Patents

Literature

34results about How to "Improve testing standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

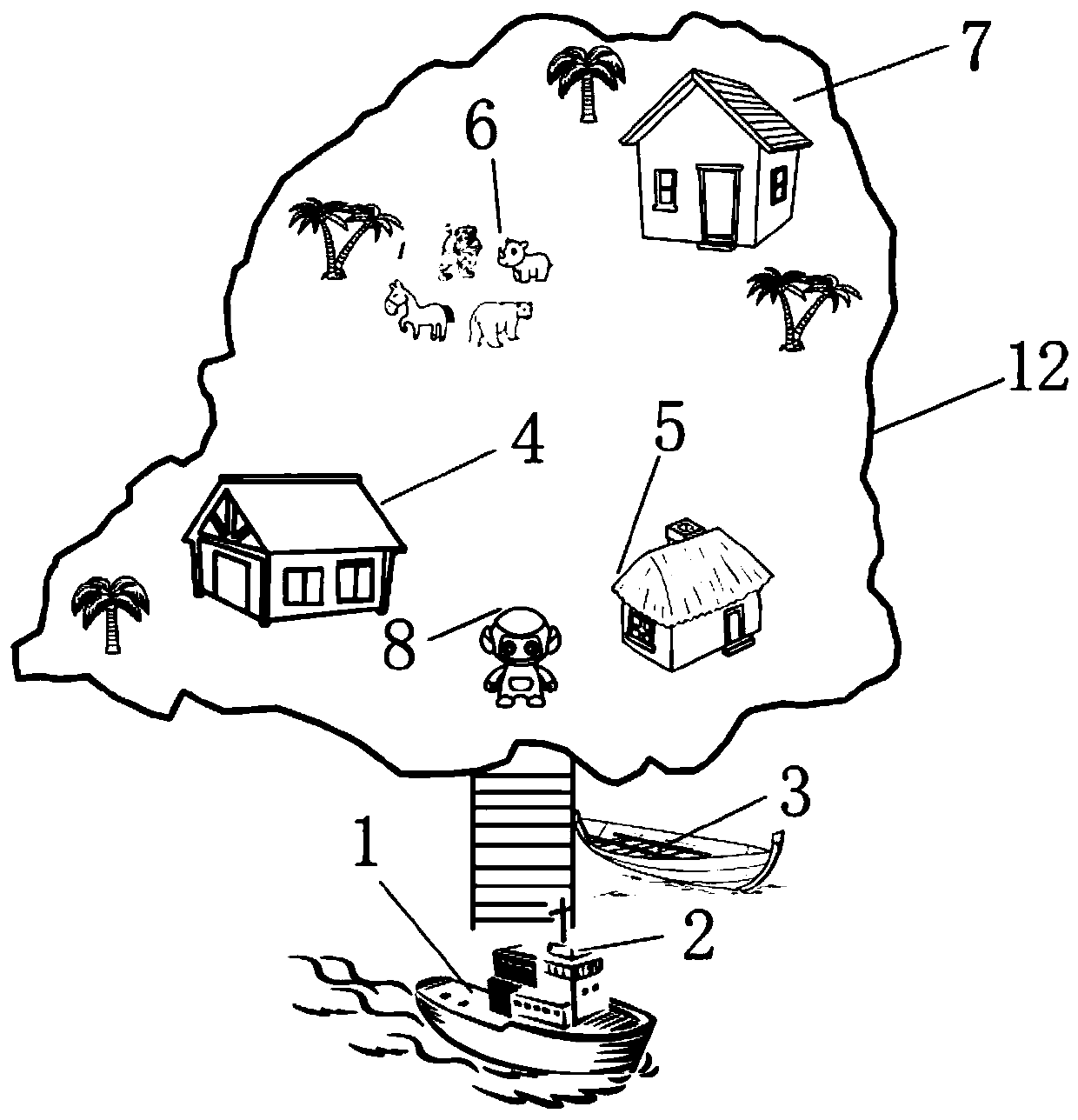

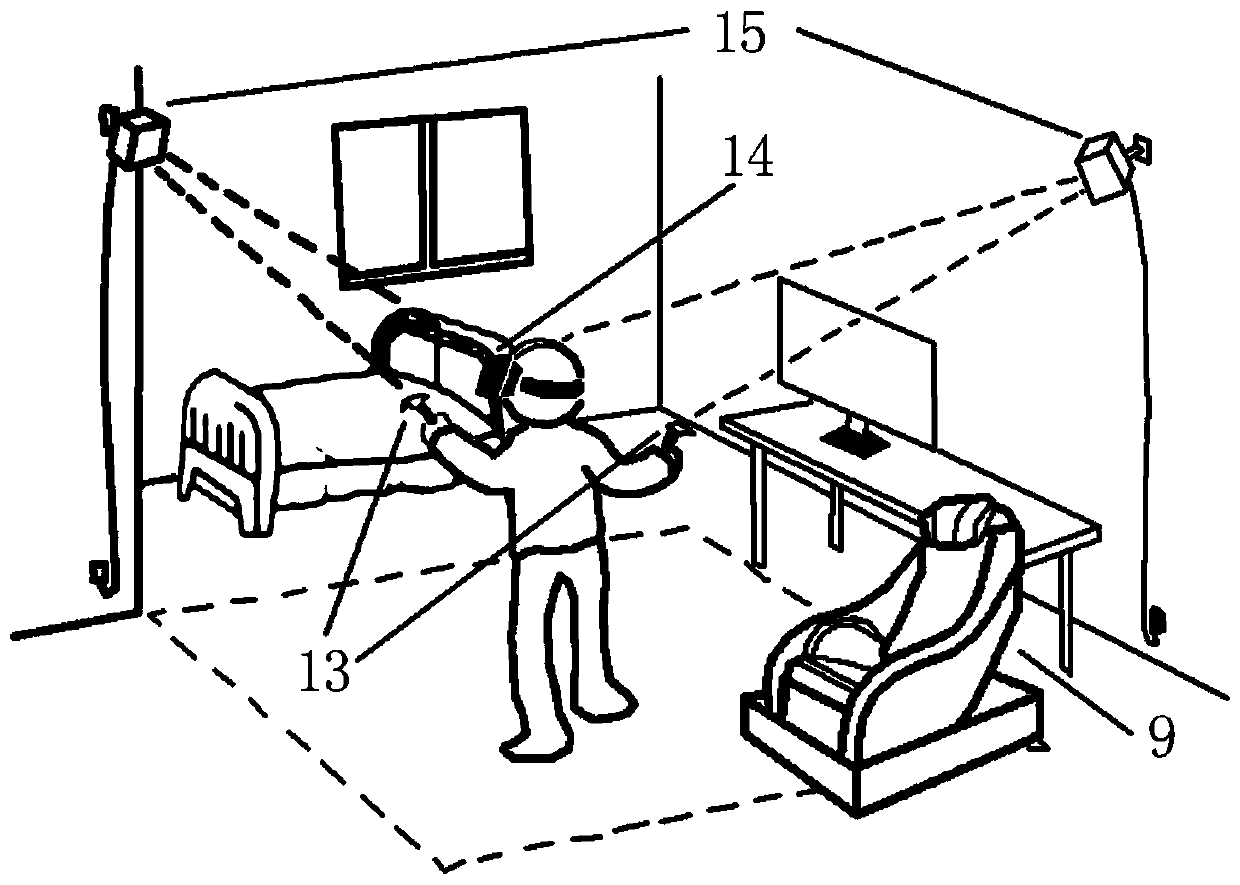

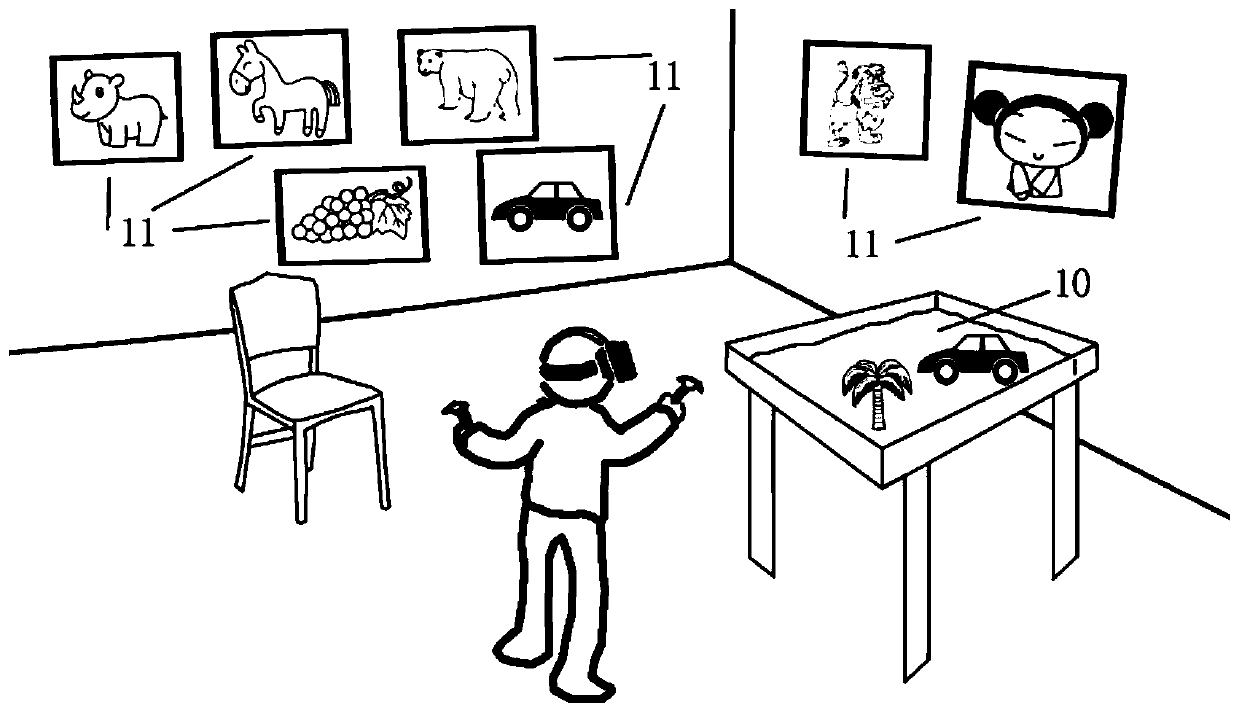

Psychological testing treatment system based on virtual reality

InactiveCN109949896AMeet the testing requirementsPrevent slippingInput/output for user-computer interactionMedical simulationDiseaseInteractive design

The invention relates to a psychological testing treatment system based on virtual reality. The psychological testing treatment system comprises a reality testing system, a VR testing treatment systemand a background server system. The reality testing system is internally provided with a VR positioning unit. The reality testing system further comprises VR helmet type glasses and a VR handle. TheVR testing treatment system comprises a virtual scene which is arranged and a VR treatment island, wherein the VR treatment island comprises a plurality of testing treatment units. The background server system comprises an information collecting system, an information storage system and a control system. According to the system, standard, systematical and scientific detecting technology is combined with metal disease treatment, thereby establishing a virtual model which can detect and treat the metal disease, and forming a detecting and treating method so that interactive design of the patientis realized in the virtual scene, thereby realizing high pertinency in testing and treatment and satisfying the testing requirements of different patients.

Owner:李丰 +1

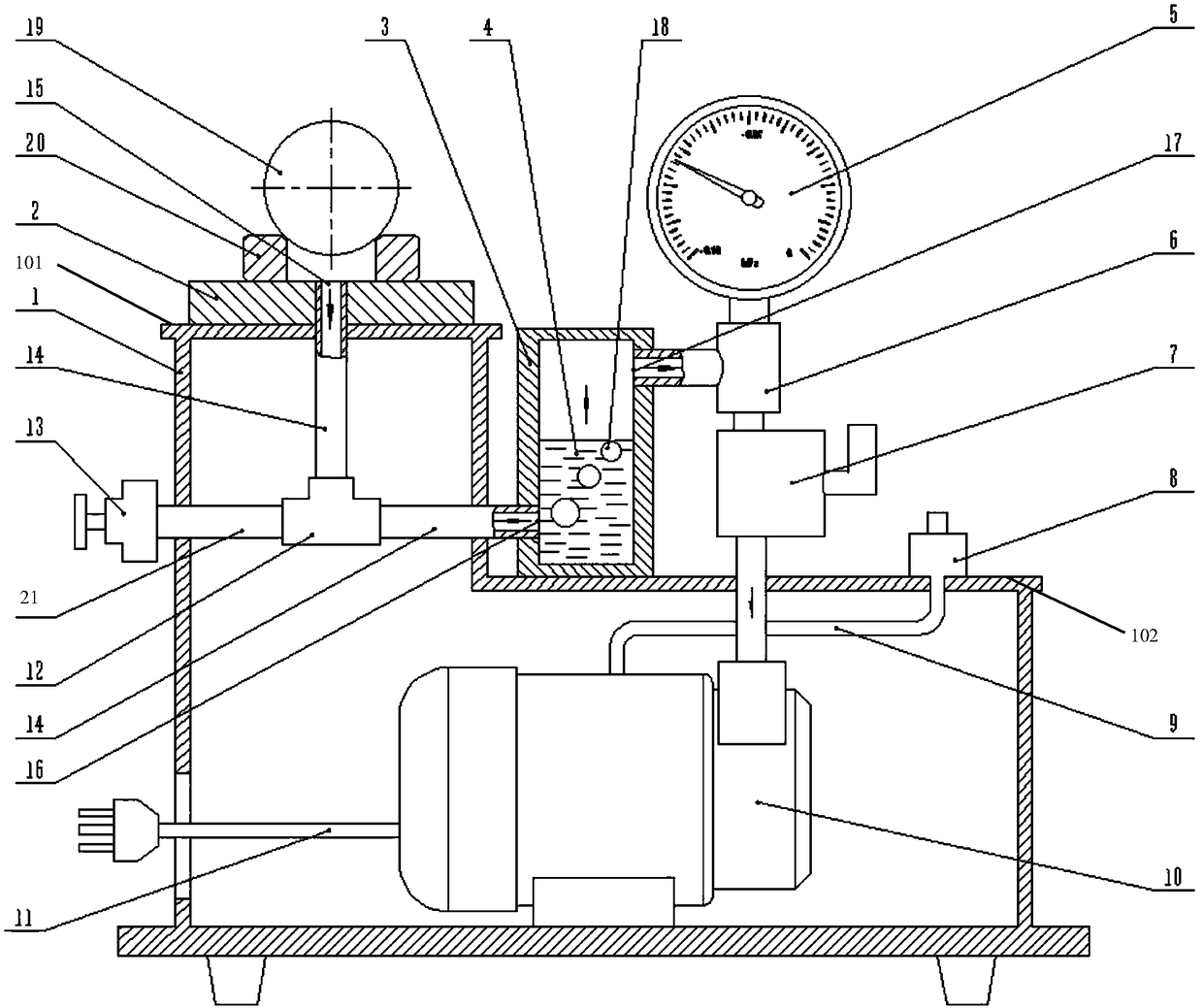

Valve pair sealability detection device and method

PendingCN108225682AShort timeObserve intuitivelyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateVacuum pressureEngineering

The invention relates to a valve pair sealability detection device and method. The device comprises a detection platform, a leakage observation chamber, a vacuum pressure meter, a pressure maintainingvalve and a vacuum pump, the detection platform is communicated with the leakage observation chamber through a pipeline, a detected valve pair is mounted on the detection platform and communicated with the pipeline through a detection platform air suction port, bubble observation liquid is filled in the leakage observation chamber, and liquid level of the bubble observation liquid is higher thanan observation box air suction port formed at a position where the pipeline is connected with the leakage observation chamber; the leakage observation chamber is connected with the vacuum pressure meter and the pressure maintaining valve through a pressure meter three-way joint, liquid level of the bubble observation liquid is lower than an observation box air exhaust port formed at a position where the leakage observation chamber is connected with the pressure meter three-way joint and the detection platform air suction port, and the pressure maintaining valve is connected with the vacuum pump. By the valve pair sealability detection device and method, sealability detection accuracy, detection efficiency and detection standards of the valve pair for an oil pump can be improved, and sealability quality of the valve pair is improved.

