Patents

Literature

8437results about How to "Improve yield rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

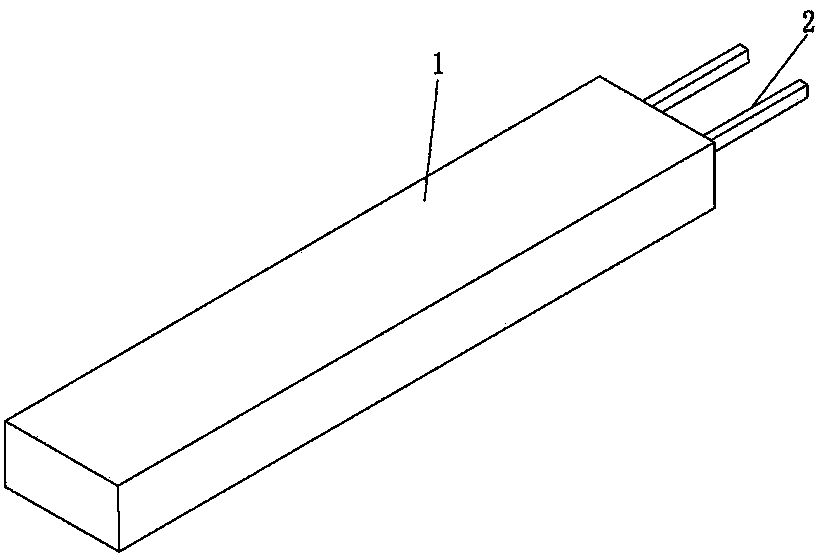

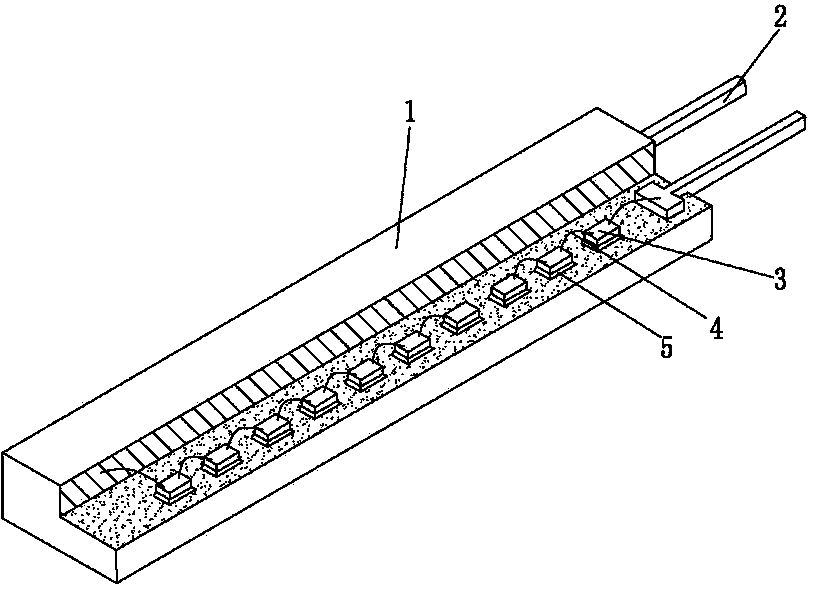

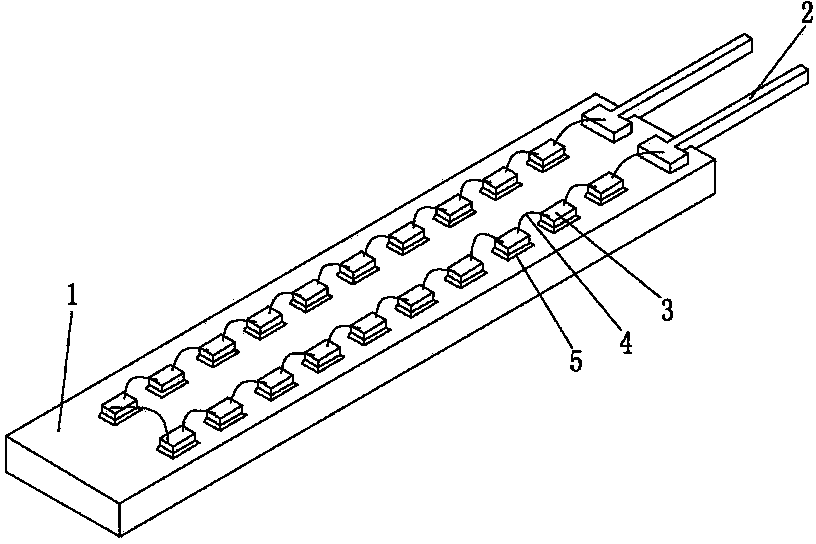

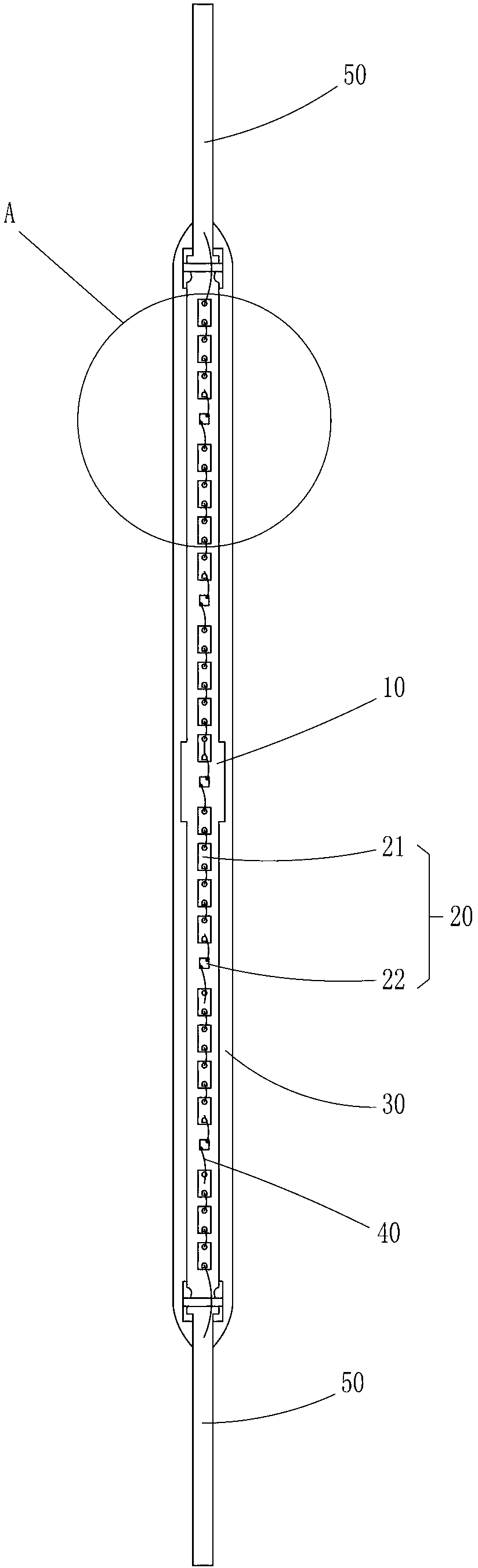

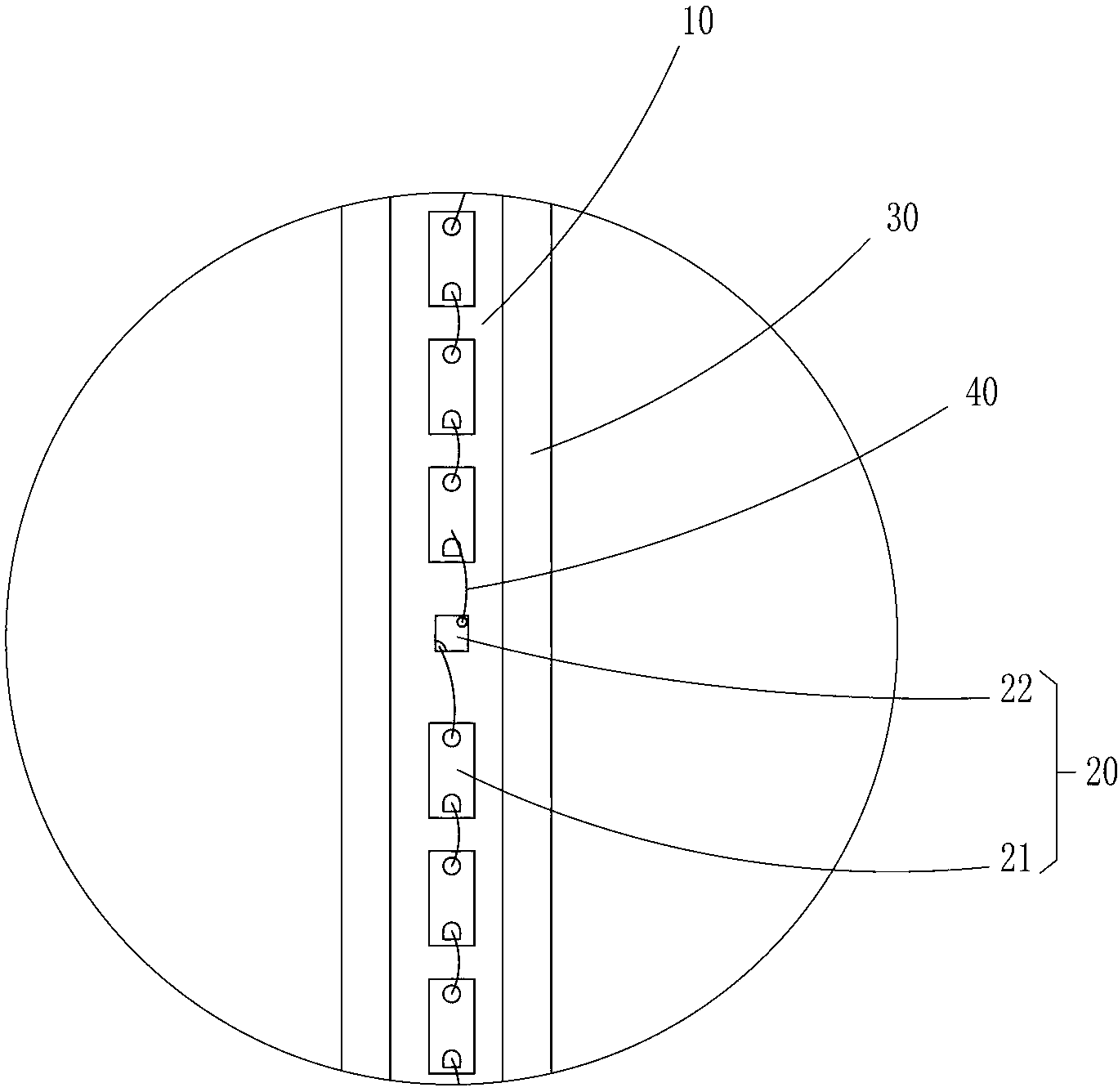

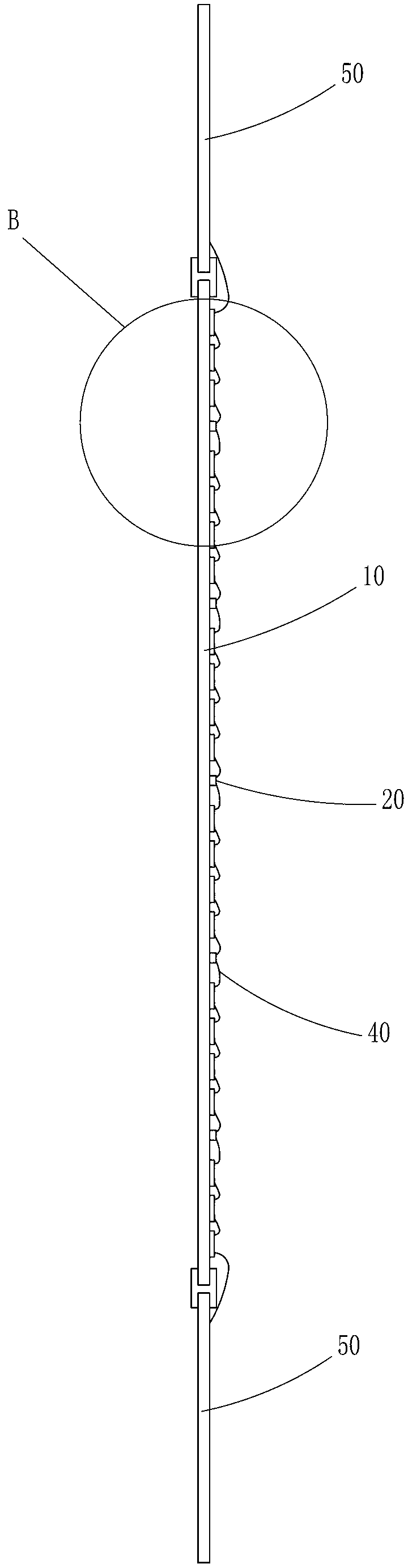

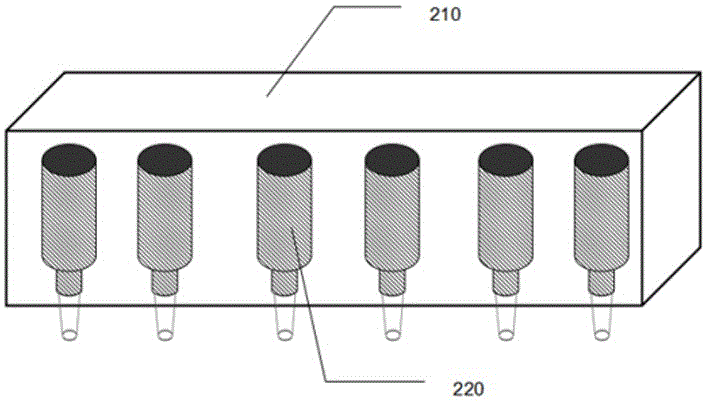

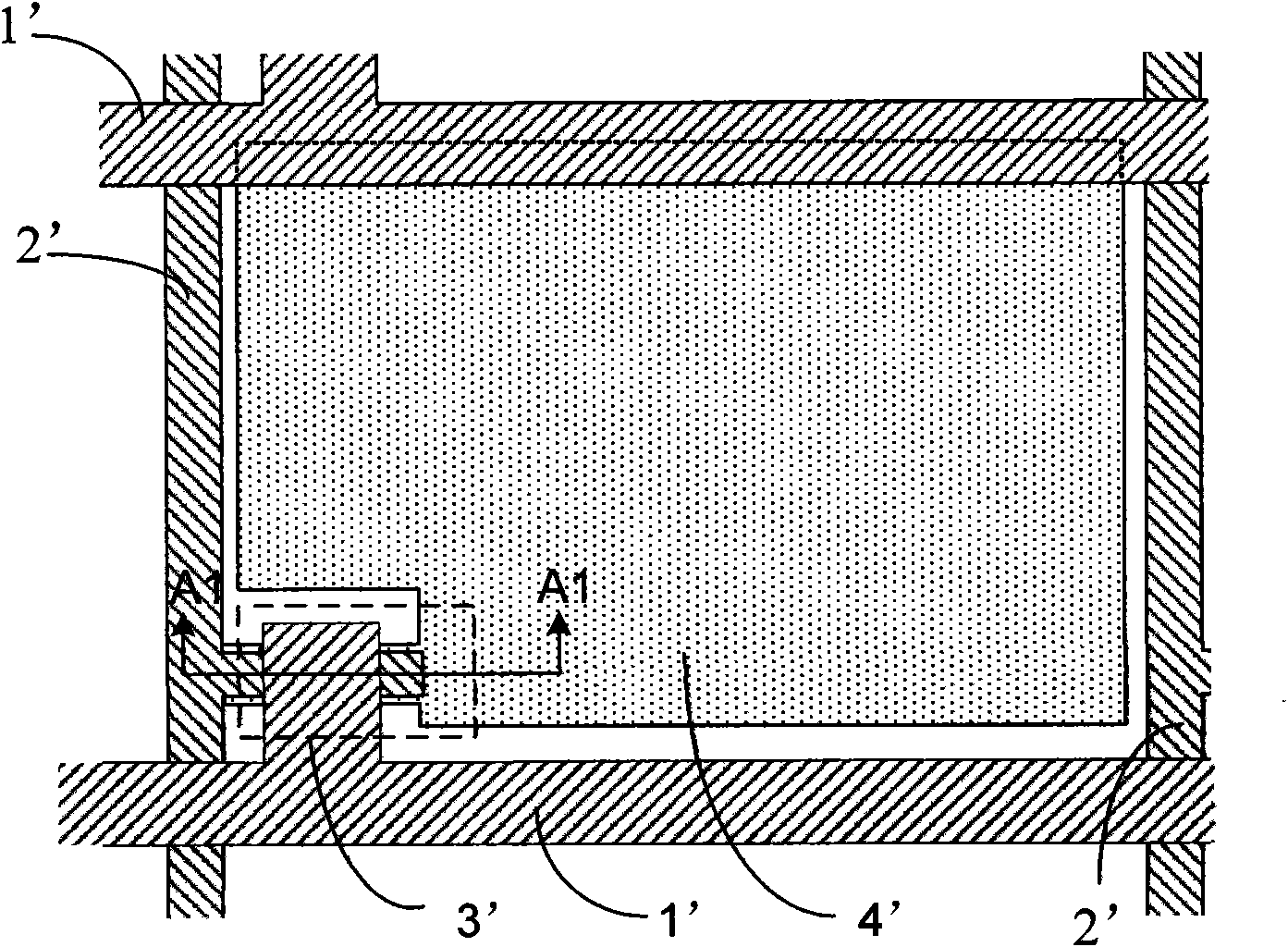

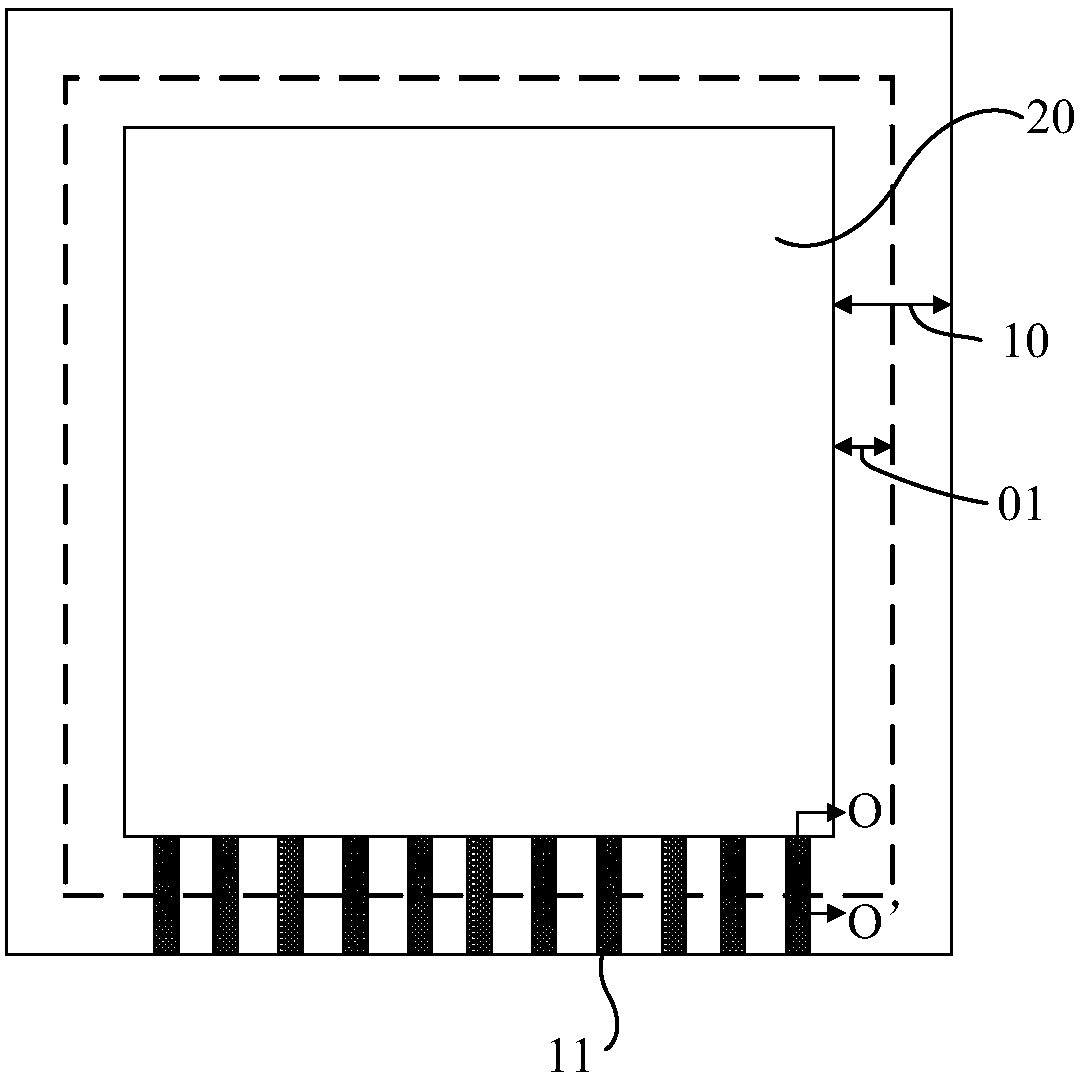

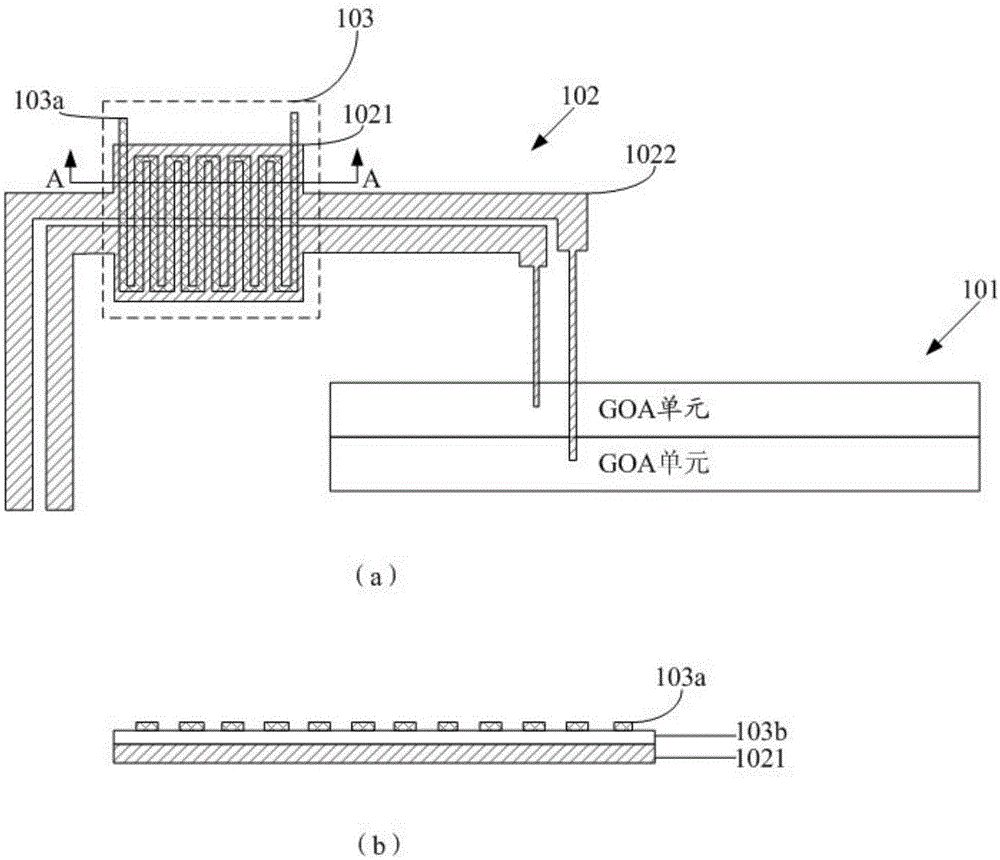

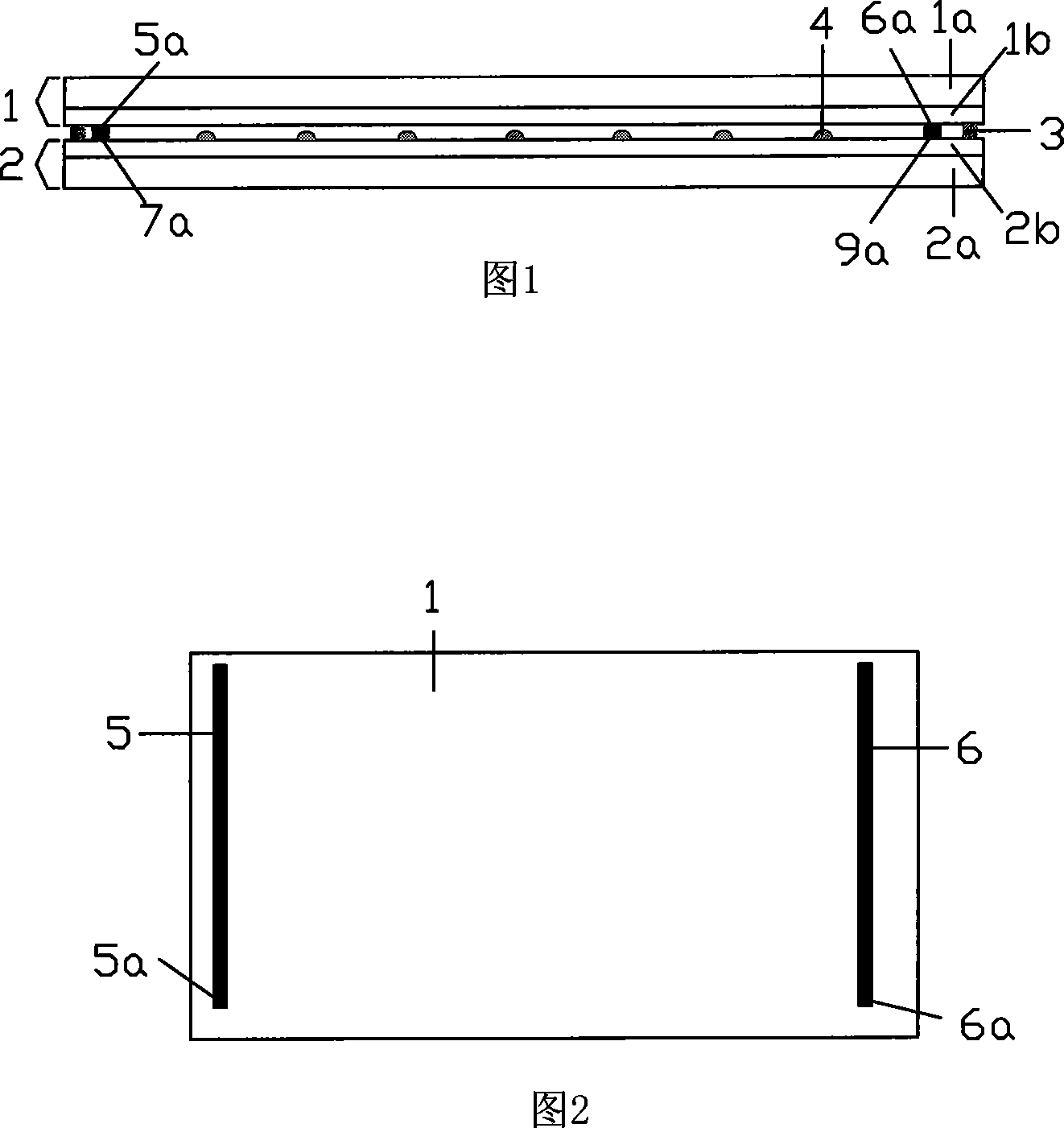

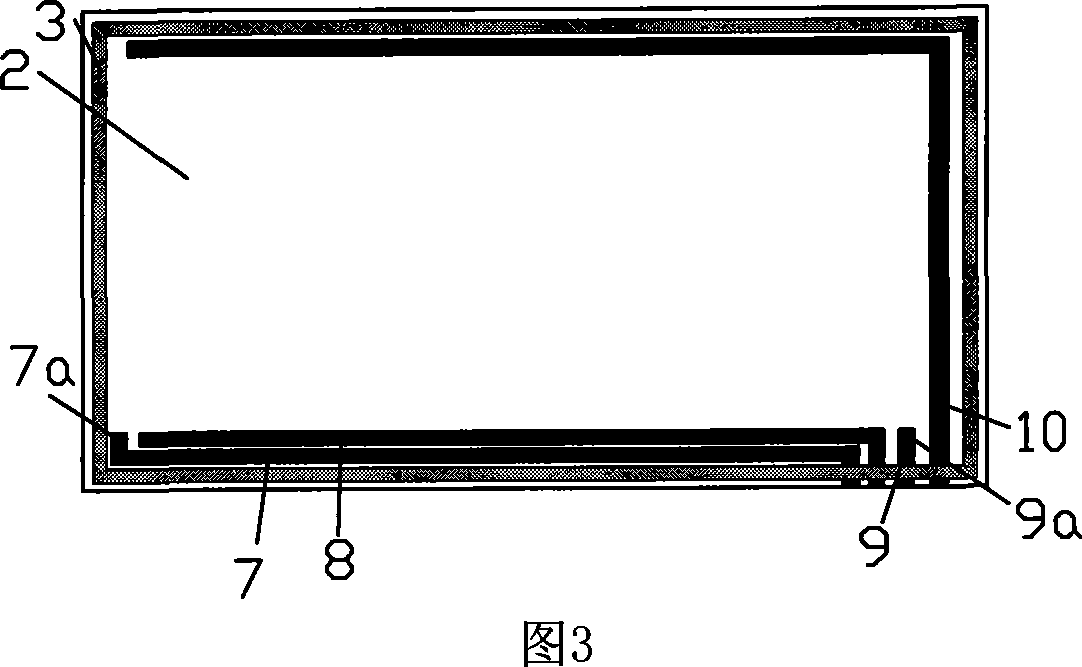

Packaging method of LED filament and LED filament

InactiveCN104319345AEnsure stabilityGuaranteed light transmittanceSemiconductor devicesLED filamentLiquid silicon

