Patents

Literature

15743 results about "Drilling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

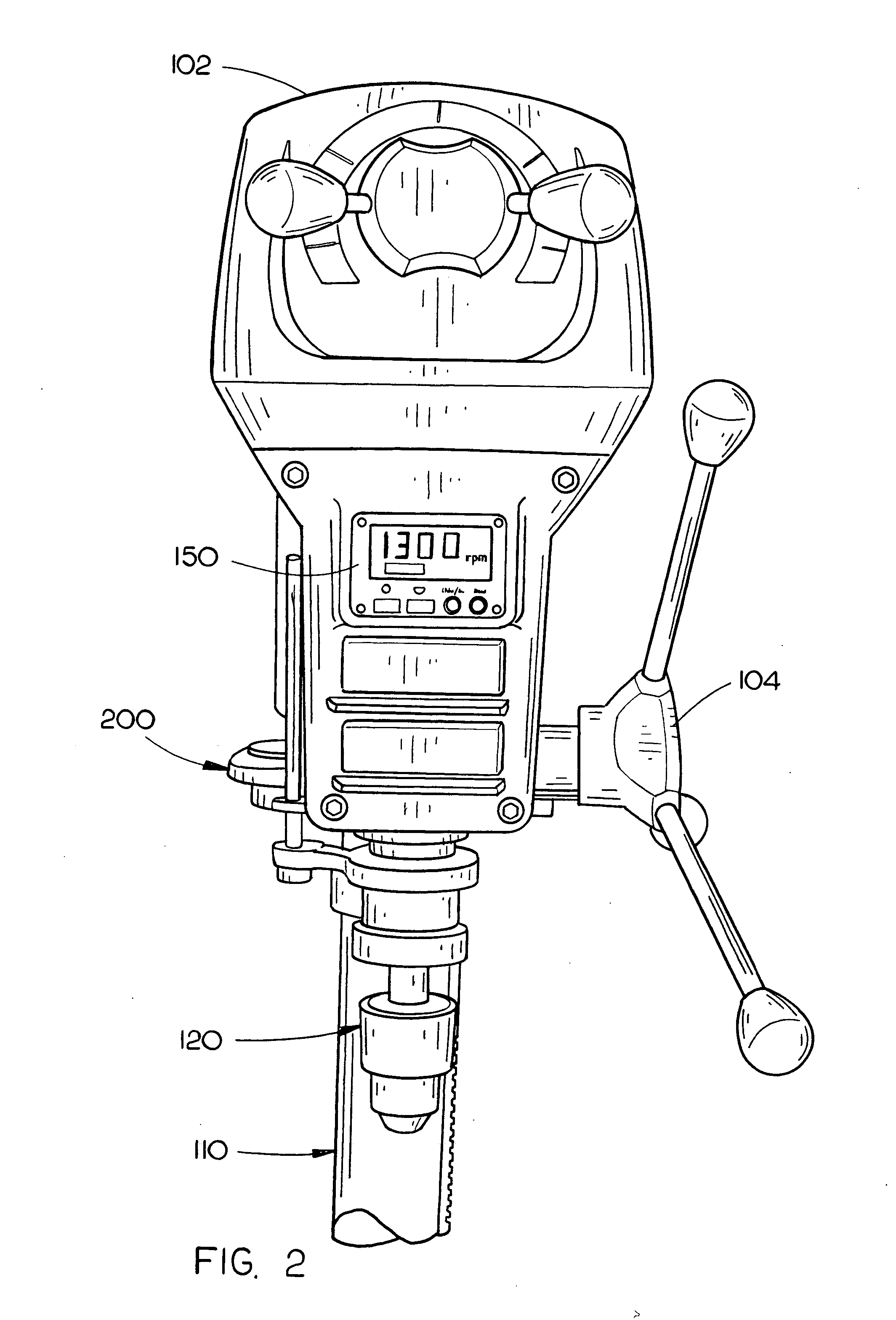

A drilling machine, called a drill press, is used to cut holes into or through metal, wood, or other materials (Figure 6-1). Drilling machines use a drilling tool that has cutting edges at its point. This cutting tool is held in the drill press by a chuck or Morse taper and is rotated and fed into the work at variable speeds.

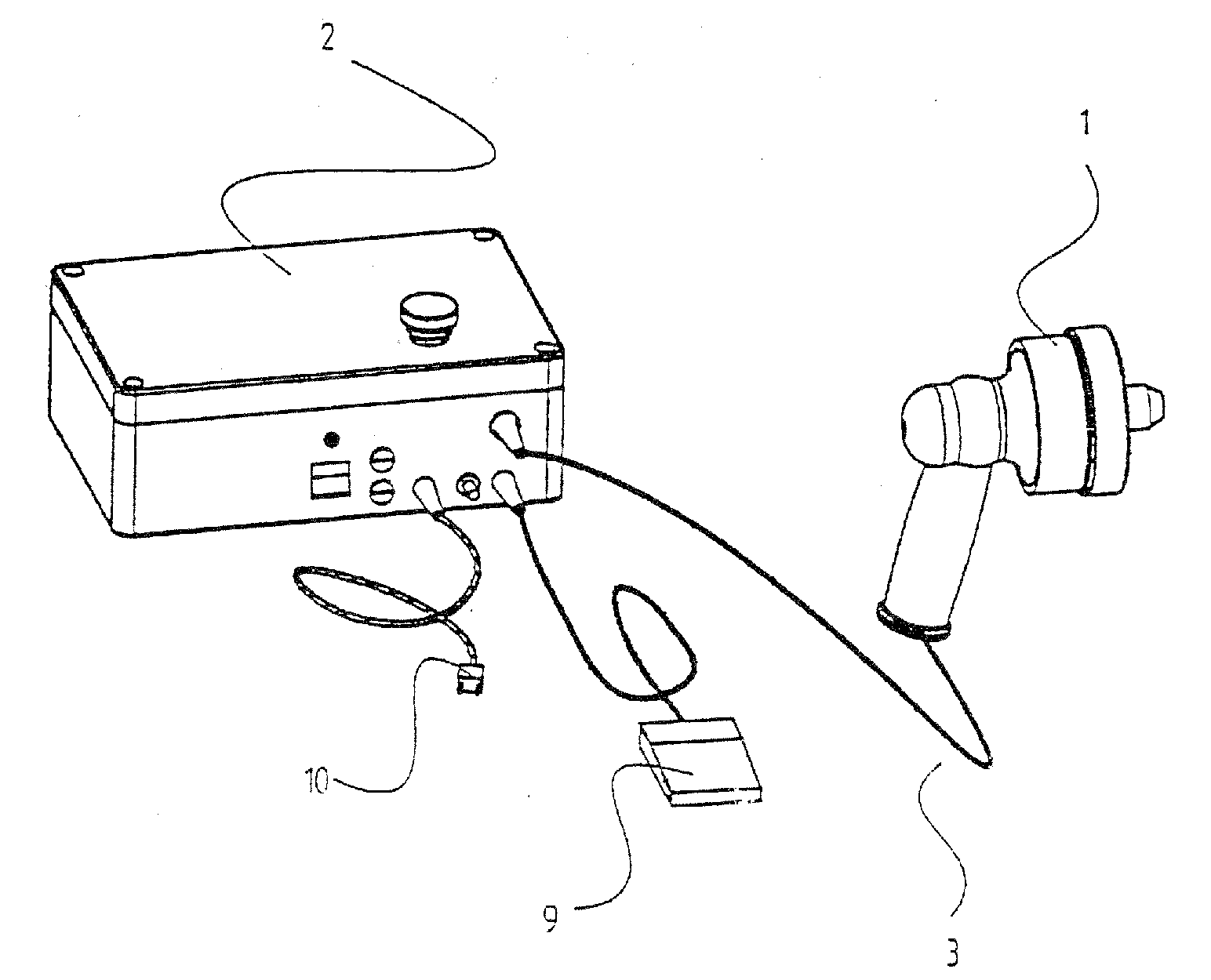

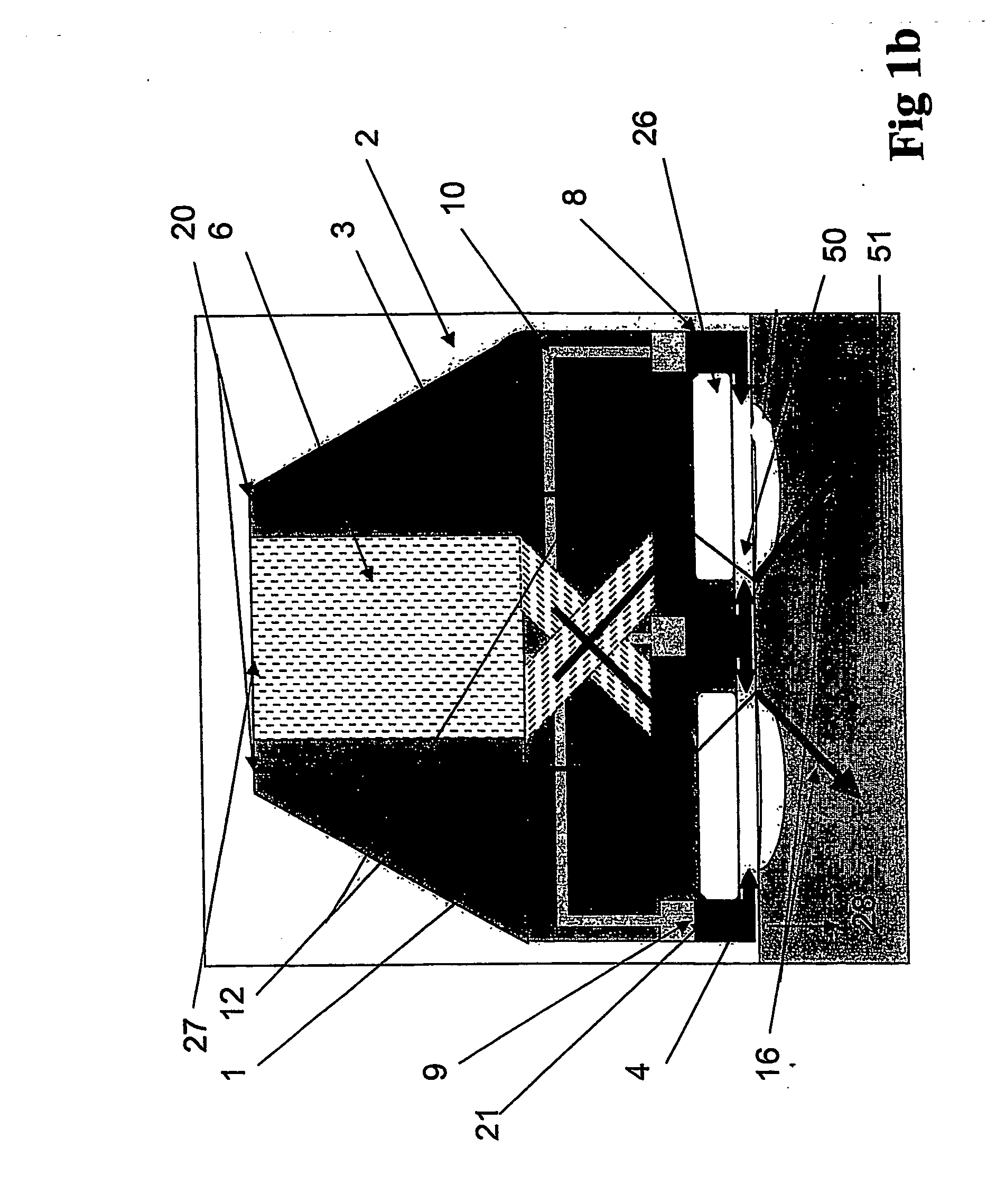

Minimally-Invasive Approach to Bone-Obstructed Soft Tissue

InactiveUS20080177268A1Improve shielding effectLow magnetic susceptibilitySurgeryMagnetic susceptibilityImaging quality

The subject invention pertains to a method and apparatus for placing a minimally-invasive access with respect to a patient's bone or other non-soft tissue. The subject invention can use a drilling machine incorporating an ultrasound motor. The subject drilling machine can be applied to sample, for example, bone biopsies under MRI control. In a specific embodiment, the subject ultrasound motor can be completely manufactured of non-magnetic materials, such as plastics, titanium, and titanium alloy, or ceramics and piezoceramics. The subject drilling apparatus can be placed into an MRI near field without influencing the image quality, and without the drilling apparatus itself being disturbed by the MRI magnet, gradient, or high-frequency field. The subject invention can incorporate good shielding with the subject drilling apparatus use of these materials, and can achieve minimal, if any, image distortions or so-called artifacts. Thus, the subject invention can involve the problem by use of non-magnetic materials of low magnetic susceptibility for the design of an actuation unit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

