Patents

Literature

510results about How to "Construction quality is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

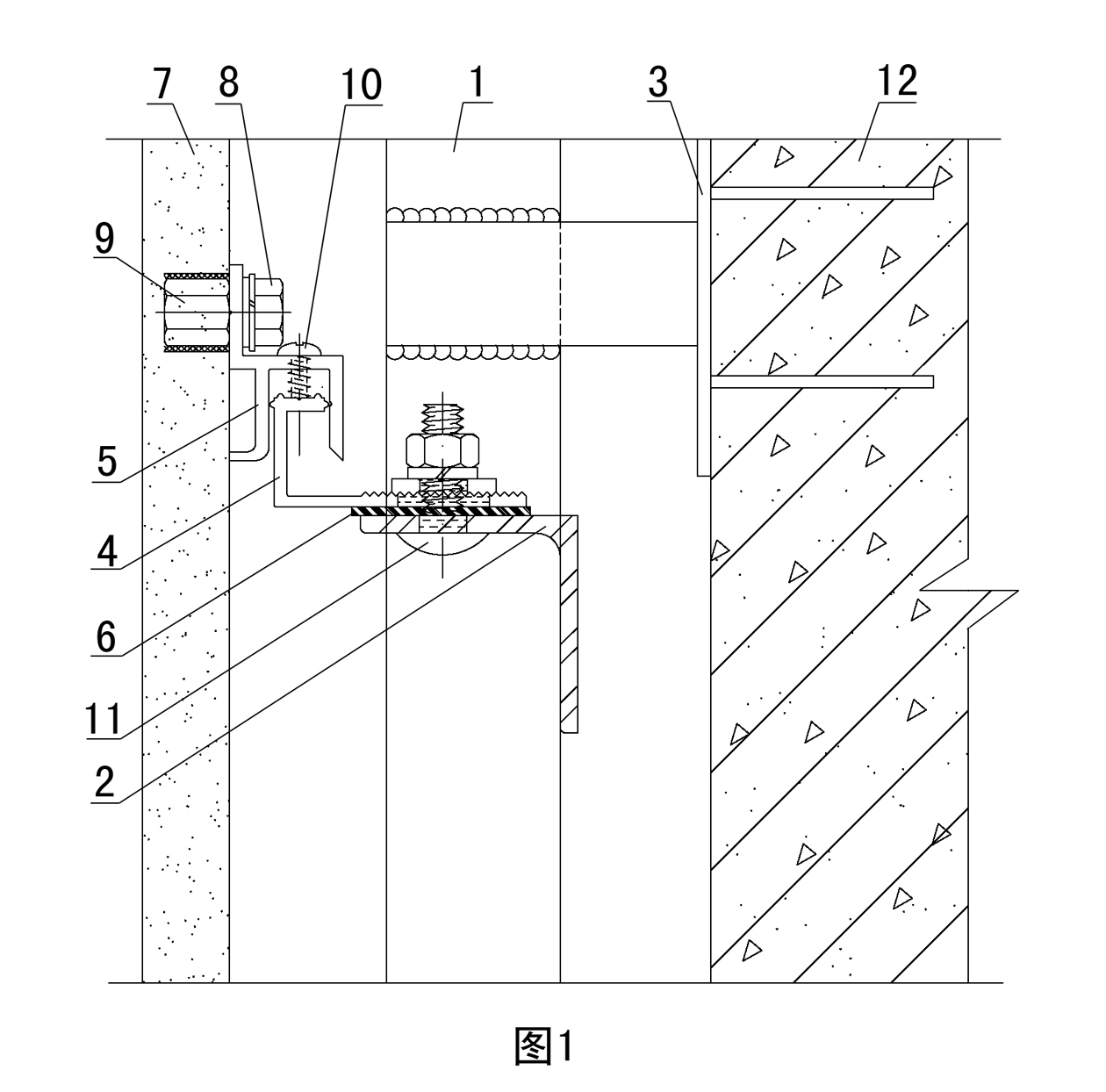

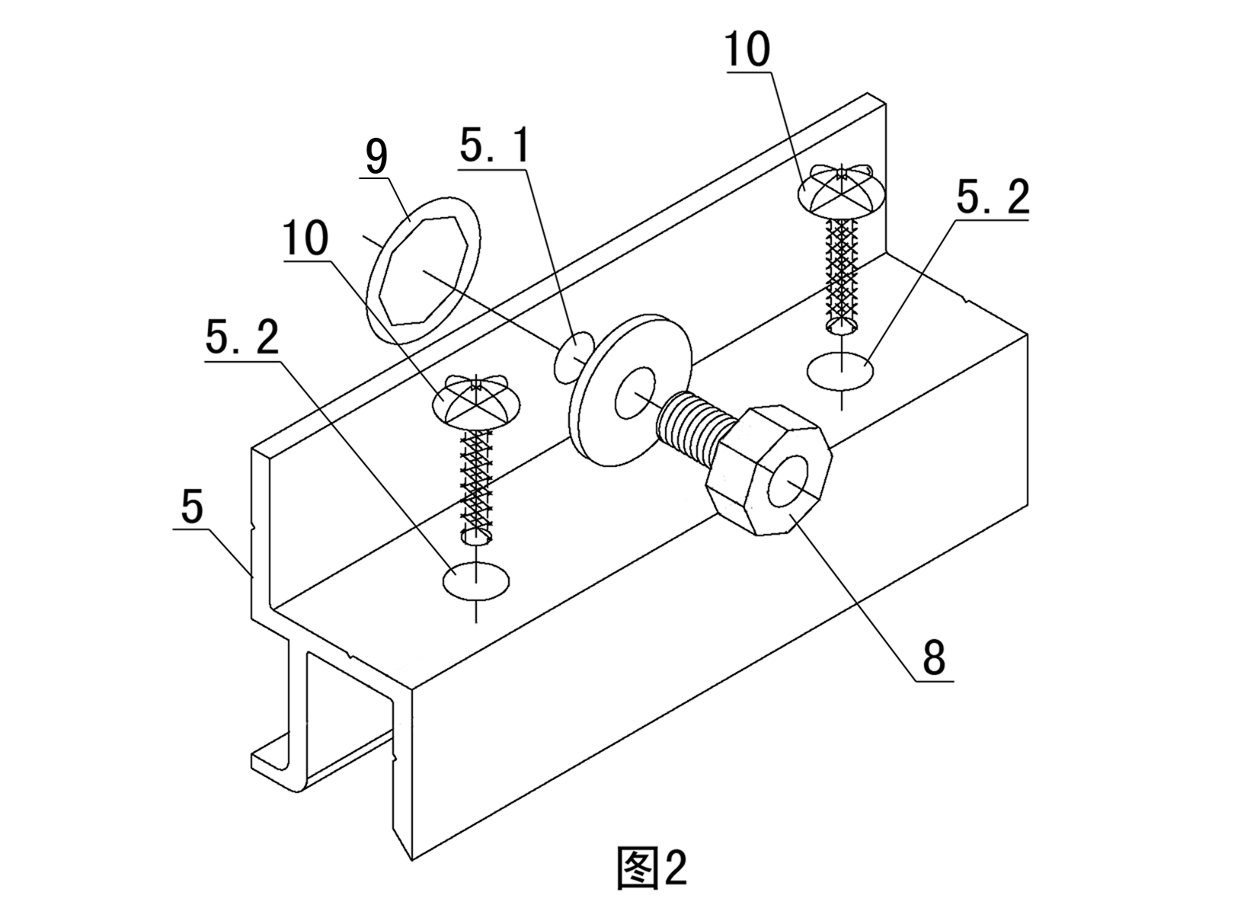

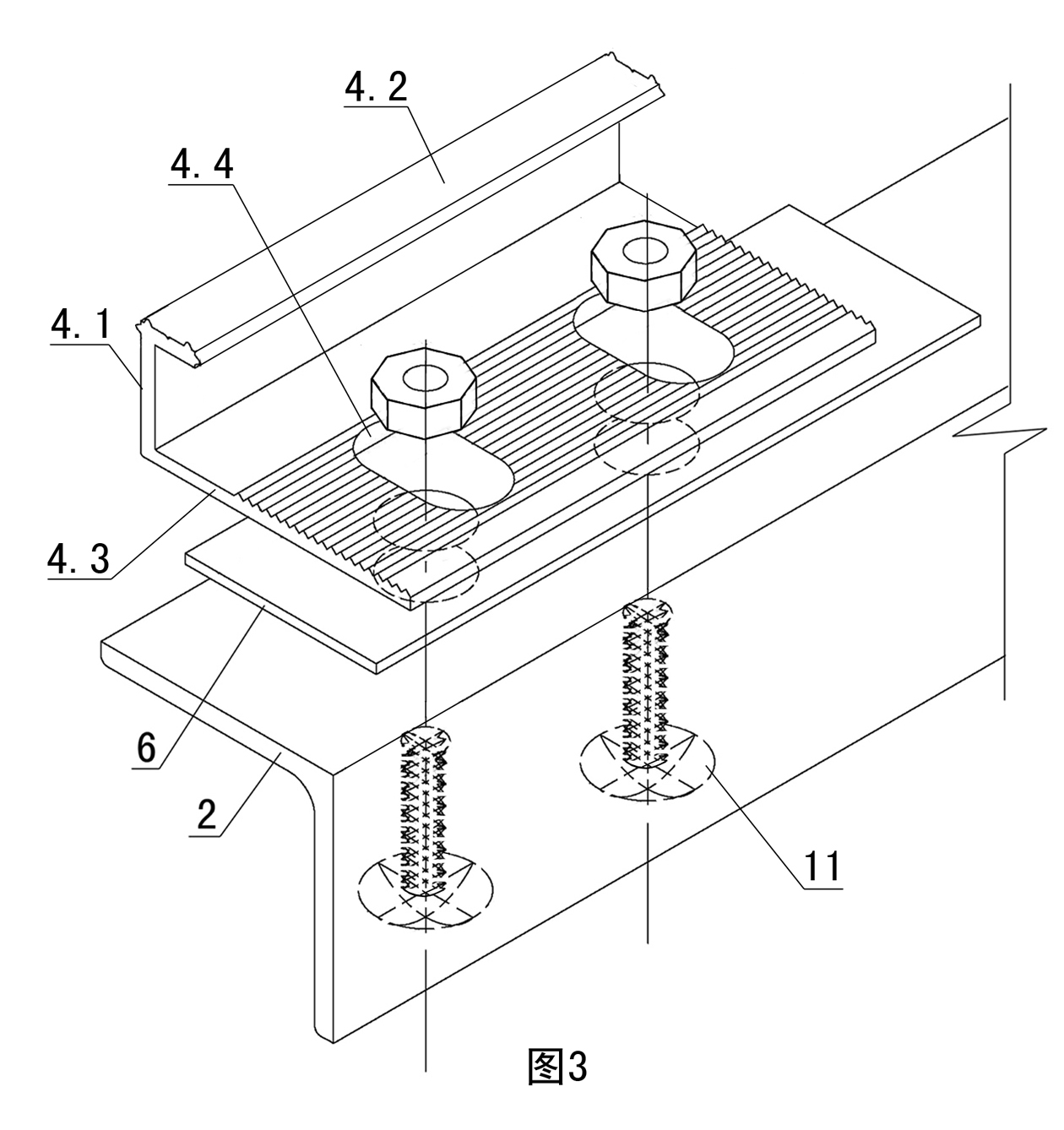

Three-dimensionally adjustable disconnectable curtain wall connecting device and construction method thereof

ActiveCN101956438ASolve the adjustmentSolve the different size of the board seamCovering/liningsWallsVertical deflectionKeel

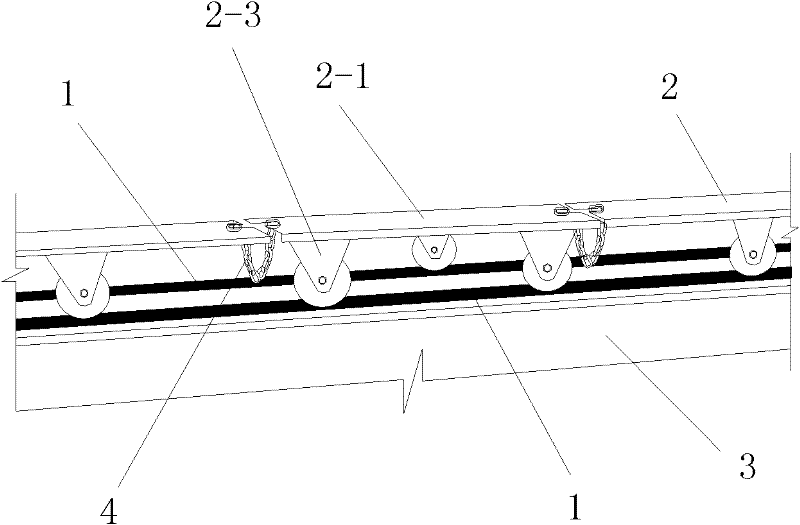

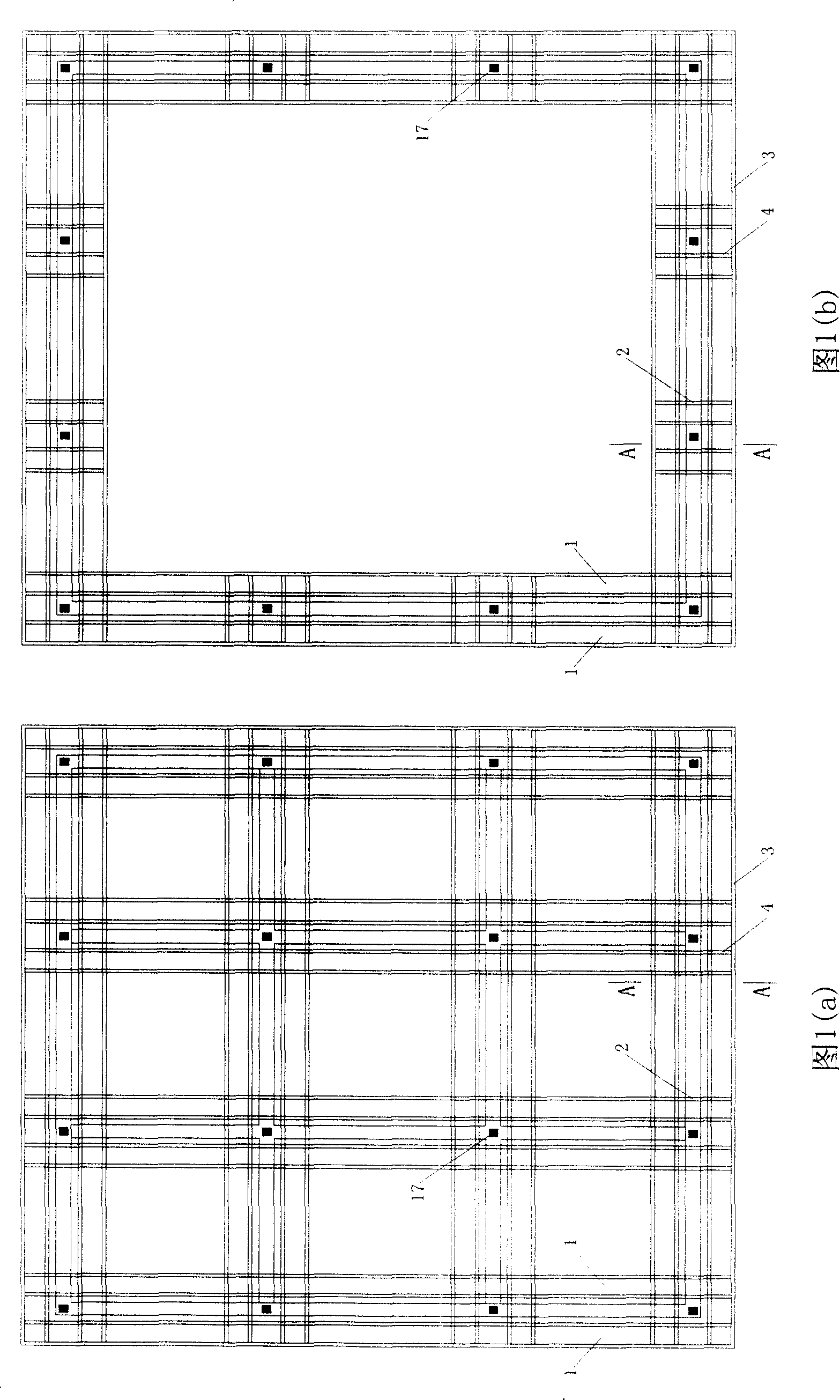

The invention relates to a three-dimensionally adjustable disconnectable curtain wall connecting device. In the three-dimensionally adjustable disconnectable curtain wall connecting device, the section of a back pendant has a chair shape; a back bolt hole is formed at the back of the chair and is in threaded connection with an embedded nut at the back of each curtain wall plate through a back bolt; the back chair legs have L shapes and are propped against the back of each curtain wall plate; a jackscrew bolt hole is formed on the chair surface and is connected with an adjustable supporting piece of which the upper end is embedded between the front and back chair legs through a jackscrew bolt; the adjustable supporting piece is formed by connecting a supporting plate, a vertical plate and an adjusting plate to be a whole; the supporting plate is in top contact connection with the jackscrew bolt; the thread height of the jackscrew bolt is more than the longitudinally adjusting distance of each curtain wall plate; and a long round hole vertical to the wall body is formed on the adjusting plate. The device solves the problems that the position of each curtain wall plate cannot be adjusted, the plate gaps are different in sizes, the curtain wall plates are staggered with one another and the like so as to guarantee the appearance of the curtain wall and overcomes the defect that the installation of the traditional curtain wall plates completely depends on the control level and the vertical deflection of keels at the same time, so that the construction quality can be controlled easily.

