Patents

Literature

12586 results about "Production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

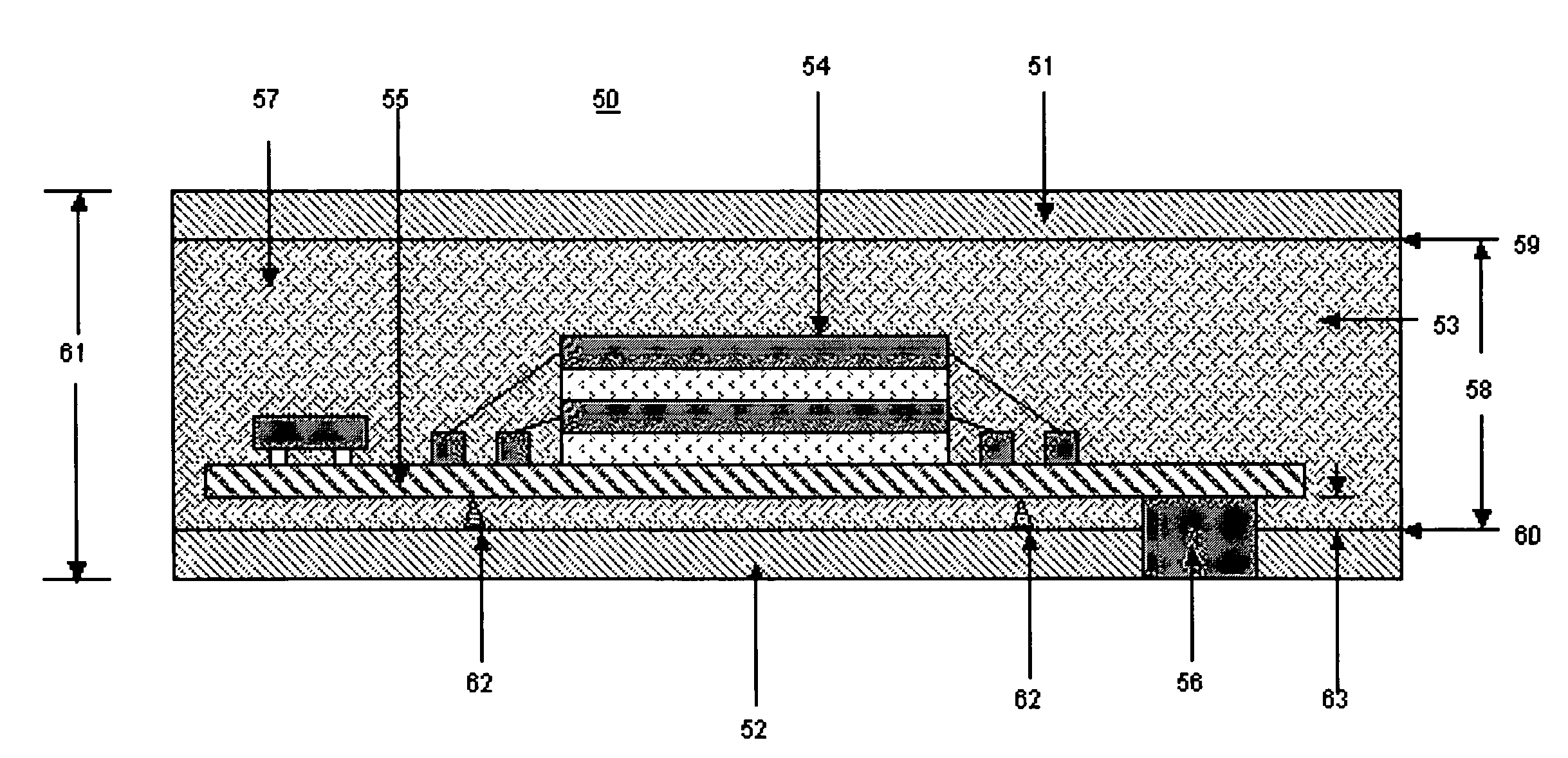

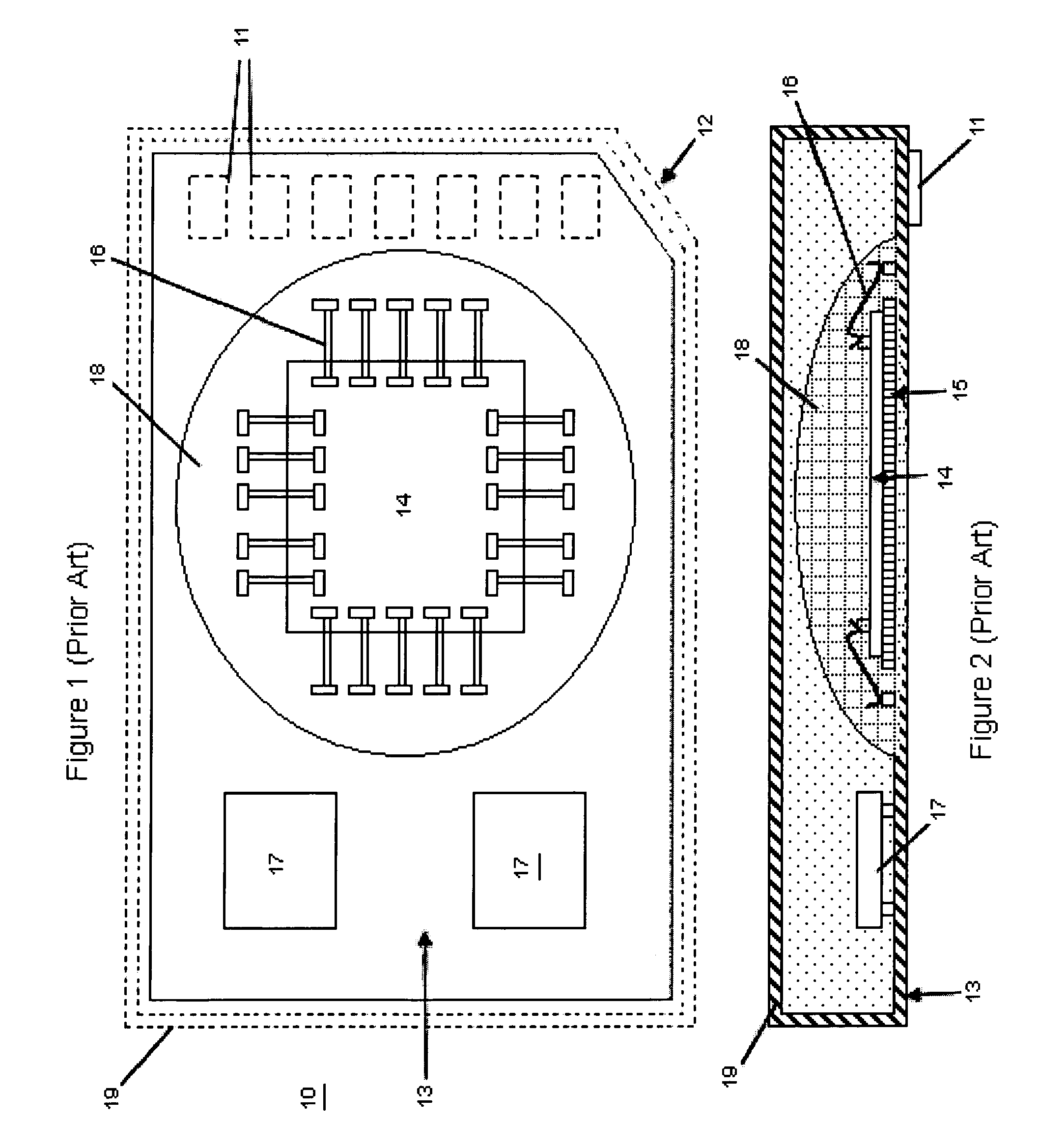

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

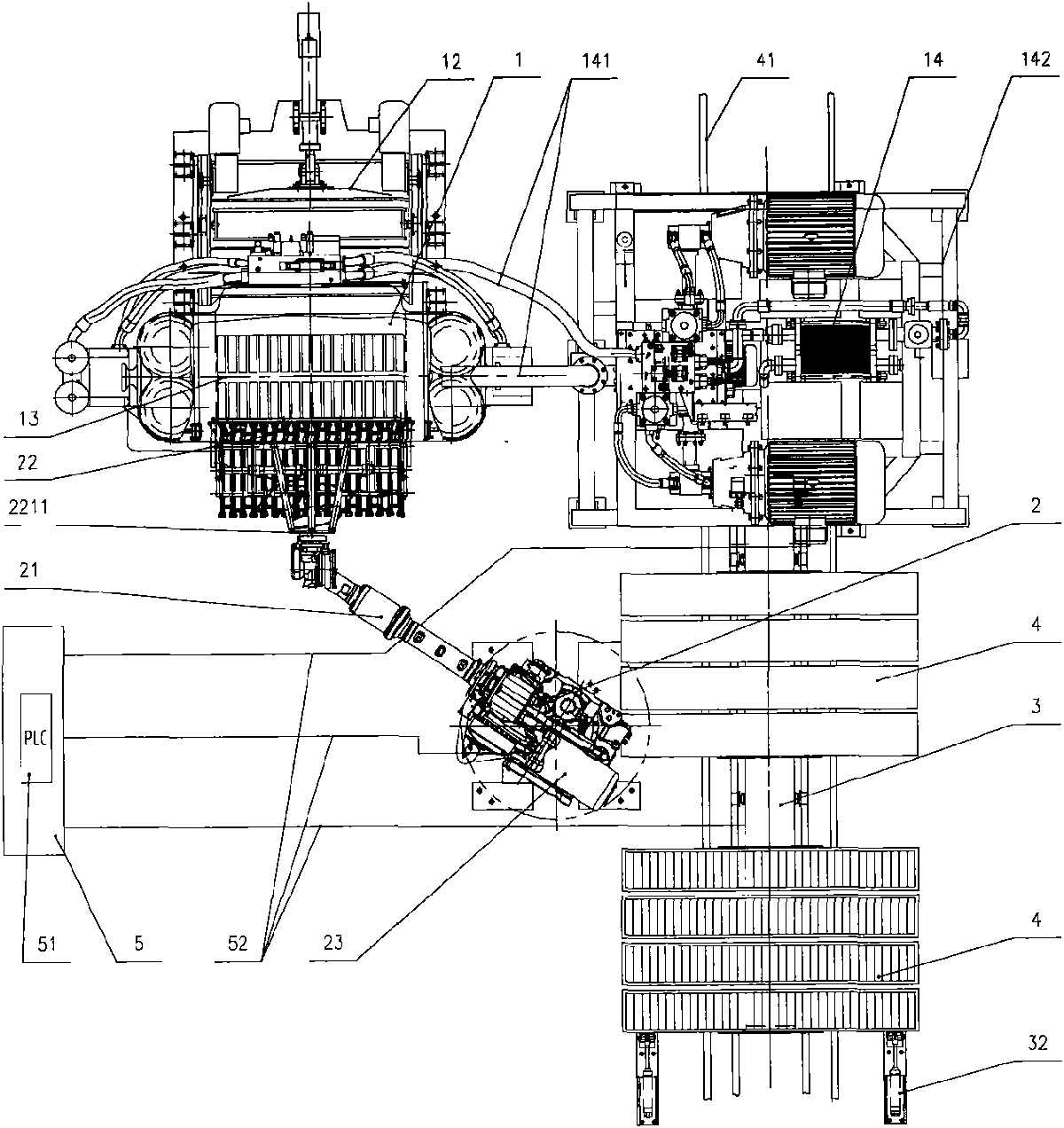

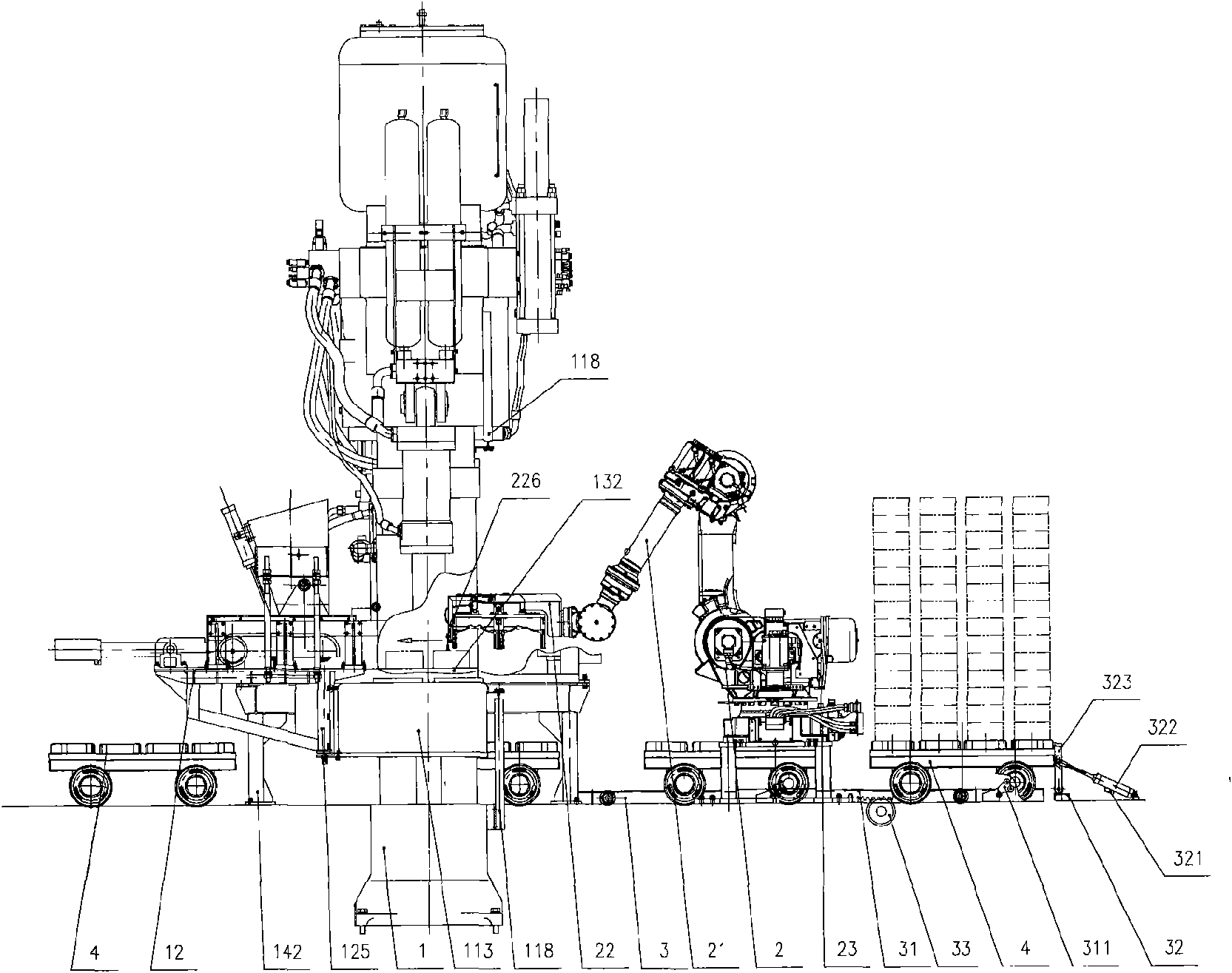

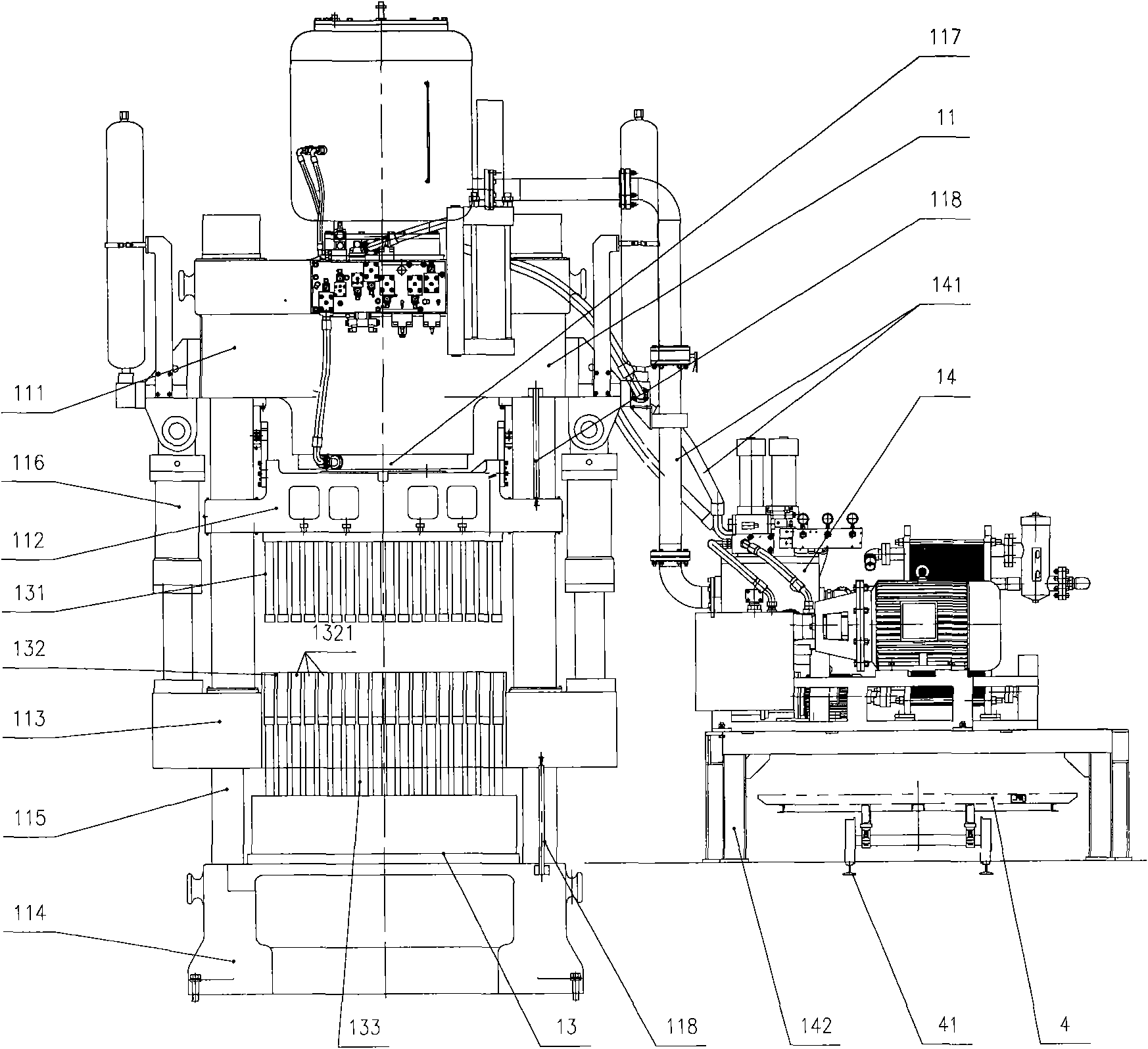

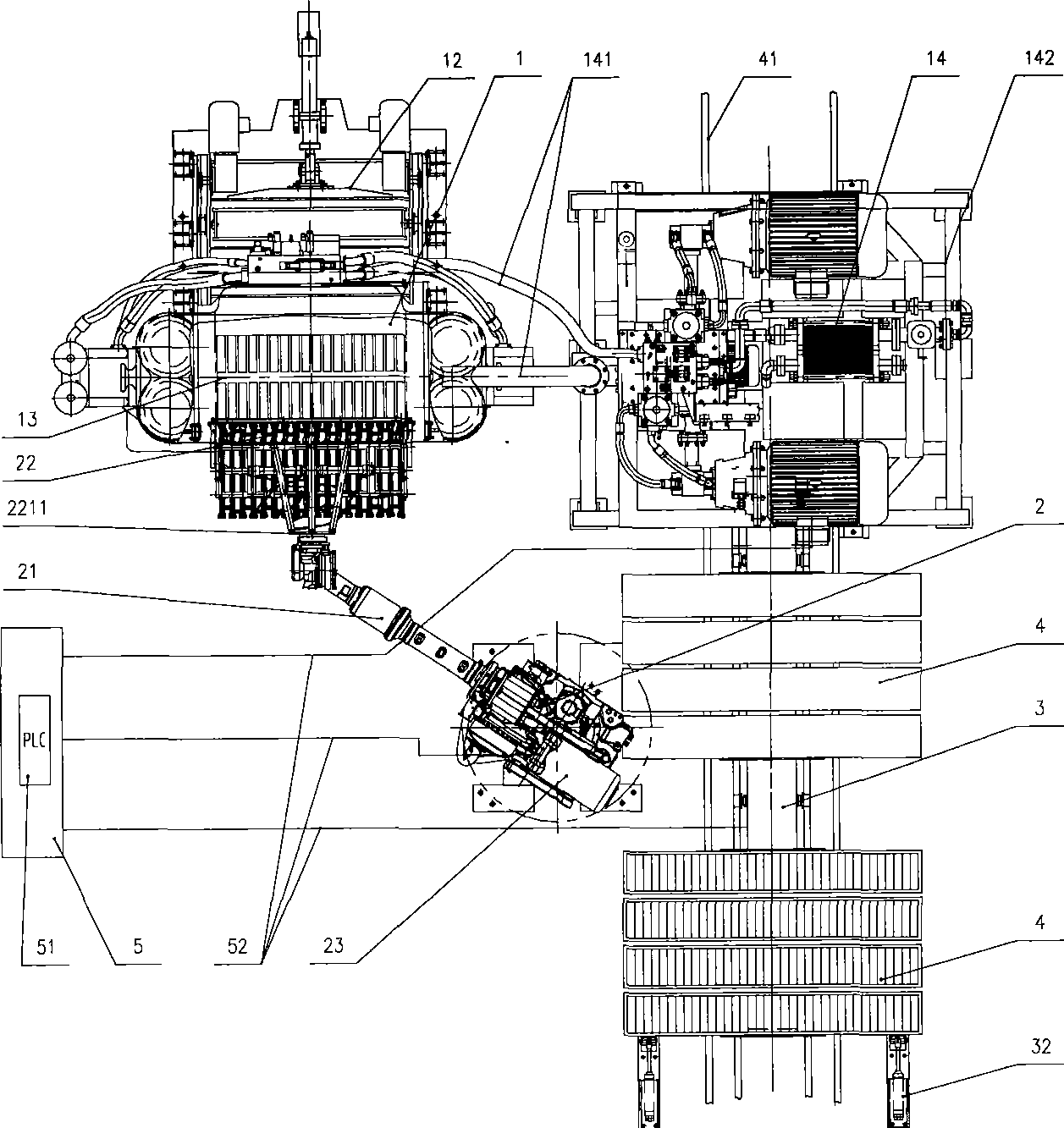

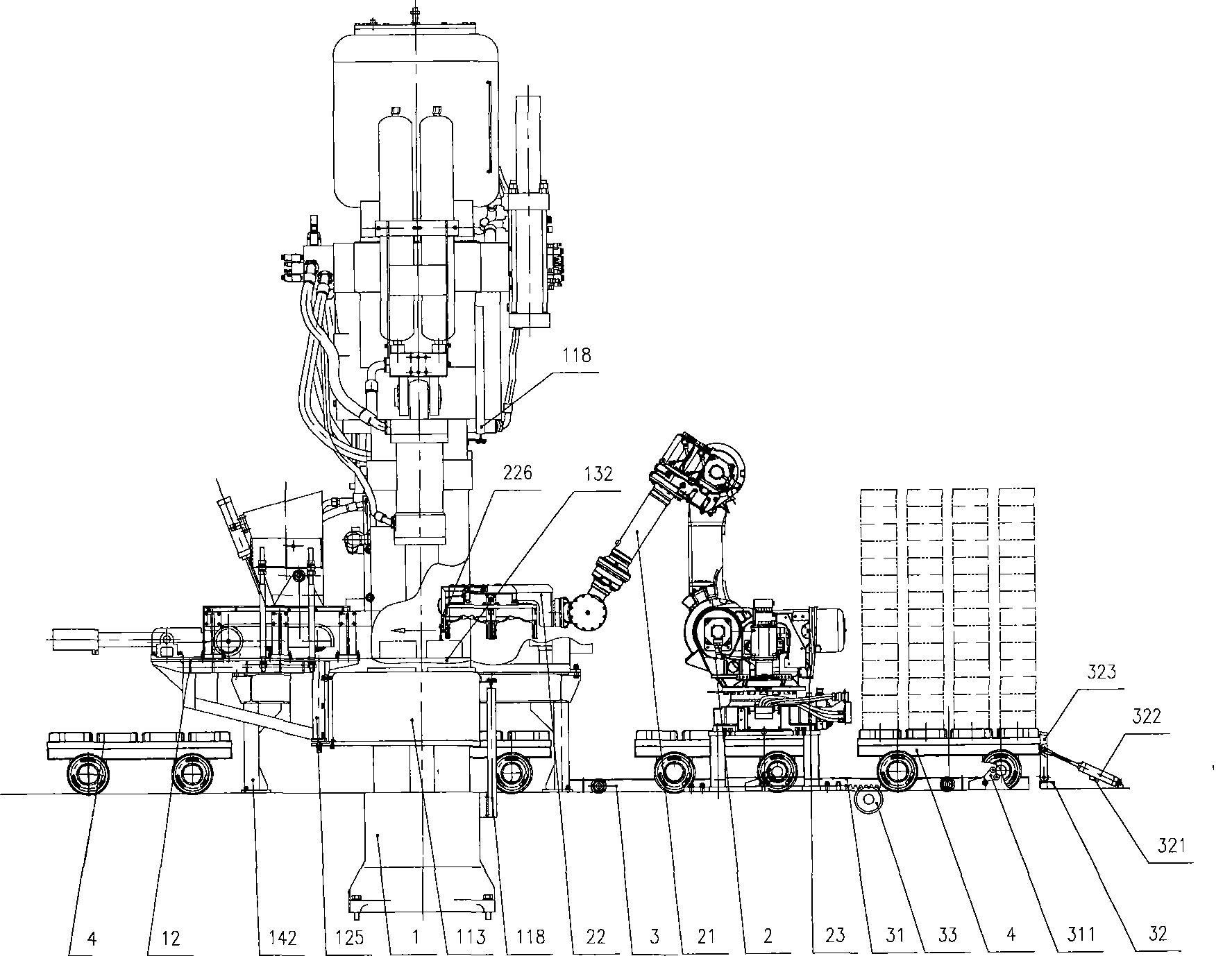

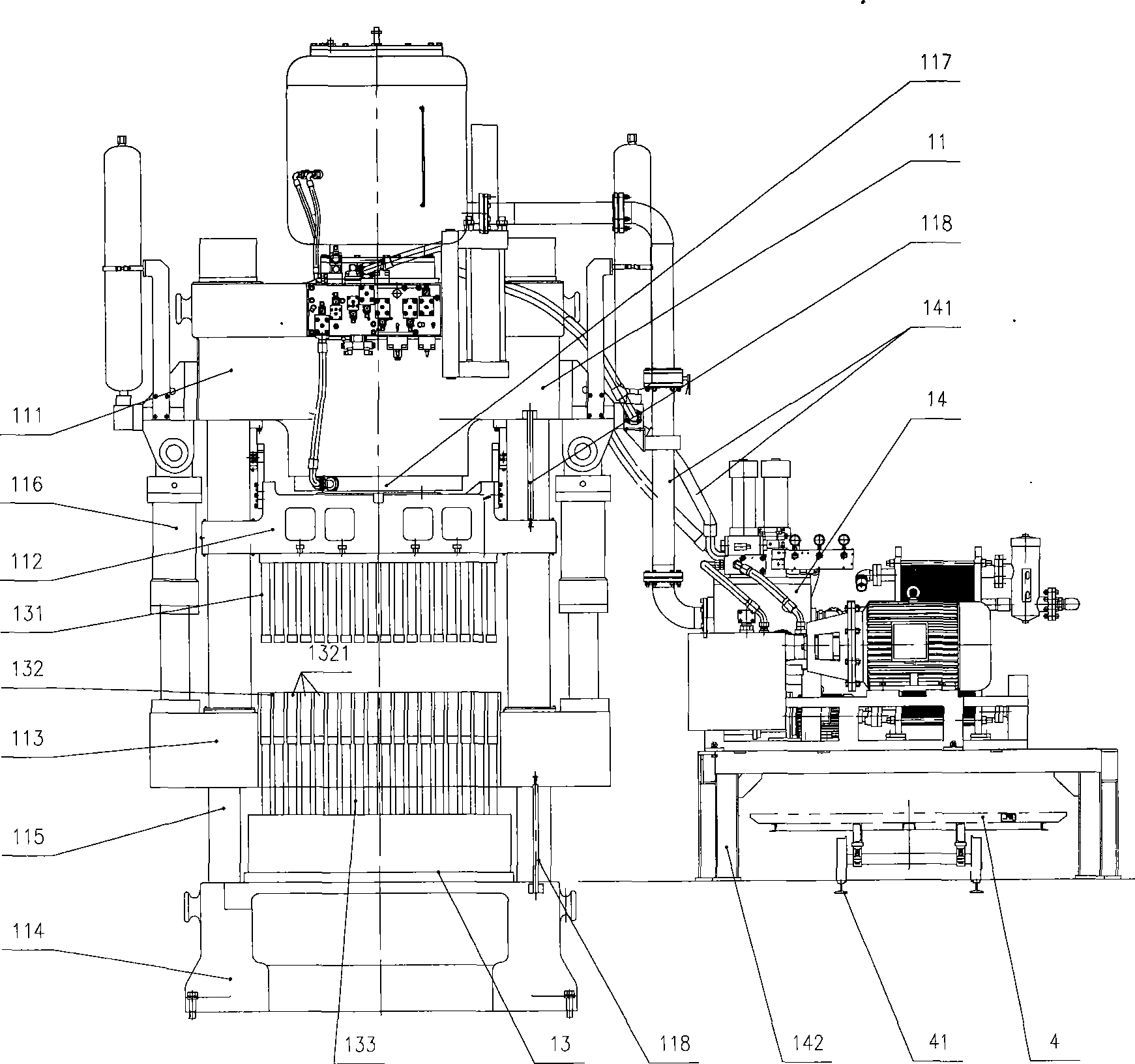

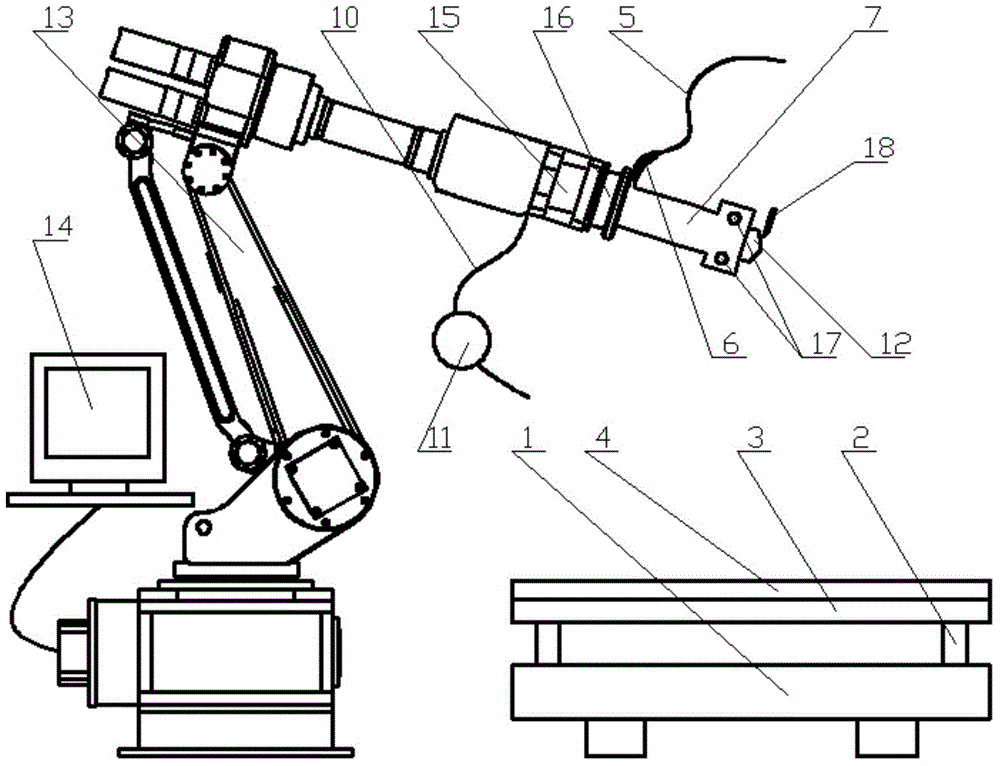

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

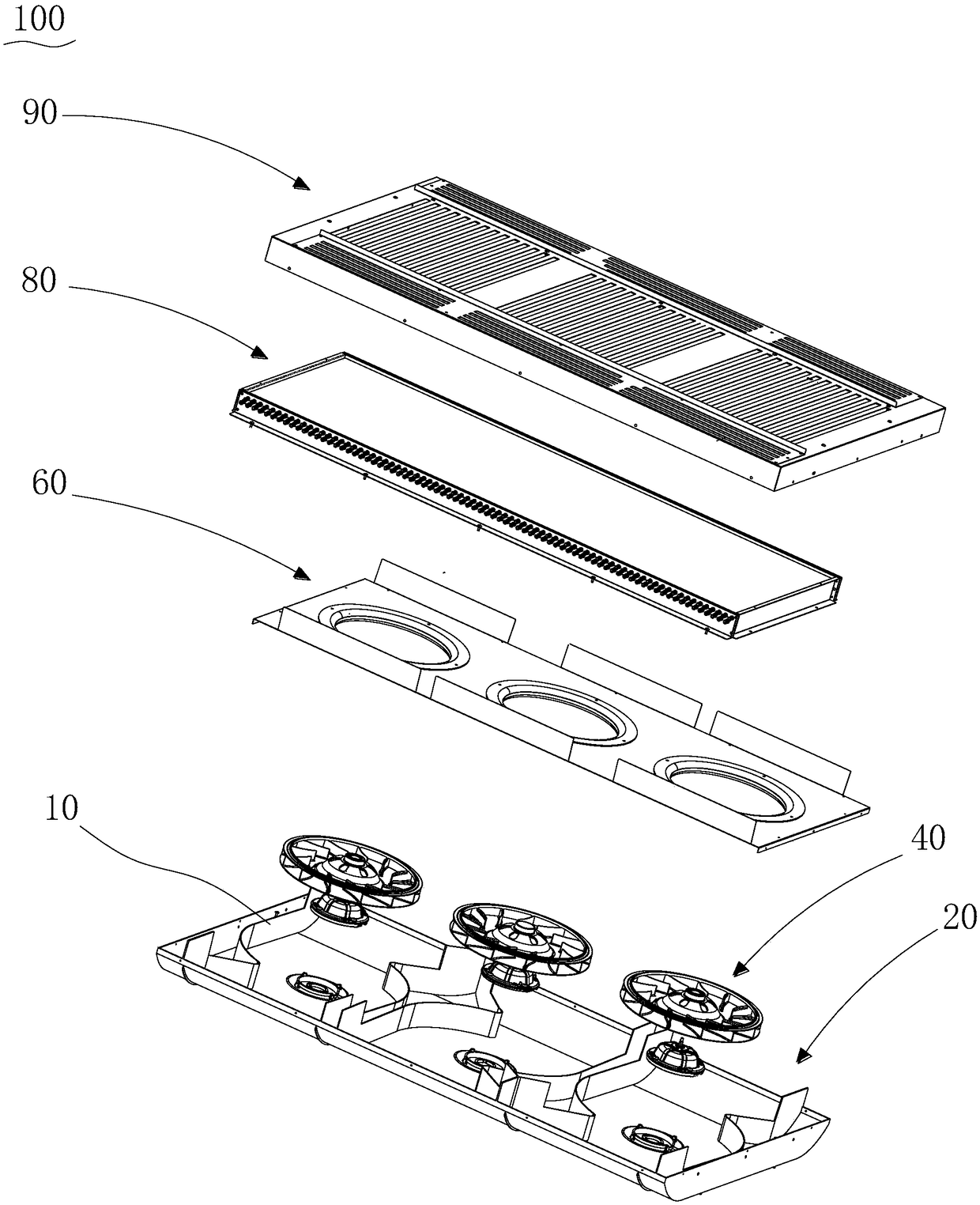

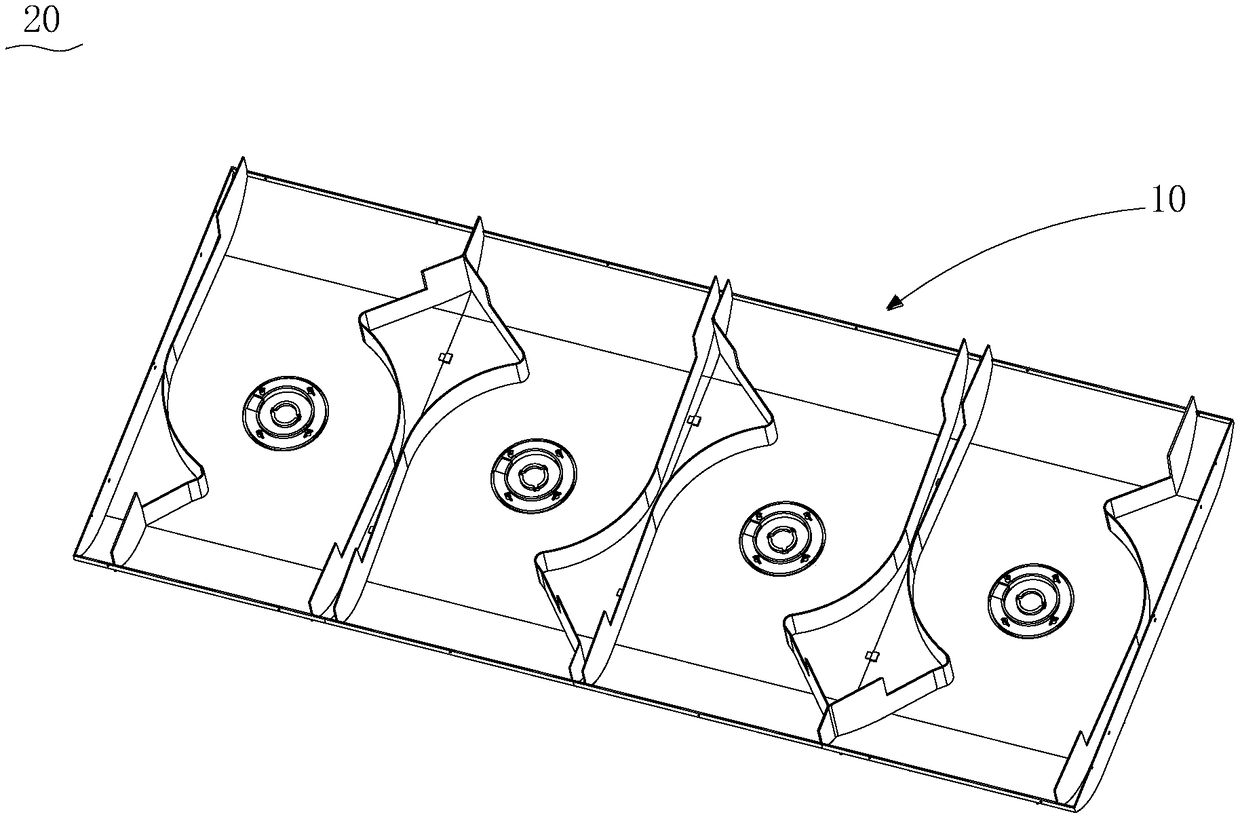

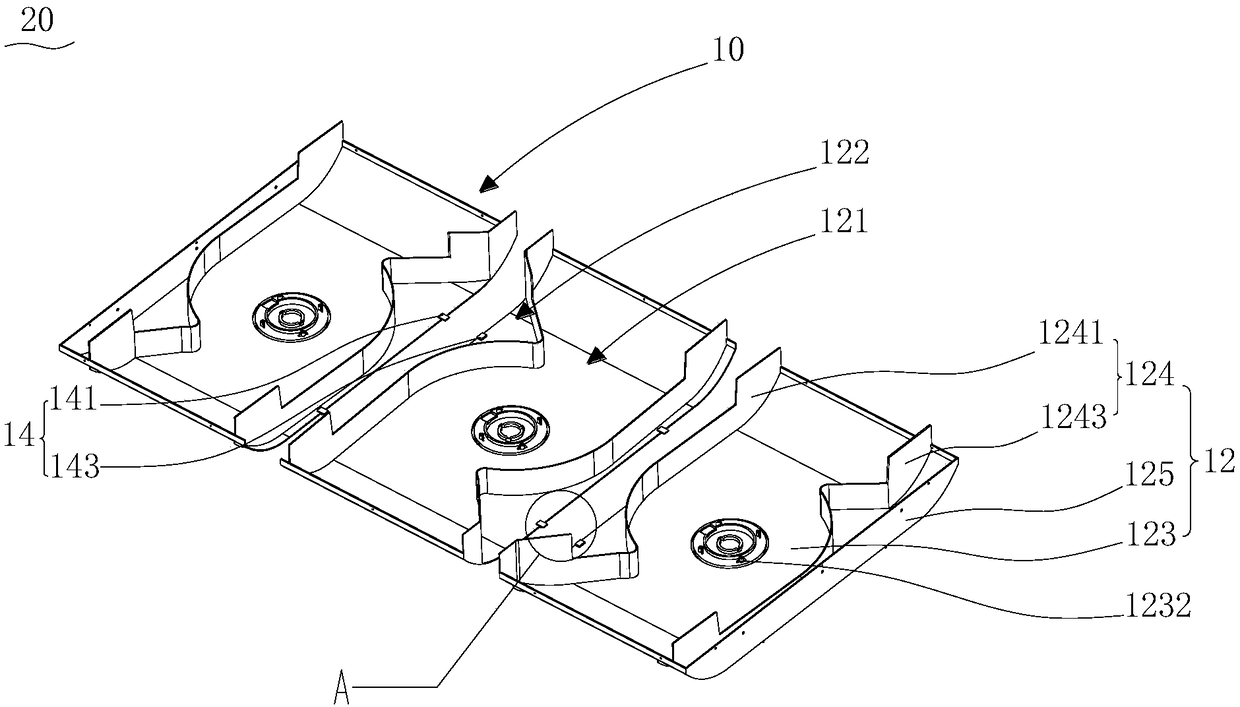

Air channel module and air channel structure with air channel module and air conditioner

InactiveCN109000352AReduce design costReduce manufacturing costDucting arrangementsLighting and heating apparatusEngineeringFan blade

The invention relates to an air channel module and an air channel structure with the air channel module and an air conditioner. The air channel module comprises an air channel main body and a connecting assembly, wherein the air channel main body comprises an air field area in which an airflow air channel is formed, and the airflow air channel is provided with two opposite air outlets; the connecting assembly is arranged on the air channel main body; and a plurality of air channel modules can be connected with each other by virtue of respective connecting assemblies so as to form the air channel structure with a plurality of air field areas. According to the air channel module, different number of air channel modules can form different air channel structures so as to install different number of fan blades, so that the air channel module can be applied to series of products with different heat transfer periods, and the different air channel structures do not need to be independently designed and manufactured according to the products with the different heat transfer periods, so that the design and production cost is effectively reduced, and the production cycle is shortened.