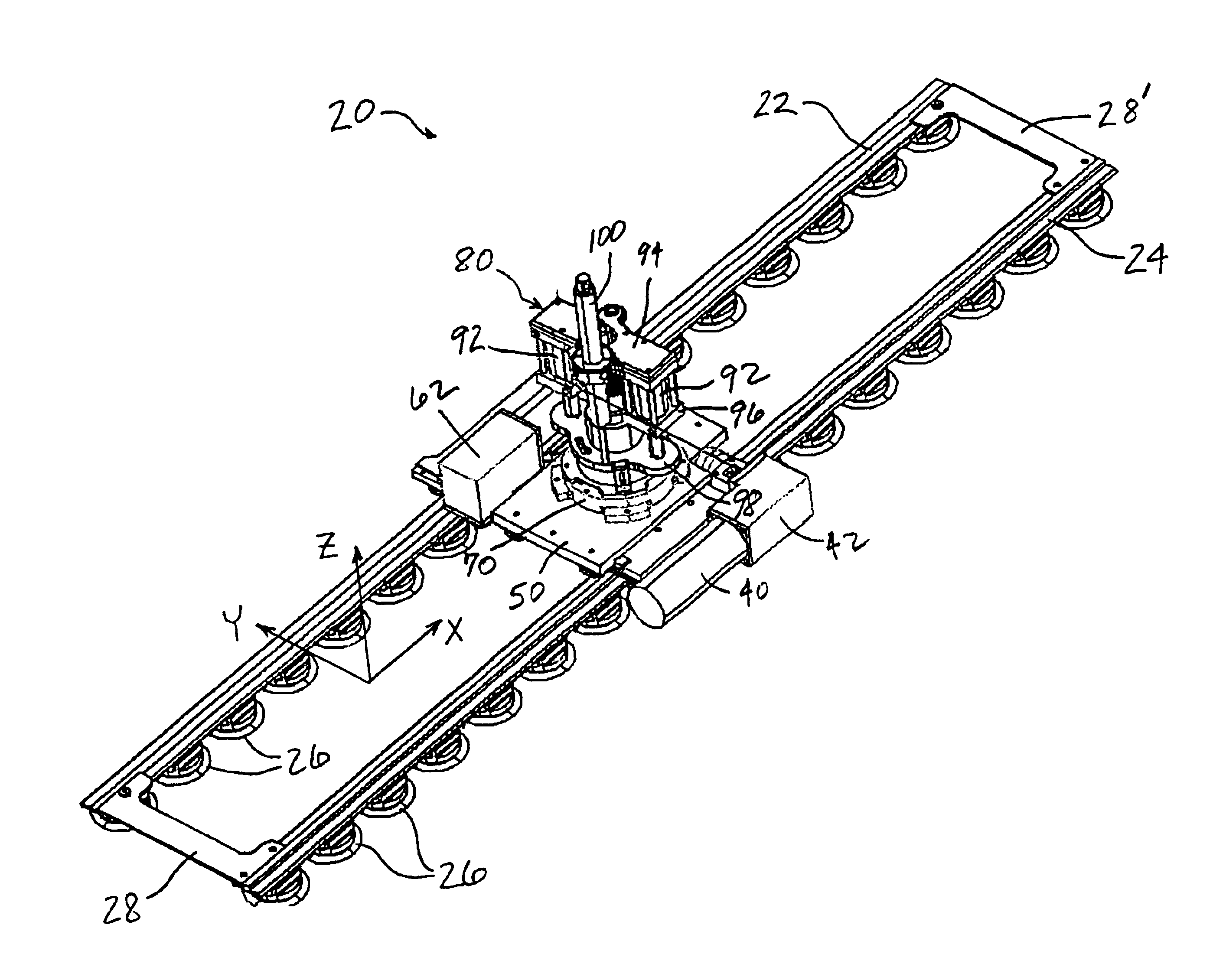

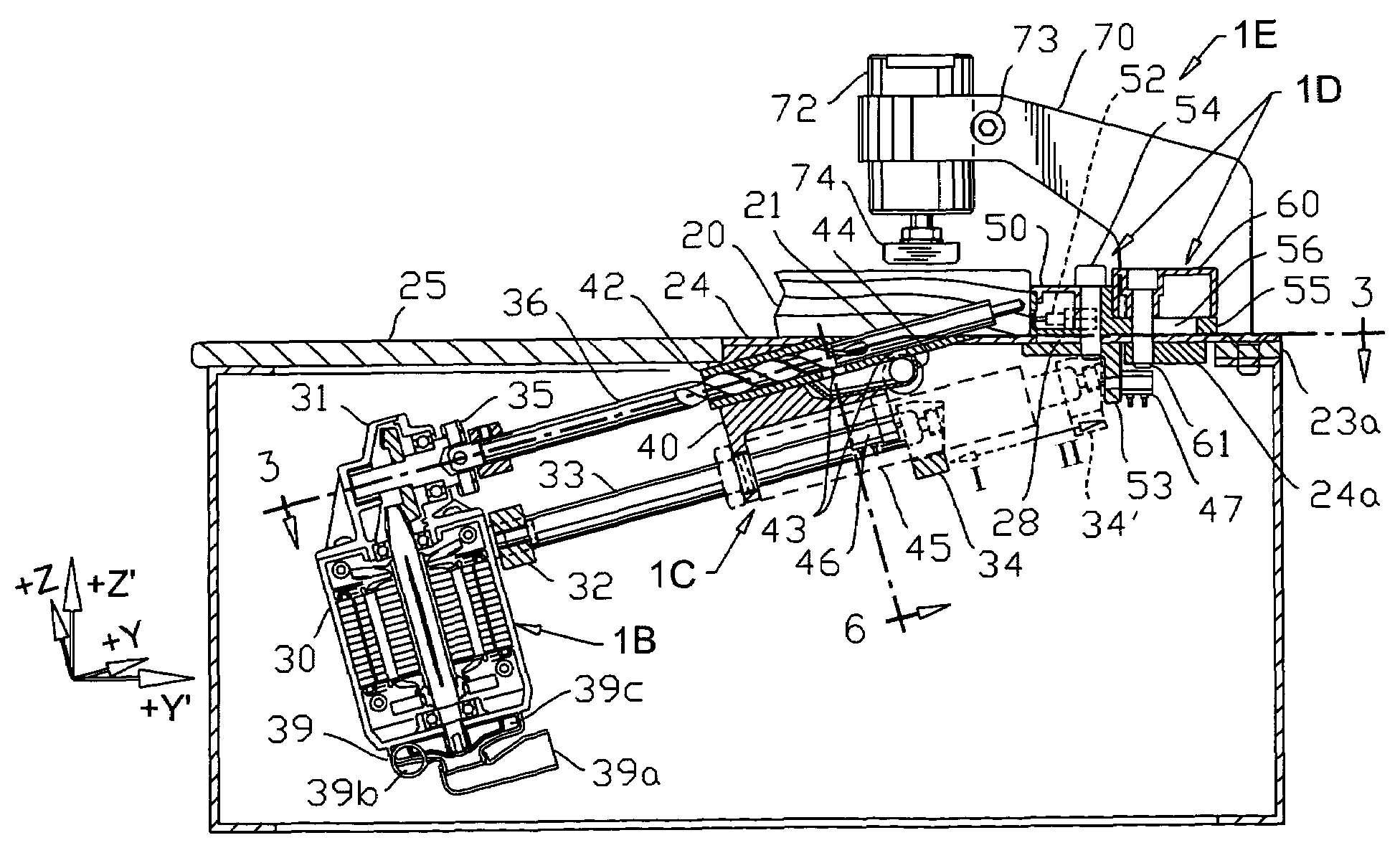

Flexible track drilling machine

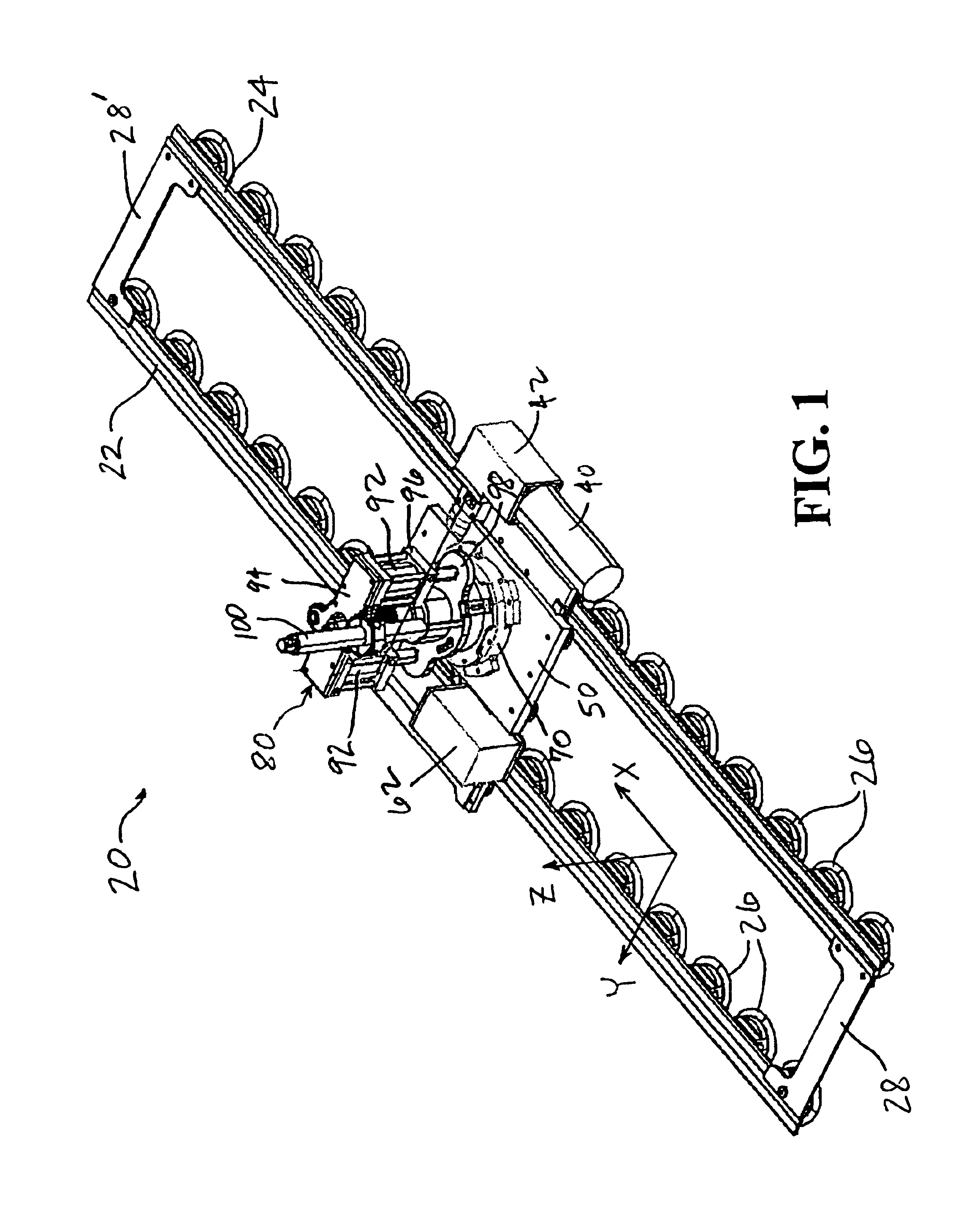

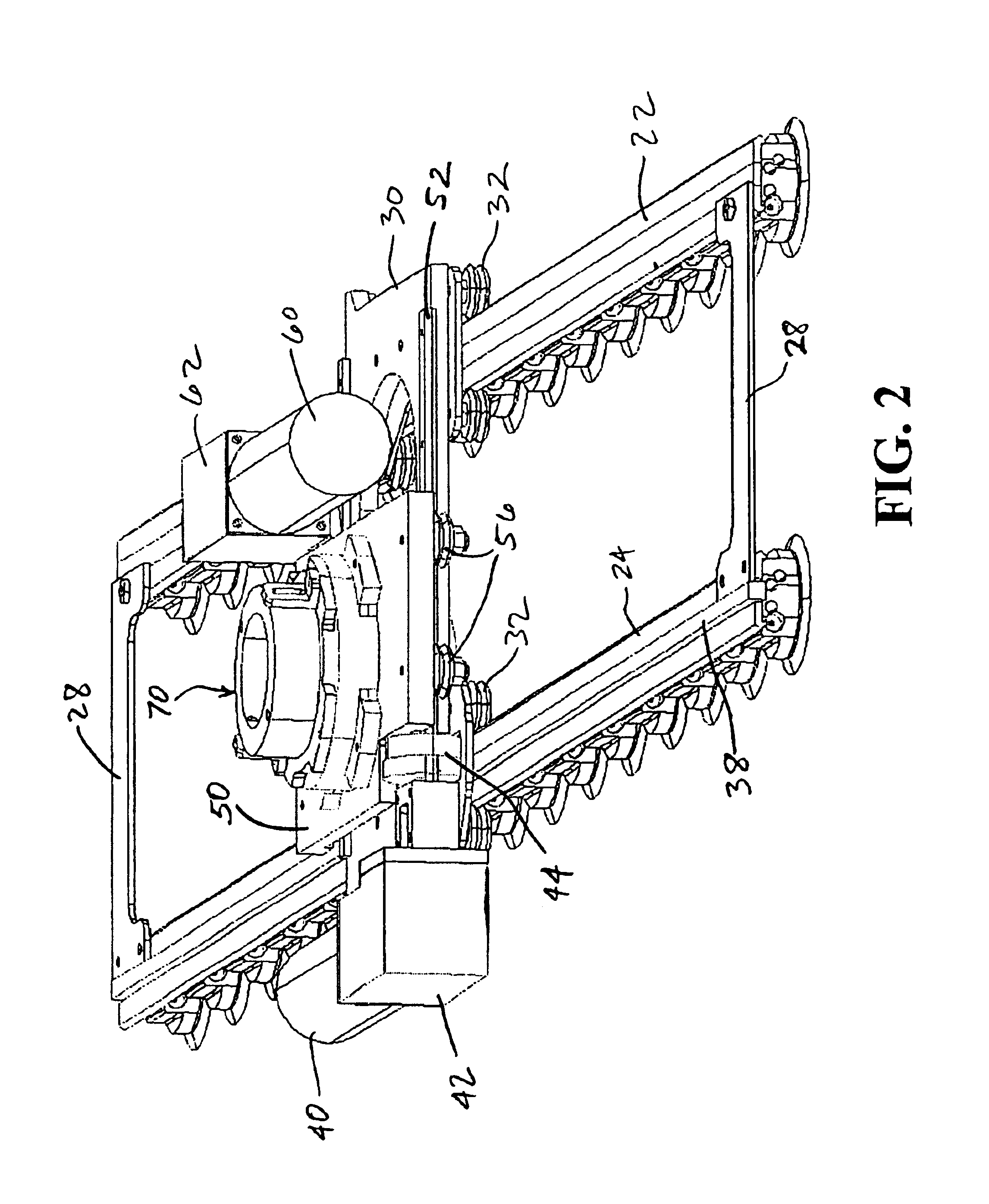

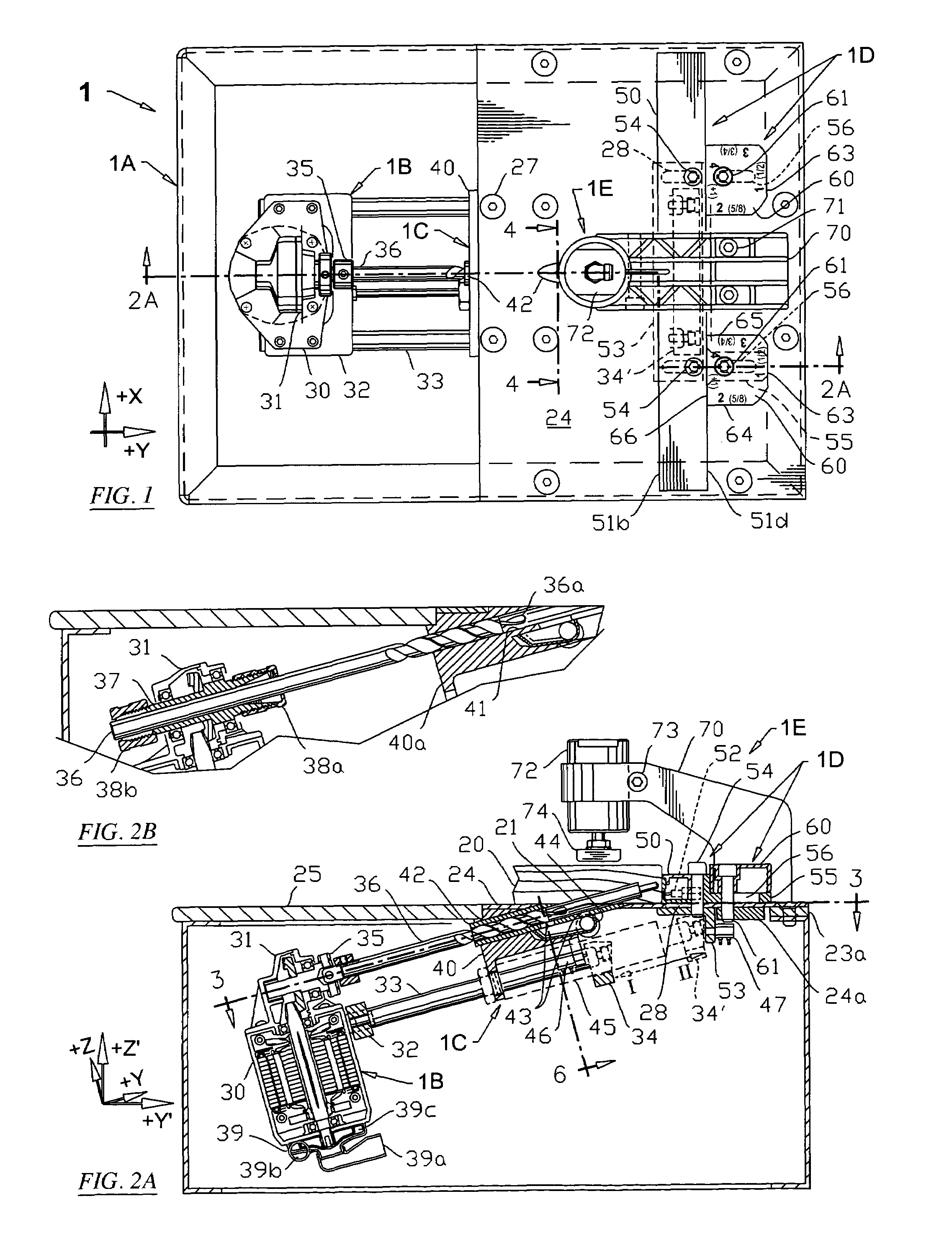

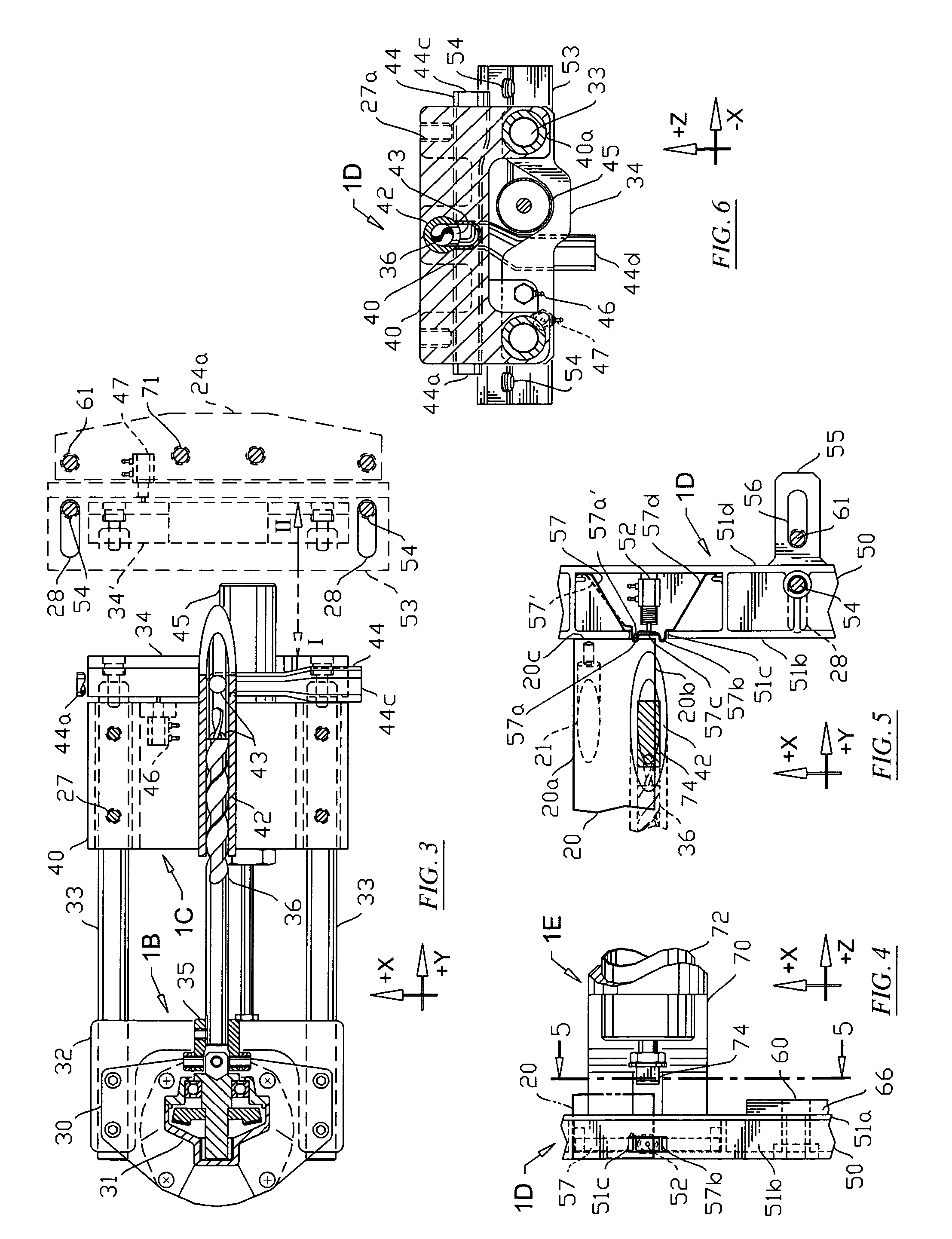

InactiveUS6843328B2Prevent movementLower pre-loading forcesProgramme controlDrilling rodsEngineeringThree dimensional surface

A flexible track drilling machine employs a pair of rails that are flexible in one direction to conform to a non-flat workpiece surface and are substantially stiff in a direction parallel to the workpiece surface. The rails are attached to the workpiece by vacuum cups spaced along each rail. An X-axis carriage is slidably mounted on the rails by rollers mounted on flexible spring plates affixed to the carriage. A drill or other device to be positioned is mounted on a Y-axis carriage that is slidably connected to the X-axis carriage. The three-dimensional surface of the workpiece is mathematically transformed into a two-dimensional flat pattern, and the positioning of the carriages is controlled based on the flat pattern.

Owner:THE BOEING CO

Method, Drilling Machine, Drill bit and Bottom Hole Assembly for Drilling by Electrical Discharge by Electrical Discharge Pulses

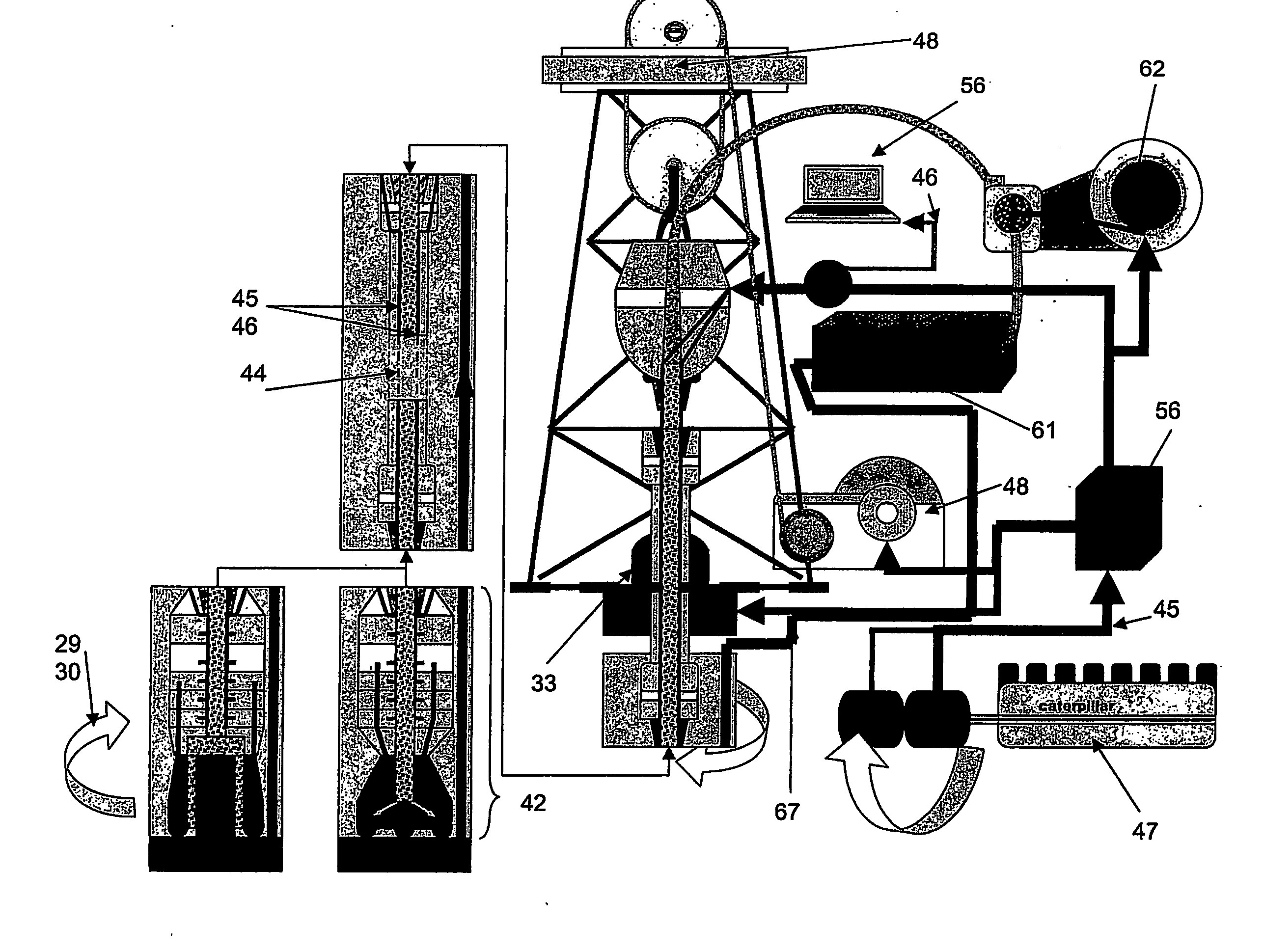

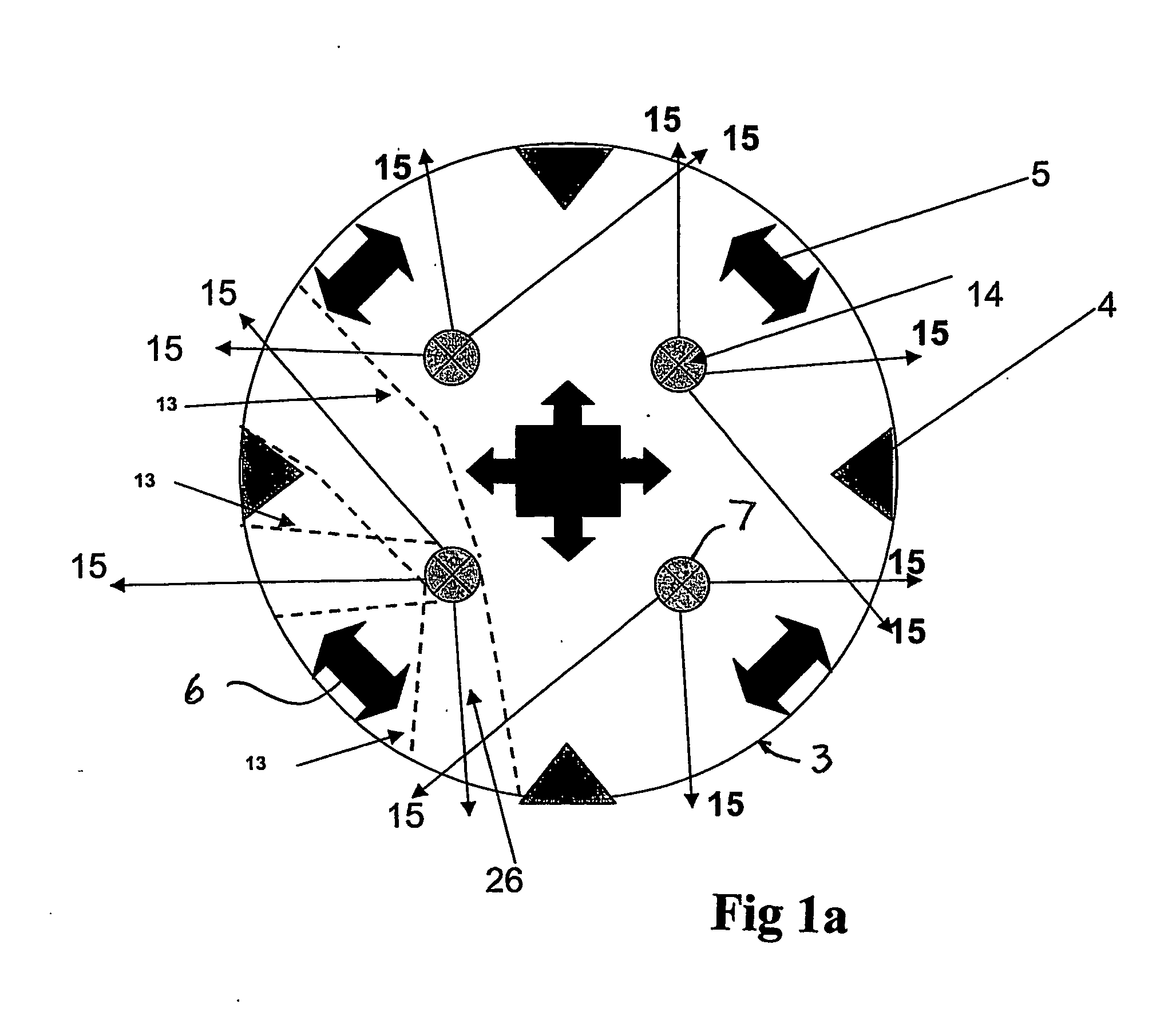

ActiveUS20090133929A1Efficiently provideIncrease drilling speedDrill bitsDisloding machinesElectric dischargeClosed loop

Machine for ground drilling, with a circulating fluid, by the utilization of electric discharge generated by high-voltage pulses between electrodes. It may comprise: —A drill-bit 1 with electrodes movable relative to each other, so that bottom-hole physical contact be secured for all the electrodes 4 on all bottom-hole topographies. —Pointed hydraulic nozzles for jetting the fluid, to remove primary cuttings and with pressure expansion across the nozzles 7 at no less than 4 MPa. —A high-voltage pulse generator deployed down-hole at a minimum distance from the drill-bit 1. —A rotating or oscillating bit causing the borehole cross-sectional excavation to occur, and electric discharge between a plurality of electrodes situated on the bit face along one or a few radii and tangents. —A bottom hole assembly for annular hole-making with core storage, transportation, down-hole closed loop discharge fluid circulation. A discharge fluid storage may be incorporated. A drilling method is also described.

Owner:UNODRILL

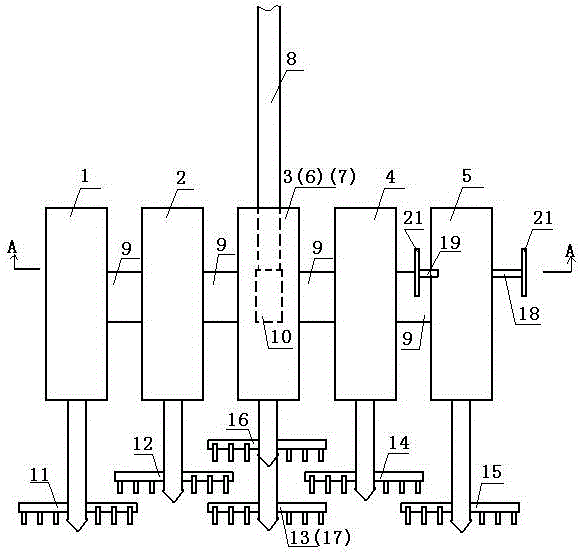

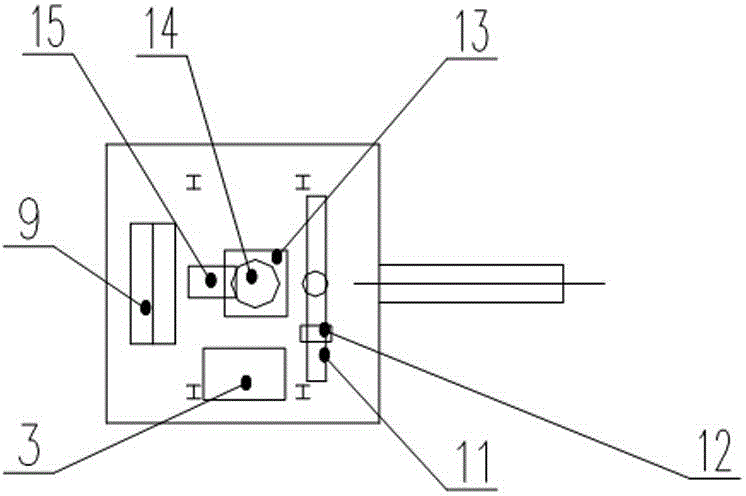

T-shaped stirring drilling machine

ActiveCN104612141AStrong bending resistanceImprove anti-seepage effectBulkheads/pilesGravity centerEngineering

The invention discloses a T-shaped stirring drilling machine. A motor A, a motor B, a motor C, a motor D, a motor E, a motor F and a motor G form a T-shaped structure; the motor A and the motor B, the motor B and the motor C, the motor C and the motor D, the motor D and the motor E, as well as the motor F and the motor G are fixedly connected through a connection rod A; the motor C is fixedly connected with the motor F through a connection rod B; the lower end of a drilling rod is fixed at the gravity center position of the T-shaped structure and is fixed on the connection rod B; a connection rod C is fixed on the right of the motor E; an arc-shaped plate is fixed at the right end of the connection rod C; the position, which leftwards rotates by 120 degrees by taking the center of the motor E as a circle center, of the connection rod C is fixed on a connection rod E; an arc-shaped plate is fixed at the outer end of the connection rod E; the position, which rightwards rotates by 120 degrees by taking the center of the motor E as the circle center, of the connection rod C is fixed on a connection rod D, and an arc-shaped plate is also fixed at the outer end of the connection rod D.

