Digital control section steel sawing, drilling and welding integrated production line

A production line and section steel technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as large capital occupation, long production cycle, and inability to improve the comprehensive utilization rate of production resources and production area of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] In order to clearly illustrate the technical characteristics of the present solution, the present invention will be further described below through specific implementation modes and in conjunction with the accompanying drawings.

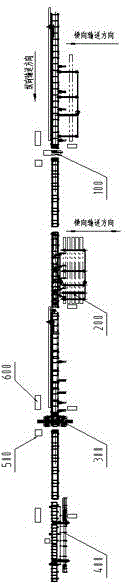

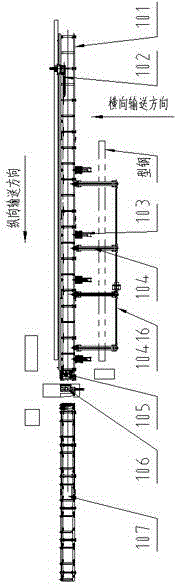

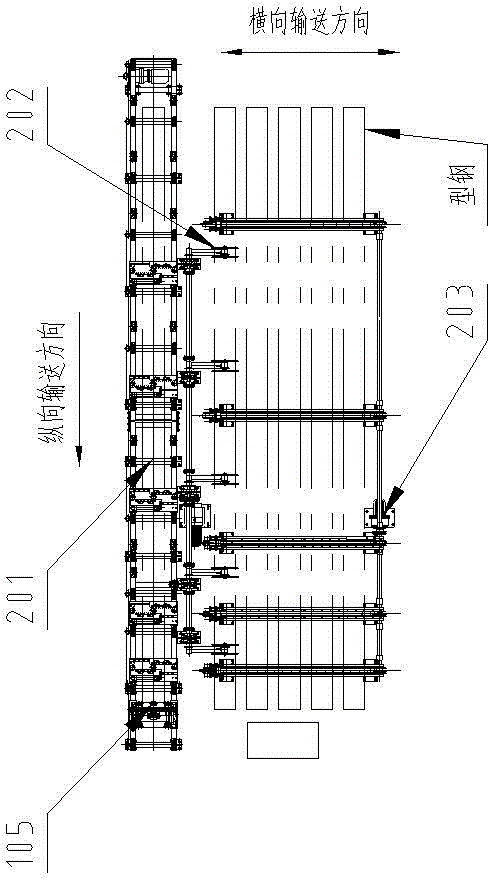

[0096] Such as Figure 1 to Figure 52 As shown, a CNC sawing, drilling, and welding integrated production line for section steel includes a CNC sawing machine production line 100, a buffer storage device 200, a CNC drilling machine production line 300, a flip welding forming production line 400, a hydraulic system 500 and an electrical control system 600.

[0097] The CNC sawing machine production line 100 includes a main sawing machine 106, which is provided with a pressing device and a support roller 10608 installed on the sawing bed 10601 through an outer spherical bearing with a seat 10609, and the sawing main machine 106 The rear part is provided with a sawing machine discharge channel 107, and the front part of the sawing main frame 106 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com