Patents

Literature

147results about "Moulding plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

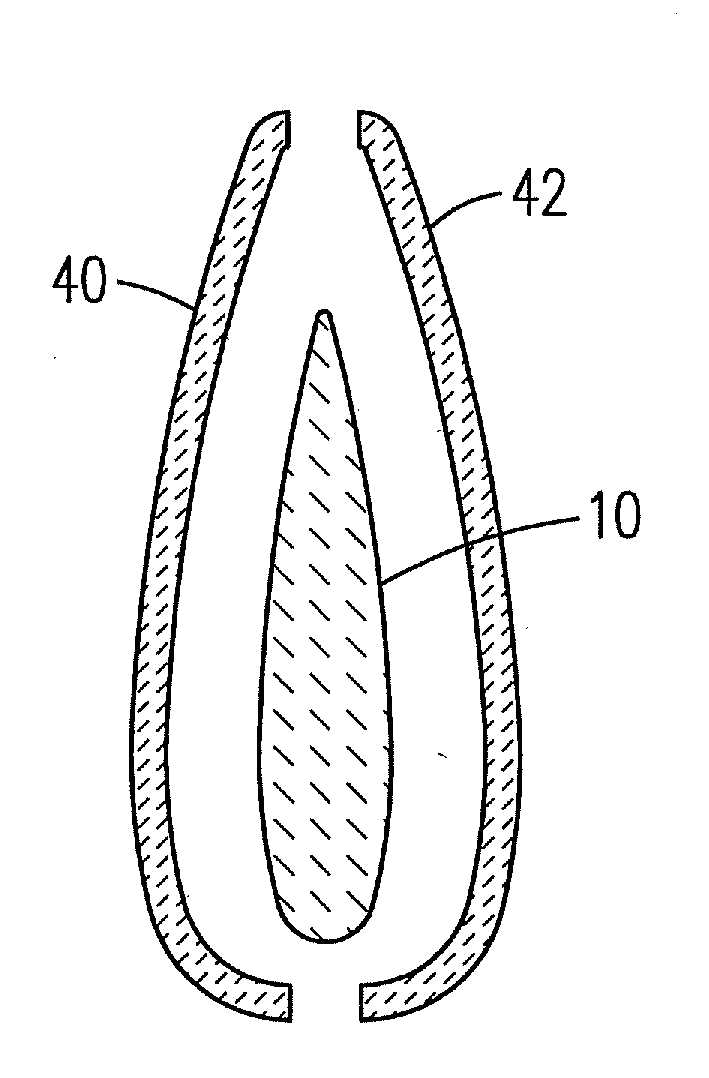

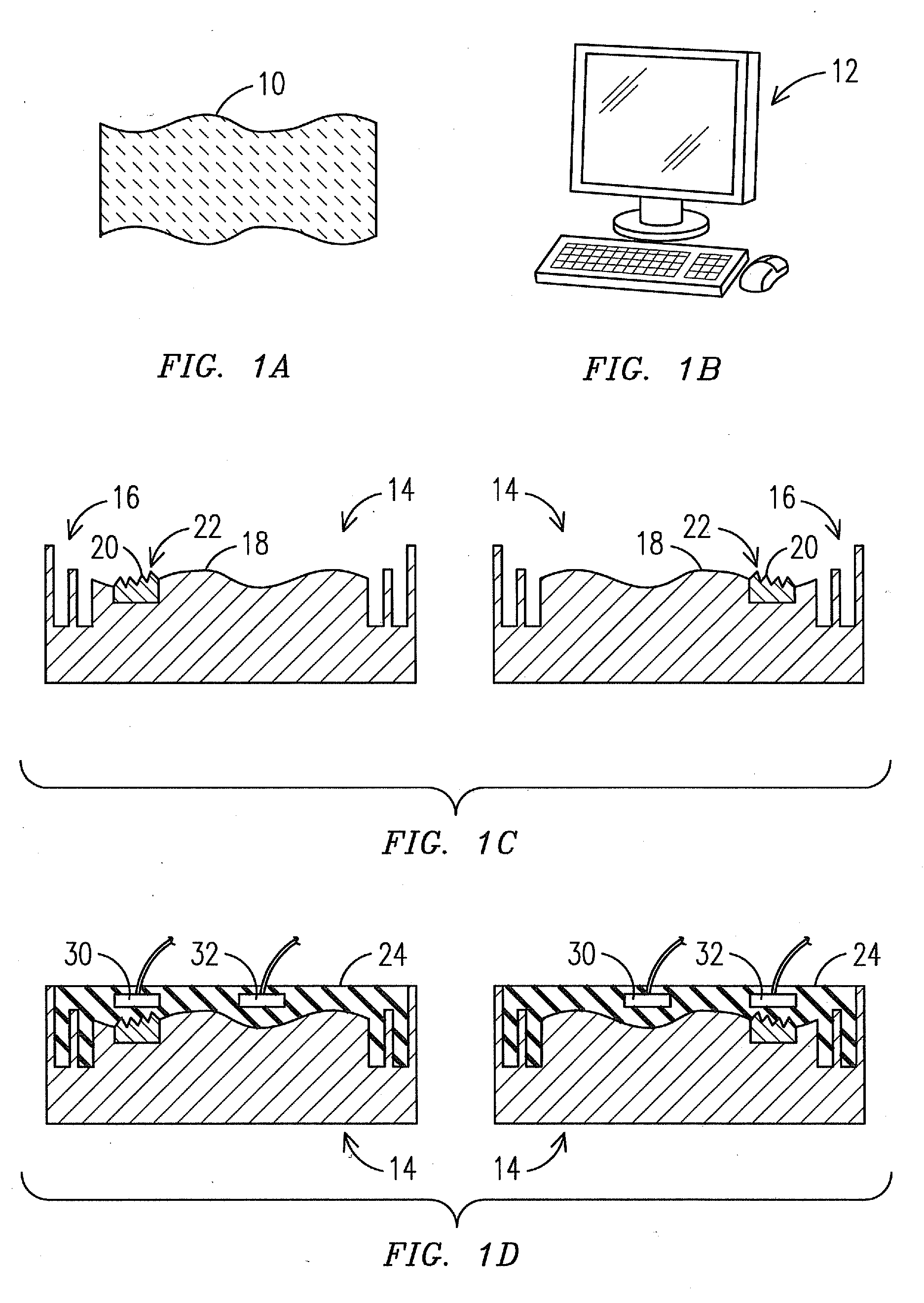

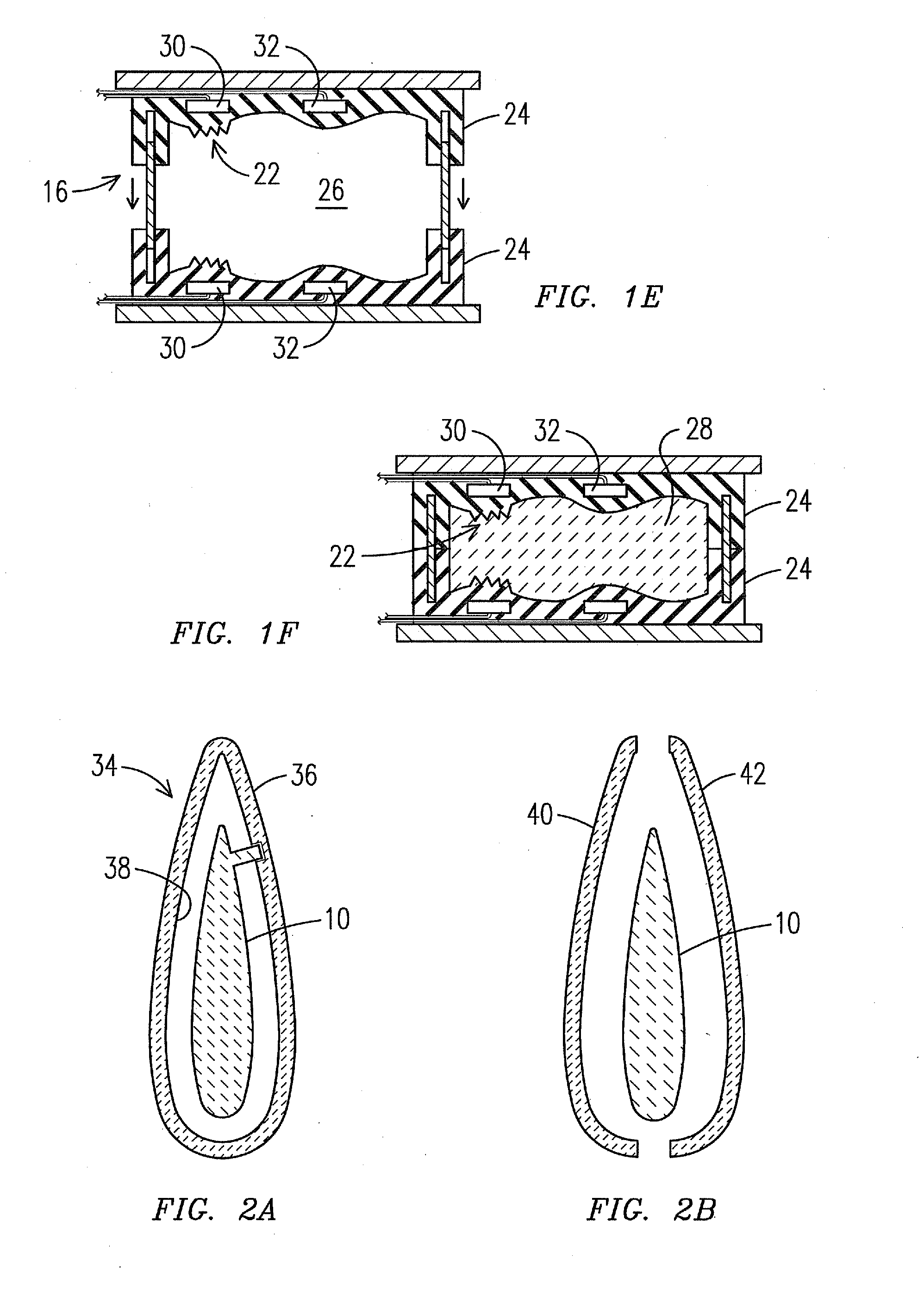

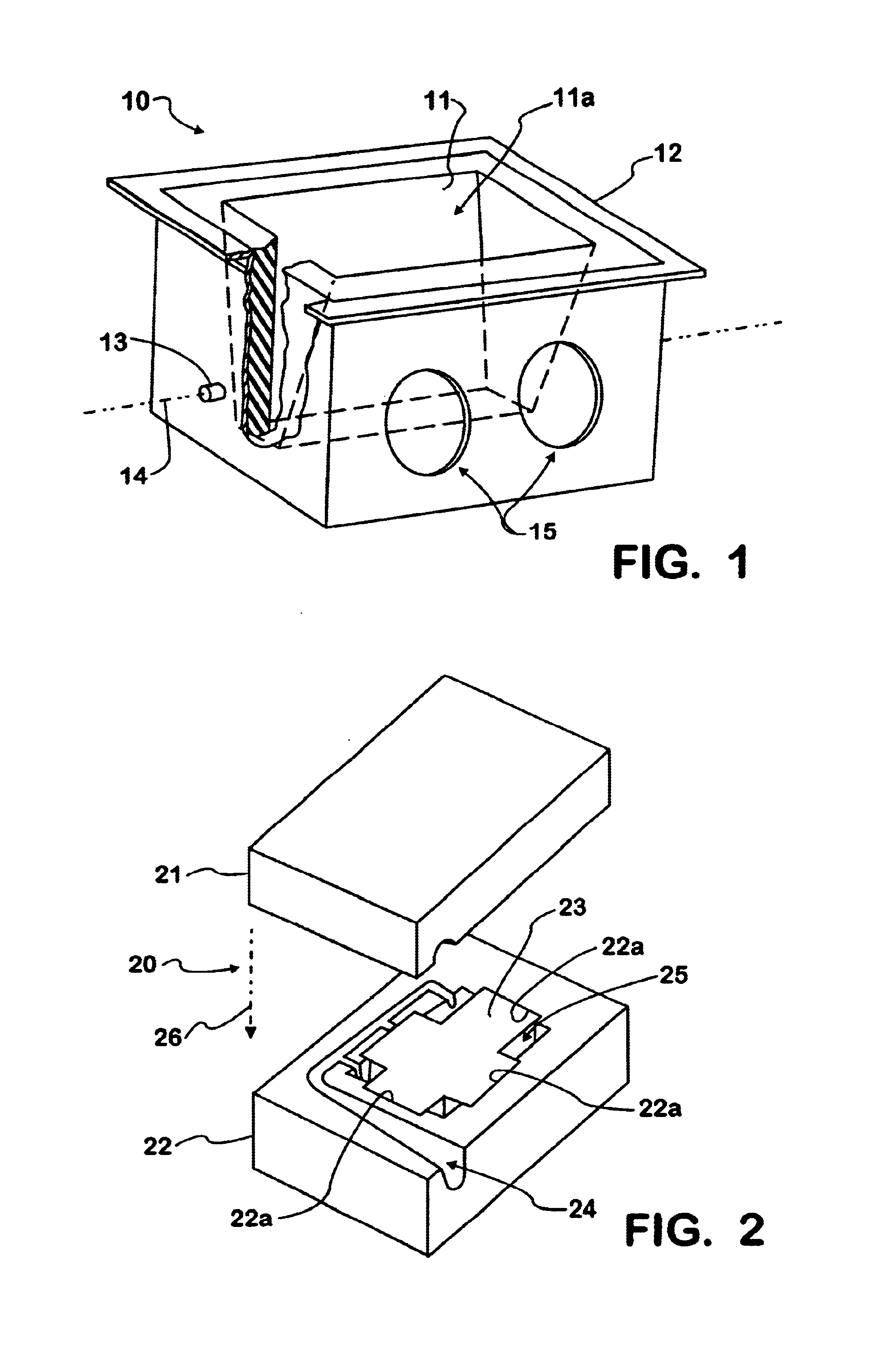

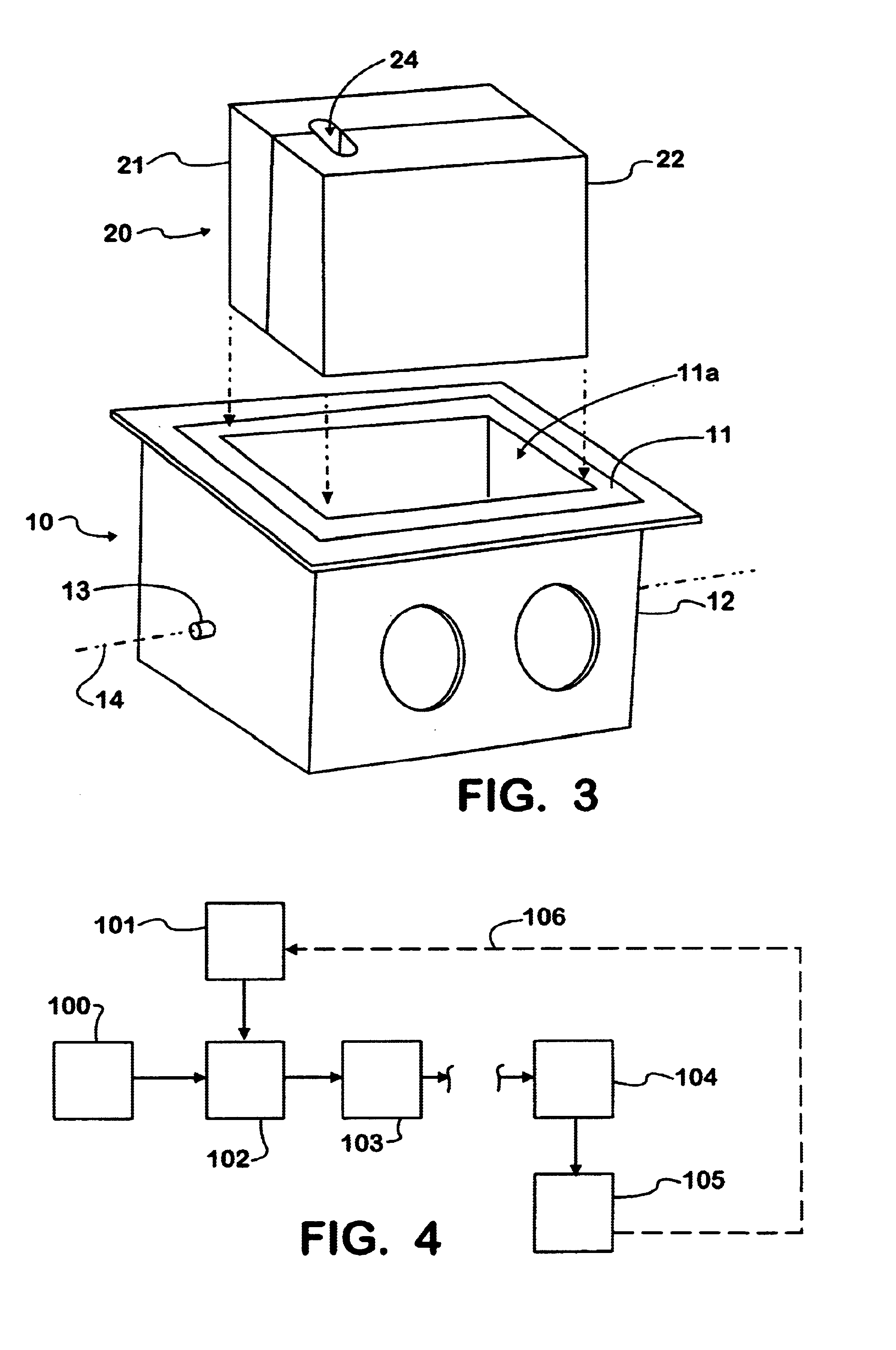

Waxless precision casting process

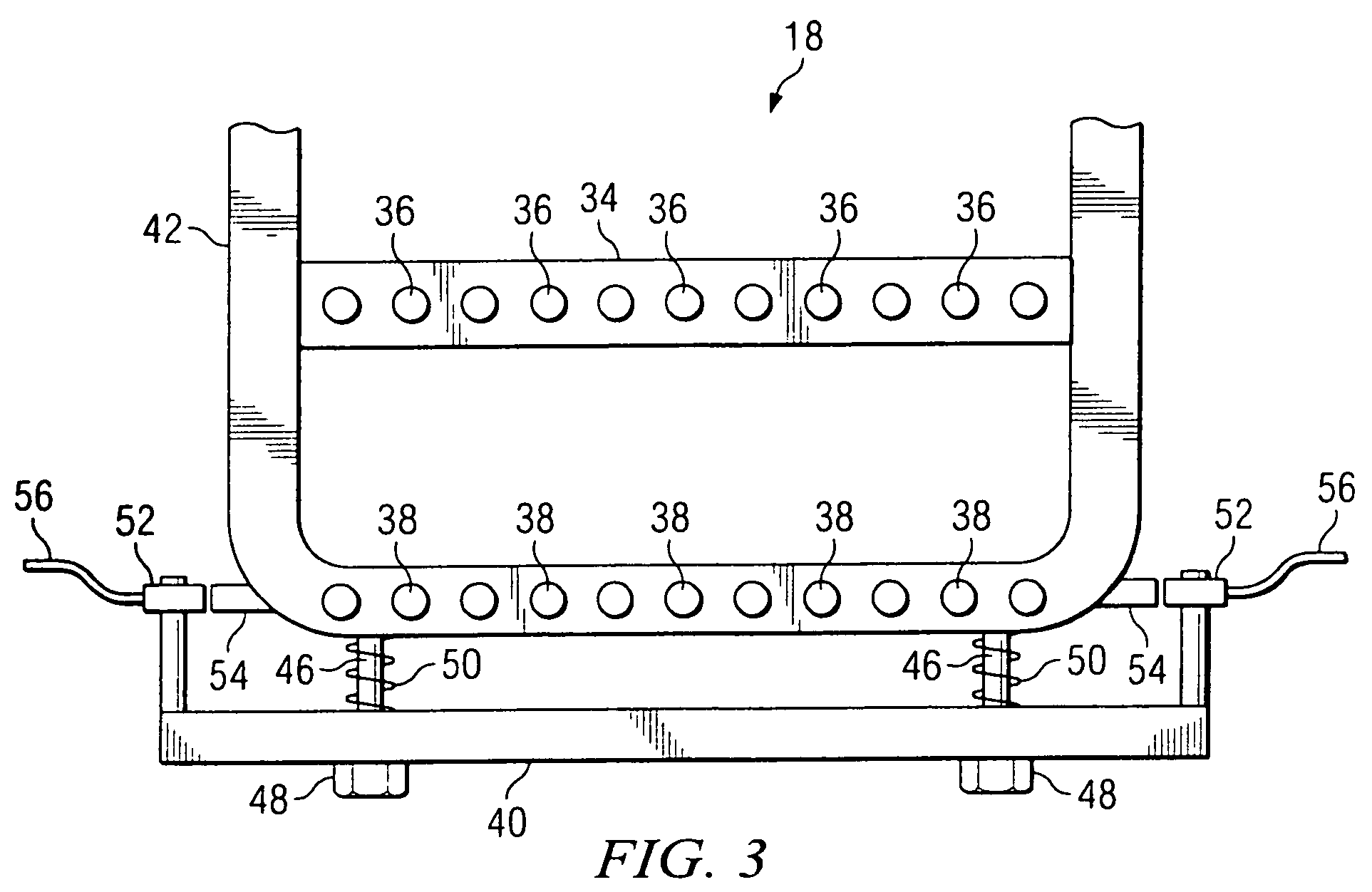

Alloy products are produced with a waxless casting process. A model of a ceramic casting vessel (34) defining a desired product shape is digitally divided into sections (10, 40, 42). Each section is translated into a soft alloy mater tool (14) including precision inserts (20) where needed for fine detail. A flexible mold (24) is cast from each master tool, and a section of the ceramic casting vessel is cast from the respective flexible mold. The vessel sections are assembled by aligning cooperating precision features (58, 60) cast directly into each section and the alloy part is cast therein. No wax or wax pattern tooling is needed to produce the cast alloy product. Engineered surface features (54) may be included on both the interior and exterior surfaces of the shell sections.

