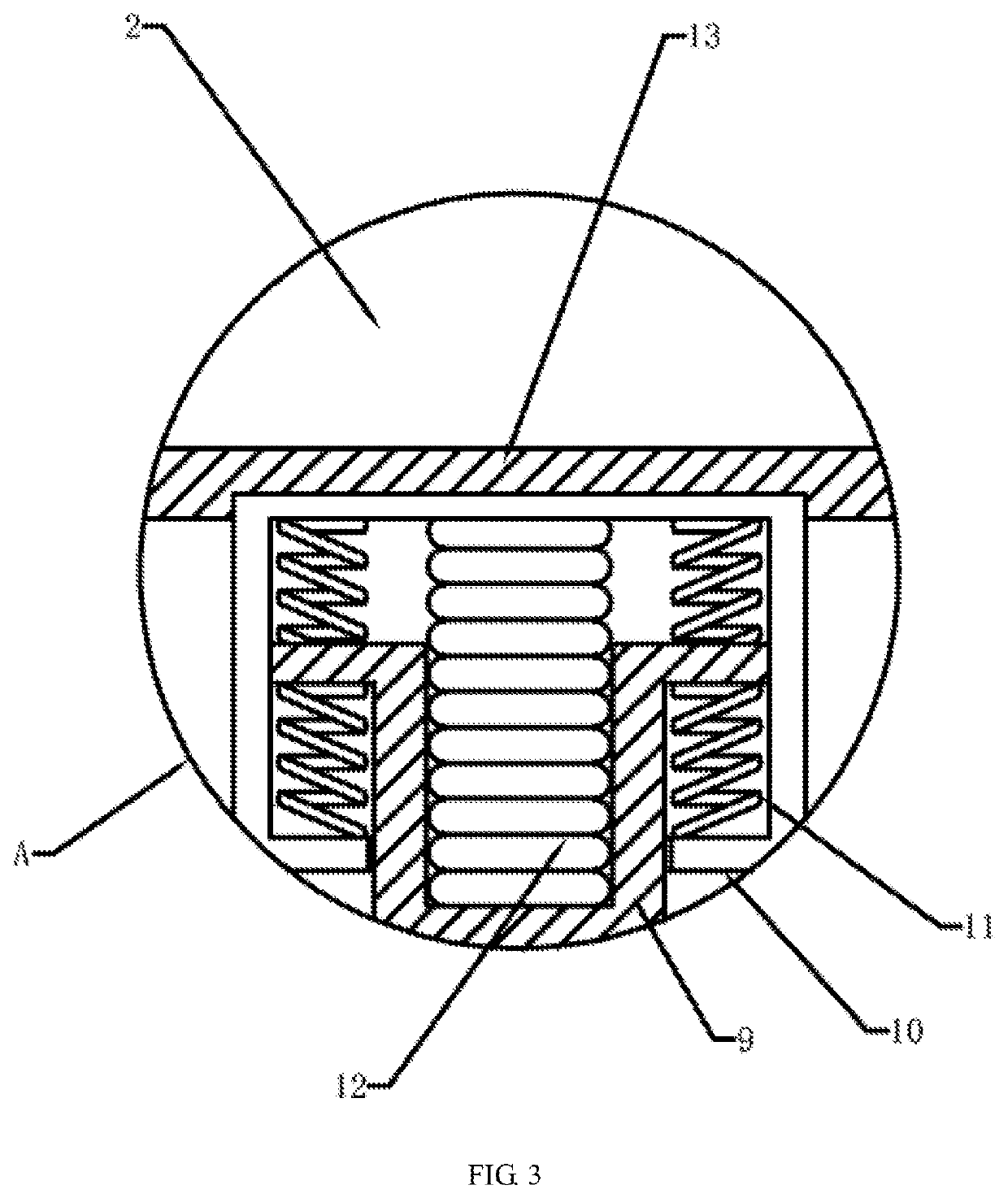

Tensile prestress rubber earthquake isolation support

InactiveCN101806097ASimple structureSeismic isolation mechanism is clearBridge structural detailsShock proofingVulcanizationStressed state

The invention relates to a prestress rubber earthquake isolation support and belongs to the field of structural earthquake isolation control. The tensile prestress rubber earthquake isolation support consists of upper and lower connecting steel plates, an internal thin steel plate, an internal rubber layer, a prestress steel strand and an anchorage device. The internal thin steel plate and the internal rubber layer are alternately overlapped; and the internal thin steel plate, the internal rubber layer and an external rubber protective layer are connected with the upper and lower connecting steel plates by high-temperature and high-pressure vulcanization, and the internal prestress steel stand is connected with the upper and lower connecting plates by the anchorage device. In the prestress rubber support, the insufficient tensile strength is compensated by the large tensile pressure bearing capacity of the rubber support; and before the support bears a service load, a pressure stress is applied in advanced, so that the support, in high-level earthquake, maintains a pressed or low-tensile stress state for ensuring the safety of a earthquake isolation structure system. The support has a simple structure, applies a clear earthquake isolation mechanism and is suitable for earthquake isolation control of large structures with high earthquake-resistance requirements, such as high-rise buildings, tower structures and large-span bridges.

Owner:BEIJING UNIV OF TECH

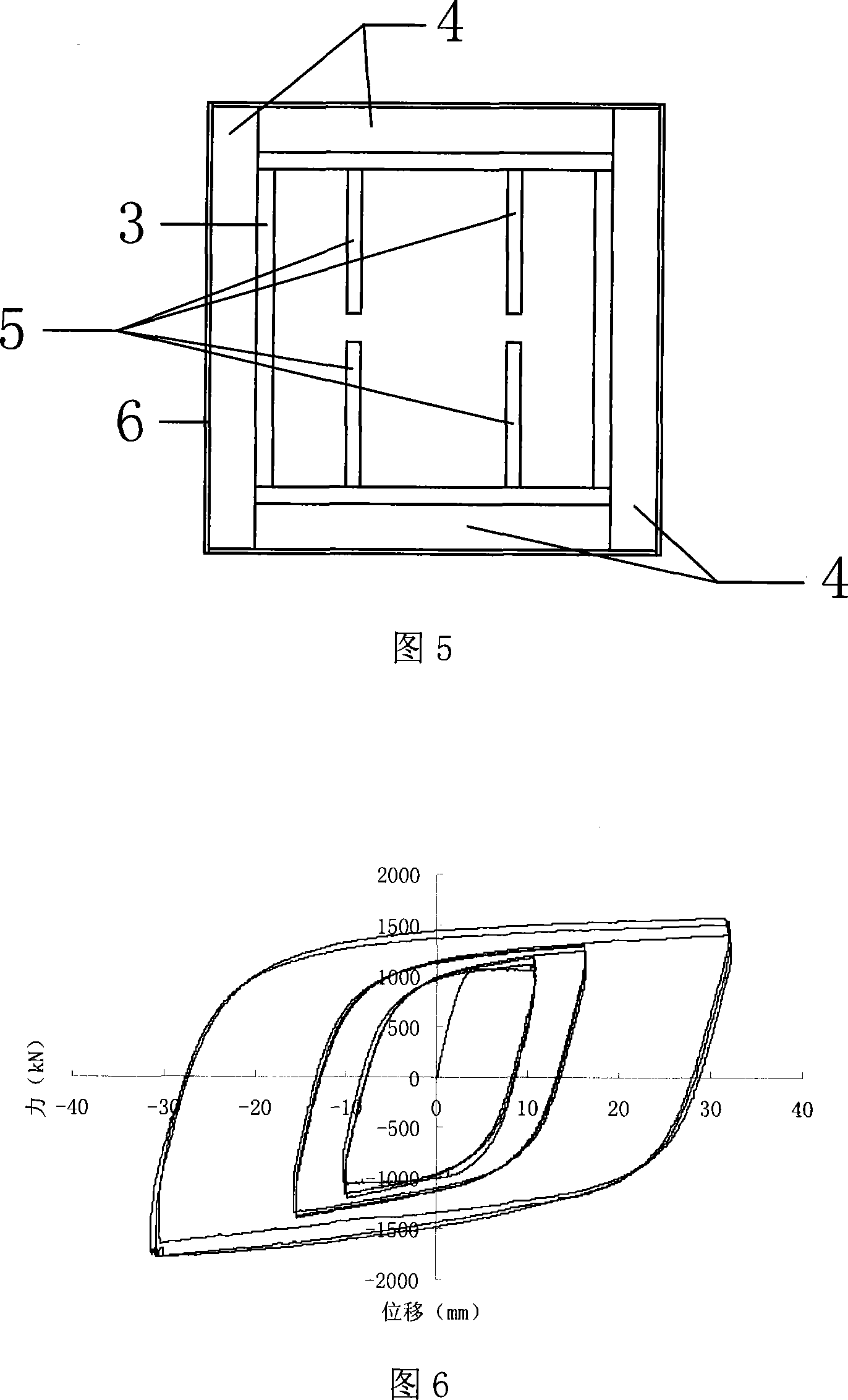

High-rise vertical shearing energy-consuming steel plate wall structure system

The invention belongs to the structural engineering technical field, and more particularly relates to a structural system which cuts an energy-consumption steel plate wall in high level and vertically. The structural system consists of a wall, the two sides of which are connected with thin steel plates, which is taken as an energy-consumption component and other optional structural components; the system is provided with a steel plate wall which is connected with the two sides of a column in a run-through way in a certain intermediate span, and the steel plate wall is used in vertical cutting energy-consumption when the structure suffers from dynamic action such as earthquake or oscillating wind, etc. The horizontal anti-lateral force system of the structure can be the system of frame support, a frame steel plate wall, a frame combined wall, a concrete shear wall and a concrete shear cylinder, etc. The wall, the two sides of which are connected with thin steel plates, refers to the steel plate wall, the two sides of which are connected with the column or the wall; the structural system which cuts an energy-consumption steal plate wall in high level and vertically which is provided by the invention is a multiple high-level structural system which is suitable for an earthquake region; has the advantages of definite failure mode, high bearing capacity, large anti-lateral stiffness, concentrated damage and being convenient for reparation, etc.; has good earthquake-resistance performance and good capacities of tensibility and hysteresis energy-consumption; therefore, the structural system which cuts the energy-consumption steel plate wall in high level and vertically is a superior anti-earthquake and energy-consumption component.