Owner:GREE ELECTRIC APPLIANCES INC

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

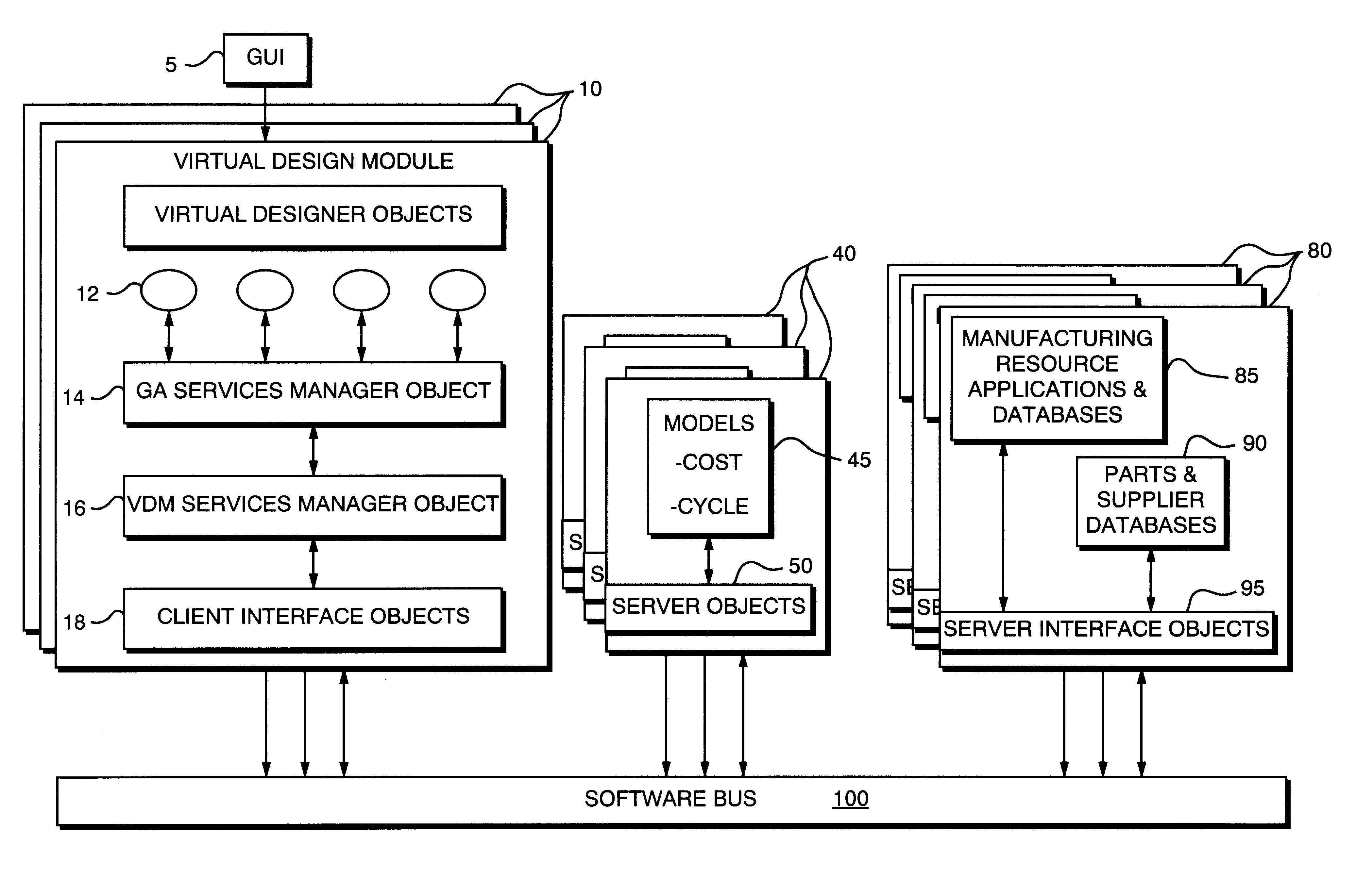

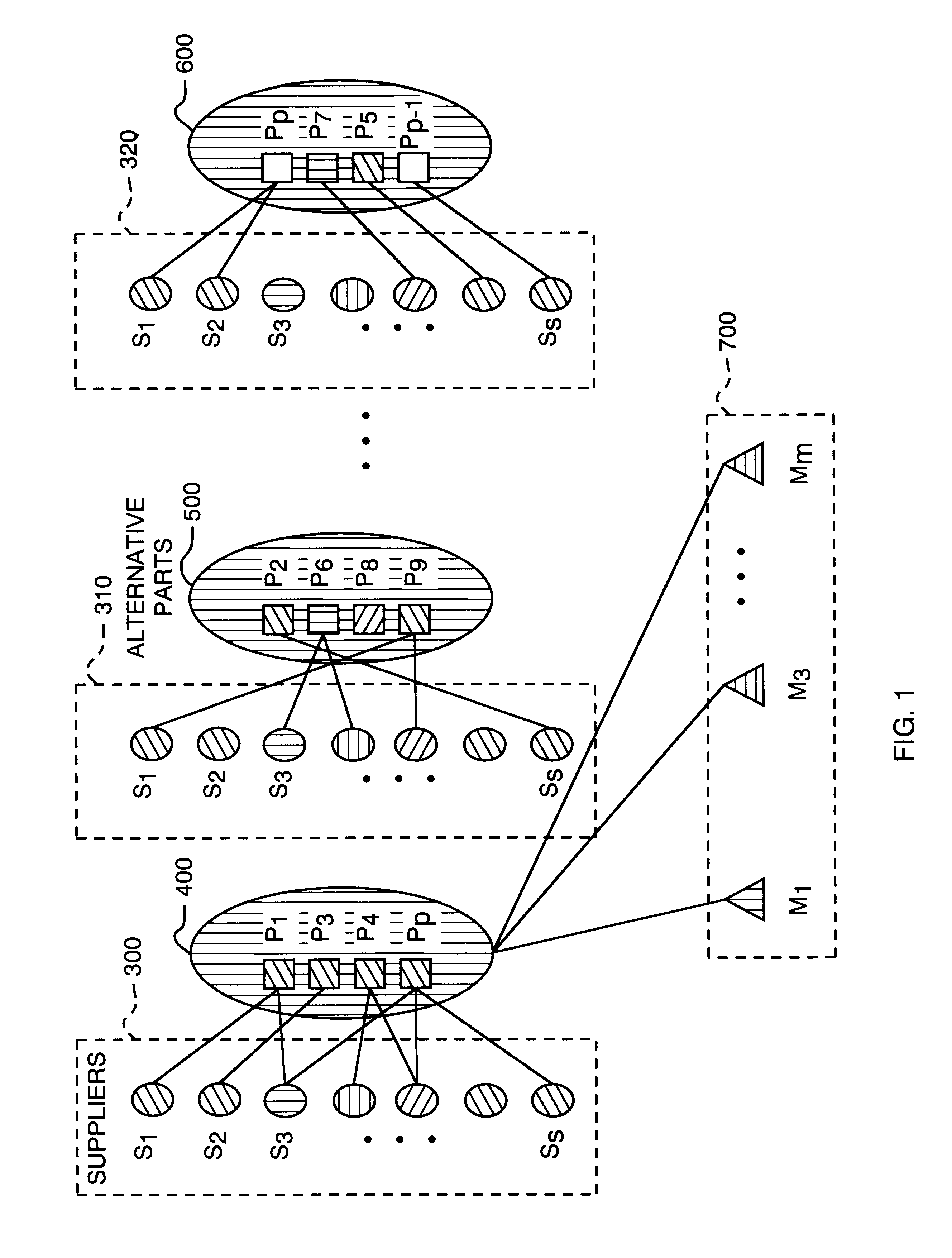

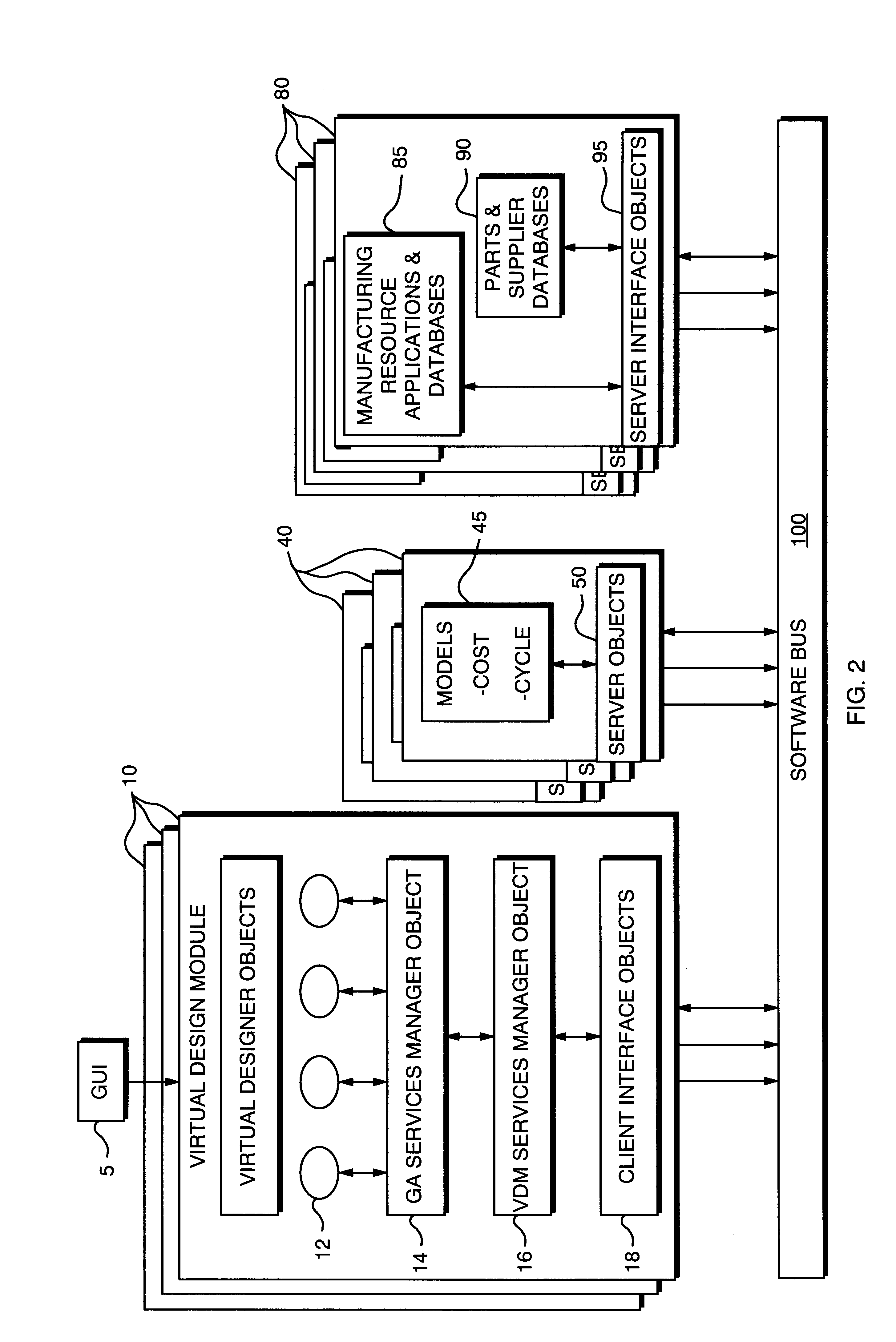

Virtual design module

A Virtual Design Module (VDM) used in a networked design environment generates manufactured product designs that are near optimal in terms of cost and production cycle time by using design data files containing alternative parts and manufacturers information. Numerous product design alternatives are considered and evaluated in terms of design-manufacturing-parts-supplier feasibility and real-time information on cost and production cycle time for realization. The VDM generates a population of new designs with appropriate board design information to allow for design-manufacturer-supplier decision making and determines the feasibility of each member of the current generation of designs and rejects designs that are not feasible. The VDM triggers Mobile Software Agents (MSA) that obtain data for parts availability, cost, lead time and manufacturer data for manufacturing availability, cost and lead time for each feasible member of the current generation of designs and return the data. In one application for printed circuit board design, the VDM evaluates each member of the current generation of designs by calculating cost, lead-time and value using a J function. The VDM then improves board designs through selection and use of board design modifiers. The process continues until optimized designs are obtained. Optimized board designs are output as results to an operator.

Owner:RENESSELAER POLYTECHNIC INST

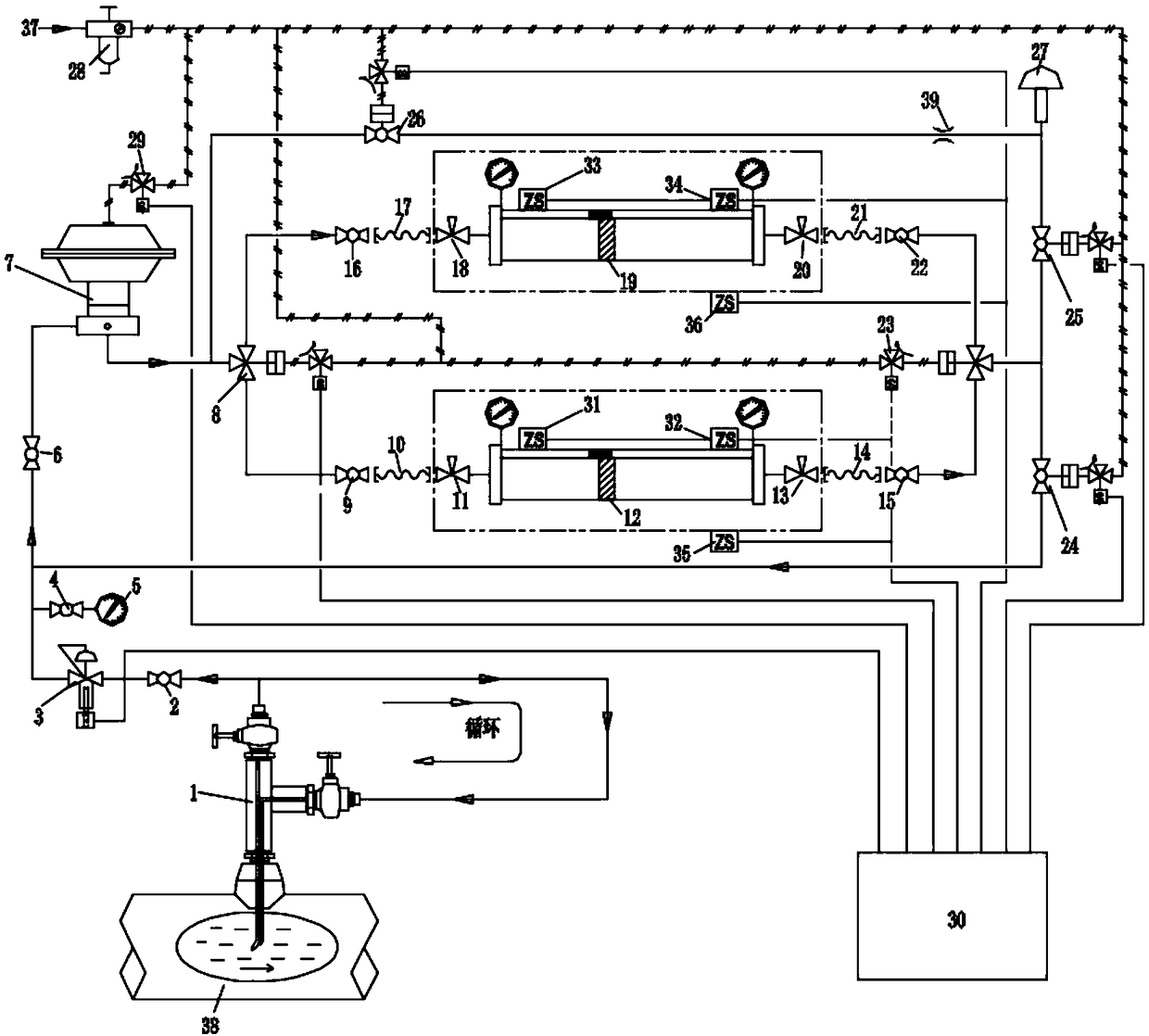

Automatic natural gas continuous-sampling control system

PendingCN109141990ARealize continuous samplingRepresentativeWithdrawing sample devicesControl systemProduct gas

The invention belongs to the technical field of natural gas detection and particularly relates to an automatic natural gas continuous-sampling control system. The system includes a reducing valve anda sampling probe connected with a natural gas pipe. An inlet of the reducing valve is connected with an outlet of the sampling probe, an outlet of the reducing valve is divided into two paths, one path is connected with a pneumatic membrane sampling pump, and the other path is connected with outlet ends of a first constant-pressure sampling steel bottle and second constant-pressure sampling steelbottle. The system also includes a full-automatic natural gas replacement system. The automatic natural gas continuous-sampling control system can achieve continuous sampling. Since sampling is conducted once every certain time interval until the constant-pressure sampling steel bottles are fully filled, sampled gas can completely represent a fluid medium in a whole production cycle and have representativeness.

