High-activity antibacterial peptide-containing matrix for garden seedling cultivation, as well as preparation and application thereof

An antimicrobial peptide and high-activity technology, applied in the agricultural field, can solve the problems of composting time affected by seasons, insufficient maturity of planting substrates, and limited number of microorganisms, so as to facilitate large-scale commercial production, reduce the frequency of fertilization and pesticide application, Good effect of water and fertilizer retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

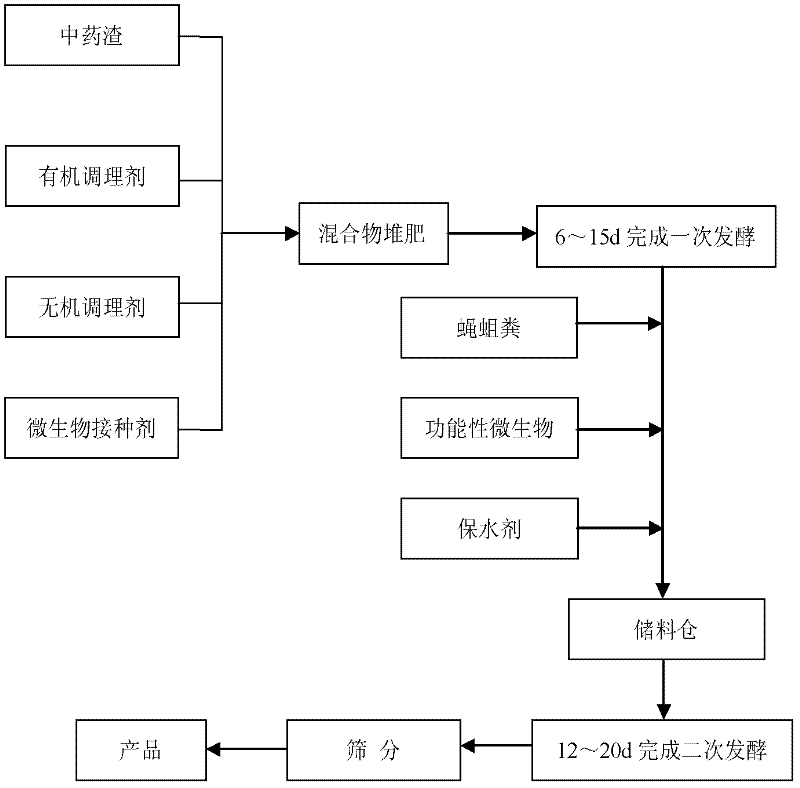

[0051] The preparation method of the garden nursery stock cultivation matrix that contains high active antimicrobial peptide comprises the following steps (such as figure 1 shown):

[0052] (1) 7300kg of Chinese medicine dregs (composed of licorice dregs, Radix Radix dregs, Scutellaria baicalensis and Schisandra chinensis), 1500kg of mushroom dregs, 600kg of fly ash and 100kg of organic material decomposing agent (Hubei Qiming Biological Engineering Co., Ltd. Co., Ltd. production; the same below) mixed evenly, the resulting mixture carbon nitrogen ratio (C / N) (mass ratio) 25:1, pH 7.0, the mass percentage of organic matter is 55%. After adjusting the water content to 55%, aerobic composting, after 8 days, the product of the first fermentation is obtained;

[0053] (2) The product of the first fermentation is then mixed with 200kg of fly maggot droppings, 150kg of Glomus mosseae (CGMCC No.3451) and 150kg of acrylamide-acrylic acid salt copolymer cross-linked product (Zhongke A...

Embodiment 2

[0059] The preparation method of the garden nursery stock cultivation matrix that contains high active antimicrobial peptide comprises the following steps (such as figure 1 shown):

[0060] (1) 6000kg of traditional Chinese medicine residues (composed of licorice residues, Radix Radix Radix, Scutellaria chinensis and Schisandra chinensis residues), 2100kg of organic additives (composed of straw, wood chips, soy sauce residues, cow dung and humic acid), 1200kg Inorganic additives (composed of alkali-making waste slag and phosphate rock powder) and 230kg of compound biological fermentation agent (produced by Nanjing Dadi Lvjin Biotechnology Co., Ltd.; the same below) are mixed evenly, and the carbon-nitrogen ratio (C / N) (mass Ratio) 28:1, pH 8.0, and the mass percentage of organic matter is 50%. After adjusting the water content to 52%, aerobic composting, after 12 days, the product of the first fermentation is obtained;

[0061] (2) The product of the first fermentation is th...

Embodiment 3

[0066] The preparation method of the garden nursery stock cultivation matrix that contains high active antimicrobial peptide comprises the following steps (such as figure 1 shown):

[0067] (1) 7500kg of traditional Chinese medicine dregs (composed of licorice residue, Radix Radix Radix dregs, Scutellaria baicalensis and Schisandra chinensis residue), 1500kg of organic additives (composed of yeast waste liquid, furfural residue, distiller's grains, vinegar residue and bean cake), 600kg of inorganic additives (composed of peat soil and porous grass moss) and 40kg of microbial decomposing agents (composed of organic material decomposing agents and biological fermentation decomposing agents (produced by China Beijing Shennong Caihe Biotechnology Co., Ltd.; the same below)) are mixed evenly, The resulting mixture has a carbon-to-nitrogen ratio (C / N) (mass ratio) of 20:1, a pH of 6, and a mass percentage of organic matter of 45%. After adjusting the water content to 48%, aerobic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com