Owner:TONGJI UNIV

Assembled framework beam-column joint adopting cover plate connection and construction method thereof

InactiveCN103104039AReliable strengthSolve the problem of smooth vertical force transmissionShock proofingEarthquake resistanceReinforced concrete

The invention relates to an assembled reinforced-concrete framework beam-column joint adopting cover plate connection. The joint comprises a corbel of a precast column and a precast beam, wherein the end face of the corbel and the end face of the precast beam are respectively provided with a concave groove and a convex block which are matched with each other and are used for carrying out embedded fixing, steel plates are pre-buried in facades of the two sides of the connection part between the corbel and the precast beam, and steel cover plates are arranged at the outer sides of the steel plates pre-buried in facades of the two sides of the corbel and the precast beam and are fixedly welded to the steel plates pre-buried in the facades of the two sides of the corbel and the precast beam after the corbel and the precast beam are fixed in an embedding manner. A corresponding construction method comprises the steps of precasting, mounting and filling mortar in gaps. The joint and the corresponding construction method have the advantages that the strength of an assembled segment is enabled not to become a weak link of a structure under the action of a load, and the assembled segment has adequate earthquake resistance; the assembled segment is enabled to smoothly carry out internal force transmission and exert a connecting function; and the on-site assembling time is minimized, and the construction process is simple, convenient, fast and safe.

