Patents

Literature

300results about How to "High green strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

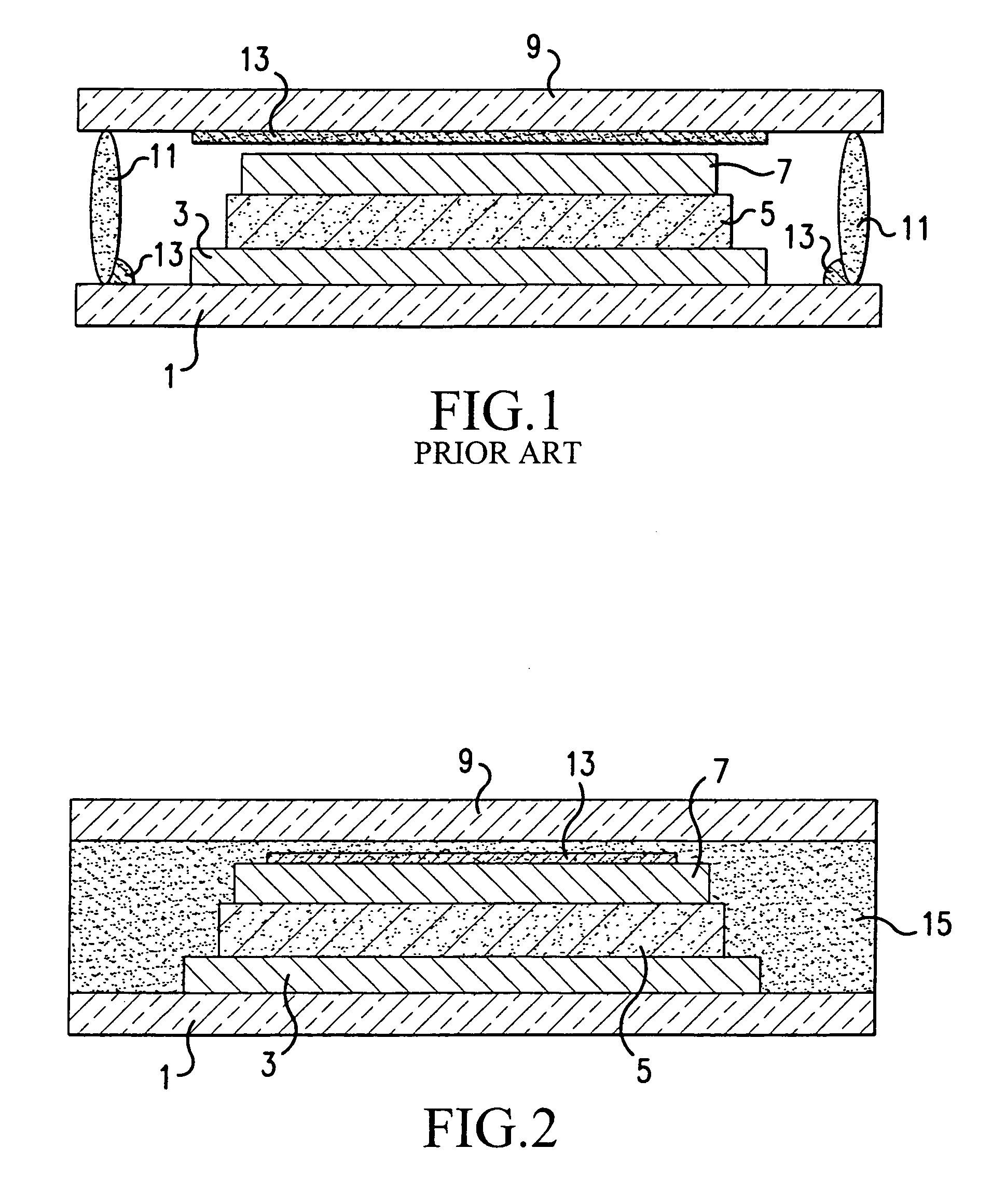

Cure on demand adhesives and window module with cure on demand adhesive thereon

InactiveUS6355127B1Improve stabilityHigh green strengthManual label dispensersGlass/slag layered productsActive agentSide chain

In one embodiment the invention is An adhesive composition comprisinga) a polymer having a flexible backbone and a reactive moiety capable of cross-linking,b) a particle comprising an active agent encapsulated in an encapsulating agent wherein the active agent comprises a catalyst for cross-linking of the reactive moiety, a curing agent for the reactive moiety, an accelerator for the curing reaction or a mixture thereof; and the encapsulating agent comprises a side chain crystallizable polymer wherein the active agent is not substantially extractable from the particle at ambient conditions in a first extraction after particle formation.This composition is used in binding two subtracters together.