Owner:泛华建设集团有限公司

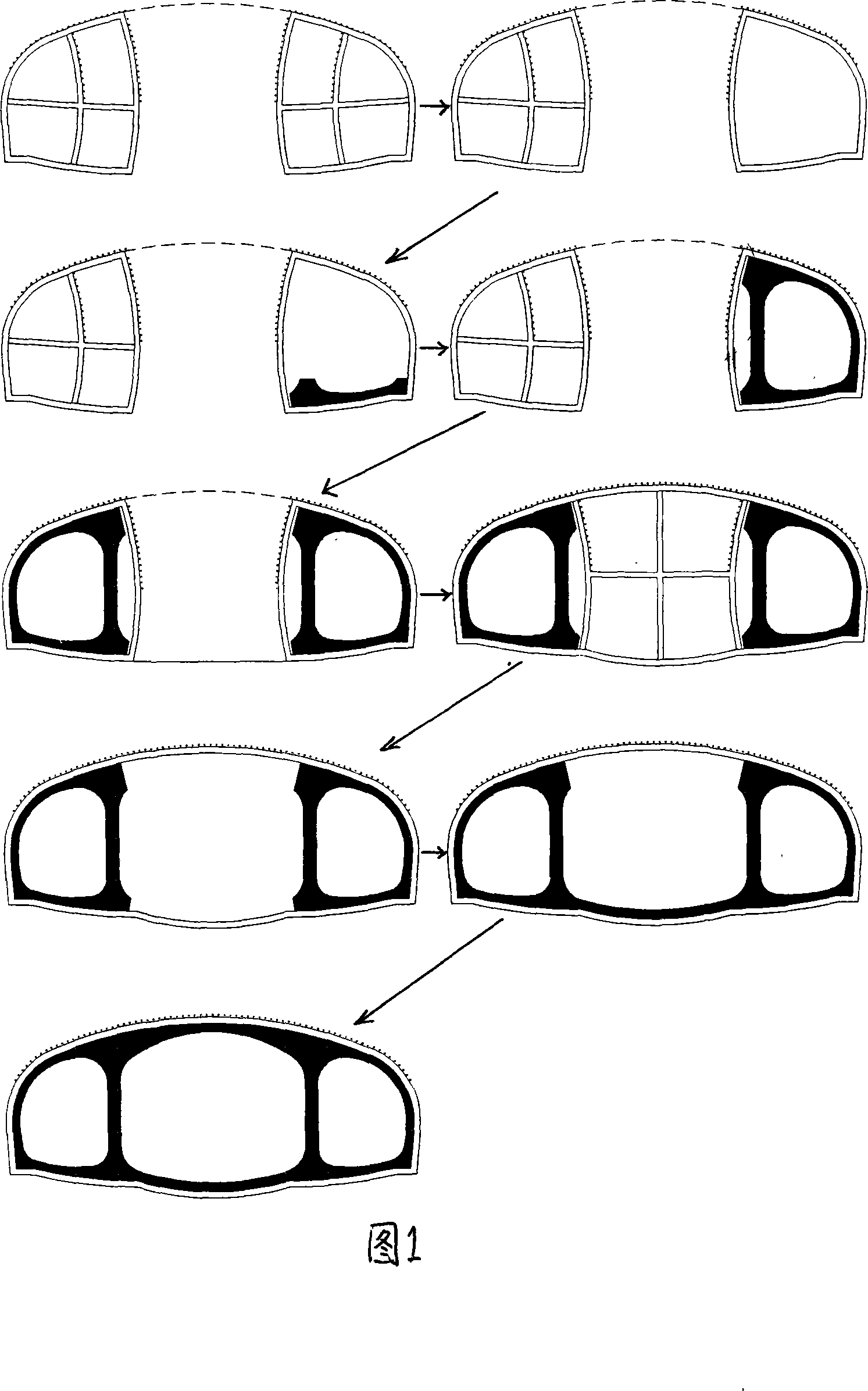

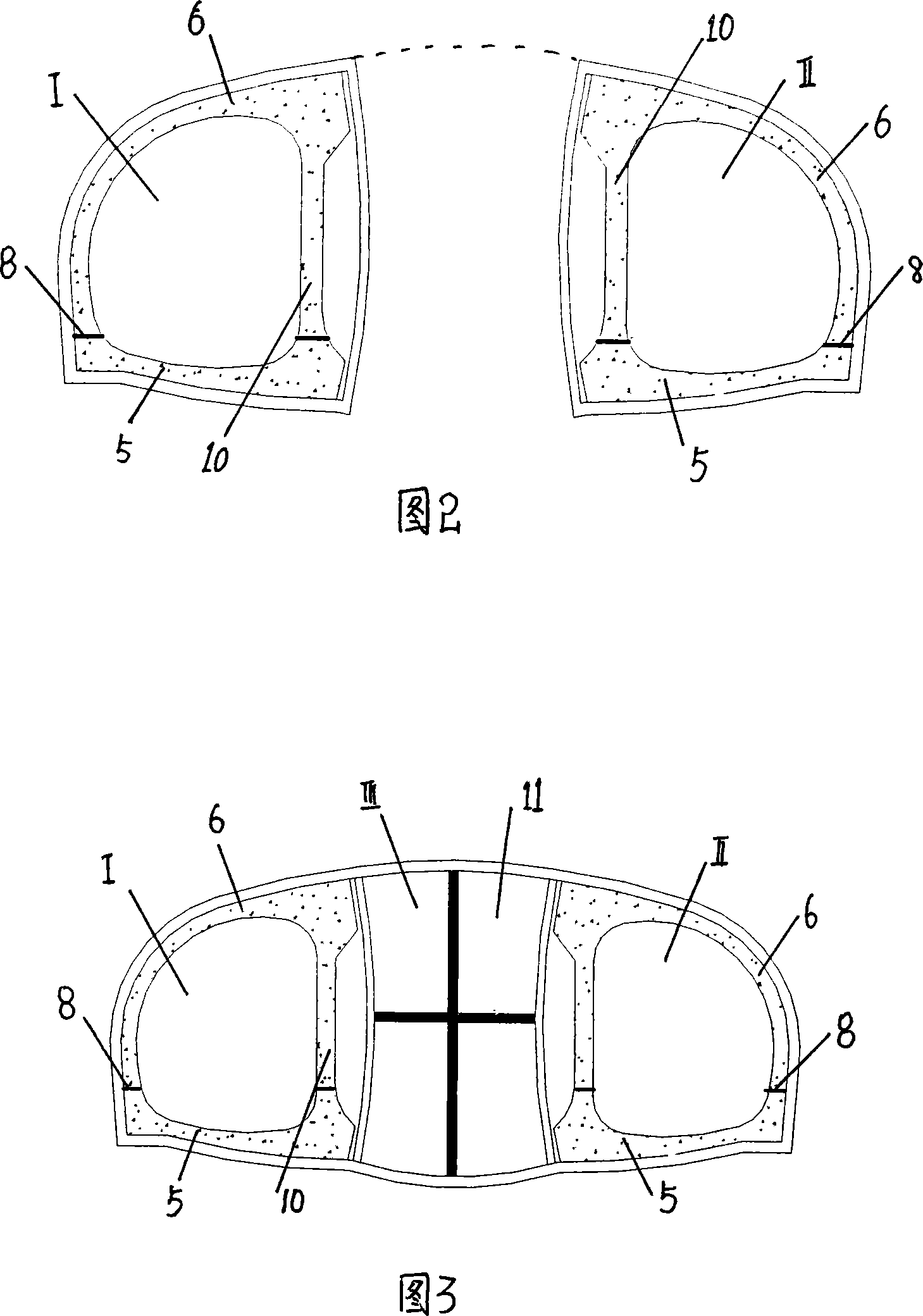

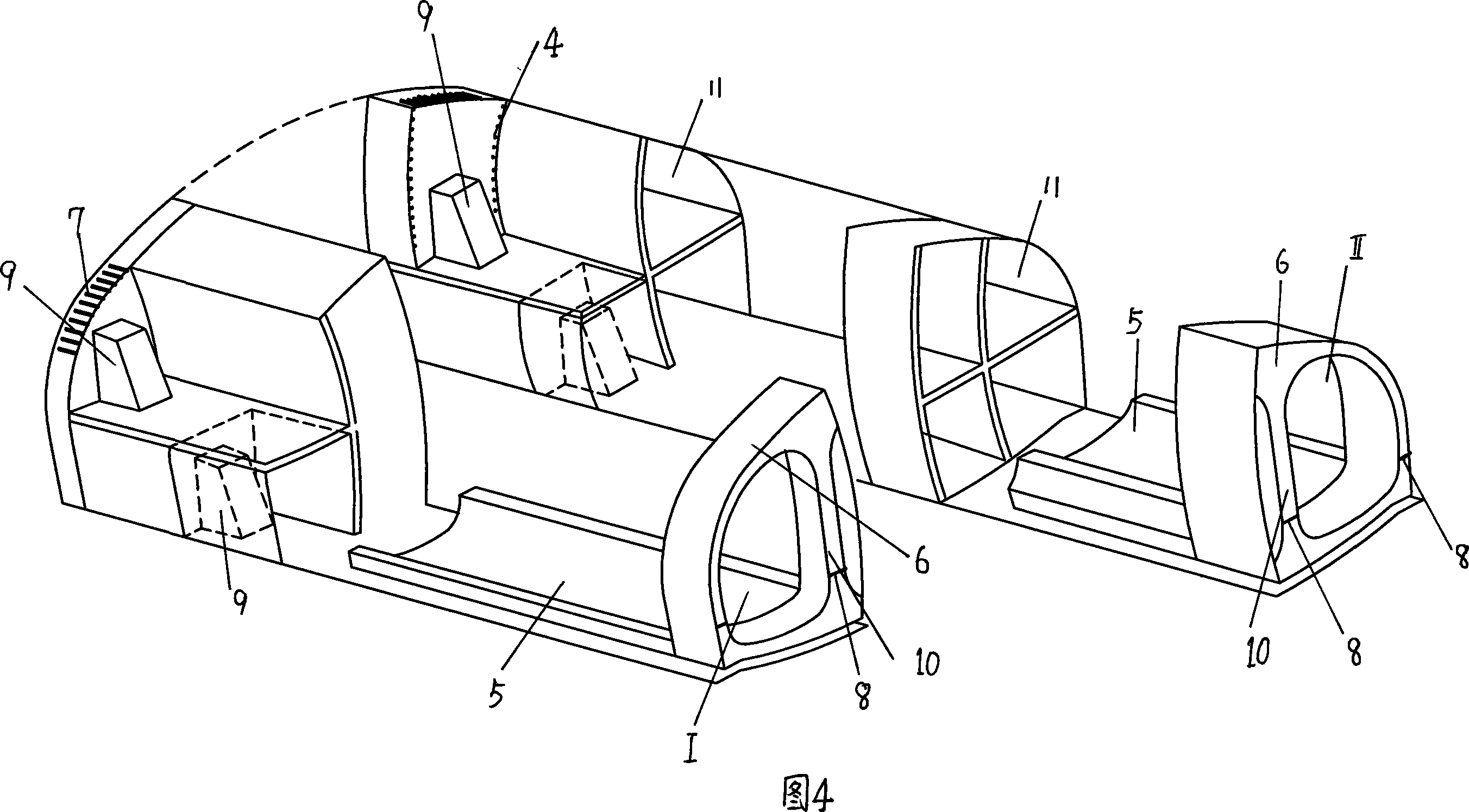

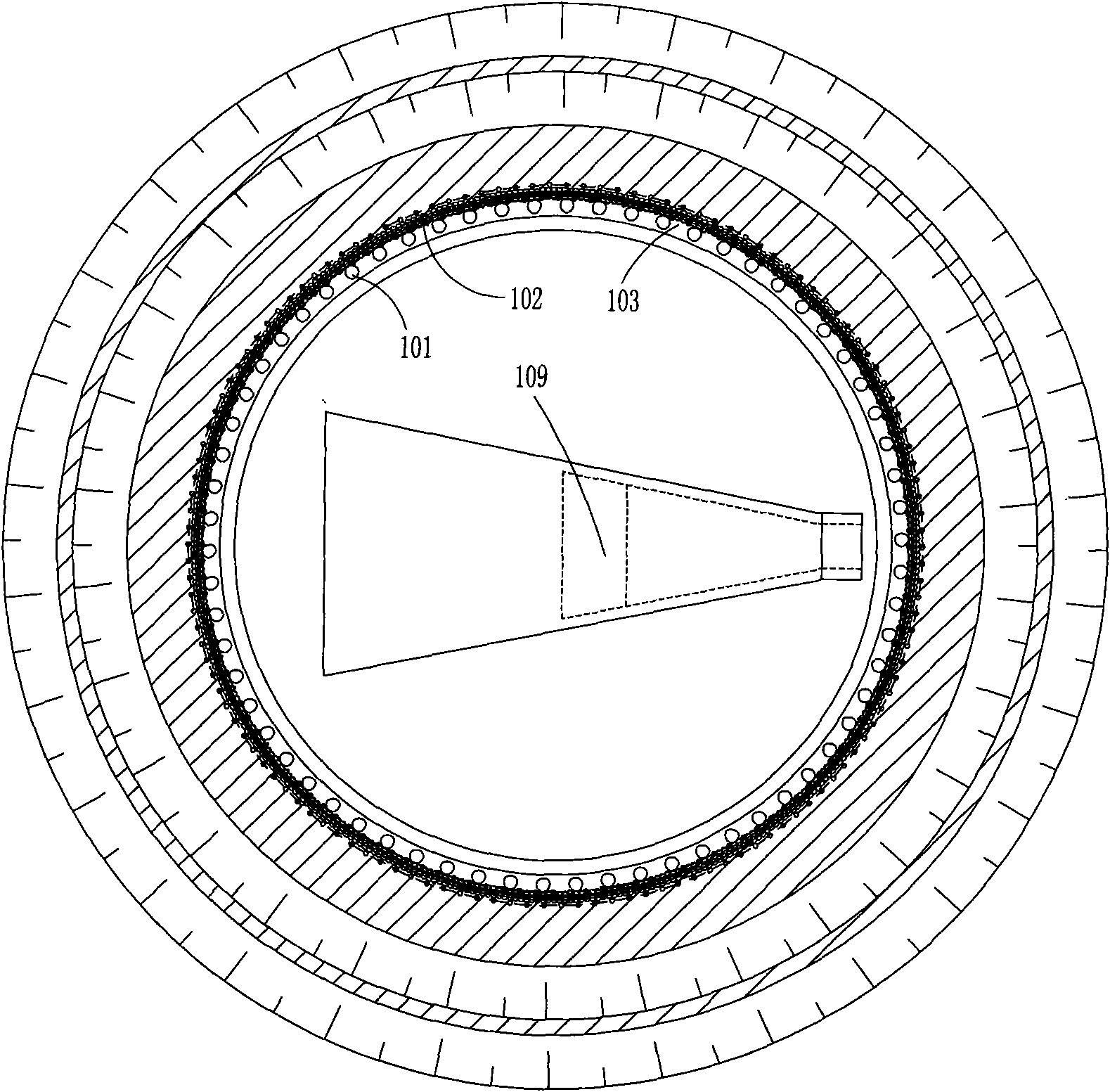

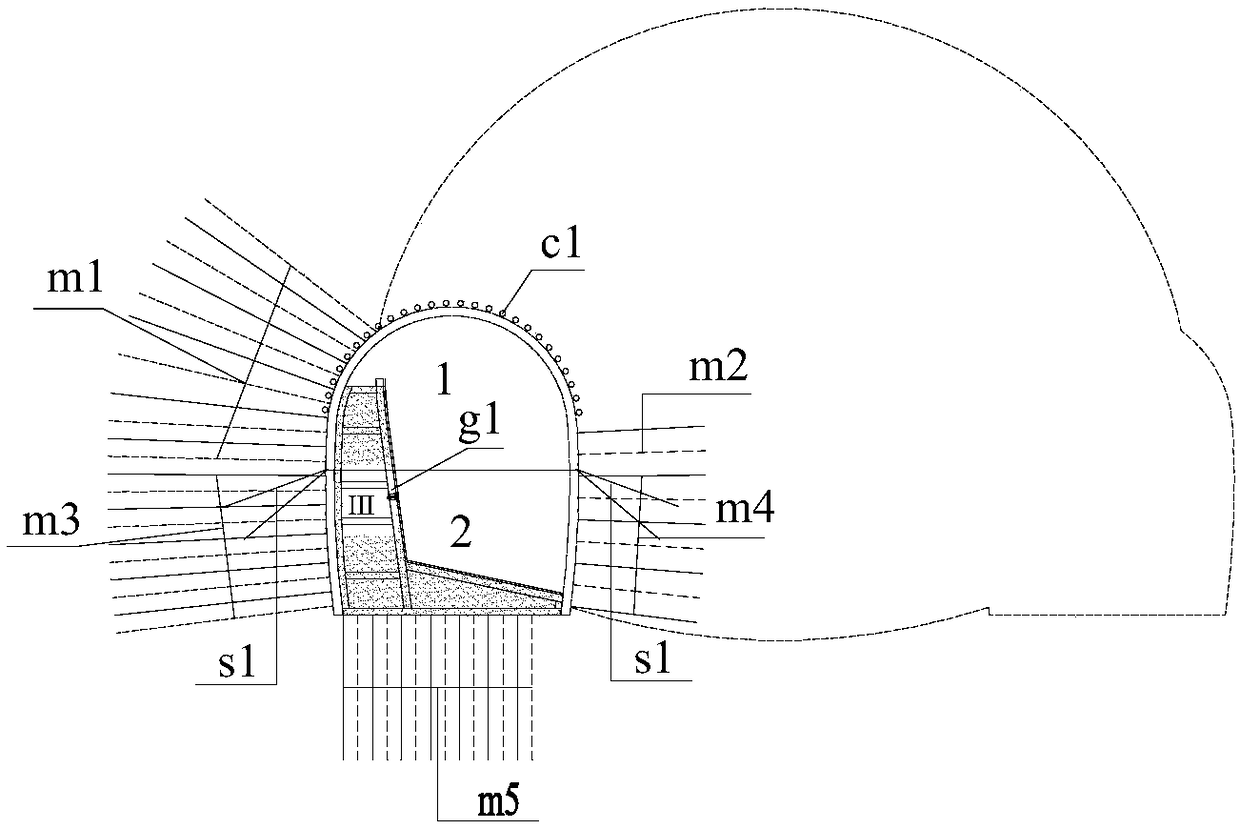

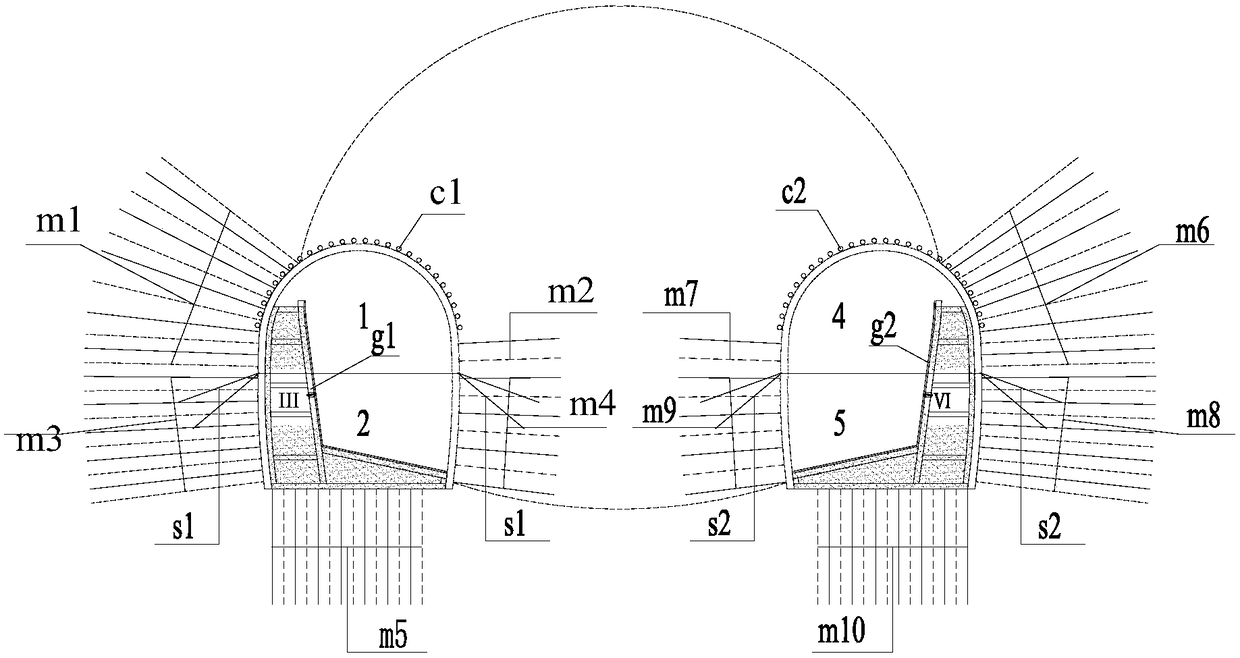

Three-connected-arch tunnel double-side cavity construction method for soft geological

InactiveCN101196116AReasonable division of single excavation areaSuitable for manual excavationUnderground chambersTunnel liningEnvironment effectWall rock

The invention relates to the technical field for the engineering of large-section tunnel, in particular to an engineering method for the double lateral tunnel of a three-arc tunnel on soft and weak geological condition, which resolves the problem of longer duration for the exposure of wall rock, easy deformation of tunnel and poor waterproof effect in existing tunnel engineering method. The invention comprises: (1) excavation of lateral tunnel; (2) lining of later tunnel: first of all, dismantle the primary support of the whole section, then pour the arc invert secondary lining and arc section secondary lining with the construction joint being configured at the lower section of the middle wall for the lateral tunnel; (3) after the circular lining a left lateral tunnel I and a right lateral tunnel II on a same section, excavate and line a middle tunnel III. This method realizes simple equipment and convenient engineering; with the construction sequence of building the lateral tunnel and then the middle tunnel, the invention gives full play to the supporting function of the secondary lining of the middle wall, so as to reduce the load borne by the primary support of the arc section of middle tunnel and elevate the safety coefficient; the invention reduces the settlement and impact on peripheral environment, so as to ensure the stability and safety of the excavation working face; small number of construction joint and high working efficiency.

Owner:CHINA RAILWAY 12TH BUREAU GRP

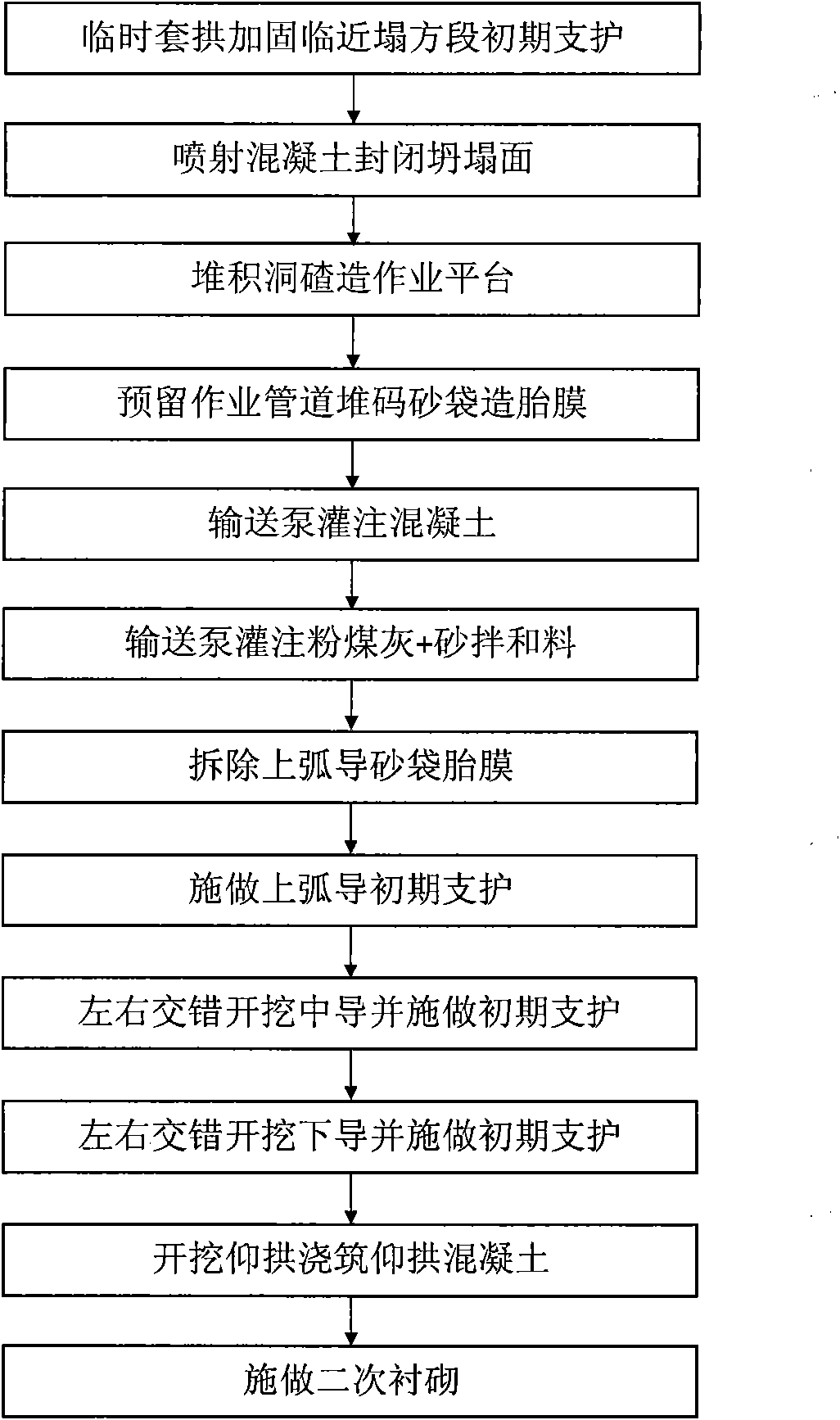

Construction method for dealing with tunnel collapses

ActiveCN101781990AEasy to get materialsLow costUnderground chambersTunnel liningTunnel constructionShotcrete

The invention relates to the tunnel construction field, in particular to a construction method for dealing with tunnel collapses to solve the existing problems such as high security risks, construction difficulty and failures to guarantee the construction quality. To achieve such purposes, the construction method comprises the following steps: solidifying the preliminary bracing of the adjourning landslides with temporary umbrella arches, and sealing off the collapse surface with spraying concrete after the collapsed cave is stabilized. The method also requires building of a working platform with ruins in the cave, and laying of sand bags on the platform to form an arch-shaped solid membrane. A concrete solidified ring is built by infusing concrete through the reserved pipeline. On top of the concrete solidified ring, a buffer ring is formed by infusing the solidified ring with sands and fly ash mixture, then the supporting system of the cave is constructed when the required strength of the concrete solidified ring is met. With the construction method, the security of the construction can be guaranteed with no quality or security risk to the collapsed section. The materials required in the method are easily available and cheap. Compared with the traditional construction methods, the new construction method can save up to 30 percent of material cost, 50 percent of risk charges, and 20 percent of labor expense for each linear meter of similar collapsed tunnels. The method of invention is efficient, safe, economical and risk-free.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

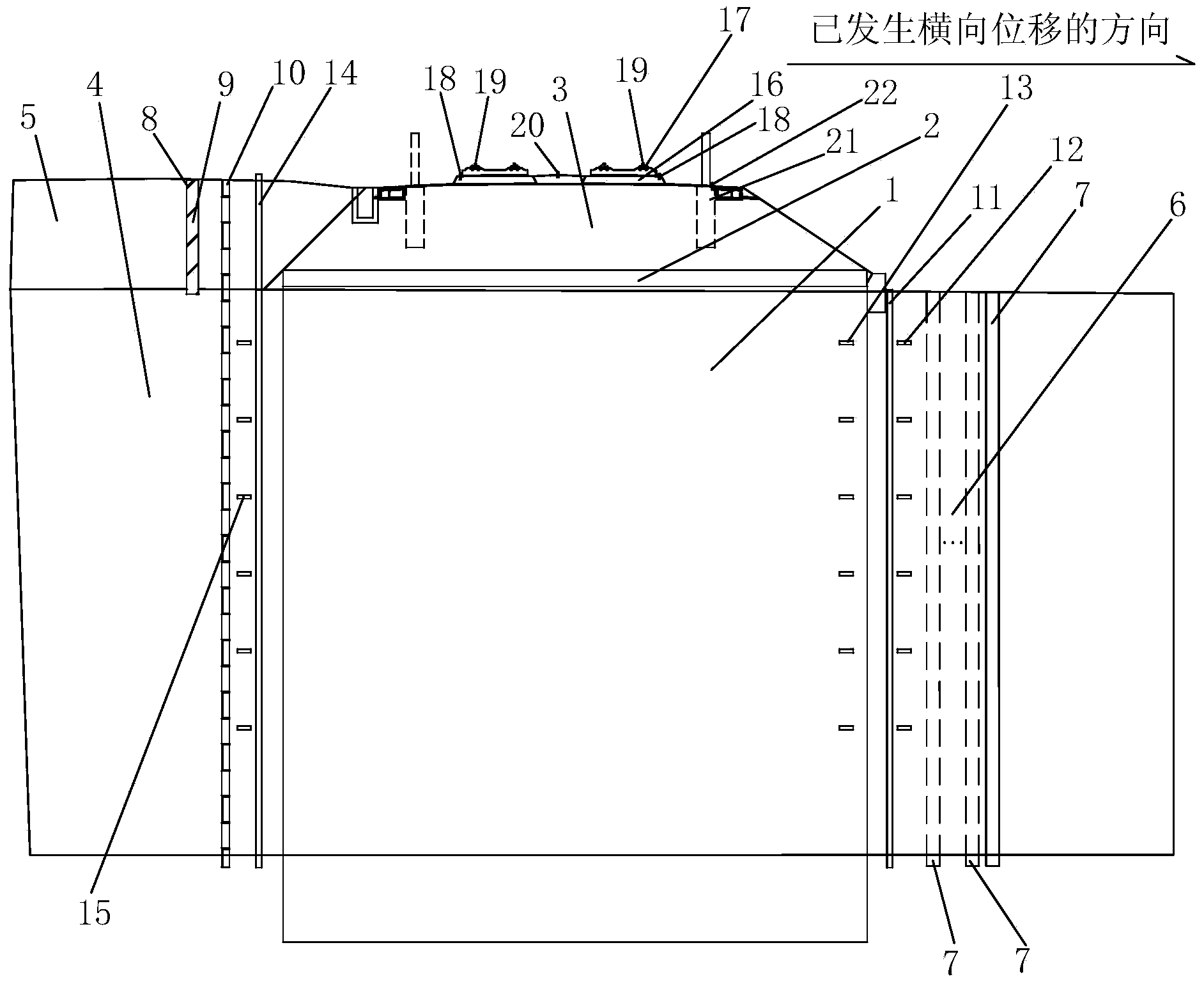

Correcting method for high speed railway ballastless track subgrade in soft soil area

ActiveCN103821039AConstruction quality is easy to controlFlexible and controllable operationRailway tracksLateral displacementInjection pressure

The invention discloses a correcting method for high speed railway ballastless track subgrade in a soft soil area. The correcting method comprises the following steps that 1, when the lateral displacement of the high speed railway embankment occurs , a deformation groove and a plurality of stress relief apertures are formed in an asymmetrical load region, the deformation groove is filled with rigid foam, and the stress relief apertures are filled with grits and rubbles; 2, a first row jet-grouting pile is arranged in a second soft stratum area, the instantaneous injection pressure generated by the construction of the first row jet-grouting pile is utilized to drive a pile foundation reinforcement area located at the bottom of the high speed railway embankment to conduct the displacement from the second soft stratum area to a first soft stratum area, the pile foundation reinforcement area drives a subgrade reinforcement bed course located above the pile foundation reinforcement area and the high speed railway embankment to move simultaneously, and the correcting for the high speed railway subgrade is achieved; 3, the deformation groove is densely filled with the rubbles plus 5% of cement. An acting force is applied on subgrade deeps, the subgrade drives the subgrade body to conduct a movement, so that the purpose of correcting the lateral displacement of the subgrade is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

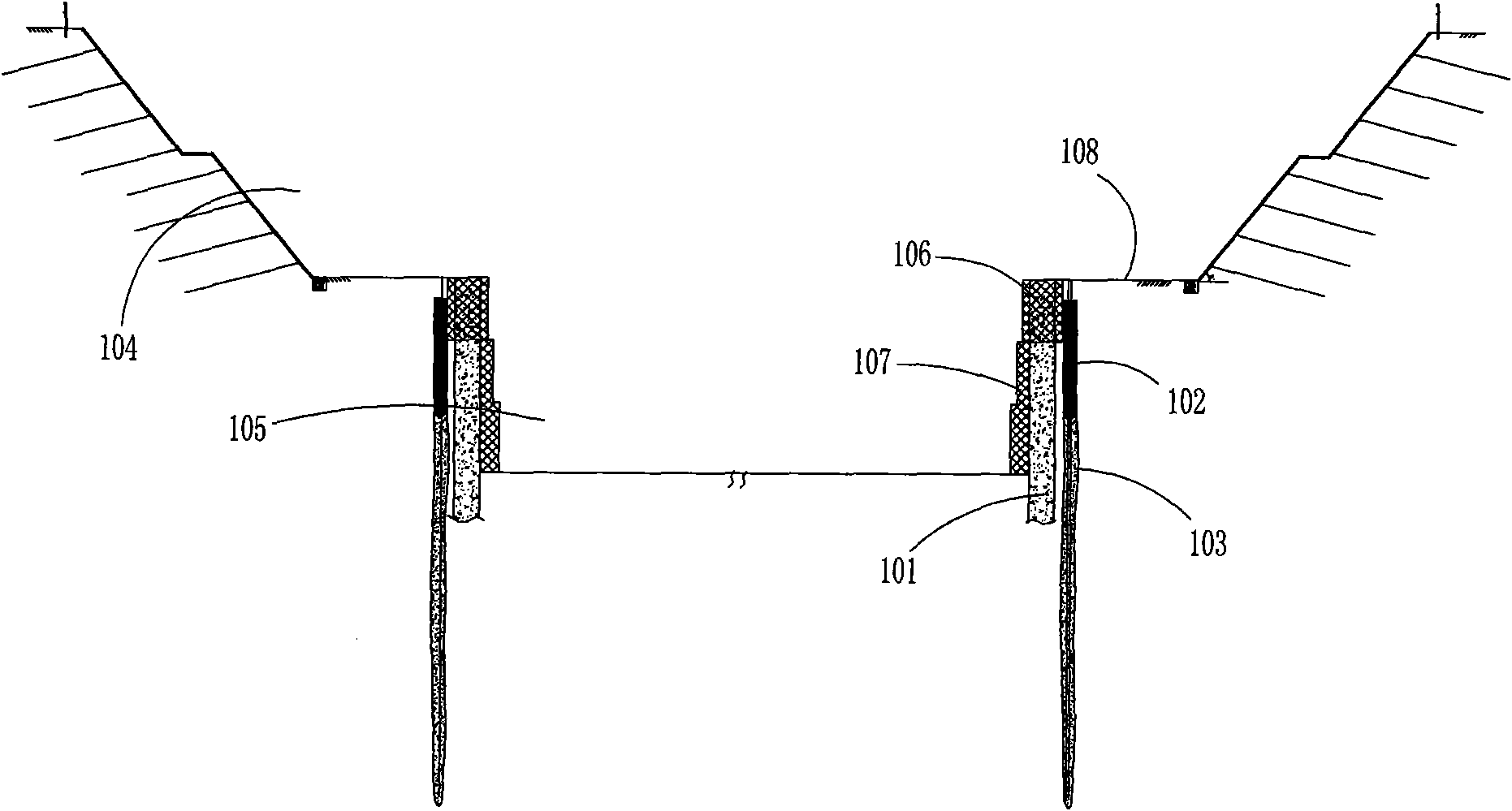

Combined support-excavated geologically solutional deep foundation pit and construction method thereof

ActiveCN101892668APrevent landslidesImprove the support effectExcavationsSoil massReinforced concrete

The invention discloses a combined support-excavated geologically solutional deep foundation pit and a construction method thereof. The deep foundation pit is characterized by consisting of an upper slope foundation pit and a lower vertical foundation pit; the construction method thereof comprises the steps that: in case of vertical excavation of the deep foundation pit, the periphery of the foundation pit is supported and reinforced by reinforced concrete support piles to prevent the foundation pit from collapse owing to lateral pressure of soil mass; then a high pressure jet grouting pile waterproof curtain is adopted for performing water sealing on soil mass outside the support piles and a bedrock internal grouting curtain is adopted for performing water sealing on geological situations in rocks, such as solution cavity, solution, crack and the like; and in the process of layered excavation, an annular continuous concrete slab wall is adopted for the soil mass and the rocks at the periphery of the foundation pit to form a continuous arch ring lagging. The construction method according to the invention can effectively guarantee the safe, stable, fast and effective excavation of the geologically solutional deep foundation pit.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

