Patents

Literature

313 results about "Aluminum magnesium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium Aluminum Silicate is a naturally occurring mineral derived from refined and purified clay that is used primarily as a thickener in cosmetics and beauty products.

SiO2 enriched nano composite heat preserving and thermal insulating paste and preparing process thereof

The invention relates to SiO2 nano composite thermal insulation paste, which is characterized in that the form of the SiO2 nano composite thermal insulation paste is a paste mixture, and the dried paste mixture becomes micro pores, nano holes and a fiber structure compound. The paste comprises the following components by weight percentage: 20 to 50 percent of SiO2 nano aerogel, 0 to 30 percent of inorganic closed-hole micro-bead material, 7 to 15 percent of expanded pearlite, 0 to 1 percent of bentonite, 2 to 6 percent of penetrating agent, 10 to 20 percent of adhesive, 3 to 6 percent of calcium silicate fiber, 0 to 5 percent of magnesium aluminum silicate fiber, 0 to 5 percent of aluminum silicate fiber, 0 to 40 percent of water, 0.1 to 2 percent of flame retardant, and 3 to 7 percent of pigment. A preparation device is a vacuum intake and stirring device.

Owner:上海暄洋化工材料科技有限公司

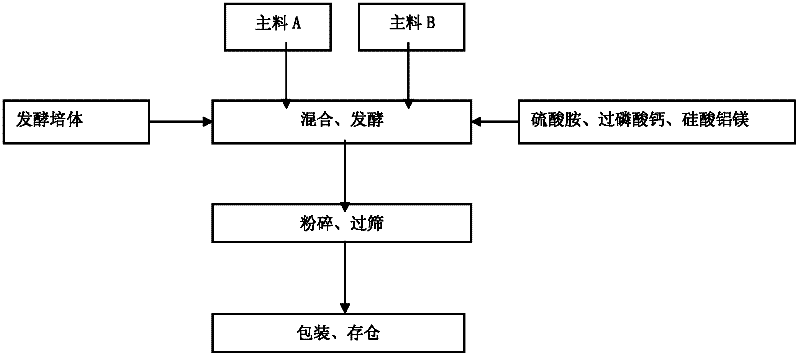

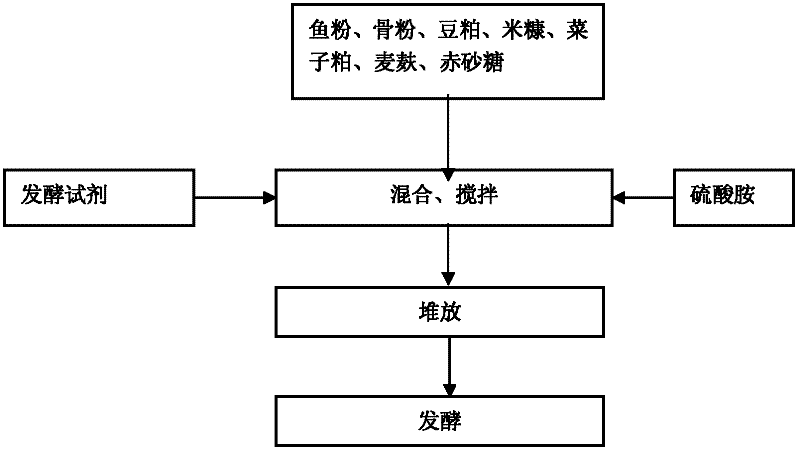

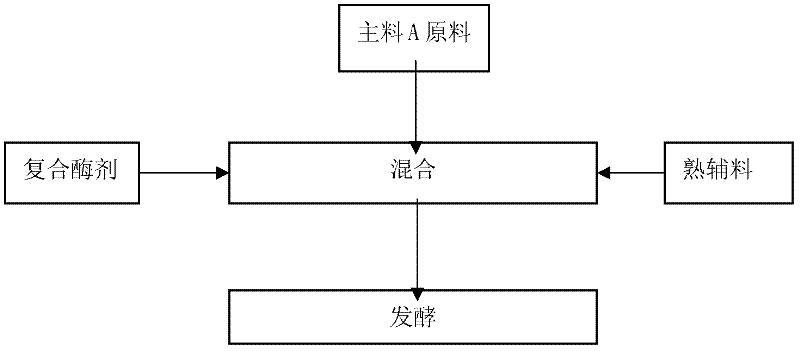

Biologic organic fertilizer and preparation method thereof

ActiveCN102584364APromote sustainable developmentBio-organic fraction processingOrganic fertiliser preparationEcological environmentAdditive ingredient

The invention discloses a biologic organic fertilizer and a preparation method thereof. The technical problem is solved, so that the prepared biologic organic fertilizer has multiple functions and high efficiency. The biologic organic fertilizer comprises the following raw materials in part by mass: 600 to 1,000 parts of major ingredient A, 30 parts of fermentation culture body, 50 parts of ammonium sulfate, 50 parts of calcium superphosphate and 50 parts of magnesium aluminum silicate powder, wherein the major ingredient A is livestock excrement and / or urban living garbage. The preparation method comprises the following steps of: uniformly mixing 600 to 1,000 parts of major ingredient A, 30 parts of fermentation culture body, 50 parts of ammonium sulfate, 50 parts of calcium superphosphate and 50 parts of magnesium aluminum silicate powder, stacking, fermenting and rotting for 20 to 25 days. Compared with the prior art, the invention has the advantages that: a large quantity of regenerative organic waste resources are used; the waste is turned into wealth; and the biologic organic fertilizer prepared by a pollution-free treatment method of a comprehensive biologic technology is applied widely, so that the sustainable development of agricultural and ecological environments is promoted.

Owner:陆少英

Insecticidal Compositions Suitable For Use in Preparation of Insecticidal Liquid Fertilizers

ActiveUS20080206361A1Improve physical stabilityBiocideDead animal preservationSucroseAluminum magnesium silicate

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers comprising a pyrethroid, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester are disclosed.

Owner:FMC CORP

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers

ActiveUS8029827B2Improve physical stabilityBiocideDead animal preservationAluminum magnesium silicateSucrose

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers comprising a pyrethroid, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester are disclosed.

Owner:FMC CORP

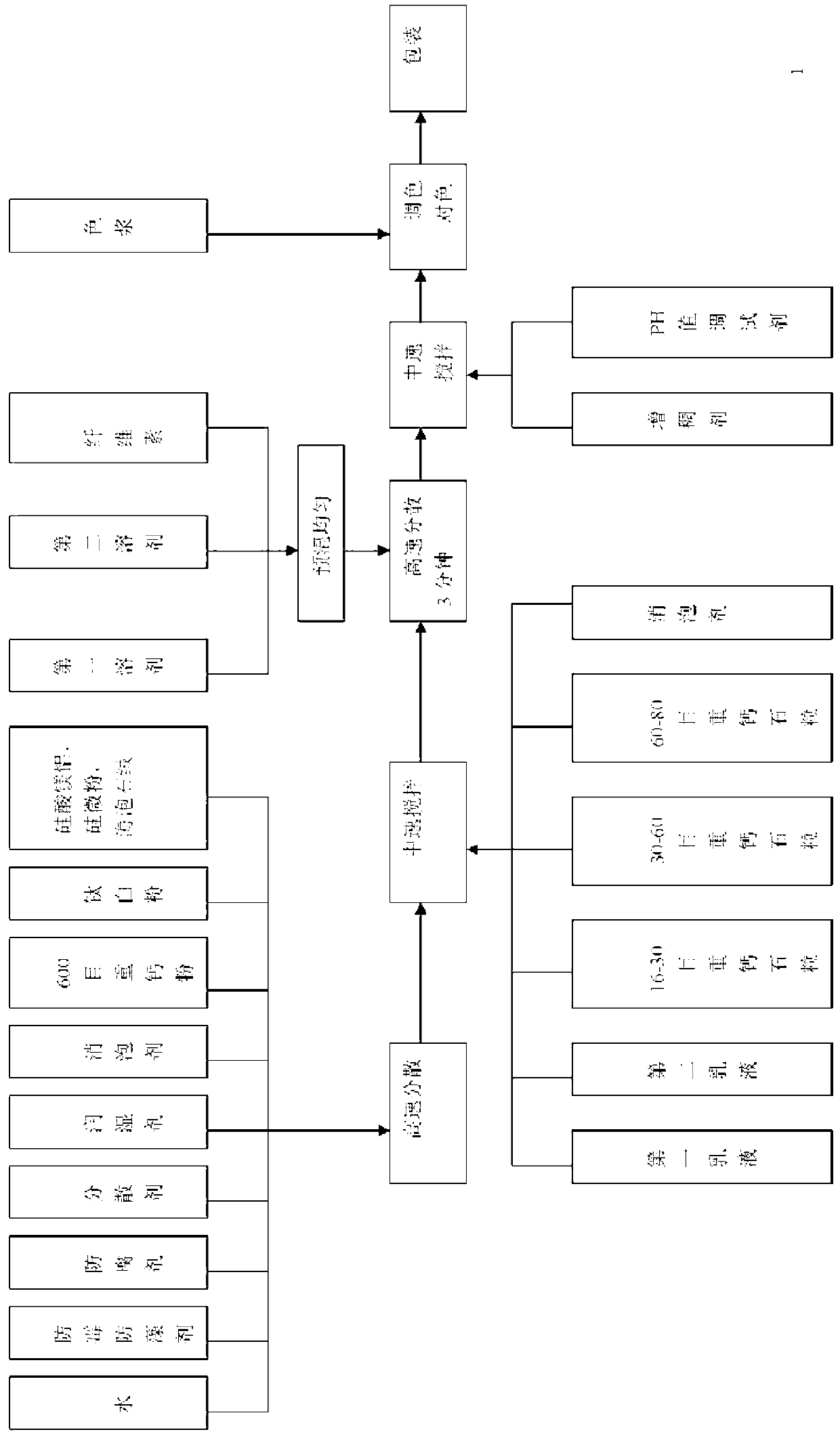

Elastic texture paint and preparation method thereof

ActiveCN102993887AGood flexibilityImprove impact resistanceCoatingsCelluloseAluminum magnesium silicate

The invention discloses elastic texture paint. The elastic texture paint comprises the following components: water, anti-mildew algaecide, preservative, dispersing agent, wetting agent, defoaming agent, 600-mesh calcium powder, titanium dioxide, aluminum-magnesium silicate, sepiolite velvet, silica powder, the first emulsion, the second emulsion, 16-30-mesh stone grain, 30-60-mesh stone grain, 60-80-mesh stone grain, the first solvent, the second solvent, cellulose and thickener. The elastic texture paint has the following excellent performances: multiple natural decoration effects, excellent flexibility, impact resistance, water resistance and air permeability and a good sound adsorption effect, and has the characteristics of simplicity in construction, capacity of creating decoration effects of strong texture and different styles by different construction methods, small bridging cracks, abundant expression forms and colors, and environmental protection, which cannot be realized by maishi paint or flat painting, can be extensively applied to all new buildings including exterior wall decoration projects of the public buildings and residential buildings, and has an extensive market prospect.