Owner:SICHUAN AOWEI OIL EXTRACTION EQUIP CO LTD

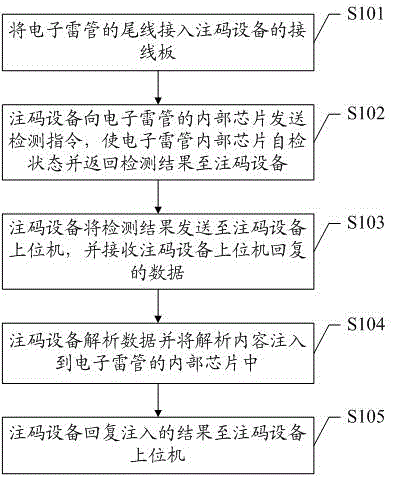

Code injection method and system for electronic detonator

InactiveCN105928424AImprove testing standardsImprove factory qualityDetecting faulty hardware by power-on testPrintingDetonatorCode injection

The invention discloses a code injection method and a code injection system for an electronic detonator. The code injection method comprises the following steps: A. the tail line of the electronic detonator is connected to a wiring board of code injection equipment; B. the code injection equipment sends a detection instruction to an inside chip of the electronic detonator, so that the inside chip of the electronic detonator enters a self-detection state and returns the detection result to the code injection equipment; C. the code injection equipment sends the detection result to an upper computer of the code injection equipment and receives data replied by the upper computer of the code injection equipment; D. the code injection equipment analyzes the data and injects the analysis content into the inside chip of the electronic detonator; and E. the code injection equipment replies the injected result to the upper computer of the code injection equipment. The method and the system can automatically detect whether the tail line of the electronic detonator is in contact with the wiring board in real time to detect and inject code, can improve the working efficiency, can improve the detection standard of electronic detonators leaving factory, can improve the delivery quality of the electronic detonators, and can guarantee good performance of the electronic detonators leaving factory.