Owner:ZHENGZHOU UNIV

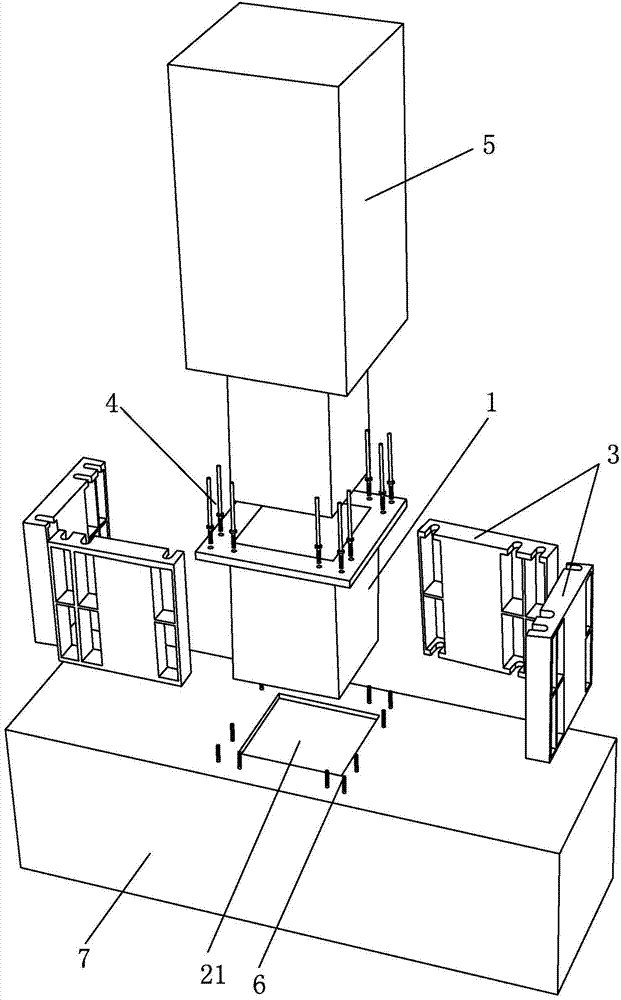

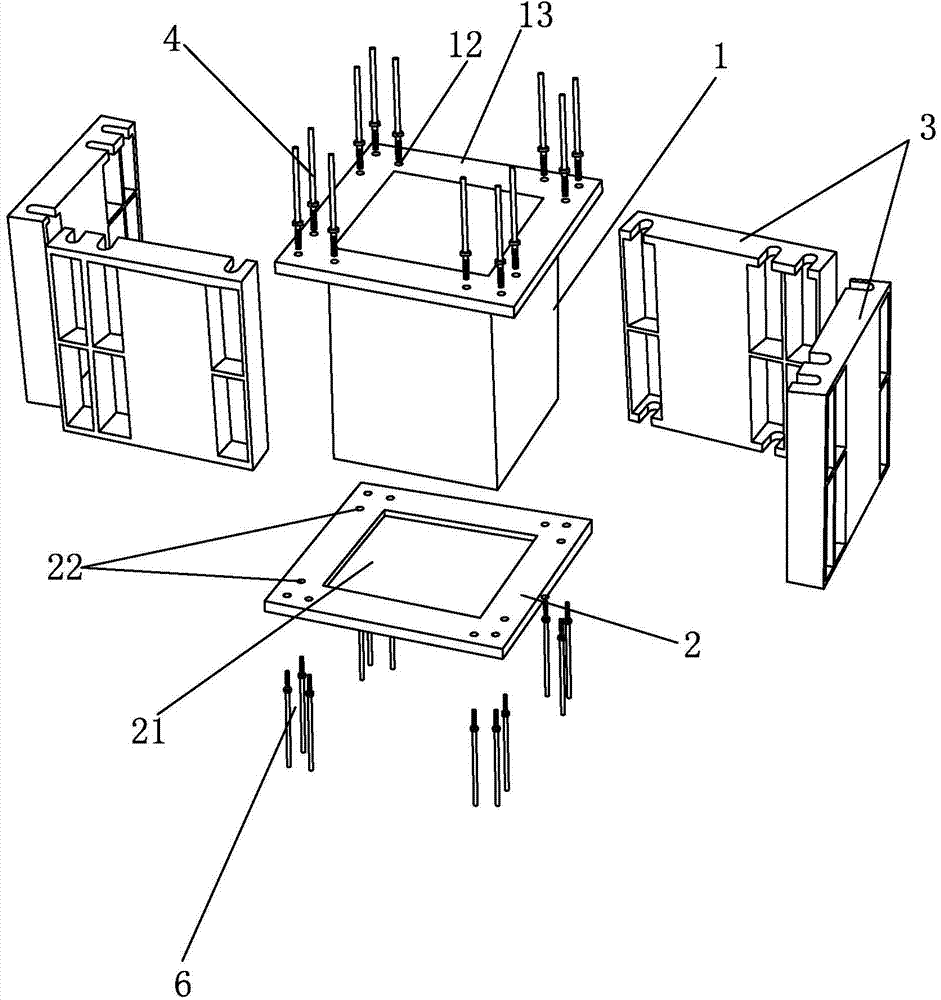

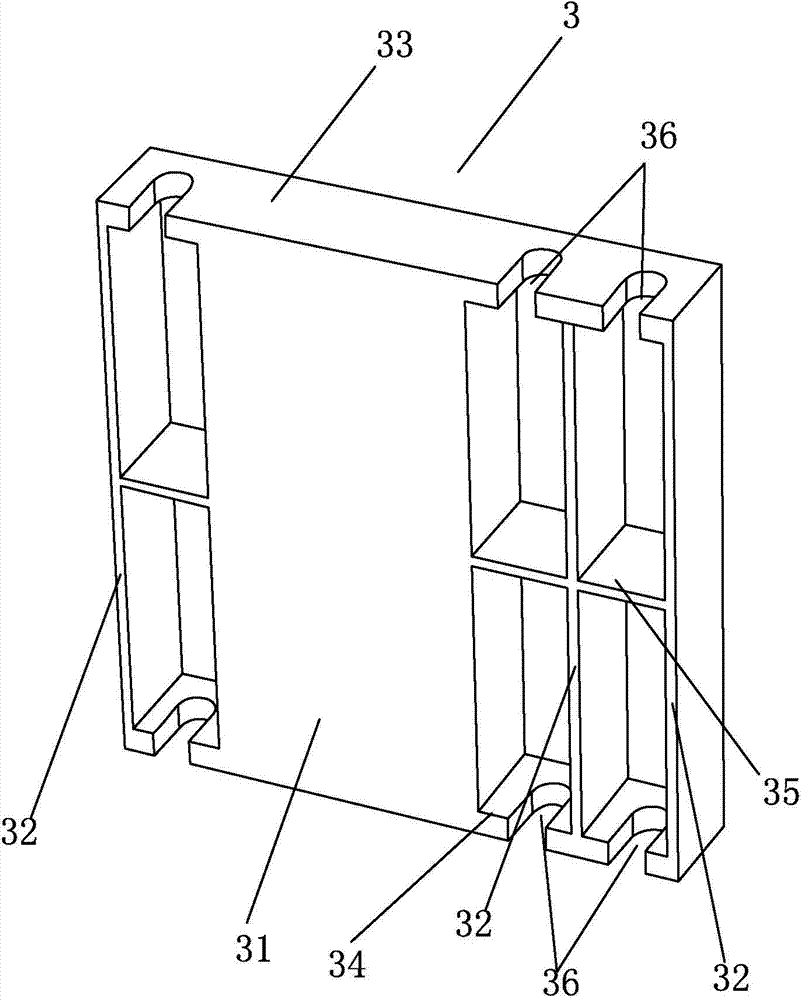

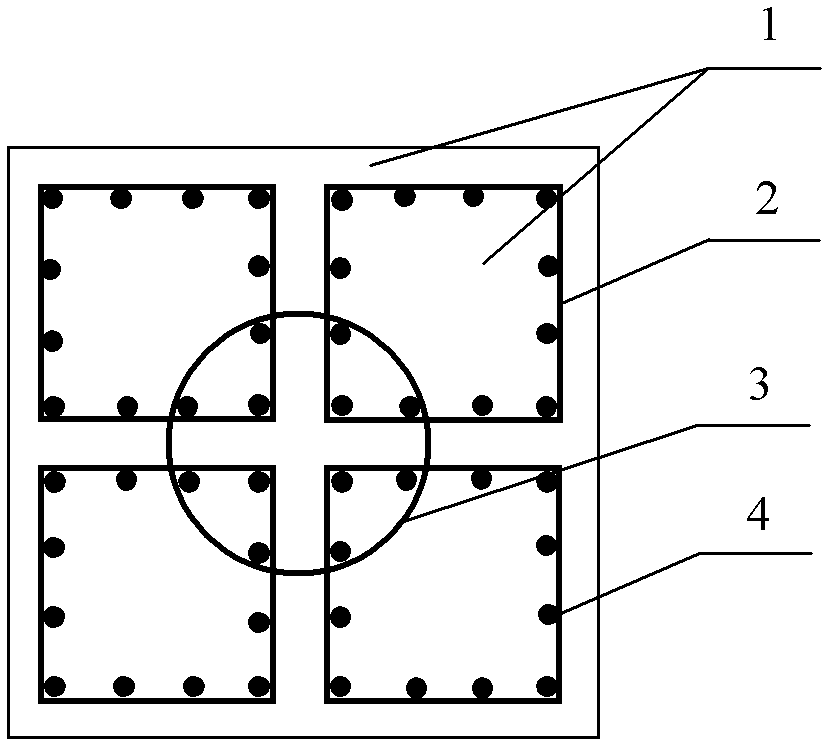

Earthquake damage replaceable combination column structure

InactiveCN104847052AImprove controllabilityImprove seismic performanceStrutsPillarsEarthquake resistanceSteel tube

The invention discloses an earthquake damage replaceable combination column structure which comprises a core square steel pipe, a ground beam end plate and four replaceable steel boxes. The core square steel pipe is arranged on the ground beam end plate, the lower end of the core square steel pipe is closed, the upper end of the core square steel pipe is fixedly connected with an RC column through a plurality of first fixedly connecting structures and provided with an opening containing the lower end of the RC column, the ground beam end plate is fixedly arranged on a ground beam through second fixedly connecting structures, and the four replaceable steel boxes are detachably arranged on walls of the core square steel pipe respectively to surround the core square steel pipe. After an earthquake, only the peripheral replaceable steel boxes can be subjected to buckling failure, the core square steel pipe is only slightly destructed or not destructed, controllability of a destruction position is realized on the premise of ensuring vertical bearing capacity, earthquake resistance is excellent, the column is reset after the earthquake, the replaceable steel boxes are detached and replaced by intact steel boxes, and the structure is rapidly repaired after the earthquake.

Owner:HUAQIAO UNIVERSITY +1

Recycled aggregate concrete and preparation method thereof

InactiveCN105174852AImproves microscopic stress-strain performanceWide variety of sourcesSolid waste managementEpoxySodium sulfate

The invention discloses recycled aggregate concrete and a preparation method thereof. The recycled aggregate concrete comprises the following raw materials by weight percent: 15 to 20 percent of cement, 5 to 15 percent of water, 15 to 25 percent of third mixed additive, 38 to 63 percent of coarse aggregate, 0.3 to 1 percent of modified wood fiber-containing polyurethane modified epoxy resin flexibilizing emulsion, 0.1 to 0.5 percent of lauryl sodium sulfate, 0.1 to 0.5 percent of sodium gluconate, 0.1 to 0.5 percent of water glass, 0.5 to 1 percent of polyacrylate, and the sum of weight percent of the raw materials is 100 percent; and the coarse aggregate is the waste concrete renewable coarse aggregate or a mixture of waste concrete renewable coarse aggregate and natural coarse aggregate. The renewable aggregate concrete has good impact resistance, earthquake resistance and crack resistance, the pressure resisting strength of the recycled aggregate concrete in 28 days can reach 80 to 100 MPa, and the recycled aggregate concrete is applicable to a load-bearing structure.

Owner:FUJIAN JIANGXIA UNIV

Bracing steel sleeve flection restriction support component

ActiveCN101220616AImprove featuresImprove energy consumptionShock proofingEarthquake resistanceBuckling-restrained brace

The invention relates to an improved flection-restraining support member which includes: a core part, an inner sleeve part, an outer sleeve; wherein, the core part consists of a core board and a ribbed stiffener for the core board; the inner sleeve part consists of an inner sleeve wallboard, an inner sleeve ribbed stiffener and a core board restraining board, the outermost layer is the outer sleeve; no clearance is left between the core board restraining board and the core board. The invention also provides a method for manufacturing the improved flection-restraining support member. The flection-restraining support has good returning-delaying characteristics and energy-consuming performance and is an effective energy-consuming member, which can reach 1 / 70 deformation amount, meet the 1 / 50 floor displacement distortion requirement of building under rarely-happen earthquake and can greatly improve the earthquake resistance of the building structure; furthermore, the material and manufacture are all realized in China, which greatly reduces the cost of the support and lays a foundation for generalization and application.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

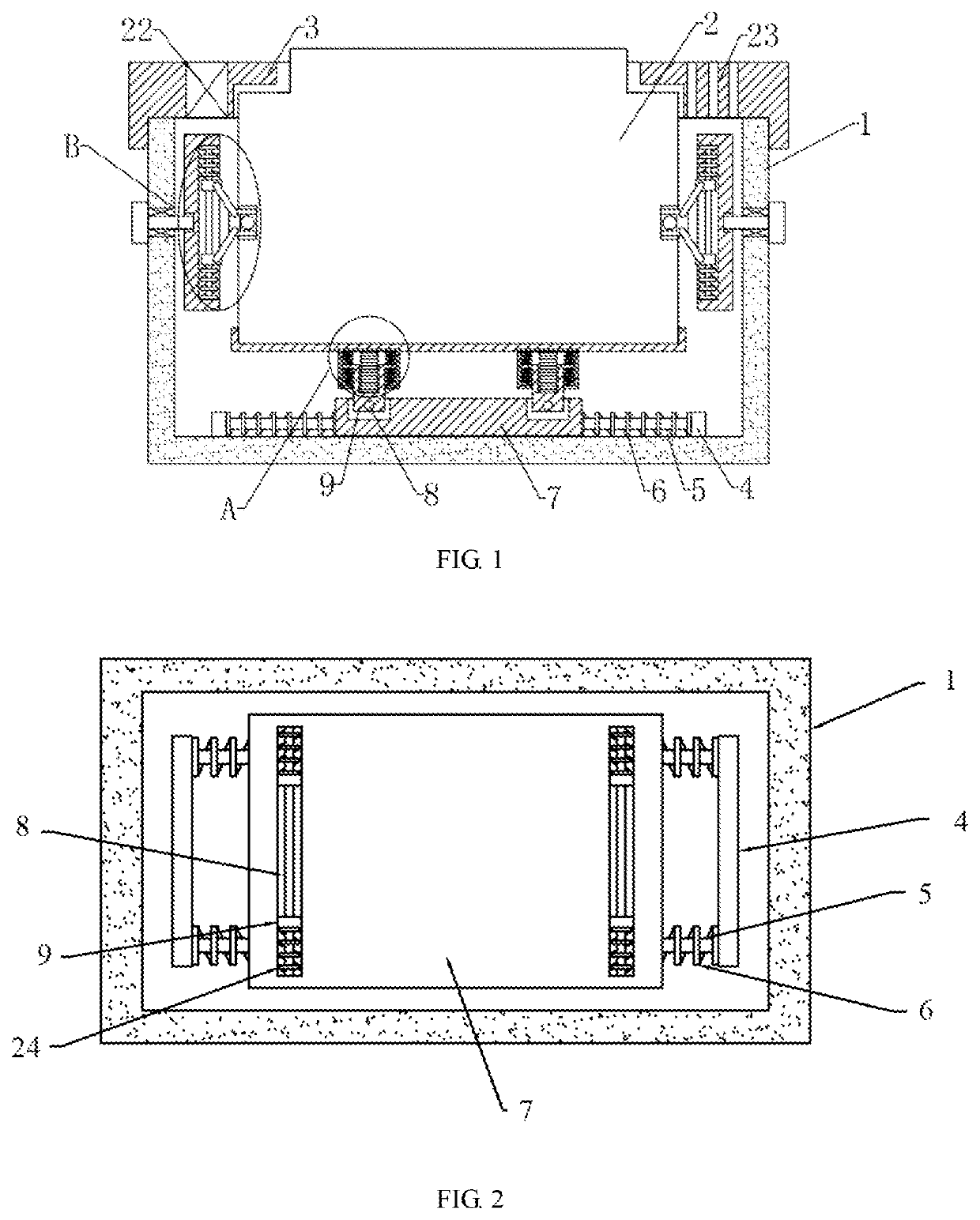

Echelon utilization battery pack with good seismic resistance

ActiveUS20210344075A1Improve the safety of useIncrease airflowVent arrangementsSecondary cellsEarthquake resistanceMechanical engineering

Disclosed is an echelon utilization battery pack with good seismic resistance. The echelon utilization battery pack involves a battery pack body and a battery, wherein the battery pack body is of a hollow cuboid structure, fixed seats are fixed at two ends of the inner bottom of the battery pack body, first fixed shafts are fixed between the two fixed seats, the first fixed shafts are slidably connected with a mounting seat in a sleeving mode, a first sliding groove is formed in the top of the mounting seat, second fixed shafts are fixed in the first sliding groove, and the two ends of the second fixed shafts are slidably connected with first sliding blocks.