Owner:JEREH TIANJIN PETROLEUM ENG & TECH

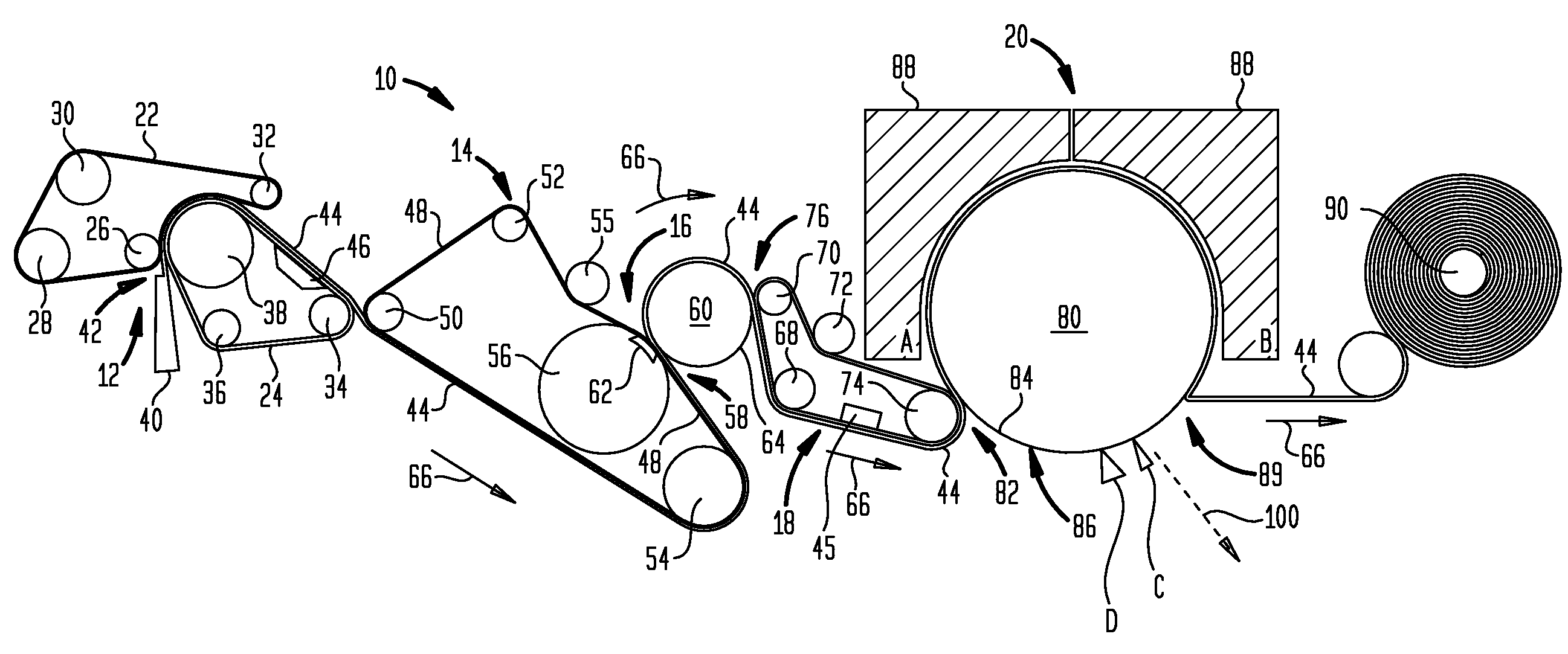

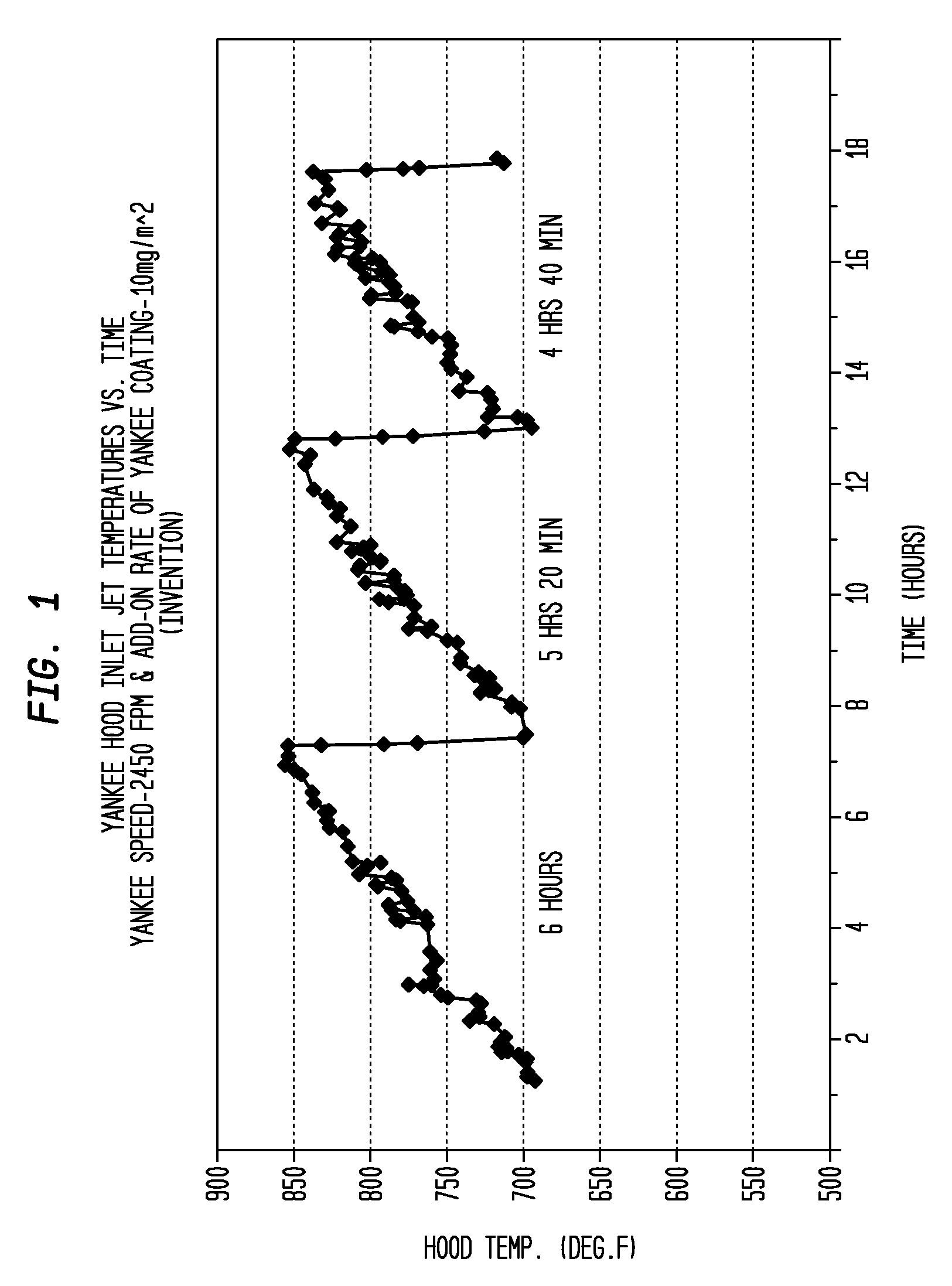

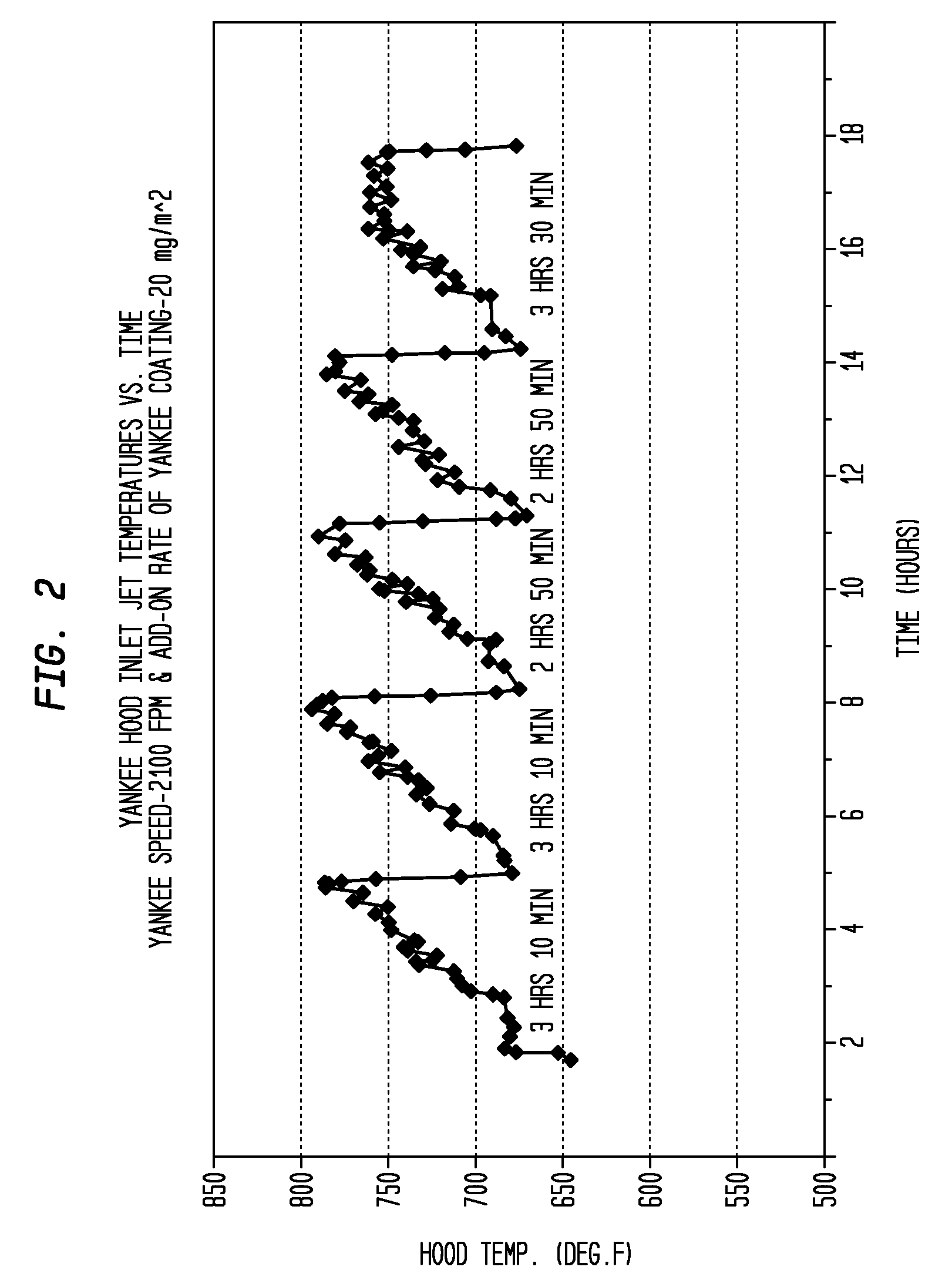

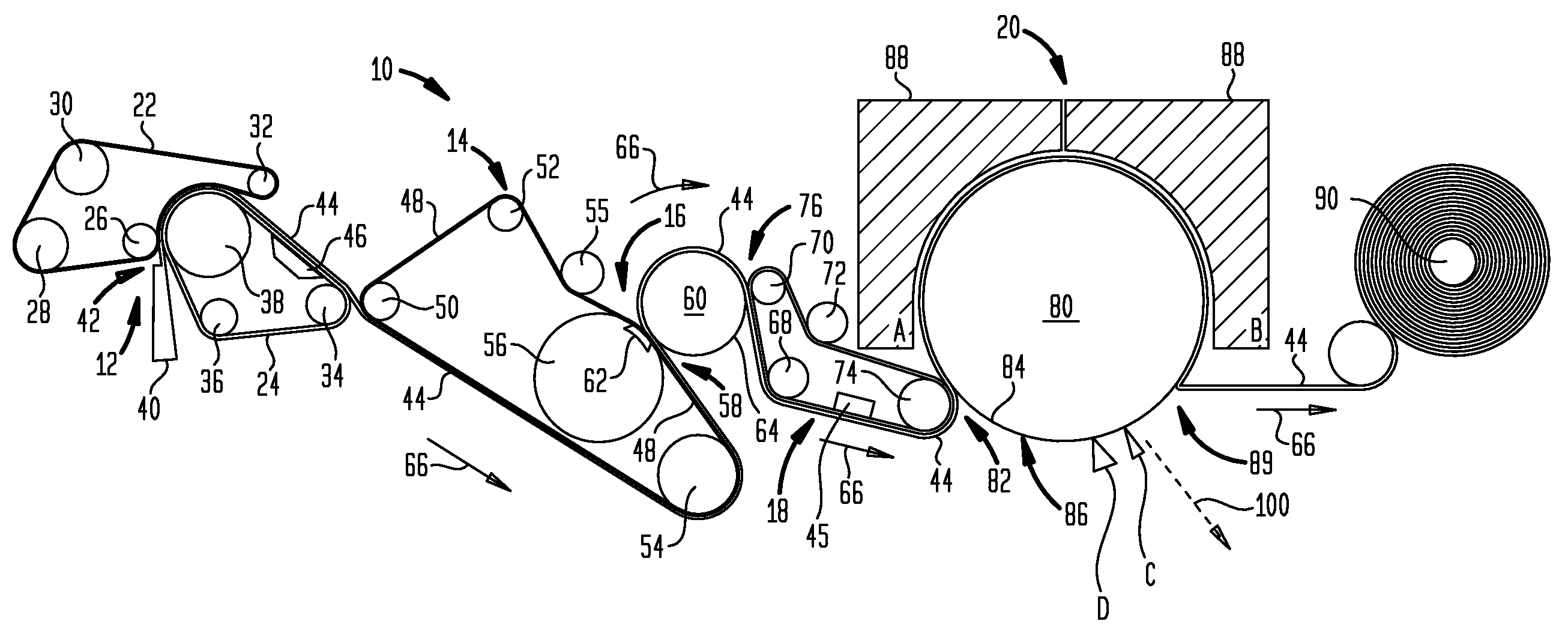

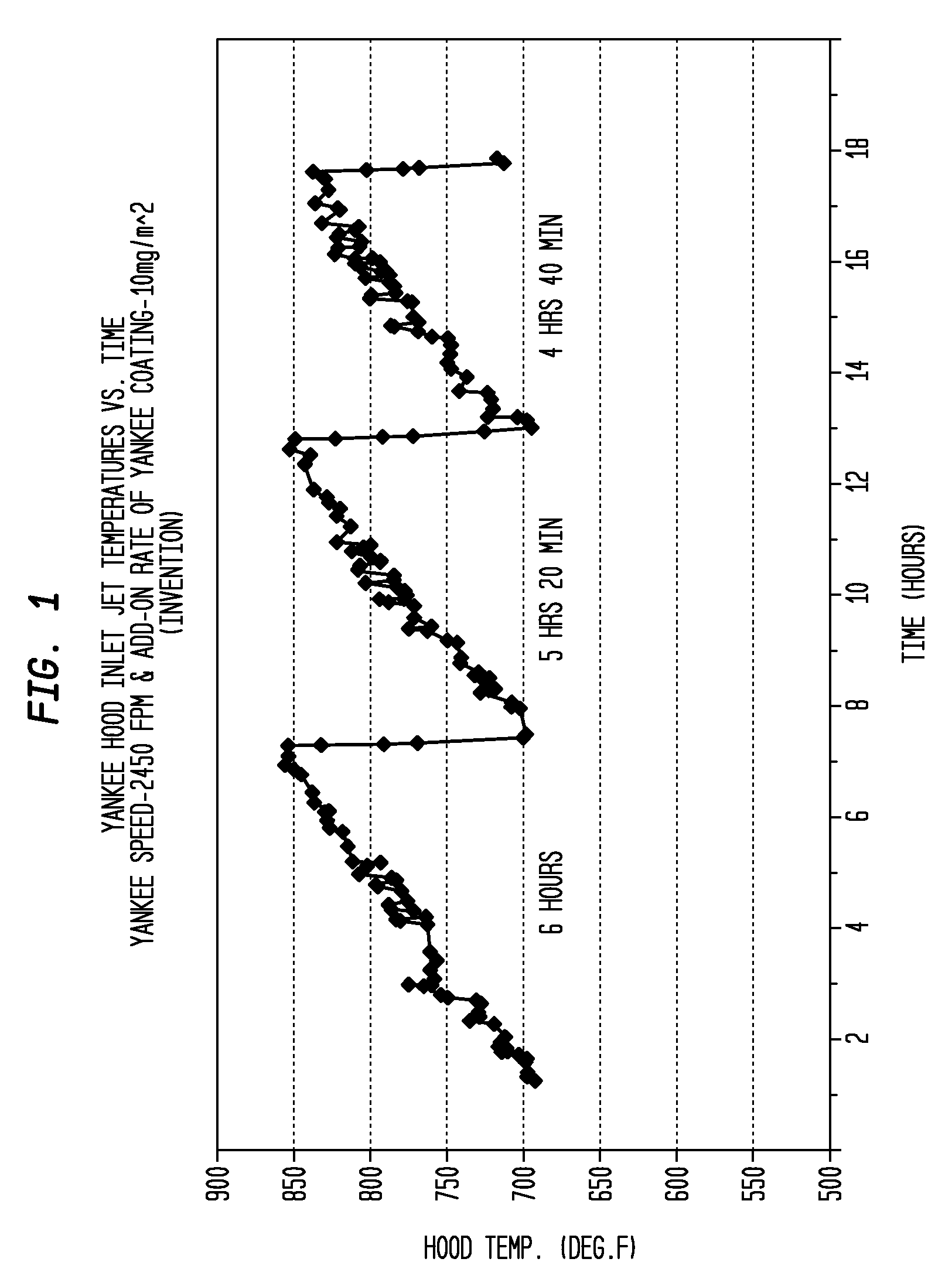

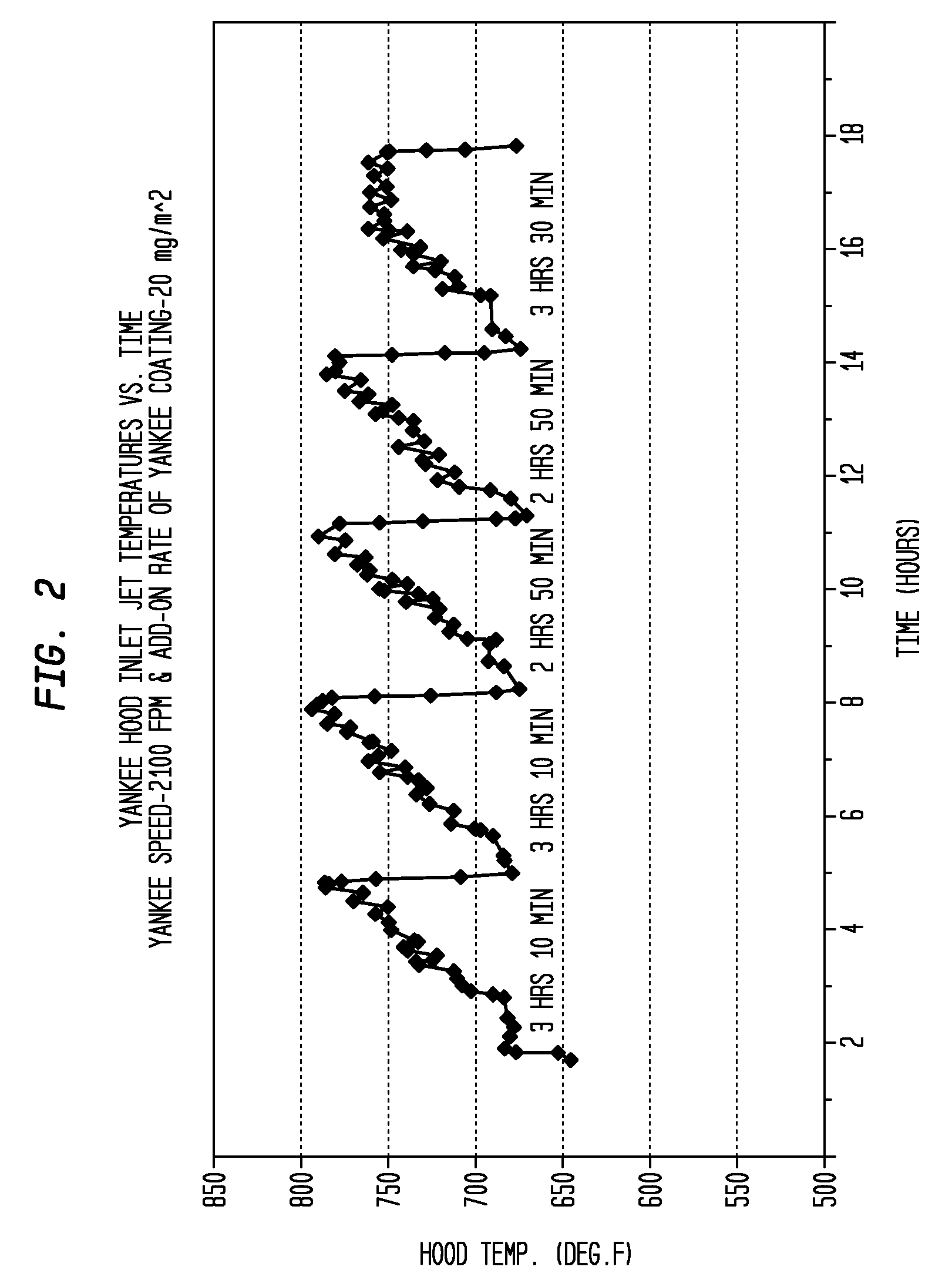

Fabric-crepe process with prolonged production cycle and improved drying

ActiveUS7608164B2Increases the amount of production available from a paper machineKeep dryNon-fibrous pulp additionDrying using combination processesAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

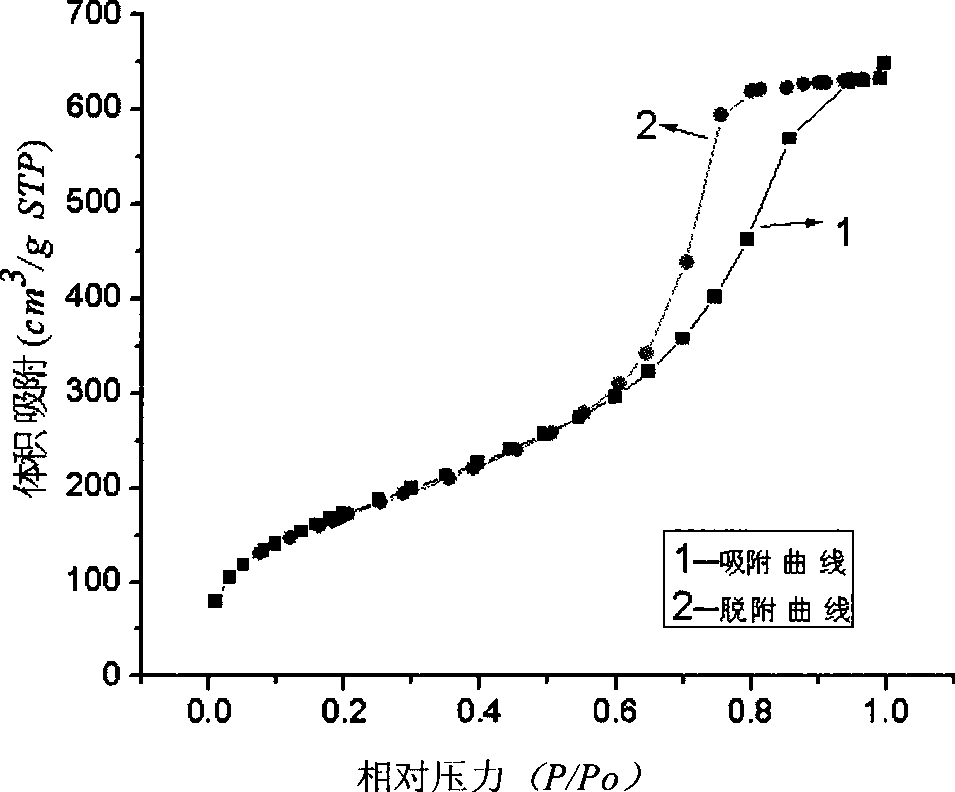

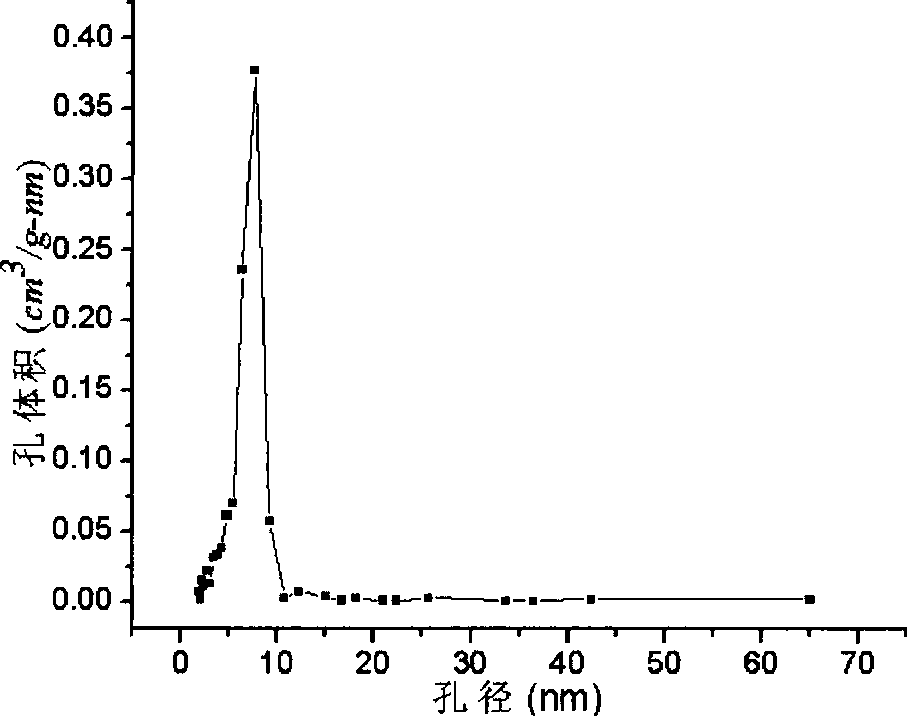

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

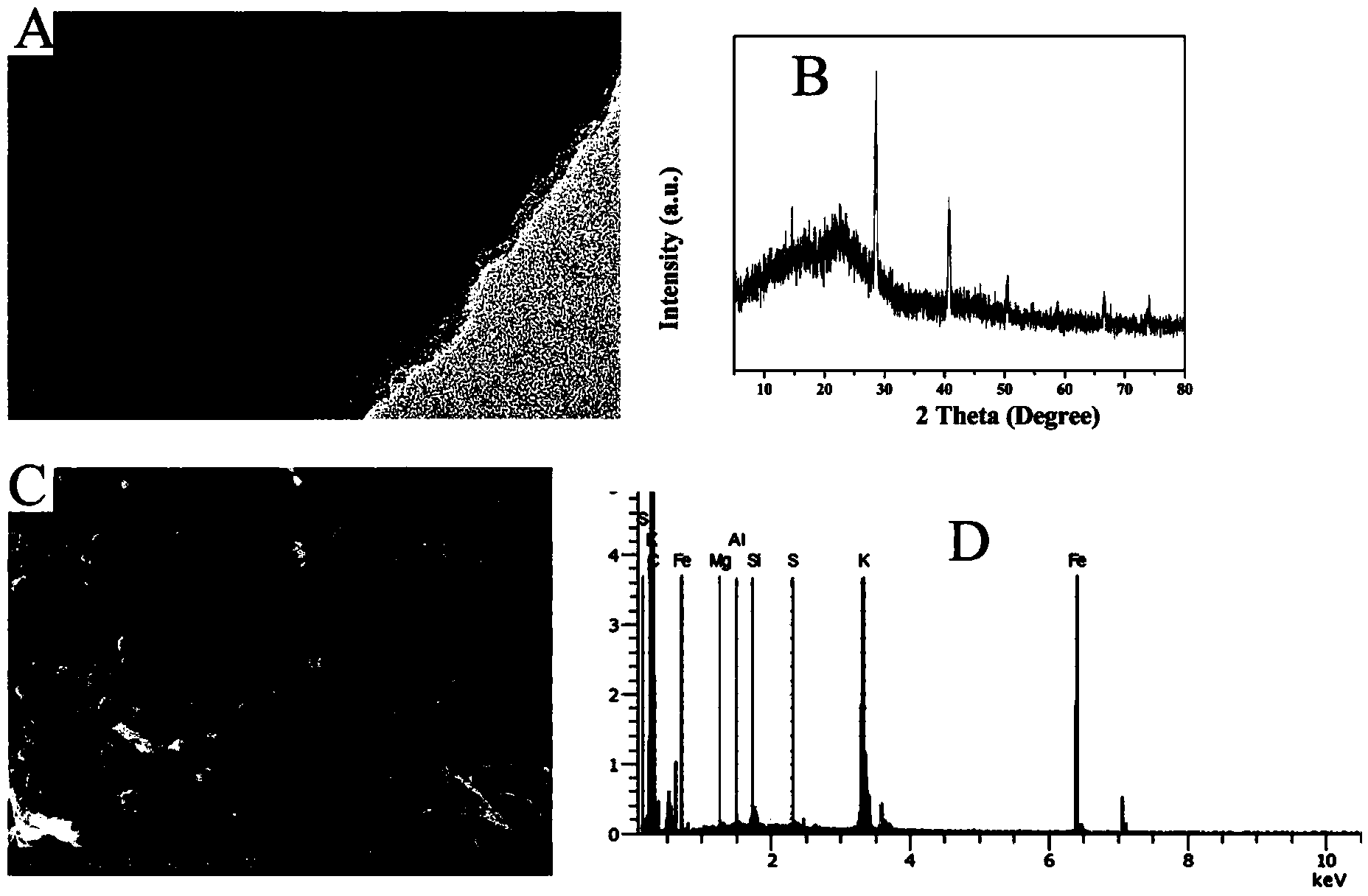

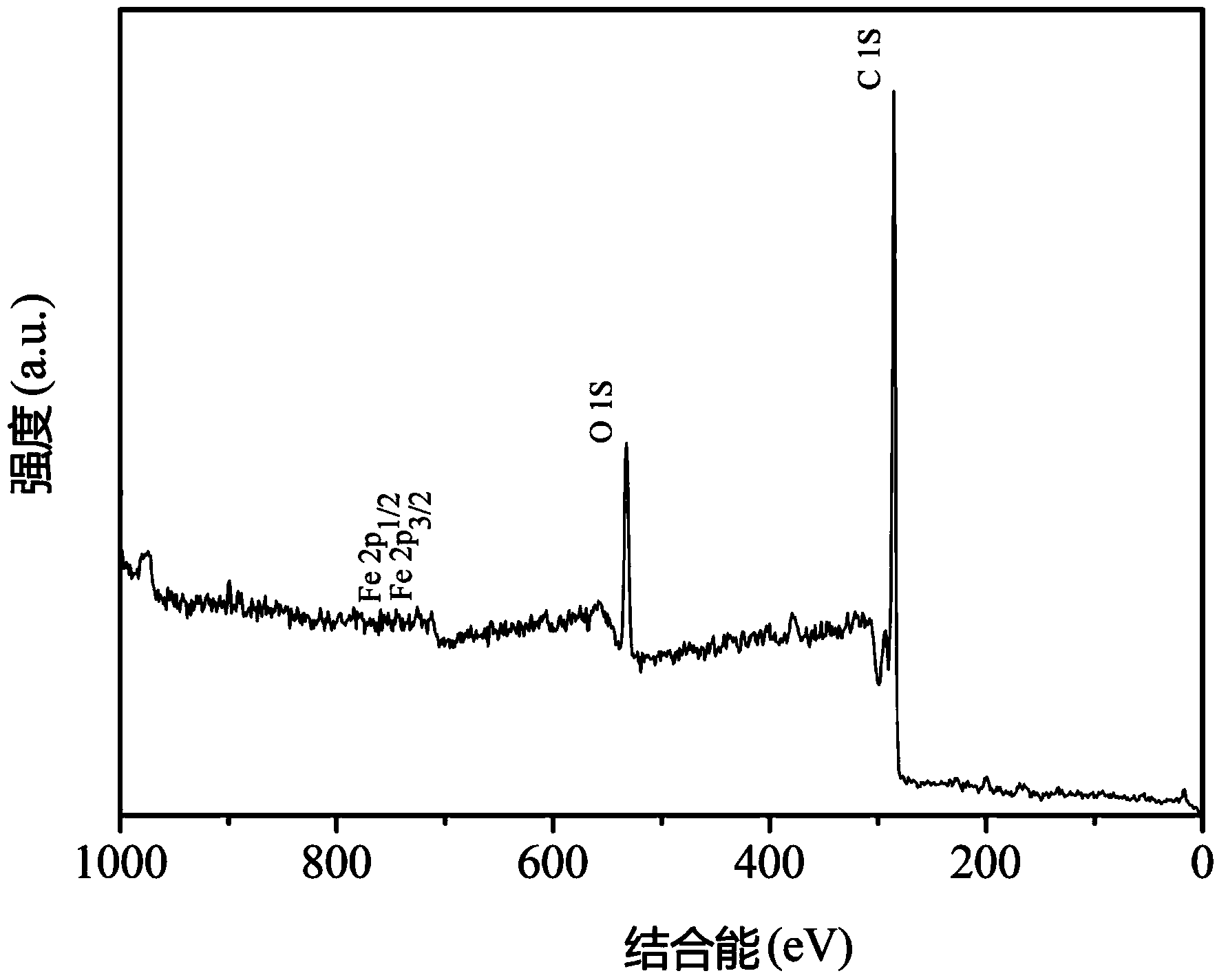

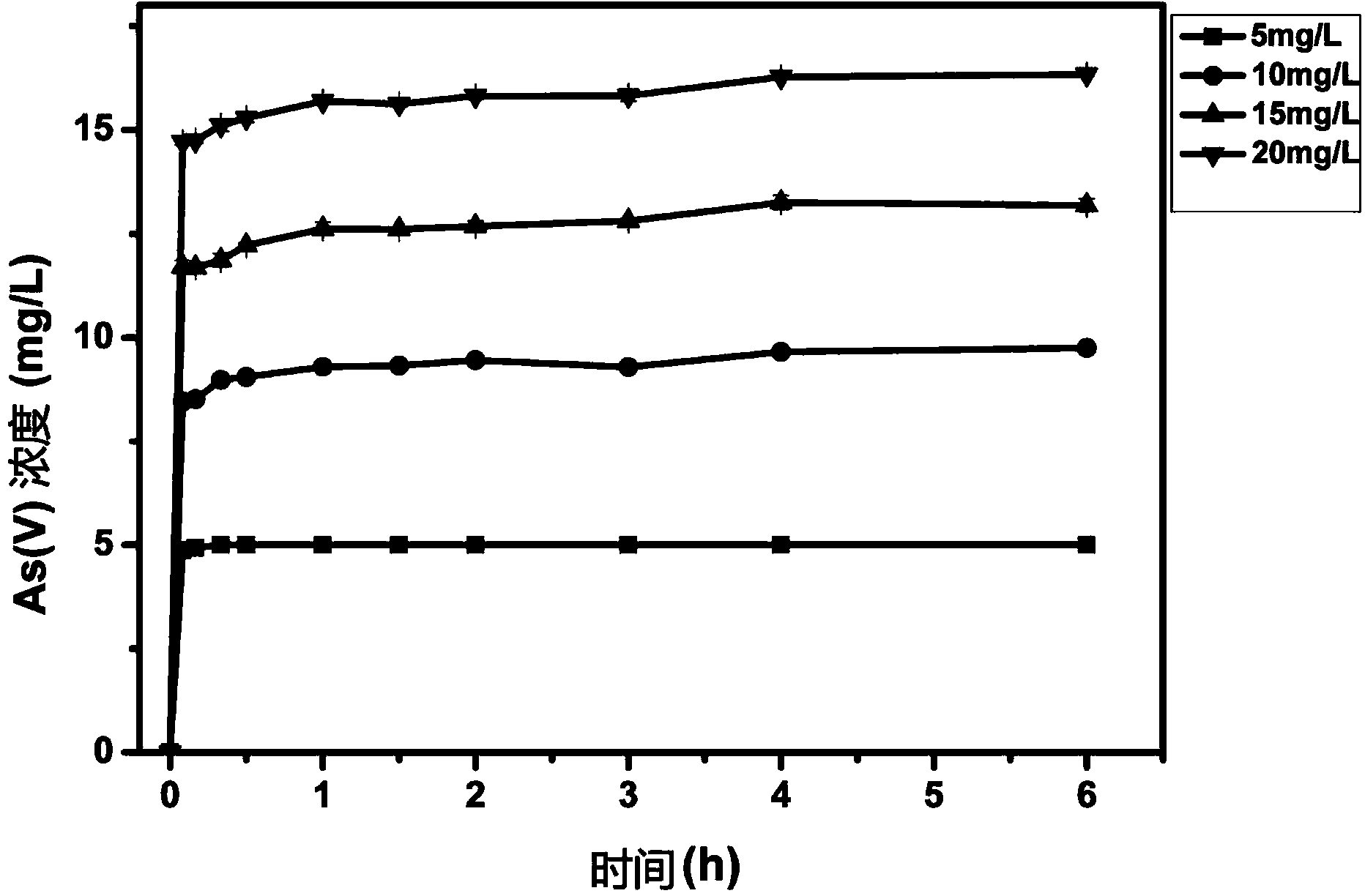

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

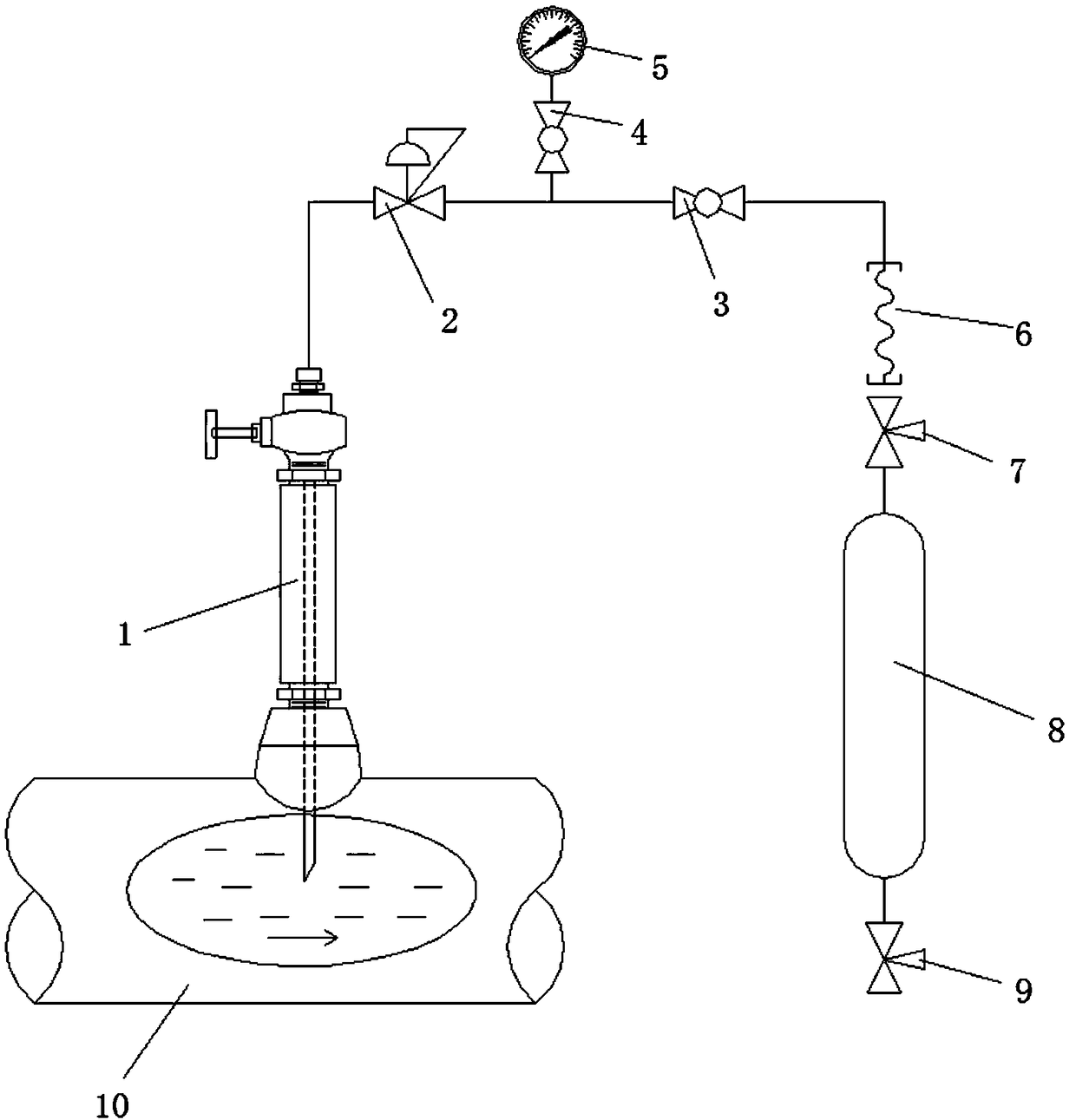

Channeling preventing and plugging agent and construction method for controlling plugging and sealing channeling by utilizing channeling preventing and plugging agent

ActiveCN105086967AExtend the production cycleEnhanced overall recoveryDrilling compositionSealing/packingEngineeringTemperature resistance

The invention provides a channeling preventing and plugging agent and a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The channeling preventing and plugging agent comprises a high-temperature-resistance pre-plugging agent serving as a pre-posed pre-plugging plug, an enhanced gel plugging agent serving as an intermediate enhanced plug and a high-strength resin plugging agent serving as a postposed sealing plug. The channeling preventing and plugging agent has the characteristics of high temperature resistance, long-term stability, good plugging performance and the like. The invention further provides a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The method has a simple constructing process, and can be used for constructing after the channeling preventing and plugging agent is directly prepared on the spot. The channeling preventing and plugging agent can be used for effectively solving the adverse impact of the steam / air channeling phenomenon of a heavy oil thermal production well on production, and has an important effect on prolonging the production cycle of a heavy oil well and improving the recovery efficiency.