Owner:GUANGDONG NATURAL COATING CHEM CO LTD

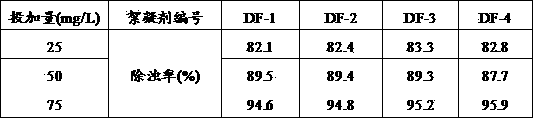

Multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and preparing method thereof

ActiveCN103420468AImprove flocculation efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationPhosphateAluminium silicate

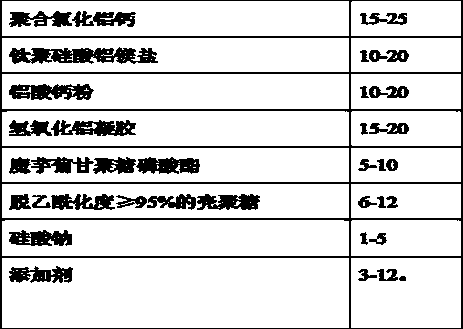

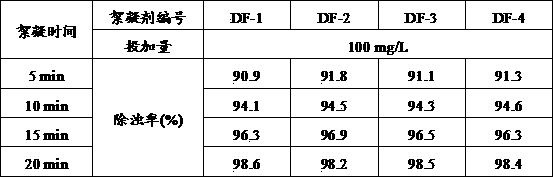

The invention relates to a multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and a preparing method of the multi-element composite flocculant. The flocculant comprises polymeric aluminium, titanium polysilicic acid aluminium silicate, calcium aluminate powder, aluminium hydroxide gel, konjac glucomannan phosphate, chitosan, sodium silicate and an additive, wherein the deacetylation degree of the chitosan is larger than or equal to 95%. Through appropriate selection of components and proportion, the multi-element composite flocculant has the advantages of being high in flocculation efficiency, small in dosage, wide in temperature application range and pH application range and the like. The multi-element composite flocculant can be used for treatment and purification of the printing and dying wastewater and the textile wastewater and has wide industrialized application prospects and market values.

Owner:广州市豫泉净水材料有限公司

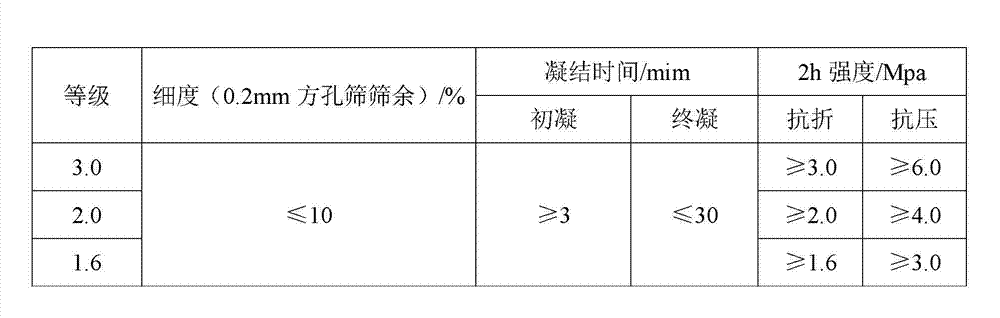

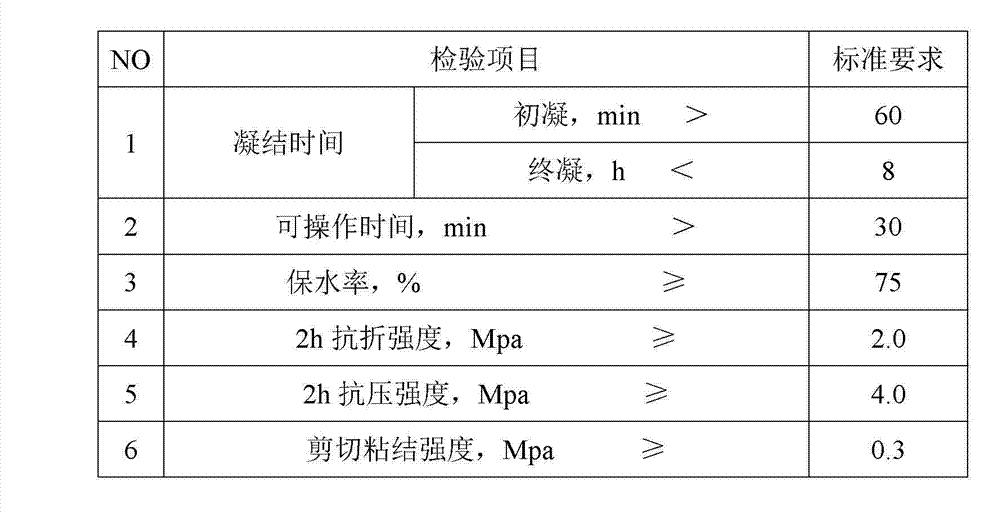

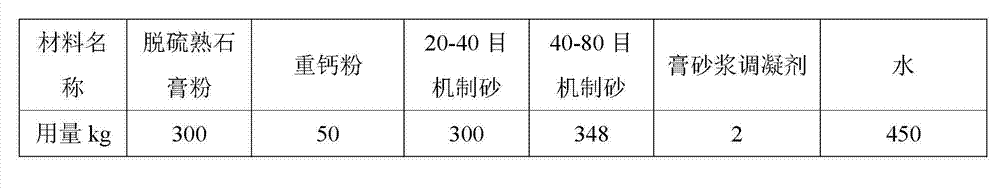

Thickening time control agent used for gypsum mortar, and preparation method thereof

ActiveCN103482898AMeet quality requirementsEasy to manufactureSodium BentoniteAluminum magnesium silicate

The invention relates to an additive of gypsum mortar and a preparation method of the additive, and more specifically discloses a thickening time control agent used for gypsum mortar. The thickening time control agent comprises following ingredients, by weight, 23 to 27% of anhydrous citric acid, 18 to 22% of anhydrous sodium pyrophosphate, 7 to 8% of hydroxy propyl methyl cellulose ether, 4.5 to 5.5% of sodium tripolyphosphate, 9 to 11% of pregelatinized starch, 18 to 22% of sodium bentonite, 9 to 11% of polycarboxylate superplasticizer and 2.2 to 2.8% of inorganic aluminum magnesium silicate gel. The thickening time control agent is added into gypsum mortar which is prepared by taking desulfurated gypsum powder as a gelling material, so that thickening time of gypsum mortar can be adjusted by adjustment of the amount of the thickening time control agent according to the difference of construction environment and temperature, and operation time can be prolonged appropriately according to requirements.

Owner:俞锡贤

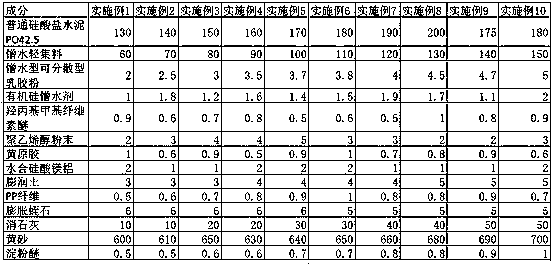

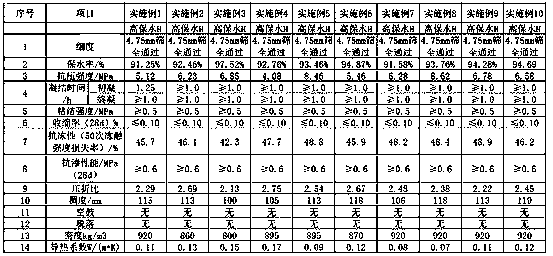

Machine-spraying light-weight plastering mortar and preparation method thereof

The invention discloses machine-spraying light-weight plastering mortar and a preparation method thereof. The machine-spraying light-weight plastering mortar is prepared from the following componentsin parts by mass: 130 to 200 parts of ordinary silicate cement, 60 to 150 parts of hydrophobic lightweight aggregate, 2 to 5 parts of hydrophobic re-dispersible latex powder, 1 to 2 parts of hydrophobic agent, 0.5 to 1 part of HPMC (hydroxypropyl methyl cellulose), 2 to 5 parts of polyvinyl alcohol, 0.5 to 1 part of xanthan gum, 1 to 2 parts of hydrate aluminum-magnesium silicate, 3 to 5 parts ofbentonite, 0.5 to 1 part of PP (polypropylene) fibers, 5 to 6 parts of expanded vermiculite, 10 to 50 parts of slaked lime, 600 to 700 parts of yellow sand, and 0.5 to 1 part of starch ether. The machine-spraying light-weight plastering mortar can be sprayed by a machine, so that the working efficiency of the wall plastering can be greatly increased and is five times or above of the manual construction speed, and the construction period is shortened. The problems that the traditional manual plastering construction efficiency is low, the consumption of materials is vast, dust pollution exists in the field, and the labor cost is increased can be solved; and the machine spraying construction quality is good, the safety performance is high, and no bubble or dropping can be produced.