Owner:XINJIANG CHUANGANDA ELECTRONICS TECH DEV

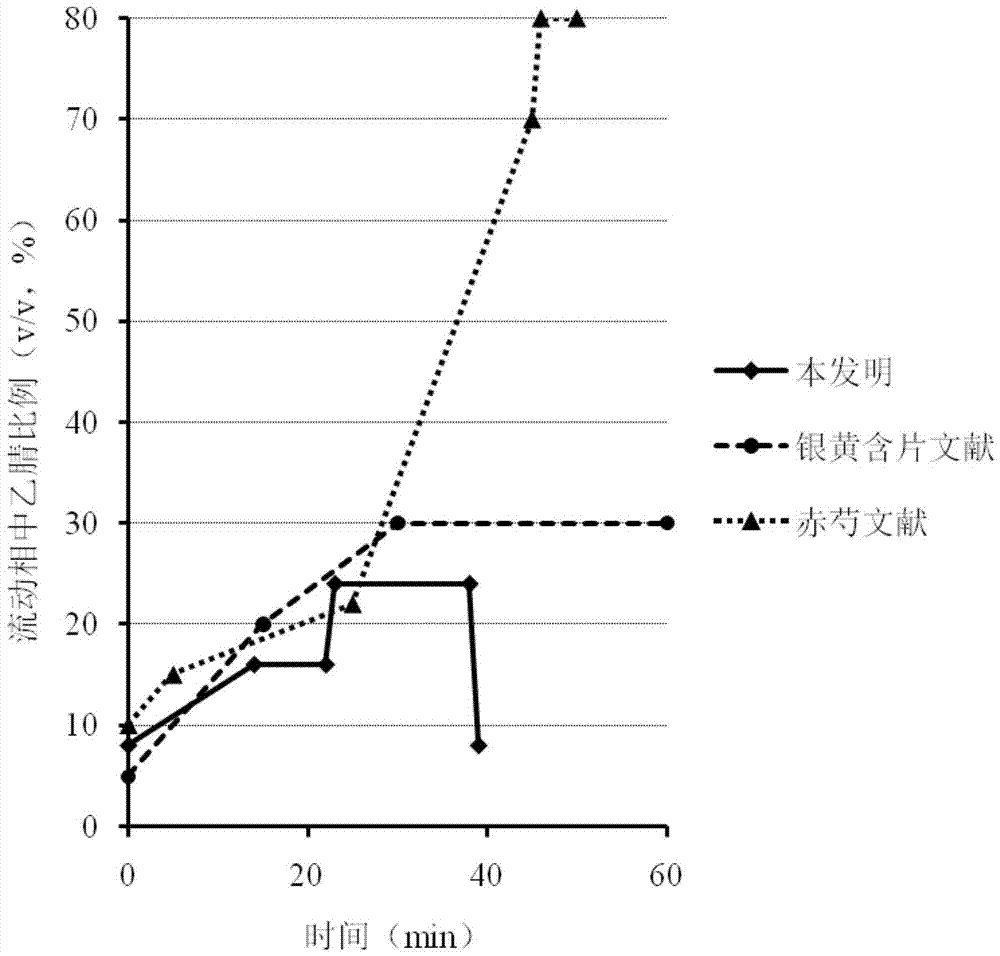

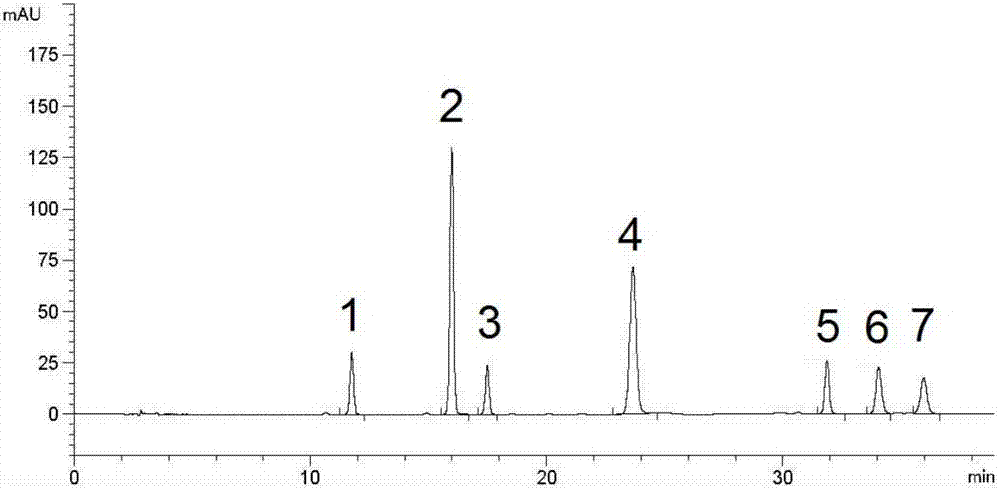

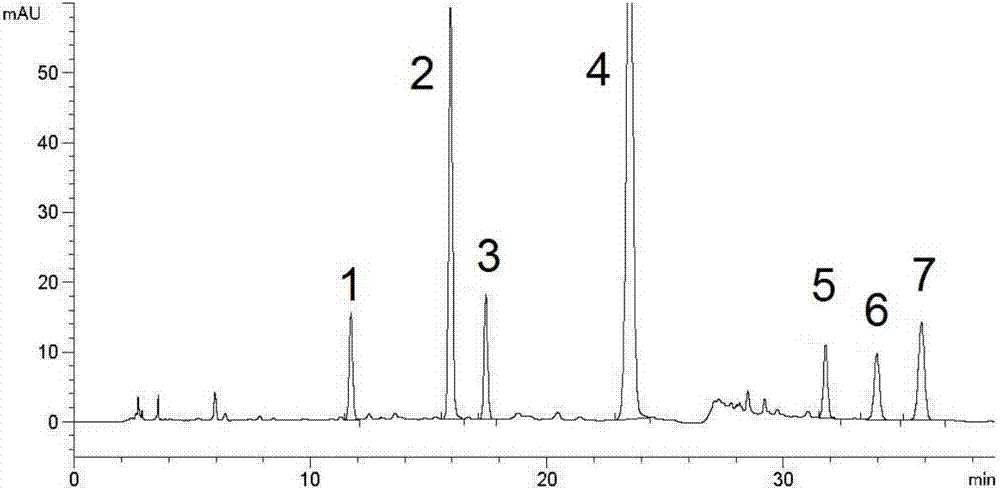

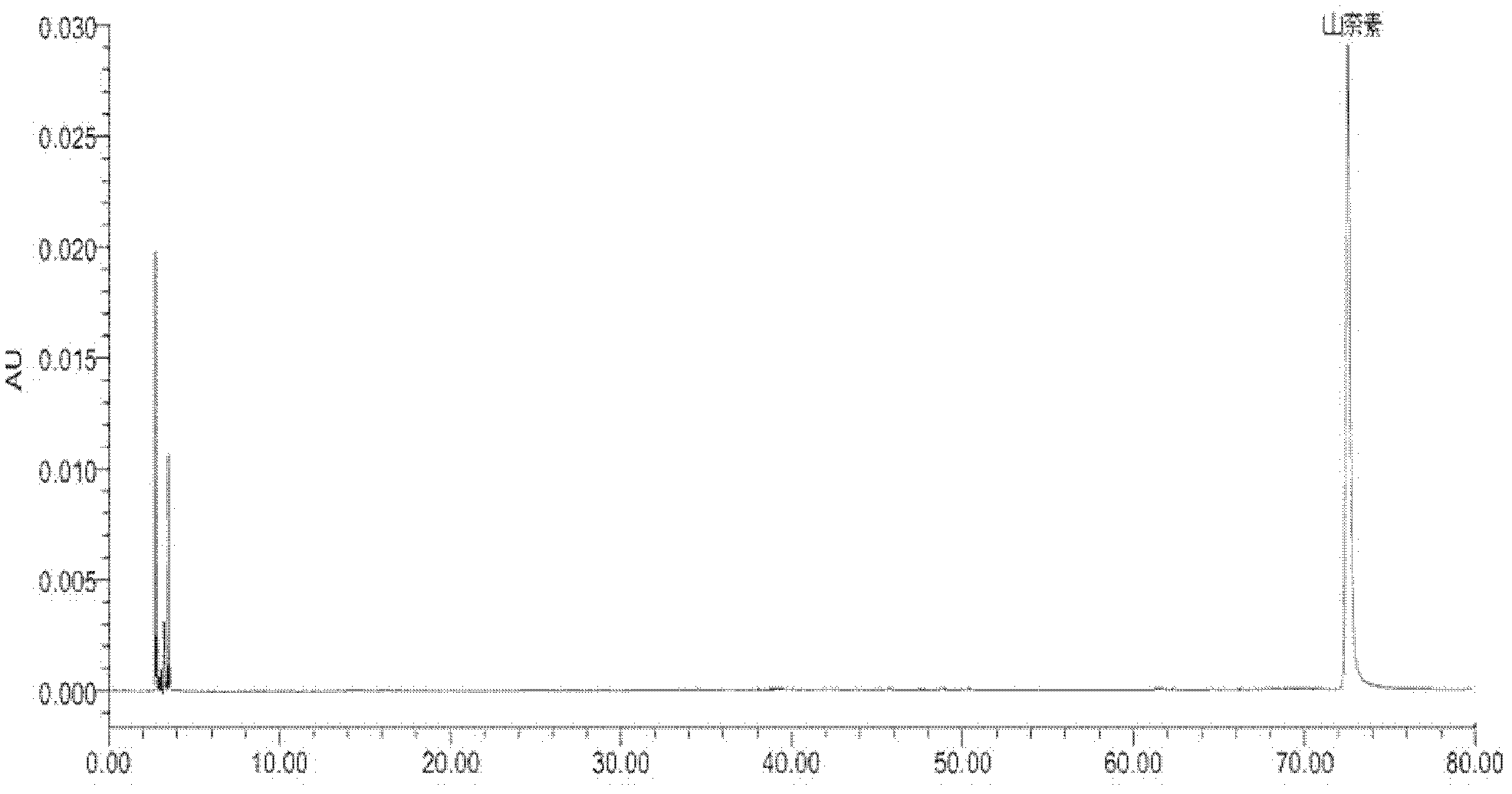

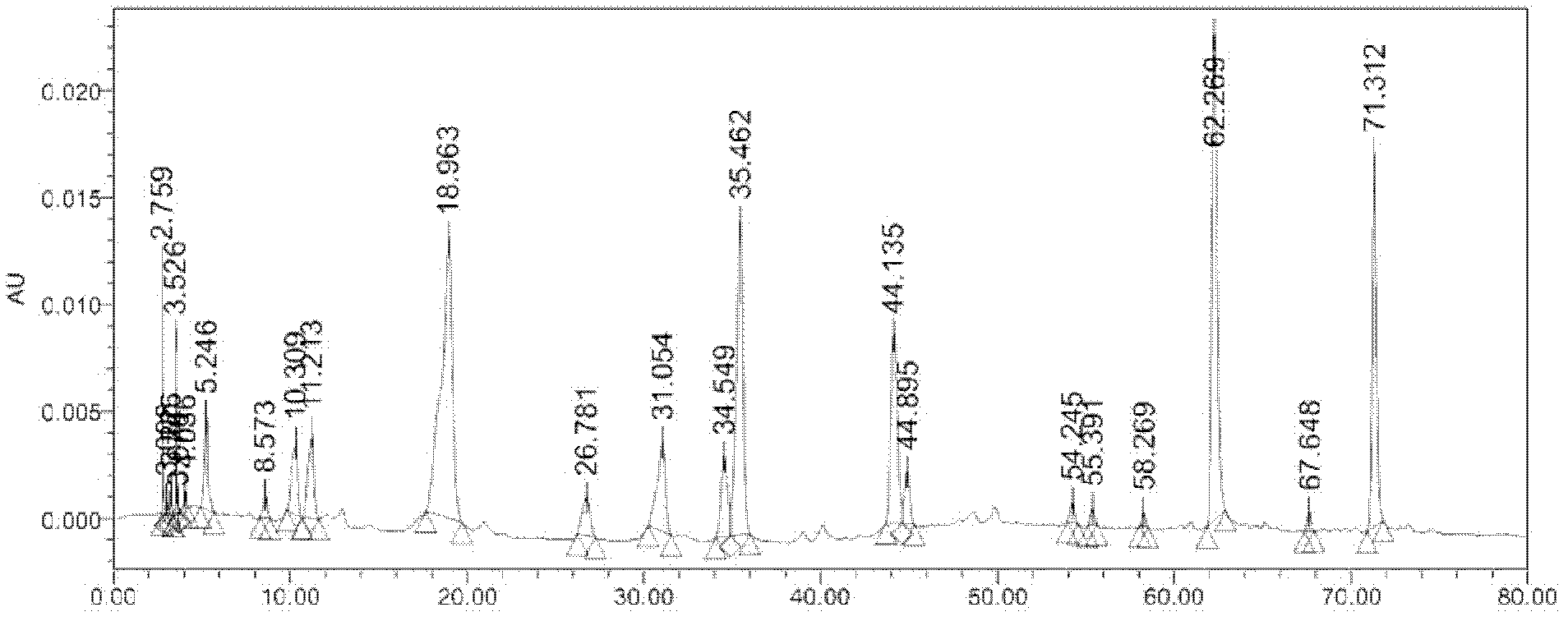

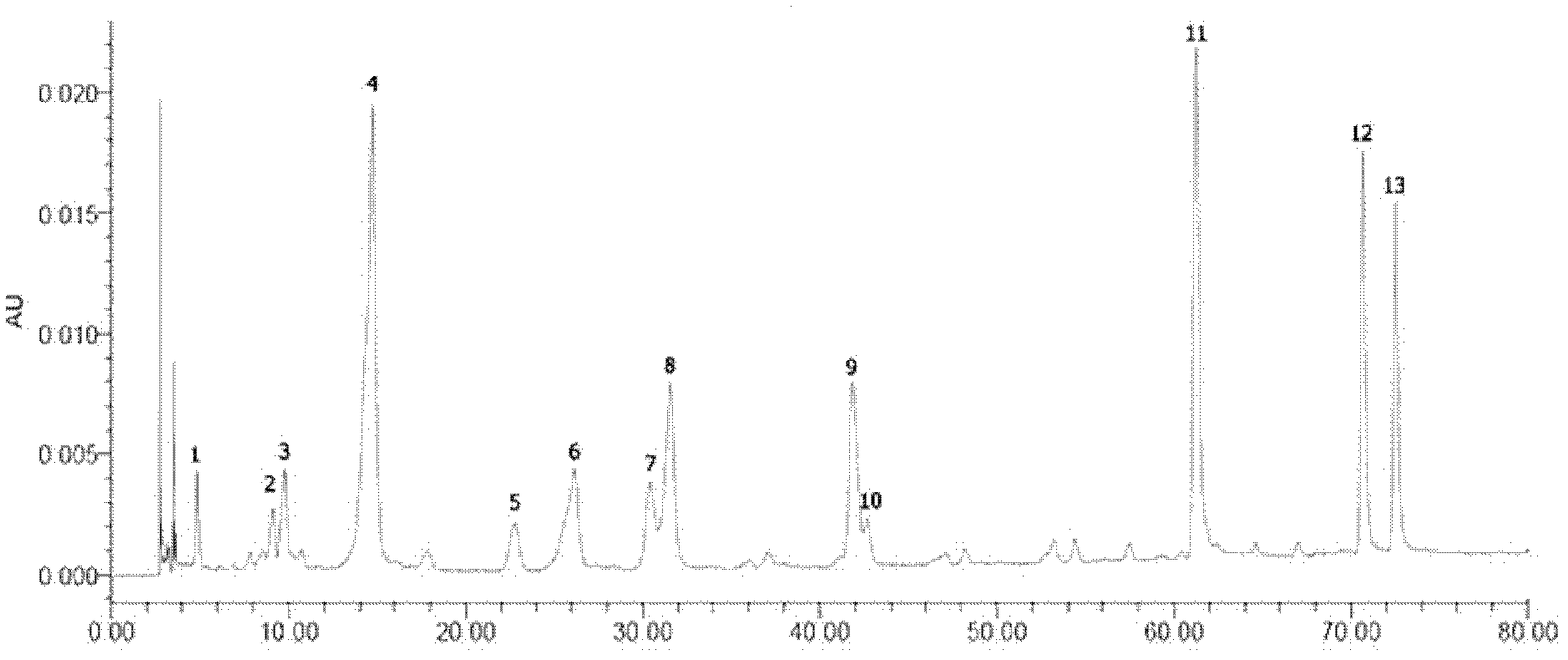

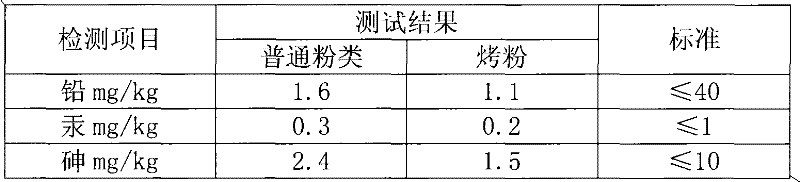

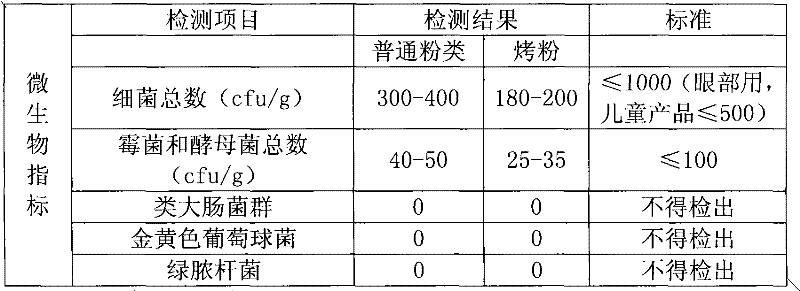

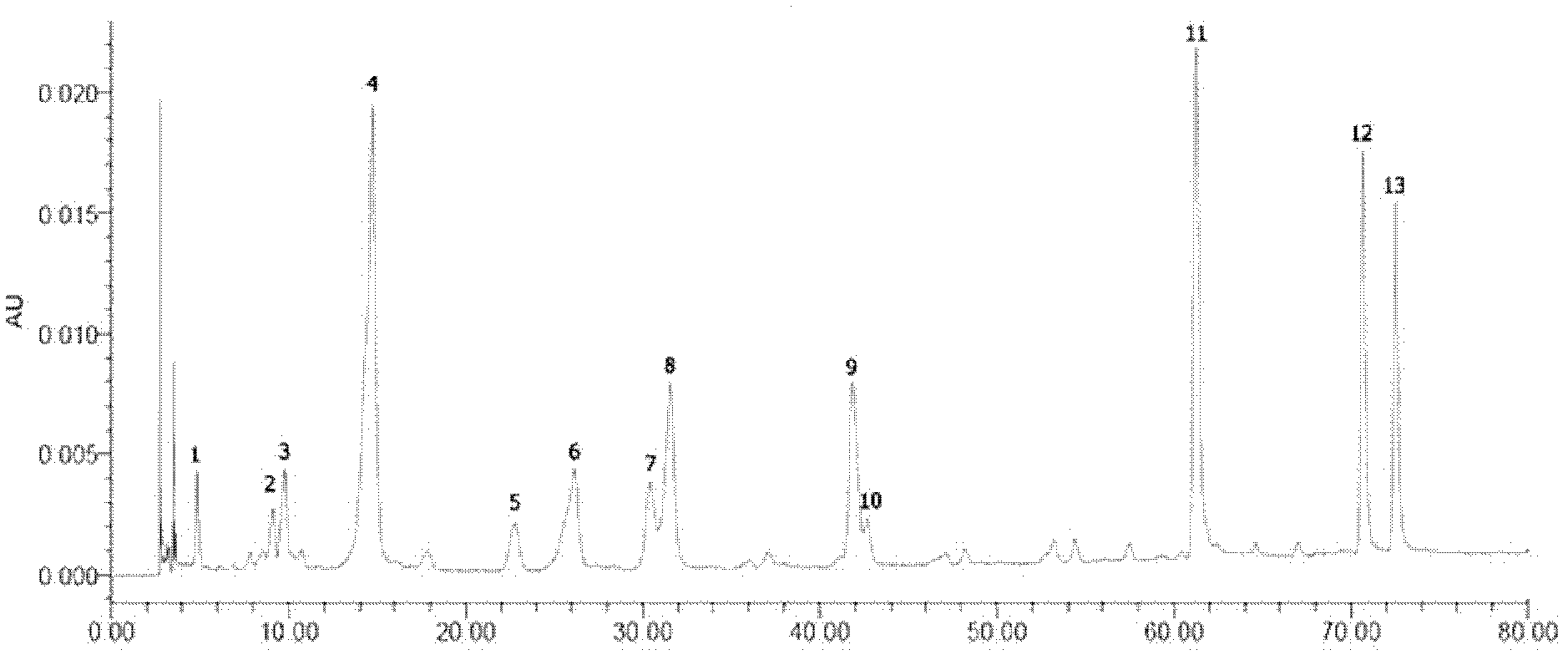

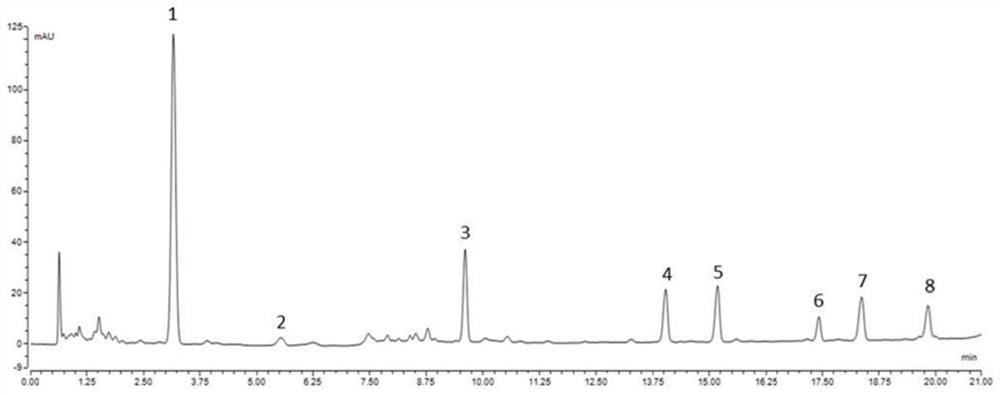

Multi-index component content measuring method for roots of common peonies and honeysuckles in Chinese herbal medicine compound preparation

The invention discloses a multi-index component content measuring method for the roots of common peonies and honeysuckles in a Chinese herbal medicine compound preparation. The multi-index component content measuring method has the advantages that a chromatographic condition is used for measuring content of paeoniflorin and six caffeoylquinic acids in the Chinese herbal medicine compound preparation comprising the roots of the common peonies and the honeysuckles, simplicity and convenience in operation are achieved, and analysis data are accurate; gradient elution conditions are reasonable, and when both chromatographic peak shapes and separation degrees of target components are considered, detection time is shortened greatly; analysis time of analysts is saved due to simultaneous detection of the seven components, and working efficiency is improved; the proportion of organic phases in mobile phases is low, testing cost is lowered, and environmental pollution is reduced.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

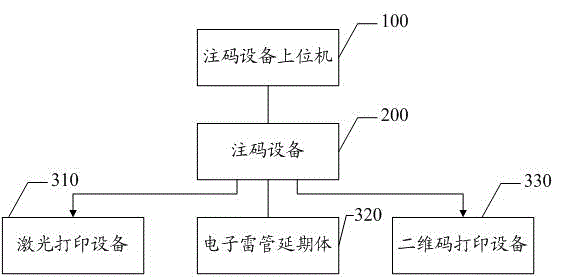

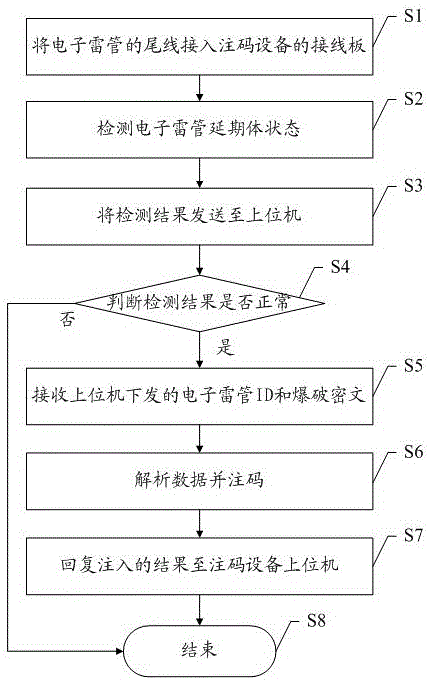

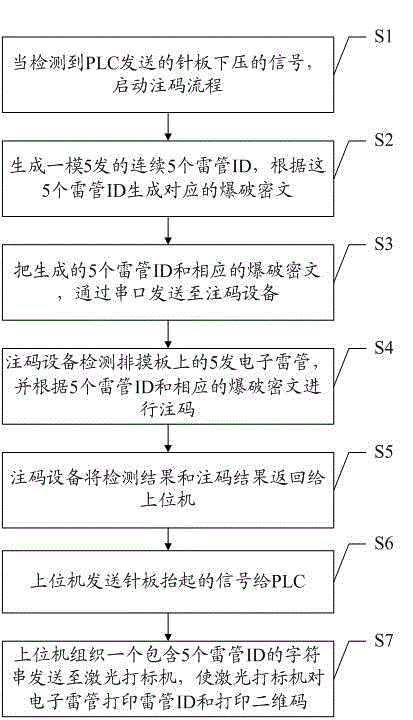

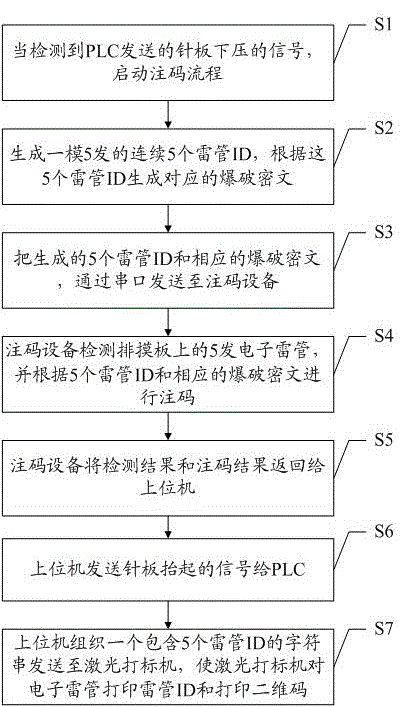

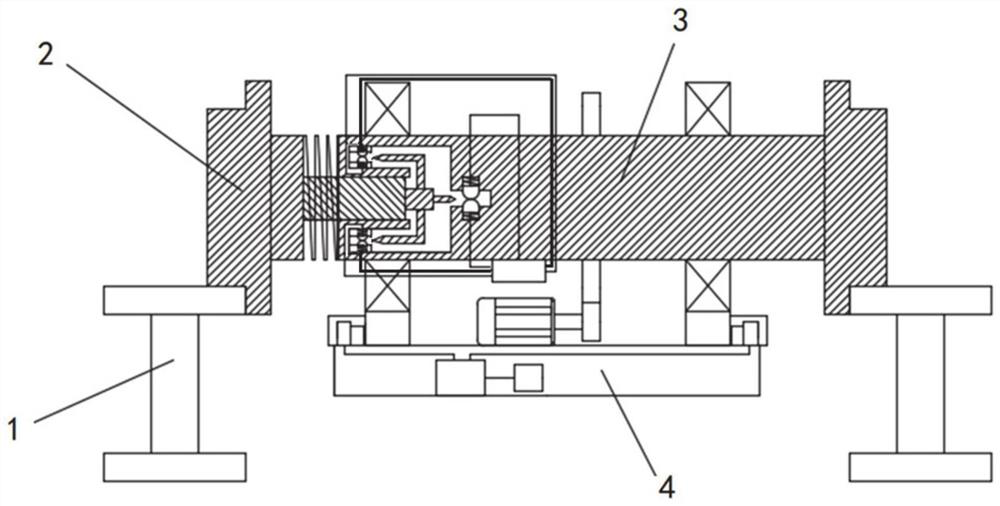

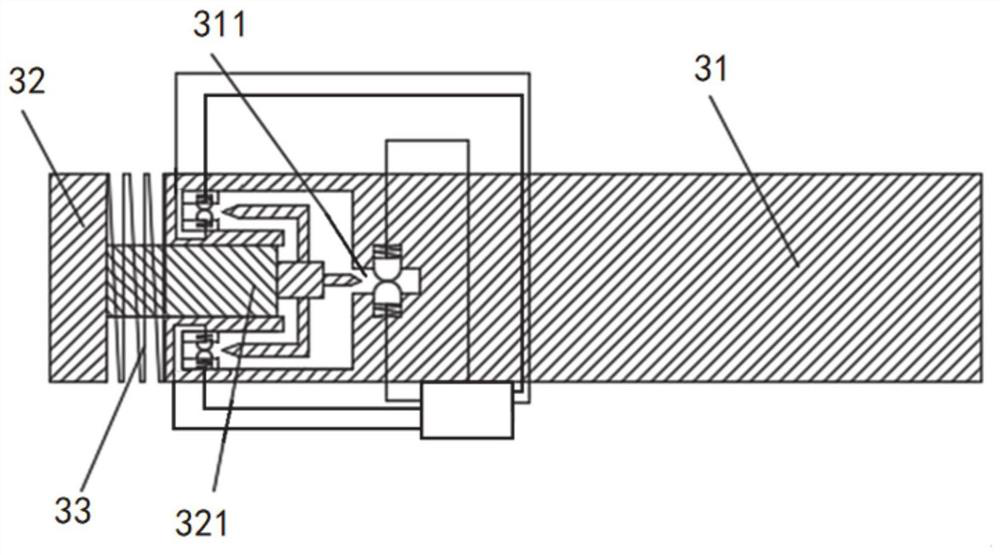

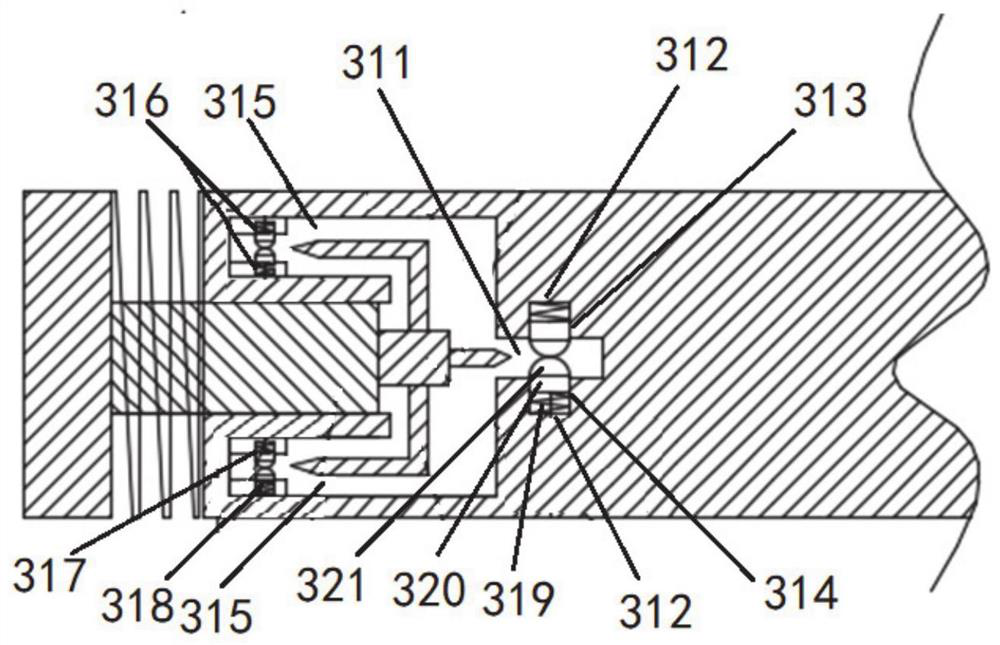

Upper computer realization method of code marking device used for production of electron detonators