The invention discloses a packaging method of an LED filament. The packaging method of the LED filament includes the steps that a liquid silicon resin and fluorescent powder mixture is injected into a mould, and a metal conductive pin is arranged at one end of the silicon resin and fluorescent powder mixture inside the mould; the mould is removed after being heated and solidified, and silicon resin and fluorescent powder colloid with the metal conductive pin at one end is obtained; a plurality of LED chips are installed on the silicon resin and fluorescent powder colloid, and the LED chips are mutually connected through a wire and then connected to the metal conductive pin to form a conductive path; the silicon resin and fluorescent powder colloid with the LED chips is put into the mould, and a liquid silicon resin and fluorescent powder mixture is injected into the mould to cover the LED chips and the wire; the mould is removed after being heated and solidified, and the packaged LED filament finished product with a supporting frame is obtained. The LED filament is packaged without the supporting frame, and the quality problems of low yield, low light transmittance of the supporting frame and the like are resolved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

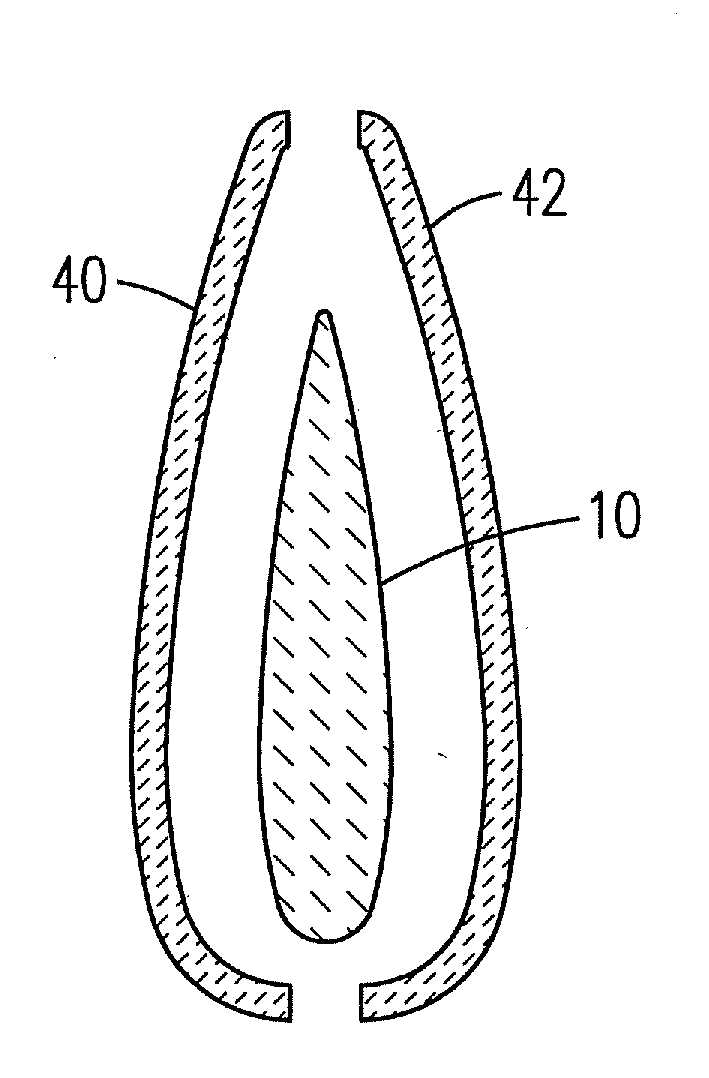

Waxless precision casting process

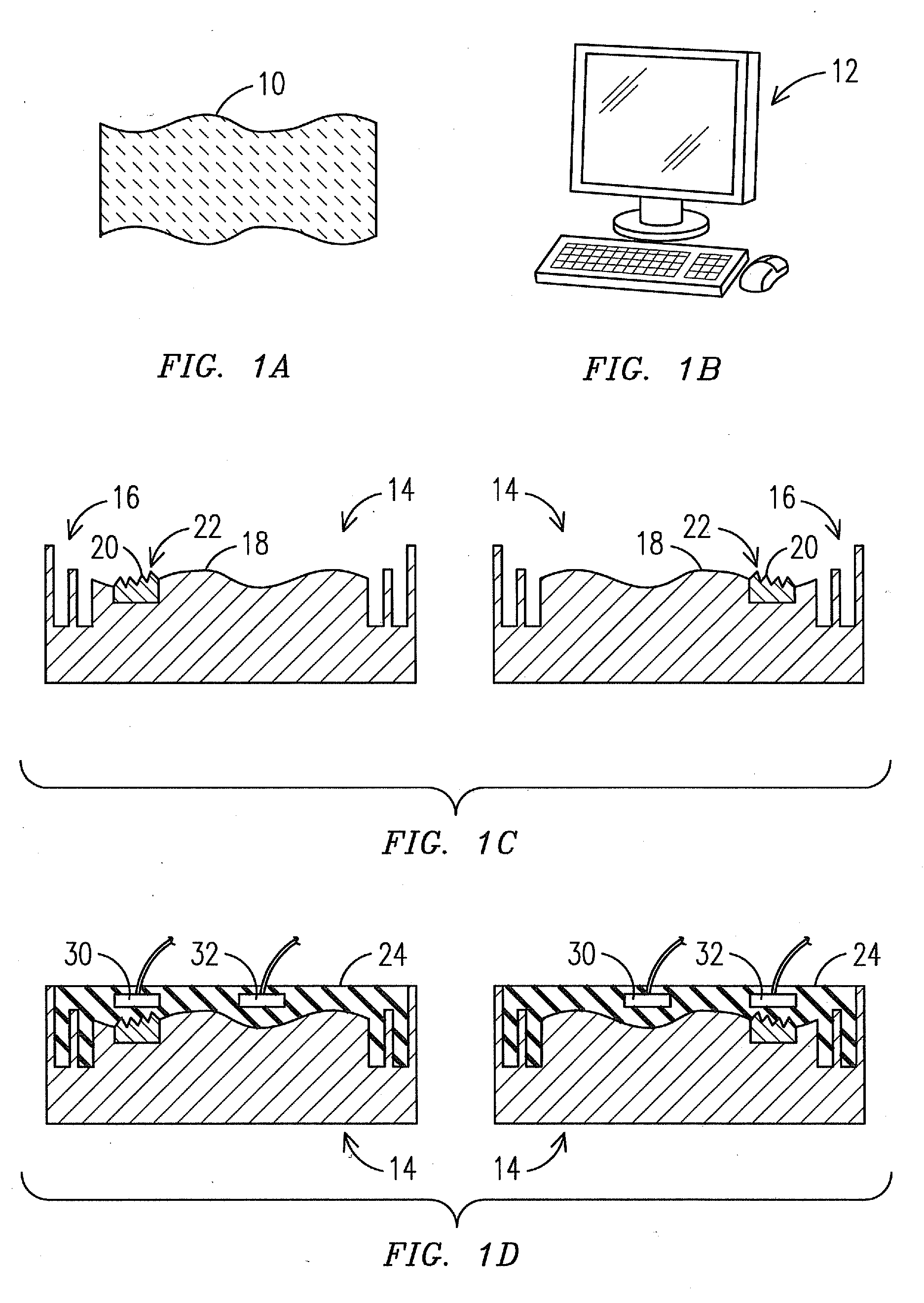

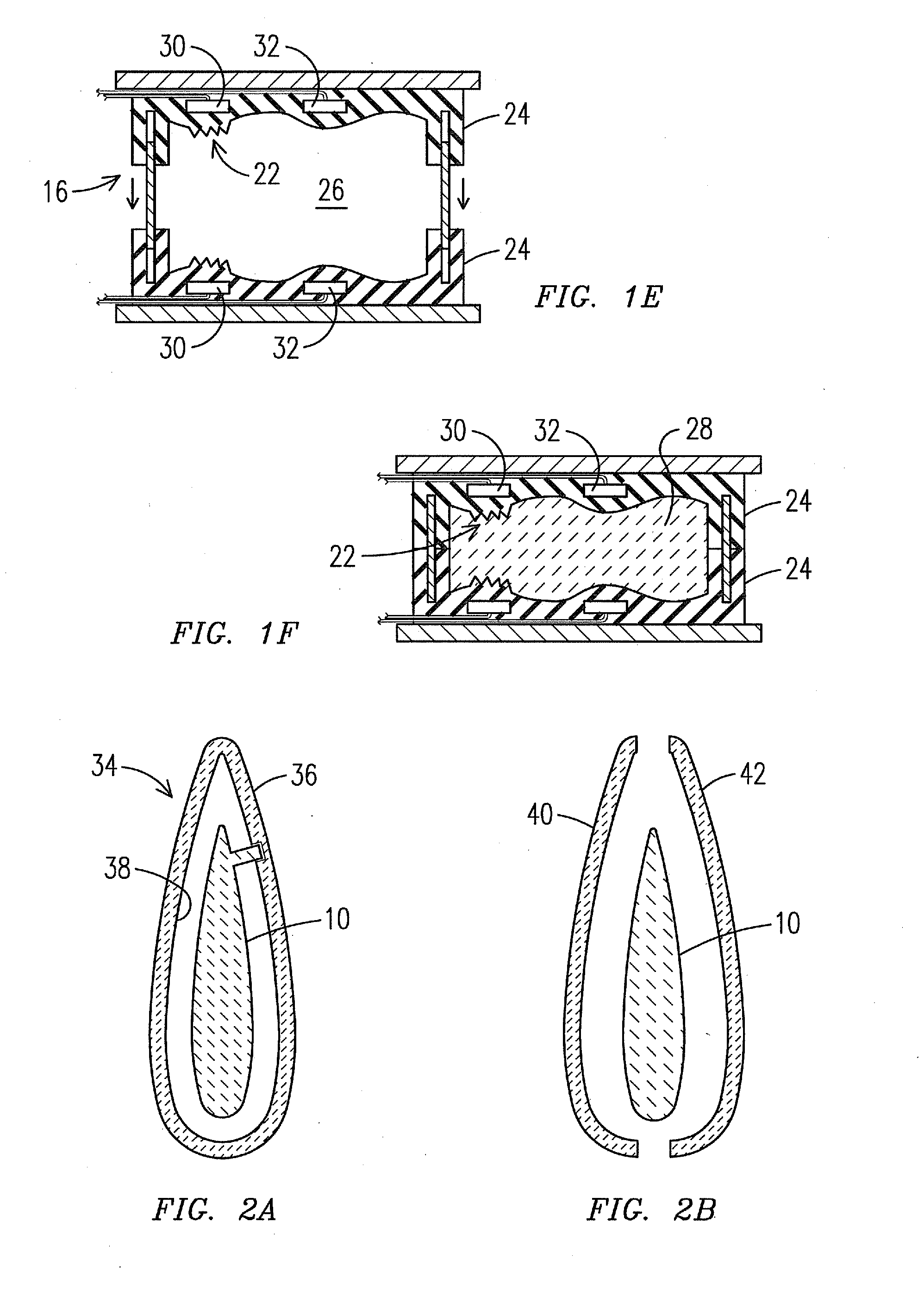

Alloy products are produced with a waxless casting process. A model of a ceramic casting vessel (34) defining a desired product shape is digitally divided into sections (10, 40, 42). Each section is translated into a soft alloy mater tool (14) including precision inserts (20) where needed for fine detail. A flexible mold (24) is cast from each master tool, and a section of the ceramic casting vessel is cast from the respective flexible mold. The vessel sections are assembled by aligning cooperating precision features (58, 60) cast directly into each section and the alloy part is cast therein. No wax or wax pattern tooling is needed to produce the cast alloy product. Engineered surface features (54) may be included on both the interior and exterior surfaces of the shell sections.

Owner:MIKRO SYSYTEMS INC +1

LED (light-emitting diode) lamp and filament thereof

ActiveCN103322525AGood colorIncrease the light output angleLight source combinationsPoint-like light sourceEngineeringSealant

Owner:SHENZHEN RUNLITE TECH

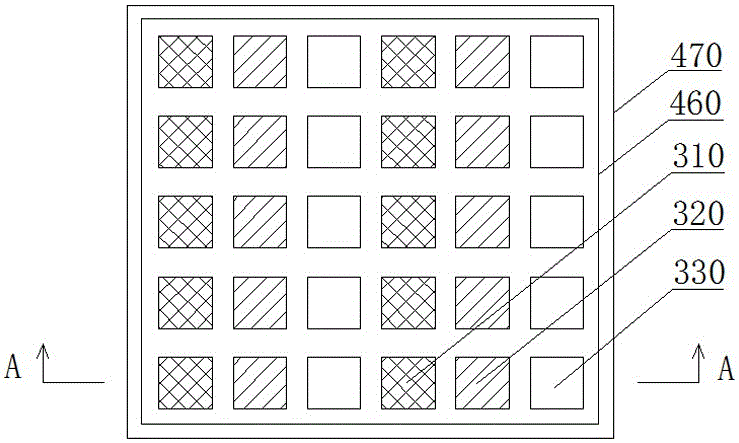

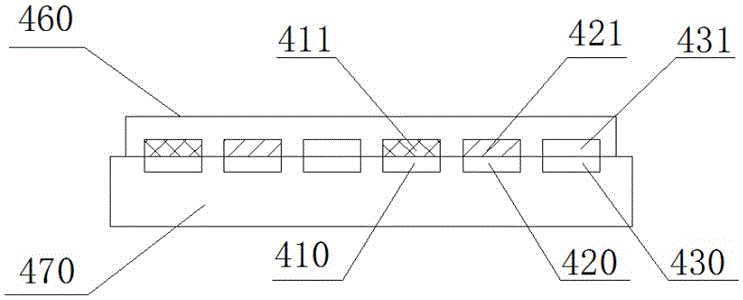

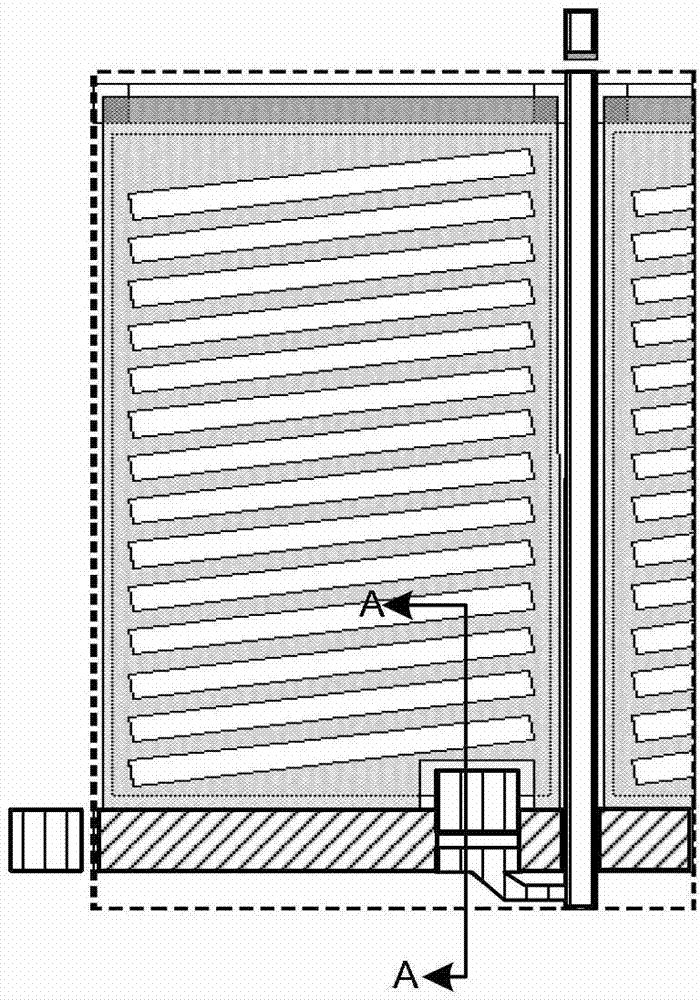

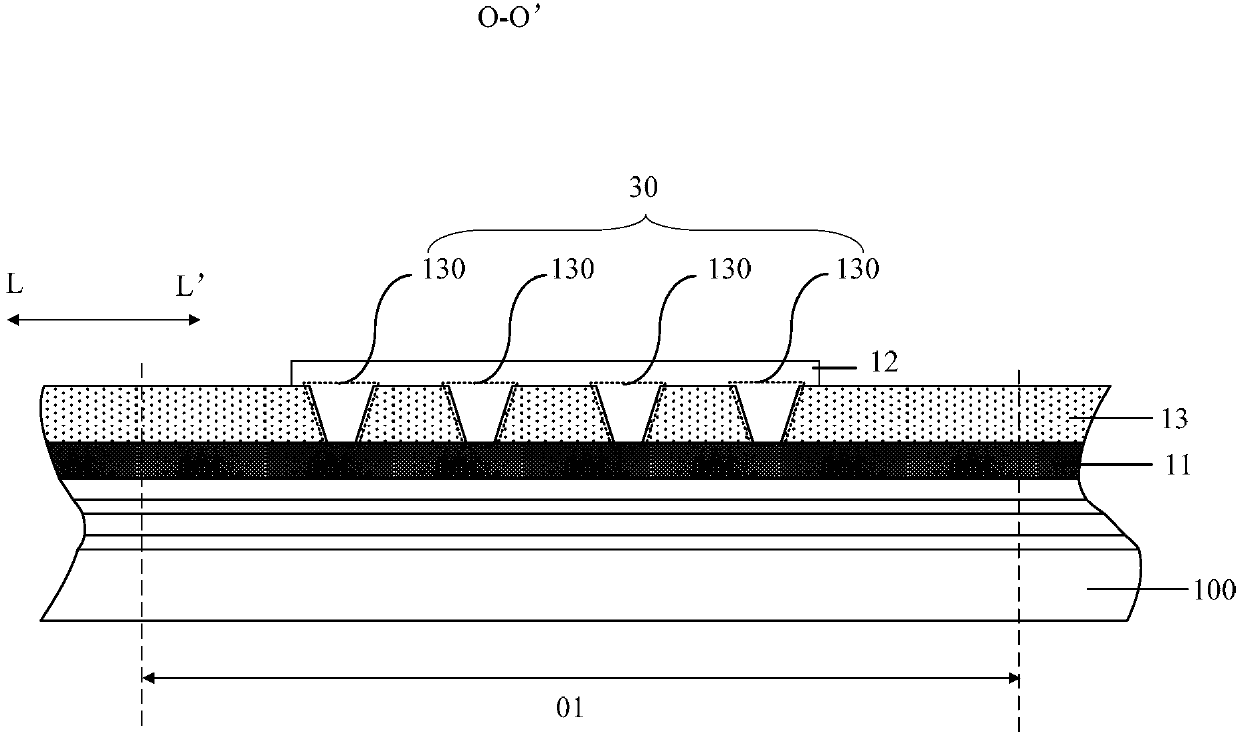

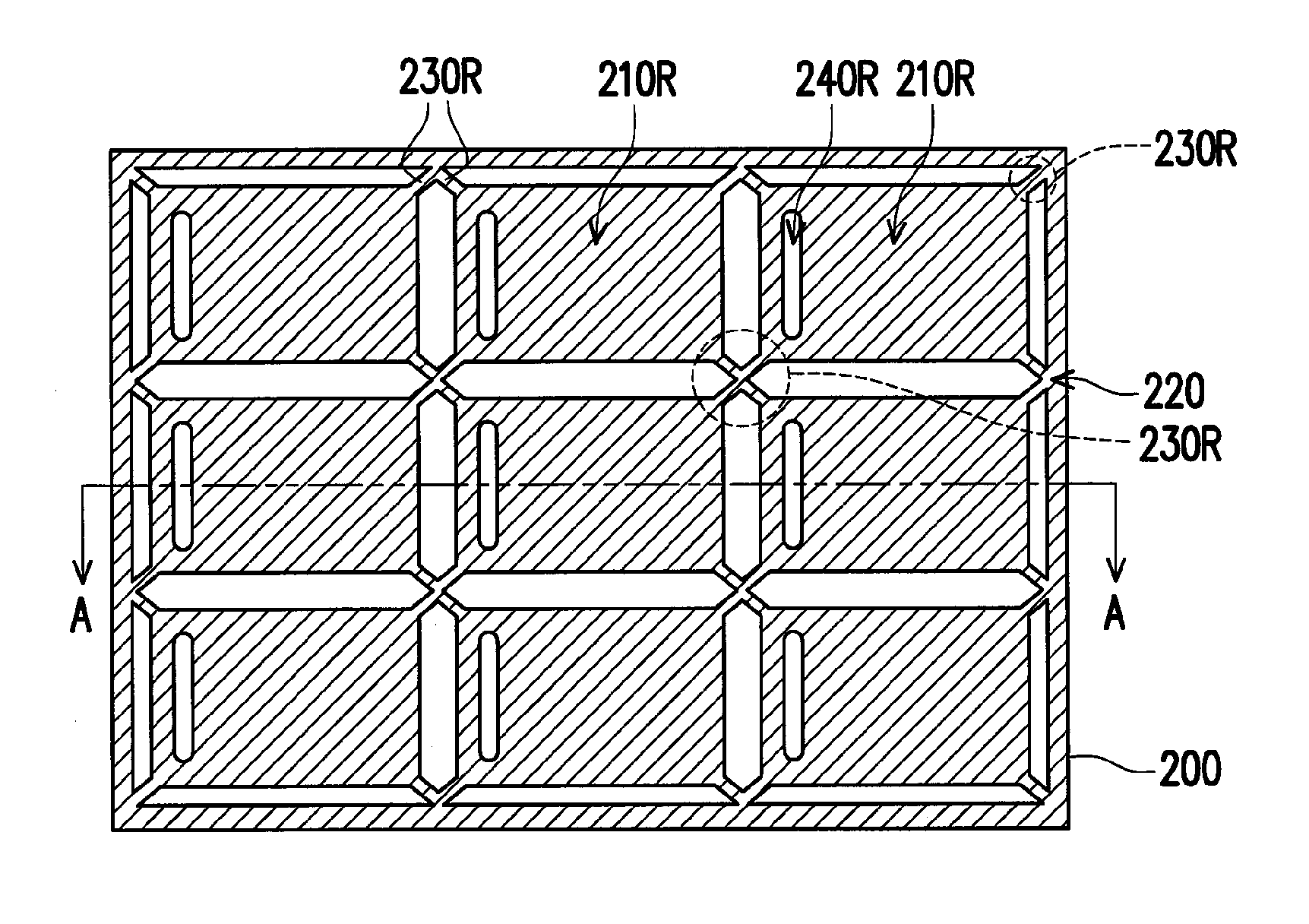

Micro-LED (Micro-light emitting diode) array backlight source-based ink-jet printing quantum dot display device

ActiveCN106356386AAvoid difficultyImprove the display effectSolid-state devicesSemiconductor devicesLed arrayBatch operation

The invention relates to a Micro-LED (Micro-light emitting diode) array backlight source-based ink-jet printing quantum dot display device, which comprises a Micro-LED substrate, wherein a plurality of RGB (red, green and blue) pixel units arranged in an array are arranged on the Micro-LED substrate; each RGB pixel unit comprises a red quantum dot unit, a green quantum dot unit and a transparent unit; each red quantum dot unit comprises a Micro-LED chip and a red quantum dot material, and the red quantum dot material is excited by blue light emitted by the Micro-LED chip to emit red light; each green quantum dot unit comprises a Micro-LED chip and a green quantum dot material, and the green quantum dot material is excited by blue light emitted by the Micro-LED chip to emit green light; each transparent unit comprises a Micro-LED chip and a transparent material, and the transparent material is used for directly transmitting blue light emitted by the Micro-LED chip; a transparent material for packaging is arranged outside the RGB pixel units. According to the device, an ink-jet printing technology is adopted for film forming of quantum dots, so that the problems of complexity and low yield of an RGB tri-color process for manufacturing a Micro-LED full-color product are solved, and batch operation is realized.