Owner:南通重矿金属新材料有限公司

Simple and convenient thin metal sheet drilling machine device

InactiveCN106984698AImplement manual controlRealize manual control up and down switching mobile workMetal-working feeding devicesPositioning devicesThin metalDrive shaft

The invention discloses a simple and convenient thin metal sheet drilling machine device. The device comprises a device body. An operating groove is formed in the end face of the right side of the device body. A switching cavity is formed in the portion, on the left side of the operating groove, of the device body. A first inner spline shaft and a second inner spline shaft are arranged on the inner walls of the upper side and the lower side of the switching cavity correspondingly. A first sliding groove is formed in the inner wall of the left side of the switching cavity. A sediment groove is formed in the inner bottom wall of the first sliding groove. A first guide rod is arranged between the inner bottom wall of the sediment groove and the inner top wall of the first sliding groove. A first sliding block extending rightwards is slidably connected to the first guide rod in a matched mode. A first spring is arranged on the outer surface of the first guide rod located at the bottom of the first sliding block in a surrounding mode. A right extending section of the first sliding block extends into the switching cavity and abuts against the inner wall of the right side of the switching cavity in a sliding fit mode. A motor is arranged in the first sliding block in the switching cavity. Driving shafts are arranged at the ends of the upper side and the lower side of the motor. A transmission cavity is formed in the portion, above the switching cavity, in the device body. The device is simple in structure, convenient to operate, low in manufacturing and maintaining cost, high in drilling speed and stability and good in drilling quality.

Owner:衢州市洼帝尔数控设备有限公司

Pocket hole drilling machine

ActiveUS7374373B1Wear minimizationDrilling/boring measurement devicesThread cutting machinesEngineeringActuator

A pocket-hole drilling apparatus for drilling pocket-holes in a workpiece is disclosed. In one embodiment, an initiation switch actuates clamping the workpiece and the movement of a drilling module to cut a pocket-hole. The drilling module has a motor and a step-drill mounted thereon, which is slidably mounted on a guide module. The axis of the drilling module movement intersects work surface. In another embodiment, a movable fence provides the adjustability of pocket-hole depth. In yet another embodiment, two actuator tips are disposed in a fence to prevent the drilling of a pocket-hole through the sidewall of a workpiece. In still another embodiment, a short stroke clamping actuator is used to prevent human finger injury. In still another embodiment, a blower or an ejector pump is used to remove wood chips, wherein the blower is either attached to a drilling motor or to a separate blower motor; the ejector pump is mounted near the drill guide. In still another embodiment, two pocket-drills are slidably mounted on a block so as to drill two pocket-holes and to adjust pocket-hole spacing. In still another embodiment, a mounting structure is disposed either underneath or above the work surface to mount drilling module(s) so as to drill multiple pocket-holes into a wide workpiece at one setup. In still another embodiment, a drill guide forms a clearance for the cutting edges of the step-drill to minimize wear on the edges. In a further embodiment, an actuator provides both clamping and drilling movements, wherein the actuator is an electric motor or a hand lever.

Owner:KREG ENTERPRISES

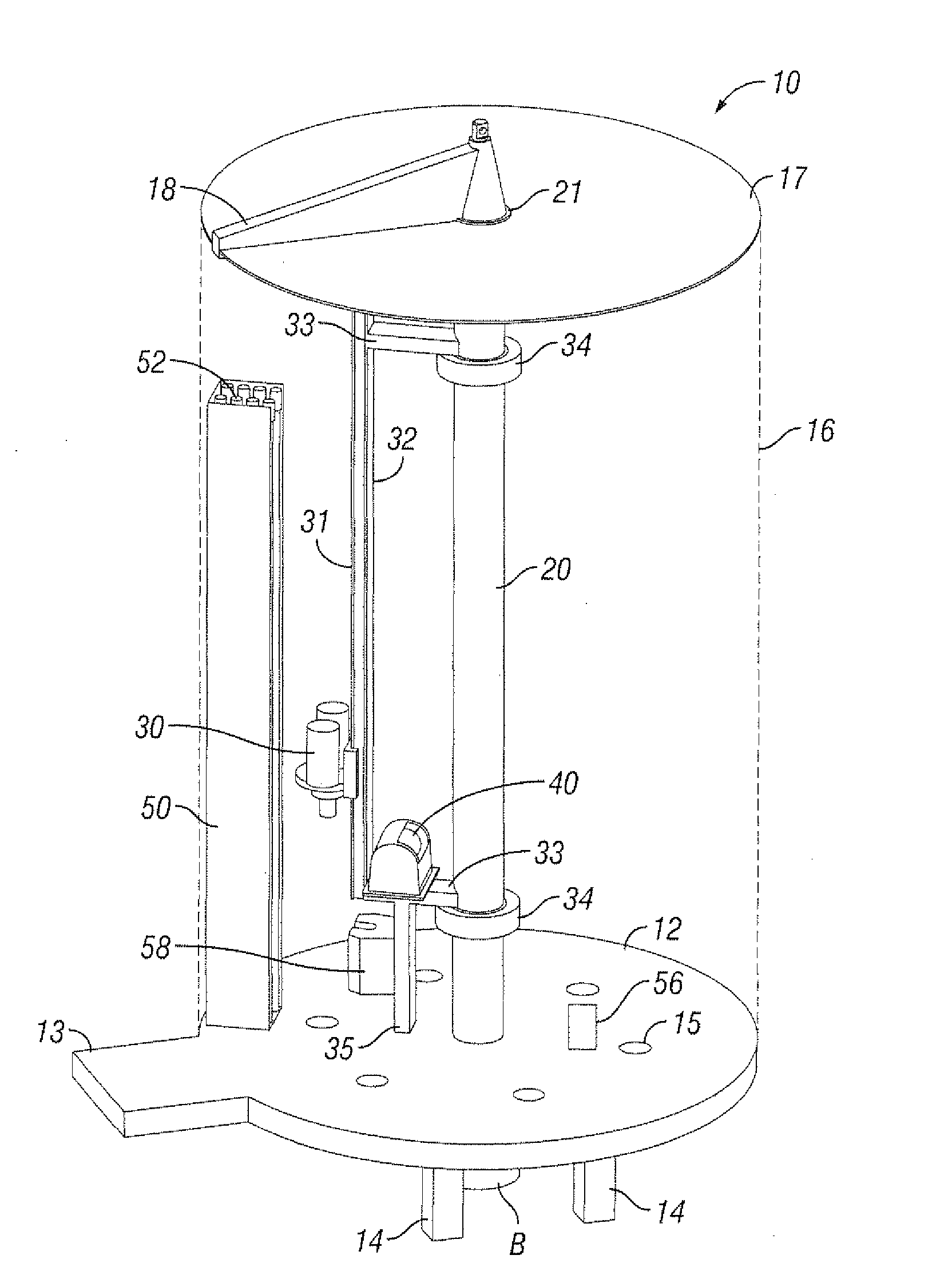

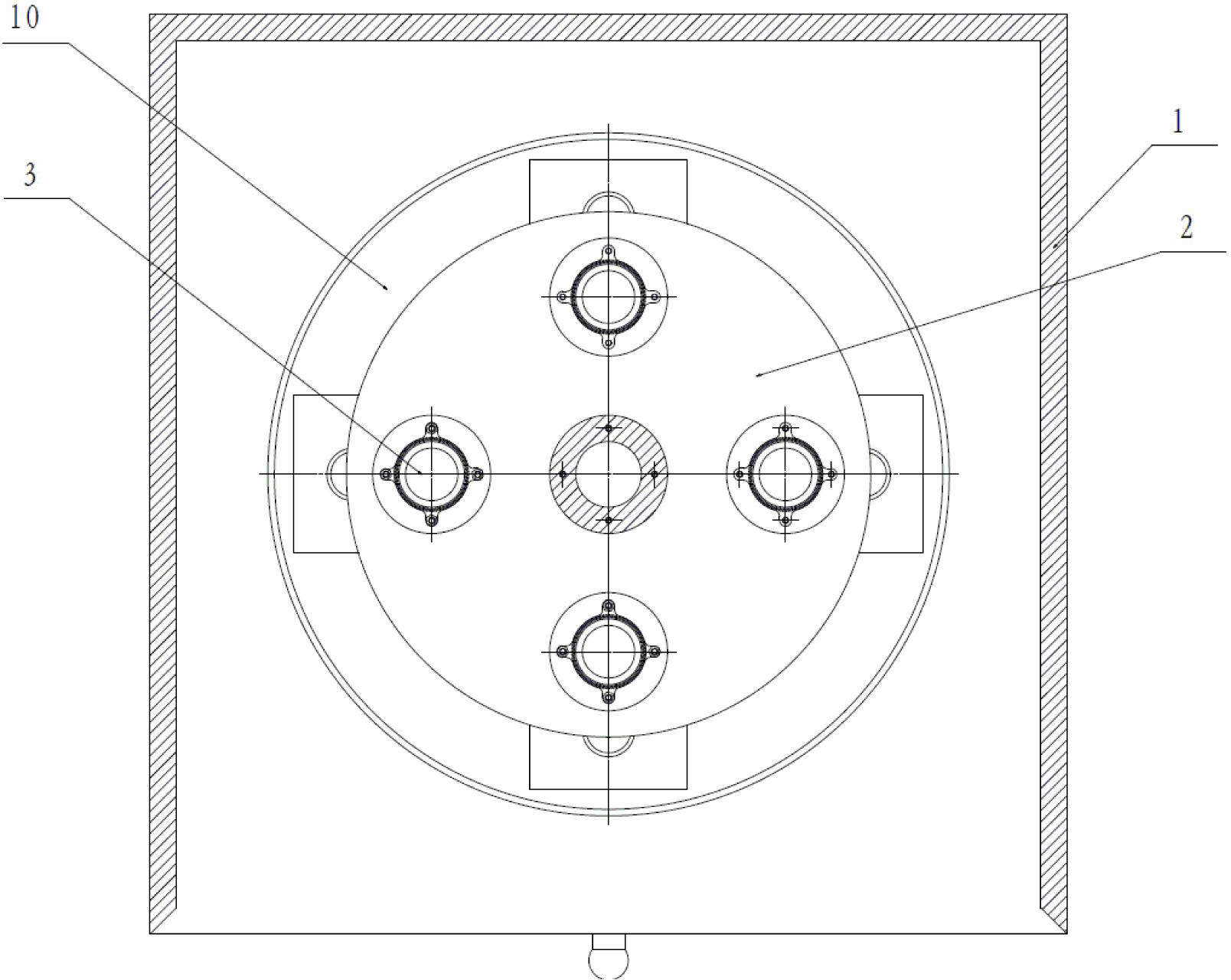

Gatherer of deep soil of moon

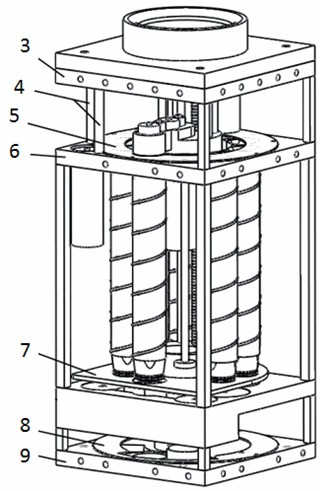

ActiveCN102359891APrevent leakageRecycling is simple and reliableWithdrawing sample devicesMotor driveLunar soil

The invention discloses a gatherer of deep soil of the moon. An upper end surface of a housing of the gatherer is provided with a drilling machine and mechanical arm connecting device. A first separator plate, a second separator plate and a third separator plate are installed in the housing from top to bottom. A screw driving motor is installed on the first separator plate and drives a screw by a gear. A slide block in cooperation with the screw is fixed on a slider. Four guide rods pass through four through holes located at an end of the slider. A drill pipe driving motor is installed in the middle of the four guide rods. The drill pipe driving motor drives a drill pipe connector by a gear. Electromagnet driven wedges are arranged in the drill pipe connector. The electromagnet driven wedges stretch out from pin grooves of inner conical surfaces of corresponding drill pipes. A drill pipe rotating disk is installed in the center of the second separator plate. The drill pipe rotating disk is in cooperation with a drill pipe rotating disk driving motor by a gear. The third separator plate is arranged under a clamping device. Multiple drills are installed on a drill rotating disk along a circumferencial direction. On the third separator plate, a drill rotating disk driving motor is in cooperation with the drill rotating disk by a gear. A lunar soil bag is enclosed in the drill pipes having hollow structures. The gatherer of deep soil of the moon has the characteristics of compact structure, small floor space, high reliability of a transmission mode, large drilling and production depth, large sampling amount and simple and reliable sample recovery.

Owner:ZHEJIANG UNIV

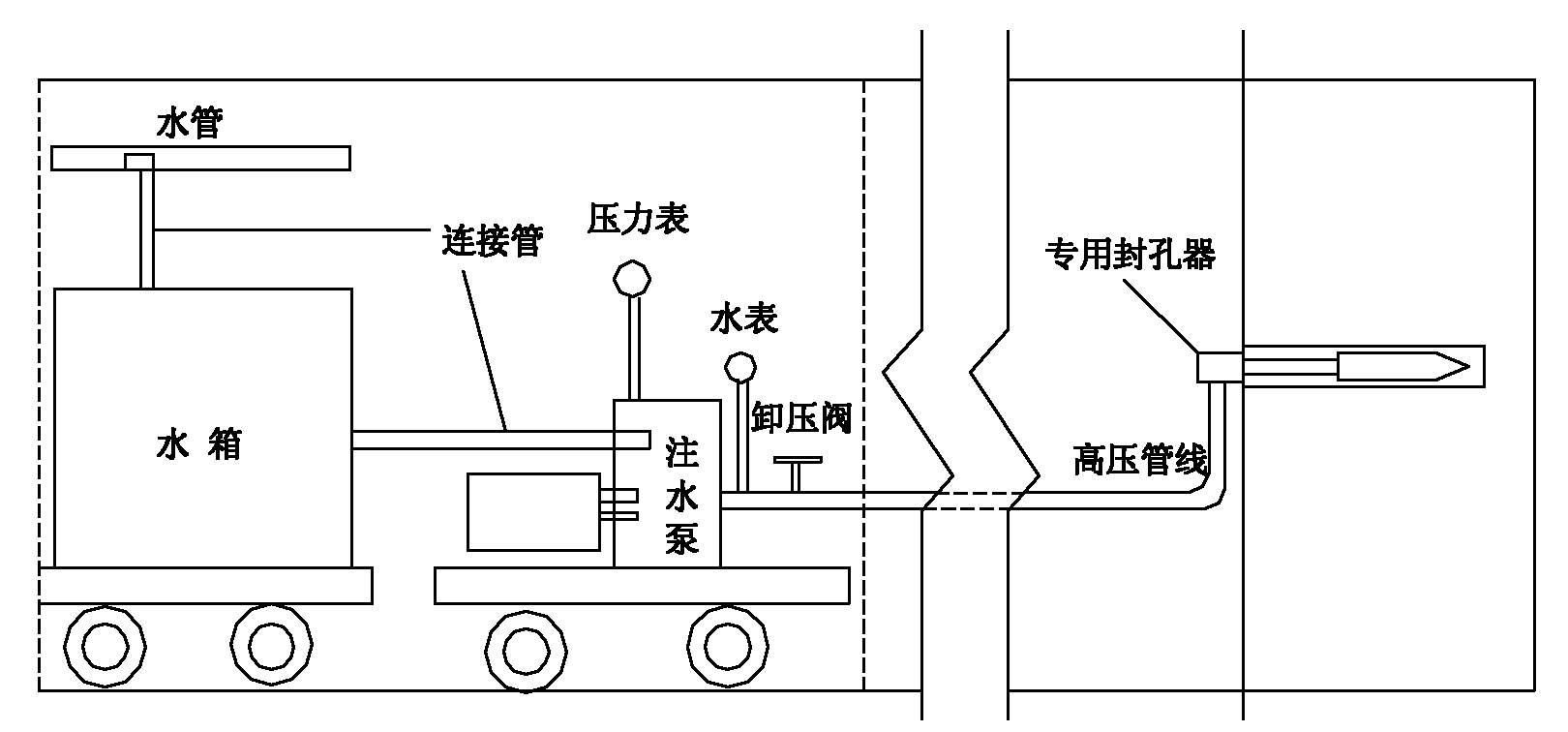

Method for integrated comprehensive management of gas in low-permeability single coal bed

InactiveCN102121395AReduce outstanding riskImprove breathabilityDrilling rodsFluid removalSocial benefitsHydraulic fracturing

The invention relates to a method for integrated comprehensive management of gas in a low-permeability single coal bed, which can effectively solve the problem of comprehensive management and utilization of the gas. A technical scheme of the method comprises the following steps of: firstly, drilling holes, wherein a high-torque drilling machine and a rifle or a trihedral drill stem are used for solving the phenomenon of clamping the drill stem caused by collapsing and jetting of the holes in the hole drilling process; and then, performing hydraulic fracturing permeability improvement on the coal body, drilling holes for pre-split blasting, performing gas drainage, and recycling the drained gas, thereby implementing the integrated management of the gas. With the method provided by the invention, the permeability of the coal body is improved, a pre-draining rate of the gas is improved, and the drained gas is recycled, so that the drilled holes are radically prevented from being blocked in the construction process, the problem of difficulties in draining the gas in the low-permeability coal bed with a drilling tool having insufficient capability in the drilling construction is solved, consequently, outburst risk of the coal and the gas is reduced, outburst accidents of the coal and the gas are reduced and even avoided, and mine production safety and lives of coal mine workers are ensured, so that the method brings great economic and social benefits.