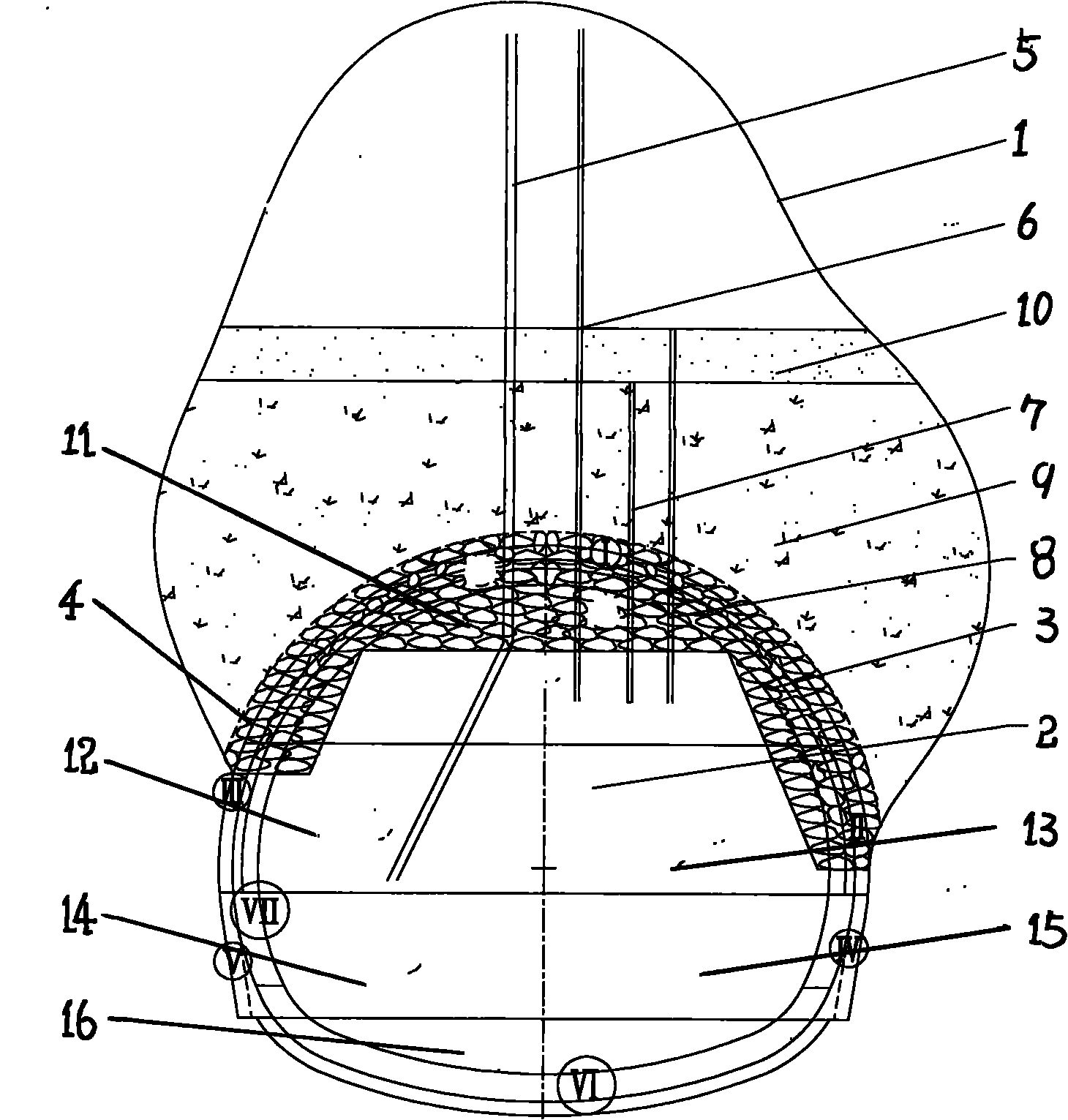

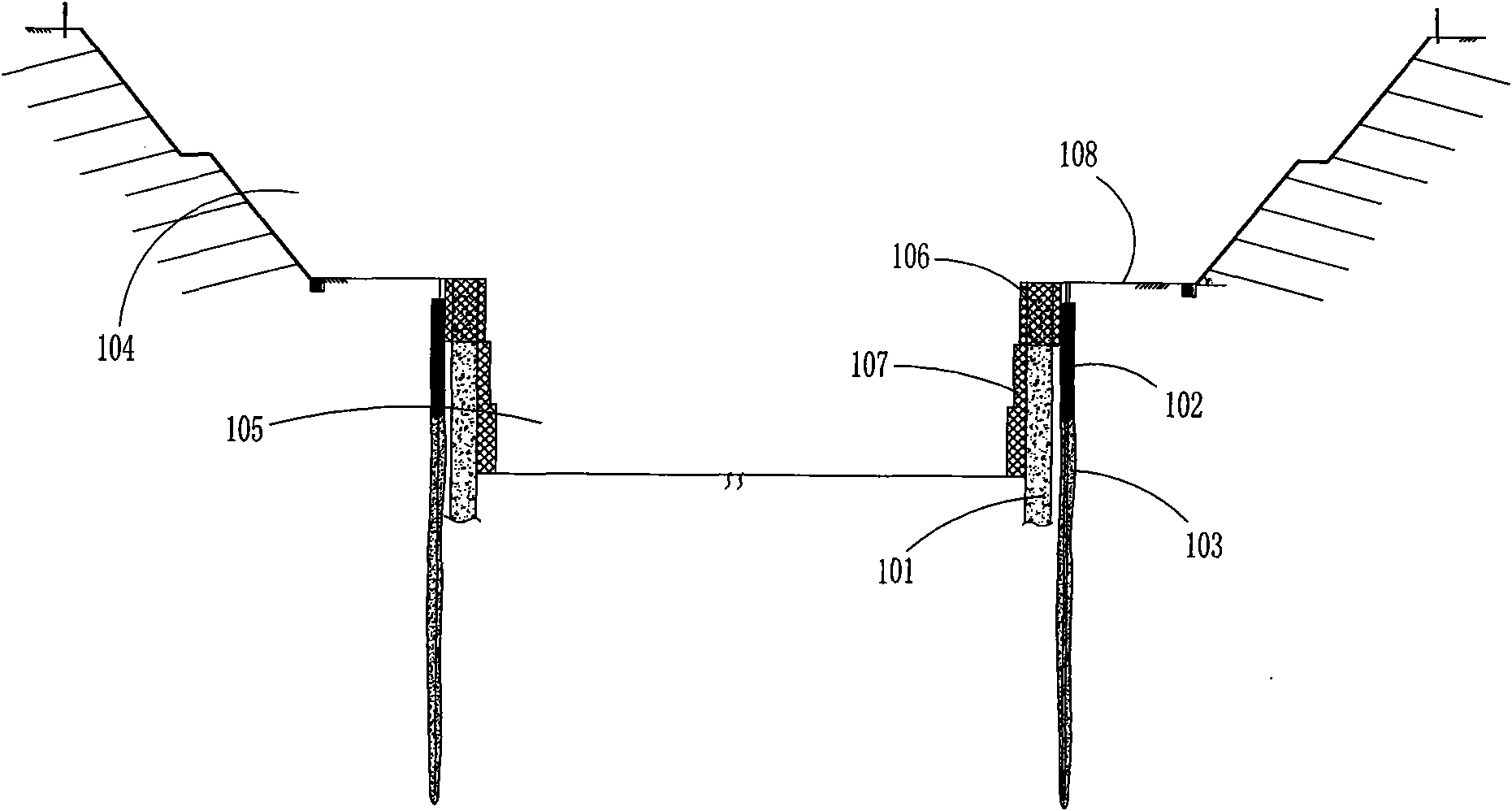

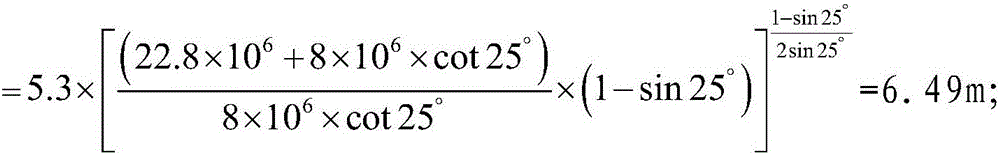

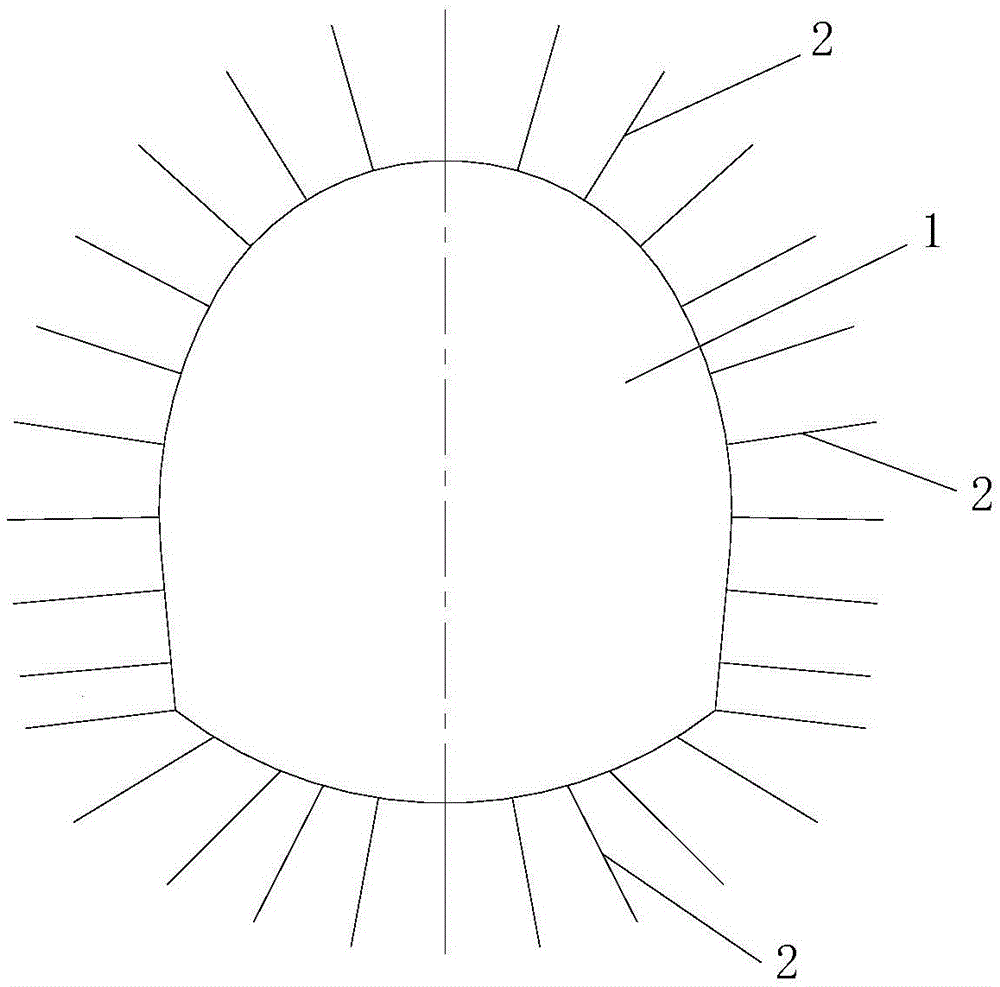

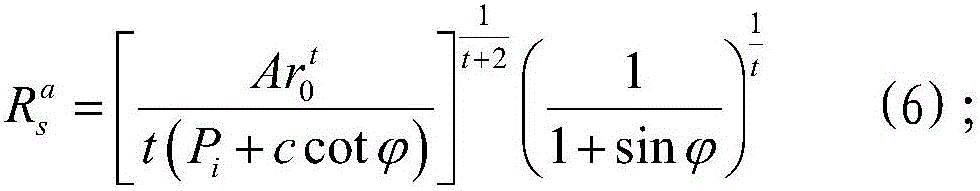

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

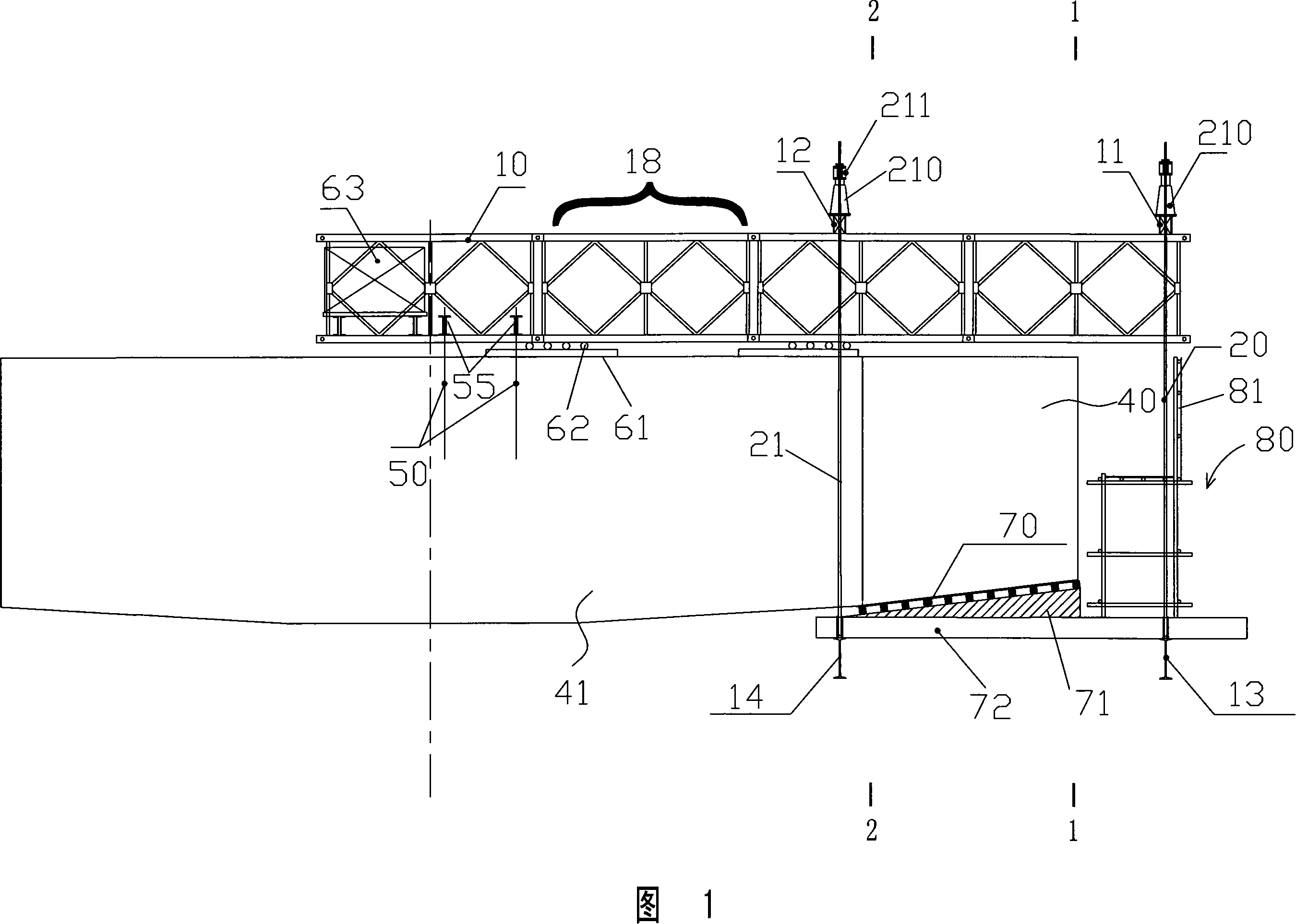

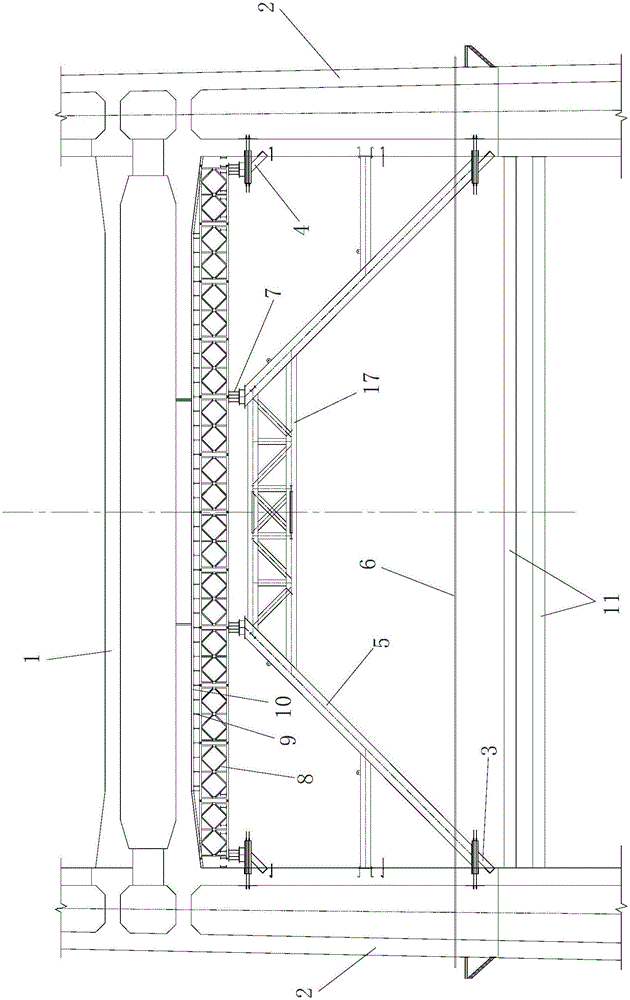

Beret truss type hanging basket and assembling method thereof

InactiveCN101148861ASpeed up preparationReduce manufacturing costBridge erection/assemblyEngineeringHanging basket

Owner:HONGRUN CONSTR GROUP STOCK

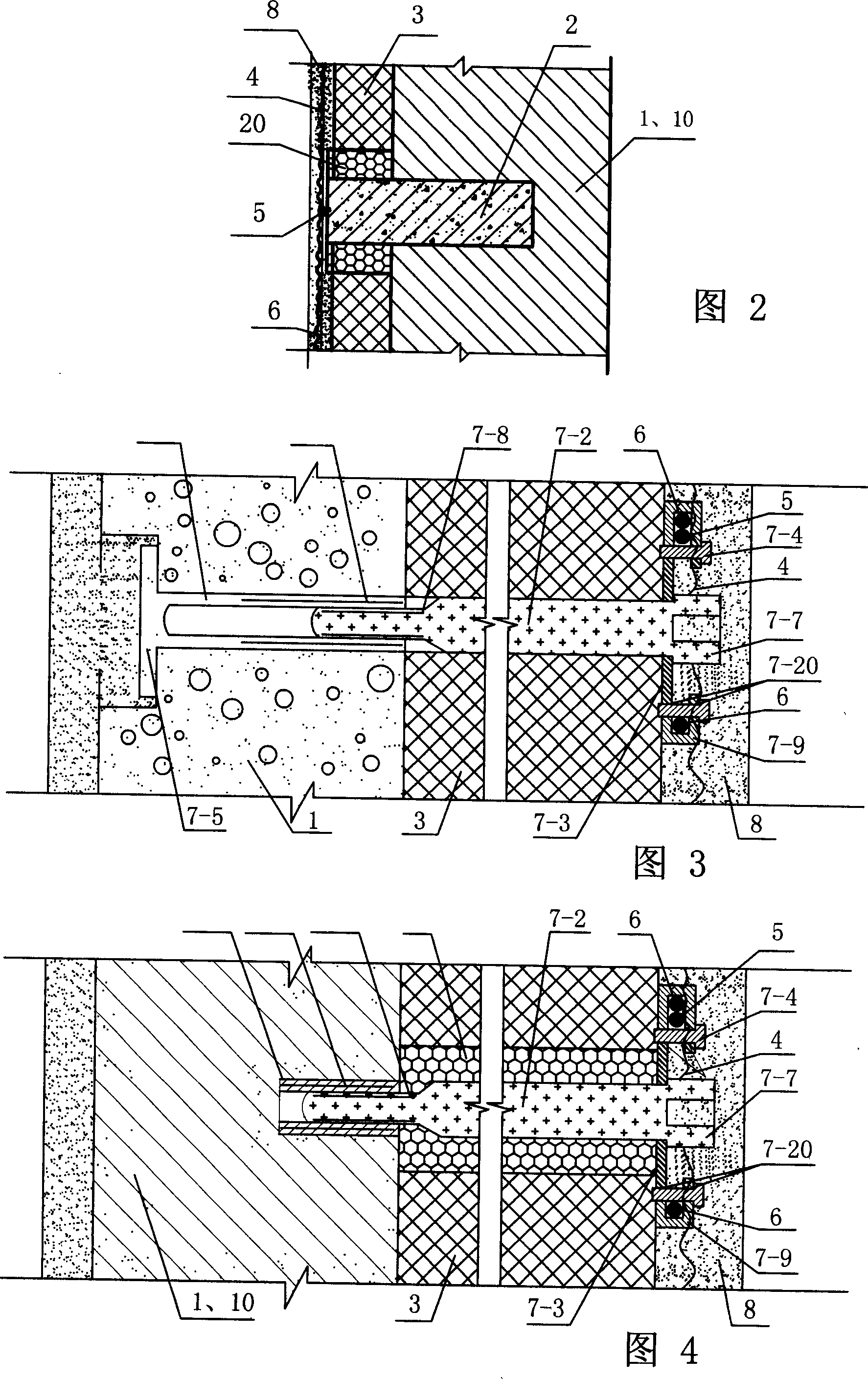

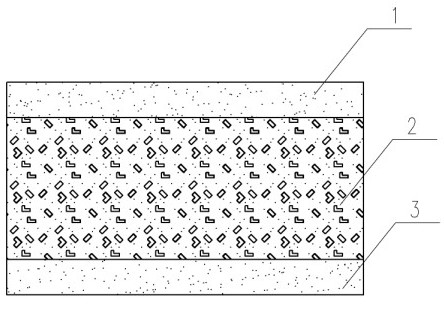

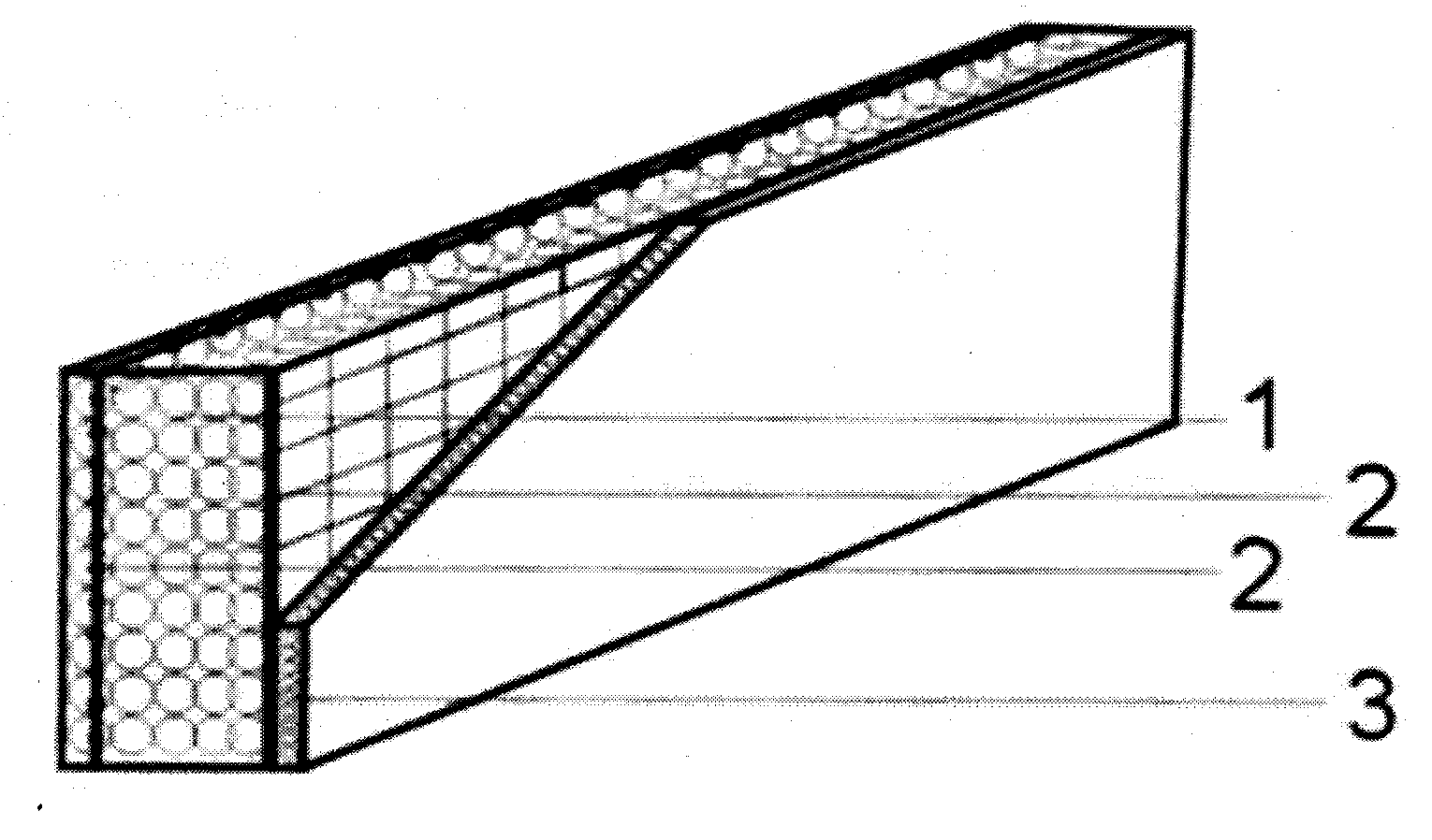

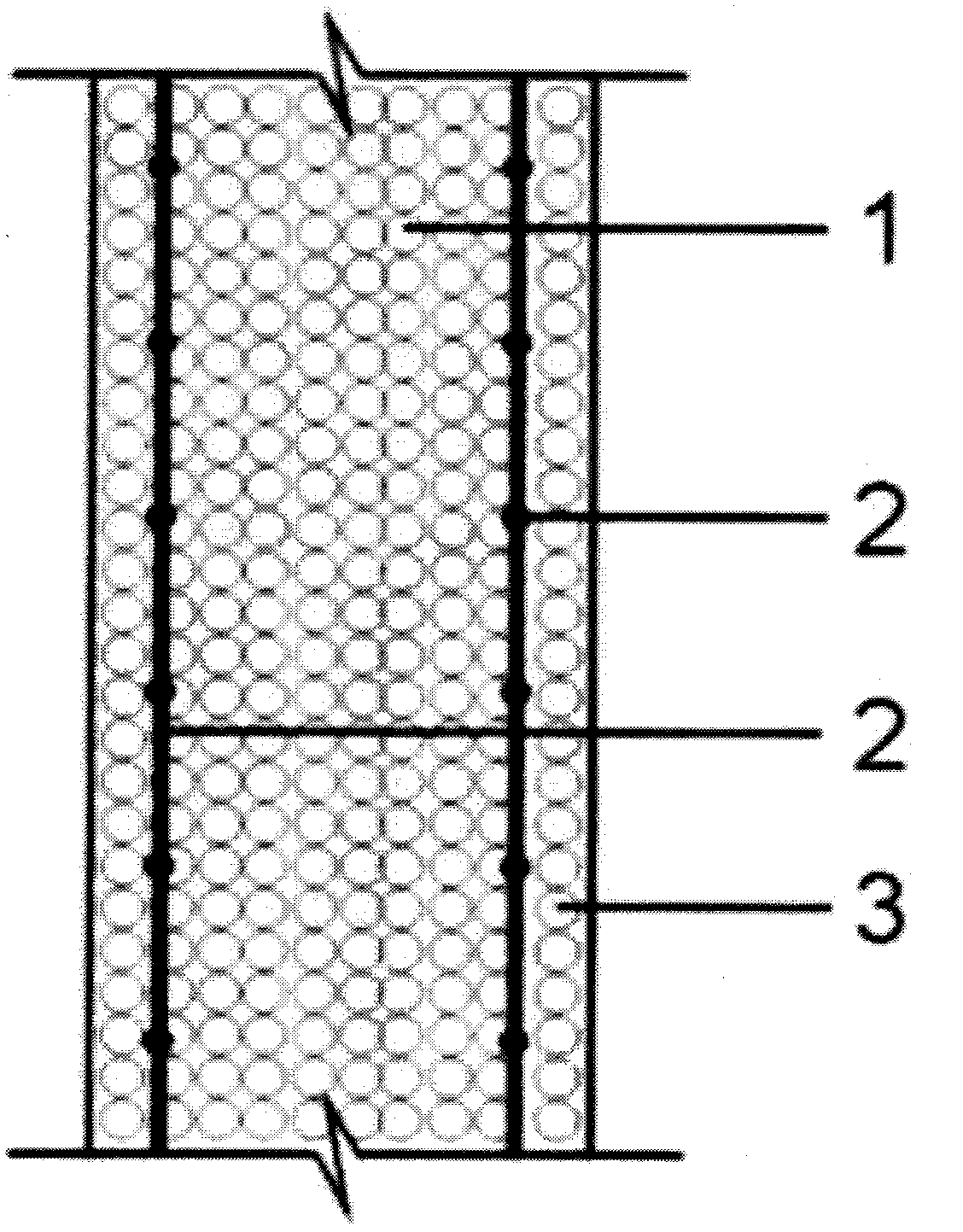

Thermal-insulating binded composite wall with supporter

InactiveCN1982554AStrong construction feasibilityReduce thermal bridgesWallsClimate change adaptationVertical barInsulation layer

Supported bundling insulated composite wall, relates to outer insulated composite wall for buildings. The purpose of this invention is to solve the problem that existing blocks have their heat bridge, great impact the energy-saving of construction and can not reach the low heat transfer coefficient of the wall. The inner terminal of concrete cantilever strutting piece (2), the level connecting link (7) and plastic bulging nails (9) of the invention are fixed within the concrete structure of the main building (10) or basal wall (1), the outer terminal of concrete cantilever strutting piece (2) and the level connecting link (7) are connecting fixed with vertical steel bars (5) in the outer protective layer, an insulating layer (3) is fixed outer flank of basal wall (1) by plastic bulging nails (9)outer flank of insulating layer (3) is the vertical steel bars (5), out or inside of the bars is set with metal network (4), the outer ends of metal network (4), the vertical bars (5) and the plastic bulging nails (9) are fixed together, the protective layer (8) built by cement mortar or pisolith concrete is found outside the insulation layer (3).the present invention is safe, durable ,with good heat-insulating and fire resisting properties.

Owner:吴淑环

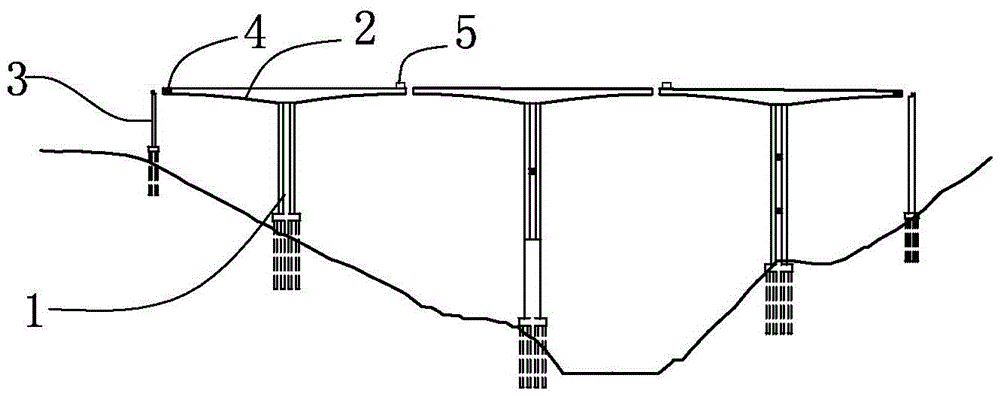

Asymmetrical casting construction method of side span of rigid frame bridge with extra high piers and long span length

InactiveCN105484158AIncrease the lengthShorten the lengthBridge erection/assemblyHanging basketEngineering

The invention provides an asymmetrical casting construction method of a side span of a rigid frame bridge with extra high piers and a long span length. The asymmetrical casting construction method comprises the following steps that after each T-shaped structure of each main pier is symmetrically cast to have largest cantilevered ends in a suspended manner, a hanging basket on one side of the side span of each main pier is continuously moved forward, and an asymmetrical suspended casting segment is cast on the side of the side span in a suspended manner; when the asymmetrical suspended casting segments are constructed, cantilever brackets for 0# block construction of transition piers are directly adopted as side span cast-in-place brackets for constructing side span cast-in-place segments; after the casting of the side span cast-in-place segments is completed, the hanging baskets for constructing the asymmetrical suspended casting segments are put down and moved forward, front cross beams of bottom baskets of the hanging baskets are placed on the side span cast-in-place brackets, rear cross beams of the bottom baskets of the hanging baskets are suspended and hung on baseplates and flange plates of tank beams to be used as side span closing hanging baskets, and the casting construction of side span closing segments is performed; after the side span closing segments meet design requirements, the side span closing hanging baskets are detached, and the side span construction is completed.