Owner:MIKRO SYSYTEMS INC +1

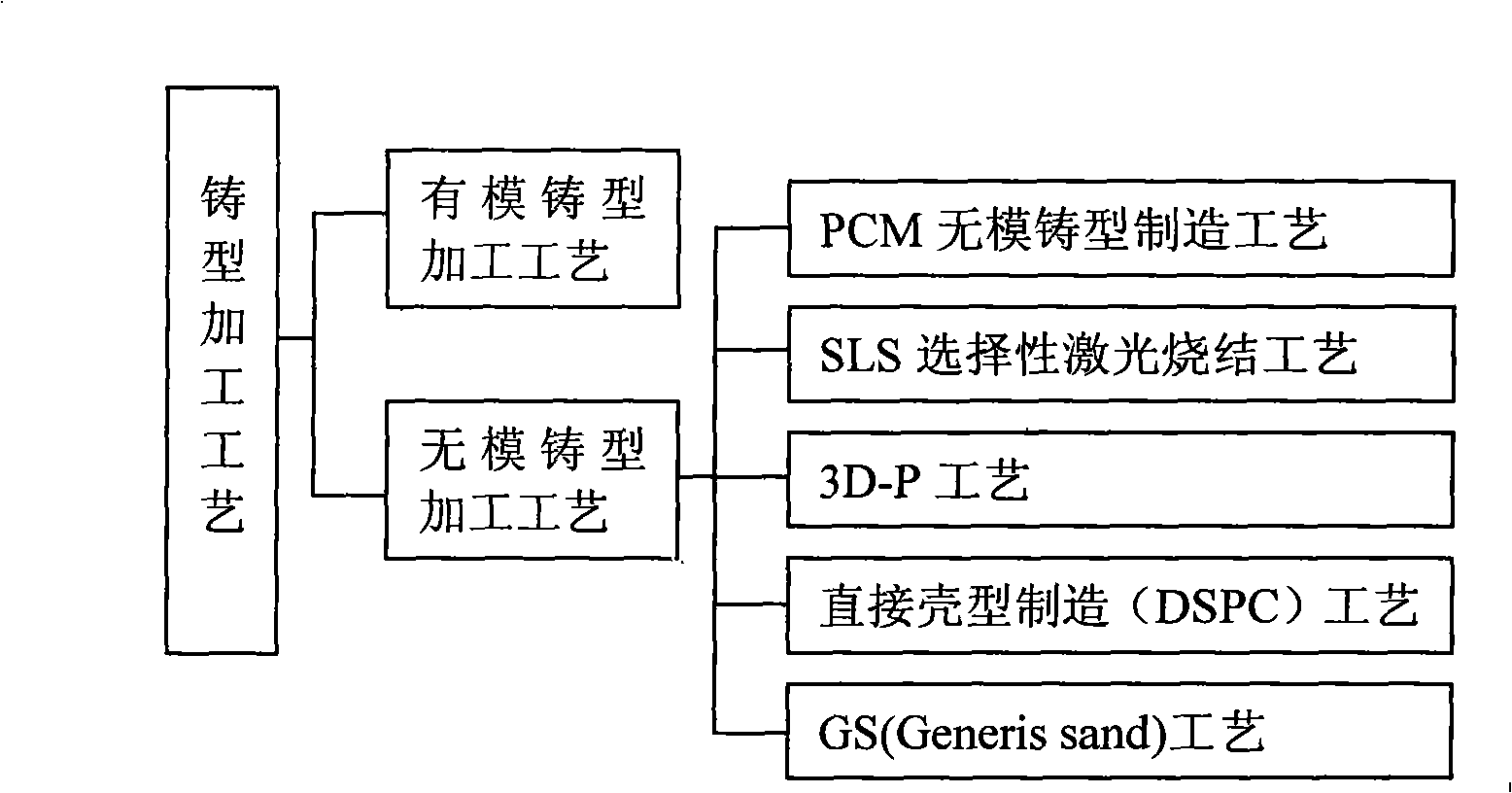

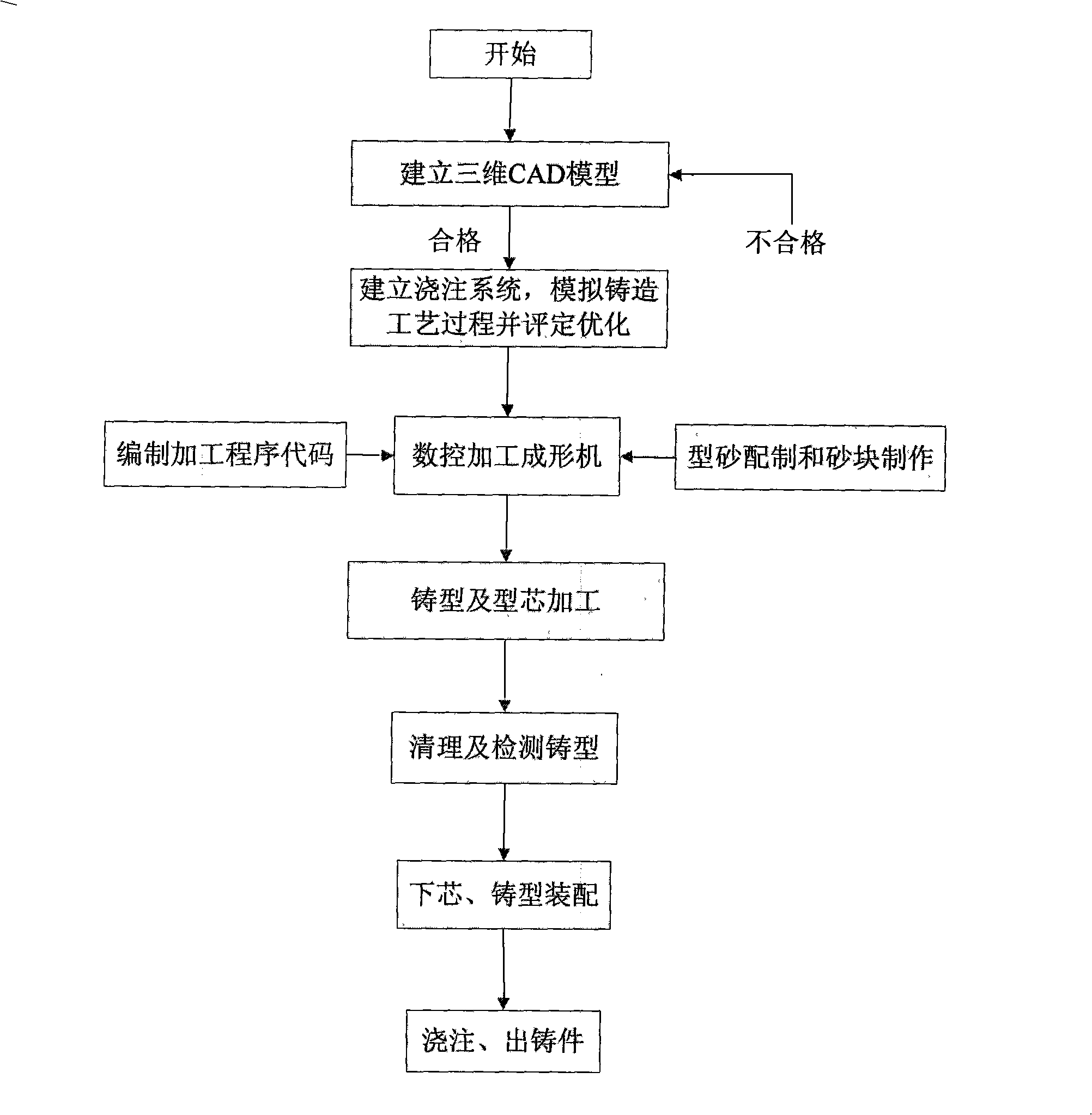

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

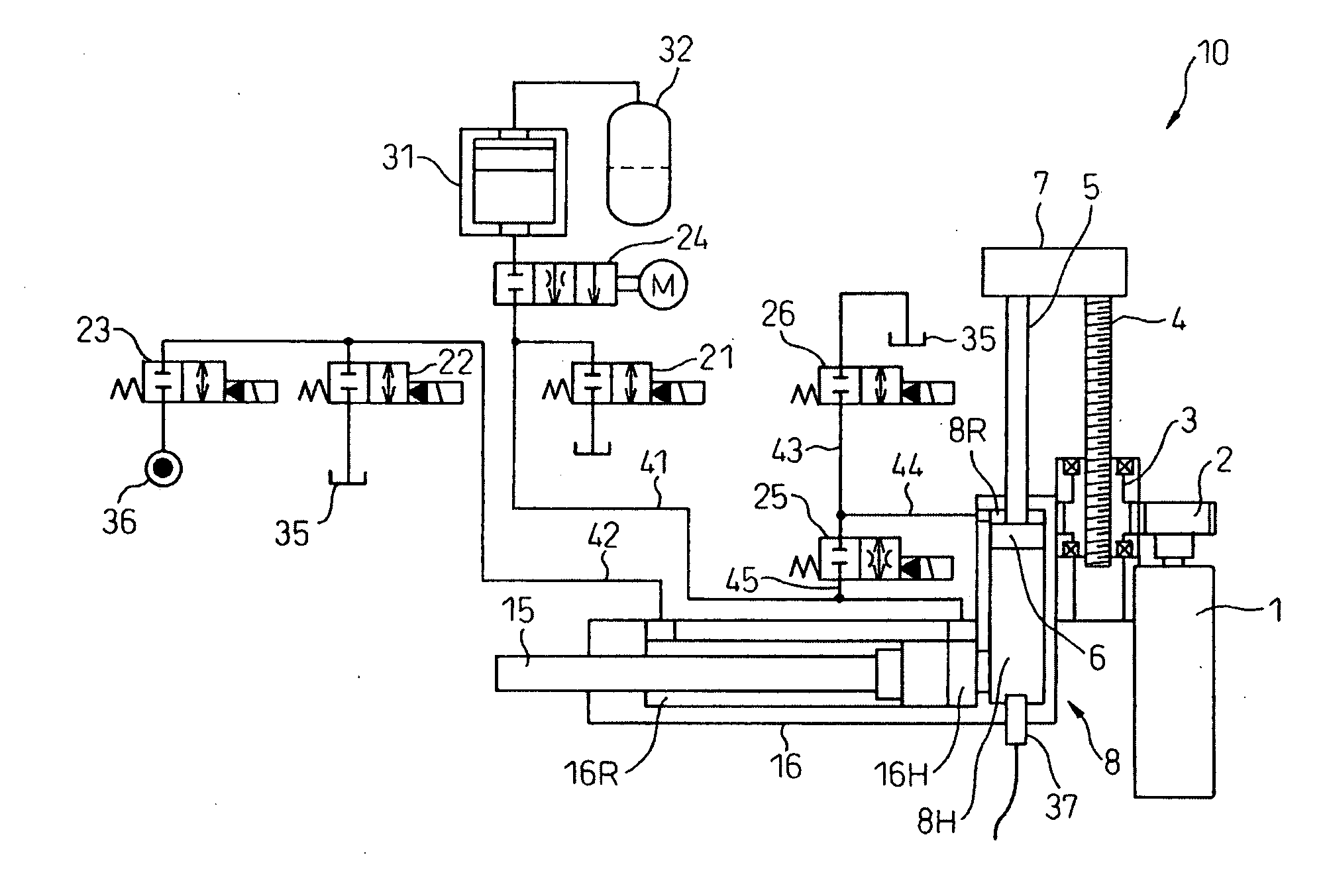

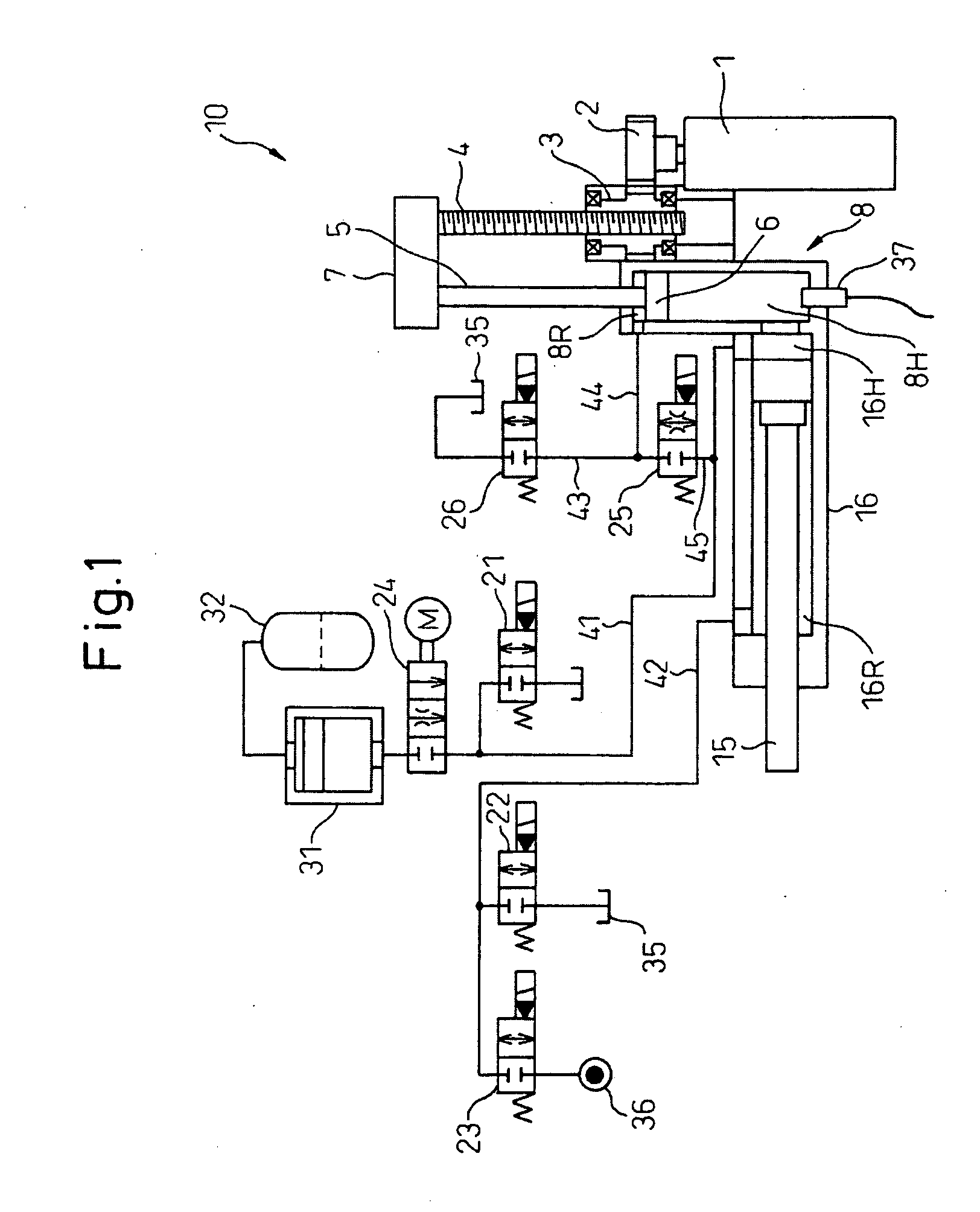

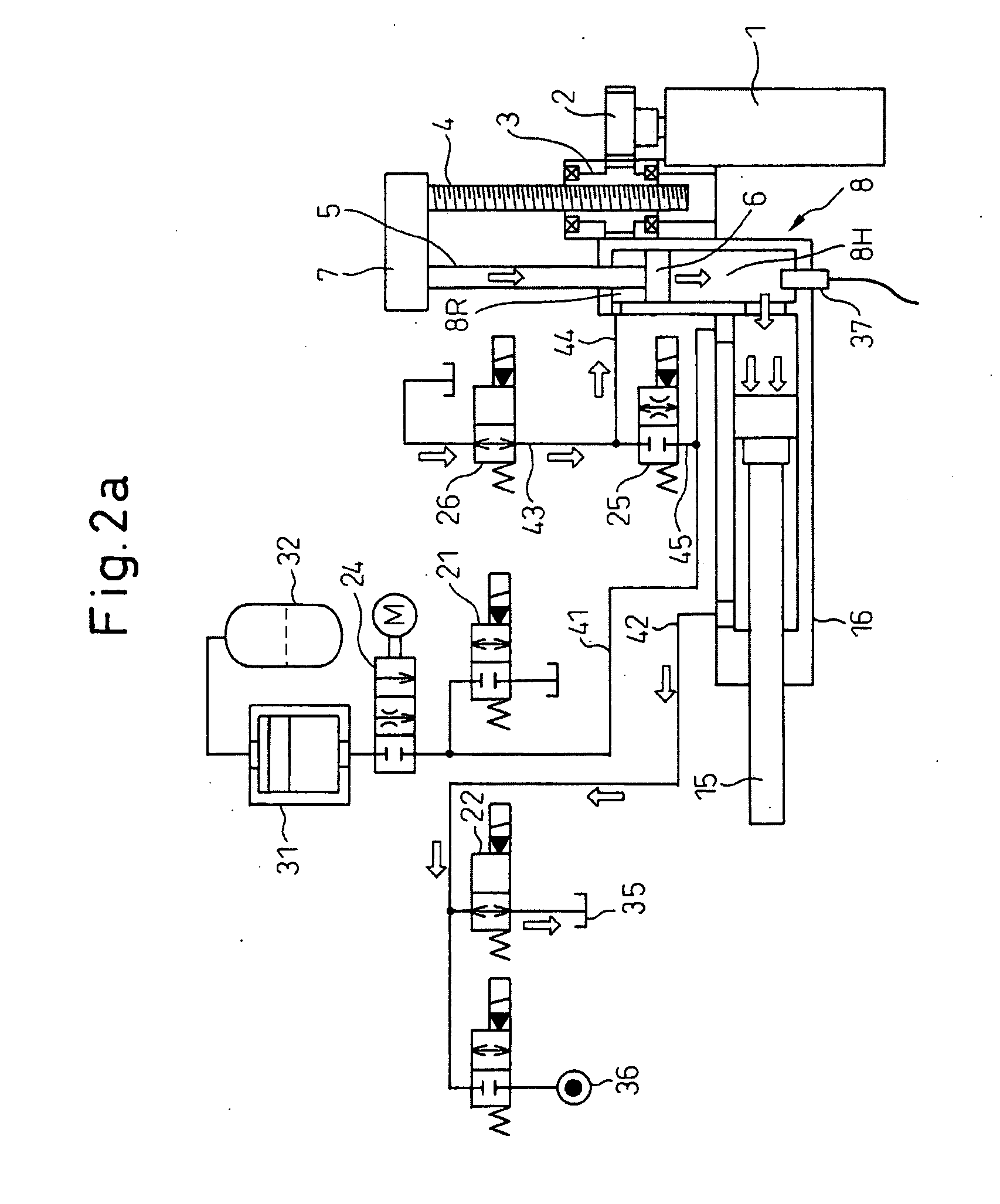

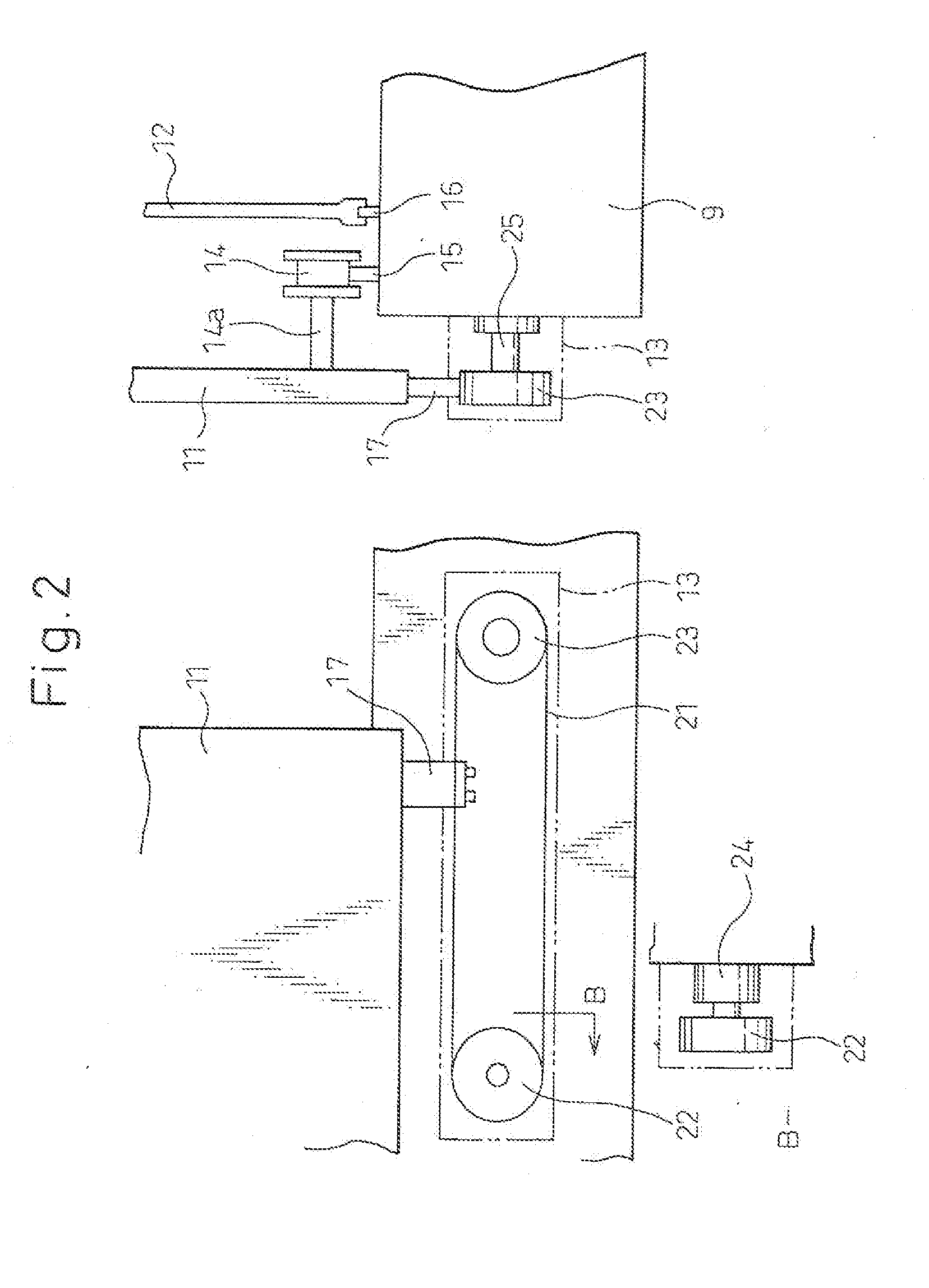

Injection device for die casting machine

InactiveUS20090242161A1Reducing necessary maximum torqueLower injection costsMoulding plantsCasting safety devicesHydraulic cylinderPower flow

In a hybrid injection system of a die casting machine, the occurrence of a large electric power loss can be prevented by avoiding a large current at a pressure-holding step and the size of a motor is reduced.In an injection system comprising an injection cylinder (16) housing an injection piston (15) for injecting molten metal to a mold and an electric booster (8) of hydraulic cylinder type, a head chamber (8H) to the electric booster communicates fluidly with a head chamber (16H) of the injection cylinder, causing a booster piston rod (5) to be housed in the electric booster (8) to move linearly and thus pressing under pressure to move the injection piston to perform injection molding. Because a stop valve (25) is provided in a pipe that causes the head chamber (16H) of the injection cylinder to communicate with a rod chamber (8R) of the booster (8), it is possible for the pressure of the hydraulic oil to act on a head area of the electric booster at a pressure-increasing step for increasing pressure of the molten metal, and for pressure of the hydraulic oil to act on a rod area of the electric booster at a pressure-holding step for holding pressure of the molten metal.

Owner:UBE MASCH CORP LTD

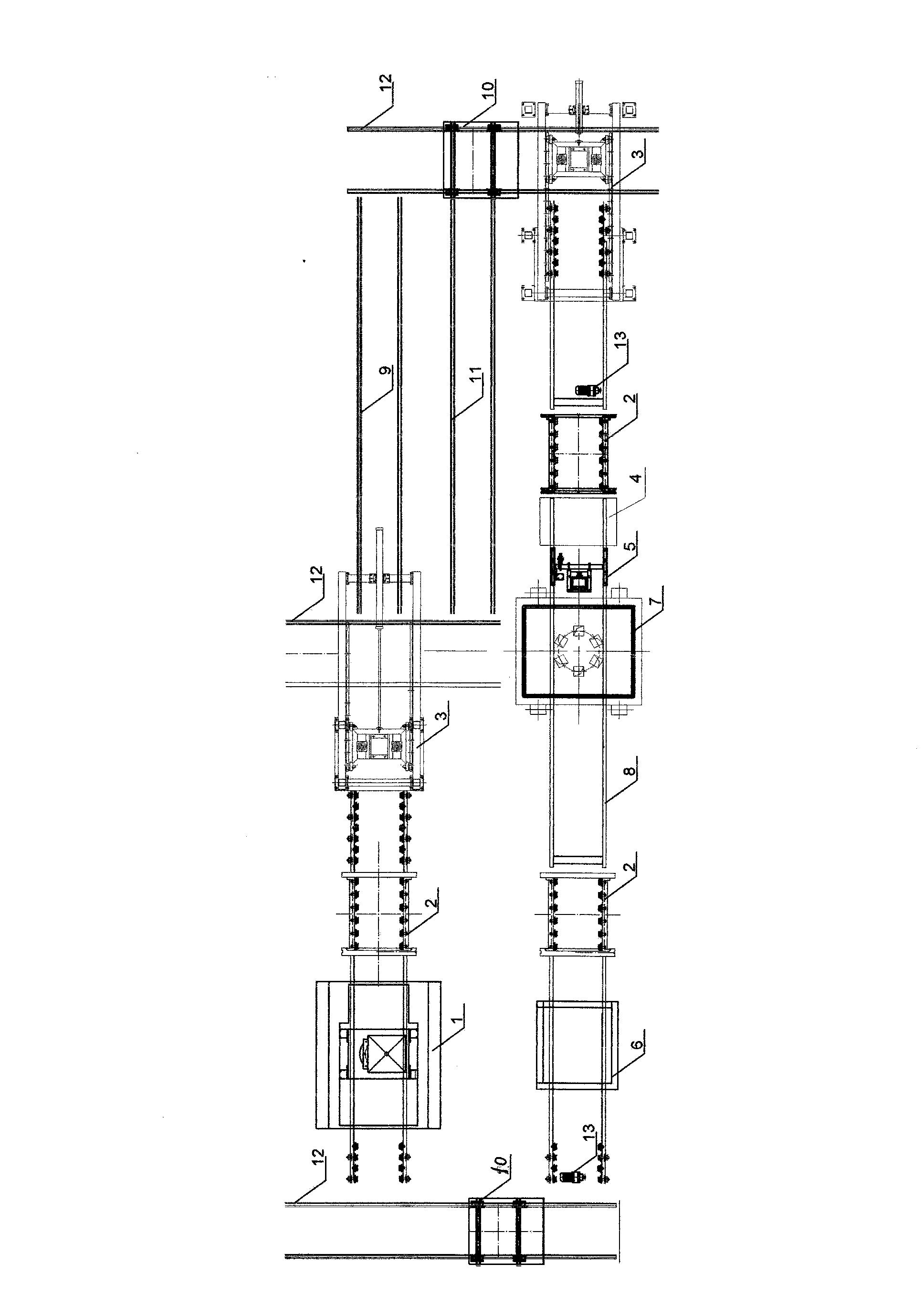

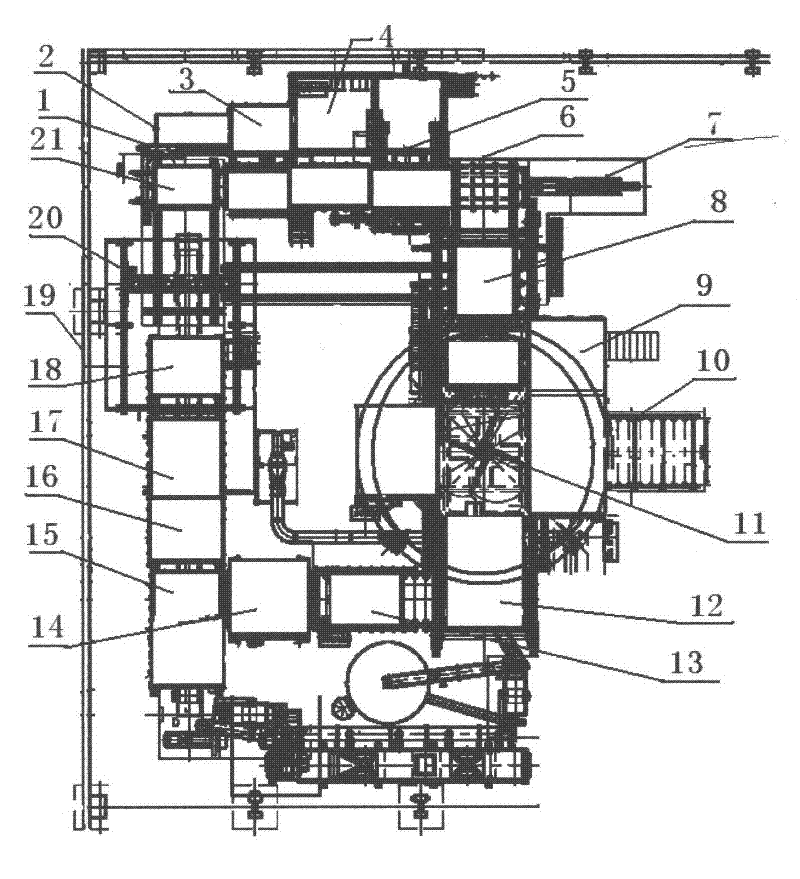

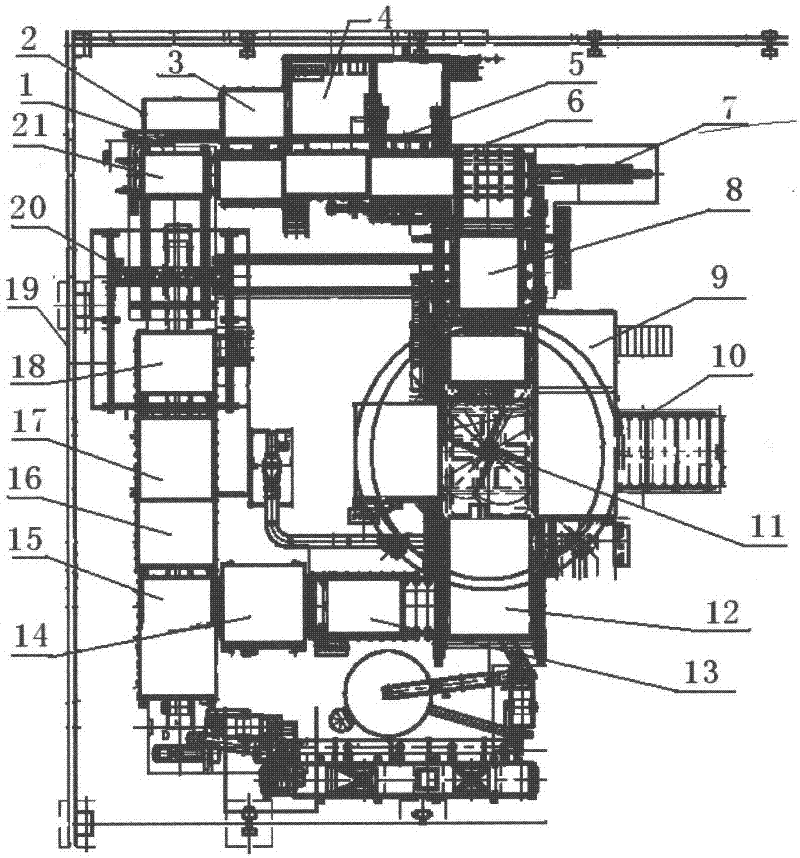

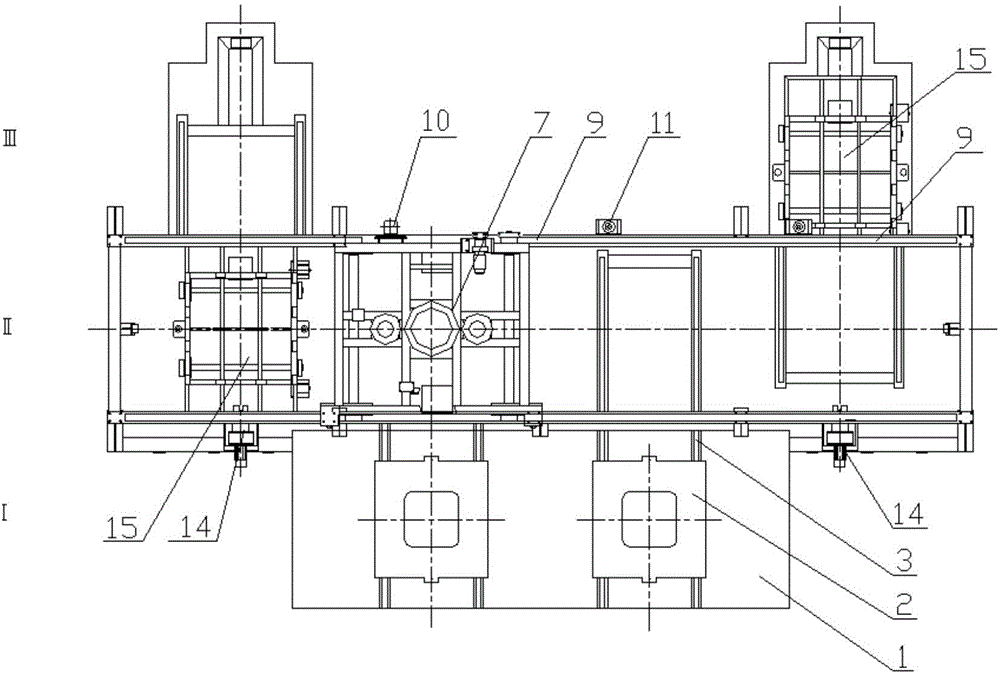

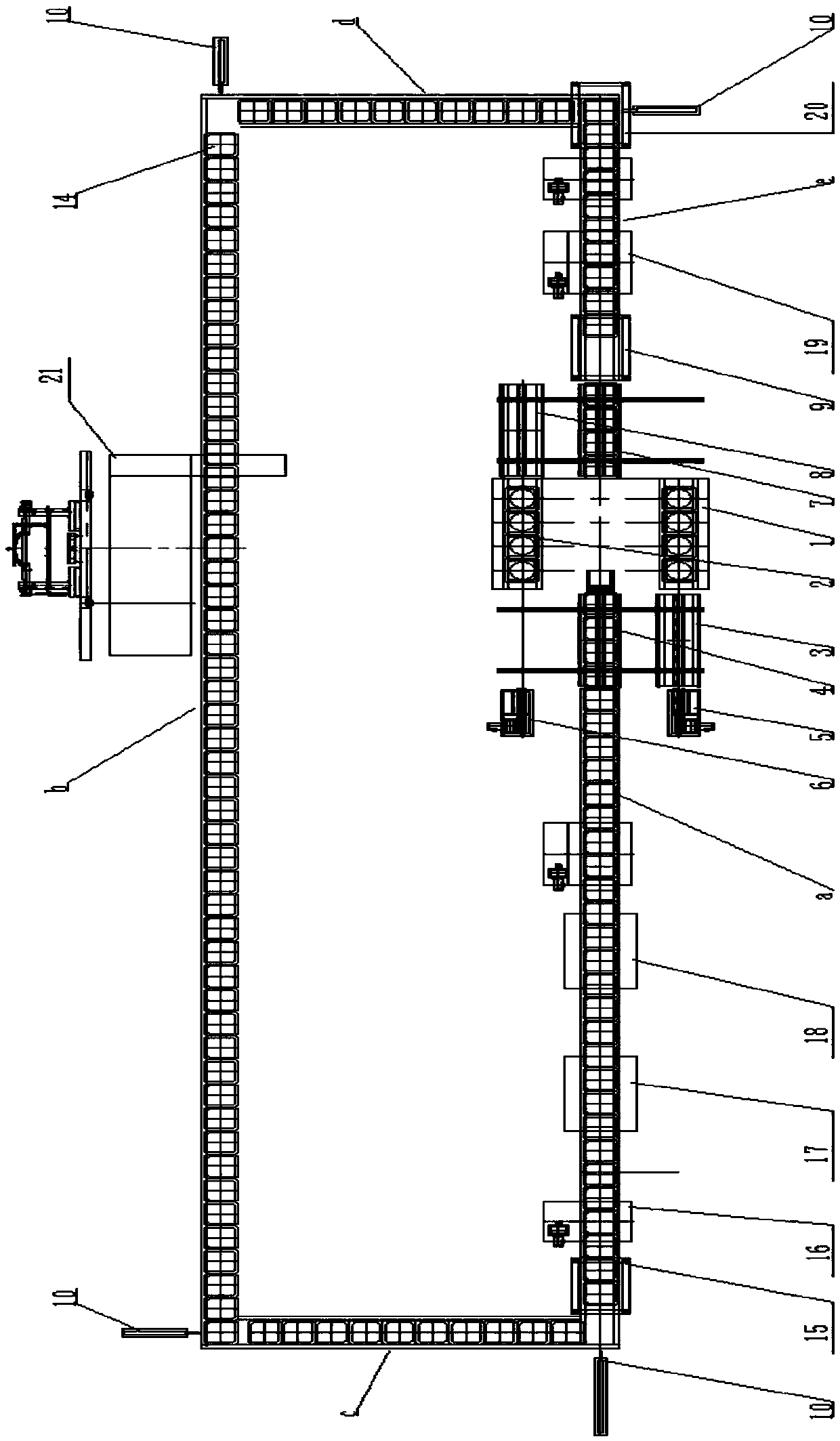

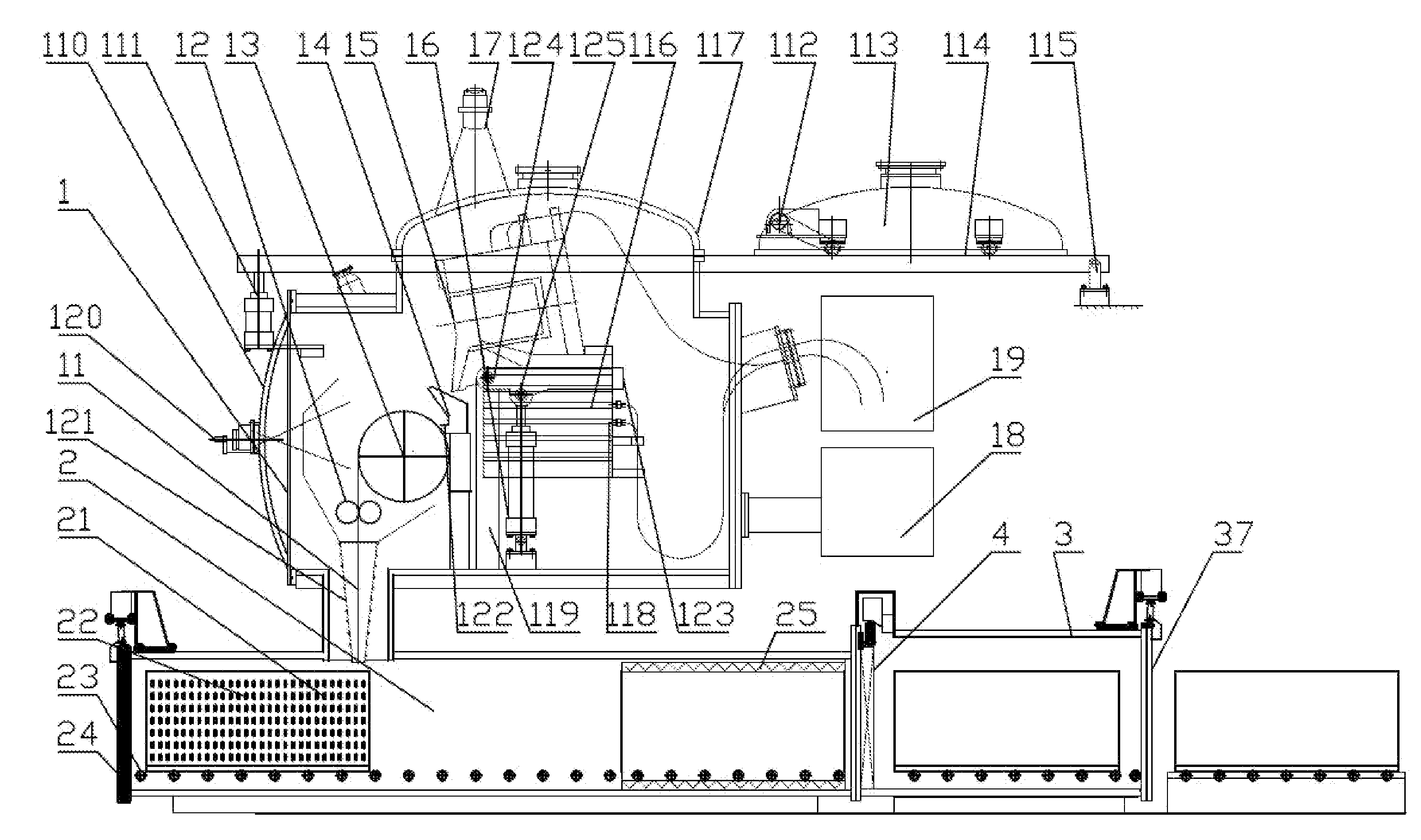

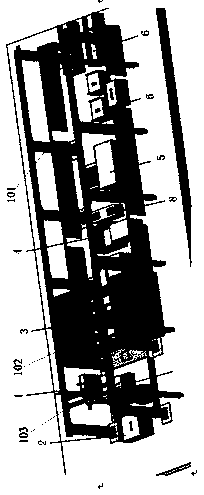

Automatic iron mold sand lined production line

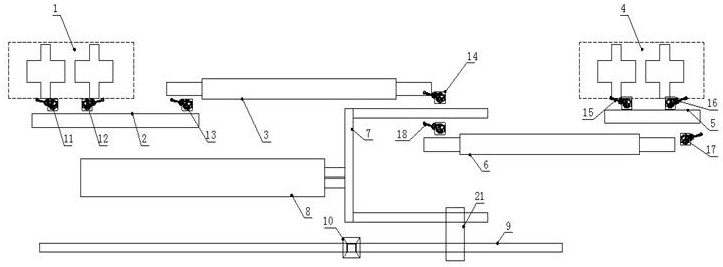

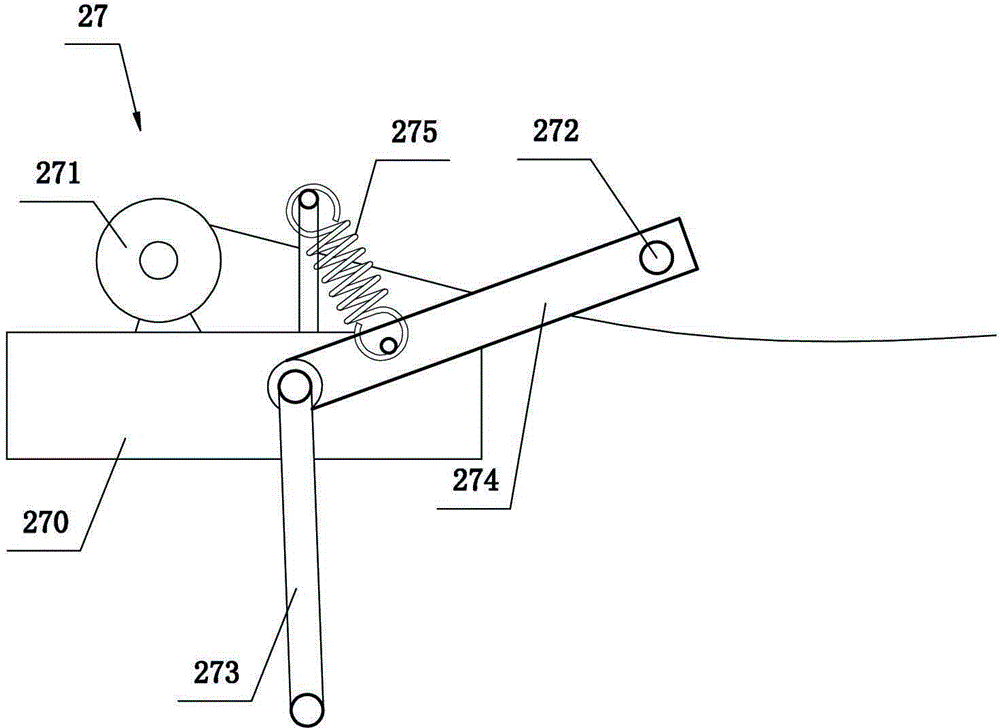

An automatic iron mold sand lined production line relates to a production line which is used when the iron mold sand is lined on a female mold in the production process of a crankshaft, and mainly aims at solving the problems that the conventional iron sand lined production line for producing the crankshaft is large in land occupation area, low in working efficiency and the like. The automatic iron mold sand lined production line comprises a double-station sand ejector, three mold turnover machines, two mold opening-closing machines, a perforation sand shakeout machine, a shifting machine, a female mold cooling device and a vibration sand shakeout machine; and the automatic iron mold sand lined production line also comprises a plurality of sections of tracks, a plurality of sections of casting line tracks and three sections of cart tracks, each section of tracks is fixedly disposed on a track support, each section of tracks is provided with a plurality of driving wheels and a plurality of driven wheels, the driving wheels are connected with one another through a chain, the driving wheels and the driven wheels are disposed at intervals, a plurality of motors are fixedly dispsed on the track support, and the driving wheels are connected with chain wheels which are disposed on power output shafts of the motors through chains. The automatic iron mold sand lined production line has the advantages of small land occupation area, low labor intensity of workers, good safety and fast production speed.