Owner:FUZHOU UNIV

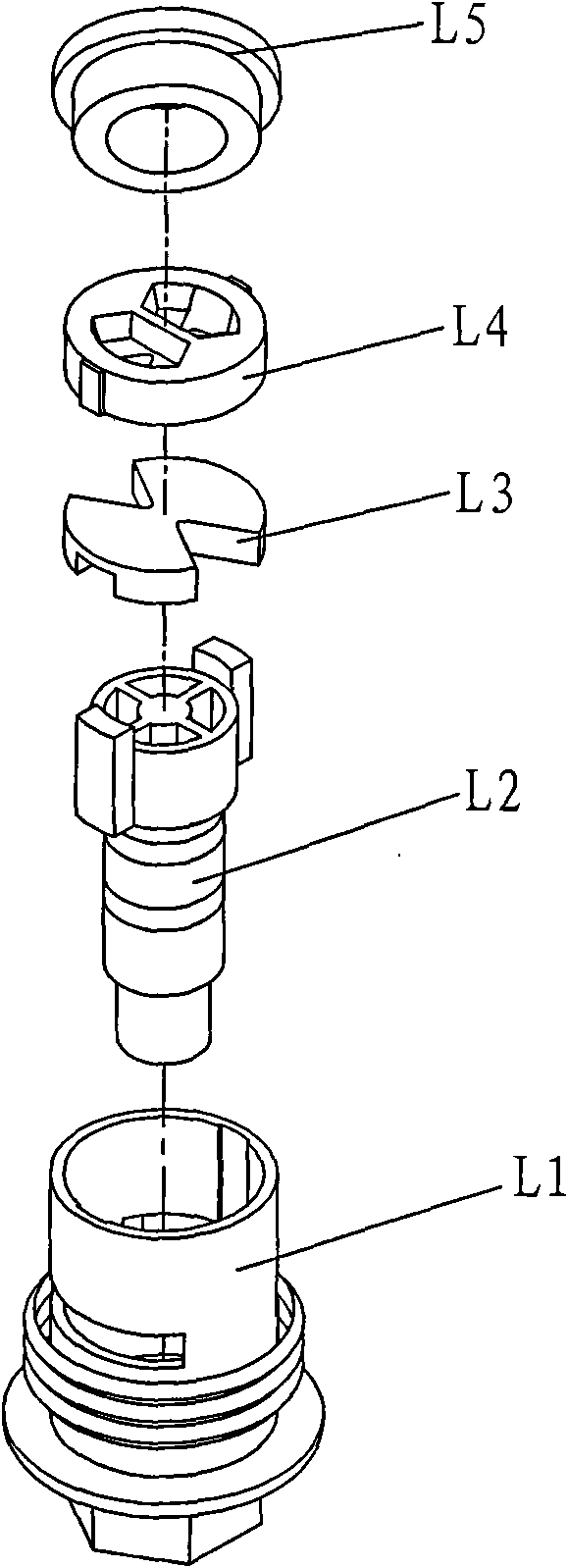

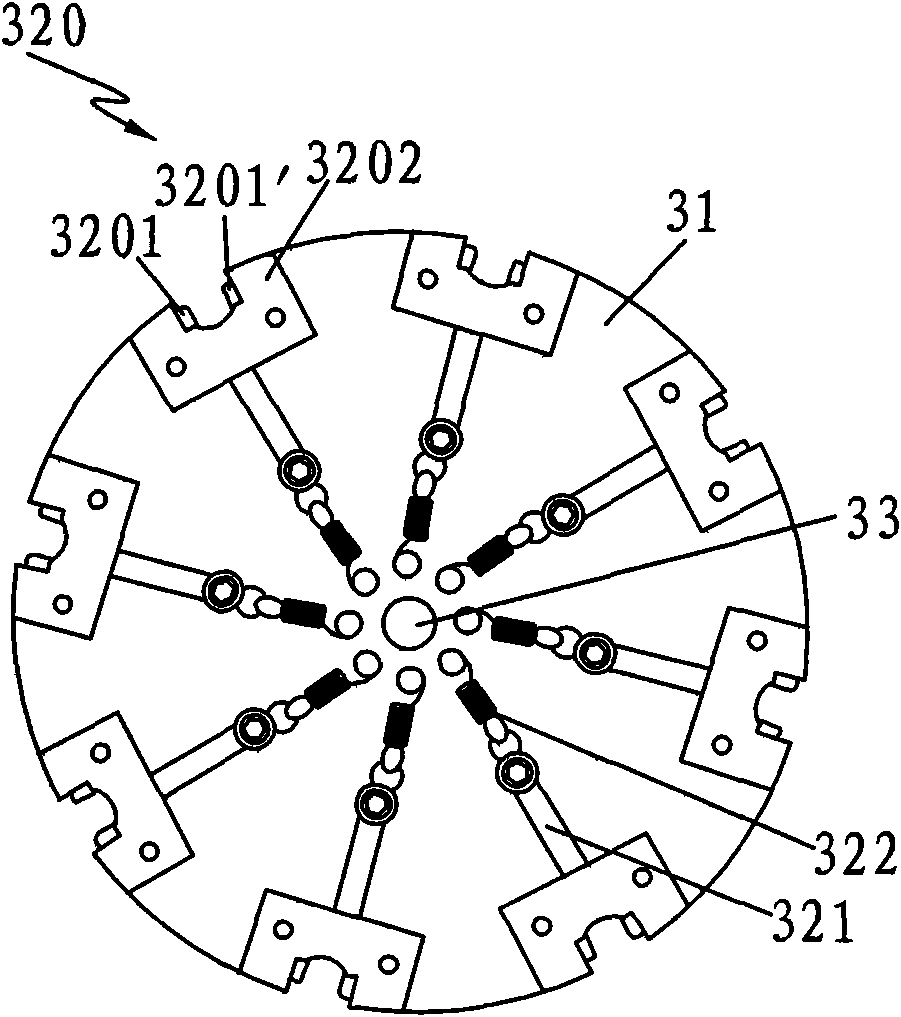

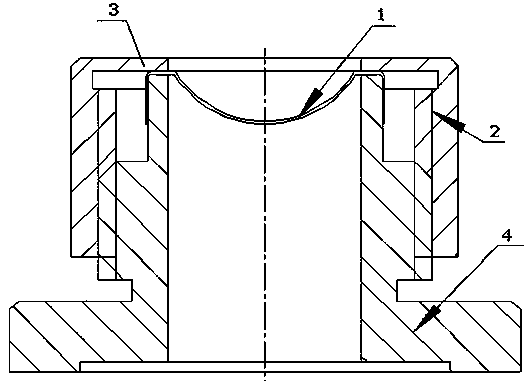

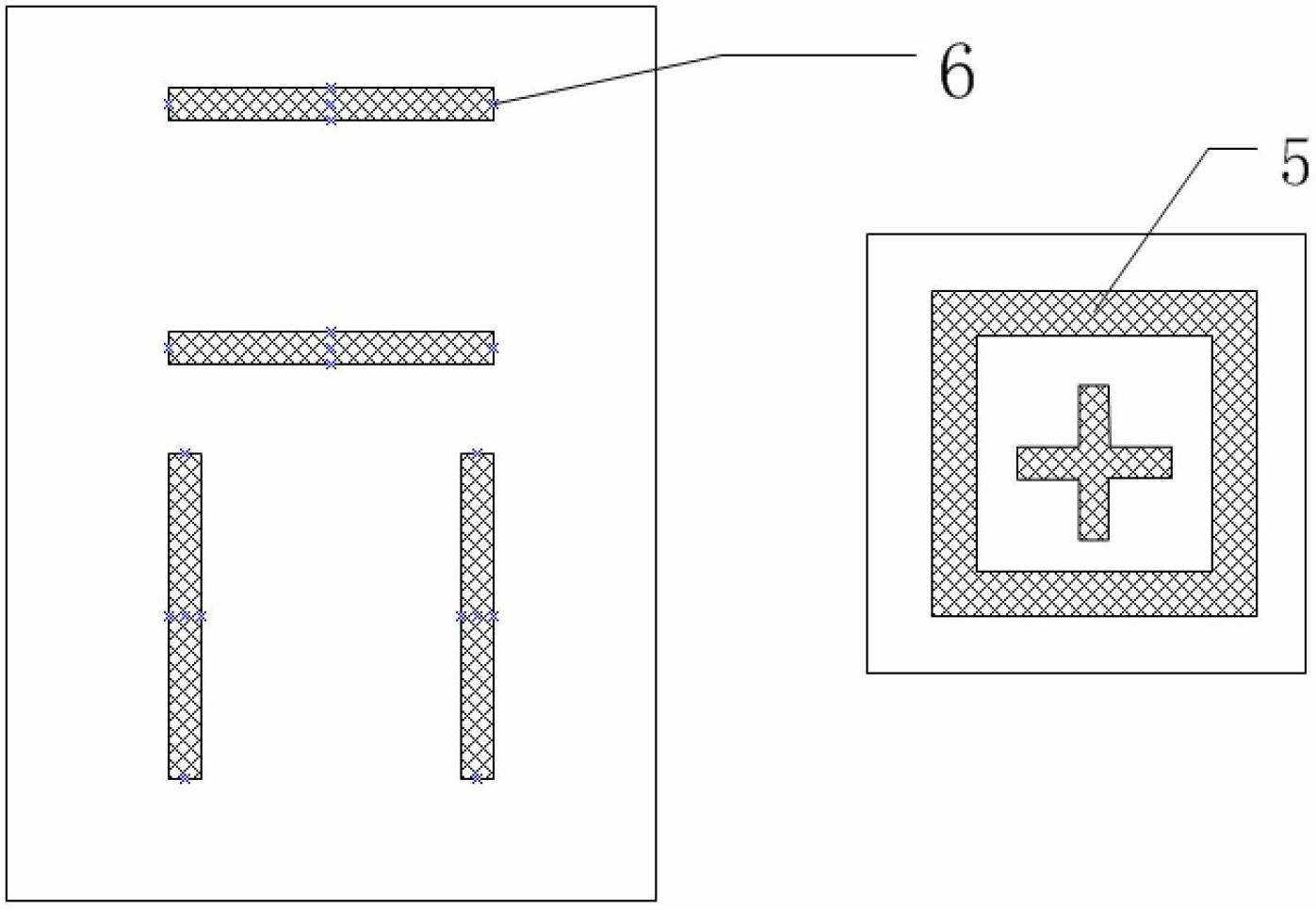

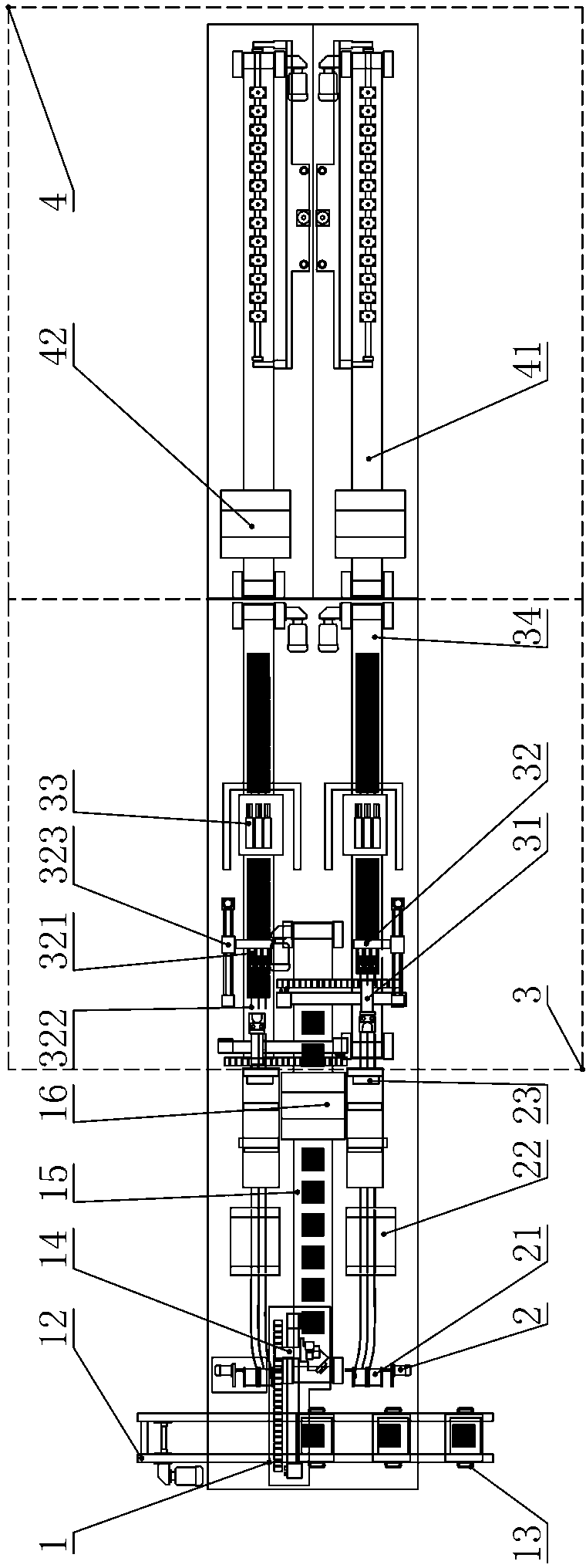

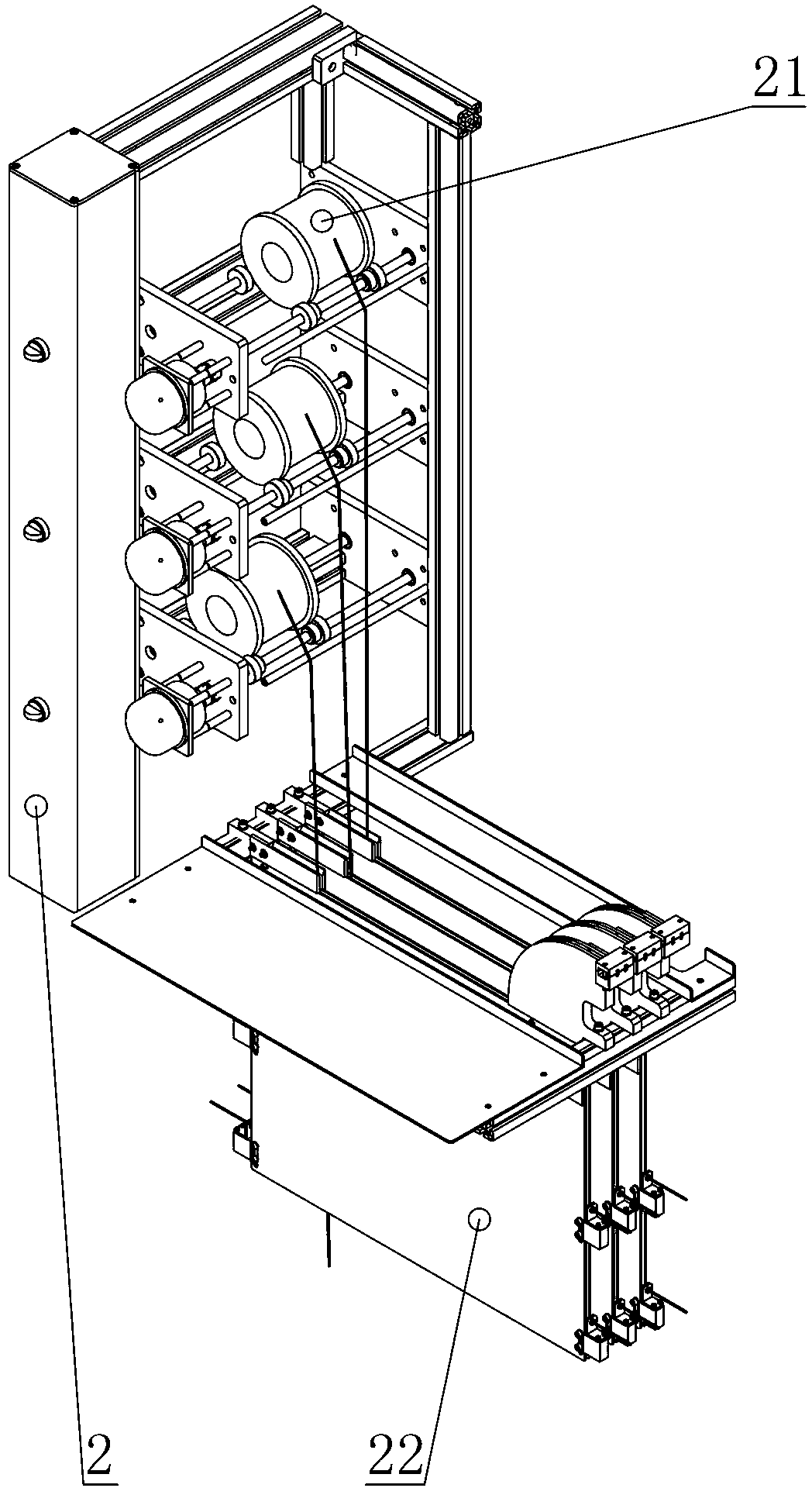

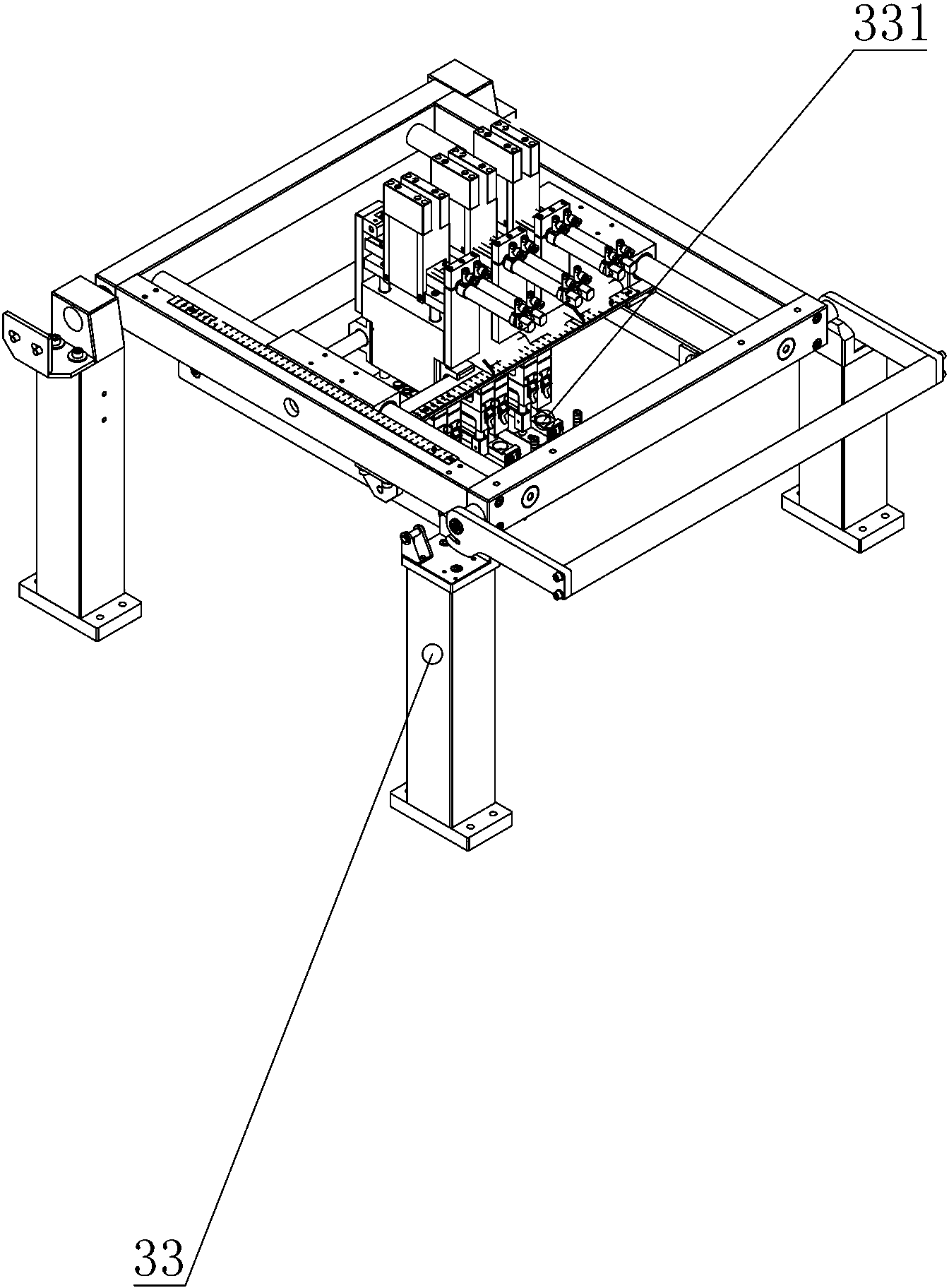

Method for assembling faucet valve core and fully automatic assembly machine

InactiveCN101590595ASmall footprintIncrease productivityAssembly machinesWork holdersEngineeringFully automatic

The invention discloses a method for assembling a faucet valve core and a fully automatic assembly machine. Before the assembly of the valve core, all parts are first sorted by a specially arranged vibration disk, then conveyed to specific positions through conveying pipes, and finally assembled into a whole through the action of a mechanical clamp and the positioning of a worktable. The middle of the fully automatic assembly machine is a working turntable; the periphery of the working turntable is provided with part vibration sorters; and the sorted parts are conveyed to the locking end of the turntable to assemble the core. The fully automatic assembly machine is provided with secondary pressure supplementing and product quality inspecting equipment. The fully automatic assembly machine adopts a circular production turntable to complete the assembly of the valve core, thereby having the advantage of small space occupation; and the working turntable cooperate with mechanical hands at the ends of the part conveying pipes to rotate a certain angle to complete a next assembly step, so the production efficiency is high.

Owner:苏锦波

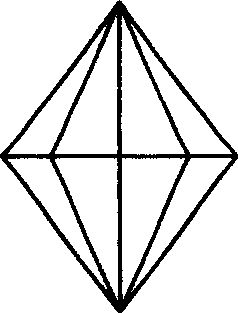

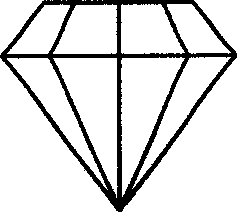

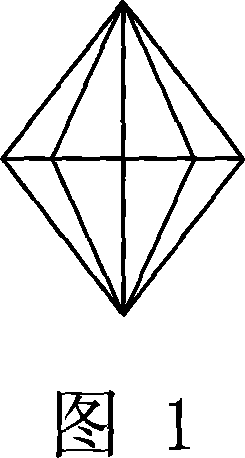

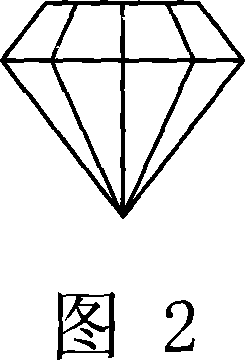

Method for polishing and grinding hydrant drill end and special polishing grinder

ActiveCN101073876AImprove processing efficiencyImprove qualityEdge grinding machinesConvex sideEngineering

The invention is concerned with simulation diamond end face polishing-grinding machining method and the expert polishing-grinding machining. Set stuff and put molding plastics-absorption tray on fixture tray and make the concave face of plastics-absorption tray upside, and the simulation diamond adsorbs on the convexity of the bottom to plastics-absorption tray. Set plastics-absorption tray on the polishing-grinding machining and mill the tine end of simulation diamond on calm millstone. The polishing-grinding machining relates rack with a level millstone at its middle, and there are two level trays. They are centrosymmetric to the axis of millstone on top of millstone and have plastics-absorption tray on them. There is up and down equipment for tray on top of level tray which connecting with two turning axes on two sides of millstone with level rack, and the other end of turning axis has running equipment of turning axis. It has large machining amount of each time, high produce efficiency, good ratio to excellent stuff, long work time, easy operation without waste of material.