Owner:ROAD & BRIDGE INT +1

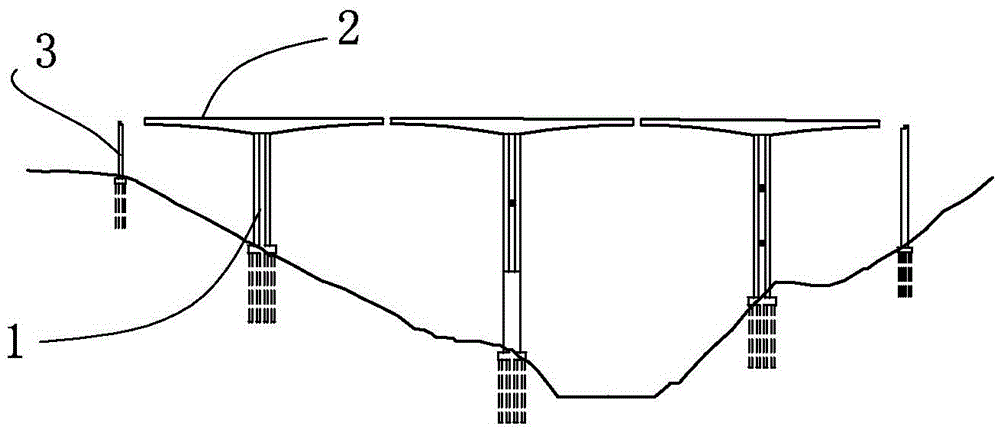

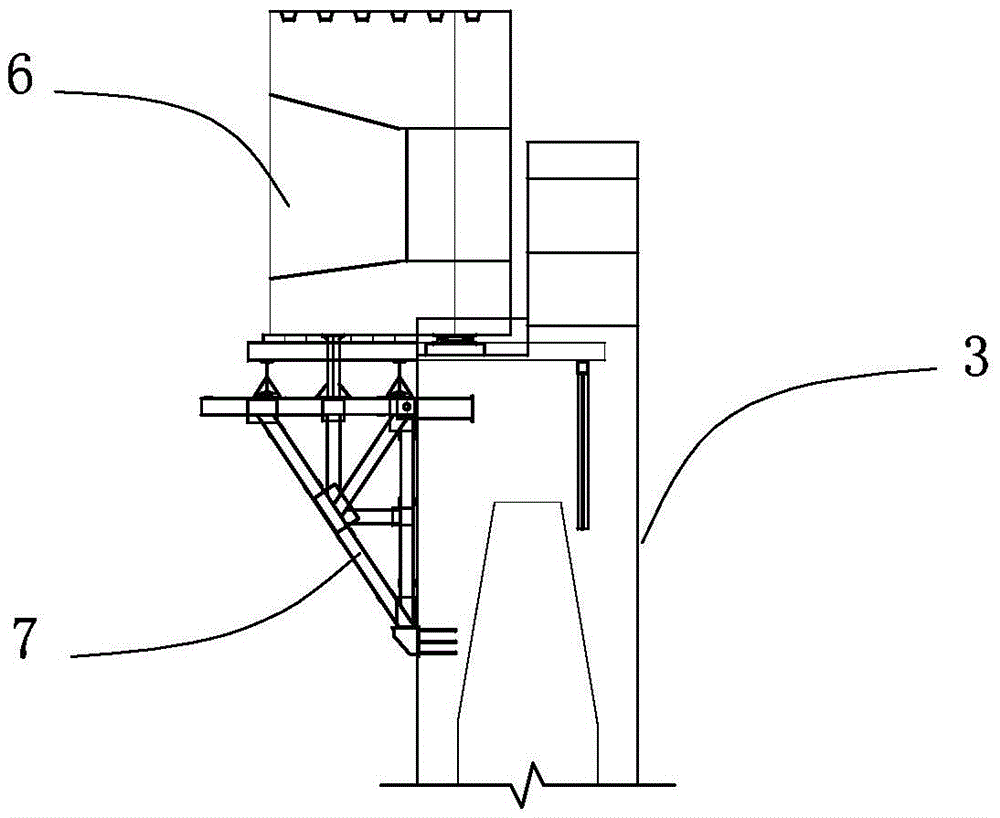

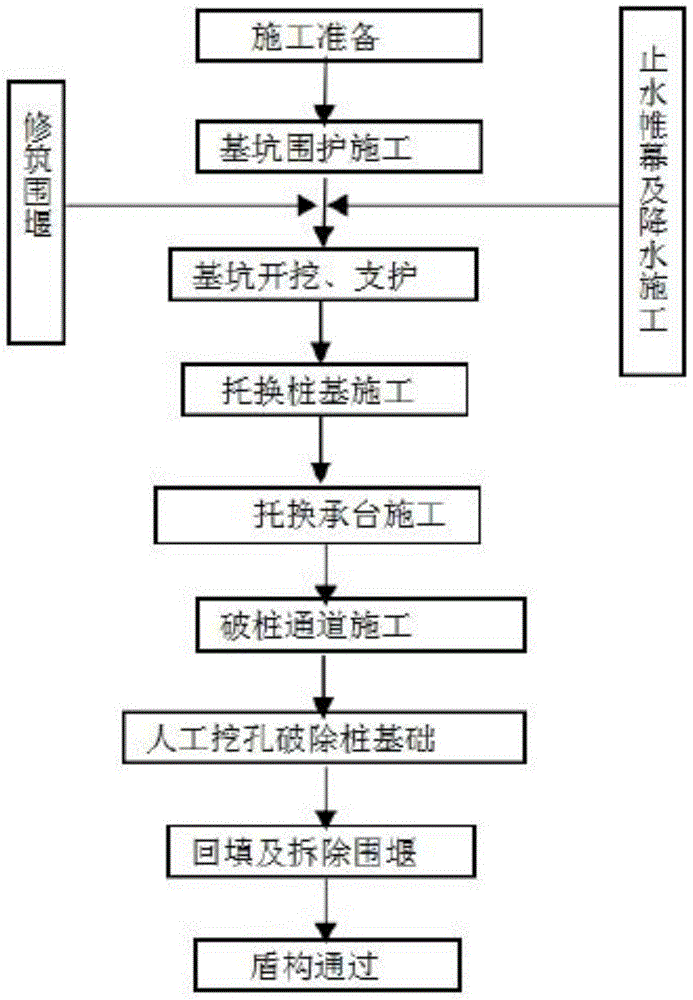

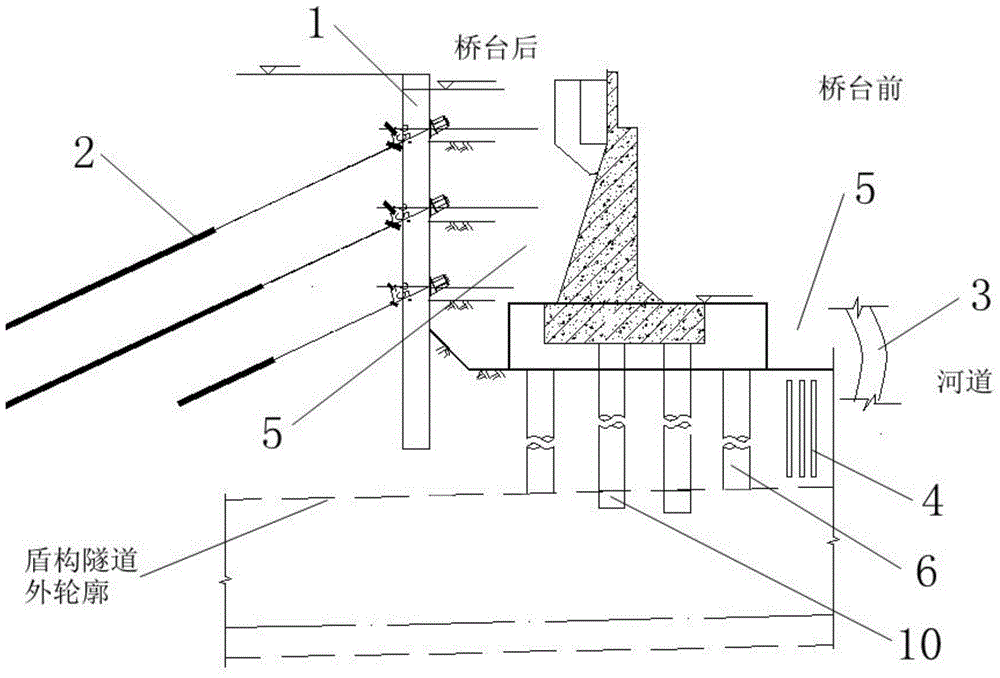

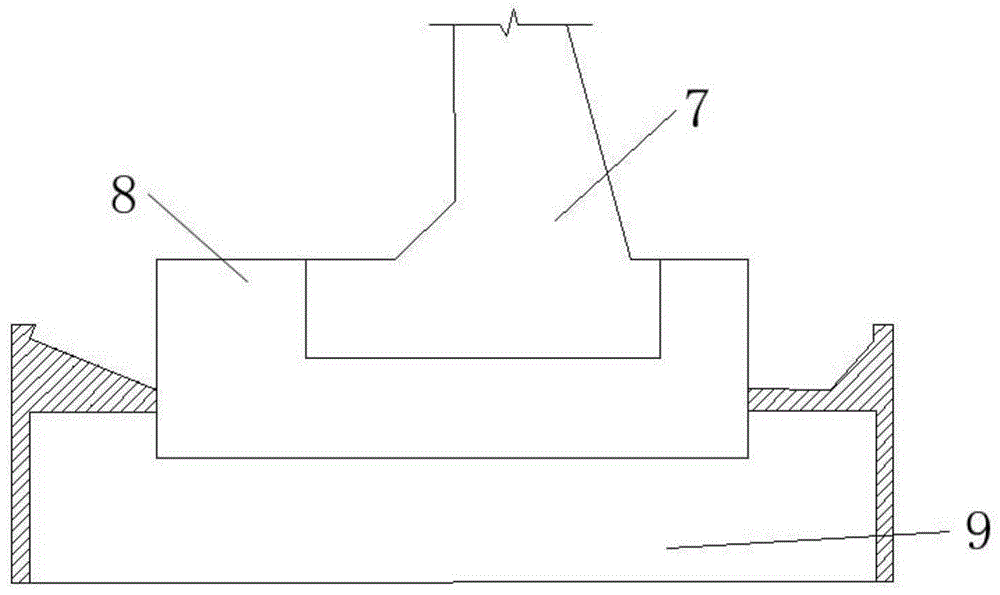

Construction method for cropping bridge pile foundation at sandy gravel stratum of abyssal region

InactiveCN105672348ALow costConstruction quality is easy to controlBulkheads/pilesSocial benefitsCofferdam

The invention discloses a construction method for cropping a bridge pile foundation at a sandy gravel stratum of an abyssal region. A passive underpinning principle is adopted; firstly, an enclosing structure is constructed behind an existing bridge abutment by a certain distance, and a temporary cofferdam is constructed in a river, so that operation space is provided; an underpinning pile foundation and an underpinning bearing table are constructed in the enclosing structure, and dead loads of an existing bridge is transferred to an underpinning pile and the underpinning bearing table; and a pile breaking channel is dug below the underpinning bearing table, and the pile is finally removed with a manual hole digging method. According to the method, on the premise that the construction quality is guaranteed, the construction schedule can be quickened, the manufacturing cost is reduced, and influences of underpinning construction on existing buildings, pipes and ground transportation are reduced; and the construction method has the technical advancement and has social benefits and economic benefits.

Owner:CHONGQING UNIV

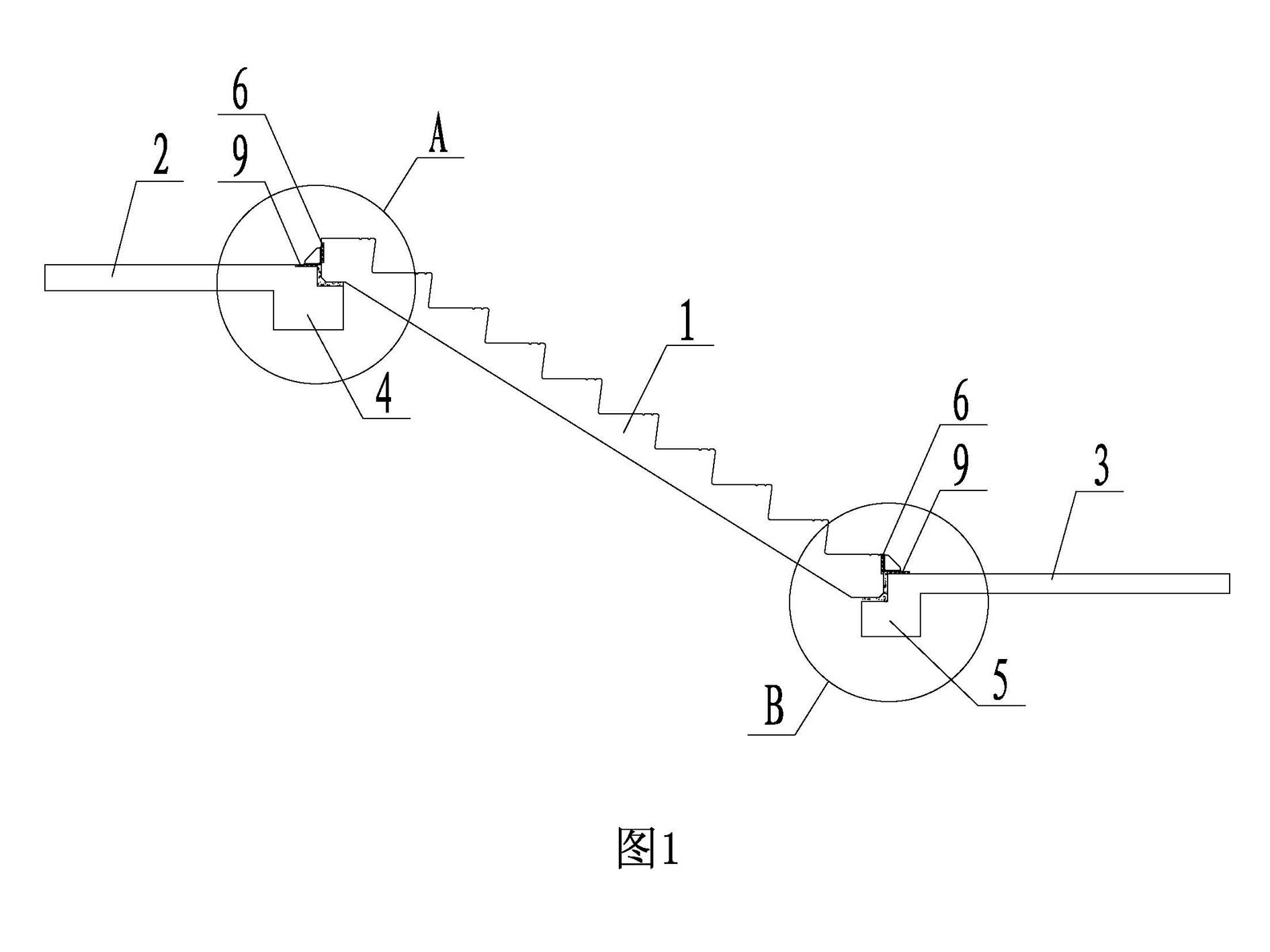

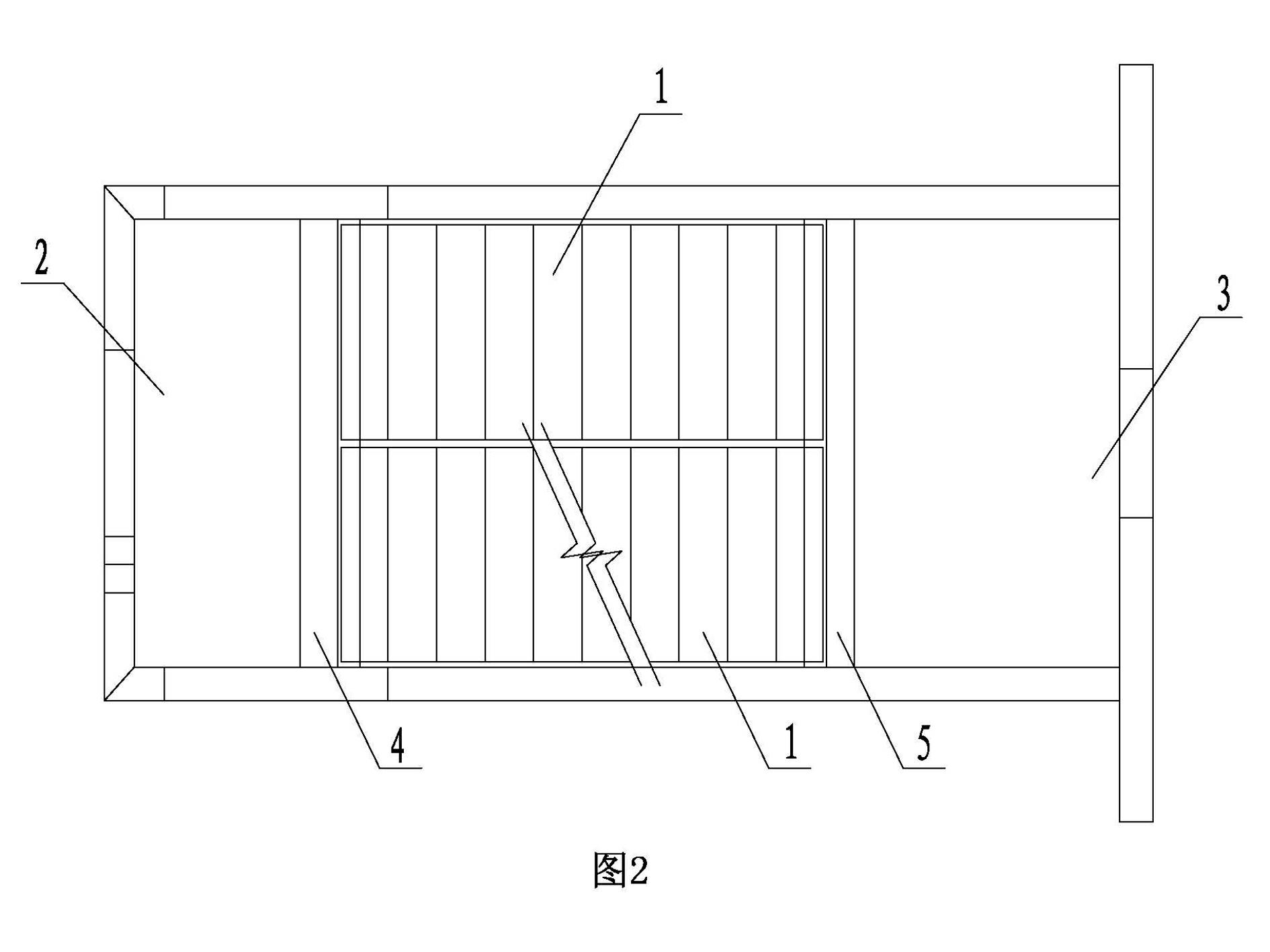

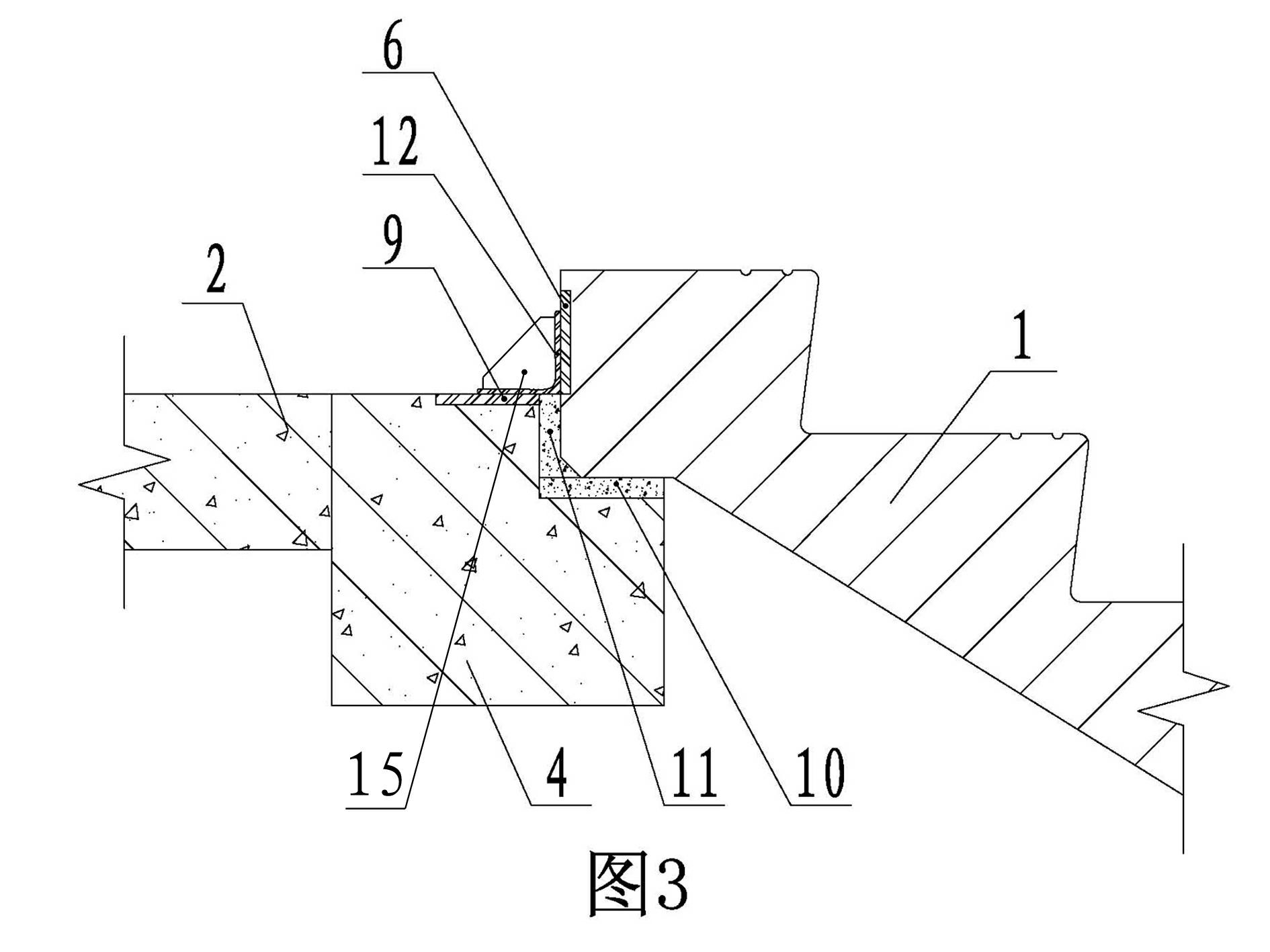

Quick-mounting type concrete stair and mounting method thereof

InactiveCN102661017AOvercome the technical defects of complex construction technologyOvercome the cumbersome defects of the prefabrication processBuilding material handlingStairwaysArchitectural engineeringRebar

Owner:BEIJING URBAN CONSTR FIFTH CONSTR GRP

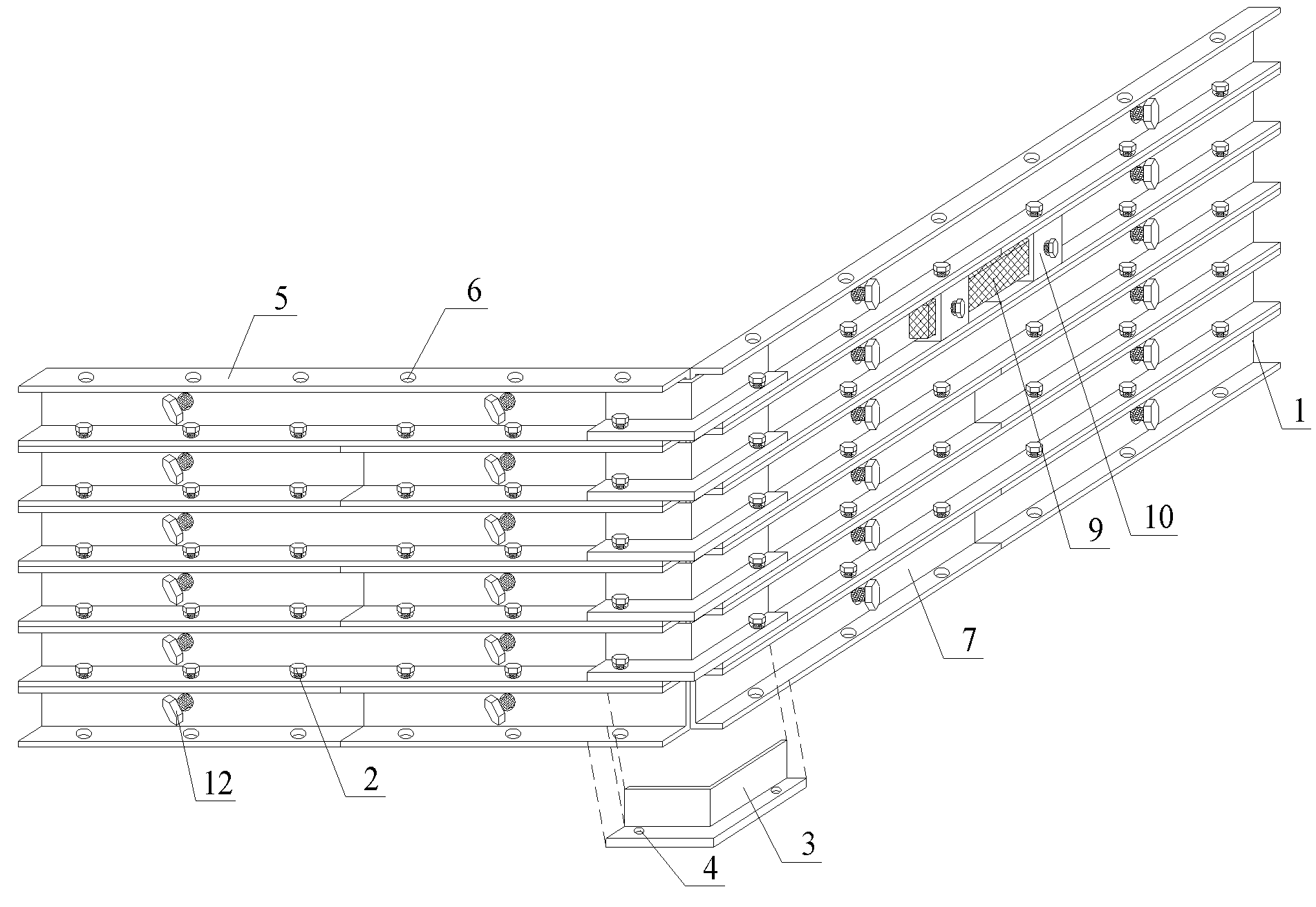

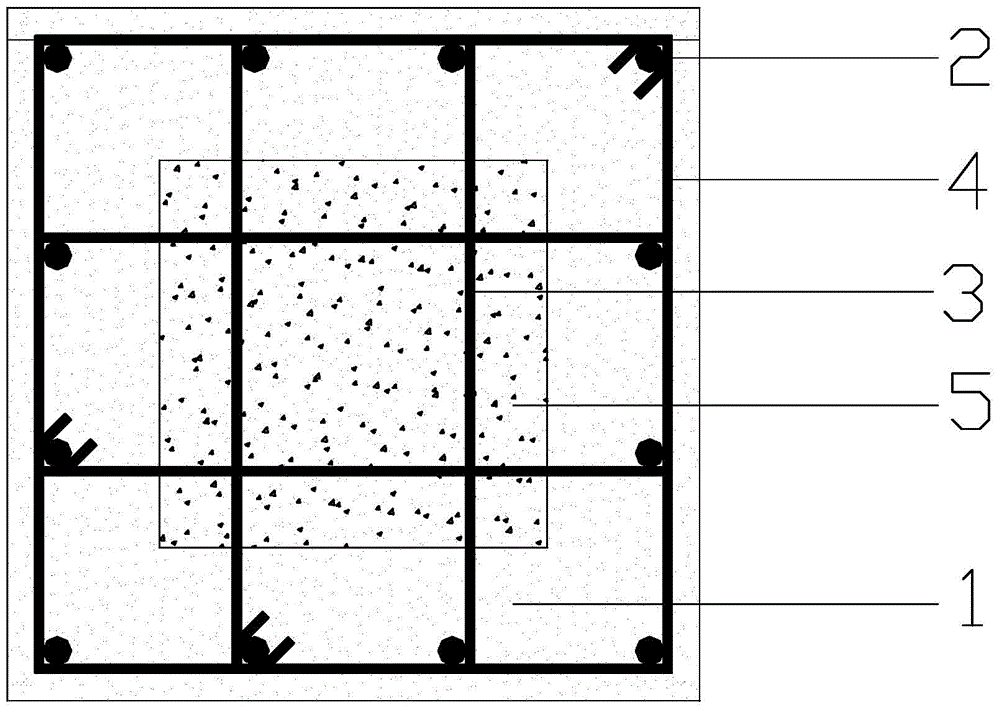

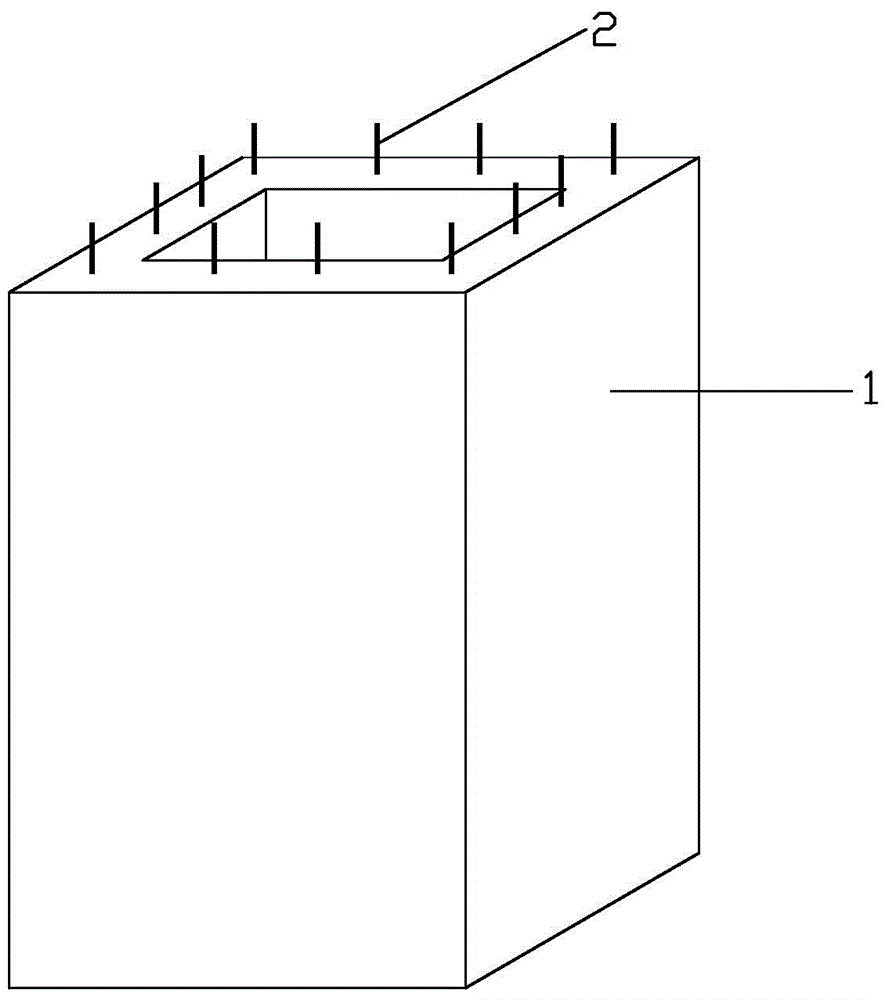

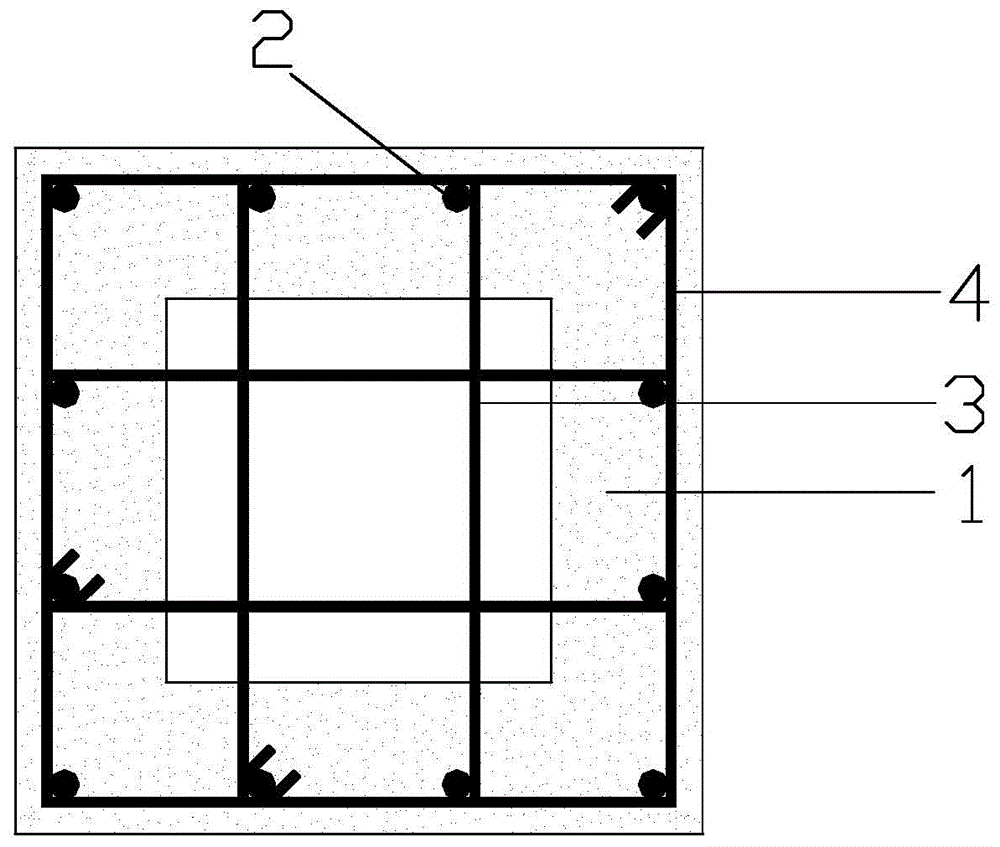

Template for construction

InactiveCN102071796AHigh mechanized production efficiencyEasy to manufactureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallBearing capacity

The invention discloses a template for construction, which comprises groove-shaped modules (1), and bolts or pins (2). The template for construction is spliced by a plurality of mutually connected groove shaped modules (1) through the bolts or pins (2), wherein a connecting block (3) arranged at a corner of the template has an L-shaped or groove-shaped section; the connecting blocks (3) are arranged at internal corners and external corners of the template for construction, have strong rigidity, can connect the templates in different directions into a whole; and the L-shaped and groove-shaped connecting blocks (3) arranged at the internal corners of the template can plug gaps on the end parts of the groove-shaped modules (1) to prevent concrete from flowing out. The template for construction is easy to manufacture and convenient to assemble and disassemble, has high rigidity, high bearing capacity and long service life, and can be used in construction of concrete uprights, shear walls and beams; and the connecting blocks (3) can be used for connecting corners of an upright template, a shear wall template and a beam template.