Owner:苏州大乘环保新材有限公司

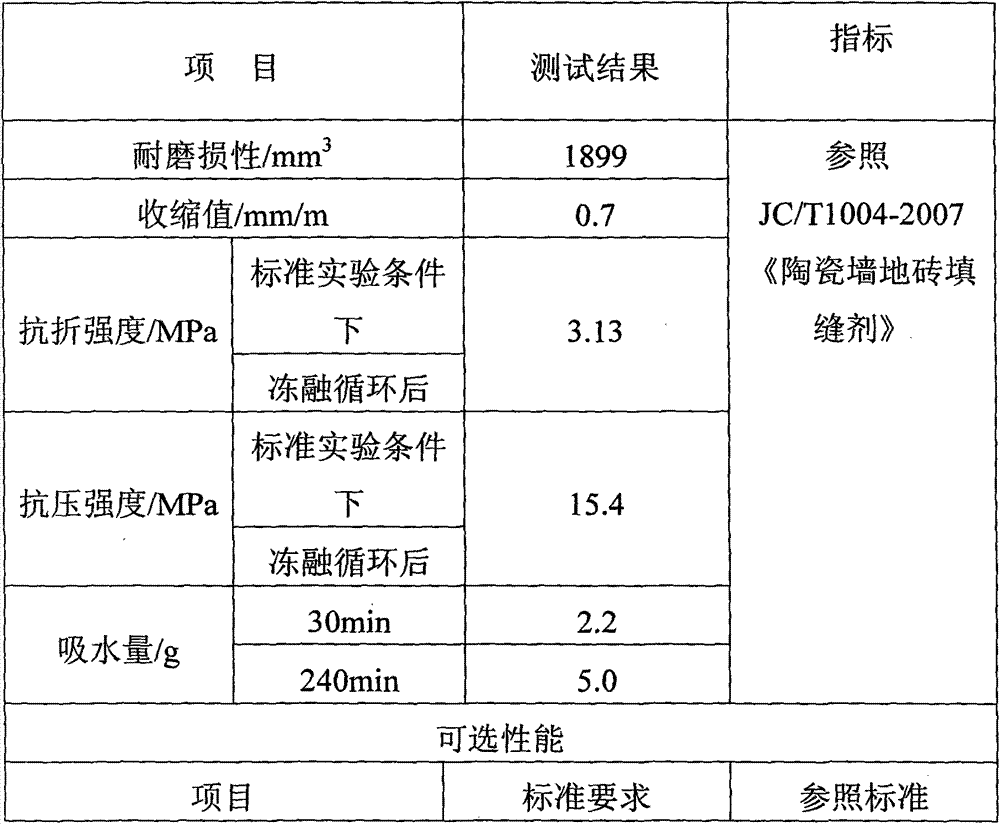

Bright caulking compound and construction method thereof

InactiveCN104743990AImprove performanceOvercome disadvantagesAluminum magnesium silicateSuperplasticizer

The invention relates to a bright caulking compound. The bright caulking compound is prepared from the following raw materials by weight: 35 to 45 parts of common white Portland cement, 20 to 40 parts of quartz powder, 5 to 10 parts of light calcium, 1 to 3 parts of starch, 10 to 30 parts of heavy calcium carbonate powder, 0.15 to 0.25 part of hydroxypropyl methyl cellulose, 5 to 10 parts of pure acrylic glue powder, 0.08 to 0.1 part of a polycarboxylate superplasticizer, 0.1 to 0.3 part of an antifoaming agent, 0.2 to 0.3 part of an organosilicon water repellent, 0.1 to 0.4 part of aluminum-magnesium silicate, 0.4 to 0.6 part of a brightener, 1.5 to 3 parts of pigment, 0.3 to 0.5 part of a dispersant and 0.1 to 0.3 part of cellulosic fiber. According to the invention, since various properties of the caulking compound are improved through addition of proper additives, disadvantages of traditional cement-based caulking compounds are overcome, problems of a reactive resin type caulking compound are perfectly solved, the caulking compound disclosed in the invention has excellent resistance to corrosion, mildew, permeation, water, scrubbing, wear and contamination, excellent shrinkage deformation capability and other excellent properties, cost is saved, and production and construction steps are simplified.

Owner:FOSHAN JIAMITE WATERPROOF MATERIAL CO LTD

High-thermostability water-based paint containing nanometer wollastonite for lost foam casting and manufacturing method of water-based paint

InactiveCN105057571AImprove breathabilityImprove thermal stabilityFoundry mouldsFoundry coresWater basedAluminum magnesium silicate

The invention relates to the technical field of lost form casting and in particular to high-thermostability water-based paint containing nanometer wallastonite for lost foam casting and a manufacturing method of the water-based paint. According to the paint, high-alumina bauxite and violet lime stone powder with the different grain sizes are used as refractory aggregates, so that the permeability of a coating is good, the thermostability is better, and the high heat resistance and impact resistance are good; a nanometer wollastonite, aluminum-magnesium silicate and sodium carboxymethylcellulose mixed sizing agent is used as a suspending agent, so that the paint has the good suspension property and thixotropy, a polyethylene wax emulsion is dispersed into the coating, then the flatness of the surface of the coating can be improved, the sand prevention stickiness is improved, rapid melting is performed in the pouring process, and the permeability of the coating is further improved; and the obtained paint is good in stickiness, the coating strength is uniform, the permeability is good, the thermostability is good, the size is stable, molten metal is not polluted, stripping is easy after casting is finished, and the quality of castings is effectively improved.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Aluminum-magnesium silicate compound and synthetic method thereof

InactiveCN101613110AHigh purityEasy to prepareAluminium silicatesChemical synthesisAluminium sulfate

The invention provides an aluminum-magnesium silicate compound, a synthetic method thereof and aluminum-magnesium silicate obtained by the method. The aluminum-magnesium silicate comprises the following ingredients in percentage by weight: 14.28-18.79 aluminum, 6.86-16.71 magnesium and 6.73-16.64 silicon, and the ratio of the aluminum to the magnesium is 0.5-1.2 or 1.4-2.8. The method comprises the following steps: (1) respectively dissolving magnesium sulfate and aluminum sulfate in water and mixing and stirring the obtained solutions; (2) dissolving sodium silicate in water to form a sodium silicate solution, adding a sodium hydroxide solution, stirring uniformly and adding to the solution of the step (1) to react; and (3) adding solid calcium chloride or an aqueous solution of calcium chloride to the reaction mass of the step (2) to stir, react and form the aluminum-magnesium silicate. The method can be used for obtaining the aluminum-magnesium silicate by chemical synthesis to fill in the gap of a chemical mass synthesis method and is simple and easy to operate, and the obtained aluminum-magnesium silicate has high purity and good stability and reaches a medicinal level.

Owner:HAINAN YONGTIAN PHARMA INST

Co-Formulations of Bifenthrin with Encapsulated Crop Protection Agents For Use with Liquid Fertilizers

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers are disclosed, the compositions comprising bifenthrin, an encapsulated crop protection agent, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester.

Owner:FMC CORP

Waterborne ultralow-VOC-content high-weatherability real stone paint and preparation method thereof

The invention discloses a waterborne ultralow-VOC-content high-weatherability real stone paint and a preparation method thereof. The waterborne ultralow-VOC-content high-weatherability real stone paint is prepared from the following raw materials by weight: 9 to 11 parts of pure acrylic emulsion, 4 to 6 parts of silica sol, 0.2 to 0.3 part of a compatibility stabilizing agent, 9 to 11 parts of deionized water, 0.2 to 0.25 part of cellulose, 0. 1 to 0.3 part of an antifoaming agent, 0.1 to 0.2 part of an antiseptic, 1 to 1.5 parts of an antifreezing agent, 0.6 to 0.8 part of a film forming aid, 65 to 75 parts of sintering colored sand, 0.5 to 1.0 part of aluminum-magnesium silicate and 0.1 to 0.5 part of a thickening agent. The real stone paint provided by the invention has the characteristics of healthiness, environmental protection, excellent water resistance, stain resistance and weatherability, excellent slipperiness in construction, simplicity, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water-based paint containing nano-zinc oxide and with enhanced high heat retaining property for evanescent mold casting and preparation method thereof

InactiveCN105057569AGood suspensionImprove thixotropyFoundry mouldsFoundry coresWater basedPyrophyllite

The invention relates to the technical field of evanescent mold casting, in particular to water-based paint containing nano-zinc oxide and with enhanced high heat retaining property for evanescent mold casting and a preparation method thereof. Pyrophyllite powder and quartz sand with different grain sizes are used as refractory aggregates of the water-based paint, so that the air permeability of a coating is good, and the coating is even and smooth. Mixed slurry of nano-zinc oxide, aluminum-magnesium silicate and sodium carboxymethylcellulose is used as a suspending agent which enables the water-based paint to be good in suspension property and thixotropy, and the heat retaining property of the coating is further improved. The air permeability of a coating surface can be improved after microcrystalline cellulose disperses in the coating. The paint coating prepared through the method is firm, insulated, compact, permeable and easy to clean; the liquid metal is not polluted and the surface quality of a casting is improved effectively.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Wear-resistant and high temperature-resistant ceramic mold material and preparation method thereof

The invention discloses a wear-resistant and high temperature-resistant ceramic mold material and a preparation method thereof. The material is prepared by aluminum magnesium silicate, nanometer cerium dioxide, nanometer zirconium dioxide, aluminum oxide, yttrium oxide, silicon carbide, chromium, nickel, iron, copper, sulfur, borax, carbon fibers, tributyl tin trichloride, butyl methacrylate and ethylenediamine; the raw materials are put in a ball mill for ball milling to obtain stable suspension slurry after being mixed in proportion; tributyl tin trichloride, butyl methacrylate and ethylenediamine are added for ball milling and vacuum foam removal, are injected in a mold for in-situ solidification and colloidal molding, are dried at room temperature, are demolded and dried, are charged in a furnace, and remove glue in vacuum; nitrogen is introduced for heating and pressurization; the furnace is stopped through power failure; and the raw materials are discharged from the furnace after cooling to prepare the wear-resistant and high temperature-resistant ceramic mold material. The mold structure has excellent heat stability, wear resistance and high-temperature resistance, also has excellent toughness, thermal shock resistance and mechanical strength, and prominently prolongs the mold service life.