ActiveCN105216454AImprove yield rateImprove testing standardsDuplicating/marking methodsTypewritersDetonatorTechnical standard

The invention discloses an upper computer realization method of a code marking device used for production of electron detonators. The method comprises the steps that five produced detonator IDs and corresponding explosion cryptographs are sent to the code marking device through a serial port; the code marking device detects five electron detonators on a row template and carrying out code marking according to the five produced detonator IDs and the corresponding explosion cryptographs; the code marking device returns a detection result and a code marking result to an upper computer; the upper computer sends a pin plate lifting signal to a PLC; the upper computer organizes a character string containing the five detonator IDs and sends the character string to a laser marking machine, and the laser marking machine is enabled to print the detonator IDs and two-dimensional codes to the electron detonators. According to the invention, the production yield of the electron detonators is improved, automatic detection and code marking are realized, the detection standard of the electron detonators leaving a factory is improved, and the good performance of the electron detonators leaving the factory are ensured. Real time management and control over the electron detonators are realized.

Owner:SHENZHEN DACHENG CHUANGANDA ELECTRONICS SCI & TECH DEV

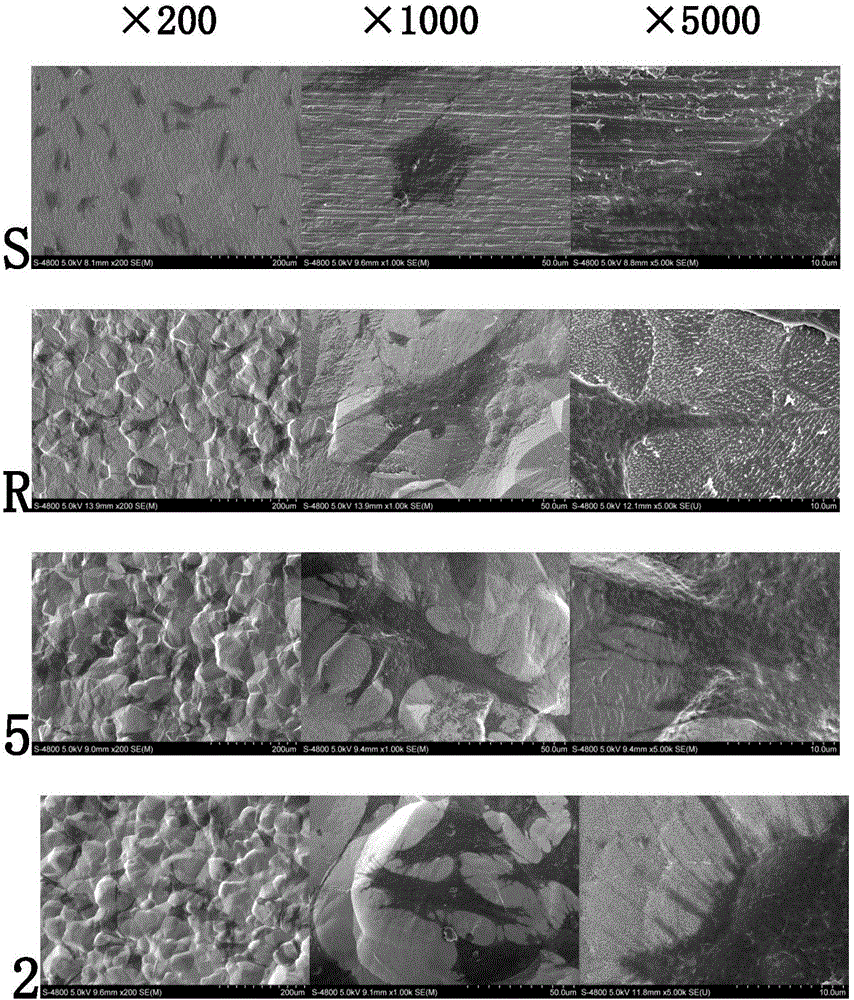

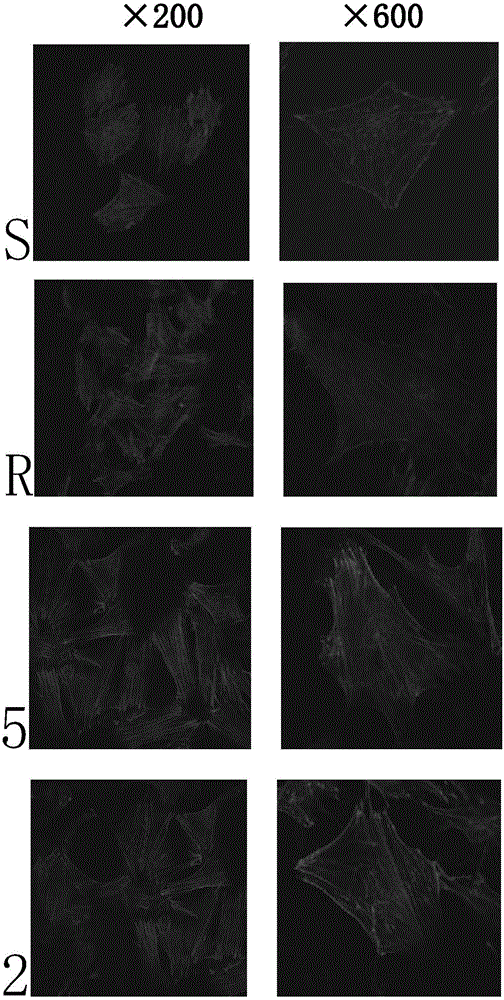

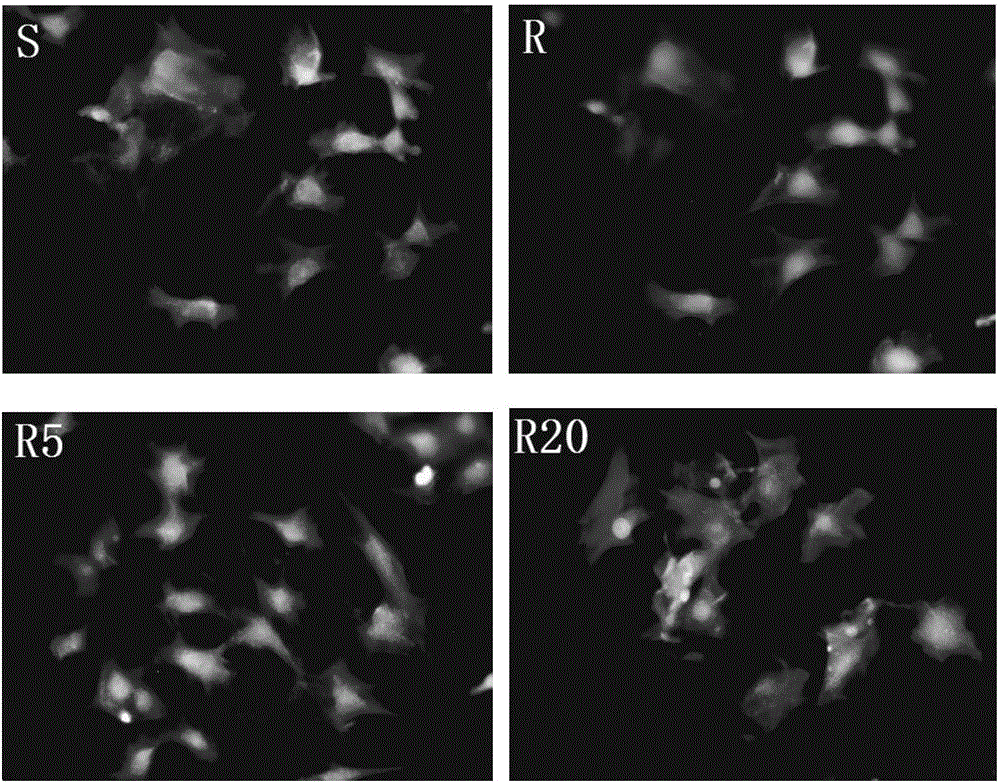

Method for detecting and evaluating in-vitro cell morphology and osteogenic function of surface of bone substitute implant

InactiveCN105112493AImprove testing standardsImprove detection levelMicrobiological testing/measurementColor/spectral properties measurementsCell adhesionNa k atpase activity

The invention discloses a method for detecting and evaluating in-vitro cell morphology and osteogenic function of the surface of a bone substitute implant, and belongs to the technical field of biomaterial detection. The method is characterized by comprising the following steps: taking the bone substitute implant to be detected and evaluated, firstly, observing the cell morphology, cytoskeleton morphology and skeleton protein distribution condition, then detecting cell activity, cell adhesion on the surface of the material and alkaline phosphatase activity in cells, then detecting collagen secretion and the external parts of the cells, and remembering the mineralization degree, and finally, determining the cell morphology as well as the expression condition of framework related genes and osteogenesis related genes. According to the method, biological reference is better provided for optimal design of the surface of the bone substitute implant, and on the basis of the prior art, lots of detecting methods are added, and part detecting methods are improved, so that the method is comprehensive and systematical, and passes the cytology and molecule biology cross comprehensive evaluation, and important guiding significances are provided for optimal research of the surface of the bone substitute implant.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Production method of eyebrow pencil refill

ActiveCN111000736ASilky touchOvercoming powdery foundationCosmetic preparationsMake-upProcess engineeringCaking

The invention belongs to the field of beauty, and particularly relates to a production method of an eyebrow pencil refill. The production method comprises the following steps: heating and mixing, grinding, baking, extruding, baking and freezing. The eyebrow pencil refill produced through the production method solves the technical problems of unnatural caking, poor oil resistance and poor water resistance of existing products in the using process. The maximum powder content of the refill can reach 70%, the refill is smooth, fin and skin-friendly in the using process, caking is avoided, and themakeup time on eyebrows is greatly prolonged.