Owner:PETROCHINA CO LTD

Wood carbonization treatment method

ActiveCN1868704AAvoid defectsQuality improvementWood treatment detailsCarbonizationSaturated water vapor

A carbonization process for increasing the quality of wood by continuous gradient heating method includes such steps as heating to 120-140 deg.C, eating to 160-240 deg.C, spraying atomized water for slowly cooling to 100 deg.C, filling the saturated steam at 100 deg.C to return the water content back to 4-6%, and cooling to 15-30 deg.C.

Owner:ZHEJIANG SHIYOU TIMBER

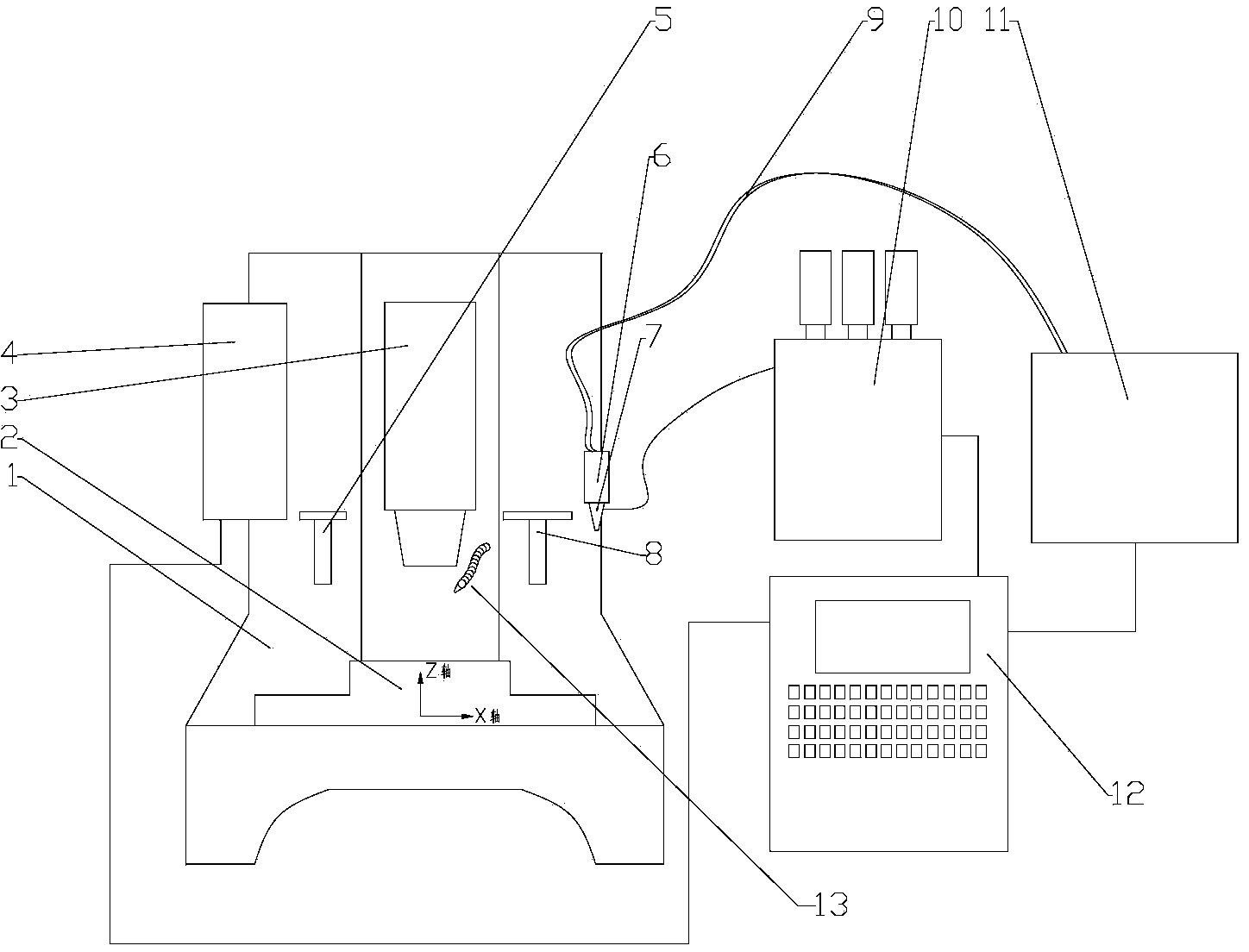

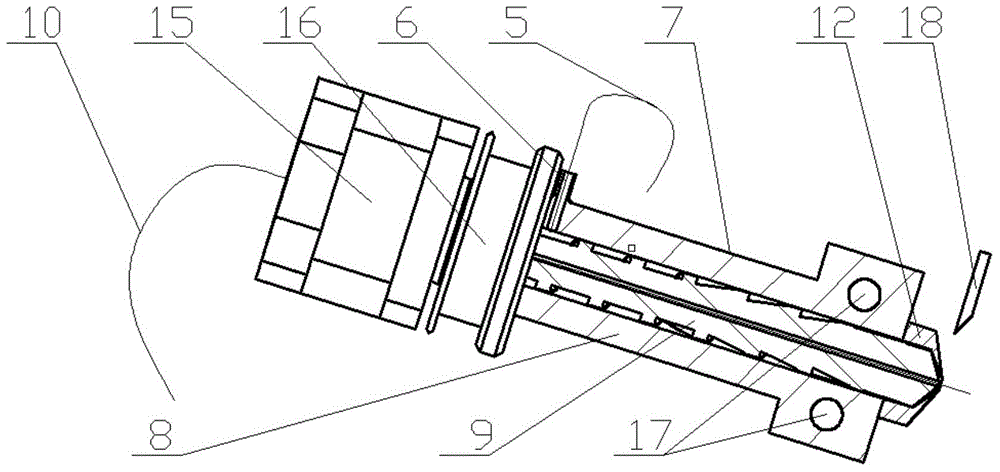

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

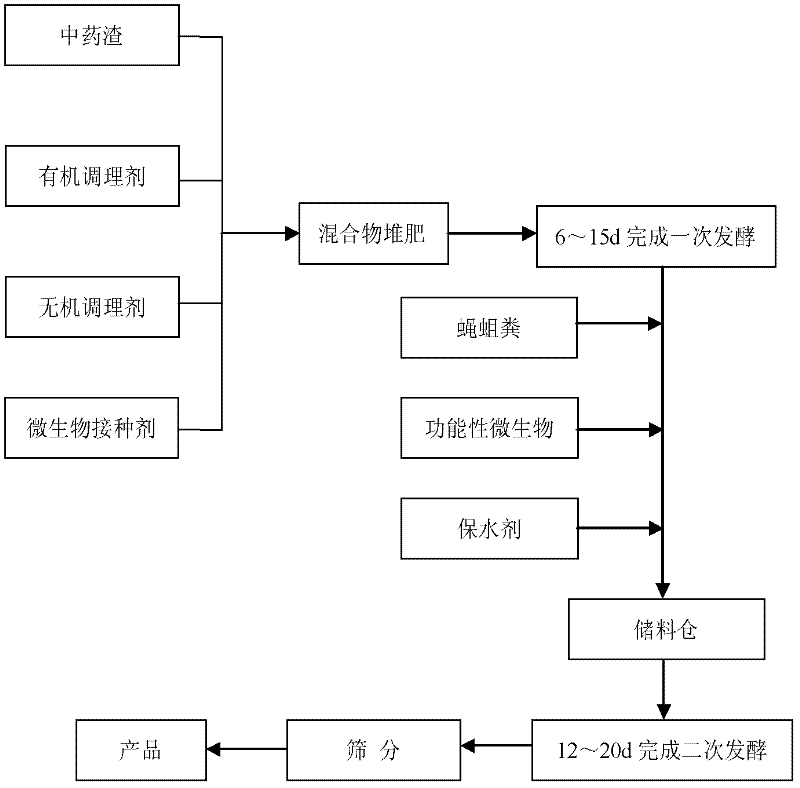

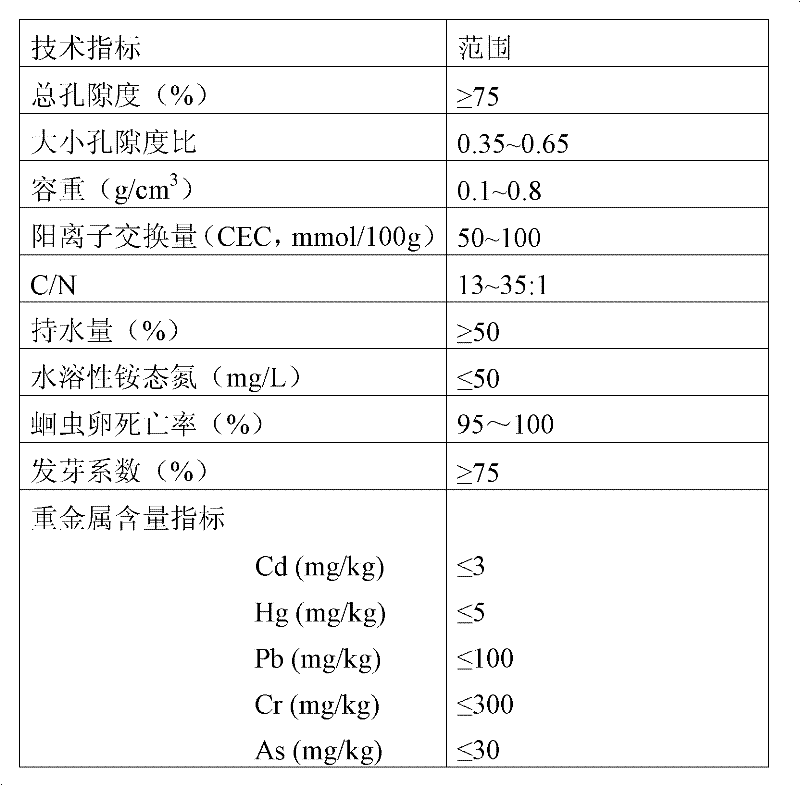

High-activity antibacterial peptide-containing matrix for garden seedling cultivation, as well as preparation and application thereof

ActiveCN102408280ADevelop circular economyRich in nutrientsFertilizer mixturesEcological environmentHousefly

The invention discloses a high-activity antibacterial peptide-containing matrix for garden seedling cultivation, as well as a preparation method and application thereof. The high-activity antibacterial peptide-containing matrix for garden seedling cultivation is prepared from the following components: Chinese medicament residues, organic additives, inorganic additives, microbial blends, housefly larva excrement, functional microbes and a water retention agent, wherein the functional microbes have the effects of activating matrix nutrition, exogenously fixing nitrogen, antagonizing pathogenic microorganism, reinforcing absorbing capability of seedling roots to nutrition and promoting seedling growth. Furthermore, the matrix for garden seedling cultivation has comprehensive nutrient elements, stable performance, strong buffer capability, and good water and fertilizer retaining performance; and the preparation method has simple production process, short production period, wide sources and low cost of raw materials, no environmental pollution and convenience in large-scale commercial production. The matrix for garden seedling cultivation can be used for raising and cultivating garden green seedlings, and can also be used for repairing and improving the ecological environment.

Owner:广州普邦园林股份有限公司 +1

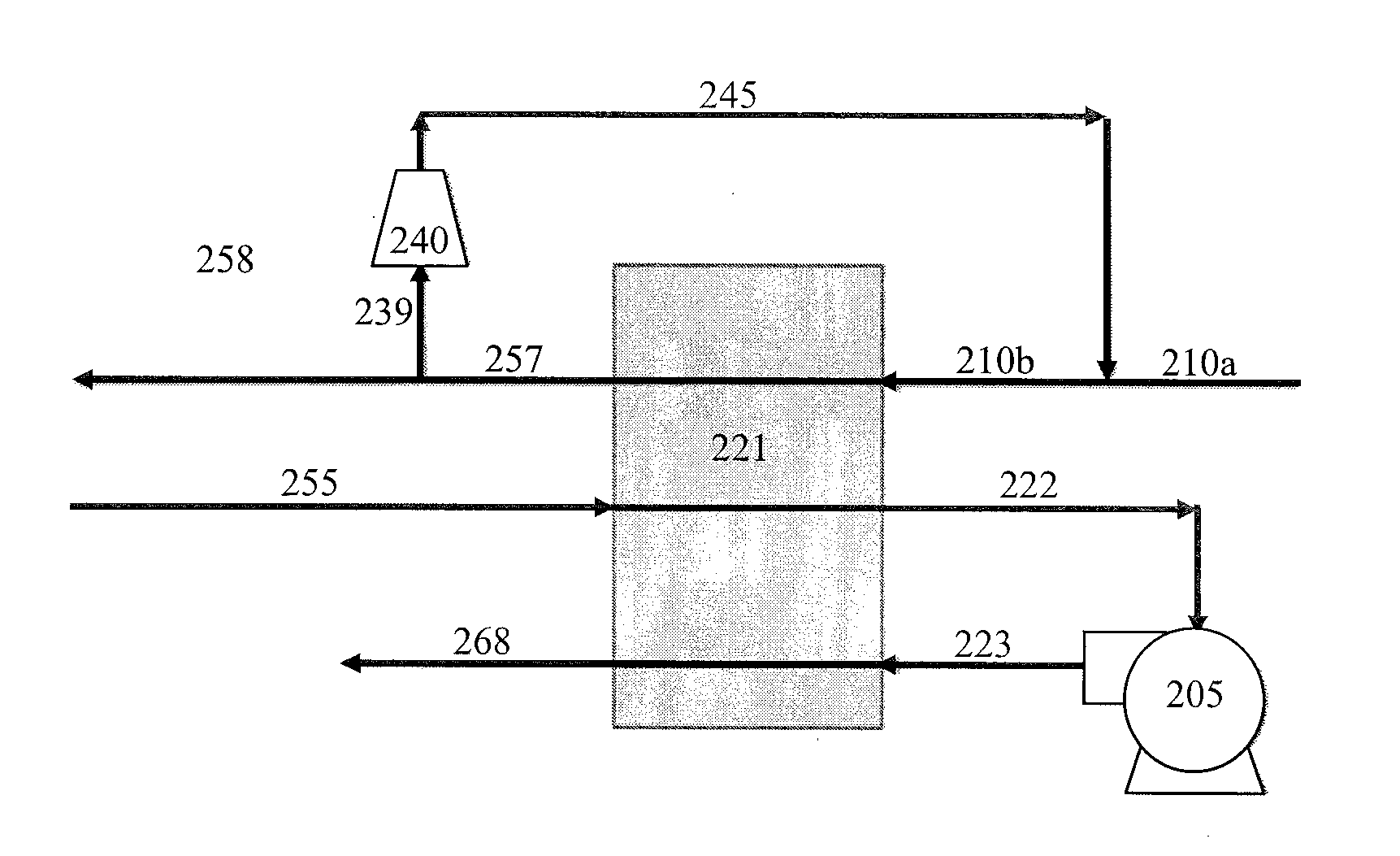

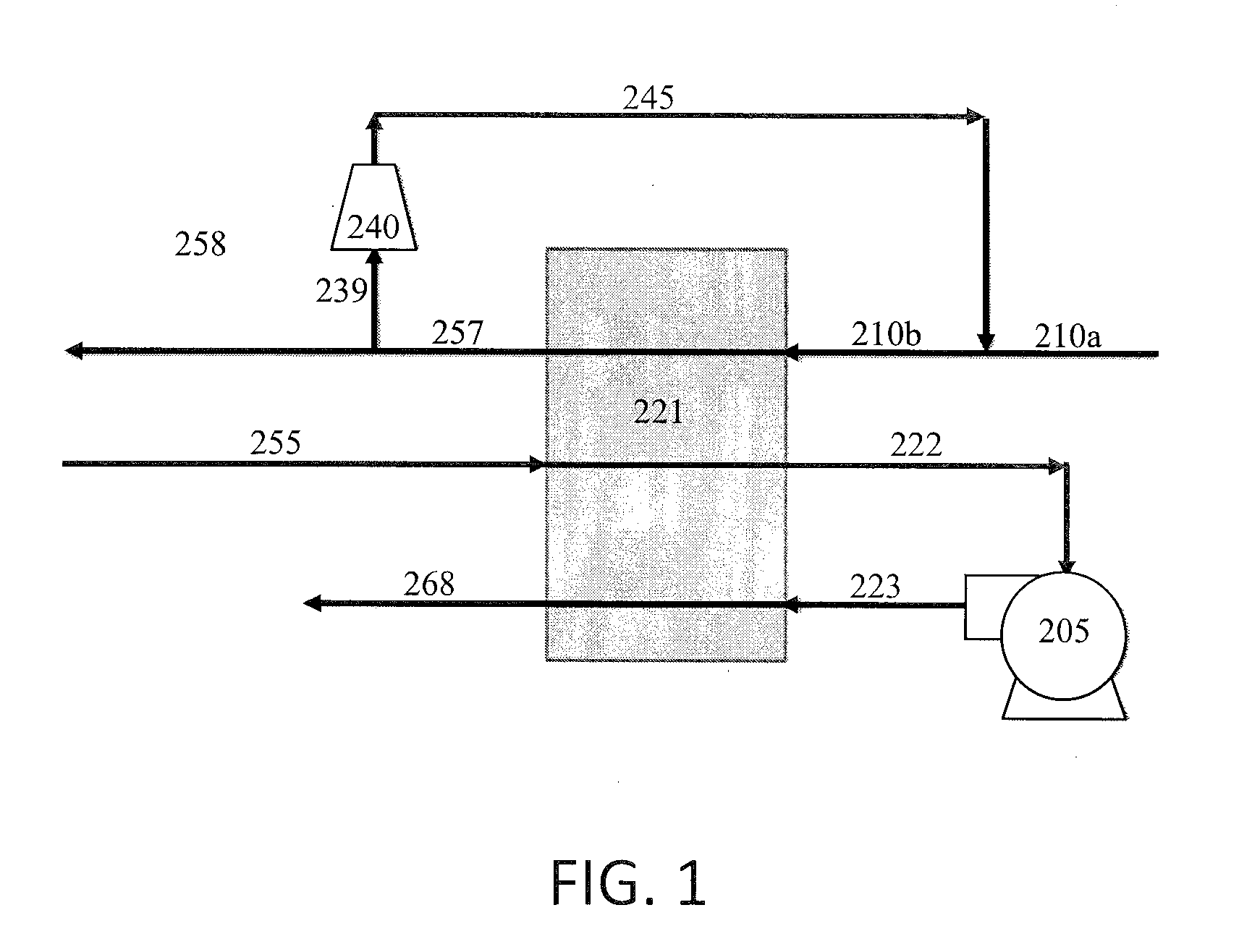

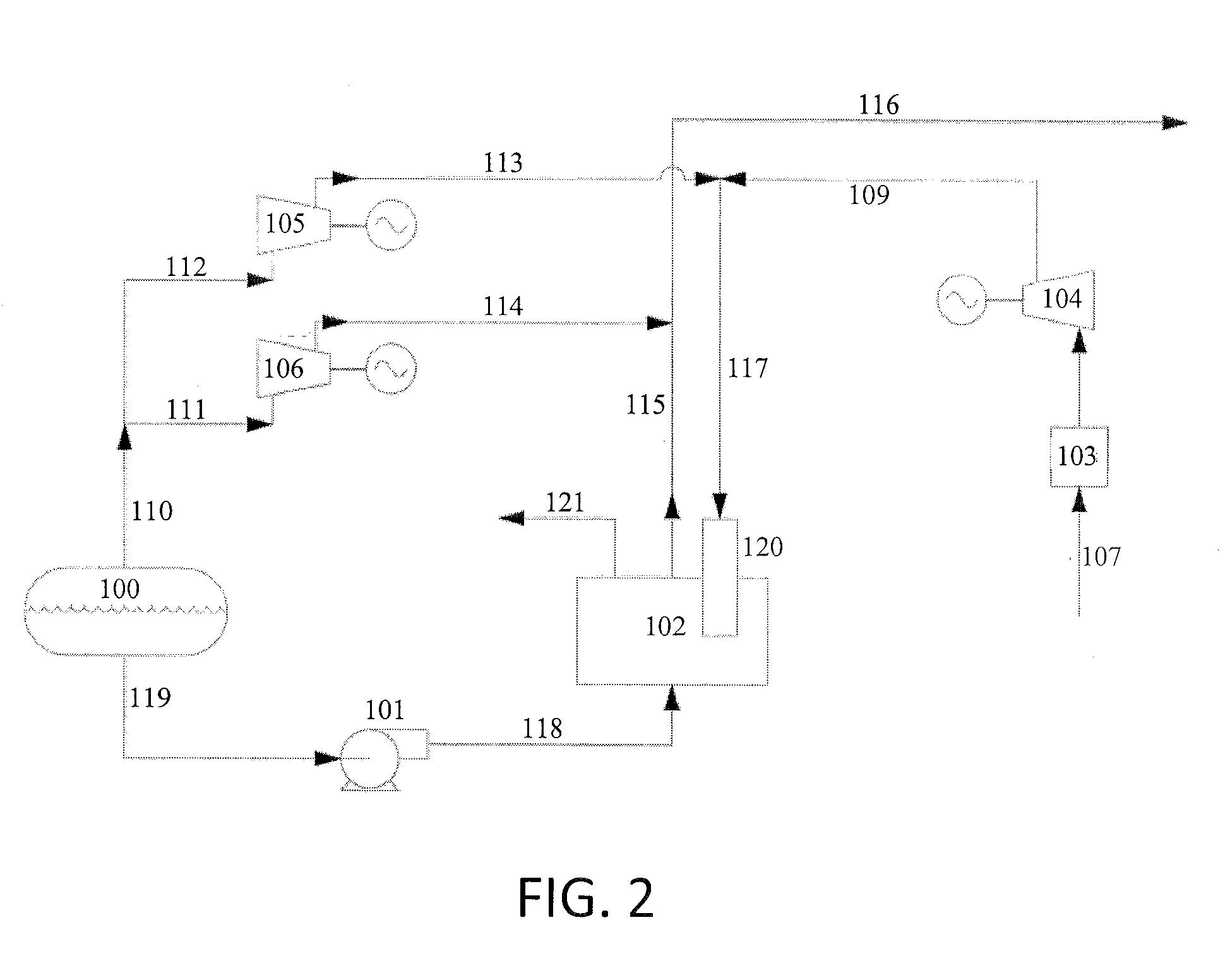

Integrated LNG gasification and power production cycle

ActiveUS20130104525A1Improve efficiencyLow costSolidificationLiquefactionCombustorProcess engineering

The present disclosure provides an integrated power generating system and method and liquefied natural gas (LNG) vaporization system and method. More particularly, heat from a CO2 containing stream from the power generating system and method can be used to heat the LNG for re-gasification as gaseous CO2 from CO2 containing stream is liquefied. The liquefied CO2 can be captured and / or recycled back to a combustor in the power generating system and method.

Owner:8 RIVERS CAPTTAL LLC

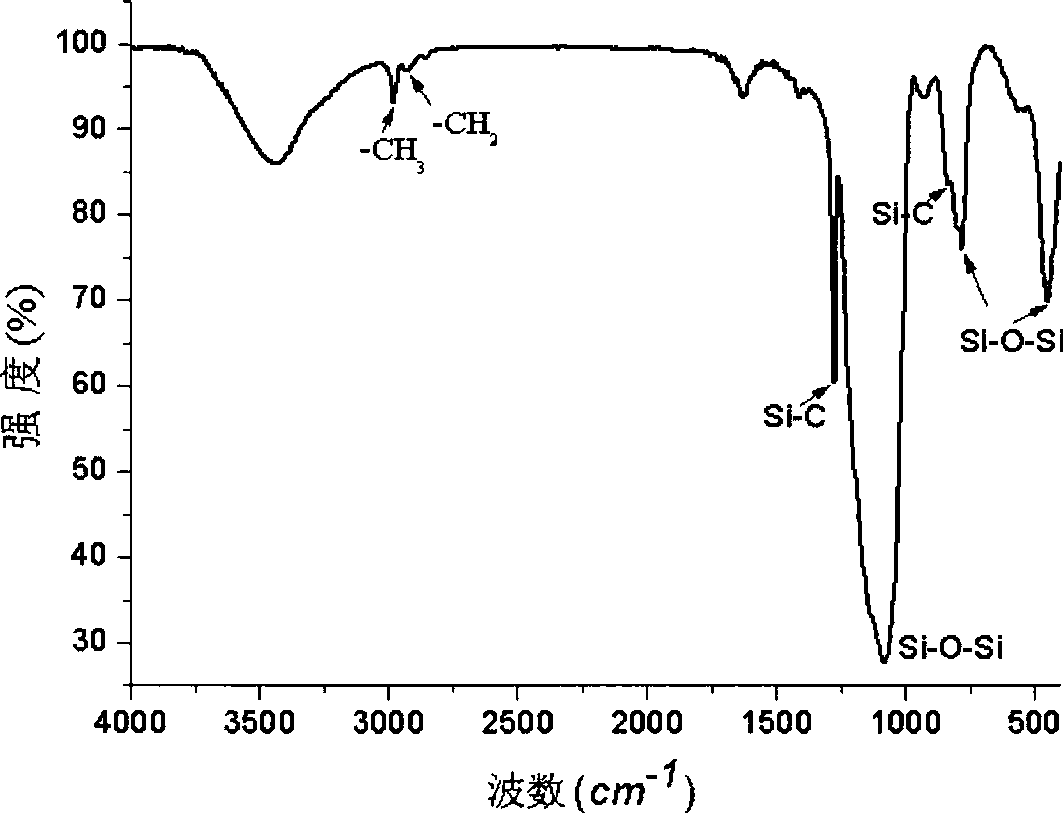

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

Multi-degree-of-freedom 3D printer of fiber reinforced composite material and printing method thereof

The invention discloses a multi-degree-of-freedom 3D printer of a fiber reinforced composite material and a printing method thereof. The 3D printing can be performed with any angle and any movement locus by making use of the flexibility of a manipulator; and a 3D printing head mounted on the multi-degree-of-freedom 3D printer can perform the 3D printing of a high-strength short fiber reinforced composite material, and can perform the splicing and the weaving of continuous resin-based long fiber to produce a structural body of a continuous fiber reinforced resin-based composite material. The multi-degree-of-freedom 3D printer can precisely control the orientation of reinforced fiber in a composite material part in the 3D printing process, and can realize the quick production of the composite material part with specific mechanical, electric and thermal performances and a complex structure. Meanwhile, a mold customized beforehand and a pretreated fiber prepreg tape are not needed in the process; and the multi-degree-of-freedom 3D printer is not only suitable for the production of large parts, but also suitable for the large-batch production of small parts, so that the production cost and the production period are largely reduced, and the wide application of the composite material parts is further promoted.