Owner:LIAOYANG FUXIANG CRANKSHAFT

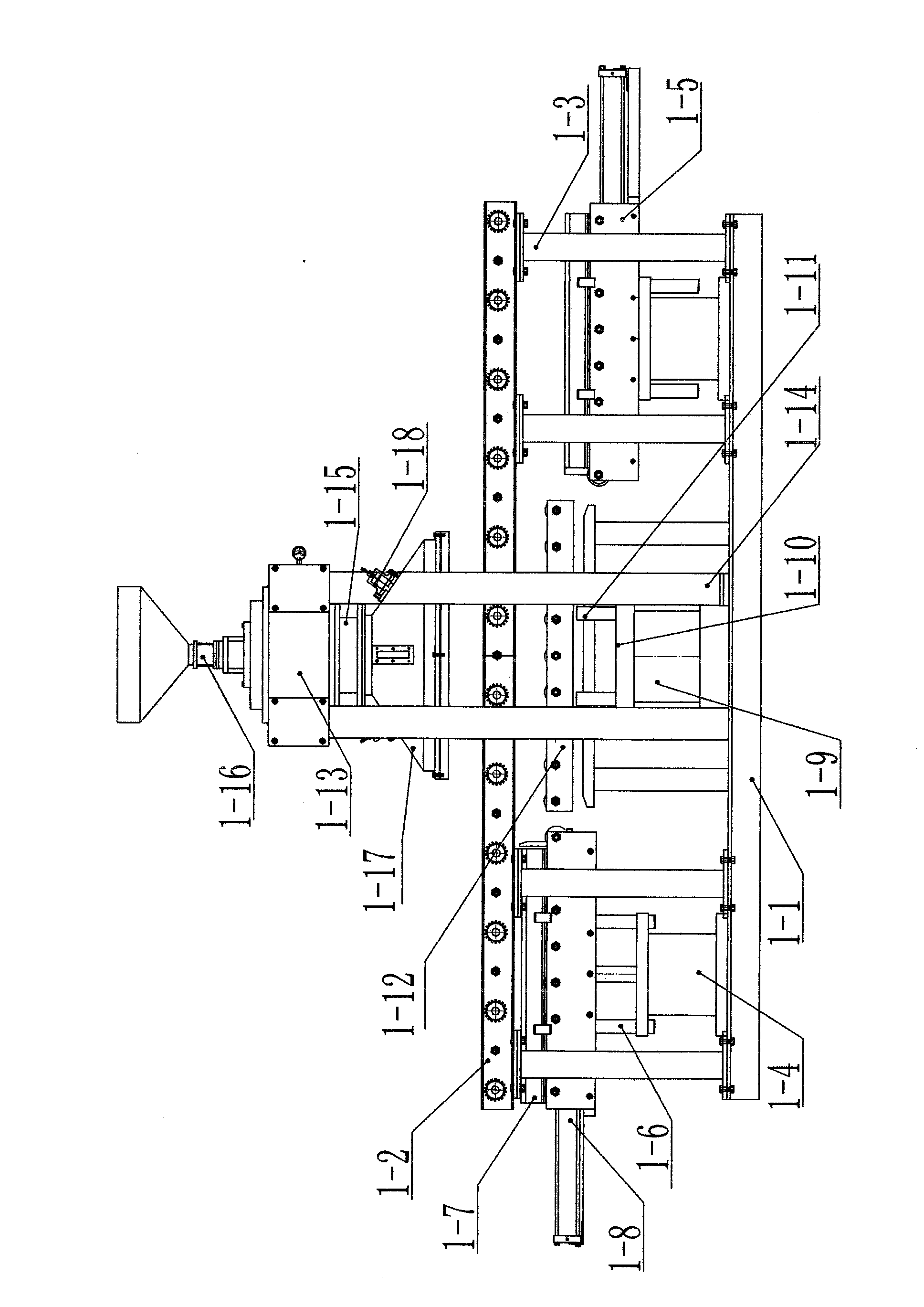

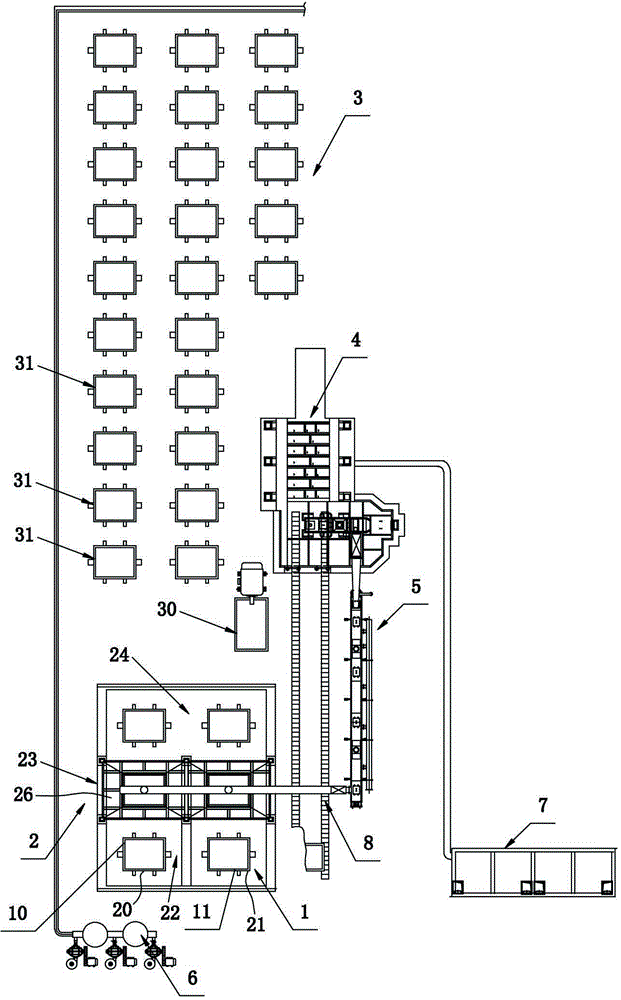

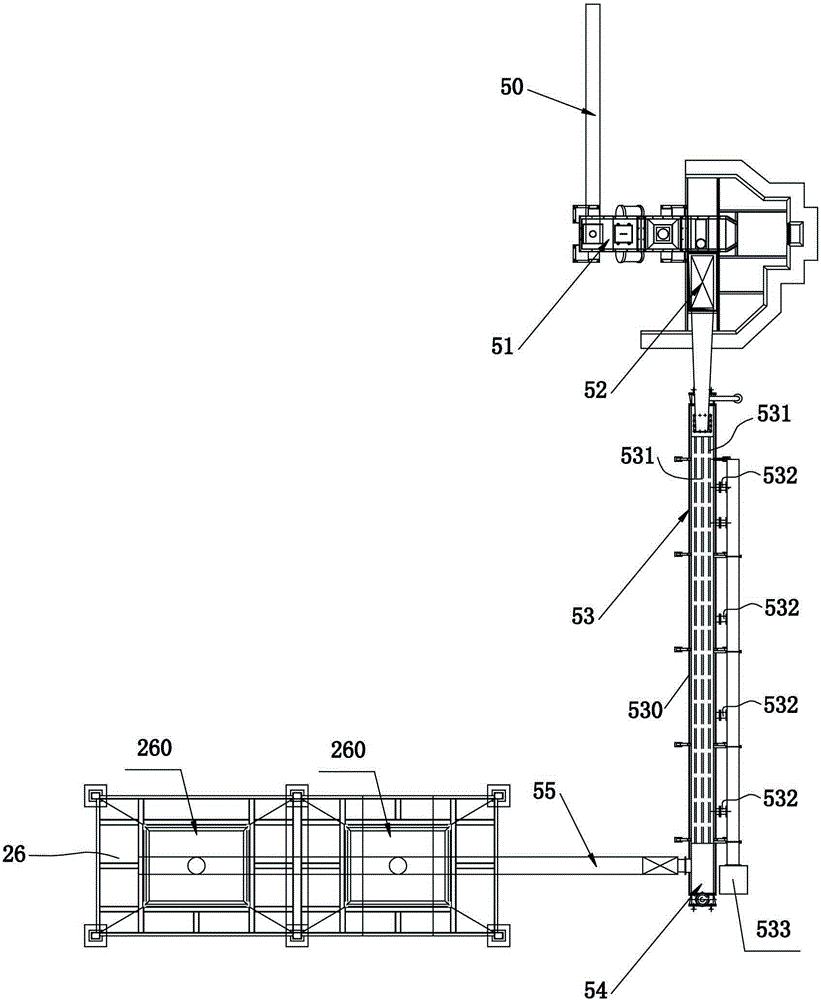

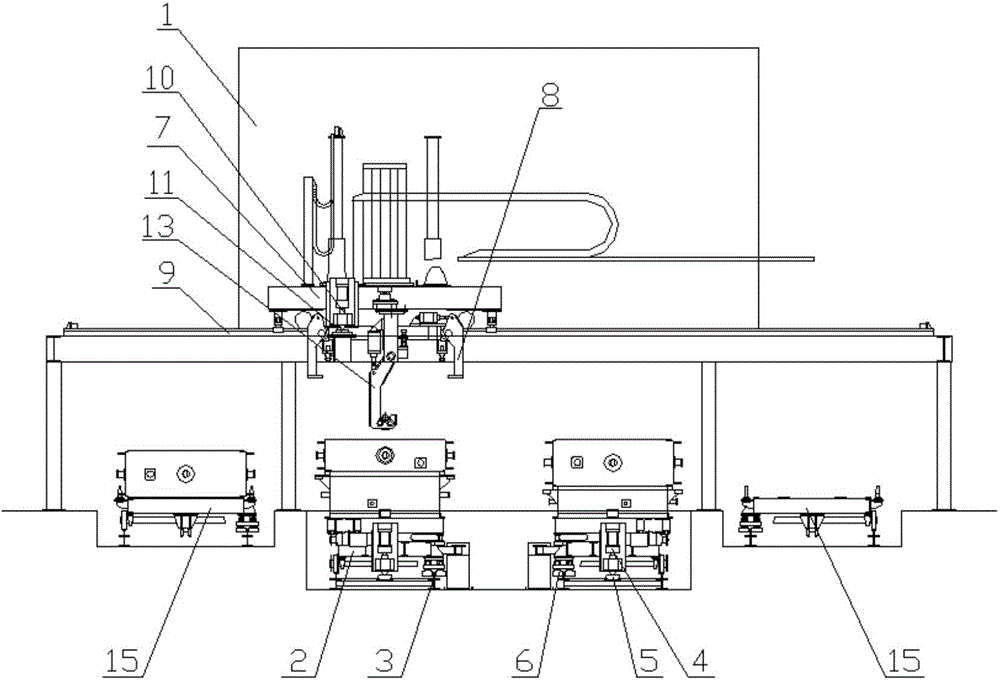

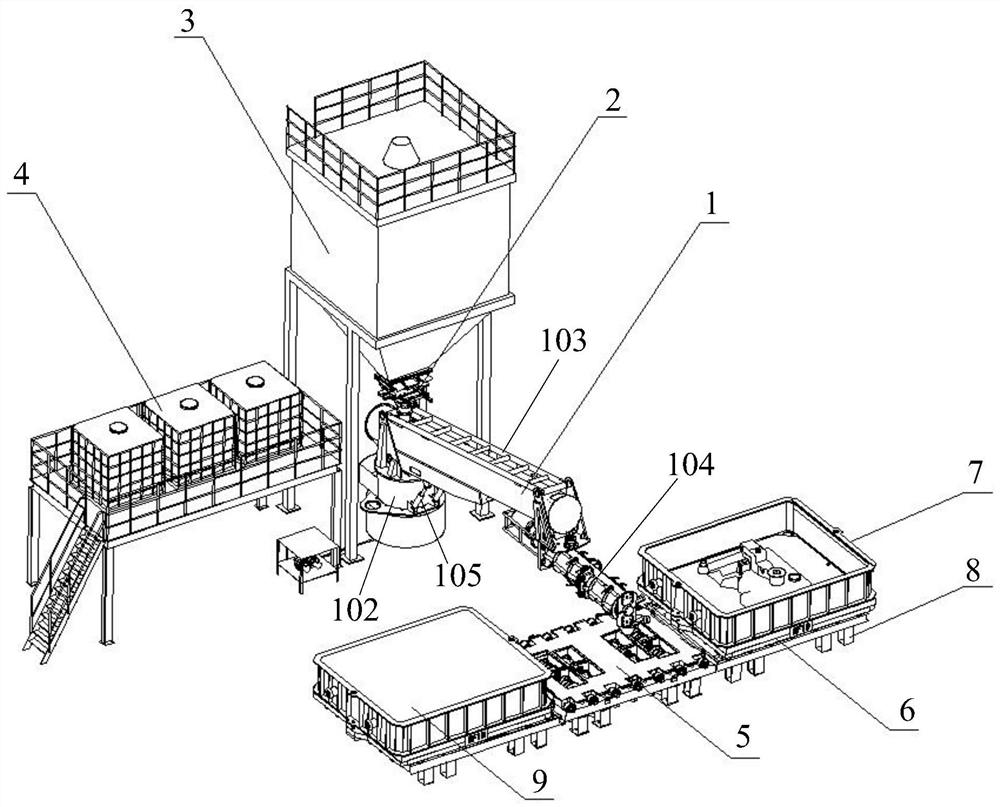

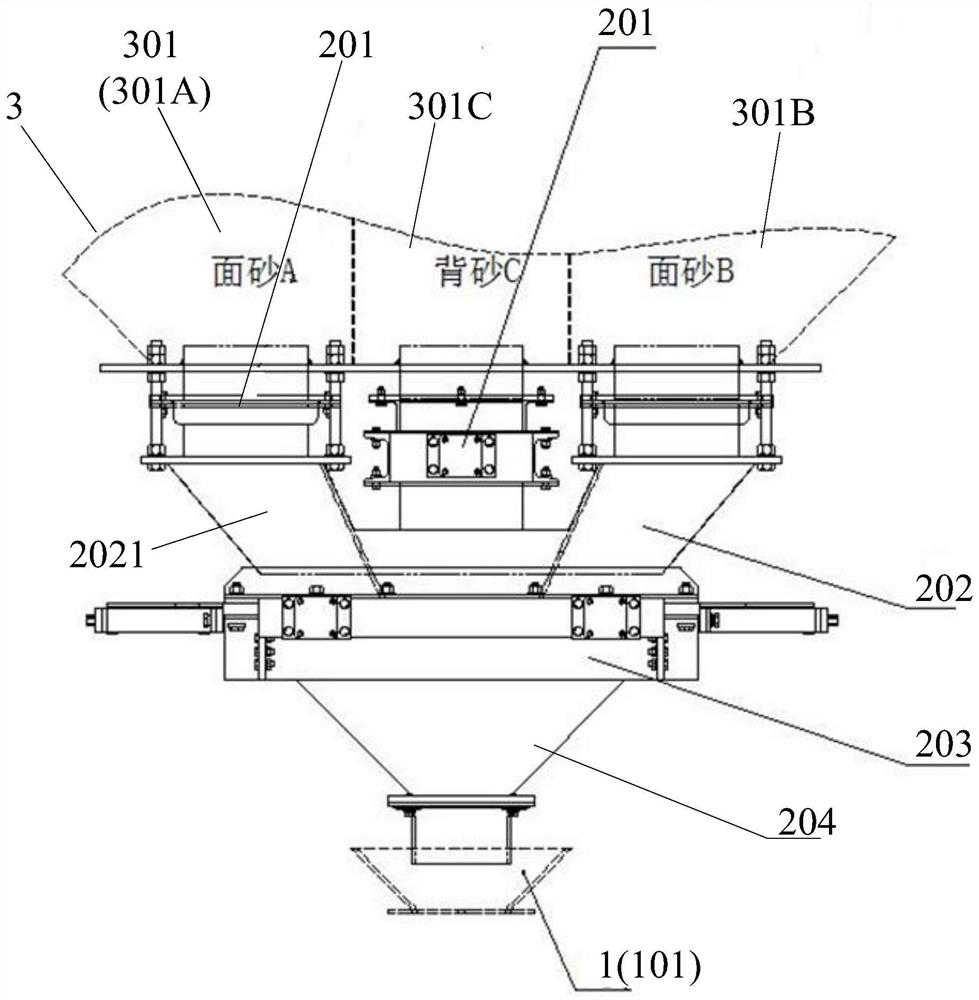

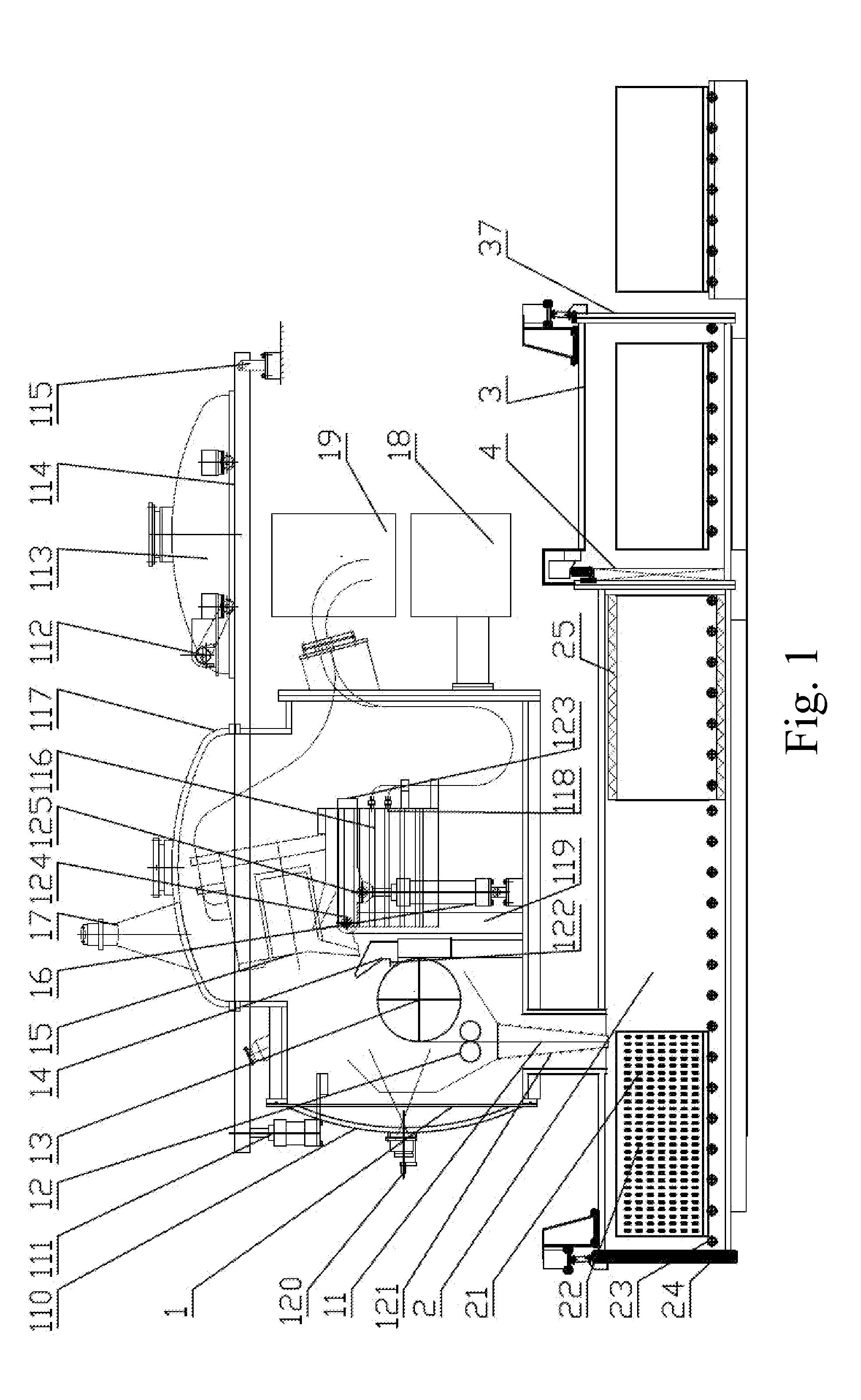

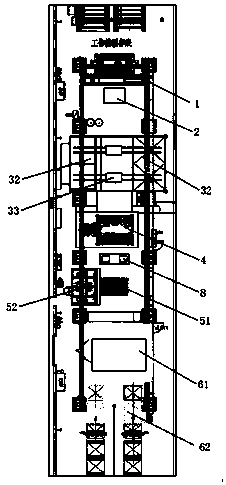

Fully automatic precision core assembly molding production line, casting production line and production method thereof

ActiveCN102284683AReduce labor intensityHigh degree of automationCasting plantsMoulding plantsProduction lineWorking environment

The invention discloses an automatic precision core assembly moulding production line, a casting production line and a production method thereof, wherein the core assembly moulding production line comprises an outer die core making area, an outer die core delivery line, an outer die core surface-drying furnace, a mould cavity core making area, a mould cavity delivery line, a mould cavity surface-drying furnace and a core assembly delivery line; a robot I with transportation and assembly functions is disposed on the core assembly moulding production line; the casting production line further comprises a pouring line and a robot II with a transportation function; all the sand cores used by the core assembly are produced, delivered and assembled on the core assembly moulding production line; moreover, all the actions are realized by a highly-automatic method, and robots are used for core assembly, so that the automation degree is high, the labour intensity of workers is low, the working environment is good, the production efficiency is high, the energy is saved, the consumption is decreased, the process stability is good, and the product precision is high; the sand cores used by the core assembly are shot by a cold-box core making machine; and the cast product has a high dimensional precision, a good appearance quality and a high production efficiency.

Owner:CMCU ENG

Vacuum-forming production line capable of recycling sand

ActiveCN104475678AImprove utilization efficiencyRecycling timing shortenedMoulding plantsFoundry mouldsFoundryProduction line

The invention discloses a vacuum-forming production line capable of recycling sand. The vacuum-forming production line comprises a casting mold frame mechanism, a vacuum forming mechanism, a casting mechanism, a sand-casting separation mechanism, a sand recovering mechanism, an electric block device and a crane, wherein the vacuum forming mechanism is used for filling sand into the casting mold frame mechanism and laminating the two sides of the sand; the casting mechanism is used for filling metal melted liquid into the laminated casting mold frame mechanism; the crane is coordinated with the travelling of the electric block device; an inlet of the sand recovering mechanism is communicated with the sand-casting separation mechanism, and an outlet of the sand recovering mechanism is communicated with the vacuum forming mechanism. According to the vacuum-forming production line disclosed by the invention, the sand recovering mechanism is arranged to automatically collect, cool and return sand and remove impurities after foundry; the whole sand recovery process can be automatically finished by the machine, so that the working procedure of manual processing can be avoided, a mass of manpower and material resources can be reduced, the sand utilization efficiency can be greatly improved, the sand recovery timing sequence can be shortened, and the production efficiency can be improved.

Owner:FUJIAN BAOSHAN MACHINERY

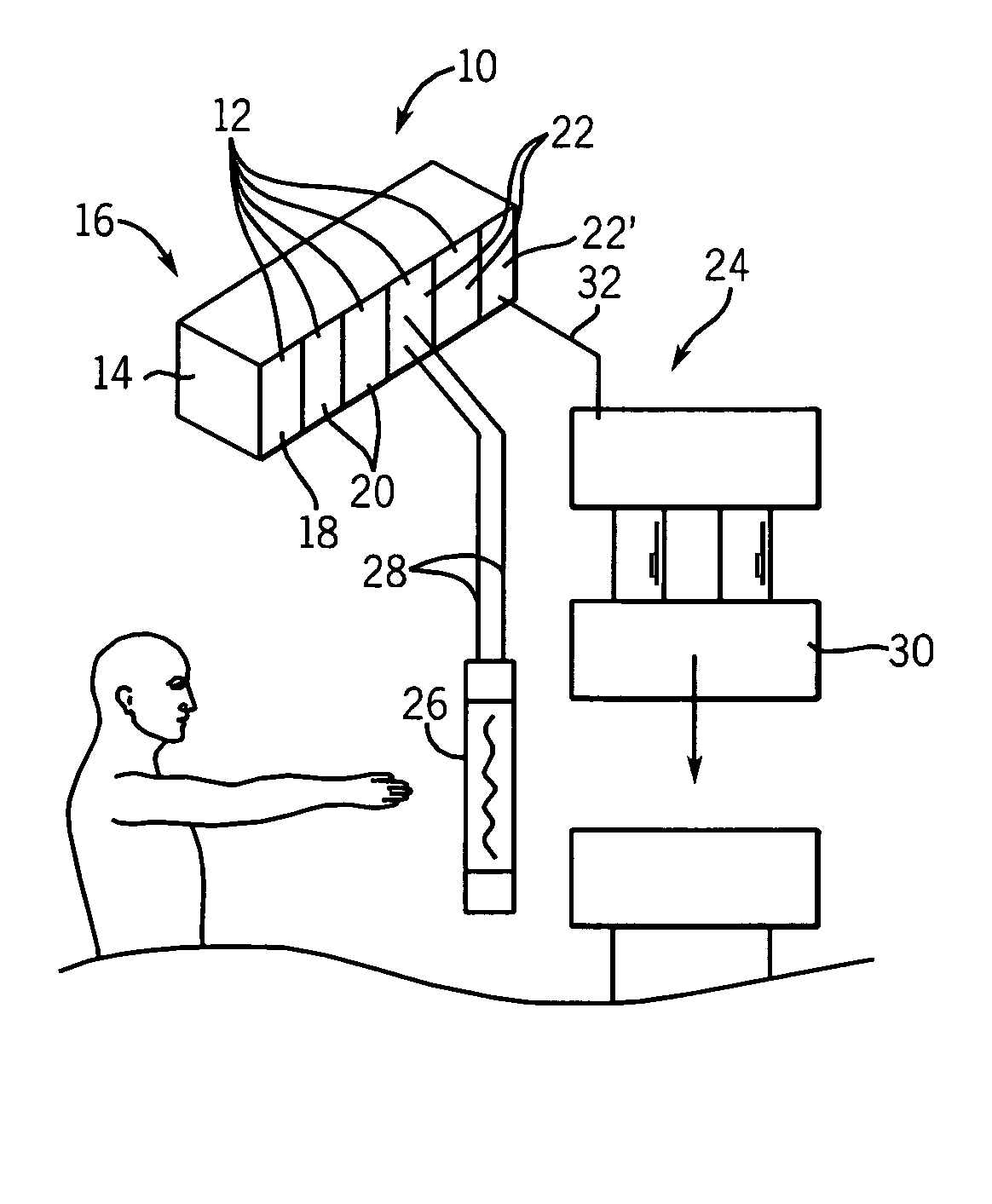

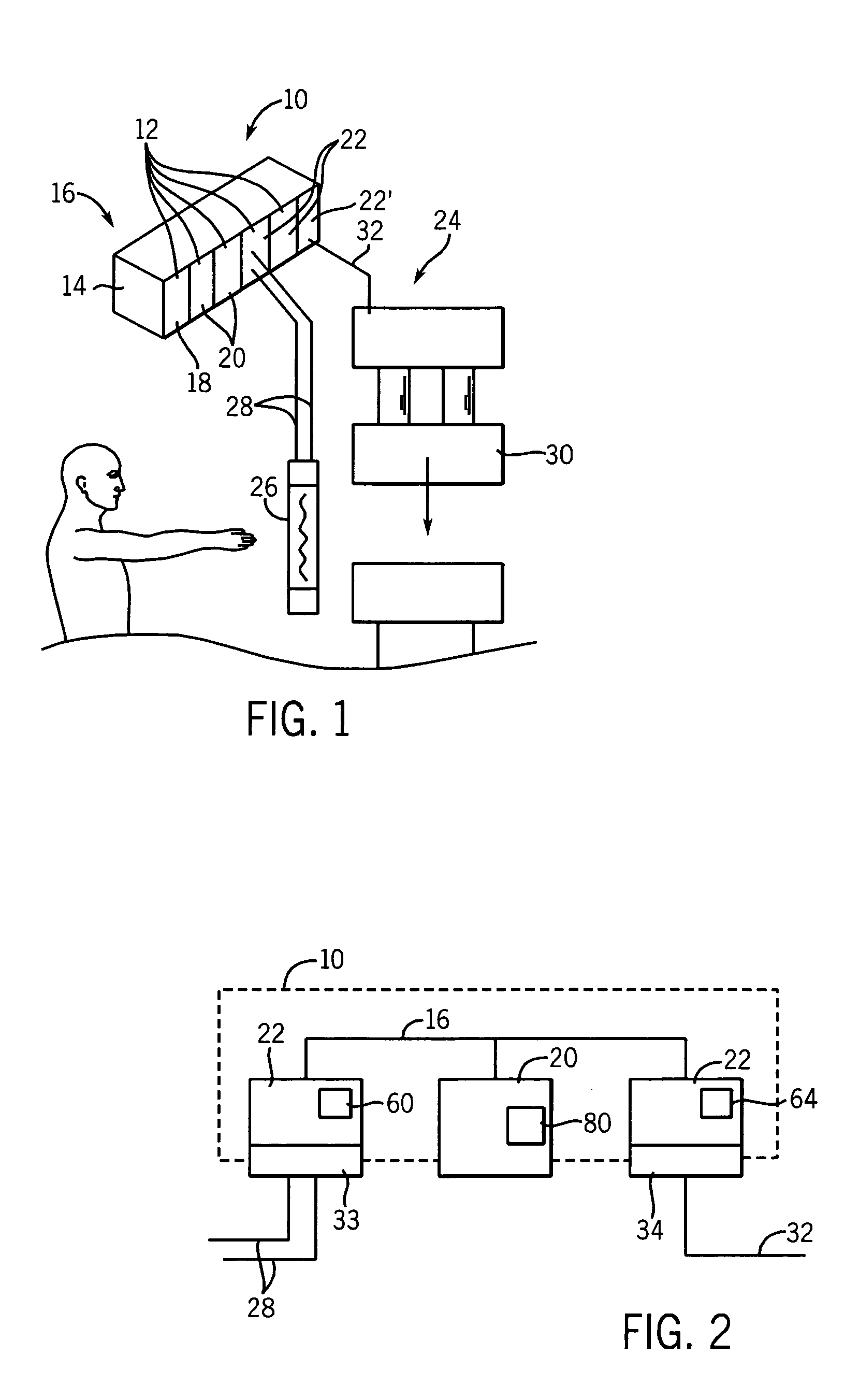

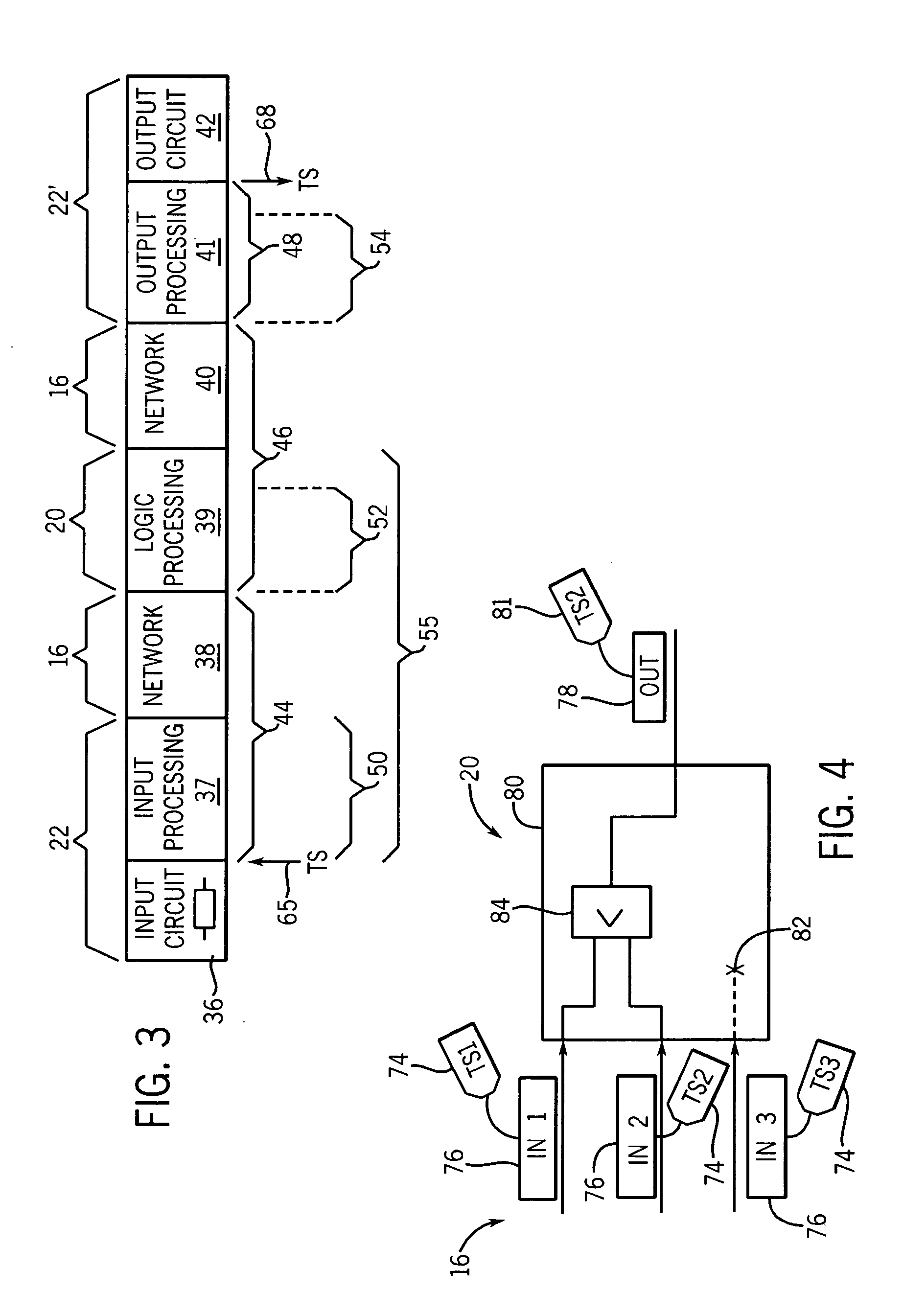

Safety controller with safety response time monitoring

ActiveUS20050081117A1Increase speedElectric signal transmission systemsMoulding plantsPropagation delaySignal processing