Owner:苏州工业园区黛宜菲化妆品有限公司

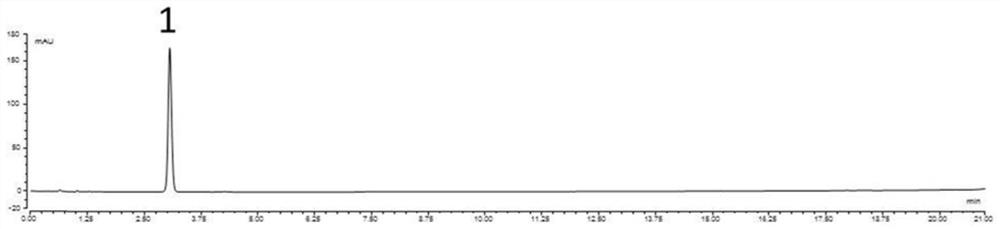

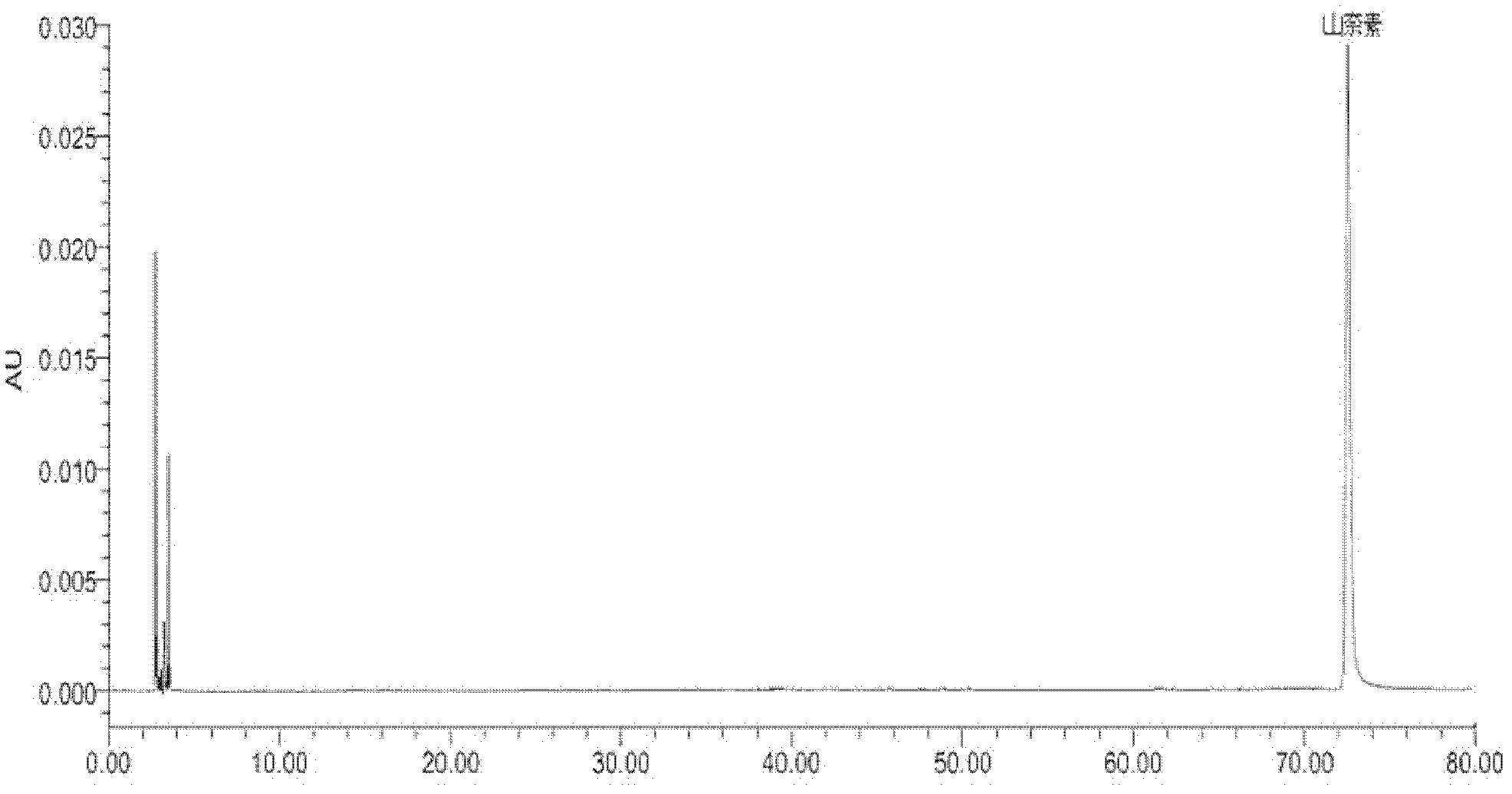

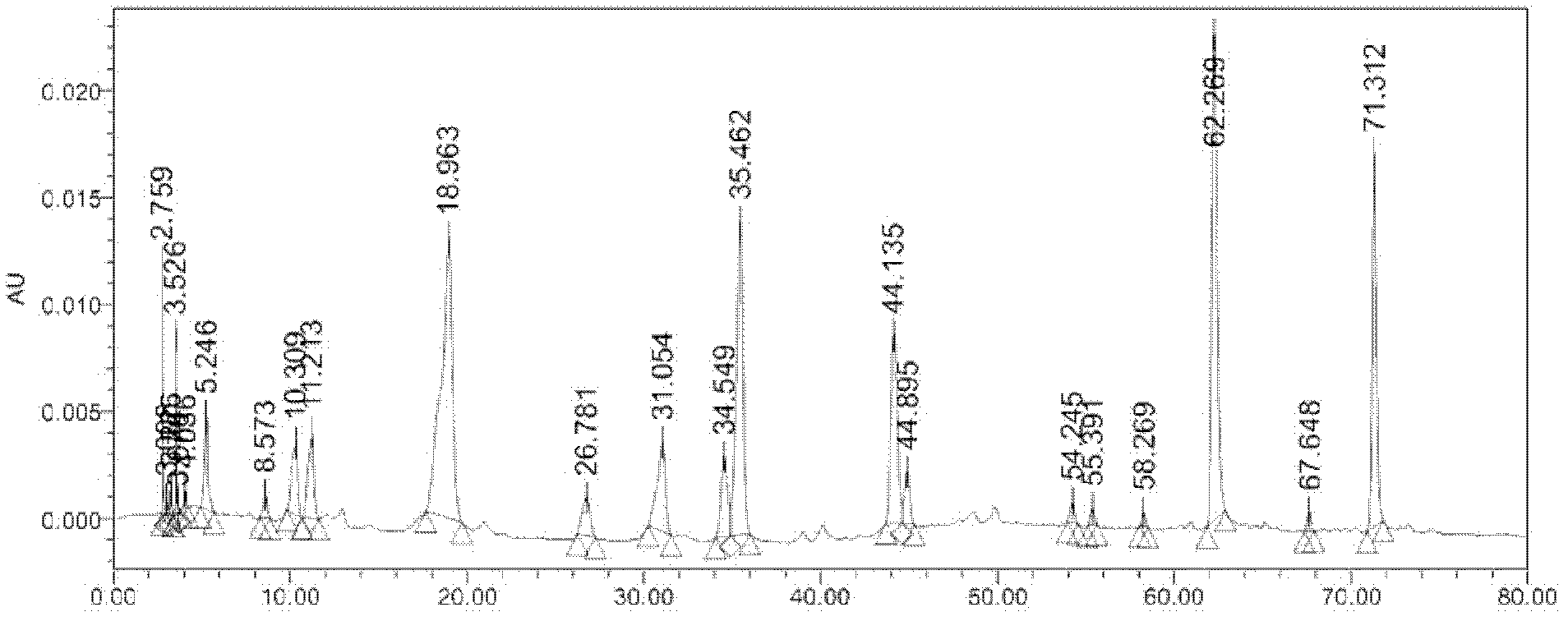

Detection method for flavone component in clematis filamentosa dunn, and application thereof

ActiveCN102426207AThe content accurately reflectsStrong specificityComponent separationClematisKaempferide

The present invention discloses a detection method for a flavone component in clematis filamentosa dunn, and an application thereof. According to the present invention, a kaempferide-containing methanol solution is adopted as a reference substance solution; a high performance liquid chromatography method is adopted to carry out qualitative and / or quantitative analysis for the flavone component in a prepared clematis filamentosa dunn solution requiring detection. The method of the present invention can be applicable for detections of the flavone component in extracts, preparations, decoction pieces or medicinal materials, and no interference is generated to the negative result, wherein the extracts contain the clematis filamentosa dunn component, and the extracts are prepared by the same or the similar extraction methods. In addition, the method of the present invention has strong specificity and good reproducibility, such that the uniform, stable, effective and controllable preparation assortment of the clematis filamentosa dunn can be effectively ensured, and the process normalization, the quality stability and the quality uniformity are ensured.

Owner:SOUTH CHINA AGRI UNIV

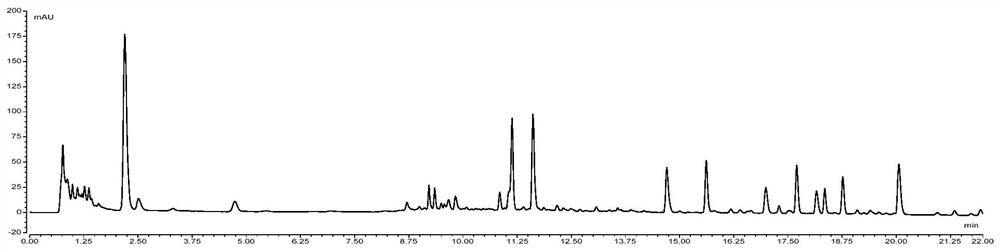

Detection method of lipid-lowering and blood-circulation-promoting capsule

InactiveCN102507837AImprove testing standardsEasy to operateComponent separationBiotechnologyClematis

The invention discloses a detection method of a lipid-lowering and blood-circulation-promoting capsule. The lipid-lowering and blood-circulation-promoting capsule is a capsule preparation prepared from a prescription consisting of 100g of sicklesenna seed, 1,500g of curcuma, 2,000g of oriental water plantain, 500g of radix pseudoginseng and 2,000g of root of cream clematis. According to the detection method of the lipid-lowering and blood-circulation-promoting capsule, disclosed by the invention, a new improvement is carried out on a content determination standard such that science evidence is provided for authenticity judgment and quality control of products when the determination standard of the lipid-lowering and blood-circulation-promoting capsule is improved; furthermore, a sample test through the detection method is simple and convenient to operate based on repeated tests for many times; and based on continuous verification tests such as feminine interference and the like, no feminine interference exists, the reproducibility is excellent, and the exclusivity is strong; and the control capability on quality of the products is improved while the quality detection standard is improved.

Owner:唐秋海

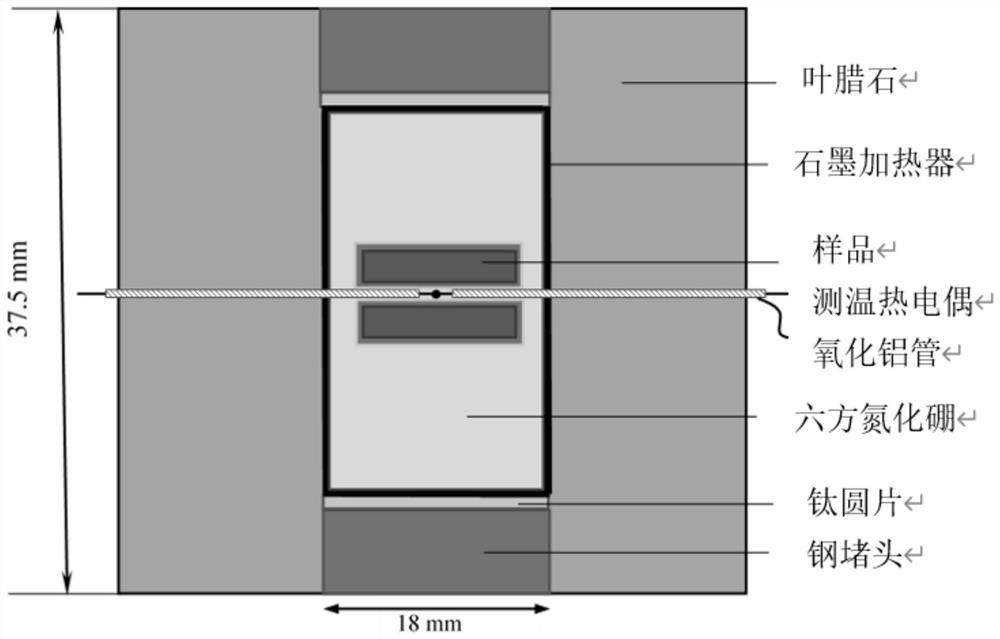

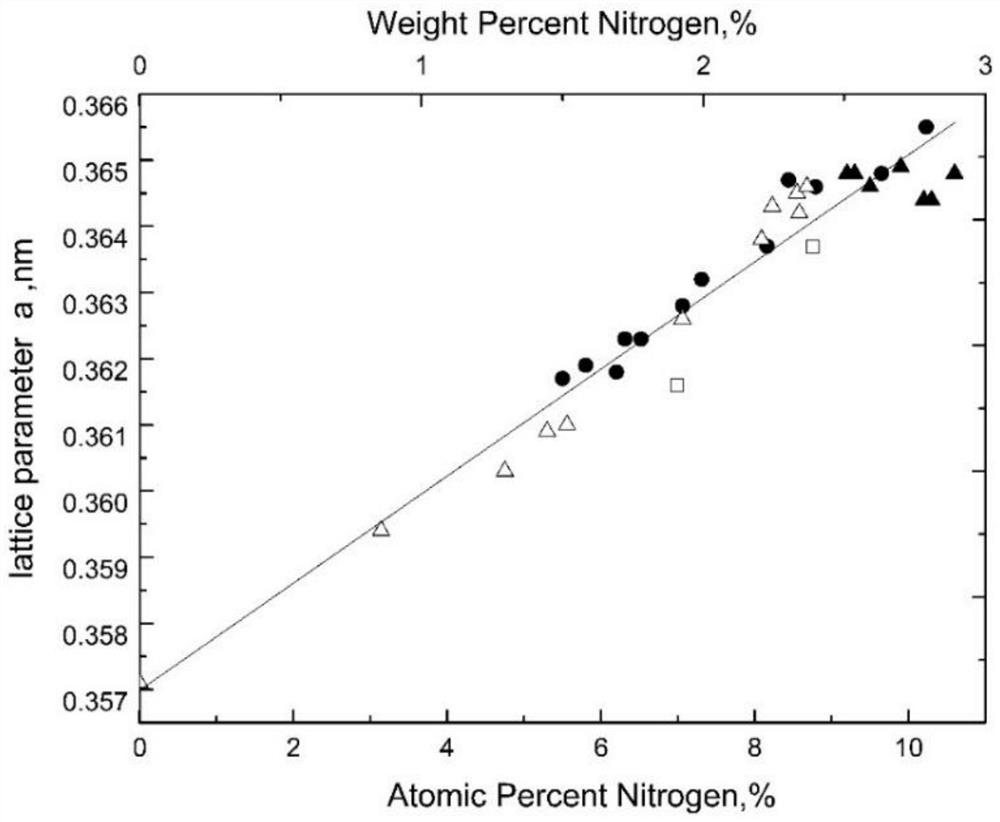

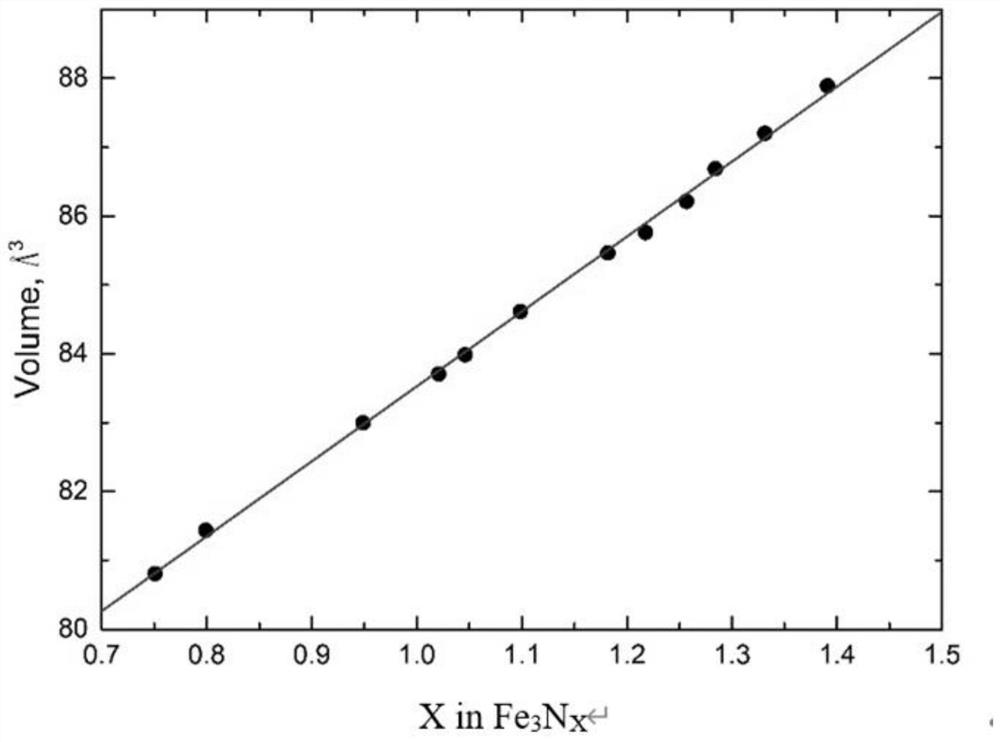

Preparation method of N-standard sample suitable for electron probe analysis

PendingCN113138204ANot volatileImprove testing standardsMaterial analysis using wave/particle radiationIron nitridePhysical chemistry

The invention relates to a preparation method of an N-standard sample suitable for electron probe analysis, which is suitable for an iron-based alloy system. According to the method, mixed micro powder of iron nitride and metal iron is used as an initial raw material, ultrahigh pressure is used as an auxiliary sintering condition, and a Fe-N blocky sample is obtained through a solid-phase reaction method. According to the method, the X-ray diffraction technology is used for firstly confirming that a sample is composed of a single phase, meanwhile, lattice parameters of phase crystals are obtained, and the N content is determined according to the corresponding relation between the lattice parameters and the N content. Electronic probe quantitative analysis is carried out on element distribution of the sample, and it is proved that distribution of the N element is completely uniform. The invention further proves and establishes a linear relationship between N percentage content and probe signal strength. The linear relationship shows that the Fe-N sample prepared by the method can be used as a standard sample for analyzing the content of the electronic probe N element, and is applied to quantitative analysis of the N element of an iron-based alloy system, especially the field of steel.

Owner:WUHAN UNIV OF TECH

Preparation method of jade glaze daily porcelain with high thermal stability and high strength

The invention provides a preparation method of jade glaze daily porcelain with high thermal stability and high strength. Raw materials of the formula comprise a SiO2 mineral, an AL203 mineral, a K20 mineral, a B203 mineral, a ZnO mineral, a boron-zinc frit, a zirconium white frit and a solvent. The preparation method comprises the following steps of: a, burdening, ball-milling and mixing; b, refining and ageing; c, blank forming; d, drying and cooling; e, glazing and glaze firing; and f, finished product detecting and discharging. Through cooperation of the above procedures, the proportion ofporcelain raw materials can be changed by adding the boron-zinc frit and the zirconium white frit; the reaction among the porcelain raw materials is better; moreover, crystal phase development compactness is promoted, refractory substances such as free quartz are reduced, the density of the porcelain body is improved, cracking of a porcelain finished product in the firing process is prevented, thestrength of the porcelain finished product is improved, meanwhile, the glaze surface on the surface of the porcelain shows jade appearance, and the overall appearance of the porcelain is also improved while daily use is met.