Owner:XI AN JIAOTONG UNIV

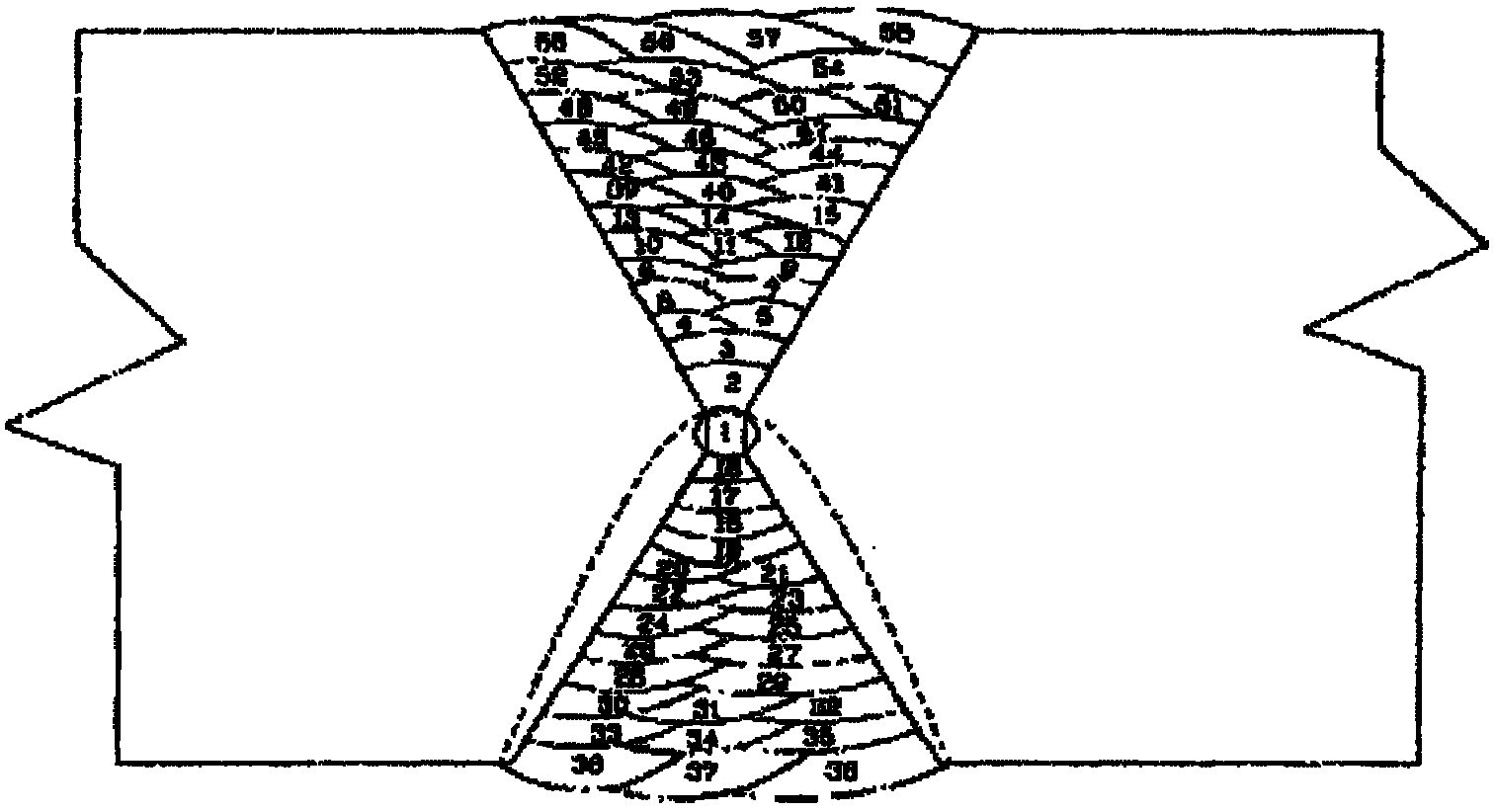

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Liquid infusion method for producing linaloe on aquilaria sinensis trees

ActiveCN101755629AIncrease productionShorten the production cycleBiocidePlant growth regulatorsInfusion methodMedicine

The invention belongs to biological technical field, in particular to a liquid infusion method for producing linaloe on aquilaria sinensis trees. The method includes of drilling on the aquilaria sinensis trunk, gradually dropping a linaloe catalyst into the aquilaria sinensis tree body through the liquid infusion method; the operation is repeated every 2-3 months, after 6-12 months, the chocolatebrown oil-like material and the yellowish-brown discolored eaglewood formed in the trunk is cut and is dried to obtain the linaloe; the linaloe catalyst is mixed up by a phytohormone solution and a chemical reagent solution; the chemical reagent is ferric salt or sodium salt. The process of the invention has simple technique, convenient operation, can greatly increase production quantity of the linaloe and greatly shorten the production period of the linaloe through the inducing method, has good linaloe-forming effect, can effectively ease the contradiction between supply and demand for sinensis, is applicable to large-scale standardization and commercialization production, provides a new effective path for protecting, developing and utilizing the aquilaria sinensis tree resources, and has important economical, social and ecological benefits.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI HAINAN BRANCH

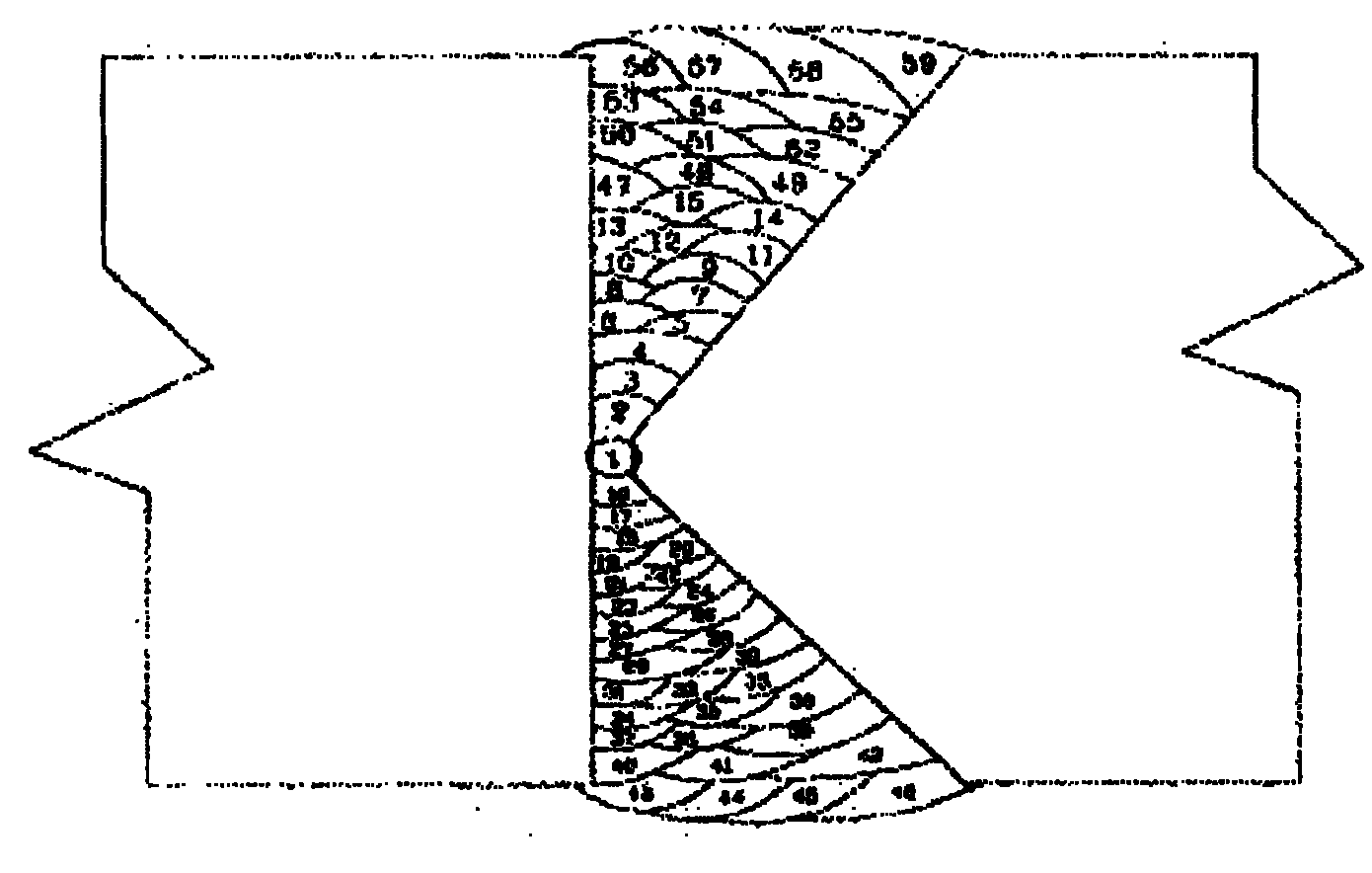

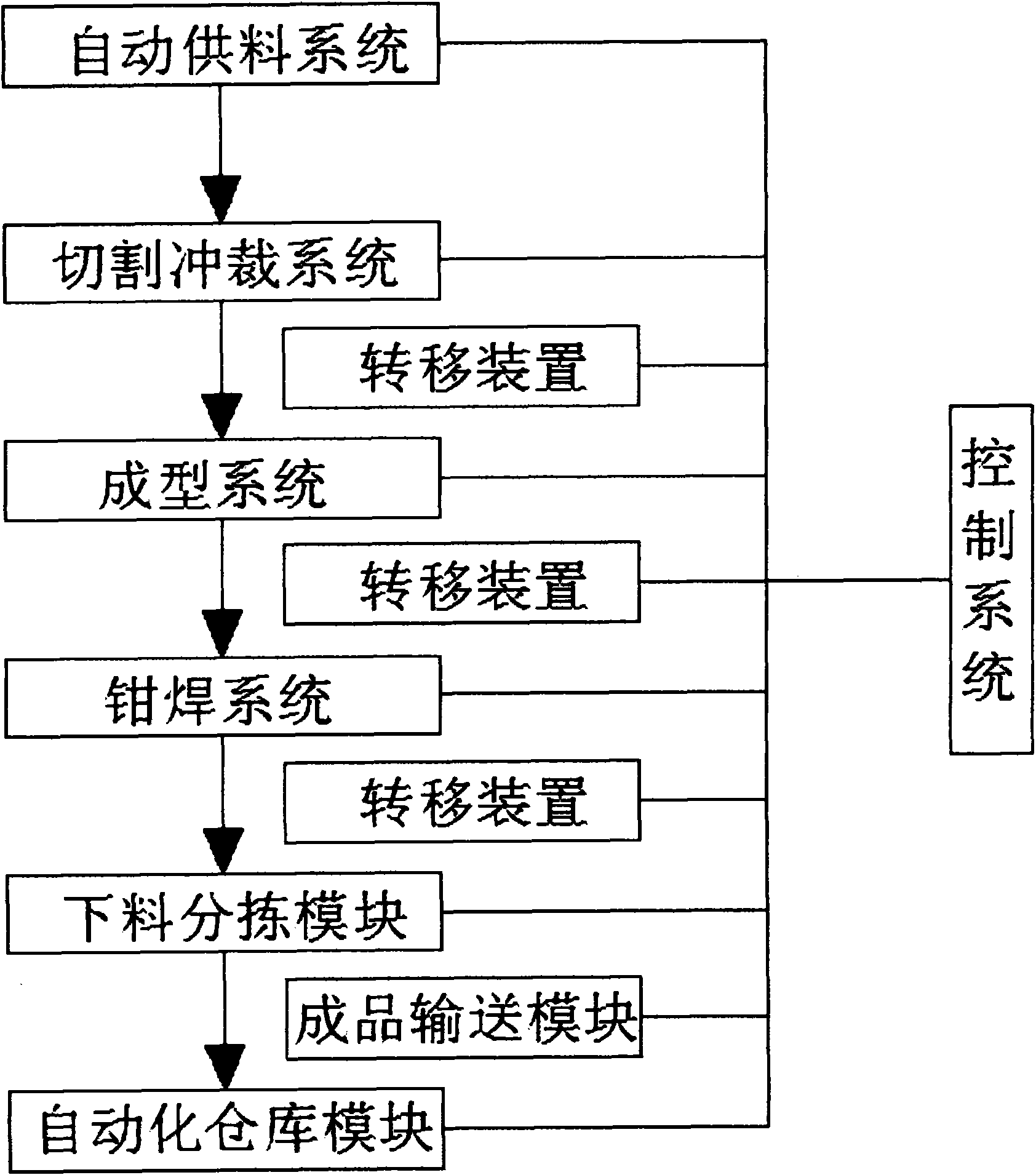

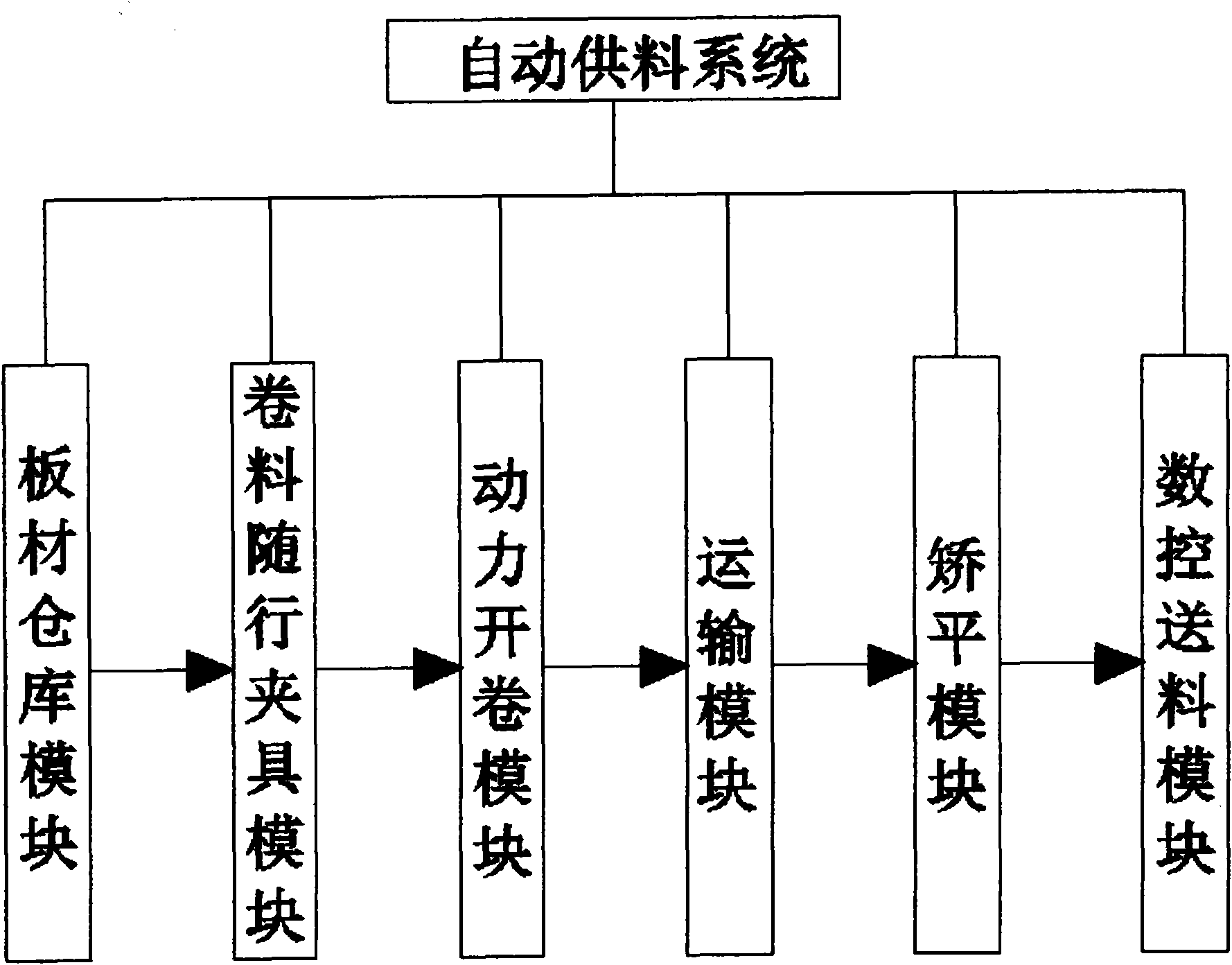

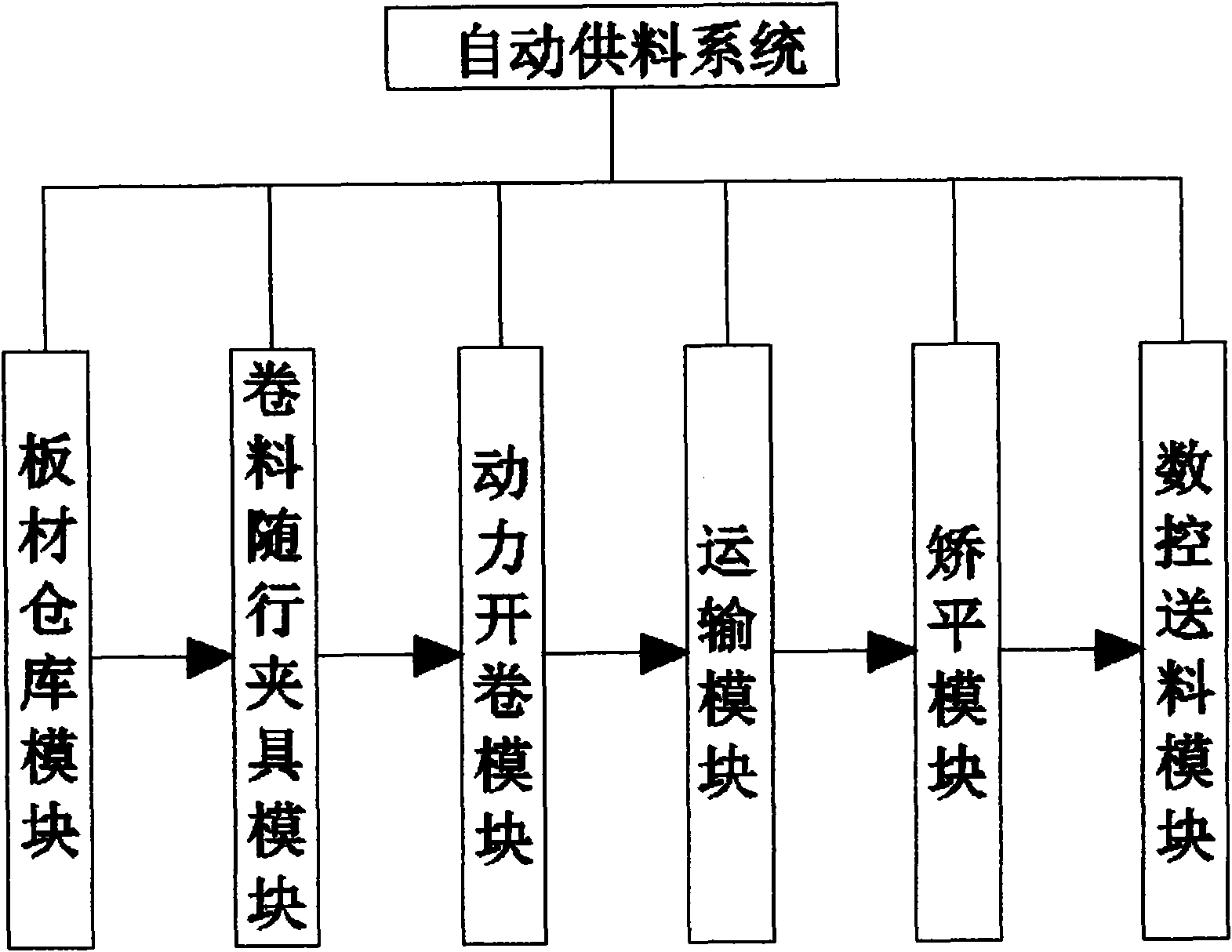

Method for forming metal plates and flexible production line thereof

InactiveCN102009323AReasonable structure layoutSimple molding processOther manufacturing equipments/toolsProduction lineControl system

The invention discloses a method for forming metal plates, which comprises the following steps of: 1) setting an automatic feeding system; 2) setting a cutting blanking system; 3) setting a forming system; 4) setting a pliers welding system; 5) arranging the systems in turn along the trend of a production line, wherein one side corresponding to the production line is provided with a transfer device; and 6) setting a control system. The invention also discloses a flexible production line for implementing the method for forming the metal plates. The method has a simple and easy forming process and a low cost, guarantees the product quality, and meets requirements on diversified production; and the flexible production line is reasonable in structural layout, mixes a one-line multi-station technique and a multi-term co-line production technique together, can efficiently process and prepare various products with different types and shapes at the same time, and not only meets the requirements on product diversification, but also effectively shortens the product production cycle, reduces the cost, and increases the competitive power of an enterprise.