Owner:虞雅仙

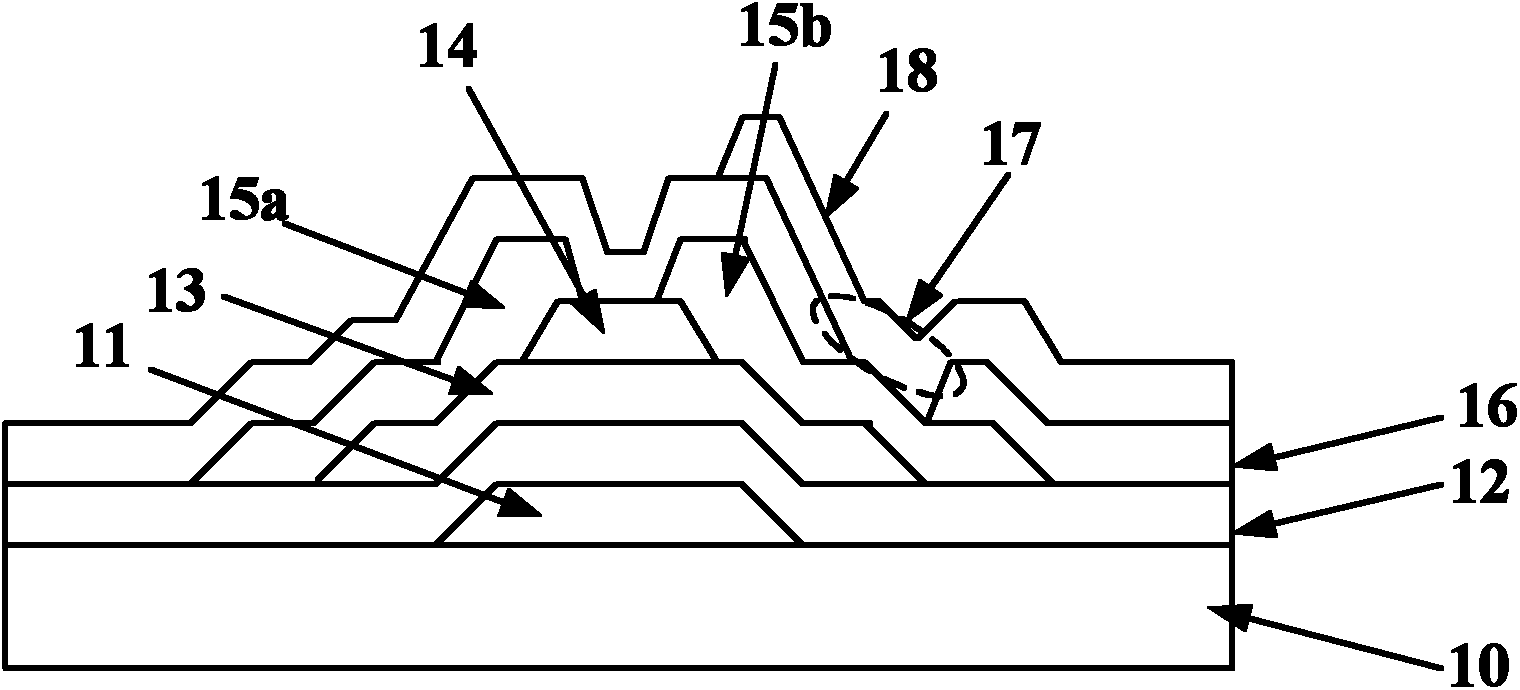

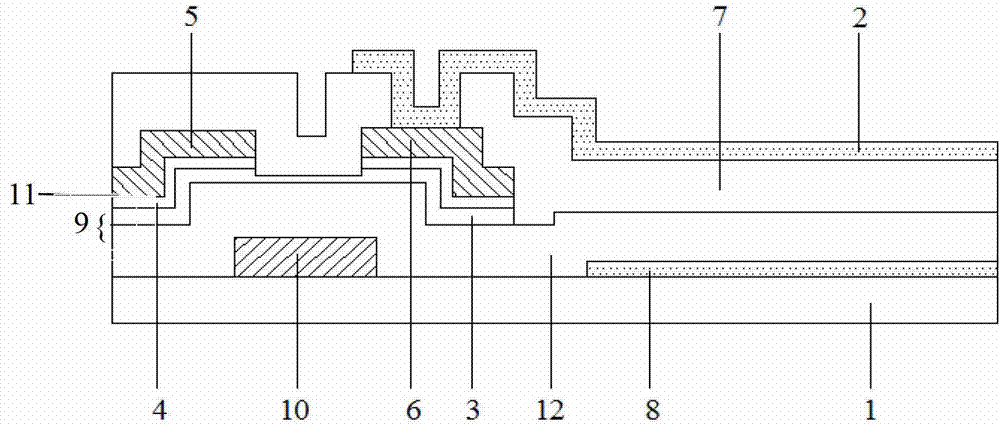

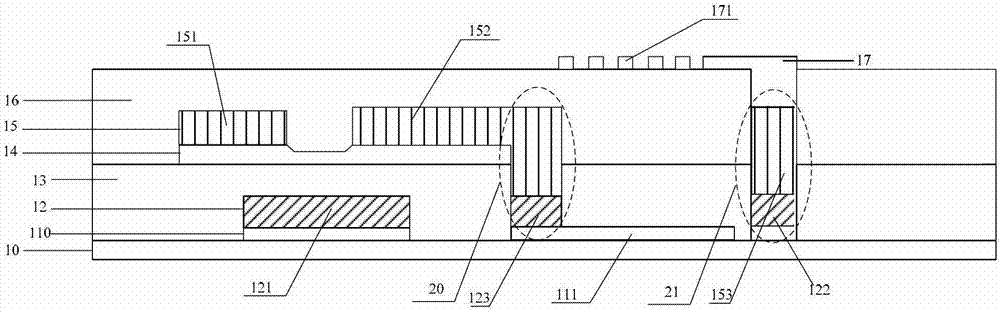

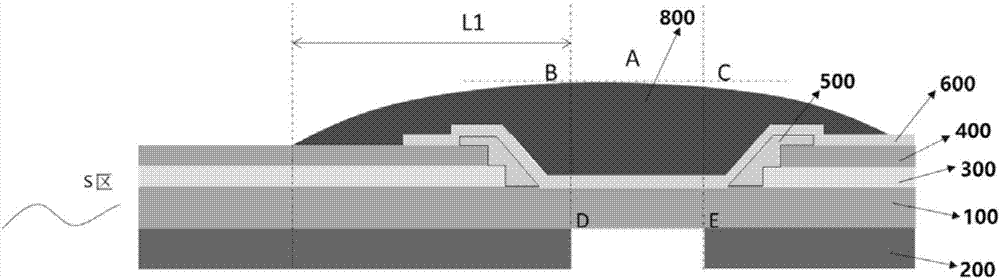

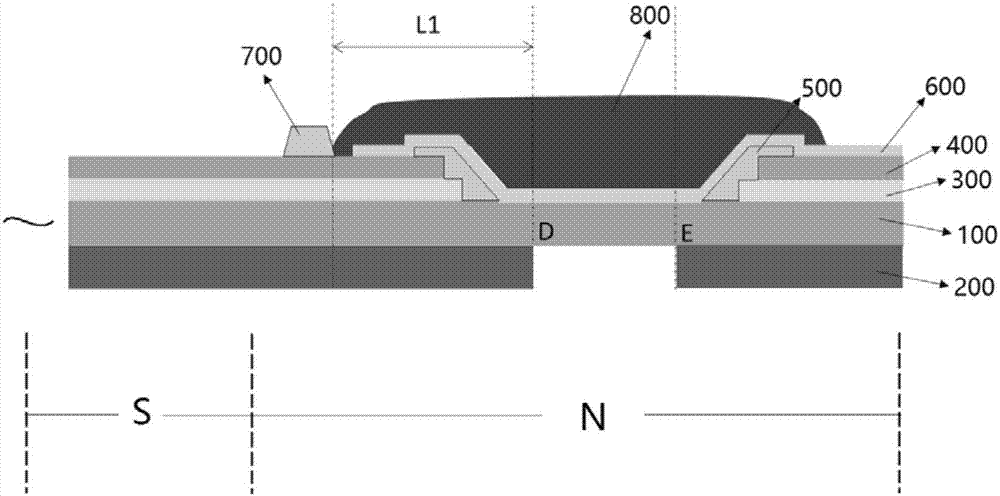

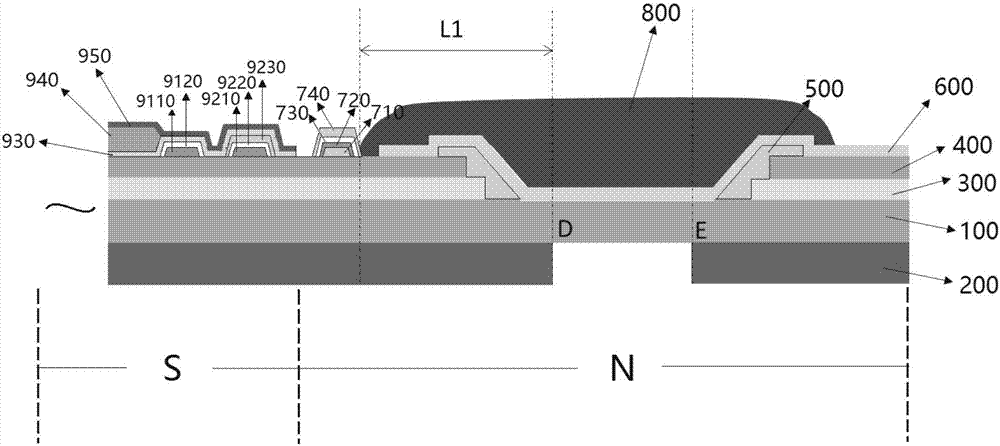

Thin-film transistor, array substrate and manufacturing method and display device thereof

ActiveCN102651401AImprove yield rateAvoid destructionTransistorSolid-state devicesInsulation layerManufacturing technology

The embodiment of the invention provides a thin-film transistor, an array substrate and a manufacturing method and a display device thereof, relating to the technical field of displays, and aiming to avoid damage of an active layer of a semiconductor caused by direct illumination and etching, thereby improving the performance of a thin-film transistor (TFT) device. The thin-film transistor comprises a grid electrode, a grid insulation layer, a semiconductor active layer, an etching blocking layer, a source electrode and a drain electrode; the etching blocking layer covers the semiconductor active layer; and a first through hole and a second through hole are formed on the etching blocking layer; the source electrode of the thin film transistor is in contact with the semiconductor active layer through the first through hole; and the drain electrode of the thin film transistor is in contact with the semiconductor active layer through the second through hole. According to the embodiment of the invention, the manufacturing method is used for manufacturing the thin-film transistor and the array substrate, as well as the display device which utilizes the thin-film transistor and the array substrate.

Owner:BOE TECH GRP CO LTD

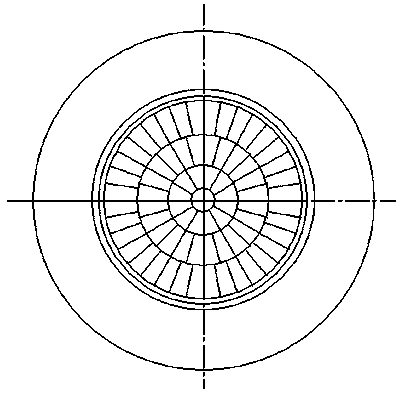

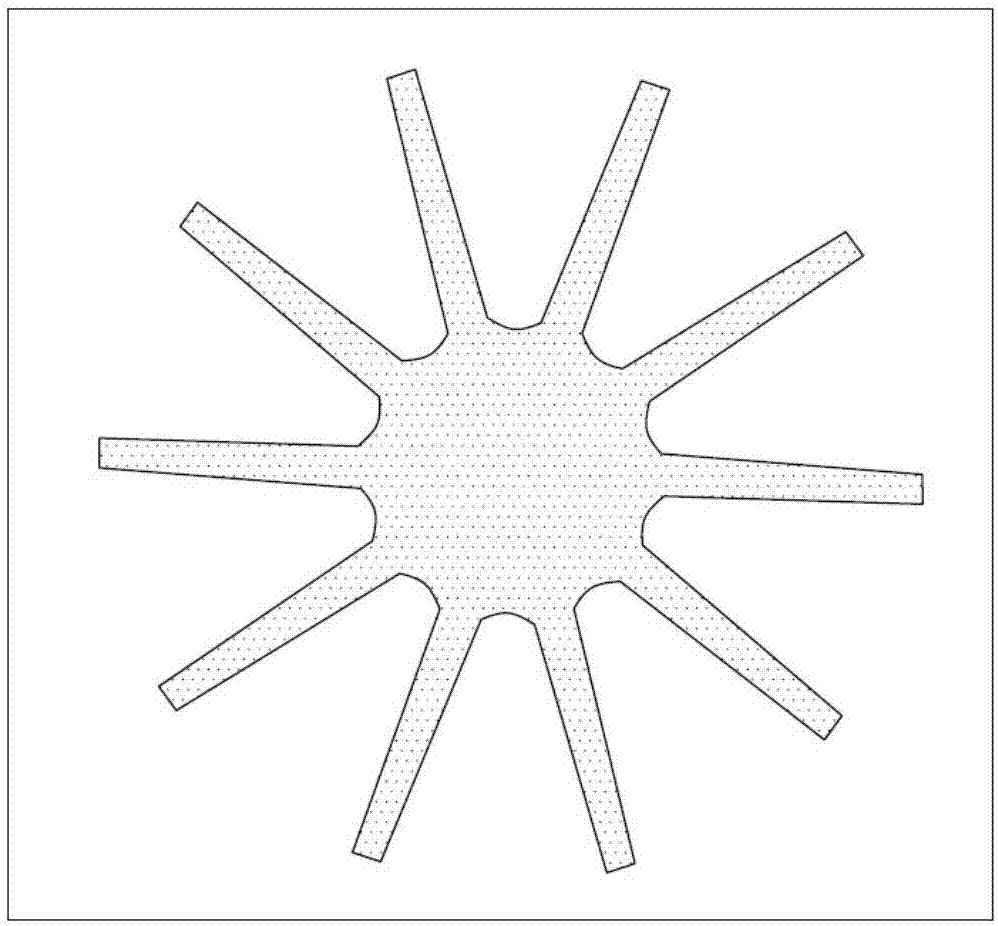

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

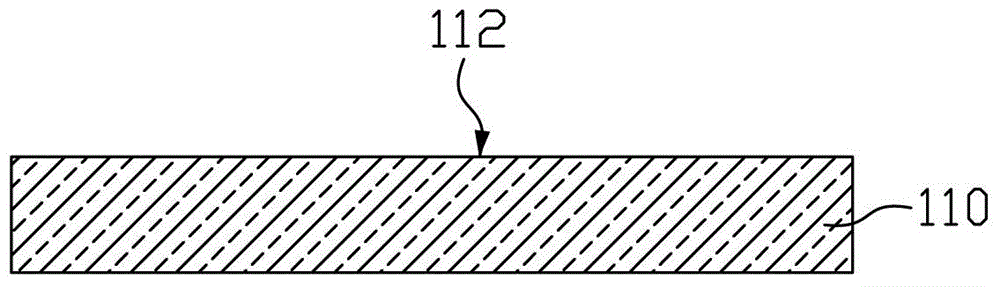

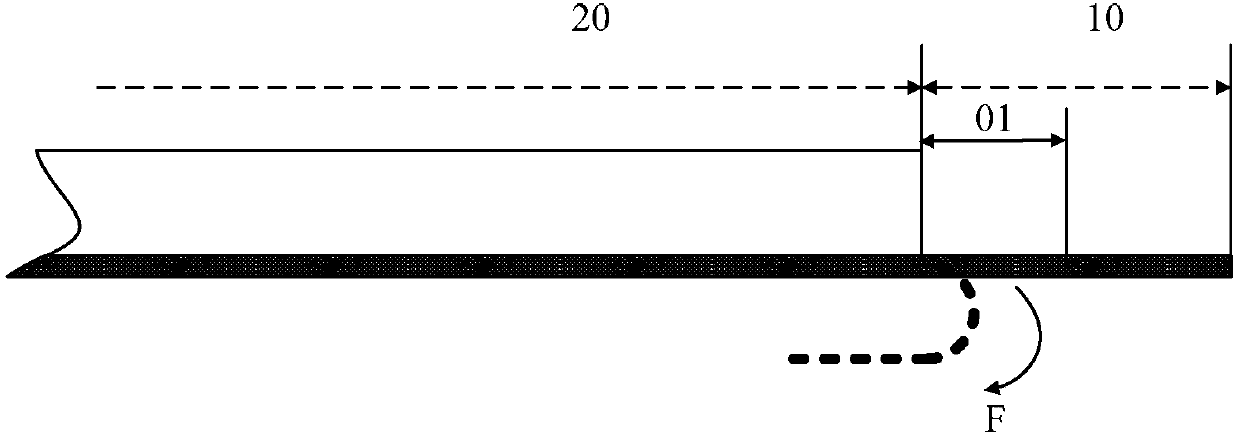

Fabrication method of flexible organic electroluminescence diode display

ActiveCN103337478AOvercoming scrapping challengesOvercome difficult productionSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeDisplay device

The invention provides a fabrication method of a flexible organic electroluminescence diode display. The fabrication method comprises the following steps: providing a rigid substrate; attaching a flexible substrate onto the rigid substrate through an adhesive layer; fabricating an organic light-emitting display layer on the flexible substrate; packaging the organic light-emitting display layer to form a packaging layer; separating the rigid substrate from the flexible substrate; carrying out power on-test to a product obtained after the rigid substrate is stripped; cutting the product to form a FOLED (Flexible Organic Light-Emitting Diode) display unit; defining light-emitting zone on the FOLED display unit and non light-emitting zone located beyond the light-emitting zone; arranging the organic light-emitting display layer aligned with the light-emitting zone; supplying power to at least FOLED display units which are in display state; overlapping substrates of at least two FOLED display units through para-position, so that the non light-emitting zone of one FOLED display unit is overlapped with the light-emitting zone of the other FOLED display unit.

Owner:HISENSE VISUAL TECH CO LTD

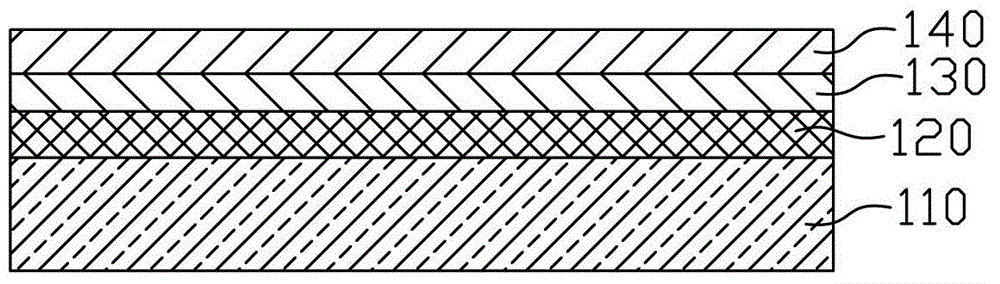

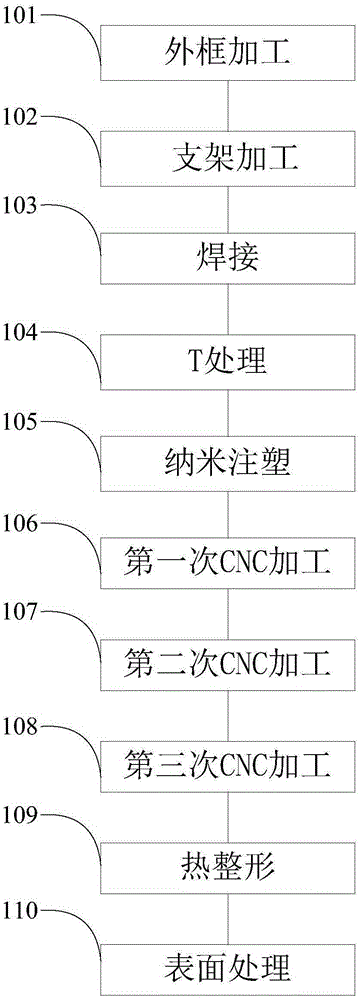

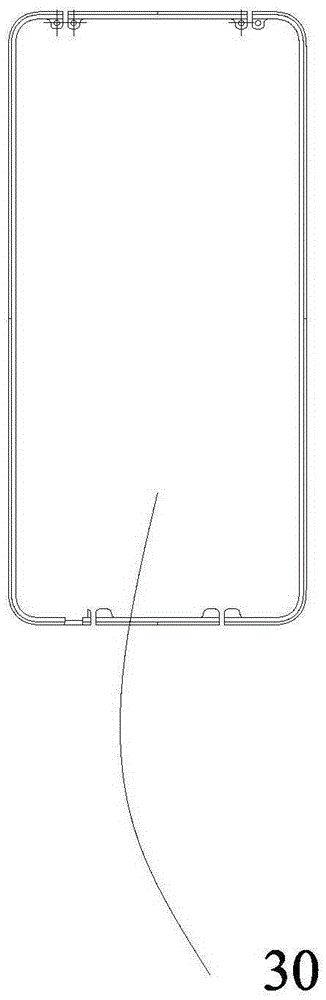

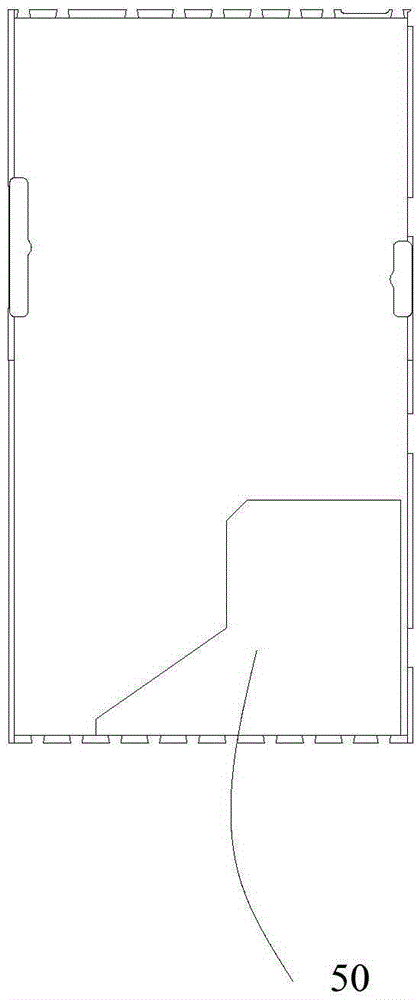

Mobile phone shell and shell manufacturing process thereof

InactiveCN105306632ASolve dense pore defectsImprove yield rateOther manufacturing equipments/toolsTelephone set constructionsMobile phoneTime processing

The invention provides a shell manufacturing process. The shell comprises an aluminum alloy frame and an aluminum alloy bracket combined with the aluminum alloy frame, the shell manufacturing process sequentially comprises frame manufacturing, bracket manufacturing, welding, T processing, nanometer injection molding, first time CNC processing, second time CNC processing, third time CNC processing, thermal shaping and surface processing steps, and the surface of the aluminum alloy shell of the shell has metal luster. By means of the manner, the shell manufacturing process provided by the invention has the advantages of few manufacturing procedures, short period, raw material saving, higher yield and lower manufacturing cost. The invention further provides a mobile phone shell with metal luster and manufactured by the shell manufacturing process.

Owner:SHENZHEN TINNO WIRELESS TECH

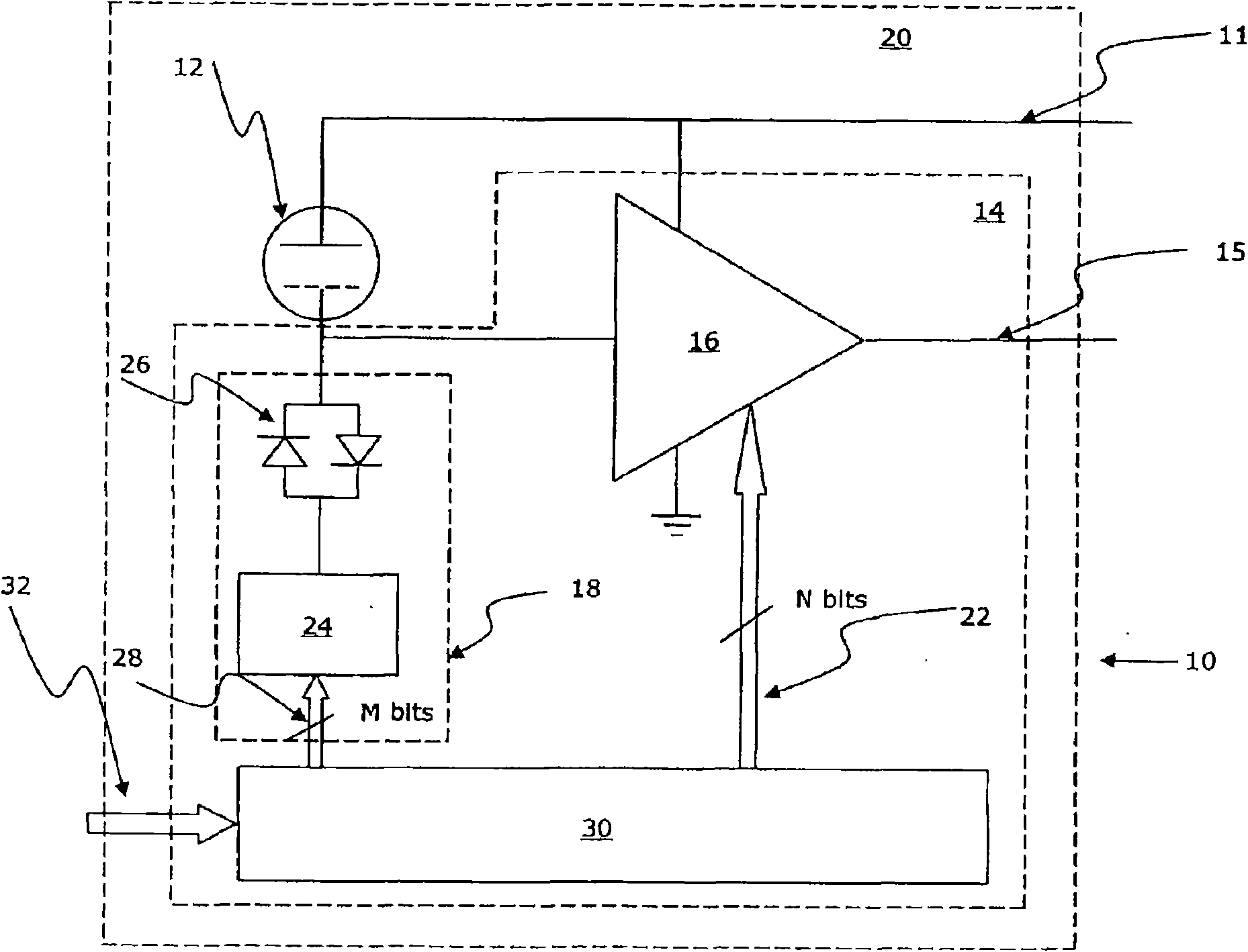

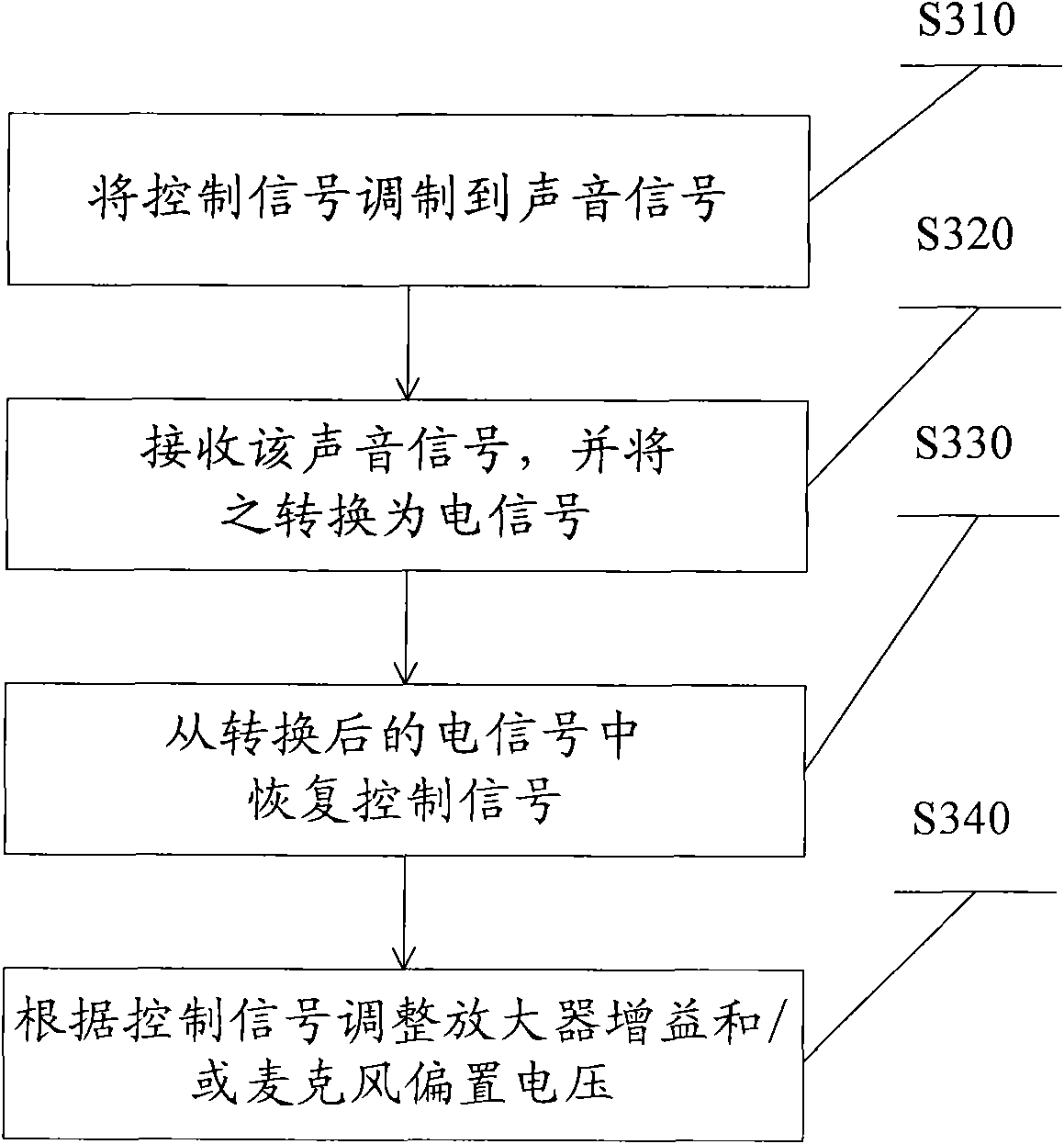

Method and device for calibrating sensitivity of microphone

ActiveCN101621728AFree pin connectionQuick calibrationElectrical apparatusElectricityAudio power amplifier