Owner:吴方伯

Construction method for processing saline soil roadbed by separation layer

The invention relates to a construction method for processing a saline soil roadbed by a separation layer, comprising the following steps: the separation layer is arranged in a mode that compound geomembranes cover a gravel soil separation layer; the compound geomembranes are laid according to the width of the cross section of the roadbed; firstly, an inner compound geomembrane is laid; then an outer compound geomembrane is laid; the compound geomembranes are flatly laid and tightly adhered to the surface of the roadbed; the gravel soil separation layer is laid on the compound geomembranes and is filled and laminated by layers; the compound geomembranes cover the gravel soil separation layer; gravel soil is filled between the separation layer and the original roadbed surface layer; and the degree of compaction of the top layer is above 97%. According to the construction method disclosed by the invention, the saline soil can be effectively prevented from carrying out salt expansion, corroding and the like on the roadbed, a road surface structure layer can be prevented from damaging, the construction is convenient, the cost of engineering construction can be lowered, the curing cost is reduced, and the stability and the service life of the roadbed can be improved. The practice proves that the scheme brings a better technical effect in the saline soil roadbed construction.

Owner:河南省新开元路桥工程咨询有限公司

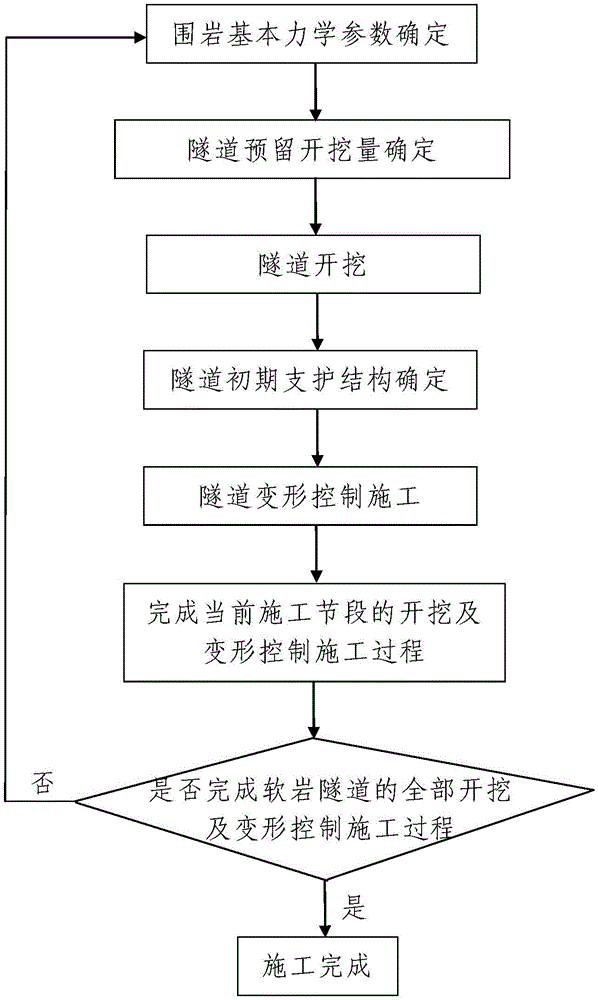

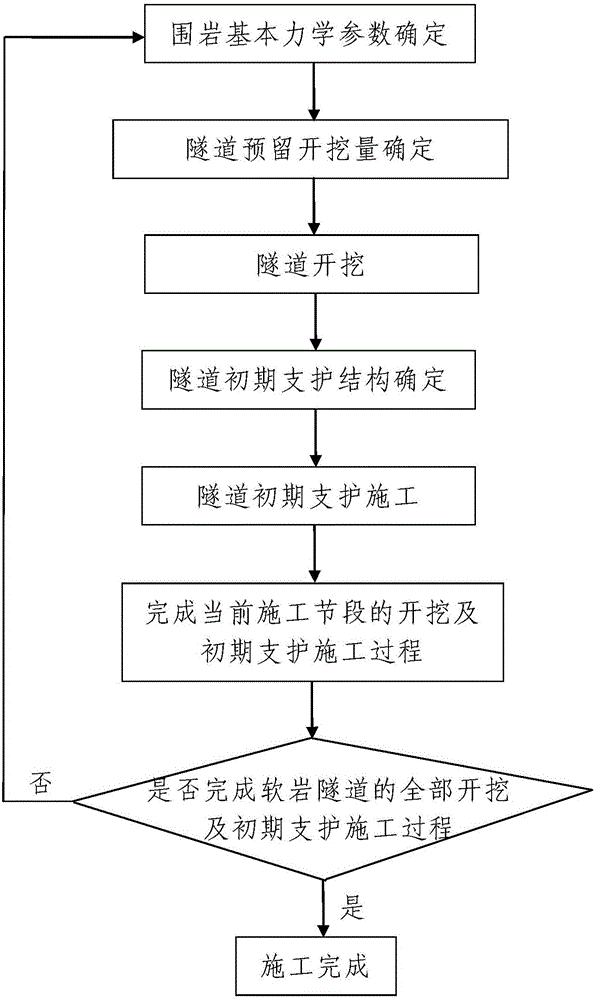

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

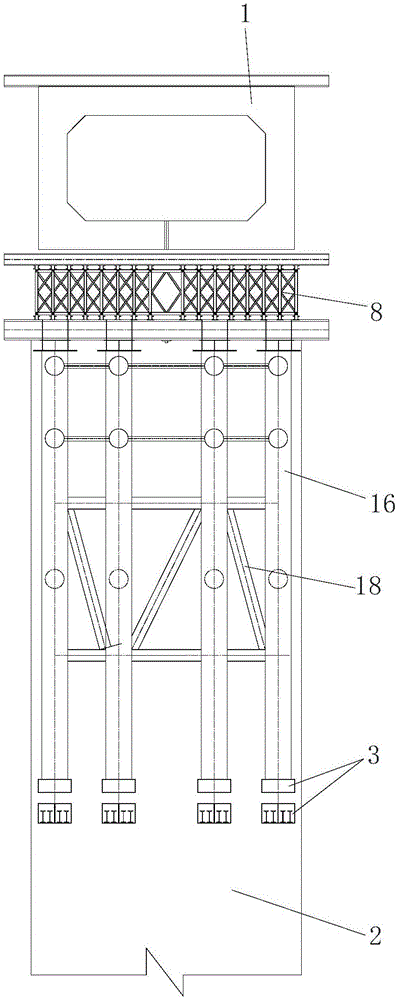

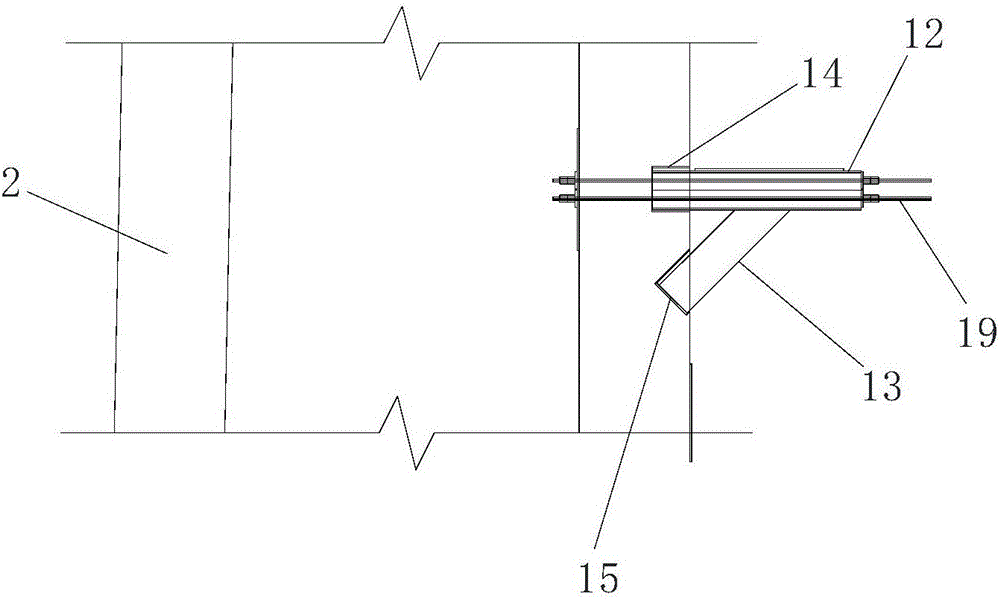

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

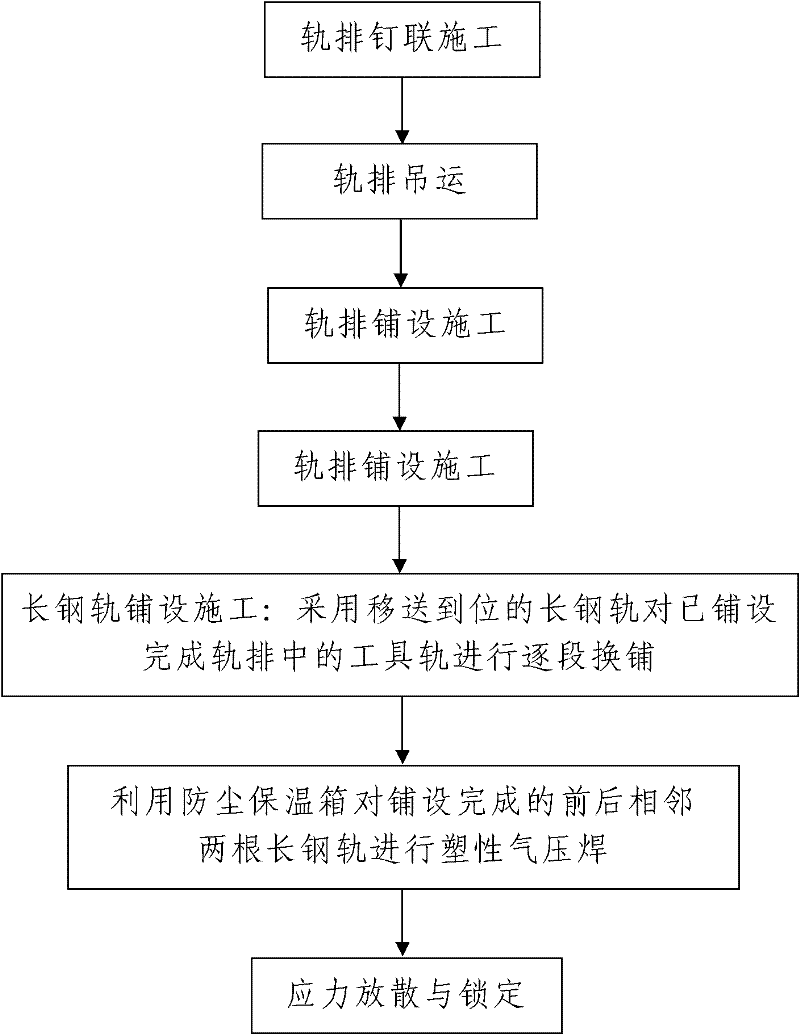

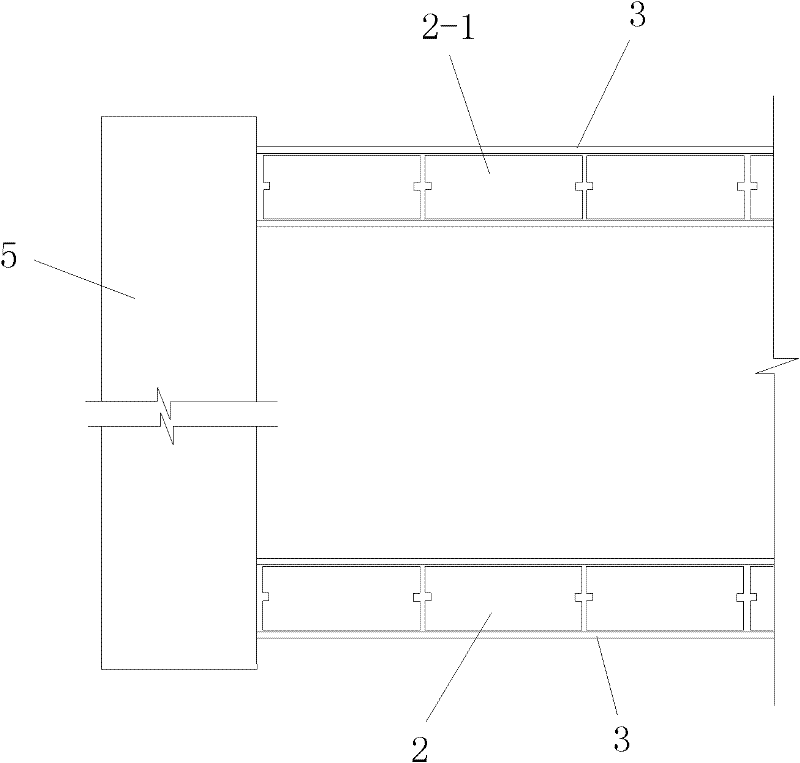

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

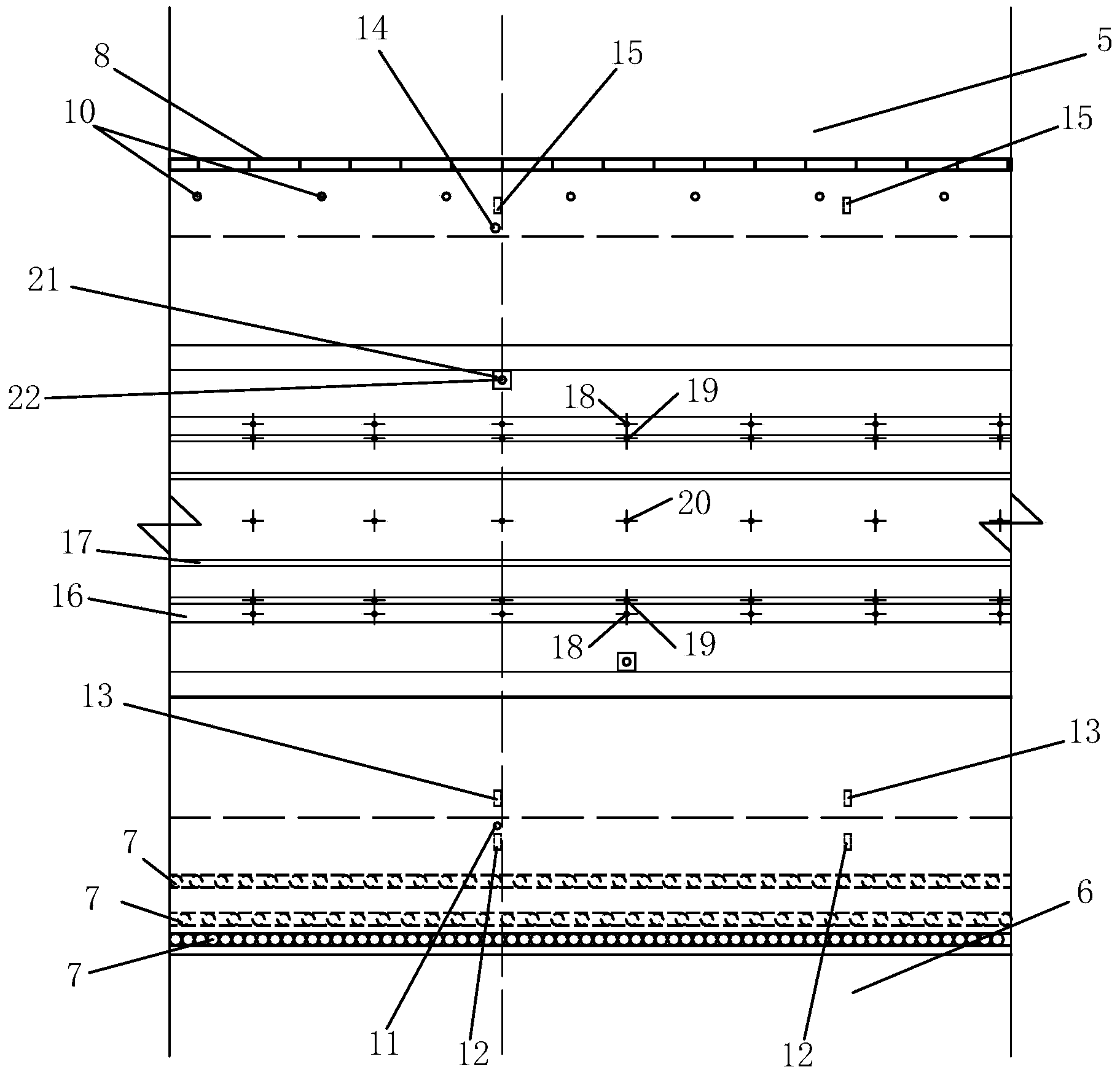

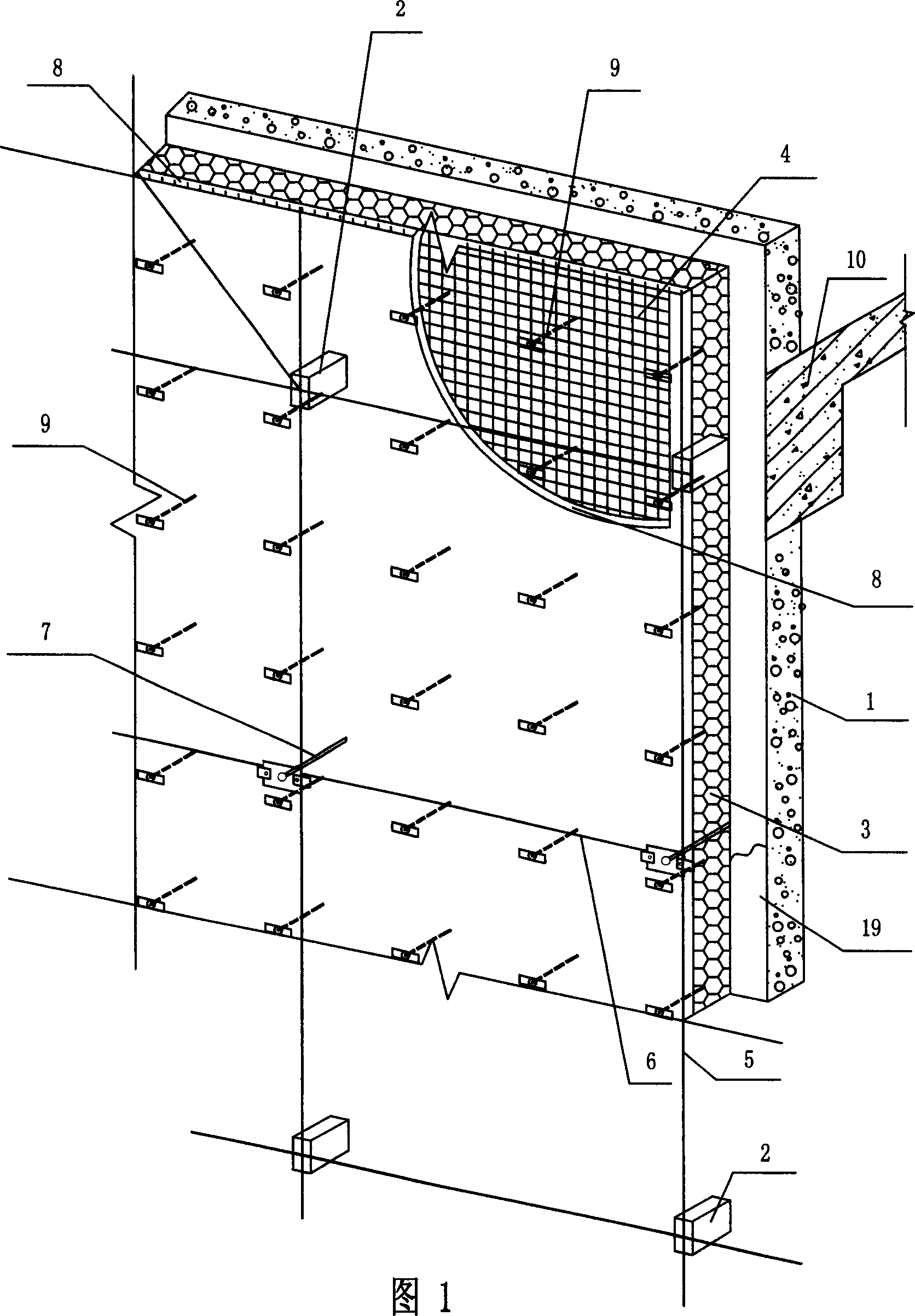

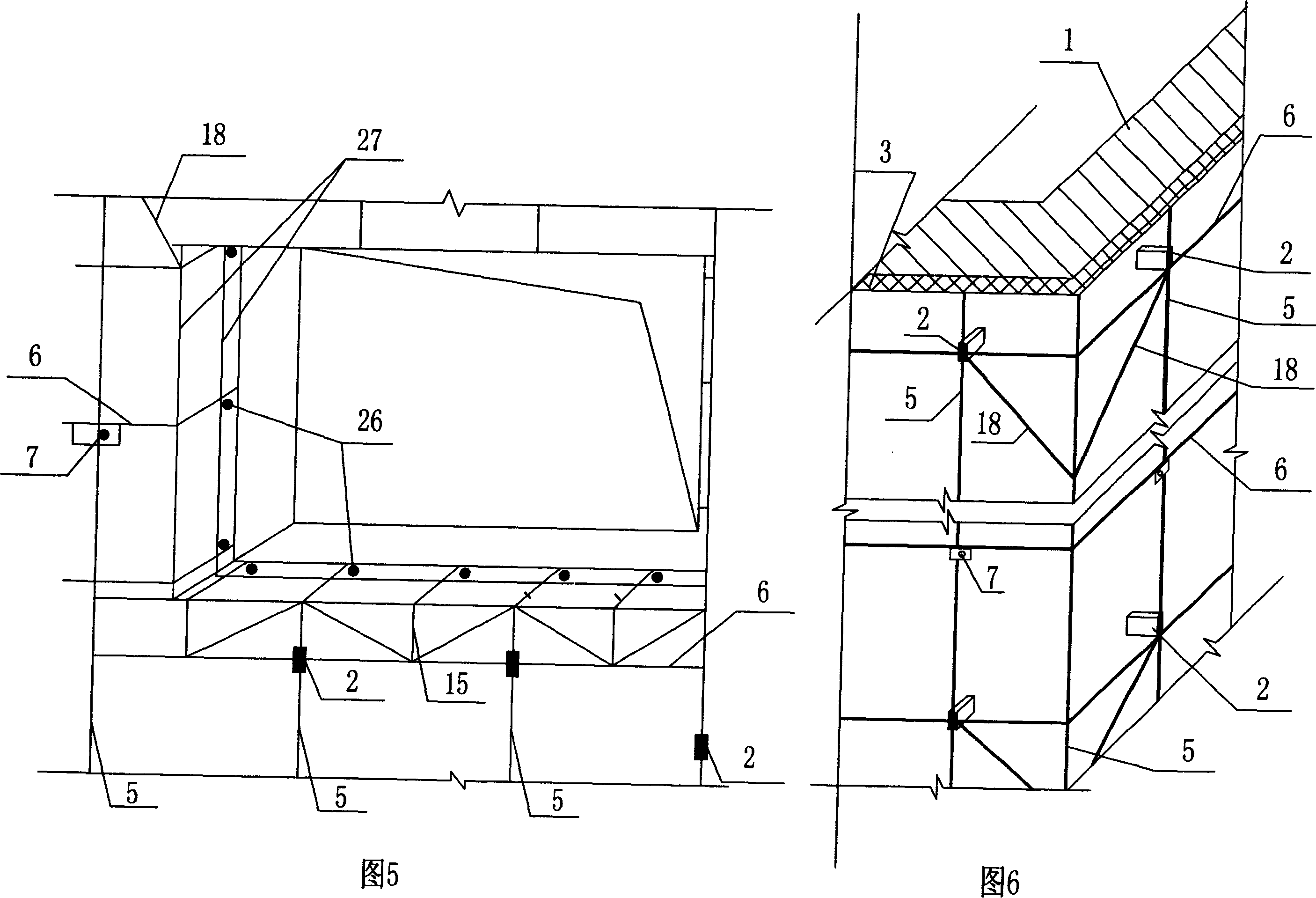

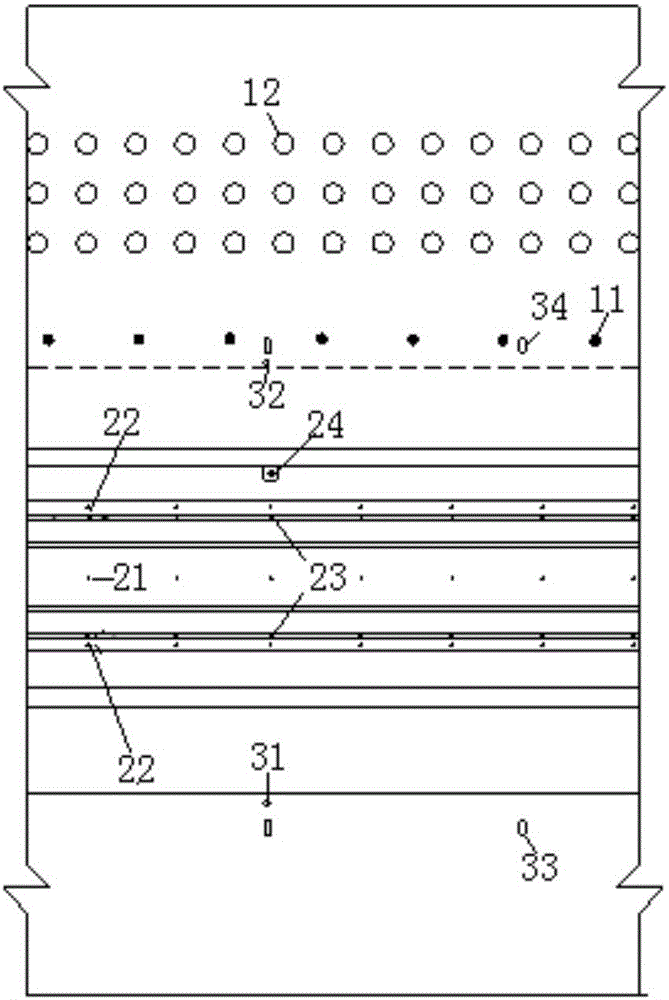

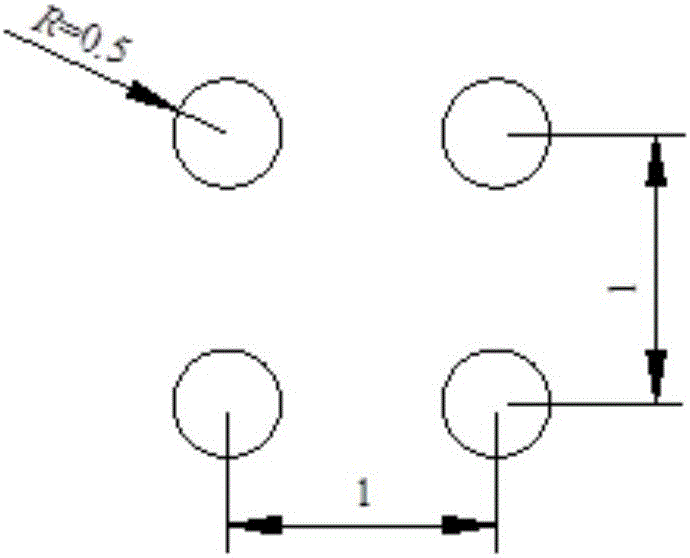

Steel pillar supporting type integral self-lifting steel platform scaffold template system and constructing method thereof