Owner:吴申龙

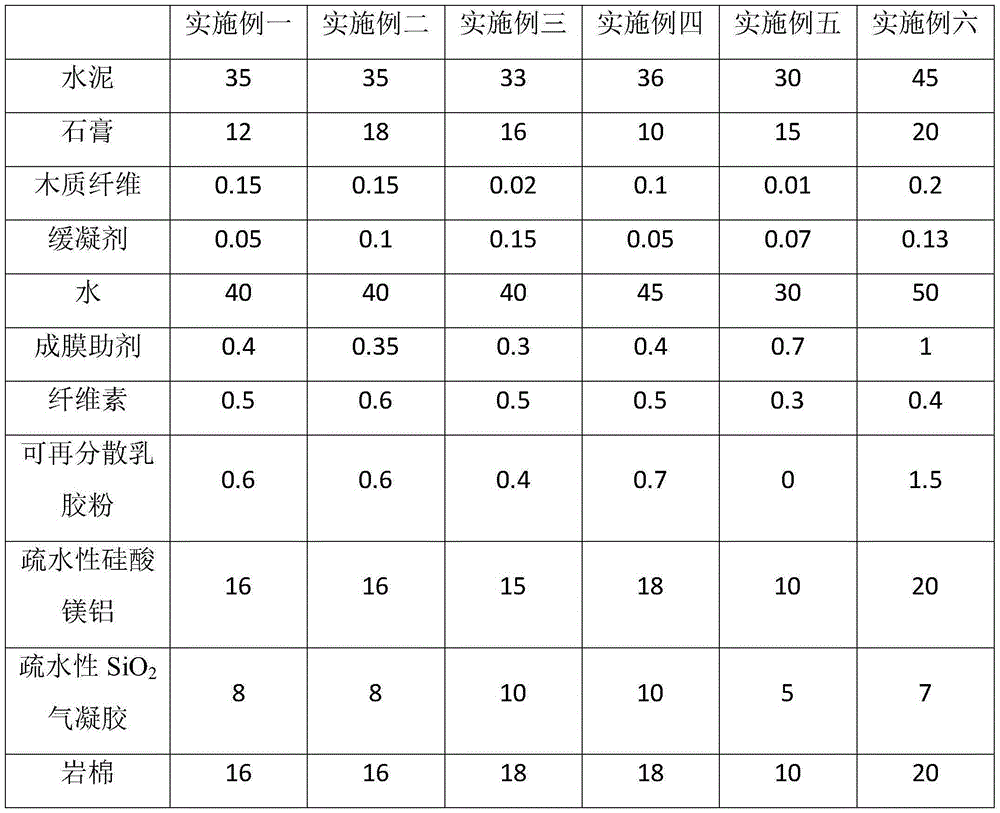

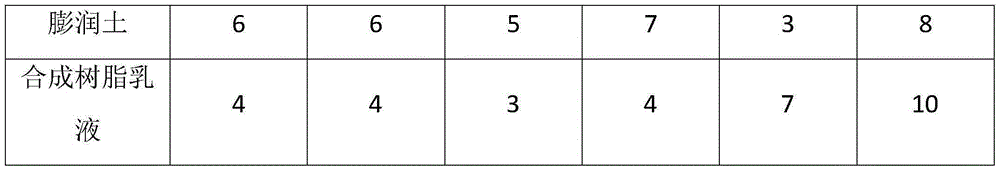

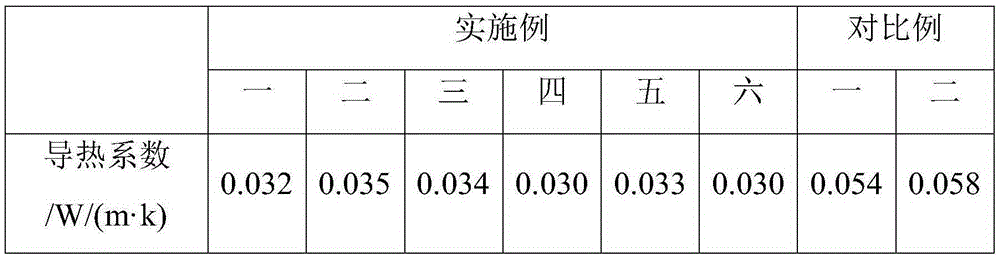

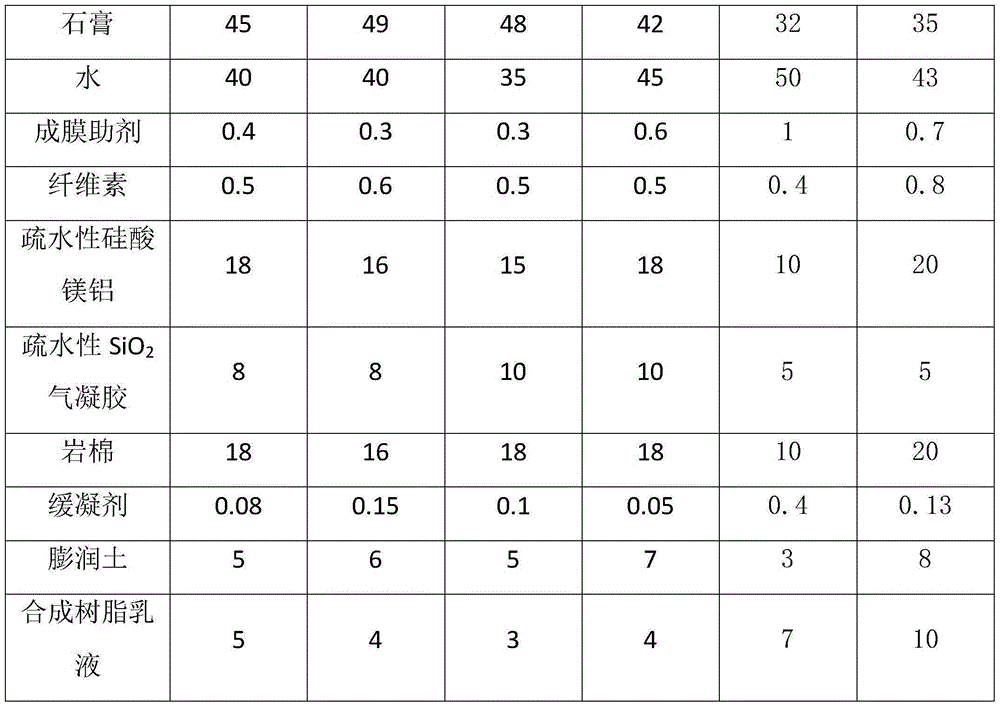

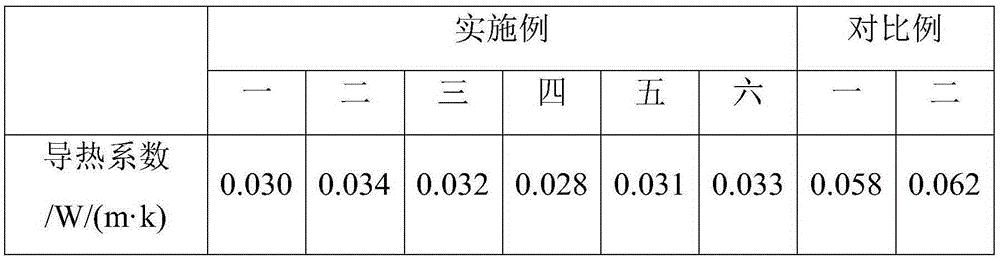

Two-component efficient and light external wall insulation material and preparation method thereof

The invention belongs to the field of insulation building materials and discloses a two-component efficient and light external wall insulation material and a preparation method thereof. The insulation material comprises a component 1 and a component 2, wherein the component 1 is prepared from, by mass, 30-45 parts of cement, 10-20 parts of gypsum, 0.01-0.2 part of wood fiber and 0.05-015 part of retarder; the component 2 is prepared from, by mass, 0.3-1 part of coalescing agent, 0.3-0.6 part of cellulose, 0-1.5 parts of redispersible latex powder, 10-20 parts of hydrophobic aluminum-magnesium silicate, 5-10 parts of hydrophobic SiO2 aerogel, 10-20 parts of rock wool, 3-8 parts of bentonite and 3-10 parts of synthetic resin emulsion. The insulation material is low in heat conductivity coefficient, good in insulation effect, high in fire resistance rating and convenient to construct.