Owner:ANHUI LVWO RECYCLING ENERGY TECHNOLOGY CO LTD

Building column-truncating, replacing and seismic-isolating support construction method and supporting device

InactiveCN103741832AImproving and enhancing resilience to earthquakesLow costBuilding material handlingShoresEarthquake resistanceReinforced concrete column

The invention relates to a building column-truncating, replacing and seismic-isolating support construction method and a supporting device. The construction method includes 1), mounting the supporting device, namely mounting the supporting device around an original-structure reinforced concrete column where a seismic-isolating support is needed to be mounted; 2), after the supporting device is mounted, truncating the column at a position where the seismic-isolating support is mounted; 3), disposing the seismic-isolating support in the position to complete mounting of the rubber seismic-isolating support. Seismic isolating technology is applied onto an existing building by utilizing a supporting system, so that cost for reinforcement and reconstruction is greatly lowered, earthquake resistance of the building is effectively improved and enhanced, a mode which is safer, more economical and more environment friendly is brought to proprietors, and a novel reinforcement method solution and a more scientific anti-seismic mode are provided for old buildings positioned in seismic areas.

Owner:KUNMING TIANJIAOLI REINFORCING TECH ENG +1

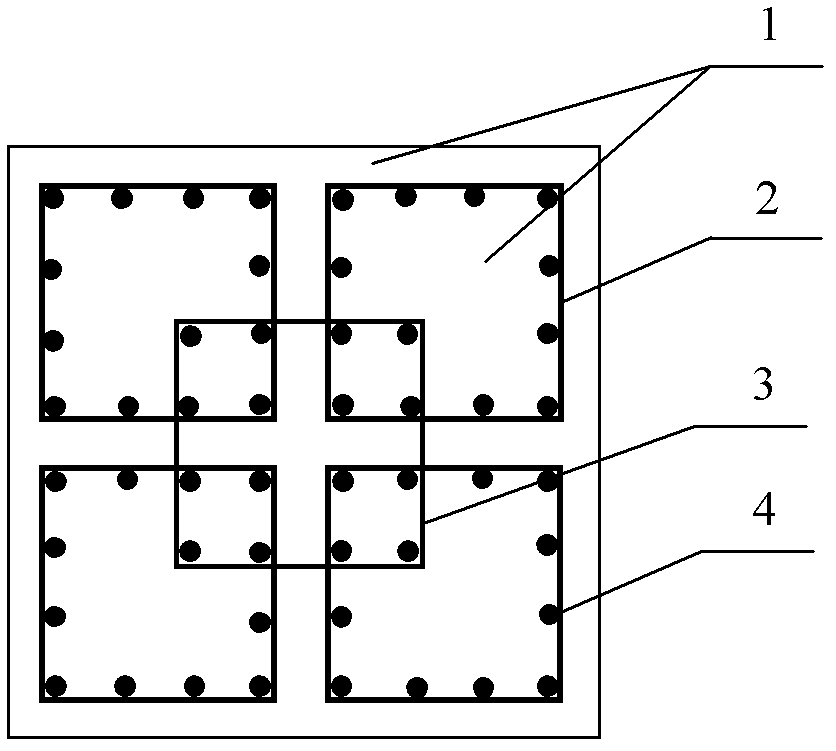

High-seismic-resistance light high-intensity reinforced column

InactiveCN102561595AImprove column deformabilityReduce the weight of the structureStrutsPillarsRebarEngineering

The invention relates to a high-seismic-resistance light high-intensity reinforced column and is characterized in that the high-seismic-resistance light high-intensity reinforced column is formed by depositing concrete after a reinforcement cage is assembled, wherein the reinforcement cage comprises four fission stirrups with equal sections, a center positioning stirrup, and longitudinal bards, the space between the external limbs of the two adjacent fission stirrups ranges from 25 mm to 200 mm; the center positioning stirrup is partially overlapped with the stirrup part of each limb of the four fission stirrups with equal sections, a plurality of longitudinal ribs are arranged on the inner sides of the fission stirrups and the positioning stirrup; at least one longitudinal rib is arranged in the overlapping part between the fission stirrup and the positioning stirrup, and the fission stirrup and the positioning stirrup are fixed into a whole; and the weights of the raw materials in the concrete are as follows: 130 kg / m3 to 180 kg / m of water, 160 kg / m3 to 500 kg / ms of cement, 50 kg / m3 to 250 kg / m of mineral admixtures, 100 kg / m3 to 400 kg / m of light aggregates, 300 kg / m3 to 900 kg / m of broken stones, 650 kg / m3 to 850 kg / m of sand, and 4 kg / m3 to 15 kg / m3 of water reducers. The high-seismic-resistance light high-intensity reinforced column has the advantages of high seismic performance, deformability, strong bearing capacity, and lightness.