Owner:ESSEX SPECIALITY PROD INC +1

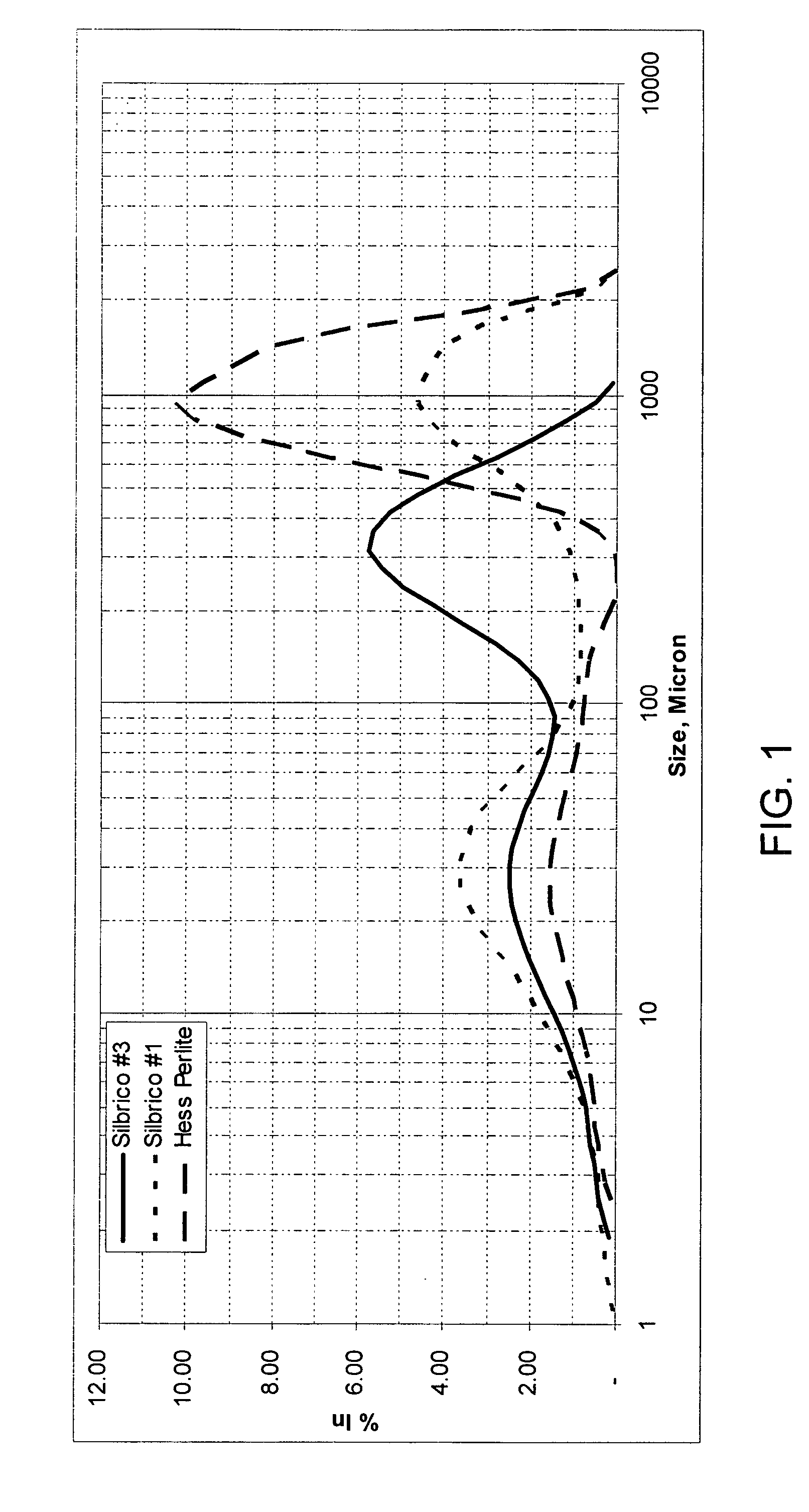

Acoustical gypsum board panel and method of making it

ActiveUS20080299413A1Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

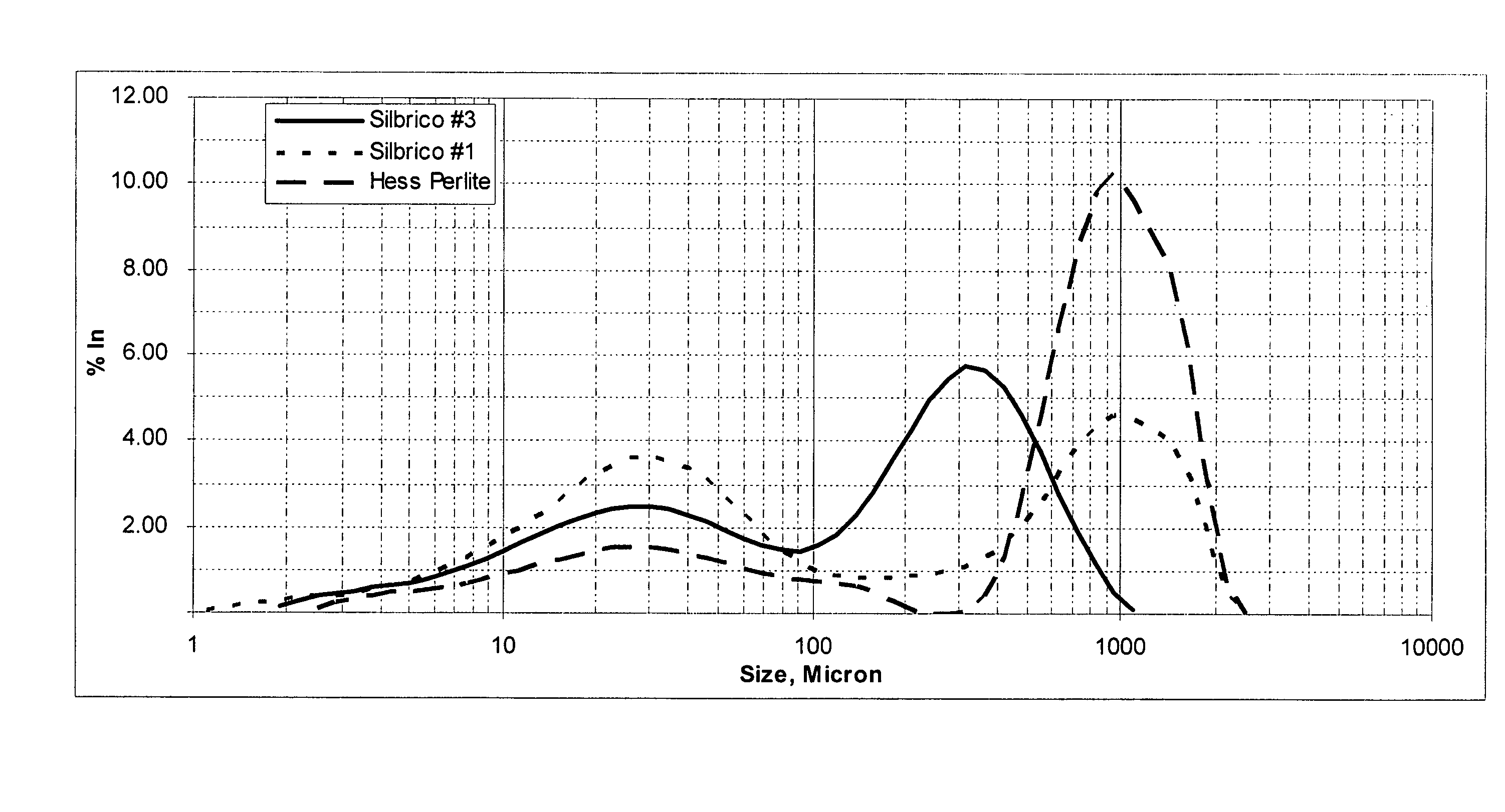

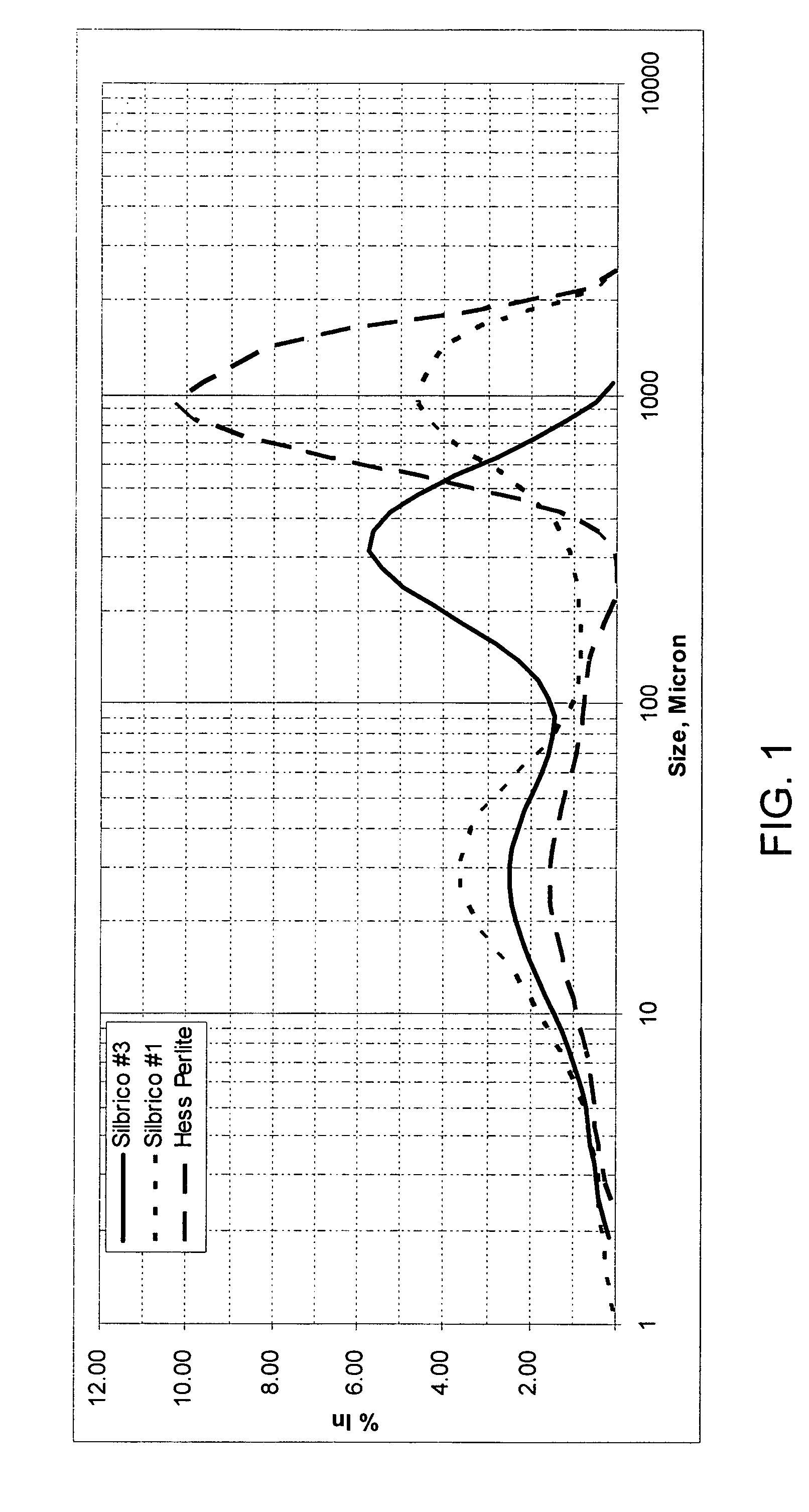

The acoustical product of the present invention comprises an acoustical product including a matrix of calcium sulfate dihydrate crystals and expanded perlite distributed throughout the matrix. The expanded perlite has a particle size distribution with at least 10% of the perlite having a particle diameter of 700 microns or more, and the amount of expanded perlite to calcium sulfate dihydrate is about 35% to about 75% by weight, based upon the dry weight of the calcium sulfate dihydrate. A dispersing agent and glass fibers having a particle length of about ¼ inch to about 1 inch are dispersed throughout the gypsum matrix.

Owner:UNITED STATES GYPSUM CO

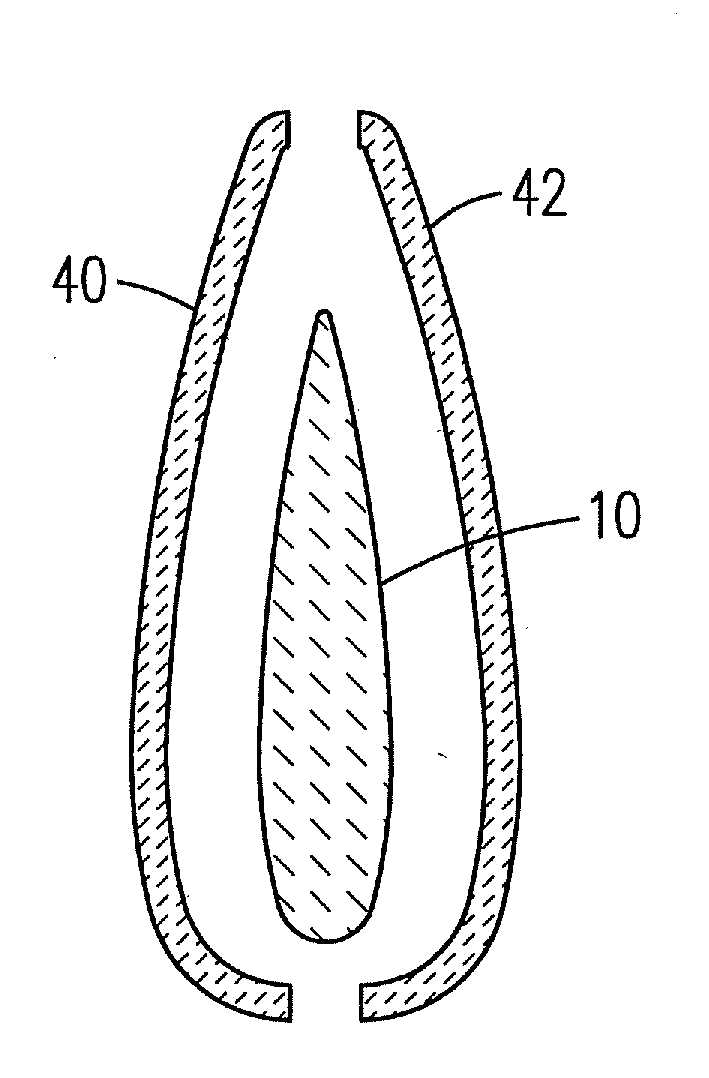

Waxless precision casting process

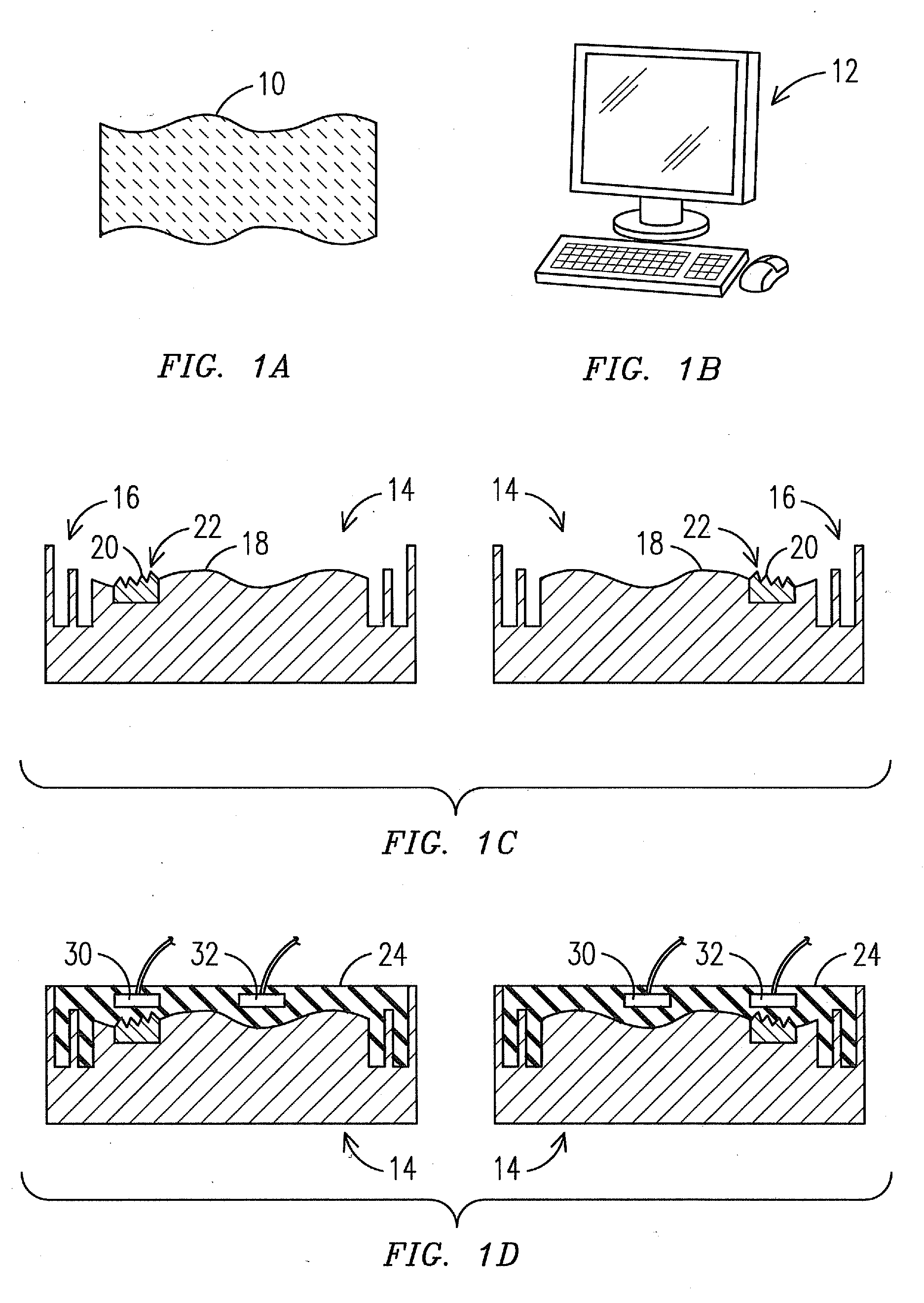

Alloy products are produced with a waxless casting process. A model of a ceramic casting vessel (34) defining a desired product shape is digitally divided into sections (10, 40, 42). Each section is translated into a soft alloy mater tool (14) including precision inserts (20) where needed for fine detail. A flexible mold (24) is cast from each master tool, and a section of the ceramic casting vessel is cast from the respective flexible mold. The vessel sections are assembled by aligning cooperating precision features (58, 60) cast directly into each section and the alloy part is cast therein. No wax or wax pattern tooling is needed to produce the cast alloy product. Engineered surface features (54) may be included on both the interior and exterior surfaces of the shell sections.

Owner:MIKRO SYSYTEMS INC +1

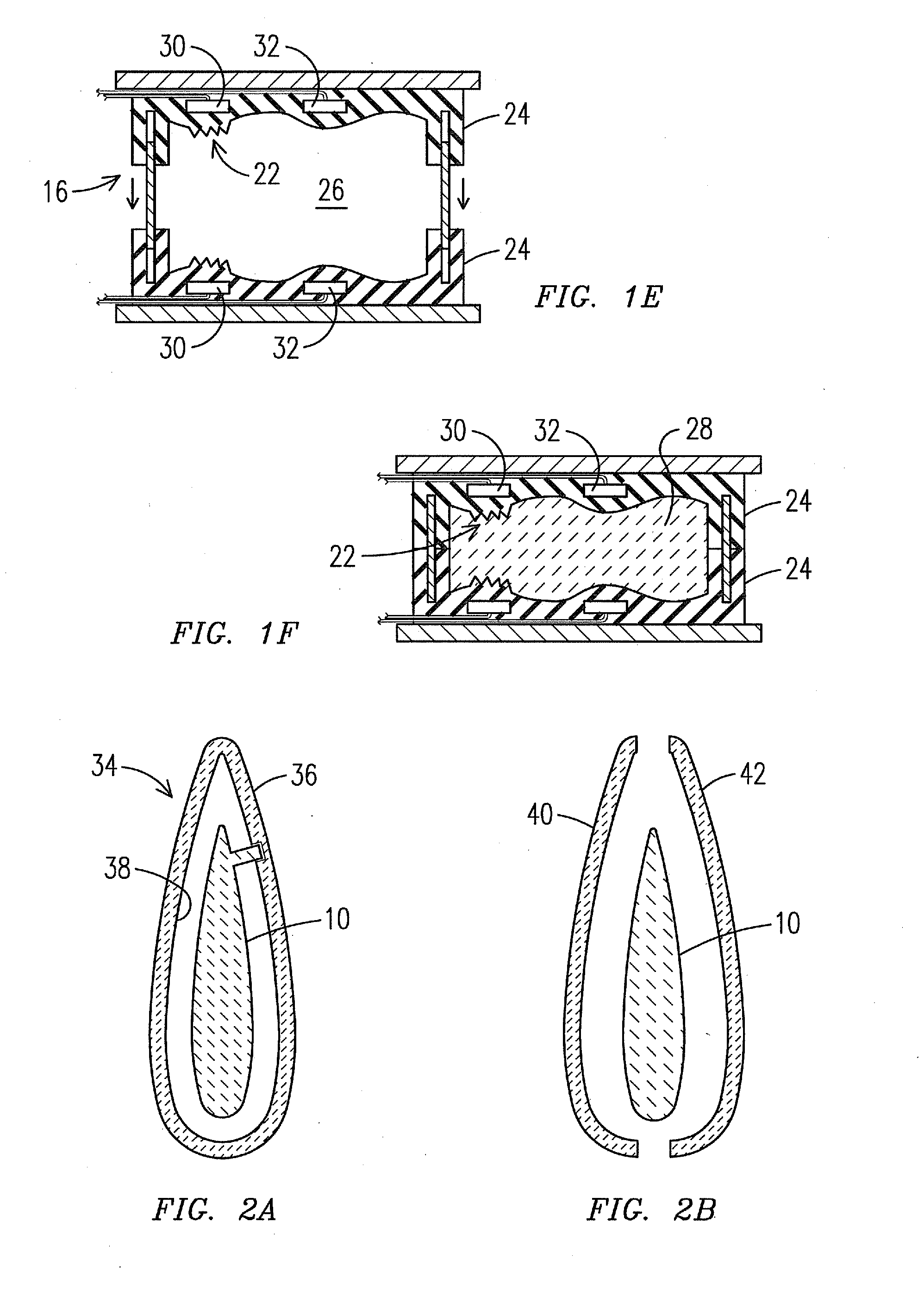

Fast baking process of environment protecting water and air permeable brick in roller kiln