Owner:CHONGQING XINGYU POLYMER PAINT +1

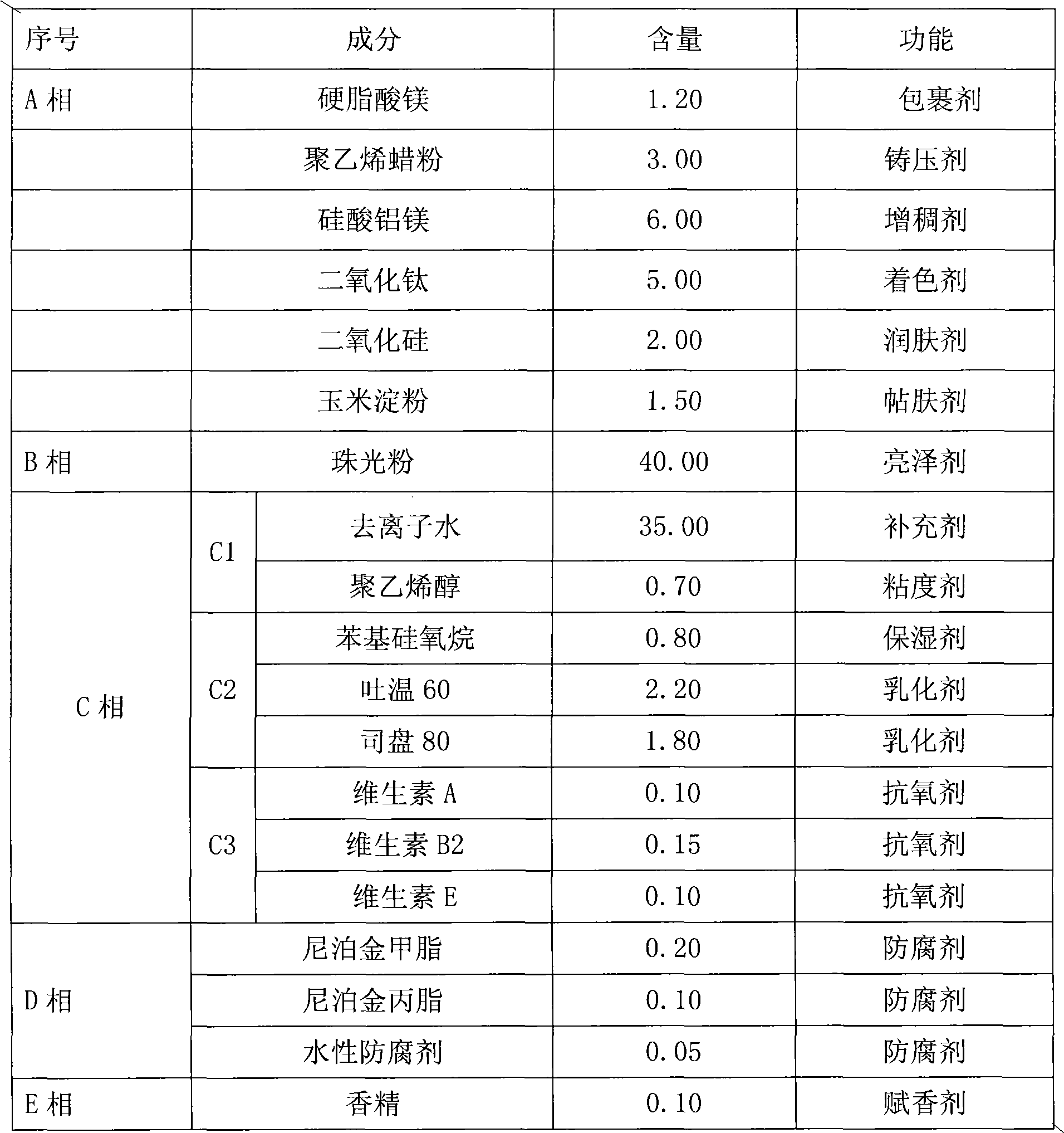

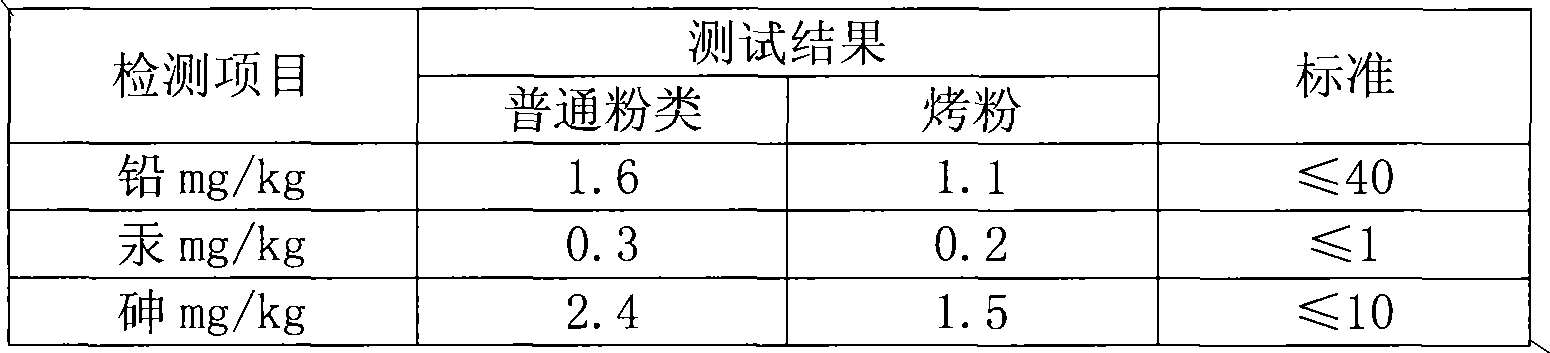

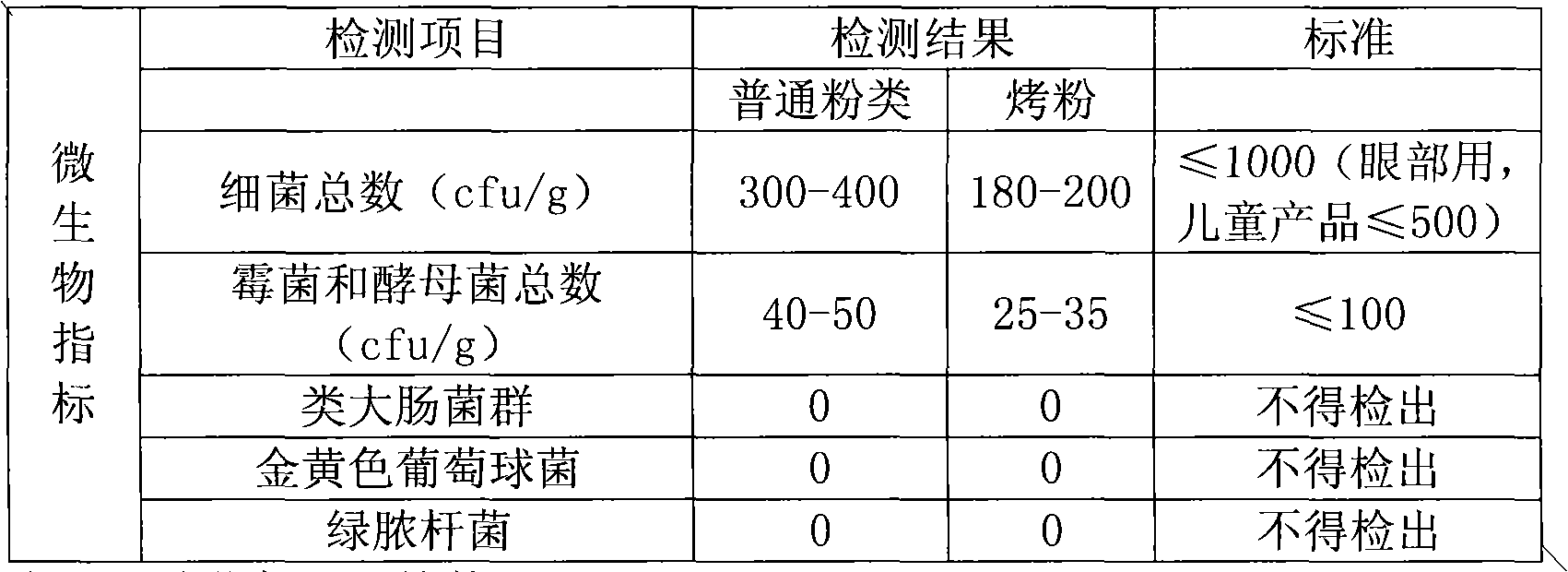

Baking powder and preparation method thereof

ActiveCN102048656AGood colorImprove testing standardsCosmetic preparationsBody powdersPolyvinyl alcoholAntioxidant

The invention provides a baking powder and a preparation method thereof. The baking powder comprises the following components in percentage by weight: 1-4 percent of magnesium stearate, 1-3 percent of polyethylene wax powder, 4-7 percent of magnesium aluminum silicate, 4-6 percent of titanium dioxide, 1-3 percent of silicon dioxide, 1-2 percent of maize starch, 20-50 percent of pearl powder, 0.5-2 percent of phenylsiloxane, 0.5-1 percent of polyvinyl alcohol and proper antioxidant, emulsifier and deionized water. The baking powder can be applied uniformly, is smooth and easy to color.

Owner:浙江美雪化妆品有限公司

Water-coating-sand colorful paint and preparation method thereof

InactiveCN106752482AHigh elongationImprove water resistanceAnti-corrosive paintsCelluloseAluminum magnesium silicate

The invention relates to a water-coating-sand colorful paint and a preparation method thereof. The paint includes, by weight, 15-20 parts of a resin compound emulsion, 30-45 parts of compound powder, 3-5 parts of an additive, 30-50 parts of color sands, and 20-30 parts of water, wherein the resin compound emulsion is prepared by mixing acrylic pure acrylic emulsion and silicone acrylic emulsion. The additive includes, by weight, 0.3-0.5 parts of dodecanoate, 0.8-1.2 parts of propylene glycol, 0.2-0.4 parts of a wetting agent X-405, 0.2-0.4 parts AMP-95 neutralizing amine, 0.5-0.8 parts of an ammonium salt dispersant, 0.2-0.4 parts of a defoamer, 0.7-1 part of a DR-72 alkali swelling thickener, 1-1.2 parts of aluminum-magnesium silicate, 0.3-0.5 parts of cellulose, and 0.5-1 part of a liquid stabilizer. Compared with the prior art, the paint has good water resistance, extensibility and stain resistance, is low in preparation cost, is good in storage stability, is easy to construct and saves labor hour.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

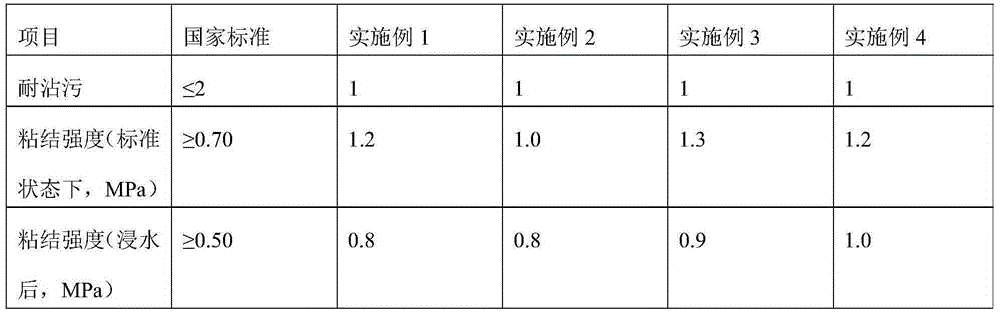

Non-cement-based caulking compound and construction method thereof

The invention relates to a non-cement-based caulking compound. The non-cement-based caulking compound is prepared from the following raw materials by weight: 10 to 20 parts of acrylic acid copolymerization emulsion, 40 to 60 parts of heavy calcium carbonate, 28 to 40 parts of quartz powder, 3 to 5 parts of metakaolin, 0.06 to 0.1 part of hydroxypropyl methyl cellulose ether, 4 to 5 parts of titanium dioxide, 0.4 to 0.6 part of a water reducer, 0.2 to 0.3 part of a water repellent, 0.2 to 0.3 part of a liquid antifoaming agent, 0.4 to 0.6 part of an antiseptic, 0.1 to 0.3 part of a wetting dispersant, 0.2 to 0.5 part of aluminum-magnesium silicate and 0.1 to 0.2 part of an anti-skinning agent. According to the invention, since various properties of the caulking compound are improved through addition of proper additives, disadvantages of traditional cement-based caulking compounds are overcome, problems of a reactive resin type caulking compound are perfectly solved, and the caulking compound disclosed in the invention has excellent resistance to corrosion, mildew, permeation, water, scrubbing, wear and contamination, excellent shrinkage deformation capability and other excellent properties and enables cost to be saved; and in construction, the caulking compound can be applied in a manner resembling squeezing of toothpaste out of a tube, so production and construction steps are simplified.

Owner:FOSHAN JIAMITE WATERPROOF MATERIAL CO LTD

Modified textile insertion pnenolic aldehyde supporting ring, guiding ring and its production method

Disclosed is a modified textile insertion pnenolic aldehyde supporting ring, guiding ring and its production method, which comprises the components (by weight portion) of fabric 15-30%, thermosetting phenolic resin 50-70%, polytetrafluoroethylene resin 0-10%, aluminium silicate magnesite powder 0-10%, molybdenum disulfide 0-10%, graphite 0-10%. The preparation process comprises fabric gumming, drying, forming, curing, cooling down, demoulding, renovating and cutting.