Owner:WUHAN UNIV OF TECH

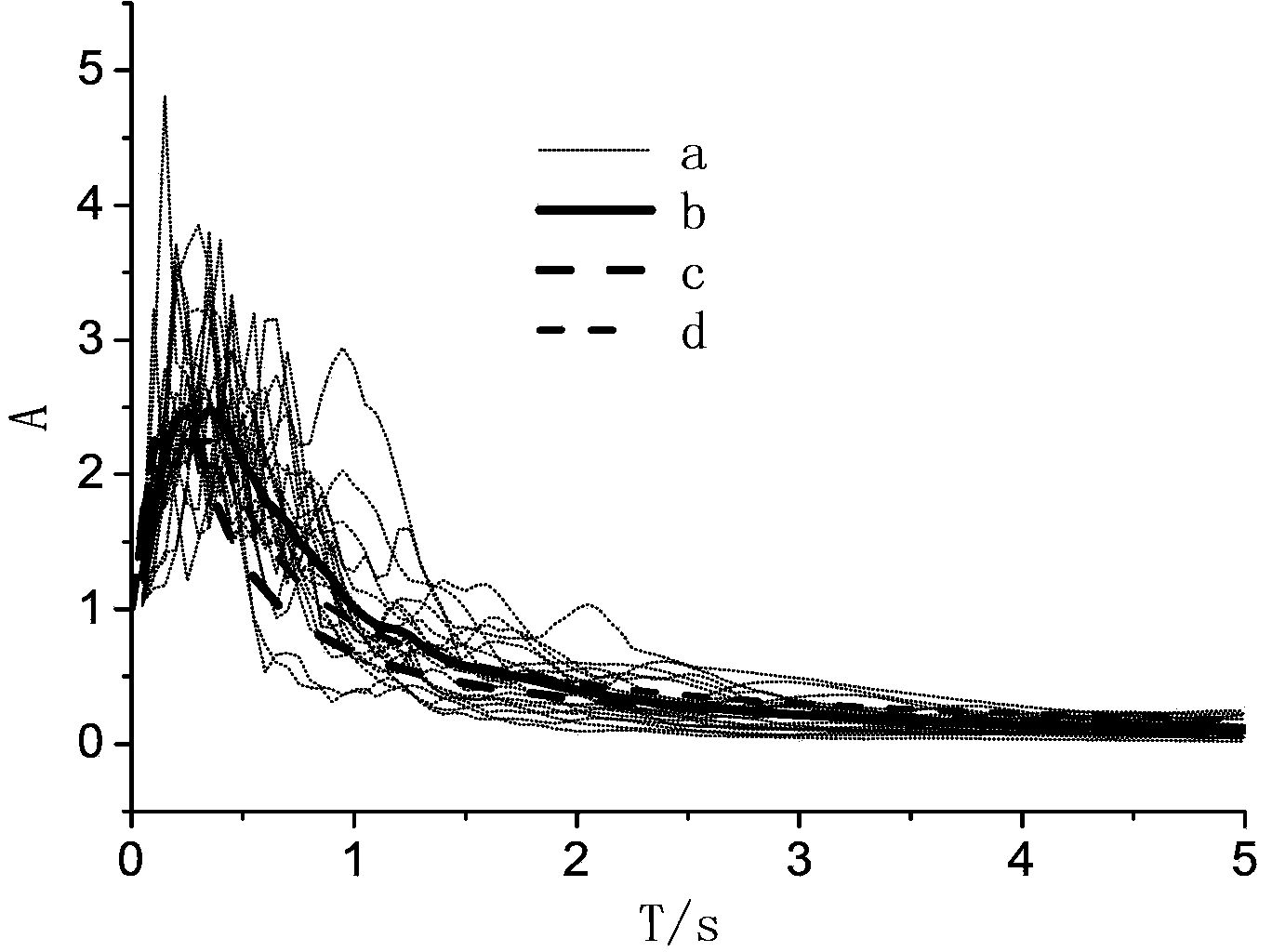

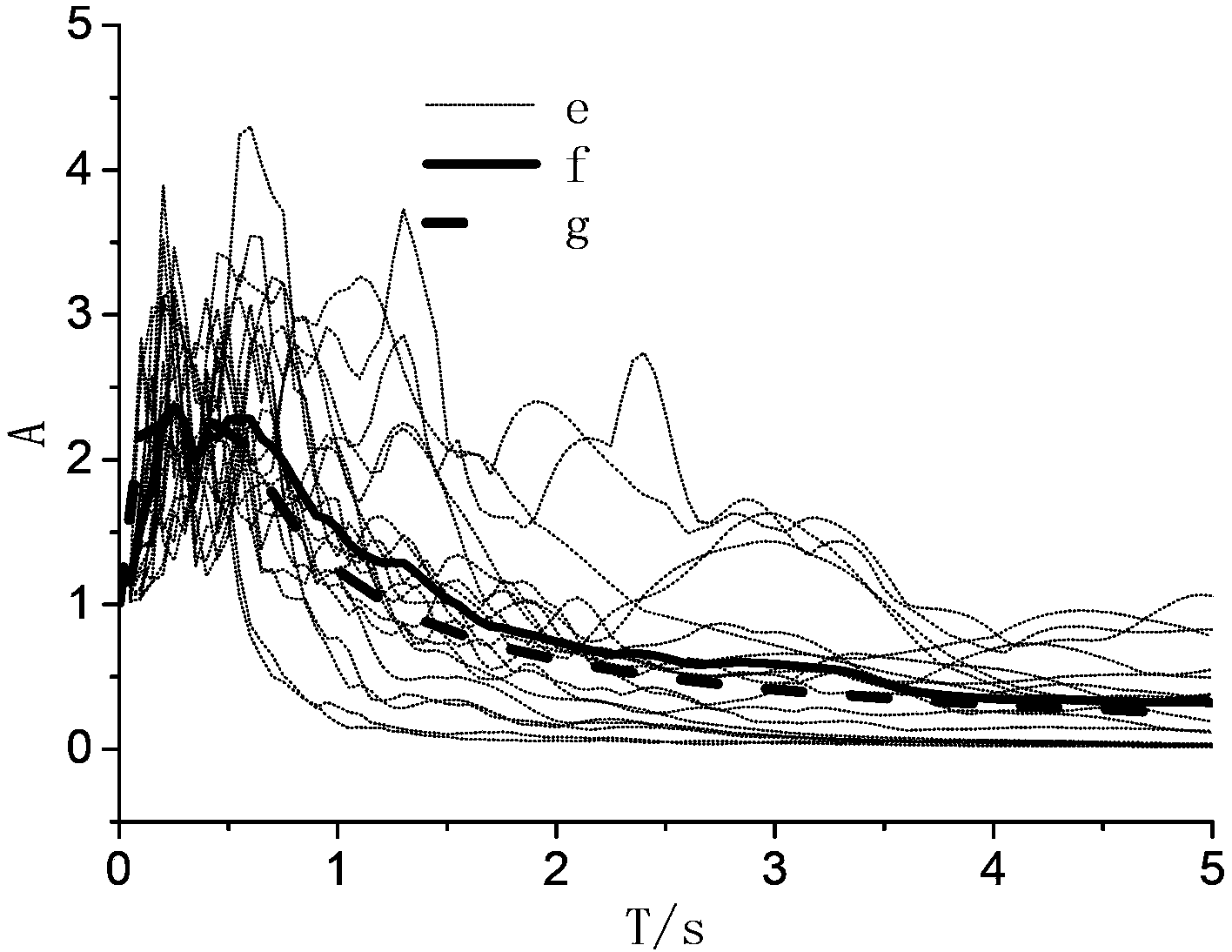

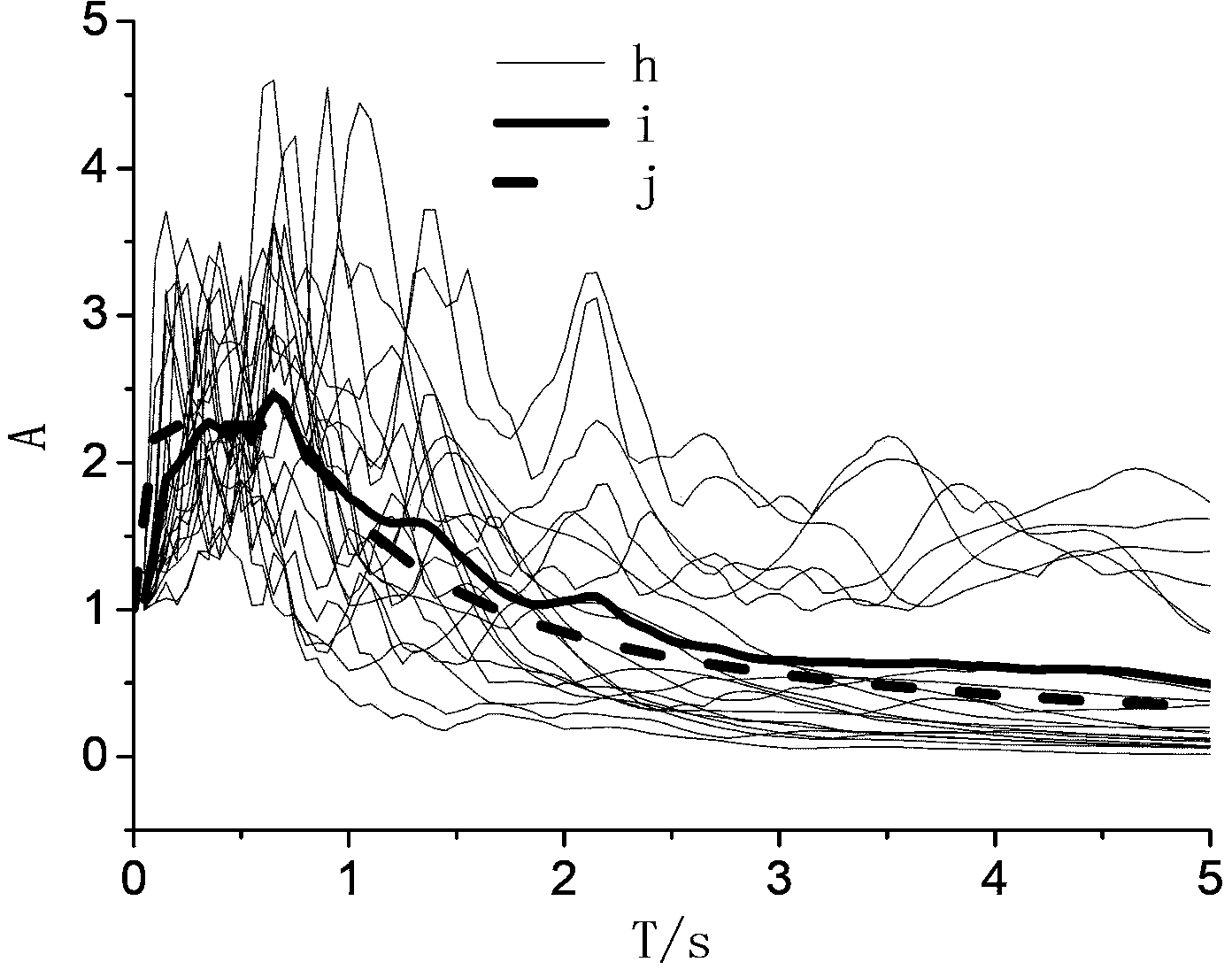

Selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures

The invention discloses a selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures to meet the earthquake-resistant requirements of the complex structures such as a high-pier long-span girder bridge, a cable-stayed bridge, a suspension bridge and a super high-rise building. The method comprises the steps that firstly, alternative earthquake waves which meet different site conditions such as earthquake magnitude, distance, an acceleration peak value and long cycle characteristics are selected in an American PEER strong earthquake record database, and a primary-selection database is formed; secondly, the minimum relative weighted average error of spectrum values of alternative earthquake wave response spectrums and design response spectrums in the primary-selection database near previous orders of periodic points of platforms stages and the complex structures is used as a double-control index according to site conditions, and the specific input earthquake waves are determined to meet the requirement that a time-procedure analysis result is in accordance with response spectrum analysis analytic statistics. According to the selection method, engineering realization is easy to achieve, and the method is compared with multiple mode decomposition reaction spectrum methods. In addition, due to the fact that the earthquake waves are selected in the appointed primary-selection database, similar classification of the site conditions is ensured, and the quality of input earthquake waves is ensured.