Owner:ROCKWELL AUTOMATION TECH

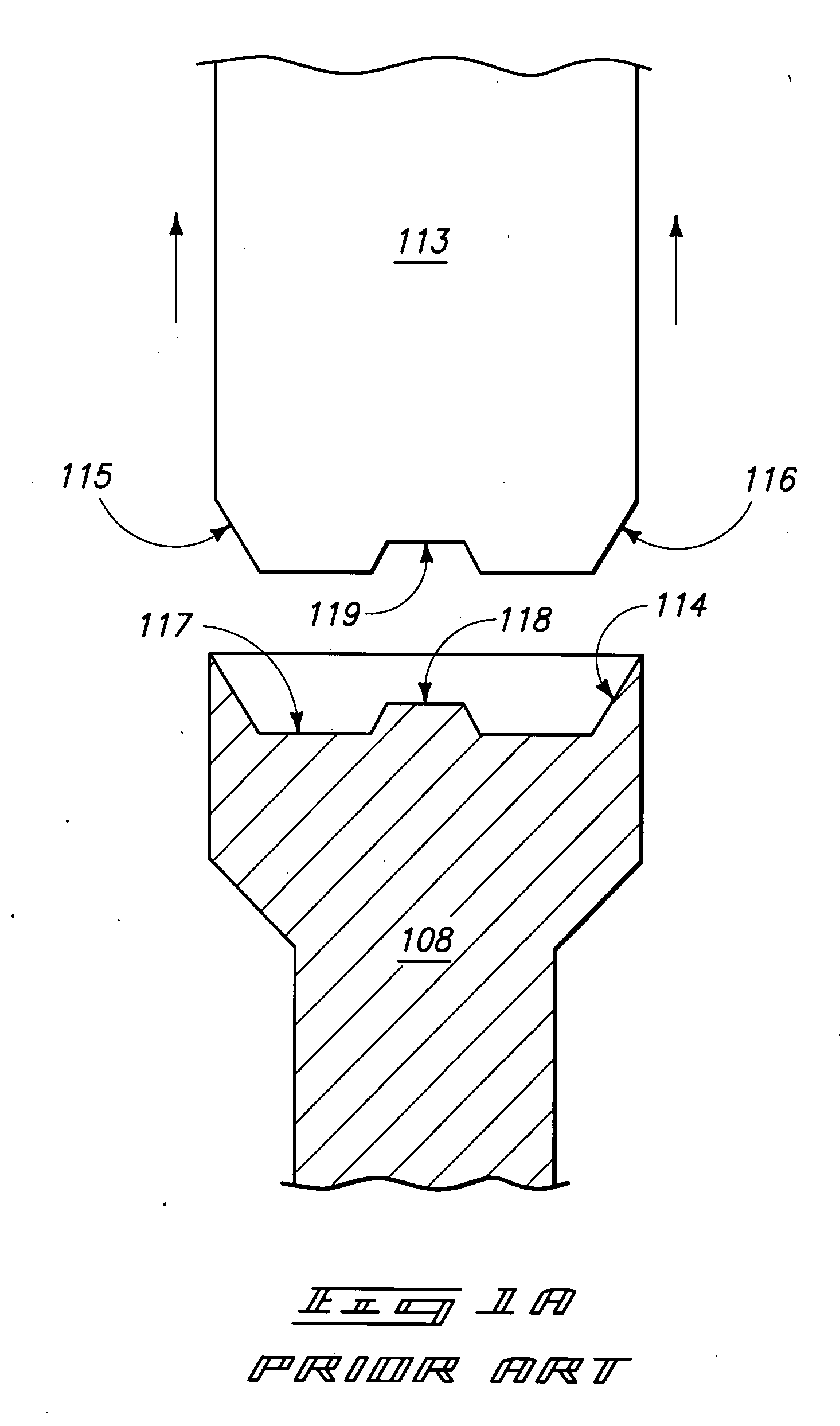

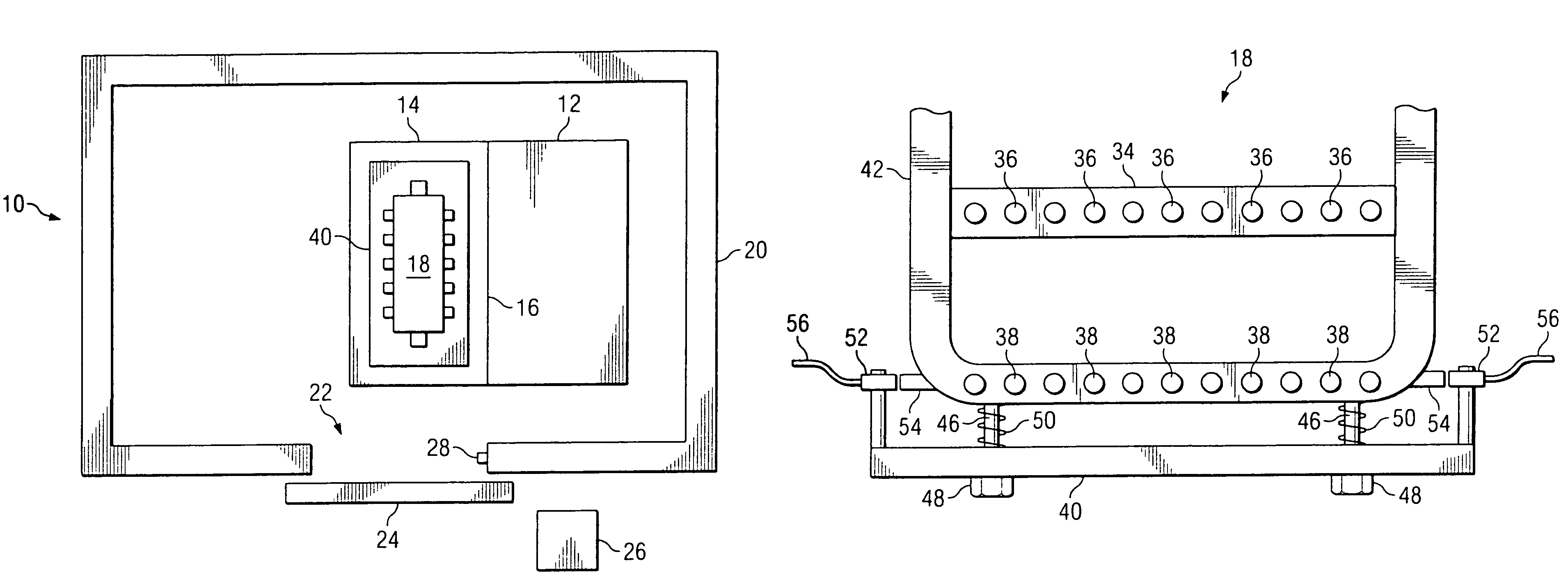

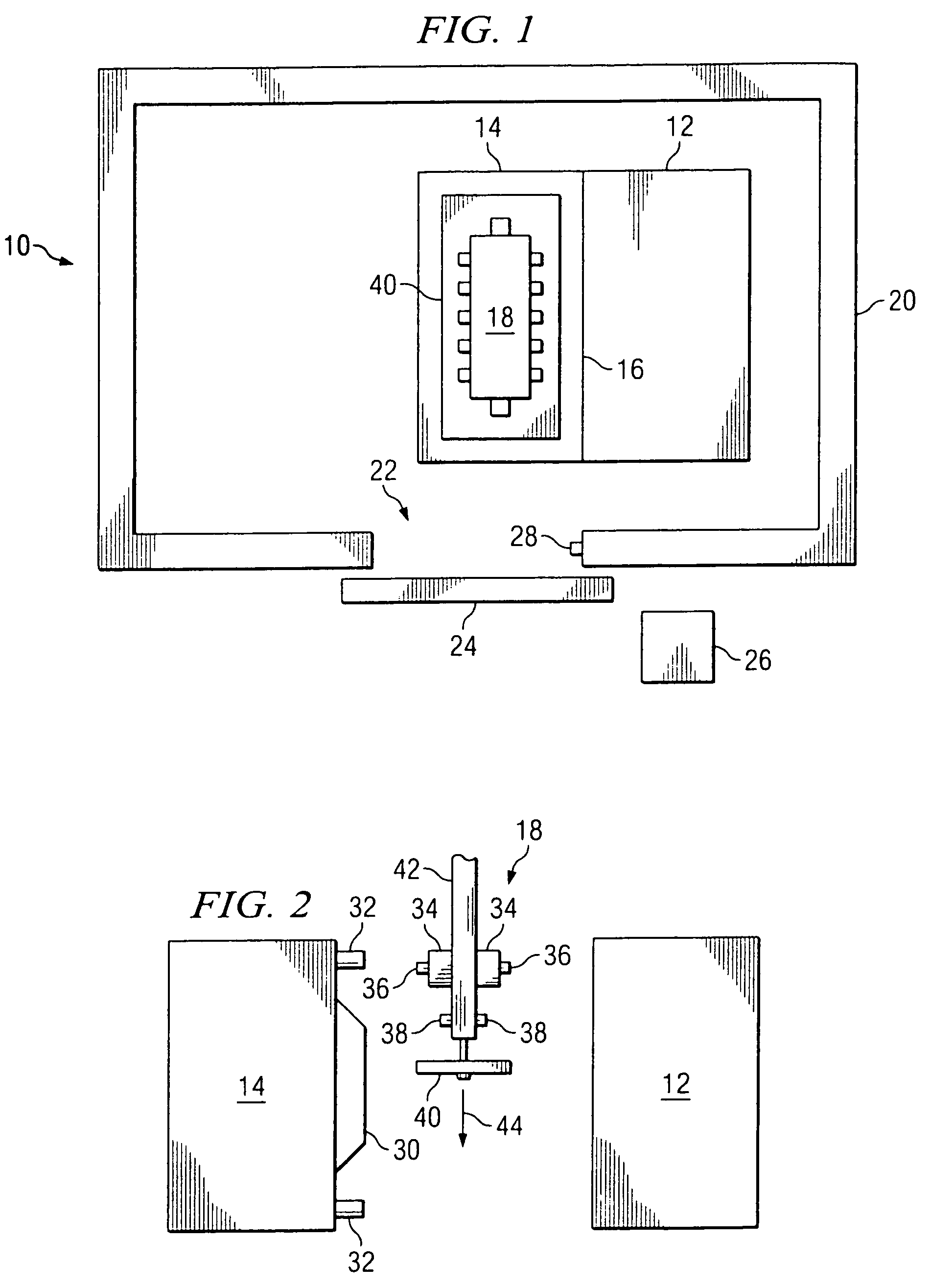

Automated variable dimension mold and bottom block system

A molten metal mold and bottom block system, including apparatus and method embodiments, which may include a mold cavity framework with a first side, a second side opposite the first side, a third side, and a fourth side opposite the third side, each side including an inner surface and the inner surfaces defining a mold cavity, and wherein one or more of the sides are movably mounted relative to the second side, and are controllably moved during the casting. This system may also include embodiments wherein the castpart produced has a tapered form at one or both of the castpart ends. Aspects of this invention may be considered to be a castpart shrinkage management system or a castpart form or profile control system due to the advantage of increased controls of castpart form during the casting process.

Owner:WAGSTAFF INC

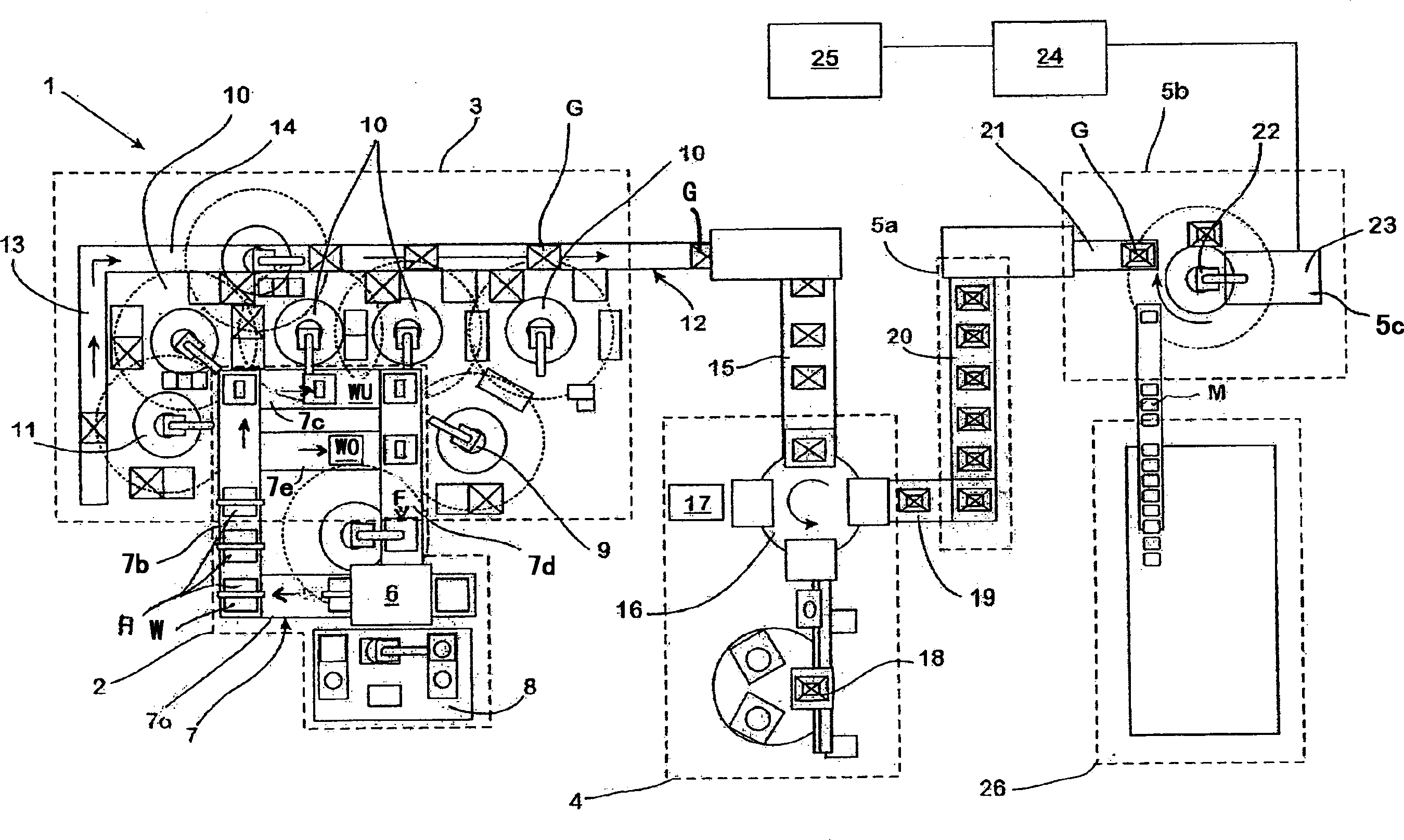

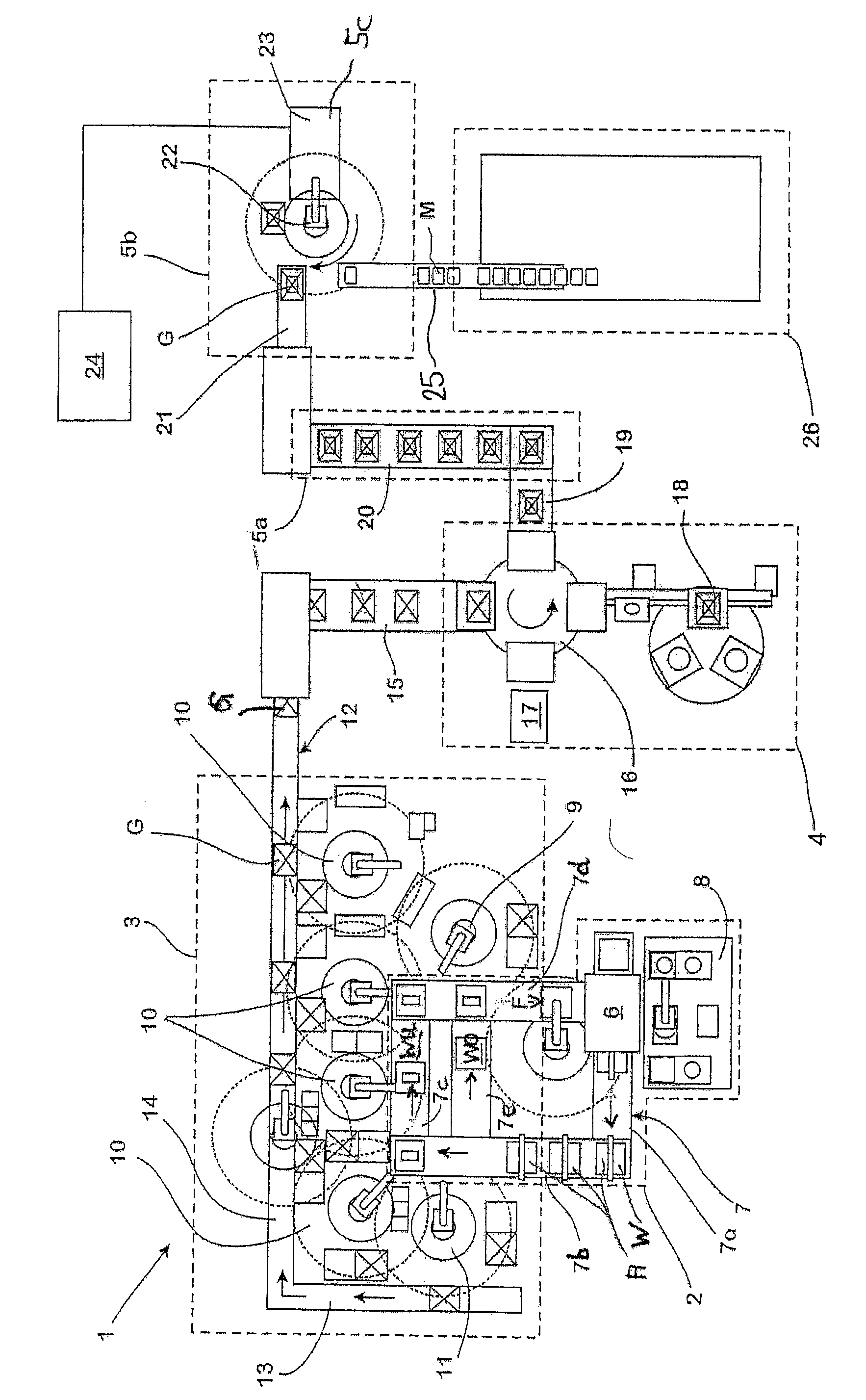

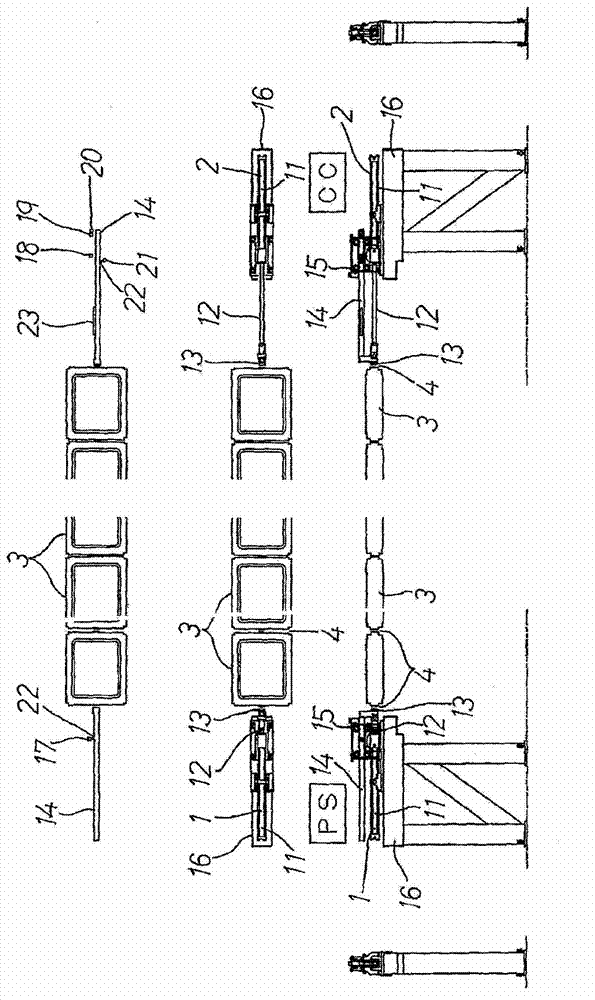

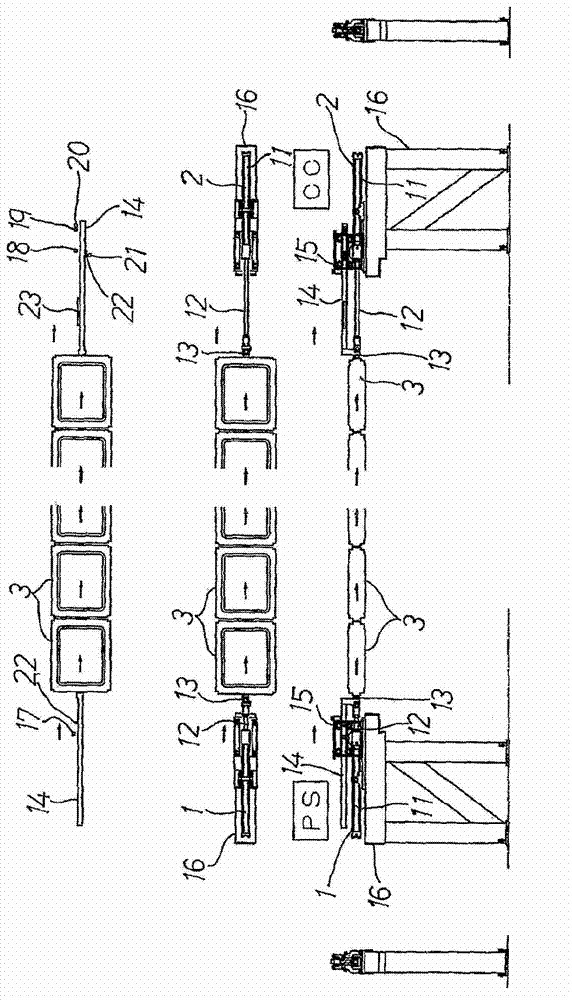

Production line and method for the continuous production of cast parts from a molten metal, in particular a molten light alloy

The invention relates to a production line for the continuous production of cast parts (M) from a molten metal, in particular a molten light alloy. Said line comprises several functional units including a core production unit (2) for producing cast cores, a mould assembly unit (3) for mounting casting moulds (G) that are configured as core packets, a casting unit for casting the molten metal into the casting moulds (G), a cooling unit (5a) for cooling the molten metal that is contained in the respective casting moulds (G) and a demoulding unit (5b) for removing the casting mould (G) from the cast part (M), during which process the mould is destroyed. A production line of this type permits the economic and flexible production of heavy-duty cast parts with complex forms, in particular motor blocks. To achieve this, the successive continuous functional units (2 5b) are directly interconnected by a respective transport unit (12,19) and the rate at which the production line (1) ejects the finished cast parts (M) depends on the rate at which the core manufacture unit (2) delivers the cast cores it has produced.

Owner:HYDRO ALUMINUM ALUCAST

Method for producing cylinder cover of compressor of heavy duty truck

InactiveCN102756101AReduce dosageReduce total gas productionMoulding plantsFoundry mouldsProduction lineEngineering

The invention discloses a method for producing a cylinder cover of a compressor of a heavy duty truck, and adopts a box-free vertical molding line continuous manufacturing technology. The technology comprises the following steps: (1) using a core shooter to prepare a sand core, and assembling the prepared sand core into the whole shell mold of a forming casting; (2) preparing a sand mold on the production line with a molding external mold, that is, preparing a cavity for placing the whole shell mold of the forming casting and a sand mold for placing a concreting system; and 3), lowering the whole shell mold of the forming casting into the sand mold with well made molding line to cast the forming casting. The method has the advantages that the dosage of the precoated sand can be effectively reduced, so as to reduce the total gas emission quantity produced by the precoated sand during casting; and due to the high pressure head of the casting system, the casting can bear high pressure, the compactness of the whole casting is favorable, and particularly, air leakage caused by casting defects such as loose materials and cold shut on the thin wall of the inner cavity during pressure testing can be effectively reduced. According to the method, production efficiency of automated equipment can be effectively improved, and the qualified rate of the casting can be improved.