Owner:GUANGDONG SITONG GROUP

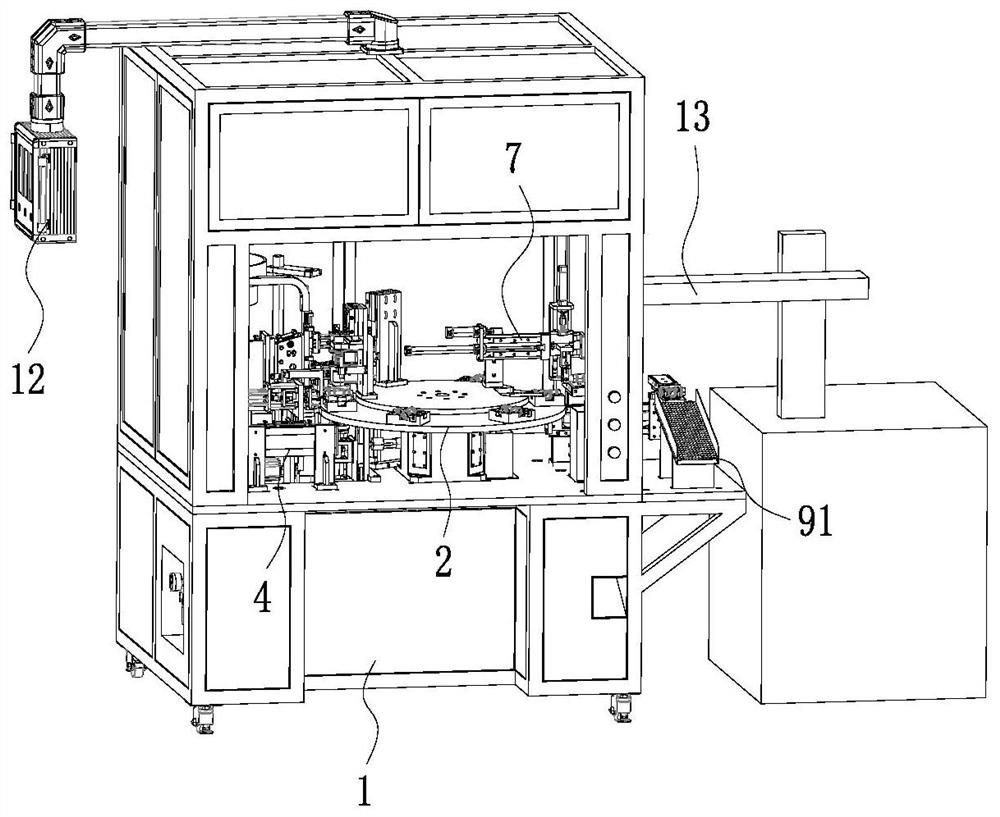

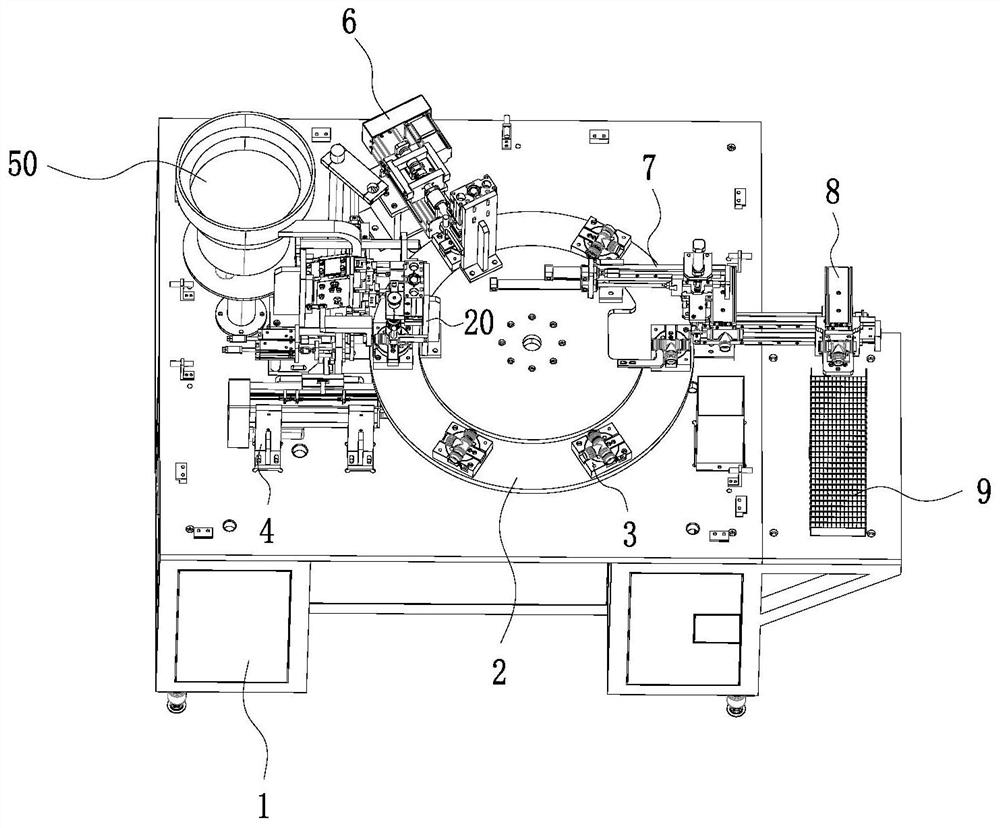

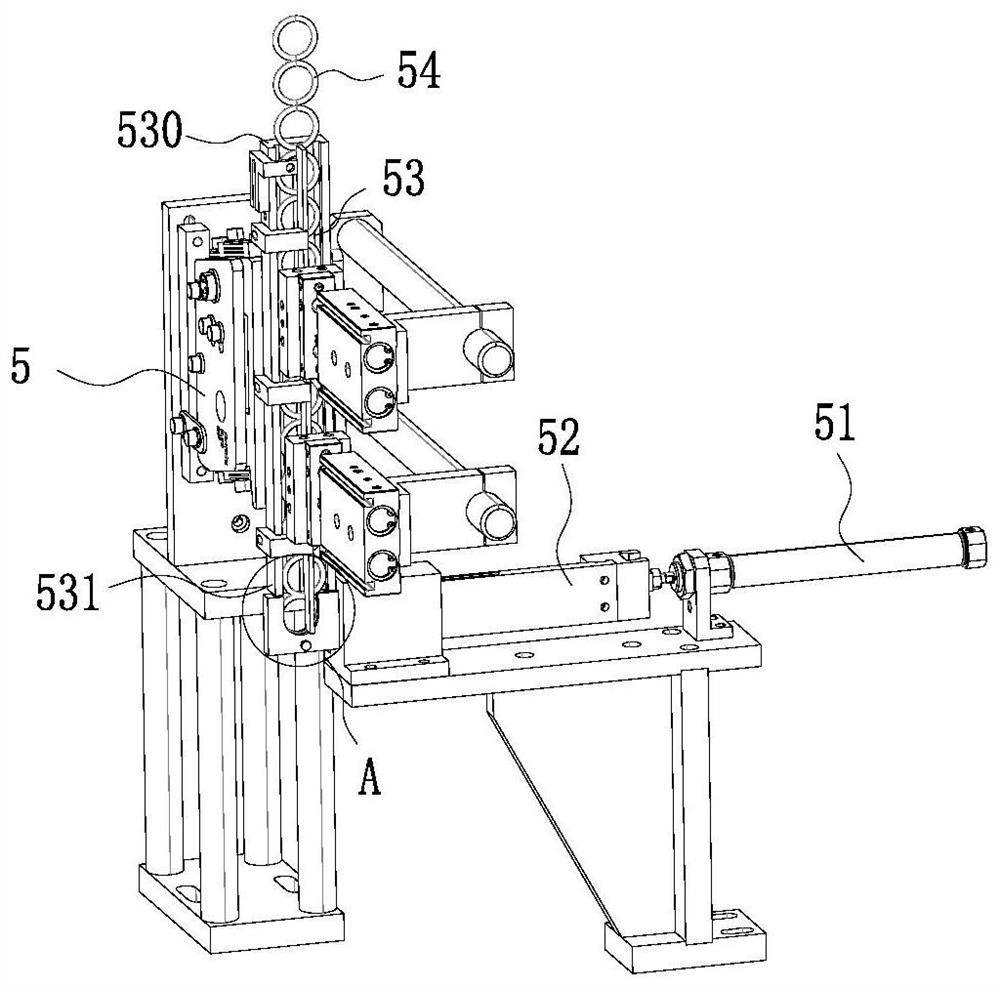

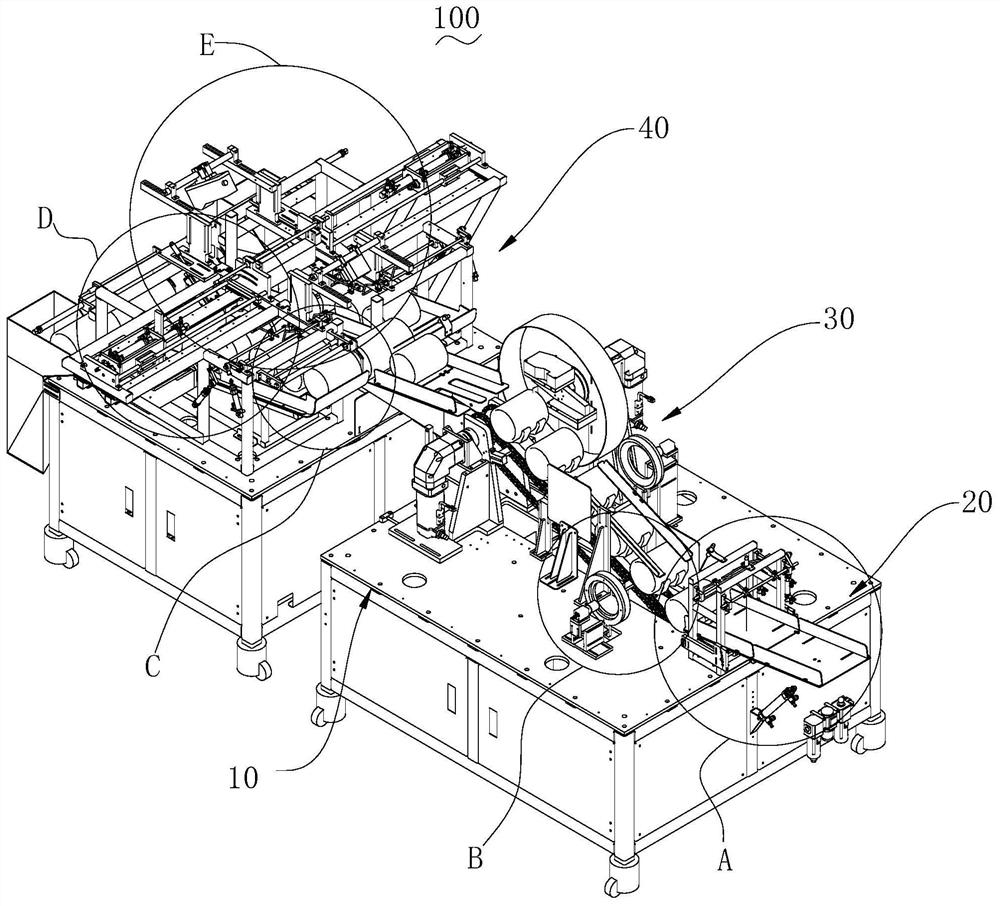

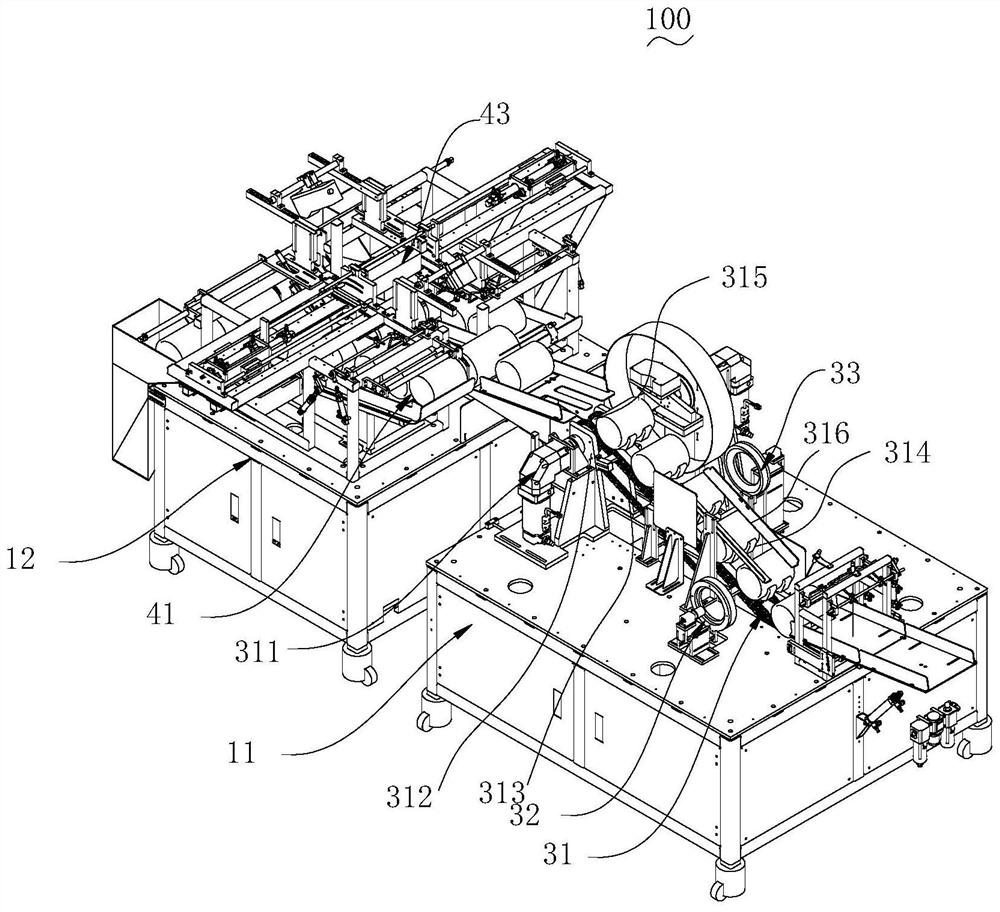

Sealing ring assembly production line of clamping-pressing type pipe fitting

PendingCN112427942AReduce manual laborReduce labor costsAssembly machinesFluid pressure measurementManufacturing engineeringIndustrial engineering

The invention provides a sealing ring assembly production line of a clamping-pressing type pipe fitting. The production line comprises a rotary disc, an assembly station, a detection station, a material taking station, a marking and sorting station and a controller. The assembly station, the detection station, the material taking station and the marking and sorting station are arranged in the circumferential direction of the rotary disc. A first driver and at least five pipe fitting stations used for containing pipe fittings to be machined are arranged on the rotary disc, the first driver is used for controlling the rotary disc to rotate to enable the pipe fitting stations to sequentially pass through the assembly station, the detection station and the material taking station, and finallythe marking and sorting device is used for sorting out the qualified pipe fittings. The production line has the advantages that the production line can automatically assemble, detect, mark and sort the pipe fittings, and the production efficiency of the pipe fittings can be improved.

Owner:ZHEJIANG HAILIANG

Bulking brick

The invention provides an energy-saving and environment-friendly swelling brick, which relates to a material for building. In order to overcome the deficiency caused by common clay red bricks which consumes a great land resources and energy, and has serious pollution, small size but heavy deadweight, poor heat insulation performance, and increase of the total construction cost; the swelling brick of the invention takes argillo-arenaceous rock as main material, which enters a high temperature rotary furnace to charge oxygen and pressure for swelling after crushing and screening, then a secondary heating is performed after producing the swelling body, finally the shape is formed by mechanical squeezing. The swelling body after shaped by squeezing also can be mixed with the cement, the fly ash and the concrete additive. After mechanically agitating and watering, the swelling body is conveyed to a silo for squeezing to form the swelling brick which is characterized by light weight, rigid body, heat insulation, and fire resistance, nontoxic and being durable, thus being an ideal energy-saving building brick.