Owner:DALIAN MARITIME UNIVERSITY

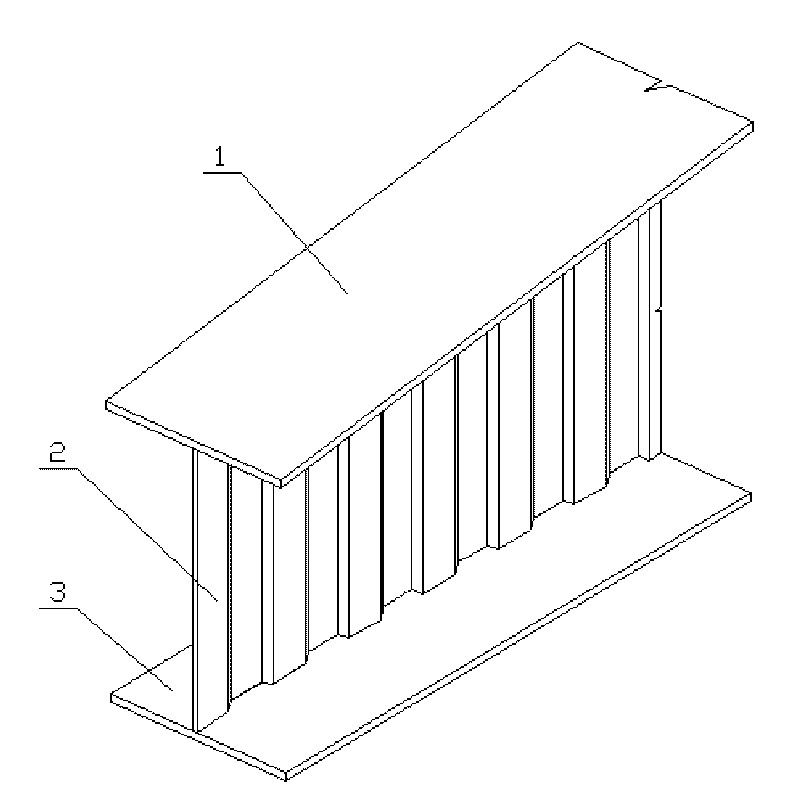

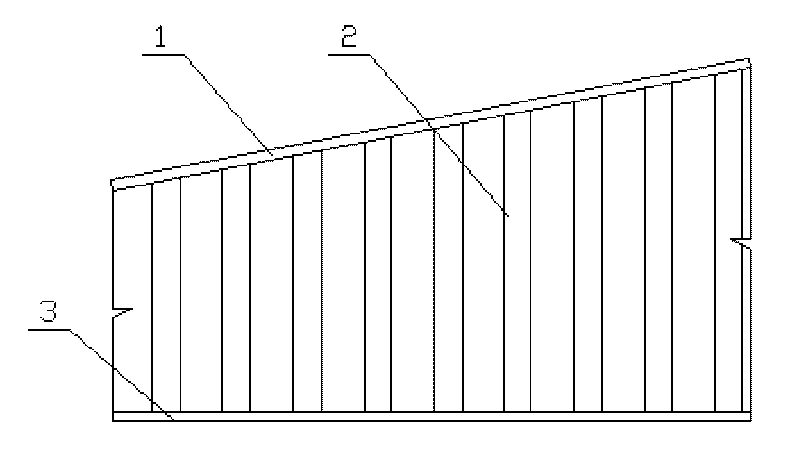

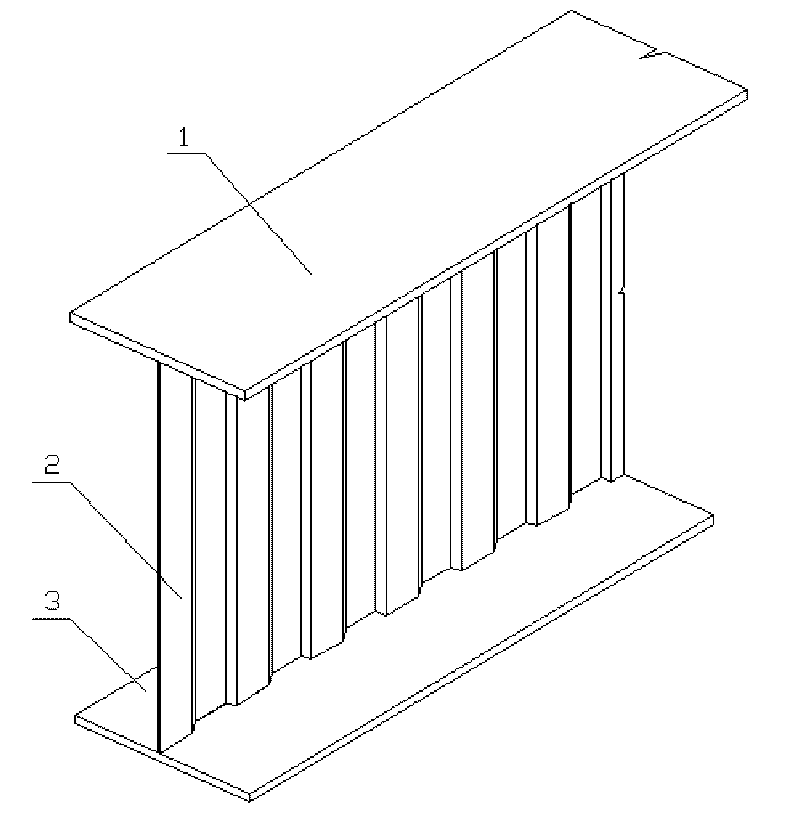

Steel column and beam structure with corrugated steel web and special welding device thereof

InactiveCN101761184AReduce weightImprove seismic performanceWelding/cutting auxillary devicesGirdersEarthquake resistanceDrive wheel

The invention relates to a steel column and beam structure used in the building and a welding device thereof, particularly discloses a steel column and beam structure with a corrugated steel web and a special welding device thereof. The steel column and beam structure comprises an upper wing plate, a lower wing plate and a web plate arranged between the upper wing plate and the lower wing plate, wherein the upper wing plate and the lower wing plate are made of plates with the thickness of 4-30mm, the web plate is a corrugated steel web plate with the thickness of 4-10mm, and the surfaces of the upper wing plate, the lower wing plate and the web plate are prepared with 50-500Mu m of roughness; the welding device of the steel column and beam structure with the corrugated steel web comprises a welding tractor and a welding gun arranged on the welding tractor, wherein tool sliding bars which are symmetrical are arranged on the welding tractor, a magnetic adsorption piece is arranged at the bottom of the welding tractor, four driving wheels are symmetrically arranged at two sides of the magnetic adsorption piece, and a track positioning retainer is arranged in a bracket at the middle part of the welding tractor. The middle web plate adopts the corrugated steel web plate, the steel beam and column with the corrugated steel web is welded by using the special welding device, therefore, the invention has the advantages of light weight and strong earthquake resistance.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