Owner:DONGGUAN YOUMAI INDAL EQUIP

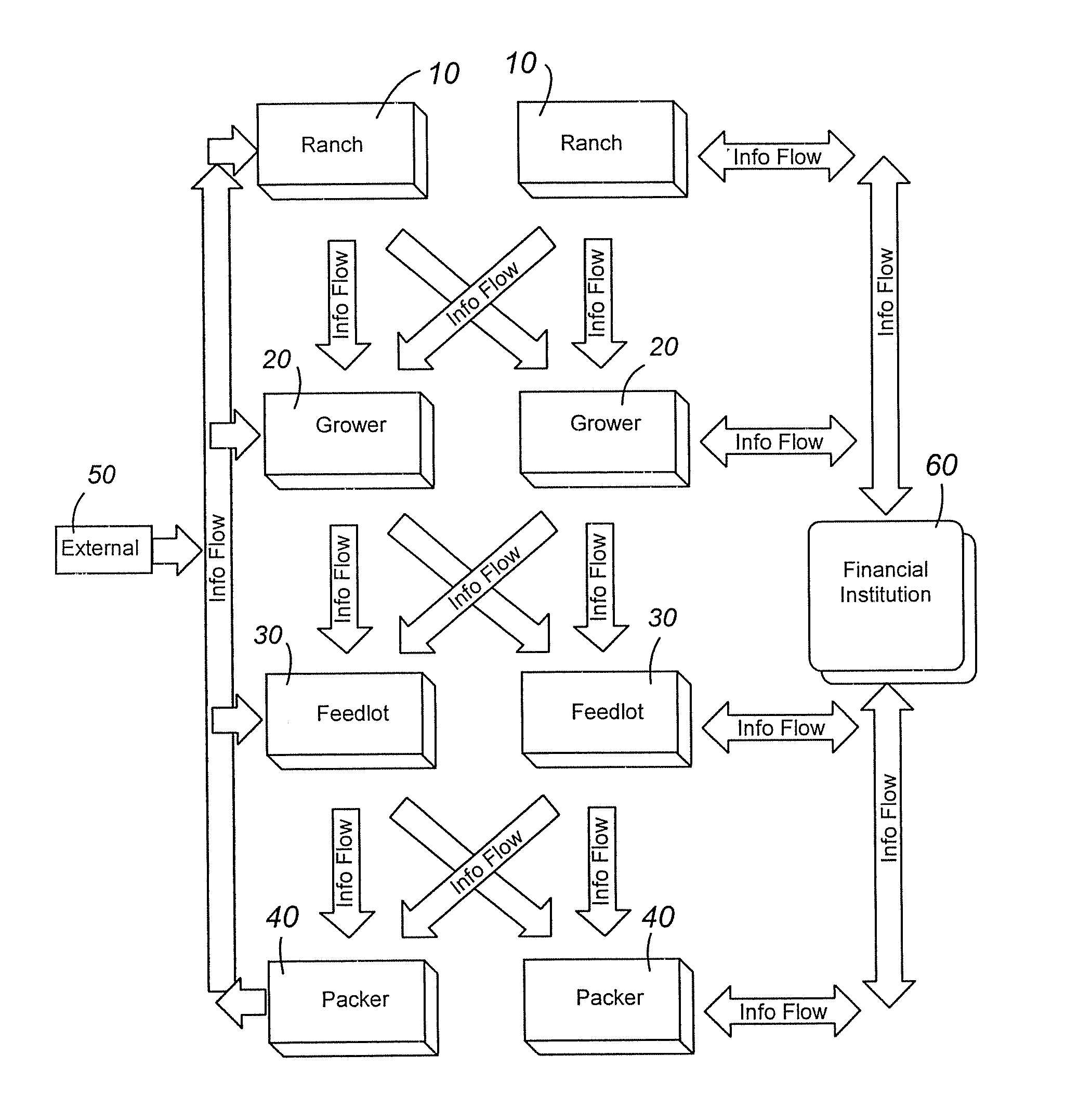

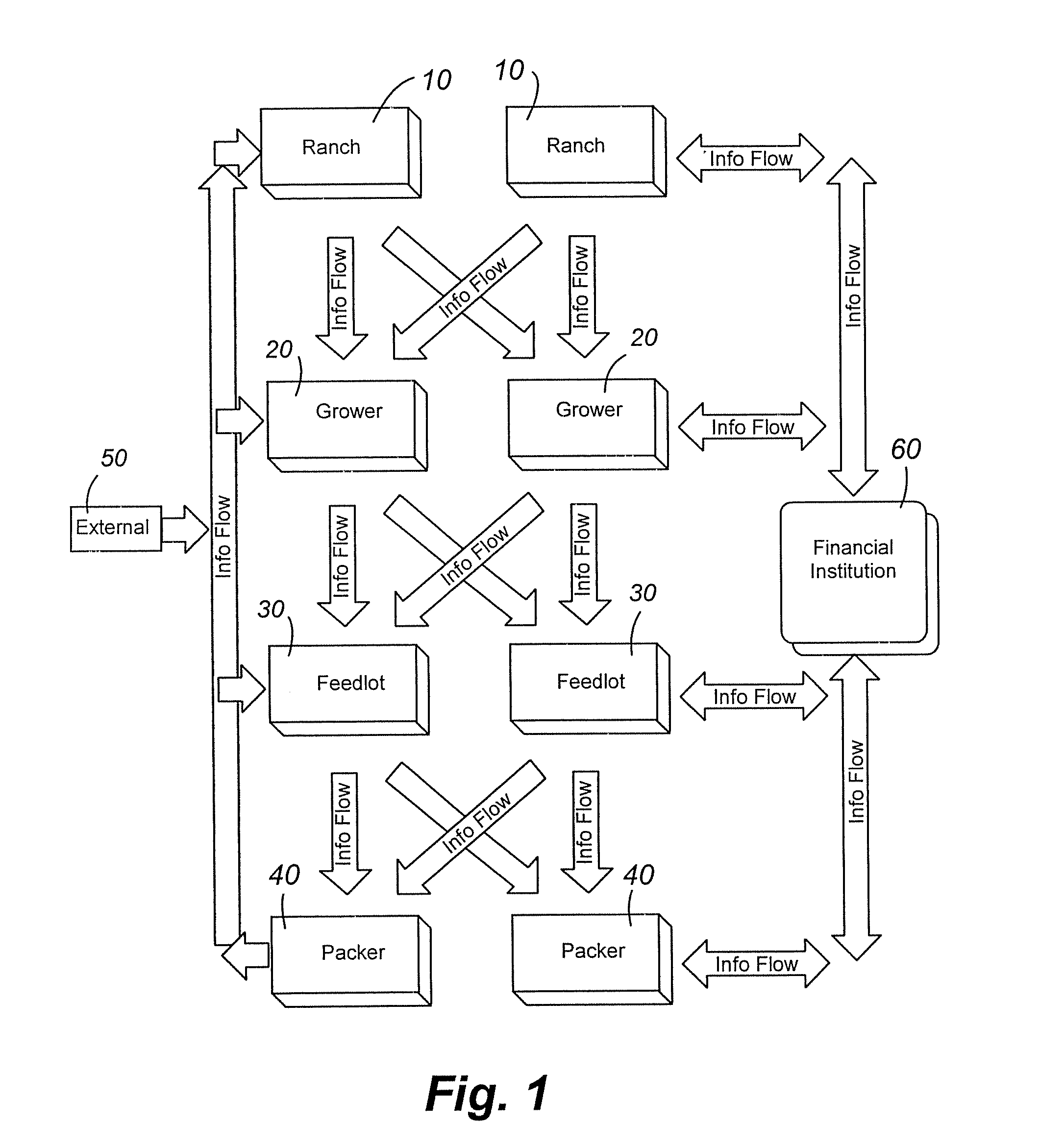

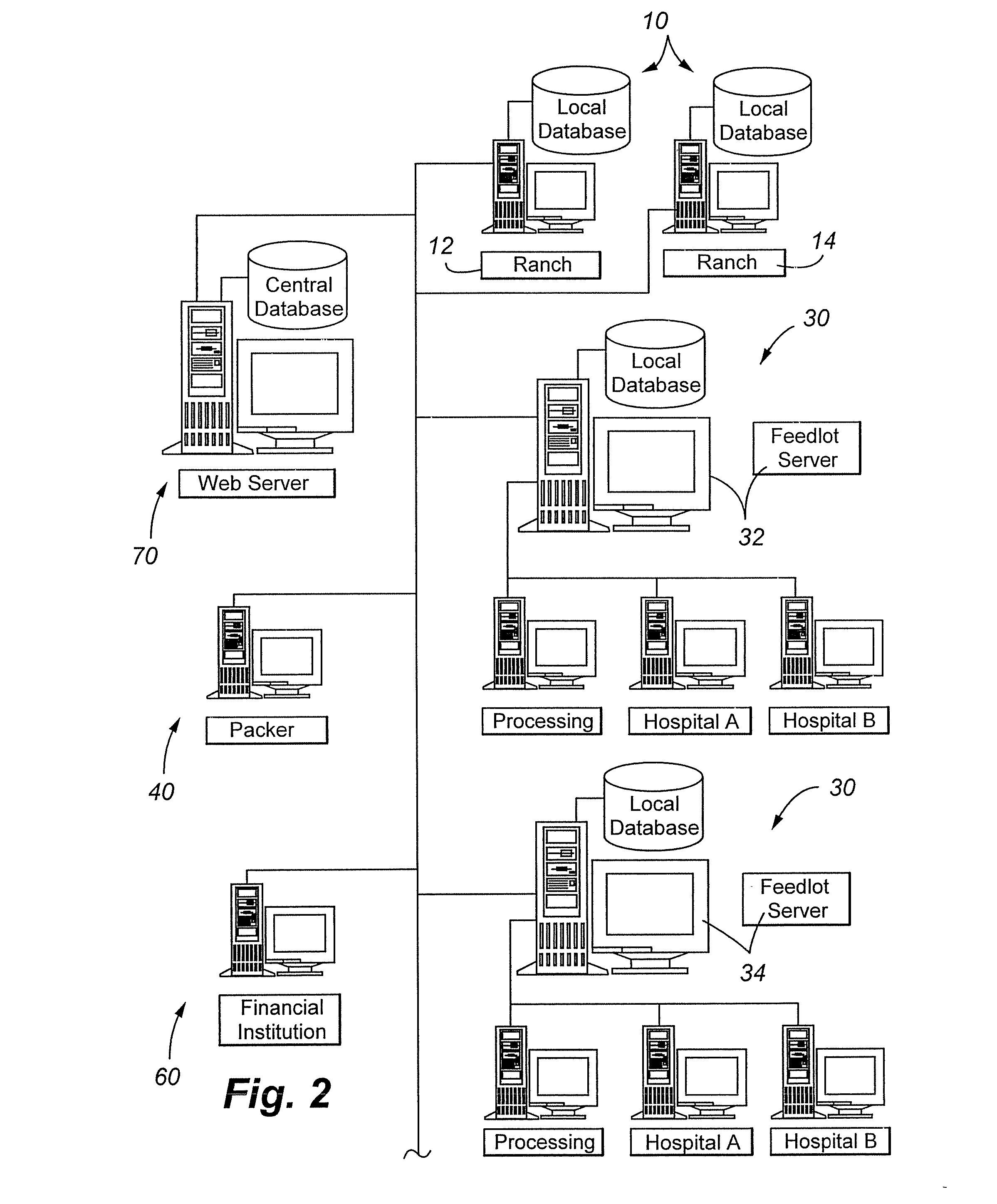

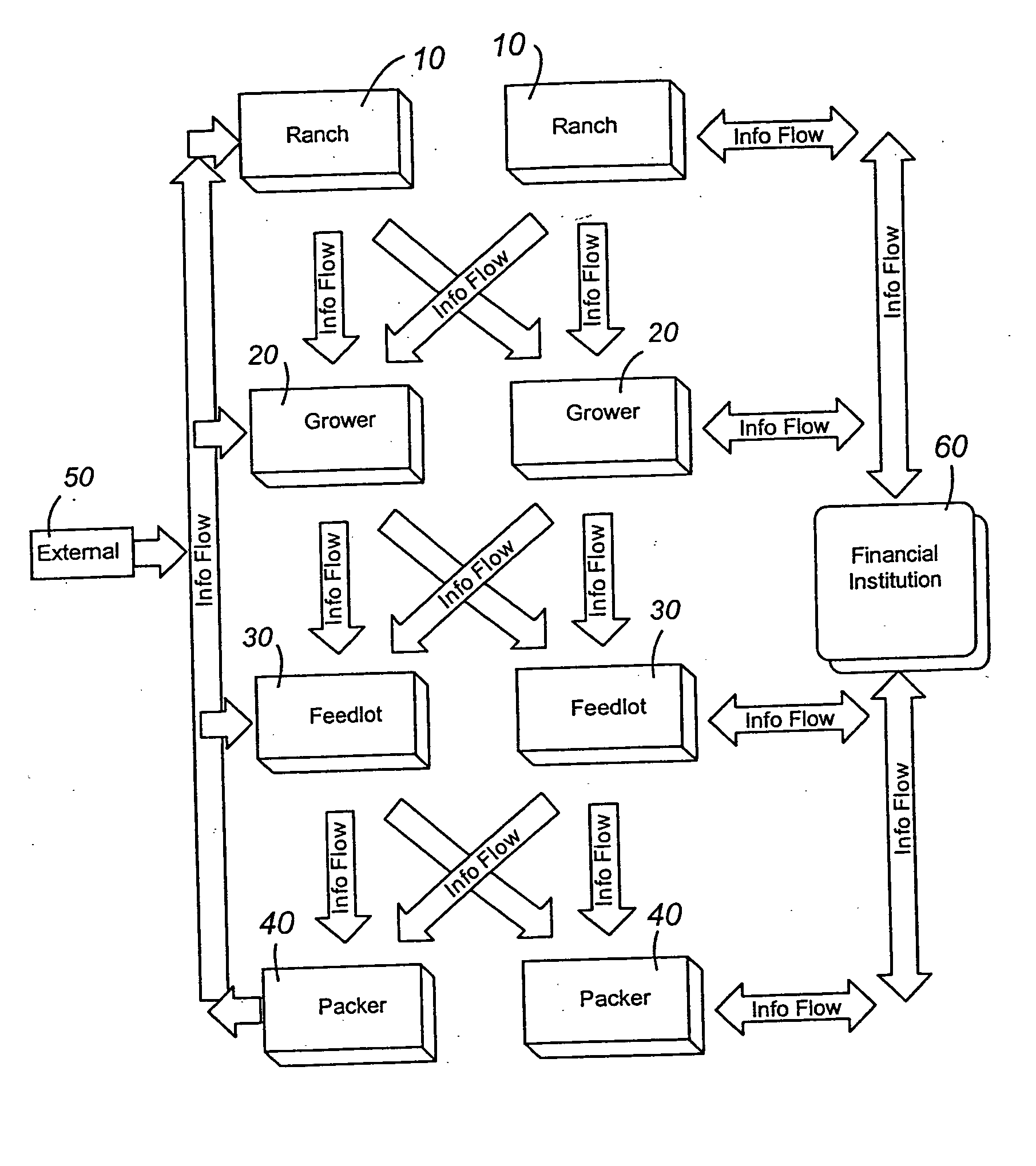

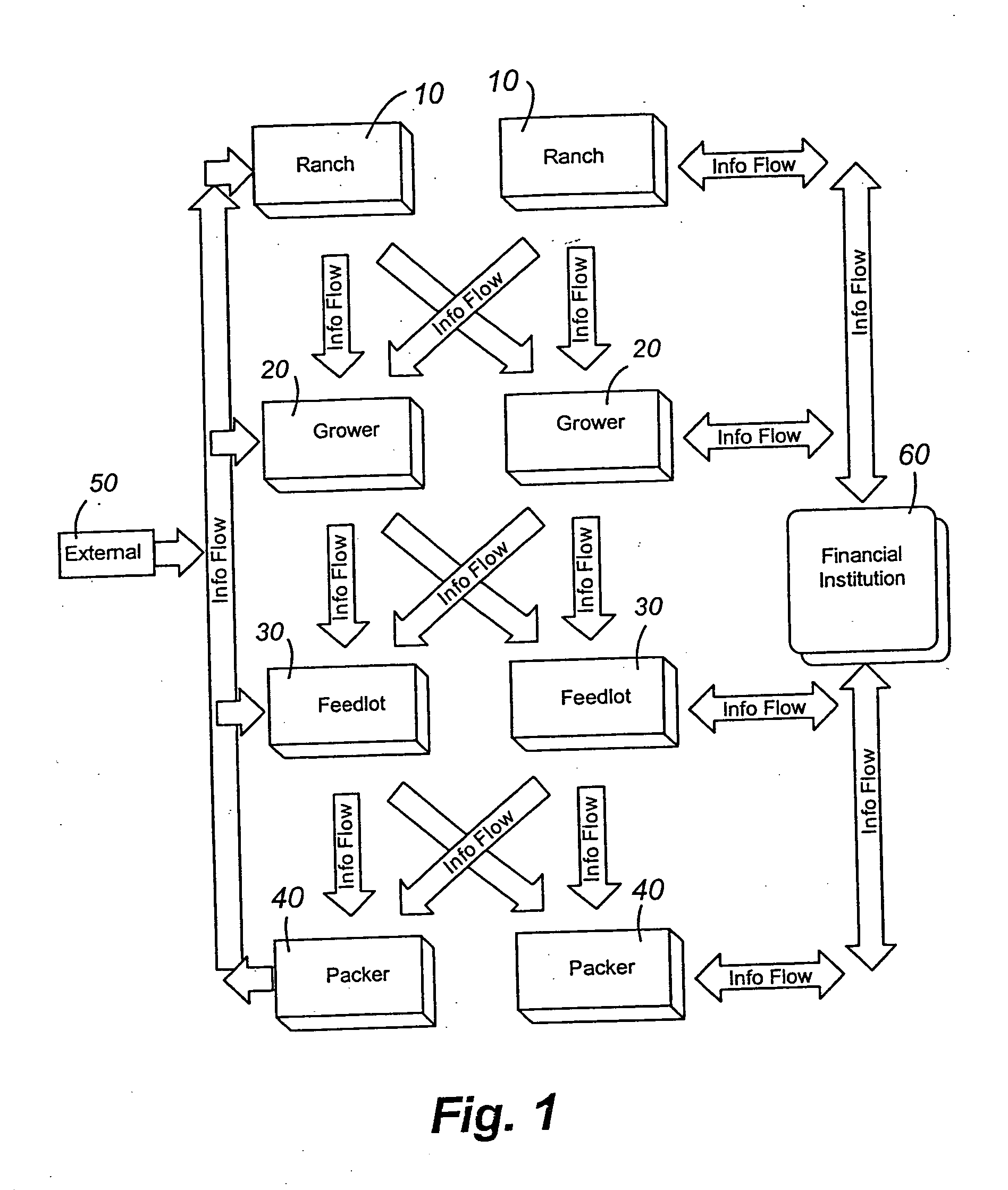

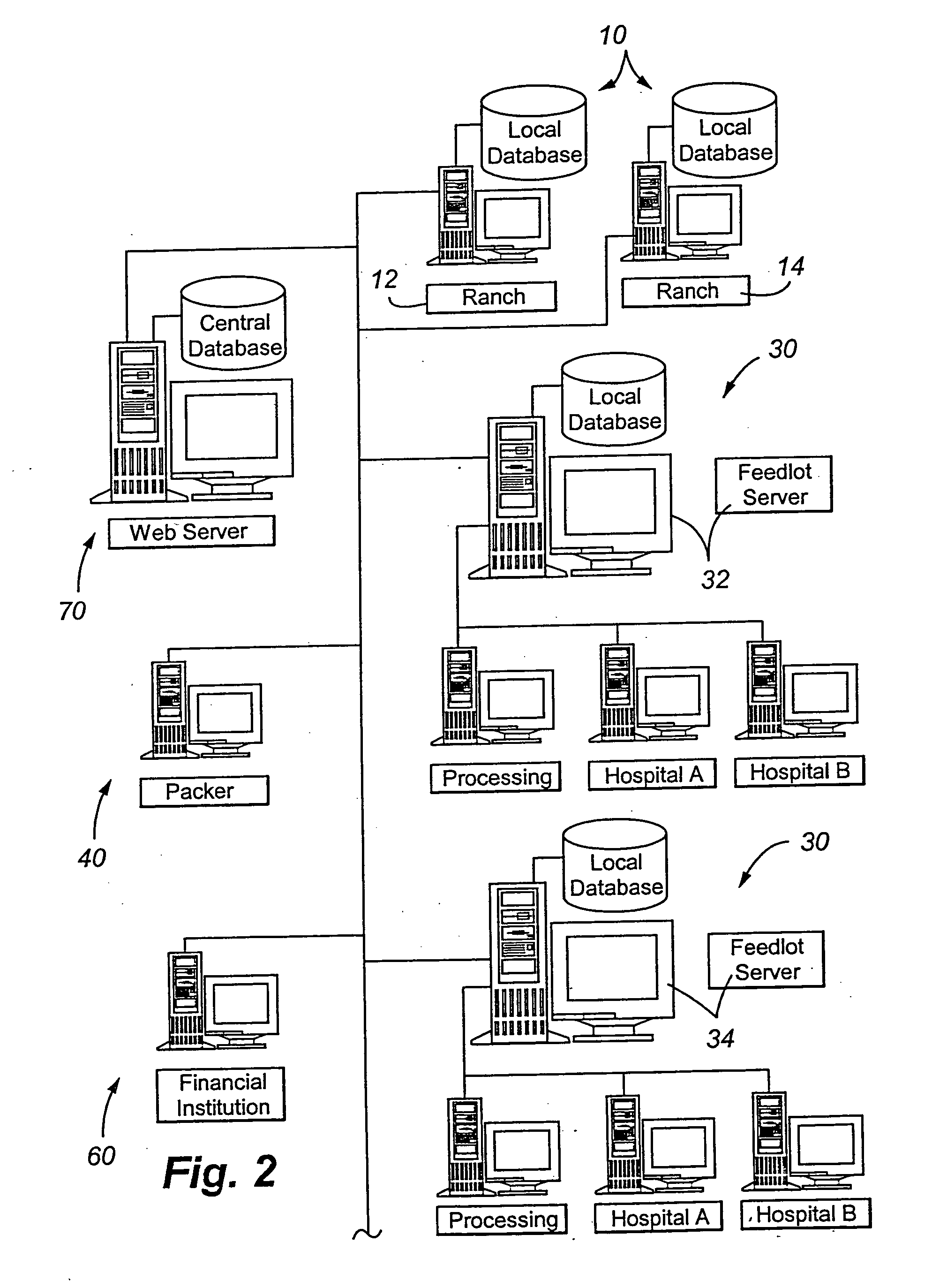

Cattle Management System and Method

ActiveUS20060185605A1Improve abilitiesRealize functionAnimal feeding devicesAnimal housingHeifer calfSynthetic data

A cattle management system and method are provided for managing numerous routine and non-routine management activities. The system and method incorporate a data processing system wherein comprehensive data is gathered and maintained on each individual animal as well as on selected groups of animals. Preferably, a central database is used which allows enhanced functionality with respect to not only data entry and data transfer, but also with respect to providing system generated management recommendations. Some significant functionality of the present invention includes the ability to track the location of each individual animal by utilizing unique identification data for each animal, recording all monitored events that take place at each location during the animal's production cycle, managing feeding operations at a feed lot wherein ration changes can be automatically triggered by parameters and rules established for each feed lot, and reporting the events and locations as required to government entities, financial institutions, and other entities within the cattle industry.

Owner:ANIMAL HEALTH INT

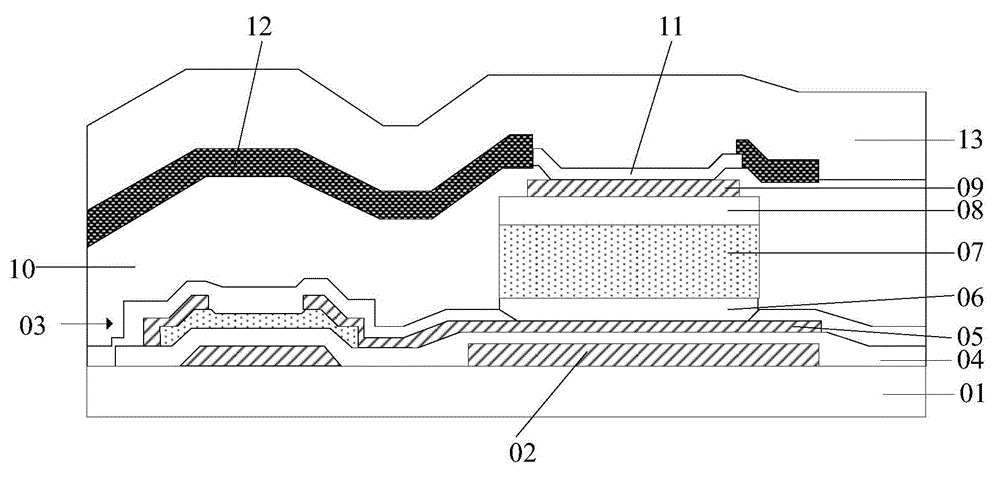

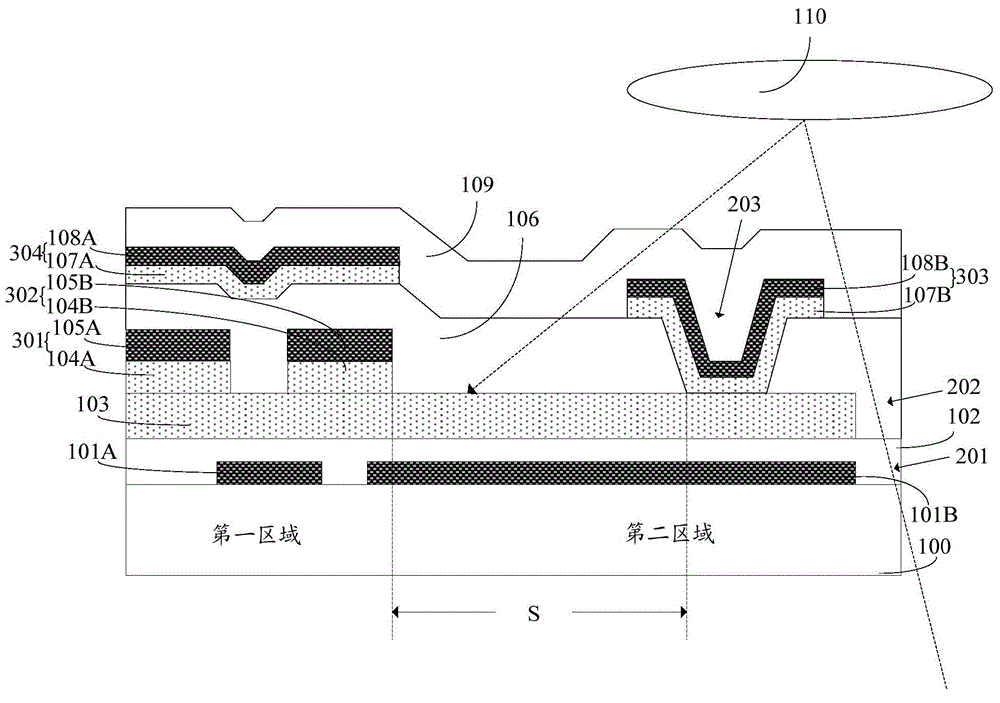

Photoelectric sensor and manufacturing method thereof

ActiveCN105336751AHigh-resolutionReduce thicknessRadiation controlled devicesImage resolutionEngineering

The invention provides a photoelectric sensor and a manufacturing method thereof. The photoelectric sensor comprises a pixel unit arranged on the substrate; and the pixel unit includes a photodiode and a thin-film transistor. A drain structure of the thin-film transistor servers as a cathode structure of the photodiode, so that the area occupied by the pixel can be reduced and the resolution ratio of the photoelectric sensor can be improved. Moreover, the anode structure and the cathode structure of the photodiode are arranged in a transverse mode, so that the thickness of the photoelectric sensor can be effectively reduced and thus the photoelectric sensor has advantages of small size and high resolution ration. Besides, the manufacturing method of the photoelectric sensor can be combined with the traditional LCD manufacturing method, thereby simplifying the production process of the photoelectric sensor, reducing the production cycle, and effectively reducing the production cost.