The invention relates to a method for calibrating sensitivity of a microphone, comprising the following steps: receiving a power supply voltage signal and a sound input signal; judging whether the power supply voltage signal meets a preset condition or not, if so, entering a calibrating mode to continue, and otherwise, stopping; restoring a clock signal from a sound signal; restoring a data signal from the power supply voltage signal; and regulating the amplifier gain and / or microphone bias voltage according to the clock signal and the data signal. A microphone calibrating circuit applying the method comprises a clock restoring module, a data signal restoring module, a gain regulating and controlling and register interface module and a storage, wherein the clock restoring module is used for restoring the clock signal from an output signal of a sound / electricity switching assembly; the data signal restoring module is used for restoring the data signal from the power supply voltage signal, the gain regulating and controlling and register interface module is used for writing amplifier gain regulating data into the storage according to the output of the clock restoring module and the data signal restoring module, and the storage is used for receiving the amplifier gain regulating data from the gain regulating and controlling and register interface module and is used as the grain arrangement when an amplifier normally operates.

Owner:SHANDONG GETTOP ACOUSTIC

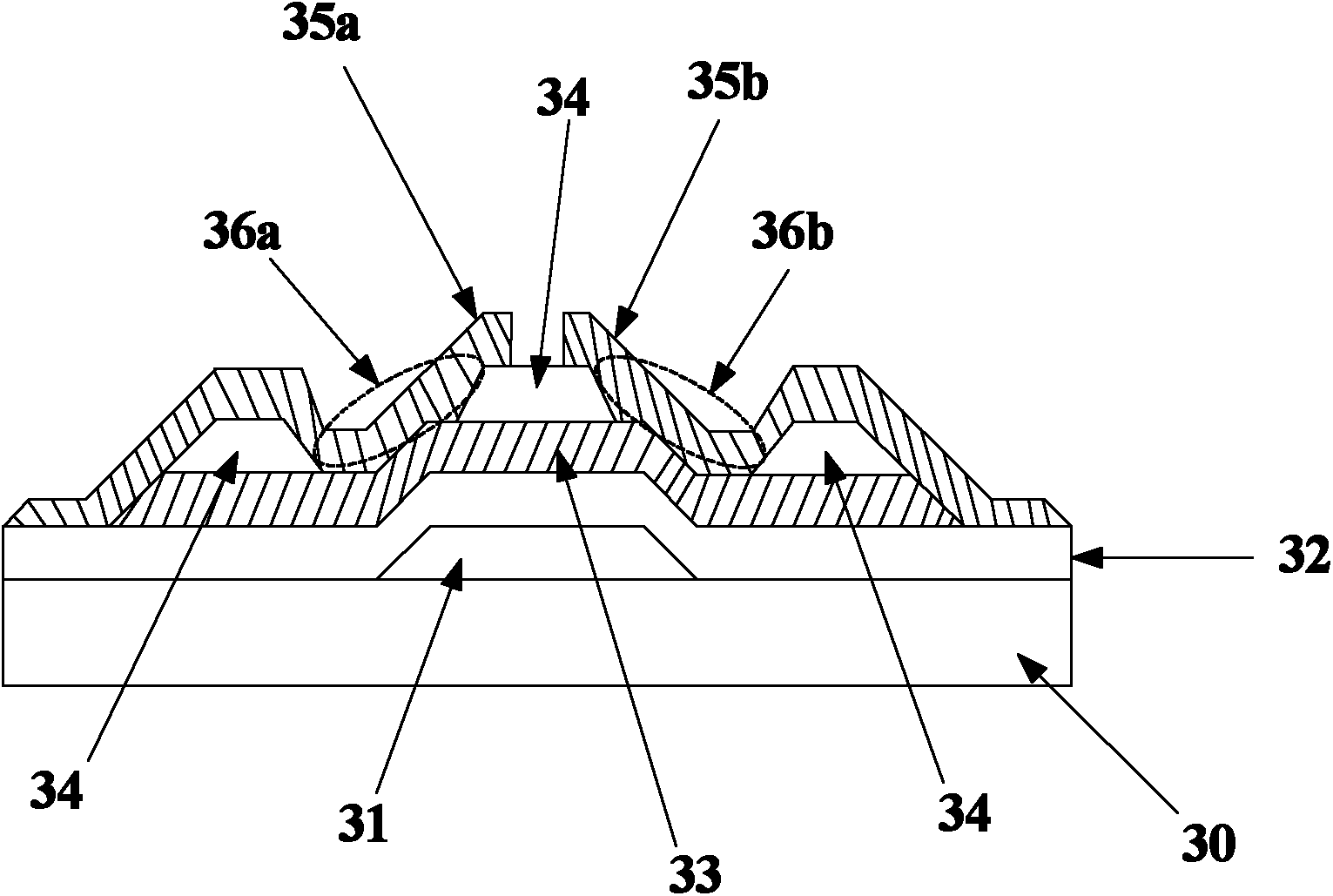

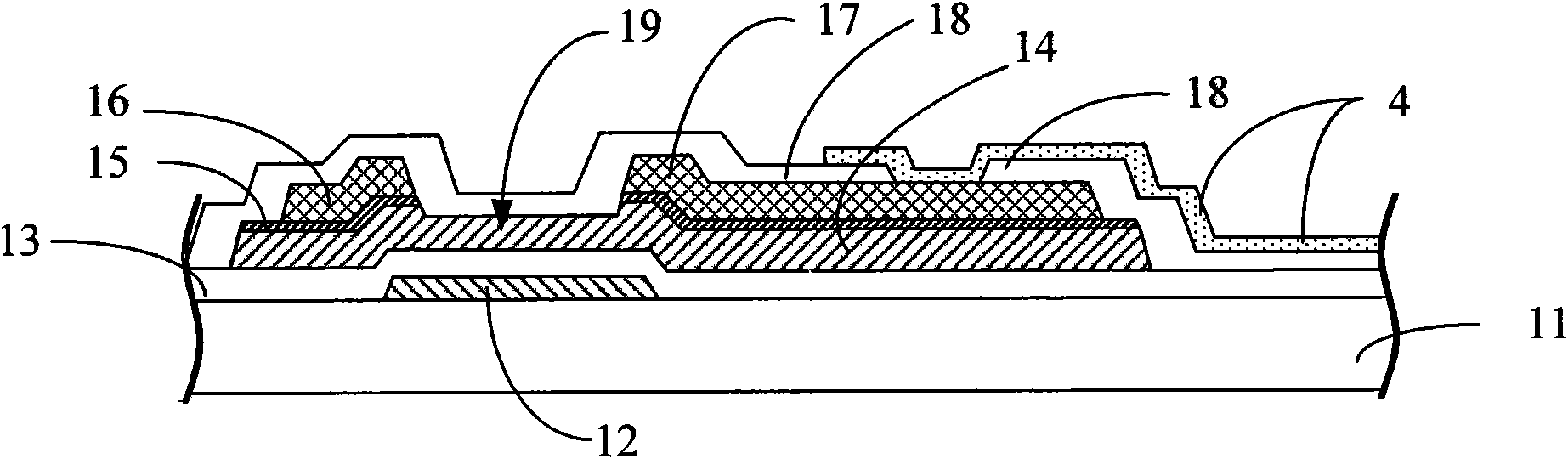

Array substrate, manufacture method of array substrate and display device

ActiveCN103208491AReduce the number of timesReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingComposition processDisplay device

The invention discloses an array substrate, a manufacture method of the array substrate and a display device and relates to the display field. The using times of a picture composition process in the array substrate manufacture process can be decreased, accordingly the manufacture cost if effectively reduced, and the yield is improved. The array substrate comprises a substrate body, a grid electrode, a grid insulating layer, an active layer, a source electrode, a drain electrode and an insulation protecting layer, wherein the grid electrode, the grid insulating layer, the active layer, the source electrode, the drain electrode and the insulation protecting layer are sequentially arranged on the substrate body. A pixel electrode, a public electrode, a first lead wire hole connected with the pixel electrode and the drain electrode and a second lead wire hole connected with the public electrode and a public electrode wire are further arranged on the substrate body, the pixel electrode is arranged on the substrate body, and the grid electrode is directly arranged on a transparent conducting layer which is arranged on the same layer together with the pixel electrode. The pixel electrode is connected with the drain electrode through a first metal connecting layer arranged in the first lead wire hole, and the first metal connecting layer and the grid electrode are arranged on the same layer.

Owner:BOE TECH GRP CO LTD +1

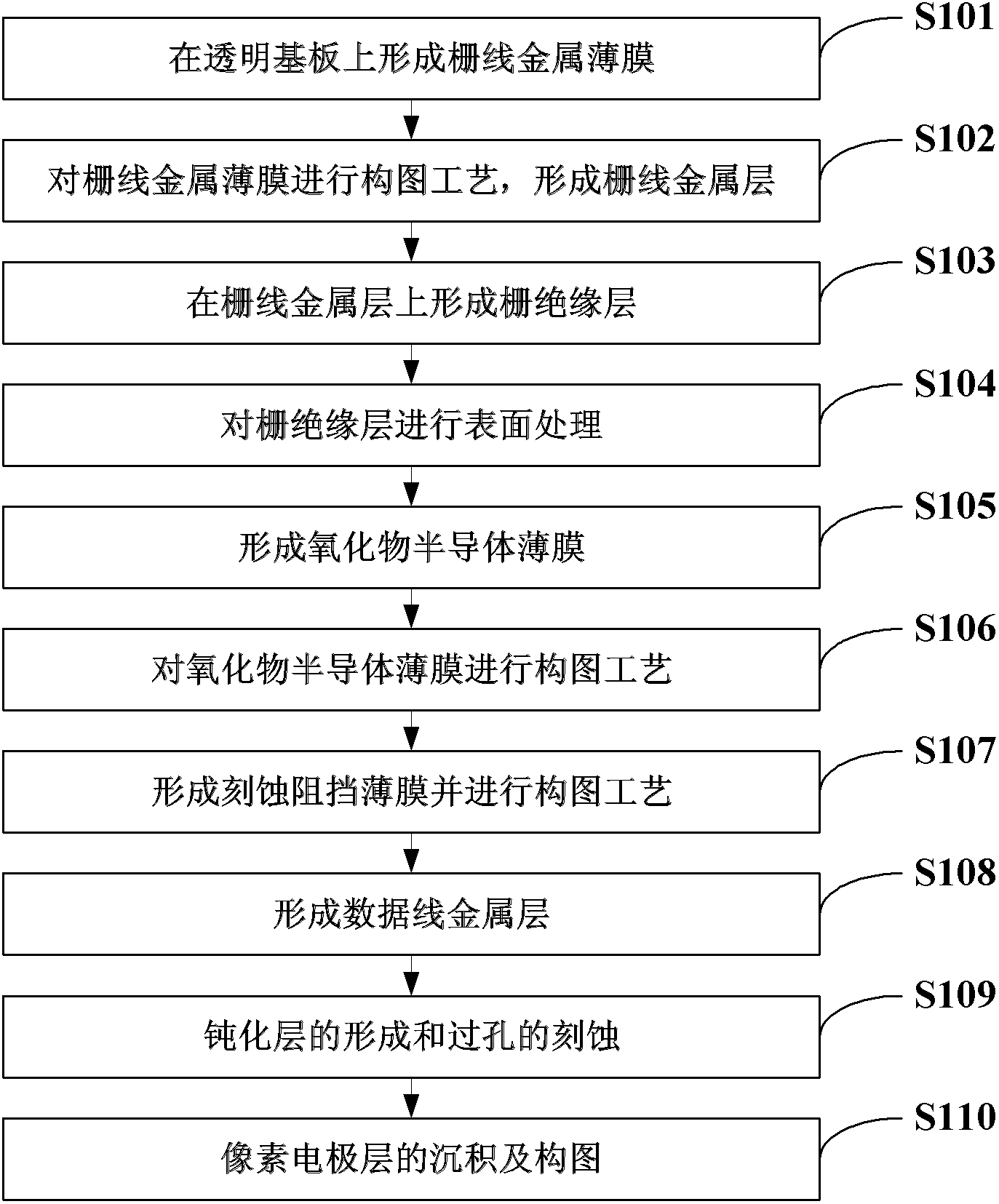

TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array base plate and manufacturing method thereof

ActiveCN101894807ASimplify processing difficultyImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayComposition process

The invention discloses a TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array base plate and a manufacturing method thereof. The manufacturing method comprises the steps of: sequentially depositing a transparent conductive thin film, a source-drain metal thin film and a doped semiconductor thin film on a transparent base plate; forming a figure which comprises a doped semiconductor layer, a source electrode, a drain electrode, a data line and a pixel electrode by a first composition process; depositing the semiconductor thin film; forming a figure which comprises a TFT channel and a semiconductor layer by a second composition process; depositing an insulating thin film and a grid metal thin film; and forming a figure which comprises a grid line and a grid electrode by a third composition process. In the invention, three composition processes are used for manufacturing the TFT-LCD array base plate with a top grid structure. Compared with the traditional three composition processes for manufacturing the array base plate, the manufacturing method of the invention does not need a lift-off peeling process, largely simplifies the process difficulty, and enhances the product yield.

Owner:BOE TECH GRP CO LTD +1

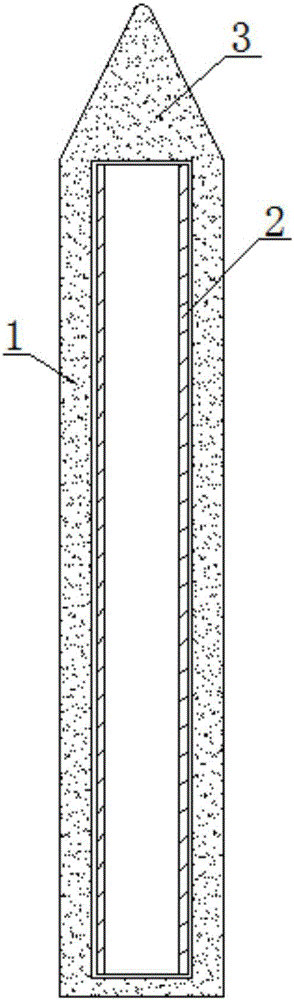

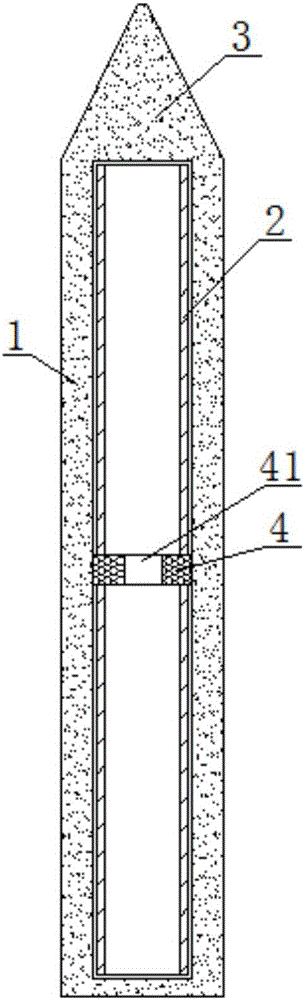

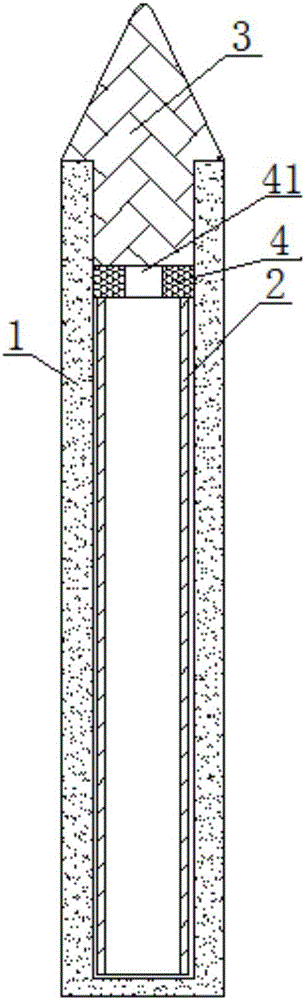

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

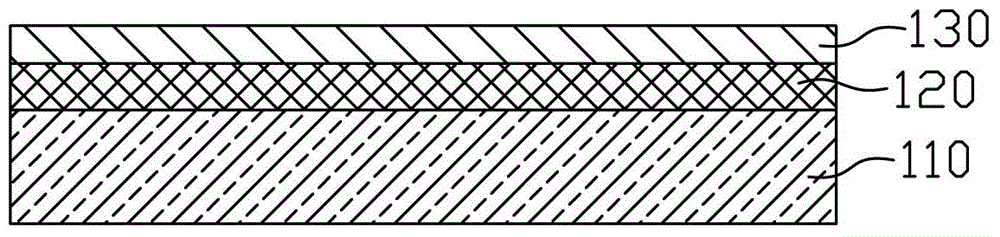

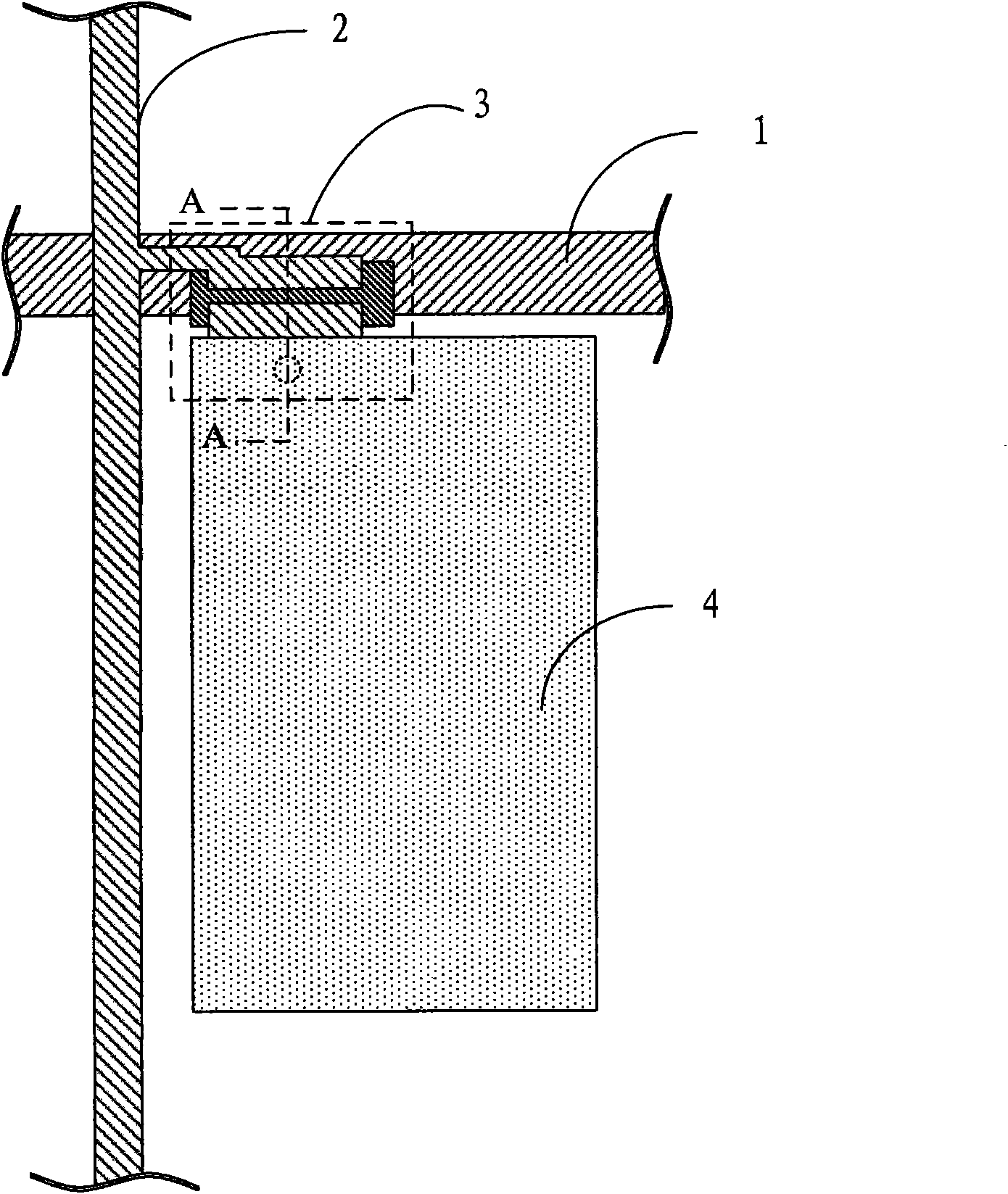

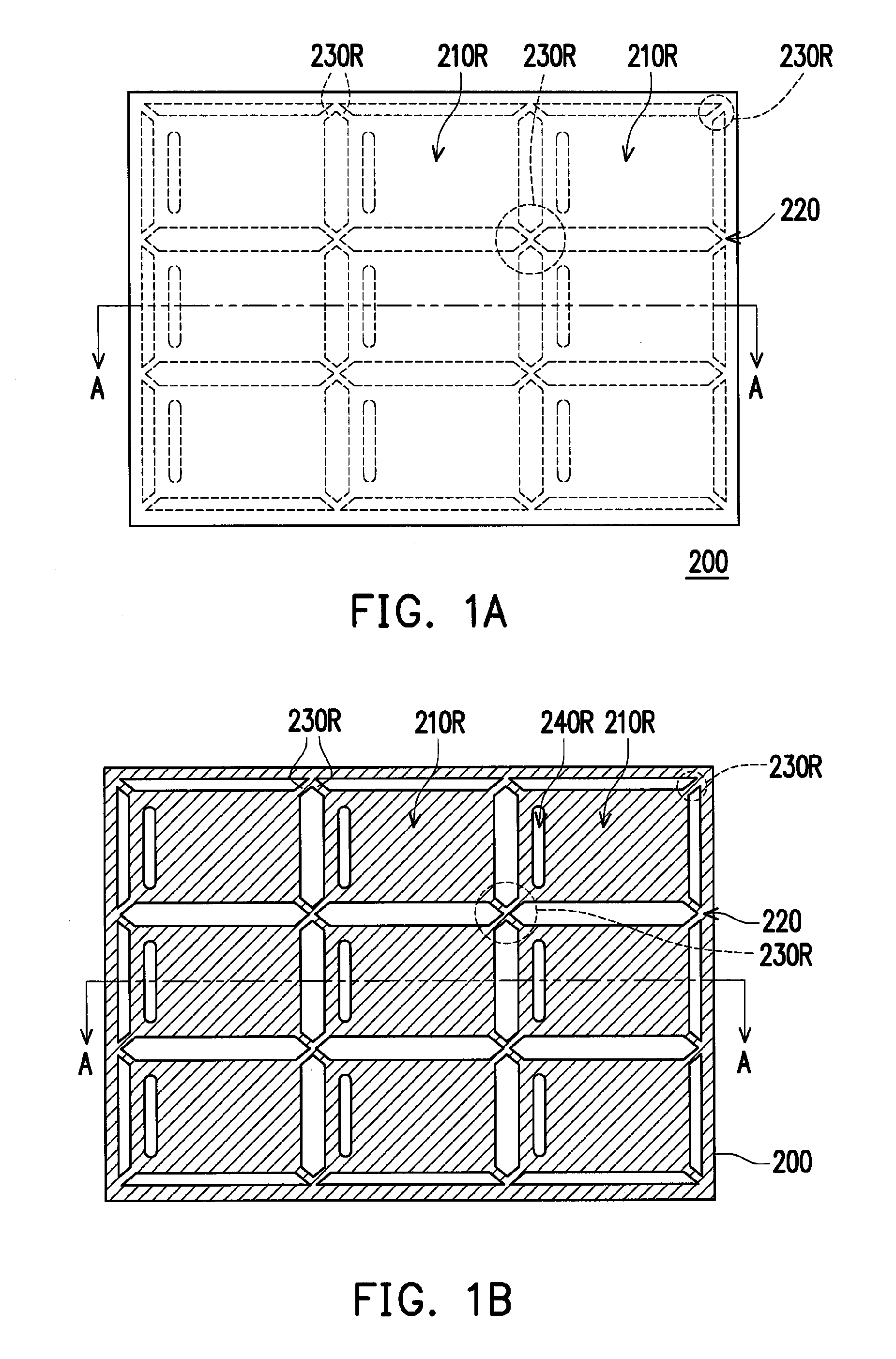

Flexible array substrate as well as manufacturing method and flexible display thereof

ActiveCN107123667ANarrow widthImprove thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a flexible array substrate as well as a manufacturing method and a flexible display thereof. The flexible array substrate comprises a flexible substrate, a display region arranged on one side of the flexible substrate, a non-display region arranged at the periphery of the display region, a protective layer used for covering a source and drain electrode layer of the non-display region and a protective layer block wall arranged on one side, close to the display region, of the non-display region and used for limiting a width of the protective layer. According to the flexible array substrate provided by the invention, the protective layer block wall is arranged on one side, close to the display region, of the non-display region and can limit a glue material from flowing toward a light emitting region when the protective layer of a bending region is manufactured, so that the width of the protective layer can also be limited while the uniformity of the coating thickness of the protective layer is guaranteed, a climbing region can be effectively shortened, and realization of the narrow frame effect is facilitated.