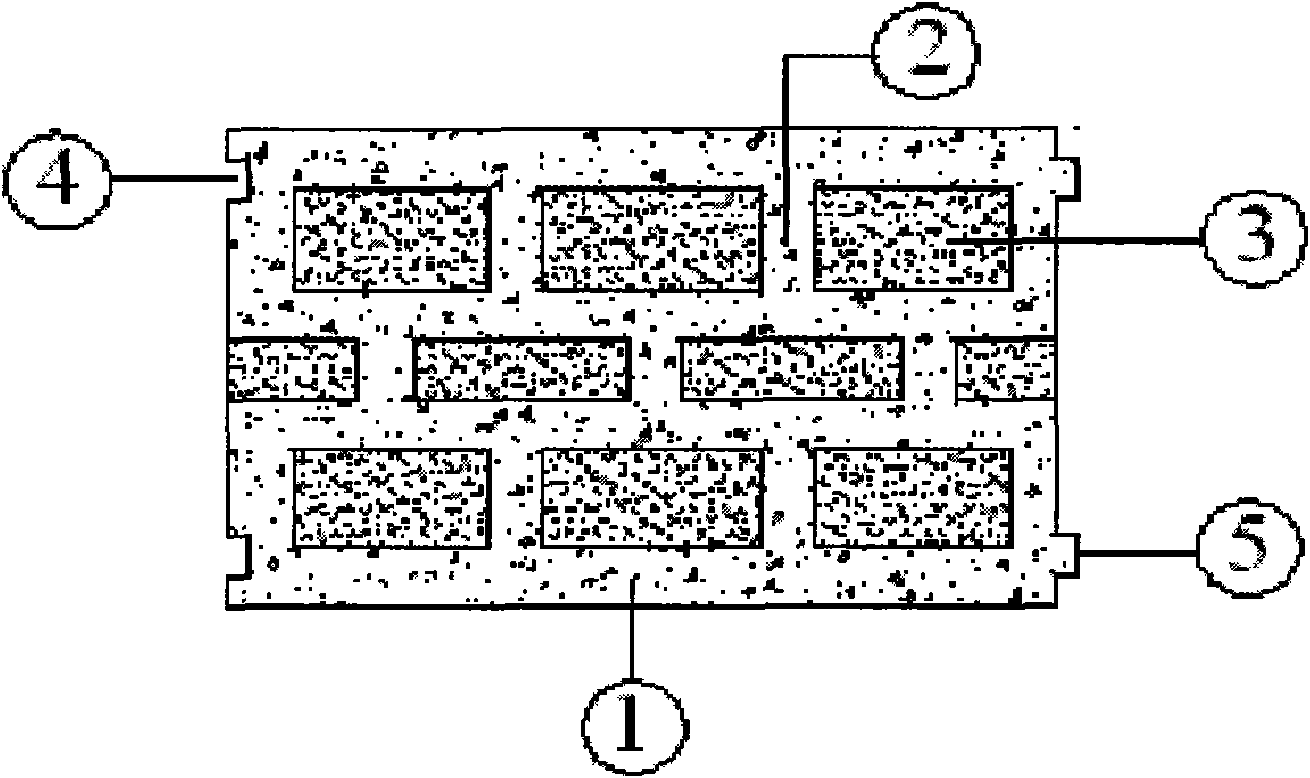

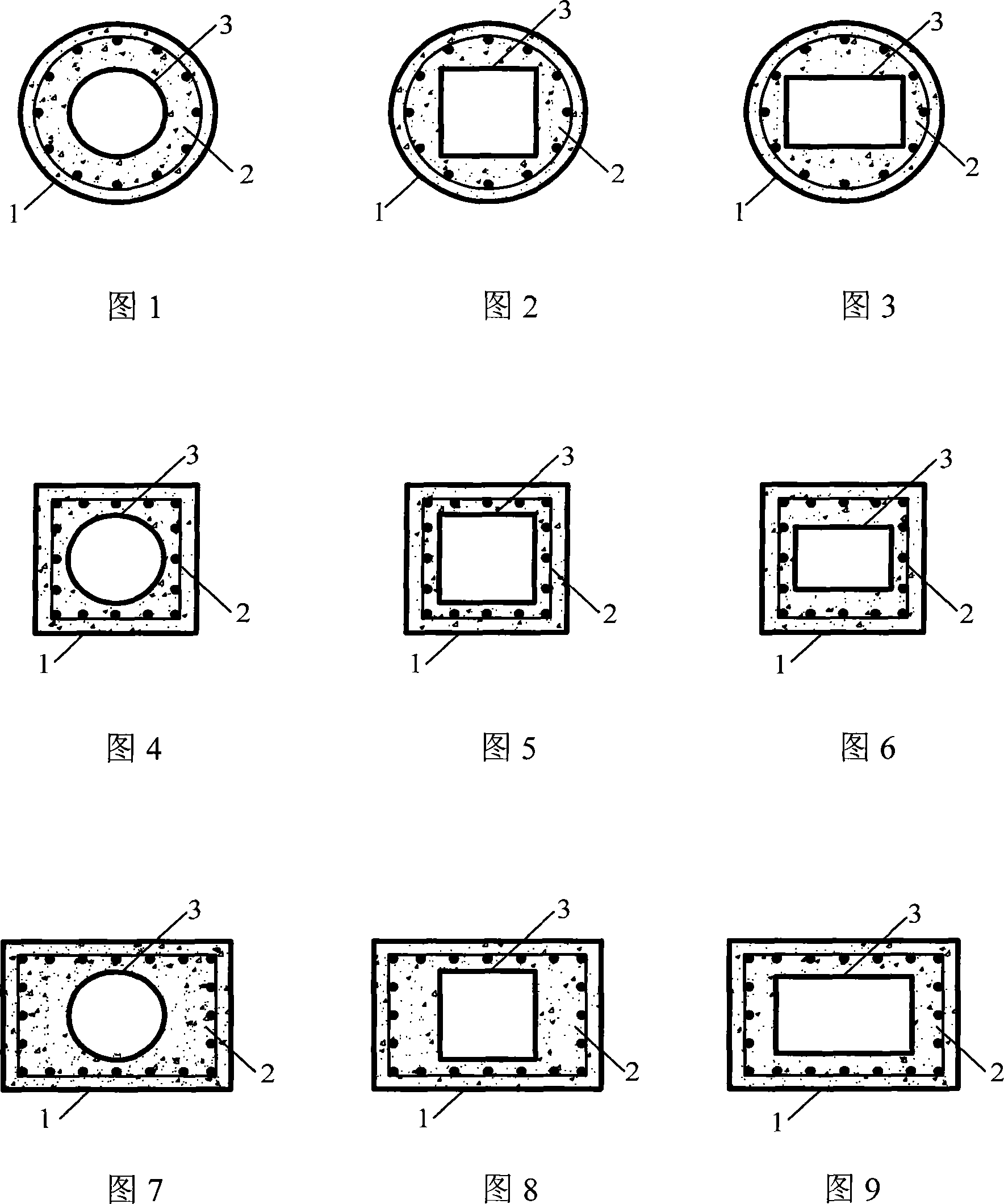

Combined masonry of recycled concrete block with light heat-insulation mortar bed and manufacturing method thereof

InactiveCN101603337APrevent agingImprove thermal insulation performanceConstruction materialWallsEarthquake resistanceInsulation layer

The invention relates to a combined masonry of a recycled concrete block with a light heat-insulation mortar composite heat-insulation layer and a manufacturing method thereof, and belongs to a novel energy-saving recycled concrete block combined masonry and a manufacturing method thereof. The combined masonry is built by straight type, T type, L type and cross type recycled concrete blocks with the light heat-insulation mortar composite heat-insulation layers. The blocks consist of recycled concrete block walls and recycled concrete block ribs, wherein the hollow parts of the recycled concrete blocks are filled with light heat-insulation mortar beds; the end parts of the blocks are provided with grooves 4 or convex keys 5; and the grooves at the end parts of the straight type, L type, T type and cross type recycled concrete blocks are mutually occluded and interlocked into a whole. The combined masonry has the excellent performances of light weight, high intensity, good overall performance, energy conservation, heat insulation, waste utilization, sound insulation, earthquake resistance, simple and convenient construction, and the like.

Owner:BEIJING UNIV OF TECH +1

Installation process for autoclaved lightweight concrete board partition wall

The invention relates to installation process for autoclaved lightweight concrete board partition wall, which is characterized in the process includes steps of: cleaning the field, paying out, Z type piece welding, installing corner units or U-type card, in-situ installing the board, regulating, installing hook bolts and other accessories, welding and twisting for fixture, performing anti-corrosive treatment at the welding point, filling mineral wool in the slot, slot repairing / injecting glue, cleaning and inspecting. The beneficial effect is that features of the ALC board is capable of ensuring strength, security and reliability of the connection at the connecting point, and rotation capability in the plane. When relatively large horizontal displacement occurs in the structure, the wall board rotates and moves along, thus the horizontal force transmitted by the structure is dispelled. Therefore, the partition wall has excellent earthquake resistance, and is especially suitable for buildings in earthquake areas, typhoon areas, high-rise steel structure buildings, and part of buildings which has relatively vibration, relatively large displace and deformation. The popularization of the installation process for the ALC board partition wall is capable of bringing benefits to the building construction.

