Triangular pyramidal jet grouting pile alloy drill bit

An alloy drill bit, triangular cone technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems that the drill bit is easy to be ground or broken, and cannot drill to the design depth, etc. Extensive, technologically mature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

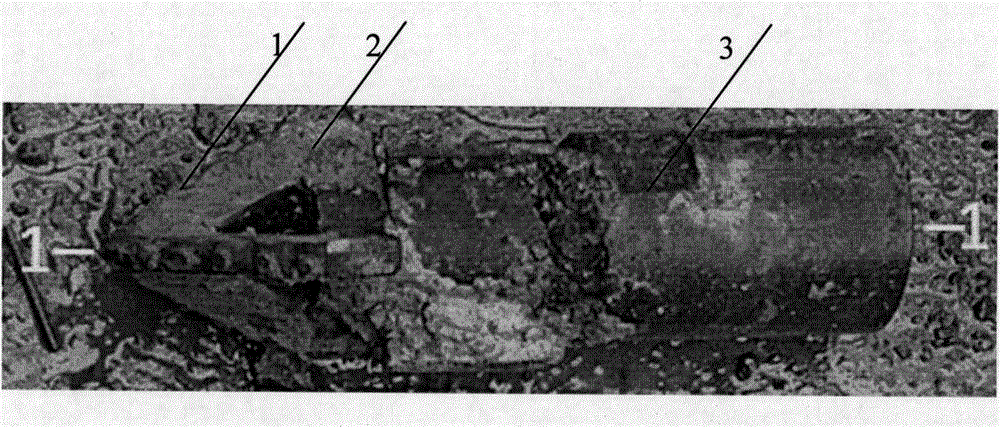

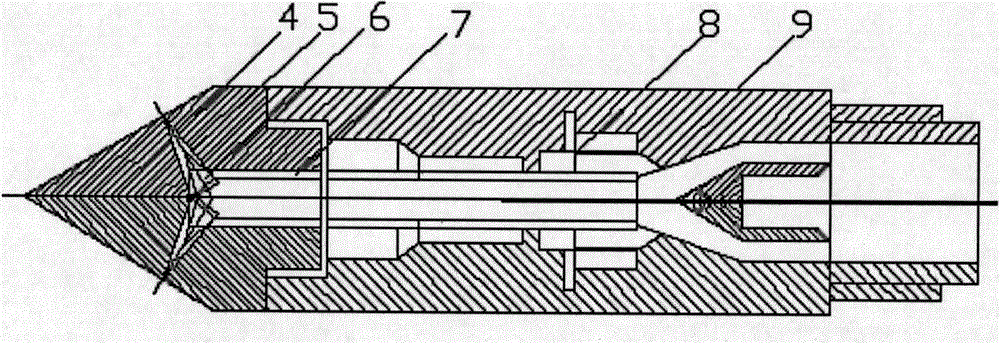

[0010] figure 1 The drill bit alloy block (1), the drill bit (2), and the drill body (3) in the middle form a triangular cone-shaped rotary jet grouting pile alloy drill bit. figure 2 The pipe tip (4), outer nozzle (5), inner nozzle (6), inner pipe (7), outer pipe (8), and outer pipe male joint (9) in the middle constitute the triangular cone-shaped rotary grouting pile alloy drill bit. Internal structure. The triangular cone-shaped rotary jet grouting pile alloy drill bit is a double-spraying head, which is a device for realizing coaxial slurry jetting and drilling. Two nozzles for coaxial jetting of slurry gas are arranged at the nozzle, and the nozzles of the gas are in a ring shape and sleeved outside the high-pressure slurry nozzle. When drilling, the triangular cone-shaped rotary jet grouting pile alloy drill bit is high-pressure water jetted out from the inner nozzle (6) through the inner pipe (7) and punched to destroy the soil, and the high-pressure gas is surrounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com