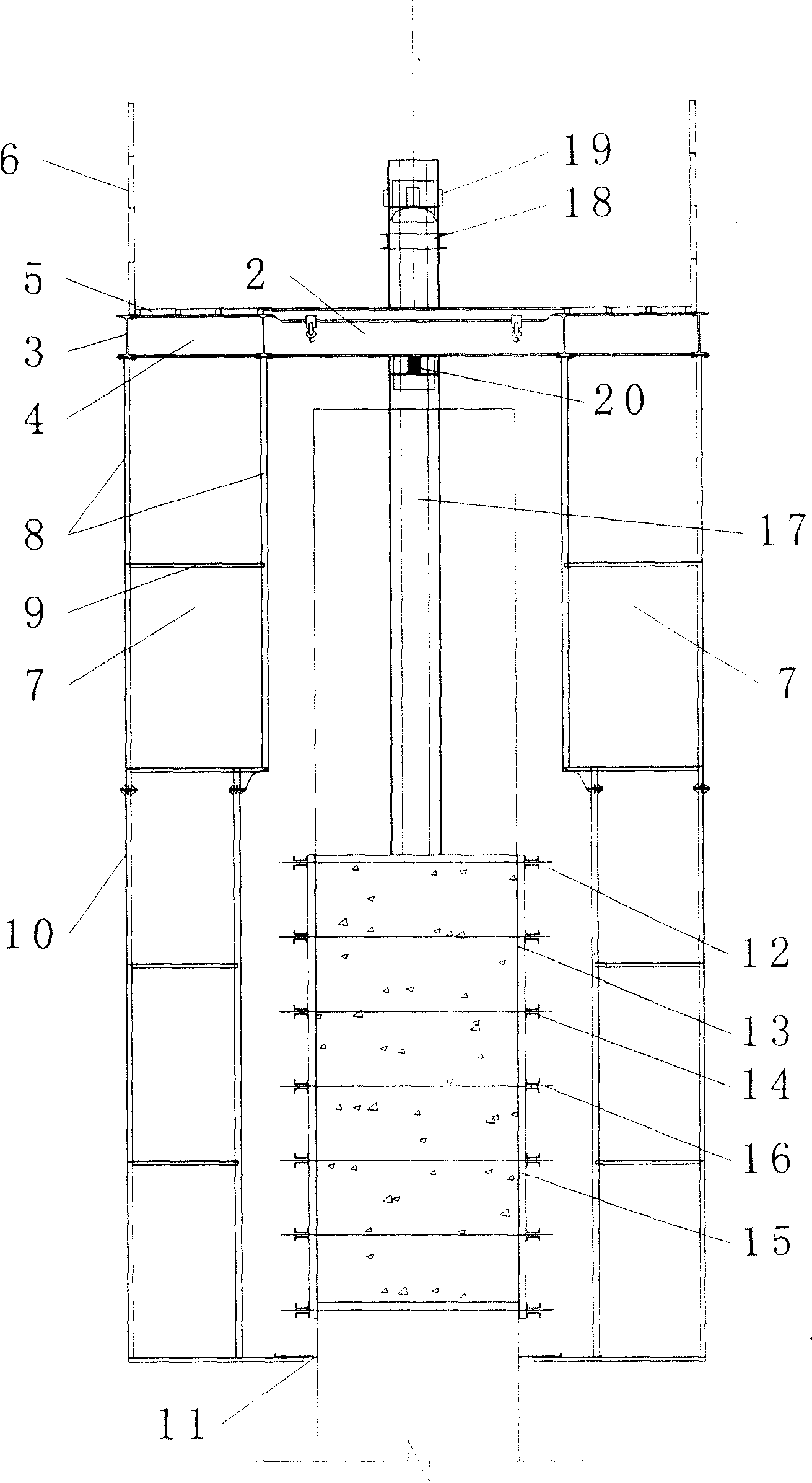

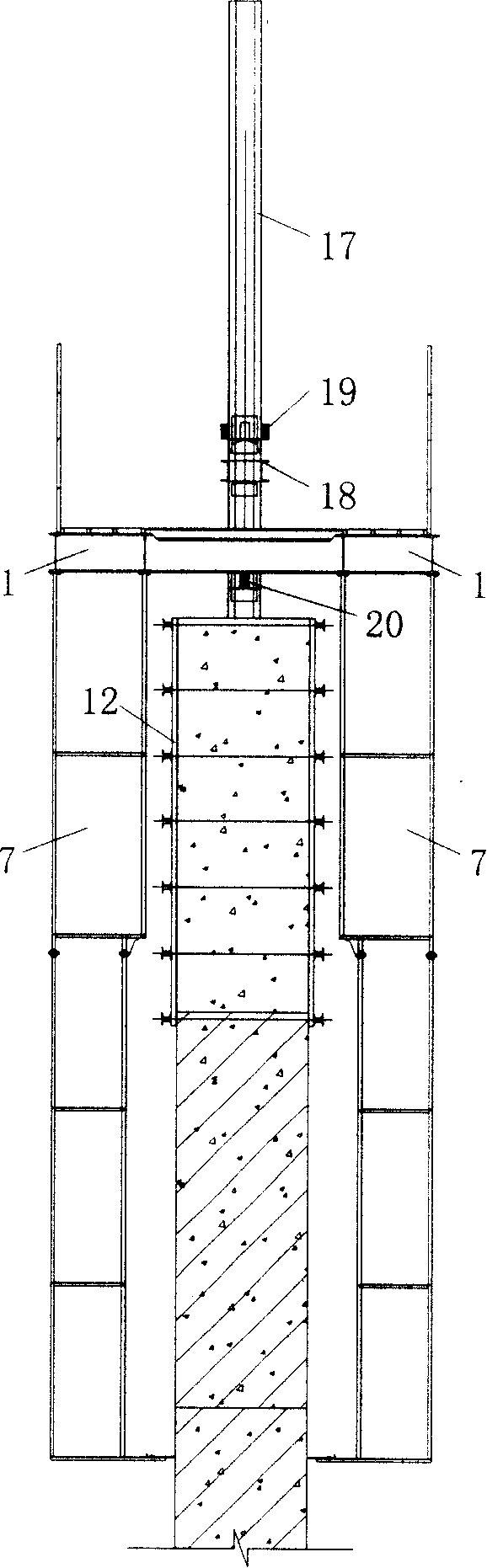

ActiveCN101191382AShort construction periodConstruction quality is easy to controlForms/shuttering/falseworksBuilding material handlingFalseworkSteel columns

The invention relates to a steel column supporting type integrated self-hoisting steel platform scaffold template system. The invention is characterized in that: the system comprises a steel column which is buried in a concrete construction, wherein, an integrated steel platform is arranged along the whole concrete construction, the integrated steel platform is arranged on the steel column, which is provided with a hoisting machine; the hoisting machine is positioned above the integrated steel platform, and connected with the integrated steel platform through a lift link; the lower part of the integrated steel platform is provided with a scaffold; large templates are respectively arranged along the two sides of the whole concrete construction; large templates of the two sides are connected through splint bolts and fixed on the concrete construction. The large templates are hoisted through a hoist which is fixed on the integrated steel platform. The invention has the advantages of short construction period, safety and reliability, easy control of construction quality, etc.

Owner:SHANGHAI CONSTR NO 1 GRP

Prefabricated reinforced concrete column with high-performance concrete frame and construction method

The invention discloses a prefabricated reinforced concrete column with a high-performance concrete frame, which adopts a thought of partially prefabricating and partially casting in situ, and is composed of a prefabricated part and a cast-in-situ part. The prefabricated reinforced concrete column with the high-performance concrete frame comprises a prefabricated high-performance concrete hollow column, longitudinal bars arranged in the prefabricated high-performance concrete hollow column along the length direction of the column, reinforcing steel bars and stirrups which are equidistantly paved on the cross section of the prefabricated high-performance concrete hollow column, the reinforcing steel bars crossing the central cavity of the prefabricated high-performance concrete hollow column, and the end heads of the reinforcing steel bars connected to the inner sides of the stirrups, and cast-in-situ common concrete filled in the central cavity of the prefabricated high-performance concrete hollow column. The invention further provides a construction method of the prefabricated reinforced concrete column, the prefabricated high-performance concrete hollow column is capable of generating an annular constraining force on the cast-in-situ common concrete, and thus improving the bearing capacity of the prefabricated reinforced concrete column, improving the overall performance and anti-seismic property of the structure, improving the deformation capacity of the member during transport and hoisting processes, and achieving comprehensive improvement and enhancement of the stress performance and the user performance of the prefabricated reinforced concrete member.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

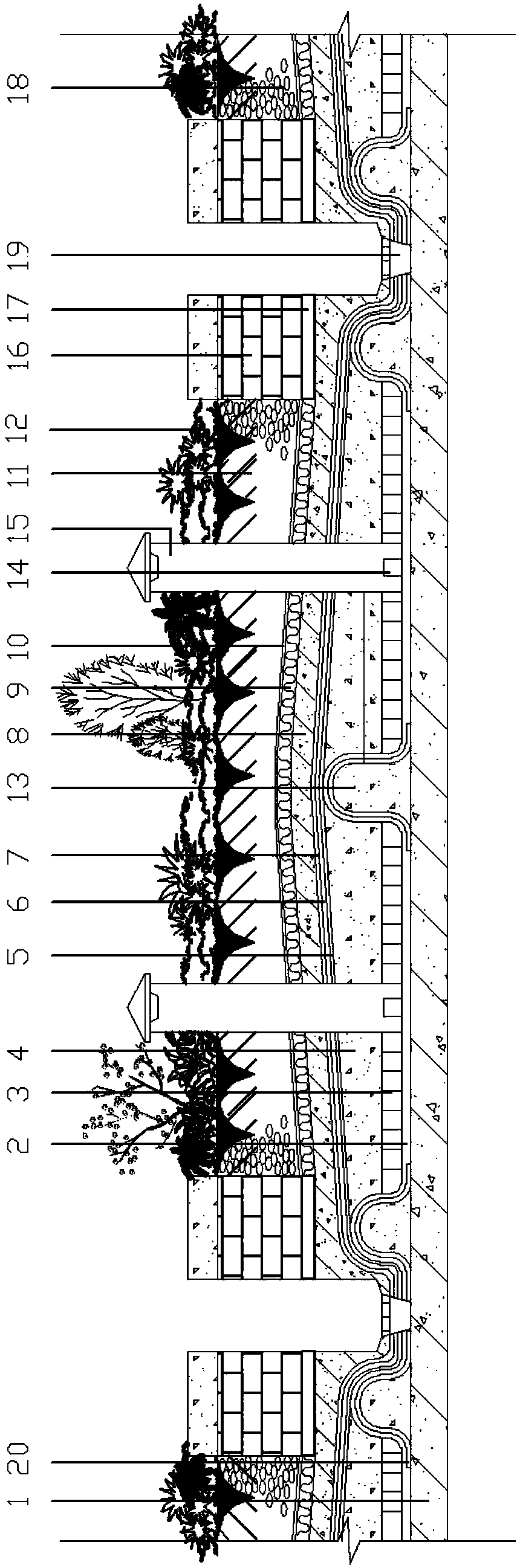

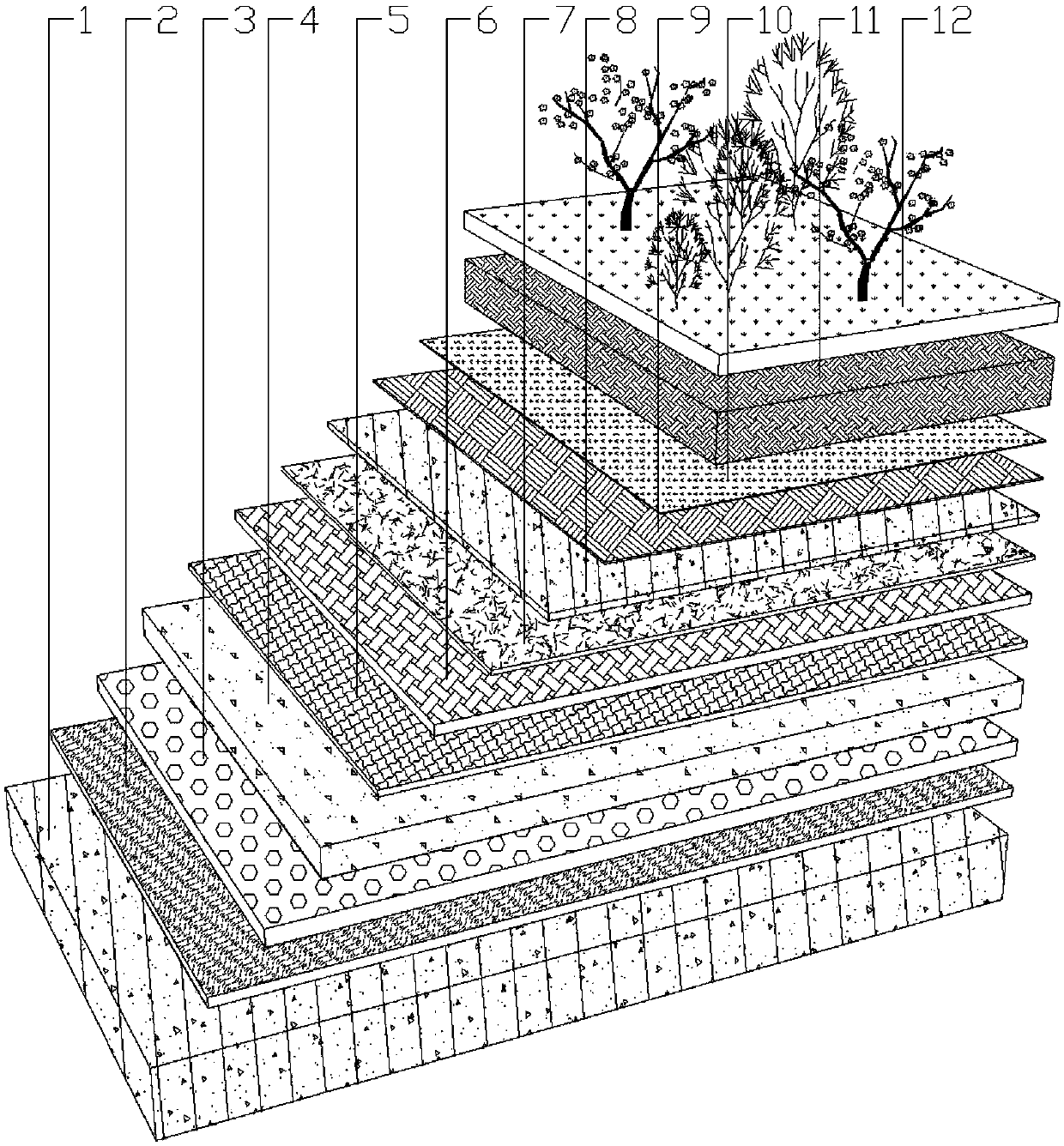

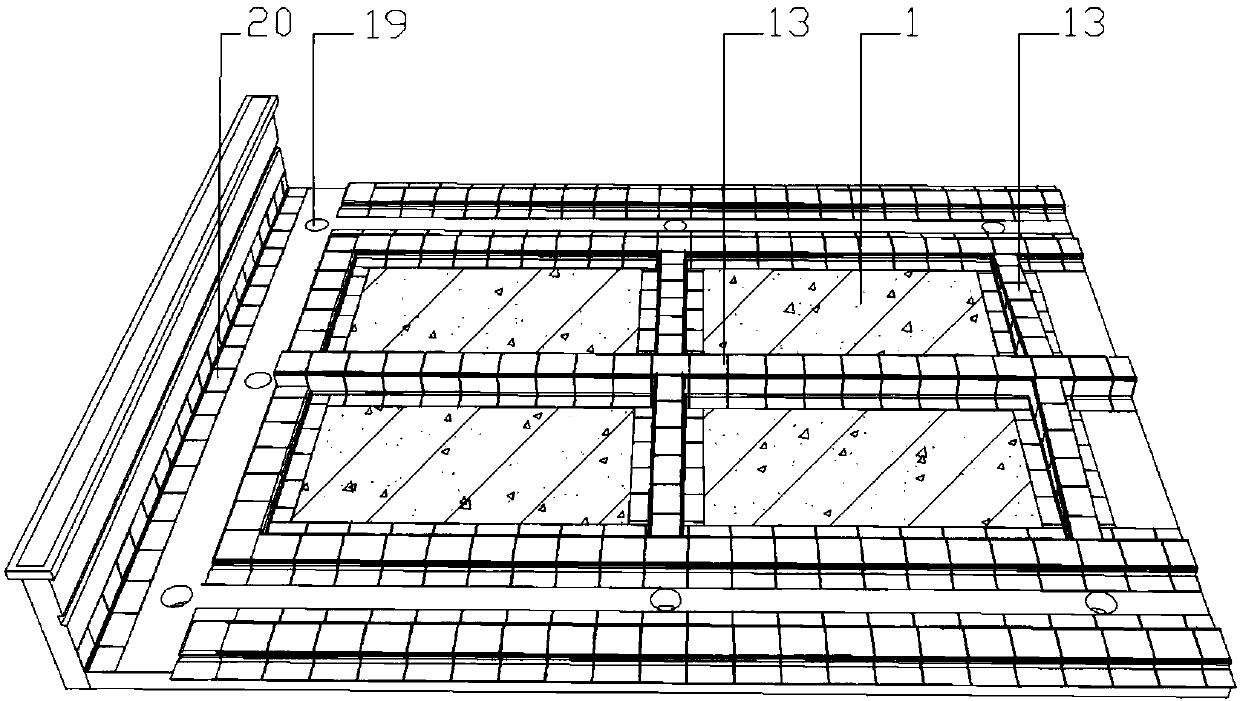

Construction method for planting roof structure

ActiveCN107060226AReduce loadGuaranteed waterproof reliabilityRoof improvementHops/wine cultivationSocial benefitsVegetation

The invention discloses a super large area planting roof structure and a construction method thereof. The construction method includes the following steps of (1) roof structure layer processing, (2) roof structure separate warehouse and additional layer construction, (3) composite waterproof layer construction, (4) insulating layer construction, (5) roof structure exhaust system construction, (6) slope asking layer construction, (7) ordinary coiled material waterproof layer construction, (8) root resistance puncturing separating root waterproof layer construction, (9) asphalt felt isolating layer construction, (10) rigidity protecting layer construction, (11) drainage ditch barricade construction, (12) water drainage and impounding layer construction, (13) drainage system construction, (14) filtering layer construction, (15) planting dielectric layer construction, and (16) vegetation layer construction. The great effects on the heat preservation, heat insulation, water proof and virescence of the super large area planting roof structure are achieved, the technology is simple, the operation is easy, the construction quality is great, and the economic benefits and the social benefits are huge.

Owner:WUHAN CONSTR ENG

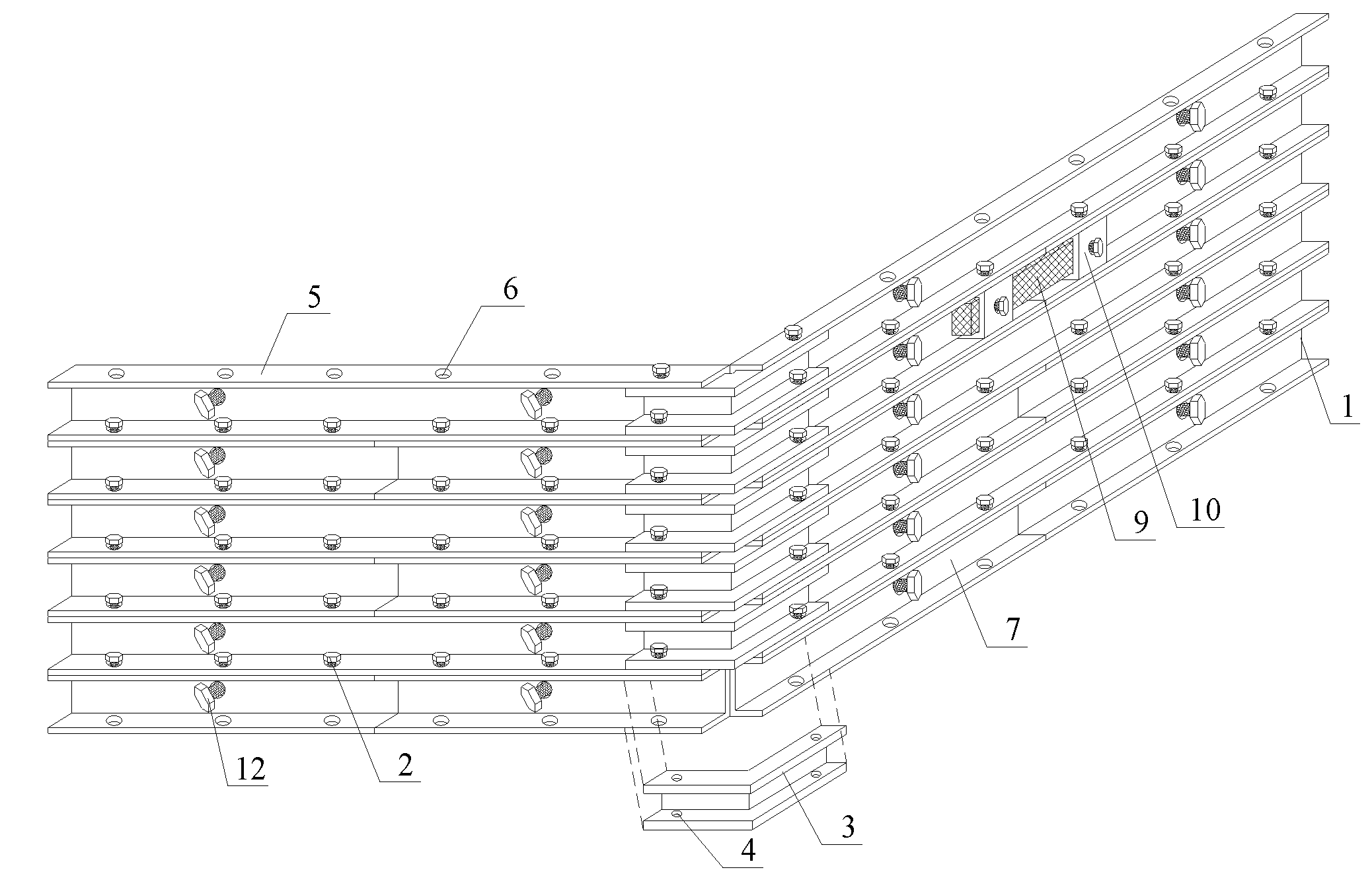

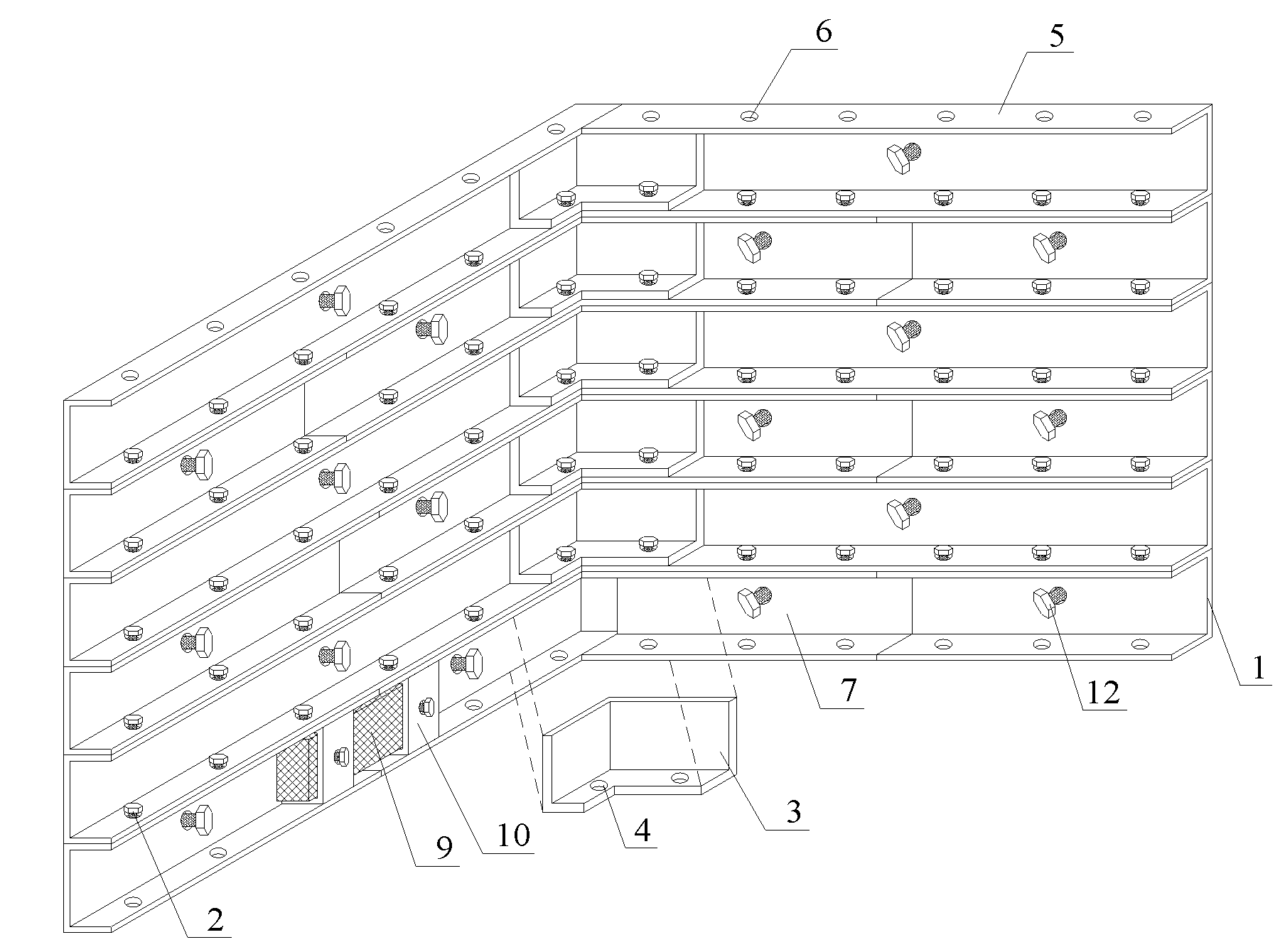

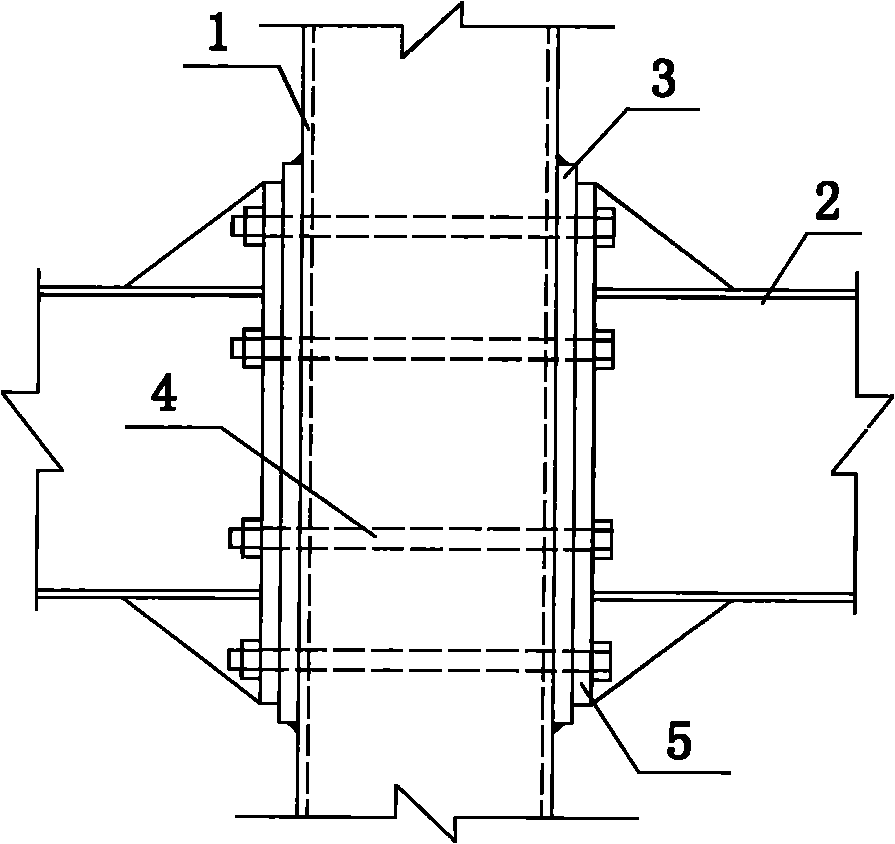

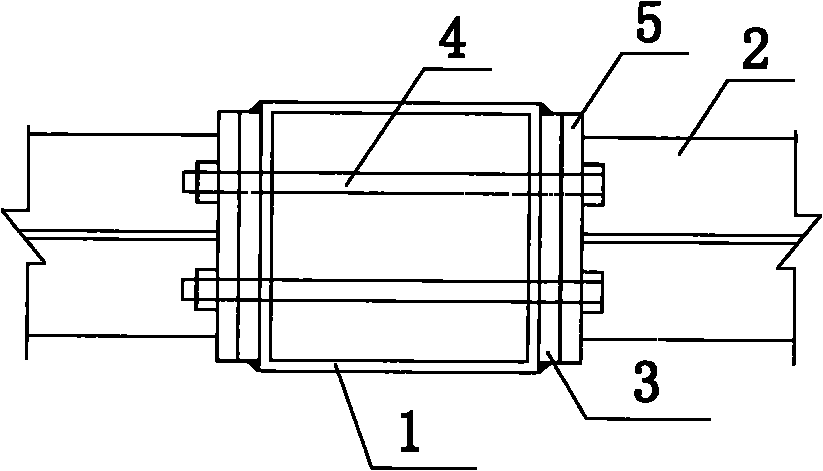

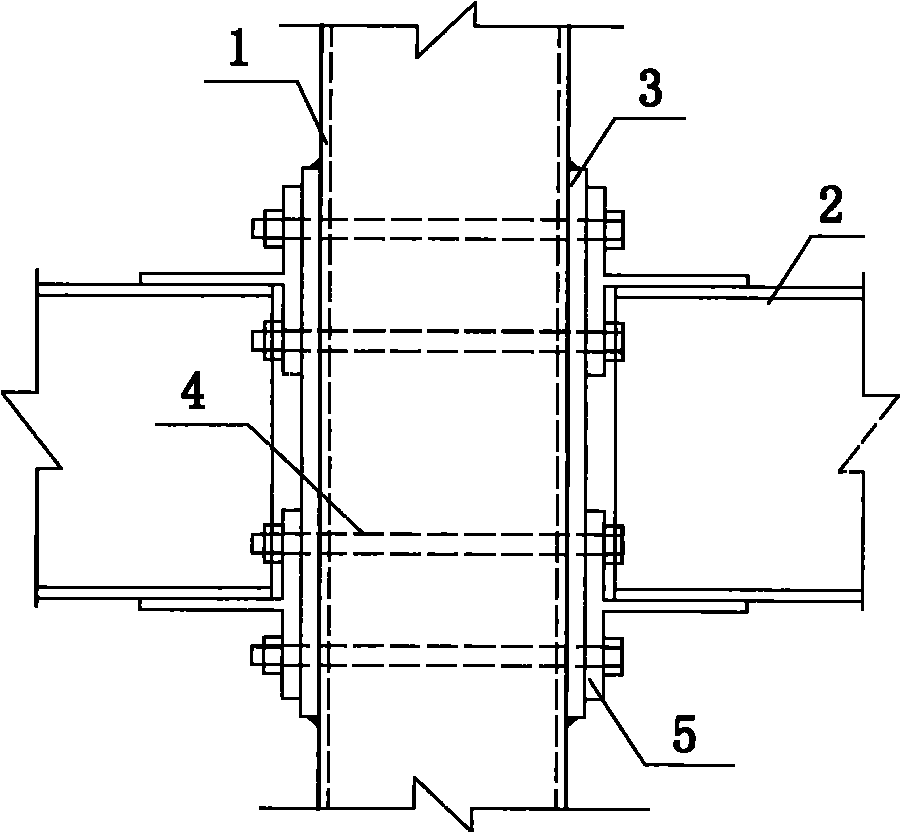

Rectangular steel pipe column and I-steel beam sleeve steel plate bolt connecting node

InactiveCN101942866AFast constructionConstruction quality is easy to controlBuilding constructionsSheet steelShock resistance

The invention discloses a rectangular steel pipe column and I-steel beam connecting node structure in the technical field of construction steel structure engineering, which comprises a rectangular steel pipe column 1, an I-steel beam 2, a sleeve steel plate 3 and a high-strength bolt 4, wherein the steel plate 3 is sleeved at a node of the rectangular steel pipe column 1; the sleeve steel plate is connected with the rectangular steel pipe column by peripheral fillet welding or power-on rivet welding; a bolt hole or a thread hole is opened in the corresponding position of the high-strength bolt; an end plate or a T-shaped connecting member 5 is welded at the end part of the I-steel beam 2; and the rectangular steel pipe column 1 and the end plate or the T-shaped connecting member 5 at the end part of the I-steel beam are connected by the high-strength bolt 4. The rectangular steel pipe column and I-steel beam connecting node of the invention finishes all welding in a factory, just needs bolt connection in a construction field and has the advantages of high node rigidity and bearing, especially high node shock resistance and low energy consumption.