Owner:BOE TECH GRP CO LTD

Flexible array substrate and preparation method thereof, display substrate and display device

ActiveCN107946317AReduce bending stressReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides a flexible array substrate and a preparation method thereof, a display substrate and a display device, and relates the technical field of display. The probability of fracture of the signal lines in the bonding area caused by bonding can be reduced. The flexible array substrate comprises a display area and a non-display area. The non-display area comprises the bonding area adjacent to the display area. The bonding area comprises the signal lines and auxiliary lines which are arranged on the underlying substrate, and the auxiliary lines are arranged on one side back to the underlying substrate of the signal lines. The area of the insulating layer in which the bonding area is overlapped with different signal lines is provided with different concave part groups formed by multiple concave parts which are arranged along the extension direction of different signal lines, and the auxiliary lines cover the concave part groups.

Owner:BOE TECH GRP CO LTD

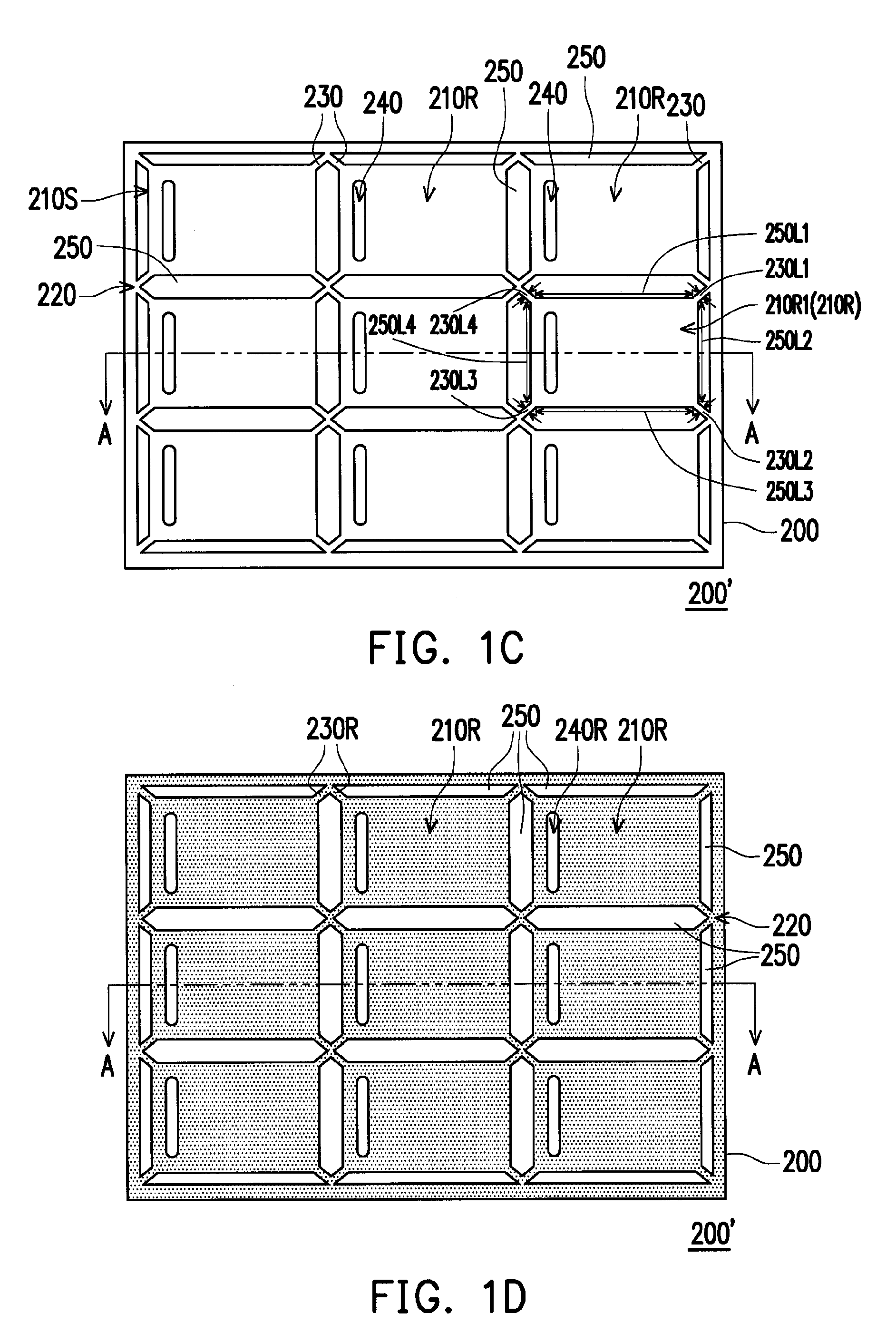

Reinforced glass cell and method for fabricating the same and cover glass having the reinforced glass cell

InactiveUS20130037308A1Increase production rateImprove yield ratePrinted circuit detailsCellulosic plastic layered productsEngineeringCover glass

A method of fabricating a reinforced glass cell including the following steps is provided. First, a mother glass having a plurality of glass cell predetermined regions is provided. A portion of the mother glass disposed on the outer edge of each glass cell predetermined region is removed, so as to form at least one through trench and at least one linking bridge. Herein, the through trench exposes the periphery section of each glass cell predetermined region, and the glass cell predetermined regions are formed as an entire patterned mother glass by the linking bridges. A reinforcing process is performed to the entire patterned mother glass, so that the exposed periphery sections of the glass cell predetermined regions are formed into reinforced sections. The linking bridges are removed so as to separate the glass cell predetermined regions having the reinforced sections to form a plurality of reinforced glass cells.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

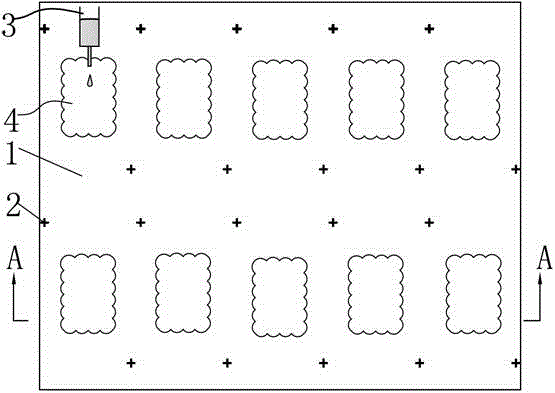

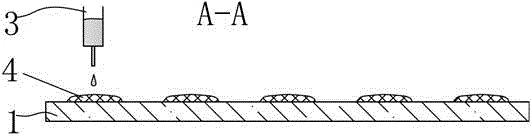

Method for manufacturing capacitive touch screen

InactiveCN102722301AGuaranteed StrengthExtended service lifeInput/output processes for data processingNumerical controlIndium tin oxide

The invention relates to a capacitive touch screen used on electronic equipment, in particular to a method for manufacturing the capacitive touch screen. The method mainly comprises the following steps of: cutting large glass into small pieces; performing computer numerical control (CNC) machining; making charged coupled device (CCD) positioning marks on the upper surface of a large transparent substrate in an array mode according to the size of product glass, and dispensing an ultraviolet (UV) adhesive in the position range of each CCD positioning mark; performing chemical strengthening to form the product glass; accurately superposing the product glass to the CCD positioning marks of the large transparent substrate, adhering and curing; plating an indium tin oxide (ITO) film on each piece of product glass, and photoetching; plating a metal film, and photoetching; attaching to a flexible printed circuit board (FPC); and separating the product glass from the large transparent substrate. By the method, a module which consists of two glass substrate products in the prior art is formed by one piece of product glass, so that the defects in the prior art can be overcome, machining efficiency is effectively improved, yield is high, and production cost is reduced.

Owner:ZHEJIANG XINGXING TECH CO LTD

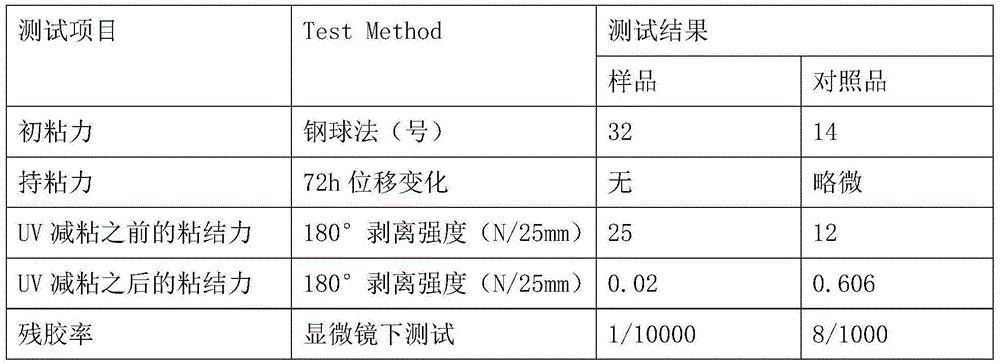

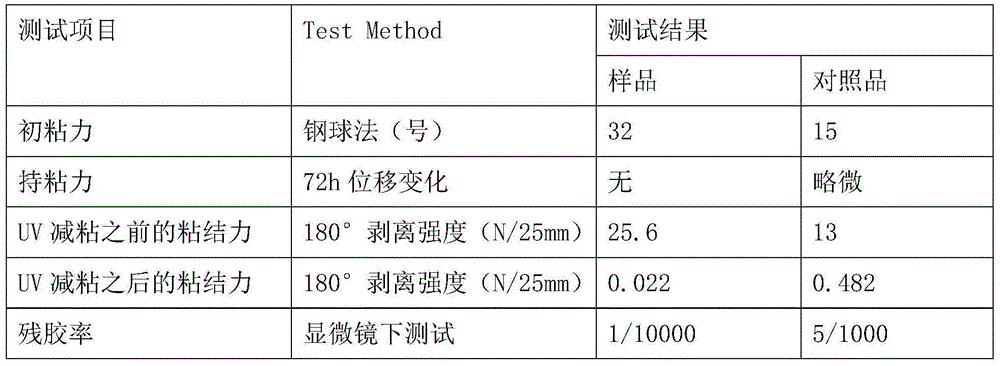

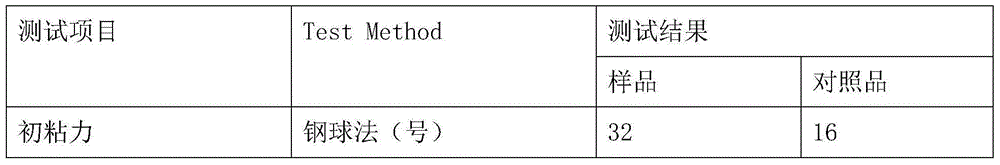

Bi-component cured UV viscosity-decreasing adhesive

ActiveCN105086730AImprove initial tack performanceImprove yield ratePolyurea/polyurethane coatingsAdhesiveDiluent

The invention relates to a bi-component cured UV viscosity-decreasing adhesive. The bi-component cured UV viscosity-decreasing adhesive comprises two components of the component A and the component B. The component A is composed of, by weight, 35-60 parts of cured resin, 22-45 parts of photosensitive monomers, 2-10 parts of photopolymerization initiators, 2-15 parts of diluents and 2-10 parts of auxiliaries, wherein the cured resin is resin containing hydroxyl or resin containing carboxyl; the component B is one of a curing agent containing NCO and a curing agent containing sulfydryl or a mixture of the curing agent containing NCO and the curing agent containing the sulfydryl, the curing agent containing NCO is isocyanate, the content of NCO of the isocyanate ranges from 12.5% to 23.5%, and the molecular weight ranges from 200 to 600; the curing agent containing the sulfydryl is polymercaptans, wherein the content of the sulfydryl ranges from 5% to 15%; the weight of the component B is 5%-20% of that of the component A. The bi-component cured UV viscosity-decreasing adhesive has the advantages that the initial viscous force is strong after curing forming is conducted at room temperature, after UV-irradiation is conducted for decreasing viscosity, the stripping effect is good, and adhesive residues do not exist.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

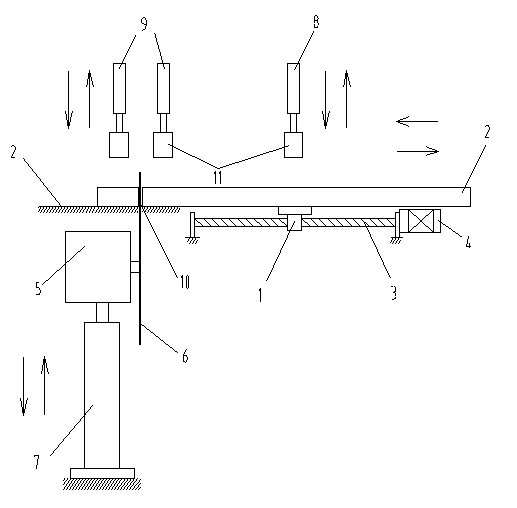

Full-automatic corner connector cutting device

ActiveCN102554343AReduce coefficient of frictionReduce noiseMetal sawing devicesBall screwEngineering

The invention relates to a full-automatic corner connector cutting device, comprising a feeding work table and a cutting work table, wherein the feeding work table moves through a ball screw, and the ball screw is connected with a servo motor; a saw blade motor is arranged below the cutting work table, a saw blade is arranged at the output end of the saw blade motor, and the saw blade motor is arranged on a cutting propulsion cylinder; and a feed pressing cylinder is arranged above the feed work table, and a sawing and cutting compressing cylinder is arranged above the cutting work table. The full-automatic corner connector cutting device has simple structure, high precision and stable operation.

Owner:TAICANG WEGOMA MACHINERY

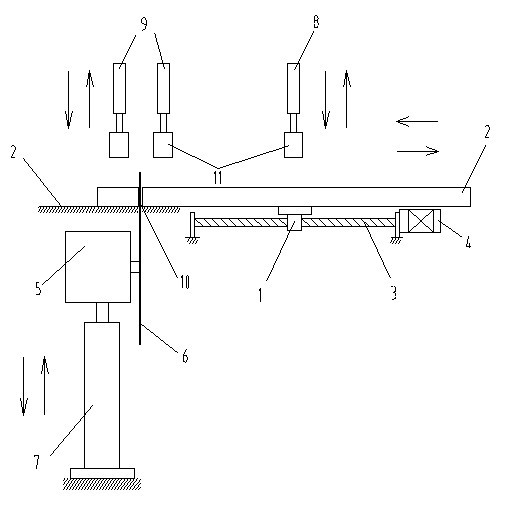

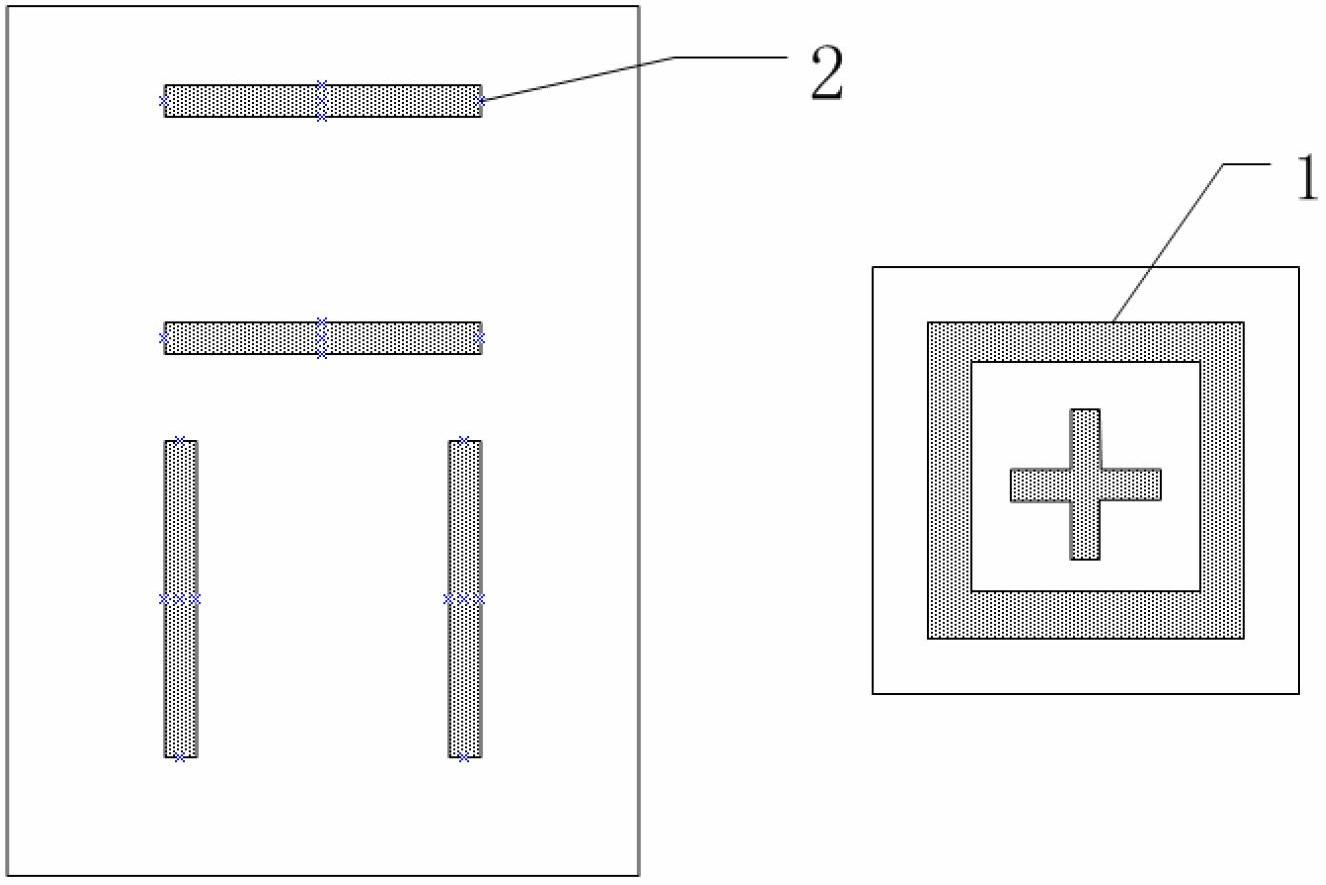

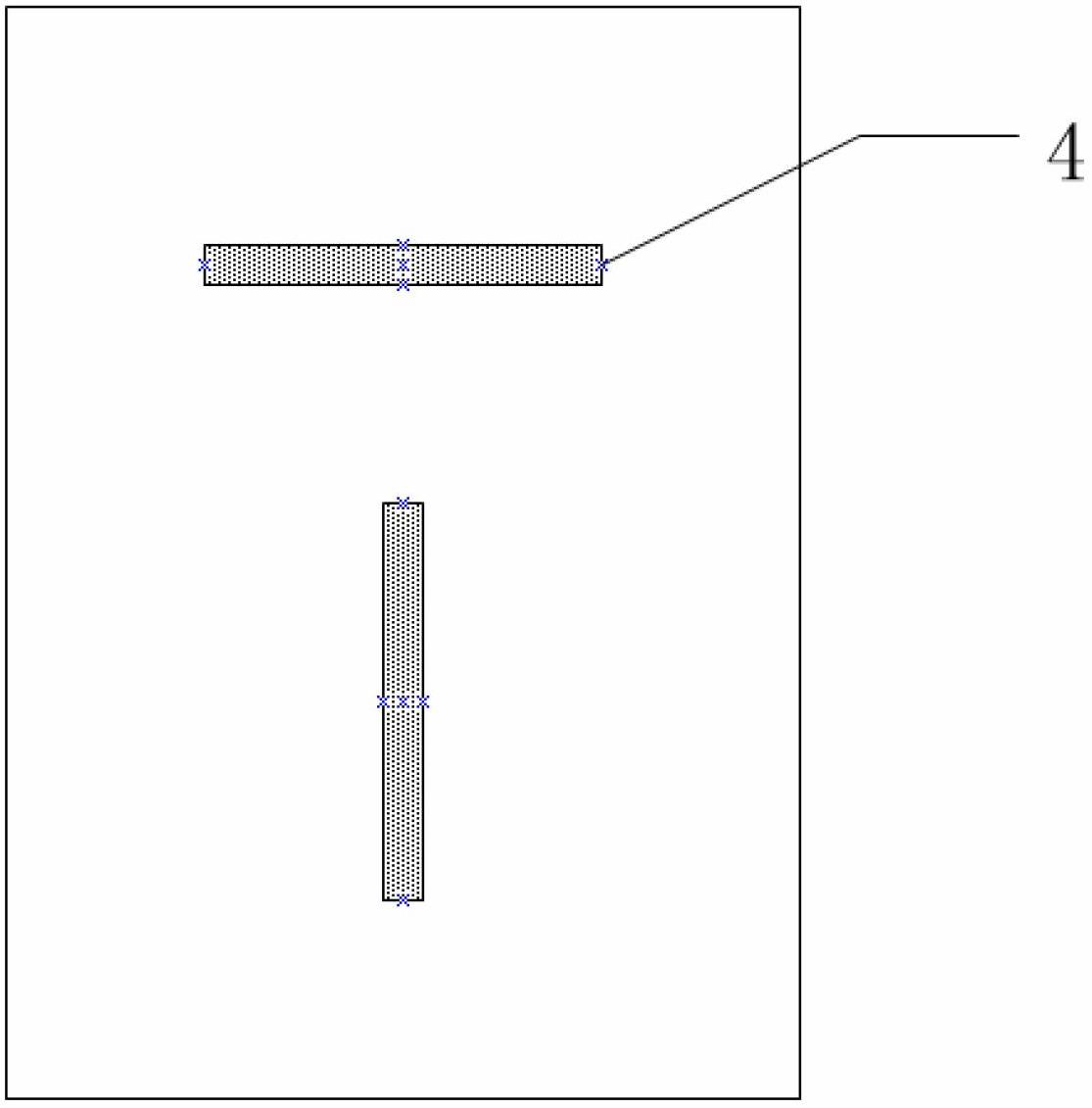

Counterpoint mark and method for using same to manufacture workpieces in exposure process

InactiveCN102692831AGuaranteed accuracyUnable to solve the problemPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer science

The invention provides a counterpoint mark, which comprises N counterpoint mark bodies. The N counterpoint mark bodies are respectively arranged on N mask plates, a first counterpoint mark body comprises a first secondary mark and a second secondary mark, and the first secondary mark and the second secondary mark are arranged on a first mask plate and are centrosymmetric about a point on the first mask plate; except for the counterpoint mark body on the first mask plate, the shapes of the counterpoint mark bodies on other mask plates are the same or similar, the ith counterpoint mark body on the ith mask plate comprises a fifth secondary mark and a sixth secondary mark, both the fifth secondary mark and the sixth secondary mark are strip-shaped and are perpendicularly crossed to form a cross, and the width of the fifth secondary mark and the width of the sixth secondary mark are proper so that the fifth secondary mark and the sixth secondary mark can penetrate through a gap between the first secondary mark and the second secondary mark and are not overlapped with the first secondary mark and the second secondary mark. The counterpoint mark can effectively solve the problem that in an exposure process in the prior art, an exposure machine cannot realize counterpoint due to loss of counterpoint graphs or counterpoint marks.