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

Acoustical gypsum board panel and method of making it

ActiveUS8057915B2Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

Owner:UNITED STATES GYPSUM CO

Methods for preparing articles from processable and dimensionally stable elastomer compositions

ActiveUS7608216B2Inhibit substantial creep and sagHigh green strengthImpression capsElectric discharge tubesElastomerVulcanization

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Composite solid electrolyte and preparation method thereof

InactiveCN109786816AReduce interface contact resistanceImprove lithium ion conductivityLi-accumulatorsGap fillingPorosity

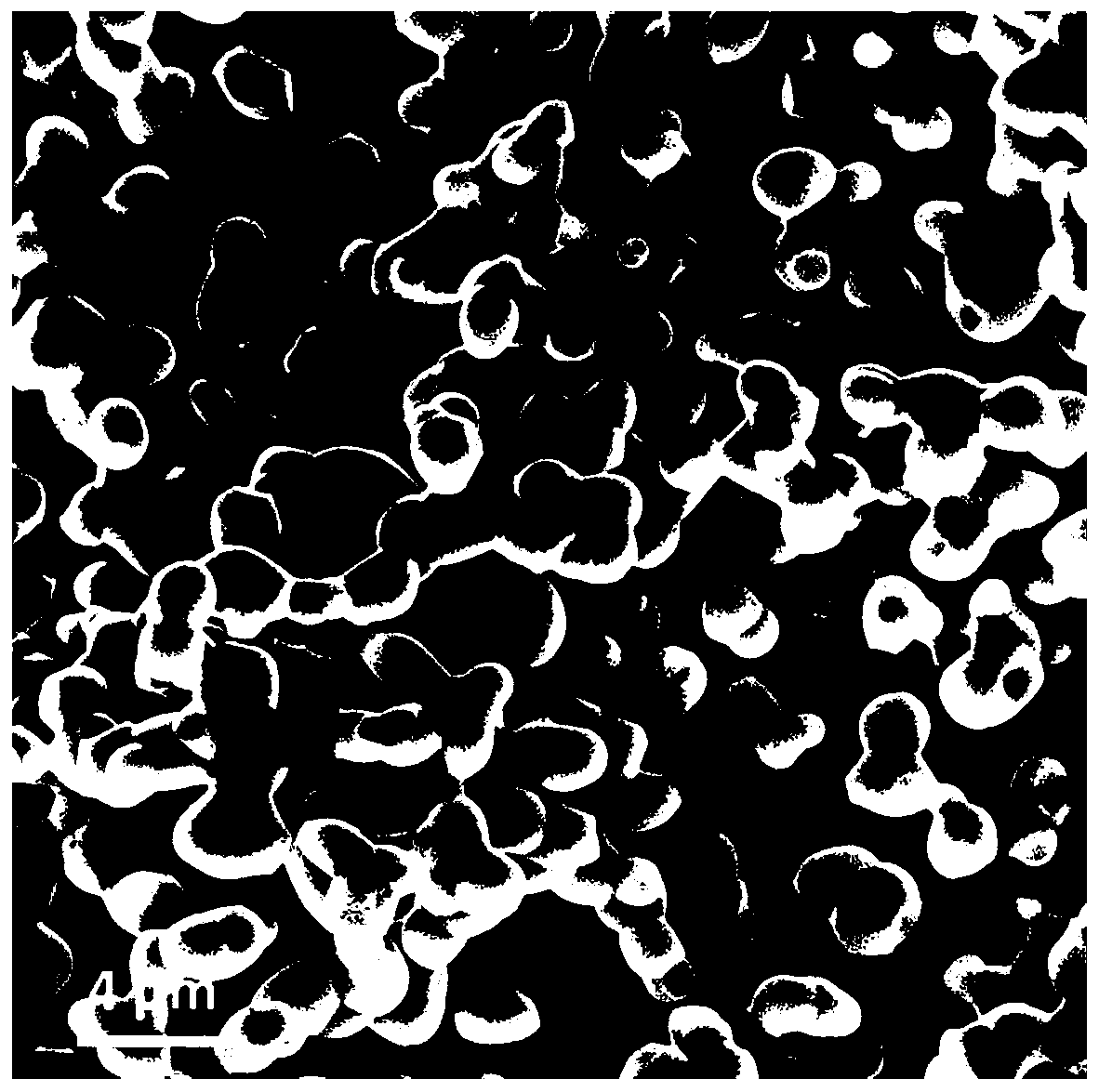

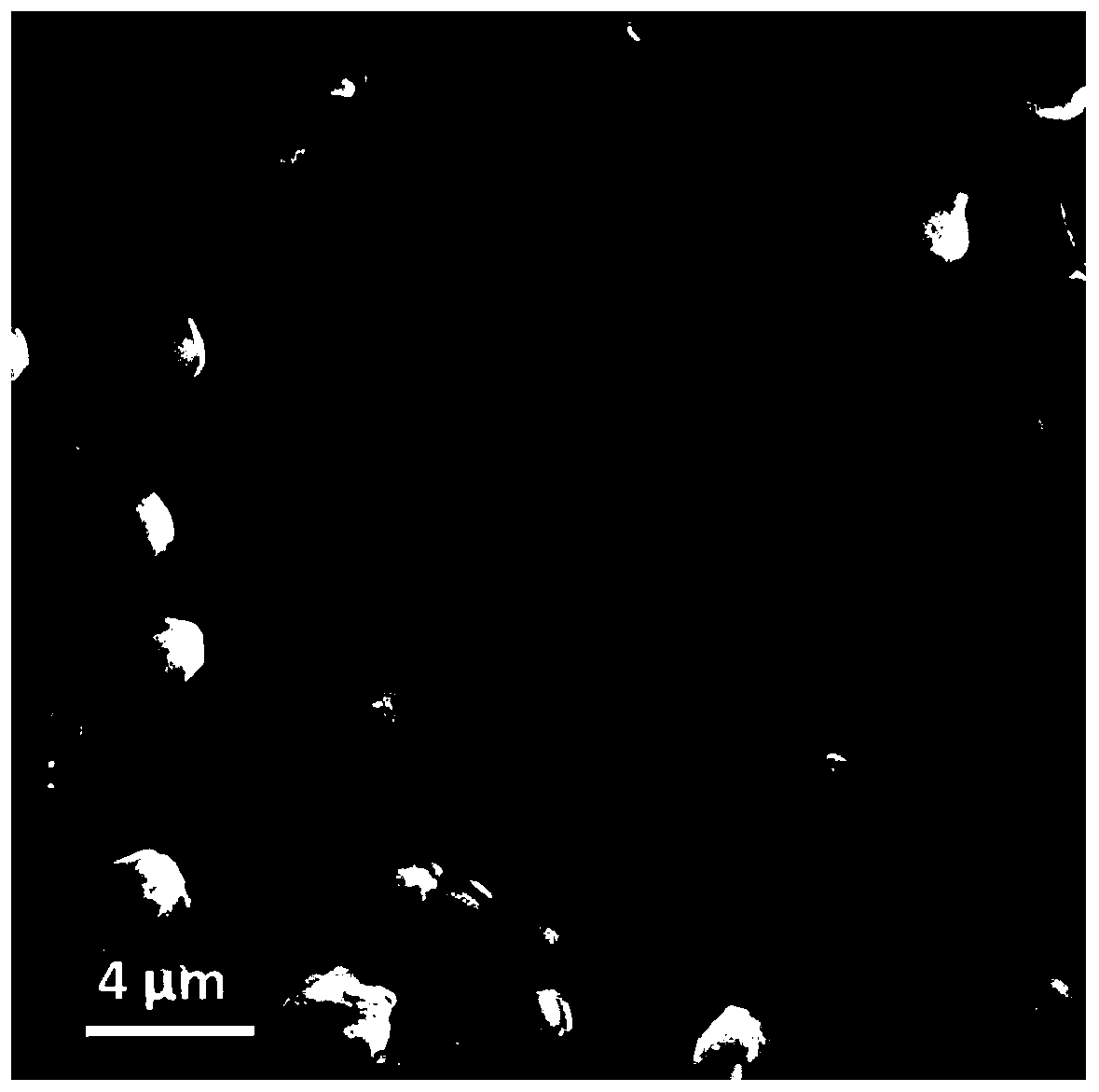

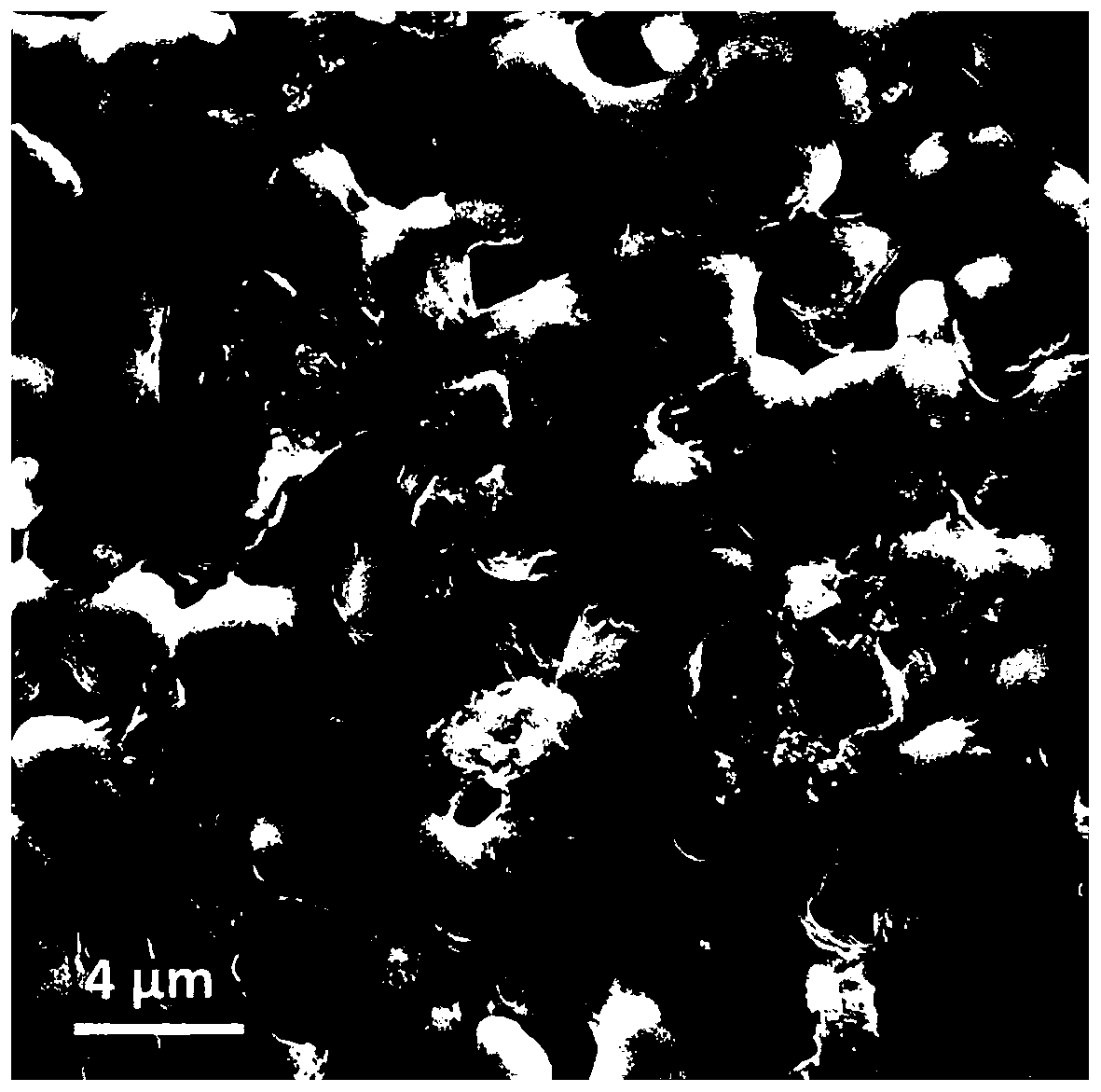

The present invention discloses a composite solid electrolyte and a preparation method thereof. The composite solid electrolyte comprises an inorganic solid electrolyte and a polymer electrolyte. Theinorganic solid electrolyte is of a porous structure; the porosity of the inorganic solid electrolyte is less than 30%; and the inside of the inorganic solid electrolyte is provided with a continuouslithium ion channel composed of particles communicating with each other. The polymer electrolyte is arranged between the inorganic solid electrolytes for filling gaps, and account for less than 30% ofthe composite solid electrolyte. The porous inorganic solid electrolyte of the invention constitutes a main frame structure, which has a porosity below 30% and is the main bearer of lithium ion transportation. The polymer electrolyte is a gap filling material, which is mainly used for improving the overall flexibility of the composite solid electrolyte and reducing the impedance of the solid-solid contact interface between the positive electrode plate and negative electrode plate.