Owner:SHANGHAI OXI TECH

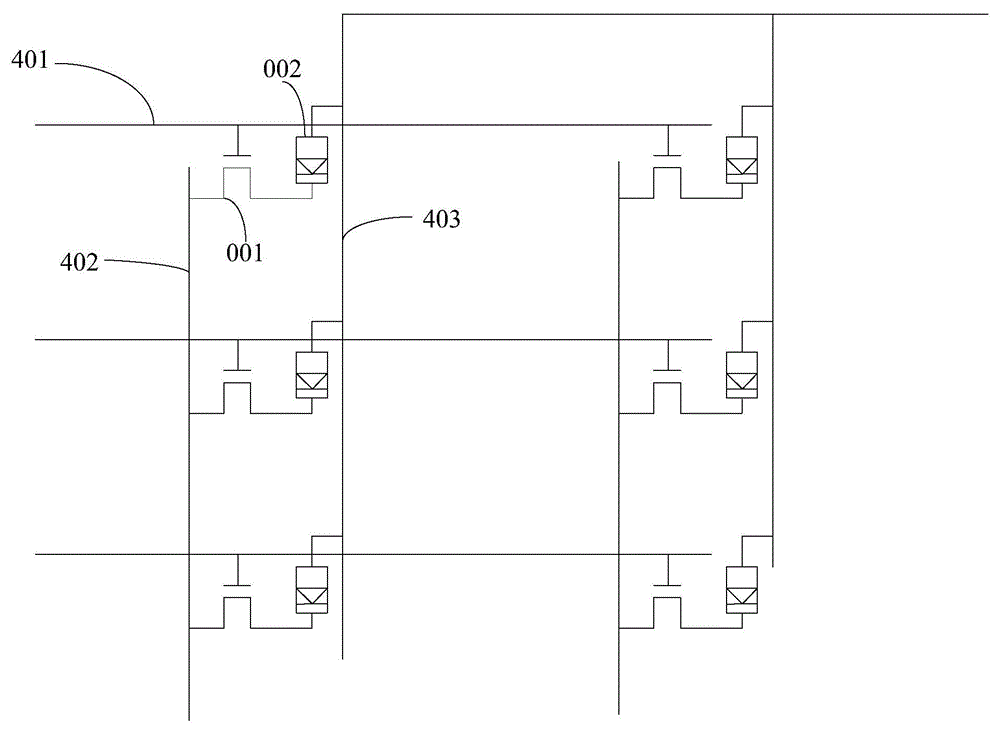

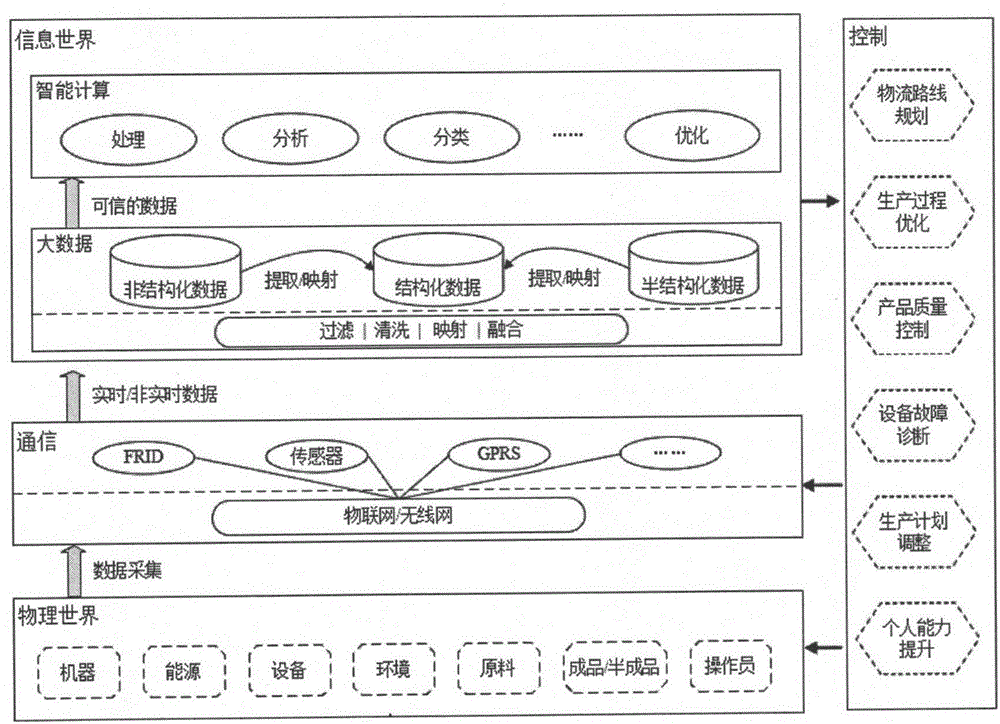

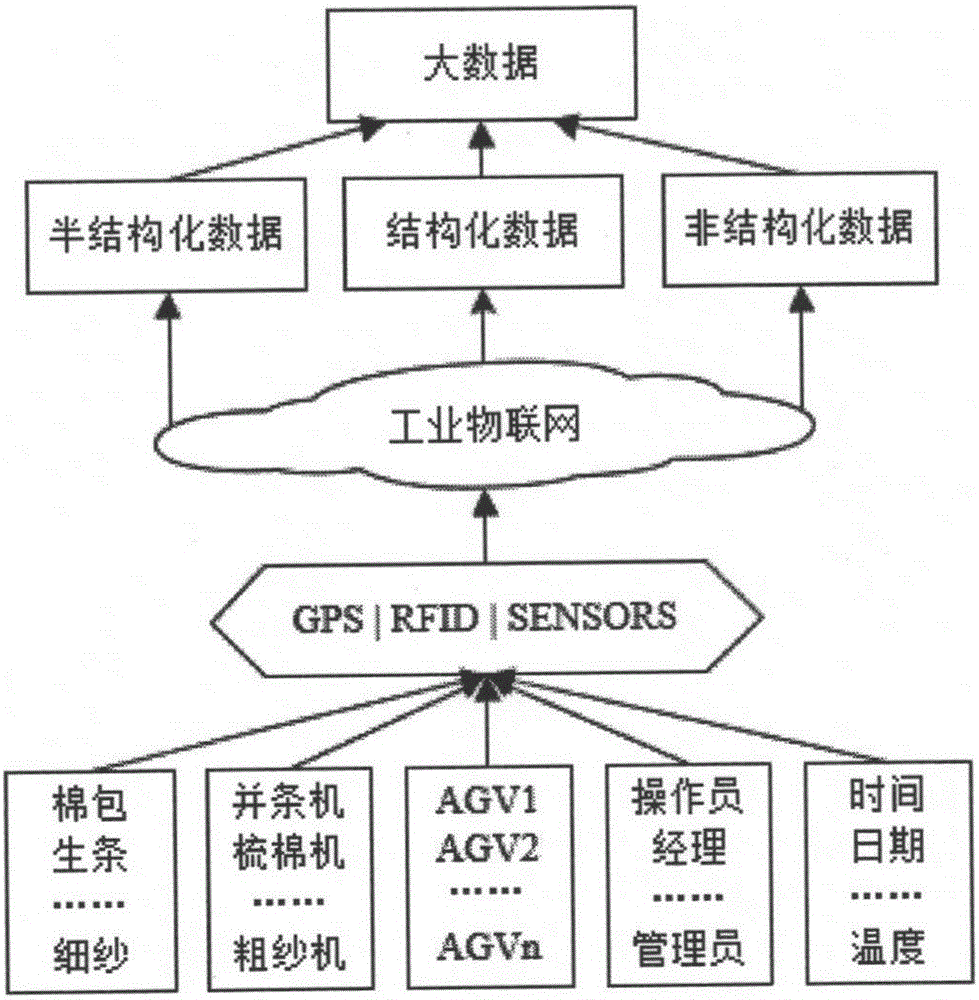

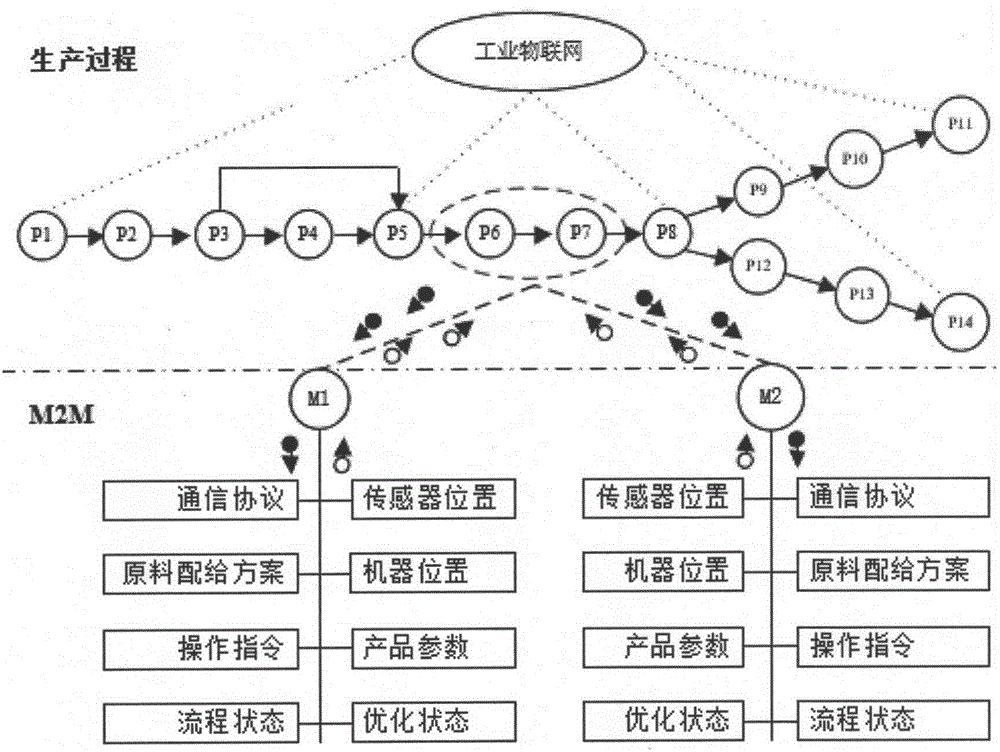

CPS architecture oriented to intelligent cotton spinning production

InactiveCN106530111ARealize intelligenceEasy to produceForecastingResourcesDecision controlDecision taking

The invention provides a CPS architecture oriented to intelligent cotton spinning production. The CPS architecture includes a sensing entity layer, a connection communication layer, a knowledge fusion layer, and a decision control layer. The sensing entity layer senses each entity of a physical world. The connection communication layer transmits the data of all entities in the physical world to an information world. The knowledge fusion layer fuses all resources required by a cotton spinning production cycle and the big data of an environment, analyzes and establishes a digital twin model. The decision control layer, by mining reliable data, forms knowledge based on cotton production, determines a variety of control decision, and commands the various entities of the physical world to work together. The CPS architecture takes the data of the whole process of cotton spinning production as a main line, takes the intelligent sensing as a core, uses the network and massive calculation as a basis, deeply integrates the calculation, communication and control, and realizes the intelligentization of the cotton spinning production process, and provides theoretical support for aspects of high-efficiently configuring various resources, optimizing a production process and improving production efficiency.

Owner:DONGHUA UNIV

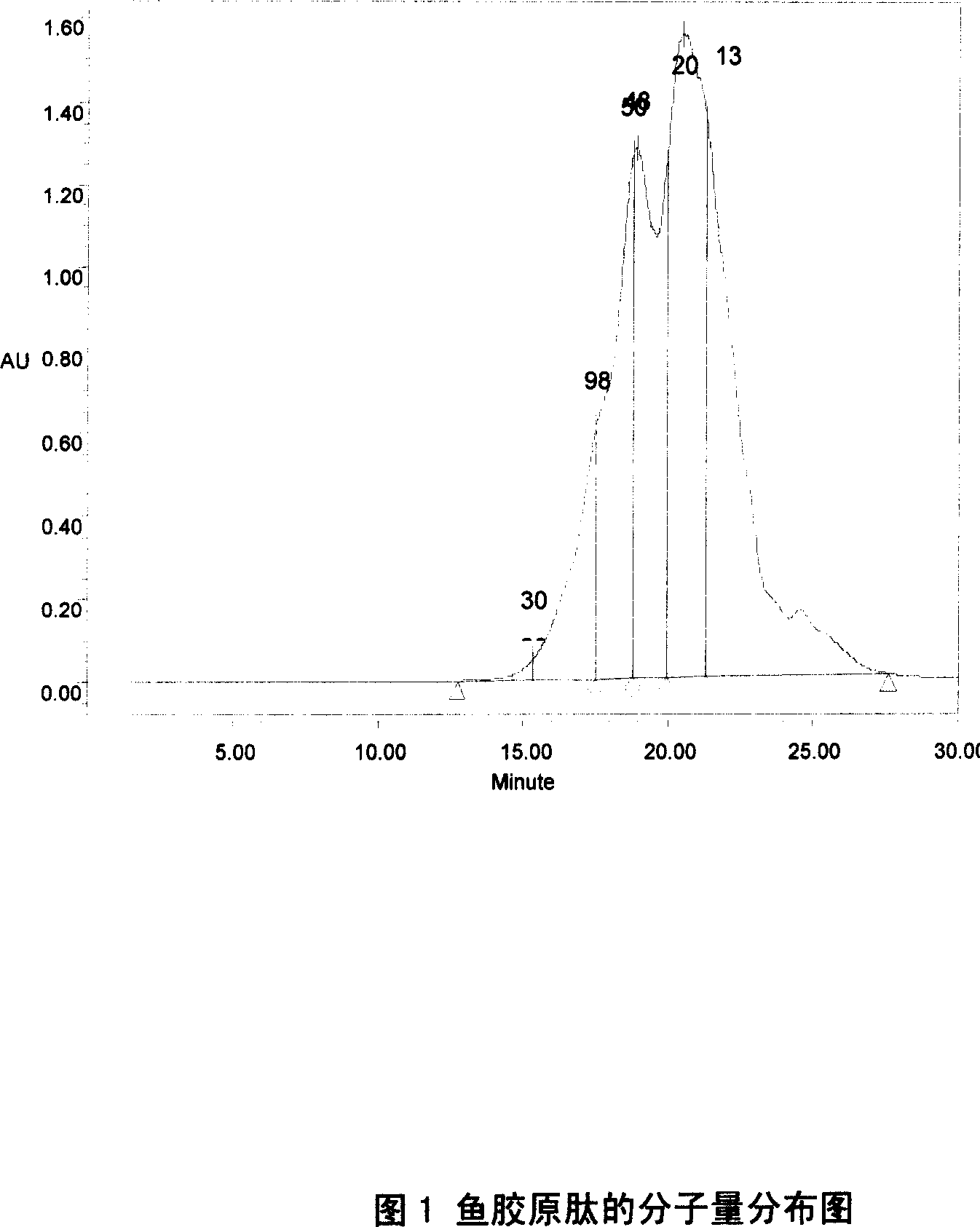

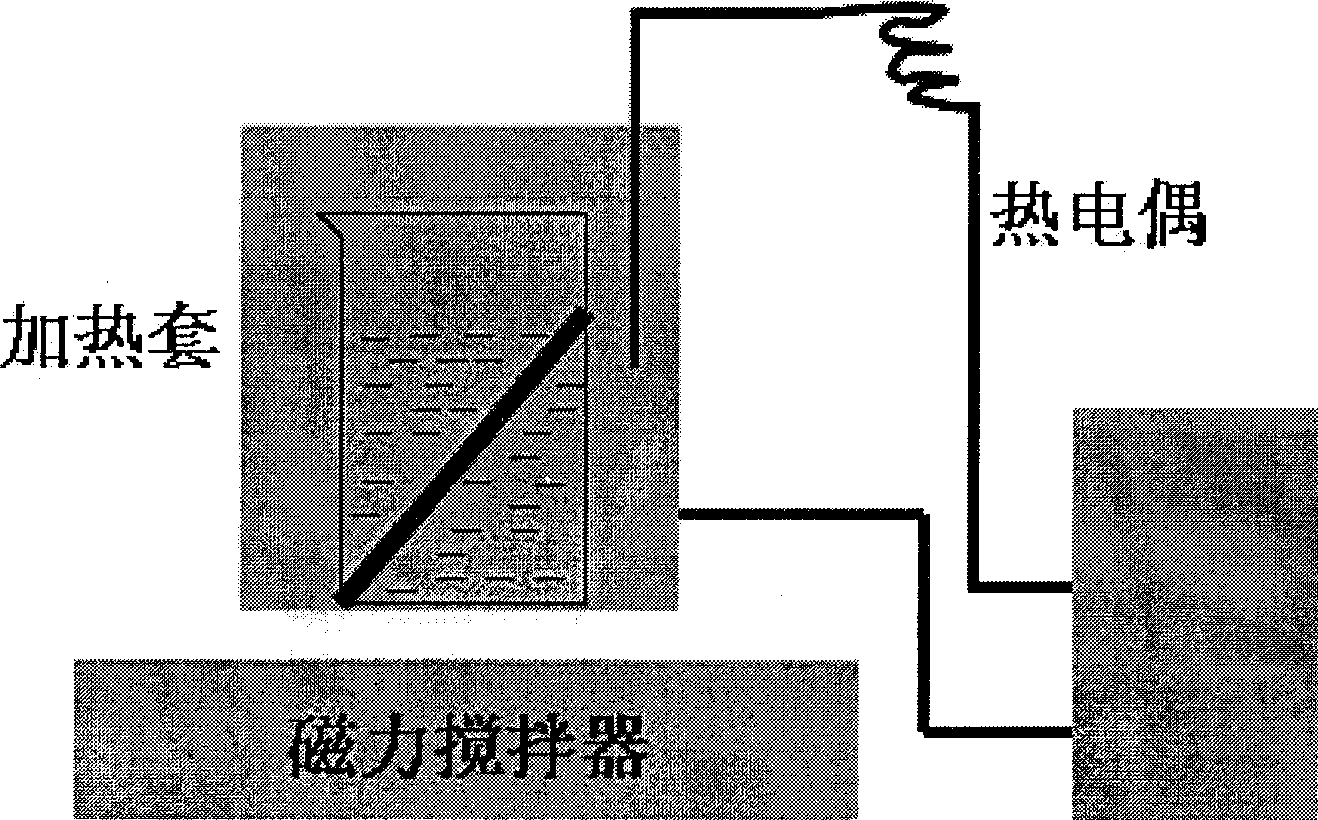

Industry method of producing fish collagen peptide from fish skin and bone by an enzyme method

ActiveCN101061827ASimple processShorten the production cycleAnimal proteins working-upComplex proteinFish products

The invention discloses a special method to extract collagen from fish peel and bone with complex prolease, which comprises the following steps: choosing salmon, AnKang fish peel and processing waste of fish product as raw material; unfreezing; washing; scaling off; degreasing; grinding; enzymolyzing; separating; de-oiling; ultra filtering; condensing; spray-drying; getting the product. This invention possesses simple craft and short production circle.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

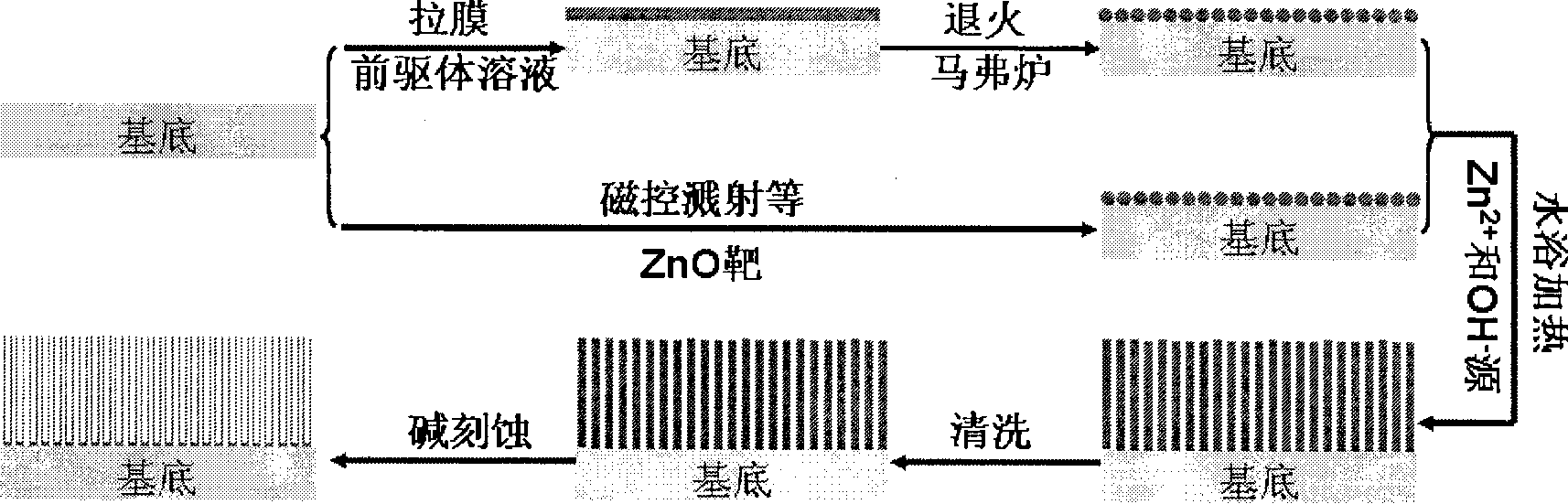

Method for synthesizing zinc oxide nano tube array by low-temperature hydrothermal method

InactiveCN101456579ALow costLow reaction temperatureZinc oxides/hydroxidesEtchingReaction temperature

The invention discloses a method for synthesizing a zinc oxide nano-tube array by a low-temperature hydrothermal method, which comprises: firstly, preparation of ZnO crystal seed layers; secondly, low-temperature hydrothermal growth of ZnO nano wires; and thirdly, chemical etching of the ZnO nano wires into ZnO nano-tubes. The method adopts the low-temperature hydrothermal method and utilizes pure chemical etching technology to synthesize the ZnO nano-tube array, does not need electrochemical assistance and a template, can prepare the ZnO nano-tubes with controllable pipe diameters on different types of substrates by controlling the concentration of a reactant, the hydrothermal growth time and the etching time of an alkali liquor, has low cost, low reaction temperature, short production cycle and high investment-return rate, can be directly performed in an aqueous solution, and does not generate toxic and harmful waste.

Owner:TIANJIN UNIV

Exploitation method of thick oil type oil deposit

InactiveCN101839127AEfficient miningReduce mining costsFluid removalDrilling compositionEconomic benefitsOil type

The invention discloses an exploitation method of a thick oil type oil deposit, which comprises the following steps of: adding a chemical agent and hot fluid into an oil layer, enabling crude oil in the oil layer to be successfully seeped to an oil well and then enabling the crude oil to be raised to the ground from the inside of the oil well. The invention has the following advantages that: the invention can effectively solve the problem of phase precipitation of the asphaltene of the crude oil in the oil layer, can effectively exploit the thick oil type oil deposit, lowers the exploitation cost of the thick oil type oil deposit greatly, prolongs the production period of the oil well, increases the yield of the oil well, enhances the final recovery ratio of the oil deposit and has easy execution, high safety and reliability and obvious economic benefit.

Owner:盘锦河升大地石油科技有限公司

Preparation method of hollow-structure metal or ceramic part

InactiveCN102351542AShort cycleShorten the production cycleCeramic shaping apparatusAdhesiveCo injection

The invention relates to a preparation method of a hollow-structure metal or ceramic part, which comprises the following steps: selecting metal or ceramic powder as the raw material, mixing, and granulating to obtain a feed material; selecting a core material; injecting the core material into a die by co-injection molding to obtain a core in hollow shape, and injecting the metal or ceramic feed material to be completely coated on the core, thereby obtaining a green body; and carrying out solvent extraction and heating on the green body to remove the adhesive and core, and sintering to obtain the hollow-structure product. The invention implements one-step molding of the hollow metal or ceramic part; from the raw material to the product, the production cycle is short, and the automation degree of equipment is high, thereby greatly enhancing the efficiency and forming a randomly complex and completely hollow die cavity; and thus, the invention can be used for preparing a completely hollow part with no joint, greatly lowers the cost of the product, and is especially suitable for preparing hollow metal and ceramic parts.

Owner:CENT SOUTH UNIV

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

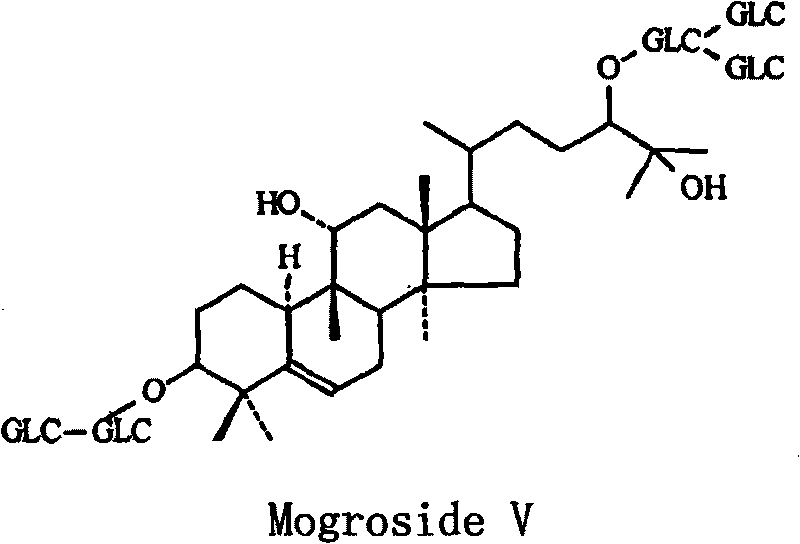

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573APromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseAdditive ingredient

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

Fabric-Crepe Process With Prolonged Production Cycle and Improved Drying

ActiveUS20080264589A1Improve productivityLower levelDrying using combination processesNon-fibrous pulp additionAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Cattle management system and method

ActiveUS20060054092A1Improve abilitiesRealize functionDrug and medicationsAnimal feeding devicesData processing systemCentral database

A cattle management system and method are provided for managing numerous routine and non-routine management activities. The system and method incorporate a data processing system wherein comprehensive data is gathered and maintained on each individual animal as well as on selected groups of animals. Preferably, a central database is used which allows enhanced functionality with respect to not only data entry and data transfer, but also with respect to providing system generated management recommendations. Some significant functionality of the present invention includes the ability to track the location of each individual animal by utilizing unique identification data for each animal, recording all monitored events that take place at each location during the animal's production cycle, and reporting the events and locations as required to government entities, financial institutions, and other entities within the cattle industry.

Owner:ANIMAL HEALTH INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com