Owner:CHINA CONSTR DONGFANG DECORATION CO LTD

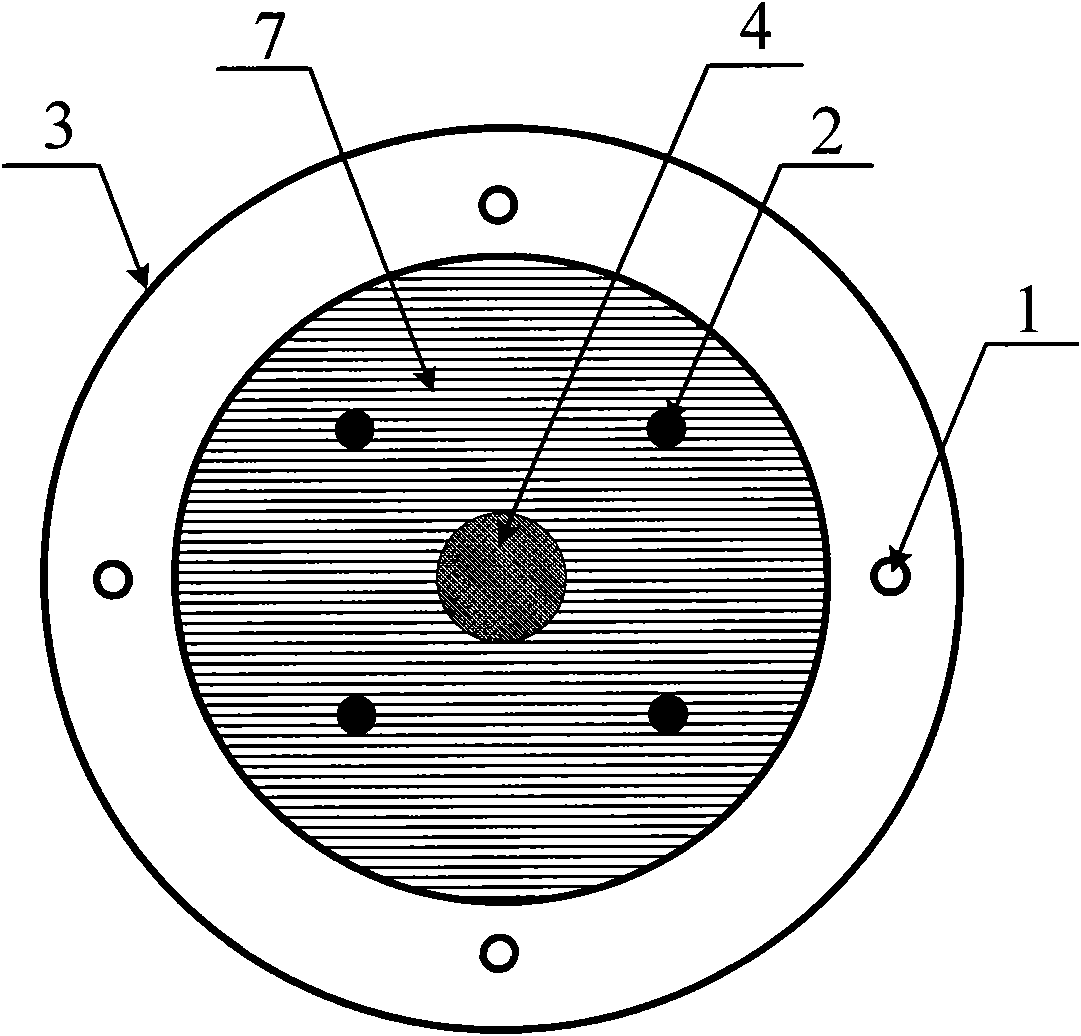

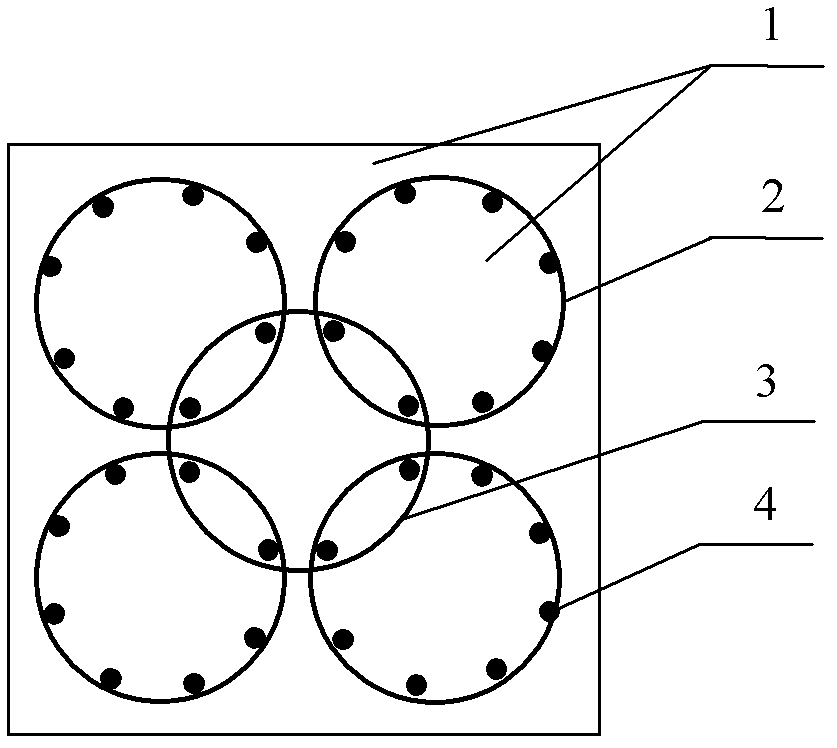

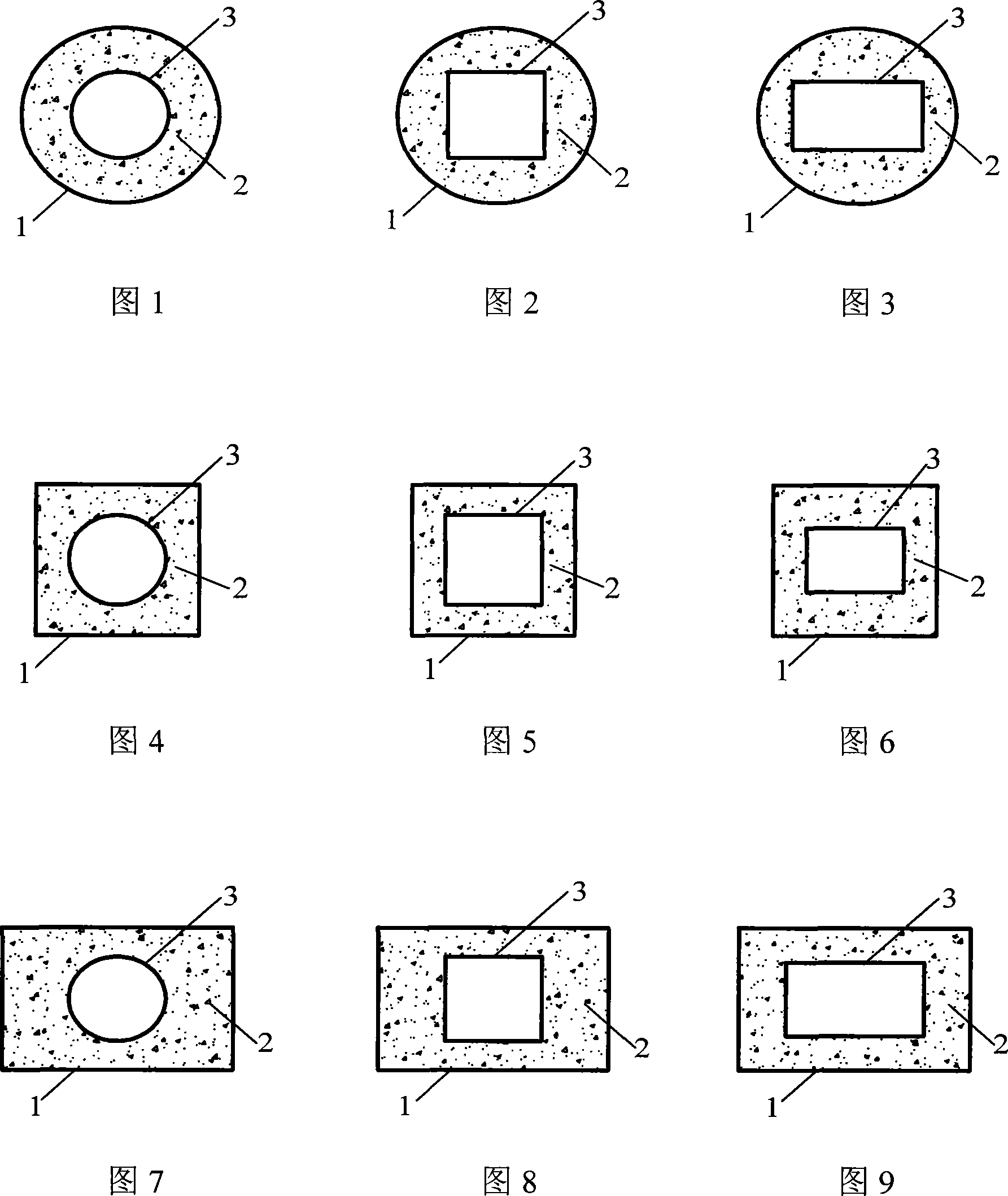

Steel pipe-FRP pipe core concrete combination structure

The invention relates to the composite structure of a steel pipe-FRP with concrete being filled inside, which is characterized in that the composite structure is a hollow pipe column which comprises a steel pipe used as a lateral wall, an FRP barrel used as a inside wall and a concrete layer which is fixedly connected between the steel pipe and the FRP barrel. The invention has good structural mechanical performance and earthquake resistance, which reduces the sole weight of the structure and strengthens the bending rigidity of the structure, thereby resulting in the convenient convey of the components and quick construction and installation; the invention is applicable to strengthen the modification works, which is especially suitable for the pole and bracing members of buildings, bridges and special structures.

Owner:HEFEI UNIV OF TECH

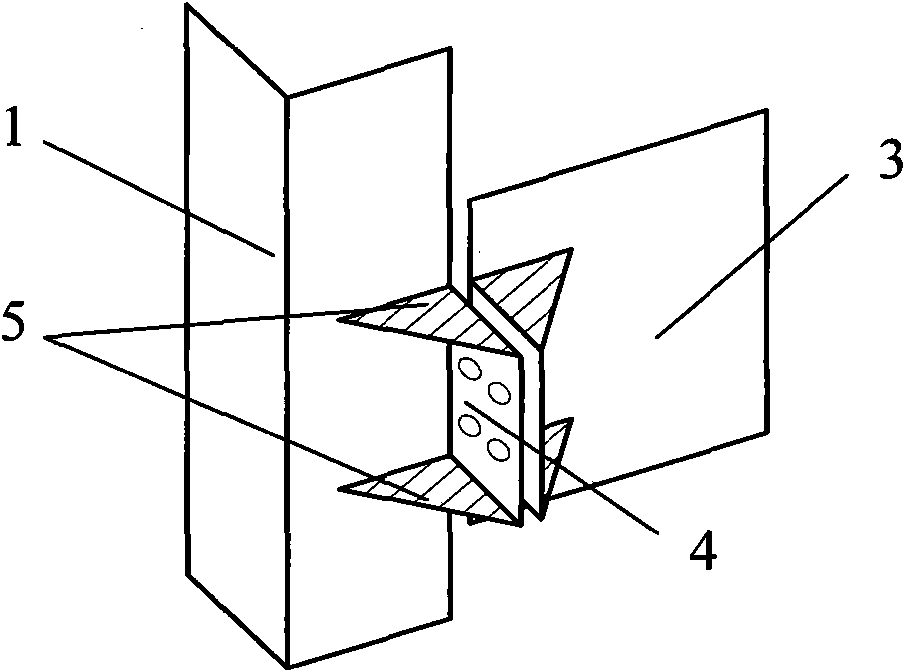

Method for carrying out earthquake-resistance and strengthening on traditional masonry structure by using steel parts

InactiveCN101906882AImprove integrityIncreased shear capacityBuilding repairsProtective buildings/sheltersEarthquake resistanceSheet steel

Owner:SOUTH CHINA UNIV OF TECH

Hollow double-layer FRP pipe concrete combination structure

ActiveCN101177966AImprove mechanical performanceIncreased bending stiffnessStrutsPillarsEarthquake resistanceReinforced concrete

The invention relates to the concrete composite structure of a hollow double-deck FRP pipe, which is characterized in that the composite structure comprises an outer FRP pipe used as a lateral wall, an FRP barrel used as an inside wall and a steel and concrete composite layer or a concrete layer which is used as a fixed connector between the outer FRP pipe and the FRP barrel. The invention has good structural mechanical performance and earthquake resistance, which reduces the sole weight of the structure and strengthens the bending rigidity of the structure, thereby resulting in the convenient convey of the components and quick construction and installation; the invention is applicable to strengthen the modification works and in particular to be applied to the poles and bracing members of buildings, bridges and special structures in severe environment such as ocean, marsh, alkaline land, etc.

Owner:HEFEI UNIV OF TECH

Cast-in-situ hollow floor for storing and recycling heat energy and preparation method thereof

InactiveCN101525919AAvoid gaining weightGuaranteed stabilityFloors improvementClimate change adaptationEarthquake resistanceEngineering

The invention relates to a cast-in-situ hollow floor for storing and recycling heat energy and a preparation method thereof, adopting the following scheme based on the prior hollow floor: each box and thin wall in the floor is communicated with each other from side faces by connective channels, so that the box and thin wall of the each floor of a whole building is communicated with each other so as to be formed as a storable and recyclable inner passage which is internally filled with hot gas to provide heat energy for the whole building. The scheme uses the characteristics of light weight and strong earthquake resistance of the prior hollow floor so as to completely use the upper face and the lower face of the floor, thereby overcoming the defect that the geotherm only can be radiated from upper side; the scheme can adopt modes such as parallel connection, series connection or multiple series, and the like, for the box and thin wall of the hollow floor, so that the required temperature in the hollow floor comes up to the required standard in a faster and more reasonable way, as well as circulation is more convenient; and the scheme also can adopt a separate control method so as to lead the inner passage of the floor of each floor and each room to be circulated or closed.

Owner:HUNAN BDF ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com