Owner:杭州阳名新能源设备科技有限公司

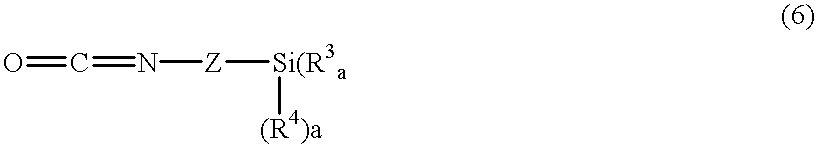

MDI-based polyurethane prepolymer with low monomeric MDI content

InactiveUS6884904B2Long application periodPromote rapid developmentCarbamic acid derivatives preparationOrganic compound preparationPolymer sciencePolyurethane adhesive

An MDI / polypropylene polyether prepolymer composition consisting essentially of at least 80 wt % perfect prepolymers and less than 2 wt % free MDI monomer suitable for use in polyurethane adhesive compositions optionally also comprising a curative for isocyanate groups.

Owner:COIM USA

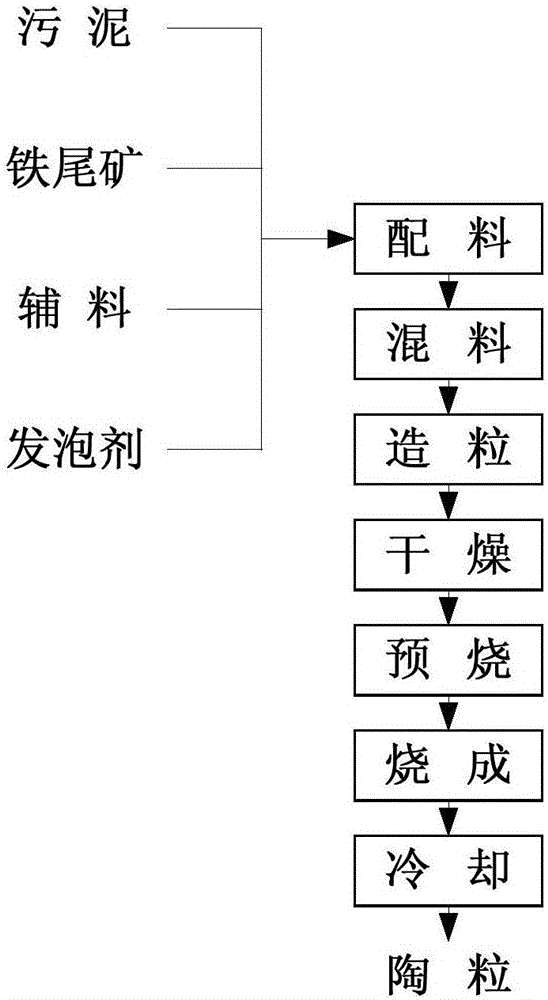

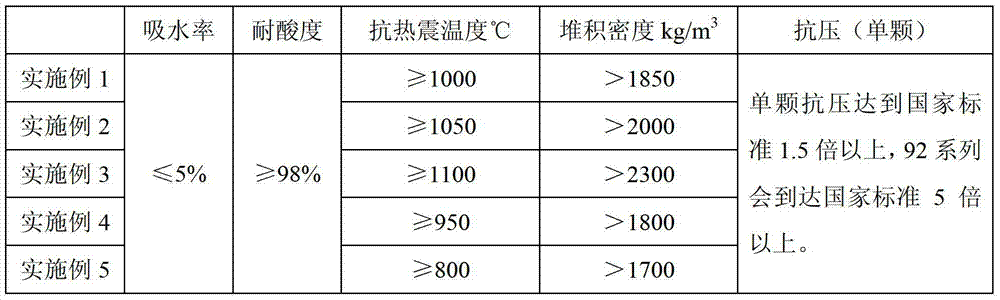

Composite solid-waste lightweight high-strength haydite and preparation method therefor

InactiveCN106242514ALightweightCorrosion resistantCeramic materials productionCeramicwareFoaming agentSludge

The invention provides composite solid-waste lightweight high-strength haydite and a preparation method therefor. The composite solid-waste lightweight high-strength haydite is mainly prepared from the following raw materials in parts by weight: 40.0-60.0 parts of iron tailings, 10.0-15.0 parts of auxiliary raw materials and 0.1-3.0 parts of foamer. The composite solid-waste lightweight high-strength haydite further contains sludge, wherein the dry sludge content of the sludge is 30.0-50.0 parts. The preparation method comprises the steps: accurately weighing the sludge, the iron tailings, the auxiliary raw materials and the foamer according to a designed ingredient proportioning ratio, and carrying out uniform mixing so as to form a uniform basic mixture; and carrying out granulating and shaping so as to obtain unburned haydite, burning the unburned haydite, and carrying out annealing and cooling, thereby obtaining municipal sludge and iron tailing cooperated haydite. The haydite is prepared from the sludge and the iron tailings, which are cooperated with each other and serve as main raw materials, so that the sludge is subjected to harmless treatment and resource-converting utilization, the sludge, which is a municipal mineral product, is used for replacing a primary mineral raw material, and thus the economic and environmental benefits are remarkable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cure on demand adhesives and window module with cure on demand adhesive thereon

InactiveUS20020010272A1Lower overall pressure dropImprove curingPolyureas/polyurethane adhesivesThin material handlingPolymer sciencePtru catalyst

In one embodiment the invention is An adhesive composition comprising a) a polymer having a flexible backbone and a reactive moiety capable of cross-linking, b) a particle comprising an active agent encapsulated in an encapsulating agent wherein the active agent comprises a catalyst for cross-linking of the reactive moiety, a curing agent for the reactive moiety, an accelerator for the curing reaction or a mixture thereof; and the encapsulating agent comprises a side chain crystallizable polymer wherein the active agent is not substantially extractable from the particle at ambient conditions in a first extraction after particle formation. In yet another embodiment the invention is a process for binding two substrates together which comprises contacting one of the substrates with an adhesive as described herein, exposing the adhesive to conditions such that the active agent is released so as to contact the active agent with the polymer, contacting the two substrates such that the adhesive is located between the two substrates, and exposing the adhesive between the substrates to curing conditions. In a preferred embodiment of this process the adhesive is activated by exposure to an infrared heating source.

Owner:THE DOW CHEM CO

Preparation method of indium tin oxide targets

The invention discloses a preparation method of indium tin oxide targets. The preparation method includes taking indium tin oxide powder with the purity higher than 99.99% and the average particle size of 0.02-2 micrometers as a main material, preparing premixed liquid from pure water, water-soluble epoxy resin and dispersing agents, subjecting the main material and the premixed liquid to ball milling sufficiently to obtain slurry capable of dispersing uniformly and flowing easily, pouring, curing and drying the slurry to obtain high-intensity green bodies, and degreasing to obtain high-quality indium tin oxide targets which are of In2O3 single-phase cubic structures, have relative density reaching 99.5%, resistivity lower than 0.1megohm / centimeter and are uniform in composition. The indium tin oxide targets are high in density and can be produced in large size and various shapes; isostatic pressing treatment to the green bodies is omitted, so that production efficiency and field can be improved greatly; nontoxic water-soluble epoxy resin serves as a gel system so that production safety coefficient can be increased greatly while pollution of industrial production to environments can be lowered greatly.

Owner:CENT SOUTH UNIV +1

Casting coated sand suitable for selective laser sintering forming and manufacturing method thereof

ActiveCN102343415AReduce dosageGood sintering strengthFoundry mouldsFoundry coresSelective laser sinteringLight absorber

The invention discloses casting coated sand suitable for selective laser sintering forming and a manufacturing method thereof. The coated sand is made from roughing sands, an organic binder, an inorganic binder, a coupling agent and a curing agent, further, additives, such as a lubricant, a light absorber and the like are not required; and the roughing sand is spherical pearl sand with the angular coefficient less than or equal to 1.1, wherein the sand grains consist of adjacent four-sieve sands or five-sieve sands. The manufacturing method of the casting coated sand comprises the following steps of: sieving the roughing sands to obtained the required four-sieve sands or five-sieve sands; carrying out thermal coating on the roughing sands by using phenolic resin powder, the coupling agentand the curing agent according to a certain proportion so as to obtain phenolic resin coated sand; and evenly mixing monoammonium phosphate fine powder and the phenolic resin coated sand which are ina certain proportion to obtain the casting coated sand suitable for the selective laser sintering forming. The coated sand laser sintering forming part has high preform strength, good forming accuracy and little gas forming amount and can be applied to a casting sand mold (core) with an intricate structure in laser fast forming, therefore, the fast trial-production and the manufacturing capacity of intricate castings are enhanced.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Powder metal composition and method for producing components thereof

The present invention concerns a powder metal composition for producing powder metal components comprising a Co-based pre-alloyed powder, with irregularly shaped particles comprising at least 15% by weight Cr and less than 0.3% by weight C, admixed with graphite. The invention also concerns a method for producing PM components by pressing of articles to shape from the powder metal composition according to the invention and sintering them.

Owner:HOGANAS AB

Diffusion coating process

ActiveUS20050095358A1Not to negatively affect quality and uniformityHigh green strengthLayered productsLaminationChemistryDeposition process

A process capable of depositing a diffusion coating of uniform thickness on localized surface regions of a component. The process makes use of an adhesive mixture containing a binding agent that is consumed as part of the deposition process so as not to negatively affect the quality and uniformity of the resulting coating. The process entails mixing a particulate donor material containing a coating element, a dissolved activator, and a particulate filler to form an adhesive mixture having a formable, malleable consistency. The adhesive mixture is applied to a surface of the component, and the component is heated to a temperature sufficient to vaporize and react the activator with the coating element of the donor material, thereby forming a reactive vapor of the coating element. The reactive vapor reacts at the surface of the component to form a diffusion coating containing the coating element.

Owner:GENERAL ELECTRIC CO

Preparation of CFC-free, highly resilient, flexible polyurethane foams, and diphenylmethane diisocyanate-based polyisocyanate mixtures modified by means of urethane groups which can be used for this purpose

InactiveUS6096238AIncrease elasticityEasy to processOther chemical processesDiphenylmethaneCarbamate

The present invention relates to a process for the preparation of CFC-free, flexible polyurethane (molded) foams by reacting A) liquid polyisocyanate mixtures containing bonded urethane groups having a content of NCO groups of from 22 to 30% by weight which are themselves prepared by reacting a mixture of diphenylmethane diisocyanates and polyphenyl-polymethylene polyisocyanates having a content of diphenylmethane diisocyanate isomers of from 55 to 99% by weight, based on the total weight, with at least one trifunctional polyoxypropylene-polyol having a hydroxyl number of from 20 to 60, with B) relatively high-molecular-weight polyhydroxyl compounds and, if desired, C) low-molecular-weight chain extenders and / or crosslinking agents, in the presence of D) blowing agents, E) catalysts and, if desired, F) auxiliaries and / or additives, and to the polyisocyanate mixtures (A) modified by means of urethane groups which can be used according to the invention.

Owner:BASF AG

Lubricant powder for powder metallurgy

InactiveUS6511945B1High green strengthEnsure durabilityTransportation and packagingMetal-working apparatusPolyethylene oxideOligomer

The invention concerns new lubricants comprising a combination of a polyethylene oxide and an oligomer amide and an improved metallurgical powder composition comprising a major amount of an iron-based powder and a minor amount of this new lubricant. Furthermore, the invention concerns a method requiring low ejection force and low ejection energy for producing green products having high green strength. The method comprises the steps of mixing an iron-based powder and optional additives with the new lubricant and compacting the obtained powder composition.