Owner:陈金奎

Two-component efficient and light internal wall insulation putty and preparation method thereof

ActiveCN105348893AHigh bonding strengthAvoid crackingFireproof paintsFilling pastesCelluloseEmulsion

The invention belongs to the field of insulation building materials and discloses two-component efficient and light internal wall insulation putty and a preparation method thereof. The insulation putty comprises a component 1 and a component 2, wherein the component 1 is gypsum which takes up 40-70 mass parts; the component 2 is prepared from, by mass, 0.3-1 part of coalescing agent, 0.4-0.8 part of cellulose, 10-20 parts of hydrophobic aluminum-magnesium silicate, 5-10 parts of hydrophobic SiO2 aerogel, 10-20 parts of rock wool, 0.05-0.4 part of retarder, 3-8 parts of bentonite and 3-10 parts of synthetic resin emulsion. The insulation putty is low in heat conductivity coefficient, good in insulation effect, high in fire resistance rating and convenient to construct.

Owner:重庆兴渝新材料研究院有限公司

Co-formulations of bifenthrin with high-melting crop protection agents for use with liquid fertilizers

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers are disclosed, the compositions comprising bifenthrin, at least one other unencapsulated crop protection agent having a melting point of about 50° C. or greater, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester.

Owner:FMC CORP

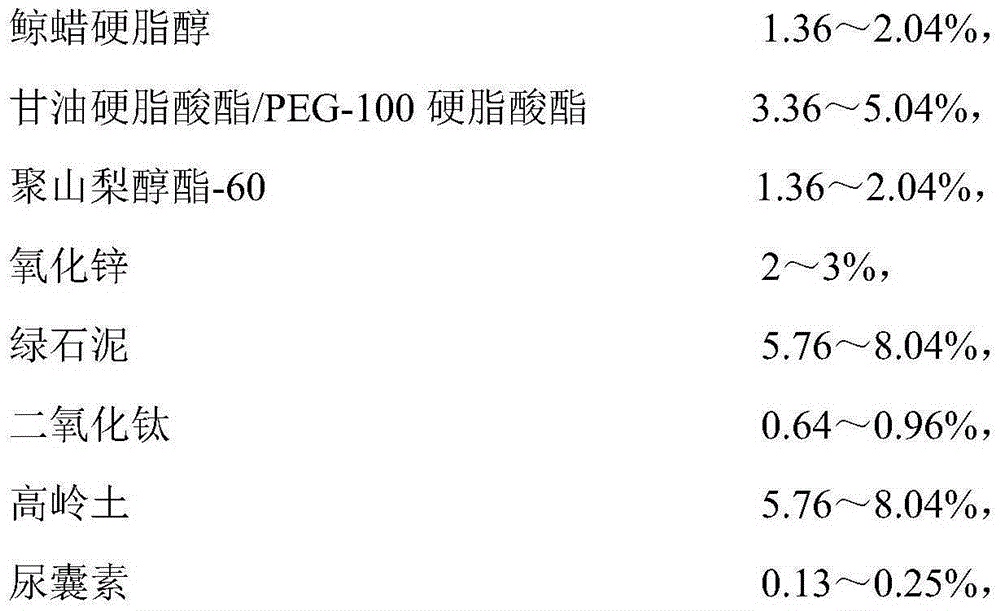

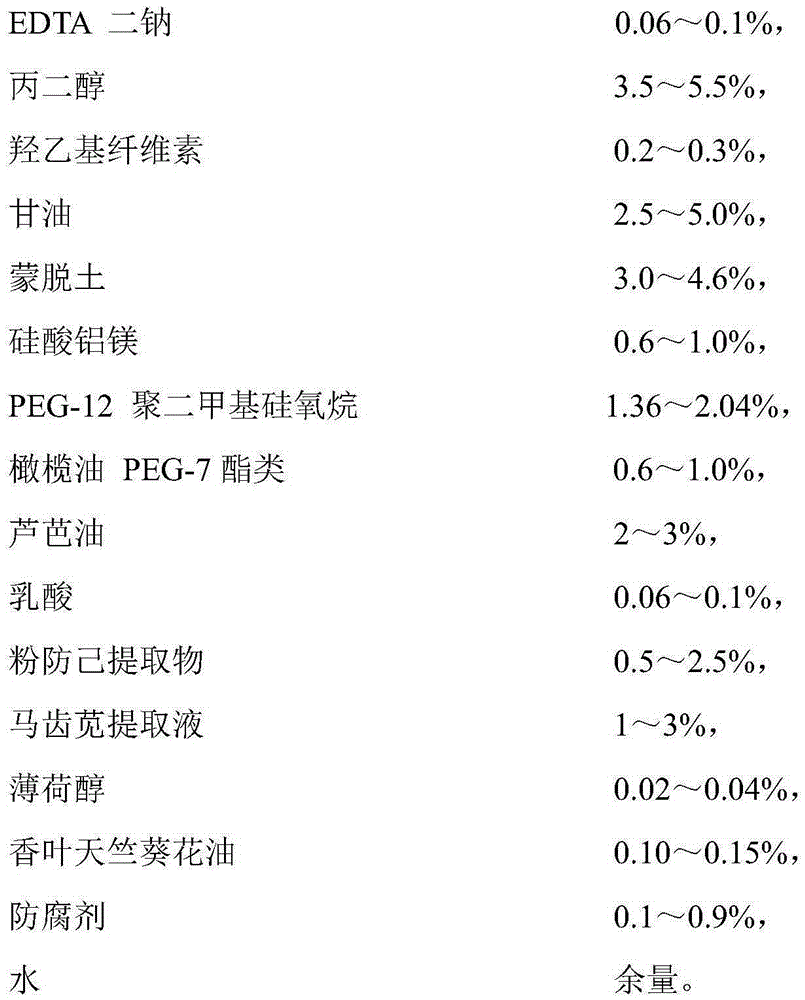

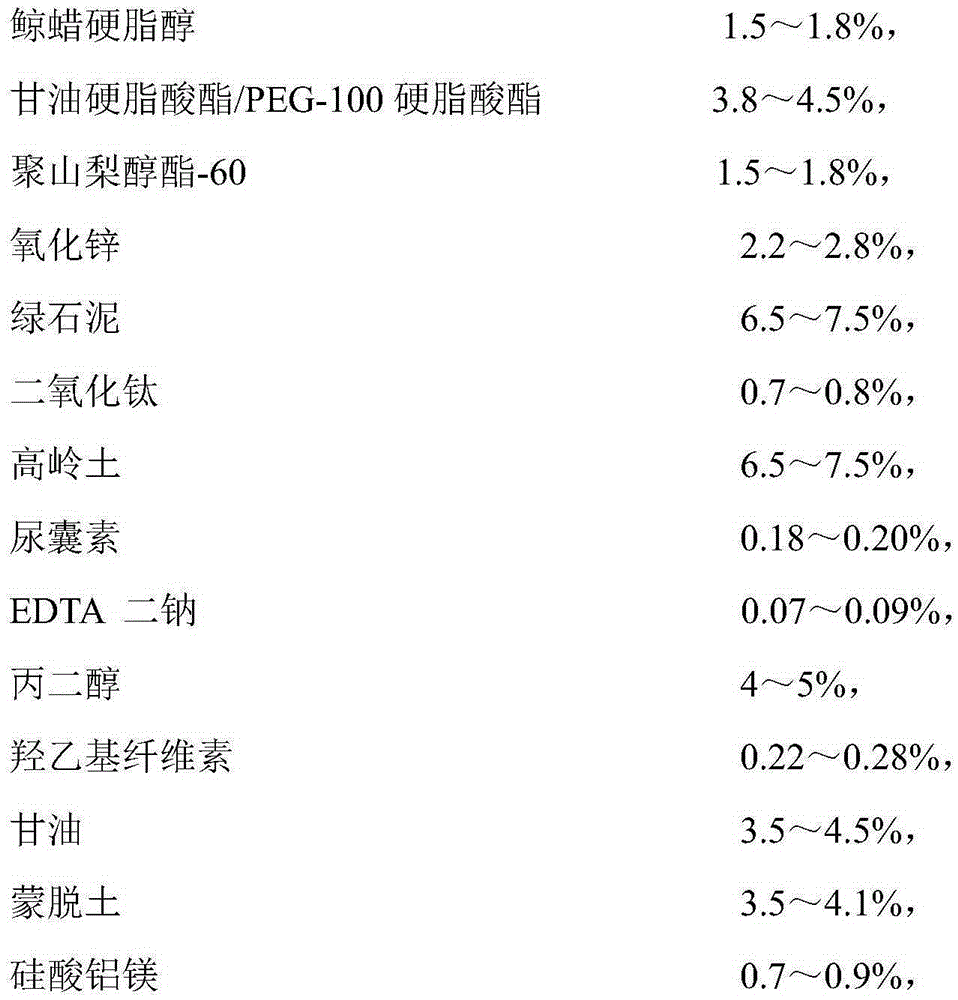

Mud facial mask containing Chinese herb extract and preparation method of mud facial mask

ActiveCN105362160AEasy to push and wipeSoft skinCosmetic preparationsAntipyreticDimethyl siloxaneLactic acid

The invention discloses a mud facial mask containing Chinese herb extract and a preparation method of the mud facial mask and aims at providing the mud facial mask which contains natural products and components and is easy to apply, resistant to inflammation and allergy and has the whitening efficacy. The facial mask is prepared from 1.36-2.04% of cetostearyl alcohol, 3.36-5.04% of glyceryl stearate / stearate PEG-100, 1.36-2.04% of polysorbate-60, 2-3% of zinc oxide, 5.76-8.04% of green clay, 0.64-0.96% of titanium dioxide, 5.76-8.04% of kaolin, 0.13-0.25% of allantoin, 0.06-0.1% of EDTA disodium, 3.5-5.5% of propylene glycol, 0.2-0.3% of hydroxyethyl cellulose, 2.5-5.0% of glycerin, 3.0-4.6% of montmorillonite, 0.6-1.0% of magnesium aluminium silicate, 1.36-2.04% of polydimethylsiloxane PEG-12, 0.6-1.0% of olive oil ester PEG-7, 2-3% of polyglycerylmetharylate and propylene glycol, 0.06-0.1% of lactic acid, 0.5-2.5% of stephania tetrandra extract, 1-3% of a portulaca oleracea extracting solution, 0.02-0.04% of menthol, 0.10-0.15% of pelargonium roseum flower oil, 0.1-0.9% of preservative and the balance water.