Owner:平顶山天安煤业股份有限公司十矿

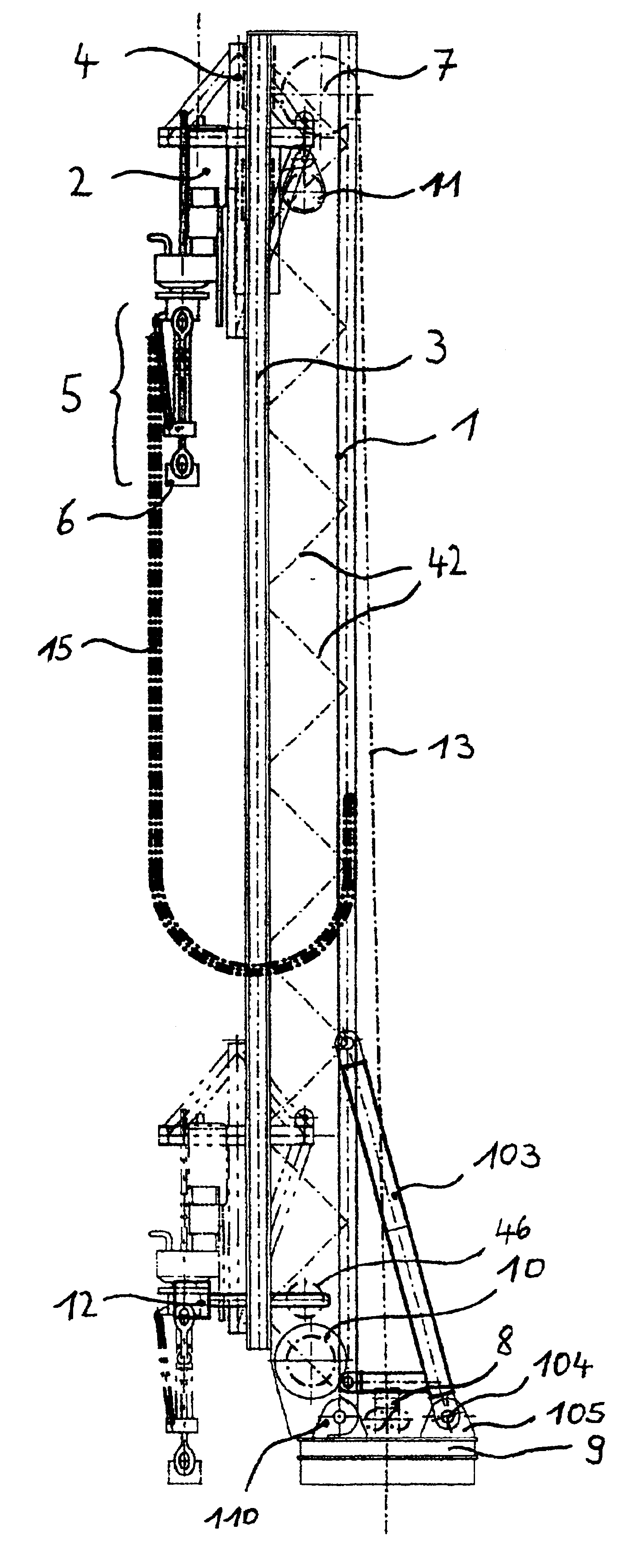

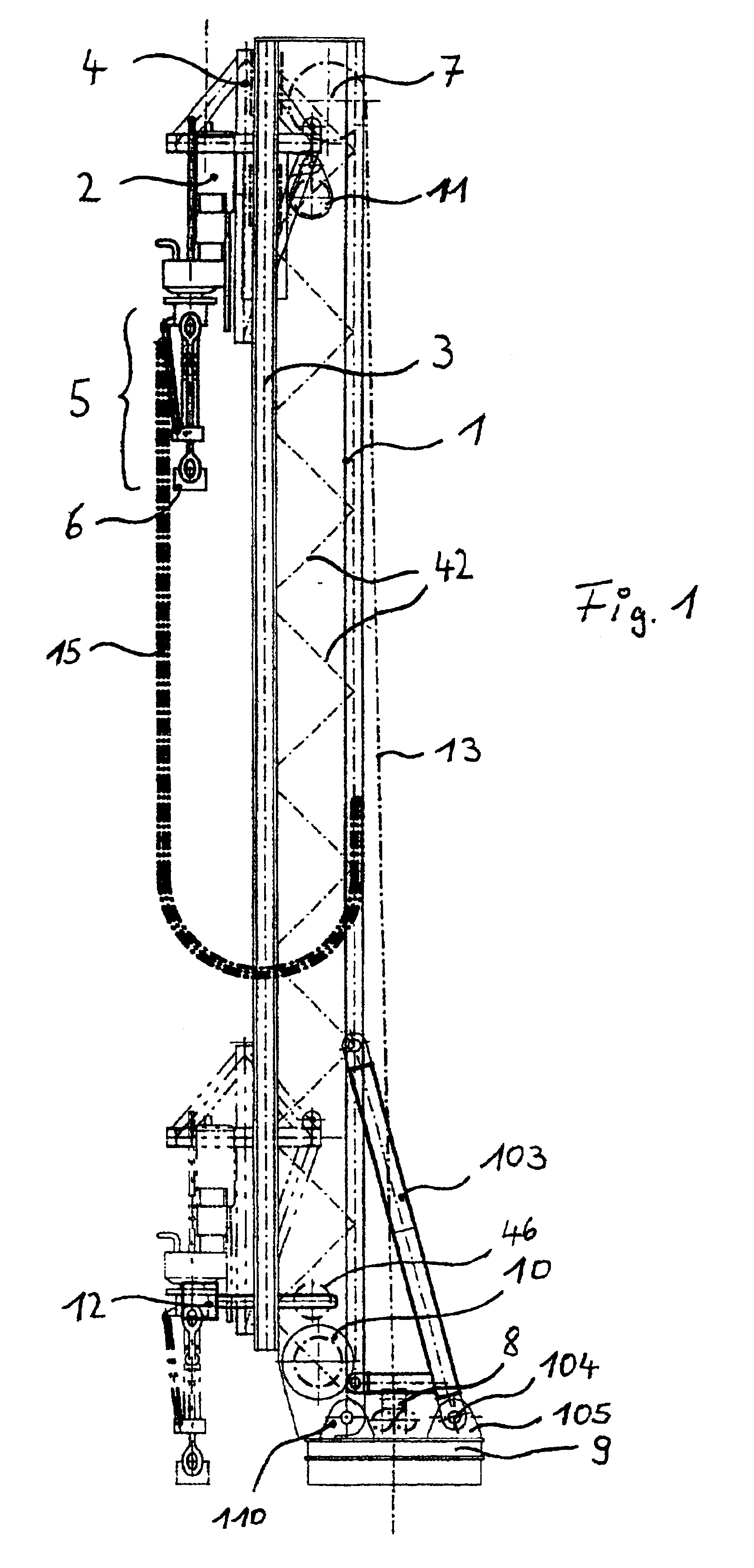

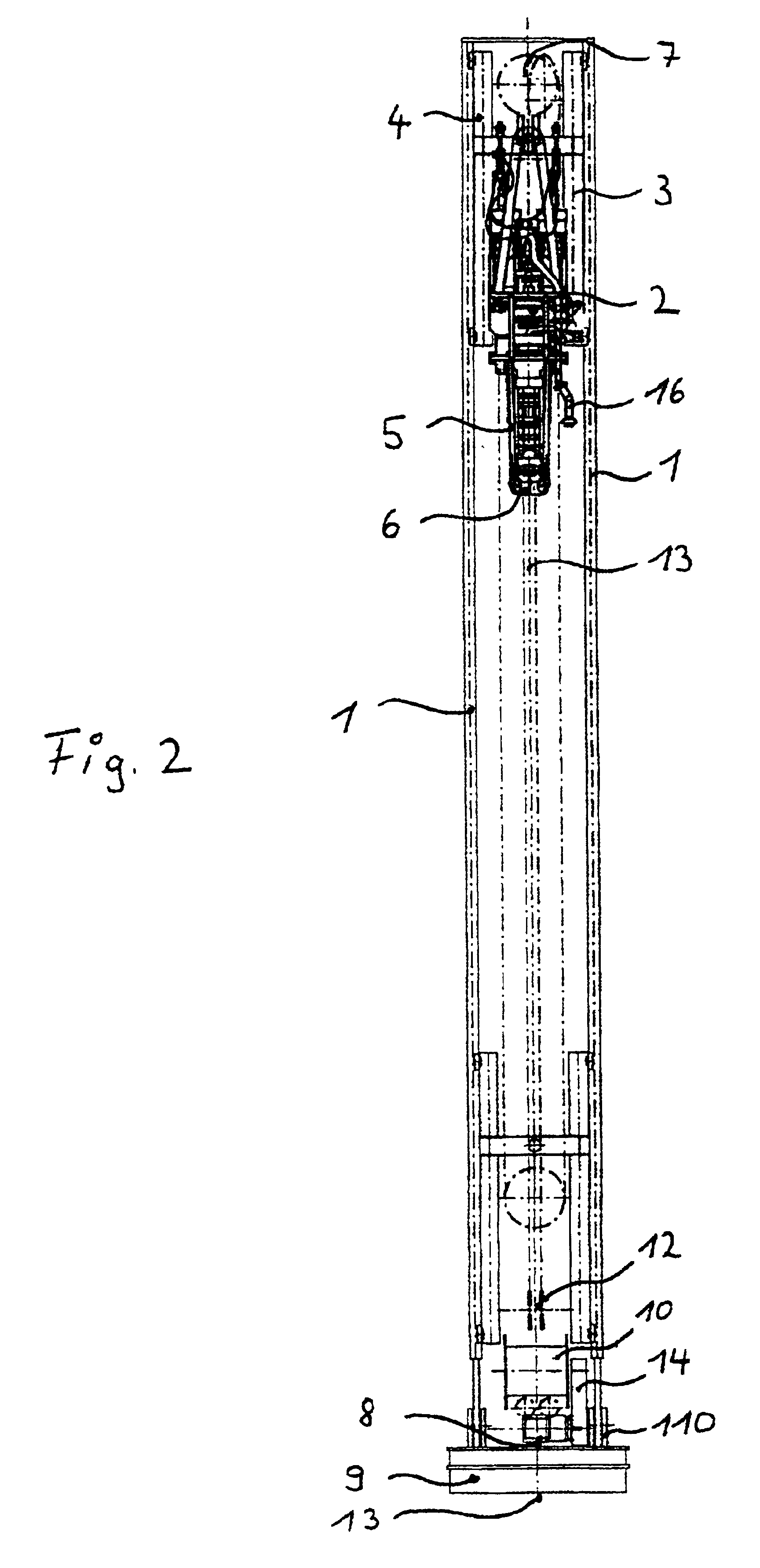

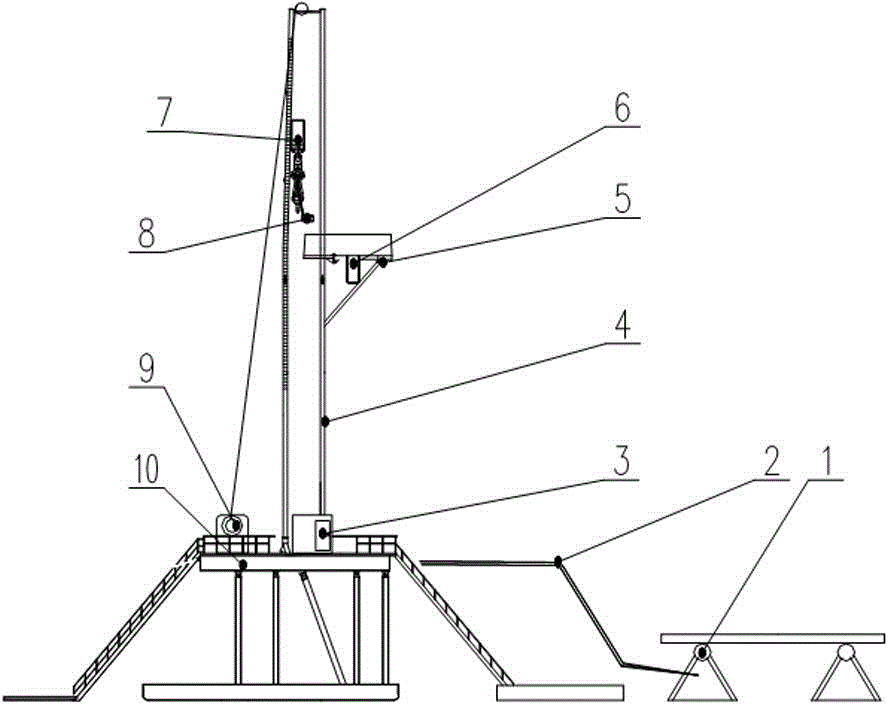

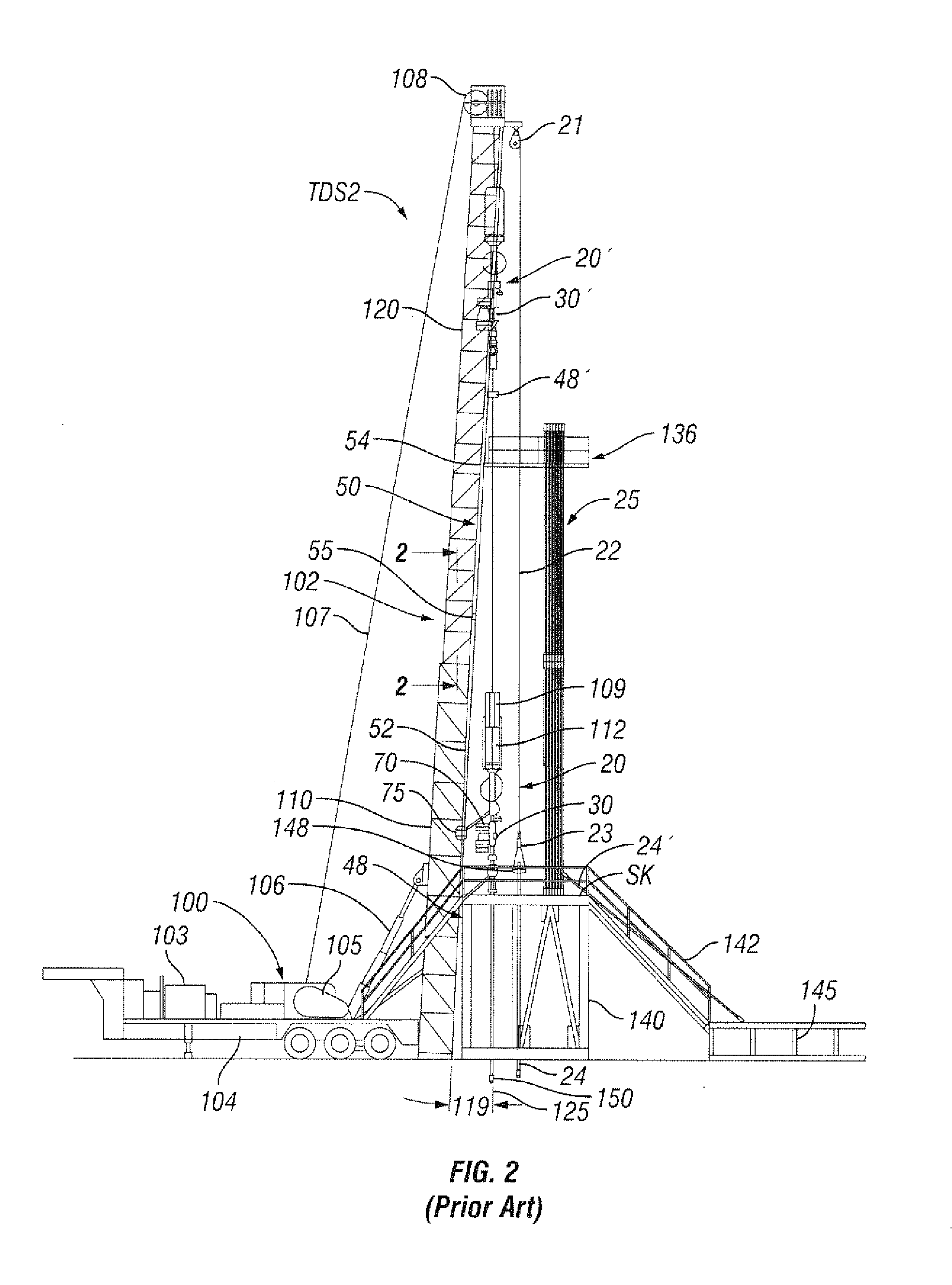

Drilling device and method for drilling a well

A drilling machine and drilling rig for exploratory drillings and producing wells, include a base mounting atop drive, and a multifunctional gripper for gripping drilling pipe from a stock and to be raised on the base for eventual positions positioning at a well center, an elevator being provided below the top drive. The base can be rotatably mounted and have a live ring at a base lower end region, the base being rotated to the pipe stock location and being rotatable to a well center as well. A drilling pipe upper end when raised on the base can be connected to the top drive, and an iron roughneck on a rig floor can be used to connect a pipe lower end to a pipe section in the well. Where two drilling machine are used, one can be used for actual drilling at the well center, and the second supplied with pipework for the operation.

Owner:BENTEC DRILLING & OILFIELD SYST

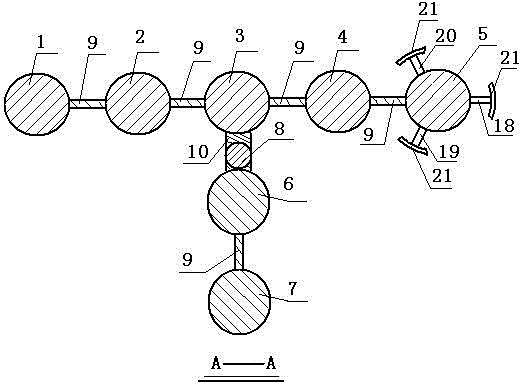

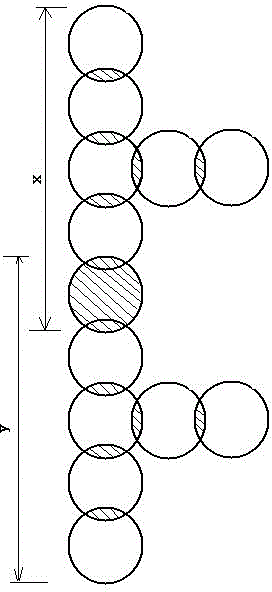

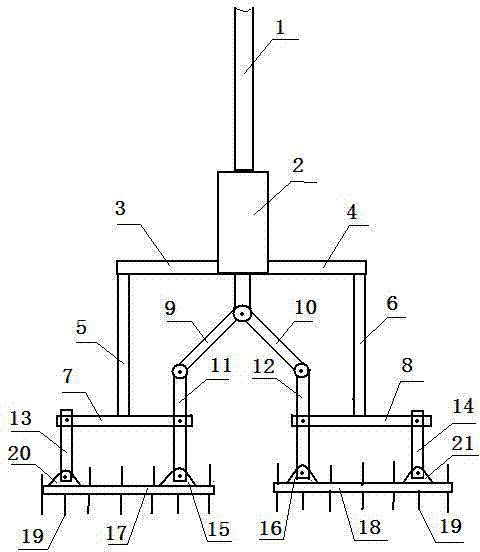

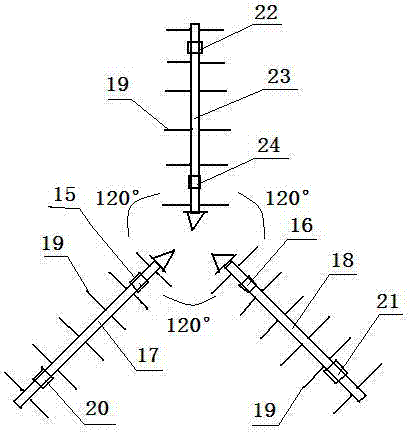

Y-shaped agitating pile drilling machine

The invention relates to a Y-shaped agitating pile drilling machine for reinforcing a soft land. A retracting oil jack drives three groups of agitating assemblies to move through a transmission rod A, a transmission rod B and a transmission rod C; a 120-degree angle is formed on a space by the three groups of the agitating assemblies; the section of a pile body formed by the Y-shaped agitating pile drilling machine is Y-shaped; the pile body of a Y-shaped agitating pile with the same volume is the pile body of the agitating pile, which has a circular section; and the bearing capability is greatly improved.