Owner:HOGANAS AB

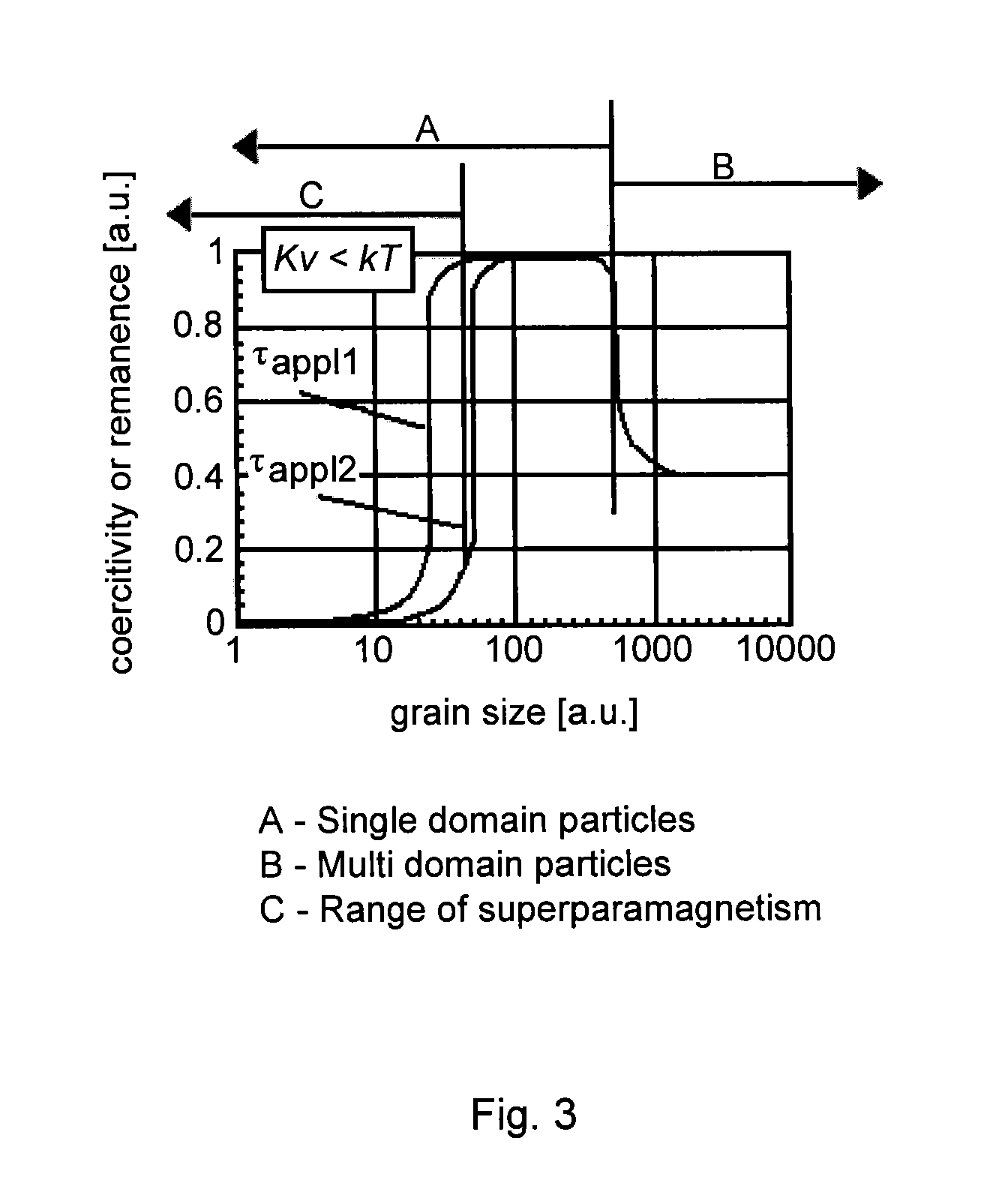

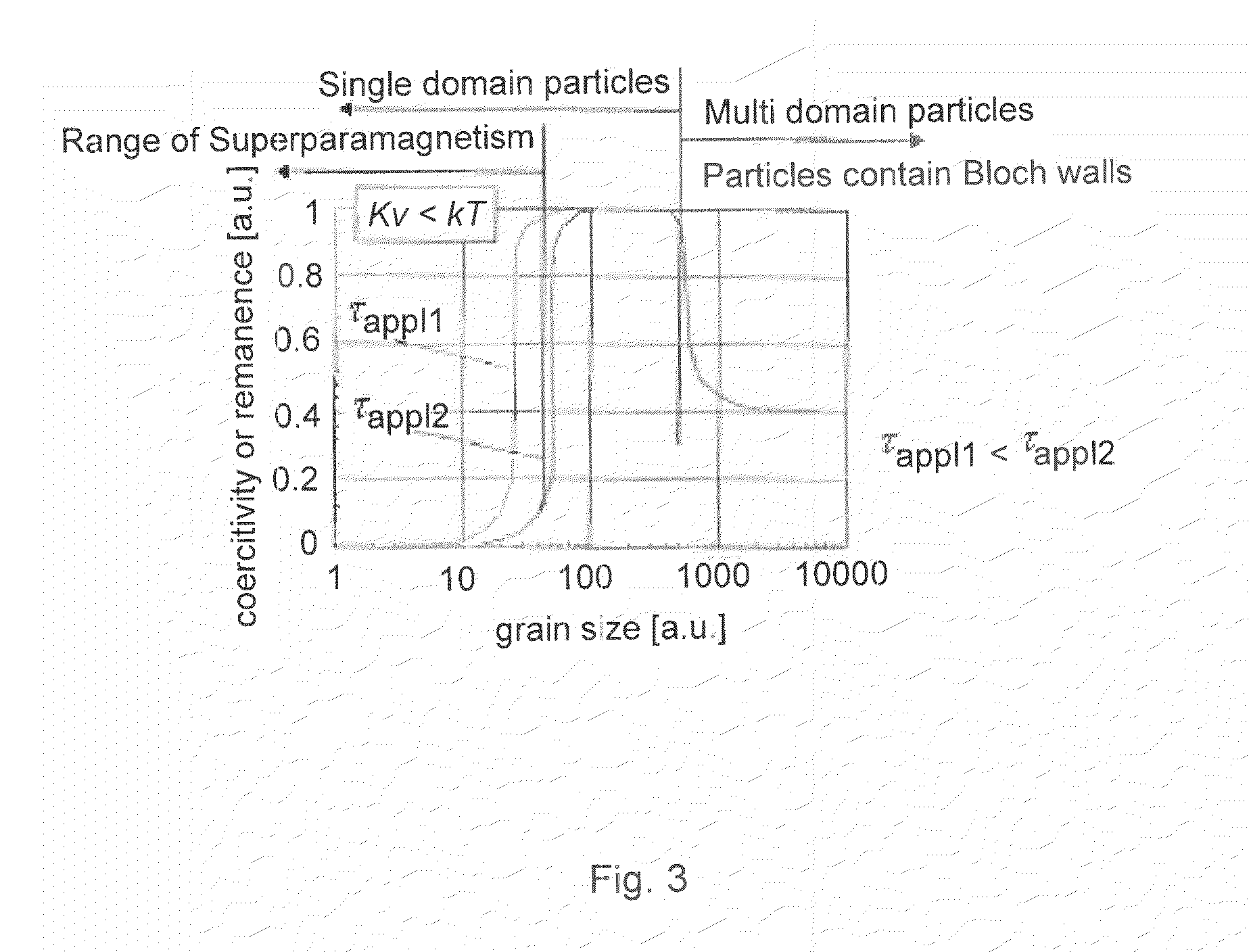

Iron oxide and silica magnetic core

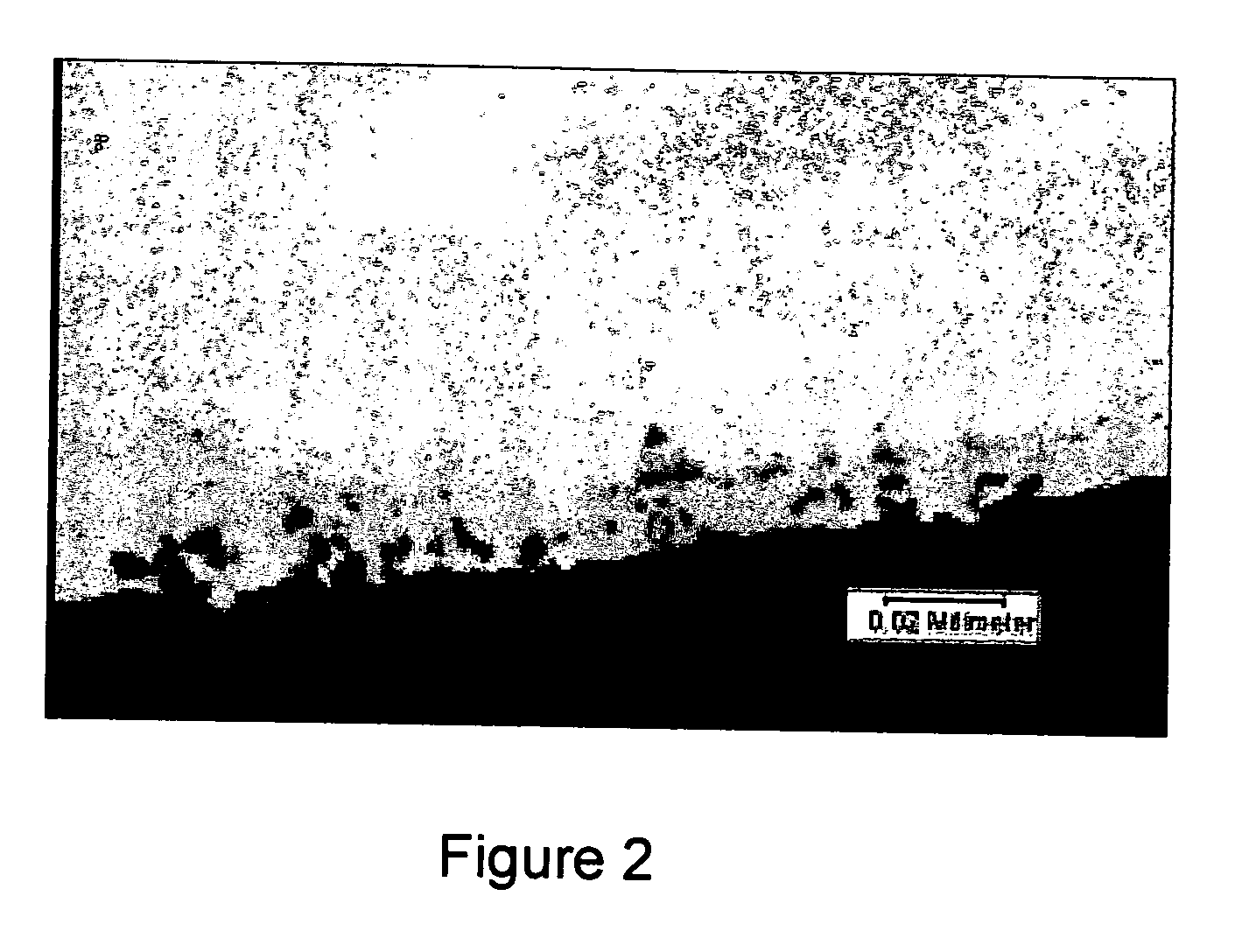

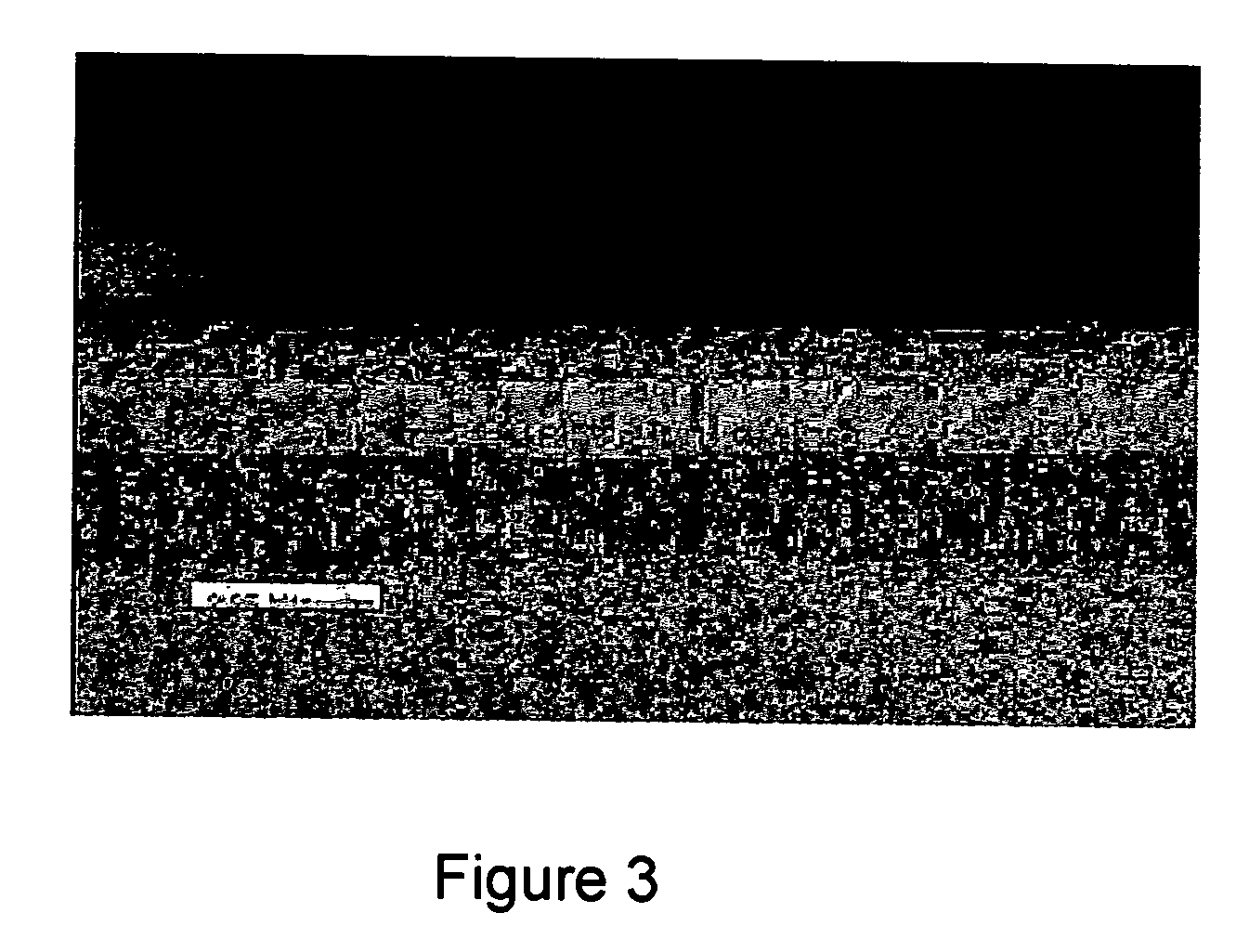

InactiveUS20130342069A1High green strengthHigh temperature toleranceMaterial nanotechnologyNanomagnetismHysteresisCore shell nanoparticles

A magnetic core of superparamagnetic core shell nanoparticles having a particle size of less than 50 nm; wherein the core is an iron oxide and the shell is a silicon oxide is provided. The magnetic core is a monolithic structure of superparamagnetic core grains of iron oxide directly bonded by the silicon dioxide shells. A method to prepare the magnetic core which allows maintenance of the superparamagnetic state of the nanoparticles is also provided. The magnetic core has little core loss due to hysteresis or eddy current flow.