Owner:广州市中通生化制品有限公司

Formula of water-based lost foam paint for low-temperature high-strength ductile iron

ActiveCN108057840AGood hangabilityImprove uniformityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention provides a formula of water-based lost foam paint for low-temperature high-strength ductile iron. The formula comprises refractory aggregate, an adhesive, a suspension agent, a surface active agent and a carrier; the refractory aggregate comprises diatomaceous earth, zircon powder, forsterite powder and flake graphite; the adhesive comprises polyving akohol and silica sol; the suspension agent comprises lithium-based bentonite and aluminum-magnesium silicate; and the surface active agent comprises a water-based defoamer, a wetting agent and a penetrating agent. The paint preparedaccording to the formula has excellent sag resistance, uniformity, thermal stability and metal oxidative corrosion resistance, and castings cast through the paint have excellent surface finish and clear outlines.

Owner:TIANJIN NINGKANG TECH

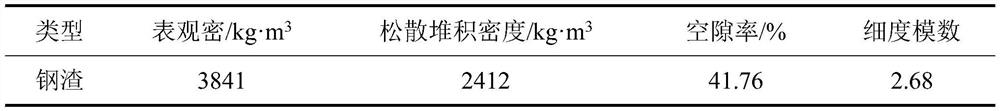

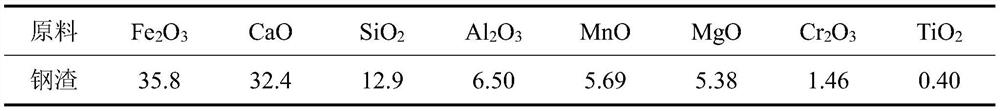

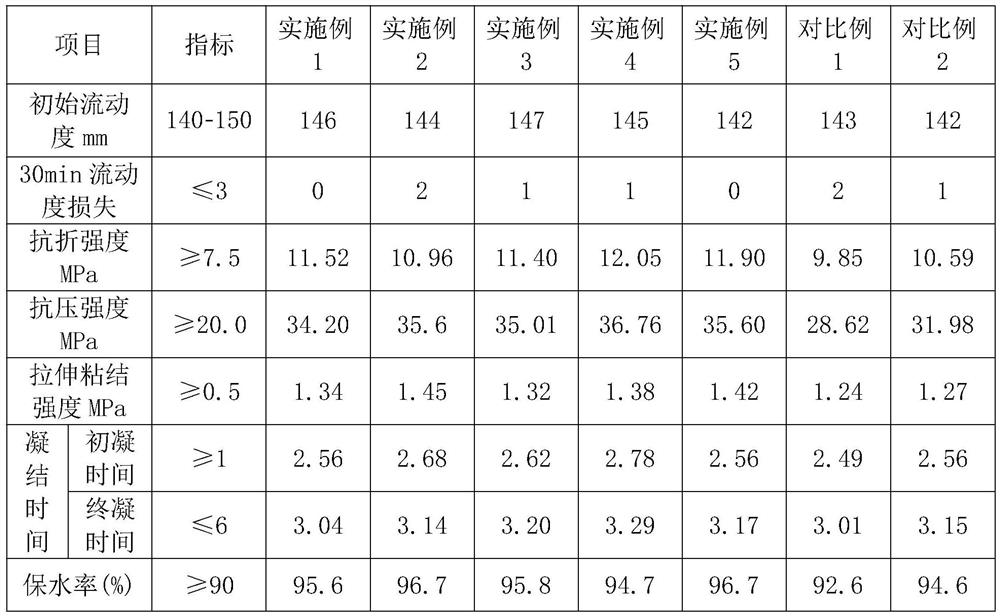

Gypsum self-leveling mortar for floor heating backfilling and preparation method of gypsum self-leveling mortar

The invention relates to gypsum self-leveling mortar for floor heating backfilling. The gypsum self-leveling mortar is prepared from the following components in parts by weight: 400 to 460 parts of gypsum powder, 100 to 140 parts of industrial solid waste residues, 30 to 70 parts of cement, 20 to 35 parts of graphite powder, 5 to 15 parts of calcium oxide, 3 to 15 parts of magnesium aluminum silicate, 9 to 15 parts of redispersible latex powder, 2 to 5 parts of a de-foaming agent, 0.5 to 1 part of a gypsum retarder, 0.5 to 1 part of a water reducing agent and 160 to 220 parts of water. According to the gypsum self-leveling mortar, the industrial waste residues are adopted as aggregates in gypsum self-leveling, the use of sand in the self-leveling mortar is reduced, the strength and abrasion resistance of the gypsum self-leveling mortar are effectively improved, and the gypsum self-leveling mortar is low in cost and stable in quality, has good abrasion resistance, compressive strength and heat-conducting property, is suitable for backfilling of different types of floor heating systems, preparation and construction are simple, and energy consumption is low.

Owner:NANJING UNIV OF TECH

High-strength silica-based graphene conductive material and preparation method thereof

The invention discloses a high-strength silica-based graphene conductive material. The high-strength silica-based graphene conductive material is prepared from the following raw materials in parts by weight: 0.3 to 1 part of coconut acid diethanolamide, 3 to 4 parts of wollastonite powder, 5 to 6 parts of ethylhexyl epoxy tetrahydrophthalate, 1 to 2 parts of chlorination-1-allyl-3-methylimidazole, 1.7 to 2 parts of phosphoric acid, 2 to 3 parts of lithium hydroxide, 0.8 to 1 part of ferrous sulfate, 0.1 to 0.2 part of glucose, 6 to 7 parts of acetylene carbon black, 81 to 90 parts of unsaturated polyester resin, 600 to 700 parts of N,N-dimethylformamide, 27 to 30 parts of graphene oxide, 26 to 30 parts of hydrazine hydrate, 7 to 10 parts of tetraethyl orthosilicate, 0.8 to 1 part of zinc acetylacetonate, 0.1 to 0.2 part of 1,2-dimethylimidazole, 1 to 2 parts of aluminum magnesium silicate, 1 to 2 parts of ammonium octamolybdate and 1 to 2 parts of polyacrylamide. Chlorination modified grapheme has good conductivity, is blended with the acetylene carbon black, and can be well dispersed in the unsaturated polyester resin to form a composite material with high conductivity.

Owner:SUZHOU ZIJIN PLASTIC

Soil restoring agent with heavy metal ion adsorption and immobilization functions, and preparation method thereof

InactiveCN105925268ACuring stabilityImprove adsorption capacityOrganic fertilisersSoil conditioning compositionsAluminum magnesium silicateSoil science

The invention provides a soil restoring agent with heavy metal ion adsorption and immobilization functions, and a preparation method thereof. The raw material formula of the soil restoring agent comprises 60-80 parts of waste soil obtained after oil decolorizing and waste white clay oil extraction, 2-5 parts of a sulfur-containing compound, 8-15 parts of aluminum magnesium silicate and 10-20 parts of humic acid. The preparation method of the soil restoring agent comprises the following steps: 1, reacting the waste soil with the sulfur-containing compound at 500-700DEG C to obtain sulfenyl group-containing modified soil with an octahedral structure; and 2, mixing the modified soil with aluminum magnesium silicate and humic acid to obtain the soil restoring agent. The soil restoring agent has the advantages of recycling of the waste white clay, excellent heavy metal ion adsorption and immobilization functions, high added values, simple preparation and low cost.

Owner:SHANGHAI LICHANG ENVIRONMENTAL ENG

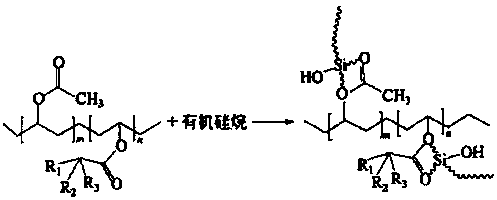

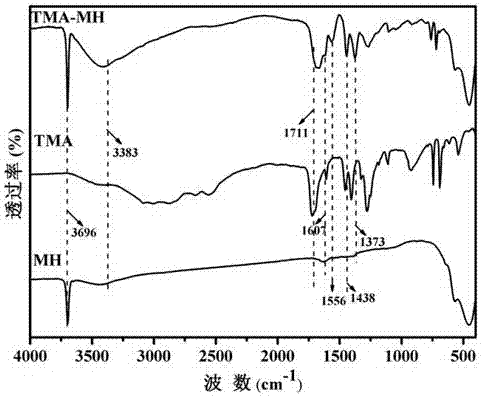

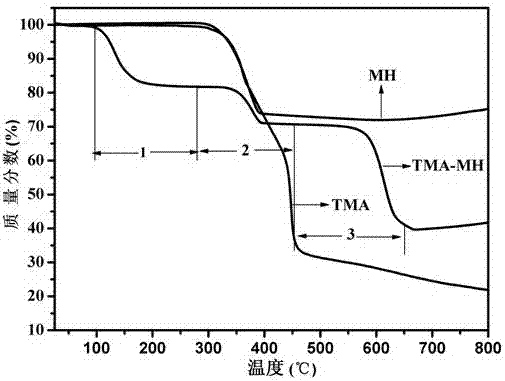

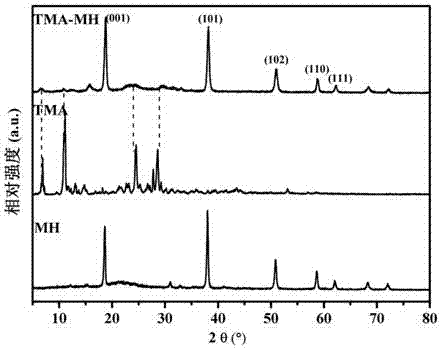

Preparation of organic-inorganic hybrid curing agent with flame retardant property and application in prepared epoxy resin

The invention discloses a preparation method of an organic-inorganic hybrid curing agent. The preparation method comprises the following steps: dissolving trimesic acid into absolute ethyl alcohol, adding magnesium hydrate, mechanically stirring for 3 to 6 h at the temperature of 50 to 75 DEG C, filtering, washing with ethyl alcohol, and carrying out vacuum drying to obtain a white powder-like solid. Epoxy resin is modified by using a combined method of flame retardant and intrinsic flame retarding, the purposes of inflaming retarding and smoke suppression are reached efficiently, and the production cost of the material is hardly increased. In terms of the thinking, the organic-inorganic hybrid curing agent with the flame retardant property is synthesized, and palygorskite clay, aluminum-magnesium silicate and magnesium gluconate are compounded, so that the prepared flame-retardant halogen-free low-smoke epoxy resin has good low-smoke and flame-retardant performances and also has good mechanical performance, and the application field of the epoxy resin is effectively expanded.