Owner:广东省韶铸集团有限公司

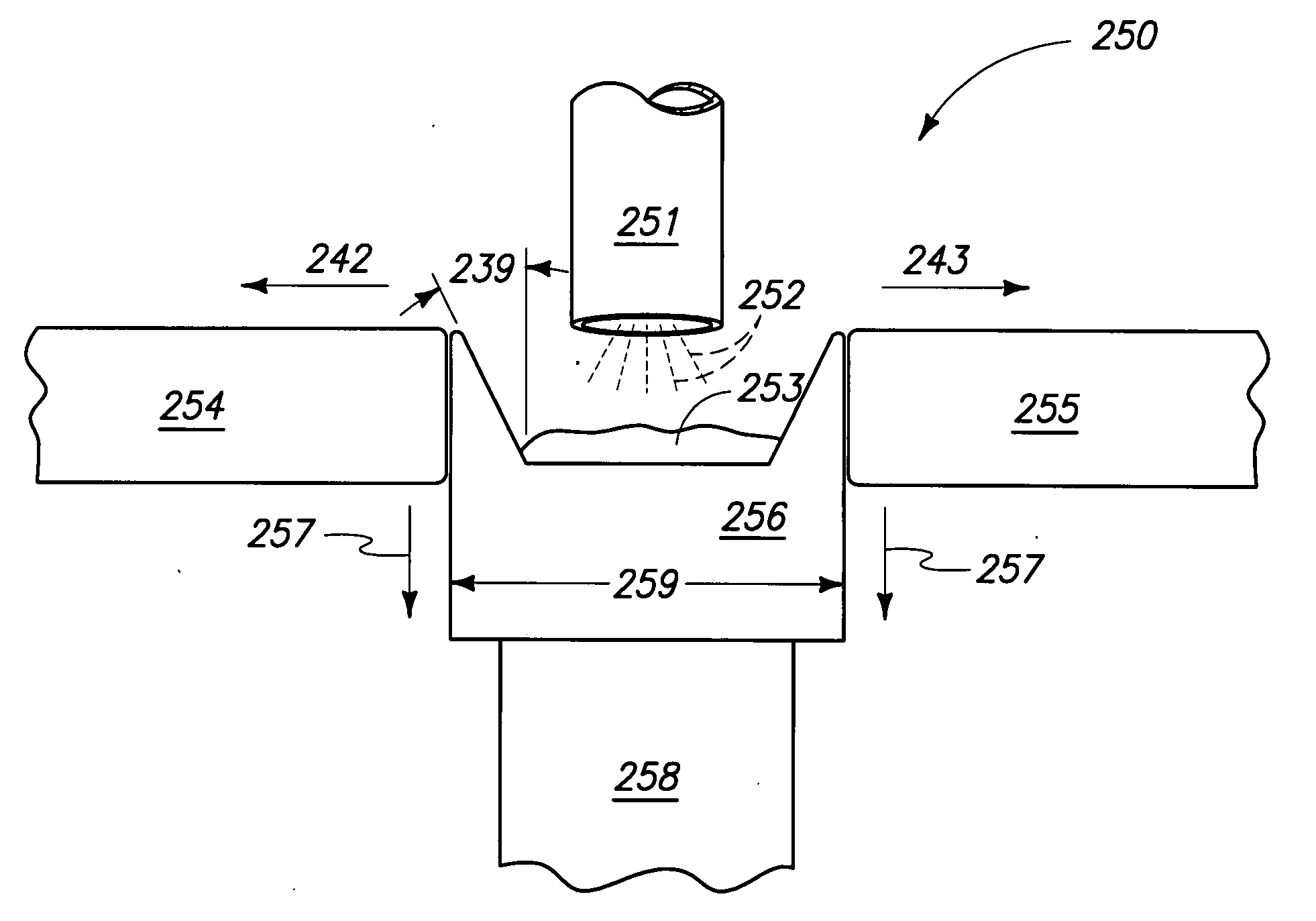

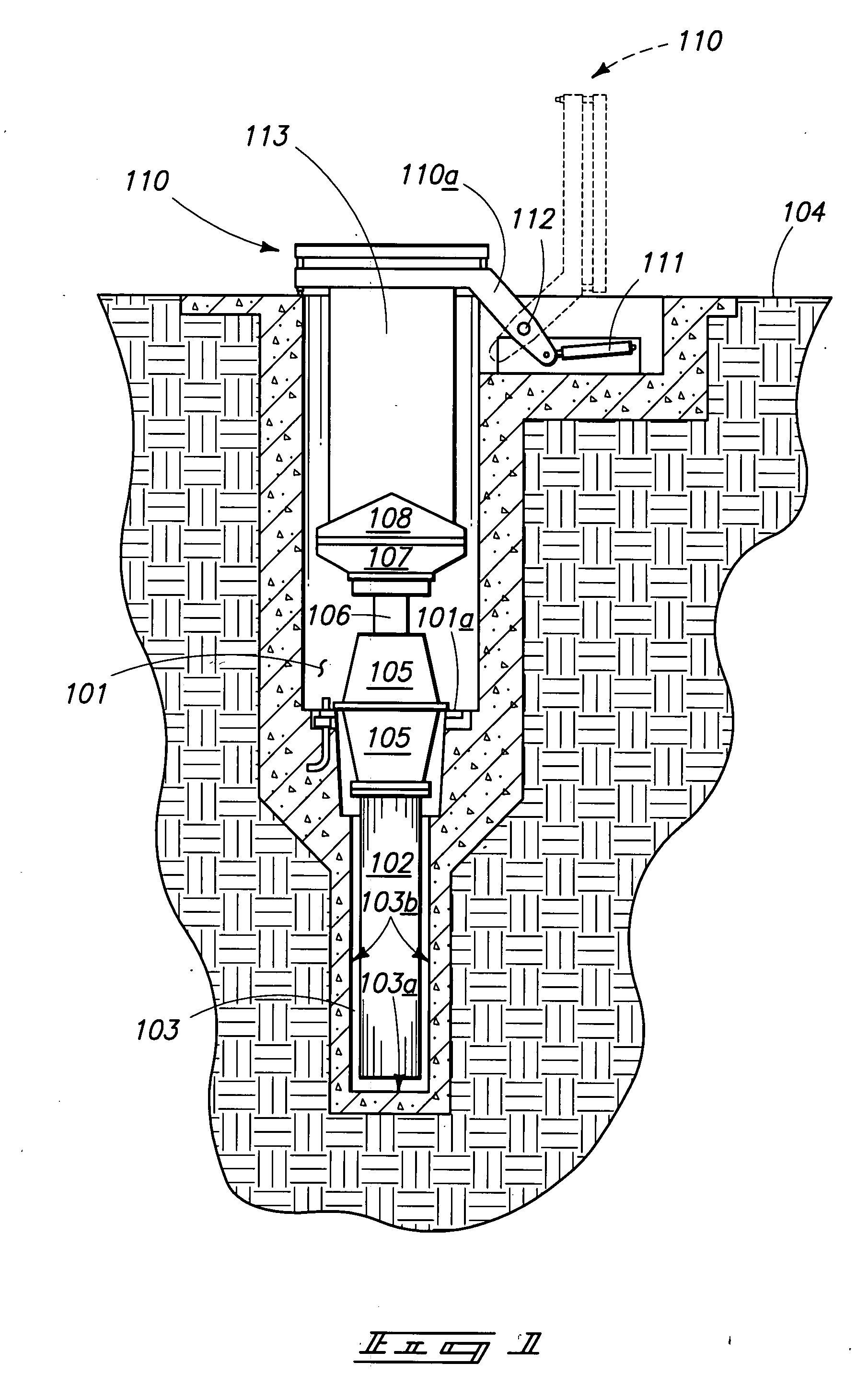

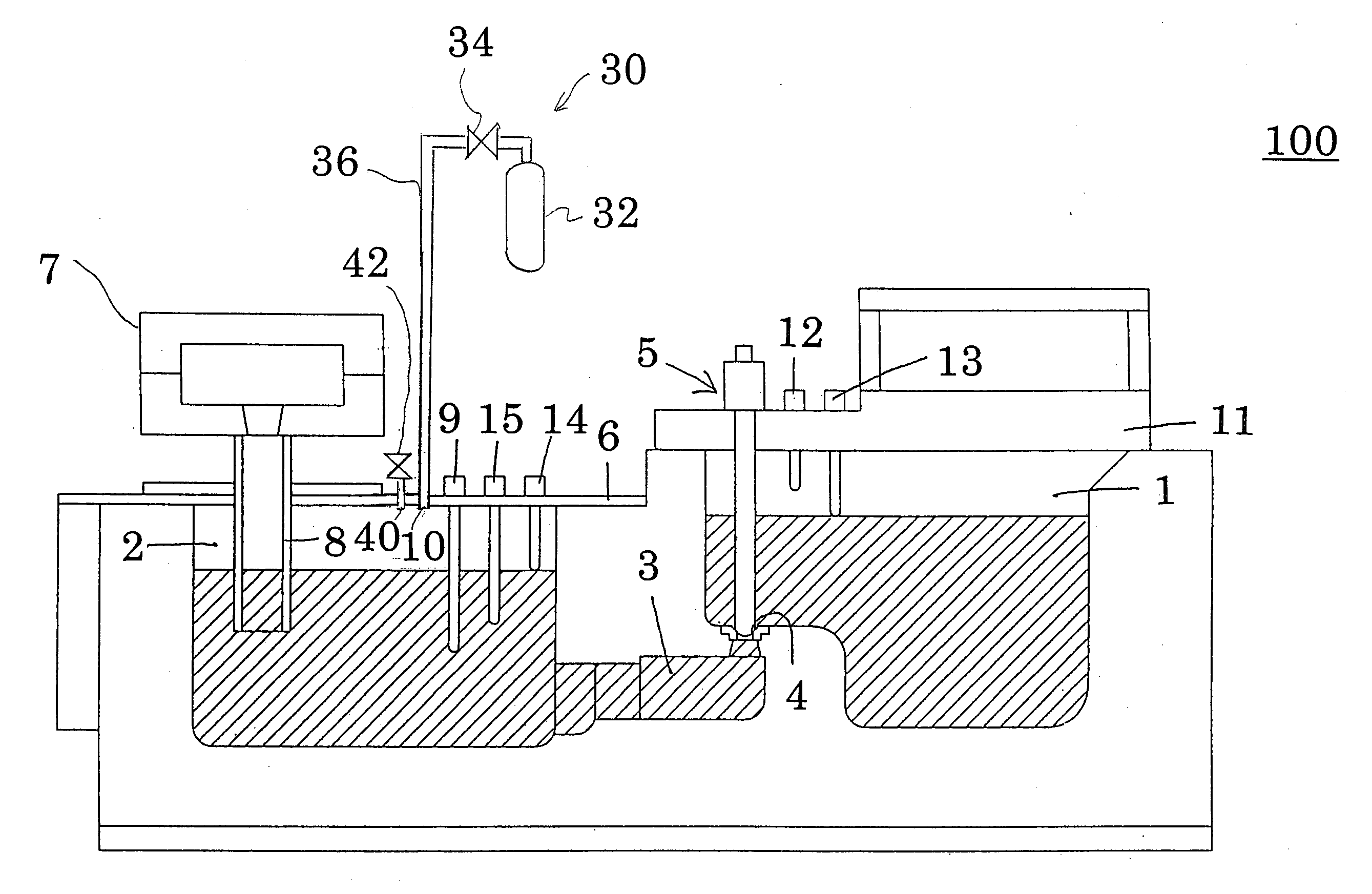

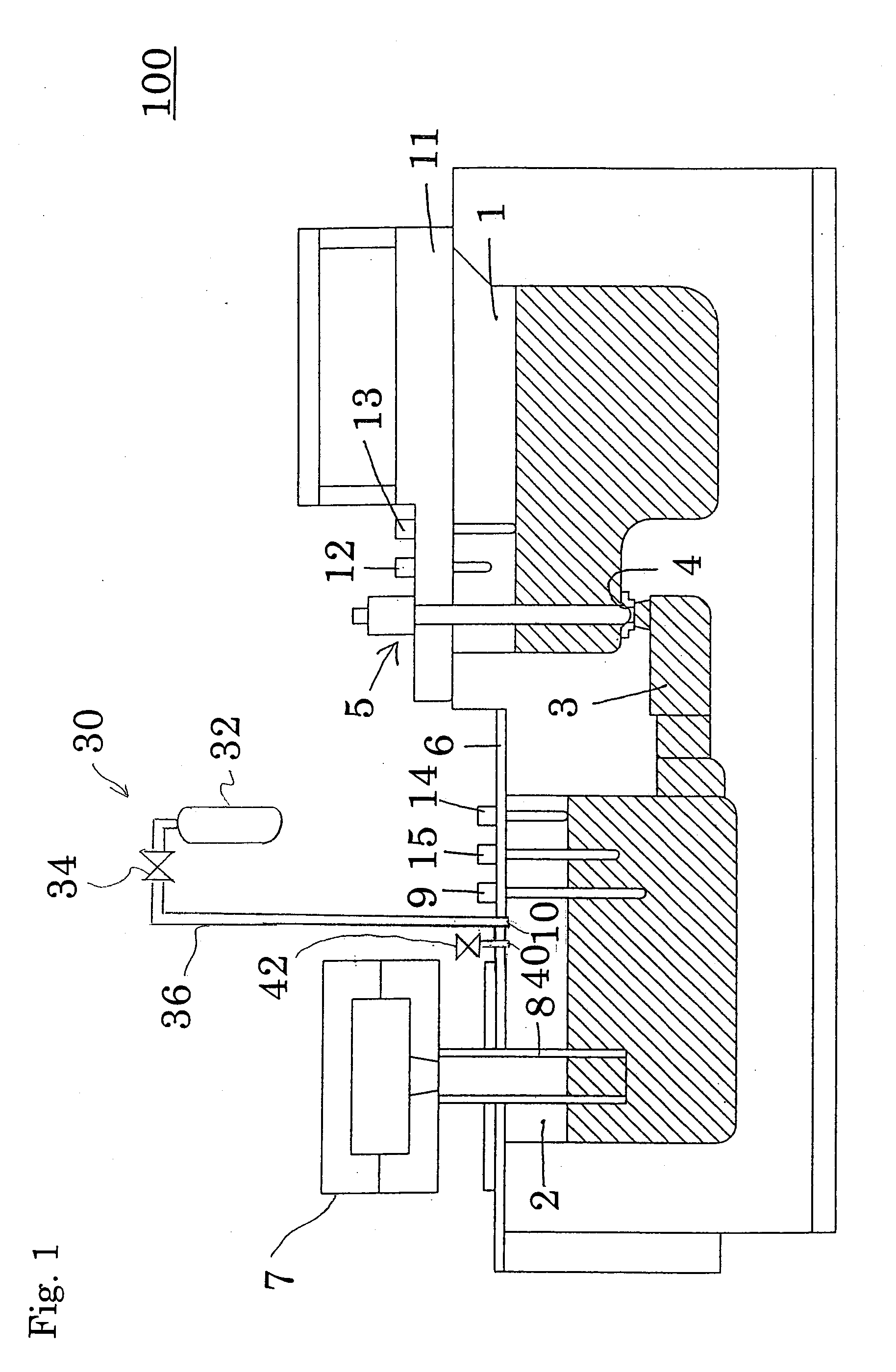

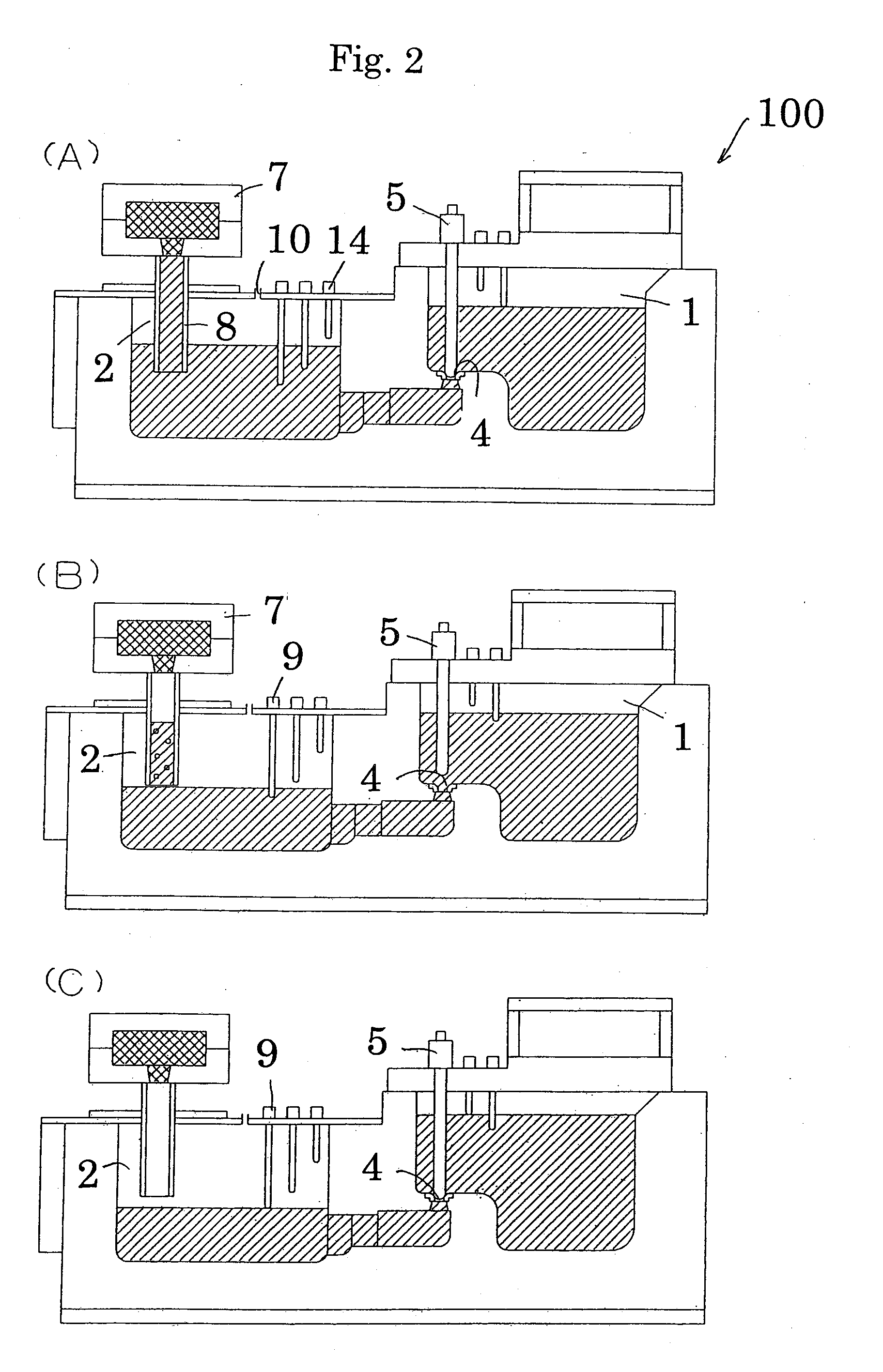

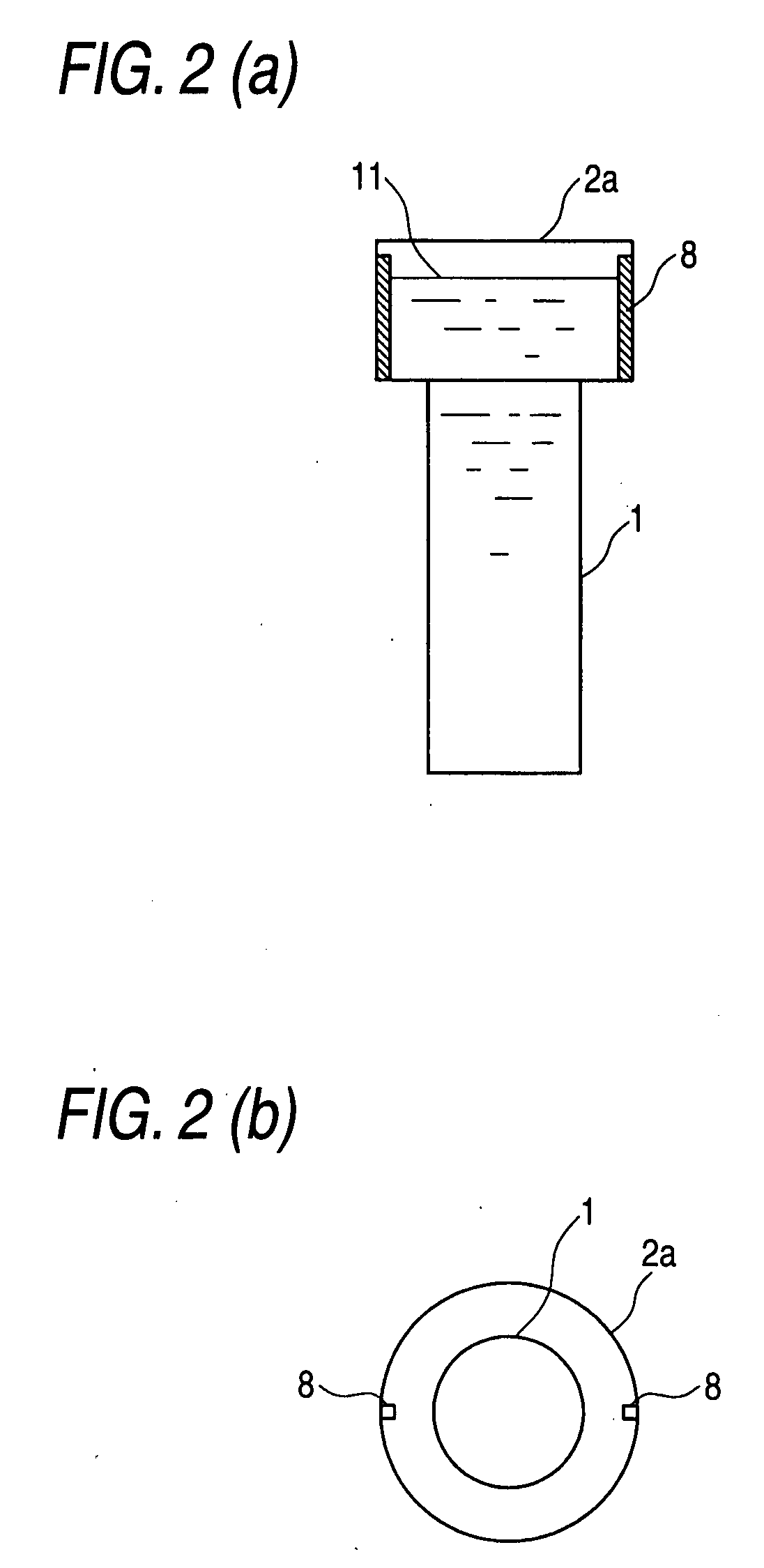

Device for low-pressure casting, a method for filling inert gas in the device, and method for producing a cast

InactiveUS20100108285A1Convenient lightingMoulding plantsCasting safety devicesPressure castingProduct gas

The object of the present invention is to provide a device for low-pressure casting wherein the stalk or the guiding hole is filled with inert gas by causing the space formed over the molten metal in the pressurizing room to communicate with the stalk or the guiding hole. The device for low-pressure casting (100) wherein molten metal is supplied into a mold through a stalk (8) suspended from a gate for pouring of the mold (7) or through a guiding hole connected to the gate for pouring at one end by pressurizing the molten metal by inert gas, the device comprising: a room for holding molten metal (1); a pressurizing room (2) to be in communication with the room for holding molten metal through a hole for communication (4), wherein a bottom end of the stalk (8) enters the pressurizing room or another end of the guiding hole is connected to the pressurizing room, and wherein the molten metal is pressurized by inert gas; an on-off valve (5) for opening and shutting the hole for communication; a sensing means (15) for sensing that the space over the molten metal in the pressurizing room communicates with the stalk or the guiding hole; and a means (30) for supplying inert gas to an upper part of the pressurizing room.

Owner:SINTOKOGIO LTD

Safety door automatic opening/closing device in injection molding machine and the like and method of controlling the same

InactiveUS20100287841A1Reduce the burden onLow costMoulding plantsCasting safety devicesEngineeringInjection molding machine

A safety door automatic opening / closing device is capable of freely (arbitrarily) setting and controlling the opening / closing speed and the open position to shorten a waiting time required to open / close a safety door and capable of eliminating a touch switch; and a method of controlling the same.

Owner:UBE MASCH CORP LTD

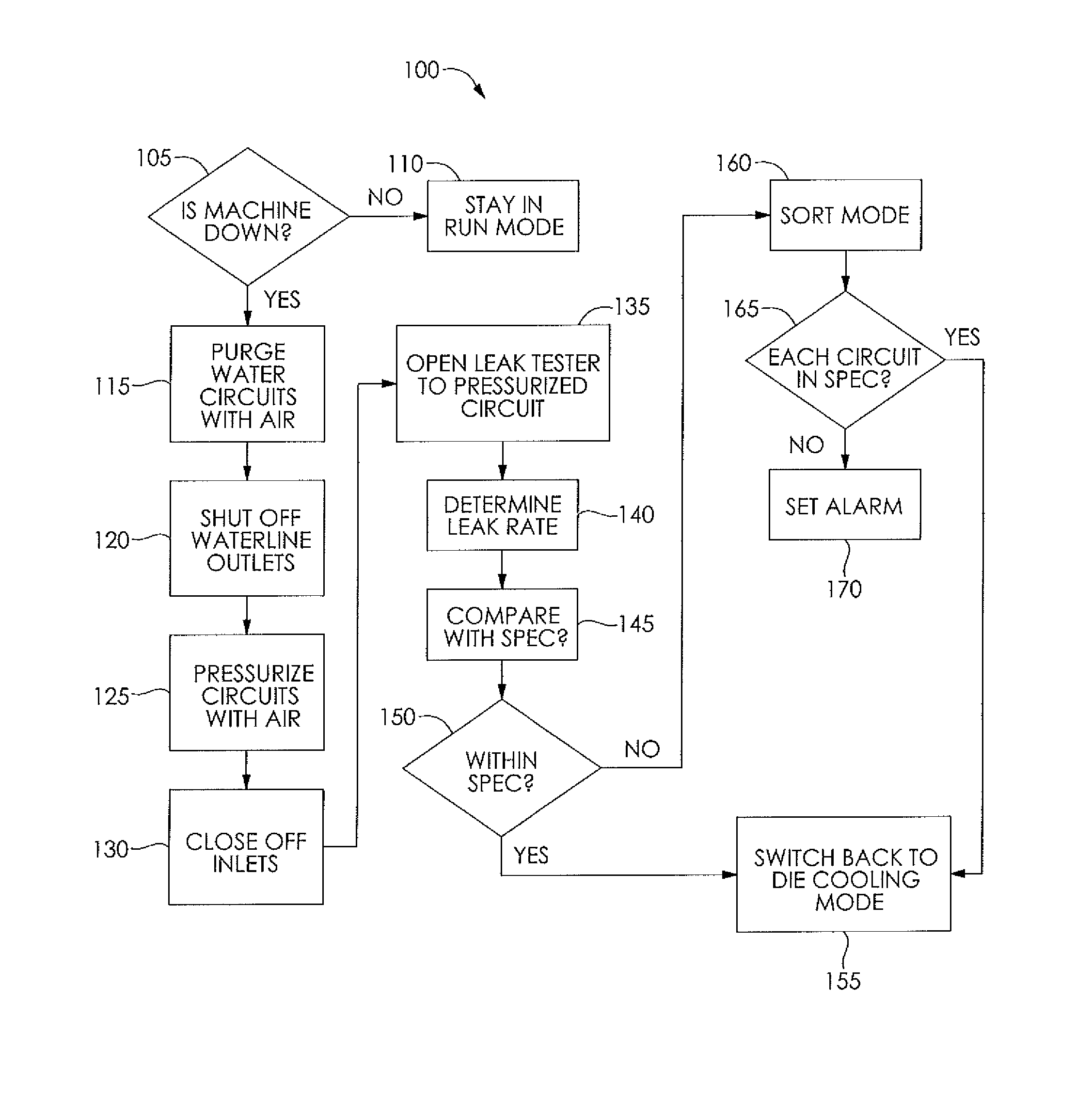

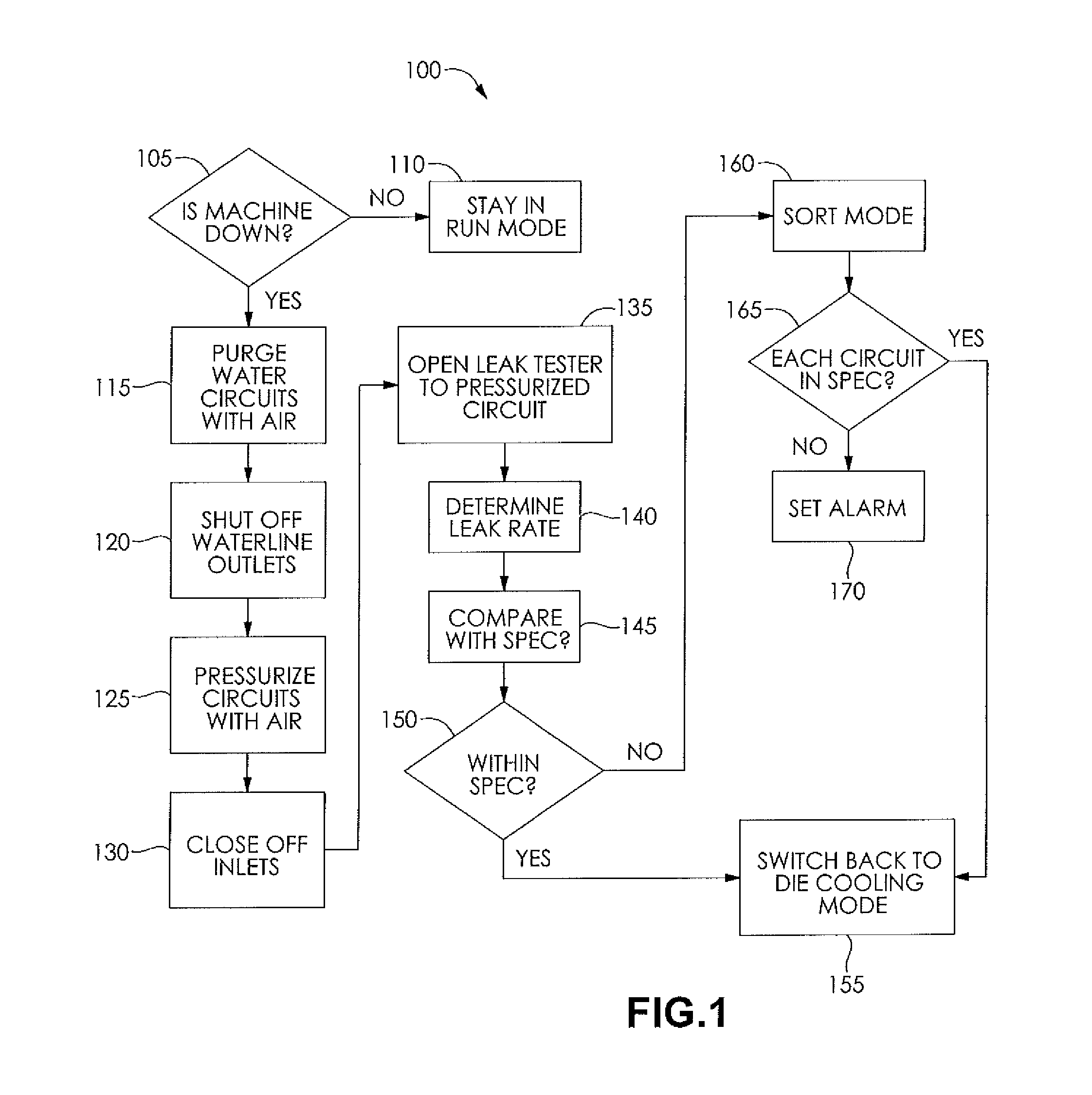

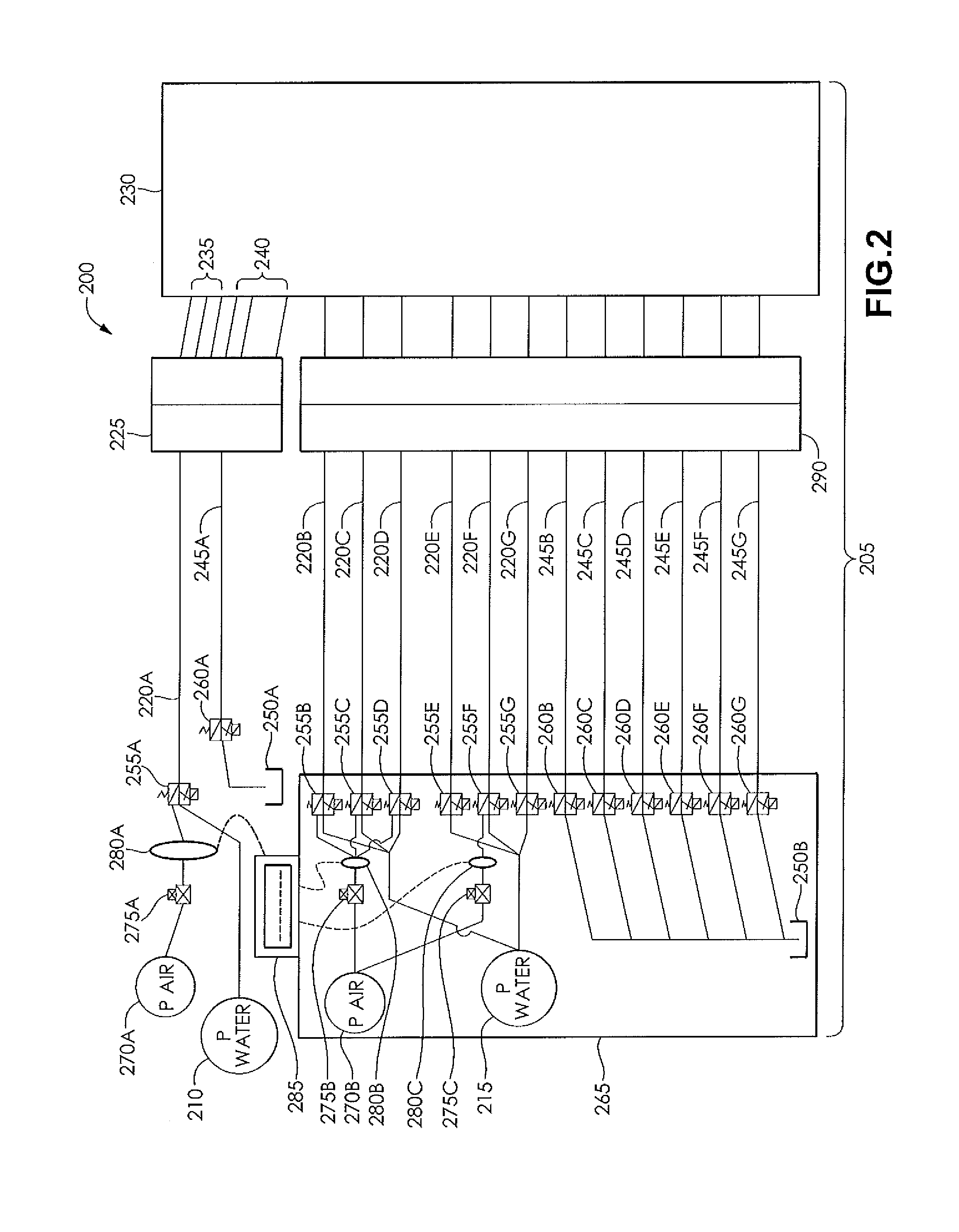

Die coolant system with an integral and automatic leak test

Systems and methods allow detection and location of die coolant leaks while a die is in a die cast machine and at operating temperature. The testing can be performed during normal down time of the die casting assembly and repeated as desired. Cooling circuits of the die can be tested in zones where zones are sorted to identify particular cooling circuits as having leaks as necessary. Valving, leak sensors, air decay units, and added machine control are provided in the die cooling system to enable onboard leak testing of the die while installed in the die casting machine.

Owner:GM GLOBAL TECH OPERATIONS LLC

Turntable vacuum moulding production line

InactiveCN102328035AReasonable and beautiful layoutSave spaceMoulding plantsProduction lineBox model

The invention relates to a turntable vacuum moulding production line which comprises a shakeout transfer trolley, an electromagnetic iron absorption mechanism, a pouring mechanism, box closing manipulators, a box returning motor roller way, a box opening space motor roller way and a box opening space. In the invention, multiple pairs of upper and lower box models are arranged in a circular automatic moulding ring respectively; the models are continuously subjected to coating, spraying, drying, empty box fastening, sand addition, compaction, smoothening and back film coating, wherein all operations can be automatically performed, except for the spraying which is manually operated. Two rapping box closing manipulators are arranged between two moulding rings so as to perform rapping, box turning and box closing on the lower and upper boxes respectively. The closed moulding boxes are continuously arranged in the pouring moulding ring and sequentially subjected to pouring, cooling and box opening, wherein manual pouring is adopted generally, and other processes can be realized automatically; and due to the automatic moulding line, the production efficiency is greatly improved, and the moulding of 20 models can be realized per hour.

Owner:青岛双星铸造机械有限公司

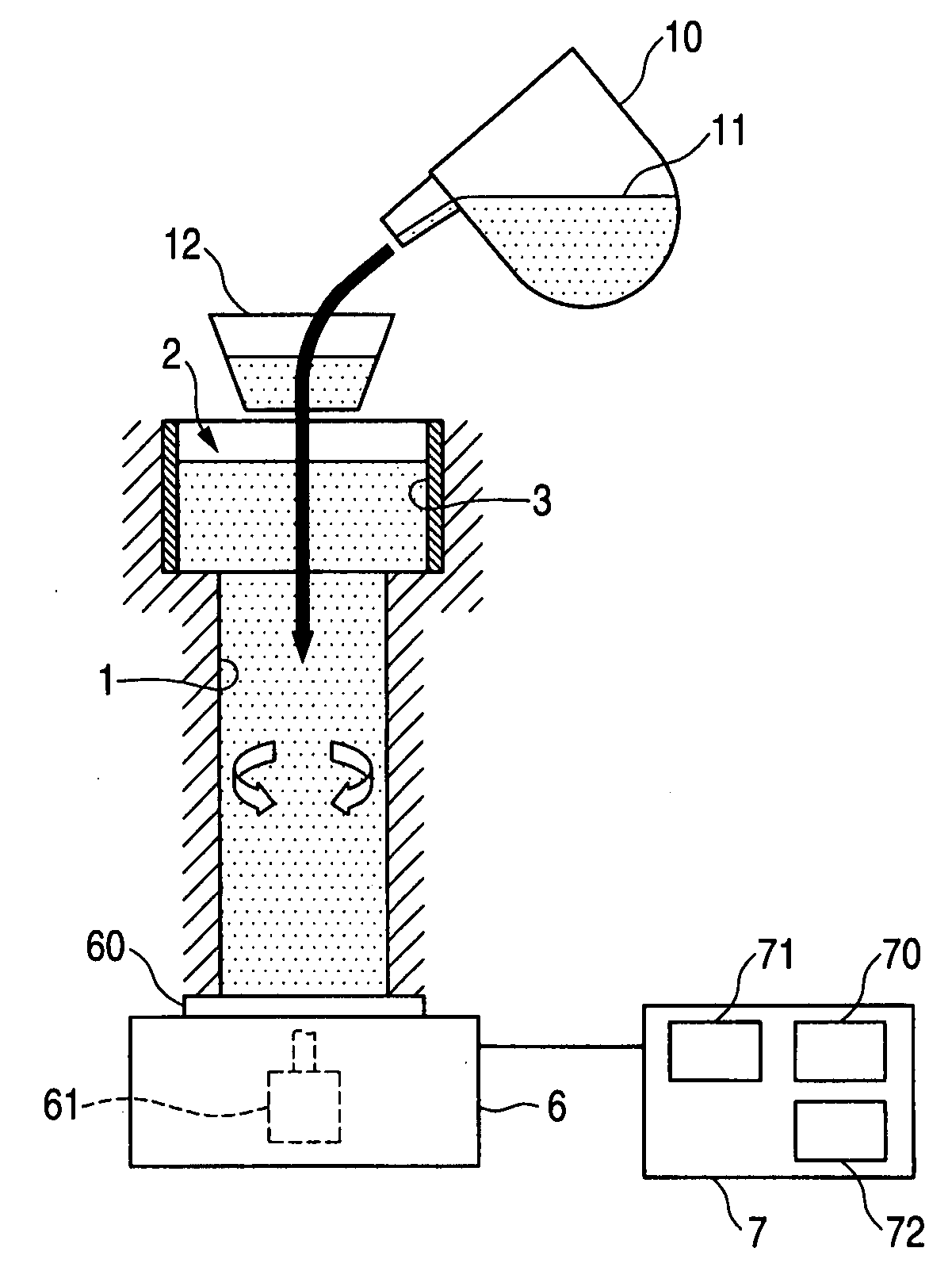

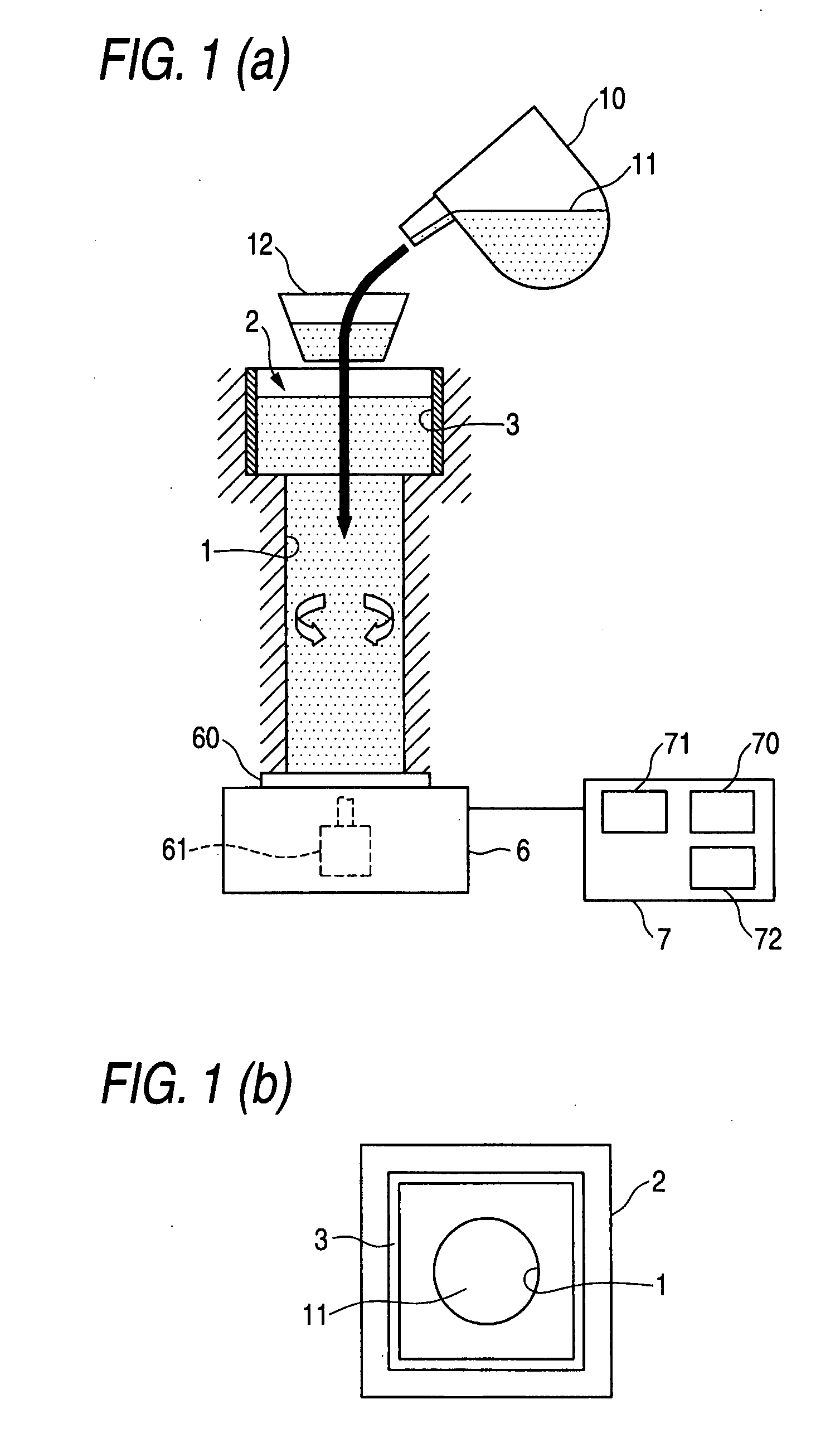

Casting Method And Casting Apparatus

ActiveUS20080169078A1Fine homogenous structureImprove ductilityMolten metal pouring equipmentsMolten metal supplying equipmentsTime segmentMetallic materials

The present invention has an object of preventing segregation during the casting of Mg alloy or the like containing additive elements having a great difference of specific gravity to obtain a cast having a good quality.A casting mold 1 having a molten metal received therein is rotated in one direction by a rotary device 7 with the vertical axis as a rotary axis while solidifying the molten metal for a predetermined period of time, and, after the predetermined period of time is lapsed, the casting mold 1 is rotated in the direction opposite the direction of rotation for a predetermined period of time, and the rotation in the opposing directions is repeated so that the molten metal is solidified. The molten metal can be shaken and agitated without roughening the surface of the molten metal to uniformalize the distribution of temperature of the molten metal in the casting mold. The production of segregates can be minimized and a fine homogenous structure can be obtained. Thus, a metallic material excellent in ductility and strength can be obtained.