Owner:TOYOTA JIDOSHA KK

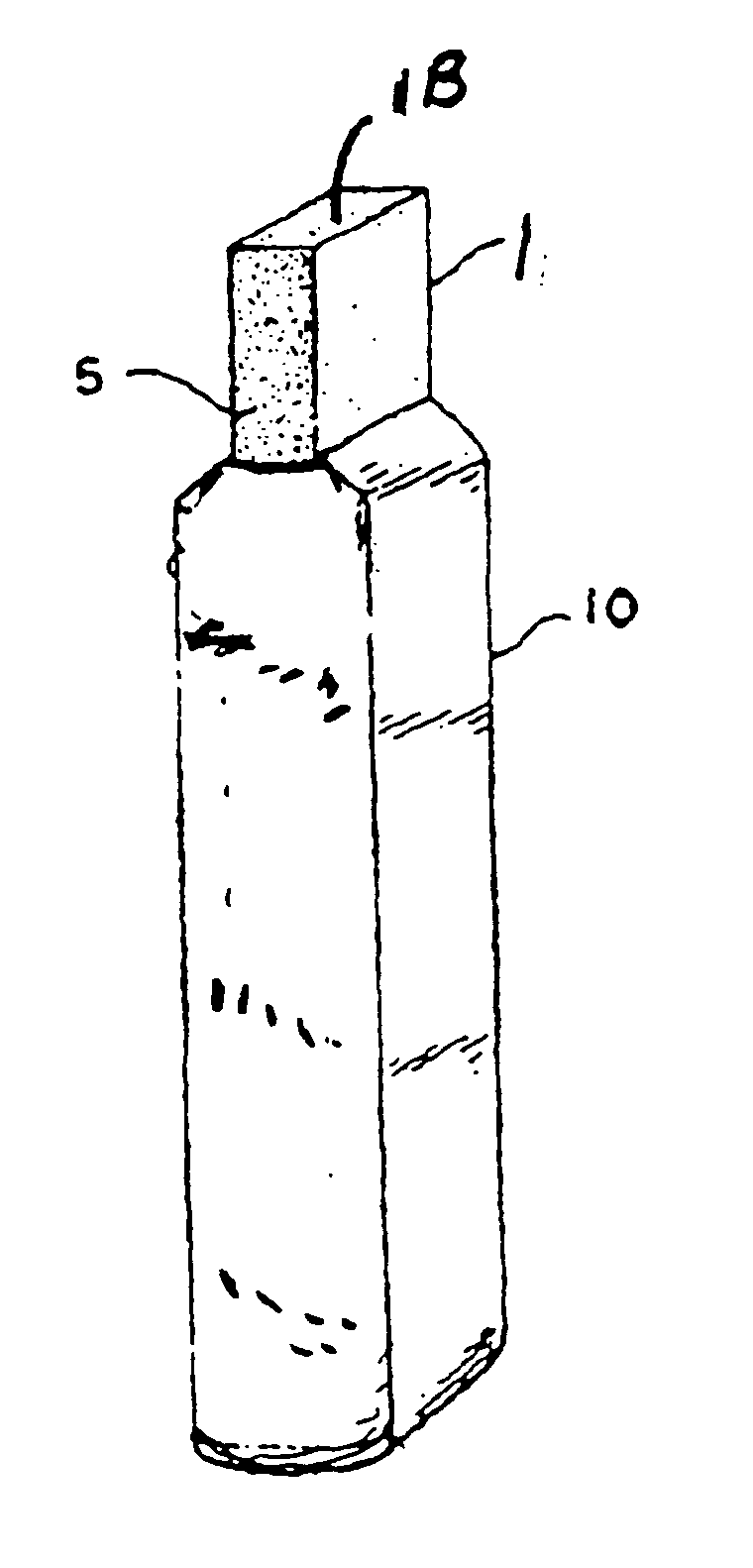

Investment casting mold and method of manufacture

InactiveUS20050199366A1Efficient use ofUniformity is assuredFoundry mouldsFoundry coresFiberInvestment casting

The invention relates to a investment casting shell molds and their method of manufacture. The method entails mixing fiber and refractory filler to form a dry blend; mixing the dry blend with a binder sol to form a refractory slurry, and employing the refractory slurry to produce an investment casting shell mold.

Owner:BUNTROCK IND INC

Ceramic material, compositions and methods for manufacture thereof

InactiveUS20070149383A1Improve textureSurface highlightGlass/slag layered productsMetal layered productsSilicate mineralsSILICONE DIOXIDE

The present invention relates to a method of producing a ceramic material comprising the steps of: a) mixing a first clay composition comprising silica and a silicate mineral with a second clay composition; and b) firing the mixed clay composition from step a) to form a ceramic product. The present invention also relates to an engobe clay composition, sanitary ware and methods of productions thereof.

Owner:CAROMA IND LTD

Ceramic material, compositions and methods for manufacture thereof

InactiveUS20080300129A1Reduce cracking and chippingExcellent glaze appearanceClaywaresSilicate mineralsSilicon dioxide

The present invention relates to a method of producing a ceramic material comprising the steps of: a) mixing a first clay composition comprising silica and a silicate mineral with a second clay composition; and b) firing the mixed clay composition from step a) to form a ceramic product. The present invention also relates to an engobe clay composition, sanitary ware and methods of productions thereof.

Owner:CAROMA IND LTD

Preparation method of porous slurry green body

The invention relates to a preparation method of a porous slurry green body, belonging to the technical field of ceramic and refractory materials. The method comprises five steps of: foam preparation, slurry blending, foam and slurry mixing, green body pouring and green body maintenance. The invention specifically comprises the following steps of: prefabricating bubbles in advance under the action of compressed air through a foaming device by adopting a physical foaming agent so as to provide fine, uniform and stable bubbles; and mixing high-alumina cement, Suzhou clay, pyrophyllite, lime and calcium carbonate according to a required proportion and then adding water to prepare a prefabricated slurry, wherein in the slurry, the high-alumina cement is used as one of ingredients to provide aluminum oxide and calcium oxide, and meanwhile, the characteristics of fast-solidification and fast-hardening of the high-alumina cement are adopted to accelerate the solidification and the hardening of pouring a green pouring body so as to ensure that on one hand, the bubbles are fixed as soon as possible to reduce bubble loss, and on the other hand, the green body is enhanced to reduce the deformation of the green body. The invention can easily prepare a green body with a drying density of 0.34-0.45kg / m<3>, and the compression strength of a corresponding drying green body is 0.15-0.50MPa.

Owner:NANJING TECH UNIV

Method for rubber sheet surface layer radiation vulcanization

The invention discloses a method used for rubber sheet surface or uneven radiation curing, an electronic beam generated by an electronic accelerator is utilized to irradiate a rubber sheet, the incident beam energy is reasonably adjusted to realize the rubber sheet surface or uneven radiation curing; a device provided by the invention comprises the electronic accelerator and a beam downside device thereof, the beam downside device consists of an irradiation box protected by limited oxygen, and a transmission device, the irradiation box is arranged directly under the radiation window of the electronic accelerator, the titanium window arranged at the top part of the irradiation box corresponds to the titanium window of the irradiation box, the transmission device causes the rubber sheet to pass through the irradiation box at uniform speed, the electronic beam generated by the electronic accelerator irradiates the rubber sheet through the titanium window of the irradiation box, thereby fulfilling the surface curing of the rubber sheet. The surface radiation curing of the rubber sheet is performed under the normal temperature and the normal pressure, and the process is simple, the productivity effect is high, the degree of curing is easy to be adjusted, the environmental pollution is less, the green strength of the rubber material processed by the radiation is high, the structure and the performance are stable, the thermal stability of the product is good, the ozone resistance property is strong and the anti-aging property is provided, and the service life of the product is prolonged.