Owner:BOE TECH GRP CO LTD

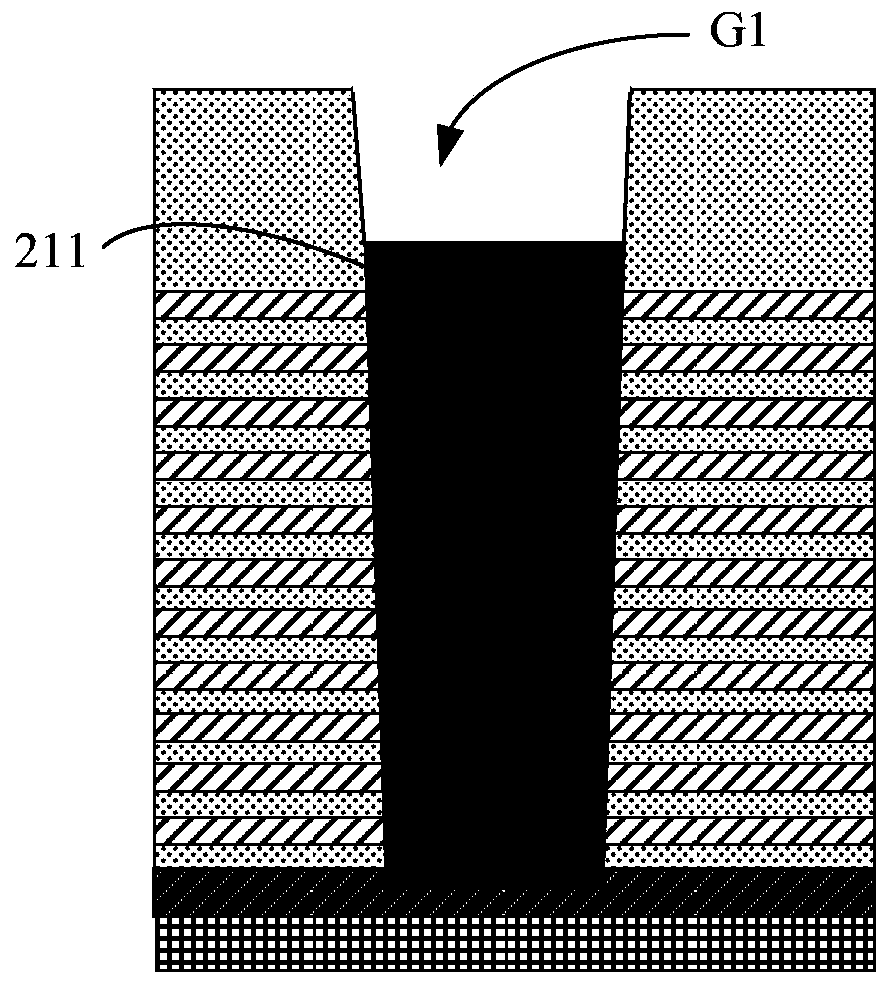

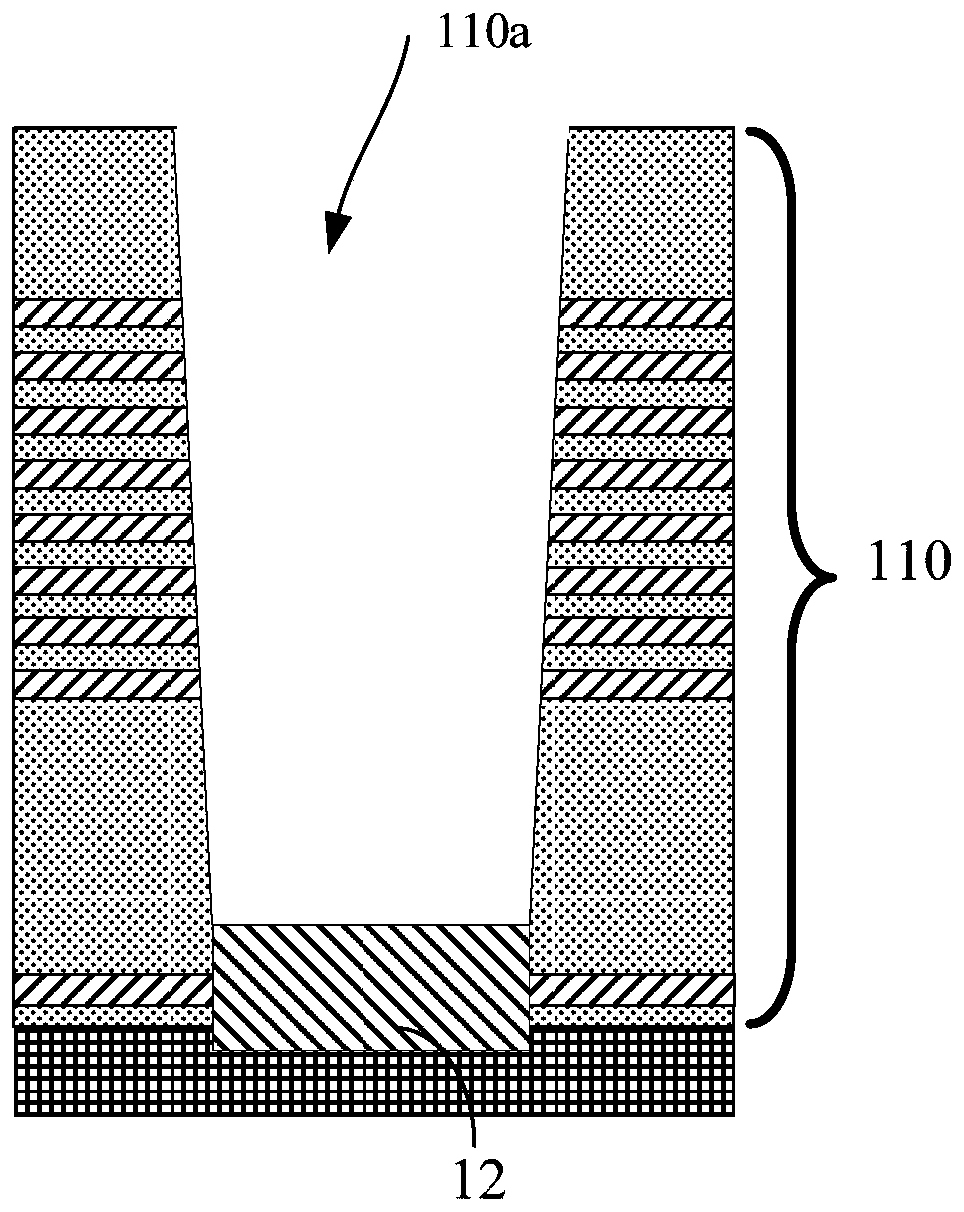

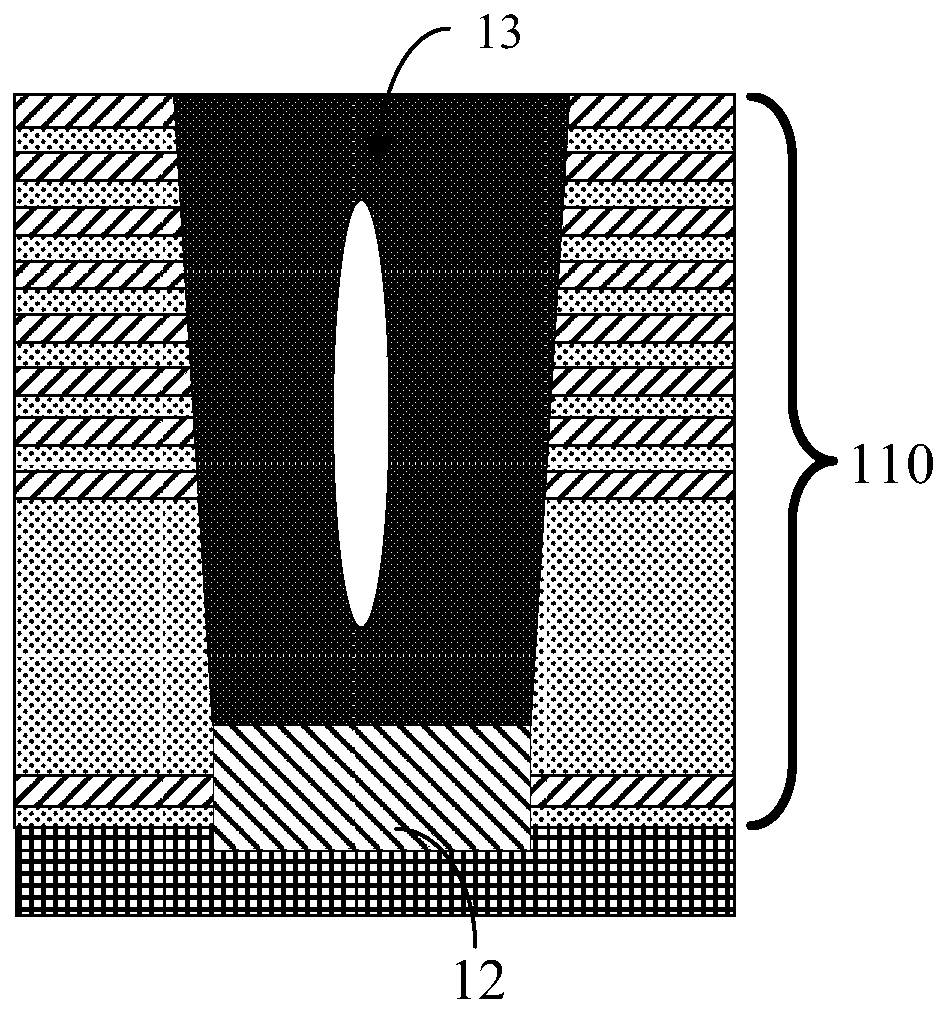

Three-dimensional memory device and preparation method thereof

ActiveCN109712977AAvoid destructionReduce processing costsSolid-state devicesSemiconductor devicesEngineeringPolycrystalline silicon

The invention provides a preparation method of a three-dimensional memory device. The method includes the following steps: sequentially forming an etching stop layer, a first stack, and first channelholes exposing the etching stop layer on a first substrate; forming a first polysilicon plug on a first sacrificial material layer filled in each of the first channel holes, and disposing a carrier wafer thereon; removing the first substrate, and forming a second stack and second channel holes on the other side of the etching stop layer to expose the etching stop layer; removing the etching stop layer between each of the first channel holes and each of the second channel holes, and removing the first sacrificial material layer; covering sidewalls of the first channel holes and the second channel holes with protective layers, and etching parts of the first stack and the second stack exceeding the remaining etching stop layer along radial directions of the channel holes, and removing the protective layers to form a through channel hole; and filling the through channel hole form a single channel. The invention also provides the three-dimensional memory device.

Owner:YANGTZE MEMORY TECH CO LTD

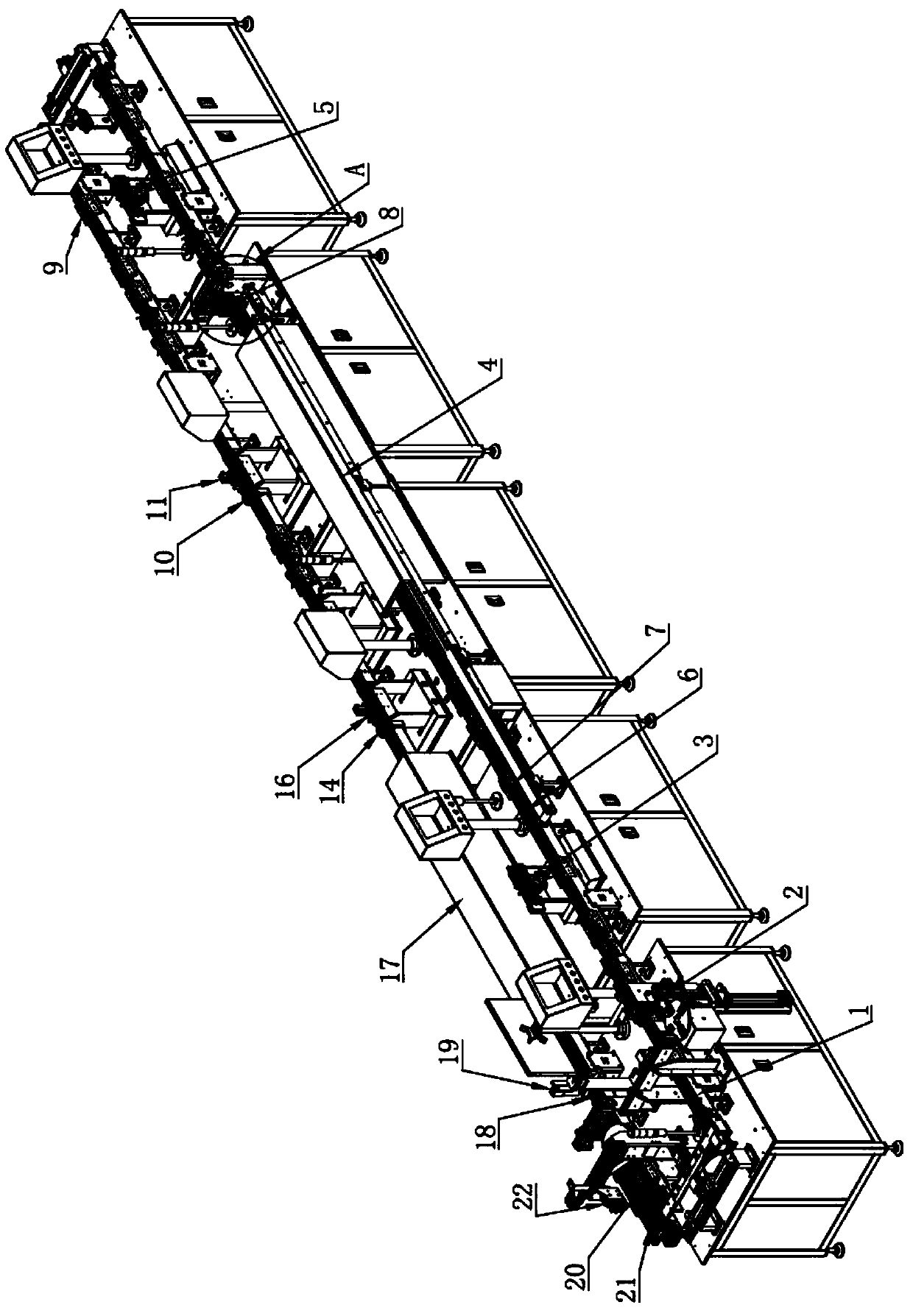

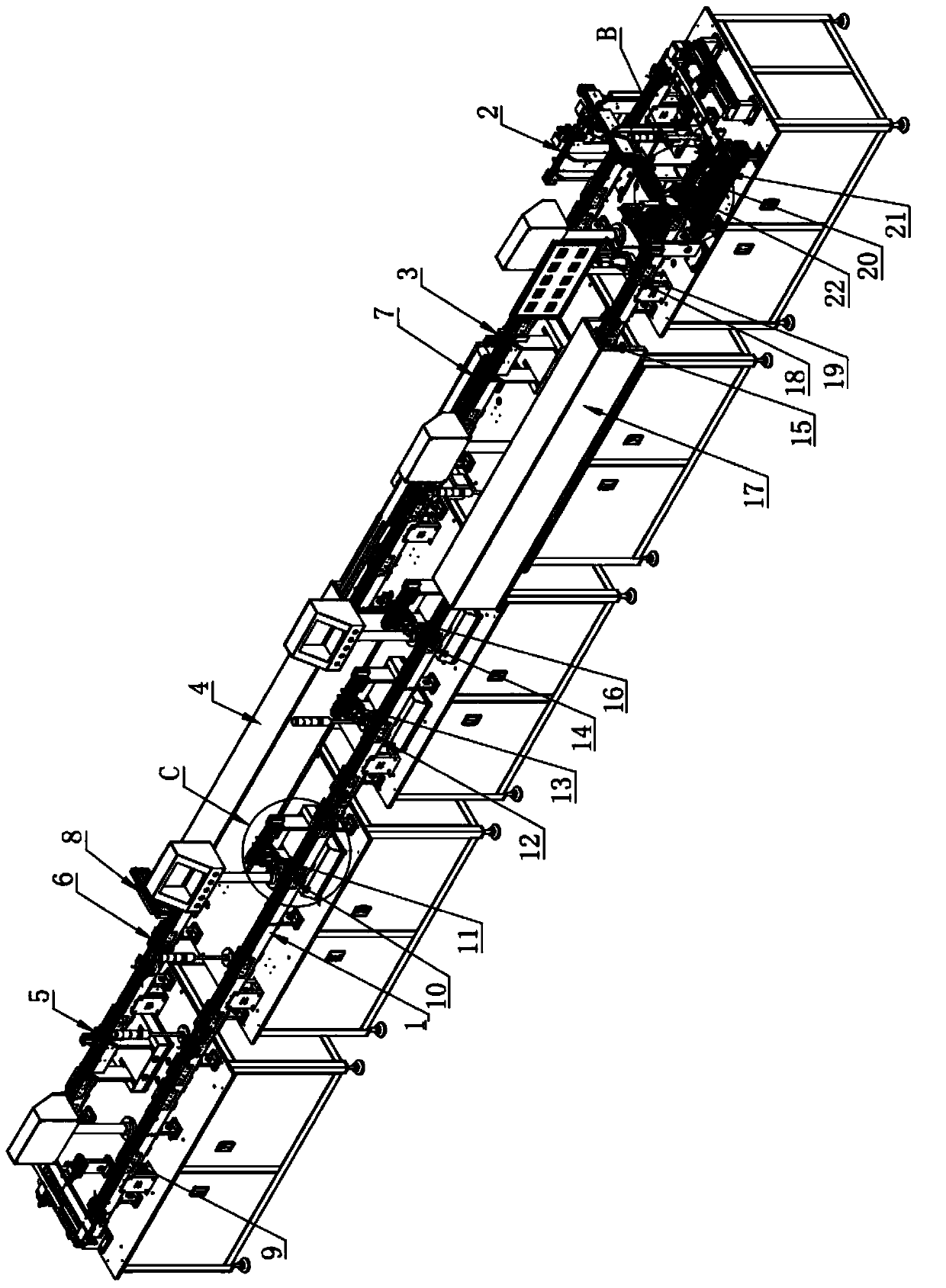

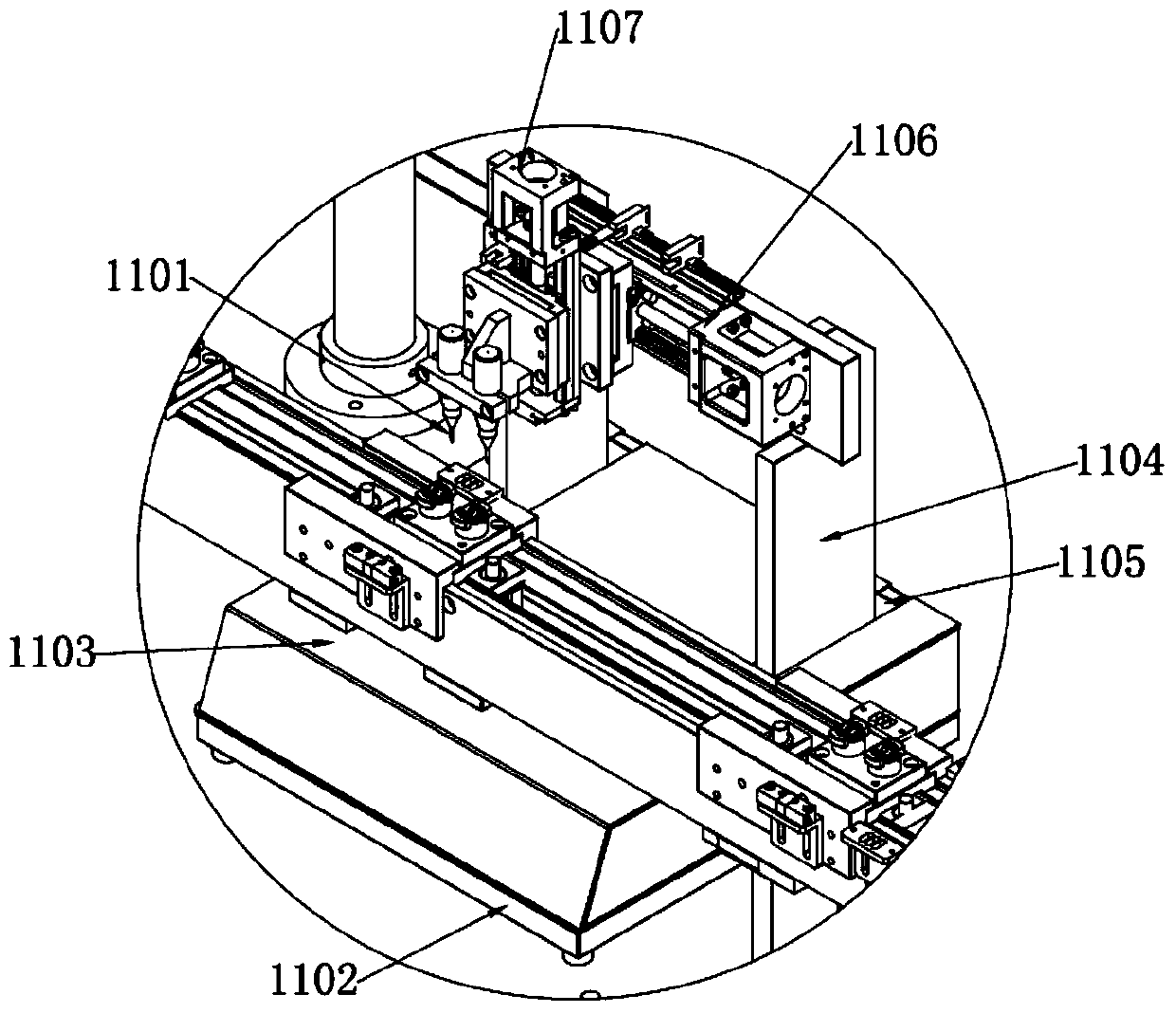

Sound membrane module assembling equipment of loudspeaker

ActiveCN103731790AConsistent operation processIncrease productivityElectrical transducersMotor driveEngineering

The invention discloses sound membrane module assembling equipment of a loudspeaker. The equipment comprises an automatic drive assembly line and automatic flow process devices arranged at one side edge of the automatic drive assembly line. The automatic flow process devices are a sound membrane feeder, a sound membrane center automatic dispensing machine, a first glue solidification machine and a first lead dispensing machine sequentially, the automatic drive assembly line is provided with more than four stations, a horizontal moving belt and a motor driving the horizontal moving belt to drive, the horizontal moving belt bears a jig, the jig passes through the stations in sequence, and each station corresponds to one automatic flow process device. The equipment further comprises a manual upper sound coil gland station, an automatic sound coil gland taking mechanism and a lead arrangement station. Assembling processes are carried out in a flow line production mode, operation procedures can be consistent, the automatic flow process devices are arranged on the assembly line, production efficiency is promoted, invested labor cost is reduced, meanwhile the number of in-transit jigs is reduced, and the problem of concentricity cannot occur.

Owner:SANKYO PRECISION HUIZHOU

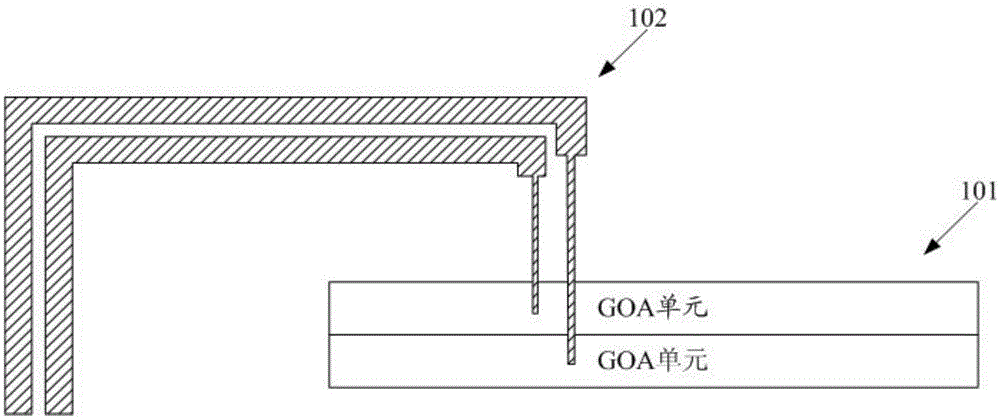

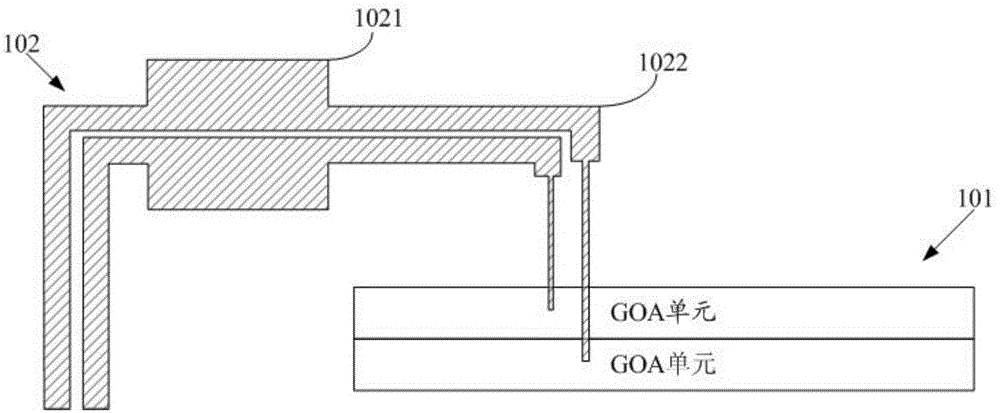

Gate line drive circuit of array substrate and display device

ActiveCN104090436AImprove yield rateReduce short circuitStatic indicating devicesSemiconductor/solid-state device detailsCapacitanceGate driver

An embodiment of the invention provides a gate line drive circuit of an array substrate and a display device, belongs to the technical field of displaying and aims to reduce short circuit of a GOA (gate driver on array) unit caused by ESD (electro-static discharge) and to increase yield of a GOA circuit. The GOA circuit comprises the GOA unit and an STV (vertical start pulse) signal line electrically connected with the GOA unit; the STV signal line comprises a first portion and a second portion; the GOA circuit further comprises a first transparent electrode and an insulting layer arranged between the first transparent electrode and the first portion; the first transparent electrode, the first portion and the insulating layer form a first capacitor. The GOA circuit according to the embodiment is applicable to the technical field of displaying.

