Triangular conical chemical churning pile alloy bit

An alloy drill bit, triangular conical technology, applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., can solve the problems that the drill bit is easy to be ground or broken, and cannot drill to the designed depth, so as to overcome the difficulty of pile formation and the scope of application Extensive, the effect of overcoming technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

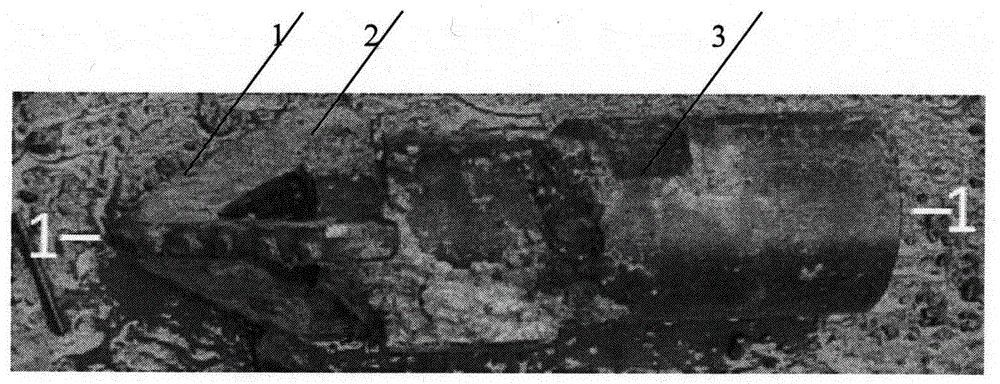

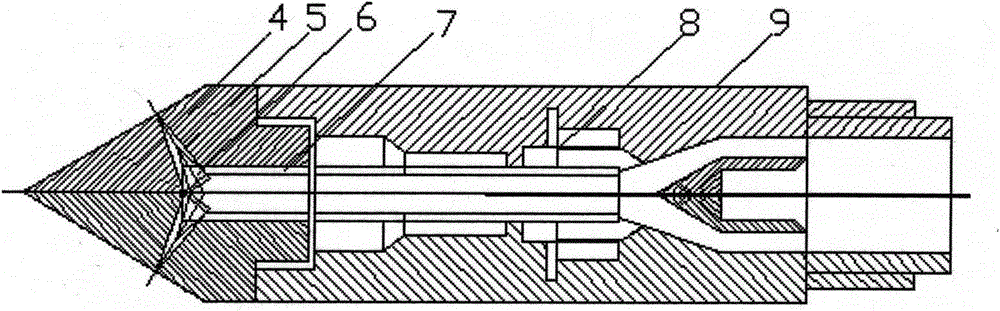

[0010] figure 1 The drill bit alloy block (1), the drill bit (2), and the drill body (3) form the alloy drill bit of the triangular conical rotary spraying pile, figure 2 The pipe tip (4), outer nozzle (5), inner nozzle (6), inner pipe (7), outer pipe (8) and outer pipe male joint (9) constitute the triangular conical rotary spray pile alloy drill bit internal structure. The alloy drill bit of the triangular conical rotary spraying pile is a double nozzle, and the double nozzle is a device for realizing the coaxial spraying and drilling of slurry and gas. There are two nozzles for slurry gas coaxial injection at the nozzle, and the gas nozzles are ring-shaped and set outside the high-pressure slurry nozzle. When the triangular conical jet jet pile alloy drill bit is drilling, the high-pressure water is sprayed out from the inner nozzle (6) through the inner pipe (7) to punch and destroy the soil, and the high-pressure gas is surrounded by the outer nozzle (5) through the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com