Owner:BEIJING RADIATION APPL RES CENT +1

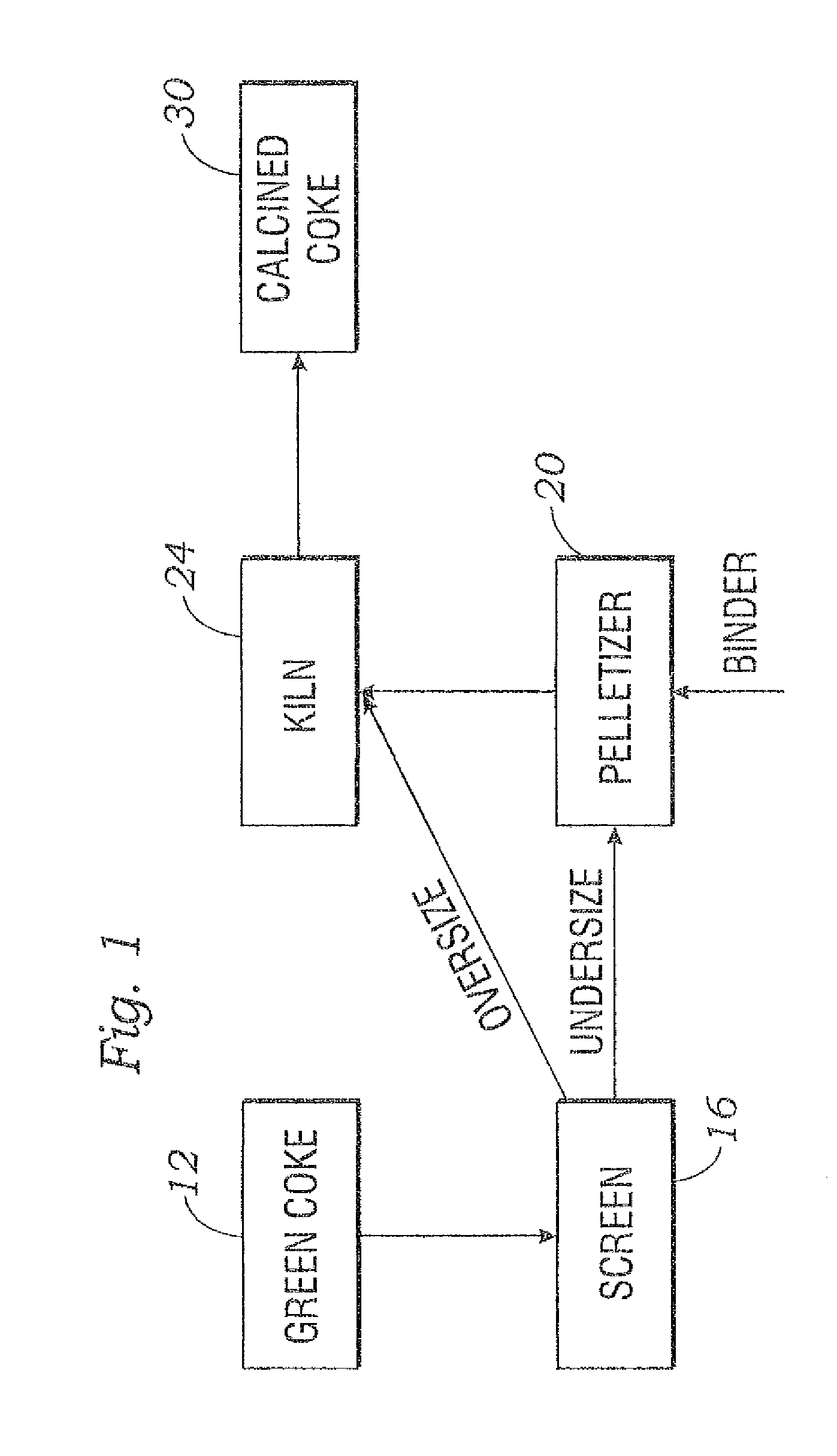

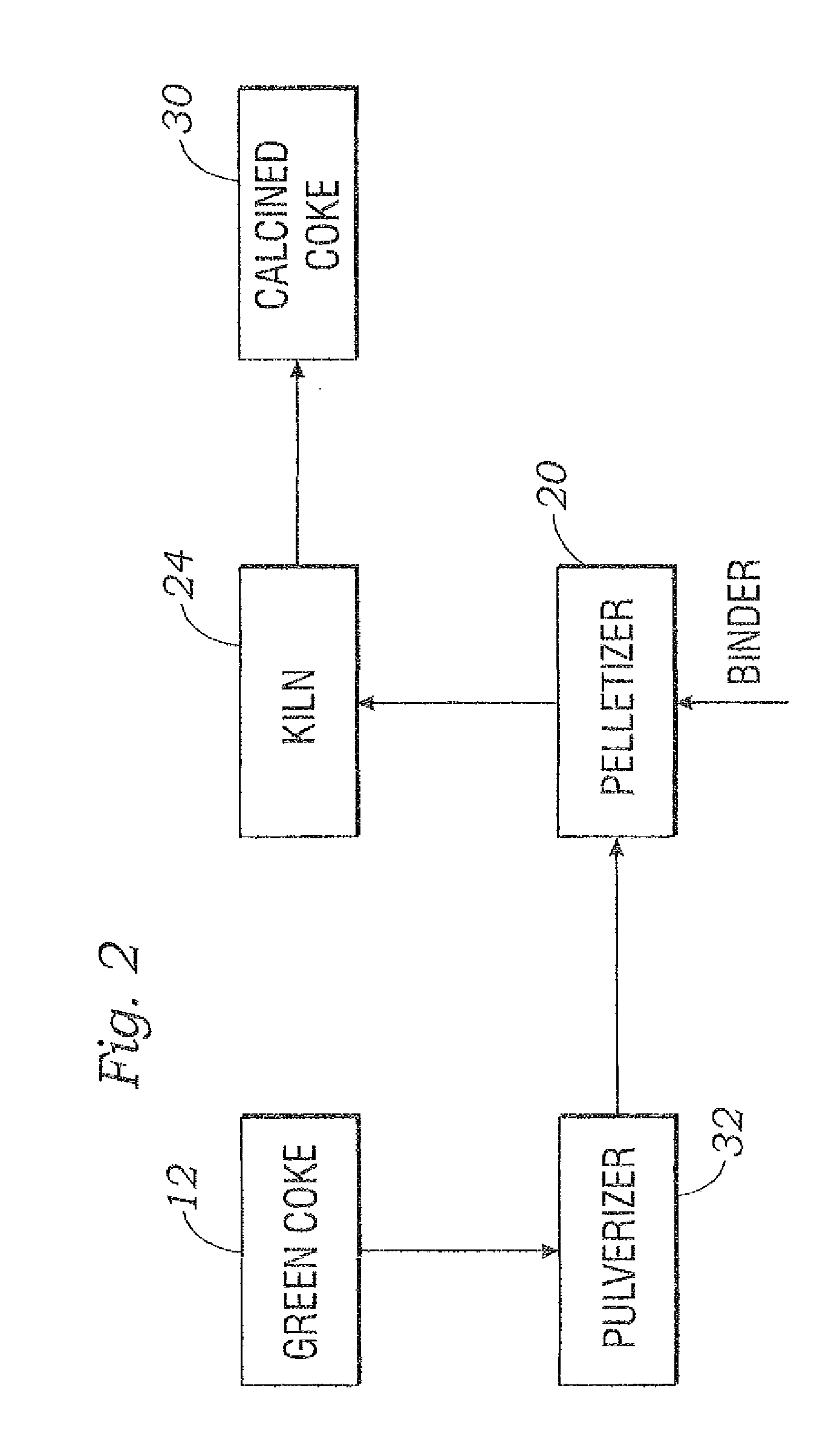

Pelletization and calcination of green coke using an organic binder

ActiveUS20120210635A1Easy to controlHigh green strengthSolid fuelsWaste based fuelPetroleum cokeCalcination

A method of calcining green petroleum coke which includes separating the green coke having a particle size of between 0.1 mm and 50 mm into undersized and oversized fractions, pelletizing the undersized fraction with a binder to form pelletized coke, combining the oversized fraction and the pelletized coke to form a feed mixture, and calcining the feed mixture to form calcined coke. The method includes the addition of a pulverization step wherein all the green coke is pulverized before pelletization and the pellets are then calcined to produce a pelletized calcined coke product.

Owner:RAIN CII CARBON LLC

Novel reactive hot melt adhesives

InactiveUS20050215702A1Long open timeHigh green strengthManual label dispensersPolyureas/polyurethane adhesivesHot-melt adhesiveDiol