Owner:日照阳光电力设计有限公司 +2

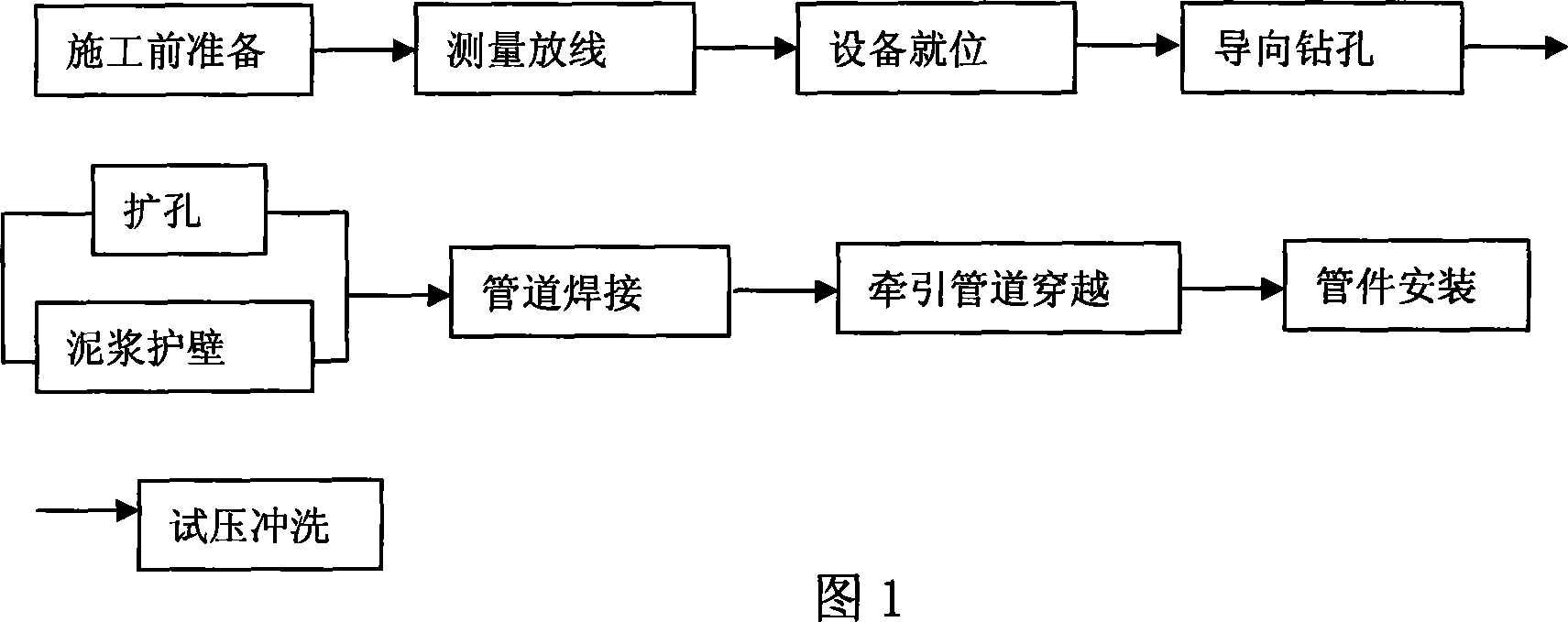

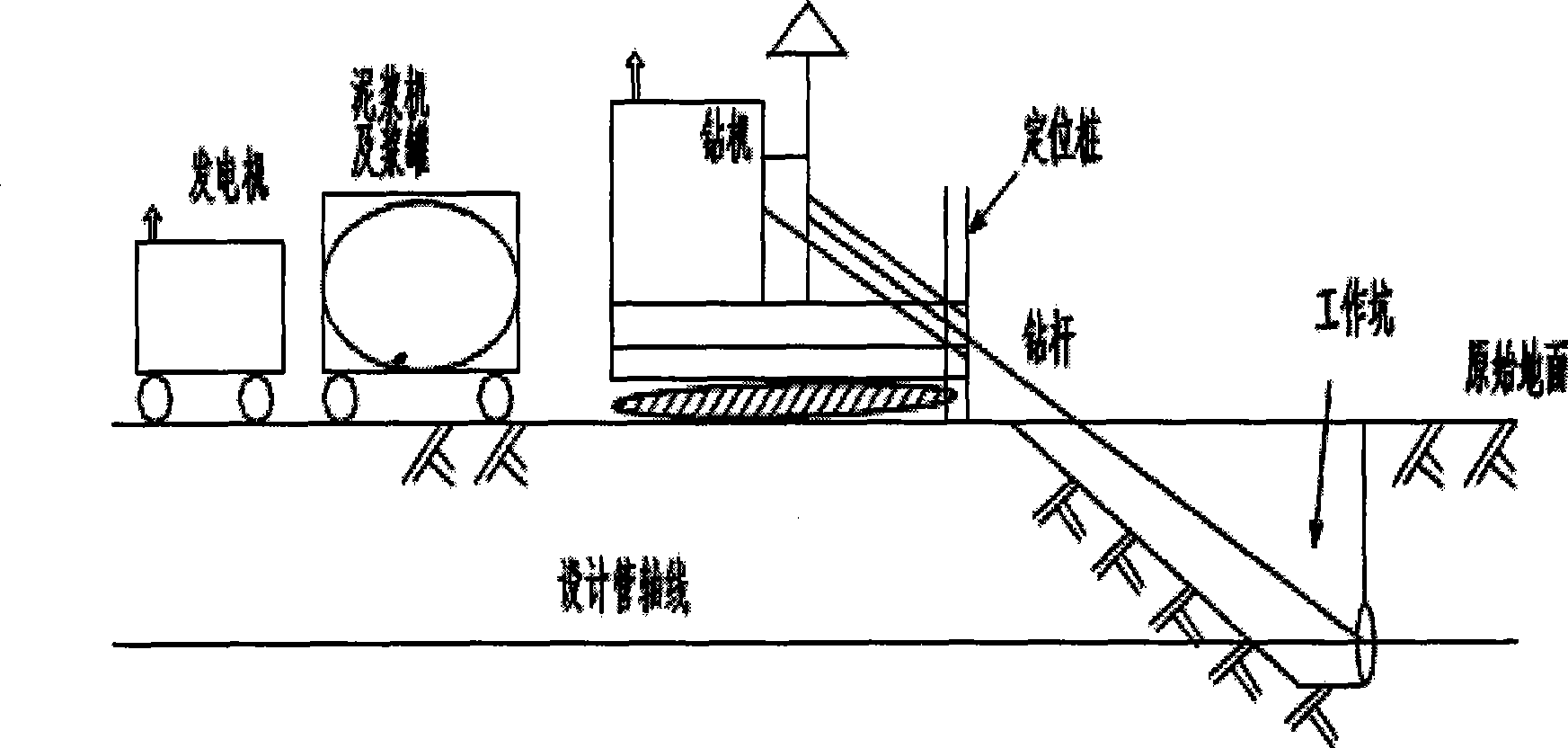

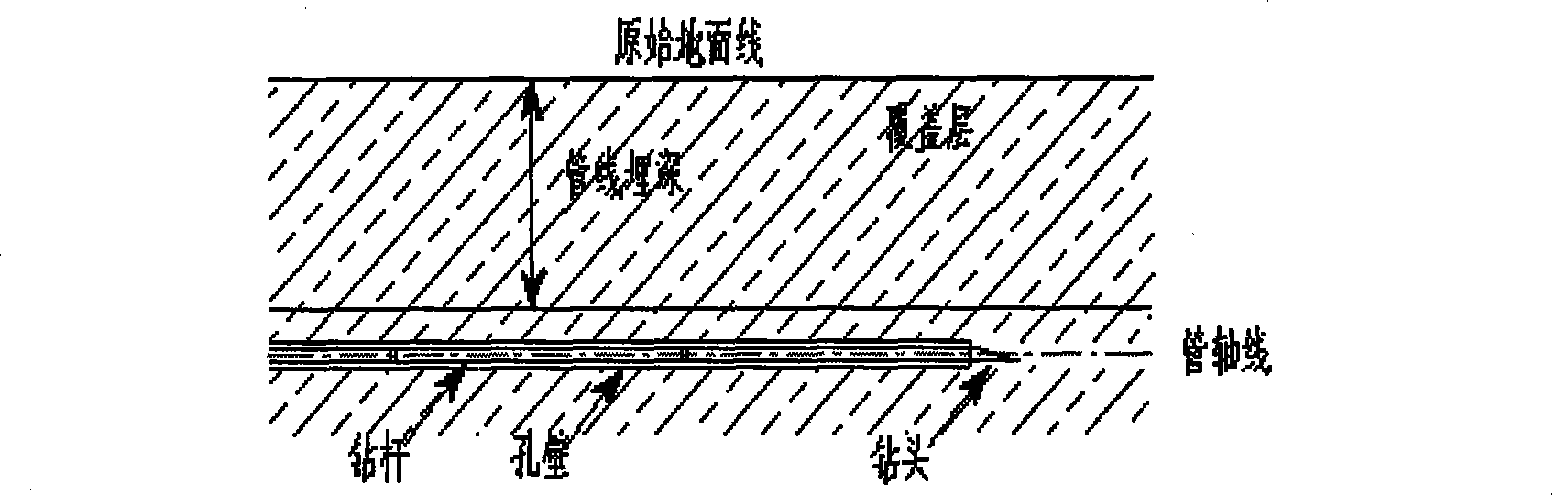

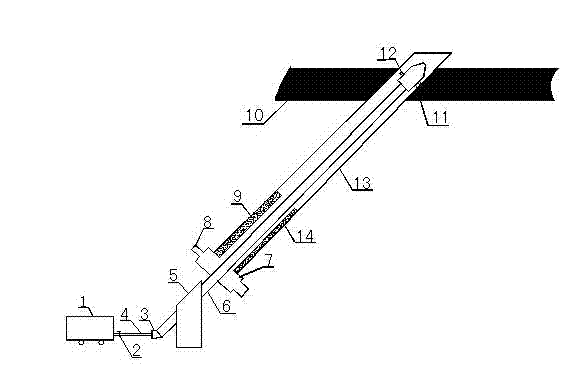

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

Electronic drill depth indicator

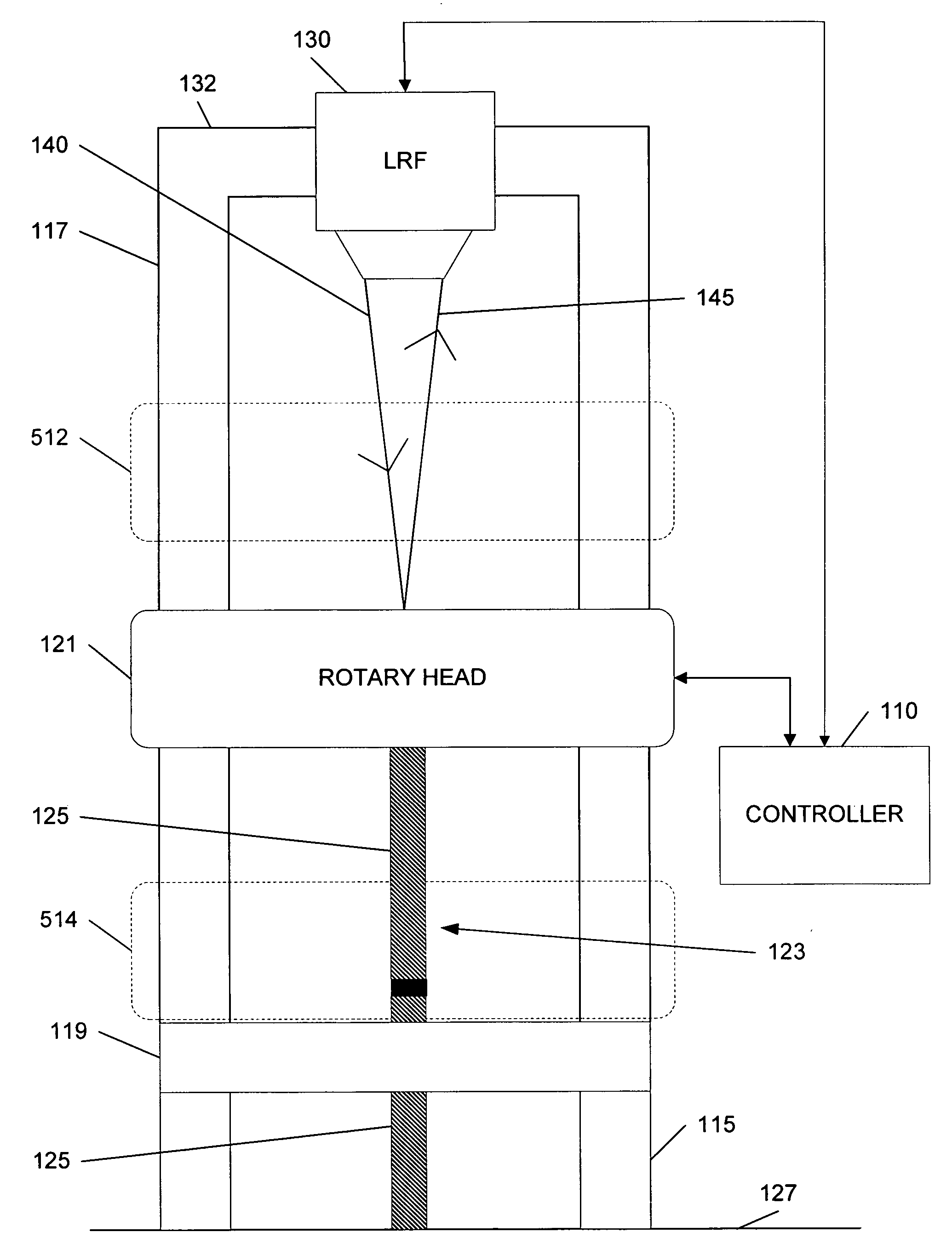

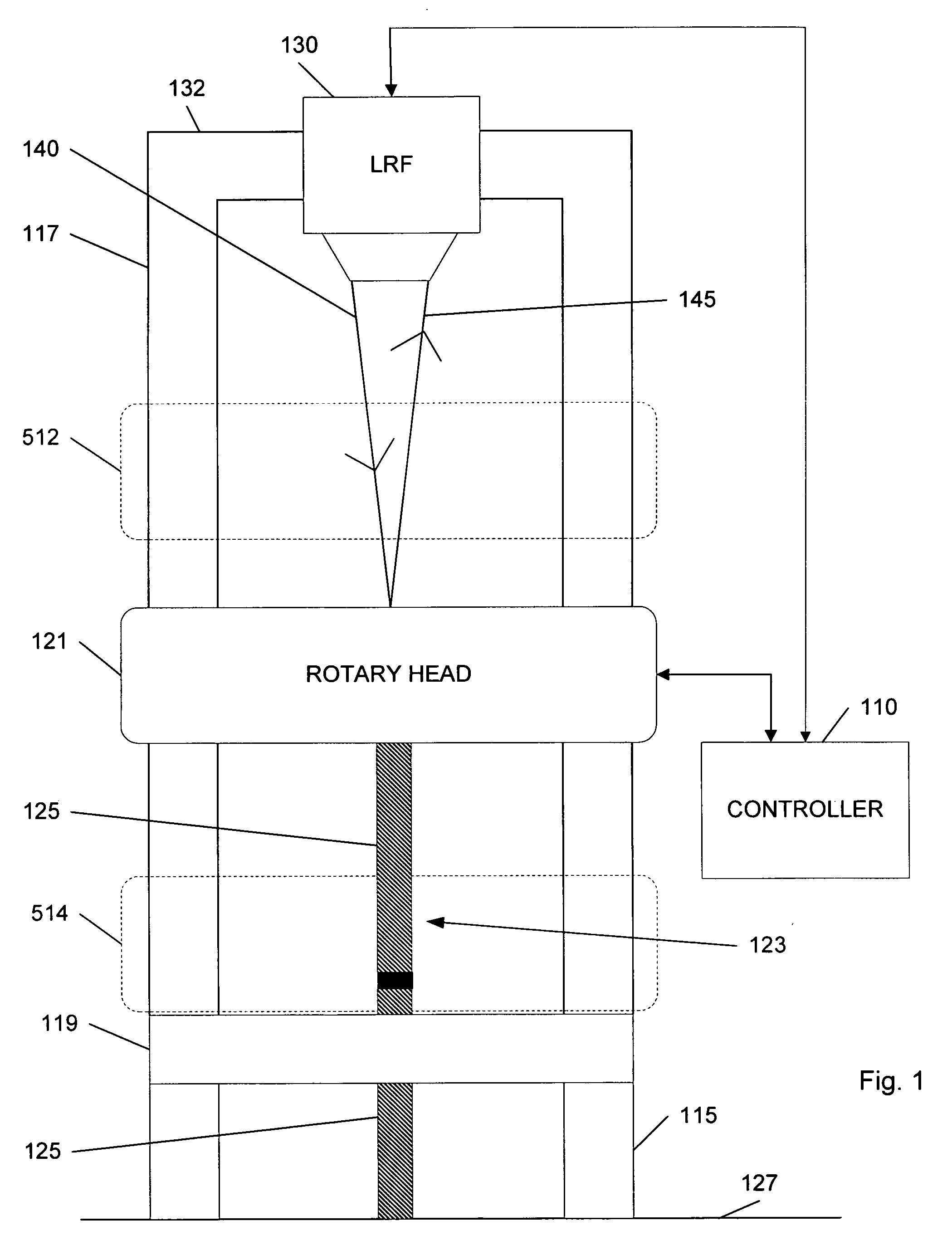

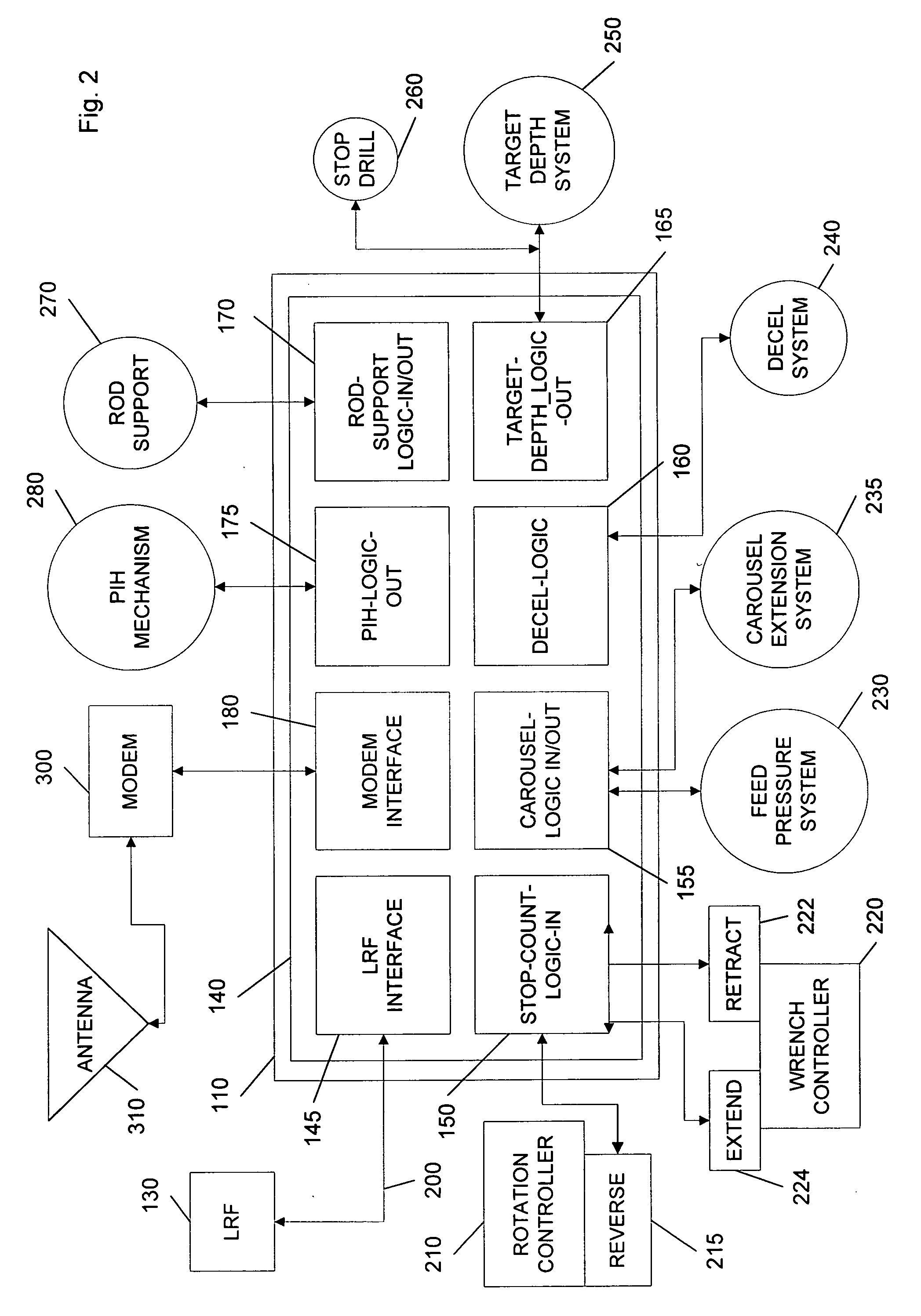

InactiveUS20050169717A1Easy CalibrationEasy to installSurveyDrilling/boring measurement devicesLaser rangingLaser rangefinder

A system for determining a depth of a hole drilled by a drilling machine. The system can include a drill string including one or more drill rods, wherein each of the one or more drill rods has a length; a target; a laser range finder configured to determine a plurality of distance readings, wherein each of the plurality of distance readings includes a distance value between the laser range finder and the target; and a controller configured to obtain the plurality of distance readings from the laser range finder. The controller processes the plurality of distance readings to produce a calculated distance between the laser range finder and the target. The controller may also use the calculated distance and the length of each of the one or more drill rods included in the drill string to determine the depth of the hole drilled by the drilling machine.

Owner:ATLAS COPCO DRILLING SOLUTIONS

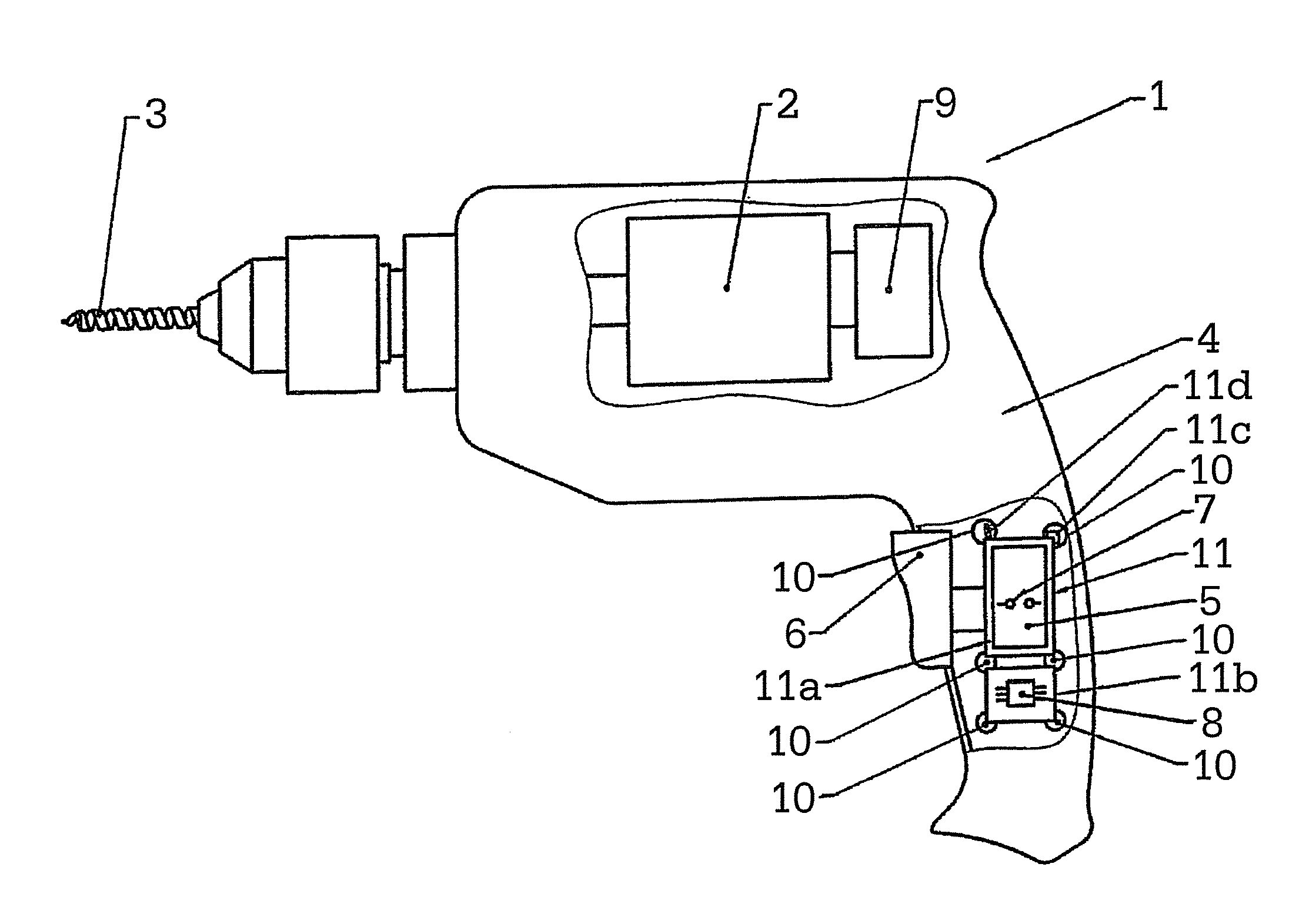

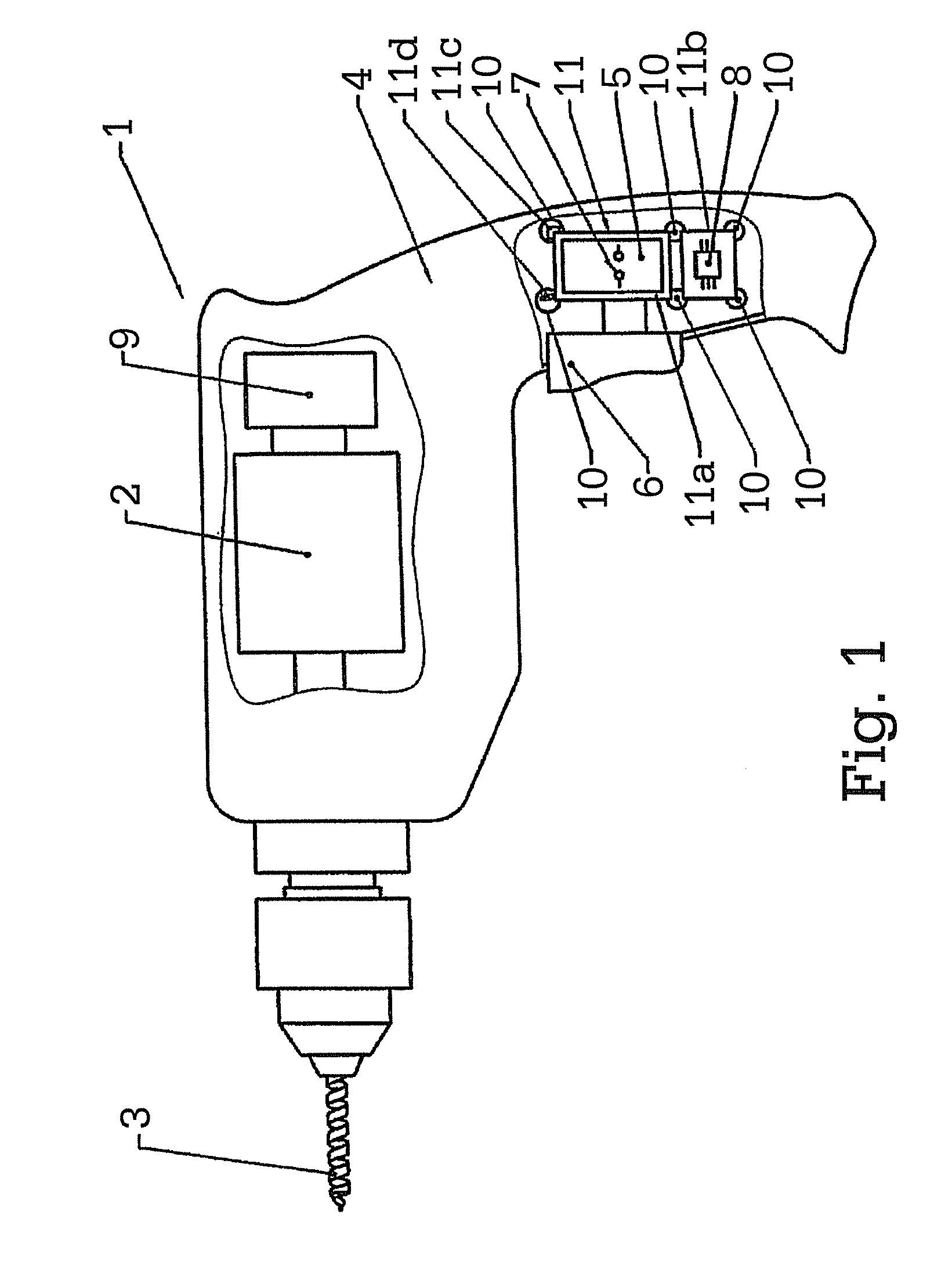

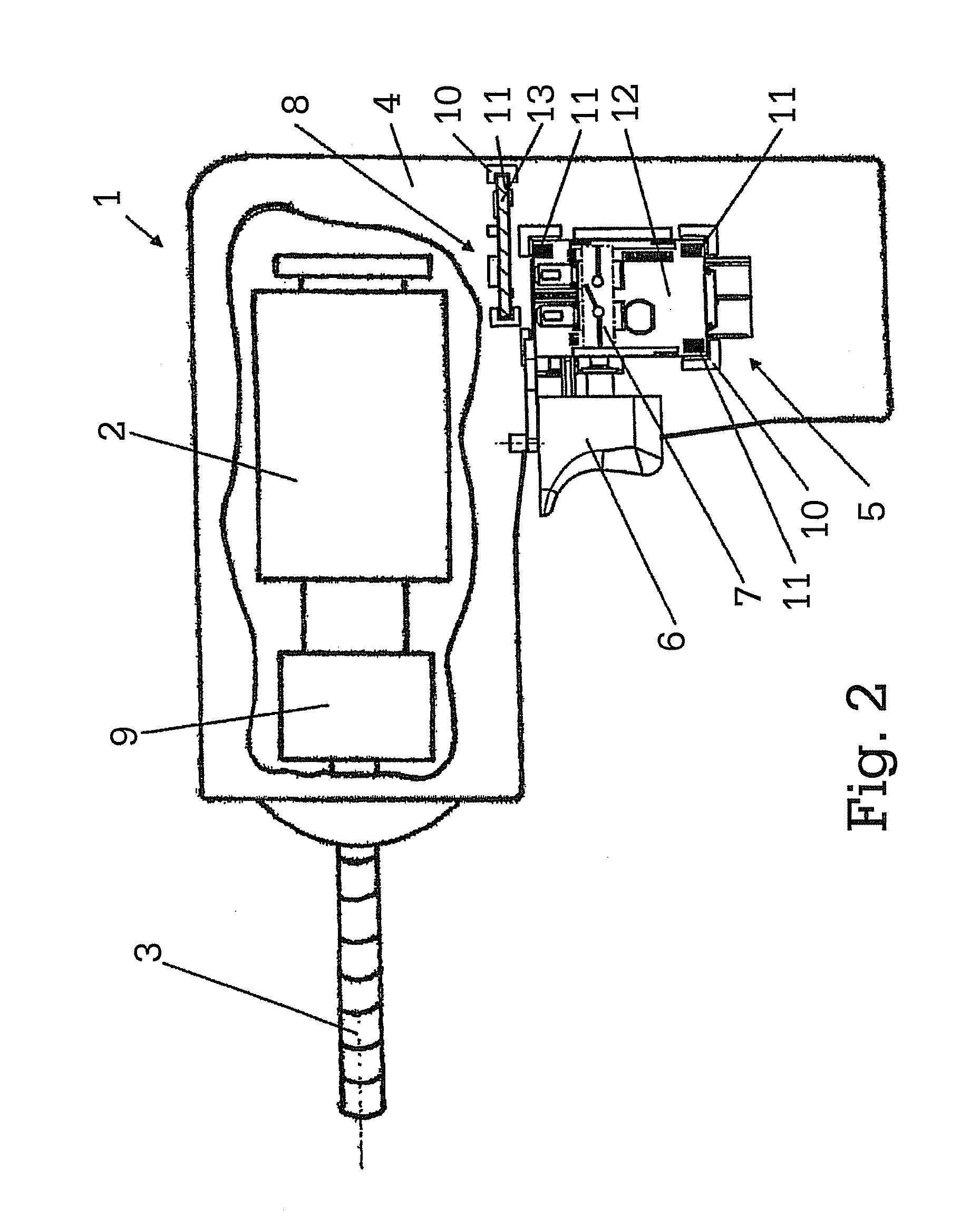

Power tool

ActiveUS20100314147A1Reduce and in power toolEffective dampingOperator-supported drilling machinesPortable percussive toolsElectricityEngineering

The invention relates to a power tool, such as an impact drilling machine, impact screwdriver, saber saws, grinders, or the like, comprising a housing. In the housing, an electric motor and an electric or electronic module that is attached to holders in the housing, for example, an electric switch or electronics, are provided. Between the holders in the housing and the electrical or electronic modules, a vibration decoupling element is disposed.