Owner:HONDA MOTOR CO LTD +1

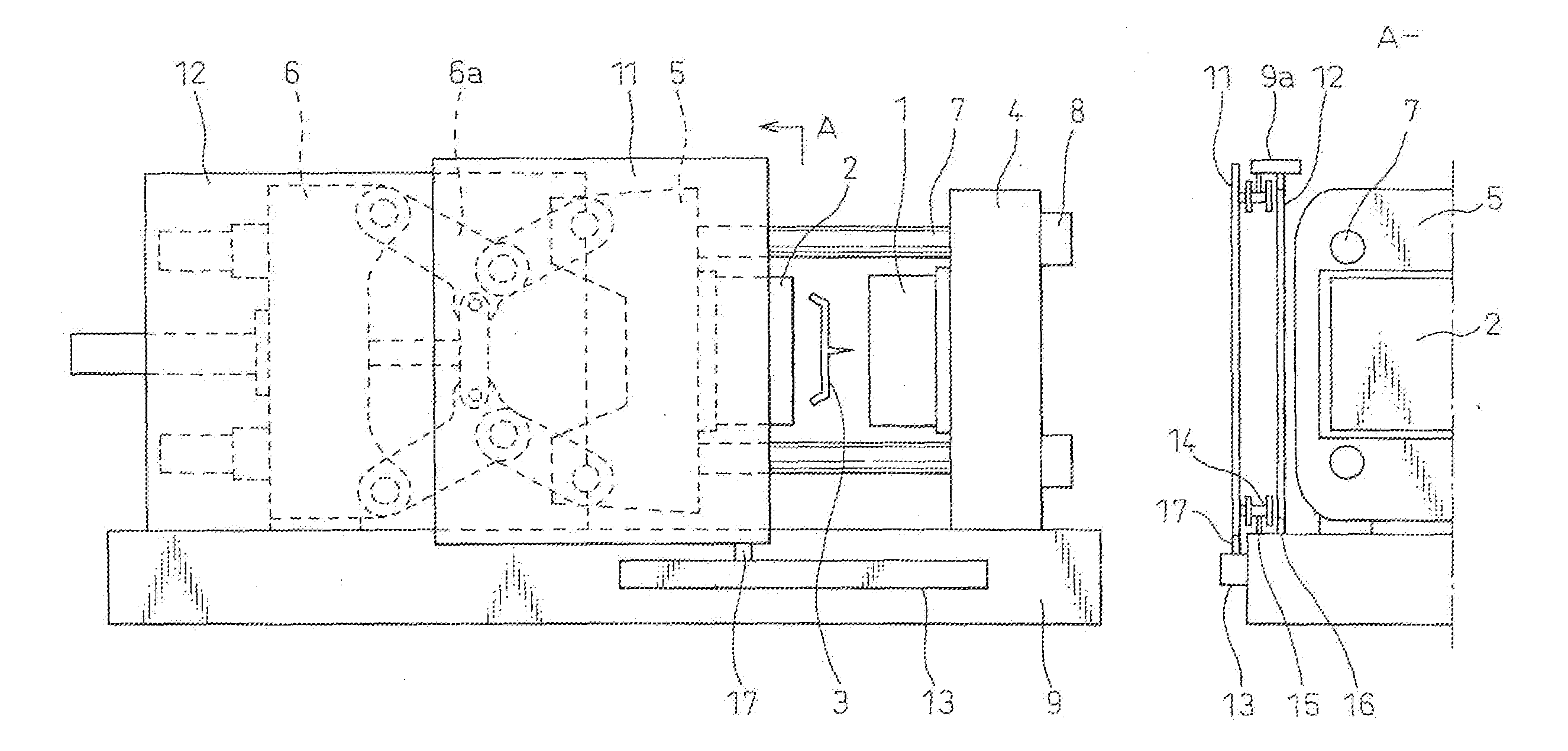

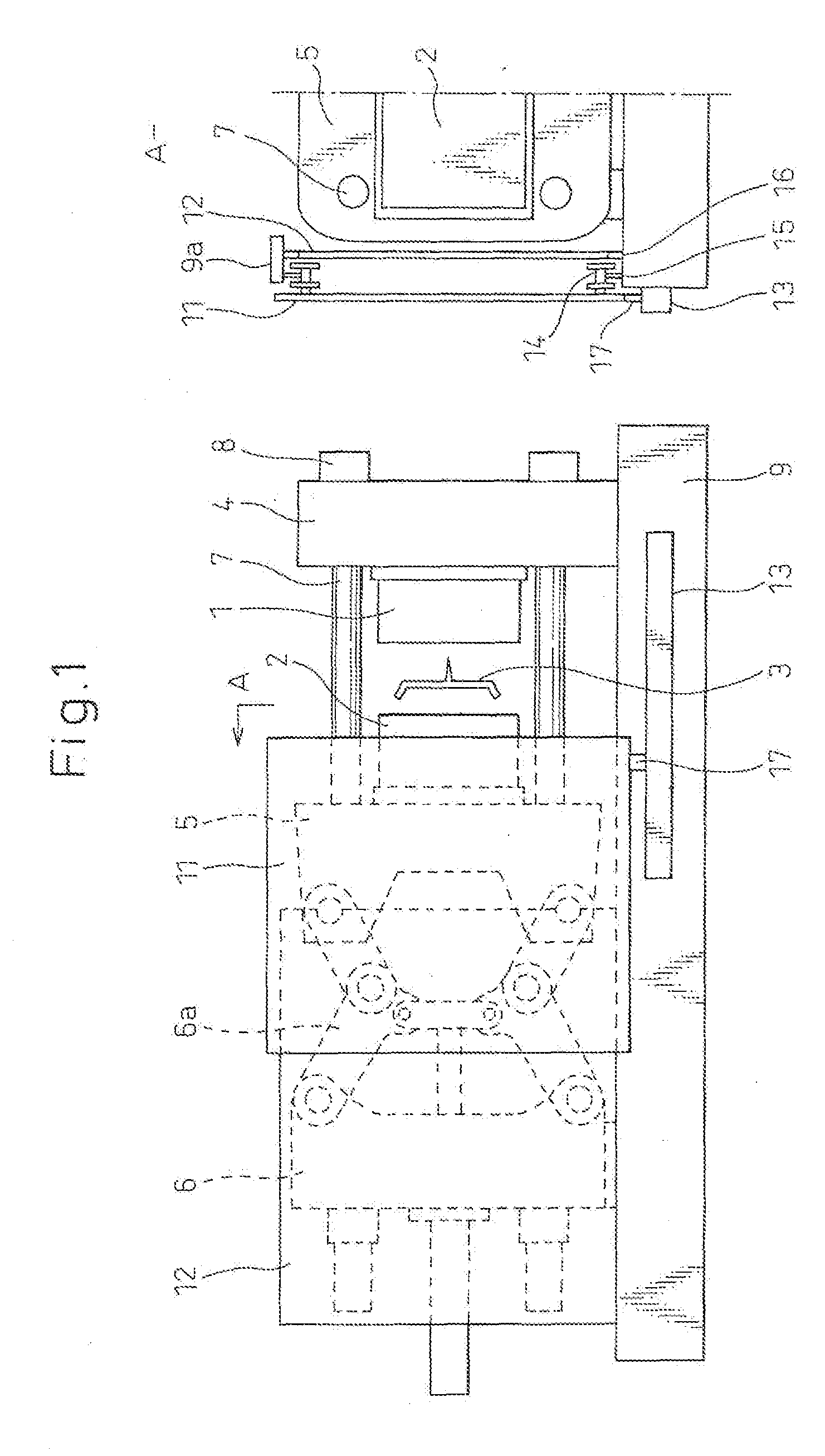

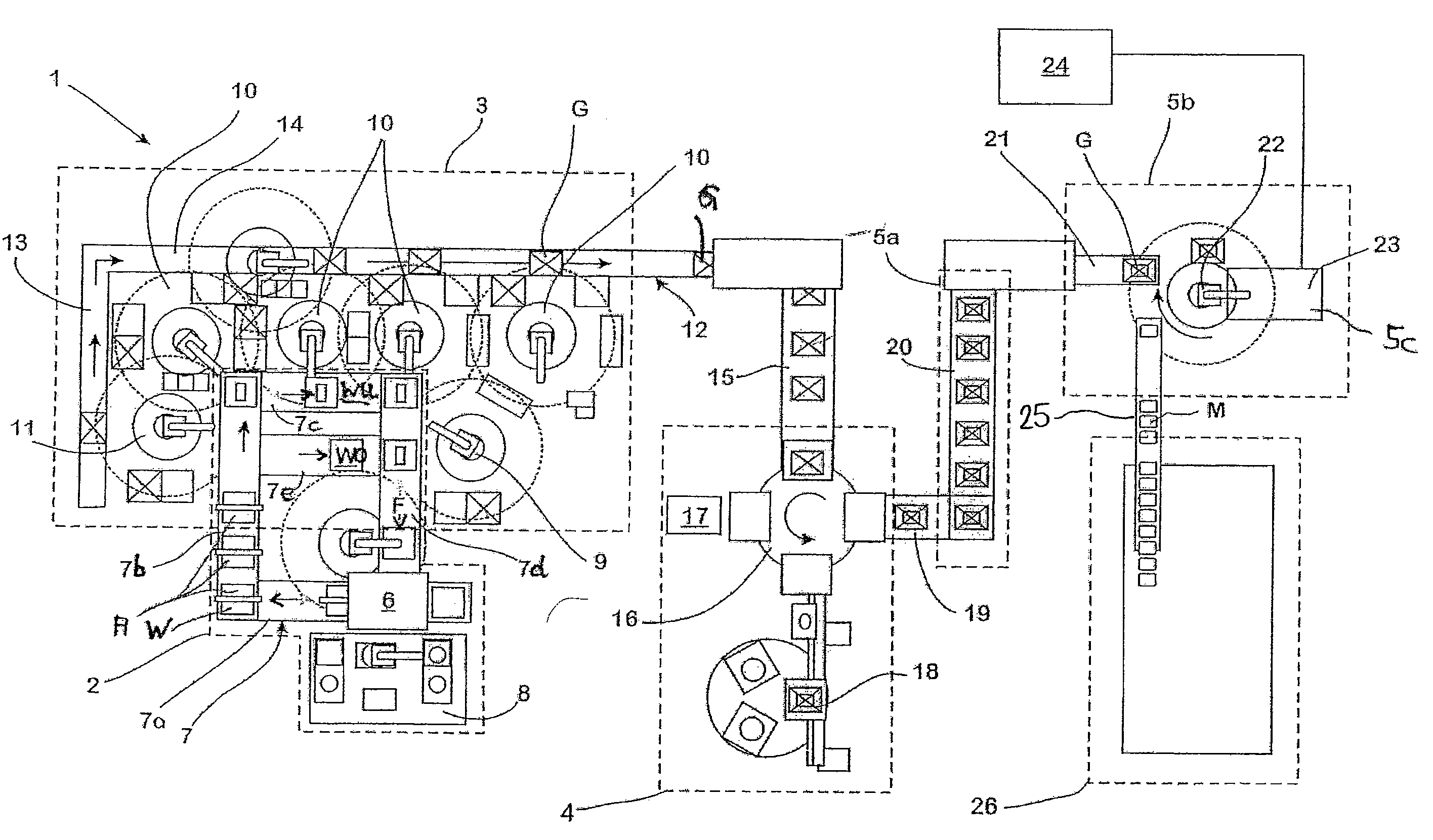

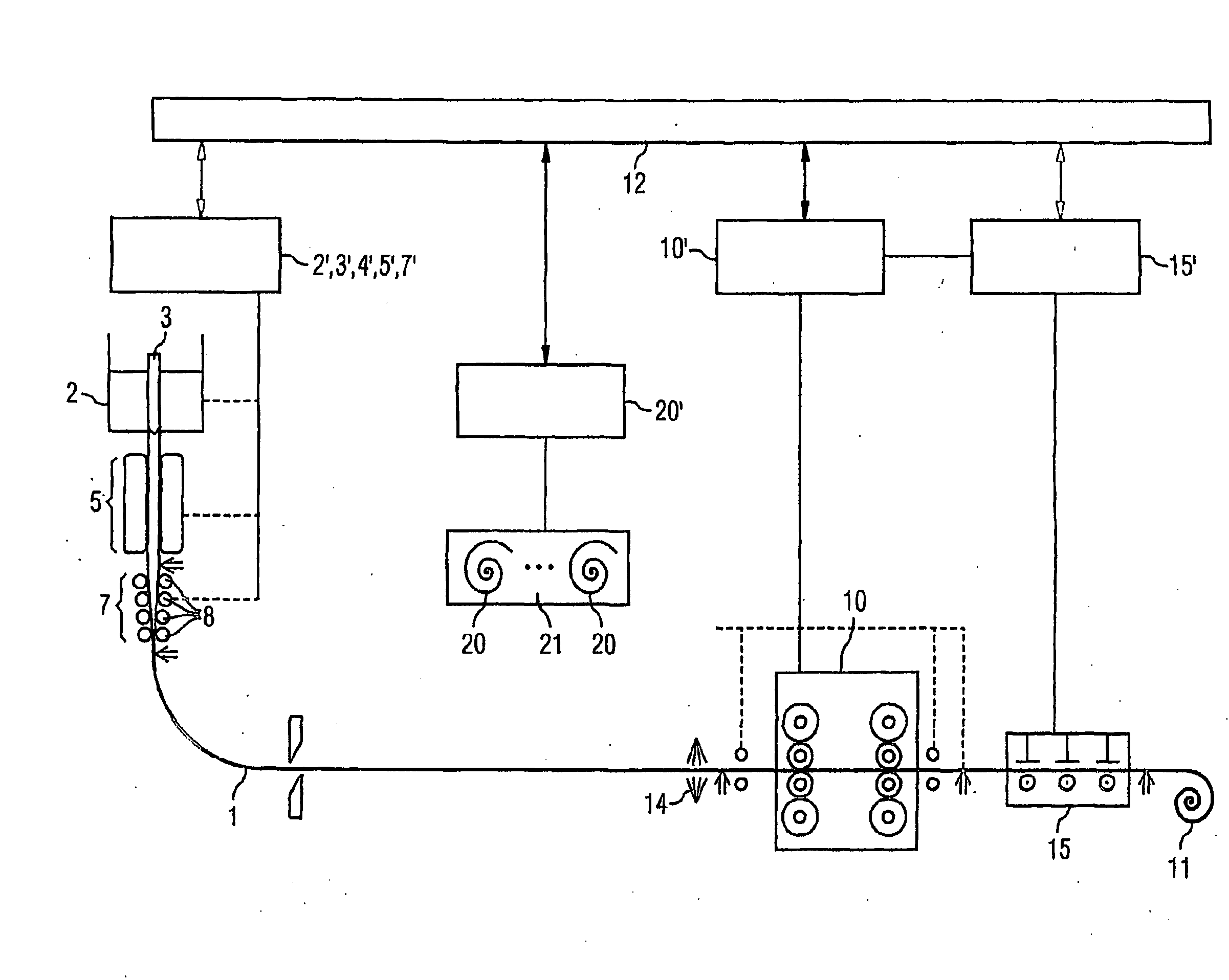

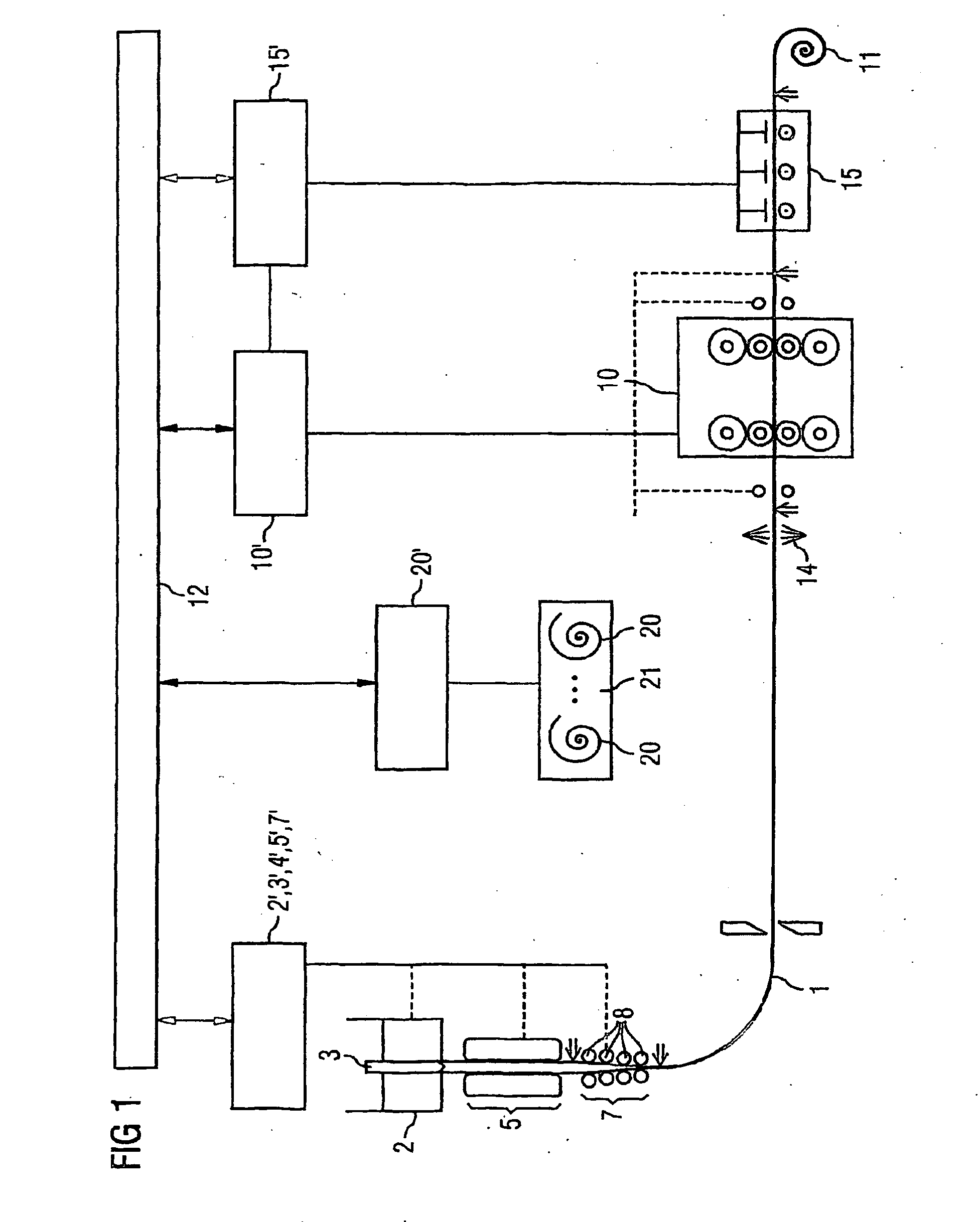

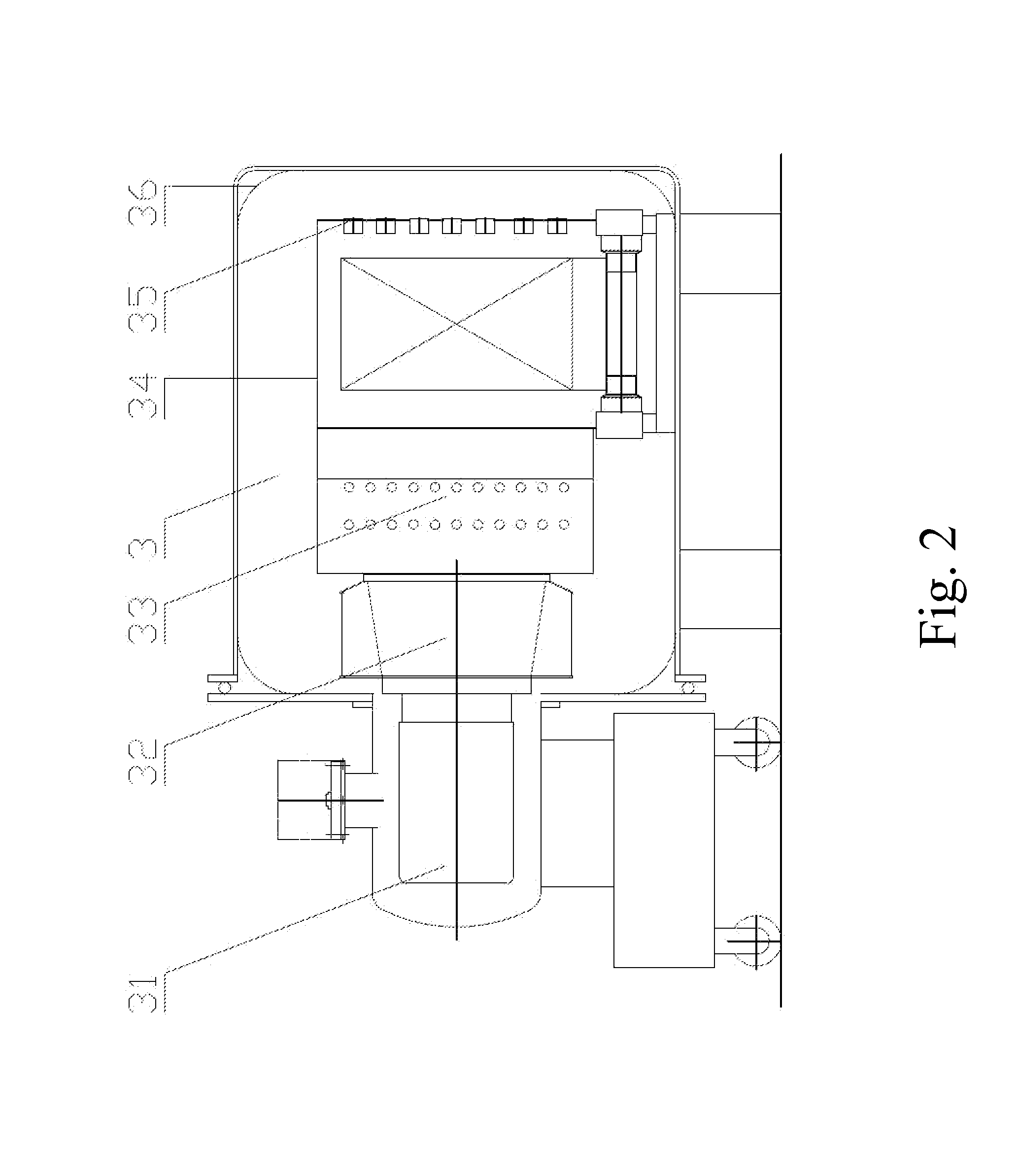

Production line and method for the production of cast parts, from a metallic melt, in particular a light molten metal, which takes place in a continuous cycle

InactiveUS7588070B2Increase load capacityForm is therefore complexPig casting plantsMoulding plantsProduction lineCycle time

The invention relates to a production line for the production of cast parts (M) from a metallic melt, in particular a light molten metal, which takes place in a continuous cycle, comprising a plurality of functional units, including a core production unit (2) for the production of casting cores, a mould assembly unit (3) for assembling casting moulds (G) formed as core packages, a casting unit for filling the molten metal into the casting moulds (G), a cooling unit (5a) for cooling the molten metal respectively contained in the casting moulds (G), and a demoulding unit (5b) for destructive removal of the casting mould (G) from the cast part (M). A production line of this type allows economical and flexible production of cast parts, in particular motor units, with a high loading capacity and complex form according to the invention in that the functional units (2 to 5b) successively passed through in each case are directly connected to each other by a respective conveying device (12, 19), and in that the cycle time with which the production line (1) ejects finished cast parts (M) is determined by the cycle time with which the core production unit (2) supplies the casting cores produced by the core production unit.

Owner:HYDRO ALUMINUM ALUCAST

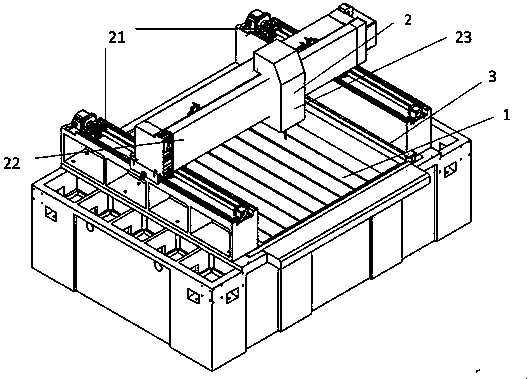

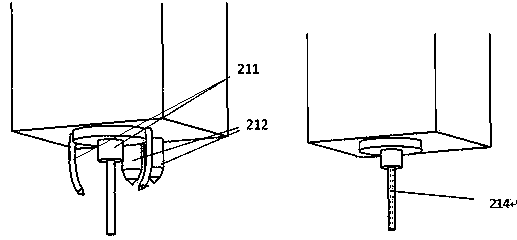

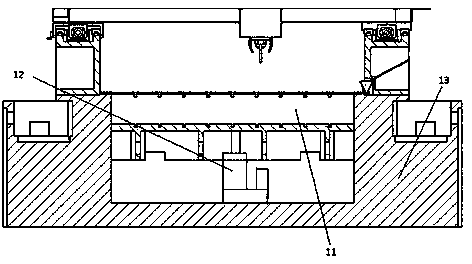

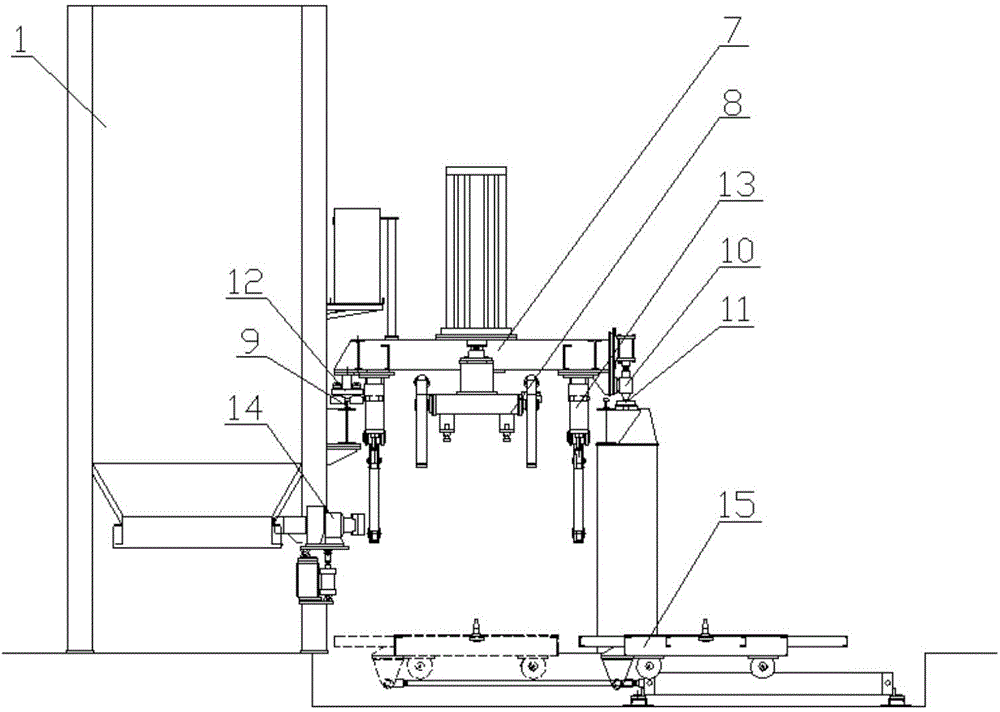

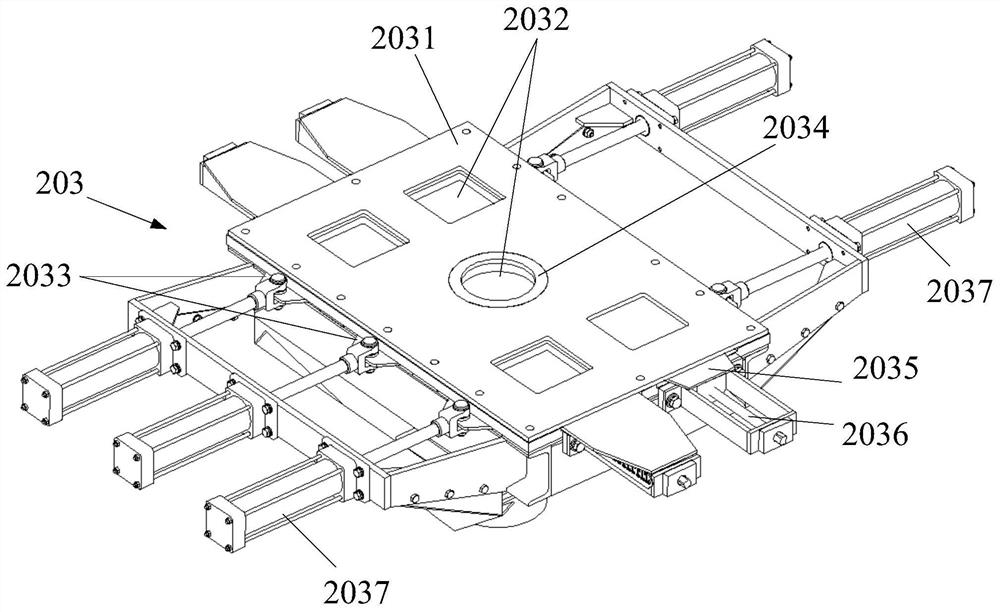

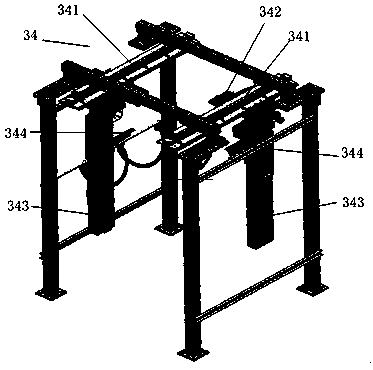

Sand mould composite molding equipment

ActiveCN103769537AQuality improvementImprove forming efficiencyMoulding plantsFoundry mouldsCasting moldEngineering

The invention provides sand mould composite molding equipment which comprises a planar motion system, an exhausting dust collection system, a motion control system and the like, and is characterized by further comprising a molding sand feeding system, a resin injection system, a cutting system, a multifunctional platform system and the like. When a casting mold is thick, heavy and large in size and suitable for cutting molding, a multi-shaft planar motion system is adopted to drive the cutting system to complete the cutting molding of the casting mold; when the casting mold is provided with a complicated internal cavity structure and suitable for dispersed / accumulated molding, the multi-shaft planar motion system is adopted to drive the resin injection system to perform dispersed / accumulated molding on the casting mold under the assistance of the multifunctional platform system and the molding sand feeding system; the sand mould composite molding with the bottom to be cut and the top to be accumulated can also be performed. With adoption of the sand mould composite molding equipment, the cutting molding, the dispersed / accumulated molding and the sand mould composite molding of a large or medium casting mold with any shape can be realized, so that the equipment investment is greatly reduced; in addition, a proper molding manner can be selected, the manufacturing speed and quality of the casting mold can be improved, and the sand mould composite molding equipment has the value of popularization and application.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

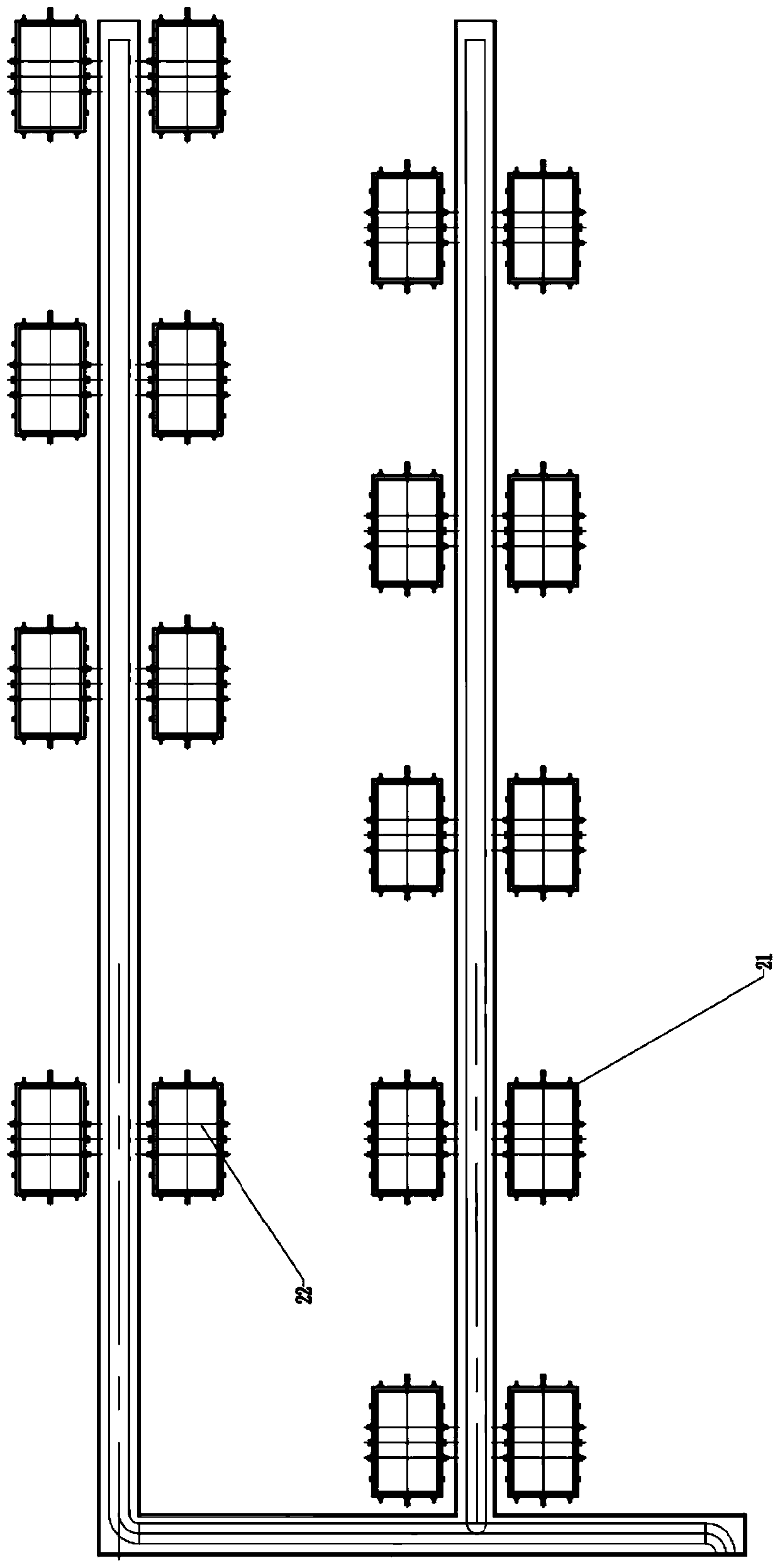

Production line for V-method modeling

InactiveCN104139166AImprove first-time success rateMake sure it's connectedMoulding plantsProduction rateRobot hand

The invention provides a production line for V-method modeling. The production line comprises a modeling region, a mould overturning and mould assembling region and a loam core discharging region which are arranged in sequence, wherein the modeling region comprises two sets of modeling trolleys arranged on a guide rail; the mould overturning and mould assembling region comprises a mould overturning machine, an elevated trackway arranged above the mould overturning machine, and a mechanical arm trolley arranged on the elevated trackway; and the loam core discharging region comprises a transportation trolley arranged on the guide rail. According to the production line for the V-method modeling, a traditional production mode that a task is finished by allocating and transporting a casting mould to different stations through the reciprocating of a travelling crane is changed so that the production rate is improved and the occupied area of equipment in a workshop is reduced; and the production line can produce compactly and is operated at high speed, so that the labor force is saved and the safe production is greatly facilitated.