Owner:NANJING UNIV OF TECH

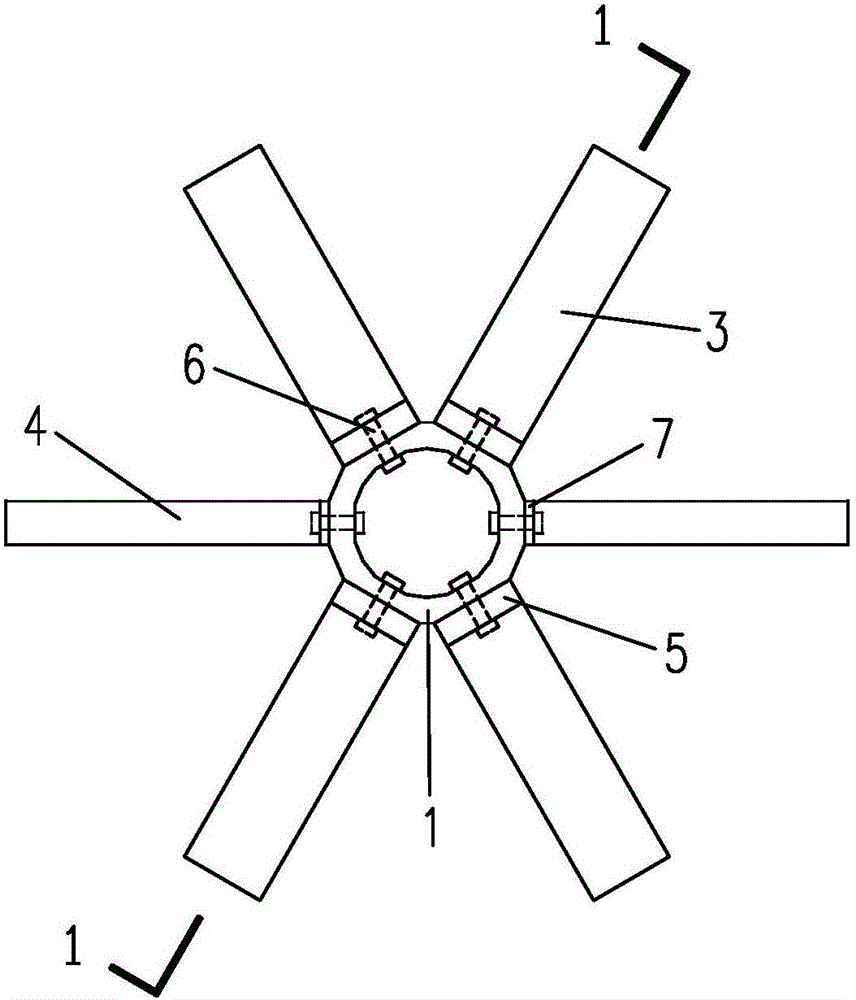

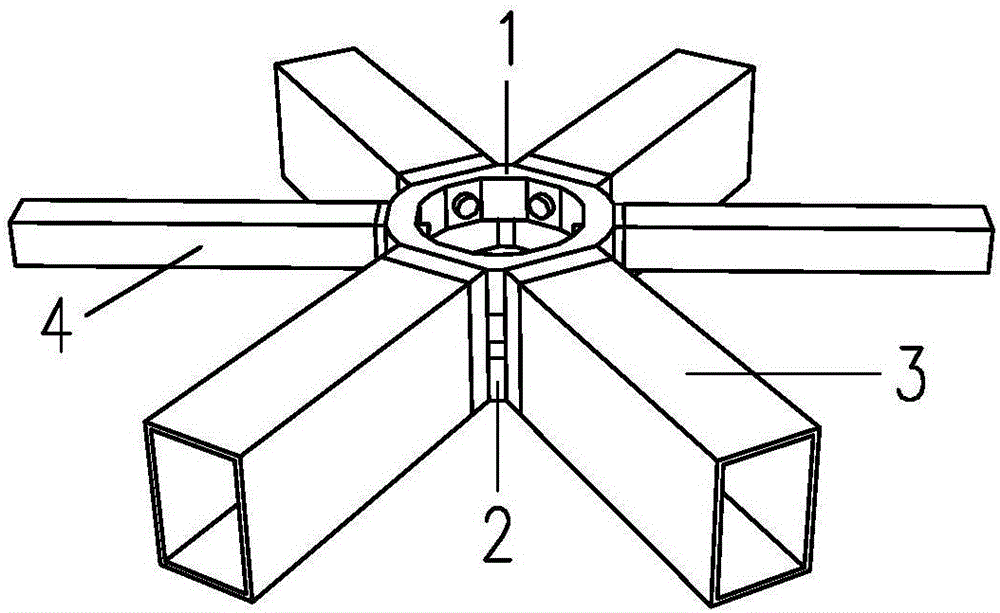

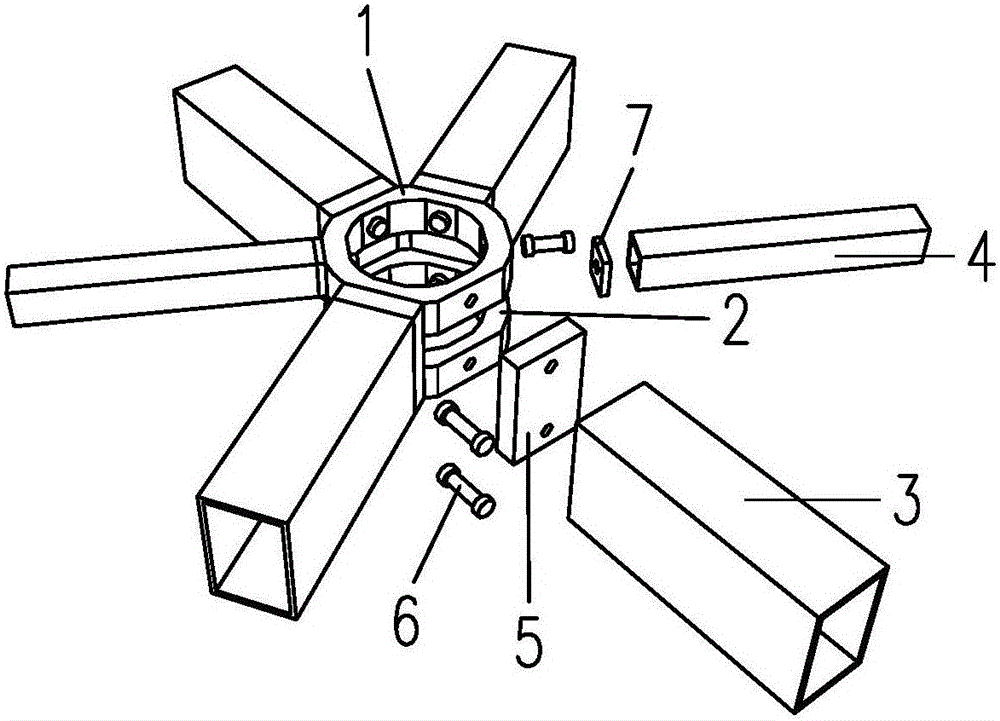

Single-layer space lattice structure assembled double-ring node

InactiveCN105821963ALow machining accuracy requirementsReduce the impactBuilding constructionsStructural engineeringMechanical property

The invention discloses a single-layer space lattice structure assembled double-ring node, which mainly comprises five parts including center upper and lower node rings, I-shaped connecting elements, a large sealing plate, a small sealing plate, high-strength screw bolts, major rod elements and minor rod elements, wherein the center upper and lower node rings are provided with screw bolt holes; the wing edge parts of the I-shaped connecting elements are provided with screw bolt holes; the large sealing plate and the small sealing plate are rectangular steel plates; the large sealing plate is welded with the I-shaped connecting elements; the small sealing plate is provided with screw bolt holes, and is welded with the rod ends of the minor rod elements; the high-strength screw bolts are connected with the upper and lower node rings and the I-shaped connecting elements; the upper node ring and the small sealing plate are connected; the major rod elements and the minor rod elements are rectangular steel pipes. The node rings can be only connected with the major rod elements and can be connected with both the major rod elements and the minor rod elements; a certain angle can be formed between the node rings and the rod elements. The node provided by the invention can be applicable to a single-layer space lattice structure, and has the characteristics that the mechanical property is good; the assembling performance is high; the construction speed is high; the construction quality can be easily controlled; the construction cost is low, and the like.

Owner:SOUTHEAST UNIV

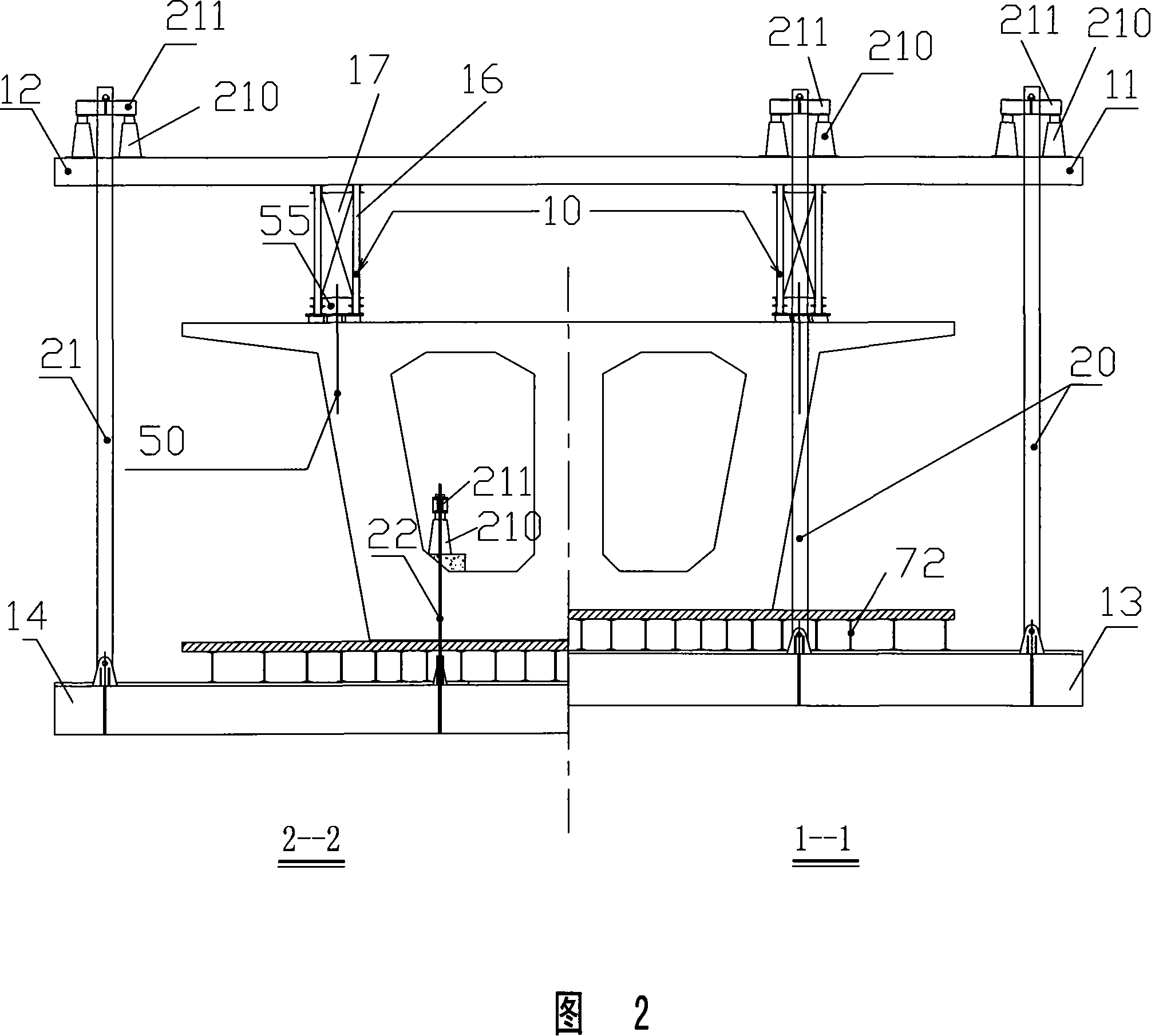

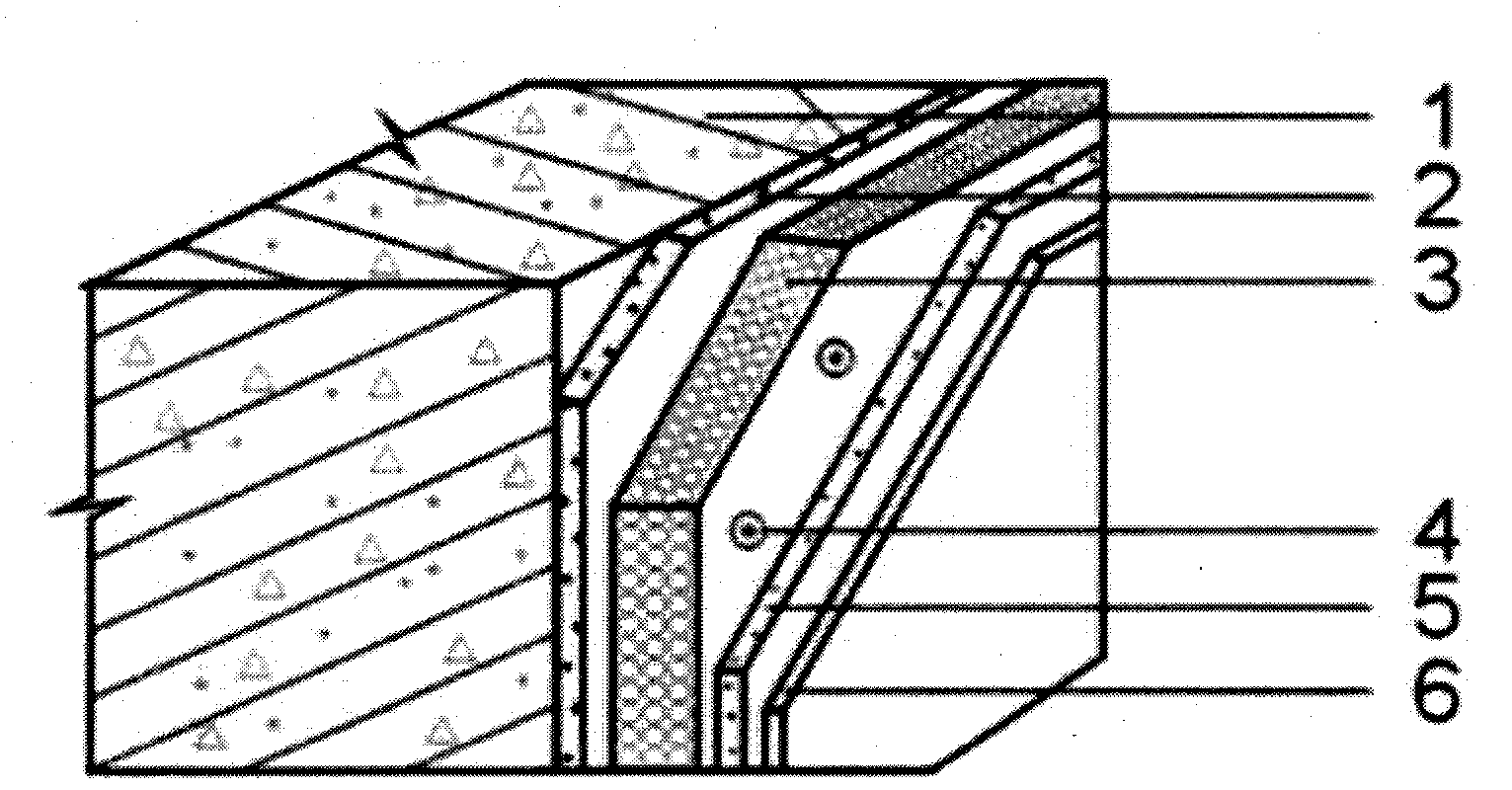

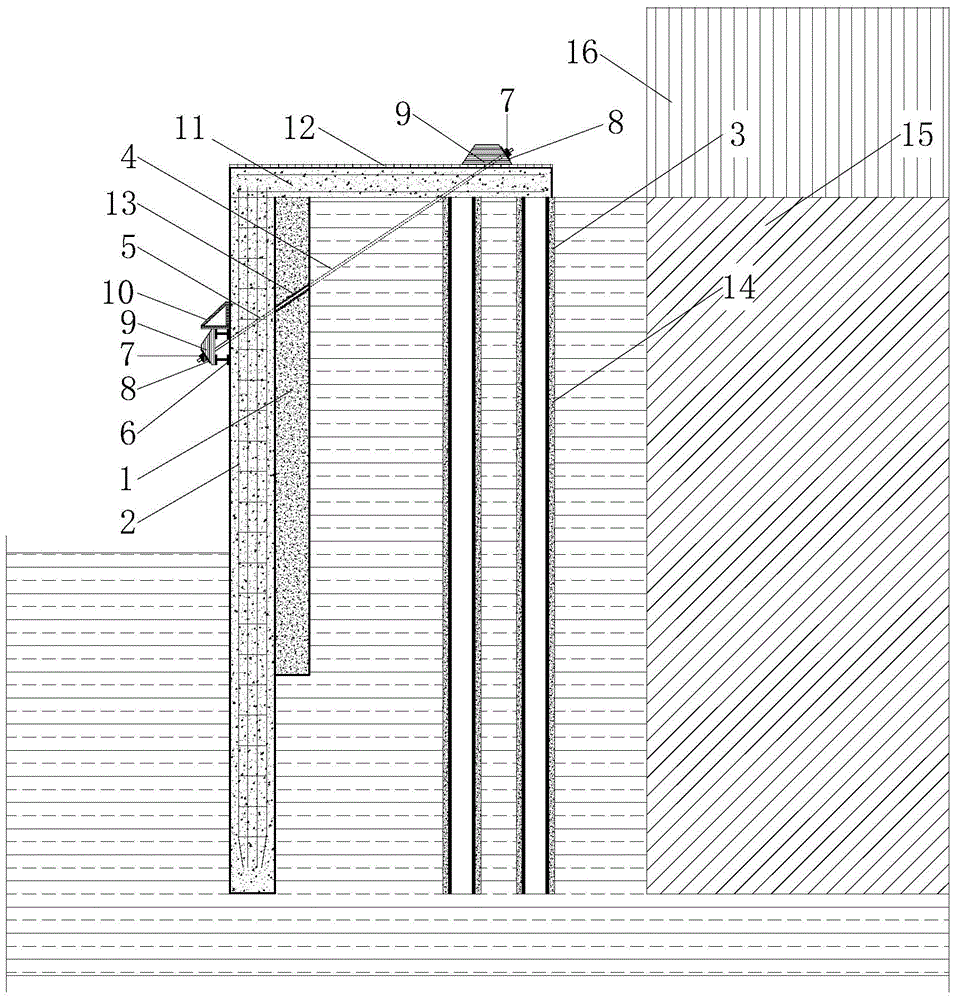

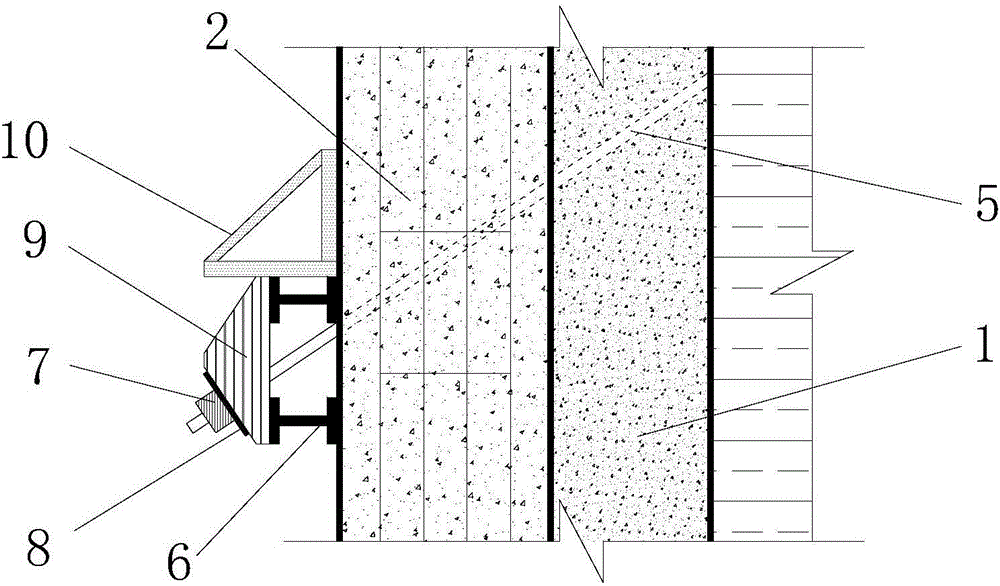

External thermal-insulation wall of mechanical anchoring gridding reinforcing rib inorganic modified foam thermal-insulation board

ActiveCN103174226AGuaranteed flatnessHigh tensile strengthCovering/liningsWallsSurface layerThermal insulation

The invention discloses an external thermal-insulation wall of a mechanical anchoring gridding reinforcing rib inorganic modified foam thermal-insulation board. The external thermal-insulation wall is sequentially composed of a base layer wall body 4, a leveling and binding layer 5, a gridding reinforcing rib inorganic modified foam thermal-insulation board 6, plastic expansion anchor bolts 7, a thin troweling protective surface layer 8 and a surface detective layer 9 on the base wall body from inside to outside. The external thermal-insulation wall is characterized in that the leveling and binding layer 5 is adopted to bond the base layer leveling and the gridding reinforcing rib inorganic modified foam thermal-insulation board 6 in an auxiliary mode in one step, the bonding is only used for ensuring planeness during installation of an external thermal-insulation system, then the plastic expansion anchor bolts 7 are used for anchoring the gridding reinforcing rib inorganic modified foam thermal-insulation board 6, and all loads of the external thermal-insulation system are enabled to completely borne by the plastic expansion anchor bolts 7 and are directly transferred to the base layer wall body 4. Through combination of the gridding reinforcing rib inorganic modified foam thermal-insulation board 6 and the plastic expansion anchor bolts 7, tensile strength, anti-bending strength and stability of a thermal-insulation layer are largely improved.

Owner:SHANGHAI ONE GOLD ENERGY SAVING TECH

Drainage pipeline non-excavation grouting repair construction method

The invention belongs to the technical field of underground water supply and drainage pipeline leakage repair, and particularly relates to a drainage pipeline non-excavation grouting repair construction method. According to the method, excavation does not need to be carried out, and leakage to the earth surface can be prevented. The method comprises the steps of scene investigation, positioning, internal support mounting, placement of a drilling machine and a grouting device, grout production, drilling, grouting, hole sealing, machine moving and the like. The drainage pipeline non-excavation grouting repair construction method has the advantages that a flow cross section is small in loss after repairing is carried out; the flow is basically lossless; the grouting operation is easy, and the grouting effect is easy to control; construction is easy and convenient; the construction period is short; no special equipment is needed; the engineering cost is low; the application range is wide; and in the whole repairing process, a road surface is not required to be excavated.