Owner:MARQUARDT GMBH SCHLOSSTRASSE 16 7201 RIETHEIM-WEILHEIM 1 WEST GERMANY

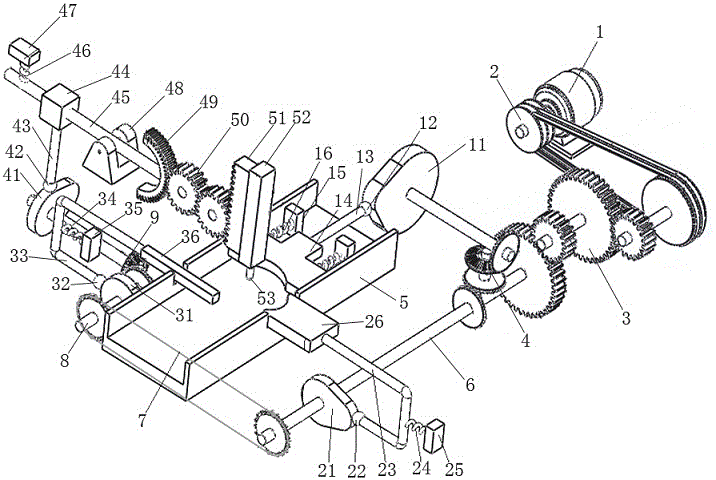

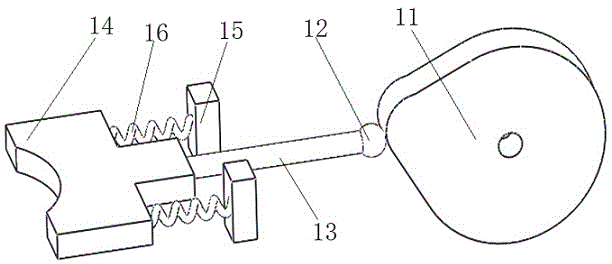

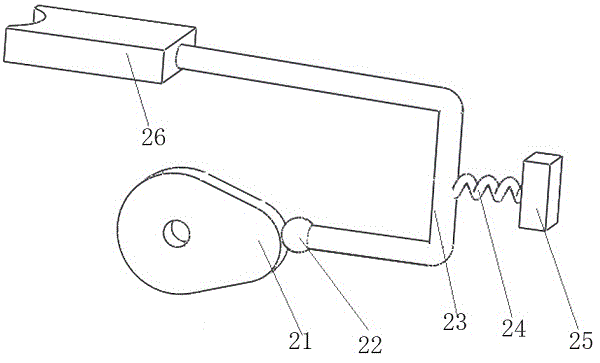

Double-drive coaxial forward and reverse output spiral rock-entering drilling machine

ActiveCN103670264ANo pollution in the processImprove reliabilityConstructionsToothed gearingsGear wheelEngineering

The invention relates to a double-drive coaxial forward and reverse output spiral rock-entering drilling machine which comprises double input motors, an input shaft, an output shaft, an outer sleeve, four cycloid gear mechanisms and four planetary speed reduction mechanisms. The double input motors are respectively meshed with a gear wheel on the input shaft via pinions, the outer sleeve is coaxially sleeved on the output shaft via a bearing, four eccentric bearings are serially connected into the input shaft and are respectively connected into center holes of four cycloid gears, outer gears are arranged on the outer sides of the cycloid gears and are meshed with internal teeth of a housing case, outer holes are respectively formed in the left side and the right side of each cycloid gear, pins are respectively coaxially and movably arranged in the outer holes and are connected with the output shaft, a center wheel is connected onto the output shaft, and planet gears are uniformly distributed at the peripheral edge of the center wheel in a meshed manner and are meshed with an inner gear ring of the outer sleeve.

Owner:山东卓力桩机有限公司

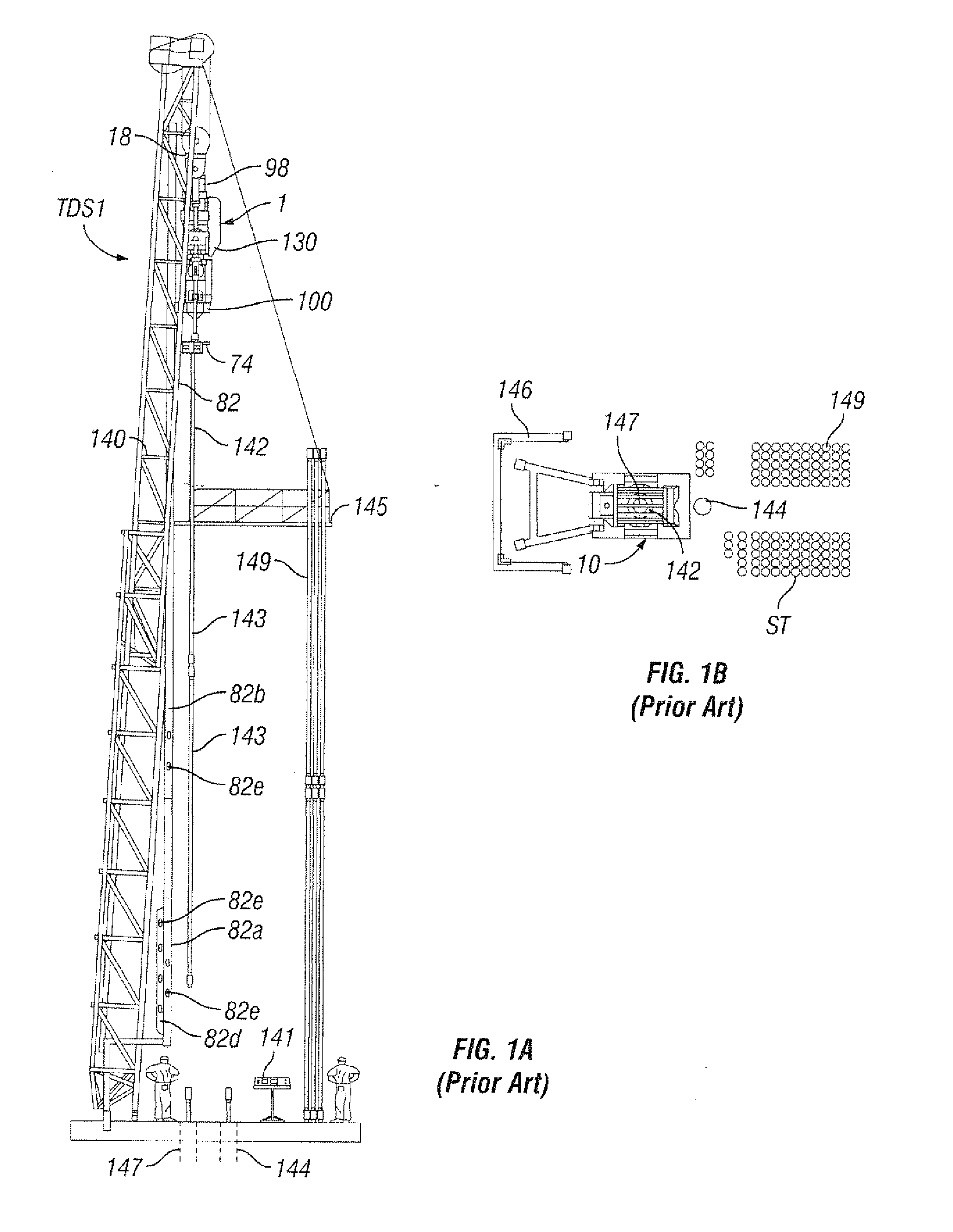

Automatic operation system of drilling string

The invention discloses an automatic operation system of a drilling string. The automatic operation system mainly consists of an automatic catwalk machine, a drilling floor manipulator, a power clip, an iron driller, a power hanging clip, a monkey board pipe arrangement manipulator, a top drive, a winch, a driller integrating control system and the like. The automatic operation system has the advantages that after the automatic operation system is arranged on a petroleum drilling machine, the automatic drilling operations, such as lifting and lowering of the drilling string in the drilling floor, drilling, drill lifting, drill lowering, and stand discharging, are realized; the automation degree of the drilling machine is improved, and the problems of high labor intensity, high risk and low efficiency caused by overhead operation and multi-person matching operation in the existing drilling string operation method are solved; the defects of decreasing of local labor intensity, and failure of reducing of number of operators and improvement of operation efficiency caused by using of one or several automatic devices of the existing drilling machine are overcome.

Owner:CHINA PETROCHEMICAL CORP +1

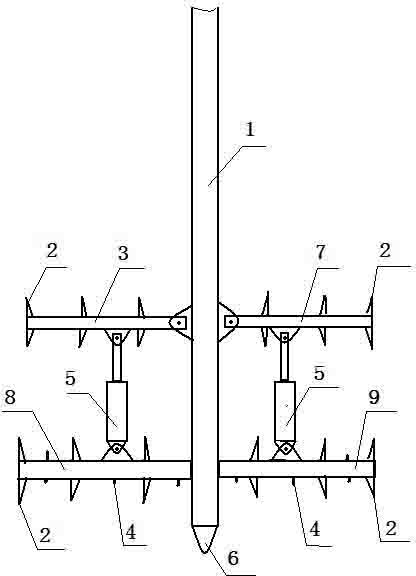

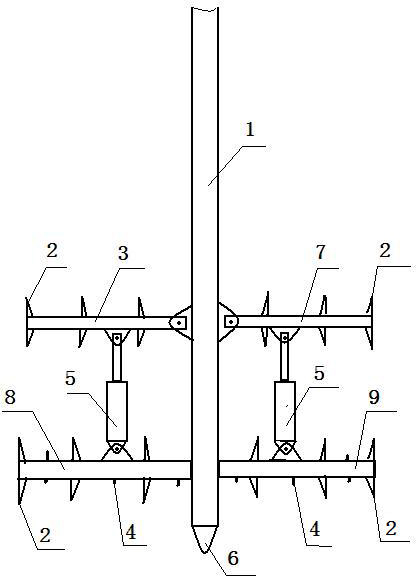

Drilling machine of three-dimensional stirring pile

The invention relates to a drilling machine of a three-dimensional stirring pile for enforcing of soft geology. The drilling machine comprises a drilling rod and a drilling bit at the lower end of the drilling rod, wherein a stirring rod C is arranged on the left side of the drilling rod, the right end of the stirring rod C is fixed on the drilling rod, a stirring rod D is arranged on the right side of the drilling rod, the left end of the stirring rod D is fixed on the drilling rod, and a plurality of drilling teeth and injected holes are arranged on the stirring rod C and the stirring rod D. A stirring rod A is arranged at the left end of the drilling rod, the right end of the stirring rod A is in pin connection with the drilling rod, the middle of the stirring rod A is in pin connection with the stirring rod C through a hydraulic cylinder, a stirring rod B is arranged at the right end of the drilling rod, the left end of the stirring rod B is in pin connection with the drilling rod, the middle of the stirring rod B is in pin connection with the stirring rod D through the hydraulic cylinder, and a plurality of drilling teeth are arranged on the stirring rod A and the stirring rod B.

Owner:张永忠

Multi-function multi-hole drilling rig

A multi-function multi-hole rig is disclosed which, in certain aspects, includes multiple machines for accomplishing rig functions, e.g. drilling machine(s), tripping machine(s), casing machine(s), and / or cementing machine(s), for producing multiple usable wellbores one after the other. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

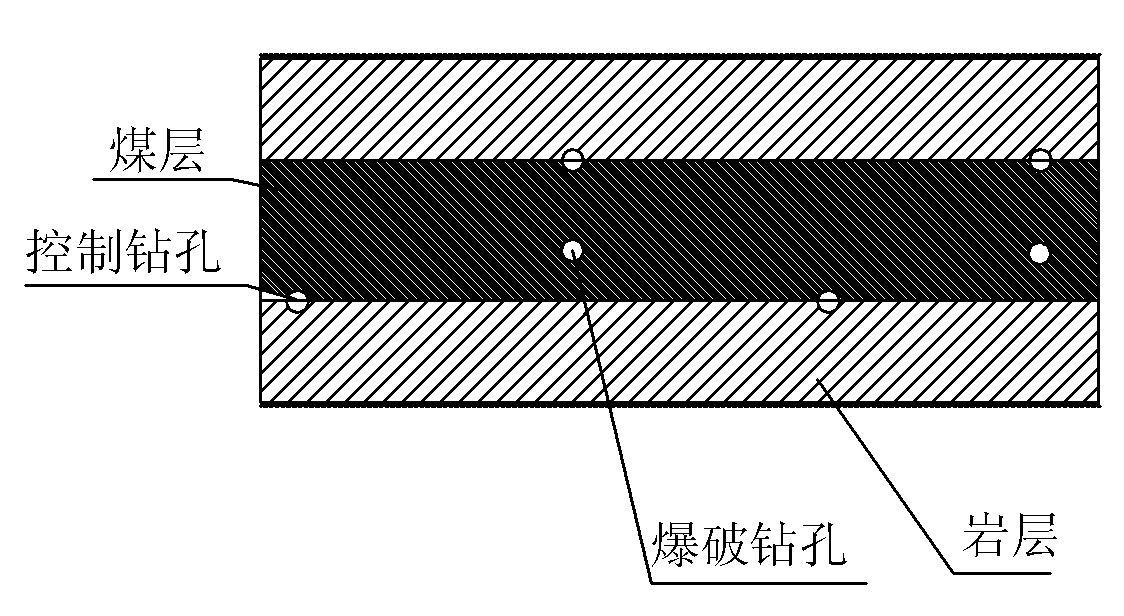

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

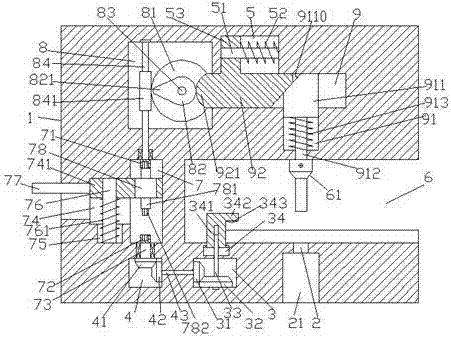

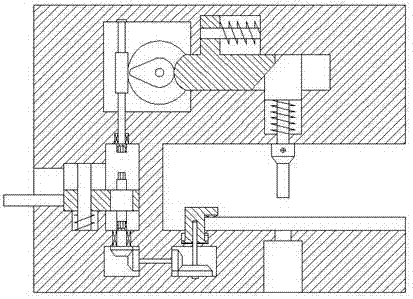

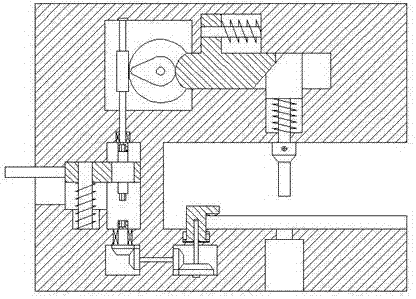

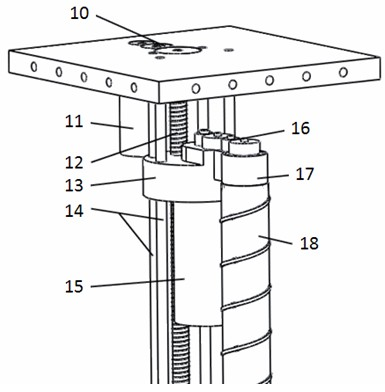

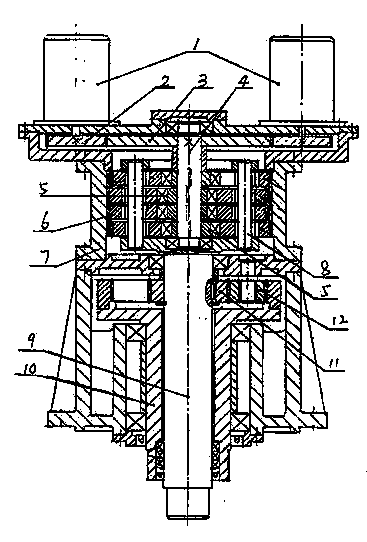

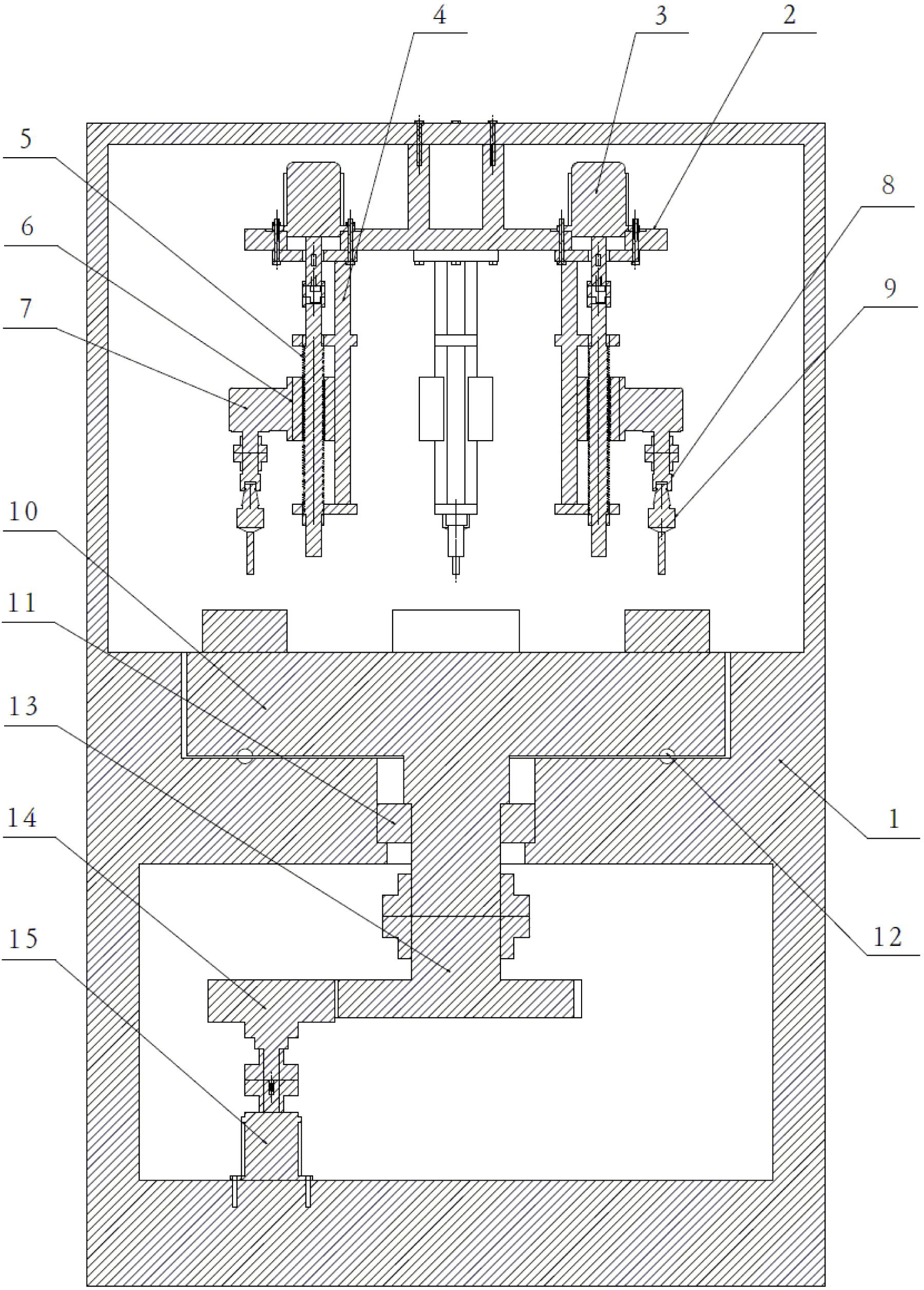

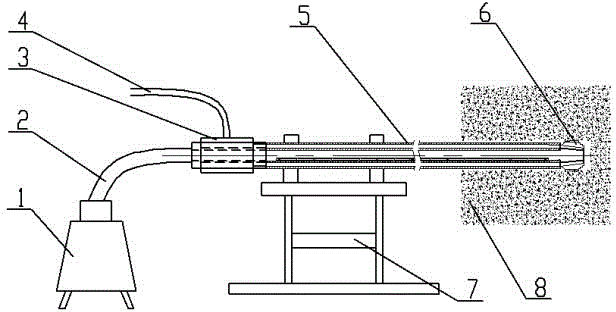

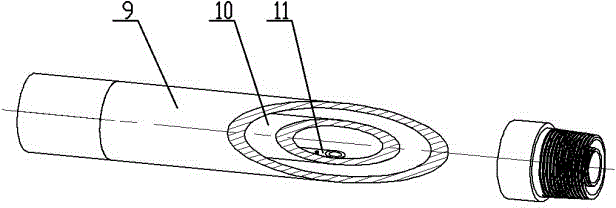

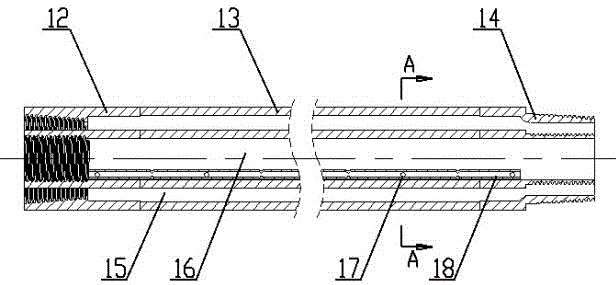

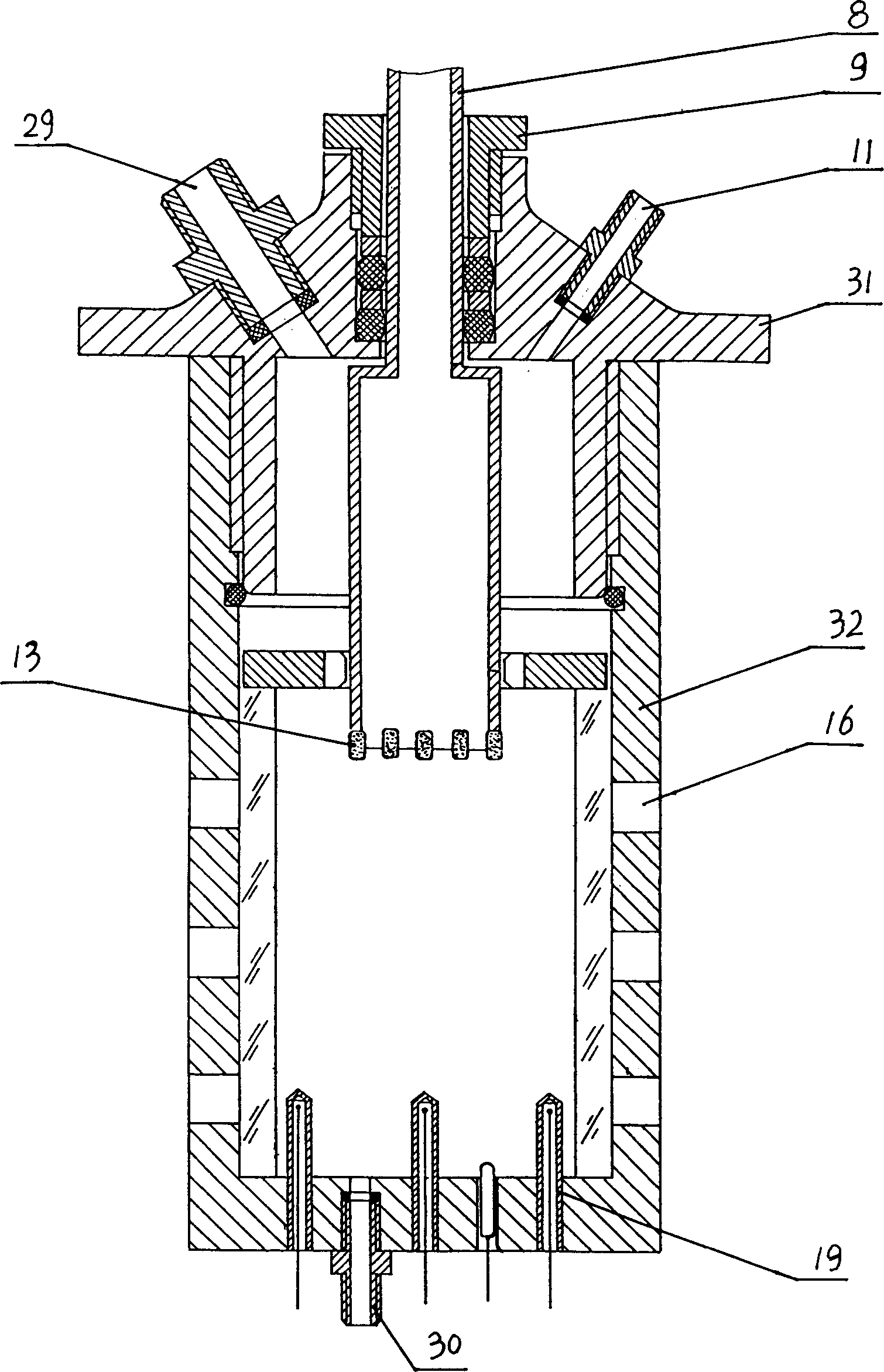

Compound vibration drilling device

InactiveCN105499626AStrong structural versatilityWide adaptabilityBoring/drilling machinesEngineeringAxial vibration

The invention relates to a compound vibration drilling device which is applied to various drilling machines and the drilling procedure of a processing center. The compound vibration drilling device mainly consists of three parts, namely a machine body, an ultrasonic torsion vibration system and a low-frequency axial vibration system, wherein the machine body plays a role of connecting and fixing the other two parts on the basis of the original processing function. The compound vibration drilling device realizes required ultrasonic torsion vibration by enabling the ultrasonic torsion vibration system to drive a drilling bit; the low-frequency axial vibration system drives a workpiece to realize low-frequency axial vibration; proper rotating speed and feeding amount can be selected by a drilling parameter setting system of the machine to perform compound vibration drilling processing. The compound vibration drilling device has the characteristics of high structural generality, high material applicability and the like, can develop respective advantages of different vibration drilling methods in ultrasonic, low frequency, torsion and axial direction, and is favorable for improving the drilling quality and realizing high-precision inner-hole drilling.