Owner:夏汝明

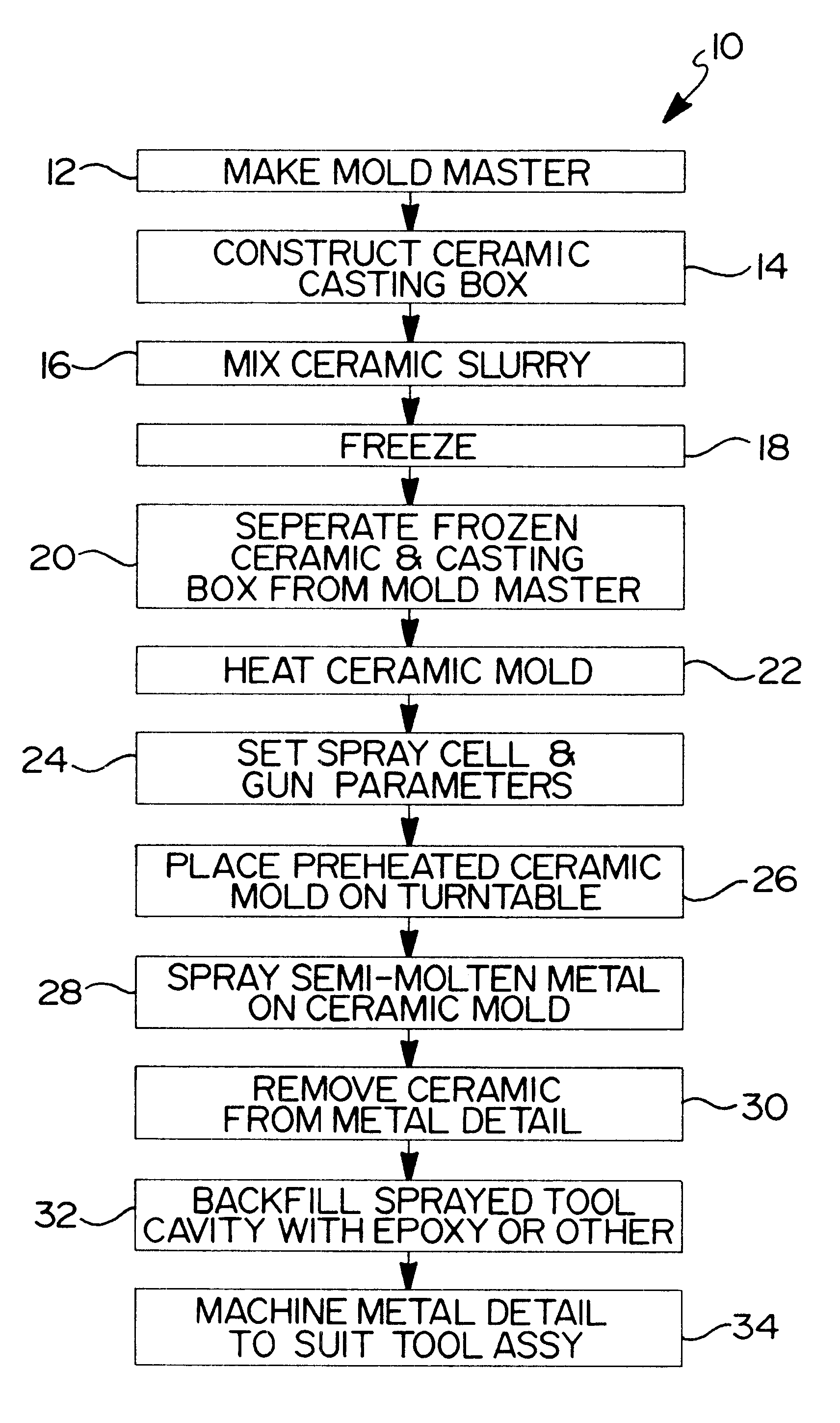

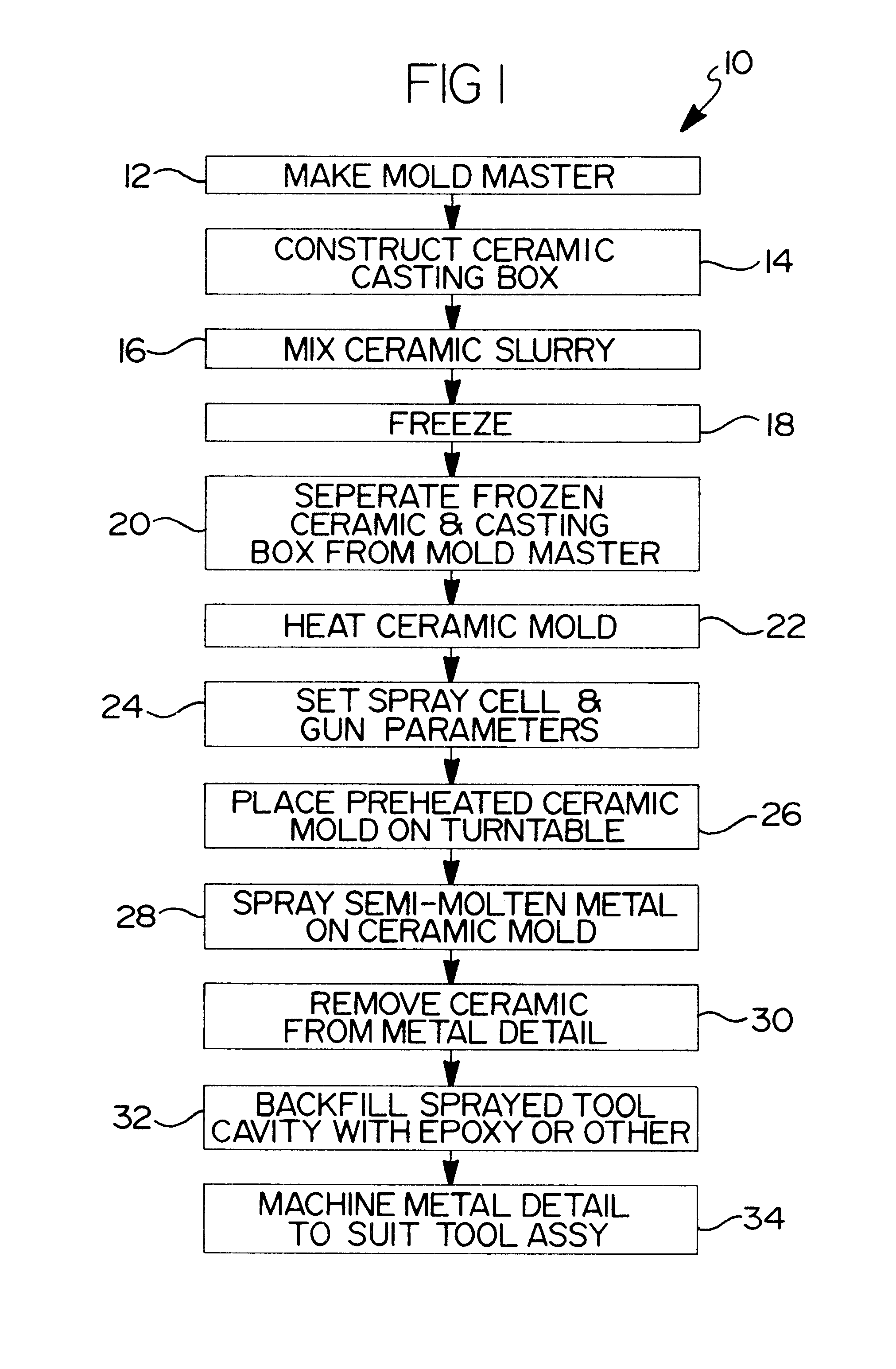

Method of making a spray formed rapid tool

InactiveUS6513567B2Additive manufacturing apparatusMoulding plantsThermal sprayingMetallic materials

A method of making a spray formed rapid tool includes the steps of making a model of a desired tool and constructing a ceramic pattern as the inverse of the model. The method also includes the steps of heating the ceramic pattern and thermally spraying a metal material against the ceramic pattern to form a desired tool.

Owner:FORD MOTOR CO

Casting mold production line and casting production line

ActiveCN105499518AIncrease the running tempoIncrease productivityCasting plantsMoulding plantsProduction lineMolding machine

The invention discloses a casting mold production line which comprises an input trolley, an output trolley and at least two molding machines. The input trolley and the output trolley are arranged on the two sides of the molding machines respectively. The sides, away from the molding machines, of the input trolley and the output trolley are provided with pushing devices respectively. The input trolley and the output trolley can move to correspond to the molding machines respectively. According to the casting mold production line, the input trolley moves to correspond to the molding machine, the pushing devices push sand boxes on the input trolley into the molding machines, the sand boxes inside the molding machines are pushed onto the output trolley, the output trolley transports the sand boxes to the next production line, the input trolley is returned and continuously loads the sand boxes, the sand boxes are transported to other molding machines, and the steps are repeatedly executed. It is obvious that the operation takt of the sand boxes is accelerated due to the arrangement of the input trolley and the output trolley, and the production efficiency is improved.

Owner:NINGGUO ZHICHENG MACHINERY MFG

Die casting reciprocator safety bar

An automated reciprocator for applying lubricant to the cavity of a die casting system having a safety bar for preventing the reciprocator from injuring a person or damaging equipment which may be present in the reciprocator travel path. The safety bar is movably carried on the lower side of the reciprocator and includes a sensor to detect relative movement between the safety bar and the reciprocator. The proximity sensor is coupled to a control system. If the safety bar contacts an object as the reciprocator is moving down, the sensor signals the control system and the reciprocator is stopped.

Owner:PACE IND LLC A DELAWARE CO

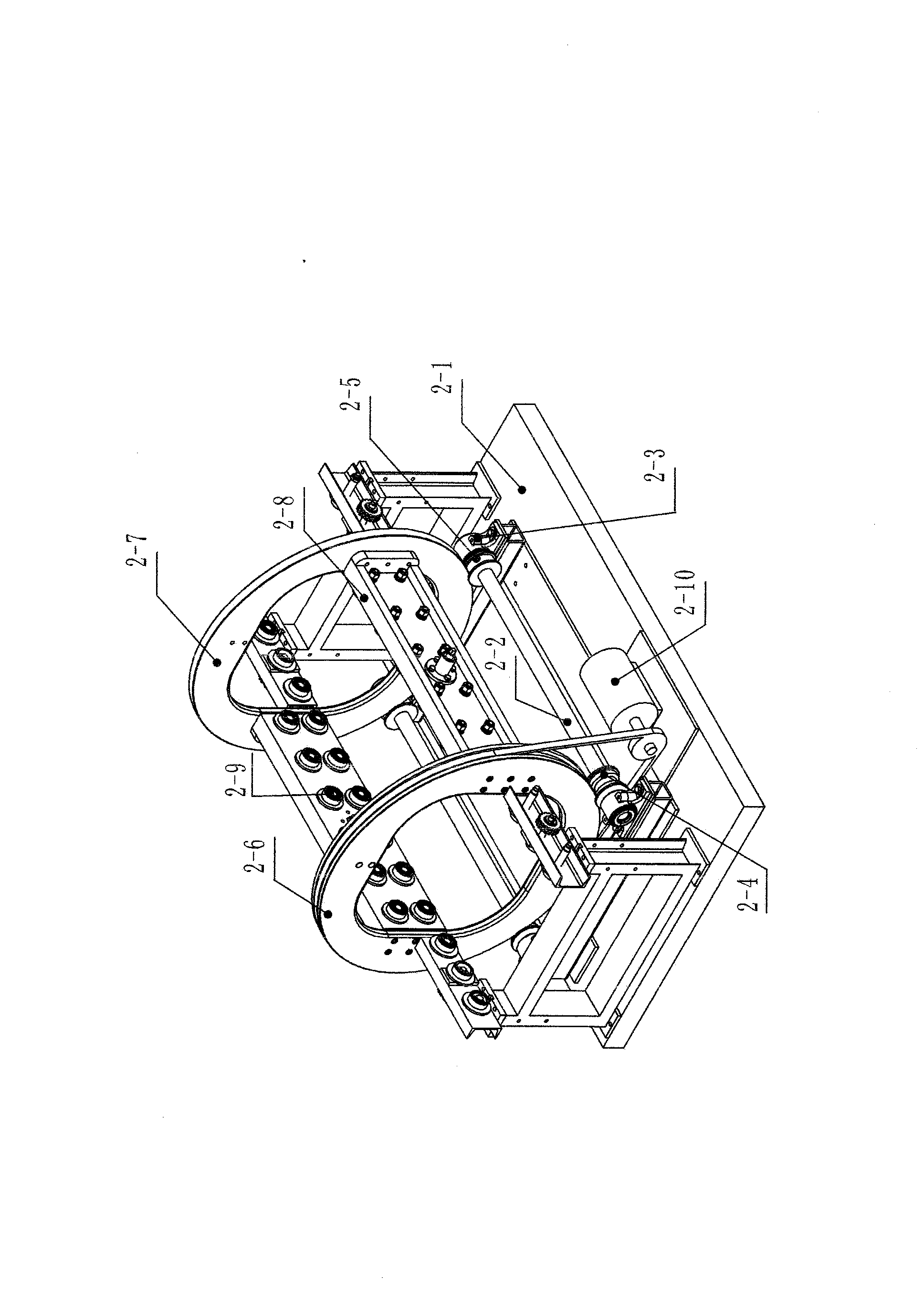

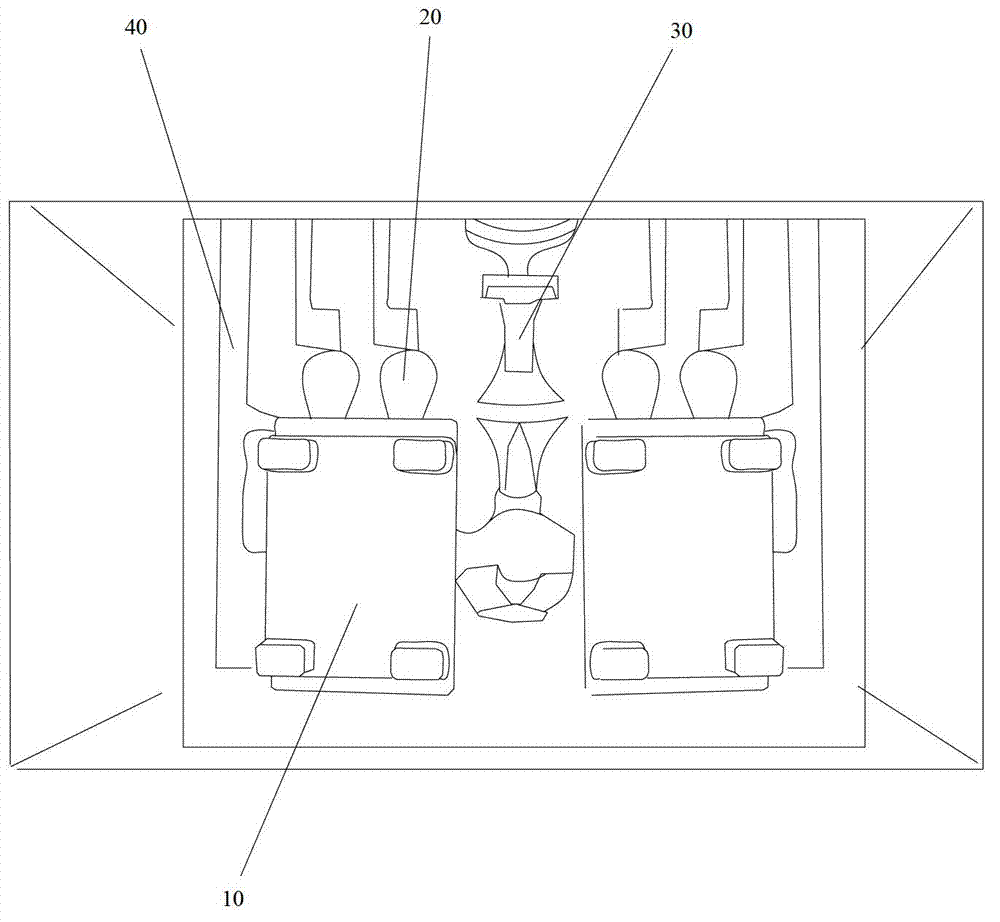

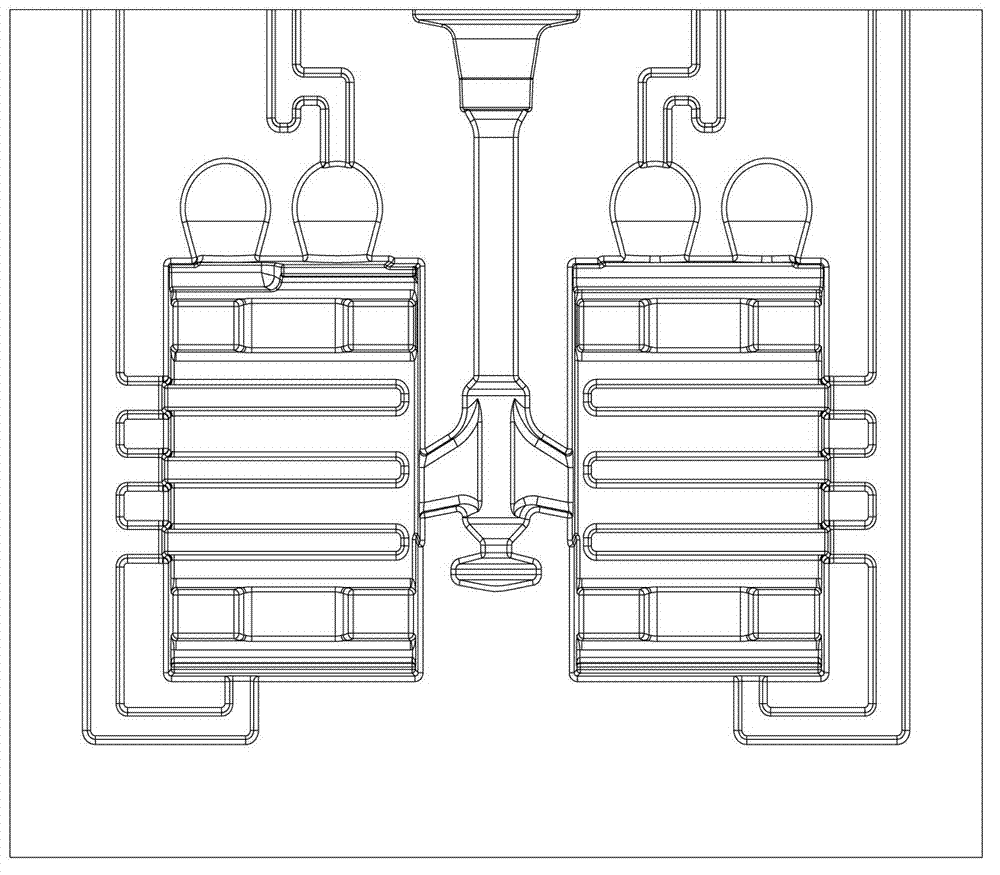

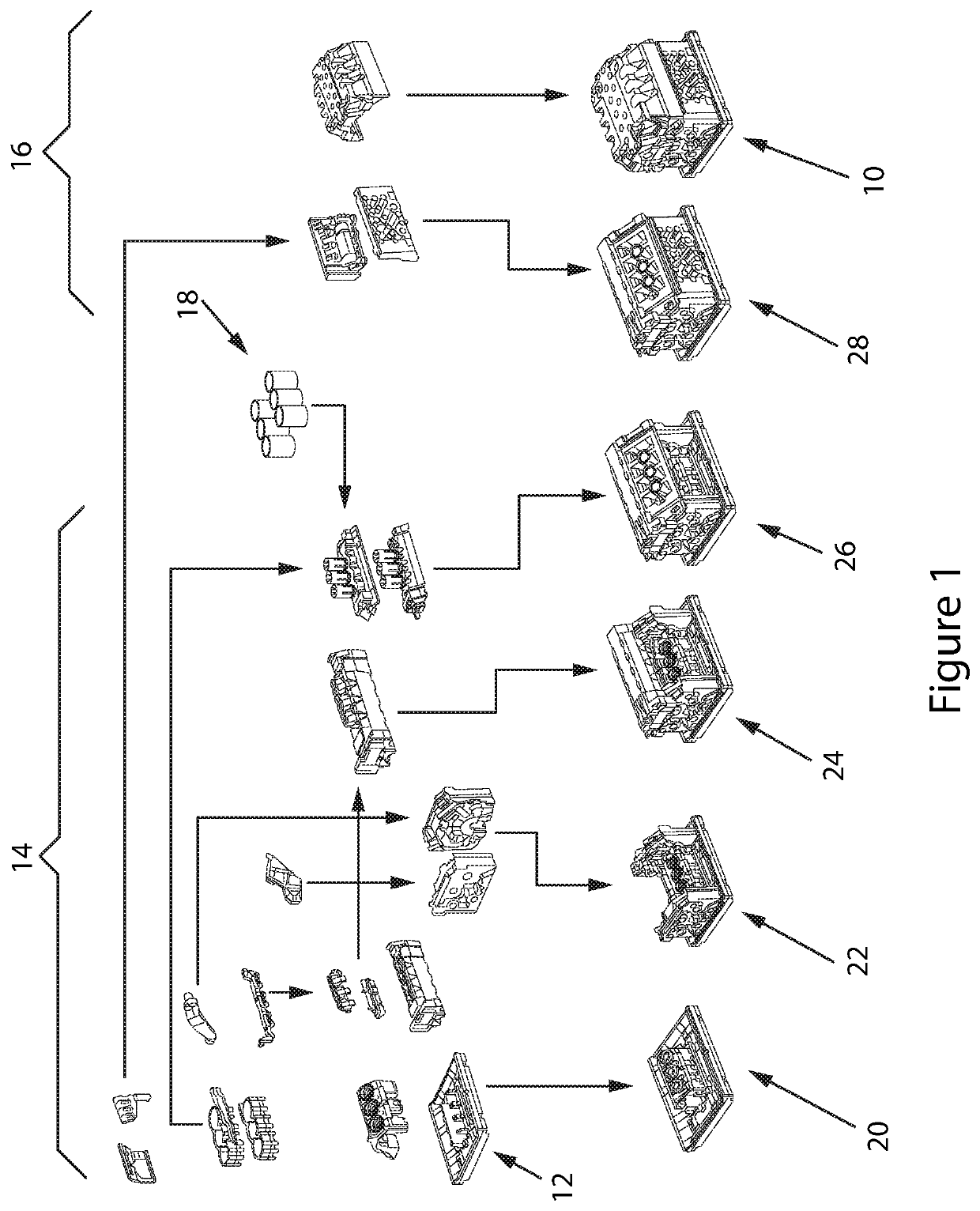

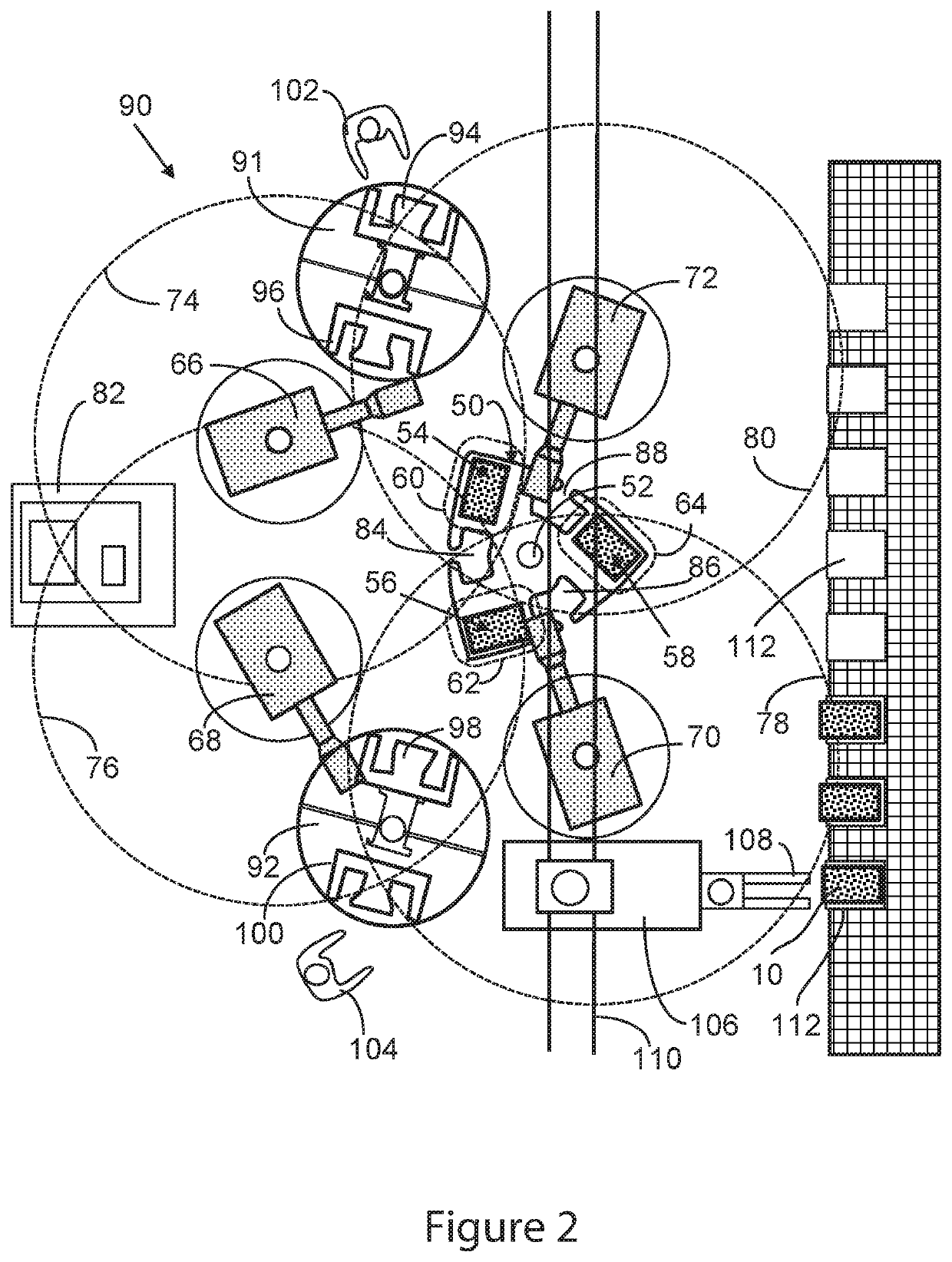

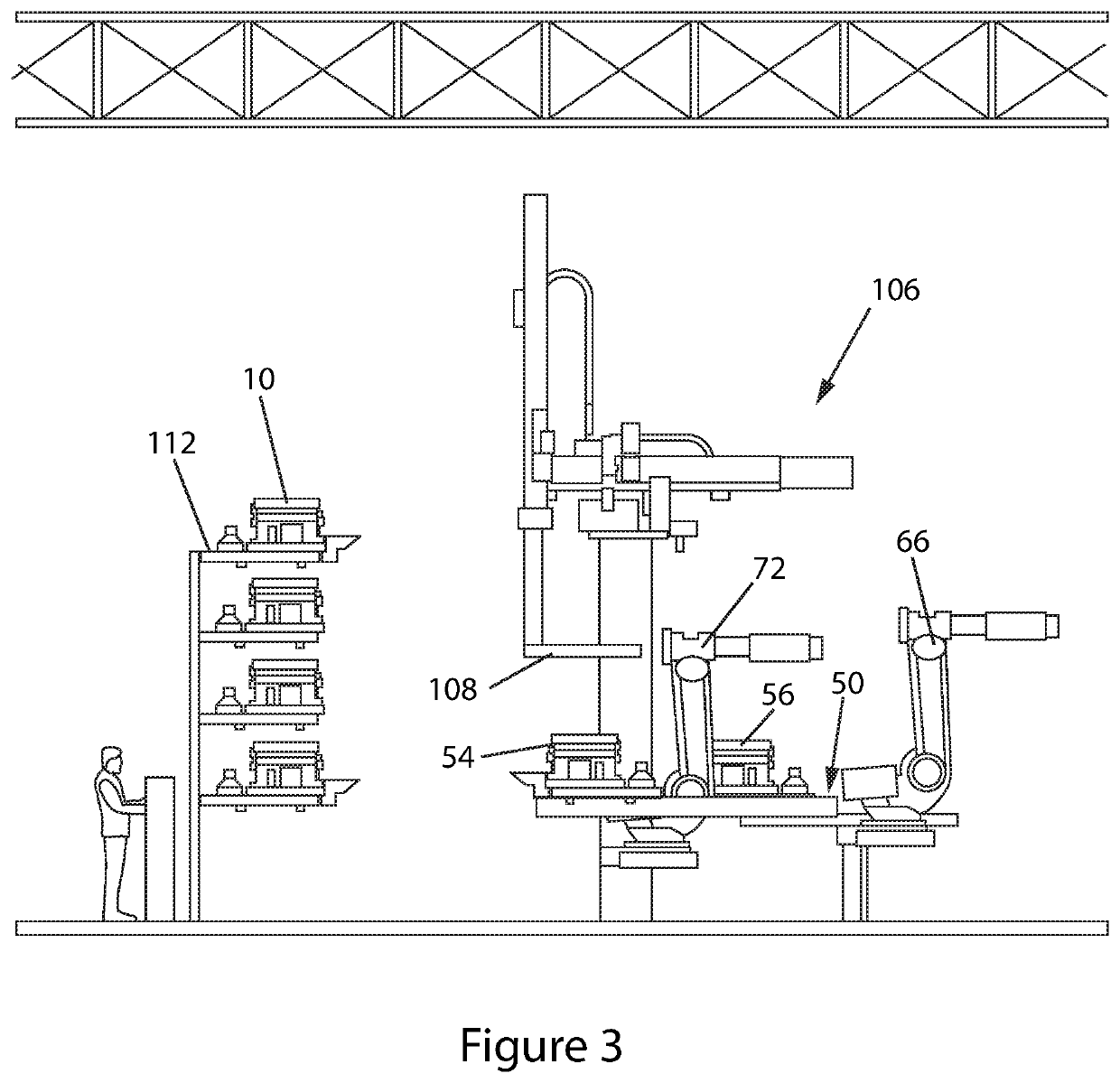

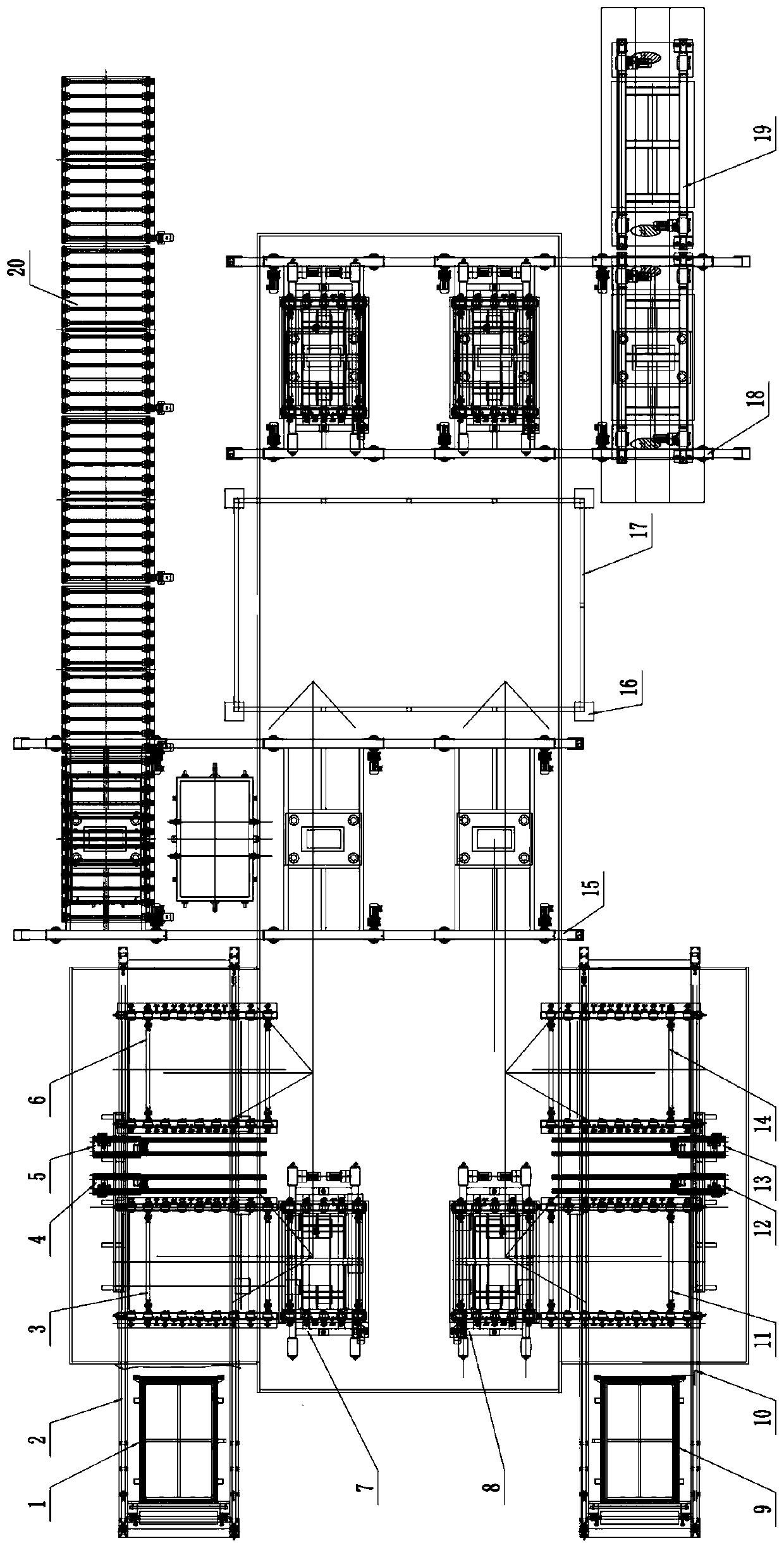

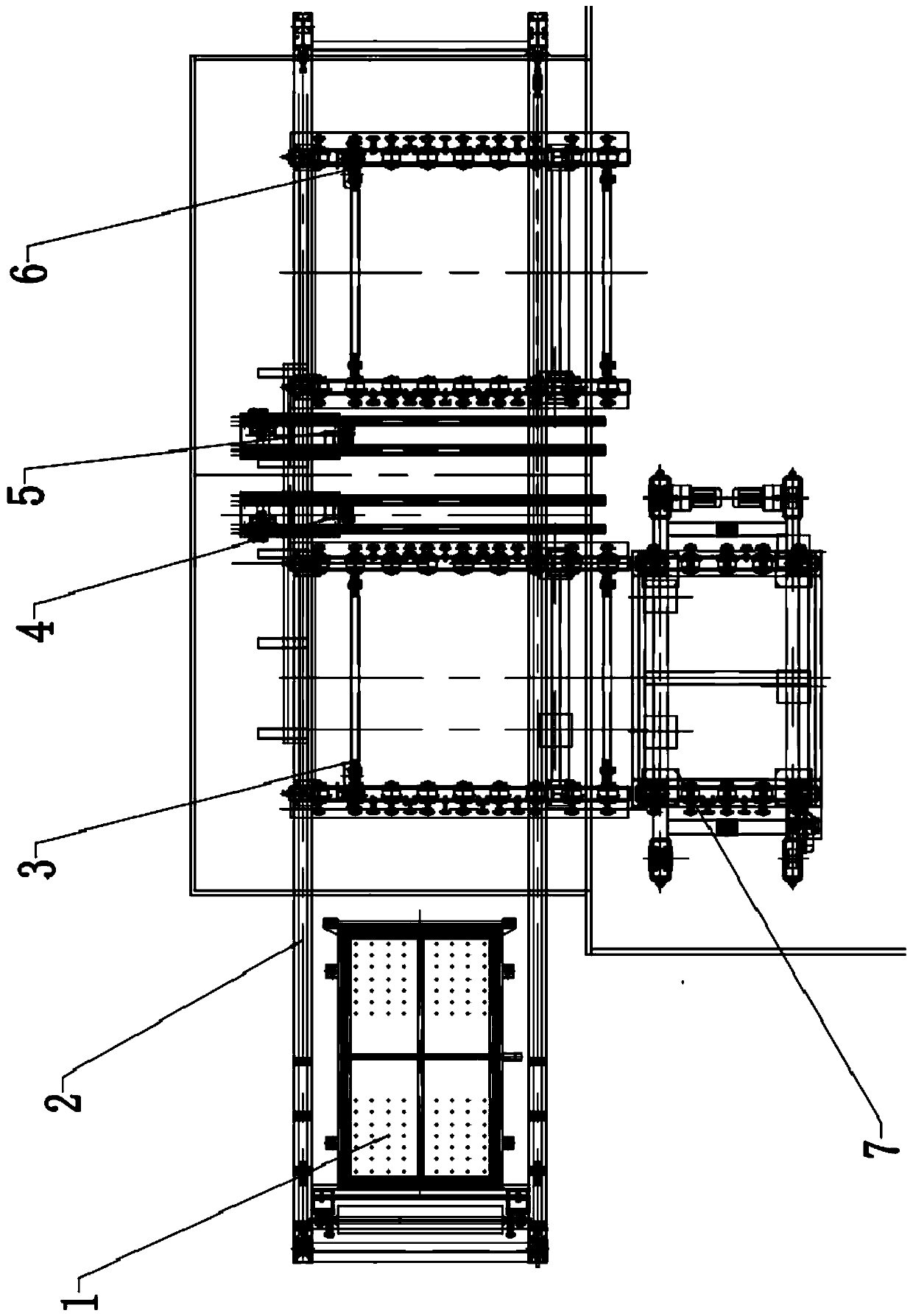

Automated assembly cell and assembly line for producing sand molds for foundries

ActiveUS20200316675A1Improve efficiencyLower cost of capitalCasting plantsMoulding toolsFoundryCylinder head

A mold assembly cell for sand mold production comprising a turntable wherein sand cores and other mold parts (which together cooperate to define the casting cavity of the sand mold) are automatically and progressively assembled following a sequential pre-programmed schedule by programmable robots located in proximal relationship with the turntable and a core shooting machine. The assembly turntable rotates clockwise or counterclockwise to permit placement of progressively more-complete mold packages in each of at least three assembly stations to allow the robots to reach the molds being assembled at different angles for simultaneously setting the sand cores and other parts of the mold according to said pre-programmed assembly schedule. Also a mold assembly line comprising a plurality of the foregoing assembly cells to form sand molds for casting complex-geometry aluminum parts, such as aluminum engine blocks and cylinder heads, with greater flexibility, efficiency and productivity.