Owner:NORTHWEST NORMAL UNIVERSITY +1

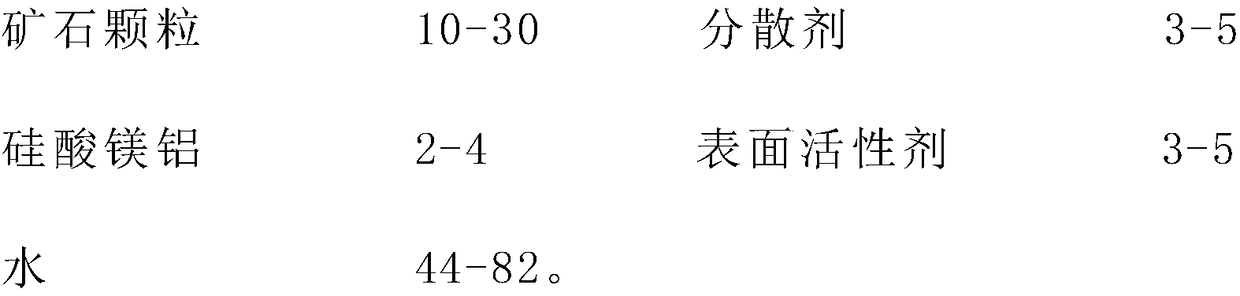

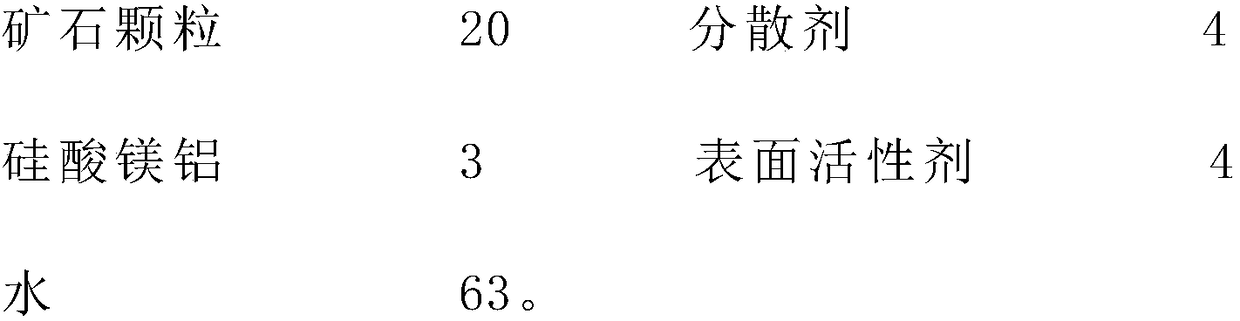

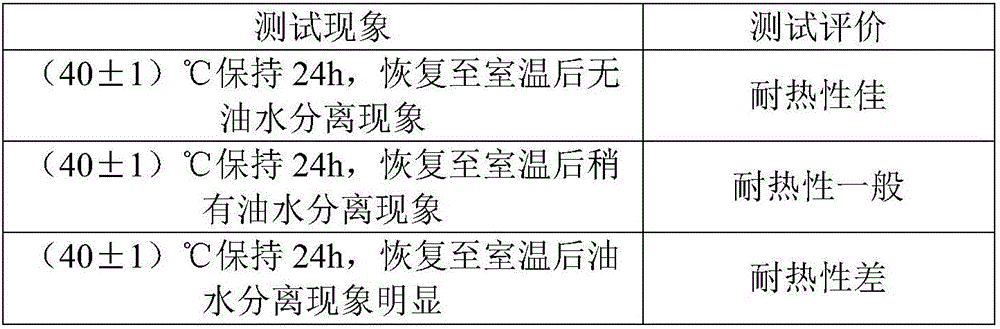

Ore water-based suspension liquid applied to fire-fighting material and preparation process of ore water-based suspension liquid

InactiveCN109432683AImprove stabilityEvenly suspendedFire extinguisherWater basedAluminum magnesium silicate

The invention provides ore water-based suspension liquid applied to a fire-fighting material and a preparation process of the ore water-based suspension liquid. Components of the ore water-based suspension liquid mainly comprise ore particles, a dispersion agent, aluminum-magnesium silicate, a surface active agent and water. The physical and chemical property of the ore water-based suspension liquid is stable, the ore water-based suspension liquid can be stored and transported under the room temperature for a long time, the fire-fighting material is evenly suspended in the ore water-based suspension liquid, and the fire extinguishing effect can be obviously improved; and the technology can also be applied to preparation of electric battery fire extinguishing materials.

Owner:张平 +4

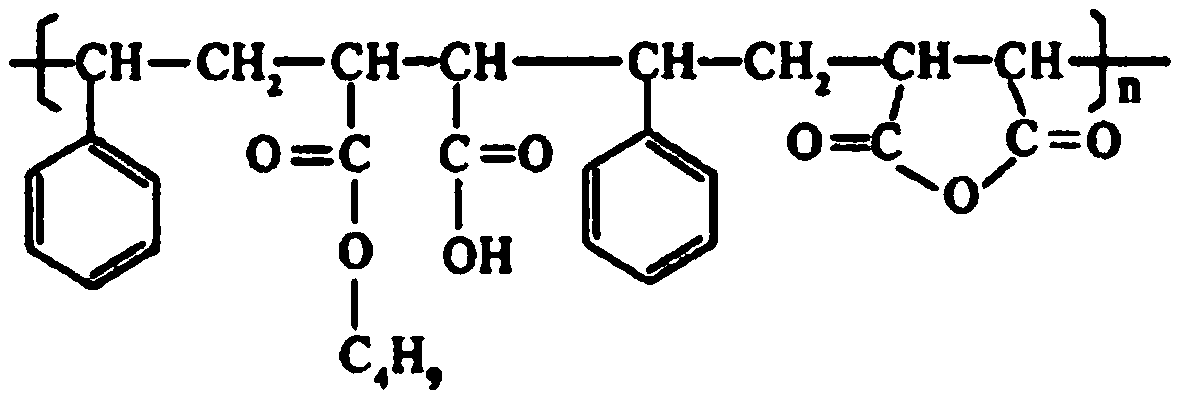

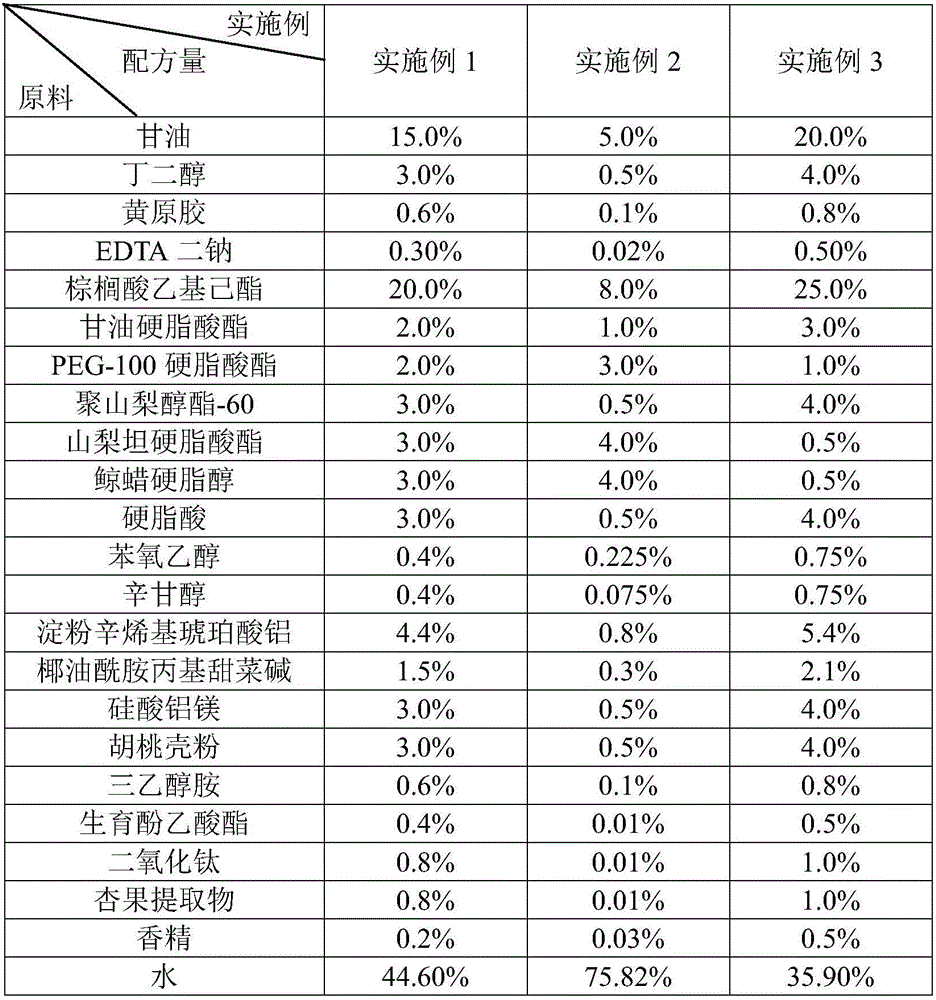

Facial scrub and preparation method thereof

InactiveCN106727022AKeep MoisturizedReduce solubilityCosmetic preparationsToilet preparationsAluminum magnesium silicateEthylhexyl palmitate

The invention discloses a facial scrub and a preparation method thereof. The facial scrub comprises a moisturizing agent, xanthan gum, disodium EDTA, ethylhexyl palmitate, an emulsifying agent, a thickening agent, aluminum starch octenylsuccinate, cocamidopropyl betaine, aluminum magnesium silicate, walnut shell powder, triethanolamine, tocopheryl acetate, titanium dioxide, a skin conditioning agent, a functional additive and water, wherein the moisturizing agent is selected from one or more of glycerol and butanediol; the emulsifying agent is selected from one or more of glyceryl stearate, PEG-100 stearate, polysorbate-60 and sorbitan stearate; and the thickening agent is selected from one or more of cetostearyl alcohol and stearic acid. The facial scrub has the advantage of improving the scrubbing effect in the presence of water.

Owner:HANGZHOU FACECARE COSMETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com