Owner:BOE TECH GRP CO LTD +1

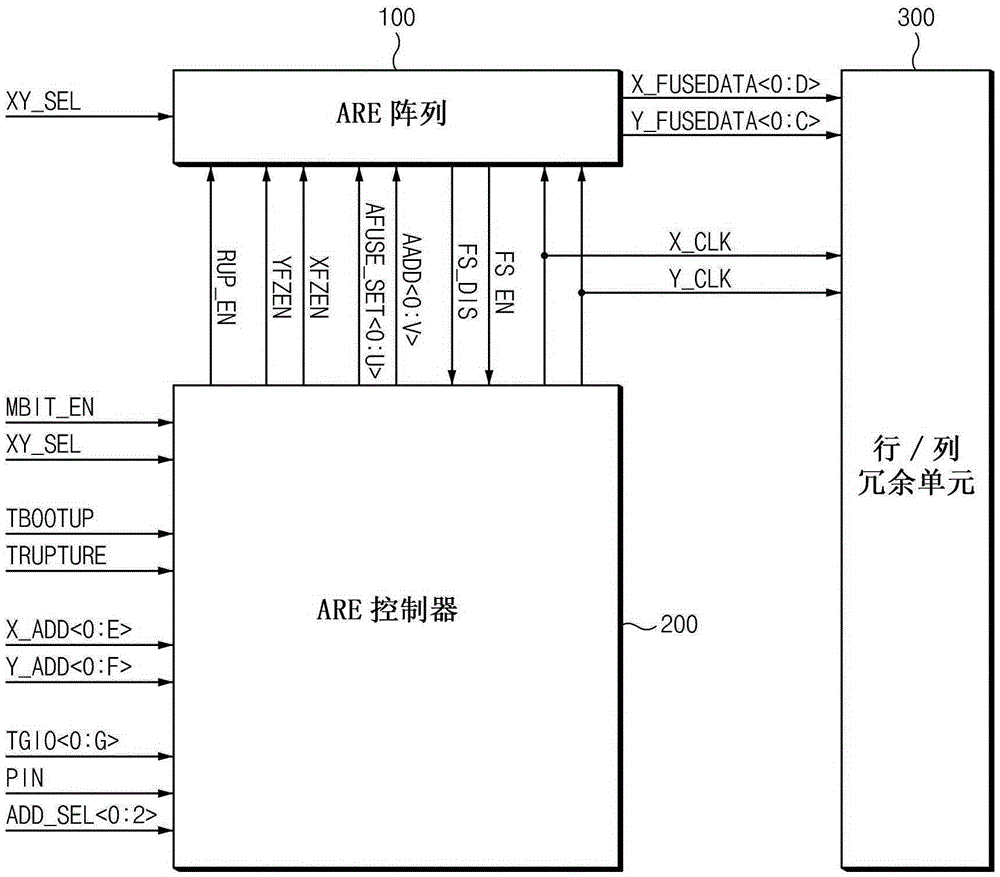

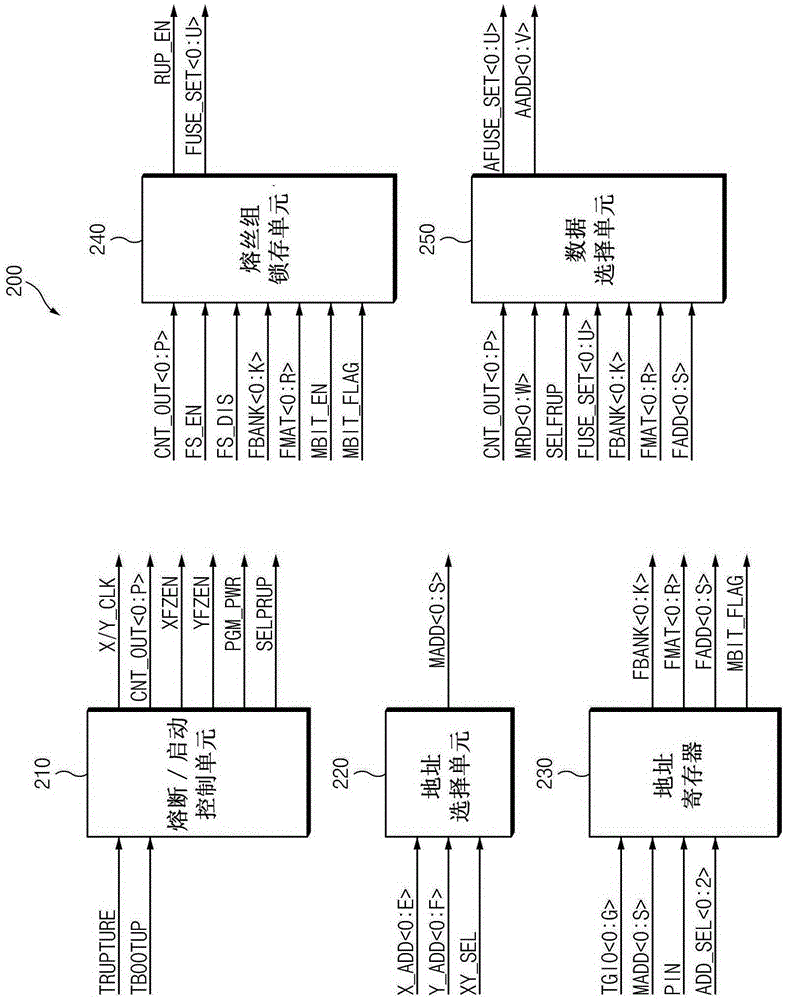

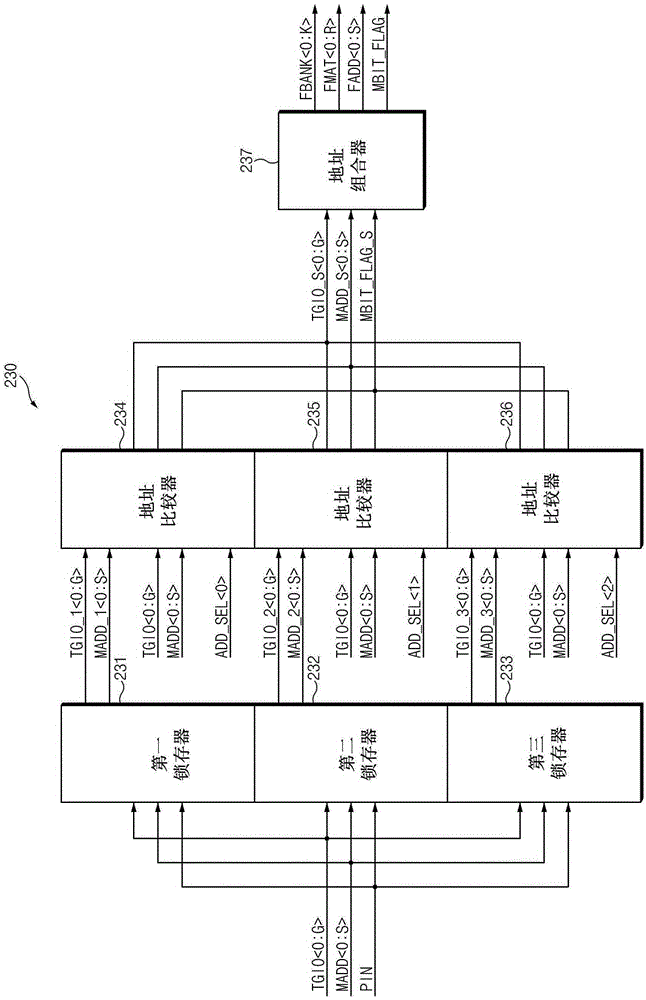

Self repair device and method thereof

A self repair device may include: an electrical fuse array configured to store bit information of a failed address in a fuse; an electrical fuse controller configured to store a row address or column address corresponding to a failed bit when a failure occurs, generate a repair address by comparing a failed address inputted during a test to the address stored therein, output a rupture enable signal for controlling a rupture operation of the electrical fuse array, and output row fuse set data or column fuse set data in response to the failed address; and a row / column redundancy unit configured to perform a row redundancy or column redundancy operation in response to the row fuse set data or the column fuse set data applied from the electrical fuse array.

Owner:SK HYNIX INC

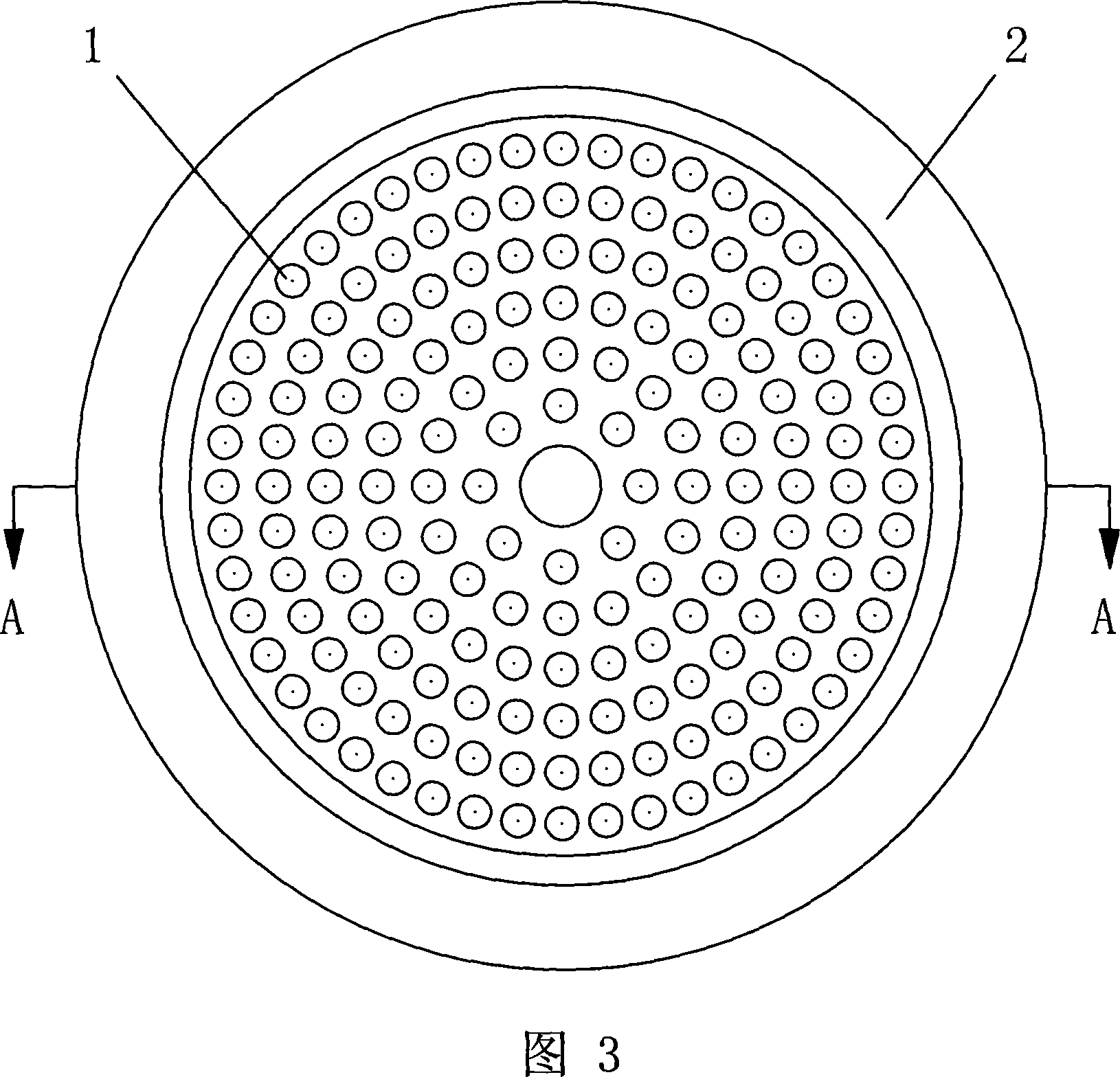

Solar cell crystal silicon wafer series welding machine

InactiveCN103182579AImprove work efficiencyAchieve integrationFinal product manufactureHeating appliancesEngineeringSolar cell

The invention discloses a solar cell crystal silicon wafer series welding machine, which comprises a welding mechanism and a welding assisting mechanism which is directly or indirectly connected with the welding mechanism, wherein the welding assisting is an automatic feeding mechanism, a welding strip feeding mechanism or an automatic discharging mechanism. The automatic feeding mechanism, the welding strip feeding mechanism, the welding mechanism and the automatic discharging mechanism are sequentially connected. All mechanisms work cooperatively and can realize the continuous, rapid and stable welding of cells.

Owner:深圳市晶拓光伏自动化设备有限公司

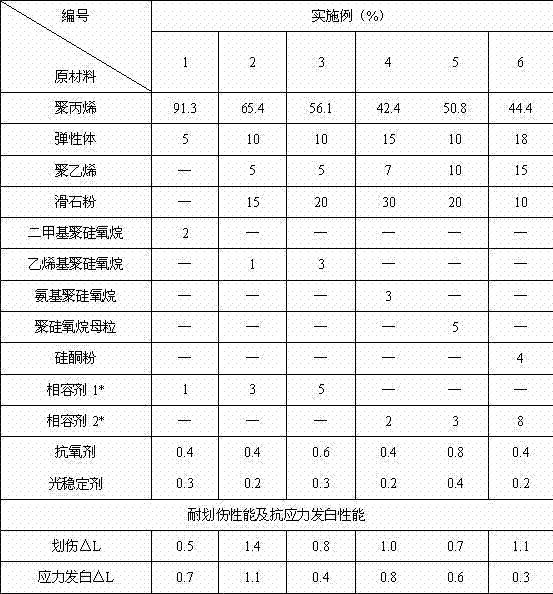

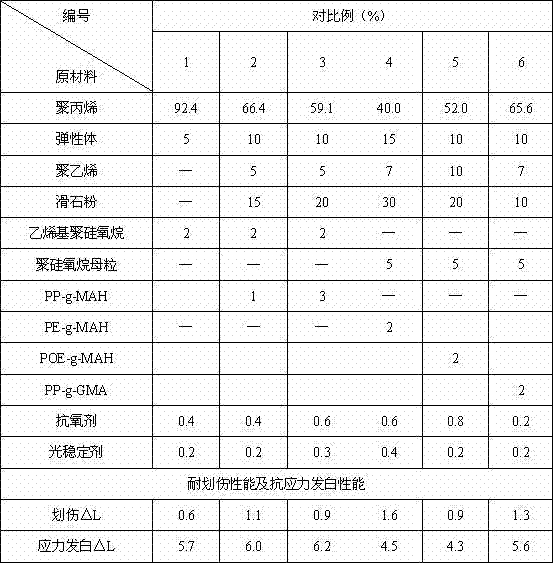

Scratching-resistant and stress-whitening prevention polypropylene compound and preparation method

The invention discloses a scratching-resistant and stress-whitening prevention polypropylene compound, which comprises, by weight, 40% to 95% of polypropylene, 2% to 20% of elastomers, 0% to 15% of polyethylene, 0% to 30% of talcum powder, 1% to 5% of scratching-resistant agent, 0.5% to 8% of compatilizer, 0.1 % to 1% of oxidation inhibitor and 0.1% to 0.5% of light stabilizer, wherein the compatilizer is polyolefin organosilicon copolymer or alkyl modified polysiloxane. The preparation method of the scratching-resistant and stress-whitening prevention polypropylene compound includes steps offirstly, taking all components by weighing according to the percentage, mixing the polypropylene, the elastomers, the polyethylene, the scratching-resistant agent and the compatilizer in a high-mixing machine for one to three minutes, then adding the talcum powder, the oxidation inhibitor and the light stabilizer to be mixed together for one to three minutes, and obtaining pre-mixed materials; and secondly, melting and extruding the pre-mixed materials by a double-screw extruder, and pelleting in a vacuum state so as to obtain the scratching-resistant and stress-whitening prevention polypropylene, wherein the temperature of each area of screws ranges from 190 DEG C to 230 DEG C. The scratching-resistant and stress-whitening prevention polypropylene compound has the advantages that scratching resistance is improved by the aid of polysiloxane scratching-resistant agent, the problem of serious stress whitening of workpieces during injection molding, mounting and using due to introductionof the scratching-resistant agent is solved, and pass rate of products is high.

Owner:WUHAN JINFA TECH CO LTD

Method for making Electric impedance type glass/glass type touch screen

ActiveCN101082713AAvoid breakingImprove yield rateStatic indicating devicesGlass/slag layered productsGlasses typeAdhesive

The invention discloses a making method of resistance-typed glass / glass typed touching screen, which comprises the following steps: etching pattern on the transparent conductive layer of lower glass base to make dispersing separating point; making electrode and binder on the lower glass base; etching pattern on the transparent conductive layer of upper glass base to make electrode thereon; binding upper and lower glass bases; sealing the rim; using etching liquid to etch to the needed depth; cutting two pieces of glass base according to the size of touching screen; obtaining the product. The invention has high reliability, simple technique and low cost, which can prevent glass from cracking.

Owner:TRULY OPTO ELECTRONICS

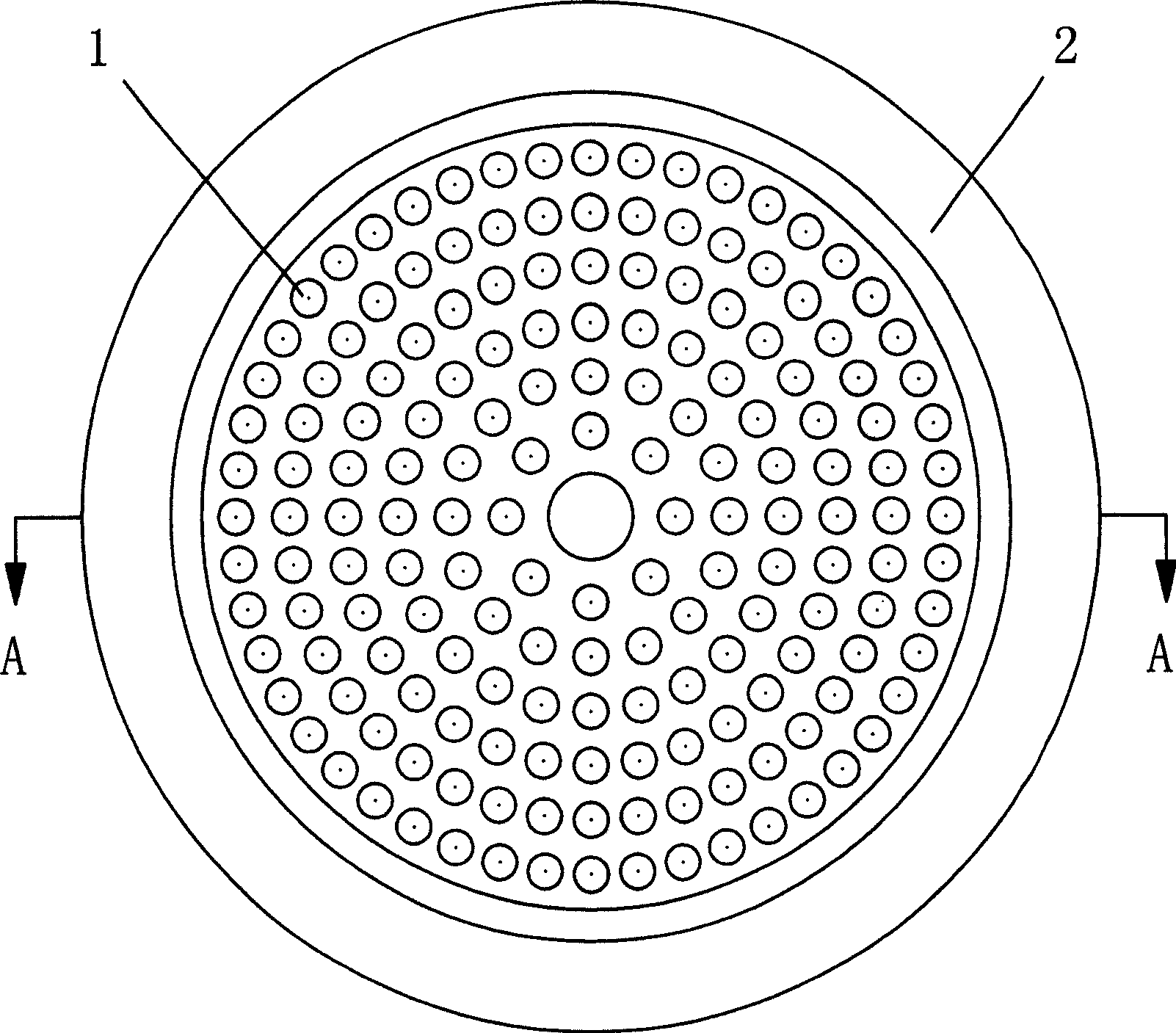

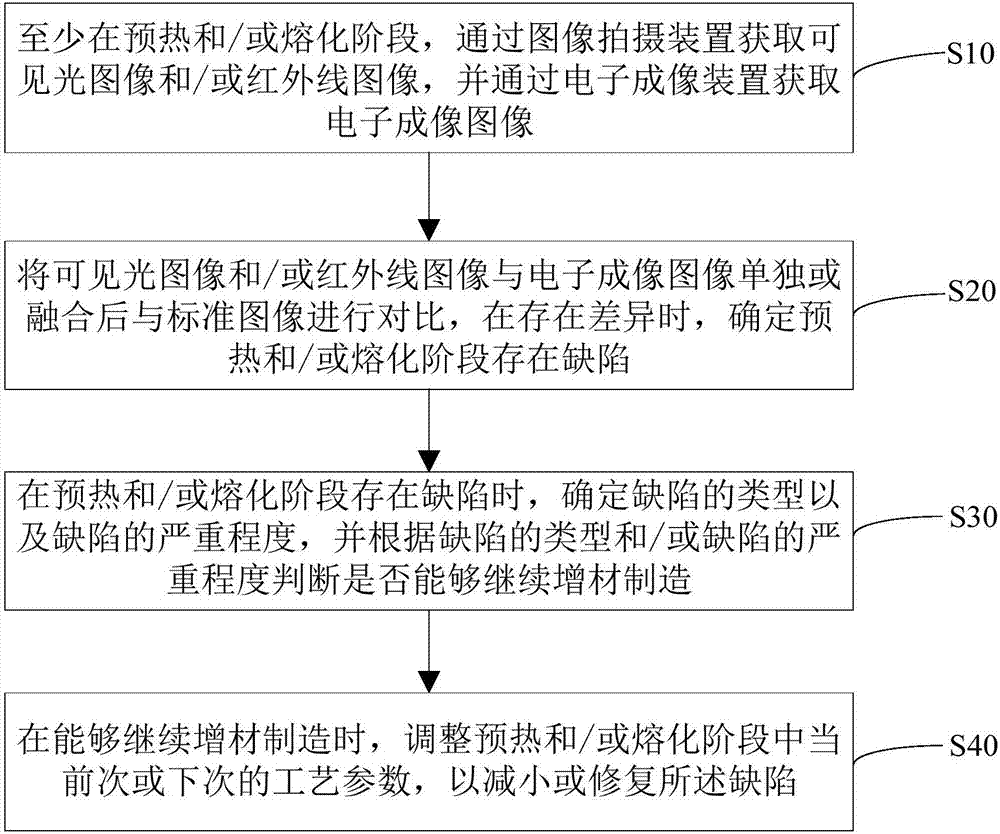

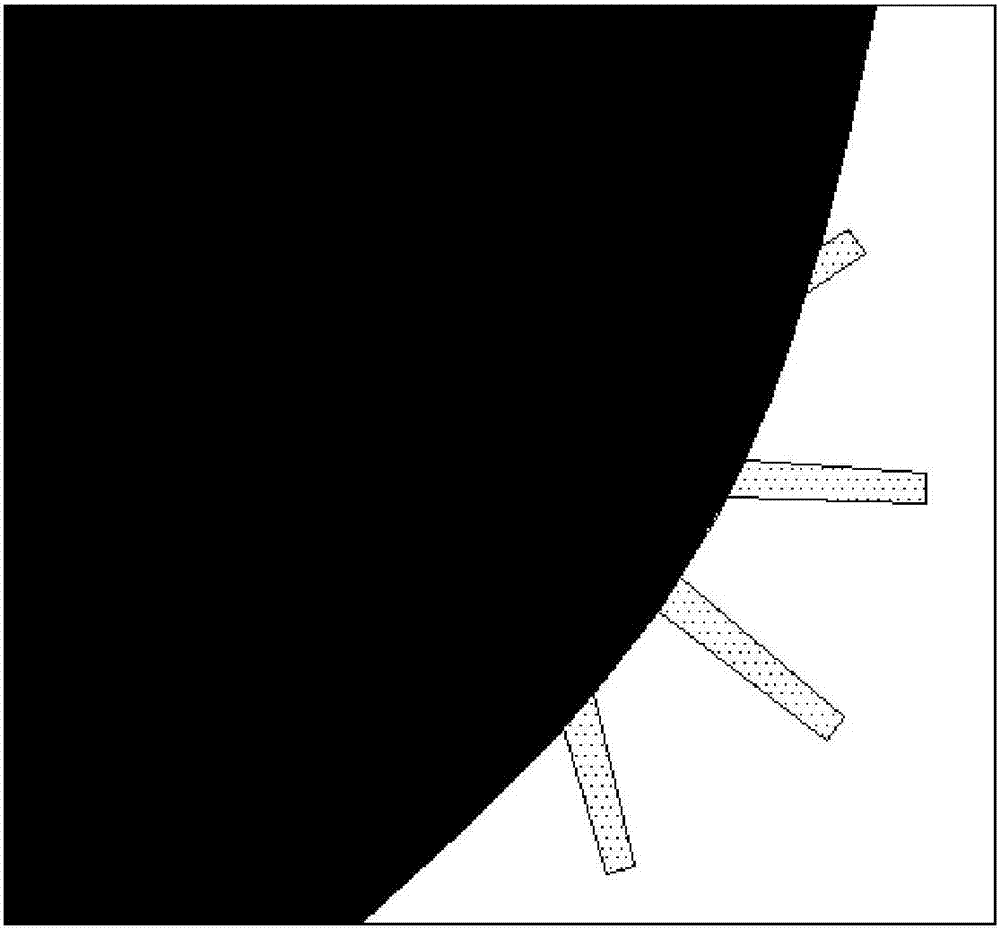

Additive manufacturing defect detection method and additive manufacturing apparatus

ActiveCN106990114AAccurate detectionAvoiding Defect Detection LagsAdditive manufacturing apparatusOptically investigating flaws/contaminationEngineeringAdditive layer manufacturing

Belonging to the field of additive manufacturing, the invention discloses an additive manufacturing defect detection method. The method includes: at least in the preheating and / or melting stage, acquiring a visible light image and / or infrared image through an image shooting device, and acquiring an electronic imaging image through an electronic imaging device; contrasting the visible light image and / or infrared image and the electronic imaging image with a standard image independently or after fusion, if a difference exists, determining the existence of a defect at the preheating and / or melting stage. The invention also discloses an additive manufacturing apparatus, which consists of a forming chamber, the image shooting device, and the electronic imaging device. According to the invention, the visible light image and / or infrared image can be acquired by the image shooting device, the electronic imaging image is acquired through the electronic imaging device, and the images are contrasted with the standard image independently or after fusion, and whether a defect exists can be judged according to the contrast result. The method and the device provided by the invention have the advantages of accurate detection, low probability of false detection or leak detection, and avoids the problem of defect detection lag in existing defect detection.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com