Deviation correcting structure and deviation correcting method for asymmetrical earth fill load deviation of high-speed railway roadbed

A high-speed railway-based, asymmetric technology, applied in infrastructure engineering, roads, tracks, etc., to avoid secondary offset, flexible and controllable operation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

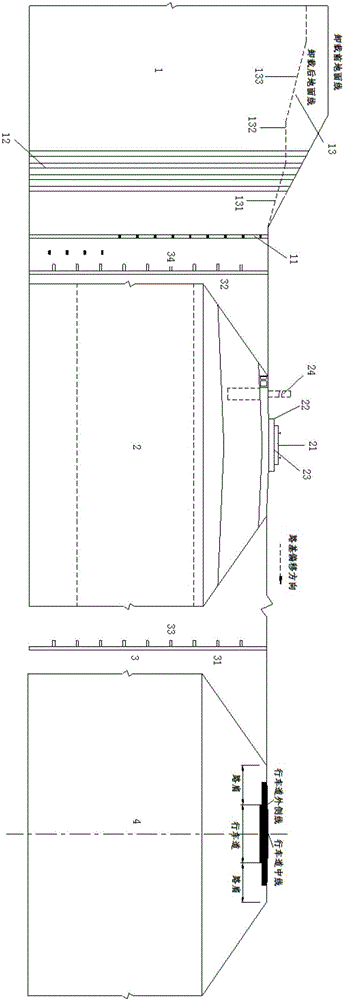

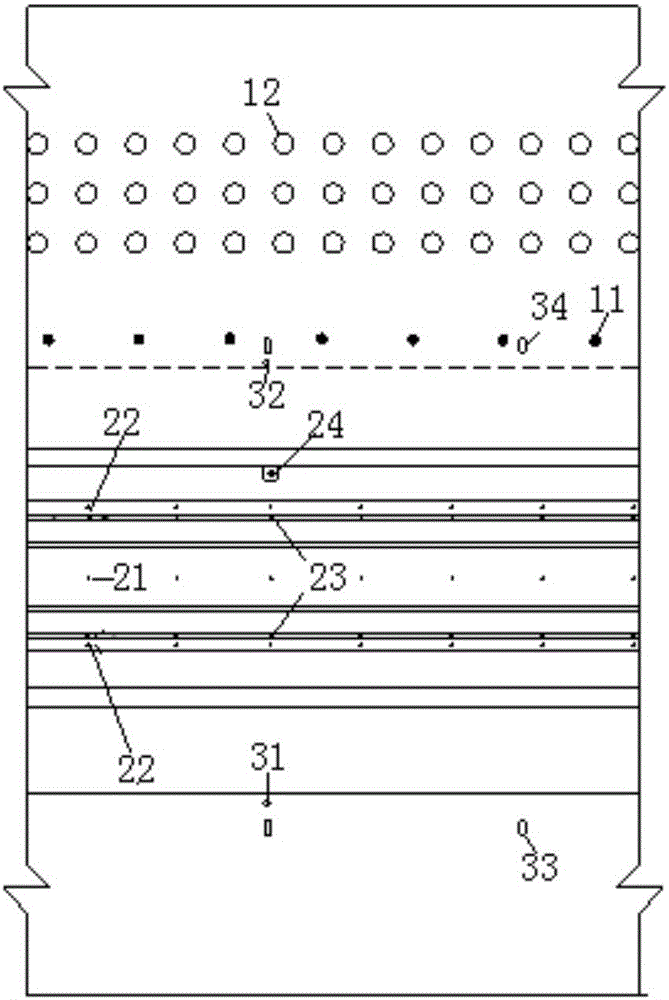

[0032] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

[0033] like Figure 1-4 As shown, the applicable object of the present invention is the ballastless track of the high-speed railway, including the subgrade reinforcement area, the cushion layer at the top of the reinforcement area, the subgrade body, the track slab, the rail, the uneven loading area and the subgrade offset area.

[0034] The method includes the following steps:

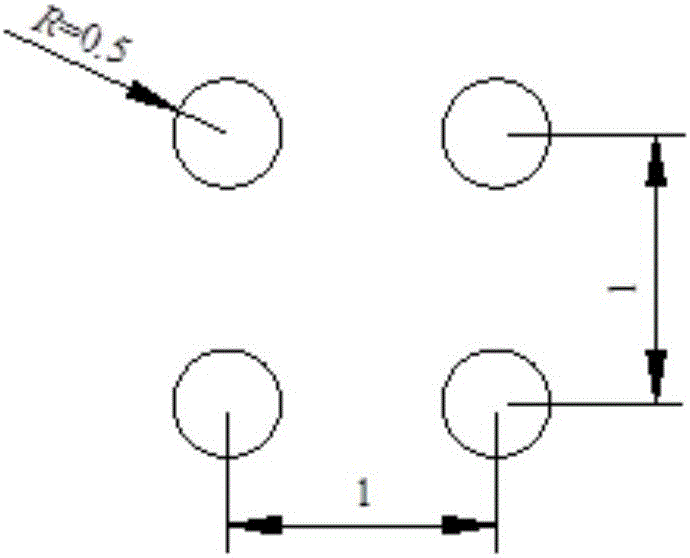

[0035] Step 1: When the high-speed railway embankment adjacent to the existing structure is subjected to asymmetric surcharge and lateral displacement occurs to the other side of the embankment, multiple rows of stress relief holes are arranged in the surcharge area, and the bottom of each stress relief hole enters the holding area as much as possible. Stress layer, and fill the hole with a material that can prevent the stress release hole from collapsing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com