Owner:NEMAK S A B DE

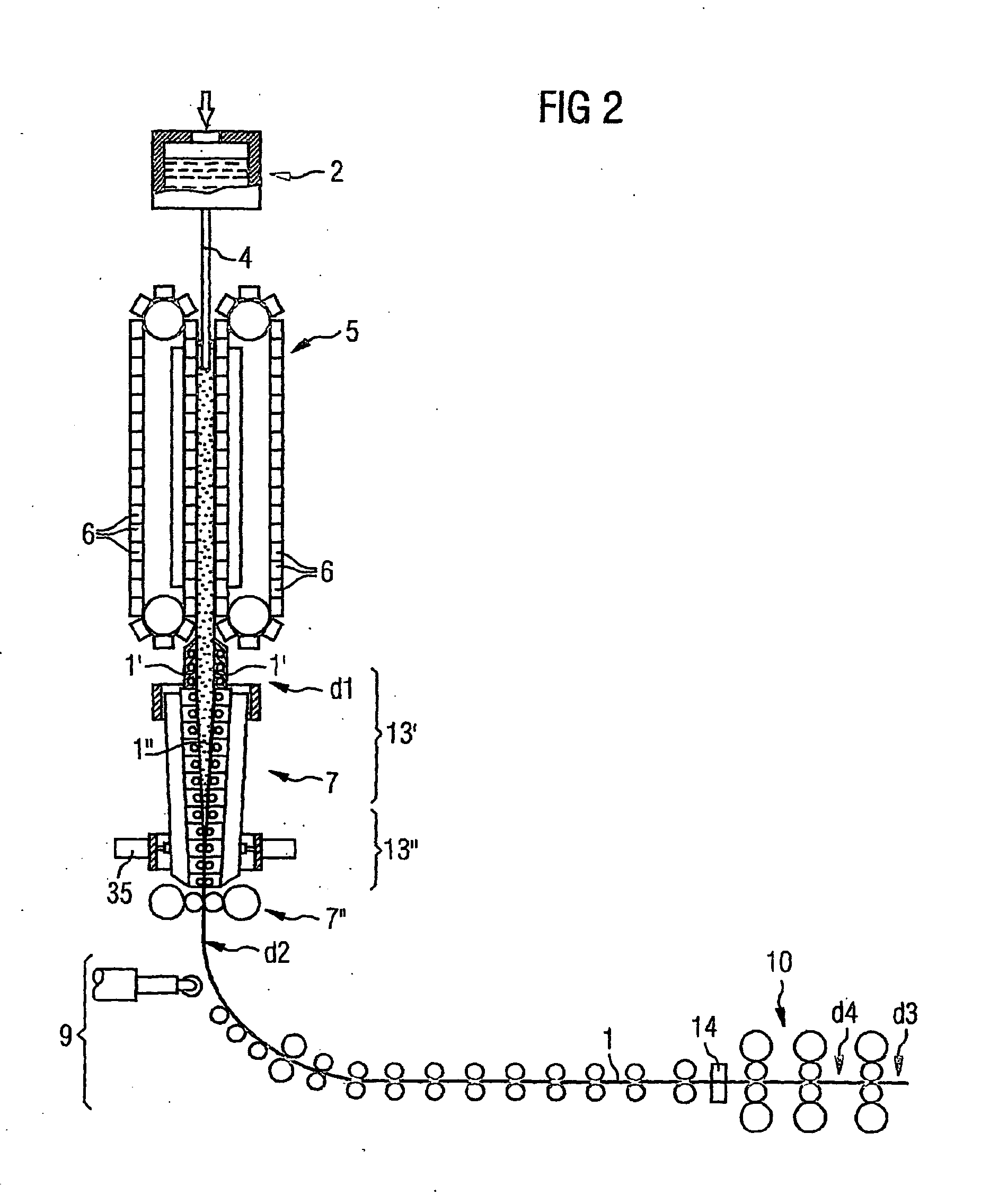

Continuous Casting and Rolling Installation For Producing a Steel Strip

InactiveUS20080135203A1Easy to operateTemperature control deviceMoulding plantsControl systemMathematical model

In order to produce a steel strip (1), a continuous casting and rolling installation comprises a liquid steel storage device (2), a liquid steel charging device (3), a vertically operating casting device (5) with a revolving mold (6), a reduction device (7) with a plurality of roll pairs (8), a diverting device (9) for diverting the cast steel strip (1) into a horizontal position, a horizontally operating rolling mill (10) and a winding device (11), which are controlled via individual technological control loops (2′ to 11′). In order to adjust the technological control loops (2′ to 11′) in an integrated manner, it also comprises a control system (12) which connects the installation parts (2 to 11) or components with regard to control, operates on the basis of mathematical models (17), and coordinates the individual installation parts (2 to 11) with regard to the interaction thereof, while taking into consideration the effects of the control steps of an installation part (2 to 11) upon installation parts (2 to 11) following in the direction of mass flow. The control system (12) contains a material model (17), by means of which a thermal behavior of the steel or steel strip (1) from the steel storage device (2) to the winding device (11) can be modeled using path tracking. The technological control loops (2′ to 11′) are controlled at the correct times according to the modeled thermal behavior of the steel or steel strip (1).

Owner:SIEMENS AG

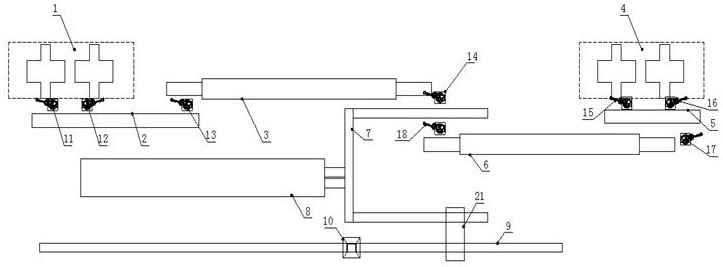

F-shaped molding production line, F-shaped molding production method and V technique casting method

ActiveCN110170615AImprove work efficiencyReduce styling timeMoulding plantsFoundry mouldsProduction lineMaterials science

The invention discloses an F-shaped molding production line, an F-shaped molding production method and a V technique casting method. The F-shaped molding production line comprises a first guide rail,and a first roller bed, a second roller bed, an empty case roller bed, a drenching sand adding device and a film removal table which are sequentially arranged along the extension direction of the first guide rail, wherein a first trolley which can move along the first guide rail is arranged on the first guide rail in matching mode, the first trolley carries a first vibrating compaction table, thefirst vibrating compaction table is used for receiving upper negative pressure cases conveyed on the first roller bed or the second roller bed, and drives the upper negative pressure cases to sequentially pass through the empty case roller bed and the drenching sand adding device correspondingly for empty box inverting and sand adding, and finally the upper negative pressure cases are conveyed tothe film removal table. By adopting the mode of arranging two guide rails and matching two roller beds with each guide rail, the effects that one V technique molding line can simultaneously produce two types of castings, waiting time of the vibrating compaction table is fully used, improvement of work efficiency of each component can be realized, and overall molding time is reduced are achieved.

Owner:QINGDAO SHENGMEI MACHINERY

Intelligent sand mixer system

PendingCN111842809ARealize variable sand supplyImprove firmnessMoulding plantsMould handling/dressing devicesMaterial supplyGeotechnical engineering

The invention provides an intelligent sand mixer system which belongs to the field of casting. The system comprises a sand mixer, a feeding valve, a sand storehouse, a liquid material supply device, and a vibrating table. The sand storehouse is used for storing molding sand and supplying the sand mixer through the feeding valve. The sand storehouse is arranged above the sand mixer. The feeding valve is used to control the type and amount of sand supplied. The feeding valve is arranged between the sand storehouse and the sand mixer. The liquid material feeding device is used for storing binderand curing agent and supplying to sand mixer. The sand mixer is used for conveying molding sand, mixing molding sand with binder and curing agent and outputting mixture for forming sand mold. The vibrating table is arranged under a sand outlet of the sand mixer, used for bearing the model and a sand box sleeved on the model, and used for vibrating the mixture in the sand box. The system reduces the labor intensity, improves the quality of the sand mold and saves the cost.

Owner:WUXI XINAN FOUNDARY MACHINERY

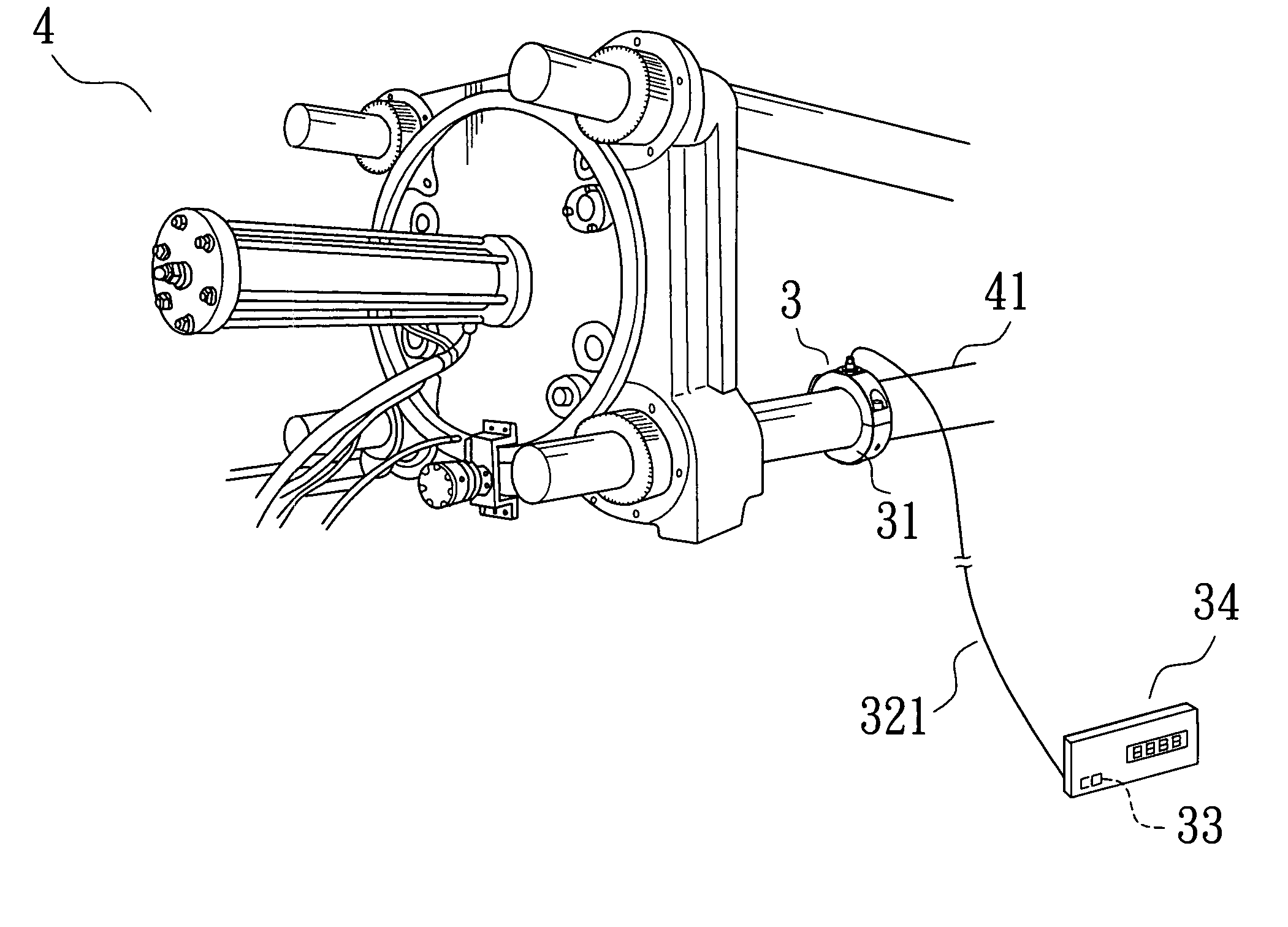

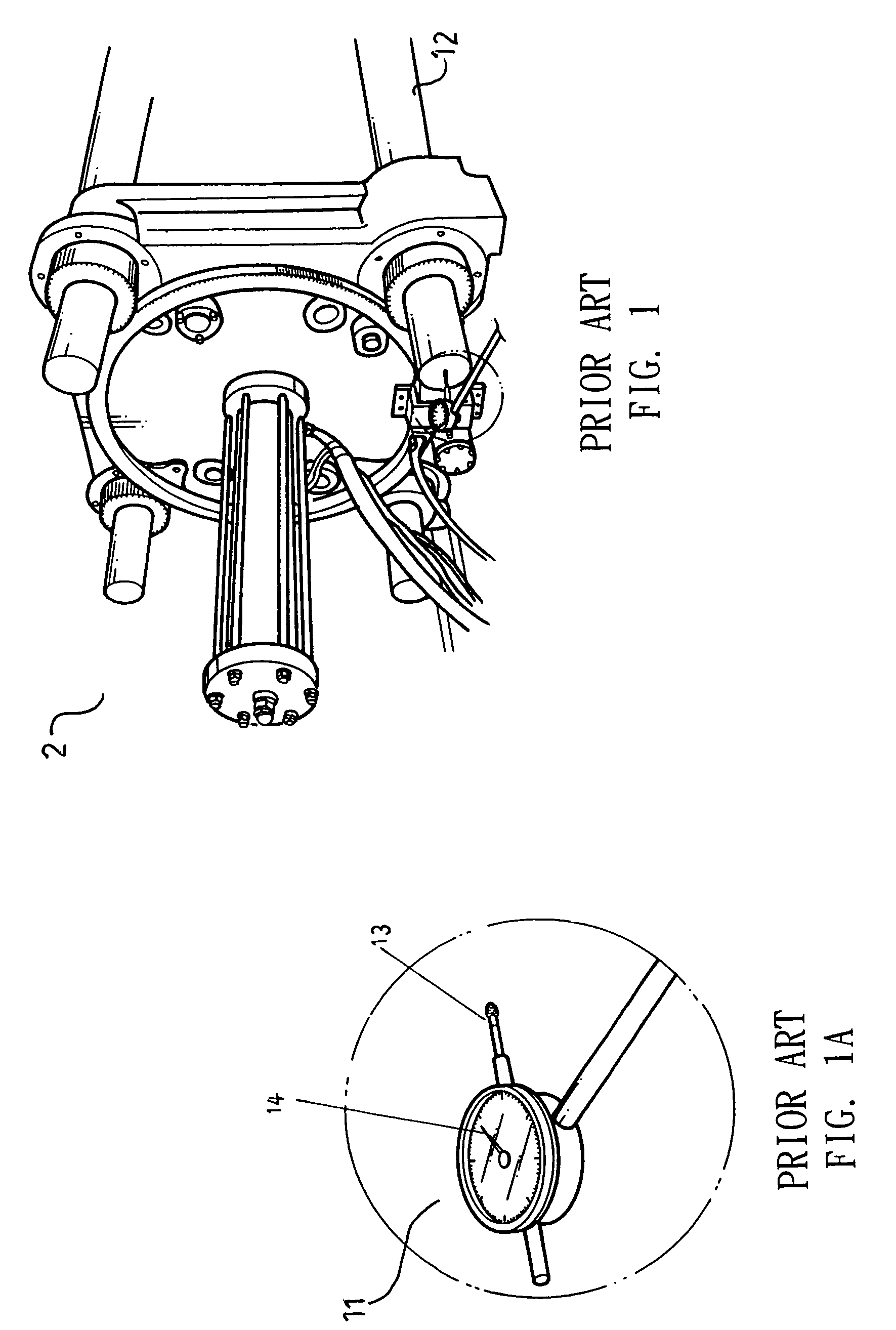

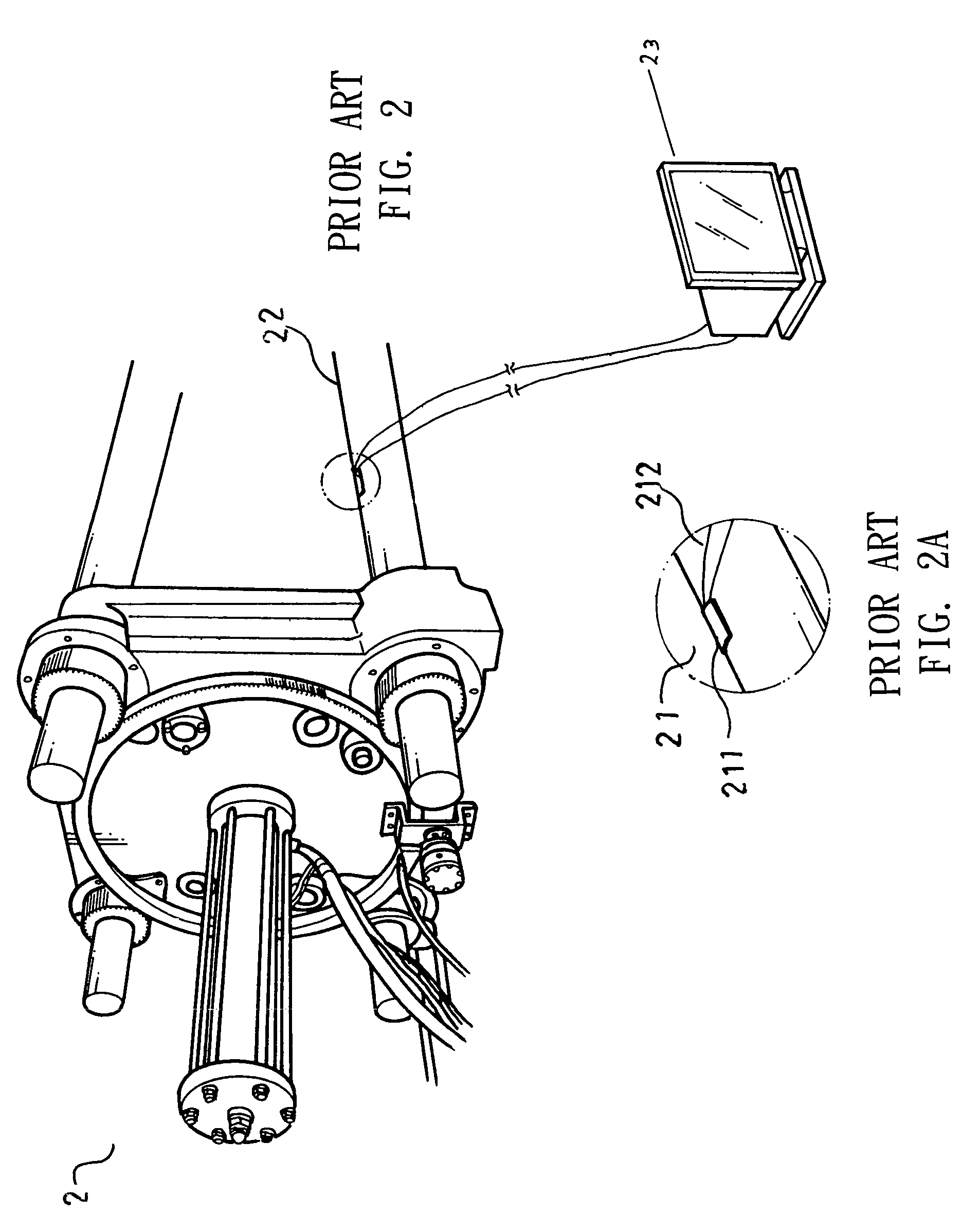

Clamping force sensor system

Owner:LEE TONY

Vacuum induction melting and strip casting equipment for rare earth permanent magnetic alloy

ActiveUS20140352909A1Avoids uneven slice stirringReduce coolingReversible hydrogen uptakeMoulding plantsIsolation valveRare earth

A vacuum induction melting and strip casting equipment for rare earth permanent magnetic alloy includes a vacuum induction melting and strip casting chamber, a material receiving heat preservation treatment chamber, a cooling chamber and an isolation valve. The isolation valve is located between the material receiving heat preservation treatment chamber and the cooling chamber, the vacuum induction melting and strip casting chamber is located above the material receiving heat preservation treatment chamber, an outlet of a material guiding tube of the vacuum induction melting and strip casting chamber is corresponding to the material receiving heat preservation treatment chamber. Water-cooled electrodes, a vacuum pumping device, an inert gas introduction pipeline, a temperature measurement mechanism, a pressure gauge, a vacuum gauge and a safety valve are provided on the vacuum induction melting and strip casting chamber. The present invention improves the production efficiency and has high production performance and good consistence.

Owner:SHENYANG NORTH VACUUM TECH CO LTD

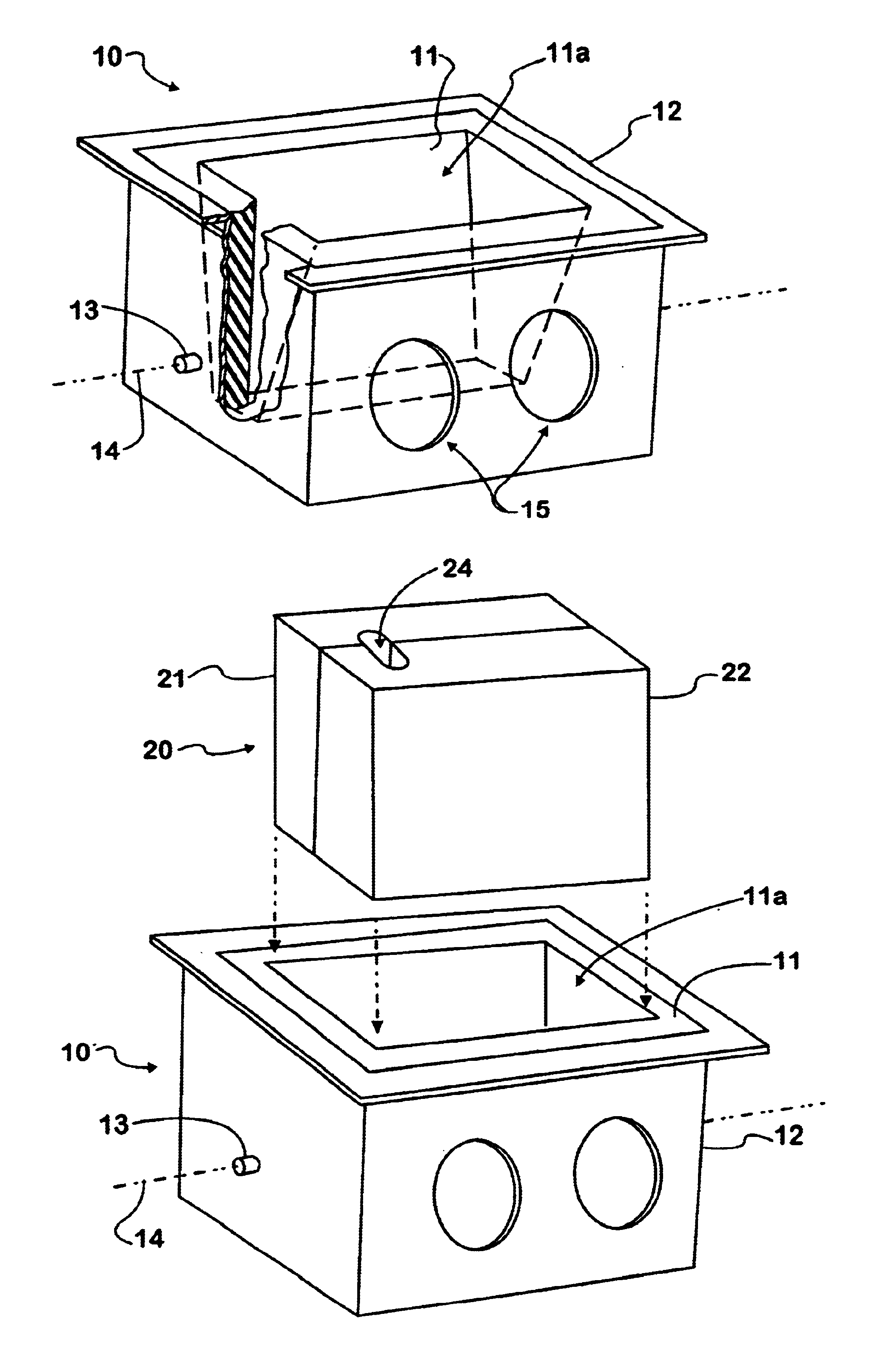

Casting method and apparatus

InactiveUS6923239B2Environmental cost is eliminatedEliminate usePig casting plantsMoulding plantsCylinder headAlloy

The use of green sand is eliminated by replacing green sand molds with all core sand assemblies that provide, during casting, both the internal and external surfaces of a casting, such as a cylinder head or engine block. In the process, a mold is formed from the same core sand that is used to form the core elements defining the internal passageways of the casting. A mold-core carrier is constructed with downwardly converging sides that hold assembled mold and core elements together, without fasteners, during transportation and pouring of the molten iron alloy into the mold-core assembly and the cooling period to form the casting. After the casting is formed, the core sand from both the mold elements and core elements is recovered, and may be recycled and processed to form further mold elements or core elements or both.

Owner:INT TRUCK INTPROP LLC

Automatic sand mold casting mold forming production line and method

InactiveCN111496198AWeight increaseGuaranteed cleanlinessMoulding toolsMoulding plantsProcess engineeringCasting mold

The invention relates to an automatic sand mold casting mold forming production line which comprises a truss robot, a feeding device, a sand removing device, a coating device, a drying device and a core assembling device. The truss robot is mounted on two parallel sliding rails, and can slide along the sliding rails, and the sliding rails are mounted on stand columns. The sand removing device comprises an automatic sand removing room, a manual sand removing room and a transferring trolley. The truss robot can place workpieces on the transferring trolley, and the transferring trolley can transfer the workpiece to the automatic sand removing room and the manual sand removing room. According to the automatic sand mold casting mold forming production line, unmanned operation can be achieved inthe whole process, the labor cost is reduced, rigid grabbing points do not need to be additionally arranged, and the demolding difficulty is reduced; the grabbing process and the like are high in repeated positioning precision, sand molds cannot be damaged, the sand core rejection rate is low, and all sand molds can be compatible; and due to the fact that sand mold production is mixed routing production, the time wasted by replacing fingers and other accessories is greatly shortened, and the production cost is reduced.

Owner:烟台冰轮智能机械科技有限公司

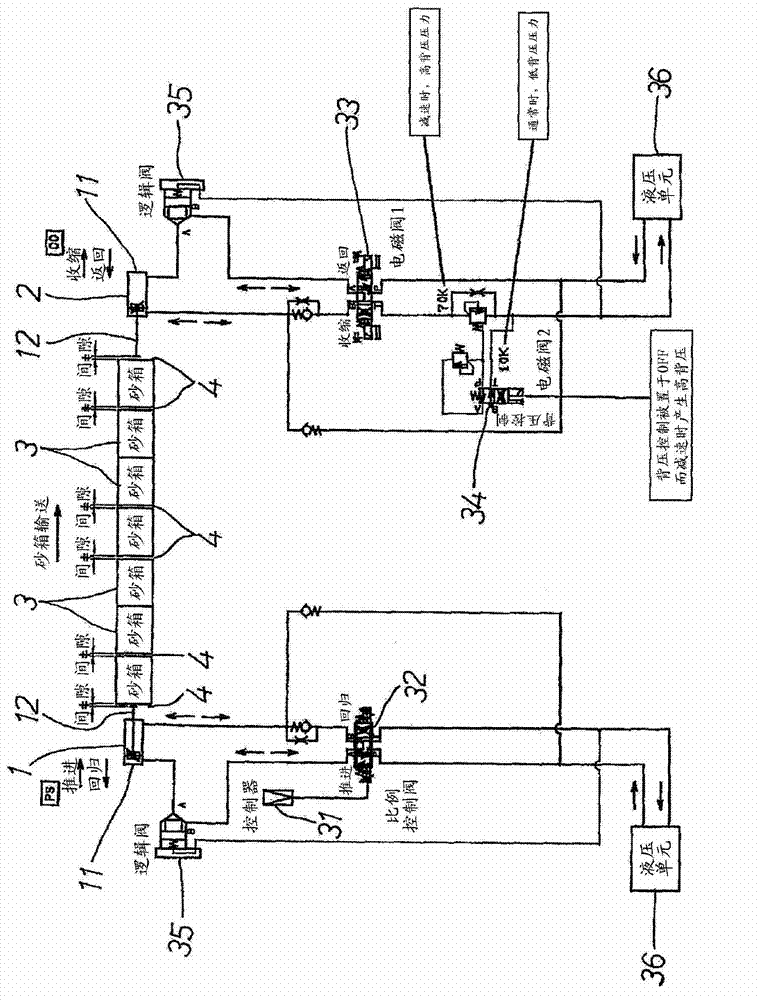

Conveying method and device for conveying sand box set with temperature change through hydraulic cylinder

The present invention provides a conveying method and a device for conveying a sand box set without sand box stop position error when large thermal expansion amount of the sand box exists. The conveying method provided by the invention comprises the following steps: sand box gathering step in which a hydraulic push cylinder (1) operates for pushing the sand box set (3) which is configured in series to a hydraulic buffer cylinder (2) and eliminating a clearance (4); a conveying step in which the hydraulic push cylinder (1) operates in high speed and the hydraulic buffer cylinder (2) is switched to a high-back-pressure state for reducing speed in a speed reduction area, thereby conveying the sand box set (3) for a distance which is equivalent with the size of one sand box; and a final step for further retreating the hydraulic buffer cylinder (2) after the sand box set (3) is stopped, thereby forming a clearance (4) between the hydraulic buffer cylinder (2) and the sand box set (3).

Owner:SINTOKOGIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com