Owner:HENAN INST OF SCI & TECH

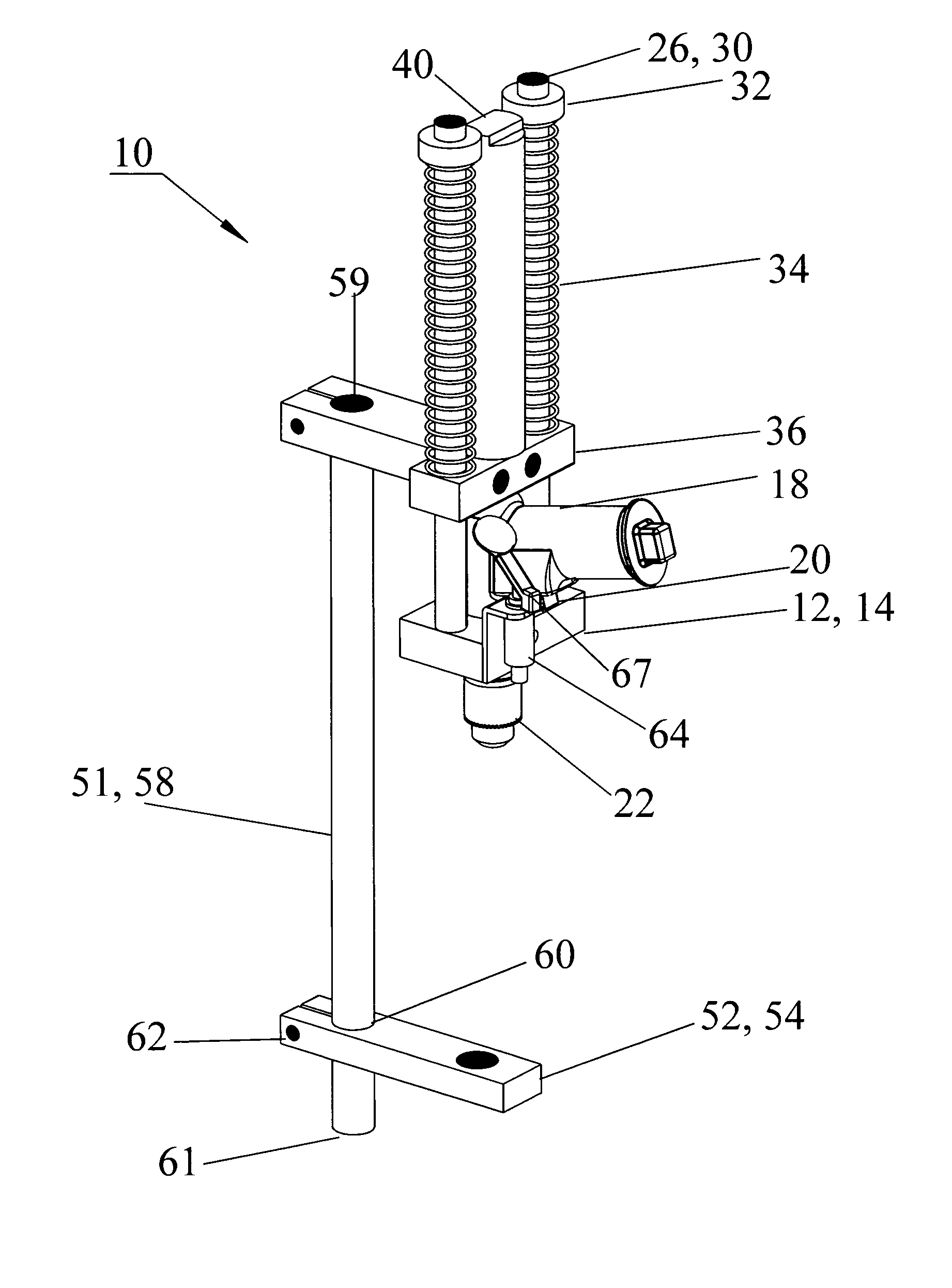

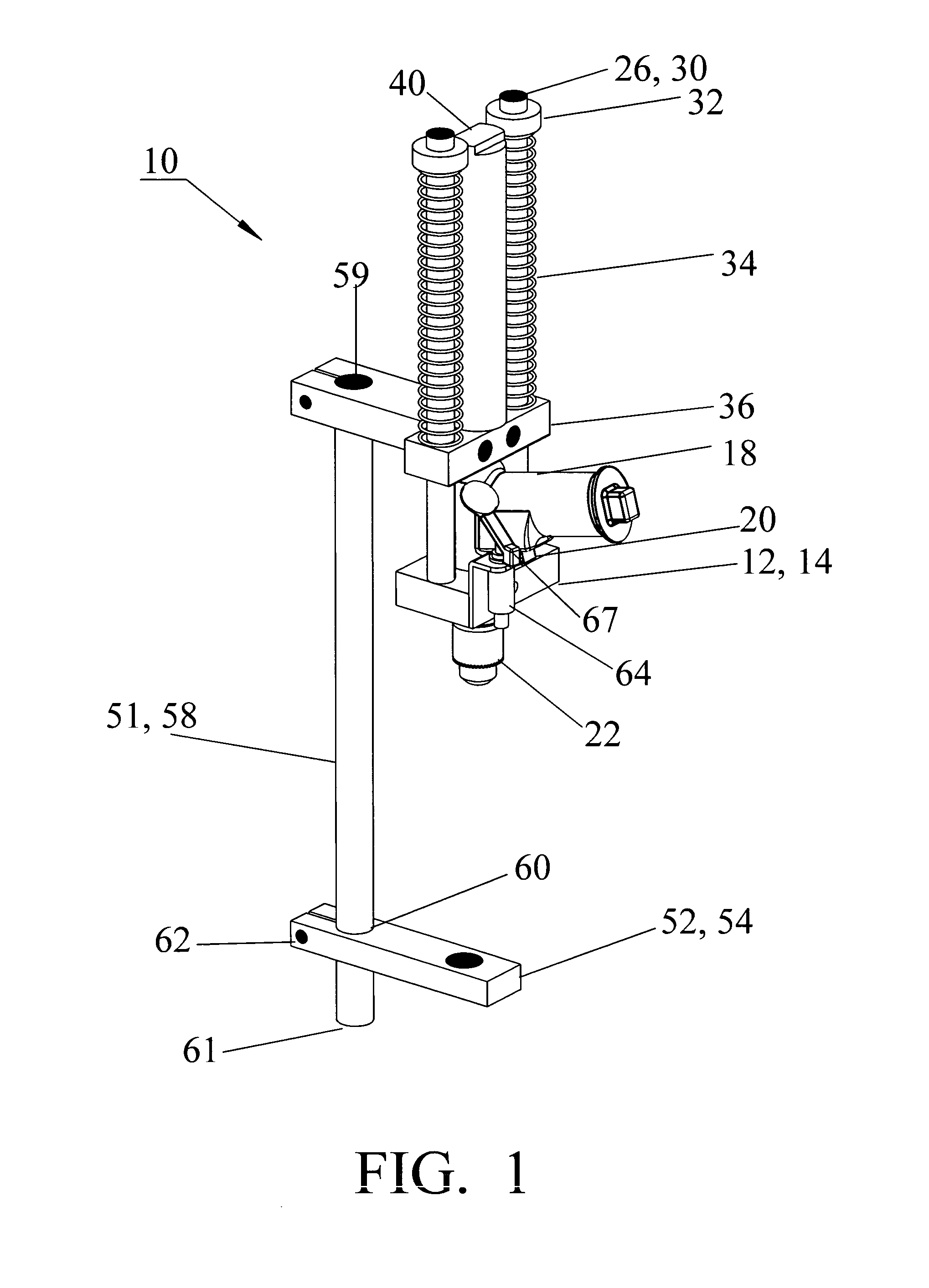

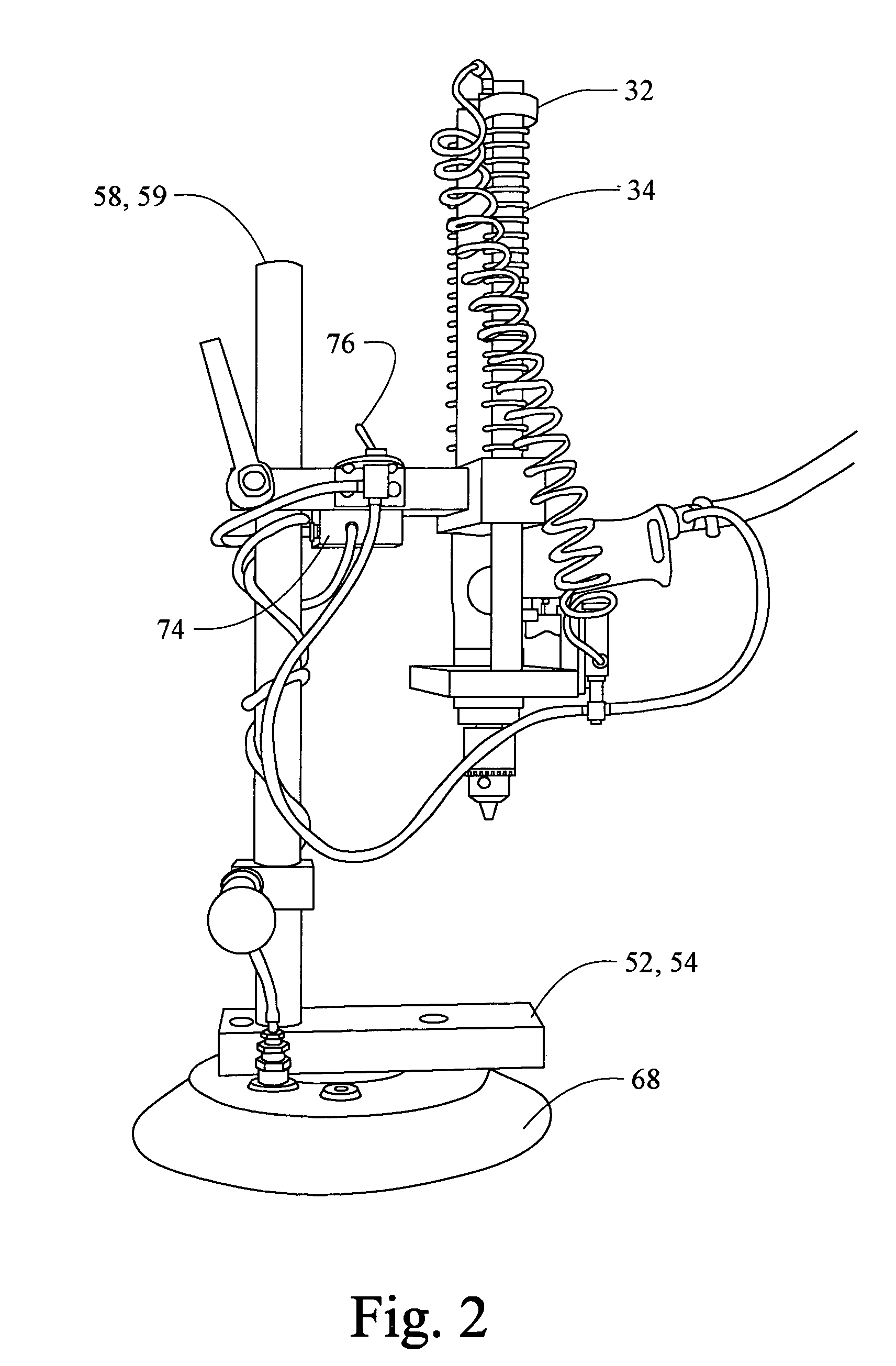

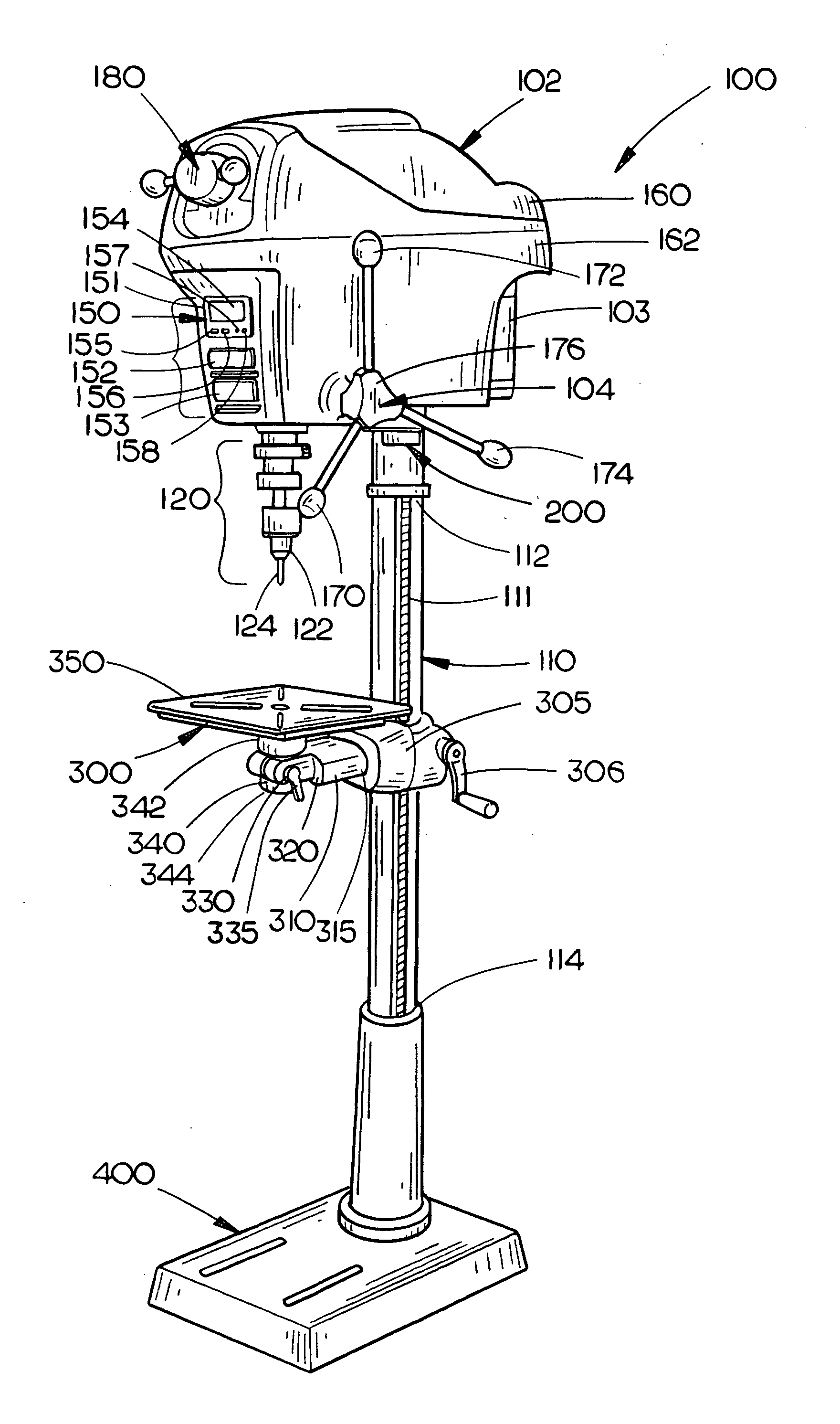

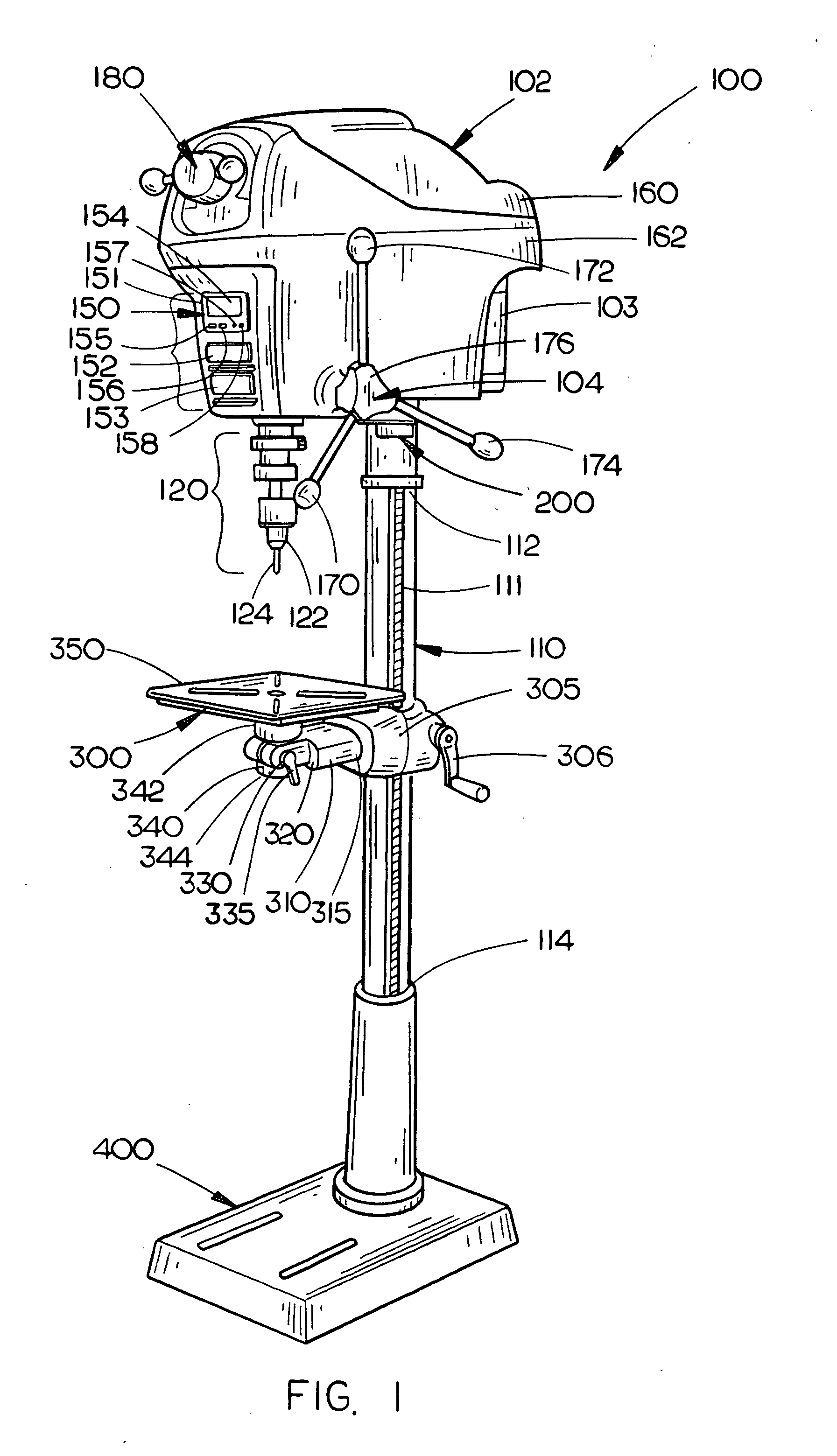

Power assisted drill press

InactiveUS7108459B1Quick and easy securingEasily suppliedDrilling/boring measurement devicesThread cutting machinesEngineeringVariable pressure

A power assisted drill press having a feed cylinder fed by a variable pressure regulator which allows a user to controllably feed a bit and work material together while activating a drill motor to rotate the bit. An embodiment of the power assisted drill press utilizes a suction cup and venturi system for attachment of the press to a surface work material. The drill press uniquely allows a person to variably activate the feed cylinder and also activate the drill motor with a single hand.

Owner:MUELLER THOMAS L MUELLER TOD BEVERLY H & MUELLER JOSEPH E

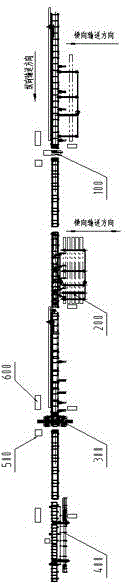

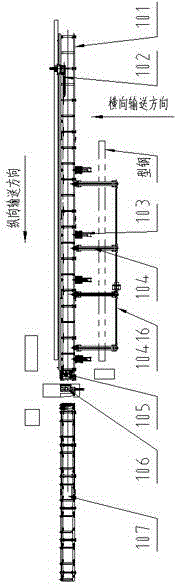

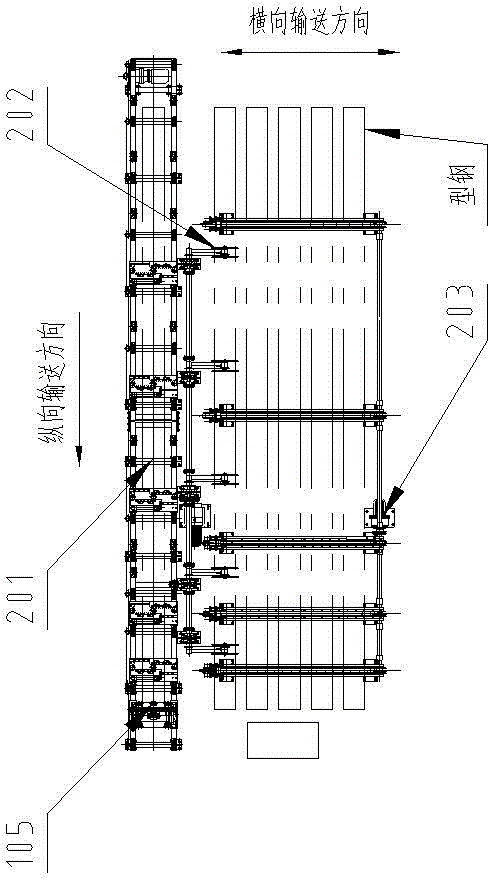

Digital control section steel sawing, drilling and welding integrated production line

ActiveCN102909563AIncrease productivityImprove machining accuracyOther manufacturing equipments/toolsMetal working apparatusProduction lineEngineering

The invention discloses a digital control section steel sawing, drilling and welding integrated production line. The digital control section steel sawing, drilling and welding integrated production line comprises a digital control sawing machine production line, a buffer storage device, a digital control drilling machine production line, a turnover welding forming production line, a hydraulic system and an electric control system, wherein the digital control sawing machine production line and the digital control drilling machine production line comprise a sawing host and a drilling host; a discharge channel is arranged at the rear part of the host; a charge channel is arranged at the front part of the host; roller shafts and side positioning rollers are arranged on the discharge channel and the charge channel; a side pushing device is also arranged on one side of the charge channel; and a digital control length calculating positioning device is mounted at one end of the charge channel close to the host. The buffer storage device is arranged to prevent workpieces from being overstocked due to different production rhythms of the sawing host and the drilling host, is used for bearing and conveying the finished sawed workpieces and can enable the workpieces to pass freely; a turnover charge device can turn the workpieces which cannot be drilled temporarily onto a buffer horizontal charge channel; and the turnover welding forming device can turn over freely by 360 DEG.

Owner:济南天辰智能装备股份有限公司

Drill press

InactiveUS20060104731A1Improve efficiencyEasy to operateDrilling/boring measurement devicesThread cutting feeding devicesControl systemEngineering

A power tool control system connected with a drill press provides a system for determining operational settings for the drill press and / or structural factors of a workpiece to be operated upon by the drill press. For instance, the power tool control system may establish a visual indication of the axis of operation of the drill press upon a workpiece and / or determine the thickness, structural composition, and / or moisture content of a workpiece. The determined axis of operation and / or structural factor is utilized to determine the operational settings of the power tool.