Owner:河南万里交通科技集团股份有限公司

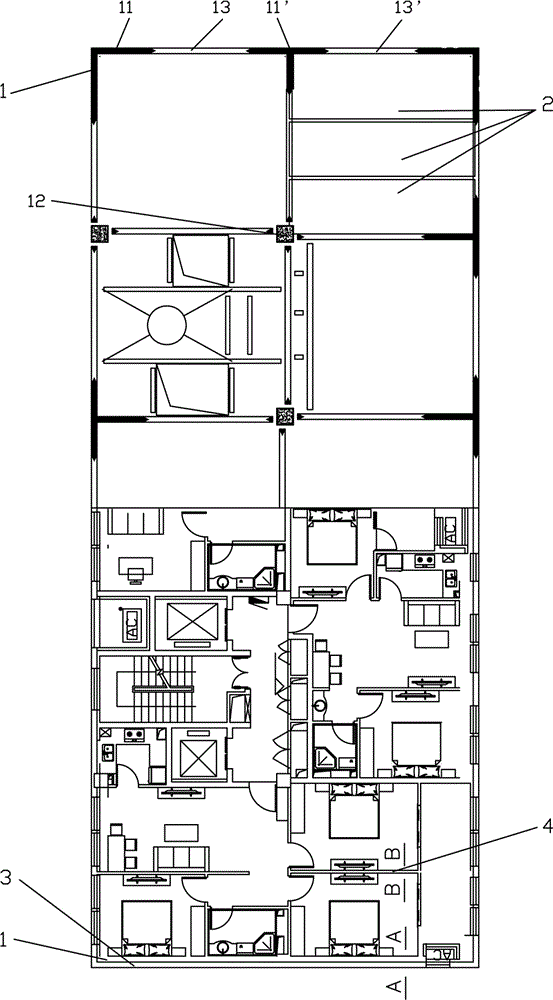

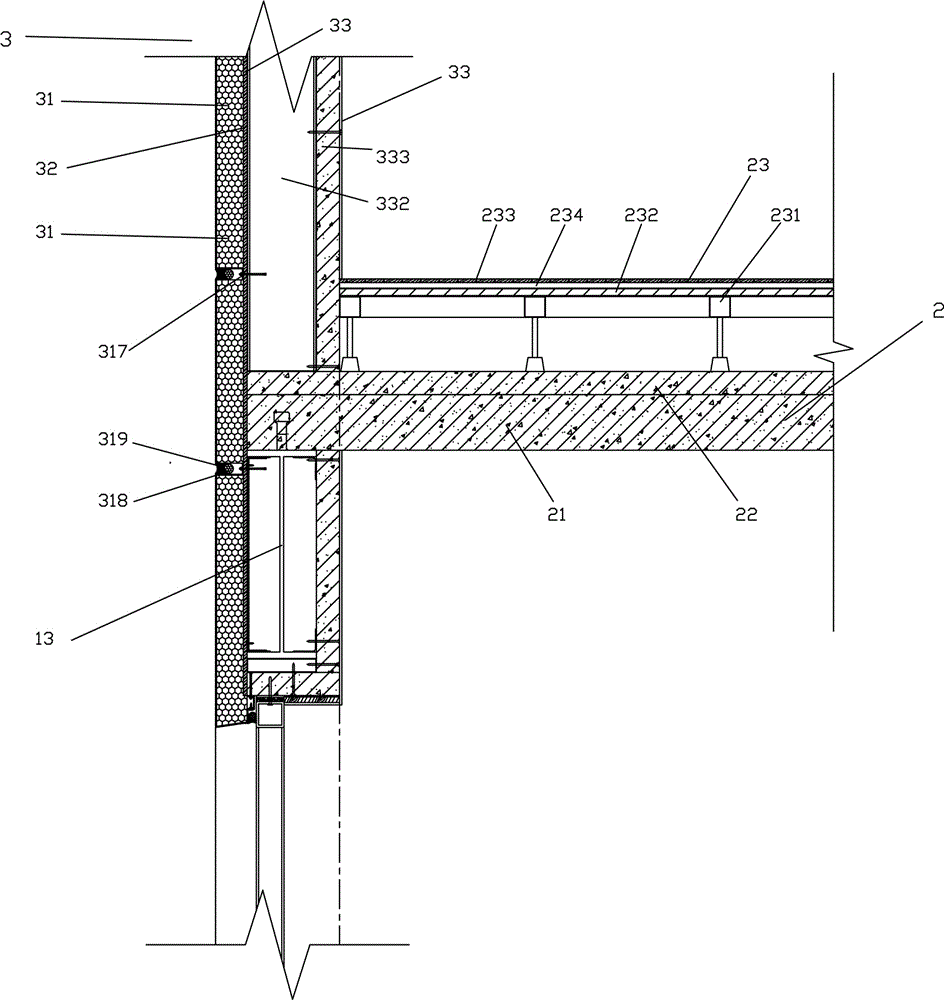

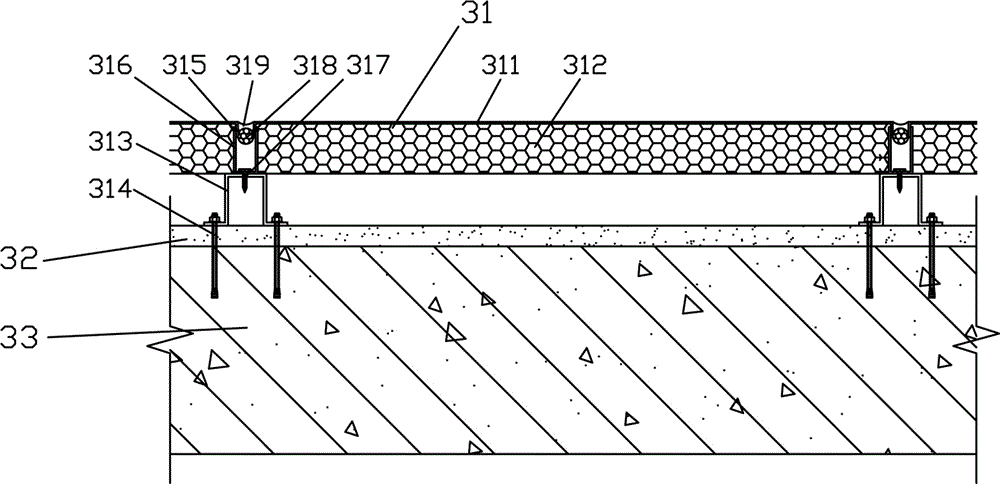

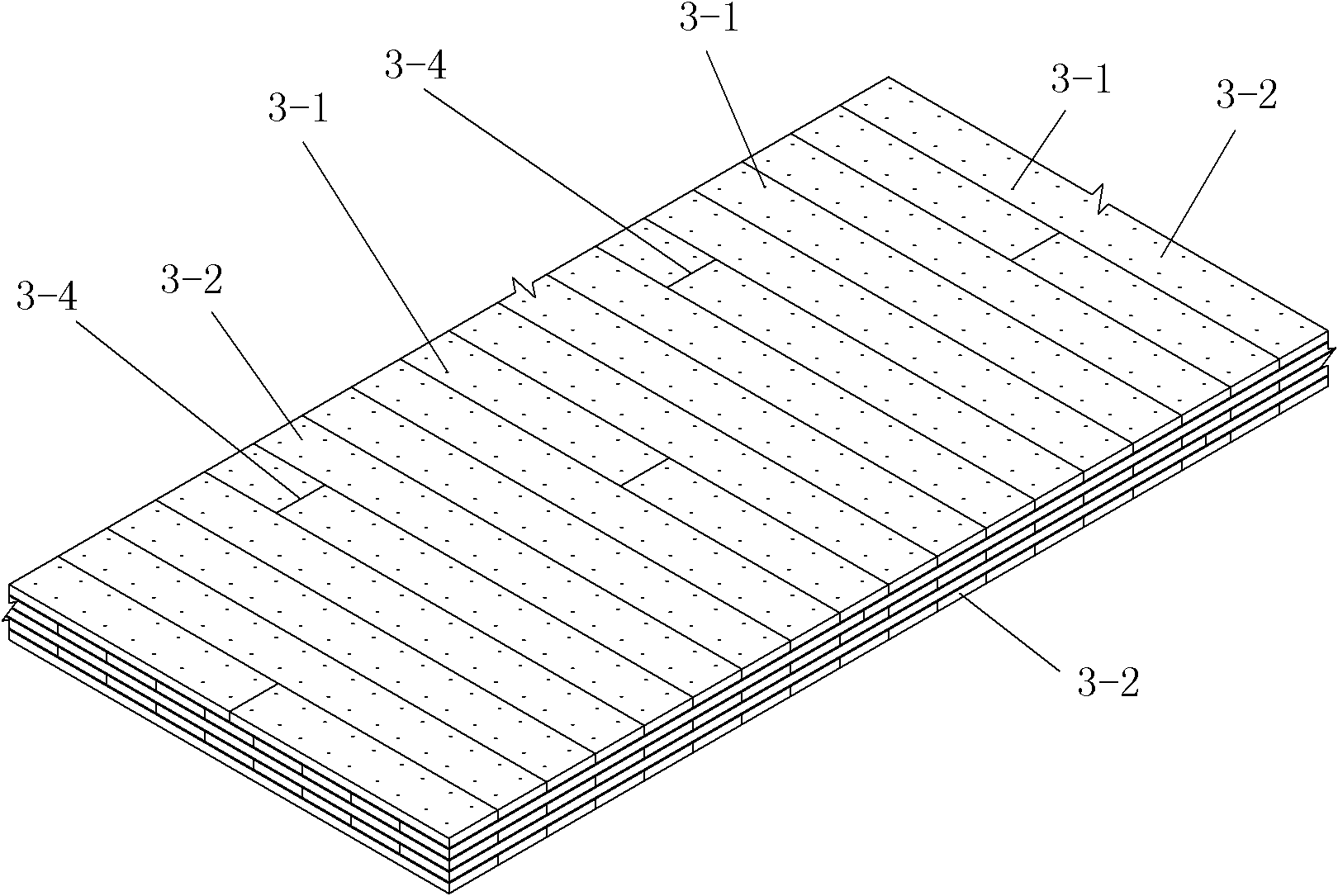

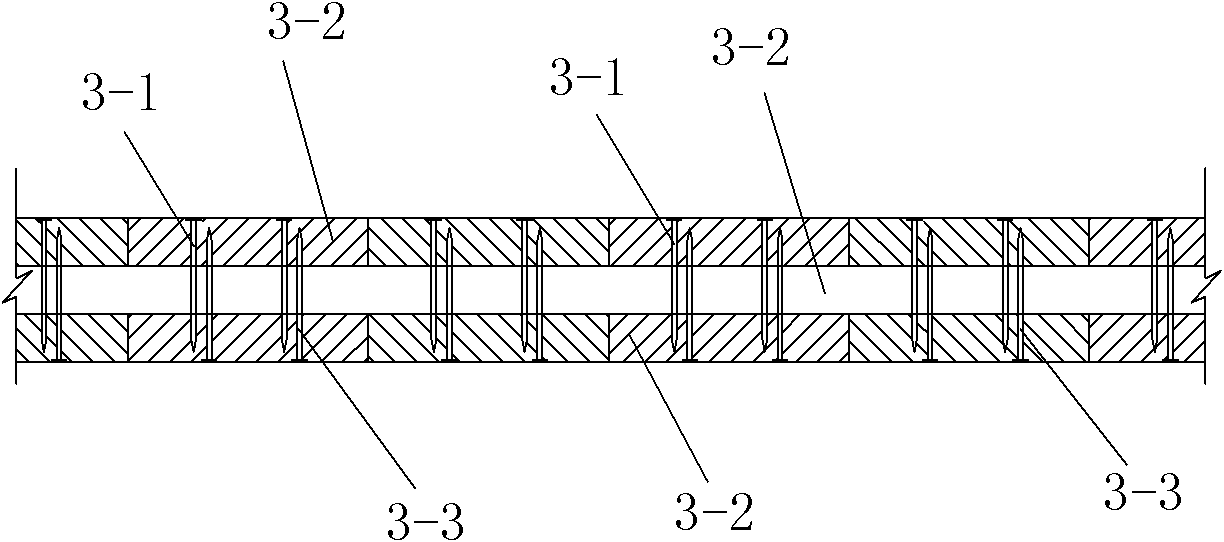

Assembled steel structure building system and construction method thereof

The invention provides an assembled steel structure building system and a construction method thereof. The assembled steel structure building system comprises a steel structure framework system, an assembled and integrated floor system, an assembled outer wall system and an assembled inner wall system; the steel structure framework system comprises double layers of steel plate concrete combined shear wall, steel tube concrete pillars, H-shaped steel beams and connection joints. The steel beams in the steel framework system serves as supports of the assembled and integrated floor system, and the assembled and integrated floor system comprises a precast concrete bottom plate, a cast-in-situ concrete super-position layer and an overhead floor layer located on the cast-in-situ concrete layer. The assembled outer wall system comprises a heat preservation and decoration integrated plate system, a waterproof interface layer and a base wall. According to the assembled steel structure building system, the design concept of separating a supporting body from a filling body is adopted, a large-span space capable of being divided flexibly can be provided, and the assembled steel structure building system and the construction method thereof have the advantages of being high in construction speed, reliable in quality and good in anti-seismic property.

Owner:SHANGHAI IRON & STEEL TECHN INST

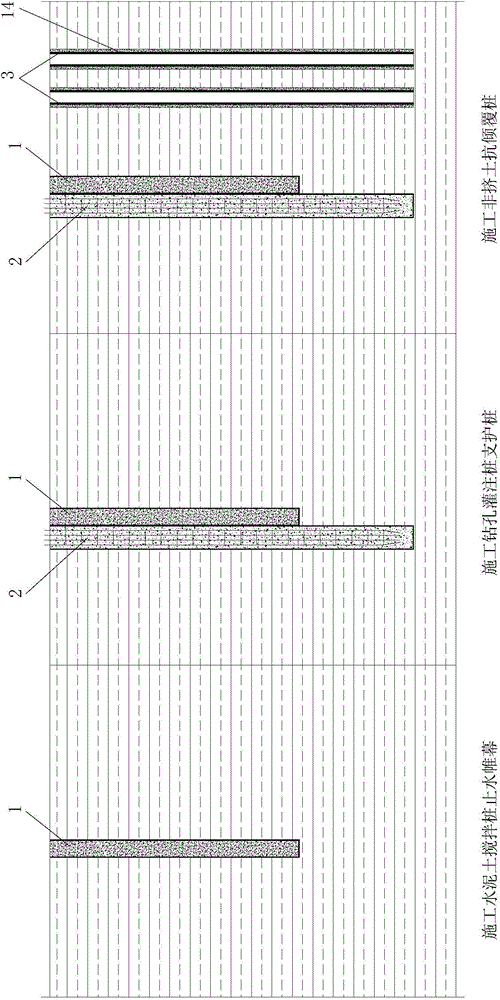

Maintenance structure for foundation pit next to existing building and construction method

ActiveCN104612160AEnsure safetyEnsure stabilityExcavationsArchitectural engineeringEconomic benefits

The invention relates to a maintenance structure for a foundation pit next to an existing building. The maintenance structure is characterized by mainly comprising a cement mixing pile water stop curtain, a cast-in-situ bored pile support pile, non-soil-squeezing anti-overturning piles and a slant pull rod, wherein the cast-in-situ bored pile support pile, the cement mixing pile water stop curtain and the non-soil-squeezing anti-overturning piles are sequentially arranged on the outer side of a foundation pit excavation side boundary from inside to outside; a raft plate is arranged in a pile body top area from the non-soil-squeezing anti-overturning piles to the cast-in-situ bored pile support pile, and a continuous perforated steel plate is arranged on the top of the raft plate; the upper portion of the slant pull rod is arranged on the continuous perforated steel plate on the tops of the non-soil-squeezing anti-overturning piles, the lower portion of the slant pull rod is arranged on the outer side of the cast-in-situ bored pile support pile, and the two ends of the slant pull rod are each fixed with an anchorage device, a base plate and a pedestal. The foundation pit maintenance structure effectively solves the technical problem that the foundation pit next to the existing building is hard to support, and has good technical and economical benefits.

Owner:ZHONGDA CONSTR

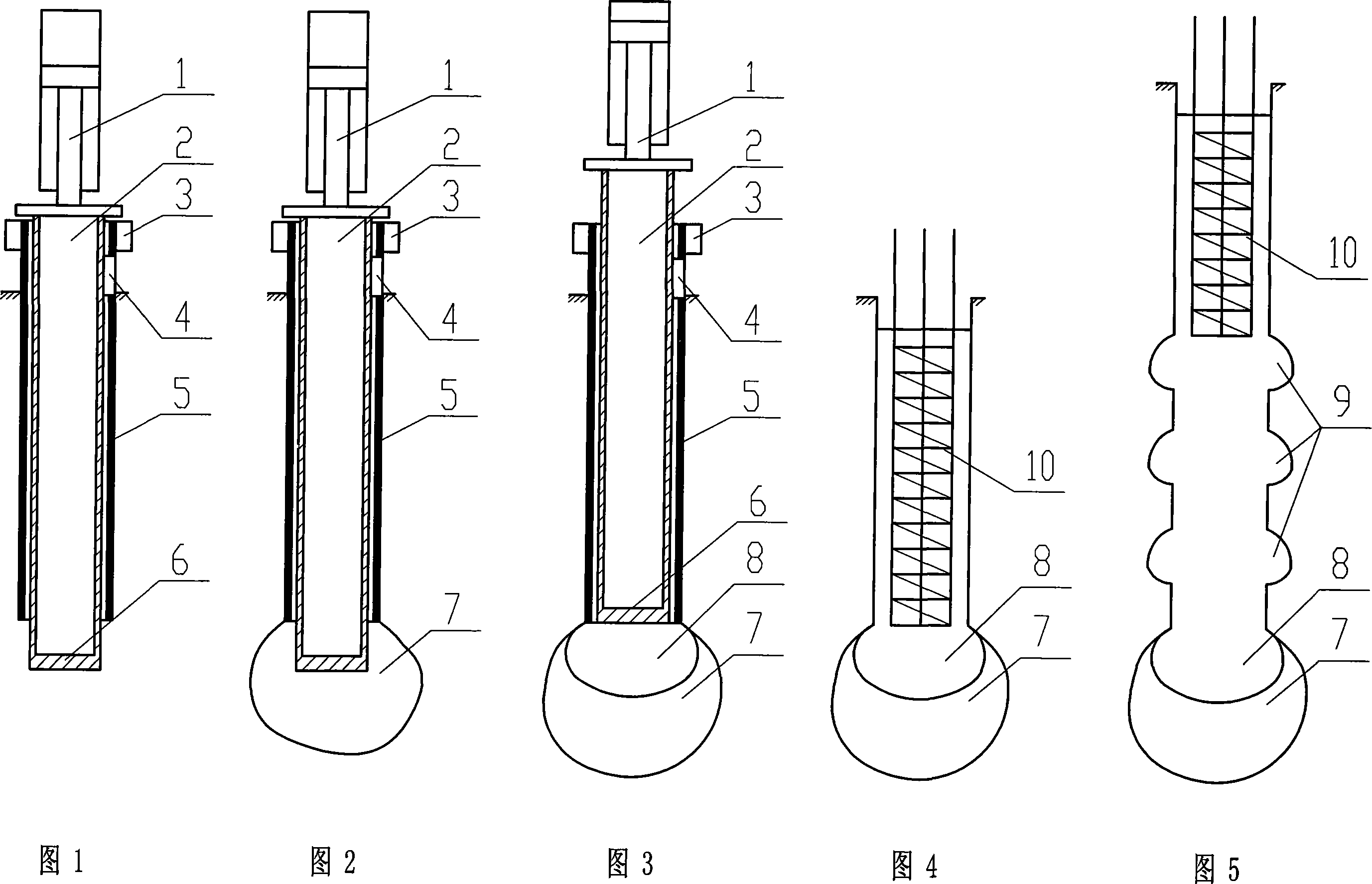

Construction device and construction technique for concrete pipe base

InactiveCN101126239AImprove bearing capacityUniform load capacityBulkheads/pilesHydraulic cylinderCarrying capacity

The invention discloses a construction device and the construction technology of a concrete pile foundation, which is applied to the construction of the foundation project of the bored concrete pile in the building field. The device comprises a top pressure type static pile pressing-in machine, a hydraulic cylinder connected with a pressure gauge a retaining cylinder connected with the top pressure type static pile pressing-in machine and an internal tube, the length of the internal tube is longer than that of the retaining cylinder; a flat head blanking plug is arranged at the lower end of the internal tube; a vibration device is arranged on the retaining cylinder and a feed inlet is opened on the side wall of the retaining cylinder. The key points of the construction technology are that: the builders rubbish is utilized to form a loose bearing platform at the bottom of the pile end, then the no-slump concrete is used for building a solid bearing platform on the loose bearing platform at the bottom of the pile end; a plurality of middle bosses are formed at the different heights of the pile; then the file is finished by lifting the internal tube, placing a reinforcing cage, casting and vibrating the concrete. The pile made according to the invention has high and uniform carrying capacity; the carrying capacity of the bearing platform can be read from a pressure gauge, which reduces the artificial error.

Owner:张立军

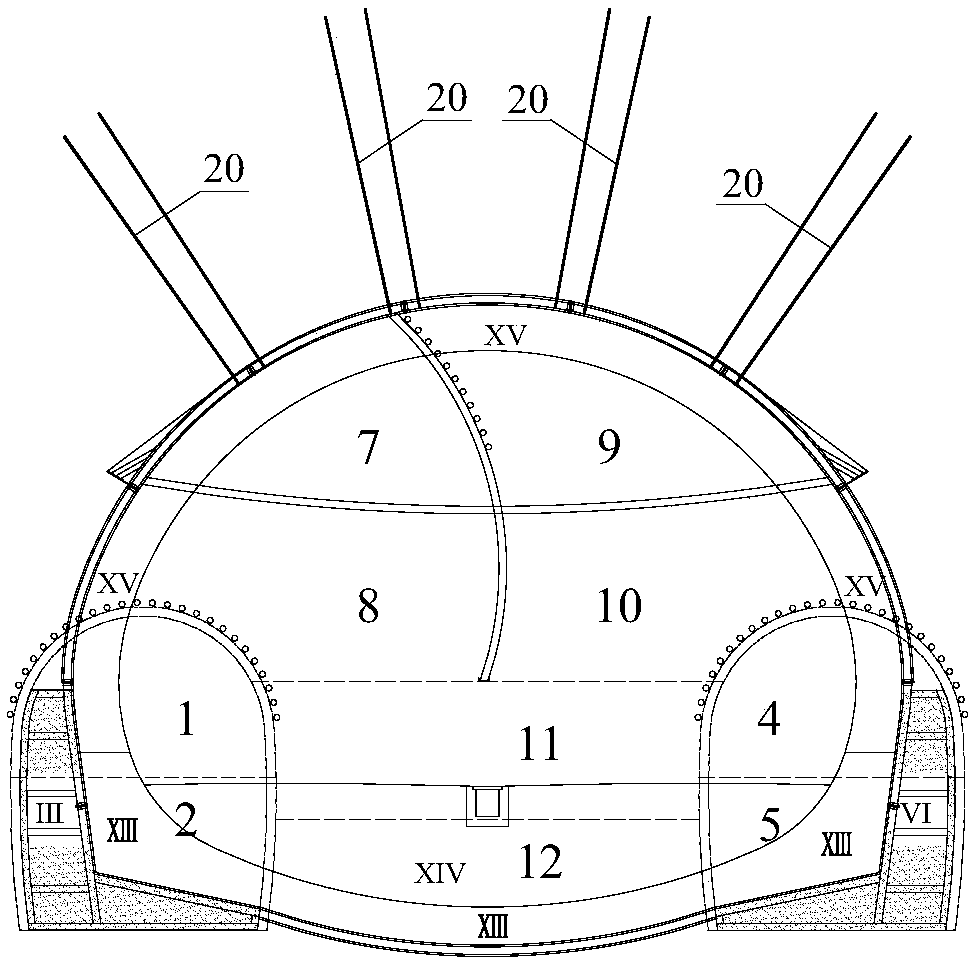

Double-side-wall composite cross method construction method for large-span tunnel under complex geological condition

InactiveCN108487911AControl vault sinkingGood structural strengthUnderground chambersTunnel liningClerestorySupport system

The invention provides a double-side-wall composite cross method construction method for a large-span tunnel under the complex geological condition. The double-side-wall composite cross method construction method is used for solving the technical problems that during construction of a soft rock large-span tunnel, arch crown settlement is not easy to control and a support structure is prone to deforming, optimizing structural force, improving construction convenience and determining construction safety. According to the double-side-wall composite cross method construction method, pilot tunnelson the two sides are constructed firstly, and primary support side wall foundations are constructed in the pilot tunnels to serve as a bearing foundation of an upper primary support system, so that the problems that during construction of the soft rock large-span tunnel, arch crown settlement is not easy to control and the support structure is prone to deforming are solved; bases only serve as thebearing foundation of primary support, under the premise that the stability of the arch wall primary support system is guaranteed, an arch wall secondary lining can still be constructed through an integral formwork trolley, the technique is simple and convenient, the integrity of the secondary lining is guaranteed, the waterproof effect is good, and the construction quality is controllable; and the pilot tunnels on the two sides adopt the excavated section of an arc-shaped arch crown, compared with conventional pilot tunnels constructed through a double-side-wall heading method, the structureforce is more excellent, construction is convenient, and the construction quality of the support system is easy to ensure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

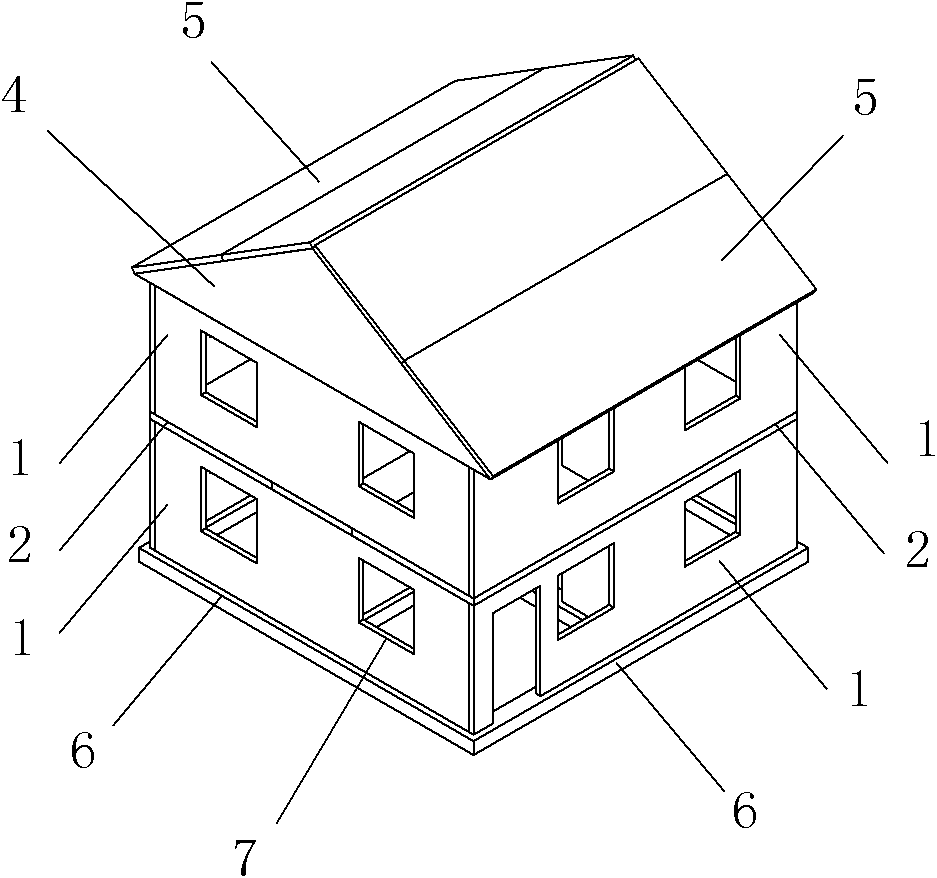

Wooden structure house and building process thereof

InactiveCN102174859ASimple structureClear mechanical propertiesRoof covering using slabs/sheetsBuilding roofsBasementOn board

The invention discloses a wooden structure house and a building process thereof. The wooden structure house comprises a house main body structure and a roof structure, wherein every floor of the house main body structure comprises a plurality of wall bodies 1; the adjacent floors are separated by a floor plate; the wall bodies 1 and the floor plate are an integrated composite board or are formed by splicing a plurality of composite boards arranged on the same plane; the integrated composite board is formed by piling a plurality of layers of wooden boards with same shapes and sizes; and the wooden board is formed by splicing a plurality of wooden plate strips which are arranged on the same plane. The building process comprises the following steps of: 1, on-site constructing foundation and basement, factory-prefabricating and transporting the integrated composite boards; and 2, using the prefabricated composite boards to assemble the wooden structure house on the spot. The wooden structure house in the invention is simple in construction process, controllable in construction quality, low in input investment, rational in structural stress of the built house, beautiful in shape, wide in application range and convenient for prefabricating the integrated boards and suspending on the spot.

Owner:杨岳华

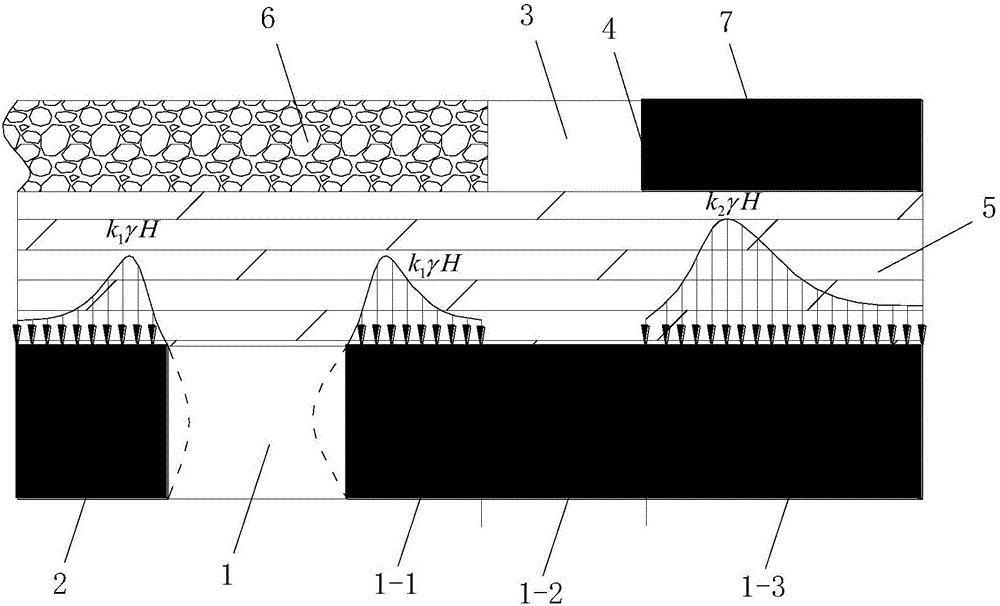

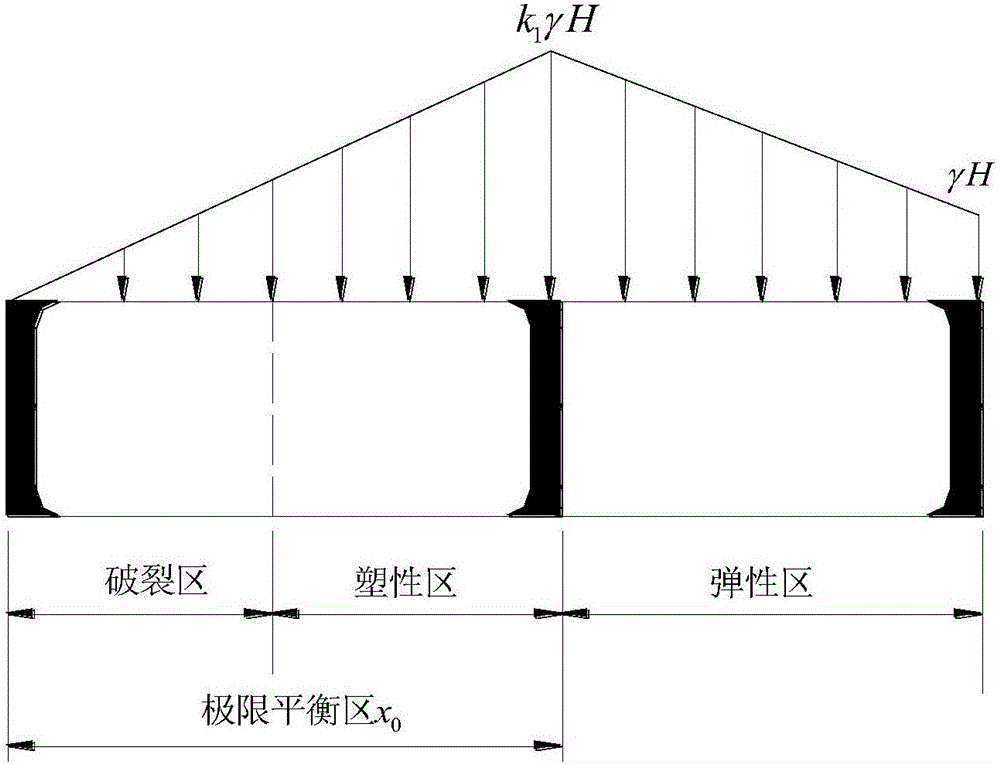

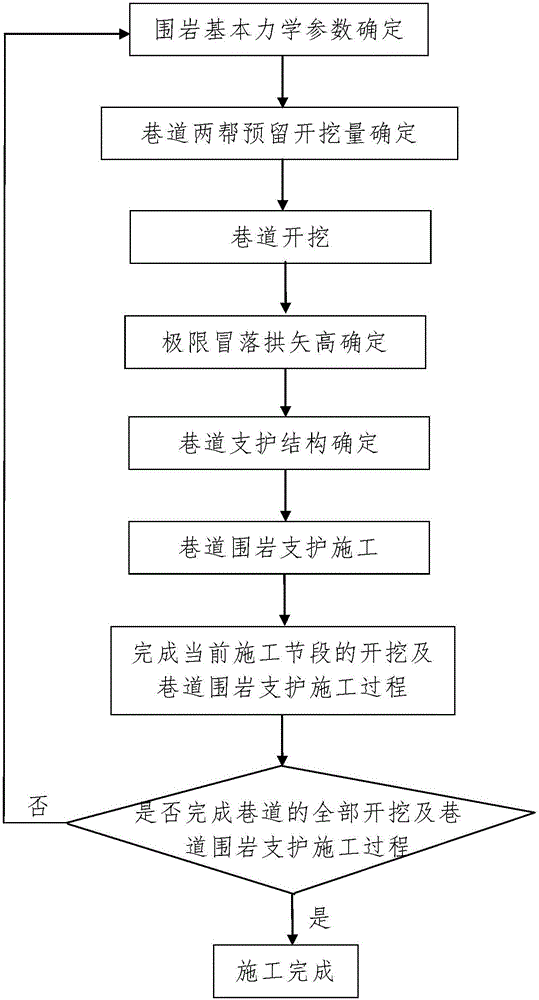

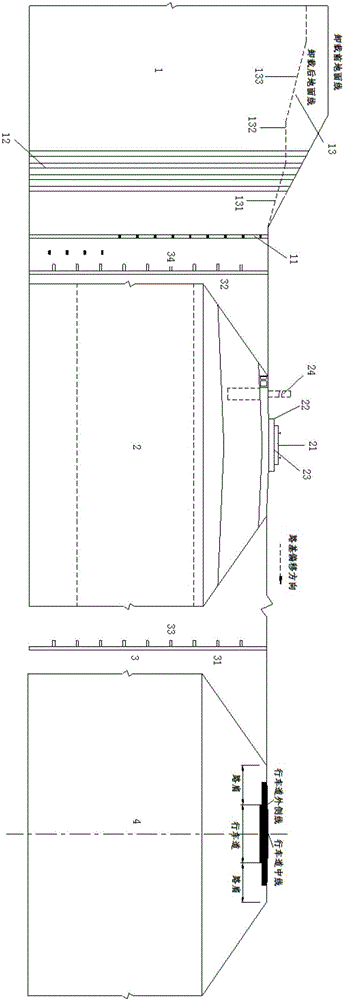

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

Deviation correcting structure and deviation correcting method for asymmetrical earth fill load deviation of high-speed railway roadbed

InactiveCN105951538ARotary grouting pile technology is matureConstruction quality is easy to controlRailway tracksFoundation engineeringEngineeringControllability

The invention relates to a deviation correcting structure and deviation correcting method for asymmetrical earth fill load deviation of a high-speed railway roadbed. The structure and the method are used for performing unloading deviation correction on the high-speed railway roadbed deviation near the existing structure in a soft soil area. The structure consists of an asymmetrical earth fill load region, a roadbed structure region, a roadbed deviation region and an existing structure region which are in sequential distribution in parallel, wherein high-speed railway steel rails are laid on the surface of the roadbed structure region; at least one stress release hole belt and a plurality of rows of chemical churning piles are arranged in a connecting position of the asymmetrical earth fill load region and the roadbed structure region in the extending direction of the high-speed railway steel rail; and an unloading slope is also arranged on the surface of the asymmetrical earth fill load region. Compared with the prior art, the structure and method have the advantages that the control is easy; the operation is flexible; safety and controllability are realized; and the application prospects are wide, and the like.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com