Owner:黑龙江省三江君合新材料科技开发有限公司

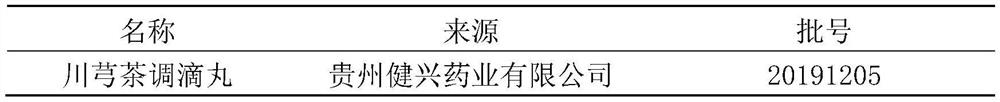

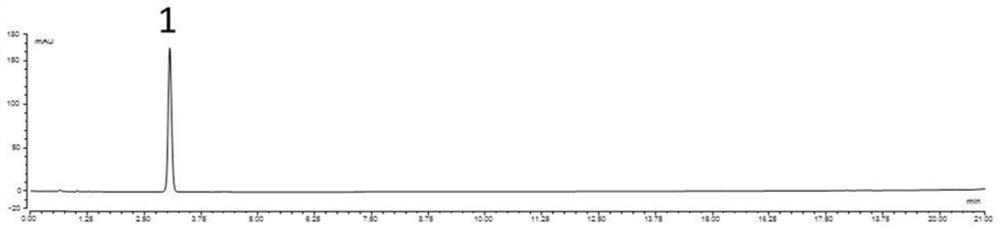

A kind of detection method of Chuanxiong Tea Concoction Dropping Pill

ActiveCN113552276BOptimized thin layer identificationQuality assuranceComponent separationBiotechnologyMedicinal herbs

The invention relates to a detection method for Chuanxiong Cha Tiao dripping pills. The detection method comprises the identification and inspection of thin layers of Chuanxiong and Qianghuo medicinal materials in the dripping pills, and the determination of the content of ferulic acid in the dripping pills. Through the methodological investigation, the detection method has the effects of strong specificity, good durability and good recovery rate.

Owner:贵州健兴药业有限公司

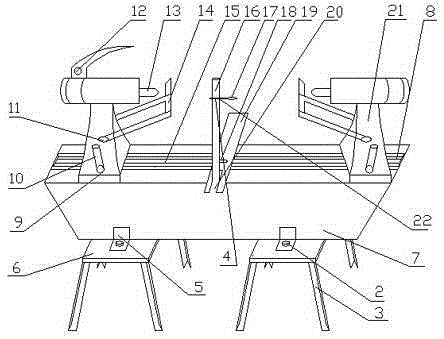

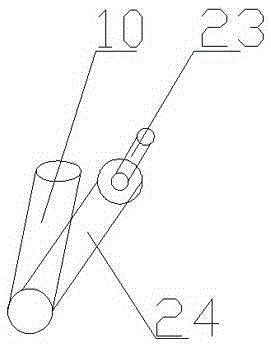

Safe operation device for quality inspection

ActiveCN105277351AImprove stabilityQuality improvementVehicle testingMachine part testingVisual inspectionEngineering

The invention, which belongs to the technical field of the mechanical quality detection, discloses a safe operation device for quality inspection. The safe operation device is composed of a support frame, a fixation sheet, a fixation plate, a fixation seat, a first quality inspection device, a rotating handle, an operation rod, a support rod, a fixation rod, a sliding block, a cross bar, and a second quality inspection device. The fixation seat and the fixation plate are connected by the fixation sheet; and the fixation sheet is fixed on the fixation plate by a screw. The support frame is arranged at the lower end of the fixation plate; a groove is formed in the top of the fixation seat; sliding rails are arranged at the two sides of the groove; and the first quality inspection device and the second quality inspection device are installed in the groove. The cross bar is installed at the upper end of the groove by a sliding block; an empty slot is formed in one end of the cross bar; and the support rod is installed on the upper end of the empty slot. According to the safe operation device, the fixation sheet is fixed on the fixation plate by the screw, thereby enhancing stability between the fixation seat and the fixation plate substantially.

Owner:荆江半轴(湖北)有限公司

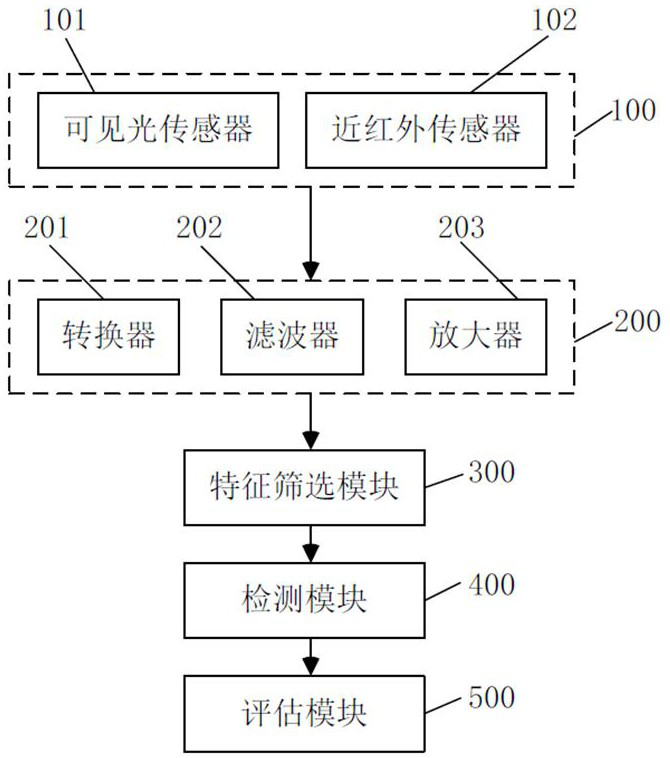

Seed activity and health on-line rapid detection system and detection method

PendingCN114088645AWon't hurtAvoid damageInvestigation of vegetal materialColor/spectral properties measurementsData acquisitionBiology

According to the seed activity and health on-line rapid detection system and detection method, a data acquisition module obtains a reflected light RGB surface array image and a near-infrared image of a seed through a visible light sensor and a near-infrared sensor; a data preprocessing module obtains surface information and internal components of the seeds through a converter, a filter and an amplifier; a feature screening module performs effective feature screening on the seed information through a clustering algorithm and establishes feature spaces respectively; the detection module is used for detecting seed characteristics according to a qualitative and quantitative relation between seed activity and health; and the evaluation module provides comprehensive evaluation of the seed quality level through a seed activity and health detection evaluation model. The method is clear in logic, and compared with a traditional seed detection method, the detection speed and the detection accuracy are improved, and damage to the seeds is reduced.

Owner:YANGZHOU UNIV +1

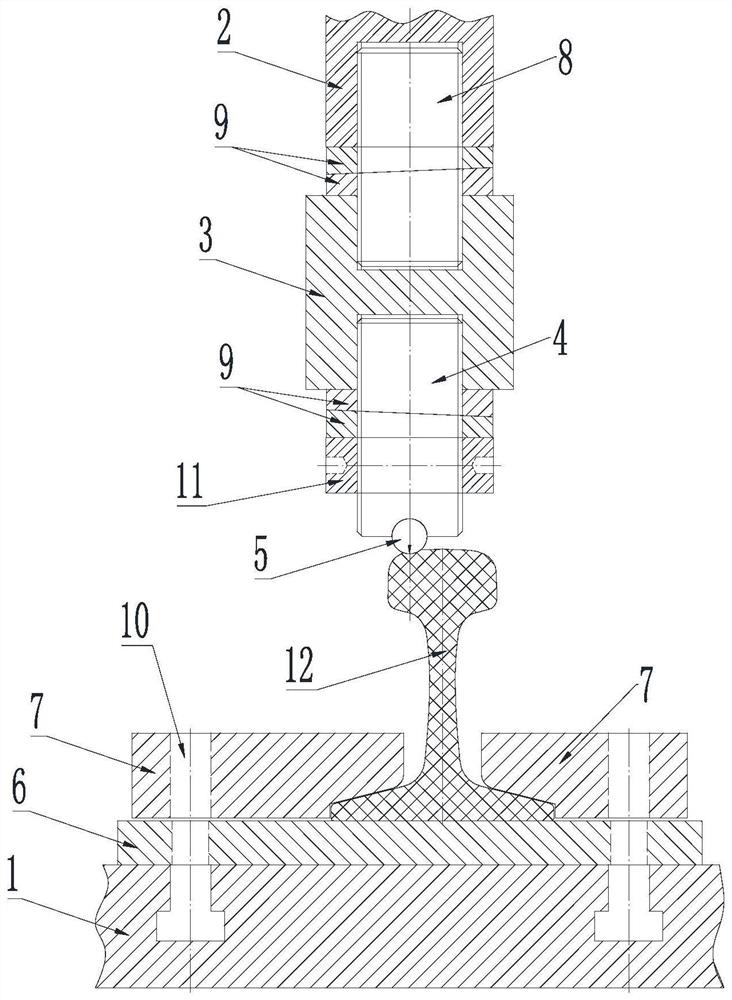

Rail joint rail head eccentric loading-rail waist fatigue test device and test method

ActiveCN109507050BEasy to processStable structureMachine part testingMaterial strength using repeated/pulsating forcesStructural engineeringSteel ball

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

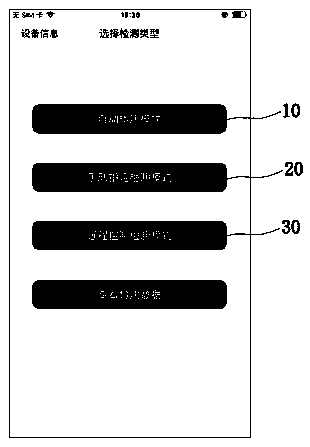

Method for testing mobile phone software function app

PendingCN111464381AThe testing process is not time consumingShorten the timeSoftware testing/debuggingData switching networksTestwareMobile phone

The invention provides a method for testing a mobile phone software function app. The testing method comprises the following steps that 1, a mobile phone testing app software automatically obtains information of a local system; 2, a to-be-tested app function type is selected and acquired; 3, a single-point test mode of the test app is selected; 4, a test mode is selected for testing the app function module; 5, data is stored automatically by the test app: recording time, people, test items, test steps, detection process data and results; 6, the API protocol of the automatic calling test item of the app function is tested; wherein a server completes an instruction of a to-be-tested app function; 7, the test is finished. Compared with the prior art, due to the adoption of the structure, thetest process of searching the test button does not consume time, the time is short, and the subjectivity of the detection process is reduced, so that the detection standard is improved, and meanwhile,the test result has inquirability and traceability.

Owner:转转一零二四(北京)科技有限公司

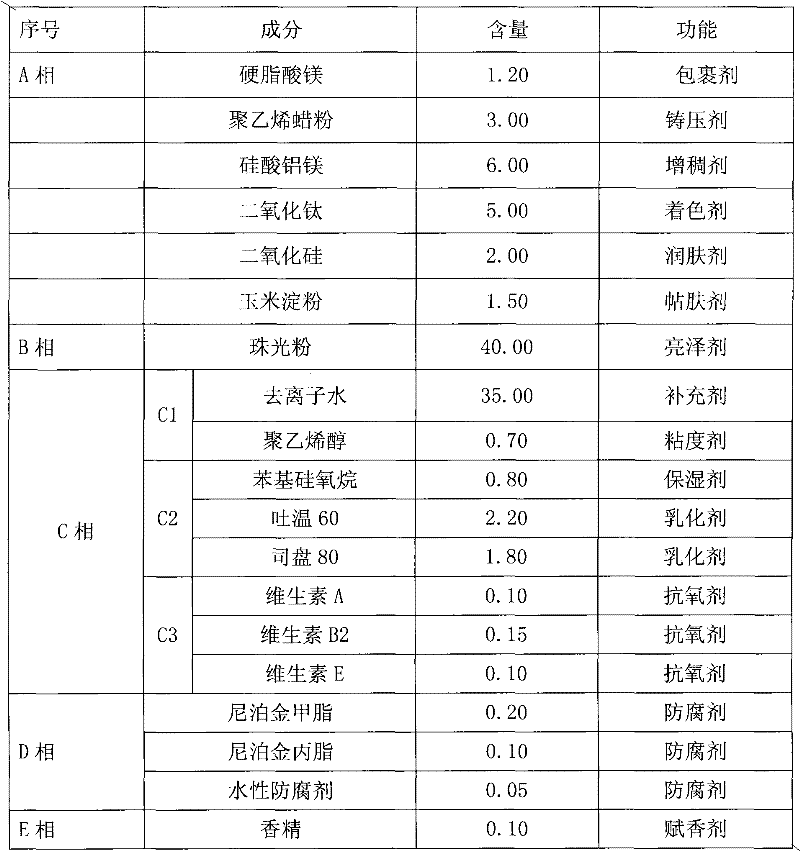

Baking powder and preparation method thereof

ActiveCN102048656BGood colorImprove testing standardsCosmetic preparationsBody powdersPolyvinyl alcoholAntioxidant

The invention provides a baking powder and a preparation method thereof. The baking powder comprises the following components in percentage by weight: 1-4 percent of magnesium stearate, 1-3 percent of polyethylene wax powder, 4-7 percent of magnesium aluminum silicate, 4-6 percent of titanium dioxide, 1-3 percent of silicon dioxide, 1-2 percent of maize starch, 20-50 percent of pearl powder, 0.5-2 percent of phenylsiloxane, 0.5-1 percent of polyvinyl alcohol and proper antioxidant, emulsifier and deionized water. The baking powder can be applied uniformly, is smooth and easy to color.

Owner:浙江美雪化妆品有限公司

Detection and correction method for salutation pose of young pioneer

ActiveCN108596067AEasy to observeAvoid simultaneous use of unrecognized issuesImage enhancementImage analysisPattern recognitionPostural orientation

The invention provides a detection and correction method for a salutation pose of a young pioneer. The method comprises the steps of performing real-time imaging and display by utilizing a video apparatus, performing dynamic tracking by human face identification, and outlining a detected human face by using a highlighting color; setting a specific region in a display screen of the video apparatus,outlining a human face in the specific region by using an identification color different from the highlighting color, and marking a user corresponding to the human face as a locked user; and detecting whether the locked user wears a red scarf or not and whether the red scarf is worn in a standard manner or not, if the locked user does not wear the red scarf in the standard manner, giving a voiceprompt, if the locked user wears the red scarf in the standard manner, performing right arm position and right hand pose detection, performing evaluation for enabling the locked user to adjust the pose in real time according to a display video, and until the evaluation meets the standard, finishing the salutation pose detection and correction. The detection and correction method for the salutationpose of the young pioneer assists the young pioneer to finish the salutation pose detection and correction, thereby saving the manpower resources and improving the correction efficiency.

Owner:中少科普(北京)教育科技有限公司

Pipeline inspection device

ActiveCN112517411BImprove detection efficiencyImprove testing standardsOptically investigating flaws/contaminationSortingFace detectionEngineering

The invention provides a pipeline inspection device, which includes a frame body, a feed assembly, an end surface inspection assembly and an outer surface inspection assembly, the feed assembly, the end surface inspection assembly and the outer surface inspection assembly are connected in sequence and Installed on the frame body, the end face detection component includes a transmission unit, a left end face detection unit and a right end face detection unit, the transmission unit communicates with the feeding component, and the left end face detection unit and the right end face detection unit are respectively set On both sides of the transmission unit, the outer surface detection component includes a detection unit and a delivery unit, the delivery unit transports the product to the detection unit, the detection unit detects the outer surface of the product, and the pipeline inspection By setting the end face detection component and the outer surface detection component, the device not only detects both ends of the pipe but also the outer surface of the pipe. While improving the detection efficiency, it not only improves the detection standard, but also standardizes the manufactured products.