Owner:CHANG TYPE INDAL

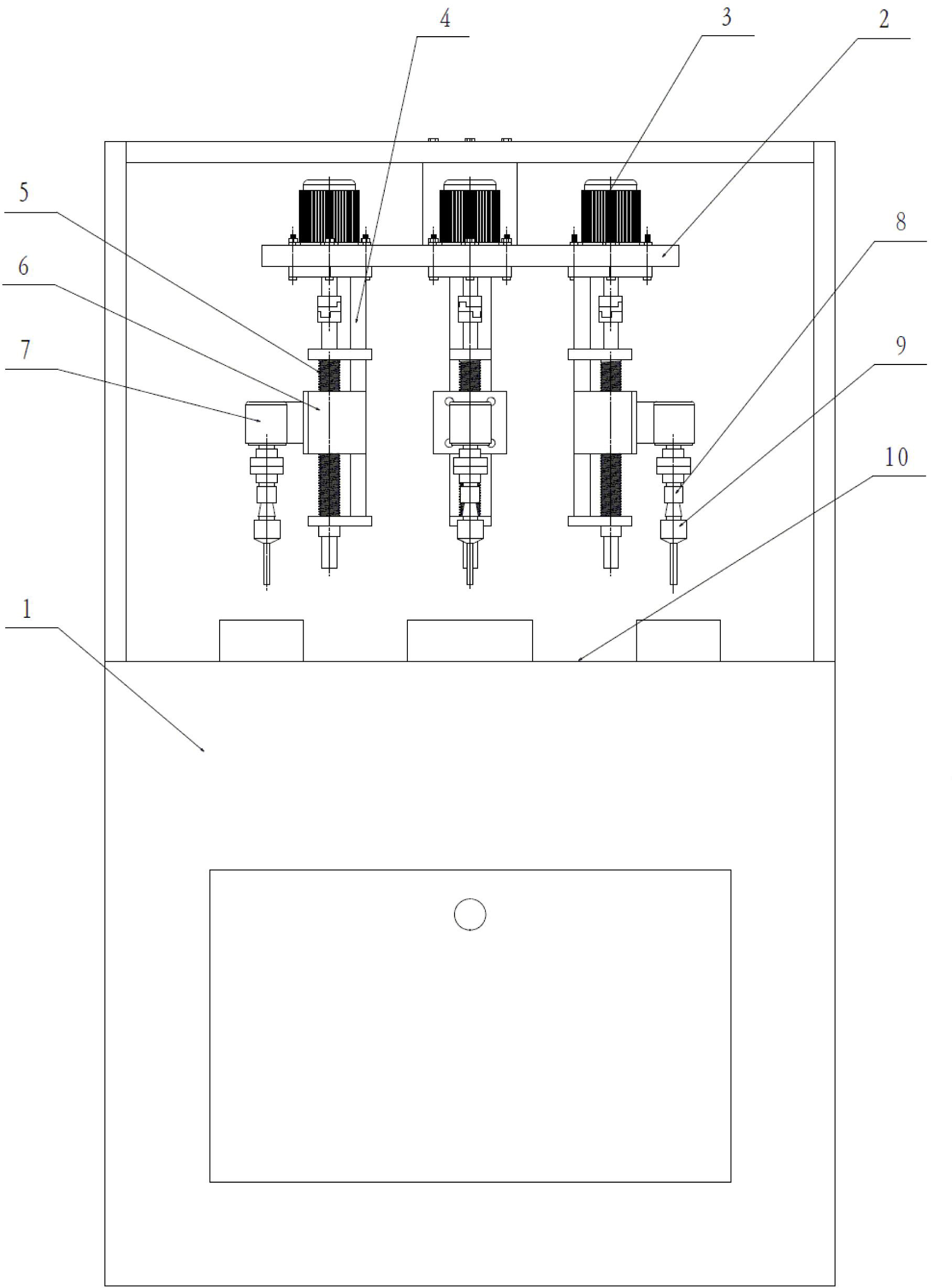

Multi-station speed-governing numerically-controlled drilling machine

InactiveCN102009201AIncrease productivityReduce the number of employeesFeeding apparatusOther manufacturing equipments/toolsControl theoryMachine tool

The invention provides a multi-station speed-governing numerically-controlled drilling machine, which comprises a machine tool body in vertical arrangement. A rotary table device and a tool are arranged on the machine tool body. The tool is arranged above the rotary table device. The rotary table device comprises a rotary motion control servo motor and a rotary table, and drives the rotation of the rotary table by the rotary motion control servo motor. A plurality of stations are arranged on the rotary table. The tool comprises a plurality of integral type tool units. Each integral type tool unit is connected with a feed servo motor, and controls the feeding of the tool in the integral type tool units by using the feed servo motor. Each integral type tool unit is provided with a speed-governing motor, and controls the rotation speed of the tool by the speed-governing motor. The multi-station speed-governing numerically-controlled drilling machine machines a plurality of parts at the same time and finishes the multi-operation machining of the same one hole or hole system by the rotation of the rotary table so as to machine the multi-station streamline part, improve the production efficiency and reduce the labor number.

Owner:林颖

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

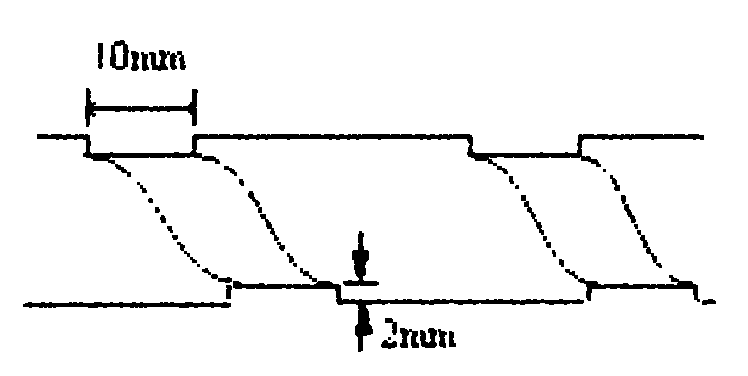

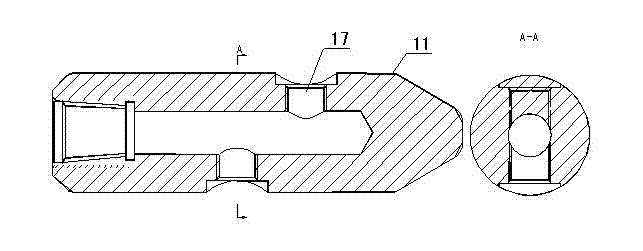

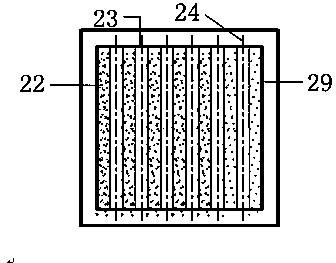

Double-layer internal deslagging and anti-blocking drilling tool for soft and outburst coal seam drilling, and use method of drilling tool

ActiveCN103556944AExternal setup is simpleEfficient dust removalDrilling machines and methodsSlagCoal

The invention discloses a double-layer internal deslagging and anti-blocking drilling tool for soft and outburst coal seam drilling, and a use method of the drilling tool. The drilling tool comprises a rotary sealing water supply device or a rotary sealing air supply device, a double-layer internal deslagging and anti-blocking drilling rod and a central backflow drilling bit, wherein the rotary sealing water supply device or the rotary sealing air supply device is connected with the double-layer internal deslagging and anti-blocking drilling rod on a drilling machine, and the central backflow drilling bit is mounted at the front end of the double-layer internal deslagging and anti-blocking drilling rod. The use method of the drilling tool comprises the steps that a drilling system is started; an air flow or a water flow enters an outer layer channel of the double-layer internal deslagging and anti-blocking drilling rod and reaches the bottom of a drilling hole; the air flow or the water flow reverses out drilling cuttings formed by drilling bit coal breaking along an inner layer channel of the double-layer internal deslagging and anti-blocking drilling rod to enter a slag tapping dust collector connected with the tail part of the drilling rod; and deslagging and dust collection are accomplished. The drilling tool is novel in design; the deslagging is accomplished in a cavity of the drilling rod, so that influences of drilling hole shrinkage and hole wall buckling failure on a drilling hole deslagging space can be avoided effectively; the deslagging is accomplished in the inner layer channel of the drilling rod, so that the dust collection is more effective; and drilling, anti-sloughing and dust collection integrated operation is realized.

Owner:HENAN POLYTECHNIC UNIV

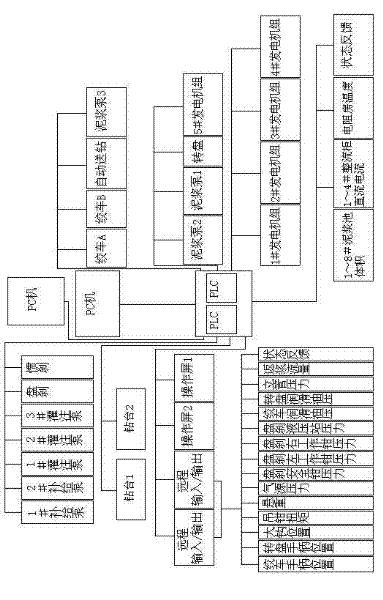

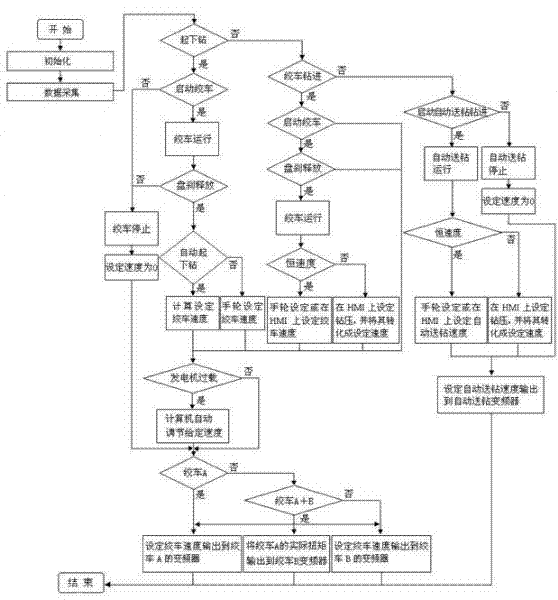

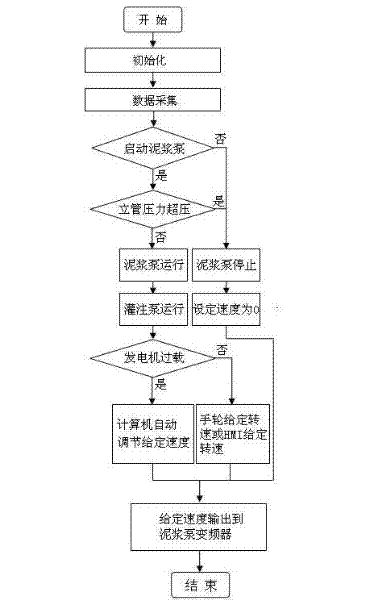

Automatic control system and method of petroleum drilling machine

ActiveCN102305059AEasy to operateRealize centralized controlFlushingAutomatic control for drillingAutomatic controlAutomatic train control

The invention relates to the field of oil-field drilling operation and provides an automatic control system and method of a petroleum drilling machine. The automatic control system comprises a master station and a plurality of slave stations, wherein a winch, an automatic driller, a rotary table and a mud pump are centrally controlled so that processes of well drilling operation can be dynamically, accurately and automatically controlled and good operation environment and work environment are provided for operating personnel.

Owner:四机赛瓦石油钻采设备有限公司

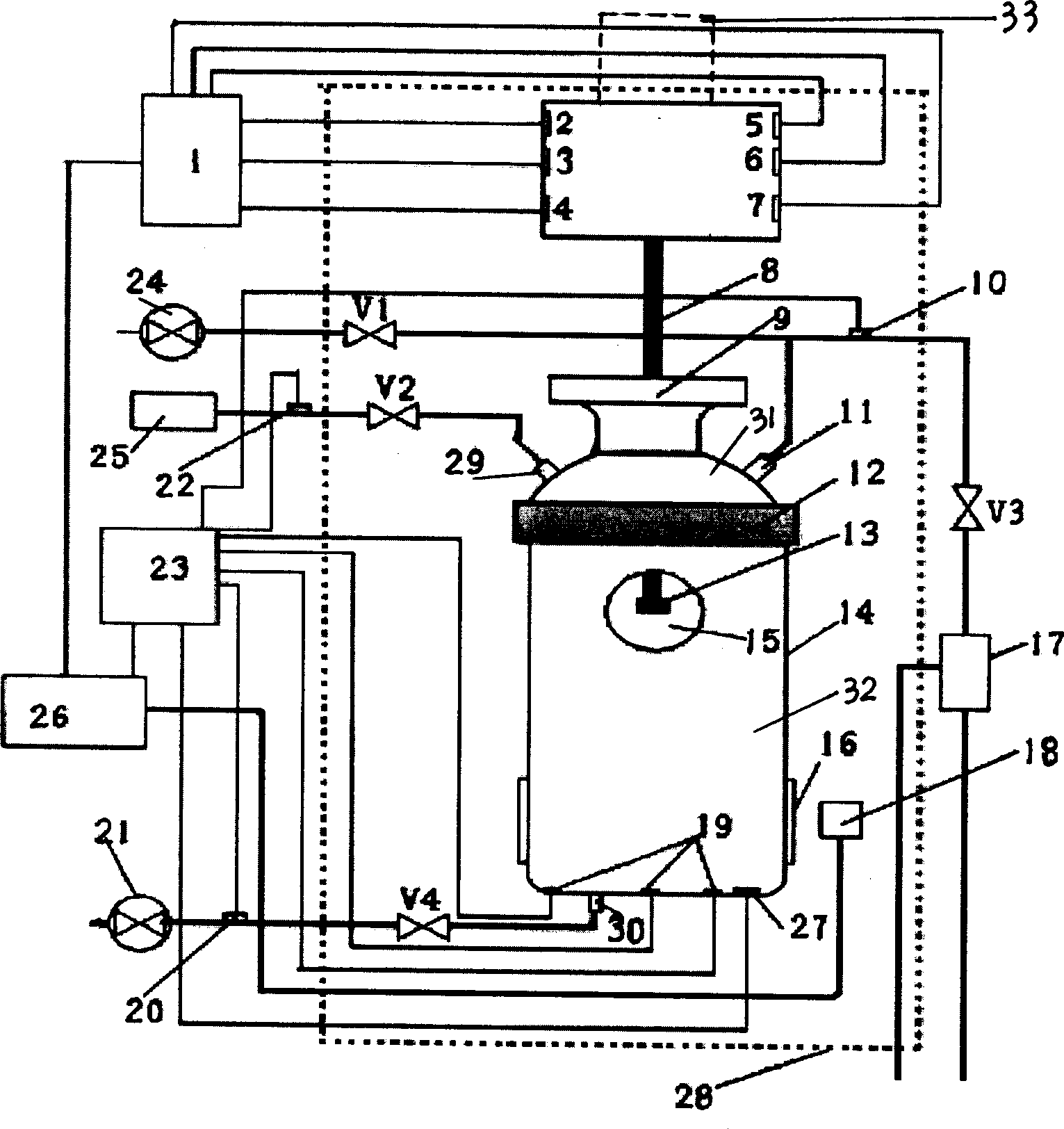

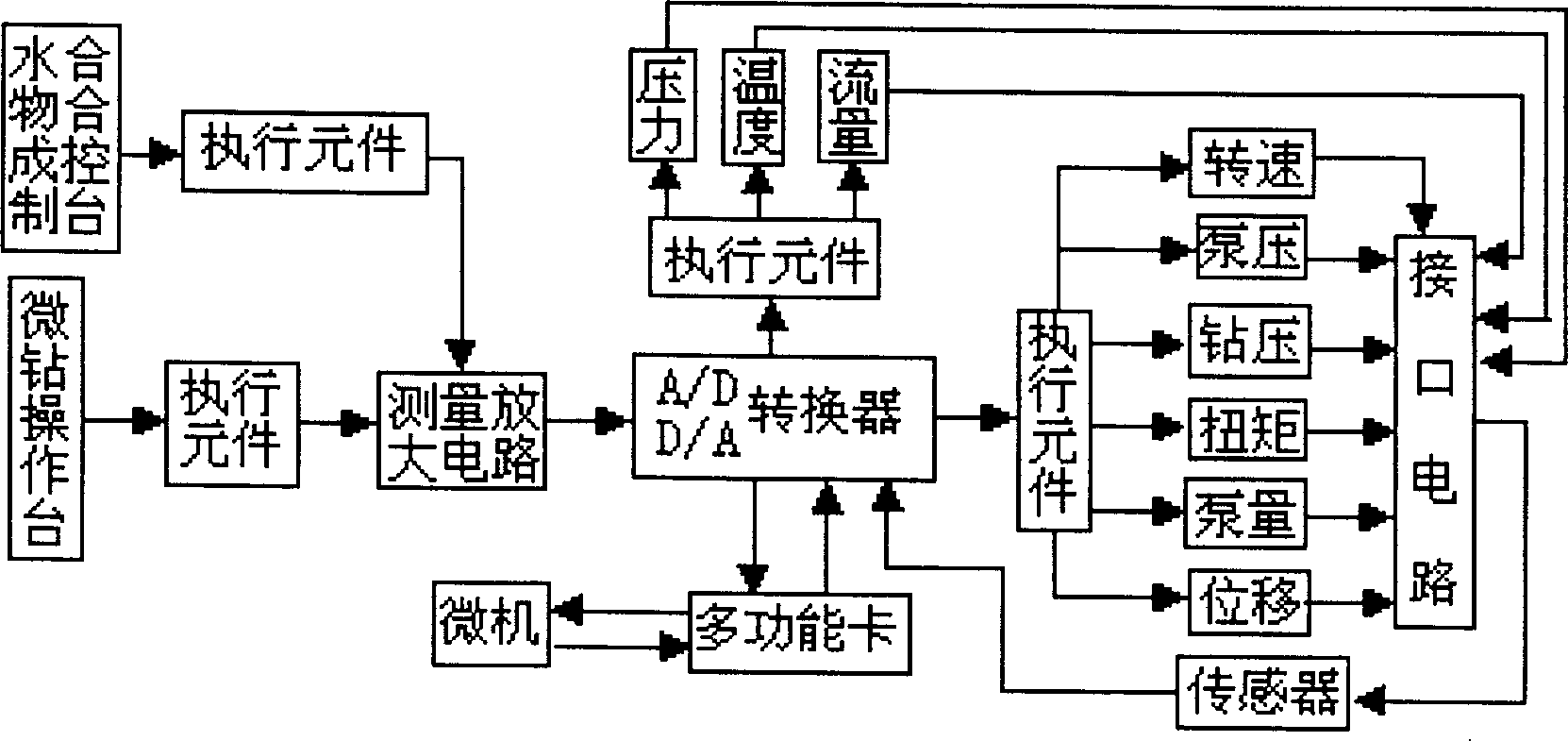

Comprehensive test equipment for natural gas hydrate

InactiveCN1440832AVersatileHigh degree of automationChemical/physical/physico-chemical processesData acquisitionVacuum pump

The comprehensive test equipment for natural gas hydrate consists of gas supplying and pressurizing unit, vacuum pump and gas / liquid separating and collecting unit, reactor, high and low temperature test box, mini drilling system with mini drilling machine and drilling rod, detection system, microphotography system, data collecting system, microcomputerized data processing system connected together. The equipment may be used in simulating synthesis research and decomposing test research as well as in the research of drilling control and exploiting method, etc.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

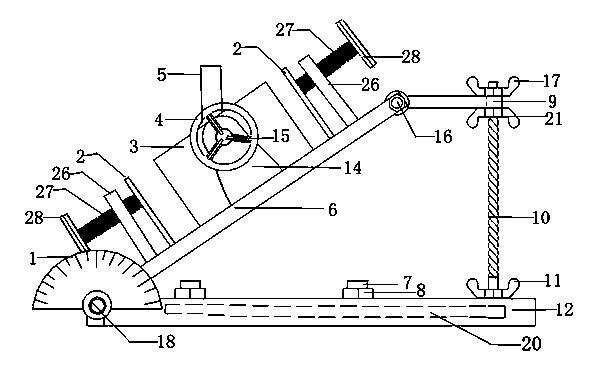

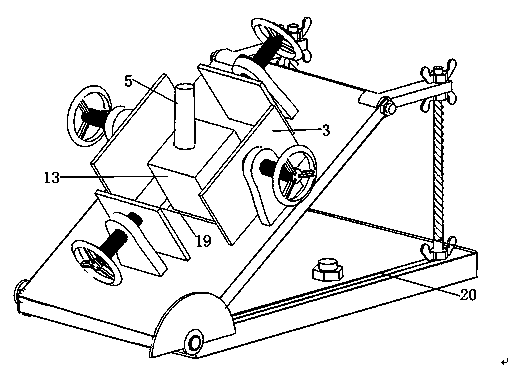

Test device of model for manufacturing rock masses containing interlayers and test method thereof

InactiveCN103983494ASimple structureEasy to operatePreparing sample for investigationUsing mechanical meansTest efficiencyDiameter ratio

The invention discloses a test device of a model for manufacturing rock masses containing interlayers and a test method thereof. The test device of the model for manufacturing the rock masses containing interlayers comprises a semicircular angle device, an upper baffle, a lower baffle, a left side plate, a right side plate, a circular turntable, a core-drilling machine drill bit, a flat plate, a flat plate angle control rod, a fixed screw rod, a base plate, an interlayer model test piece, a U-shaped plate and a guide slot. The test method comprises the following test steps: arranging the rock masses according to an outline central line and fixing the rock masses; manufacturing interlayer materials and casting the model, fastening the test piece, drilling the core, replacing the core-drilling machine drill bit, changing the position of the test piece to drill repeatedly and cutting to obtain the test pieces with different height-diameter ratios or obtain the test pieces with different interlayer inclination angles; then carrying out mechanical test. The test device is simple in structure and suitable for manufacturing the test pieces with different interlayer thicknesses, inclination angles and height-diameter ratios; according to a core-drilling and cutting machining device, by making full use of the existing device, the influence on the mechanical properties of the test pieces caused by different conditions can be analyzed, coring of irregular rock samples taken in the site can be carried out directly, so that the test efficiency is improved and the test time is shortened.

Owner:CENT SOUTH UNIV

Slurry wall protection construction method for bored pile

InactiveCN104120716AResolve skewSolve the problem of pile body concrete with mudBulkheads/pilesSlurry wallArchitectural engineering

The invention discloses a slurry wall protection construction method for a bored pile. The slurry wall protection construction method includes the following steps that step 1, a pile hole is positioned; step 2, a pile casing is buried; step 3, a drilling machine is in place; step 4, qualified slurry is prepared; step 5, hole forming and hole clearing are performed; step 6, a steel reinforcement cage is lifted for placing; step 7, underwater concrete is cast. According to the slurry wall protection construction method for the bored pile, operation is easy, the problems that the pile hole deviates, and pile body concrete is mixed with slurry are solved, and the construction method is suitable for slurry wall protection hole forming bored pile engineering of soft and hard soil layers high in underground water level in industrial and civil buildings.

Owner:杨哲

Semi-automatic drill lathe

InactiveCN104858477ASimple structureLow costFeeding apparatusPositioning apparatusLinear motionSemi automatic

The invention discloses a semi-automatic drill lathe which comprises a machine frame, a first spindle, a second spindle, a power system, a feeding mechanism, a positioning mechanism, a clamping mechanism and a knife feed mechanism, wherein the power system comprises a motor, a belt transmission unit and a gear transmission unit; power output by the motor is divided into two parts through the belt transmission unit and the gear transmission unit; one part of the power is transmitted to the feeding mechanism through a bevel gear, so as to control the feeding and withdrawing of the feeding mechanism; the other part of the power is transmitted to the first spindle; the clamping mechanism is controlled through the rotation of the cam driven by the first spindle; the first spindle transmits the power to the second spindle through chain transmission, so as to control the cam to rotate, and control the positioning mechanism to position a workpiece; a rack of the knife feed mechanism and a drill conduct reciprocating linear motion under the control of a gear. The semi-automatic drill lathe is simple in structure, compact in integral structure, stable in work, and worth of popularization.

Owner:HOHAI UNIV CHANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com