Owner:HENKEL KGAA

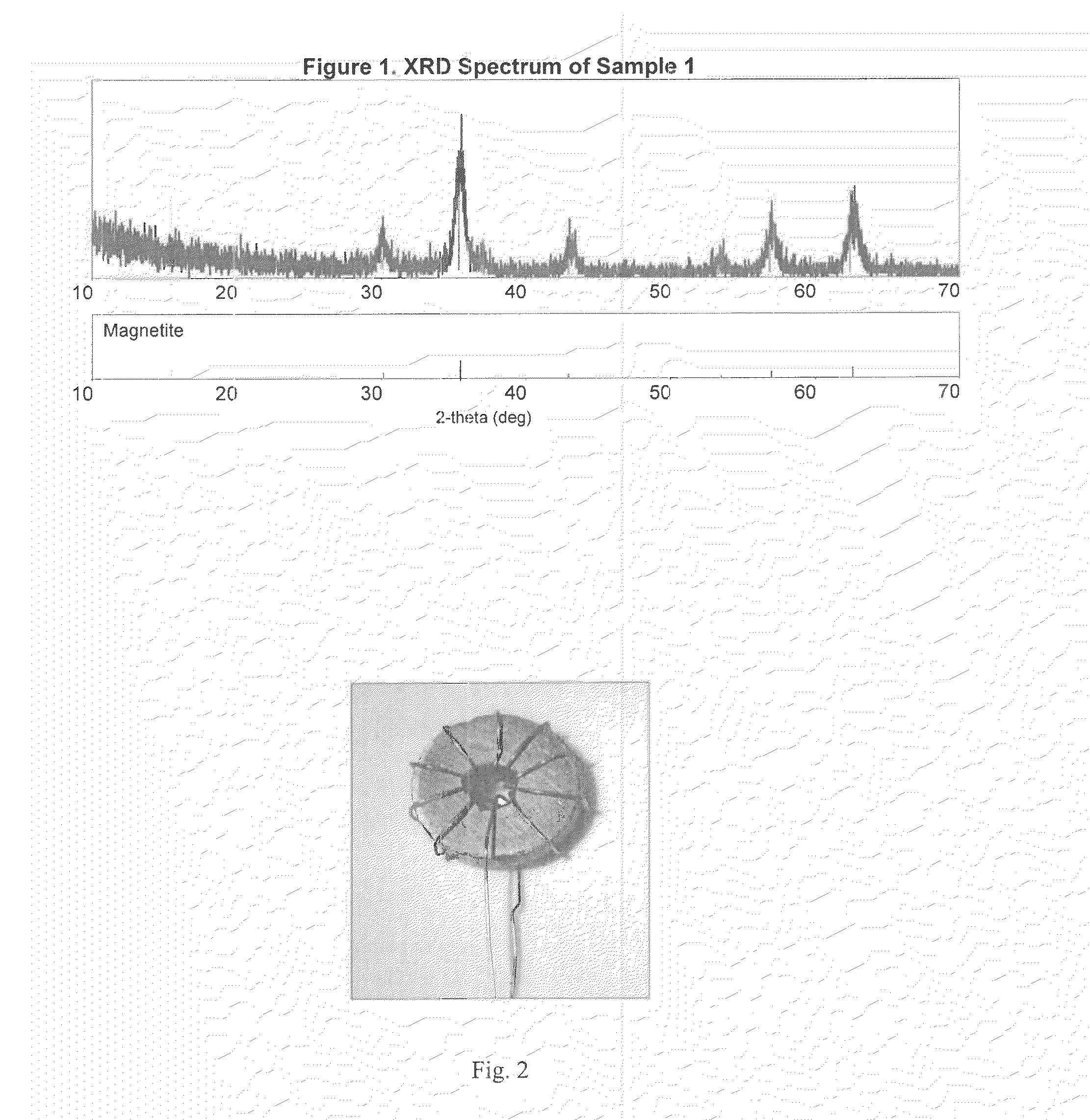

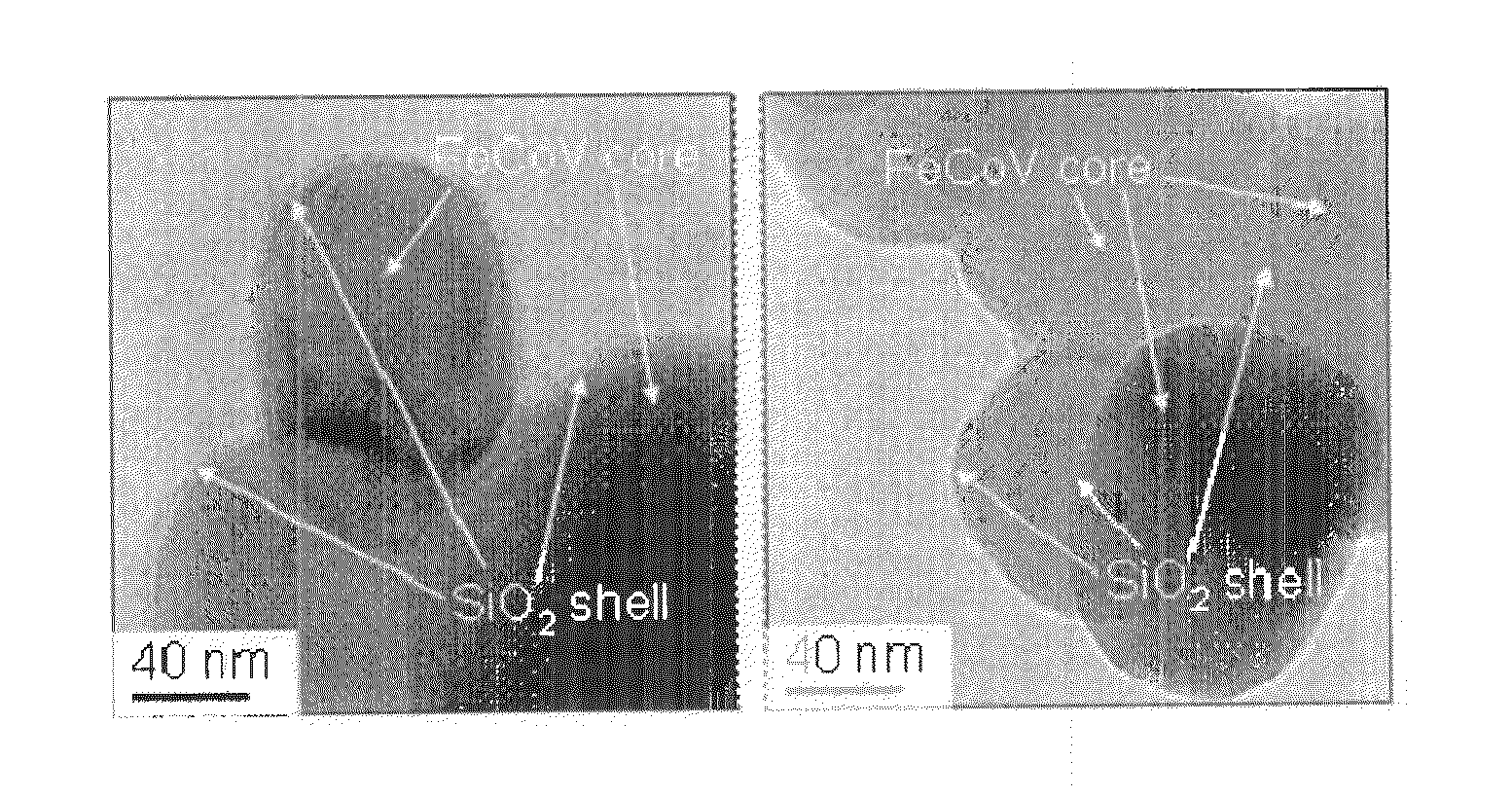

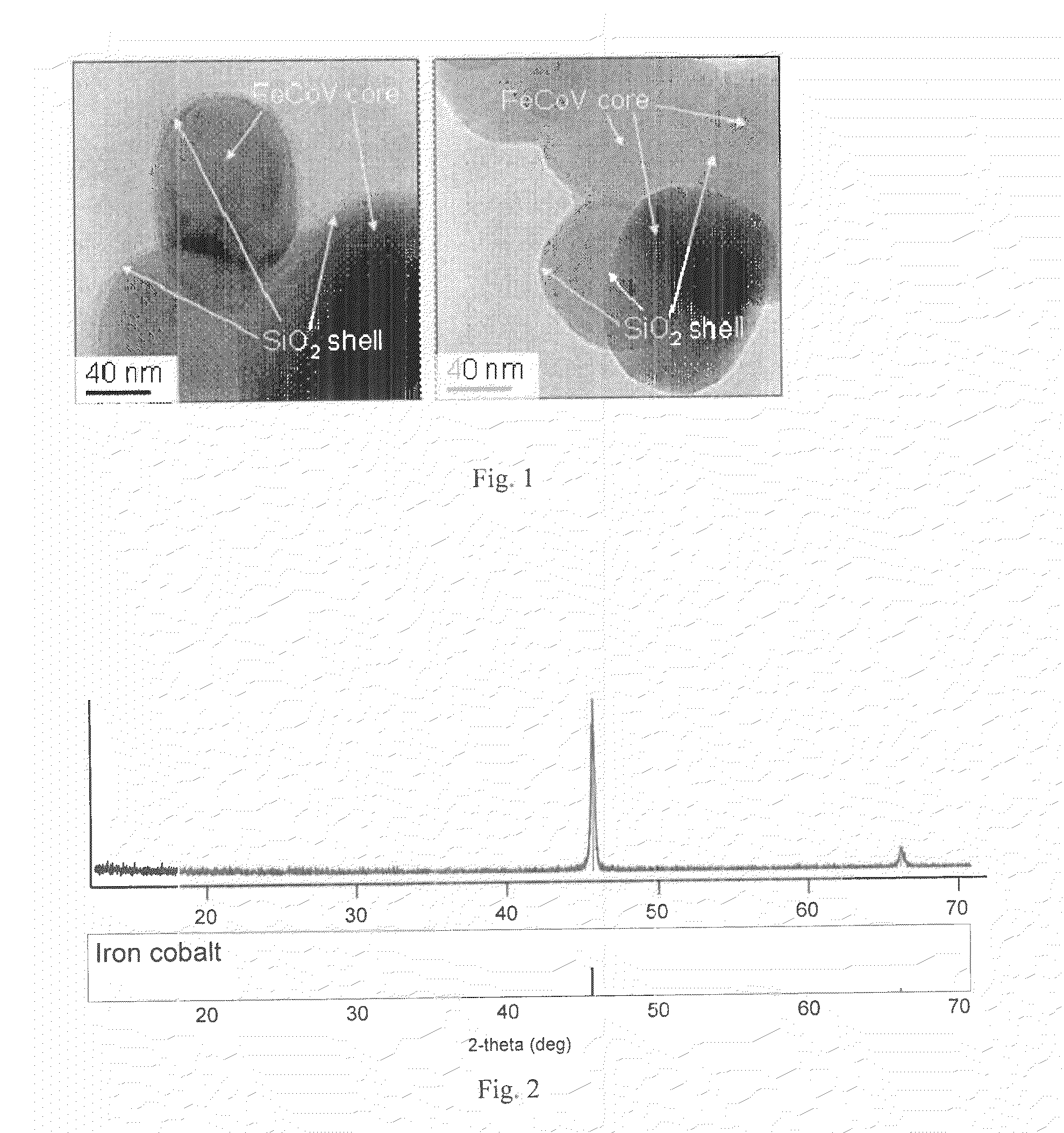

Iron cobalt ternary alloy nanoparticles with silica shells

InactiveUS20140027667A1High green strengthImprove mechanical propertiesMaterial nanotechnologyTransportation and packagingCore shell nanoparticlesSuperparamagnetism

Superparamagnetic core shell nanoparticles having a core of a iron cobalt ternary alloy and a shell of a silicon oxide directly on the core and a particle size of 2 to 200 nm are provided. Methods to prepare the nanoparticles are also provided.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

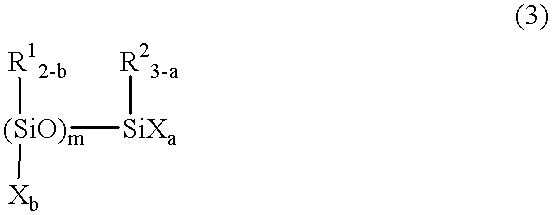

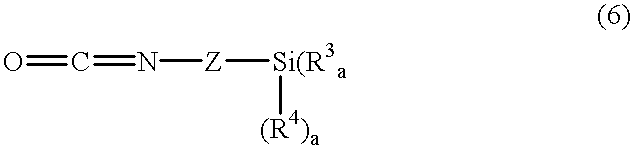

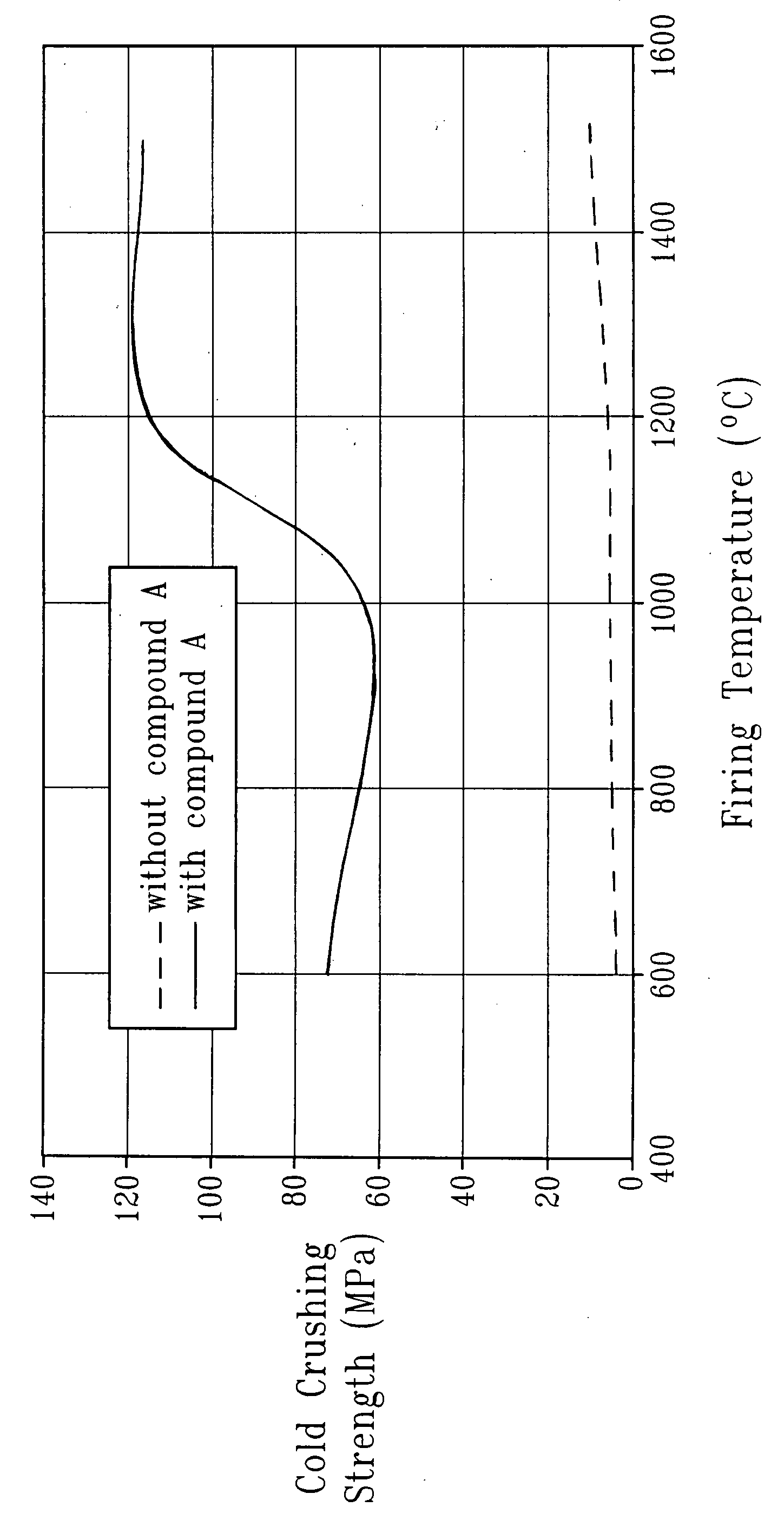

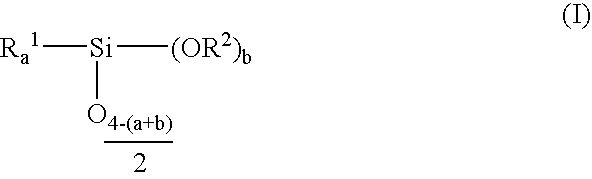

Reactive liquid ceramic binder resin

InactiveUS20080034794A1High green strengthWeaken energyGlass shaping apparatusAryl radicalMaterials science

A reactive liquid ceramic binder suitable for the production of ceramic products from ceramic powders is provided. The reactive liquid ceramic binder contains organo-modified siloxane compounds, wherein the liquid organo-modified siloxane compounds contain organoalkoxysiloxane units according to general formula (I)whereinR1=alkyl radical and / or aryl radical,R2═H and / or alkyl radical with 1 to 4 carbon atoms,a≧0 and ≦2, andb<0 and ≦3,with the proviso that a+b≧1 and ≦4.

Owner:EVONIK DEGUSSA GMBH

Radial truck tire air-tight layer component and preparation process thereof

InactiveCN102604243AImprove stabilityImprove thickness uniformityTyresPneumatic tyre reinforcementsVulcanizationEngineering

The invention belongs to the technical field of processing of rubber tires, and particularly relates to a radial truck tire air-tight layer component and a preparation process thereof. The radial truck tire air-tight layer component comprises the following substances in parts by mass: 100 parts of rubber substrate, 40-100 parts of reinforcing system, 1-10 parts of anti-aging system, 4.7-15 parts of vulcanization system, 0-20 parts of radiation crosslinking sensitizer and 0-50 parts of additive aid. The method comprises the following steps of: mixing other substances except a vulcanizing agent, discharging glue, and adding the vulcanizing agent for preparing a rubber compound; and rolling the prepared rubber compound to obtain an air-tight layer sheet of 3-5 millimeters in thickness, performing cobalt source radiation treatment in the air to obtain the radial truck tire air-tight layer component, wherein the radiation dosage of the air-tight layer sheet is 5-50 kGy. The air-tight layer component which is subjected to radiation pretreatment has the advantages of high Green strength, high structural size stability, high air tightness, and capability of improving the tire quality at a lower radiation dosage.

Owner:河南省科学院同位素研究所有限责任公司 +1

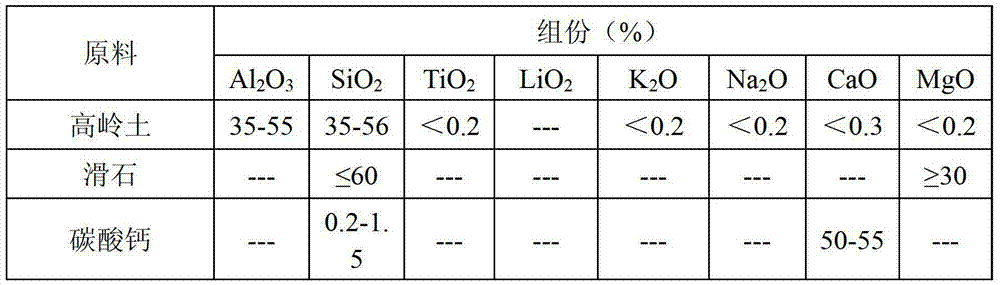

Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

The invention discloses a method for preparing an inert porcelain ball by using an aluminum oxide dust-recovery powder and belongs to the technical field of new materials. A lot of aluminum oxide dust-recovery powder is used in the formulation of the method disclosed by the invention, the cost is obviously reduced, meanwhile a waste material is used and the environment is protected. According to the method disclosed by the invention, a composite sintering aid comprising calcium carbonate, talcum, and spodumene mineral powder is added into the formulation to facilitate the formation of magnesia-alumina spinel and mullite for enhancing in the product so as to improve the thermal shock resistance and strength of a product; a little kaolin is added into the formulation for improving the plasticity of a perform body, promoting molding conveniently and improving the strength of a green body; meanwhile in order to reduce the high energy consumption caused by wet ball milling, the powder for preparing the inert porcelain ball disclosed by the invention is subjected to continuous dry wet milling; the inert porcelain ball prepared by the method disclosed by the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance and the like, is excellent in comprehensive performance, and is completely suitable for requirements for a catalyst carrier and supporting performance in various industries.

Owner:JINGANG NEW MATERIALS

Composite component of meridian tyre cord fabric layer and air barrier and preparation technology

ActiveCN101612867ASimple production processIncrease productivitySpecial tyresPneumatic tyre reinforcementsRadial tireEngineering

The invention discloses a composite component of meridian tyre cord fabric layer and air barrier and a preparation technology. Base material rubber, an aging-proof system, a reinforcing system, a vulcanization system and a radiosensitizer are mixed at a ratio to form a mixture; the rubber mixture is mixed to smelt in an internal mixer to be prepared into a tyre body cord fabric layer component and a lining air barrier component respectively according to the production technology of the tyre body cord fabric layer and the lining air barrier component; then the tyre body cord fabric layer component and the lining air barrier component are compounded into an integral composite component on a compound machine; an electron accelcrator is used for radiating the composite component; under the condition of limited-oxygen radiation, radiation prevulcanization is carried on the composite component of the tyre cord fabric layer and the lining air barrier. The composite component of the tyre cord fabric layer and the air barrier, which is radiated by the invention, has high Green strength, stable structure size and performance, saves raw material, has small radiation dose and high production efficiency and is favourable for environment protection.

Owner:BEIJING RADIATION APPL RES CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com