Owner:杭州君辰机器人有限公司

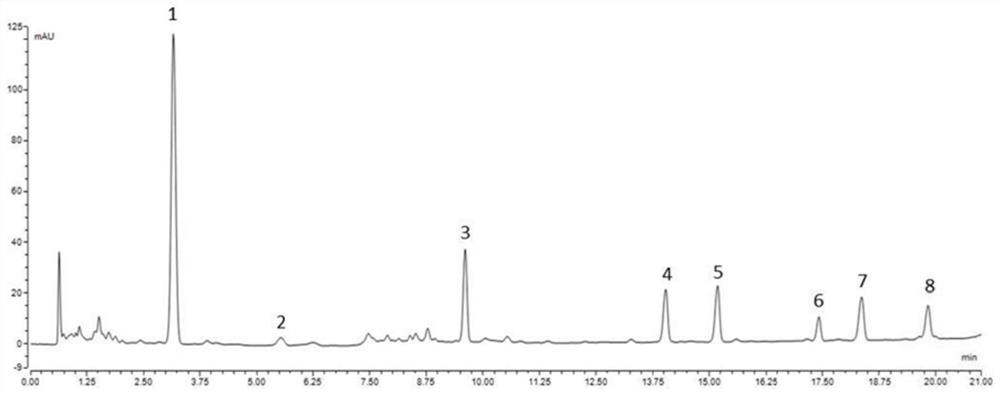

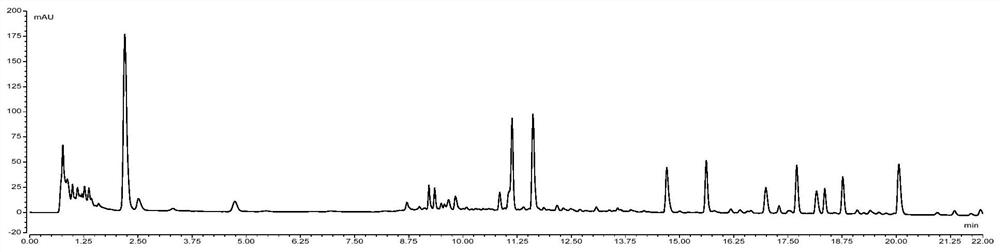

Method for determining content of six index components of gastrodia elata in Qingda granules

The invention provides a method for determining contents of six index components of gastrodia elata in Qingda granules. According to the method, a preparation method of a test solution is improved; the preparation method comprises the following steps: taking Qingda granules under a loading amount difference item, grinding, precisely weighing, adding a phosphoric acid aqueous solution, weighing, carrying out ultrasonic treatment, cooling, supplementing the reduced weight with the phosphoric acid aqueous solution, carrying out centrifugal treatment, taking the supernatant, passing through a polyamide column, adding an elution solvent for elution, collecting eluent, adding the phosphoric acid aqueous solution to a constant volume, shaking up, and taking subsequent filtrate. The method is rapid and accurate, can effectively control the quality of gastrodia elata, also realizes qualitative research on gastrodia elata and scutellaria baicalensis in Qingda granules, and provides a basis for development of the Qingda granules and other preparations. Interference of other three medicinal materials in the Qingda granules on gastrodia elata can be reduced, other impurity components in the gastrodia elata can be greatly reduced, six index components are enriched, the purity of the index components is improved, and miscellaneous peak interference is reduced.

Owner:JIANGYIN TIANJIANG PHARMA

A host computer implementation method of coding equipment for electronic detonator production

ActiveCN105216454BImprove yield rateImprove testing standardsDuplicating/marking methodsTypewritersDetonatorTechnical standard

Owner:SHENZHEN DACHENG CHUANGANDA ELECTRONICS SCI & TECH DEV

Automatic track spacing detection device and detection method

ActiveCN113532256AQuick Auto DetectEfficient automatic detectionUsing electrical meansElectric/magnetic roughness/irregularity measurementsDrive shaftTrackway

The invention discloses an automatic track spacing detection device and method. The automatic track spacing detection device comprises a driving shaft and rolling wheels arranged at the two ends of the driving shaft. The driving shaft comprises a first shaft body and a second shaft body, and a first spring is arranged between the first shaft body and the second shaft body. An opening is formed in the end, opposite to the second shaft body, of the first shaft body, and a first conductive part and a second conductive part which are in contact with each other are arranged in the opening. A detection sliding rod extending into the opening is connected to the second shaft body, and a first insulating insertion rod is connected to the front end of the detection sliding rod. The first insulating insertion rod can be inserted between the first conductive part and the second conductive part when the distance between the first shaft body and the second shaft body is reduced so as to block the electrical connection between the first conductive part and the second conductive part. According to the invention, efficient detection of too large and too small track spacing can be realized, the automation degree is high, the contact is accurate, and the phenomena of wrong detection and missing detection are avoided.

Owner:CRRC QINGDAO SIFANG CO LTD

Detection method for flavone component in clematis filamentosa dunn, and application thereof

ActiveCN102426207BThe content accurately reflectsStrong specificityComponent separationBiotechnologyMedicinal herbs

Owner:SOUTH CHINA AGRI UNIV

A kind of content determination method of Gastrodia elata 6 index components in Qingda granules

ActiveCN111929378BRealize Qualitative ResearchEffective quality controlComponent separationMedicinal herbsO-Phosphoric Acid

The invention provides a method for determining the content of six index components of Gastrodia elata in Qingda granules. The method improves the preparation method of a test solution. Weigh, add phosphoric acid aqueous solution, weigh, sonicate, let cool, supplement the lost weight with phosphoric acid aqueous solution, centrifuge, take the supernatant to pass through a polyamide column, add elution solvent for elution, and collect the eluate , and then add phosphoric acid aqueous solution to volume, shake well, and take the continuous filtrate. The method is fast and accurate, and can effectively control the quality of Gastrodia elata. It also realizes the qualitative study of Gastrodia elata and Scutellaria baicalensis in Qingda granules, and provides a basis for the development of Qingda granules and other preparations. The invention can reduce the interference of the other three medicinal materials in the Qingda granules to Gastrodia elata, and can greatly reduce other impurity components in the Gastrodia elata, enrich 6 kinds of index components, improve the purity of the index components, and reduce the interference of miscellaneous peaks.

Owner:JIANGYIN TIANJIANG PHARMA

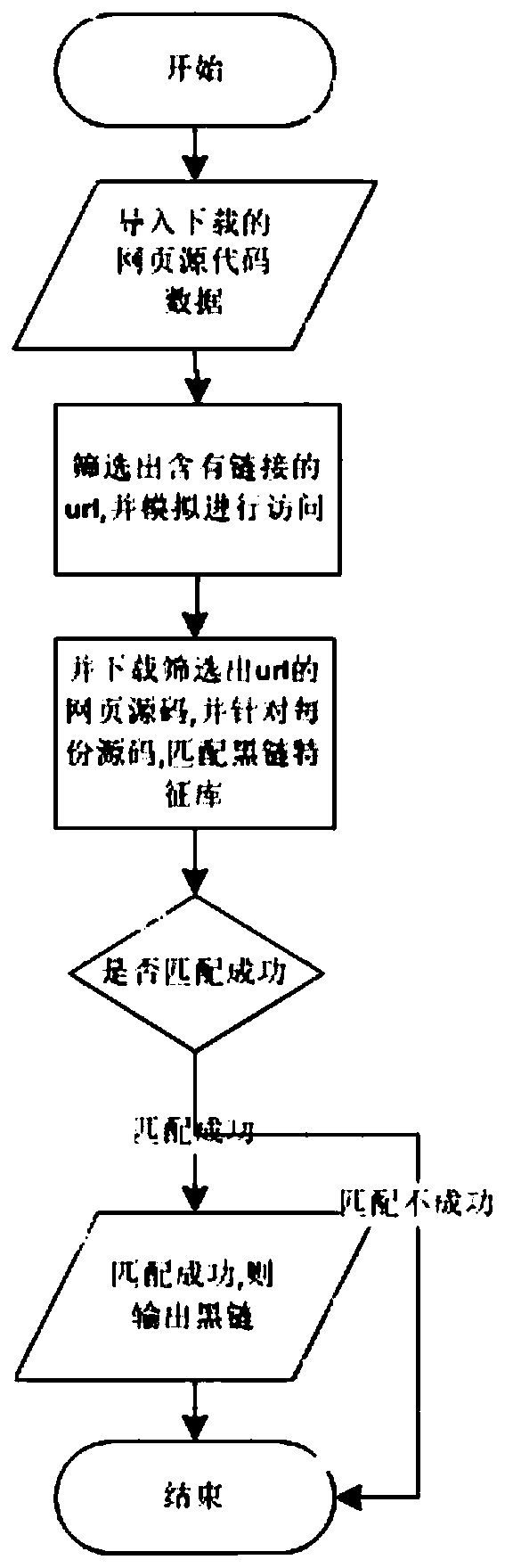

Environment-based vulnerability scanner

InactiveCN110298177AImprove testing standardsImprove accuracyPlatform integrity maintainanceUniform resource locatorData mining

The invention discloses an environment-based vulnerability scanner, and belongs to the field of network security. The method comprises the following steps: creating a violation characteristic databaseS1, importing a uniform resource locator URLx of existing black chain violation characteristics; downloading the webpage file H1 of the access request; creating a regular expression REGEX of the webpage format; creating a webpage link feature database S2 in a user-defined mode; obtaining URLz containing links on the webpage file H1, and detecting whether the URLz conforms to the webpage format ornot by utilizing a regular expression REGEX (URLz); if it is detected that the URLz conforms to the webpage format through REGEX (URLz), detecting whether the URLz exists in the violation feature database S1 or not by inquiring the violation feature database S1, if yes, judging that the URLz is a black chain, and otherwise, judging that the URLz is not a black chain. According to the method, through actual requirements in work, the problems of labor cost and low efficiency caused by traditional vulnerability scanning are solved, the black chain recognition rate is increased, and the hidden black chain is recognized.

Owner:电子科技大学成都学院

Energy-saving environment protection bulking brick

The invention provides an energy-saving and environment-friendly swelling brick, which relates to a material for building. In order to overcome the deficiency caused by common clay red bricks which consumes a great land resources and energy, and has serious pollution, small size but heavy deadweight, poor heat insulation performance, and increase of the total construction cost; the swelling brick of the invention takes argillo-arenaceous rock as main material, which enters a high temperature rotary furnace to charge oxygen and pressure for swelling after crushing and screening, then a secondary heating is performed after producing the swelling body, finally the shape is formed by mechanical squeezing. The swelling body after shaped by squeezing also can be mixed with the cement, the fly ash and the concrete additive. After mechanically agitating and watering, the swelling body is conveyed to a silo for squeezing to form the swelling brick which is characterized by light weight, rigid body, heat insulation, and fire resistance, nontoxic and being durable, thus being an ideal energy-saving building brick.

Owner:黑龙江省三江君合新材料科技开发有限公司

A kind of preparation method of 410 stainless steel strip material for nuclear power

ActiveCN109675927BReduce defectsImprove testing standardsMeasuring devicesMetal rolling arrangementsNuclear powerSS - Stainless steel

The invention discloses a method for preparing a 410 stainless steel strip for nuclear power, which comprises the following steps: step 1, performing nondestructive flaw detection treatment on a 410 stainless steel forged slab; step 2, subjecting the treated slab to first annealing, hot rolling and the second annealing; step 3, surface treatment and pickling of the hot-rolled slab after the second annealing; step 4, cold rolling; step 5, carrying out non-destructive flaw detection treatment on the cold-rolled slab; After the treatment, the cold-rolled slab is cut and rolled; Step 7, annealing the cold-rolled plate, and then finishing; Step 8, performing non-destructive testing on the stainless steel plate; Step 9, removing the flaw detection blind area of the treated stainless steel plate, Then carry out strip rolling; Step 10, anneal the finished strip to obtain 410 stainless steel strip for nuclear power. The method of the invention can effectively eliminate the opening and closing defects generated in the processing process, ensure the smooth progress of the plate in the strip rolling and other processes, and improve the product yield.

Owner:西安诺博尔稀贵金属材料股份有限公司

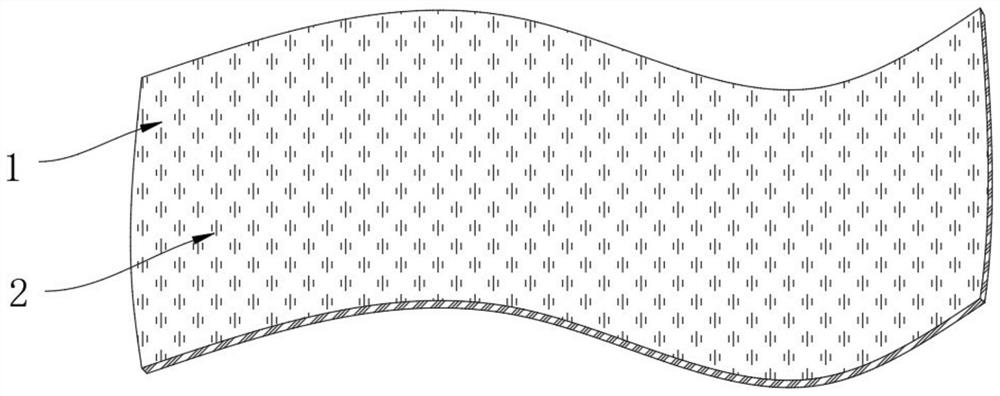

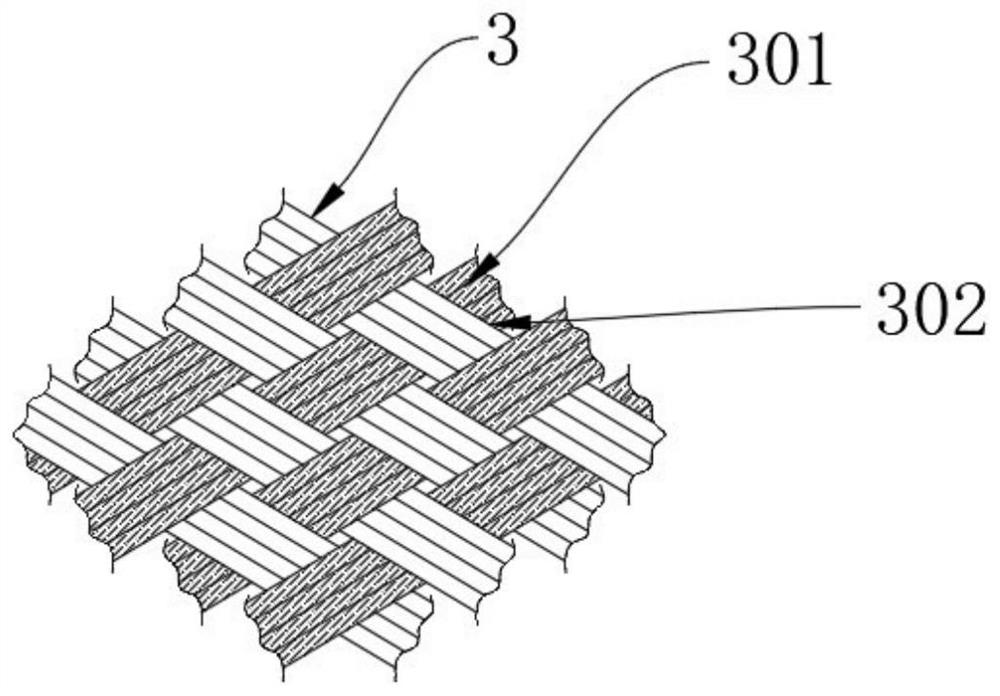

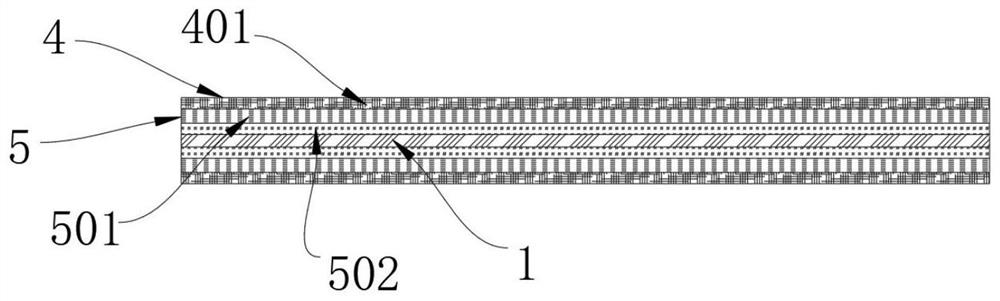

Warp-wise bubbling crape fabric

InactiveCN113334872AImprove testing standardsHigh strengthSynthetic resin layered productsPolymer scienceKapok fiber

The invention relates to the technical field of home textile suit fabrics and hotel fabrics, and provides a warp-wise bubbling crape fabric which comprises a crape fabric body and bubbling cloth, the bubbling cloth is arranged on the surface of the crape fabric body, and a reinforcing structure is arranged in the crape fabric body. The reinforcing structure comprises warp-wise filament yarn, weft-wise filament yarn and twisted filament yarn, the warp-wise filament yarn is arranged inside the crape fabric body. An antibacterial structure is arranged on the surface of the crape fabric body and comprises an antibacterial layer, kapok fibers and chitosan fibers, and the antibacterial layer is arranged on the surface of the crape fabric body. The weft-wise filament yarn is arranged on the warp-wise filament yarn, and the warp-wise filament yarn and the weft-wise filament yarns are arranged in an interwoven mode, so that the defects that an existing crape fabric bubbling in the warp direction is low in strength, prone to fuzzing and pilling and the like are overcome.

Owner:JIANGSU MINGYUAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com