Bridge prefabricated hollow pier column post-poured connecting structure and construction method

A technology for connecting structures and hollow piers, which is applied in the direction of infrastructure engineering, bridges, bridge parts, etc., can solve problems such as failure to take into account the positioning problem, connection strength problems, difficulty in accurate positioning of bridge piers, and low slip resistance of the connecting surface. , to achieve the effect of easy control of construction quality, enhancement of the overall stability of the structure, and shortening of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In this embodiment, the concrete design parameters and construction technical requirements, the manufacturing process of the steel casing, the trapezoidal steel rib plate and the fan ring connecting steel plate, etc. will not be described in detail, and the embodiment of the structure related to the present invention will be focused on.

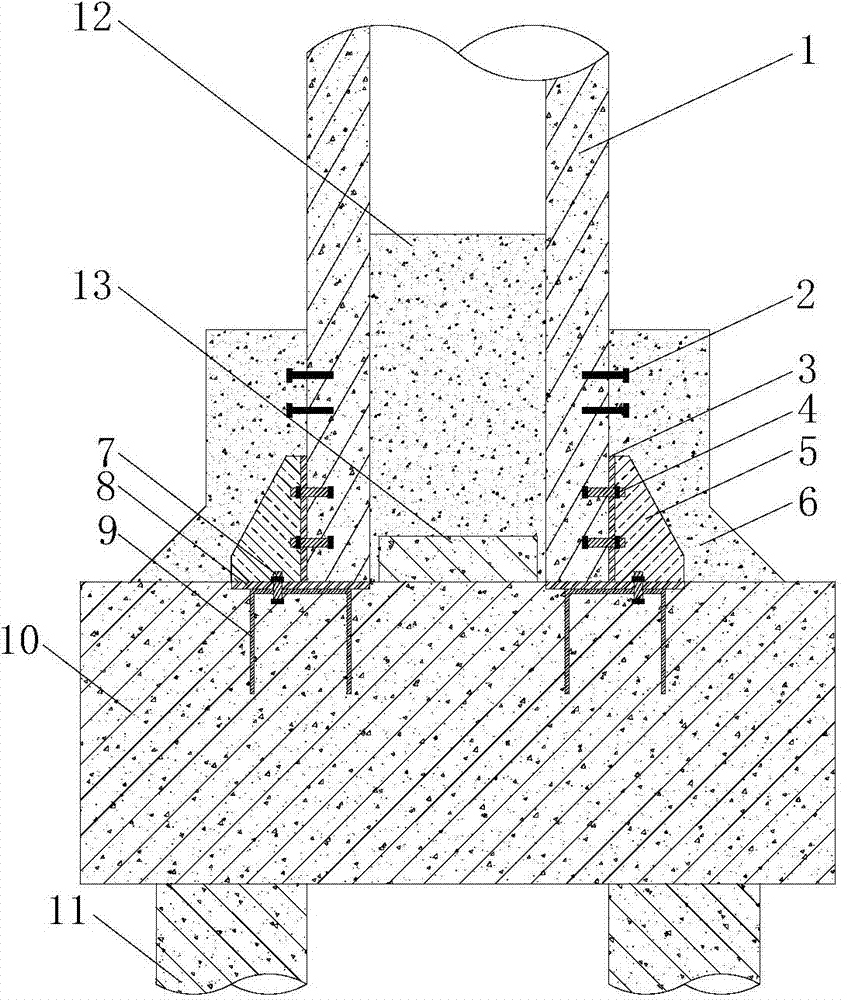

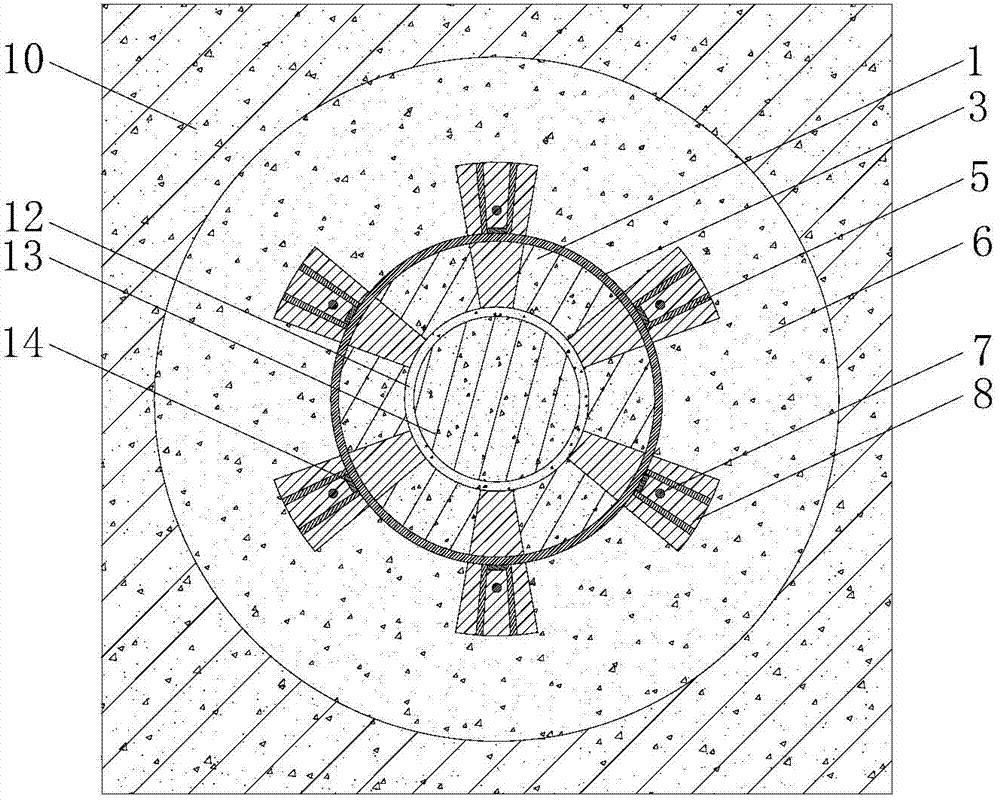

[0032] figure 1 It is a longitudinal section view of the bridge prefabricated hollow pier post-cast connection structure of the present invention, figure 2 It is a cross-sectional view of the connection surface between the prefabricated hollow pier column and the foundation of the bridge of the present invention.

[0033] refer to figure 1 As shown, a bridge prefabricated hollow pier post-cast connection structure includes a prefabricated hollow pier 1 , a pier post foundation 10 and a post-cast concrete pier wall 6 .

[0034] The top surface of the pier foundation 10 pre-embeds the connecting steel plate 8 and the high-strength b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com